Double network structure macromolecule hydrogel preparation method based on full physical cross-linking

A technology of polymer hydrogel and network structure, which is applied in the field of preparation of double network structure polymer hydrogel to achieve high mechanical strength, low cost and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

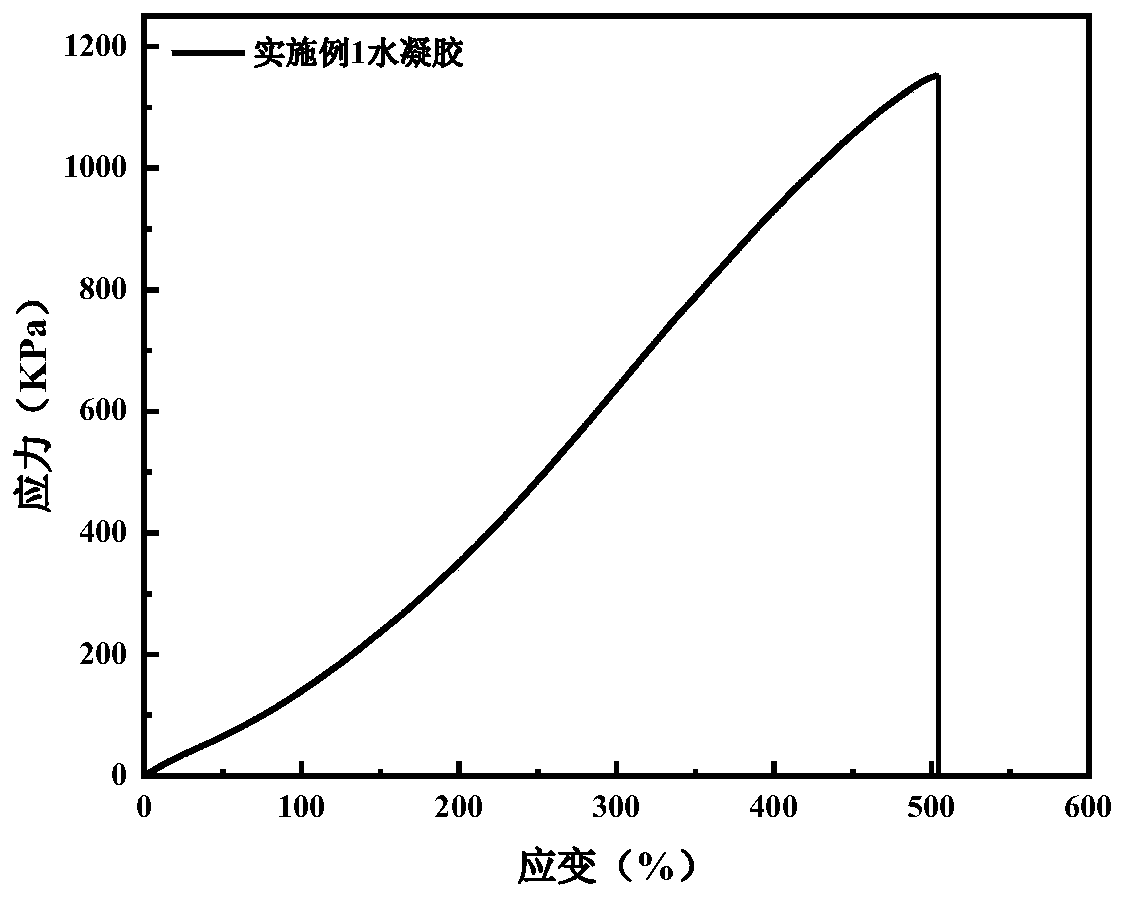

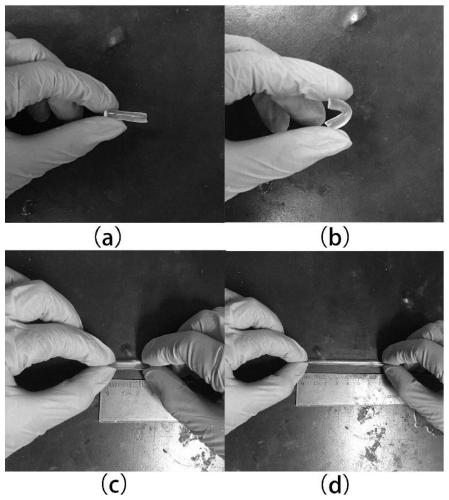

Embodiment 1

[0036] The method for preparing a double network structure polymer hydrogel based on full physical crosslinking provided in this embodiment includes the following specific steps:

[0037] 1) Preparation of polyvinyl alcohol solution:

[0038] Add a certain amount of polyvinyl alcohol to quantitative deionized water to make the mass fraction of the solution 20wt%, and stir vigorously at 96°C for 10 hours until the polyvinyl alcohol is completely dispersed in the water to obtain a polyvinyl alcohol solution;

[0039] 2) Preparation of RDS Lithium Diatomite Dispersion:

[0040] Add 0.10g of RDS Lithium-Ionite into 10mL of water, and then ultrasonically disperse for 55 minutes until the RDS Lithium-Ionite is completely dissolved in the water;

[0041] 3) Preparation of the first network of double network hydrogel:

[0042] Add 4g of acrylamide to the RDS lithium-atomite dispersion with a mass concentration of 0.10g / 10mL prepared in step 2), stir well for 40 minutes to dissolve it in the solu...

Embodiment 2

[0047] The preparation method of the double network structure polymer hydrogel based on full physical crosslinking provided in this embodiment includes the following specific steps:

[0048] 1) Preparation of polyvinyl alcohol solution:

[0049] Add a certain amount of polyvinyl alcohol to quantitative deionized water to make the mass fraction of the solution 10wt%, and stir vigorously at 97°C for 12 hours until the polyvinyl alcohol is completely dispersed in the water to obtain a polyvinyl alcohol solution;

[0050] 2) Preparation of RDS Lithium Diatomite Dispersion:

[0051] Add 0.25g of RDS Lithium-Ionite into 6mL of water, and then ultrasonically disperse for 60 minutes until RDS Lithium-Ionite is completely dissolved in the water;

[0052] 3) Preparation of the first network of double network hydrogel:

[0053] Add 10g of acrylamide to the 0.42g / 10mL RDS Lithium Diatomite dispersion prepared in step 2), stir well for 50 minutes to dissolve it in the solution, and then slowly add it...

Embodiment 3

[0056] The preparation method of the double network structure polymer hydrogel based on full physical crosslinking provided in this embodiment includes the following specific steps:

[0057] 1) Preparation of polyvinyl alcohol solution:

[0058] Add a certain amount of polyvinyl alcohol to quantitative deionized water to make the mass fraction of the solution 15 wt%, and stir vigorously at 95°C for 8 hours until the polyvinyl alcohol is completely dispersed in the water to obtain a polyvinyl alcohol solution;

[0059] 2) Preparation of RDS Lithium Diatomite Dispersion:

[0060] Add 0.05g of RDS Lithium Oxide into 14mL of water, then ultrasonically disperse for 50 minutes until the RDS Lithium Oxide is completely dissolved in the water;

[0061] 3) Preparation of the first network of double network hydrogel:

[0062] Add 2g of acrylamide to the RDS lithium-atomite dispersion with a mass concentration of 0.036g / 10mL prepared in step 2), stir well for 30 minutes to dissolve it in the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com