Exhaust device, pressure cooker cover and pressure cooker

A technology of exhaust device and pressure cooker, applied in pressure cooker, kitchen utensils, home utensils and other directions, can solve problems such as inconvenience of operation, and achieve the effect of simple operation and simple exhaust operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

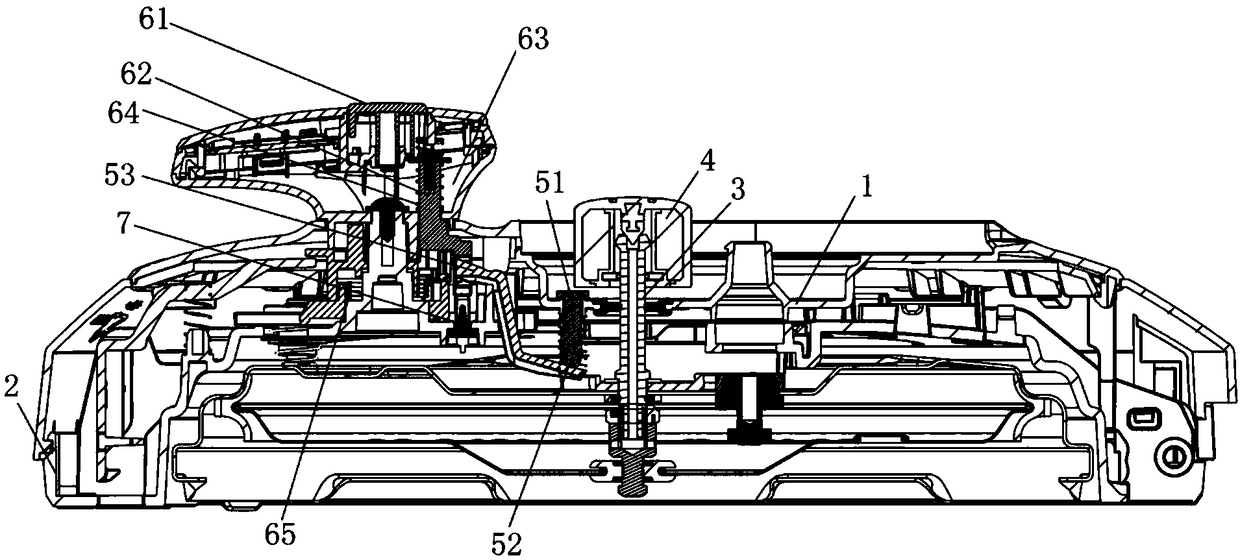

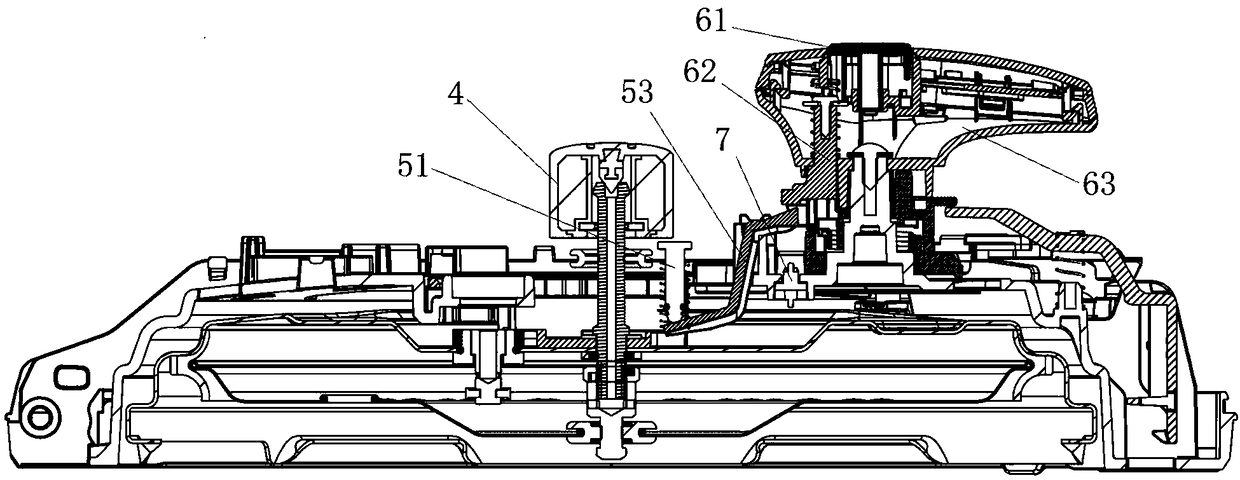

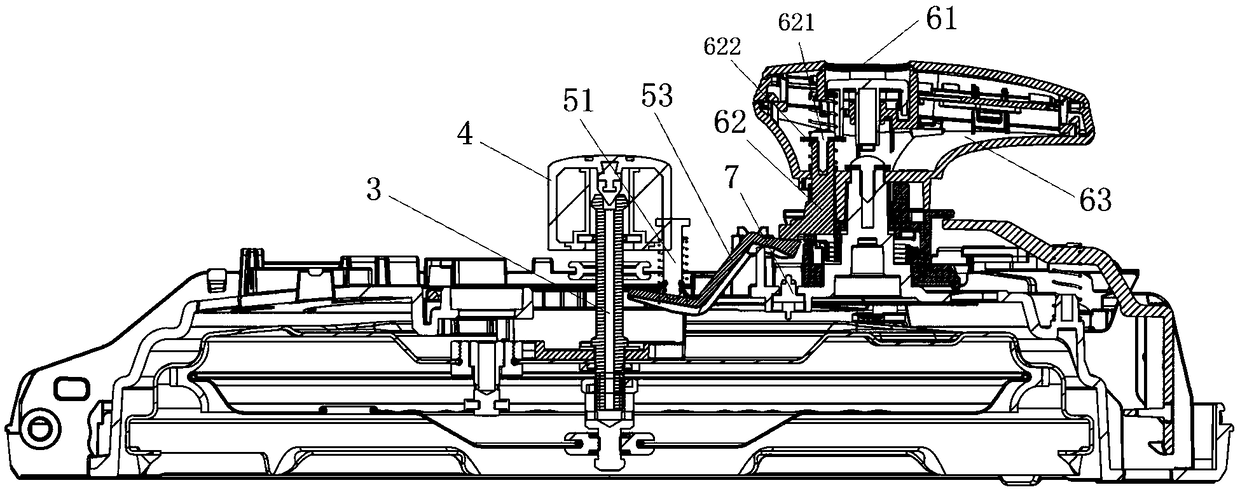

[0068] This embodiment provides an exhaust device, which is used on a pressure cooker; specifically, such as Figure 1 to Figure 11 As shown, the exhaust device in this embodiment includes: a pressure limiting valve 4, a push rod assembly, and a control assembly. Wherein, the pressure limiting valve 4 is fastened on the exhaust pipe 3 of the pressure cooker. The ejector rod assembly is used to jack up the pressure limiting valve 4 to exhaust the exhaust pipe 3 of the pressure cooker. The control assembly is used to control the ejector rod assembly; wherein, the control assembly includes: a control structure, a pressing rod 62 and a limit structure 7 . Wherein, the control structure is arranged on the lid of the pressure cooker. The pressing rod 62 can move to a set position under the control of the control structure, so as to apply a force to the ejector rod assembly, so that the ejector rod assembly pushes up the pressure limiting valve 4 . The limiting structure 7 is arra...

Embodiment 2

[0071] Preferably, this embodiment provides an exhaust device. Compared with the previous embodiment, the control structure in this embodiment can rotate relative to the cover of the pressure cooker lid; wherein, as Figure 6 and Figure 7 , Figure 10 and Figure 11 As shown, after the exhaust of the pressure cooker is completed, the control structure needs to be rotated to separate the pressing rod 62 from the limit structure 7, so that the pressing rod 62 is far away from the set position. When the ejector rod assembly is not affected by the pressing rod 62, it can Reset, and the pressure limiting valve 4 is fastened on the exhaust pipe of the pressure cooker again.

[0072] In this embodiment, through the above configuration, the user only needs to slightly rotate the control structure to realize the reset of the pressure limiting valve 4 , and the operation is simple.

Embodiment 3

[0074] Preferably, this embodiment provides an exhaust device, compared with the above embodiments, such as Figure 1 to Figure 10 As shown, the control structure in this embodiment includes a pressing member 61 . Wherein, the pressing member 61 is used to press the upper end of the pressing rod 62 to press the pressing rod 62 to a set position. Preferably, the pressing member 61 can be configured as a button, or a button or other structures.

[0075] Preferably, the control structure in this embodiment further includes a handle 63 ; wherein the handle 63 is used to be installed on the lid of the pressure cooker and can rotate relative to the surface cover 1 ; the pressing member 61 is installed on the handle 63 . Preferably, the grip portion of the handle 63 is arranged on the surface cover of the pressure cooker lid, and the lower end of the handle 63 is placed in the pressure cooker lid and connected to the inner lid through a rotating mechanism.

[0076] Preferably, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com