Patents

Literature

1488results about How to "Improve interface performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

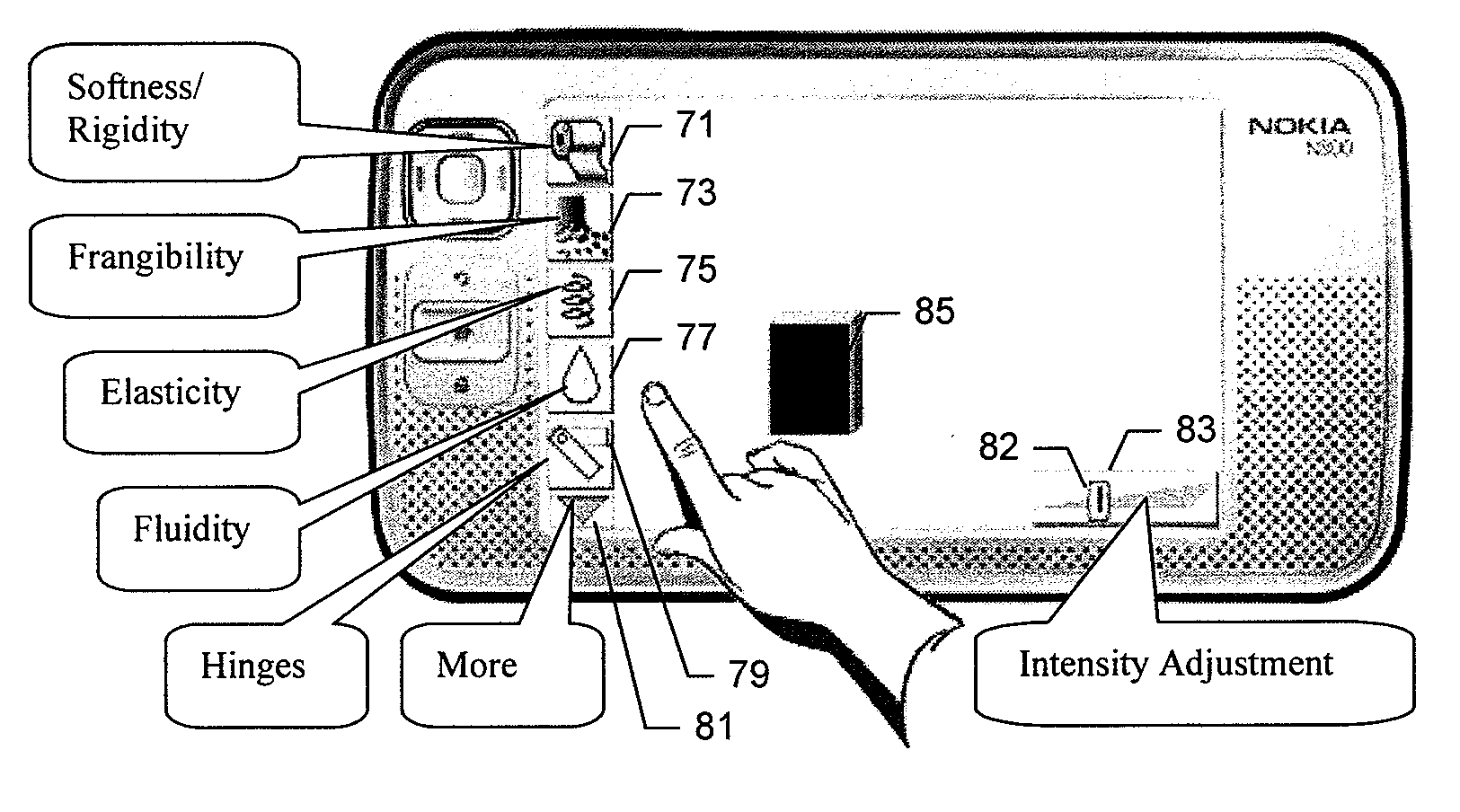

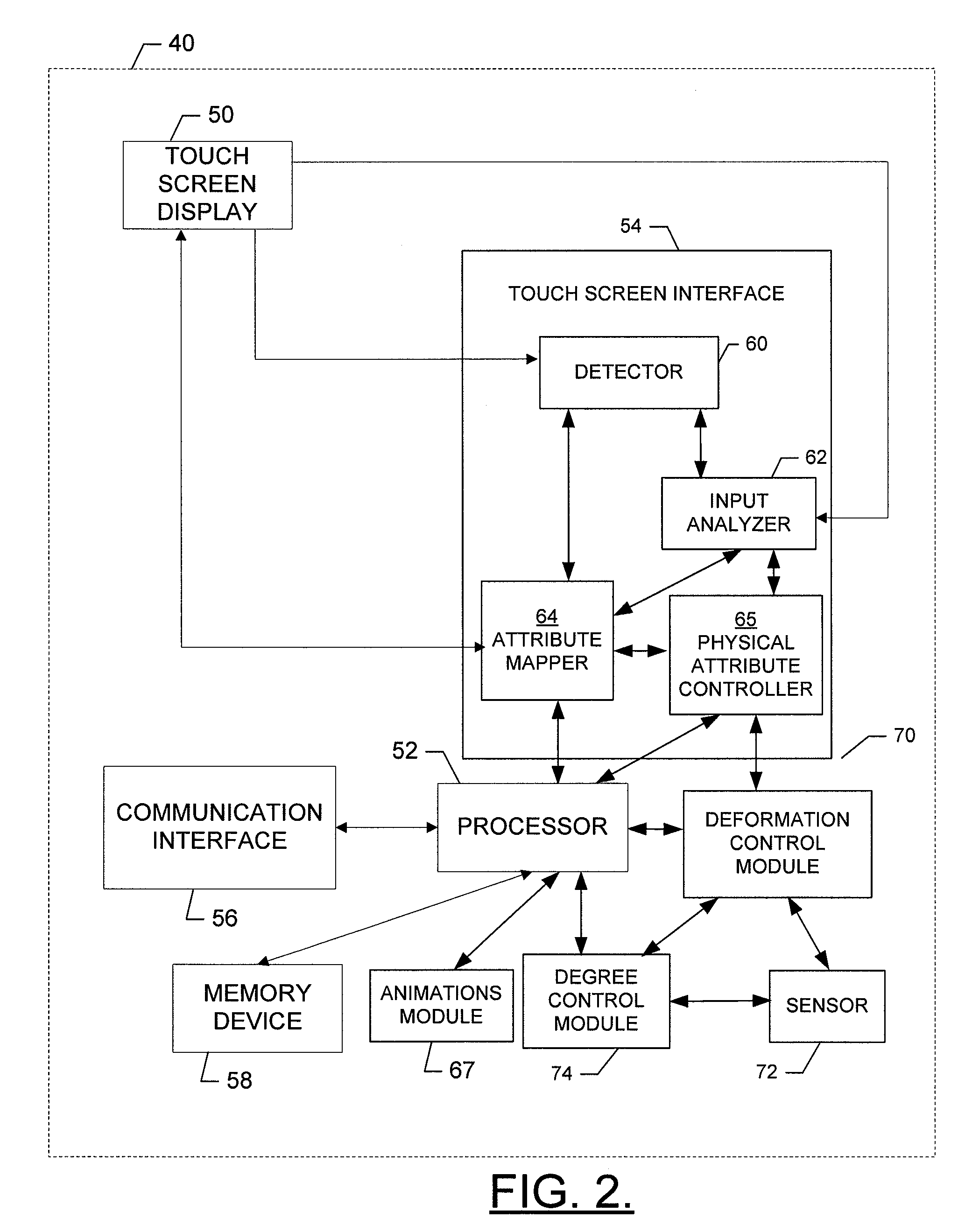

Method, apparatus and computer program product for creating graphical objects with desired physical features for usage in animation

ActiveUS20100289807A1Improve experienceIncrease capacityCathode-ray tube indicatorsInput/output processes for data processingGraphicsAnimation

An apparatus for modifying one or more physical attributes and properties of a graphical element and transferring these physical attributes and properties to a graphical object for usage in an animation may include a processor and a memory storing executable computer program code that cause the apparatus to at least perform operations including receiving a selection of a physical attribute(s) among a plurality of physical attributes and adjusting an intensity associated with the selected physical attribute. The computer program code may further cause the apparatus to assign the physical attribute to a graphical element(s) and modify one or more physical properties of the graphical element based on the selected physical attribute and the adjusted intensity. The computer program code may further cause the apparatus to transfer the modified physical properties of the graphical element to a graphical object. A corresponding method and computer program product are also provided.

Owner:EC BENTO HONG KONG LTD

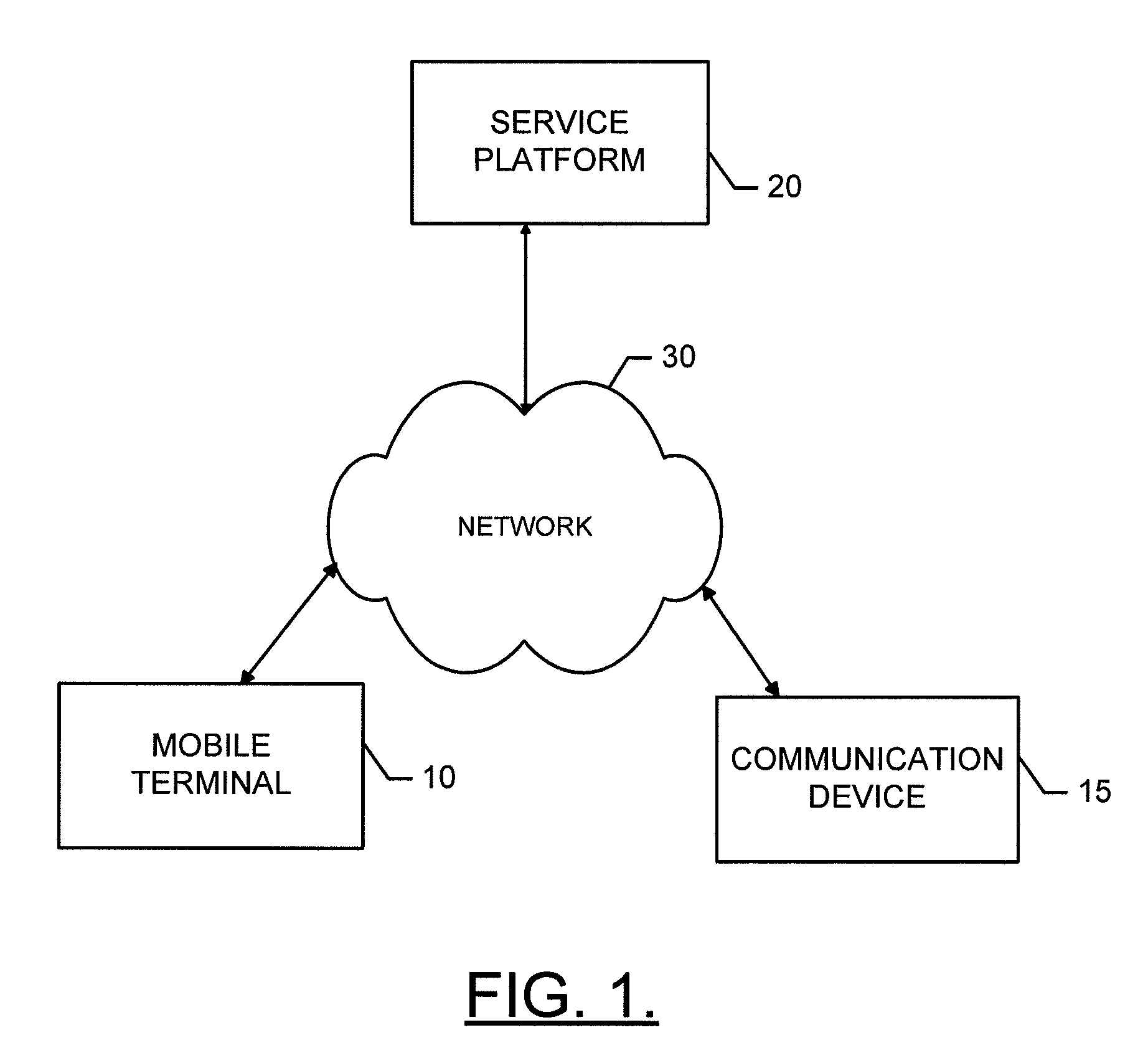

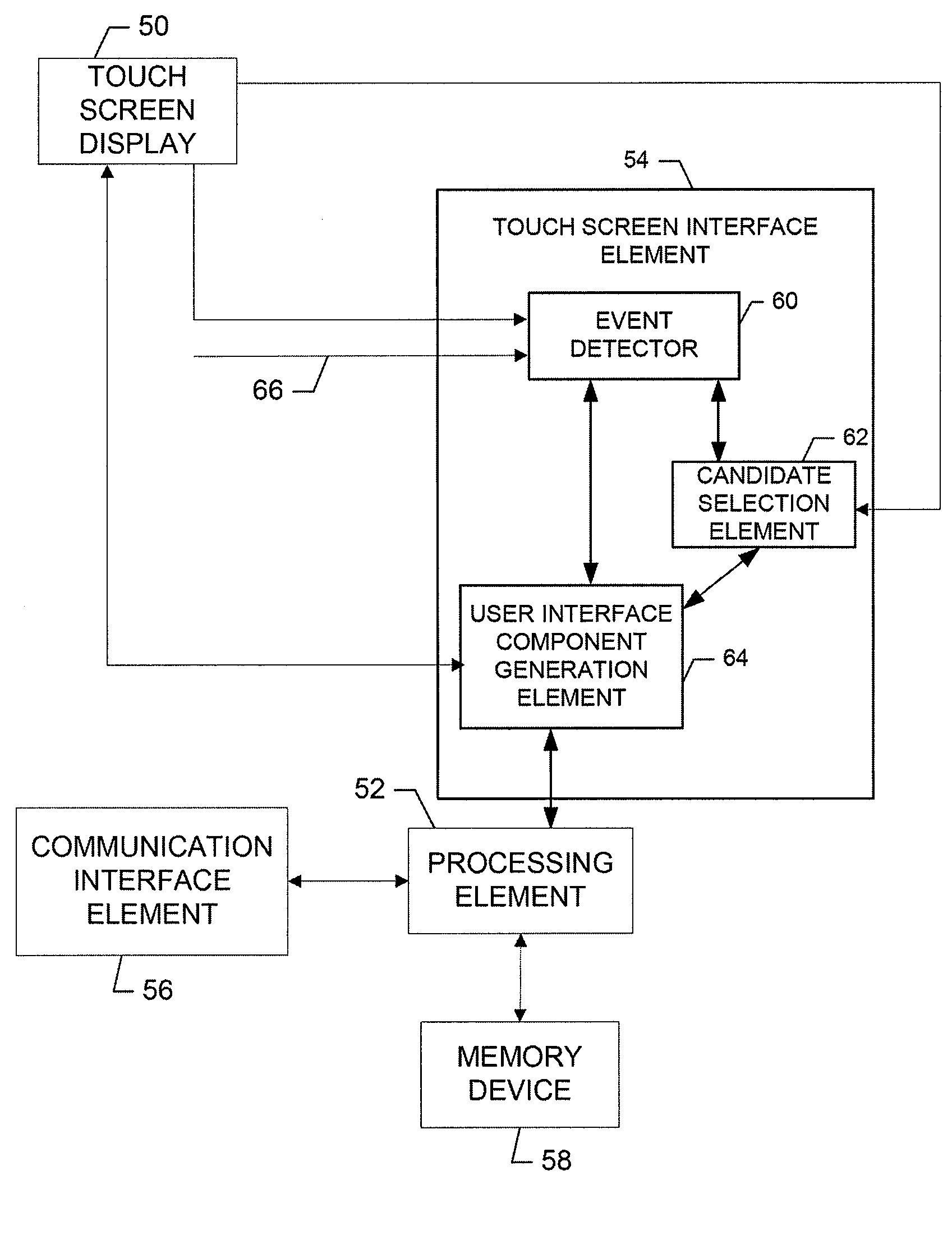

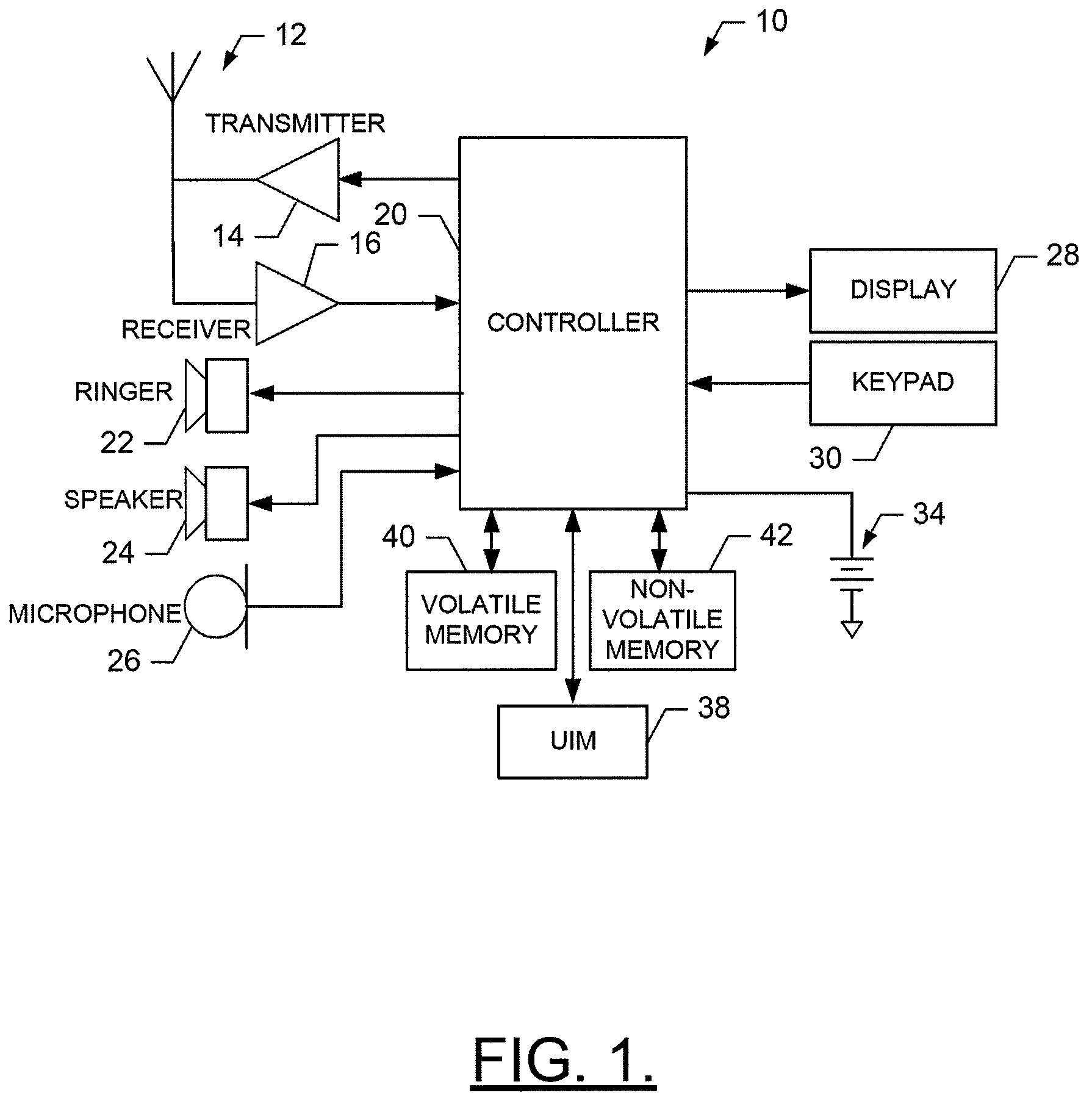

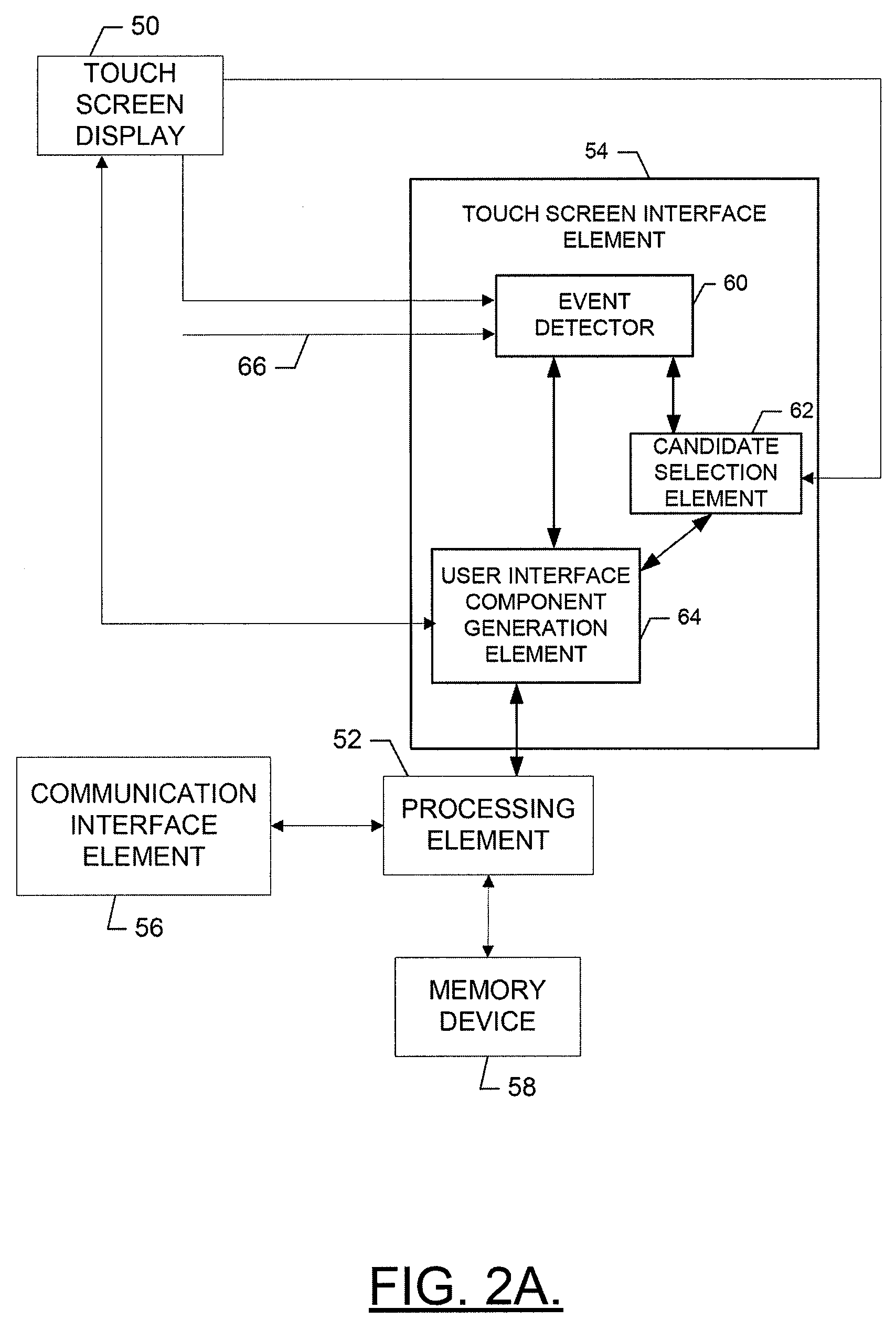

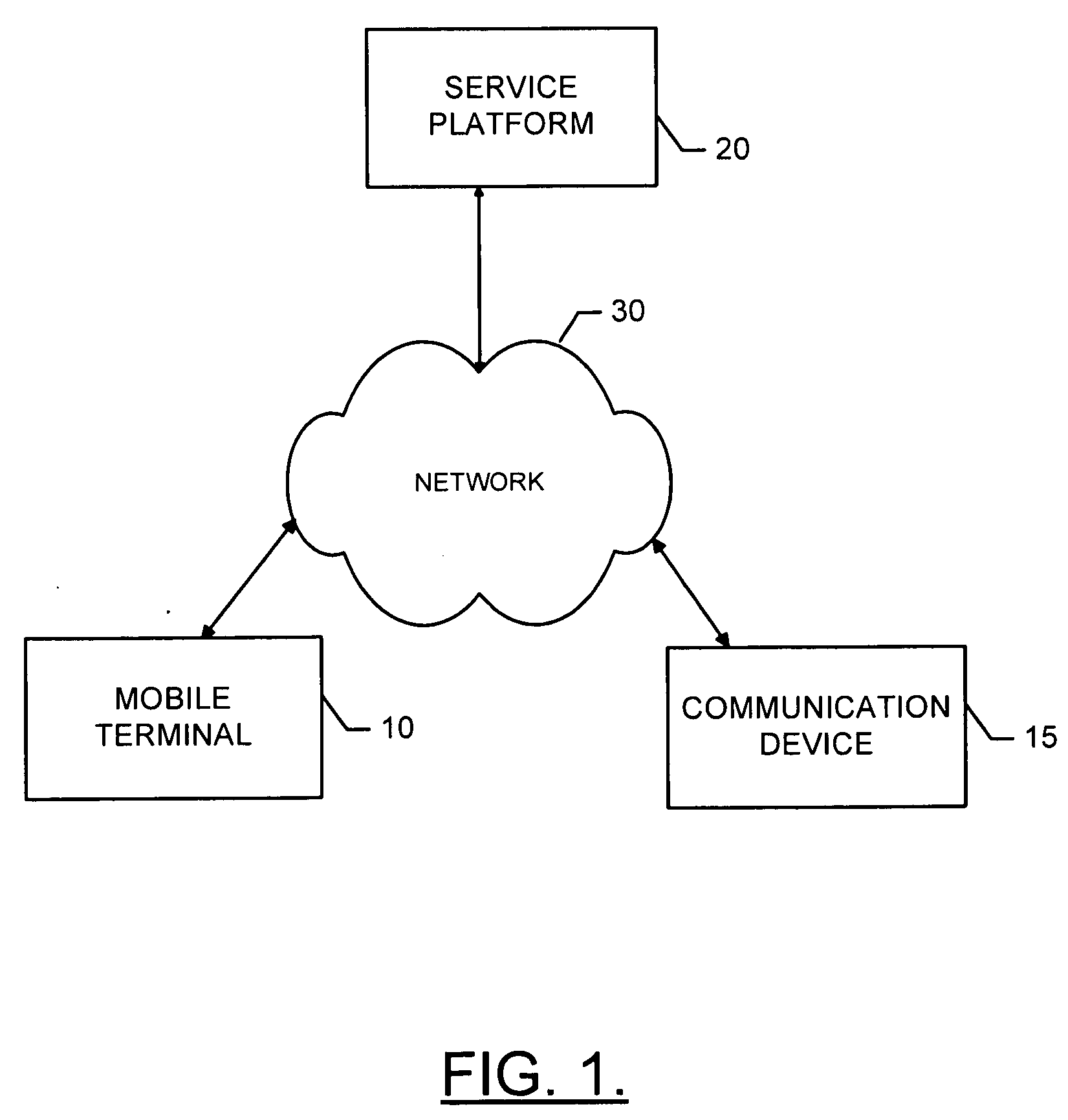

Method, Apparatus and Computer Program Product for Providing an Object Selection Mechanism for Display Devices

InactiveUS20090006958A1Increase capacitySimple interfaceInput/output processes for data processingDisplay deviceProcessing element

An apparatus for providing an object selection mechanism for touch screen devices may include a processing element. The processing element may be configured to receive an indication of a detection of an event associated with a display, determine a type of the event, determine a candidate object associated with the type of the event, and generate a user interface component based on the determination of the candidate object.

Owner:NOKIA CORP

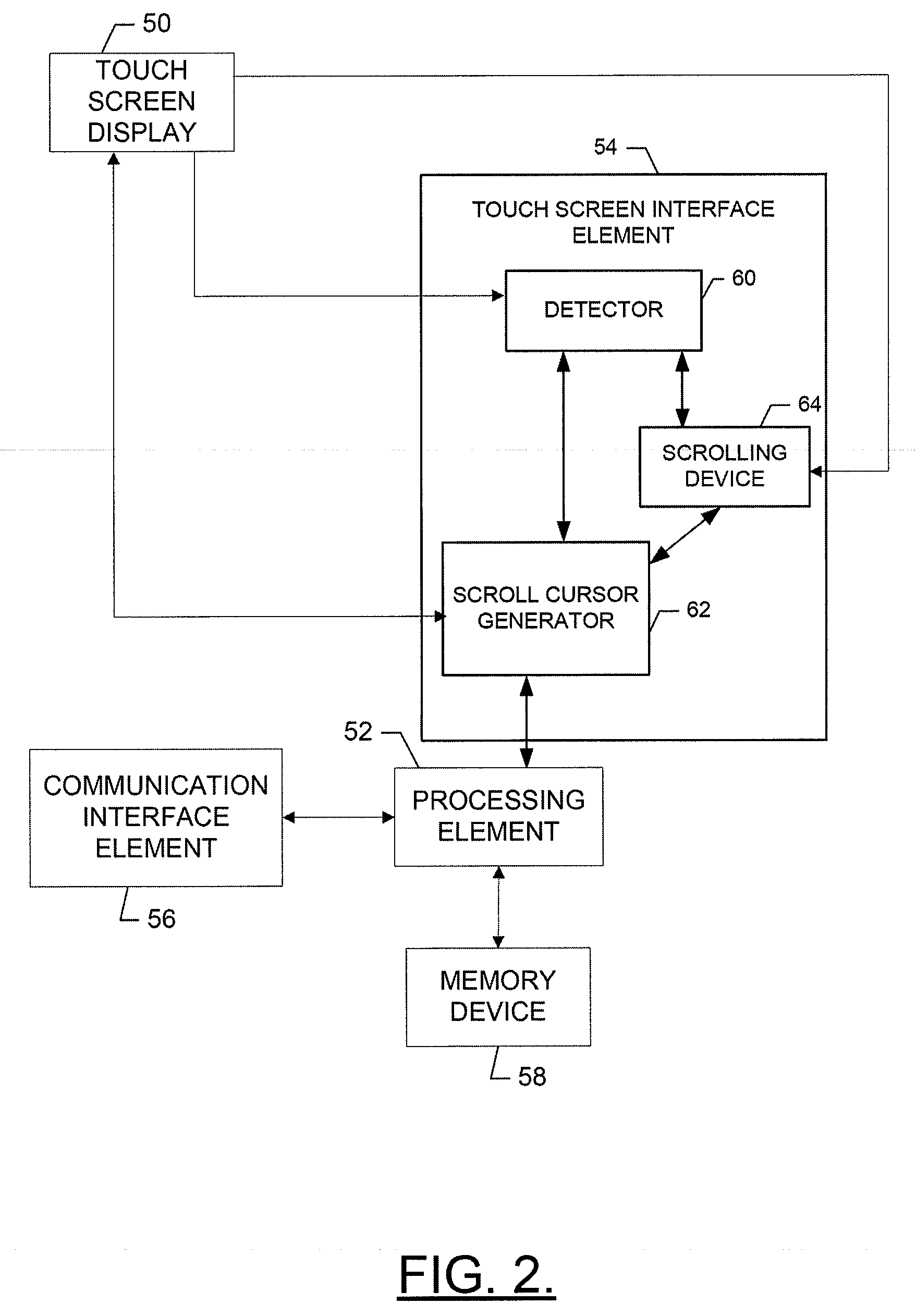

Method, Apparatus and Computer Program Product for Providing a Scrolling Mechanism for Touch Screen Devices

InactiveUS20090002324A1Improved scrolling functionalityEasy to useInput/output processes for data processingDisplay deviceTouchscreen

An apparatus for providing a scrolling mechanism for touch screen devices may include a detector, a scroll cursor generator and a scrolling device. The detector may be configured to receive an indication of a detection of a touch event at a touch screen display generating a content view of at least a portion of a content page. The scroll cursor generator may be in communication with the detector and may be configured to generate a scroll cursor at a touch position corresponding to movement of an object associated with the touch event. The scrolling device may be in communication with the scroll cursor generator and may be configured to provide scrolling over the content page in response to the scroll cursor contacting a predefined portion of the content view.

Owner:NOKIA CORP

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

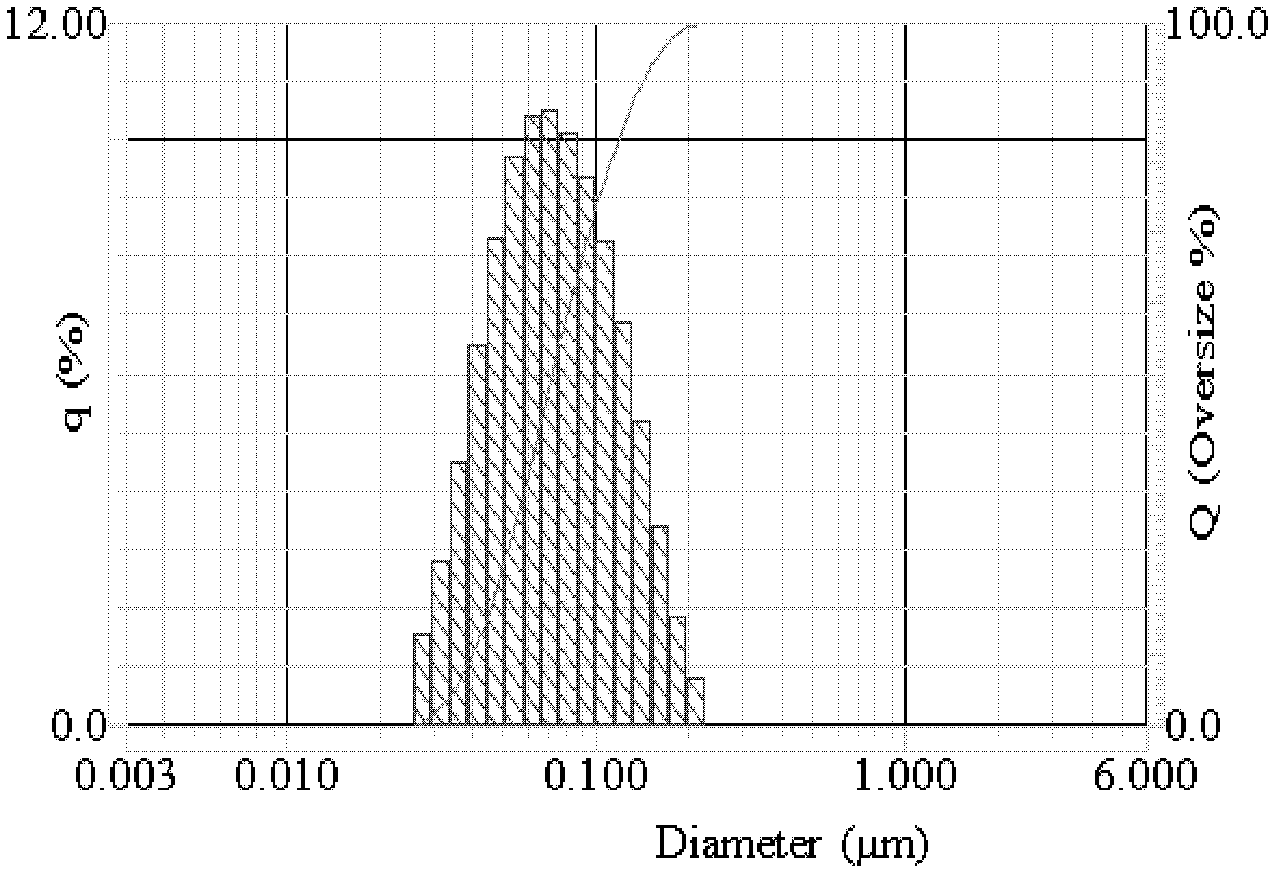

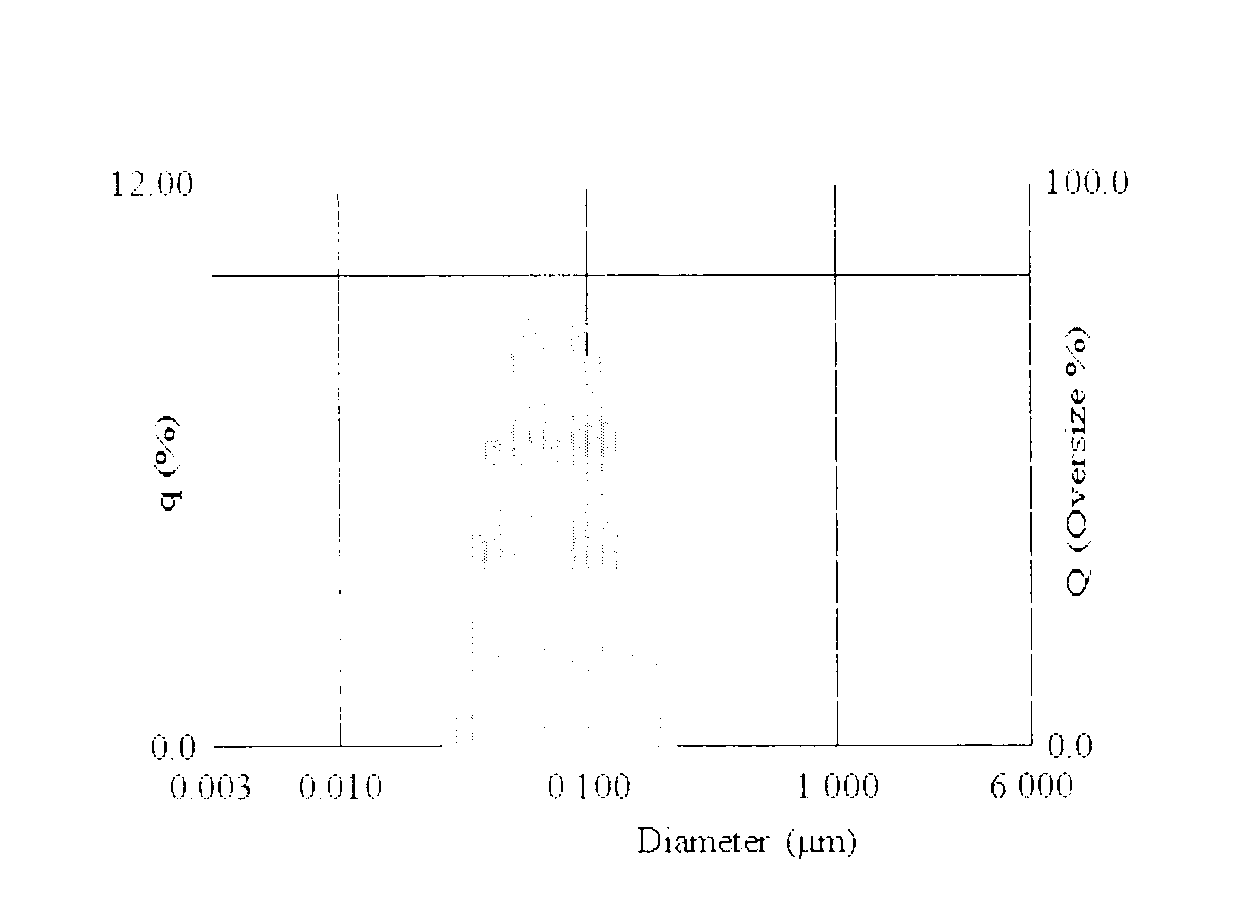

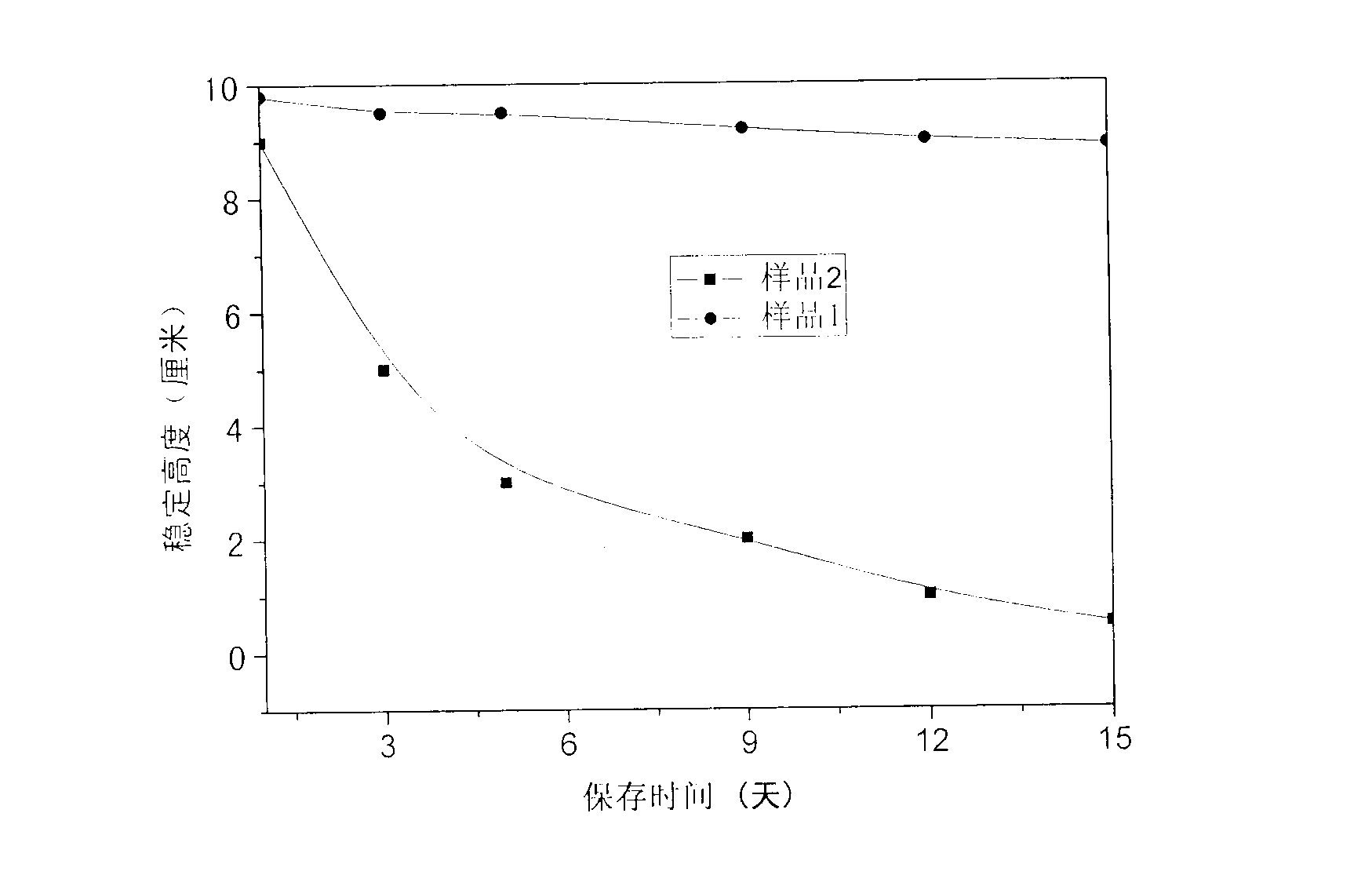

Process for preparing nano SiO2 modified carbon fiber emulsion pasting agent

ActiveCN1632217AImprove protectionHigh strengthFibre treatmentFibre chemical featuresCarbon fibersEmulsion

A preparation method of a nano-SiO2 modified carbon fiber emulsion sizing agent, which uses nano-SiO2 as a sizing resin modification material, and the modified material, sizing resin, emulsifier, dispersant, organic solvent and particle-free water are prepared in a certain weight ratio Carbon fiber-forming functional emulsion sizing agent. After the carbon fiber is impregnated with a certain concentration of modified sizing agent for an appropriate time, the strength of the carbon fiber increases by up to 8.7%; the interfacial shear strength (IFSS) of the single fiber composite material can reach up to 43.67MPa; ILSS) up to 98.7MPa.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Heat radiation material, heat radiation structure, and preparation method and application thereof

InactiveCN103205075AImprove interface performanceImprove compatibilityLayered productsHeat-exchange elementsSolventRadiation

The invention provides inorganic heat radiation nano-grade material aqueous slurry, a heat radiation material comprising the inorganic heat radiation nano-grade material aqueous slurry, and preparation methods and applications thereof. The inorganic heat radiation nano-grade material aqueous slurry comprises the components comprising, by weight, 10-25 parts of an inorganic heat radiation nano-grade material, 0.5-20 parts of a modifier solution, and 50-100 parts of a solvent. The heat radiation material comprises, by weight, 10-30 parts of the inorganic heat radiation nano-grade material aqueous slurry, 40-80 parts of aqueous high-molecular resin, 20-30 parts of latex, 10-40 parts of a film-forming auxiliary agent, 0.5-5 parts of an auxiliary agent, and 5-20 parts of a diluting agent. With the application of the inorganic heat radiation nano-grade material aqueous slurry, compatibility and system dispersion stability of the inorganic heat radiation nano-grade material and the high-molecular material are improved, such that the unique heat radiation material with excellent heat radiation performance and with the inorganic heat radiation nano-grade material aqueous slurry is obtained.

Owner:REGAL PAPER TECH

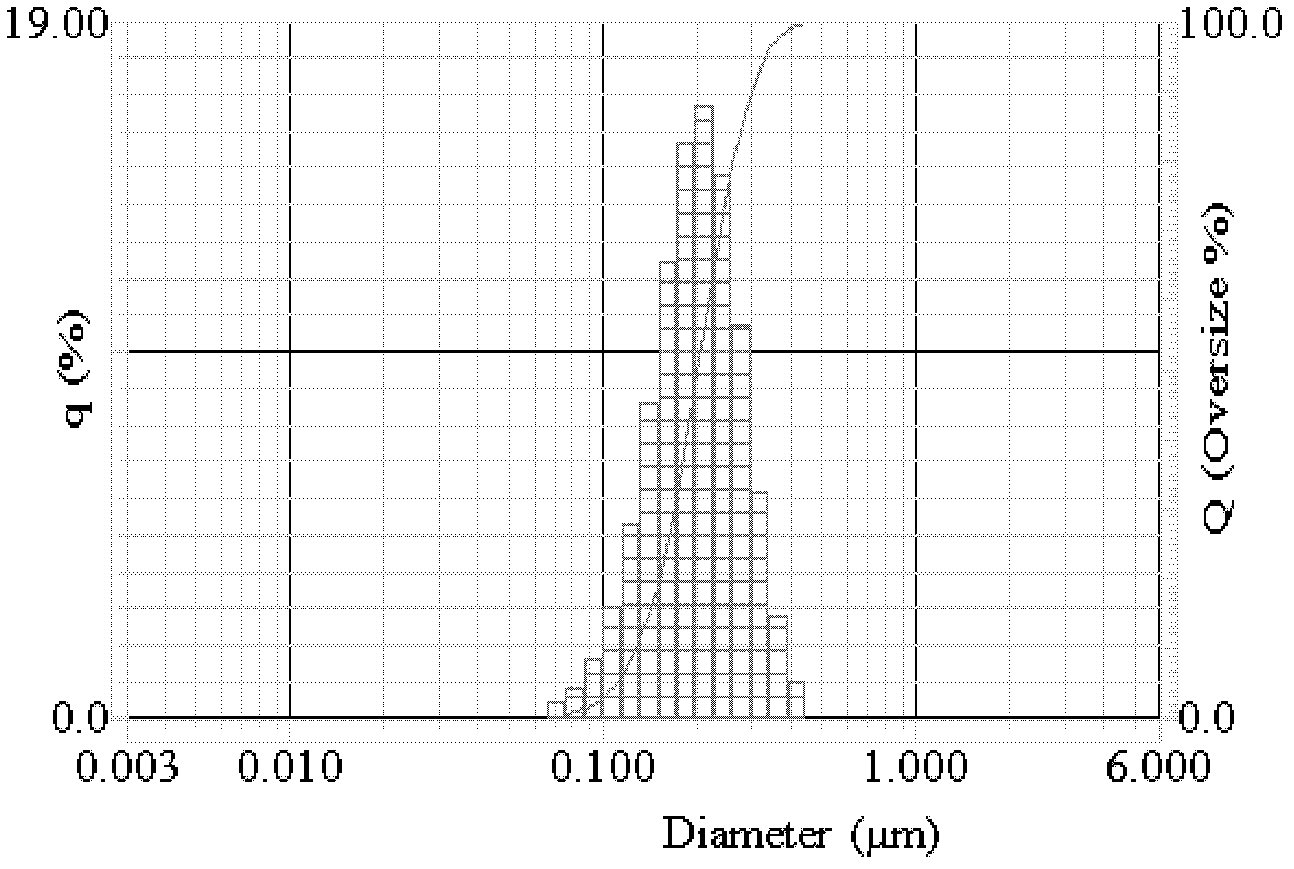

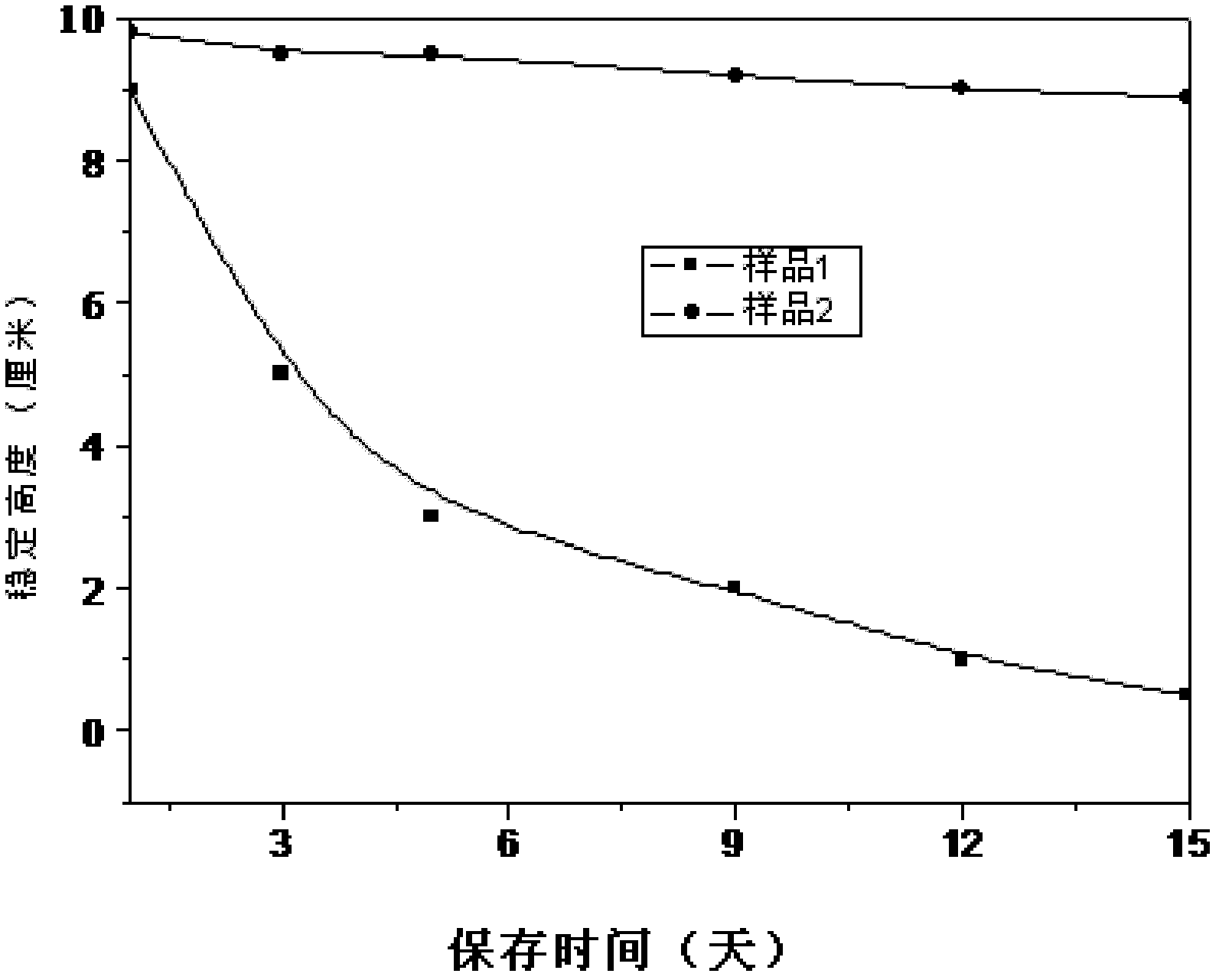

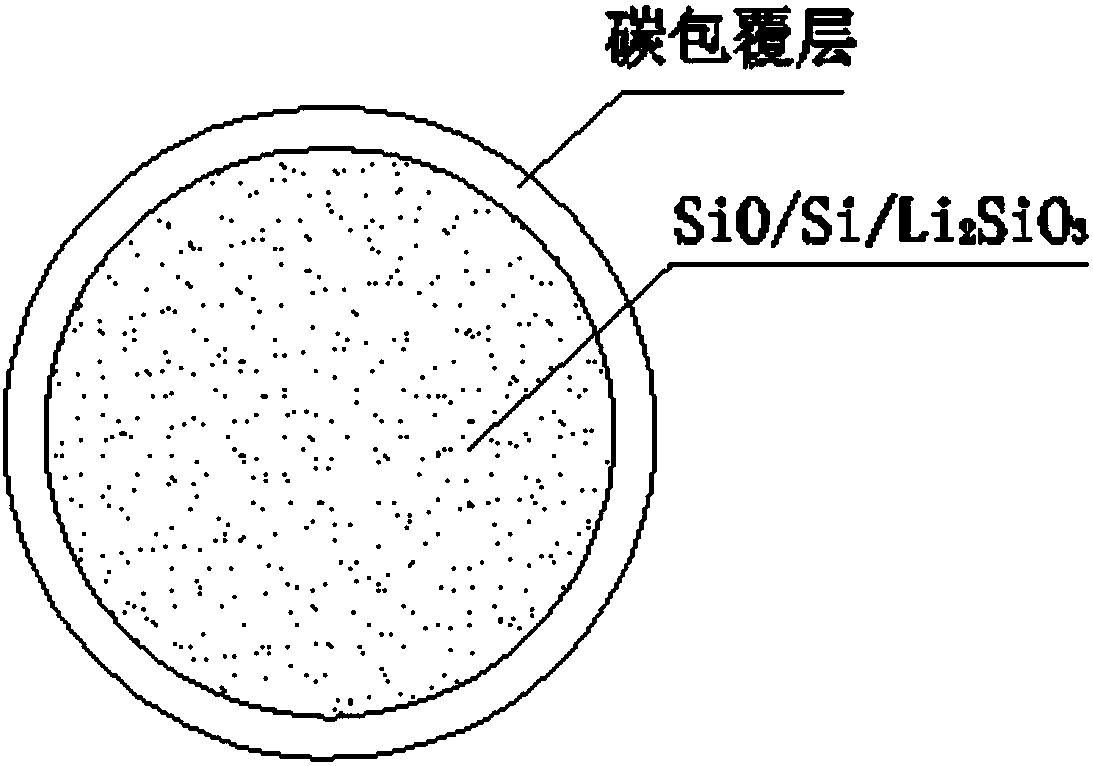

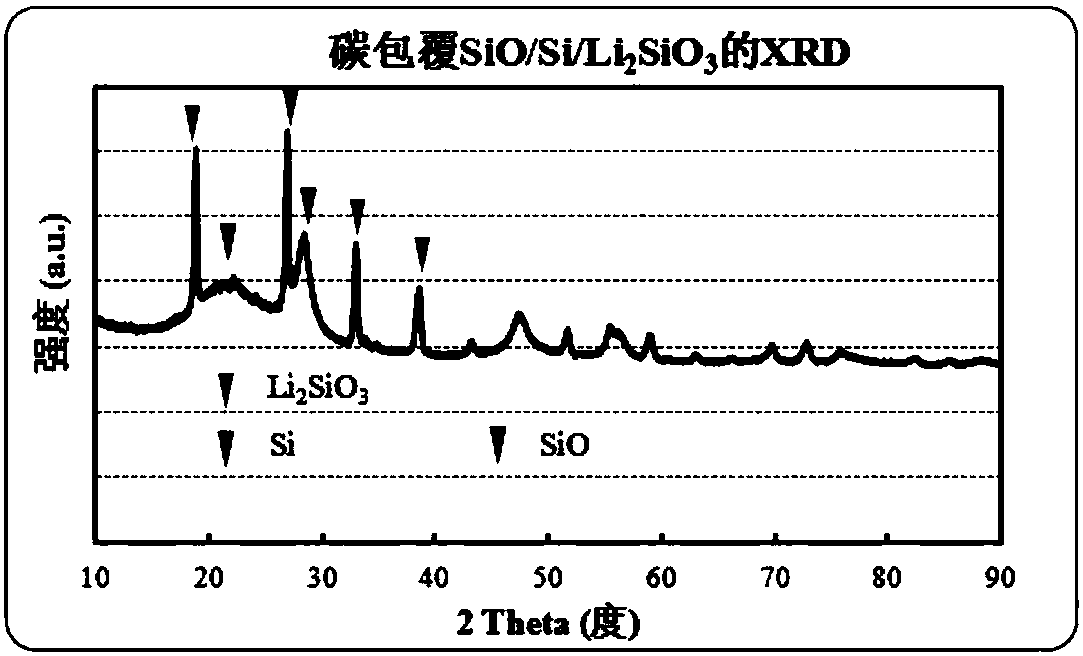

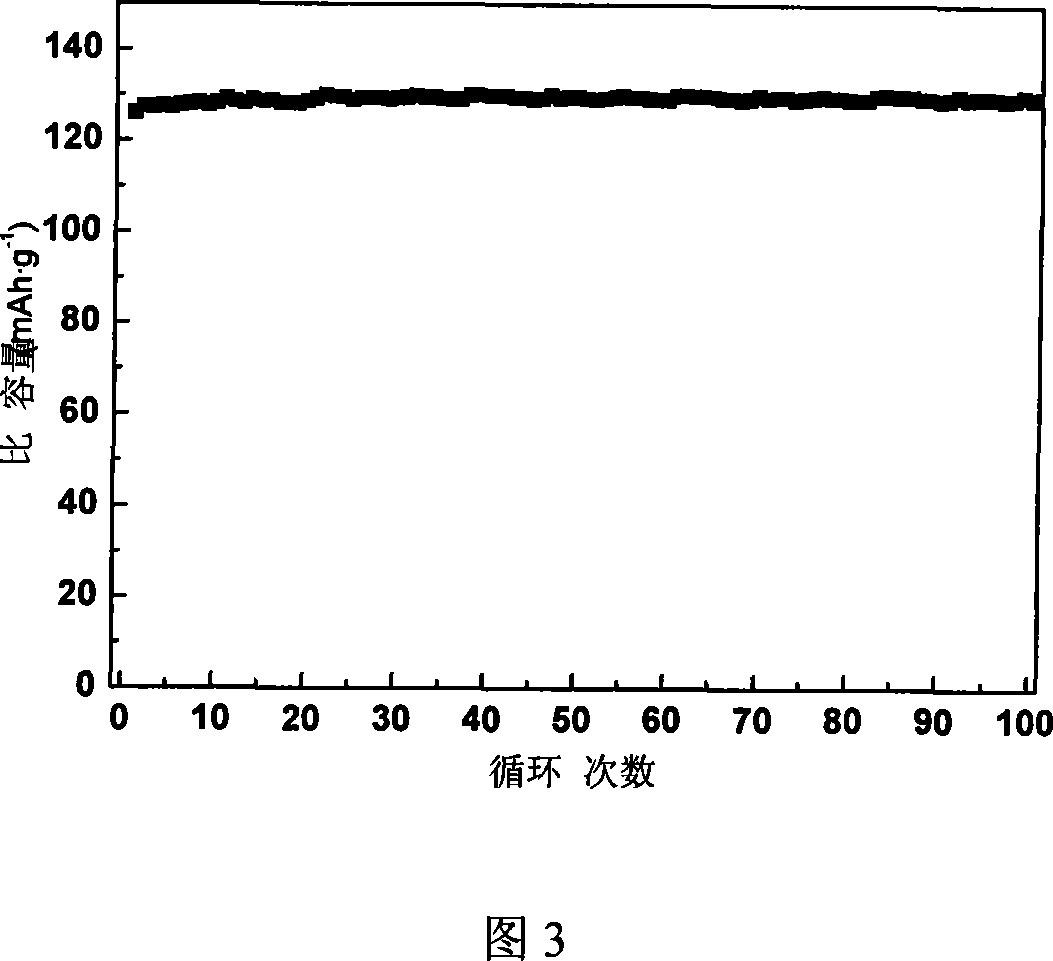

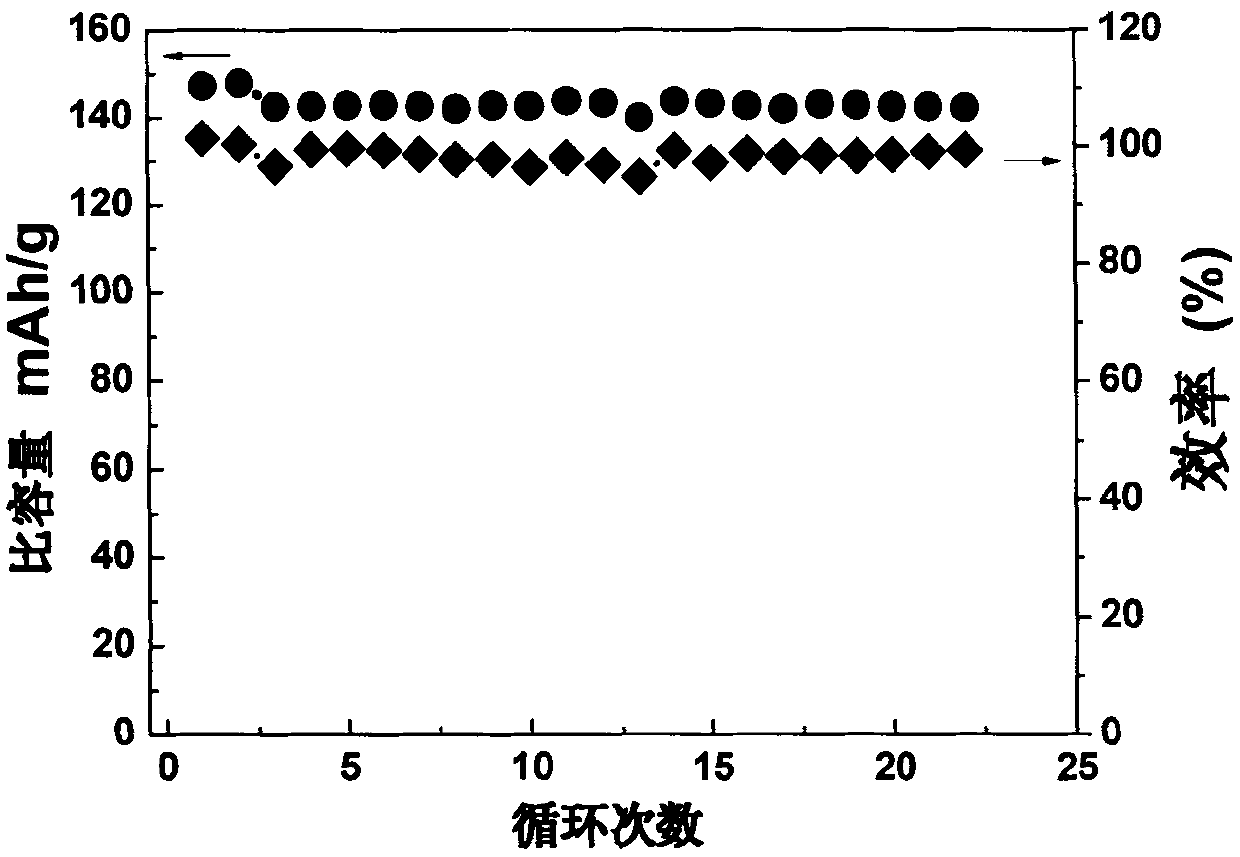

Silicon monoxide/silicon/lithium metasilicate composite negative electrode material and preparation method thereof

InactiveCN108269979AIncrease capacityImprove the first Coulombic efficiencyCell electrodesSilicon monoxideShielding gas

The invention discloses a silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The silicon monoxide / silicon / lithium metasilicate composite negative electrode material comprises a silicon monoxide / silicon / lithium metasilicate composite material and an inorganic matter coating layer. The invention also provides a preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The preparation method comprises the following steps: taking silicon monoxide and an inorganic compound of lithium element, mixing and ball-milling the silicon monoxide and the inorganic compound of the lithium element, sintering the obtained mixture in a protection gas environment, and naturally cooling the sintered mixture to obtain the silicon monoxide / silicon / lithium metasilicate composite material; and mixing and ball-milling the silicon monoxide / silicon / lithium metasilicate composite material and sintering the obtained mixture undera protection gas condition. The preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material has the advantages of simplicity, safety, low cost, and easiness in operation and industrial production, and the obtained composite negative electrode material has the advantages of high reversible capacity, excellent cycle performances and high initial Coulomb efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Multifunctional graphene electrothermal paste, multifunctional electrothermal film prepared by same, preparation method and application

ActiveCN107682943AImprove machinabilityFast heat conductionChemical industryHeating element materialsCross-linkAviation

The present invention discloses multifunctional graphene electrothermal paste, a multifunctional electrothermal film prepared by the same, a preparation method and application. The preparation methodcomprises the following steps that: (1) graphene nanoplatelets are modified by introducing inducible lipidation and cross-linking reaction groups; (2) the modified graphene, a lipidizable and cross-linking reaction emulsion and various kinds of additives are subjected to liquid phase mixing, the above dispersion liquid is induced to undergo in-situ esterification and cross-linking reaction, so that graphene-based homogeneous electrothermal paste can be formed; (3) an electrothermal paste loading matrix is modified, so that the interfacial property of the electrothermal paste and the matrix material can be enhanced; and (4) the graphene electrothermal paste can be combined with different base materials, so that electrothermal products can be prepared. The graphene electrothermal material ofthe invention has the advantages of adjustable resistivity, adjustable use voltage, adjustable heating efficiency, far infrared heating function, flame retardancy, wide application range, high safety, energy-saving performance and the like, and can be applied to home building material manufacturing, human body care, aviation equipment, medical equipment, transportation pipelines, automobiles andother fields.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Novel heat-dissipation material and preparation method thereof

InactiveCN103214772AImprove interface performanceImprove compatibility and system dispersion stabilityPolyurea/polyurethane coatingsPigment treatment with macromolecular organic compoundsSolventDiluent

The invention relates to inorganic heat-dissipation nano-material aqueous slurry and a novel heat-dissipation material containing the inorganic heat-dissipation nano-material aqueous slurry and a preparation method of the novel heat-dissipation material. The inorganic heat-dissipation nano-material aqueous slurry comprises, by weight, 10 to 25 parts of an inorganic heat-dissipation nano-material, 0.5 to 20 parts of a modifier or a modifier solution, and 50 to 100 parts of a solvent. The novel heat-dissipation material comprises, by weight, 10 to 30 parts of the inorganic heat-dissipation nano-material aqueous slurry, 40 to 80 parts of an aqueous polymer resin, 20 to 30 parts of latex, 10 to 40 parts of a film forming auxiliary agent, 0.5 to 5 parts of an auxiliary agent and 5 to 20 parts of a diluent. The novel heat-dissipation material has excellent heat-dissipation performances.

Owner:SHENZHEN VKIRIN TECH DEV

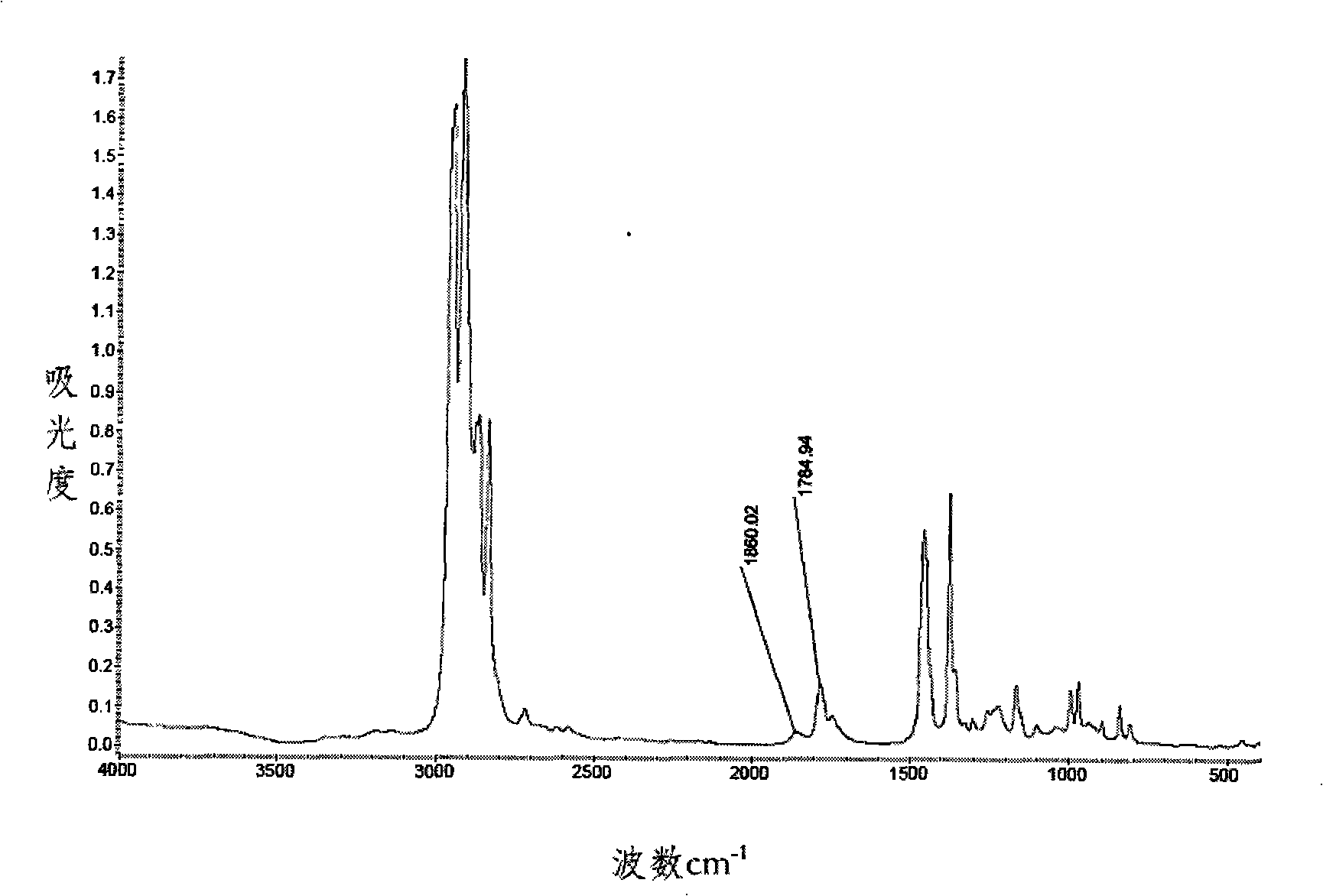

Method of preparing polypropylene graft polymer

The invention relates to a polypropylene graft polymer preparing method which is characterized in that: (a) calculated by weight parts, the polypropylene graft polymer comprises 100 parts of polypropylene, 0.1-20 parts of graft monomer maleic anhydride, 0.1-20 parts of graft monomer styrene monomer or vinyl acetate monomer, 0.01-10 parts of peroxide initiator and 1-20 parts of other vinyl monomers; (b) the graft monomers, the initiator and the polypropylene are evenly mixed; (c) the reactants are heated to reach a temperature of 70-120 DEG C and then react for 1-10 hours; and (d) after the reaction, the polypropylene graft polymer can be obtained through cooling. During the implementation of the method, no solvent, suspending medium or interfacial agent needs to be used, the obtained product can be applied without needing further treatment, for example, a compatilizer for a polypropylene composite material; and the obtained product is particularly used for improving the interfacial compatibility and dispersivity of inorganic filler and polyolefine. The conversion rate of the graft monomers of the invention is greater than 95 percent, and at least 55 percent of the graft monomers form graft polypropylene.

Owner:BEIJING UNIV OF CHEM TECH

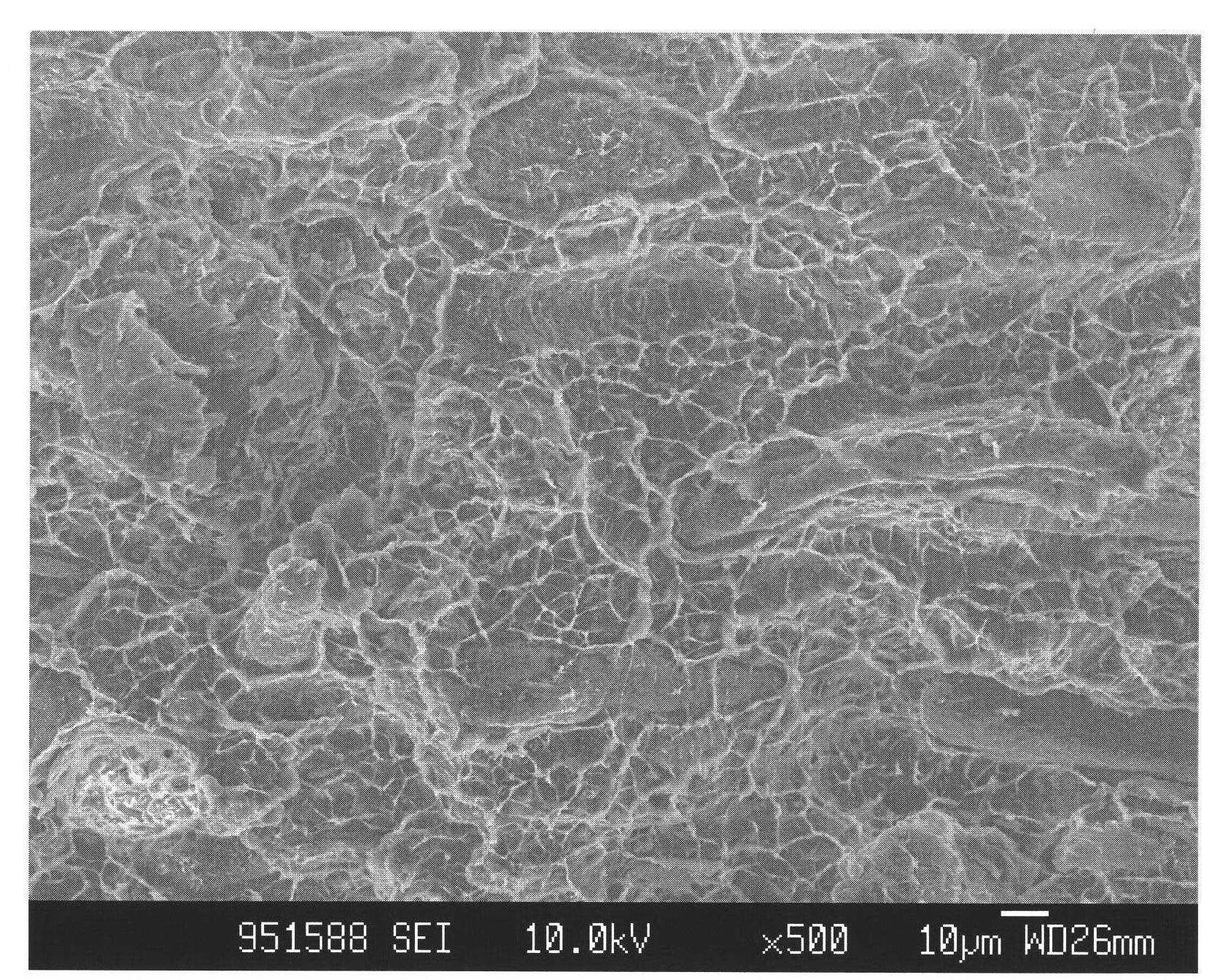

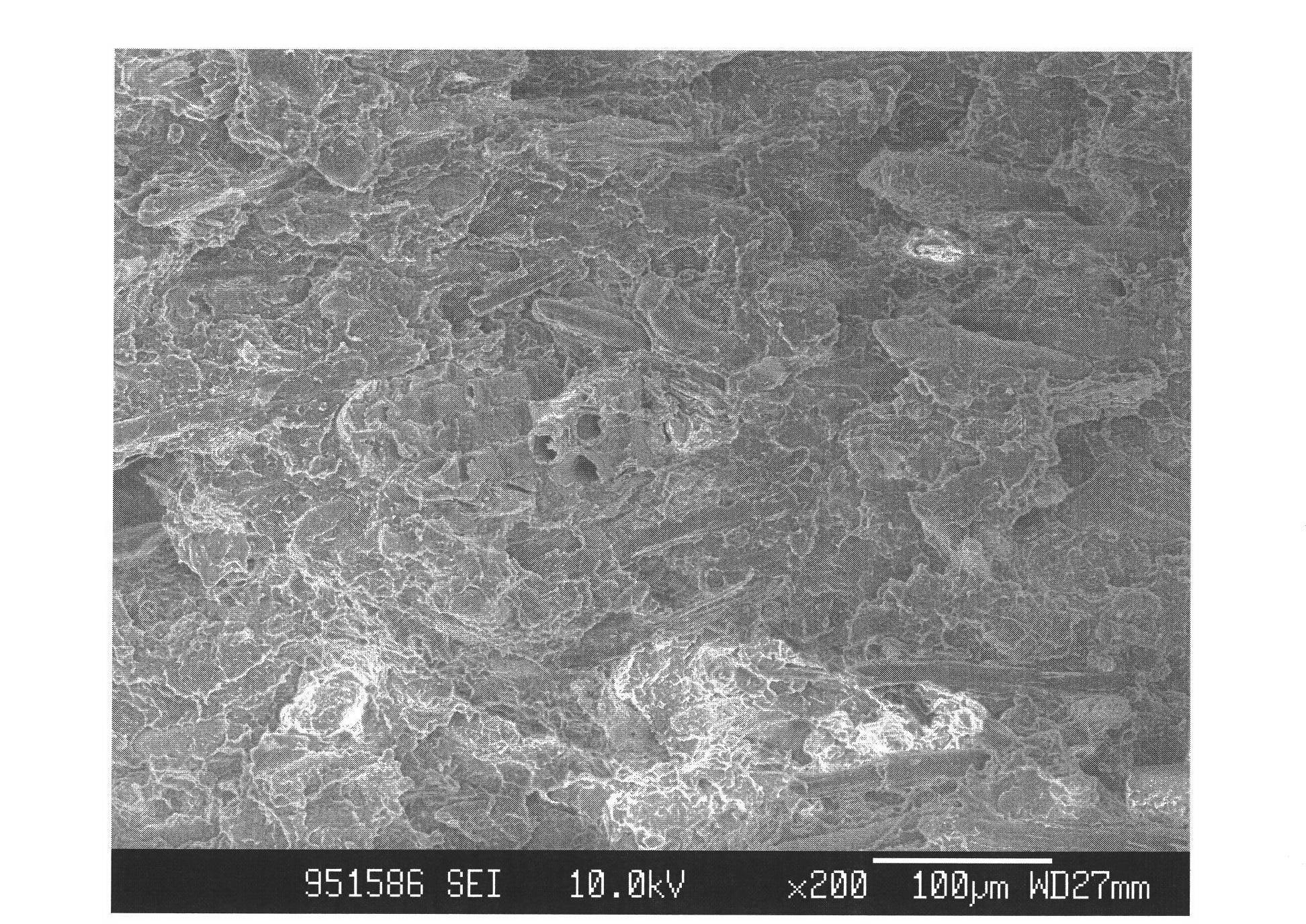

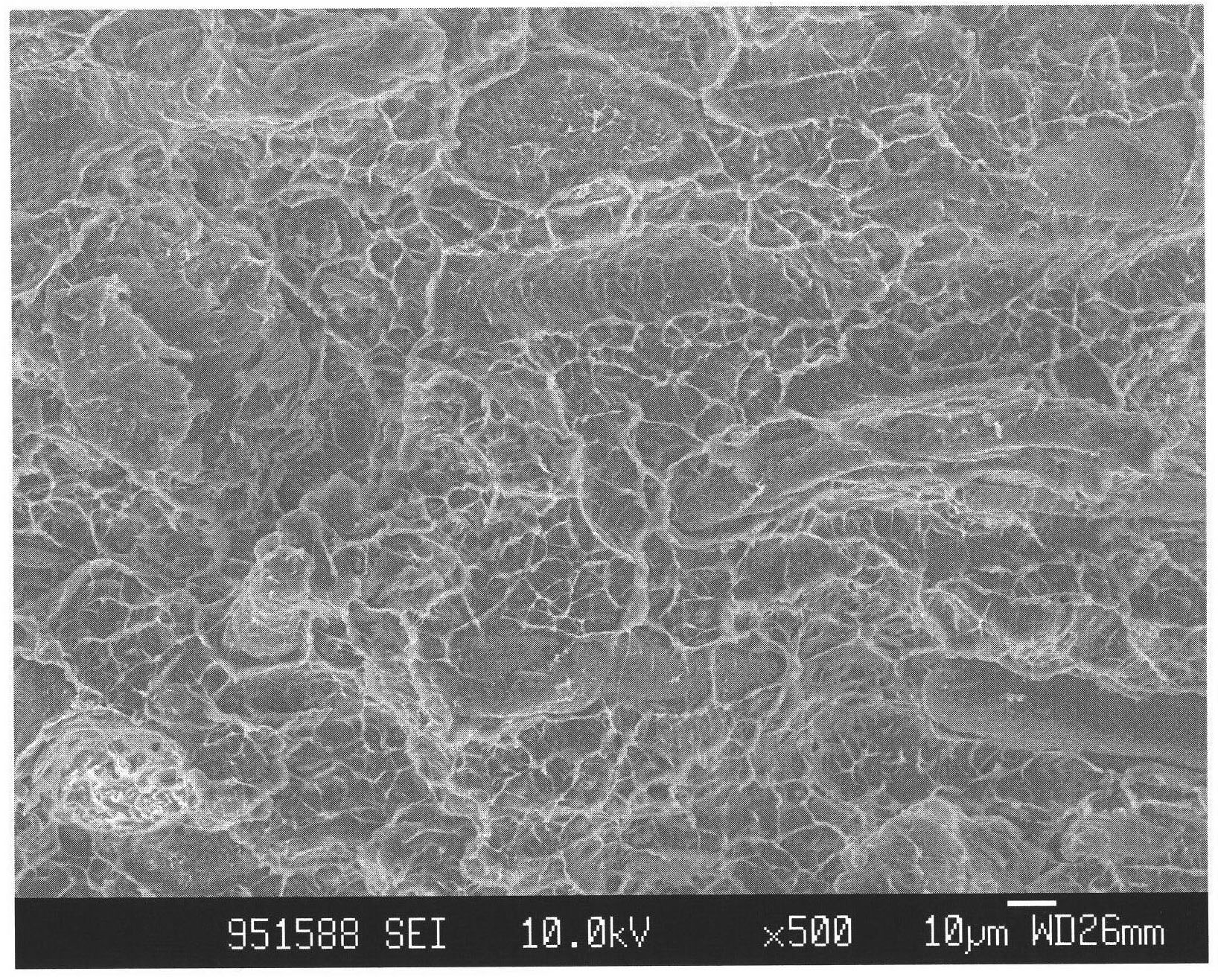

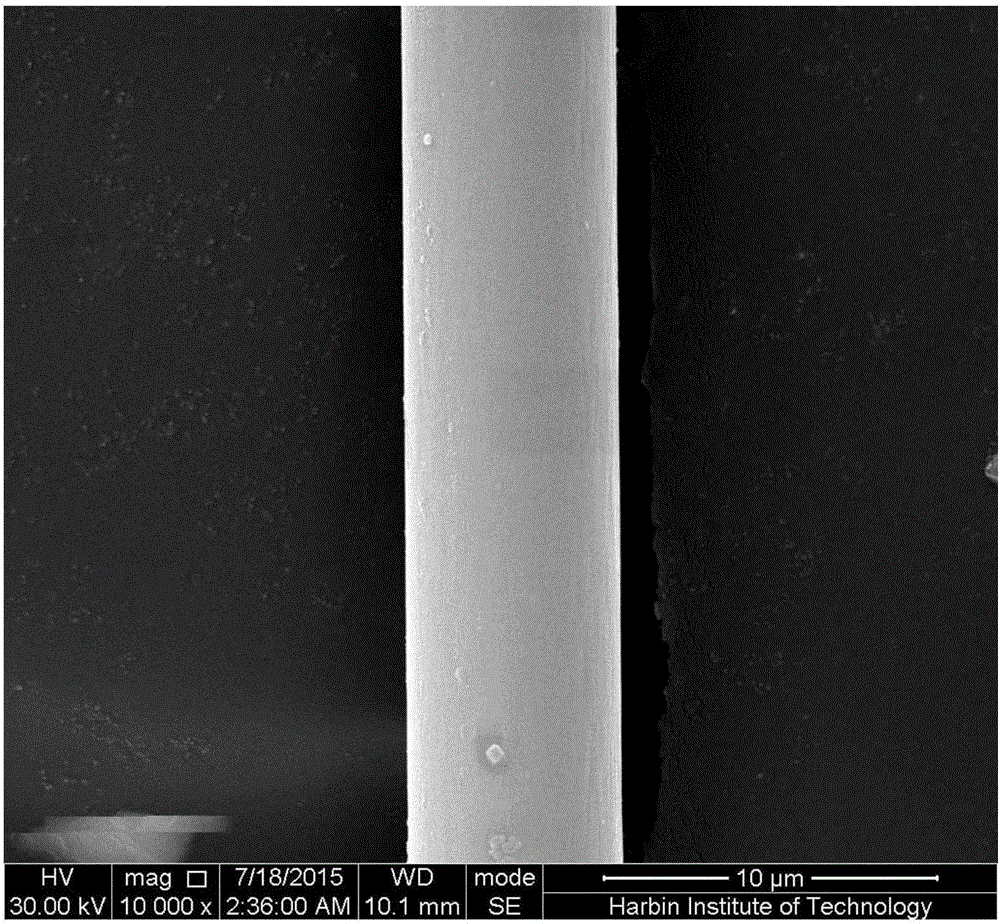

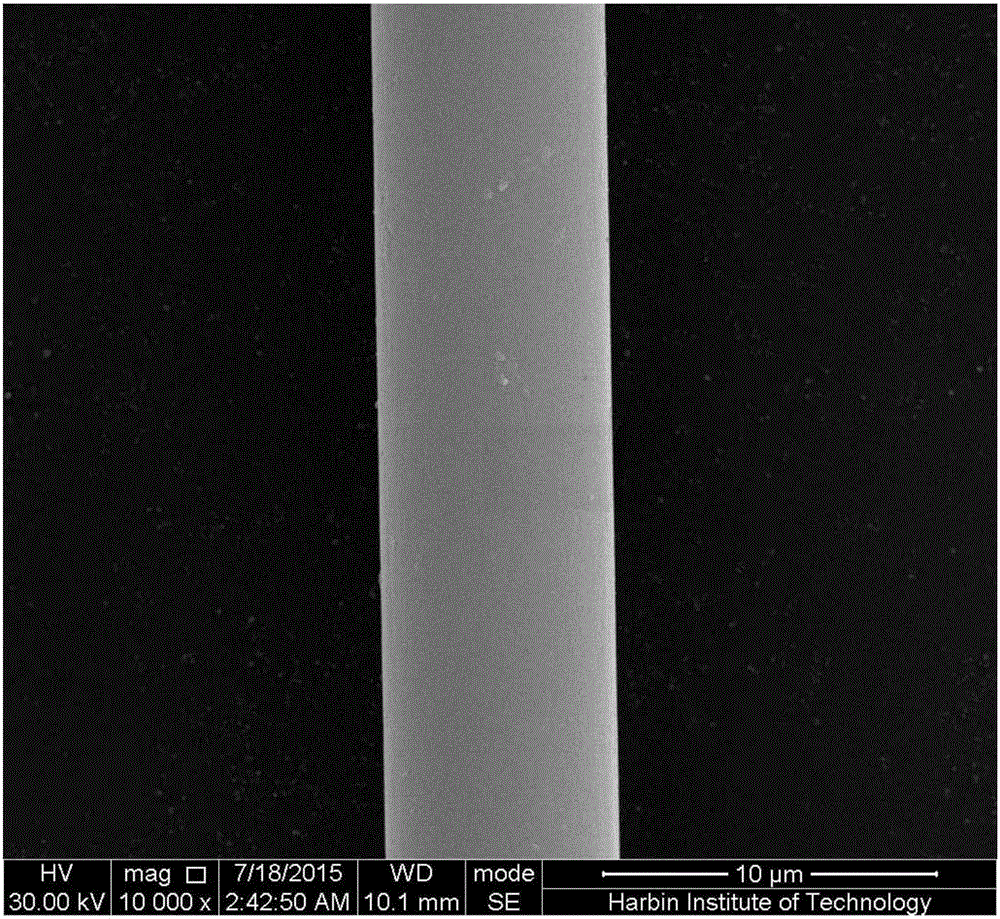

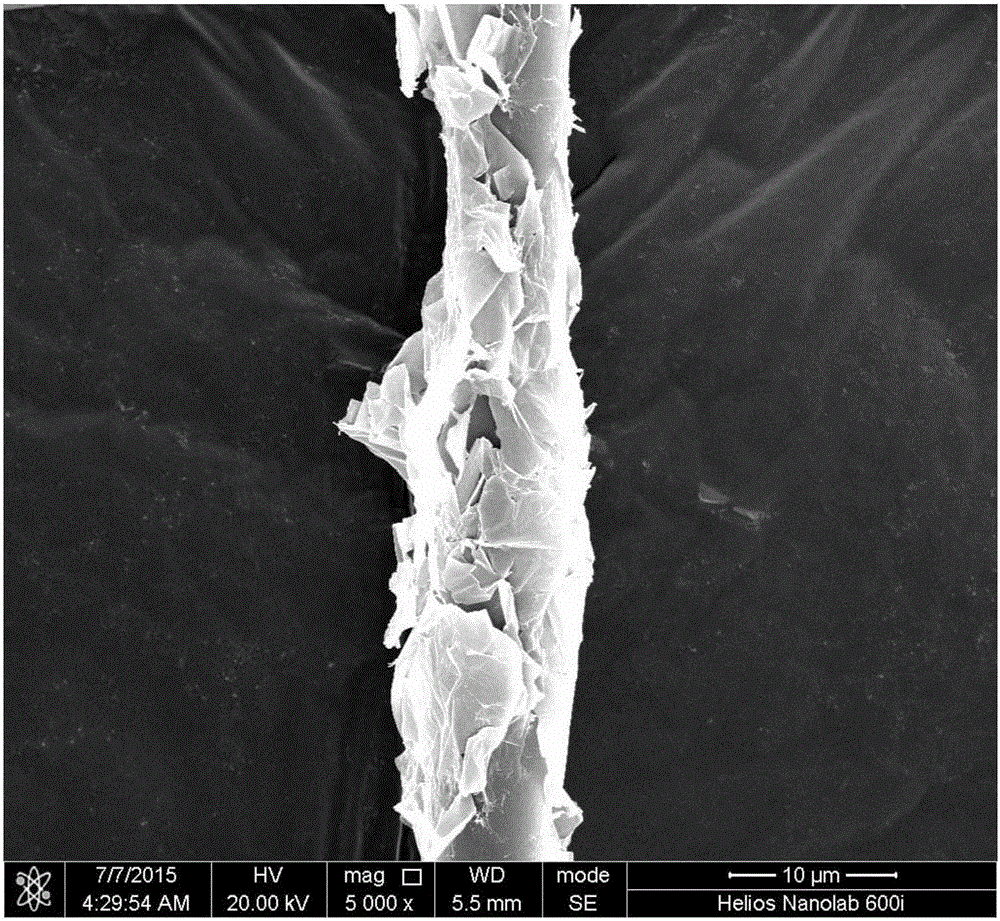

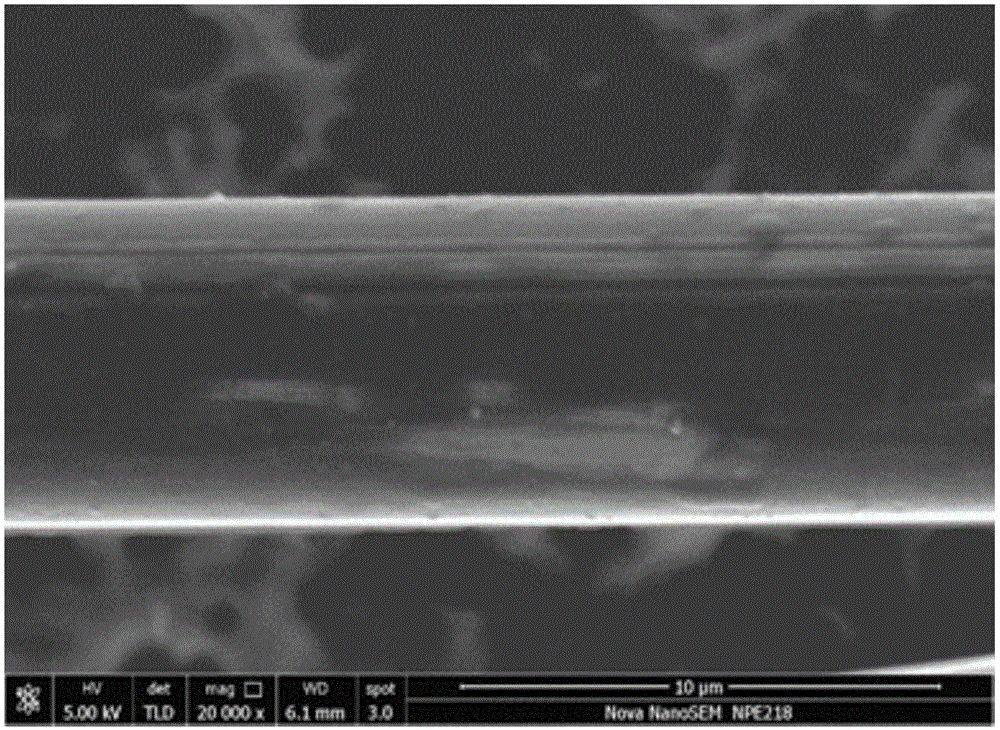

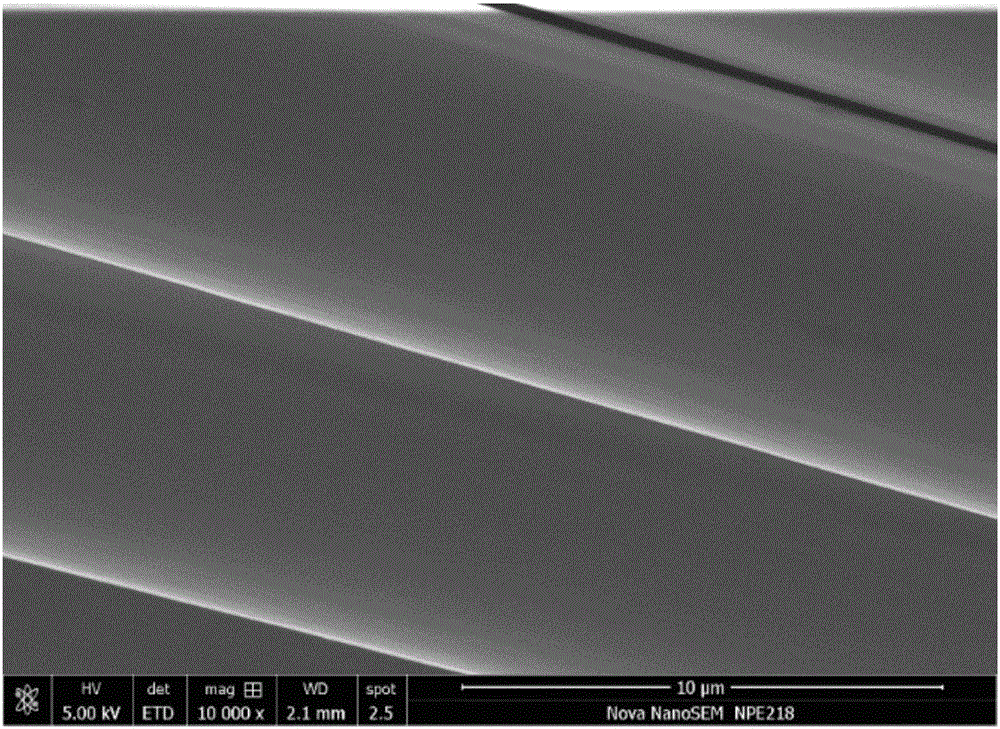

Method of chemically-grafting graphene oxide onto surface of carbon fiber

InactiveCN105239357AImprove surface roughnessImprove surface wettabilityCarbon fibresFiberCarbon fibers

A method of chemically-grafting graphene oxide onto surface of carbon fibers. The invention relates to a surface modification method of the carbon fibers and aims to solve the problems of high surface inertia, low surface energy and poor mechanical and thermal performances of the carbon fibers in the prior art. The method includes following steps: (1) preparing graphene oxide through improved Hummer's method; (2) oxidizing the carbon fibers; (3) performing surface modification amination treatment to the carbon fibers; and (4) chemically-grafting the graphene oxide onto the surface of the carbon fibers. The surface of the carbon fibers is improved significantly in wettability and adhesivity and is significantly improved in roughness after grafting, so that the strength and toughness of the carbon fiber are significantly improved, wherein the strength is increased by 20-25% than carbon fiber raw filament and the toughness is increased by 35-40% that the carbon fiber raw filament. The method is used for surface modification of the carbon fibers.

Owner:HARBIN INST OF TECH

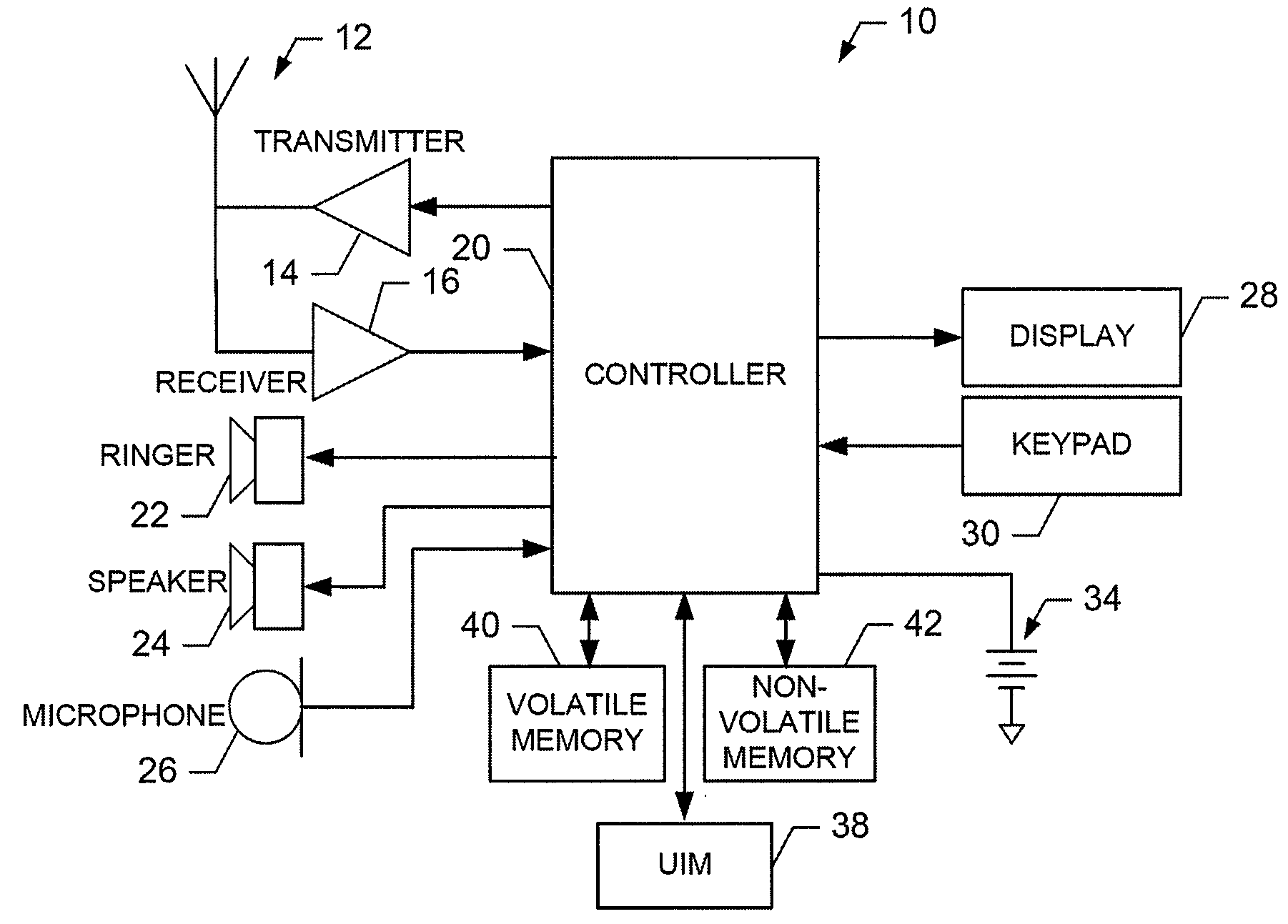

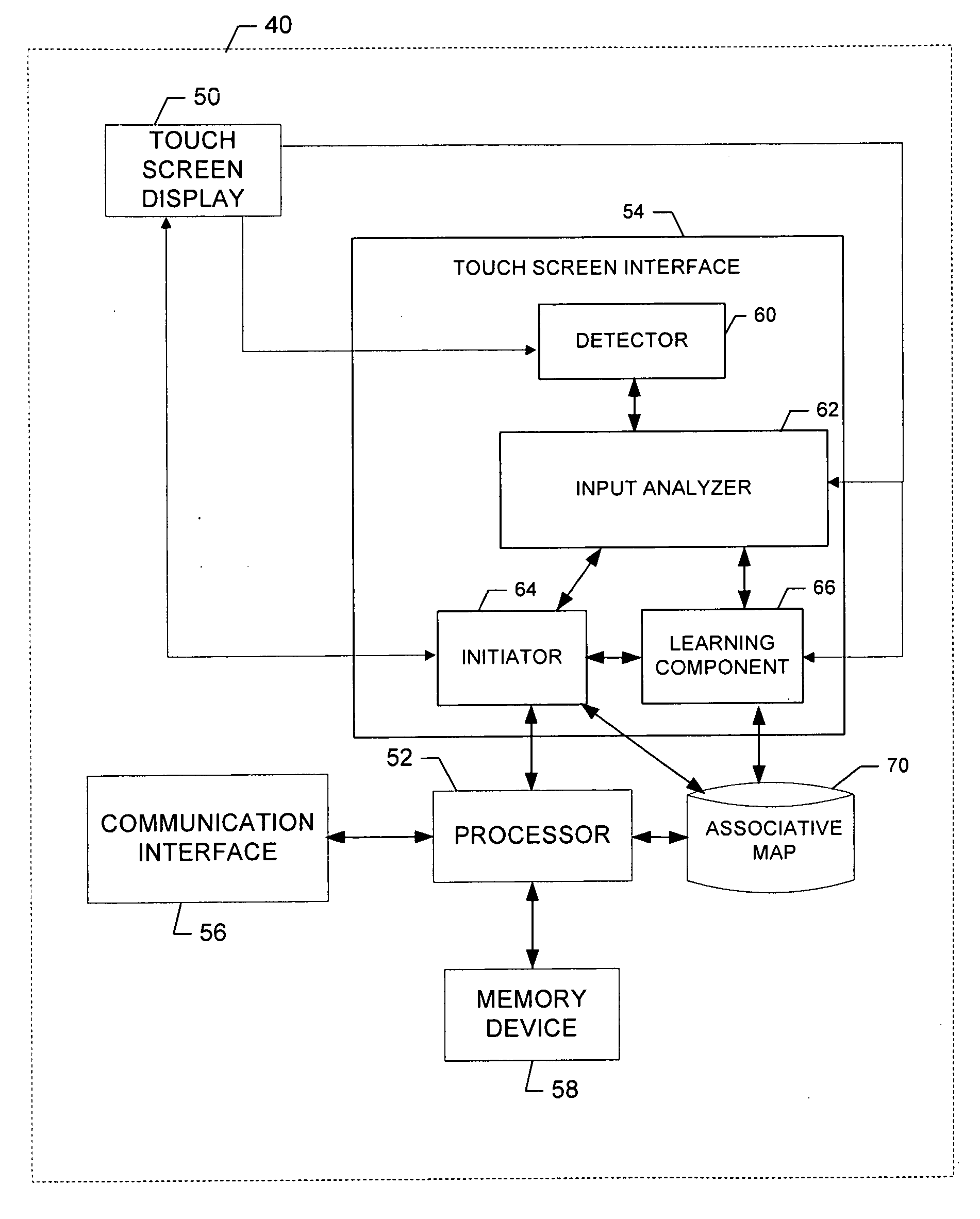

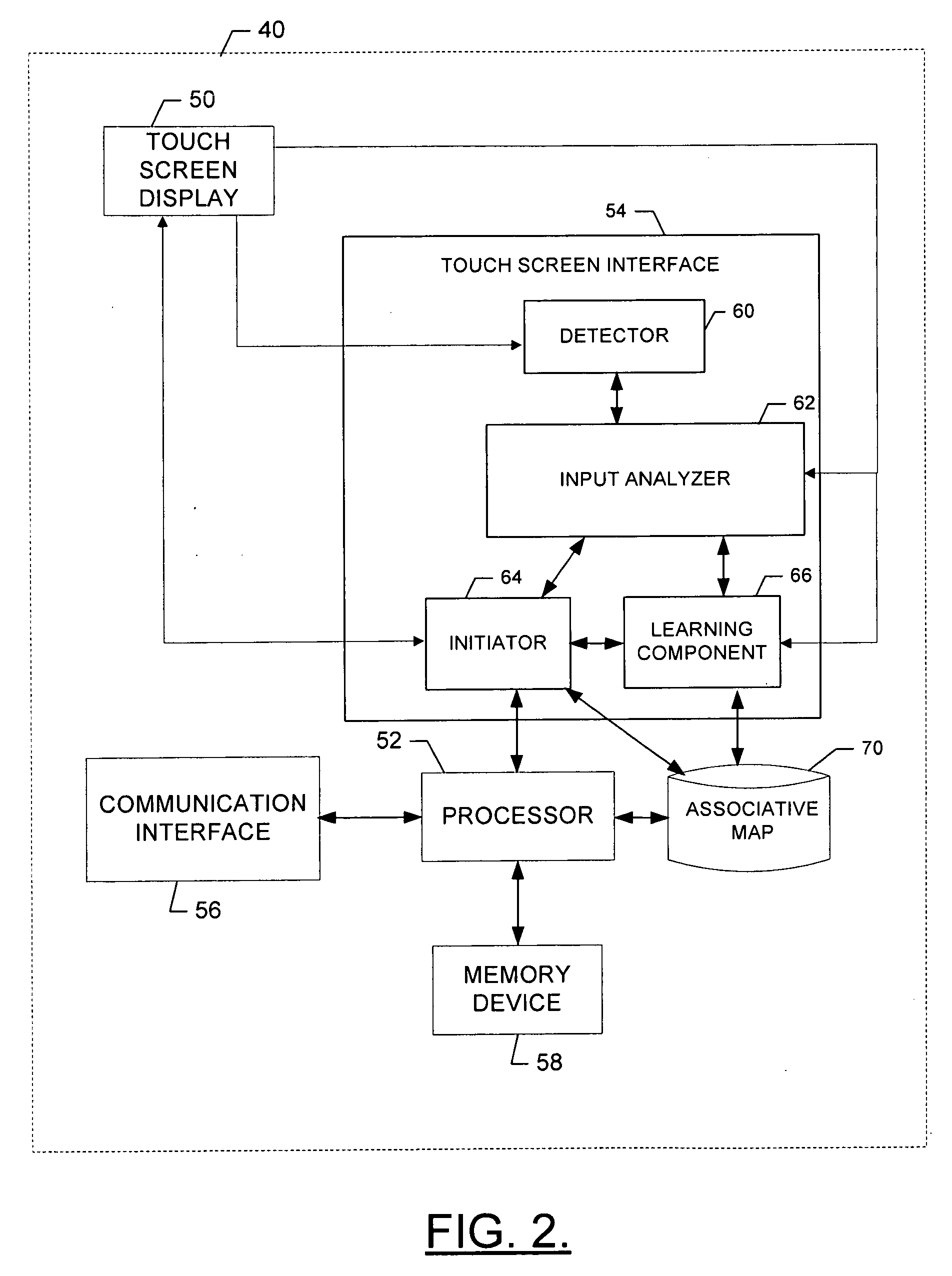

Method, apparatus and computer program product for providing a personalizable user interface

ActiveUS20100164877A1Increase capacityImprove interface performanceExecution for user interfacesInput/output processes for data processingPersonalizationGraphics

An apparatus for providing a personalizable user interface may include a processor. The processor may be configured to receive a drawing input at a touch screen display, determine whether the drawing input corresponds to a stored graphic element that is associated with a function, and initiate the function in response to determining that the drawing input corresponds to the stored graphic element. A corresponding method and computer program product are also provided.

Owner:NOKIA TECHNOLOGLES OY

Conductive graphene printing ink and preparation method thereof

The invention provides a conductive graphene printing ink. The conductive graphene printing ink is composed of 0.001-80wt% of graphene, 1-60wt% of a linking material, 0.1-30wt% of an assistant, and the balance solvent. The invention also provides a preparation method of the conductive graphene printing ink. The conductive graphene printing ink has the advantages of good toughness, good die molding performance, good adhesion and good impact resistance; chemically doped graphene and chemically modified graphene in the graphene have good conductive, mechanical and thermal performances. The molecules of the chemically doped graphene comprise one or more of polyaniline, polyacetylene, polythiophene, polyparaphenylene and polypyrrole, and the functional groups of the chemically modified graphene comprise one or more of an anilino group, a pyrryl group, an imidazolyl group, a benzenesulfonic acid group, a thienyl group, a furyl group, a phenyl group, a hydroxy group, an ester group and derivative groups thereof, so the conductive performance, the mechanical performances and the dispersion stability of graphene in the printing ink are improved.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

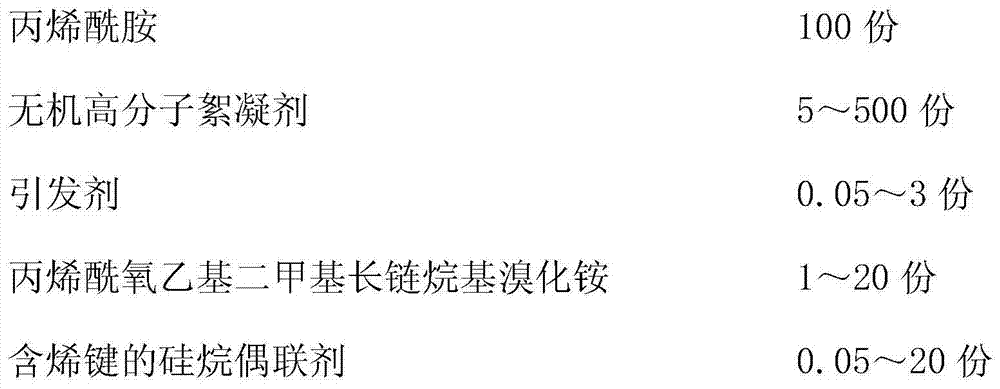

Polyacrylamide composite flocculant and preparation method thereof

ActiveCN104724808AAchieve synergistic and efficient flocculationImprove interface performanceWater/sewage treatment by flocculation/precipitationPolyacrylamidePolymerization

The invention discloses a polyacrylamide composite flocculant and a preparation method thereof. The polyacrylamide composite flocculant is synthesized in situ by the following steps: carrying out inorganic high polymer flocculant surface treatment on acrylamide, an inorganic high polymer flocculant, an initiator, acryloyloxyethyldimethyl long-chain alkyl ammonium bromide and an olefinic-bond-containing silane coupling agent, preparing the polyacrylamide in-situ composite flocculant, and the like. The acrylamide molecule is introduced to the cationic flexible long branched chain structure, so that the physical entanglement network structure can better display the bridge mesh function. By compounding the inorganic high polymer flocculant with the cationic polyacrylamide, the reactive coupling agent is adopted to modify the inorganic high polymer flocculant surface, and the coupling agent molecule participates in the acrylamide polymerization reaction to graft the inorganic high polymer flocculant molecule onto the polyacrylamide molecule, thereby enhancing the interface action between the inorganic high polymer flocculant and polyacrylamide molecule and the adsorption, neutralization, sweep mesh actions on pollutants in sewage.

Owner:四川省科学城天人环保有限公司

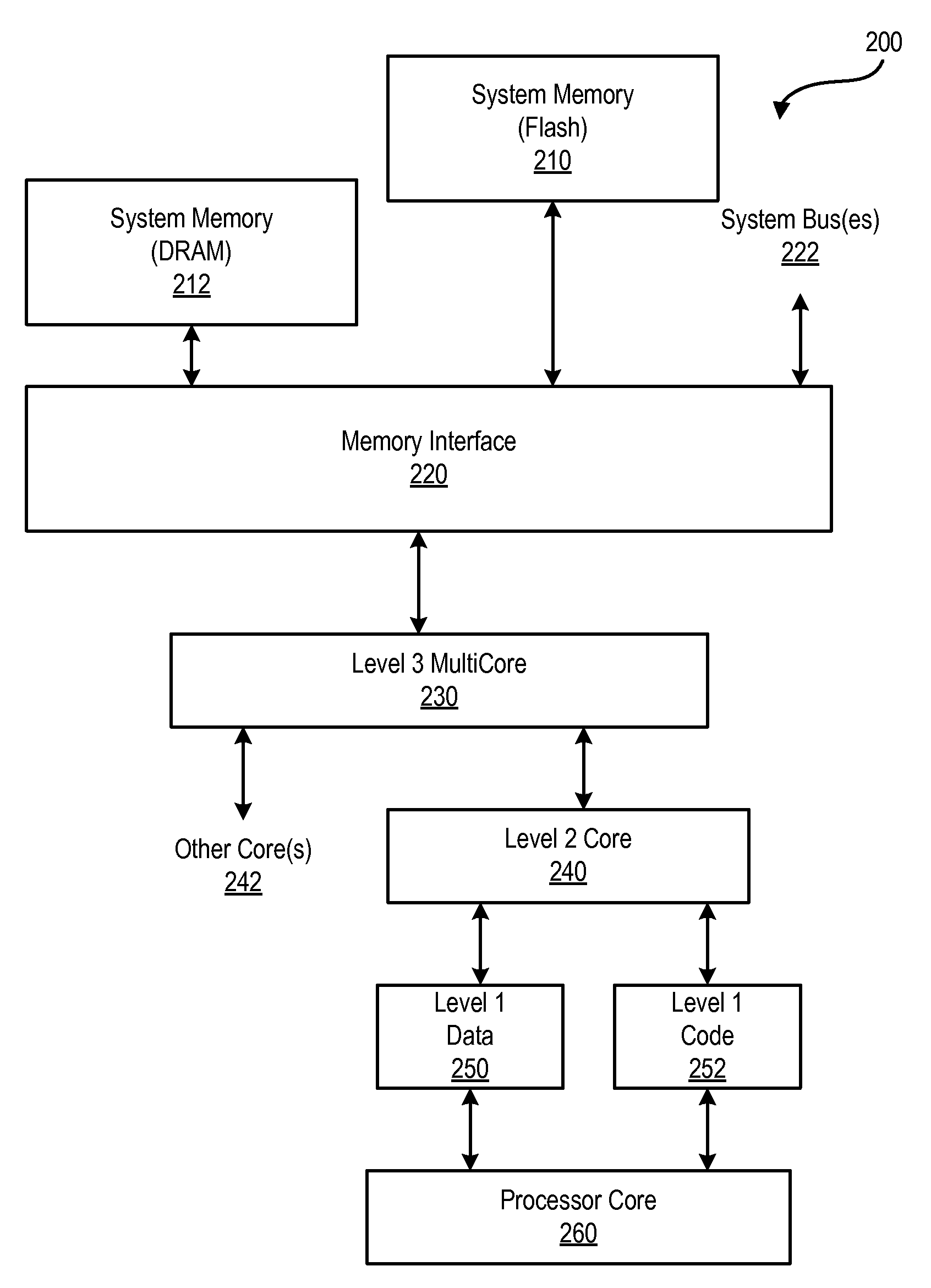

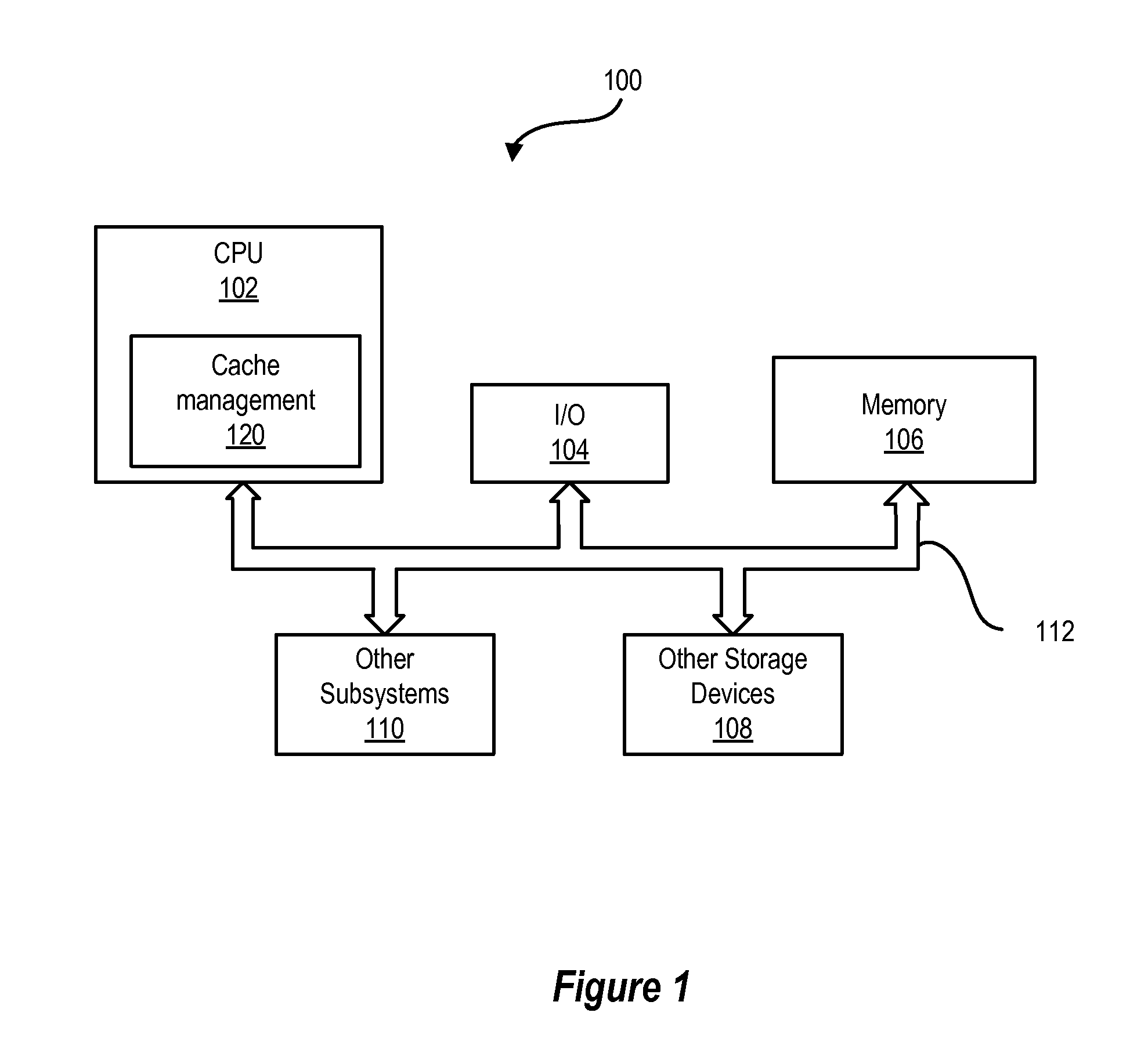

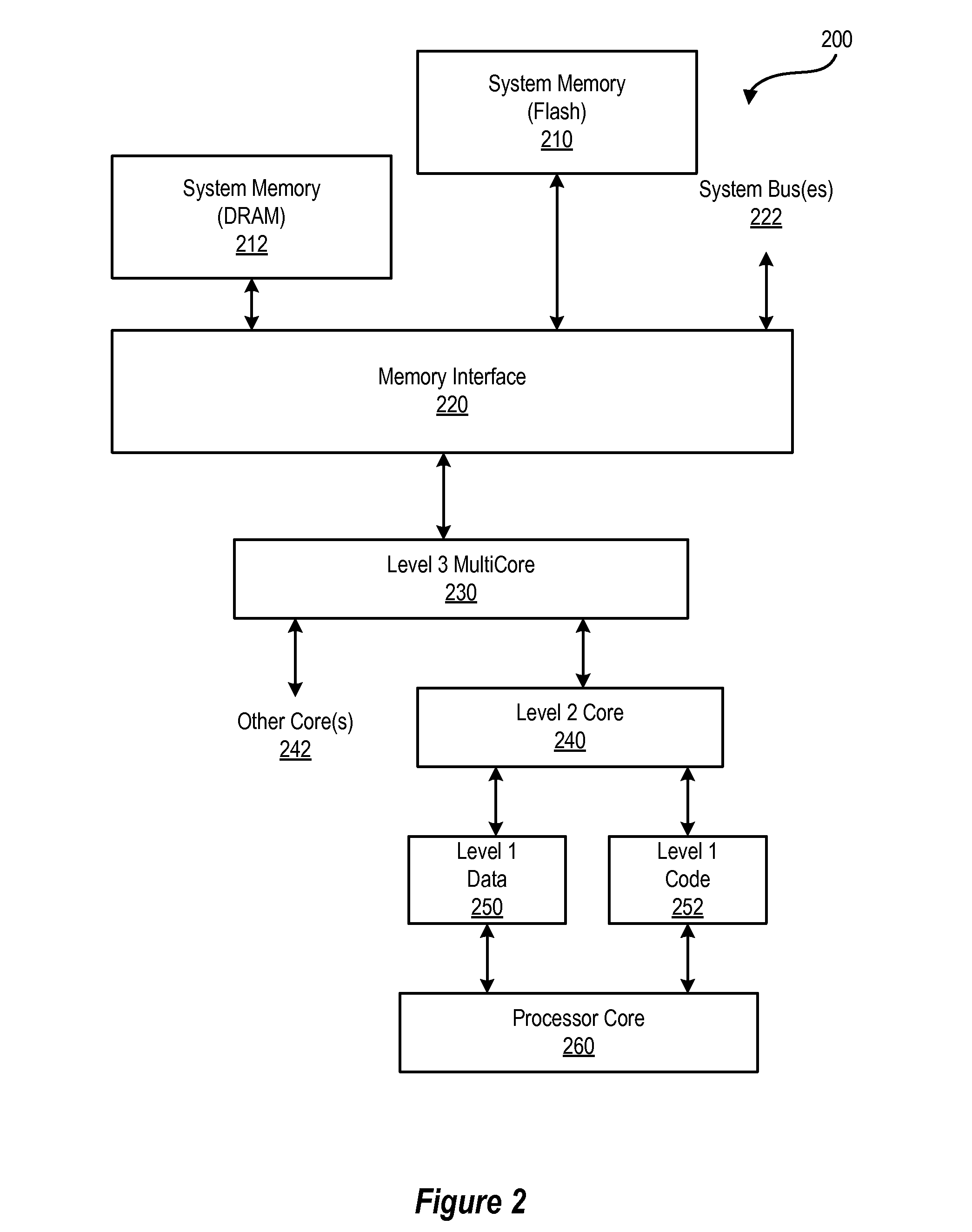

Multiple Cache Line Size

InactiveUS20100185816A1Improve performanceLow costMemory architecture accessing/allocationMemory adressing/allocation/relocationCache hierarchyParallel computing

A mechanism which allows pages of flash memory to be read directly into cache. The mechanism enables different cache line sizes for different cache levels in a cache hierarchy, and optionally, multiple line size support, simultaneously or as an initialization option, in the highest level (largest / slowest) cache. Such a mechanism improves performance and reduces cost for some applications.

Owner:DELL PROD LP

Continuous long fiber reinforced thermoplastic polyurethane material and preparation method thereof

The invention belongs to the technical field of high polymer materials and discloses a continuous long fiber reinforced thermoplastic polyurethane material and a preparation method thereof. The continuous long fiber reinforced thermoplastic polyurethane material disclosed by the invention comprises the following components in parts by weight: 200-800 parts of thermoplastic polyurethane, 800-200 parts of continuous long fiber reinforcing agent, 10-30 parts of compatilizer, 10-20 parts of antioxidant, 2-6 parts of lubricating agent and 5-10 parts of crosslinking agent. Compared with the prior art, the continuous long fiber reinforced thermoplastic polyurethane material disclosed by the invention is simple in structure, reasonable in design and strong in practicability; and a long glass fiber reinforced thermoplastic polyurethane material is adopted, thereby greatly improving the rigidity and strength of the material and obviously improving the anti-impact property and heat-resistant property of the material.

Owner:HEFEI GENIUS NEW MATERIALS

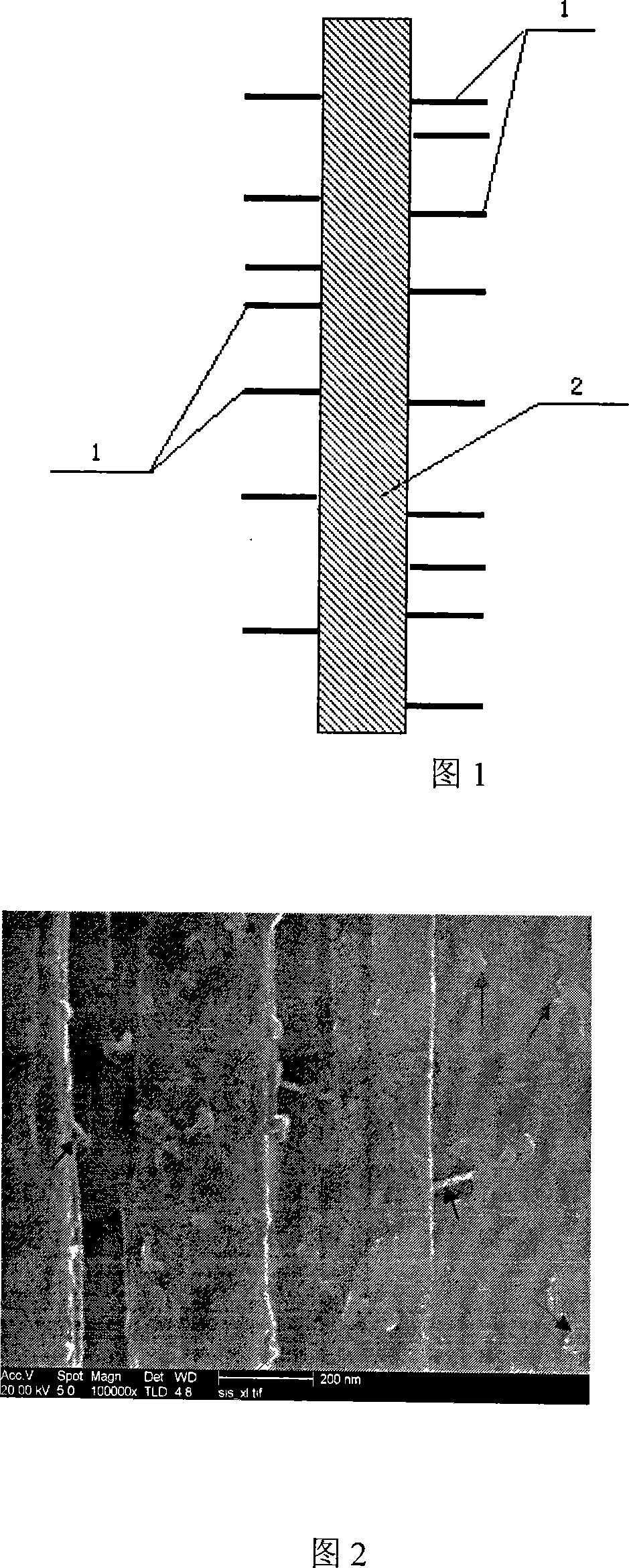

Carbon nano-tube connecting carbon fiber multi-scale reinforcing body and method for producing the same

InactiveCN101173386ATake full advantage of mechanical propertiesRealize chemical bond connectionFibre treatmentArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a multi-scale reinforcement body that carbon nano-tube is connected with carbon fiber and a preparation method aiming at solving the drawbacks of increasing rigidity at the interface, lowering toughness of material and not improving performance of resin base between the fibers and between carbon fiber plywoods after prior carbon fiber treatment is made. The multi-scale reinforcement body of carbon nano-tube connecting carbon fiber is made through combining between a carbon nano-tube decorated by 1, 6 hexamethylenediamine and carbon fiber with acyl chloride functional group on the surface. The preparation method comprises: the carbon nano-tube decorated by 1, 6 hexamethylenediamine and the carbon fiber with acyl chloride functional group on the surface are prepared before put into N,N-dimethylformamide for reaction, thereby getting the multi-scale reinforcement body of carbon nano-tube connecting carbon fiber. The invention has the advantages of big activity on the surface, a plurality of chemical activated functional groups, strong reactive activity, good cohesiveness with the base, improving shearing intensity at the interface for composite material by 127.5% to 144.7% and improving toughness for the base by 34.43% to 48.67%.

Owner:HARBIN INST OF TECH

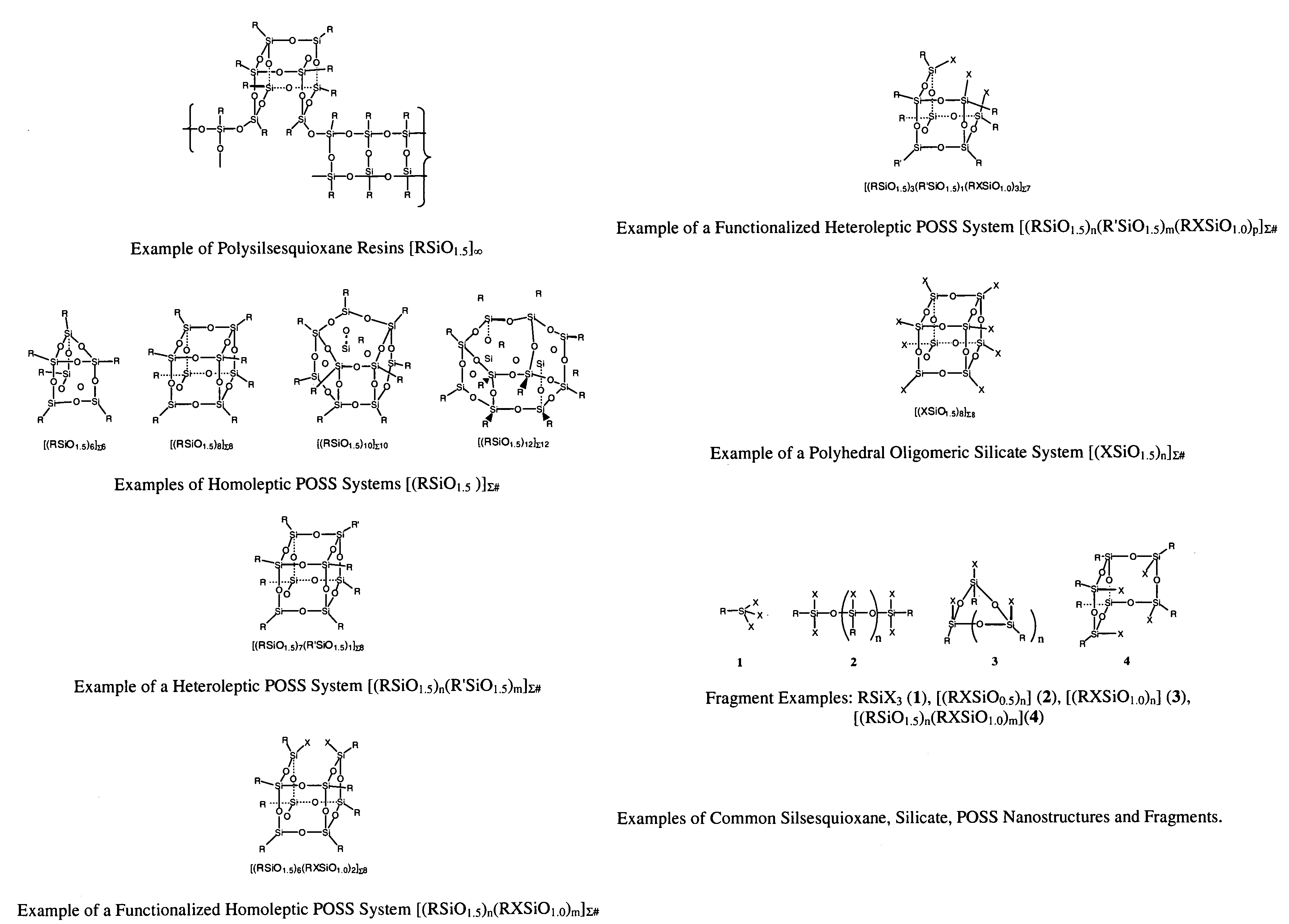

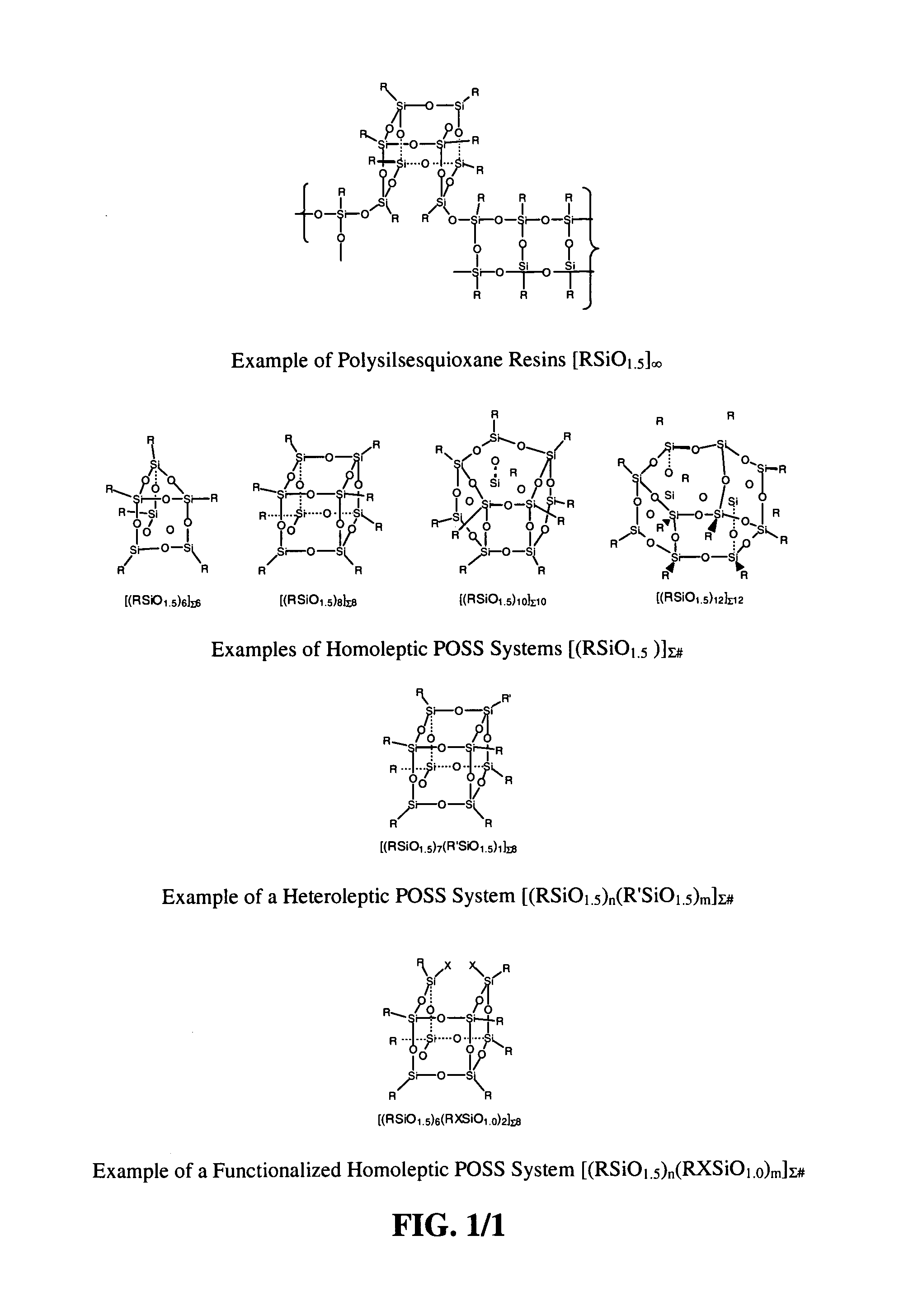

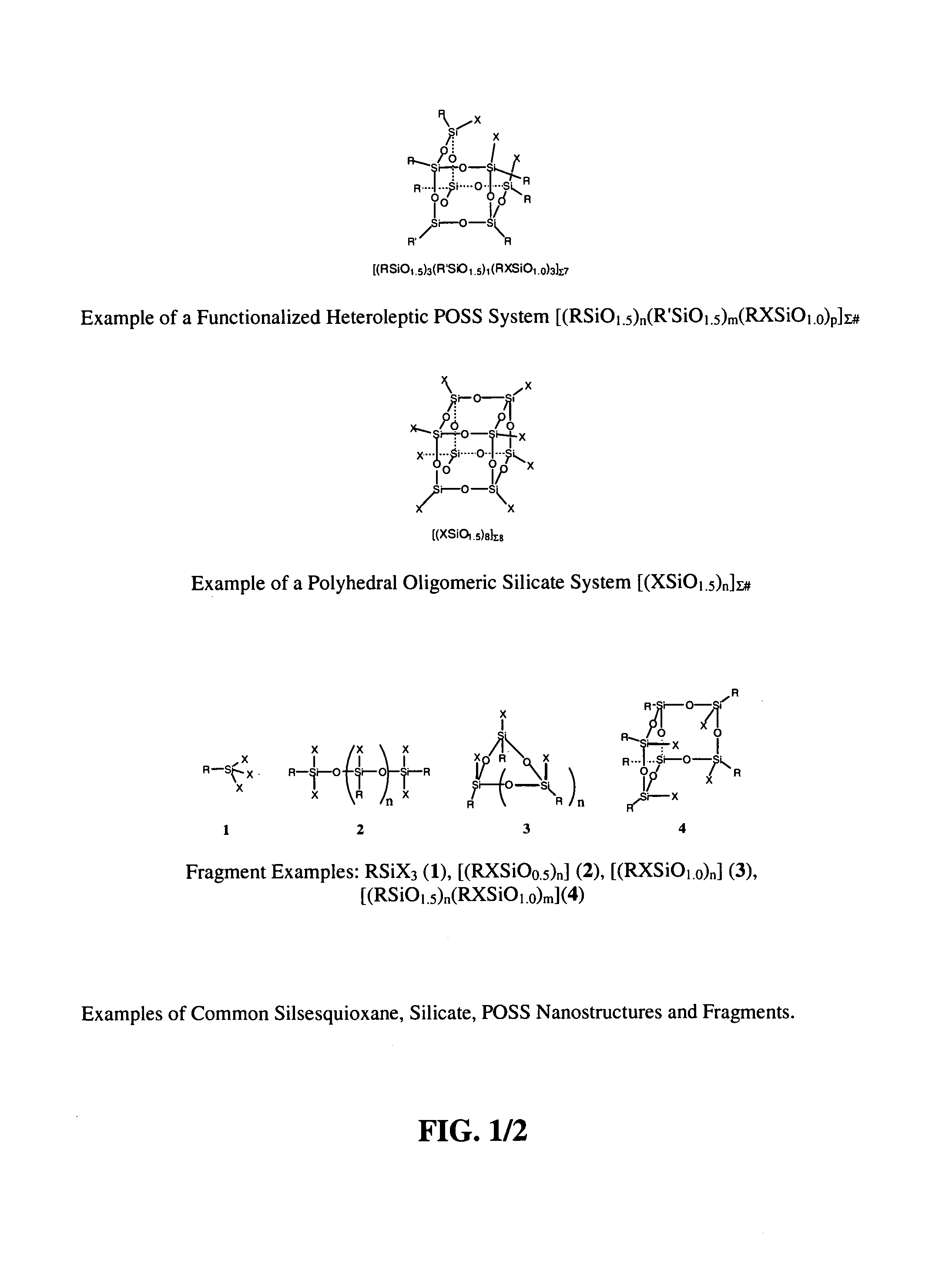

Lubrication via nanoscopic polyhedral oligomeric silsesquioxanes

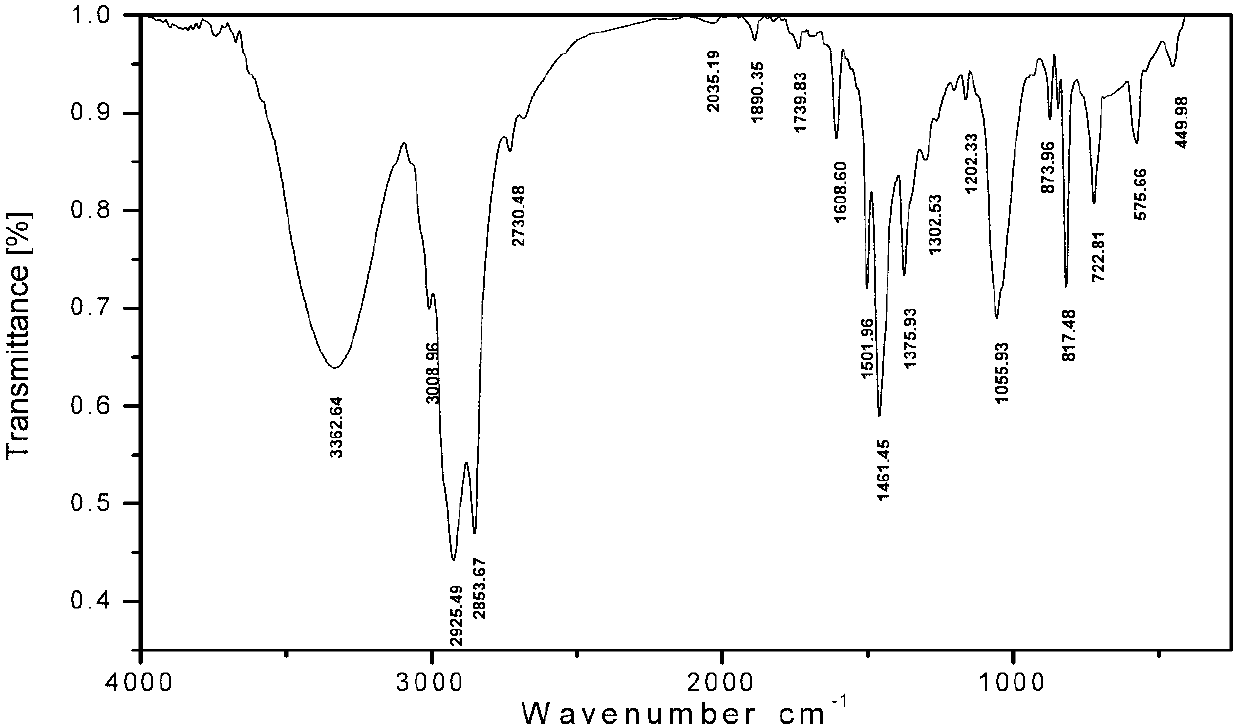

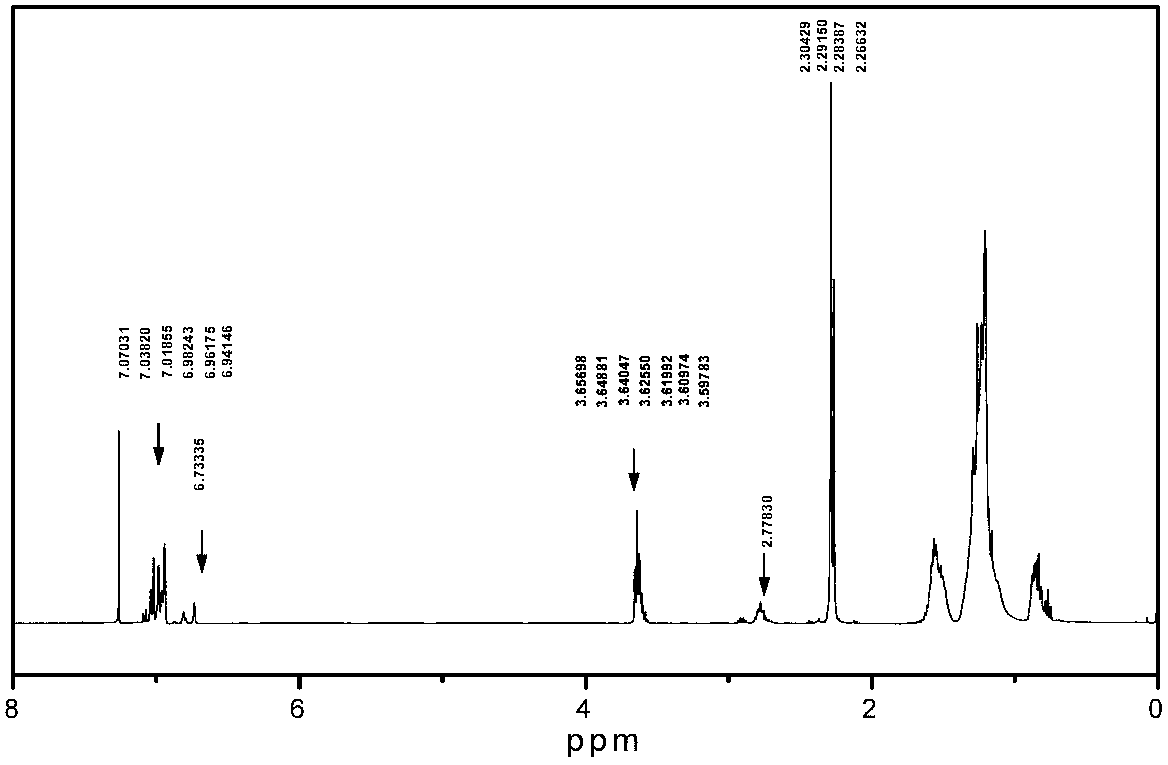

ActiveUS7217683B1Improve interface performanceIncrease frictionBearing componentsAdditivesNano sizeChemical potential

Nanoscale chemicals based on polyhedral oligomeric silsesquioxanes (POSS) and polyhedral oligomeric silicates (POS) are taught as lubricants, mold release agents, and as additives to control the viscosity, lubrication, wear, and thermal properties of conventional lubricous materials. The precisely defined nanoscopic dimensions of POSS materials enable viscosity, miscibility, and thermal properties to be (increased) or reduced (decreased) as desired. A key feature to the successful tailoring of properties is the inherent thermal and chemical stability of the POSS / POS nanostructure and the ability to control its topology and chemical potential to match that of surfaces and other materials.

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE SEC OF THE AIR FORCE

Method for preparing lithium iron phosphate as lithium ion cell positive-pole material

ActiveCN101070148AImprove interface performanceExcellent lithium ion conductivityElectrode manufacturing processesPhosphorus compoundsLithium iron phosphatePhosphate

It is a kind of preparation method of lithium iron phosphate which is an anode material of lithium ion battery, it adopts two-step technics: firstly, mix the following material such as iron, lithium and phosphate evenly and compound lithium iron phosphate of better crystal degree at lower temperature; then mix up lithium iron phosphate and composite conductive agent (inorganic conductive matter and precursor which is a carbon-contained conductive agent) sufficiently, it can get anode material of lithium ion battery which has a good electrochemistry capability through heat processing for short time at higher temperature, and the material has a good crystal performance and a strong interface function with conductive agent which makes material's conductivity of lithium ion and electron high, and it is suitable for charge / discharge of large rate. This technique's material is cheap chemical product, the composed techniques is simple, it is easy for large-scale production, the method to add conductive agent of electron is unique, electrochemistry capability of the products is of good performance.

Owner:WUXI KAITIANXING PHOTOELECTRIC MATERIAL

Method for performing amino functionalizing on carbon fiber surface

InactiveCN105113260AWill not damage the structureRetain high-strength and high-model featuresCarbon fibresFiberState of art

The invention relates to a method for performing amino functionalizing on a carbon fiber surface. The method comprises the steps that the fiber surface is coated with a copolymer coating containing a large amount of active amino by utilizing a Michael addition and Schiff base reaction of dopamine and poly-amino molecules through a one-step solution dipping method. Compared with the prior art, the method is simple in technology and mild in condition, does not damage a fiber body structure and can effectively increase active groups of the carbon fiber surface, and therefore the interface bonding property between fiber and resin is improved.

Owner:SHANGHAI JIAO TONG UNIV

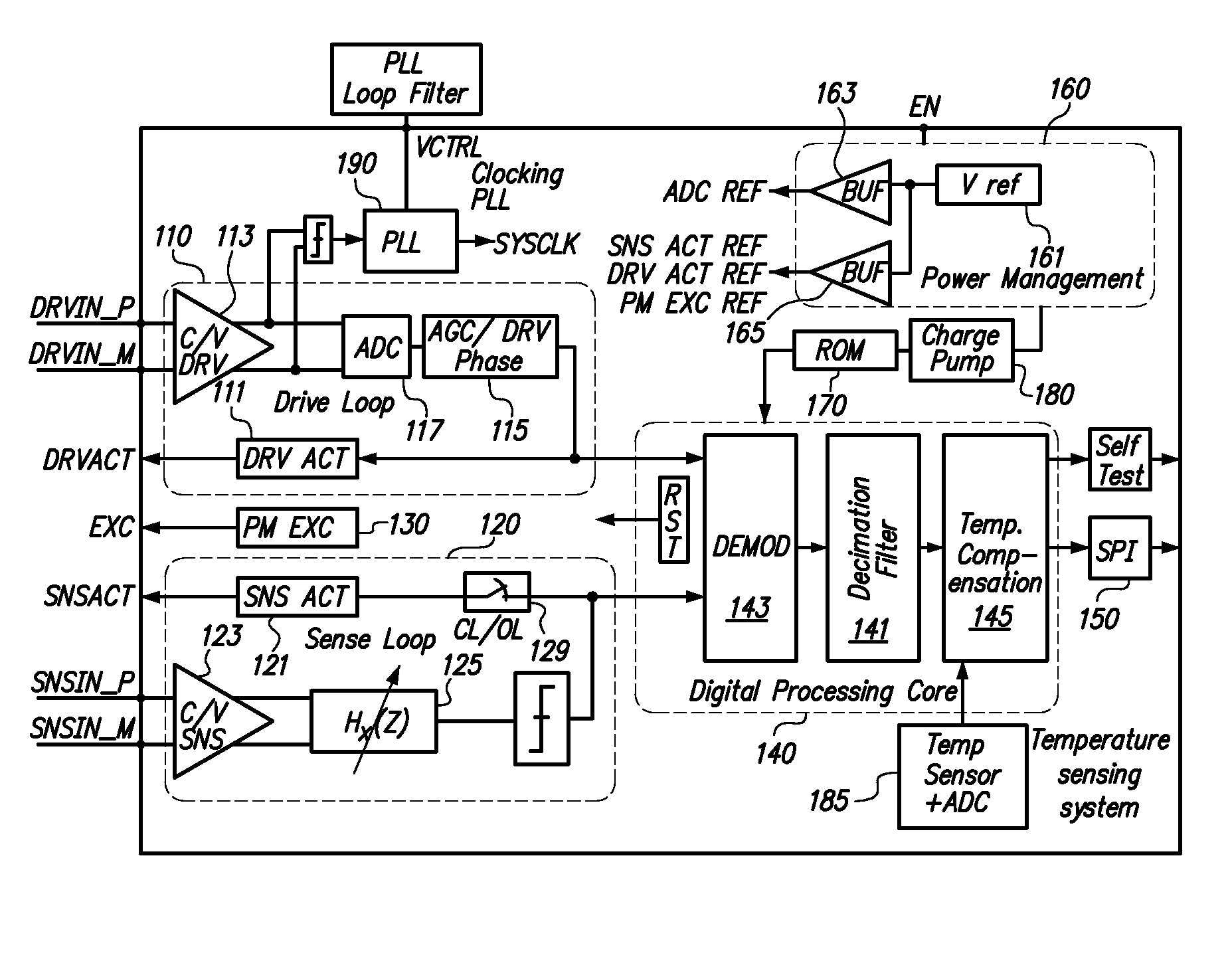

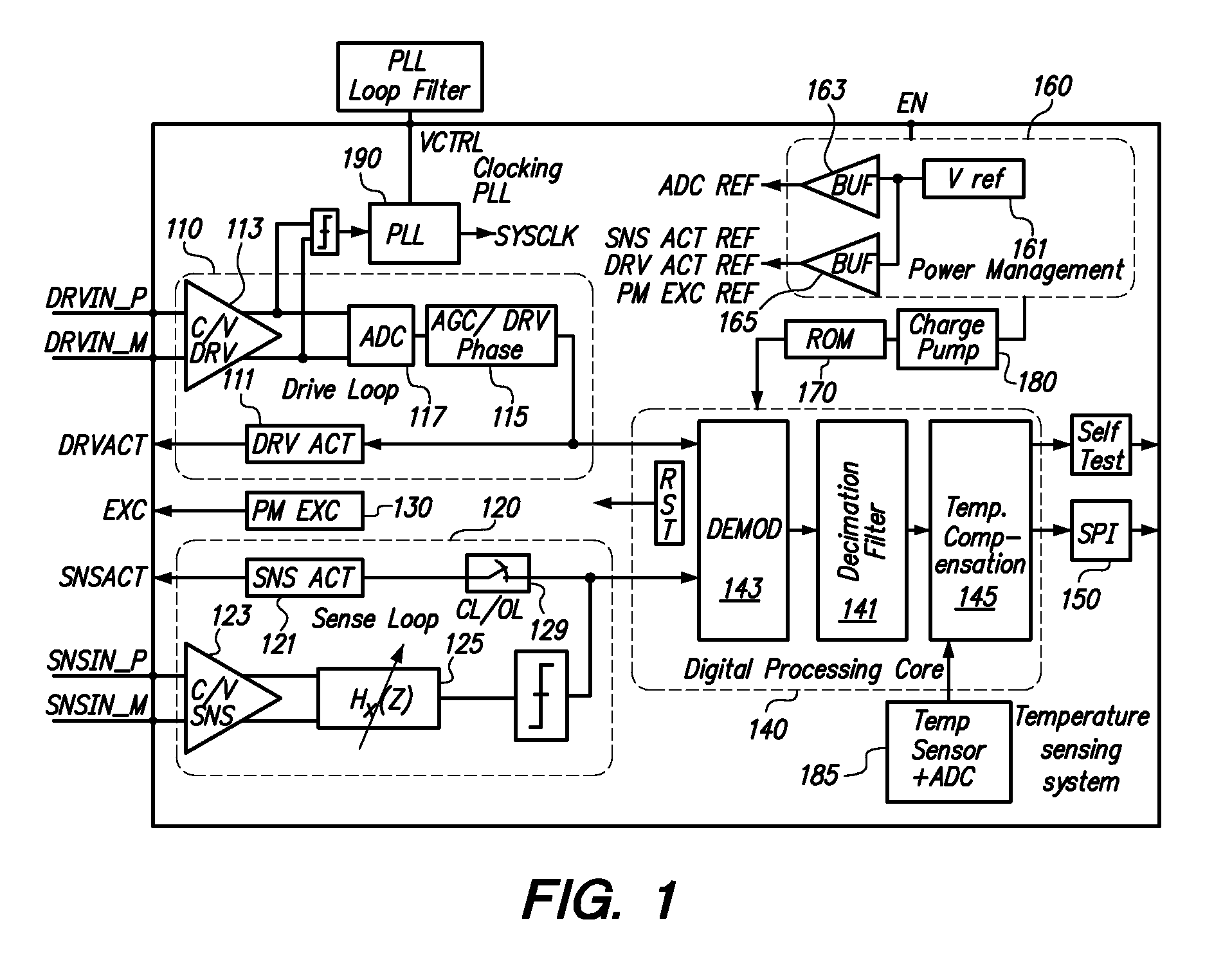

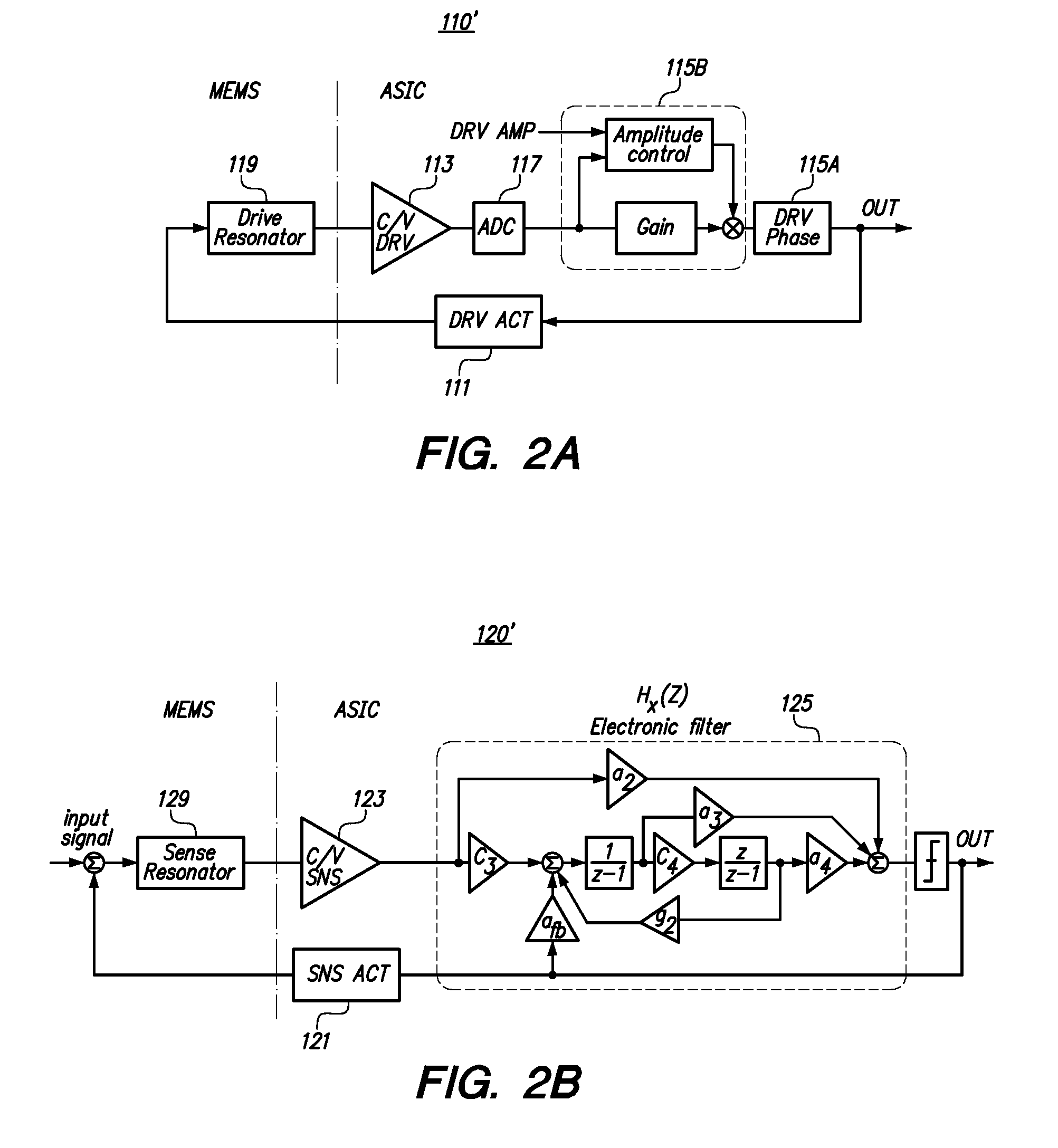

Interface for MEMS inertial sensors

ActiveUS8476970B2Improve interface performanceEnhance demodulationAcceleration measurement using interia forcesAmplifier modifications to raise efficiencyCapacitanceEngineering

In a high-performance interface circuit for micro-electromechanical (MEMS) inertial sensors, an excitation signal (used to detect capacitance variation) is used to control the value of an actuation signal bit stream to allow the dynamic range of both actuation and detection paths to be maximized and to prevent folding of high frequency components of the actuation bit stream due to mixing with the excitation signal. In another aspect, the effects of coupling between actuation signals and detection signals may be overcome by performing a disable / reset of at least one of and preferably both of the detection circuitry and the MEMS detection electrodes during actuation signal transitions. In a still further aspect, to get a demodulated signal to have a low DC component, fine phase adjustment may be achieved by configuring filters within the sense and drive paths to have slightly different center frequencies and hence slightly different delays.

Owner:SHENZHEN GOODIX TECH CO LTD +1

Method for preparing functionalized graphene and composite material of functionalized graphene

InactiveCN102862976AGood dispersionImprove interface performanceMaterial nanotechnologyCarbon compoundsEpoxyOrganic solvent

The invention discloses a method for preparing functionalized graphene and a composite material of the functionalized graphene. The method for preparing the functionalized graphene comprises the following steps of: performing Friedel-Crafts reaction on natural graphite which is taken as a raw material to obtain modified graphite, extracting, purifying, and uniformly dispersing in an organic solvent with ultrasonic to form stable graphene suspension liquid. The method for preparing the composite material comprises the following steps of: adding epoxy resin into the graphene suspension liquid, stirring for dissolving, uniformly mixing with ultrasonic, distilling under reduced pressure to remove the organic solvent to obtain a graphene / epoxy resin composite; and adding an epoxy resin curing agent, an accelerant and micrometer silver sheets sequentially, and heating for curing to obtain the composite material of a graphene polymer, namely a graphene / epoxy resin conducting composite material. The edge functionalized graphene has a high interaction between functional groups at the edge and a polymer matrix, so that the dispersion of the graphene in the polymer matrix can be promoted, the agglomeration degree can be reduced, and the interface performance of the composite material can be enhanced.

Owner:SOUTH CHINA UNIV OF TECH

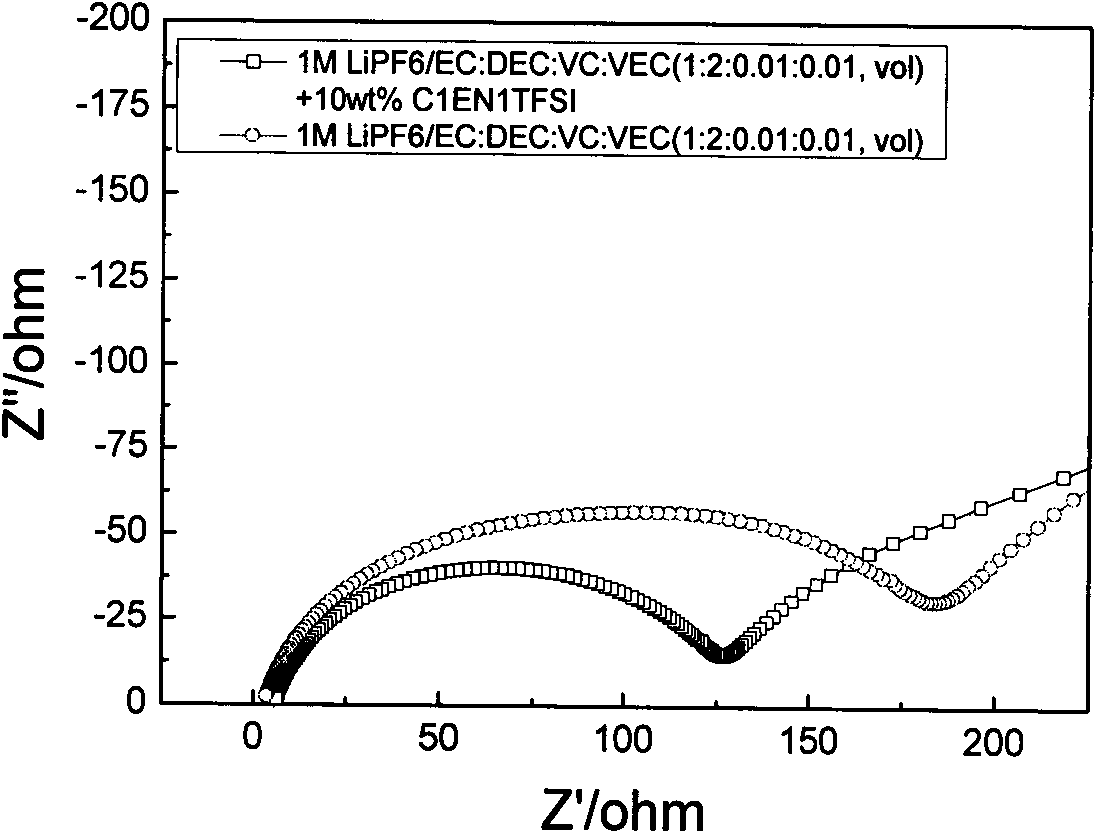

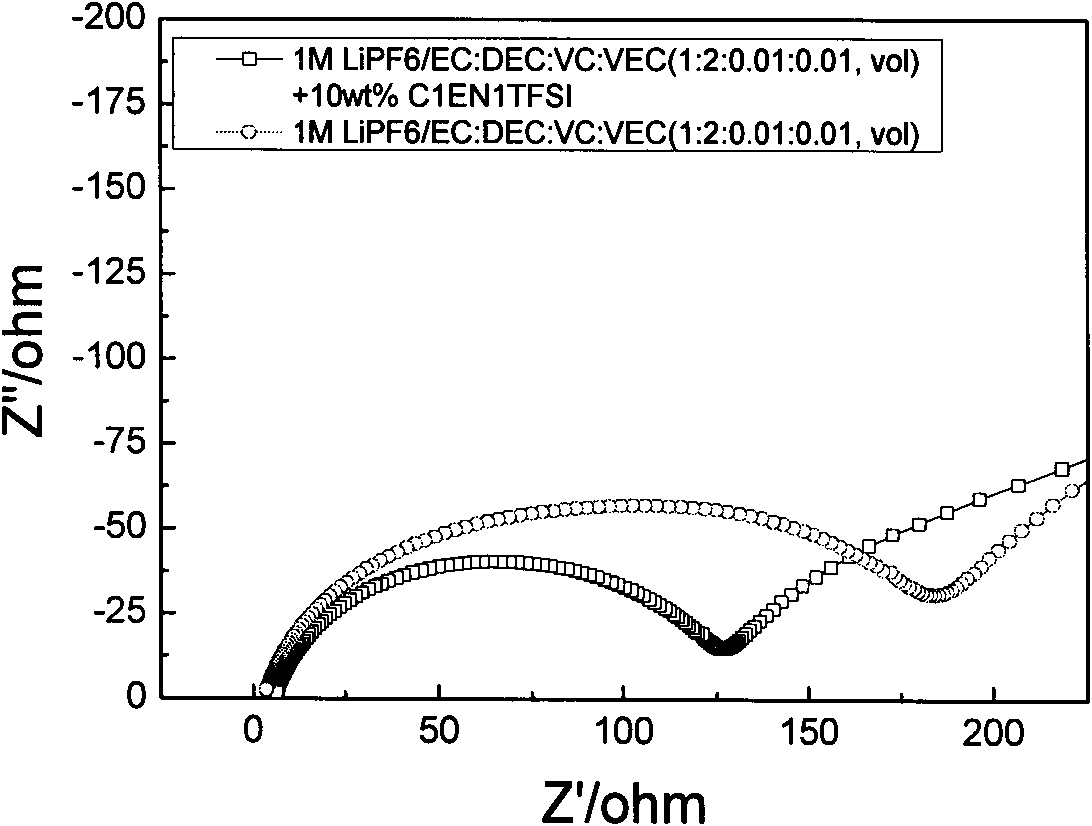

Organosiloxane room temperature ionic liquid electrolyte material and its application in electrochemical power storage device

InactiveCN102372732AImprove interface performanceFacilitated dissociationGroup 4/14 element organic compoundsHybrid capacitor electrolytesChemical structureElectrical battery

The invention provides an organosiloxane room temperature ionic liquid electrolyte material and its application in an electrochemical power storage device. The material is room temperature ionic liquid whose cationic chemical structural formula contains organosiloxane, and the cationic chemical structural formula is as represented by formula I in the specification. In the formula I, R1, R2 and R3 are selected from same or different C1-C10 alkyl groups; M is an ether chain having a structure like (CH2)nO[(CH2)mO]x(CH2)y, wherein, n and m are integers of 0 to 10, and x and y are integers of 0 to 10; R4, R5 and R6 are selected from same or different C1-C10 alkyl groups or alkyloxy groups or -O-SiR7R8R9, wherein, R7, R8 and R9 are C1-C10 alkyl groups or hydrogen, and at least one of R7, R8 and R9 is an alkyl group. The organosiloxane room temperature ionic liquid provided in the invention can be applied in lithium ion batteries as an electrolyte material or an additive; oxygen atoms of the ether chain in the cationic chemical structural formula of the ionic liquid and lithium ions Li<+> can undergo complexation, which promotes dissociation degree of lithium salt in the ionic liquid; furthermore, a cationic skeleton both contains hydrophobic organosilicon groups and hydrophilic ether (polyether) chain segments, which is favorable for improving interfacial properties of batteries.

Owner:GUANGZHOU ZHONGKE LIXIN MATERIALS TECH

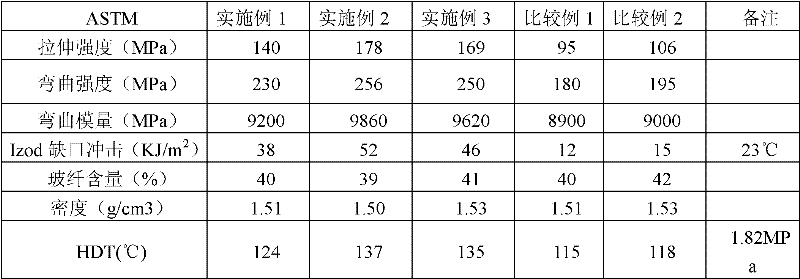

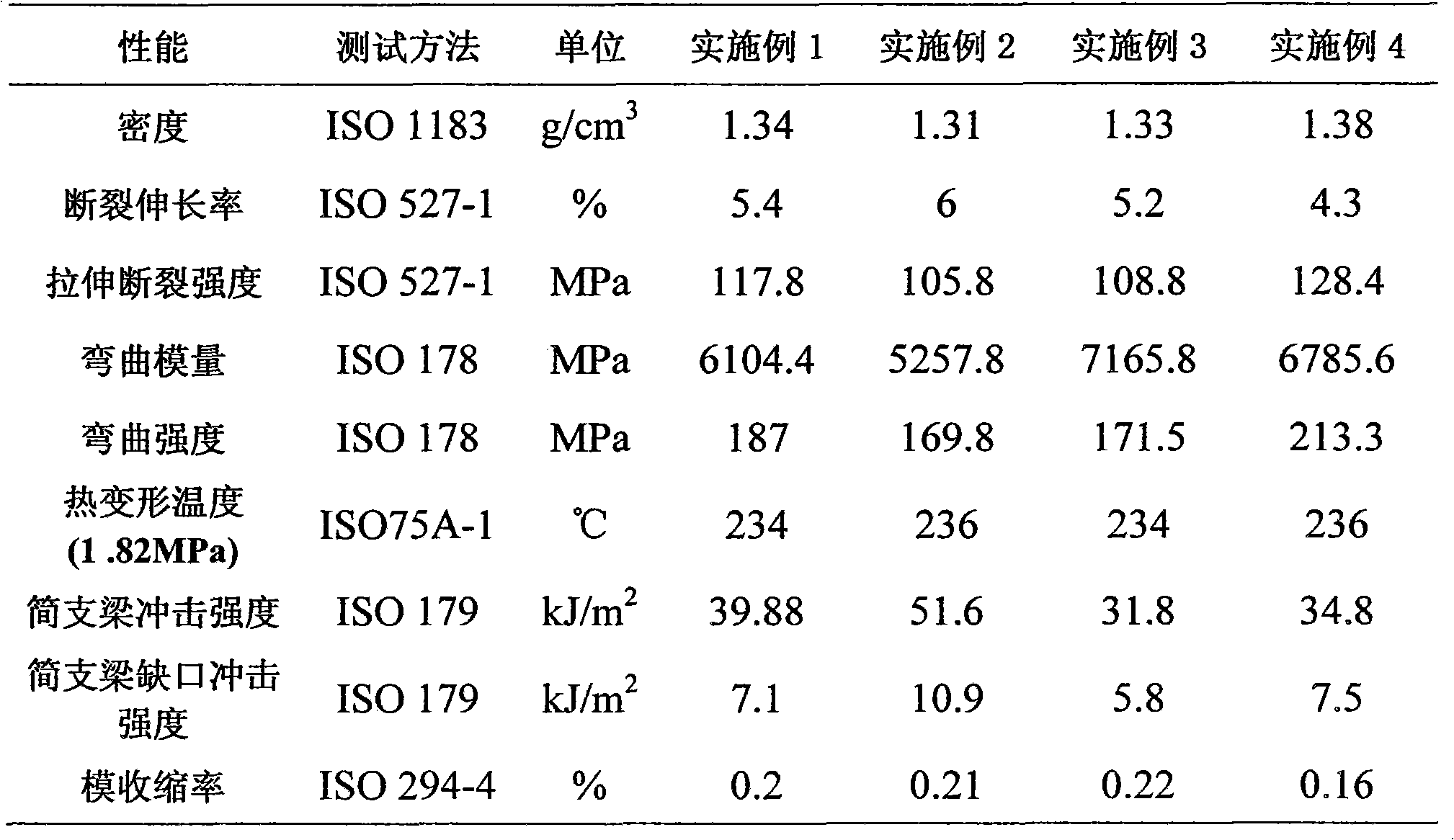

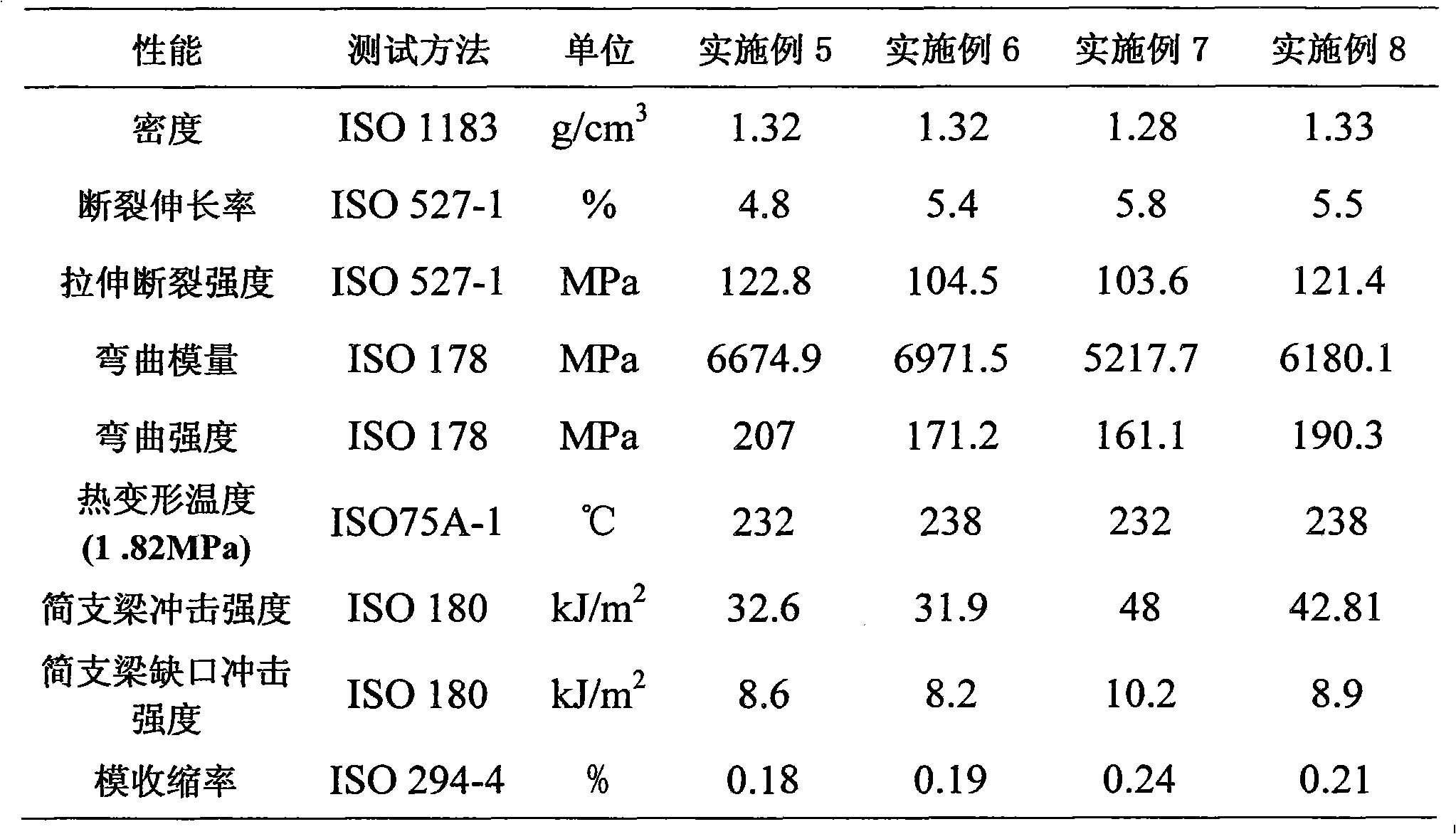

Warpage resistance nylon 6 composite material for vehicle air conditioning air door and preparation method thereof

InactiveCN101580636AHigh impact strengthImprove liquidityAir-flow control membersGlass fiberFlexural modulus

The invention discloses a warpage resistance nylon 6 composite material for a vehicle air conditioning air door and a preparation method thereof. The composite material is composed of nylon 6 chips, fiberglass, glass microballoons, compatilizer, antioxidizer, a coupling agent and a lubricating agent. The preparation method includes the following steps: (1) after being uniformly mixed, the nylon 6 chips, the compatilizer, the antioxidizer, the coupling agent and the lubricating agent are added into a double screw extruder on the first segment of a barrel, the glass microballoons are added by a side feeding machine on the fourth segment of the barrel, and the fiberglass is added by the side feeding machine on the sixth segment of the barrel; and (2) after being extruded outside, the prepared particles are dried and cooled, and finally the warpage resistance nylon 6 composite material for the vehicle air conditioning air door can be obtained. The warpage resistance nylon 6 composite material prepared by the invention has the advantages of extremely high flexural modulus, high fluidity and favorable dimension stability, solves the problem of warpage of a large finished piece caused by material shrinkage, and guarantees the assembly of the finished piece.

Owner:合诚技术股份有限公司

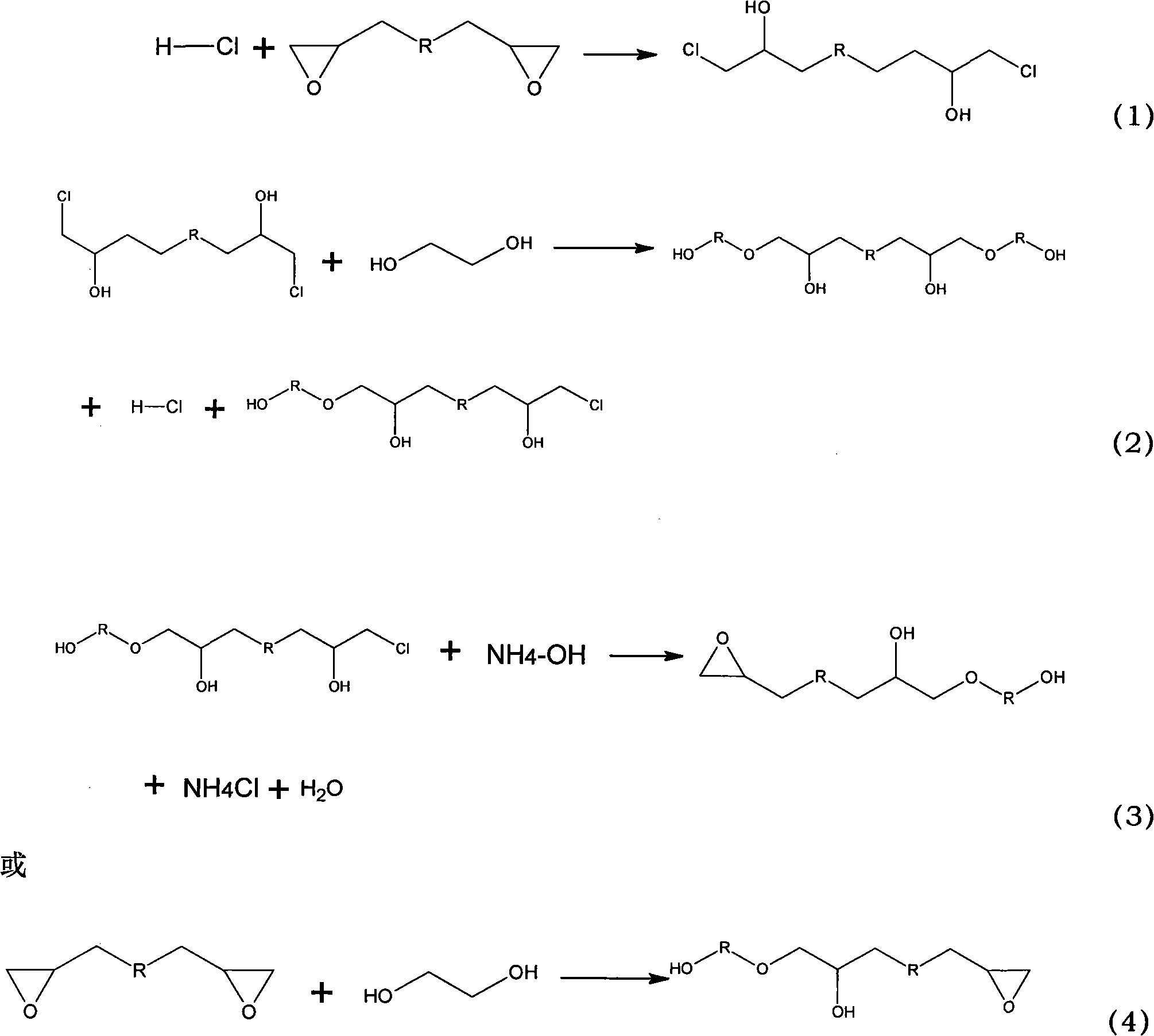

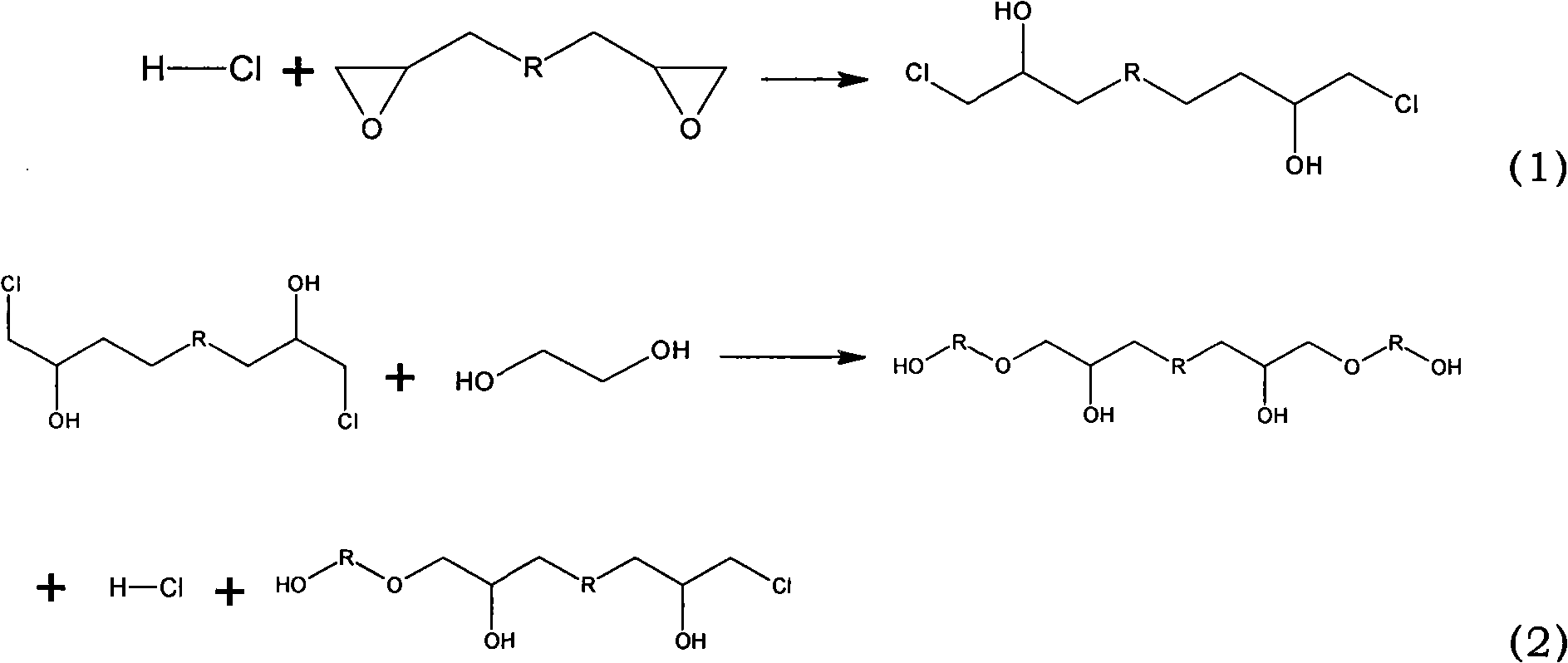

Oil displacement composition containing betaine type surfactant and application thereof

ActiveCN102757775AImprove adsorption capacityImprove stabilityFluid removalDrilling compositionNon ionicSURFACTANT BLEND

The invention provides an oil displacement composition containing a betaine type surfactant and application thereof, particularly application thereof in tertiary oil recovery. The oil displacement composition is composed of the following components: 1-30 parts by weight of a composite surfactant and 0-25 parts by weight of a polymer, wherein the composite surfactant is a combination of the betaine type surfactant (I) and an non-ionic surfactant (II) in a weight ratio of (10-90):(90-10): formula (I), wherein in the formula (I), m and n are integers from 0 to 19 but are equal to 0 asynchronously, R1 is H, C1-8 alkyl, phenyl or C1-8 alkyl phenyl, R3 is C1-8 alkyl, and R4 is C1-8 alkyl, and X is shown in the specification; and in the formula (II), R is H, C1-8 alkyl, phenyl or C1-8 alkyl phenyl, x and y are integers from 0 to 19 and are equal to 0 asynchronously, and z is an integer from 3 to 25.

Owner:PETROCHINA CO LTD

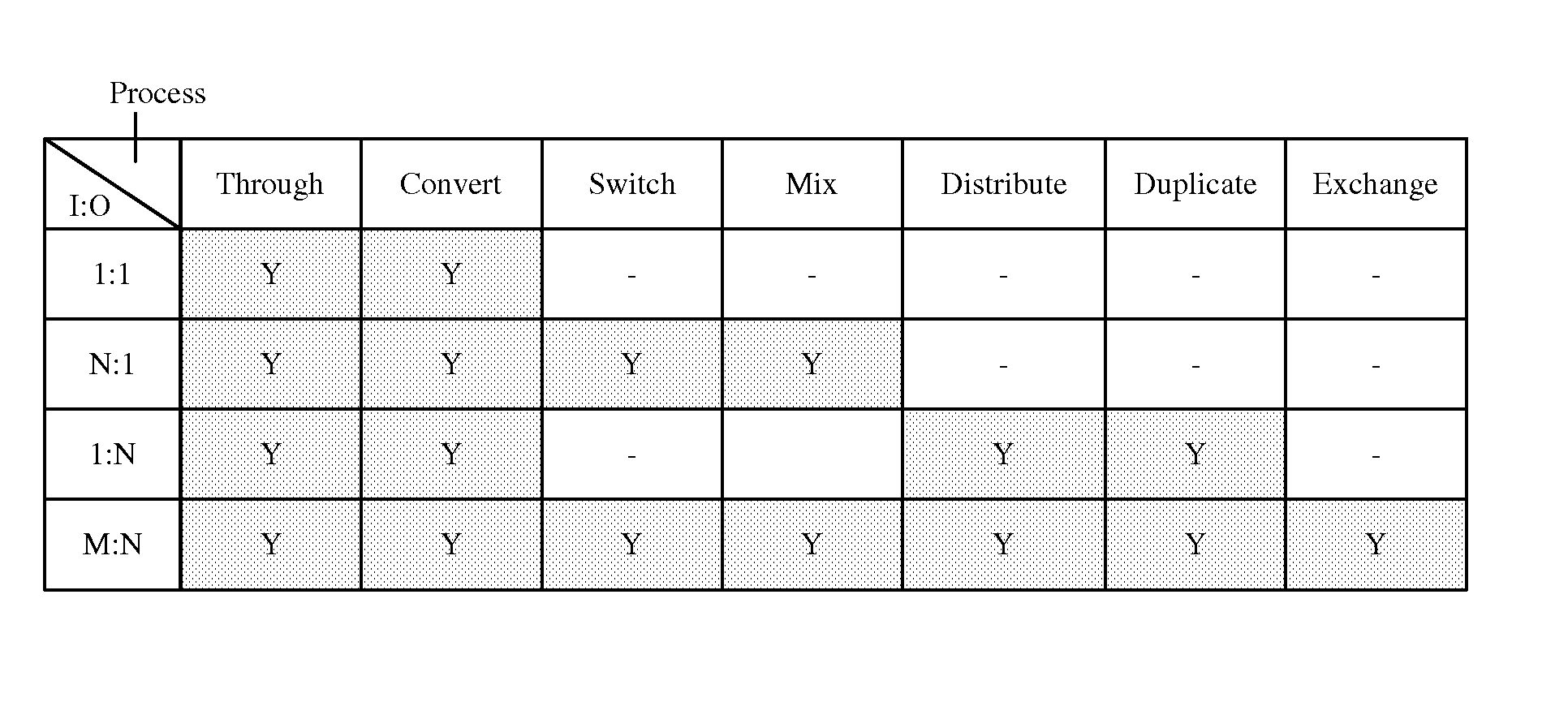

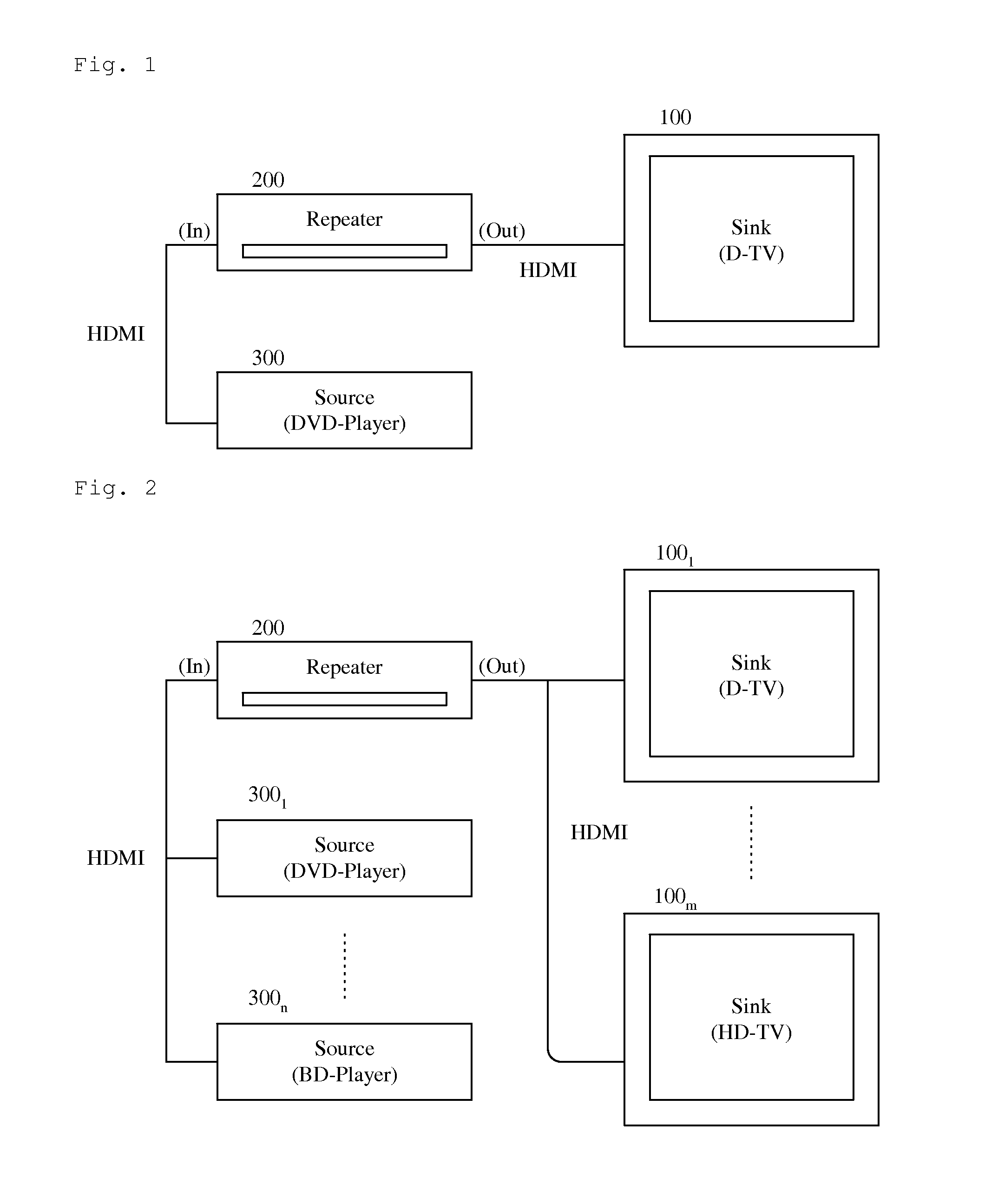

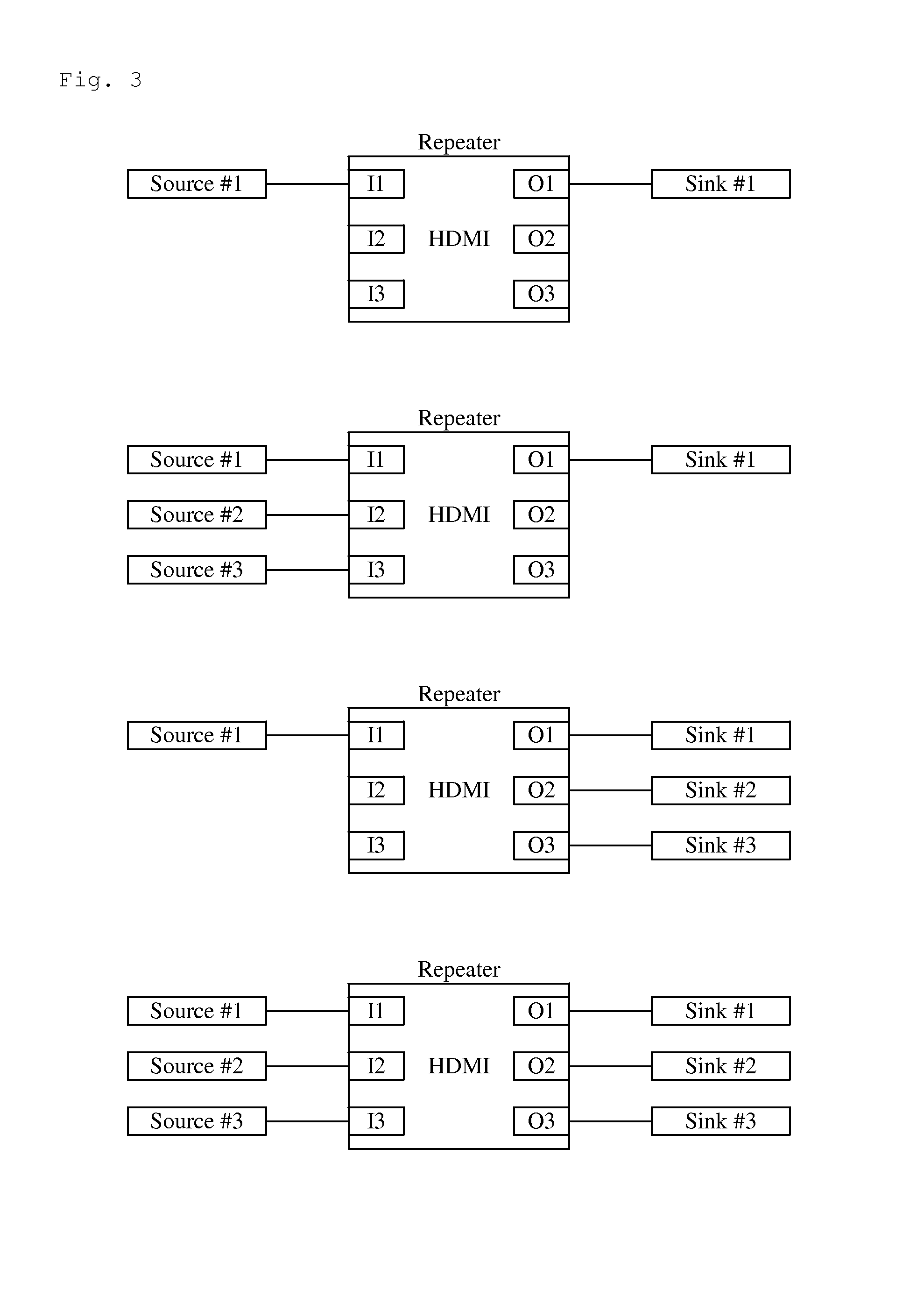

Method for controlling interface

InactiveUS8839334B2Improve user convenienceImprove interface performanceTelevision system detailsStatic indicating devicesComputer scienceEmbedded system

The method for controlling interface according to one embodiment of the present invention comprises the steps of: detecting the state of connection with one or more sink devices and one or more source devices which are connected to input and output ports of a multimedia interface module; identifying one or more operation modes available for the detected connection state; and transmitting device information of the one or more sink devices to the one or more source devices, the device information being selectively edited in accordance with a requested operation mode among the identified operation modes. Therefore, various operation modes such as Through, Convert, Switch, Mix, Distribute, Duplicate and Exchange can be chosen for effective operation, thereby enhancing the convenience of the user and increasing the performance of interface between the sink devices and source devices.

Owner:HUMAX CO LTD

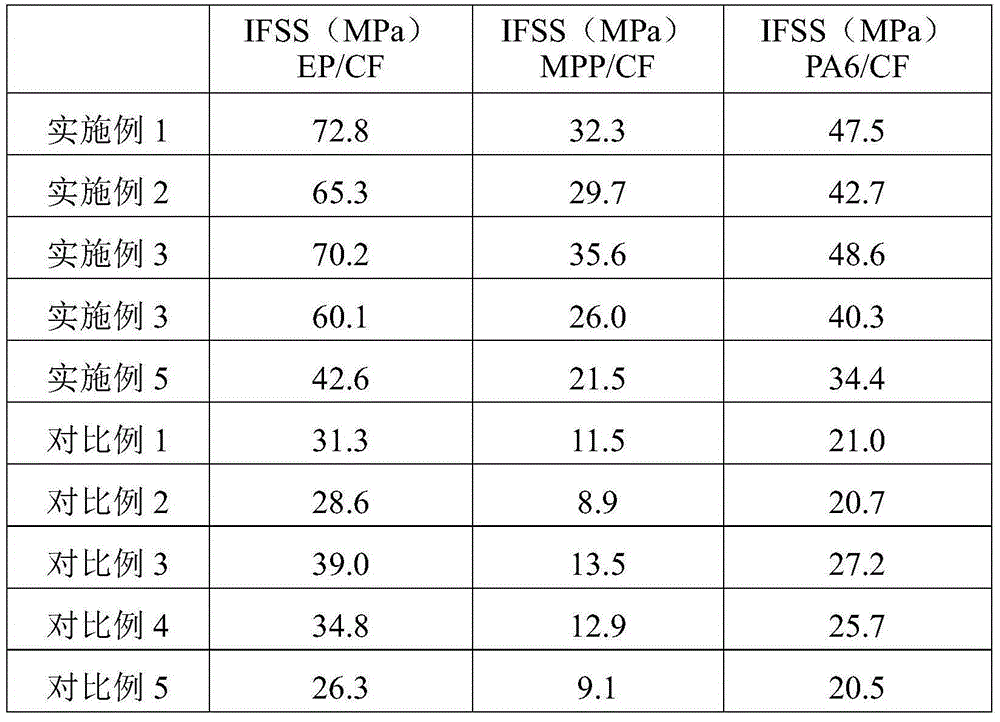

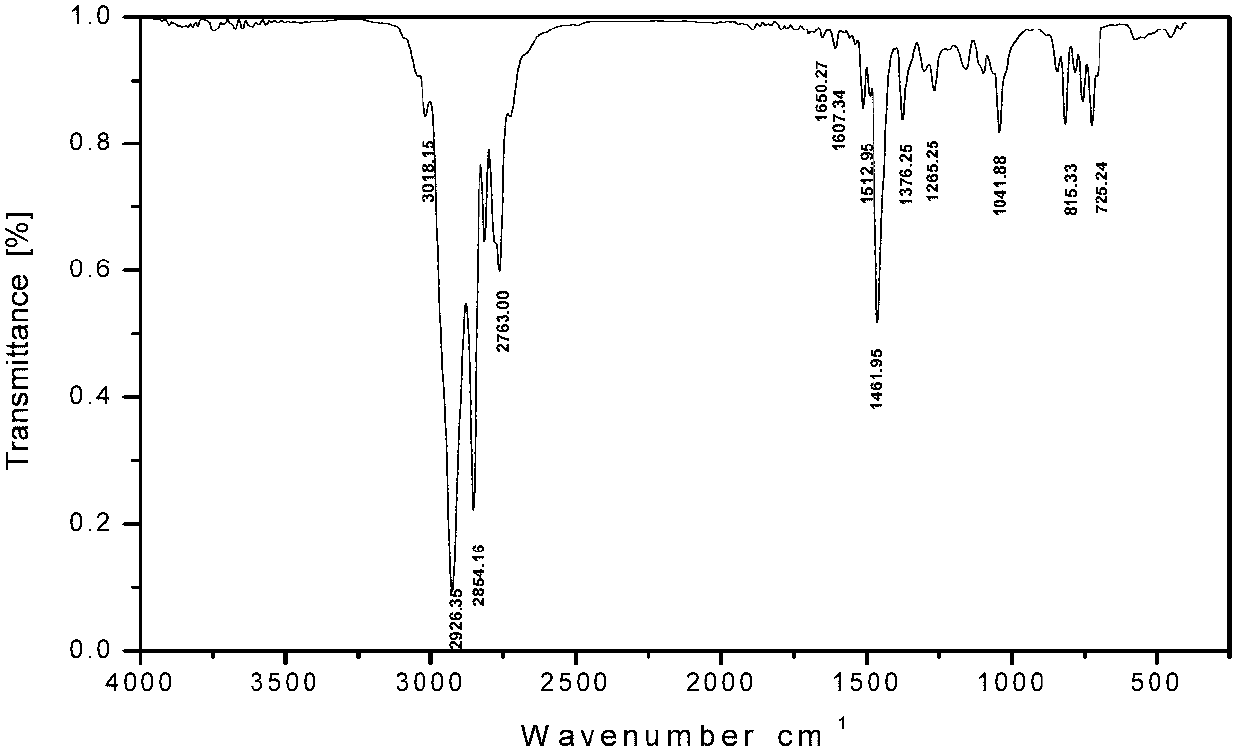

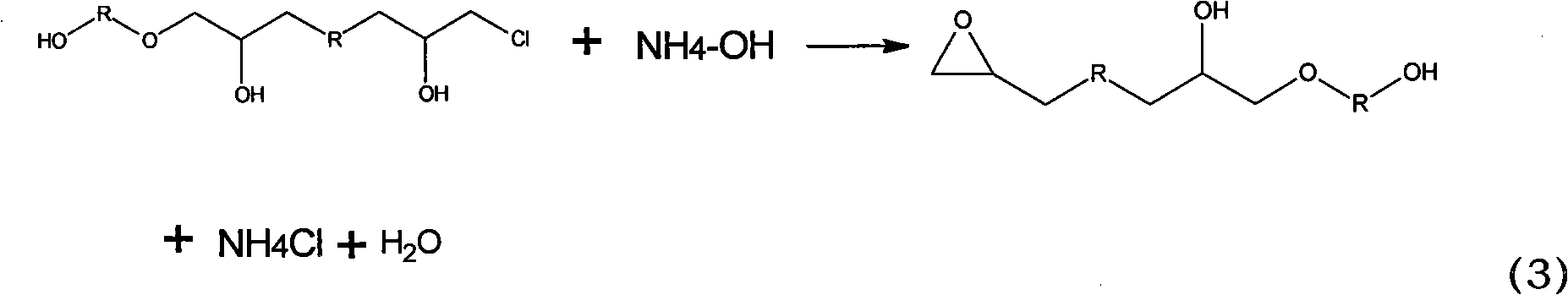

Polyalcohol modified epoxy resin carbon fiber emulsion sizing agent component and preparation method thereof

The invention discloses a polyalcohol modified epoxy resin carbon fiber emulsion sizing agent component and a preparation method thereof. The method comprises the steps of ring-opening the preparing modified epoxy. The modified epoxy resin has hydropathy, can be dissolved in water, and can be prepared into a modified epoxy emulsion under certain conditions. The modified epoxy emulsion is the polyalcohol modified epoxy resin carbon fiber emulsion sizing agent component. A foreign emulsifying agent is added in the preparation process, and the modified epoxy emulsion belongs to a self-emulsifying system without breaking the emulsion and demixing and has controllable and proper viscosity, good standing stability, excellent pH value stability and high-temperature stability. The foreign emulsifying agent does not remain on the fiber after the sizing; and compared with the carbon fiber without being sized, the carbon fiber coated with the sizing agent component has less broken filament amount and good bundling performance, and can ensure that the interface performance is improved because of a structure that one end of the modified epoxy resin is a polyether bond and the other end is an epoxy group.

Owner:BEIHANG UNIV

Double-component ceramic tile interface agent as well as preparation method and using method thereof

The invention aims at solving a ceramic tile dropping problem caused by low water absorption and a smooth interface of the existing ceramic file, especially a vitrified porcelain tile, and provides a double-component ceramic tile interface agent for improving interface performance and construction performance of a ceramic tile. The double-component ceramic tile interface agent comprises a component A and a component B, wherein the component A comprises cement, quartz sand, metakaolin and a thickener; the component B comprises a water reducing agent, a flexibilizer, a penetrating agent, a dispersing agent, an antifoaming agent, a bactericide, an accelerator, a season regulator and water. According to the invention, two strength forming materials of multiple polymers and cement are used at the same time, so that possibility of forming an interface for a second time is reduced, and bonding strength of the interface agent and the ceramic tile is improved. Besides, while construction time is ensured, setting time is shortened, construction performance is effectively improved, and long-term aesthetic sense of the ceramic tile is ensured.

Owner:湖北鲁邦建材股份有限公司

Method for interface modification of carbon/carbon composite material by graphene/polymer coating

A method for interface modification of carbon / carbon composite material by graphene / polymer coating, relates to a carbon / carbon composite material modification method. The method aims to resolve the disadvantage that the modification carbon / carbon composite material prepared by existing interface modification methods could not endure high temperature. The method comprises the following steps: 1, oxidizing graphite to obtain oxidized graphite powder; 2, preparing a solution of oxidized graphene; 3, purification; 4, preparing the graphene; 5, preparing a graphene / polymer coating solution; 6, coating carbon fibers; 7, carbonization processing. The method is advantageous in that: 1, the operation is simple and the cost is low; and 2, interface properties of the carbon / carbon composite material prepared by the method are improved by 20-80%, macroscopic mechanical properties of the carbon / carbon composite material prepared by the method are improved by 3-30%, and ablation resistance properties of the carbon / carbon composite material prepared by the method are improved by 10-50%, compared with those of the untreated materials. The method is mainly used for preparing interface modification carbon / carbon composite materials.

Owner:HARBIN INST OF TECH

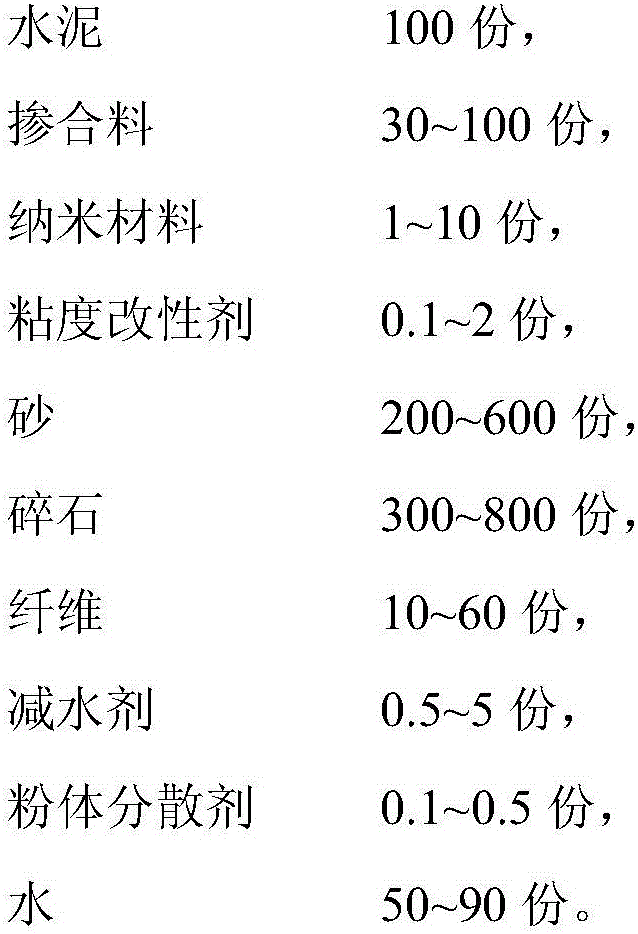

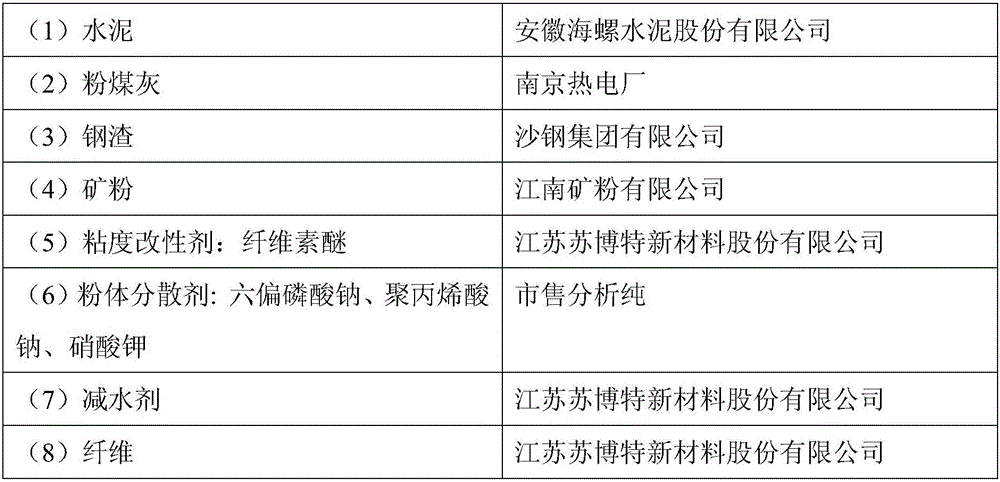

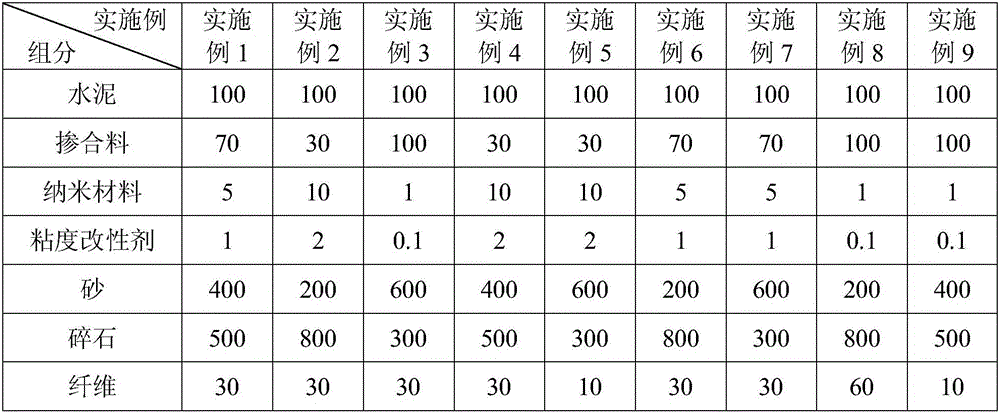

Concrete with common strength and high elastic modulus and preparation method thereof

The invention discloses concrete with common strength and high elastic modulus and a preparation method thereof. The concrete with common strength and high elastic modulus, disclosed by the invention, is prepared from the following components in parts by mass: 100 parts of cement, 30-100 parts of an admixture, 1-10 parts of a nano material, 0.1-2 parts of a viscosity modifier, 200-600 parts of sand, 300-800 parts of crushed stones, 10-60 parts of fibers, 0.5-5 parts of a water reducing agent, 0.1-0.5 part of a powder dispersant and 50-90 parts of water. After the concrete with common strength and high elastic modulus, disclosed by the invention, is subjected to standard curing or natural curing for 28d, the strength grade of the concrete is C40-C50, and the elastic modulus can reach 50GPa or more; and the concrete has excellent working performance and endurance performance.

Owner:JIANGSU SOBUTE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com