Patents

Literature

1285 results about "Aromatic diamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel metallic compositions

InactiveUS7071287B2Reduce nitrogen contentSuperior physical and electrical propertyMaterial nanotechnologyCell electrodesImidePolymer science

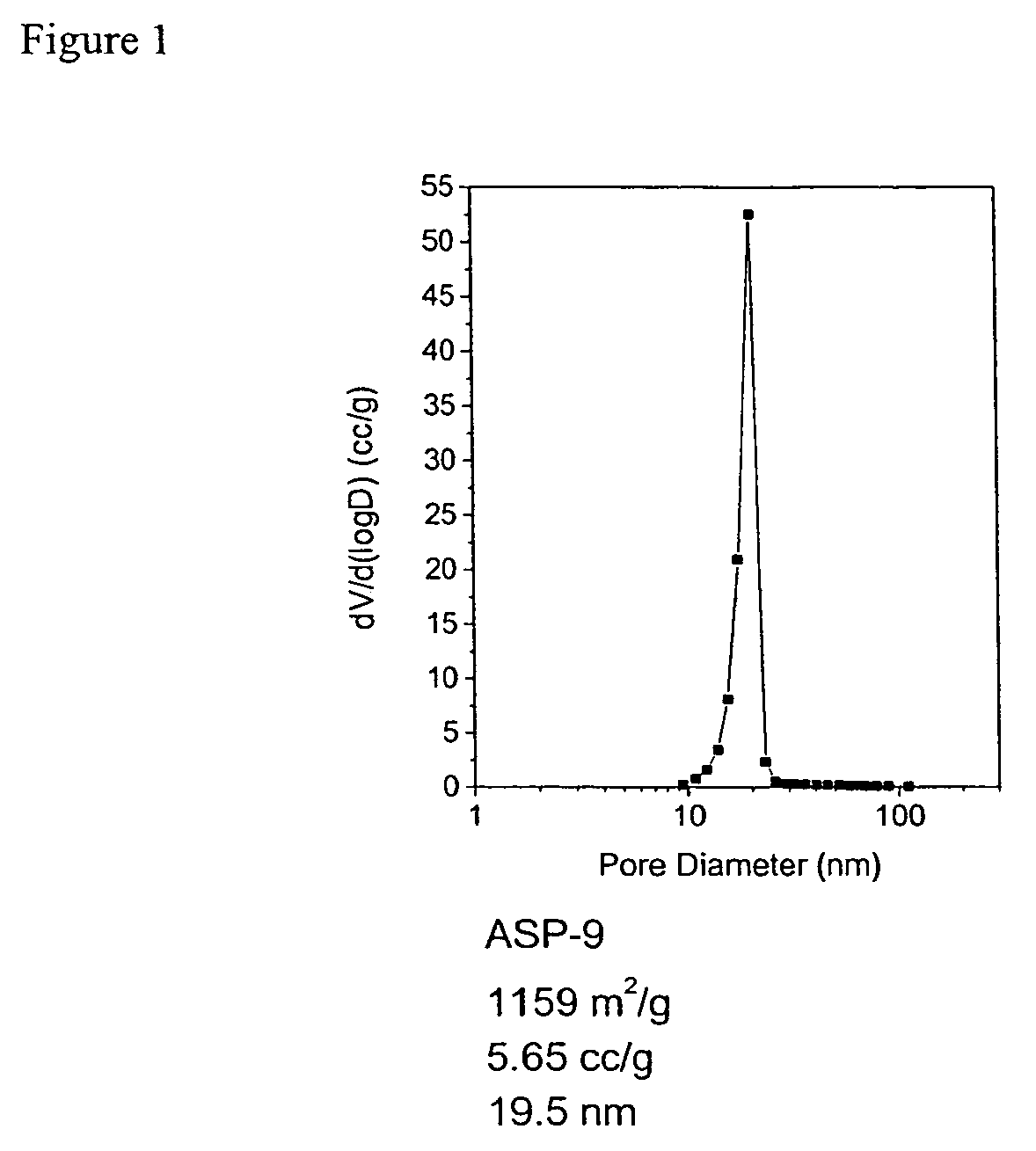

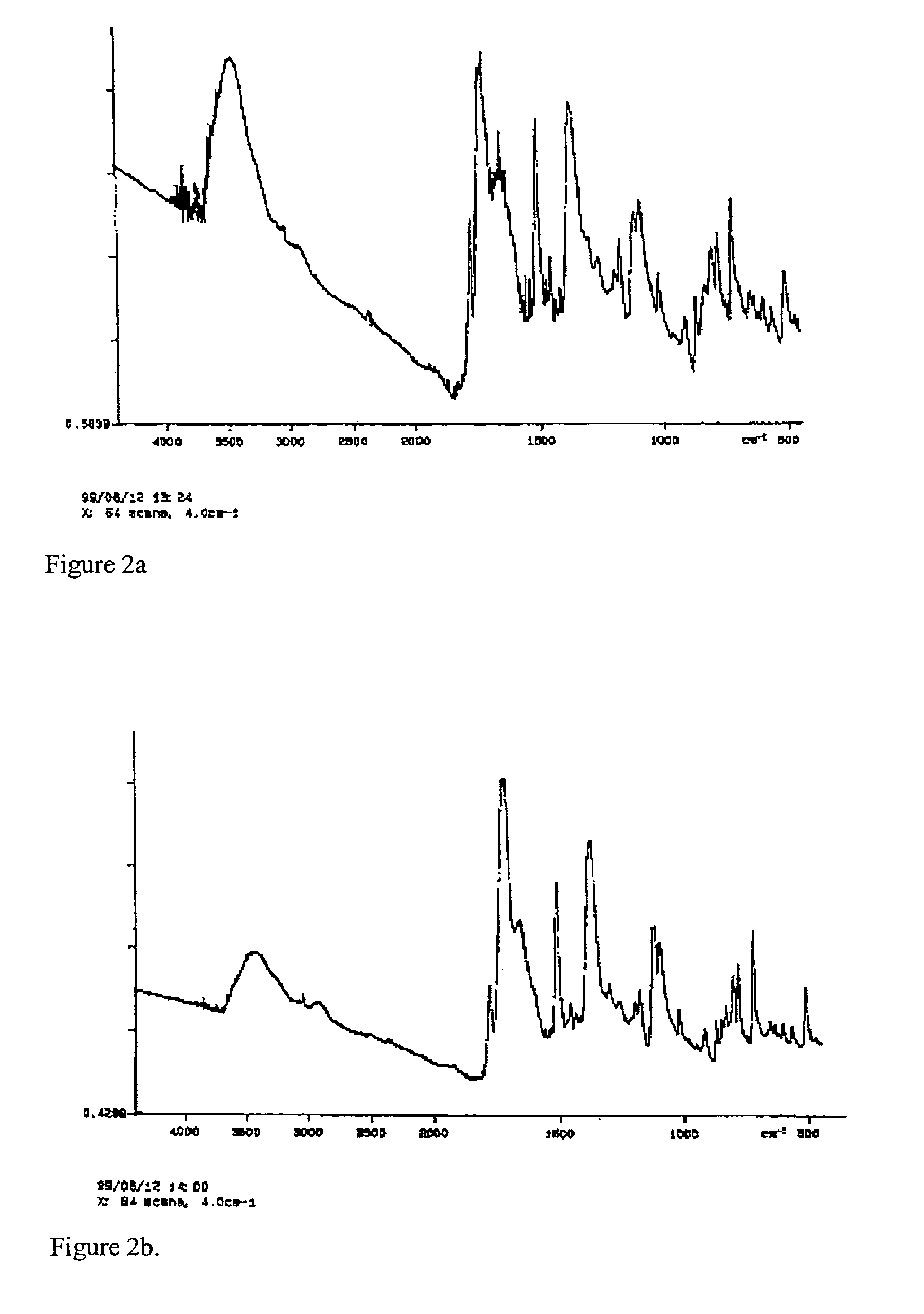

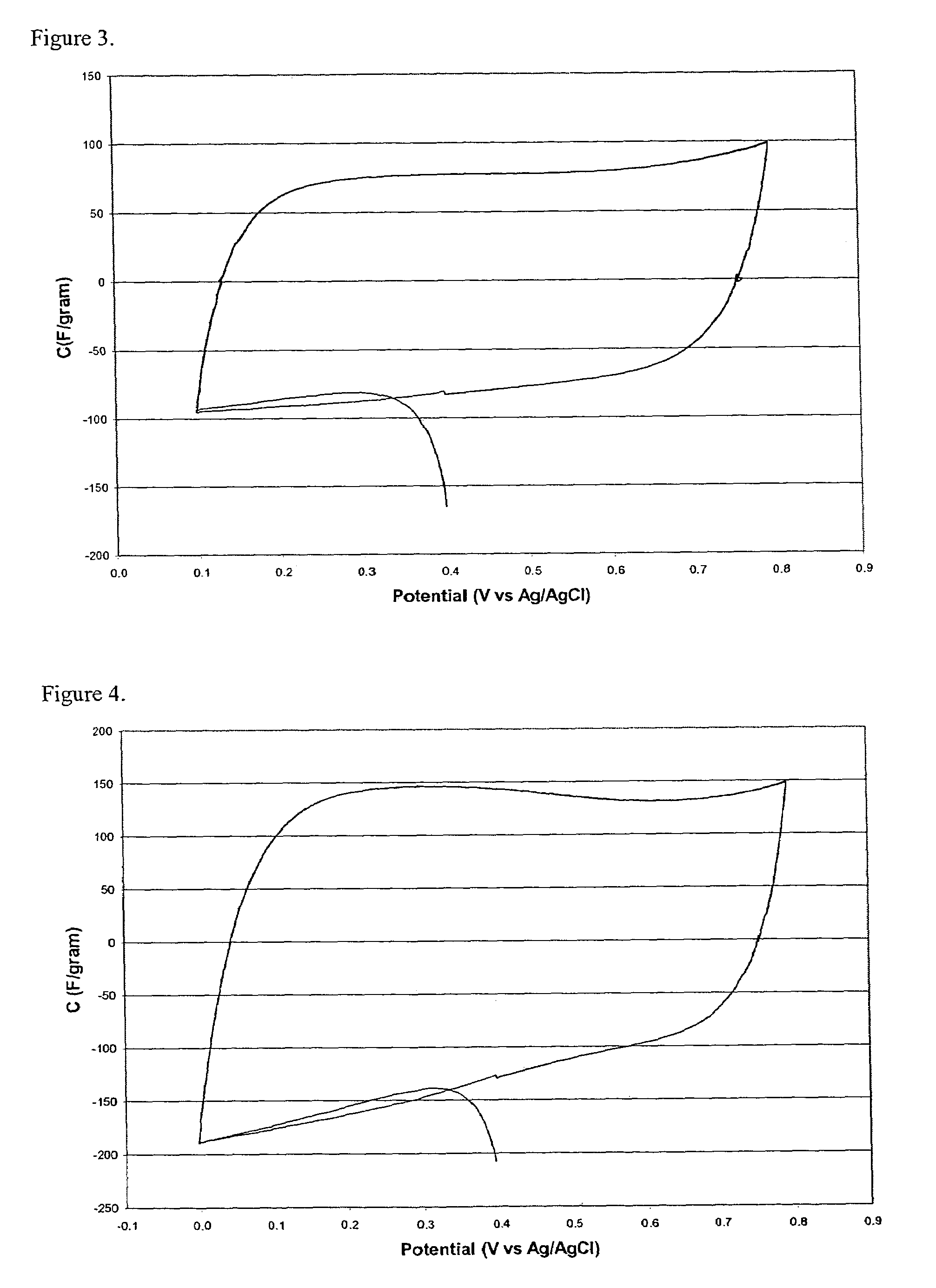

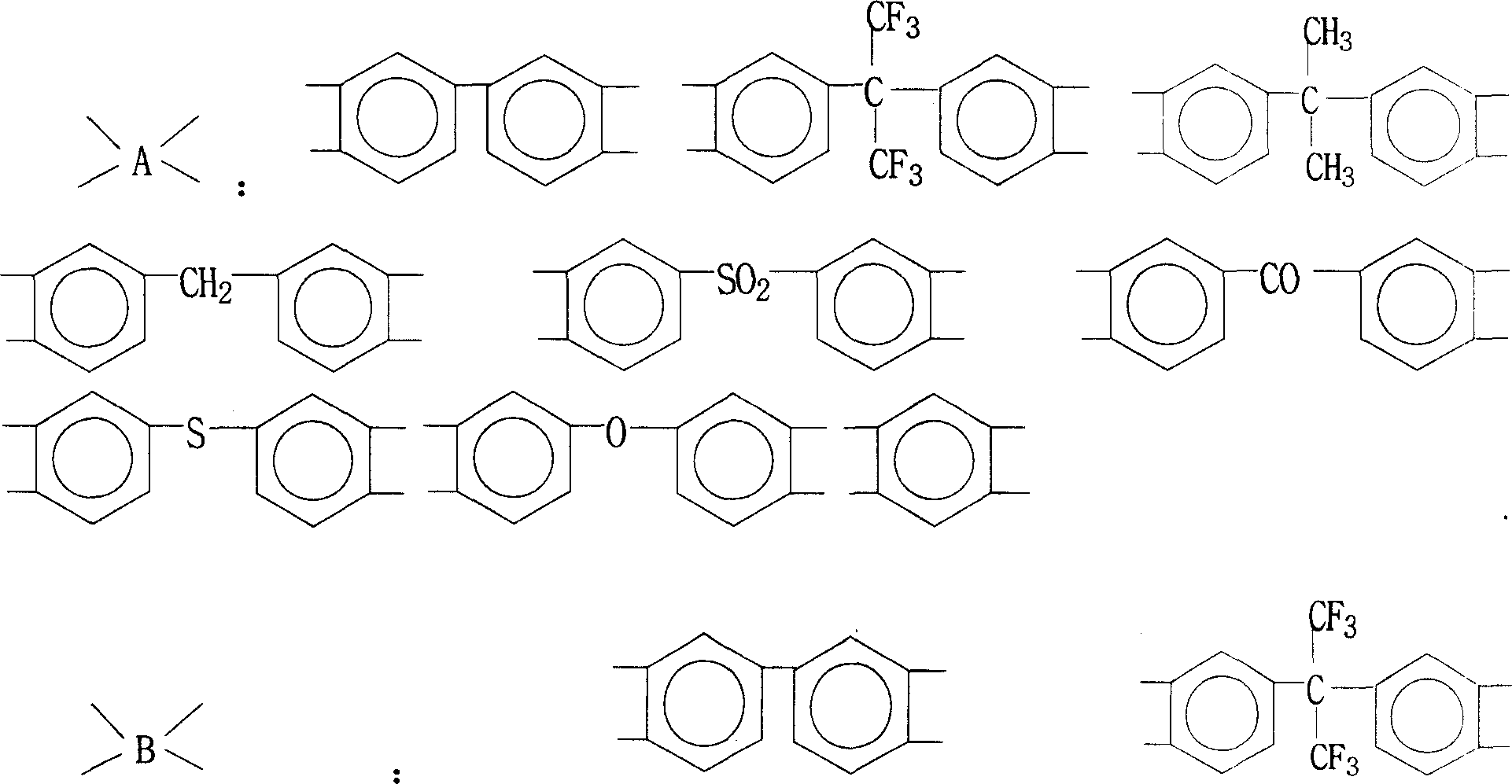

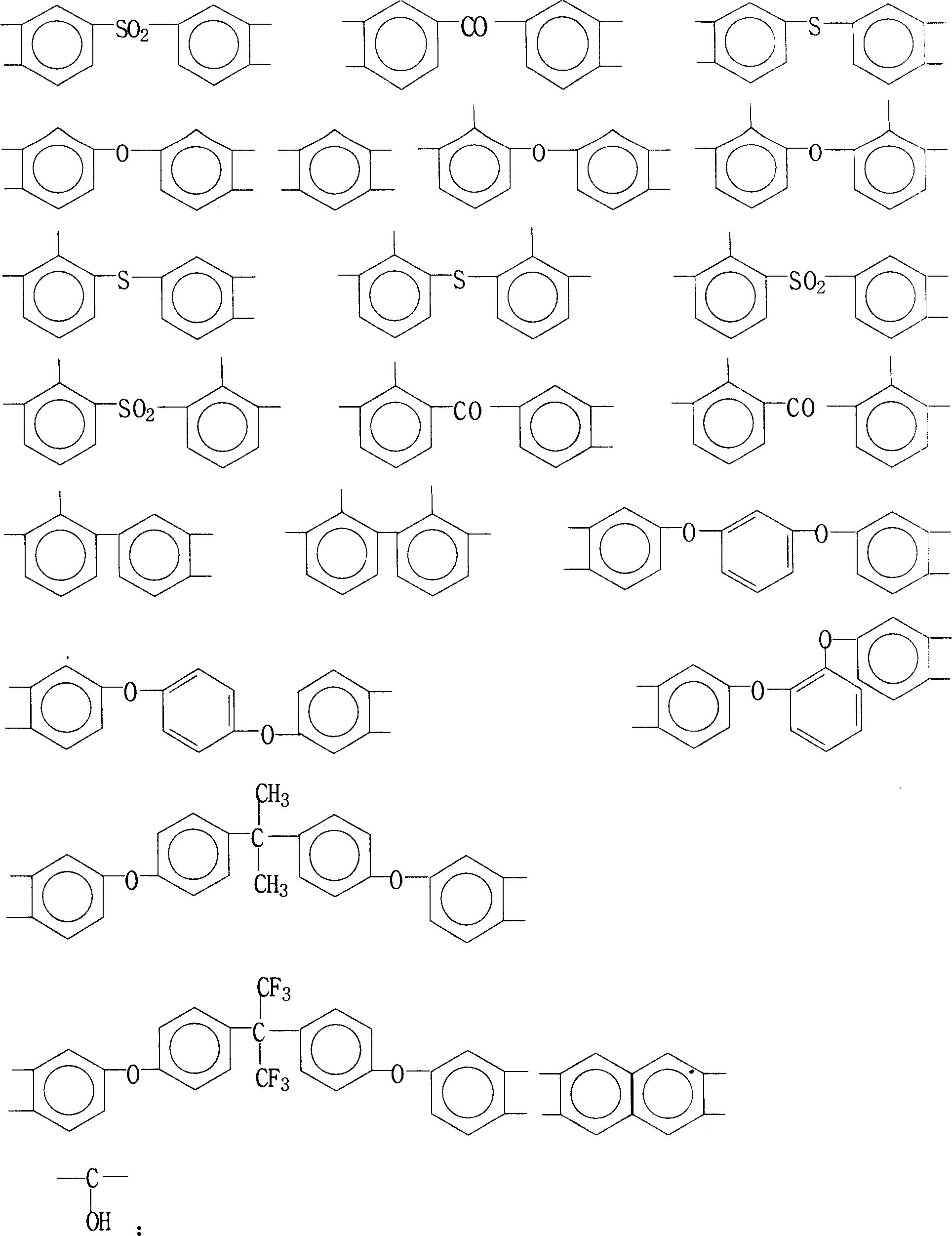

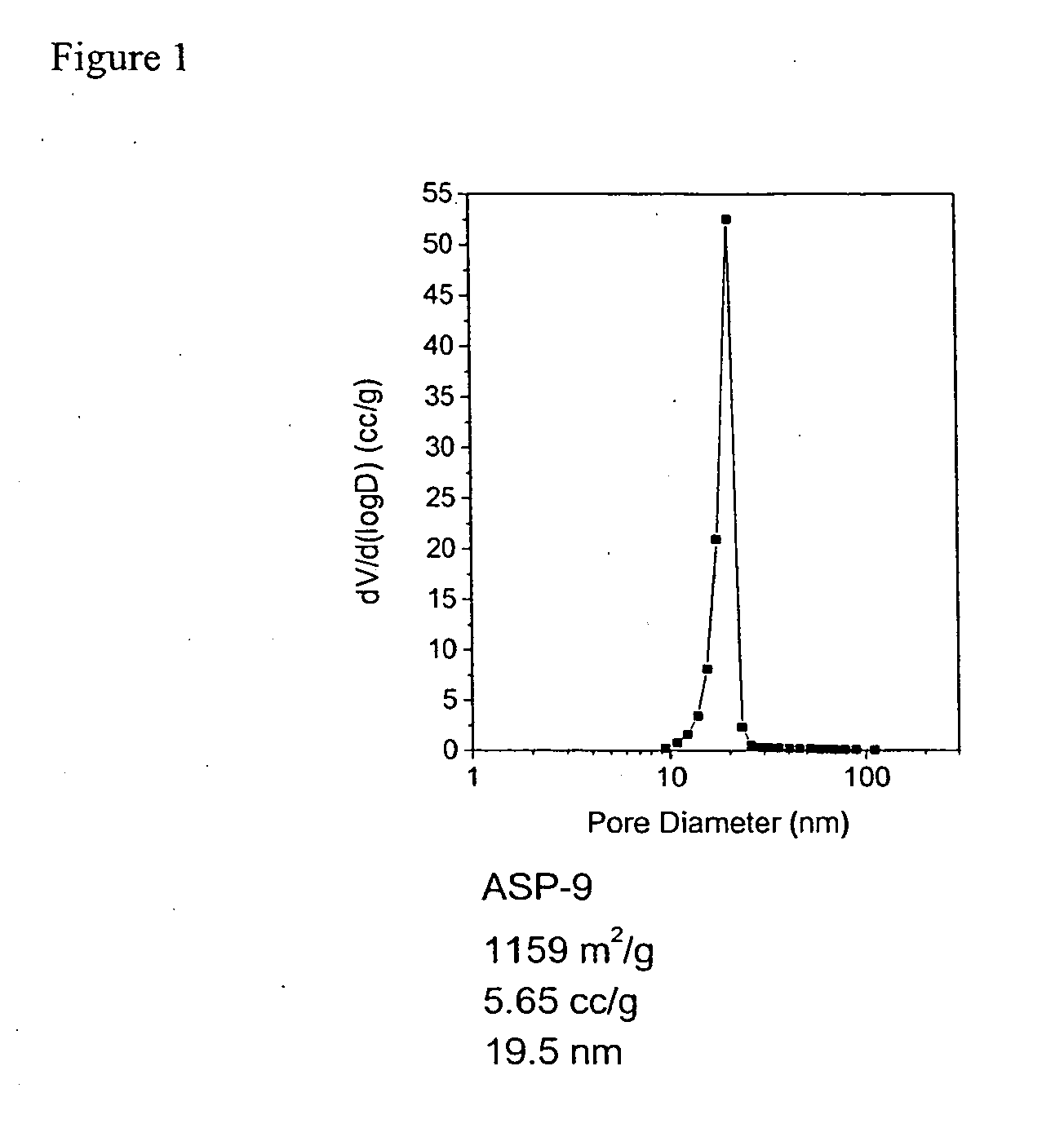

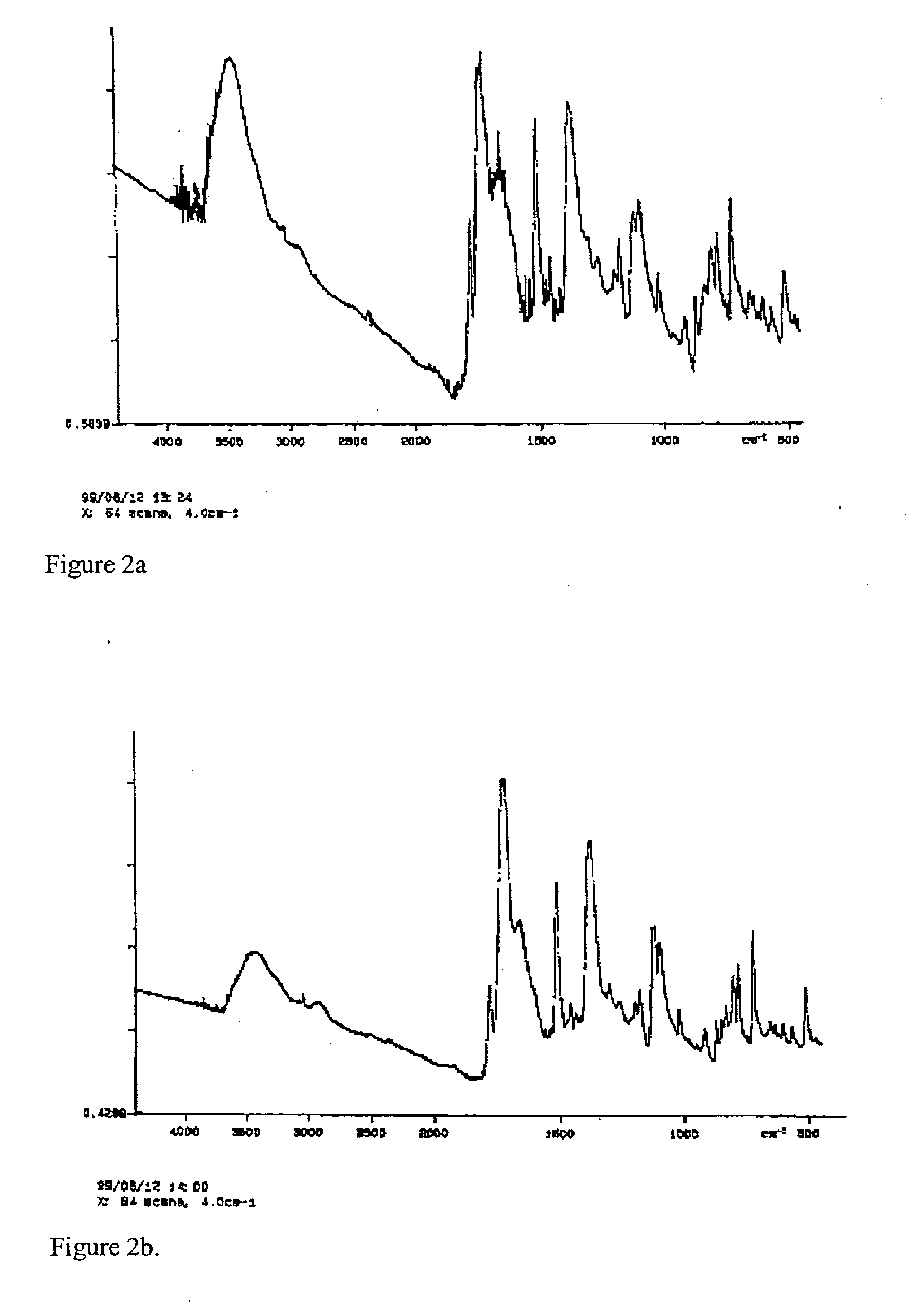

A preparation process of polyimide aerogels that composed of aromatic dianhydrides and aromatic diamines or a combined aromatic and aliphatic diamines is described. Also descried is a process to produce carbon aerogels derived from polyimide aerogel composed of a rigid aromatic diamine and an aromatic dianhydride. Finally, the processes to produce carbon aerogels or xerogel-aerogel hybrid, both of which impregnated with highly dispersed transition metal clusters, and metal carbide aerogels, deriving from the polyimide aerogels composed of a rigid aromatic diamine and an aromatic dianhydride, are described. The polyimide aerogels and the polyimide aerogel derivatives consist of interconnecting mesopores with average pore size at 10 to 30 nm and a mono-dispersed pore size distribution. The gel density could be as low as 0.008 g / cc and accessible surface area as high as 1300 m2 / g.

Owner:ASPEN AEROGELS INC

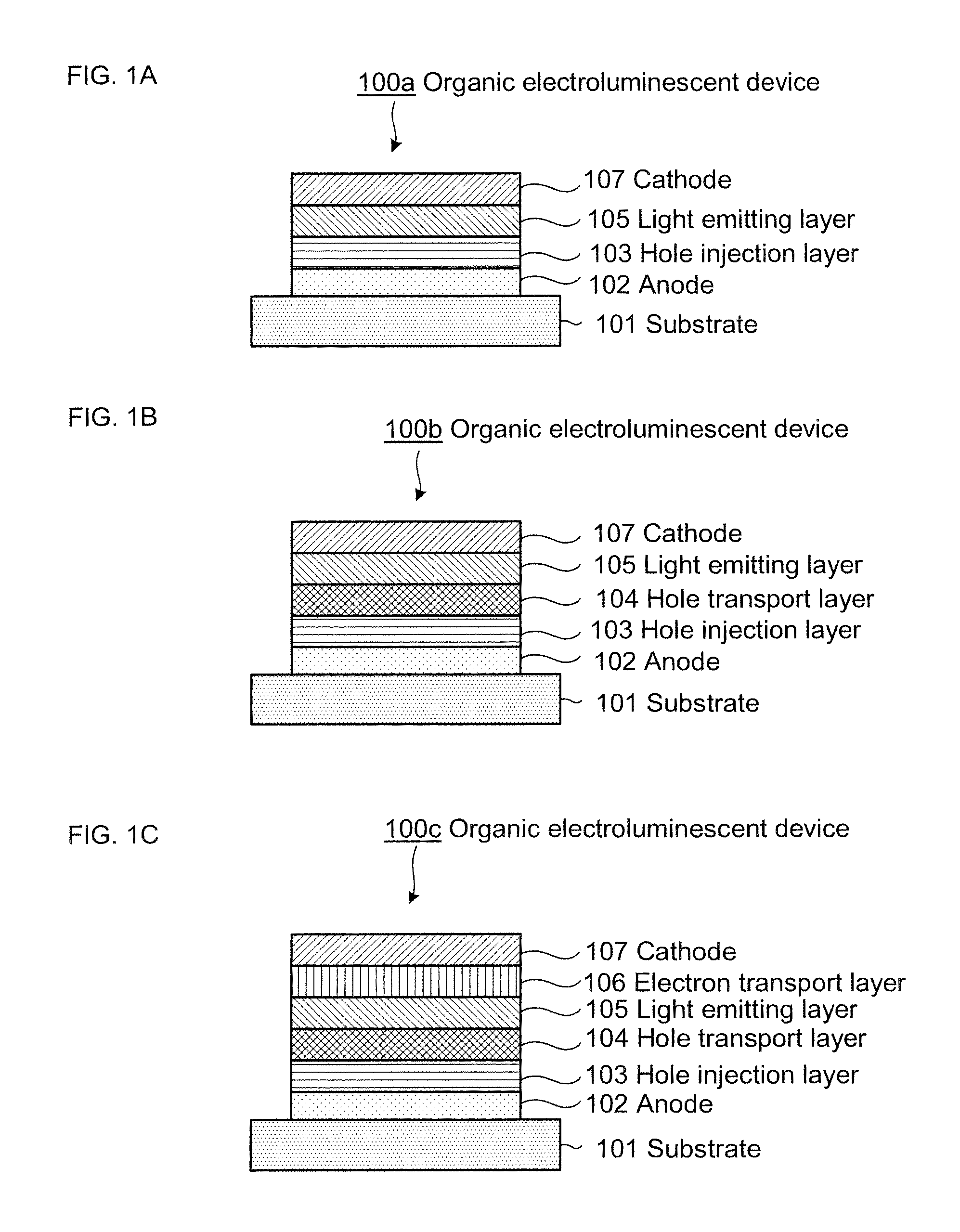

Compositions for organic electroluminescent device and organic electroluminescent device

InactiveUS20060182993A1Reduce inactivationChange propertiesDischarge tube luminescnet screensDuplicating/marking methodsSolubilityHole injection layer

Disclosed are compositions for an organic electroluminescent device favorably used for forming a hole injection layer and a hole transport layer of the organic electroluminescent device by a wet film forming method. The compositions for the organic electroluminescent device, which are composite solutions prepared by dissolving hole transport materials such as aromatic diamine compounds and an electron acceptor such as tri(pentafluorophenyl)boron in a solvent that contains an ether solvent and / or an ester solvent whose water solubility at 25° C. is 1 weight % or less in the solvent, with a concentration of 10 weight % or higher in the compositions.

Owner:MITSUBISHI CHEM CORP

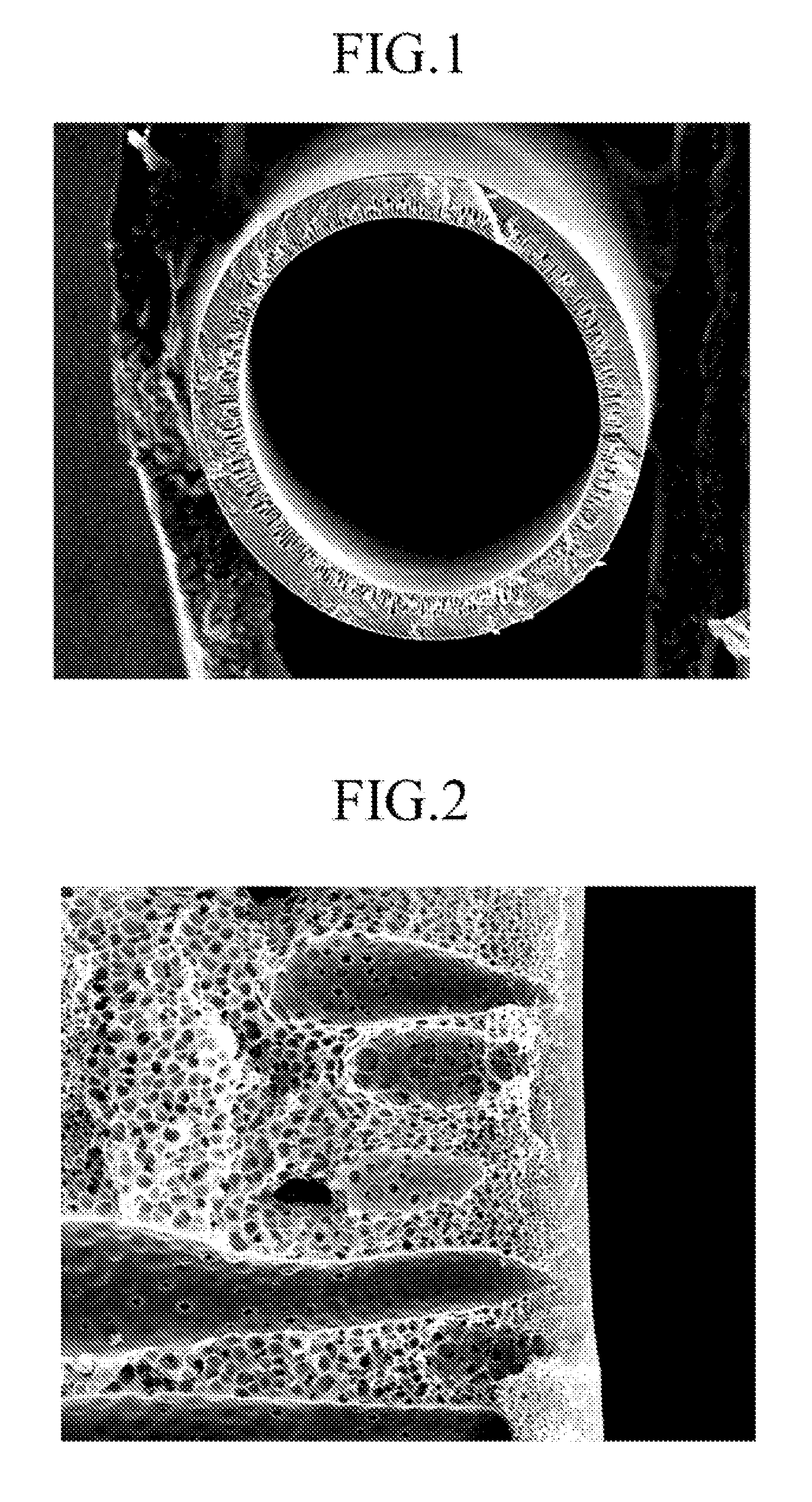

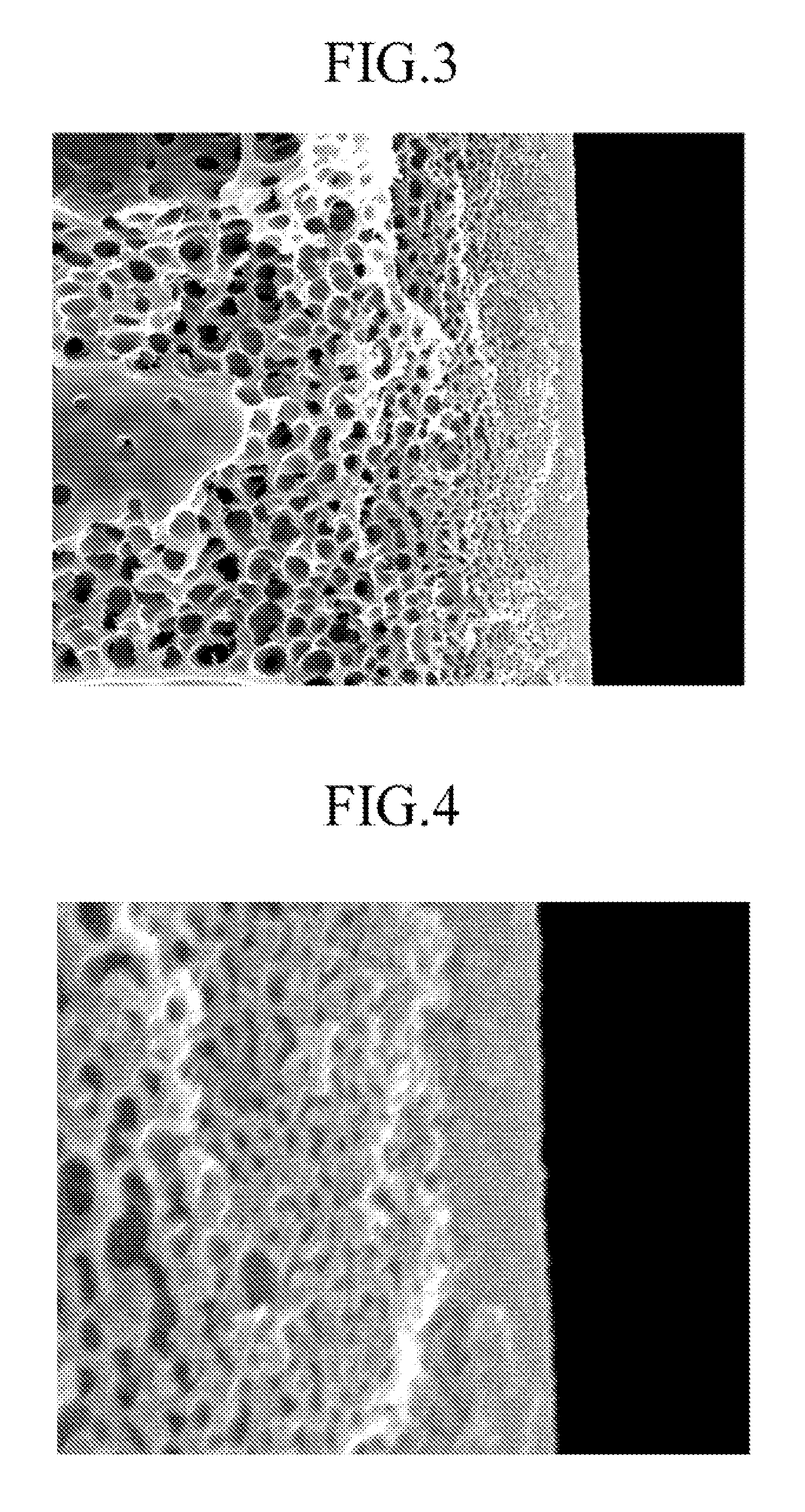

Polyimide aerogels, carbon aerogels, and metal carbide aerogels and methods of making same

InactiveUS20040132845A1Reduce nitrogen contentSuperior physical and electrical propertyMaterial nanotechnologySiliconPolymer scienceCarbide

A preparation process of polyimide aerogels that composed of aromatic dianhydrides and aromatic diamines or a combined aromatic and aliphatic diamines is described. Also descried is a process to produce carbon aerogels derived from polyimide aerogel composed of a rigid aromatic diamine and an aromatic dianhydride. Finally, the processes to produce carbon aerogels or xerogel-aerogel hybrid, both of which impregnated with highly dispersed transition metal clusters, and metal carbide aerogels, deriving from the polyimide aerogels composed of a rigid aromatic diamine and an aromatic dianhydride, are described. The polyimide aerogels and the polyimide aerogel derivatives consist of interconnecting mesopores with average pore size at 10 to 30 nm and a mono-dispersed pore size distribution. The gel density could be as low as 0.008 g / cc and accessible surface area as high as 1300 m<2> / g.

Owner:ASPEN AEROGELS INC

Large scale process for polymerization of dapbi-containing polyaramid

A method for obtaining an aromatic polyamide crumb from an aromatic diamine and an aromatic diacid chloride, which aromatic polyamide comprises 5(6)-amino-2-(p-aminophenyl)benzimidazole terephthalamide units and has a relative viscosity ηrel of at least 3, by: (1) adding at least monomers (i)-(iii) in N-methyl pyrrolidone as solvent wherein (i) is 0-30 mole % para-phenylenediamine (PPD), (ii) is 20-50 mole % 5(6)-amino-2-(p-aminophenyl)benzimidazole (DABPI), (iii) is 49.05-50.05 mole % terephthaloyl dichloride (TDC), and optionally calcium chloride to obtain a CaCl2 / aromatic diamine molar ratio less than 0.5, and an aromatic diamine / aromatic diacid chloride ratio between 0.99 and 1.01; (2) mixing the monomers and the optional calcium chloride to a homogenous mixture having a monomer concentration of 5 to 12 wt %; followed by (3) adding calcium chloride to the homogeneous mixture to obtain a CaCl2 / aromatic diamine molar ratio 0.6-1.0; and (4) polymerizing the mixture.

Owner:TEIJIN ARAMID BV

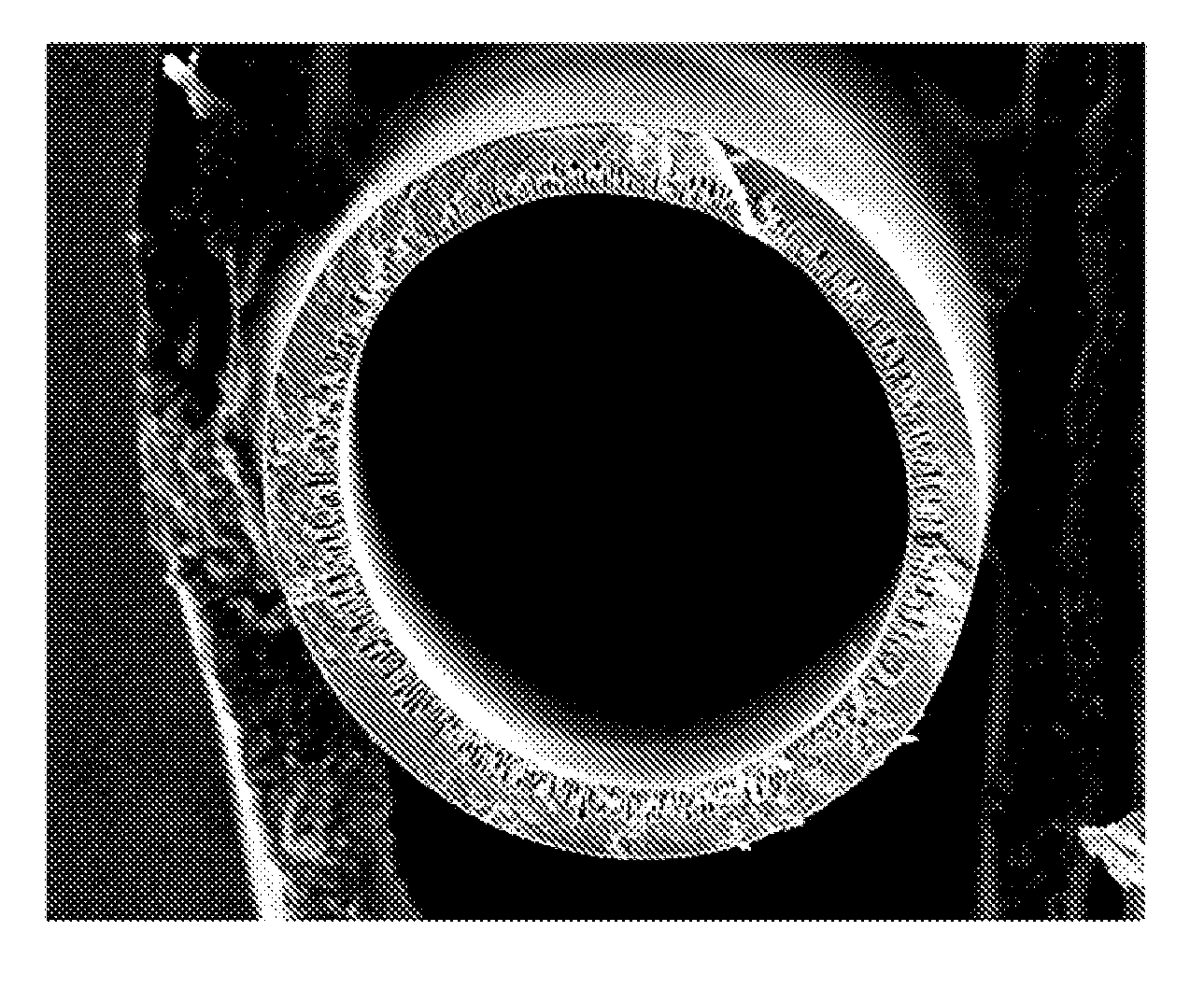

Hollow fiber, dope composition for forming hollow fiber, and method of making hollow fiber using the same

InactiveUS20090297850A1Improve permeabilityHigh selectivitySuture equipmentsCosmetic preparationsHollow fibreFiber

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Colorless highly-transparent polyimide film as well as preparation method and application thereof

The invention discloses a colorless highly-transparent polyimide film as well as a preparation method and an application thereof. The film is prepared from semi-aromatic polyimide resin of which the structural formula is shown as formula I, wherein Al is an alicyclic structure, R1 is an aromatic diamine structure containing fluorine and sulfone, R2 is another aromatic diamine structure, and n:m=(0-400):1. The film has excellent optical transparency, colorless transparency of the film with great thickness (greater than or equal to 100 mu m) can be realized, the initial light-transmitting wavelength is below 300nm, and the light transmittance in a visible region is greater than or equal to 90%; and meanwhile, the film shows excellent heat resistance and mechanical property, and has important application values in the manufacturing of the photoelectric devices such as a solar battery, a display, an electronic book, an electronic label, a photoelectric sensor and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

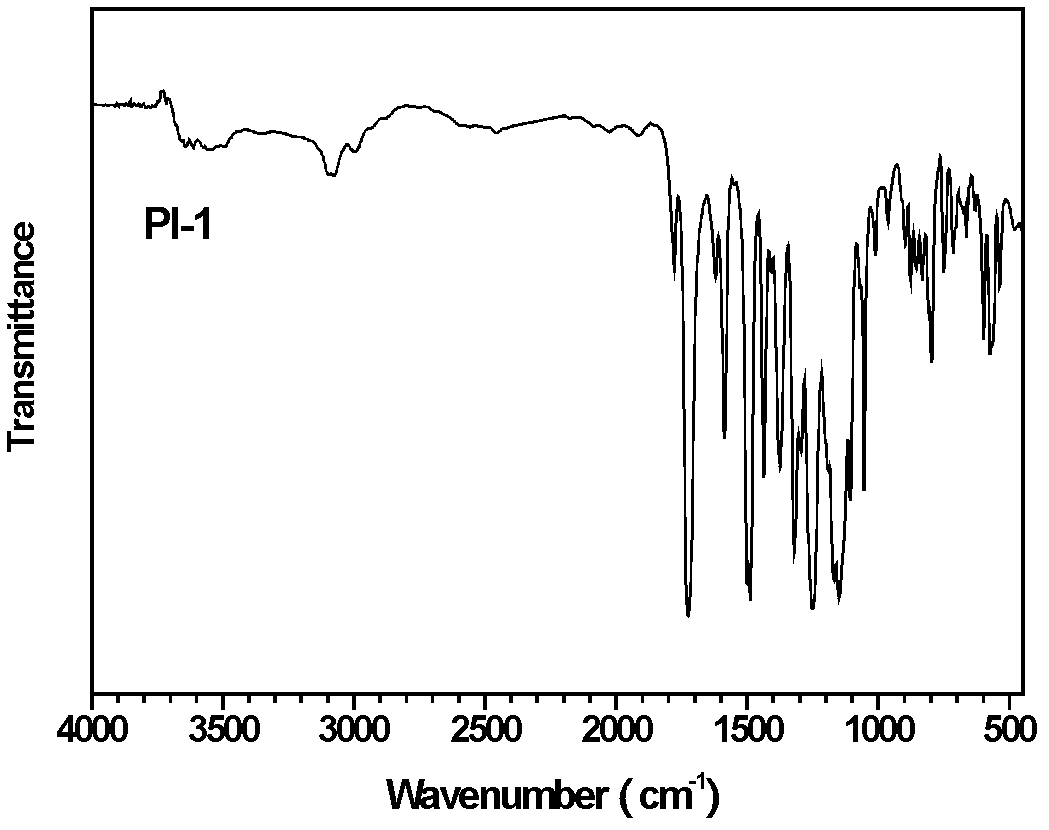

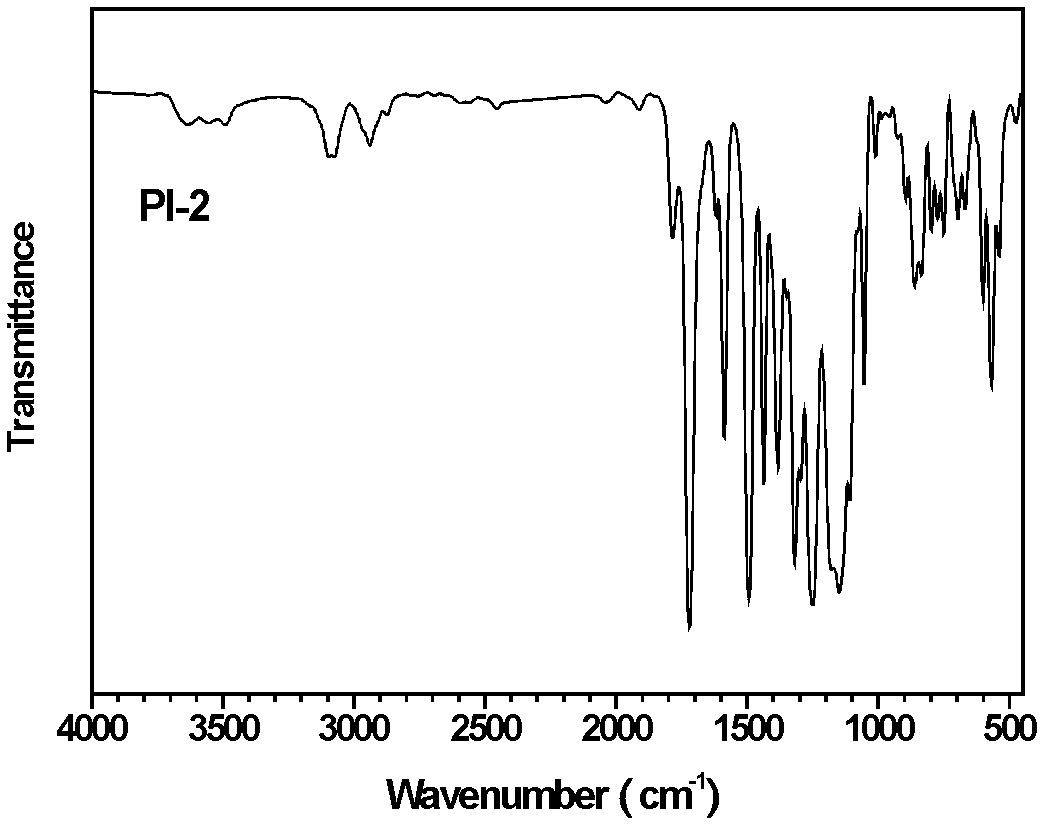

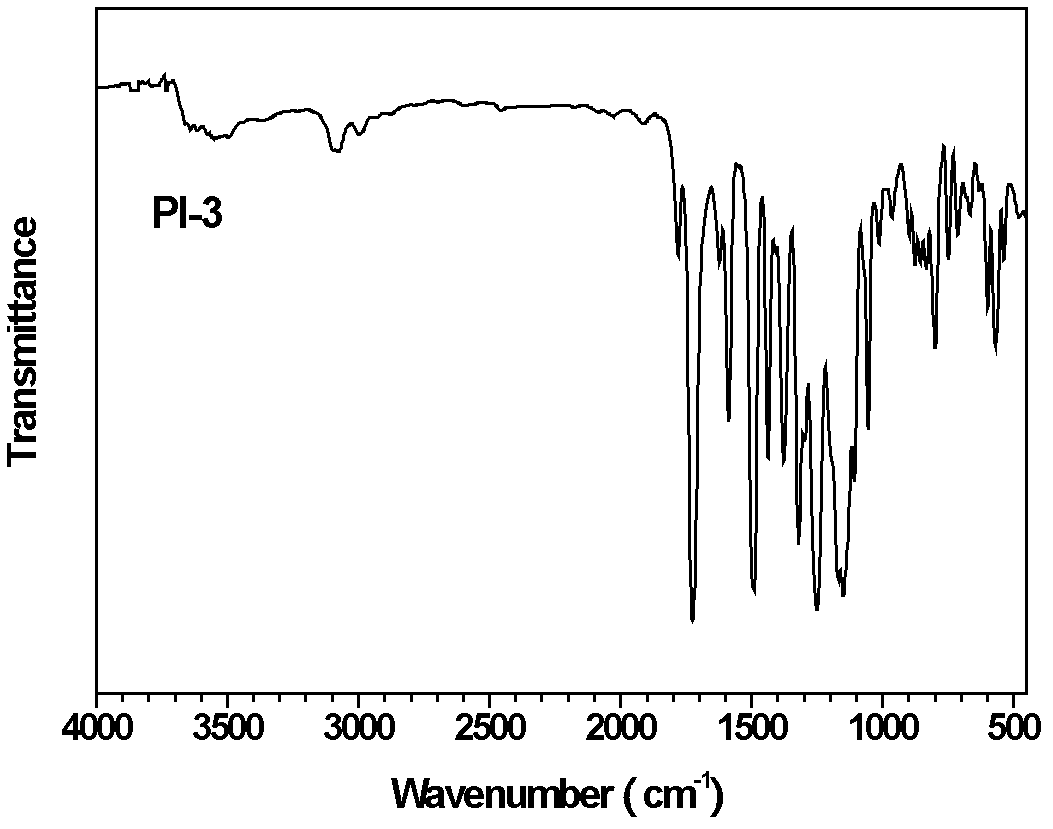

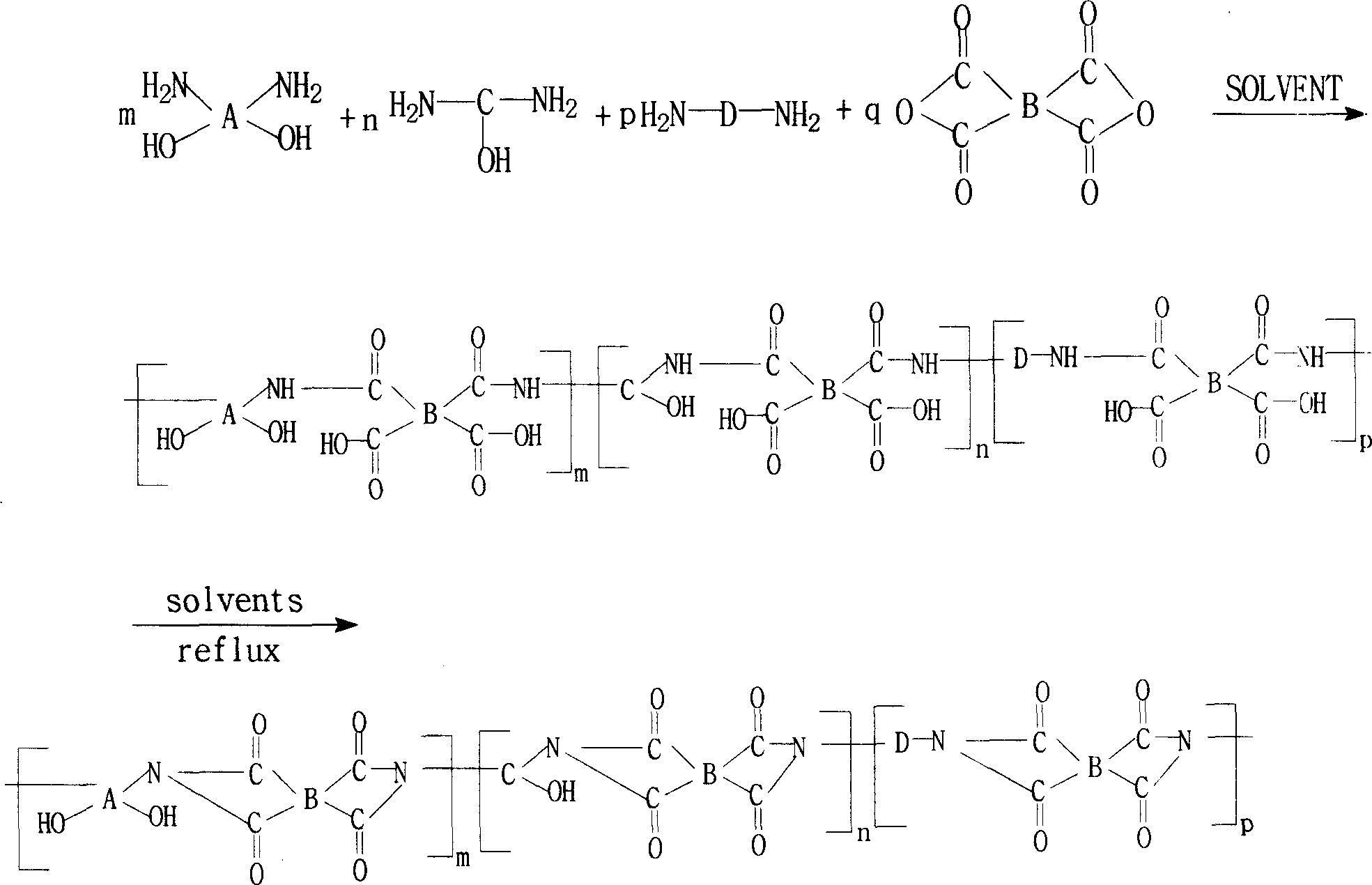

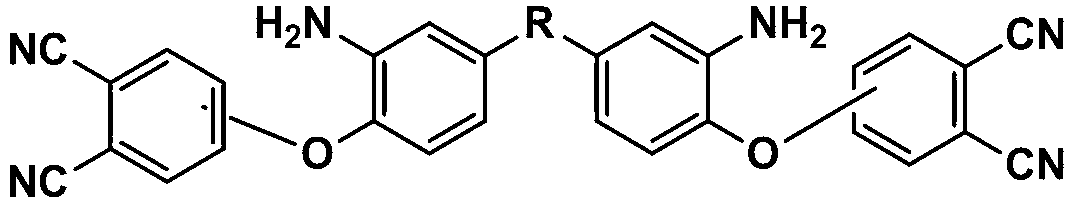

Method for preparing binder of polyimide of containing phenolic hydroxyl group

This invention discloses a method for preparing phenolic hydroxyl-containing polyimide adhesive. The method comprises: (1) reacting phenolic hydroxyl-containing aromatic diamine, or its mixture with other aromatic diamines, with aromatic dianhydride at a mol ratio of 1:1 in strongly polar non-proton organic solvent at 0-10 deg.C for 4-8 h to obtain uniform, transparent and viscose polyhydroxyamic acid solution; (2) adding azeotropic dehydrator in nitrogen atmosphere, heating, performing imidization reaction under refluxing and dehydration at 120-160 deg.C for 1-6 h, and cooling to room temperature to obtain phenolic hydroxyl-containing polyimide adhesive. The volume ratio of azeotropic dehydrator to strongly polar non-proton organic solvent is 1 :( 1-5). The method has such advantages as easy operation, no special requirement for equipment, and high product quality. The phenolic hydroxyl-containing polyimide adhesive has such advantages as short adhesion and curing time, low energy consumption, and high adhesiveness to copper foil and polyimide thin film, and can be used to produce bi-layer flexible printed circuit boards.

Owner:DONGHUA UNIV

Aerogel metallic compositions

InactiveUS20050131163A1Reduce nitrogen contentSuperior physical and electrical propertyMaterial nanotechnologyCell electrodesCarbideAccessible surface area

A preparation process of polyimide aerogels that composed of aromatic dianhydrides and aromatic diamines or a combined aromatic and aliphatic diamines is described. Also descried is a process to produce carbon aerogels derived from polyimide aerogel composed of a rigid aromatic diamine and an aromatic dianhydride. Finally, the processes to produce carbon aerogels or xerogel-aerogel hybrid, both of which impregnated with highly dispersed transition metal clusters, and metal carbide aerogels, deriving from the polyimide aerogels composed of a rigid aromatic diamine and an aromatic dianhydride, are described. The polyimide aerogels and the polyimide aerogel derivatives consist of interconnecting mesopores with average pore size at 10 to 30 nm and a mono-dispersed pore size distribution. The gel density could be as low as 0.008 g / cc and accessible surface area as high as 1300 m2 / g.

Owner:ASPEN AEROGELS INC

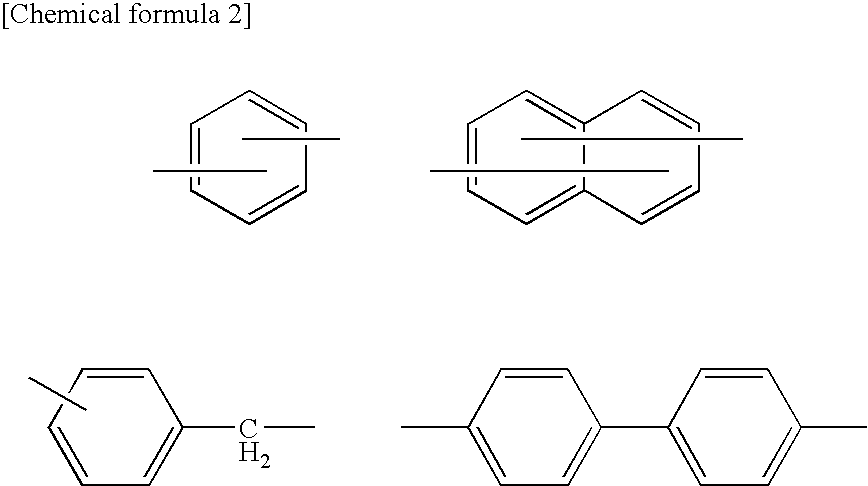

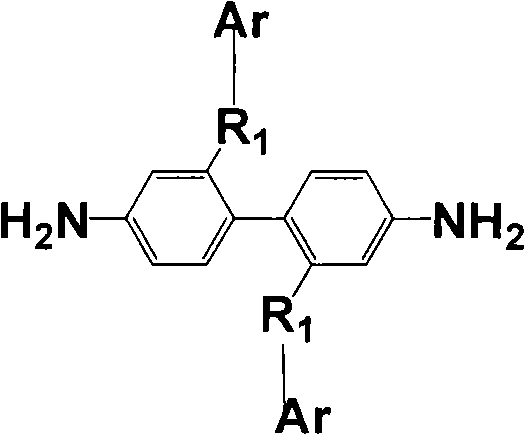

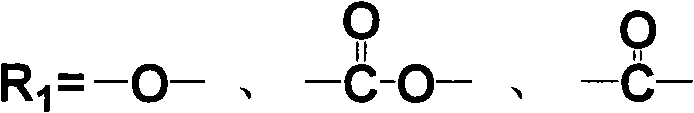

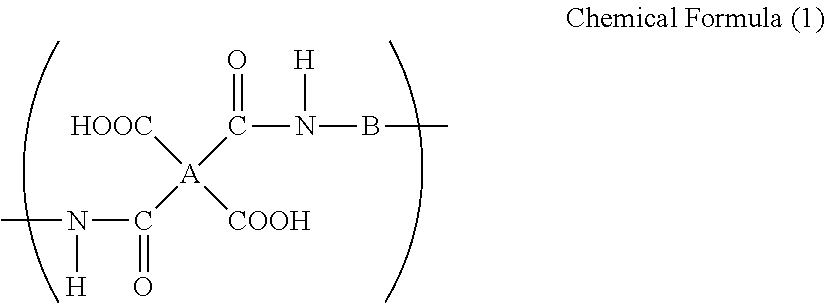

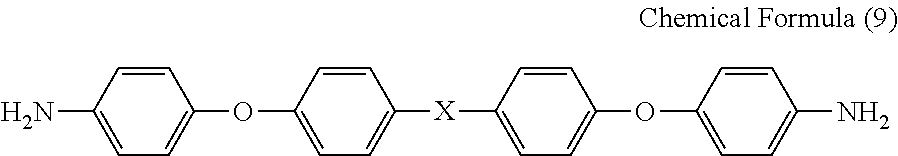

Aromatic diamines and polyimides based on 4,4'-bis-(4-aminophenoxy)-2,2' or 2,2',6,6'-substituted biphenyl

This invention relates the novel diamines, the polyimide oligomers and the polyimides derived therefrom and to the method of preparing the diamines, oligomers and the polyimides. The thermoplastic polyimides derived from the aromatic diamines of this invention are characterized as having a high glass transition temperature, good mechanical properties and improved processability in the manufacture of adhesives, electronic and composite materials for use in the automotive and aerospace industry. The distinction of the novel aromatic diamines of this invention is the 2,2',6,6'-substituted biphenyl radicals which exhibit noncoplanar conformation that enhances the solubility of the diamine as well as the processability of the polyimides, while retaining a relatively high glass transition temperature and improved mechanical properties at useful temperature ranges.

Owner:UNITED STATES OF AMERICA

Transparent polyimide film and preparation method thereof

The invention discloses a transparent polyimide film. The transparent polyimide film is prepared from a copolymer of aromatic dianhydride and aromatic diamine, and can be modified by adding inorganic materials or inorganic nano-materials into the polymer. The thickness of the film is 25-100 microns, and the Tg temperature range is 180-350 DEG C; the film has low heat expansion coefficient with 3-30 ppm under the Tg temperature, has cutoff wavelength of 550 nm measured by an ultraviolet spectrophotometer and has average transmission rate of 85 percent or more in the range of 380-780 nm. The invention also discloses a preparation method of the transparent polyimide film. The film is high in mechanical property, high in heat stability and suitable for transparent electric conductive films, film transistor substrates, flexible printed circuit boards, solar battery flexible substrates, flexible substrates for flexible display of a new generation of OLED, and the like.

Owner:饶先花

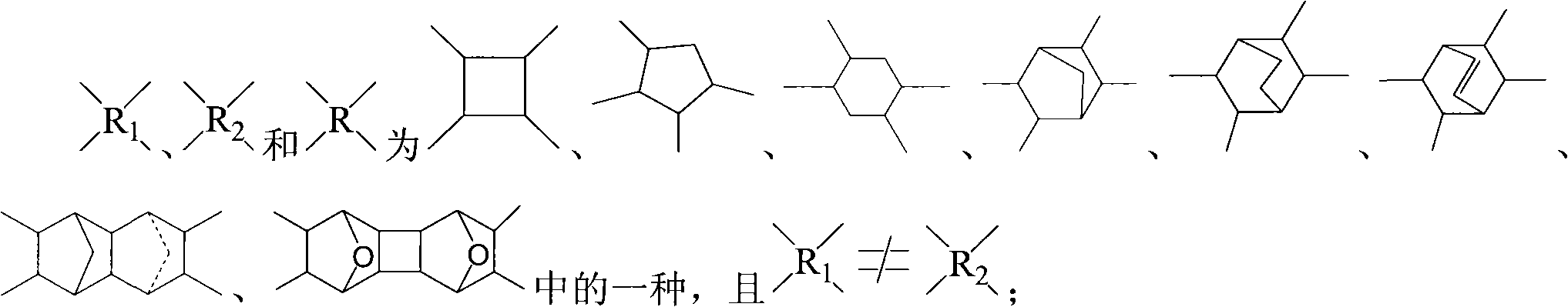

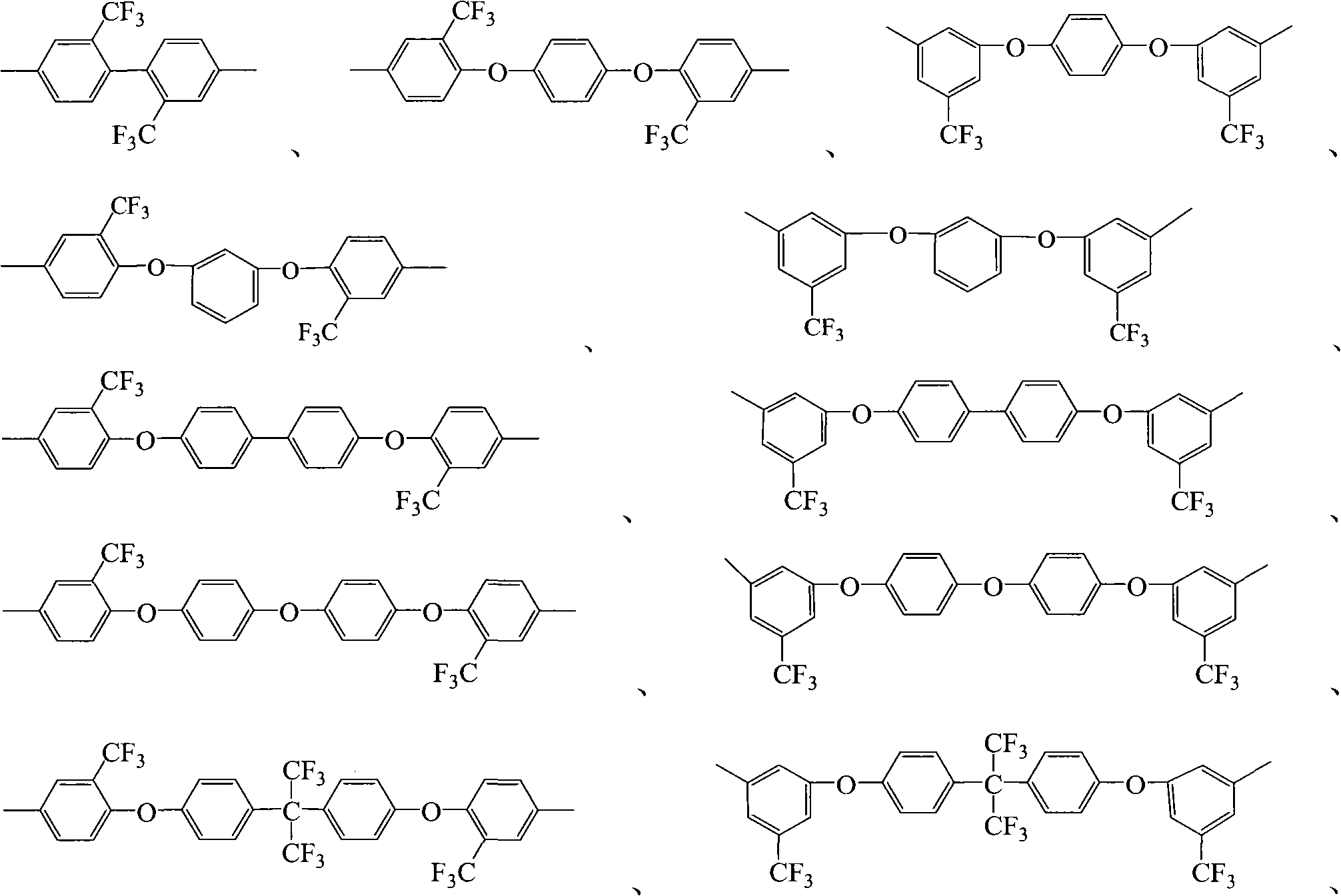

New type fluorine-containing copolyimide and preparation method thereof

InactiveCN101831074AAchieve colorless transparencyImprove performanceUltraviolet absorptionElectromagnetic shielding

The invention relates to new type fluorine-containing copolyimide and a preparation method thereof. The fluorine-containing copolyimide is obtained by condensation copolymerization of three monomers, i.e. the fluorine-containing copolyimide is prepared by the steps of carrying out condensation copolymerization reaction on one type of alicyclic dianhydride monomer and two types of fluorine-containing aromatic diamine monomers, or two types of the alicyclic dianhydride monomers and one type of the fluorine-containing aromatic diamine monomer in an aprotic polar solvent at low temperature, and then carrying out a thermal imidization reaction, and the new type fluorine-containing copolyimide has the advantages of high transparency, good heat resistance and the like. A fluorine-containing copolyimide film has a glass transition temperature of 200 DEG C to 350 DEG C, and is colorless and transparent; the ultraviolet absorption cutoff wavelength is between 270nm and 340 nm; the light transmittance at 450 nm is between 88% and 98%; and the fluorine-containing copolyimide film has good processing performance, and can be used as a bottom plate of a solar cell, a liquid crystal display material, a flexible transparent conductive film substrate material, an electromagnetic shielding material and the like.

Owner:UNIV OF SCI & TECH LIAONING

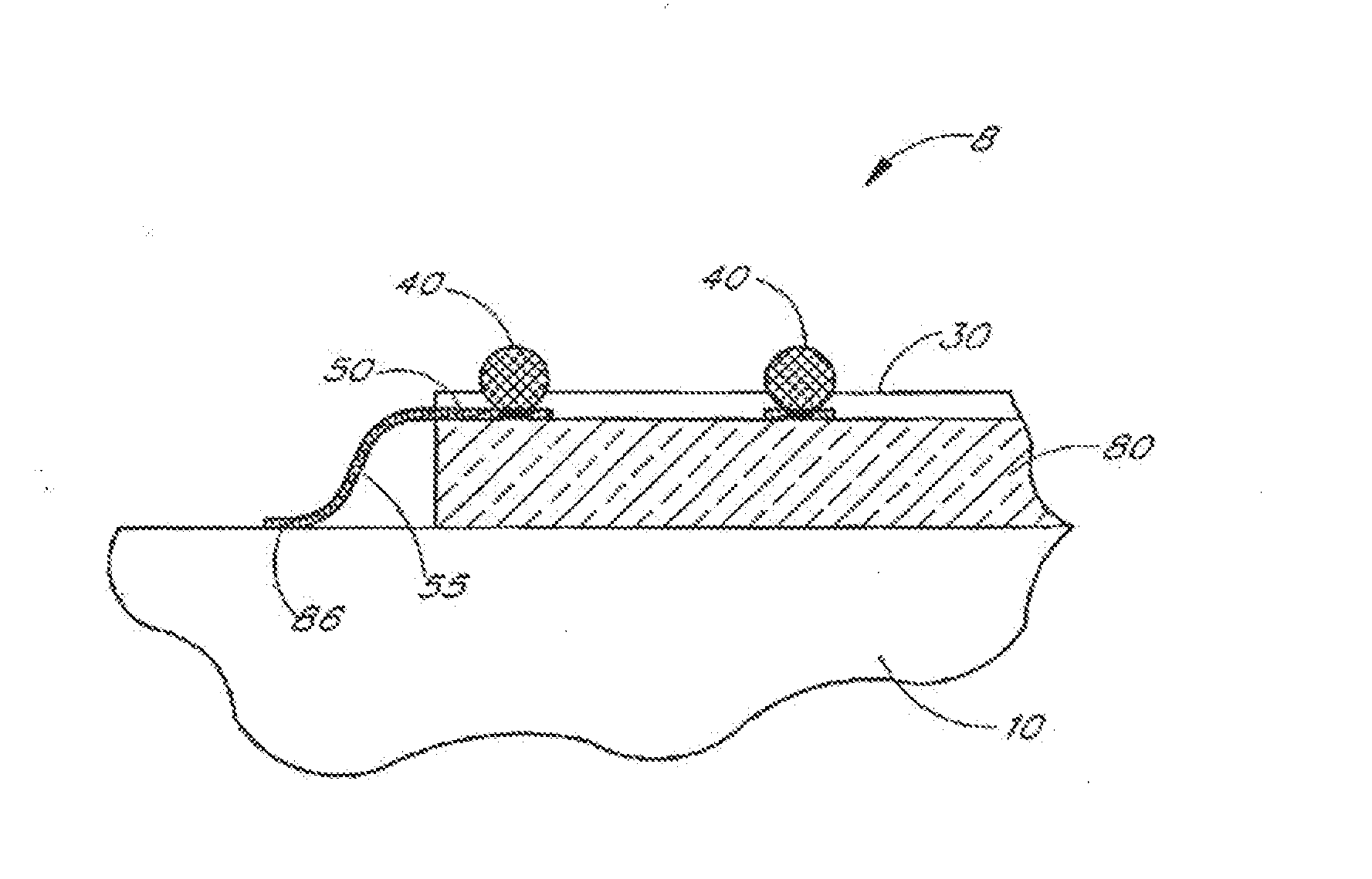

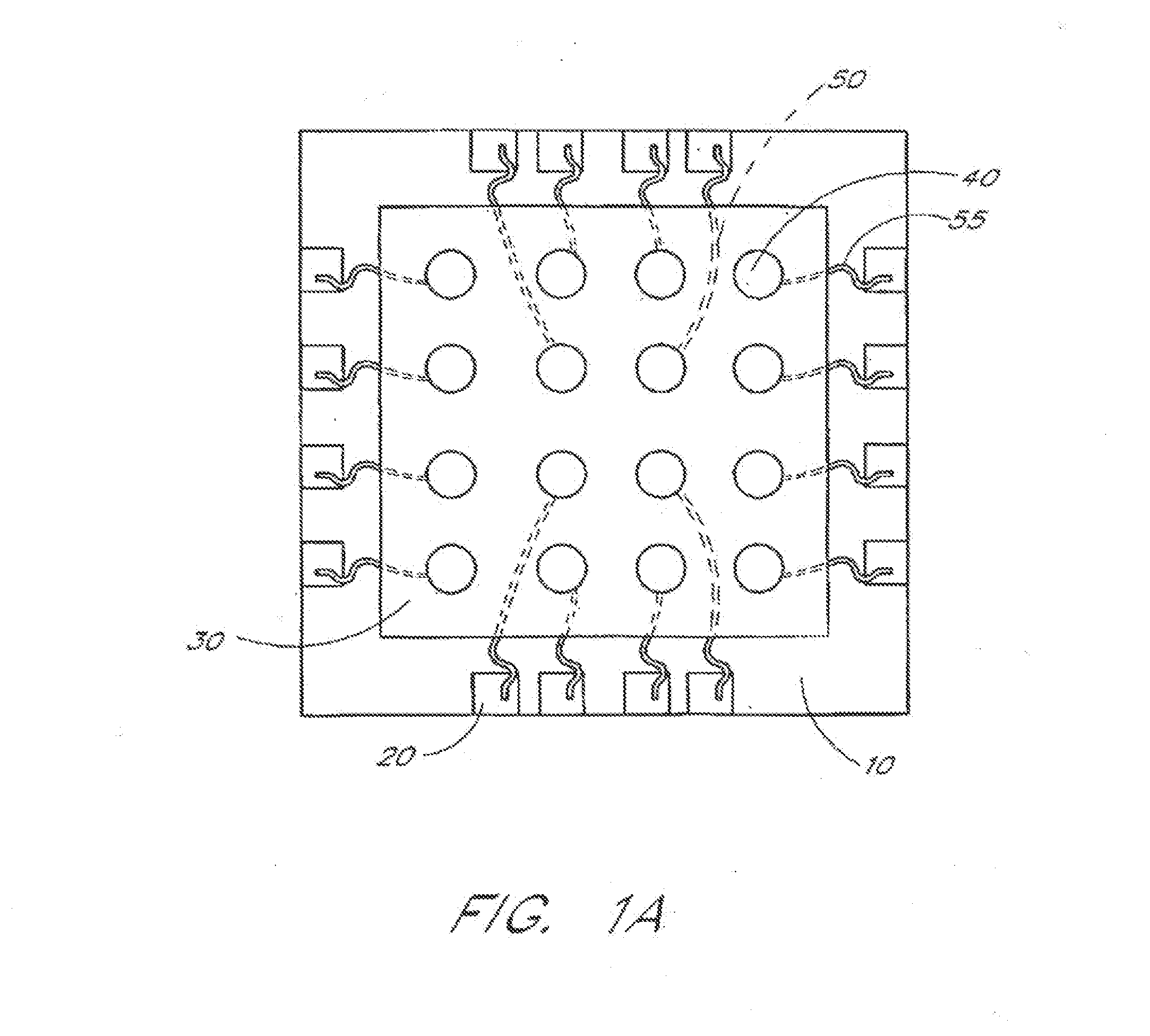

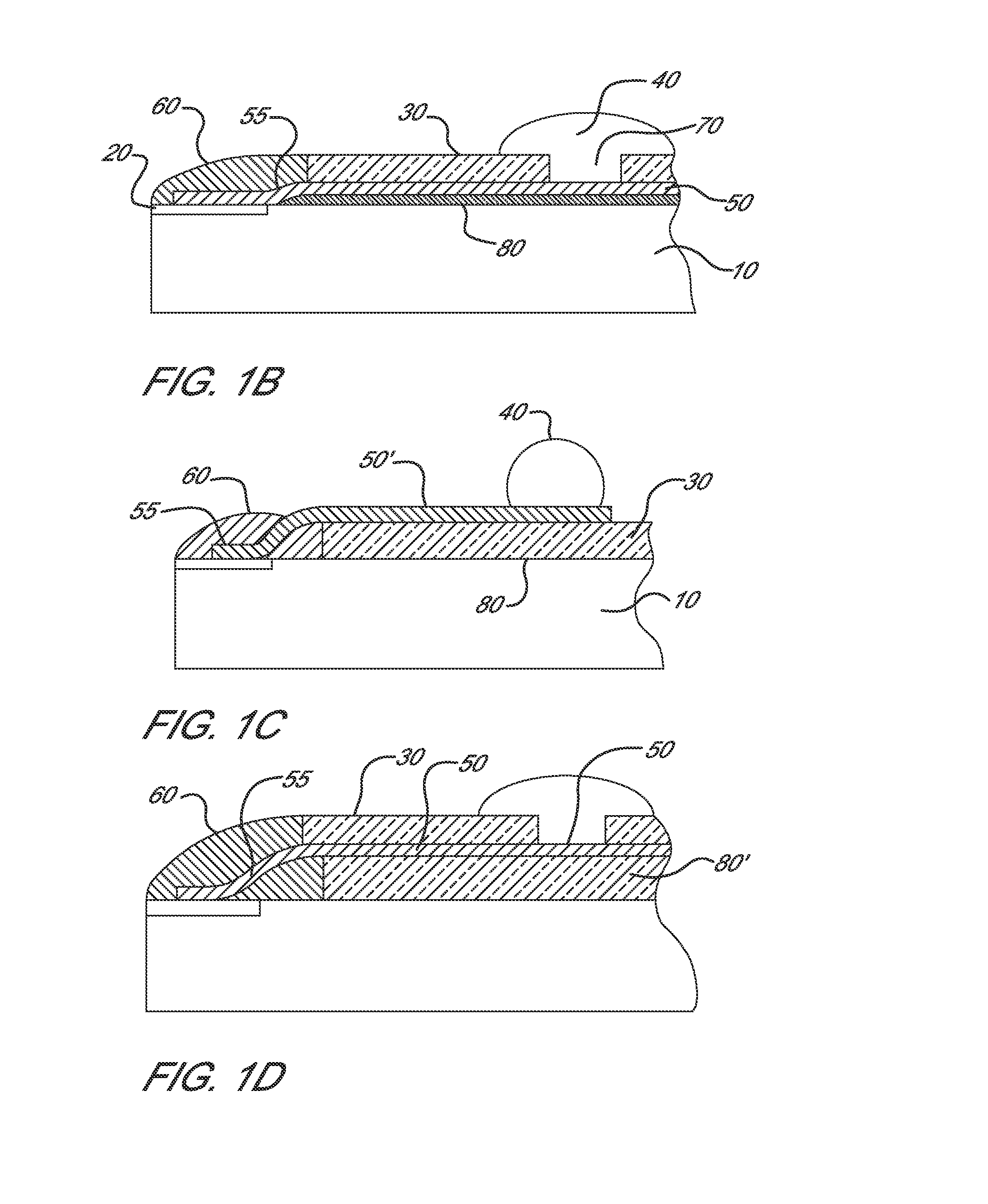

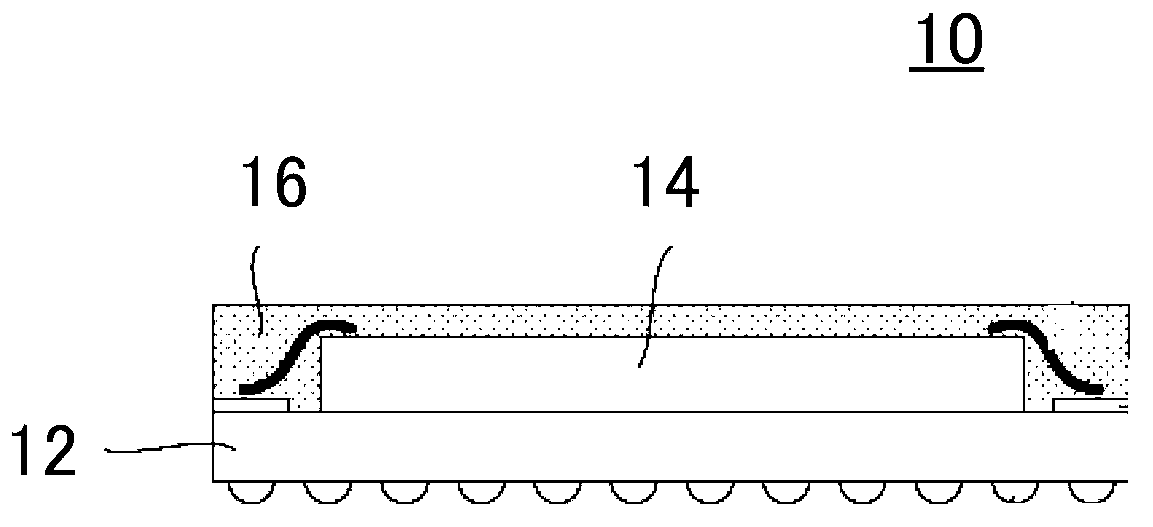

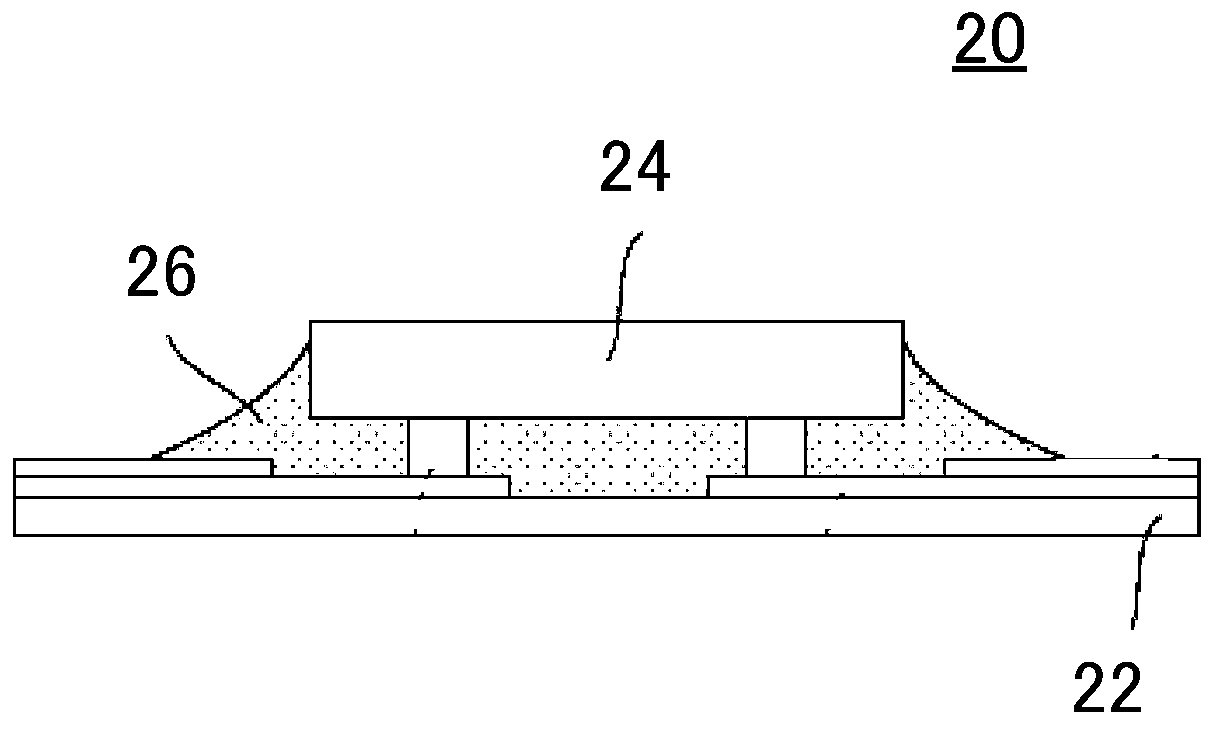

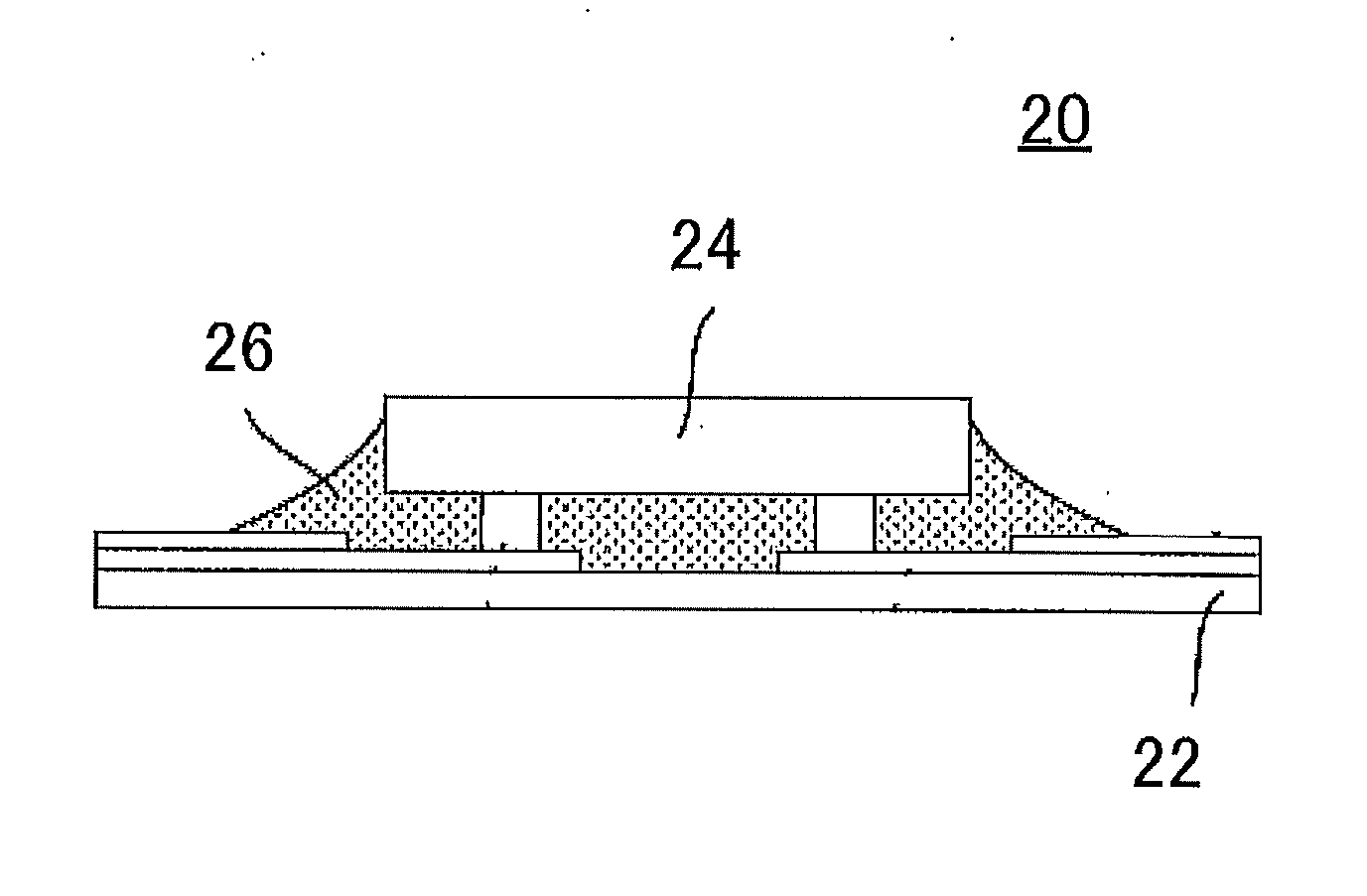

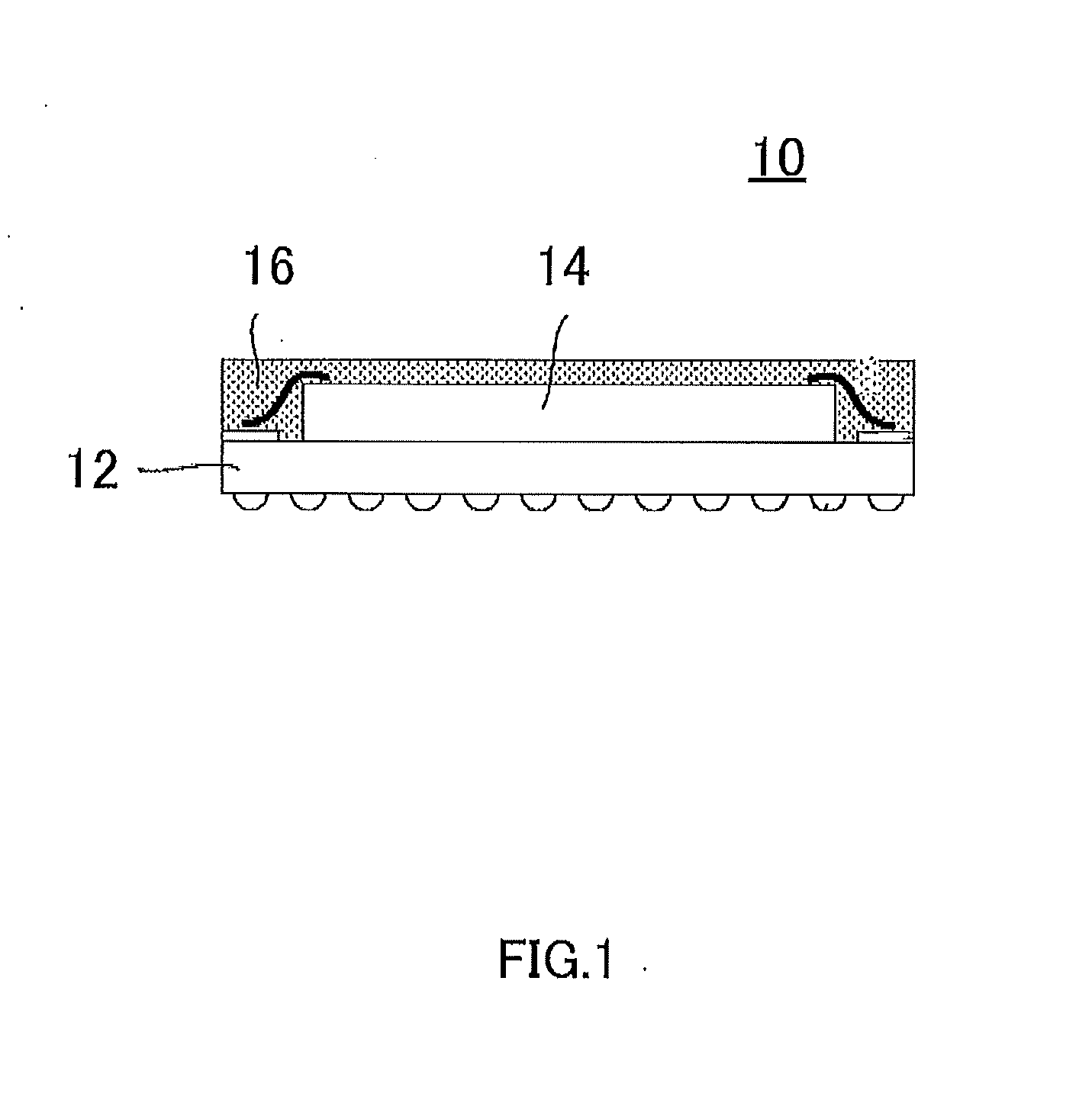

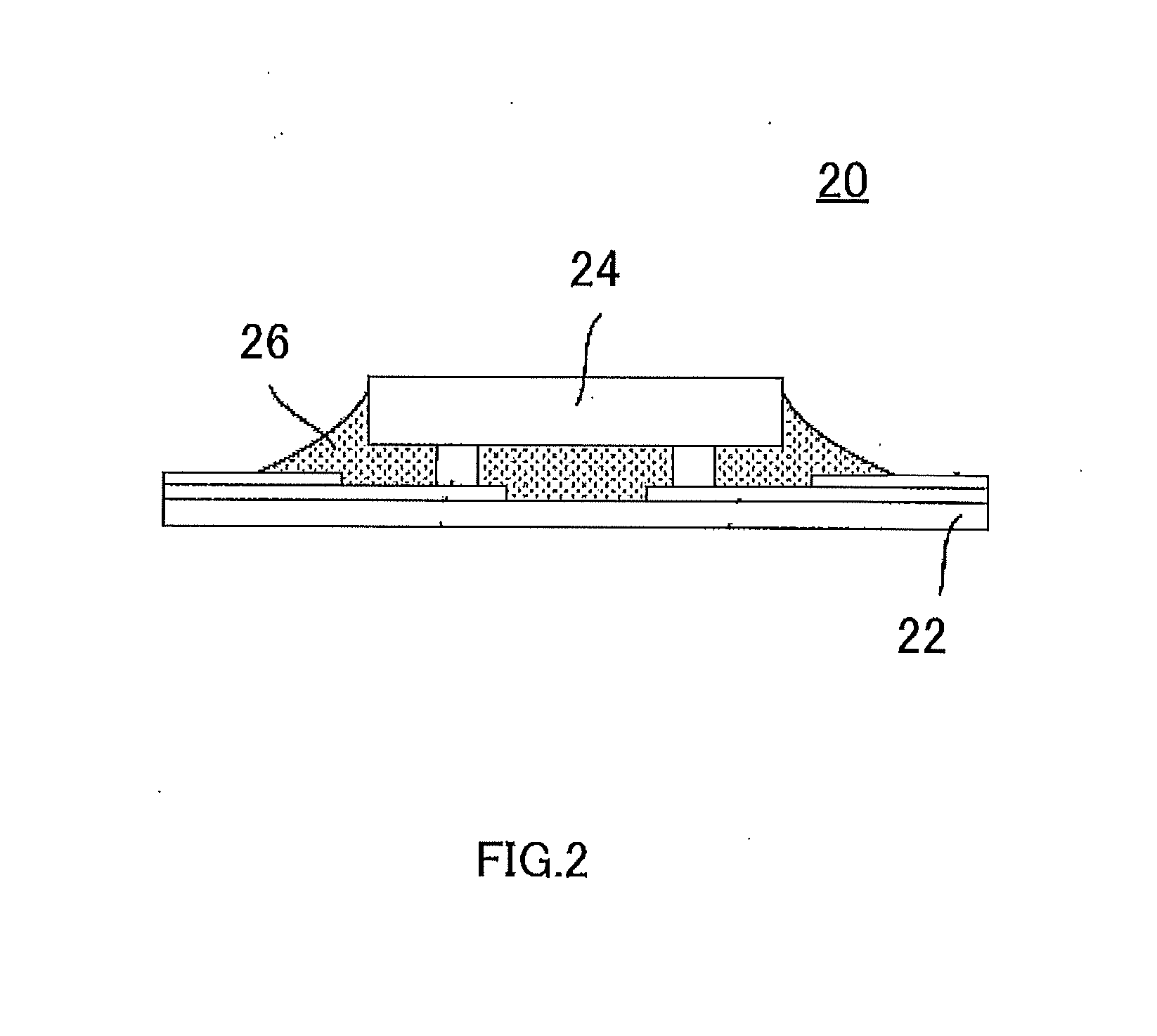

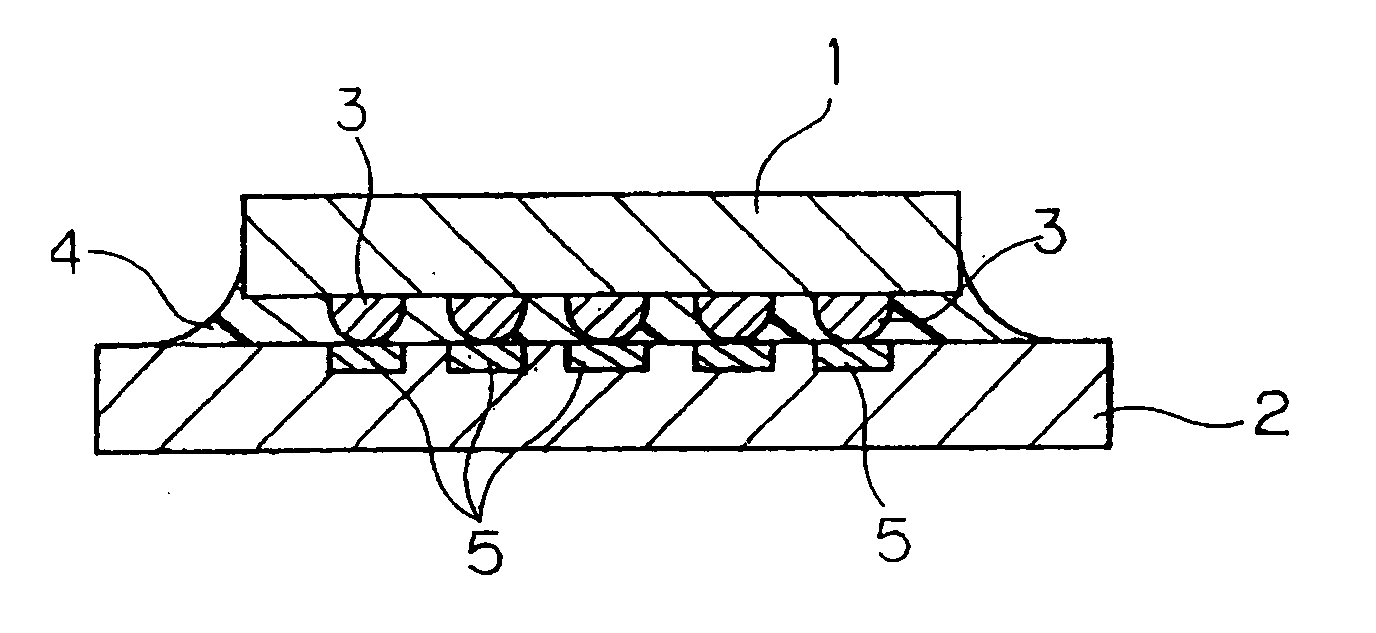

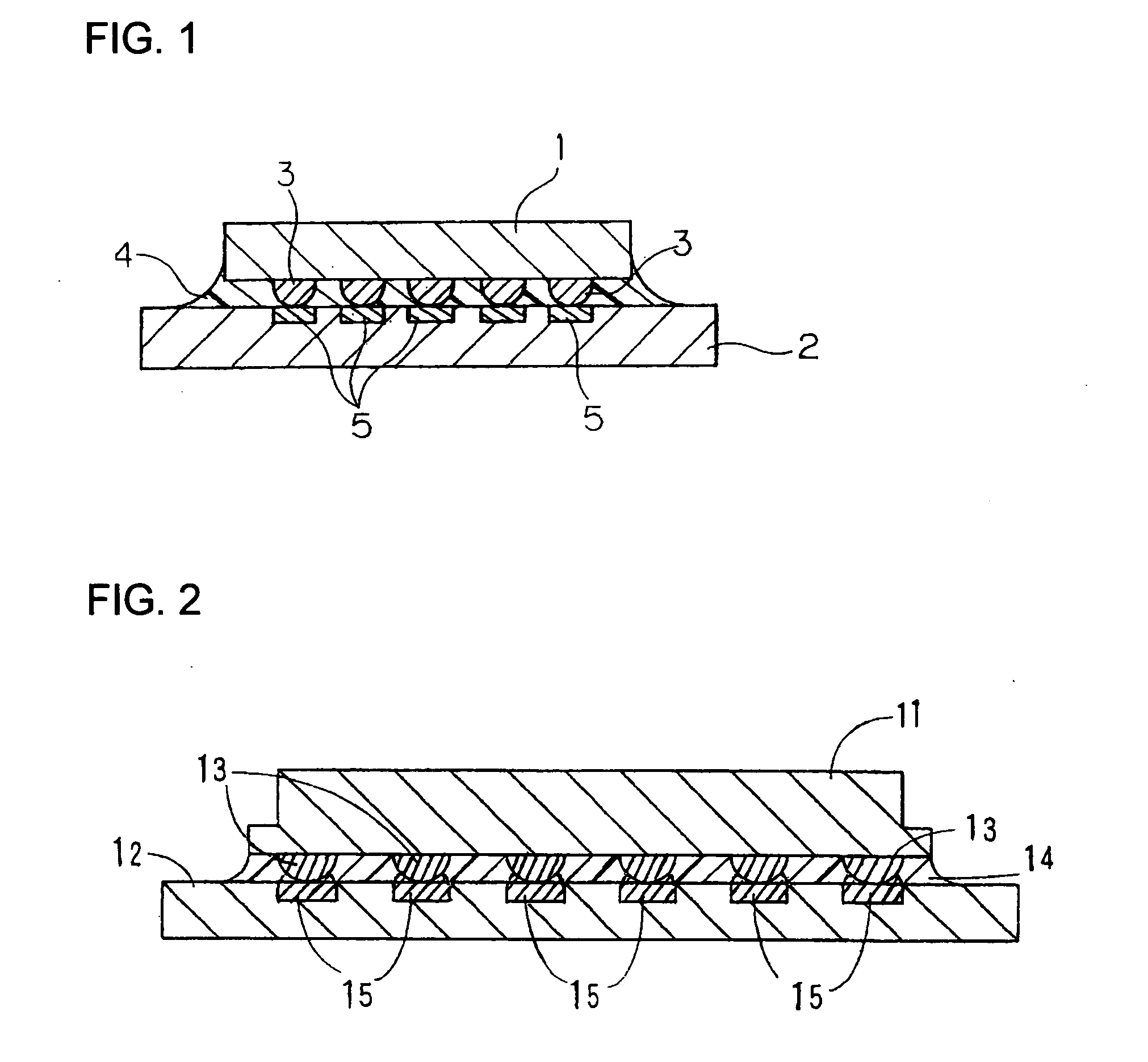

Interposer films useful in semiconductor packaging applications, and methods relating thereto

InactiveUS20120292086A1Semiconductor/solid-state device detailsSynthetic resin layered productsInterposerSemiconductor package

An interposer film for IC packaging is disclosed. The interposer film comprises a substrate that supports a plurality of electrically conductive domains. The substrate is composed of a polyimide and a sub-micron filler. The polyimide is derived from at least one aromatic dianhydride component selected from rigid rod dianhydride, non-rigid rod dianhydride and combinations thereof, and at least one aromatic diamine component selected from rigid rod diamine, non-rigid rod diamine and combinations thereof. The mole ratio of dianhydride to diamine is 48-52:52-48 and the ratio of X:Y is 20-80:80-20 where X is the mole percent of rigid rod dianhydride and rigid rod diamine, and Y is the mole percent of non-rigid rod dianhydride and non-rigid rod diamine. The sub-micron filler is less than 550 nanometers in at least one dimension; has an aspect ratio greater than 3:1; is less than the thickness of the film in all dimensions.

Owner:EI DU PONT DE NEMOURS & CO

A preparation method of gum-free flexible copper-coating plate

PendingCN101157077AImprove heat resistanceGood flexibilityPretreated surfacesCoatingsDielectricCopper foil

The invention discloses a preparation method for a non-glue type flexible copper clad laminate. The invention has the method that monomer aromatic diamine is dissolved in non-protonic polar solvent, and aromatic tetracid dianhydride with the equal molar is added into the solution, thereby generating polyamic acid solution with 10 to 30 percent of the solid content in a polyamic way; dehydrating agent and catalyst are dropwise added into the solution, and the chemical imidization is performed at 10 to 80 DEG C, thereby obtaining polyimide precursor solution; the polyimide precursor solution is coated on the copper foil surface with the 60 to 70 micron thickness, and heated to remove the solvent, and the thermal imidization is further performed at 250 to 300 DEG C, thereby obtaining the non-glue type flexible copper clad laminate. The non-glue type flexible copper clad laminate of the invention has the excellent heat resistant performance, is suitable for the non-lead welding meeting the environmental protective requirement, has small crimpability, good dimensional stability, better mechanical strength, high peel strength, and high flexibility resistance, and simultaneously has lower thermal expansion coefficient, dielectric constant, and water absorption.

Owner:湖北省化学研究院

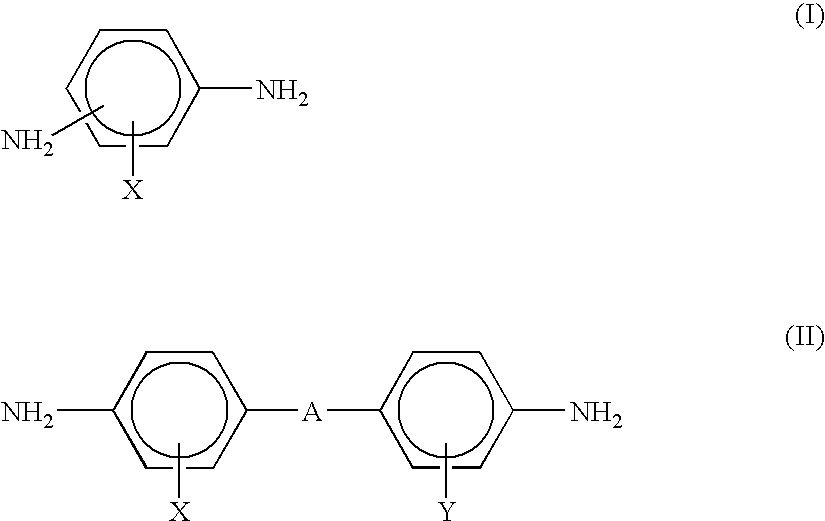

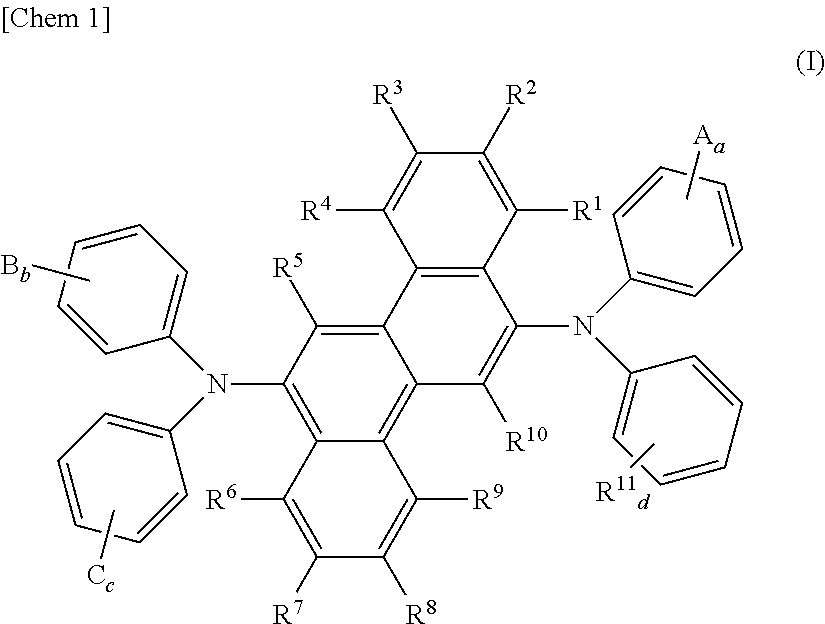

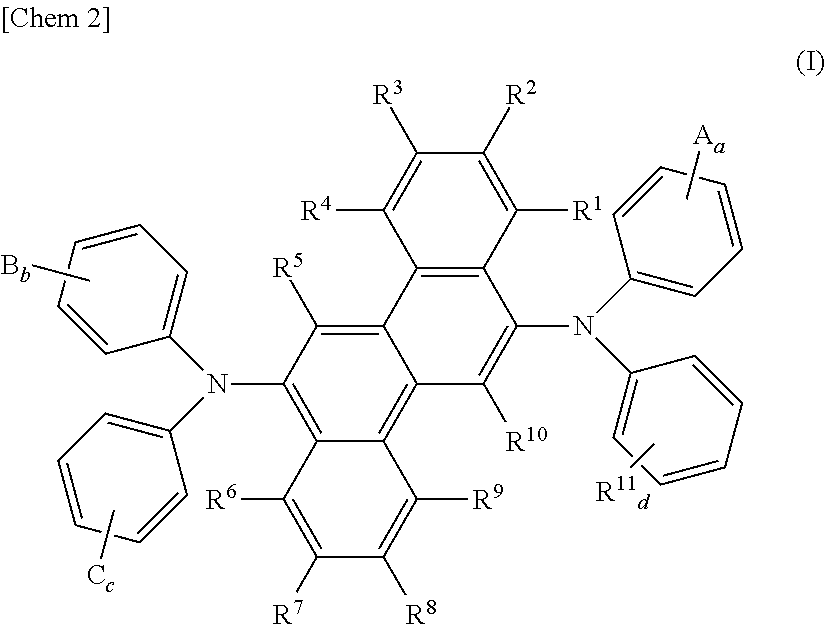

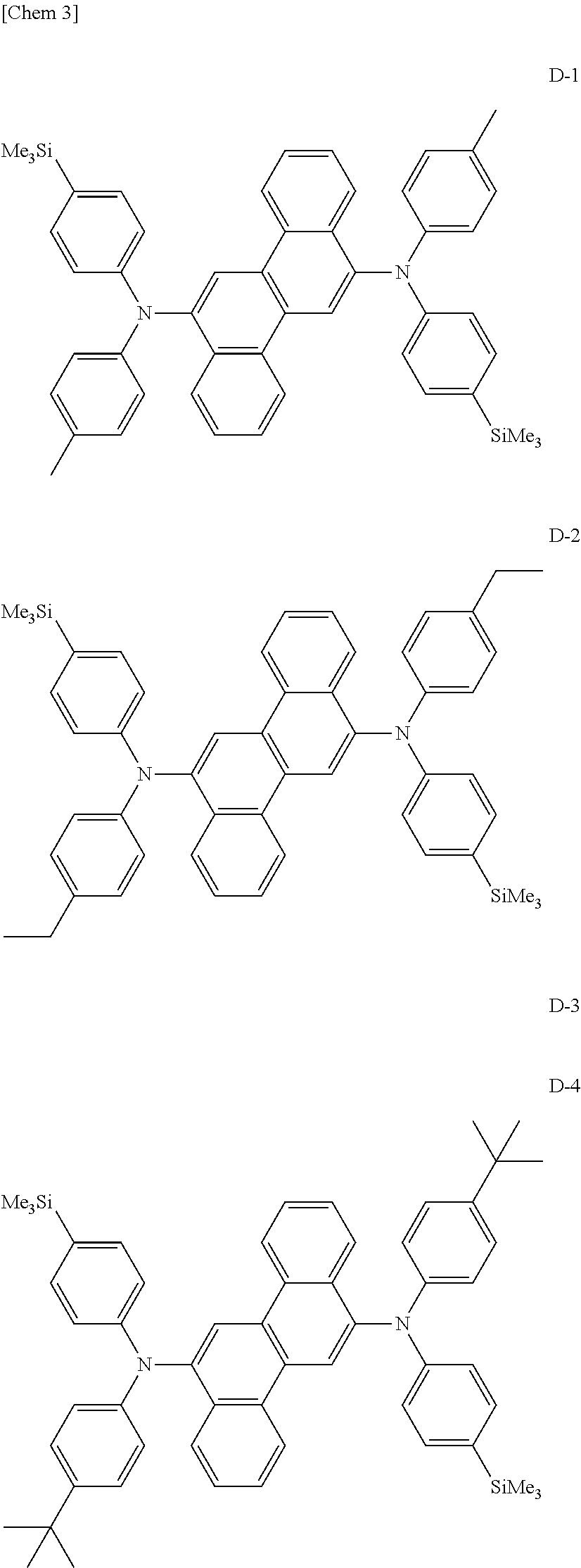

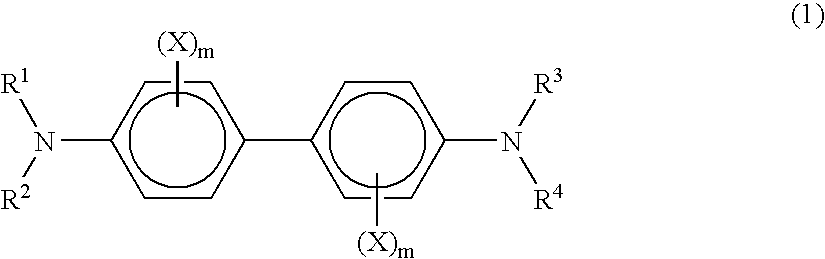

Aromatic diamine derivative and organic electroluminescent device using the same

InactiveUS20110006289A1High luminous efficiencyNot easy to deteriorateGroup 4/14 element organic compoundsSolid-state devicesSilyleneOrganic electroluminescence

Disclosed is an aromatic diamine derivative represented by the following general formula (I), which has a chrysene structure in which a phenyl group having a substituted or unsubstituted silyl group is a substituent for an amino group. Also disclosed is an organic electroluminescence device including an organic thin film layer formed of one or more layers including at least a light emitting layer and interposed between a cathode and an anode, in which at least one layer of the organic thin film layer contains the aromatic diamine derivative by itself or as a component of a mixture, the device having a long lifetime and high luminous efficiency. (In the formula, R1 to R10 each independently represent a hydrogen atom, an alkyl group having 1 to 50 carbon atoms, or the like, and R11 represents a substituted or unsubstituted alkyl group having 1 to 50 carbon atoms or the like, and at least one of A, B, and C represents a substituted or unsubstituted silyl group, and the others each represent a hydrogen atom, a substituted or unsubstituted alkyl group having 1 to 50 carbon atoms, or the like, a, b, c, and d each independently represent an integer of 1 to 5.)

Owner:IDEMITSU KOSAN CO LTD

Novel fire resistant polyimide foam and method of producing the same

The invention relates a novel high temperature resistant polyimide foam and the preparation process thereof is as follows: (1) firstly, 2, 3, 3', 4'-biphenyl tetracarboxylic dianhydride or 2, 3, 3', 4'-biphenyl tetracarboxylic dianhydride and another type of aromatic dianhydride are heated and refluxed in a fatty alcohol solution so as to change the tetracarboxylic dianhydride into diacid diester; (2) in accordance with a certain proportion, the obtained diacid diester is synthesized into a precursor solution with one type or more of aromatic diamine and a blocking agent of acetylenyl benzene and a certain quantity of foam stabilizer is added into the solution; (3) the solution is heated to remove tiny molecule volatile matter and obtain a polymide precursor powder; and (4) the precursor powder is filled into a mould to be frothed at high temperature and carries out imidization so as to obtain the polyimide foam. The density of the novel high temperature resistant polyimide foam is 10 kg / m<3> to 500 kg / m<3> and the vitrified transformation temperature is over 350 DEG C; and the foam is characterized by excellent high temperature resistance, low temperature resistance, mechanical properties and functions of anti flaming, heat insulation or noise reduction.

Owner:SHENZHEN HIFUTURE ELECTRIC

Polyimide resin composition and laminate including same

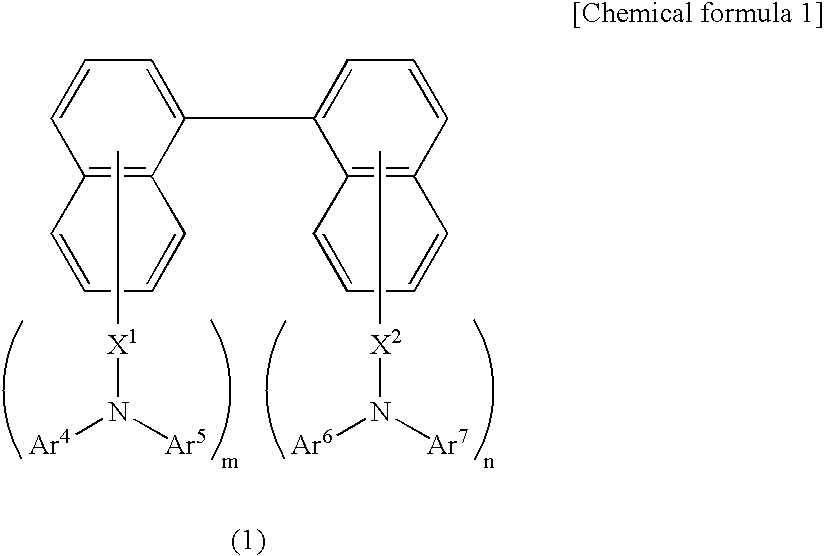

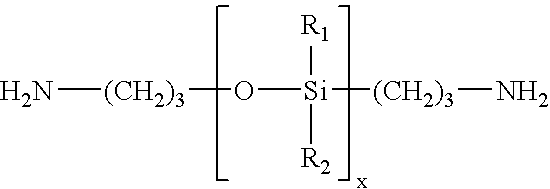

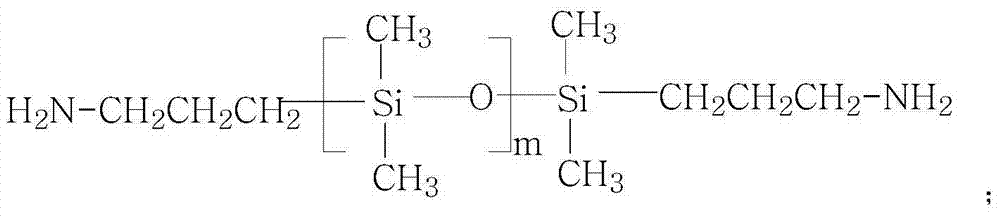

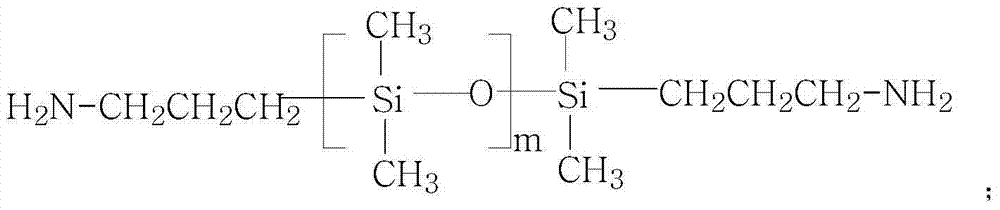

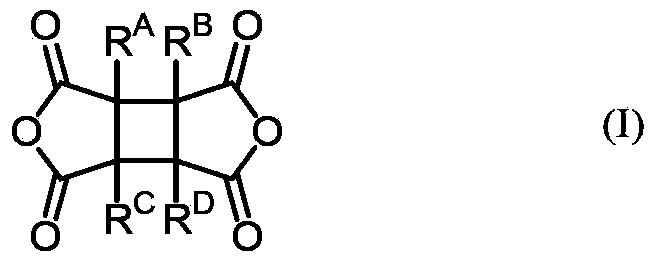

ActiveCN103298855AHigh viscosity elasticGood flexibilityImpression capsElectrolytic capacitorsPolyresinGreek letter alpha

The present invention addresses the problem of providing a resin composition including a polyimide that is soluble in a solvent and from which a resulting film will be highly viscoelastic and flexible at high temperatures. In order to resolve this problem, a polyimide resin composition includes a polyimide including polycondensate units of tetracarboxylic dianhydride and diamine, wherein either the tetracarboxylic dianhydride includes a dianhydride (alpha 1) represented by general formula (1) or the diamine includes an aromatic diamine (beta 1) represented by general formula (2) and the diamine includes an aliphatic diamine (beta 2) represented by general formula (3) or (4), the sum amount of the dianhydride (alpha 1) and aromatic diamine (beta 1) contained therein being 5-49 mol% with respect to the sum of the tetracarboxylic dianhydride and the diamine, and the amine equivalent thereof being 4,000-20,000. In the formula (3), R1 is an aliphatic chain; H2N-R2-NH2... (4), in the formula (4), R2 is an aliphatic chain.

Owner:MITSUI CHEM INC

Polyimide resin composition and laminate including polyimide resin composition

InactiveUS20130288120A1Excellent solvent solubilityHigh viscoelasticityImpression capsElectrolytic capacitorsViscoelasticityHigh heat

To provide a resin composition that contains a solvent-soluble polyimide and can provide a film exhibiting high viscoelasticity and flexibility at high temperatures. To attain this, a polyimide resin composition is provided that includes a polyimide having a polycondensation unit of a tetracarboxylic acid dianhydride and a diamine, wherein the tetracarboxylic acid dianhydride includes an (α1) tetracarboxylic acid dianhydride represented by general formula (1), or the diamine includes an (β1) aromatic diamine represented by general formula (2), the diamine includes an (β2) aliphatic diamine represented by general formula (3) or (4), a total amour of the (α1) tetracarboxylic acid dianhydride and the (β1) aromatic diamine is 5 to 49 mol % with respect to a total amount of the tetracarboxylic acid dianhydride and the diamine, and an amine equivalent of the polyimide is 4,000 to 20,000.

Owner:MITSUI CHEM INC

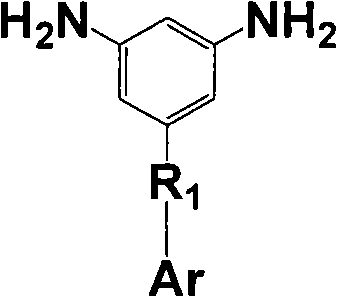

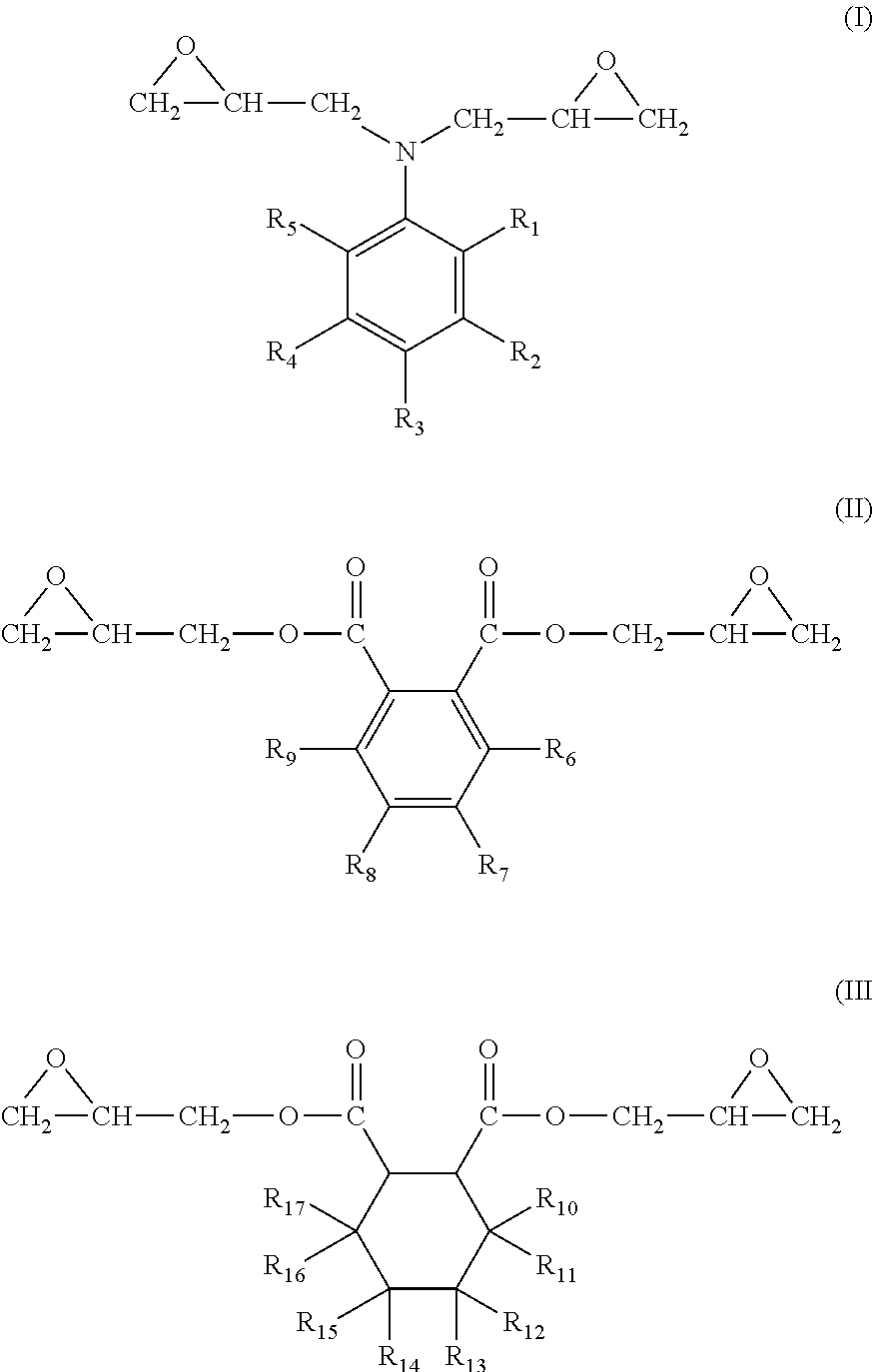

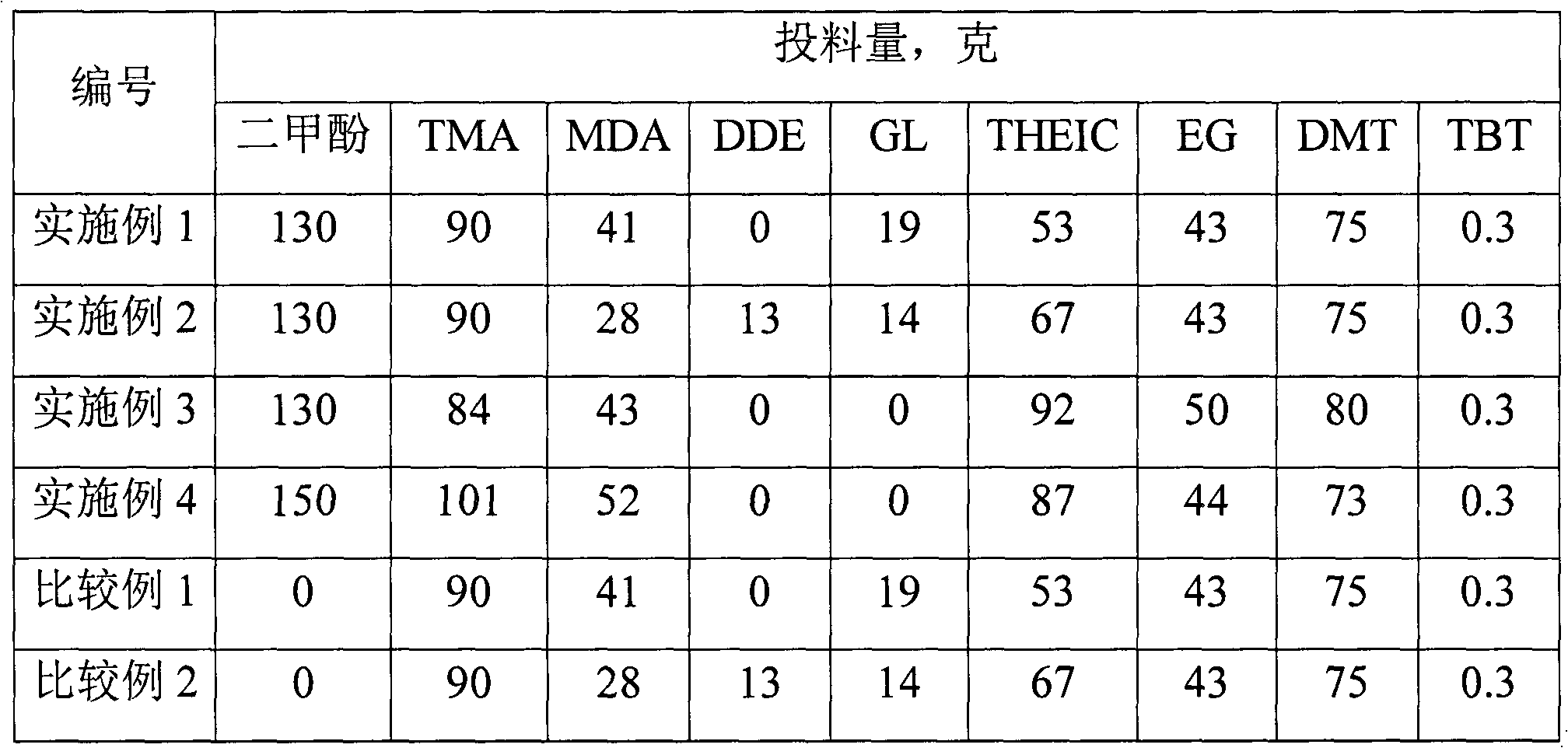

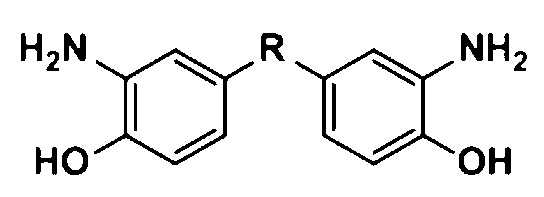

Aromatic diamine with phthalonitrile pendant group, preparation method thereof and polyimides or polyamide prepared therefrom

InactiveCN101307013ARegulating processabilityRegulatory usabilityPreparation by carboxylic acid amide dehydrationFiberSide chain

The invention discloses an aromatic diamine containing o-phthalonitrile side group. The structure formula of the aromatic diamine is shown as the right formula. The invention also discloses a method for preparing the aromatic diamine and polyimide and daiamid which are prepared by taking the aromatic diamine containing the o-phthalonitrile side group as one of raw materials. The o-phthalonitrile side group in the aromatic diamine is positioned on the side chain, thereby adjusting the degree of crosslinking with adjusting the polymer molecular weight and widening the application of the polyimide and the daiamid in a thick-wall composite material or a composite material element with a complicated shape and the fields of membrane material and fiber.

Owner:SICHUAN UNIV

Binder resin composition for electrode, electrode mixture paste, and electrode

ActiveUS20120168688A1Small degree of swellingIncreased fracture energyHybrid capacitor electrodesElectrolytic capacitorsDiaminodiphenyl etherCarboxylic acid

The present invention relates to a binder resin composition for an electrode, including a polyamic acid and a solvent, wherein the polyamic acid is (i) a polyamic acid which includes a tetracarboxylic acid component including 10 to 100 mol % of 4,4′-oxydiphthalic acid and 90 to 0 mol % of 3,3′,4,4′-biphenyltetracarboxylic acid and / or pyromellitic acid and a diamine component including an aromatic diamine having 1 to 4 aromatic rings, (ii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 10 to 90 mol % of p-phenylene diamine and 90 to 10 mol % of 4,4′-diaminodiphenyl ether, or (iii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 40 mol % or more of a bis[4-(4-aminophenoxy)phenyl] compound.

Owner:UBE IND LTD

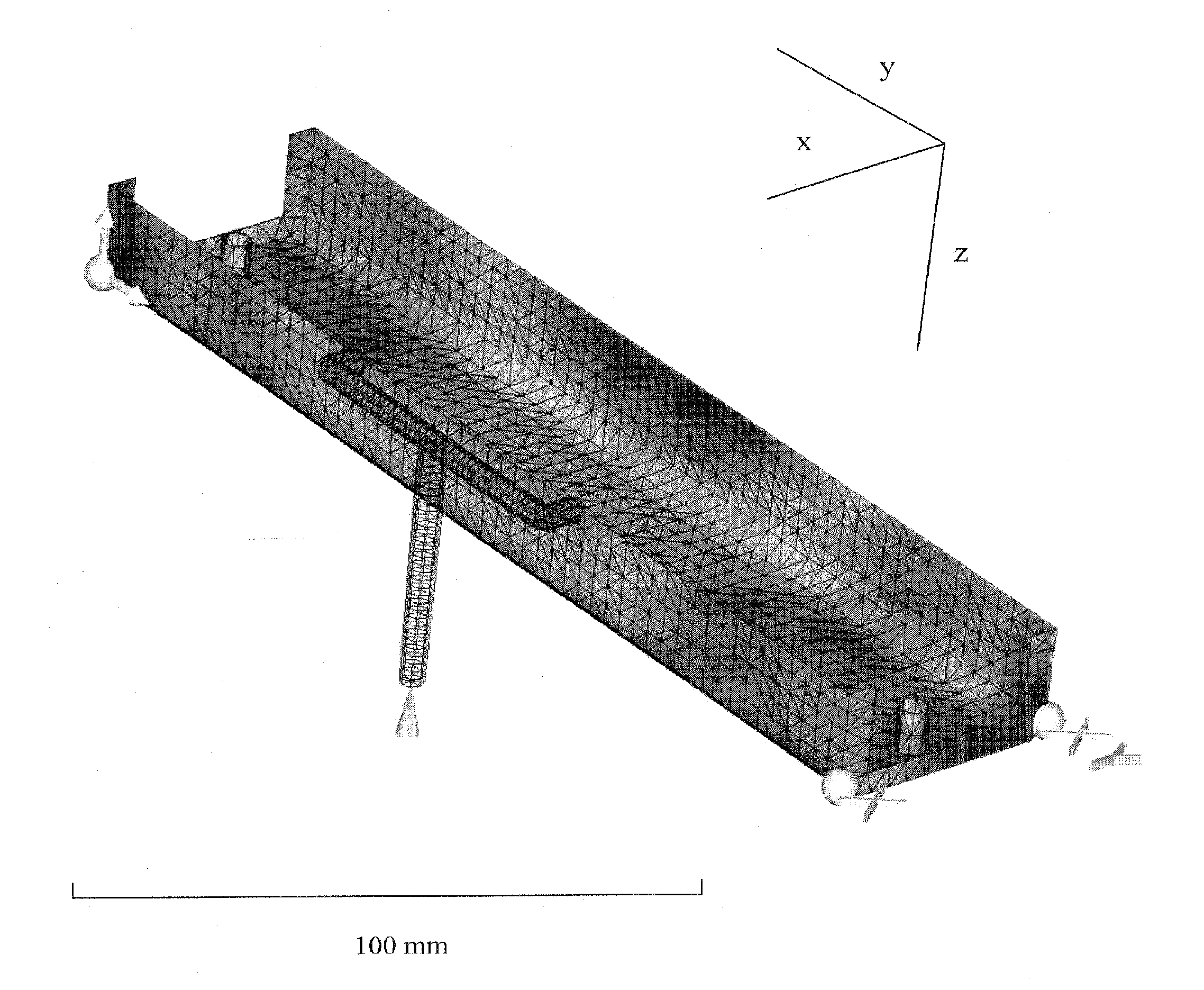

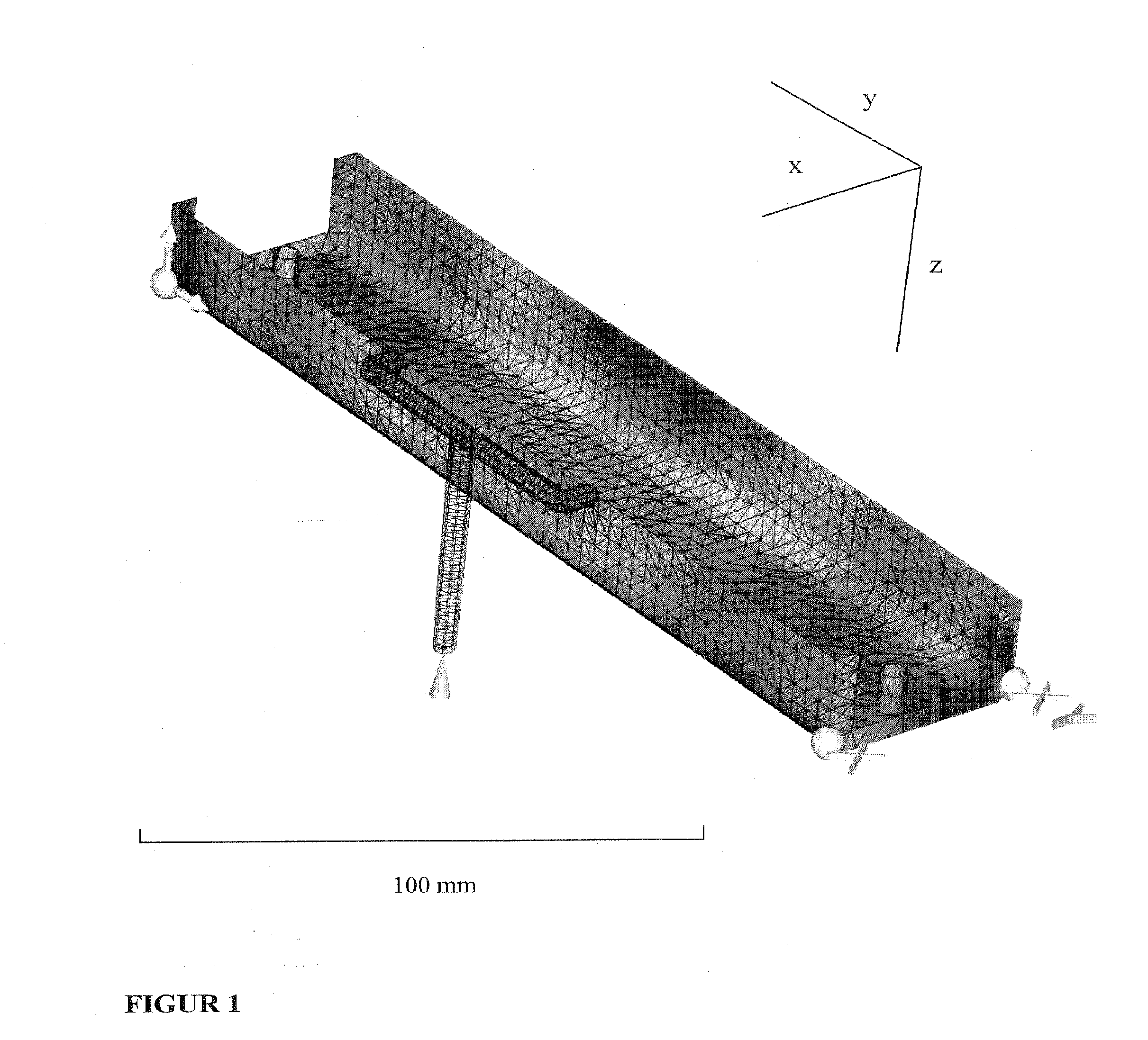

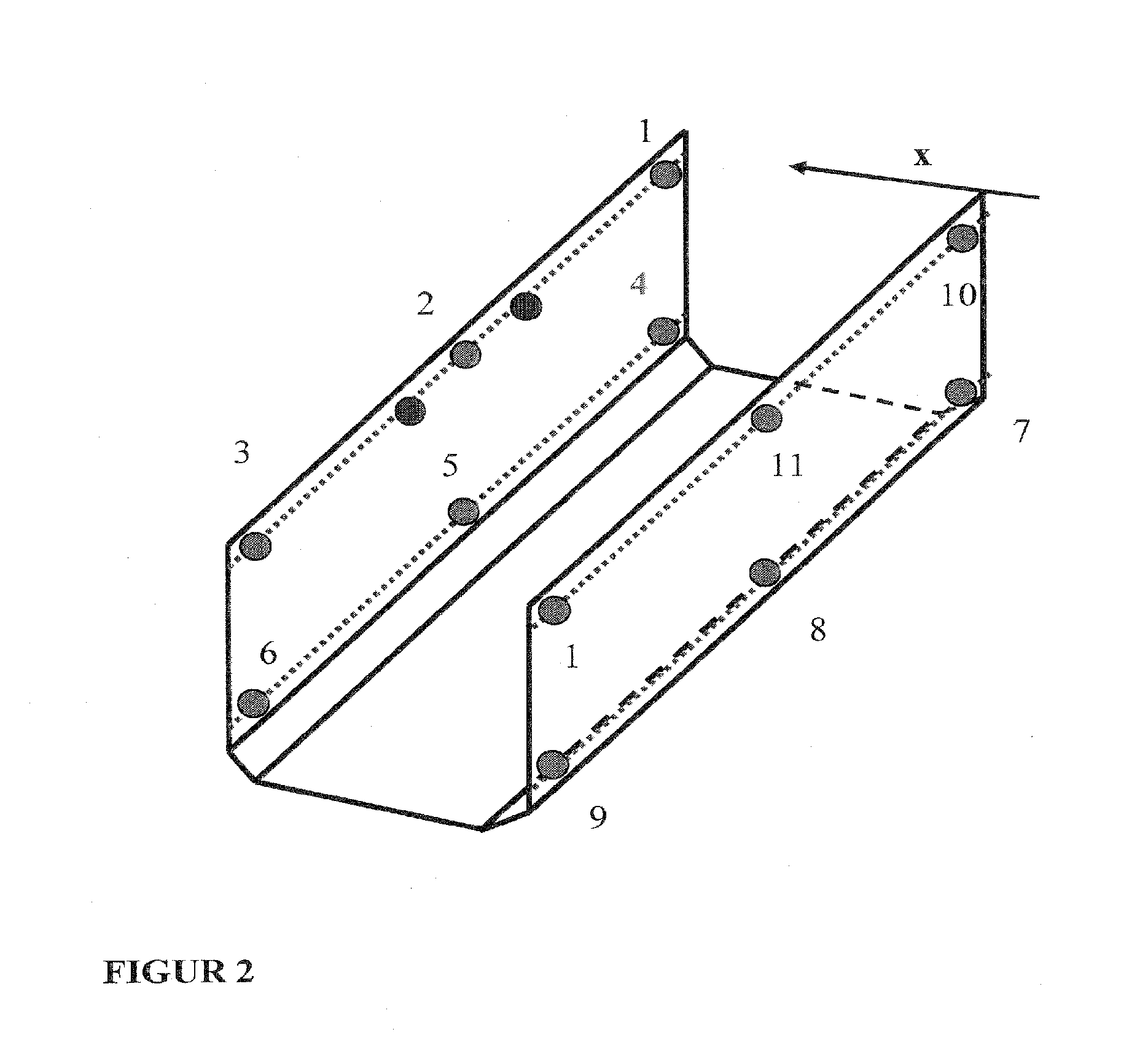

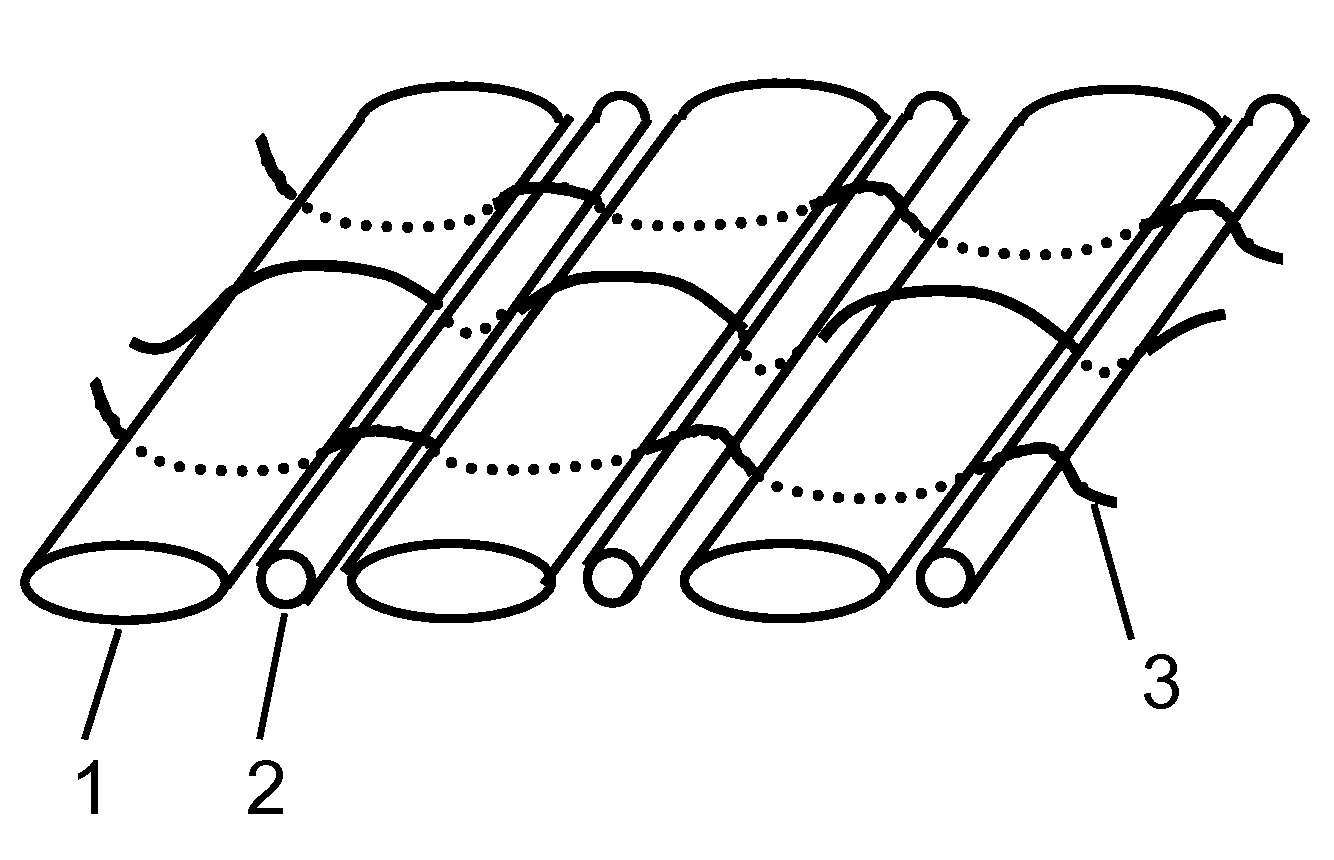

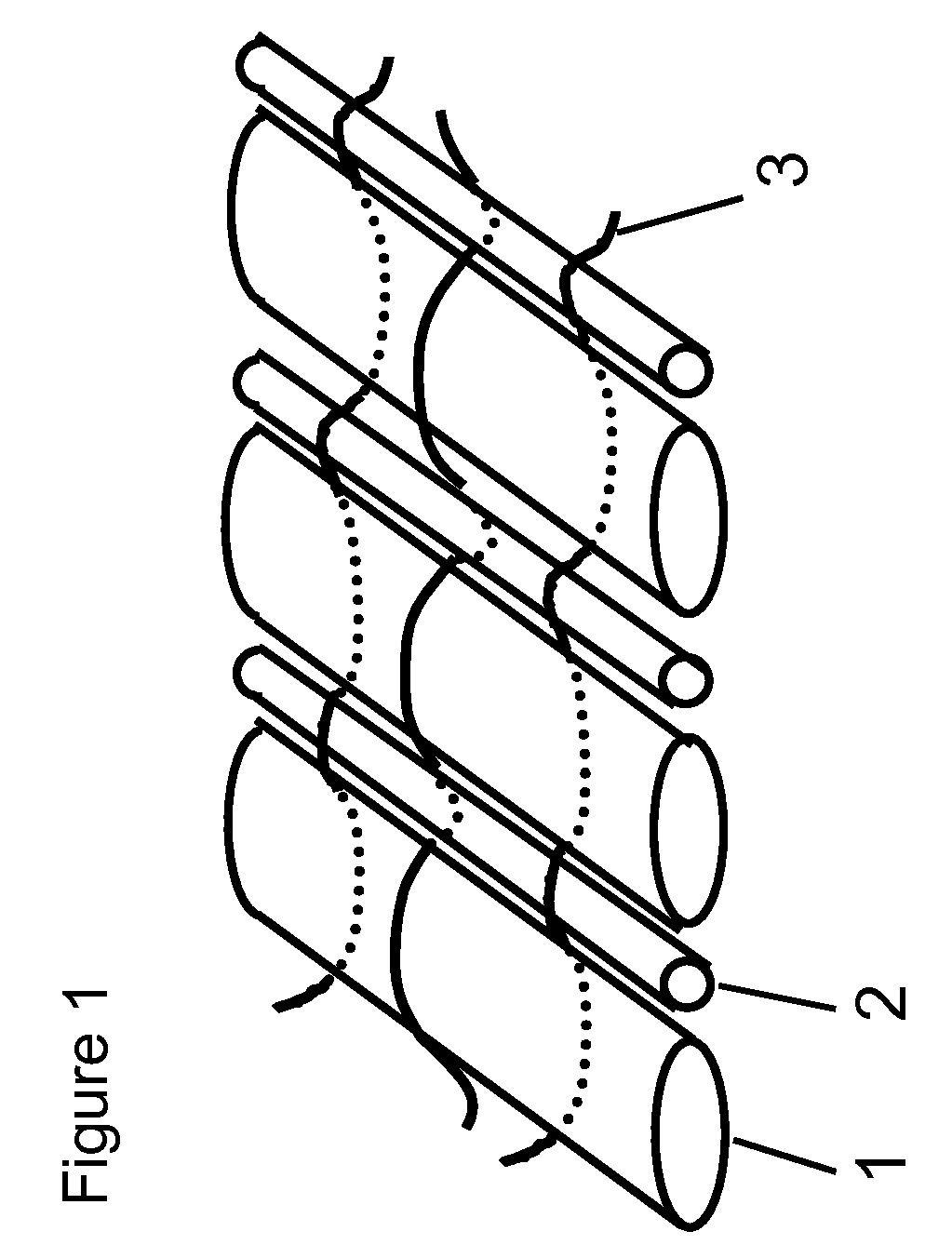

Polyamide molding materials reinforced with glass fibers and injection molded parts thereof

ActiveUS20110240930A1High transversal rigidityLow viscosityMaterial nanotechnologyConductive materialFiberCarbon fibers

The present invention relates to reinforced polyamide molding materials with high notch impact strengths, comprising low viscous polyamides and flat glass fibers as a reinforcing medium, characterized in a polyamide matrix, comprising the following components: (A) 0 to 60 wt.-% of at least one aliphatic, partly crystalline polyamide with a solution viscosity, measured in m-cresol (0.5 wt-%), of ηrel less than 1.9, (B) 0 to 60 wt.-% of at least one amorphous or microcrystalline polyamide based on aliphatic, cycloaliphatic or aromatic diamines, dicarboxylic acids, lactams and / or aminocarboxylic acids, preferably with 6 to 36 carbon atoms, or a mixture of such homopolyamides and / or copolyamides, wherein the components (A) and (B) fulfill the condition: (A)+(B)=20 to 60 wt.-% and that, in the case of a mixture of components (A) and (B), at least 50 weight parts aliphatic blocks (A) are present in the mixture, and a filler component, comprising: (C) 40 to 80 wt.-% flat glass fibers with elongated shape, and the glass fibers have a non-circular cross-sectional area and a size ratio of the main cross-sectional axis to the secondary cross-sectional axis of between 2 to 5, particularly between 3 and 4, and (D) 0 to 40 wt.-% particle like or layer like fillers, with the prerequisite that carbon fibers are excluded, wherein the polyamide molding materials optionally comprise up to 5 wt.-% of further usual additives and auxiliary agents (E), and wherein the weight of the components (A) to (E) sums up to 100%.

Owner:EMS CHEM AG

Silicon-containing polyimide copper-clad plate and preparation method thereof

InactiveCN104844801AConvenient sourceSimple preparation processSynthetic resin layered productsLaminationAlkali freeCopper foil

The invention relates to a silicon-containing polyimide copper-clad plate and a preparation method thereof. The silicon-containing polyimide copper-clad plate is composed of a copper foil, an alkali-free glass cloth and silicon-containing polyimide resin. The preparation method comprises the steps of: putting organosilicon diamine and an organic solvent into a reaction kettle, conducting stirring dissolving, then adding aromatic dianhydride, adding an azeotropic dehydrating agent, carrying out heating reflux water diversion reaction to obtain a component A; putting aromatic diamine and a strong polar aprotic organic solvent into the reaction kettle, conducting stirring dissolving, adding aromatic dianhydride and maleic anhydride, and carrying out stirring reaction to obtain a component B; subjecting the component A and component B to stirring reaction at room temperature so as to obtain silicon-containing polyimide resin; using a gluing machine to dip silicon-containing polyimide resin, removing the solvent to obtain a prepreg, conducting cutting and lamination, laying copper foil, and carrying out heating pressurization curing, thus obtaining the silicon-containing polyimide copper-clad plate. The silicon-containing polyimide copper-clad plate has good electrical properties, mechanical properties, and high temperature resistance, etc. The operation process is simple, and the product has excellent comprehensive performance and has broad market prospects.

Owner:DONGHUA UNIV +1

Polysiloxane acid imide foam and method for preparing same

The invention relates to polysiloxane-imide foam and a preparation method thereof. The polysiloxane-imide foam is made by the steps: one or more than one sort of aromatic dianhydride is composed with one or more than one sort of aromatic diamine according to a certain proportion to get polyimide acid solution, then certain content of silicon-containing blocking agent, polysiloxane precursor and foam stabilizer are added sequentially, then the mixture is heated to remove small molecule volatiles so as to obtain polysiloxane precursor powder, then the powder is filled in a mould and frothed at high temperature to make soft elastic, semi-rigid and rigid polysiloxane-imide foam materials with a density of 0.01g / cm3-1.0g / cm3 and a glass transition temperature of 280 DEGC -350 DEG C. The polysiloxane-imide foam materials of the invention have good performances of high temperature resistance, low temperature resistance, flame retardancy, heat insulation and noise reduction and mechanical properties.

Owner:SHENZHEN HIFUTURE ELECTRIC

Epoxy resin composition, fiber-reinforced composite material, and method for producing the same

InactiveUS20110097568A1Low viscosityExcellent impregnationWoven fabricsThin material handlingEpoxyFiber-reinforced composite

Disclosed herein are an epoxy resin composition for fiber-reinforced composite materials which has low viscosity, high Tg, high elastic modulus, and excellent fracture toughness and a fiber-reinforced composite material using such an epoxy resin composition which has excellent thermal properties, compressive strength, impact resistance, fatigue resistance, and open-hole tensile strength and which is suitable for producing structural parts of aircraft and the like. The epoxy resin composition comprises at least a given bifunctional epoxy resin as a component (A), a liquid aromatic diamine curing agent as a component (B), and core-shell polymer particles as a component (C), wherein the core-shell polymer particles as the component (C) contain epoxy groups in their shell and have a volume-average particle size of 50 to 300 nm.

Owner:TORAY IND INC

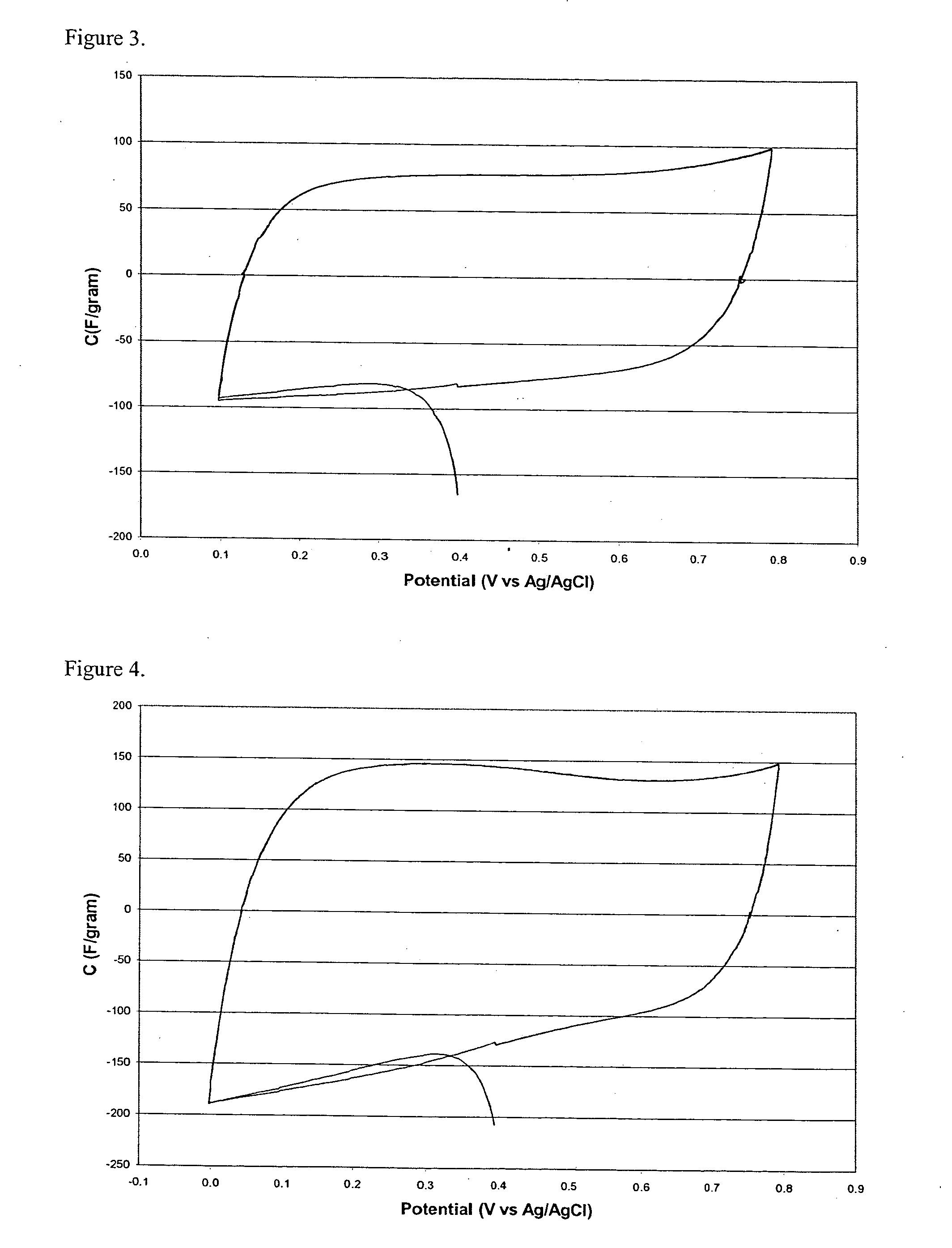

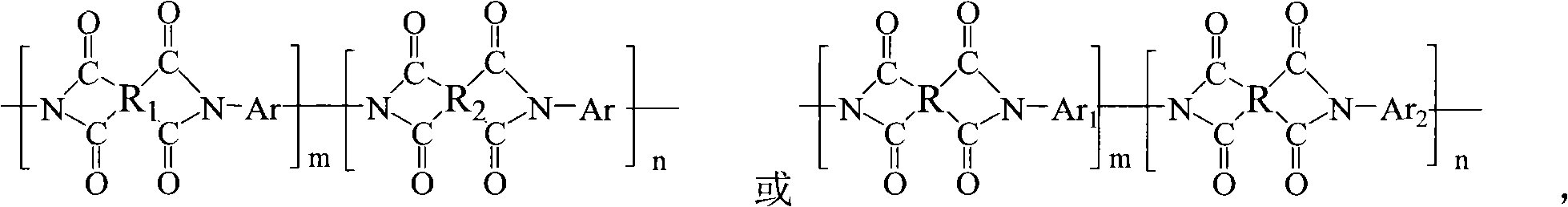

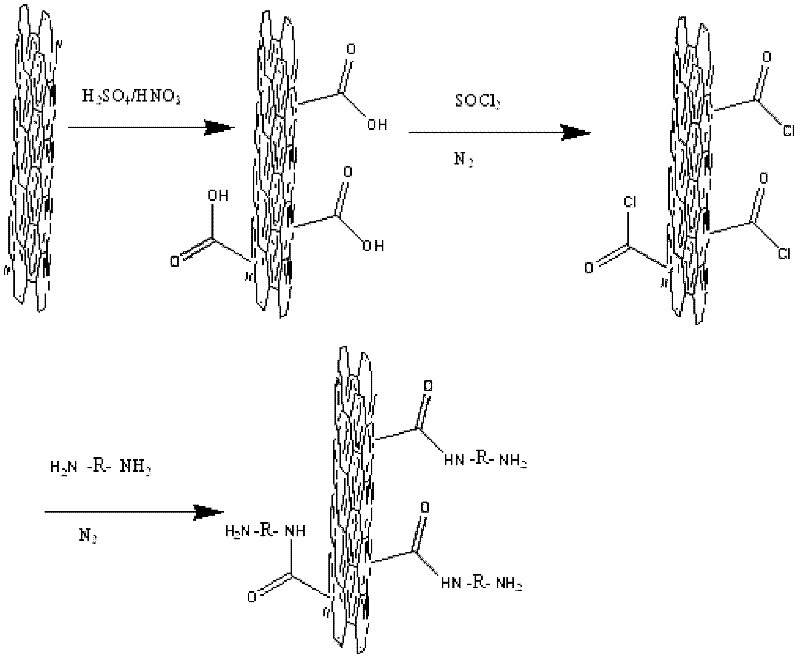

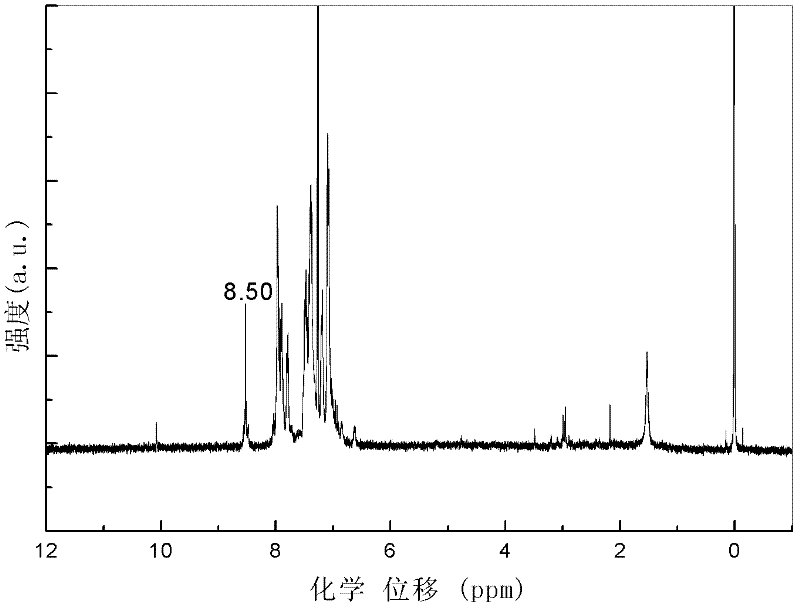

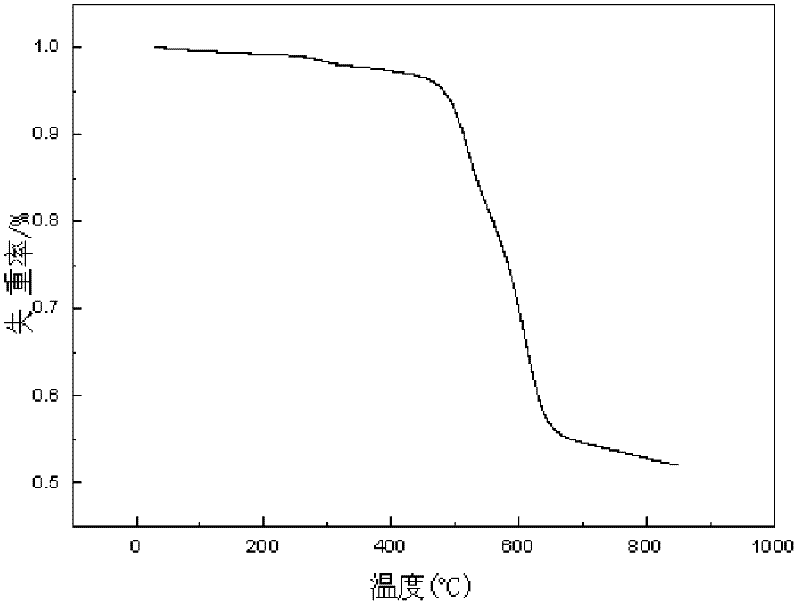

Carbon nanotube/poly-Schiff base polymer and its preparation method and application

InactiveCN102295775AImprove high temperature resistanceHas a third-order nonlinear characteristicTenebresent compositionsResponse sensitivityPolymer science

The invention relates to a carbon nanotube / poly Schiff base polymer, a preparation method thereof, and an application thereof. The invention relates to a composite material of carbon nanotube and poly Schiff base, a preparation method thereof, and an application thereof. With the polymer and the methods provided by the invention, problems of existing poly Schiff base of low photoelectrochromic response sensitivity and poor thermal stability are solved. According to the invention, aminated carbon nanotubes, aromatic diamine monomers, and dialdehyde compounds are subject to an in situ polymerization reaction, such that the product is obtained. First, aminated carbon nanotubes and part of dialdehyde compounds are mixed and heated until reflux liquid is generated; then aromatic diamine monomers and rest dialdehyde compounds are mixed and injected in batches, and the reaction is continued, such that the product is obtained. The polymer provided by the invention provides electrochromic, acidichromic, and photochromic performances, and has good thermal stability. Therefore, the polymer can be used in displays and acid-base sensors. The polymer has high electrochromic, acidichromic, and photochromic sensitivity, and provides reversible acidichromic and photochromic performances.

Owner:HEILONGJIANG UNIV

Liquid epoxy resin composition

InactiveUS20070196612A1Low viscosityEasily show solvation and swellingLayered productsSemiconductor/solid-state device detailsPolymer scienceElectrical connection

There is provided a low viscosity liquid epoxy resin composition which has excellent repairability because of the capability to remove residues at around room temperature even in the case of an electronic part device having a deficiency in the electric connection after once carrying out underfill, and what is more, wherein an electric parts device having a connected mounted structure shows high reliability. The liquid epoxy resin composition is used for resin-filling the gap between a circuit substrate and a semiconductor part on an electronic part device, wherein said electronic part device comprises a circuit substrate having an electrode part for connection and a semiconductor part having an electrode part for connection and being mounted on the circuit substrate in such a way that the electrode part of the circuit substrate and the electrode part of the semiconductor part are facing each other. In addition, the liquid epoxy resin composition comprises the following components (A) to (C) together with the following component (D). (A) A liquid epoxy resin. (B) An aromatic diamine curing agent. (C) An inorganic filler. (D) An organic additive.

Owner:NITTO DENKO CORP

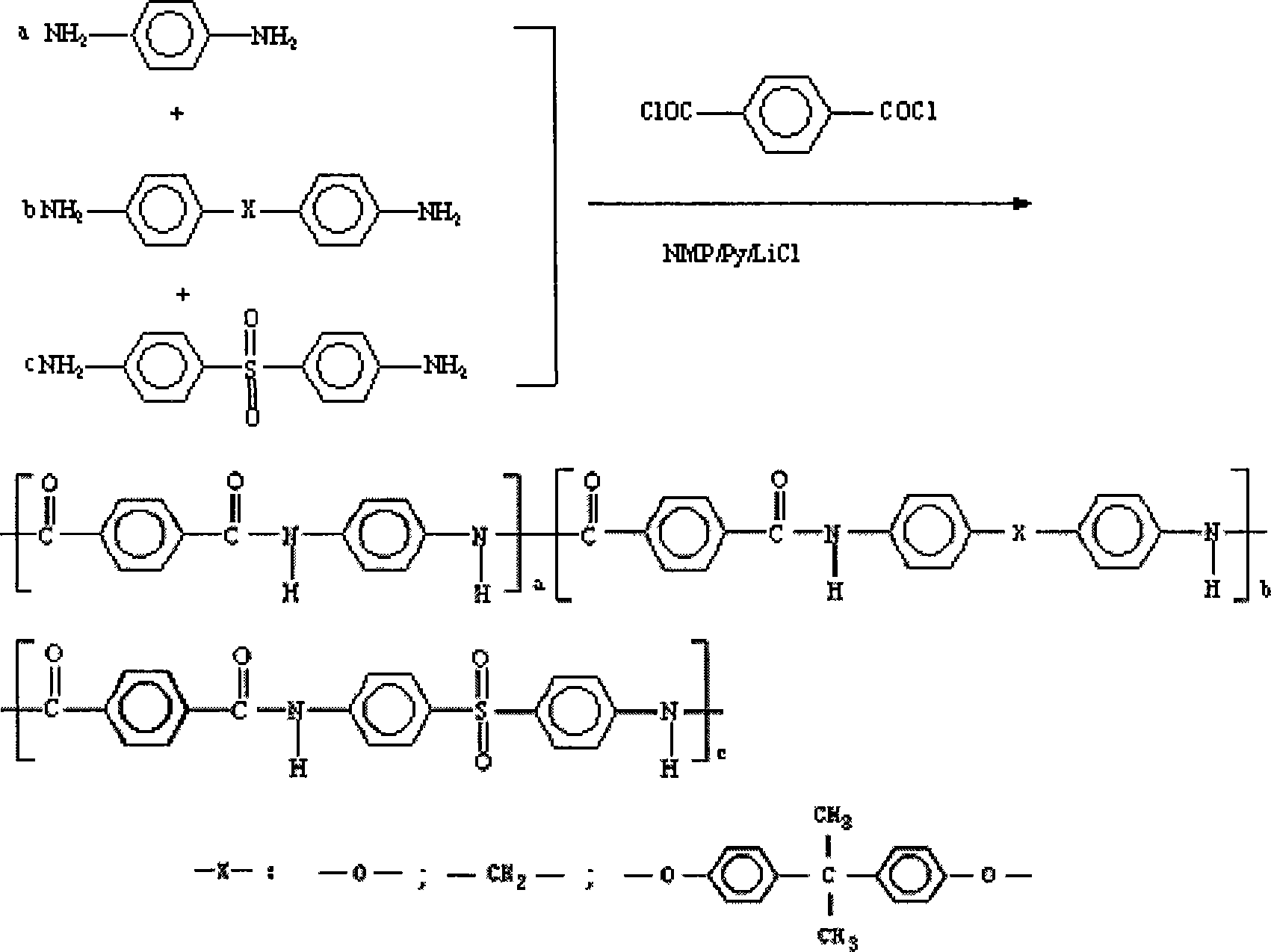

Random copolymerization polysulfonamide spinning liquid and preparation method thereof

InactiveCN101235552ADisruption of regularityImprove flexibilityMonocomponent copolyamides artificial filamentSpinning solutions preparationMetal chlorideMechanical property

The invention relates to random copolymerization poly-sulfone amide spinning fluid which is composited by three species aromatic diamine and terephthaloyl chloride and a method for preparing the random copolymerization poly-sulfone amide spinning fluid, wherein the spinning fluid takes the N-methyl-2pyrrolidone NMP as the dissolvent, monomer and the mole percent which are adopted by the method are as following: the aromatic diamine 40%-60%, the terephthaloyl chloride 60%-40%, taking the above total monomer 100% as a benchmark, further adding 1.0%-4.0% alkali chloride as the solvent. Since the method takes the manifold aromatic diamine as the monomer of the poly-reaction, which properly damages the regularity of the main chain, however, which has no effect to arrange the original crystal lattice, increasing the flexibility of the chain at various degree, the method is beneficial for orienting and crystallizing of the entire molecular chain and for improving the mechanical property of the material. The method has the advantages of simple technology, condition optimized, high operability, convenient manufacture and low cost.

Owner:SHANGHAI UNIV

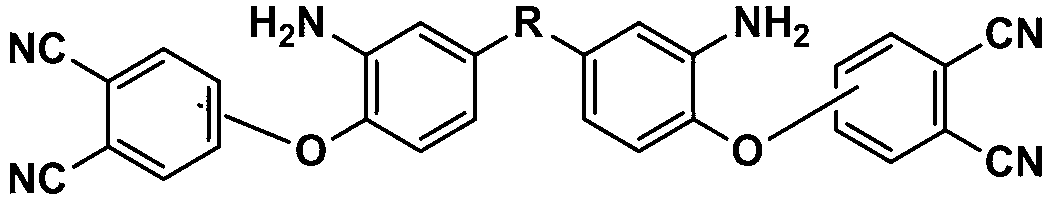

Polyester-imide wire coating enamel and preparation method thereof

InactiveCN101613572ALow costHigh imine contentPlastic/resin/waxes insulatorsCoatingsSolid componentCross-link

The invention discloses polyester-imide wire coating enamel and a preparation method thereof. The polyester-imide wire coating enamel is prepared from binary acid, triacid anhydride, aromatic diamine, dihydric alcohol, trihydric alcohol, phenol solvents, aromatic hydrocarbon solvents, a cross-linking agent and an additive, wherein the molar ratio of the binary acid to the binary acid+ the triacid anhydride is 0.3-0.5: 1; the molar ratio of the trihydric alcohol to the dihydric alcohol+ the triacid anhydride is 0.3-0.5: 1; the molar ratio of the dihydric alcohol to the binary acid+ the triacid anhydride is 0.6-1.0:1; the molar ratio of the triacid anhydride to the aromatic diamine is 2:1; the molar ratio of the phenol solvents to the triacid anhydride+ the aromatic diamine is 1-1.5: 1; and the molar ratio of the phenol solvents to the aromatic hydrocarbon solvents is 1.5-4: 1; the consumption of the cross-linking agent is calculated by the weight of effective metal components contained in the cross-linking agent and solid components in the polyester-imide wire coating enamel, and is between 0.3 and 1.3 percent; and the consumption of the additive is calculated by the weight of solid components contained in the additive and the weight of the solid components in the polyester-imide wire coating enamel, and is between 1 and 4 percent. The polyester-imide wire coating enamel can save the cost, and has high imine content as well as good heat resistance, solvent resistance and refrigerant resistance.

Owner:南通远景电工器材有限公司

Aromatic diamine containing phthalonitrile side group and synthesis method and application thereof

InactiveCN102993070AIncrease typeBreak the rigid structureCarboxylic acid nitrile preparationOrganic compound preparationImidePolymer science

The invention discloses aromatic diamine containing phthalonitrile side group, which is characterized in that the structural formula is shown in the specification, wherein R is one of CF3CCF3, CH3CCH3, O, CO and S. A preparation method of the aromatic diamine containing phthalonitrile side group comprises the following steps of: adding 4-nitrophthalonitrile or 3-nitrophthalonitrile, a compound 1, potassium carbonate and a high-boiling point solvent into a reaction container; conducting reaction for 10-24 hours at room temperature under protection of nitrogen; and then precipitating, filtering and drying. The aromatic diamine containing phthalonitrile side group can be applied to the preparation of polyimide, polyamide and polyamide-imide.

Owner:SICHUAN UNIV

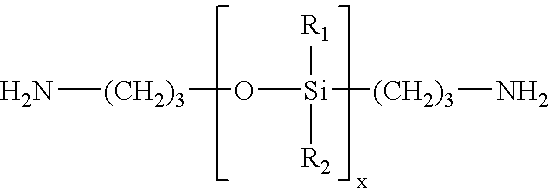

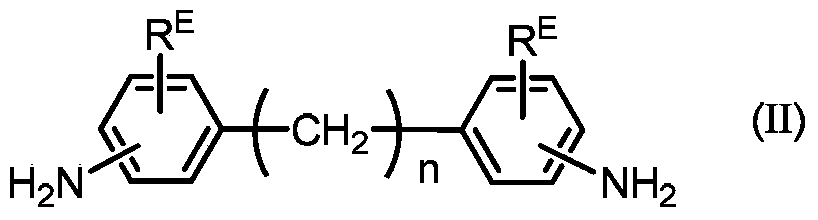

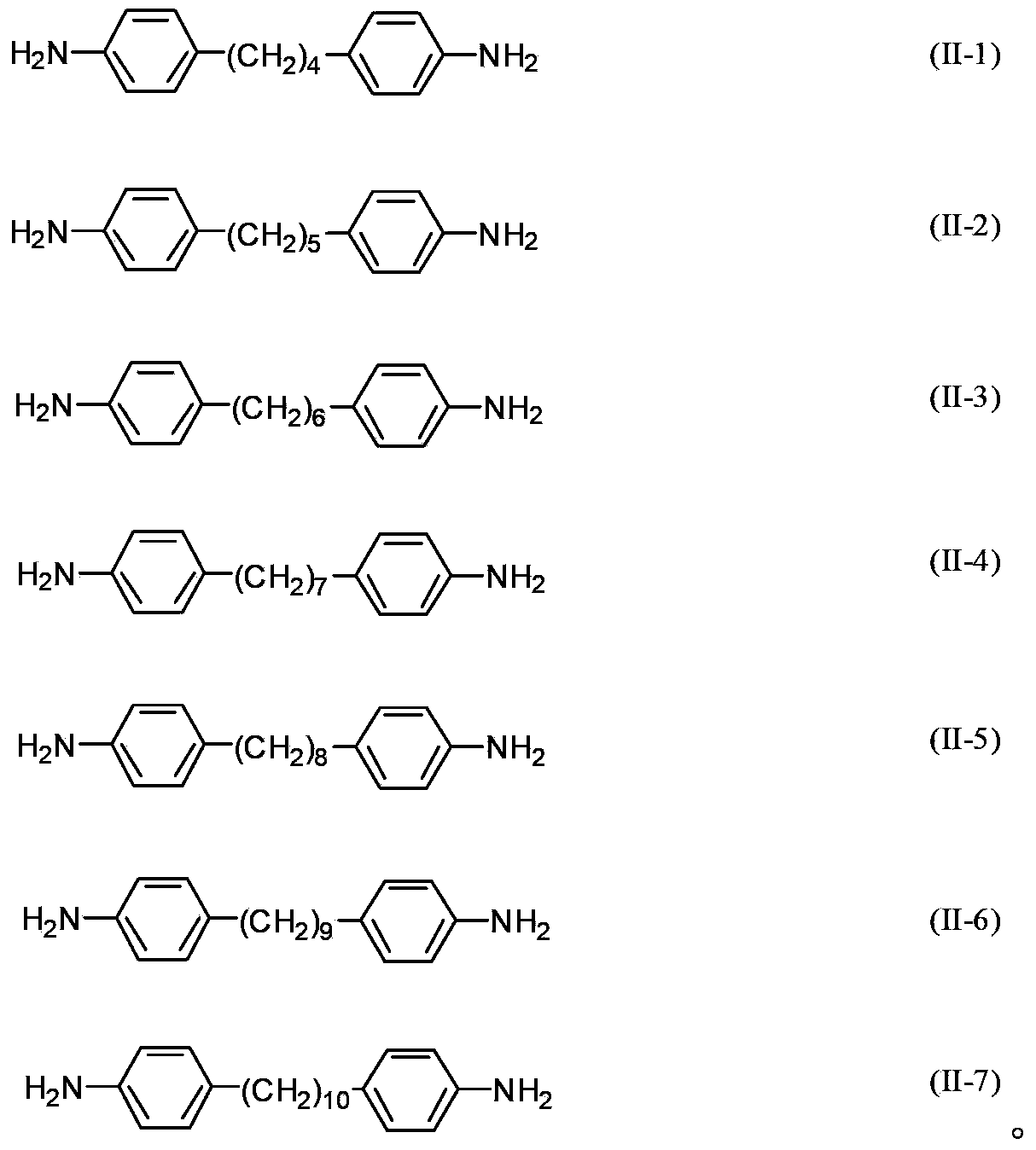

Liquid crystal alignment agent for photo alignment, liquid crystal alignment layer for photo alignment, and liquid crystal display element

ActiveCN103387833AHigh voltage retentionSmall amount of ionsLiquid crystal compositionsNon-linear opticsCarbon numberLiquid-crystal display

The invention provides a liquid crystal alignment agent for photo alignment, a liquid crystal alignment layer for photo alignment, and a liquid crystal display element. The liquid crystal alignment agent provided by the invention has a polyamide acid or a derivative thereof, the polyamide acid or the derivative thereof may be formed by reacting a mixer of cyclobutane tetracarboxylic dianhydride or tetracarboxylic dianhydride with specific aromatic diamine of an alkyl chain of a molecule with a carbon number larger than 4. With the adoption of the liquid crystal alignment agent, a liquid crystal alignment layer good in sensitivity of chemical change caused by light irradiation, excellent in alignment property of liquid molecule and high in optical transmittivity is formed. In addition, by applying the photo alignment layer to the liquid crystal display element, the liquid crystal display element with excellent display characteristics can be obtained.

Owner:JNC CORP +1

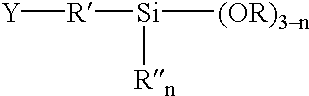

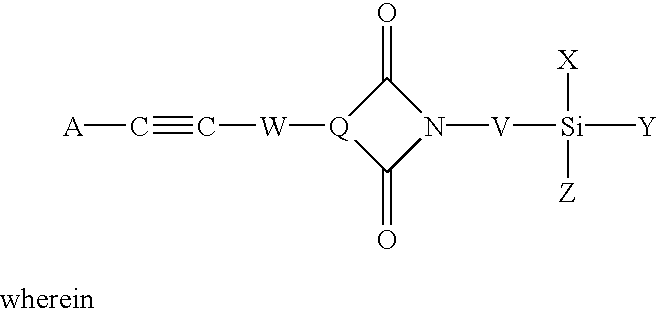

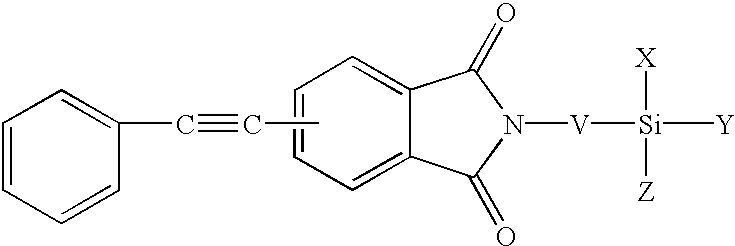

Phenylethynyl-containing imide silanes

Phenylethynyl containing imide-silanes were prepared from aminoalkyl and aminoaryl alkoxy silanes and 4-phenyletbynylphthalic anhydride in toluene to form the imide in one step or in N-methyl-2-pyrrolidinone (NMP) to form the amide acid intermediate. Controlled molecular weight pendent phenylethynyl amide acid oligomers terminated with aminoaryl alkoxy silanes were prepared in NMP from aromatic dianhydrides, aromatic diamines, diamines containing pendent phenylethynyl groups and aminoaryl alkoxy silanes. The phenylethynyl containing imide-silanes and controlled molecular weight pendent phenylethynyl amide acid oligomers terminated with aminoaryl alkoxy silanes were used to improve the adhesion between phenylethynyl containing imide adhesives and inorganic substrates (i.e. metal). Hydrolysis of the alkoxy silane moiety formed a silanol functionality which reacted with the metal surface to form a metal-oxygen-silicon (oxane) bond under the appropriate reaction conditions. Upon thermal cure, the phenylethynyl group of the coupling agent reacts with the phenylethynyl functionality of phenylethynyl containing imide adhesives and becomes chemically bonded to the matrix. The resultant adhesive bond is more durable (i.e. hot-wet environmental resistance) than adhesive bonds made without the use of the coupling agent due to covalent bond formation between the phenylethynyl containing imide-silane coupling agent or the controlled molecular weight pendent phenylethynyl amide acid oligomers terminated with aminoaryl alkoxy silanes and both the metal substrate and phenylethynyl containing imide adhesives.

Owner:SMITH JOSEPH G JR +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com