Ethylene-vinyl acetate copolymerized emulsion surface modified polyvinyl chloride resin and surface modification method thereof

A technology of vinyl acetate copolymerization and polyvinyl chloride resin, applied in the direction of coating, etc., can solve the problems of complex coupling agent treatment process, little effect on performance improvement, and difficult dispersion of materials evenly, so as to improve interfacial compatibility and effect The effect of enhancing and improving the plasticizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

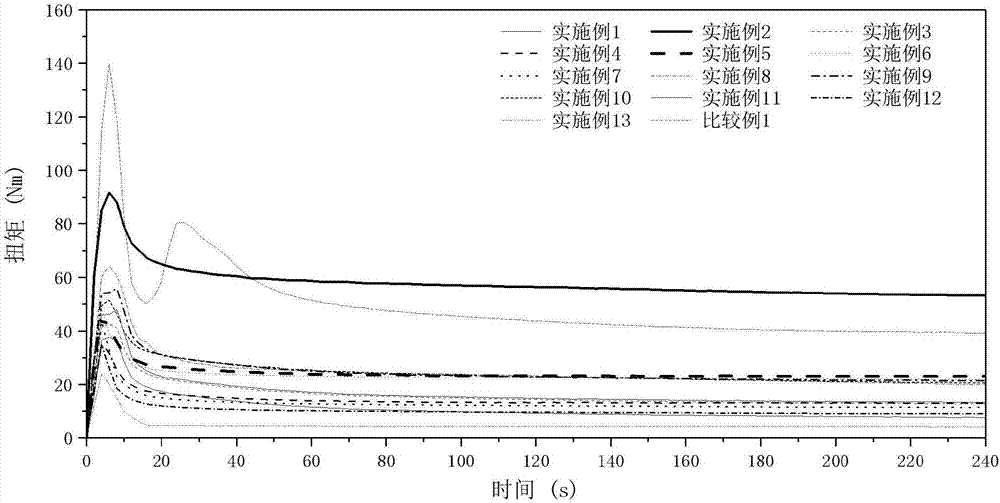

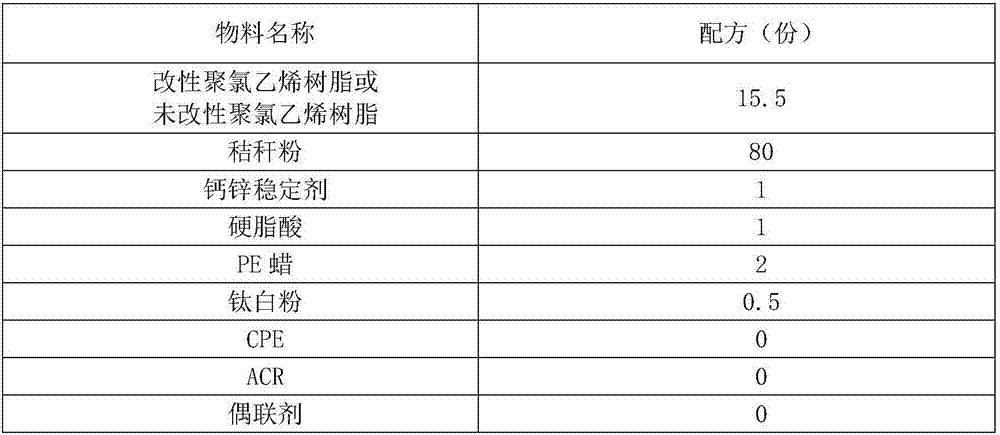

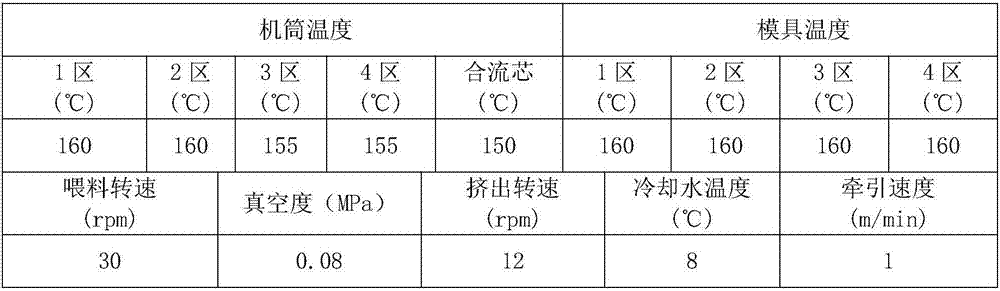

Examples

Embodiment 1

[0026] A kind of ethylene-vinyl acetate copolymer latex surface modified polyvinyl chloride resin, its surface modification method comprises:

[0027] 1) In the polyvinyl chloride resin polymerization process, after the material enters the slurry tank, add 1% ethylene-vinyl acetate copolymer emulsion (40% vinyl acetate content) and mix evenly. The mixing time is: 10min;

[0028] 2) Then filter out excess water, transfer the material to a cyclone drying bed and dry at 40°C to obtain a polyvinyl chloride resin modified by ethylene-vinyl acetate copolymer emulsion.

Embodiment 2

[0030] A polyvinyl chloride resin surface-modified by an ethylene-vinyl acetate copolymer emulsion. The surface modification method is the same as in Example 1, except that the amount of ethylene-vinyl acetate copolymer emulsion used is changed to 20%.

Embodiment 3

[0032] A polyvinyl chloride resin surface-modified by an ethylene-vinyl acetate copolymer emulsion, the surface modification method of which is the same as in Example 1, except that the amount of ethylene-vinyl acetate copolymer emulsion used is changed to 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com