Patents

Literature

811results about How to "Improve plasticizing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-resistant polyvinyl alcohol (PVA) film composition as well as fusion preparation method thereof

ActiveCN102234405ALower melt processing temperatureImprove plasticizing effectBlow moldingProcedure Agents

The invention discloses a water-resistant polyvinyl alcohol (PVA) film composition which comprises the following components in parts by weight: 100 parts of polyvinyl alcohol resin, 10-90 parts (preferably 20-50 parts) of compound plasticizing agent and 1-5 parts of processing agent, wherein the compound plasticizing agent is prepared from small molecular and high molecular plasticizing agents through compounding according to a certain proportion. The invention further discloses a preparation method of the composition. The film prepared by the method has good mechanical property, high transparency and high barrier property; the defects that PVA is easily degraded and smelled during a fusion process and PVA cannot be prepared by fusion are overcome; and the film is formed by a plurality ofmanners such as blow molding, curtain coasting, rolling and the like.

Owner:CHANGZHOU BAIJIA NIANDAI FILM TECH CO LTD

High blending flyash porcelain brick and its making method

InactiveCN1410386AImprove adhesionImprove plasticizing effectSolid waste managementClaywaresBrickGranularity

A ceramic tile with high content is flyash is prepared from flyash (60-700 wt.%), superfine kaolinite (25-40) prepared by the nano intercalation technique, and feldspar (0-10) through pretreating rawmaterials, compounding, pulping, baking, grinding, adding water and granulating, ageing, die pressing, baking, sintering and cooling. Its advantages are low cost, low hydroscopicity (less than 0.5%),and high modulus of rupture (more than 35 MPa).

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

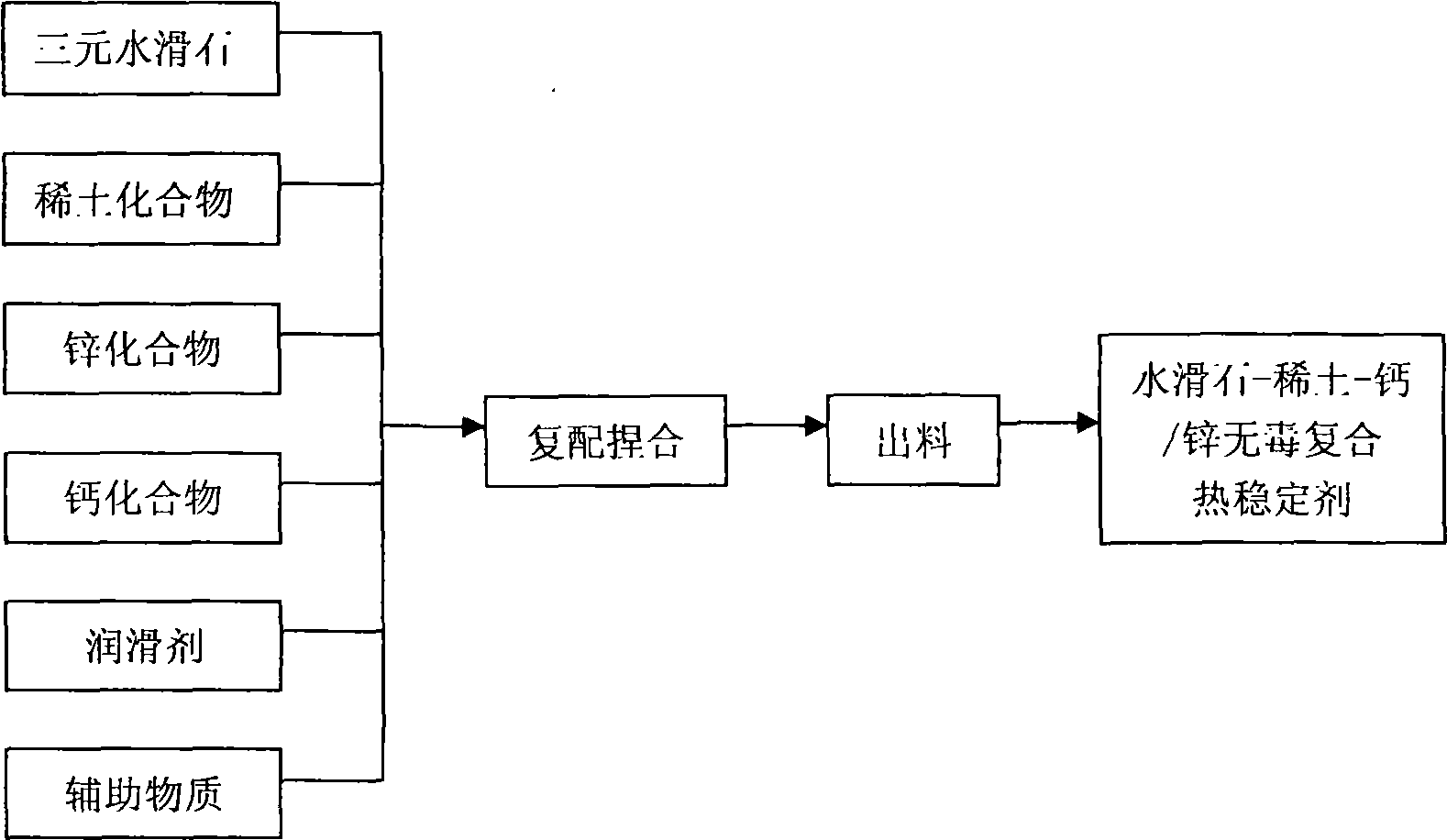

Ternary hydrotalcite-rare earth-calcium/zinc nontoxic composite heat stabilizer and preparation thereof

The invention relates to a preparation method of compound thermal stabilizer in plastic processing additive and pertains to the technical field of plastic processing additive. The invention discloses a ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer and a preparation method thereof. The invention comprises the materials of the stabilizer such as ternary hydrotalcite, organic rare earth compound, Ca compound and Zn compound, a synthetic preparation method thereof and an optimal compounding method of ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer. The ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer provided by the invention serves as a new generation high-efficiency innoxious stabilizer, can replace the traditional lead salt and expensive organic stannum thermal stabilizer and can be widely applied to the fields of PVC pipe material, section material, wire and cable, medical instrument and membrane, etc.

Owner:江西宏远化工有限公司

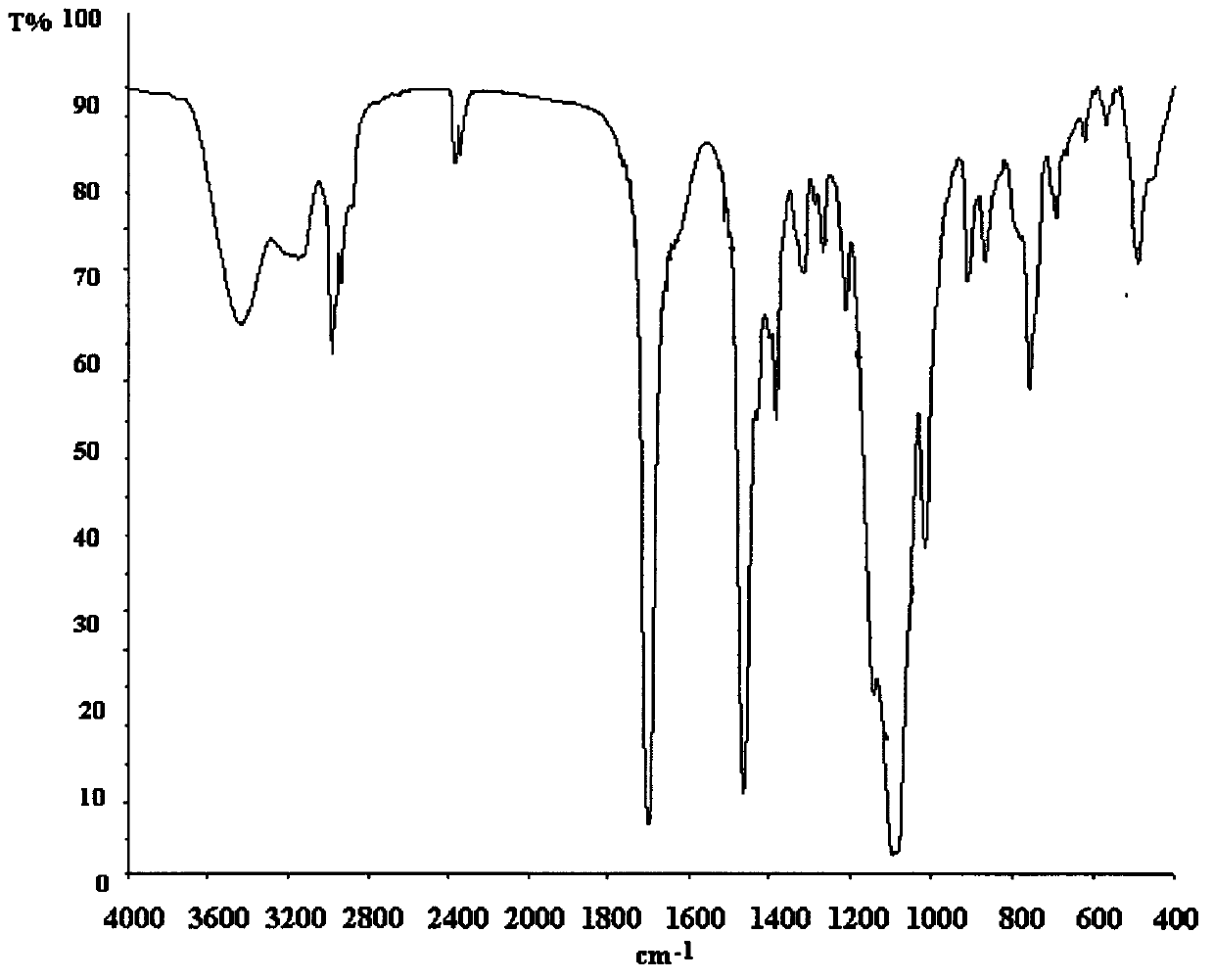

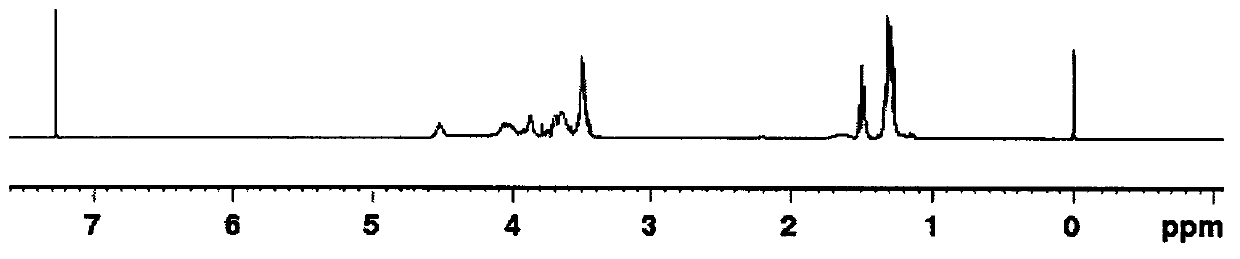

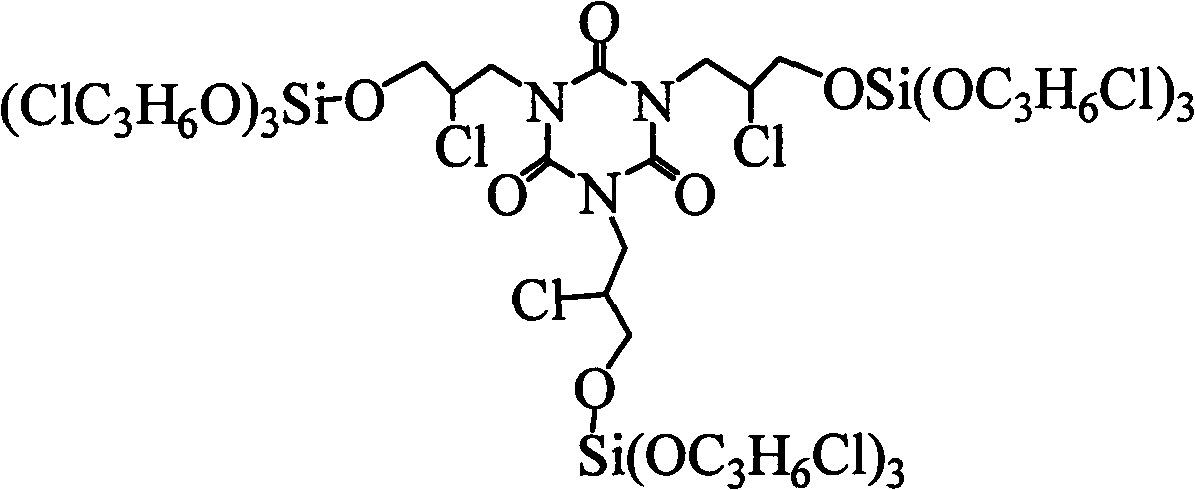

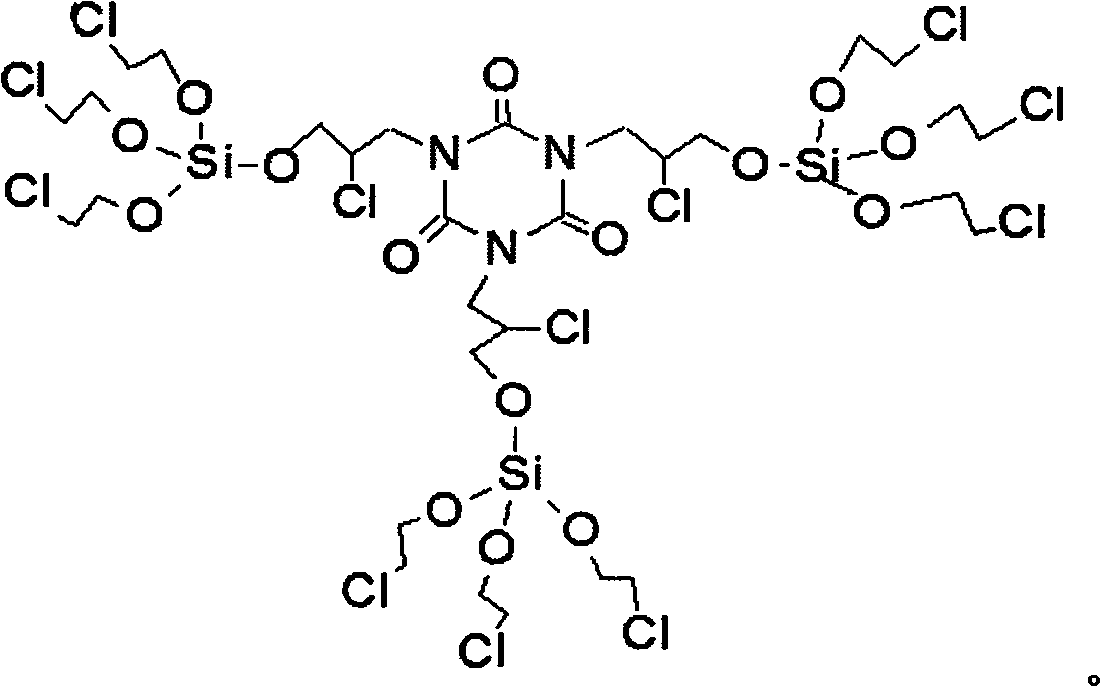

Triazinetri-tri(chloropropyl) silicate compound and preparation method thereof

ActiveCN102731549AGood symmetryStable molecular structureSilicon organic compoundsPlasticizerSilicon tetrachloride

The invention relates to a silicon-halogen synergic flame retardant triazinetri-tri(chloropropyl) silicate compound and a preparation method thereof, in particular to a tri{2-chloro-3-[tri(chloropropoxy)siacryloxy]propyl}isocyanurate compound and a preparation method thereof. The compound has the structural formula shown in the specification, wherein OC3H6Cl is OCH2CHClCH3 or OCH2CH2CH2Cl or OCH(CH3)CH2Cl. The preparation method comprises the following steps of: controlling a certain molar ratio of raw materials; enabling triepoxypropylisocyanurate to react with silicon tetrachloride at 60 DEG C for 4-6 hours in an organic solvent; adding epoxypropane and reacting at 50-60 DEG C for 4-6 hours; and purifying to obtain the product triazinetri-tri(chloropropyl) silicate. The triazinetri-tri(chloropropyl) silicate provided by the invention has good flame-retardant plasticizing property and is suitable to be used as a flame-retardant plasticizer of polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the production technology is simple, the cost is low, and the industrial production is easy to realize.

Owner:张家港市乐余科创园投资发展有限公司

Wood plastic micro foaming composite material and its processing shaping method

This invention relates to a wood plastic micro-foam composite and its processing and shaping technology, mainly including various kinds of processing accessory ingredient, such as: polyvinyl chloride resin, sanding powder, chemistry(AC) blowing agent, plasticizer, assistant blowing agent and so on, mixing uniformly in high speed mixer, extrude palletizing in single screw extruder or twin screw extruder, prepared particles form a kind of continuous uniform wood plastic micro-foam composite through single, twin screw extruder and foaming tooting, it can efficiently overcome the flaw of large density and low impact strength of common wood plastic composite. This invention provides broader reuse way for solving many industrial waste sanding powder or wood powder, can extensively process and form indoor and outdoor decoration, building doors, window products and so on.

Owner:BEIJING UNIV OF CHEM TECH

Ethylene-propylene-diene monomer rubber used for manufacturing wind energy cable and preparation method thereof

ActiveCN102617942AImprove mechanical propertiesEasy to stretchPolymer scienceDecabromobiphenyl ether

The invention discloses an ethylene-propylene-diene monomer rubber used for manufacturing a wind energy cable and a preparation method thereof. The ethylene-propylene-diene monomer rubber comprises the following components: 90-110 parts of ethylene-propylene-diene monomer rubber, 1-4 parts of anti-aging agent, 0.2-0.5 part of stearic acid, 2-9 parts of paraffin oil, 2-5 parts of lead sulfate tribasic, 1-4 parts of zinc oxide, 80-120 parts of activated kaolin, 0.3-1.5 parts of coupling agent, 0.5-2.6 parts of cross-linking agent, 0.5-2.0 parts of assistant crosslinker, 1-3 parts of semi-reinforcing carbon black, 1-4 parts of plasticizer, 0.5-2 parts of antimonous oxide, 0.5-2 parts of zinc borate, 1-5 parts of basic magnesium carbonate, 1-4 parts of antioxygen, 0.1-0.5 part of sulphur, 2-5parts of epoxidized soybean oil, 5-15 parts of decabromodiphenyl ether, 12-30 parts of antimony oxide and 2-5 parts of organic modified bentonite. The material has the advantages of wide applicable temperature range, god performance and long service life.

Owner:无锡市远登电缆有限公司

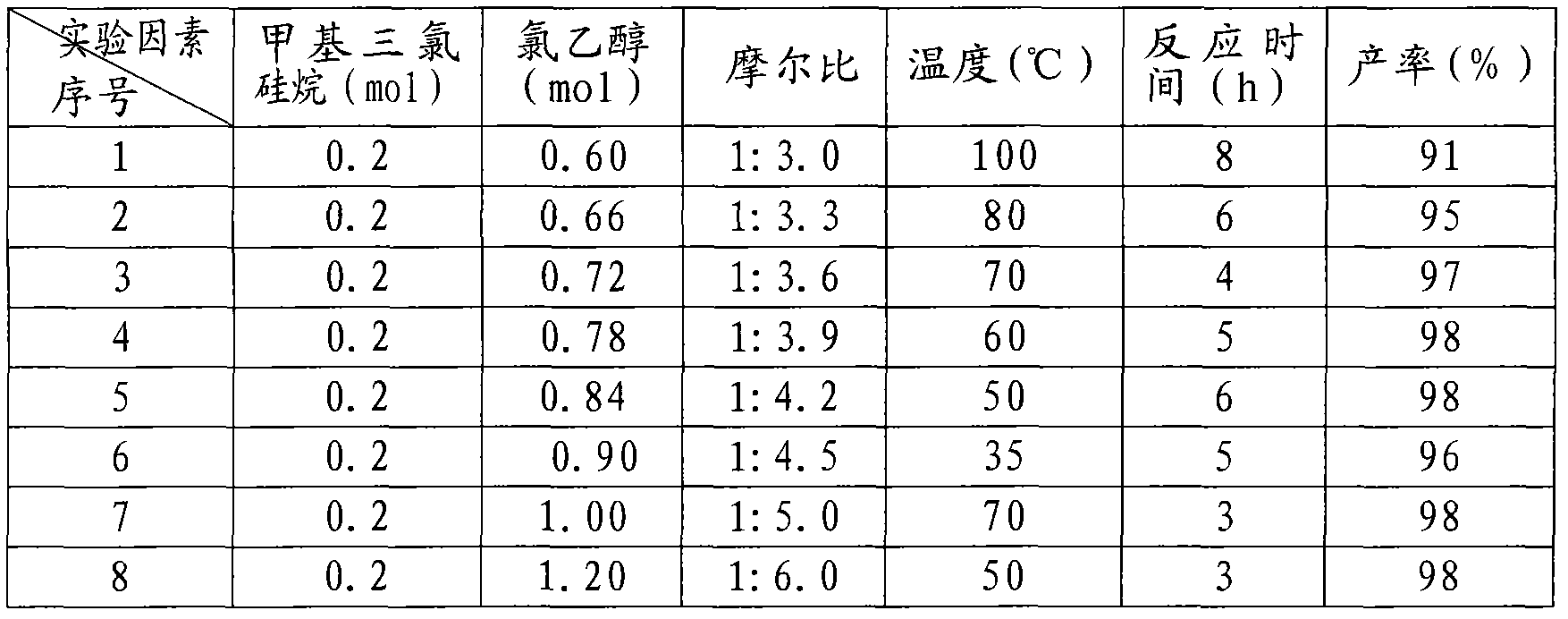

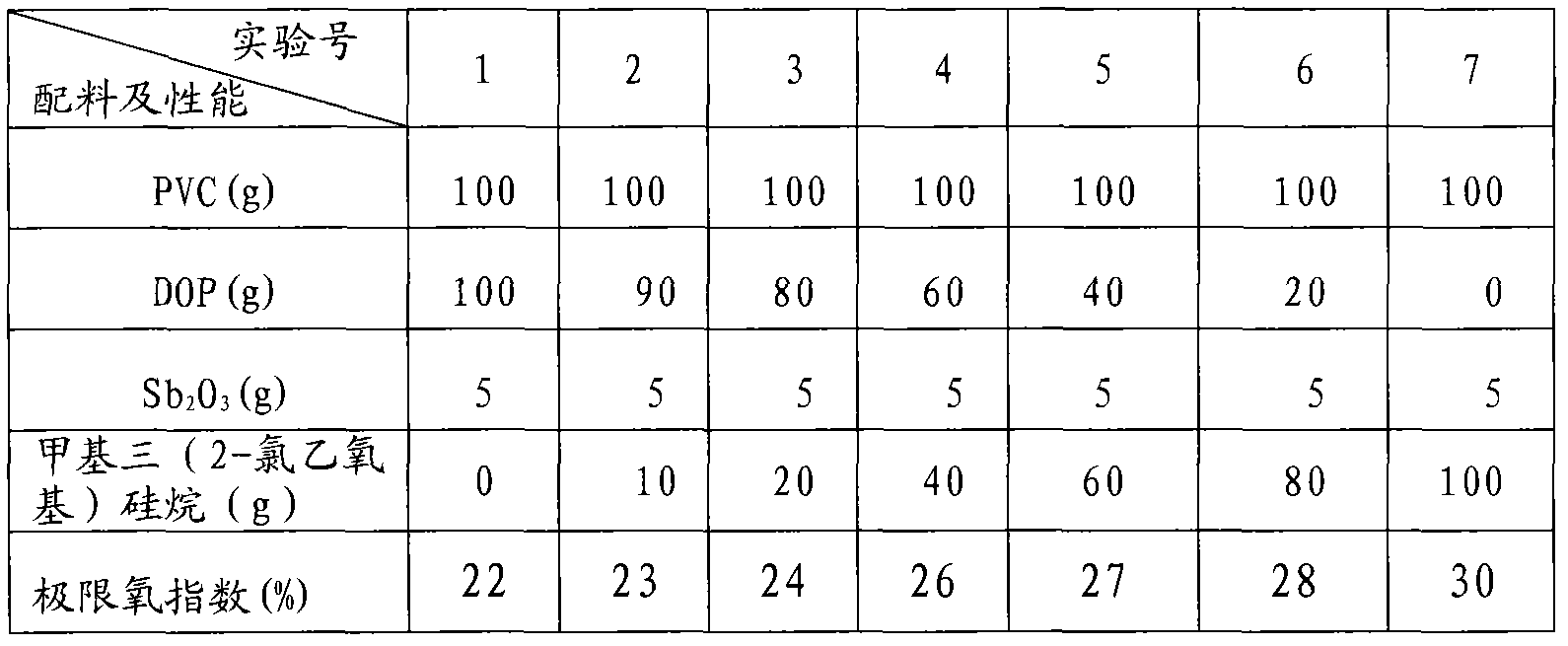

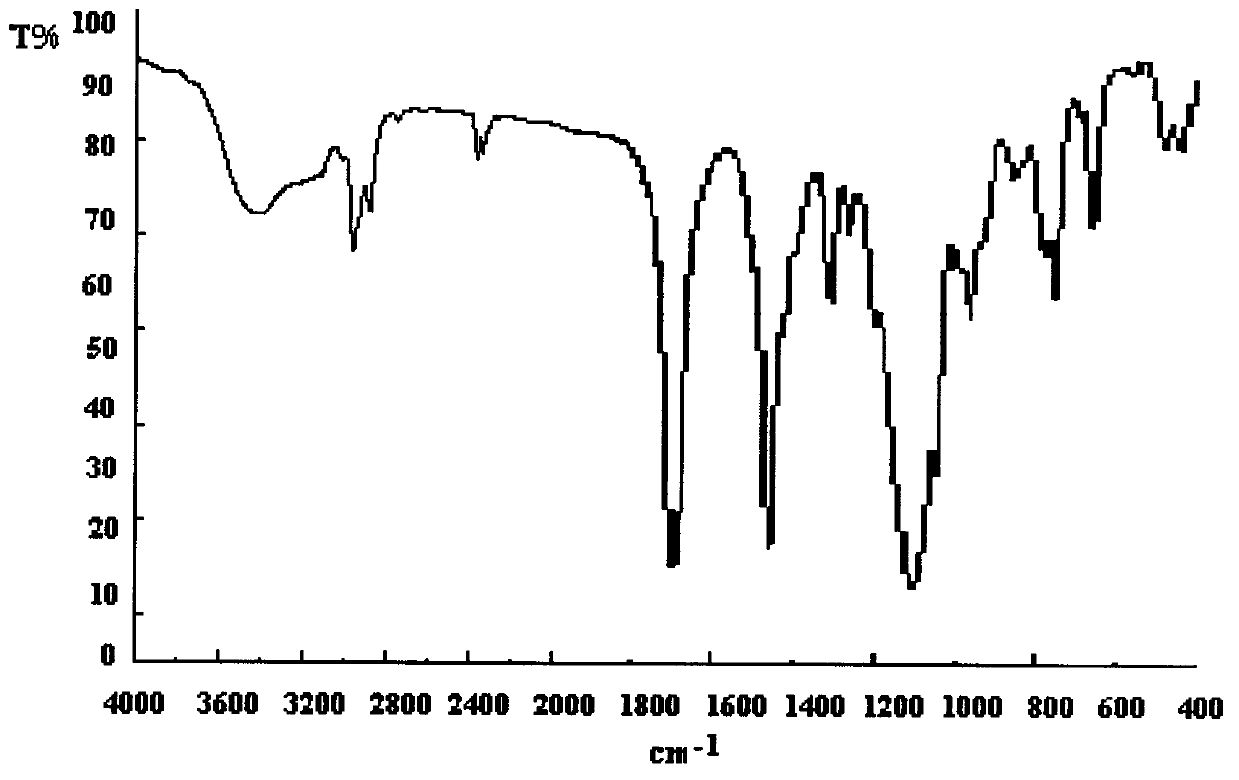

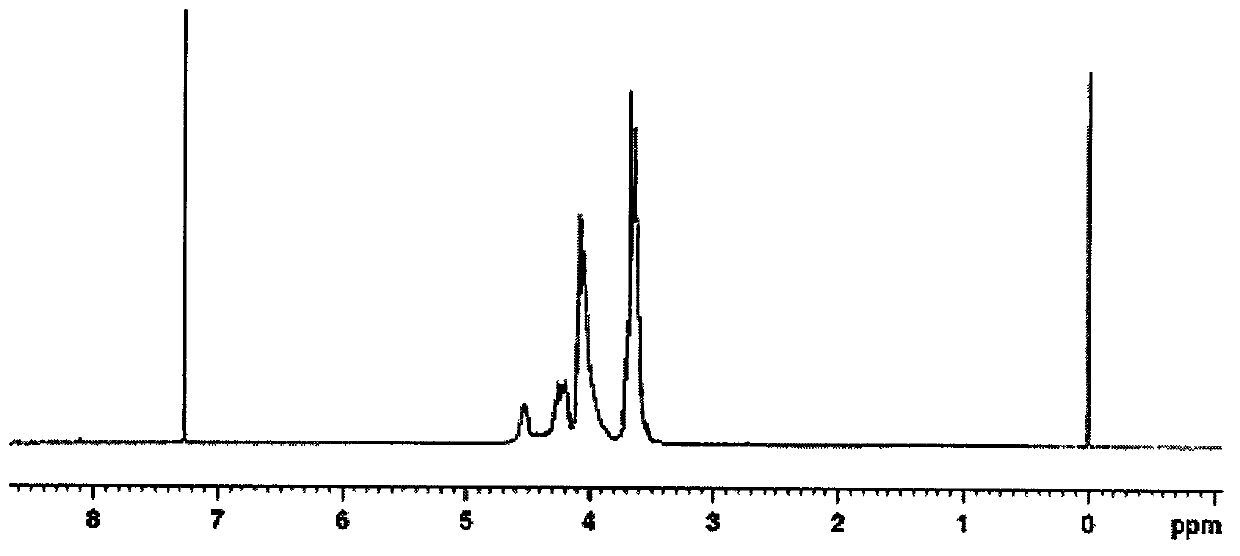

Methyl tri(2-chloroethoxy) silane compound and preparation method thereof

ActiveCN102174055AStabilize the C-Si bond structureSymmetrical ester structureGroup 4/14 element organic compoundsSilane compoundsHalogen

The invention relates to a methyl tri(2-chloroethoxy) silane compound which is used as a silicon-halogen synergistic flame-retardant plasticizer and a preparation method thereof. The methyl tri(2-chloroethoxy) silane compound has the following structural formula: CH3Si(OCH2CH2Cl)3. The preparation method of the methyl tri(2-chloroethoxy) silane compound comprises the following steps: dropwise adding and stirring chloroethanol at a certain molar ratio to methyl trichlorosilane, carrying out a reaction on the chloroethanol and the methyl trichlorosilane for a certain time at a certain temperature, and purifying after finishing hydrogen chloride release and reaction to obtain methyl tri(2-chloroethoxy) silane. The methyl tri(2-chloroethoxy) silane can be used as the good flame-retardant plasticizer, and the process for producing the methyl tri(2-chloroethoxy) silane is simple, has low equipment investment and cost and is easy to realize industrial production.

Owner:河南森远科技有限公司

Isocyanurate chloropropyl chloroethyl silicate and preparation method thereof

ActiveCN102731545AGood compatibilityHigh synergistic flame retardant performanceSilicon organic compoundsEpoxyPolyvinyl chloride

The invention relates to a nitrogen, silicon and chlorine thee-element synergic flame retardant tri{2-chloro-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate compound and a preparation method thereof. The structure of the compound is shown as a formula in the specification. The preparation method comprises the following steps: dripping organic solvent solution of triglycidyl Isocyanurate into silicon tetrachloride, and reacting for 4 to 6 hours at a temperature of between 50 and 70 DEG C; and cooling to 30 DEG C, introducing ethylene oxide under the liquid surface, reacting for 2 to 3 hours at a temperature of between 45 and 55 DEG C, and purifying to obtain the tri{2-chlor-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate. The compound has good flame retardant plasticization, and is suitable for flame retardant plasticizer such as polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the method has simple production process and low cost, and is easy for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

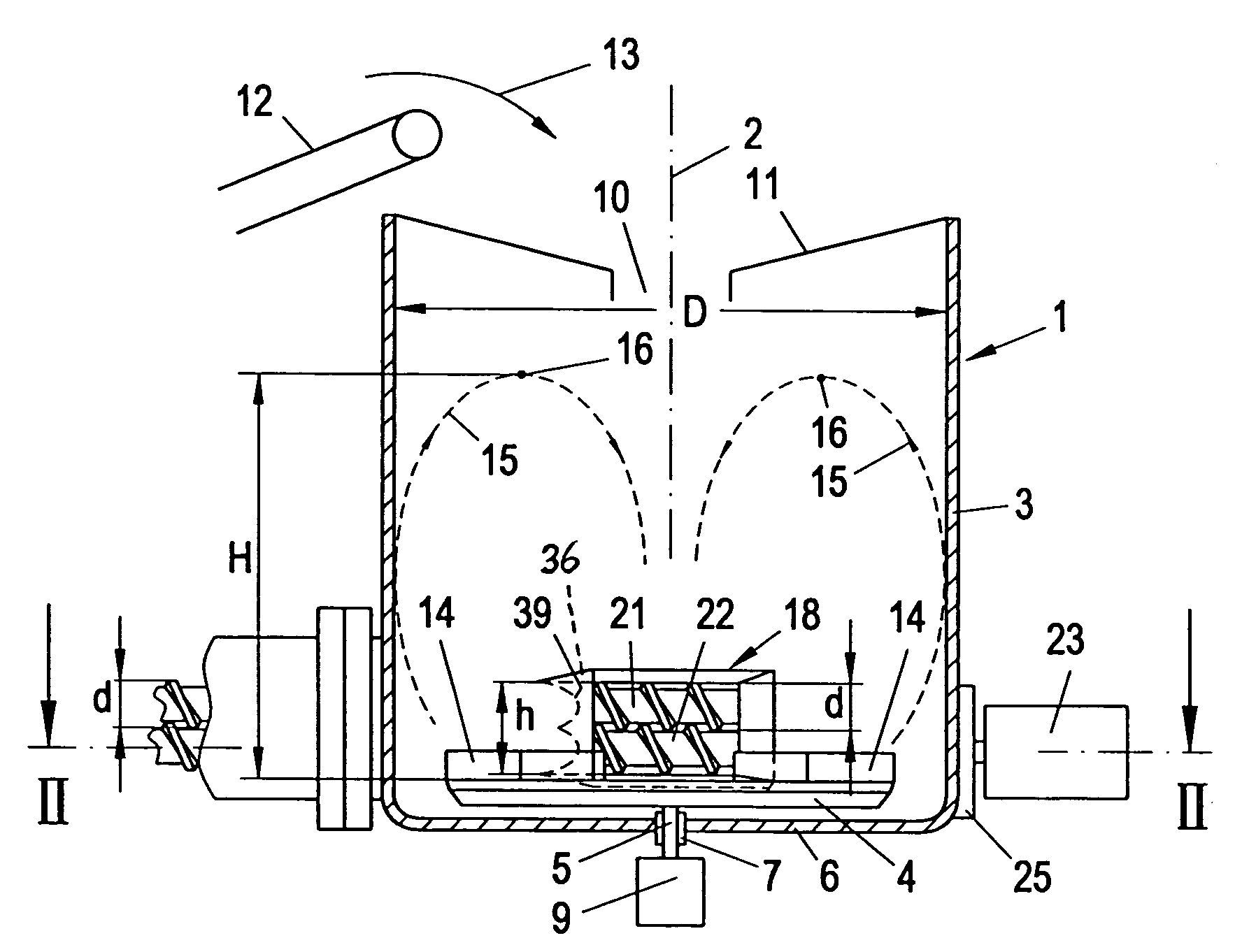

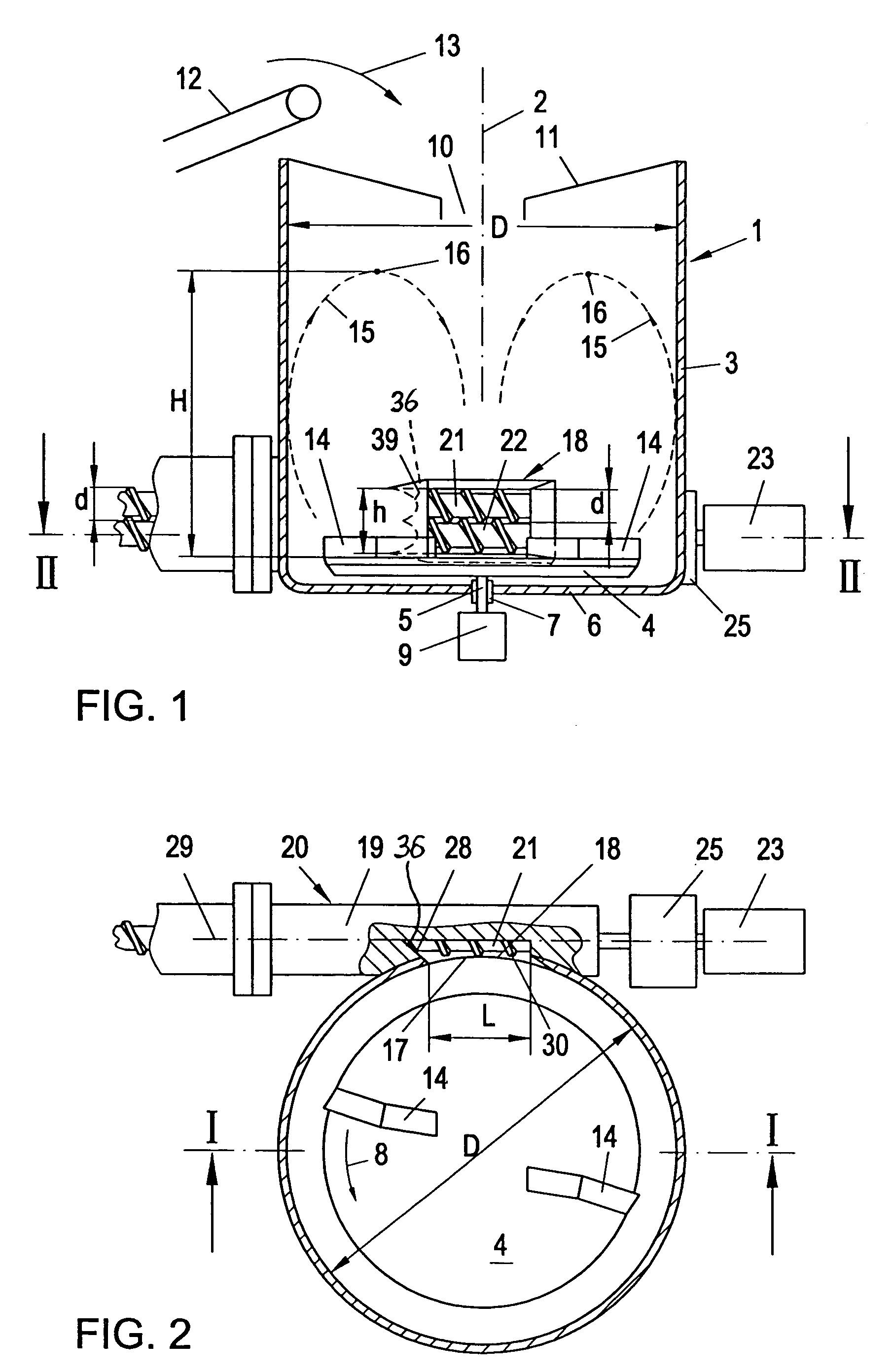

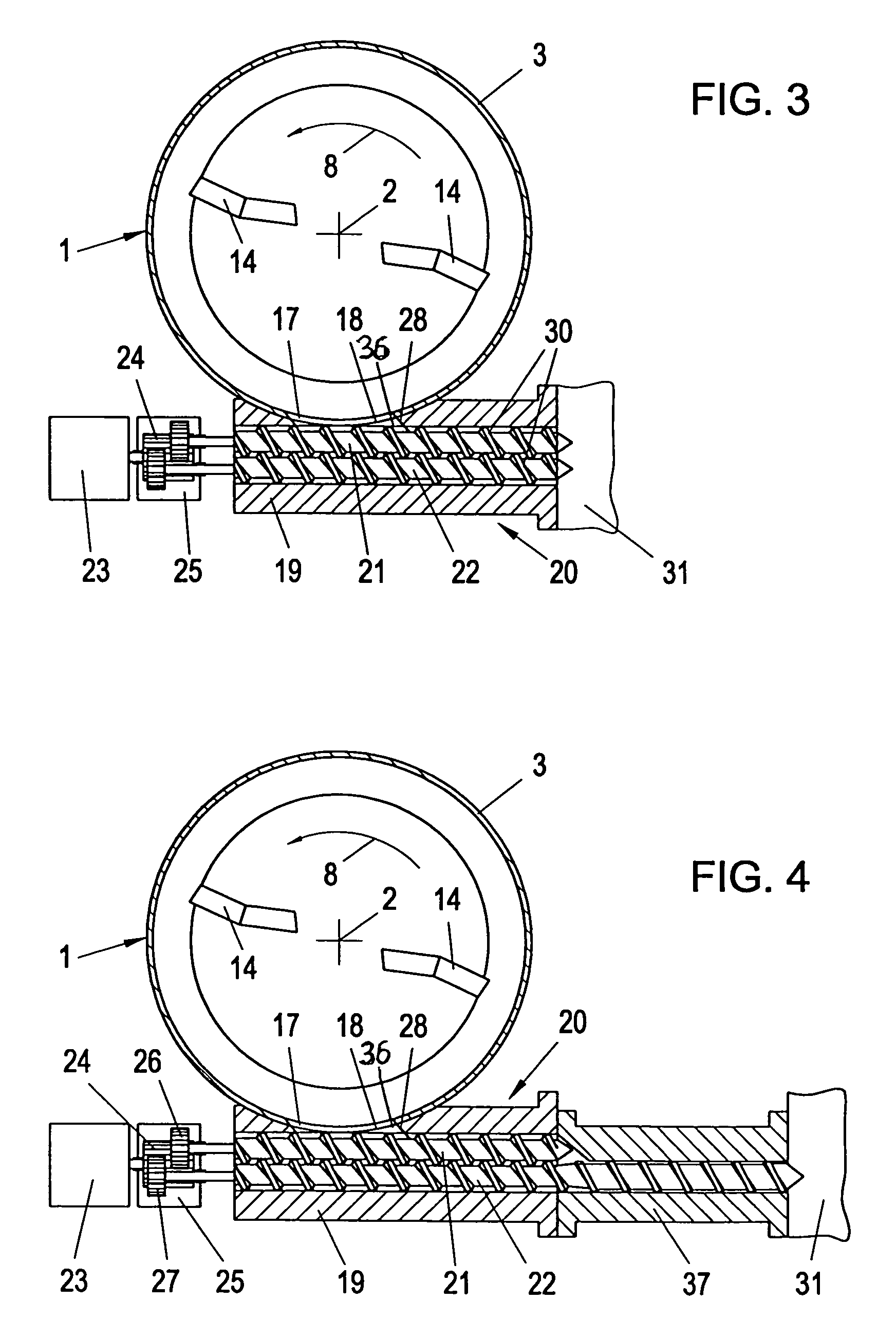

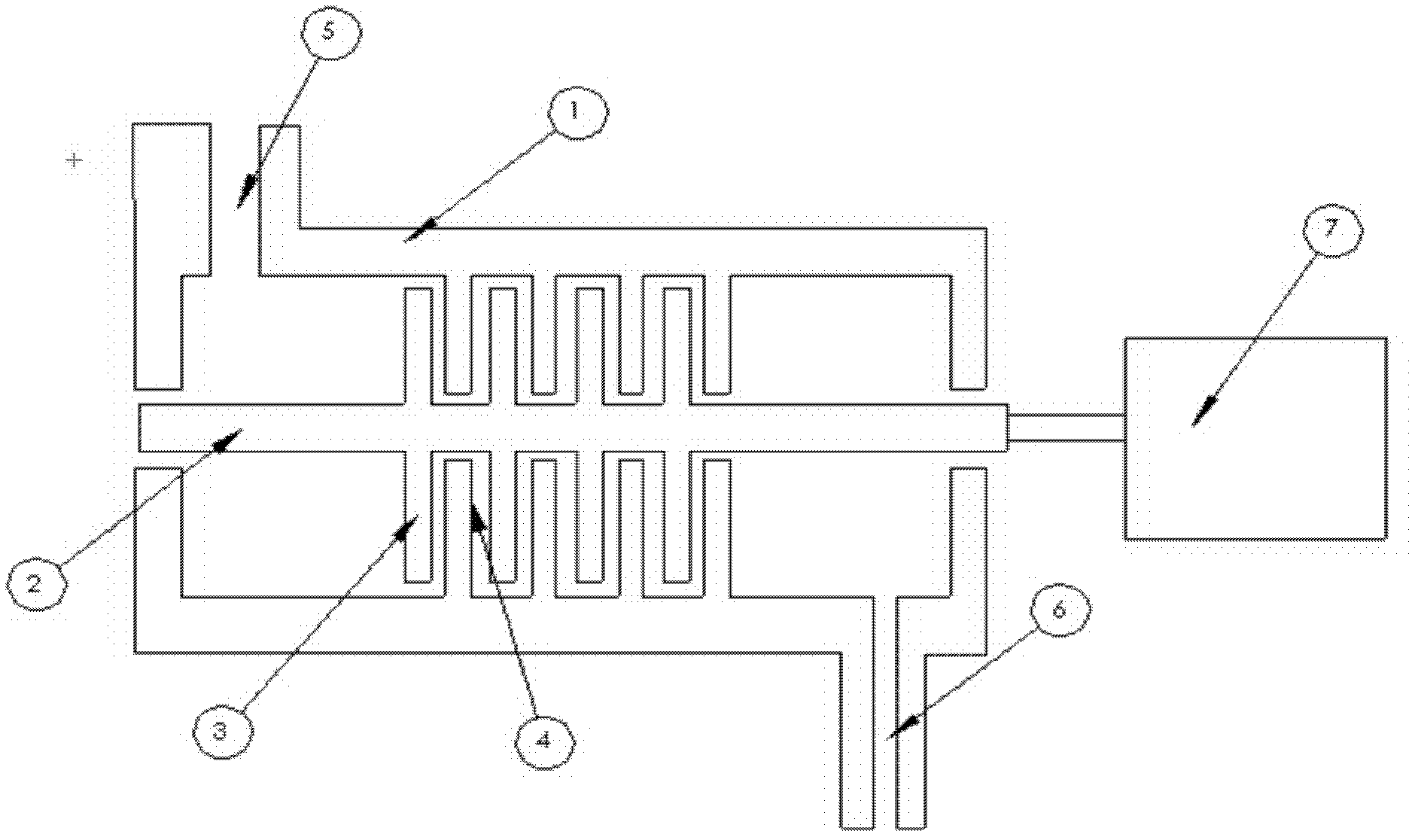

Method for processing synthetic materials for the purpose of recycling

ActiveUS7275703B2Less spaceImprove plasticizing effectTransportation and packagingRotary stirring mixersThermoplasticSynthetic materials

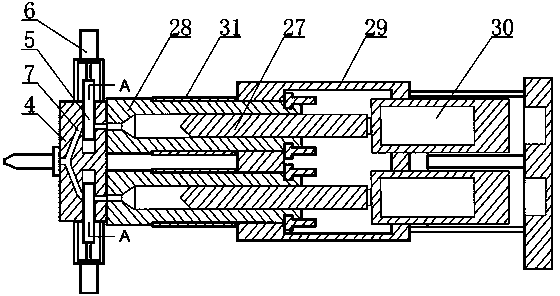

A device for the preparation of, preferably thermoplastic, plastics material for recycling purposes has a container (1) in which at least one rotating mixing and / or comminuting tool (14) is arranged. The material thus treated is fed through an outlet opening (17) which is arranged at the bottom of the container (1) and to which the feed opening (18) of a housing (19) is fluidly connected. In this housing are arranged at least two screws (21, 22) which are jointly charged with material. The diameter (D) of the container (1) and the diameter (d) of each of the screws (21, 22) are in the relationshipD=103{square root over (d2K)},whereD is the inner diameter of the circular cylindrical container (1) or the inner diameter of a hypothetical circular cylindrical container converted to the same capacity and having the same effective height,d is the screw diameter, andK is a constant greater than or equal to 50.

Owner:EREMA ENG RECYCLING MASCH & ANLAGEN GMBH

Production method of filled masterbatch formed through plasticization

The invention relates to a production method of a filled masterbatch formed through plasticization. The filled masterbatch is composed of the following components in parts by weight: 5 to 16 parts of carrier resin, 3 to 8 parts of dispersant, 75 to 90 parts of inorganic filler, and 0.5 to 2 parts of surface-active agent. The production method comprises the following steps: stirring and mixing carrier resin and dispersants at a high speed, extruding and granulating the mixture of the carrier resin and dispersants by a co-rotating twin screw extrusion machine, and considering the mixture of the carrier resin and the dispersants as a standby material; stirring and mixing inorganic fillers, the surface-active agent and the standby material at a high speed, discharging and breaking the mixture of the inorganic fillers, the surface-active agent and the standby material, extruding and granulating the mixture of the inorganic fillers, the surface-active agent and the standby material by a co-rotating twin screw extrusion machine with the slenderness ratio: 32 to 48, cooling, and screening, finally obtaining the filled masterbatch. The packed masterbatch made through the production method is good in plasticization, the dispersion effect of the inorganic fillers is good, the whiteness is high, the requirement to the equipment is low, the energy consumption is low, and the yield is high.

Owner:HECHANG GUANGXI CHEM

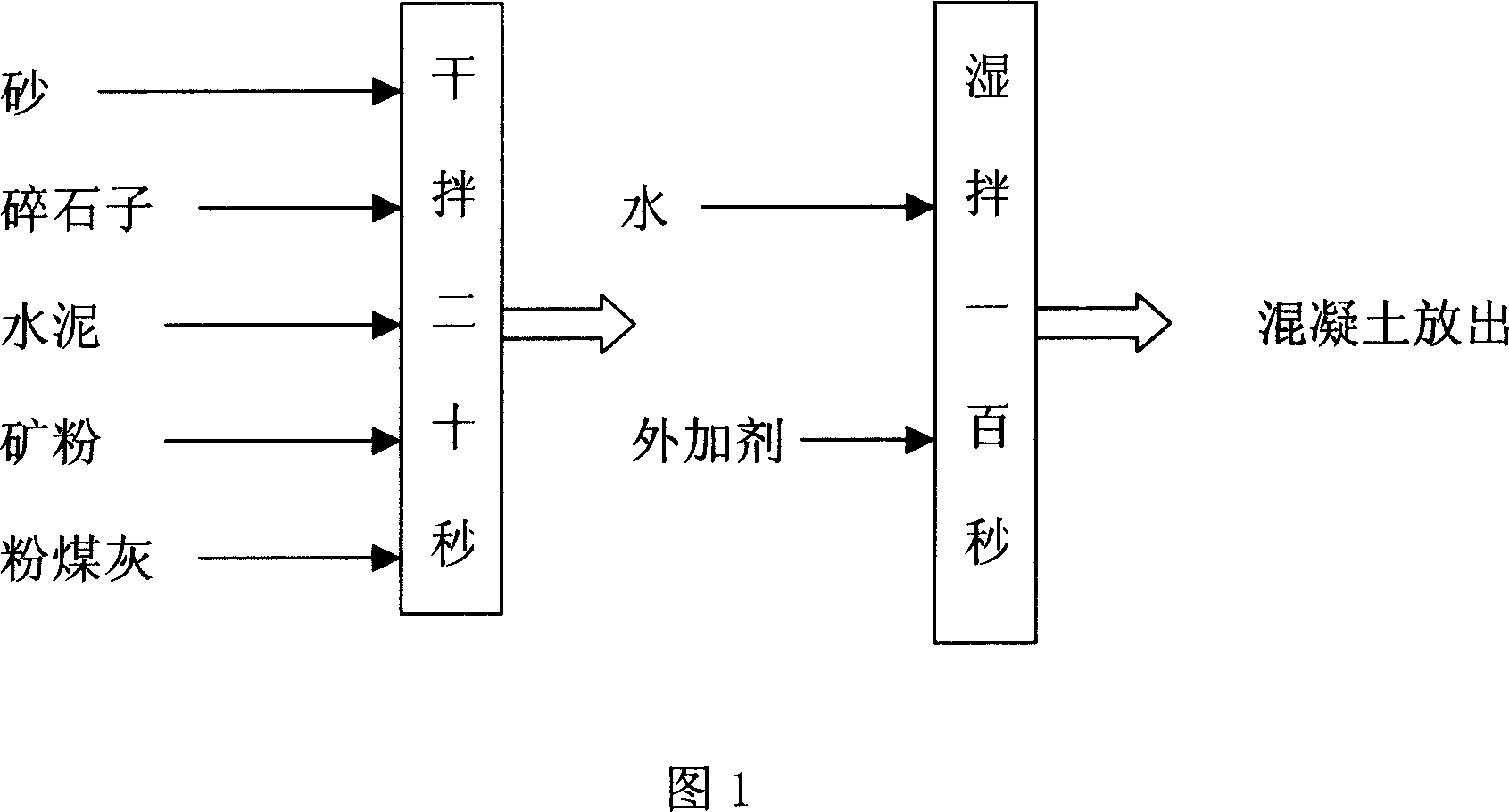

Autodensing concrete using polycarboxylic acid series additive and its technology

ActiveCN100999399AGood slump retentionWide adaptability of cementSolid waste managementSlagSilicate Cement

This invention relates to a self-compacting concrete that using polycarboxylate additive agent, mixed by aggregate, cementitious materials, additive agent and water. According to weight, sand rate of 45%, the total amount of slag and fly ash mixture is more than 30% of the total cementitious Materials, the water-cement ratio is not more than 0.4; select ordinary silicate cement of no less than 42.5; slag and fly ash ratio of 1:1; the Polycarboxylate, polyethylene oxide chain length of 10 ~ 300 Moore, the molar ratio of allyl part of 1 / 9 to 6 / 9, molecular weight of polymer is 30,000 to 80,000. It's Process: aggregate and cementitious materials by dry mixing 20 seconds later, add water and additive agent, wet mixing 00seconds then release concrete.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

Composite heat stabilizer for PVC, preparation and application thereof

The invention relates to a composite heat stabilizer used in PVC, the preparation and application thereof. The composite heat stabilizer is prepared by compounding mg-al hydrotalcite and zn-al hydrotalcite according to a certain proportion. The mg-al hydrotalcite and the zn-al hydrotalcite are reasonably modified and excellently compounded by stearic acid, which can greatly save the energy consumption, increases the efficiency, and increases the thermal stability performance. In the aspect of heat stability performance, the product is non-toxic and efficient, has low cost, good initial coloration, transparency, and excellent weather resistance and plasticity, and good compatibility with PVC. The use level of an additive in the course of processing does not influence the performance of products and is difficult to wear down process equipment. The products can directly use no-toxic products to finish the substitutions of cadmium free, lead free and bromine free of export products, further is applicable to other relative industries and fields, has wide application prospect.

Owner:CENT SOUTH UNIV

Preparation method and application of calcium carbonate particle

InactiveCN1631790ALow costGuaranteed performanceCalcium/strontium/barium carbonatesCarbonizationWater soluble

Disclosed is a method for preparing calcium carbonate particle and its application, which includes the following steps: firstly burning, digestion and carbonization limestone, obtaining the mixture of nanometic calcium carbonate and micron calcium carbonate; do compound of coupling agent of titanic ester, coupling agent of aluminatic ester and coupling agent of boric esterto form a water soluble modifier which is added into calcium carbonate to package it; after packaging heat the sera and add soap having been saponificated into it with agitate, finally acquiring the calcium carbonate particle. The calcium carbonate obtained is filled with PVC-typed material, without coacervation even the quantity is large, can decrease the cost of PVC-typed material as well as the use of some assistant with high price on the basis of assuring the performance of it, meanwhile, the procession and plasticizing performance of it can also be advanced.

Owner:上海建材(集团)有限公司

Composite toughening modifier for plastics and preparation method thereof

ActiveCN102464839AGood toughening effectReduce energy consumptionPigment treatment with macromolecular organic compoundsElastomerMethacrylate

The invention provides a composite toughening modifier for plastics and a preparation method thereof. The composite toughening modifier for plastics comprises nanometer calcium carbonate and polyacrylate elastomer coated on the nanometer calcium carbonate, wherein, the polyacrylate elastomer is formed by using a soft monomer and a hard monomer through polymerization, the soft monomer comprises one or more of acrylic acid butyl ester, isobutyl acrylate, octyl acylate, or octyl methacrylate, and the hard monomer comprises one or more of methyl methacrylate, styrene or vinyl acetate. The composite toughening modifier can be used as a filling material of a rubber and plastic material, can be used for toughening toughening cooperating with CPE to increase the impact strength of the material by more than 5 times, and the impact strength of the toughened material is increased by over more than 10 times more than that of untoughened PVC, the application range of nanometer calcium carbonate is greatly enlarged, and the cost of rubber and plastic products can be greatly reduced.

Owner:SHANGHAI HUAMING HI TECH GRP

Low-smoke halogen-free flame-retardant cable material

InactiveCN105037899ASoft textureHigh tensile strengthPlastic/resin/waxes insulatorsInsulated cablesEpoxyAntioxidant

The invention discloses a low-smoke halogen-free flame-retardant cable material, and belongs to the field of materials. The low-smoke halogen-free flame-retardant cable material solves the problem that an existing cable material is poor in mechanical property and electrical property. The low-smoke halogen-free flame-retardant cable material is composed of 50-60 parts of high density polyethylene, 20-30 parts of ethylene-ethyl acrylate copolymers, 20-30 parts of methyl vinyl silicone rubber resin, 1-3 parts of magnesium stearate, 2-5 parts of novolac epoxy resin, 15-25 parts of isopropyl phenyl diphenyl phosphate, 1-2 parts of dilauryl thiodipropionate, 10-20 parts of dimellitate, 1-2 parts of antioxidants 1010, 1-1.5 parts of antioxidants CA, 10-20 parts of maleic anhydride grafting ethylene-octylene copolymers, 5-10 parts of polysiloxane, 20-30 parts of nano magnesium hydroxide, 13-18 parts of nano clay, 3-7 parts of zinc oxide, 5-10 parts of polyethylene wax and 3-8 parts of calcium stearate. The low-smoke halogen-free flame-retardant cable material can be widely used as insulation and sheathing materials of various electric wires and cables.

Owner:国网山东莒南县供电公司 +2

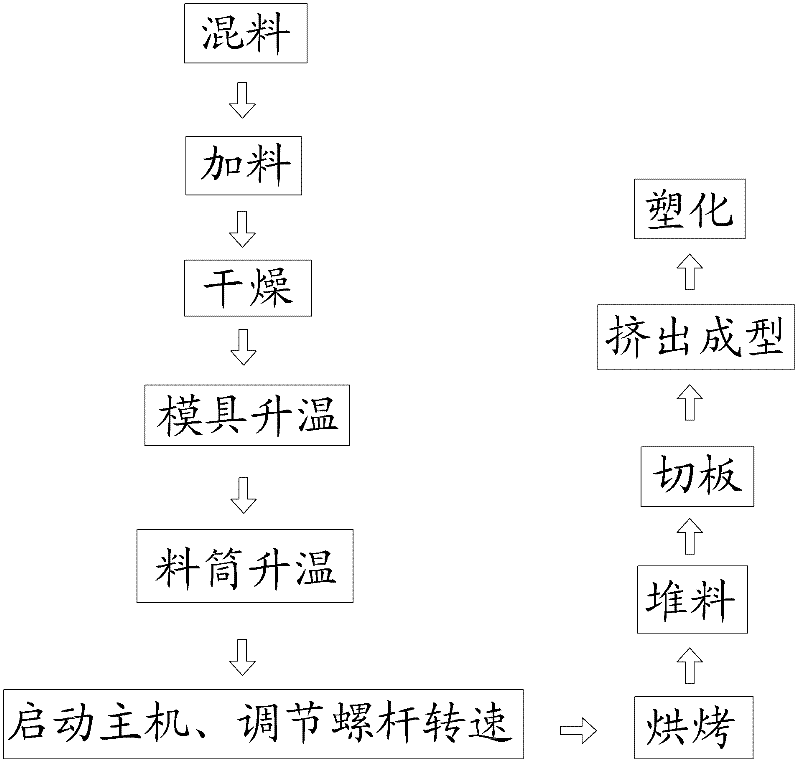

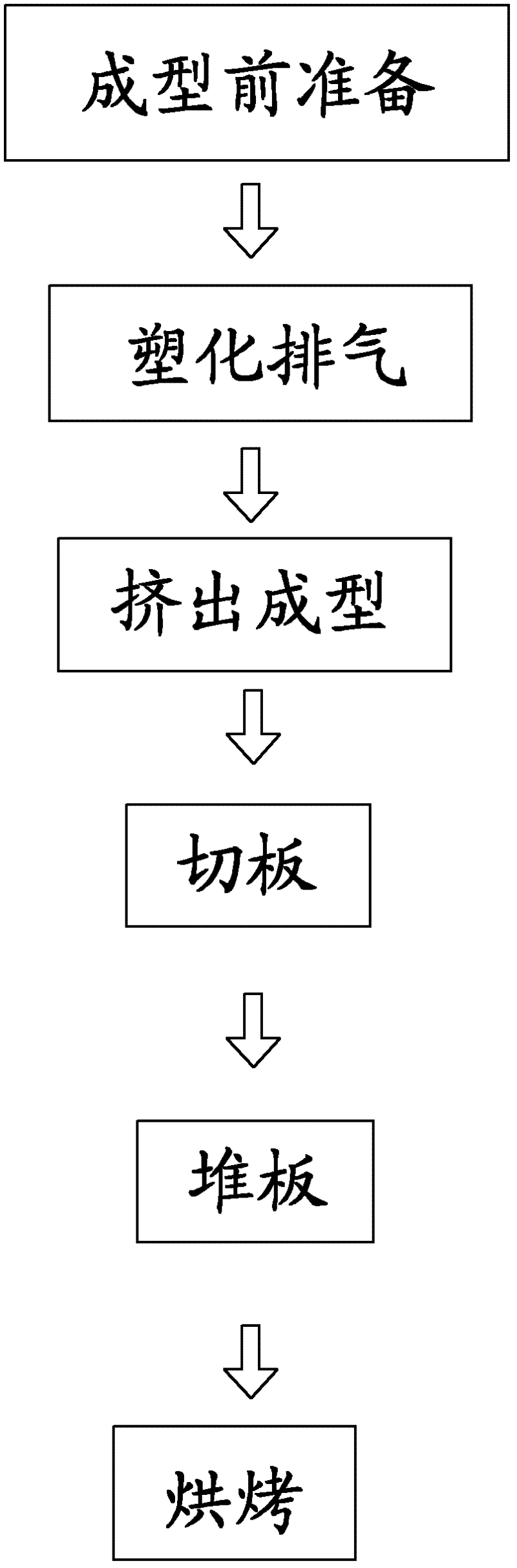

Extrusion molding method for POM (Polyoxymethylene) plate

ActiveCN102501359AIncrease production speedIncrease productivityMaterials preparationPolyoxymethylene

The invention relates to an extrusion molding method for a POM (Polyoxymethylene) plate, which successively comprises the following steps of: 1. preparing before shaping: preparing materials and adjusting equipment; 2. plastifying and venting; 3. carrying out extrusion molding; 4. cutting a plate; 5. stacking the plates; and 6. baking. Compared with the prior art, the extrusion molding method has the beneficial effects that the materials do not need to be independently baked and processed before being plastified so as to simplify the production flow, improve the production efficiency, reduce equipment input and energy consumption and lower the production cost; the energy use ratio generated in the plastifying process is improved, energy waste is reduced, and the extrusion molding method conforms to the enterprise development mode of saving energy and protecting the environment; 3. a material preparation step and an equipment regulation step can be simultaneously carried out to improve the production speed and capacity and lower production cost.

Owner:深圳市恩欣龙特种材料股份有限公司

High-gloss anti-crack adhesive for multilayer plywood and method for manufacturing multilayer plywood

ActiveCN103265921AImprove clarityImprove plasticizing effectLaminationLamination apparatusWear resistantRoom temperature

A high-gloss anti-crack adhesive for multilayer plywood is provided. The multilayer plywood is mutually glued and laminated by a single layer material. The adhesive includes a urea-formaldehyde resin adhesive and additive and added additives therein, a melamine resin adhesive and added additives therein. The preparation methods of the urea-formaldehyde resin adhesive and the melamine resin adhesive are creatively improved by inventors. The free formaldehyde in the obtained adhesive is less than 0.1%. Operation is easy, equipment is easy to get, no pollution generates, implementation is easy and price is inexpensive. The high-gloss anti-crack adhesive can be used for the multi-layer plywood, has excellent pre-pressing property, can mold at room temperature in 30-40 min, and has bonding strength >= 1.0 MPa, formaldehyde emission <= 1.0 mg / L, which is below requirements of GB / T18580-2001 E1 level, and gloss >= 85 DEG. In the environment with sudden changes in temperature, the high-gloss anti-crack adhesive has the advantages of preventing wear-resistant material cracking and bubbling as a result of thermal expansion and cool contraction.

Owner:ZHEJIANG DILONG NEW MATERIAL

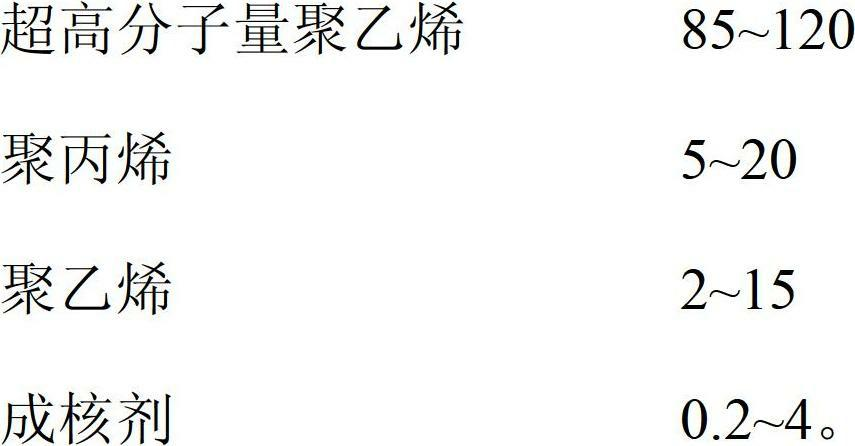

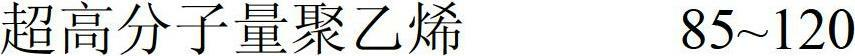

Ultra-high molecular weight polyethylene tube and production technique thereof

InactiveCN102675715ARetain raw material propertiesIncrease productivityTubular articlesPolymer scienceGraphite

The invention relates to an ultra-high molecular weight polyethylene tube which is characterized by comprising the following components in parts by weight: 85-120 parts of ultra-high molecular weight polyethylene, 5-20 parts of polypropylene, 2-15 parts of polyethylene and 0.2-4 parts of nucleating agent. The tube can also comprise graphite and plastic assistants. The polypropylene and polyethylene are blended to modify the ultra-high molecular weight polyethylene, so the prepared ultra-high molecular weight polyethylene tube not only has the properties of the raw material, but also has the good characteristics of polyethylene and polypropylene; and thus, the ultra-high molecular weight polyethylene tube is easy to process, and has the advantages of favorable plastifying effect and high production efficiency.

Owner:HEBEI BEISU PIPE IND

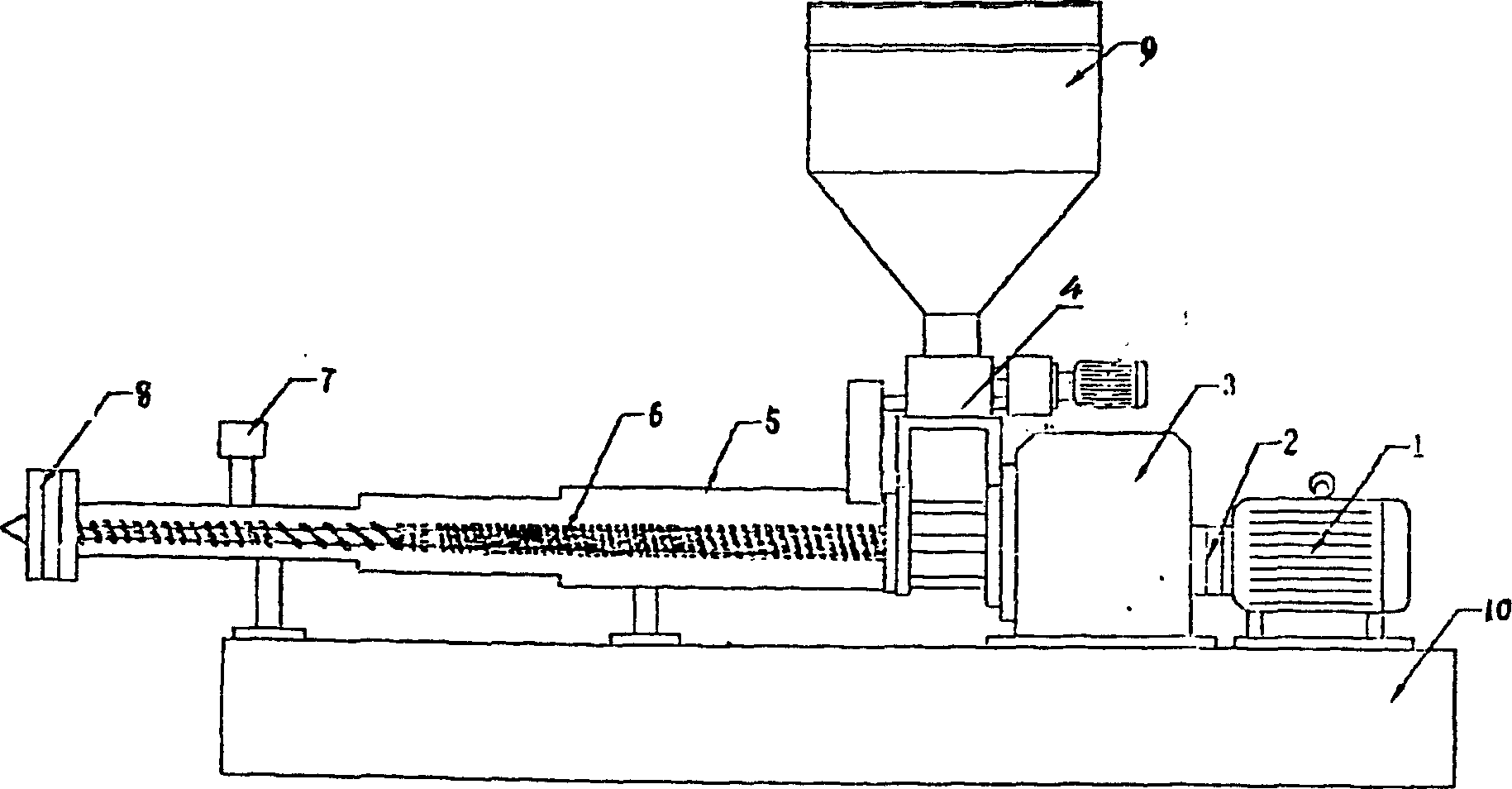

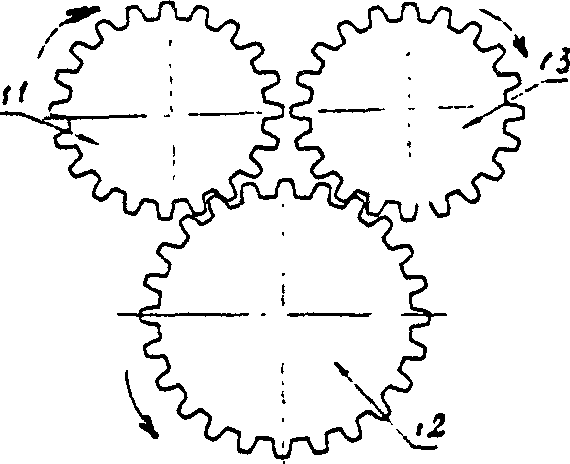

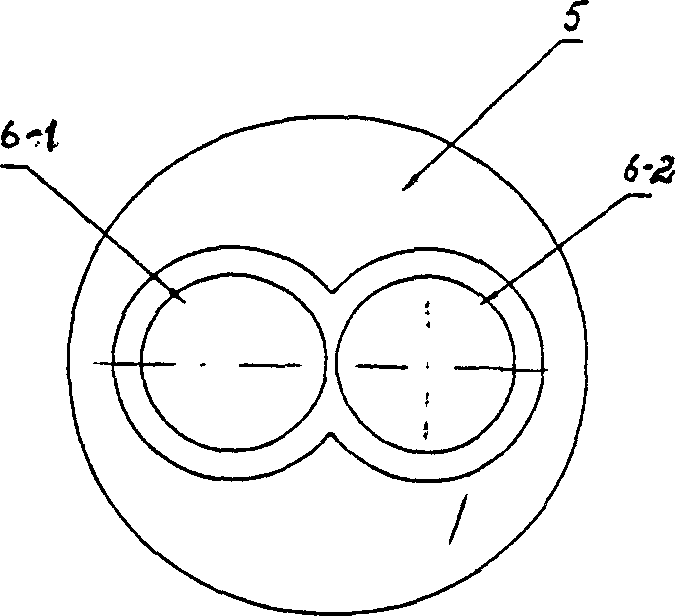

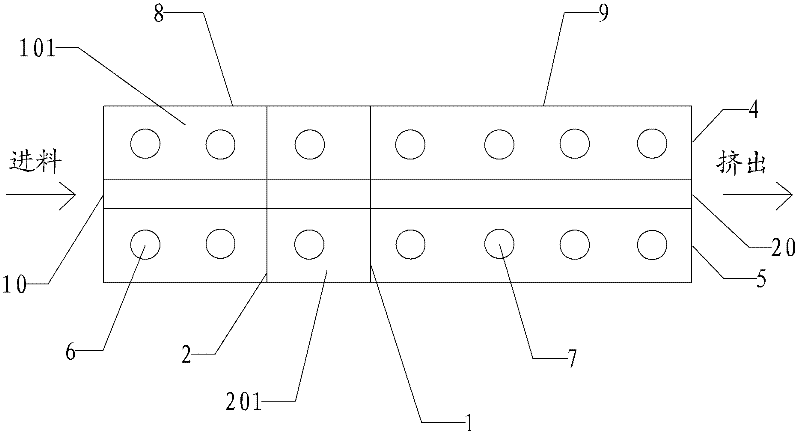

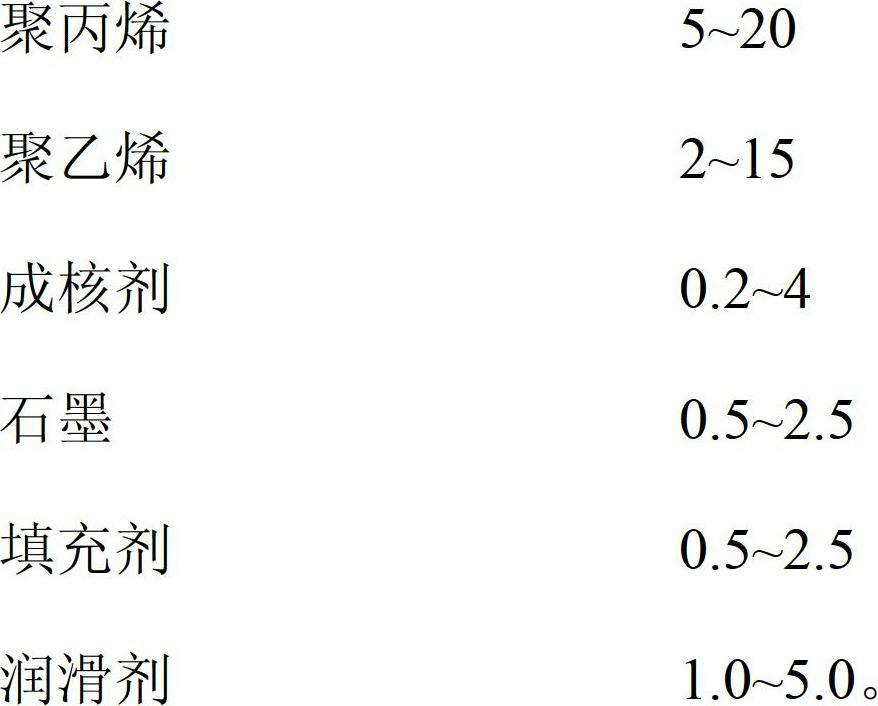

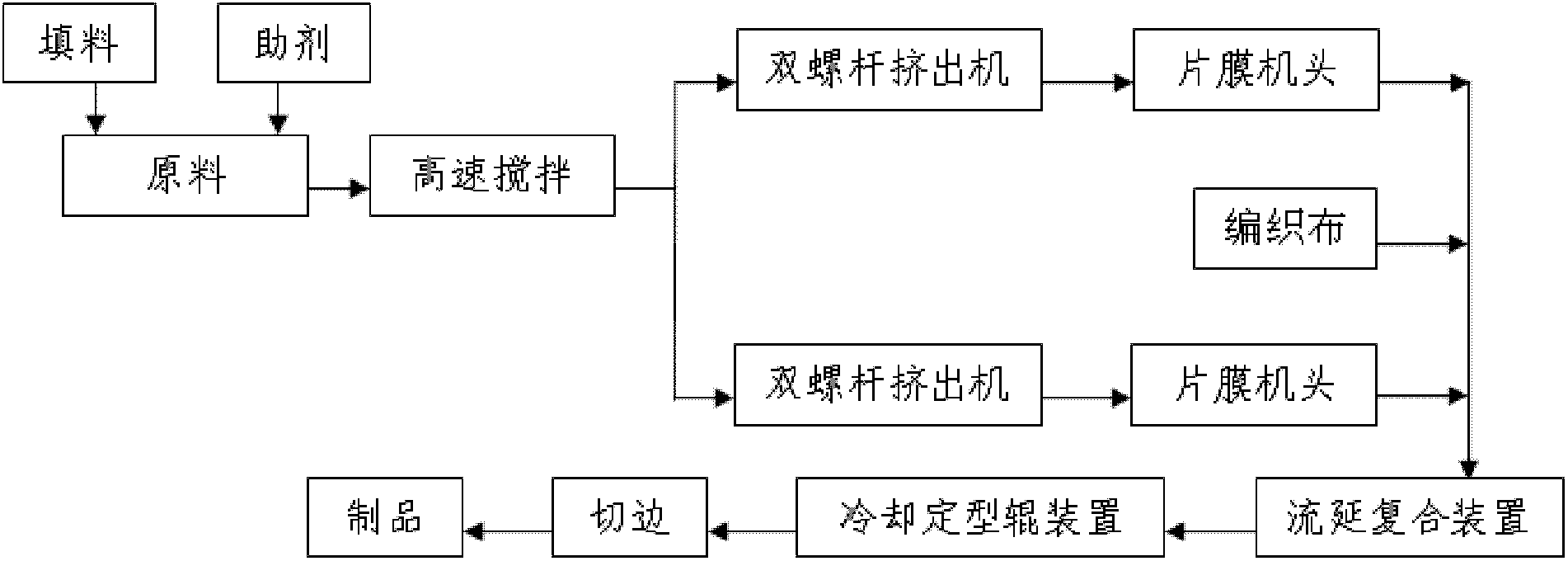

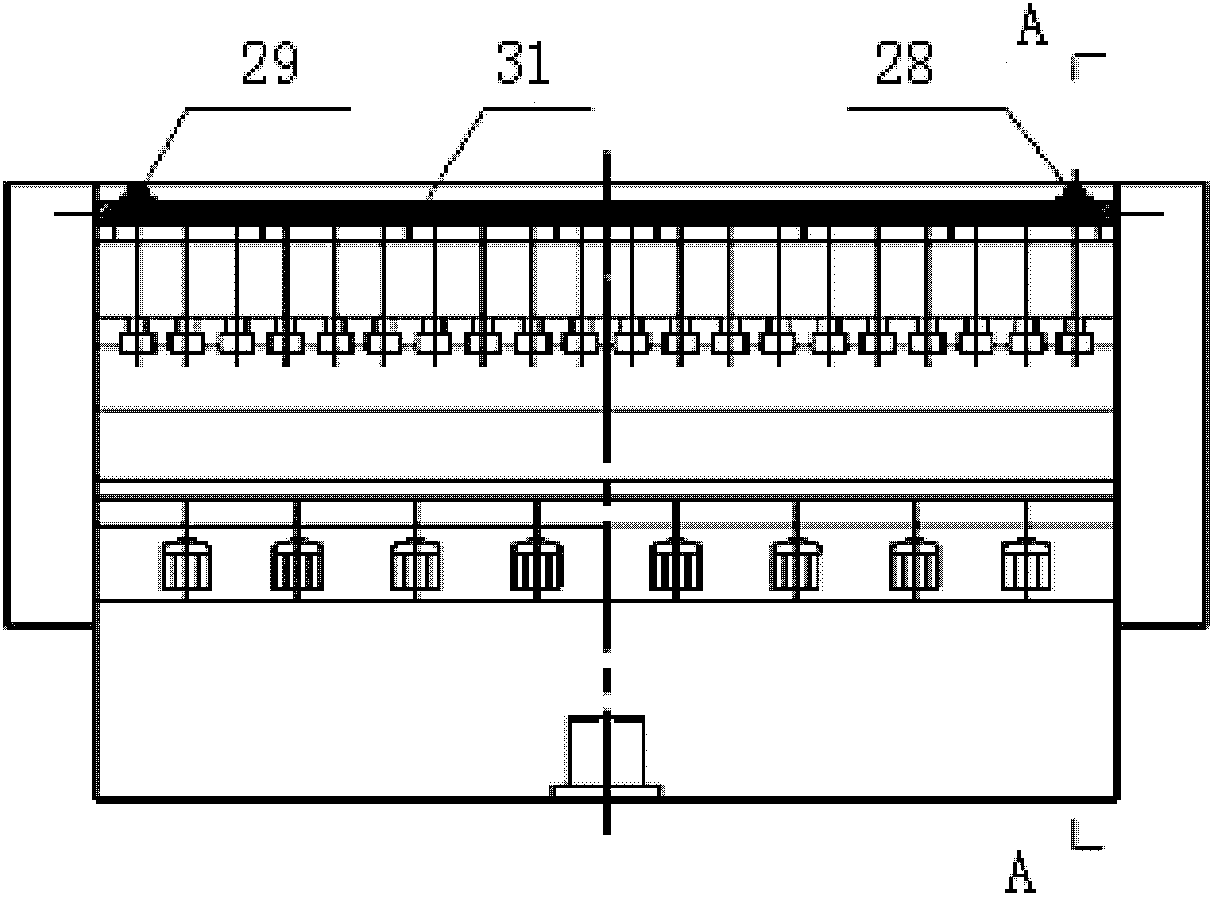

Process and equipment for continuously producing and molding dual-extrusion current coating plastic clip net film products

InactiveCN102490366AEvenly heatedImprove plasticizing effectVolumetric Mass DensitySurface structure

The invention relates to a process and equipment for continuously producing and molding dual-extrusion current coating plastic clip net film products. The process comprises the following steps of: uniformly stirring raw materials formed by mixing resin, packing and functional aids, and feeding the mixed raw materials into a twin-screw extruder; setting temperature of the extruder and the temperature of a sheet die; controlling the temperature of a die lip; staring the extruder to make a melted material flow out through the sheet die and introduced into a current coating composite roll; introducing woven cloth between two thin films and subjecting the woven cloth to composite forming; and cooling to finalize, performing roller guiding, edge shearing, flattening and finally rolling to form the clip net film product under the traction action of a traction roller. According to the process and the equipment, the melted raw materials are extruded by the twin-screw extruder, plasticized and stretched through current coating, the surface structure of the film is changed, and micropores are formed between base material plastic and packing materials, so that the density of the film is reduced. Thus, the clip net film product produced by the dual-extrusion current coating molding process has low specific gravity and light unit weight under the condition of same proportions, the equipment has a simple and reasonable structure, the production cost is a quarter of that of gluing equipment, and continuous production and molding are realized.

Owner:DALIAN PLASTICS RES INST CO LTD

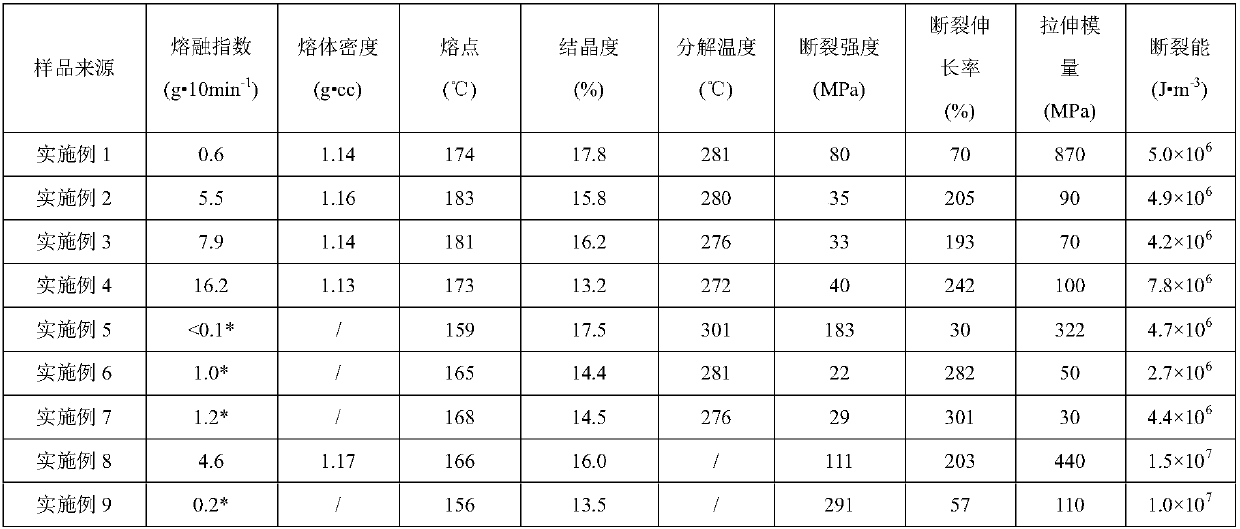

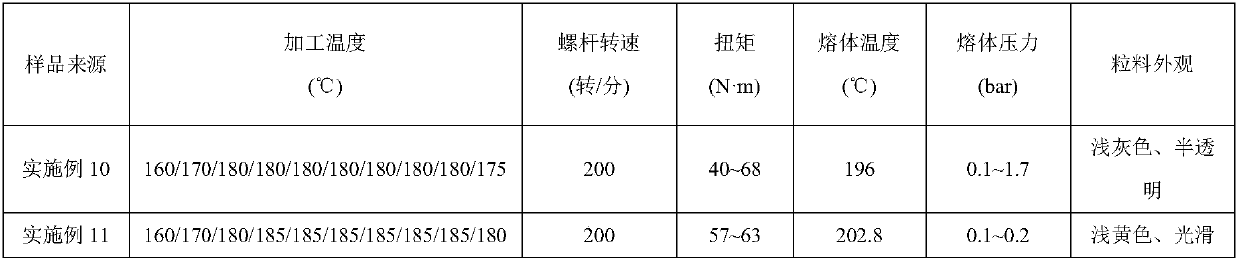

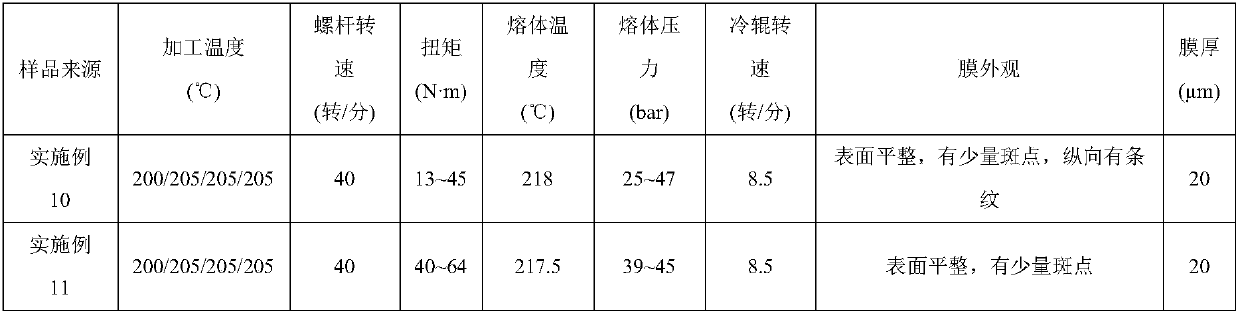

Thermoplastically modified high-fluidity polyvinyl alcohol, and thermoplastically modified high-fluidity polyvinyl alcohol casting film material and preparation method thereof

InactiveCN107936430AExpanded processing windowGood thermoplastic processabilityFlat articlesPolymer sciencePlasticizer

The invention relates to a thermoplastically modified high-fluidity polyvinyl alcohol casting film material and a preparation method thereof. A purpose of the present invention is mainly to solve theproblems of poor thermoplasticity, difficult processing, poor melt fluidity, easy thermal-oxidation degradation, difficult casting film preparation and poor mechanical property of polyvinyl alcohol inthe prior art. The technical scheme comprises that the thermoplastically modified high-fluidity polyvinyl alcohol is used, and comprises, by mass, 1) 70-99.9 parts f polyvinyl alcohol, and 2) 0.1-30parts of a plasticizer, the polyvinyl alcohol and the plasticizer are respectively introduced into a twin-screw extruder, and melt extrusion and granulation are performed through a screw rod extrusionprocessing technology to obtain the thermoplastically modified high-fluidity polyvinyl alcohol. With the technical scheme, the problems in the prior art are well solved. The method of the present invention can be used for industrial production of polyvinyl alcohol casting film materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environmentally-friendly multifunctional dust suppressant and preparation method thereof

InactiveCN103059347AReasonable formulaEasy to buy raw materialsOther chemical processesGlycerolCopper sulfate

The invention discloses an environmentally-friendly multifunctional dust suppressant and a preparation method thereof. The environmentally-friendly multifunctional dust suppressant comprises the materials in percentage by weight: 0.05-2.50% of carboxymethylcellulose, 0.05-2.50% of chitosan, 0.1-0.5% of acetic acid, 0.25-1.00% of glycerol, 0.05-0.15% of sodium alkyl benzene sulfonate, 0.01-0.05% of copper sulfate, 2-20% of magnesium chloride and the balance of water. The dust suppressant provided by the invention is remarkable in dust suppressant and loss preventative effect. Compared with other dust suppressants, the preparation method has the following advantages: the machining process is simple and convenient, the cost is lower, the dust suppressant time is long, the performance cost ratio is high, and the components are independent. The liquor of the dust suppressant is free from any toxic and side effects and corrosive effect, and the dust suppressant can be biodegradable and is free from any secondary pollution. The dust suppressant provided by the invention can be widely applied to the fields of construction sites, cement plants and coal storage and transportation and dust suppression.

Owner:青岛清泽环保有限公司

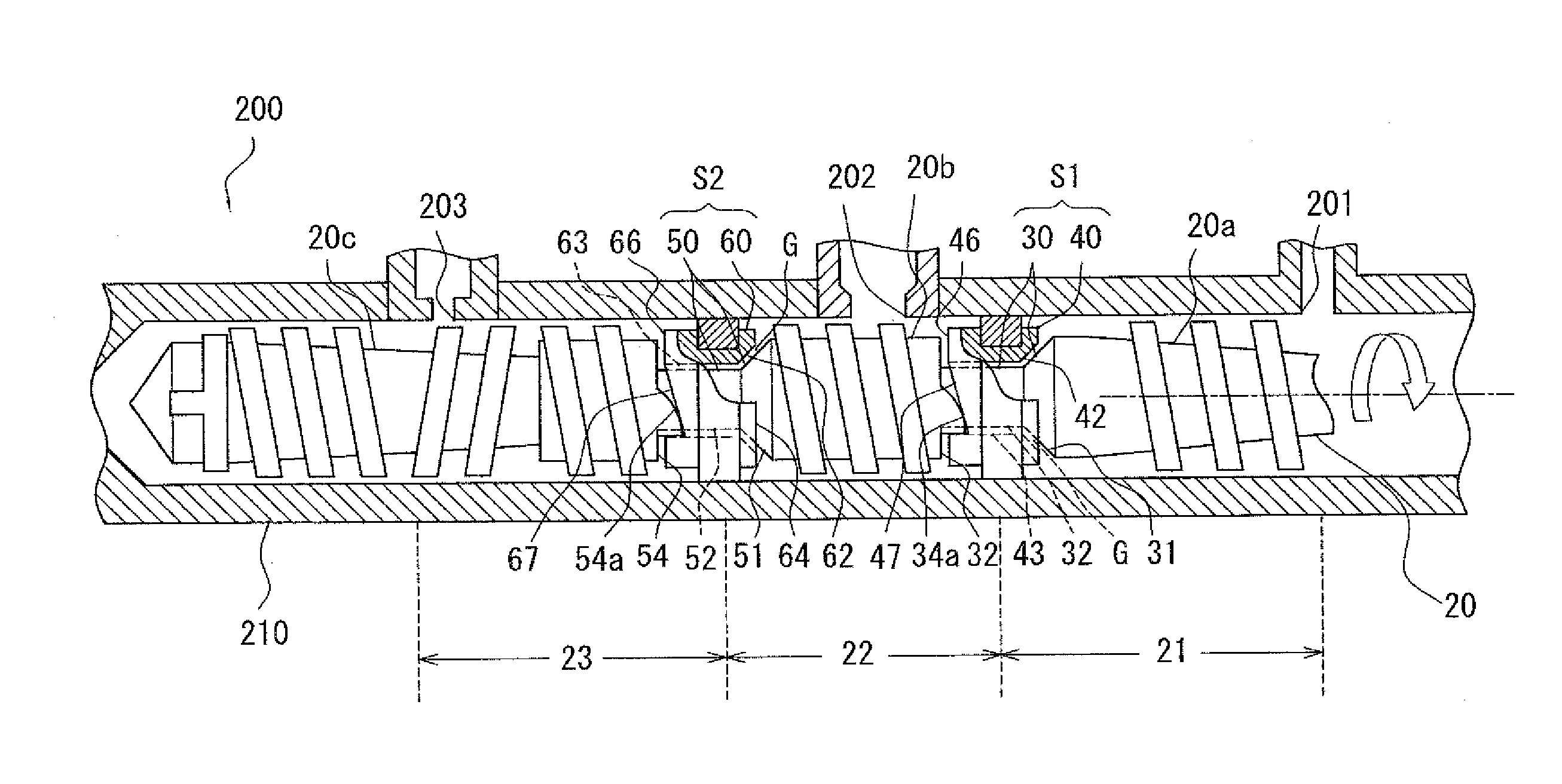

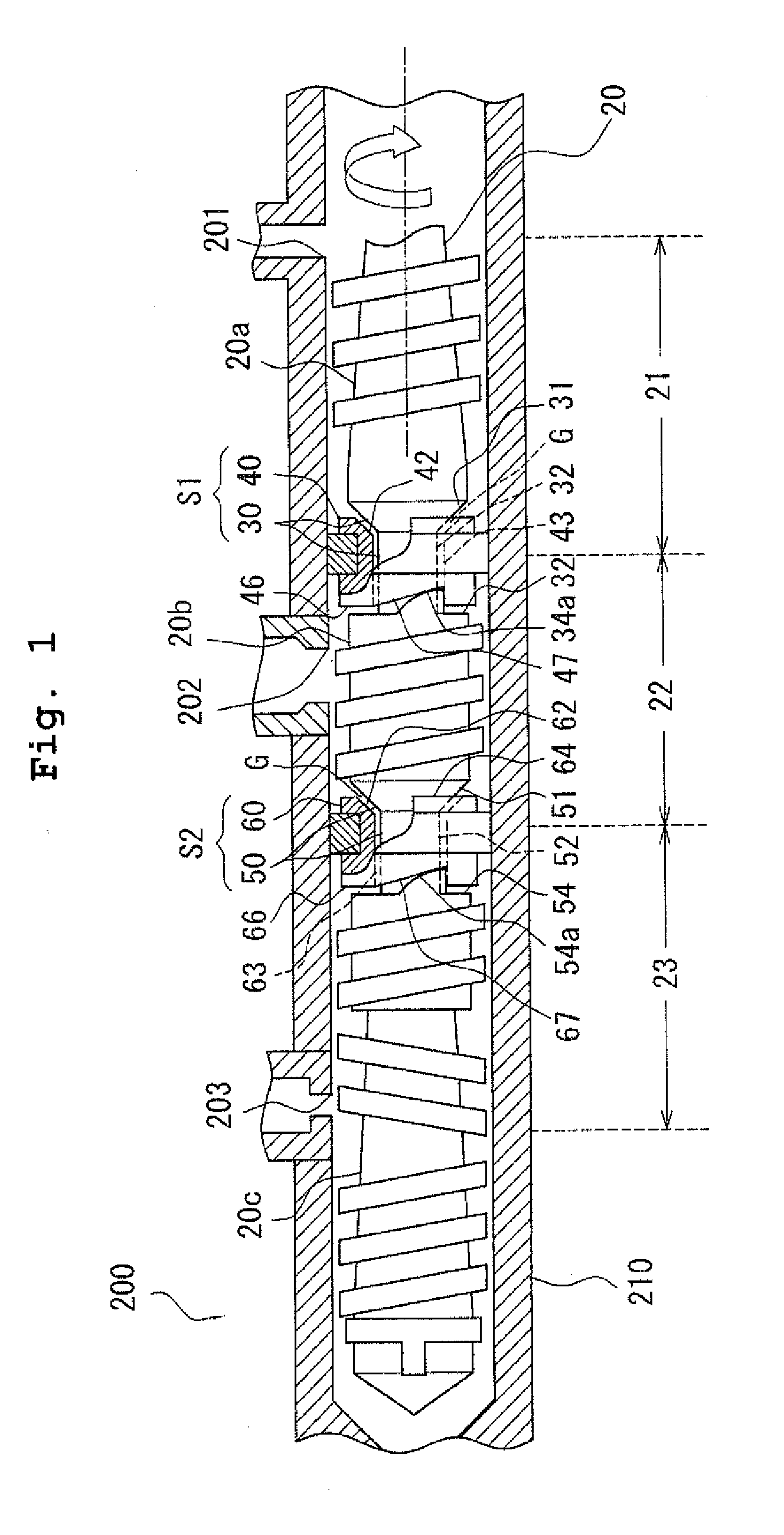

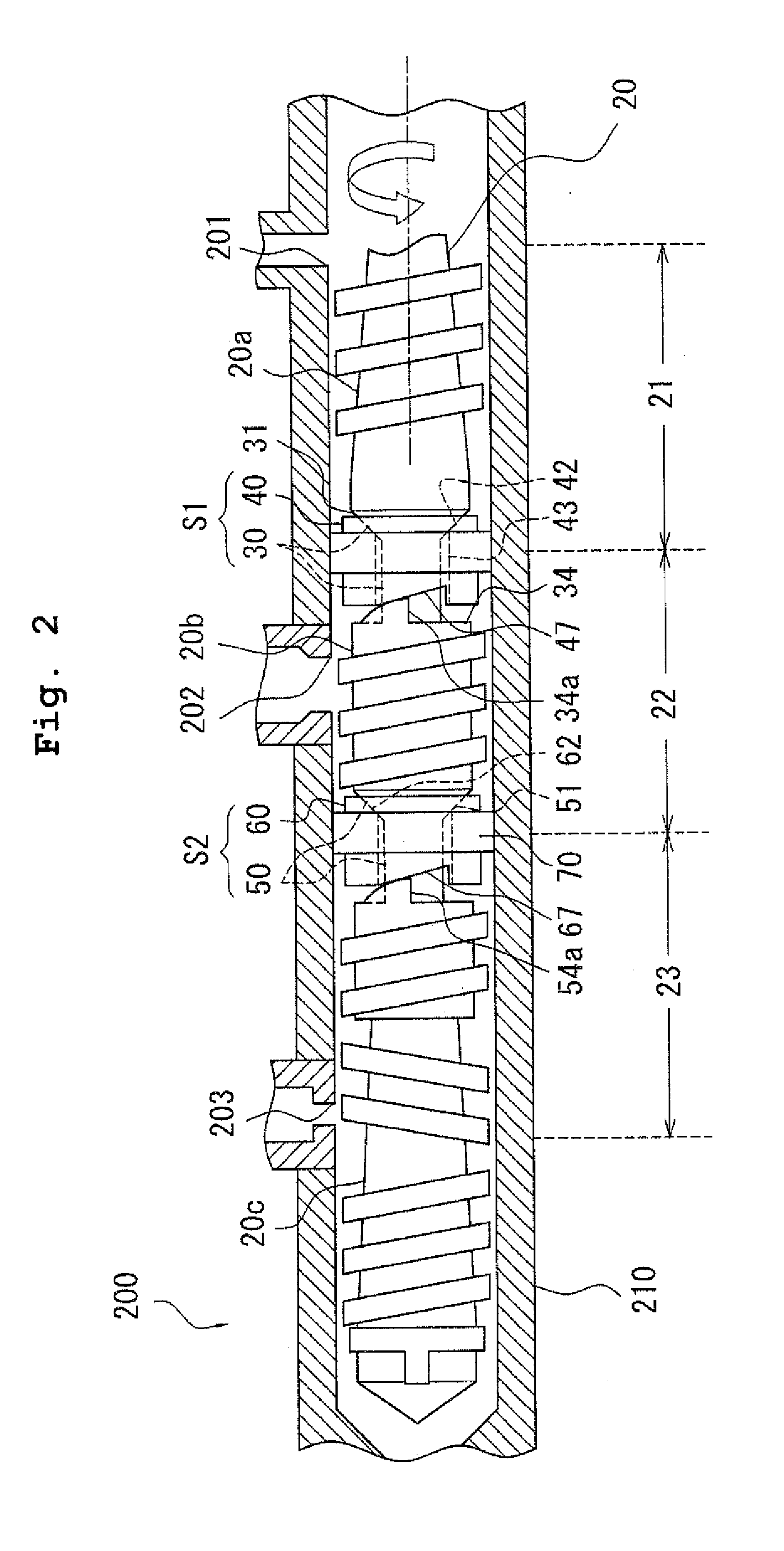

Kneading apparatus and method for producing thermoplastic resin molded product

ActiveUS20130163369A1Internal pressure also lowerImprove plasticizing effectRotary stirring mixersMixing/kneading with horizontally-mounted toolsInternal pressureEngineering

A kneading apparatus includes a plasticizing cylinder in which a high pressure kneading zone and a pressure reduction zone are formed adjacently in this order from an upstream side so that a molten resin obtained by plasticizing a thermoplastic resin and a pressurized fluid are kneaded with each other in the high pressure kneading zone, and gasified pressurized fluid, which is gasified by reducing a resin internal pressure, is separated in the pressure reduction zone from the molten resin kneaded with the pressurized fluid, a screw which is arranged rotatably and movably back and forth in the plasticizing cylinder; and a downstream side seal mechanism which is provided between the high pressure kneading zone and the pressure reduction zone and which makes communication and disconnection between the high pressure kneading zone and the pressure reduction zone in accordance with a rotation state of the screw.

Owner:MAXELL HLDG LTD

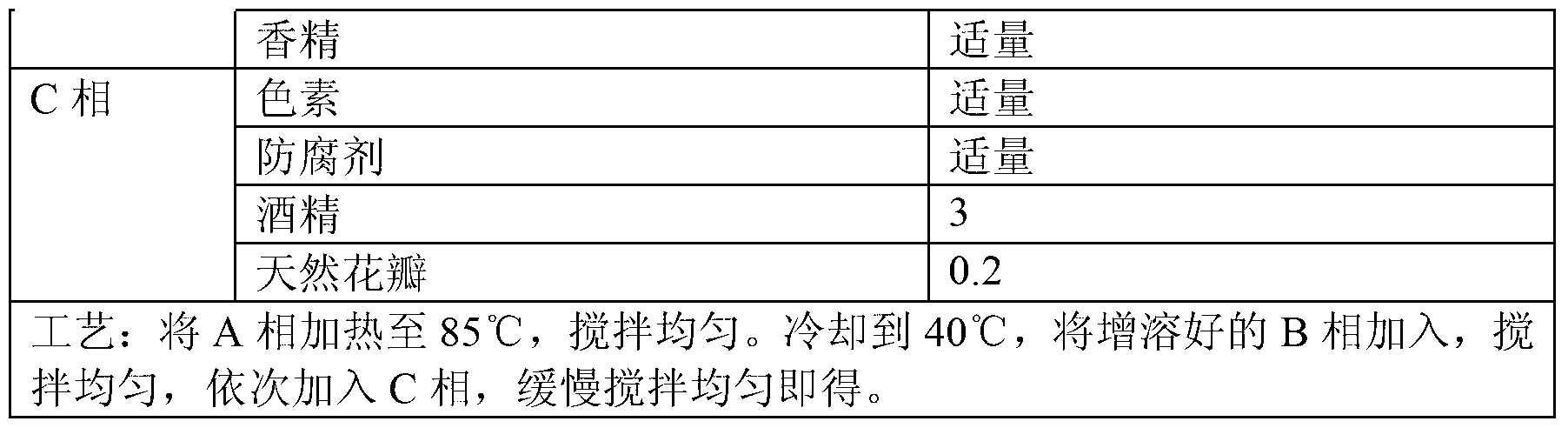

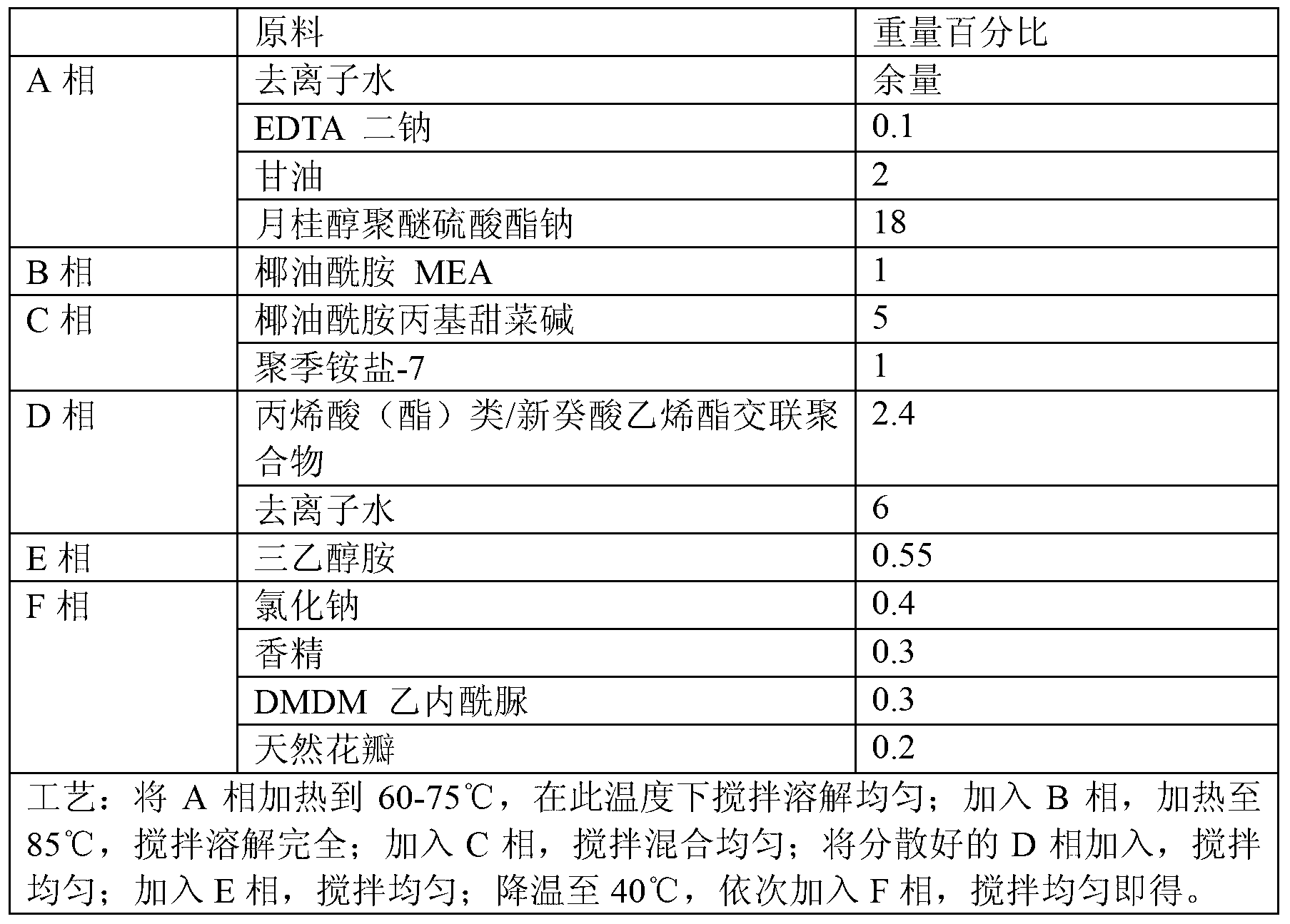

Natural flower petal and cosmetic adopting same

The invention relates to a natural flower petal. A preparation method of the natural flower petal comprises the following steps of: (1) pre-treating; (2) boiling by an alcohol; (3) leaching for the first time; (4) boiling by water; and (5) leaching for the second time. According to the preparation method disclosed by the invention, the natural flower petal is subjected to pre-treatment, alcohol boiling, first time of leaching, water boiling and second time of leaching to obtain the natural flower petal finished product; the alcohol boiling takes polyhydric alcohols as an alcohol boiling solution; the alcohol boiling solution has very good viscidity, hygroscopicity, plastifying performance, film-forming property and sterilization so that the natural flower petal subjected to the alcohol boiling has the better toughness and has very high safety and certain corrosion resistance; and when being applied to a cosmetic, the natural flower petal is not easy to crush and is easy to store, so that the natural flower petal can be widely applied into preparations of the cosmetics.

Owner:SHANGHAI ZHONGYI DAILY CHEM CO LTD

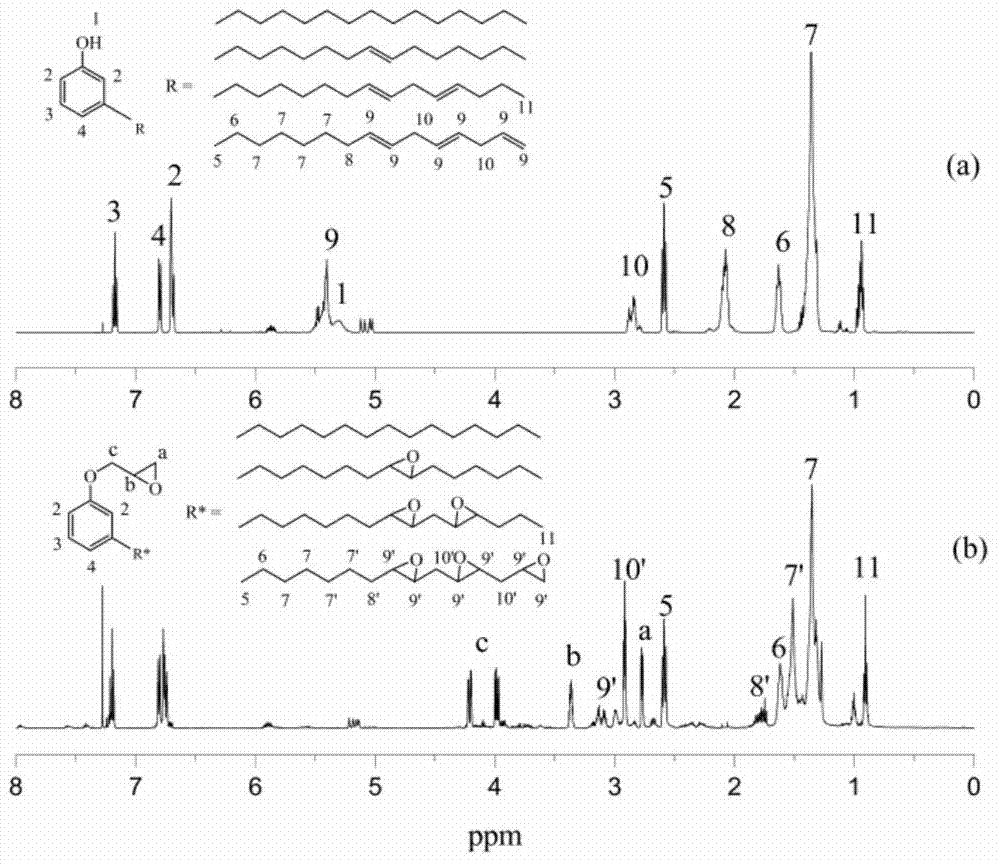

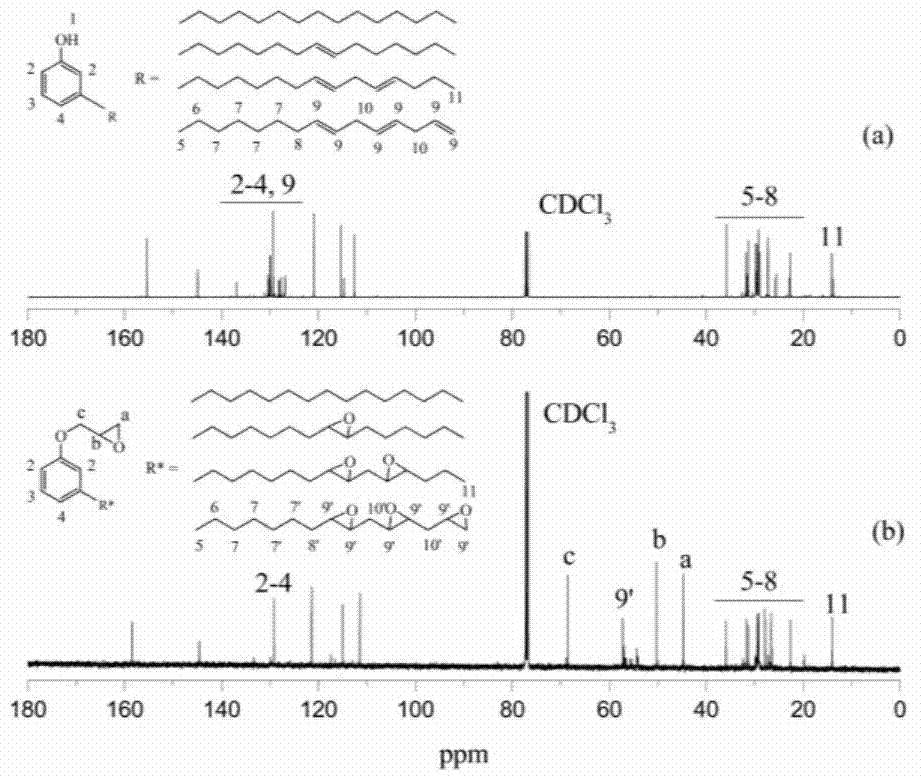

Epoxy cardanol-based glycidyl ether as well as preparation method and application thereof

InactiveCN104710388AEmission reductionSimple production processOrganic chemistryOrganic acidGlycidyl ethers

The invention discloses an epoxy cardanol-based glycidyl ether plasticizer as well as a preparation method and application thereof. The preparation method comprises the following steps: taking cardanol and epoxy chloropropane as main raw materials and carrying out ring-opening addition reaction and ring-closure reaction to synthesize an intermediate product cardanol-based glycidyl ether; and further uniformly mixing the intermediate product with organic acid and a catalyst, heating to a certain temperature, dripping a peroxide source to carry out epoxidation reaction to obtain a crude product, leaving the crude product to stand, layering, performing neutralization and dehydration on the crude product after the reaction so as to obtain an epoxy cardanol-based glycidyl ether plasticizer. The plasticizer is non-toxic, has relatively high plasticizing efficiency and can endowing resin products with favorable thermal stability and mechanical property; and moreover, by taking the cardanol which is low in cost and easy to get as raw material, the epoxy cardanol-based glycidyl ether plasticizer integrates the advantages of being environment-friendly and being reproducible, complies with the developing trend of the plastic additive industry and has wide application and favorable application prospect.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

125 DEG C irradiation crosslinking type halogen-free flame-retardant polyolefin cable material for photovoltaic cable and preparation method thereof

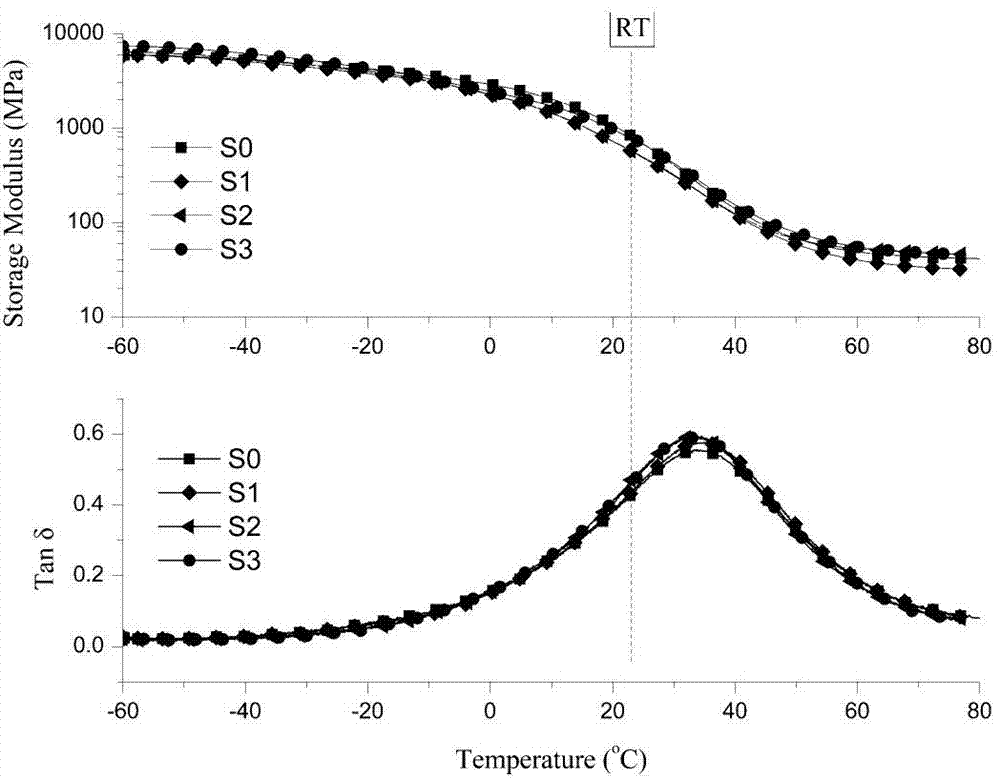

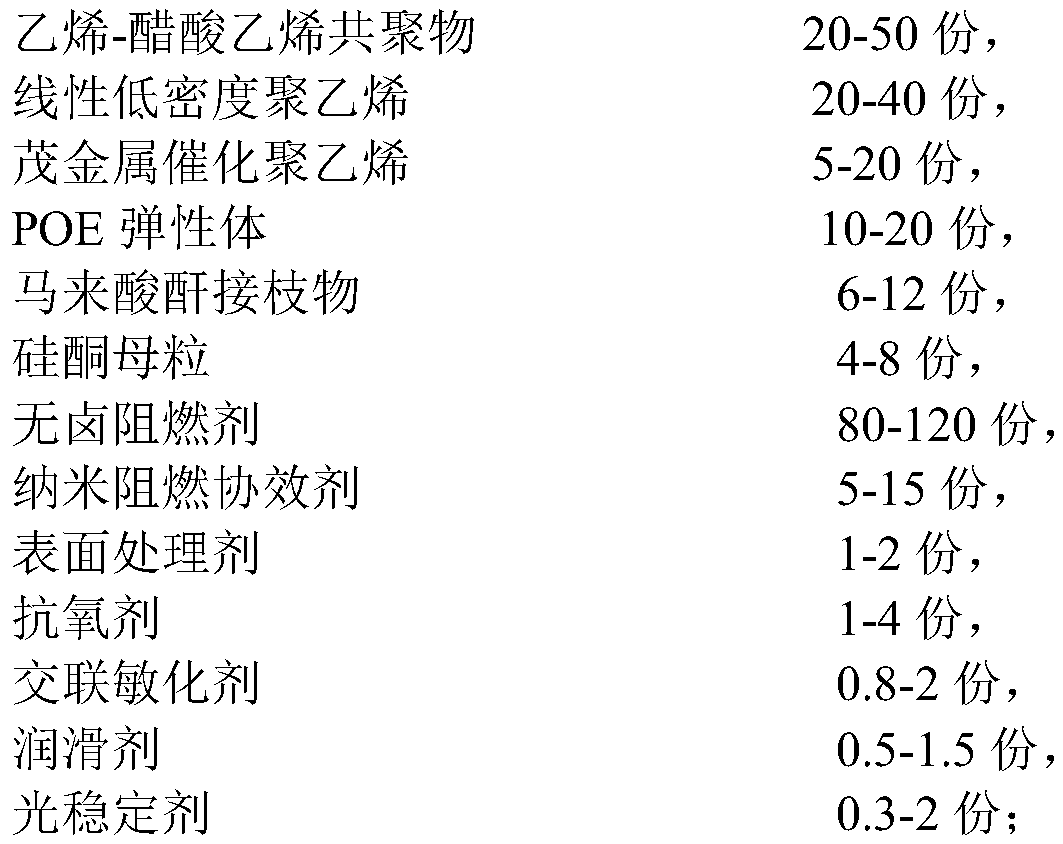

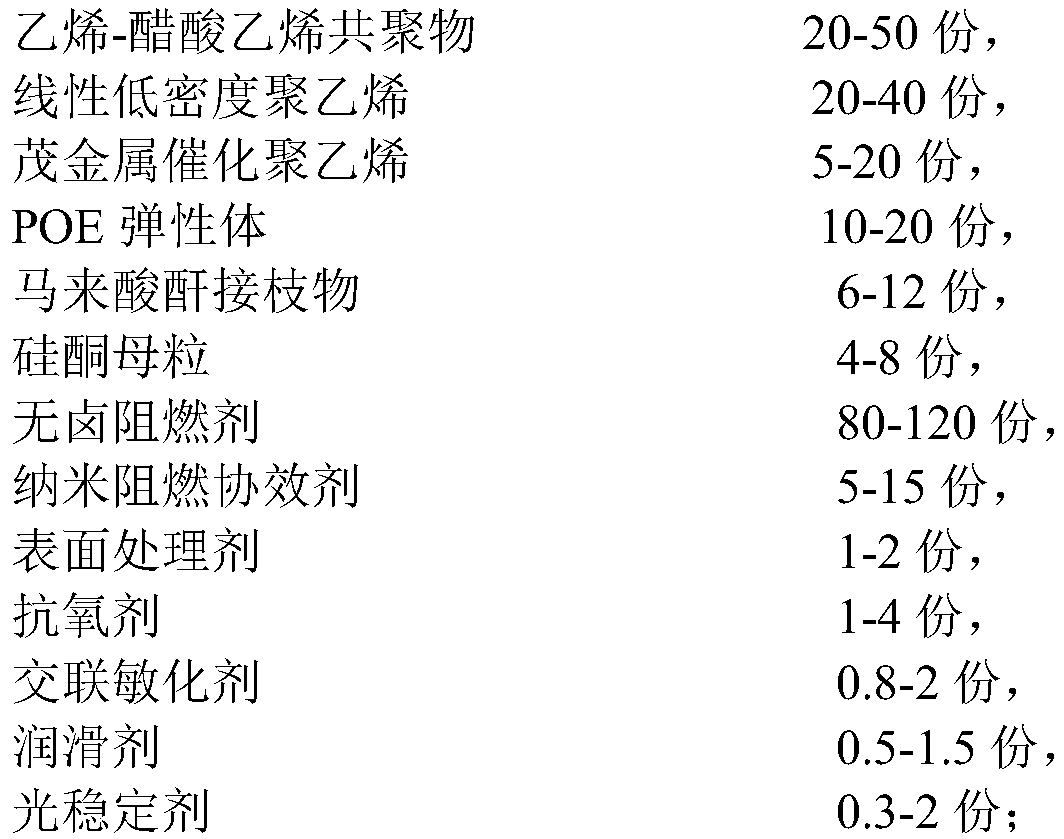

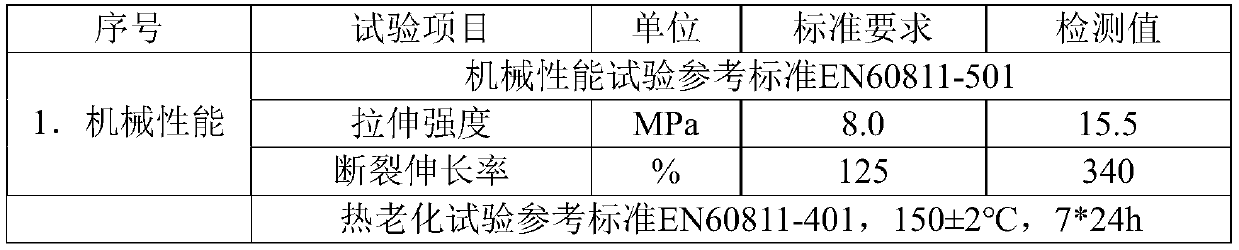

PendingCN111234358AGood mechanical propertiesEasy to operatePlastic/resin/waxes insulatorsMaleic anhydrideWeather resistance

The invention discloses a 125 DEG C irradiation crosslinking type halogen-free flame-retardant polyolefin cable material for a photovoltaic cable and a preparation method of the cable material. The cable material is prepared from, by mass 20 to 50 parts of an ethylene-vinyl acetate copolymer, 20 to 40 parts of linear low density polyethylene, 5 to 20 parts of metallocene catalyzed polyethylene, 10-20 parts of a POE elastomer, 6-12 parts of maleic anhydride graft, 4-8 parts of silicone masterbatch, 80-120 parts of a halogen-free flame retardant, 5-15 parts of a nano flame retardant synergist, 1-2 parts of a surface treating agent, 1-4 parts of an antioxidant, 0.8-2 parts of a cross-linking sensitizer, 0.5-1.5 parts of a lubricant and 0.3-2 parts of a light stabilizer. The cable material hasgood mechanical property, electrical insulation property, flame retardant property, weather resistance, aging resistance, scratch resistance, acid and alkali resistance and processability, and a photovoltaic cable prepared from the cable material can meet the requirements of German 2Pfg1169 and European EN50618 standards after being subjected to irradiation processing; the preparation method hasthe advantages of simple operation, high production efficiency and high process automation, and is beneficial to plasticization and dispersion of each raw material component.

Owner:JIANGSU SHANGSHANG CABLE GRP NEW MATERIAL CO LTD

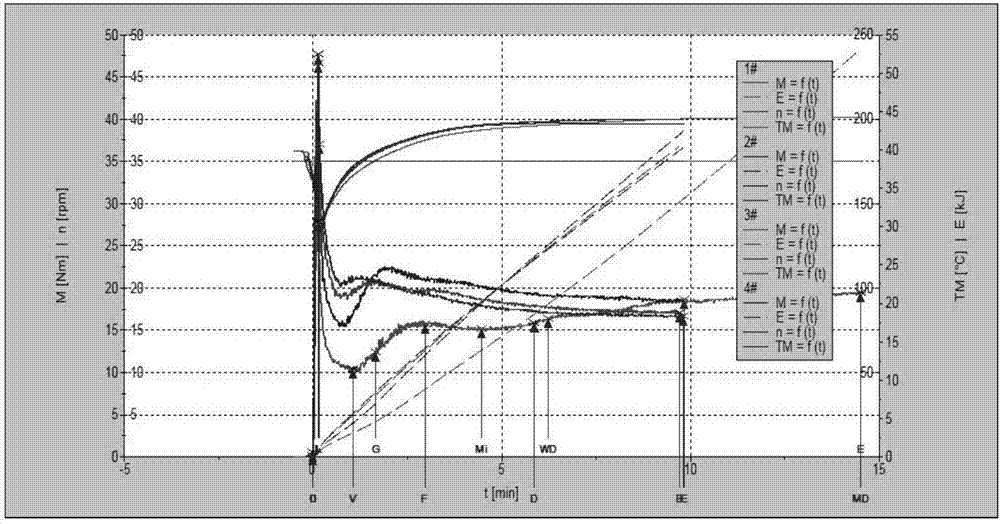

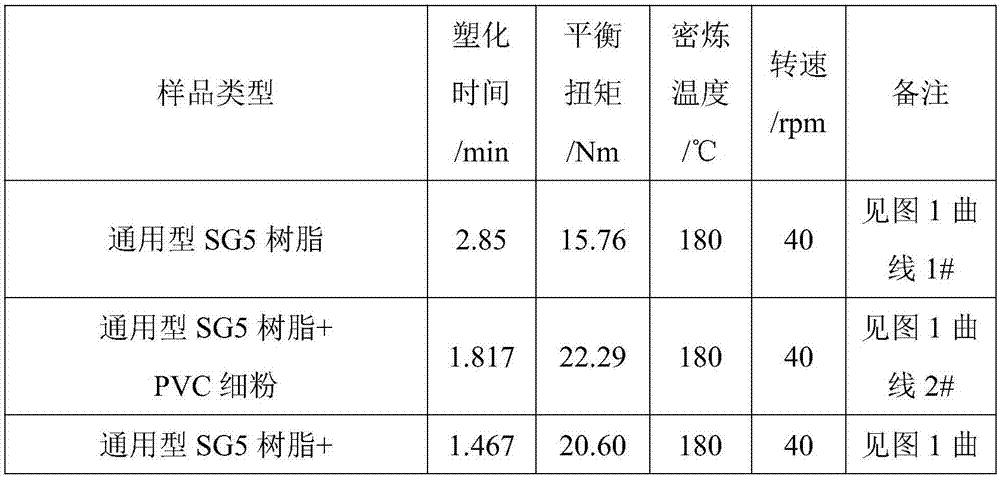

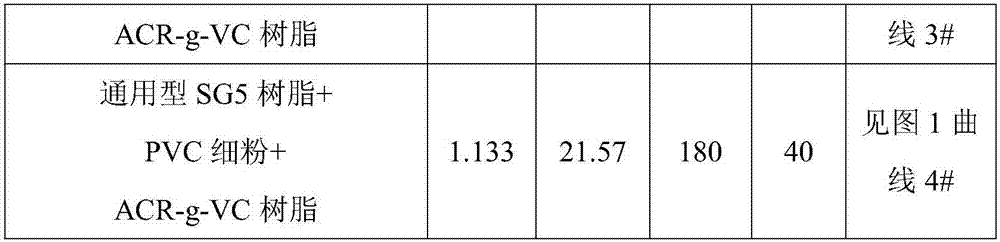

High-impact high-flowability PVC (polyvinyl chloride) formula and preparation method thereof

The invention discloses a high-impact high-flowability PVC (polyvinyl chloride) formula and a preparation method thereof. The high-impact high-flowability PVC formula is prepared from the following ingredients in parts by weight: 60 to 95 parts of PVC resin, 3 to 50 parts of ACR-g-VC resin, 3 to 15 parts of PVC fine powder, 2 to 5 parts of composite stabilizing agents, 0.5 to 2 parts of inner lubricating agents, 0.5 to 1 part of outer lubricating agents and 20 to 50 parts of calcium carbonate. A conventional extrusion process is used; low-polymerization-degree PVC fine powder and ACR-g-VC resin (chloroethylene-n-butyl acrylate graft copolymers) are added; the inner plasticization effects of low-polymerization-degree PVC resin and the chloroethylene-n-butyl acrylate graft copolymers is mainly utilized; the plasticization performance is improved in a cooperated way; the plasticization time is shortened; meanwhile, the anti-impact performance of the plastic product is obviously improved.

Owner:YIBIN TIANYUAN GRP CO LTD +1

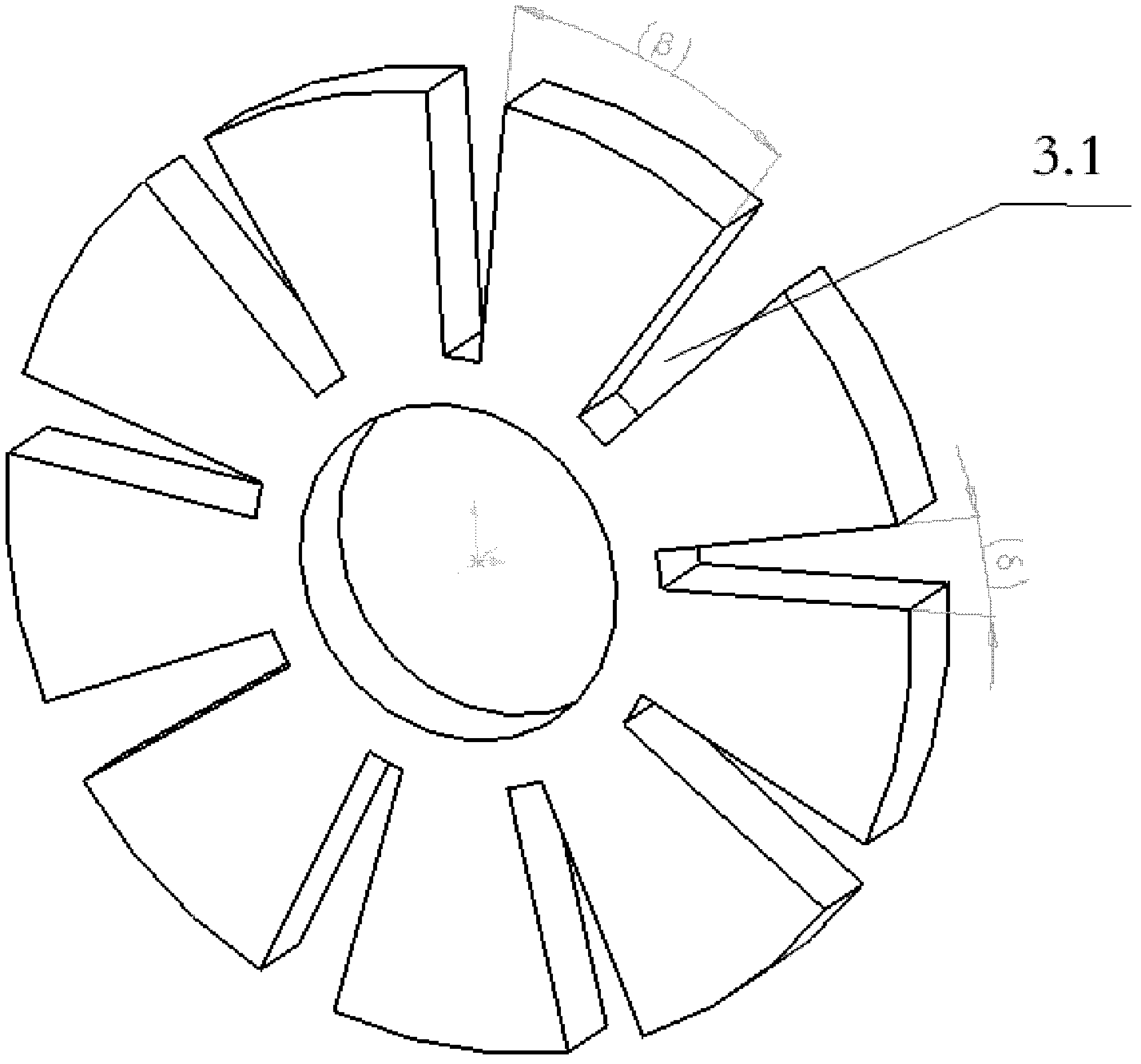

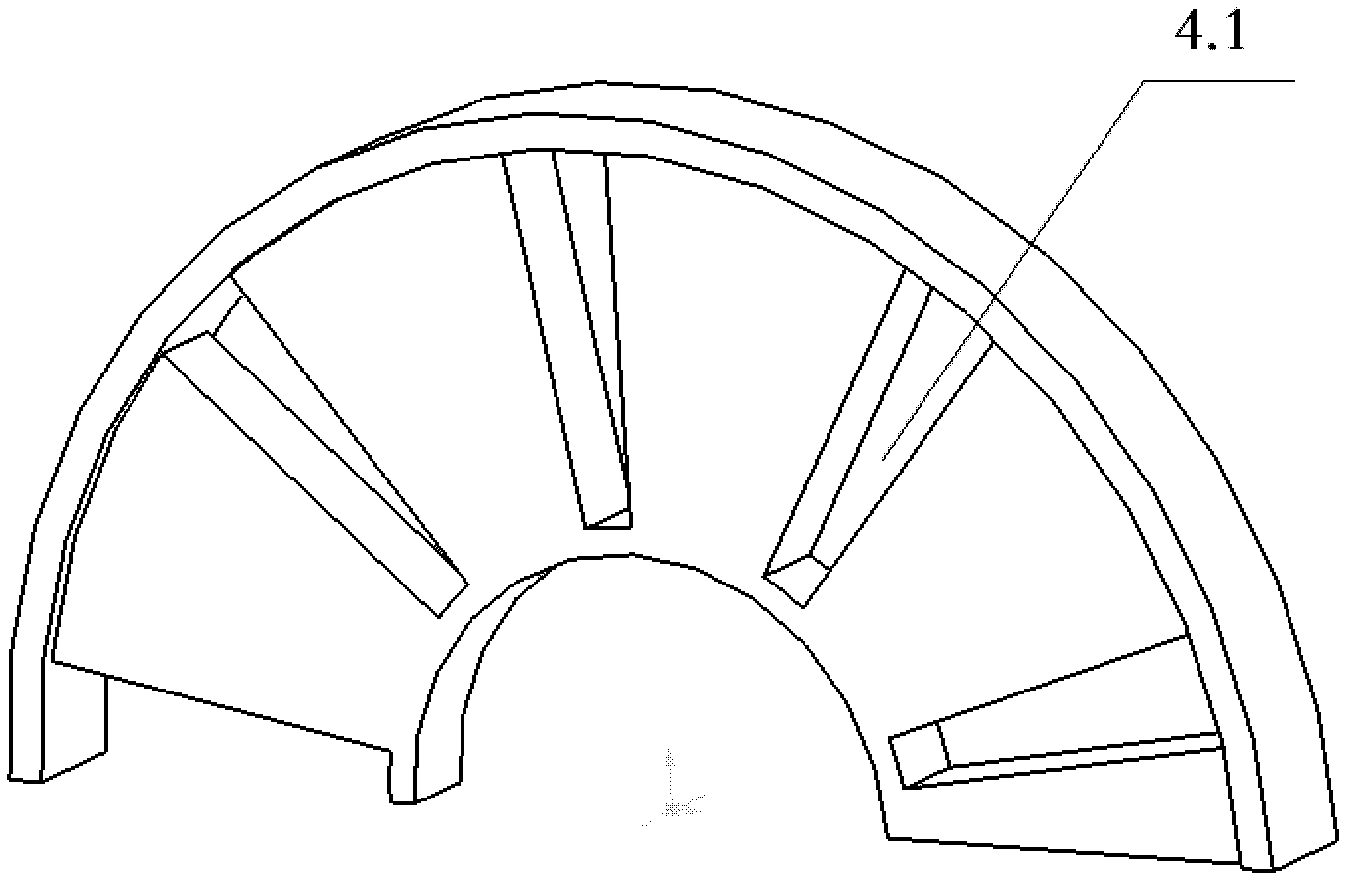

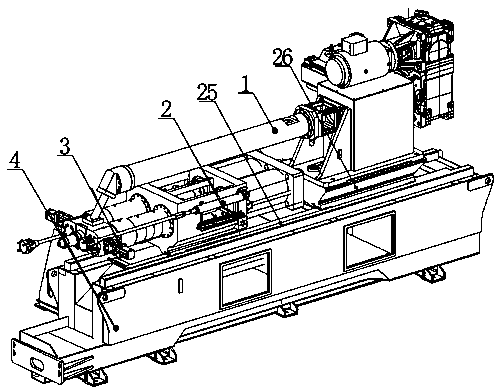

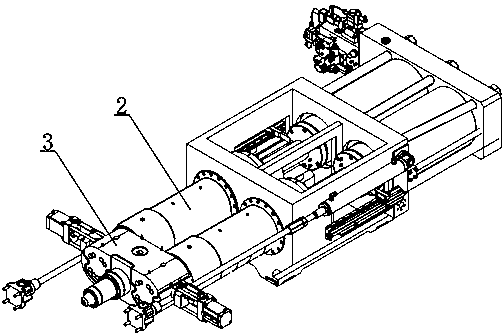

Combined impeller abrasive disk type extrusion plasticizing method and device

The invention discloses a combined impeller abrasive disk type extrusion plasticizing method and a combined impeller abrasive disk type extrusion plasticizing device. A fixed abrasive disk and a rotating abrasive disk are arranged in a charging barrel; the fixed abrasive disk is arranged on the charging barrel; and the rotating abrasive disk is arranged on a power shaft. The invention is characterized in that: the fixed abrasive disk and the rotating abrasive disk are designed to be impeller type abrasive disks are formed by making a plurality of material through grooves for allowing materials to pass through and mixing the materials on whole abrasive disks along a radial direction; impeller blades form abrasive surfaces, and channels are formed by the material through grooves between theblades of the impeller abrasive disks; a plurality of like fixed impeller abrasive disks and rotating impeller abrasive disks are overlapped alternately; the materials are forcefully pressed in from the front part of the inside of the charging barrel; then under the rotation of the rotating impeller abrasive disks relative to the fixed impeller abrasive disks, the materials pass through abrasive disk gap and blade material through grooves so as to be gradually mixed, crushed, ground, softened, subjected to heat exchange and plasticized in the constantly varying material through channels and the abrasive disk gaps; and finally, the materials are discharged from a discharge hole on the rear part of the inside of the charging barrel.

Owner:HUBEI UNIV OF TECH

Nano-montmorillonite and PET mixture forming system

The invention discloses a nano-montmorillonite and PET mixture forming system. The system is mainly composed of a rack, a mixture extruding device, an alternative feeding device and two injection devices, wherein the mixture extruding device and the two injection devices are arranged on the rack, and the alternative feeding control device is mainly composed of a valve body, two cylindrical valve elements and two oil cylinders; the two oil cylinders drive the two cylindrical valve elements to move, respectively, one of the cylindrical valve elements is used for communicating the mixture extruding device with one injection device, and closing a material injection channel communicated with the injection device, and meanwhile, the other cylindrical valve element is used for closing a channel between the mixture extruding device and the other injection device, and opening the material injection channel communicated with the injection device. The extruder and the injectors are organically integrated by the system disclosed by the invention, and an NPET pelletizing process is omitted; the system has the characteristics of simple structure, low manufacturing cost and obvious effect.

Owner:GUANGZHOU XUNZHI MACHINERY

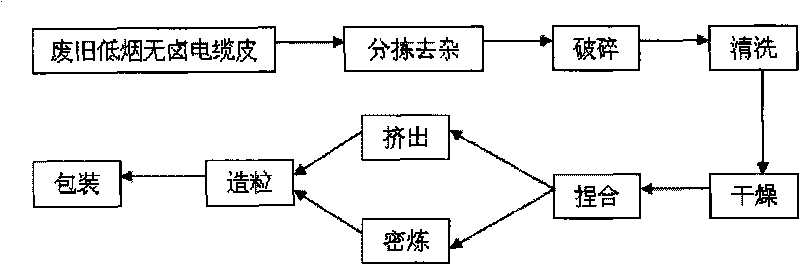

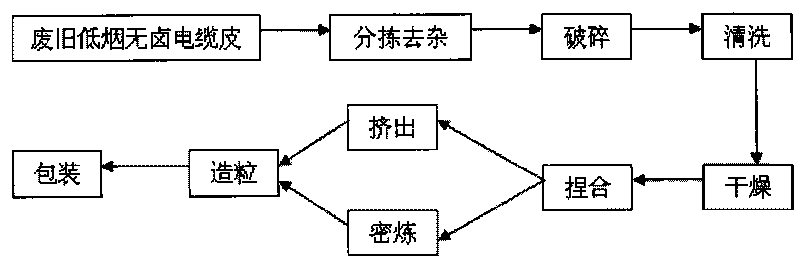

Regenerative low-smoke halogen-free cable material and preparation method thereof

ActiveCN101698751AEfficient preparationMeet the requirementsBasic electric elementsElectronic waste recyclingResource utilizationAntioxidant

The invention discloses a regenerative low-smoke halogen-free cable material and a preparation method thereof. The regenerative low-smoke halogen-free cable material comprises the following components in parts by weight: 100 parts of waste low-smoke halogen-free cable crushed material, 0.3-0.5 part of lubricant, 0.2-0.3 part of antioxidant and 0.5-0.8 part of color masterbatch. The preparation method comprises the steps of sorting for removing impurities, crushing, cleaning, drying, kneading, extruding, granulating and packing. The regenerative low-smoke halogen-free cable material of the invention has the following indexes: the tensile strength is greater than or equal to 10.0MPa, the elongation at break is greater than or equal to 150.0%, the low temperature brittleness impact temperature is -30 DEG C, the volume resistivity at 20 DEG C is greater than or equal to 1.0*10<10> omega.m, and the oxygen index is greater than or equal to 33.0%, wherein the indexes all exceed the national standards. The regeneration method of the invention can be used for preparing the regenerative low-smoke halogen-free cable material efficiently, increases the utilization ratio of resources, reduces the pollution of solids wastes, has large economic prospect and generates good social benefit simultaneously.

Owner:YANGZHOU HAONIANHUA POLYMER MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com