Patents

Literature

543 results about "Hydroxyl-terminated polybutadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroxyl-terminated polybutadiene (HTPB) is an oligomer of butadiene terminated at each end with a hydroxyl functional group. It reacts with isocyanates to form polyurethane polymers. HTPB is a translucent liquid with a color similar to wax paper and a viscosity similar to corn syrup. The properties vary because HTPB is a mixture rather than a pure compound, and it is manufactured to meet customers' specific requirements. A typical HTPB is R-45HTLO. This product consists of oligomeric units typically containing 40–50 butadiene molecules bonded together, with each end of the chain terminated with a hydroxyl [OH] group...

High-toughness photosensitive resin for 3D printing and preparation method thereof.

The invention provides a high-toughness photosensitive resin for 3D printing and a preparation method thereof. The photosensitive resin comprises a photosensitive resin (maleable photosensitive resin and rigid photosensitive resin), an active diluent, a light initiator and an additive. The method first synthesizes the toughness photosensitive resin (maleable polyurethane acrylate and epoxy modified polyurethane), and then the maleable photosensitive resin is mixed with the rigid photosensitive resin, active diluent, light initiator and additive. The maleable photosensitive resin is prepared from a polymer soft segment, which is a mixture of one or more selected from of polypropyleneoxide glycol ether, PTMG, hydroxyl-terminated polybutadiene, hydroxyl-terminated styrene butadiene rubber, hydroxyl-terminated butadiene acrylonitrile rubber and hydroxyl-terminated polysiloxane, and a polymer hard segment of toluene diisocyanate or isophorone diisocyanate, through hydroxyethyl acrylate or epoxypropanol termination. The photosensitive resin is applicable to DLP or SLA type 3D printers for modification of the existing 3D printing photosensitive resin, has excellent bending strength, and can directly print out elastic models.

Owner:QINGDAO UNIV OF SCI & TECH

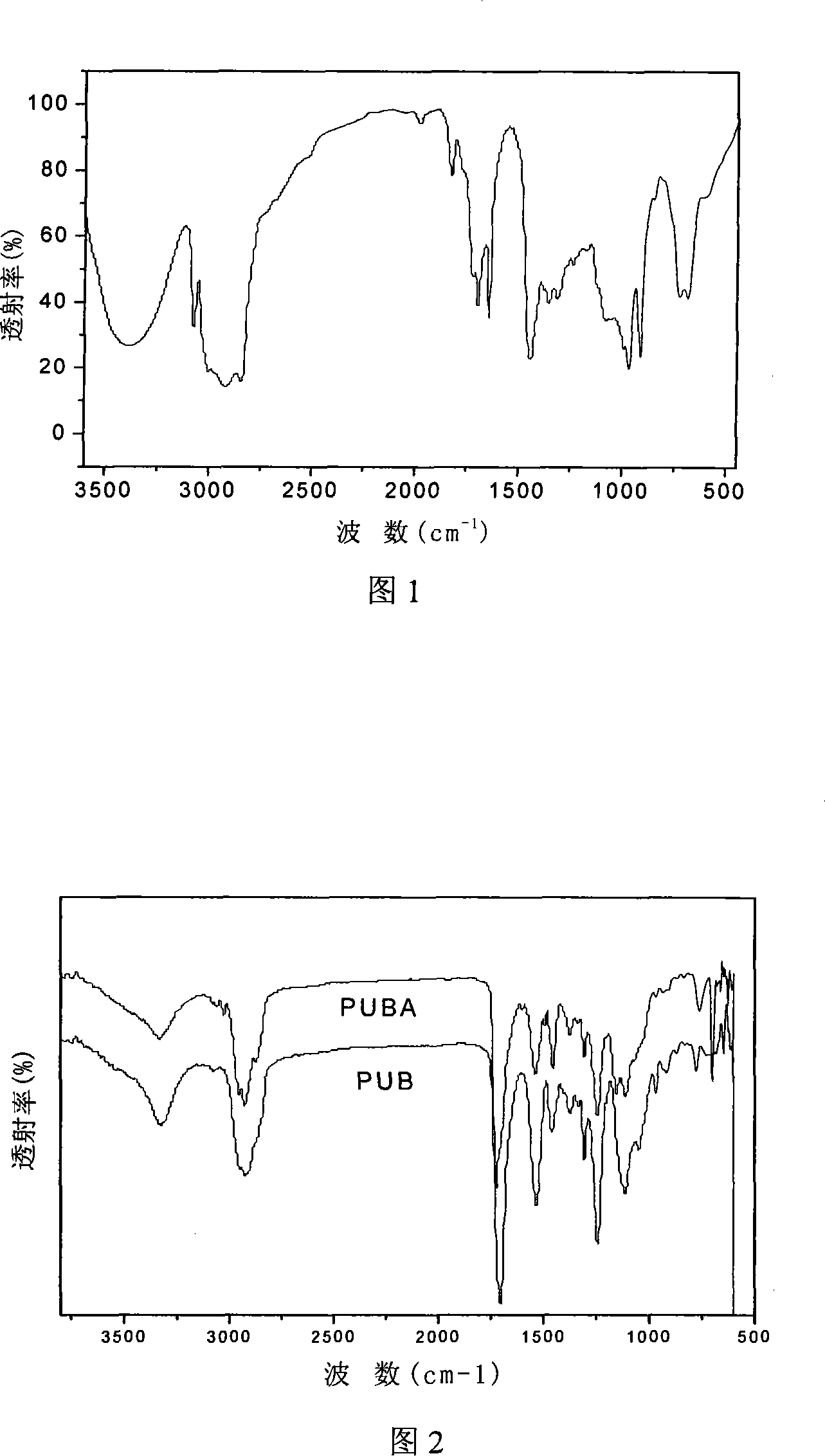

Method for preparing polybutadiene-base water polyurethane and modified emulsion thereof

InactiveCN101235129ASolve the problem of environmental protectionGood compatibilityPolymer scienceAlcohol

The invention discloses a polybutadiene aqueous polyurethane and a preparation method of relative modified emulsion, which is characterized by reacting low polymer polyatomic alcohol and hydroxy-terminated butadiene rubber and isocyanate, adding hydrophilic chain extender and catalyst to be reacted, cooling and emulsifying to obtain polybutadiene aqueous polyurethane, mixing polybutadiene aqueous polyurethane, emulsifier, water and inducer uniformly, adding ethenyl monomer to carry out emulsion polymerization to obtain polybutadiene aqueous polyurethane modified emulsion. The invention uses hydroxy-terminated butadiene rubber to synthesize aqueous polyurethane which can be modified by ethenyl to obtain environment-friendly, stable and low temperature resistant aqueous resin with better mechanical property. The resin can be used in weaving, leather processing, paint and adhesive or the like.

Owner:ANHUI UNIVERSITY

Thermosetting resin composition containing modified polyimide resin

InactiveUS20070088134A1Poor processing propertyHigh elastic modulusPrinted circuit aspectsPrinted circuit manufactureElectrical conductorFlexible circuits

Thermosetting resin compositions which comprise: (A) at least one modified linear polyimide resin obtained by reacting a bifunctional hydroxyl-terminated polybutadiene, a diisocyanate compound, and a tetracarboxylic acid anhydride, and (B) at least one thermosetting resin selected from the group consisting of an epoxy resin, a bismaleimide resin, a cyanate ester resin, a bis-allyl-nadi-imide resin, a vinylbenzyl ether resin, a benzooxazine resin, a polymer of bismaleimide and diamine, and mixtures thereof, are useful as insulating materials for a flexible circuit boards and can readily have a conductor layer with excellent adhesion strength formed thereon by plating.

Owner:AJINOMOTO CO INC

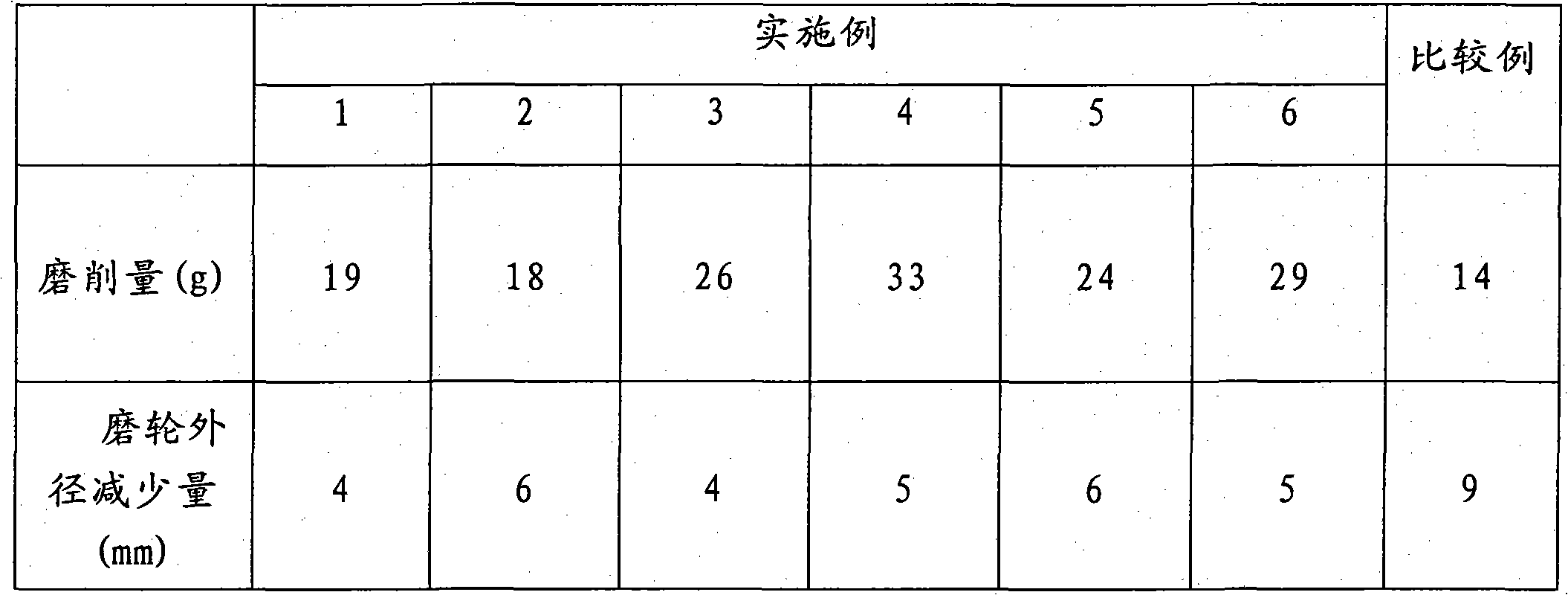

Method for preparing non-woven fabric polishing abrasive tool with high abrasion resistance

InactiveCN101913121AHigh viscosityImprove adhesionFibre typesGrinding devicesSilanesMagnesium stearate

The invention relates to a method for preparing a non-woven fabric polishing abrasive tool with high abrasion resistance. The method comprises the following steps of: taking 20 to 40 mass parts of epoxy resin, adding 4 to 25 mass parts of curing agent, 20 to 45 mass parts of abrasive, 8 to 15 mass parts of diluent, 2 to 8 mass parts of toughening agent, 1 to 3 mass parts of silane coupling agent and 3 to 8 mass parts of auxiliary materials into the epoxy resin, mixing the materials uniformly, then spraying the mixture onto a non-woven fabric, curing the mixture at a high temperature, and then performing punch forming, wherein the toughening agent comprises reactive epoxy toughening agent, terminal carboxyl liquid nitrile rubber and / or terminal carboxyl polybutadiene liquid rubber; the silane coupling agent comprises gamma-aminopropyltriethoxysilane, gamma-glycidyl ether oxypropyl trimethoxy silane and / or gamma-(methacryloyloxy) propyltrimethoxysilane; and the other auxiliary materials comprise 2,4,6-tri(dimethylaminomethyl) phenol DMP-30 accelerator, wax powder, graphite, pigment, magnesium stearate and / or zinc stearate. The non-woven fabric polishing abrasive tool is mainly used for polishing treatment of metal surfaces.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation method of rapid UV-cured fluorine-containing hydrophobic polyurethane elastic coating layer

InactiveCN104910344AIncrease elasticityReduce dosagePolyurea/polyurethane coatingsUltraviolet lightsDouble bond

The invention relates to a preparation method of a rapid UV-cured fluorine-containing hydrophobic polyurethane elastic coating layer. The method comprises the following steps: reacting diisocyanate with hydroxyl-terminated polybutadiene (HTPB) to generate an isocyanato-terminated prepolymer, carrying out a chain extension reaction by using dihydric alcohol, blocking by using hydroxy acrylate to synthesize double bond terminated polyurethane resin, and compounding the obtained resin with a diluent, a photo-crosslinker, a fluorine-containing acrylate monomer, a silane coupling agent and a photoinitiator, and curing under ultraviolet light to form the coating layer. A mercapto group-containing crosslinker is added to improve the curing efficiency of the coating layer and reduce the consumption of the photoinitiator; and above fluorine-containing compound is introduced to facilitate improvement of the hydrophobicity and the pollution resistance of the surface of the coating layer.

Owner:JIANGNAN UNIV

Steam hot aerosol fire-extinguishing composite and application method and fire extinguishing device thereof

ActiveCN101554520AWide variety of sourcesLess corrosiveFire rescueFire extinguisherSodium bicarbonateEpoxy

The invention provides a steam hot aerosol fire-extinguishing composite which contains 30-80wt percent of oxidant, 10-60wt percent of fuel additive and 2-30wt percent of cohesion solidification molding auxiliary agent. The oxidant can be one or more of the following substances: potassium salt, strontium salt, ammonium salt, magnesium salt, nitrocellulose and nitroglycerin; the fuel additive can be one or more of the following substances: azos, azoles, amino-guanidine nitrate, sodium bicarbonate, melamine, cyanoguanidine, carbamide, hexamine, triaminoguanidine nitrate, olefin, saccharose, aluminium powder, magnesite powder and magnesium-aluminium alloy power; the cohesion solidification molding auxiliary agent can be one or more of the following substances: phenol formaldehyde resin, ethoxyline resin, glycidyl azide, urethane rubber, hydroxyl-terminated polybutadiene, polyisobutylene, acetyl tributyl citrate, carboxymethyl cellulose, polyvinyl alcohol phenolic resin and acrylic resin. The invention also provides a fire extinguishing method and a fire extinguishing device adopting the composite. The invention has strong fire extinguishing capacity and fewer hazardous materials and can be applied to different places.

Owner:JIANGXI TSINGHUA IND CO LTD

Compound carbon nanotube and rubber material and preparation method thereof

The invention discloses a compound carbon nanotube and rubber material and a preparation method thereof. The compound material comprises the following components by mass: 100 parts of a mixed carbon nanotube and rubber material, 1-3 parts of stearic acid, 53-65 parts of carbon black, 5-8 parts of nano-zinc oxide, 1.5-2.5 parts of an anti-ageing agent D, 2-3.5 parts of an anti-ageing agent 4020, 0.4-0.8 part of a vulcanization accelerator CZ, 0.3-2 parts of a scorch retarder CTP and 2-3 parts of sulfur, wherein the mixed carbon nanotube and rubber material is a mixed material of 26 parts of an HTPB (hydroxyl-terminated polybutadiene)-coated carbon nanotube mixture and 74 parts of rubber, and the HTPB-coated carbon nanotube mixture is an HTPB-coated carboxylic multi-walled carbon nanotube. The preparation method comprises the following steps: rolling the mixed rubber material and the rubber, vulcanizing, plastifying, adding the materials, mixing, and vulcanizing to obtain the compound carbon nanotube and rubber material. Therefore, the compound carbon nanotube and rubber material has the advantages of good dispersity and stronger bonding force of a carbon nanotube and rubber interface.

Owner:SUZHOU HUADONG RUBBER

Wear-resistant and heatproof modified polyurethane rubber cable material

InactiveCN105602238AImprove performanceGood wear resistance and heat resistancePlastic/resin/waxes insulatorsPolymer sciencePolyvinyl alcohol

The invention discloses a wear-resistant and heatproof modified polyurethane rubber cable material which comprises the following raw materials: modified polyurethane, acrylate rubber, ethylene-propylene-diene monomer, nitrile butadiene rubber, epoxy resin, polyether glycol, toluene diisocynate, polyvinyl alcohol, diisobutyltin dilaurate, polyvinyl chloride, hydroxyl-terminated polybutadiene, hydroxyl-terminated polyalcohol, isocyanate, vinyltriethoxysilane, dibutyltin dilaurate, silicone oil, a carbon nanotube, organic modified montmorillonoid, nano alumina powder, talc powder, bamboo carbon fiber, chlorinated paraffin, silicon dioxide, zinc oxide, stearic acid, nano aluminum hydroxide, a flame retardant, an anti-aging agent, a plasticizer, an antioxidant and an accelerant. The modified polyurethane rubber cable material disclosed by the invention has excellent wear-resistant and heatproof properties.

Owner:ANHUI DUJIANG CABLE GROUP

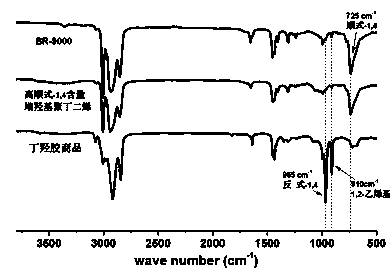

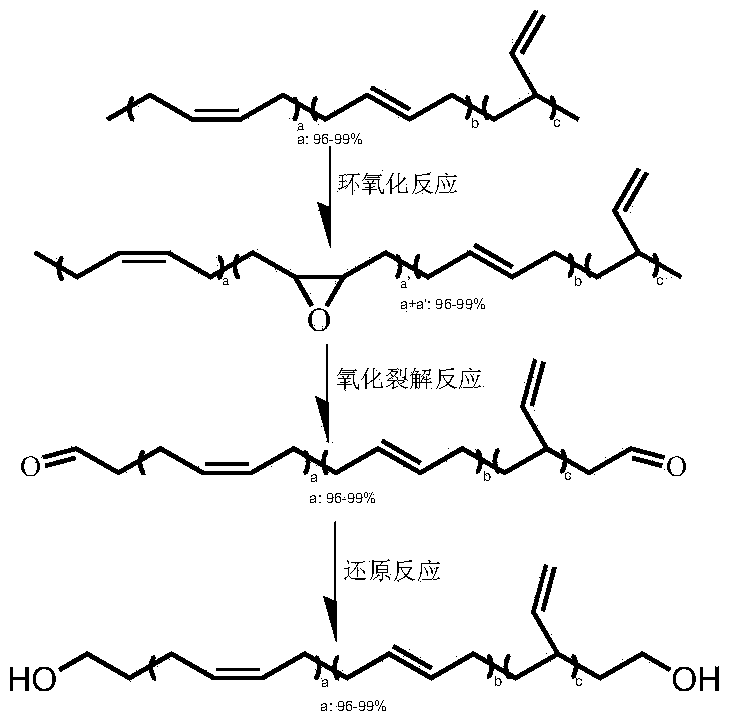

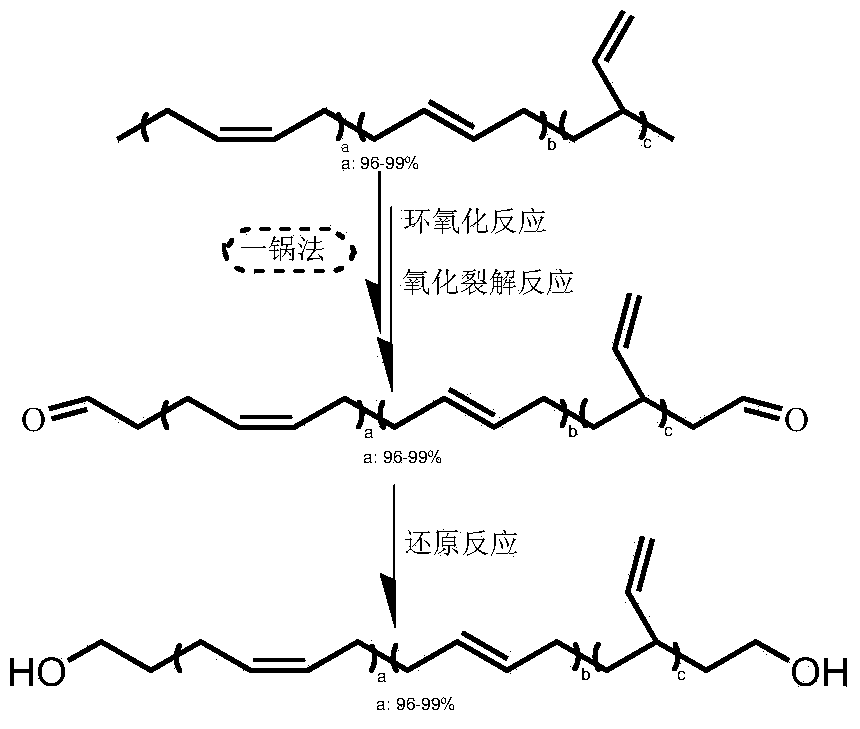

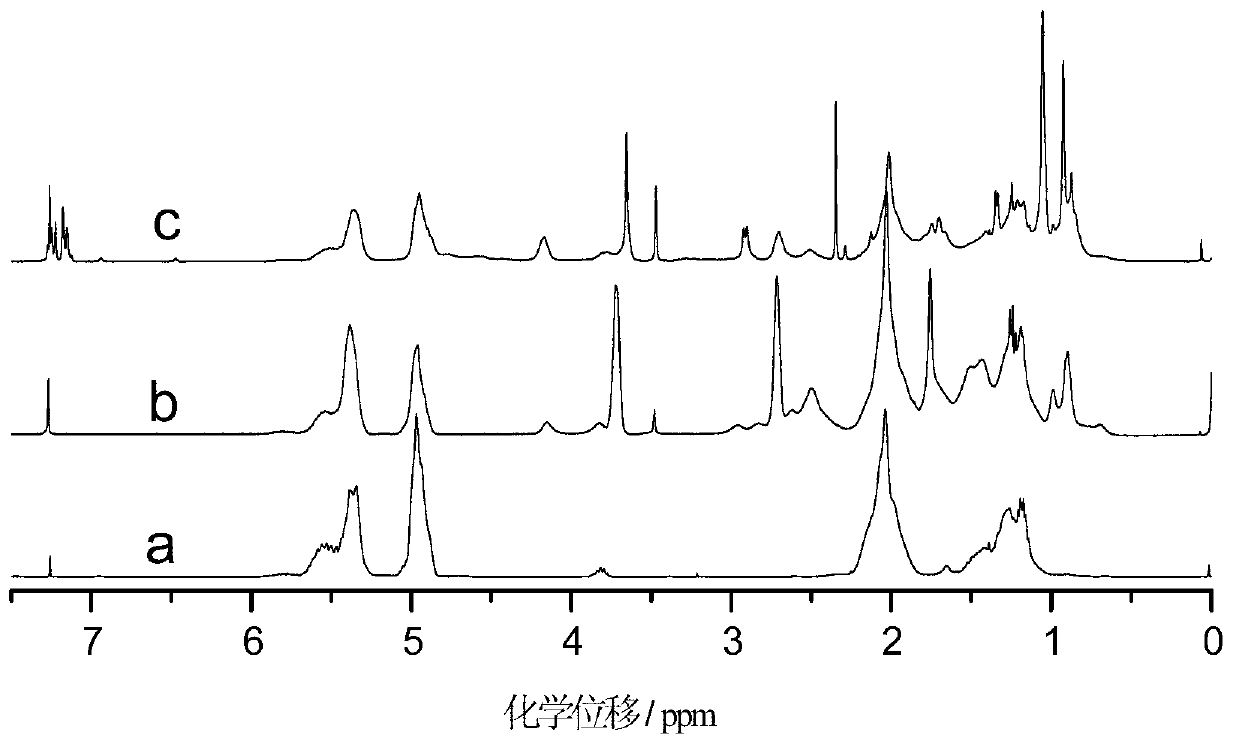

High-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber and preparation method thereof

The invention discloses a high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber and a preparation method thereof. The method includes following steps: (1) preparing epoxidized butadiene rubber from butadiene rubber; (2) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the epoxidized butadiene rubber; (3) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the butadiene rubber in a one-pot manner; (4) reducing the high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber to prepare the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber. In the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber is prepared from the butadiene rubber and the content of cis-1,4 can reach 95.0-99.0%. A number-average molecular weight of the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be regulated between 2000 g / mol and 10000 g / mol. A molecular weight distribution is 1.2-3.0 and a degree of functionality is 1.9-2.2. On the basis of excessive supply in raw rubber of butadiene rubber and increased tensing situation of petroleum sources, by means of the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be prepared through oxidative pyrolysis of the butadiene rubber, so that the method has a quite important practical significance.

Owner:ZHEJIANG UNIV

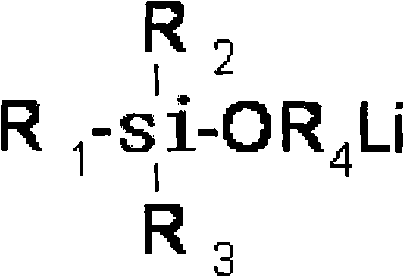

Preparation for low molecular weight hydroxy-terminated polybutadiene

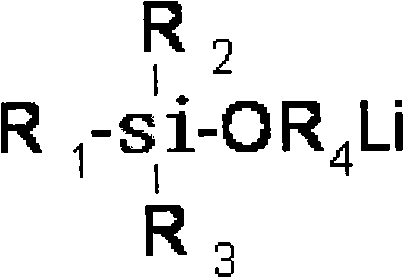

The invention provides a method for preparing hydroxyl-terminated polybutadiene of low molecular weight. The method adopts butadiene as a monomer, lithium alkylide of aliphatic series which contains silane protecting hydroxyl as an evocating agent, an organic non-polar compound as a solvent, an epoxy compound as an end capping reagent and fluoride as a detaching reagent for protecting groups. Anion polymer technology is adopted and polymerization is carried out at a temperature of 20 to 80 DEG C in the environment of inert gases; a prepolymer obtained goes through acid hydrolysis and a series of hydroxyl-terminated polybutadiene fluid rubber with narrow molecular distribution and controllable molecular weight is obtained. In the process of preparing hydroxyl-terminated polybutadiene polymer of the invention, the polymer does not encounter with a fake gel phenomenon during the process of end capping and detaching protecting group and the polymerization process is easy for control; the micro-structure of molecular chains is adjustable and controllable. The obtained hydroxyl-terminated polybutadiene has a molecular weight distributing index less than or equal to 1.2; the average functionality is close to 2; the cured products of hydroxyl-terminated polybutadiene have extremely good mechanical property and can be applied to the fields of rocket technology, optical fiber communication technology, etc.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

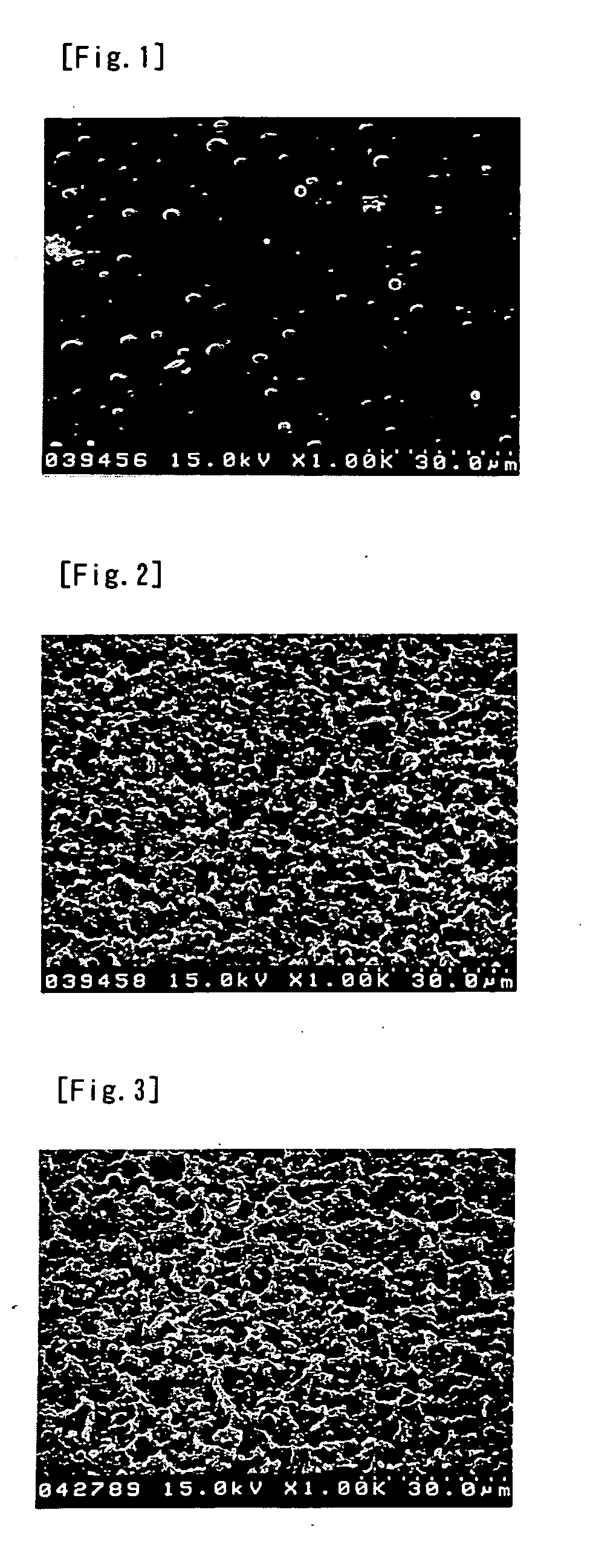

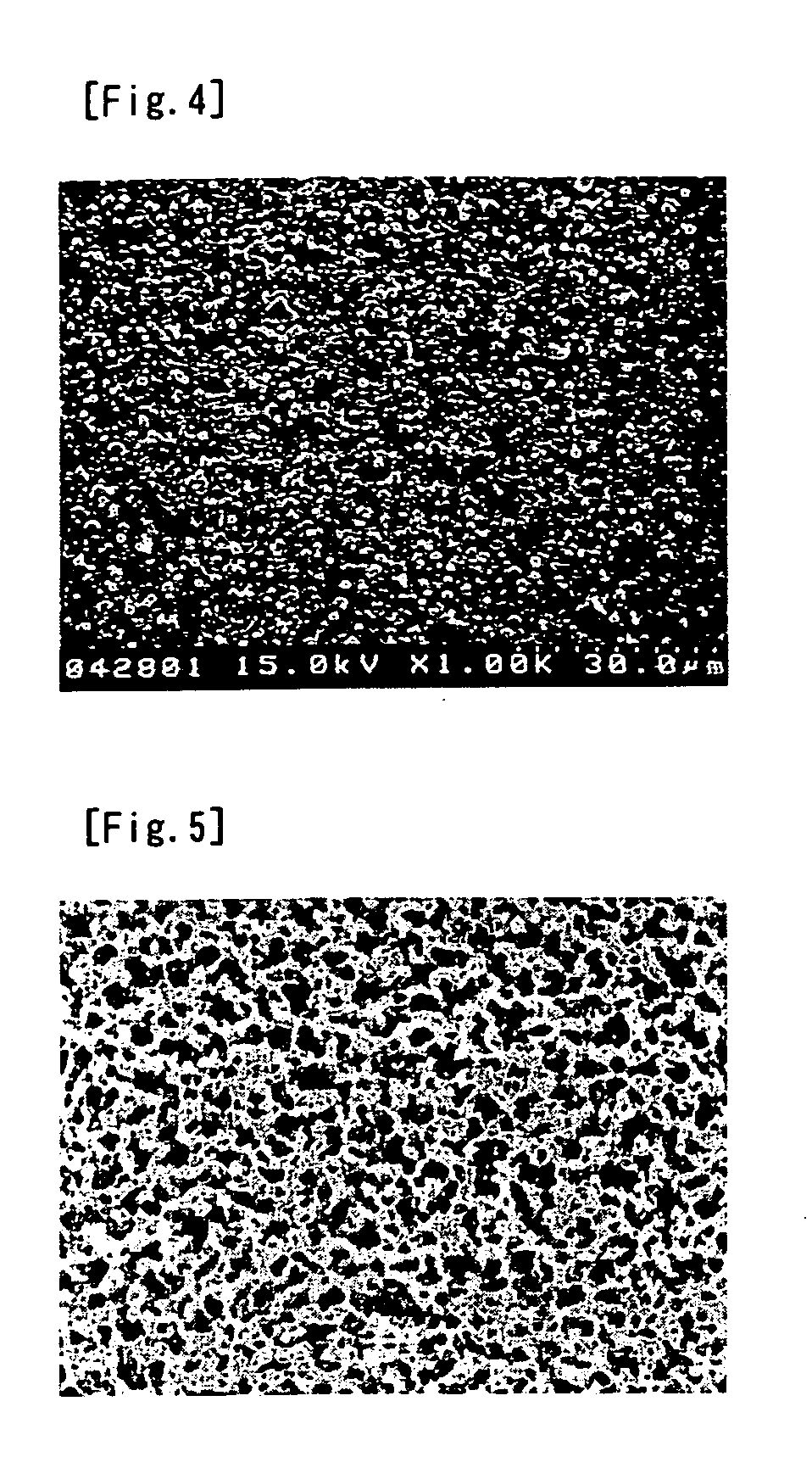

Method for modifying cyanate ester resin by hydroxyl-terminated polybutadiene

The invention relates to a method for modifying cyanate ester resin by hydroxyl-terminated polybutadiene, which comprises the following steps: adding hydroxyl-terminated polybutadiene rubber into the cyanate ester resin with the addition quantity of 5 to 30 weight percent; heating and melting the mixture to be uniformly mixed; heating the mixture to 120+ / -15DEG C for pre-polymerization for 10 to 60 min; carrying out casting and curing; uniformly heating at 130 to 200 DEG C for 7 to 10h for curing; and obtaining the modified cyanate ester resin with good performance. The modified system improves the curing process of the resin system, reduces the curing temperature of the resin system, shortens of the curing time, reduces the manufacture cost of the materials, the impact toughness of the cured modified cyanate ester resin is obviously improved, and the thermal stability is maintained. Because the modification system has good compatibility, the modification system does not need solvents, and the invention belongs to a direct method with the advantages of no pollution and simple operation.

Owner:NANJING UNIV

Polyurethane sealing pouring adhesive and its preparing process

InactiveCN101210167ASimple preparation processEasy to controlOther chemical processesPolyureas/polyurethane adhesivesAdhesiveSealant

The invention provides a polyurethane potting sealant, which is composed of a component A and a component B. The polyurethane potting sealant includes a diluting agent containing fatty acid methyl ester or dioctyl phthalate and a catalyst containing dibutyltin laurate or stannous octoate. The component A contains (by weight percentage) hydroxyl-terminated polybutadiene (HTPB) 60% to 80%, the diluting agent 10% to 25%, and carbon black 5% to 15%. The component B contains (by weight percentage) liquefied diphenylmethane-diisocyanate (DMI) 80% to 95% and the catalyst 5% to 20%. The polyurethane potting sealant of the invention has the advantages of low potting viscosity, good leveling property and less formation of air vents.

Owner:TIANJIN LANGRUNSICHUANG TECH DEV

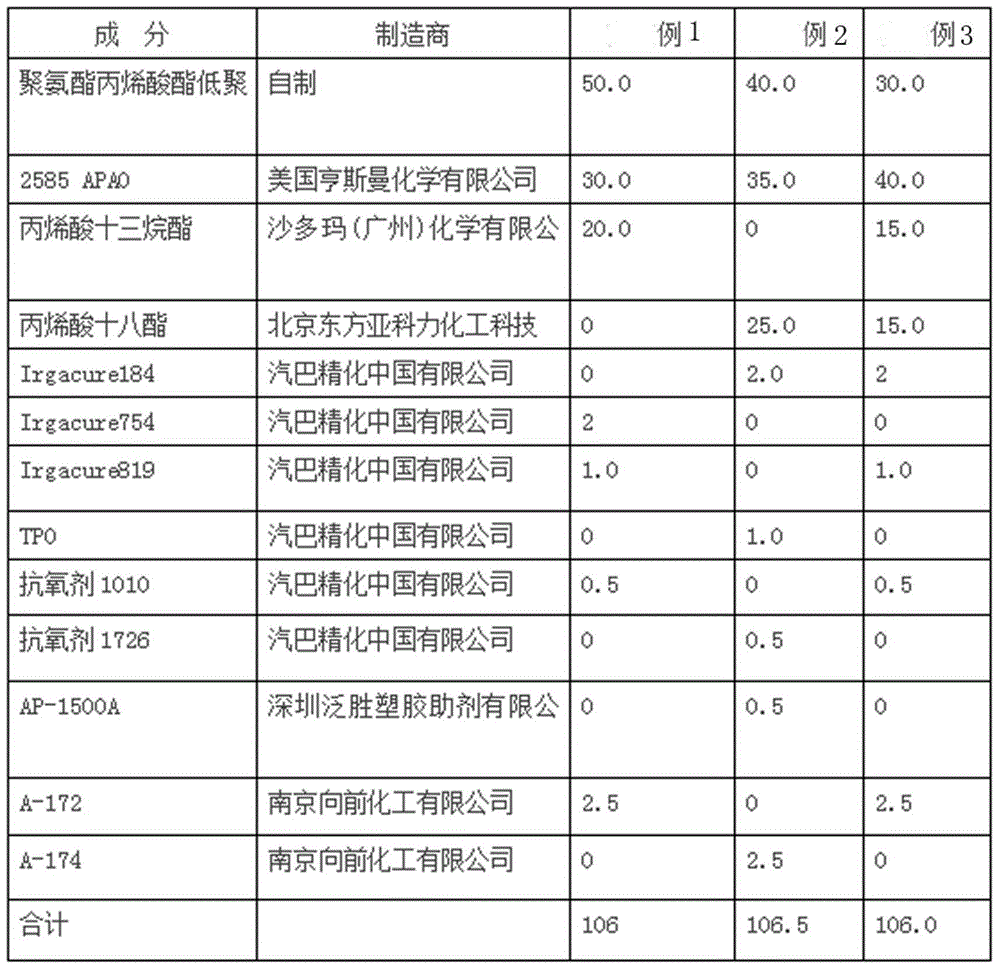

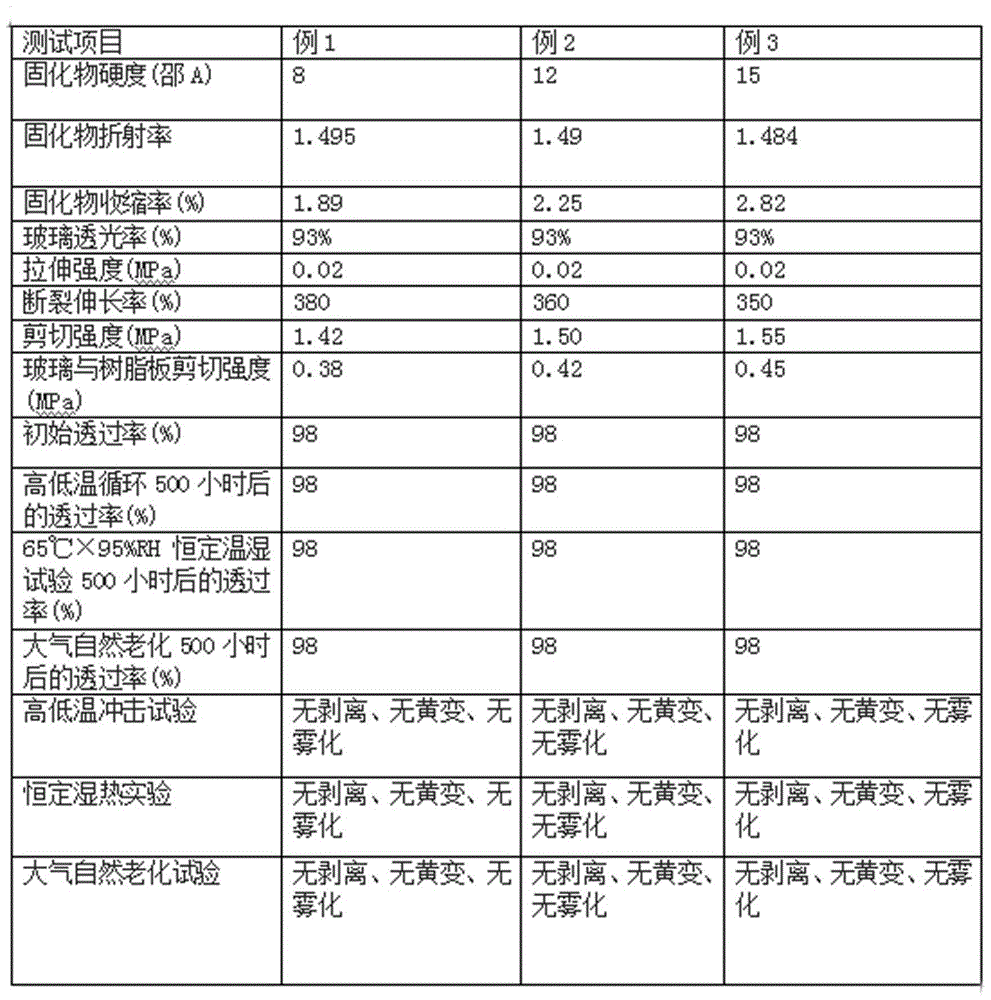

Ultra-flexible polyurethane acrylate resin and liquid-state optical adhesive composition thereof

InactiveCN104892890AImprove performanceFulfil requirementsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveRefractive index

The invention discloses ultra-flexible polyurethane acrylate resin and a liquid-state optical adhesive composition thereof, and belongs to the technical field of polymer synthesis. The ultra-flexible polyurethane acrylate resin has a refractive index of 1.51, resin chromaticity APHA of 30, viscosity of 0.25 million of mPa.s, Tg lower than minus 40 DEG C and molecular weight of 10000-100000. The ultra-flexible polyurethane acrylate resin is prepared from the raw materials comprising liquid-state hydroxyl-terminated polybutadiene, aliphatic and / or alicyclic diisocyanate, a polymerization inhibitor, a catalyst, a solvent and hydroxyalkyl acrylate. A preparation method for the ultra-flexible polyurethane acrylate resin comprises the following steps: uniformly mixing the liquid-state hydroxyl-terminated polybutadiene, the aliphatic and / or alicyclic diisocyanate, the polymerization inhibitor, the catalyst and the solvent to obtain a mixture; then, adding the hydroxyalkyl acrylate into the mixture to react, thereby obtaining the ultra-flexible polyurethane acrylate resin. The ultra-flexible polyurethane acrylate resin has Tg lower than minus 40 DEG C, good flexibility and resin chromaticity APHA of 30. The liquid-state optical adhesive prepared by taking the resin disclosed by the invention as a main component has the advantages of high bonding strength and low shrinkage ratio.

Owner:深圳市浩力新材料技术有限公司

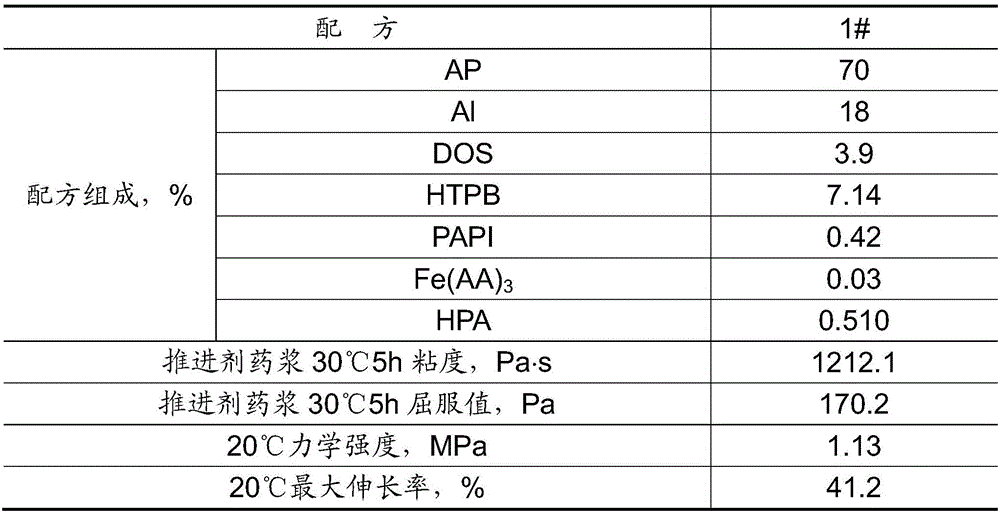

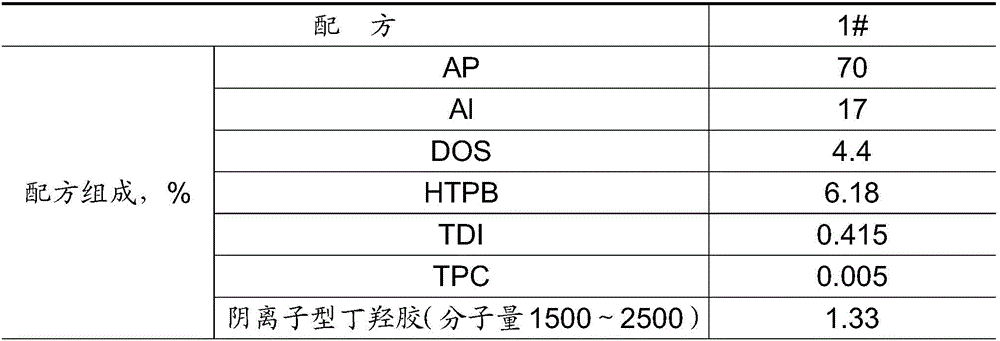

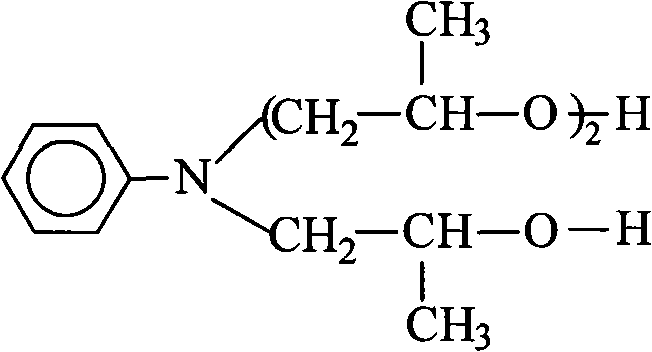

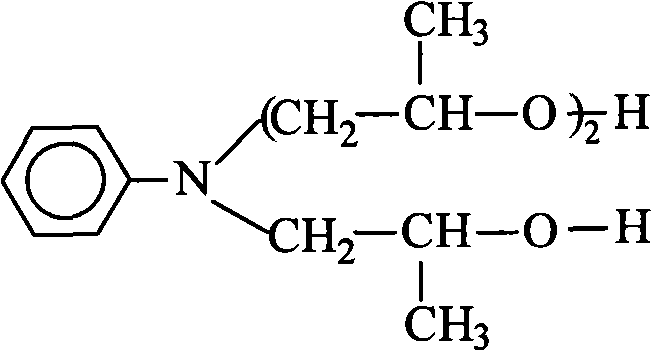

Room-temperature curing propellant

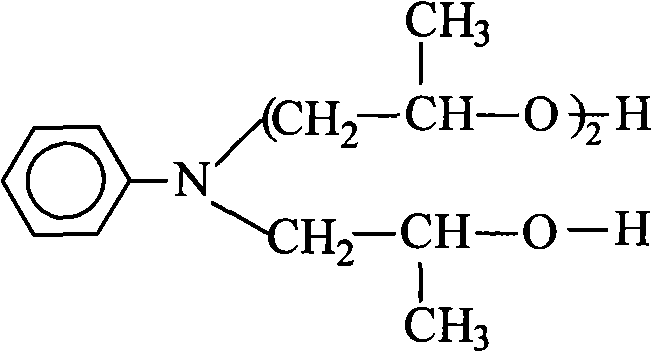

ActiveCN106831279AGood mechanical propertiesReduced activityExplosivesPressure gas generationAnilineMethylene diphenyl diisocyanate

The invention relates to a room-temperature curing propellant. The room-temperature curing propellant is prepared from the following components in percentage by mass: 69 to 77% of AP (ammonium perchlorate), 10 to 18% of Al (aluminum) powder, 1 to 5% of plasticizer DOS, 7 to 10% of adhesive HTPB and curing agent, 0.005 to 0.05% of curing catalyst, and 0.2 to 2.0% of network adjusting agent, wherein the network adjusting agent is an alcohol or amine compound with two degrees of functionality, and is one or combination of N-isopropyl alcohol-N-isopropyl ether-aniline, anionic HTPB (hydroxyl-terminated polybutadiene) or N,N'-dihydroxy(diisopropyl)aniline HPA; the curing agent is one or combination of PAPI (polyaryl polymethylene isocyanate), MDI (methylene diphenyl diisocyanate), XDI (xylylene diisocyanate), or TDI (toluene diisocynate). The room-temperature curing propellant has the advantages that the propellant with effective solid content of more than 85% is mixed and cast at the temperature of 20 to 35 DEG C, and can reach a curing point within 7d after curing; the normal-temperature mechanical strength can reach 0.85MPa or above, and the elongation rate is more than 35%.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

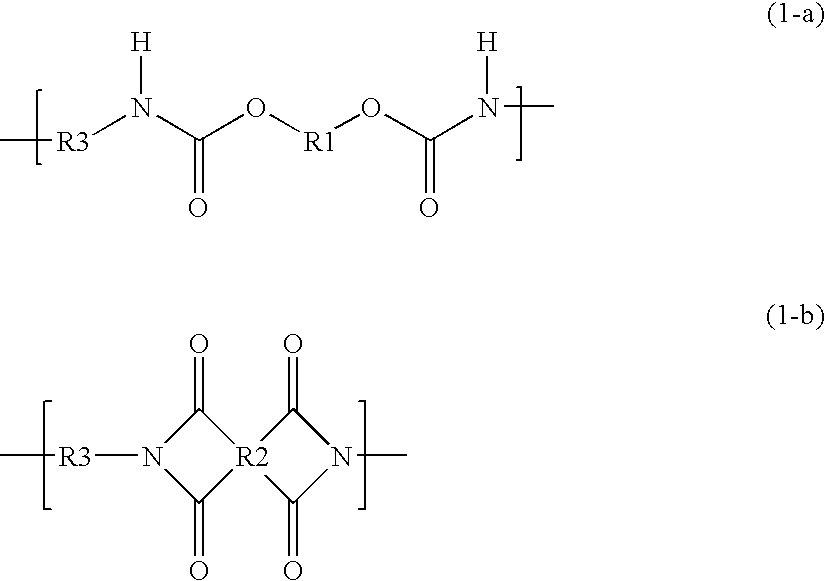

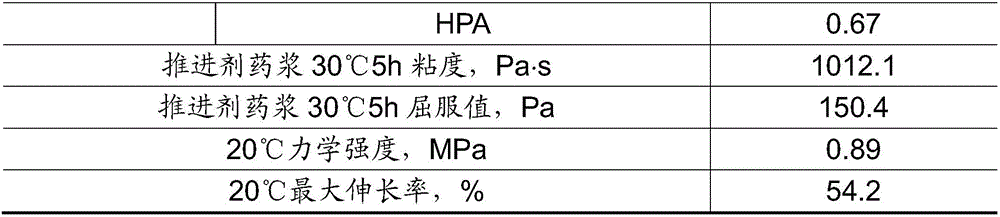

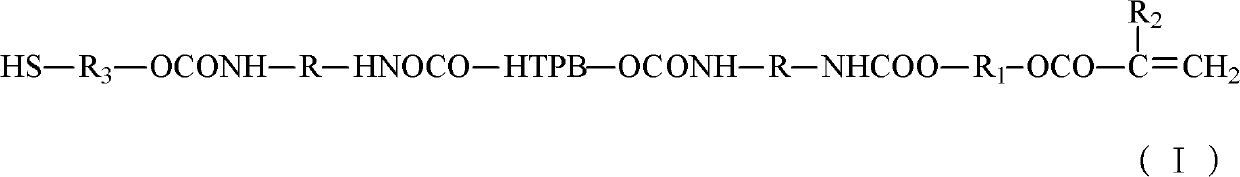

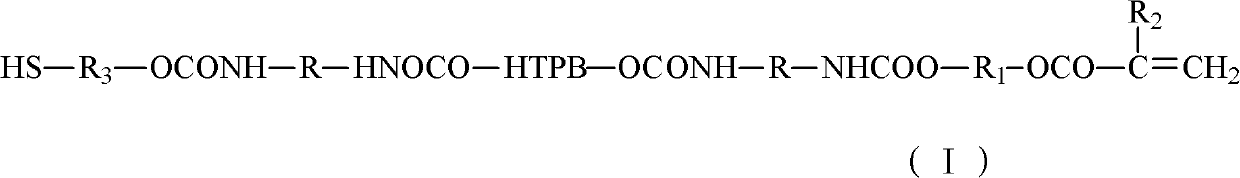

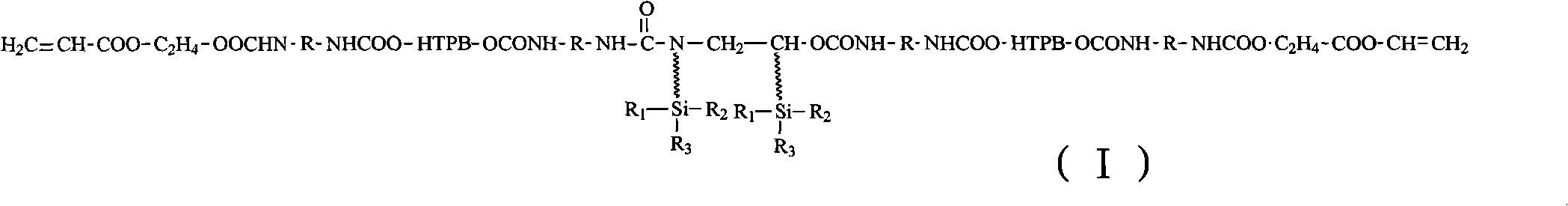

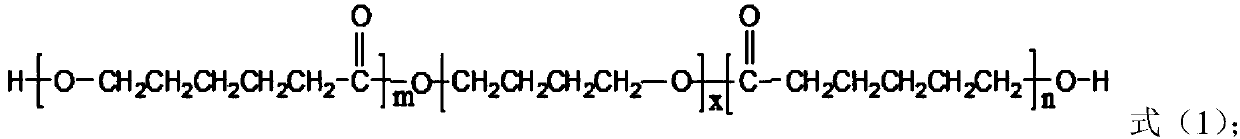

Photocuring resin and preparation method thereof

The invention discloses a photocuring resin and a preparation method thereof. The photocuring resin is characterized in that the photocuring resin is thiol-modified hydroxyl-terminated polybutadiene (HTPB) type polyurethane acrylate the structural formula of which is shown in a general formula (I), wherein R represents one or more of toluene diisocynate, isophorone diisocyanate, diphenylmethane diisocyanate and hexamethylene diisocyanate, R1 represents one or more of -C2H4-, -C3H6- and C4H8-, R2 represents one or two of -H and -CH3, and R3 represents one or more of mercaptoethanol, 6-mercaptohexan-1-ol, 3-sulfydryl-1-hexyl alcohol, 16-mercaptohexadecan-1-ol and thiol.

Owner:YANTAI DARBOND TECH

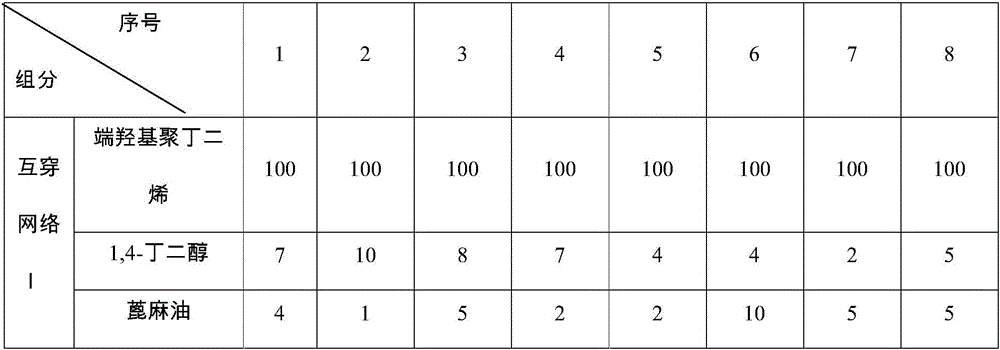

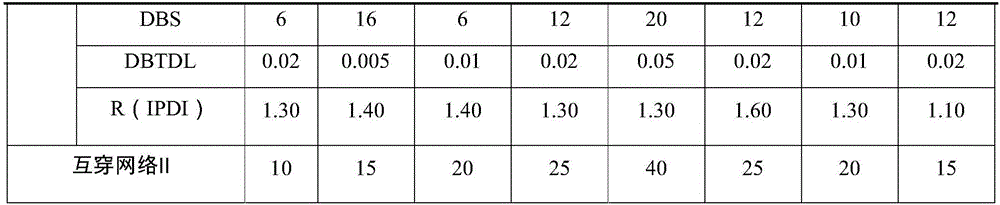

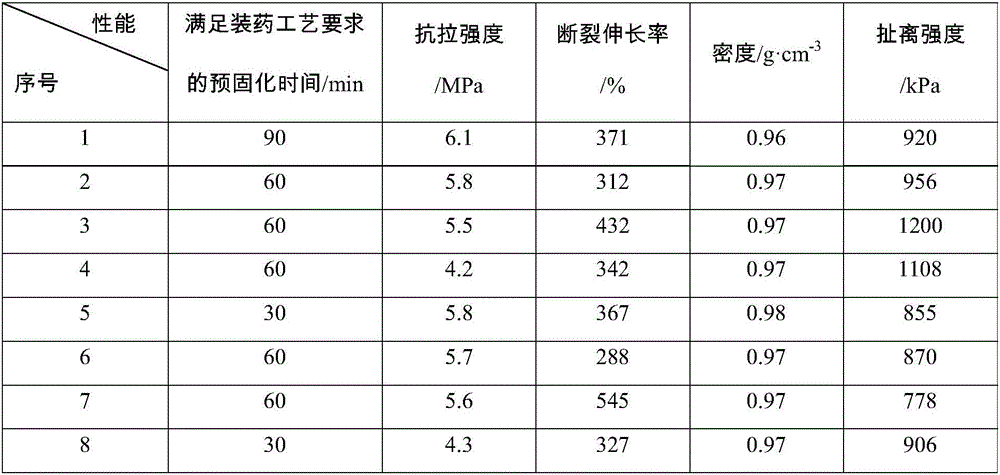

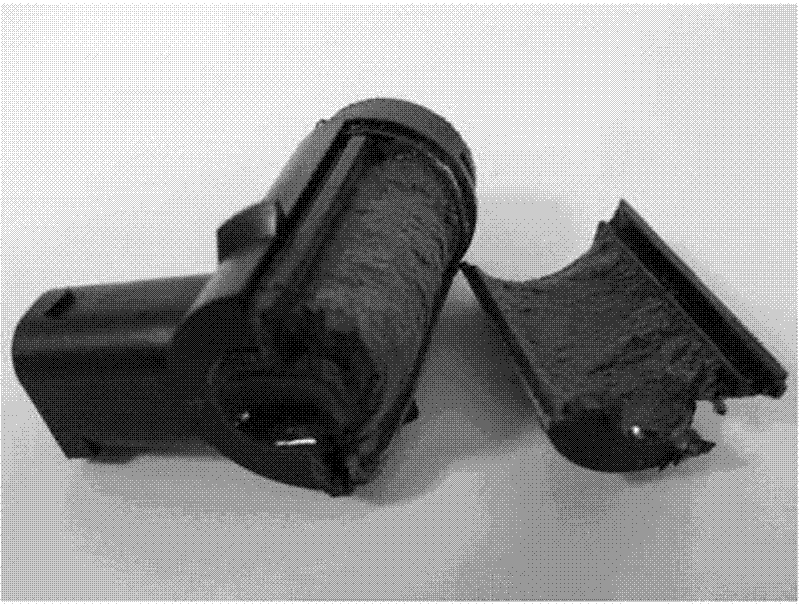

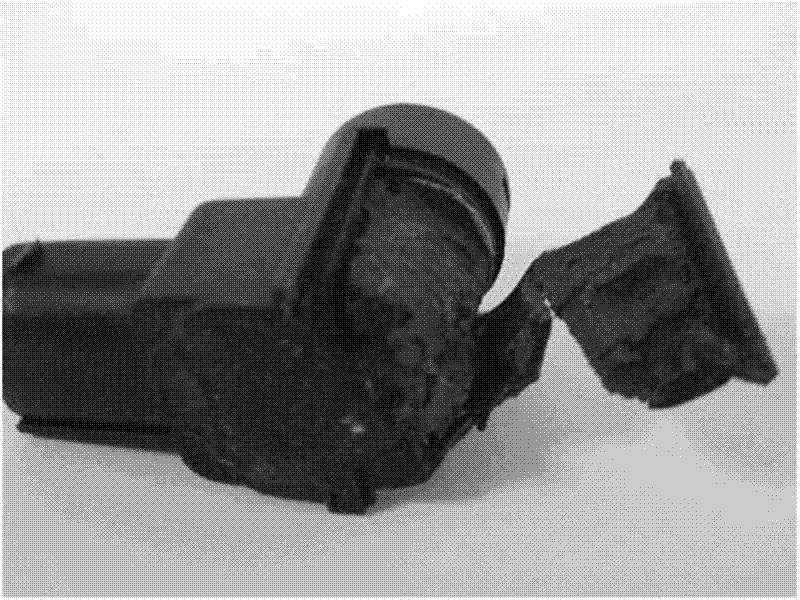

Liner material for improving interfacial bonding of HTPB propellant and preparation method thereof

The invention discloses a liner material for improving interfacial bonding of an HTPB propellant and a preparation method thereof. The liner material provided by the invention comprises two parts, namely an interpenetrating polymer network I and an interpenetrating polymer network II, wherein the interpenetrating polymer network I comprises a curing agent of isocyanate, a chain extender of dihydric alcohol or diamine, a cross-linking agent of a multiple active functional group compound and a plasticizer, and also comprises adhesives comprising hydroxyl-terminated polybutadiene, nitrine or polyether and other hydroxyl-terminated macromolecule dihydric alcohols. The interpenetrating polymer network II comprises an epoxy resin, polyacrylate, polyurethane, polysiloxane, a vinyl ester resin and other resins. According to the invention, a novel technology can be provided to adapt to a propellant liner, so that the interfacial bonding property between the liner and the propellant is improved.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Liquid rubber based adhesive containing Nano montmorillonite and preparation method

InactiveCN1760301AImprove adhesionReduce manufacturing costNon-macromolecular adhesive additivesConjugated diene hydrocarbon adhesivesCross-linkPolymer science

A liquid rubber adhesive containing montmorillonite nanoparticles with high T-type stripping strength and adhesion is prepared through cationic exchange reaction of montmorillonite, intercalation combining with hydroxy terminated polybutanediene liquid rubber, and cross-linking by toluene diisocyanate (TDI) to obtain nano-montmorillonite / polyurethane / hydroxy terminated polybutanediene liquid rubber adhesive.

Owner:SHANGHAI UNIV OF ENG SCI

Polyurethane sealing material and preparation method thereof

ActiveCN104530366AImprove mechanical propertiesExtended gel timeOther chemical processesPolyureas/polyurethane adhesivesEpoxyPlasticizer

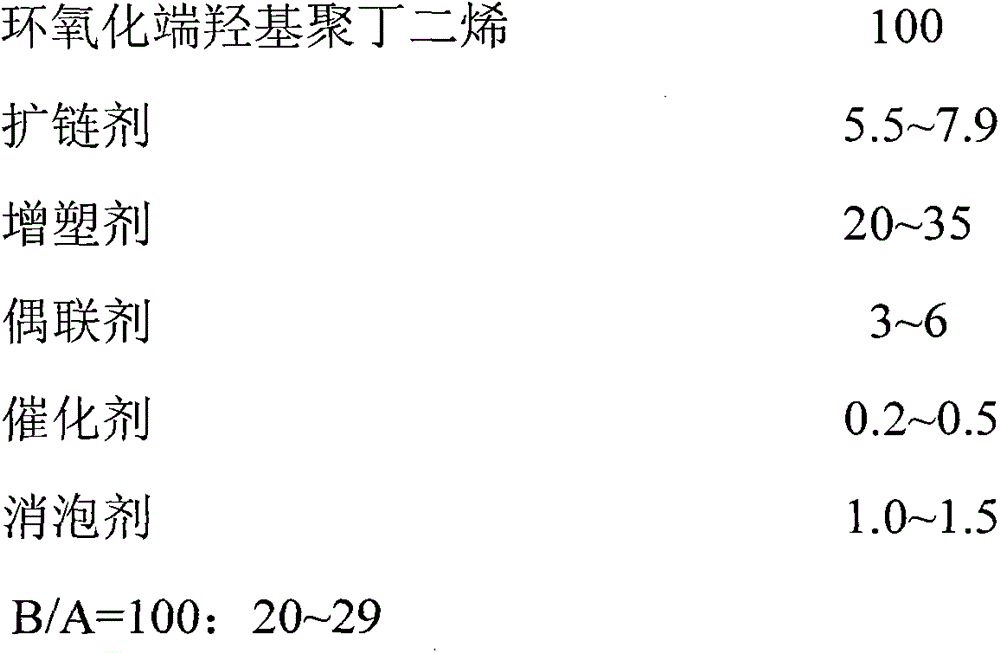

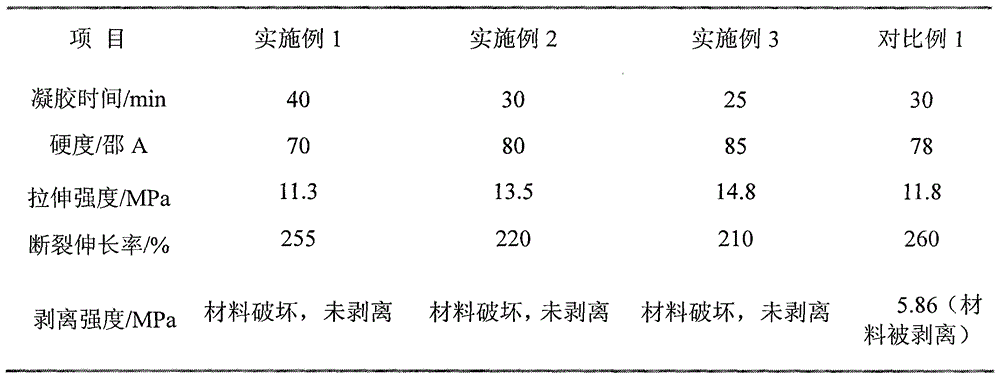

The invention discloses a polyurethane sealing material comprising the following components in parts by mass: 100 parts of isocyanate and 10-20 parts of a plasticizer in a component A, and 100 parts of epoxy hydroxyl-terminated polybutadiene, 5.5-7.9 parts of a chain extender, 20-35 parts f a plasticizer, 3-6 parts of a coupling agent, 0.2-0.5 part of a catalyst and 1.0-1.5 parts of a defoaming agent in a component B, wherein the ratio of B to A is 100:(20-29), the hydroxyl value of the epoxy hydroxyl-terminated polybutadiene is 0.8-2.0mmol / g, and the epoxy value is 1.5-3.5mmol / g. The material disclosed by the invention can be solidified at room temperature, is long in gelation time and good in flowability, has high bonding strength with metals particularly good bonding property with base materials of stainless steel and the like, and is especially suitable for encapsulation of large-scale internal structure complex components and cables. The polyurethane sealing material disclosed by the invention is prepared by adopting a one-step process, and the obtained material has hardness of 70-85A and is good in mechanical property.

Owner:LIMING RES INST OF CHEM IND

Epoxy resin composition for prepreg, carbon fiber prepreg and carbon fiber compound material

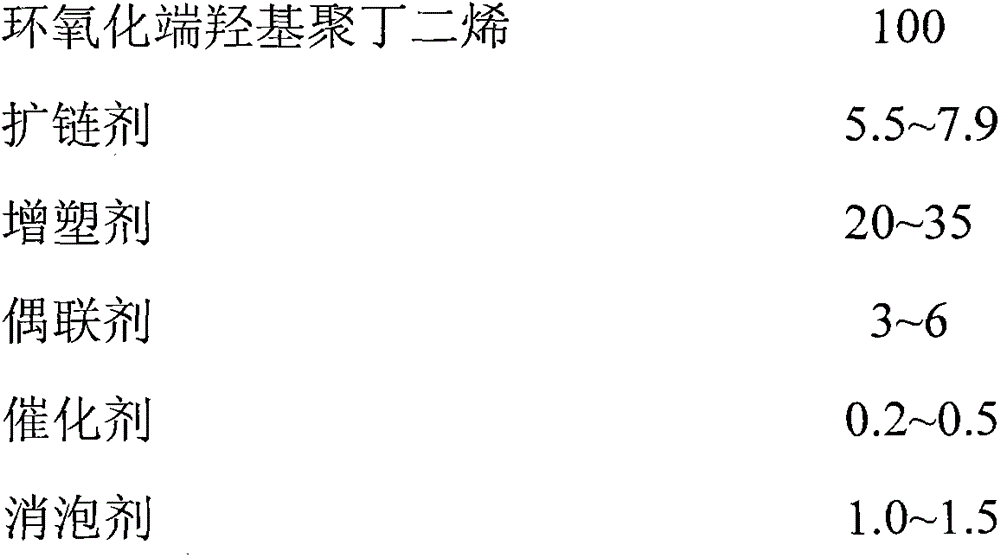

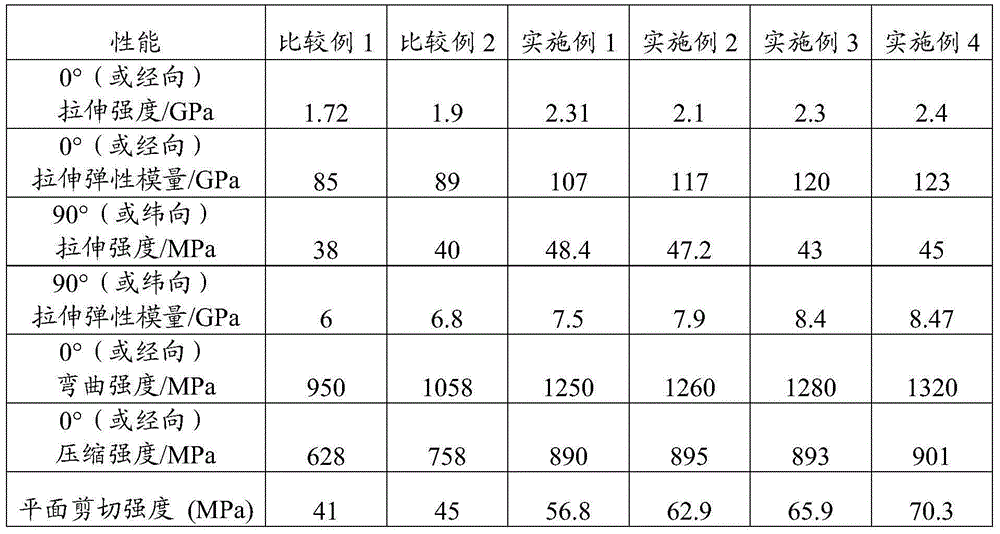

The invention provides an epoxy resin composition for prepreg. The epoxy resin composition comprises epoxy resins, modified epoxy resins and a curing agent; liquid rubber comprises one kind or several kinds of carboxyl nitrile liquid rubber, hydroxy-terminated copolybutadiene butyronitrile liquid rubber, hydroxy-terminated copolybutadiene polybutadiene liquid rubber, carboxyl terminated polybutadieneliquid rubber, hydroxyterminated copolybutadiene polyisoprene liquid rubber, carboxyl terminated polyisoprene liquid rubber, polyurethane modified liquid rubber, liquid silicon rubber and liquid polysulfide rubber. The liquid rubber is used for modifying an epoxy resin basal body, so that the binding force between a system for using epoxy resins as basal bodies, and a carbon fiber material interface is improved, and the mechanical property of the fibers is further improved. The invention further provides carbon fiber prepreg and a carbon fiber compound material. The stretching strength of the carbon fiber compound material provided by the invention at 0 degree (or in the radial direction) is 2.4GPa, the bending strength is 1320MPa, and the plane cutting strength is 70.3MPa.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Heat-resistant wear-resistant tear-resistant modified polyurethane rubber cable material

InactiveCN105694436AImprove wear resistanceImprove tear resistancePlastic/resin/waxes insulatorsPolymer scienceWear resistant

The invention discloses a heat-resistant wear-resistant tear-resistant modified polyurethane rubber cable material. The heat-resistant wear-resistant tear-resistant modified polyurethane rubber cable material is prepared from the following raw materials: modified polyurethane elastomer, neoprene, butyl rubber, ethylene propylene diene monomer, epoxy resin, ethyl acetate, polytetramethylene glycol, trimethylolpropane, polyethylene tetrahydrofuran ether glycol, hydroxyl-terminated polybutadiene, polycaprolactone glycol, MBOCA, hydroxyl-terminated butyl cyanide rubber, dibutyltin dilaurate, triethoxysilane, fumed silica, aluminum silicate, stearic acid, molybdenum disulfide, quartz powder, bentonite, zinc oxide, sulfur, accelerant M, anti-aging agent D, magnesium oxide, anti-aging agent 4040, hexanediol and chitosan. The modified polyurethane rubber cable material has excellent heat-resistant wear-resistant tear-resistant performance.

Owner:ANHUI DUJIANG CABLE GROUP

Polyurethane resin potting adhesive with high bonding strength and preparation method thereof

InactiveCN102643623AHigh bonding strengthGood adhesionOther chemical processesPolyureas/polyurethane adhesivesPolymer scienceAlcohol

The invention discloses a polyurethane resin potting adhesive with a high bonding strength, which is composed of a component A and a component B. The component A comprises castor oil and polyether polyatomic alcohol in parts by weight; the component B comprises hydroxyl-terminated polybutadiene, MDI (diphenylmethane diisocyanate), an accelerating agent and an additive; the molar ratio of hydroxyls of the hydroxyl-terminated polybutadiene to isocyanate radicals of the MDI is 0.06-0.25; and the MDI contains no less than 80 wt% of 4,4'-MDI and residues of isomerism homologues of the MDI or the modified MDI which contains no less than 80 wt% of the 4,4'-MDI isomer. The polyurethane resin potting adhesive disclosed by the invention has the high bonding strength and particularly has good bonding performance with plastic materials (PA66) including nylon and the like; and the polyurethane resin potting adhesive has good electric performance, lower inner stress and excellent heat impact resistance and is particularly suitable for potting and packaging electronic elements which have more demanding requirements on the inner stress, such as a reversing radar, a tire pressure monitor and the like.

Owner:ELANTAS ZHUHAI CO LTD

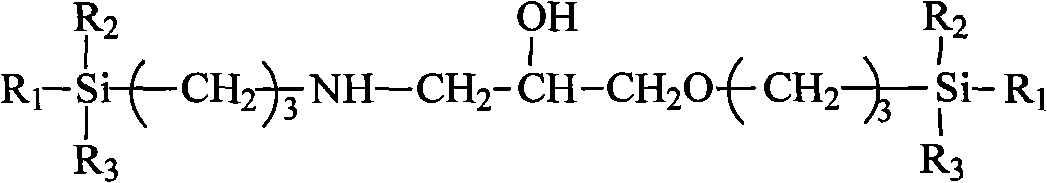

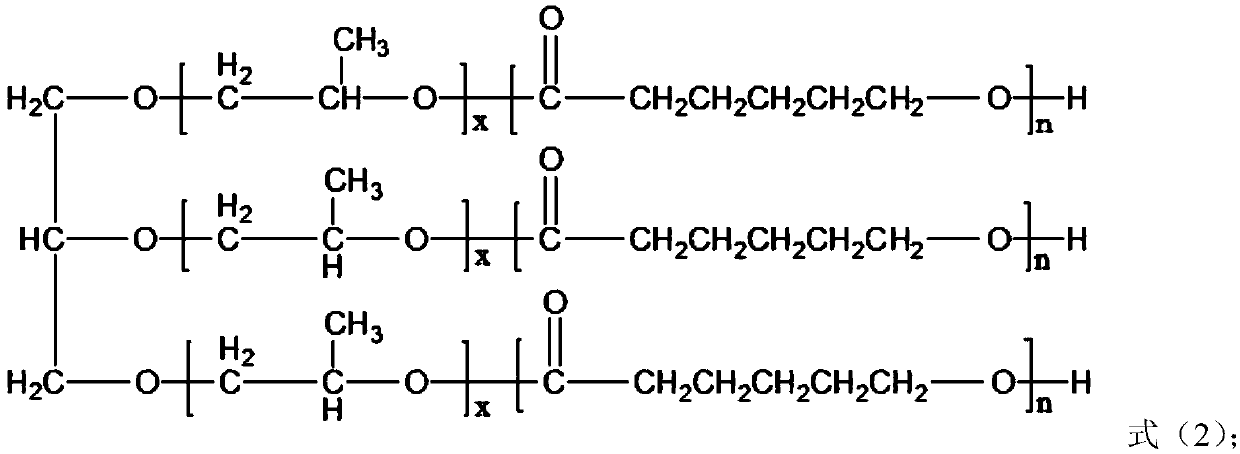

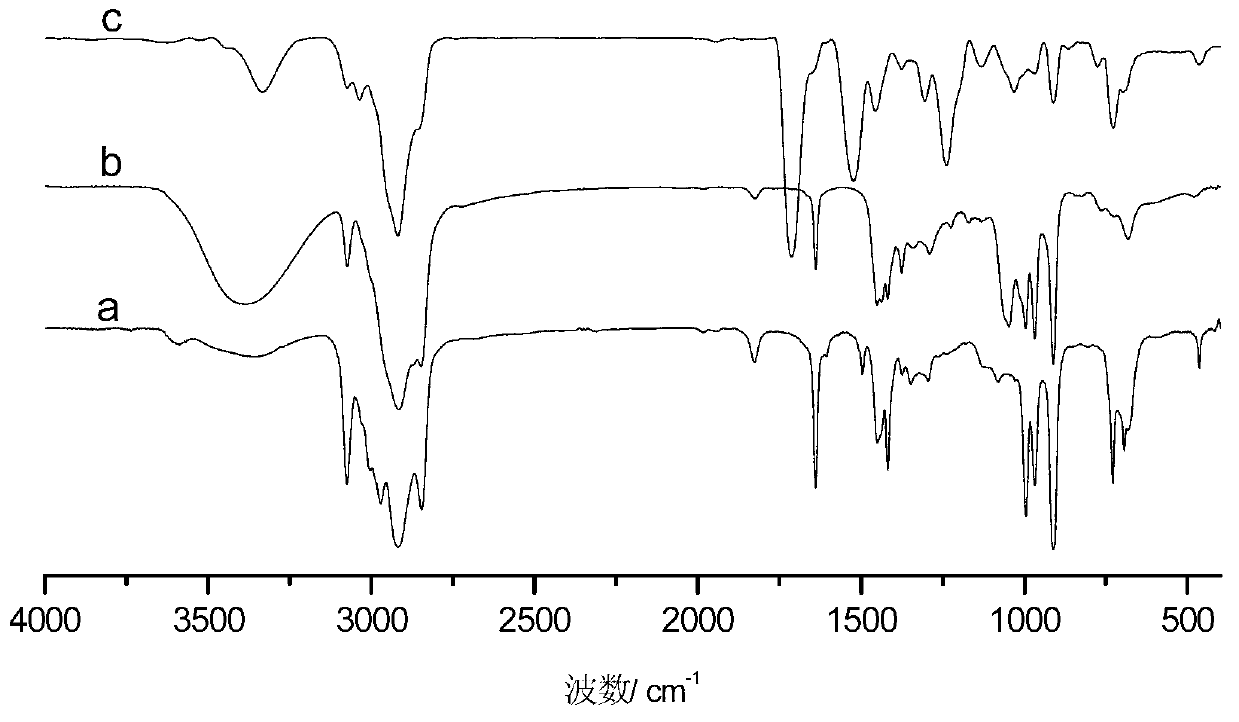

Light-cured resin with low water absorption and preparation method thereof

InactiveCN102010494ALow water absorptionReduce manufacturing costUrethane acrylateHydroxyl-terminated polybutadiene

The invention relates to a light-cured resin with low water absorption and a preparation method thereof. The light-cured resin is silicane modified hydroxyl-terminated polybutadiene type urethane acrylate. The preparation method comprises the following steps of: 1) reacting an epoxy silicane coupling agent with a primary amine silicane coupling agent to generate a modified silicane chain extender; 2) reacting hydroxyl-terminated polybutadiene with diisocyanate to generate polyurethane prepolymer 1; 3) reacting the modified silicane chain extender with the polyurethane prepolymer 1 to generate polyurethane prepolymer 2; and 4) reacting the polyurethane prepolymer 2 with hydroxyl acrylate to generate the silicane modified hydroxyl-terminated polybutadiene type urethane acrylate.

Owner:YANTAI DARBOND TECH

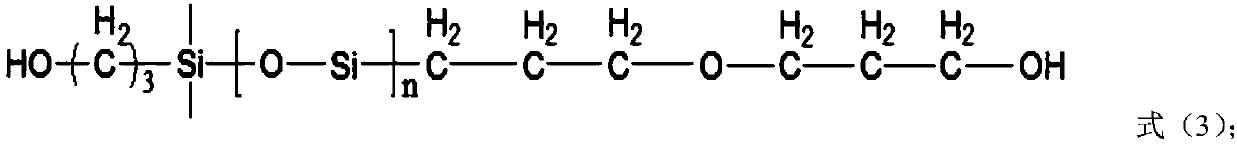

Polyurethane damping cushion with high cold resistance and preparation method thereof

ActiveCN107602817ADisruption of regularityImprove low temperature performanceSide reactionCaprolactone

The invention provides a polyurethane damping cushion with high cold resistance and a preparation method thereof. The polyurethane damping cushion is prepared in the manner of crosslinking a componentA with a component B; the component A is a polyalcohol composition and comprises the following raw materials: caprolactone modified polyether polyol, polyether polyol, hydroxyl terminated polybutadiene, primary hydroxyl terminated siloxane, a chain extender, a catalyst, a foam stabilizer and a foaming agent; the component B is NCO-terminated isocyanate prepolymer and comprises the following raw materials: caprolactone modified polyether polyol, 4,4-diphenylmethane diisocyanate and a side reaction inhibitor. The polyurethane damping cushion with high cold resistance prepared according to the invention has excellent damping property, excellent dynamic fatigue resistance and obviously improved low-temperature performance and can be applied to the field of construction of the Moscow-Kazan high-speed rails and the rails in cold areas, such as, Northern Europe and Siberia and the field of automobile damping in extreme cold areas.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

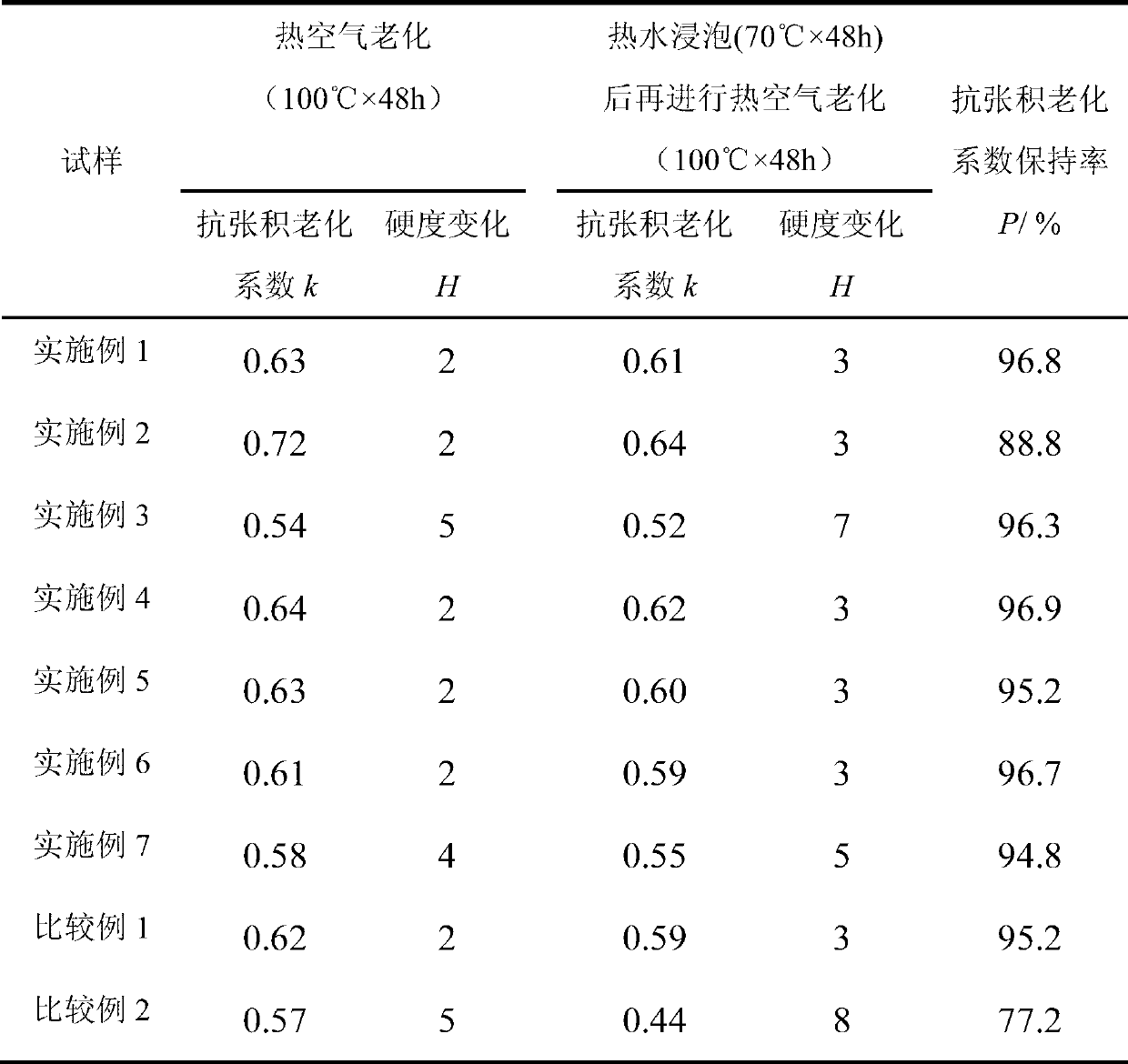

Macromolecule hindered phenol antioxidant, preparation method of macromolecule hindered phenol antioxidant, and application of macromolecule hindered phenol antioxidant

InactiveCN103130978AExcellent thermal and oxidative aging resistanceImprove performanceThiolDouble bond

The invention discloses a macromolecule hindered phenol antioxidant, a preparation method of the macromolecule hindered phenol antioxidant, and application of the macromolecule hindered phenol antioxidant. Under the action of thermal initiators, a sulfydryl-alkene click reaction is generated between sulfydryl in functional mercaptan and double bonds in hydroxyl-terminated polybutadiene under the temperatures of 50-70 DEG C to prepare sulfur-containing polyhydroxy polybutadiene; then under the temperatures of 30-50 DEG C, hydroxy in the sulfur-containing polyhydroxy polybutadiene reacts with secondary-position isocyanato in isophorone diisocyanate to obtain additive products secondary-position isocyanato-containing isocyanato; and then under the temperatures of 60-80 DEG C, the additive products react with bisphenols antioxidant to prepare the macromolecule hindered phenol antioxidant. The macromolecule hindered phenol antioxidant is good in thermo-oxidative aging performance, high in efficiency, and good in anti-extraction performance, and can be widely used in anti-aging of materials such as rubber and plastic.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing high performance urethane elastomer for thermal barrier coating

ActiveCN101358030AIncrease elasticityFriction-resistantPolyurea/polyurethane coatingsPolymer scienceThermal insulation

The invention provides a preparation method of a thermal insulation coating high-performance polyurethane elastomer. After the reaction of terminal hydroxyl polybutadiene liquid rubber and polyisocyanate, polyurethane is added for reaction for 3 to 4.5 hours at 85 to 90 DEG C to produce isocyanate-terminated prepolymer; a certain amount of heat insulating filler is added in the prepolymer and is mixed evenly to produce component A; chain extender, antioxidant, curing agent and solvent are mixed evenly according to a certain portion to produce component B; the component A and the component B with the weight portion of 3: 1 to 6: 1 are mixed, stirred evenly, cured at room temperature to produce the thermal insulation coating high-performance polyurethane elastomer. The process of the invention used to synthesize the thermal insulation coating high-performance polyurethane elastomer is more reasonable, the product has higher quality and better comprehensive properties. The test date shows that the tensile strength is 3.50 to 5.80MPa, the elongation at break is more than 220 percent, the bond strength is more than 10.0MPa, the glass transition temperature is less than 60 DEG C below zero, the solidification shrinkage rate is less than 0.1 percent. The product is mainly applicable to aerospace industry.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

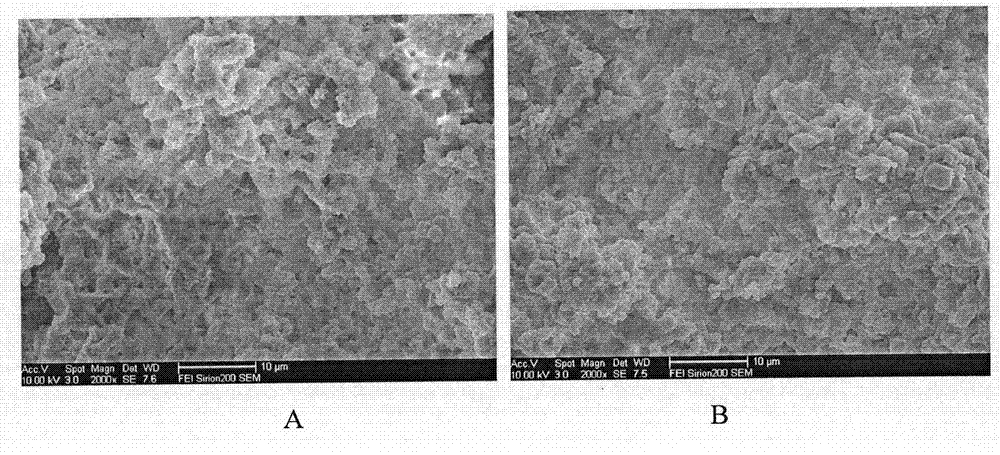

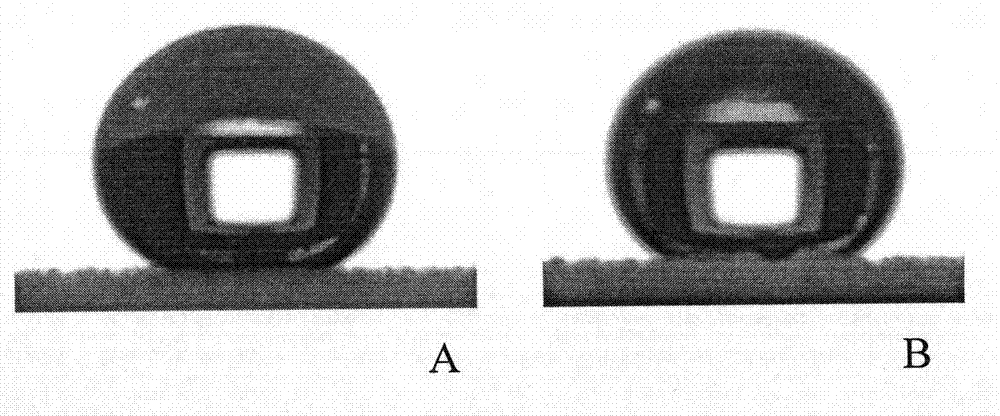

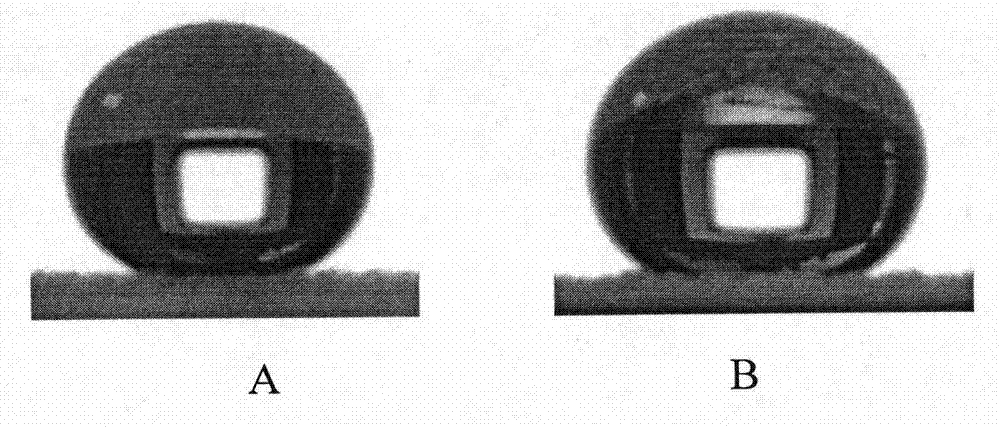

Preparation method of composite superhydrophobic coating possessing abrasion-resistance performance

InactiveCN104327703AWear-resistantImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsEthylenediamineEpoxy

The invention relates to a preparation method of a composite superhydrophobic coating possessing abrasion-resistance performance, which comprises the following steps: 1)performing prepolymerization on hydroxyl terminated polybutadiene and toluene diisocyanate at 70 DEG C for 1 hour to synthesize to obtain a polyurethane performed polymer, mixing the polyurethane performed polymer and acetone and diluting to a polyurethane performed polymer solution; 2)under the condition of 300-500r / minute of the stirring speed, adding the polyurethane performed polymer solution drop by drop in an acetone solution of ethene diamine, performing chain extension to obtain polyurethane sol; and 3)adding epoxy resin E-44, amino silicon oil and diethylenetriamine to polyurethane sol to form a spraying liquid, spraying the spraying liquid on a matrix, and forming a microscopic ordered dimpling structure which is the composite superhydrophobic coating on the surface after solidification. The method has the advantages of simple process and easy construction, the obtained composite superhydrophobic coating has excellent abrasion resisting performance after abrasion resistance test according to American material and test association standard (ASTM) D-968-05.

Owner:山东天汇防水股份有限公司

Synthesis of liquid end hydroxy styrene-butadiene rubber

The present invention relates to the synthesis of end hydroxy styrene-butadiene liquid rubber, and is especially the free radical polymerization of butadiene monomer and styrene monomer inside organic ketone or C1-C6 organic alcohol solvent in the presence of organic peroxide as initiator. The present invention features the polymerization mode with batchwise added material. The end hydroxy styrene-butadiene liquid rubber of the present invention has high molecular weight, narrow molecular weight distributing range, functionality near 2, copolymerized chain segment of butadiene and styrene in the multi-molecular chain, and excellent comprehensive product performance. The product may be used in solid tyre, polyurethane adhesive, solid rubber plasticizer, elastic polyurethane material, and other fields.

Owner:BC P INC CHINA NAT PETROLEUM CORP

Method for synthesizing liquid rubber-epoxy resin polymer

Using the fluid rubber of acrylonitrile-polybutadiene end-capped with hydroxy and the multi-isocyanate to react and then the prepolmer of acrylonitrile fluid rubber end-capped with isocyanate was obtained; using the fluid rubber of polybutadiene end-capped with hydroxy and the multi-isocyanate to react and then the prepolymer of polybutadiene fluid rubber end-capped with isocyanate was obtained. According to the ratio of 10-40 / 90-60, the above two prepolymers were mixed, and then the mixed prepolymer was obtained. The optimum multi-isocyanate are TDL and MDI. The fluid bisphenol epoxy resin with the style A and the flexible epoxy resin were matched pair again according the ratio of 80-50 / 20-50. The built-epoxy resin then obtained. followed by the reaction between the isocyanate in the mixed prepolymer and the hydroxyl in the built-epoxy resin, so as to lead the fluid rubber in the built-epoxy resin by the form of chemical bonding. Finally, the polymer of fluid rubber- epoxy resin was obtained.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Polyester-rubber composite tyre and its production method

ActiveCN1788970AReduce distortionIncrease elasticitySpecial tyresTyresPolyesterManufacturing technology

The present invention relates to compound tyre producing technology, and is especially one kind of compound polyurethane-rubber tyre and its production process. The compound polyurethane-rubber tyre has optimized and modified recipe of polyurethane of oligomer polyhydric alcohol / tetrafuran-propylene oxide copolymer-p-phenylenediisocyanate system and polyurethane of oligomer polyhydric alcohol / hydroxy-eliminated polybutadiene-diphynel methane diisocyanate system; tyre surface treatment; and casting to form the green tyre in compound structure. The compound tyre has less heat produced during running, high heat resistance, applicability to high speed running and long service life as well as simple production process and low cost.

Owner:BESTIRE XINXING NEW MATERIAL TECH CO LTD

Preparation of organic silicon modified polyurethane elastic body and application thereof

The invention relates to an organic silicon modified polyurethane elastic body composition which comprises the following components (in parts by weight): 100 parts of polyurethane prepolymers, 5-20 parts of HTPB (Hydroxyl-Terminated Polybutadiene), 5-25 parts of HTLN, 3-15 parts of poly-dimethyl siloxane, 0.1-1.0 part of catalyst, 3-10 parts of solidifying agents and 0-30 parts of solvents. The invention also relates to a method for preparing the organic silicon modified polyurethane elastic body, which comprises the following steps of: reacting the composition not containing the solidifying agents for 3-6h at 80-120 DEG C by stirring at a high speed (1000-5000rpm) in a nitrogen atmosphere, and removing the solvents and other micromolecules in a vacuum state; then adding the solidifying agents, uniformly stirring and mixing at the high speed, injection molding, pre-solidifying for 1-2 days at a room temperature, and then solidifying for 4-7 days at 55-65 DEG C. The synthesized organic silicon modified polyurethane elastic body has the advantages of favorable wear resistance, high elasticity and excellent weather-resistance and moist heat-resistance stability.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com