High-impact high-flowability PVC (polyvinyl chloride) formula and preparation method thereof

A high-fluidity, high-impact technology, applied in the field of PVC, can solve the problems of high melt viscosity, high processing temperature, poor thermal stability, etc., achieve good fluidity, reduce processing temperature, and improve flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

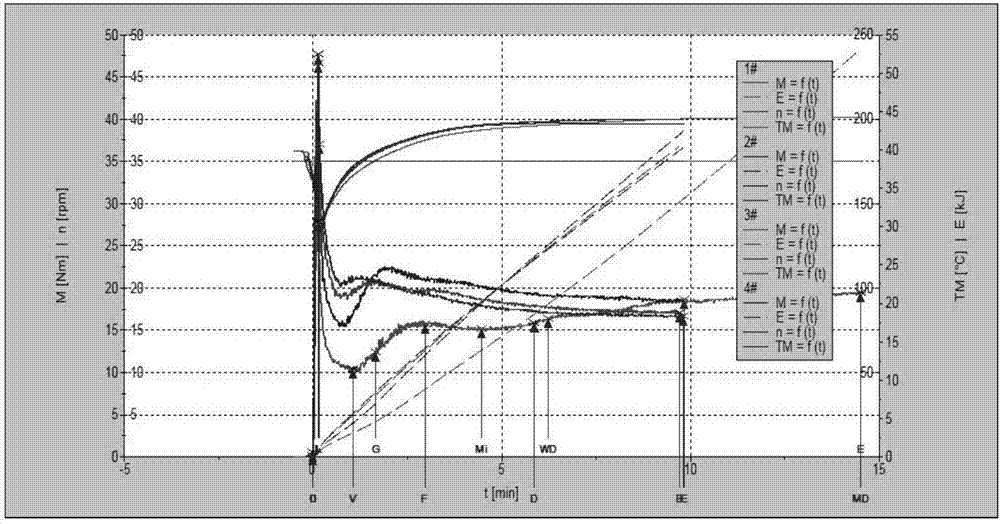

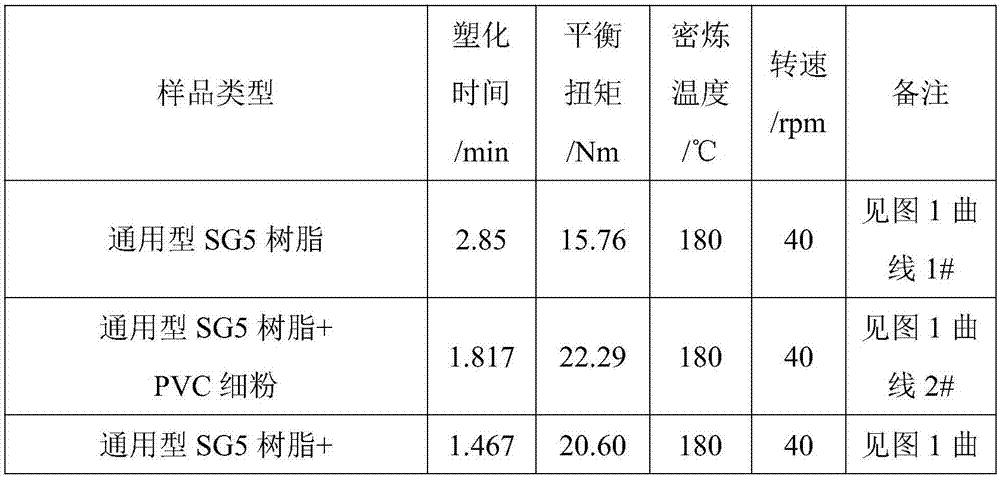

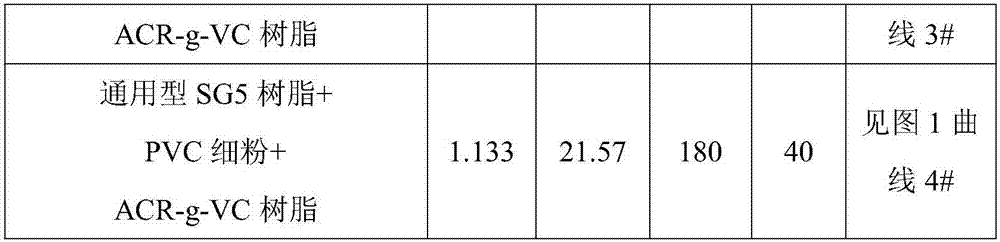

Image

Examples

Embodiment 1

[0046] The high-impact high-flow PVC formulation of the present embodiment consists of the following components in parts by weight:

[0047] PVC resin (SG5): 85 parts; ACR-g-VC resin: 5 parts

[0048] PVC fine powder: 10 parts; composite stabilizer: 3 parts

[0049] Internal lubricant: 0.5 parts External lubricant: 0.5 parts

[0050] Calcium carbonate: 10 parts.

[0051] The ACR-g-VC resin of this embodiment is a graft copolymer of vinyl chloride and n-butyl acrylate, and its degree of polymerization is equivalent to that of SG5; PVC fine powder is a low-molecular-weight polyvinyl chloride with a particle size less than 20um and a degree of polymerization of 300-800 . The composite stabilizer is selected from any one or more of organic tin, calcium stearate, barium stearate, cadmium stearate, zinc stearate, and magnesium stearate. The internal lubricant is stearic acid, and the external lubricant is oxidized polyethylene wax; the filler is nanometer calcium carbonate.

[...

Embodiment 2

[0055] The high-impact high-flow PVC formulation of the present embodiment consists of the following components in parts by weight:

[0056] PVC resin (SG5): 47 parts; ACR-g-VC resin: 50 parts;

[0057] PVC fine powder: 3 parts; composite stabilizer: 3.5 parts;

[0058] Internal lubricant: 0.5 parts; External lubricant: 0.5 parts;

[0059] Calcium carbonate: 15 parts.

[0060] The ACR-g-VC resin is a graft copolymer of vinyl chloride and n-butyl acrylate, and its degree of polymerization is equivalent to that of SG5. The PVC fine powder is low molecular weight polyvinyl chloride with a particle size of less than 20um and a degree of polymerization of 300-800.

[0061] The composite stabilizer is selected from one or more composites of organotin, calcium stearate, barium stearate, cadmium stearate, zinc stearate and magnesium stearate.

[0062] The internal lubricant of the present embodiment is stearic acid, and the external lubricant is oxidized polyethylene wax.

[0063...

Embodiment 3

[0067] The high-impact high-flow PVC formulation of the present embodiment consists of the following components in parts by weight:

[0068] PVC resin (SG5): 74 parts; ACR-g-VC resin: 20 parts

[0069] PVC fine powder: 6 parts; composite stabilizer: 3.5 parts

[0070] Internal lubricant: 0.5 parts; External lubricant: 0.5 parts

[0071] Calcium carbonate: 10 parts.

[0072] The ACR-g-VC resin in this example is a graft copolymer of vinyl chloride and n-butyl acrylate, and its degree of polymerization is equivalent to that of general-purpose SG5 resin.

[0073] The PVC fine powder in this embodiment is low molecular weight polyvinyl chloride with a particle size of less than 20 um and a degree of polymerization of 300-800. The composite stabilizer in this embodiment is selected from one or more composites of organotin, calcium stearate, barium stearate, cadmium stearate, zinc stearate, and magnesium stearate.

[0074] The internal lubricant is stearic acid, and the external...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com