Preparation method of phenolic hydroxyl group containing polyimide powder

A technology of phenolic hydroxyl polyimide containing phenolic hydroxyl groups, which is applied in the field of preparation of high-temperature-resistant high-performance aromatic heterocyclic polymer powders, can solve the problems of difficult wastewater treatment, strong pungent odor, and high production costs, and achieve effective Conducive to environmental protection, easy solvent recovery, and product cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

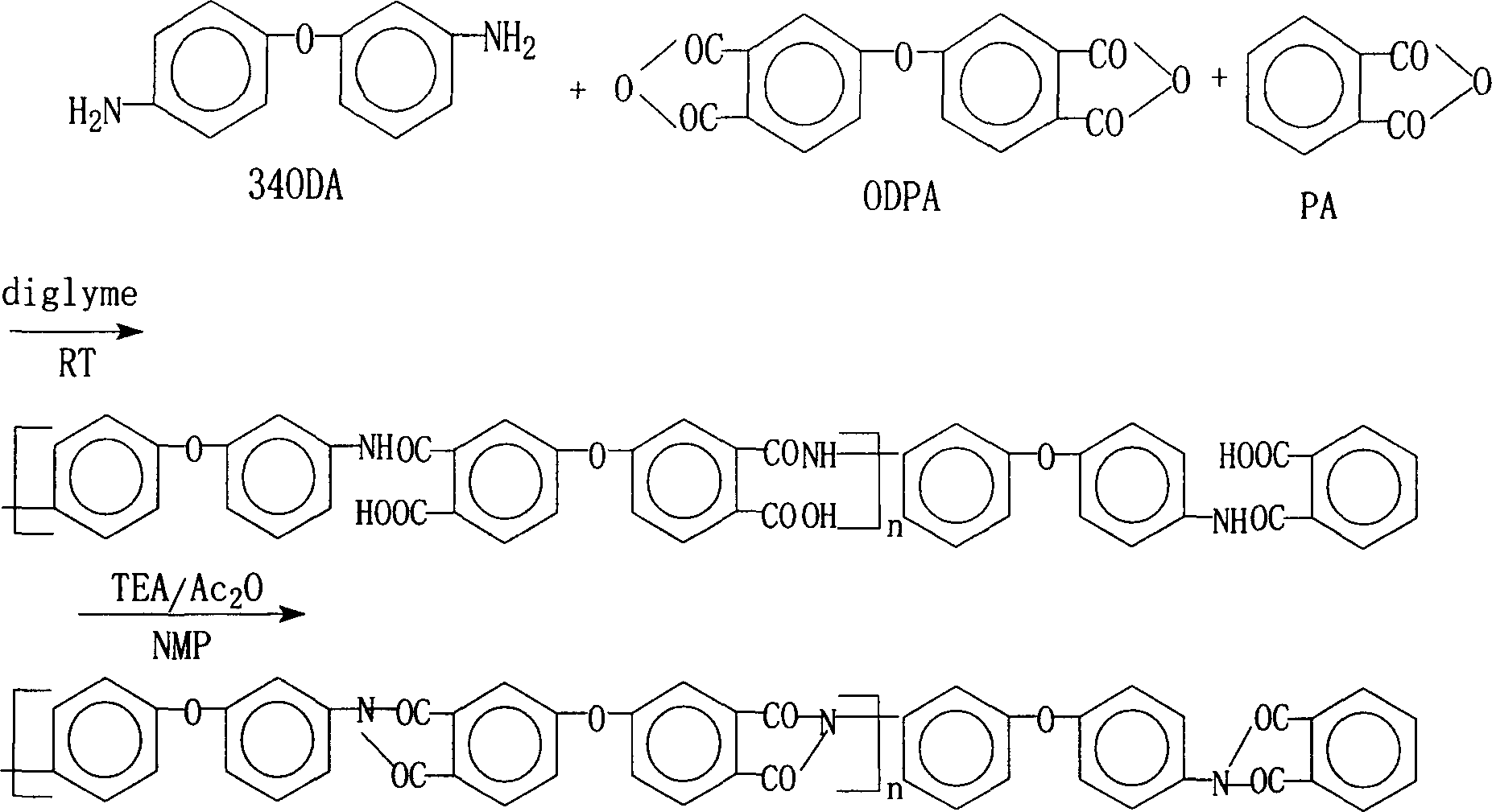

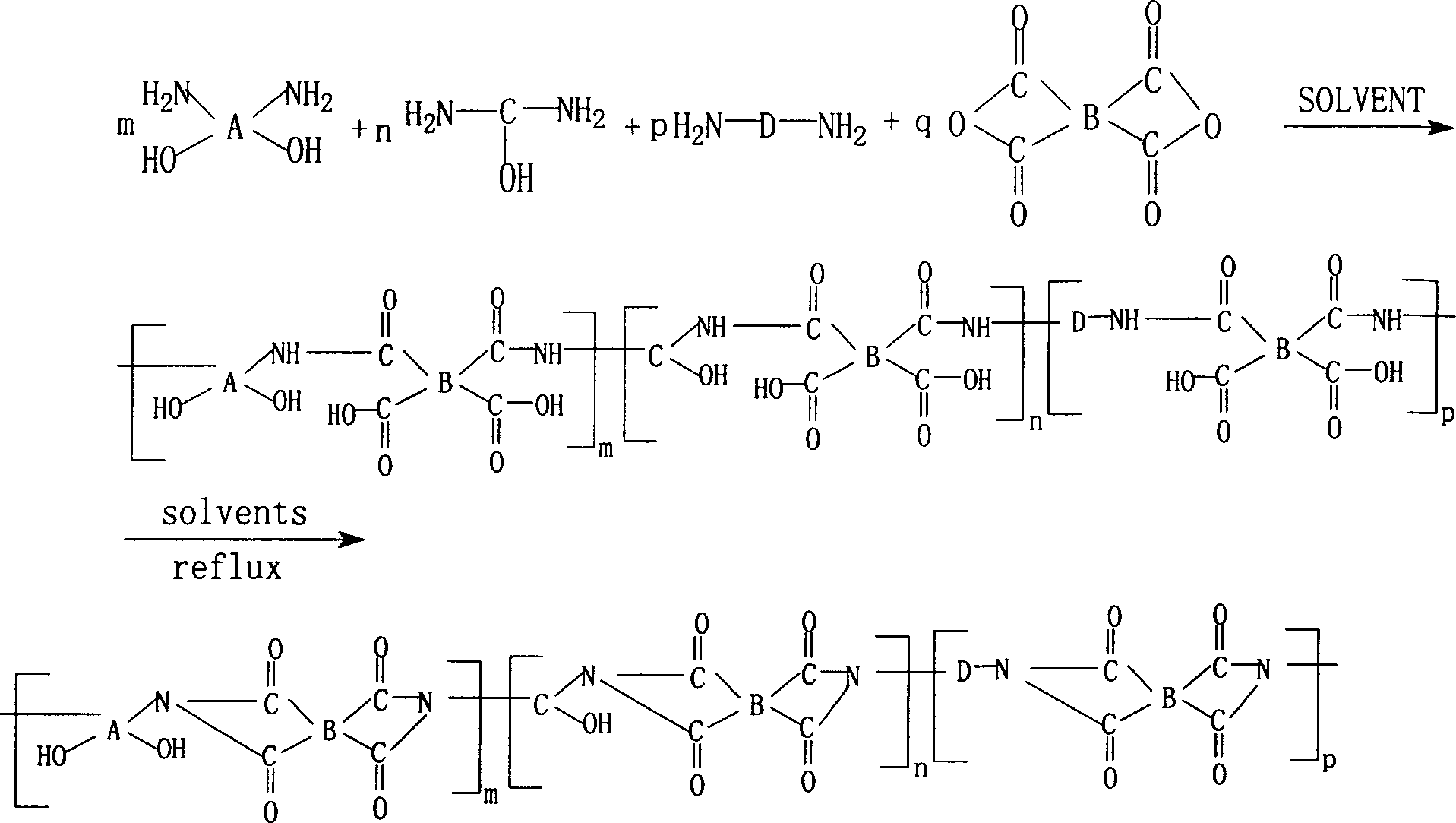

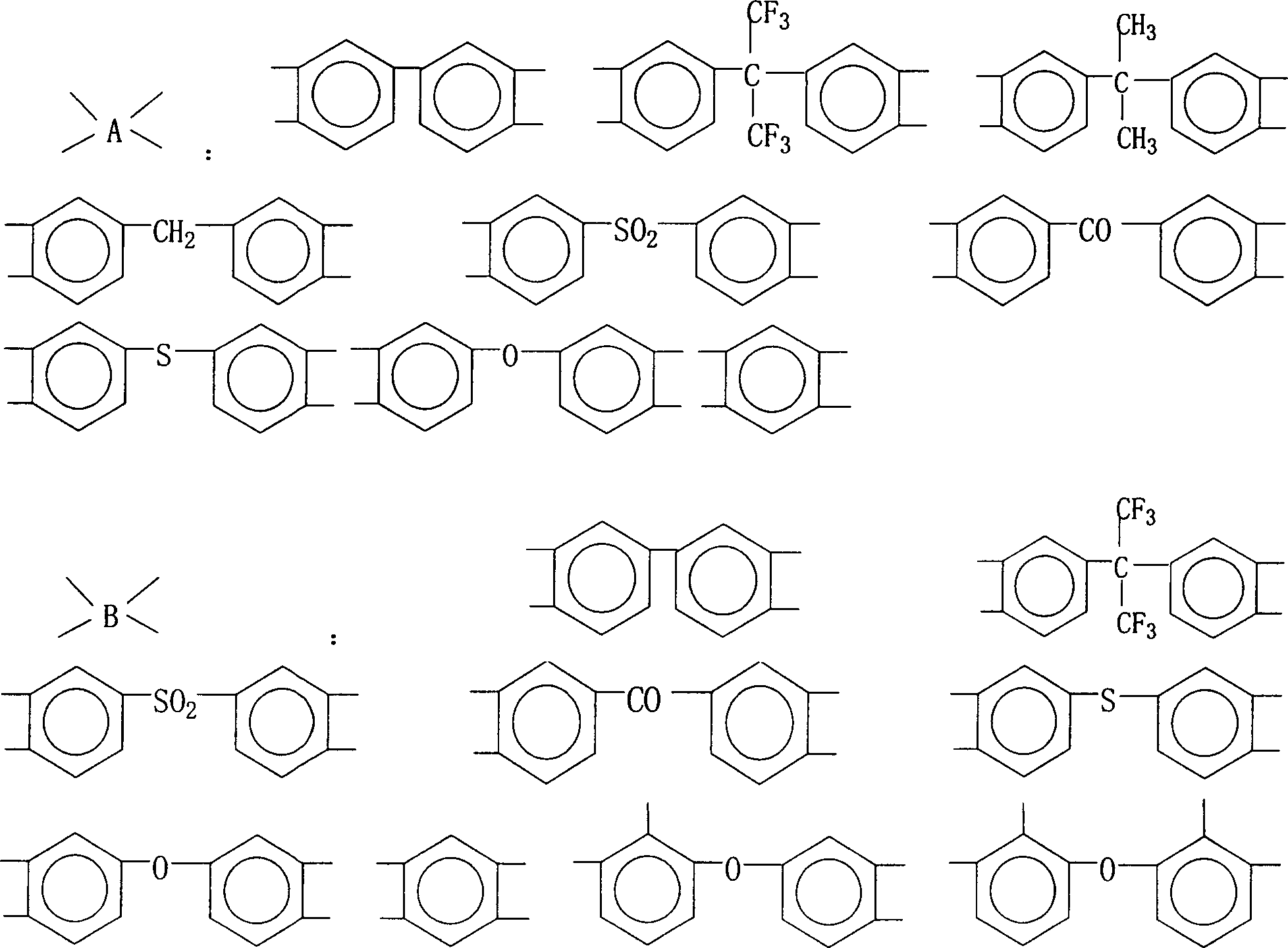

Method used

Image

Examples

Embodiment 1

[0029] Add 25.8 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl) propane (B3A4HPP) into the polymerization bottle, add 400 milliliters of N-methyl-2-pyrrolidone (NMP), and feed Nitrogen, cooled to 5°C in an ice-water bath, stirred to make it completely dissolved, then added 21.8 grams (0.1 moles) of pyromellitic dianhydride (PMDA) powder, stirred and reacted for 3 hours, and viscous poly-o-hydroxyamide was obtained acid solution. Subsequently, nitrogen gas was introduced, 40 ml of toluene was added, the temperature was raised to reflux, and the temperature was maintained at 140° C. for 18 hours. A yellow solid powder was precipitated in the reaction flask, the heating system was turned off, stirred rapidly, cooled to room temperature naturally, filtered and washed to obtain polyimide powder containing phenolic hydroxyl groups. There is an obvious OH absorption peak in the infrared spectrum absorption spectrum (3400cm -1 ), the characteristic absorption peak of the imine...

Embodiment 2

[0031] Add 25.8 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl)propane (B3A4HPP) into the polymerization bottle, add 450 milliliters of N-methyl-2-pyrrolidone (NMP), and feed Nitrogen, ice-water bath cooling to 5 ° C, stirring, to make it completely dissolved, add 10.9 grams (0.05 moles) pyromellitic dianhydride (PMDA) powder and 14.7 grams (0.05 moles) 3,3',4,4' - Tetraformic acid biphenyl dianhydride (BPDA) powder, after stirring and reacting for 3 hours, a viscous poly-o-hydroxyamic acid solution was obtained. Subsequently, nitrogen gas was introduced, 500 ml of toluene was added, the temperature was raised to reflux at 160°C, and after keeping for 5 hours, part of the toluene was distilled off. A yellow solid powder was precipitated in the reaction flask, the heating system was turned off, stirred rapidly, cooled to room temperature naturally, filtered and washed to obtain polyimide powder containing phenolic hydroxyl groups.

Embodiment 3

[0033] 12.9 g (0.05 mol) of 2,2-bis(3-amino-4-hydroxyphenyl)propane (B3A4HPP) and 18.3 g (0.05 mol) of 2,2-bis(3-amino-4-hydroxyphenyl) -1,1,1,3,3,3-hexafluoropropane (B3A4HPFP) was added to the polymerization bottle, 400 ml of N,N-dimethylacetamide (DMAc) was added, nitrogen gas was introduced, and the ice-water bath was cooled to 0 ℃, stirring, after making it completely dissolved, add 10.9 (0.05 mol) gram of pyromellitic dianhydride (PMDA) powder and 14.7 gram (0.05 mol) of 3,3',4,4'-tetracarboxylic biphenyl dianhydride (BPDA) powder, after stirring and reacting for 12 hours, a viscous poly-o-hydroxyamic acid solution was obtained. Subsequently, nitrogen gas was introduced, 600 ml of toluene was added, the temperature was raised to reflux, and after being kept at 120° C. for 5 hours, part of the toluene was distilled off. A yellow solid powder was precipitated in the reaction flask, the heating system was turned off, stirred rapidly, cooled to room temperature naturally, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com