Patents

Literature

36results about How to "Reduce the amount of condensate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

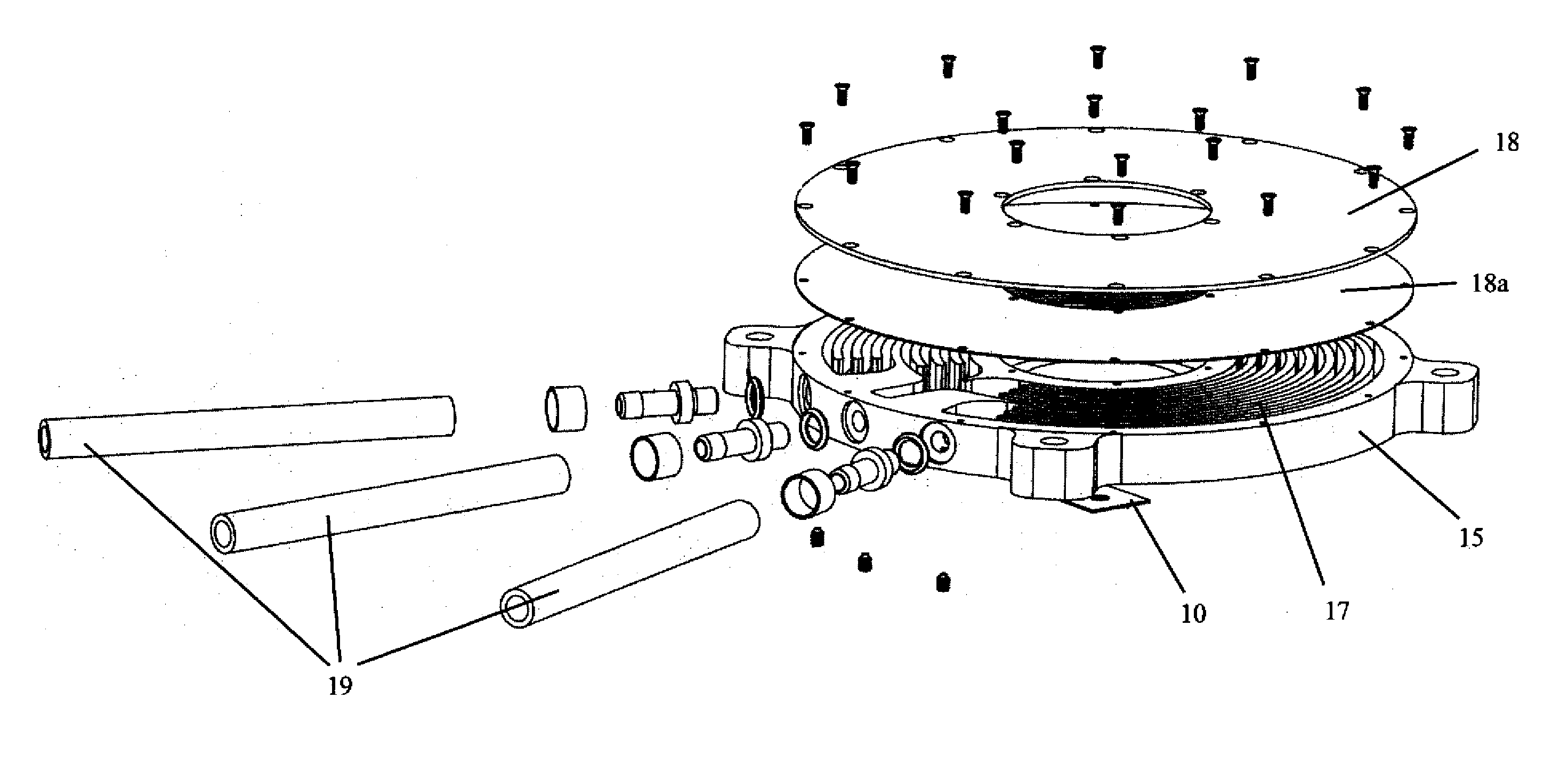

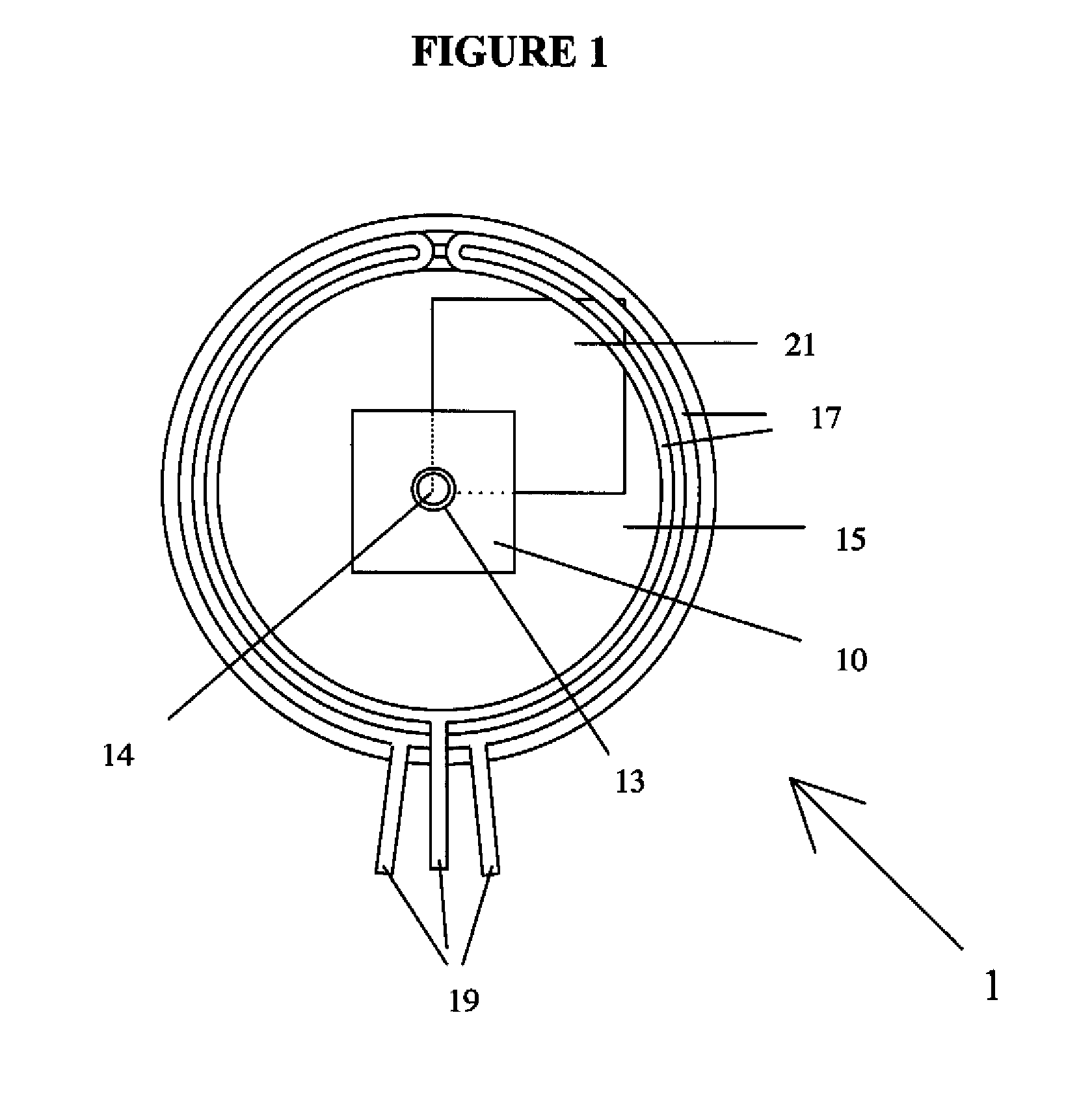

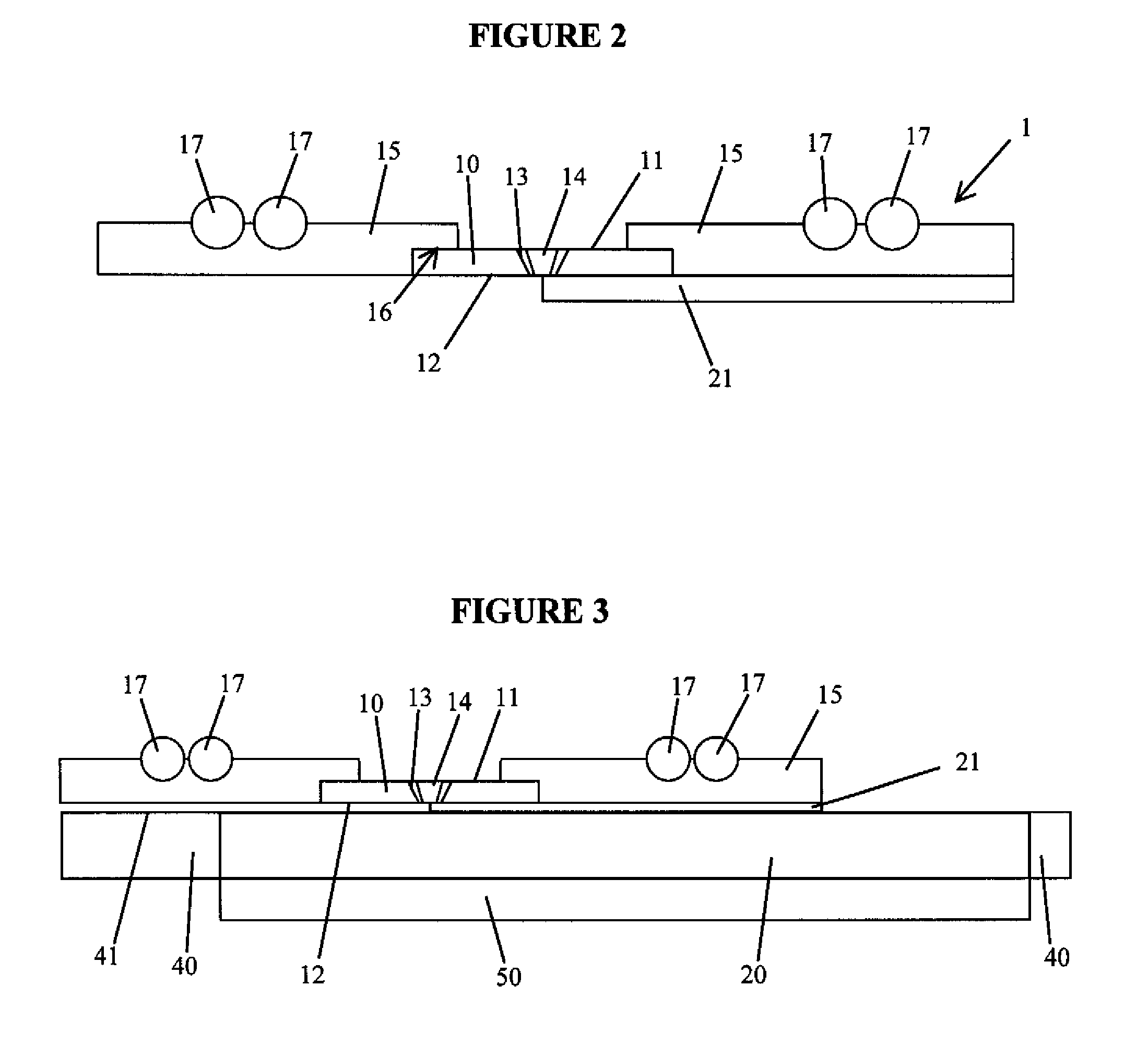

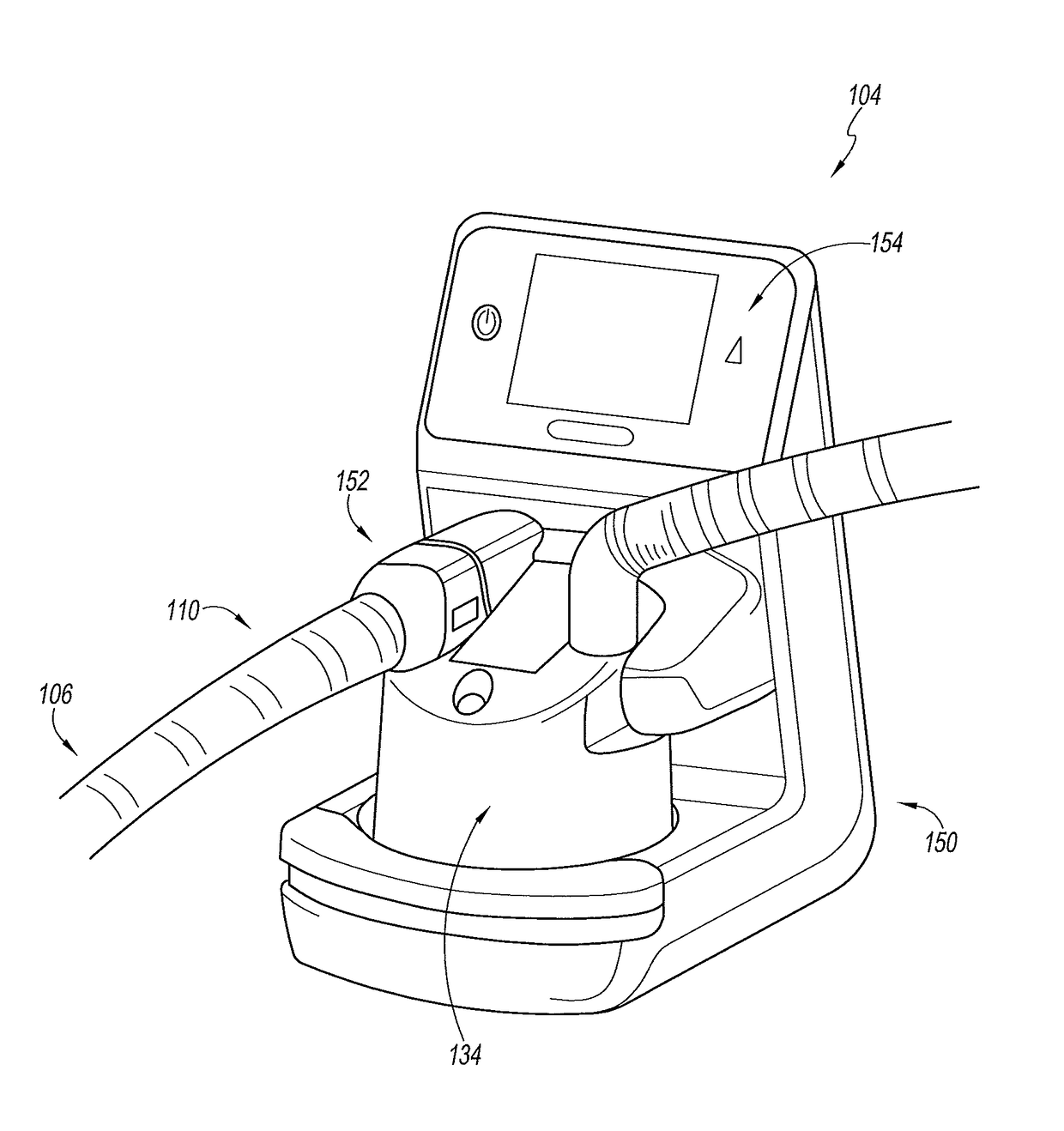

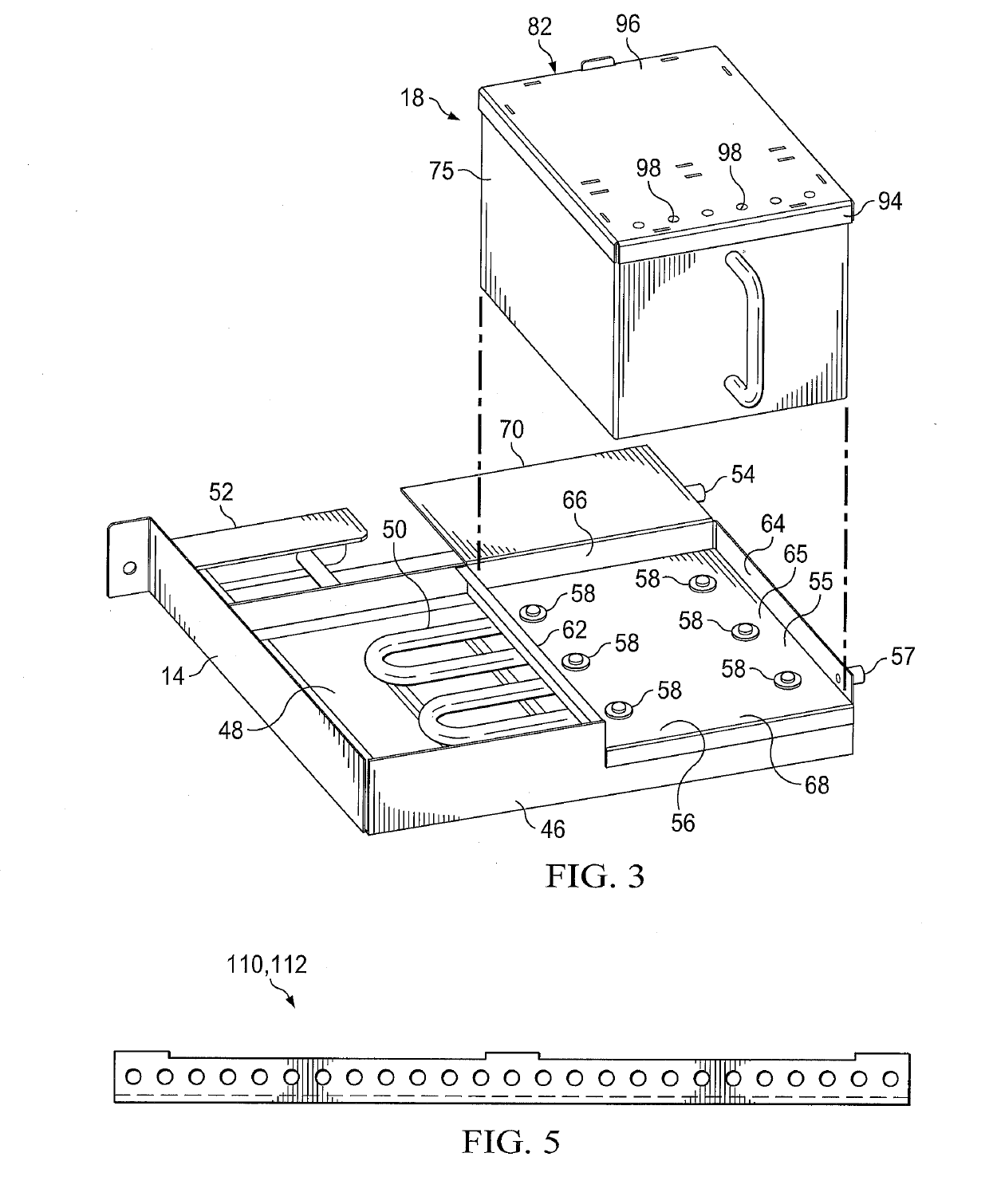

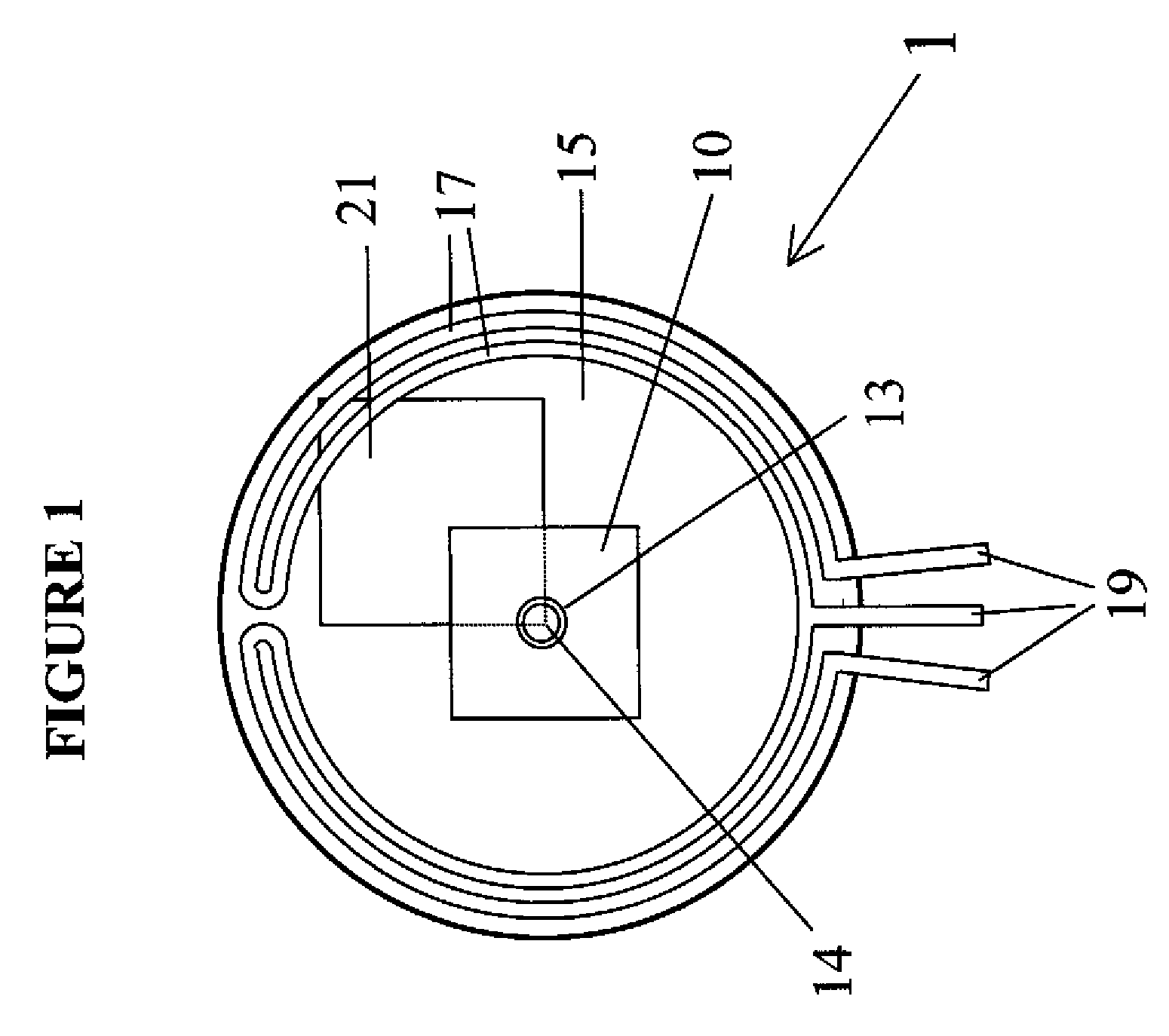

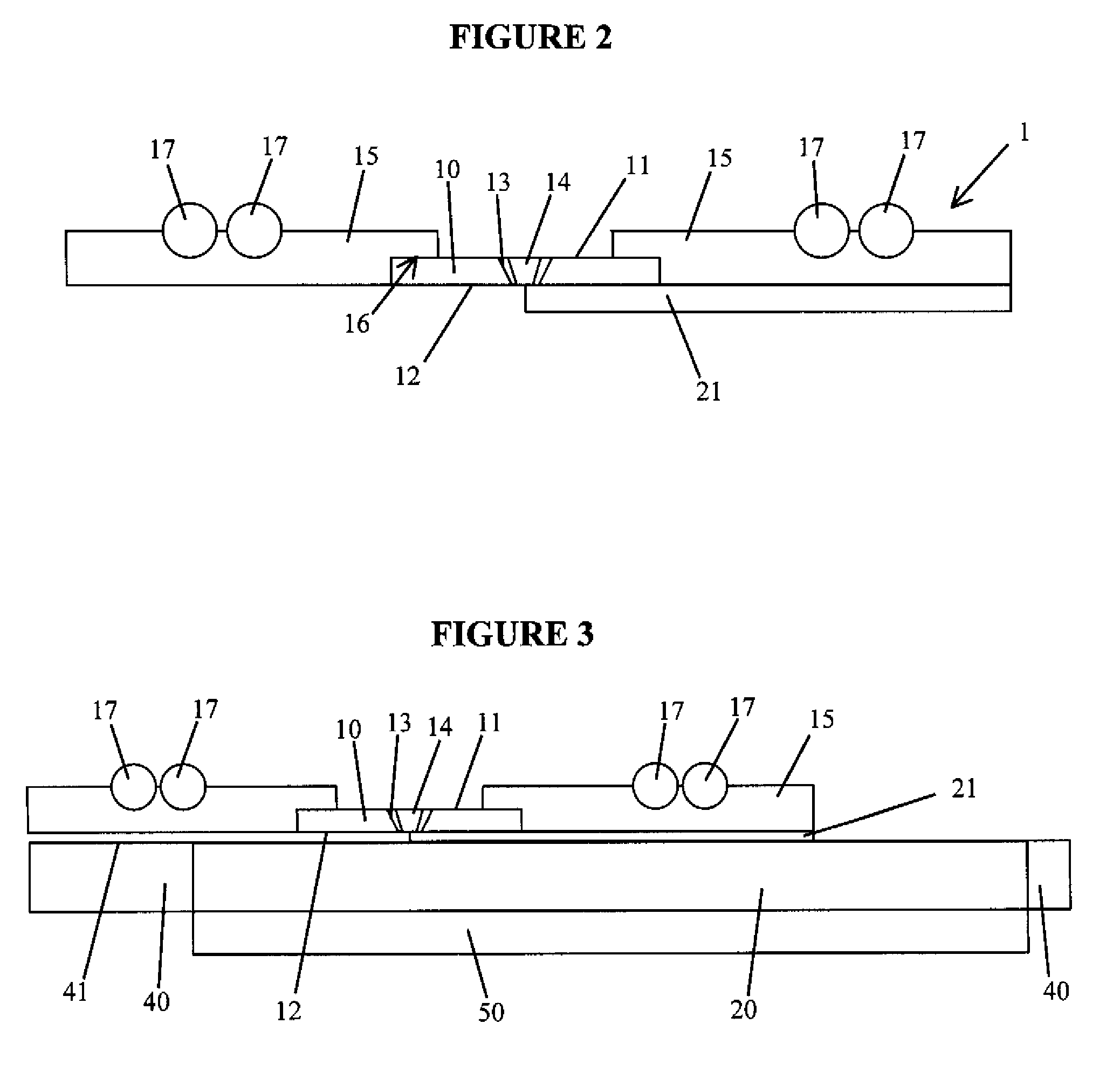

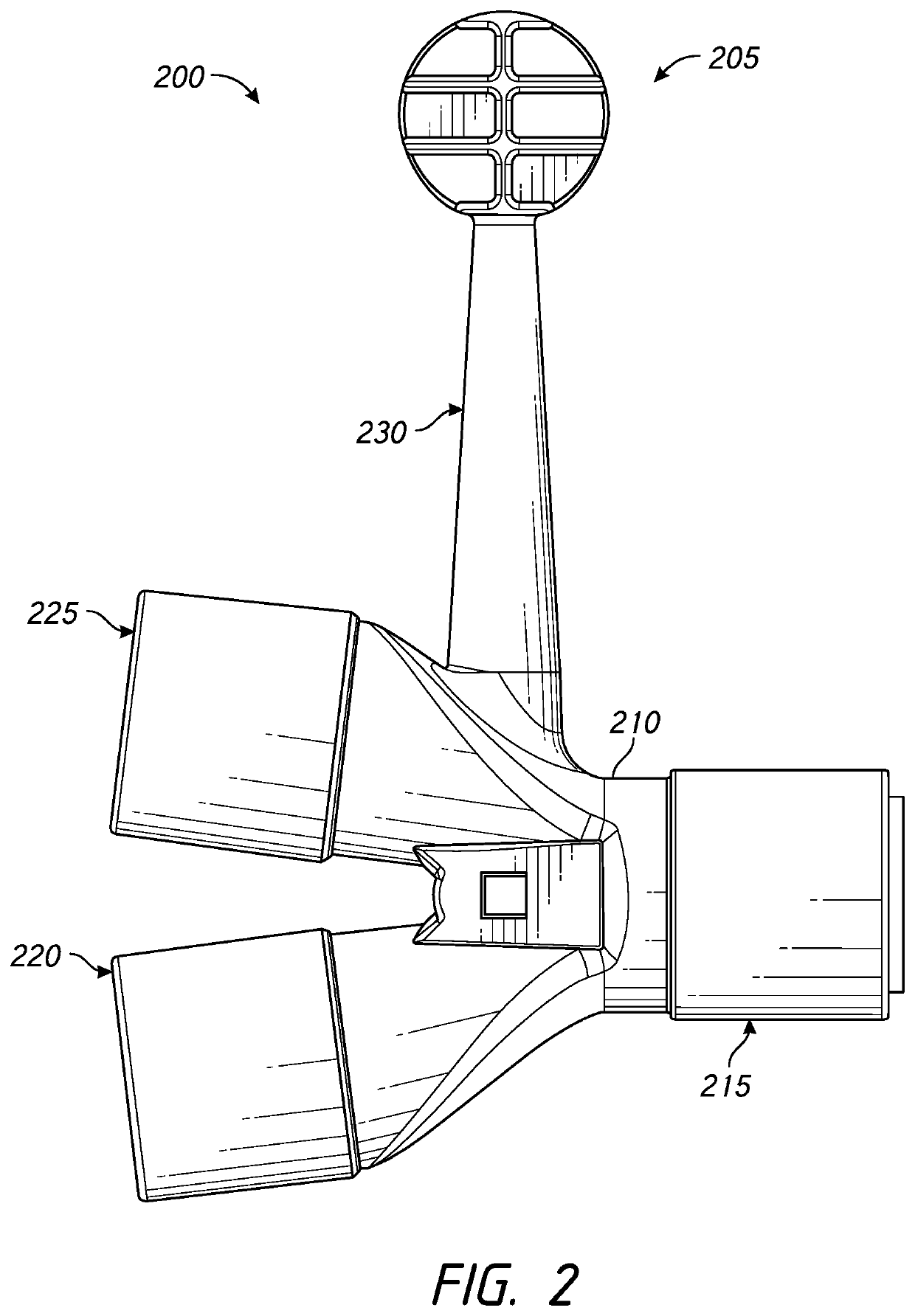

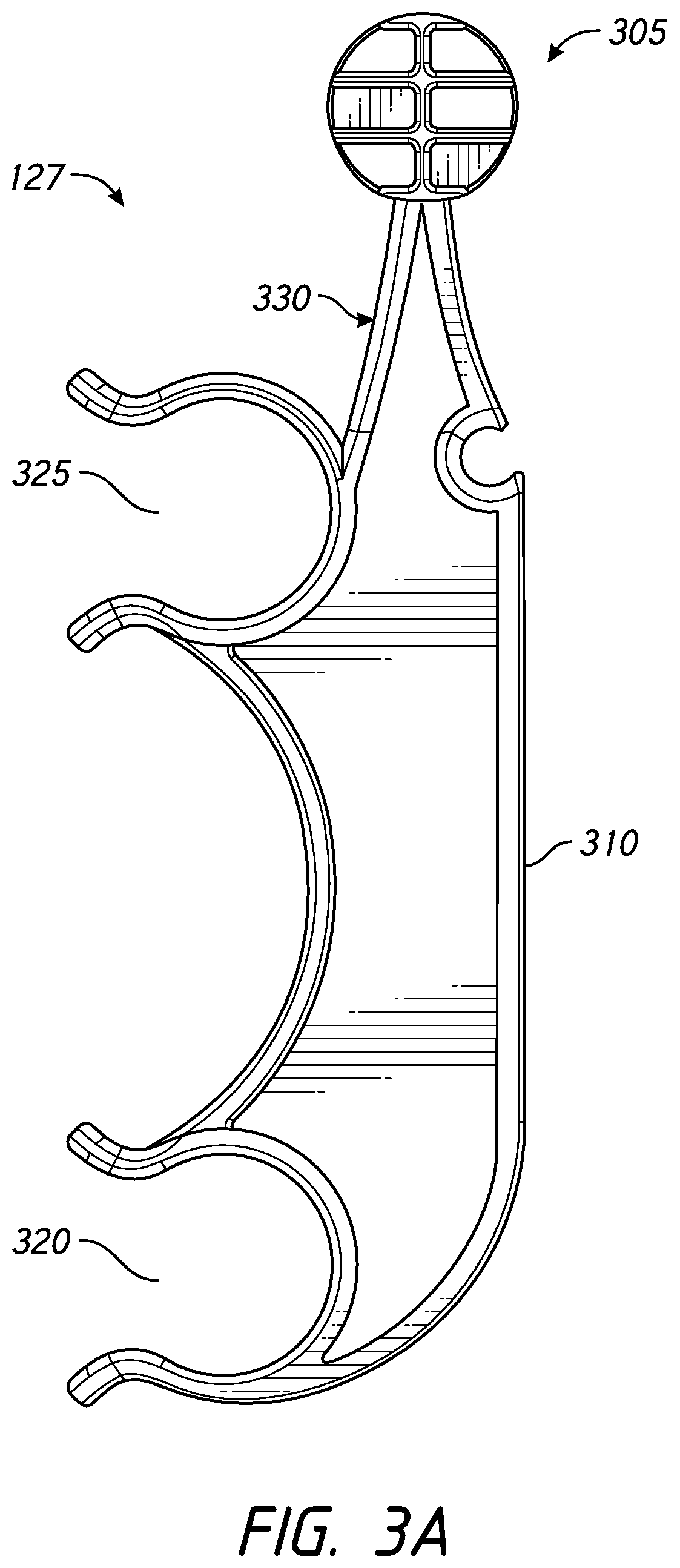

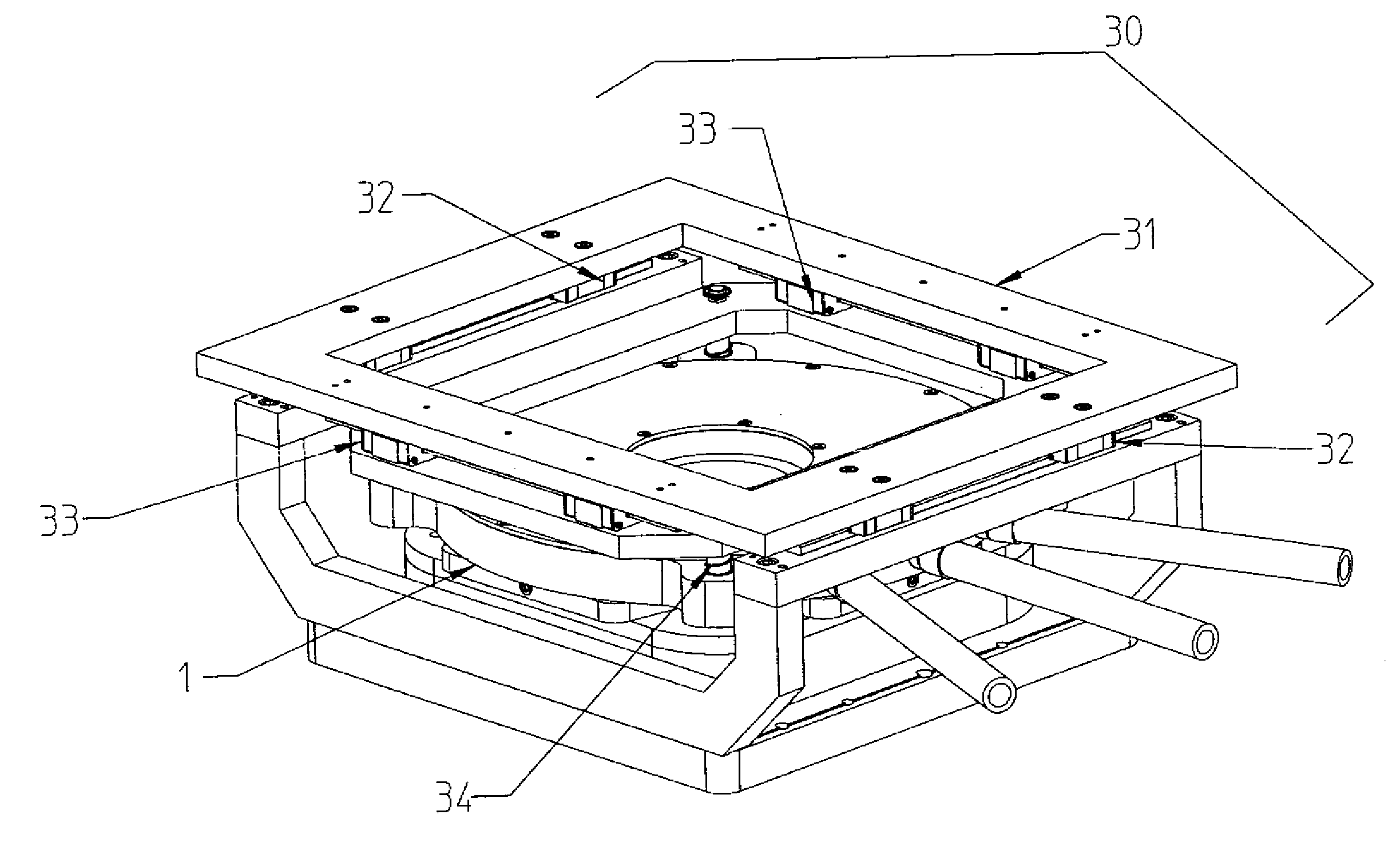

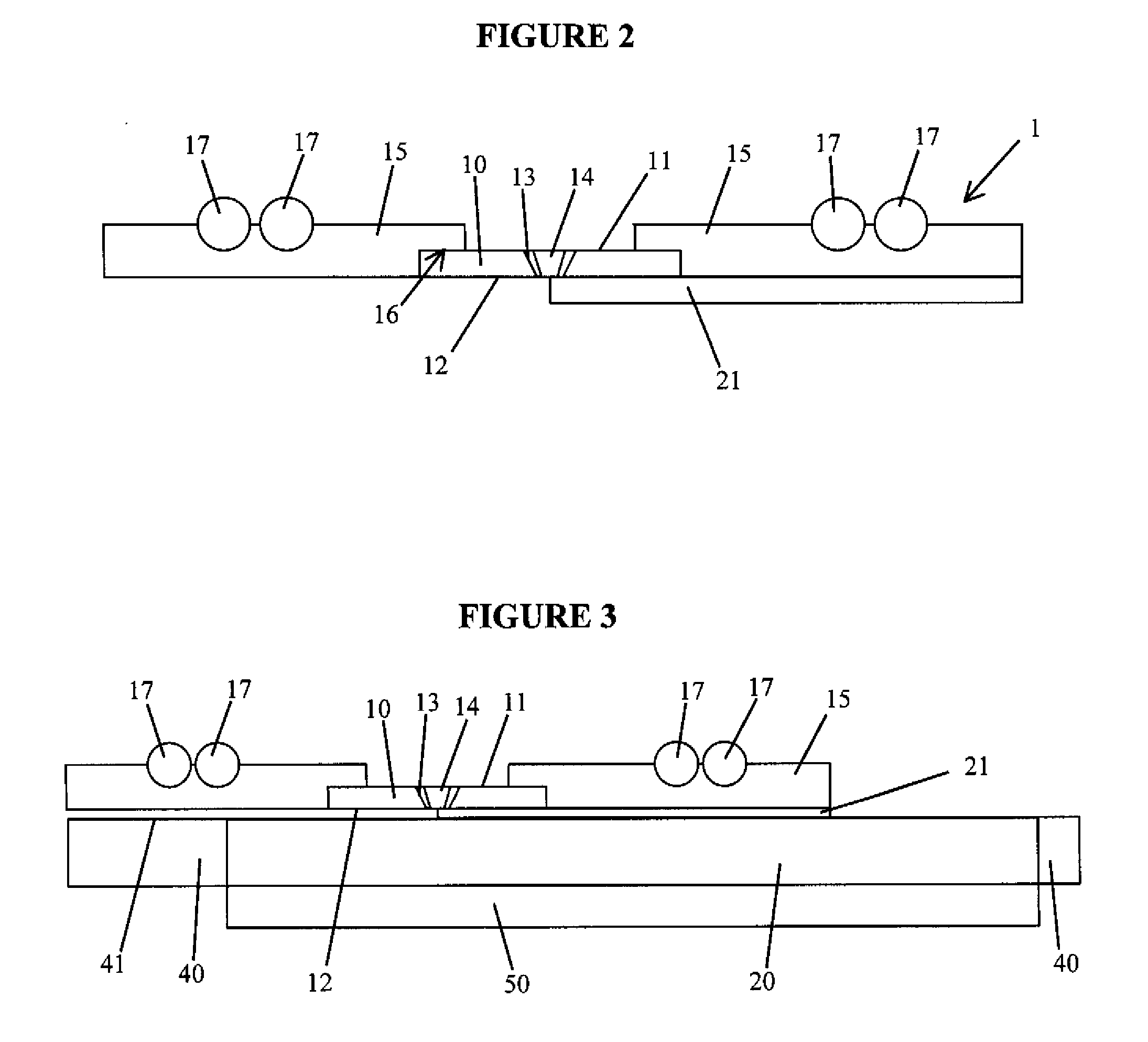

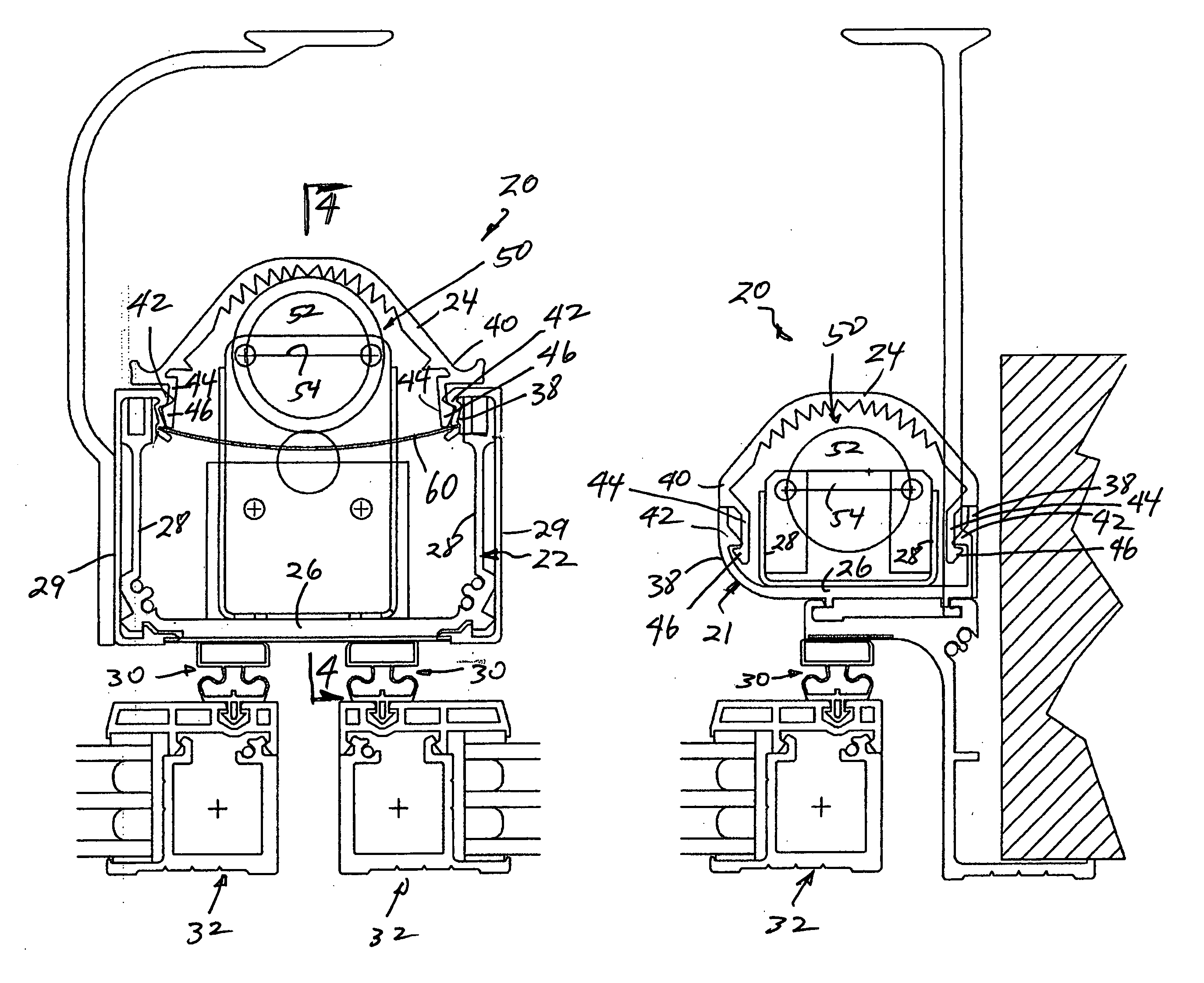

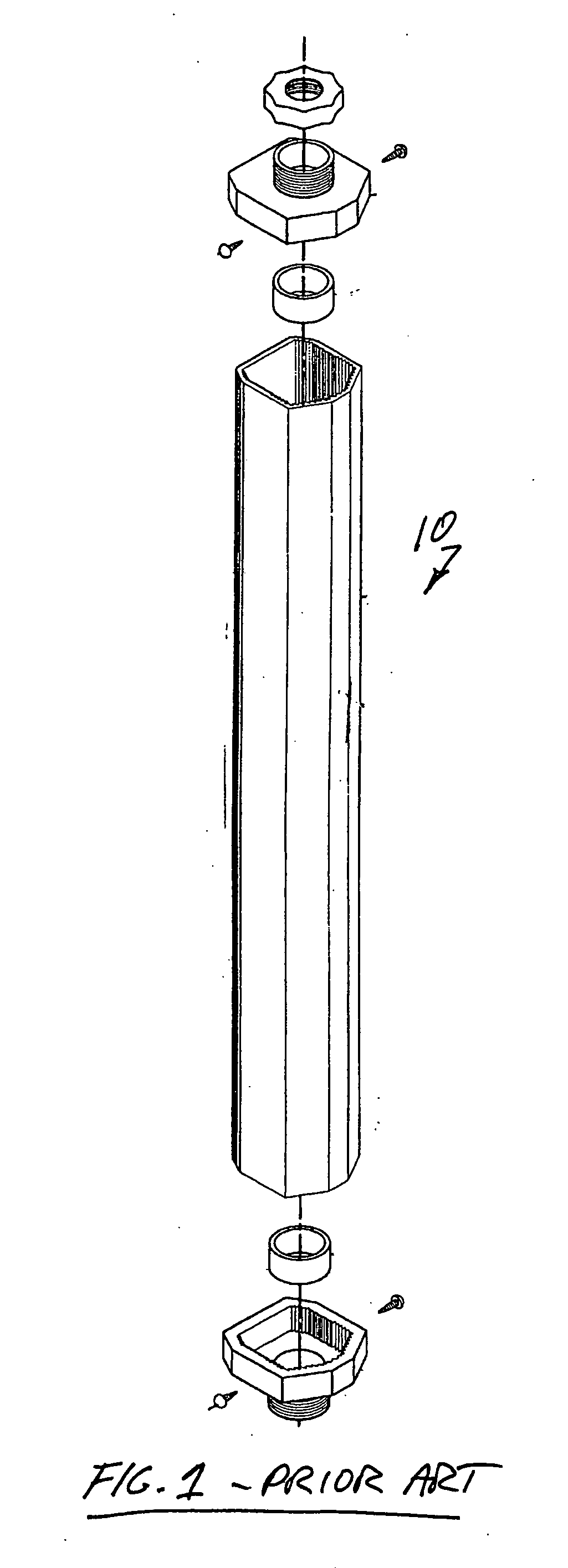

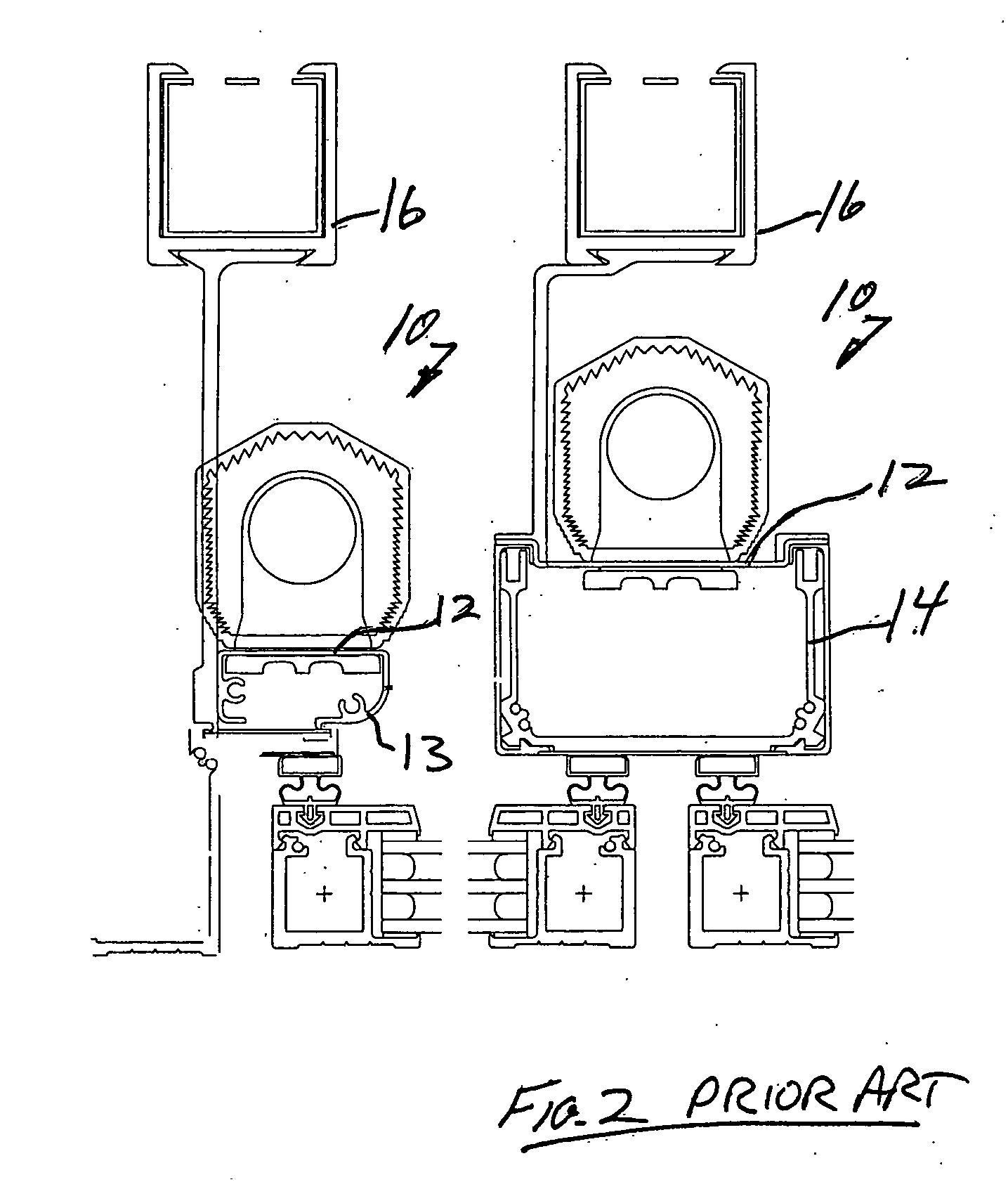

Low profile clamp for use with apparatus for thermal control in the analysis of electronic devices

InactiveUS20090146359A1Eliminate reflection lossReduce frictionPositioning apparatusMetal-working holdersElectronSilicon

A heat spreader comprising a sheet of transparent diamond with an aperture therein that accommodates a solid-immersion lens (SIL). The heat spreader may be mounted within a clamp which allows the heat spreader to move freely across the Device Under Test (DUT) whilst maintaining a very high degree of planarity and contact between the diamond and the silicon substrate of the DUT. The DUT is secured to its electrical interface with a low profile clamp, the DUT may be held within the clamp by a mechanism that applies a pressure to the sides of the DUT package.

Owner:PRESTO ENG

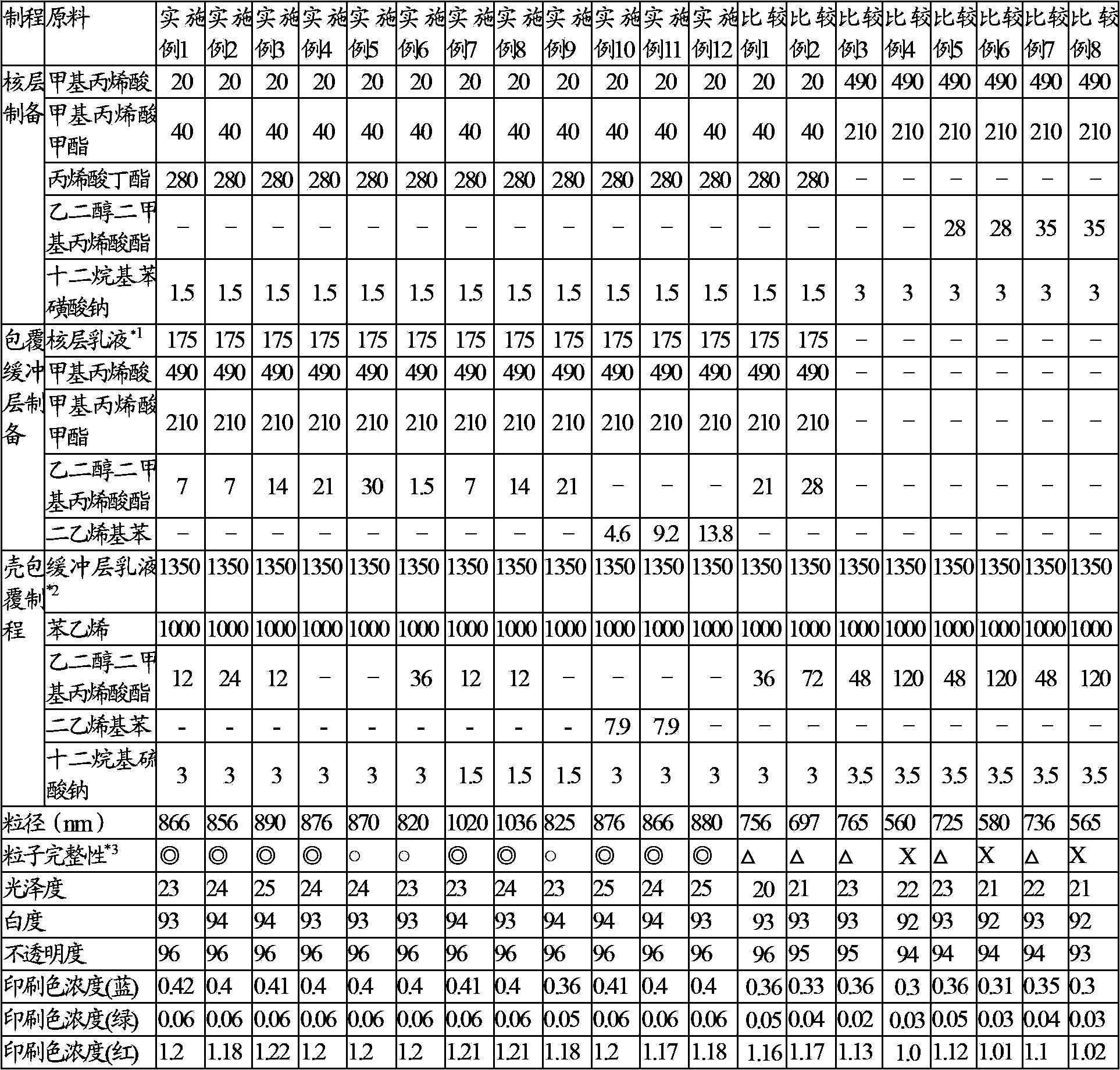

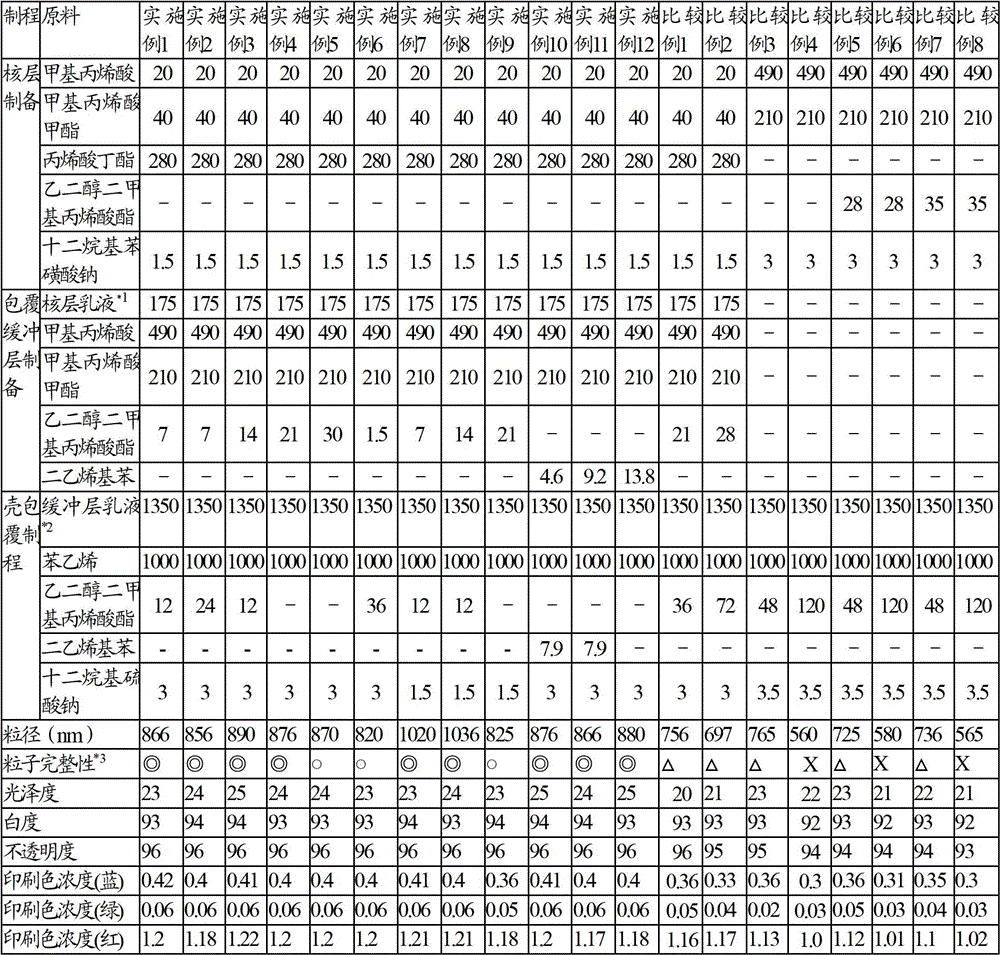

Preparation method of hollow polymer microspheres

ActiveCN103524653AImprove stabilityWell mixedPowdery paintsEmulsion paintsPolymer scienceMicrosphere

The invention discloses a preparation method of hollow polymer microspheres. Hollow particles with buffer layers are prepared by a three-stage reaction process; the hollow particles are complete in structure, uniform in particle diameter, applied to a plastic or a paper coating, high in gloss, whiteness and non-transparency, and have characteristics of good printing color concentration and printing water resistance.

Owner:NANYA PLASTICS CORP

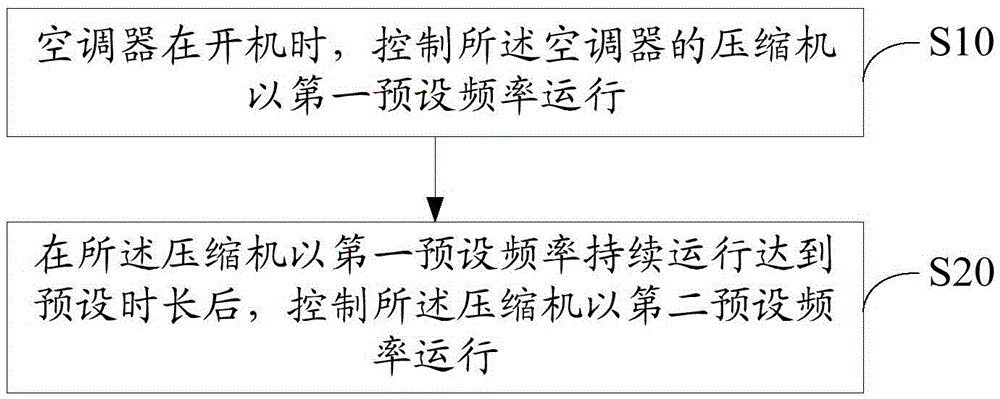

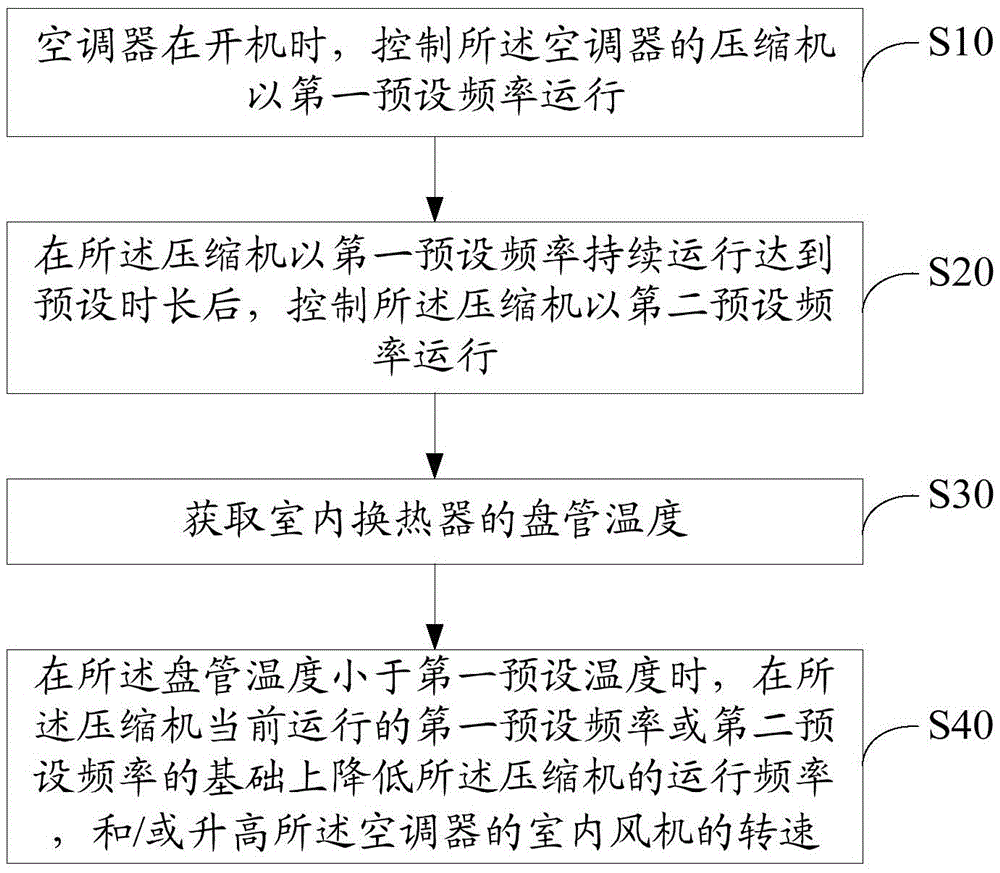

Water blowing prevention control method for air conditioner and air conditioner

InactiveCN105571084AReduce the amount of condensateSpeed up dischargeCondensate preventionSpace heating and ventilation safety systemsControl theoryPrevention control

The invention discloses a water blowing prevention control method for an air conditioner. The water blowing prevention control method comprises the following steps: when the air conditioner is switched on, controlling a compressor of the air conditioner to operate at a first preset frequency; after the compressor is kept operating at the first preset frequency for preset time, controlling the compressor to operate at a second preset frequency, wherein the first preset frequency is smaller than the second preset frequency. The invention further discloses the air conditioner. According to the water blowing prevention control method and the air conditioner, the amount of condensed water produced when the air conditioner is just switched on can be effectively reduced; furthermore, the condensed water discharging speed can be increased after the air conditioner is switched on for preset time, thus effectively preventing the water blowing phenomenon.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

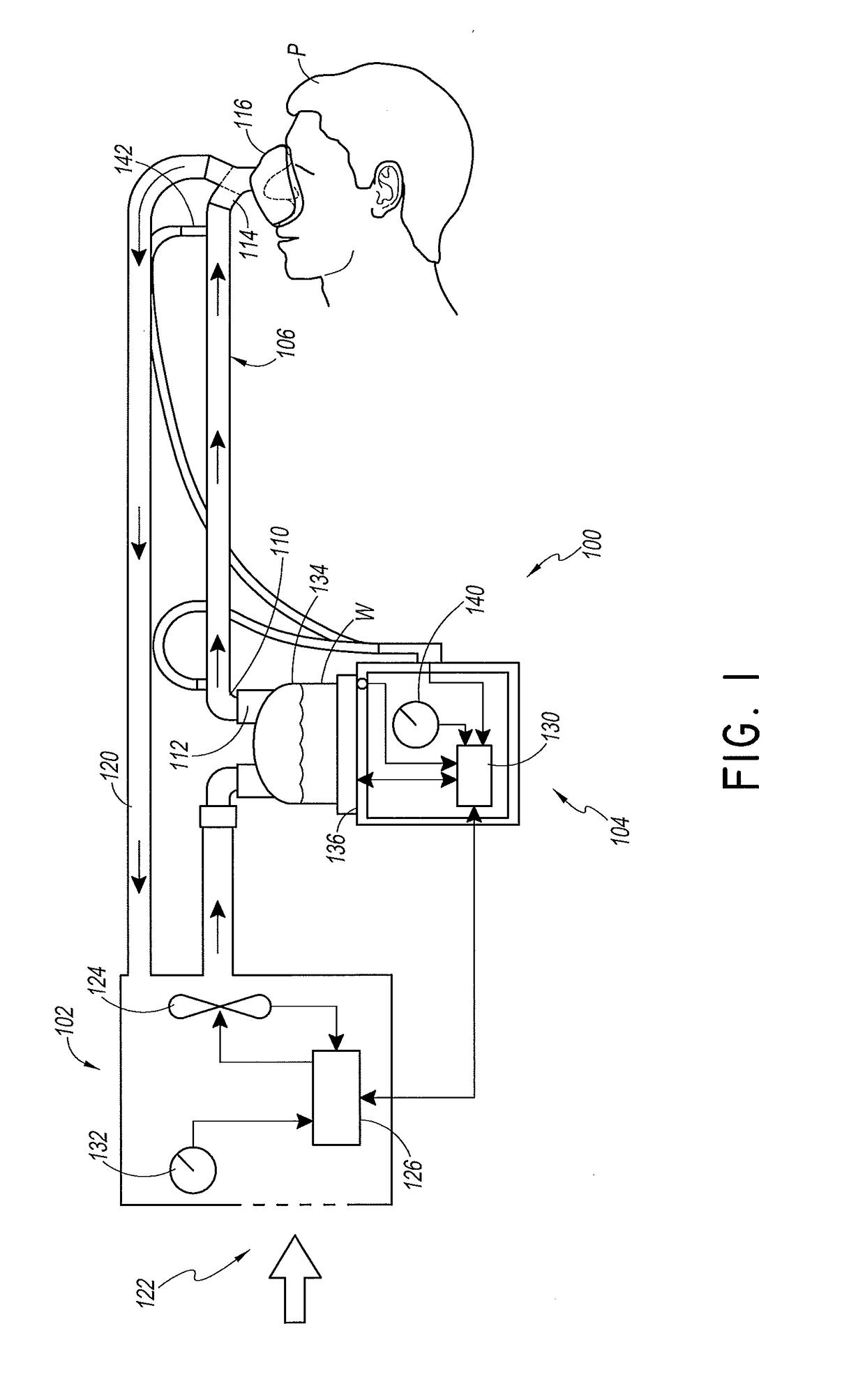

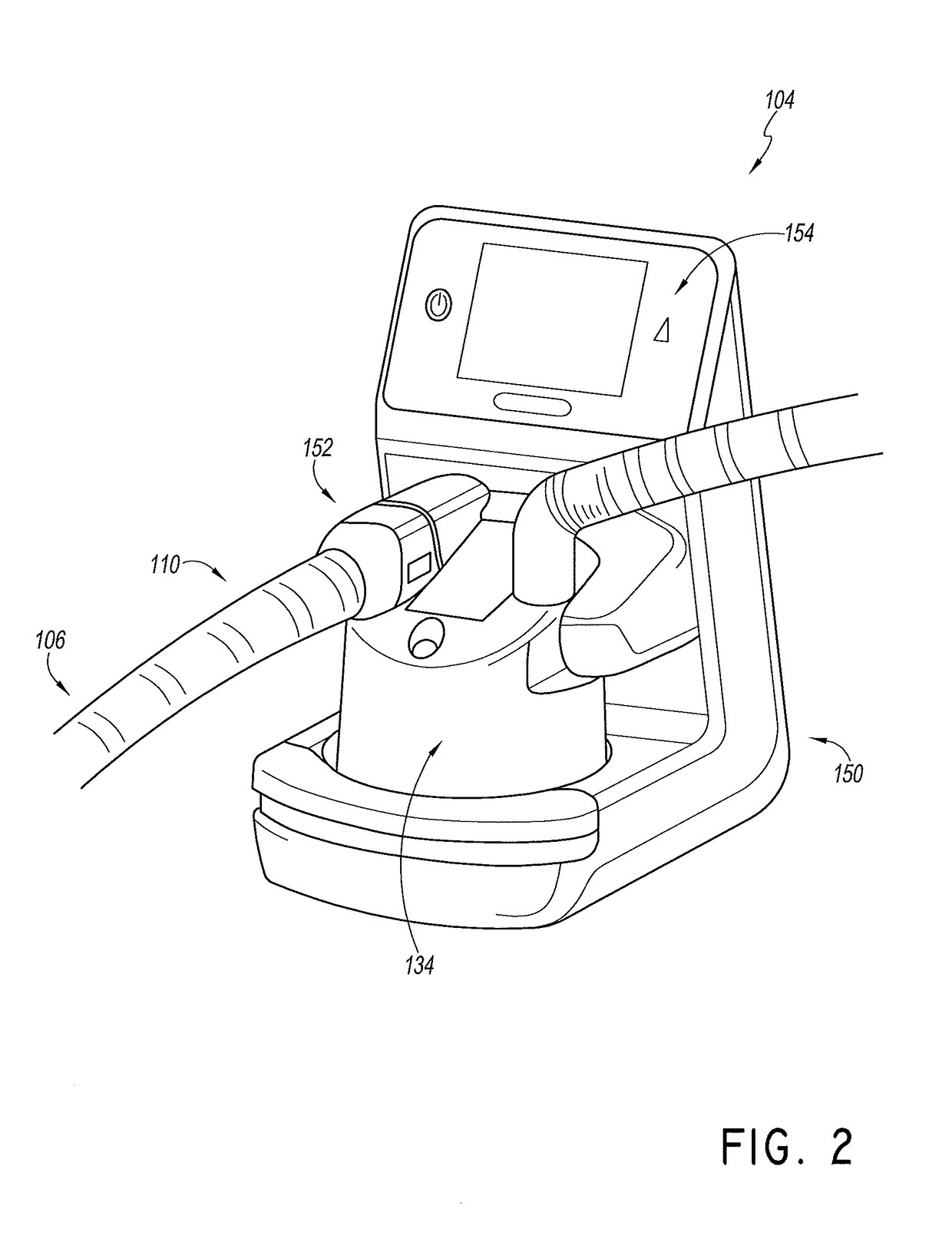

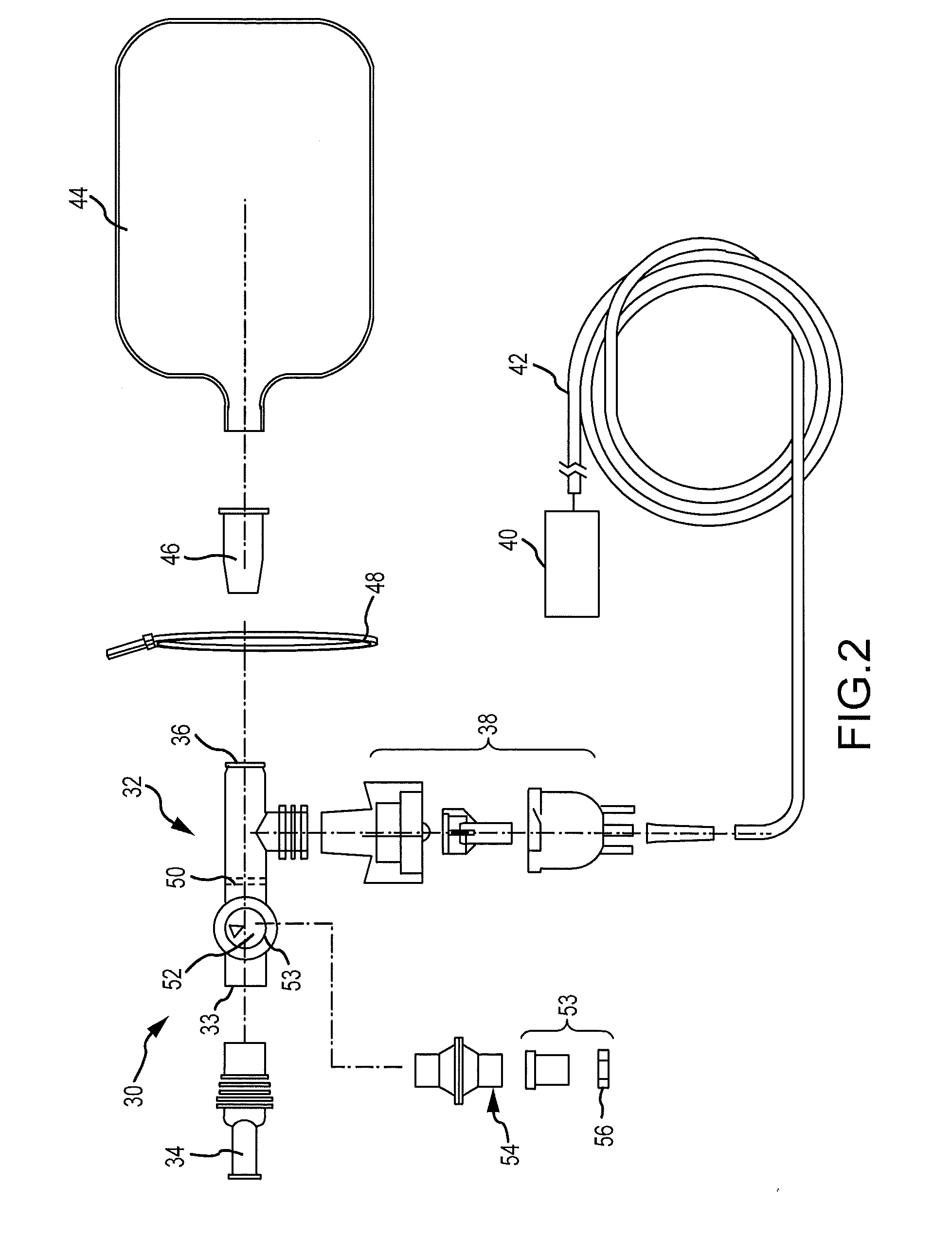

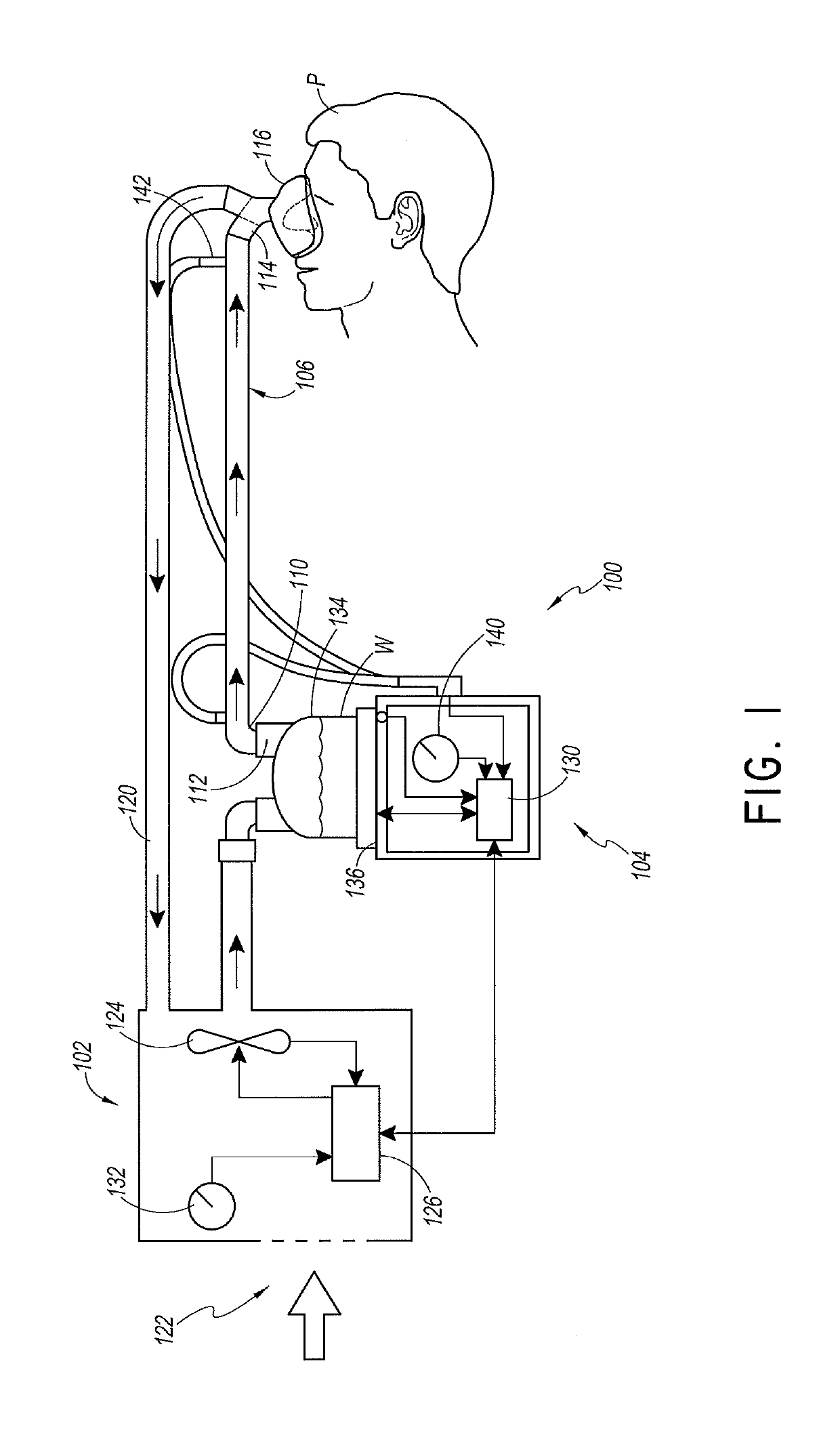

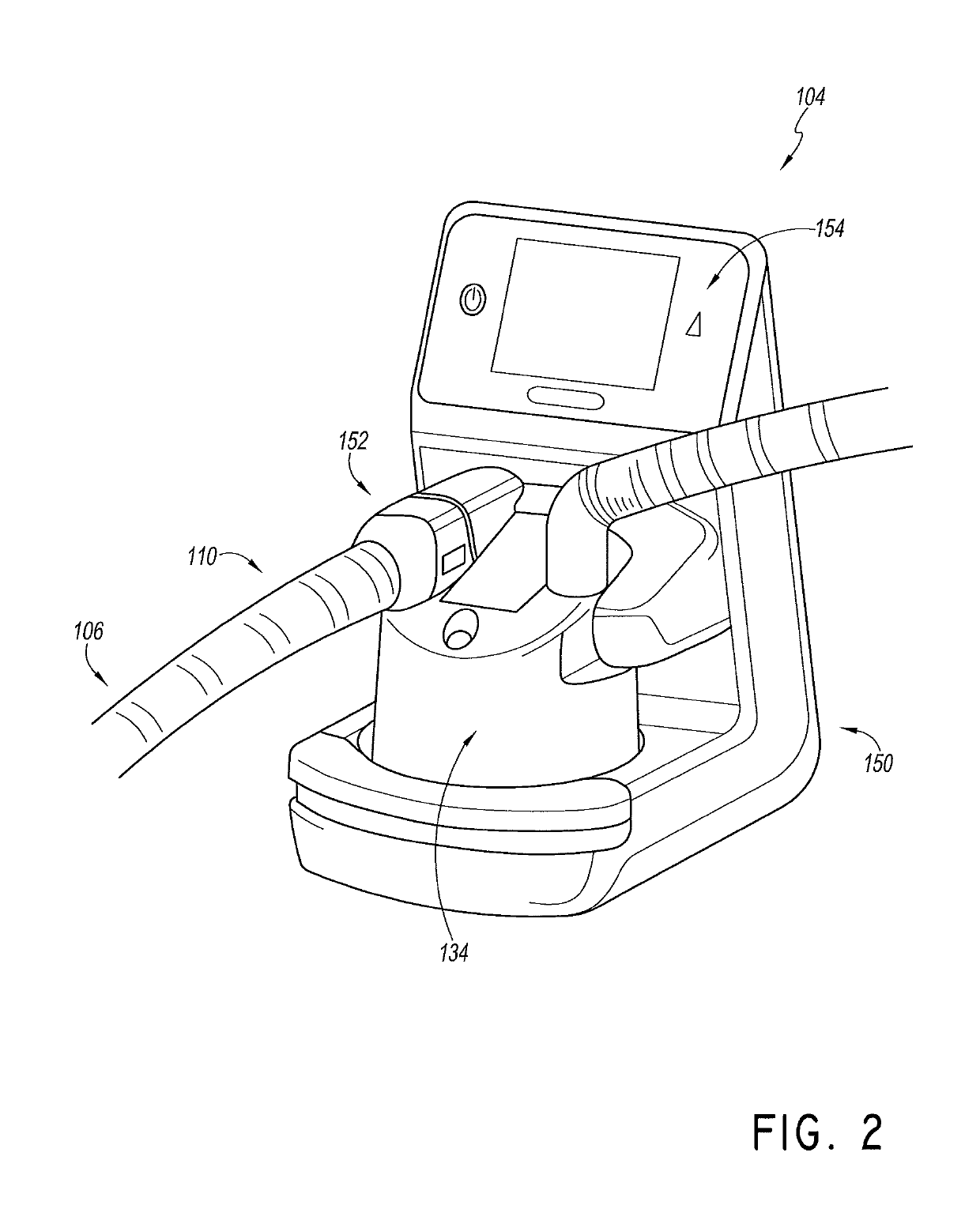

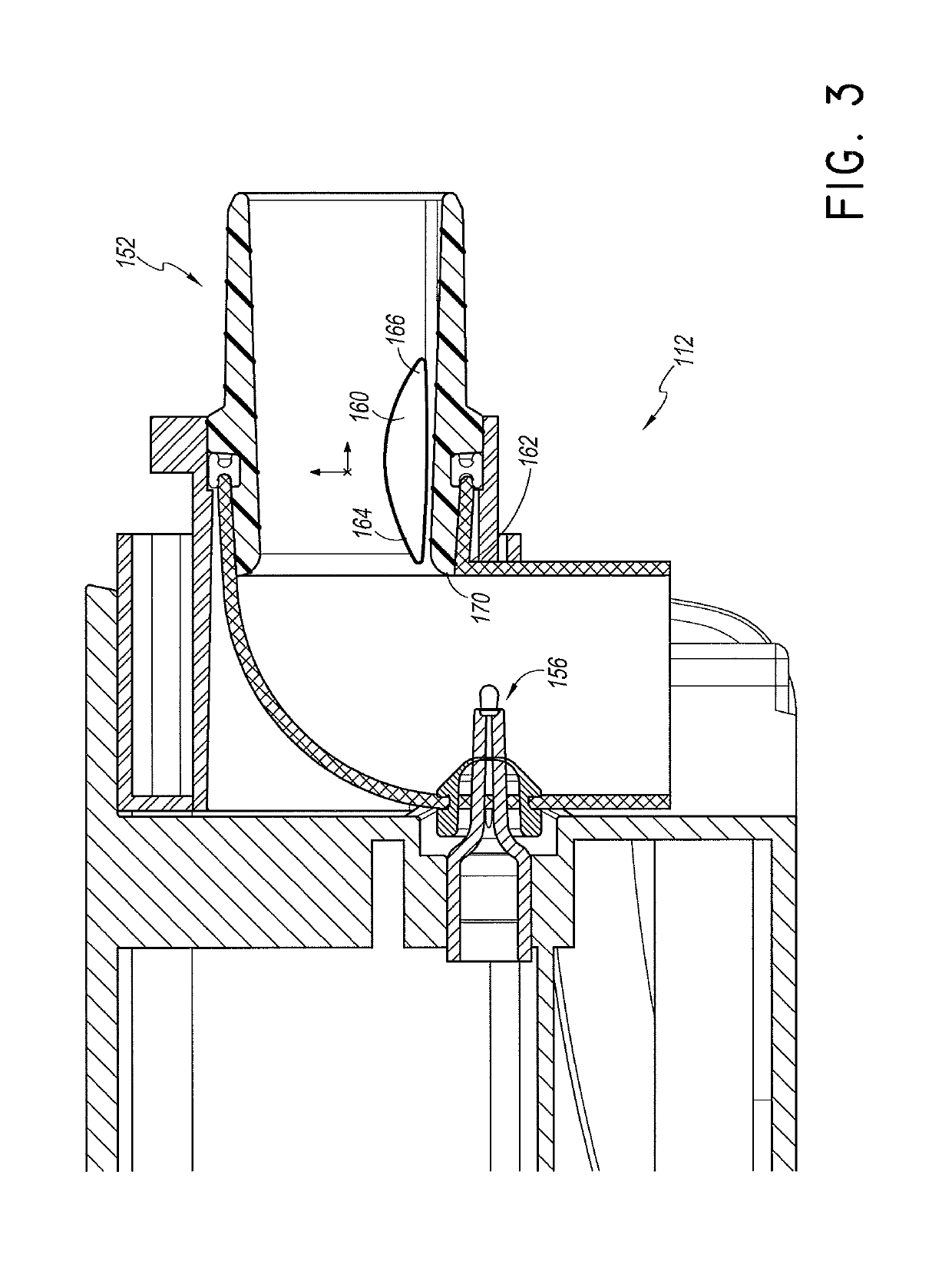

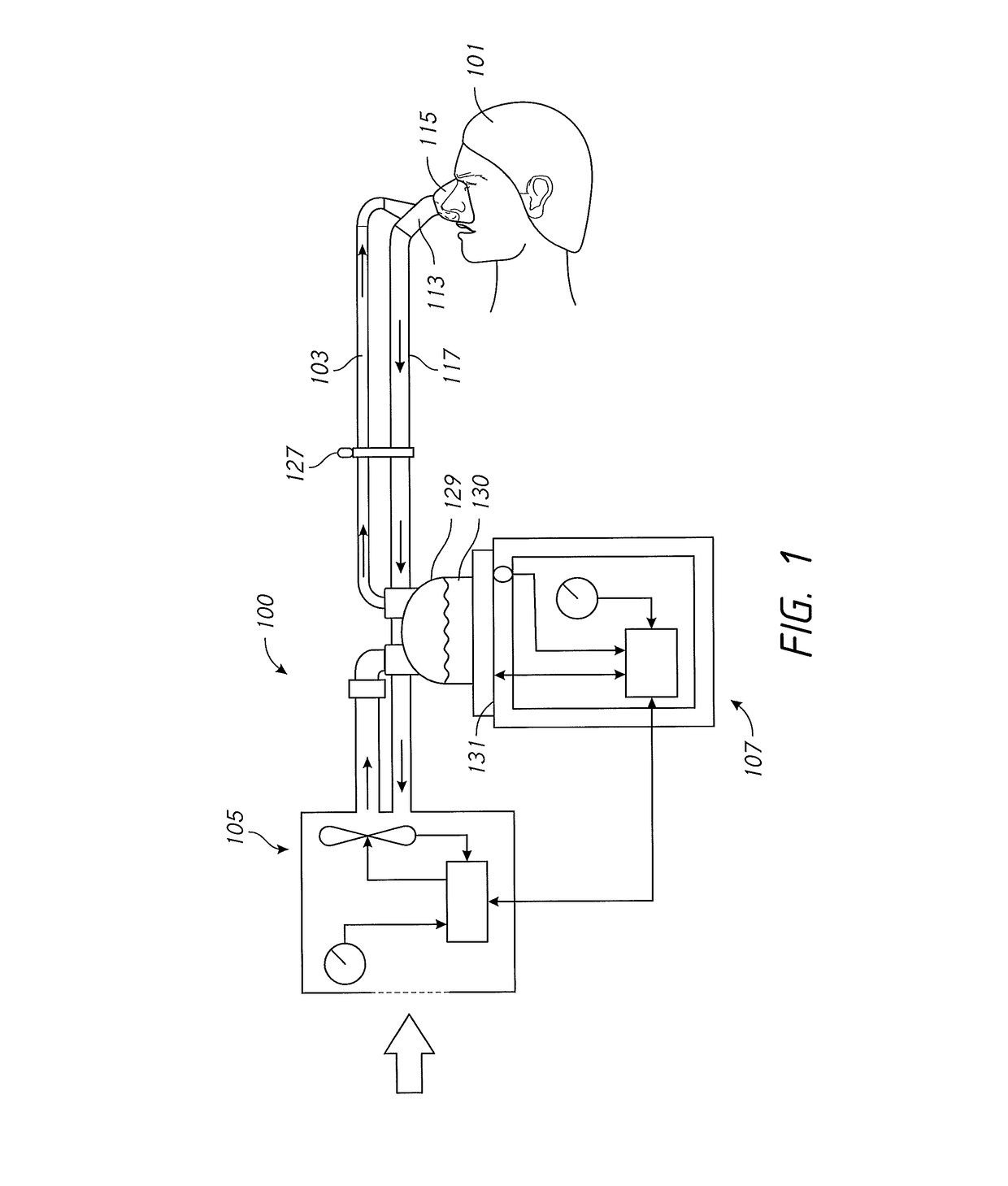

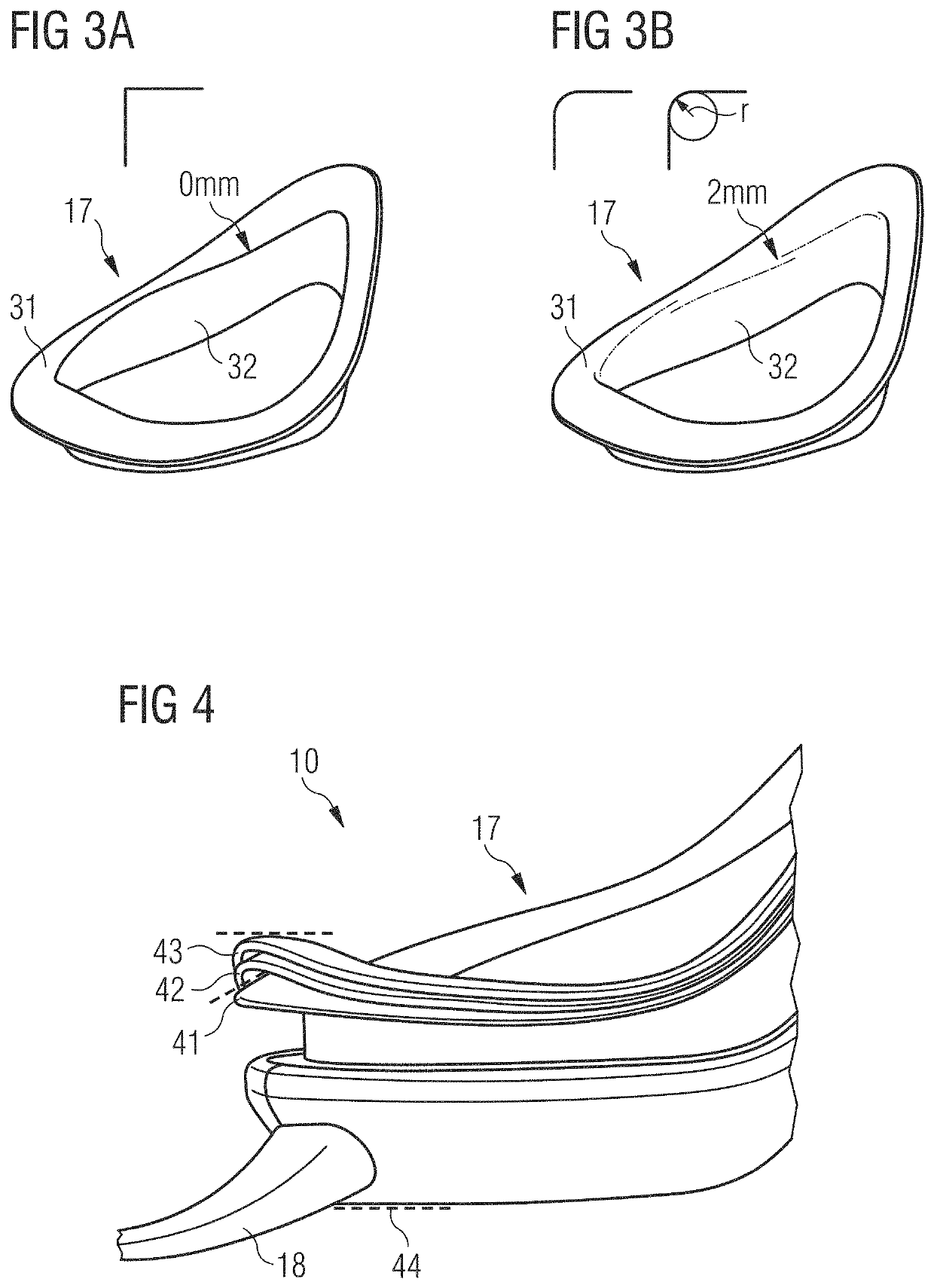

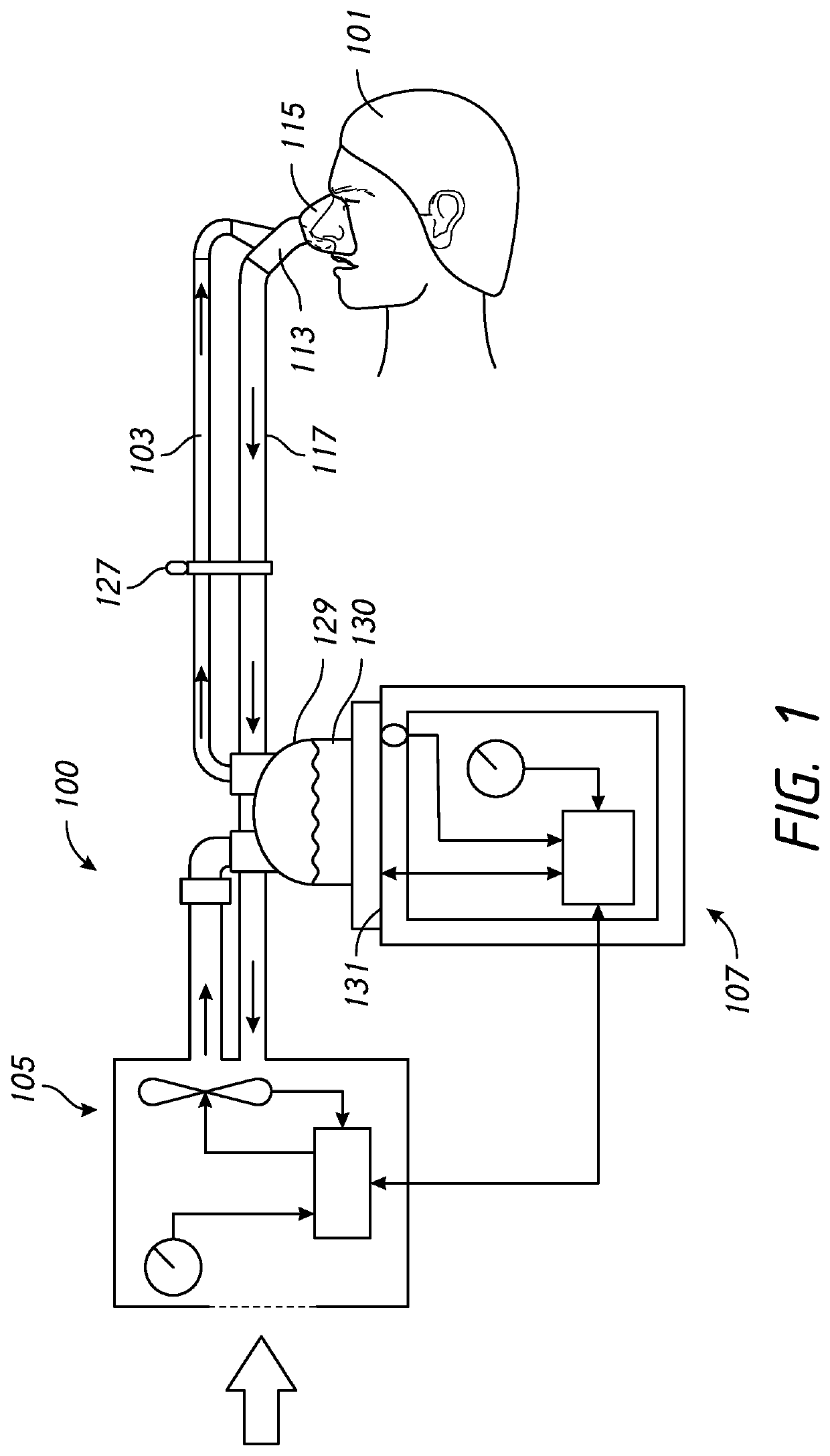

Respiratory humidification system

ActiveUS20170173293A1Improve fluid characteristicReduce recyclingRespiratorsLighting and heating apparatusCatheterEngineering

A system provides warm, humidified gas to a patient via a patient interface. Horizontal connections can be used between the humidification chamber and conduit. To reduce the likelihood of condensate flowing back to the humidification chamber, or dead space or gases recirculation regions occurring within the gases flow path, a raised portion is positioned inside of the flow path to improve flow characteristics and to provide a barrier for condensate back flow. The raised portion also reduces the amount of condensate that is formed in the system and provides better flow characteristics for sensing purposes.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Reservoir system for gas delivery to a patient

ActiveUS20110277754A1Prevent pneumoniaMuch effortRespiratory masksMedical devicesProduct gasBreathing system

Owner:WESTMED

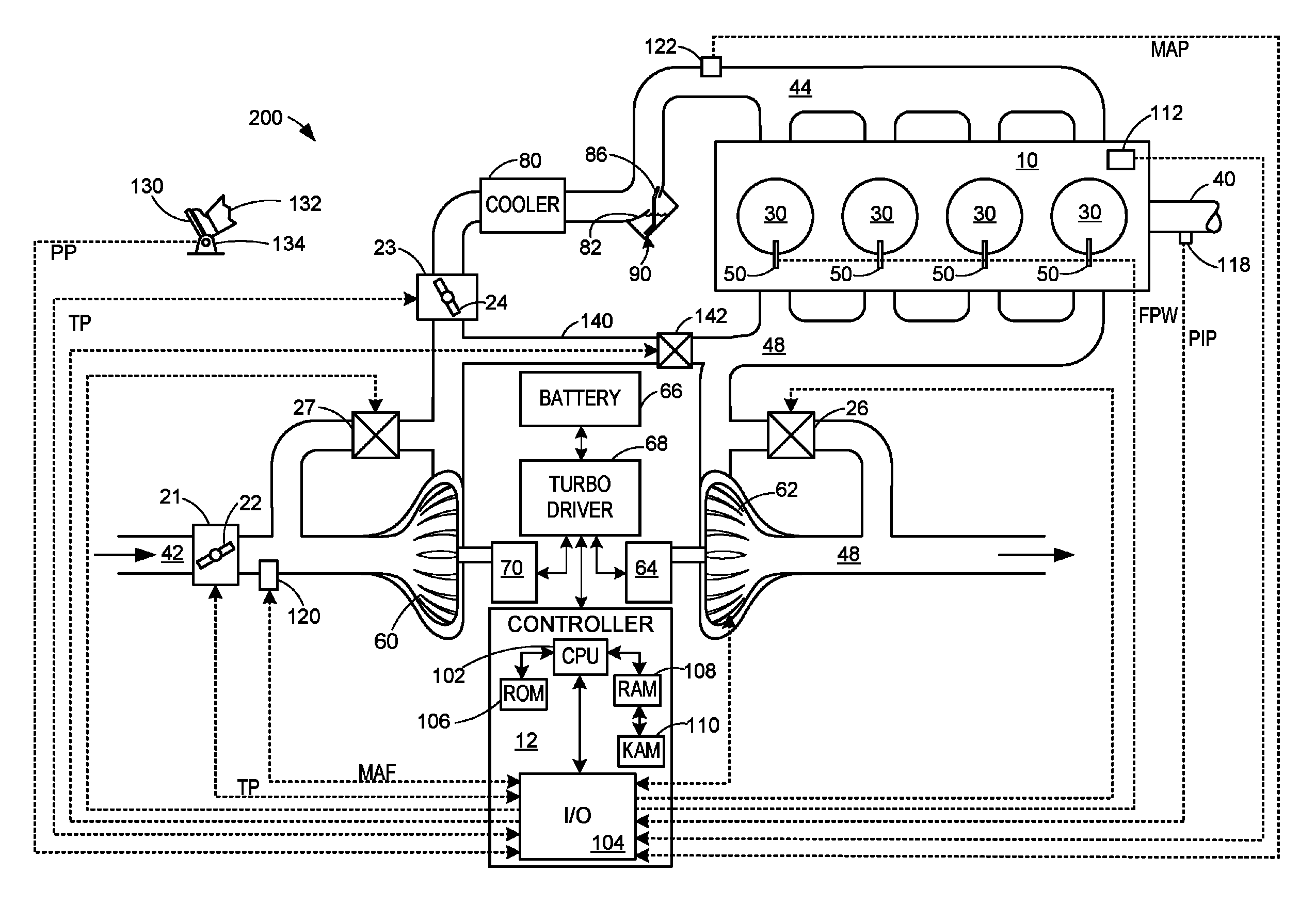

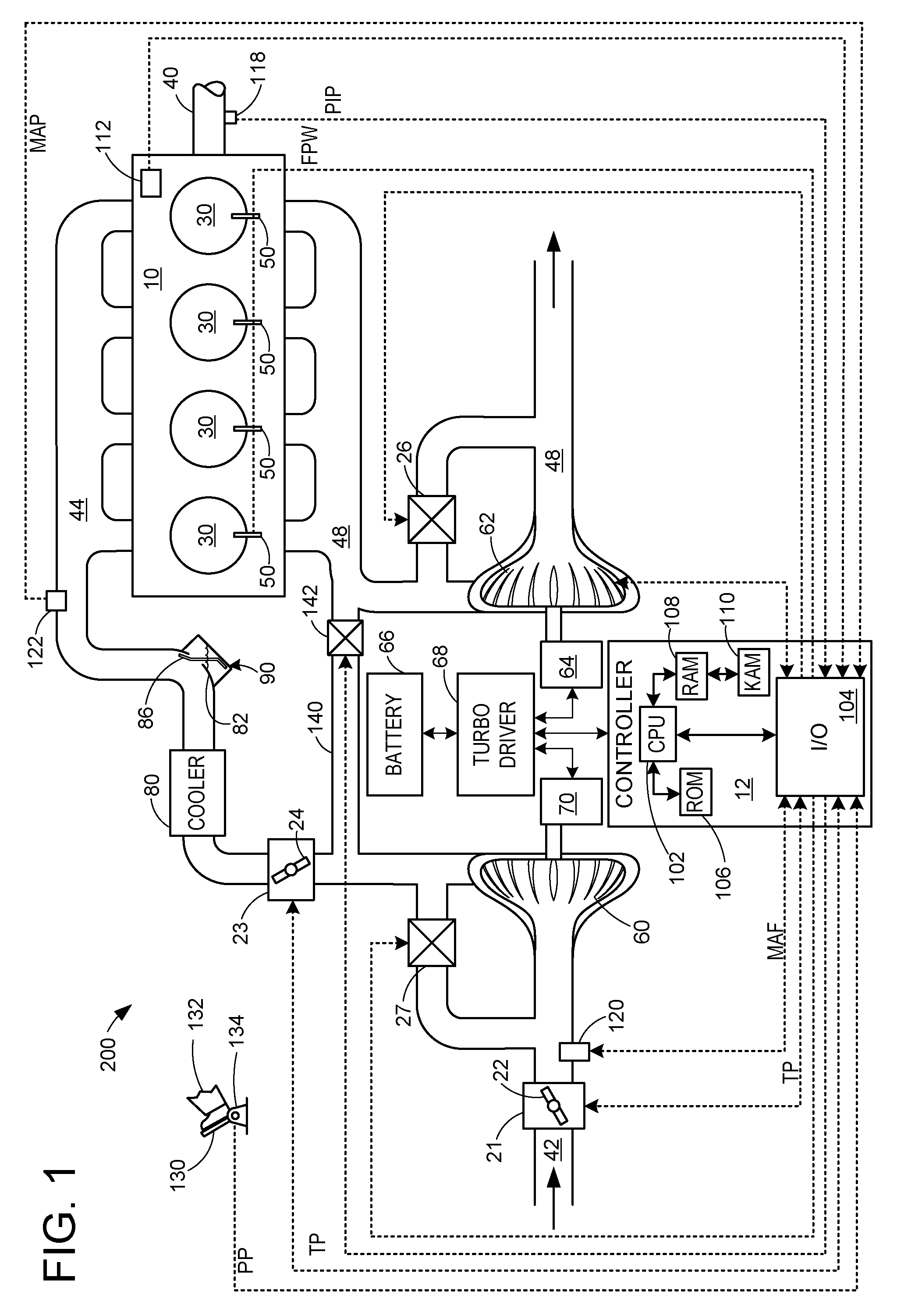

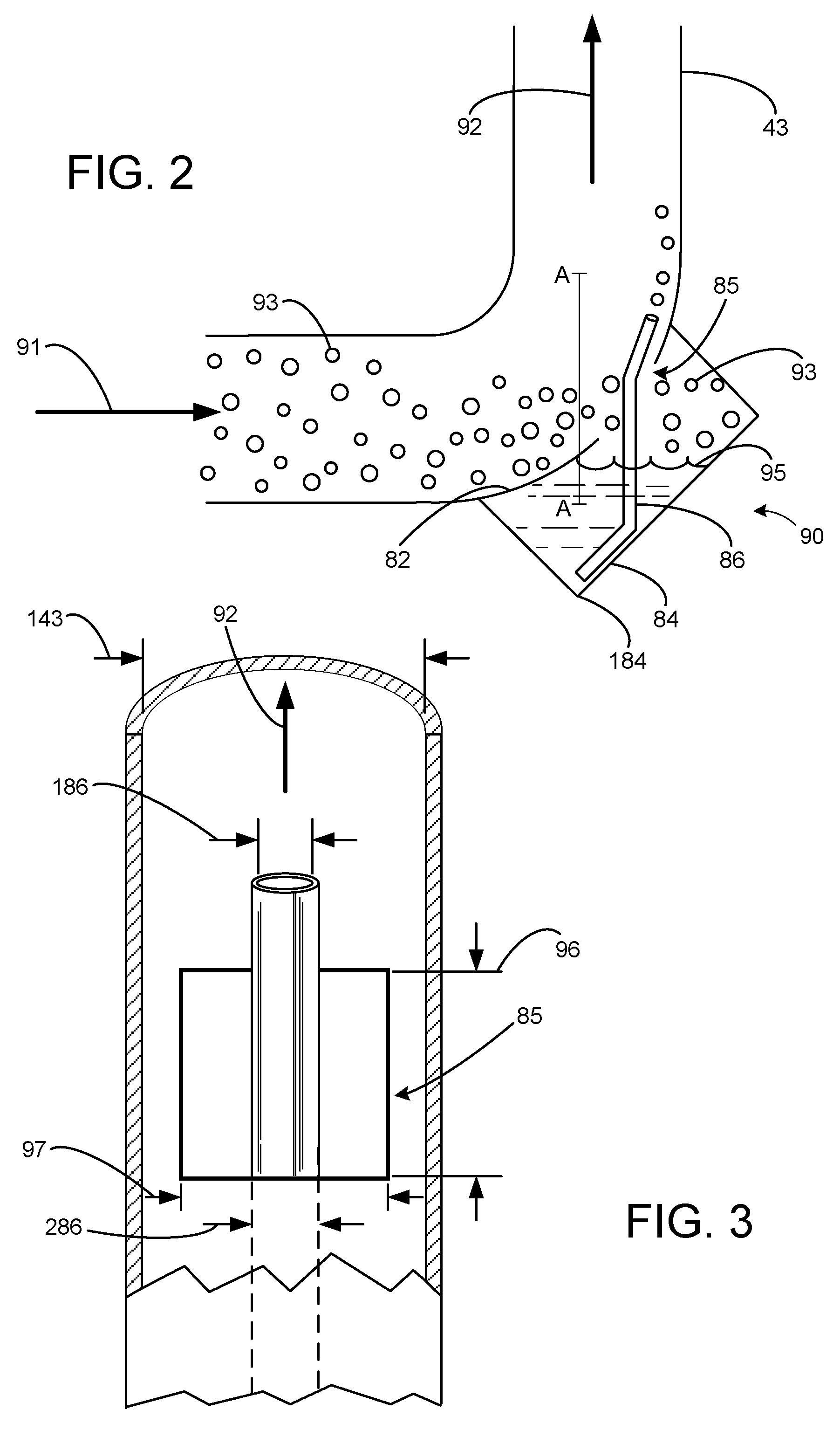

Condensation trap for charge air cooler

ActiveUS9010112B2Reduce the amount of condensateReduce the amount requiredInternal combustion piston enginesIce removalCondensation trapChiller

Various systems and methods are described for a charge air cooler coupled to an engine. One example method comprises collecting condensate discharged from the cooler in a condensation trap coupled to an outside surface of a bend in an outlet duct of the cooler; during a first condition, temporarily storing the condensate in a reservoir of the condensation trap; and, during first and second conditions, releasing the condensate to the outlet duct in a direction of airflow via a tube.

Owner:FORD GLOBAL TECH LLC

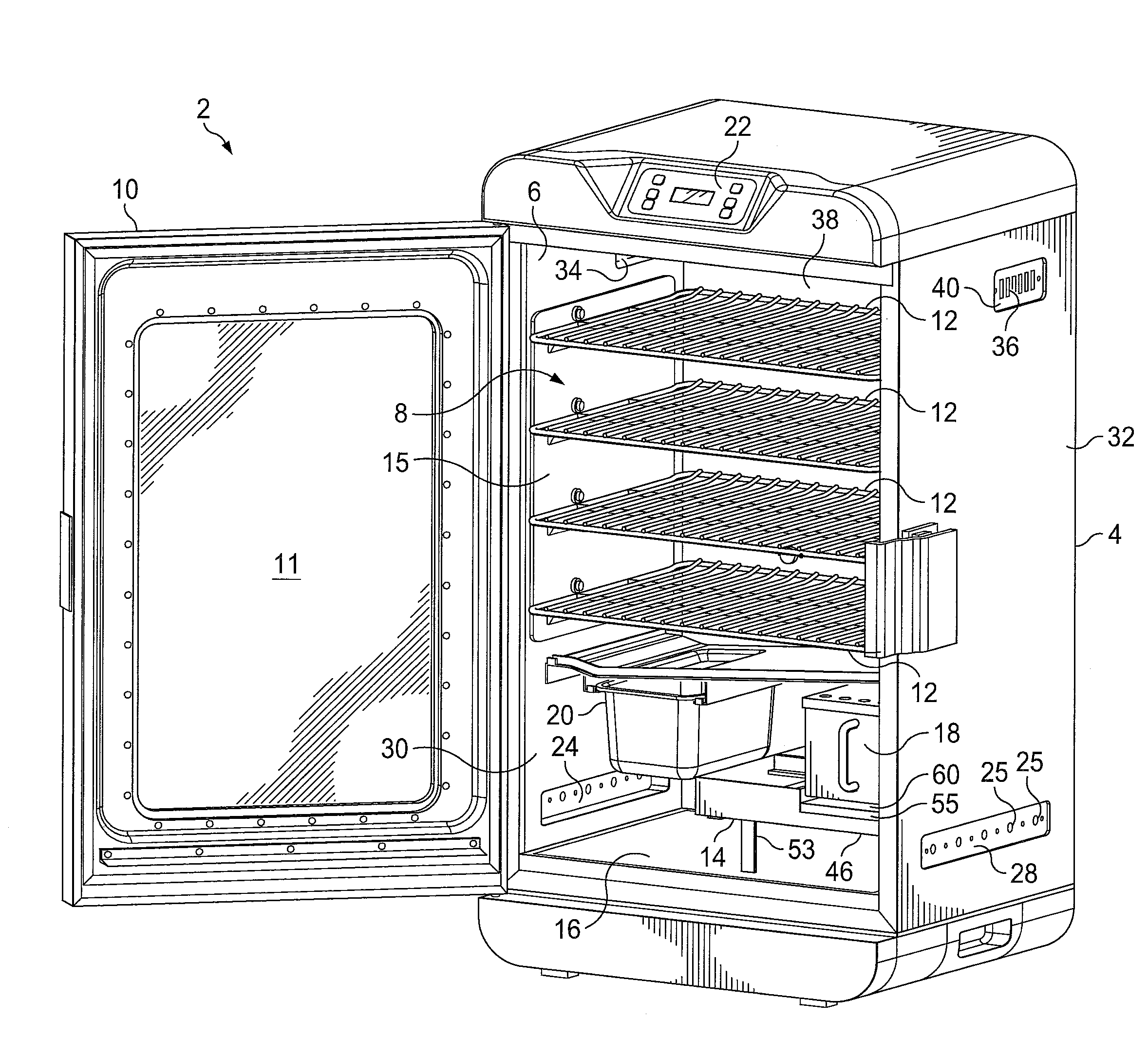

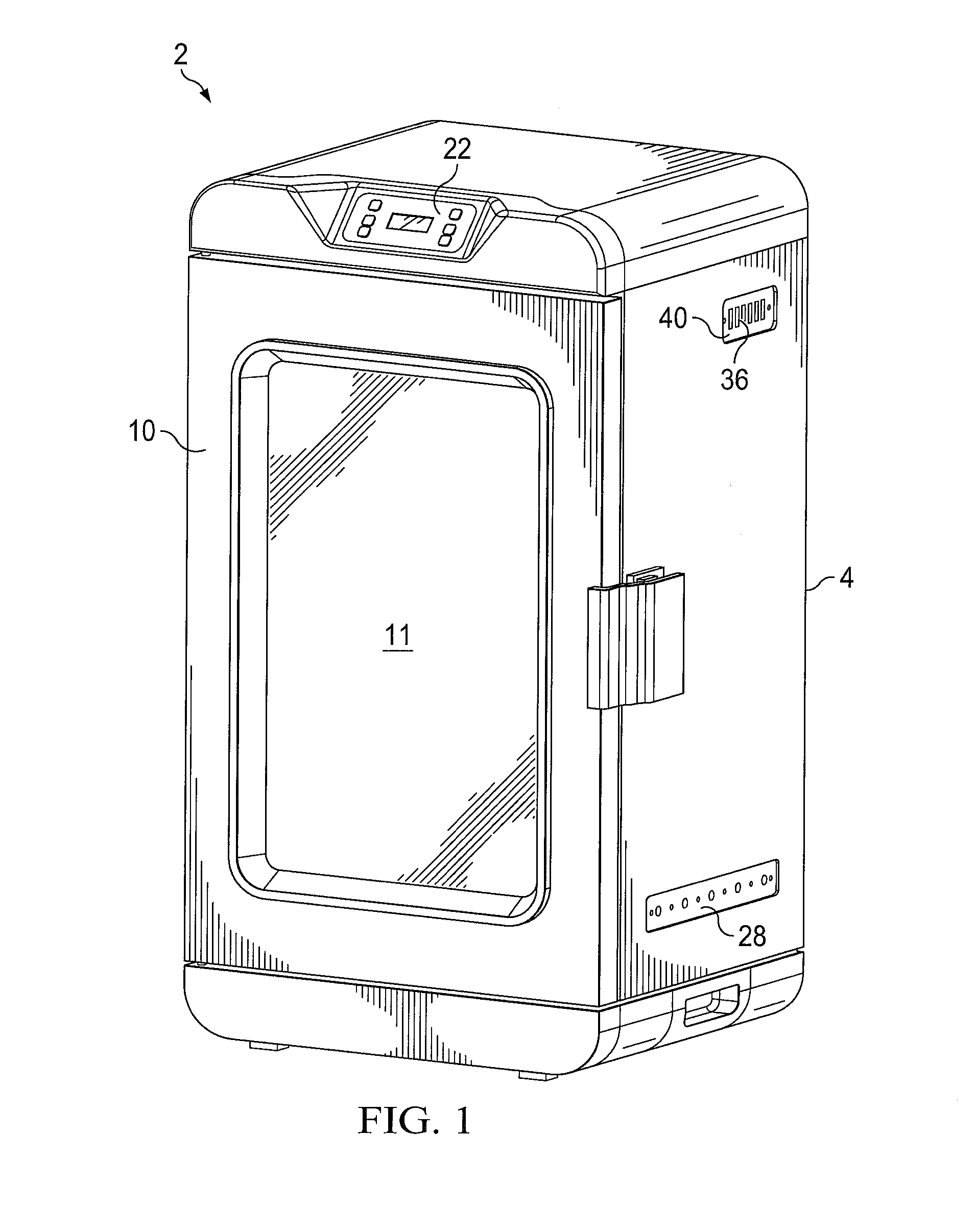

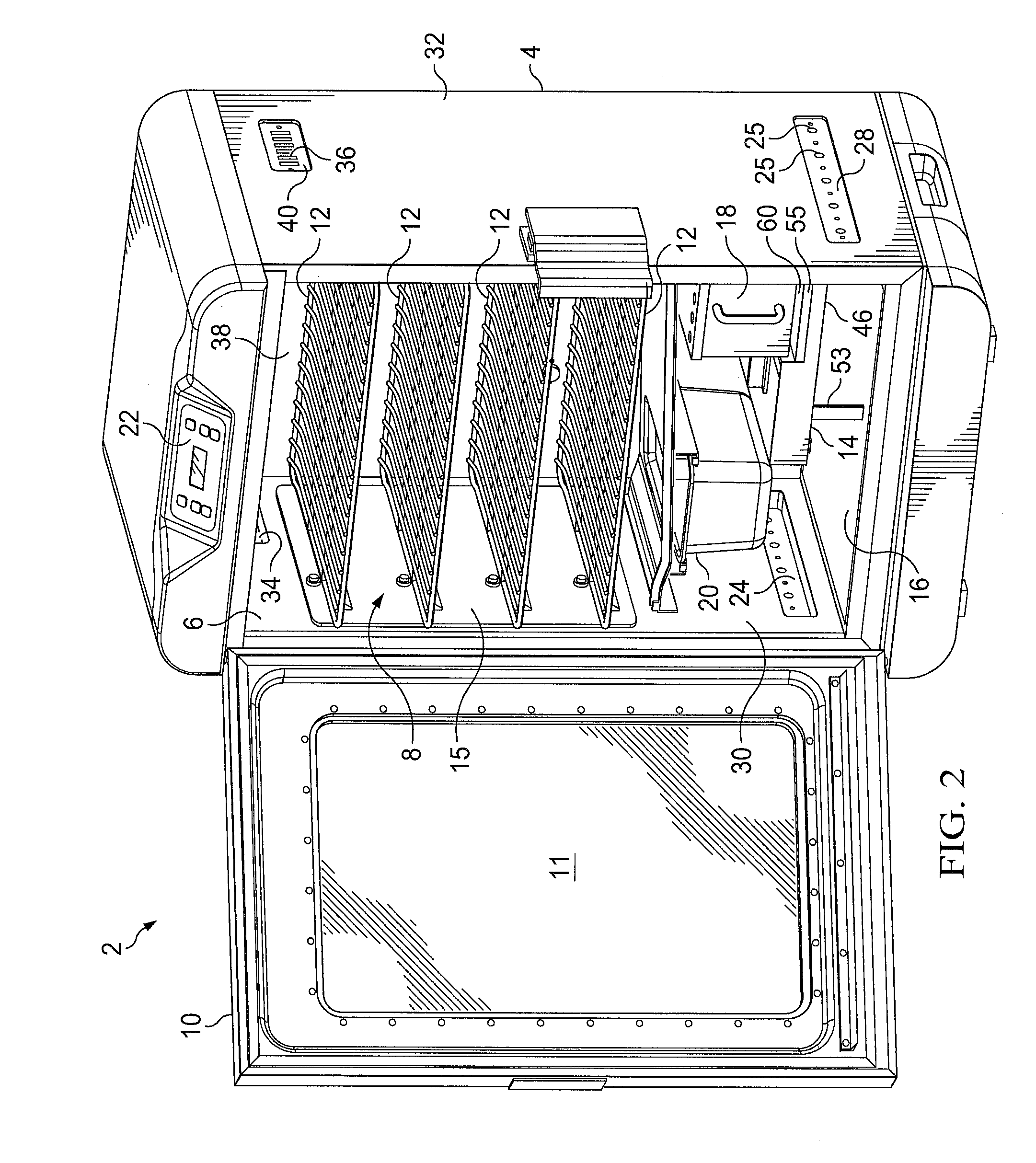

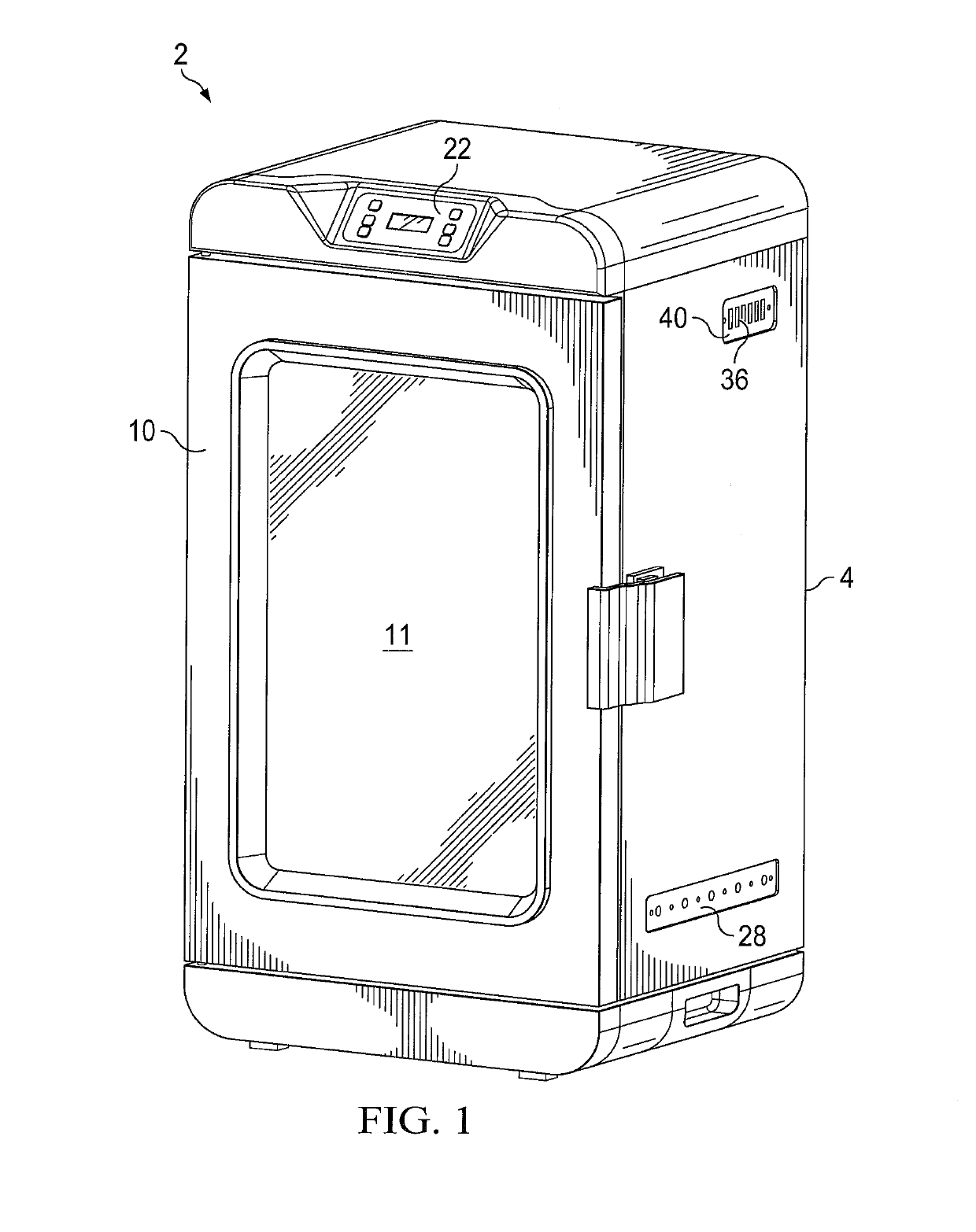

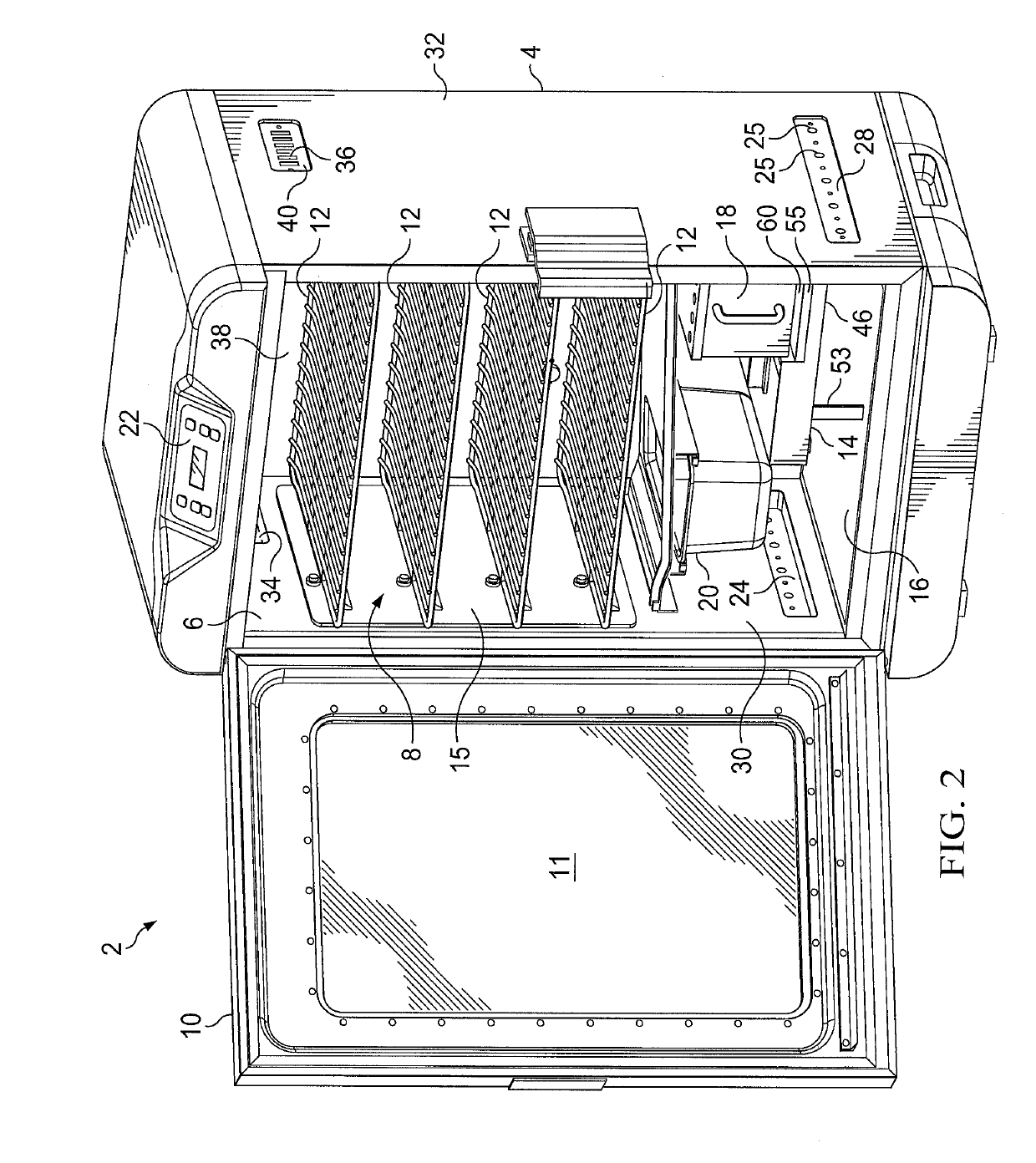

Vertical electric cooker and smoker and smoke box

ActiveUS20170020148A1Reduce heat transferReduce temperature transferMeat/fish preservationClimate change adaptationWorking pressureBalanced flow

A vertical electric cooker and smoker having lower air intake vents and upper exhaust vents which together create a more balanced flow and distribution of smoke and reduce the operating pressure of the system to allow a much larger load of wood chips to be used without refilling. A smoke box is also provided for holding and properly combusting the larger quantity of wood chips in an oxygen deficient environment. The smoke box has a false bottom and discharges the smoke through a circuitous exhaust flow path. Also, the electric heating elements of the cooking and smoking apparatus are contained in an assembly which provides an air gap beneath the smoker box and also shields the smoker box to prevent the wood chips in the smoker box from becoming overheated.

Owner:W C BRADLEY CO

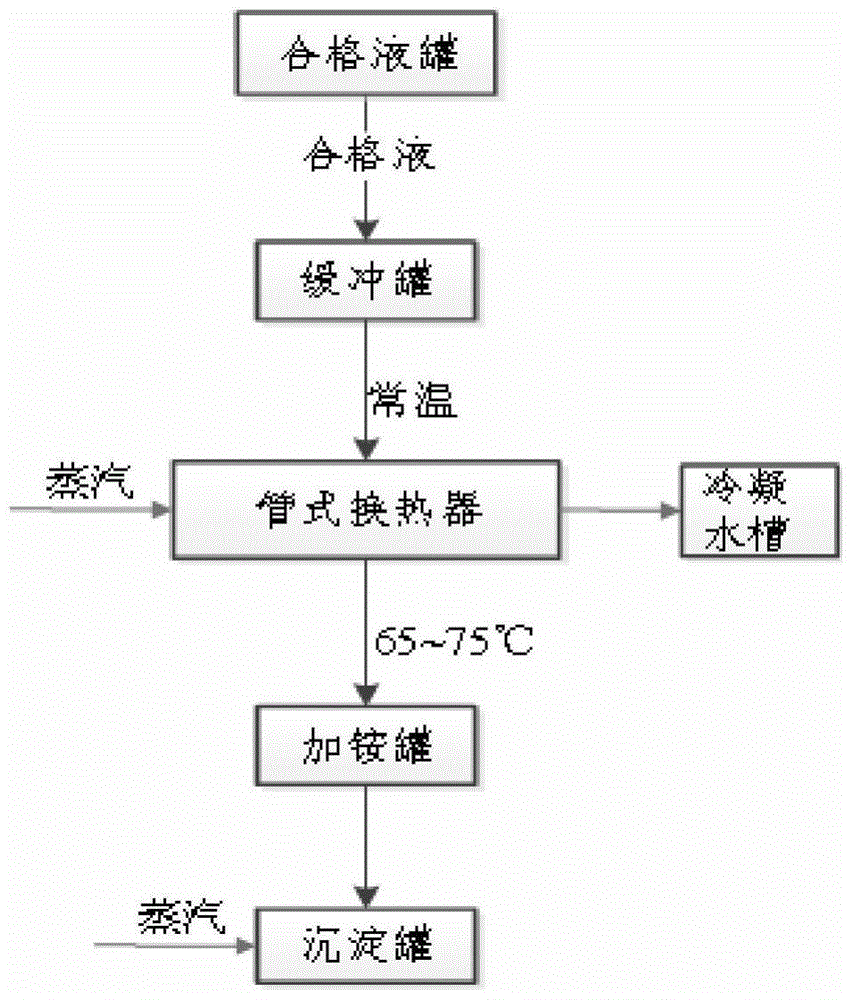

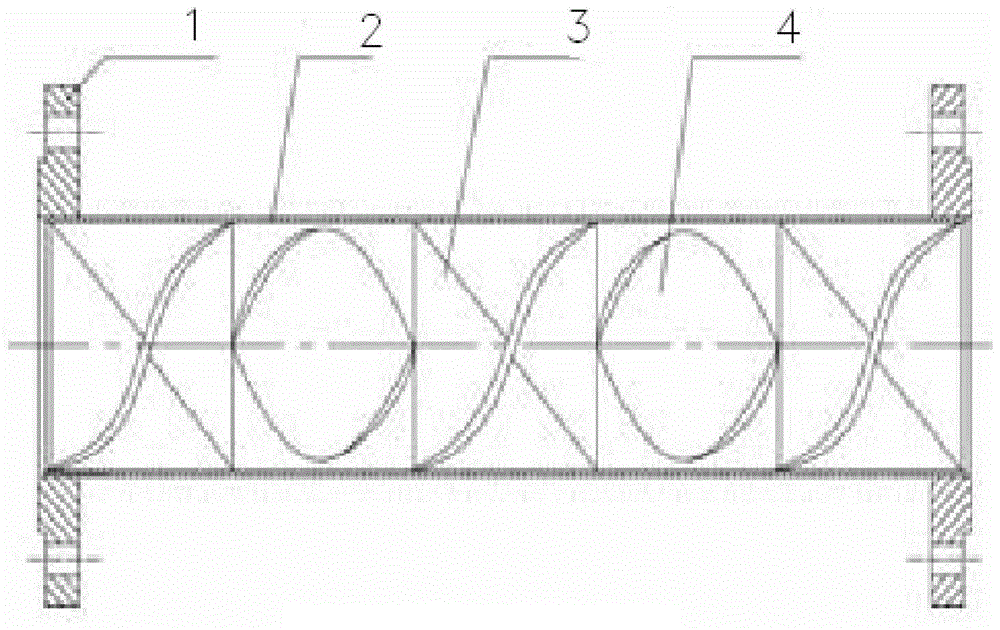

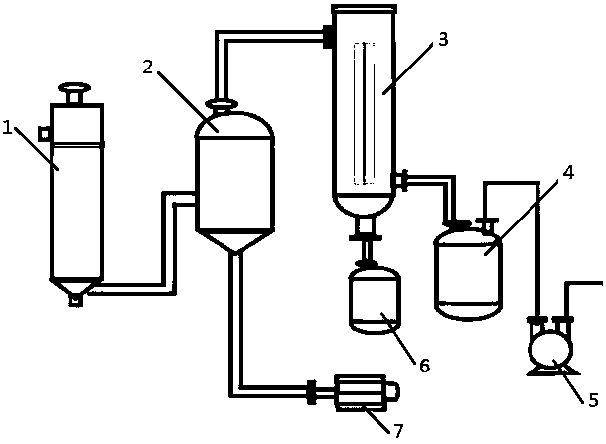

Vanadium pentoxide preparation method

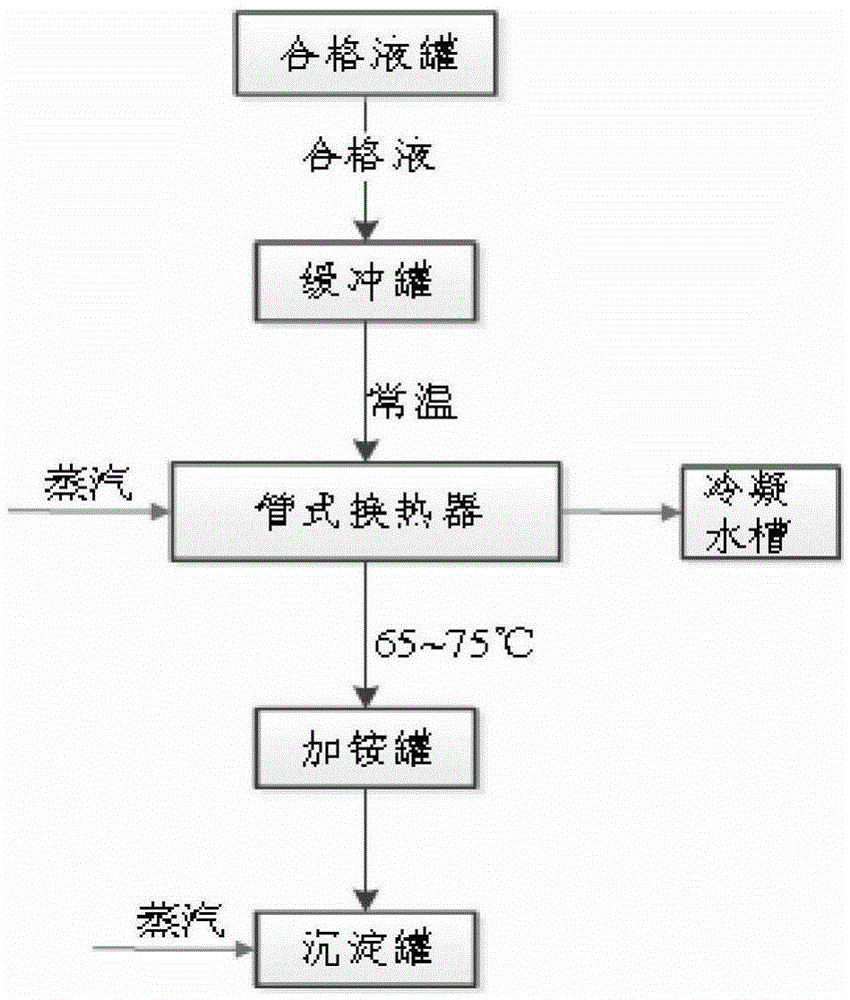

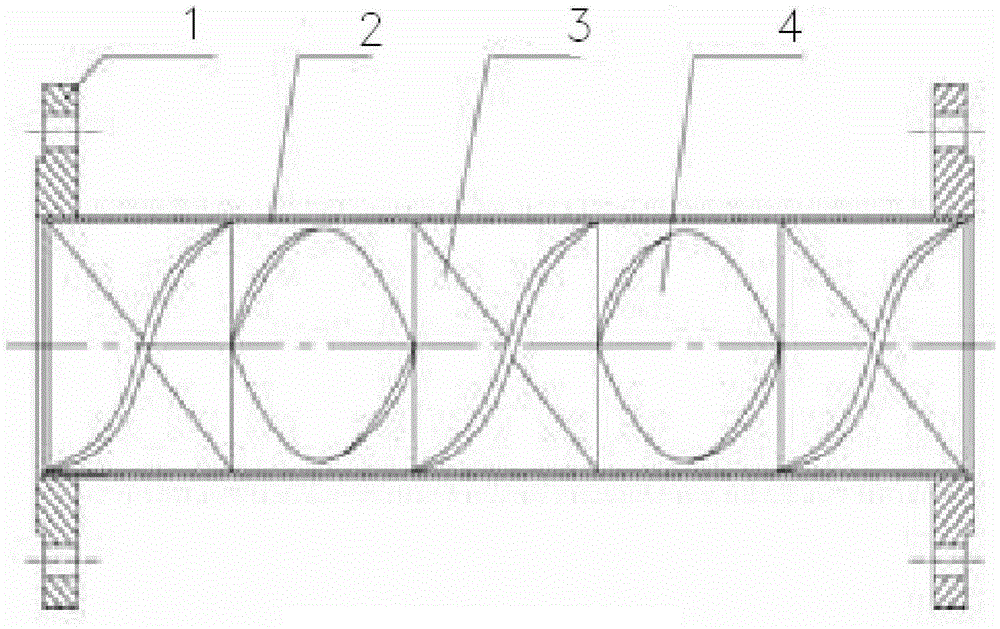

The invention belongs to the field of hydrometallurgy and particularly relates to a vanadium pentoxide preparation method. The preparation method comprises the following steps that (a) the temperature of acidic vanadium liquid rises from normal temperature to 65-75 DEG C in the preheating process of a vanadium precipitation process by using a static mixer pipe and utilizing steam heat exchange; (b) the acidic vanadium liquid subjected to heat exchange is added into an ammonium tank, ammonium sulfate is added, and stirring is performed to obtain mixed liquid; (c) the mixed liquid is added into a sedimentation tank, stirring is performed, a pH value is regulated to be 1.5-2, and steam heating is performed to reach 90 DEG C to boiling so as to obtain an ammonium poly-vanadate solution; (d) precipitate obtained after the ammonium poly-vanadate solution precipitates is washed, dried and calcinated to obtain vanadium pentoxide. The flowing state of the acidic vanadium liquid in the pipe is changed by utilizing a mixing unit body fixed in the static mixer pipe, the formation of a laminar flow bottom layer is inhibited to enable the acidic vanadium liquid to rapidly disperse in the pipe, the temperature distribution of all parts of the solution tends to be uniform, the formation of a scale layer is retarded, and the production efficiency of the vanadium pentoxide is improved.

Owner:攀钢集团西昌钒制品科技有限公司

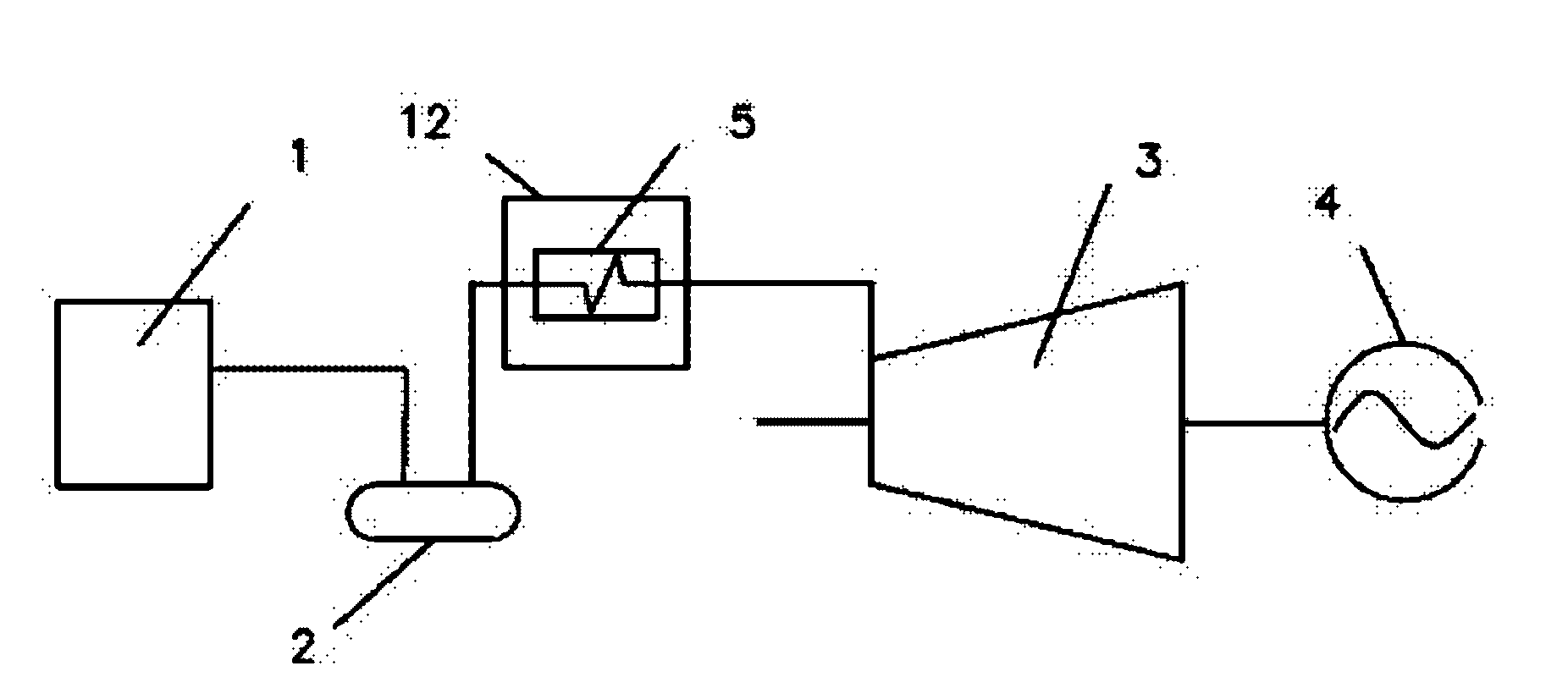

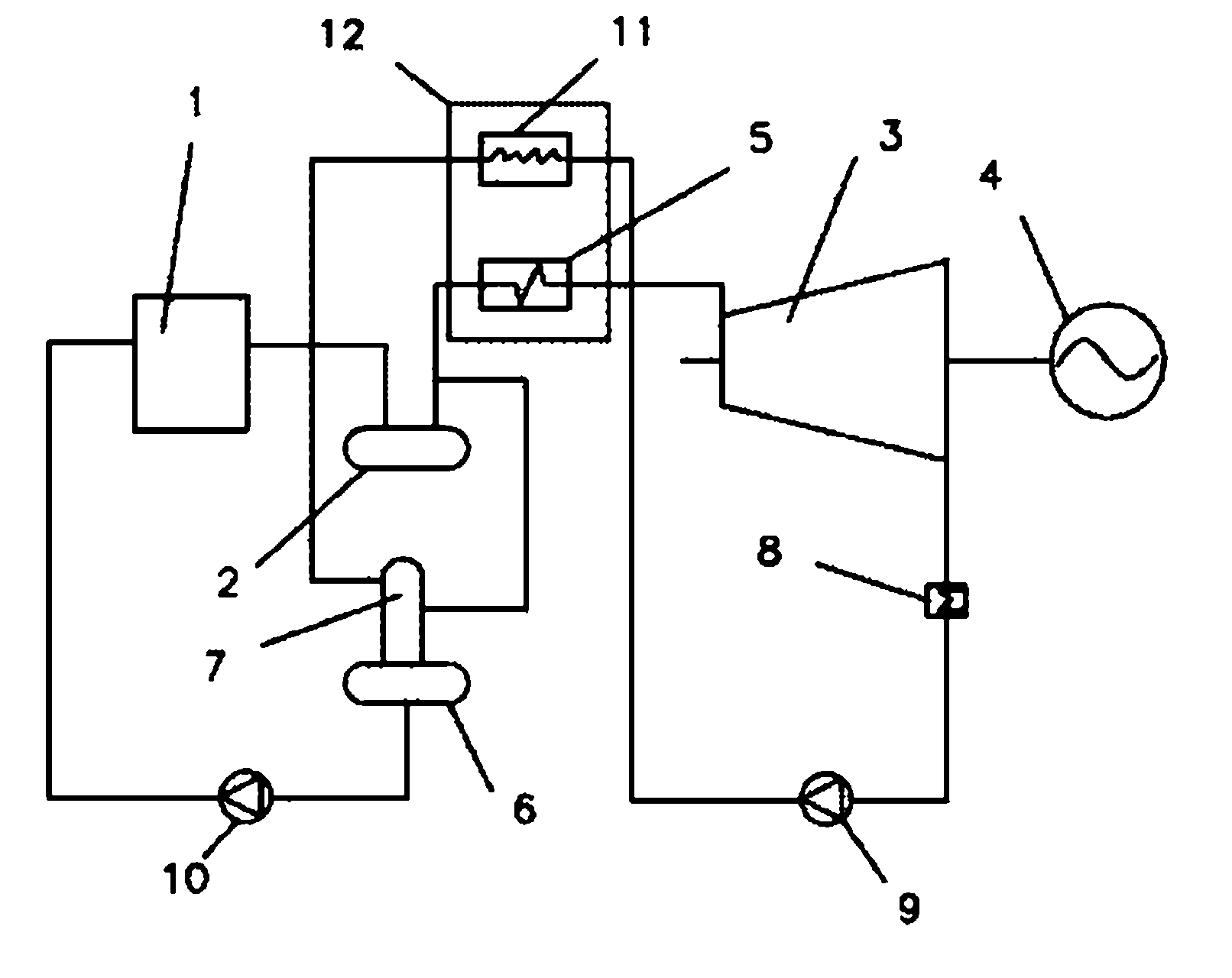

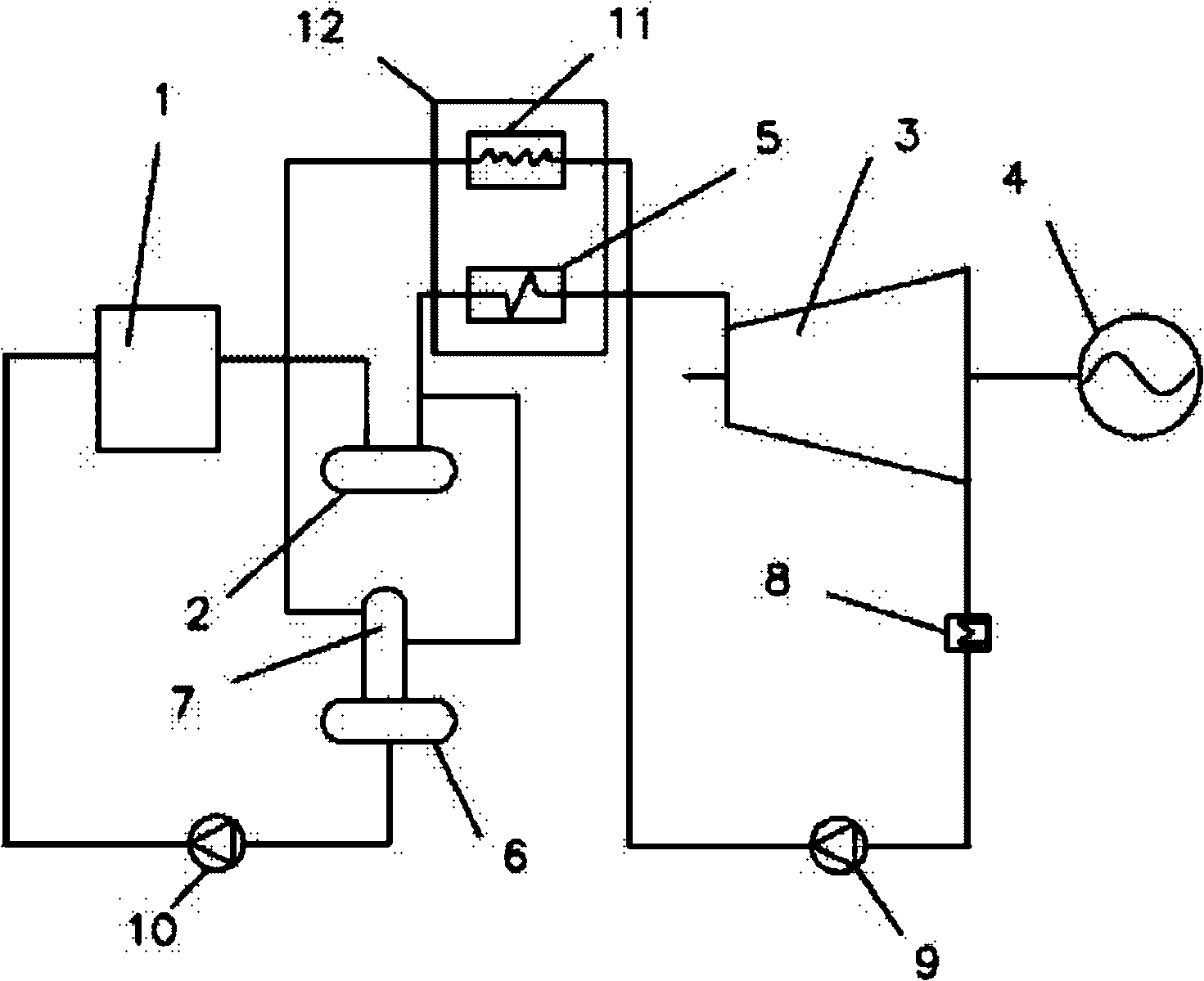

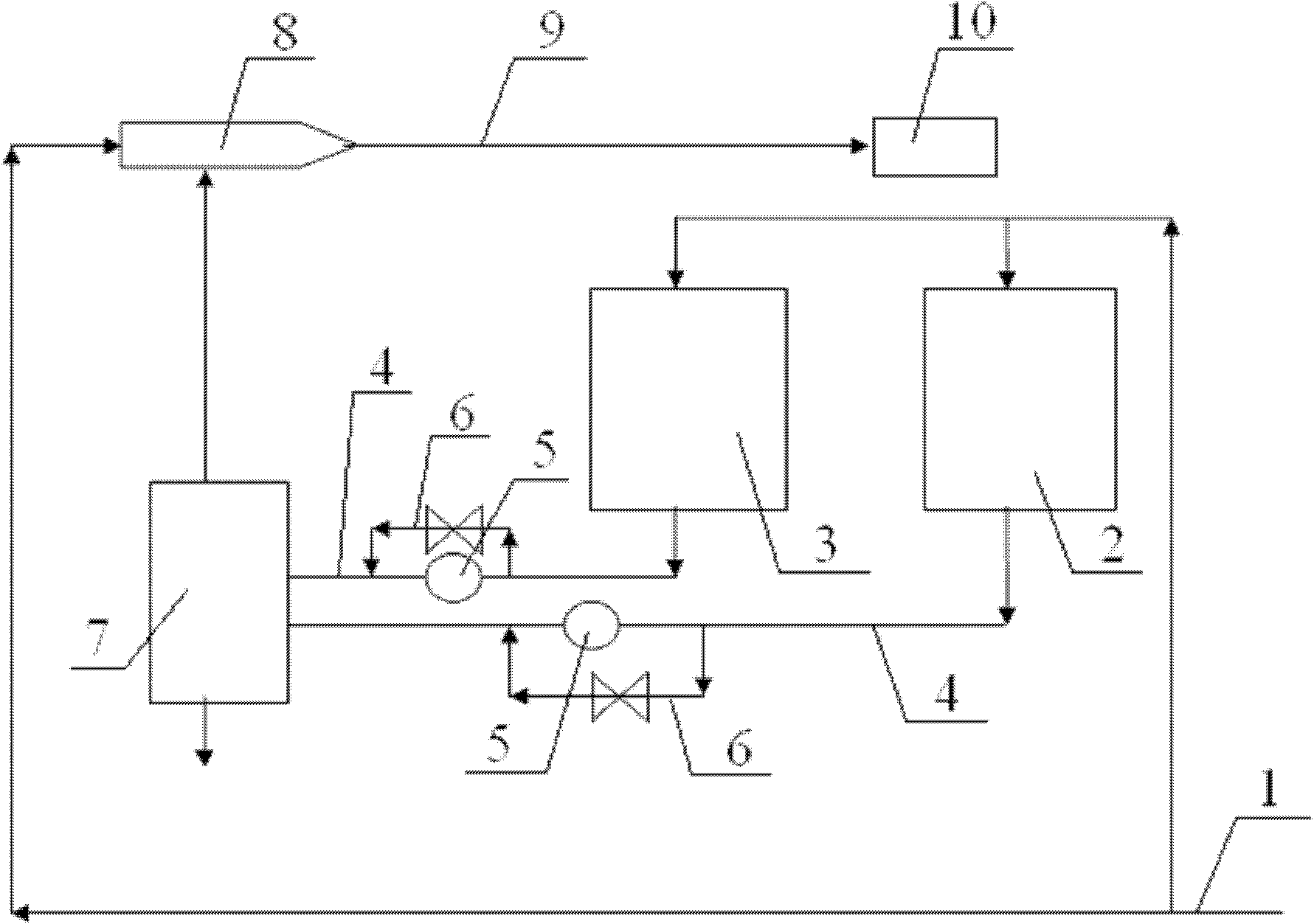

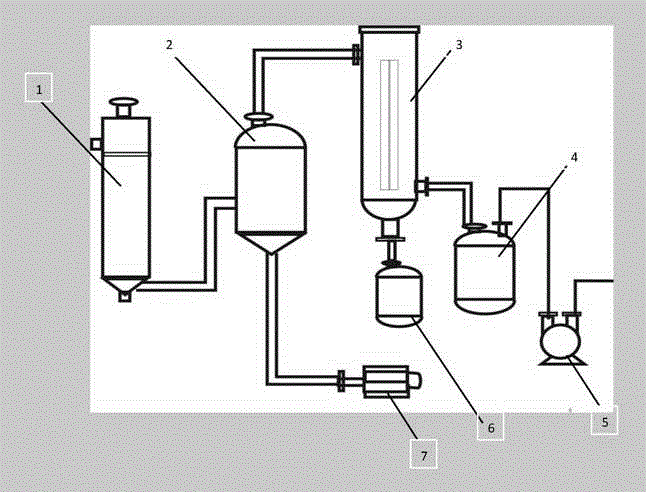

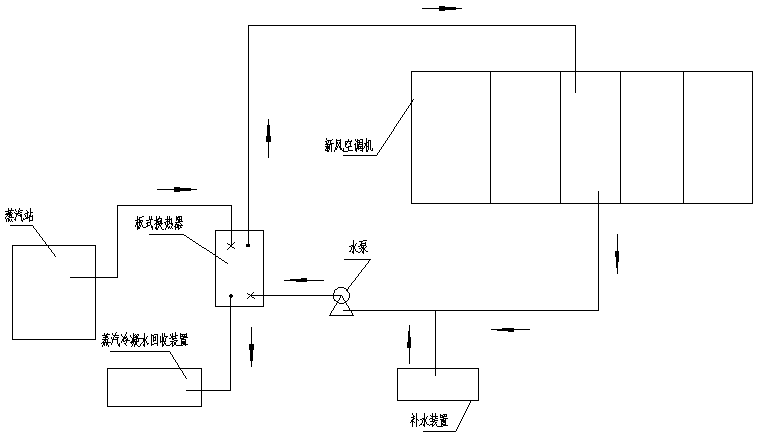

Converter waste heat generating system

InactiveCN101864507AReduce the amount of condensateGuaranteed to workManufacturing convertersMachines/enginesSuperheaterEngineering

The invention discloses a converter waste heat generating system, which comprises a waste heat boiler, a heat accumulator, a steam turbine unit, and a generator set. A steam outlet of the waste heat boiler is connected with a steam inlet of the heat accumulator. The converter waste heat generating system is characterized in that the converter waste heat generating system also comprises a heating furnace with a superheater, and a steam outlet of the heat accumulator is connected with a steam inlet of the steam turbine unit through the superheater. Due to voltage stabilization of the heat accumulator, the converter waste heat generating system converts intermittent and unstable steam generated by the waste heat boiler into continuous and stable steam, and guarantees the normal work of the steam turbine unit; and by heating moisture contained in saturated steam into vapor by the superheater, the vapor becomes dry steam. Therefore, the condensate water generated when the vapor works in the steam turbine unit is effectively reduced, and the normal work of the steam turbine unit is guaranteed. In addition, the steam specific enthalpy is increased, so that the generating efficiency is improved.

Owner:ZHEJIANG XIZI UNITED ENG

Respiratory humidification system

ActiveUS10449319B2Improve fluid characteristicReduce recyclingRespiratorsLighting and heating apparatusCatheterEngineering

Owner:FISHER & PAYKEL HEALTHCARE LTD

Vertical electric cooker and smoker and smoke box

ActiveUS10426176B2Reduce the amount requiredReduce the temperatureMeat/fish preservationClimate change adaptationElectricityWorking pressure

Owner:W C BRADLEY CO

Hot-air drying system of paper machine

ActiveCN102733243AStable Temperature RequirementsImprove thermal energy efficiencyDryer sectionHigh pressureHeat pump

The invention relates to a hot-air drying system of a paper machine. The hot-air drying system comprises a flash tank, a heat pump, a dry-side heat exchanger, a wet-side heat exchanger and connecting pipelines, wherein an air inlet of the dry-side heat exchanger and an air inlet of the wet-side heat exchanger are connected with a main steam inlet pipeline, air exhaust pipelines at air outlets are respectively connected with the flash tank, the heat pump is connected with the flash tank, a main steam pipeline of the heat pump is connected with a drying cylinder, and high-pressure steam is guided to spray by the main steam pipeline so as to guide secondary steam in the heat pump into the drying cylinder. Compared with the prior art, the hot-air drying system provided by the invention can reduce the steam usage amount of the heat exchangers, reduce the quantity of condensation water of the flash tank after the steam enters into the heat exchangers, improve and enhance the drying efficiency, and appropriately enhance the speed of the paper machine, thereby achieving the aims of increasing production and reducing cost.

Owner:上海东冠纸业有限公司

Apparatus for thermal control in the analysis of electronic devices

InactiveUS8424594B2Reduce the amount requiredReduce amount of condensation formingMaterial analysis using wave/particle radiationFault location by increasing destruction at faultEngineeringElectric devices

A heat spreader comprising a sheet of transparent diamond with an aperture therein that accommodates a solid-immersion lens (SIL). The heat spreader may be mounted within a clamp which allows the heat spreader to move freely across the Device Under Test (DUT) while maintaining a very high degree of planarity and contact between the diamond and the silicon substrate of the DUT. The DUT is secured to its electrical interface with a low profile clamp, the DUT may be held within the clamp by a mechanism that applies a pressure to the sides of the DUT package.

Owner:PRESTO ENG

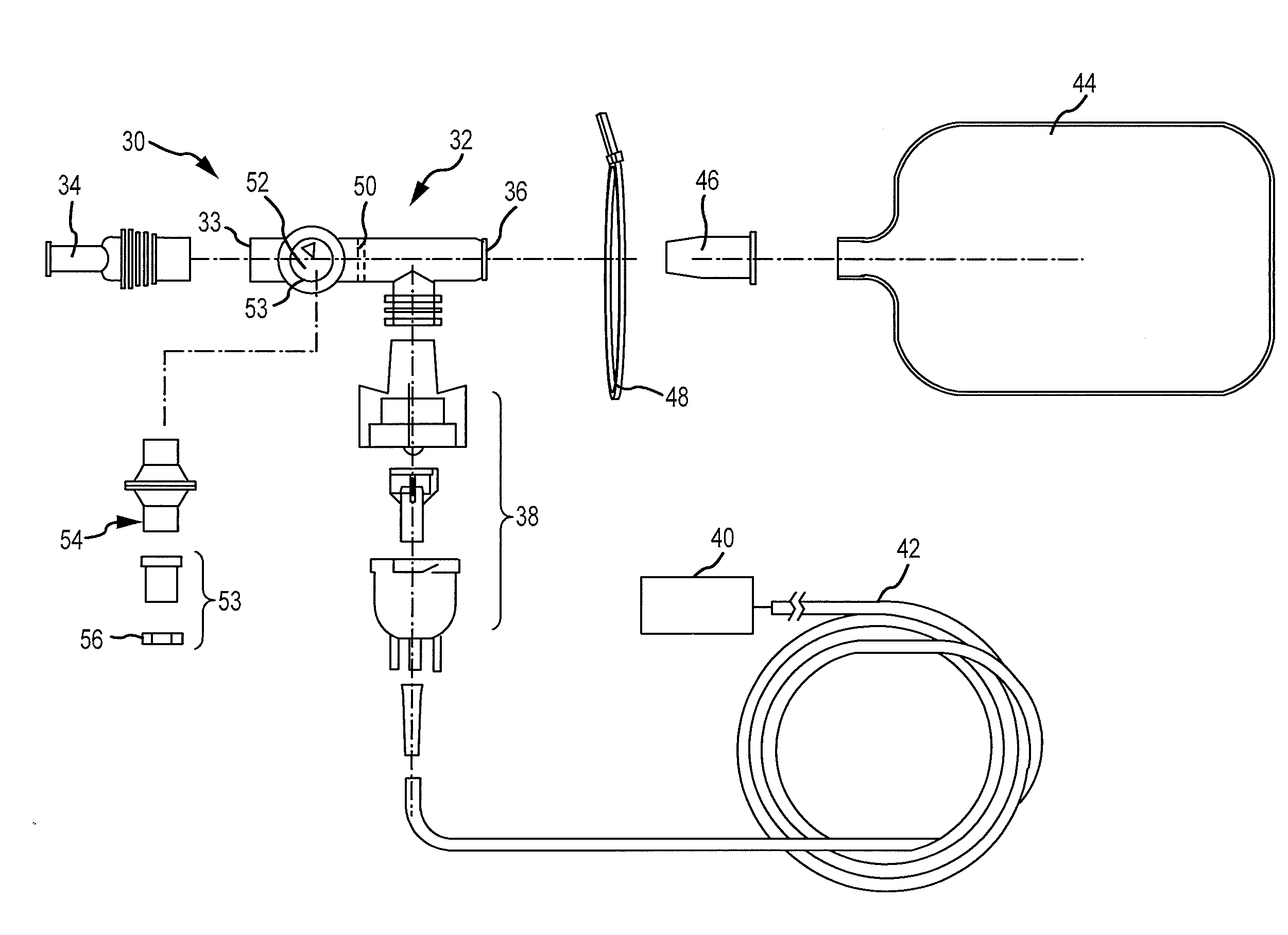

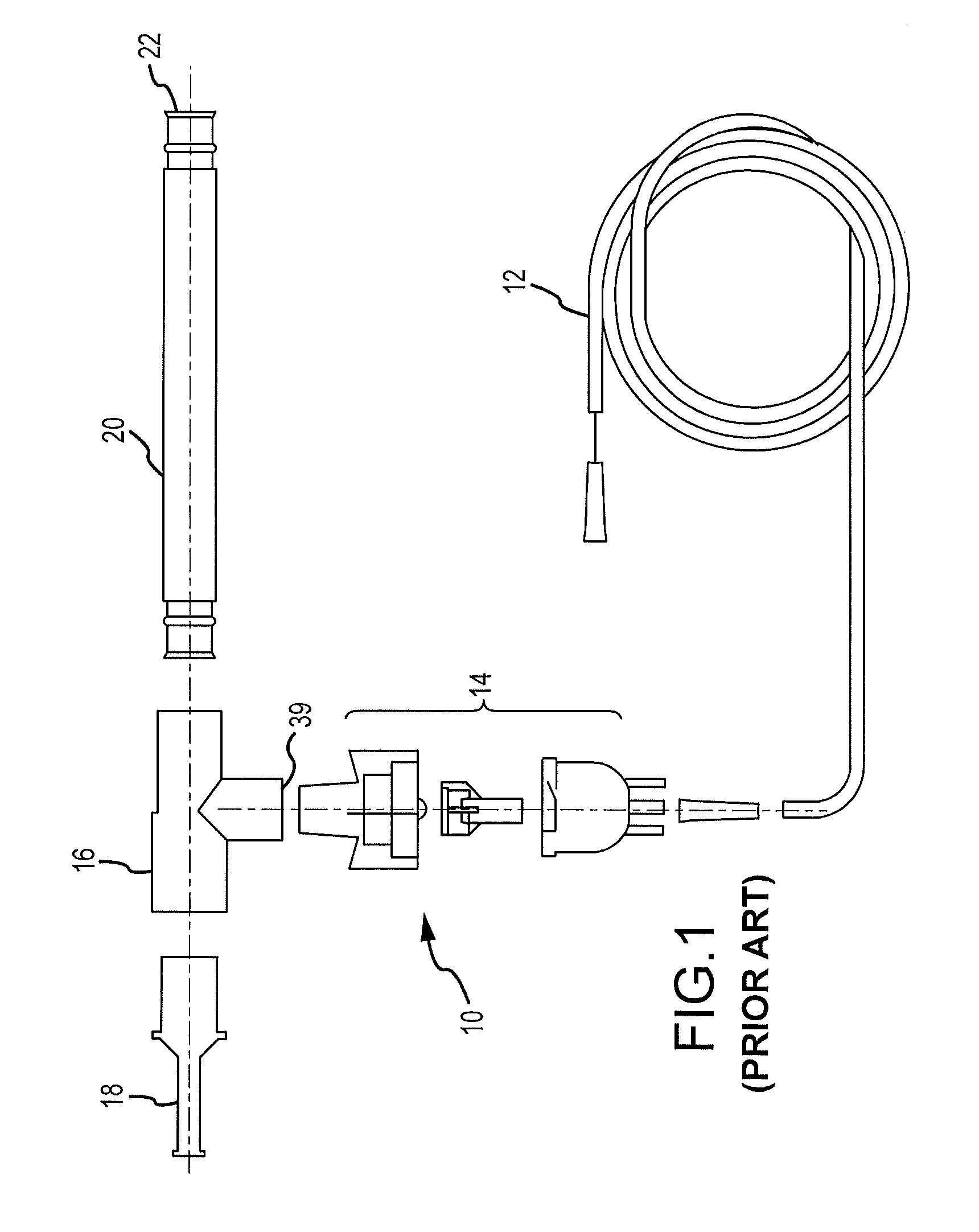

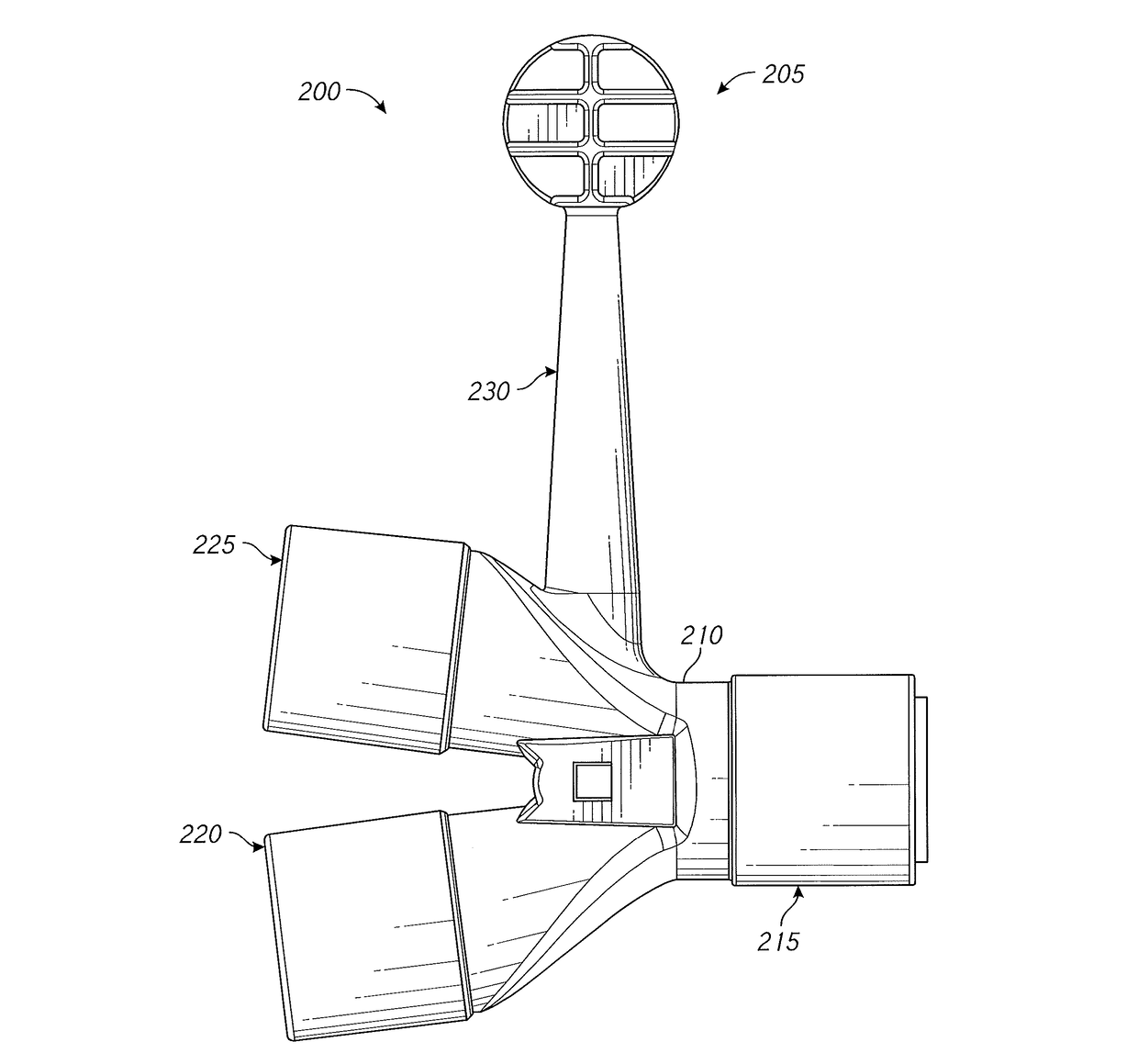

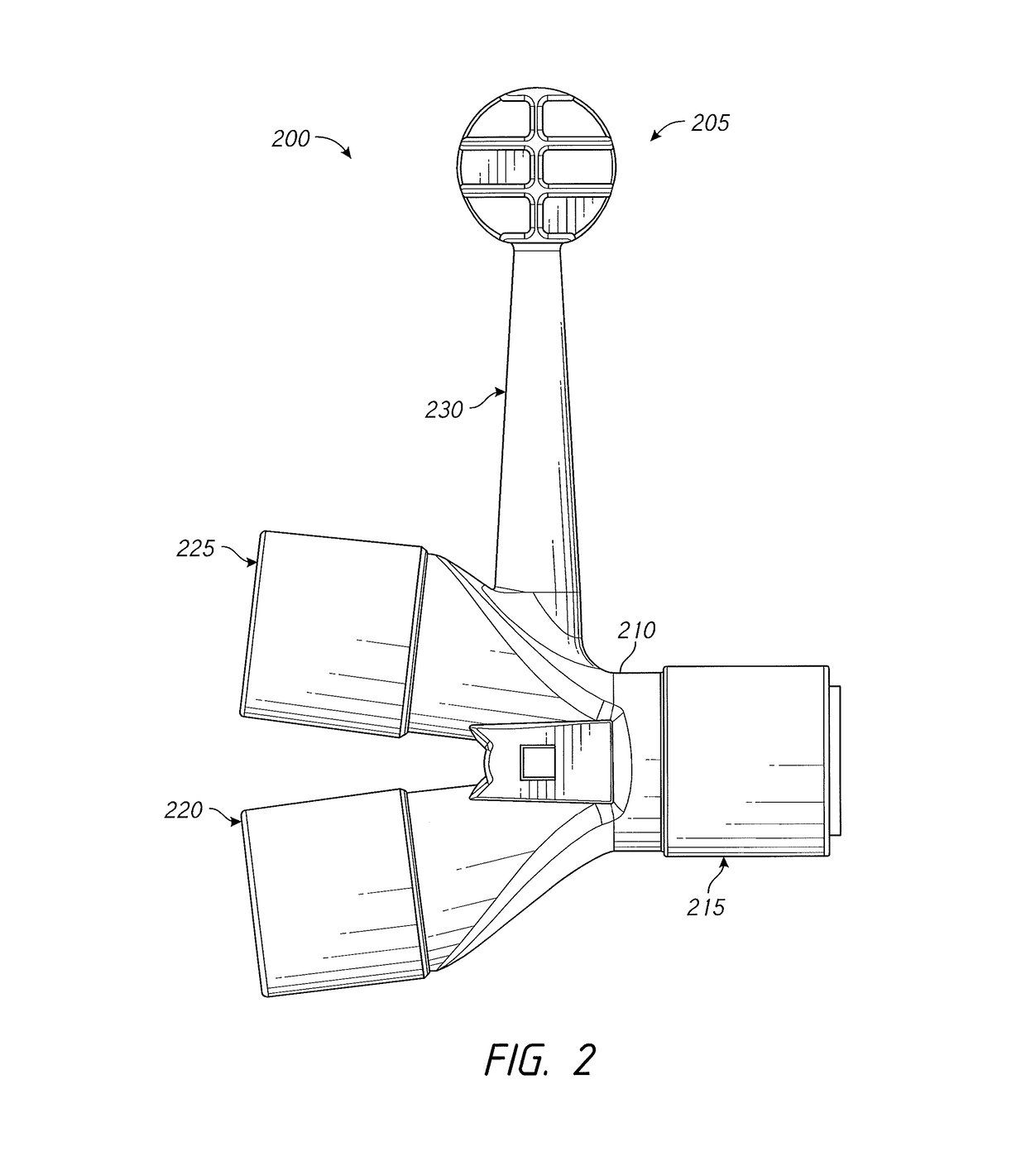

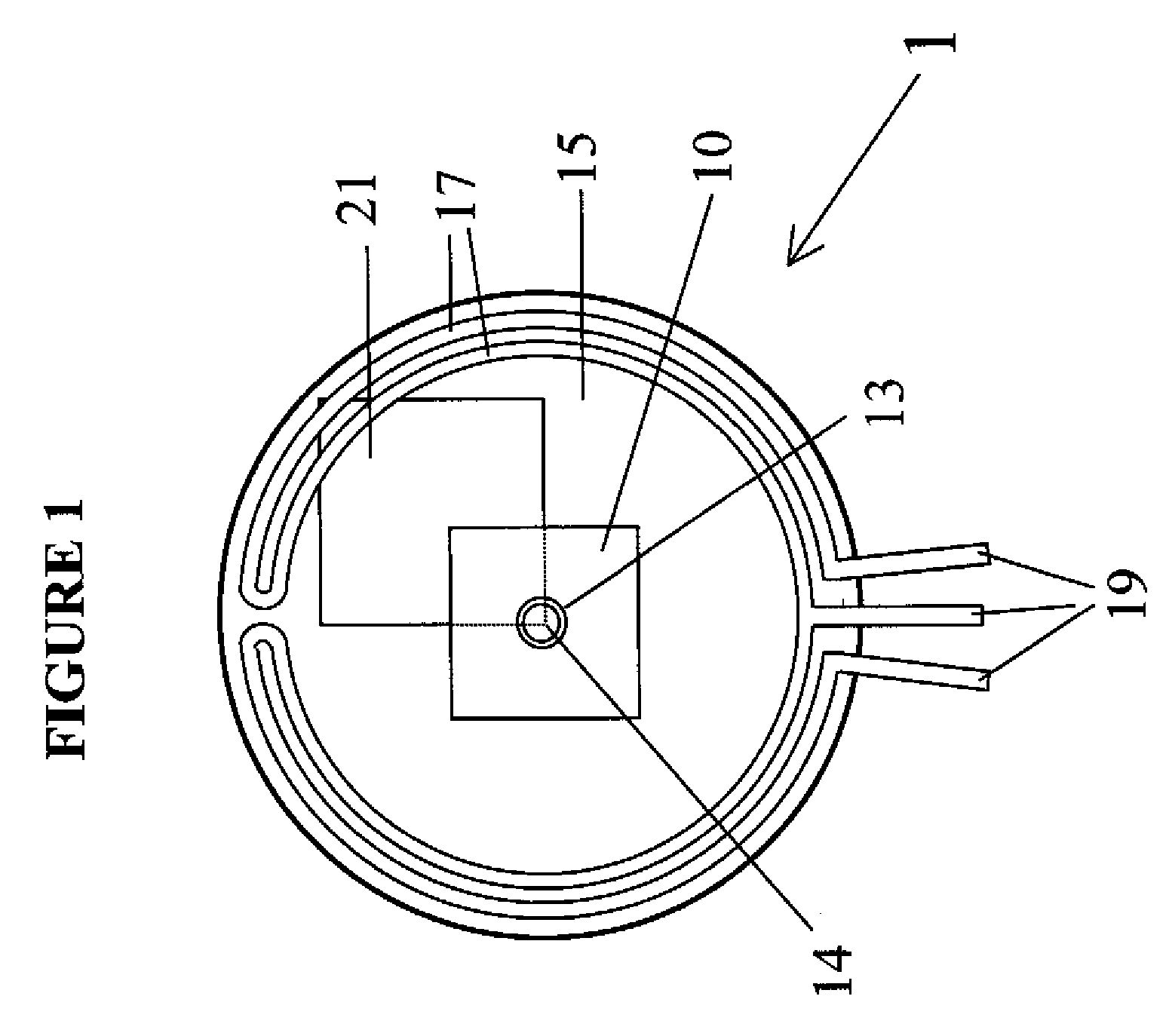

Connectors for respiratory assistance systems

InactiveUS20170246417A1Reduced effectivenessReduce the amount of condensateRespiratorsMedical devicesCatheterEngineering

Connectors for respiratory assistance systems are disclosed that are configured to at least decrease the proportion of condensate that drains into an inspiratory conduit. The connectors include a setup that causes the portion of a wye-piece connected to an expiratory conduit to be positioned below the portion of the wye-piece connected to the inspiratory conduit. The connector can alternatively, or additionally, include a wye-piece that includes a ball attached to the wye-piece adjacent the inspiratory conduit port such that when the ball is connected to a medical stand, the expiratory conduit port is positioned below the inspiratory conduit port. The connector can alternatively or additionally include a circuit hanger that includes a cradles for both conduits and a ball attached to the circuit hanger adjacent the inspiratory conduit cradle such that when the ball is connected to a medical stand, the expiratory conduit cradle is positioned below the inspiratory conduit cradle. The connector can alternatively or additionally include a coaxial wye-piece that includes an inspiratory branch, an expiratory branch, and a patient end. The tip of the inspiratory branch that is internal to the coaxial wye-piece may have a lip and a narrowed diameter, features which obstruct or reduce condensate from entering the inspiratory branch and the inspiratory conduit regardless of the coaxial wye-piece orientation or position.

Owner:FISHER & PAYKEL HEALTHCARE LTD

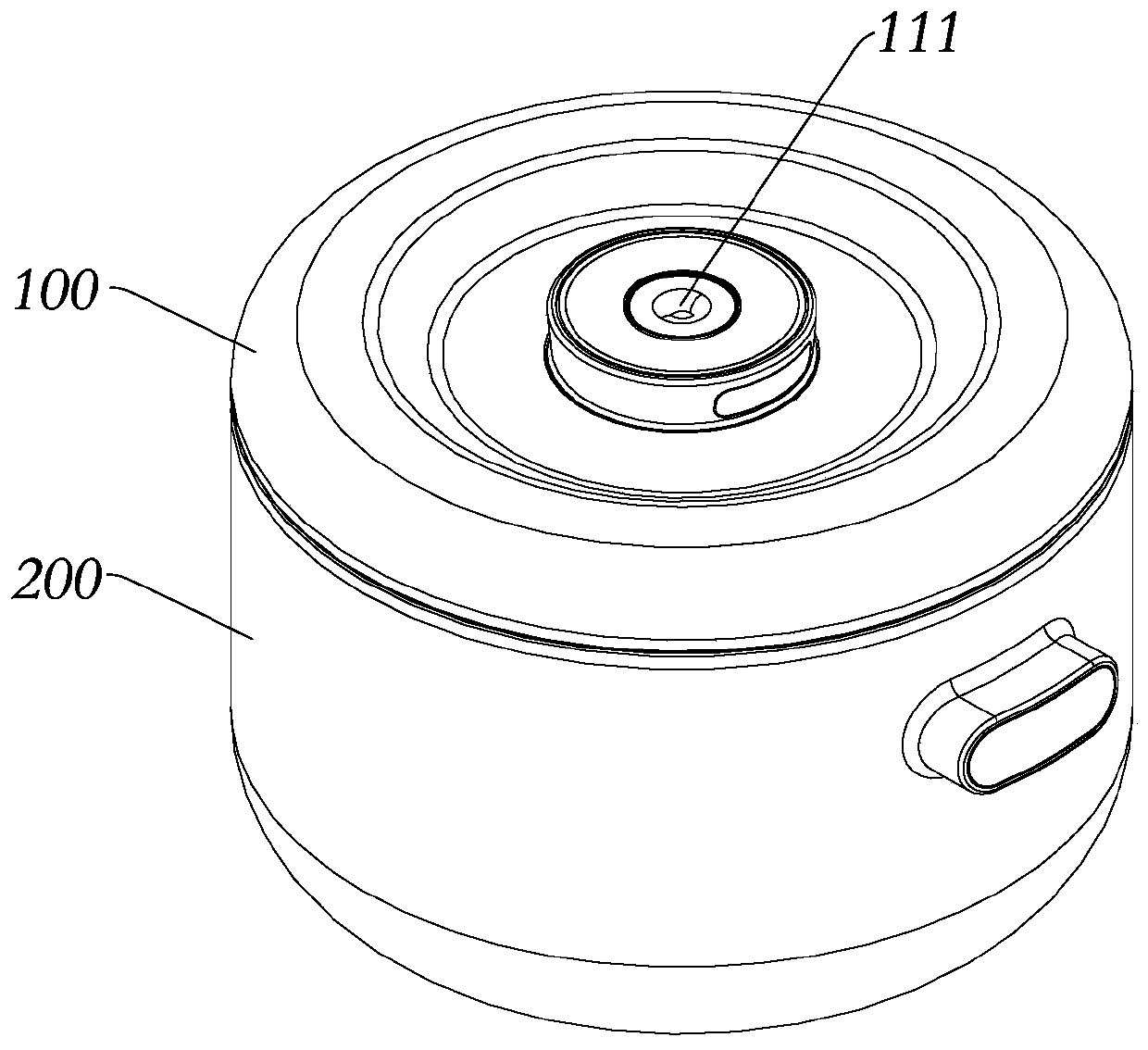

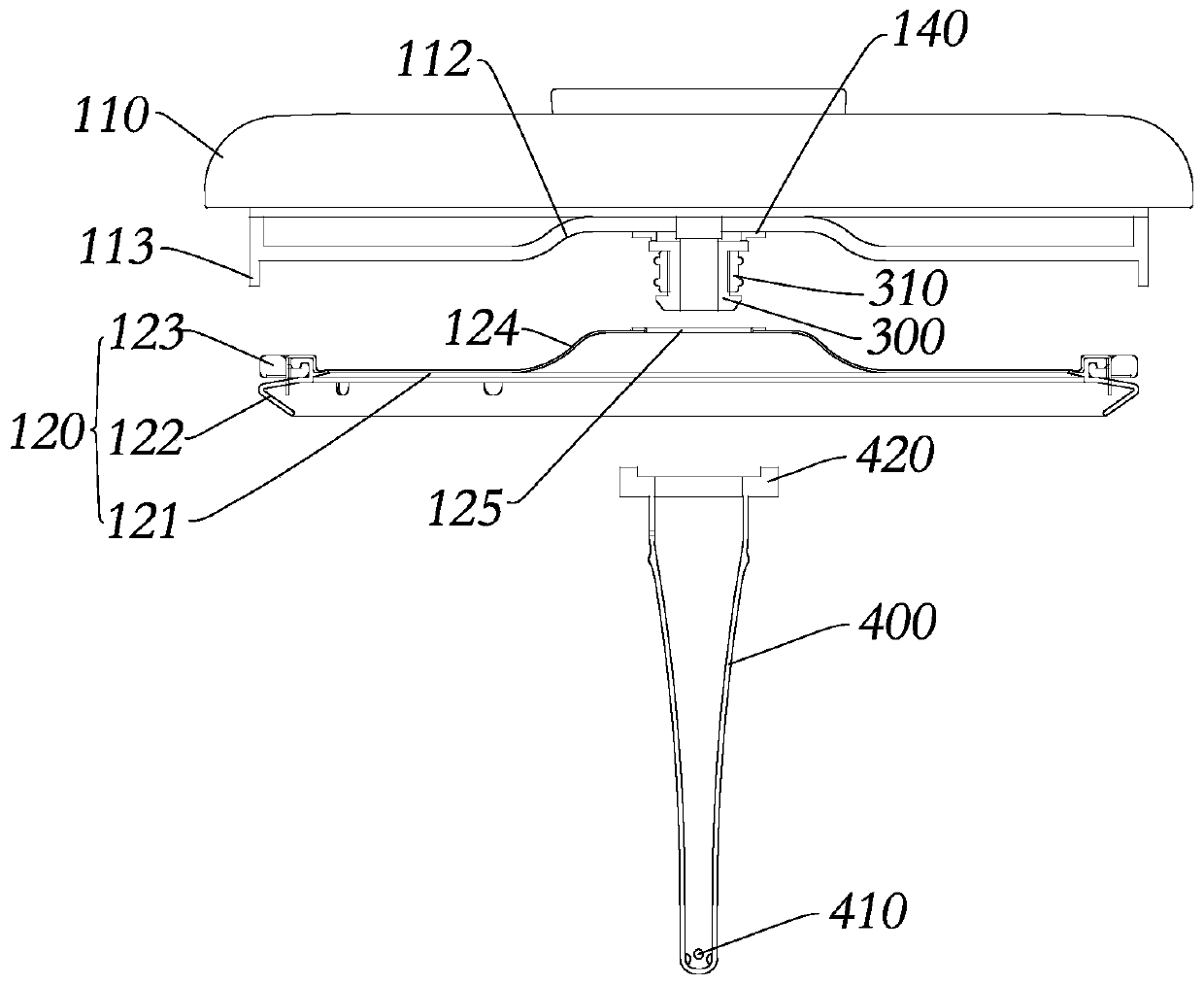

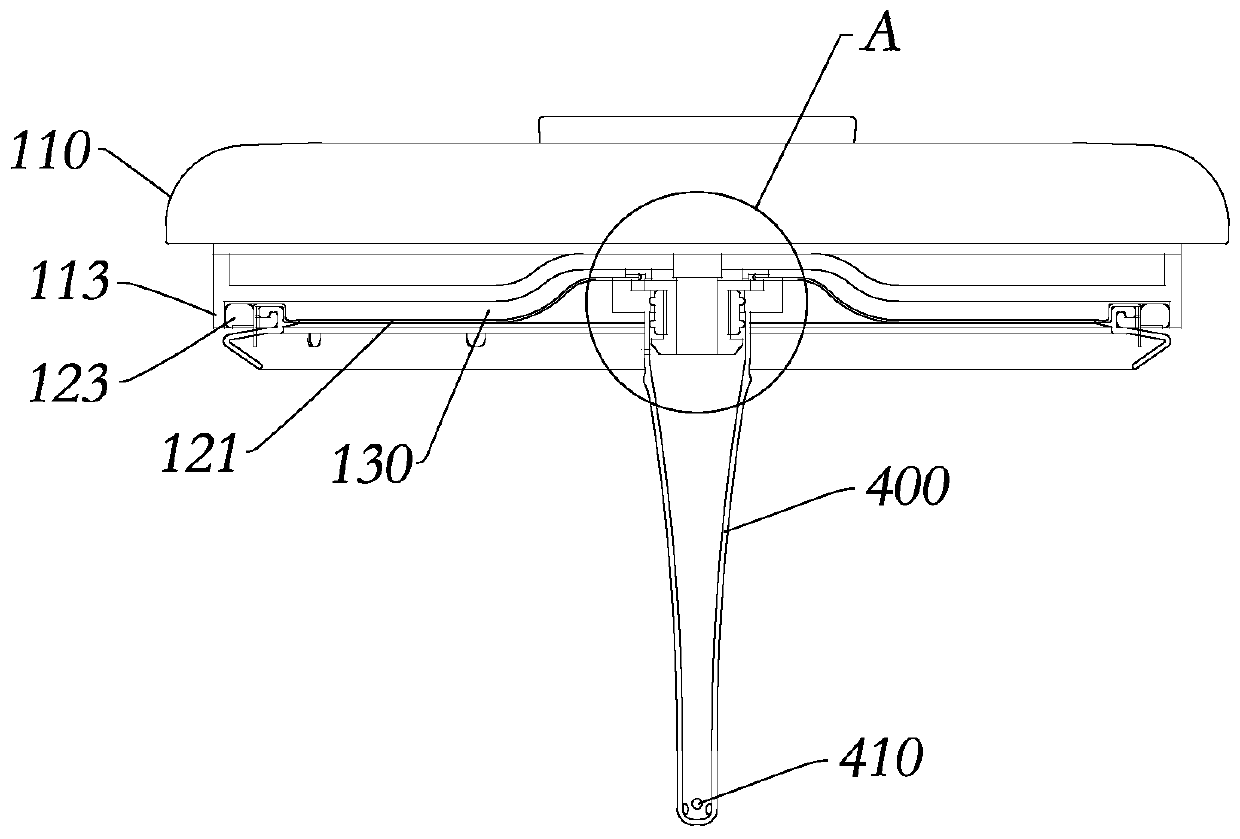

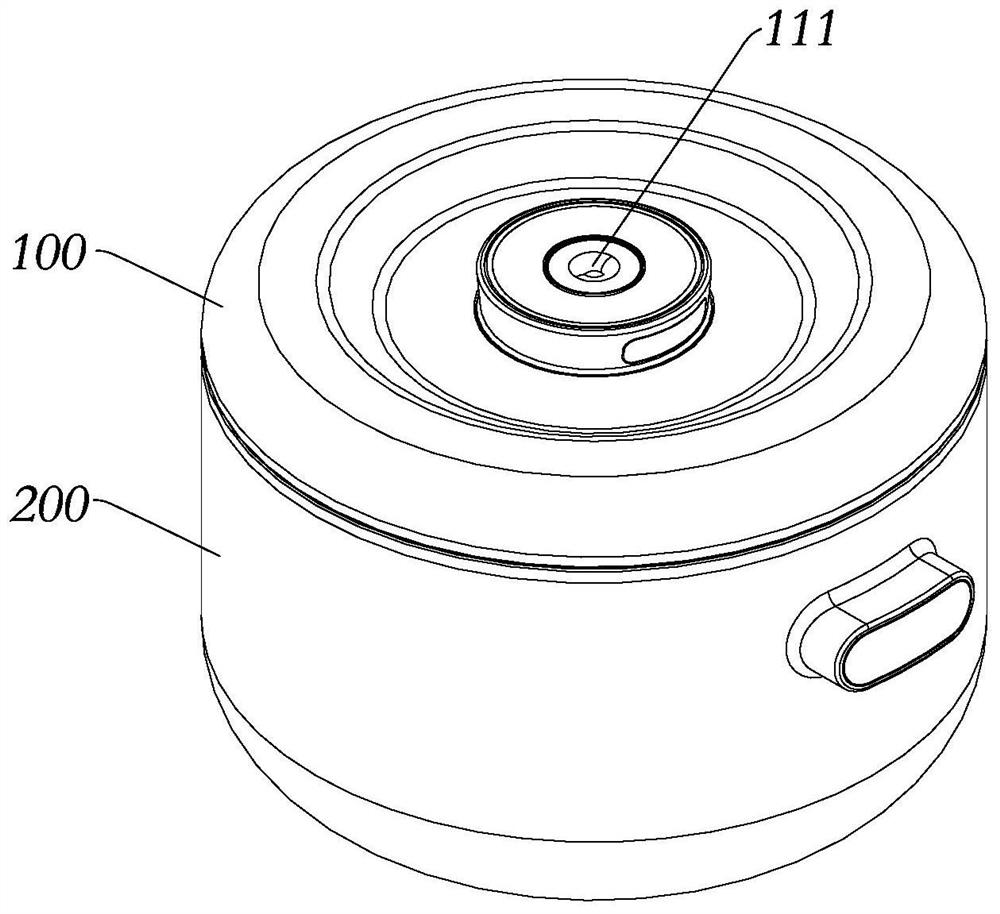

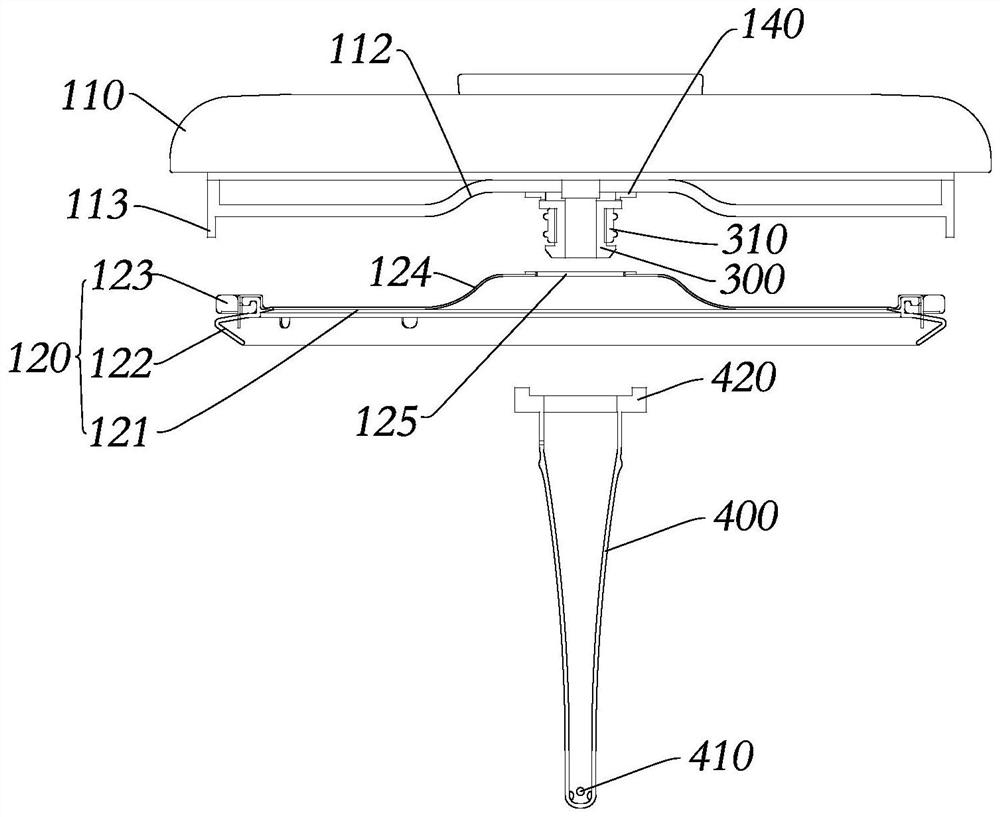

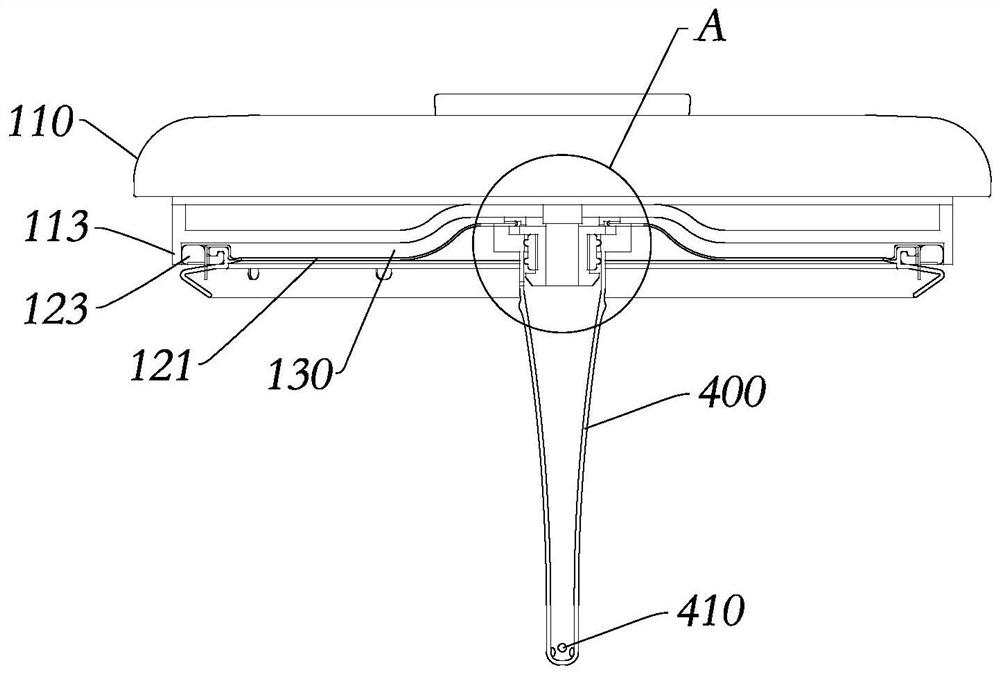

Cooking pan using steam heating, and steam heating type cooking utensil

ActiveCN110338641AExtend your lifeReduce entryBoiling over preventionCooking-vessel lids/coversEngineeringSteam heating

The invention discloses a cooking pan using steam heating, and a steam heating type cooking utensil, belongs to the field of kitchen household appliances, and solves the problem that a pan cover of acooking pan in the prior art is inconvenient to clean. The cooking pan provided by the invention comprises a pan body and a pan cover, wherein the pan cover comprises an outer cover and an inner cover; the outer cover covers the pan edge of the pan body; and the inner cover and the pan body are matched to form a cooking chamber. The cooking pan further comprises a steam guide pipe, wherein a projected air inlet connector is arranged on the inner side of the outer cover and penetrates through the inner cover; and the steam guide pipe can be detachably arranged on the air inlet connector and axially positions the inner cover. The cooking pan provided by the invention adopts the design of the detachable inner cover, so that the inner cover can be conveniently and independently cleaned.

Owner:JOYOUNG CO LTD

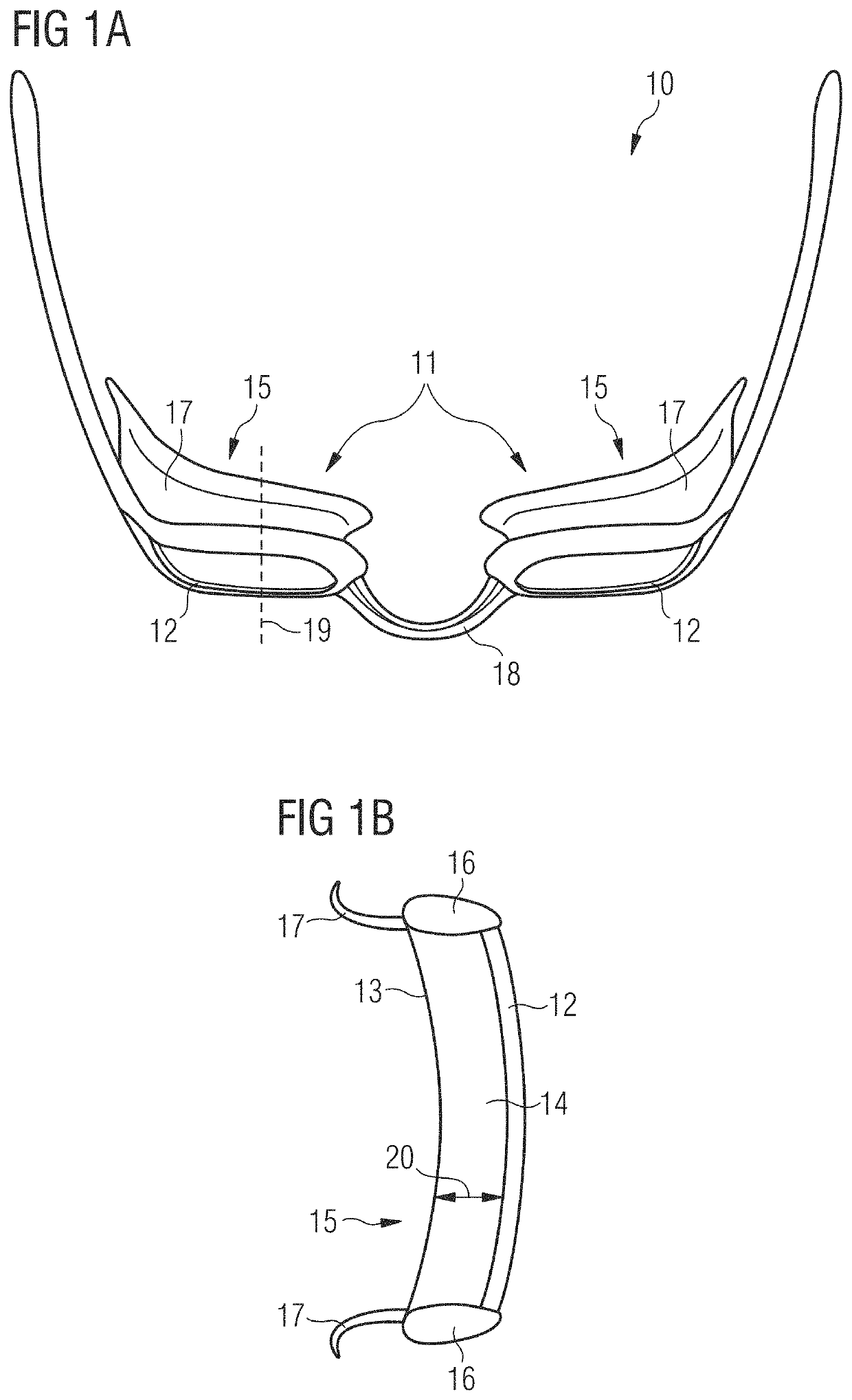

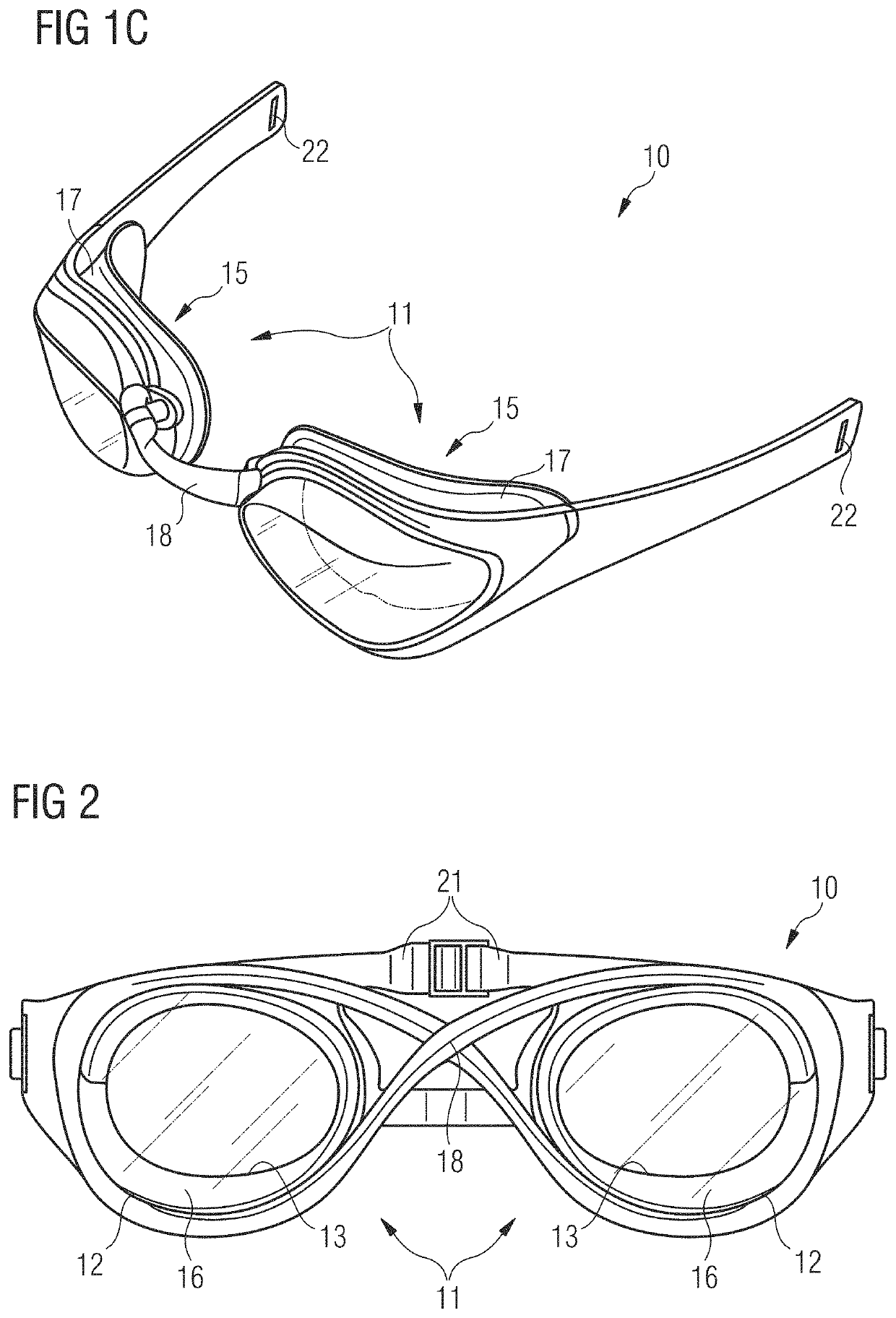

Swimming goggle

ActiveUS20190381361A1Optimal level of comfort and efficacyReduce humidityDetails involving processing stepsImage analysisEngineering

Owner:ADIDAS

Connectors for respiratory assistance systems

PendingUS20200289780A1Reduced effectivenessReduce the amount of condensateRespiratorsMedical devicesPhysical medicine and rehabilitationEngineering

Connectors for respiratory assistance systems are disclosed that are configured to at least decrease the proportion of condensate that drains into an inspiratory conduit. The connectors include a setup that causes the portion of a wye-piece connected to an expiratory conduit to be positioned below the portion of the wye-piece connected to the inspiratory conduit. The connector can alternatively, or additionally, include a wye-piece that includes a ball attached to the wye-piece adjacent the inspiratory conduit port such that when the ball is connected to a medical stand, the expiratory conduit port is positioned below the inspiratory conduit port. The connector can alternatively or additionally include a circuit hanger that includes a cradles for both conduits and a ball attached to the circuit hanger adjacent the inspiratory conduit cradle such that when the ball is connected to a medical stand, the expiratory conduit cradle is positioned below the inspiratory conduit cradle. The connector can alternatively or additionally include a coaxial wye-piece that includes an inspiratory branch, an expiratory branch, and a patient end. The tip of the inspiratory branch that is internal to the coaxial wye-piece may have a lip and a narrowed diameter, features which obstruct or reduce condensate from entering the inspiratory branch and the inspiratory conduit regardless of the coaxial wye-piece orientation or position.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Apparatus for thermal control in the analysis of electronic devices

InactiveUS20090146055A1Eliminate reflection lossReduce frictionMaterial analysis using wave/particle radiationHeat exchange apparatusSolid immersion lensSilicon

A heat spreader comprising a sheet of transparent diamond with an aperture therein that accommodates a solid-immersion lens (SIL). The heat spreader may be mounted within a clamp which allows the heat spreader to move freely across the Device Under Test (DUT) whilst maintaining a very high degree of planarity and contact between the diamond and the silicon substrate of the DUT. The DUT is secured to its electrical interface with a low profile clamp, the DUT may be held within the clamp by a mechanism that applies a pressure to the sides of the DUT package.

Owner:PRESTO ENG

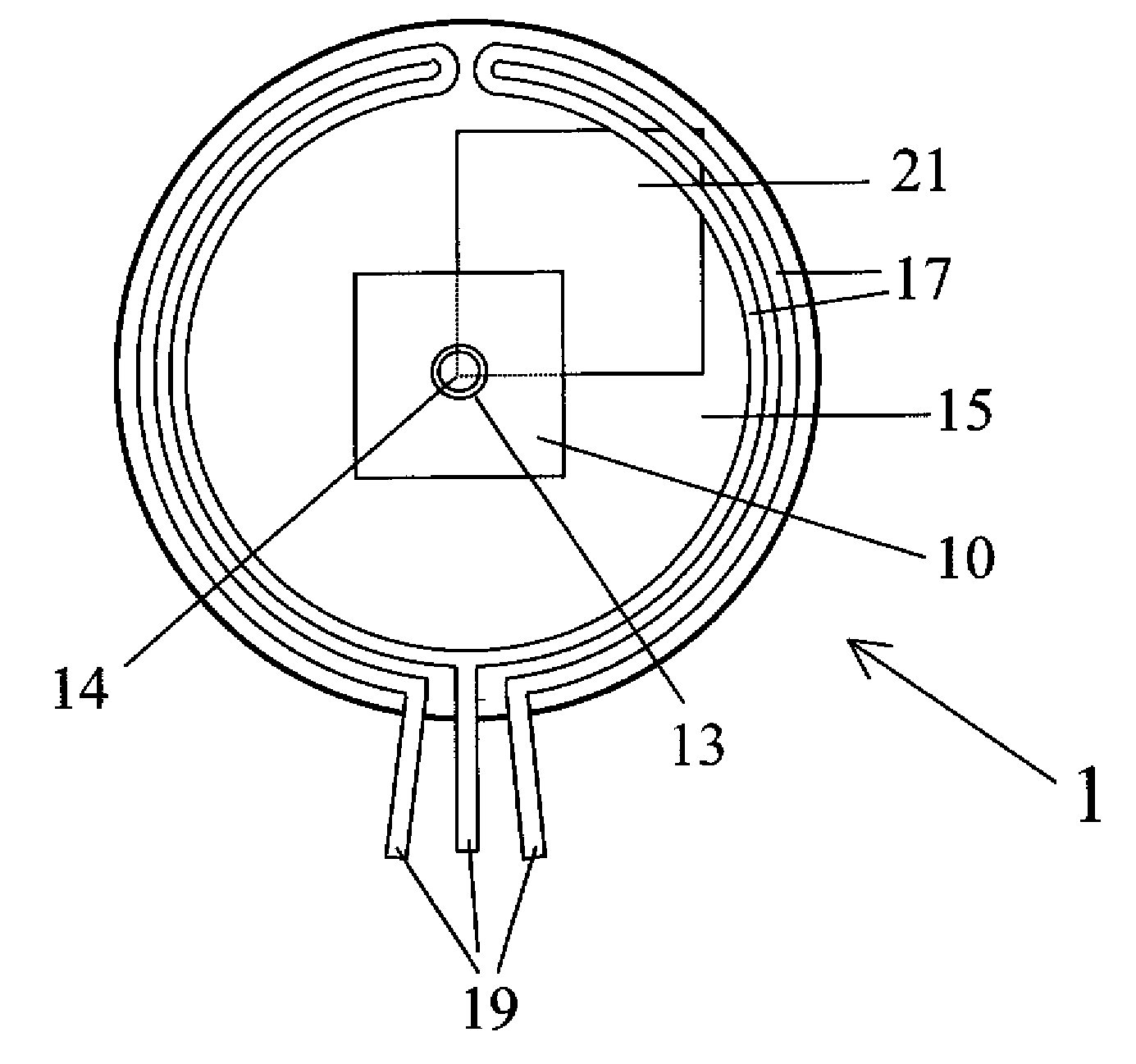

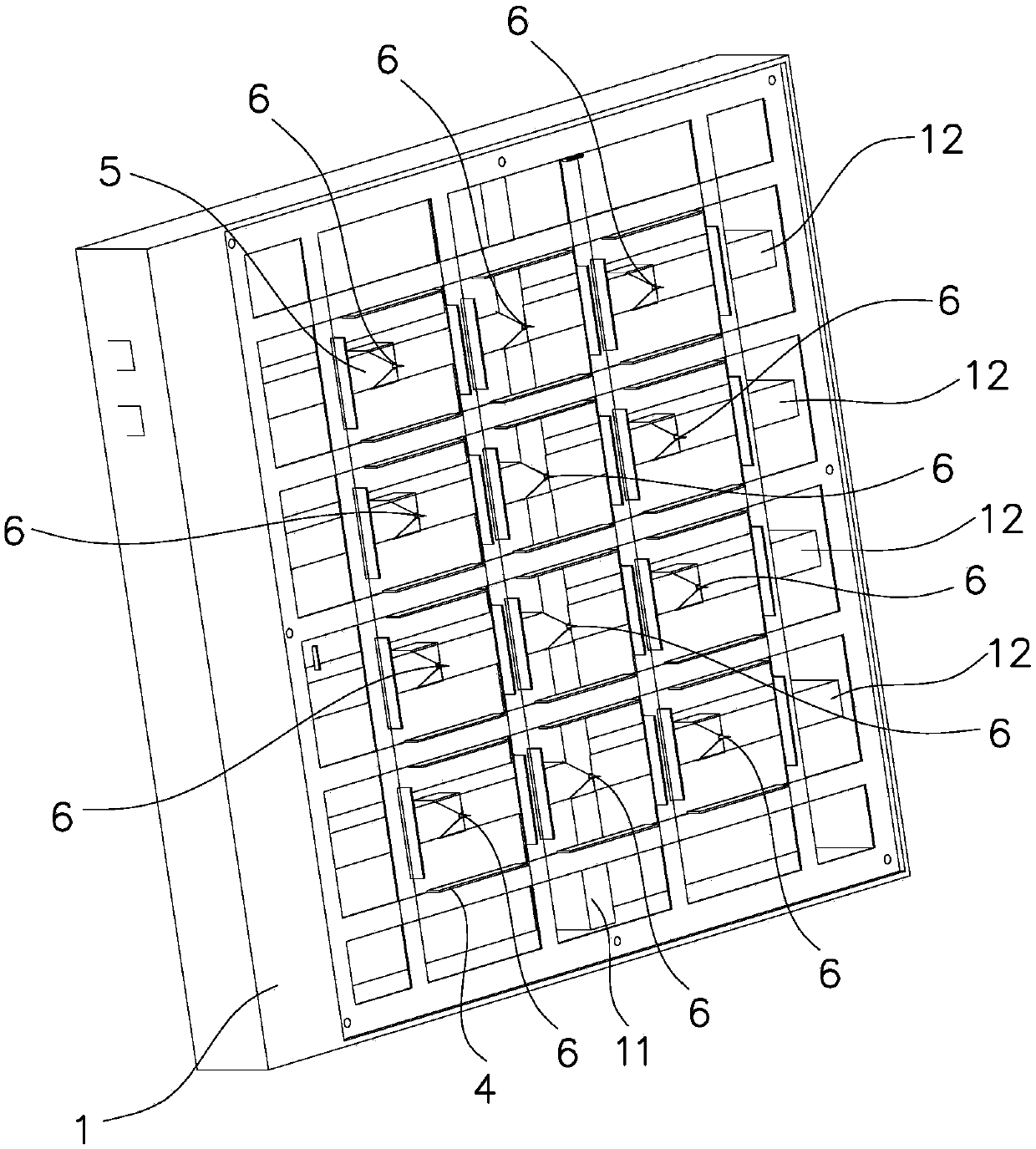

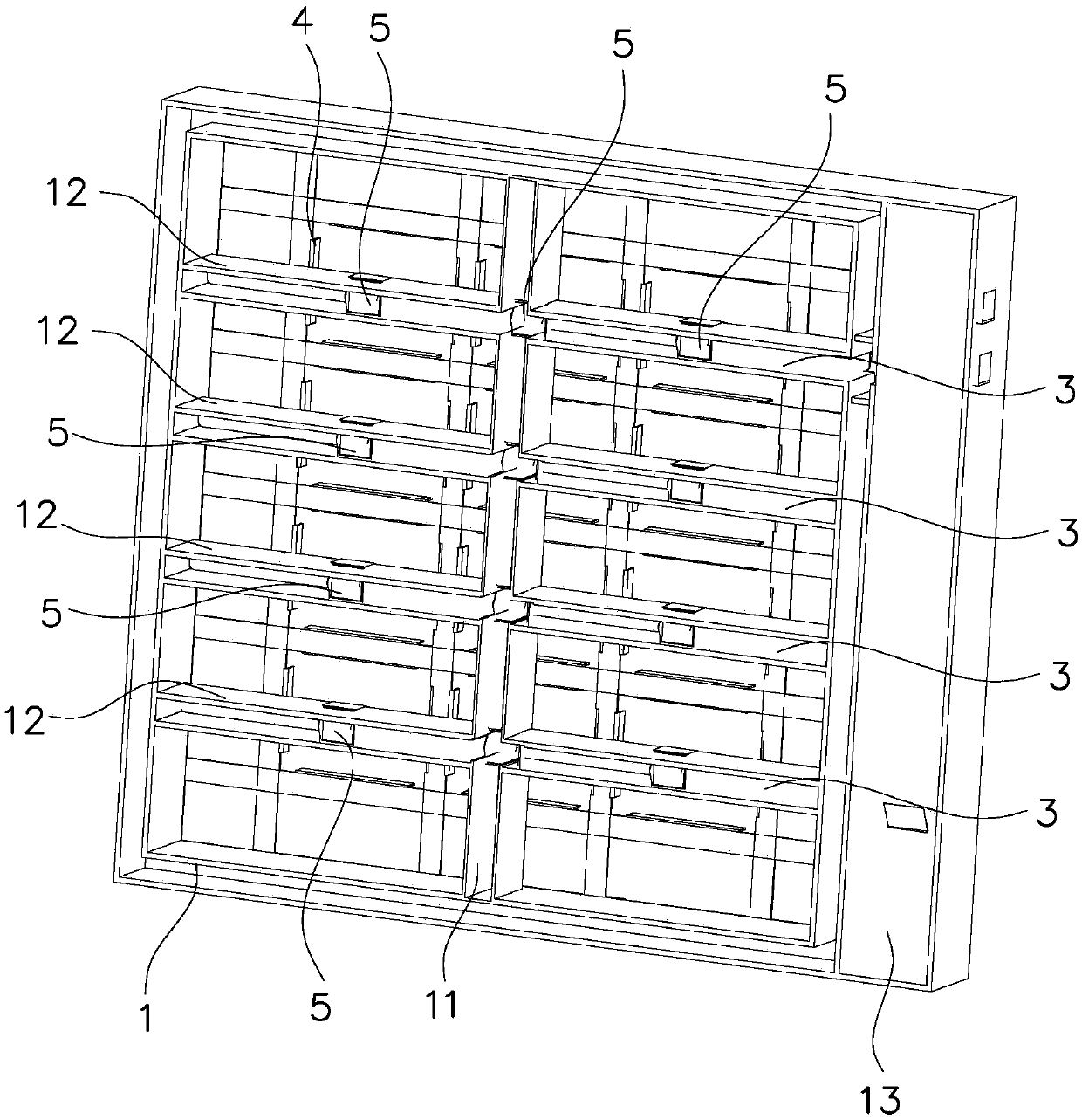

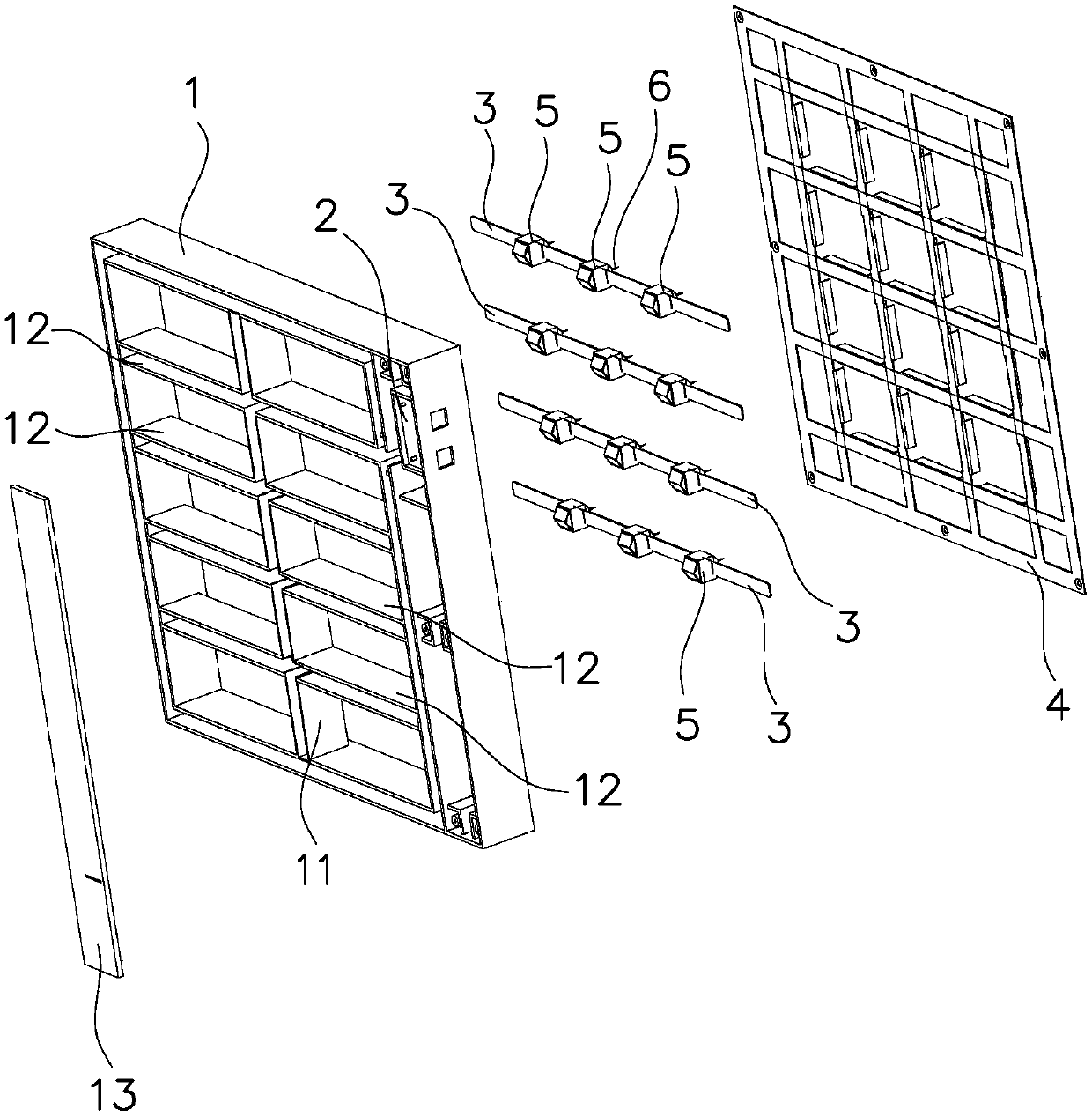

Negative ion generator and air filtering device provided with negative ion generator

PendingCN111129958AEnhance the effect of generating negative ionsIncrease concentrationMechanical apparatusMachines using electric/magnetic effectsAir filterEngineering

The invention provides a negative ion generator including a frame, and a high-voltage pack, a discharge electrode and a grounding electrode are installed on the frame. The high-voltage pack is electrically communicated with the discharge electrode; the negative ion generator is characterized in that a semiconductor refrigeration module is mounted on the frame; the semiconductor refrigeration module comprises an outer frame, a conducting strip and a refrigeration semiconductor, the outer frame is fixed on the frame, the conducting strip and the refrigeration semiconductor are arranged in the outer frame, the conducting strip is electrically connected with the discharge electrode, a negative ion probe is mounted on the conducting strip, a head of the negative ion probe extends forwards out of the outer frame, and a hot end of the refrigeration semiconductor is close to the conducting strip. The negative ion generator has the advantages that the semiconductor refrigeration module is mounted on the frame; the negative ion probe is installed on the conducting strip of the semiconductor refrigeration module, the hot end of the refrigeration semiconductor is close to the conducting strip,so that heat generated by the hot end can be transmitted to the negative ion probe, the negative ion generation effect of the negative ion probe is enhanced, and the negative ion generation concentration is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

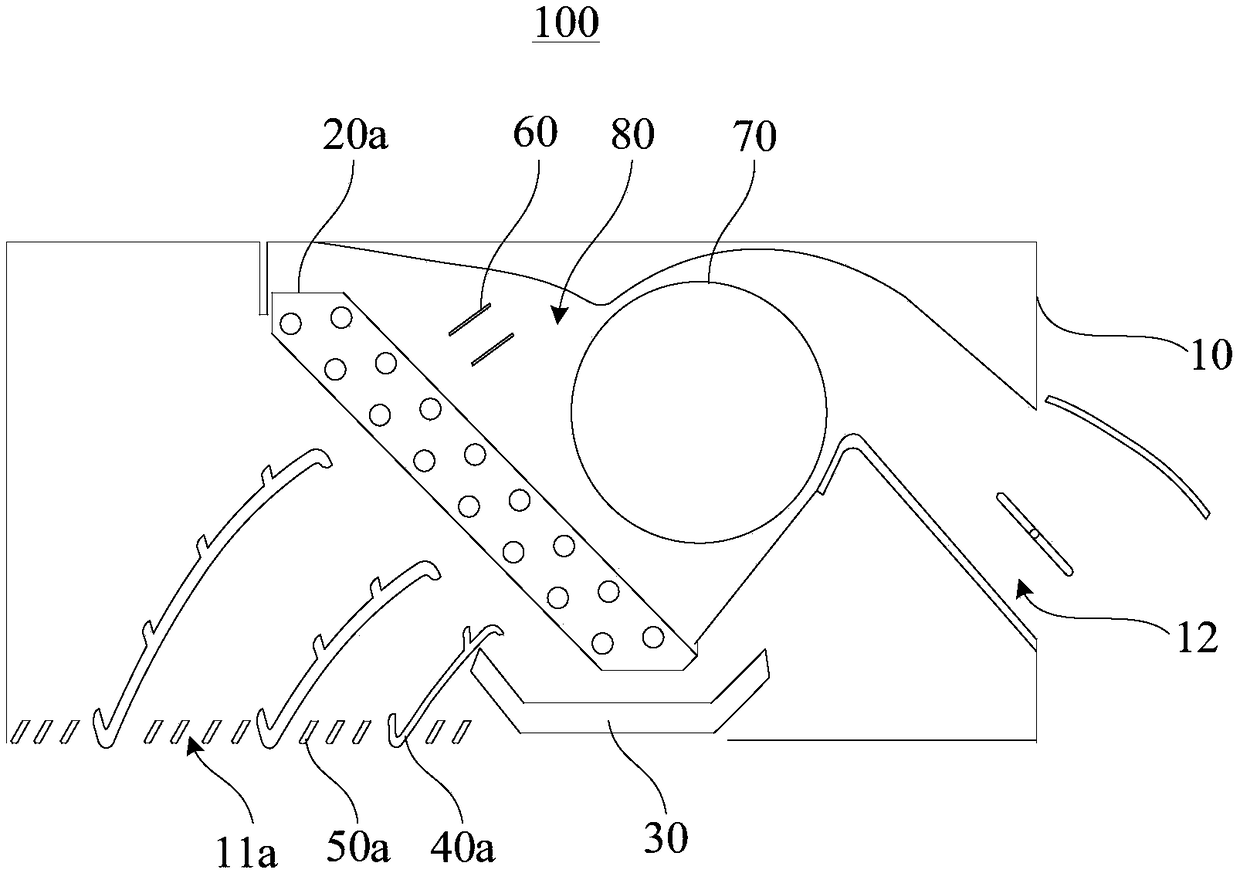

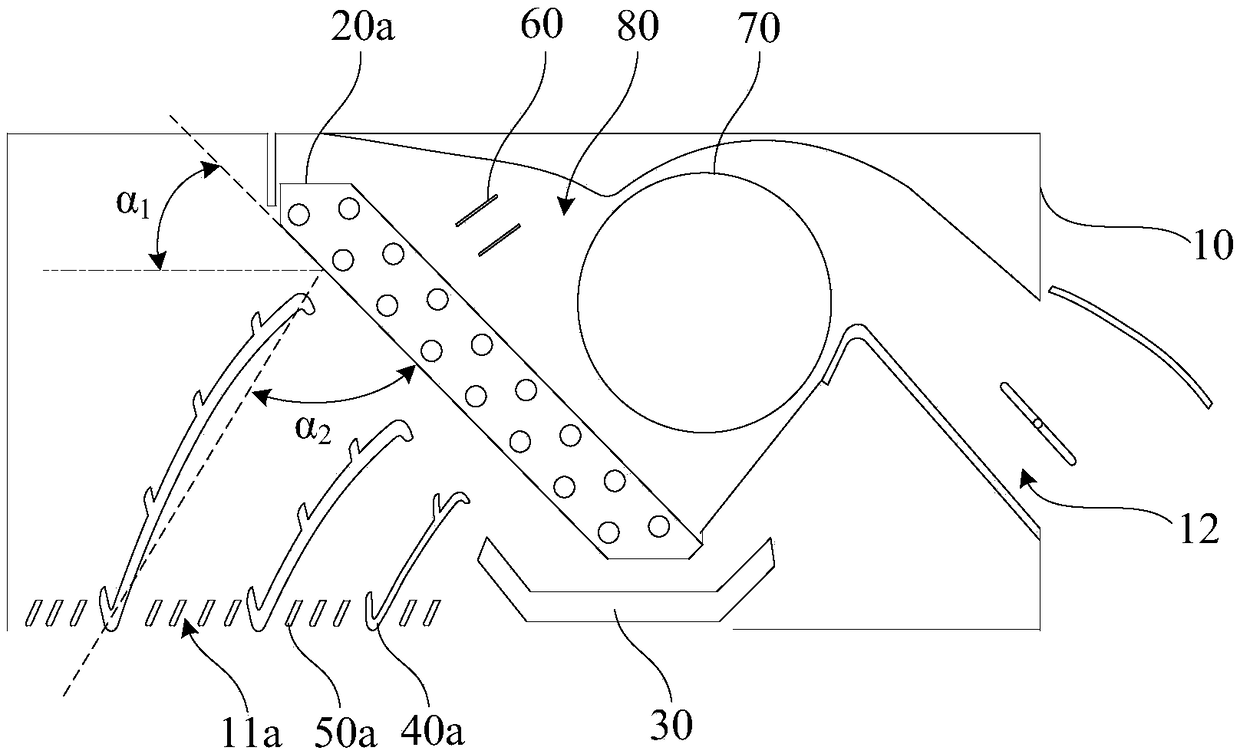

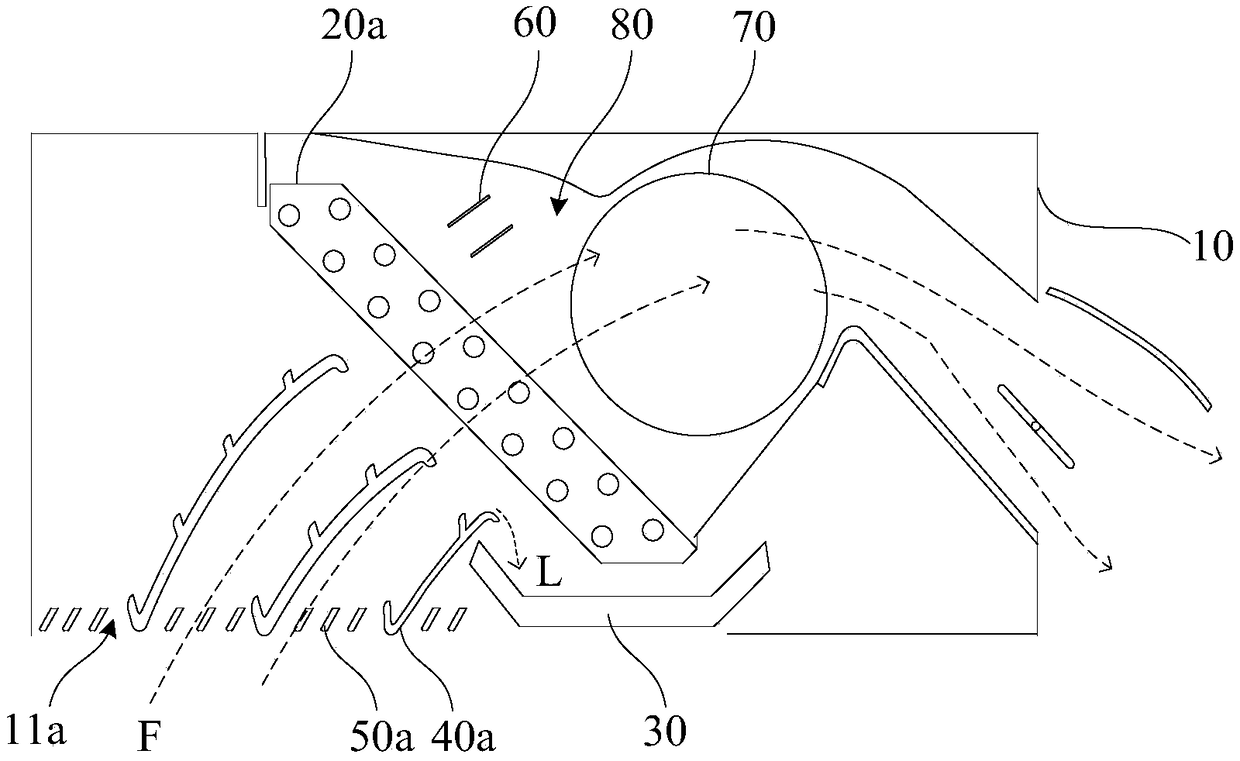

Air-conditioner indoor unit and air conditioner

PendingCN108775623AAvoid drippingReduce drippingCondensate preventionLighting and heating apparatusEngineeringHeat exchanger

The invention discloses an air-conditioner indoor unit and an air conditioner, wherein the air conditioner comprises the air-conditioner indoor unit. The air-conditioner indoor unit comprises a shell,a first heat exchanger, a main water receiving tray and a plurality of auxiliary water receiving trays. First air inlets are formed in the rear end of a bottom plate of the shell, the first heat exchanger is arranged in the shell and inclines backward, and the main water receiving tray is arranged at the lower end of the first heat exchanger. The auxiliary water receiving trays comprise a plurality of first auxiliary water receiving trays arranged below the first heat exchanger, the first auxiliary water receiving trays are sequentially arranged at intervals along the inclined surface of thefirst heat exchanger in the up and down direction, and projections of the first auxiliary water receiving trays on the bottom plate of the shell are connected end to end; and at least part of the water receiving surfaces of the first auxiliary water receiving trays extend downward to the first air inlets. According to air-conditioner indoor unit, condensed water falling down into a room can be reduced, and comfortable experience of users is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Preparation of hollow polymer microspheres

ActiveCN103524653BImprove stabilityWell mixedPowdery paintsEmulsion paintsPolymer scienceMicrosphere

The invention uses a three-stage reaction process to prepare hollow particles with a buffer layer. The particle structure is complete and the particle size is uniform. It is applied to plastic or paper coatings. It has high gloss, whiteness and opacity, and has good printing color concentration and Good water resistance for printing.

Owner:NANYA PLASTICS CORP

Chemical waste liquid negative pressure recovery device

InactiveCN104628064ALow operating costImprove evaporation efficiencyWater treatment parameter controlWater/sewage treatment by heatingLiquid wasteAutomatic control

The invention relates to a chemical waste liquid negative pressure recovery device. The chemical waste liquid negative pressure recovery device comprises a heater, an evaporator, a condenser and a liquid seal groove and is characterized by also comprising a water ring pump unit for vacuumizing and a small-sized condensate buffer tank, wherein the heater, the evaporator, the condenser and the liquid seal groove are sequentially connected; the outlet formed in the bottom of the evaporator is connected with a discharge pump; the condenser is connected with the small-sized condensate buffer tank and a liquid level switch is arranged at the side wall of the inner top of the small-sized condensate buffer tank; a temperature and pressure sensor is arranged in each of the heater, the evaporator and the condenser; and a PLC automatic control system is adopted in the device. By adopting the water ring pump unit instead of a steam jet pump unit, the problems that too much circulating water is evaporated, the loss in the cooling water is too large and the recycling effect is poor when the waste liquid is recovered by virtue of negative pressure suction-filtration process manner during the practical production are solved.

Owner:TIANJIN BOHUA ZHONGHE CHEM

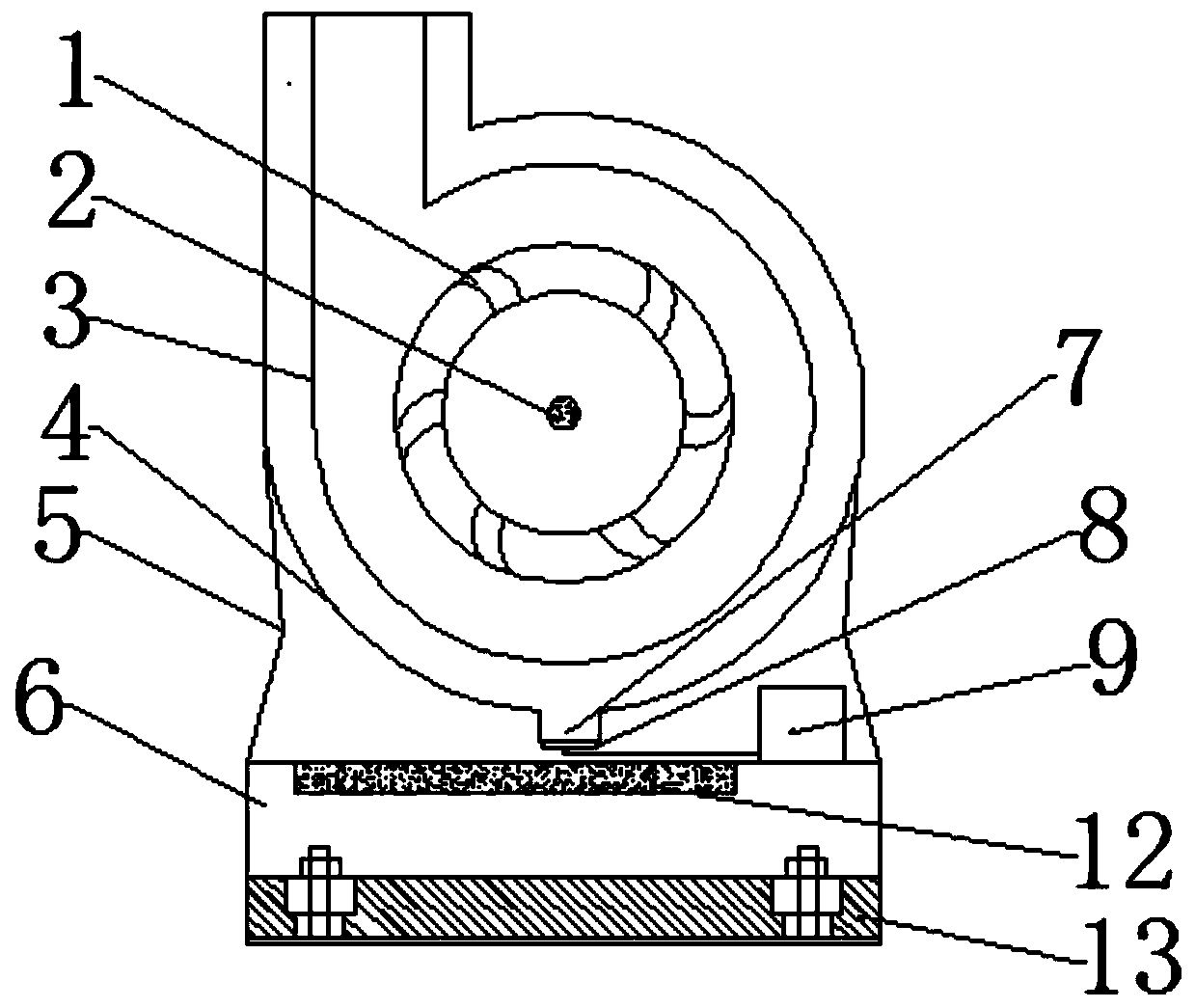

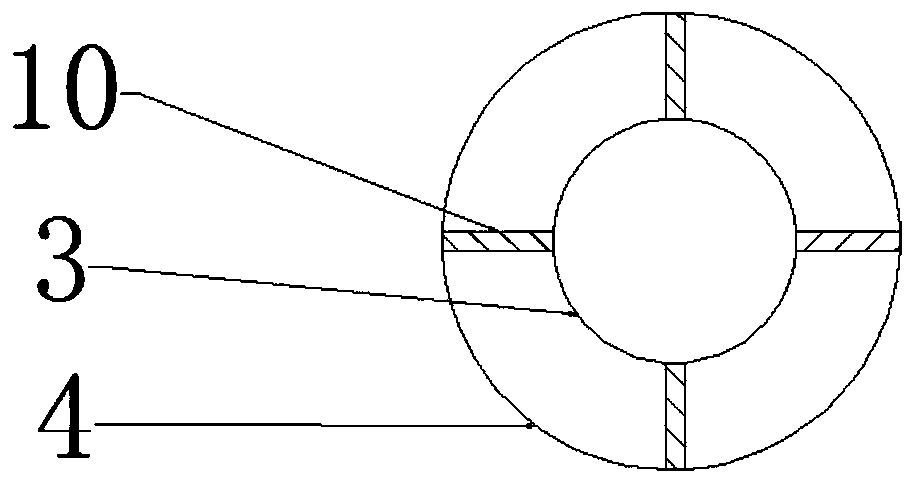

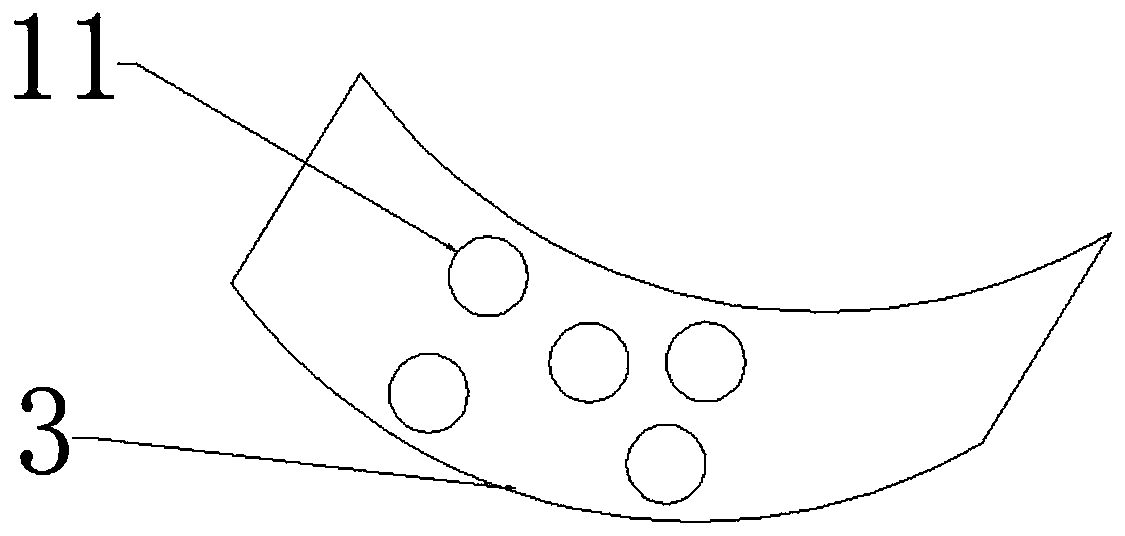

Centrifugal fan for wet devulcanizer

PendingCN110541832AReduce the amount of condensateReduce corrosionPump componentsRadial flow pumpsImpellerAgricultural engineering

The invention discloses a centrifugal fan for a wet devulcanizer. The centrifugal fan comprises an impeller; a motor is connected to the center of the impeller through a bearing; a first outer shell is arranged at the external of the impeller; an upper port position of the first outer shell is welded with an upper port of a second outer shell through a connecting rod; the two sides of the second outer shell are connected with brackets; the brackets are connected to a base; a liquid storage tank is formed in the bottom of the second outer shell; and a detachable sealing piece is arranged at thelower end of the liquid storage tank. The centrifugal fan for the wet devulcanizer is simple in structure and convenient to use, can improve the corrosion resistance to prolong the service life, andcan return condensed alkali liquid into a devulcanizing tower to reduce waste of the alkali liquid.

Owner:CHENGXI SHIPYARD

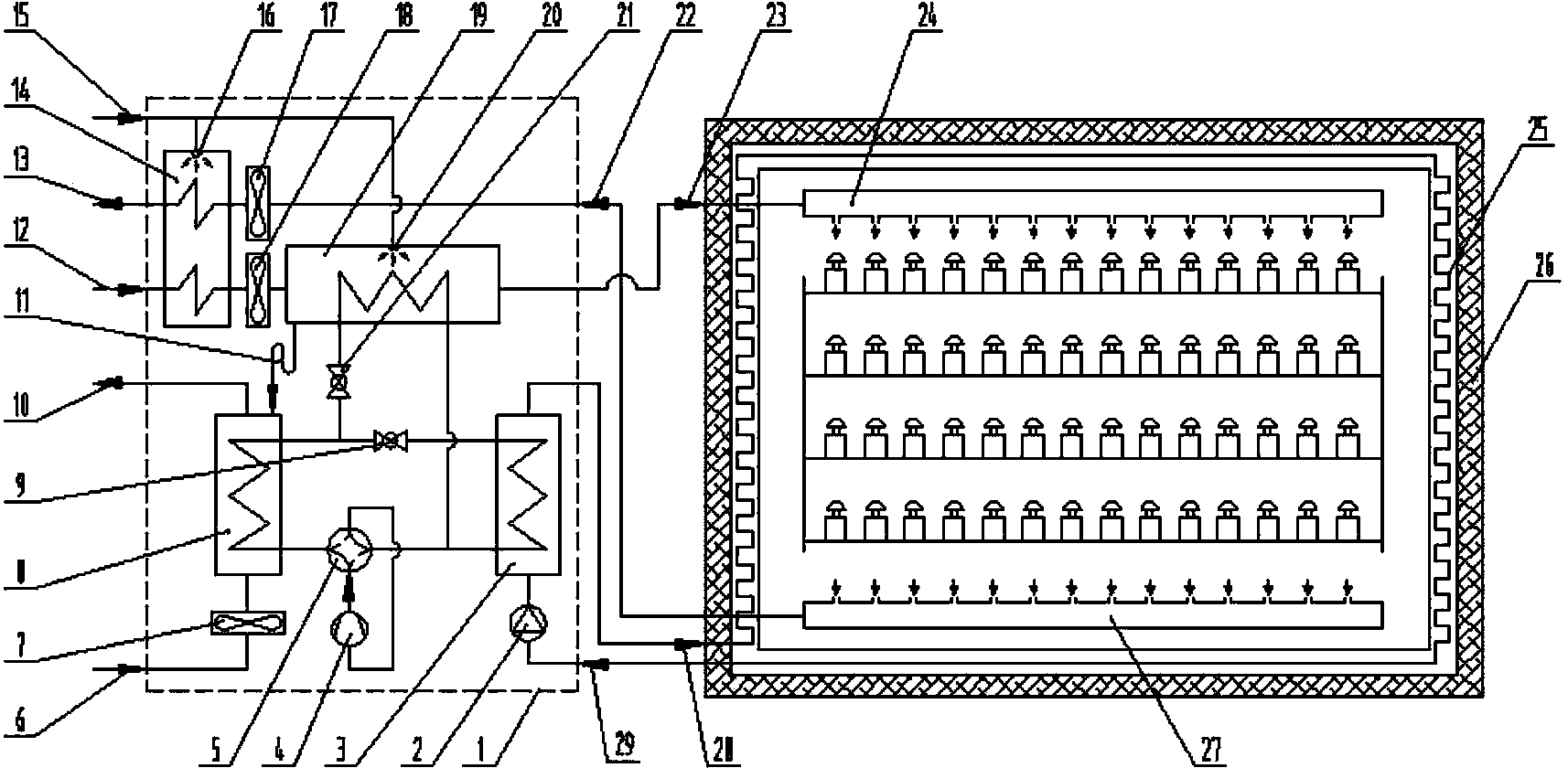

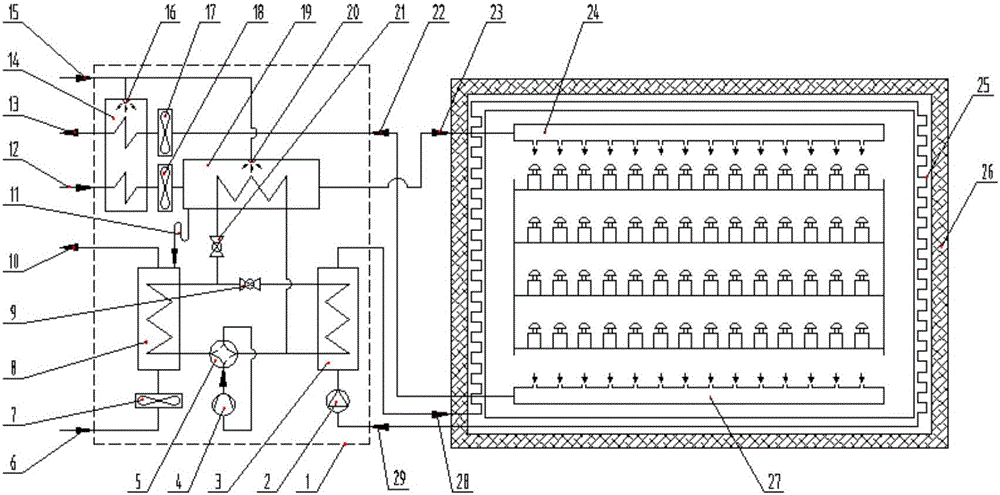

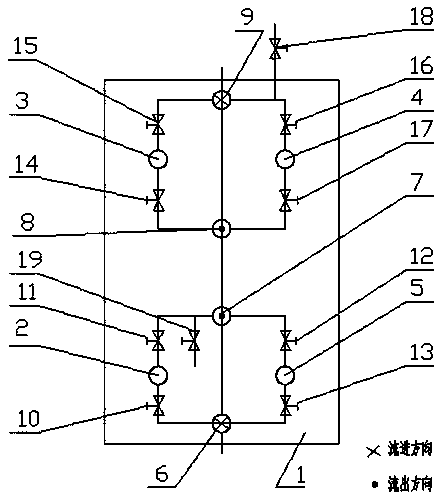

Air conditioning system used for crop culture room

InactiveCN103486672AIn line with the natural environmentEasy to installCondensate preventionLighting and heating apparatusAtmospheric airOperation mode

The invention discloses an air conditioning system used for a crop culture room. The air conditioning system comprises a culture room which is internally provided with an air supply box and an air return box, and an independent air conditioning unit which is arranged outside the culture room, wherein the wall body inside the culture room is internally nested with a plurality of wall coils from bottom to top or from top to bottom, one side of the independent air conditioning unit is correspondingly communicated with the air supply box, the air return box and the wall coils arranged in the culture room through a primary air pipe, an exhaust pipe, a water supply pipe and a water return pipe, and the other side of the independent air conditioning unit is communicated with the atmosphere environment through an environment air inlet, an environment air outlet, a primary air inlet and an exhaust port, and is provided with a humidification water pipe. When the air conditioning system is used for heating, a heat pump operation mode is started, and when the air conditioning system is used for refrigerating, a refrigerating operation mode is started. Due to the adoption of the air conditioning system, the culture room is more suitable for the natural environment characteristic for crop growth, and is convenient to arrange and operate, safe and sanitary in production and low in energy consumption.

Owner:广西农垦昌菱农场有限公司

An air-conditioning system for a crop cultivation room

InactiveCN103486672BIn line with the natural environmentEasy to installCondensate preventionLighting and heating apparatusAtmospheric airEngineering

The invention discloses an air conditioning system used for a crop culture room. The air conditioning system comprises a culture room which is internally provided with an air supply box and an air return box, and an independent air conditioning unit which is arranged outside the culture room, wherein the wall body inside the culture room is internally nested with a plurality of wall coils from bottom to top or from top to bottom, one side of the independent air conditioning unit is correspondingly communicated with the air supply box, the air return box and the wall coils arranged in the culture room through a primary air pipe, an exhaust pipe, a water supply pipe and a water return pipe, and the other side of the independent air conditioning unit is communicated with the atmosphere environment through an environment air inlet, an environment air outlet, a primary air inlet and an exhaust port, and is provided with a humidification water pipe. When the air conditioning system is used for heating, a heat pump operation mode is started, and when the air conditioning system is used for refrigerating, a refrigerating operation mode is started. Due to the adoption of the air conditioning system, the culture room is more suitable for the natural environment characteristic for crop growth, and is convenient to arrange and operate, safe and sanitary in production and low in energy consumption.

Owner:广西农垦昌菱农场有限公司

A kind of preparation method of vanadium pentoxide

The invention belongs to the field of hydrometallurgy and particularly relates to a vanadium pentoxide preparation method. The preparation method comprises the following steps that (a) the temperature of acidic vanadium liquid rises from normal temperature to 65-75 DEG C in the preheating process of a vanadium precipitation process by using a static mixer pipe and utilizing steam heat exchange; (b) the acidic vanadium liquid subjected to heat exchange is added into an ammonium tank, ammonium sulfate is added, and stirring is performed to obtain mixed liquid; (c) the mixed liquid is added into a sedimentation tank, stirring is performed, a pH value is regulated to be 1.5-2, and steam heating is performed to reach 90 DEG C to boiling so as to obtain an ammonium poly-vanadate solution; (d) precipitate obtained after the ammonium poly-vanadate solution precipitates is washed, dried and calcinated to obtain vanadium pentoxide. The flowing state of the acidic vanadium liquid in the pipe is changed by utilizing a mixing unit body fixed in the static mixer pipe, the formation of a laminar flow bottom layer is inhibited to enable the acidic vanadium liquid to rapidly disperse in the pipe, the temperature distribution of all parts of the solution tends to be uniform, the formation of a scale layer is retarded, and the production efficiency of the vanadium pentoxide is improved.

Owner:攀钢集团西昌钒制品科技有限公司

Cooking pots and steam-heating cooking appliances for steam heating

ActiveCN110338641BExtend your lifeReduce entryBoiling over preventionCooking-vessel lids/coversThermodynamicsMechanical engineering

Owner:JOYOUNG CO LTD

Integrated mullion and fluorescent lamp assembly for a commercial display refrigerator

InactiveUS20060285329A1Avoid condensationConvenient lightingShow cabinetsElectric circuit arrangementsIceboxEngineering

An integrated mullion and fluorescent lamp assembly for a display refrigerator comprising a mullion including an open-ended rear side, a longitudinal lens removably positioned over the open-ended rear side of the mullion and a lamp assembly positioned within the mullion, whereby heat from the lamp assembly heats the mullion.

Owner:COMML REFRIGERATOR DOOR

Recovery device for chemical waste liquid

InactiveCN107789850ALow operating costsContinuous and stable productionWater treatment parameter controlEvaporator accessoriesLiquid wasteVacuum pumping

The invention provides a recovery device for chemical waste liquid. The recovery device for chemical waste liquid comprises a heater, an evaporator, a condenser and a liquid sealing tank which are connected in sequence, wherein the upper part of the heater is provided with a feed inlet; the bottom outlet of the evaporator is connected with a discharging pump; a small condensate buffer tank is connected to the condenser; and the heater, the evaporator and the condenser are all provided with temperature sensors and pressure sensors. The recovery device for chemical waste liquid further comprisesa water ring pump unit for vacuum pumping; and the device uses a PLC automatic control system. The recovery device has the beneficial effects that the device is obtained based on reconstruction of existing equipment, and is low in operation and running cost; the waste liquid evaporation device has high evaporation efficiency, is simple to operate, and adopts a full negative pressure system to ensure clean and safe production and reduction in environmental pollution; the recovery device adopts the PLC automatic control system, so operation is safe and simple, the amount of condensate is reduced, and good recycling effect of cooling water is achieved.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

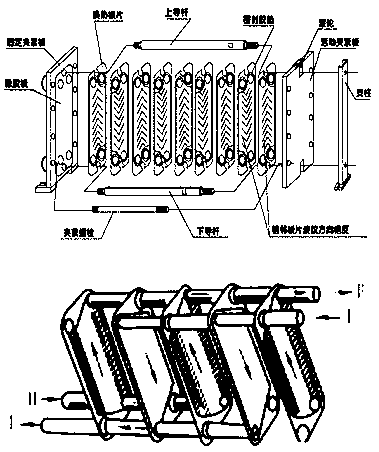

High-performance plate heat exchanger capable of performing switching and back flushing

PendingCN110631396AExcellent stability and aging resistanceExtended use timeFlush cleaningStationary plate conduit assembliesCondensed waterEngineering

The invention provides a high-performance plate heat exchanger capable of performing switching and back flushing. The high-performance plate heat exchanger comprises a plate heat exchanger main body,tee joints, upper end valves, lower end valves and a back flushing valve. The plate heat exchanger main body is the same with a general plate heat exchanger in structure, and comprises multiple rectangular thin metal heat exchange plates, a movable clamping plate, a fixed clamping plate, a sealing rubber pad, an upper guide rod, a lower guide rod and a clamping bolt; the multiple heat exchange plates are arranged in parallel, and are fixedly connected through the upper guide rod and the lower guide rod; one ends of the upper guide rod and the lower guide rod are connected with the fixed clamping plate, and the other ends are connected with the movable clamping plate; and the fixed clamping plate and the movable clamping plate are fixedly connected through multiple tightening bolts. The high-performance plate heat exchanger has the advantages of effective reduction of the replacement frequency of the sealing rubber pad, reduction of the maintenance workload, saving of the spare part replacement and labor cost, guarantee of the heat exchange efficiency, reduction of the vapor condensed water quantity and relief of the environmental protection pressure.

Owner:南京中电熊猫液晶材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com