Patents

Literature

96results about How to "High impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

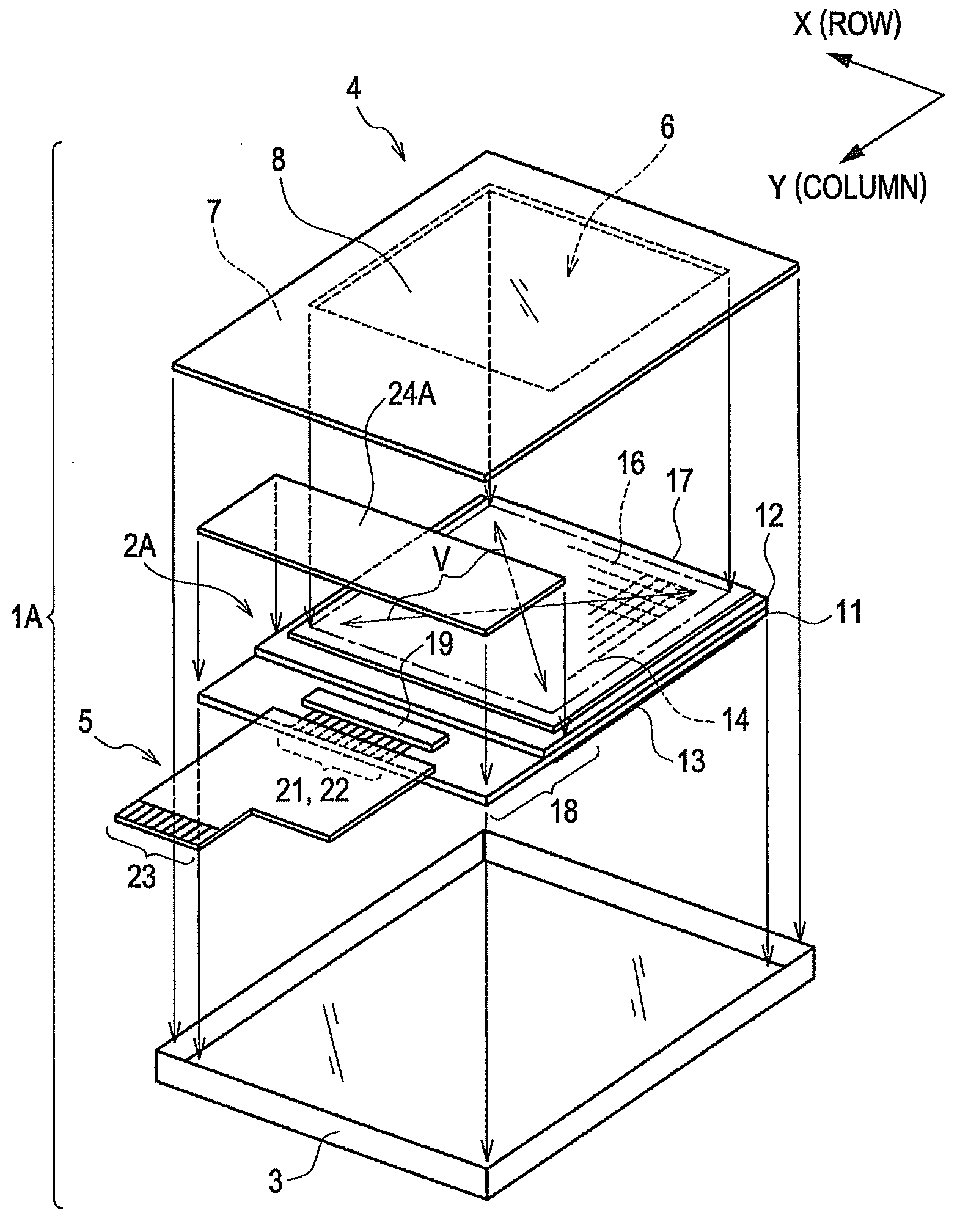

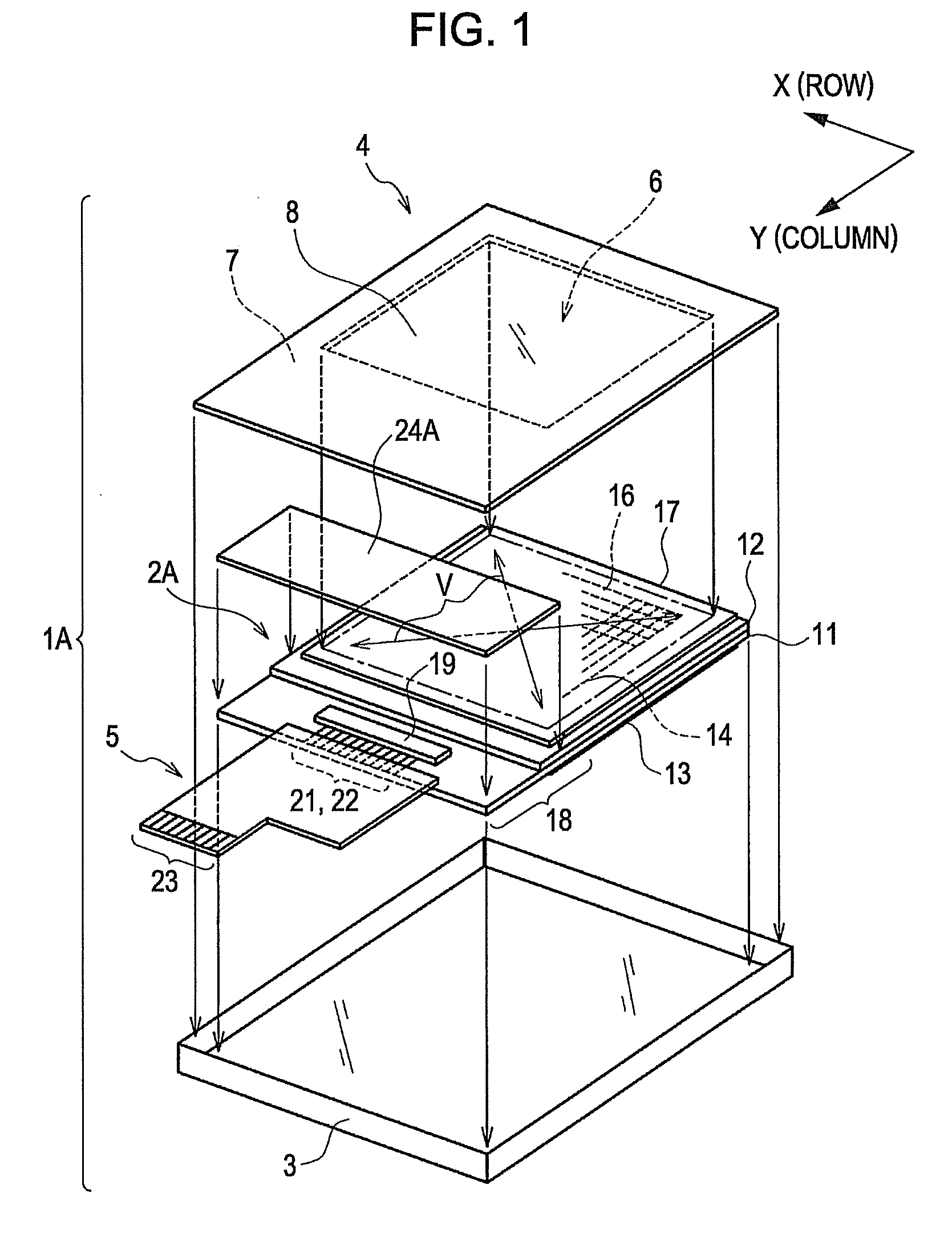

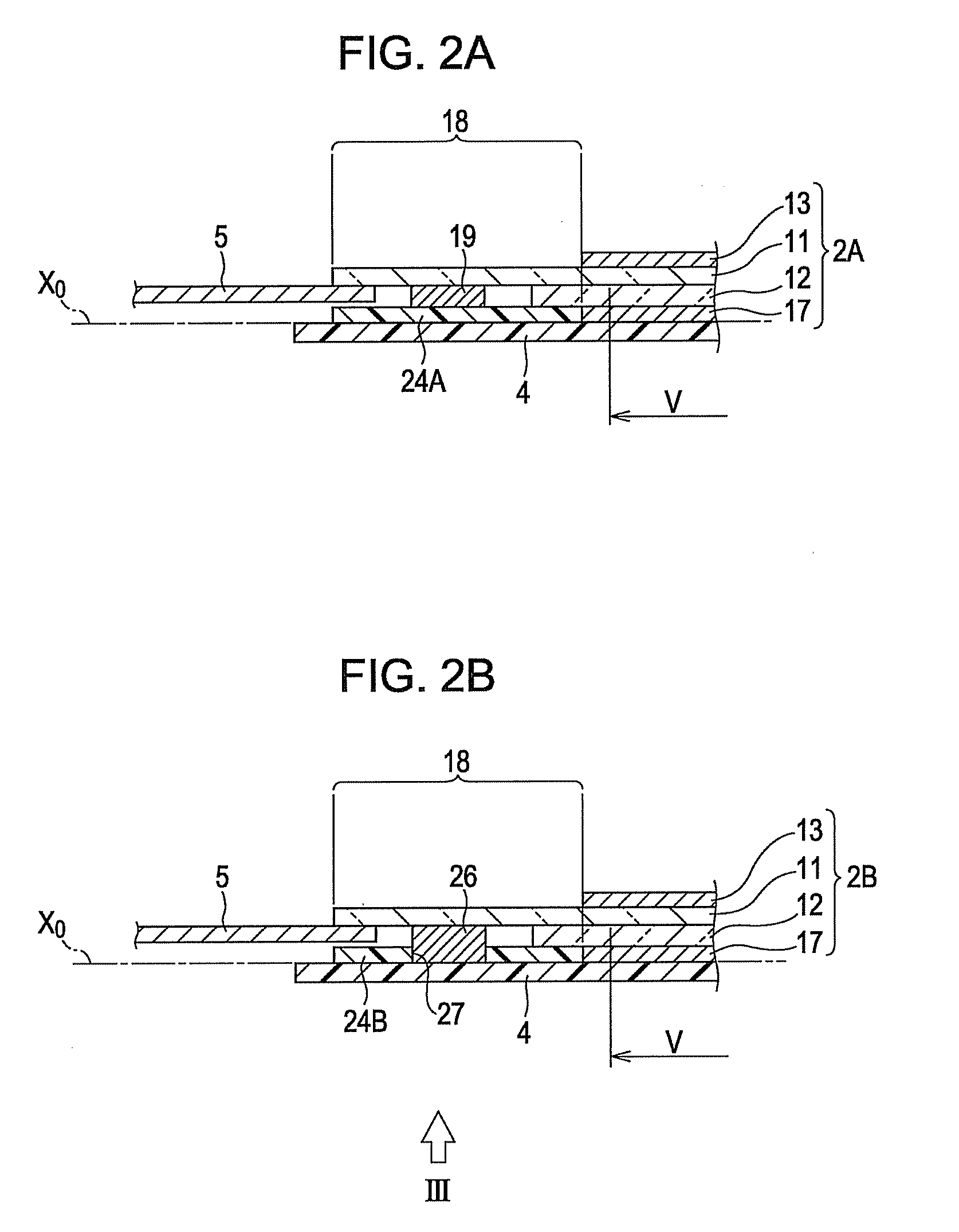

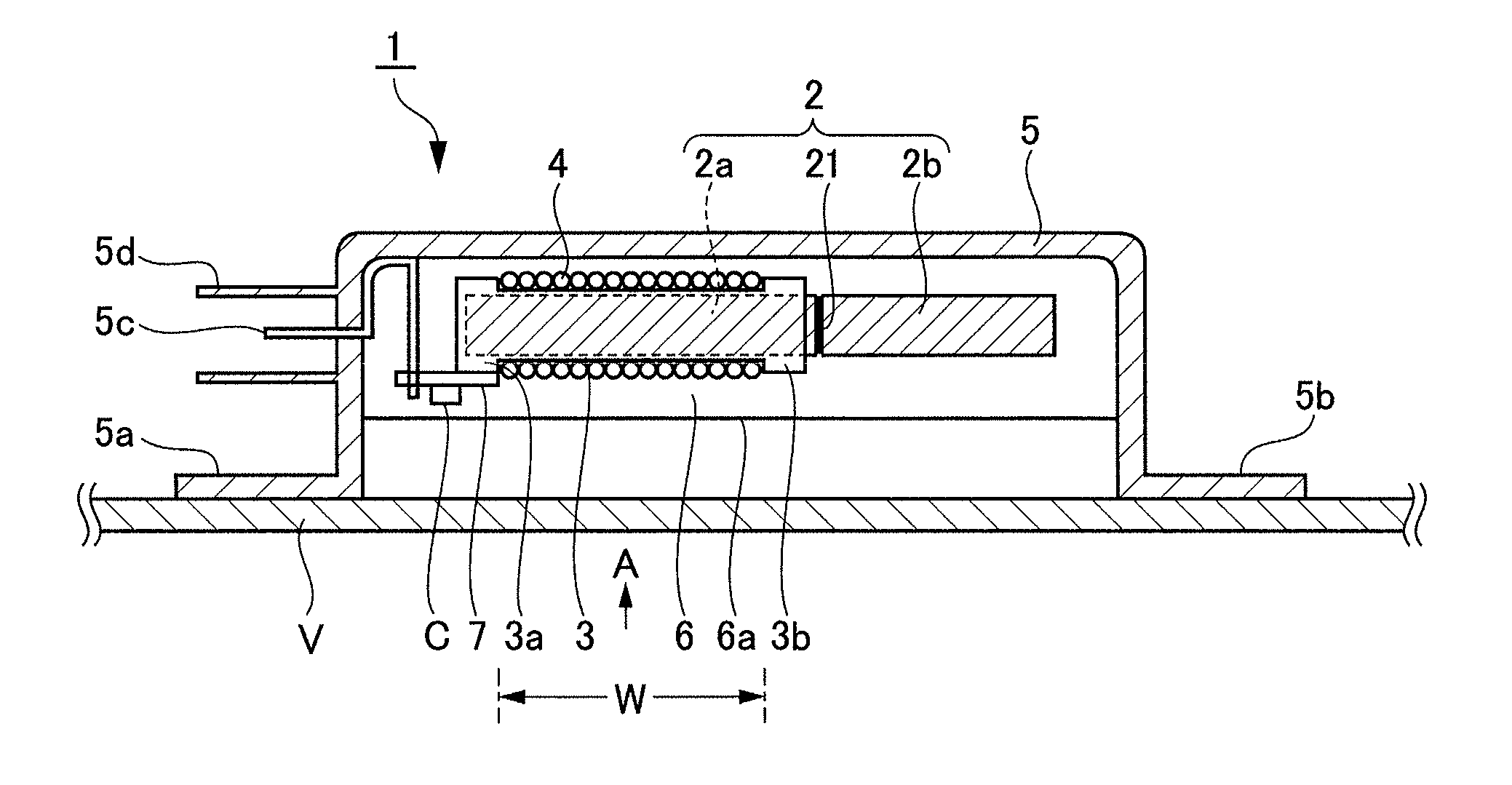

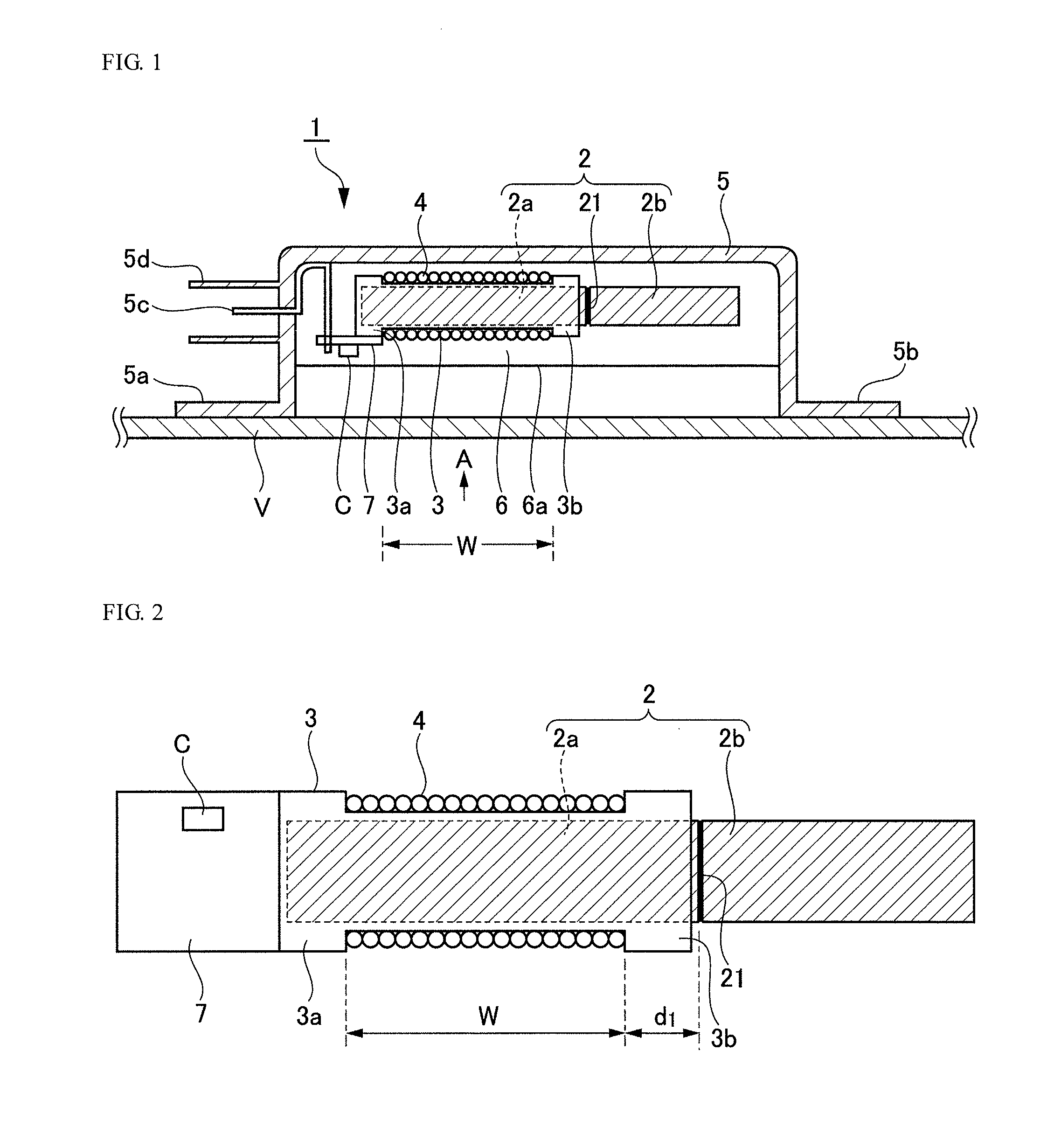

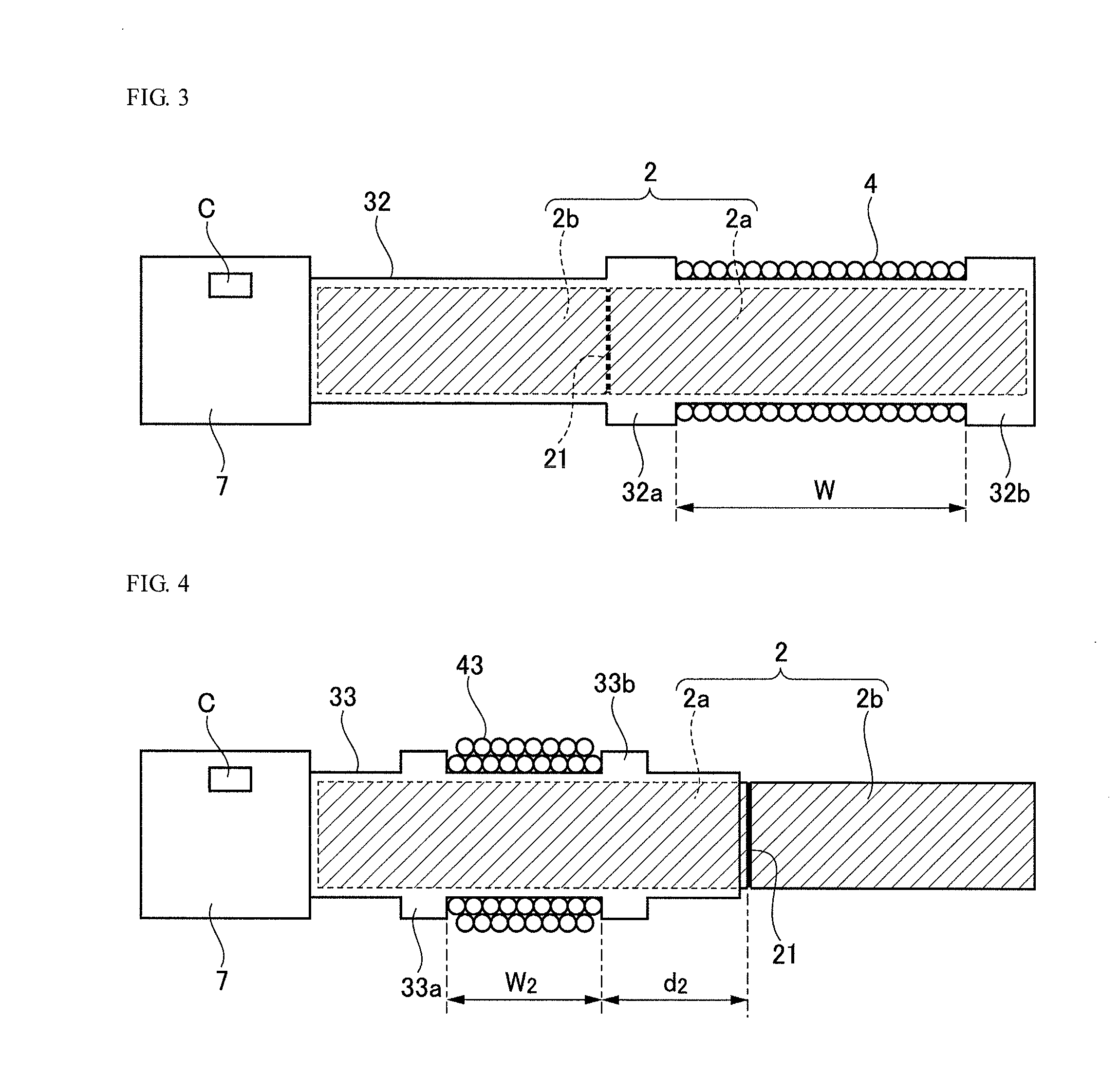

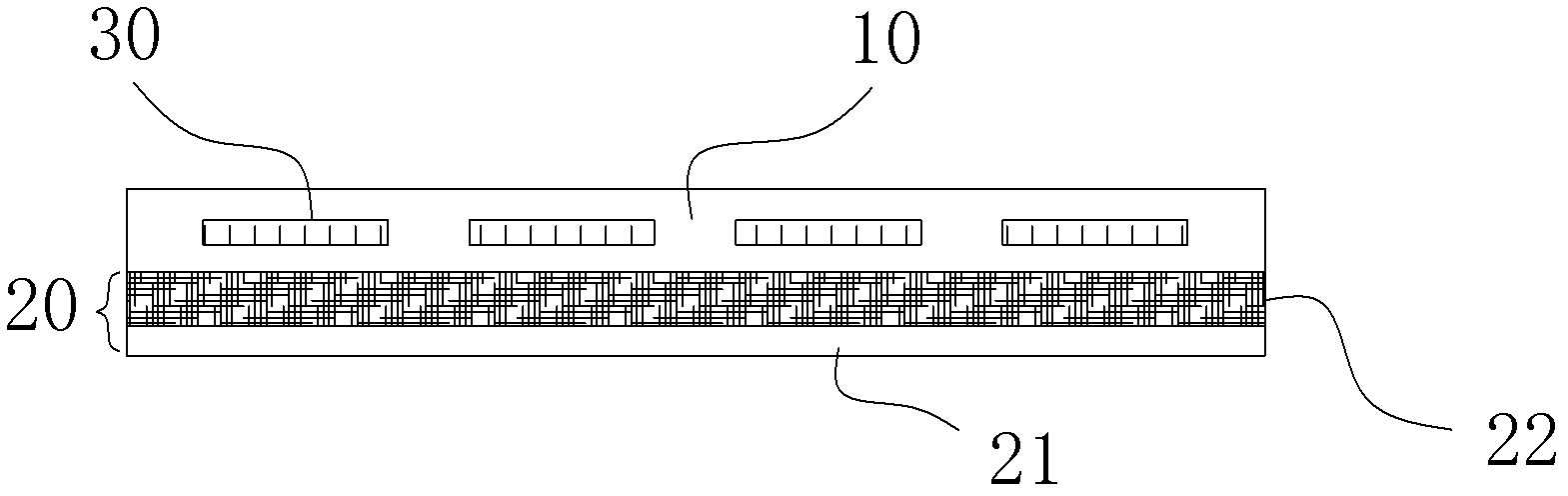

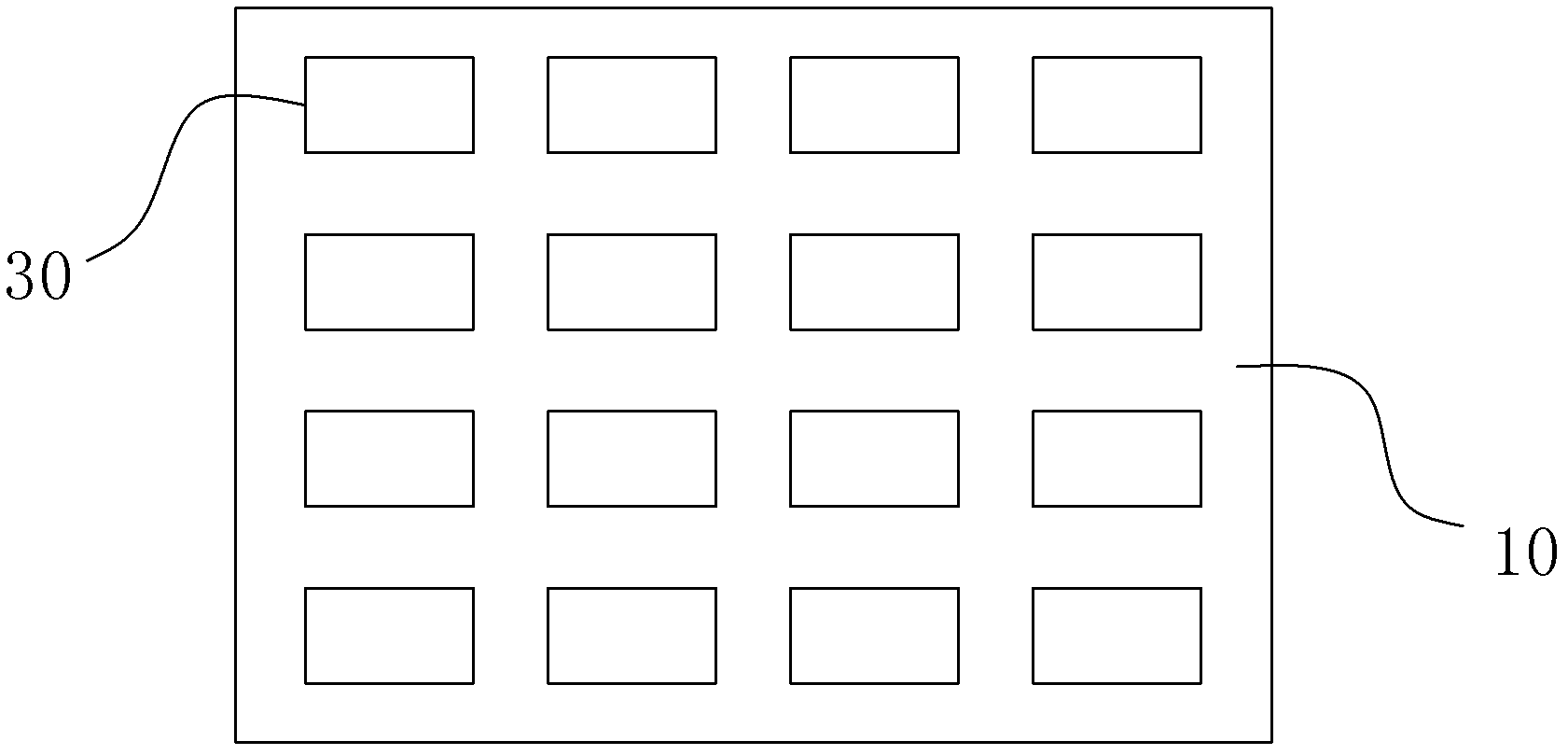

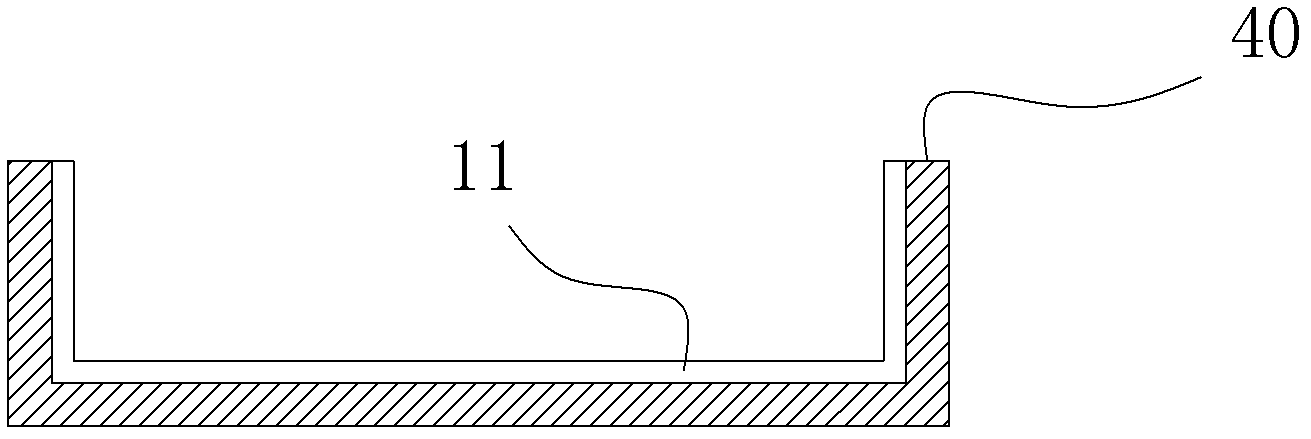

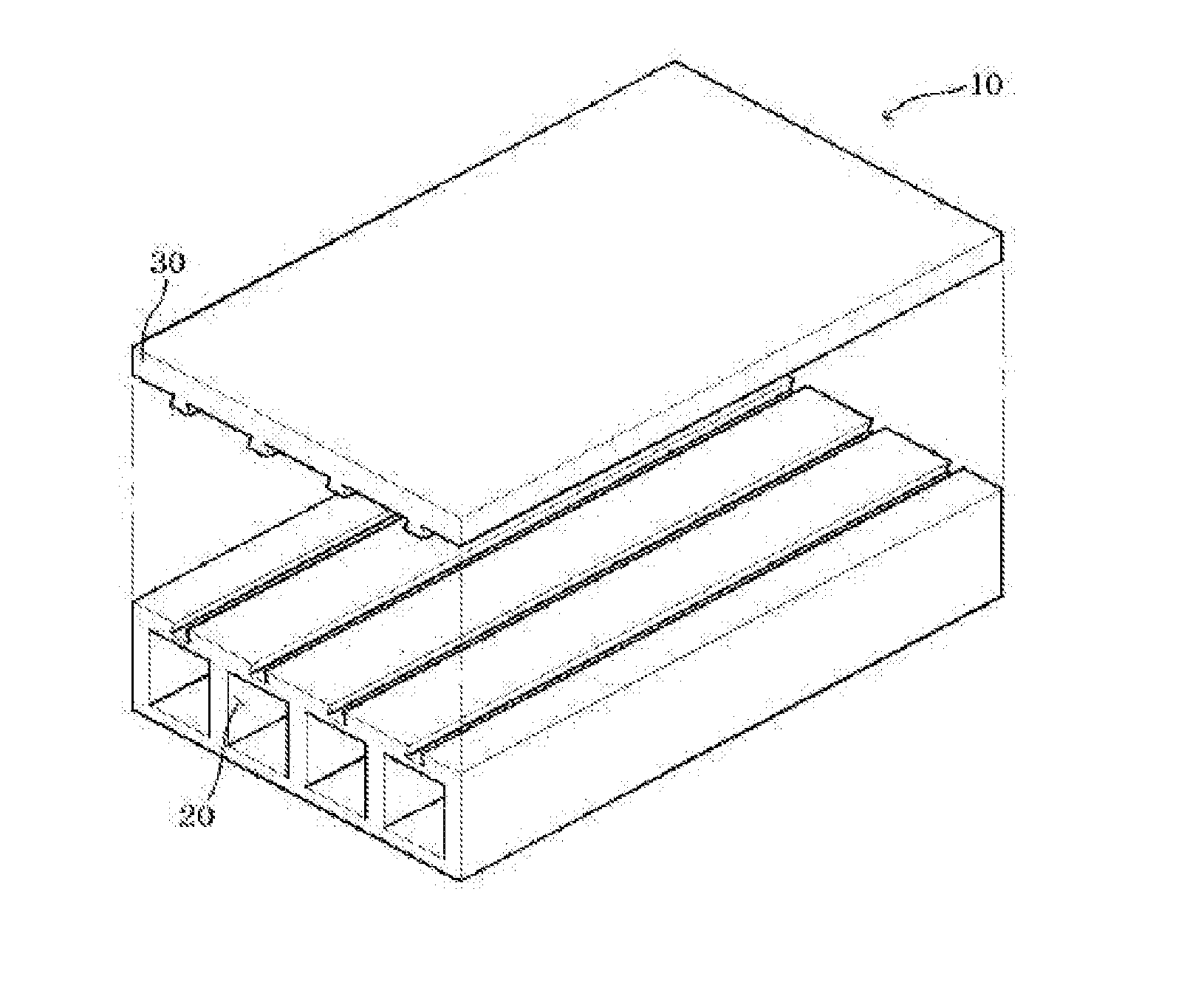

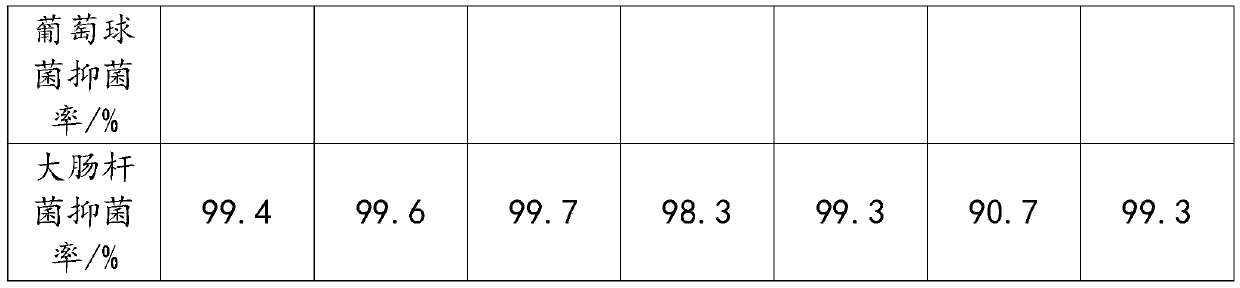

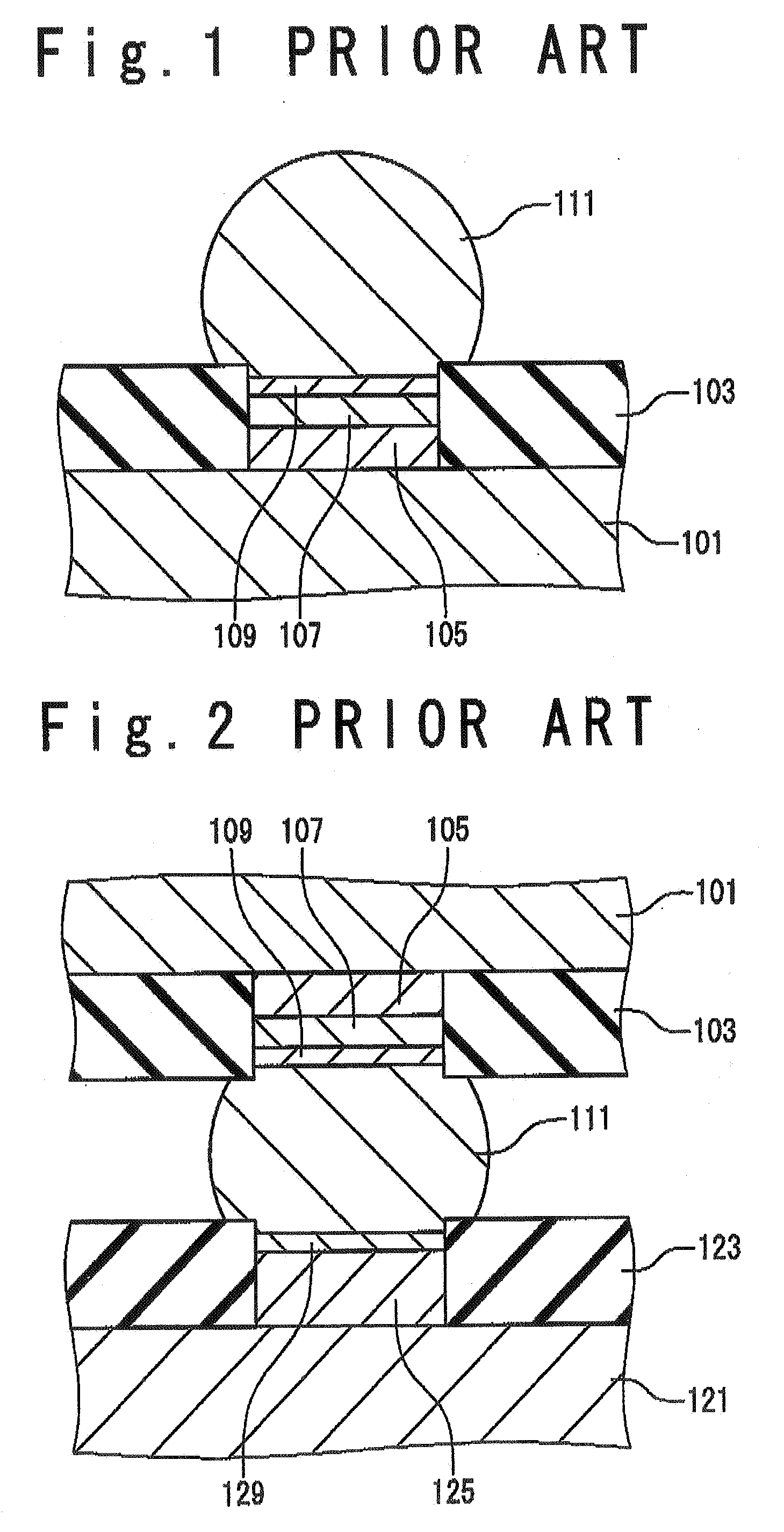

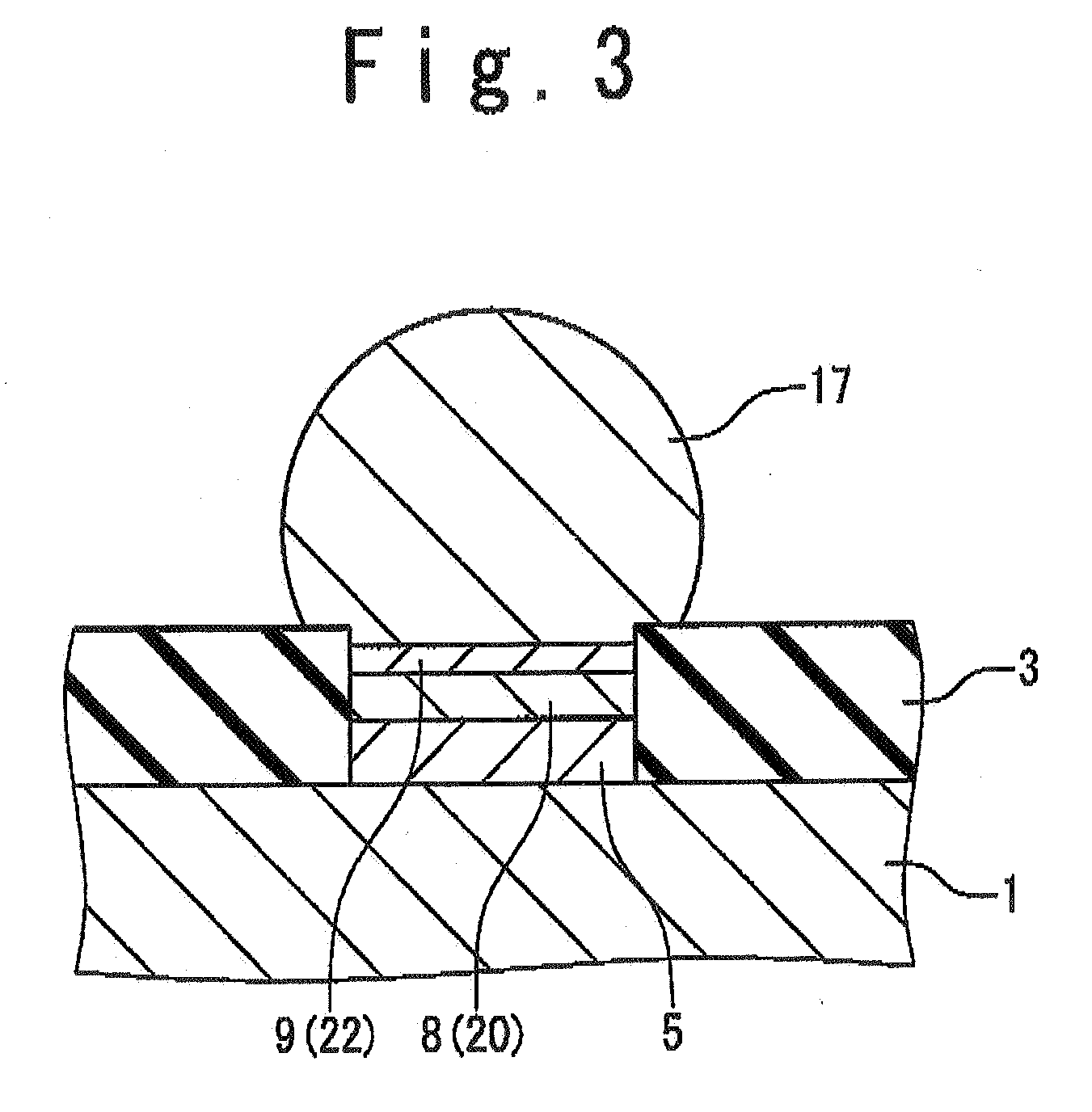

Electro-optical device and electronic apparatus

ActiveUS20090213534A1High impact resistancePrevent be damageDigital data processing detailsCasings/cabinets/drawers detailsEngineeringSurface plate

Owner:EPSON IMAGING DEVICES CORP +1

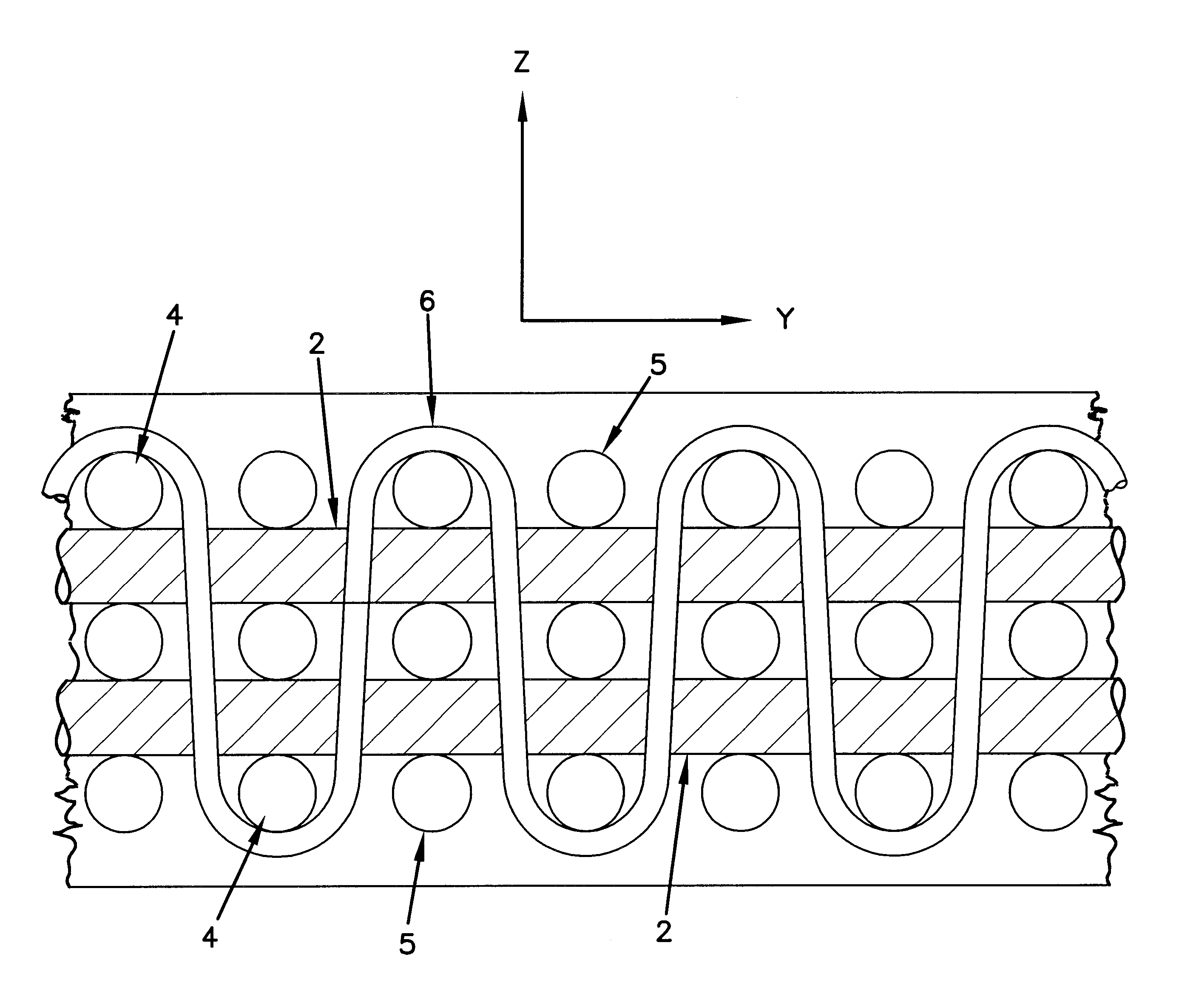

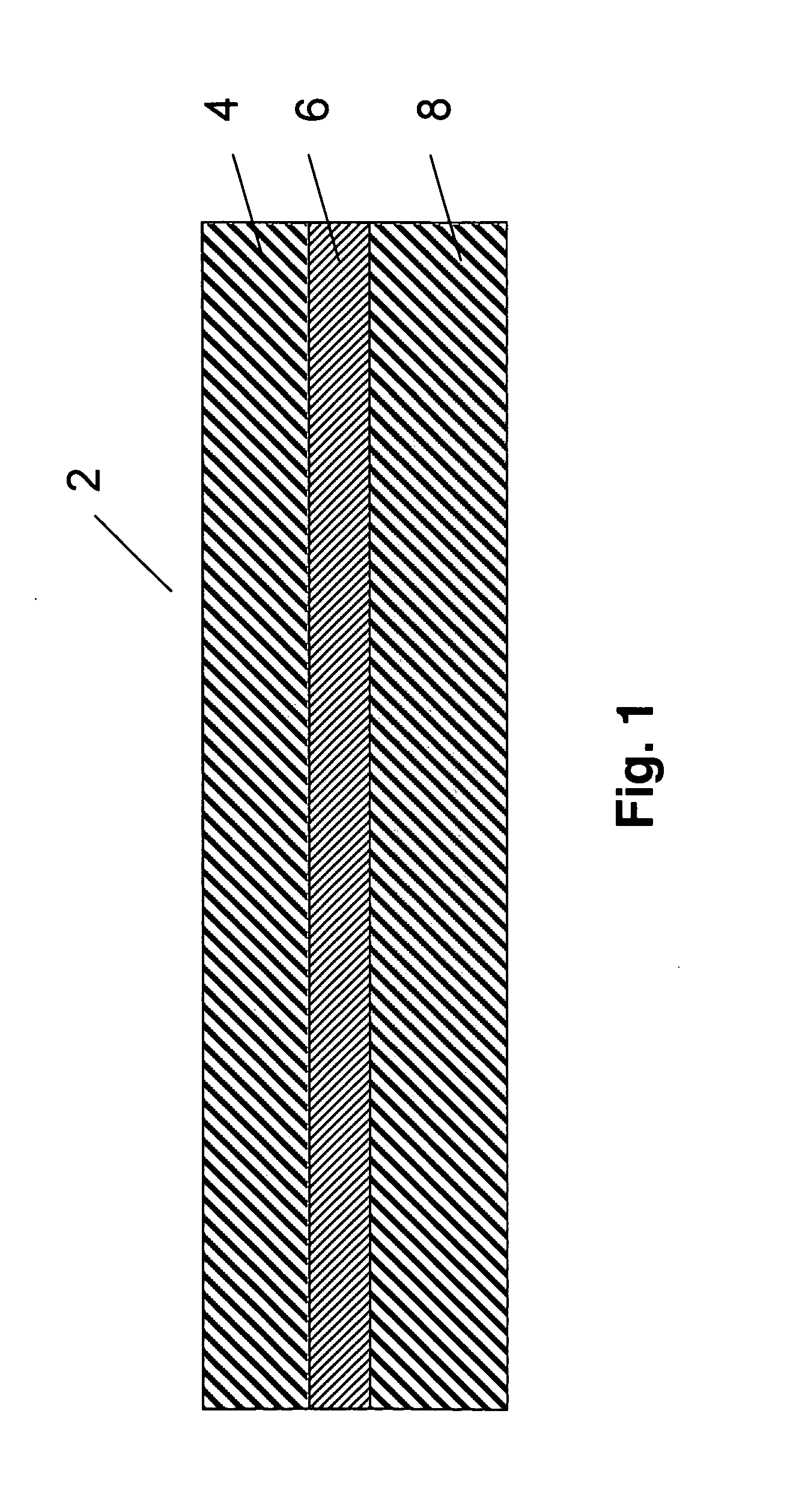

Hard impact resistant composite

InactiveUS6358603B1Improved performance characteristicHigh impact resistanceLayered productsTowersHigh energyComposite structure

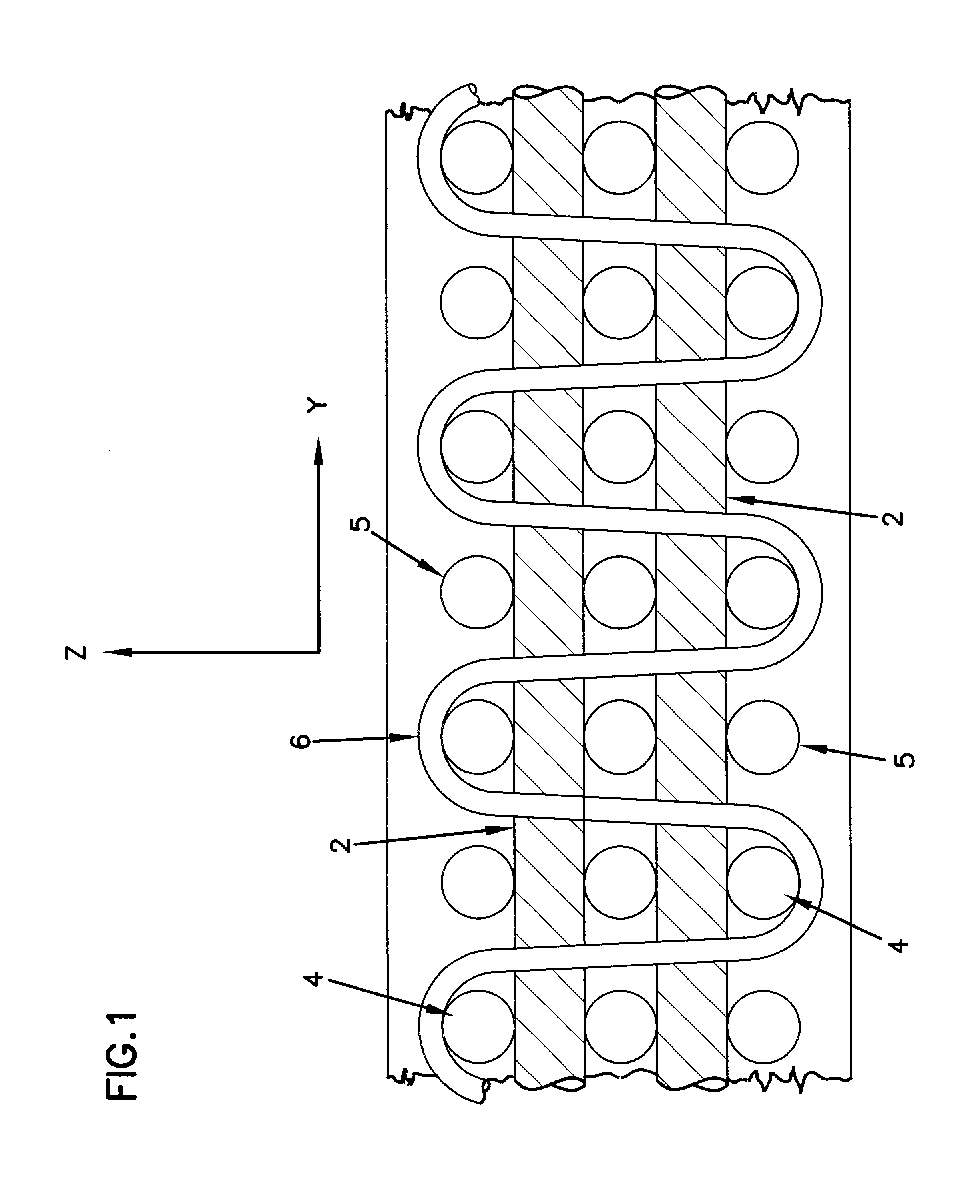

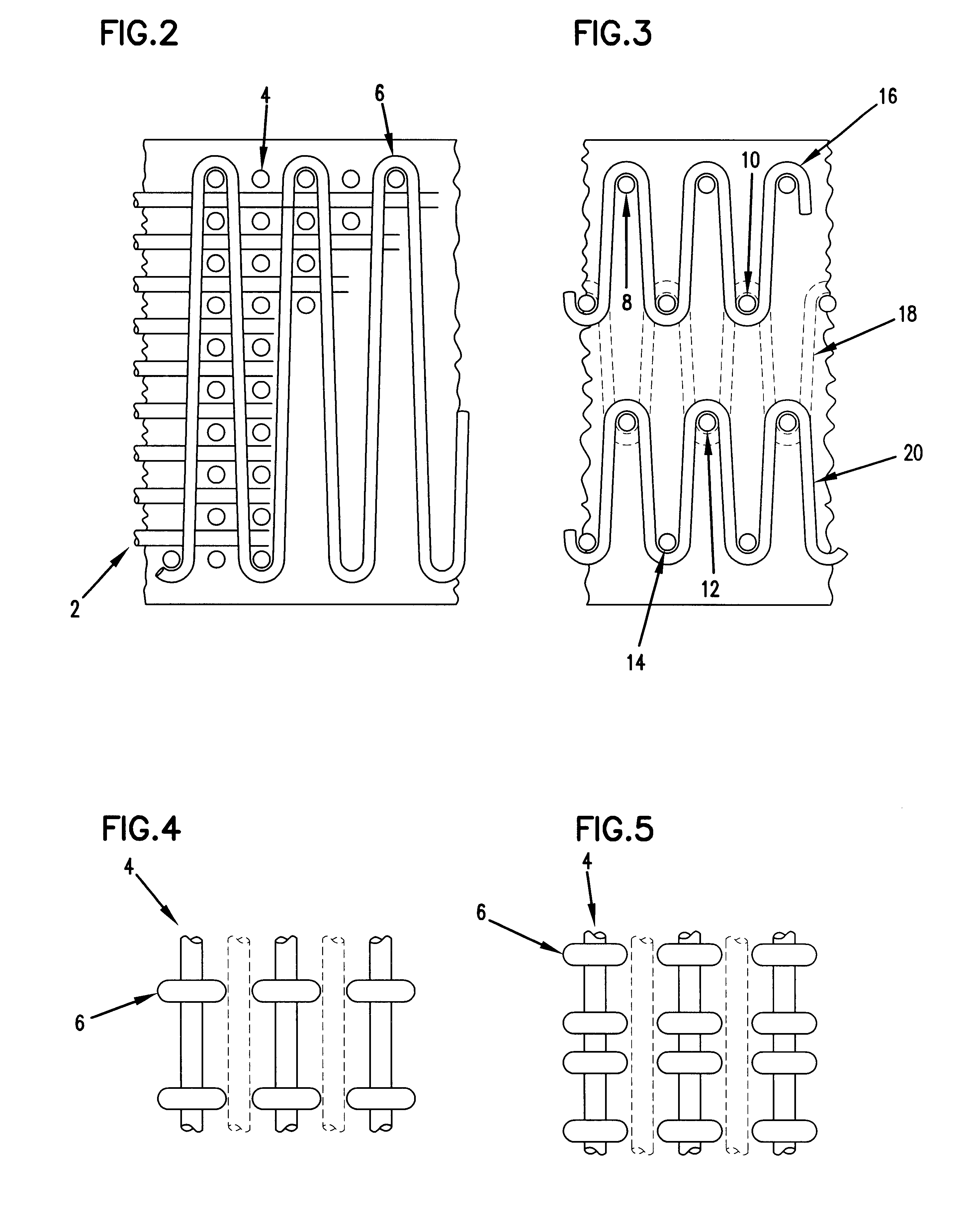

A shaped article, at least one domain of which has a three-dimensionally reinforced composite structure comprising of a matrix and a reinforcing system (2, 4, 5, 6), the reinforcing system comprising bodies such as bars, wires, cables, or plates embedded in the matrix and extending three-dimensionally in first (4, 5) second (2) and third (6) dimensions therein, the reinforcing system being tension interlocked in at least one dimension in that reinforcement components extending in the first and / or second dimension are tension interlocked to reinforcement components extending in the same dimension(s), but at a transverse distance therefrom, by transverse reinforcement components extending in a dimension transverse, to a plane or surface defined by the reinforcement in the first and / or second dimension. The matrix is preferably a dense cement-based matrix prepared from cement, microsilica, a concrete superplaticiser and water, or a metallic matrix. The shaped articles are capable of absorbing high energy with retention of a substantial degree of internal coherence, e.g. under exposure to high velocity impact.

Owner:COMPOSHIELD

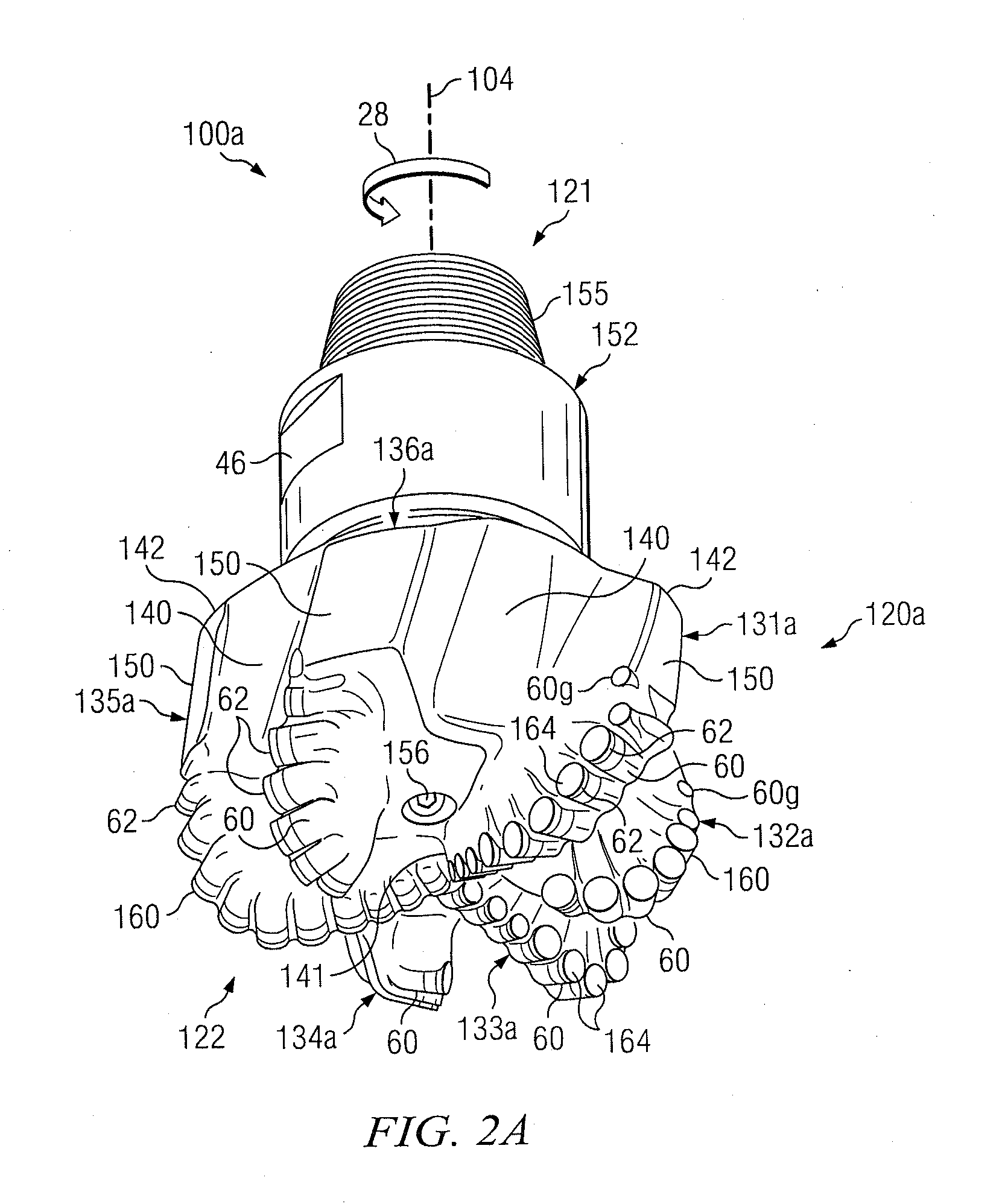

PDC Bits with Mixed Cutter Blades

ActiveUS20120152624A1Improve performanceHigh impact resistanceGeometric CADDrill bitsWear resistantDesign tool

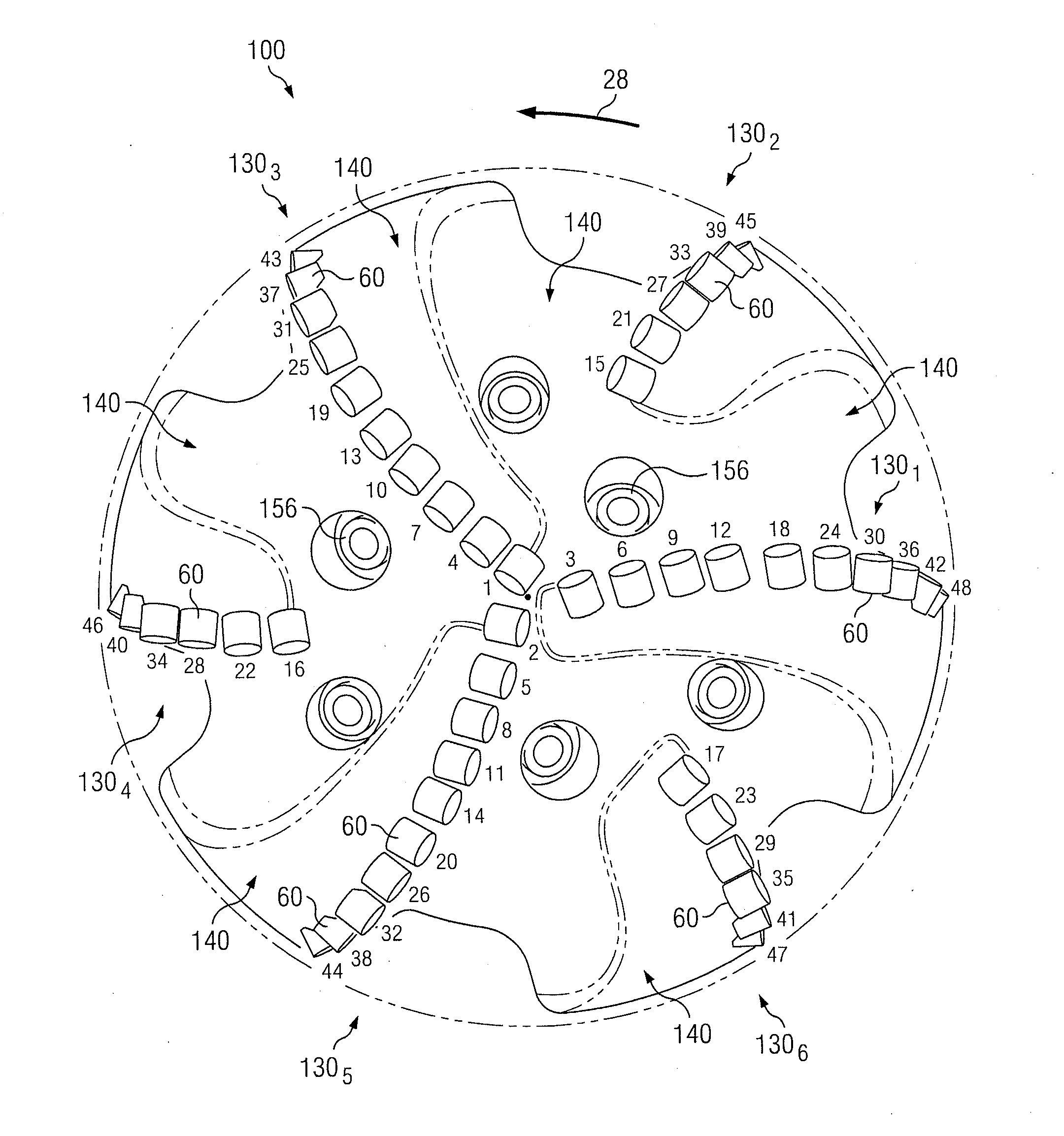

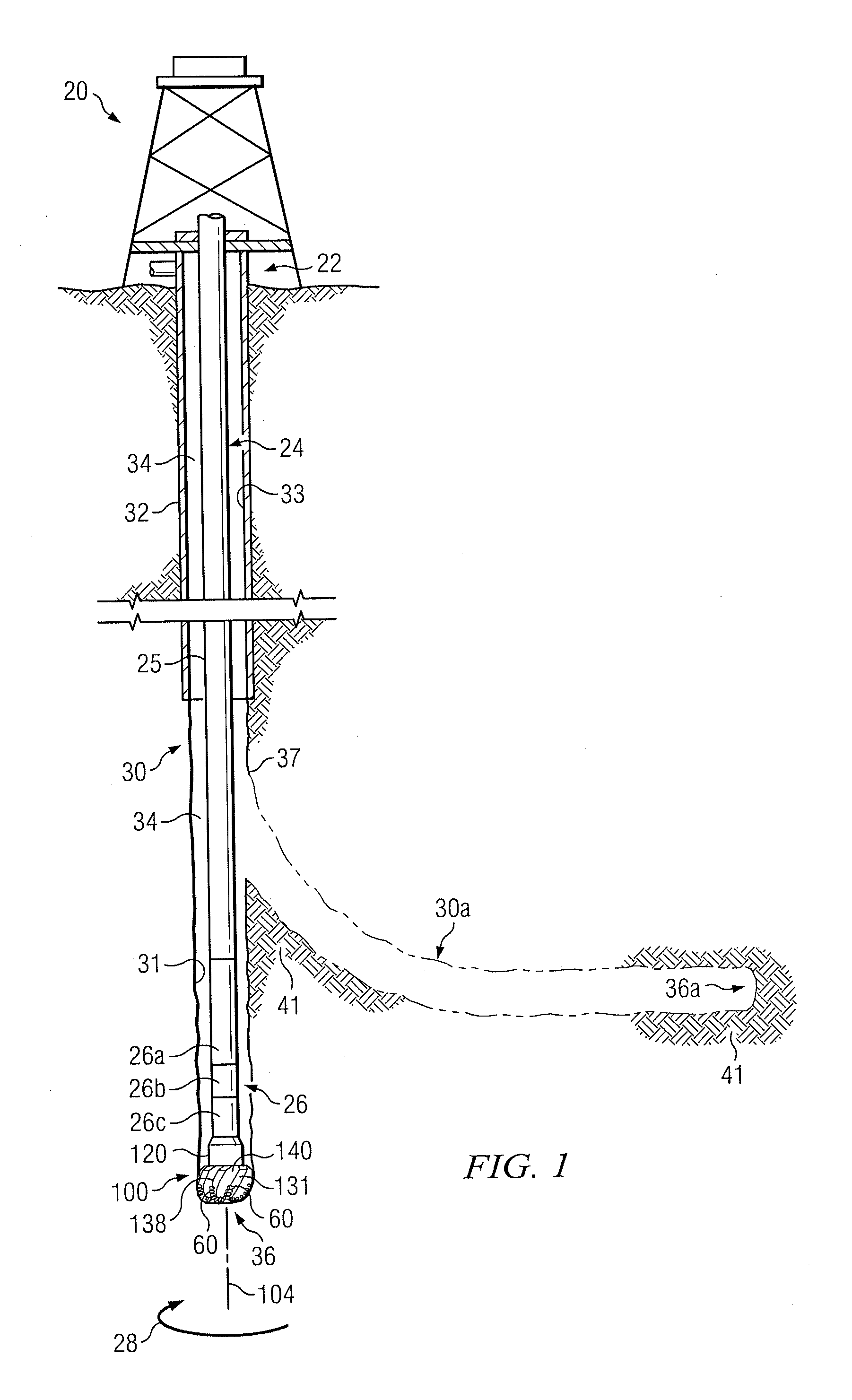

Downhole drilling tools designed and manufactured to minimize or reduce imbalance forces and wear by disposing cutting elements in cutter groups and cutter sets in a level of force balance and by placing impact and / or wear resistant cutters on blades subject to high impact forces and / or large loadings. Manufacturing costs may be reduced by placing inexpensive cutters on blades not subject to high impact forces and / or loadings. Some embodiments comprise designing downhole tools with combinations of thicker blades to receive high impact forces and / or loadings with thinner blades. Some embodiments comprise designing downhole drilling tools with optimized fluid-flow properties. Designing methods may comprise performing simulations on a designed tool, evaluating respective forces acting on cutters during simulated engagement with a downhole (uniform and transitional) and / or evaluating wear on cutters and bit, and / or CFD simulations to evaluate fluid-flow optimization on a tool. Various cutter layout procedures and algorithms are described.

Owner:HALLIBURTON ENERGY SERVICES INC

Multi-layer rotationally molded low permeation vessels and method for manufacture thereof

ActiveUS20080145582A1Low costHigh impact resistanceSynthetic resin layered productsContainer/bottle contructionThermoplasticPolymer chemistry

A multiple walled enclosure with low permeation properties and rugged impact resistance useful as a fuel tank or chemical container. The enclosure is made by rotomolding a first charge of thermosetting polymer into an outer layer, then rotomolding a charge of EVOH or other low permeation thermoplastic into a second layer, then rotomolding a second charge of thermosetting polymer into a third layer so that the low permeation thermoplastic layer is fully enclosed by layers of thermoset polymer. The preferred thermosetting polymer is crosslinkable polyethylene and the preferred low permeation thermoplastic is EVOH.

Owner:CENTRAL

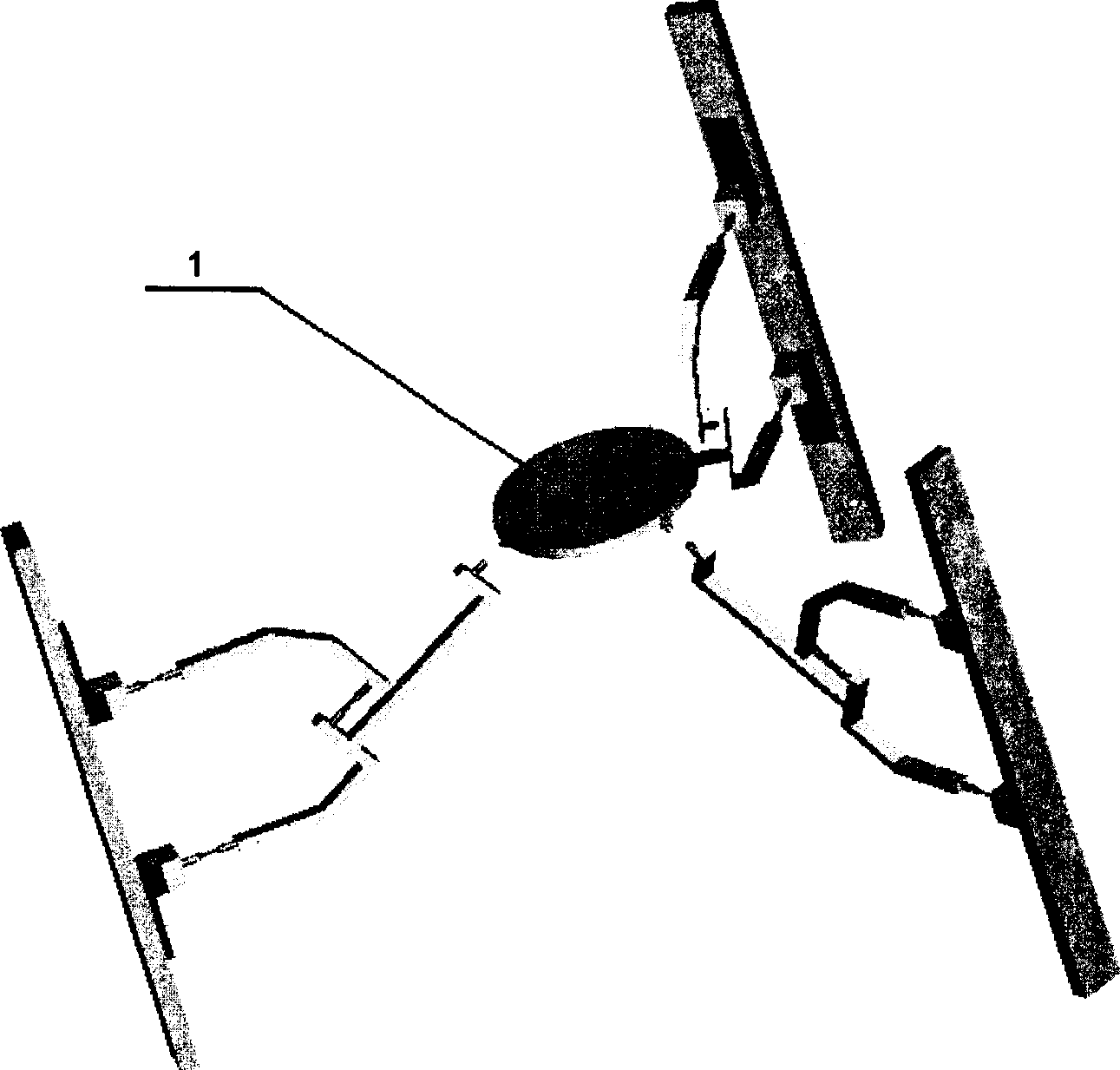

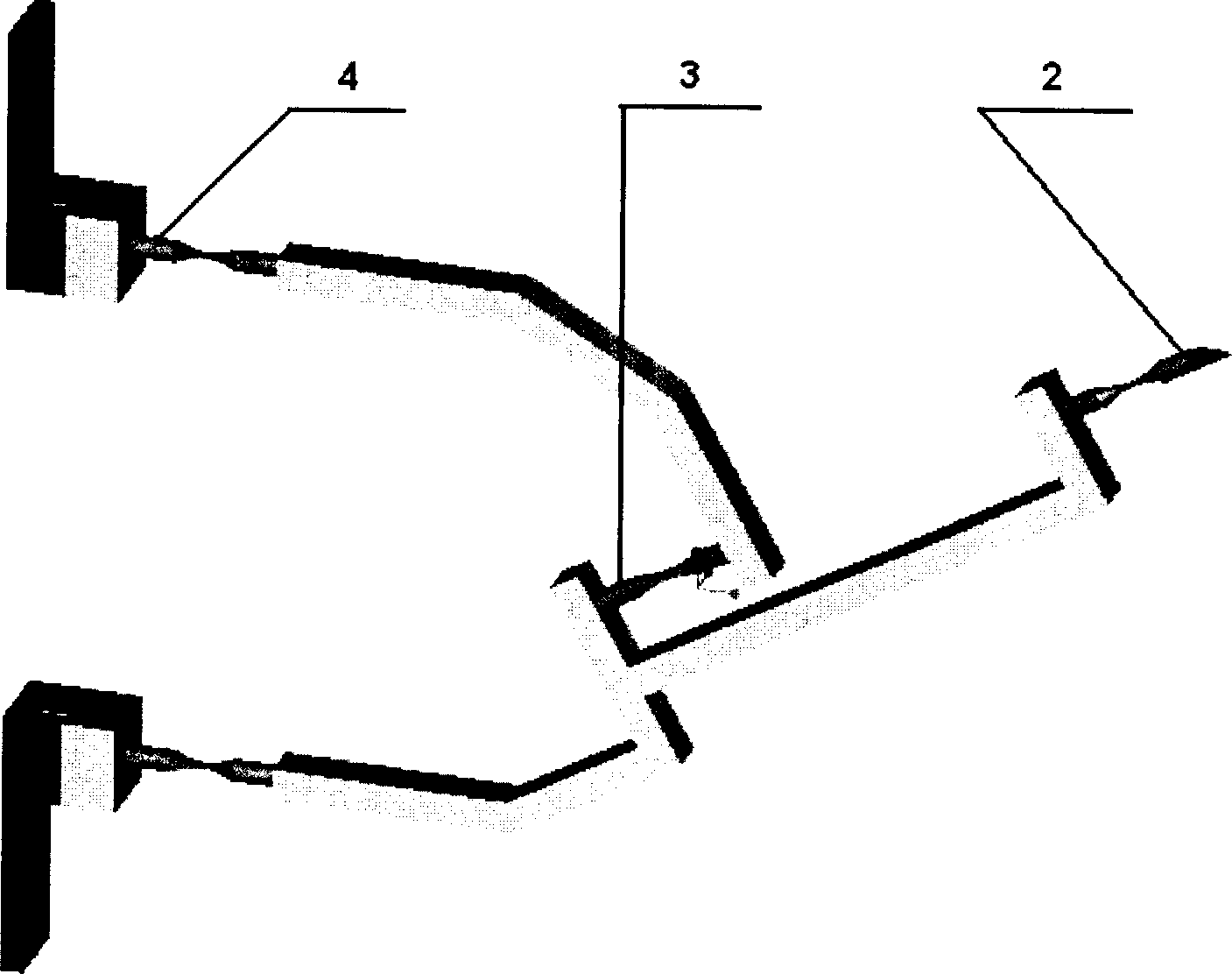

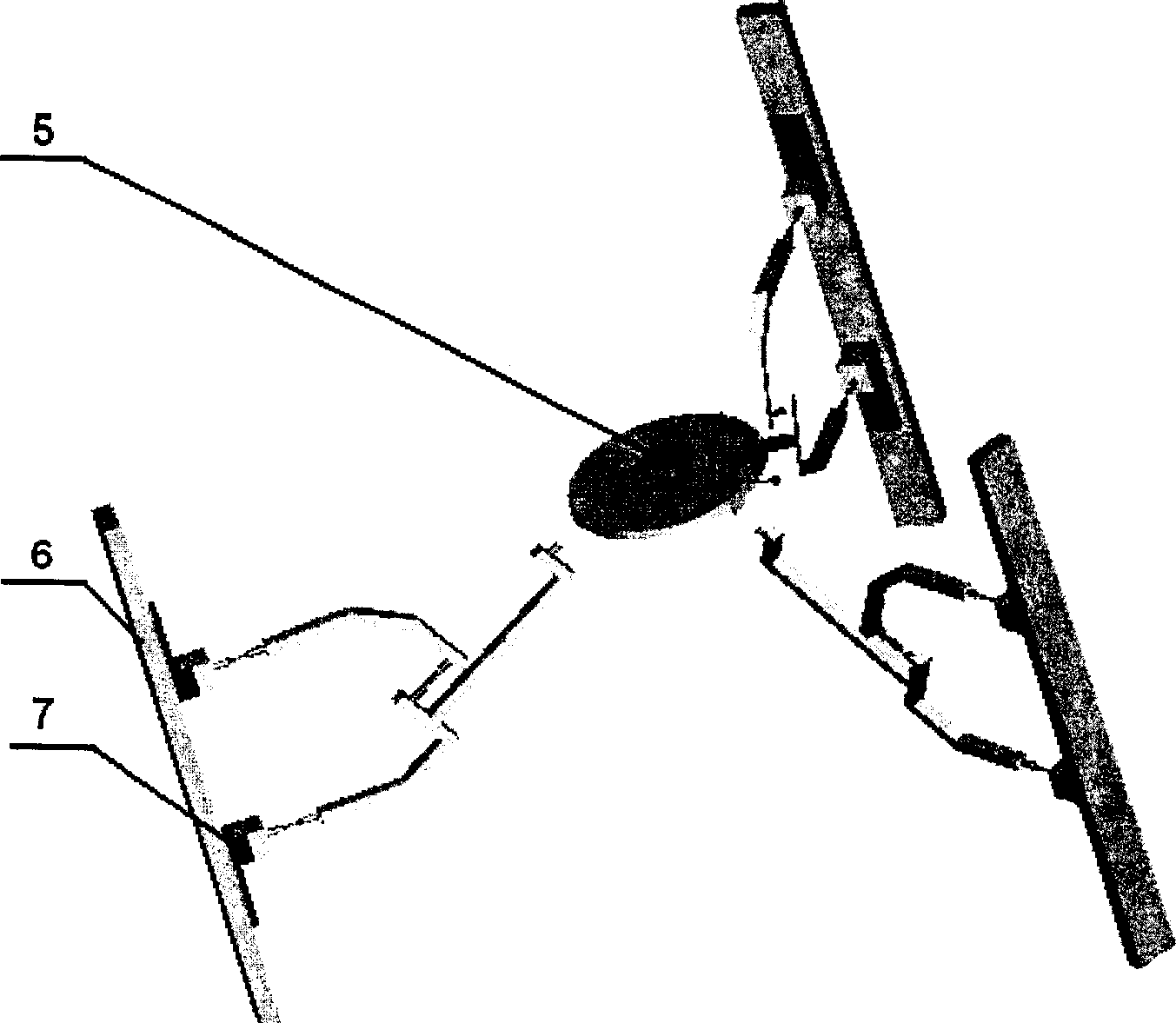

3-PPTTRS six freedom degree parallel precise jiggle robot

InactiveCN1788942AStraight line bigWide rangeMicromanipulatorLarge fixed membersImage resolutionRange of motion

The 3-PPTTRS six-freedom parallel precise micro robot consists of five parts, including a 3-PPTTRS mechanism, a flexible hinge pair, a hydrostatic screw-nut mechanism, a hydraulic oil supplier and an opened numerically controller. The robot has six freedoms, linear X, Y and Z motion range of 10 mmX10 mmX10 mm, linear resolution of 0.01 micromX0.01 micromX0.01 microm, rotation motion range of 10 degX16 degX10 deg, and rotation resolution of 0.023 degX0.055 degX0.023 deg, and is superior to available similar robots. The present invention has capacity of bearing great impact load, great weight load and relatively large precise installing range, combines the macro and micro motion system tightly, and has practical application value in micro displacement field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

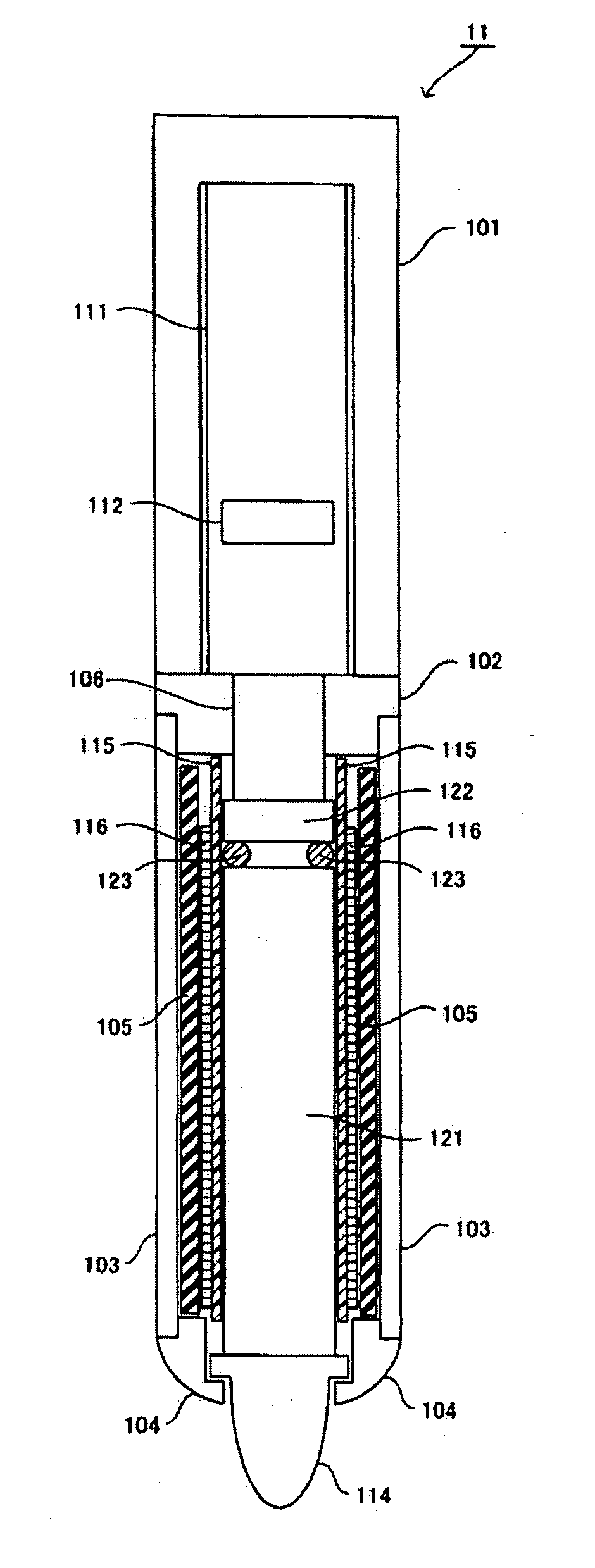

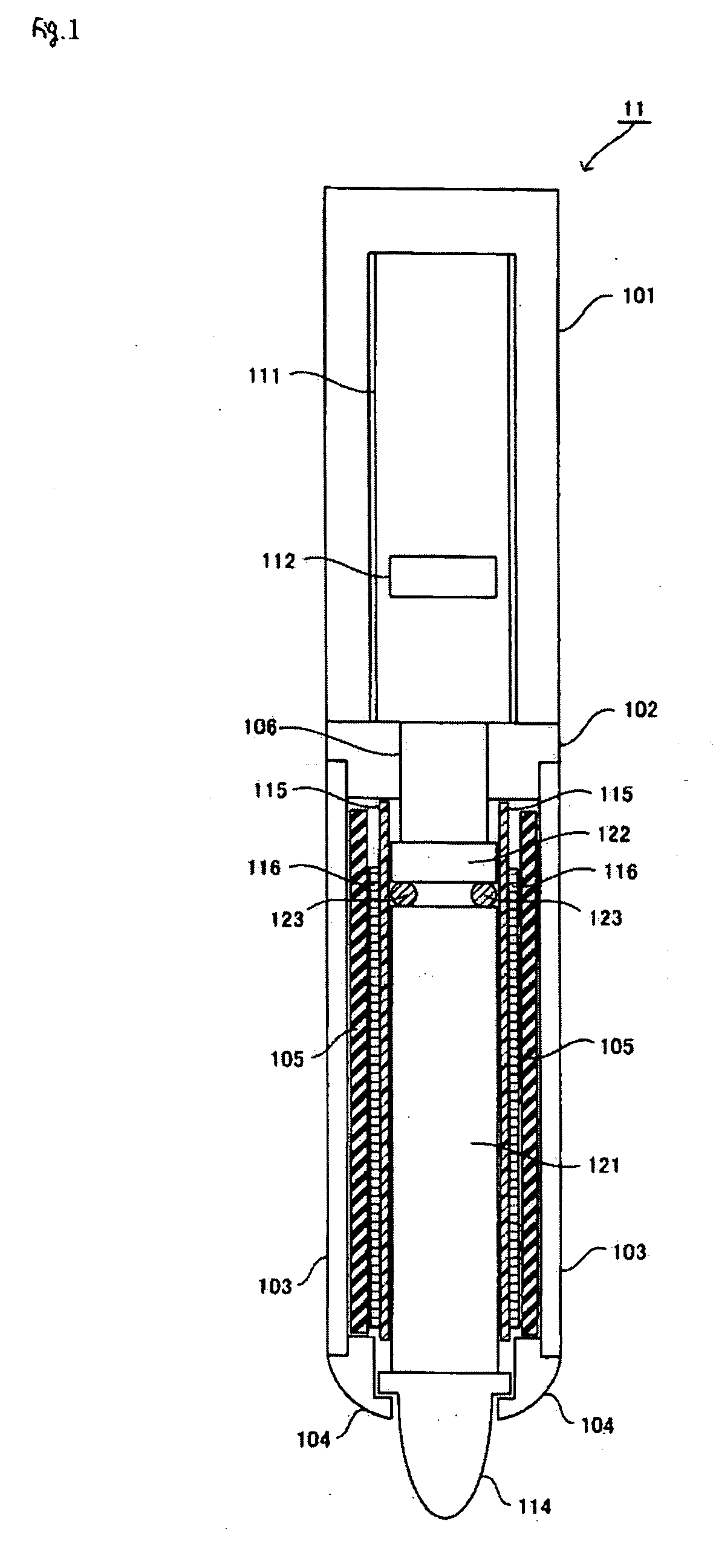

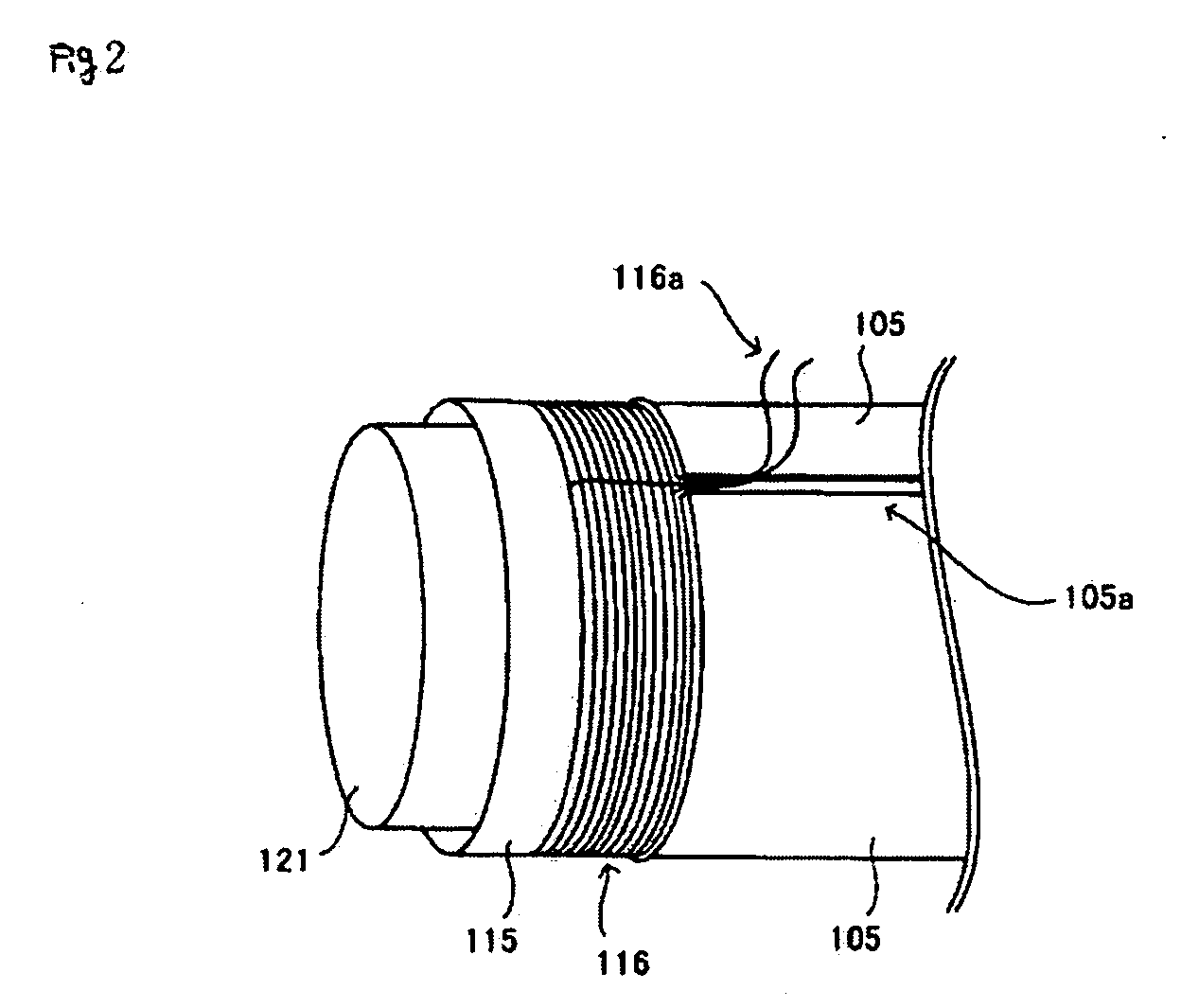

Coordinate indicator

InactiveUS20060060393A1High impact resistanceAvoid damageTransmission systemsGraph readingMagnetic coreInput device

In a coordinate indicator used for an input device of electronic equipment, to miniaturize the entire indicator as well as to secure resistance to impact and reliability by reducing components in size. A coordinate indicator includes a casing composed of an upper case, a substrate holder, a ceramic pipe, and an edge case; a center core, a ferrite core A moving together with the center core during operation, and a ferrite core B fixed to oppose the ferrite core A, which are accommodated within the casing. Around a tube accommodating part of the ferrite core A and the entire ferrite core B therein, a coated conducting wire is wound so as to form a coil.

Owner:WACOM CO LTD

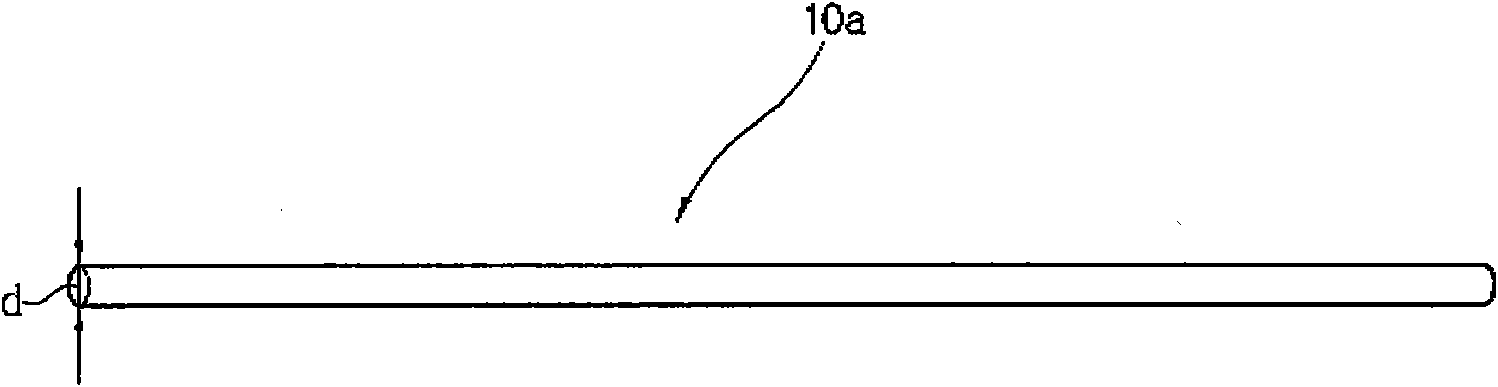

Bar antenna

ActiveUS20150116171A1High impact resistanceHigh outputLoop antennas with ferromagnetic coreAntenna adaptation in movable bodiesBobbinEngineering

A bar antenna comprises: a bar core configured to connect at least two of core pieces in series, a bobbin covering at least a portion of the bar core, a winding wound in a predetermined range of the bobbin, and a case having the bar core and the bobbin disposed therein, wherein the bar core and the bobbin are sealed by filling in the case with a potting material, and the bar core is configured to be bendable with respect to a predetermined external force at a connection portion of the at least two of core pieces.

Owner:MURATA MFG CO LTD

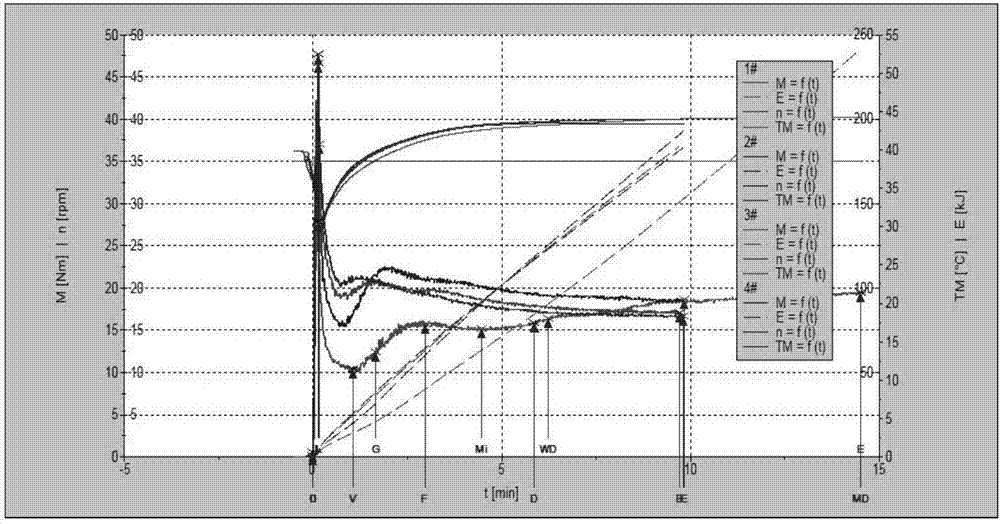

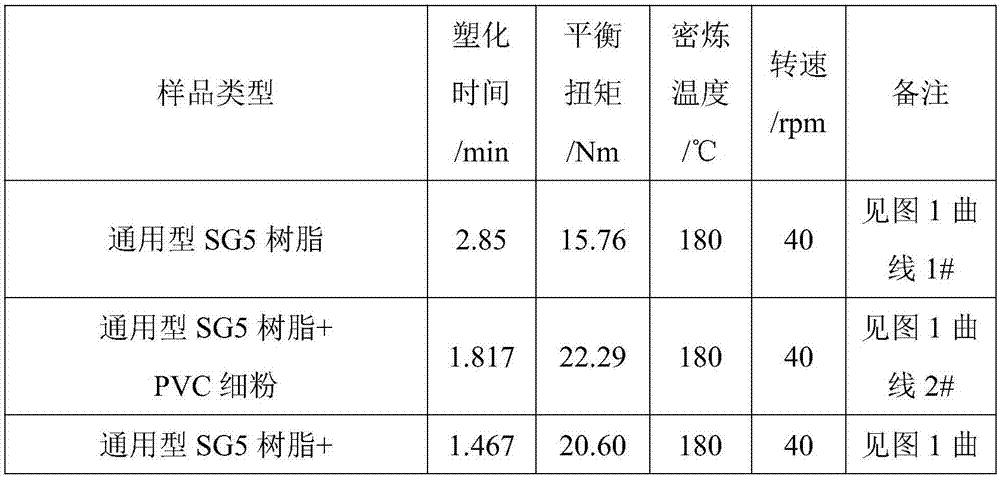

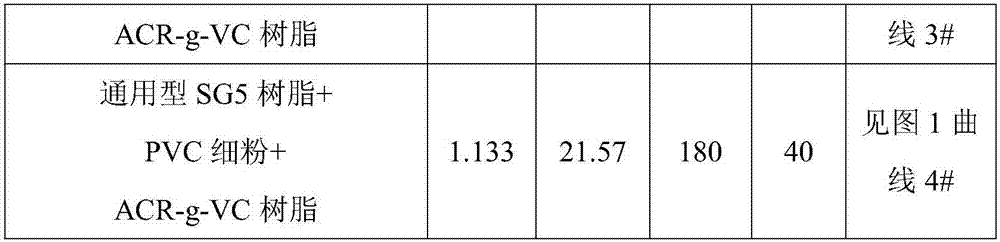

High-impact high-flowability PVC (polyvinyl chloride) formula and preparation method thereof

The invention discloses a high-impact high-flowability PVC (polyvinyl chloride) formula and a preparation method thereof. The high-impact high-flowability PVC formula is prepared from the following ingredients in parts by weight: 60 to 95 parts of PVC resin, 3 to 50 parts of ACR-g-VC resin, 3 to 15 parts of PVC fine powder, 2 to 5 parts of composite stabilizing agents, 0.5 to 2 parts of inner lubricating agents, 0.5 to 1 part of outer lubricating agents and 20 to 50 parts of calcium carbonate. A conventional extrusion process is used; low-polymerization-degree PVC fine powder and ACR-g-VC resin (chloroethylene-n-butyl acrylate graft copolymers) are added; the inner plasticization effects of low-polymerization-degree PVC resin and the chloroethylene-n-butyl acrylate graft copolymers is mainly utilized; the plasticization performance is improved in a cooperated way; the plasticization time is shortened; meanwhile, the anti-impact performance of the plastic product is obviously improved.

Owner:YIBIN TIANYUAN GRP CO LTD +1

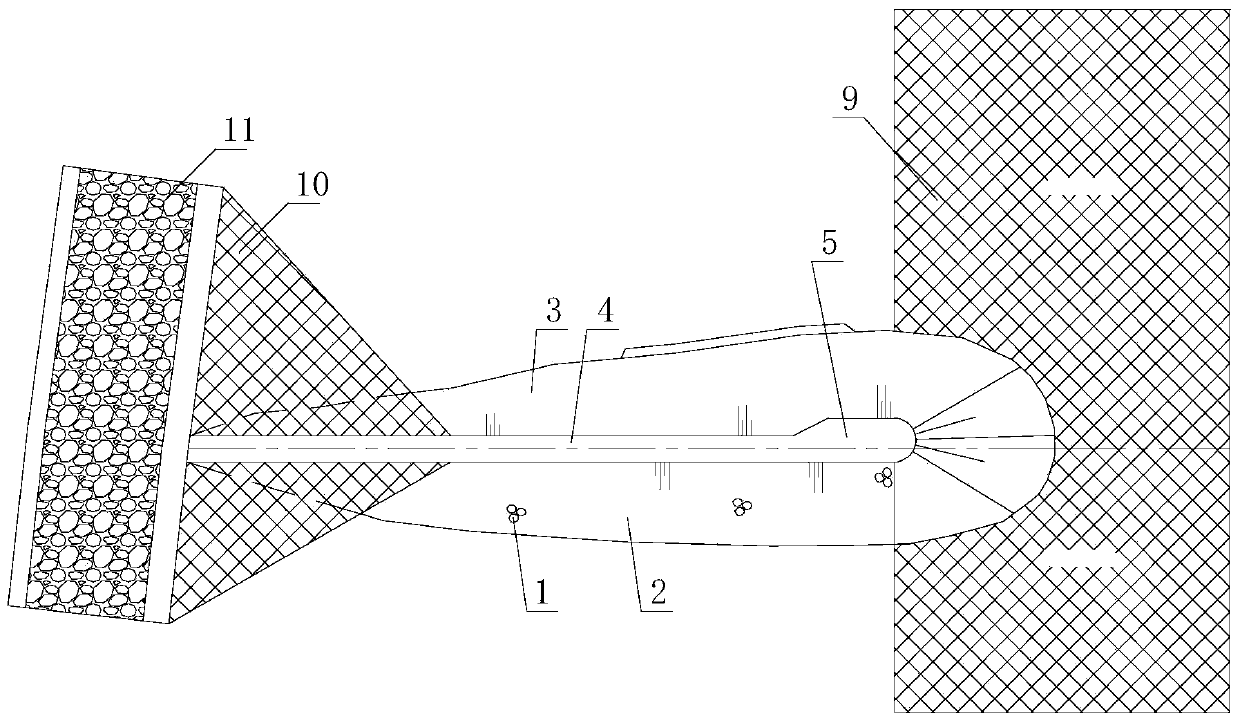

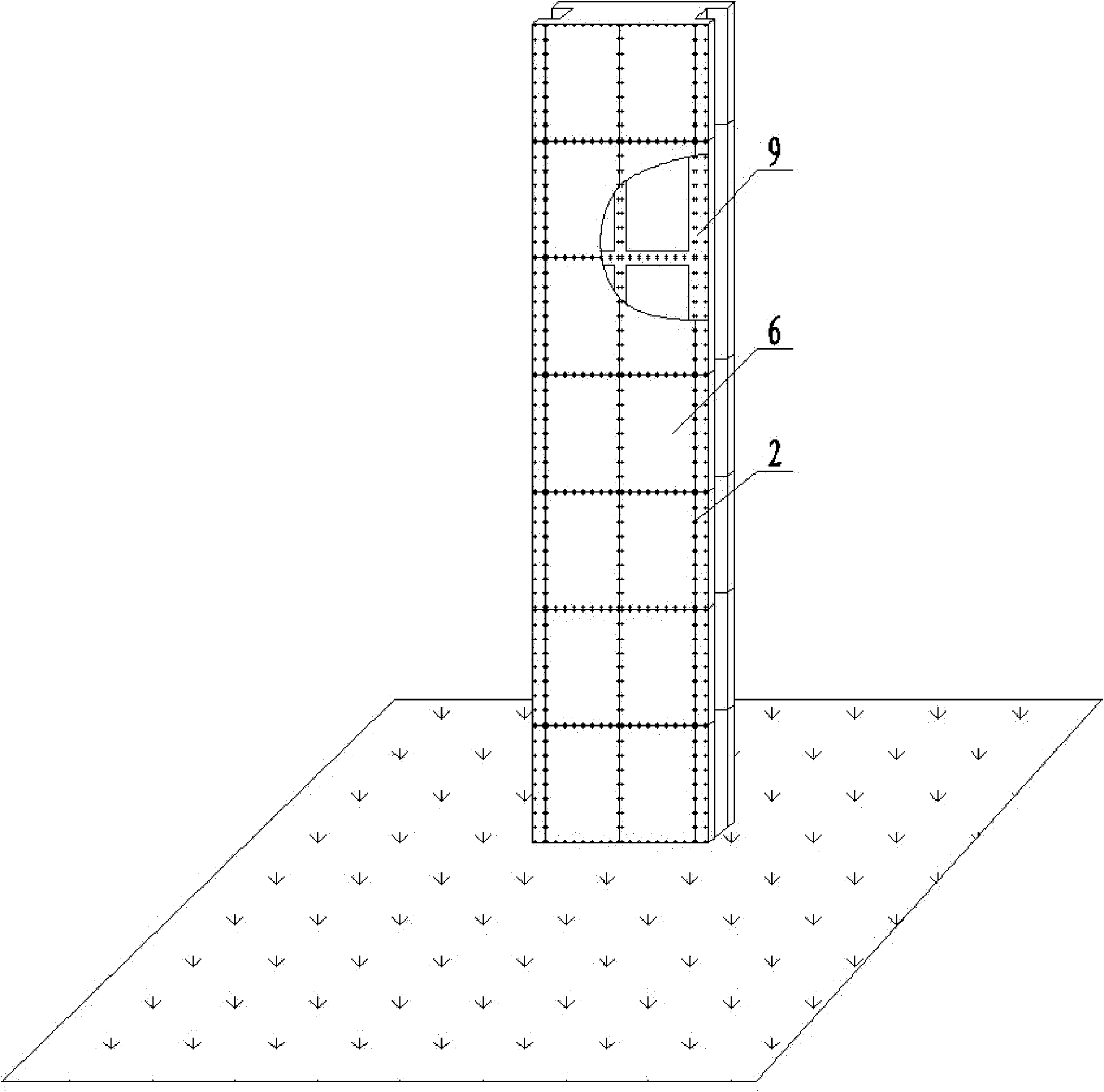

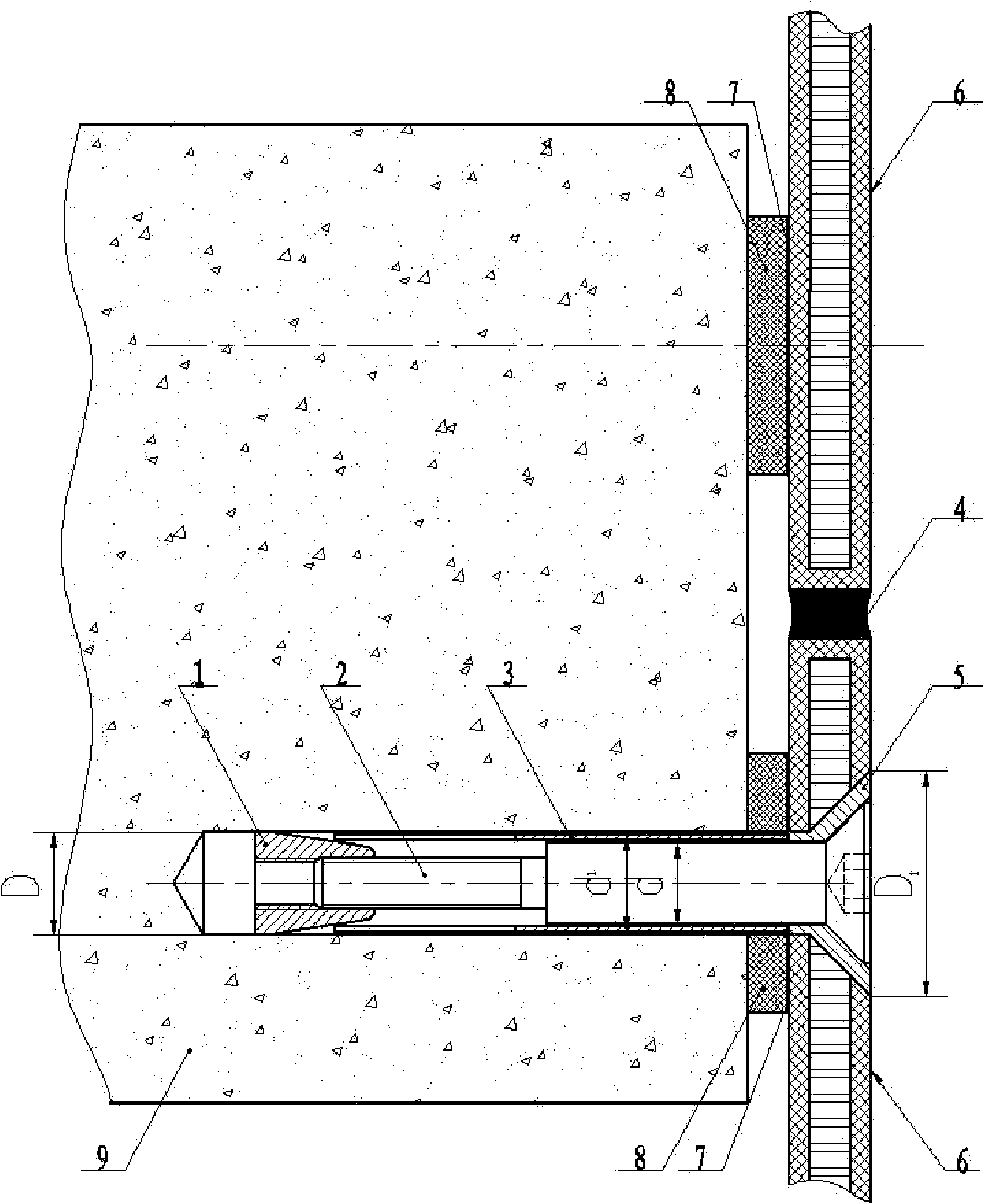

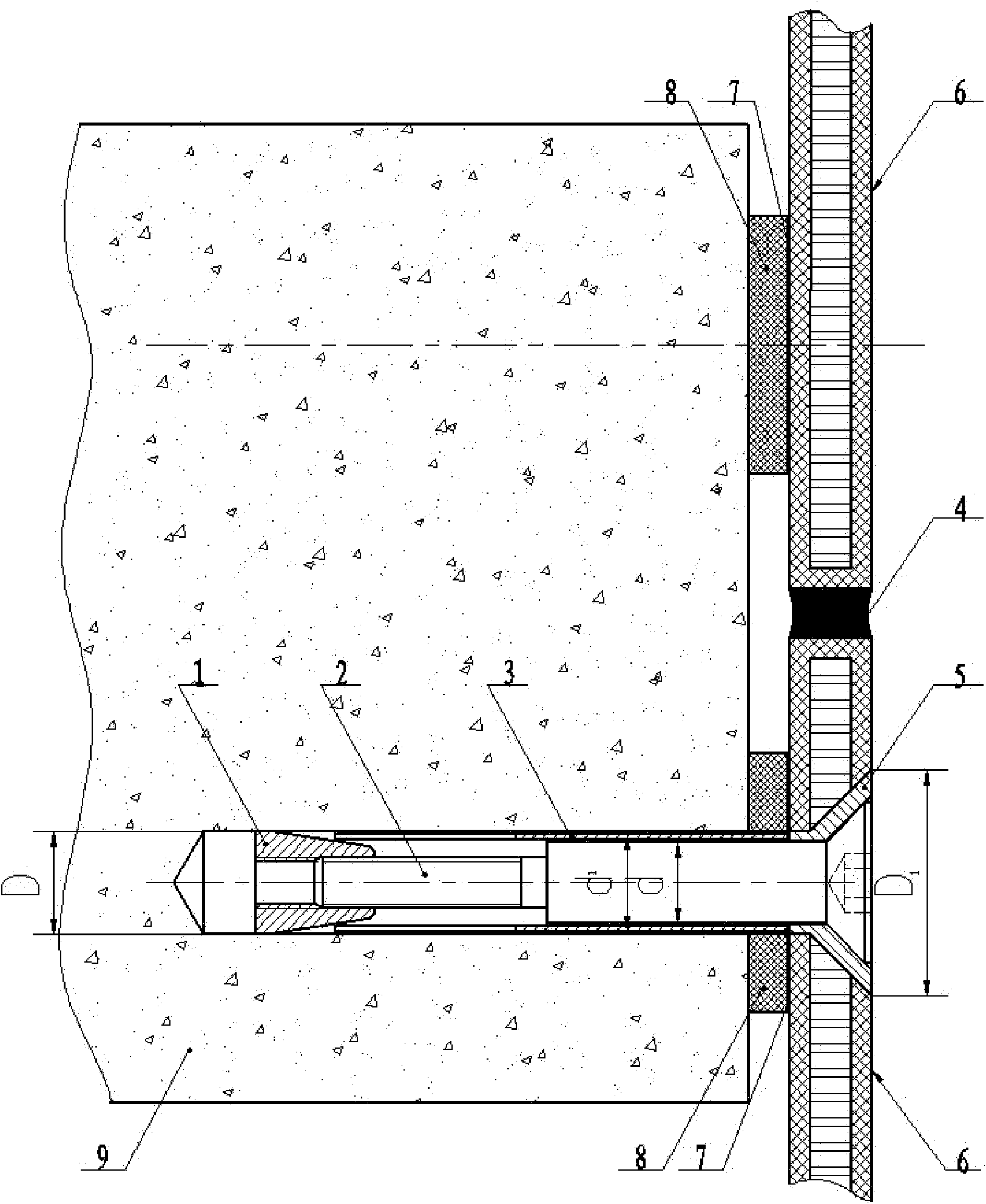

Method for improvement and protection of spur dike channel of mountain river

The invention discloses a method for improvement and protection of a spur dike channel of a mountain river. The method comprises the steps that (1) the channel improvement water level and the channel improvement line width are determined according to the direction of the channel, the planned line form, the hydrological characteristics of the river, the riverbed components and the erosion and deposition evolution characteristic, and (2) the position and the length of a spur dike are determined according to the shipping hindering characteristic of a dangerous shoal and the improvement line width. The method for improvement and protection of the spur dike channel of the mountain river is characterized by further comprising the steps that (3) a dike body structure is laid, wherein a layer of block shaped like the twisted Chinese character 'Wang' is laid on the downstream slope of a dike body; (4) the bottom of the head of the dike is protected; (5) the bottom of the root of the dike is protected; (6) a bank protection structure is arranged. The method is particularly suitable for improvement and protection of the spur dike channel of the mountain river, the strength of the root of the dike and the strength of the head of the dike can be improved, stronger current impact force can be resisted, the overall service life is prolonged, and the method has the advantages of being capable of preventing sediment accumulation, stabilizing a riverbed, protecting the ecological environment and achieving safe flood discharging.

Owner:长江重庆航运工程勘察设计院

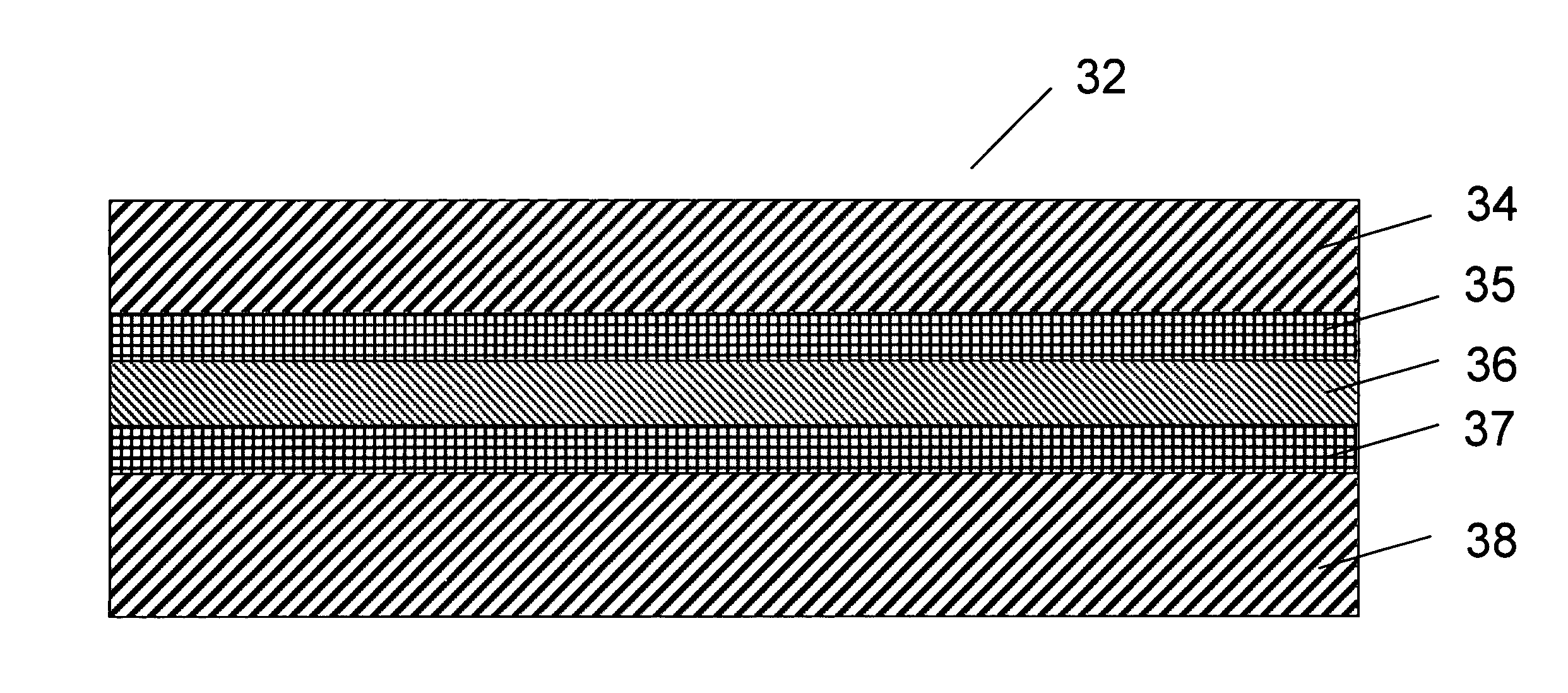

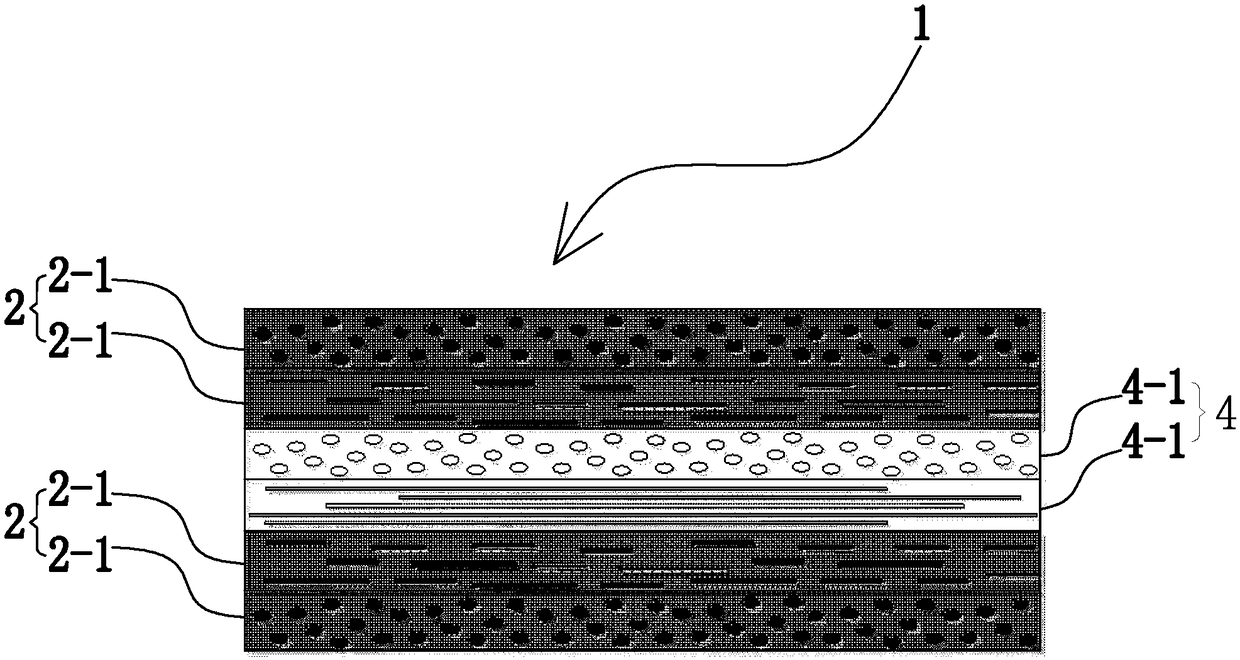

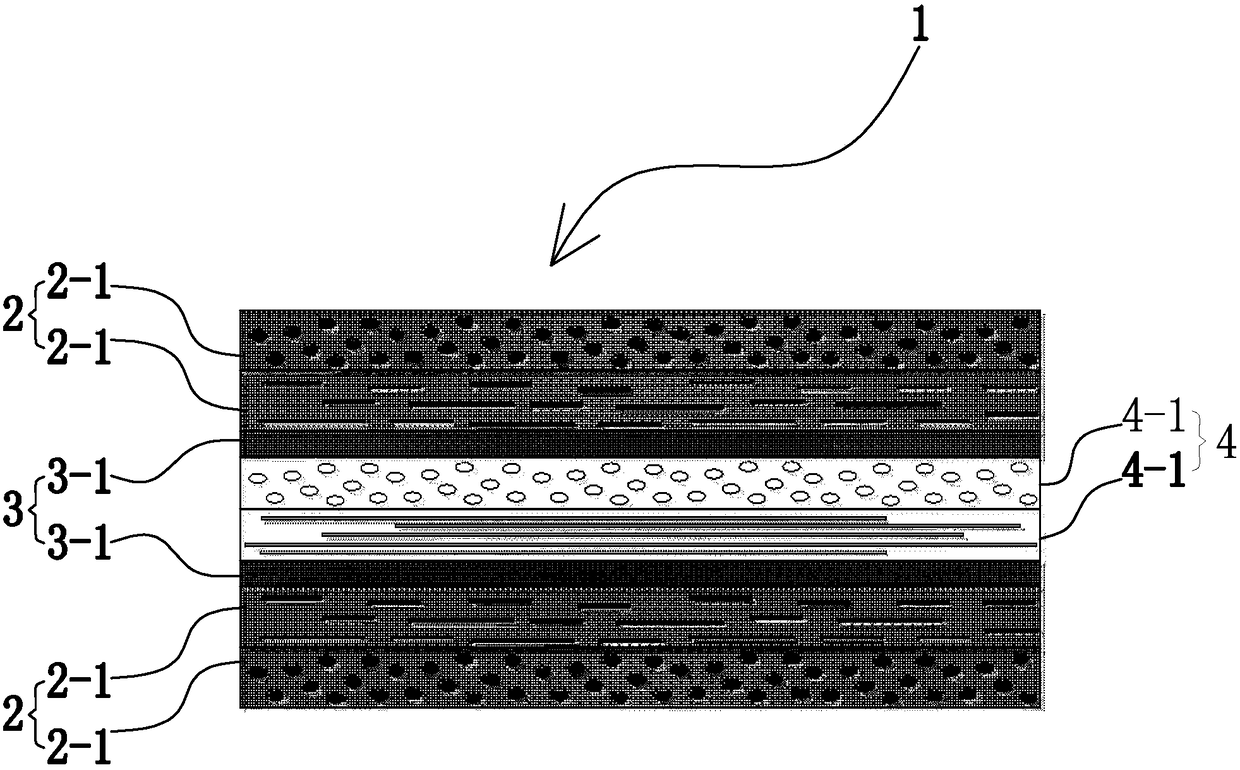

Lightweight high-impact-resistance high-modulus multilayer composite board easy in thermal forming and preparation method thereof

InactiveCN108407421ALightweight impactHigh modulusSynthetic resin layered productsFiber-reinforced compositeLarge size

The invention relates to a lightweight high-impact-resistance high-modulus multilayer composite board easy in thermal forming. The lightweight high-impact-resistance high-modulus multilayer compositeboard comprises a composite board body, and the composite board body is composited by composite lamination boards of a two-layered or multilayered structure. The lightweight high-impact-resistance high-modulus multilayer composite board has the advantages that a lightweight impact-resistant ultrahigh-molecular-weight polyethylene layer and a fiber reinforced thermoplastic composite material are combined, and the large-size board can be prepared through hot pressing; the composite board has the high strength and high impact resistance of the ultrahigh-molecular-weight polyethylene and the lightweight and high modulus of the rigid fiber reinforced composite material; meanwhile, due to the fact that the used rigid fibers are chopped fibers or long fibers, good forming performance under a heating and pressurizing condition is achieved.

Owner:嘉兴领科材料技术有限公司

Toughening polythene-polylactic acid composition

The invention relates to a toughening polyethylene-polylactic resin combination which comprises polyethylene, polylactic resin and an impact modifier. The impact modifier comprises a copolymer impact modifier composed of monomers (a), (b) and (c), wherein, the (a) is ethylene and the (b) is a kind or many kinds of alkene with a general formula CH2=CR<1>, wherein, the R<1> is an alkyl which comprises 3 to 9 carbon atoms like propyl, butyl or amyl; the (c) is a type or many types of alkene with a general formula CH2=C(R<2>)CO2R<3>, wherein, R<2> is hydrogen or an alkyl which comprises 1 to 5 carbon atoms like methyl and R<3> is glycidyl. The combination is characterized by favorable impact resistance and tractility, higher rigidity and being environmentally-friendly.

Owner:江苏英纳新材料有限公司

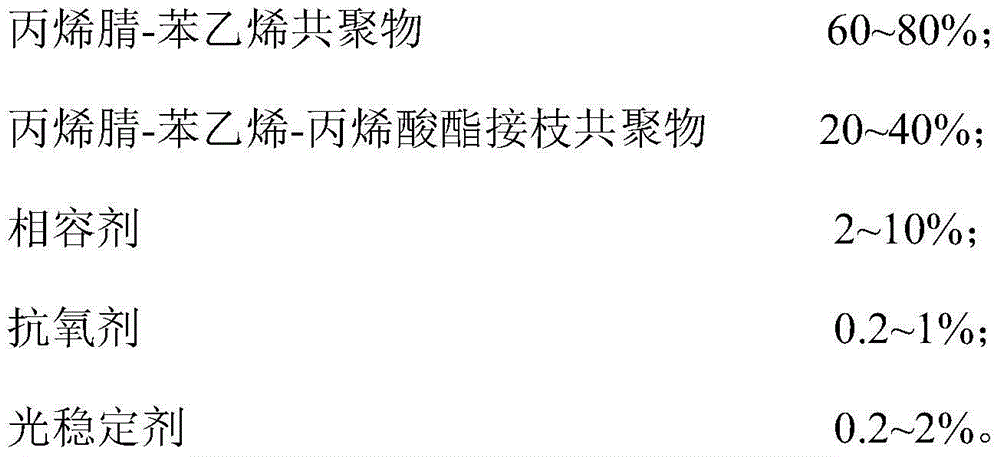

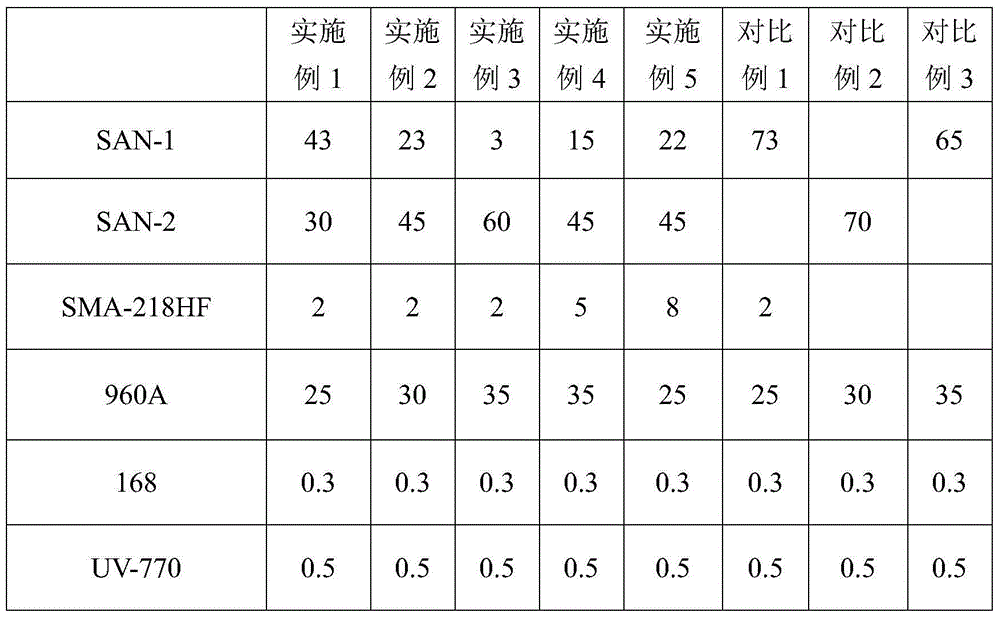

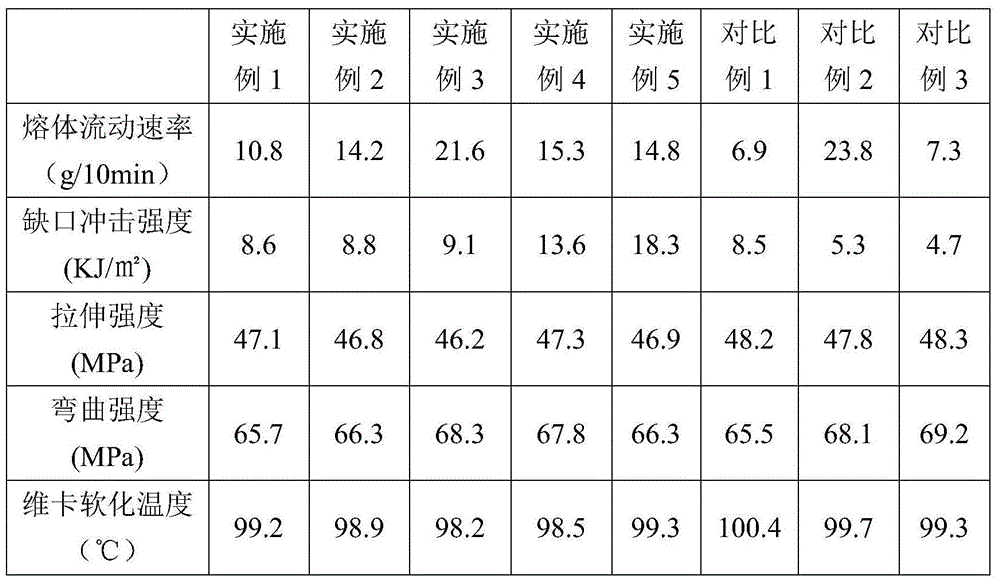

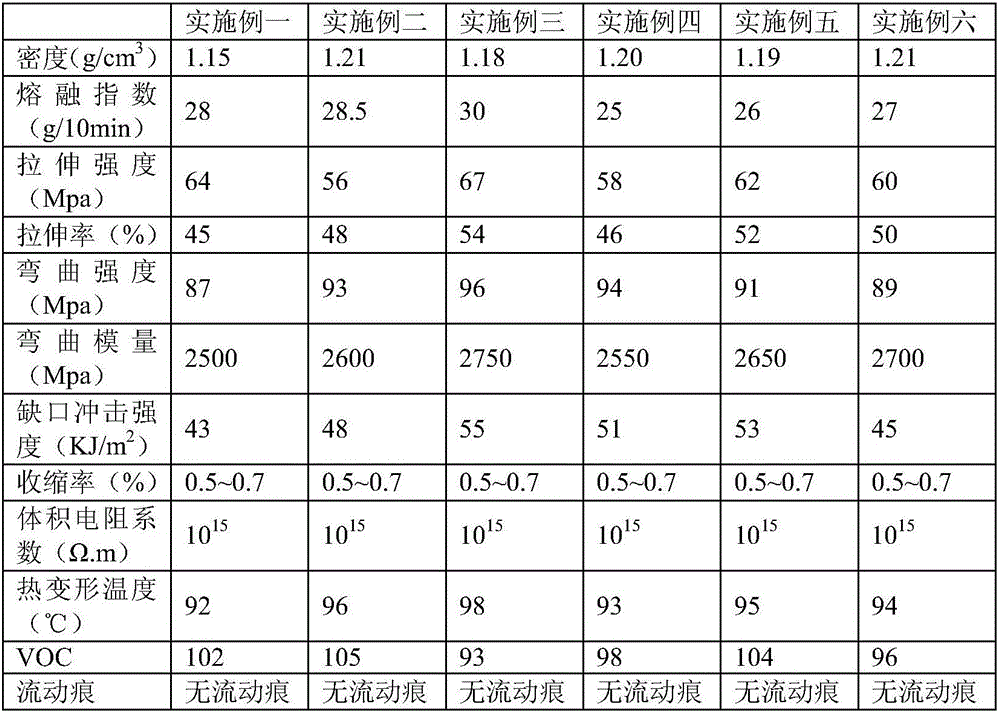

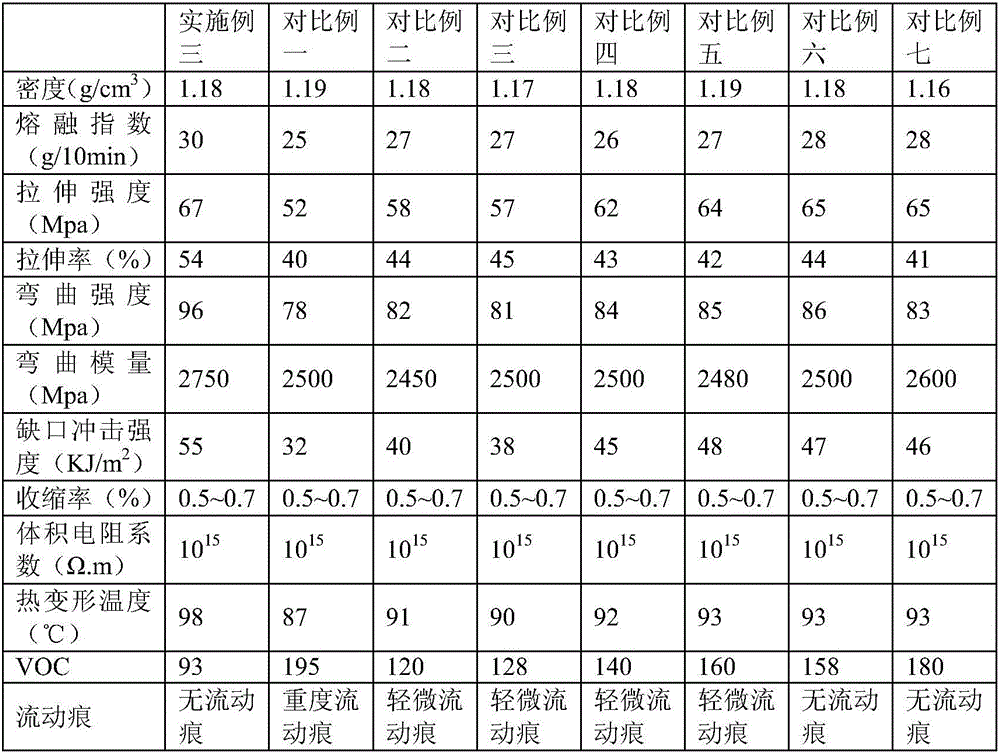

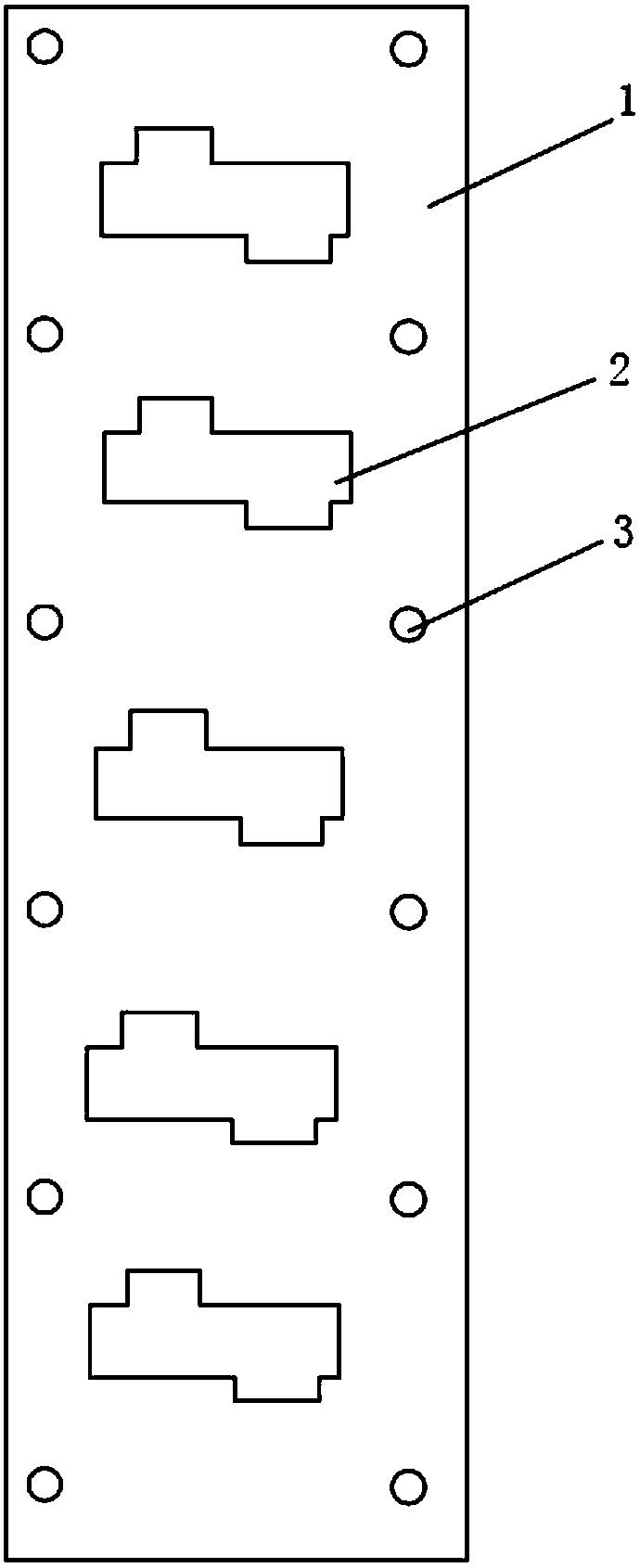

High- fluidity and high-impact ASA material and preparation method thereof

The invention discloses a high-fluidity and high-impact ASA material and a preparation method thereof and belongs to the field of polymer composite materials. The ASA material comprises the following raw materials in percentage by weight: 60-80% of an acrylonitrile-styrene copolymer, 20-40% of an acrylonitrile-styrene-acrylate graft copolymer, 2-10% of a compatibilizer, 0.2-1% of an antioxidant and 0.2-2% of a light stabilizer. The ASA material prepared by the preparation method has high impact performance and good processing fluidity, is easy to fill molded large-size abrasive tools and can be widely applied to interior and exterior decorative parts of automobiles and parts of electronic electric appliances.

Owner:SHANGHAI PRET COMPOSITES +2

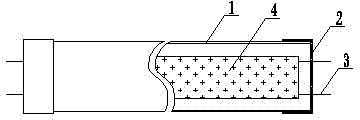

Fluorescent tube type neon light

InactiveCN102818213ASimple structureEasy to producePoint-like light sourceElectric circuit arrangementsFlexible circuitsDaylight

The invention relates to a fluorescent tube type neon light and belongs to the technical field of decorative lighting. The fluorescent tube type neon light comprises a tube casing, tube bases and electrodes. The tube bases are arranged at two ends of the tube casing, the electrodes are arranged on the tube bases, flexible circuit boards are arranged in the tube casing, beads are welded to the flexible circuit boards, two ends of each flexible circuit board are provided with an anode connector and a cathode connector which are connected with the electrodes, and a light-dispersing glue layer is arranged on an inner wall of the tube casing. The two flexible circuit boards are arranged back to back. The light-dispersing glue layer is a transparent silica gel layer mixed with artificial crystal, the tube casing is a transparent plastic pipe, and the beads are red, yellow, green, verdant, blue, purple and white. The fluorescent tube type neon light is simple in structure, easy to produce and manufacture, low in cost and convenient to use, and can not only be used for families, but also be used for shops, wineshops and pubs and the like. The advantages of a light-emitting diode (LED) light source are fully utilized, aeration is not required, a glass casing is not required, and the fluorescent tube type neon light is good in impact resistance, not easy to break, convenient to transport, wide in using range, high in light-emitting efficiency, energy-saving, electricity-saving, long in service life, uniform and soft in light color and rich and bright in color.

Owner:单文龙

PC/ABS (polycarbonate/acrylonitrile butadiene styrene) alloy and preparation process thereof

The invention discloses a PC / ABS (polycarbonate / acrylonitrile butadiene styrene) alloy and a preparation process thereof, and solves the problem that the mechanical property and the processability of the PC / ABS alloy still cannot be obviously improved. The key point of the technical scheme is that the PC / ABS alloy is prepared from the following components in parts by mass: 45 to 65 parts of PC, 35 to 45 parts of ABS, 4 to 10 parts of MBS, 2 to 5 parts of ABS-g-MAH, 2 to 5 parts of SMA, 0.1 to 0.5 part of PC-g-SMA, 0.1 to 0.5 part of PC-g-ABS, 0.5 to 1.5 parts of PET, 1 to 2 parts of black master batch, 3 to 5 parts of an adsorbent, 2 to 4 parts of an antibacterial agent, 0.1 to 0.5 part of an antioxidant and 0.5 to 1.0 part of a chemical deodorant. The PC / ABS alloy achieves the effect of improving the mechanical property and the processability of the PC / ABS alloy.

Owner:南京跃贝新材料科技有限公司

Thermoplastic Resin Composition

InactiveUS20080108750A1High impact resistanceImprove impact resistancePharmaceutical non-active ingredientsWater soluble polymersWeather resistance

An object of the present invention is to propose a novel thermoplastic resin composition having high impact resistance without degrading weather resistance even when the content of an impact modifier is small. A thermoplastic resin composition includes 100 parts by weight of a thermoplastic resin (a) and 0.5 to 20 parts by weight of an impact modifier (b) containing a graft copolymer (b-1) containing at least one (meth)acrylate flexible polymer phase and a rigid polymer phase serving as the outermost part of the graft copolymer, a water-soluble polymer compound (b-2) having a physical gel-forming property, and a gelling agent (b-3). In the thermoplastic resin composition, the content of the water-soluble polymer compound (b-2) having the physical gel-forming property is 0.01 to 3.0 parts by weight relative to 100 parts by weight of the graft copolymer (b-1) and the content of the rigid polymer phase serving as the outermost part in the graft copolymer (b-1) is 0.5 to 10 percent by weight.

Owner:KANEKA CORP

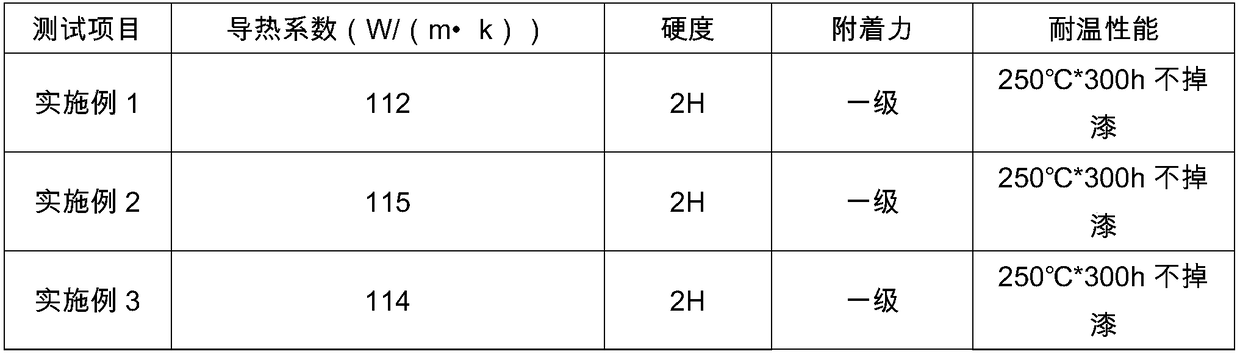

Heat dissipating ink and heat dissipating shield case preparation method

The invention relates to the technical field of heat dissipating materials, particularly to heat dissipating ink and a heat dissipating shield case preparation method, wherein the heat dissipating inkcomprises the following raw materials by weight: 60-80 parts of a polyimide modified epoxy resin, 30-45 parts of a polyvinyl chloride resin, 50-65 parts of a thermally conductive filler, 25-40 partsof a radiation heat-dissipating filler, 10-15 parts of a coupling agent, 10-15 parts of an anti-precipitation agent, 8-12 parts of a leveling agent, 15-26 parts of a pigment filler, 50-60 parts of a solvent, and 35-46 parts of a curing agent. The heat dissipating ink of the present invention has advantages of excellent heat dissipation performance, good dielectric property, good thermal stability,good toughness and good aging resistance.

Owner:GUANGDONG HERUN PRECISION METAL MATERIALS CO LTD

Invisible connected composite plate curtain wall

InactiveCN102121287ALightweight and high strengthImpact resistantWallsBuilding material handlingSingle plateLandscape structure

The invention belongs to a building enclosure, and particularly relates to an invisible connected composite plate curtain wall. The composite plate can be manufactured into an oversized unit plate with the same size as a building framework structure, mounting holes are uniformly distributed on the periphery of the plate, and a main body structure is also provided with holes matched with the mounting holes; by adopting a specially designed countersunk head expansion bolt group, the installation operations are all finished on the outer side, and invisibility of curtain wall connectors is realized; and an elastic adjusting shim plate (adjusting shim plate) between the composite plate and the main body structure can make certain adjusting compensation for unevenness of the main body structure. Compared with a glass curtain wall, the invisible connected composite plate curtain wall has the predominant advantages of light weight, high strength, impact resistance, large single plate area, connecting assembly invisibility, regular surface, bright color, safety, reliability, long service life, convenience in construction, high cost performance and the like. The curtain wall and the connecting structure thereof can be applied in the fields of landscape structures, curtain walls of framework structural buildings, enclosures and other similar decorations, and have broad application prospect.

Owner:秦皇岛耀华装备集团股份有限公司

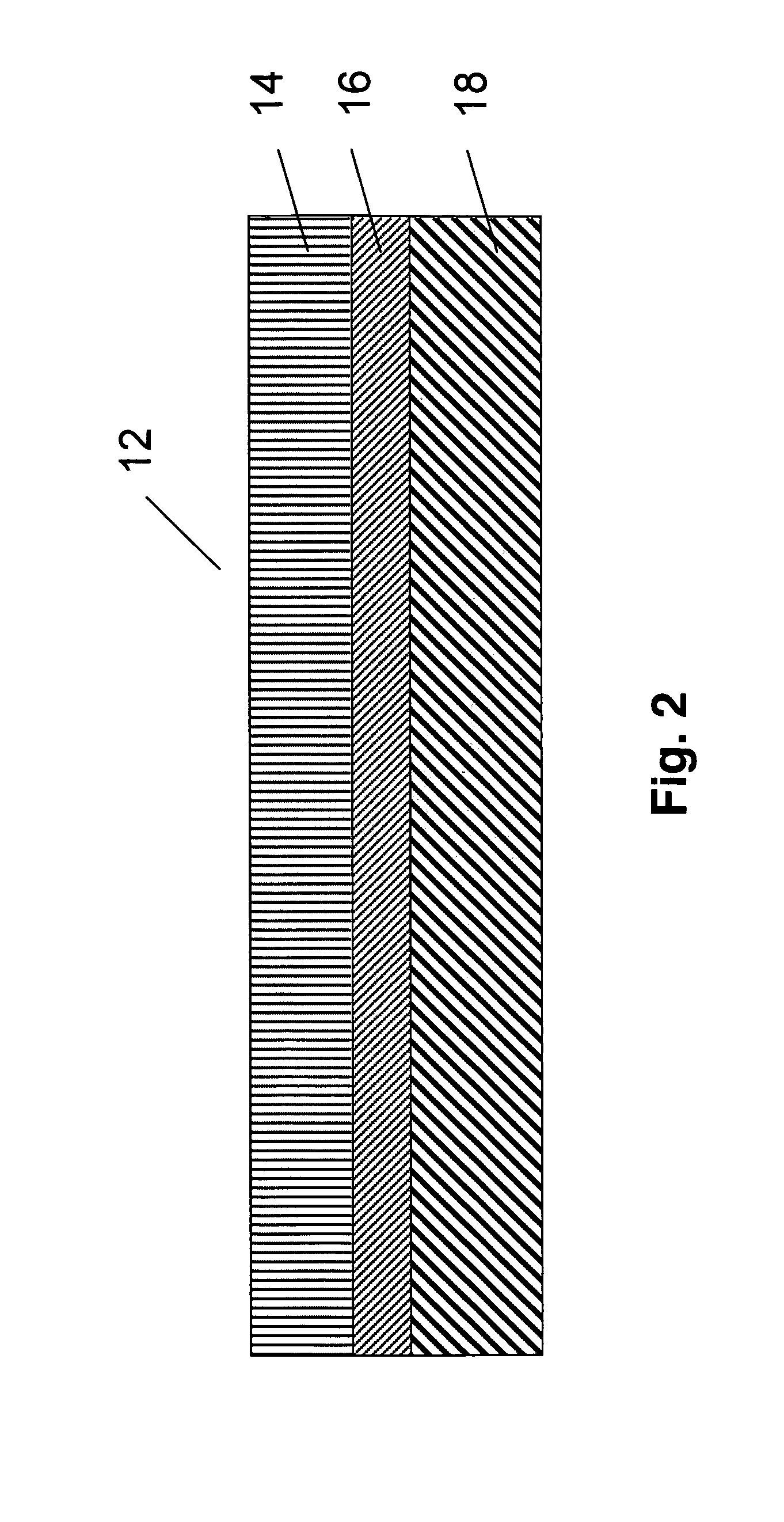

Composite material having solar cell and production method thereof

ActiveCN102431255AHigh impact resistanceLight in massSynthetic resin layered productsPhotovoltaic energy generationFiber layerVacuum pumping

The invention relates to a composite material having a solar cell for producing automobile components and a production method thereof. The composite material comprises a plurality of layers which are laminated layer upon layer and connected with each other, wherein, the layers successively comprise a high transparent resin adhesive layer and an enhancement layer from top to bottom, the solar cell is buried in the high transparent resin adhesive layer or embedded in the bottom surface. The composite material has the advantages of light weight, high strength, and low cost. The method for producing the composite material effectively and rapidly comprises the following steps: spraying a layer of glue on the surface of a die by using a high transparent resin adhesive; putting the solar cell in the die; spraying a layer of the adhesive on the superficial layer of the die again; paving carbon fibers or carbon fabrics in the die; pasting an adhesive sealant on the periphery and inner side of the die; successively paving a demolding cloth, a flow conducting cloth, and a vacuum bag film on the surface of the carbon fiber layer, and arranging a flow conducting pipe; carrying out vacuum pumping on the die, and detecting the degree of vacuum by using a leak detector; absorbing a common resin adhesive; after infiltrating the carbon fibers by the common resin adhesive and solidifying, molding a product.

Owner:CHERY AUTOMOBILE CO LTD

Highly-impact-resistant anti-static reinforced PC composite material

InactiveCN104419168AHigh impact resistanceHigh tensile strengthStatic performanceElectrical performance

The invention discloses a highly-impact-resistant anti-static reinforced PC composite material. The highly-impact-resistant anti-static reinforced PC composite material is prepared from the following components in percentage by mass: 60%-90% of PC resin, 5%-10% of an impact-resistant modifier, 2%-5% of anti-static master batches, 5%-20% of a reinforcing agent, 2%-5% of a compatilizer, 0.1%-0.5% of an antioxidant and 0.1%-2% of a lubricant. Compared with the prior art, the PC composite material has the advantages such as high anti-impact efficiency, good tensile strength, high elongation at break, good gloss and mobility, and strong processing adaptation while keeping the excellent physical, chemical and electrical performances of PC. Moreover, the highly-impact-resistant anti-static reinforced PC composite material has excellent anti-static performance, has surface resistance of 10<8-10> ohm, and has good application prospect in the fields such as electronics, cars and mechanical parts.

Owner:QINGDAO XINZHAN PLASTIC

Impact-resistant thermally-conductive polymer material and preparation method thereof

The invention discloses an impact-resistant thermally-conductive polymer material and a preparation method thereof. The polymer material comprises the following components in parts by weight: 8-22 parts of polycarbonate, 4-8 parts of styrene butadiene rubber, 3-7 parts of polyethylene glycol adipate, 3-6 parts of polytetrafluoroethylene, 2-7 parts of polyvinyl acetate, 4-8 parts of polybutadiene epoxy resin, 2-5 parts of trioctyl phosphate, 1-4 parts of tungsten carbide, 2-5 parts of chromium carbide and 3-8 parts of magnesium stearate. The preparation method comprises the following steps: (1) pulverizing tungsten carbide and chromium carbide; (2) sequentially adding the components into a high speed mixer, and mixing uniformly; (3) performing melting on the mixed components obtained in the step (2), performing mechanical extrusion on the melted mixed components in a double-screw extrusion manner, pelleting, and cooling to obtain the product. The prepared polymer material is excellent in impact strength and thermal conductivity.

Owner:苏州凯欧曼新材料科技有限公司

Lining board using of multi-layer fiber sheet

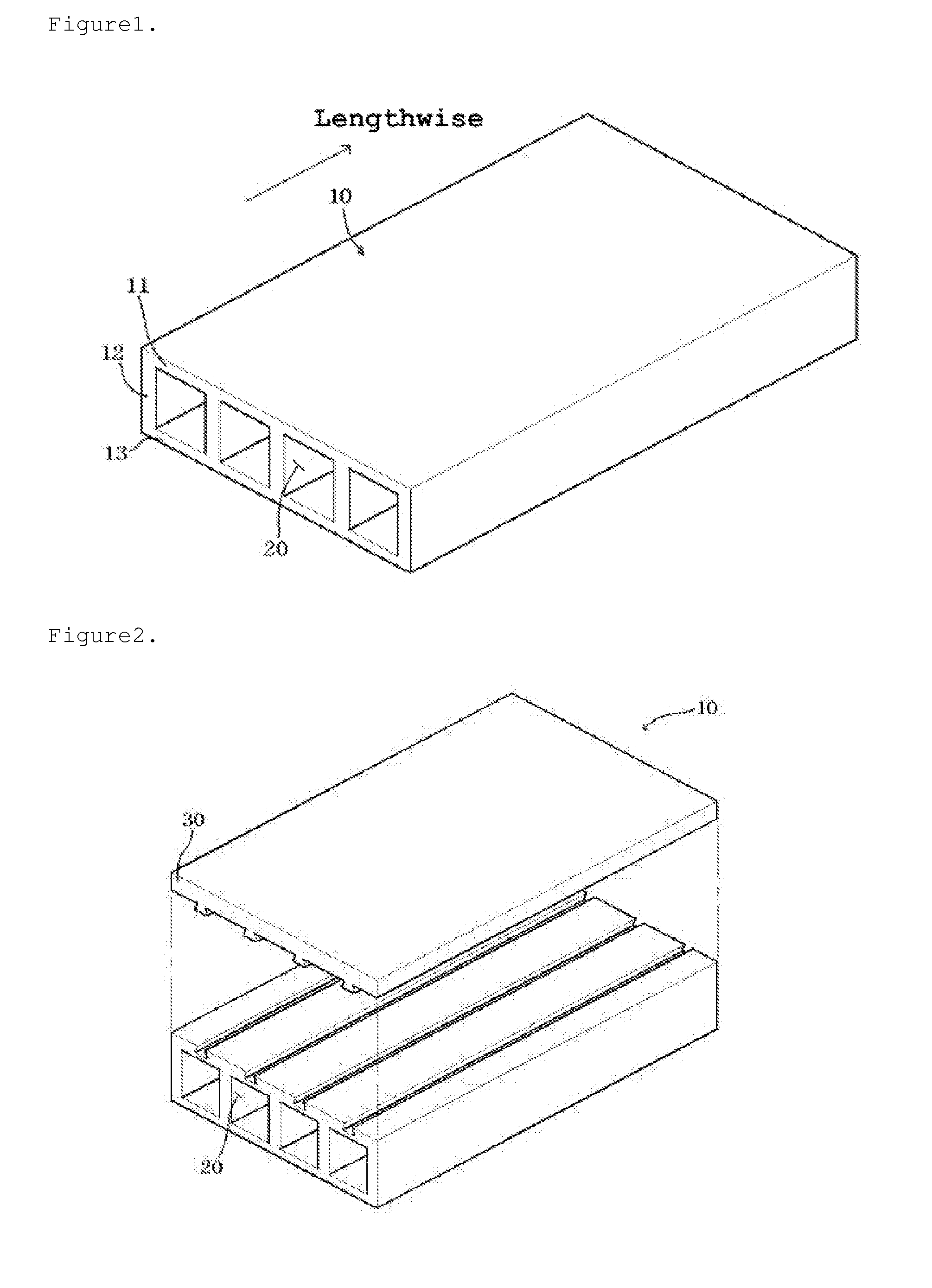

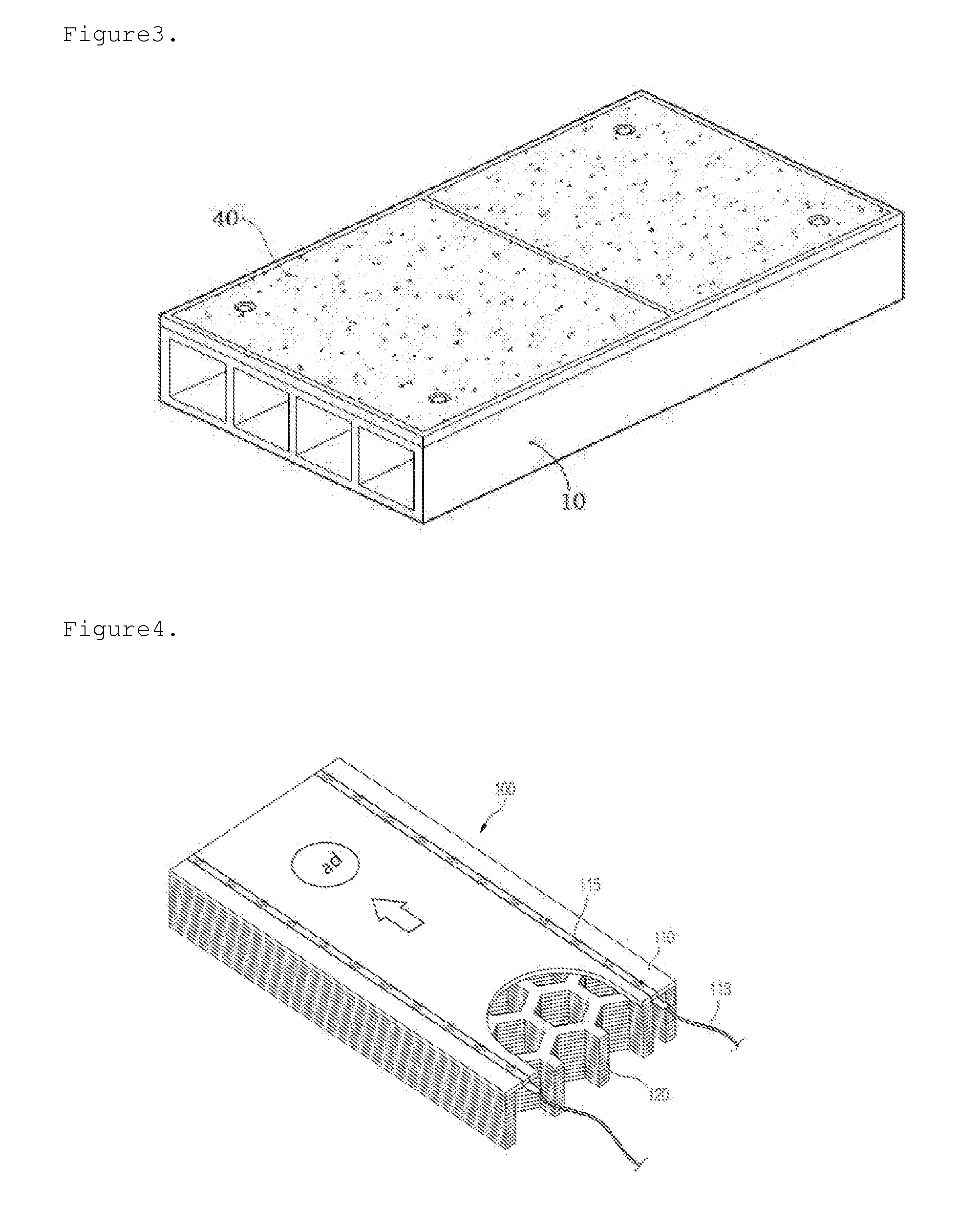

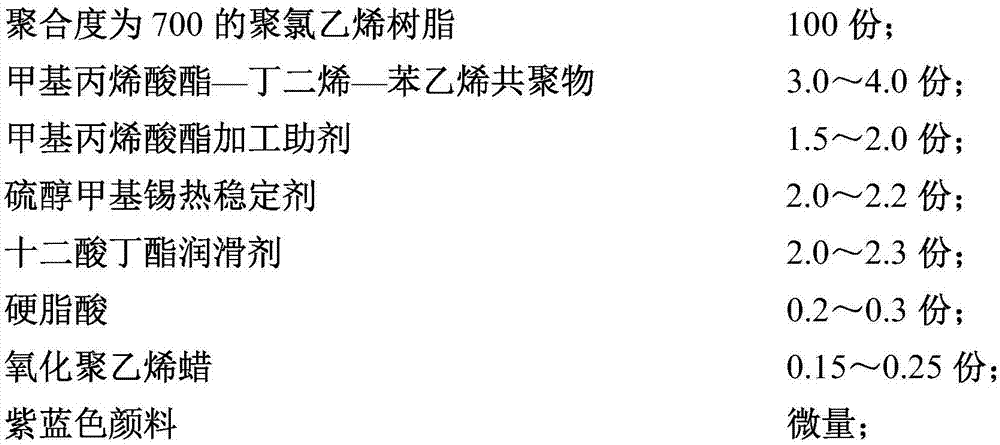

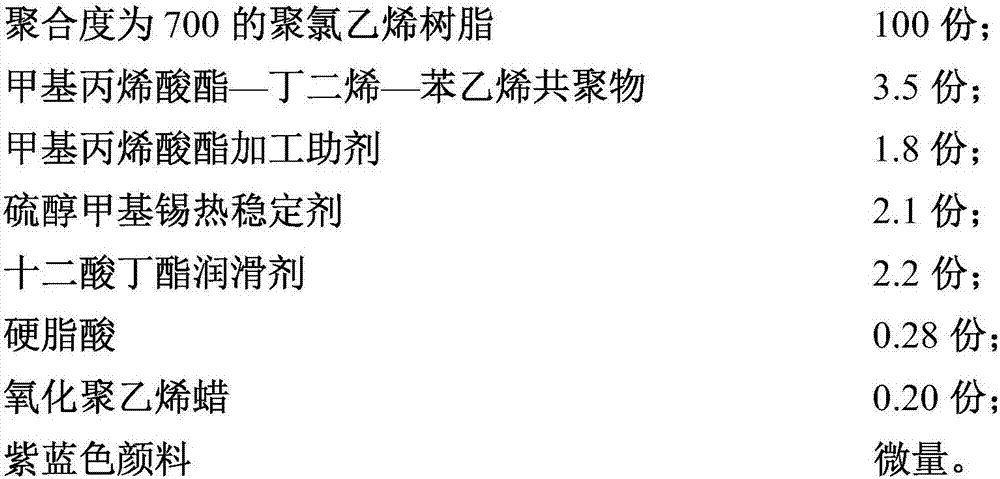

InactiveUS20130058089A1High impact-resistanceHigh noise-proofingPoint-like light sourceLighting support devicesHoneycomb structureEngineering

A lining board includes: a plate-like support structure which is made of a multi-layered fiber sheet and has a plurality of hollows; and an upper plate which is attached to the top of the support structure and has a plurality of LED leading lightings formed on the top of the upper plate. The honeycomb-structured lining board including fiber sheets stacked with a predetermined thickness has advantages of lightness, high impact-resistance and high noise-proofing due to high sound absorptiveness.

Owner:IND ACADEMIC COOPERATION FOUND KEIMYUNG UNIV

PVC (polyvinyl chloride) pellets special for ultrahigh-transparency hard medical injection molding apparatuses

ActiveCN107141646AImprove thermal stabilityTransparency has little effectMethacrylateProcedure Agents

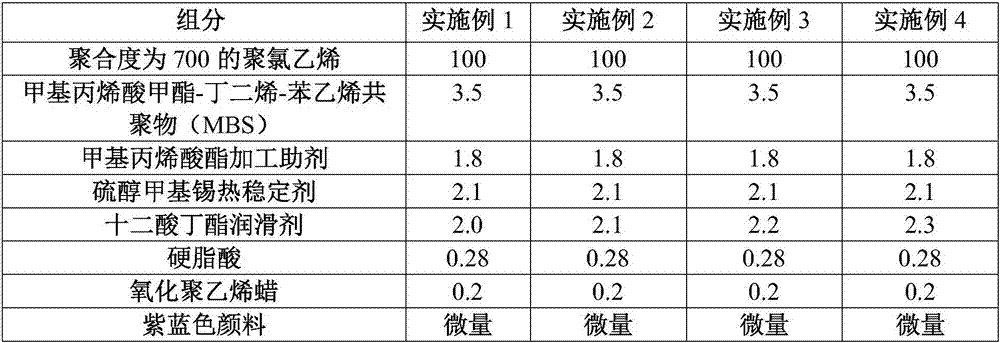

The invention discloses PVC (polyvinyl chloride) pellets special for ultrahigh-transparency hard medical injection molding apparatuses. The PVC pallets comprise, by weight, 100 parts of polyvinyl chloride resin with the degree of polymerization being 700, 3.0-4.0 parts of methacryIate-Butadiene-Styrene copolymer, 1.5-2.0 parts of methacrylate processing aid, 2.0-2.2 parts of methyltin mercaptide heat stabilizer, 2.0-2.3 parts of butyl dodecanoate lubricant, 0.2-0.3 part of stearic acid, 0.1-0.25 part of oxidized polyethlene wax and trace indigo pigment. The finished products are prepared by means of feeding the components into a high-speed heating mixer according to the proportion for high-speed mixing, performing kneading to the temperature of 123-125 DEG C prior to discharging, putting the discharged material into a low-speed cooling mixer to be cooled to room temperature to obtain mixed powder, feeding the mixed powder into a pelletizer for pelletizing, and cooling the pellets to the temperature lower than 40 DEG C prior to packaging. The medical injection molding apparatuses made of the PVC pellets have ultrahigh transparency and surface glossiness.

Owner:WUXI JIAHONG PLASTICS TECH

High impact resistance ultraviolet curing coating combination and use method thereof

InactiveCN103555187AHigh impact resistanceImprove yieldPolyurea/polyurethane coatingsPolyester coatingsMethacrylatePolyester

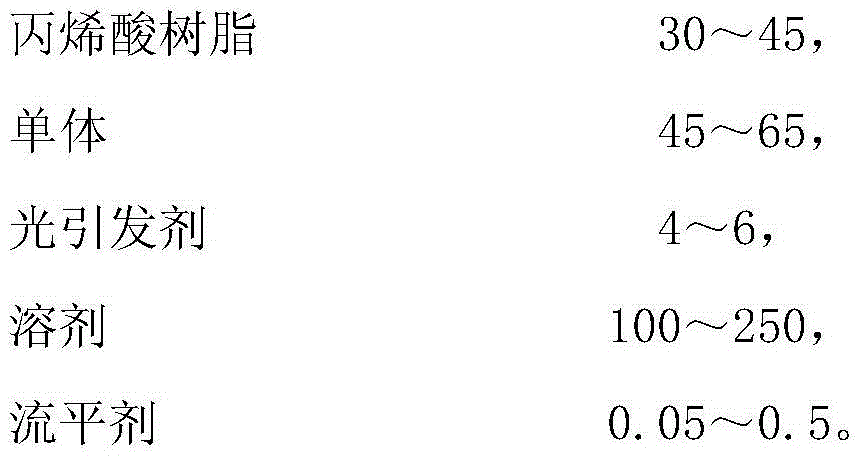

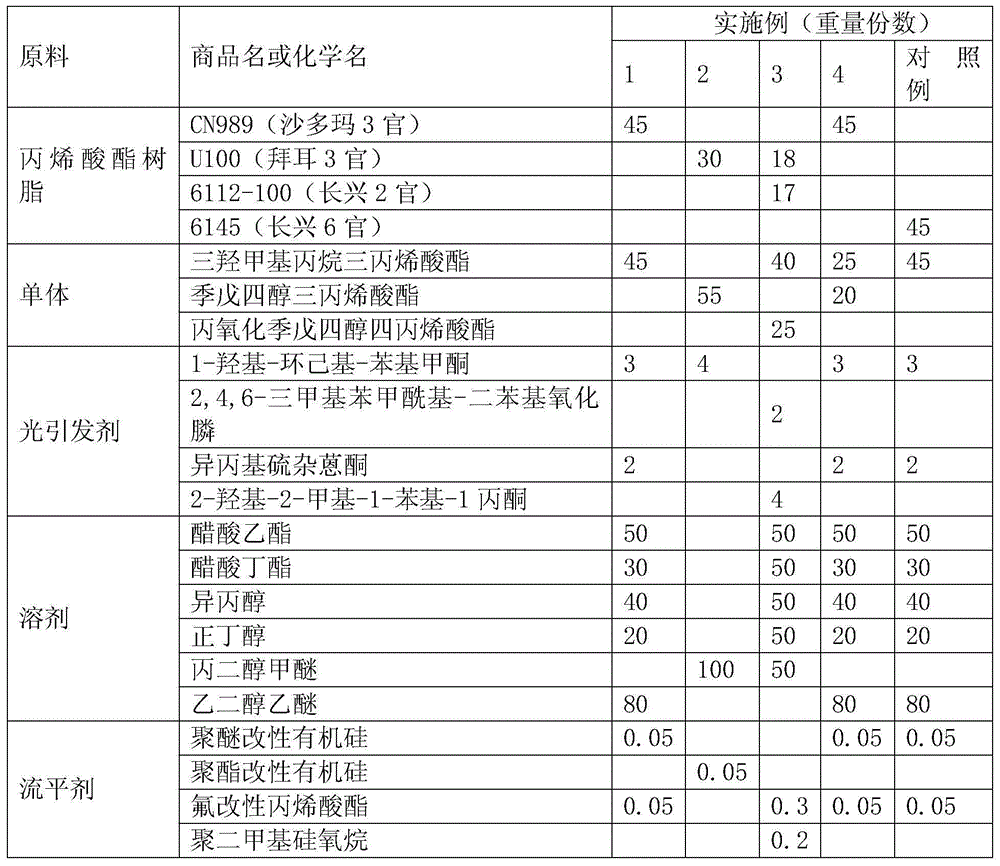

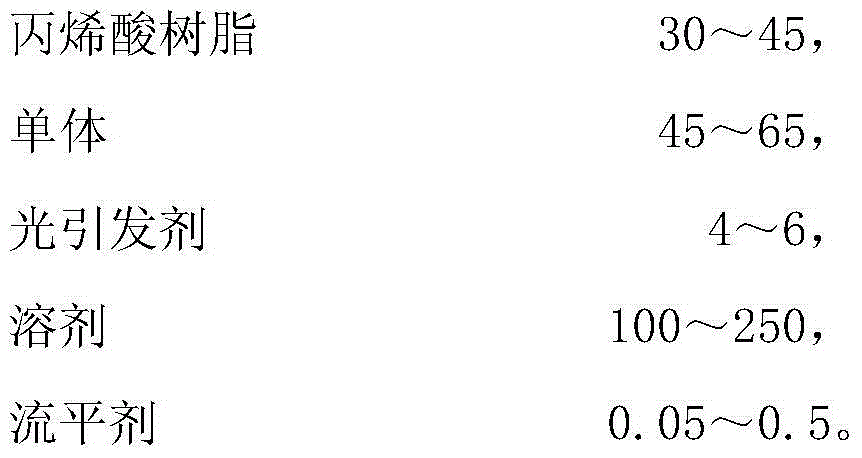

The invention discloses a high impact resistance ultraviolet curing coating combination and a use method thereof, and the high impact resistance ultraviolet curing coating combination comprises the following components: by weight, 30 ~ 45 parts of acrylic resin, 45 ~ 65 parts of a monomer, 4 ~ 6 parts of a light initiator, 100 ~ 250 parts of a solvent and 0.05 ~ 0.5 part of a levelling agent. The acrylic resin is one or a plurality of resin from low-functionality-degree aliphatic polyurethane acrylate resin, aliphatic polyester acrylate resin, aliphatic polyurethane methacrylate resin and aliphatic polyester methacrylate resin. Compared with the prior art, the impact resistance of the combination is increased to 11.3 g * 100CM compared with that of the glass, and compared with the glass, the finished product rate in subsequent cutting and carving processes is increased, and the cost is reduced.

Owner:SHANGHAI WEIKAI CHEM +1

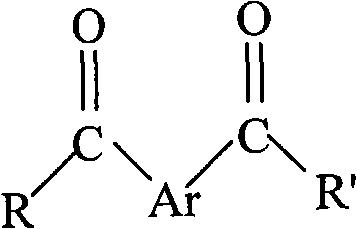

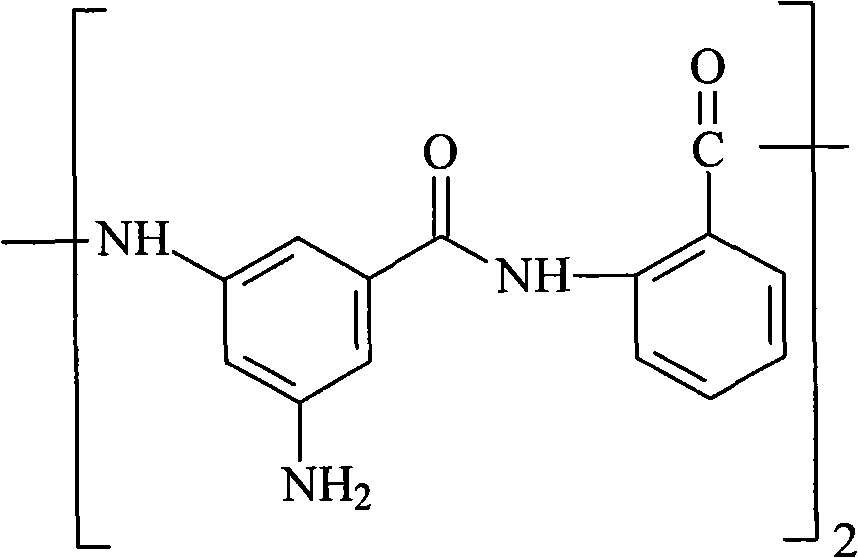

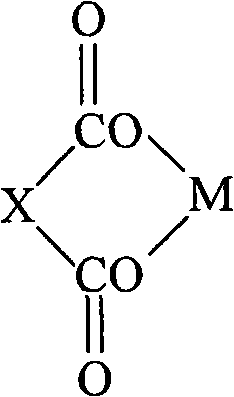

Method for preparing high tenacity and high impact polypropylene resins

A method for preparing high tenacity and high impact polypropylene resins comprises the step of melting, mixing and granulating the mixture after uniformly mixing the base material of the polypropylene resins and an additive to obtain the polypropylene resin products, wherein the melting heating temperature is controlled between 145 DEG C and 210 DEG C. The base material of the polypropylene resins is propylene-ethylene random copolymer, wherein the content of ethylene in the copolymer is 5-20wt%. The melt flow rate is 1-10g / 10min. The additive include a nucleating agent A, a nucleating agent B, a lubricating agent and an antioxidant, wherein the nucleating agent A is aromatic amide and the nucleating agent B is ortho dicarboxylic acid salt. The weight ratio of the base material of the polypropylene resins to the additive is 1000:1-10. The weight ratio of the nucleating agent A to the nucleating agent B in the additive is 1:0.2-1. When the total content of the nucleating agent A and the nucleating agent B is 1 part by weight, the lubricating agent is 2-6 parts by weight and the antioxidant is 1-5 parts by weight. The proportion of the beta crystal form in the crystalline region of the prepared polypropylene resins can be more than 85% (DSC method).

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Preparation method of high-temperature-resistant high-hardness adhesive

InactiveCN106281178AImprove mechanical propertiesImprove thermal stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesHalloysiteBenzoyl peroxide

The invention discloses a preparation method of a high-temperature-resistant high-hardness adhesive. The method includes the following steps of evenly mixing and stirring 188 unsaturated polyester resin, medical stone powder, ground calcium carbonate, argil, mica powder, nano-kaolin, wollastonite powder, epoxidized soybean oil, dispersing agent, modified hyaluronan and water according to weight parts to obtain adhesive mud, evenly mixing and stirring halloysite, sepiolite, glass beads, benzoyl peroxide and water according to weight parts to obtain a curing agent, filling the curing agent and the adhesive mud into a dual-layer thin film bag, and sealing the opening to obtain the high-temperature-resistant high-hardness adhesive. The obtained adhesive is high in polymerization density, hardness, toughness and crack resistant strength and excellent in high temperature resistance.

Owner:ANHUI SKY EYE INTELLIGENT TECH

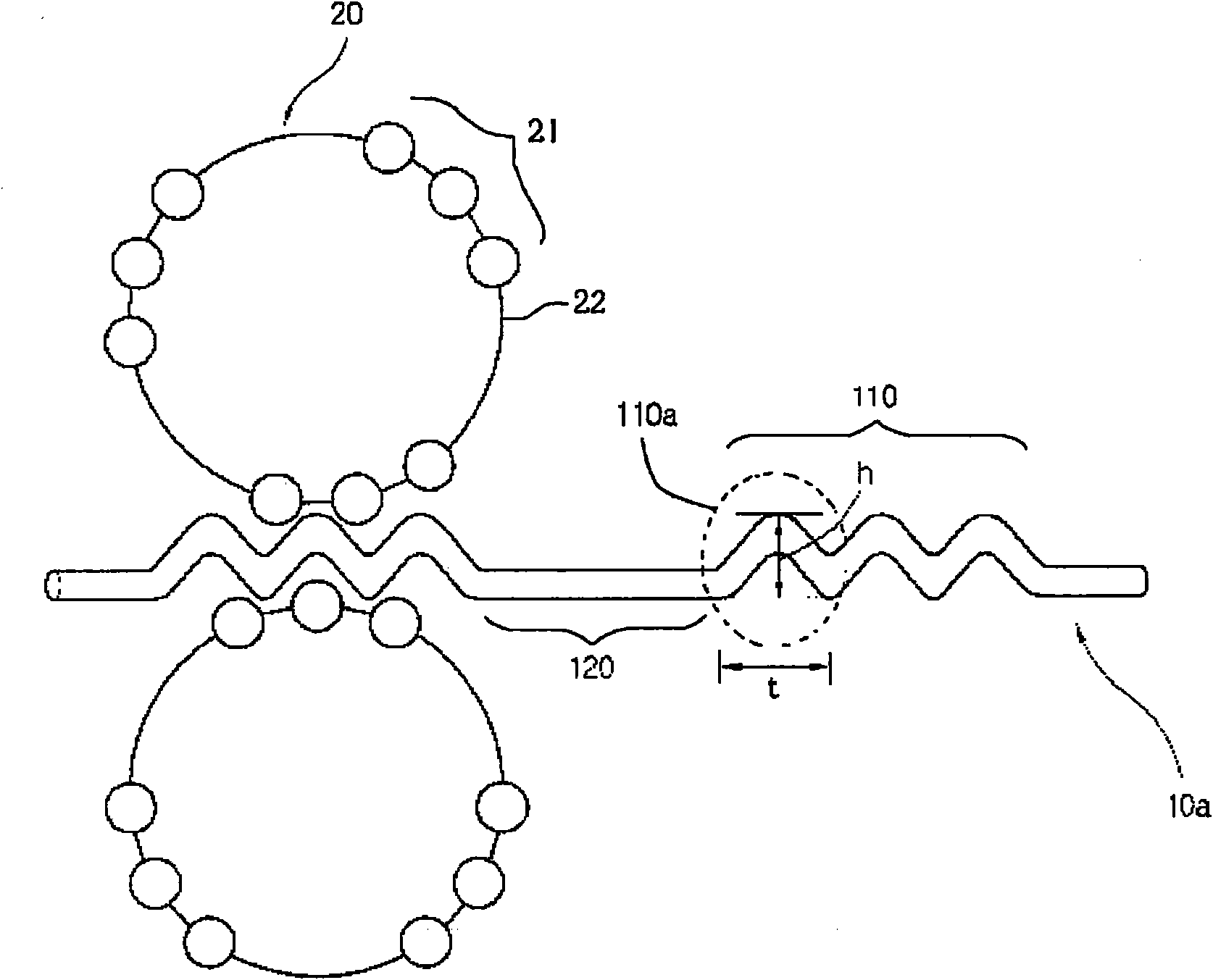

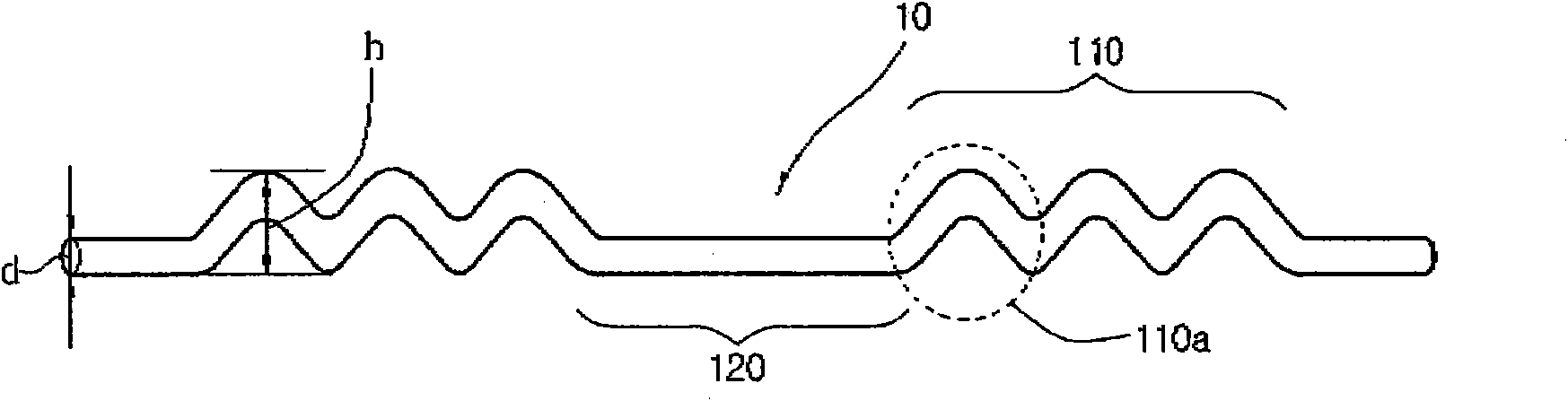

Single wire steel cord

InactiveCN101848804AEasy to twistImprove adhesionTyresPneumatic tyre reinforcementsHigh intensityEngineering

Owner:HYOSUNG CORP

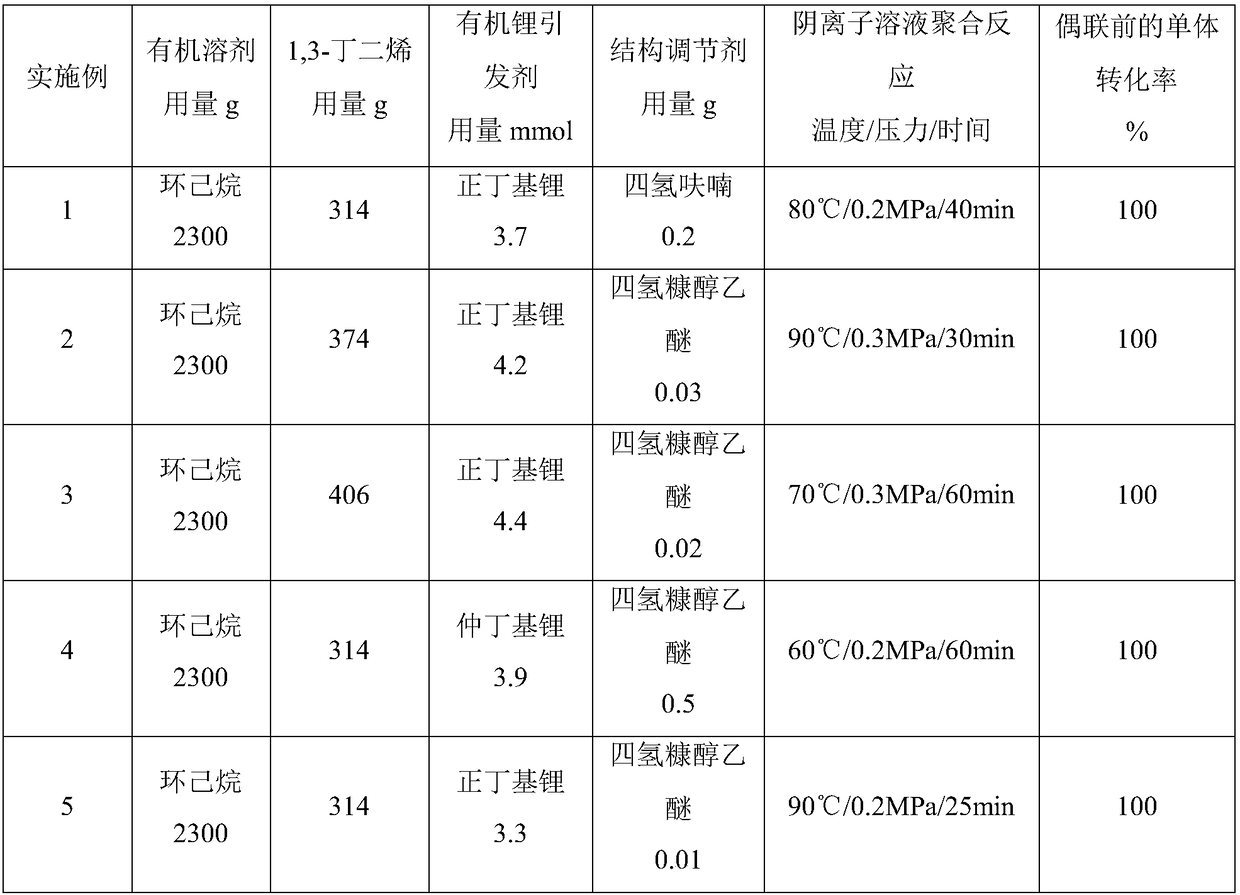

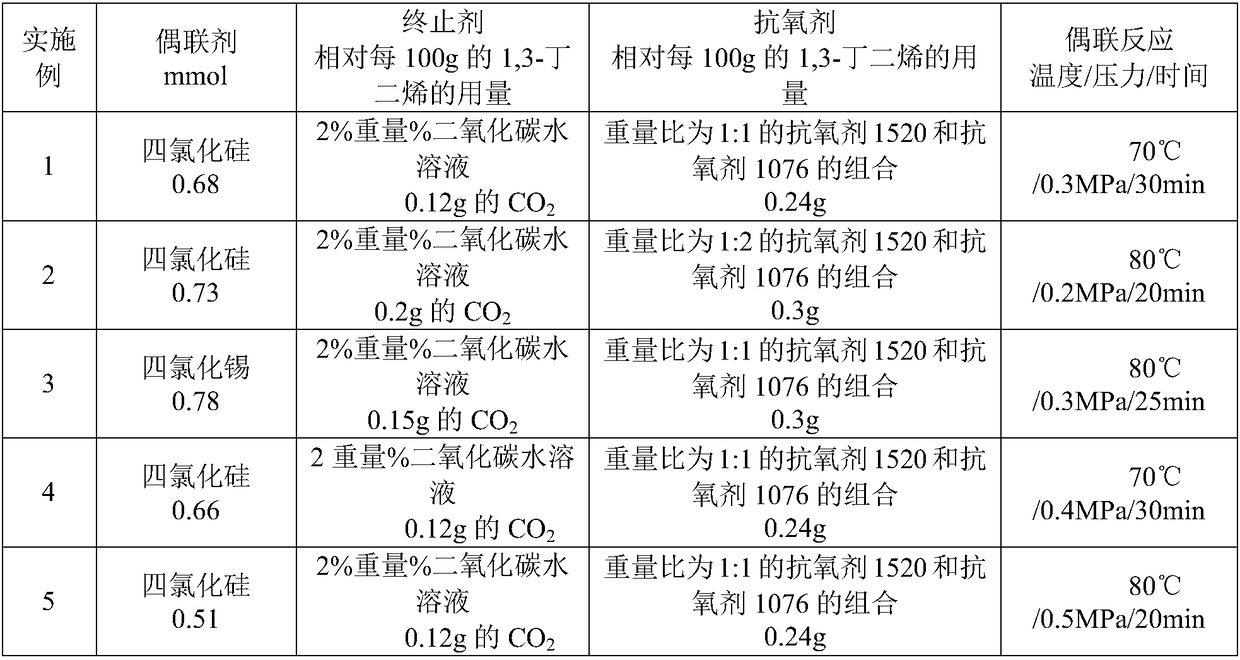

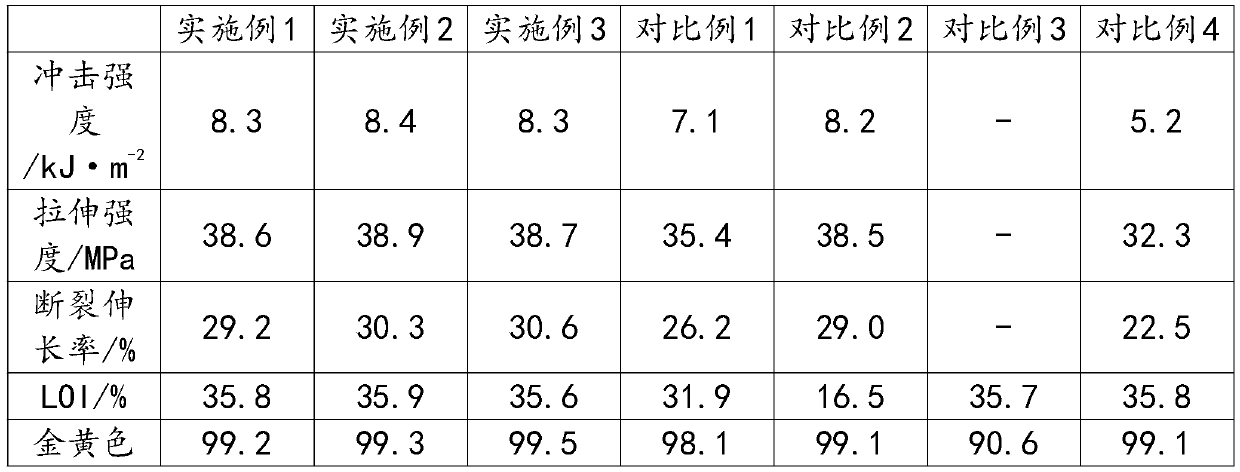

Low cis-polybutadiene rubber and preparation method thereof, HIPS (High Impact Polystyrene) resin and preparation method thereof, as well as ABS resin

ActiveCN109503747AModerate Mooney viscosityNarrow molecular weight distributionPolymer scienceMooney viscosity

The invention relates to the field of styrene resin, in particular to low cis-polybutadiene rubber and a preparation method thereof, HIPS (High Impact Polystyrene) resin and a preparation method thereof, as well as ABS resin. The molecular weight of the low cis-polybutadiene rubber is in bimodal distribution; a low-molecular-weight component in two peaks is 80,000 to 100,000 in number-average molecular weight, and is 25 to 45 percent in peak area; a high-molecular-weight component in the two peaks is 250,000 to 320,000 in number-average molecular weight, and is 55 to 75 percent in peak area. In the low cis-polybutadiene rubber, the 1,2 structural content is 6 to 20 percent by weight, the Mooney viscosity ML(1+4) at 100 DEG C is 40 to 65, and the viscosity of 5 percent by weight of a styrene solution at 25 DEG C is 80 to 120cp. The polybutadiene rubber provided by the invention has the advantages of moderate Mooney viscosity, high solution viscosity and narrow molecular weight distribution, and can be taken as a toughening agent for preparing HIPS resin or ABS resin with higher impact property..

Owner:CHINA PETROLEUM & CHEM CORP +1

High-impact resistant reinforced flame-retardant and ageing-resistant PC and PET blend alloy

InactiveCN104672870AImprove flame retardant performanceImprove aging resistanceMasterbatchAging resistance

The invention discloses a high-impact resistant reinforced flame-retardant and ageing-resistant PC and PET blend alloy. The blend alloy comprises the following components in percentage by mass: 30%-60% of PC, 10%-30% of PET, 3%-8% of an impact-resistant modifier, 5%-10% of a fortifier, 5%-10% of a flame retardant, 0.5%-2% of a light stabilizer, 2%-5% of a compatilizer, 0.1%-0.5% of antioxygen and 0.5%-1.5% of a lubricant. The blend alloy disclosed by the invention has the beneficial effects that compared with the prior art, the PET flame-retardant ageing resistant parent material is firstly prepared, and then the PC and PET blend alloy is prepared by modifying PC with the parent material, the added impact-resistant modifier and the fortifier, and the PC and PET blend alloy has the respective excellent performance of the PC and the PET, has the advantages of high impact-resistance, good mechanical performance, high strength, good flame-retardance and ageing resistance, and has very good prospect on the aspects of household appliances, automobiles, instruments and meters, electrommunication and the like.

Owner:QINGDAO JIAYIYANG IND & TRADE

Preparation method of polypropylene plastic particles

The invention discloses a preparation method of polypropylene plastic particles. The polypropylene plastic particles are prepared from the following raw materials in parts by weight: 100-120 parts ofmodified polypropylene, 16-20 parts of talcum powder, 10-15 parts of a flame retardant, 3-5 parts of a bacteriostatic agent, 2-3 parts of calcium stearate and 4-8 parts of a dispersing agent. The preparation method comprises the following steps: uniformly mixing the substances according to the formula ratio, and then carrying out melt blending, extrusion and granulation. According to the invention, the modified polypropylene is used as a plastic matrix, has higher impact resistance, and is grafted with -COOH functional groups, so that the compatibility and binding force of the matrix with theflame retardant and the bacteriostatic agent can be increased, the flame retardant, the bacteriostatic agent and the like are uniformly dispersed in the matrix, and the polypropylene particles are endowed with good flame retardance and bacteriostatic performance; and through auxiliary matching of talcum powder and calcium stearate with specific particle sizes, the rigidity of PP can be improved, the toughness of polypropylene can also be improved, and the polypropylene plastic which is excellent in mechanical property and has flame-retardant and antibacterial functions is obtained.

Owner:马健珂

Semiconductor device with solder balls having high reliability

ActiveUS20070096318A1High impact resistanceReliable connectionSemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor

A semiconductor device includes a substrate, a metal layer, an alloy layer and a Sn—Ag—Cu-based solder ball. The metal layer is configured to be formed on the substrate. The alloy layer is configured to be formed on the metal layer. The Sn—Ag—Cu-based solder ball is configured to be placed on the alloy layer. The alloy layer includes Ni and Zn as essential elements.

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com