Patents

Literature

1071results about "Ice removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

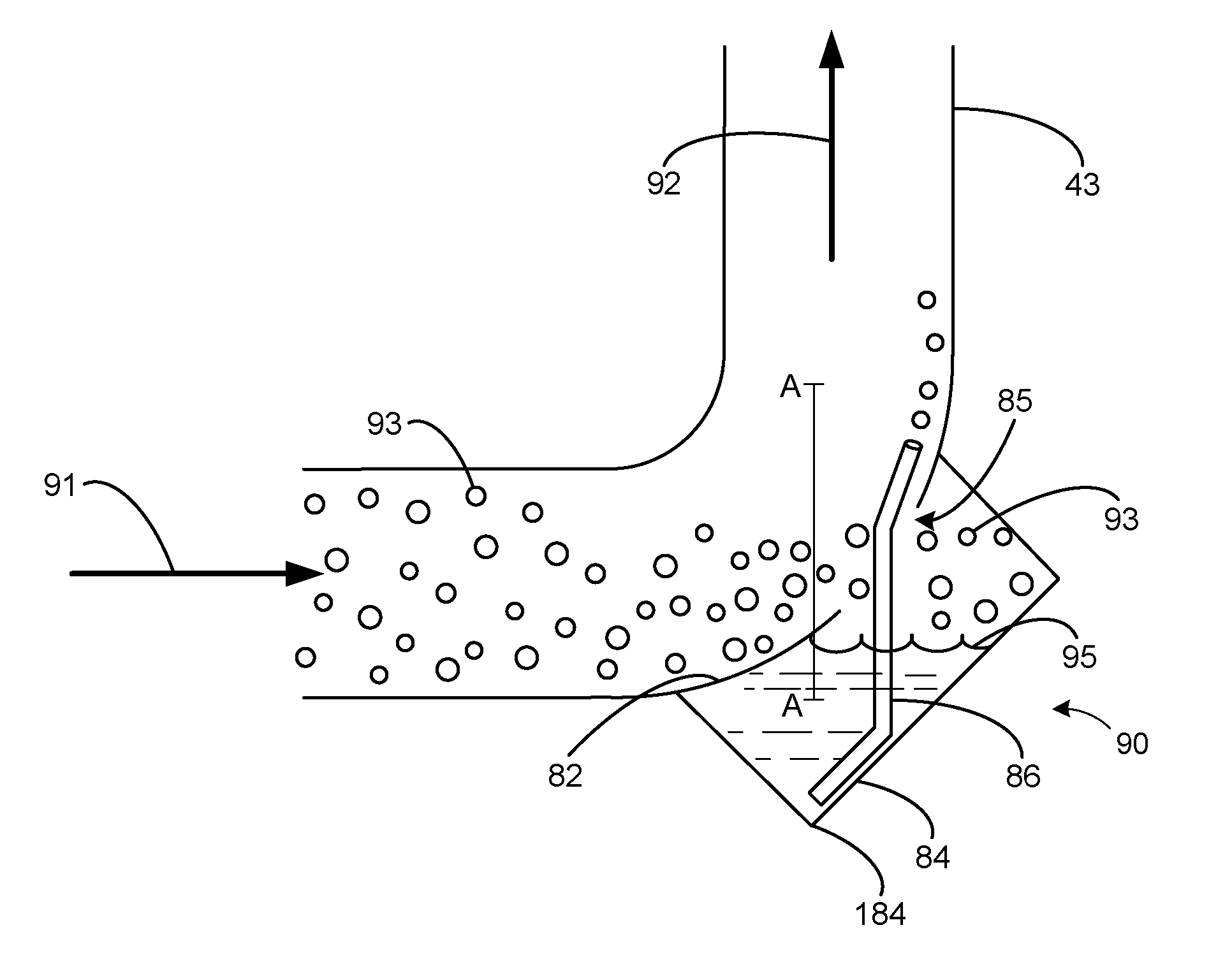

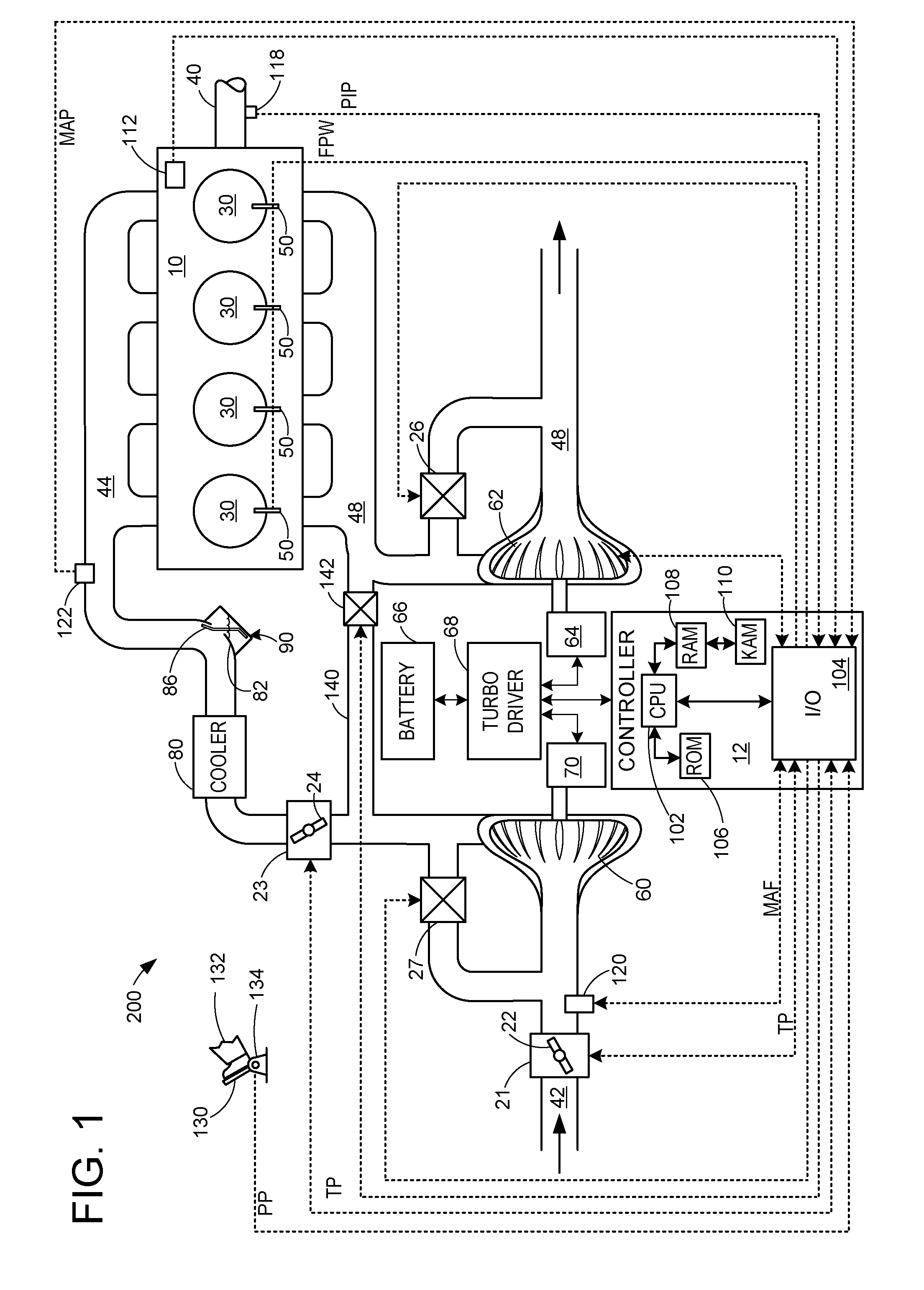

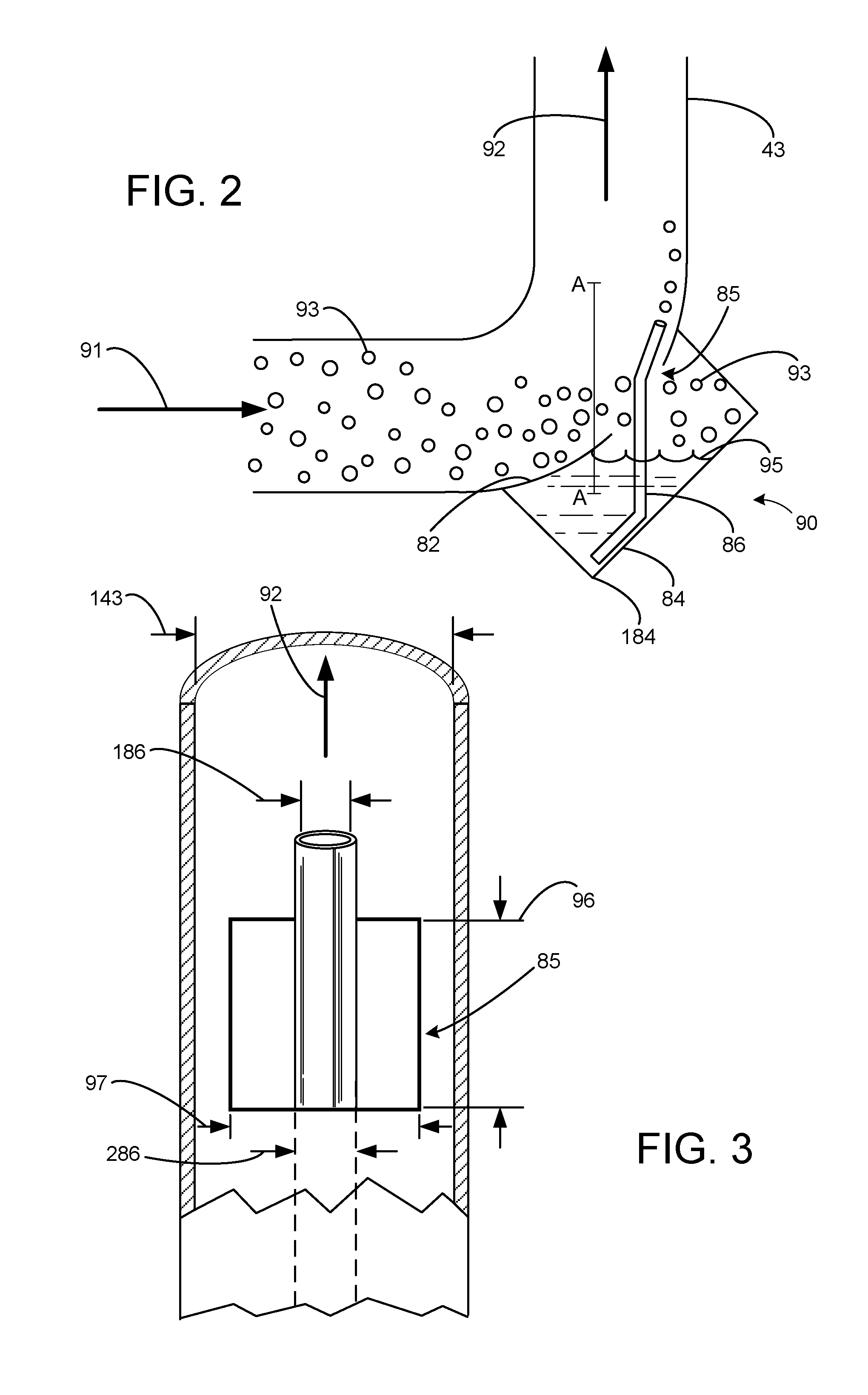

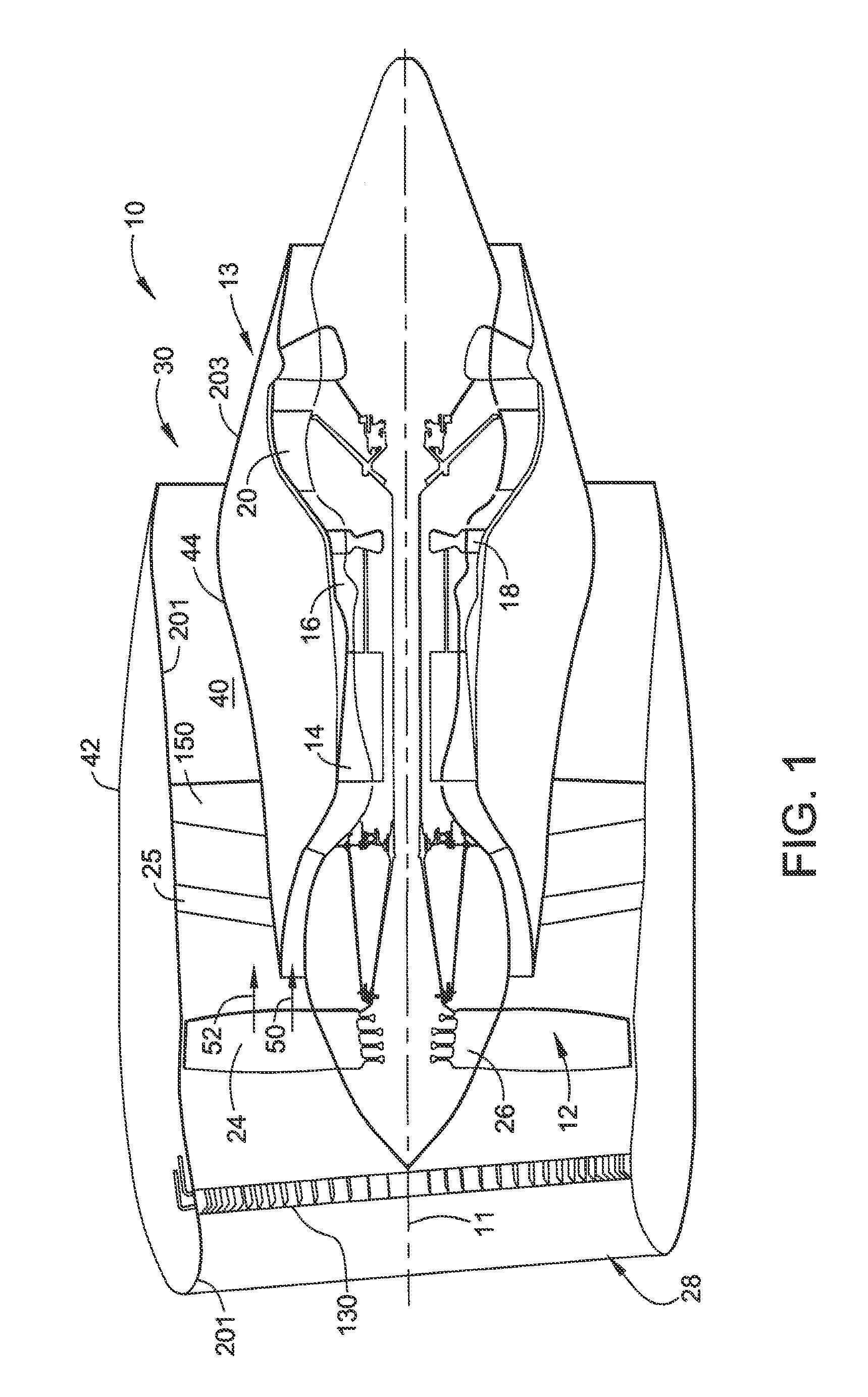

Condensation trap for charge air cooler

ActiveUS20110094219A1Reduce the amount of condensateReduce the amount requiredInternal combustion piston enginesIce removalCondensation trapChiller

Various systems and methods are described for a charge air cooler coupled to an engine. One example method comprises collecting condensate discharged from the cooler in a condensation trap coupled to an outside surface of a bend in an outlet duct of the cooler; during a first condition, temporarily storing the condensate in a reservoir of the condensation trap; and, during first and second conditions, releasing the condensate to the outlet duct in a direction of airflow via a tube.

Owner:FORD GLOBAL TECH LLC

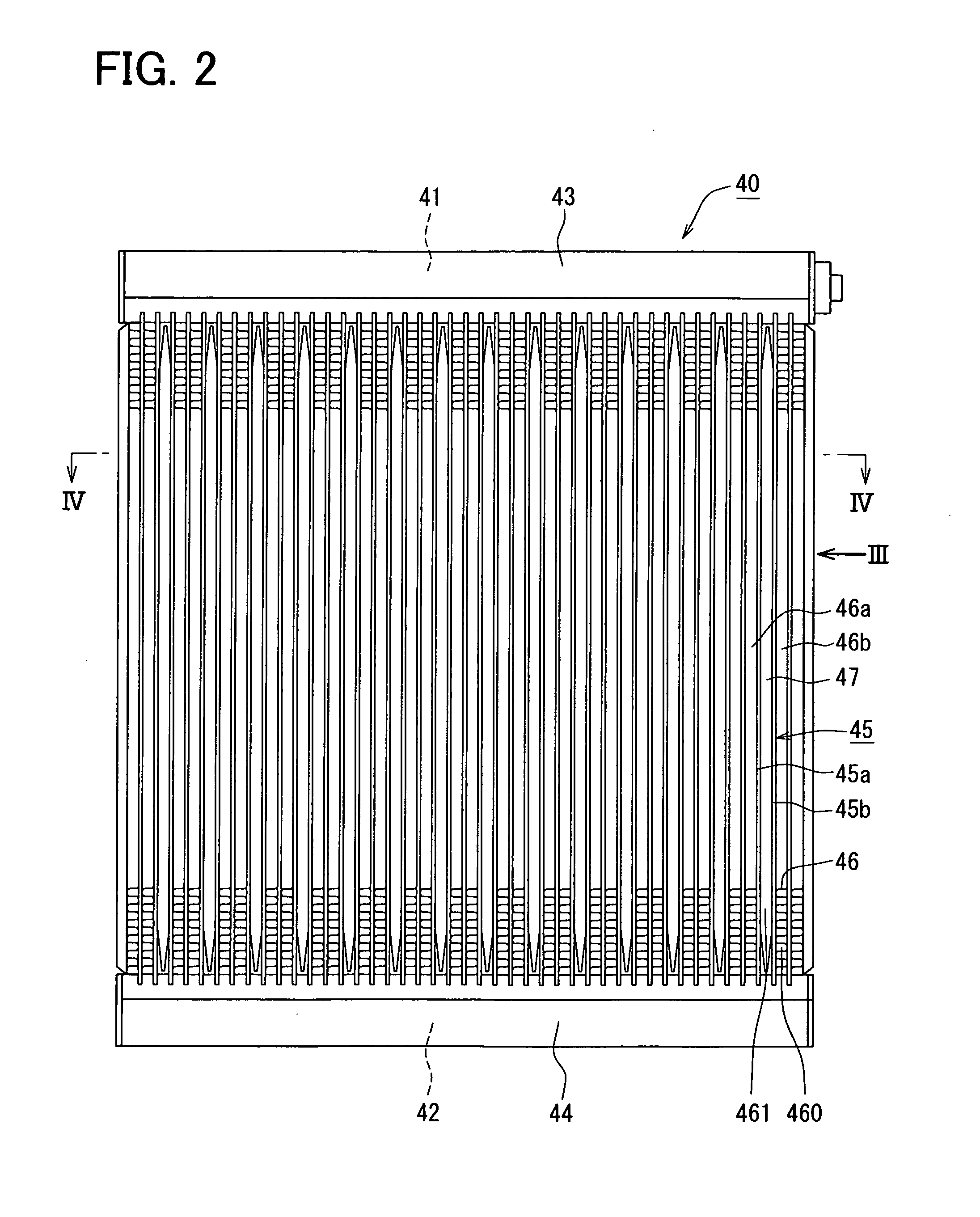

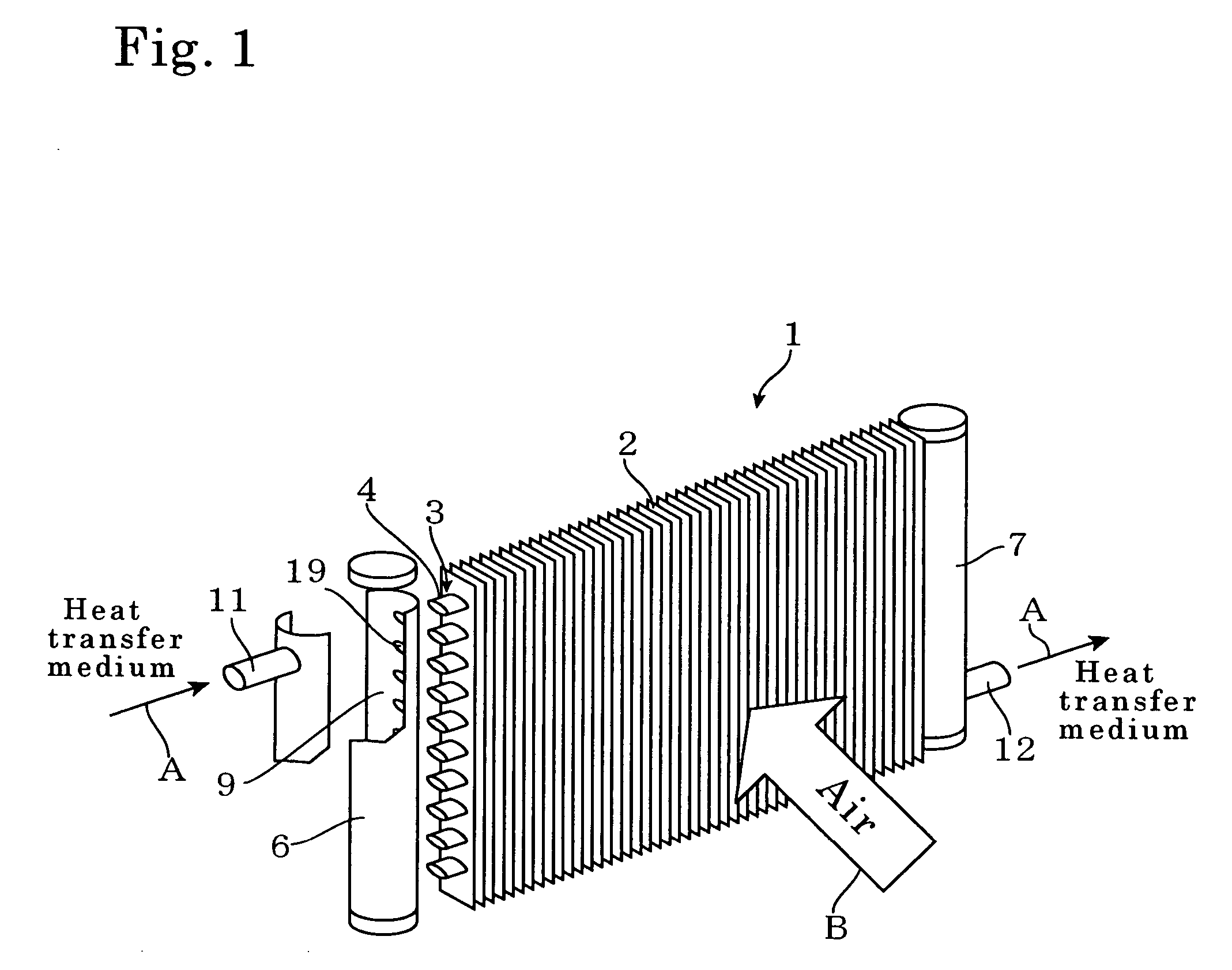

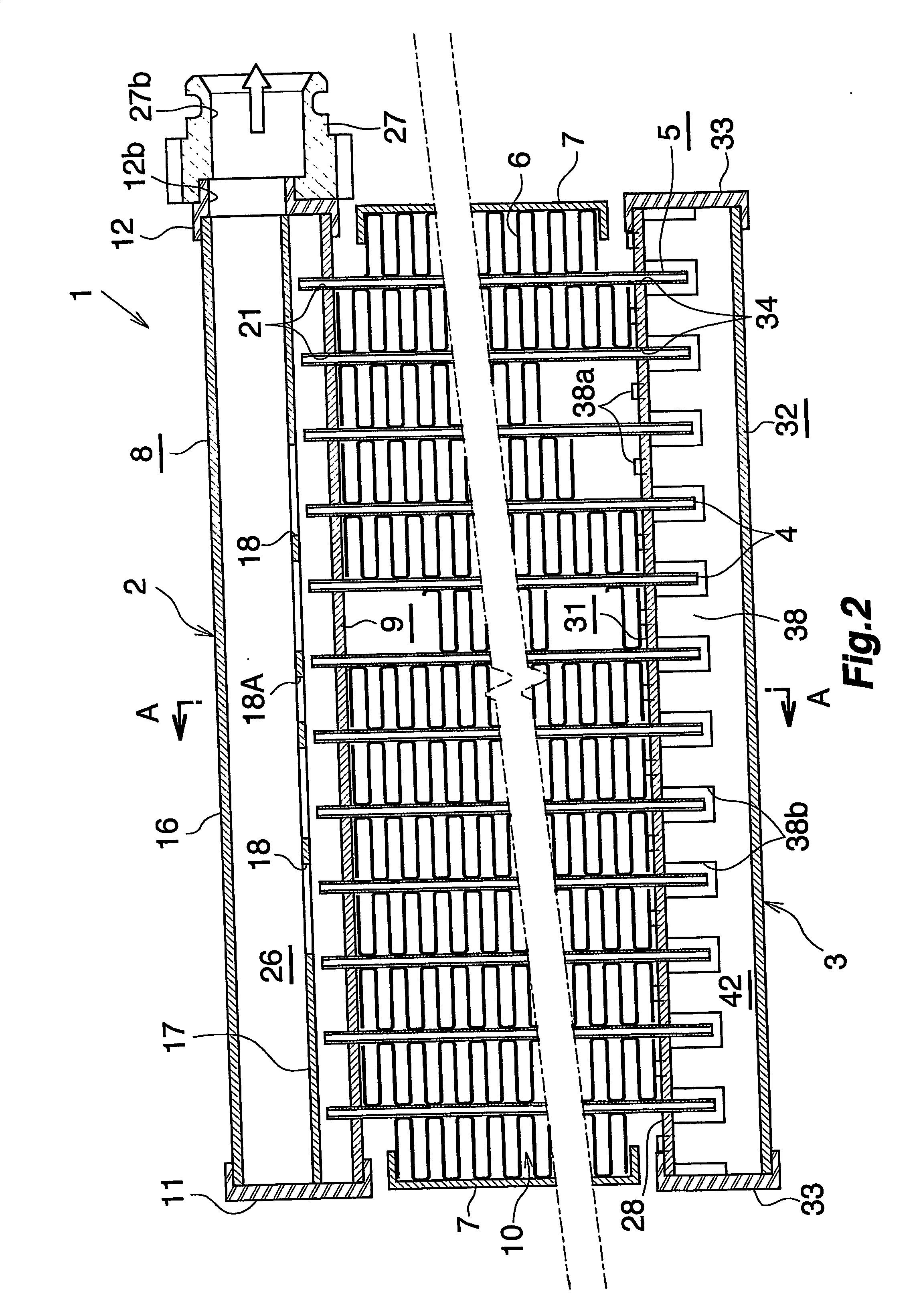

Cold-storage heat exchanger

ActiveUS20100307180A1Increase volumeReduce heat transferHeat storage plantsEvaporators/condensersPlate heat exchangerRelease time

An outer surface of a cold-storage container (or a refrigerant tube) is provided with a plurality of protrusion portions or recess portions. A cooling air passage, in which air flows to cool a space to be cooled in a cold storage time and in a cold release time of the cold storage material, is provided to contact a surface of the refrigerant tube on a side opposite to the cold storage container bonded to the refrigerant tube. The refrigerant tubes and the cold storage container form therebetween a cold-storage side air passage by the protrusion portions or the recess portions, such that air flows in the cold-storage side air passage separated from the cooling air passage. For example, the cold-storage side air passage is provided with a slanting space that causes condensed water or ice generated in the cold storage time to be drained along the cold-storage side air passage.

Owner:DENSO CORP

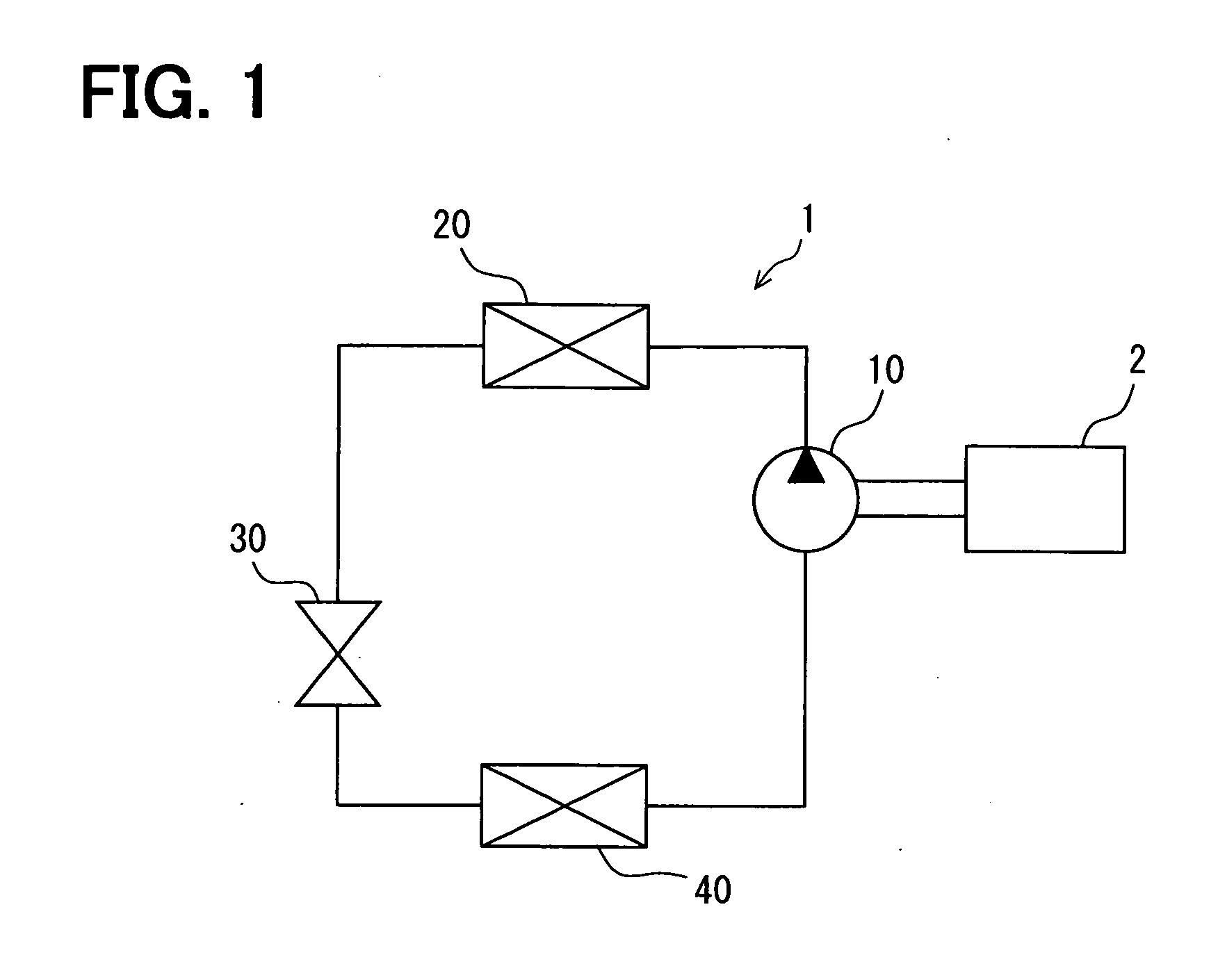

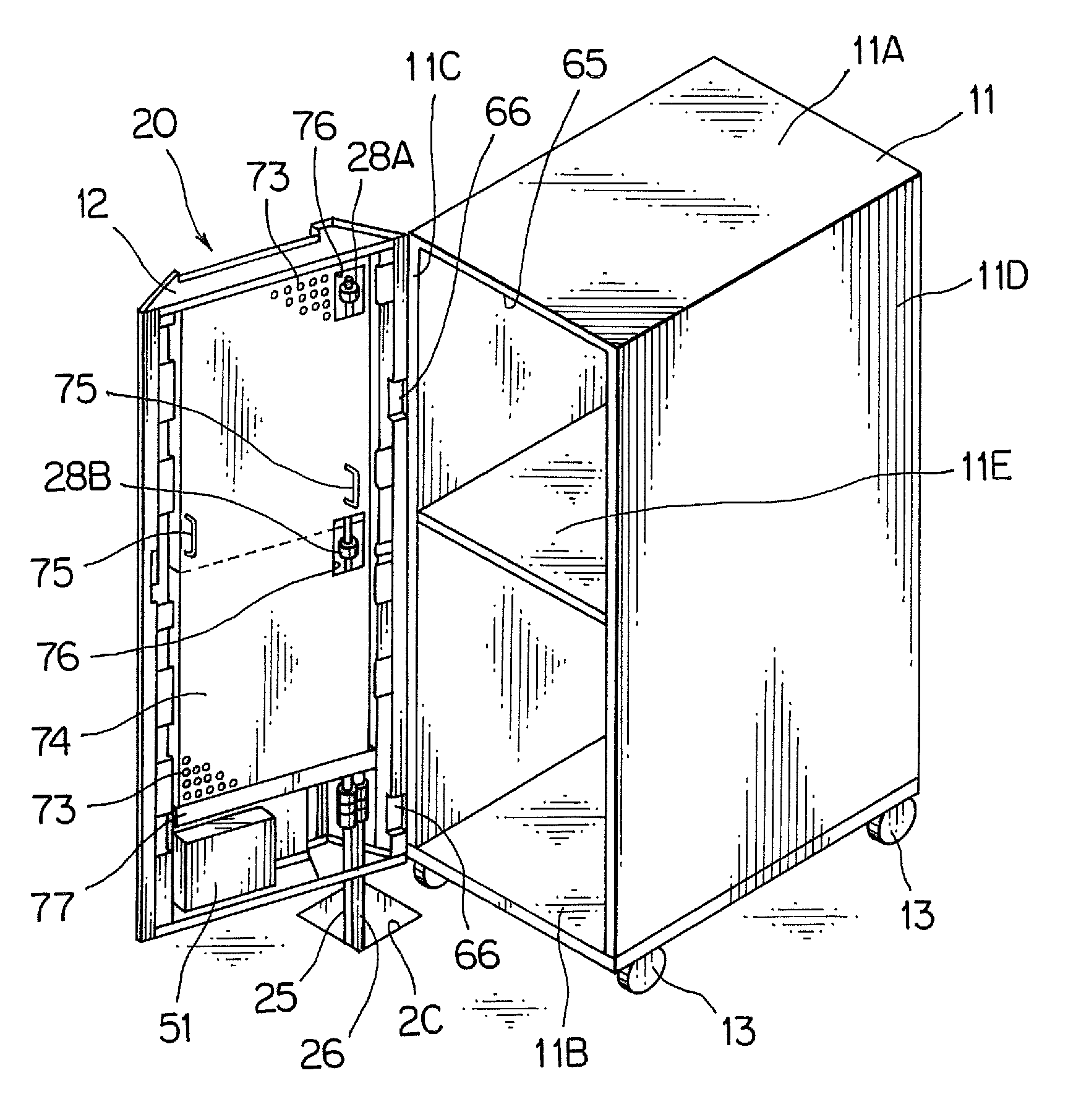

Electronic device cooling system and electronic device cooling apparatus

InactiveUS20090100848A1Avoid condensationEasy constructionCompression machines with non-reversible cycleEvaporators/condensersElectronics coolingRefrigerant

An electronic cooling apparatus has a cabinet which is open at the front and rear sides thereof and accommodates plural electronic devices each having a fan, and a rear door which is provided with an evaporator. Air blown by the fan is cooled by the evaporator and then returned to a room. An expansion valve and control. A drain pan with an extension portion having hole portions through which refrigerant pipes extend is provided. A drain hose discharges drain water from the drain pan. An exhaust heat temperature detecting unit and a control for controlling the refrigerant supply to the evaporator are provided. When the exhaust heat temperature is equal to or less than a set exhaust temperature, the controller stops the refrigerant supply to the evaporator. When the exhaust heat temperature exceeds the set temperature, the controller starts the refrigerant supply.

Owner:SANYO ELECTRIC CO LTD

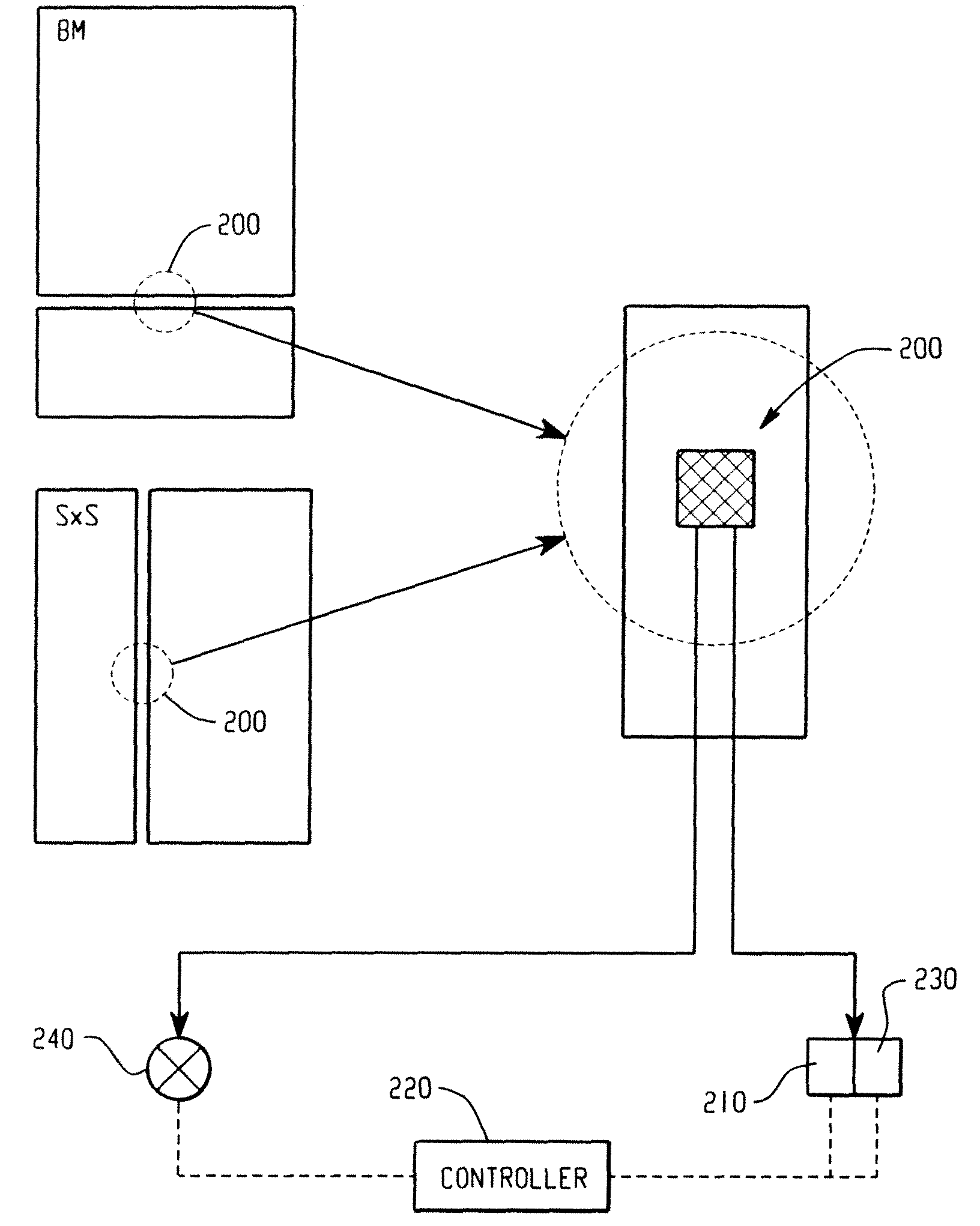

Anti-sweat heater demand supply module using temperature and humidity control

ActiveUS8434317B2Prevent short-cyclingLow costSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringPeak value

A refrigerated appliance such as a refrigerator receives a demand response signal indicating a peak demand period and operates the refrigerator in an energy savings mode by disabling an anti-sweat heater. Sensors monitor ambient temperature and humidity, and the dry bulb temperature of a preselected region where incipient moisture would likely form. Data from the sensors is sent to a controller which calculates ambient dew point and compares the dry bulb temperature of the preselected region with the calculated dew point to enable the anti-sweat heater during the peak demand period and prevent incipient formation of moisture.

Owner:HAIER US APPLIANCE SOLUTIONS INC

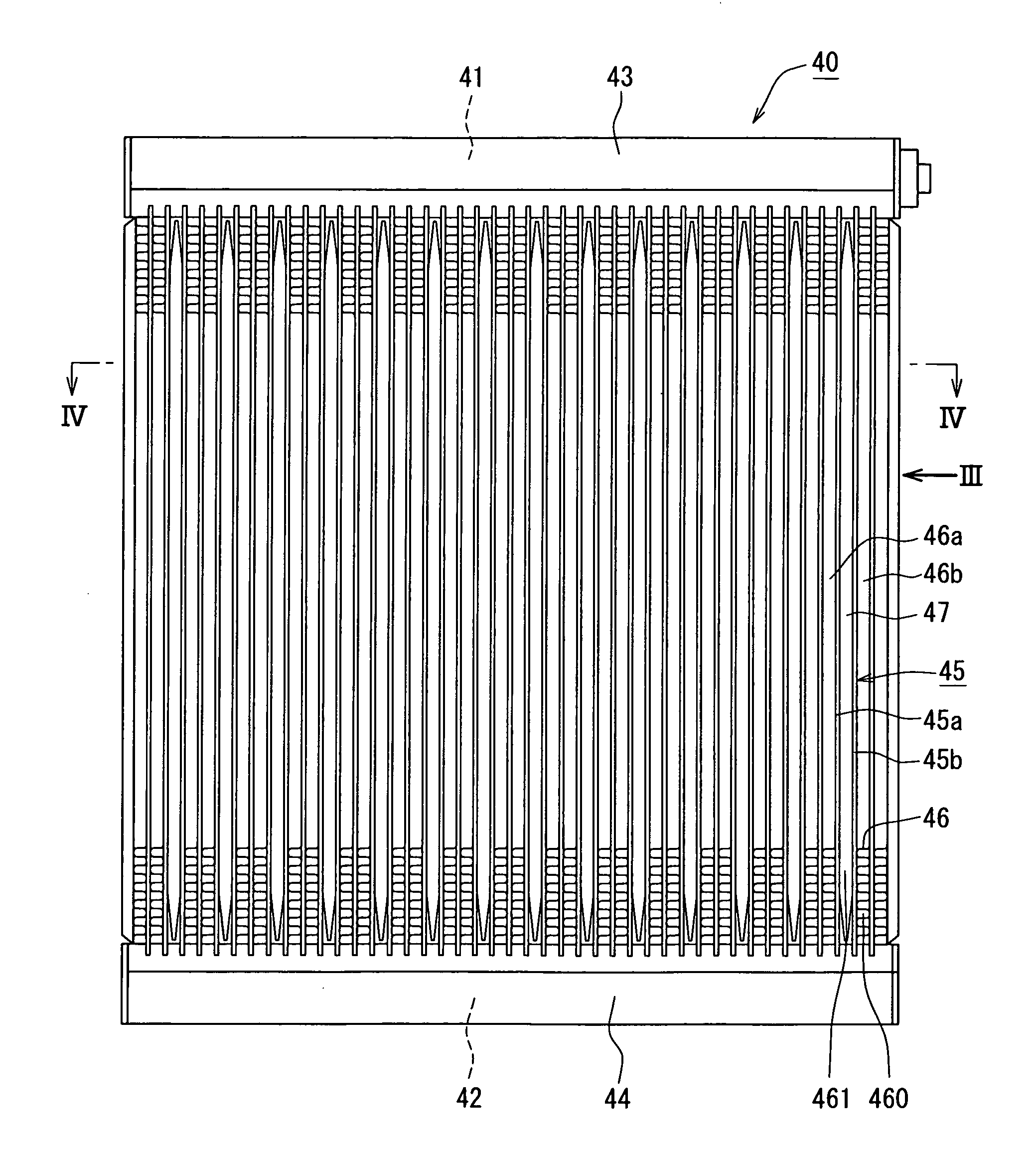

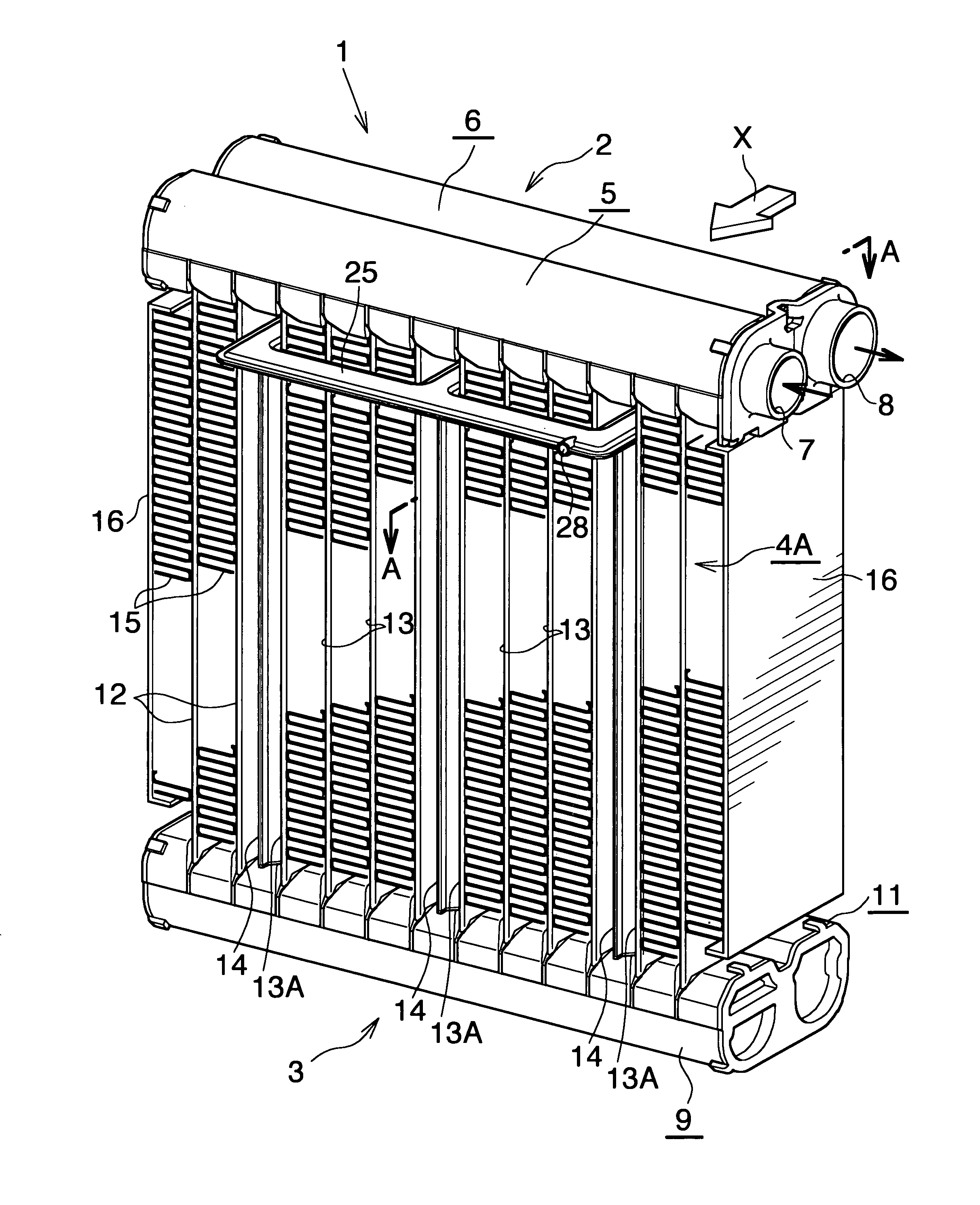

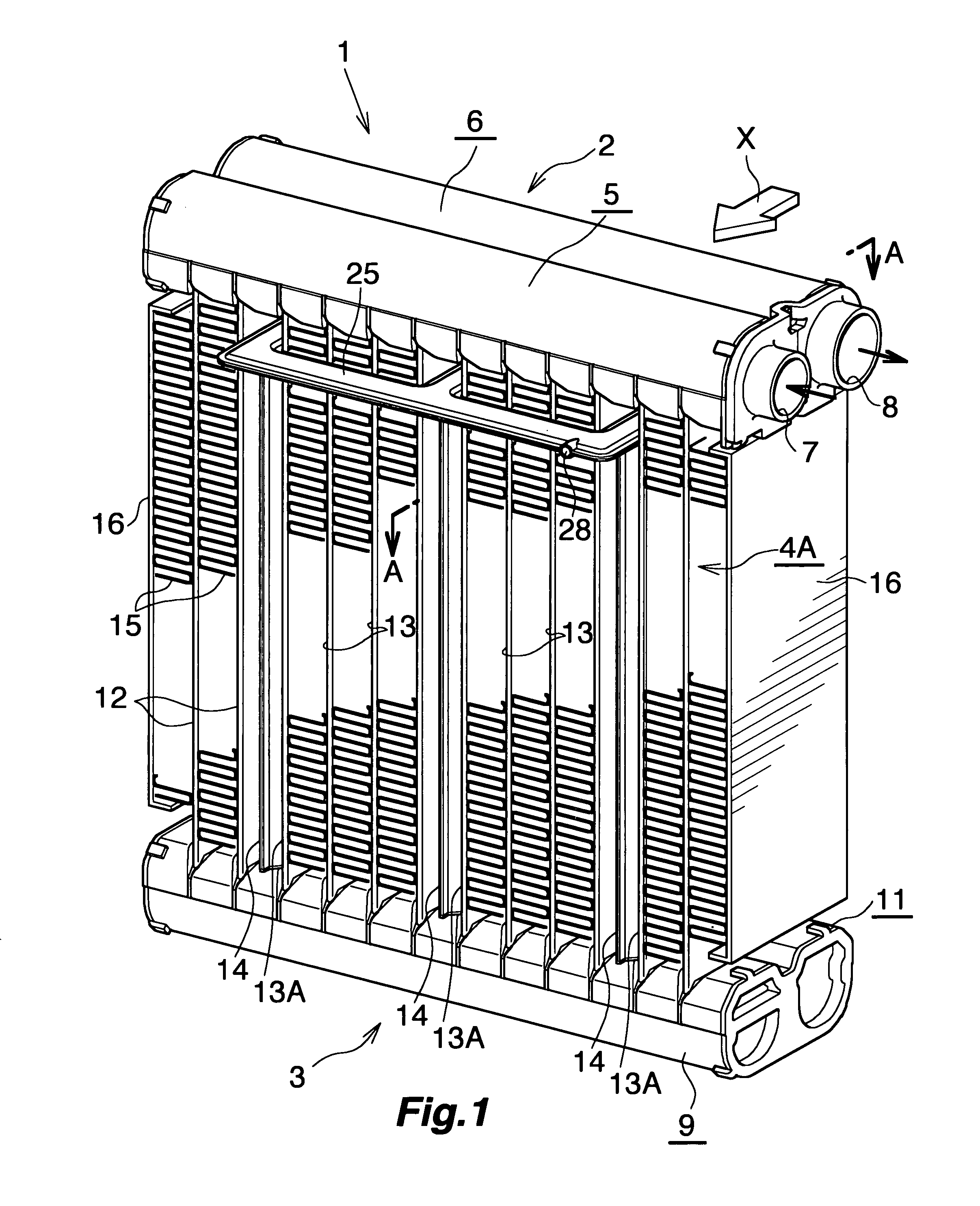

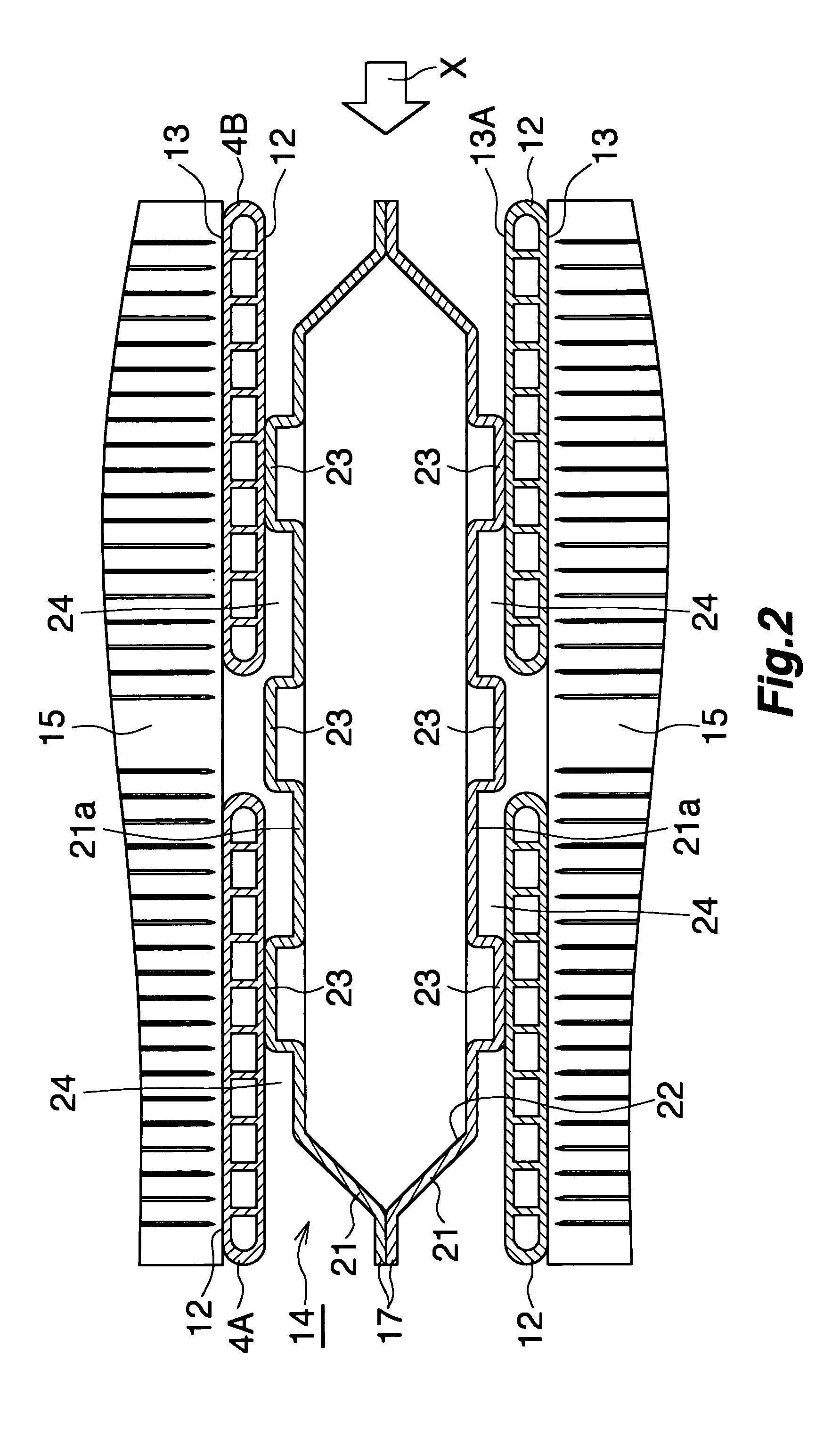

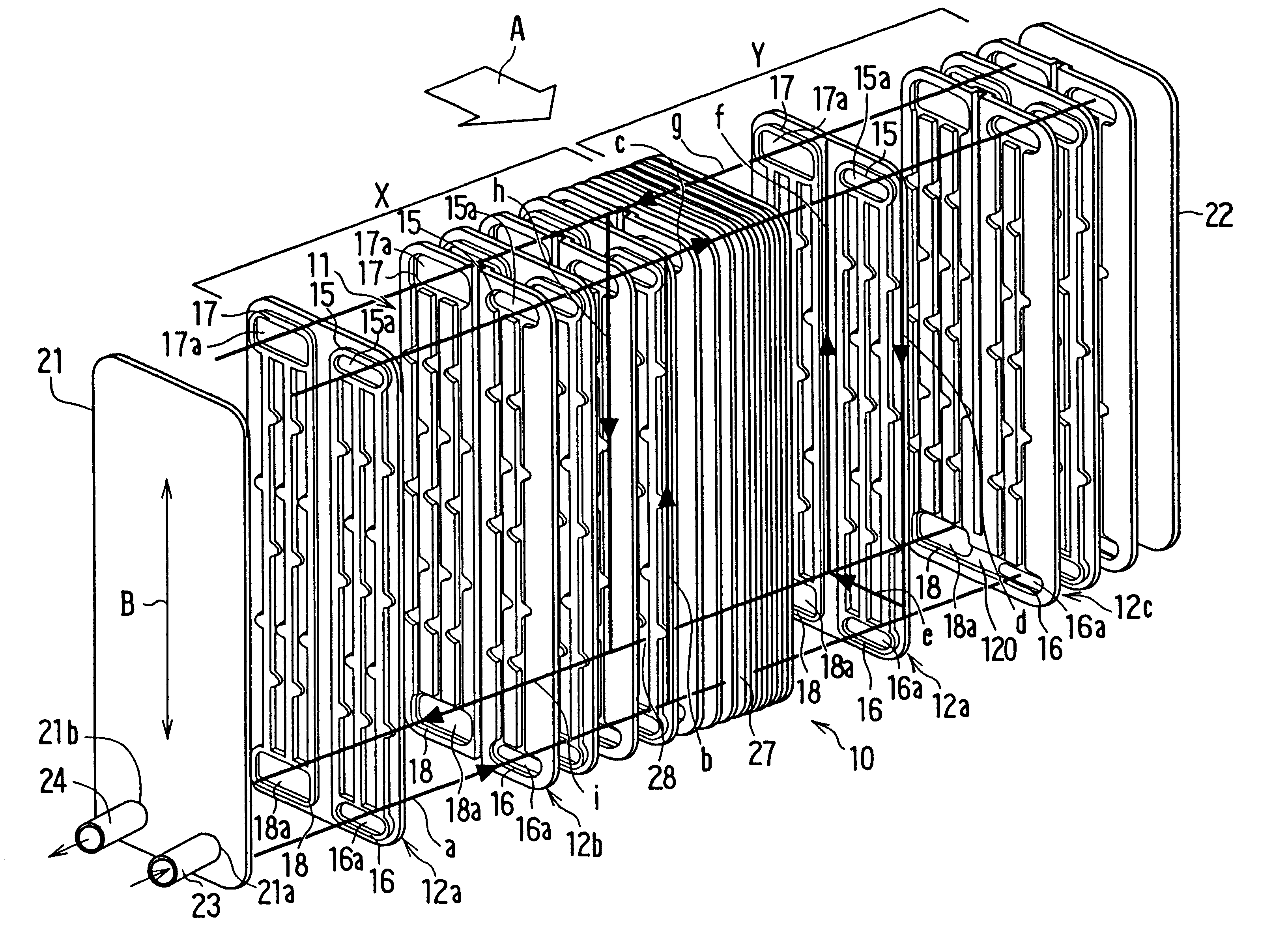

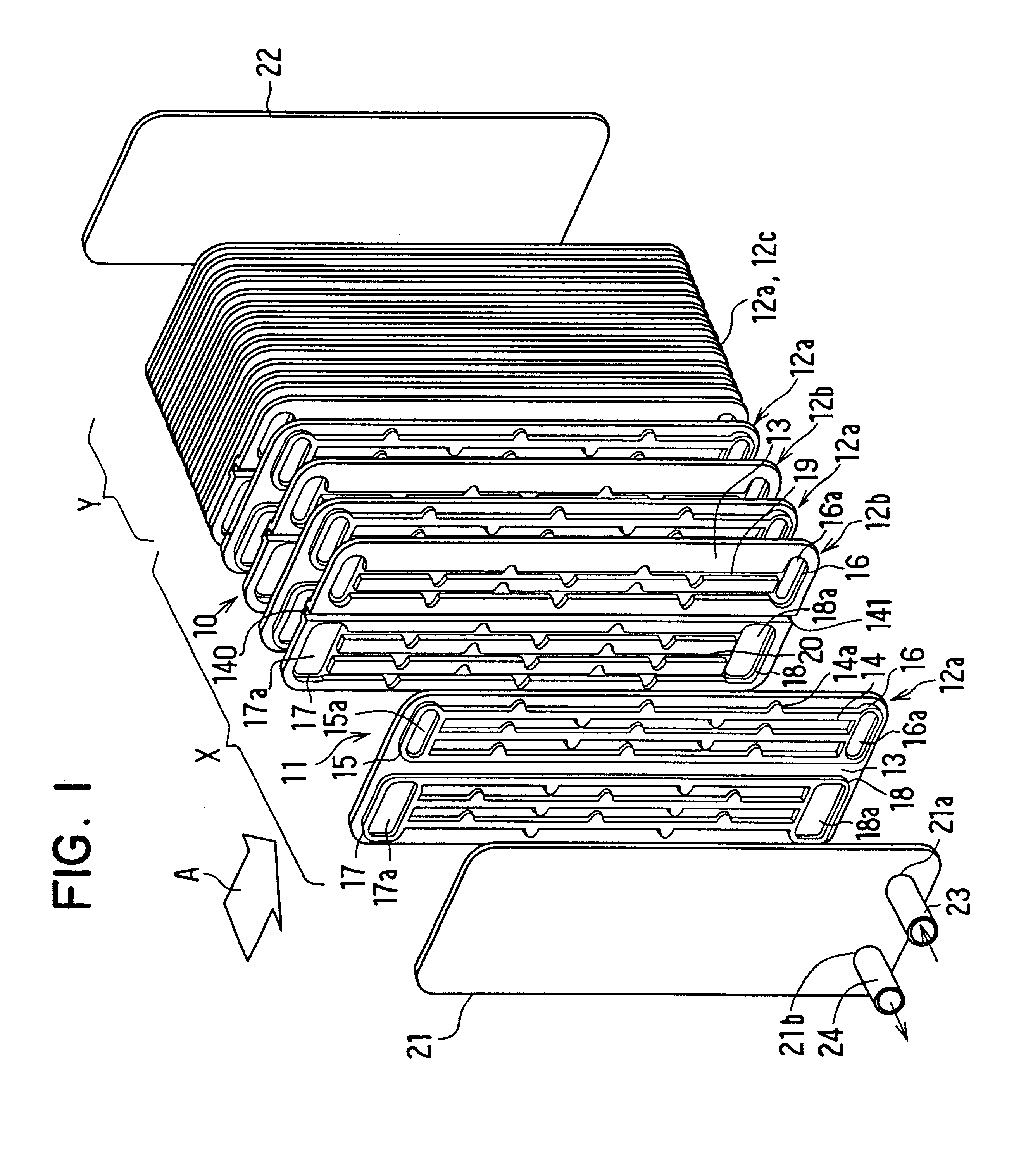

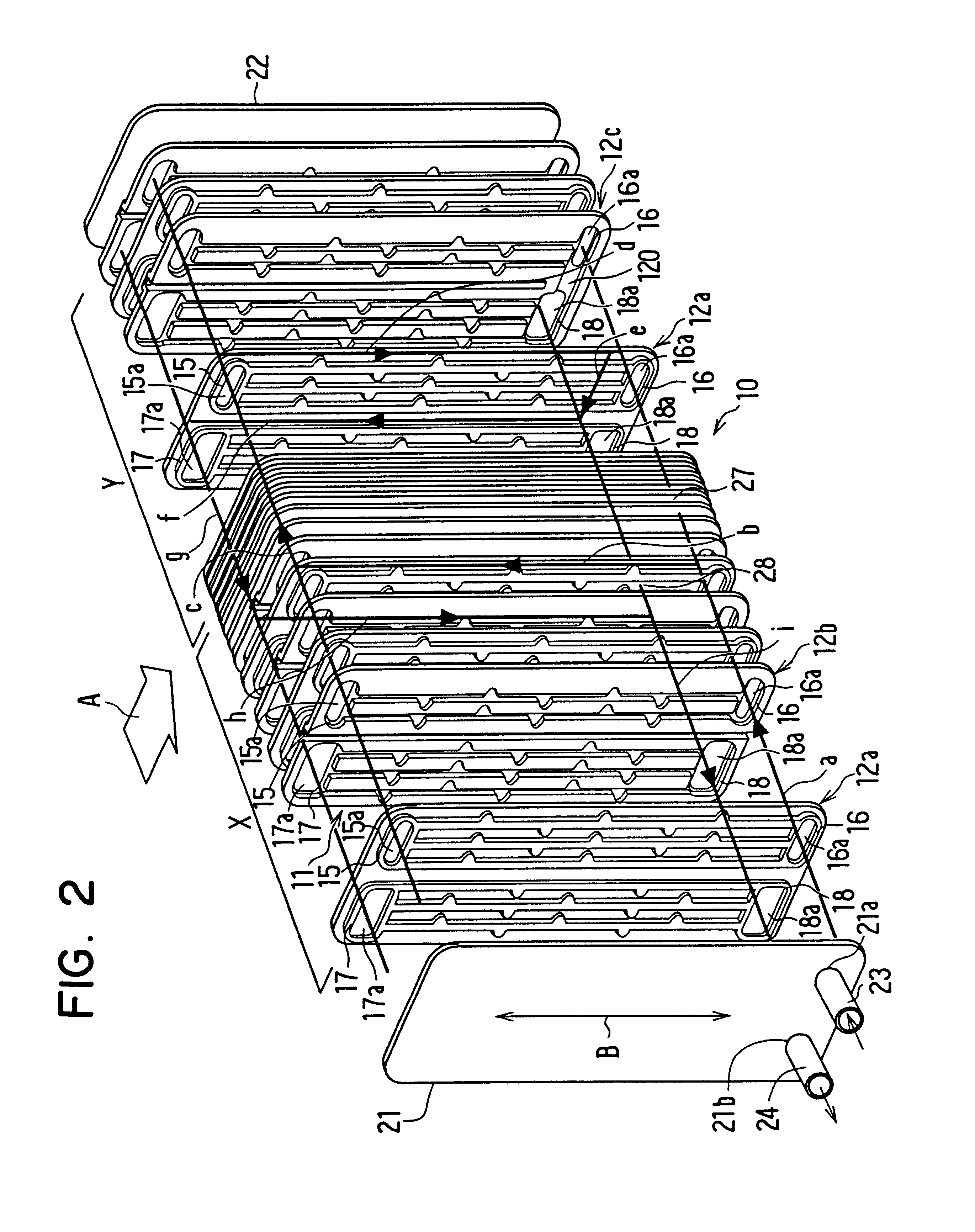

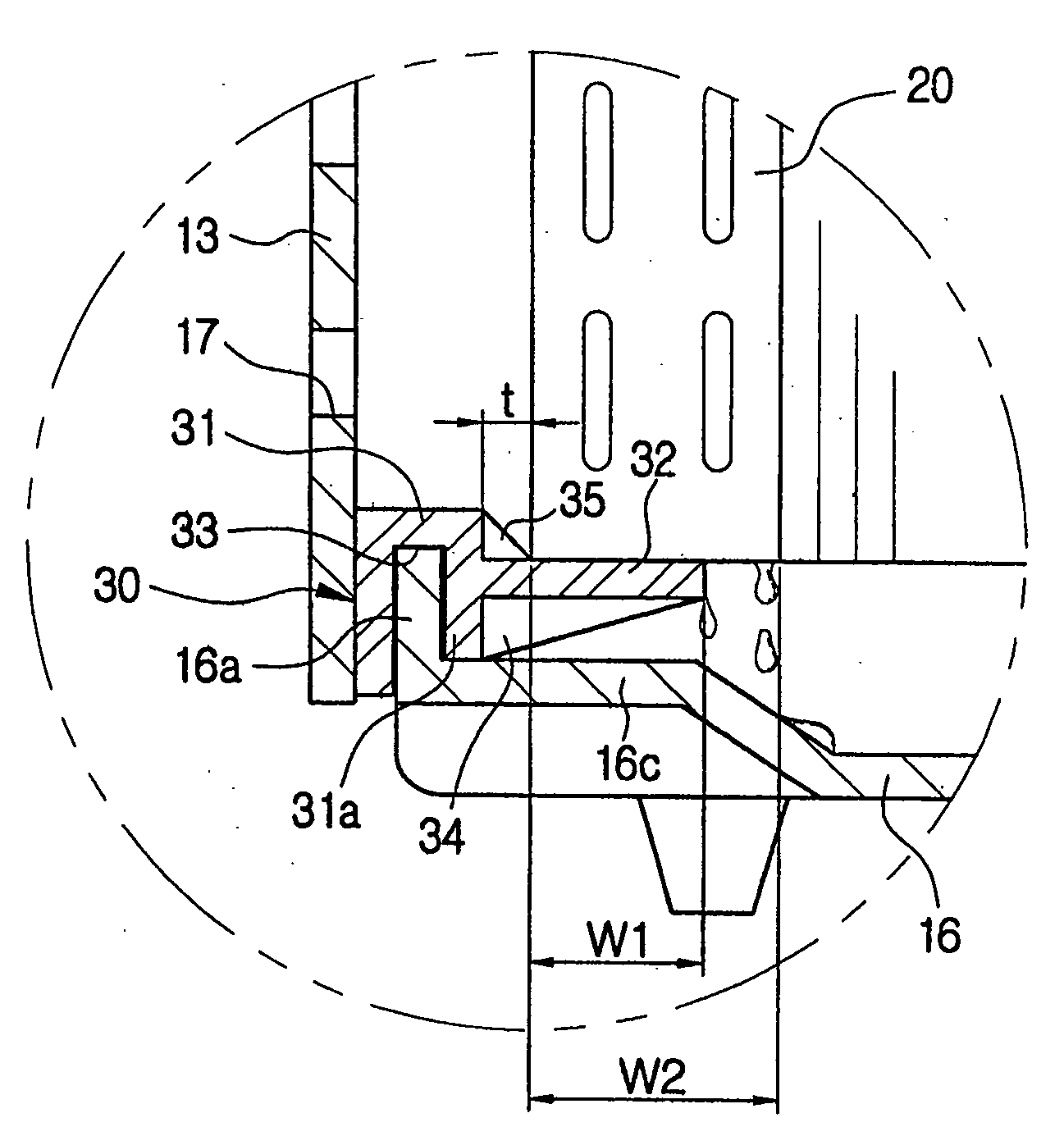

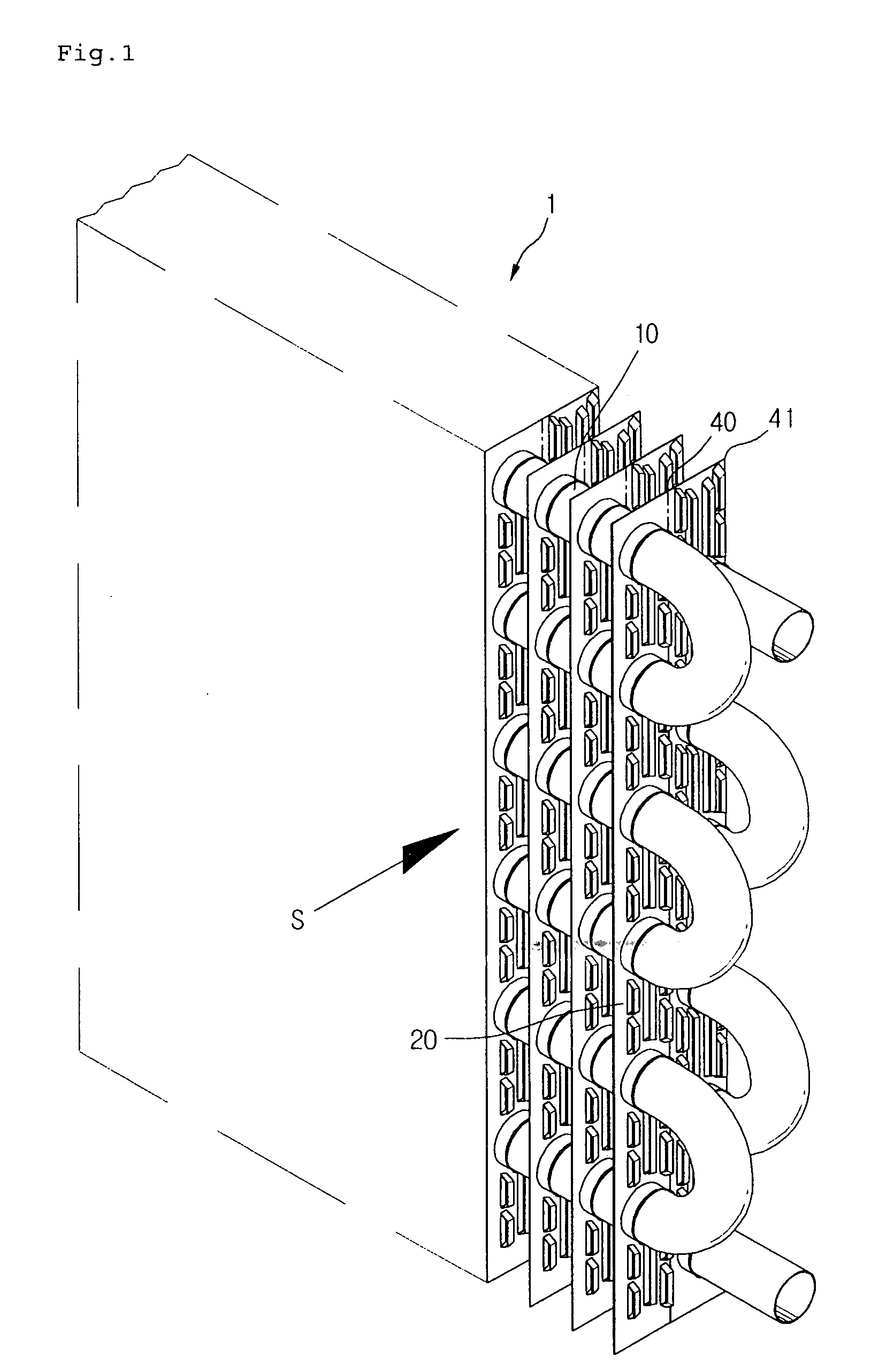

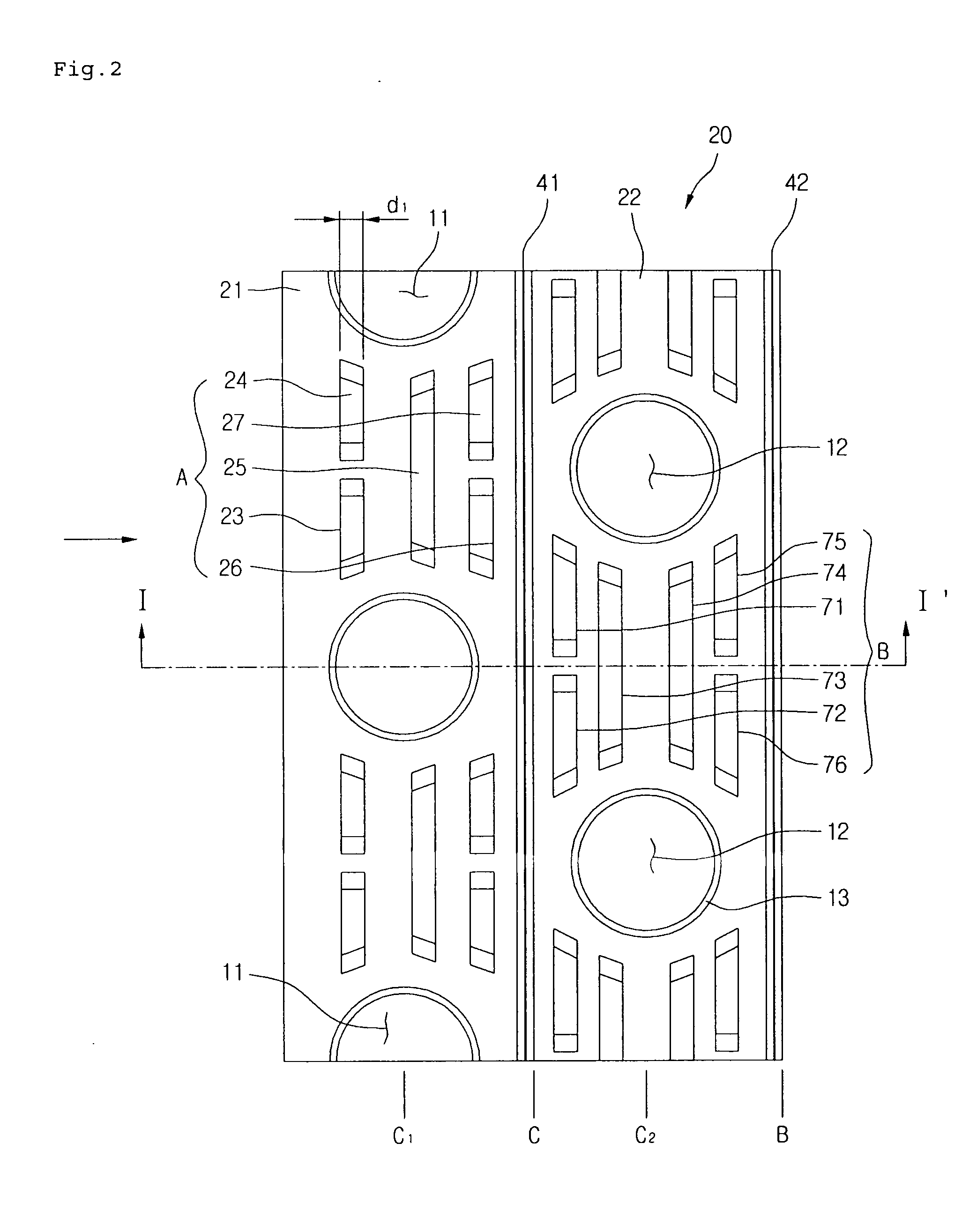

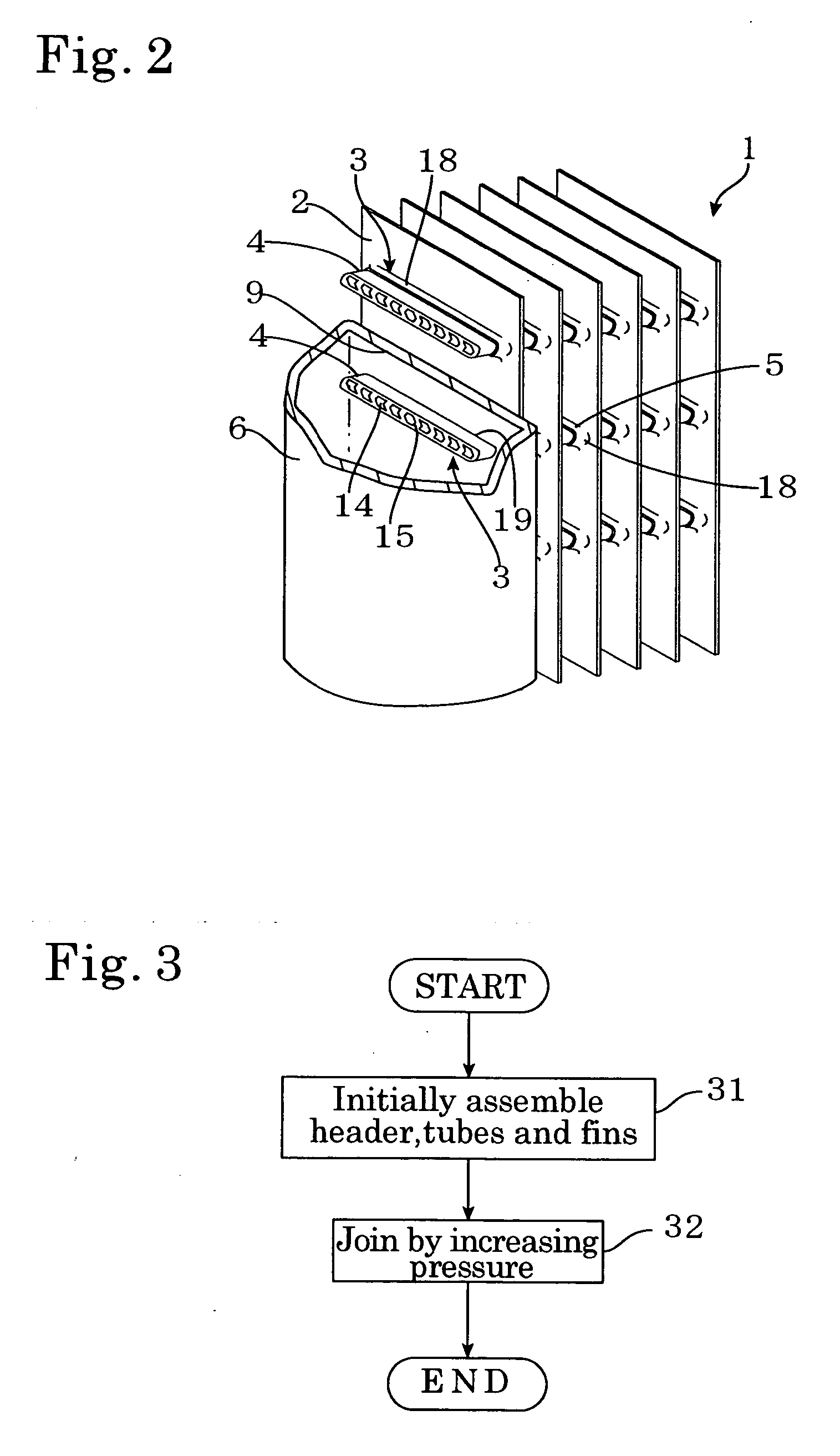

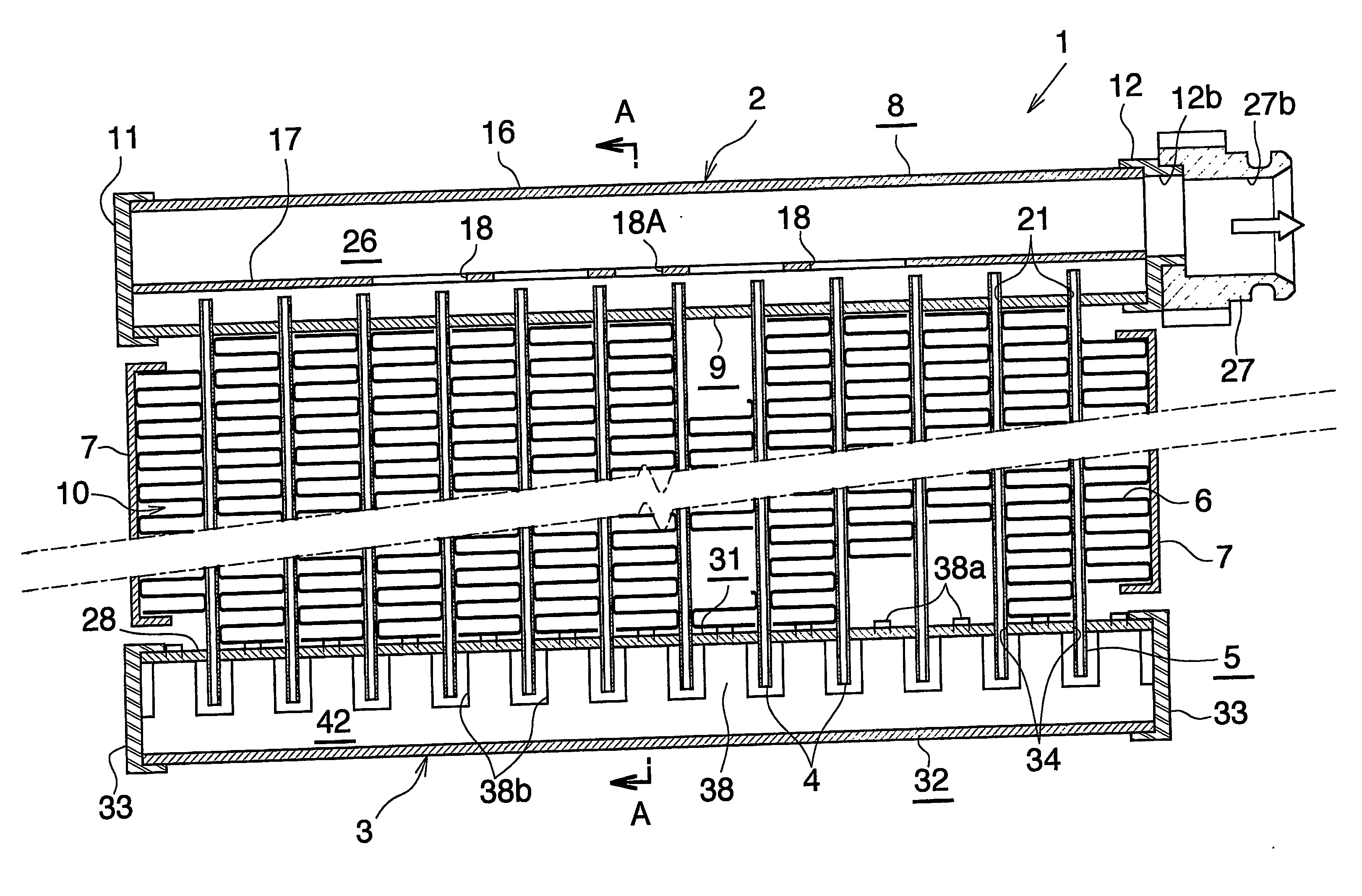

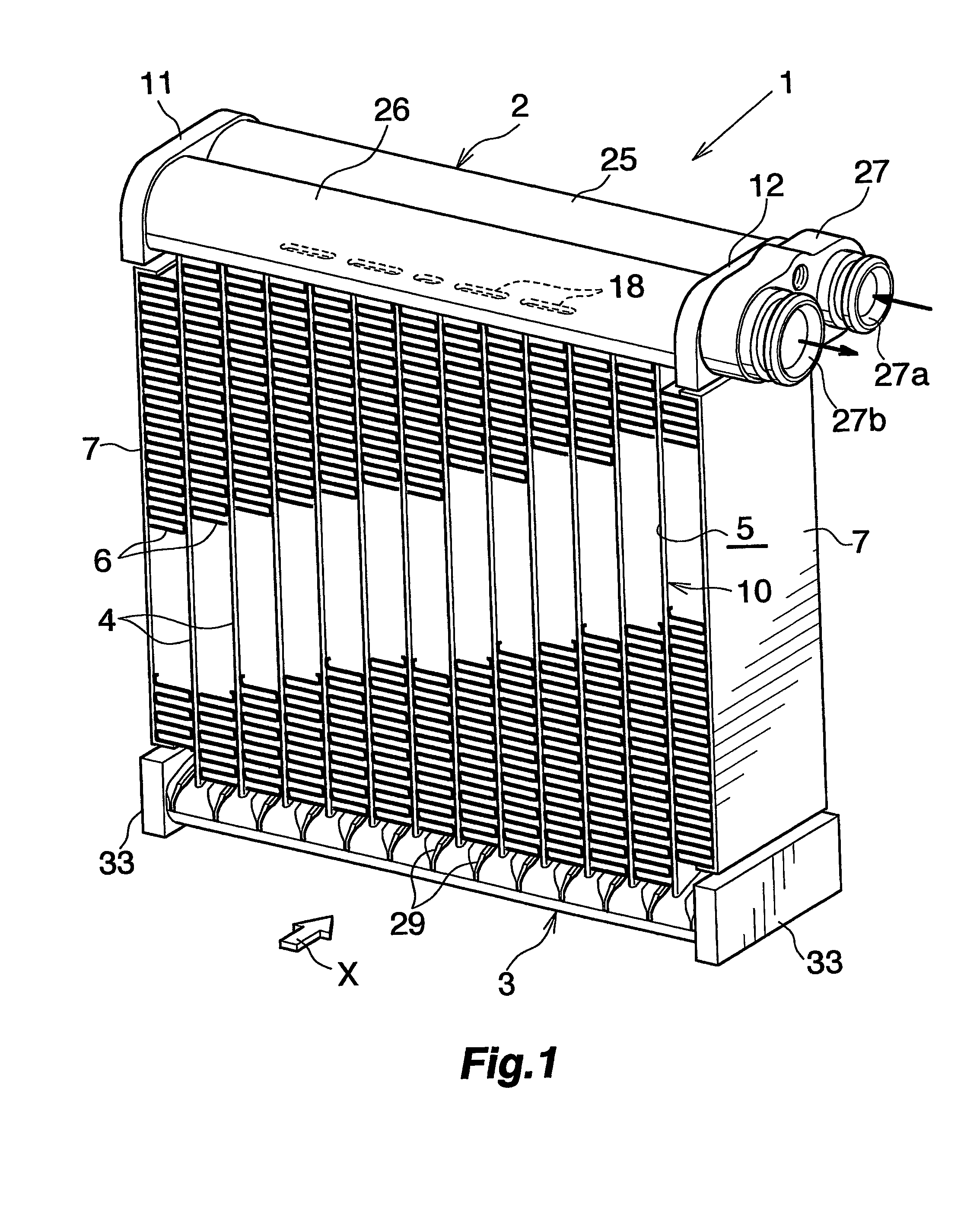

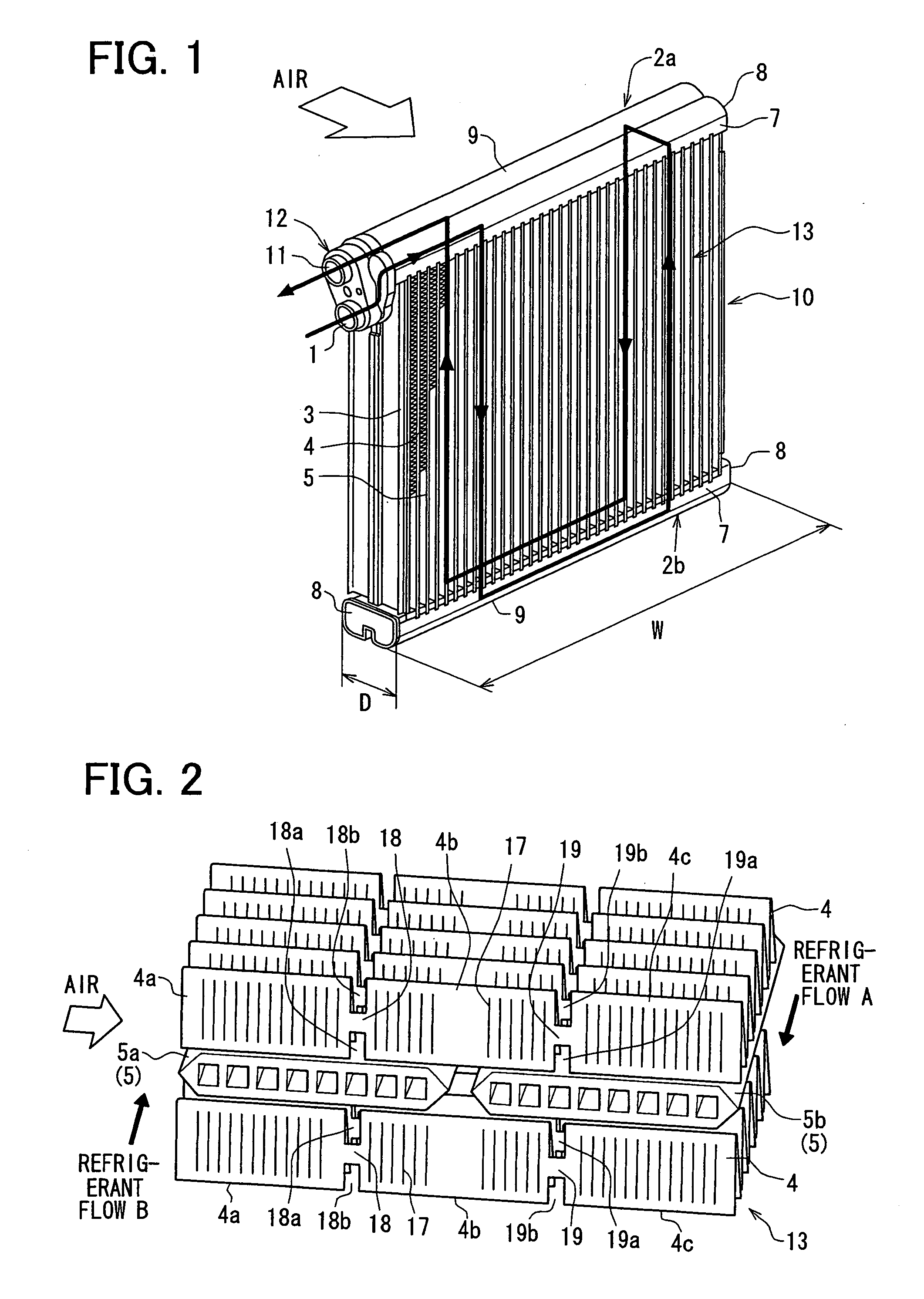

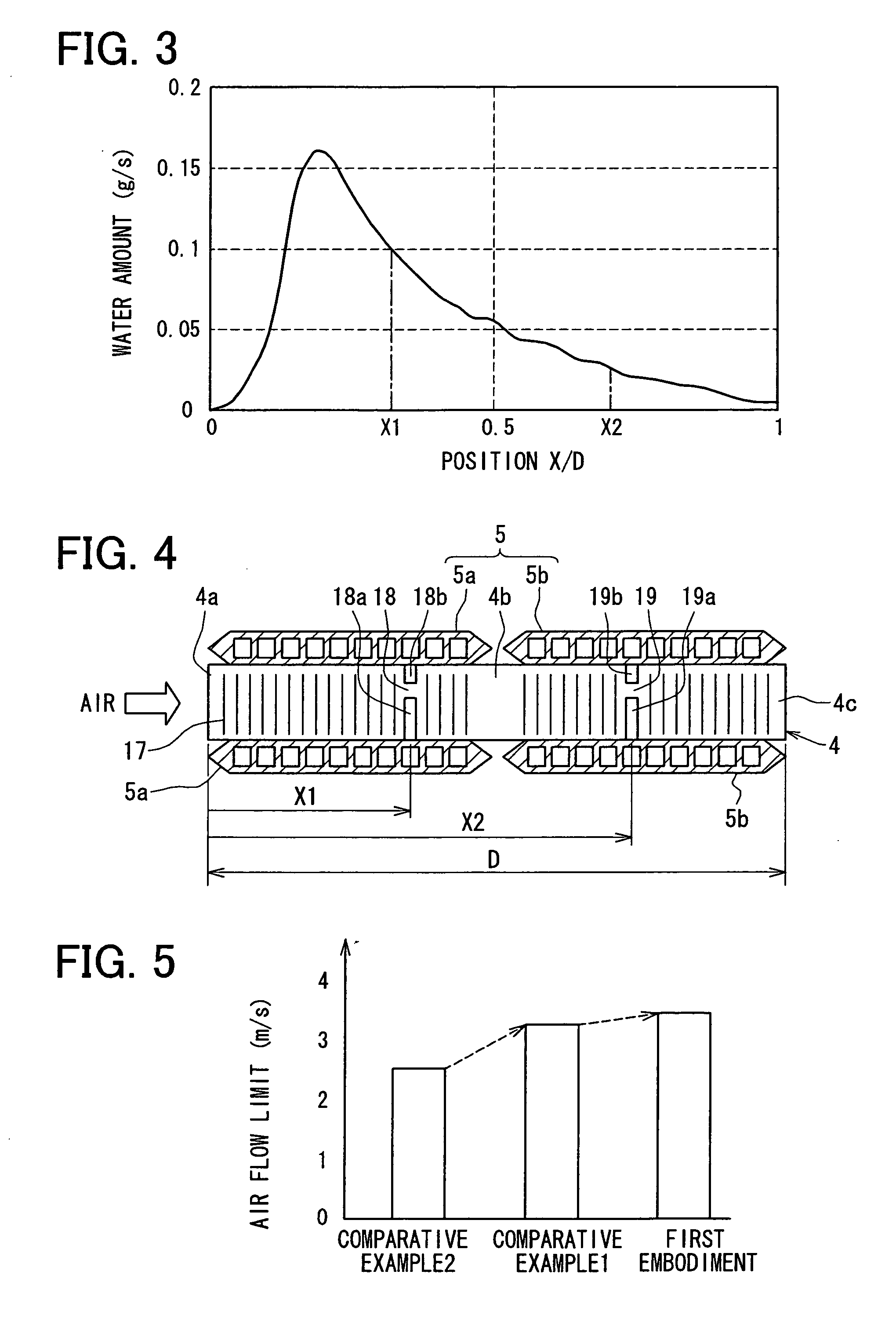

Evaporator having cold thermal energy storage function

ActiveUS20110239696A1Efficient storageDrop in cooling performance can be suppressedHeat storage plantsEvaporators/condensersCool storageThermal energy storage

An evaporator (1) with a cool storage function includes a plurality of flat refrigerant flow tubes (12) disposed in parallel such that their width direction coincides with an air flow direction and they are spaced from one another. Air-passing clearances (13, 13A) are formed between adjacent refrigerant flow tubes (12). Cool storage material containers (14) filled with a cool storage material are disposed in some (13A) of all the air-passing clearances (13, 13A), and each cool storage material container (14) is brazed to the refrigerant flow tubes (12) located on opposite sides thereof. Corrugated fins (15) are disposed in the remaining air-passing clearances (13), and each fin (15) is brazed to the refrigerant flow tubes (12) located on opposite sides thereof. Each cool storage material container (14) includes a plurality of convex portions (23) projecting outward from opposite side surfaces thereof, and projecting ends of the convex portions (23) are joined to the corresponding refrigerant flow tubes (12). This evaporator with a cool storage function can suppress a drop in cooling performance.

Owner:MAHLE INT GMBH

Heat exchanger only using plural plates

InactiveUS6401804B1Easy to detectCorrosion preventionStationary conduit assembliesEngineeringRefrigerant

Plural heat-exchanging plates for forming an evaporator have plural projection ribs. The projection ribs protrude toward outside of each pair of the heat-exchanging plates to form therein refrigerant passages through which refrigerant flows, and to form an air passage between adjacent pairs of the heat-exchanging plates. The projection ribs protrude from flat surfaces of the heat-exchanging plates toward the air passage to disturb a straight flow of air. The projection ribs are provided in each of the heat-exchanging plates to have a protrusion pitch (P1) between adjacent two, and the protrusion pitch is set in a range of 2-20 mm. Further, each of the heat-exchanging plates has a thickness of in a range of 0.1-0.35 mm, and a passage pitch (P2) between the refrigerant passages is in a range of 1.4-3.9 mm. Thus, in the evaporator formed by only using the plural heat-exchanging plates, a sufficient heat-exchanging performance can be obtained.

Owner:DENSO CORP

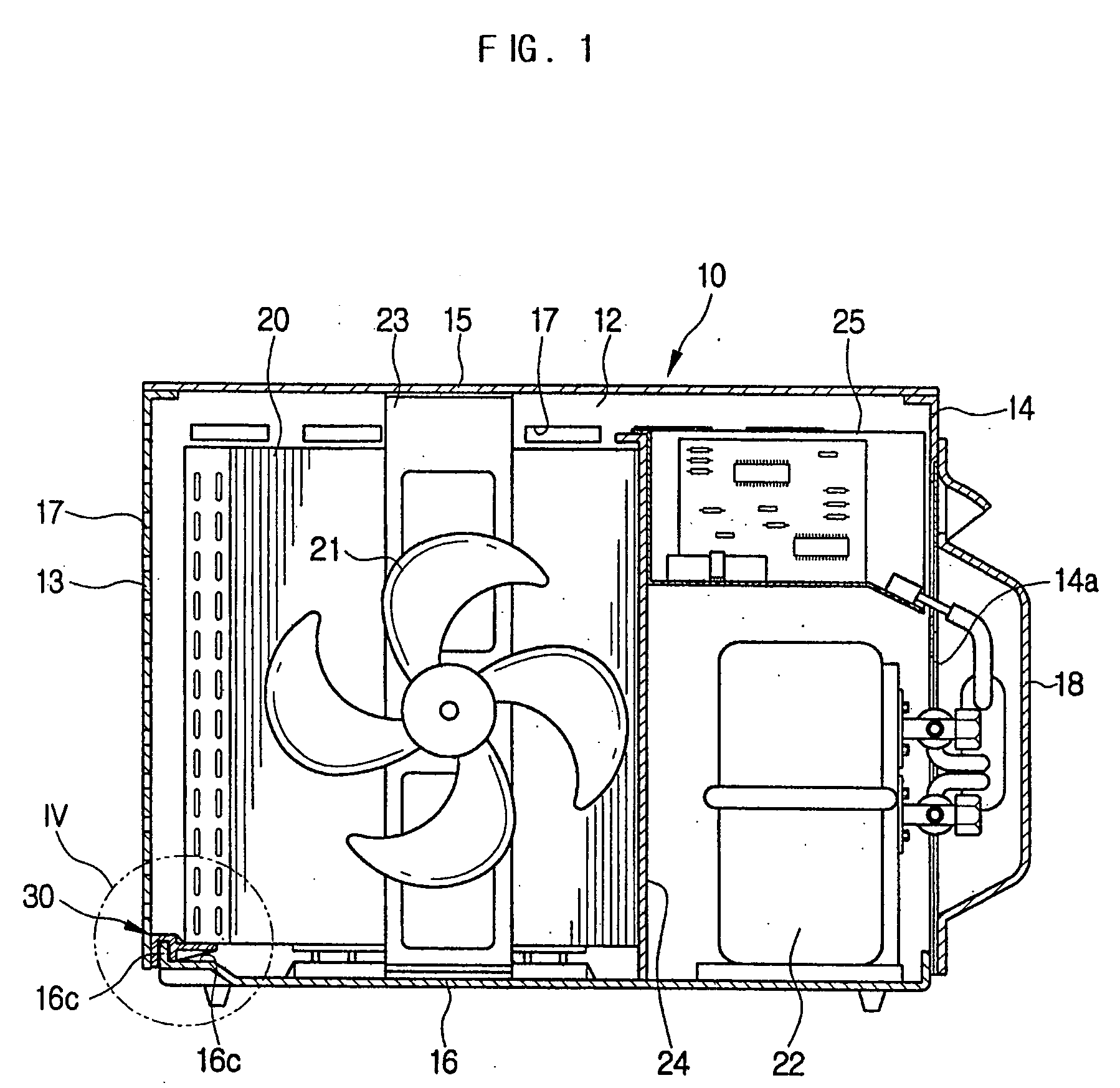

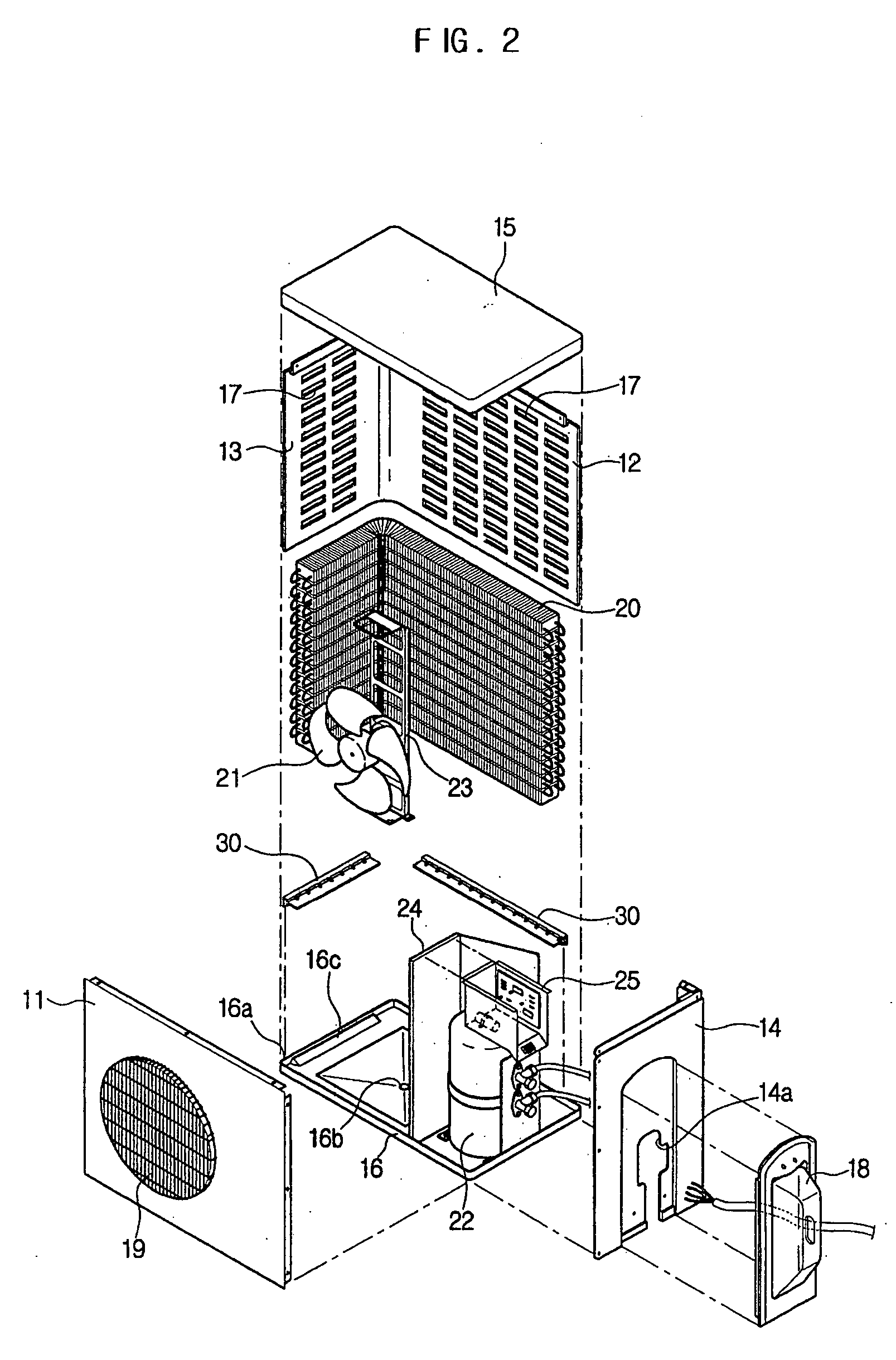

Outdoor unit for air conditioner

InactiveUS20050034471A1Easy dischargePreventing the condensed water from freezingThermal insulationCondensate preventionMechanical engineeringWaste management

An outdoor unit for an air conditioner allows condensed water generated from an outdoor heat exchanger to be easily discharged, and prevents coldness from the outdoor heat exchanger from being transmitted to a bottom of the outdoor unit, thus preventing freezing of the condensed water on the bottom. The outdoor unit includes a cabinet having a bottom panel, an outdoor heat exchanger installed in the cabinet, and a support member made of heat insulating material supporting the outdoor heat exchanger with a spacing between a lower end of the outdoor heat exchanger and the bottom panel of the cabinet, to prevent condensed water generated from the outdoor heat exchanger from freezing.

Owner:SAMSUNG ELECTRONICS CO LTD

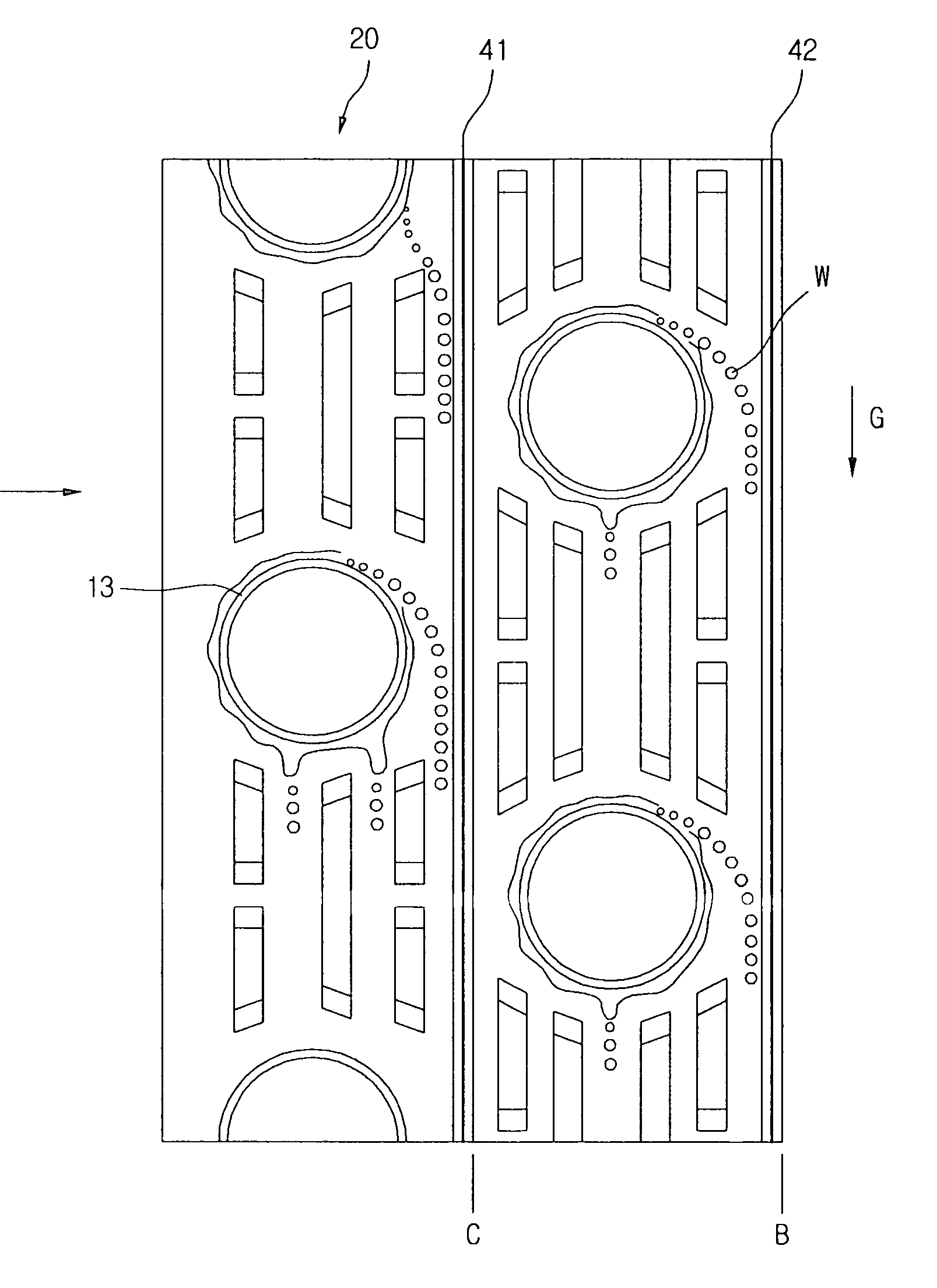

Heat exchanger and fin of the same

InactiveUS20070151716A1Avoid flowReduce power consumptionStationary conduit assembliesIce removalEngineeringRefrigerant

A heat exchanger and a fin of the same are provided. The heat exchanger includes a tube, a plurality of fins, a slit section, and a condensed water guide. The tube is arranged in at least a front row and a rear row with respect to a direction of airflow. The plurality of fins is installed with the tube passing therethrough. The slit section is formed on the fins and includes a plurality of slits. The condensed water guide is formed between at least the front row and the rear row, for guiding a draining of condensed water that is generated on a surface of the tube. A fin of the heat exchanger includes a plurality of tube insert holes, a slit section, and a condensed water guide. A refrigerant tube is inserted in the plurality of tube insert holes. The slit section includes a plurality of slits formed around the tube insert holes. The condensed water guide is formed at a rear side of one of the slits, and guides a draining of condensed water generated in a heat exchange process between refrigerant and air.

Owner:LG ELECTRONICS INC

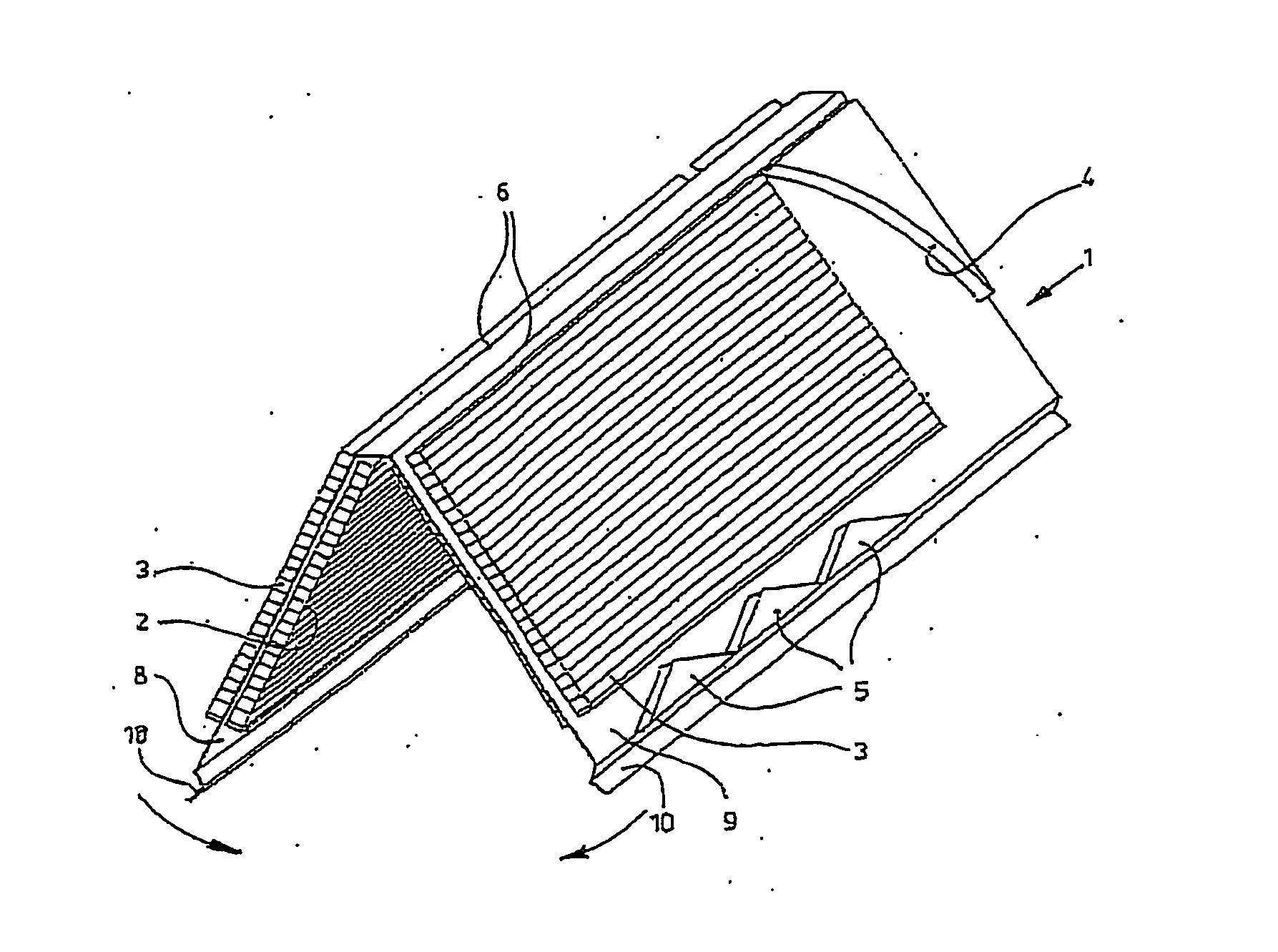

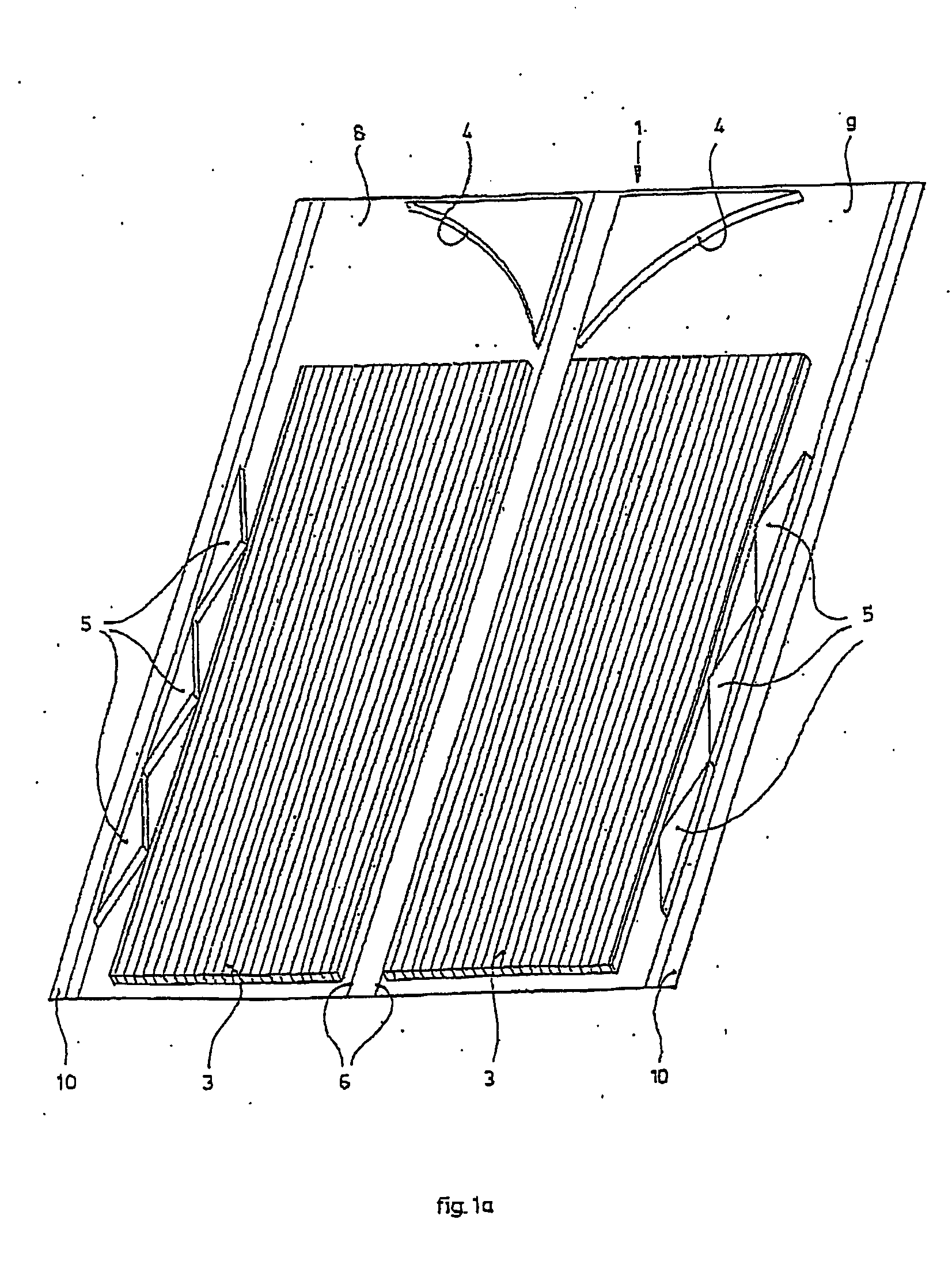

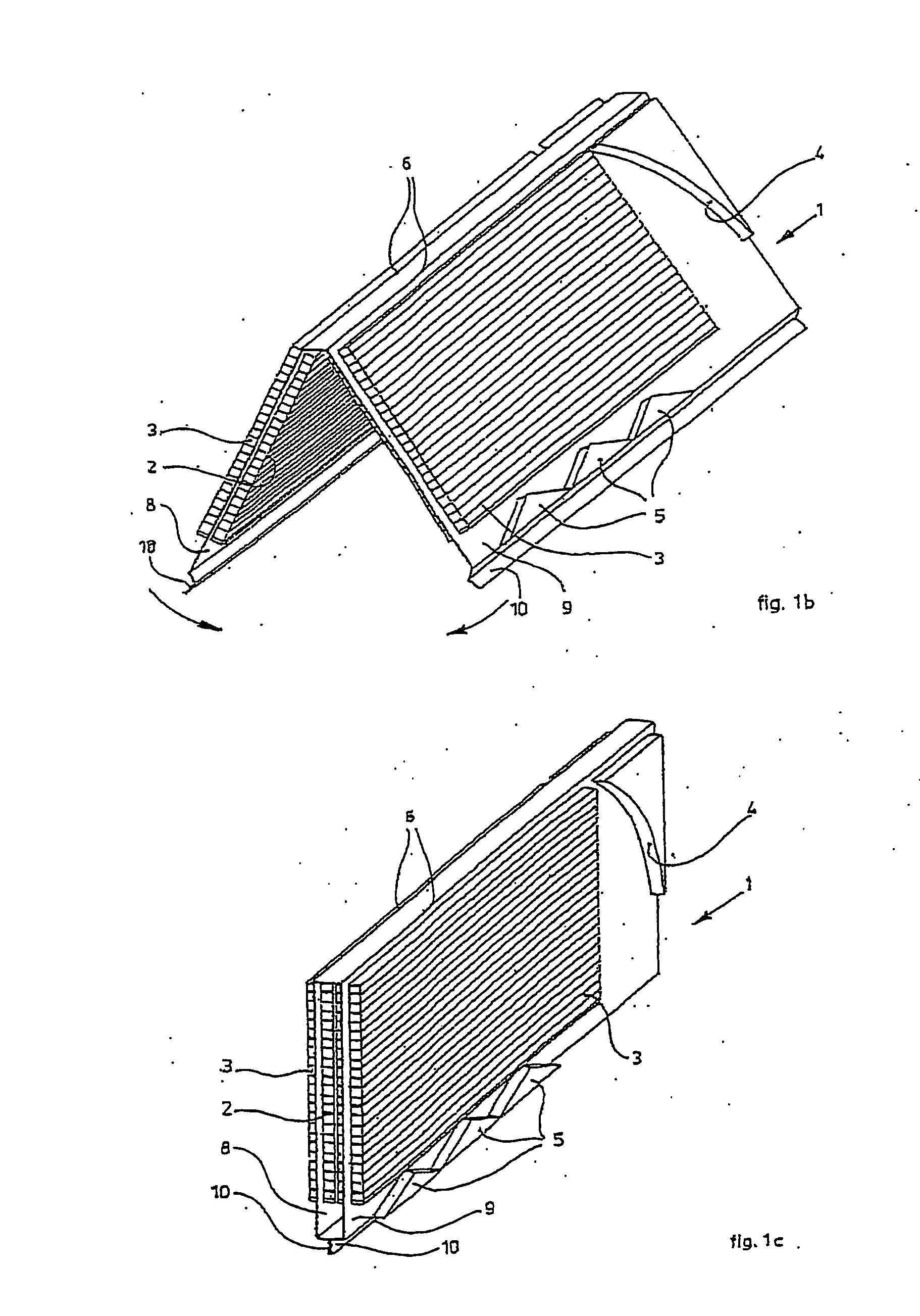

Heat exchanger and method of manufacture thereof

InactiveUS20060124287A1Improve heat transfer performanceEasy to produceSafety devices for heat exchange apparatusFree-cooling systemsEngineeringMetal

Method of manufacturing a heat exchanger from a formable laminate (1, 11, 105) of a metal layer and a heat-seal layer whereby the laminate is sealed under heat and pressure to itself or to another similar laminate to form a flow channel for a heat exchange medium. Preferably the heat exchanger includes a series of fins (3, 106, 107) formed on the laminate (1, 11, 105) to increase heat transfer and may also include a water retaining layer (204).

Owner:OXYCOM BEHEER BV

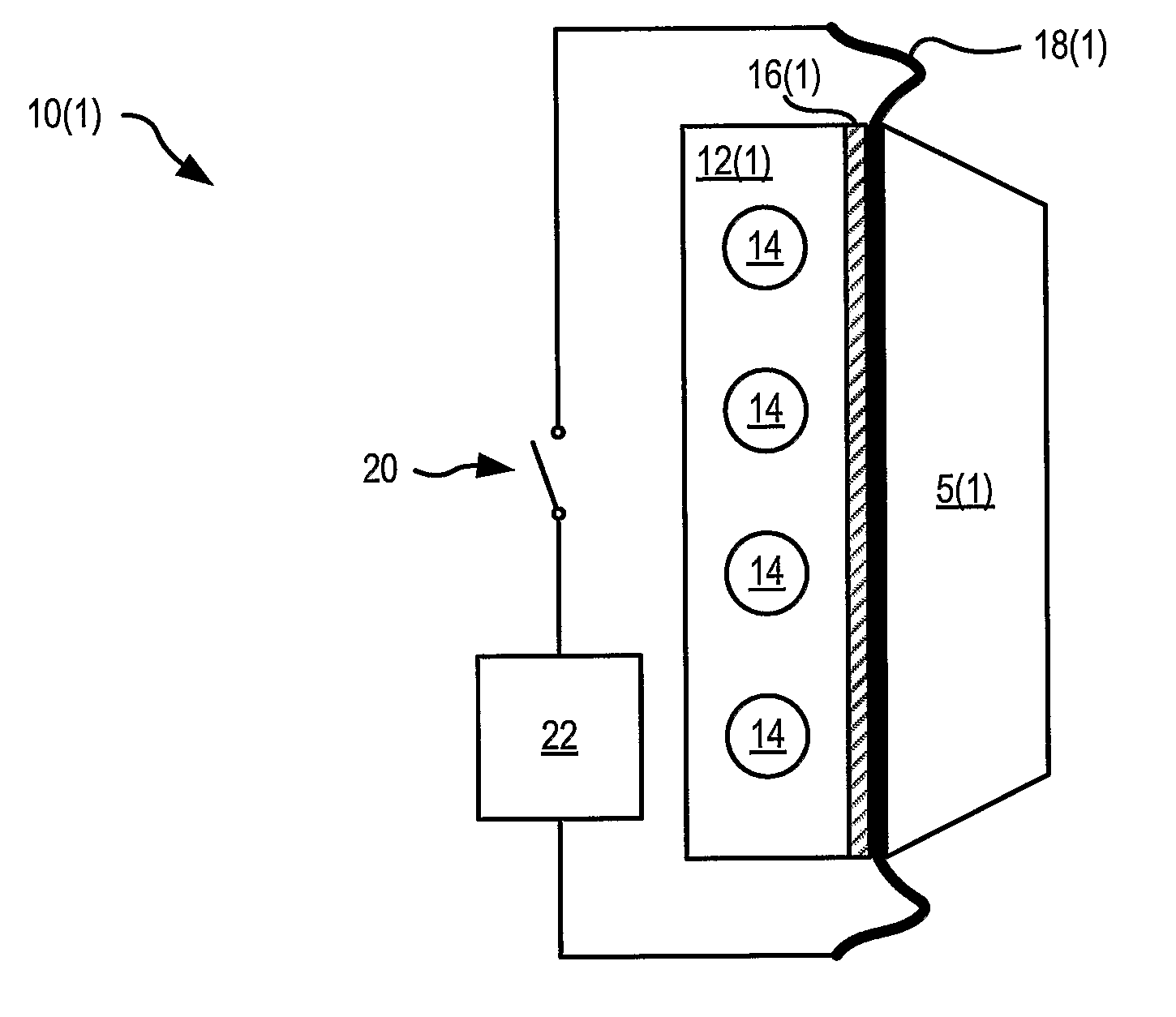

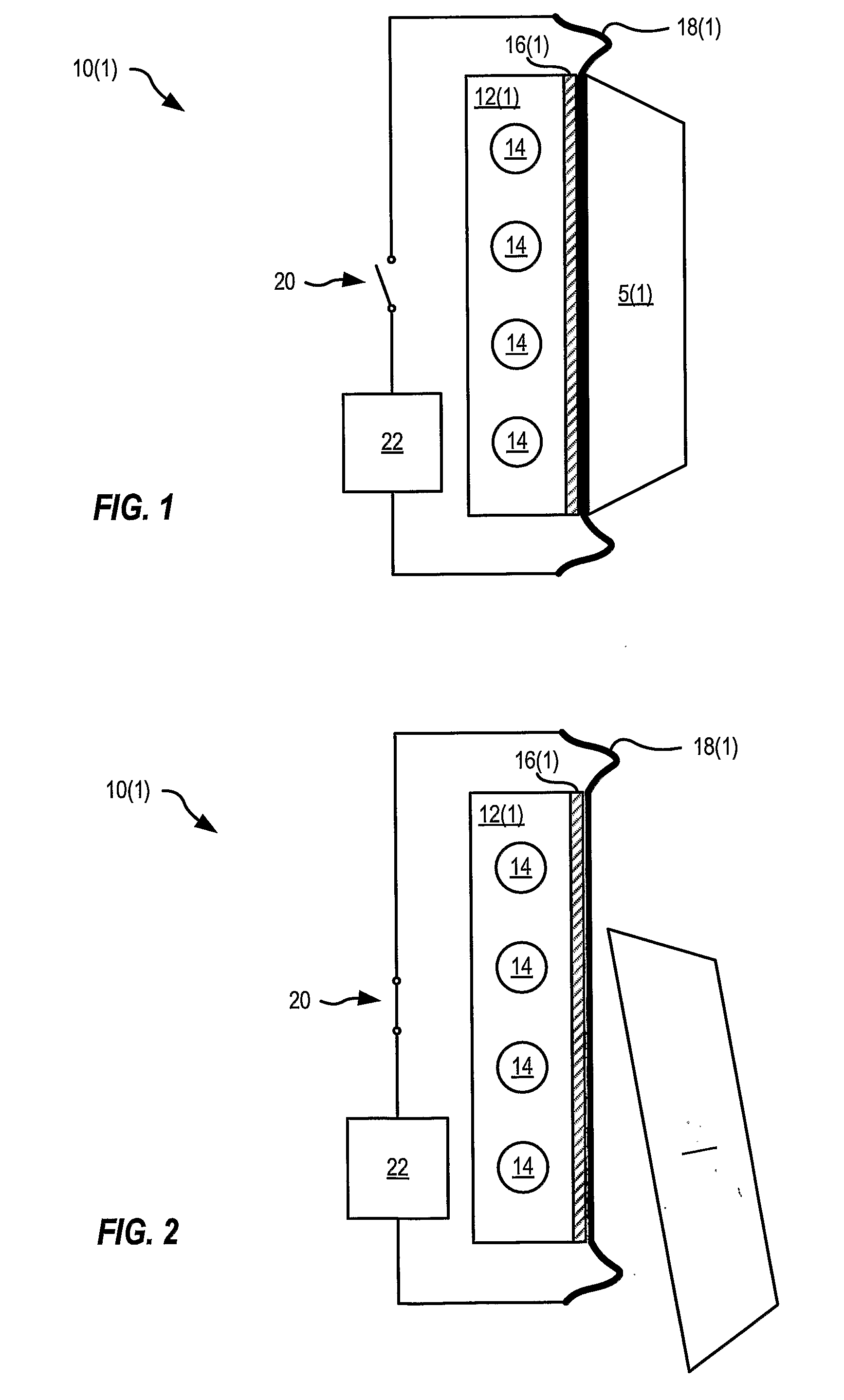

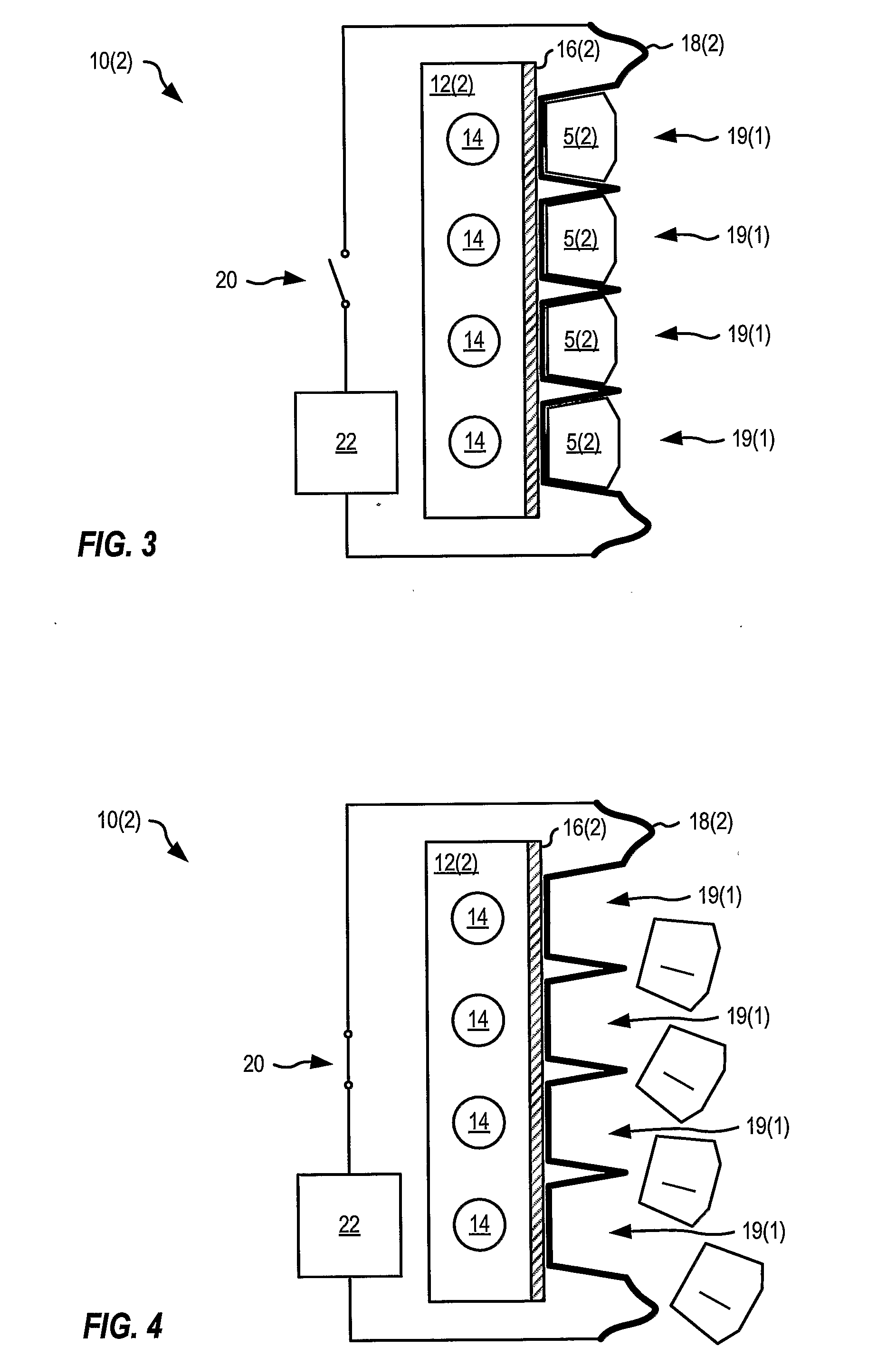

Pulse systems and methods for detaching ice

ActiveUS20090199569A1Increase temperatureDielectric heatingDe-icing equipmentsJet aeroplaneElectrical resistance and conductance

A pulse system for detaching ice includes a power supply for applying a high-power heating pulse to the interface between ice and an object such as a cold plate of an ice making system, an ice-container, a heat-exchanger, a refrigerator surface or an airplane wing. Pulse heating may be generated within a metal foil or resistive film disposed upon an object to be deiced, or a capillary tube proximate the object to be deiced. An interfacial layer of ice is melted and the ice is released from the object. A force, for example gravity, pressure of vaporization or mechanical scraping, removes the ice from the object.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

Heat exchanger

InactiveUS20100300647A1Promote atomizationReduce gas flowRecuperative heat exchangersMachines/enginesExternal combustion engineProcess engineering

A heat exchanger, in particular a charge air cooler or an exhaust gas cooler for an internal combustion engine, comprising a plurality of essentially parallel tubes and at least one collector box on the output side, the tubes each emptying into the collector box on the output side, and a gas flow flowing from the tubes into the collector box and from the collector box into an outlet of the collector box, a structure for interacting with the gas flow being provided at least one of the tubes or collector box, a condensation being transported to the outlet with the aid of the structure.

Owner:MAHLE INT GMBH

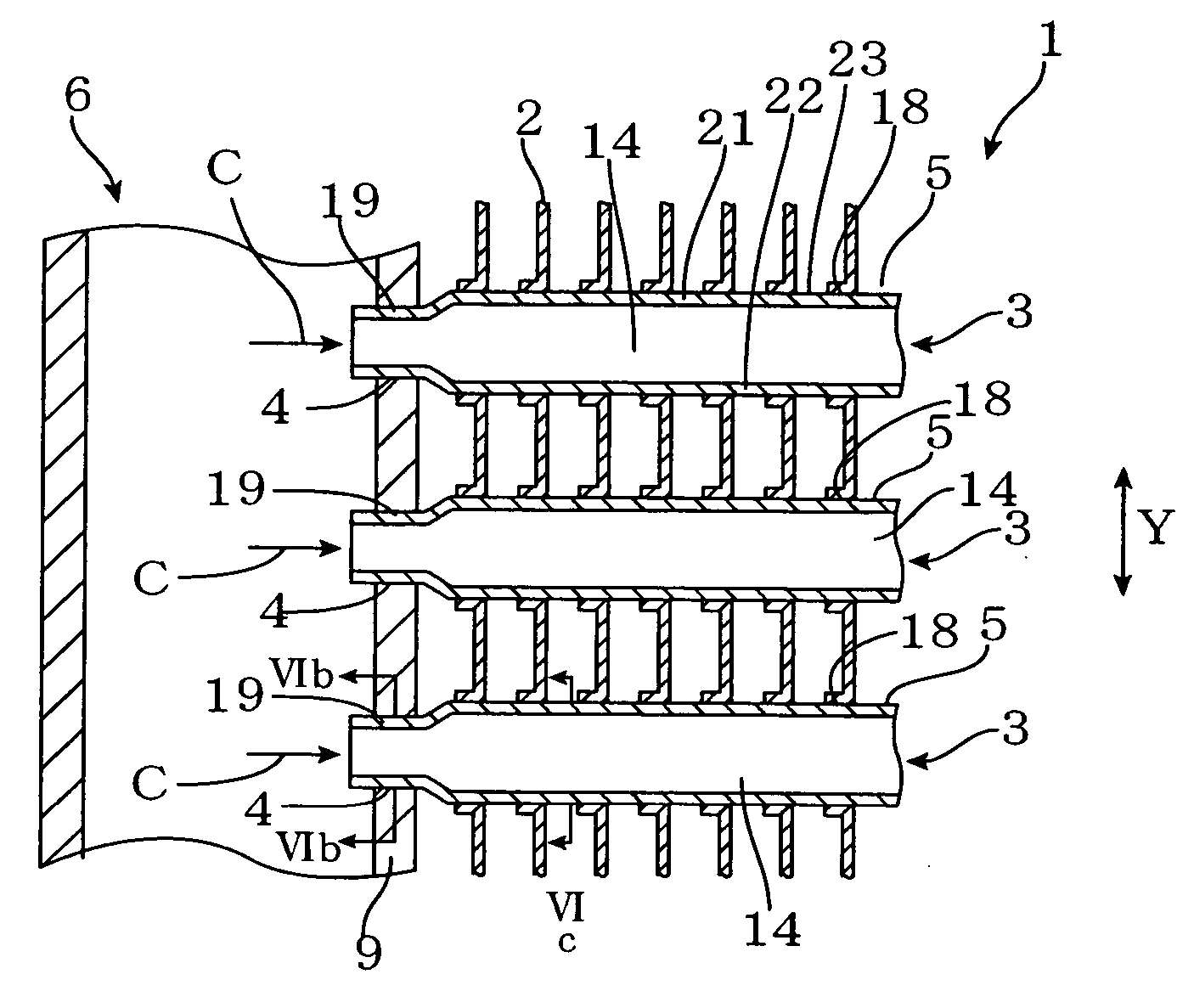

Heat exchanger and method of manufacturing the same

InactiveUS20050061494A1Increase internal pressureAdd partsStationary conduit assembliesHeat exchanger casingsInternal pressureEngineering

There is provided a method of manufacturing a heat exchanger, including a first step of mounting an end part of flat tube to a header, assembling the flat tube and fins, and sealing a part where the header and the end part is attached, and a second step of increasing an internal pressure of the flat tube to expand other part of flat tubes aside from the end parts with respect to the end part of the tube in order to make the fins and the other part of the flat tube in contact each other. According to this method of manufacturing, in the second step, the other part of the flat tube that passes through the fins is expanded, so that it is possible to mechanically join the flat tube and the fins, and a plate fin-type heat exchanger with high strength and heat exchange efficiency can be easily provided.

Owner:DENSO AIRCOOL CORP

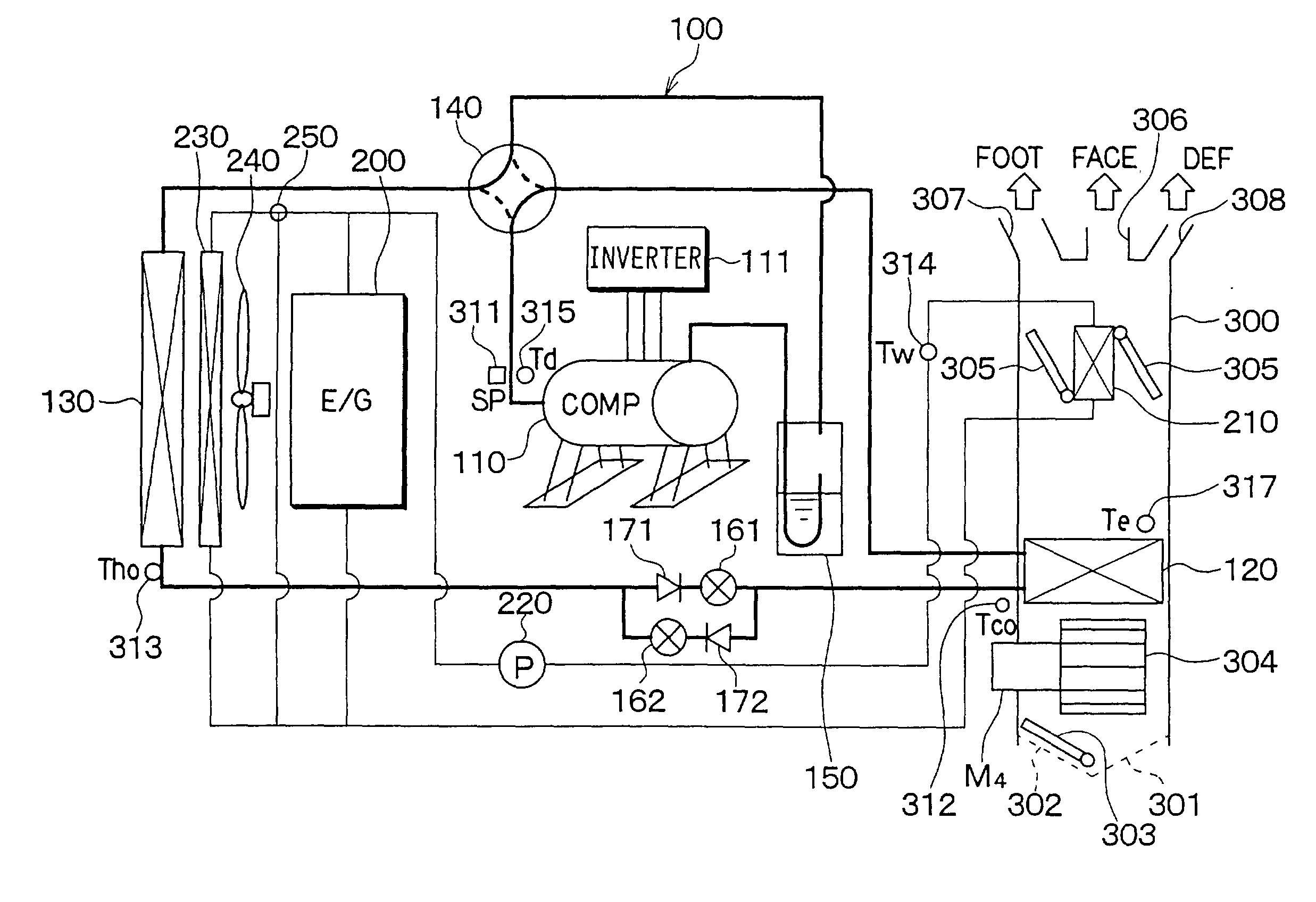

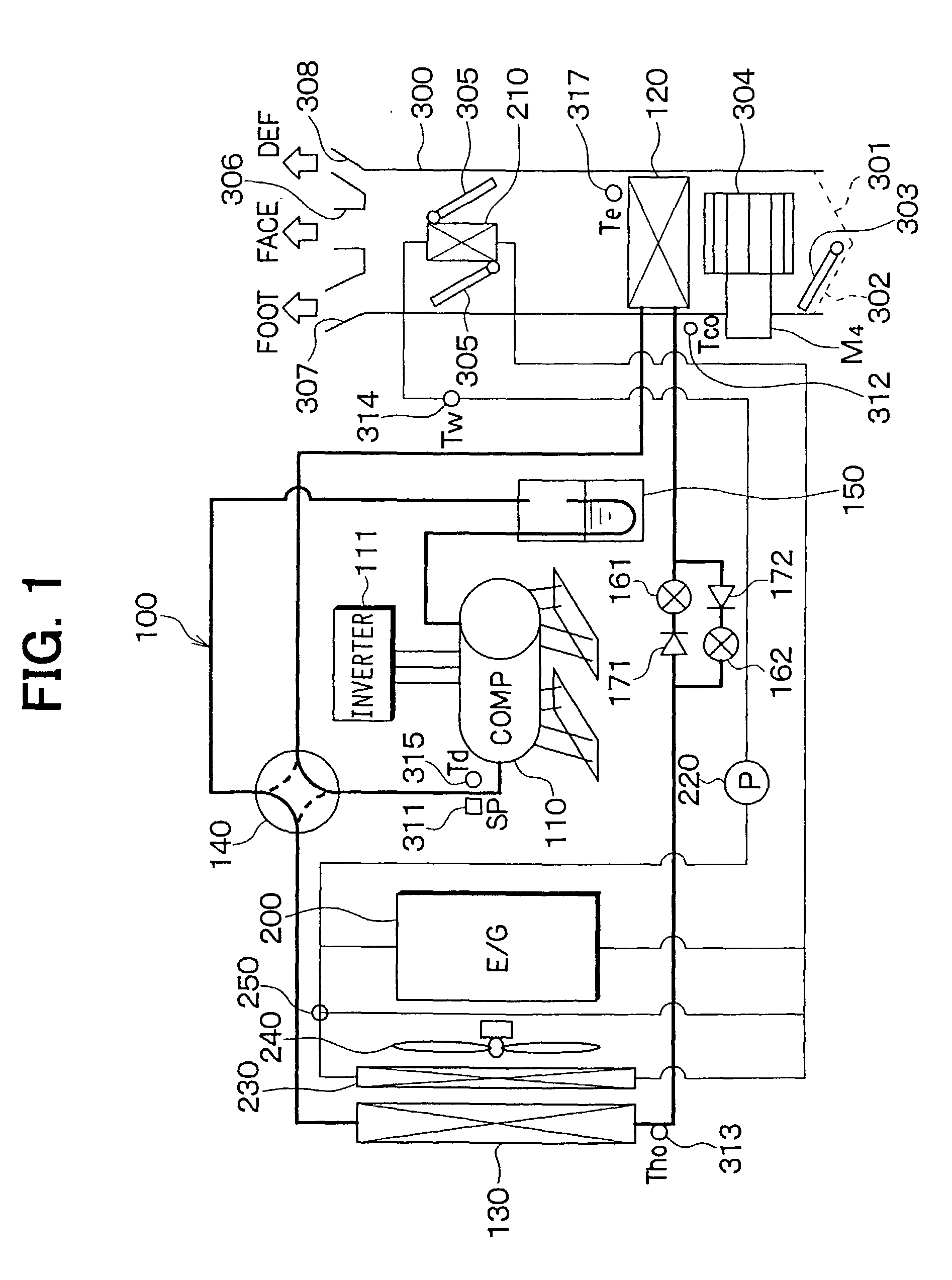

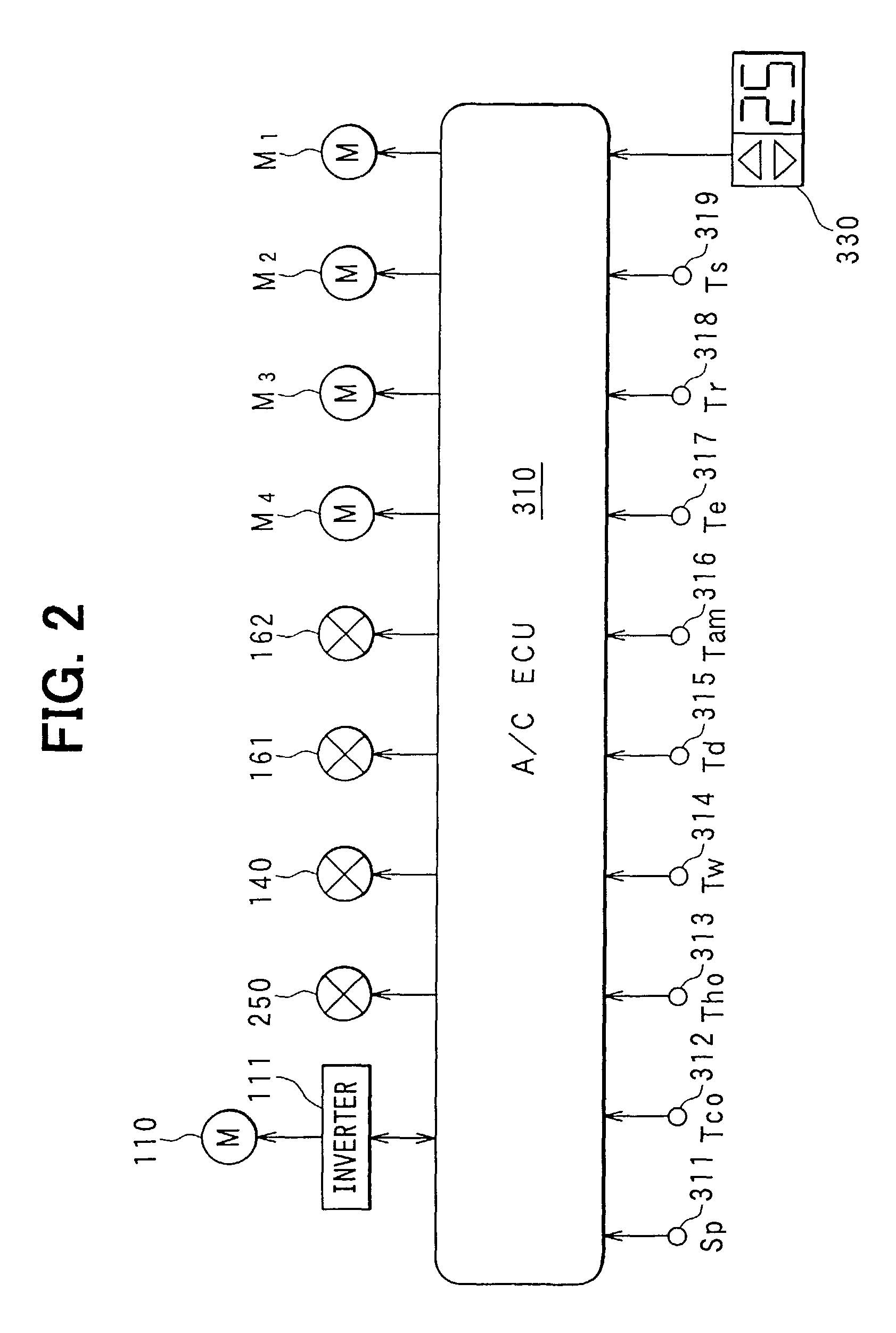

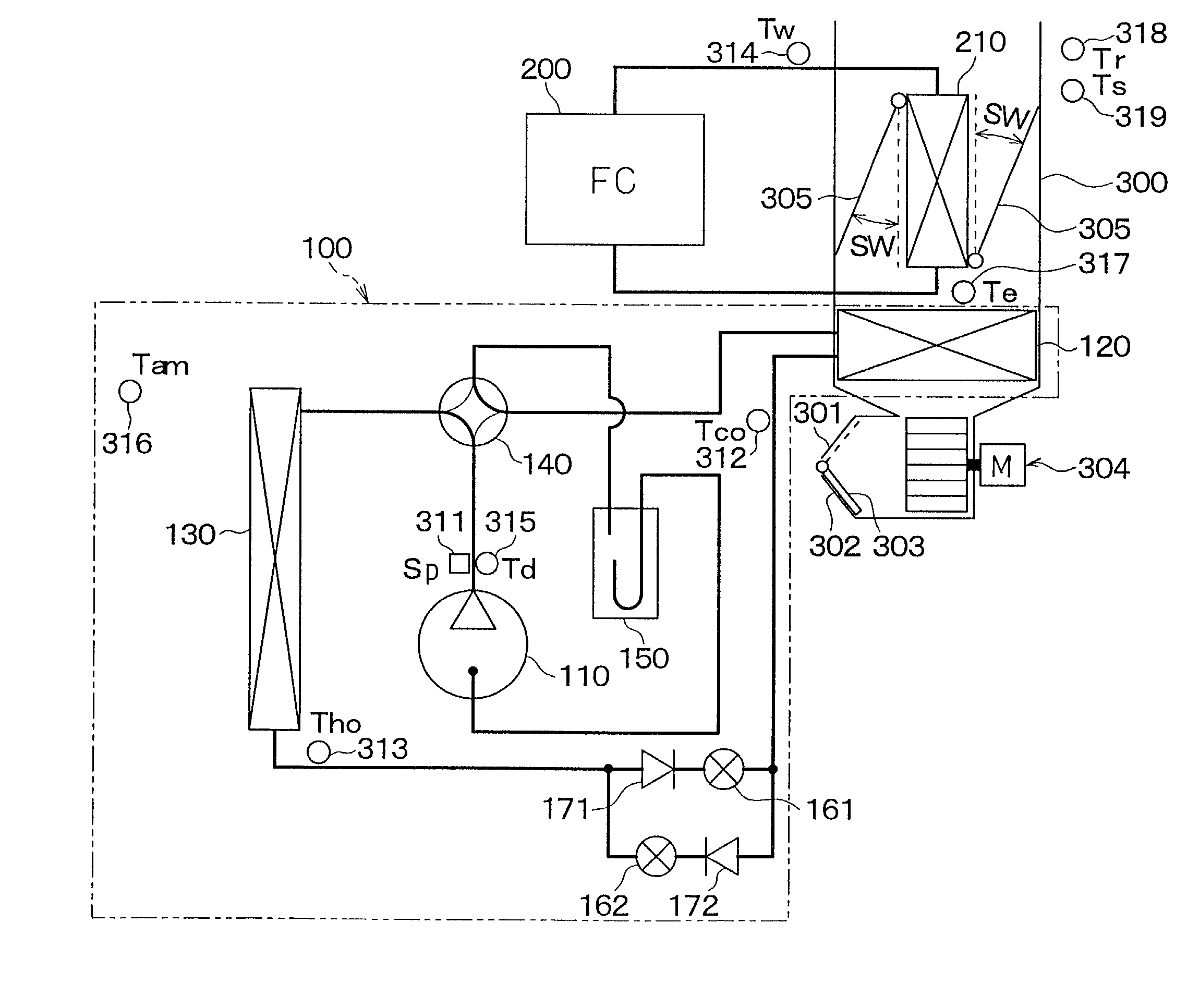

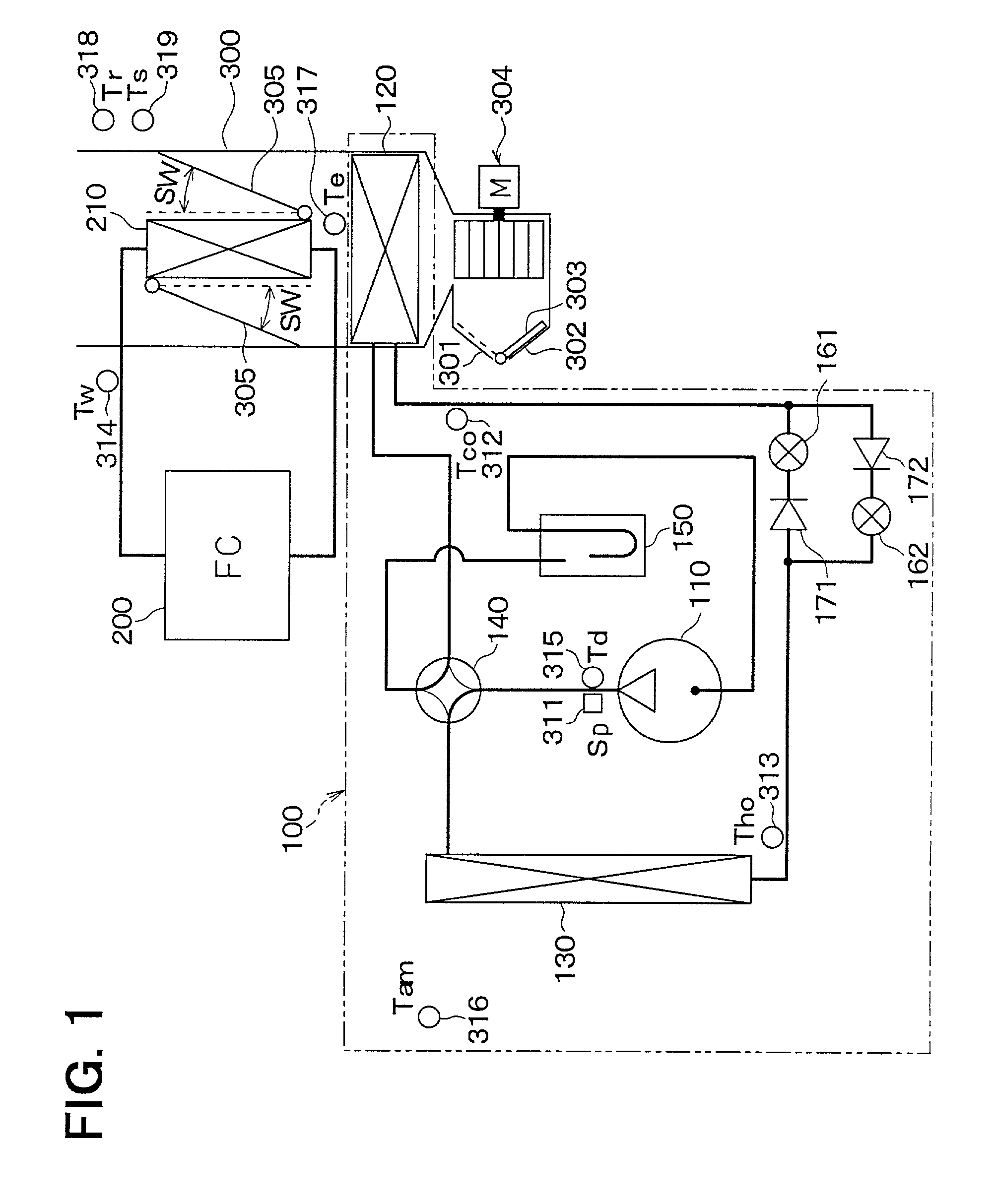

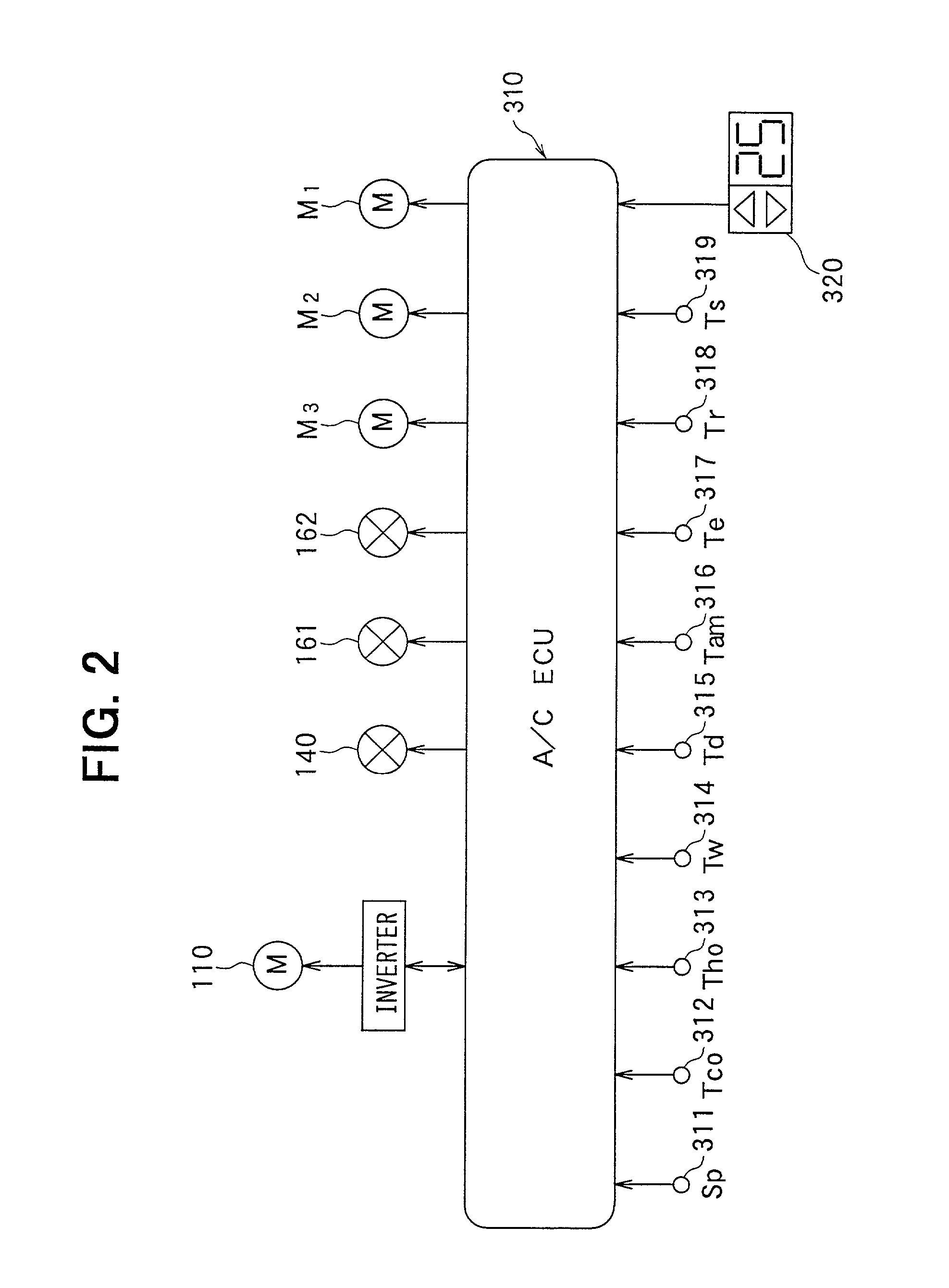

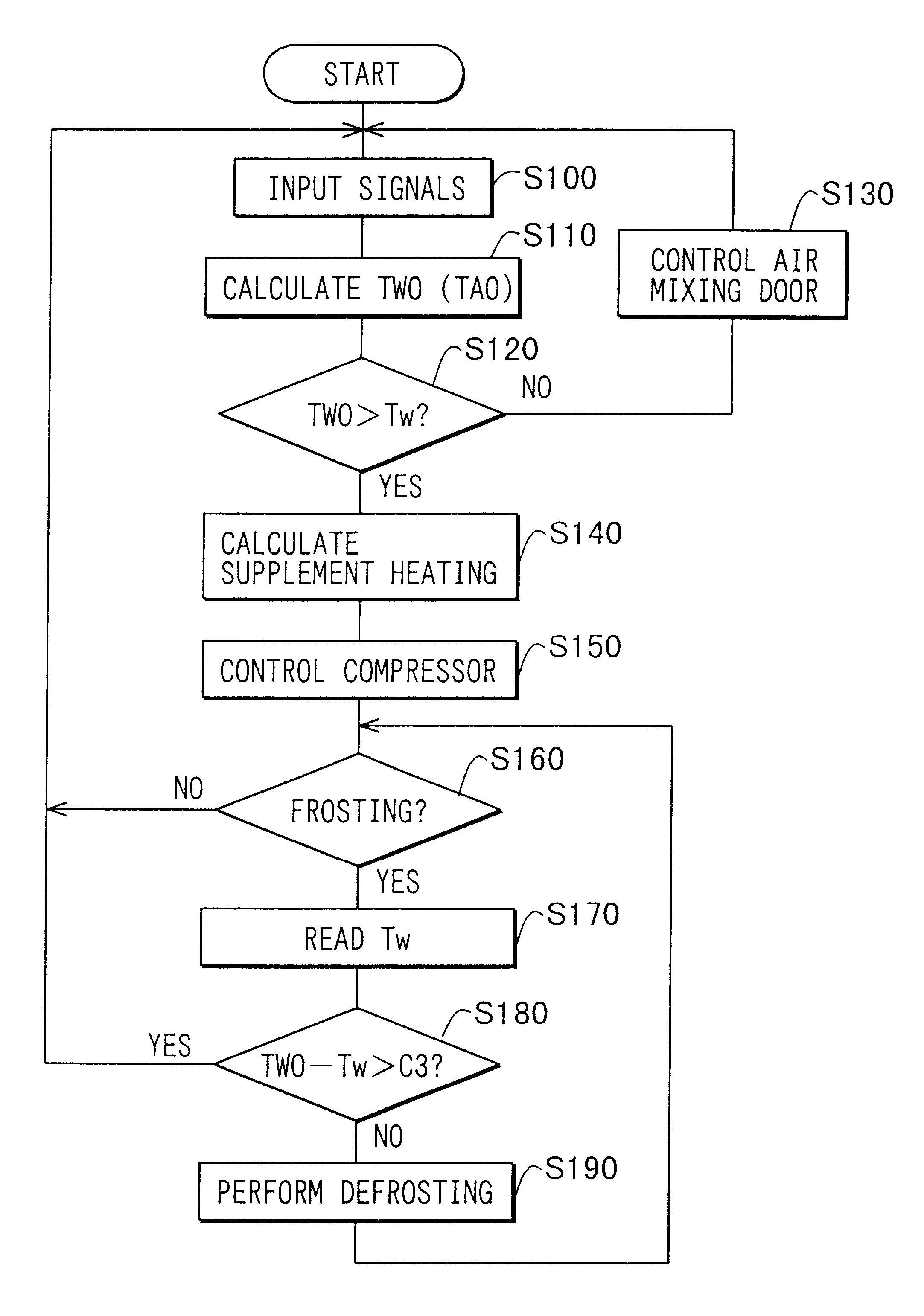

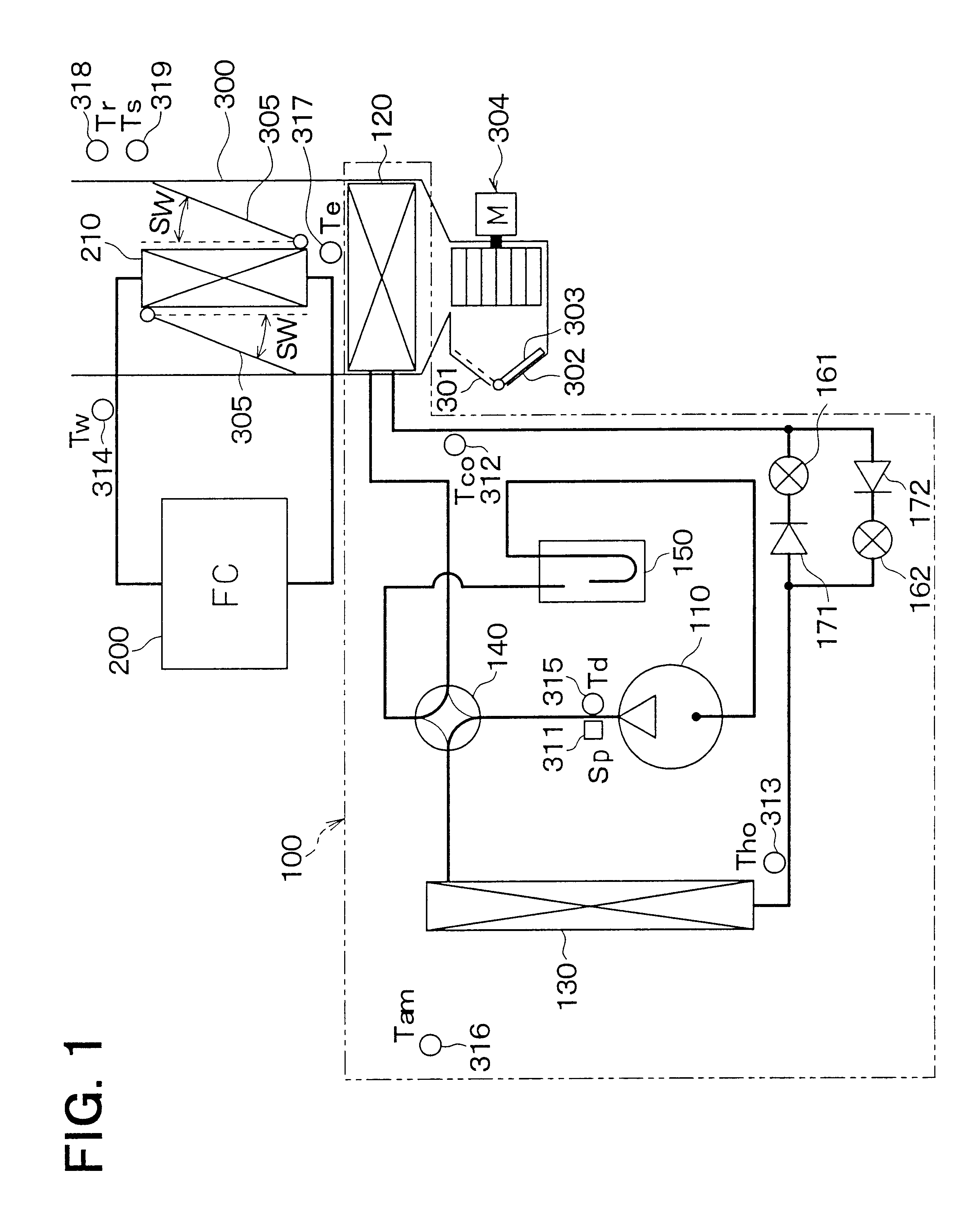

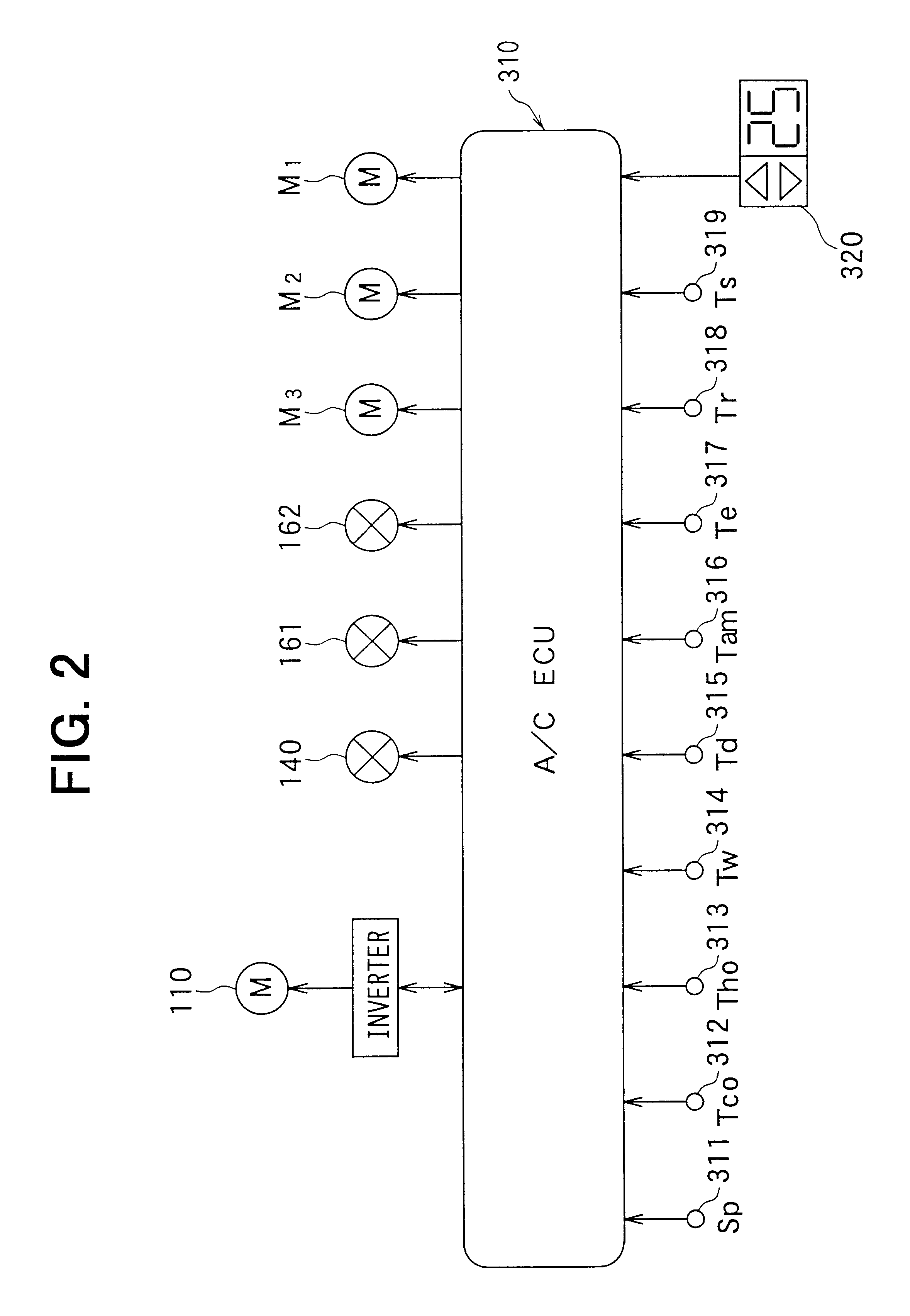

Vehicle air conditioner with defrosting operation in exterior heat exchanger

InactiveUS20030037562A1Improve securityEffectively restrict a windshield from being foggedAir-treating devicesRailway heating/coolingEngineeringHeater core

In a vehicle air conditioner for heating a passenger compartment by a heater core and a heat pump cycle, when operation of a heat pump cycle is switched from a defrosting operation to a heating assist operation, a heating degree of the heater core is increased higher than a predetermined heating degree. Further, when the operation of the heat pump cycle is switched from the defrosting operation to the heating assist operation, an air outlet mode except for a defrosting mode for defrosting a windshield is set. Further, in the defrosting operation of the heat pump cycle, the temperature of an interior heat exchanger of the heat pump cycle is set higher.

Owner:DENSO CORP

Vehicle air conditioner with defrosting operation of exterior heat exchanger

InactiveUS20020036080A1Solve the power is smallAvoid insufficient heatingAir-treating devicesMechanical apparatusEngineeringThermal water

In a vehicle air conditioner with a heat pump cycle having an interior heat exchanger and an exterior heat exchanger, when a frosting on a surface of the exterior heat exchanger is determined and when a temperature of hot water supplied to a heater core is equal to or higher than a predetermined temperature, the exterior heat exchanger is defrosted in a defrosting operation. Accordingly, the defrosting operation can be performed while a sufficient heating can be obtained.

Owner:DENSO CORP

Heat exchanger unit

InactiveUS20070204978A1Freedom of movementEfficient managementDomestic stoves or rangesAir heatersAir movementEngineering

A heat exchanger unit includes a support assembly having a support surface extending in a first plane and a heat exchanger coupled to the support surface and fixed relative to the first plane. The heat exchanger includes a first manifold and a second manifold extending in spaced relationship with one another and a plurality of tubes spaced from one another and extending between and engaging the first manifold and the second manifold. The tubes communicate fluid between the manifolds. At least a portion of each of the tubes extend angularly relative to the first plane for draining condensate along the tubes toward a common drainage point to remove the condensate from the tubes and focus the condensate to the common drainage point. The drainage of the condensate from the tubes prevents the freezing of the condensate on the tubes to prevent the blockage of air movement over the tubes by frozen condensate.

Owner:DELPHI TECH INC

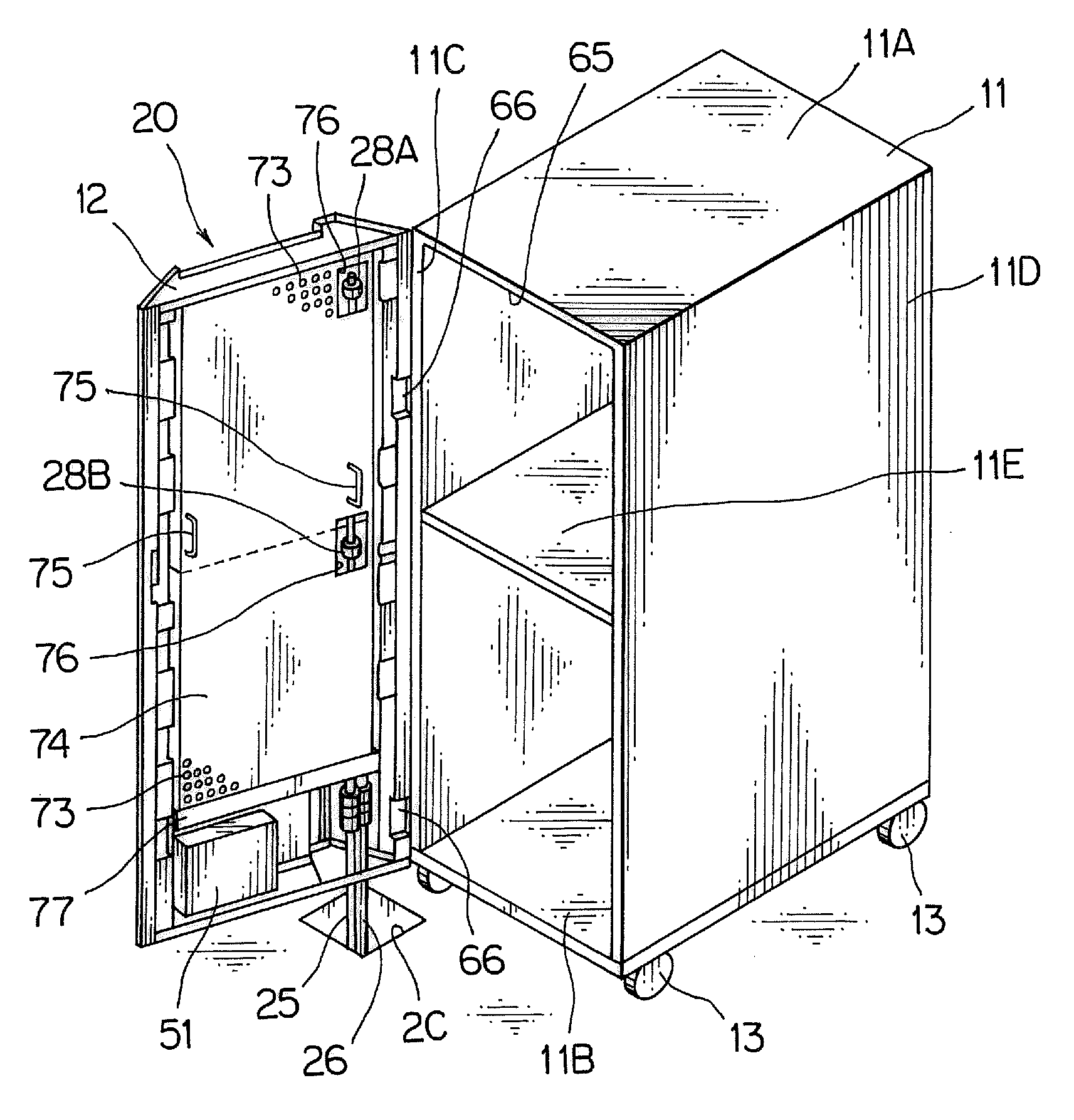

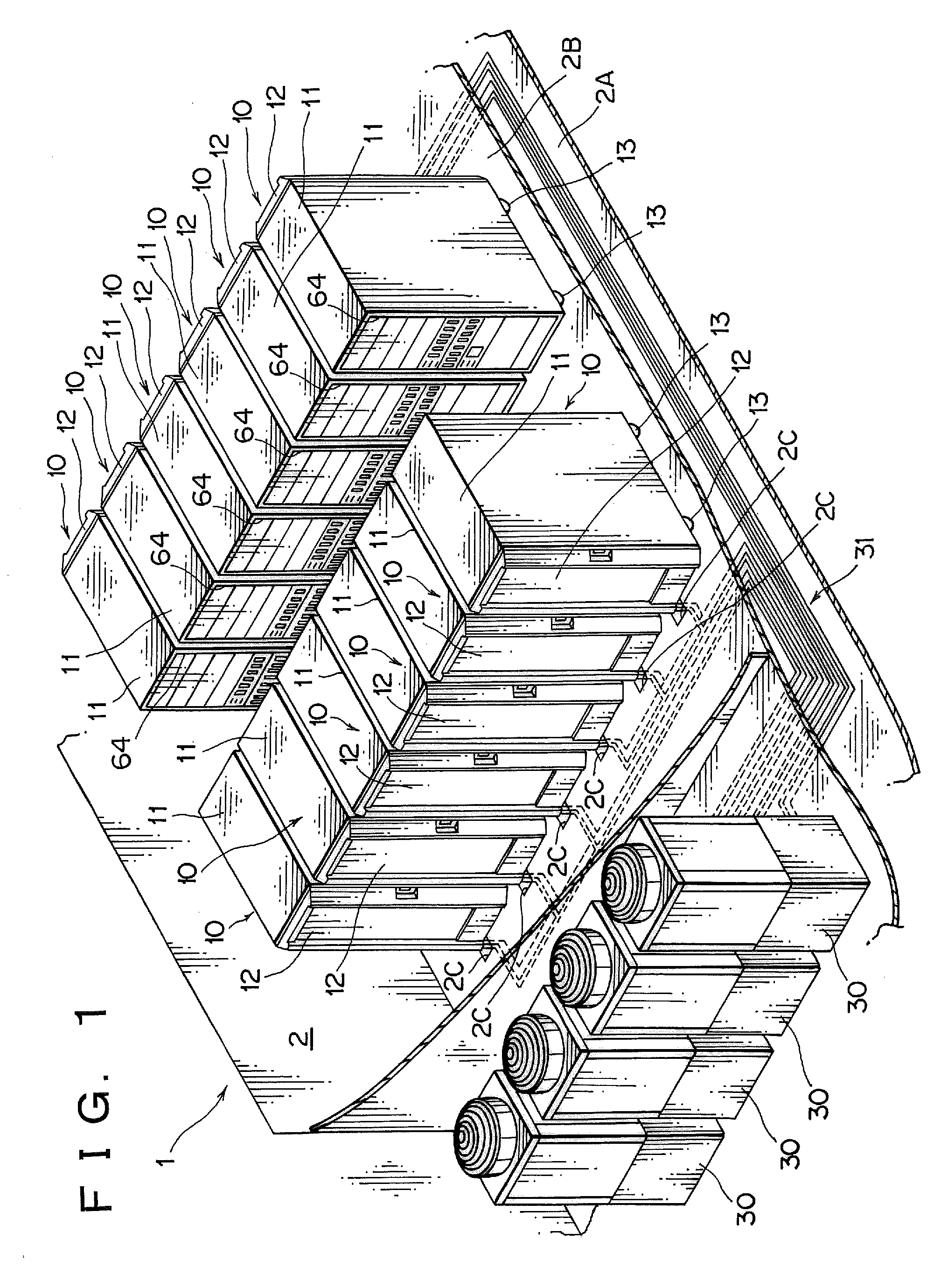

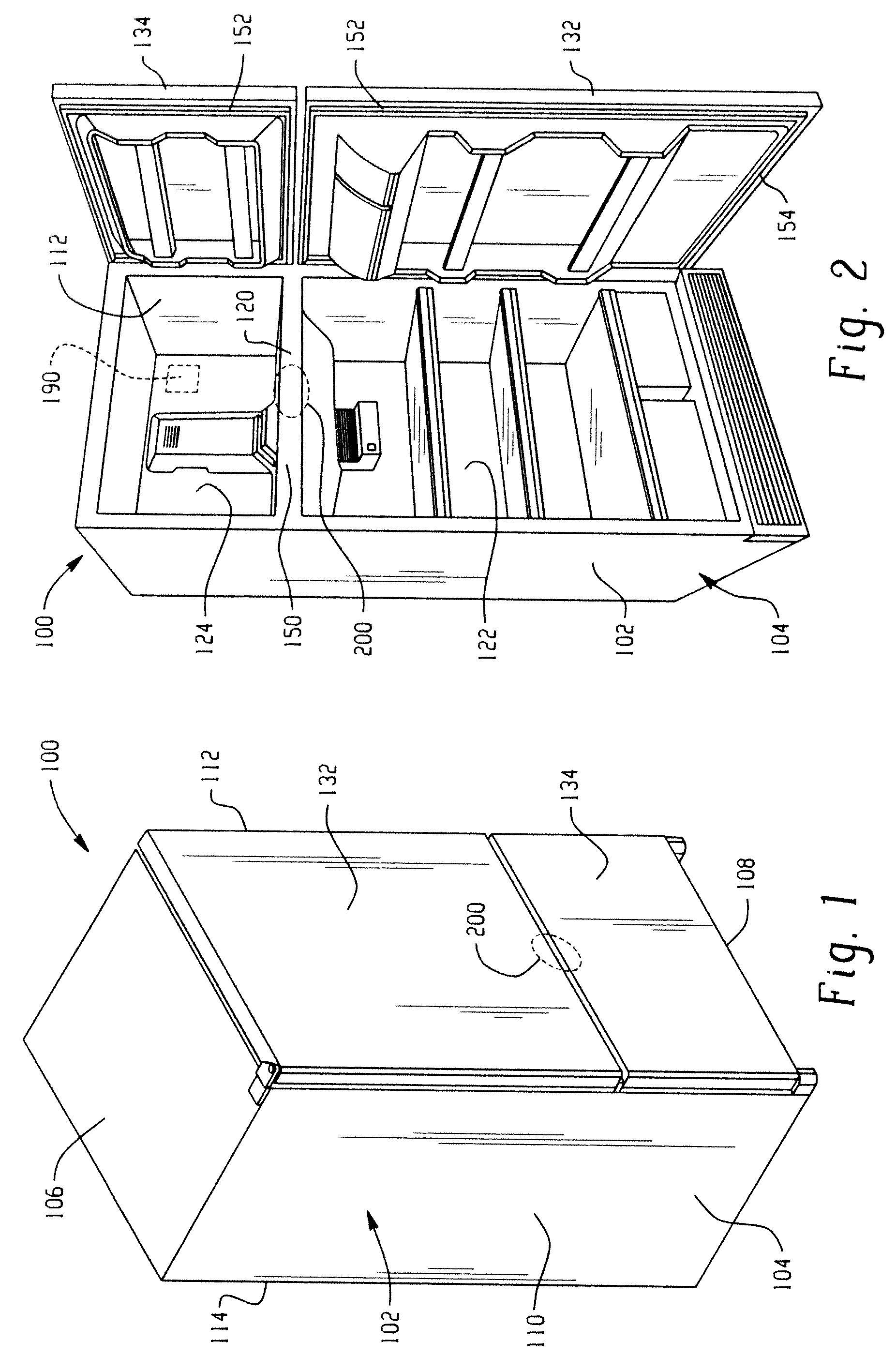

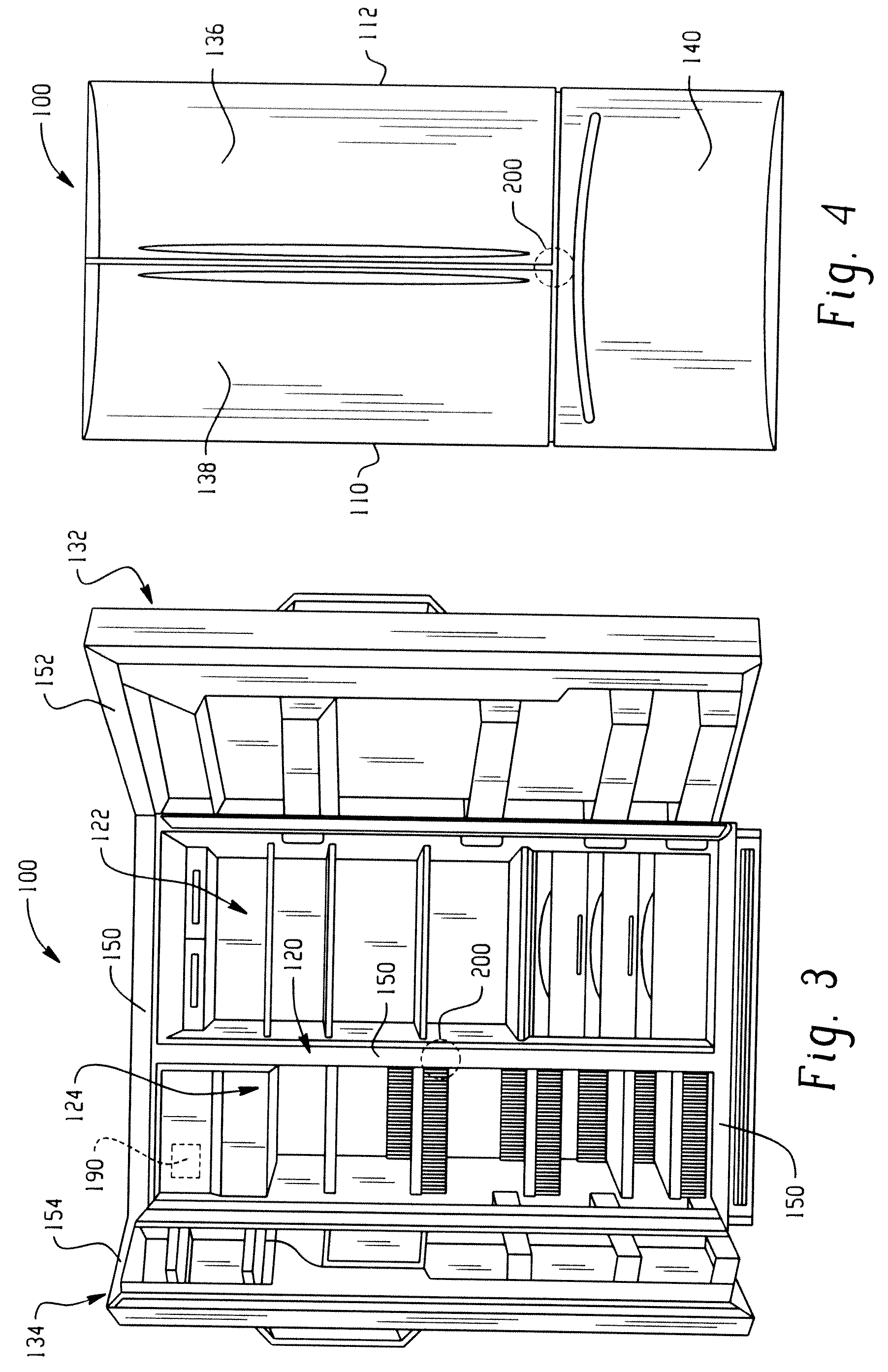

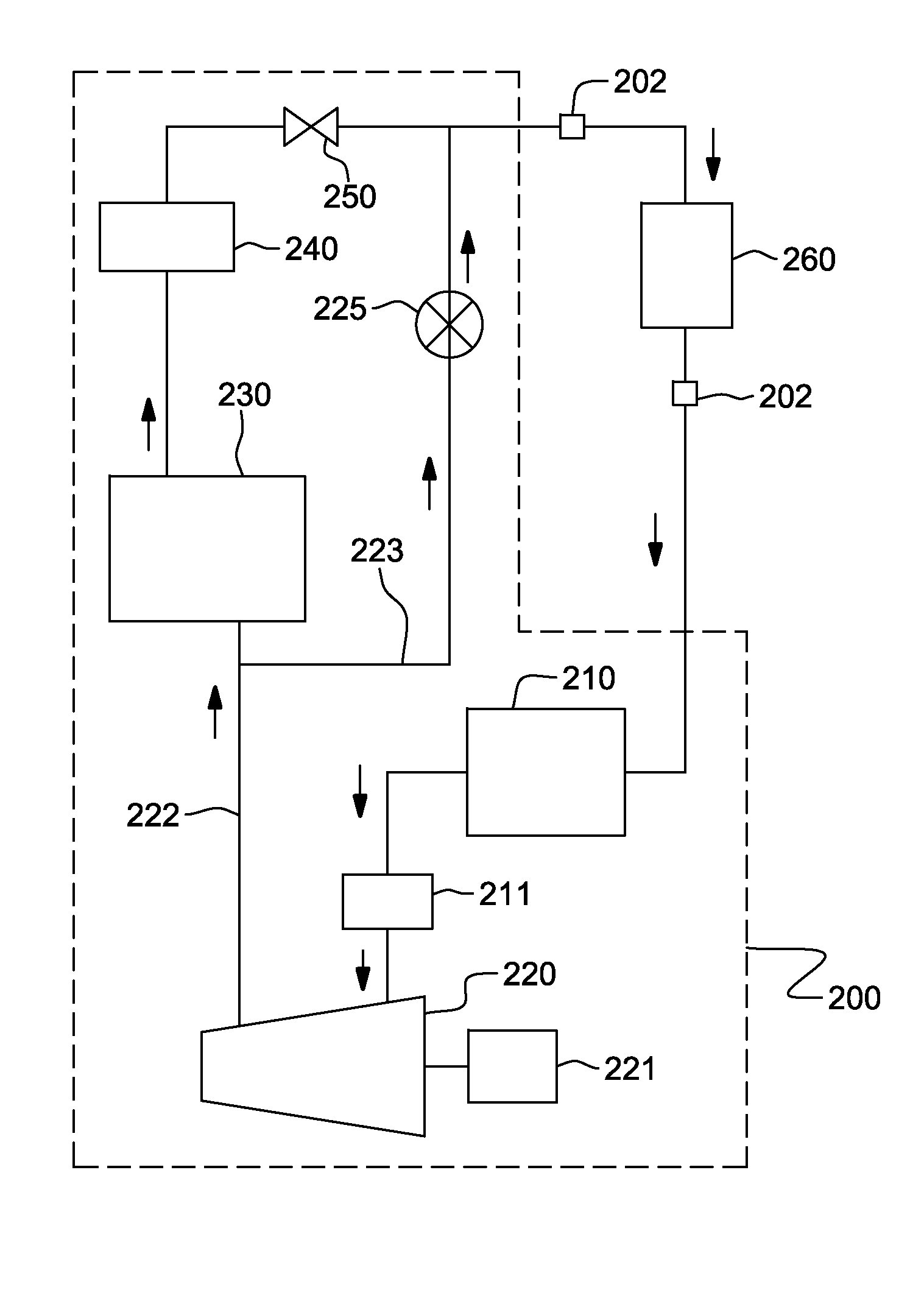

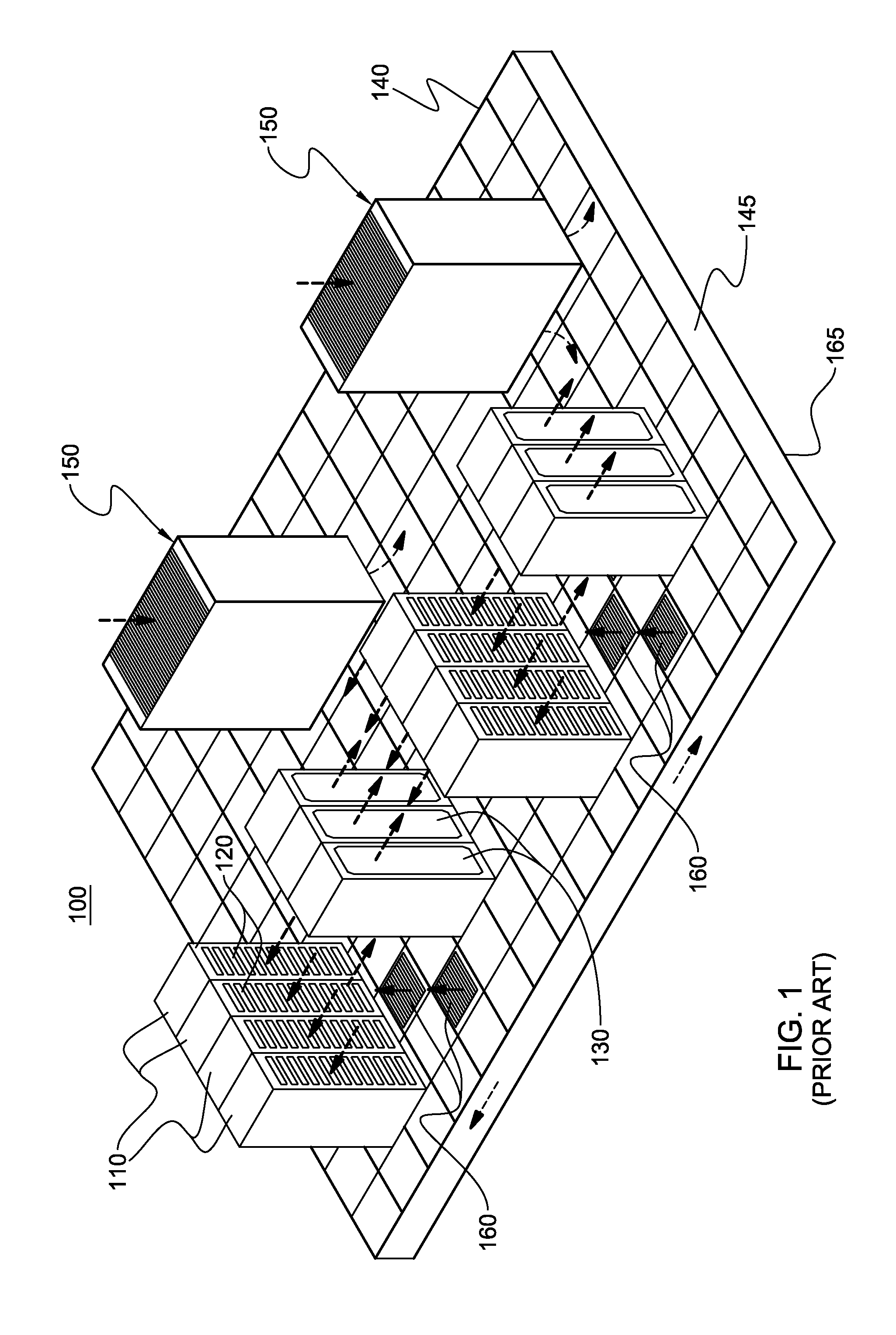

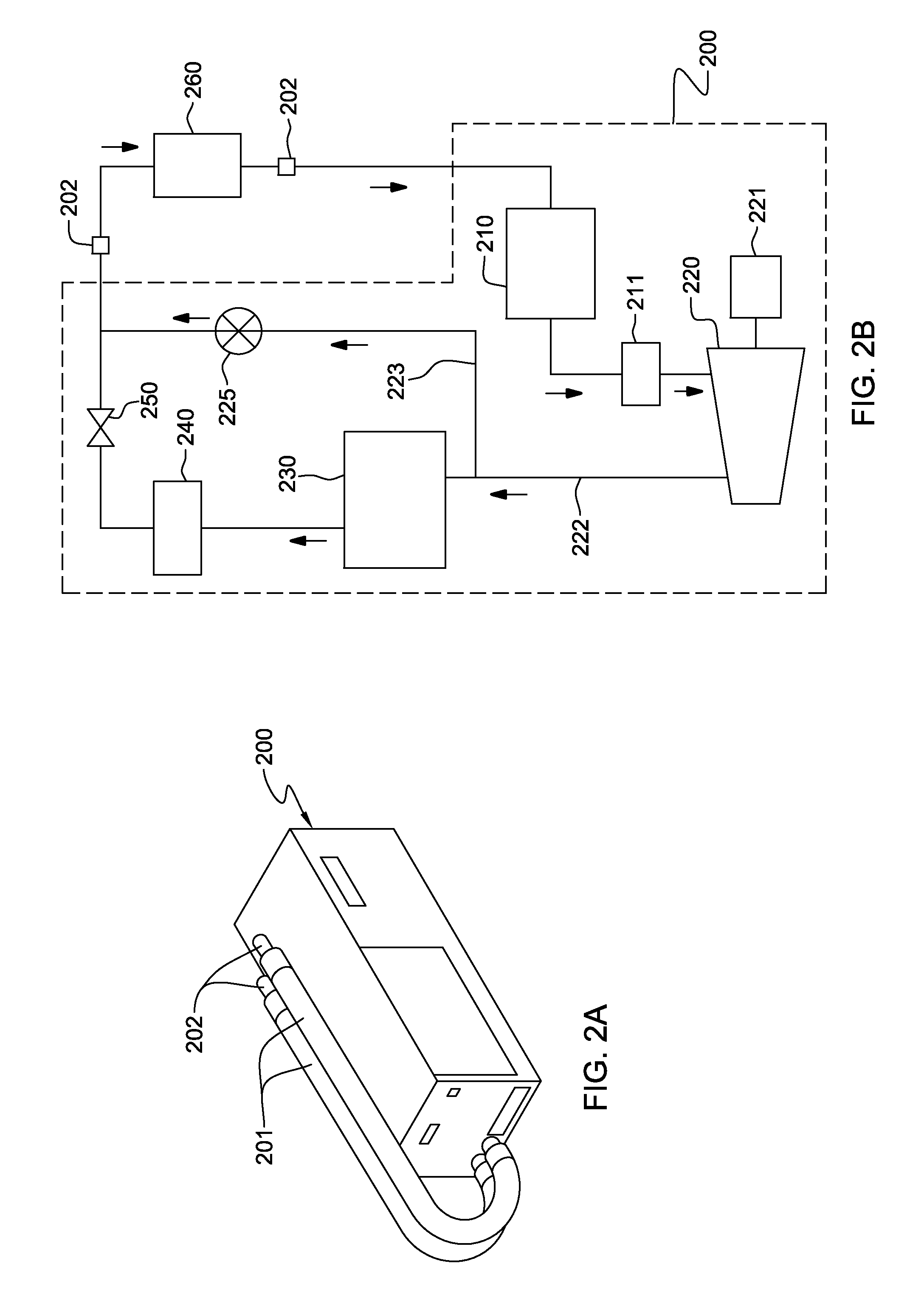

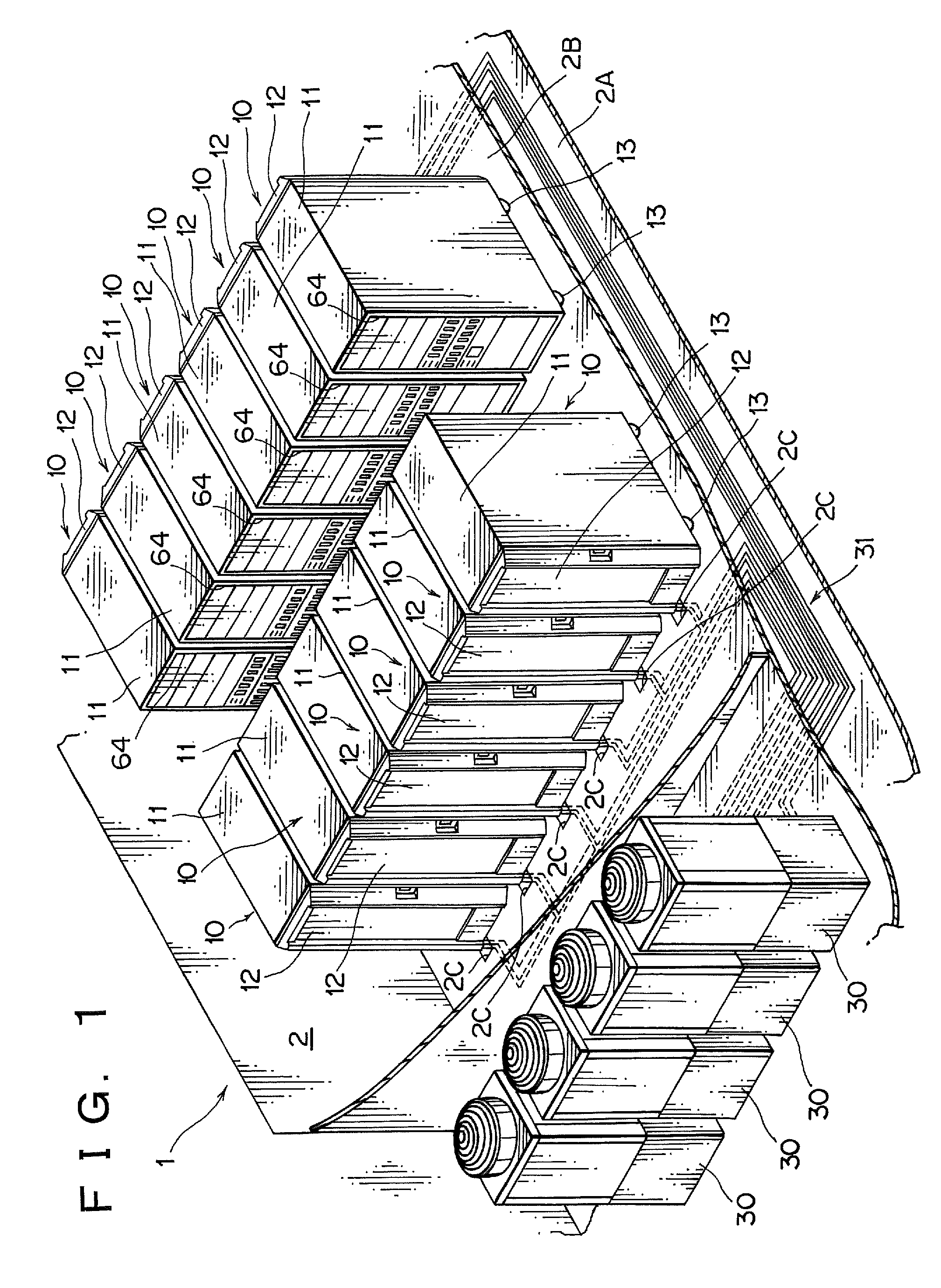

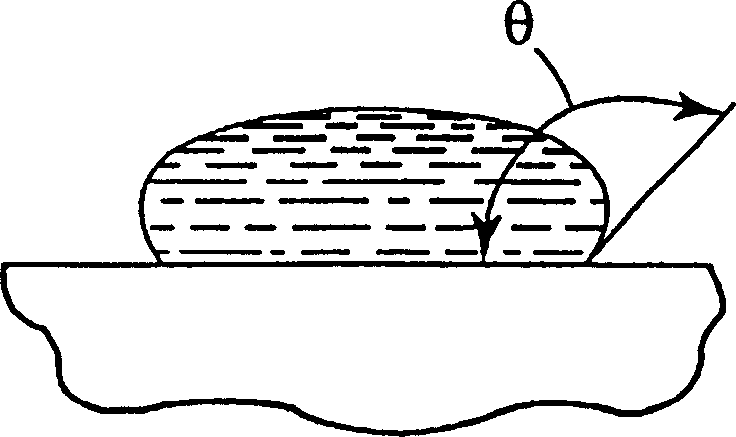

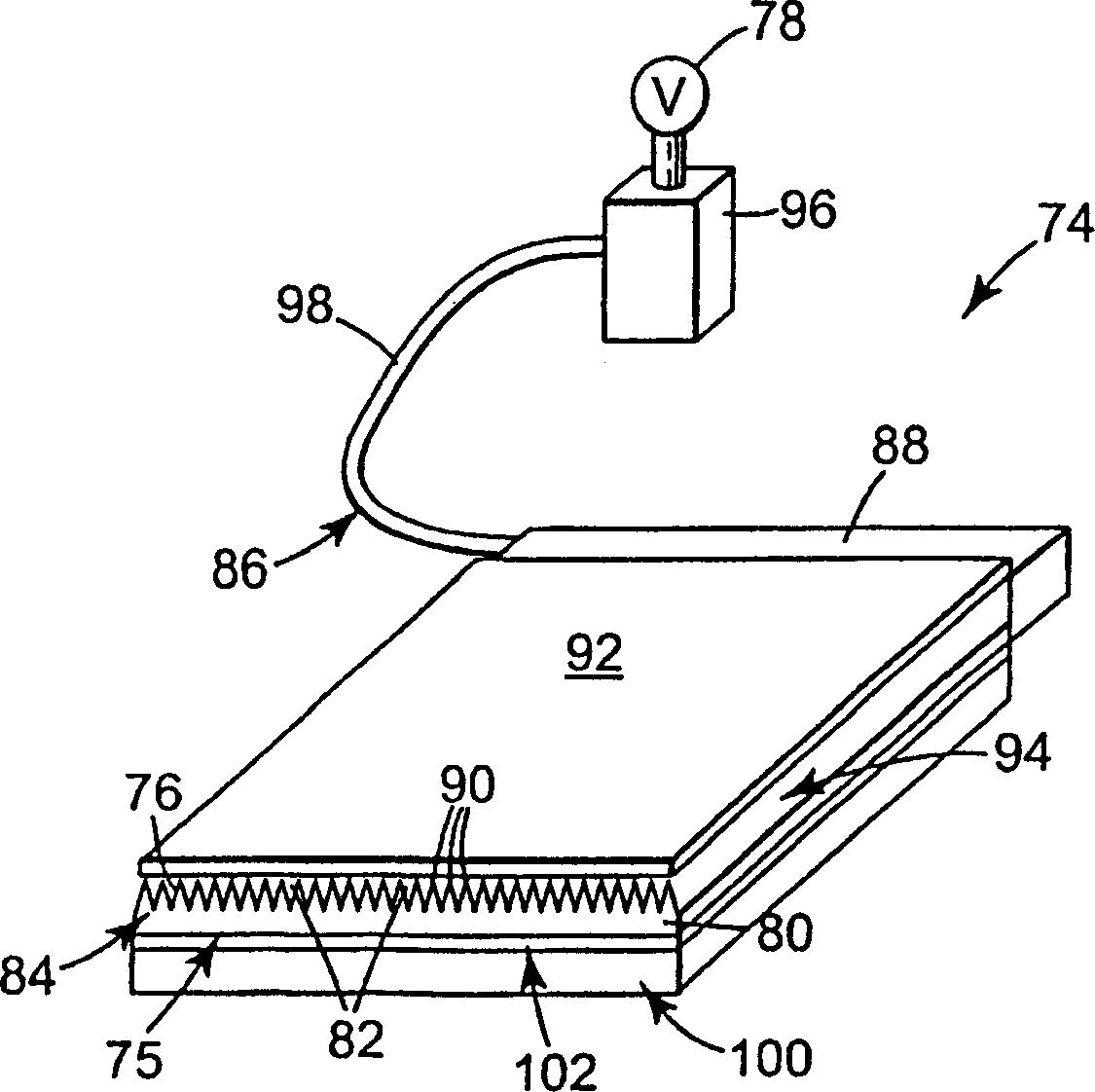

Dehumidifying cooling apparatus and method for an electronics rack

InactiveUS20110290448A1Easy to drainImprove cooling effectStationary conduit assembliesIce removalEngineeringElectronics

Dehumidifying cooling apparatus and method are provided for an electronics rack. The apparatus includes an air-to-liquid heat exchanger disposed at an air inlet or outlet side of the rack, wherein air flows through the rack from the air inlet to the air outlet side. The heat exchanger is positioned for air passing through the electronics rack to pass across the heat exchanger, and is in fluid communication with a coolant loop for passing coolant therethrough at a temperature below a dew point temperature of the air passing across the heat exchanger so that air passing across the heat exchanger is dehumidified and cooled. A condensate collector, disposed below the heat exchanger, collects liquid condensate from the dehumidifying of air passing through the electronics rack, wherein the heat exchanger includes a plurality of sloped surfaces configured to facilitate drainage of liquid condensate from the heat exchanger to the condensate collector.

Owner:IBM CORP

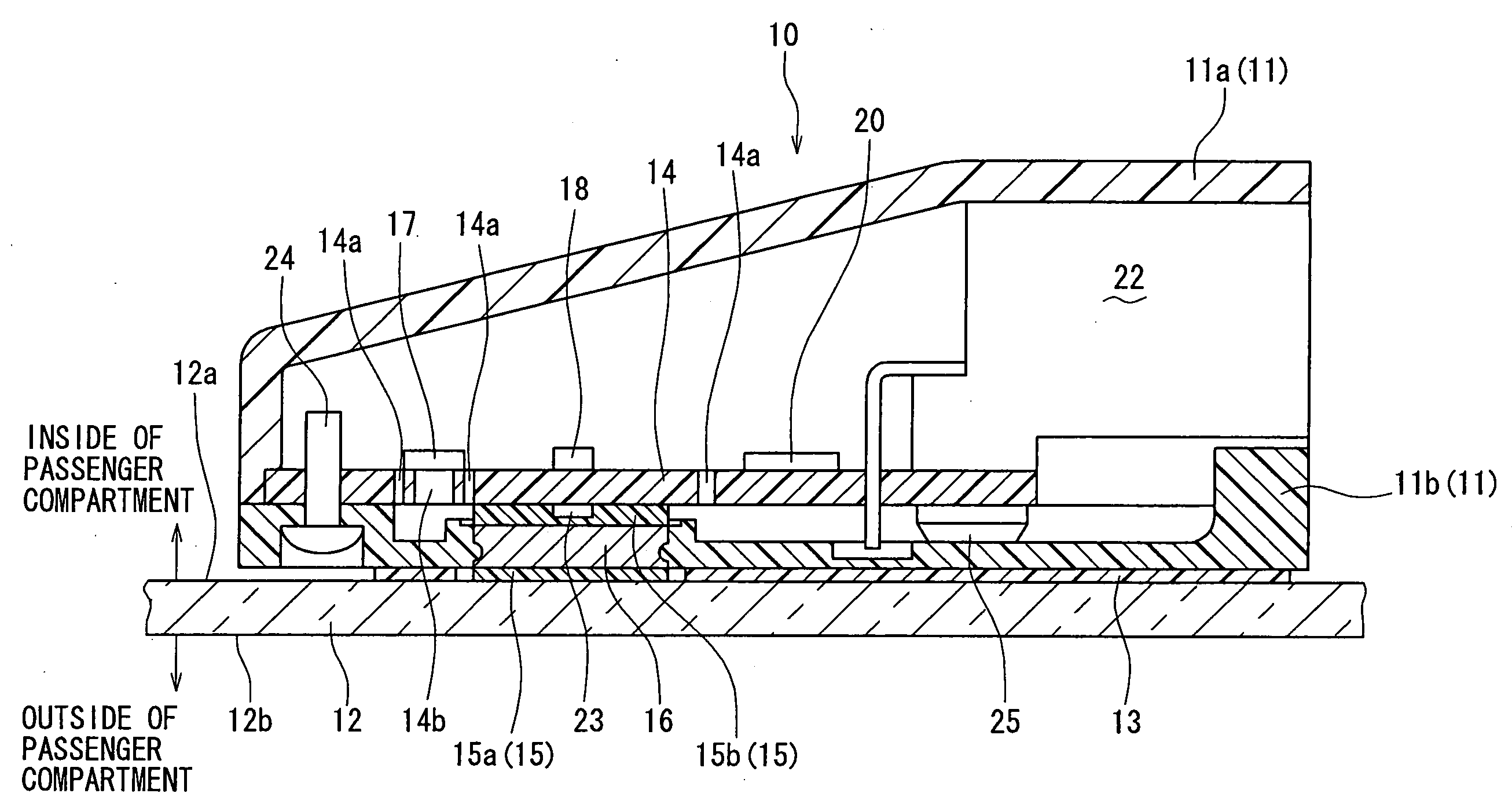

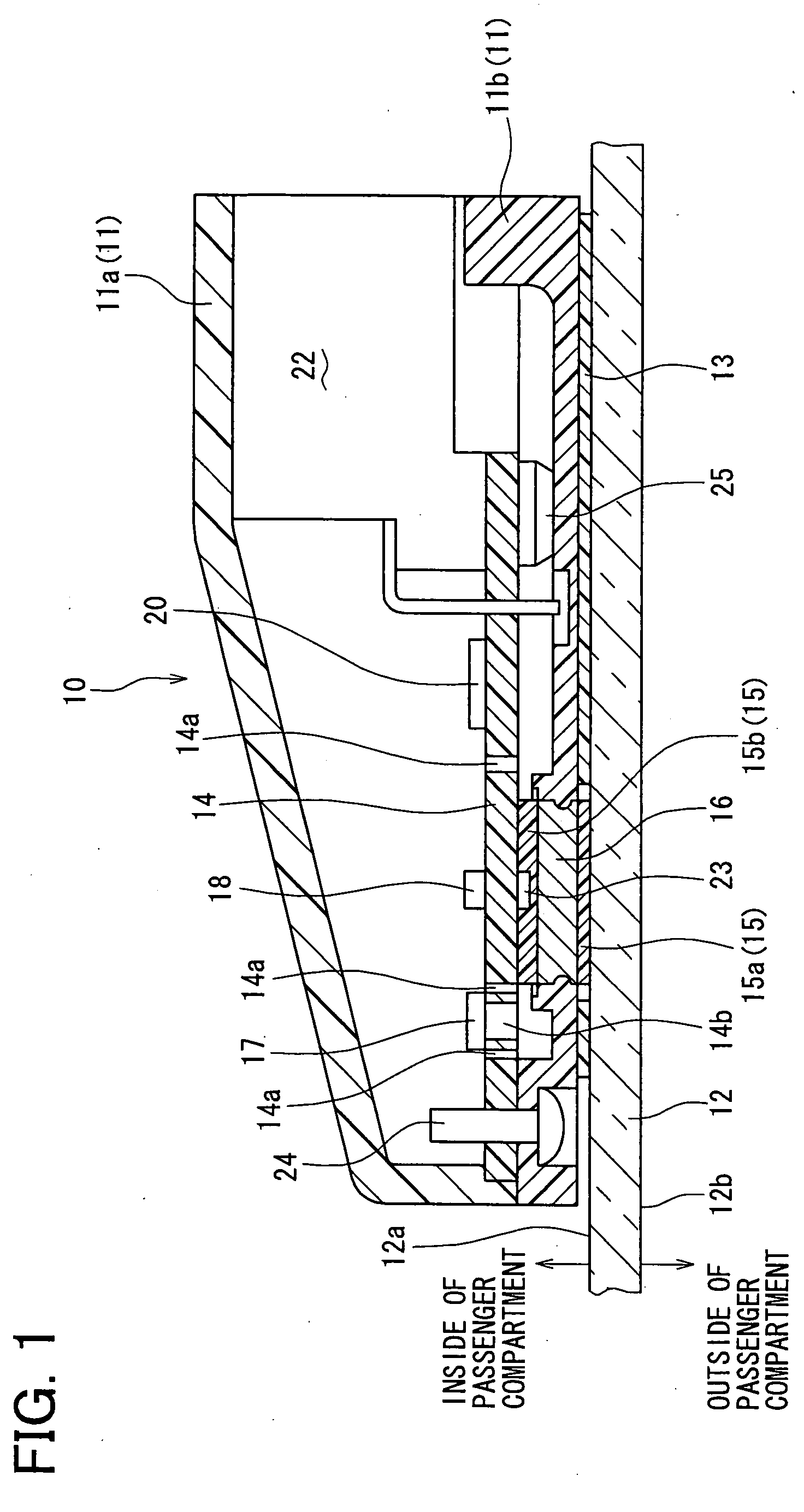

Humidity detecting apparatus and vehicular air conditioner having the same

ActiveUS20080066477A1Accurate detectionFast heat conductionSpace heating and ventilationOperation mode of machinesEngineeringMoisture sensor

A humidity detecting apparatus includes a humidity sensor for detecting a relative humidity of air on an inner side of a window glass, an air temperature sensor for detecting a temperature of the air, a glass temperature sensor for detecting a temperature of the window glass, and a glass surface relative humidity calculation unit for calculating a glass surface relative humidity based on output values of the humidity sensor, the air temperature sensor and the glass temperature sensor. A heat conductive member is disposed between the glass temperature sensor and the window glass.

Owner:DENSO CORP

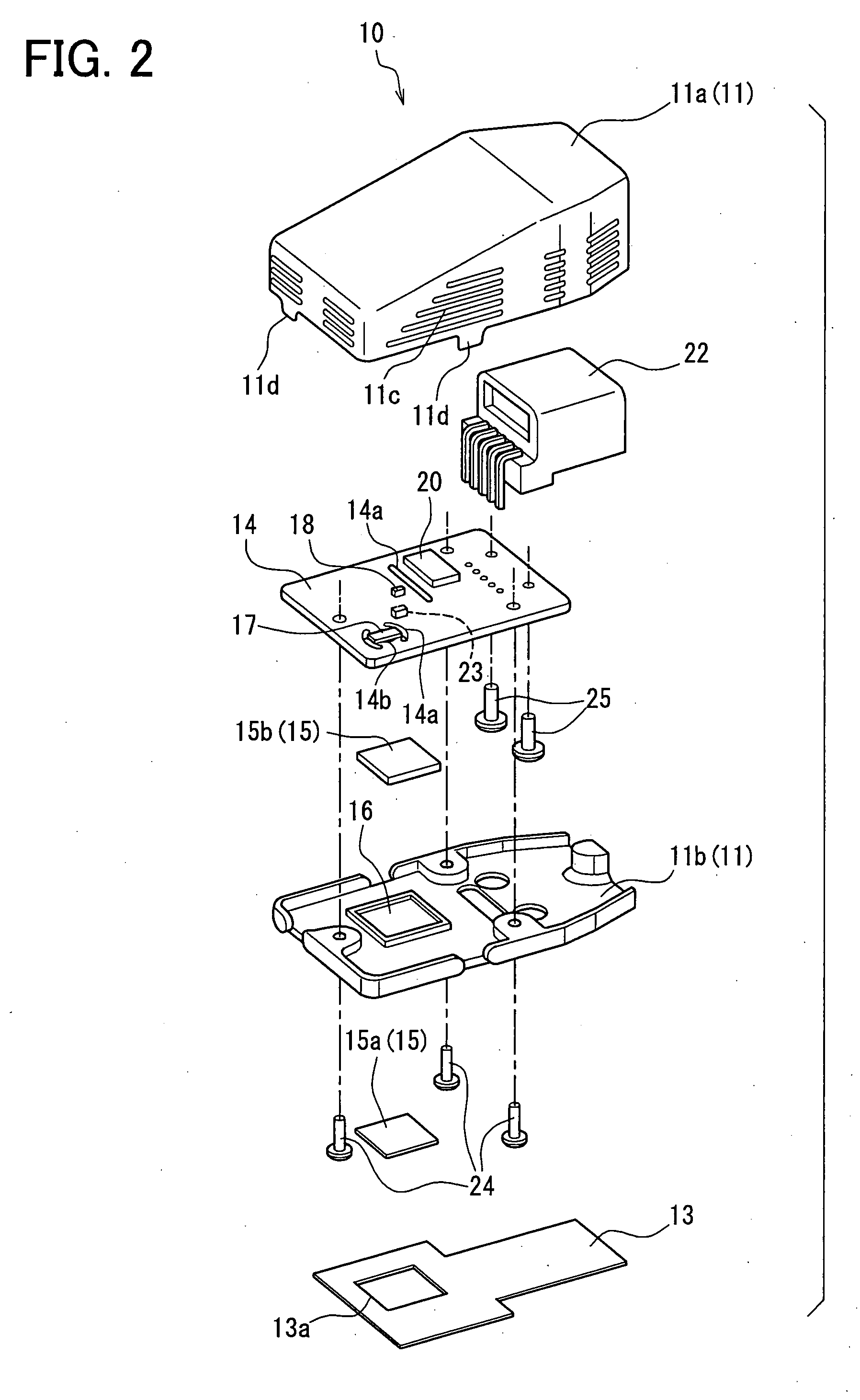

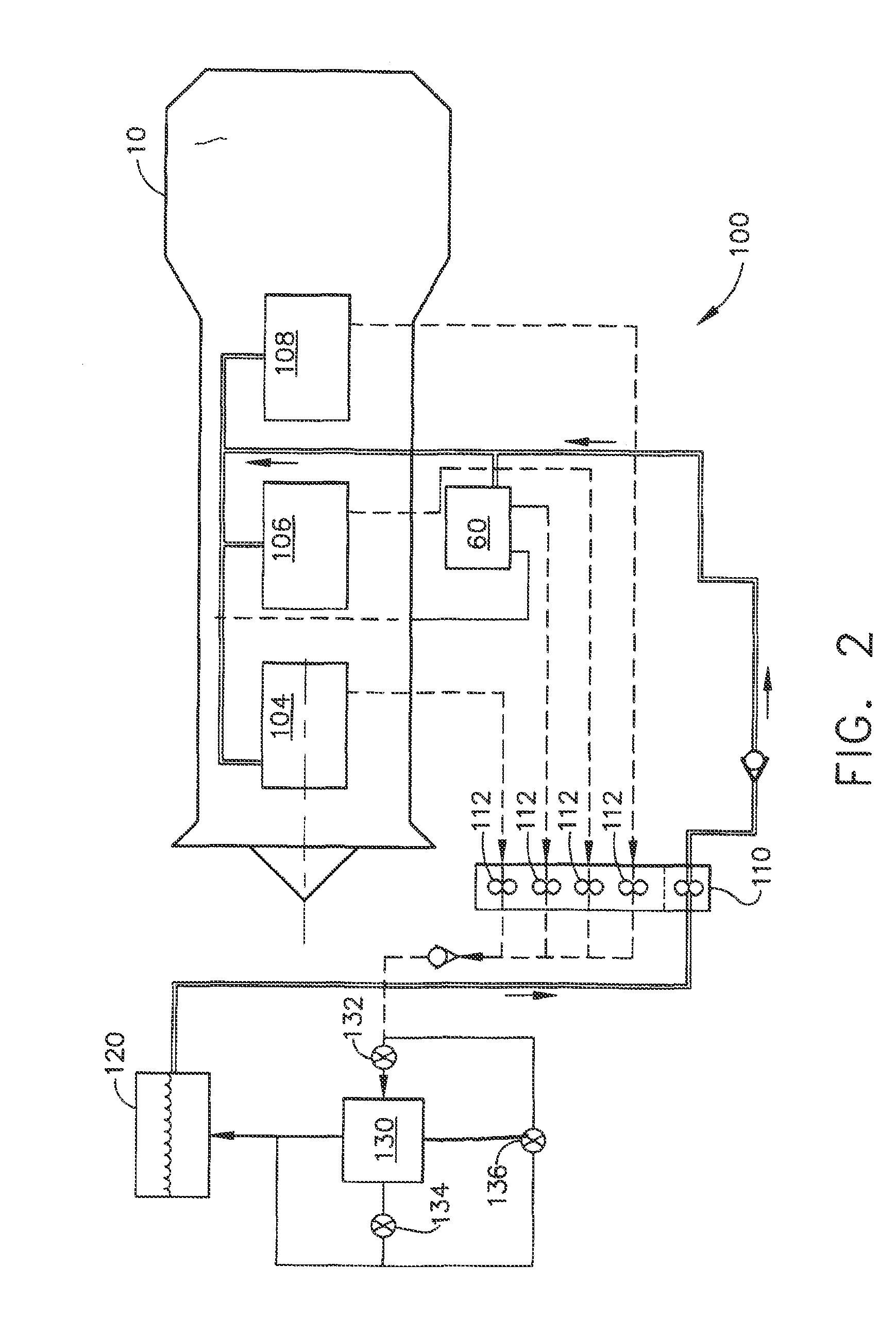

Gas turbine engine heat exchangers and methods of assembling the same

InactiveUS20140044525A1Increase temperatureWind motor controlTemperatue controlInlet channelEngineering

A heat exchanger assembly for use in a gas turbine engine includes a bypass valve and at least one body portion. The body portion includes at least one de-congealing inlet channel in flow communication with the bypass valve, a plurality of cooling channels in flow communication with the bypass valve and the at least one de-congealing inlet channel, and at least one de-congealing outlet channel in flow communication with the bypass valve and the at least one de-congealing inlet channel. The bypass valve is configured to deliver a fluid between the at least one de-congealing inlet channel and the plurality of cooling channels during a first mode of operation to facilitate reducing a temperature of the fluid. The bypass valve is further configured to deliver the fluid between the at least one de-congealing inlet channel and the at least one de-congealing outlet channel during a second mode of operation.

Owner:UNISON INDUSTRIES

Electronic device cooling system and electronic device cooling apparatus

InactiveUS8113009B2Effectively a cool electronic deviceEffectively cool electronic devices stacked and mounted in a cabinetCompression machines with non-reversible cycleEvaporators/condensersElectronics coolingEngineering

An electronic cooling apparatus has a cabinet which is open at the front and rear sides thereof and accommodates plural electronic devices each having a fan, and a rear door which is provided with an evaporator. Air blown by the fan is cooled by the evaporator and then returned to a room. An expansion valve and control. A drain pan with an extension portion having hole portions through which refrigerant pipes extend is provided. A drain hose discharges drain water from the drain pan. An exhaust heat temperature detecting unit and a control for controlling the refrigerant supply to the evaporator are provided. When the exhaust heat temperature is equal to or less than a set exhaust temperature, the controller stops the refrigerant supply to the evaporator. When the exhaust heat temperature exceeds the set temperature, the controller starts the refrigerant supply.

Owner:SANYO ELECTRIC CO LTD

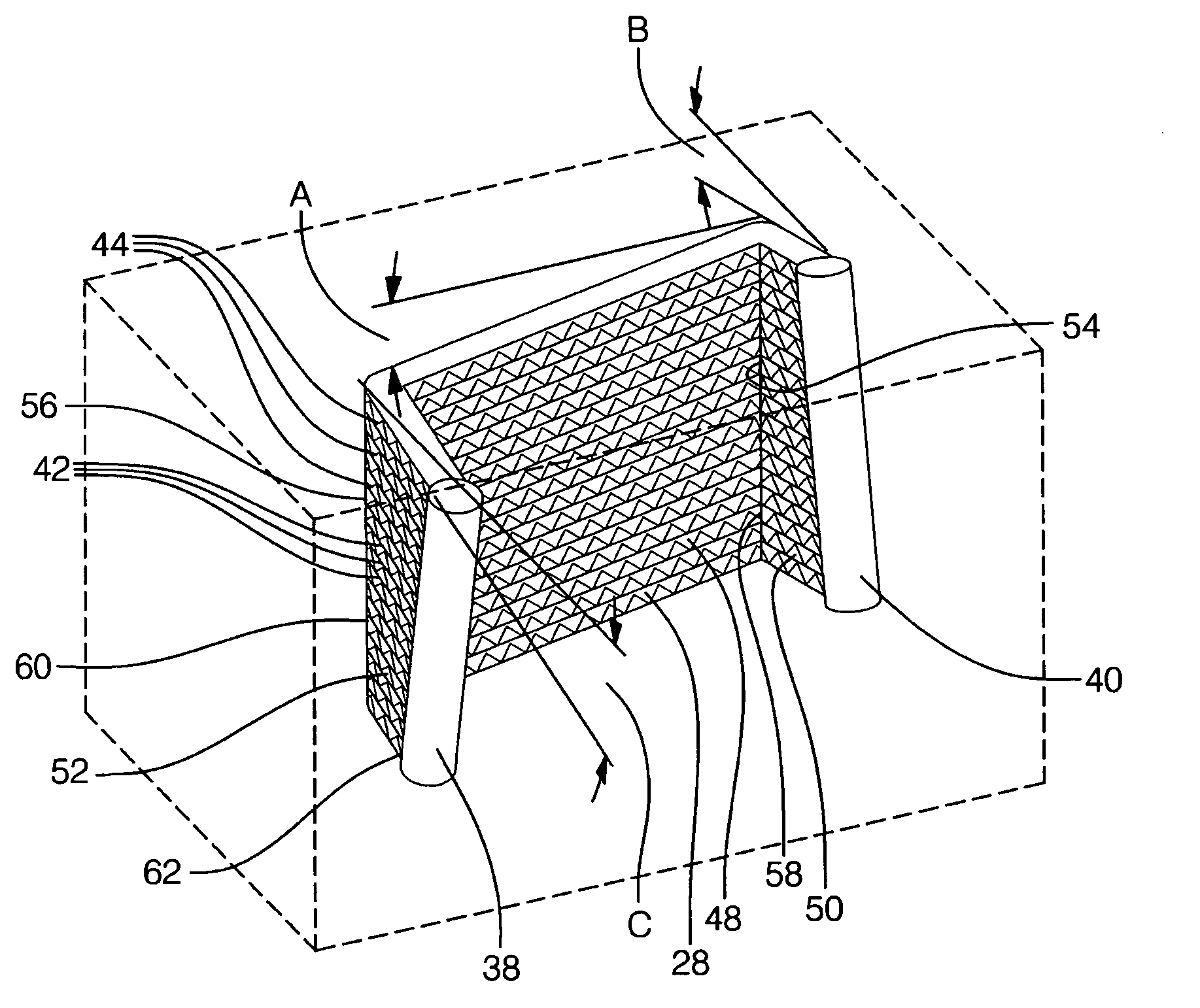

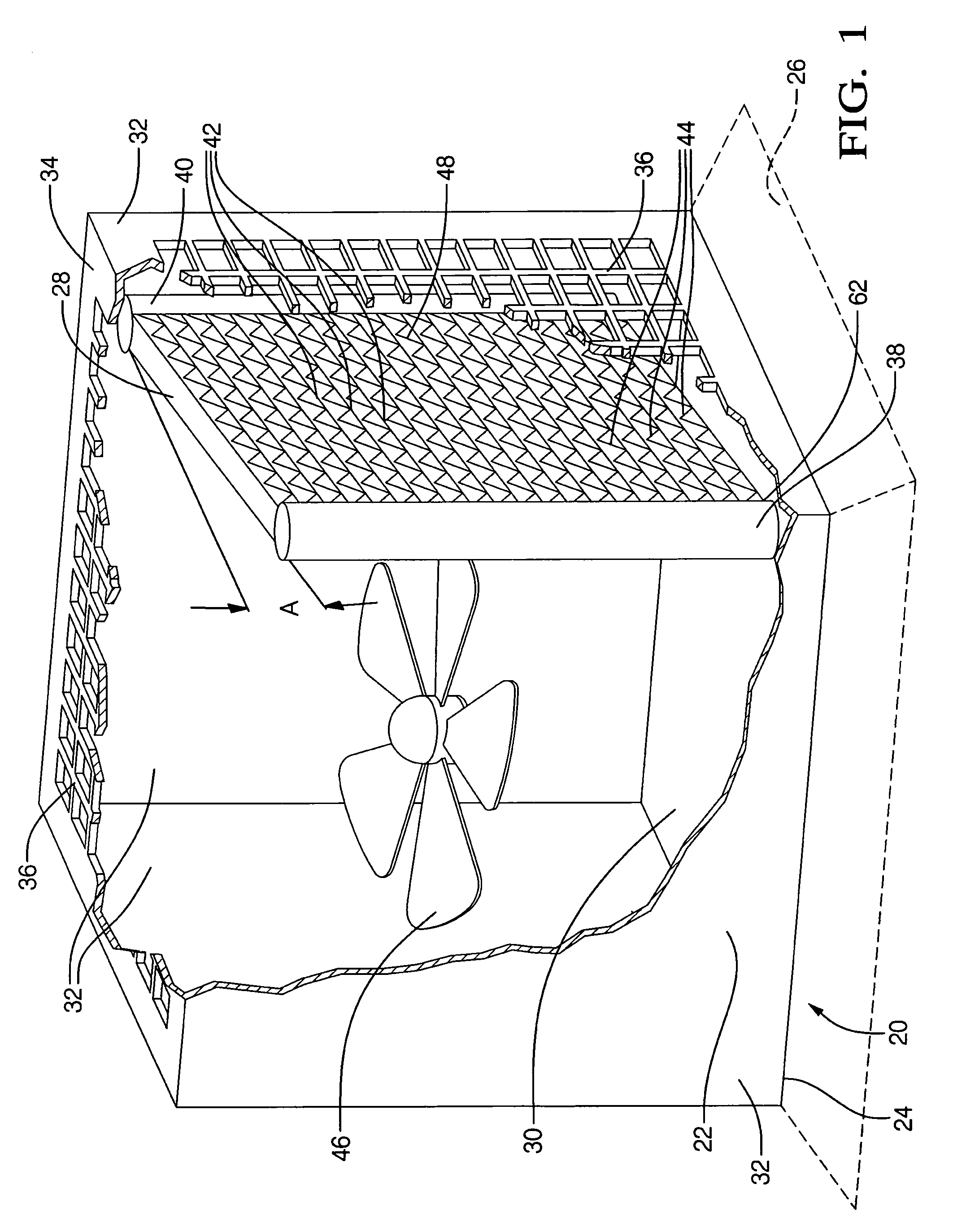

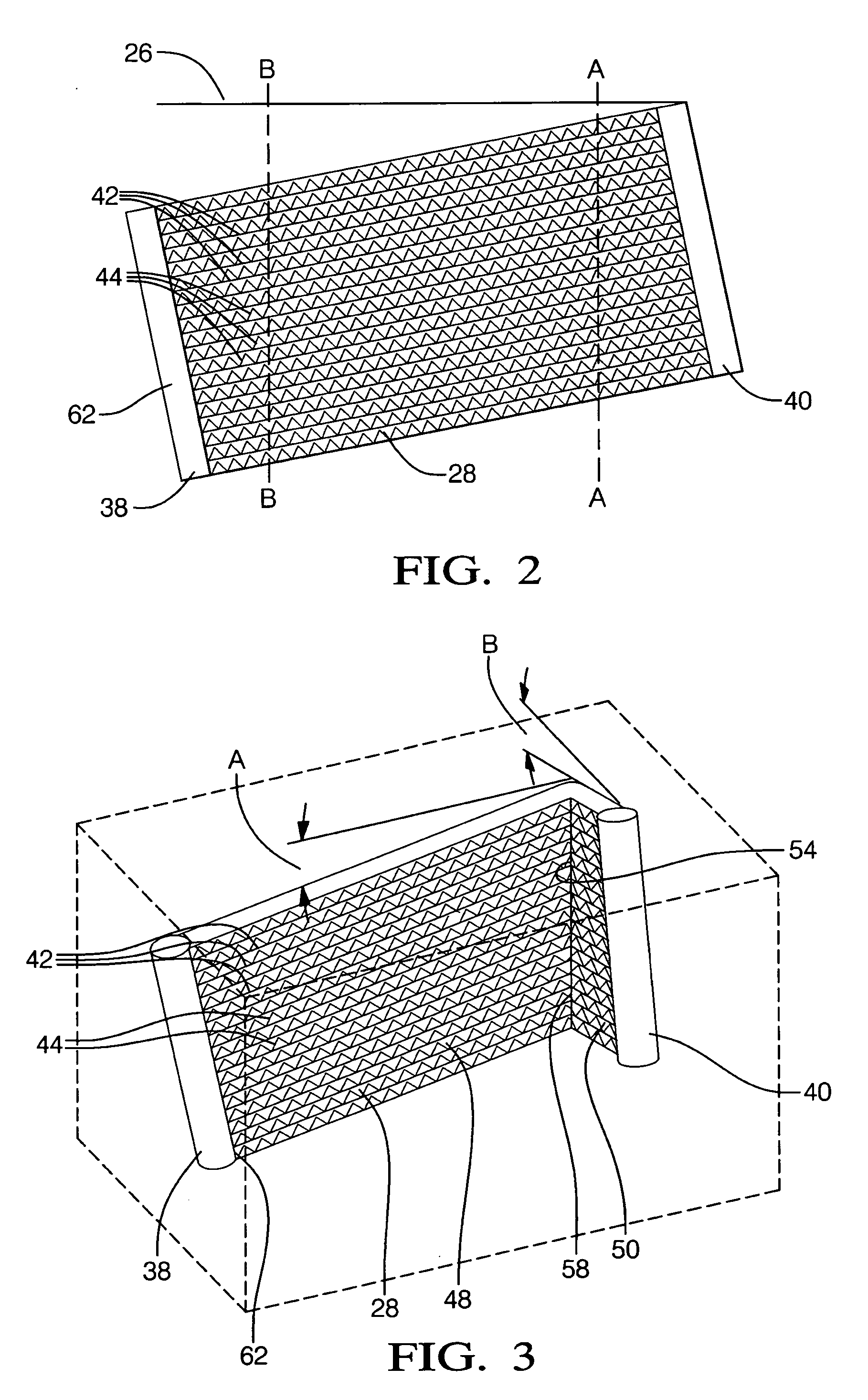

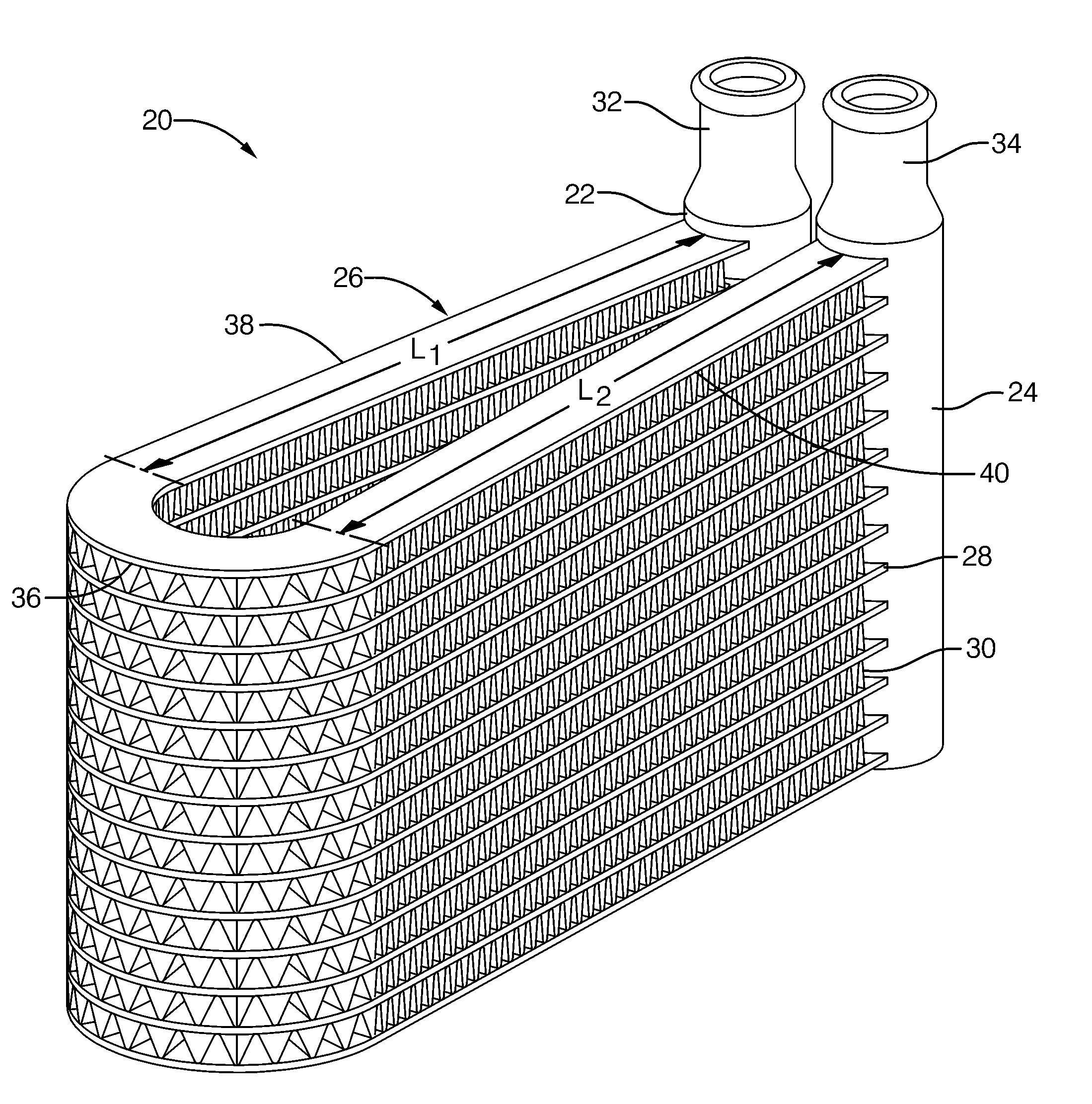

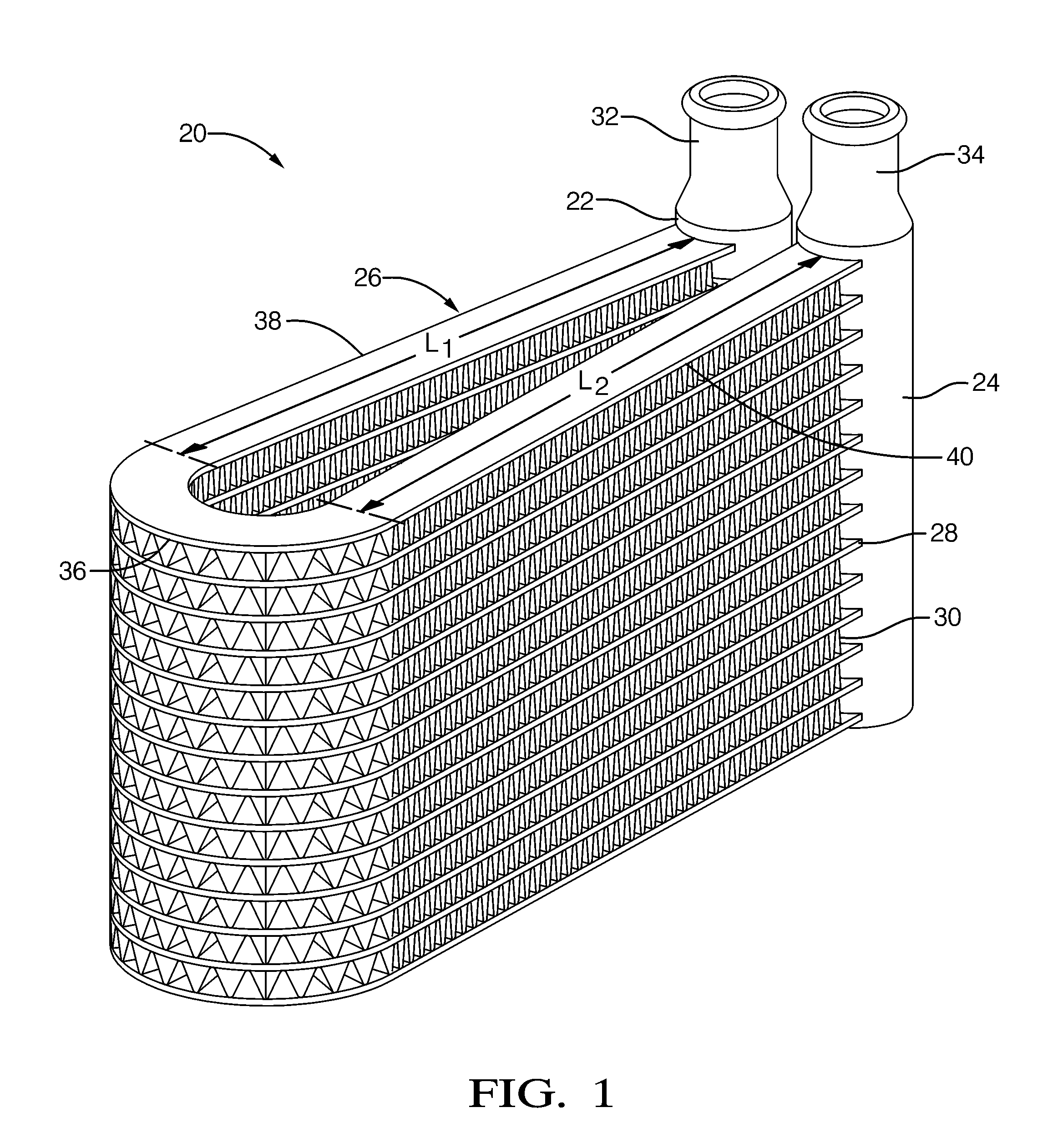

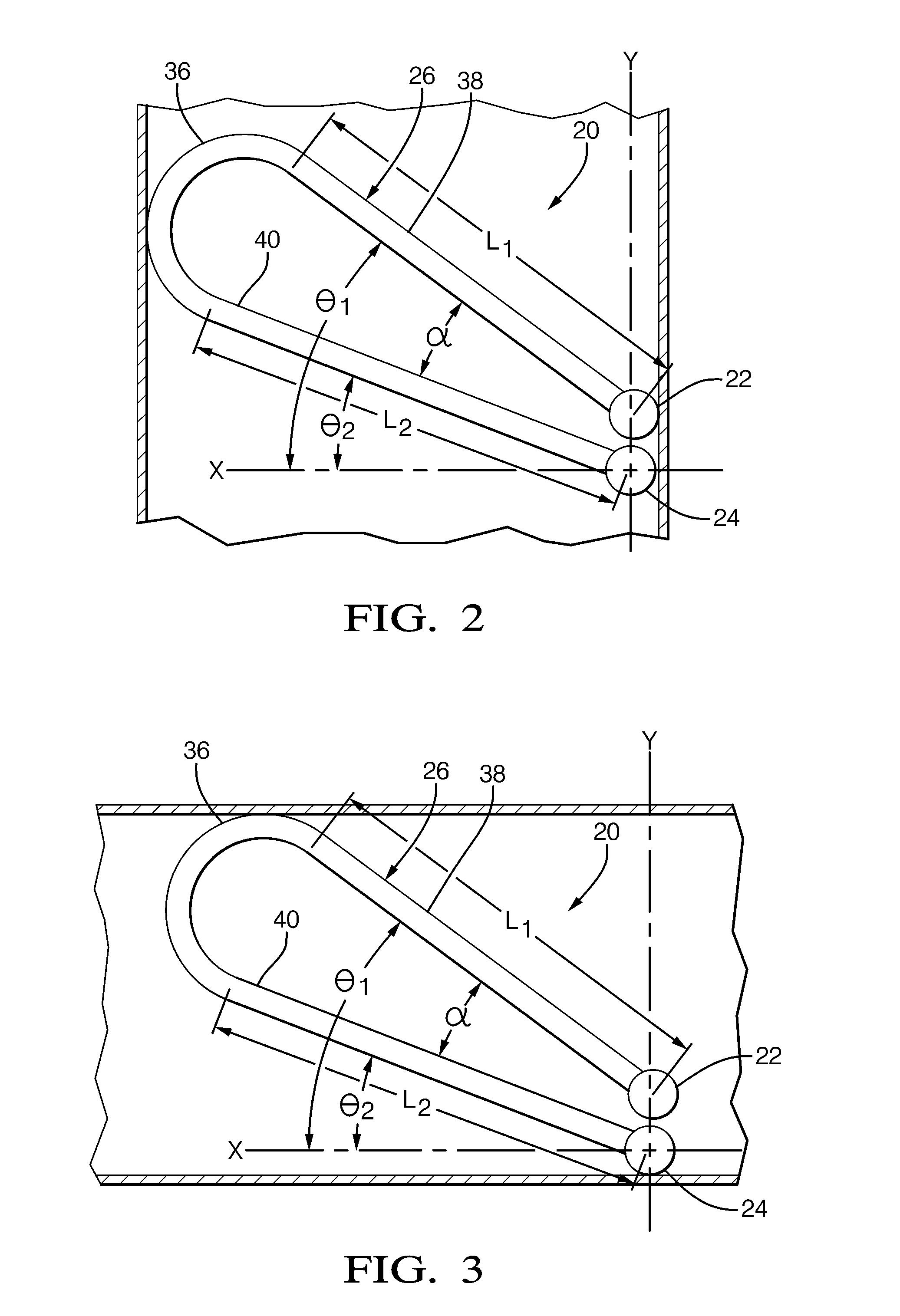

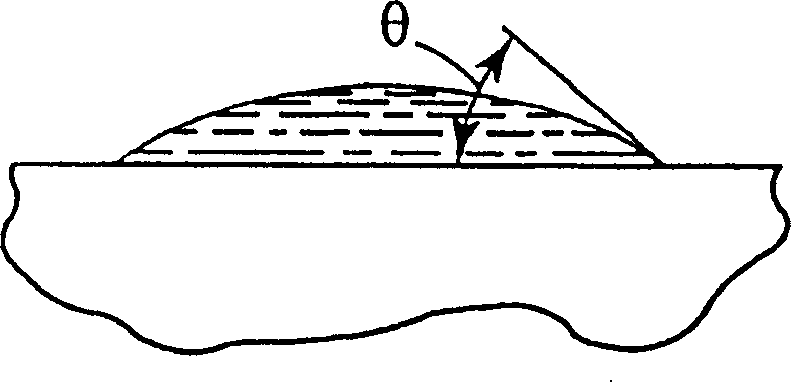

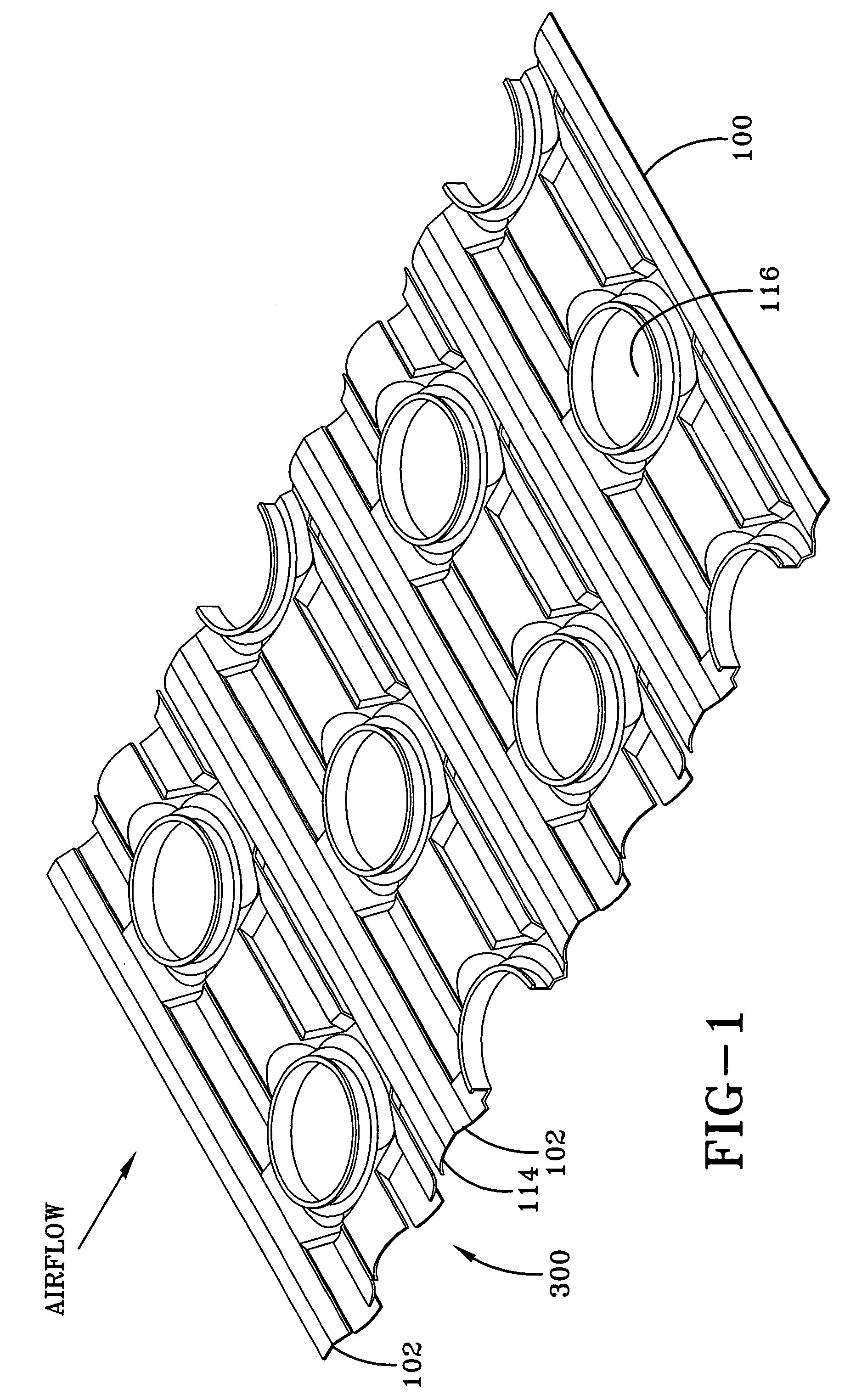

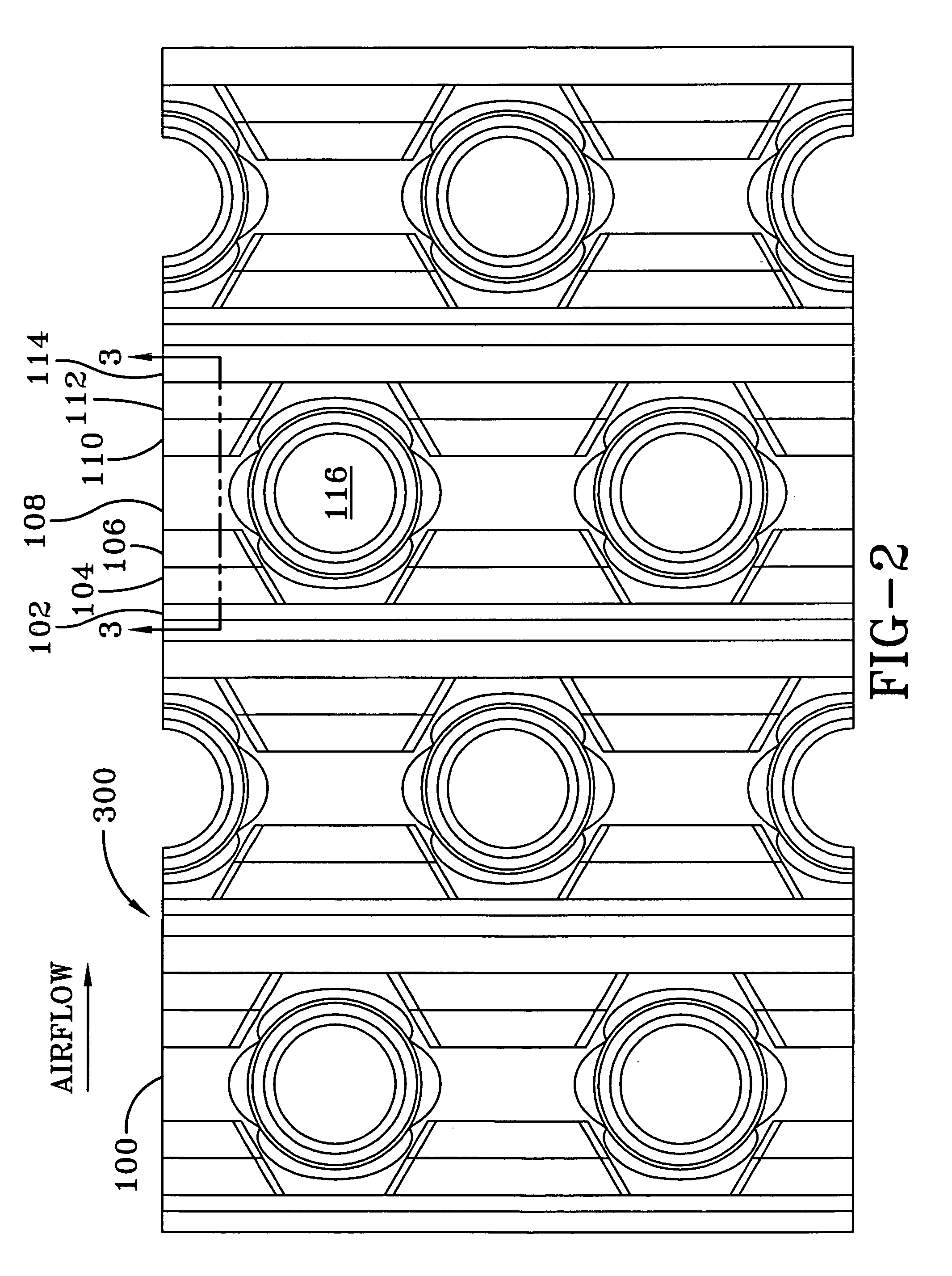

Two row bent evaporator

InactiveUS20110139425A1Improve heat transfer performanceStationary conduit assembliesHeat exchanger casingsAcute angleDrainage angle

A core (26) extends through a circular bend (28) greater than 180 degrees to define a first leg (30) between the bend (28) and an inlet manifold (22) and a second leg (32) between the bend (28) and an outlet manifold (24). The legs (30, 32) are disposed in converging relationship from the bend (28) towards the manifolds (22, 24) to define an acute angle (α) between the legs (30, 32). The manifolds (22, 24) are aligned in juxtaposed relationship along an alignment axis (Y) and the legs (30, 32) are disposed in angular relationship to a reference axis (X) to define first and second drainage angles (Θ1, Θ2) between the corresponding legs (30, 32) and the reference axis (X). The second drainage angle (Θ2) is >10 degrees and the first drainage angle is (Θ1)>20 degrees and the acute angle (α) is >10 degrees for draining condensate along the legs (30, 32) toward the juxtaposed manifolds (22, 24) to establish a common drainage point of the condensate.

Owner:DELPHI TECH INC

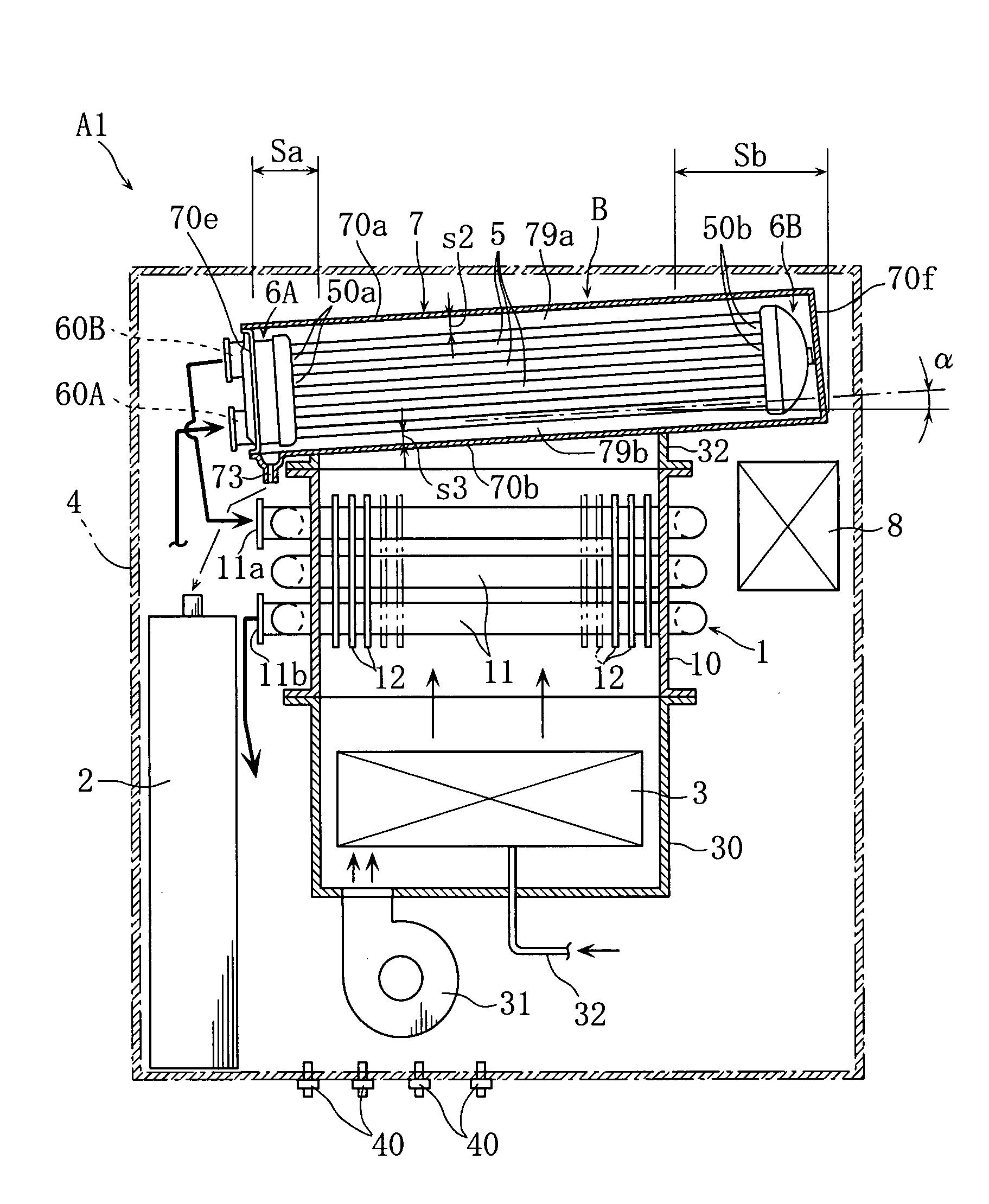

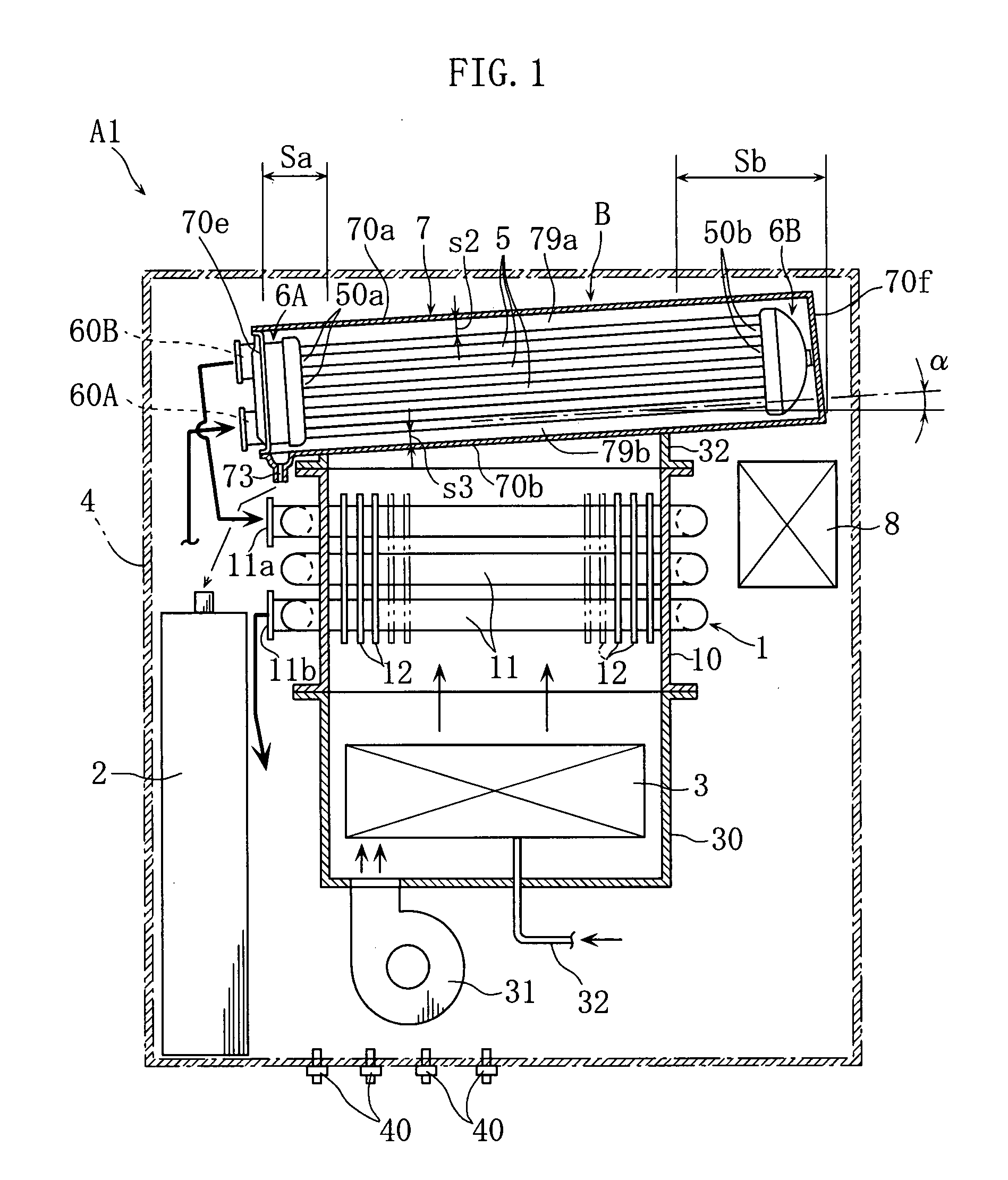

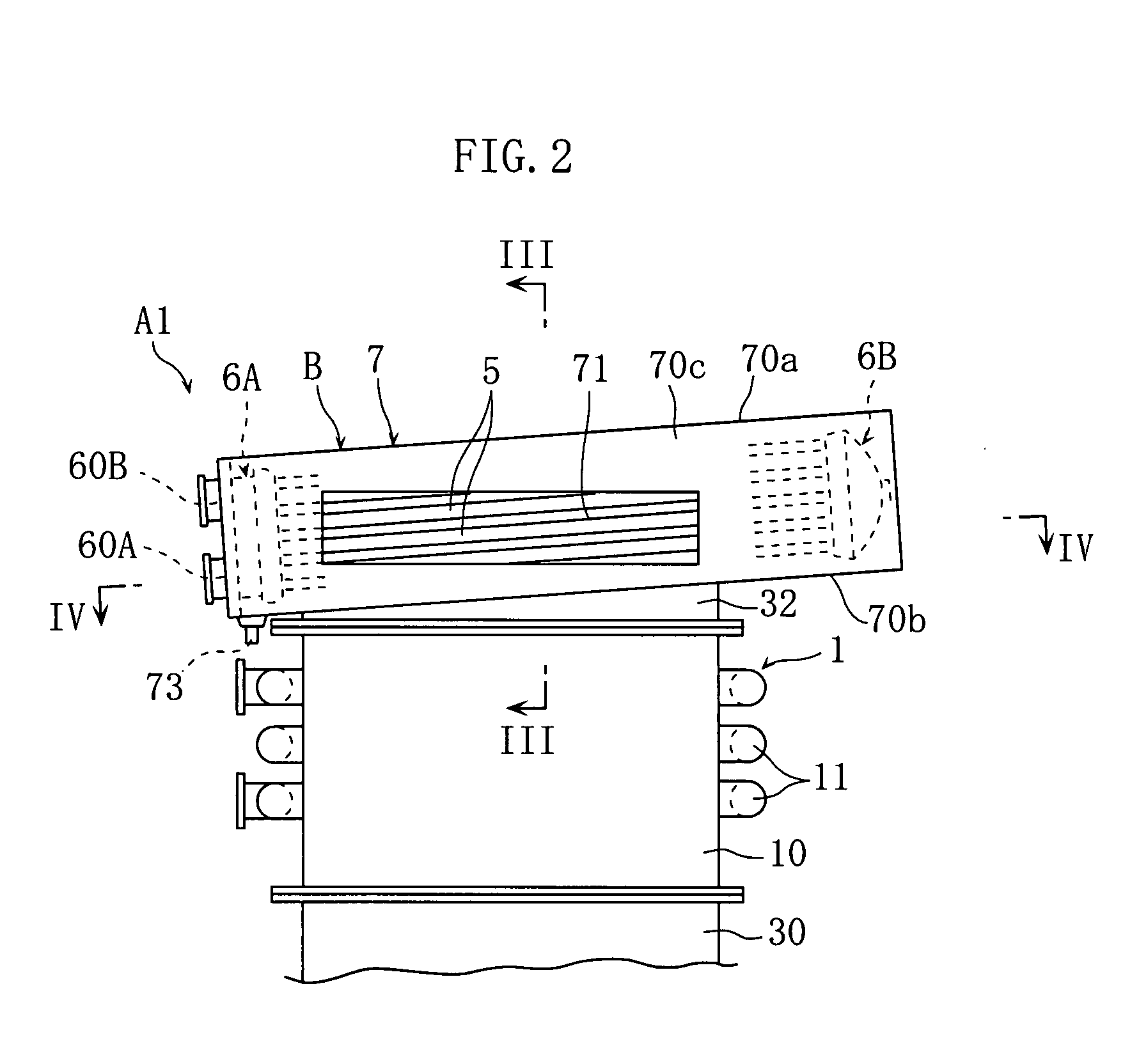

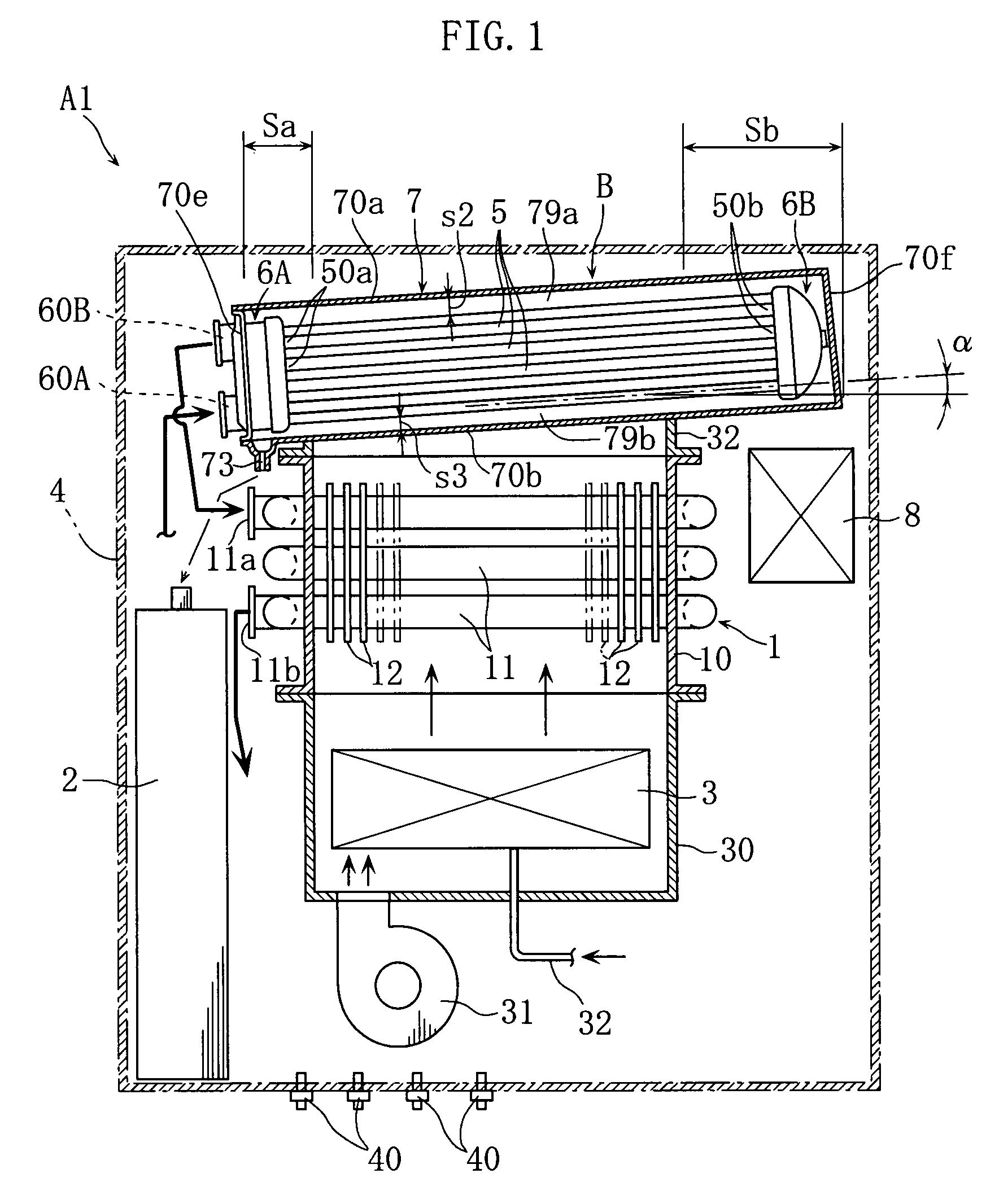

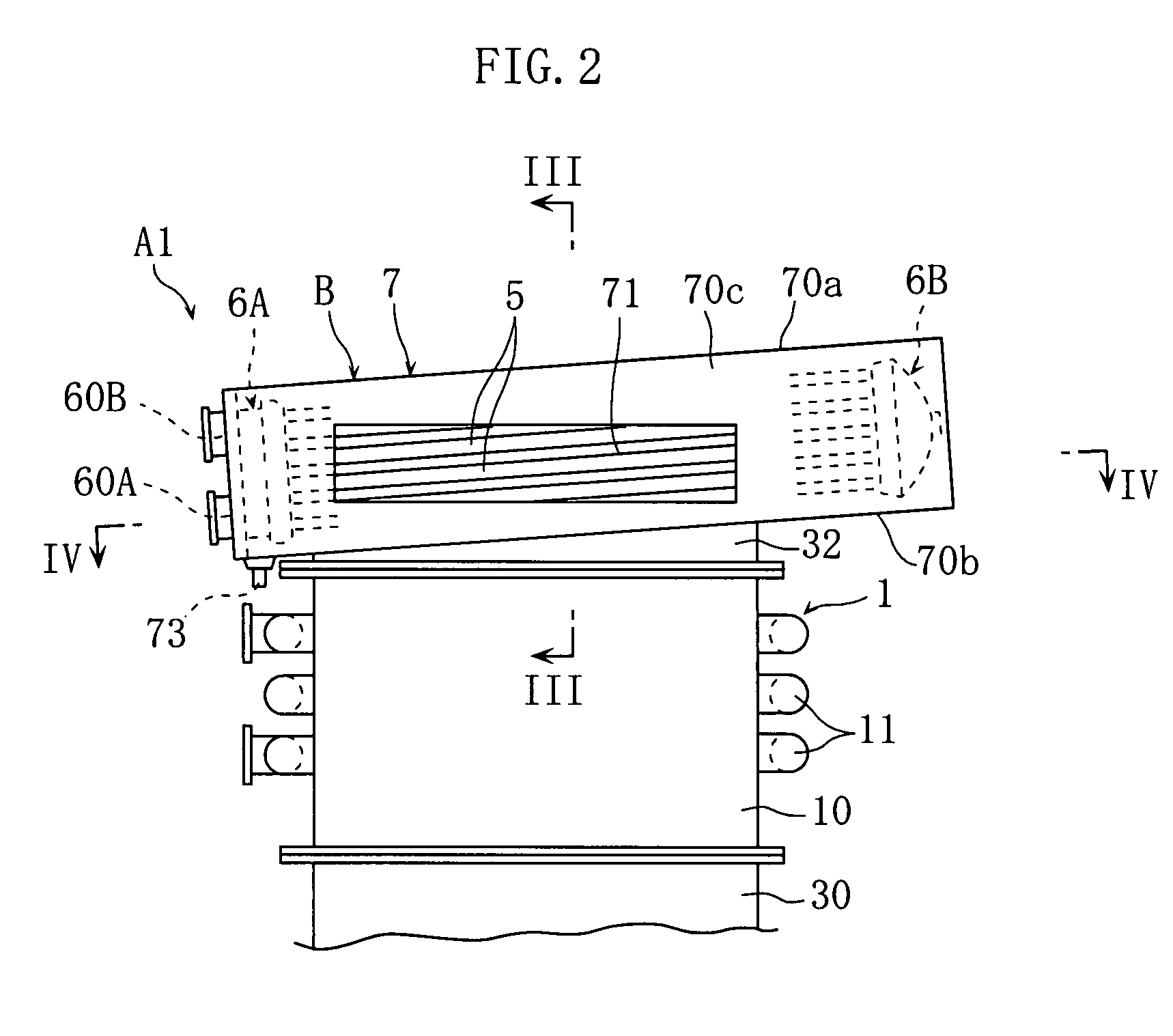

Water Heater

InactiveUS20080006226A1Energy efficient heating/coolingStationary tubular conduit assembliesGas passingEngineering

A secondary heat exchanger B for recovering latent heat from combustion gas includes water tubes 5 each of which is so inclined that a first end 50a is positioned lower than a second end 50b. Therefore, in draining water from each of the water tubes 5, water can be caused to flow smoothly into a water-inflow and hot-water-outflow header 6A connected to the first ends 50a. The secondary heat exchanger B includes a casing 7 which includes an upper wall 70a and a bottom wall 70b which are so inclined that the inner surfaces thereof extend generally in parallel with the water tubes 5, and the upper and the lower gaps 79a and 79b have constant widths s2 and s3. Therefore, the amount of heat recovery from the combustion gas passing through the gaps 79a and 79b can be increased.

Owner:NORITZ CORP

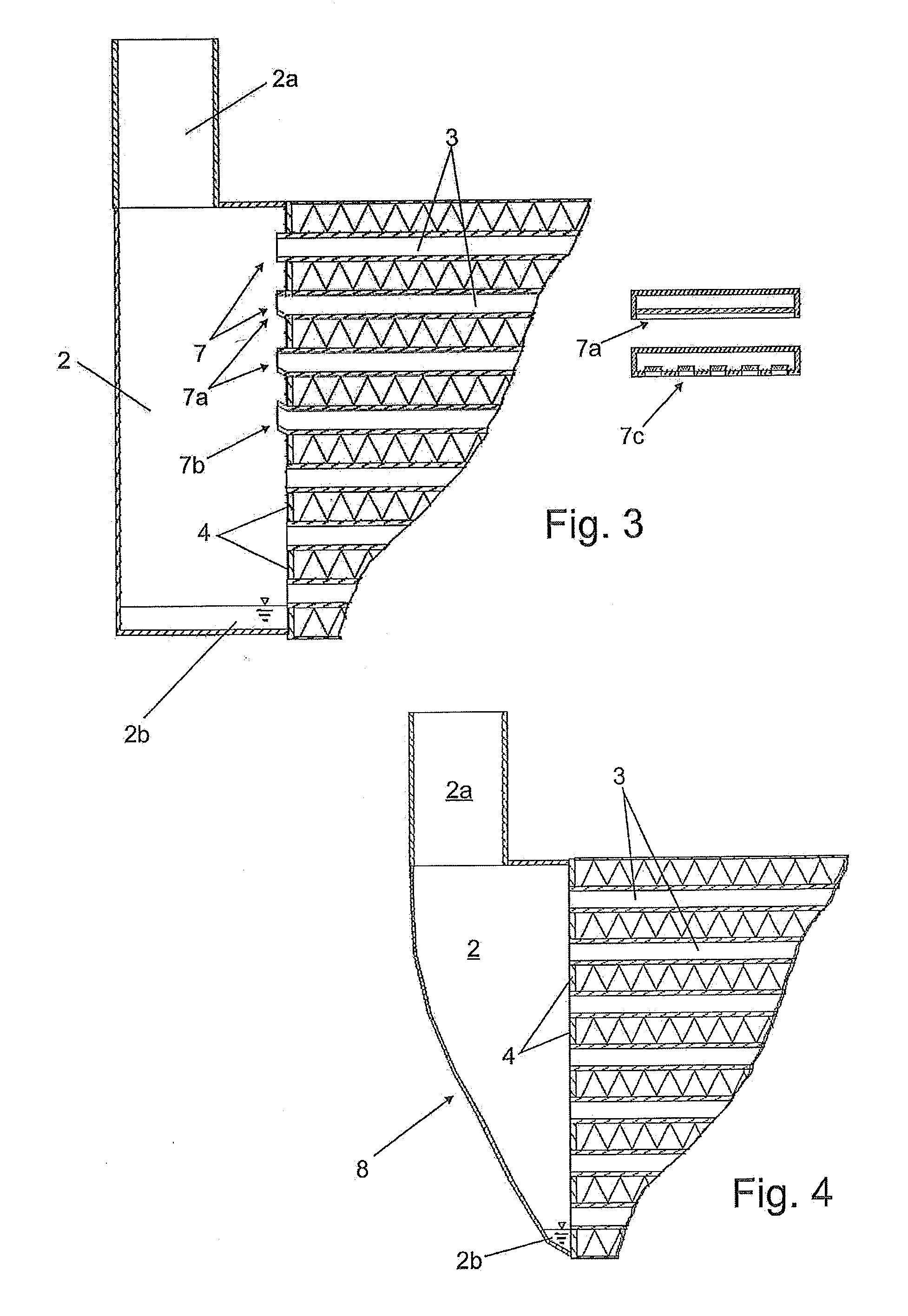

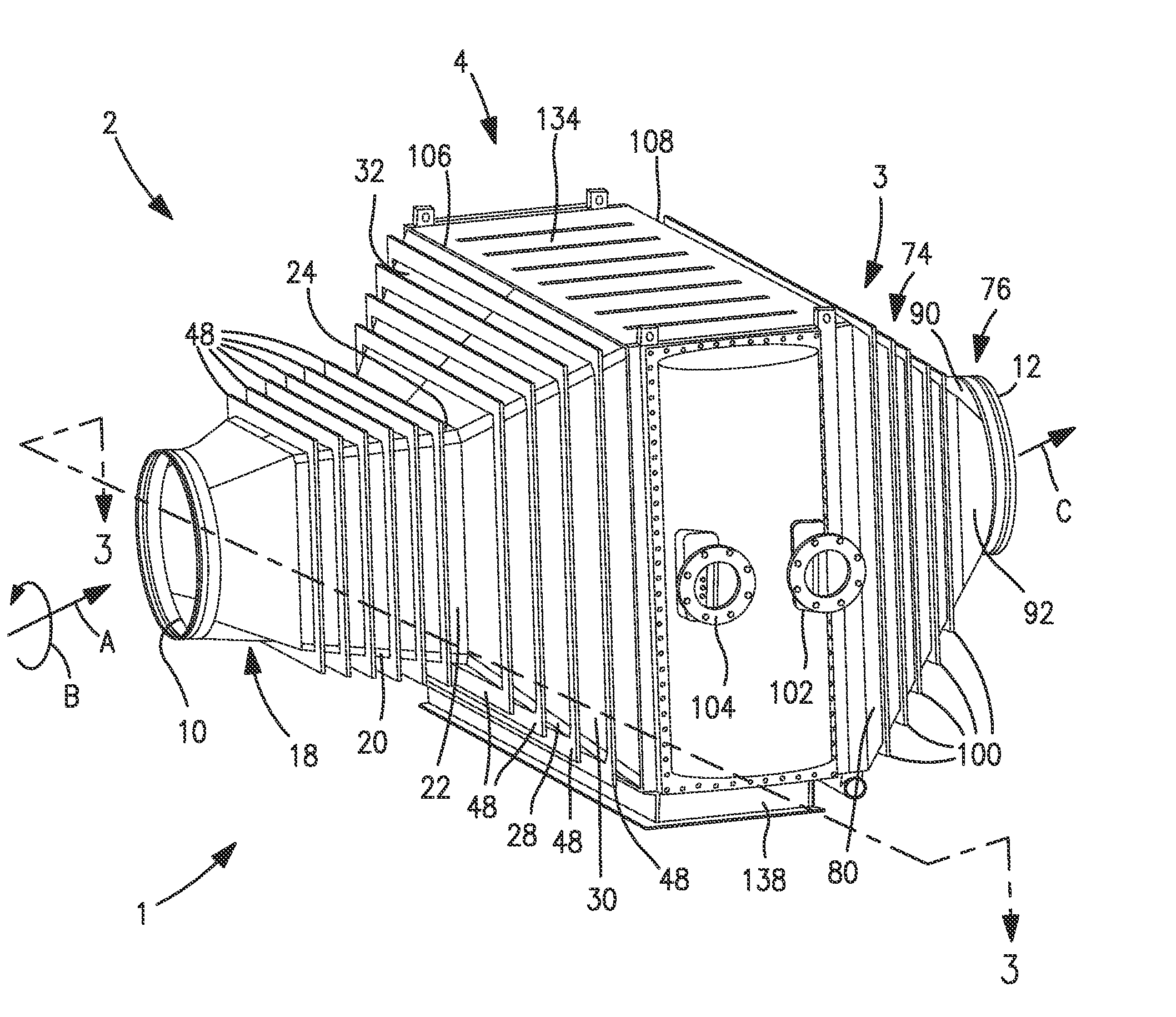

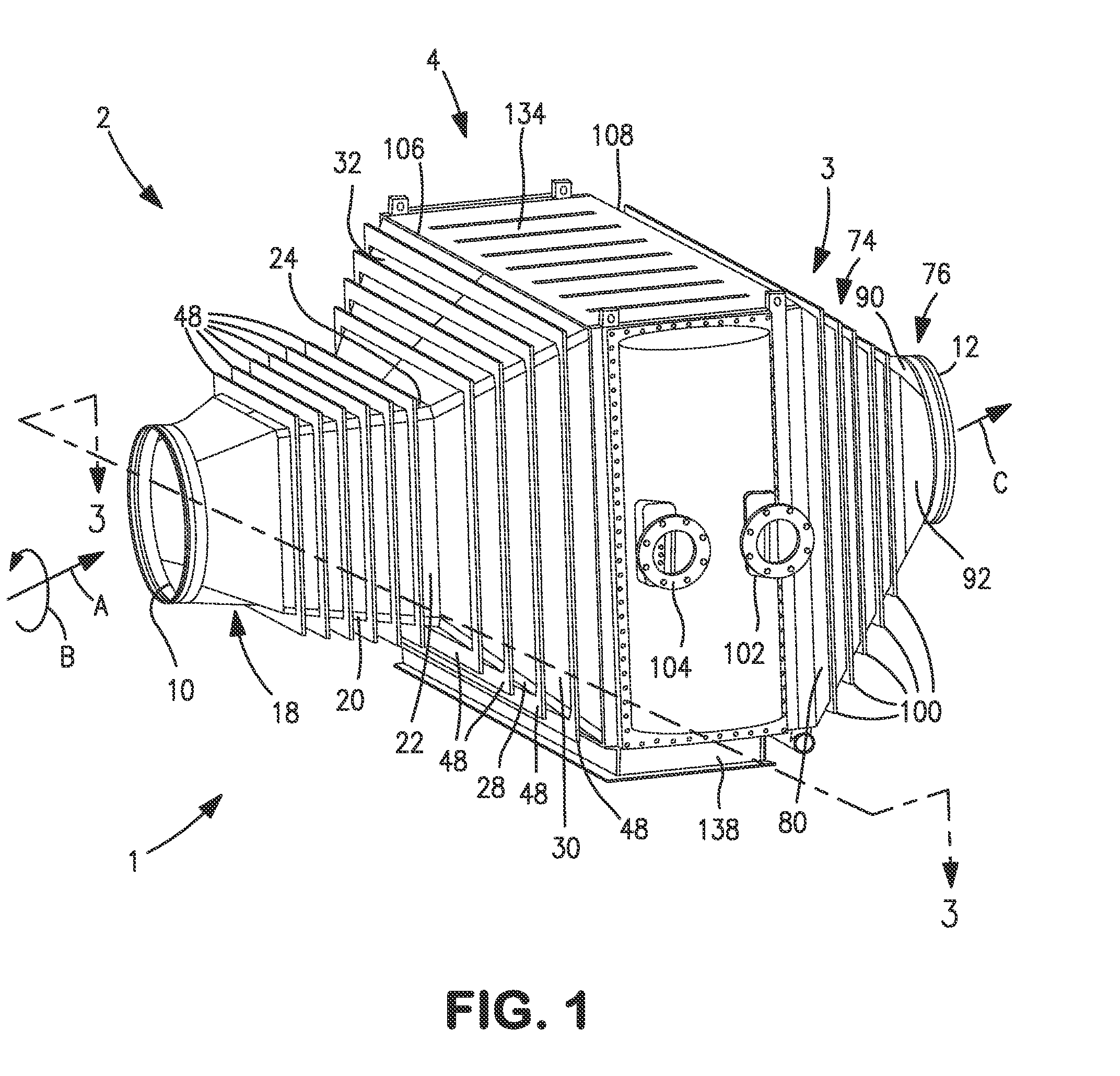

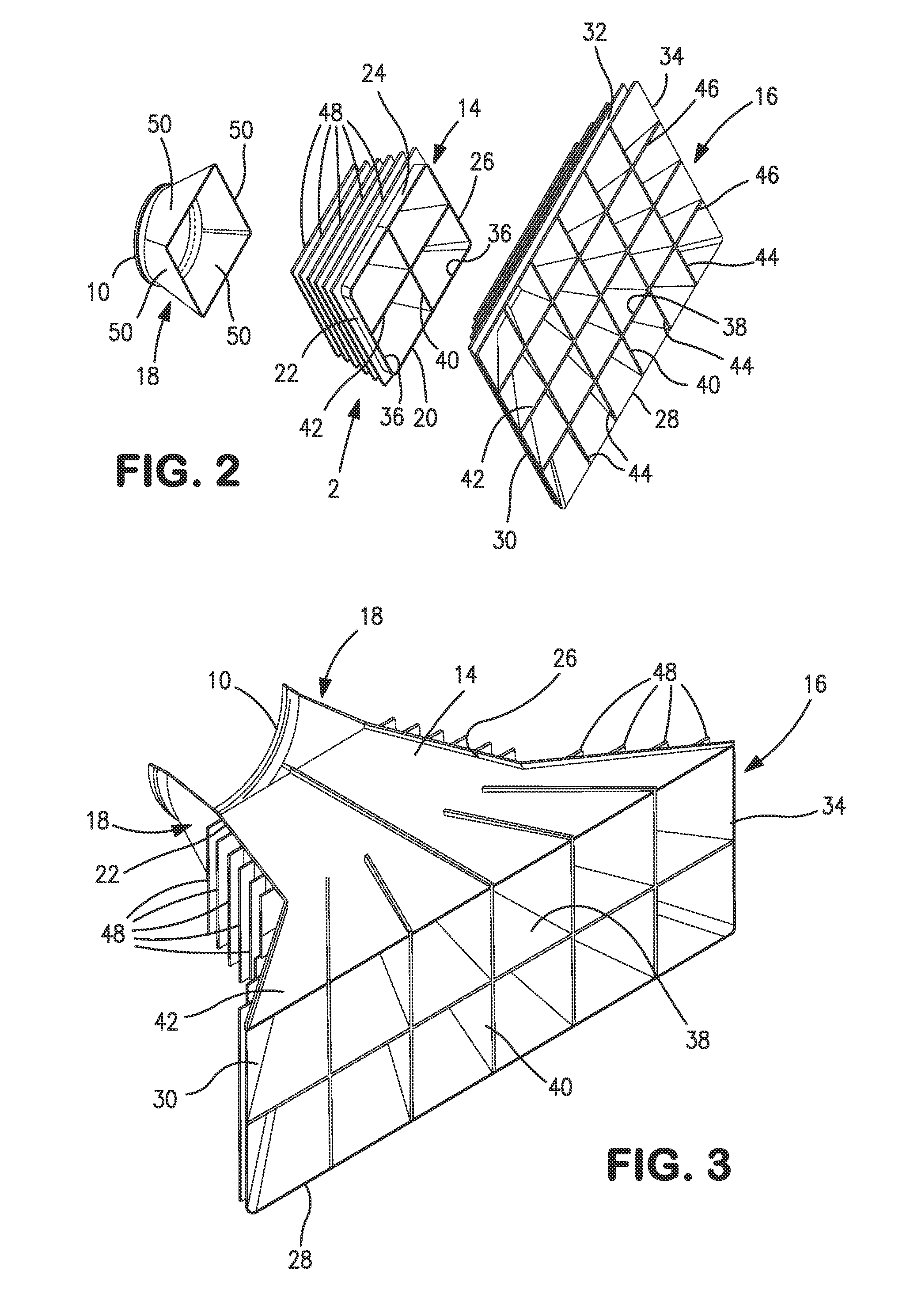

Compressed gas cooling apparatus

InactiveUS20140000841A1Lower overall pressure dropReduced flow separationReinforcing meansPump componentsEngineeringGas cooling

A compressed gas cooling apparatus in which gas from an upstream compression stage enters an inlet section from an inlet opening and flows to a heat exchanger that cools the gas. The cooled gas then flows from the heat exchanger to the outlet section where the gas is discharged from an outlet opening. Pressure drop within the apparatus is decreased by providing the inlet and outlet sections with ever increasing and decreasing cross-sectional flow areas. In order to further decrease pressure drop due to a swirl within the gas flow imparted from the upstream compression stage, the inlet section is provided with first and second subsections wherein the cross-sectional flow area of the first subsection increases at lesser rate than the second subjection. Alternatively, or in addition, the inlet section can be provided with partitions to divide the gas flow into subflows in order to lessen pressure drop from swirl.

Owner:PRAXAIR TECH INC

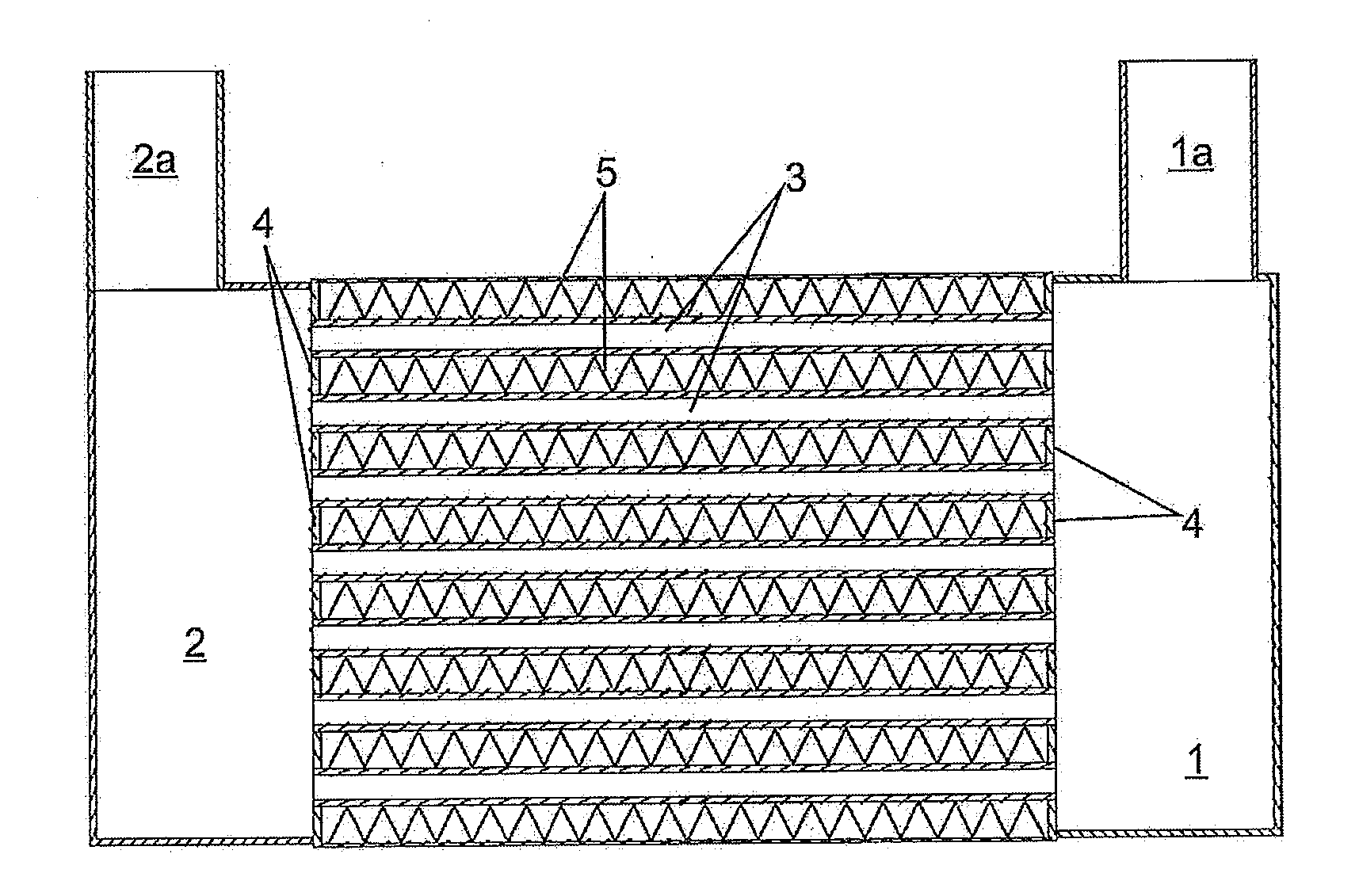

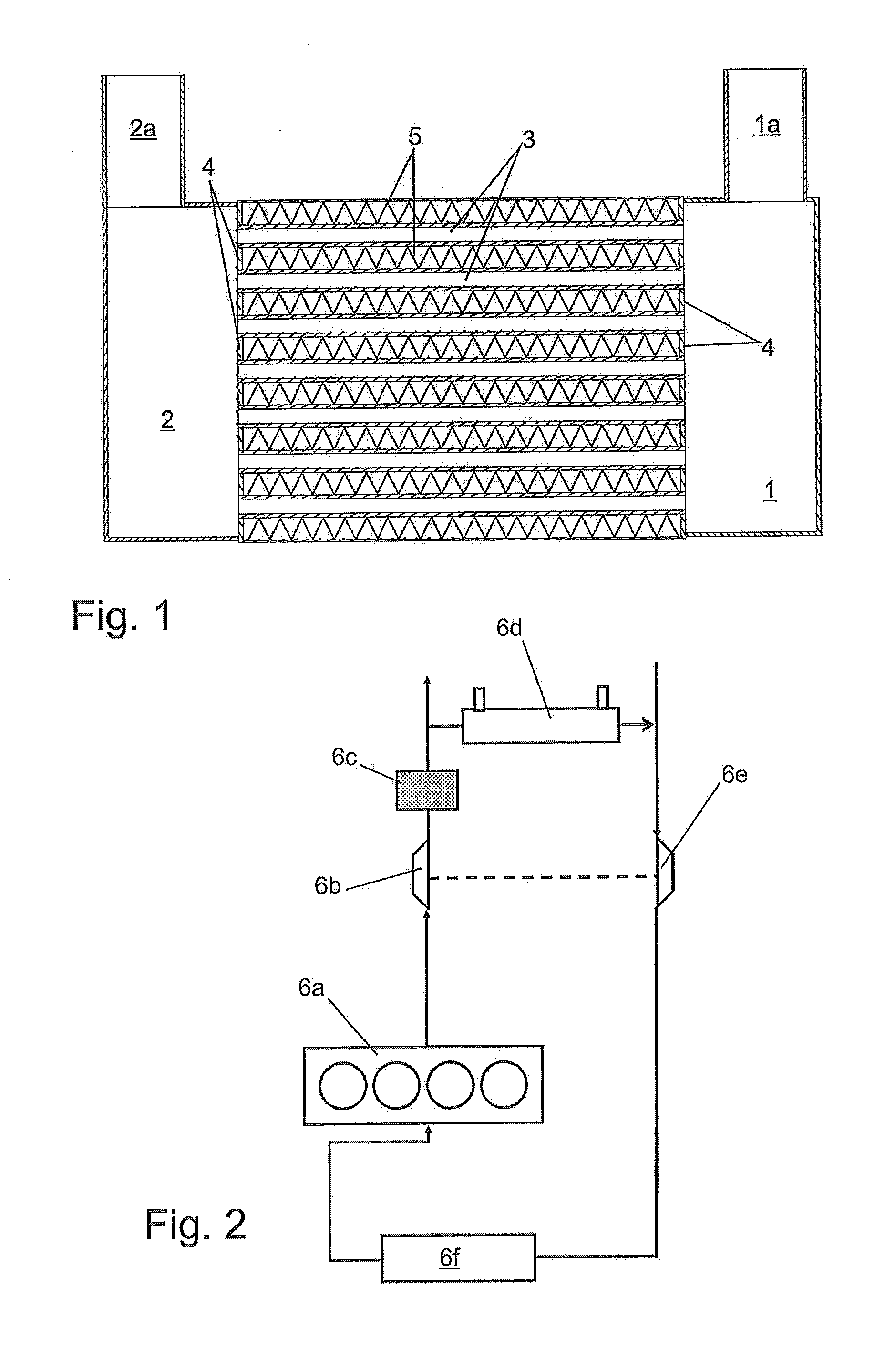

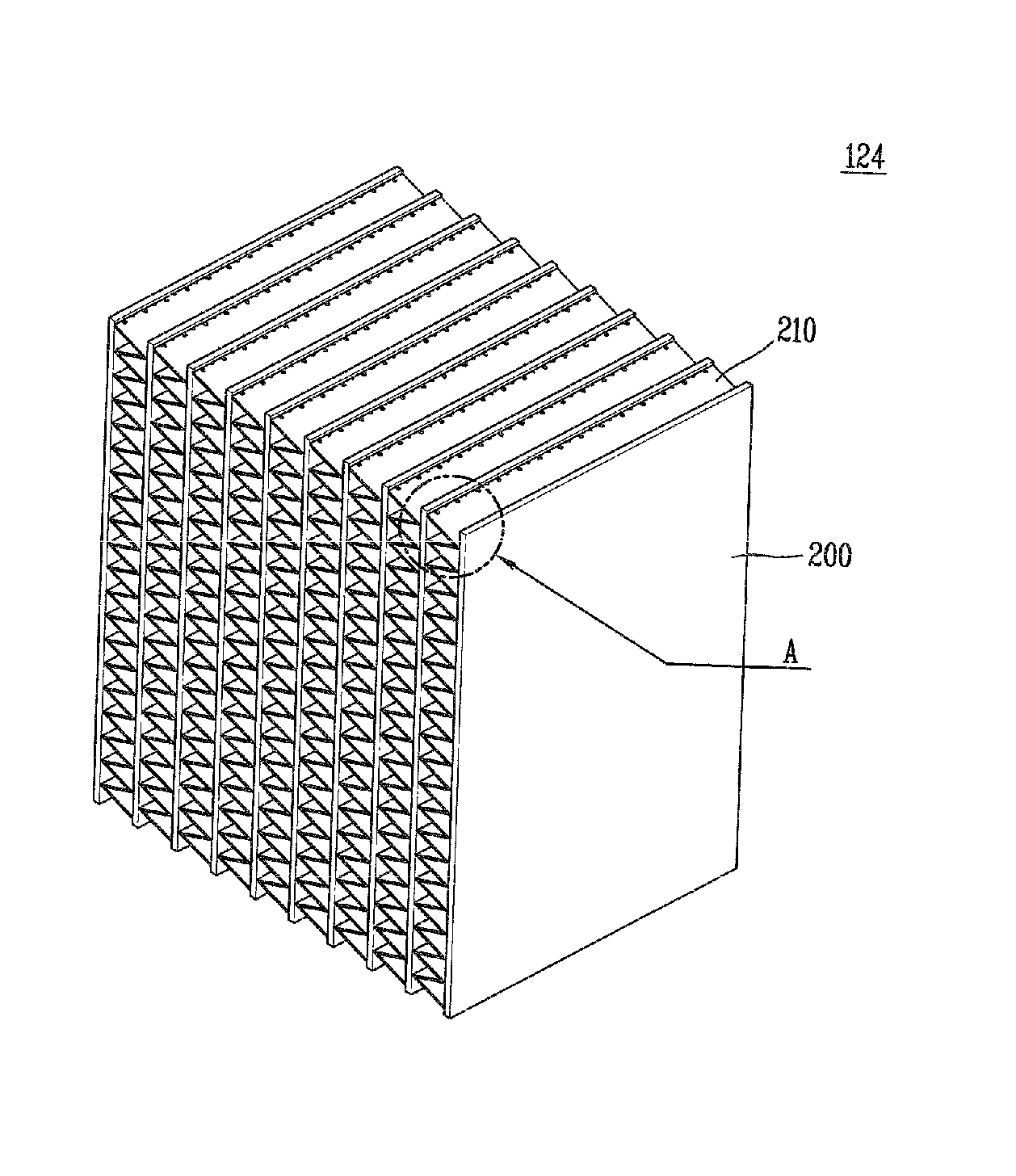

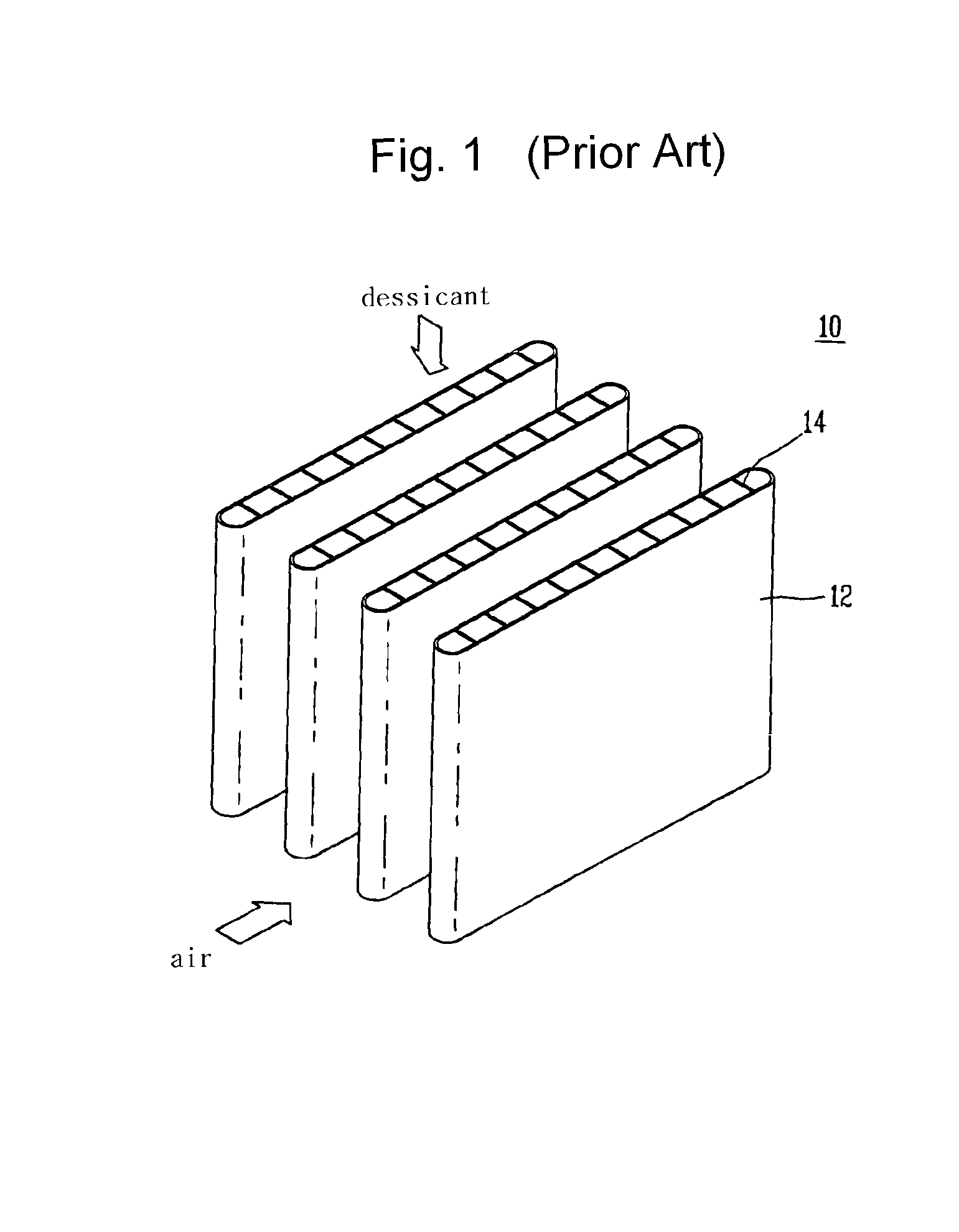

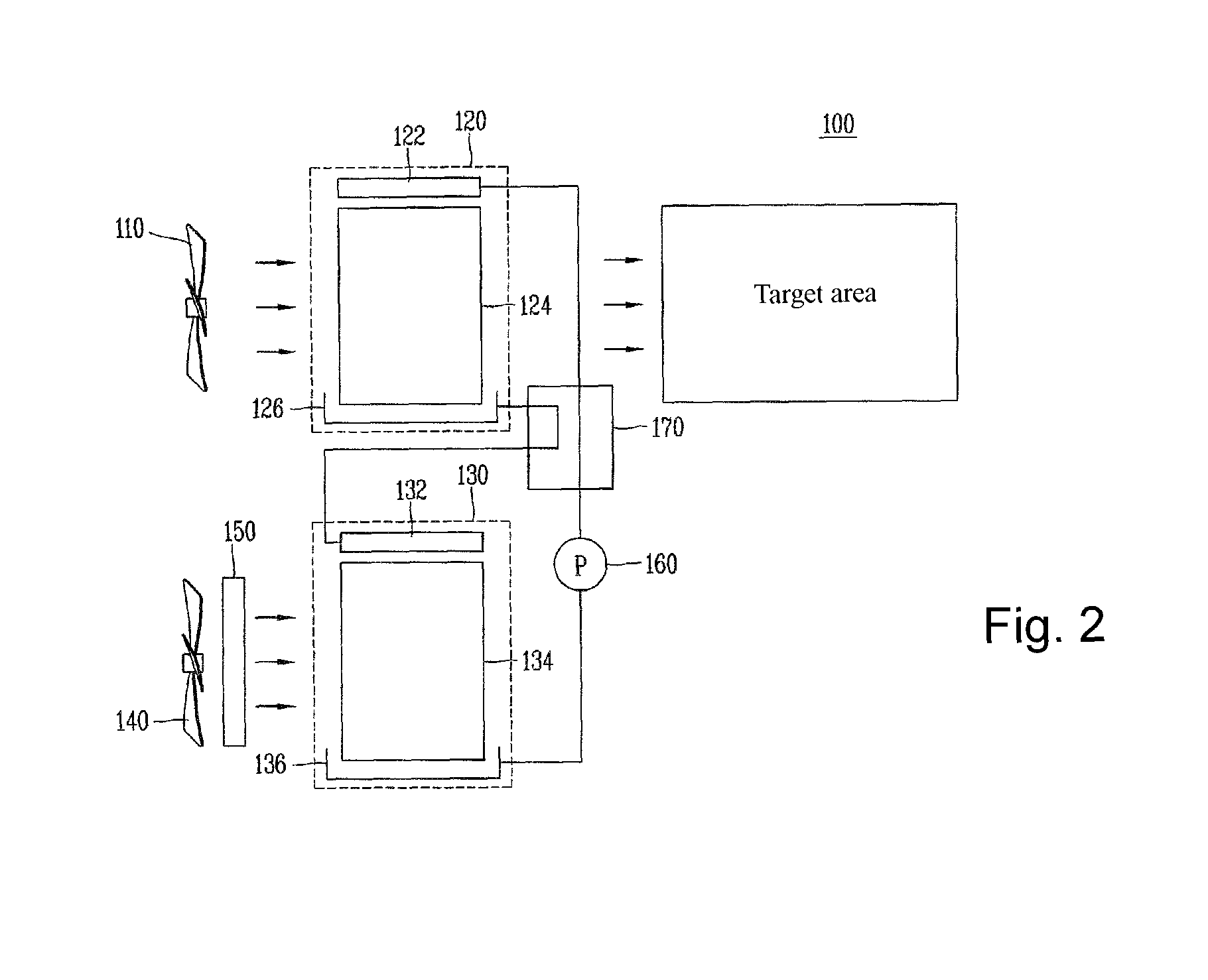

Heat exchanger for dehumidifier using liquid desiccant and dehumidifier using liquid desiccant having the same

InactiveUS8696805B2Small sizeImprove heat transfer efficiencyUsing liquid separation agentMachines/enginesEngineeringLiquid desiccant

Disclosed are a heat exchanger for a dehumidifier using a liquid desiccant and a dehumidifier using a liquid desiccant having the same. The heat exchanger for a dehumidifier using a liquid desiccant, comprises: a plurality of plate-type heat exchanger bodies to which a heat transfer medium flows through flow paths formed therein; and a plurality of plates extending between the respective heat exchanger bodies, and inclined with respect to the surfaces of the heat exchanger bodies.

Owner:KOREA INST OF SCI & TECH

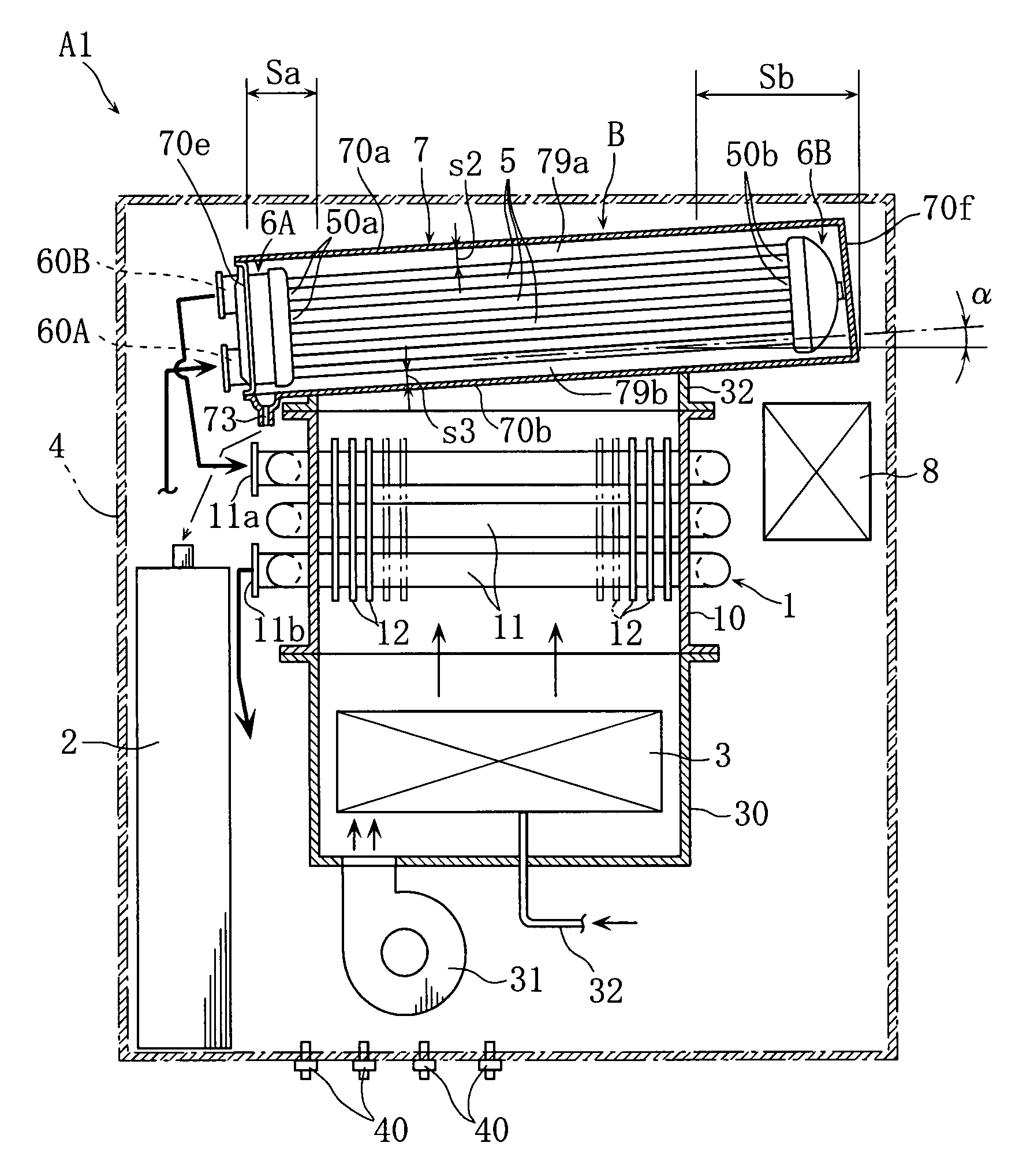

Water heater

InactiveUS7458340B2Energy efficient heating/coolingStationary tubular conduit assembliesCombustionGas passing

A secondary heat exchanger B for recovering latent heat from combustion gas includes water tubes 5 each of which is so inclined that a first end 50a is positioned lower than a second end 50b. Therefore, in draining water from each of the water tubes 5, water can be caused to flow smoothly into a water-inflow and hot-water-outflow header 6A connected to the first ends 50a. The secondary heat exchanger B includes a casing 7 which includes an upper wall 70a and a bottom wall 70b which are so inclined that the inner surfaces thereof extend generally in parallel with the water tubes 5, and the upper and the lower gaps 79a and 79b have constant widths s2 and s3. Therefore, the amount of heat recovery from the combustion gas passing through the gaps 79a and 79b can be increased.

Owner:NORITZ CORP

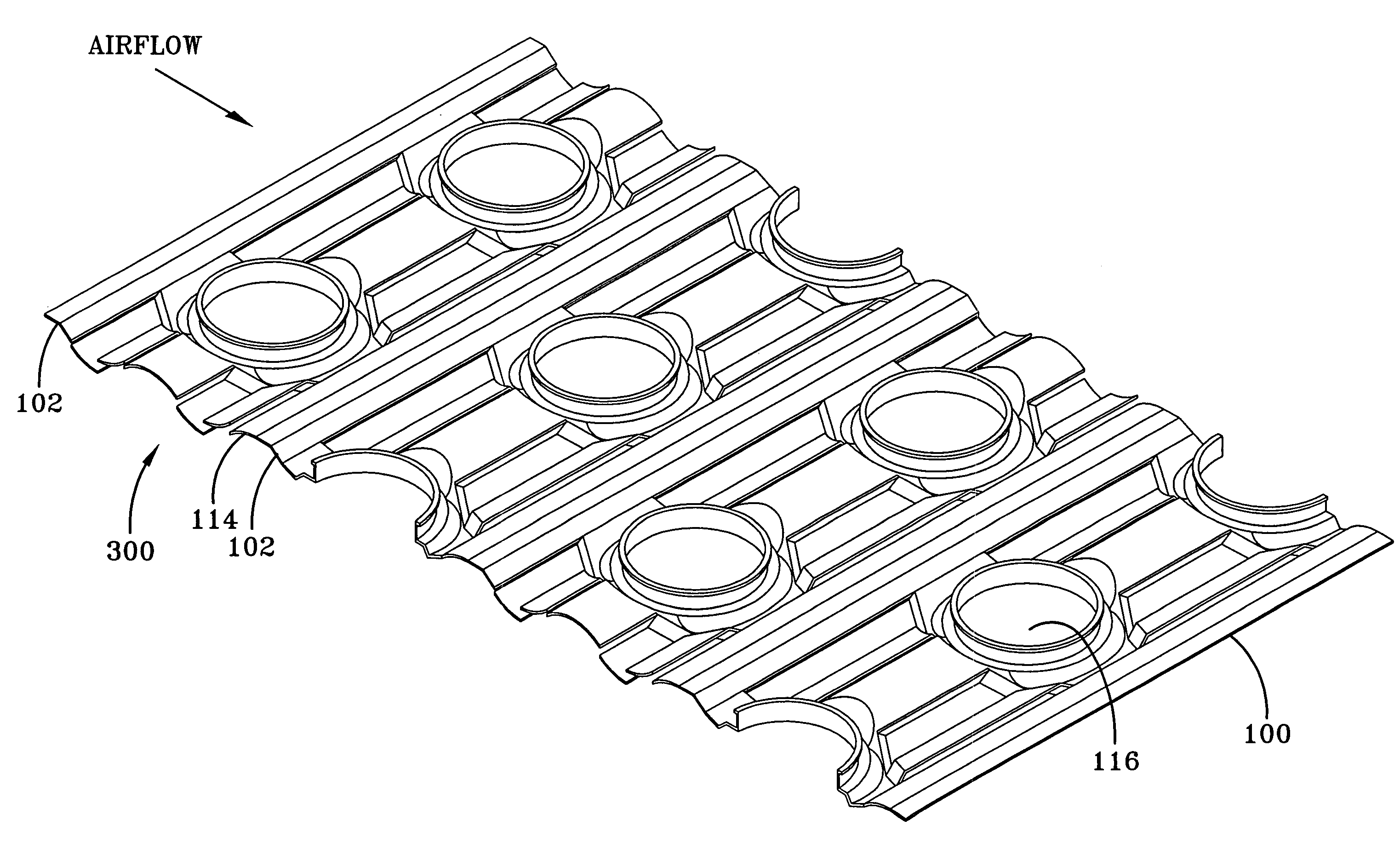

Microstructured surface film assembly for liquid acquisition and transprot

InactiveCN1489521AIncrease surface areaEasy to handleMaterial nanotechnologyLayered productsEngineeringAdjacent channel

A film or tape has one of its major surfaces defined by microstructured features including a plurality of channels defined by spaced apart protrusions. The microstructured film is able to acquire liquids and to control the directional transport of such liquids for subsequent removal therefrom. The transport can be passive or active (i.e., caused or enhanced by an applied potential). The inventive microstructured films and tapes have applications in laminate floor assemblies (for spill removal) and industrial articles such as computer keyboards and other devices and assemblies that benefit from fluid removal. The invention also has application in evaporative and condensation applications. In one embodiment, at least one cross-channel is formed on the microstructured surface to join adjacent channels for liquid flow therebetween.

Owner:3M INNOVATIVE PROPERTIES CO

High-V plate fin for a heat exchanger and method of manufacturing

InactiveUS6976529B2Improvement factorLow air-side pressure dropEvaporators/condensersStationary conduit assembliesLeading edgePlate heat exchanger

A fin for a heat exchanger coil assembly and a method of manufacturing the fin is provided. The fin includes a heat transfer enhancement pattern which appears sinusoidal in shape. The base wavy pattern of the enhancement pattern includes two wavelengths within each tube row and includes seven discrete segments. Six of the seven segments are circular arc segments. The seventh segment comprises two linear segments which form a condensate channel. The segments are arranged in a particular order at specific distances offset (above and below) from a leading edge nominal air streamline (LENAS) by a fraction of a nominal fin pitch Pf. The LENAS is related to the “normal” base wavy pattern used in other fins.

Owner:YORK INT

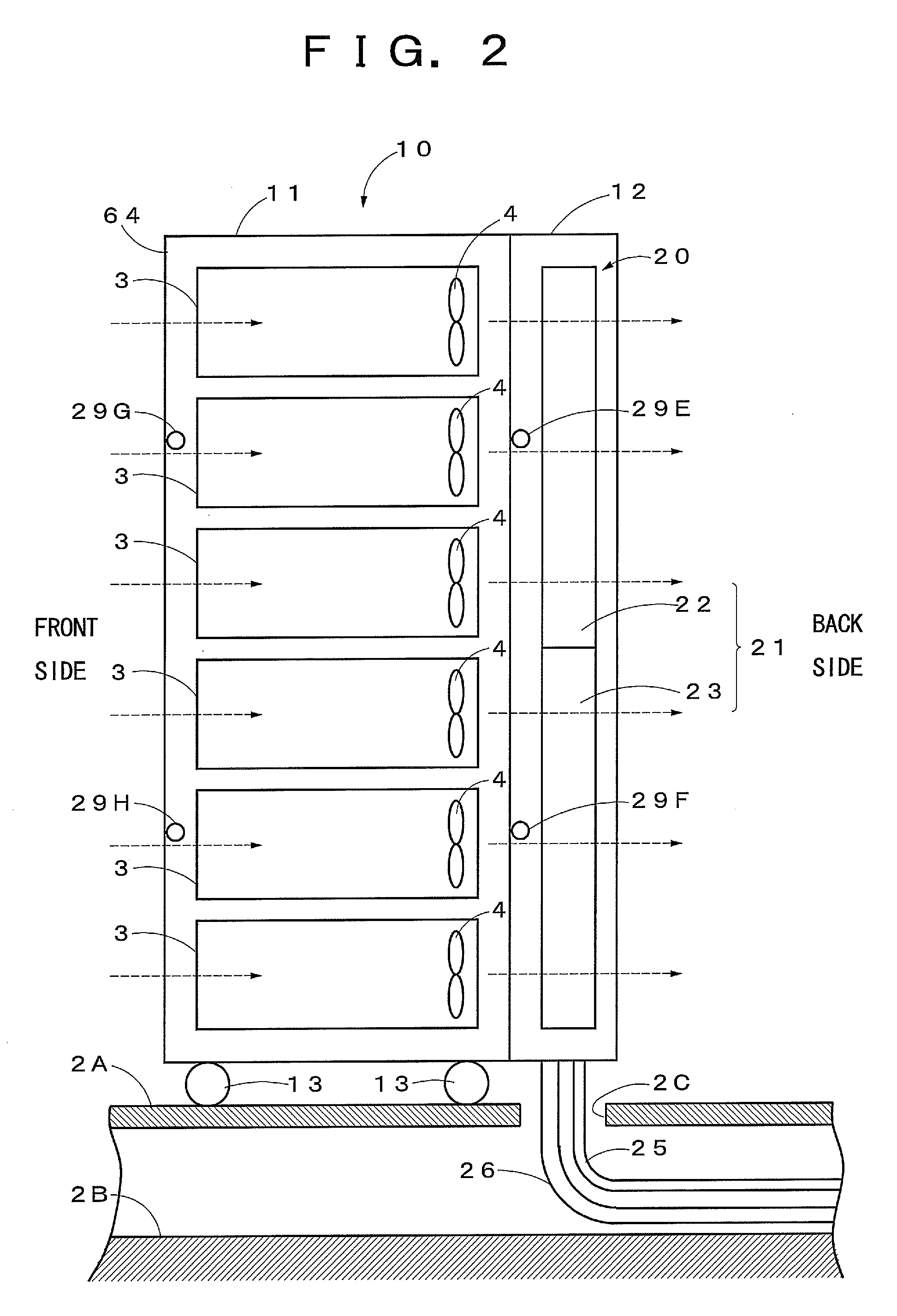

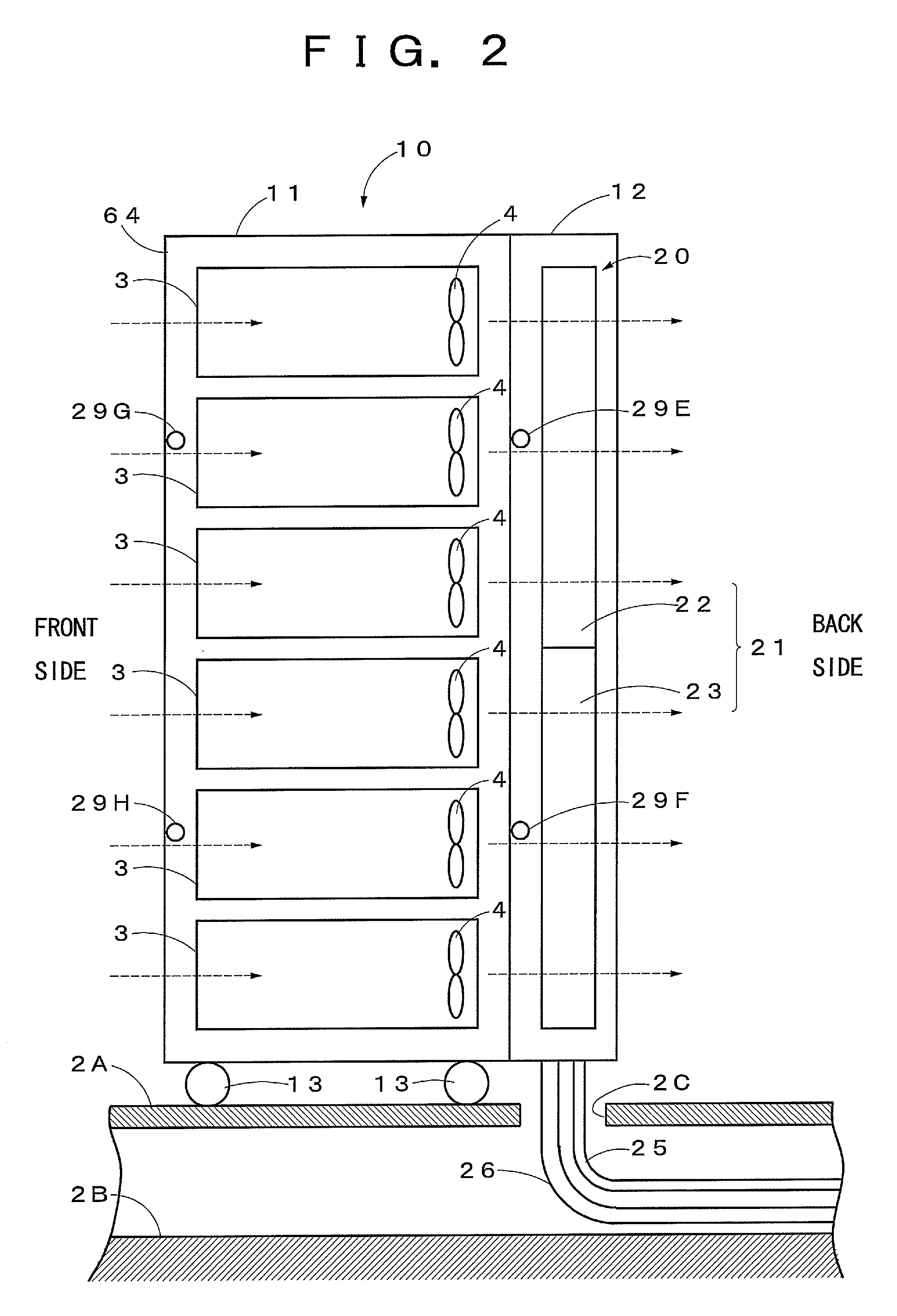

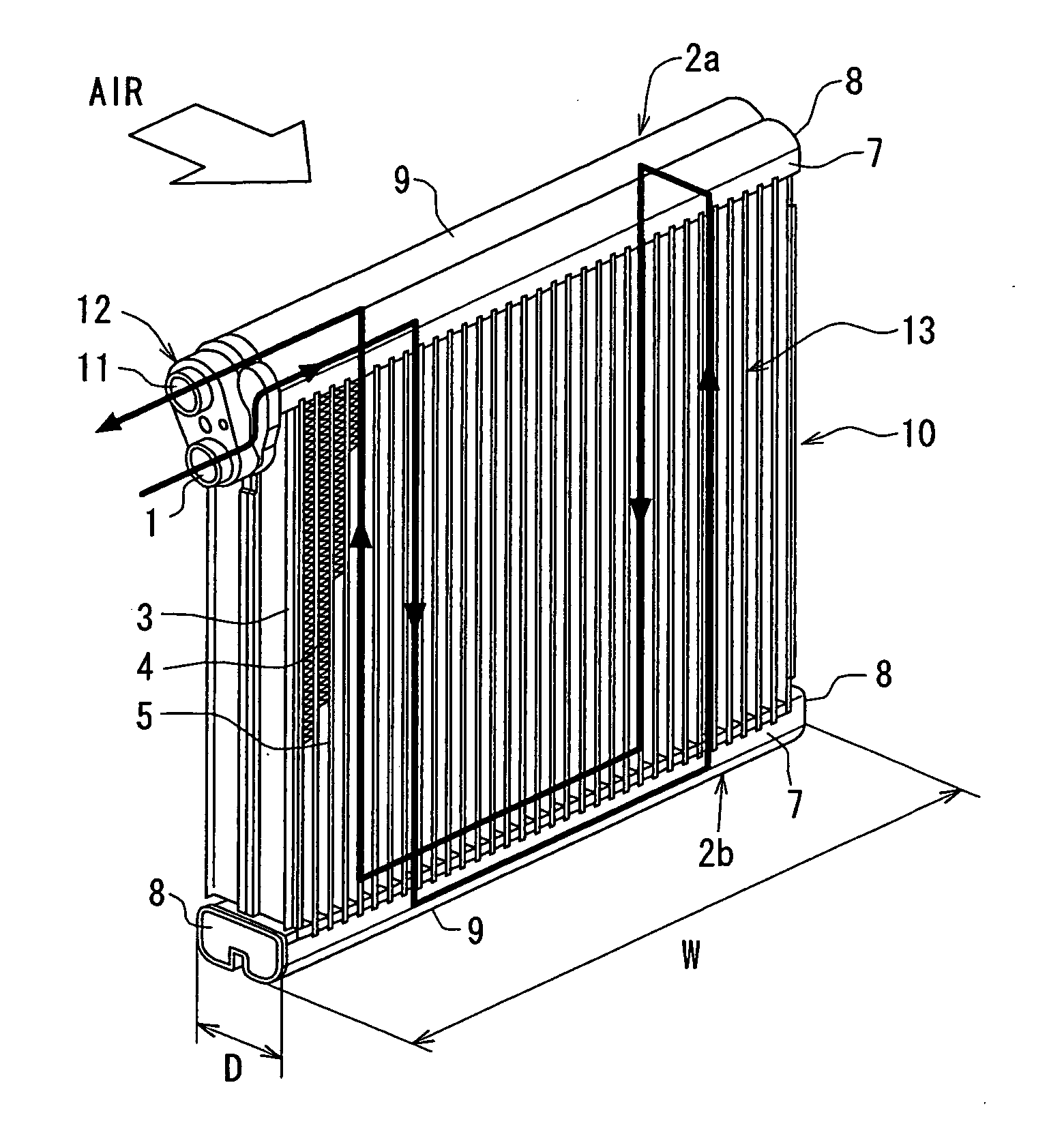

Evaporator

InactiveUS20060162376A1Speed up the flowSatisfactory performanceEvaporators/condensersStationary conduit assembliesWater flowPhysics

An evaporator 1 comprises a heat exchange core 10 comprising a plurality of tube groups 5 arranged in rows as spaced forwardly or rearwardly of the evaporator and each comprising a plurality of heat exchange tubes 4 arranged in parallel at a spacing laterally of the evaporator, and a lower tank 3 disposed at a lower end of the core 10 and having connected thereto lower ends of the heat exchange tubes 4 providing the tube groups 5. The lower tank 3 has a top surface 3a, front and rear opposite side surfaces 3b and a bottom surface 3c. The lower tank 3 is provided in each of front and rear opposite side portions thereof with grooves 29 formed between respective laterally adjacent pairs of heat exchange tubes 4 and extending from an intermediate portion of the top surface 3a with respect to the forward or rearward direction to the side surface 3b for causing water condensate to flow therethrough. Each of the grooves 29 includes a first portion 29a existing on the top surface 3a of the lower tank and having a bottom face which is gradually lowered from the intermediate portion of the top surface 3a toward a front or rear side edge thereof. The evaporator 1 can be diminished in the quantity of water condensate that will collect on the top surface 3a of the lower tank 3.

Owner:KEIHIN THERMAL TECH CORP

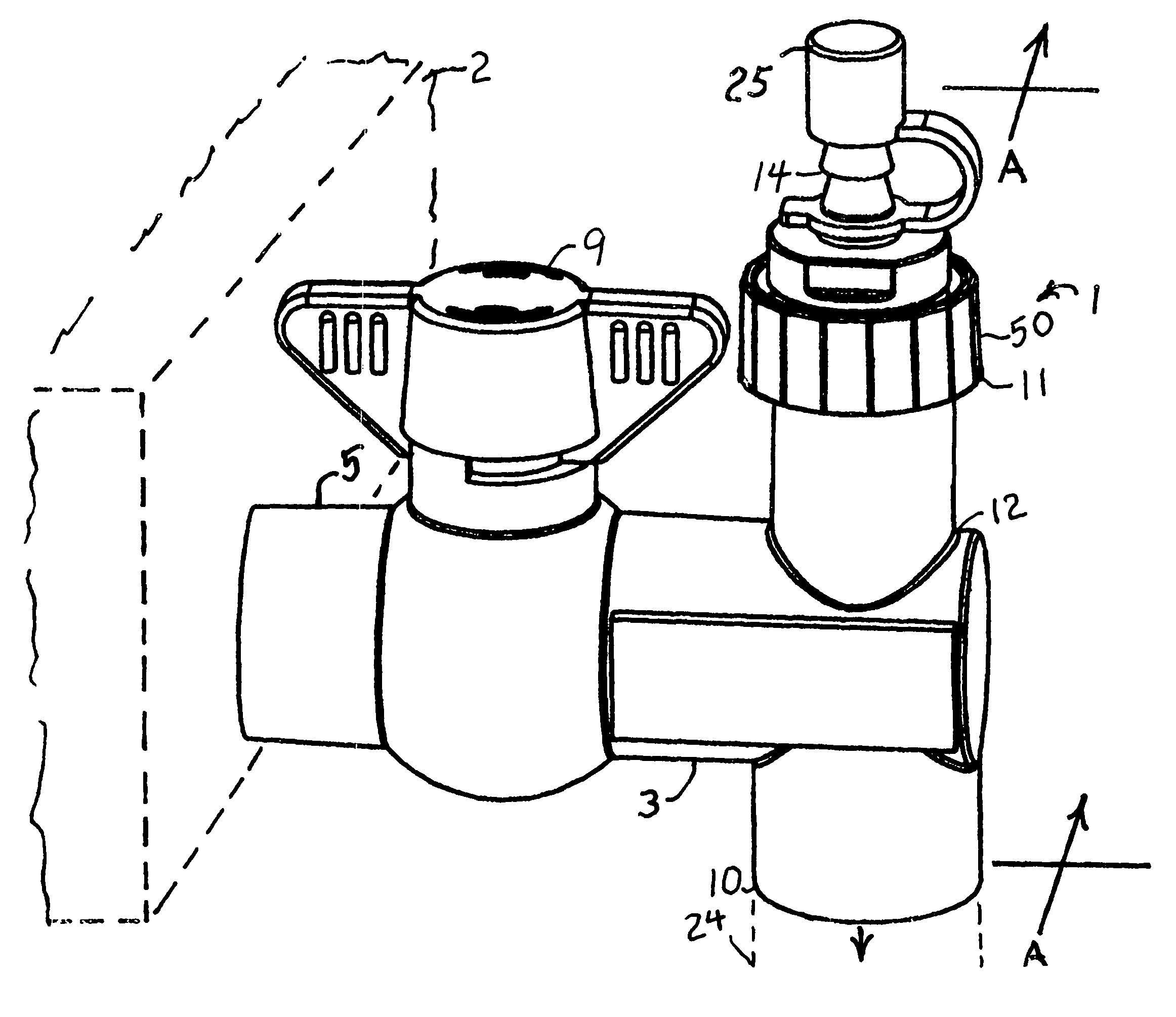

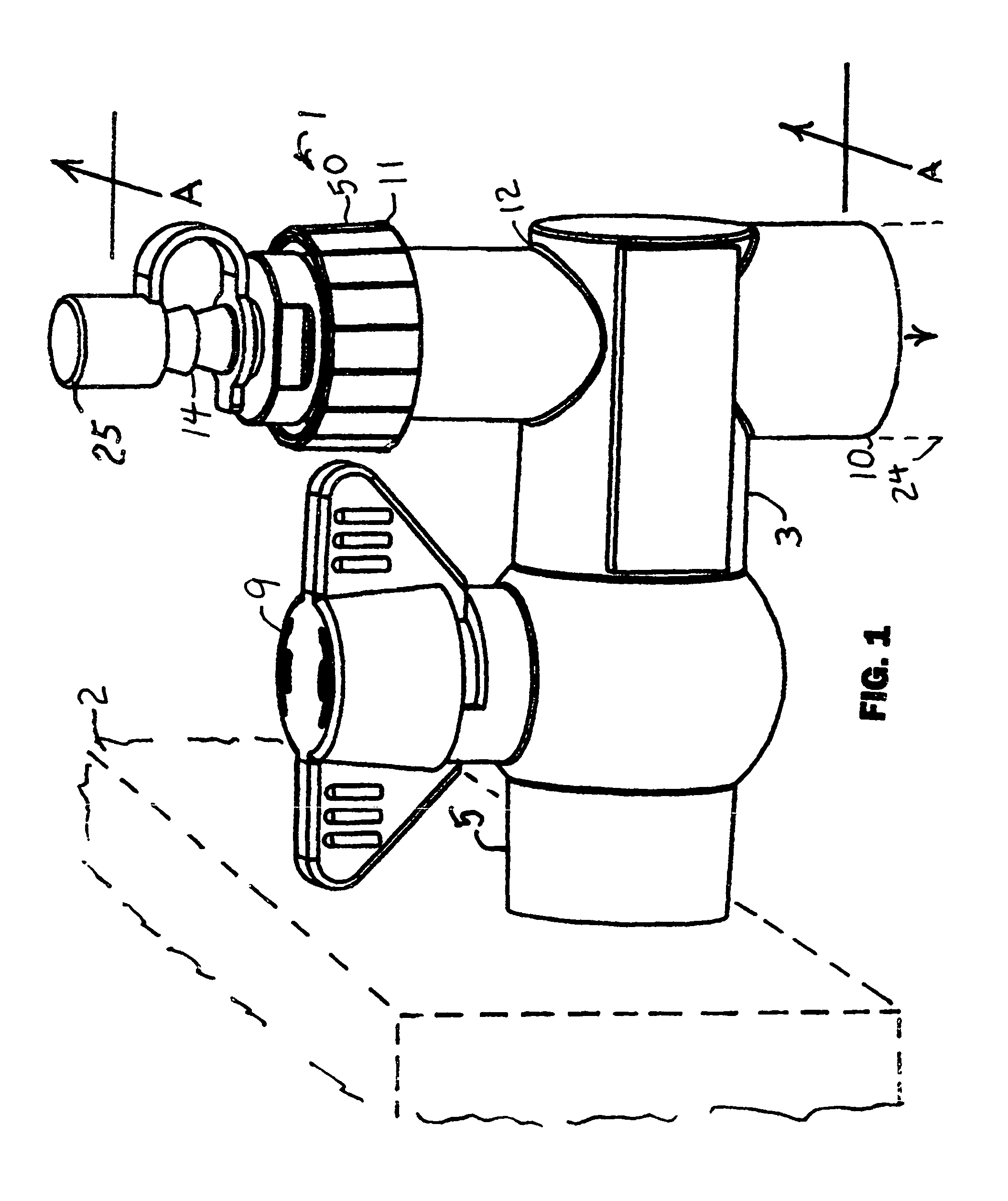

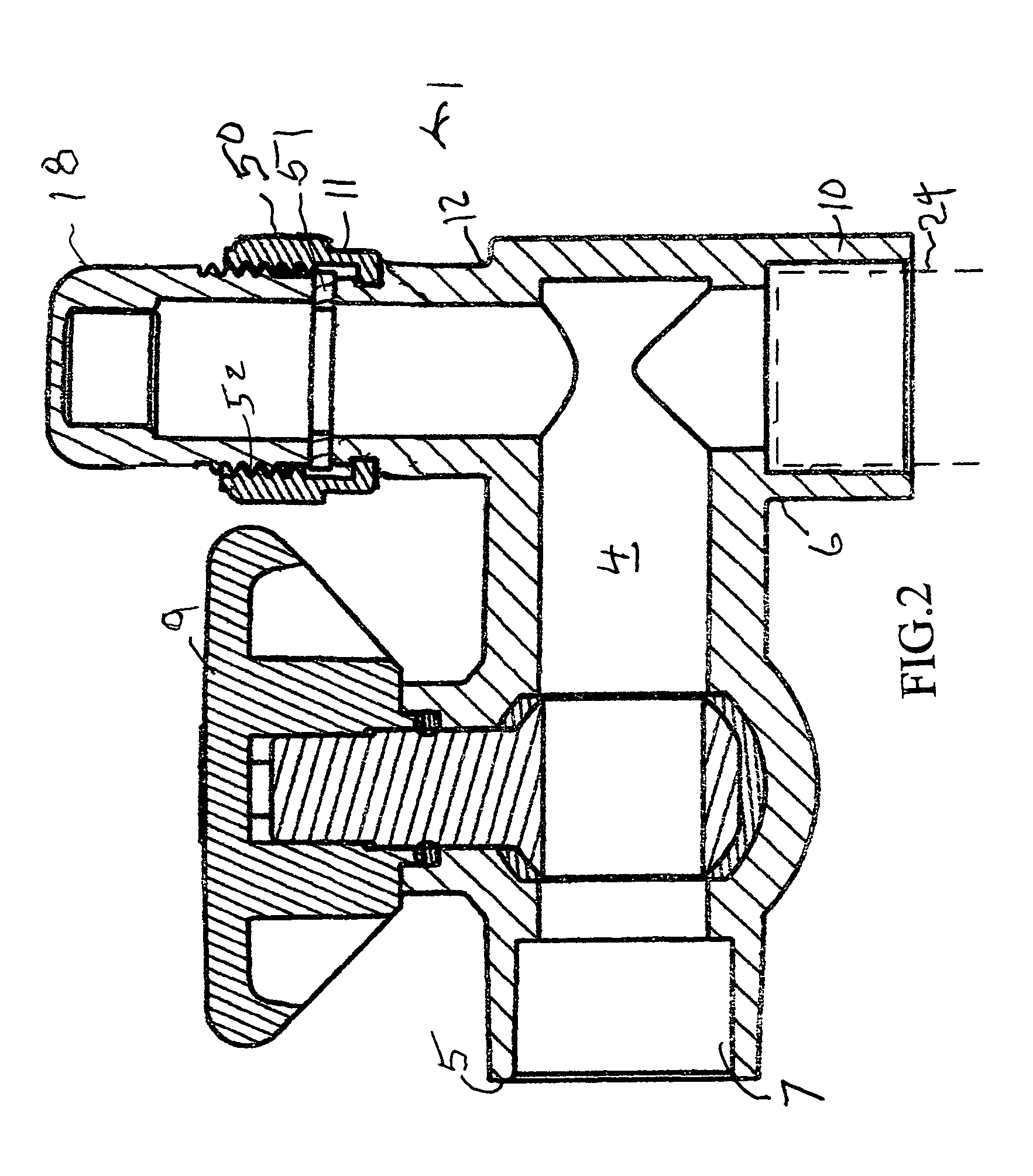

Refrigeration condensate line connectors

InactiveUS8156956B1Improve conductivityImproves overall sensor functionPlug valvesCondensate preventionNitrogenEngineering

An assembly mounts between the drain pan that collects condensate water from an air conditioner and the drain line. It includes a housing with a first end connected to the pan. A second end connects to the drain line. A shut off valve shuts off the passage to the pan while maintenance is performed. A connector is mounted on the housing between the valve and the second end. It is a female member of a water hose coupling. A male member of the coupling may be screwed in to seal it in place. Male members may have different terminations at a second end, including a barbed tube for resilient tubing, a compressed air tire valve for delivering gas, a compressed nitrogen coupling, a tapered funnel for the nozzle of vacuum / blower, and a water sensor.

Owner:COOGLE GREGORY

Vehicle air conditioner with defrosting operation of exterior heat exchanger

InactiveUS6725679B2Solve the power is smallAvoid insufficient heatingMechanical apparatusAir-treating devicesEngineeringThermal water

In a vehicle air conditioner with a heat pump cycle having an interior heat exchanger and an exterior heat exchanger, when a frosting on a surface of the exterior heat exchanger is determined and when a temperature of hot water supplied to a heater core is equal to or higher than a predetermined temperature, the exterior heat exchanger is defrosted in a defrosting operation. Accordingly, the defrosting operation can be performed while a sufficient heating can be obtained.

Owner:DENSO CORP

Evaporator

InactiveUS20070084589A1Improve performanceHigh strengthStationary conduit assembliesStationary tubular conduit assembliesEngineeringRefrigerant

In an evaporator, each fin is disposed between adjacent tubes in a tube stacking direction, and each of the tubes includes at least first and second tube parts lined to have a space therebetween in a flow direction of air passing between the adjacent tubes. The first tube part has therein a first refrigerant passage that is completely separately from a second refrigerant passage of the second tube part. Furthermore, the fin has at least one open portion that is opened from an end of the fin in the tube stacking direction to a predetermined portion, and the open portion is provided in the fin except for a position in the air flow direction, corresponding to the space. Therefore, the strength of the evaporator can be increased while condensed water on the evaporator can be effectively drained.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com