Biomass layered composite board

A composite board and biomass technology, applied in the field of biomass layered composite boards, can solve the problems of unsatisfactory physical properties such as the interface randomness and fracture energy of the composite board, and achieve improved interfacial compatibility, interface toughness and fracture energy, Improve the effectiveness of chemical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

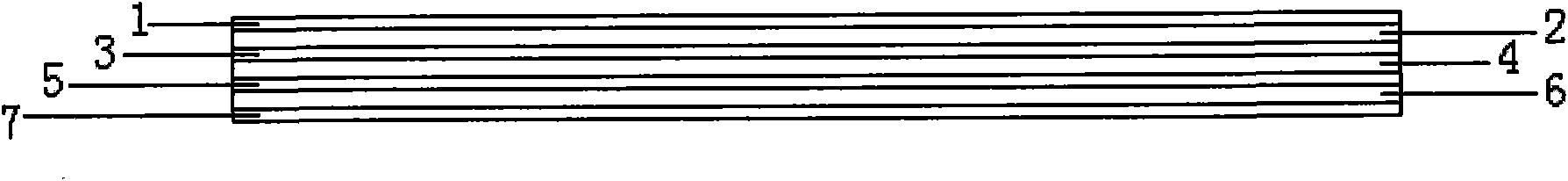

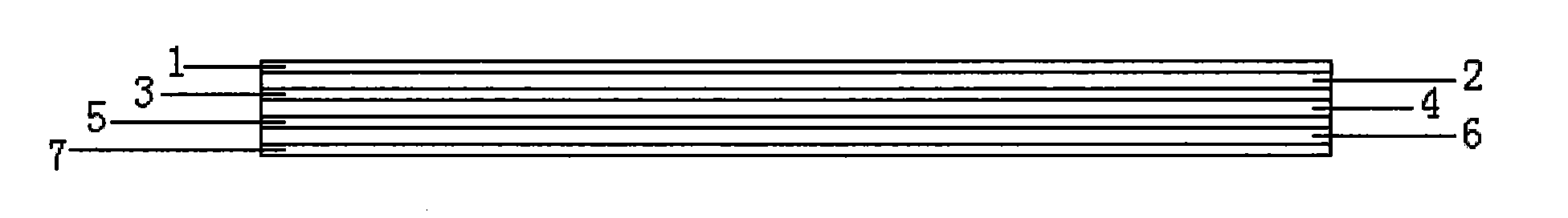

[0015] As shown in the figure, the board has an organic layer and a composite layer. The organic layer and the inorganic layer are alternately distributed. The total number of layers of the board is an odd number. The total number of layers of the board can be 3 or 5 layers. This embodiment has 3 layers, namely Organic layer 2, inorganic layer 4, organic layer 6. The organic layer is made of organic polymer material as a matrix, and inorganic polymer material is added to penetrate and mix. The inorganic layer is made of inorganic polymer material as the matrix, and organic polymer polymer material is added to penetrate and mix. The organic polymer material may be WPC, MDI, PE, PP, PS or PVC, and WPC is used in this embodiment. The inorganic polymer material may be magnesite, gypsum or Portland cement, and gypsum is used in this embodiment.

[0016] There is also a reinforcement layer made of carbon fiber or glass fiber. The reinforcement layer is located on the surface of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com