Evaporator

a technology of evaporator and evaporator body, which is applied in the direction of ice removal, stationary conduit assembly, tubular elements, etc., can solve the problems of easy generation of vibration noise due to refrigerant flow, and achieve the effect of increasing the strength of the evaporator and improving the performance of water draining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

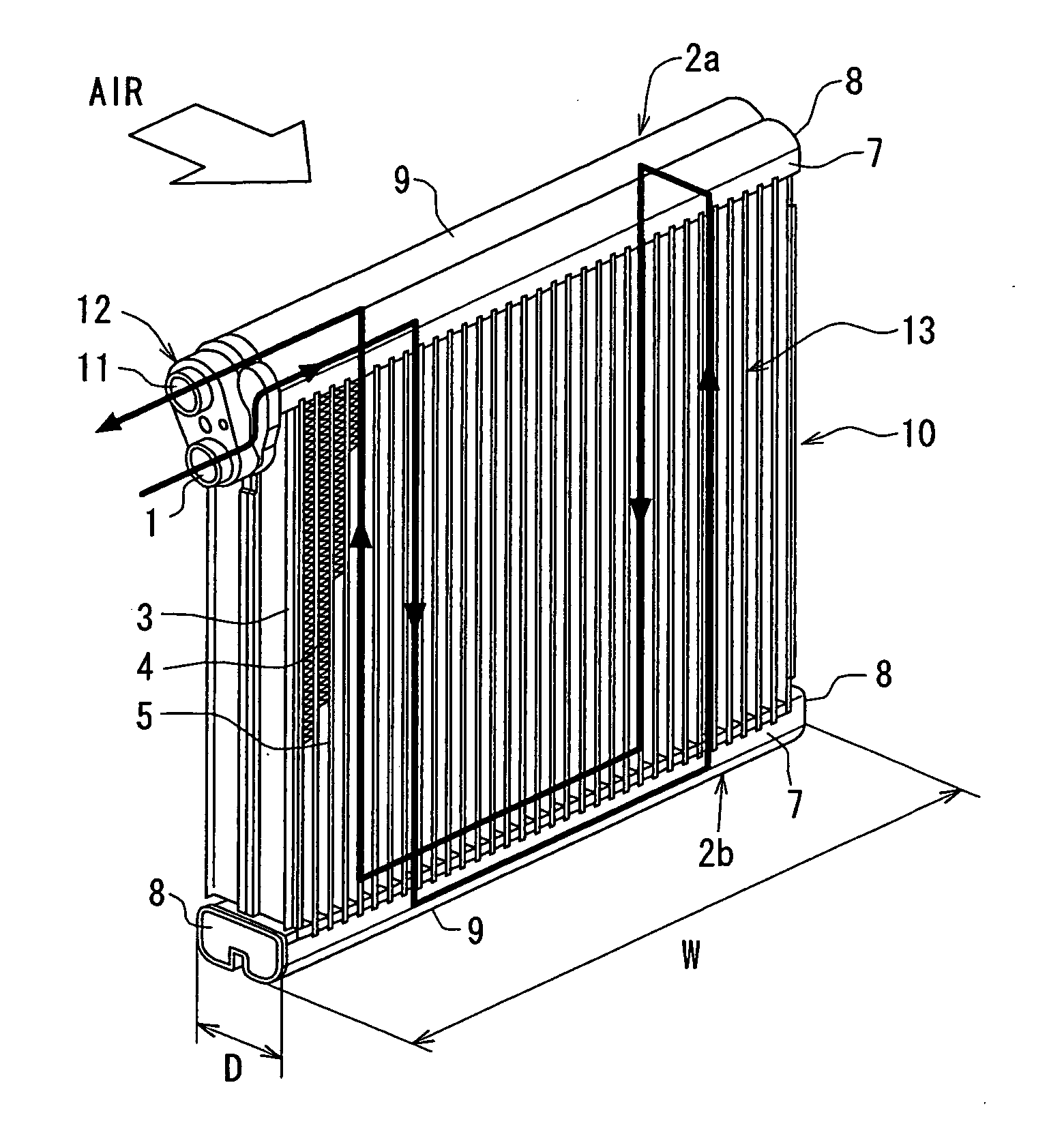

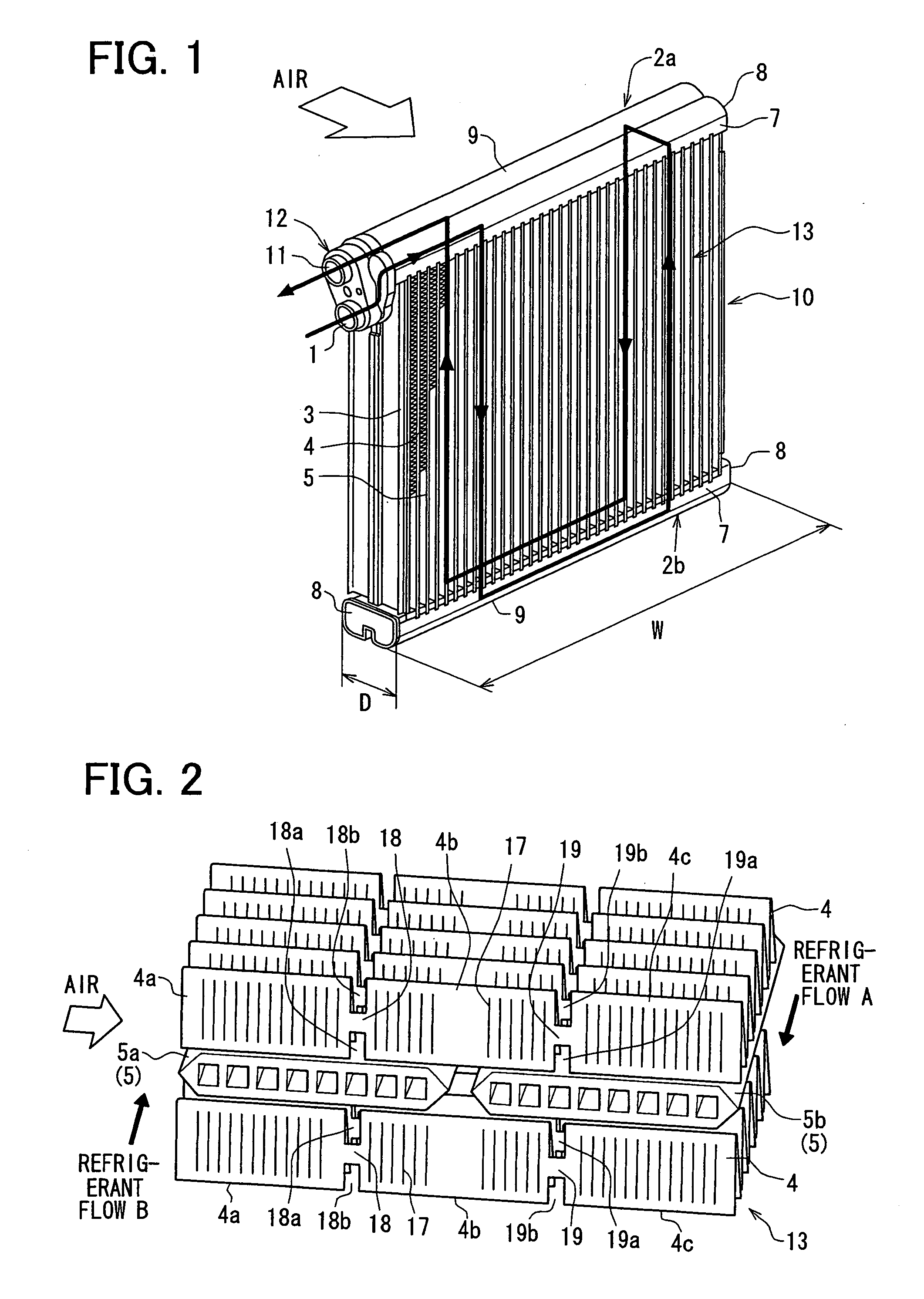

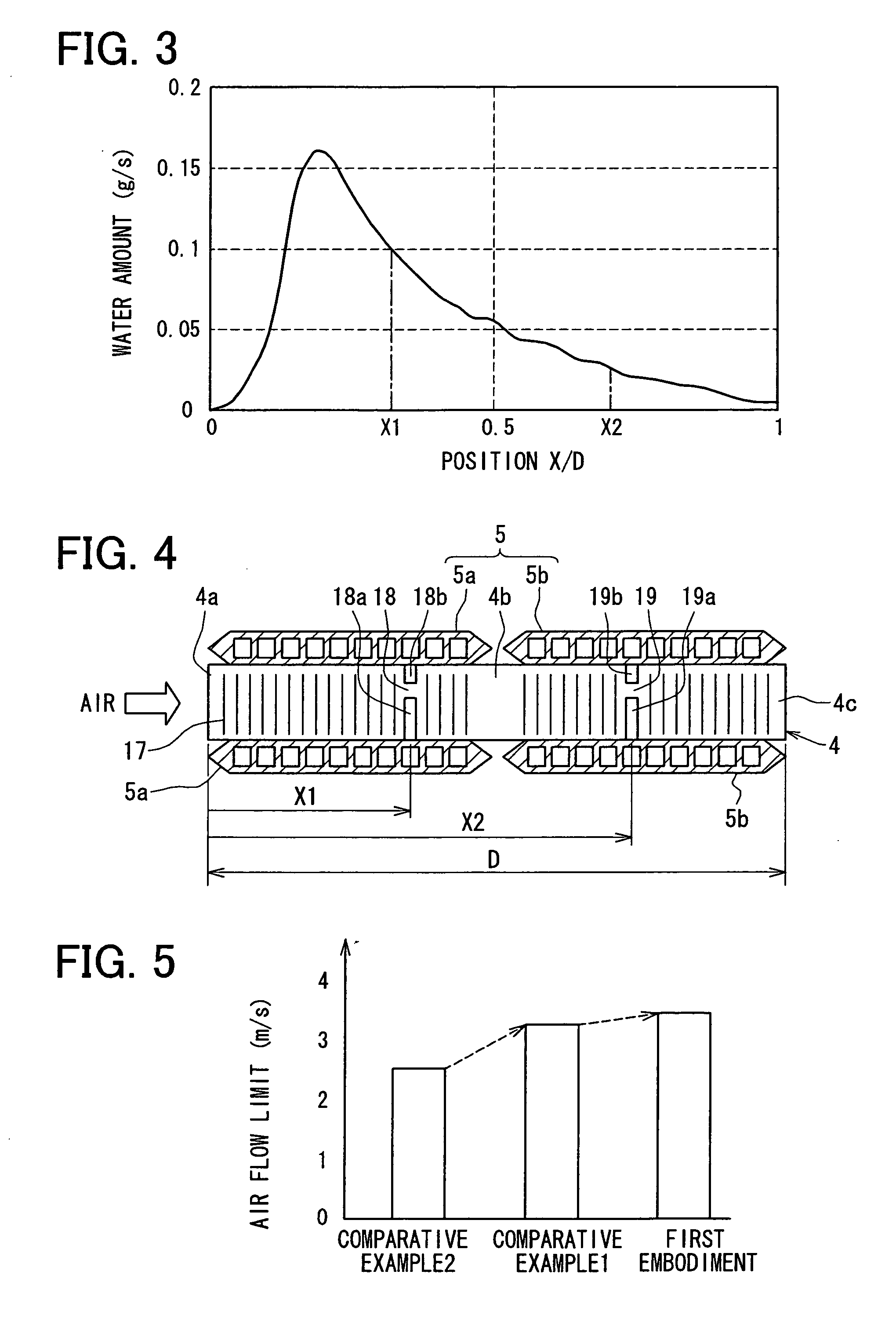

[0023] The first embodiment will be now described with reference to FIGS. 1-6. An evaporator 10 of the first embodiment is generally used in a state shown in FIG. 1, and performs heat exchange between refrigerant flowing therein and air passing therethrough.

[0024] The evaporator 10 is a part of a refrigerant cycle device that is constructed with a compressor, a refrigerant radiator, an expansion valve, etc., together with the evaporator 10. Generally, refrigerant decompressed by the expansion valve flows into the evaporator 10 from a refrigerant inlet portion 1. The refrigerant flowing into the refrigerant inlet portion 1 flows through all refrigerant paths of the evaporator 10 as in the arrows shown in FIG. 1, and then flows out of the evaporator 10 through a refrigerant outlet portion 11. Refrigerant decompressed in the expansion valve is evaporated while passing through the refrigerant paths of the core portion 13 of the evaporator 10, so that evaporated gas refrigerant flows ou...

second embodiment

[0055] The second embodiment of the present invention will be now described with reference to FIG. 7. In the second embodiment, a fin 22 is used instead of the fin 4 described in the first embodiment, and the other parts are similar to those of the above-described first embodiment. Here, the fin 22 is mainly described.

[0056] The fin 22 fixed to the tubes 5a, 5b is provided in air flow direction as shown in FIG. 7, and. is formed into a wave shape extending in the tube longitudinal direction from the first header tank 2a to the second header tank 2b. Similarly to the above-described first embodiment, plural fins 22 and the tubes 55a, 5b (5) are stacked alternately in the tube stacking direction and are brazed to form a core portion.

[0057] The fin 22 has first and second clearance portions 24, 25 each of which extends from one ridge portion of the wave-shaped fin 22 to another ridge portion of the wave-shaped fin 22 between adjacent tubes in the tube stacking direction. Therefore, t...

third embodiment

[0061] The third embodiment of the present invention will be now described with reference to FIG. 8. In the third embodiment, a fin 26 is used instead of the fin 4 described in the first embodiment, and the other parts are similar to those of the above-described first embodiment. In the third embodiment, plural slits 27a, 27b, 28a, 28b are provided at plural positions in the upstream air side area of the fin 26, upstream from the space portion between the tubes 5a, 5b in the air flow direction.

[0062] As shown in FIG. 8, the fin 26 is separated into first, second and third fin parts 26a, 26b, 26c. Specifically, the first and second fin parts 26a, 26b are partially separated from each other by first slits 27a, 27b, and the second and third fin parts 26b, 26c are partially separated from each other by second slits 28a, 28b. The first and second fin parts 26a, 26b are connected to each other by a first connection portion 27, and the second and third fin parts 26b, 26c are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com