Preparation of organic silicon modified polyurethane elastic body and application thereof

A polyurethane elastomer, polyurethane prepolymer technology, applied in mechanical equipment, engines, wind turbines and other directions, can solve the problems of poor aging resistance, delay, low, only 2.2 ~ 4.2MPa, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

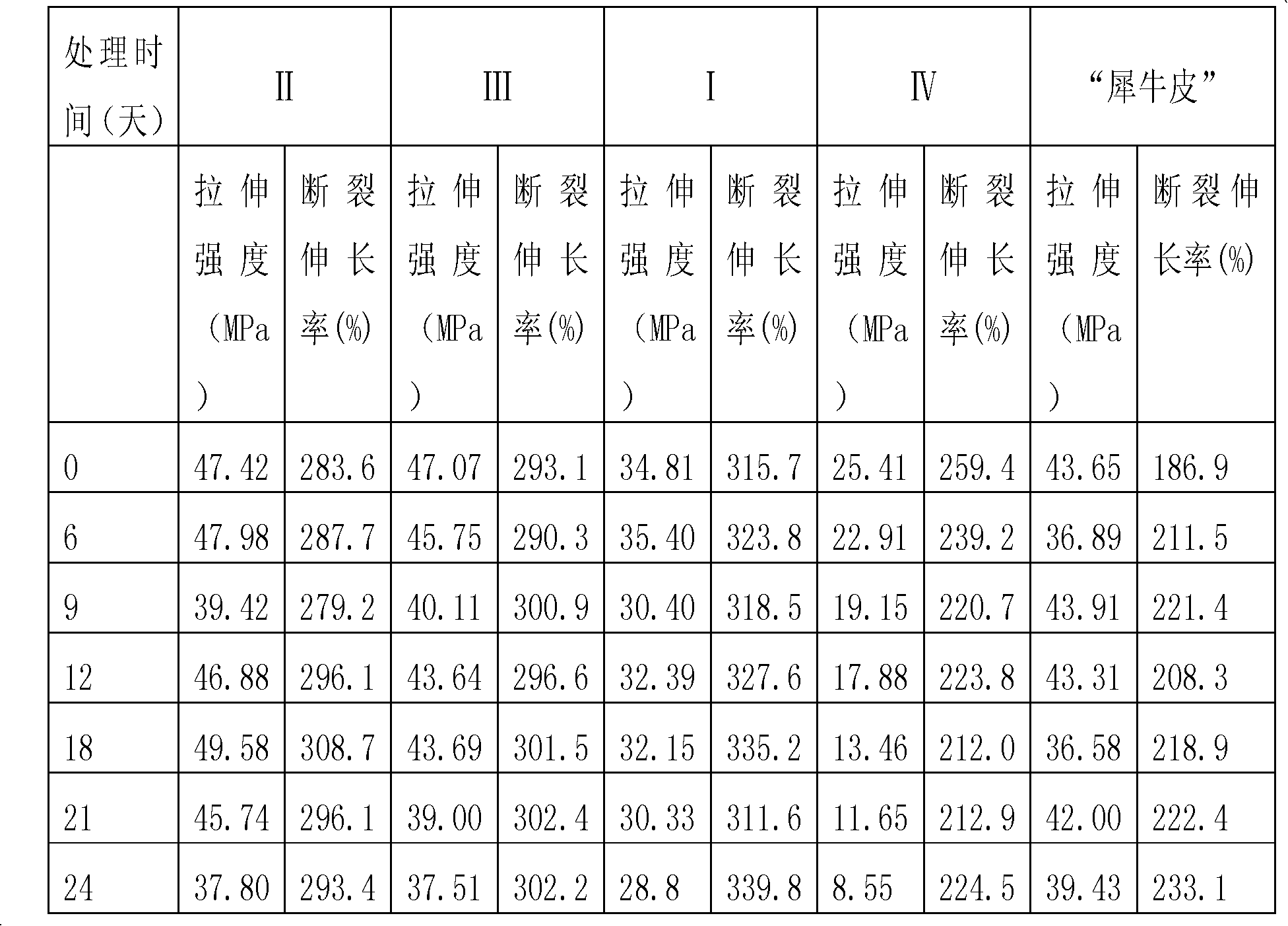

[0019] Synthesis of Example 1 Silicone Modified Polyether Polyurethane Elastomer (I)

[0020] In a closed reactor under nitrogen protection, under stirring at a rate of 2000rpm, add the following components (parts by mass) in sequence: polyether polyurethane prepolymer [tensile strength (MPa) > 25, Shore A hardness of 90 ±2, elongation at break (%) > 350, tear strength (KN / M) > 50, brittle temperature (°C) 3 ), the reaction was continued for 2h at 85±2°C and 1600rpm with stirring. Lower the temperature to 50° C., and vacuum to 50 mmHg to remove solvents and small molecular compounds. Then add 5 parts by mass of MOCA, and stir for 20 min at a rate of 1600 rpm. Injection molded in a Teflon mold, pre-cured at room temperature for 2 days, and then cured at 55-65°C for 5 days.

Embodiment 2

[0021] Synthesis of Example 2 Silicone Modified Polyether Polyurethane Elastomer (II)

[0022] Prescription and experimental operation are with embodiment 1, and difference is the polyether type polyurethane prepolymer of application following technical parameter: tensile strength (MPa)>38, Shore A hardness is 92 ± 1, elongation at break (% )>430, tear strength (KN / M)>90, brittleness temperature (°C)<-50.

Embodiment 3

[0023] Synthesis of Example 3 Silicone Modified Polyester Polyurethane Elastomer (Ⅲ)

[0024] Prescription and experimental operation are with embodiment 1, and difference is the polyether type polyurethane prepolymer of application following technical parameter: tensile strength (MPa)>45, Shore A hardness is 85 ± 2, elongation at break (% )>550, tear strength (KN / M)>75, brittle temperature (°C)<-30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com