Patents

Literature

1181 results about "Structure control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A control structure is a representation of the sequencing of message/data flow from one controller to another. A control structure could be a hierarchical - event based, where the child controllers propagate the messages/data to the parent controllers, higher up in the order and the parents take actions based on the data received.

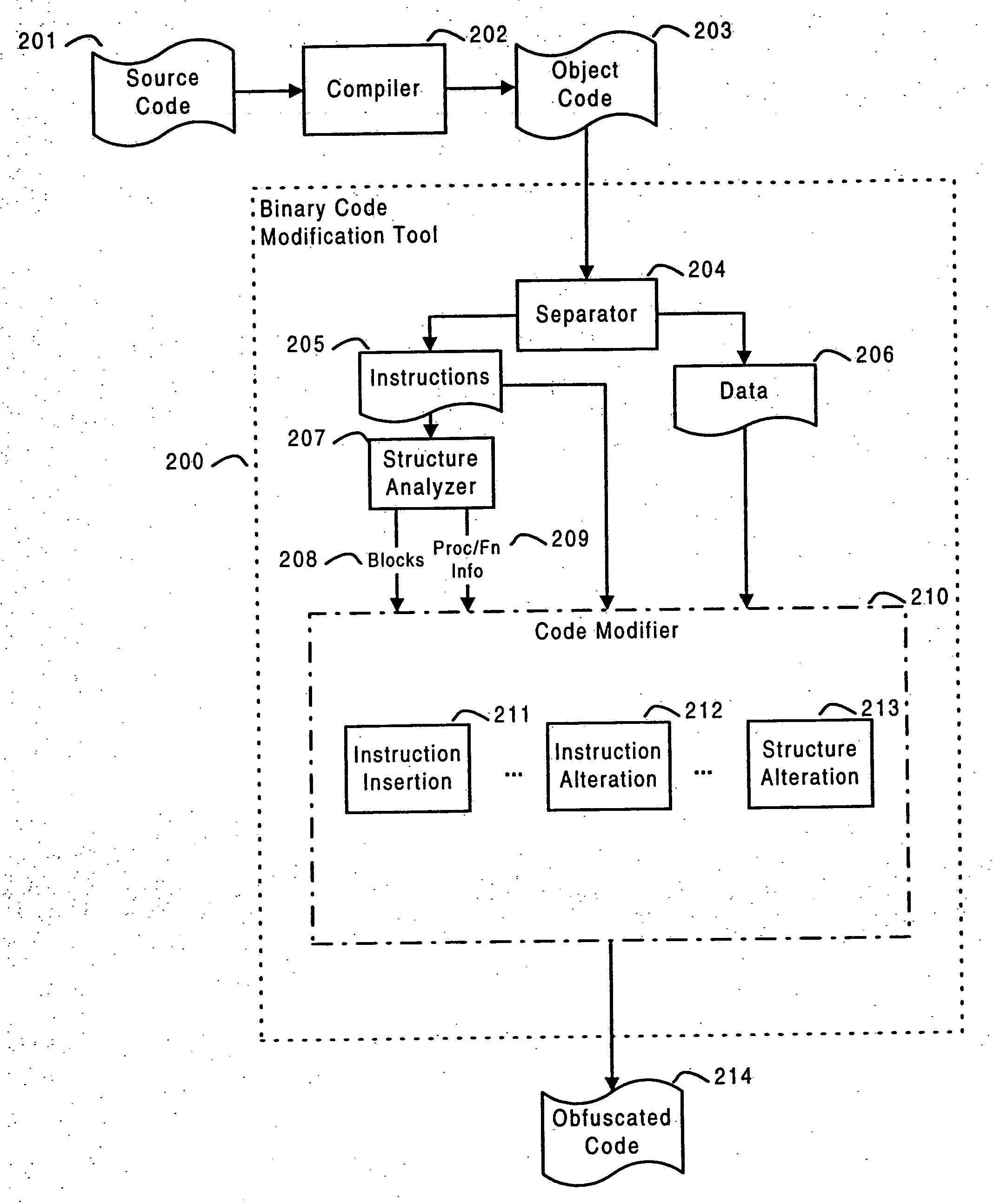

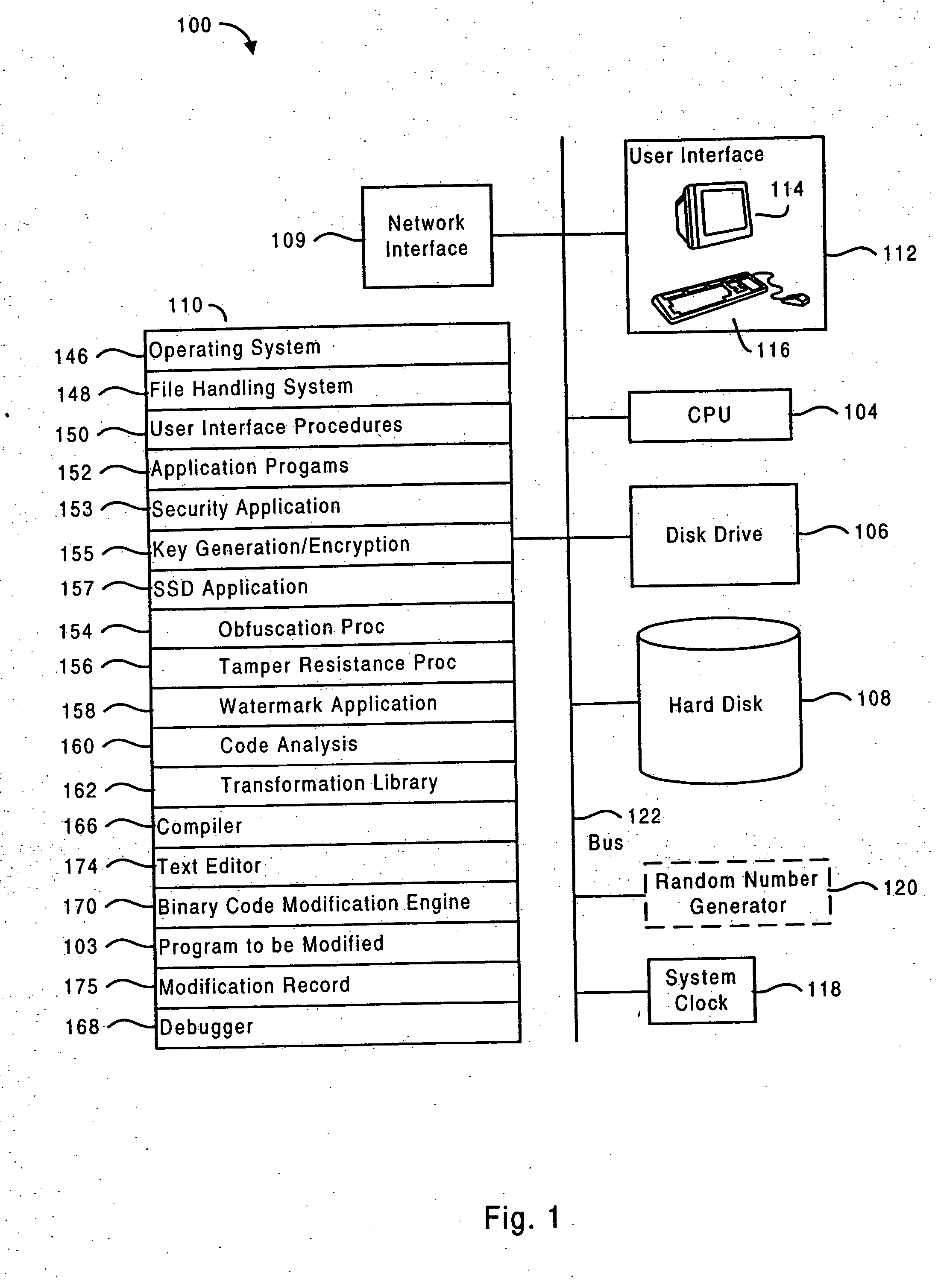

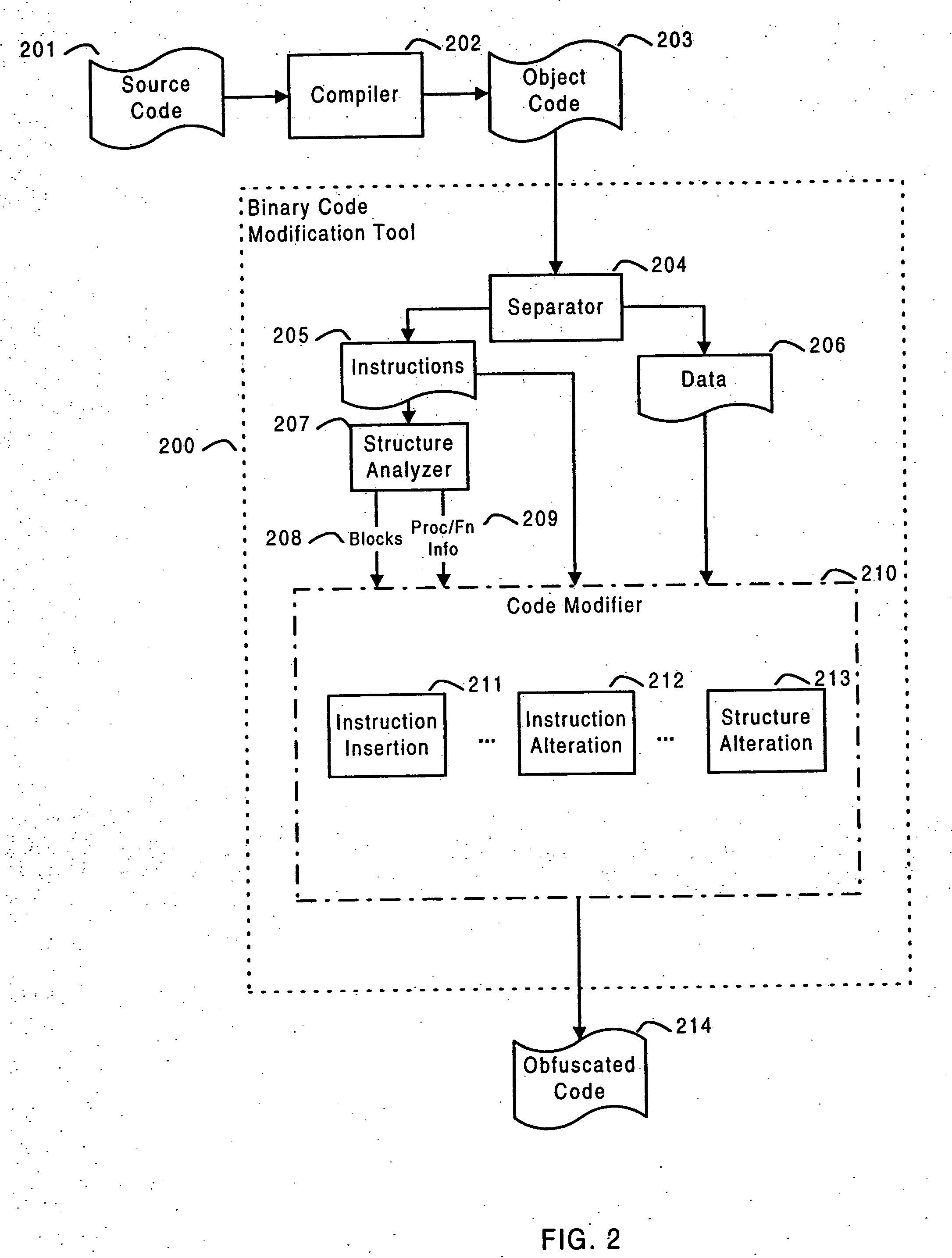

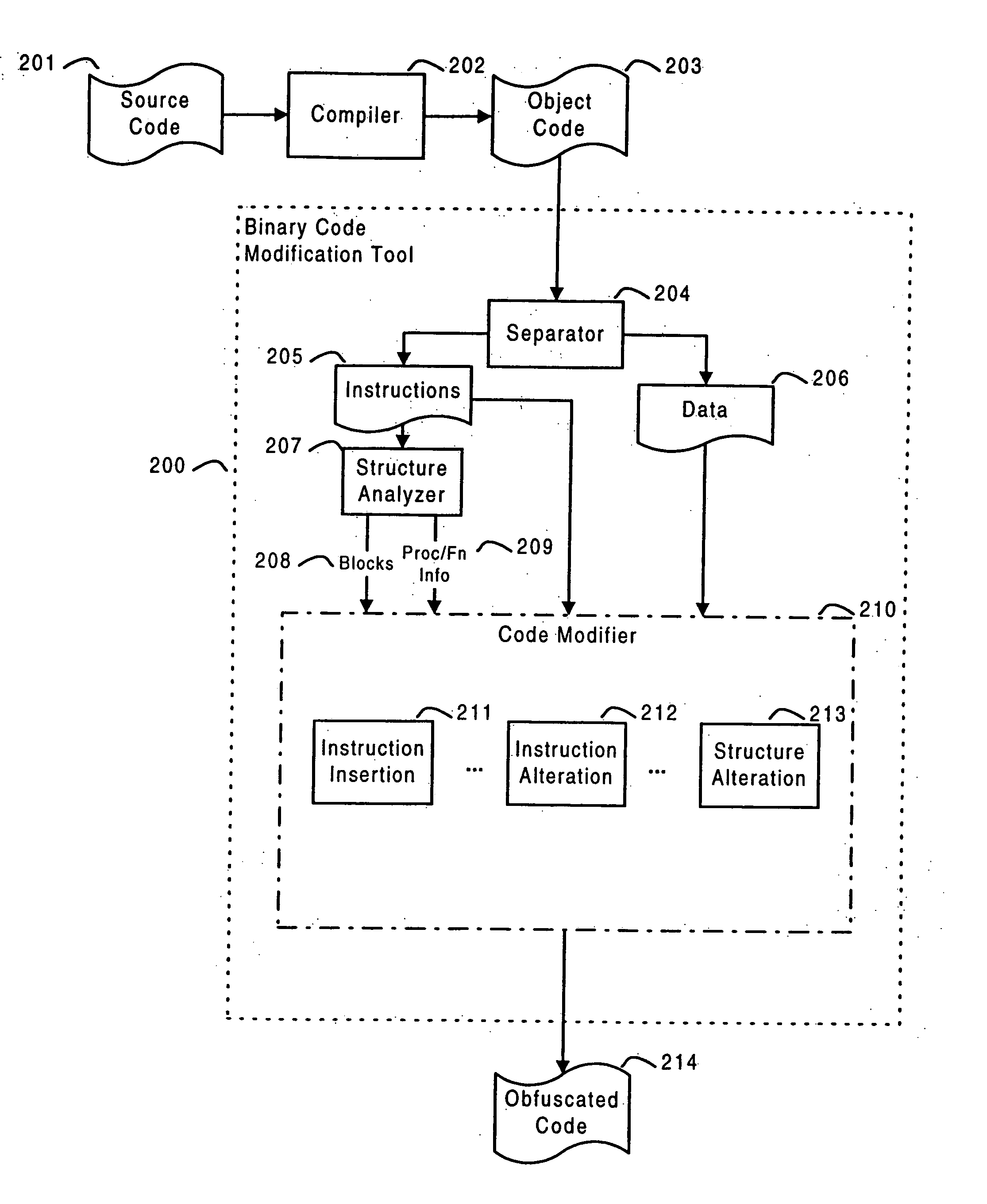

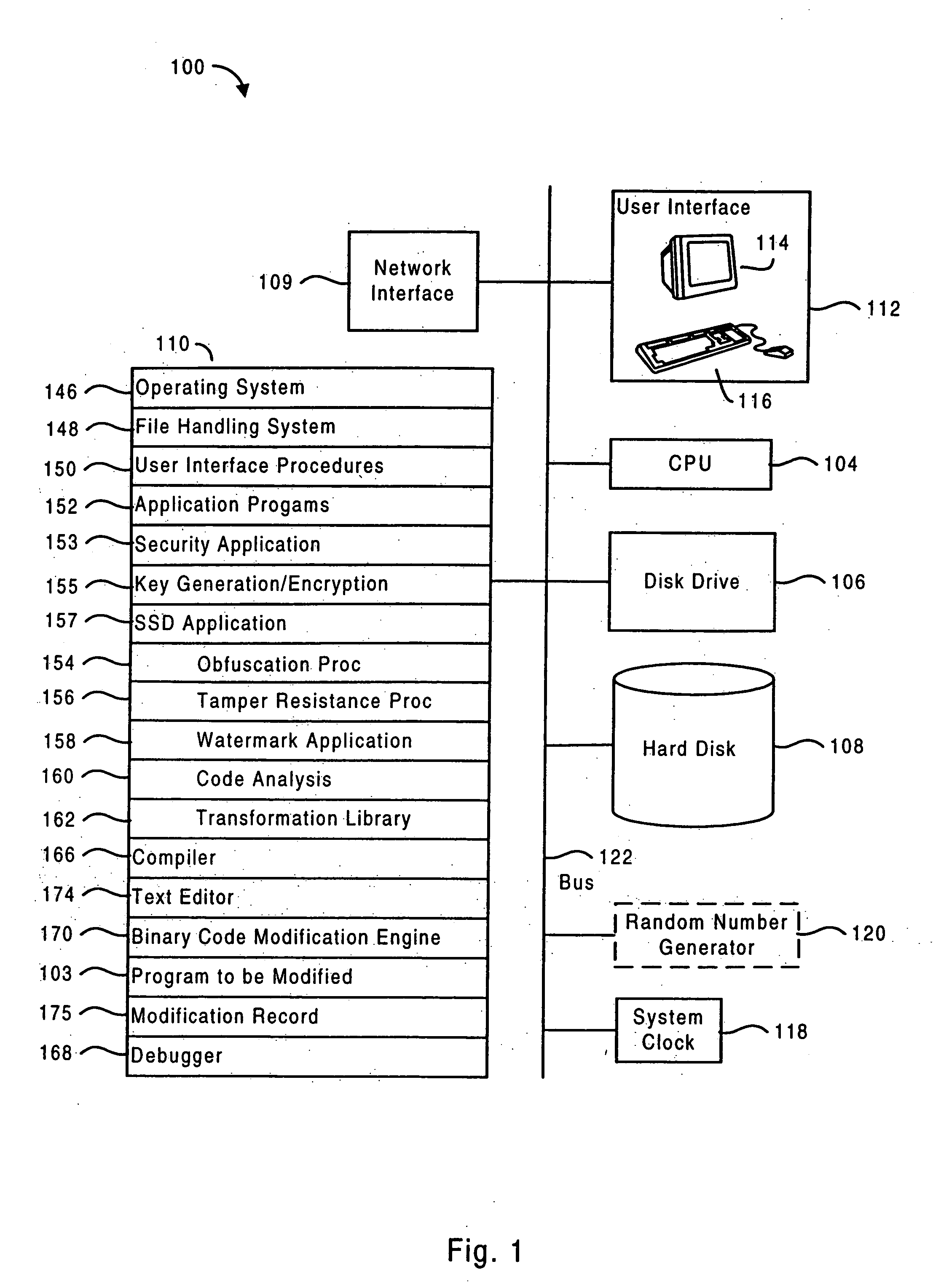

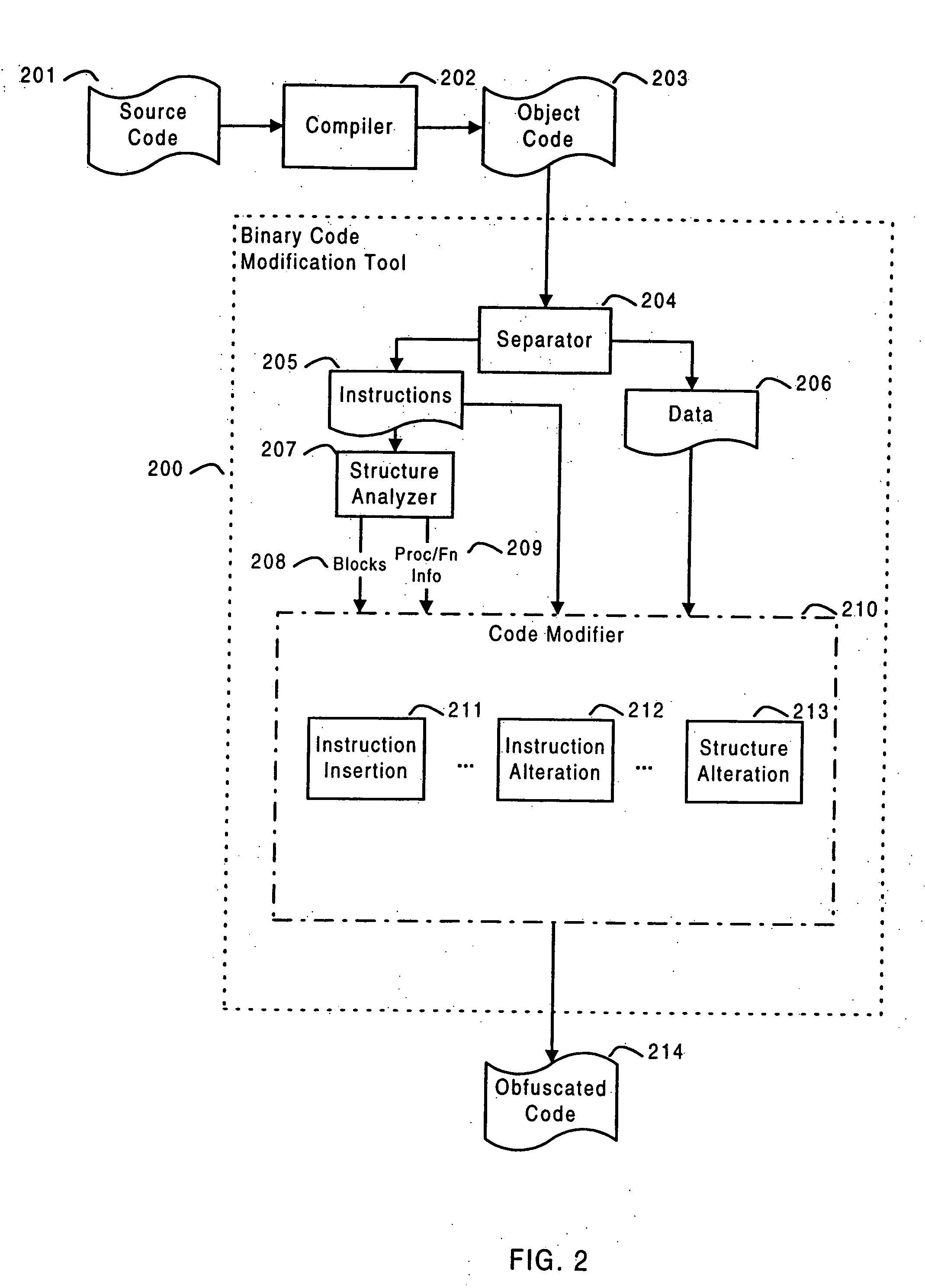

Software self-defense systems and methods

ActiveUS20050183072A1Error detection/correctionProgram/content distribution protectionTamper resistanceObfuscation

Systems and methods are disclosed for protecting a computer program from unauthorized analysis and modification. Obfuscation transformations can be applied to the computer program's local structure, control graph, and / or data structure to render the program more difficult to understand and / or modify. Tamper-resistance mechanisms can be incorporated into the computer program to detect attempts to tamper with the program's operation. Once an attempt to tamper with the computer program is detected, the computer program reports it to an external agent, ceases normal operation, and / or reverses any modifications made by the attempted tampering. The computer program can also be watermarked to facilitate identification of its owner. The obfuscation, tamper-resistance, and watermarking transformations can be applied to the computer program's source code, object code, or executable image.

Owner:INTERTRUST TECH CORP

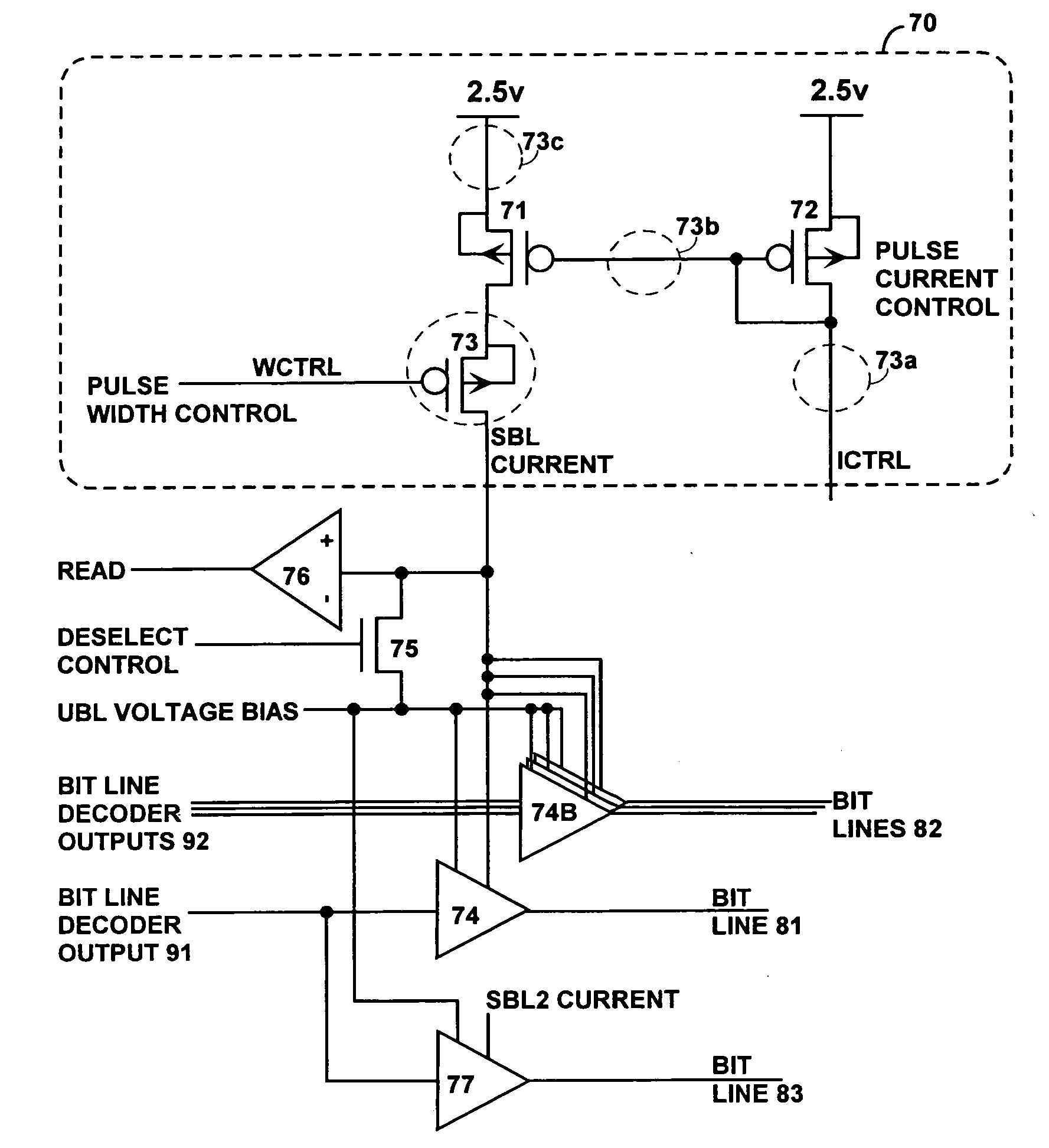

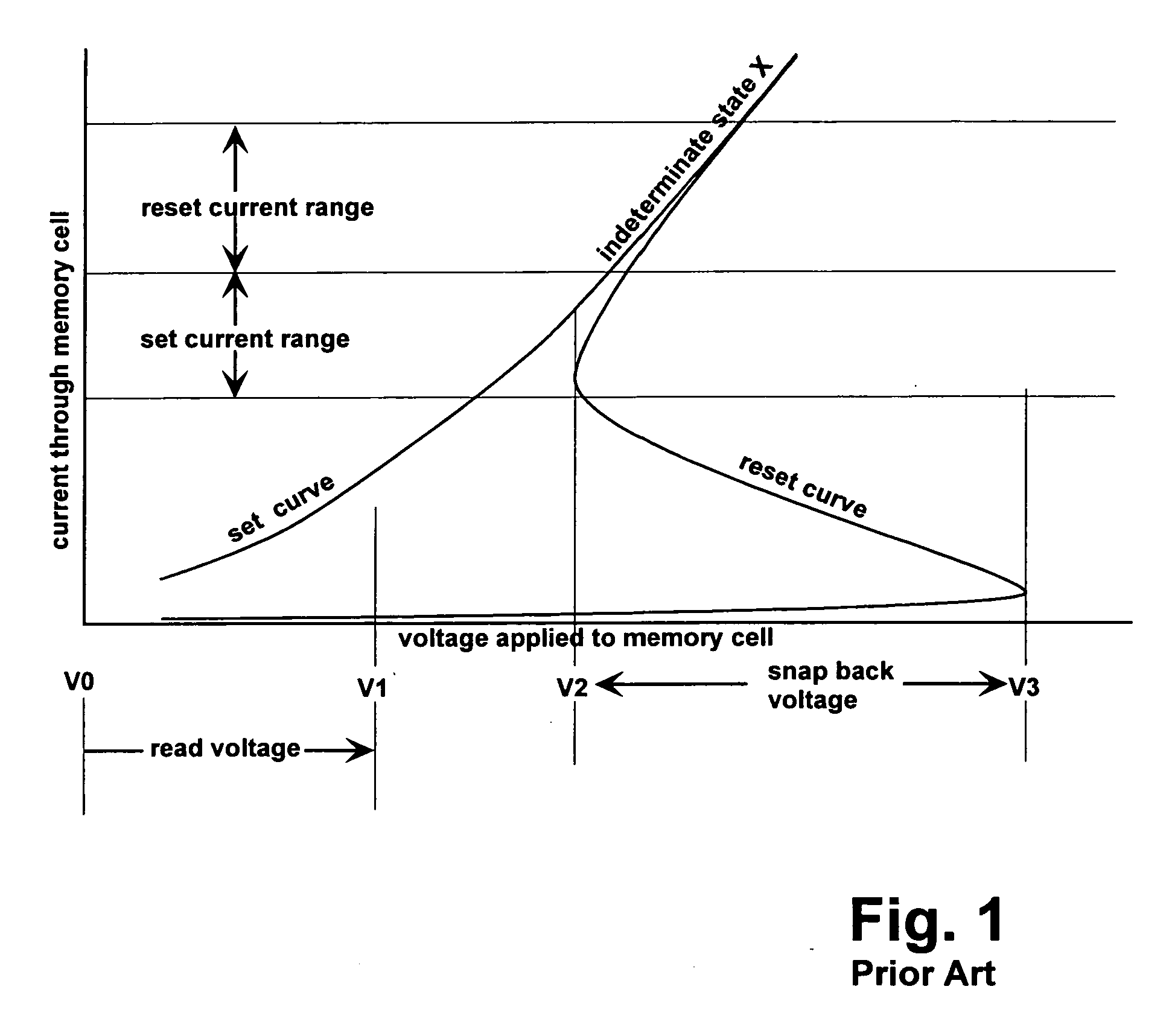

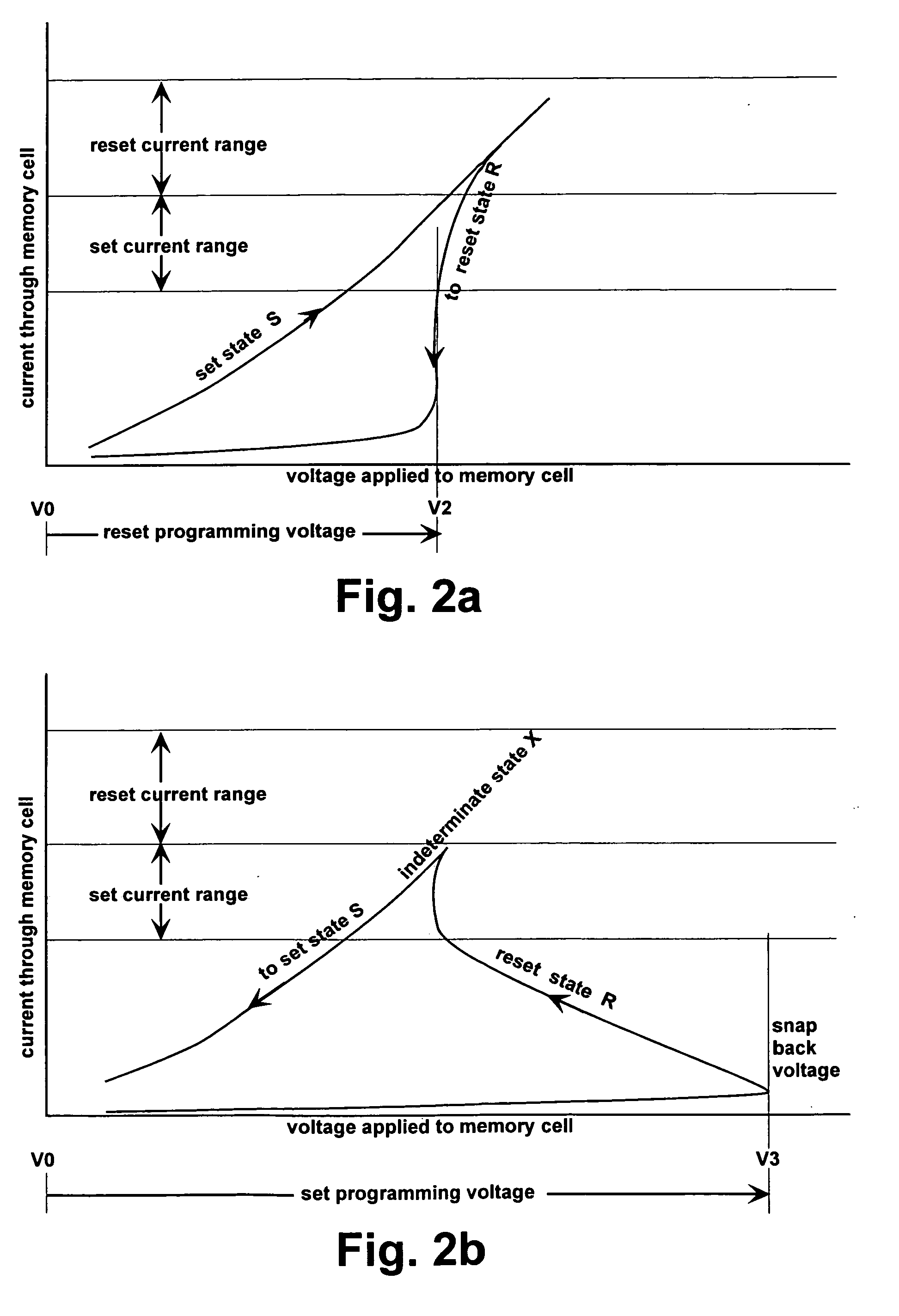

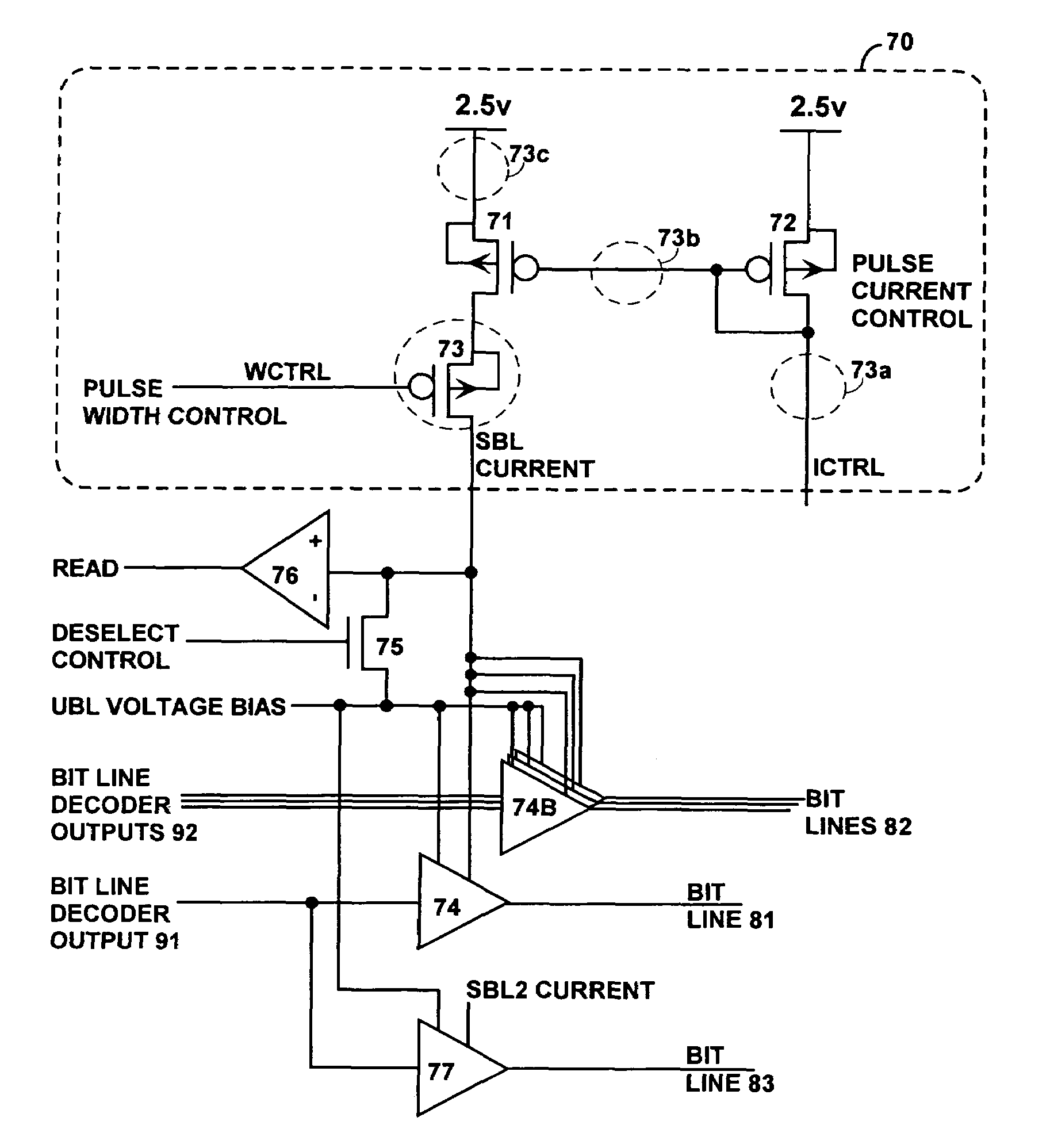

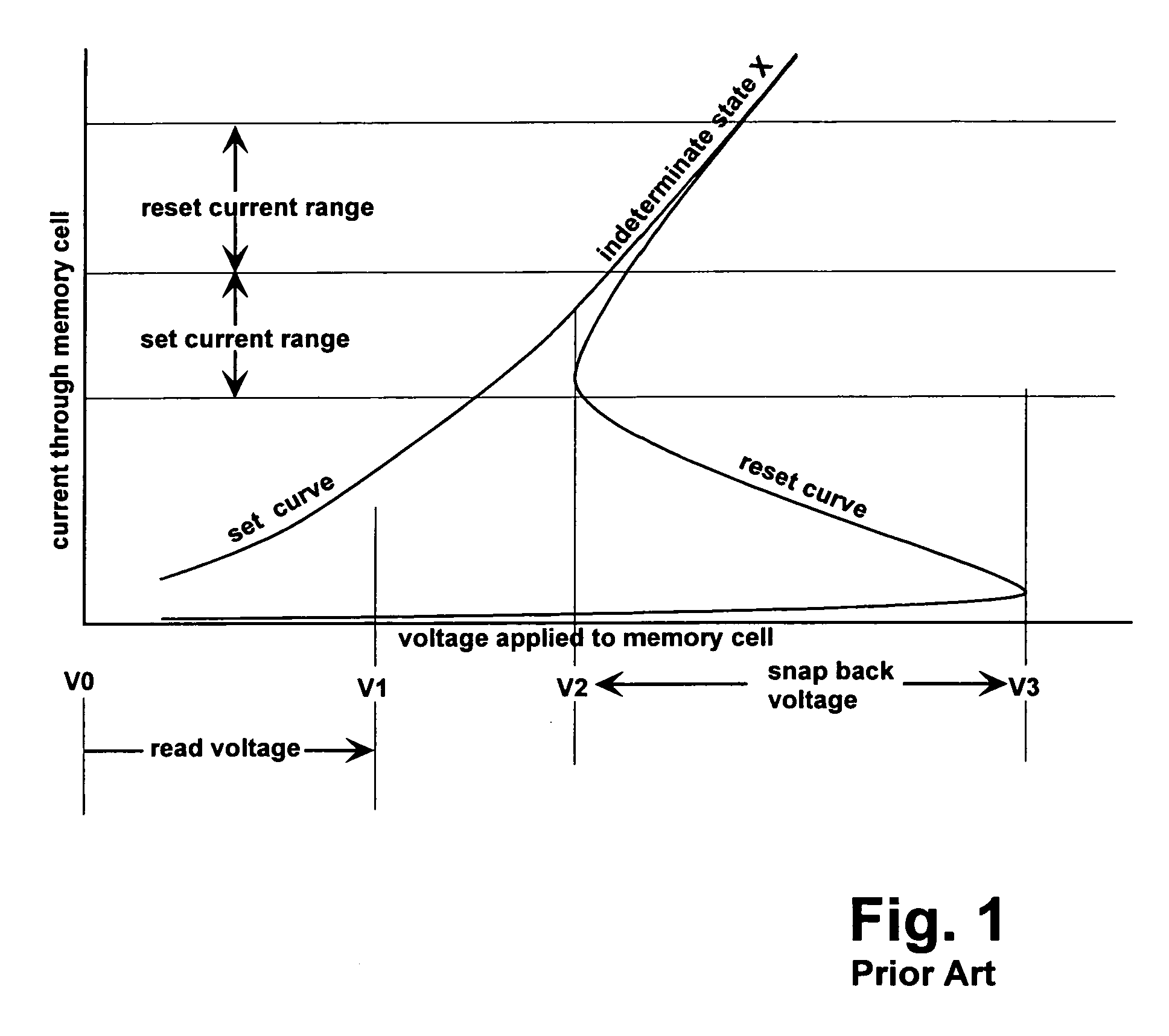

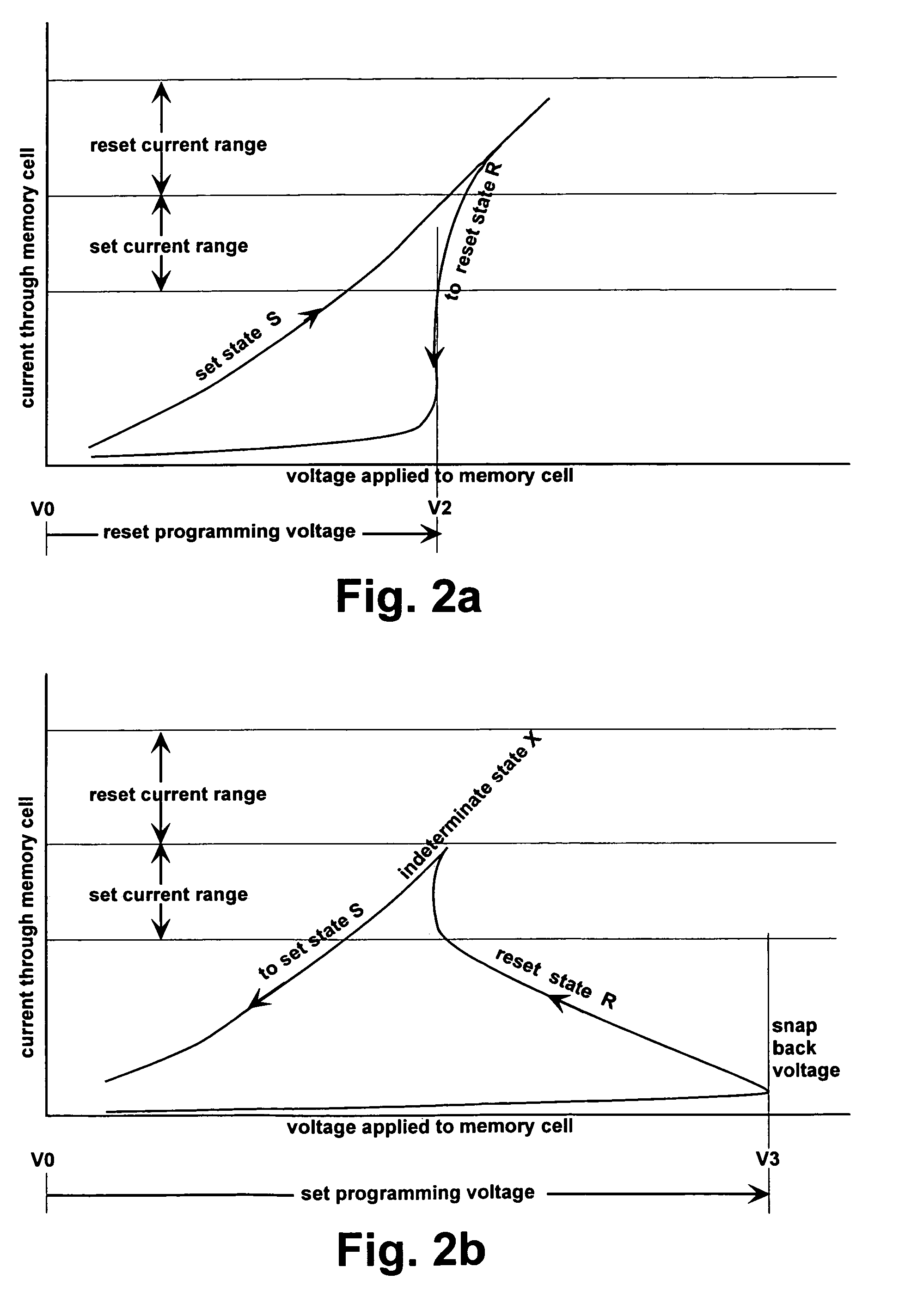

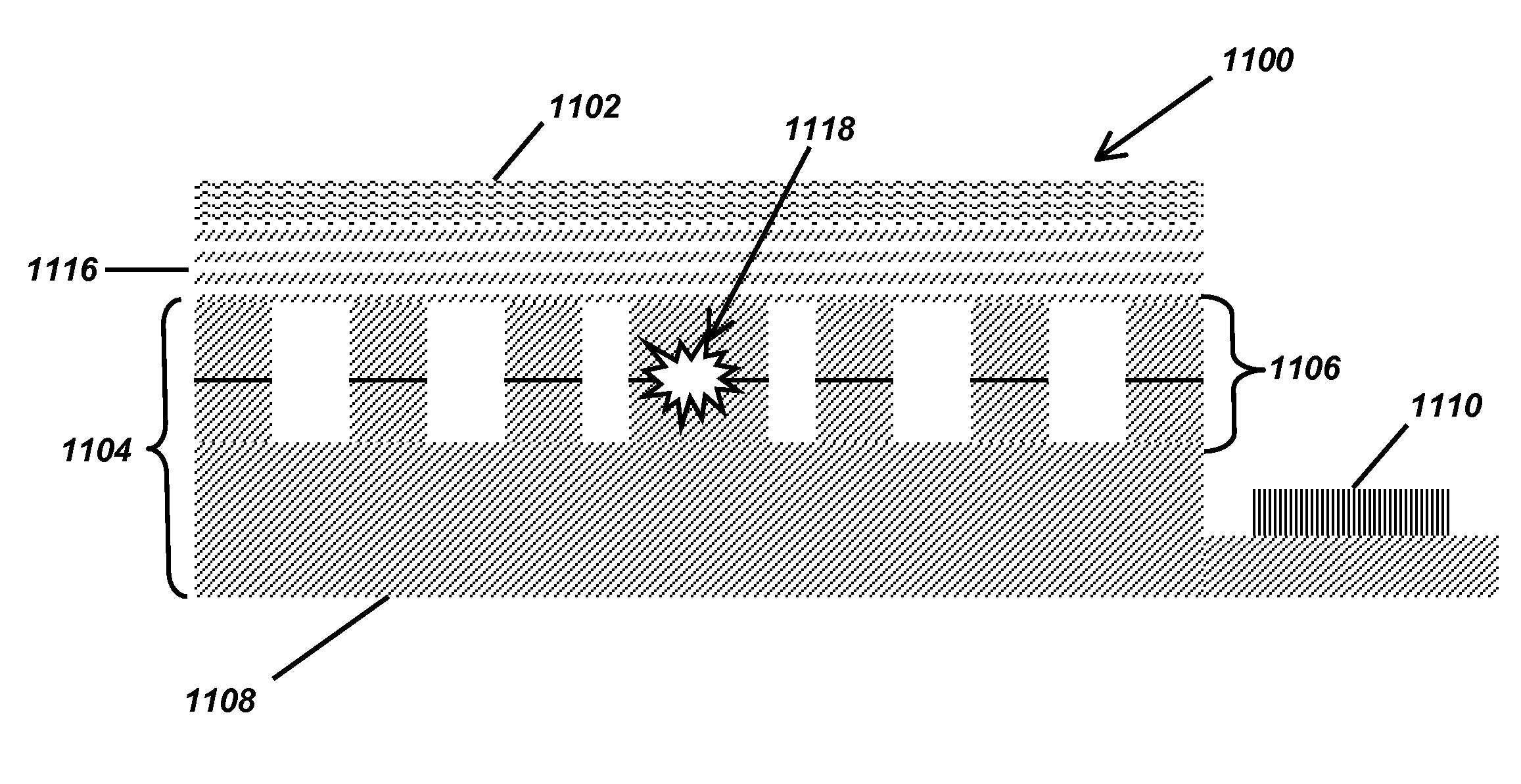

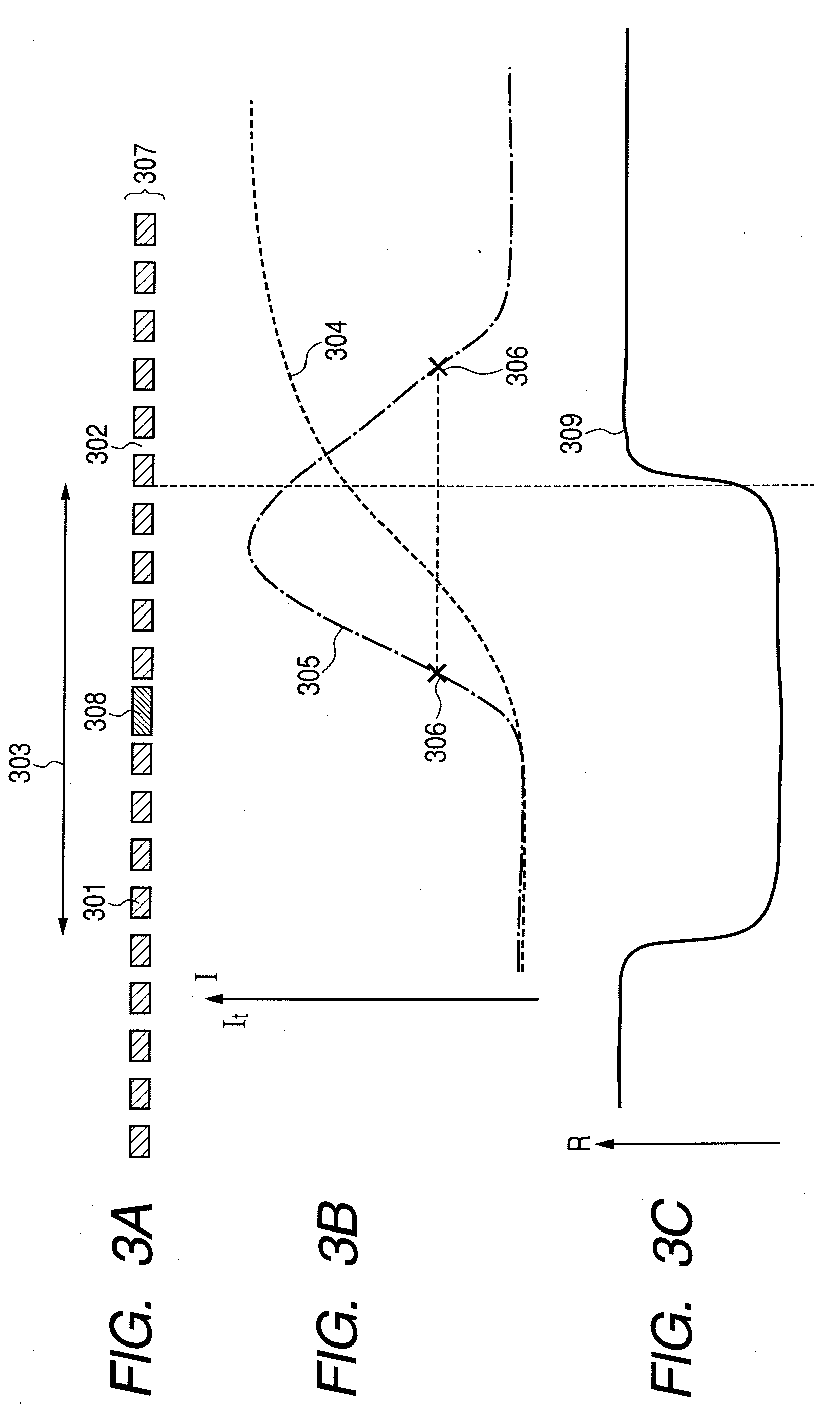

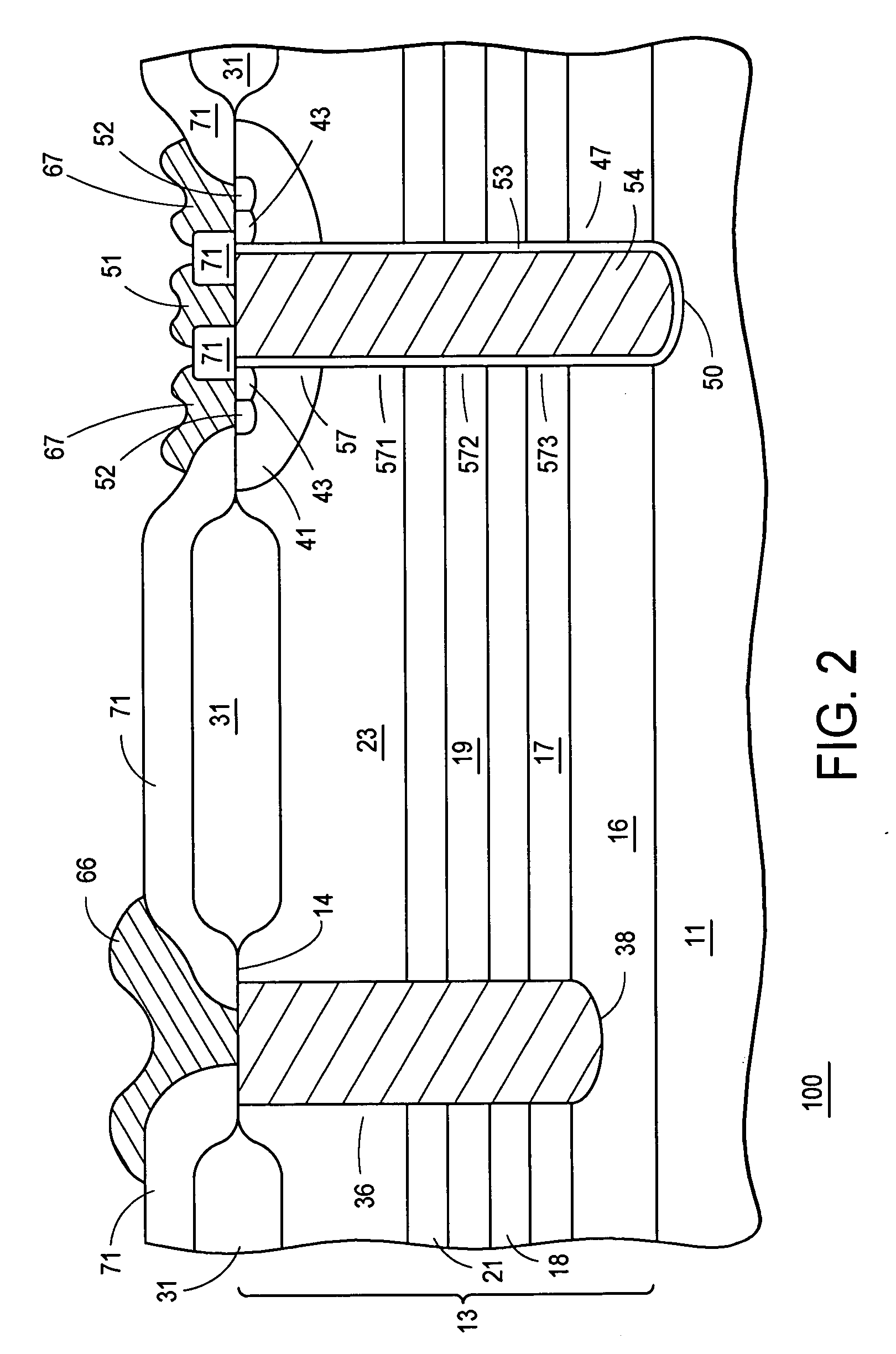

Structure and method for biasing phase change memory array for reliable writing

ActiveUS20060157679A1Minimize leakage currentReduce the possibilitySolid-state devicesDigital storageBit linePhase-change memory

A memory array having memory cells comprising a diode and a phase change material is reliably programmed by maintaining all unselected memory cells in a reverse biased state. Thus leakage is low and assurance is high that no unselected memory cells are disturbed. In order to avoid disturbing unselected memory cells during sequential writing, previously selected word and bit lines are brought to their unselected voltages before new bit lines and word lines are selected. A modified current mirror structure controls state switching of the phase change material.

Owner:SANDISK TECH LLC

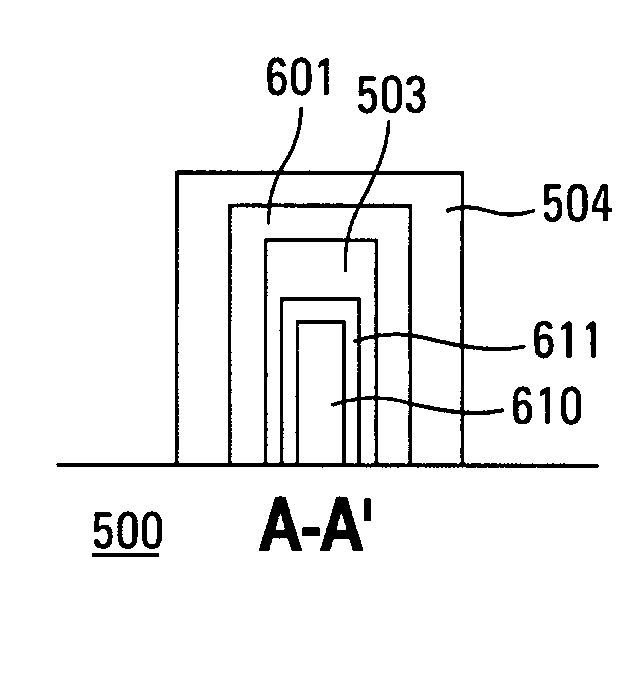

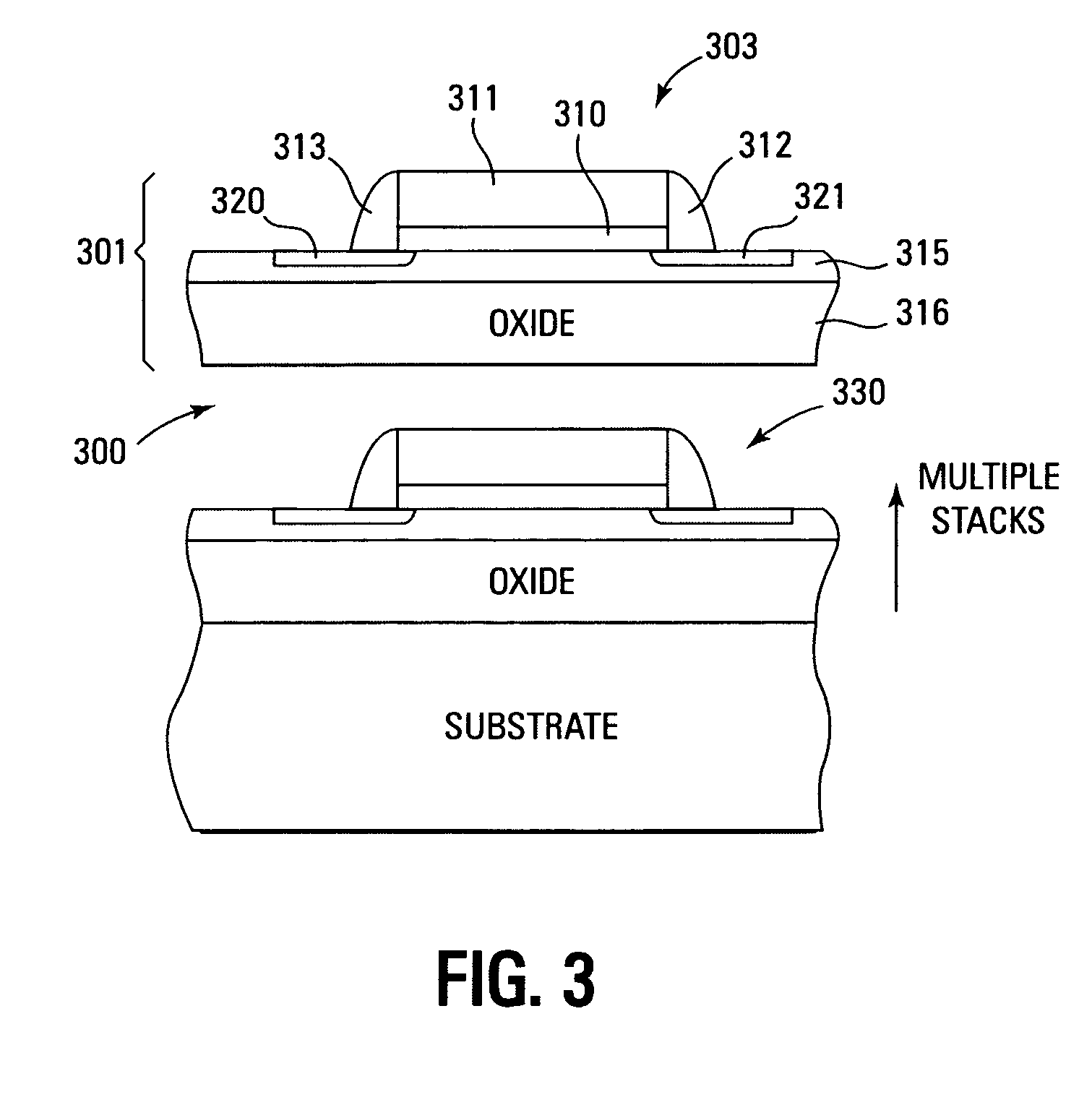

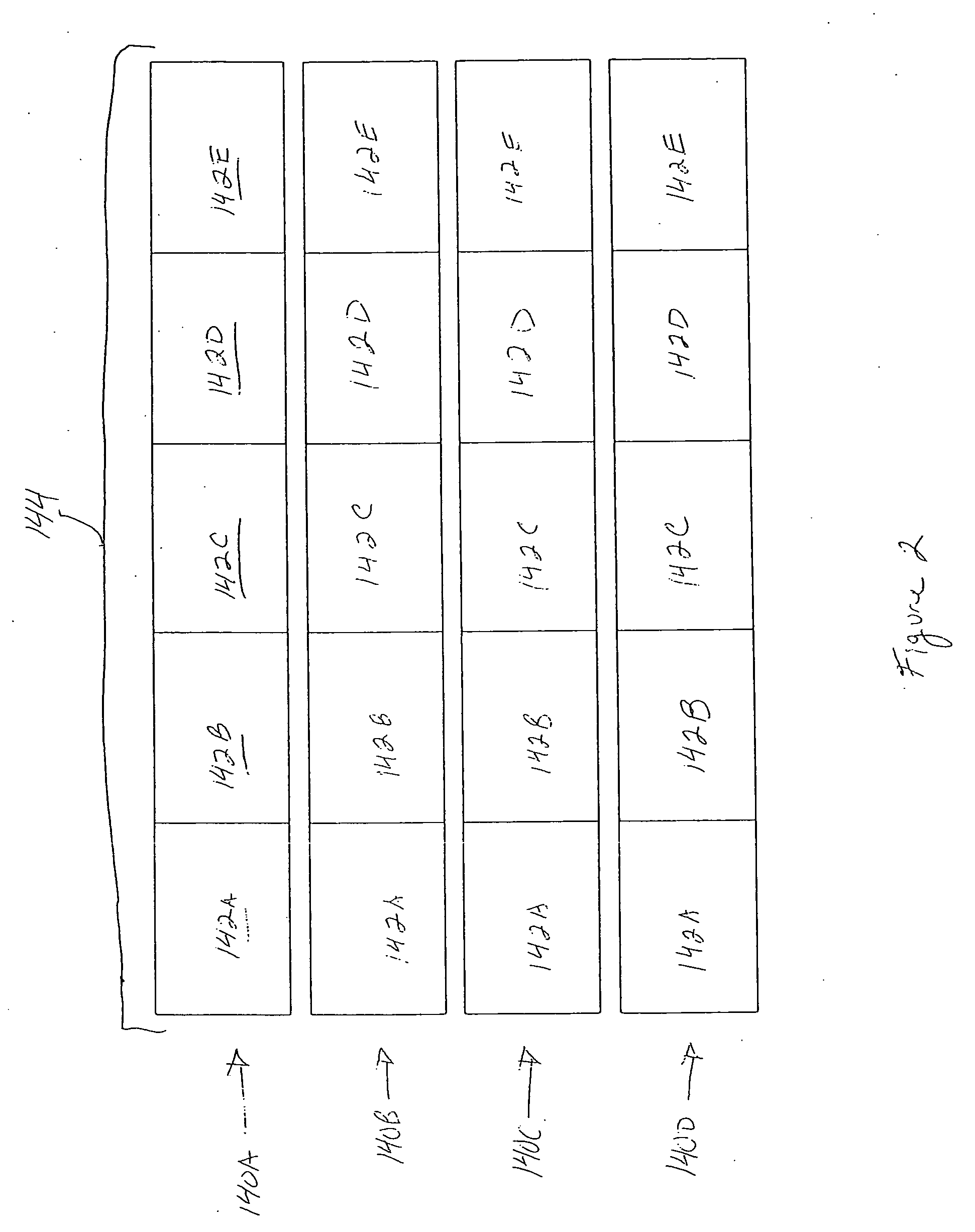

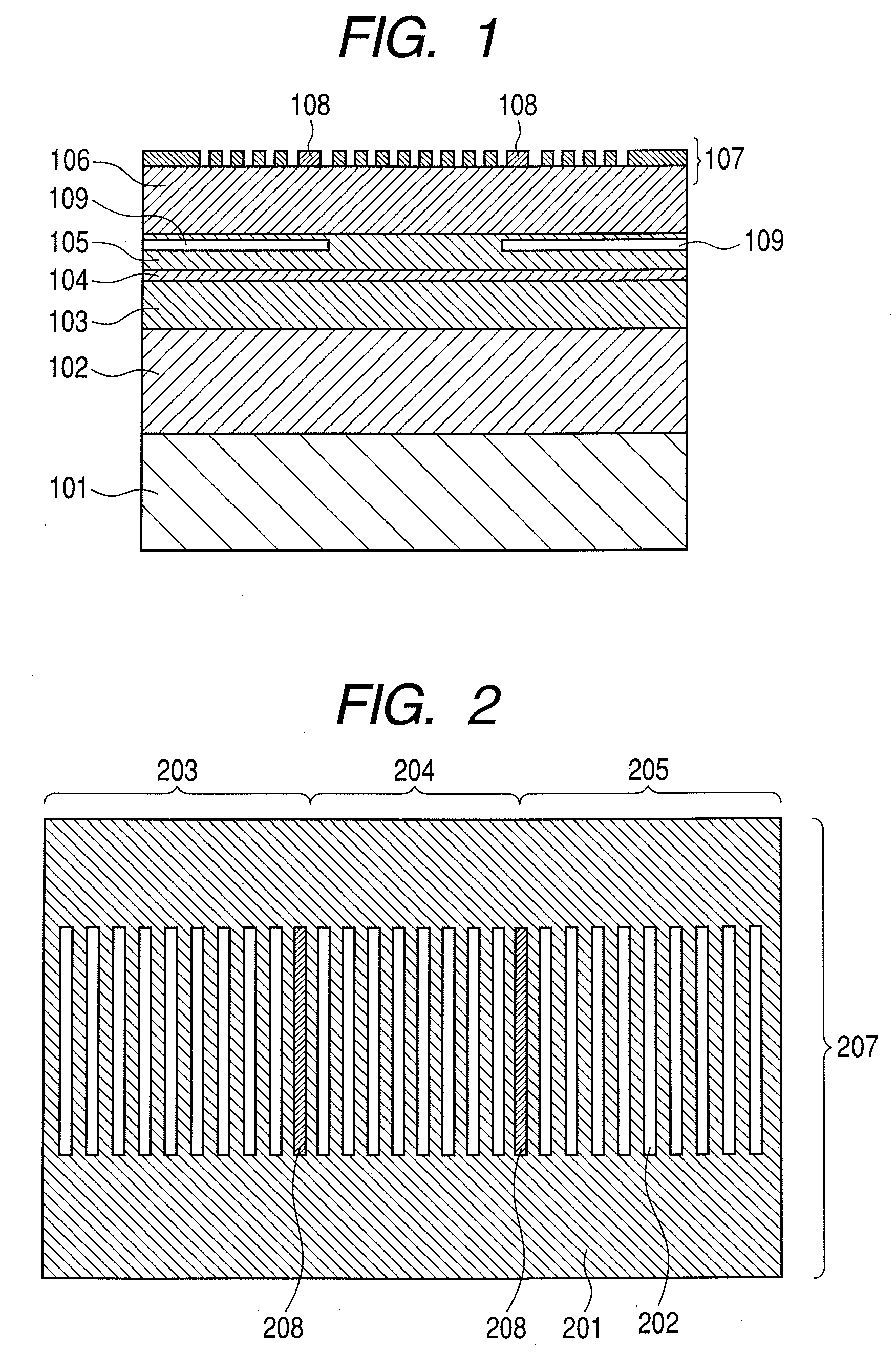

Stacked non-volatile memory with silicon carbide-based amorphous silicon thin film transistors

ActiveUS20070215954A1Solid-state devicesSemiconductor/solid-state device manufacturingAmorphous siliconTransistor

A stacked non-volatile memory device uses amorphous silicon based thin film transistors stacked vertically. Each layer of transistors or cells is formed from a deposited a-Si channel region layer having a predetermined concentration of carbon to form a carbon rich silicon film or silicon carbide film, depending on the carbon content. The dielectric stack is formed over the channel region layer. In one embodiment, the dielectric stack is an ONO structure. The control gate is formed over the dielectric stack. This structure is repeated vertically to form the stacked structure. In one embodiment, the carbon content of the channel region layer is reduced for each subsequently formed layer.

Owner:MICRON TECH INC

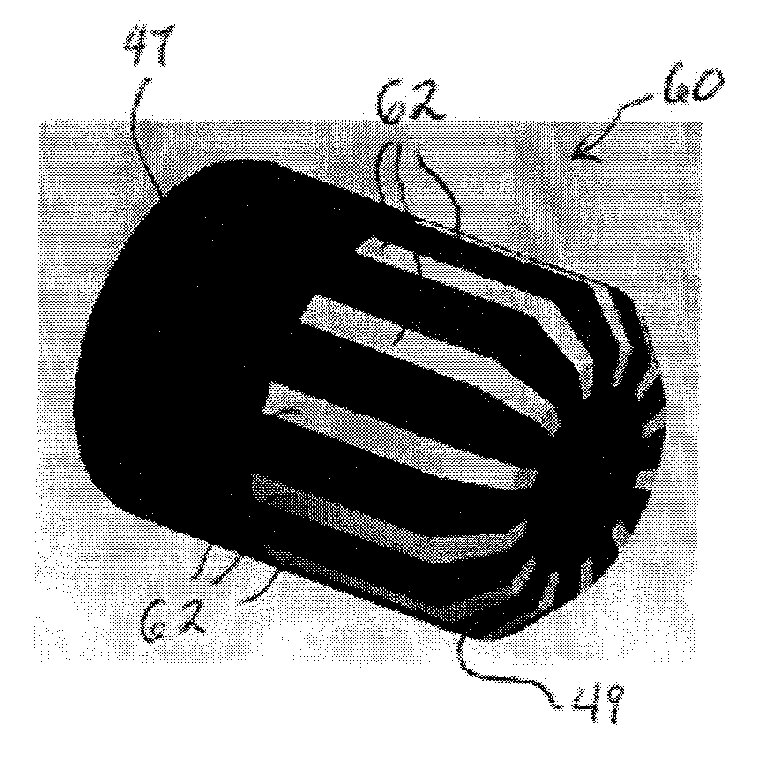

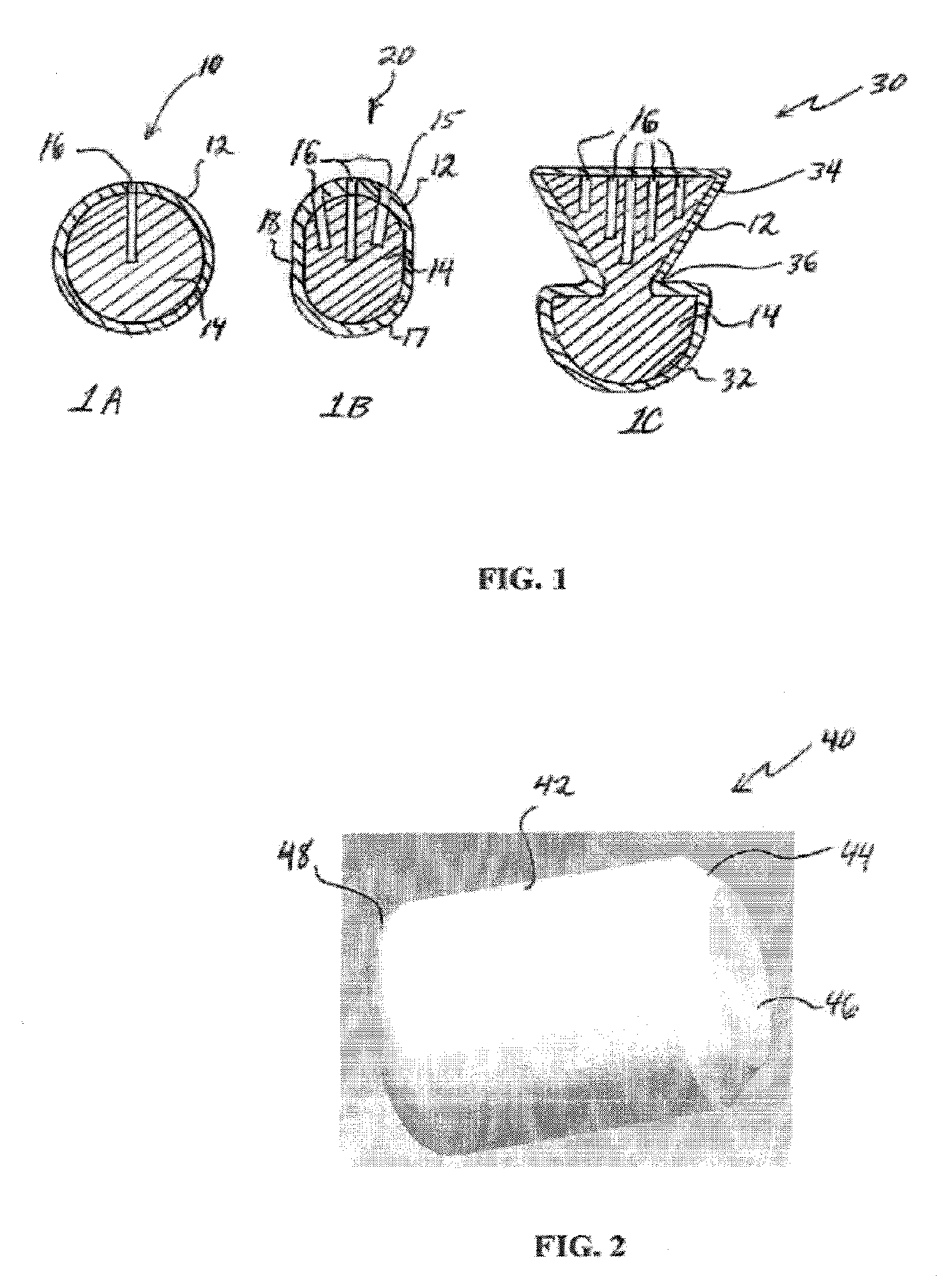

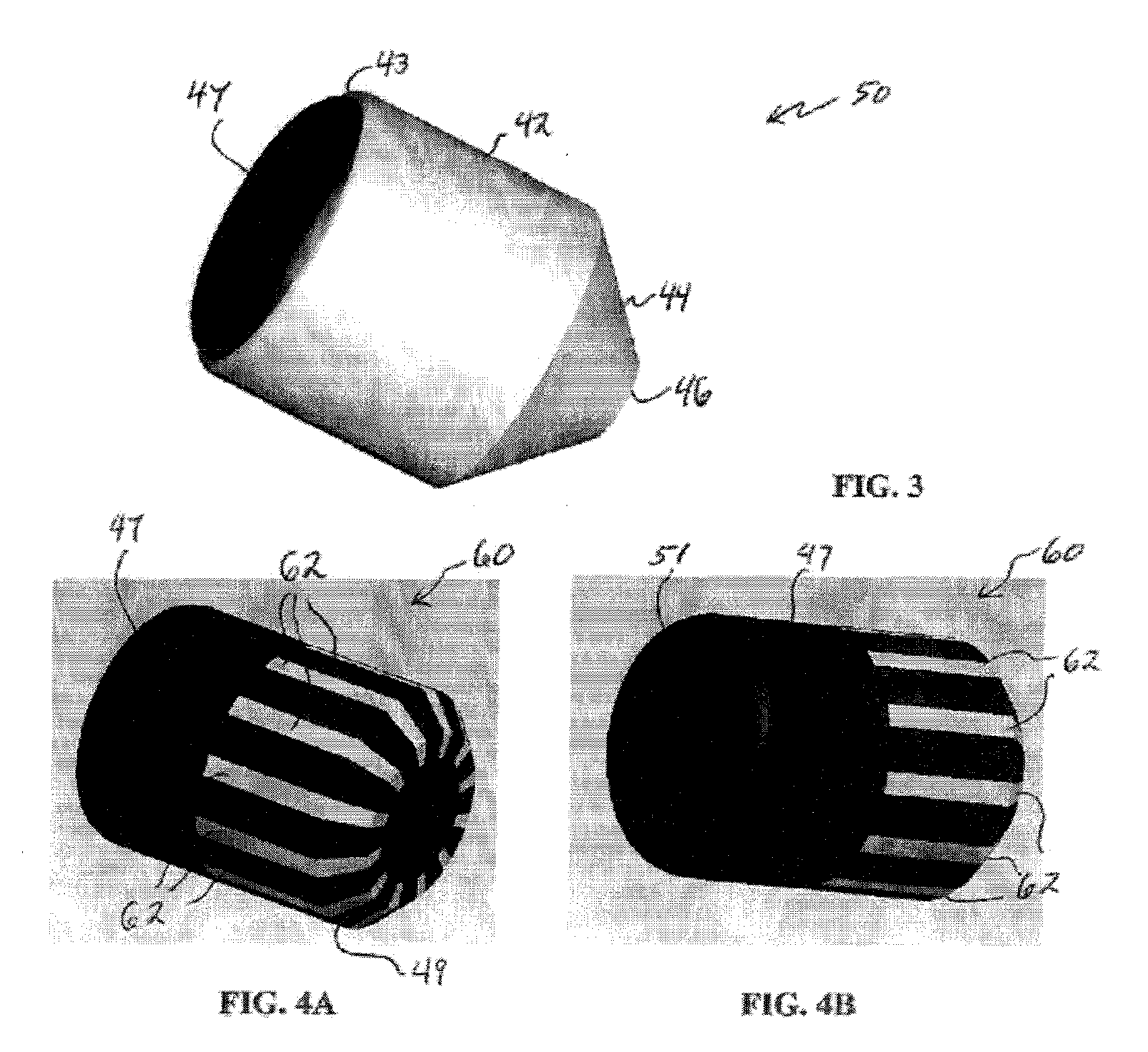

Well Operating Elements Comprising a Soluble Component and Methods of Use

Well operating elements are described, one embodiment comprising a first component that is substantially non-dissolvable when exposed to a selected wellbore environment and a second component that is soluble in the selected wellbore environment and whose rate and / or location of dissolution is at least partially controlled by structure of the first component. A second embodiment includes the component that is soluble in the selected wellbore environment, and one or more exposure holes or passages in the soluble component to control its solubility. The second embodiment may or may not include a substantially non-dissolvable component. Methods of using the well operating elements in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

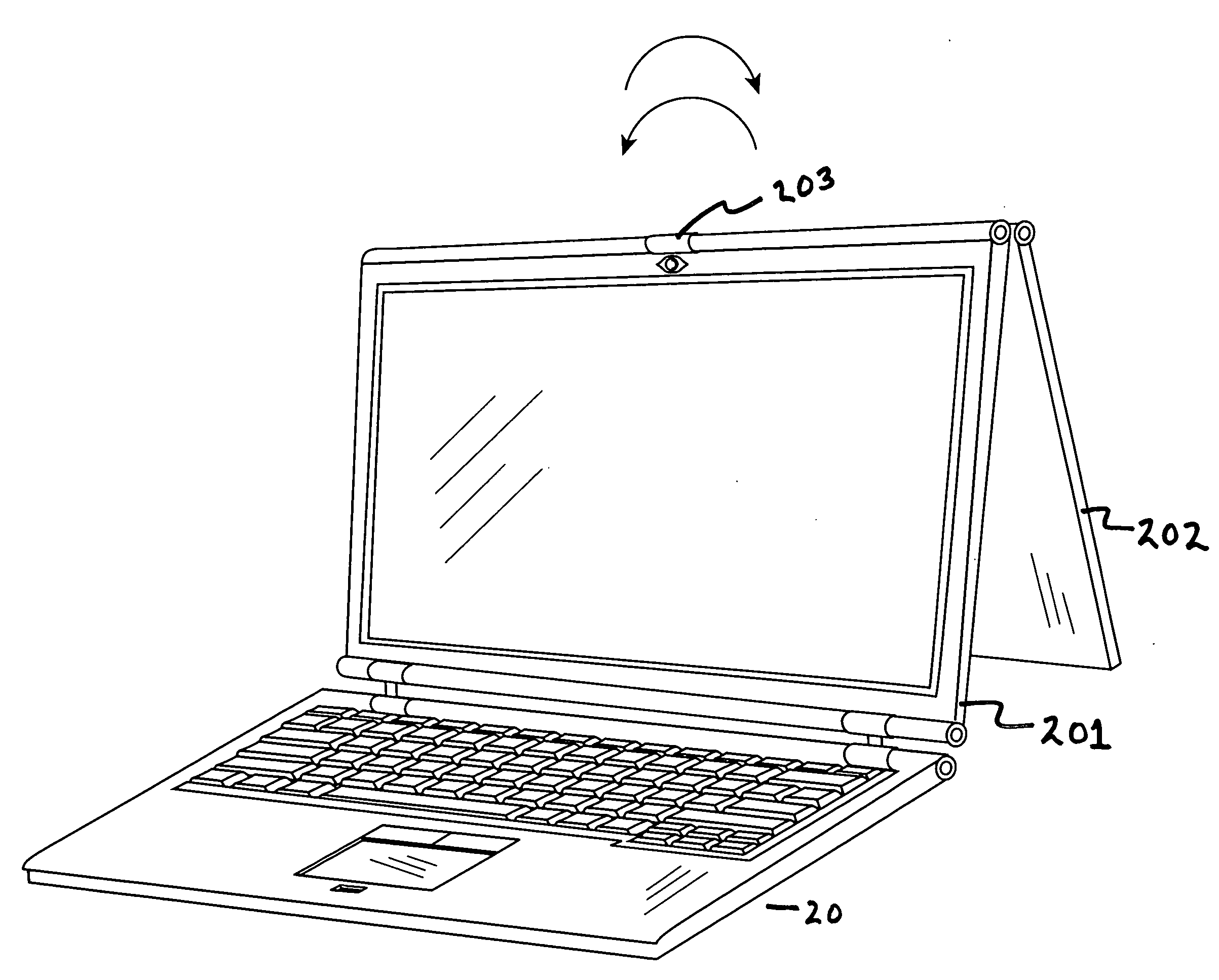

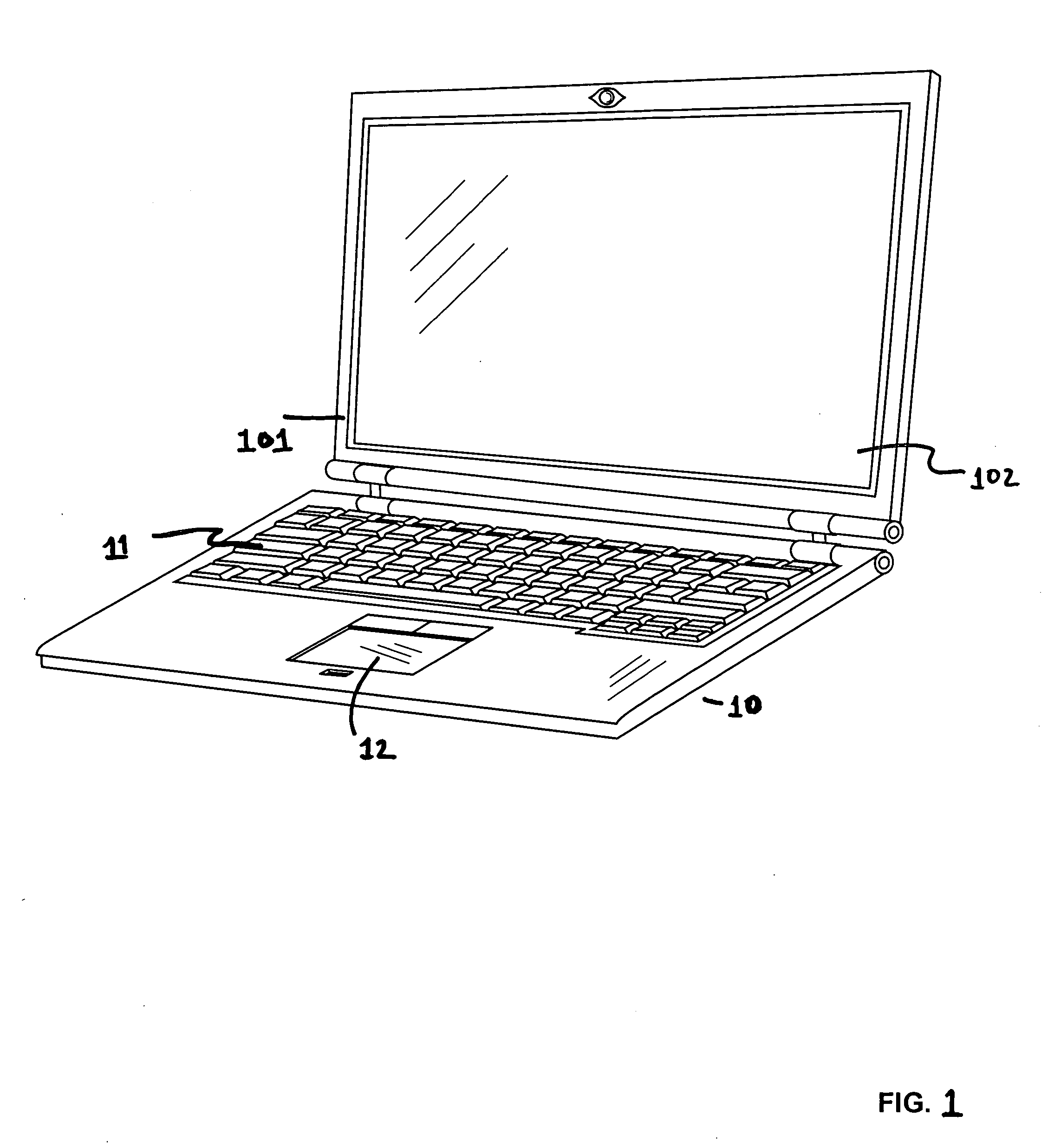

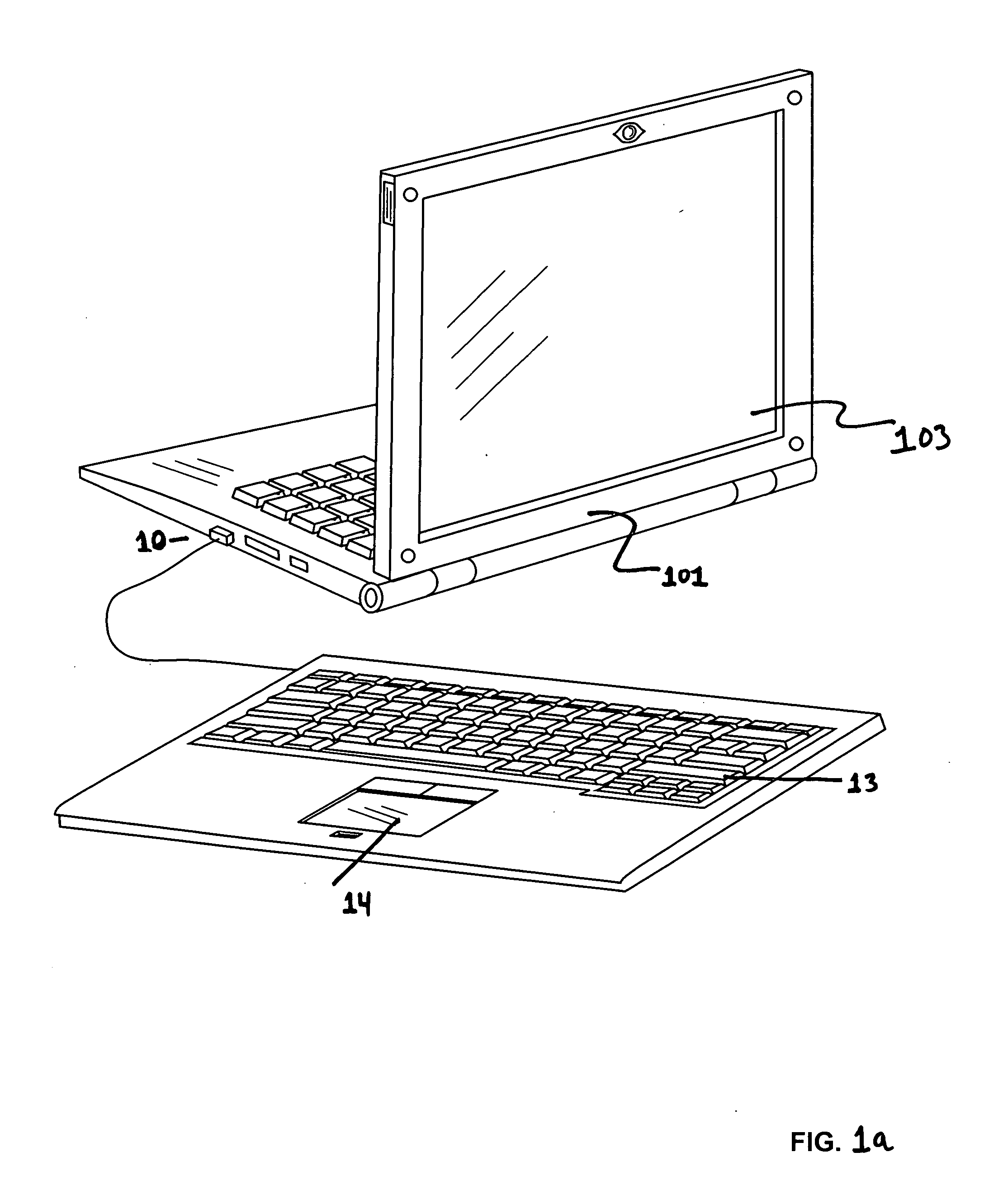

Two-sided display monitor apparatus

InactiveUS20080024388A1Cathode-ray tube indicatorsDetails for portable computersLiquid-crystal displayEngineering

A display apparatus such as liquid crystal displays (LCD) or plasma displays or any other type of thin or flat display monitor apparatus having multiple display screens. The multiple display screens either consisting of double sided display screens, being slidingly engaged in a monitor housing having rails or being attached by a multiple axis pivot structure. The screens can be either controlled by a single control structure or can be independently controlled by multiple control structure where multiple users can work on each respective screen independently from one another.

Owner:BRUCE OSCAR

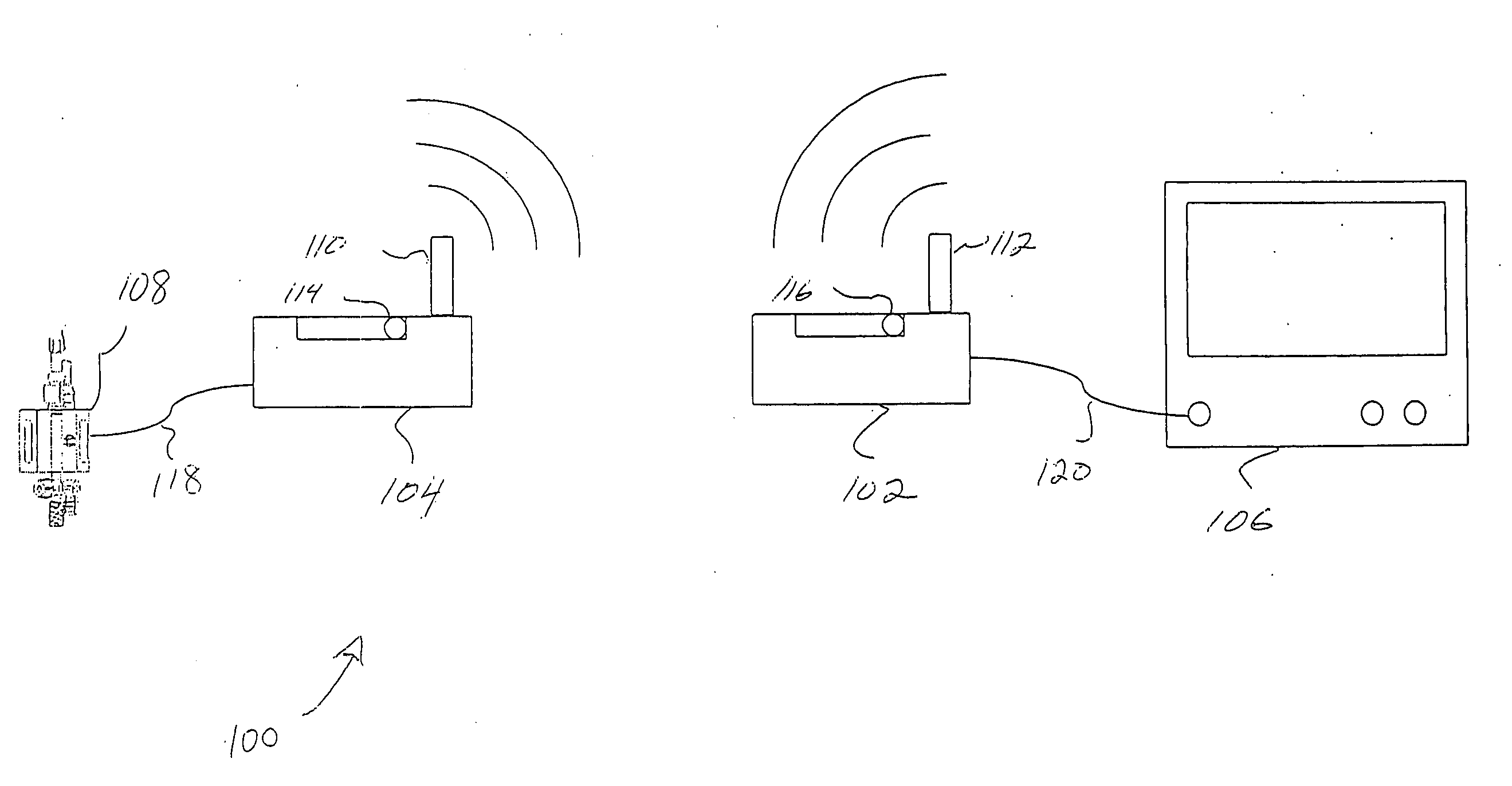

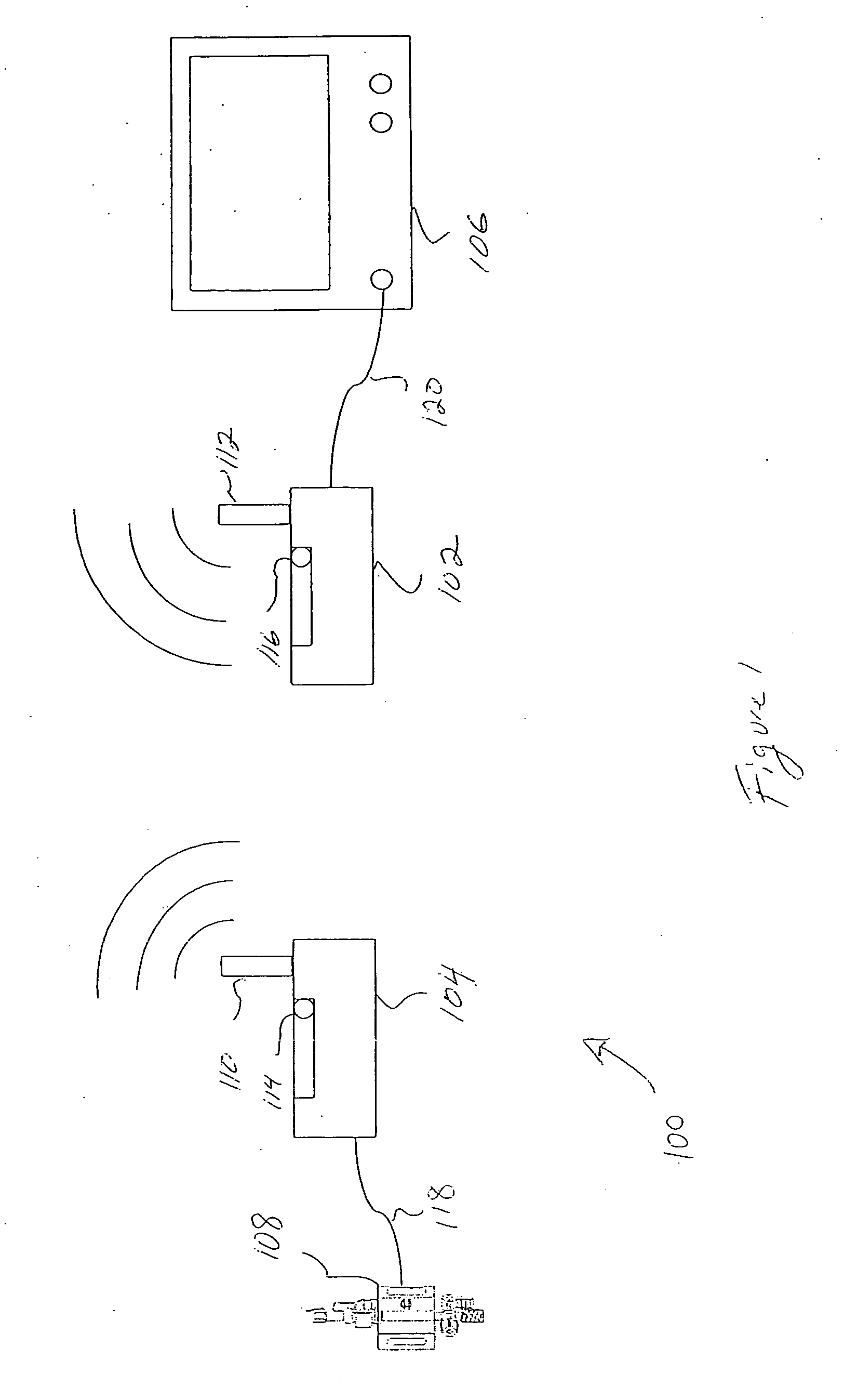

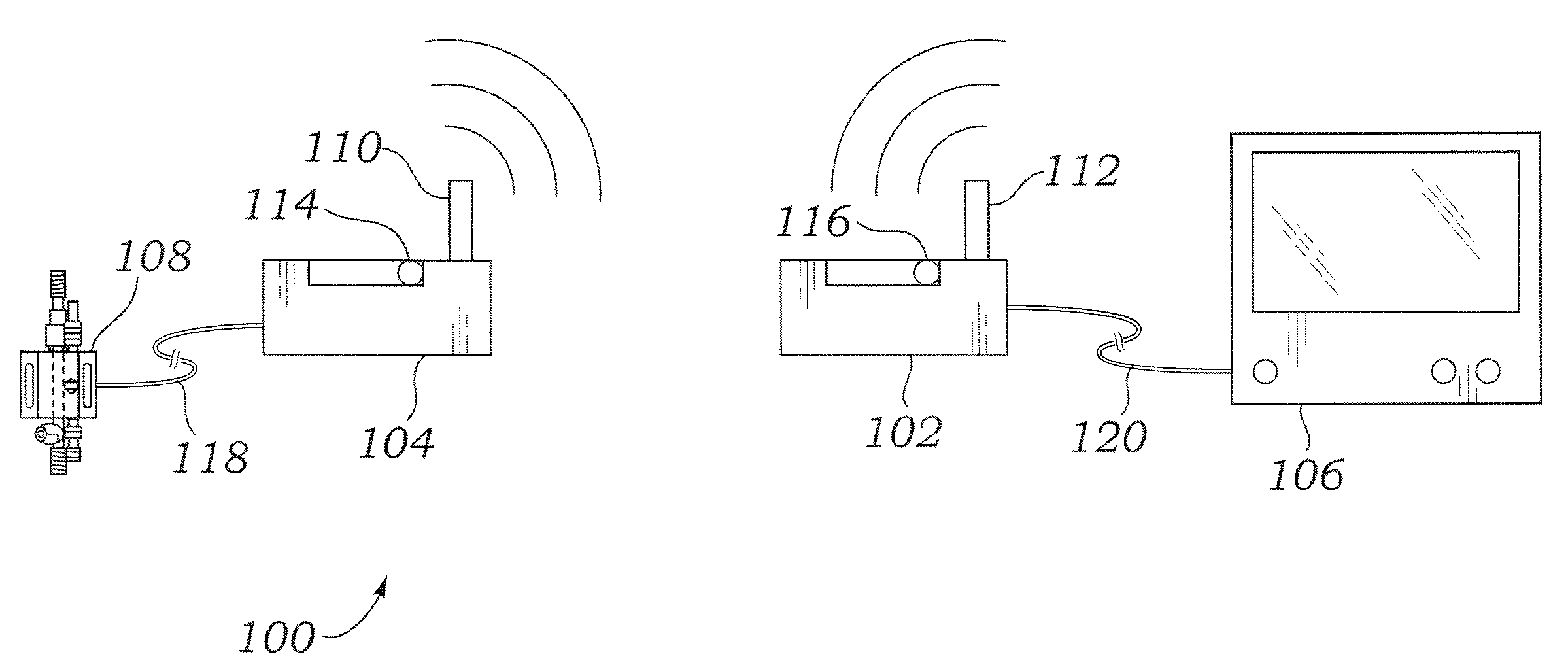

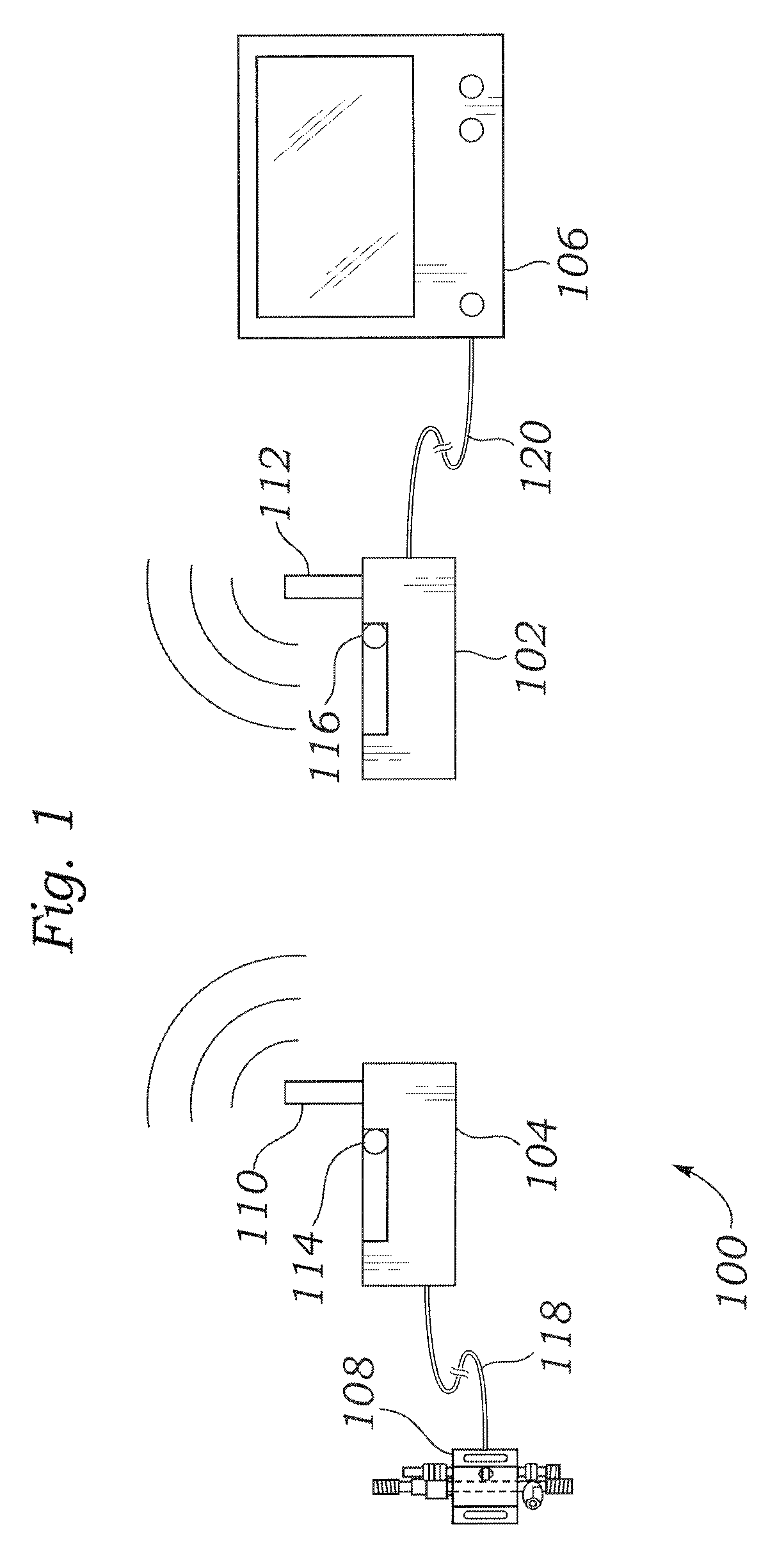

Wireless communication protocol for a medical sensor system

ActiveUS20070109117A1Improve stabilityElectric signal transmission systemsSensorsLine sensorCommunications system

In one embodiment the present invention provides a wireless communication system for medical sensor data. This communications system includes a portable unit that connects to a wireless sensor and a monitor unit that connects to a sensor monitor. Once activated, the units will self organize into a wireless communication structure controlled by the portable unit. As other pairs of units activate, they can self-organize their transmissions by joining an existing network or by creating new networks.

Owner:EDWARDS LIFESCIENCES CORP

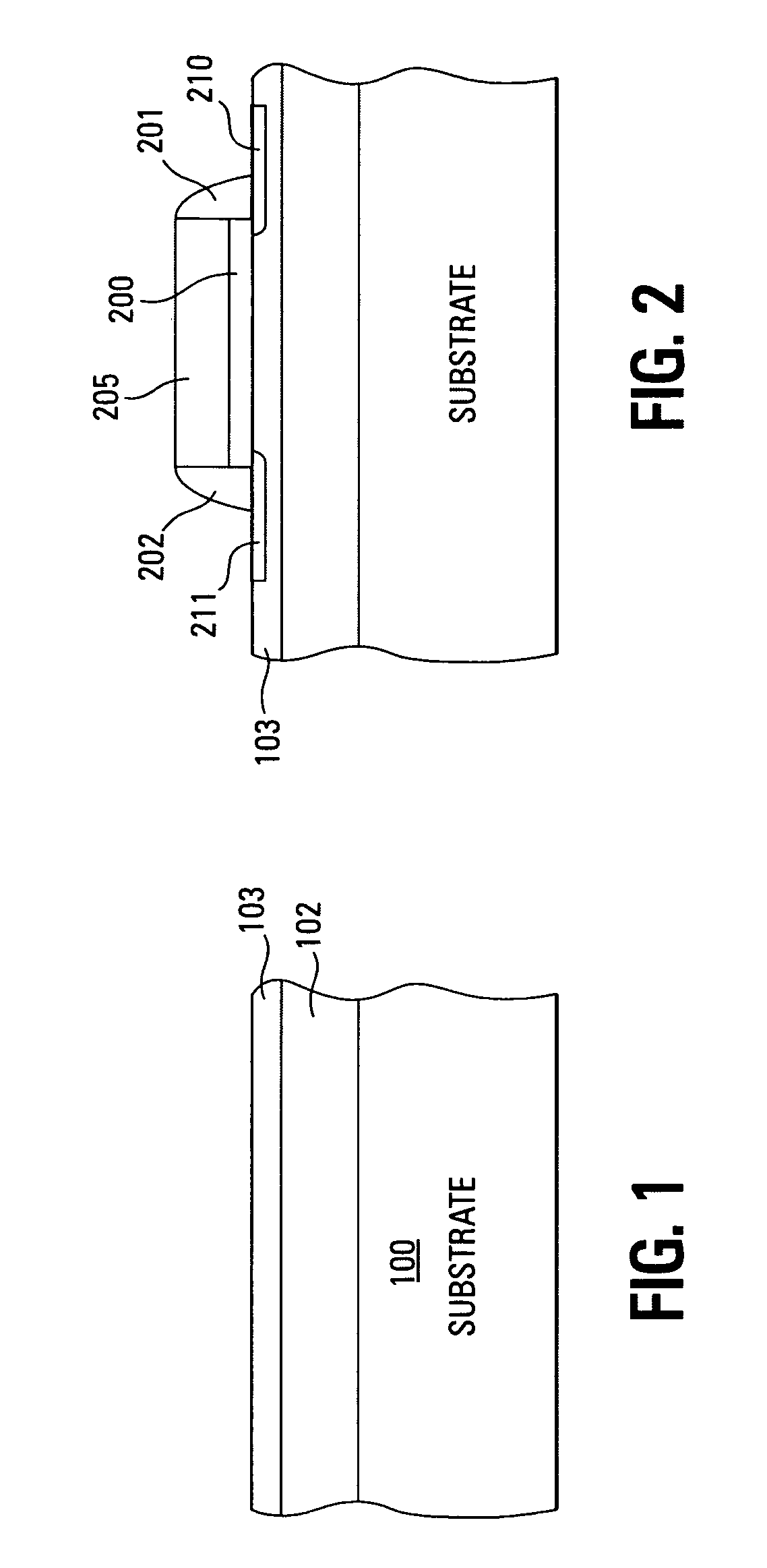

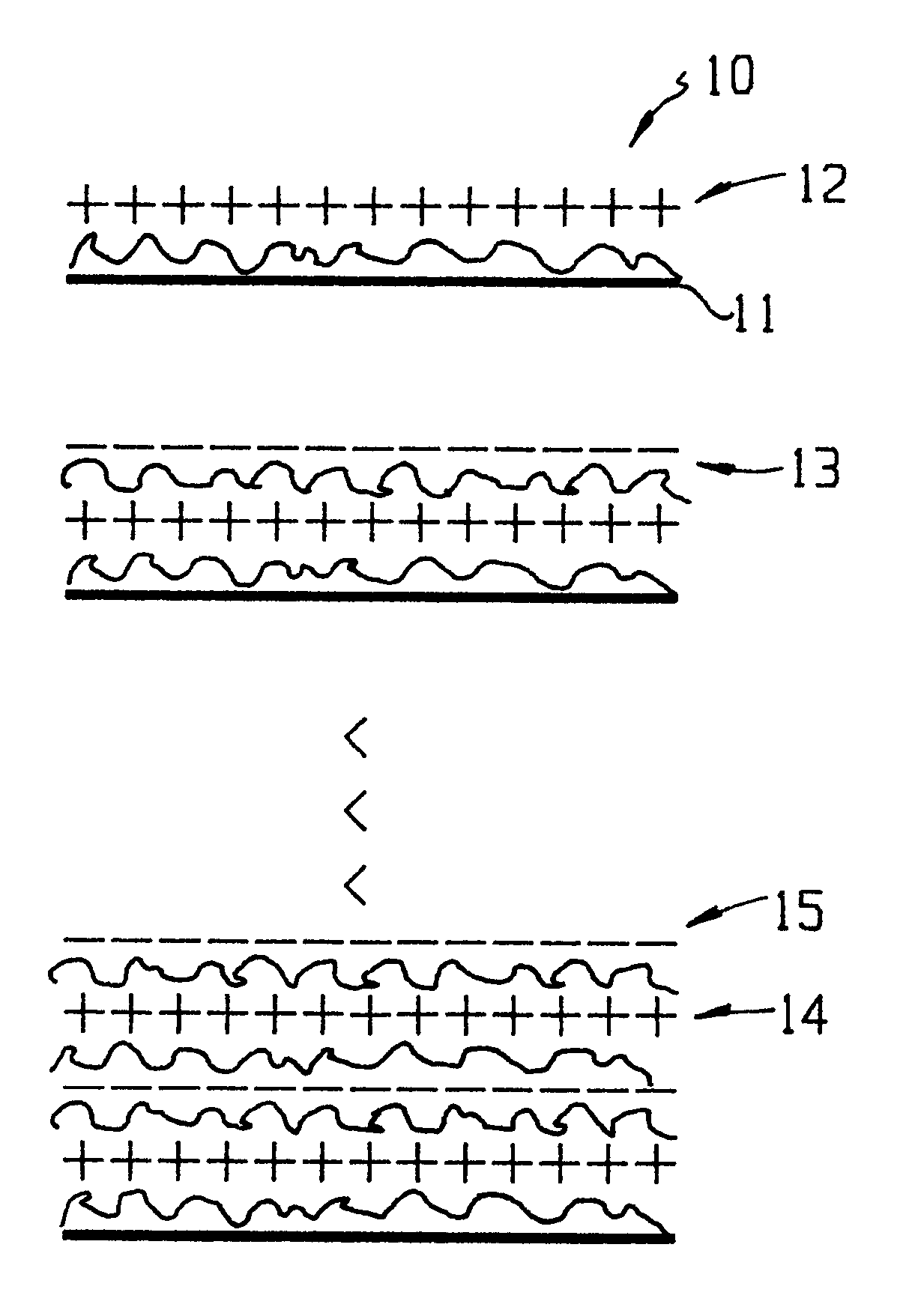

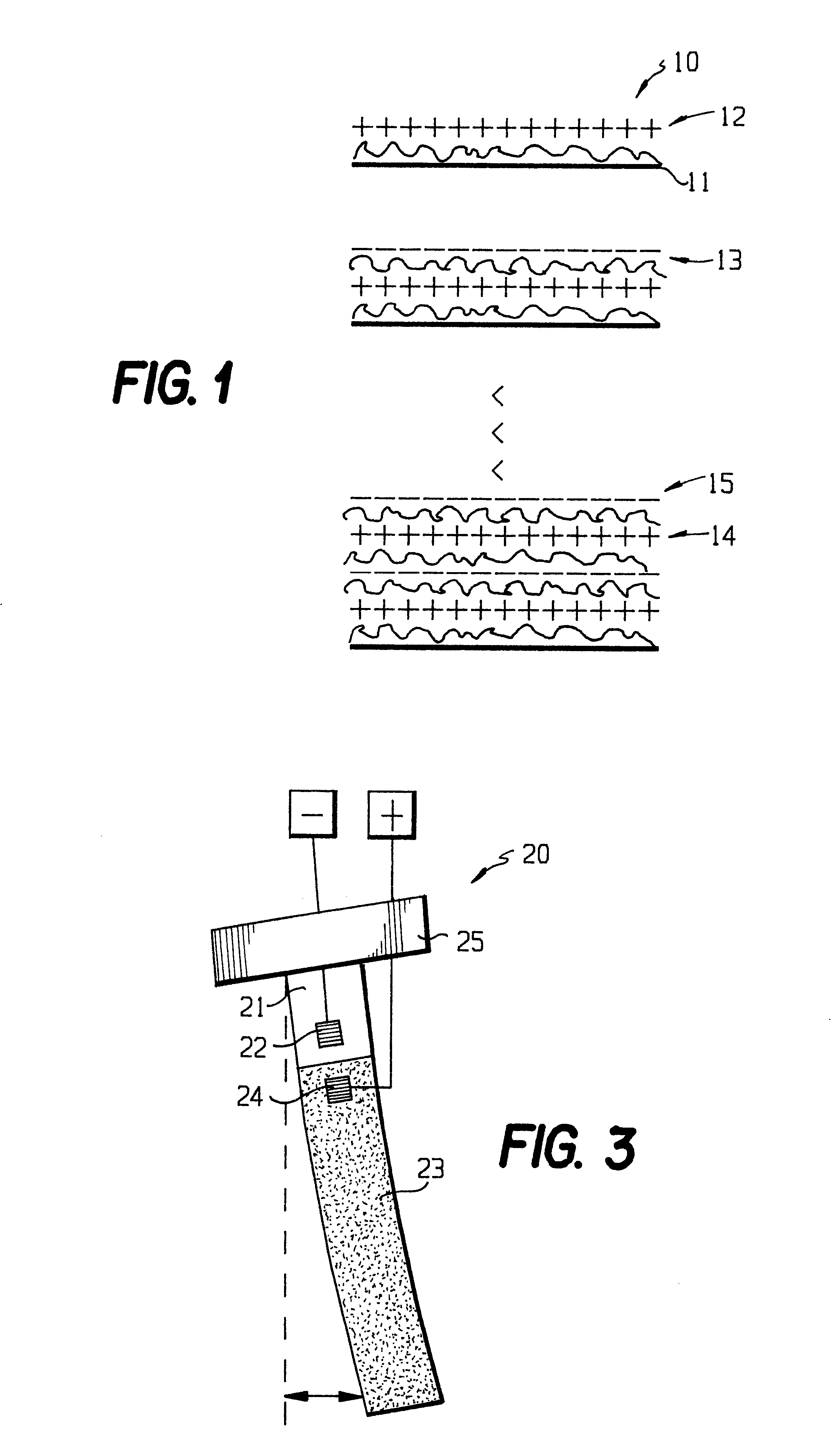

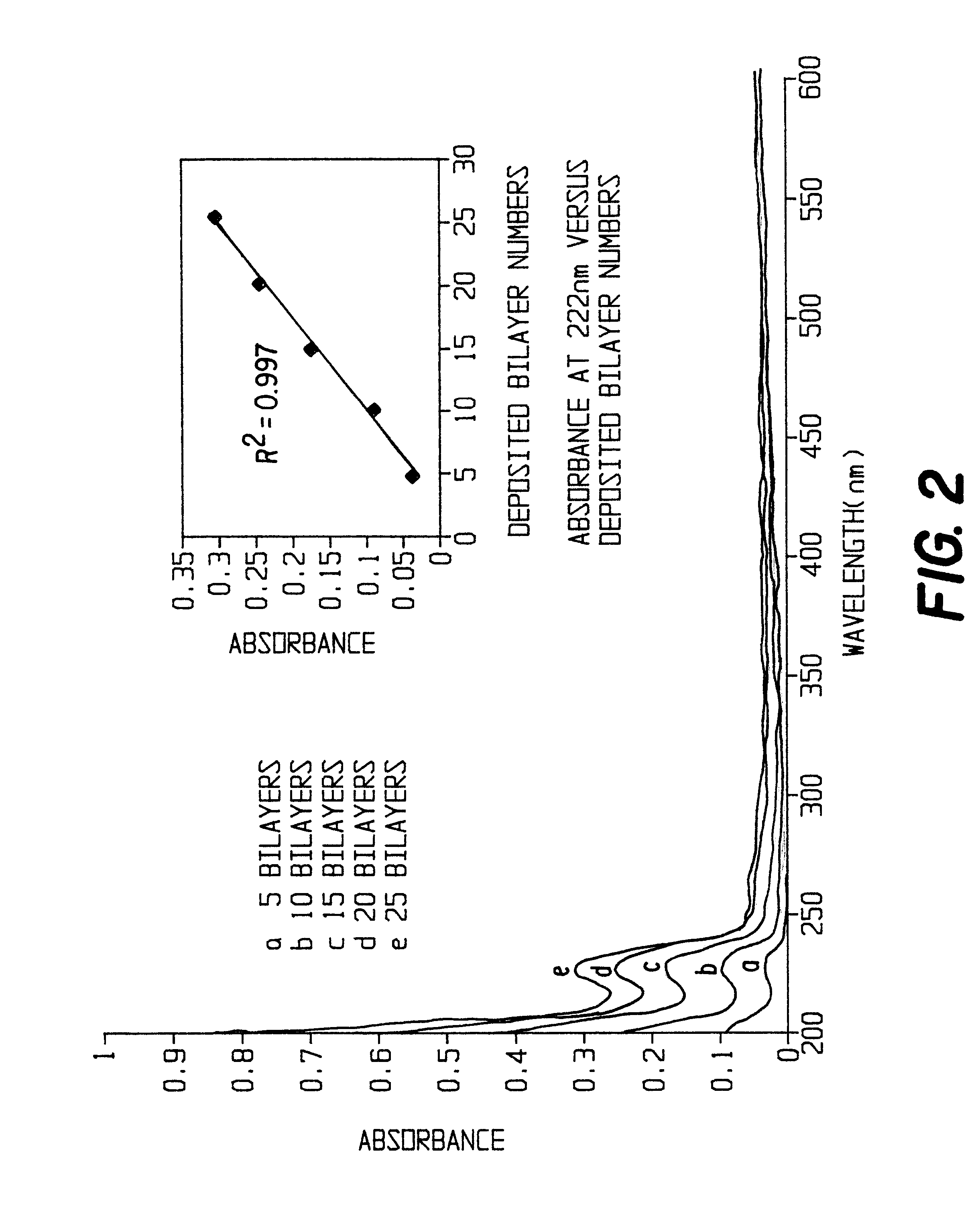

Electrostrictive and piezoelectric thin film assemblies and method of fabrication therefor

InactiveUS6447887B1Avoid misalignmentUniform propertyAnodisationMaterial nanotechnologyMolecular levelEngineering

An electrostatic self-assembly method of fabricating electrostrictive and piezoelectric thin film assemblies not only provides a thinner film than is attainable by conventional methods, but provides excellent molecular-level uniformity and precise structural control, and thus large, effective piezoelectric coefficients. The method produces a thin film assembly including (a) a substrate, and (b) a film having one or a plurality of layers disposed upon the substrate, wherein at least one of the layers includes a dipolar material, and this layer of dipolar material has a uniform thickness of at most 500 nm.

Owner:VIRGINIA TECH INTPROP INC

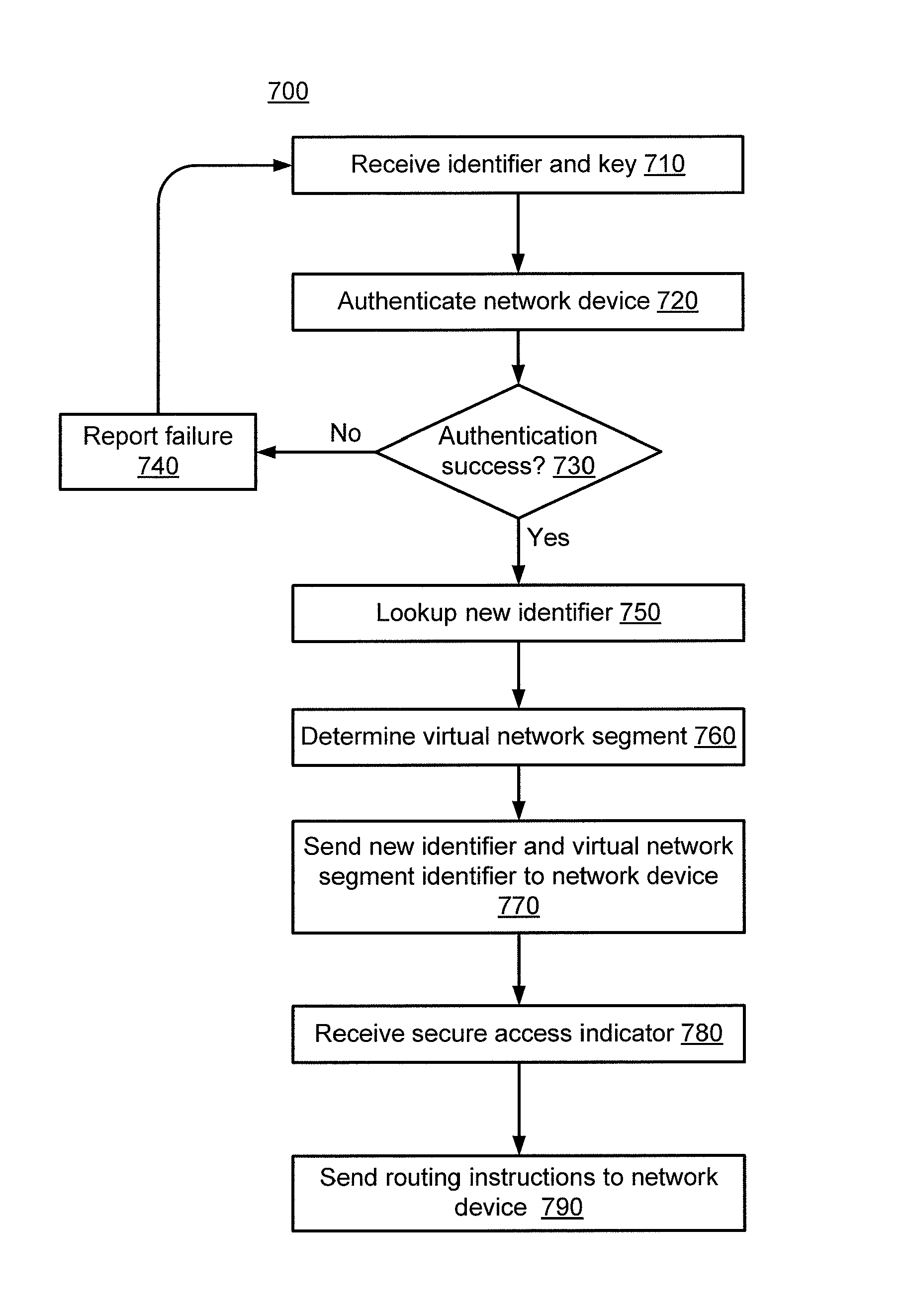

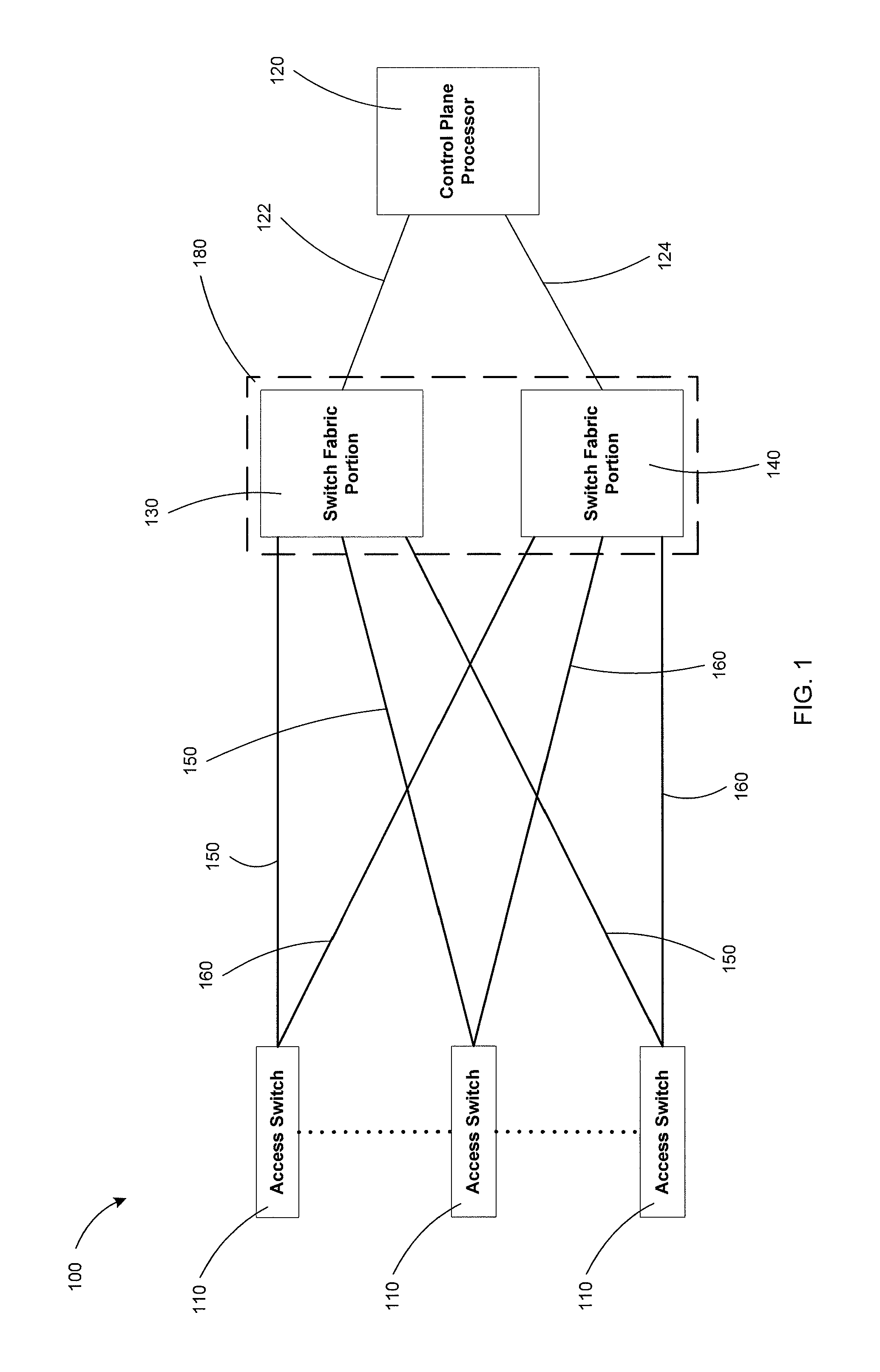

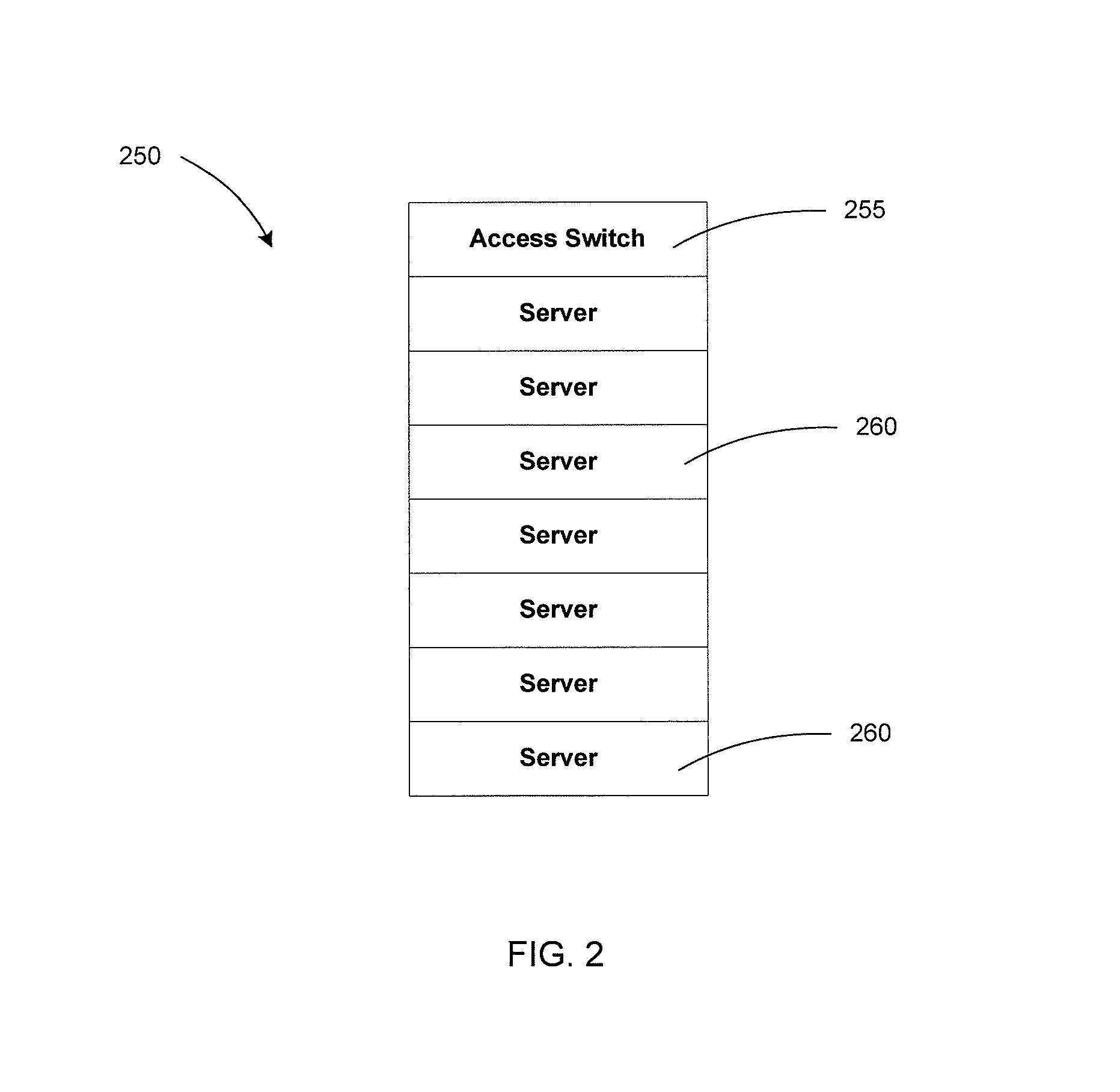

Methods and apparatus for dynamic automated configuration within a control plane of a switch fabric

ActiveUS8918631B1Multiplex system selection arrangementsCircuit switching systemsControl signalData center

In one embodiment, a method includes receiving a first identifier and a private key after a network device has been included in a data center switch fabric control plane, authenticating the network device based on the private key, sending a second identifier to the network device, and sending a control signal to the network device based on the second identifier. The first identifier is associated with the network device and unique within a segment of the data center switch fabric control plane. The second identifier is unique within the segment of the data center switch fabric control plane.

Owner:JUMIPER NETWORKS INC

Software self-defense systems and methods

ActiveUS20050204348A1Error detection/correctionProgram/content distribution protectionTamper resistanceObfuscation

Systems and methods are disclosed for protecting a computer program from unauthorized analysis and modification. Obfuscation transformations can be applied to the computer program's local structure, control graph, and / or data structure to render the program more difficult to understand and / or modify. Tamper-resistance mechanisms can be incorporated into the computer program to detect attempts to tamper with the program's operation. Once an attempt to tamper with the computer program is detected, the computer program reports it to an external agent, ceases normal operation, and / or reverses any modifications made by the attempted tampering. The computer program can also be watermarked to facilitate identification of its owner. The obfuscation, tamper-resistance, and watermarking transformations can be applied to the computer program's source code, object code, or executable image.

Owner:INTERTRUST TECH CORP

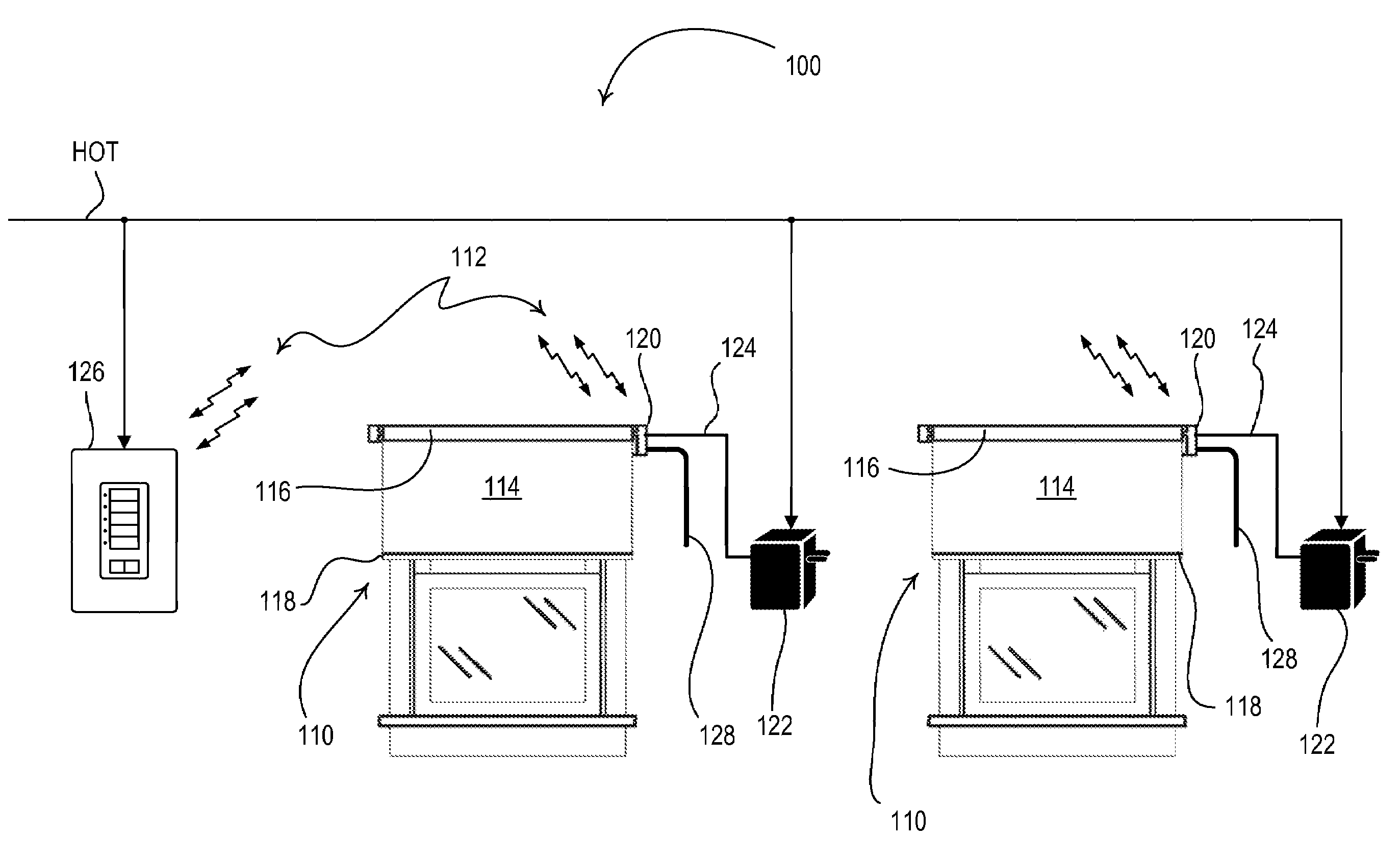

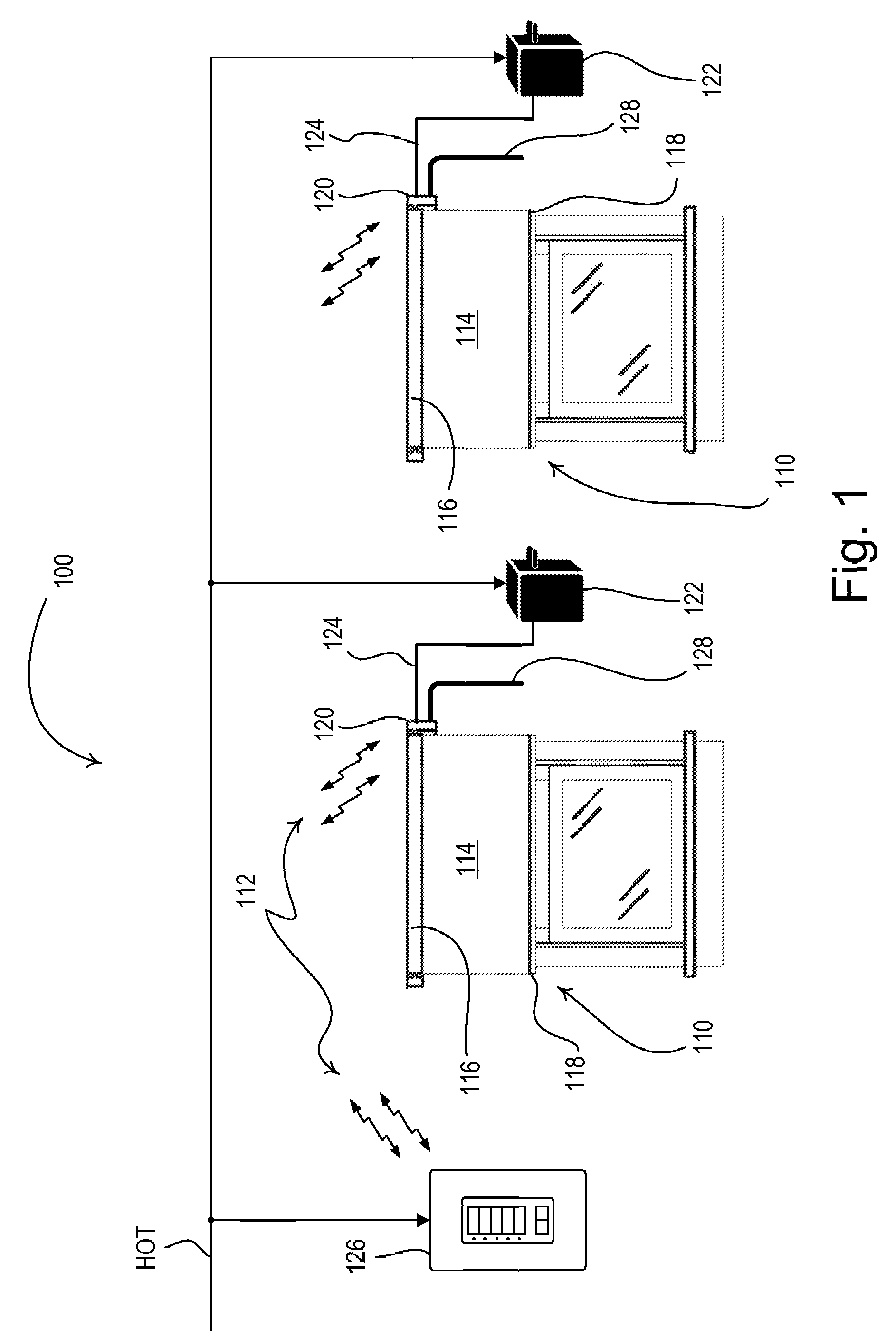

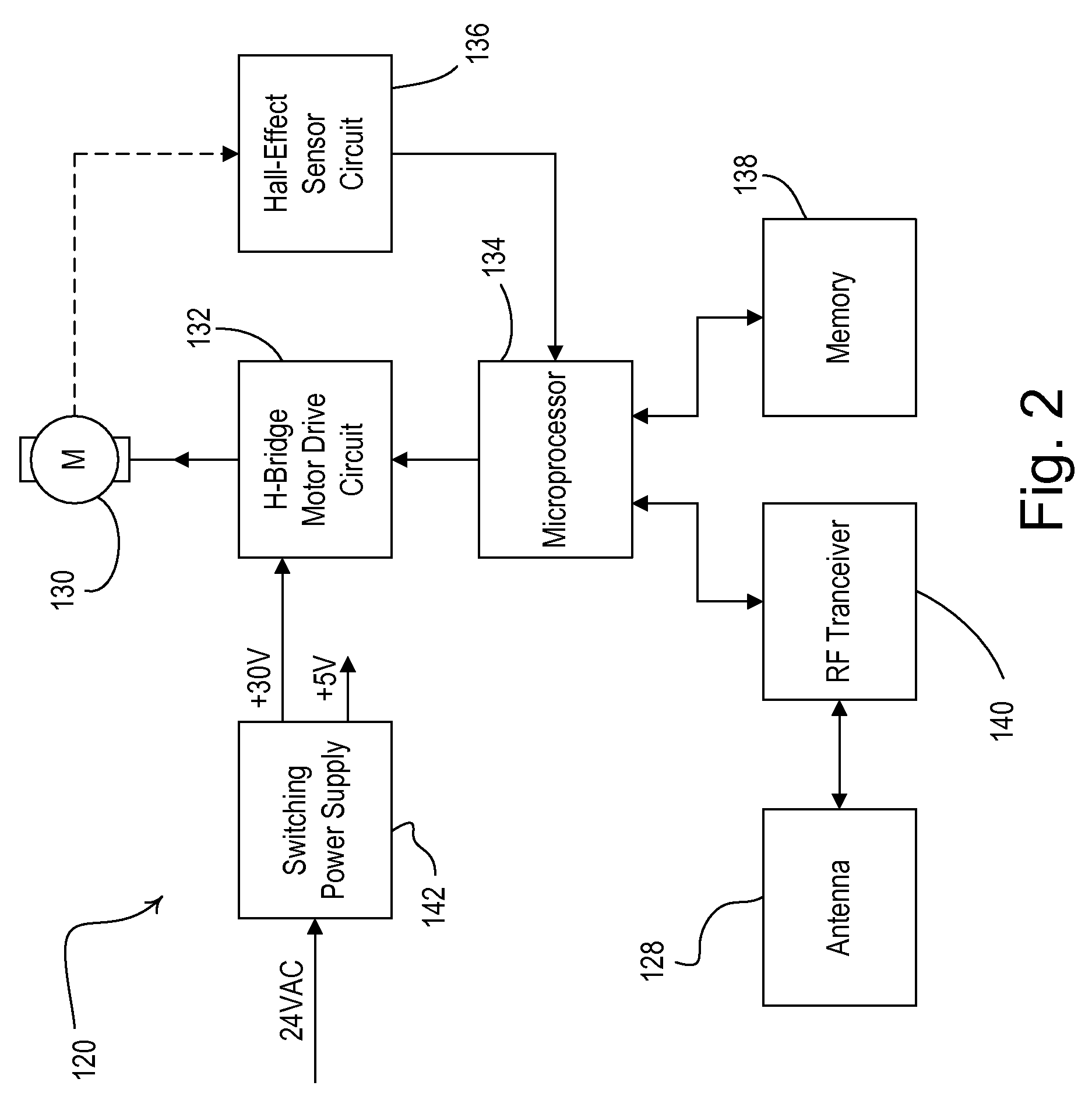

Radio-frequency controlled motorized roller shade

ActiveUS7723939B2Increase signal strengthReduce RF NoiseTelemetry/telecontrol selection arrangementsDC motor speed/torque controlCapacitanceMotor drive

Owner:LUTRON TECH CO LLC

Structure and method for biasing phase change memory array for reliable writing

ActiveUS7307268B2Reduce the possibilityMinimize leakage currentSolid-state devicesDigital storageBit linePhase-change memory

A memory array having memory cells comprising a diode and a phase change material is reliably programmed by maintaining all unselected memory cells in a reverse biased state. Thus leakage is low and assurance is high that no unselected memory cells are disturbed. In order to avoid disturbing unselected memory cells during sequential writing, previously selected word and bit lines are brought to their unselected voltages before new bit lines and word lines are selected. A modified current mirror structure controls state switching of the phase change material.

Owner:SANDISK TECH LLC

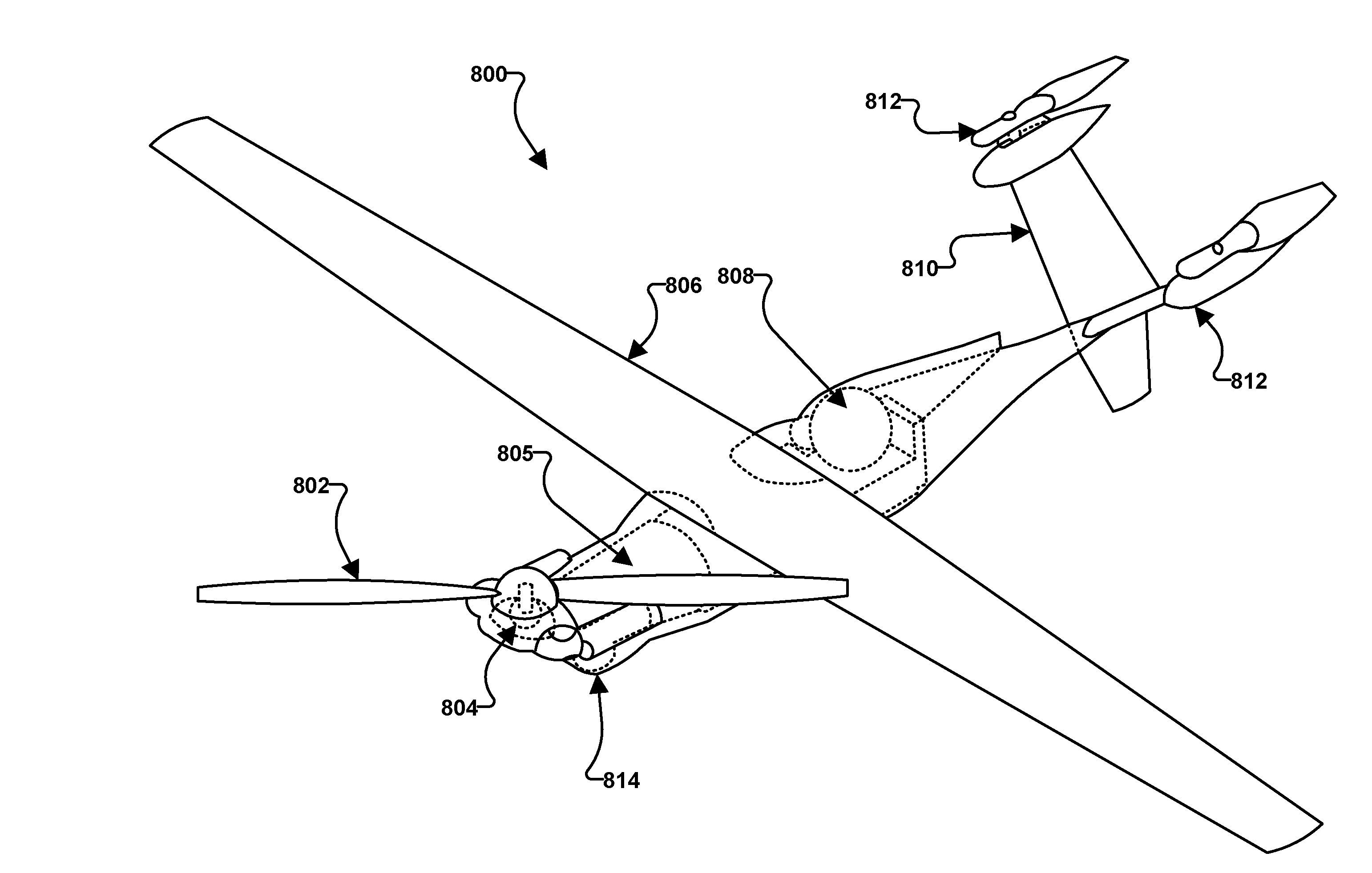

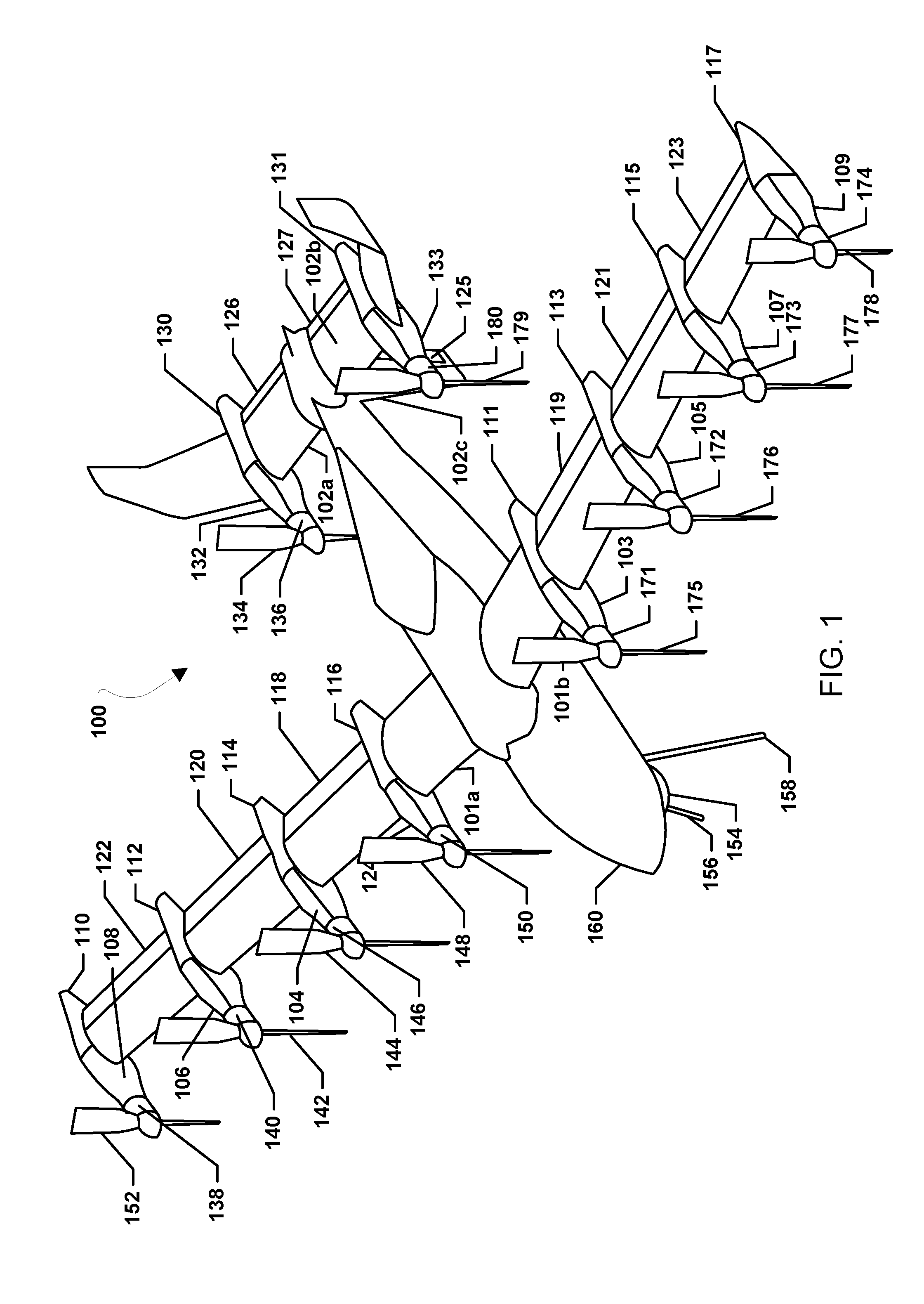

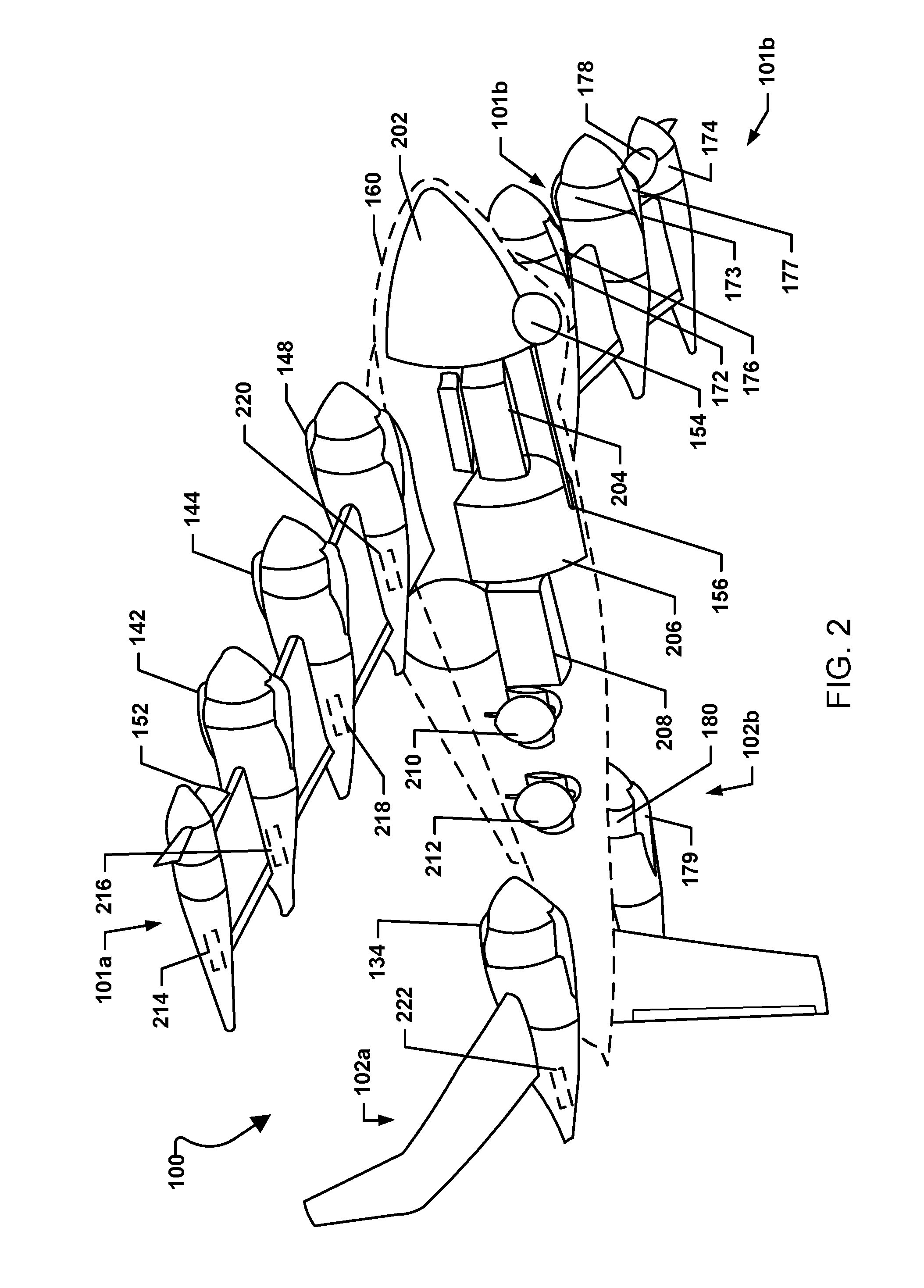

Tri-Rotor Aircraft Capable of Vertical Takeoff and Landing and Transitioning to Forward Flight

ActiveUS20160200436A1Increase rangeImprove enduranceAircraft stabilisationUnmanned aerial vehiclesJet aeroplanePropeller

Systems, methods, and devices provide a vehicle, such as an aircraft, with rotors configured to function as a tri-copter for vertical takeoff and landing (“VTOL”) and a fixed-wing vehicle for forward flight. One rotor may be mounted at a front of the vehicle fuselage on a hinged structure controlled by an actuator to tilt from horizontal to vertical positions. Two additional rotors may be mounted on the horizontal surface of the vehicle tail structure with rotor axes oriented vertically to the fuselage. For forward flight of the vehicle, the front rotor may be rotated down such that the front rotor axis may be oriented horizontally along the fuselage and the front rotor may act as a propeller. For vertical flight, the front rotor may be rotated up such that the front rotor axis may be oriented vertically to the fuselage, while the tail rotors may be activated.

Owner:NASA

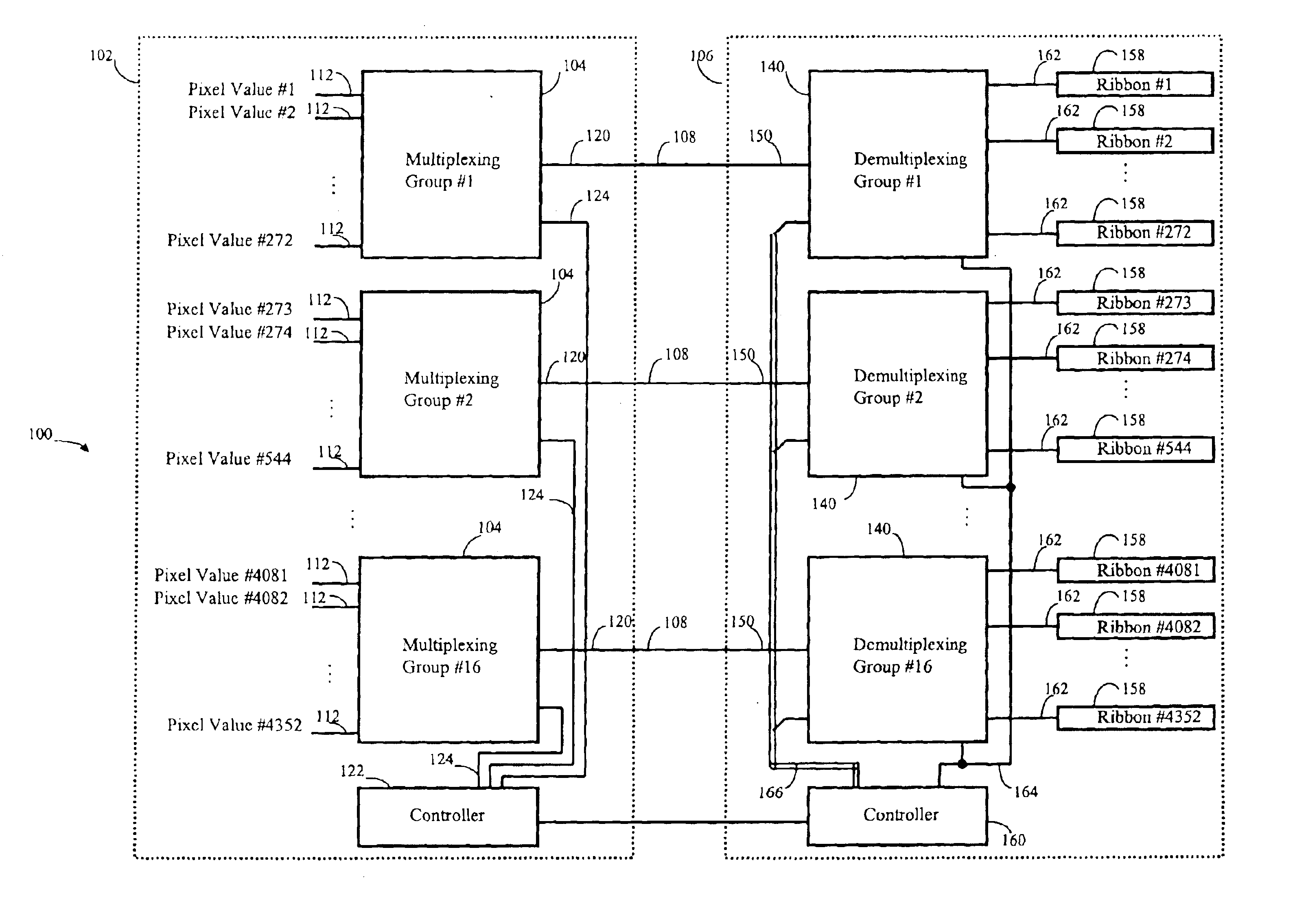

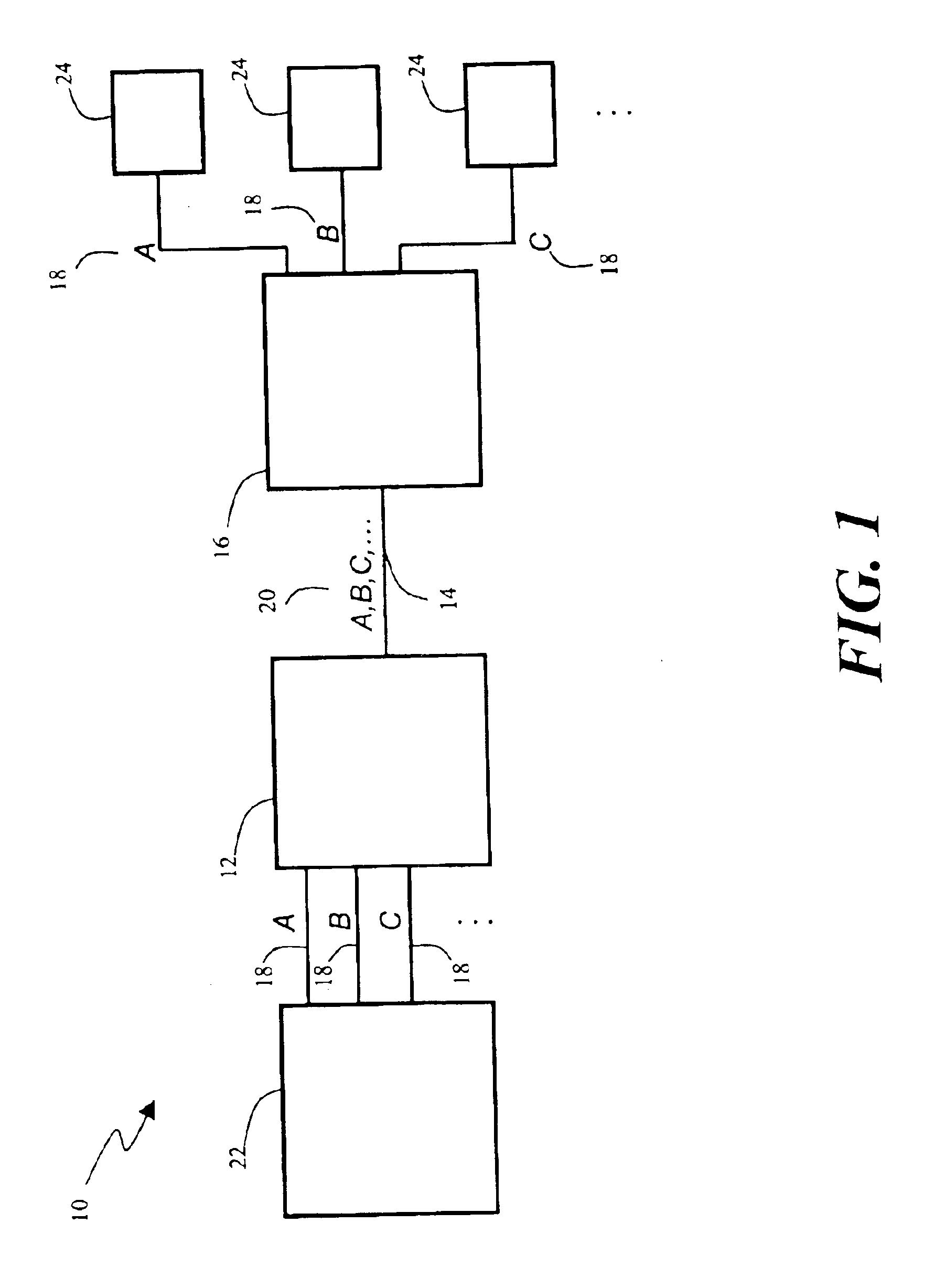

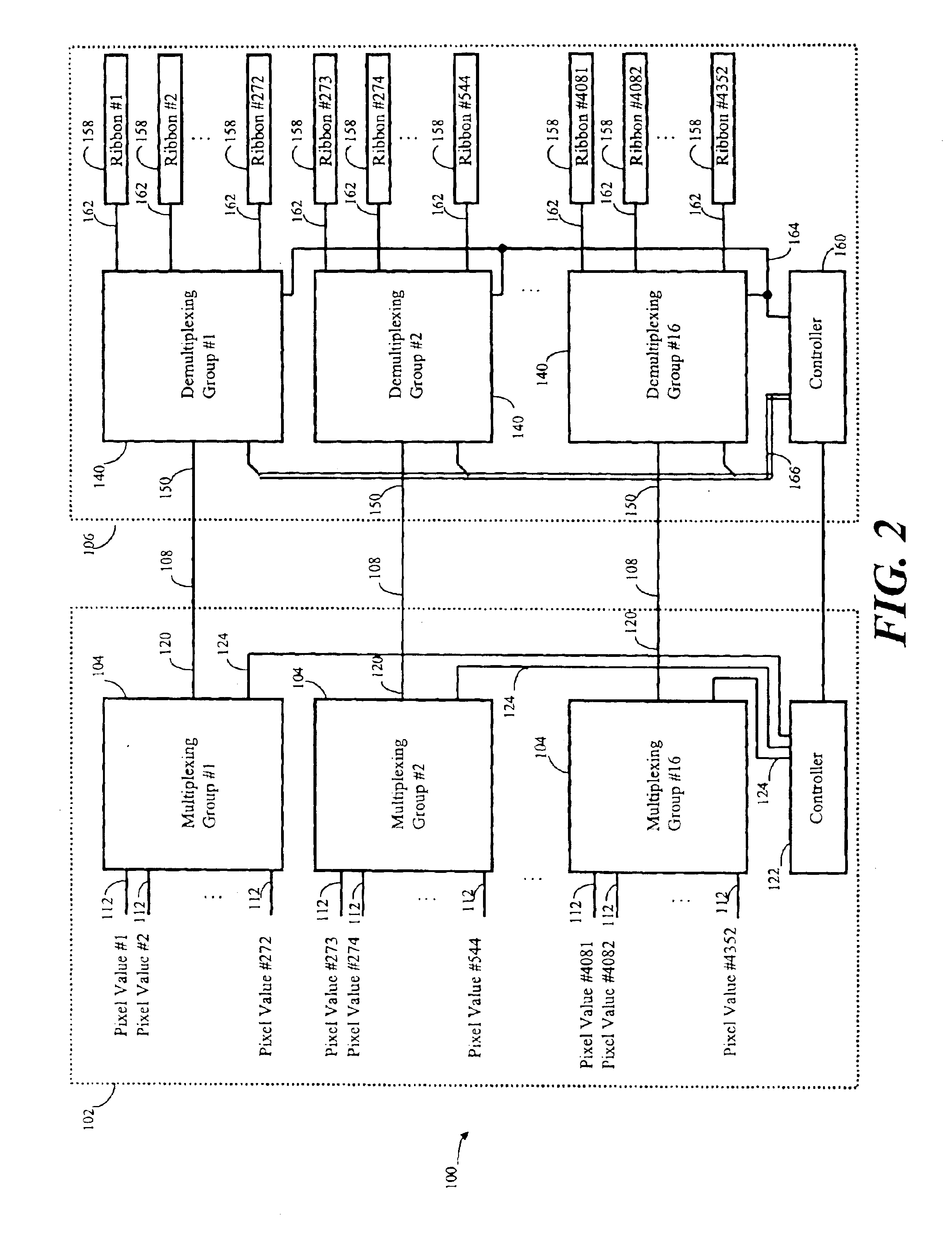

Ultra-high resolution light modulation control system and method

InactiveUS6856449B2High resolutionReduce countStatic indicating devicesNon-linear opticsMultiplexingControl system

A microscopic optical structure controller for providing singular control of individual microscopic optical structures of a microelectromechanical optical device by a multiplexed stream of individual pixel values generated by a pixel value source. The microscopic optical structure controller includes at least one interconnect coupled to the pixel value source for receiving the multiplexed stream of individual pixel values and at least one mapper communicating with the interconnect for extracting individual pixel values from the multiplexed stream and applying the individual pixel values to one or more individual microscopic optical structures according to a configurable mapping. A method and a driver for providing singular control of individual microscopic optical structures of a microelectromechanical optical device are also disclosed.

Owner:EVANS & SUTHERLAND COMP

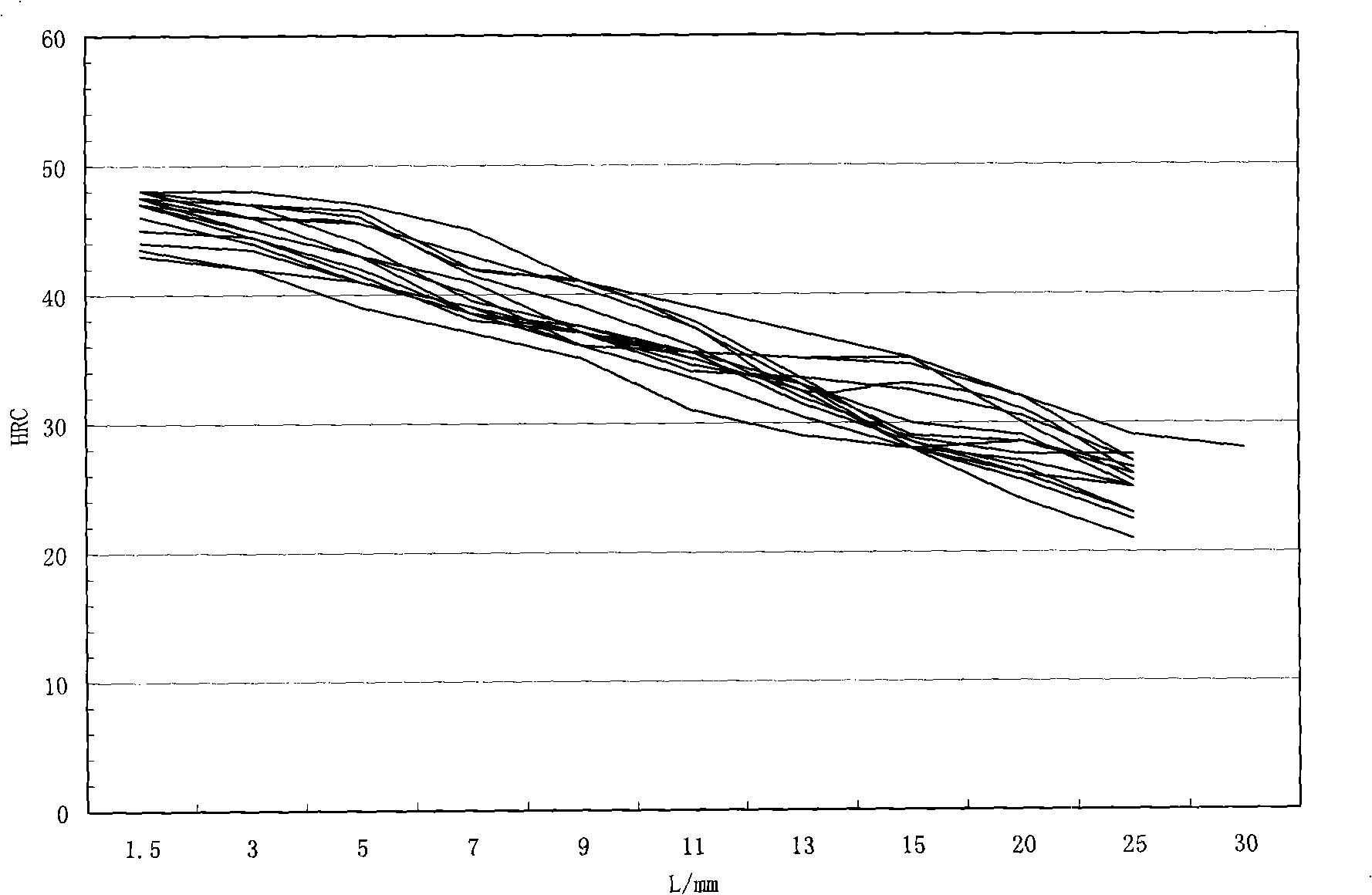

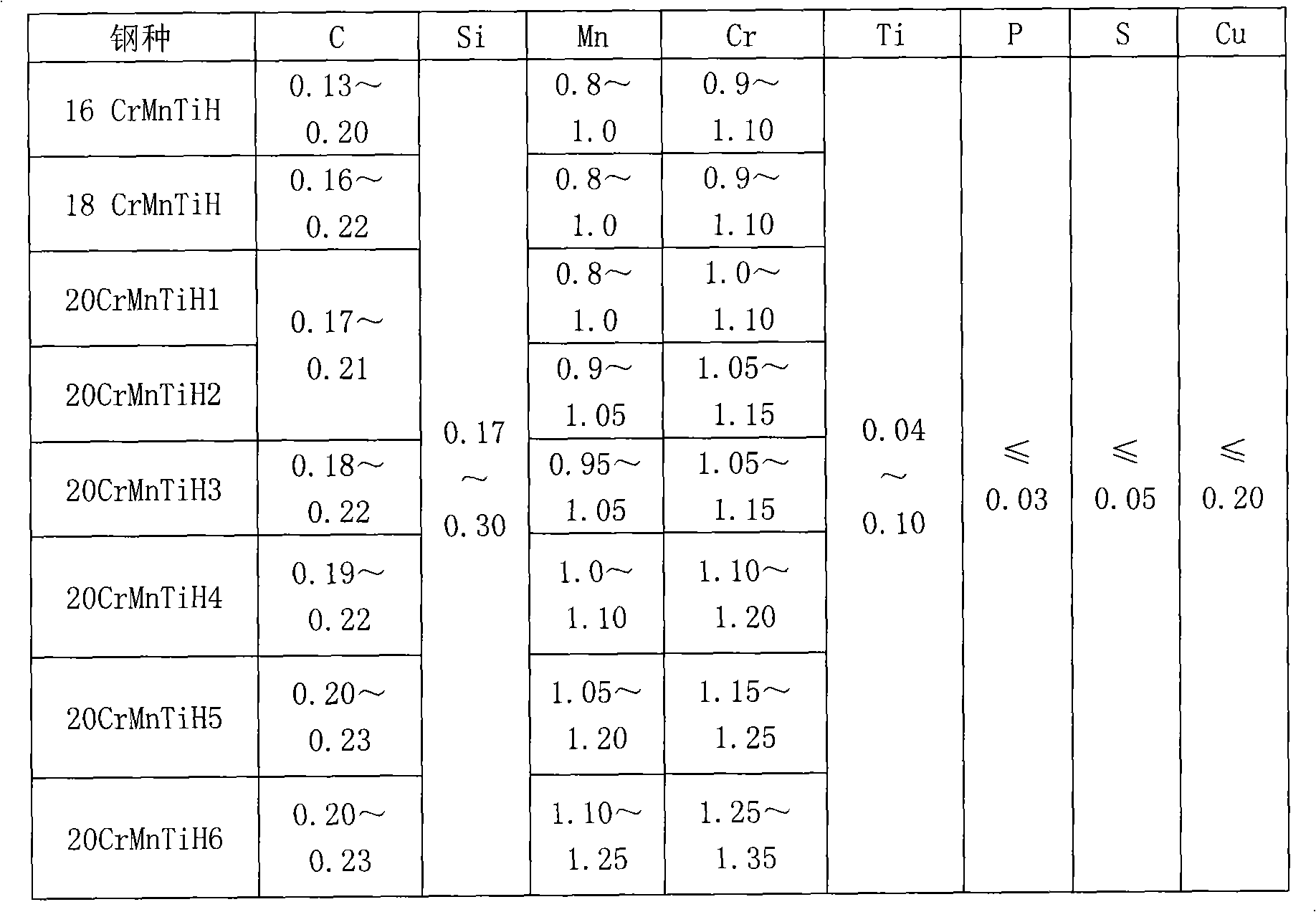

CrMnTi narrow hardenability strip pinion steels and method of manufacture

InactiveCN101289731AGuaranteed narrow hardenability band requirementsTemperature control deviceMetal rolling arrangementsChemical compositionPinion

The invention relates to CrMnTi narrow-hardenability gear steel and a method for manufacturing the same, belonging to the gear steel material and the production process thereof technical field. The chemical composition in percentage by weight of the gear steel is: 0.13-0.23 percent of C, 0.17-0.30 percent of Si, 0.80-1.25 percent of Mn, 0.04-0.10 percent of Ti, 0.90-1.35 percent of Cr, less than or equal to 0.20 percent of Cu, less than or equal to 0.050 percent of S, less than or equal to 0.030 percent of P, less than or equal to 0.05 percent of Mo, less than or equal to 0.25 percent of Ni, [O] less than or equal to 20x10<-6>, [H] less than or equal to 2.5x10<-6>, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following process steps of smelting, continuous casting, rolling and hot rolling, wherein in the step of continuous casting, the superheat degree of a tundish is controlled between 10 and 30 DEG C, and the casting speed is between 0.50 and 0.85 m / min; in the step of rolling, the heating temperature is between 1130 and 1280 DEG C, the start rolling temperature is more than or equal to 1100 DEG C, and the finish rolling temperature is between 850 and 980 DEG C. The gear steel and round steel in the specification between phi 30 and 160 mm can be produced by adopting the manufacturing method. By adopting narrow-composition steel grade design, electric furnace burden structure optimization, electric furnace end point control, grain-refining and banded structure control and other reasonable technological measures, the method effectively realizes hardenability narrowing and other objectives.

Owner:SHANDONG IRON & STEEL CO LTD

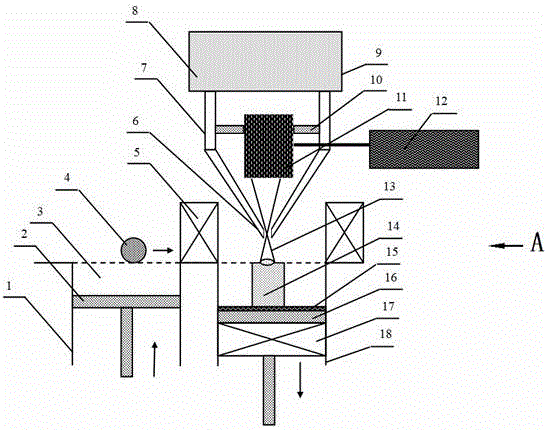

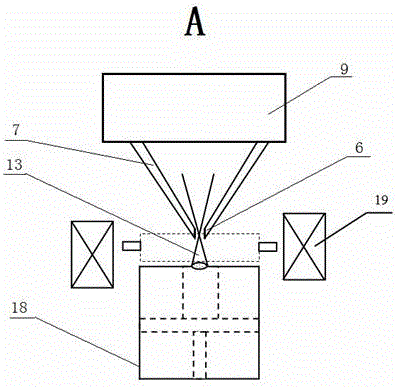

Method for manufacturing metal part solidification structure by non-contact control added material and magnetron metal 3D printing device

ActiveCN105798299ARealize online controlSelectiveAdditive manufacturing apparatusIncreasing energy efficiencyFront edgeElectromagnetic field

The invention discloses a method for manufacturing metal part solidification structure by a non-contact control added material and a magnetron metal 3D printing device. An electromagnetic field is applied in the quick solidification process of metal 3D printing; under the effect of the electromagnetic field, thermocurrent can be generated on a quickly solidified solid / liquid interface; the thermocurrent and the magnetic field are interacted to generate thermal electromagnetic force for triggering flowing of a melt; the end part of a dendritic crystal is shorn after suffering from the effect of the force to cause fragment of the dendritic crystal to form a lot of new crystal nucleus; and on the other hand, the temperature gradient of the front edge of the solid / liquid interface is slowed down through flowing of the melt, so that the constitutional supercooling of two phase regions is increased, the nucleation rate is increased. The method refines grains, improves the morphology of the grains, enables the structure to become uniform and compact, and realizes the structure control of metal 3D printing parts.

Owner:SHANGHAI UNIV

Wireless communication protocol for a medical sensor system

ActiveUS7595723B2Improve stabilityElectric signal transmission systemsSensorsWireless communication protocolCommunications system

In one embodiment the present invention provides a wireless communication system for medical sensor data. This communications system includes a portable unit that connects to a wireless sensor and a monitor unit that connects to a sensor monitor. Once activated, the units will self organize into a wireless communication structure controlled by the portable unit. As other pairs of units activate, they can self-organize their transmissions by joining an existing network or by creating new networks.

Owner:EDWARDS LIFESCIENCES CORP

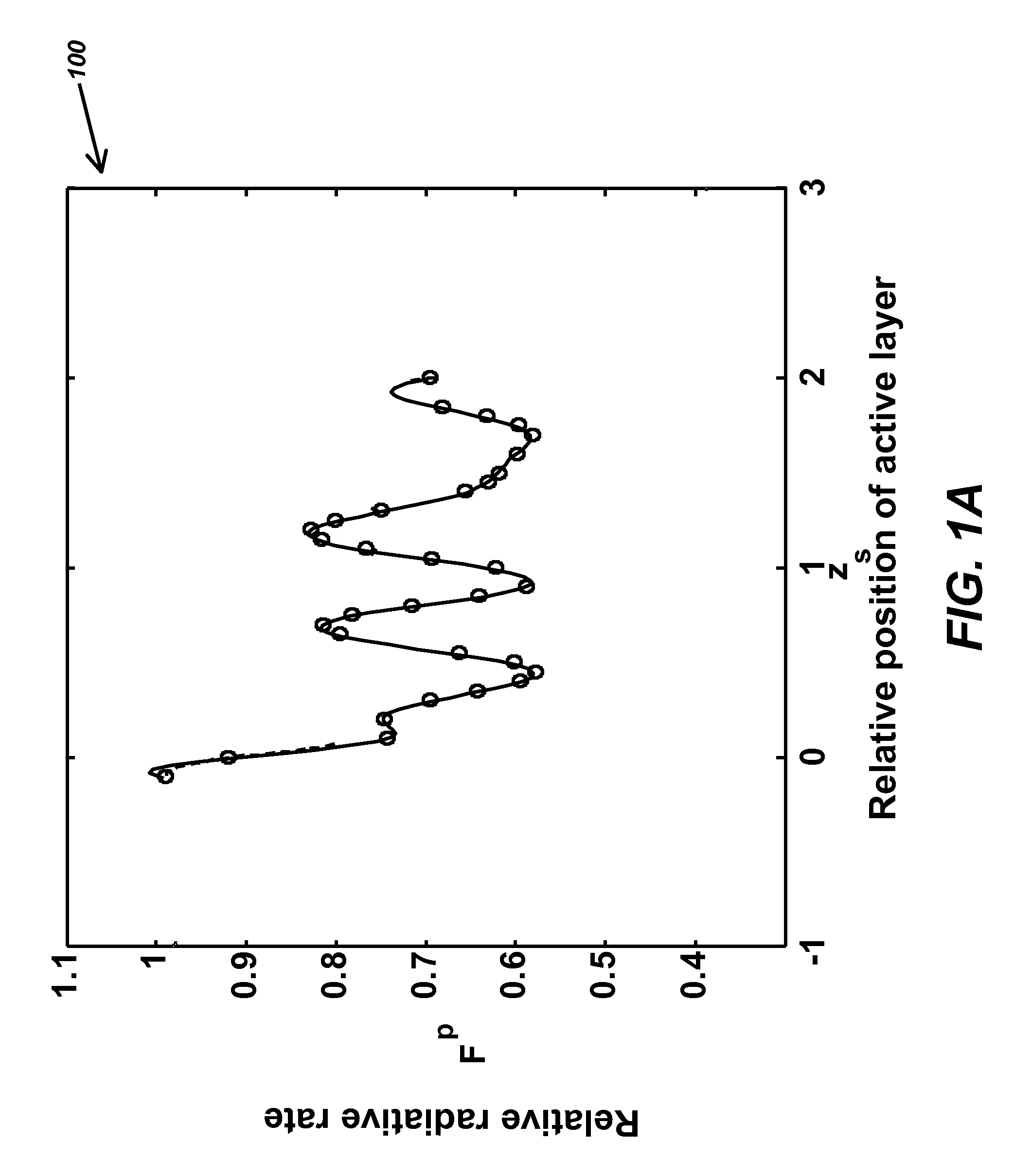

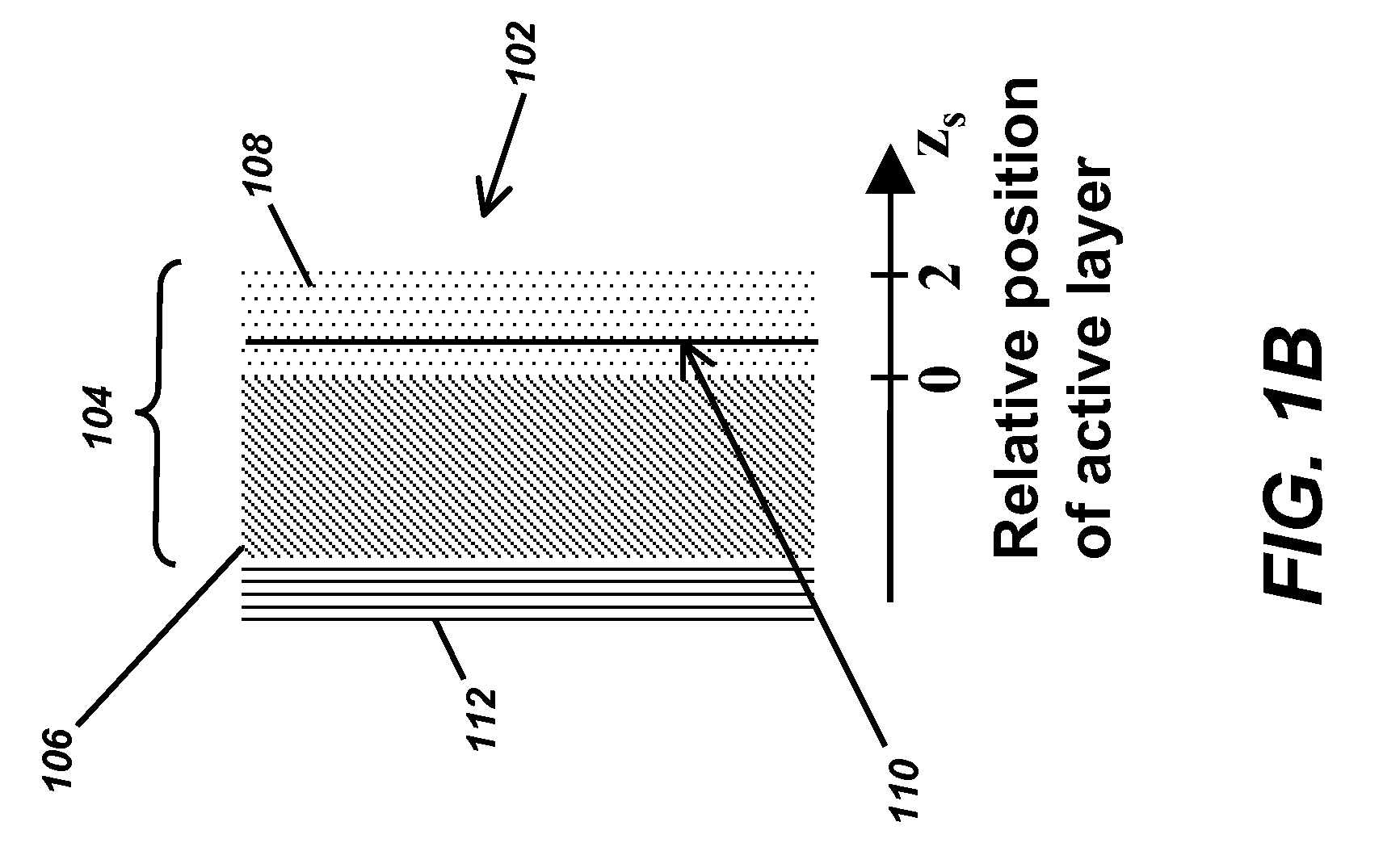

High light extraction efficiency light emitting diode (LED) with emitters within structured materials

InactiveUS20080135864A1Solid-state devicesSemiconductor/solid-state device manufacturingIn planePhotonic crystal

Light Emitting Diodes (LEDs) where the emission region, usually a (Al,In,Ga)N layer, is structured for efficient light extraction, are disclosed. The structuring is designed for light extraction from thin films, such as a photonic crystal acting as a diffraction grating. In addition, the structuring controls the in-plane emission and allows new modes into which light will be emitted. Various electrode designs are proposed, including ZnO structures which are known to lead to both excellent electrical properties, such as good carrier injection, and high transparency. Alternatively, the (Al,In,Ga)N layer can be replaced by structures with other materials compositions, in order to achieve efficient light extraction.

Owner:RGT UNIV OF CALIFORNIA

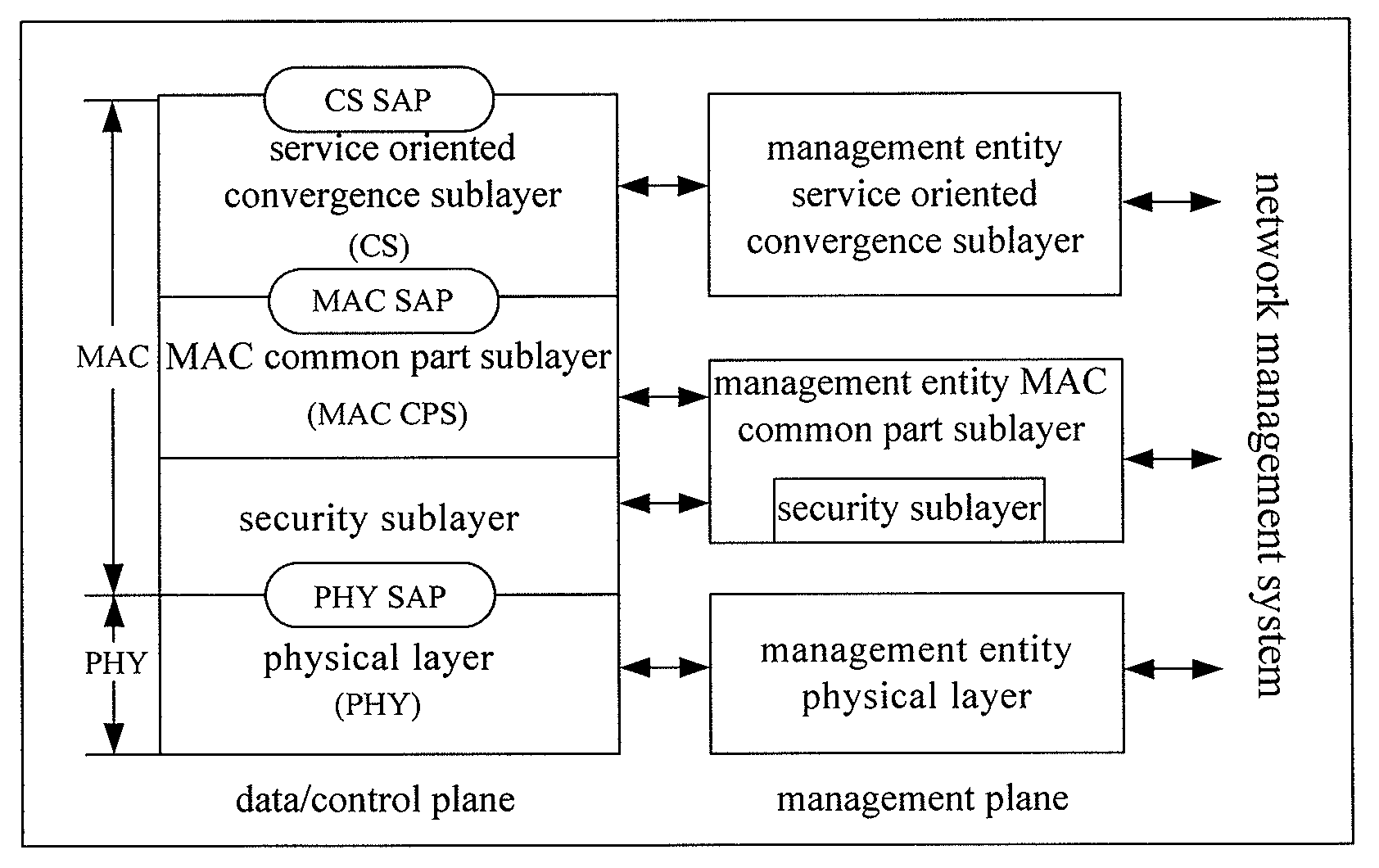

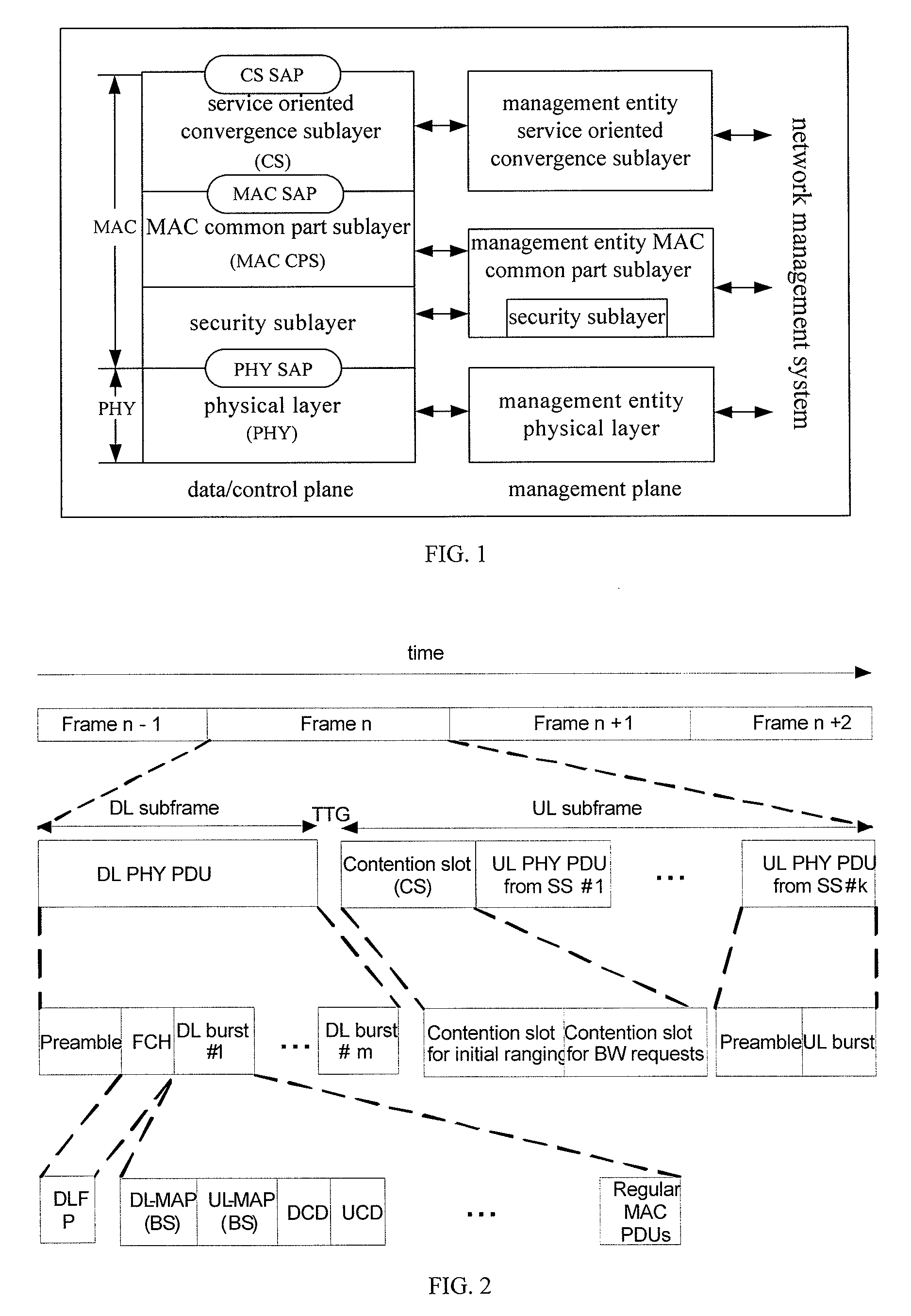

Method, system and apparatus for implementing bandwidth allocation based on a relay station

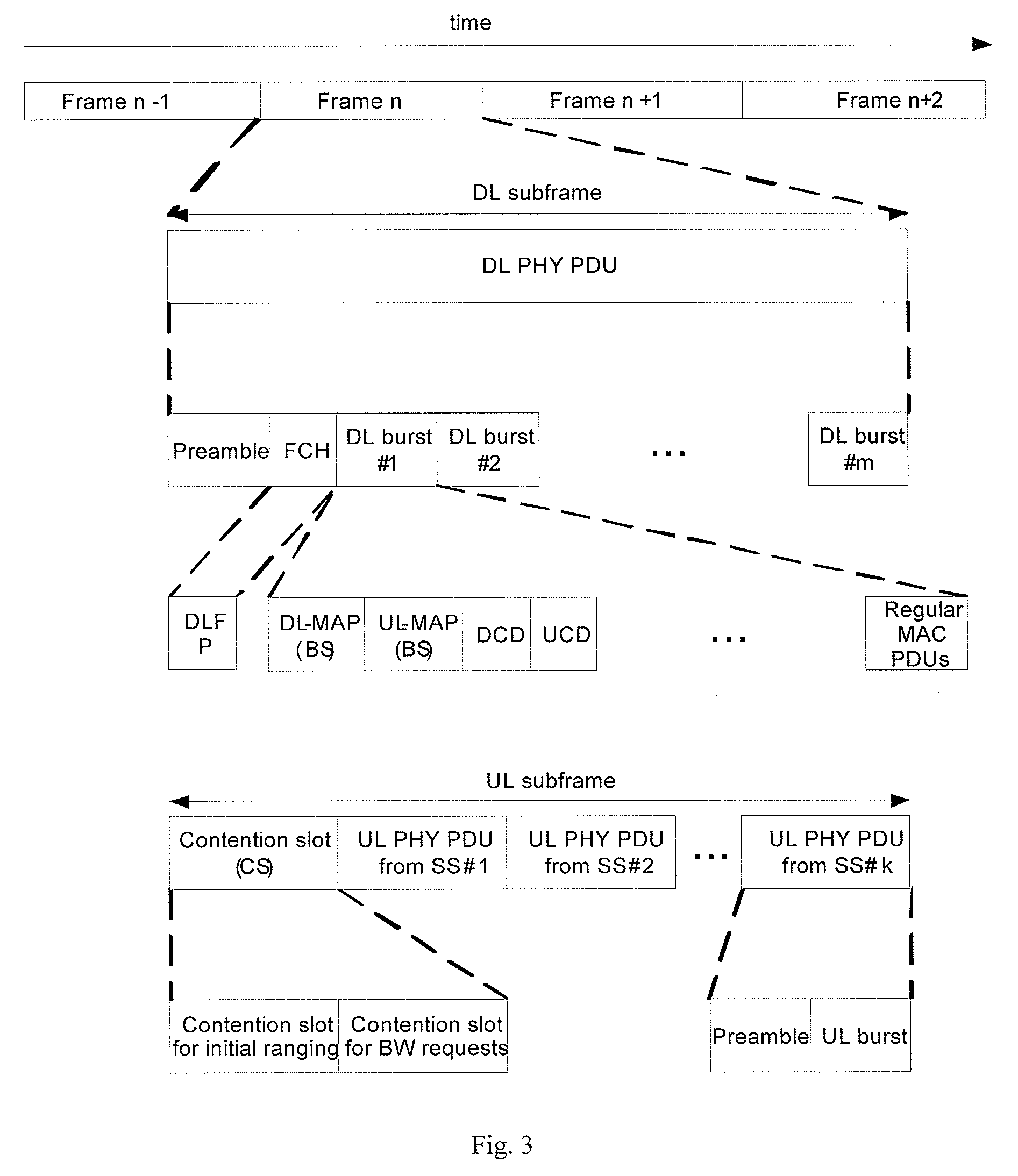

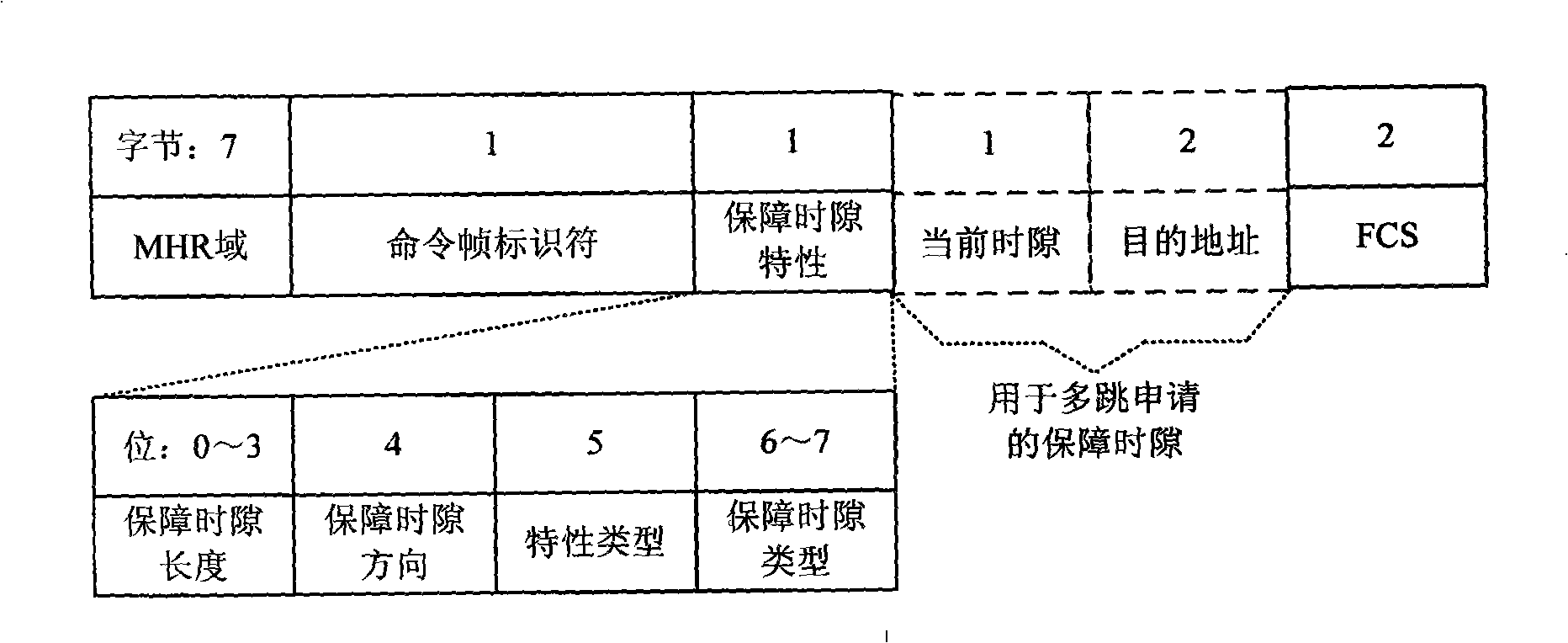

ActiveUS20080259857A1Reduce complexityEasy networkingNetwork topologiesRadio/inductive link selection arrangementsDynamic bandwidth allocationMulti hop relay

The present invention relates to a method, a system and an apparatus for implementing bandwidth allocation and scheduling management based on a relay station. A mapping information unit for controlling a RS (MAPRS) is set in a frame structure of the physical layer of a BS and an extended frame structure of the physical layer of a BS is constructed in a frame structure of the BS physical layer. The BS constructs a mapping information message MAPRS for controlling the relay station RS base on the extended frame structure of the BS physical layer, and performs bandwidth allocation and scheduling management of a communication channel of the RS by the RS according to the MAPRS message. Through the present invention, a bandwidth allocation is implemented mainly at the BS, and a service scheduling is implemented mainly at the BS. The RS only performs an uplink or downlink scheduling of the RS passively. The complexity of the RS reduced effectively. The Multi-hop relay problem is solved using a bandwidth request relay and a bandwidth allocation relay, without introducing any complex technologies and procedures of the bandwidth request, the bandwidth allocation and the scheduling management. The complexity of the BWA relay network is simplified.

Owner:HUAWEI TECH CO LTD

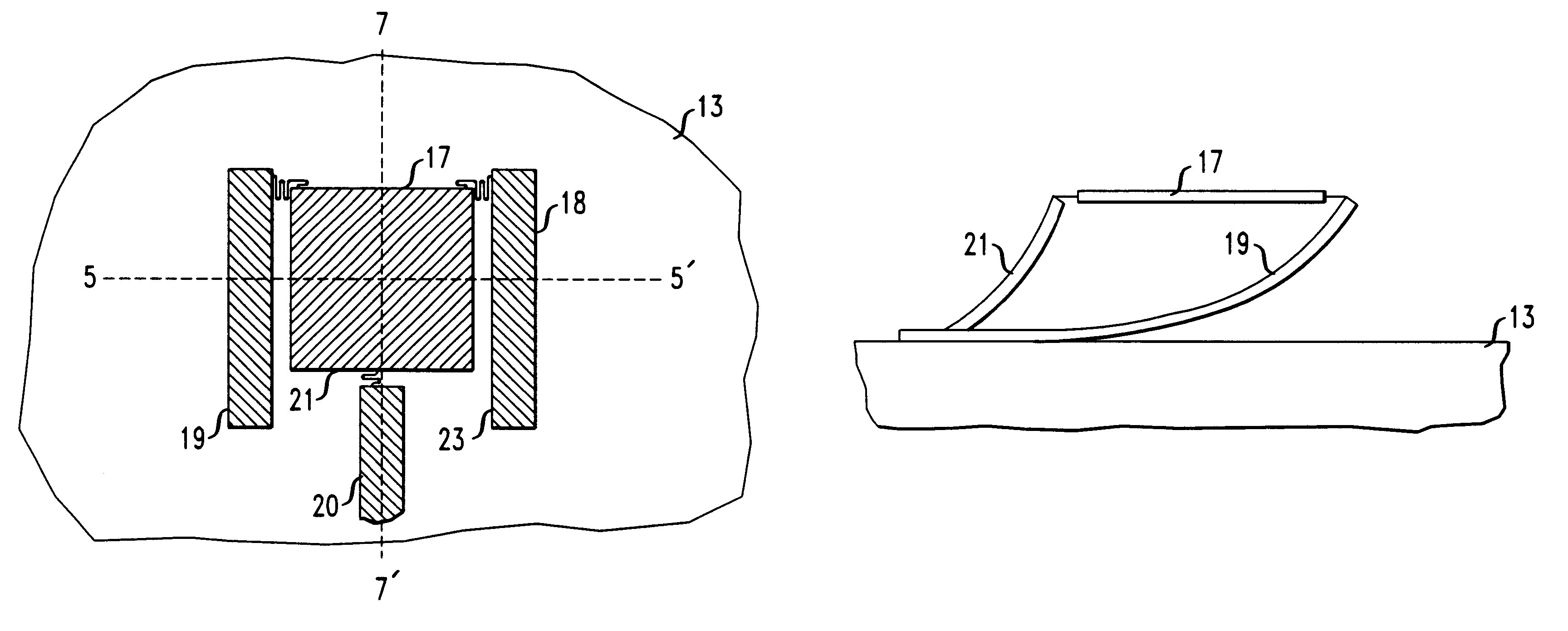

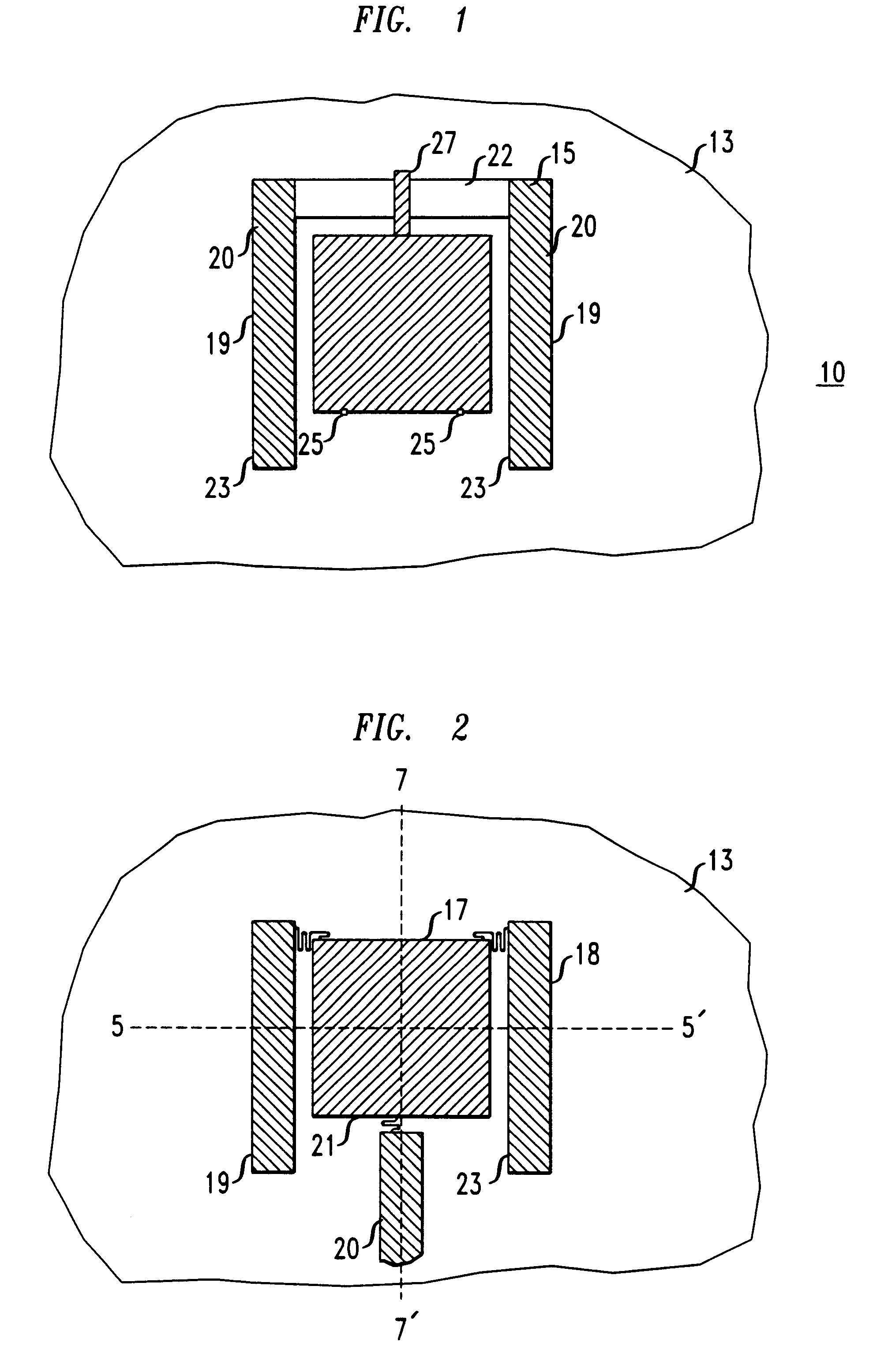

Micro-electro-mechanical optical device

An electro-mechanical structure which controls the movement of an optical device coupled thereto is disclosed. Both the electro-mechanical structure and the optical device are disposed on a substrate surface. The electro-mechanical structure controls the movement of the optical device by first lifting the optical device a predetermined distance above the plane of the substrate surface. Thereafter, the lifted optical device is moveable relative to the plane of the substrate surface in response to an electrostatic field generated between the electro-mechanical structure and the substrate.

Owner:LUCENT TECH INC

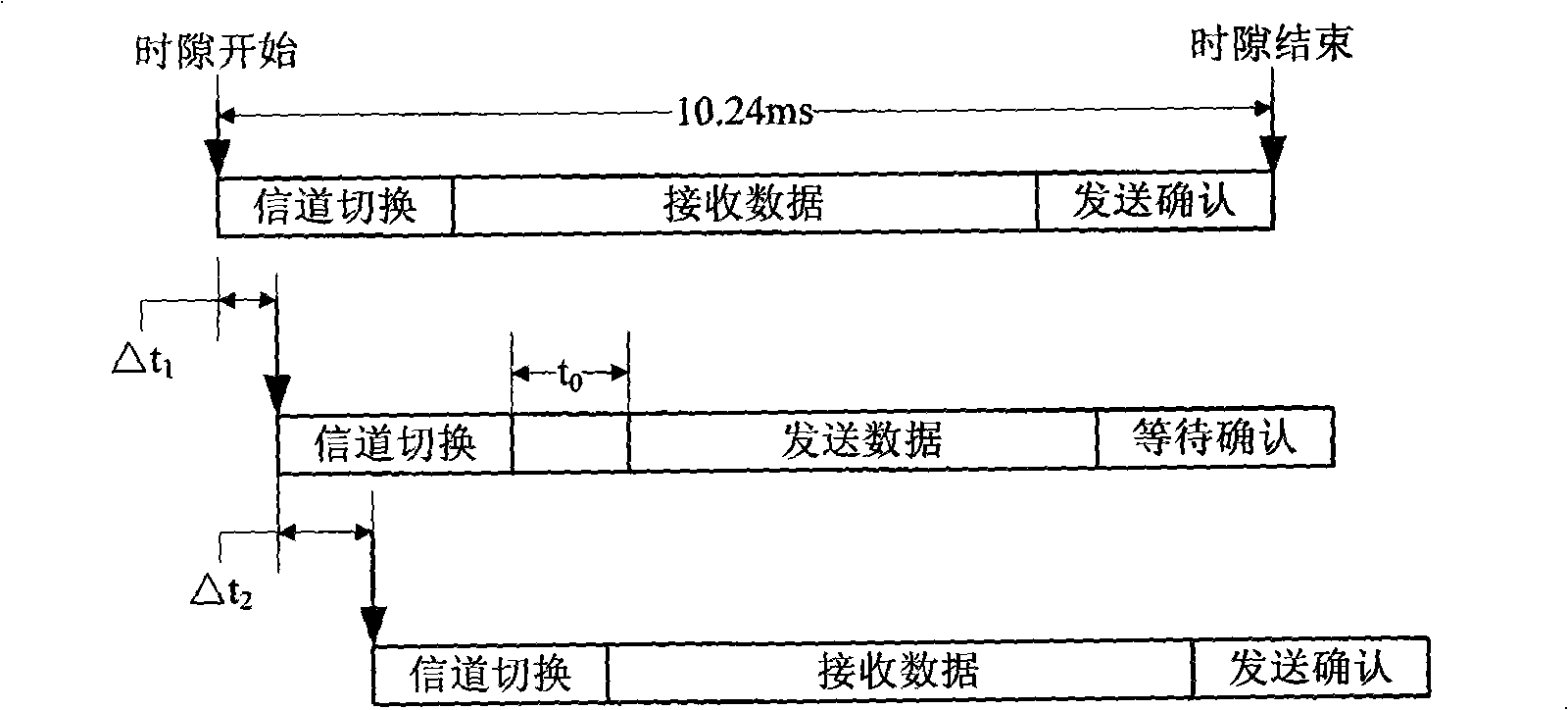

Determined communication scheduling method of industrial wireless network

InactiveCN101321127AResolve interferenceSolve communication problemsData switching networksWireless communicationAutomatic controlWireless control

The invention requests a certainty communication scheduling method for protecting industrial wireless network, relating to the field of industrial automatic control. Aiming at the problem that the existing industrial wireless network is unable to basically solve the beacon collision problem of multi-hop network, the invention redefines super-frame structure according to IEEE 820.15.4 standard. Competition stage, dedicated stage and dormant stage are defined in the super-frame structure. The communication scheduling between nodes is controlled according to the super-frame structure. The channel is changed once at the beginning of every super-frame by adopting the channel hopping technology, so that the channel sequence of the whole network is different and the take-off points of every cluster are different. The invention which solves the beacon collision problem of multi-hop network can be widely applied to the industrial wireless control network.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

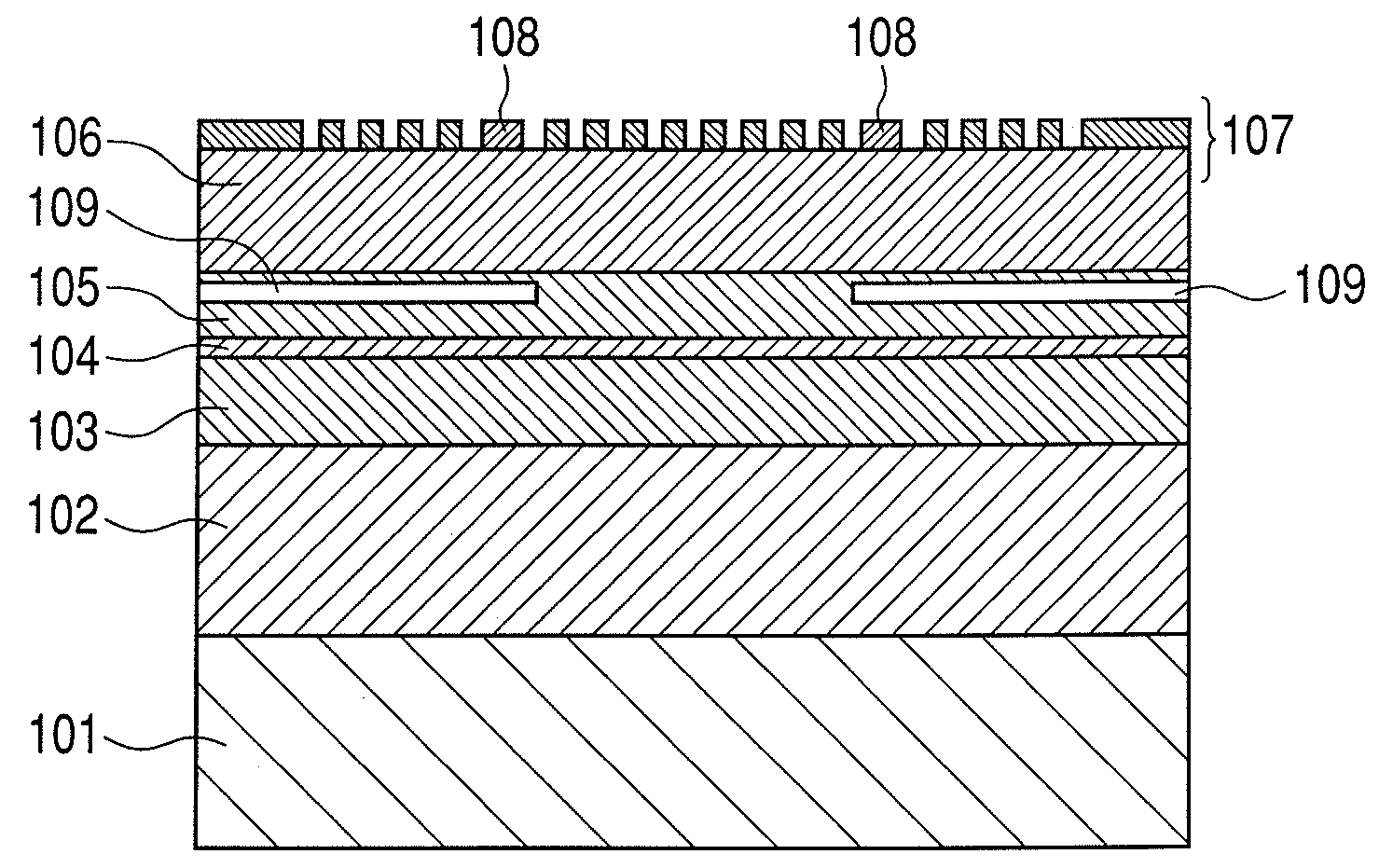

Vertical cavity surface emitting laser

InactiveUS20090196319A1Easy constructionOptical resonator shape and constructionSemiconductor lasersVertical-cavity surface-emitting laserRefractive index

A vertical cavity surface emitting laser is provided which controls the reflectivity at the middle portion and the peripheral portion of the mirror with a simple structure to cause oscillation of a single lateral mode by use of a mirror having the refractive index changing periodically in the mirror plane direction. The vertical cavity surface emitting laser.

Owner:CANON KK

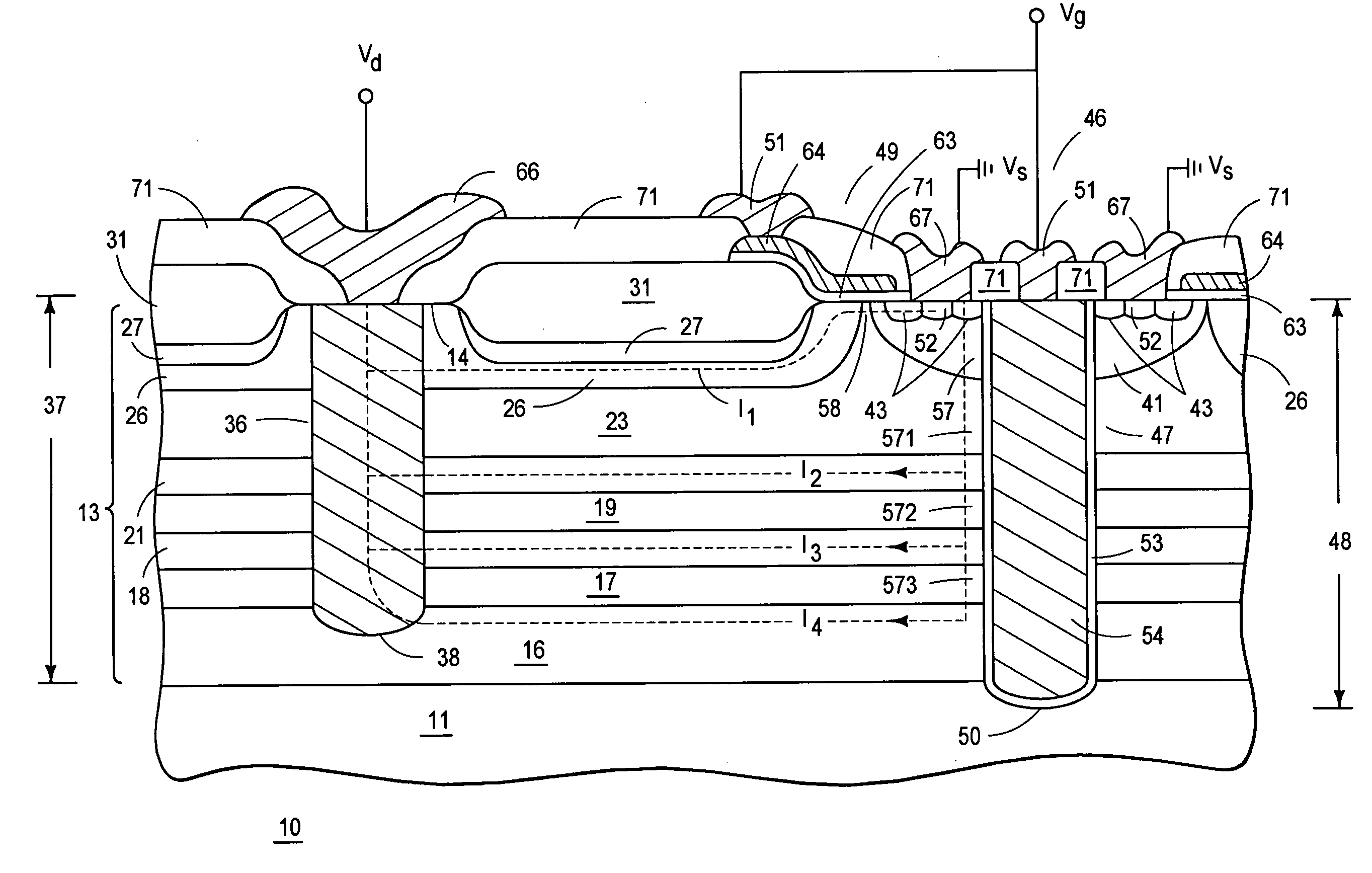

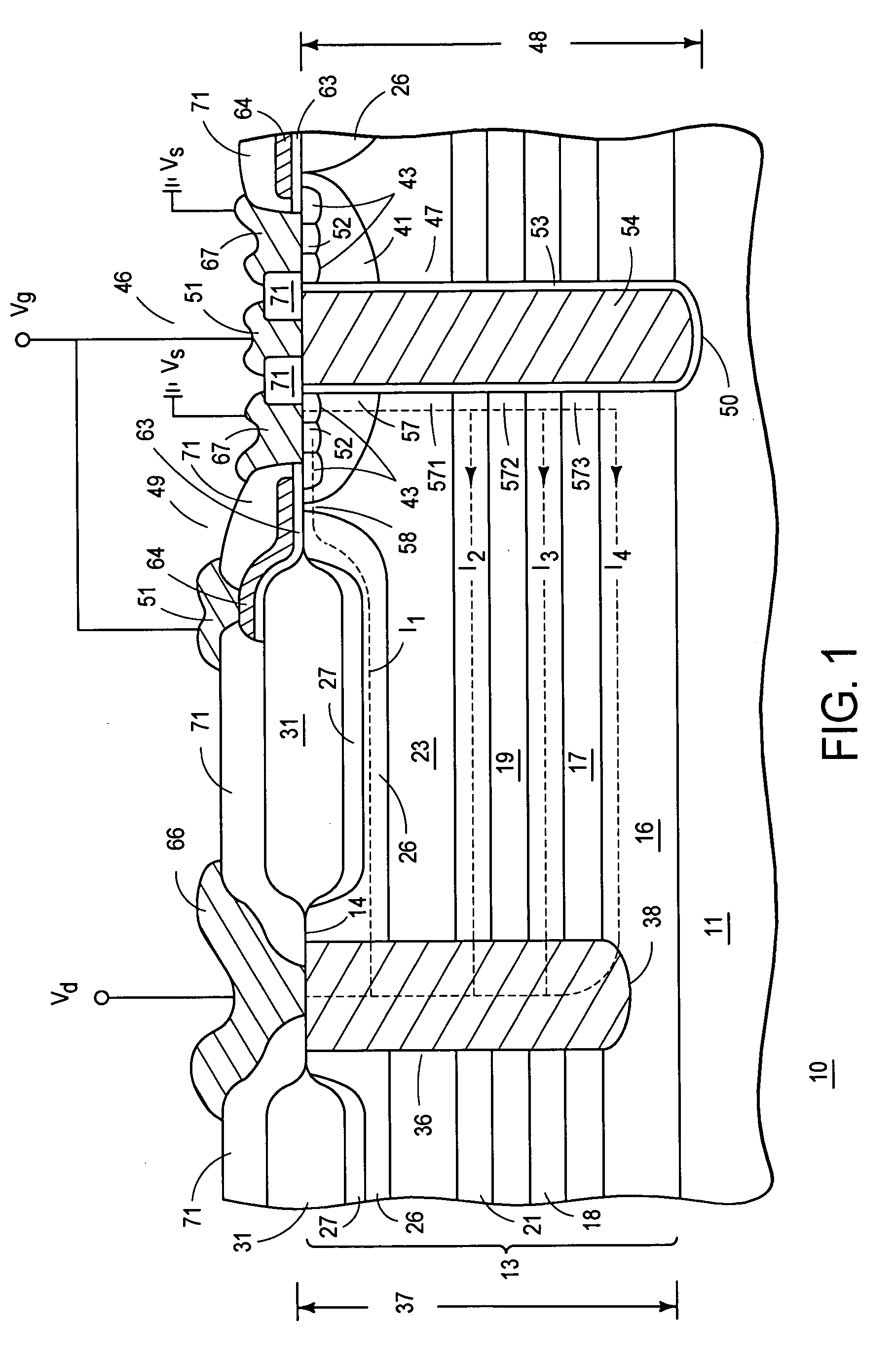

High voltage lateral FET structure with improved on resistance performance

In one embodiment, a lateral FET cell is formed in a body of semiconductor material. The body of semiconductor material includes alternating layers of opposite conductivity type that extend between a trench drain region and a trench gate structure. The trench gate structure controls at least one sub-surface channel region. The body of semiconductor material provides sub-surface drift regions to reduce on resistance without increasing device area.

Owner:SEMICON COMPONENTS IND LLC

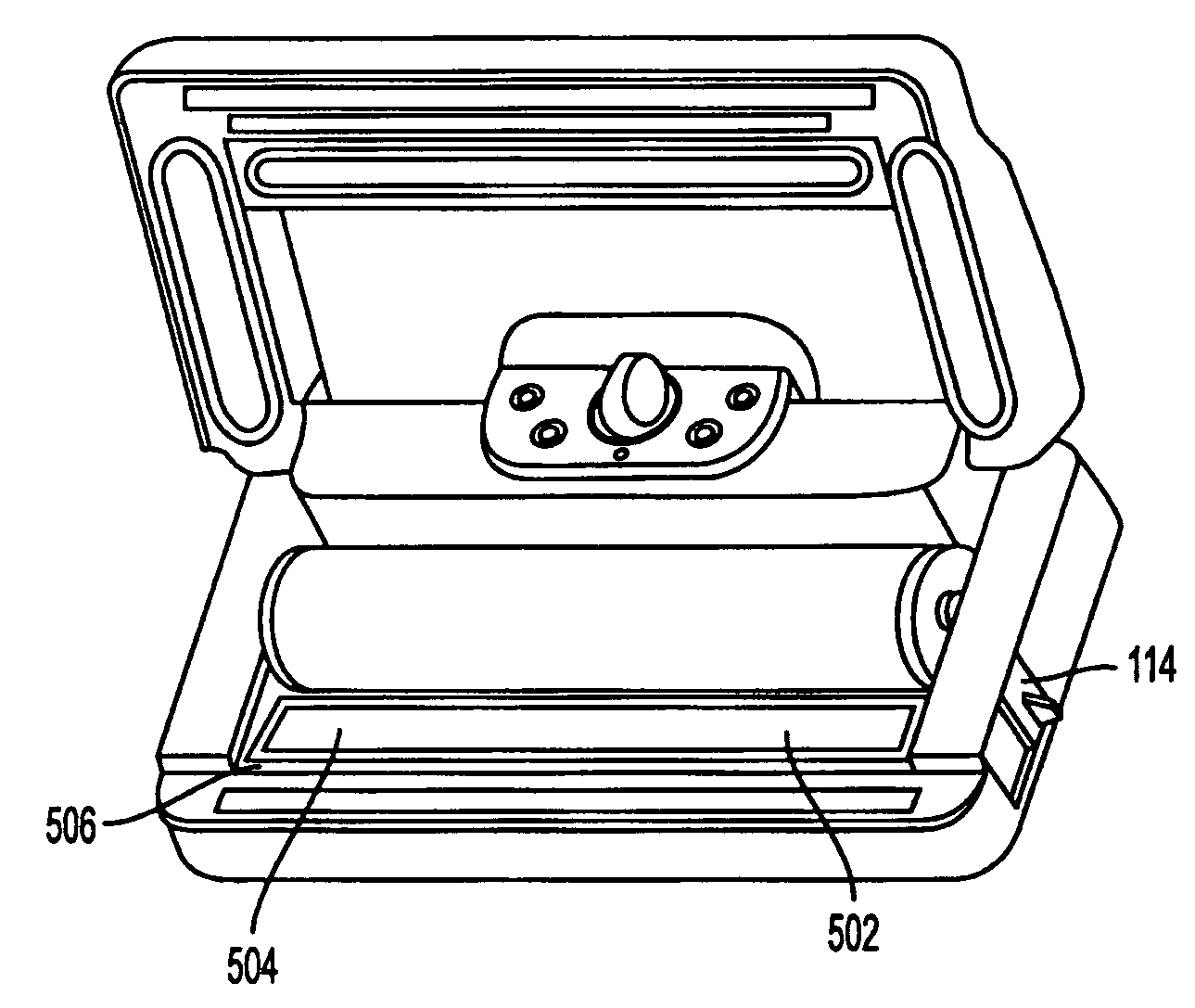

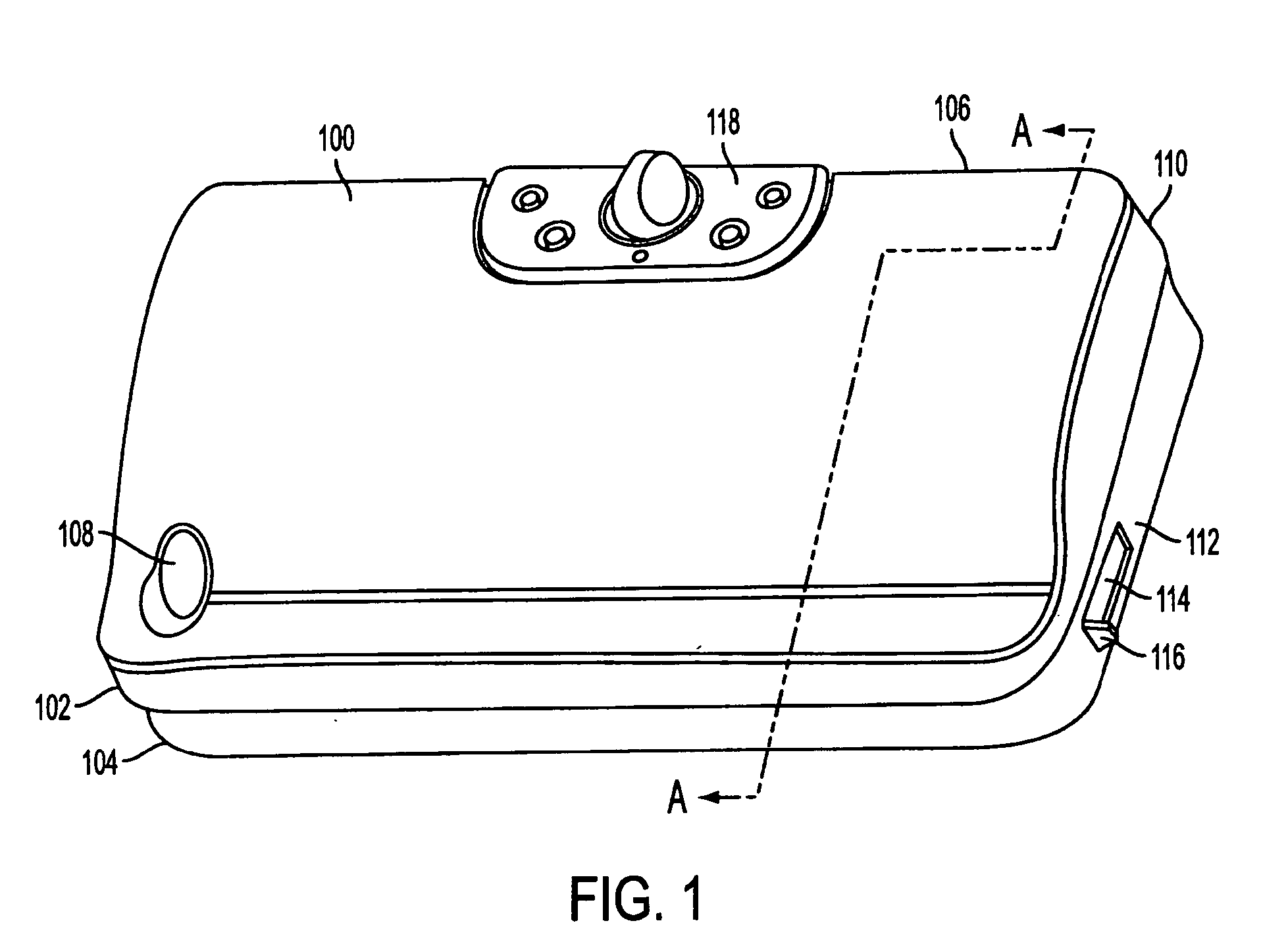

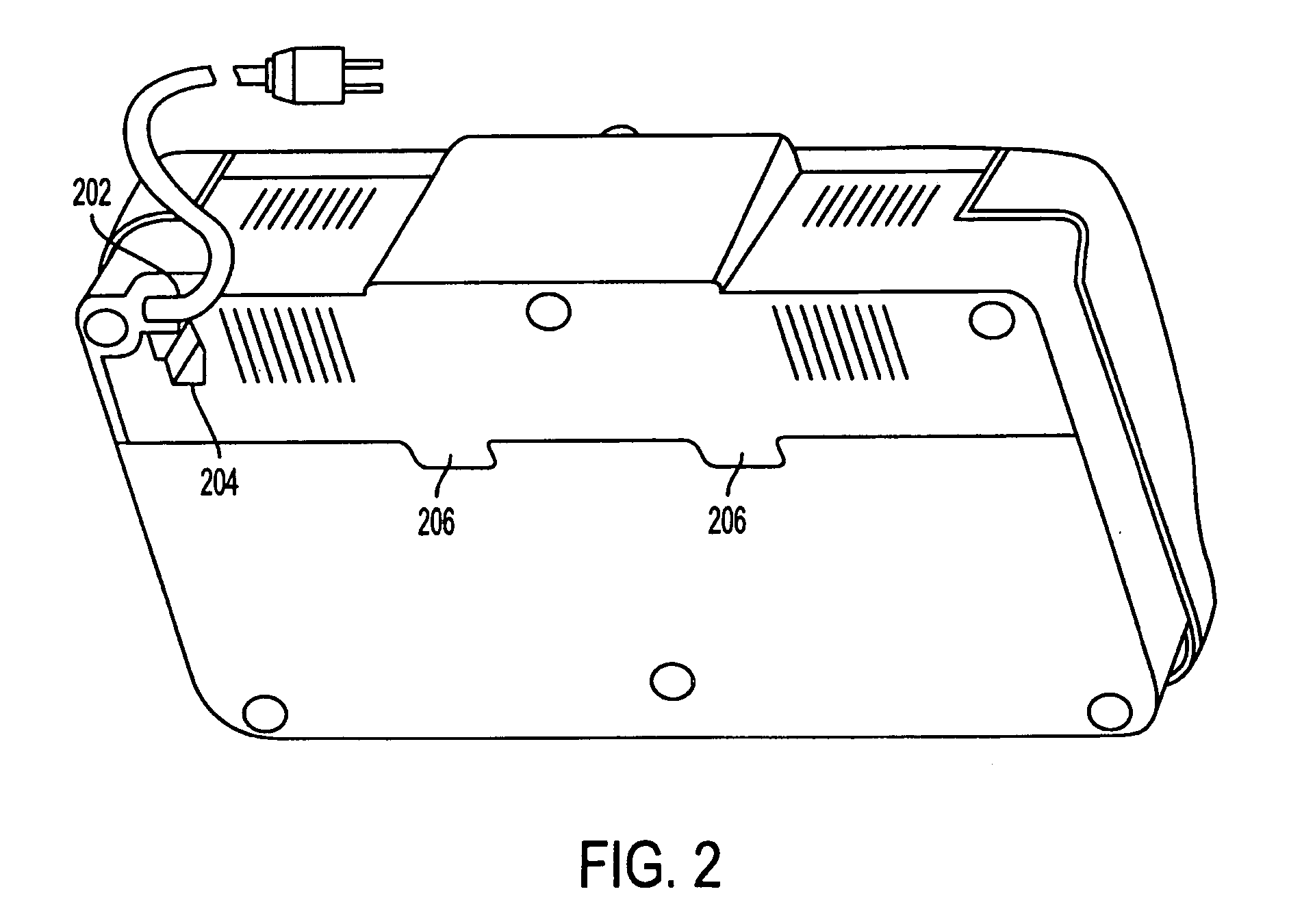

Heat sealing element and control of same

InactiveUS20050022474A1Waste of materialAvoid sealing effectWrapper twisting/gatheringPackaging under vacuum/special atmosphereTemperature controlVacuum pack

A vacuum packaging appliance for heat sealing items in a vacuum packaging plastic bag is disclosed. The appliance comprises a lid adapted to define a vacuum chamber when it is moved to a closed position relative to a trough in the base of the device. Adjacent to a trough in the lower portion of the device, a heat sealing element is placed in order to seal the contents of the bag once the vacuum packaging is complete. In another embodiment, the heat sealing element is mounted on the lid of the device and comes into contact with the vacuum bag when the lid is in a closed position. The heat sealing elements are controlled by a controller that allows operator selections of seals and sealing time adjustments based on inputs from a plurality of sensors. The controller is further able to energize one or two of the heating elements based on predetermined conditions. The methods and structures described control both heating and cooling of the heat sealing elements. The vacuum pump exhaust may also be directed below the heat sealing elements in order to cool the elements. The control and placement of the heat sealing elements allows for precise feedback and temperature control of the elements and therefore ensuring proper vacuum sealing of the containers.

Owner:TILIA INT INC

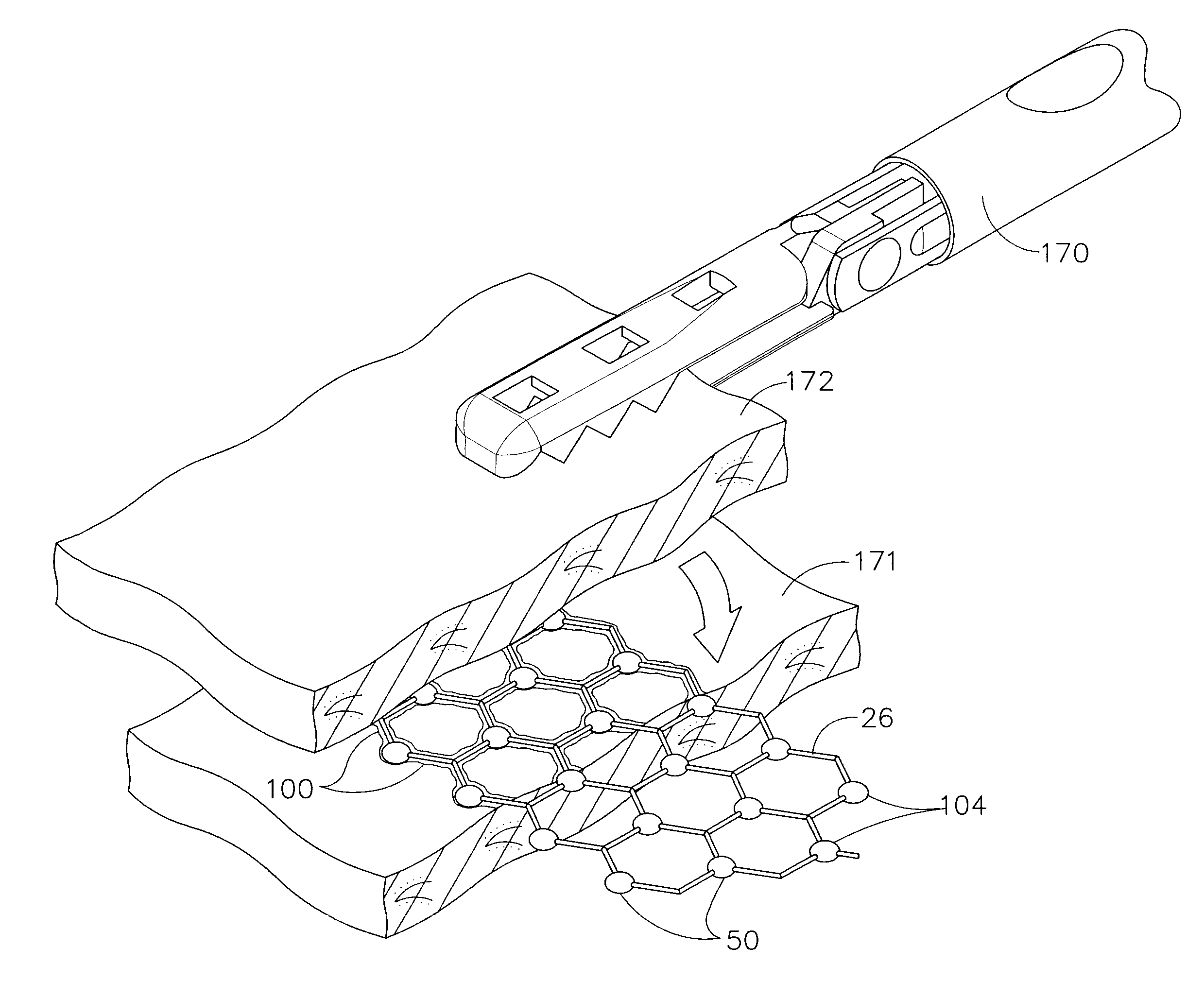

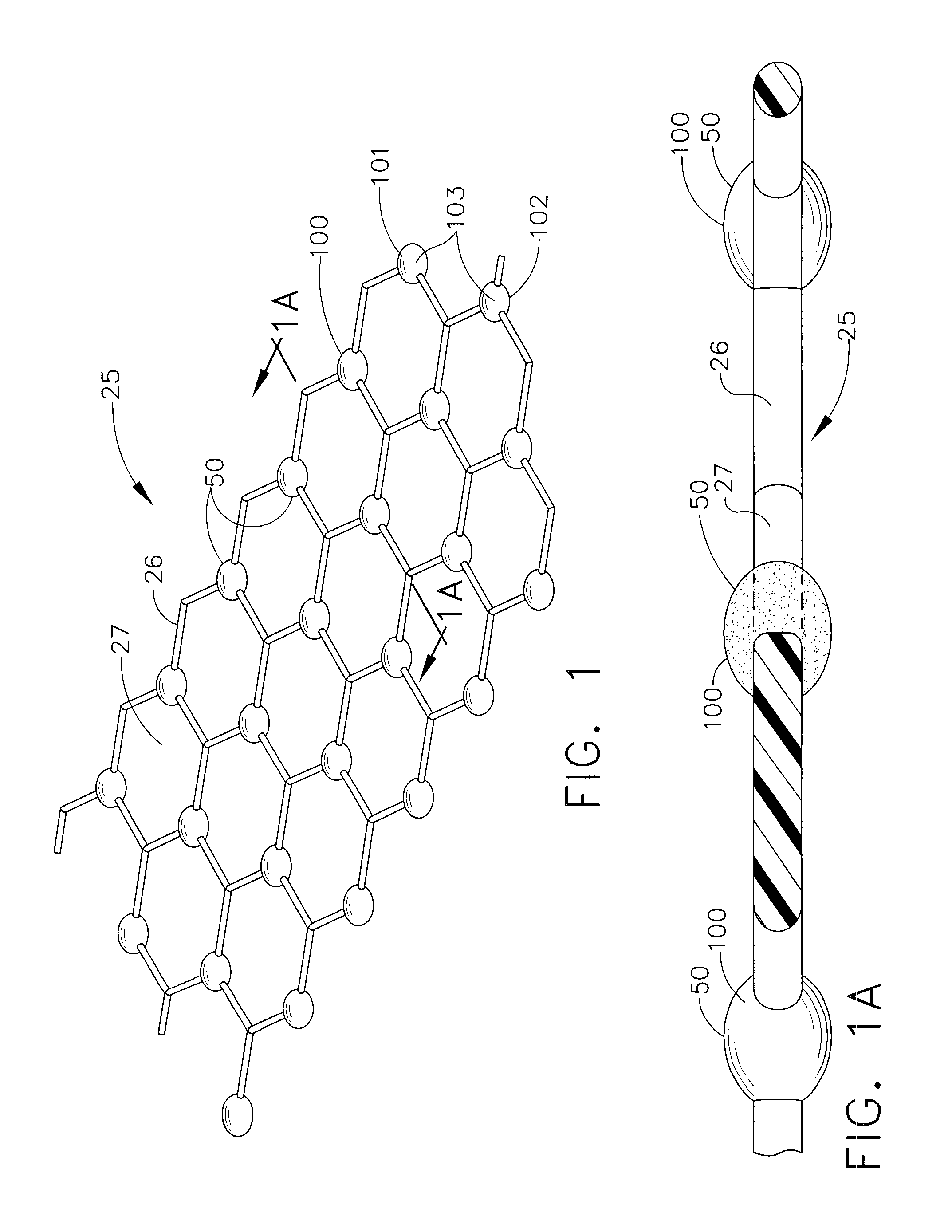

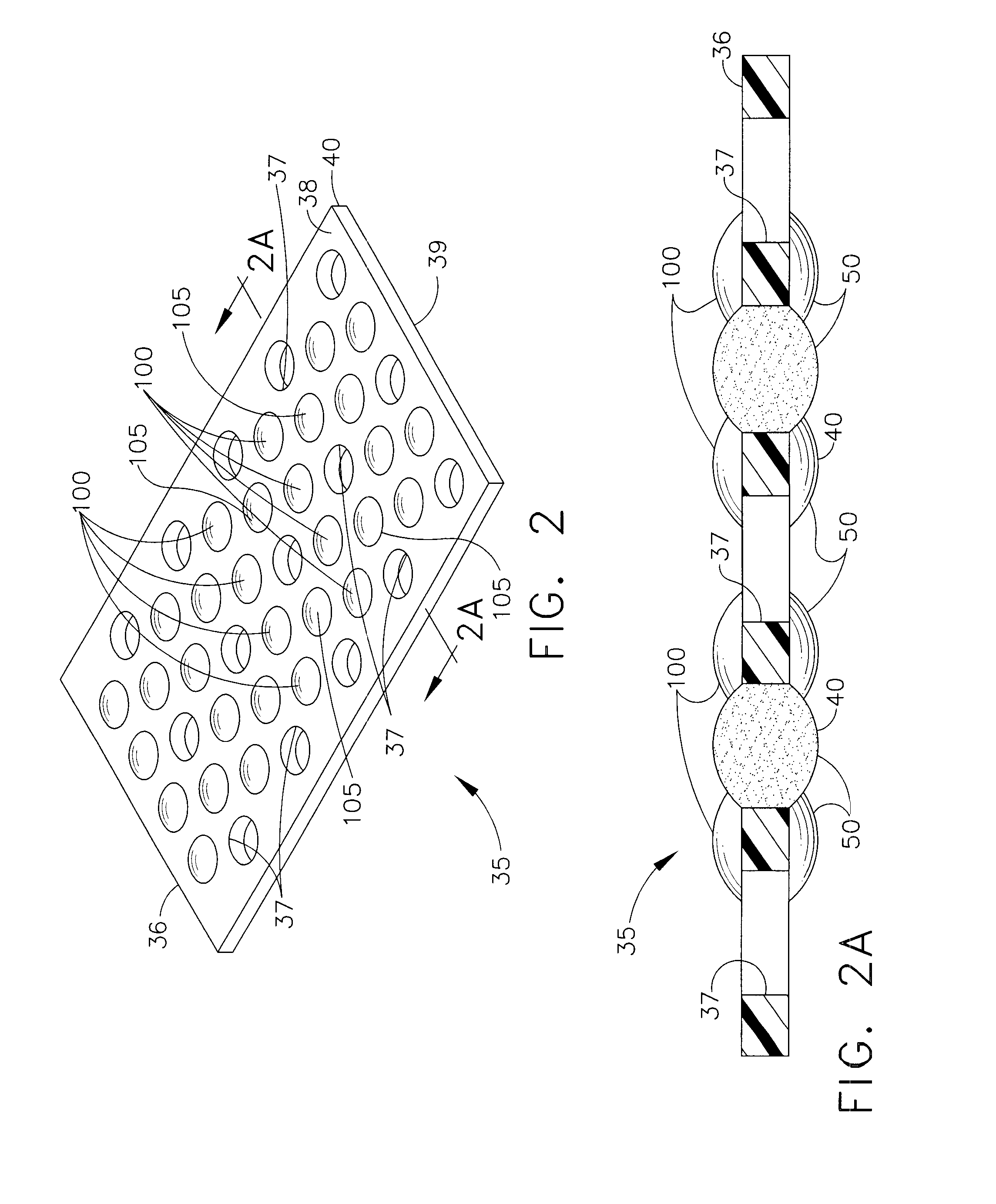

Controlled Adhesive Locations Facilitating Tissue Remodeling

A surgical implant for adhering two portions of tissue together with a polymer adhesive is disclosed. The surgical implant has a matrix structure with one or more layers and a plurality of holes for tissue growth therethrough. The matrix structure controls placement of the adhesive to minimize adhesive area and maximize tissue regrowth areas. In addition, the surgical implant can include drugs and adhesive initiators, and can include multiple layers of structure with any combination of holes, drugs, adhesives and adhesive initiators within. Additionally, the surgical implant can be surrounded by a rapidly dissolving pouch to prevent unwanted polymerization of the adhesive prior to placement in the body.

Owner:ETHICON ENDO SURGERY INC

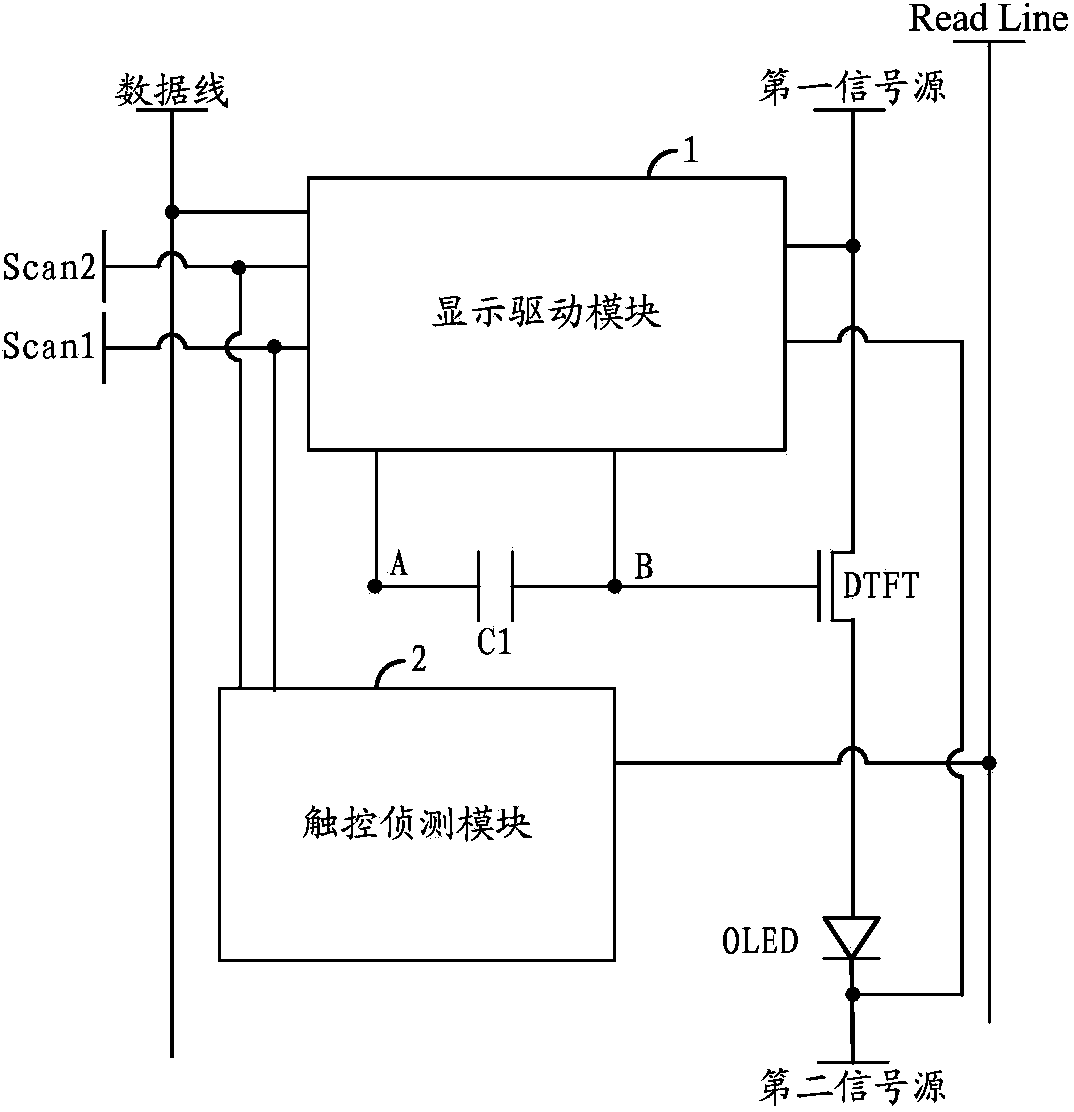

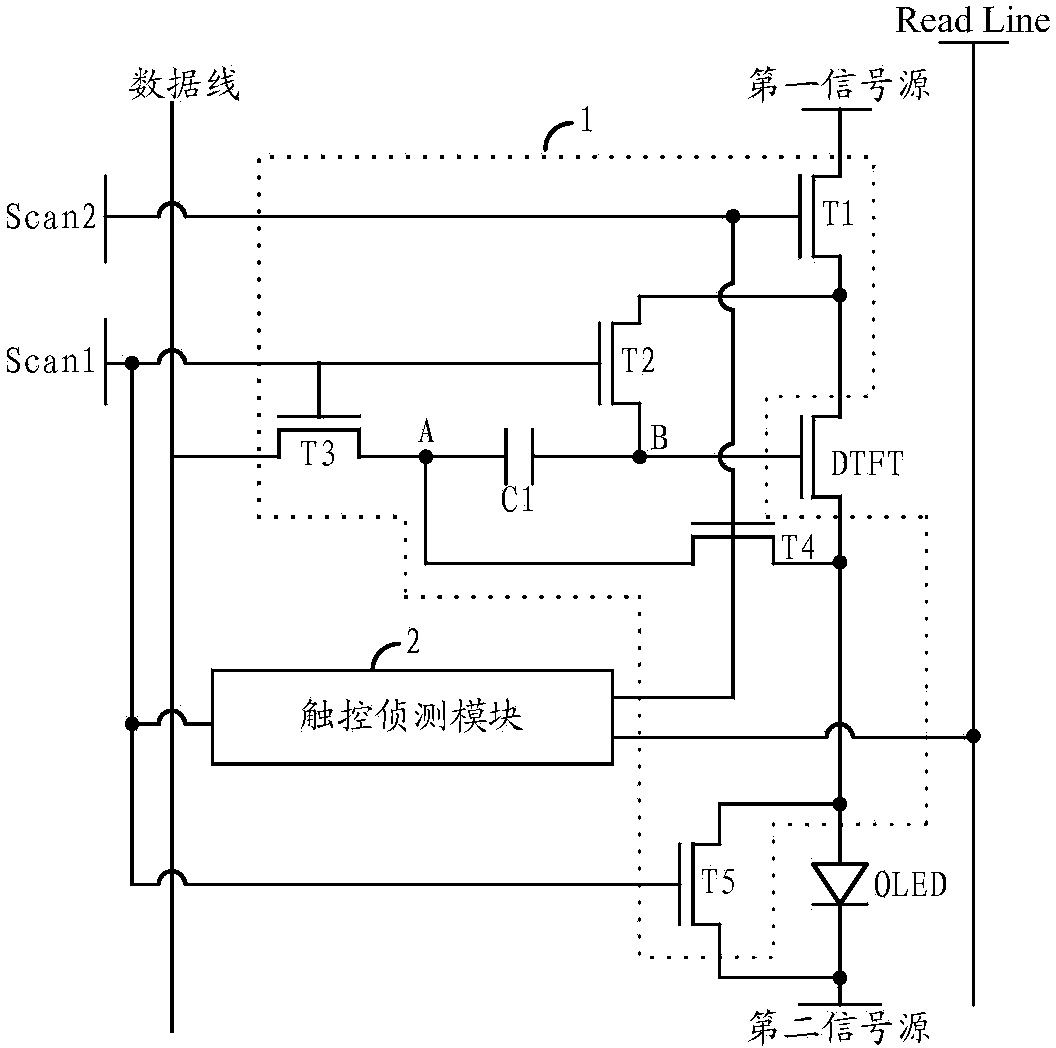

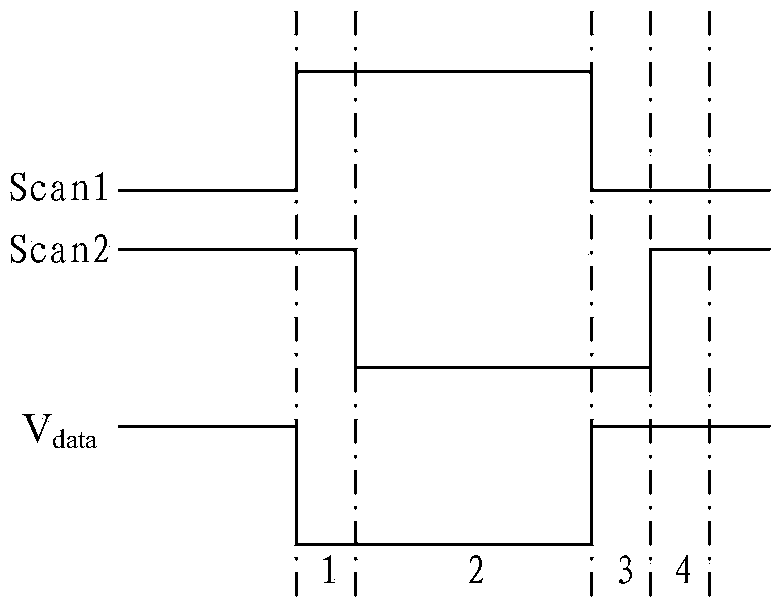

Pixel circuit, driving method of pixel circuit, organic light emitting display panel and display device

ActiveCN104252844AImprove image displayEliminate the effects ofStatic indicating devicesInput/output processes for data processingControl signalDisplay device

The invention provides a pixel circuit, a driving method of a pixel circuit, an organic light emitting display panel and a display device. Through the arrangement of a touch detection module and a display driving module realizing the multiplexing of a first scanning line and a second scanning line, the influence of the threshold value of a transistor on light emitting driving signals can be eliminated, the brightness uniformity of the organic light emitting display panel is improved, and the image display effect of the display device is improved. Meanwhile, the pixel circuit provided by the embodiment of the invention has the advantages that through adopting the arrangement of the circuit structure controlling the signal multiplexing, the display driving is realized, and meanwhile, the touch control detection can be realized, so the high-efficiency integration of the display driving and the touch control detection can be realized.

Owner:BOE TECH GRP CO LTD +1

Obturator-type silicone rubber foam material, and its preparing method and use

InactiveCN1850908ACells are fine and uniformFlat surfaceOther chemical processesPolymer scienceFoaming agent

The invention discloses an isolated cell type silicon rubber foam material and the manufacture method and the application. The feature is that it is made up of 100 portions silicone rubber, 15-80 portions reinforcing agent, 2-15 portions constitution controller, 3-15 portions foaming agent, 0-3 portions blowing promoter, and 0-4 portions coupling assistant agent, after taking radiation by electron beam or gama radiation, the silicon rubber takes coupling reaction, and the radiation dose is 5-20KGy. Decomposing foaming by heating, the silicon rubber could immediately taking electron beam or gama radiation to take the second radiation coupling, the radiation dose is 20-50KGy to improve the complex performance of the silicon rubber foam material. The invention could be used as sealing, damping, insulating, sound insulating and thermal insulating material.

Owner:SICHUAN UNIV

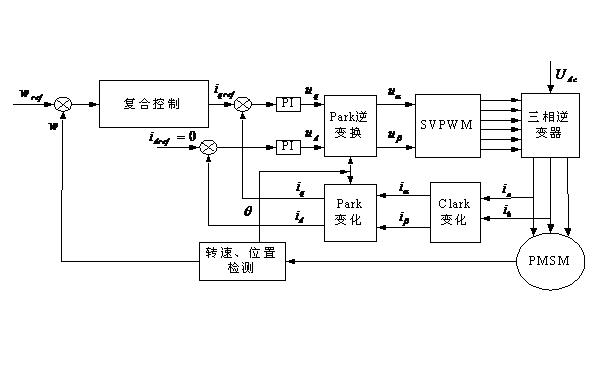

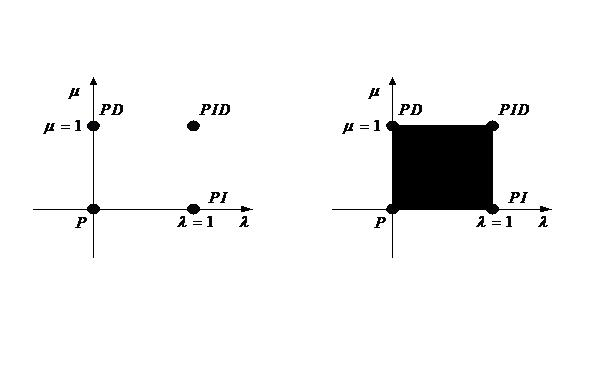

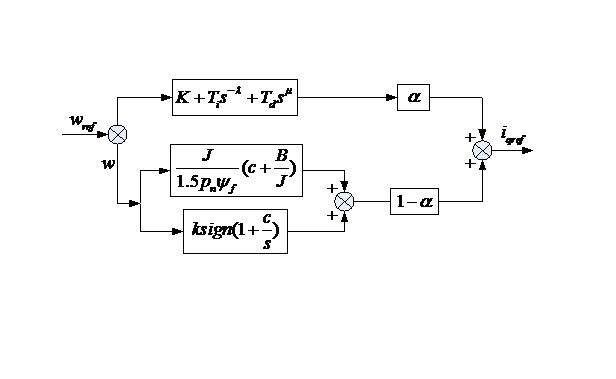

Compound control method based on vector control system of permanent magnet synchronous motor

InactiveCN102122916ALarge range of controlImprove control effectElectronic commutation motor controlVector control systemsControl systemMathematical model

The invention discloses a compound control method based on a vector control system of a permanent magnet synchronous motor. The method comprises the following steps: converting a three-phase current of the permanent magnet synchronous motor into equivalent currents on a straight shaft and a crossed shaft by utilizing a vector conversion principle; further linearly decoupling the mathematical models of shafts d and q of the permanent magnet synchronous motor by using the method of id=0; and using fractional order PIgammaDmu control and sliding mode variable structure compound control, wherein the fractional order PIgammaDmu control and the sliding mode variable structure compound control can be used for performing joint cross-feedback control on the speed ring through a variable weighting factor alpha. The compound control method based on a vector control system of a permanent magnet synchronous motor, provided by the invention, has the advantages of both the fractional order PIgammaDmu control and the sliding mode variable structure compound control during the control of the speed ring, and the favorable factors are maximized while the unfavorable factors are minimized. Compared with the traditional PID (proportional-integral derivative) control, the fractional order PIgammaDmu control has a widened control scope, thereby more flexibly matching the sliding mode variable structure to realize the compound control to the permanent magnet synchronous motor.

Owner:SUZHOU BINGLI ELECTRIC VEHICLE TECH

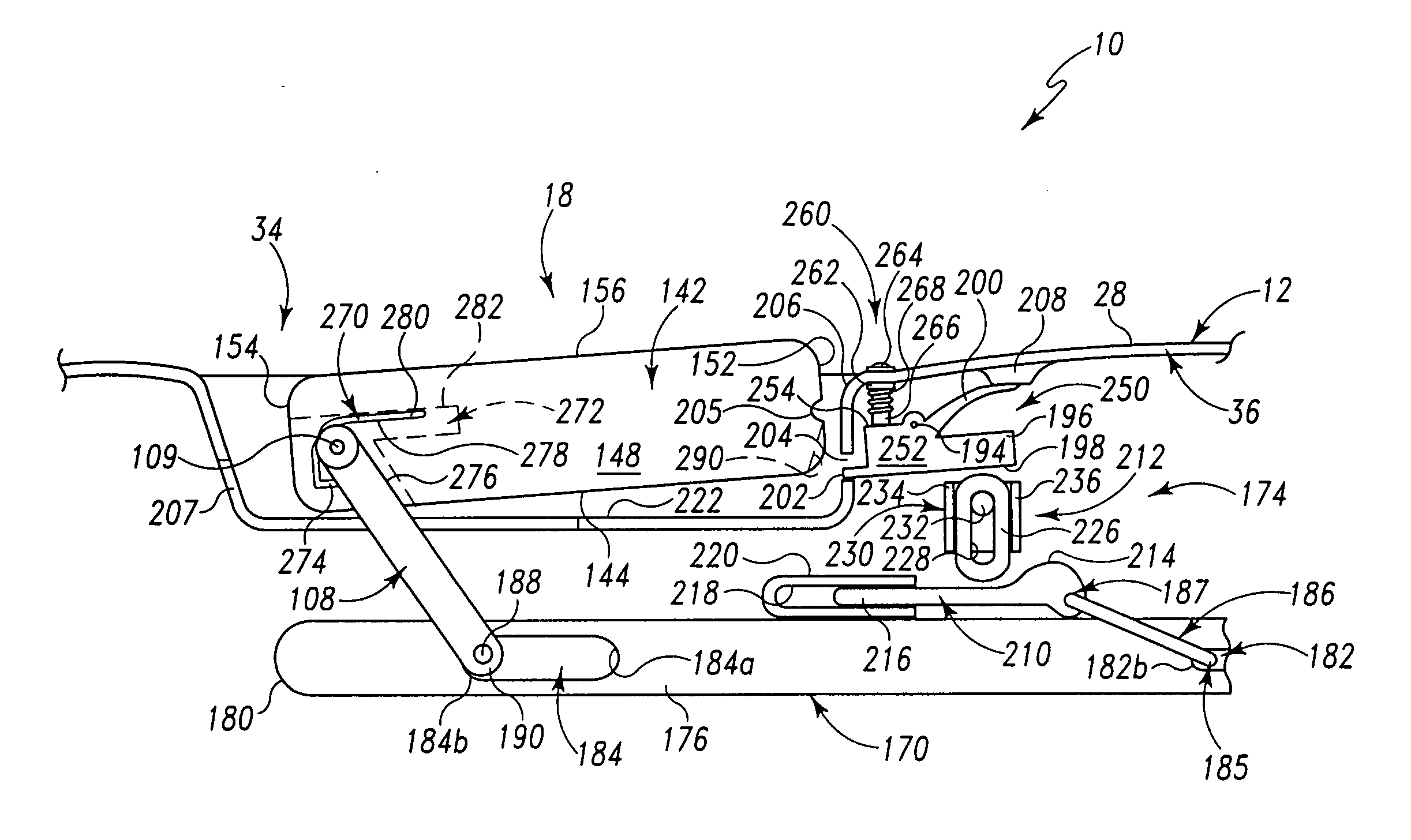

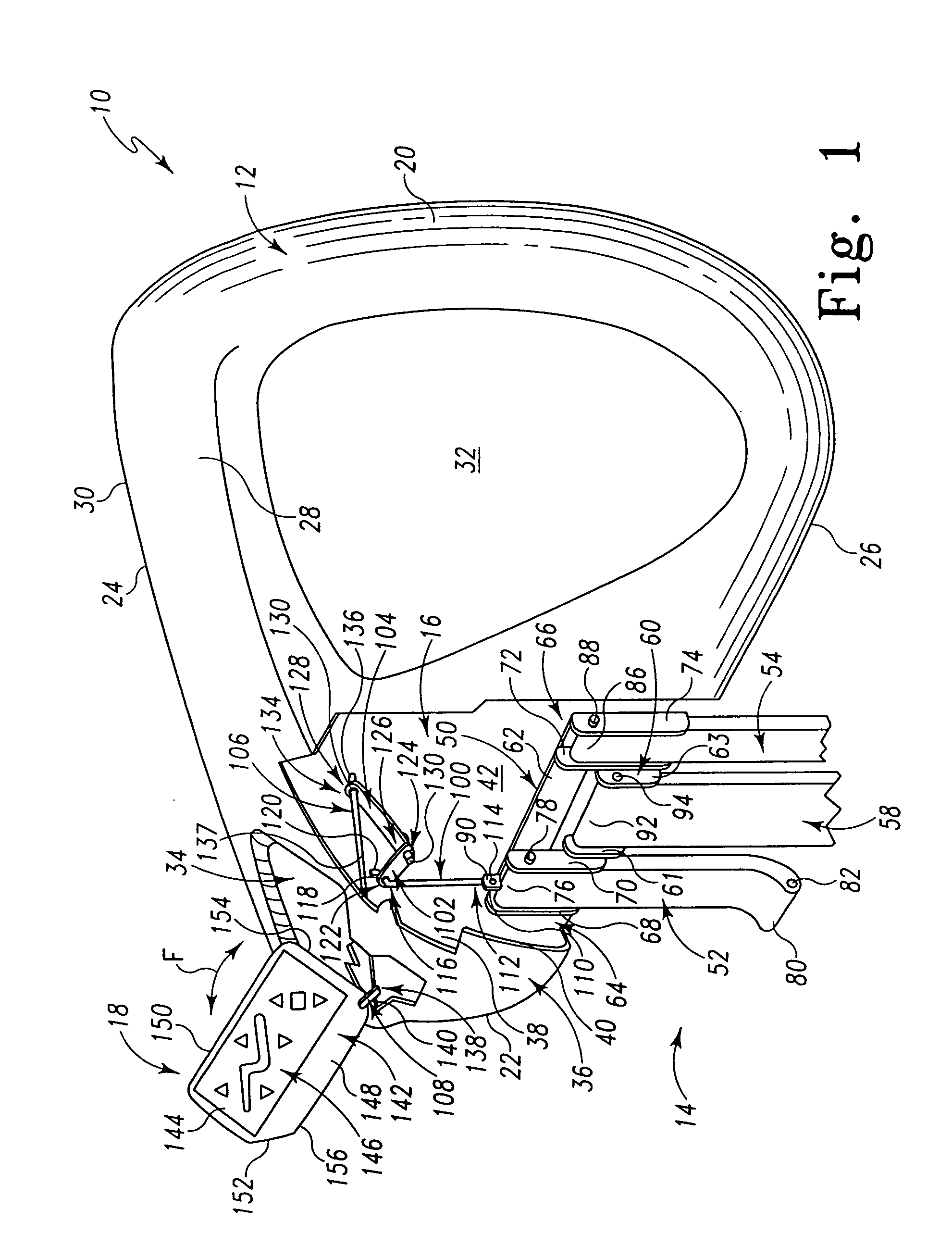

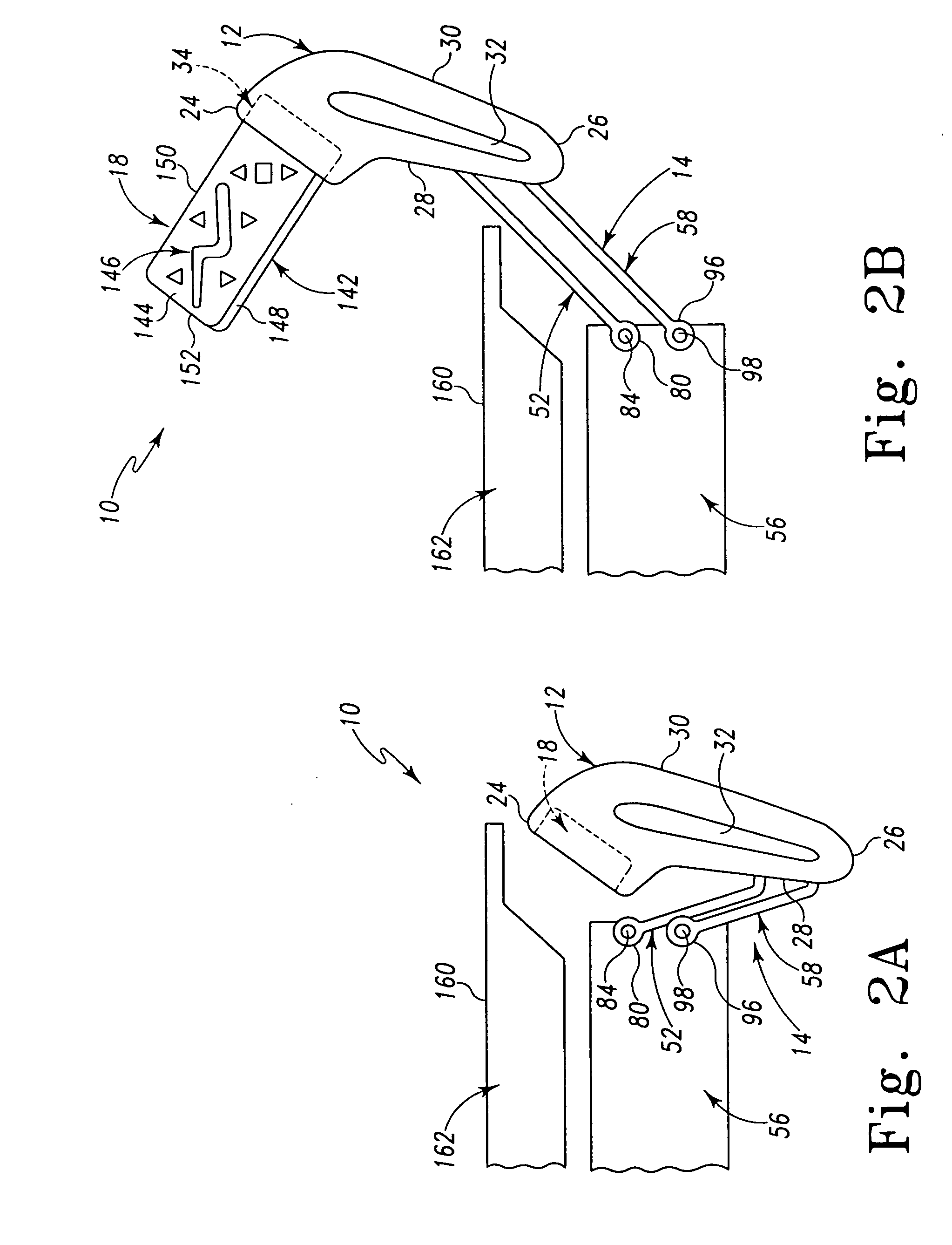

Movable control panel for a patient support

A movable control panel for a patient support is provided. The patient support includes a support structure which is movable between a raised position and a lowered position relative to a patient support. A controller is coupled to the support structure for movement between a deployed position and a stored position. A mechanism for coupling the controller to the support structure is also provided. The controller includes control switches that are operable to adjust a position of the patient support. The coupling mechanism is operable to move the controller between the deployed position and the stored position in response to movement of the support structure between the raised position and the lowered position, respectively.

Owner:HILL ROM SERVICES

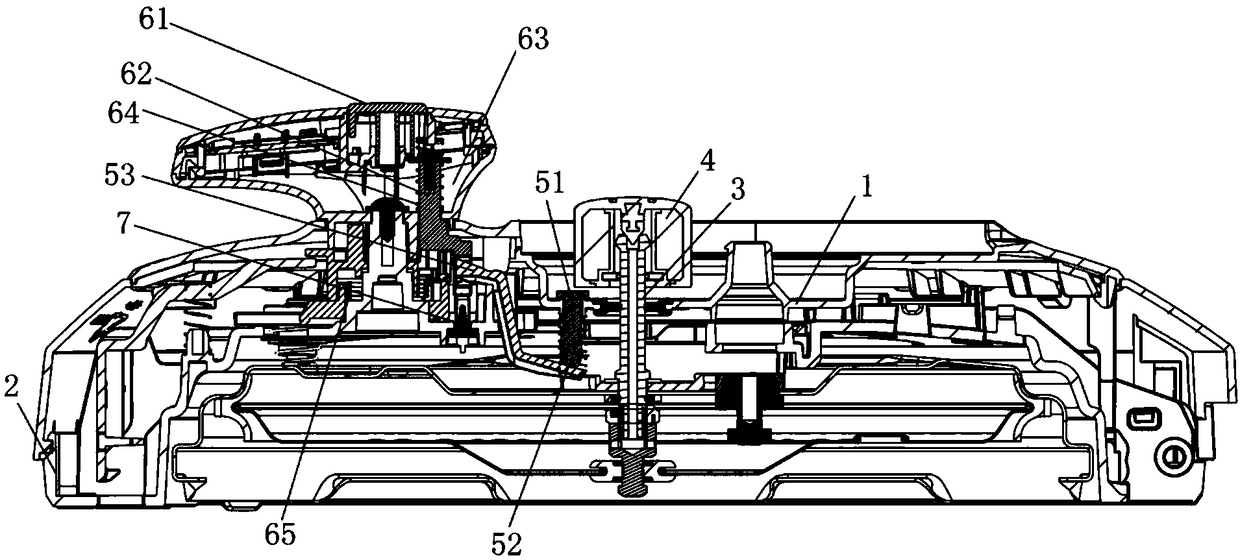

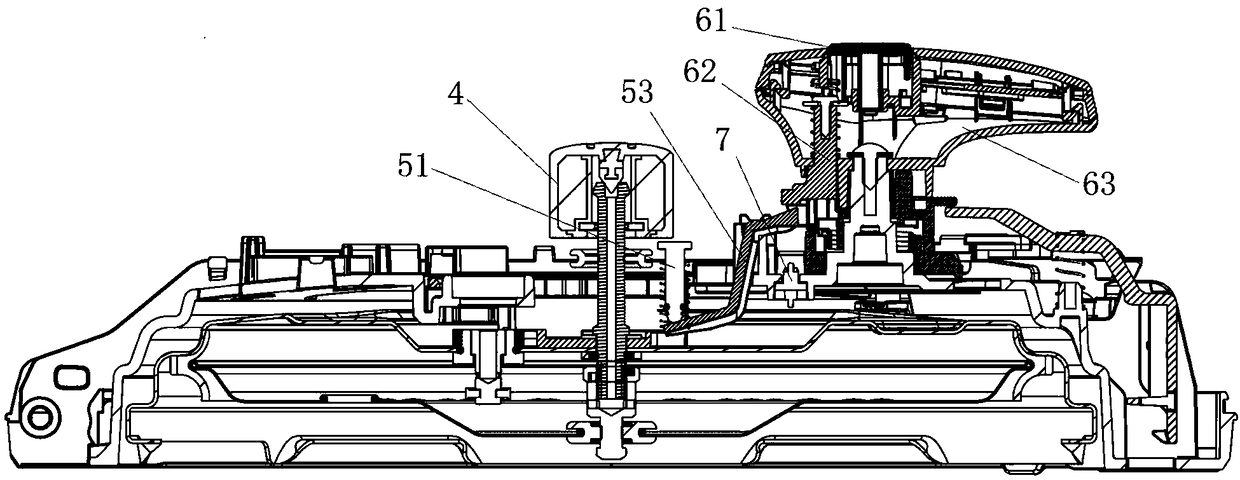

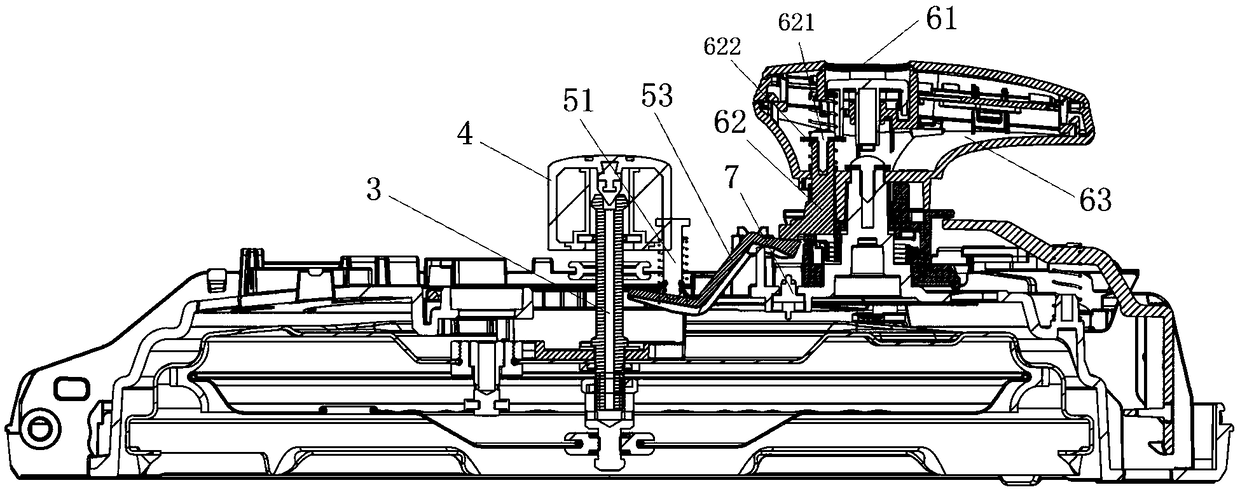

Exhaust device, pressure cooker cover and pressure cooker

ActiveCN106820957BEasy exhaust operationAchieve continuous exhaustPressure-cookersHome applianceEngineering

The invention relates to an air exhausting device, a pressure cooker cover and a pressure cooker, and belongs to the technical field of household appliances. The main technical scheme is that the air exhausting device comprises a relief valve, a jacking rod assembly and a control assembly, wherein the relief valve is buckled on an air exhaust pipe of the pressure cooker; the jacking rod assembly is used to jack up the relief valve; the control assembly comprises a control structure, a pressing rod and a limiting structure; the pressing rod can move to a set position under the control of the control structure to apply acting force to the jacking rod assembly, so that the jacking rod assembly jacks up the relief valve; the limiting structure is arranged on an inner cover of the pressure cooker cover, so as to limit the pressing rod to the set position; when the pressure cooker exhausts air, the control structure controls the pressing rod to move to the set position, and the limiting structure limits the pressing rod to the set position, so that the pressure cooker exhausts air continuously; after air exhausting of the pressure cooker is ended, the control structure controls the pressing rod to get away from the set position, so as to reset the relief valve. The air exhausting device, the pressure cooker cover and the pressure cooker are mainly used for facilitating a user to exhaust air out of the pressure cooker and reset the relief valve.

Owner:GREE ELECTRIC APPLIANCES INC

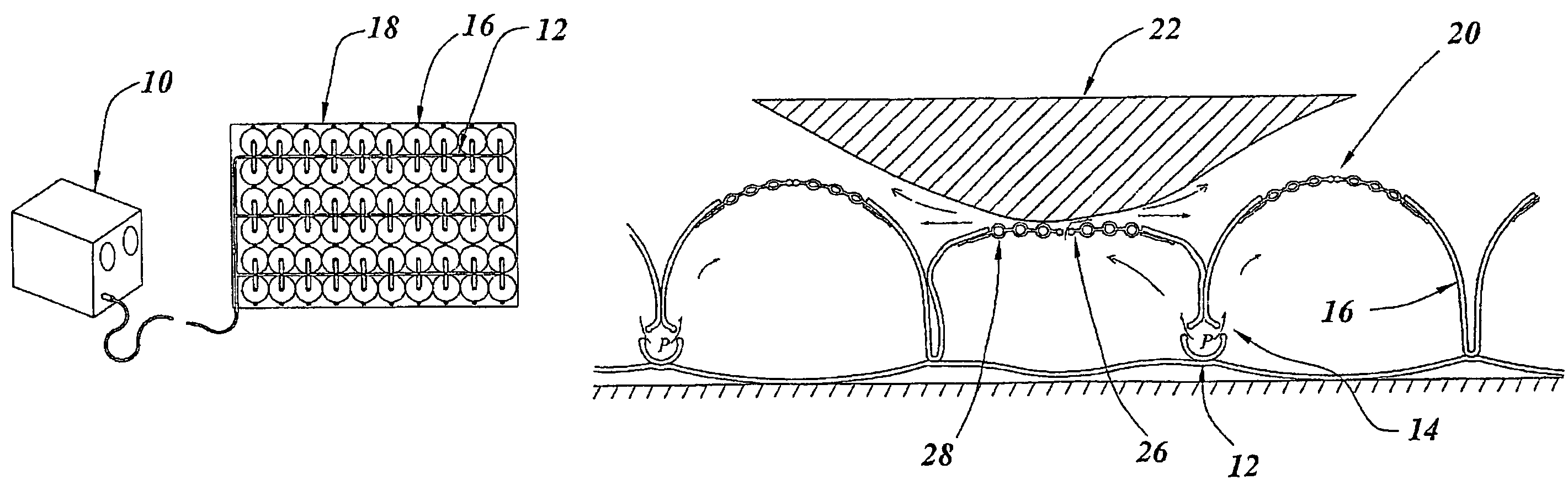

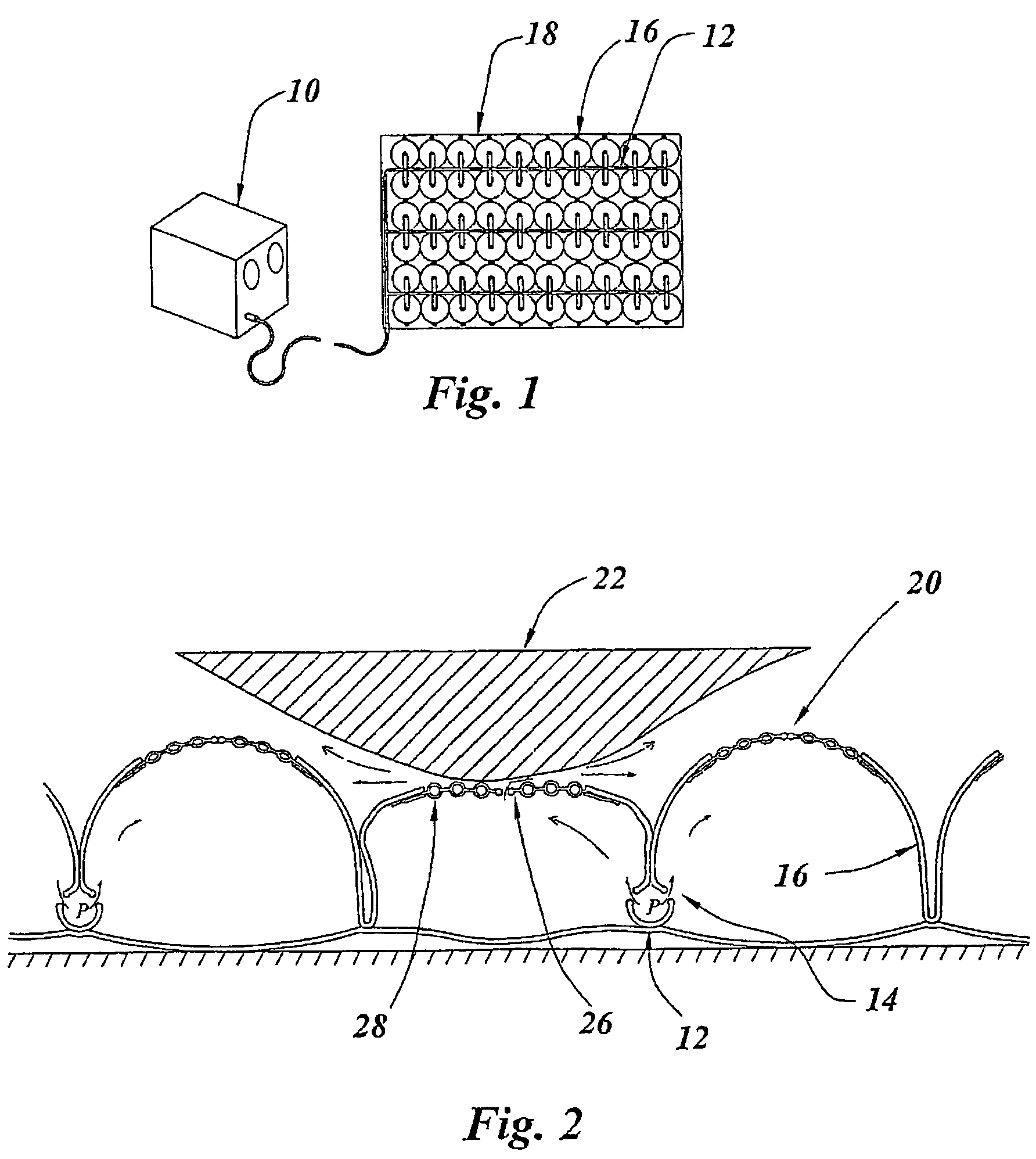

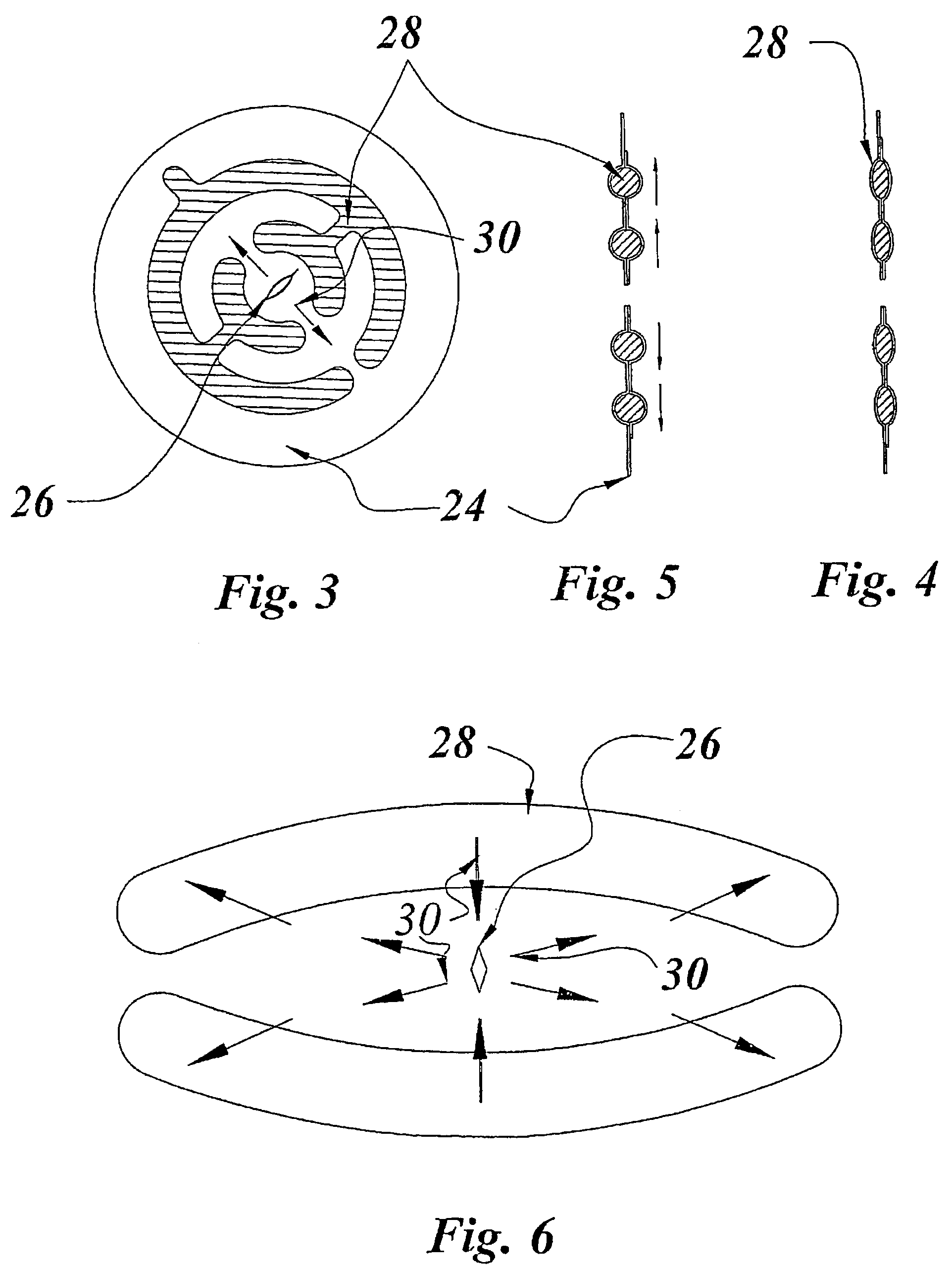

Inflatable decubitis mat with vent structures controlled by heat sensors

InactiveUS7278179B2Obvious advantagesStuffed mattressesOperating means/releasing devices for valvesEngineeringPhase change

A decubitis mat includes a plurality of individual cells (16 which are pressurized by air. A polymer sensor / vent structure (20) is mounted on the top surface of each cell and defines a plurality of polymer filled channels (28) and a vent valve (26) which is biased to a closed position. As a body resting on the mat heats the polymer, it undergoes a phase change an expands, causing biasing forces (30) which bias the vent valve to open, permitting air in the cell to be released providing air flow to the body.

Owner:TCAM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com