Heat dissipating ink and heat dissipating shield case preparation method

A technology of shielding cover and ink, which is applied in the direction of ink, household utensils, applications, etc., can solve problems such as temperature rise of electronic components, heat concentration of electronic products, dead components and other problems, and achieve improved yield rate, excellent electrical insulation performance, Effect of Excellent Heat Dissipation Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

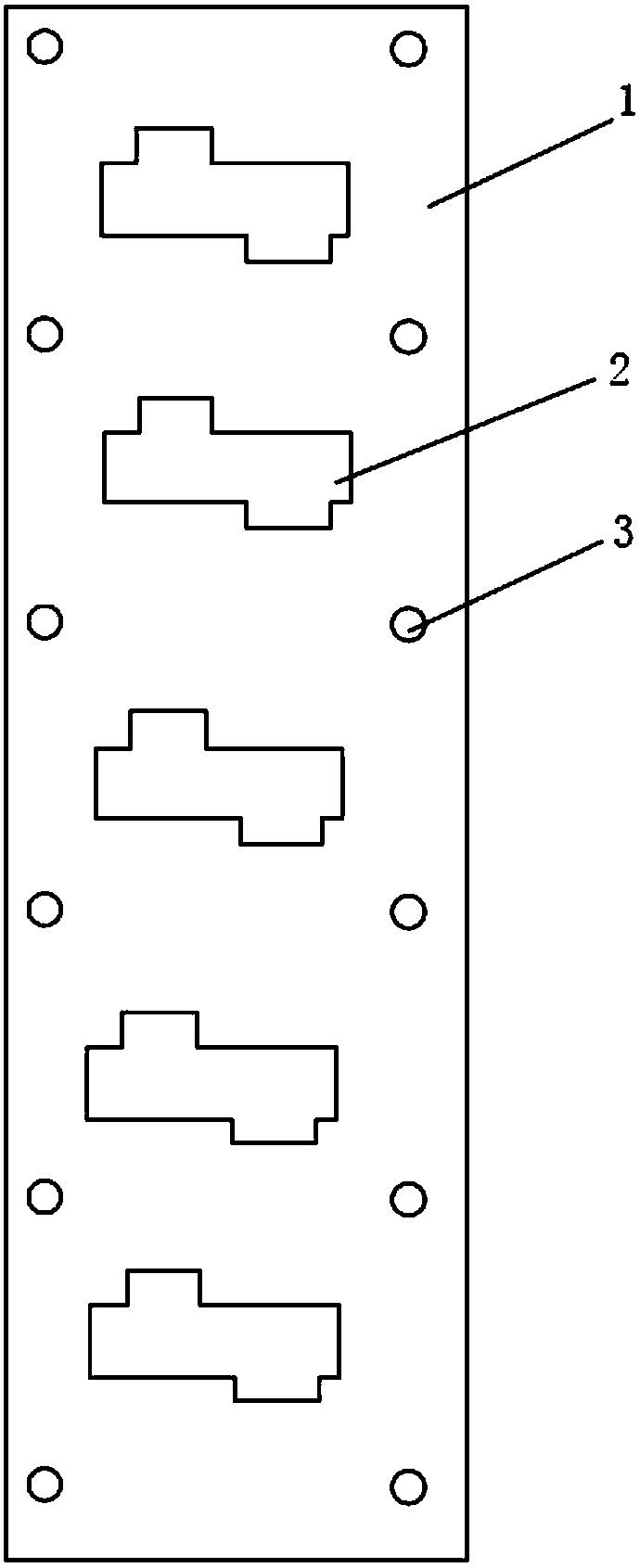

Image

Examples

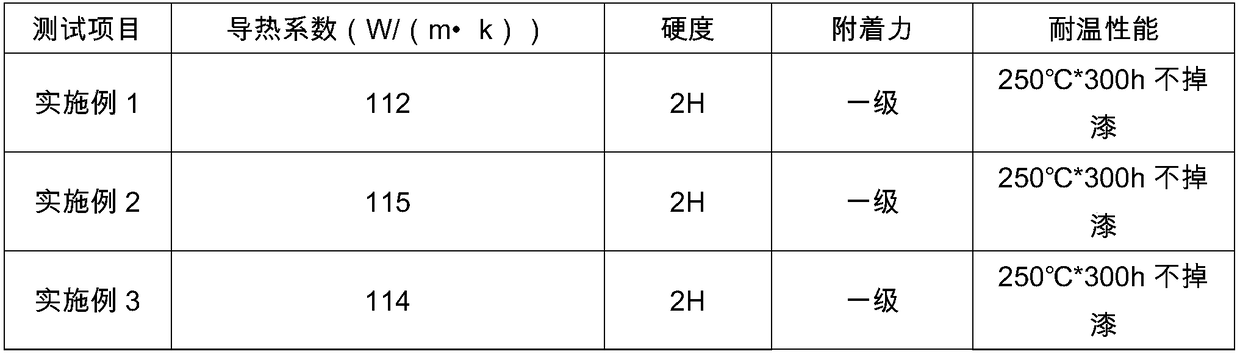

Embodiment 1

[0048] A heat dissipation ink, comprising the following raw materials in parts by weight: 60 parts of polyimide modified epoxy resin, 30 parts of polyvinyl chloride resin, 50 parts of boron nitride thermal conductive filler, 25 parts of radiation heat dissipation filler, 10 parts of γ-ammonia Propyl triethoxysilane coupling agent, 10 parts of organic bentonite anti-sedimentation agent, 8 parts of 1090 leveling agent, 15 parts of pigment and filler, 50 parts of butanone solvent, 35 parts of curing agent.

[0049] Among them, the boron nitride thermally conductive filler is nanoscale acicular boron nitride thermally conductive filler, nanoscale granular boron nitride thermally conductive filler, nanoscale fibrous boron nitride thermally conductive filler and nanoscale columnar boron nitride thermally conductive filler. 2:3:8:1.5 composed.

[0050] The radiation heat dissipation filler is a mixture of silicon dioxide and sericite powder in a weight ratio of 3:5.

[0051] The cur...

Embodiment 2

[0061] A heat dissipation ink, comprising the following raw materials in parts by weight: 70 parts of polyimide modified epoxy resin, 37.5 parts of polyvinyl chloride resin, 57.5 parts of thermal conductive filler, 32.5 parts of radiation heat dissipation filler, 12.5 parts of coupling agent, 12.5 parts Anti-settling agent, 10 parts of leveling agent, 20.5 parts of pigment and filler, 55 parts of solvent, 40.5 parts of curing agent.

[0062] Among them, the thermally conductive filler is a mixture of boron nitride and silicon carbide at a weight ratio of 2:1, and the thermally conductive fillers are nanoscale needle-shaped thermally conductive fillers, nanoscale granular thermally conductive fillers, nanoscale fibrous thermally conductive fillers, and nanoscale columnar thermally conductive fillers. The thermal conductive filler is composed of 3.5:3.5:9:1.75 by weight.

[0063] The coupling agent is a mixture of pyrophosphate titanate and vinyl tris(β-methoxyethoxy)silane in a...

Embodiment 3

[0072] A heat dissipation ink, comprising the following raw materials in parts by weight: 80 parts of polyimide modified epoxy resin, 45 parts of polyvinyl chloride resin, 65 parts of thermal conductive filler, 40 parts of radiation heat dissipation filler, 15 parts of coupling agent, 15 parts Anti-settling agent, 12 parts of leveling agent, 26 parts of pigment and filler, 60 parts of solvent, 46 parts of curing agent.

[0073] Among them, the thermally conductive filler is a mixture of alumina, magnesia, and graphene oxide at a weight ratio of 1:1:1, and the thermally conductive filler is nanoscale needle-shaped thermally conductive filler, nanoscale granular thermally conductive filler, nanoscale fibrous thermally conductive filler, and nanoscale fibrous thermally conductive filler. The filler and the nano-scale columnar thermal conductive filler are composed of a weight ratio of 5:4:10:2.

[0074] The coupling agent is a mixture of γ-aminopropyltriethoxysilane, vinyltrietho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com