Method for performing amino functionalizing on carbon fiber surface

A surface amino group and carbon fiber technology, which is applied in carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of amine group consumption and less residual amine group, and achieve mild conditions, increase amine group content, and good controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

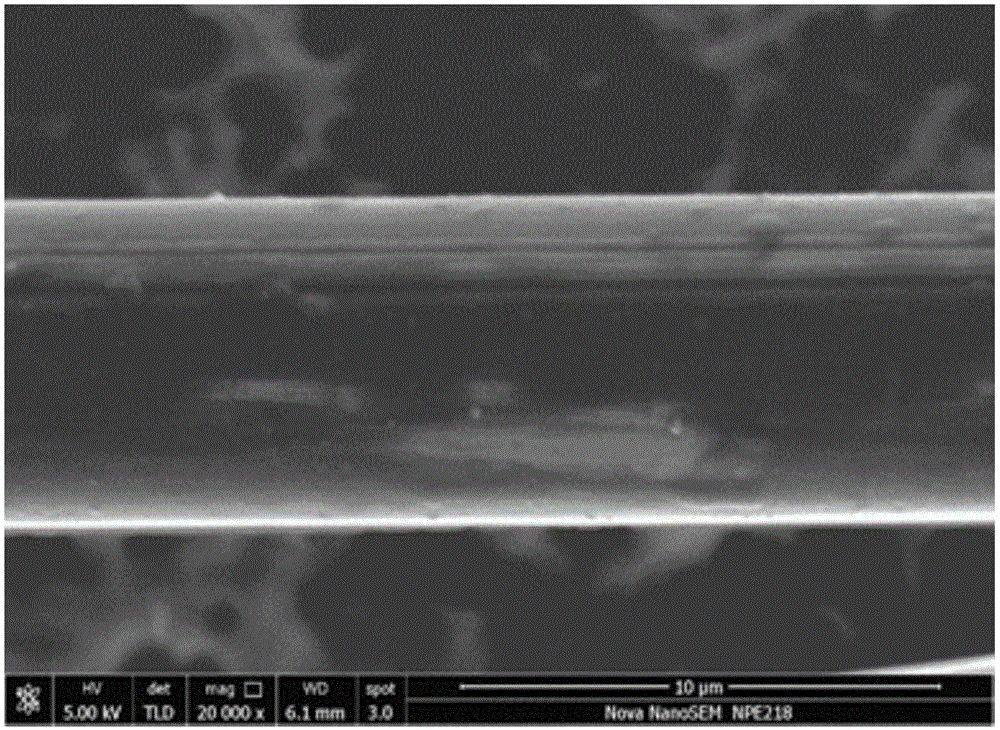

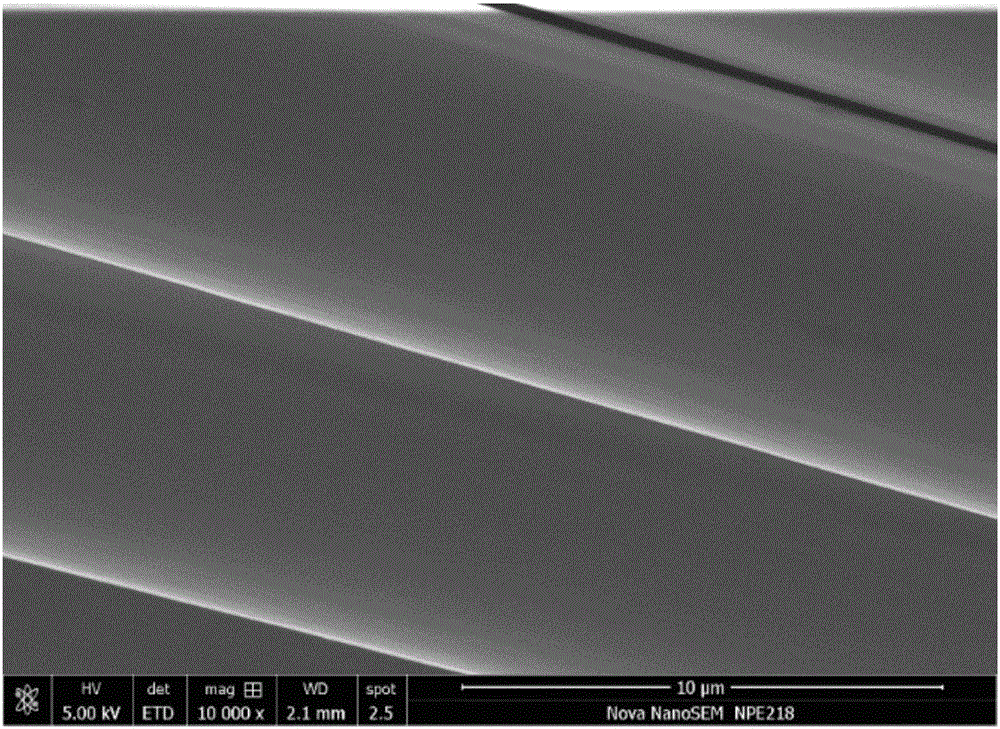

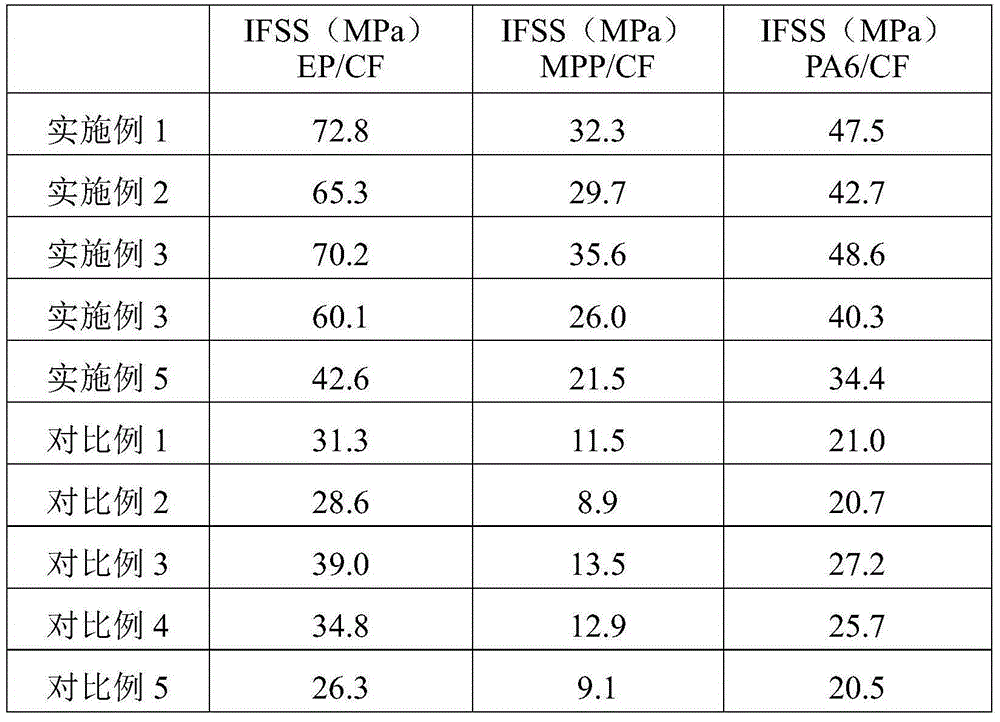

[0030] Weigh 100mg of polyethyleneimine with a molecular weight of 10000 and 200mg of dopamine (mass ratio is 0.5:1, the concentration of dopamine is 2mg / ml), dissolve in 100ml of Tris buffer solution with pH 8.5, then immerse 5gCF in the reaction system , stirred magnetically for 24 h at room temperature. After the treatment, it was fully washed with deionized water, and dried in a vacuum oven at 60° C. for 24 hours. The scanning electron micrograph of the CF prepared in this embodiment is as follows: figure 1 As shown, the scanning electron micrographs of unmodified CF are as figure 2 As shown, it can be seen that the modified CF surface is covered with a uniform polymer coating. The IFSS between the CF prepared in this example and EP, MPP, and PA6 are 72.8MPa, 32.3MPa, and 47.5MPa respectively, which are 238.7%, 316.7%, and 212.1% of the IFSS between the unmodified CF and the above three resins, Interface enhancements are noticeable.

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is that the polyethyleneimine molecular weight used is 15000, and the others are the same as embodiment 1. The IFSS between the CF prepared in this example and EP, MPP, and PA6 are 65.3MPa, 29.7MPa, and 42.7MPa respectively, which are 214.1%, 291.2%, and 190.6% of the IFSS between the unmodified CF and the above three resins, Interface enhancements are noticeable.

Embodiment 3

[0034] The difference between this embodiment and embodiment 1 is that the mass ratio of polyethyleneimine and dopamine used is 2:1, and the others are the same as embodiment 1. The IFSS between the CF prepared in this example and EP, MPP, and PA6 are 70.2MPa, 35.6MPa, and 48.6MPa, respectively, which are 230.2%, 291.2%, and 217.0% of the IFSS between the unmodified CF and the above three resins, Interface enhancements are noticeable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com