Patents

Literature

93results about How to "Increased fracture energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional protection paste for outside wall

ActiveCN101054492ALight weightReduce shear stressFilling pastesPolyurea/polyurethane coatingsPerliteMultiple function

An outside wall multi-functional protective slurry is composed of A and B components, in which A component contains elastical latex, cellulose aether, crack resistance fiber, lignified fiber, dispersant, anti mildew agent; B A component contains cement, perlite, girasol pearl, pulverized fuel ash, water reducer. The inventive outside wall multi-functional protective slurry has a perfect crack resistance and a high cohesive strength. The slurry matches with the outside wall external heat retaining and has a high cost performance. The invention accords to the industry standards of construction industry of JG / T157-2004 <> and outside wall heat retaining plaster standard and it has a certain heat insulation and heat retaining function.

Owner:南通甜港材料科技有限公司

Preparation method of lightly-crosslinked aliphatic-aromatic copolyester

ActiveCN102336896AHigh weight average molecular weightHigh elongation at breakAlcoholReaction temperature

The invention provides a preparation method of lightly-crosslinked aliphatic-aromatic copolyester. The copolyester can be synthesized and prepared from the following components: a) aromatic dibasic acid, ester, anhydride or a mixture thereof; b) aliphatic dibasic acid, ester, anhydride or a mixture thereof; c) aliphatic dibasic alcohol or alicyclic dibasic alcohol; and d) a compound with three or more esterification functional groups. The preparation method comprises the following steps: adding the four components a, b, c and d into a reaction device according to a certain ratio; vacuumizing; filling nitrogen gas; reacting at 170-230 DEG C; vacuumizing to carry out polycondensation reaction after the completion of esterification and / or interesterification; taking out the product after the completion of reaction; and cooling and molding in water to obtain the copolyester. The invention overcomes the defect of high complexity in the copolyester preparation process in the prior art. Besides, by adding the component d, the invention further improves the performance of the copolyester and widens the application range of the copolyester.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

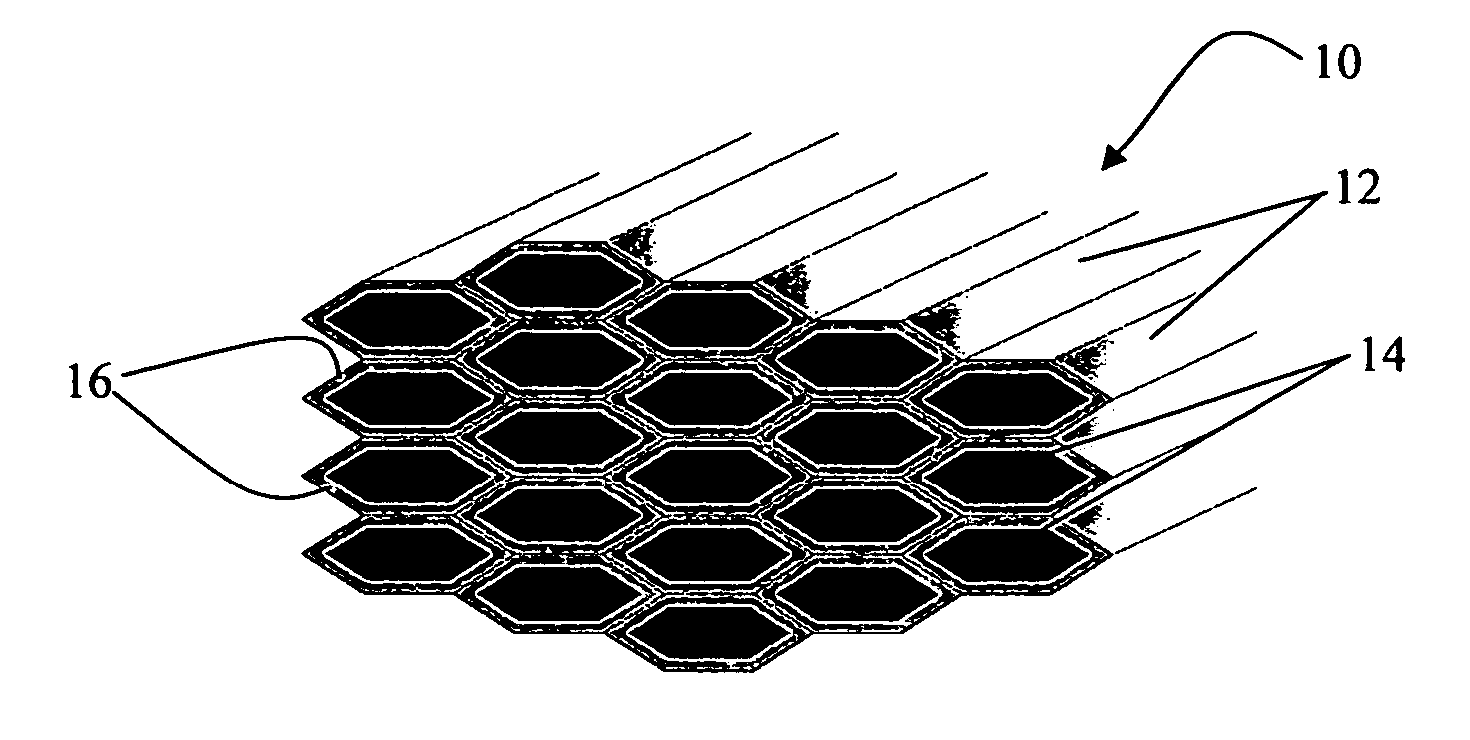

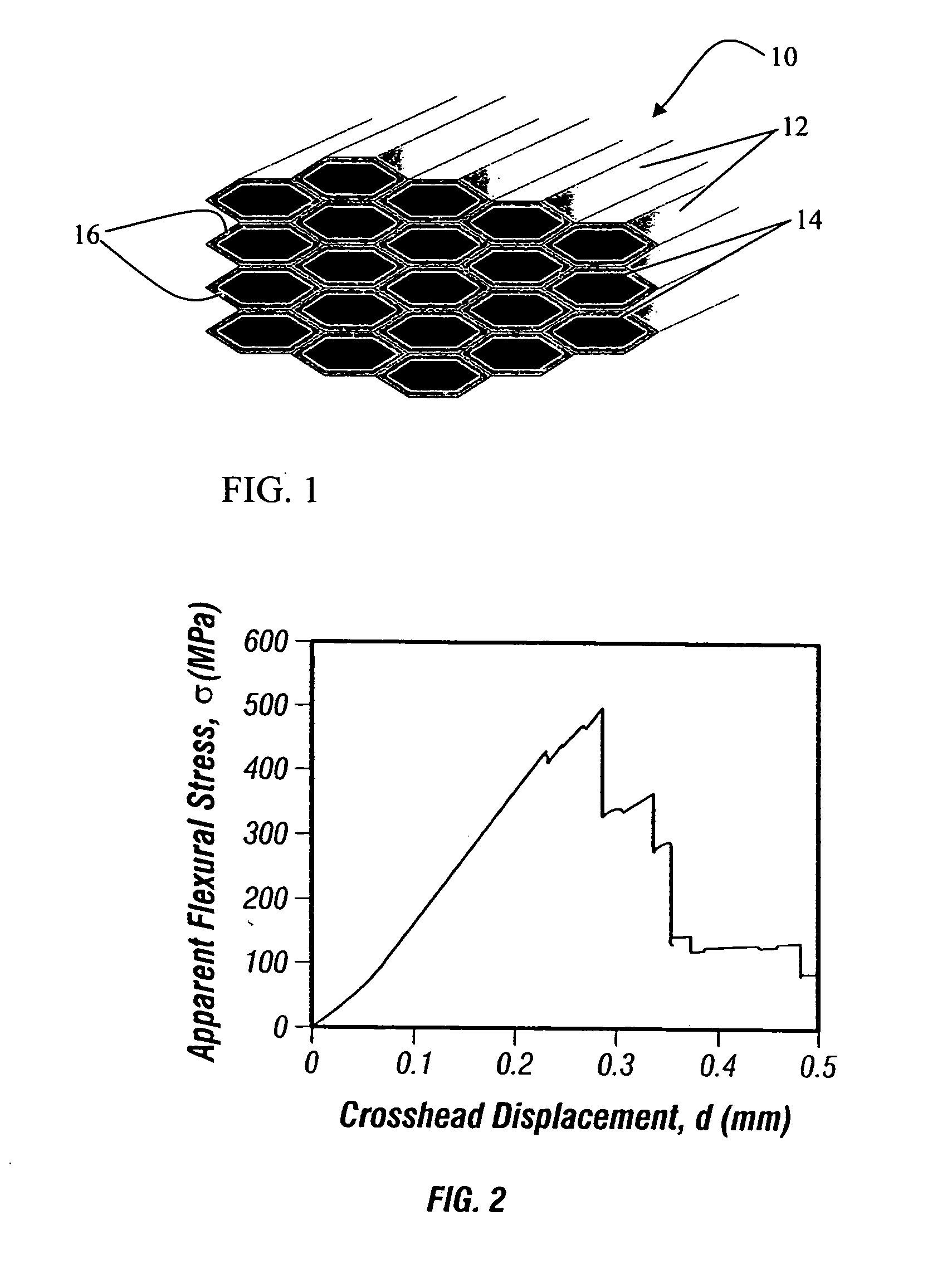

Aligned composite structures for mitigation of impact damage and resistance to wear in dynamic environments

InactiveUS20060091580A1Improve mechanical propertiesIncrease insensitivityNatural cellulose pulp/paperFilament/thread formingFiberDamage tolerance

Fibrous monolith composites having architectures that provide increased flaw insensitivity, improved hardness, wear resistance and damage tolerance and methods of manufacture thereof are provided for use in dynamic environments to mitigate impact damage and increase wear resistance.

Owner:ADVANCED CERAMICS

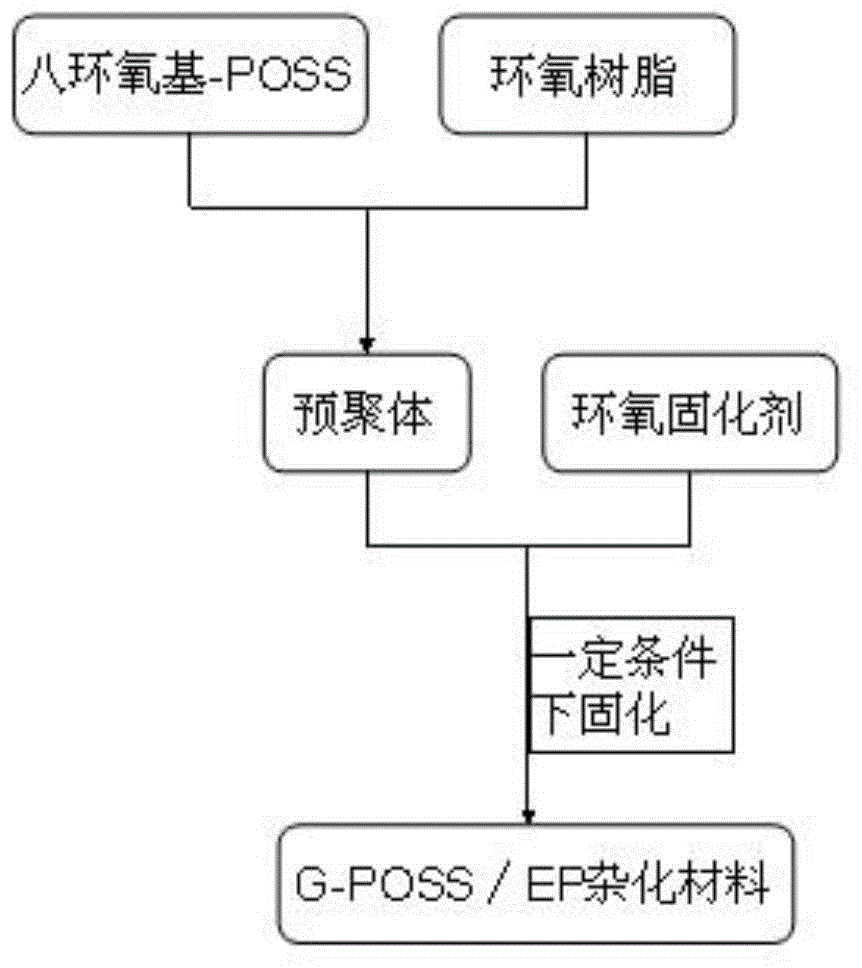

Low dielectric constant polyhedral oligomeric silsesquioxane (POSS)/ epoxy resin hybrid material and preparation method

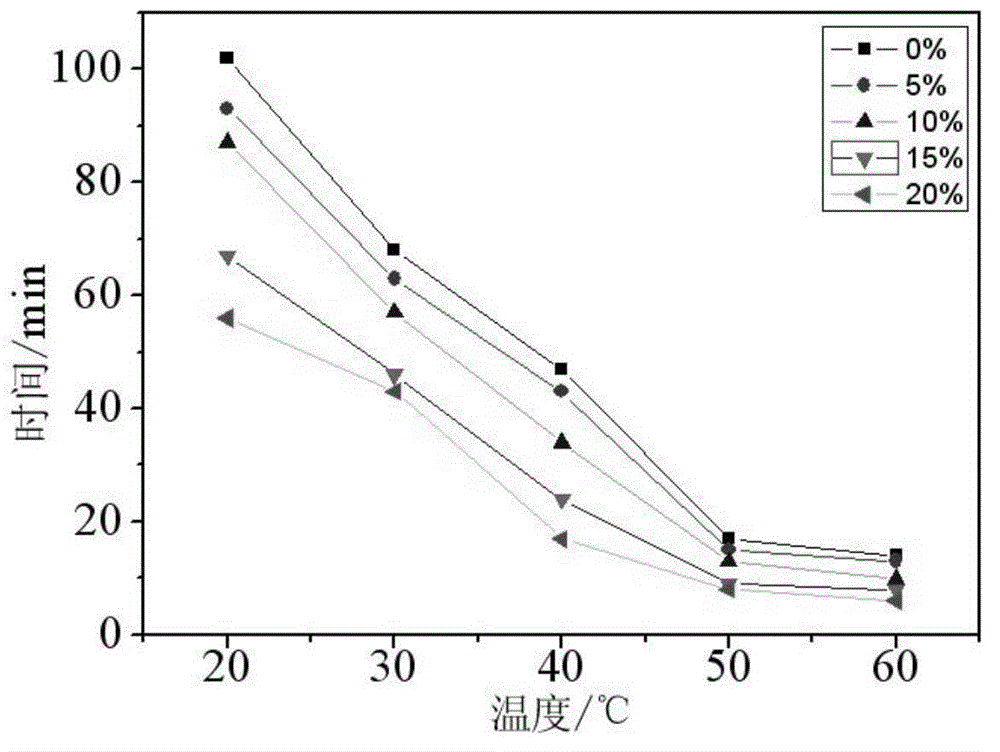

The invention relates to a low dielectric constant polyhedral oligomeric silsesquioxane (POSS) / epoxy resin hybrid material and a preparation method. Epoxy resin and eight epoxy group polyhedral oligomeric silsesquioxane (G-POSS) are evenly mixed in a 80 DEG C breaker according to a certain proportion, an equivalent amount of curing agent triethylene tetramine (TETA) (an amino group in the TETA and an epoxy group in the G-POSS, epoxy resin (EP) are measured according to a 1:1 molar rate) is added and fully stirred, after vacuum defoamation is conducted for 20-30 minutes, the mixture is slowly poured into a preheating mold, conducted solidification in a stove 50 DEG C / 2 hours, 70 DEG C / 3 hours and 80DEG C / 1 hour, cooled to room temperature along with the stove and processed for 4-6 hours after demolding. The low dielectric constant POSS / epoxy resin hybrid material is small in average grain size and excellent in transparent performance, mechanical property and dielectric property.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

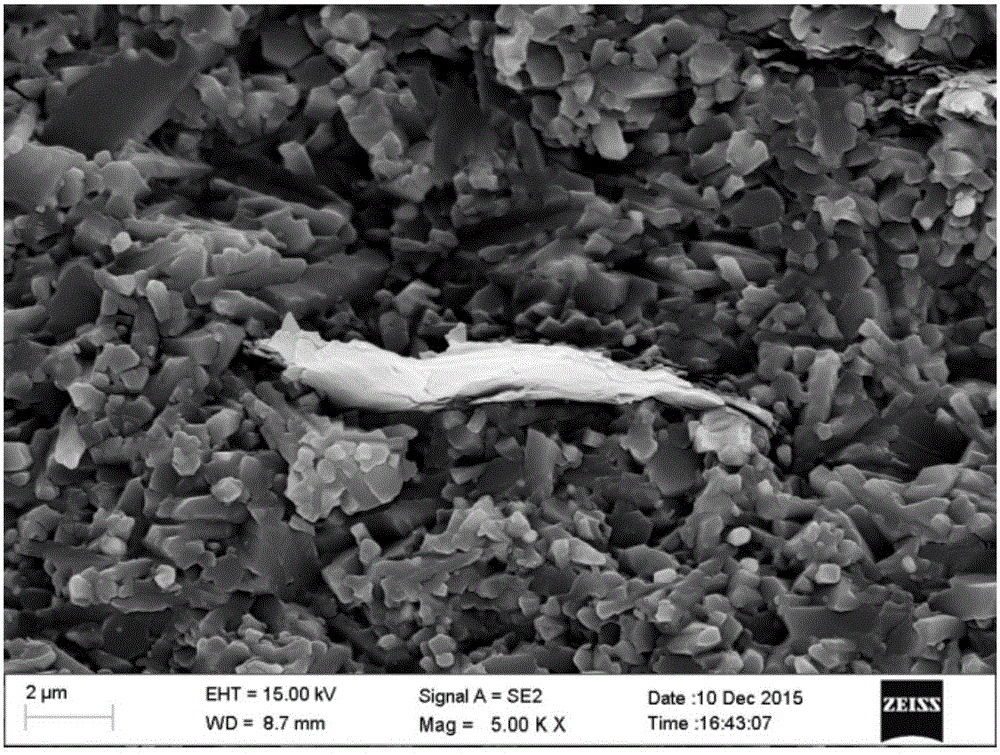

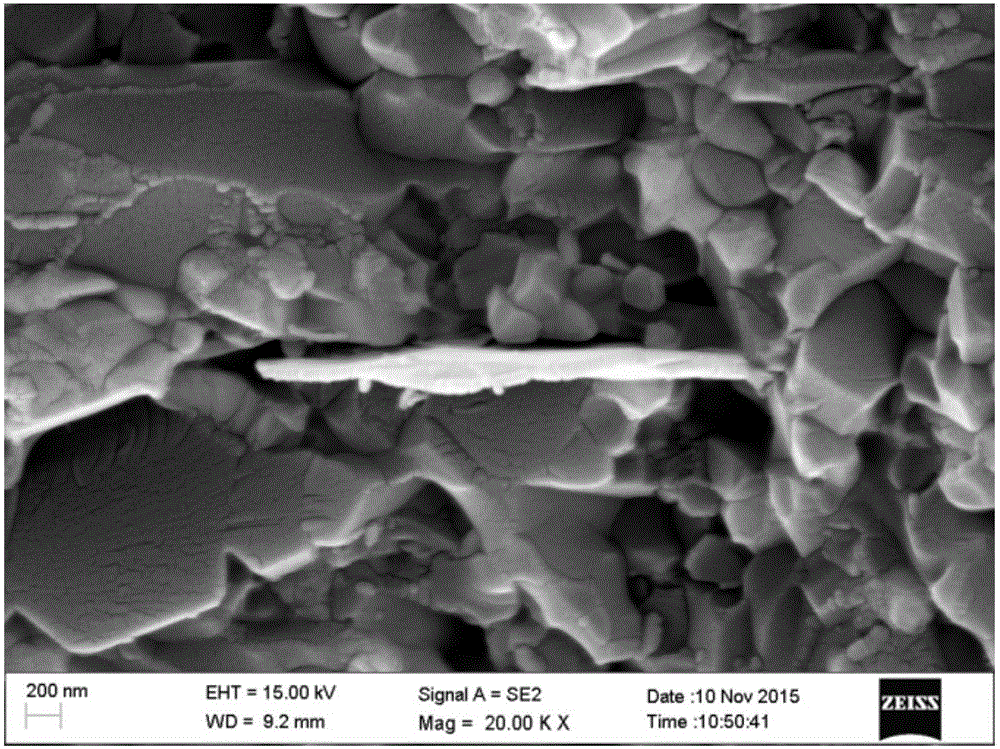

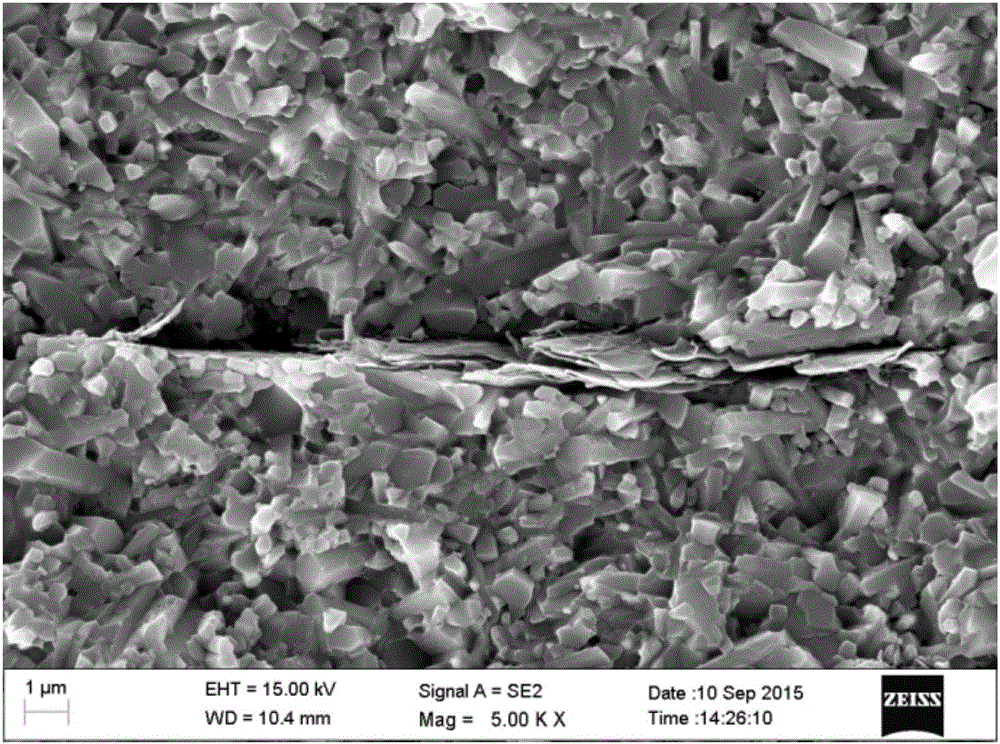

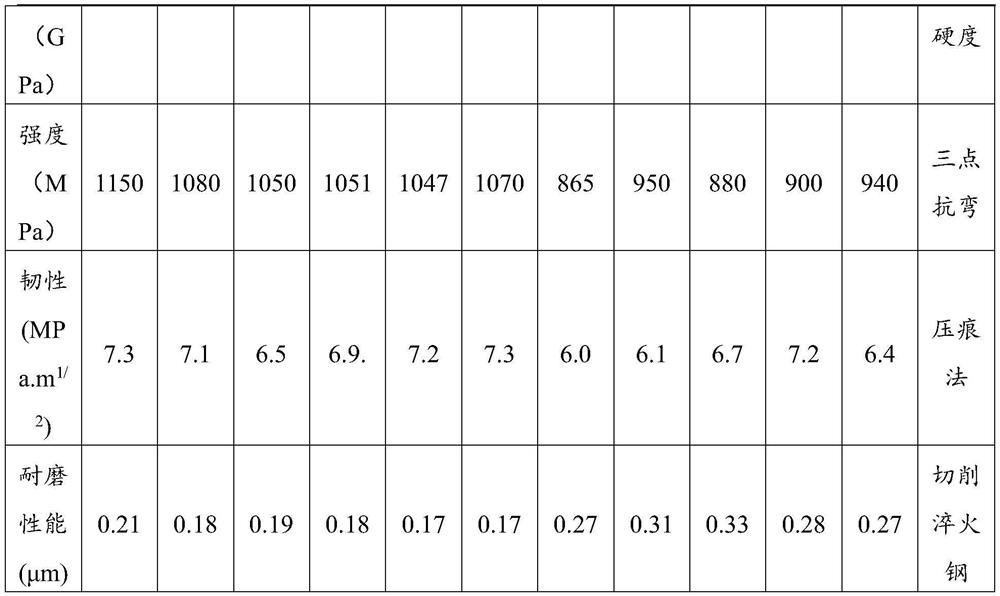

Si3N4-based ceramic cutter material with added graphene and preparation method of material

The invention relates to a Si3N4-based ceramic cutter material with added graphene and a preparation method of the material. According to the ceramic cutter material, silicon nitride serves as a matrix, graphene serves as a reinforced phase, and MgO, Al2O3 and Y2O3 serve as composite sintering auxiliaries. The ceramic cutter material is prepared through the processes of independent dispersion of raw materials, compound dispersion, ball milling, drying and screening, cold pressing and hot pressed sintering. In the Si3N4 / graphene composite ceramic cutter material, mechanical properties of the silicon nitride ceramic cutter material are remarkably influenced by graphene, the coefficient friction of the material is reduced by adding graphene, and self-lubricating performance of the material is improved.

Owner:QILU UNIV OF TECH

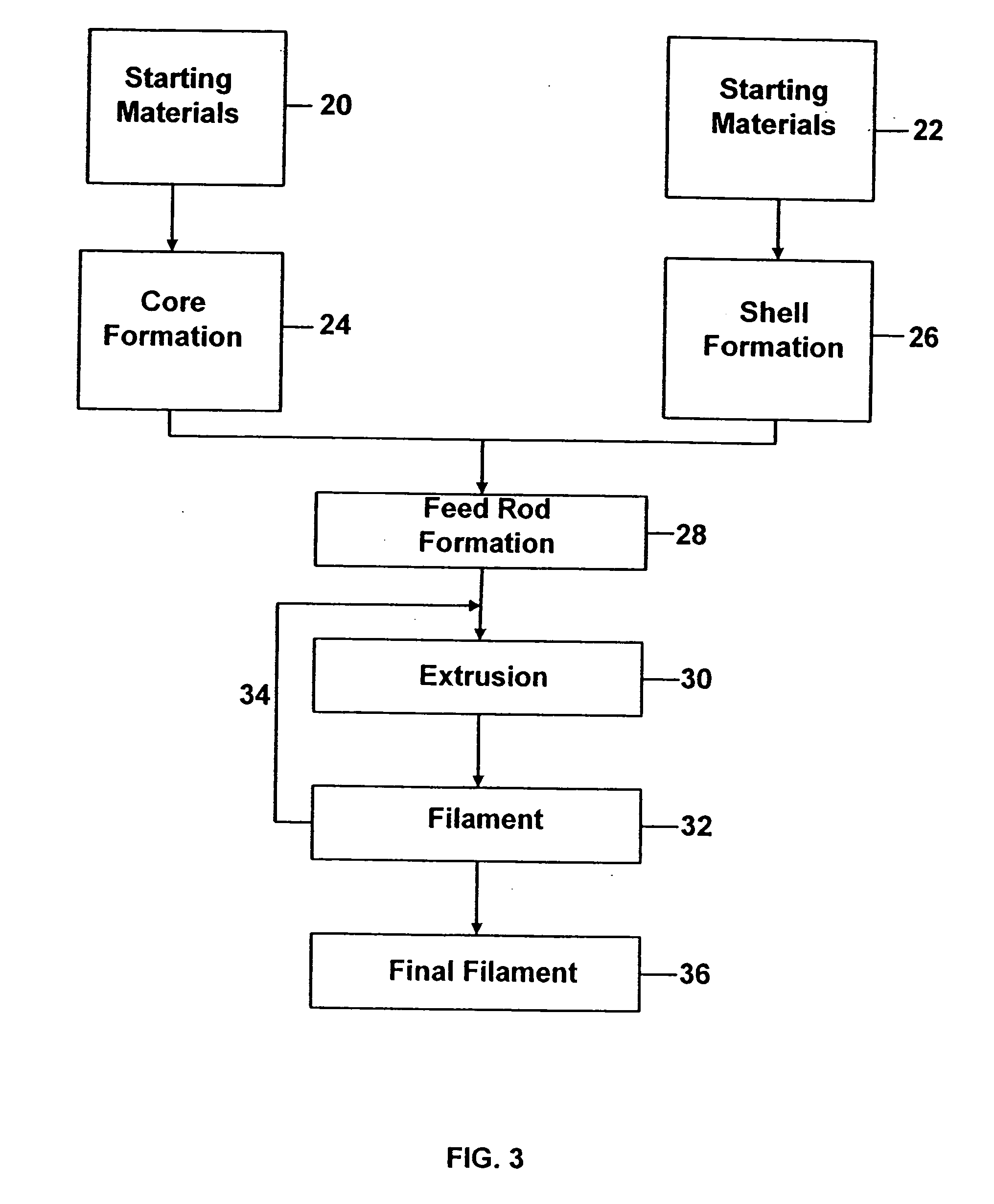

Consolidation and densification methods for fibrous monolith processing

InactiveUS6740286B2Low production costImprove effectivenessCeramic shaping apparatusClaywaresFiberPolymer science

Methods for consolidation and densification of fibrous monolith composite structures are provided. Consolidation and densification of two- and three-dimensional fibrous monolith components having complex geometries can be achieved by pressureless sintering. The fibrous monolith composites are formed from filaments having at least a first material composition generally surrounded by a second material composition. The composites are sintered in an inert gas or nitrogen gas at a pressure of no more than about 30 psi to provide consolidated and densified fibrous monolith composites.

Owner:ADVANCED CERAMICS

Silicon carbide ceramic and preparation method thereof

ActiveCN106588021AImprove sintered densityImprove bending strengthDensity distributionFlexural strength

The invention provides silicon carbide ceramic and a preparation method thereof. The preparation method includes: subjecting a ceramic main raw material, a binder accounting for 2.5-3% of weight of the ceramic main raw material and a dispersant accounting for 1.5-2.5% of the weight of the ceramic main raw material to cold isostatic pressing and liquid phase sintering. Generally, dry pressing is adopted for forming a ceramic material; during dry pressing, various performances of a material are influenced by nonuniform density distribution inside a blank caused by nonuniform pressure distribution; compared with dry pressing, cold isostatic pressing is uniform in pressurizing, pressures received by the material in all directions are identical, and sintering density, bending strength and rupture strength of the material are improved.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV +1

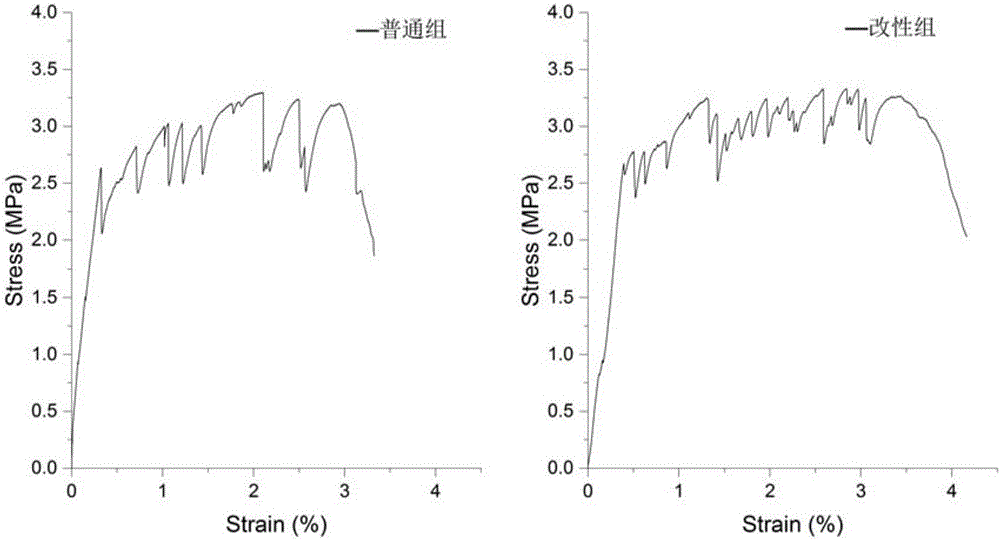

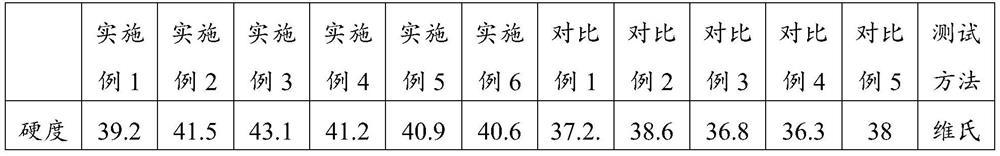

Modified fiber toughened cement-based material and preparation method thereof

The invention relates to the technical field of construction materials, and particularly relates to a modified fiber toughened cement-based material and a preparation method thereof. The cement-based material is characterized by being prepared from the following components in parts by mass: 20-30 parts of cement, 10-30 parts of admixture, 20-40 parts of sands, 10-25 parts of water, 0.1-1 part of a water reducing agent, 0.1-1 part of thickening agent and modified toughened fibers which have an adding amount being 0.3-3 percent of total volume of the materials, wherein the modified toughened fibers are prepared by soaking toughened fibers in an acid film forming material diluting solution and drying. The modified fiber toughened cement-based material can be used for further promoting toughness of an existing high-toughness cement-based material and reducing the mechanical performance degradation of the high-toughness cement-based material.

Owner:WUHAN UNIV OF TECH

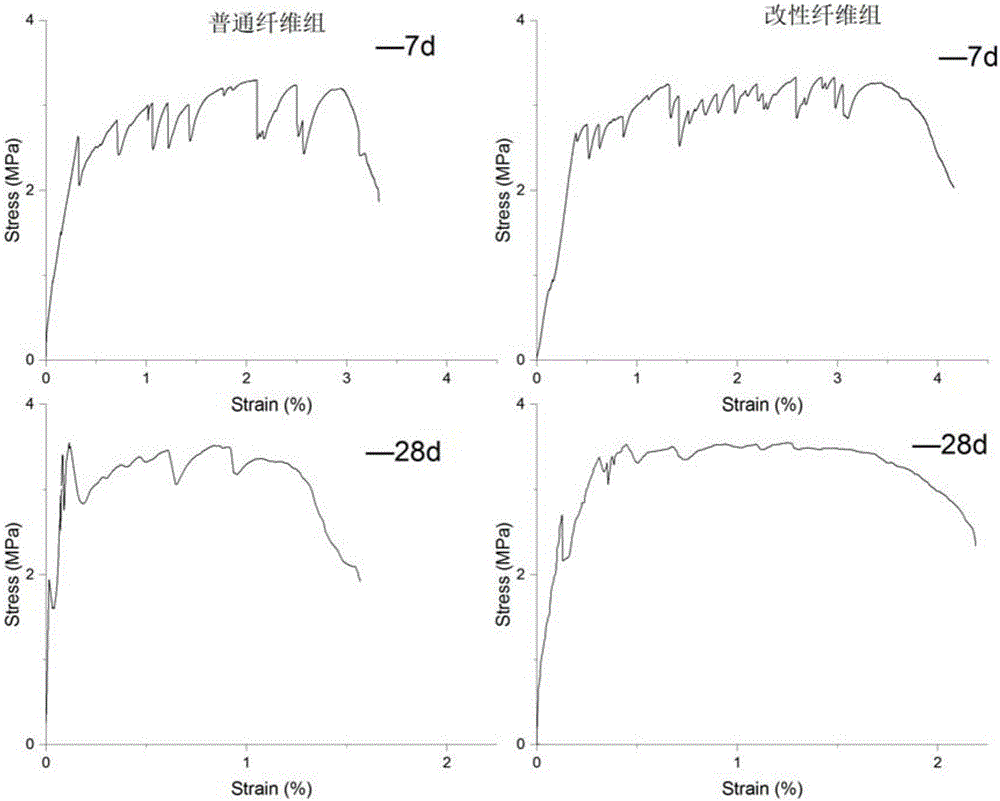

High-ductility cement based composite material and preparation method thereof

The invention discloses a high-ductility cement based composite material and a preparation method thereof. The composite material comprises cement, coal ash, clean fine river sand, a rubber powder, fiber, a water reducer, an emulsion powder, a setting accelerator and water according to certain ratio. As the composite material has high breaking energy and ultimate tensile strain, excellent crack resistance, adjustable four-point bending toughness index and reasonable compressive strength, the composite material can be applied to a sprayed concrete material in a coal mine deep mine tunnel supporting structure system, and can be applied to a prayed concrete material of primary supports for mountain tunnels, particularly large deformation tunnels and severe unsymmetrical loading tunnels for railway engineering and highway engineering.

Owner:JIANGNAN UNIV

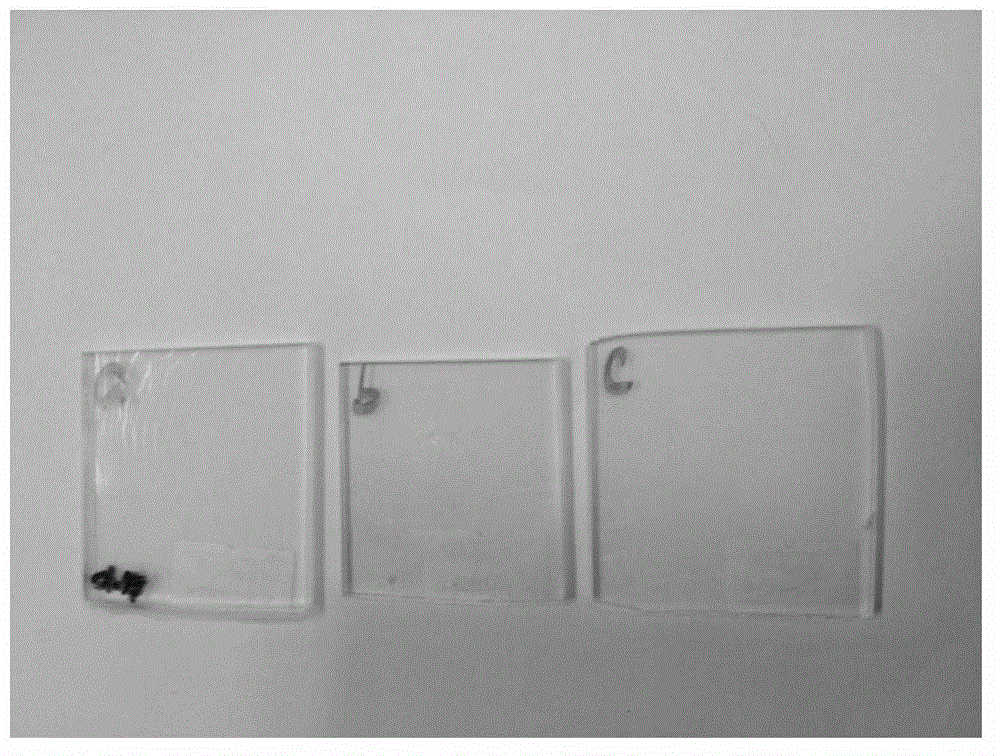

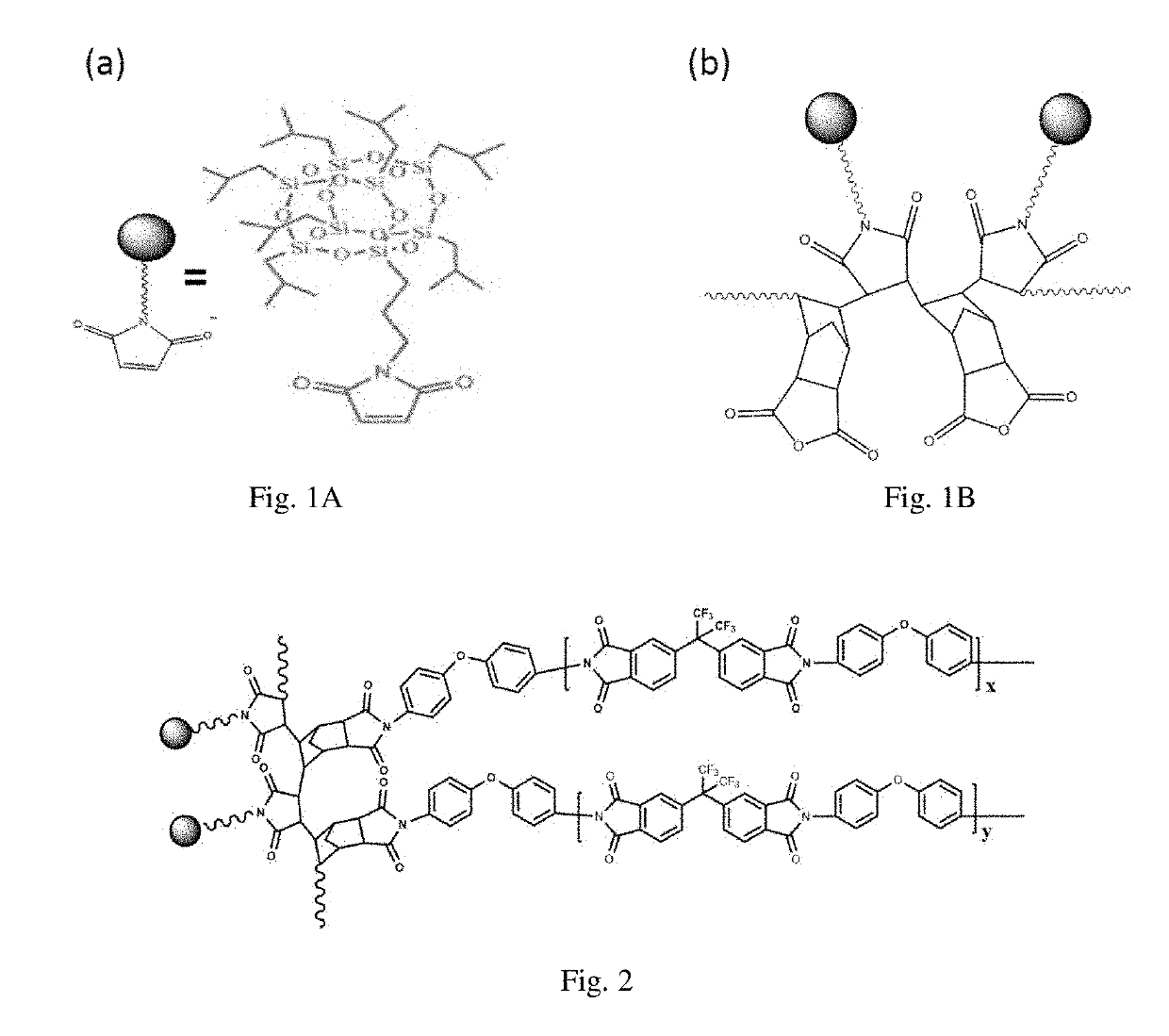

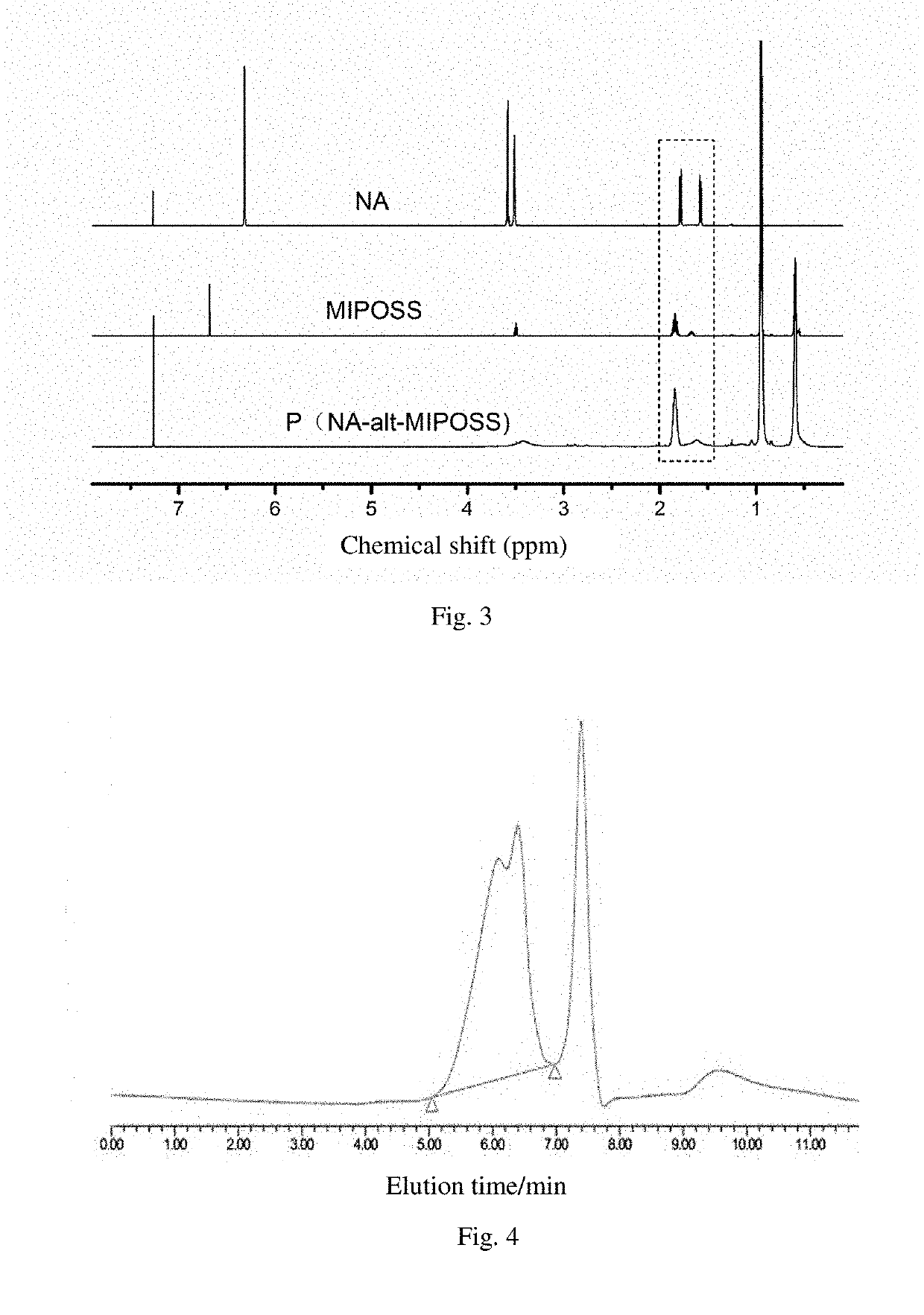

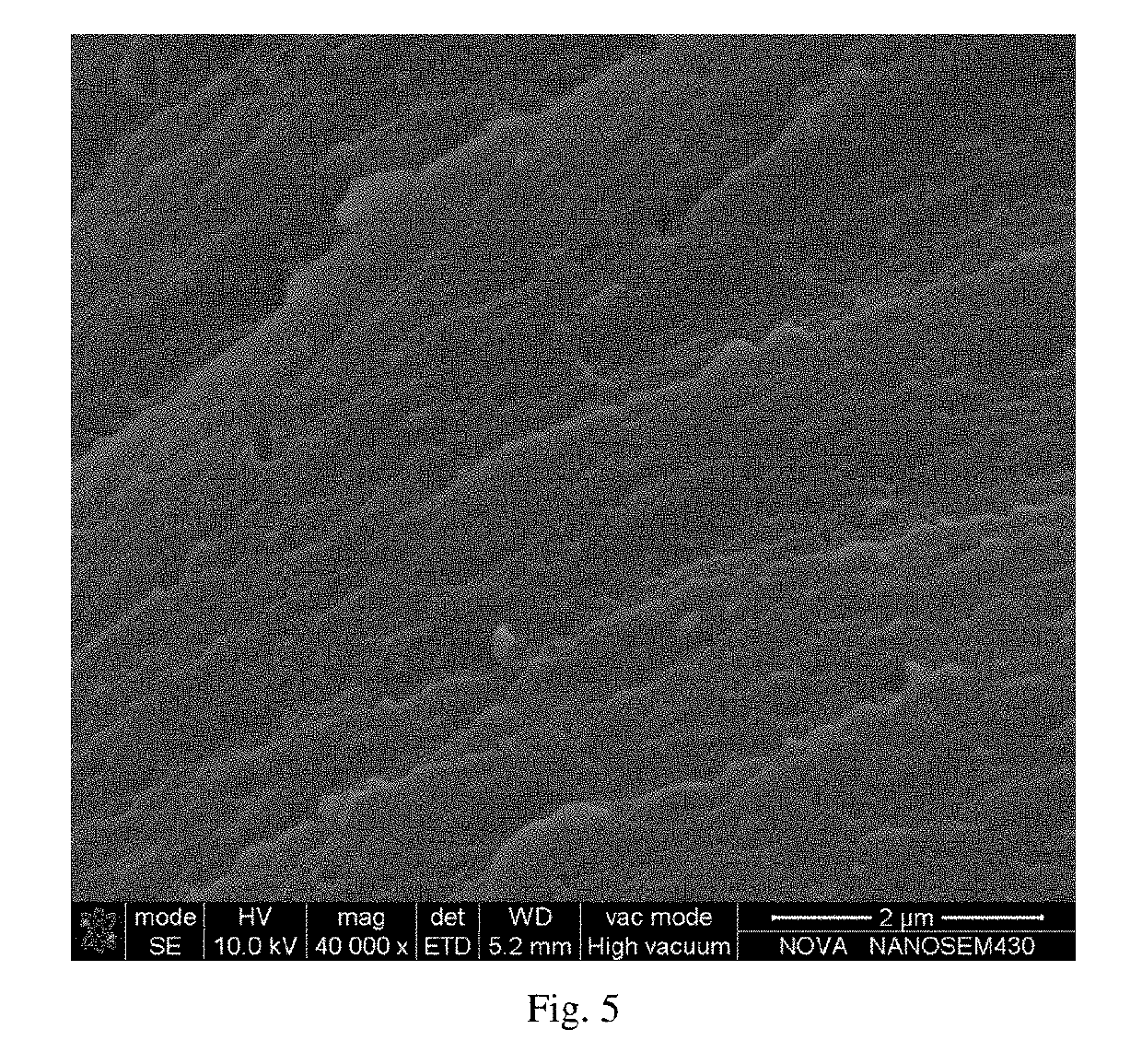

Method for preparing polyimide film having low dielectric constant and high fracture toughness

The present invention discloses a method for preparing a polyimide film having a low dielectric constant and high fracture toughness. The method comprises: first preparing an aromatic diamine solution, and then grinding and well mixing a carbic anhydride-maleimido heptaisobutyl polysilsesquioxane alternating copolymer and aromatic dianhydride; adding the mixture to the aromatic diamine solution, and then stirring to obtain a carbic anhydride-maleimido heptaisobutyl polysilsesquioxane alternating copolymer / polyamide acid solution; uniformly applying the carbic anhydride-maleimido heptaisobutyl polysilsesquioxane alternating copolymer / polyamide acid solution to a clean glass sheet, and then placing the glass sheet in a vacuum drying cabinet for treatment; cooling the treated glass sheet to room temperature and then putting same in water for ultrasonic peeling of a film, and vacuum drying the film to obtain a target product. The dielectric constant of the film obtained in the present invention is reduced to 2.2, the breaking elongation is increased by 272%, and the tensile energy is increased by 285%, so that the breaking elongation and tensile energy are greatly increased, and thus the fracture toughness is good.

Owner:SOUTH CHINA UNIV OF TECH

Multi-scale fiber reinforced cement stable gravel roadbase material

InactiveCN101660287AHigh tensile strengthImprove toughnessIn situ pavingsGlass fiberCrack resistance

The invention provides a multi-scale fiber reinforced cement stable gravel roadbase material doped with different-length fiber, such as micro-steel fiber and the like. The invention provides a methodwhich can better improve the performance of cement stable gravel roadbase material than flexible fiber and effectively improve the shrinkage crack resistance capability and mechanical property of theroadbase material. The multi-scale fiber reinforced cement stable gravel roadbase material of the invention comprises cement stable gravel and multi-scale fiber material, wherein, the multi-scale fiber material comprises micro-steel fiber and glass fiber, and the doping amount of the micro-steel fiber and the glass fiber is respectively 0.8-1.2kg / m<3>. The invention adopts multi-scale short fiber,has favorable mixture workability and even fiber dispersion and is easy to satisfy construction requirements; low fiber doping amount effectively lowers material cost; in the process of base materialcrack expansion, addition of short cut glass fiber causes to form a plurality of micro cracks, which further effectively improves impact resistance of the base material and increases crack energy.

Owner:CHONGQING UNIV

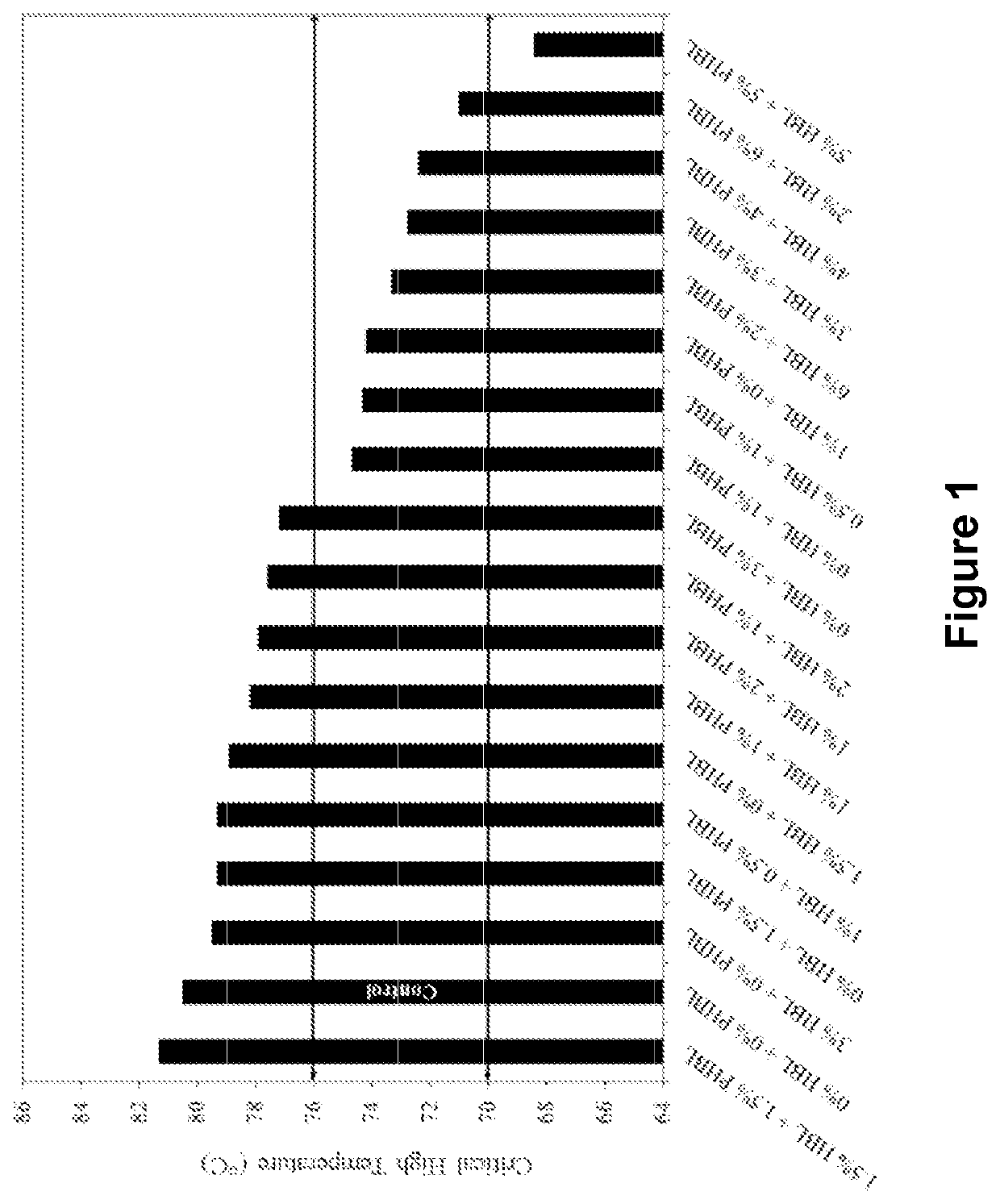

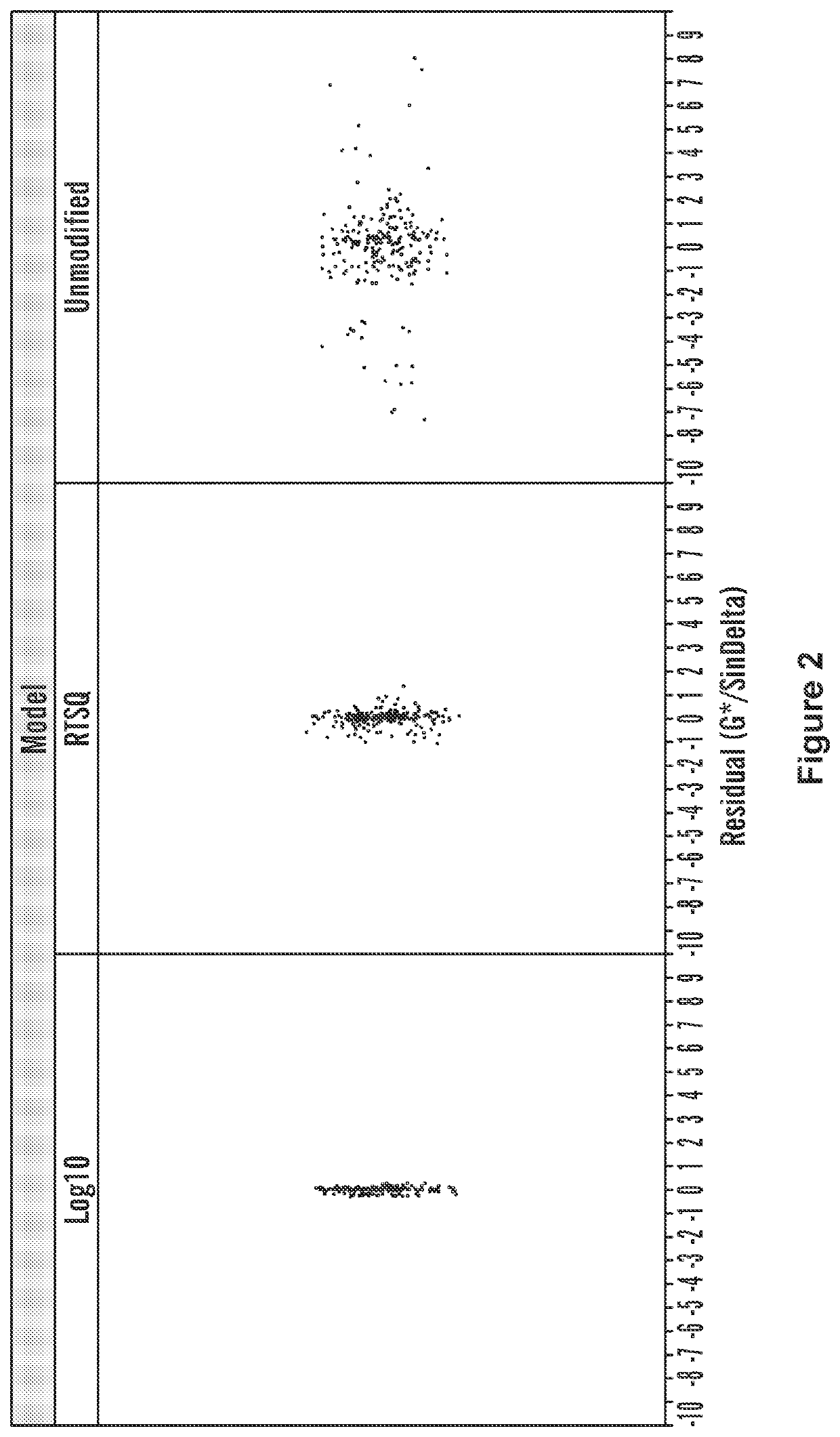

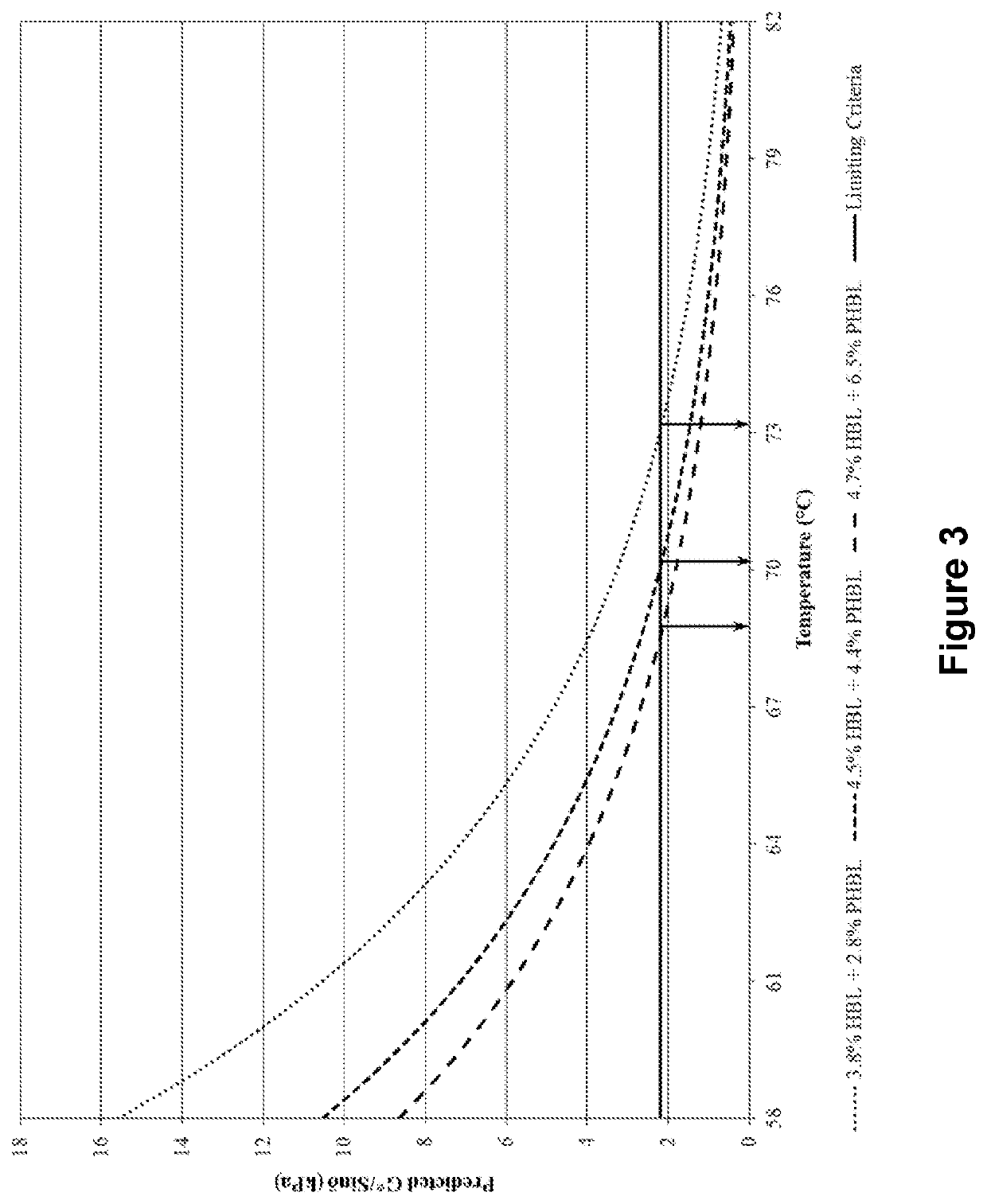

Rejuvenation of vacuum tower bottoms through bio-derived materials

ActiveUS10961395B2Reduce stiffnessReduce energy consumptionIn situ pavingsClimate change adaptationPartial hydrogenationOrganic chemistry

The present invention relates to an asphalt product. The asphalt product includes an asphalt binder and a bio-oil blend comprising a mixture of a non-hydrogenated bio-oil and a partially hydrogenated bio-oil, where the bio-oil blend is mixed with the asphalt binder to form an asphalt product having a shear stiffness of 0.20 kPa to 11,000 kPa at a temperature ranging from 25° C. to 85° C. and / or a viscosity of 0.15 Pa·s to 1.50 Pa·s at a temperature ranging from 120° C. to 165° C. The present invention further relates to methods of producing an asphalt product and methods of applying an asphalt product to a surface.

Owner:IOWA STATE UNIV RES FOUND

Biomass polymer hybrid laminated composite material and preparation method

InactiveCN103481567AHigh strengthImprove freeze-thaw resistancePress rollersLaminationWater basedCarbonization

Relating to the field of biomass composite materials, the invention provides a biomass polymer hybrid laminated composite material and a preparation method. The biomass polymer hybrid laminated composite material and the method solve the problems that great energy consumption and high production cost exist in current artificial board production processes, the product causes serious environmental pollution, and the comprehensive performance of the material is poor. According to the different material characterization characteristics of an organic polymeric material, an inorganic polymeric material or high polymer material, arbitrary interlaminar combination is carried out, thus obtaining laminated composite materials with different characterization characteristics. The method makes full use of the molding mechanism of an inorganic polymeric material and a water-based organic polymeric material under room temperature and atmospheric pressure conditions on a biomass composite multifunctional lamination compound machine, and gives full play to the interface mixing and dissolving combination advantages of polymer materials. The material provided in the invention is free of formaldehyde and phenol, can burn for 8h under 5000KJ with no naked flame, and only a slight carbonization phenomenon exists. After immersion in clear water for 30 days, the expansion rate does not exceed 8%.

Owner:林燕兵

Polycrystalline cubic boron nitride composite sheet and preparation method and application thereof

The invention provides a polycrystalline cubic boron nitride composite sheet and a preparation method and application thereof, and belongs to the technical field of superhard materials. The PCBN is prepared from the following raw materials in parts by mass through high-temperature and high-pressure sintering: 70-90 parts of CBN, 3-8 parts of nano aluminum oxide, 6-18 parts of a tungsten-titanium solid solution and 1-4 parts of a sintering aid, the sintering aid is aluminum nitride or rare earth oxide, wherein the mass ratio of the tungsten element to the titanium element in the tungsten-titanium solid solution is 1: 1. The polycrystalline cubic boron nitride composite sheet has the characteristics of high strength and high hardness.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Concrete with high toughness

The invention relates to concrete with high toughness, which is used in the technical field of constructional engineering. The concrete comprises the following components in portion by weight: 30 to 50 portions of cement, 30 to 50 portions of quartz sand, 2 to 25 portions of steel fiber, and 10 to 20 portions of water. The concrete has the advantages that the concrete has ultrahigh strength and high elastic modulus, improves breaking energy, has high toughness and high durability, prolongs the service life of a structure, does not need reinforcing bars, lowers construction cost of engineering, and can be used for pouring large-span concrete bridges and high-rise building struts and replace steel to pour large-sized pressure pipelines and the like.

Owner:朱世忠

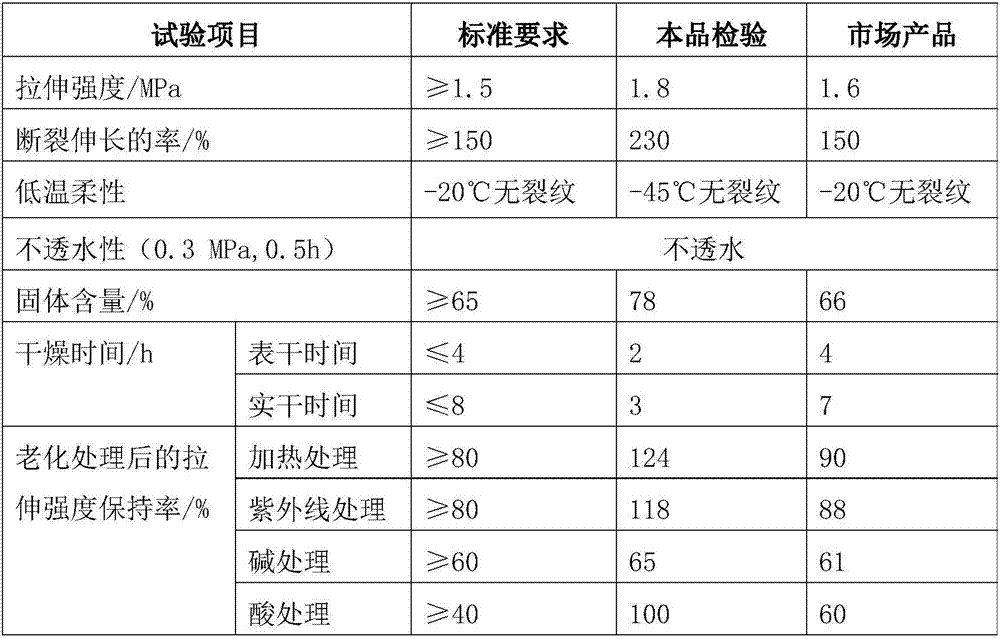

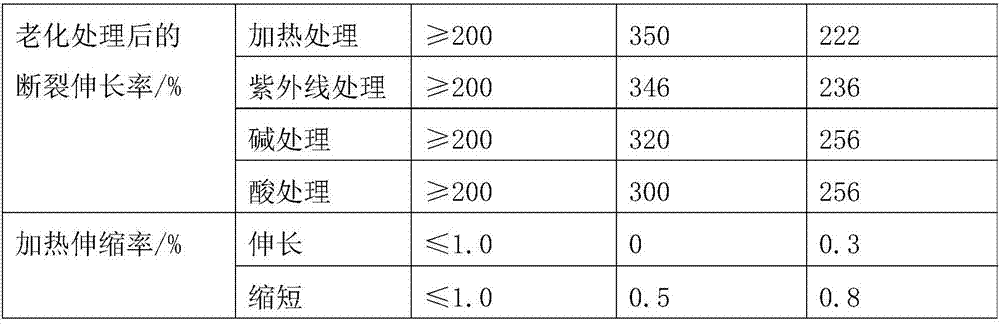

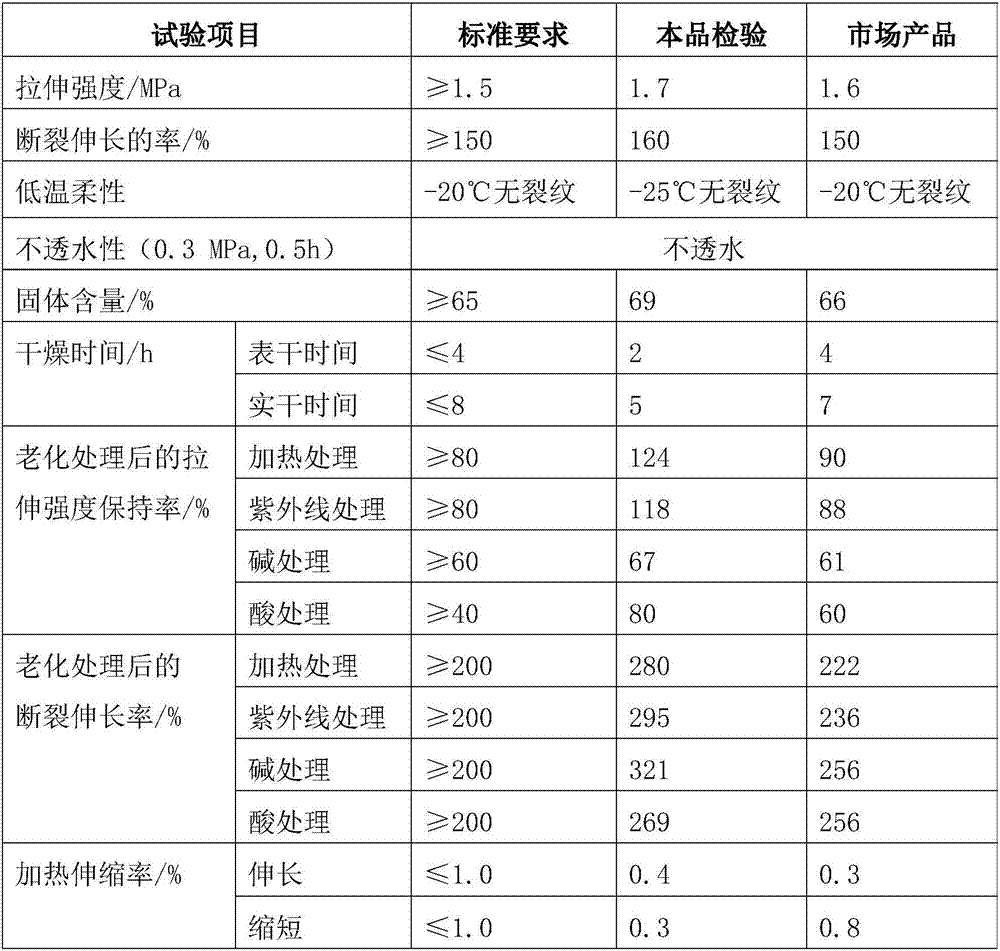

Macromolecule polymer emulsion as well as preparation method thereof and waterproof coating prepared from emulsion

The invention discloses a macromolecule polymer emulsion. The macromolecule polymer emulsion comprises the following components in parts by mass: 0.1-2 parts of neoprene latex, 3-4.3 parts of butyl latex and 45-49 parts of ethyl acrylate latex. A preparation method of the macromolecule polymer emulsion comprises the following steps: (1) preparing materials; (2) preparing a first emulsion; (3) preparing a waterproof agent; (4) preparing a second emulsion; (5) preparing an additive solution; and (6) preparing the finished product. A waterproof coating comprises the following components in parts by mass: 36-45 parts of the macromolecule polymer emulsion, 50-58 parts of composite powder and 5-6 parts of additives. The macromolecule polymer emulsion is high in elongation rate; the waterproof coating has waterproof and self-healing functions.

Owner:呼伦贝尔辰研化工新科技有限公司

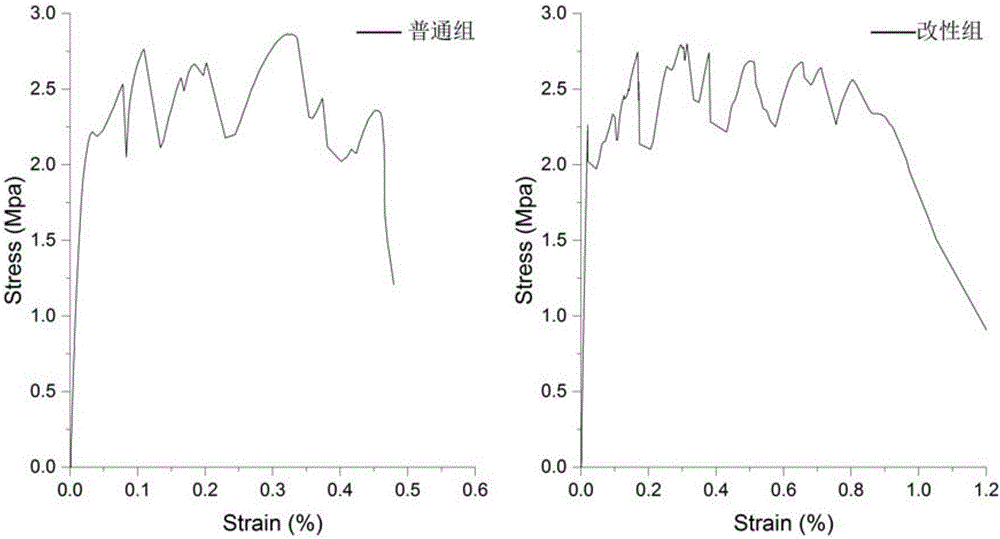

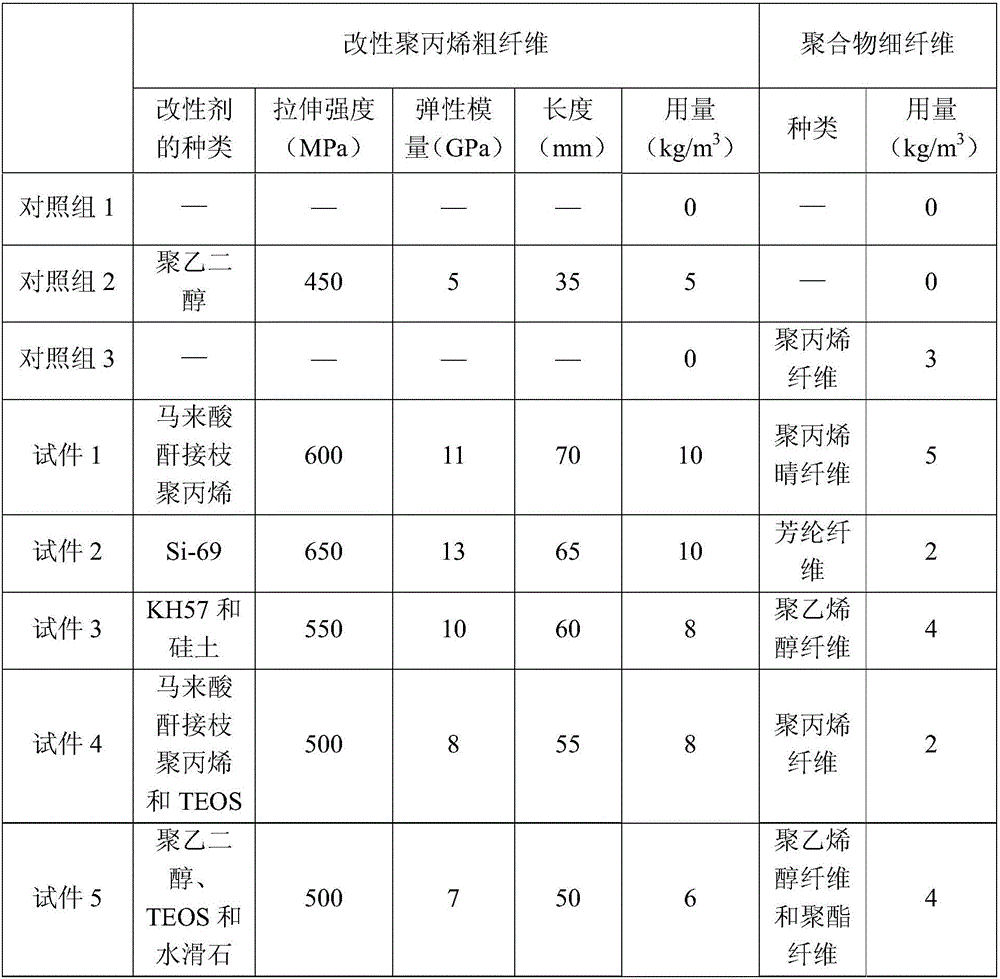

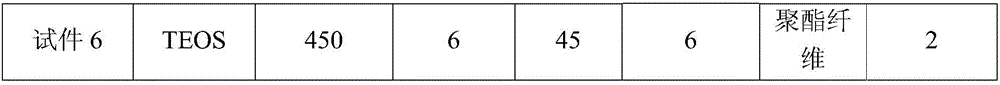

High-performance concrete pavements enhanced by hybrid fibers

The invention discloses high-performance concrete pavements enhanced by hybrid fibers and particularly discloses pavement concrete to which modified polypropylene crude fibers and polymer micro fibers are added.The modified polypropylene crude fibers are prepared in a mode that an organic modifying agent, a silane coupling agent and inorganic modified filler are subjected to melt-spinning and cold-stretching after being modified.The modified polypropylene crude fibers can effectively limit and delay generation and development of macrocrack; the polymer micro fibers can block expansion of original defects and micro cracks of concrete.The modified polypropylene crude fibers and the polymer micro fibers work in a cooperative mode, a hybrid effect can be generated, and crack resistance, stretch resistance, impact resistance, wear resistance, seepage resistance, bending resistance, fatigue resistance, shrinkage resistance, corrosion resistance, freeze thawing resistance and the like of concrete are greatly improved.The concrete can be widely applied to concrete pavements, such as a road pavement, a bridge floor, an airfield pavement, an urban road pavement, a port pavement, a traffic tunnel and an industrial building ground, engineering quality of the concrete pavements is remarkably improved, and the service life is prolonged.

Owner:宁波时科新材料科技有限公司

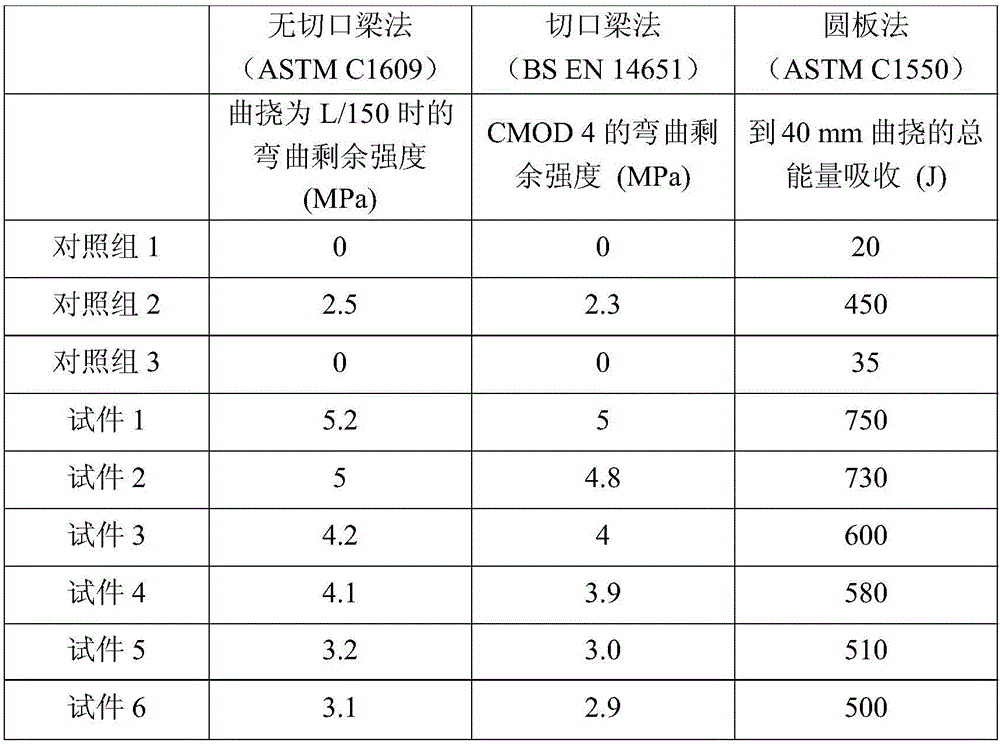

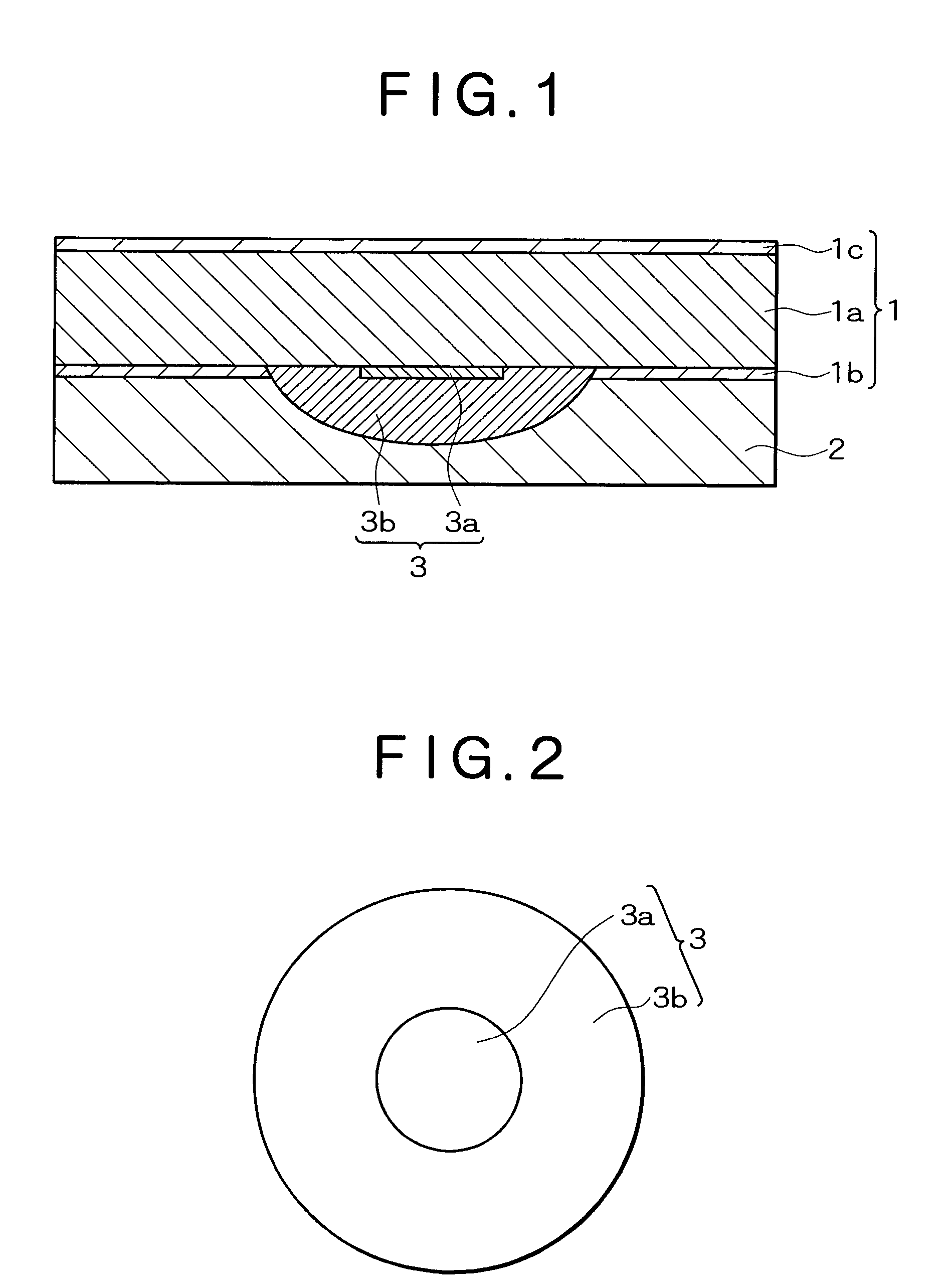

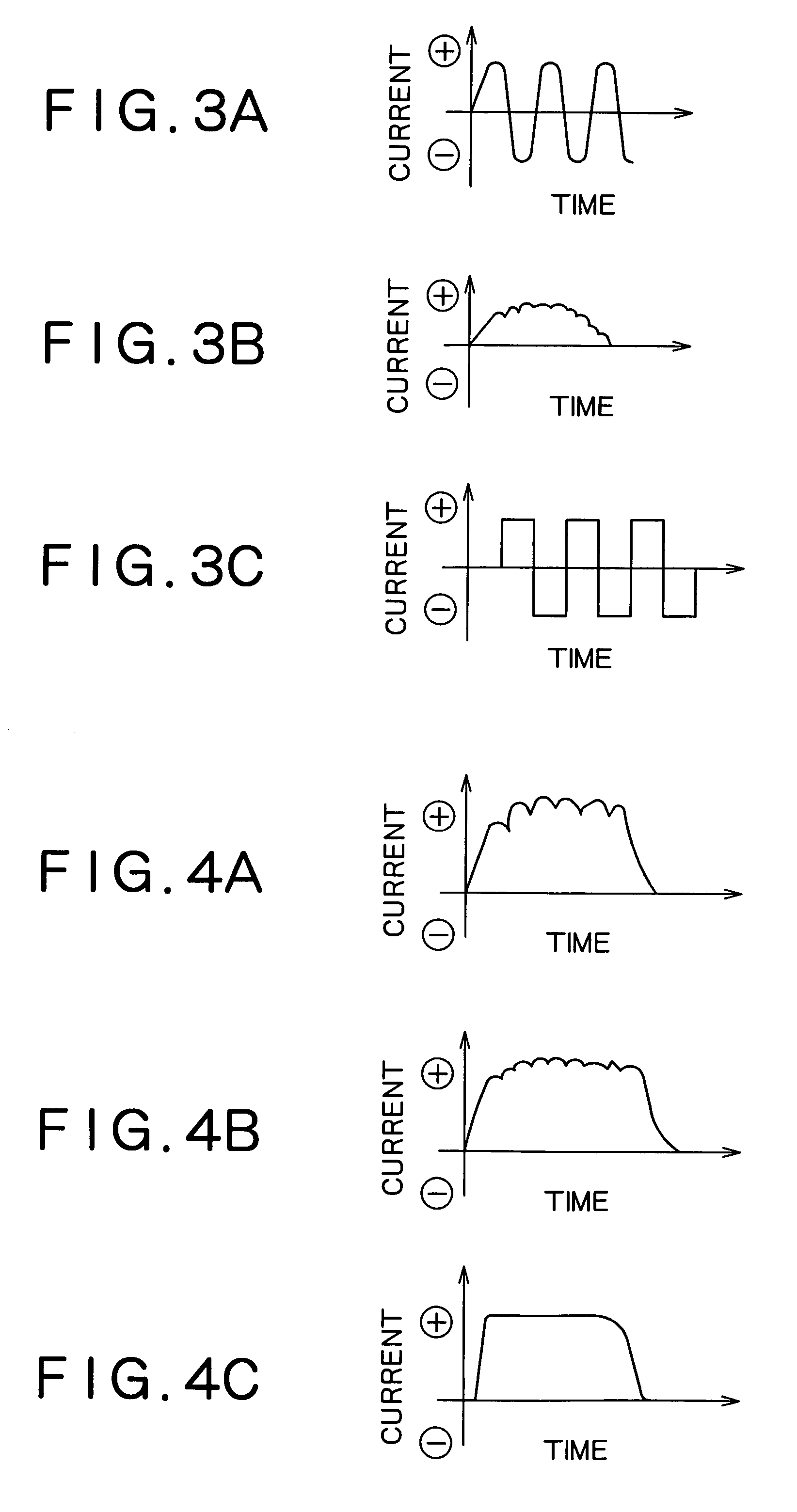

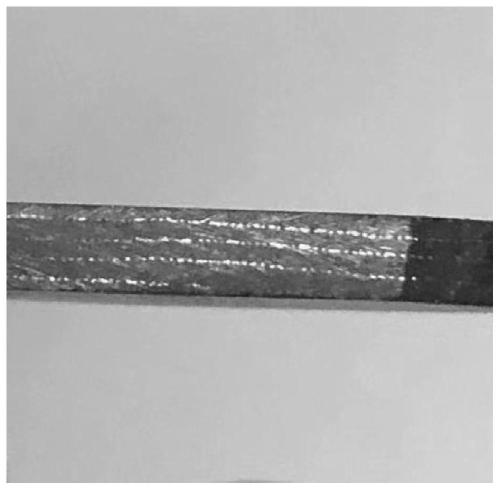

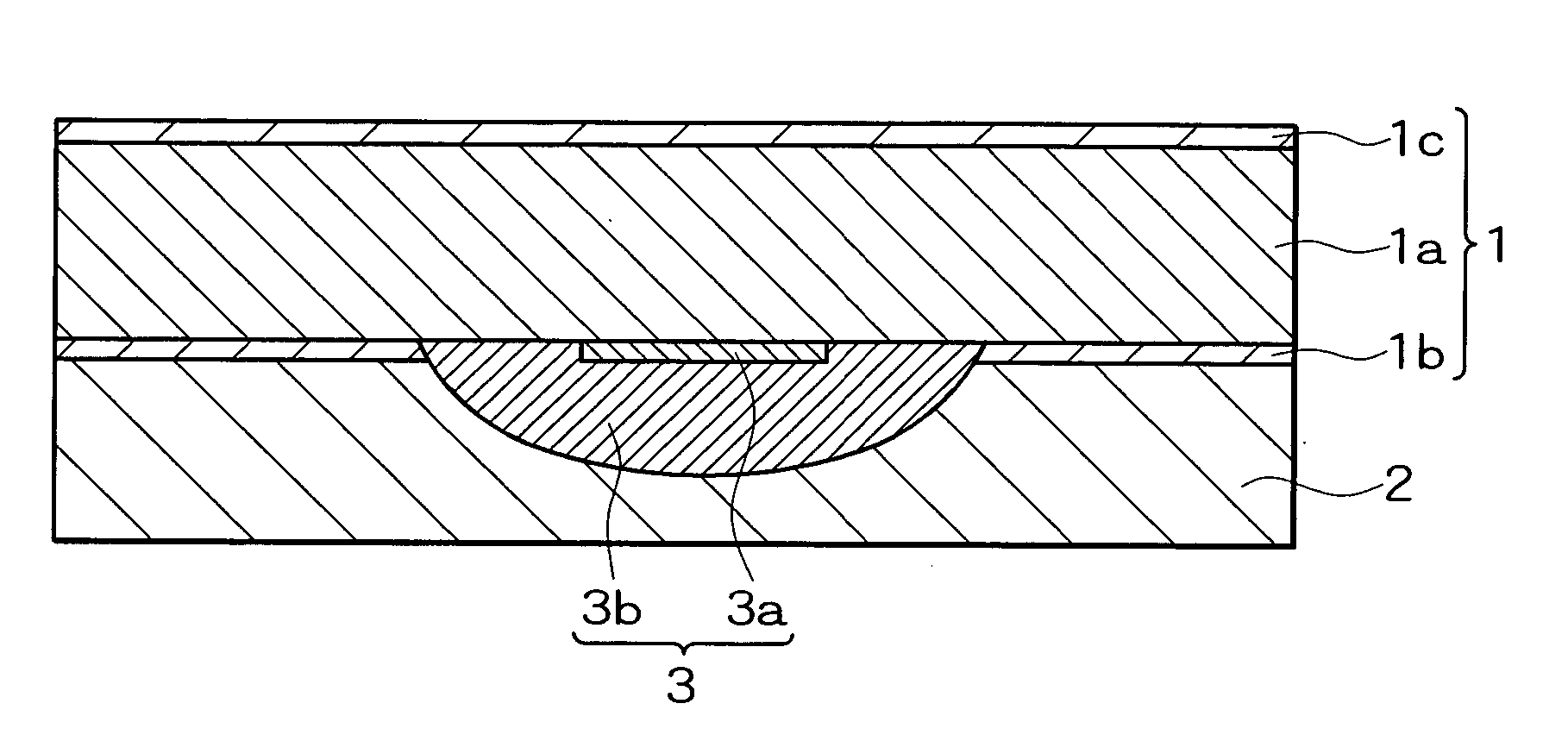

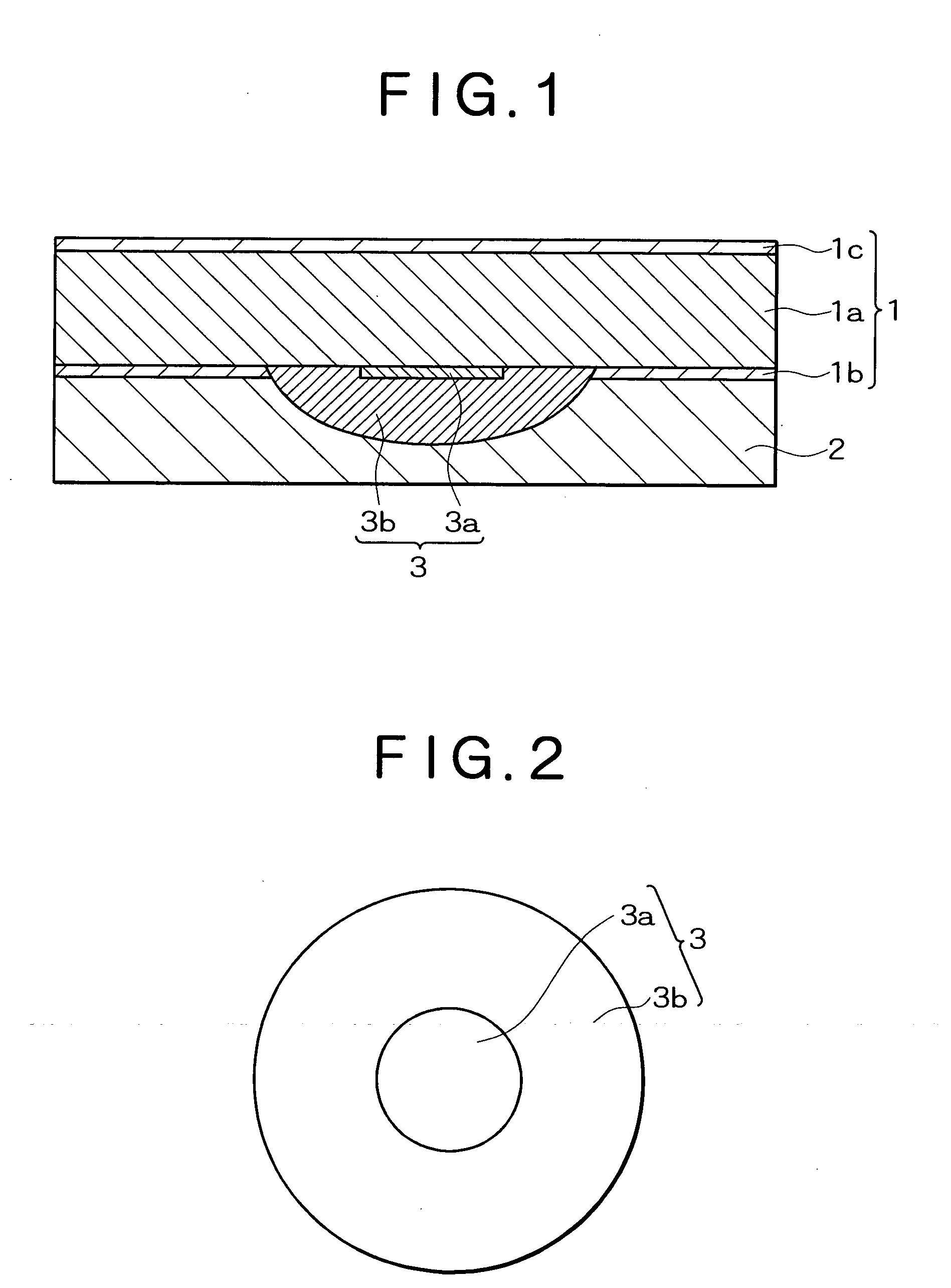

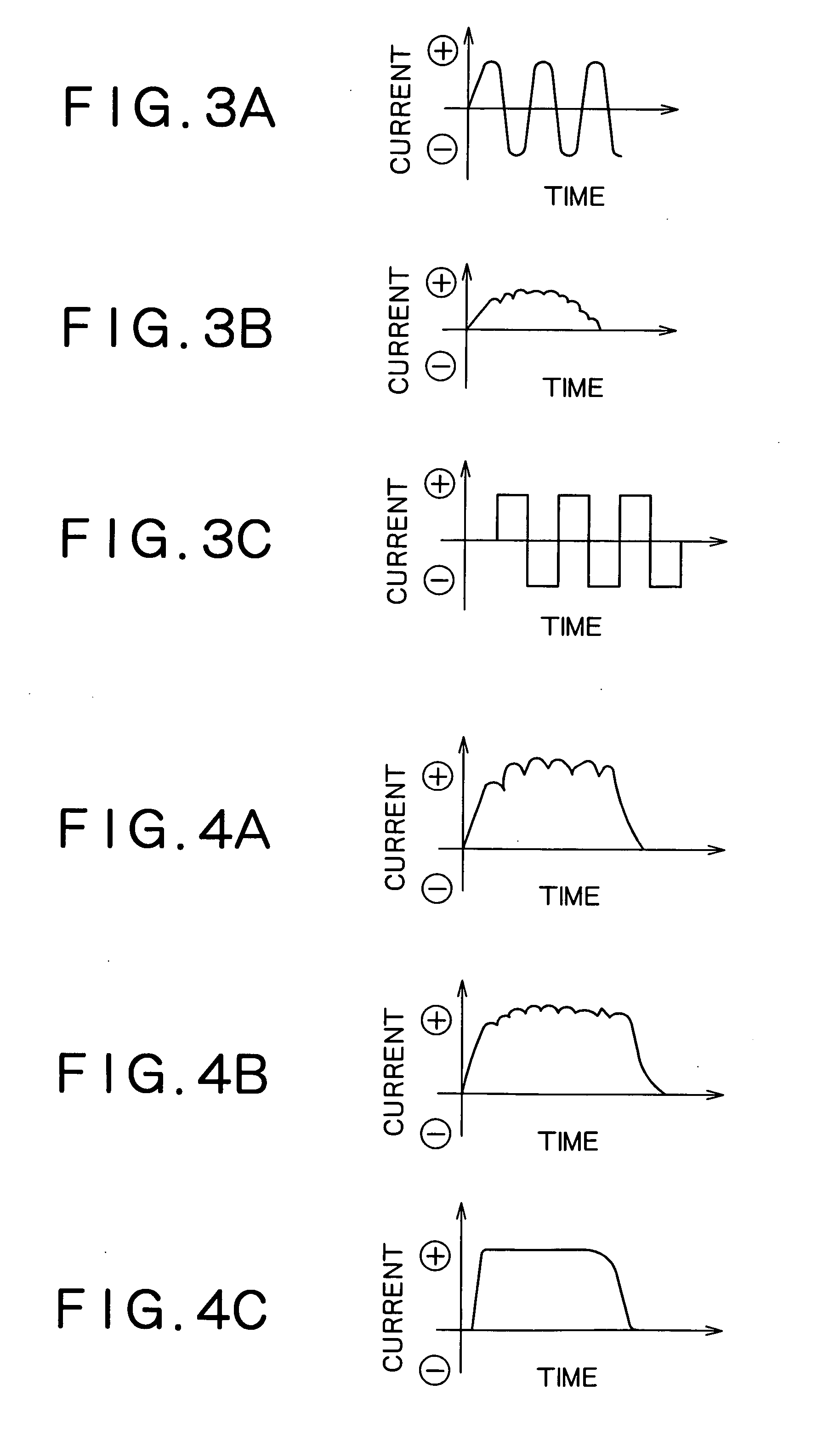

Weldment of different materials and resistance spot welding method

ActiveUS7473864B2Increased fracture energyImprove efficiencyHot-dipping/immersion processesArc welding apparatusHigh fractureSheet steel

A joined part of an aluminum-coated steel sheet and an aluminum sheet is composed of an intermetallic compound layer which exists in a region in which a part of a coated layer exists before the joining and an aluminum melted and solidified part which also exists on the side of the aluminum sheet to enclose the intermetallic compound layer. The atoms existing on the surface of the aluminum melted and solidified part are intermetallic-bonded with atoms which exist on the surface of the steel sheet except in the region in which the intermetallic compound layer exists seen in the plan view. Further, the area of the intermetallic compound layer is limited to 60% or less of the total area of the joined part at the interface between the aluminum-coated steel sheet and the aluminum sheet. Thus, the area of the aluminum melted and solidified part exceeds 40% of the total area of the joined part. The strong joining having a high fracture energy can be provided at a high efficiency.

Owner:KOBE STEEL LTD +1

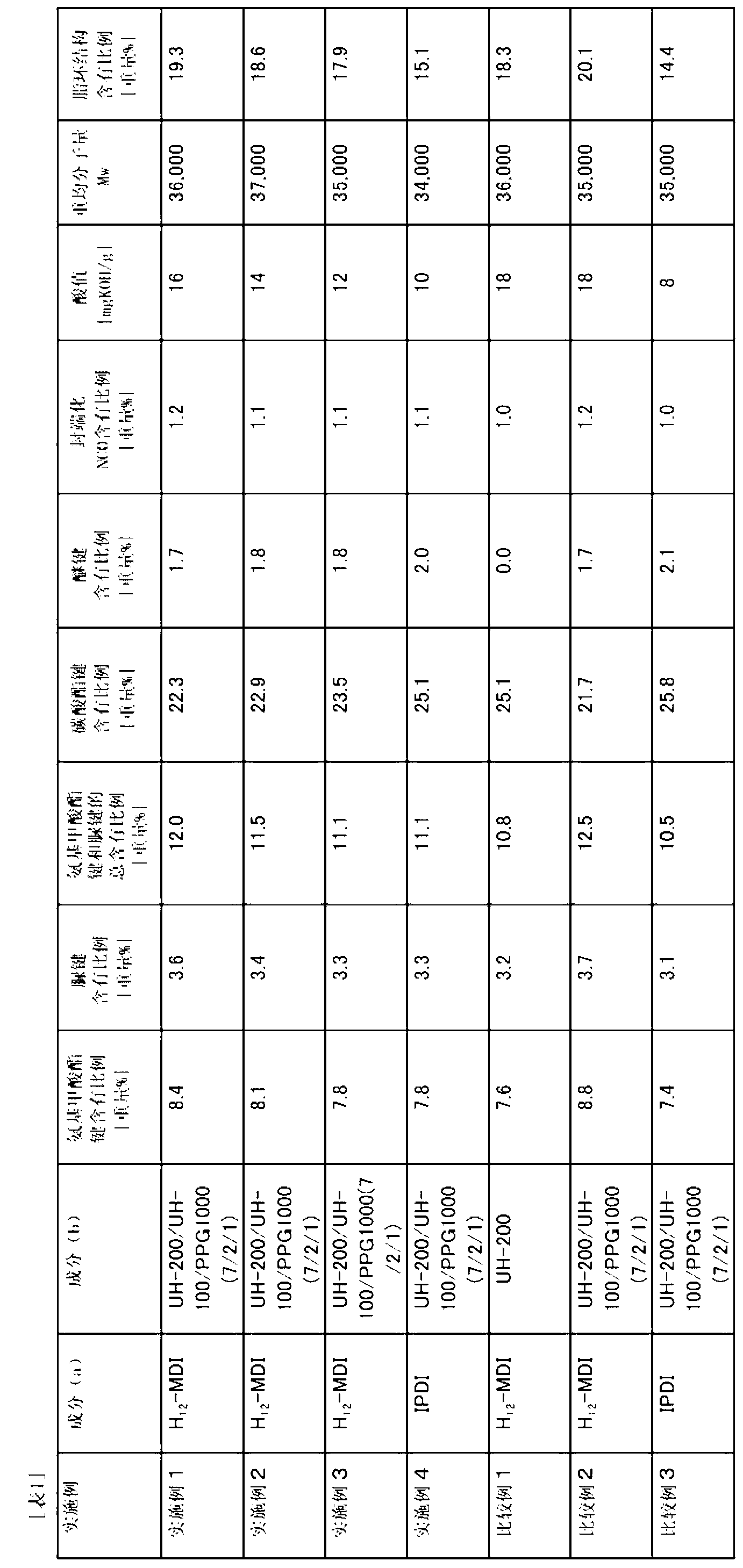

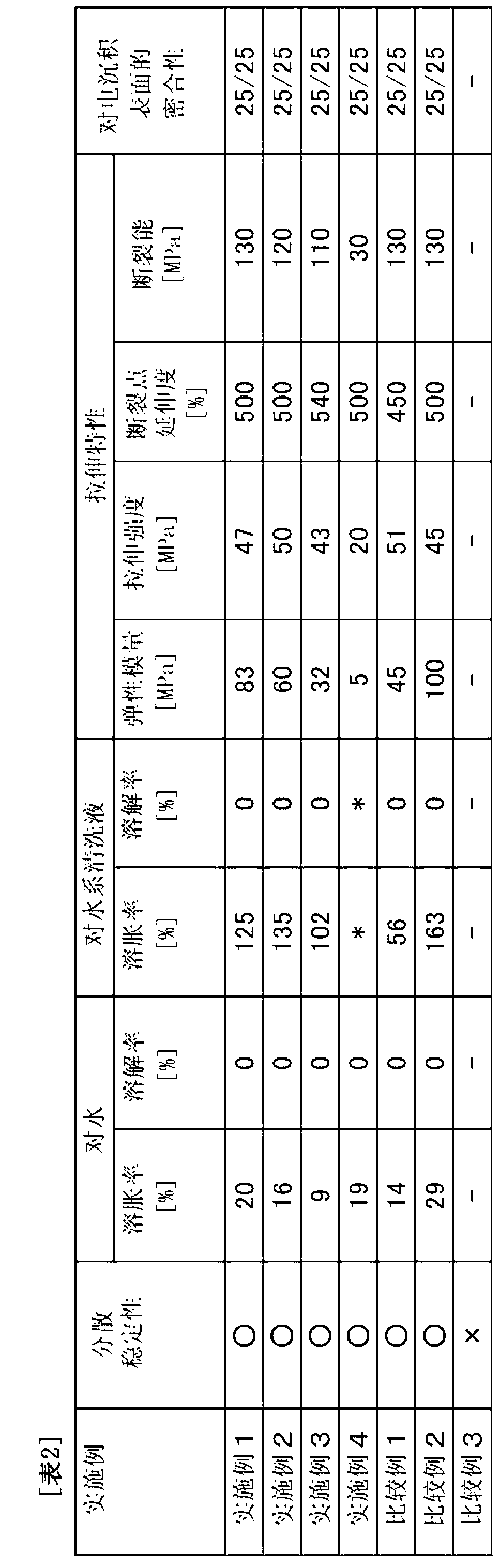

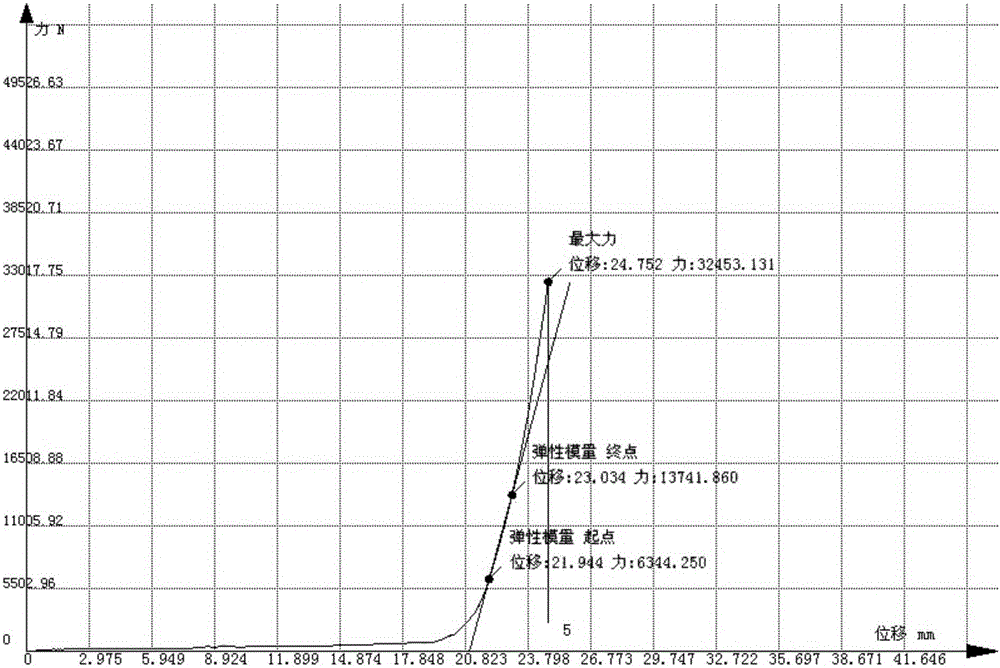

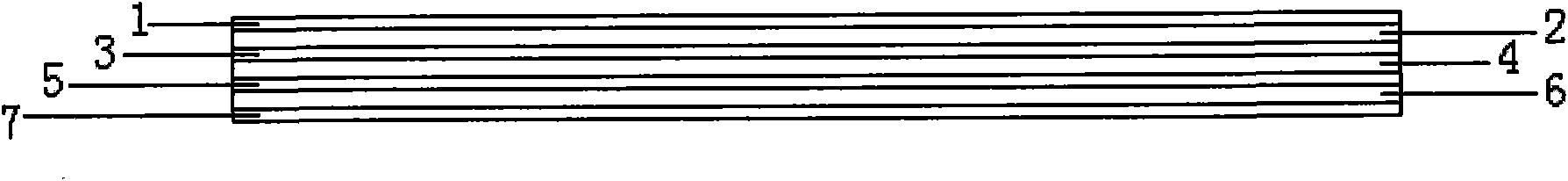

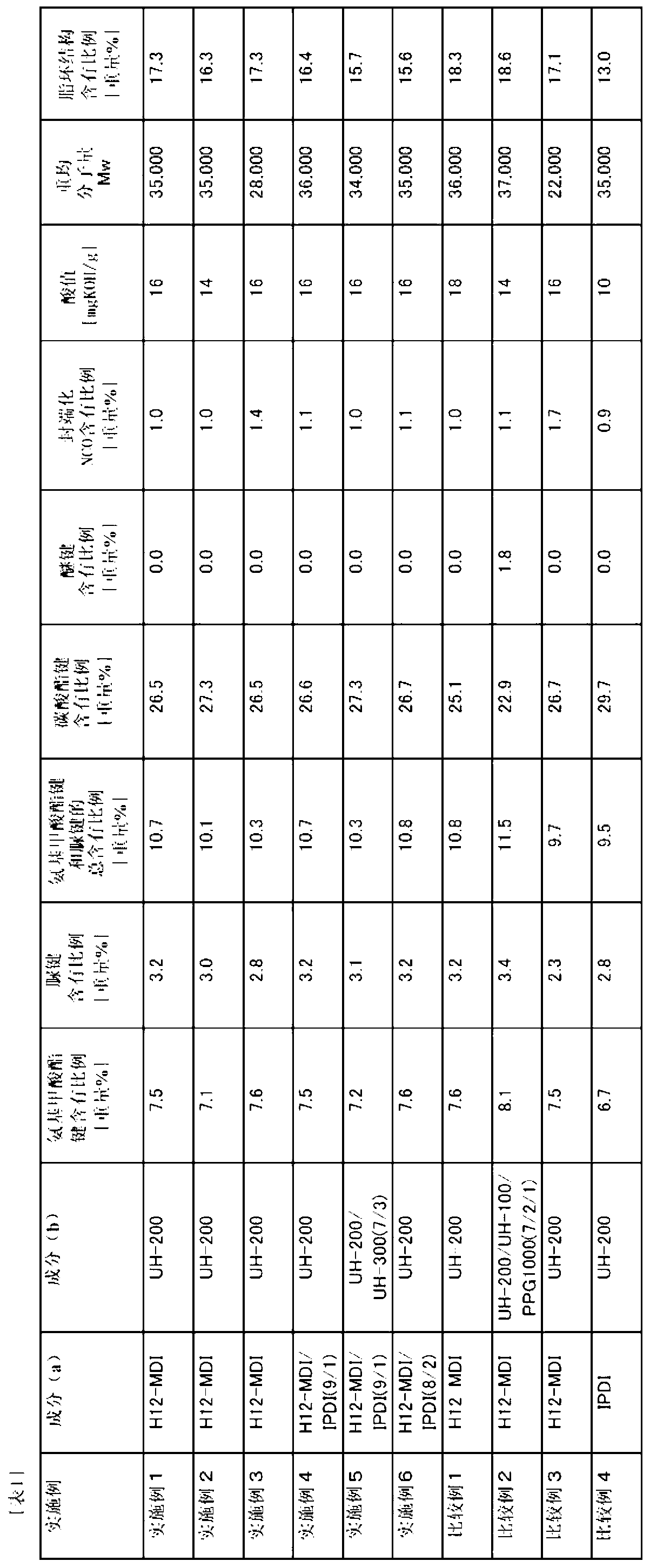

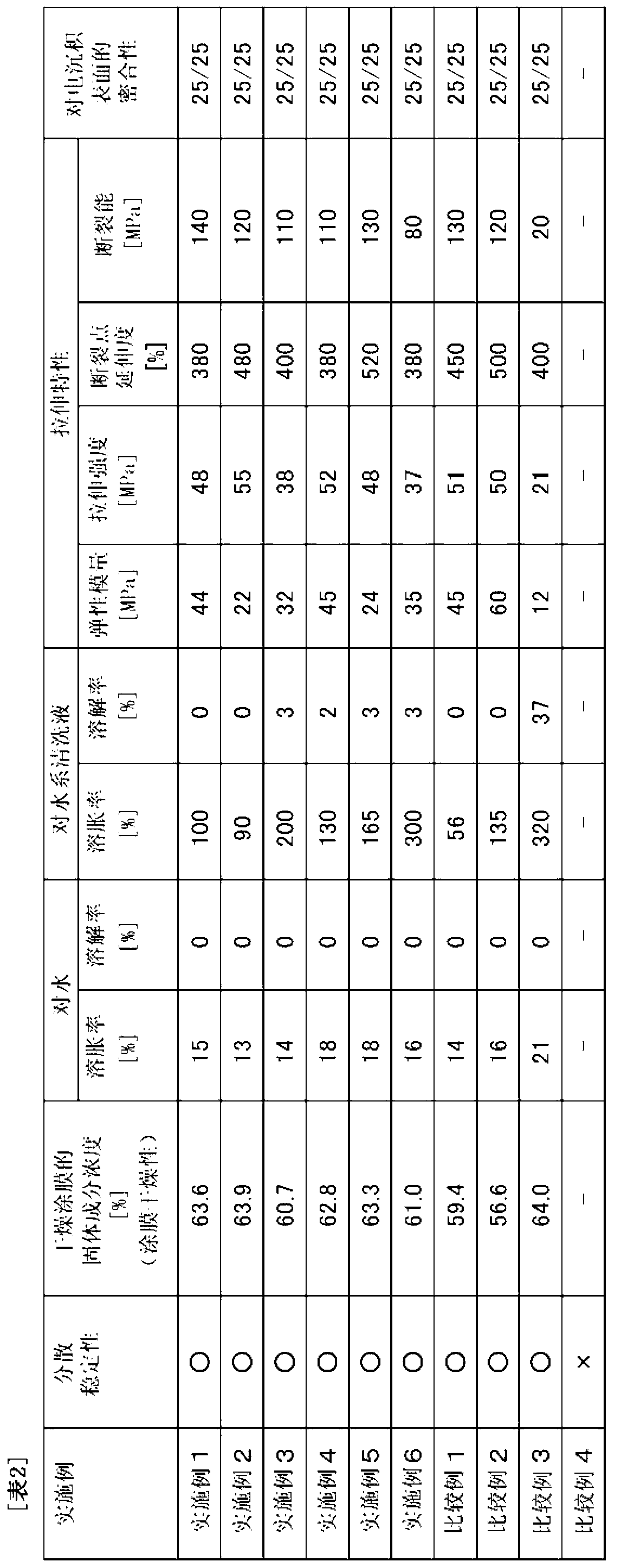

Waterborne polyurethane resin dispersion and use thereof

InactiveCN103347923AInhibit swellingHigh swelling ratePolyurea/polyurethane coatingsEmulsion paintsSolventPolycarbonate

An aqueous polyurethane resin dispersion is a dispersion of a polyurethane resin in an aqueous medium, the polyurethane resin being obtained by reacting (A) a polyurethane prepolymer obtained by reacting (a) a polyisocyanate compound, (b) a polyol compound including a polycarbonate polyol with a number average molecular weight of 400 to 3000, (c) an acidic group-containing polyol compound and (d) a blocking agent, with (B) a chain extender, the total content of urethane bonds and urea bonds being 7 to 15 wt %, the content of carbonate bonds being 15 to 40 wt %, the content of ether bonds being 0.5 to 5 wt %, the content of isocyanate groups bonded to the blocking agent being 0.2 to 2.0 wt %, each of these contents being based on solid contents, the acid value being 10 to 16 mg KOH / g. The aqueous polyurethane resin dispersion can form coating films which permit new application while exhibiting excellent water resistance and solvent resistance. A coating composition includes the dispersion. A polyurethane resin film is obtained by thermally drying a composition including the dispersion.

Owner:UBE IND LTD

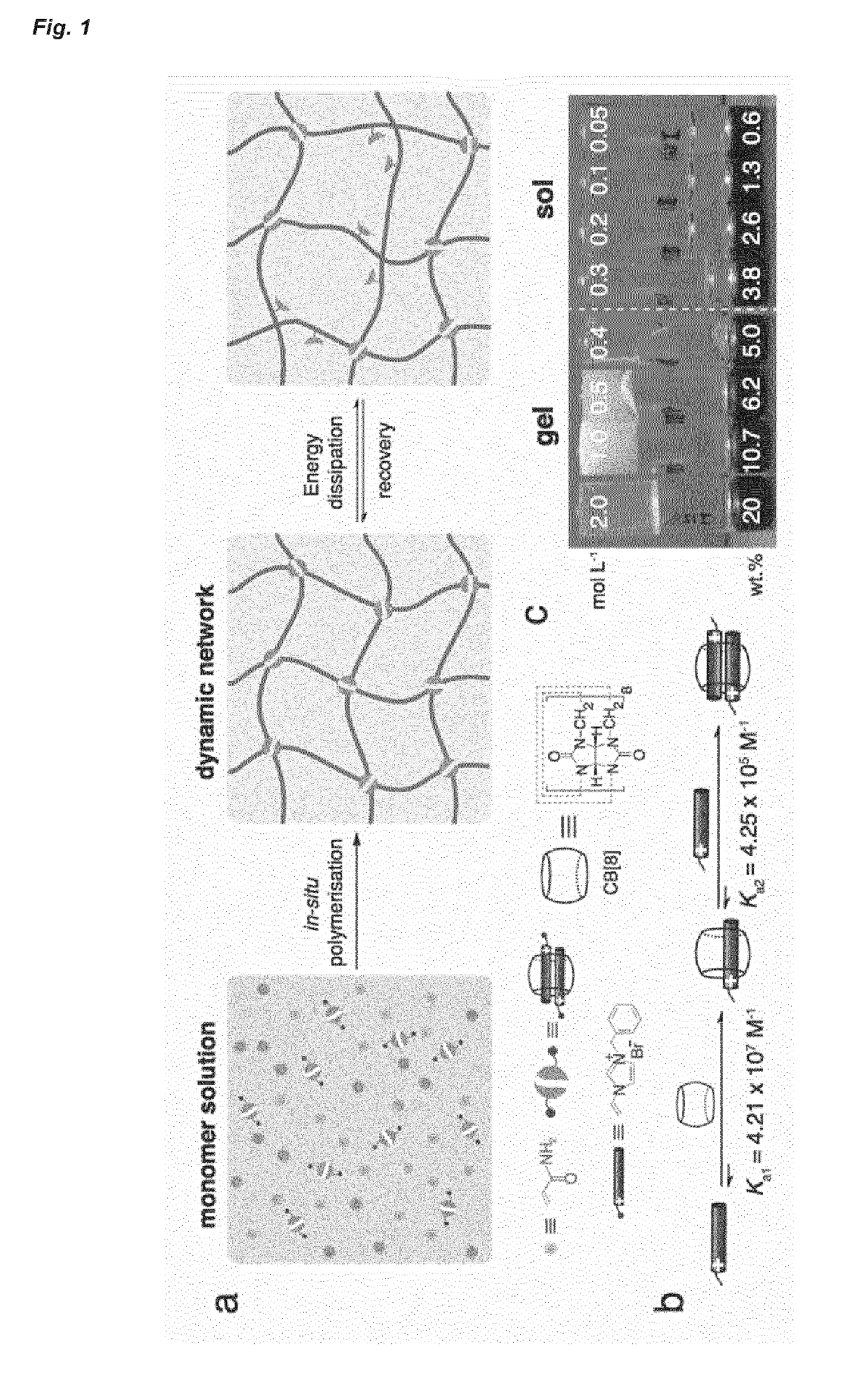

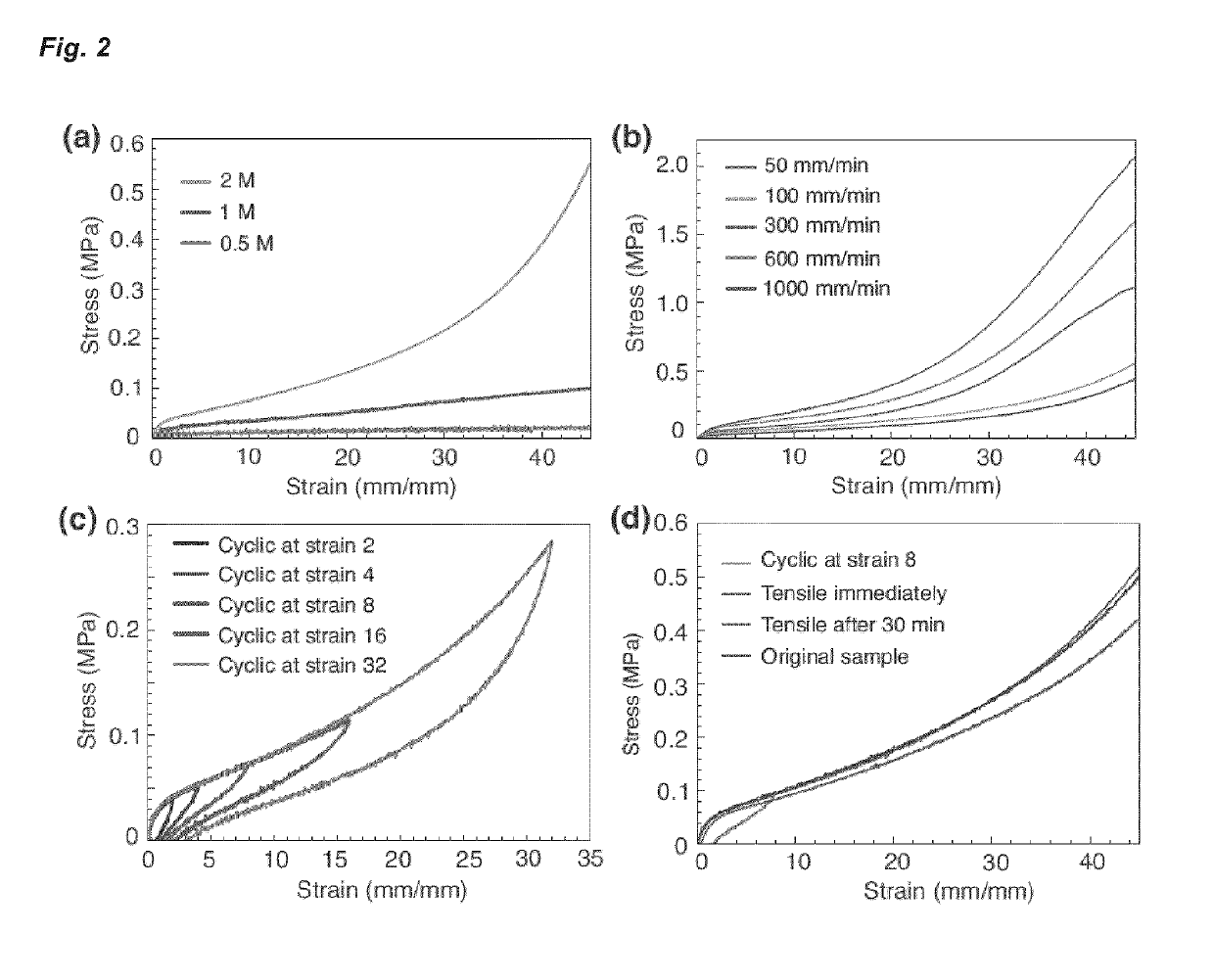

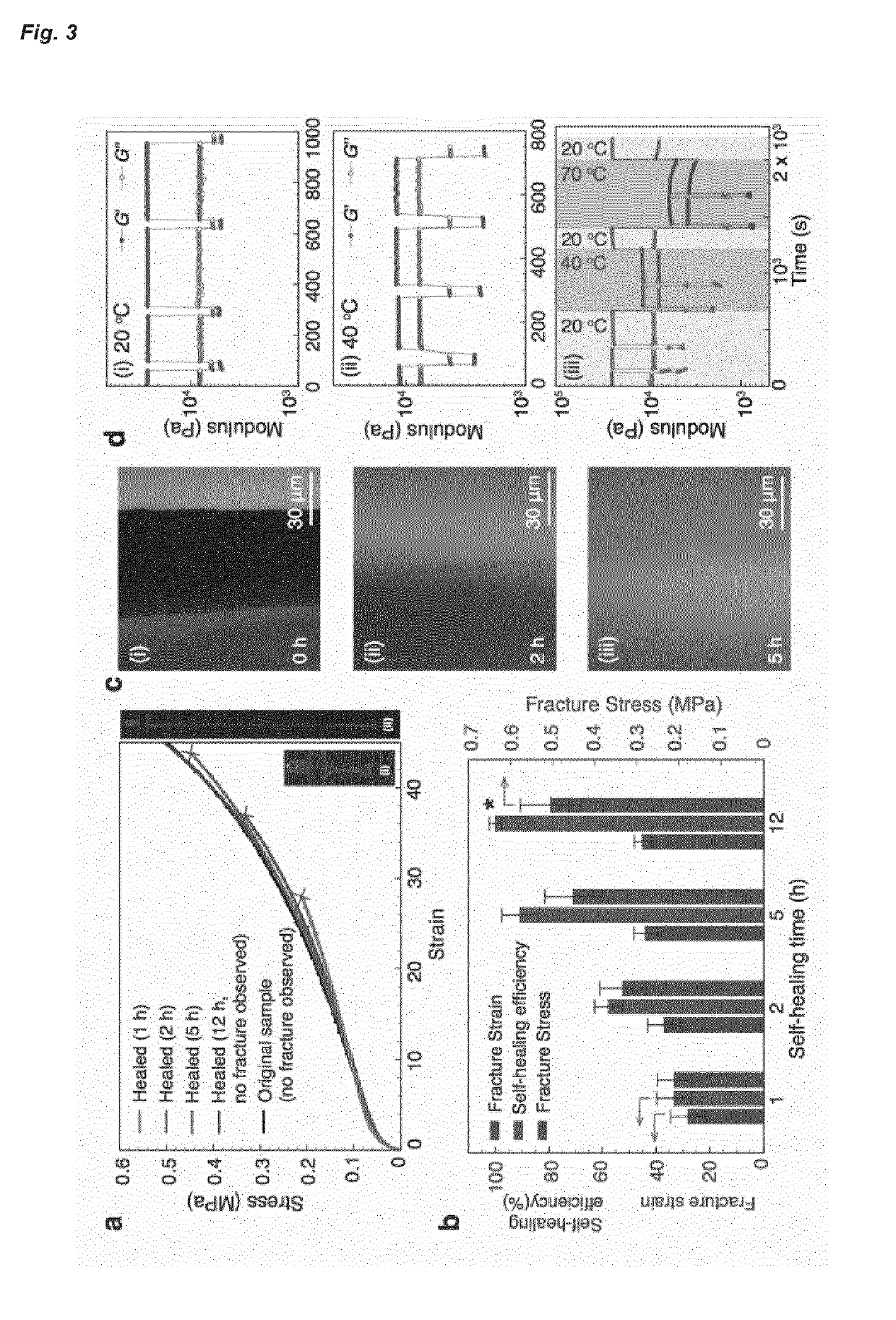

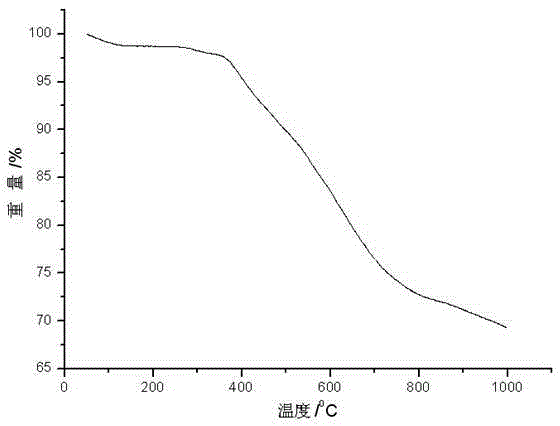

Cucurbituril-based hydrogels

ActiveUS20190263973A1Excellent mechanical physio-chemical propertyImprove propertiesSurgical adhesivesPharmaceutical non-active ingredientsCucurbiturilOrganic chemistry

The invention provides a polymerizable composition and a hydrogel obtained or obtainable from the polymerizable composition. The polymerizable composition comprises cucurbituril and a first monomer having a guest for the cucurbituril, wherein the total monomer concentration, Cmon, within the polymerizable composition is at least 0.5 M. The composition may be an aqueous composition.

Owner:SCHERMAN OREN +1

Preparing method for ablation-resistant high-ortho phenolic fibers

InactiveCN105332081AIncreased fracture energyImproves ablation resistanceMonocomponent synthetic polymer artificial filamentMelt spinning methodsRoom temperatureNitrogen

The invention discloses a preparing method for ablation-resistant high-ortho phenolic fibers. A phenolic compound and formaldehyde are mixed according to a certain proportion, then a certain amount of citric acid as a catalyst is added, and a boiling reaction is carried out for 0.5-4 h; diluted concentrated sulfuric acid is added, and the reaction continues for 30-50 min; decompression and dehydration are carried out for 0.5-2.9 h, boric acid accounting for 1-8% by mass is added for a modification reaction after the temperature reaches 90-97 DEG C, and boiling is carried out for 2 h at the constant temperature; decompression and dehydration are carried out, and dehydration is stopped when the temperature of resin reaches 110 DEG C; the resin is subjected to melt spinning at 120-160 DEG C; nascent fibers are put into a prepared curing solution, the temperature is increased to 95 DEG C gradually from the room temperature, and the nascent fibers are naturally cooled to the room temperature after constant temperature is achieved; the temperature is gradually increased for thermosetting under the nitrogen condition. The fiber strength of the high-ortho phenolic fibers ranges from 3 cN / dtex to 36 cN / dtex, the modulus ranges from 40 cN / dtex to 400 cN / dtex, and the cross-linking degree ranges from 32% to 38%.

Owner:ZHONGYUAN ENGINEERING COLLEGE

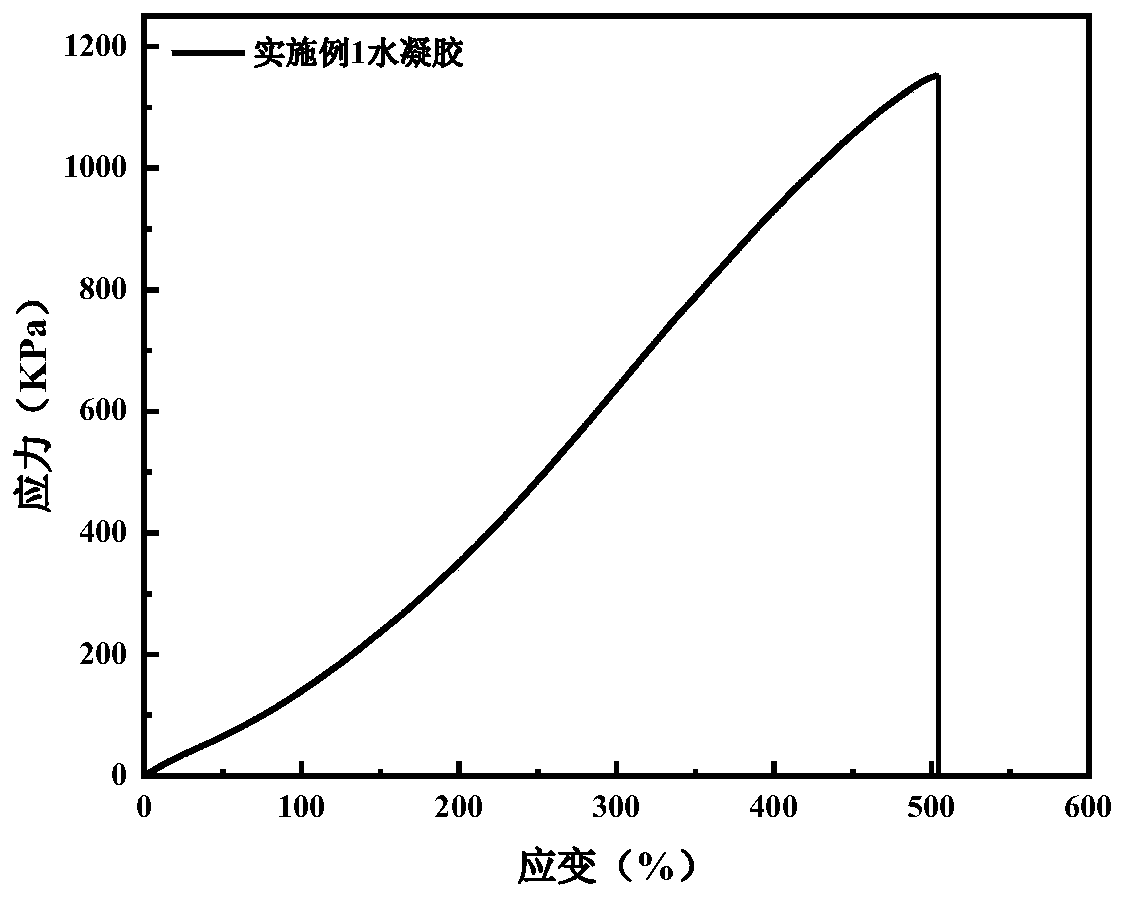

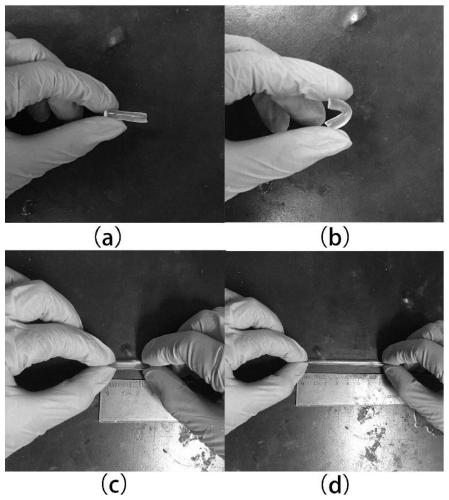

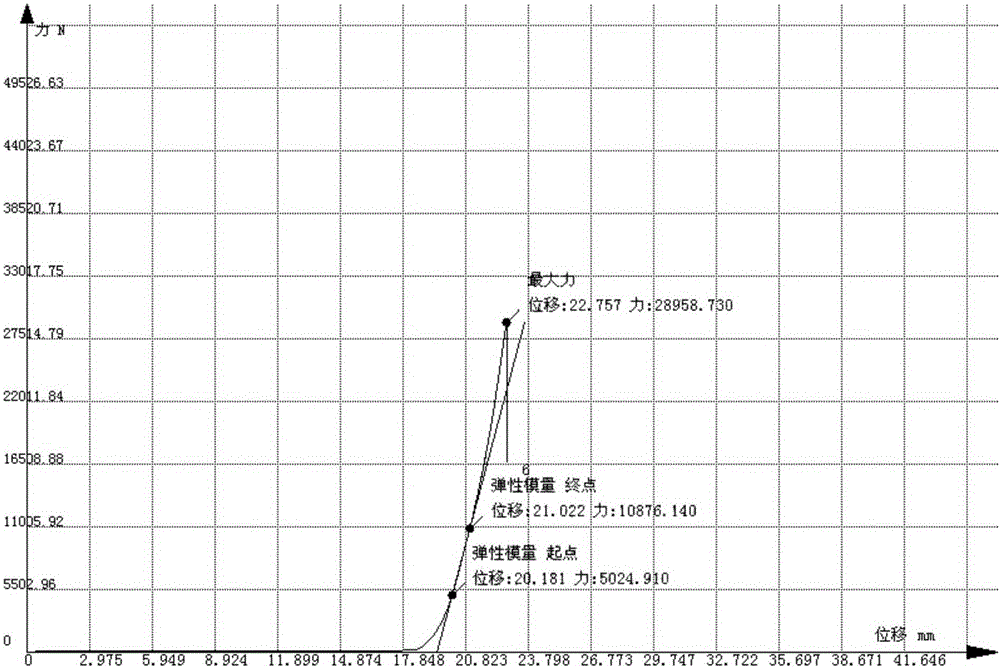

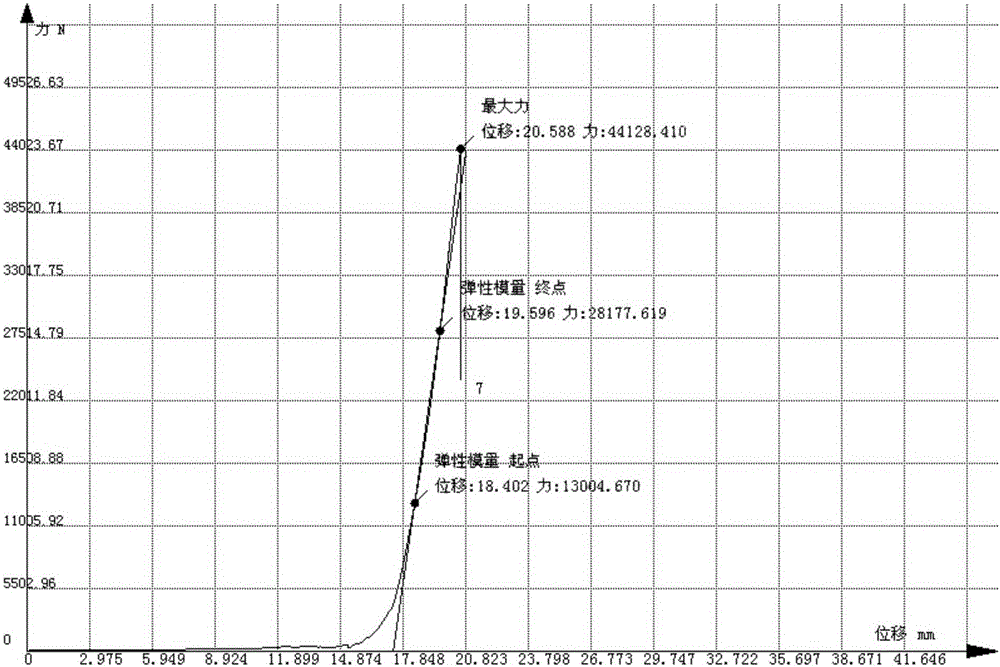

Double network structure macromolecule hydrogel preparation method based on full physical cross-linking

The invention discloses a double network structure macromolecule hydrogel preparation method based on full physical cross-linking. According to the preparation method, a large number of the hydroxyl groups and the amide groups in a macromolecule polymer easily form hydrogen bonds, RDS sol type laponite can be used as the physical cross-linking point of a polyacrylamide network, a nanometer laponite / polyacrylamide first network is prepared through free radical polymerization, and the first network is subjected to physical cross-linking with polyvinyl alcohol through a freezing / thawing circulation method to obtain a second network, such that the polyvinyl alcohol / polyacrylamide-laponite full physical cross-linking double network hydrogel is synthesized through the two-step method. Accordingto the present invention, the method has advantages of simple operation, easy control, mild preparation condition, time and space controllability, time and space selectivity, good repeatability, environmental protection, simple equipment, low cost and the like, and has broad application prospects in the fields of drug delivery and controlled release, tissue engineering, bio-bionic, artificial muscles, biosensors and the like.

Owner:WUHAN UNIV OF TECH

Reinforced concrete and preparation method thereof

The invention is used for mainly overcoming the deficiencies of low compressive strength and poor flexural strength of concrete, and provides a reinforced concrete preparation method with simple preparation process. Reinforced concrete has the advantages of light weight, high strength and high toughness and is expected to be directly applied to batch industrial production in future. The invention aims to provide the reinforced concrete including the following components in parts by weight: 11.98-12.80 parts of cement, 1.50-1.82 parts of fly ash, 1.1076-1.1143 parts of a mineral powder, 4.79-4.97 parts of water, 22.29-22.45 parts of sand, 30.9-31.9 parts of stone, and 0.368-1.389 parts of a carbon fiber composite material. The carbon fiber composite material includes epoxy resin and a carbon fiber, wherein the weight of the epoxy resin accounts for 30%-33% of the weight of the carbon fiber composite material.

Owner:ZHONGFU SHENYING CARBON FIBER +1

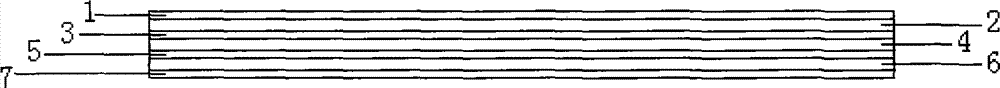

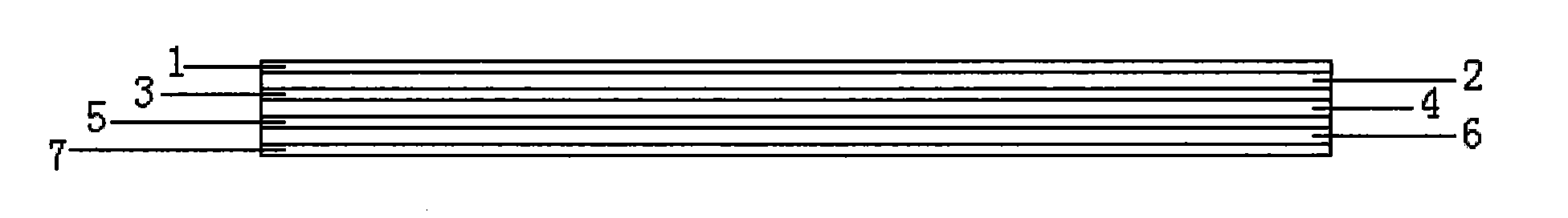

Biomass layered composite board

InactiveCN102039697AImprove interfacial compatibilityFacilitates chemical bondingWater-setting substance layered productAirplaneBiomass

The invention relates to a biomass layered composite board with excellent physical properties. The technical scheme is that the composite board has an organic layer and a composite layer; the organic layer and the inorganic layer are alternately distributed; and the total layer number of the broad is an odd number. The invention is widely applicable to buildings, furniture, indoor and outdoor decorations, and interior trims of vehicles, vessels and airplanes.

Owner:林口信安建材板业有限公司

Waterborne polyurethane resin dispersion and use thereof

InactiveCN103347922AKeep dryImprove water resistancePolyurea/polyurethane coatingsEmulsion paintsHigh rateCarbonate

An aqueous polyurethane resin dispersion exhibits excellent drying properties of coating films and gives coating films having high water resistance and on the other hand showing a high rate of swelling with respect to aqueous cleaning liquids to permit new application. The aqueous polyurethane resin dispersion is a dispersion of a polyurethane resin in an aqueous medium, the polyurethane resin being obtained by reacting (A) a polyurethane prepolymer obtained from (a) a polyisocyanate compound, (b) a polycarbonate polyol with a number average molecular weight of 400 to 3000, (c) an acidic group-containing polyol compound and (d) a blocking agent, with (B) a chain extender, the total content of urethane bonds and urea bonds being 7 to 15 wt %, the content of carbonate bonds being 15 to 40 wt %, the content of ether bonds being 0 wt %, the content of isocyanate groups bonded to the blocking agent being 0.2 to 2 wt %, each of these contents being based on solid contents, the acid value being 11 to 16 mg KOH / g, the weight average molecular weight being 25,000 to 60,000. A coating composition includes the dispersion. A polyurethane resin film is obtained by thermally drying a composition including the dispersion.

Owner:UBE IND LTD

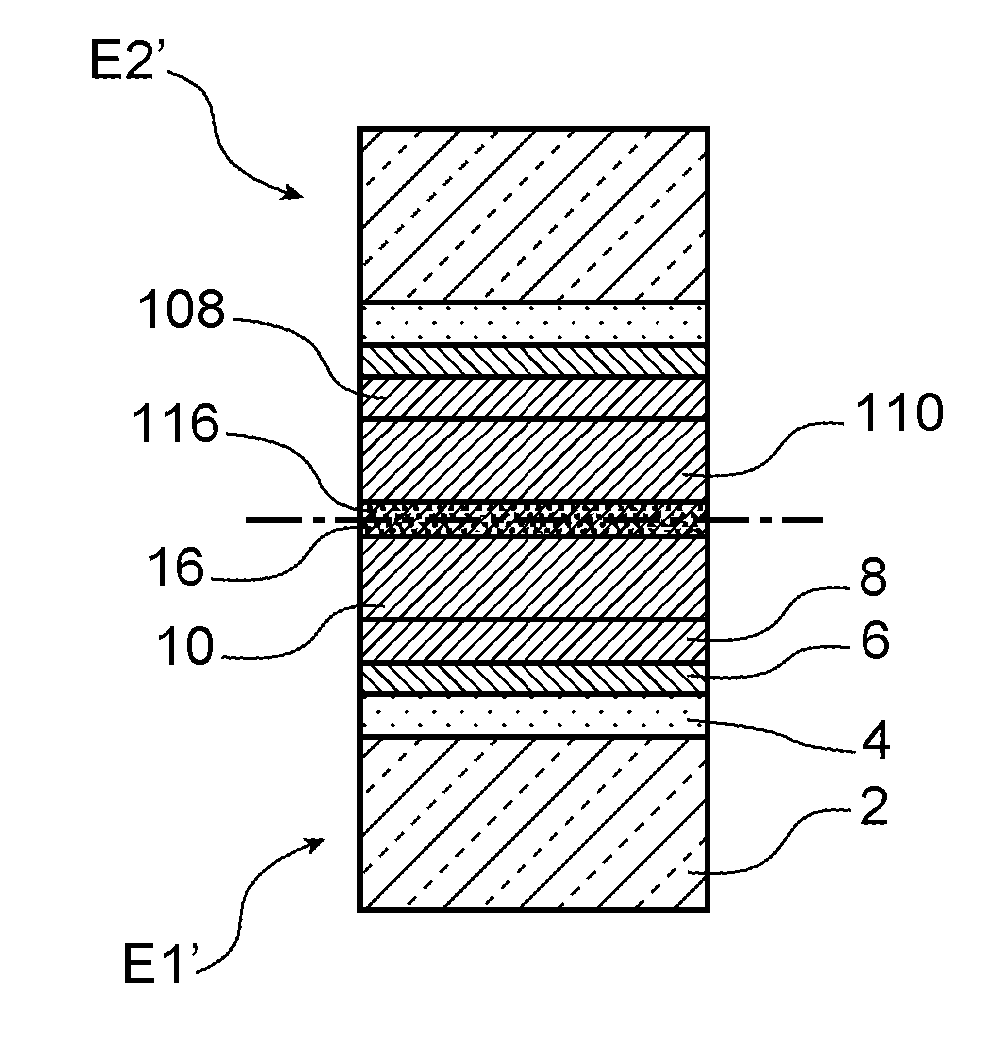

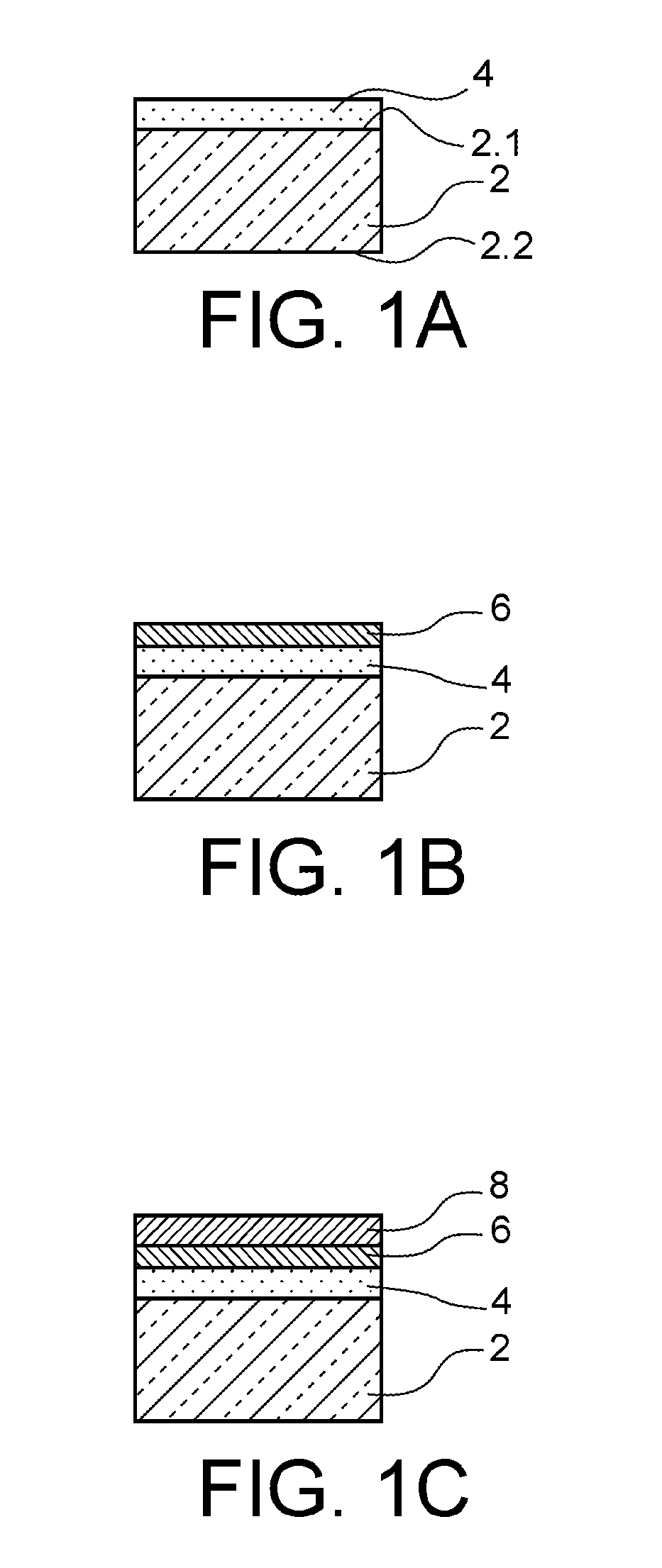

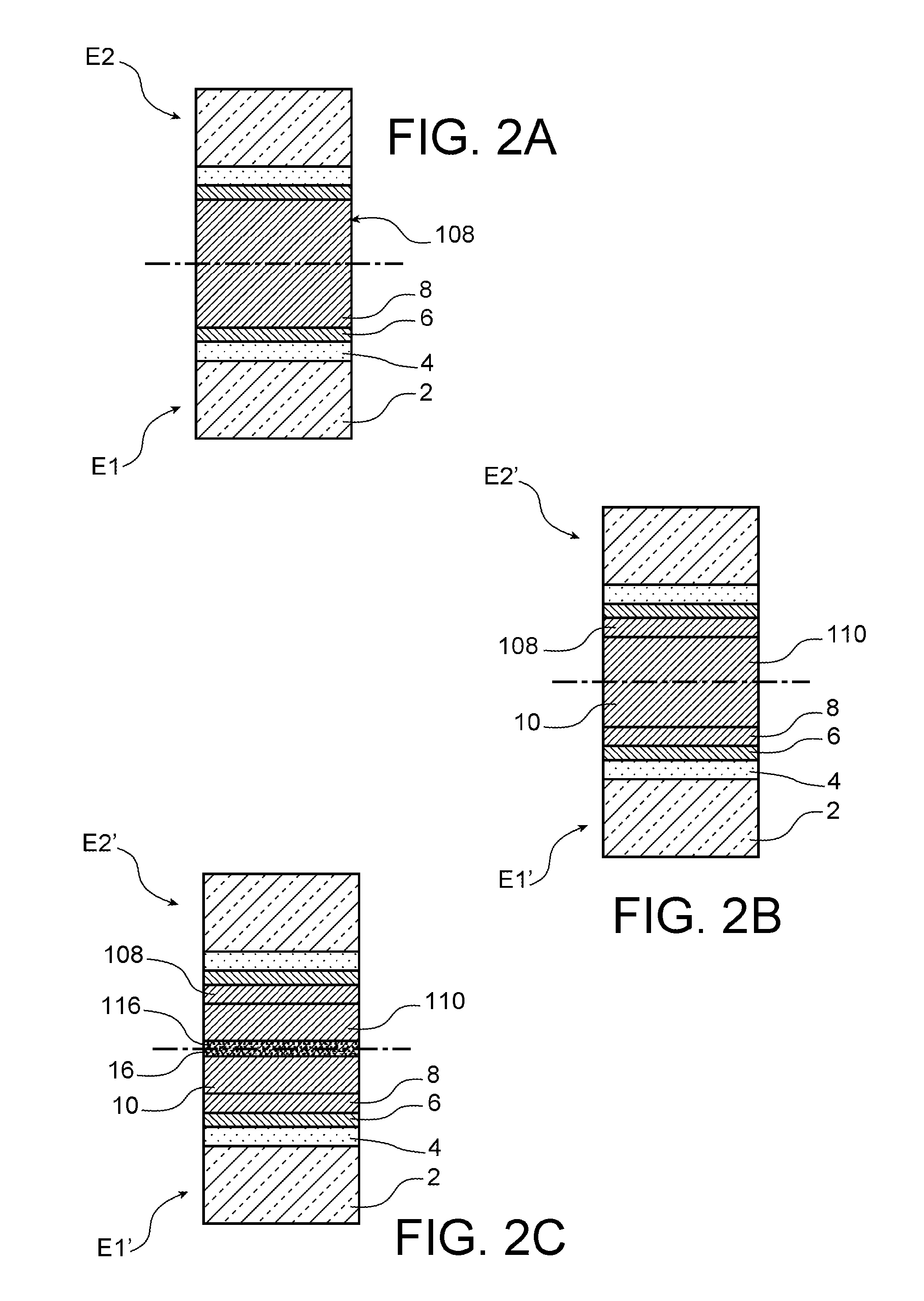

Process for producing a structure by assembling at least two elements by direct adhesive bonding

ActiveUS20170025377A1Increased fracture energyFast dynamicsSemiconductor/solid-state device detailsSolid-state devicesAtmospheric airGas phase

A method for producing a structure by direct bonding of two elements, the method including: production of the elements to be assembled and assembly of the elements. The production of the elements to be assembled includes: deposition on a substrate of a TiN layer by physical vapor deposition, and deposition of a copper layer on the TiN layer. The assembly of the elements includes: polishing the surfaces of the copper layers intended to come into contact so that they have a roughness of less than 1 nm RMS and hydrophilic properties, bringing the surfaces into contact, and storing the structure at atmospheric pressure and at ambient temperature.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Aqueous polyurethane resin dispersion and process for preparing the same

InactiveUS20110313100A1Excellent water resistance and solvent resistanceHigh modulusPolyurea/polyurethane coatingsEmulsion paintsPrepolymerUrea

An aqueous polyurethane resin dispersion which can provide a coating film having high impact resistance and hardness and excellent in adhesiveness to an electrodeposited coating surface is to be provided.It is an aqueous polyurethane resin dispersion which comprises a polyurethane resin obtained by reacting (A) a polyurethane prepolymer which is obtained by reacting (a) a polyisocyanate compound, (b) at least one polyol compound containing a polycarbonate polyol having a number average molecular weight of 400 to 3000, (c) an acidic group-containing polyol compound, and (d) a blocking agent for an isocyanate group, which dissociates at 80 to 180° C., and (B) a chain elongating agent which has reactivity with the isocyanate group, being dispersed in an aqueous medium, a sum of a content of urethane bodings and a content of urea bondings is 15 to 30% by weight in terms of solid components, a content of carbonate bondings is 8% by weight or more and less than 15% by weight in terms of solid components, and a content of an isocyanate group to which the above-mentioned blocking agent has bound is 0.2 to 3% by weight in terms of solid components and calculated on the isocyanate group.

Owner:UBE IND LTD

Tungsten mesh toughened hafnium carbonitride-based metal ceramic and preparation method thereof

ActiveCN111285691AThe preparation process is simpleShort preparation cycleCarbon nitrideThermal shock

The invention discloses tungsten mesh toughened hafnium carbonitride-based metal ceramic and a preparation method thereof. The tungsten mesh toughened hafnium carbonitride-based metal ceramic is composed of a hafnium carbonitride matrix and tungsten meshes distributed in the hafnium carbonitride matrix at intervals. The preparation method comprises the following steps: mixing HfC powder, HfN powder, carbon powder and carbon nitride powder, ball-milling the mixture, and drying and sieving the ball-milling product to obtain mixed powder, wherein in the mixed powder, the mass ratio of the HfC powder to the HfN powder is (1-7): 1; alternately stacking and laying the mixed powder and the tungsten meshes in a mold to obtain a to-be-sintered body; and performing spark plasma sintering on the to-be-sintered body to obtain the tungsten mesh toughened hafnium carbonitride-based metal ceramic. The tungsten mesh toughened hafnium carbonitride-based metal ceramic provided by the invention has excellent thermal shock resistance and ablation resistance.

Owner:CENT SOUTH UNIV

Preparation method of ductile retarding fine aggregate concrete with initial setting time of 48-72 hours

ActiveCN111533512AImprove pore structureImprove early strengthReinforced concreteArchitectural engineering

The invention discloses a preparation method of ductile retarding fine aggregate concrete with initial setting time of 48-72 hours, belongs to the technical field of building construction, and particularly relates to a preparation technology of the ductile retarding fine aggregate concrete. Cement, fly ash, slag powder and a reinforcing compacting agent are adopted to form a cementing material, and the fly ash, the slag powder and the reinforcing compacting agent not only improve the performance of a concrete mixture, but also can improve the early-stage or later-stage strength of concrete, improve the pore structure and improve the compaction performance of the concrete; meanwhile, the effects of saving resources and protecting the environment are achieved. The concrete is suitable for pier wall reinforced concrete structures in the fields of construction engineering, water conservancy engineering, traffic engineering, water transportation engineering and the like, a layer of ductileretarding concrete is poured at the root of the pier wall, and the concrete can also be suitable for underground secant piles and structural construction joints needing to be poured by several times.

Owner:JIANGSU WATER CONSERVANCY SCI RES INST +5

Weldment of different materials and resistance spot welding method

ActiveUS20050258145A1High ductile fracture energyIncreased fracture energyHot-dipping/immersion processesArc welding apparatusHigh fractureSpot welding

A joined part of an aluminum-coated steel sheet and an aluminum sheet is composed of an intermetallic compound layer which exists in a region in which a part of a coated layer exists before the joining and an aluminum melted and solidified part which also exists on the side of the aluminum sheet to enclose the intermetallic compound layer. The atoms existing on the surface of the aluminum melted and solidified part are intermetallic-bonded with atoms which exist on the surface of the steel sheet except in the region in which the intermetallic compound layer exists seen in the plan view. Further, the area of the intermetallic compound layer is limited to 60% or less of the total area of the joined part at the interface between the aluminum-coated steel sheet and the aluminum sheet. Thus, the area of the aluminum melted and solidified part exceeds 40% of the total area of the joined part. The strong joining having a high fracture energy can be provided at a high efficiency.

Owner:KOBE STEEL LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com