Preparation method of hollow polymer microspheres

A polymer and microsphere technology, which is applied in the preparation of microspheres, microcapsule preparations, coatings, etc., can solve the problems of loose compactness, and the core is not easy to form a hollow shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

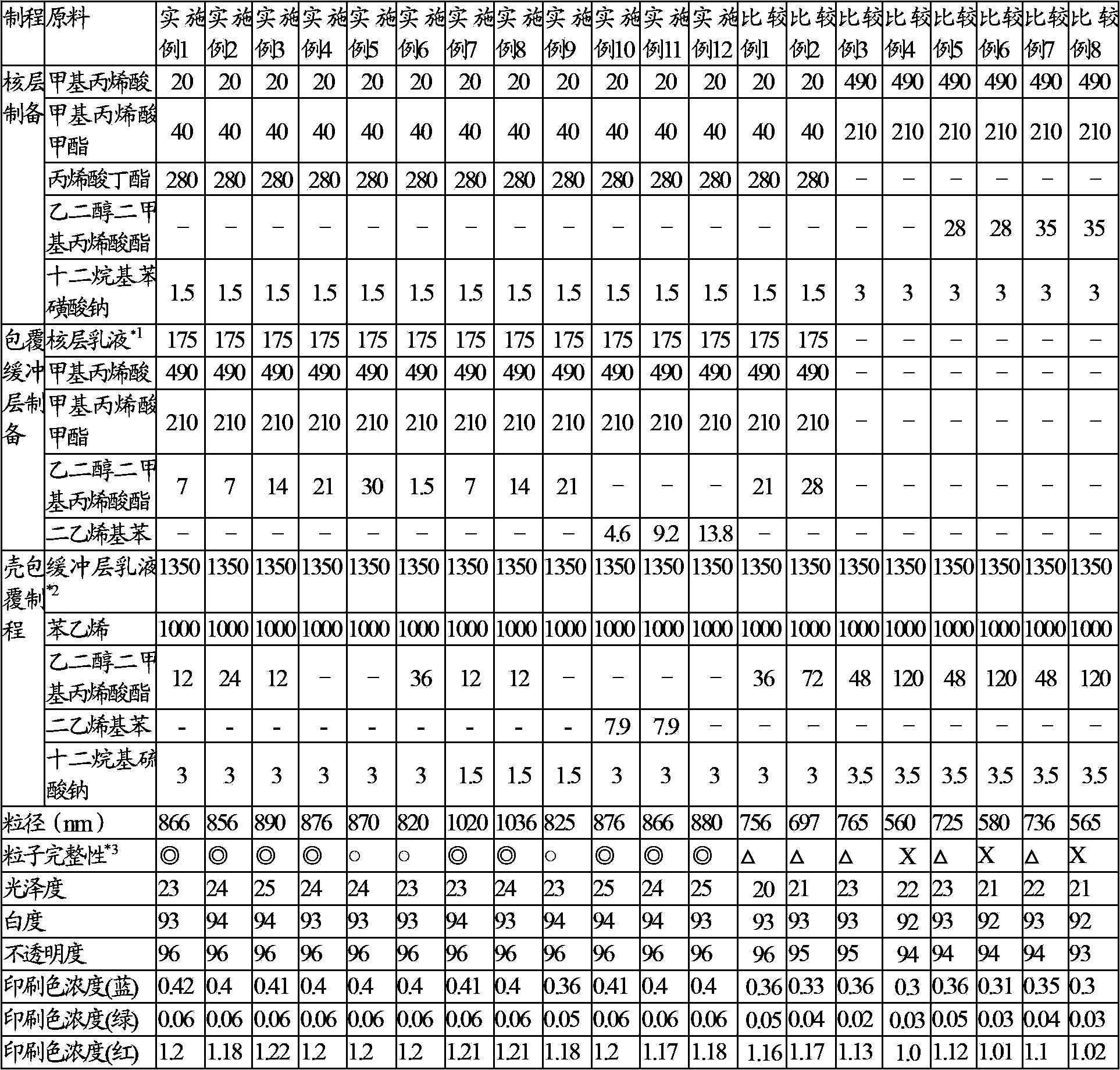

Examples

Embodiment approach

[0010] The preparation and structure control of the polymer microsphere emulsion of the present invention adopts the method of three-stage latex polymer, which is beneficial to control the uniformity of particle size and improve the water resistance, color rendering and gloss during printing. The three-stage latex polymer process is implemented as follows:

[0011] (1) Preparation of the core layer: The core layer is prepared by using the so-called seed emulsion polymerization. The seed emulsion polymerization mainly uses acrylic monomers, emulsifiers and water-soluble free initiators for emulsion polymerization. The acrylic acid (ester) monomers used are monomers selected from the following groups: methyl acrylate, methyl methacrylate, ethyl acrylate, butyl acrylate, butyl methacrylate, ethylhexyl acrylate, Monomethyl maleate, Monomethyl itaconate, Monomethyl fumarate, Acrylic acid, Methacrylic acid, Acryloxypropionic acid, Methacryloxypropionic acid, Acryloxyacetic acid, Met...

Embodiment 1

[0021] Prepare a monomer pre-emulsion consisting of 60 grams of deionized water, 1.5 grams of sodium dodecylbenzenesulfonate, 20 grams of methacrylic acid, 40 grams of methyl methacrylate and 280 grams of butyl acrylate, and prepare another 60 grams Deionized water and 5 grams of ammonium persulfate starter solution are set aside; 2000 grams of deionized water and 60.4 grams of monomer pre-emulsion are added to the reactor, and after the air in the reaction vessel is driven away with nitrogen, it is maintained under a nitrogen environment Stir and heat to 78°C, add the ammonium persulfate starter solution for 0.5 hours, and at the same time add the remaining monomer pre-emulsion to the reactor for 1.5 hours, keep the reaction at 78°C for 4 hours after the addition of monomers, and then cool To room temperature, filter to remove the condensate, and prepare a seed emulsion of the core layer with pH=2.3, average particle size 170nm, and solid content 13.5%.

[0022] Prepare monom...

Embodiment 2

[0025] Prepare a monomer pre-emulsion consisting of 60 grams of deionized water, 1.5 grams of sodium dodecylbenzenesulfonate, 20 grams of methacrylic acid, 40 grams of methyl methacrylate and 280 grams of butyl acrylate, and prepare another 60 grams Deionized water and 5 grams of ammonium persulfate starter solution are set aside; 2000 grams of deionized water and 60.4 grams of monomer pre-emulsion are added to the reactor, and after the air in the reaction vessel is driven away with nitrogen, it is maintained under a nitrogen environment Stir and heat to 78°C, add the ammonium persulfate starter solution for 0.5 hours, and at the same time add the remaining monomer pre-emulsion to the reactor for 1.5 hours, keep the reaction at 78°C for 4 hours after the addition of monomers, and then cool To room temperature, filter to remove the condensate, and prepare a seed emulsion of the core layer with pH=2.3, average particle size 170nm, and solid content 13.5%.

[0026] Prepare monom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com