Filter

A filter and filter element technology, applied in filtration and separation, filtration circuits, chemical instruments and methods, etc., can solve the problem that the exhaust effect of the filter is not optimal and reduced, and the gas in the upstream cavity may also be together with the fluid. It enters the downstream cavity, and finally reaches the downstream pipeline together with the clean filtrate, and the gas cannot be discharged in time, so as to achieve the effect of simple structure, good exhaust effect and convenient exhaust operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

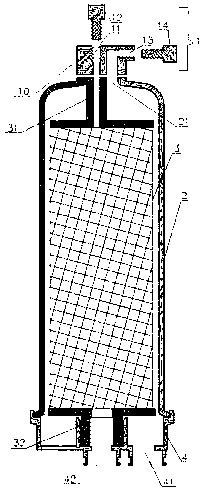

[0022] In order to make those skilled in the art better understand the technical scheme of the present invention, the following in conjunction with the attached figure 1 The present invention will be further described in detail with specific embodiments.

[0023] The filter includes an exhaust device 1 , a cylinder body 2 , a filter element 3 and a base 4 , wherein the filter element 3 is fixed inside the cylinder body 2 .

[0024] The top of the cylinder body 2 is a closed end, and an opening 21 is arranged at the center, and the open bottom is welded together with the base 4 .

[0025] The exhaust device 1 is connected to the opening 21 at the top of the cylinder 2 by welding.

[0026] The main body 10 of the exhaust device 1 is cylindrical, including an upstream exhaust port 13, an upstream exhaust port plug 14, a downstream exhaust port 11 and a downstream exhaust port plug 12, and the upstream exhaust port 13 and the downstream exhaust port 11 are juxtaposed set up.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com