Patents

Literature

4918results about How to "Save man hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

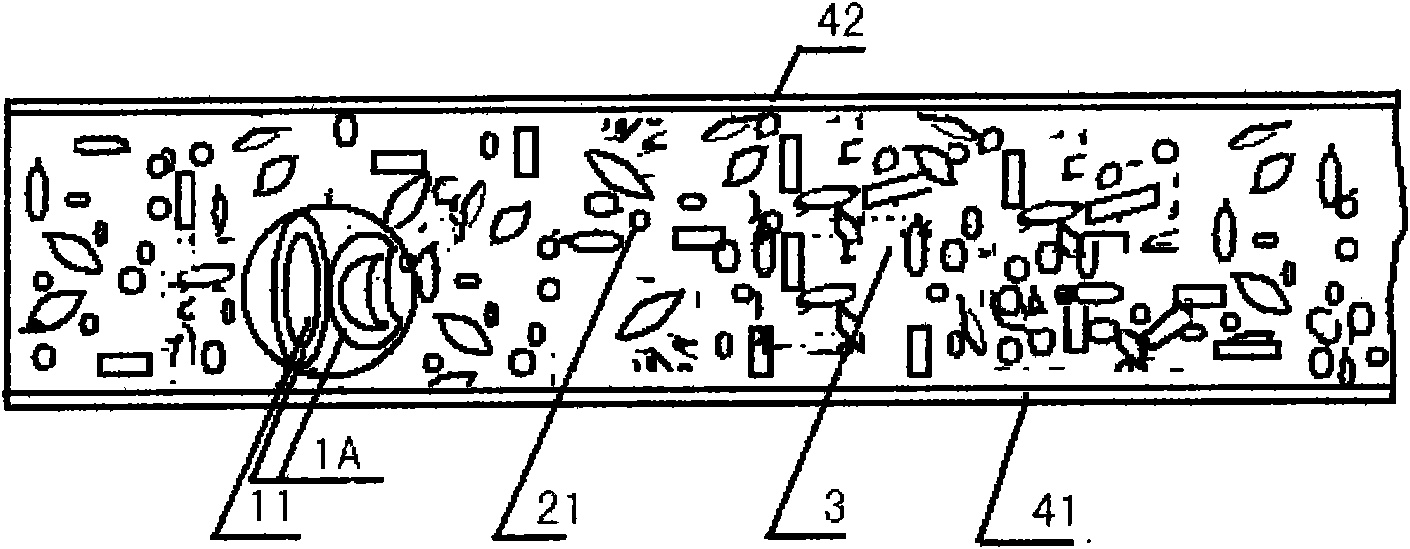

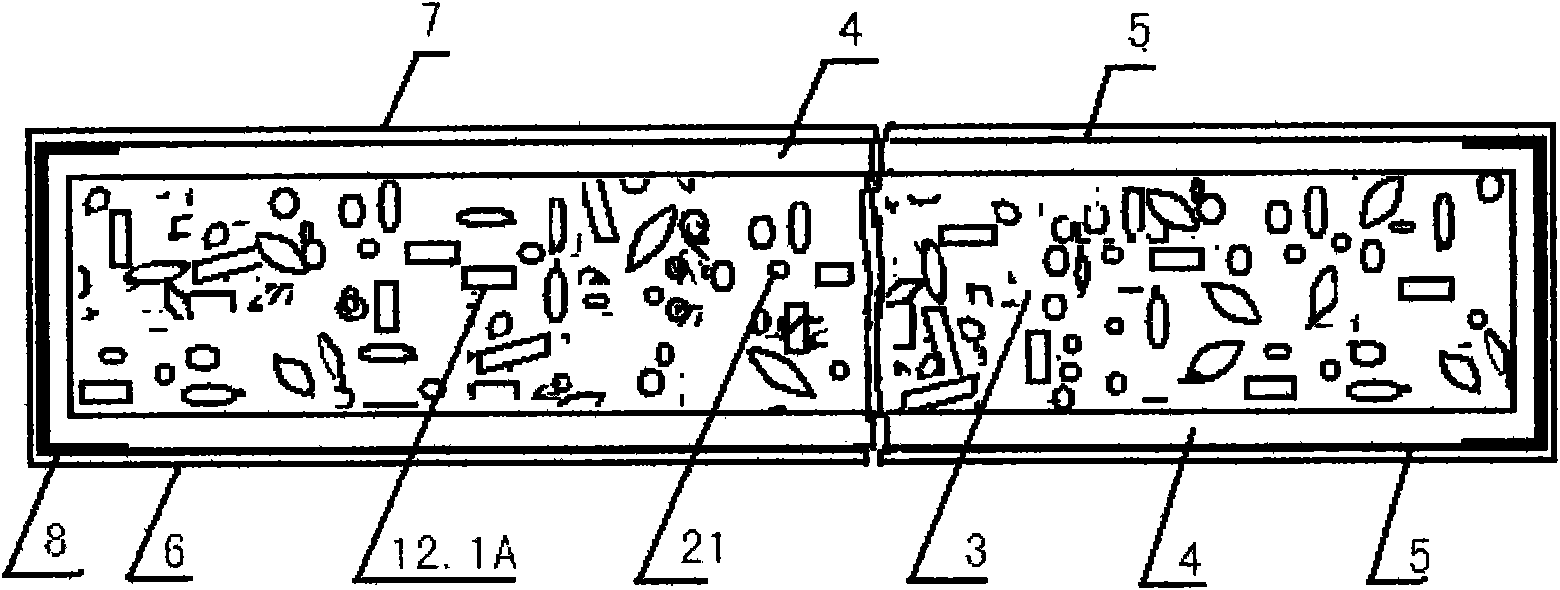

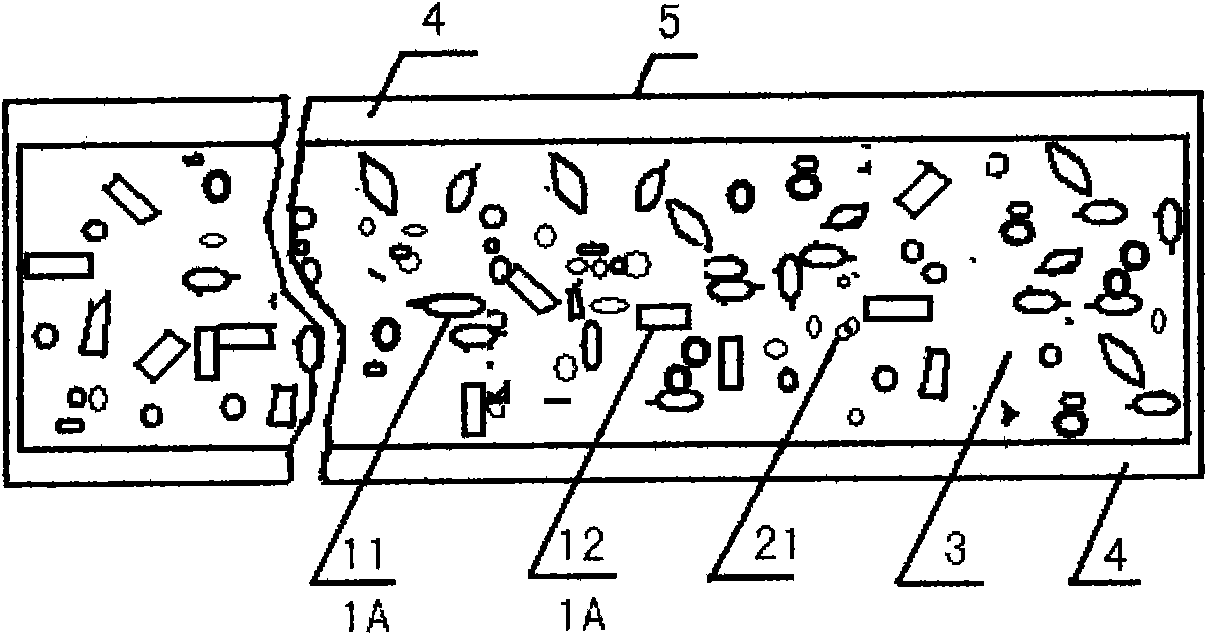

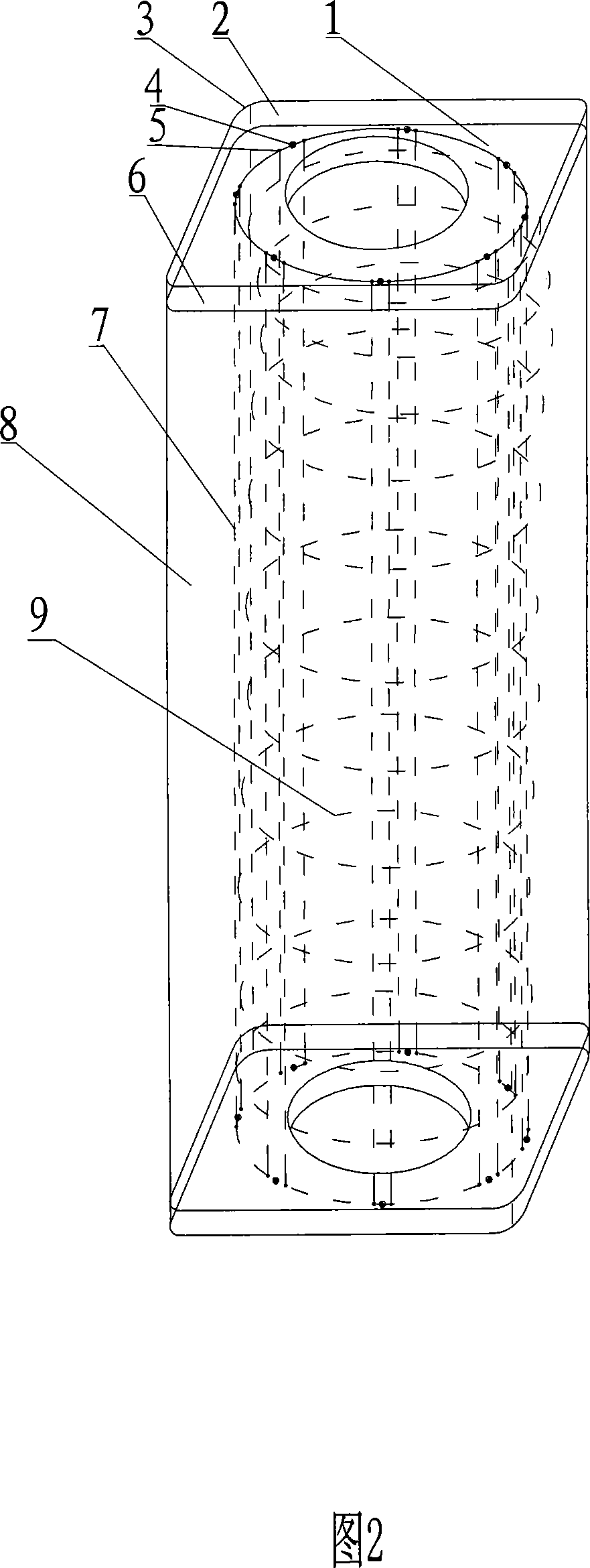

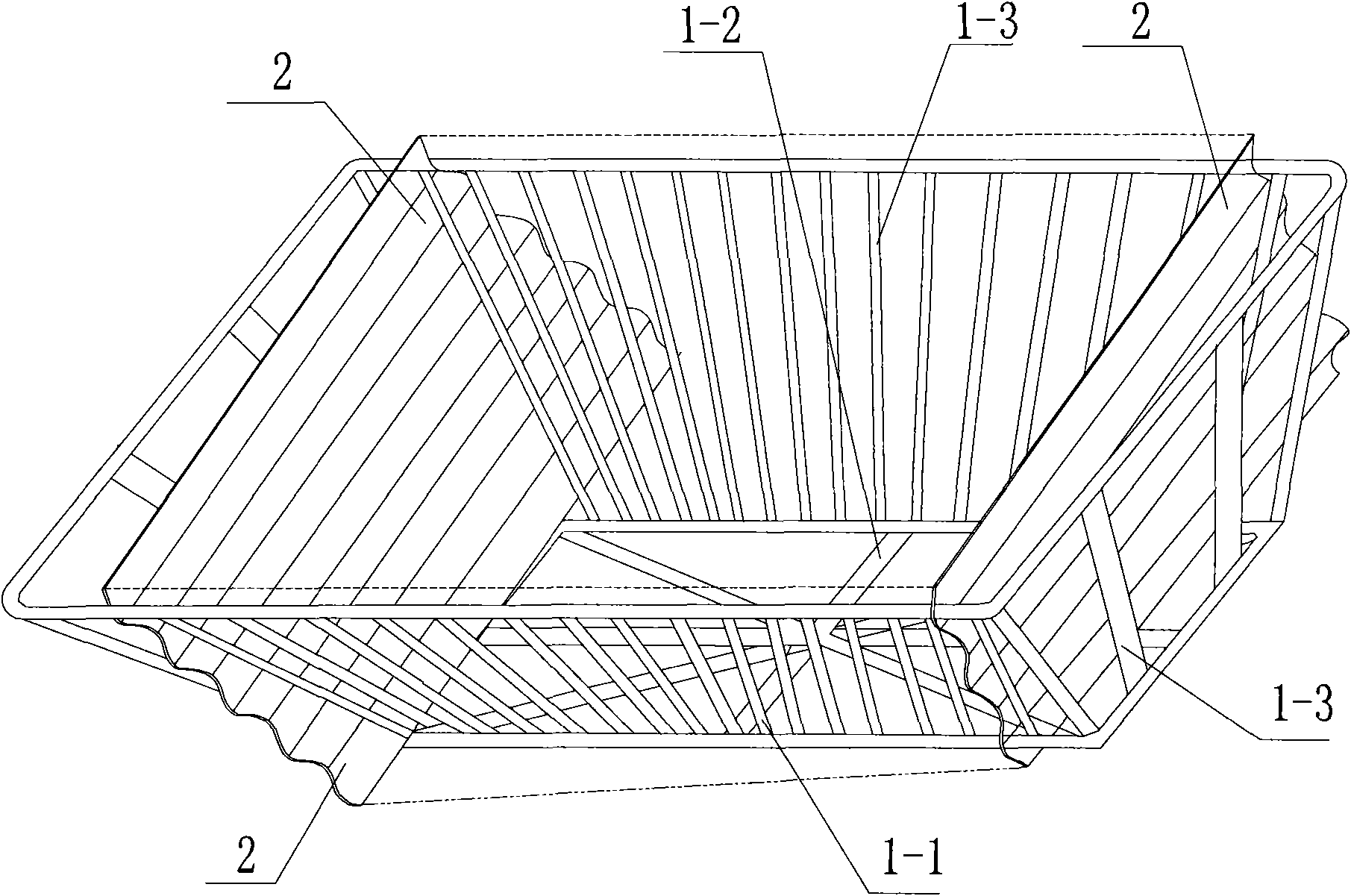

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

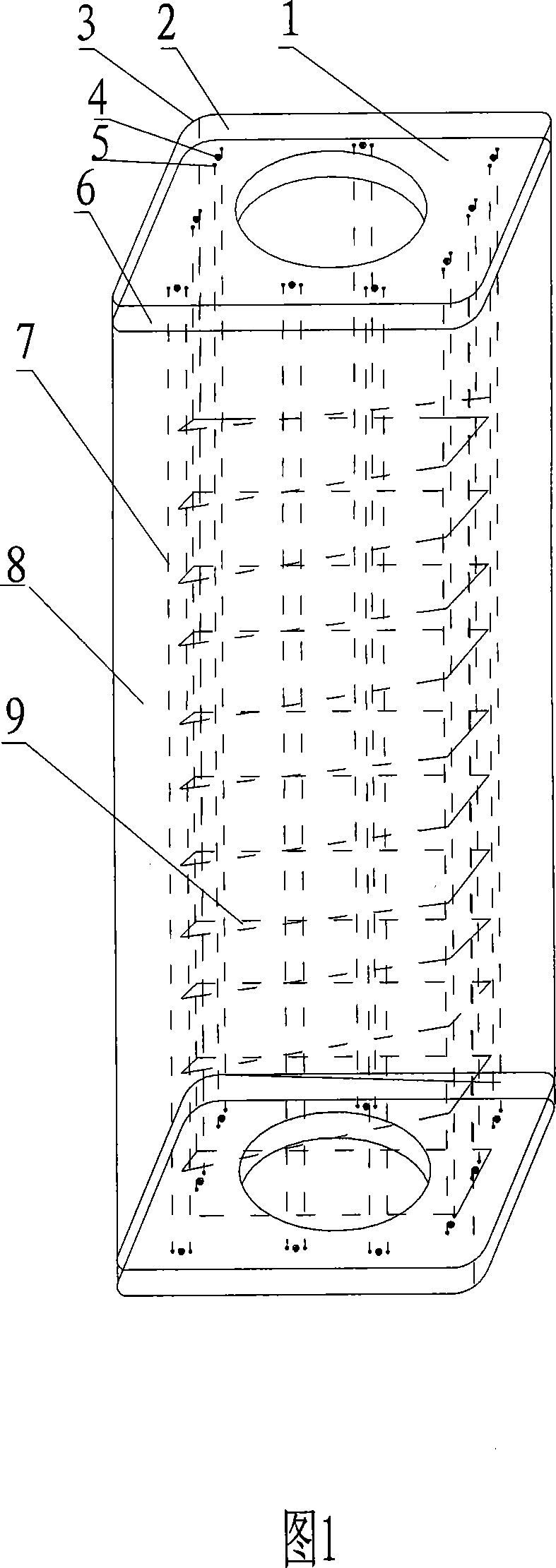

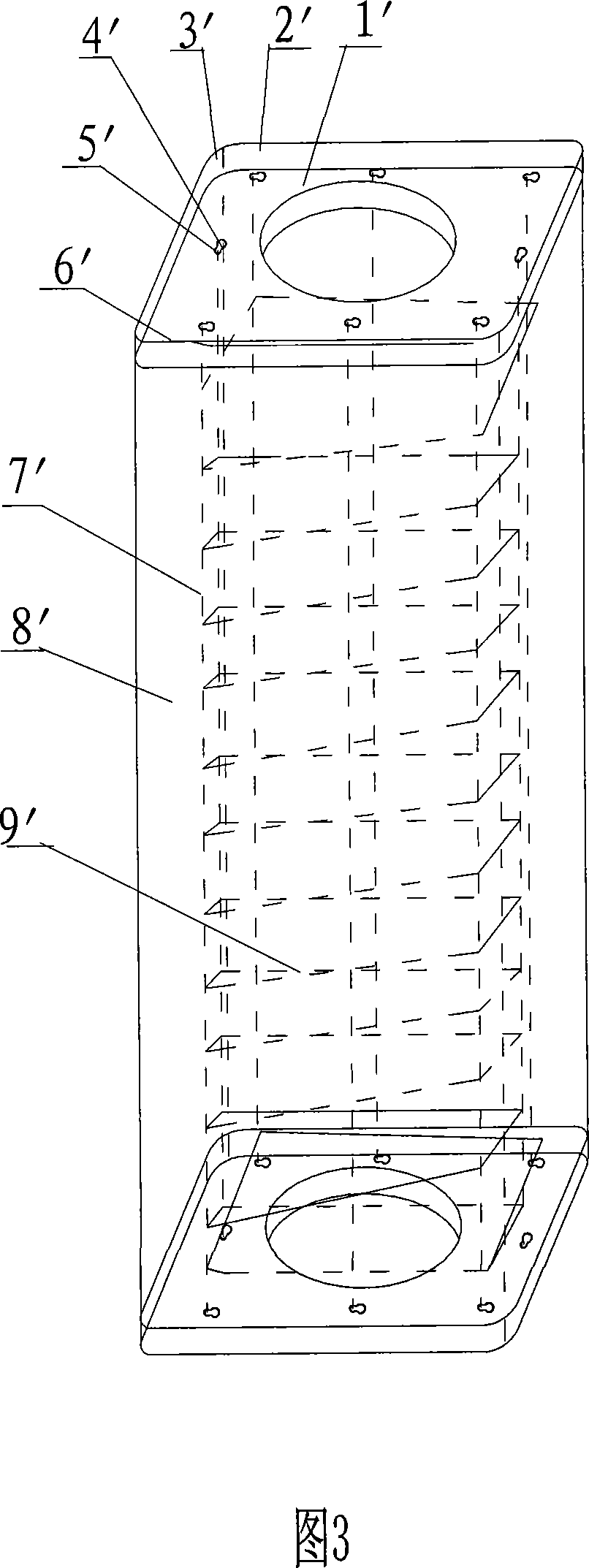

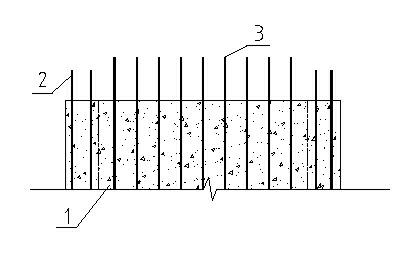

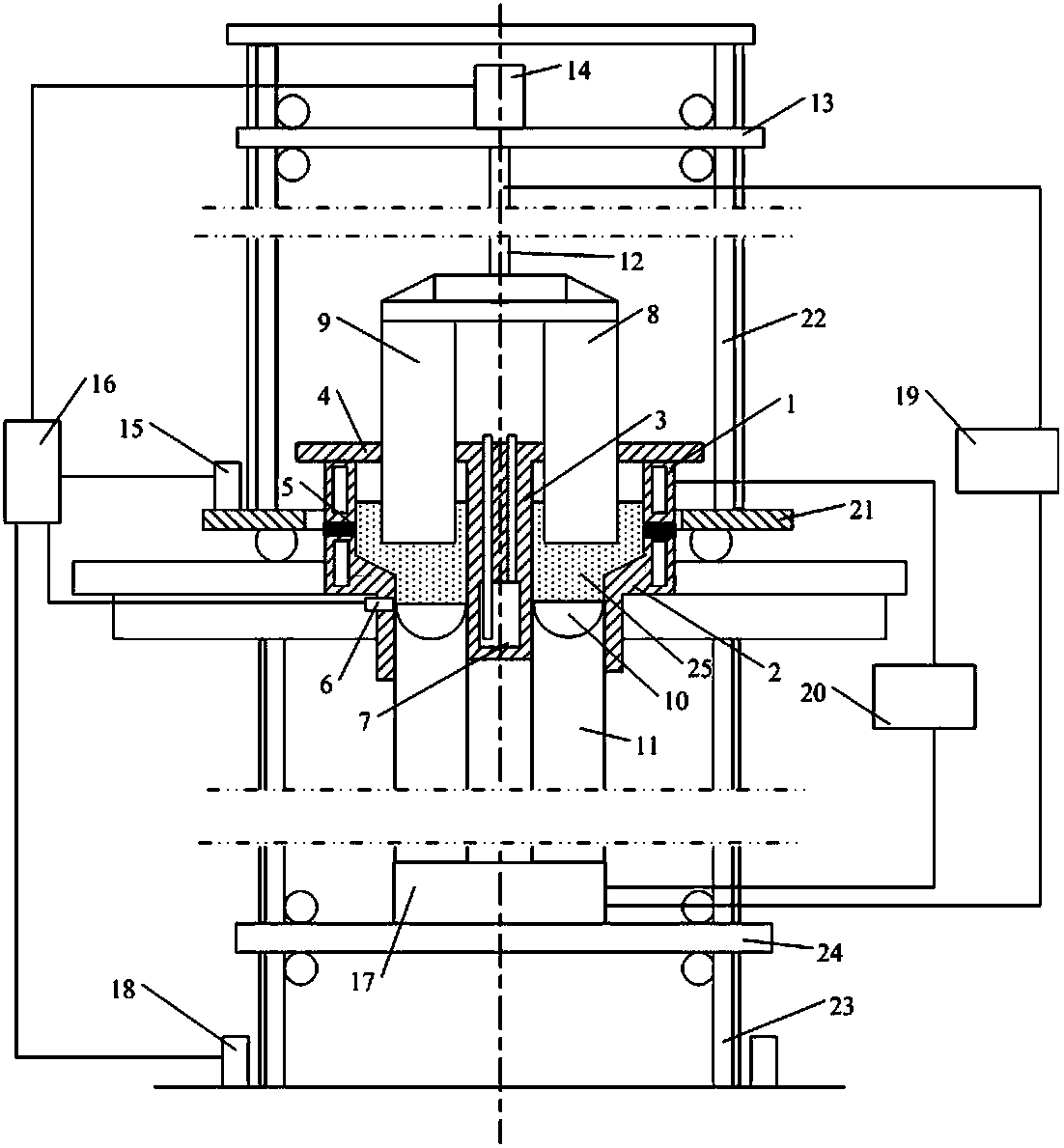

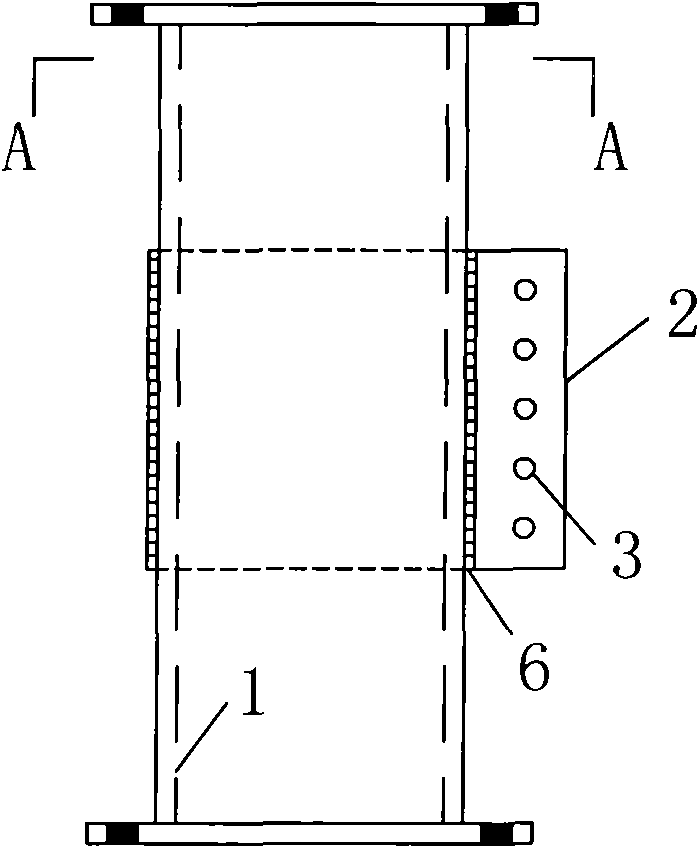

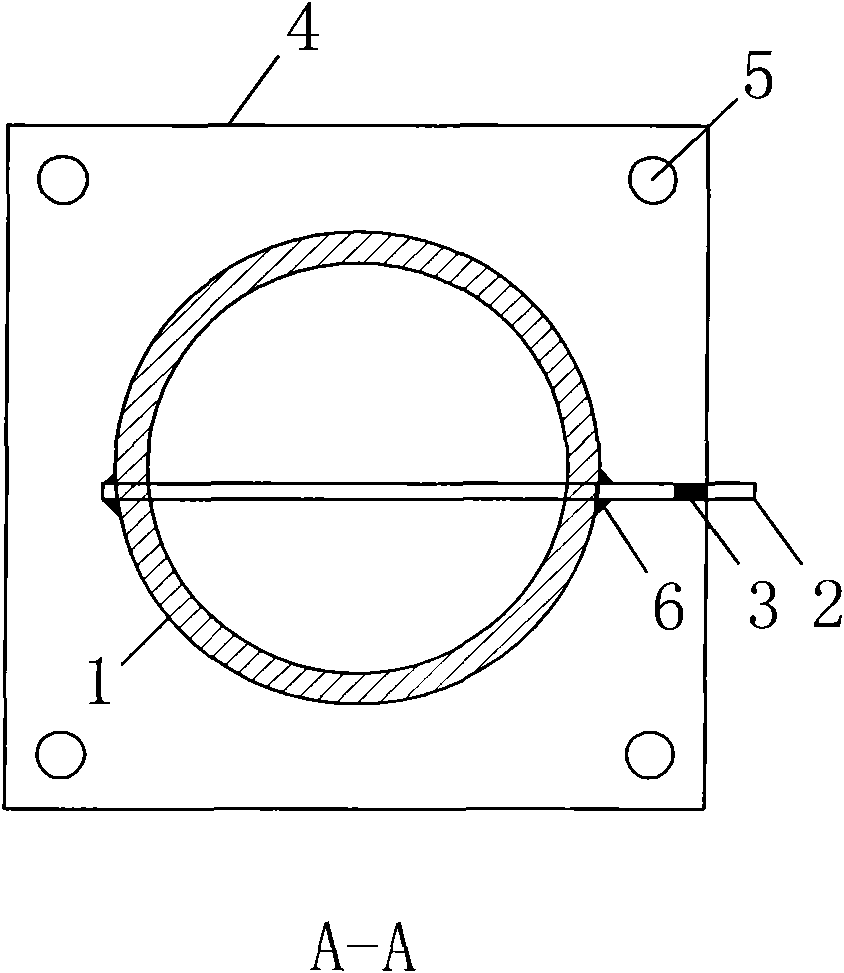

Prestress high intensity concrete square pile and its production method and moulding die

InactiveCN101054800AHigh pile rateIncrease profitCeramic shaping apparatusBulkheads/pilesHigh strength concretePre stress

The invention belongs to the architecture field, which relates to an improvement with the foundation pile shape and the structure and the manufacturing method of the foundation pile and the foundation pile shaper in the architecture field, in particular the invention is a prestressing force high strength concrete square pile and the manufacturing method thereof and the shaping device. In the invention a square terminal plate is disposed on the two ends of the square pile, and the four sides of the terminal plate is provided with a groove, while the center is equipped with a circular hole, and between the circular hole and the four sides, a strain hole and a threading hole are arranged symmetrically; a stirrp of a reinforcement cage in a twist is welded on the principal reinforcement continuously, wherein the principal reinforcement is the steel strand or the steel bar; the concrete square pile and the four-side corners of the terminal plate are in a stress elimination arc, and the pile core is a columnar mid level outlet having the same diameter with the terminal plate central circular hole. The manufacturing method is characterized in that, the principal reinforcement has the fix ed length and blanking, and the stirrp of the reinforcement cage is welded in the seam welder with the high degree of mechanisation; the principal reinforcement is stretched in a group of a whole pile fixed value, wherein the stretching performance is good and the balance is consistent; the disposable high pressure has short shaping time, low energy consumption, high product grade; the die design meets with the shaping requirement of the shape, which is convenient to use.

Owner:SHANGHAI ZHONGJI PILE IND

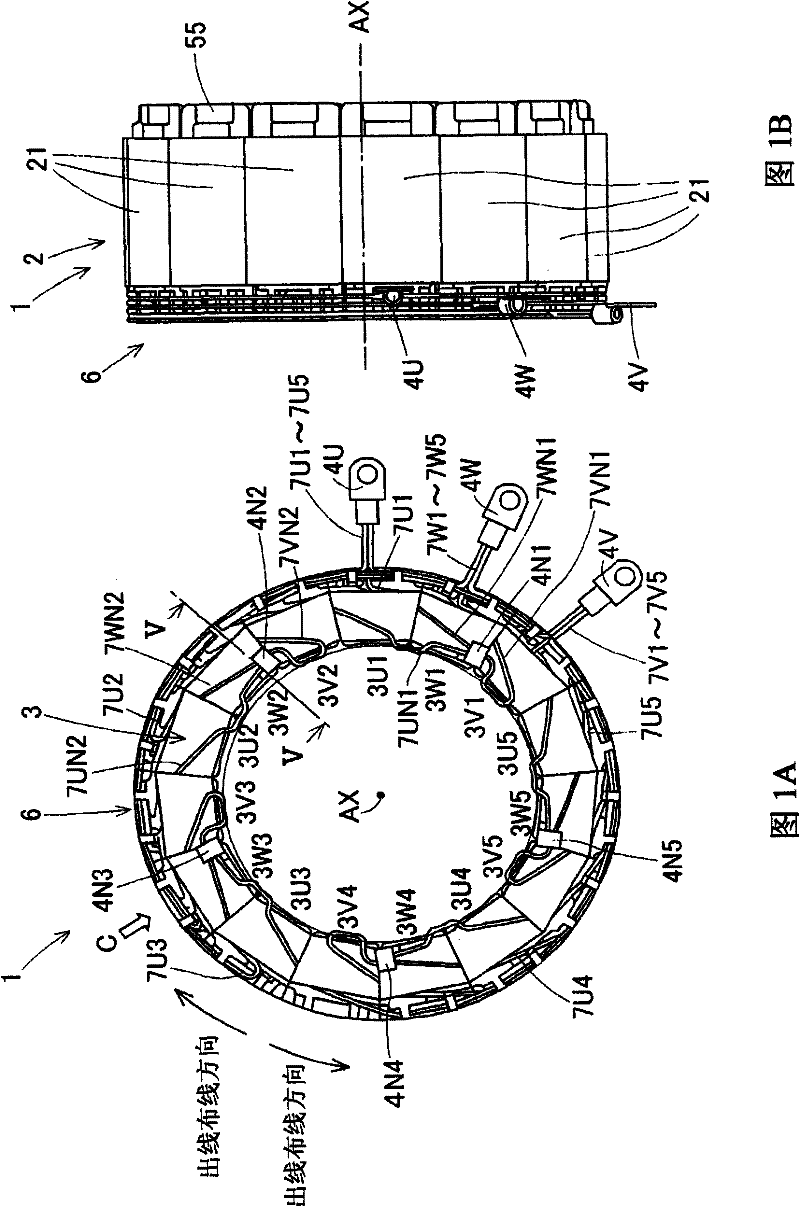

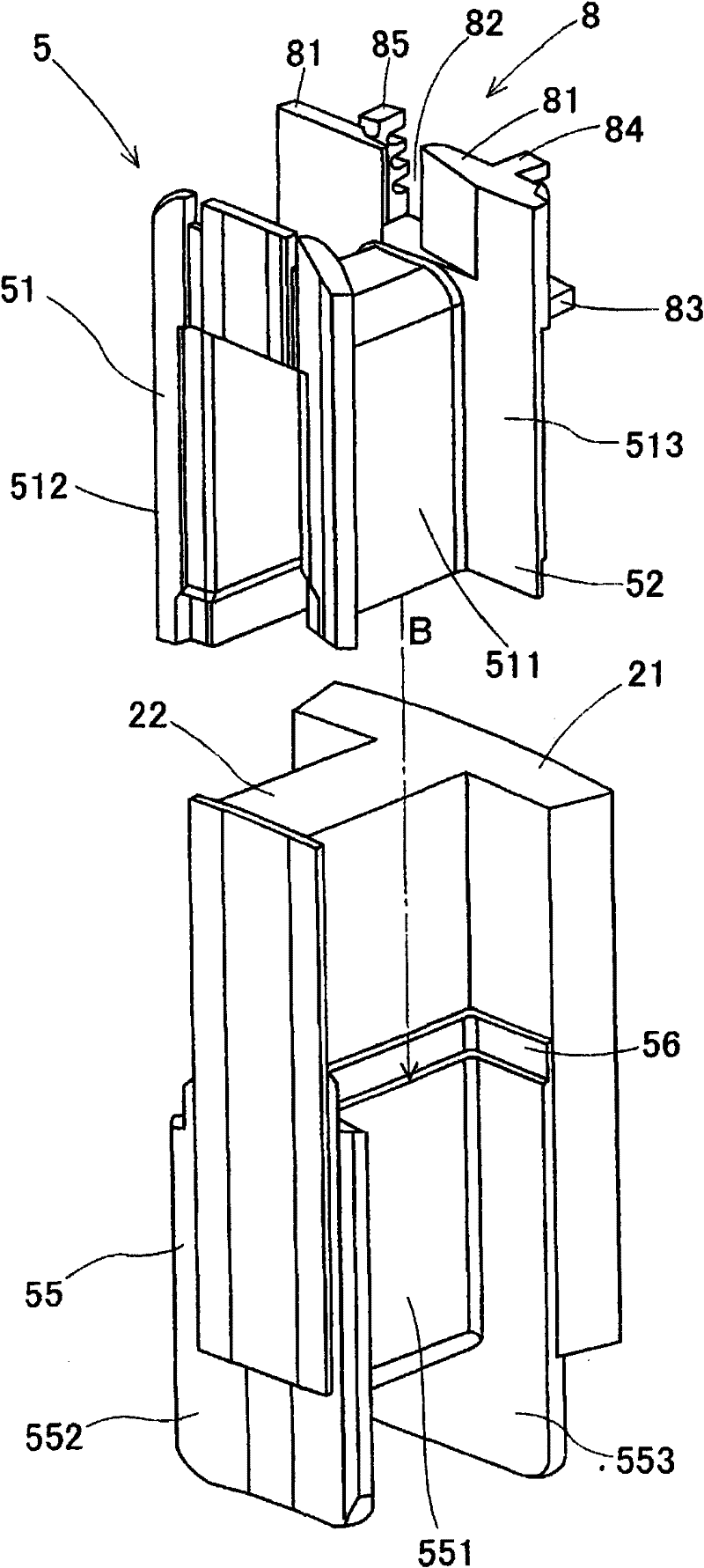

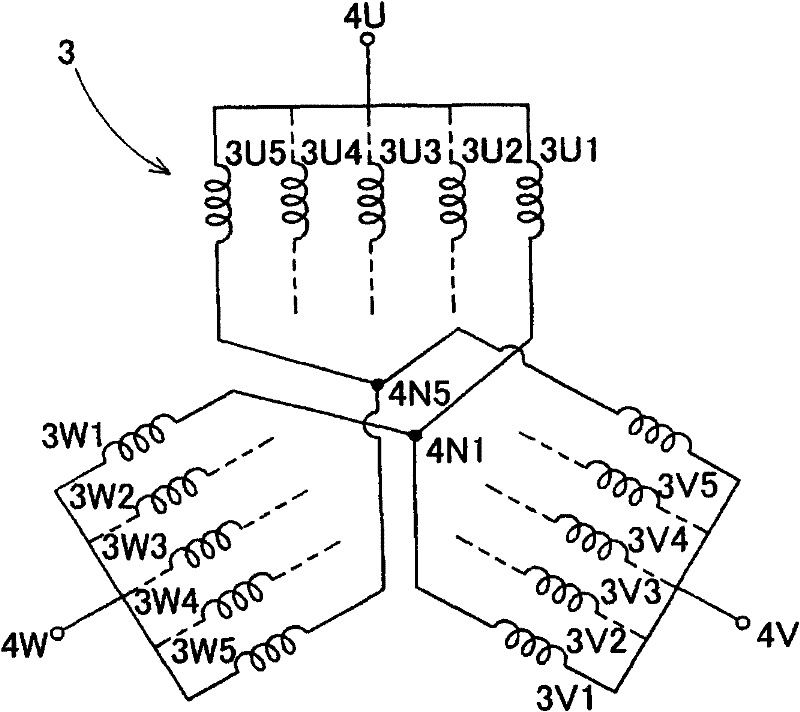

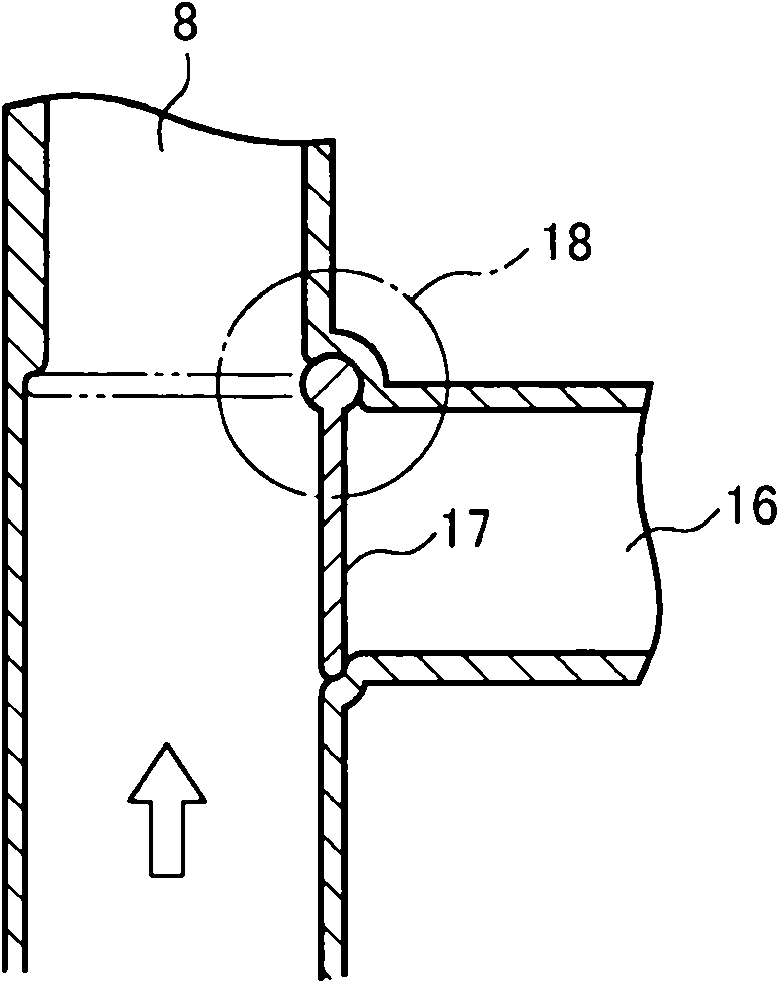

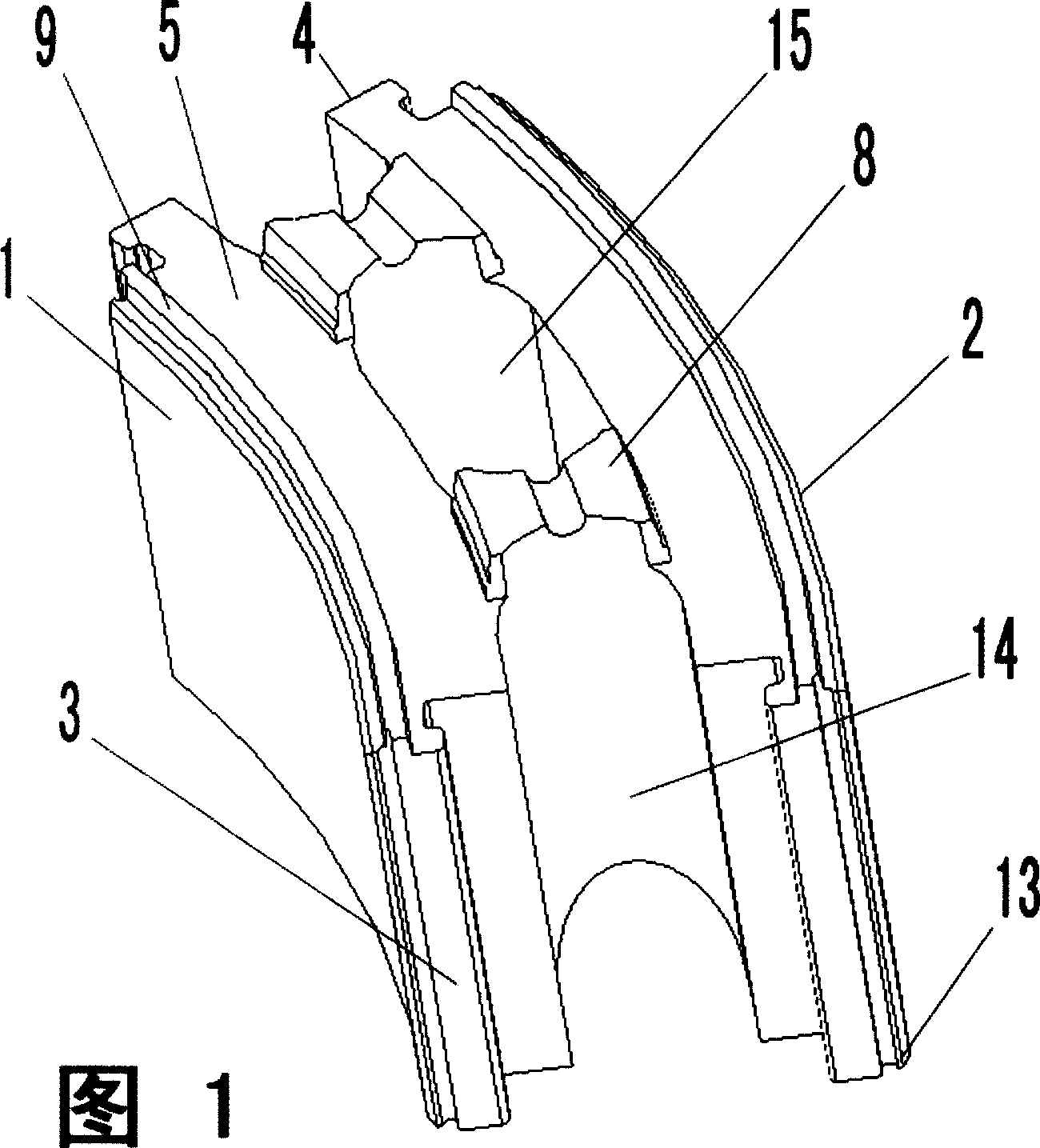

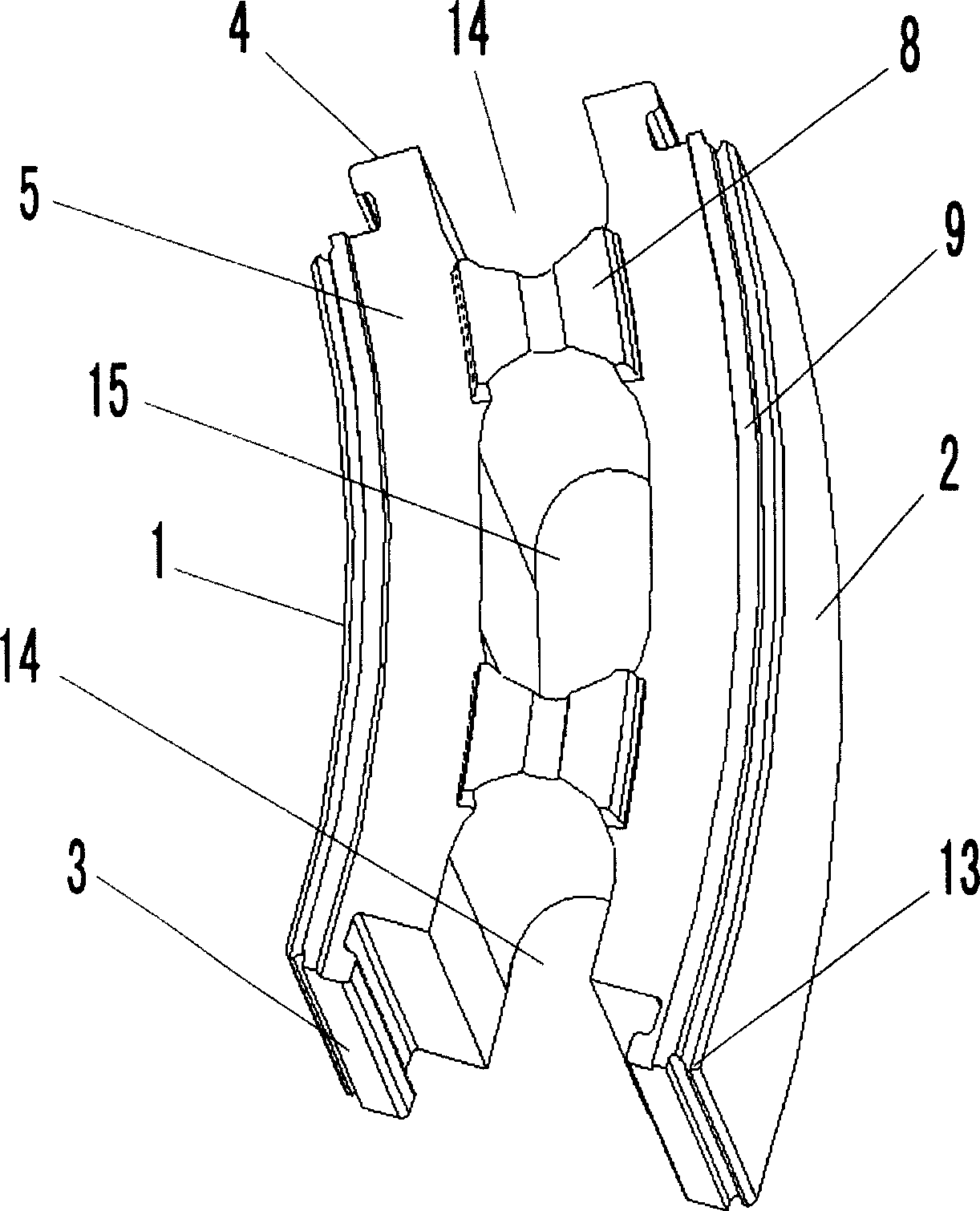

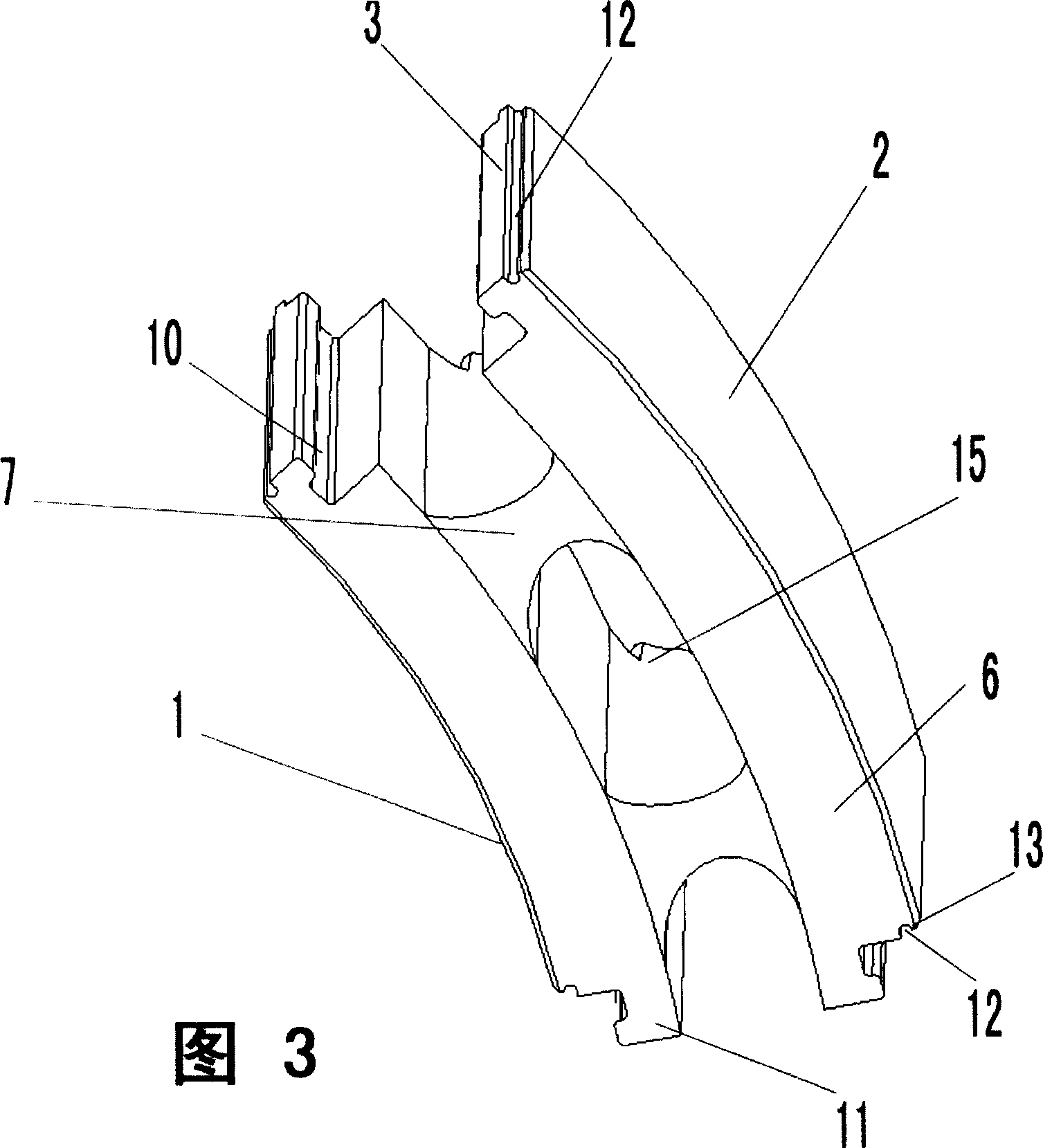

Stator for rotary electrical machine

InactiveCN102201708AReduce in quantityLow costWindings insulation shape/form/constructionMagnetic circuit stationary partsBobbinElectric machine

A stator (1, 10) for a rotary electrical machine, includes a stator core (2) in a cylinder shape and having plural magnetic pole teeth (22), which are arranged in a circumferential direction of the stator while keeping a distance therebetween and each of which protrudes in a radial direction of the stator core, a coil (3) configured with a conductive wire wound around each of the magnetic pole teeth, an insulating bobbin (5) provided between the coil and the corresponding magnetic pole tooth, and an electric power supply portion (6, 60) arranged axially outwardly of the stator core, electrically connecting the coil with an outside of the stator, and including an outgoing wire (7U1, 7U2, 7U3, 7U4, 7U5, 7V1, 7V2, 7V3, 7V4, 7V5, 7W1, 7W2, 7W3, 7W4, 7W5), which corresponds to a portion of at least one of a winding start and a winding end of the conductive wire being extended by a predetermined length, and an isolating member (8, 80) having a groove portion (86U, 86V, 86W, 96U, 96V, 96W) for accommodating and guiding the corresponding outgoing wire.

Owner:AISIN SEIKI KK

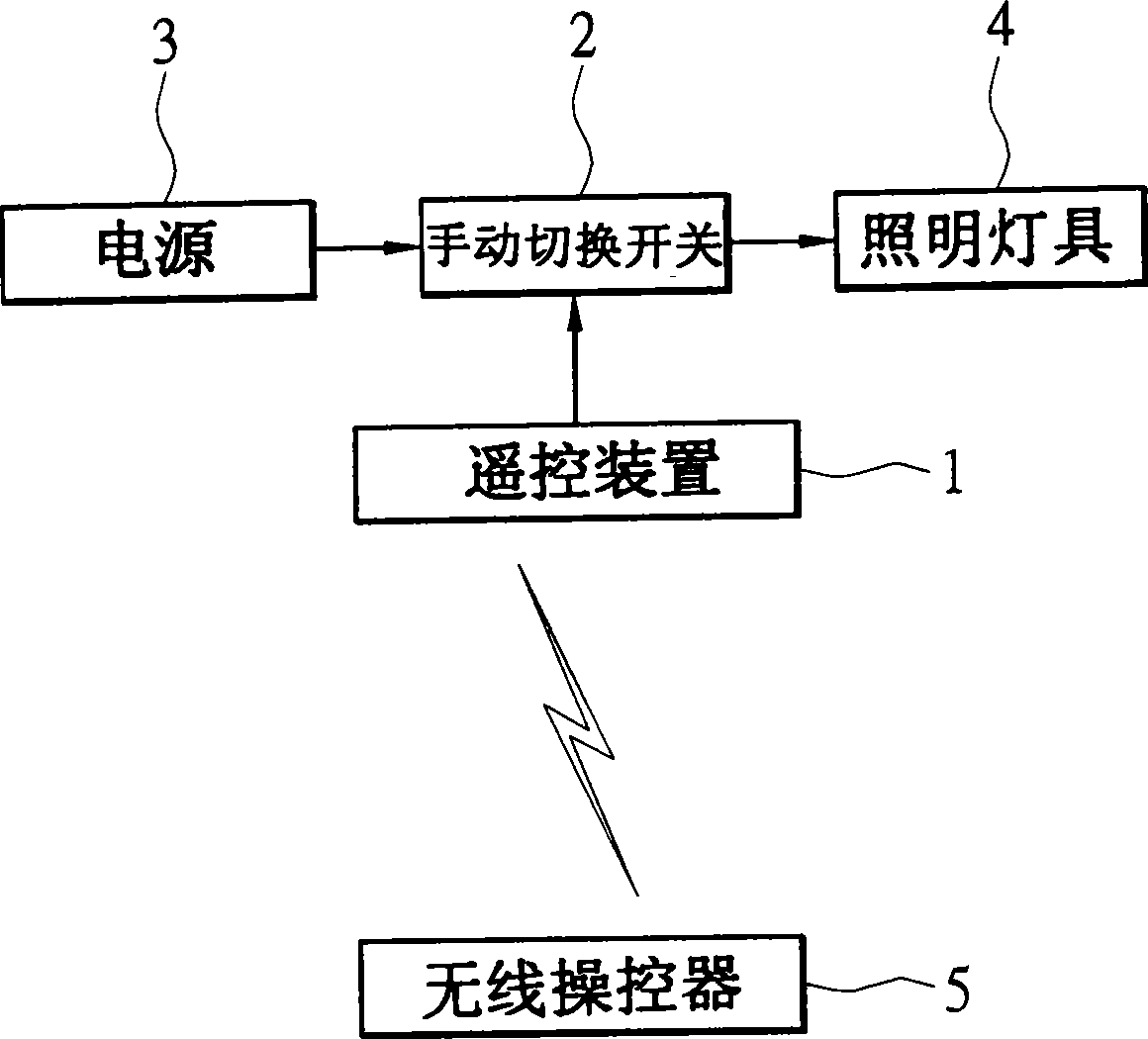

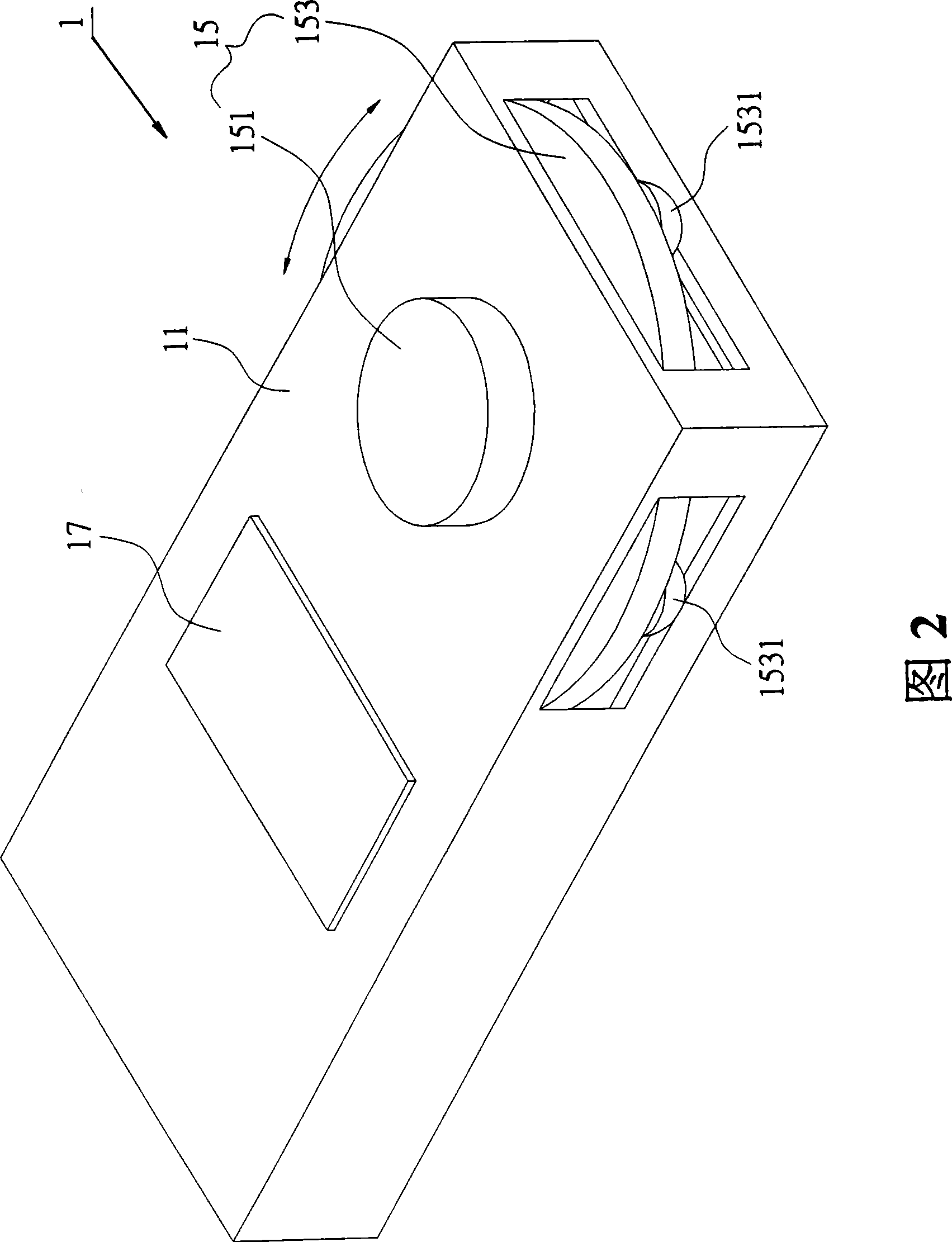

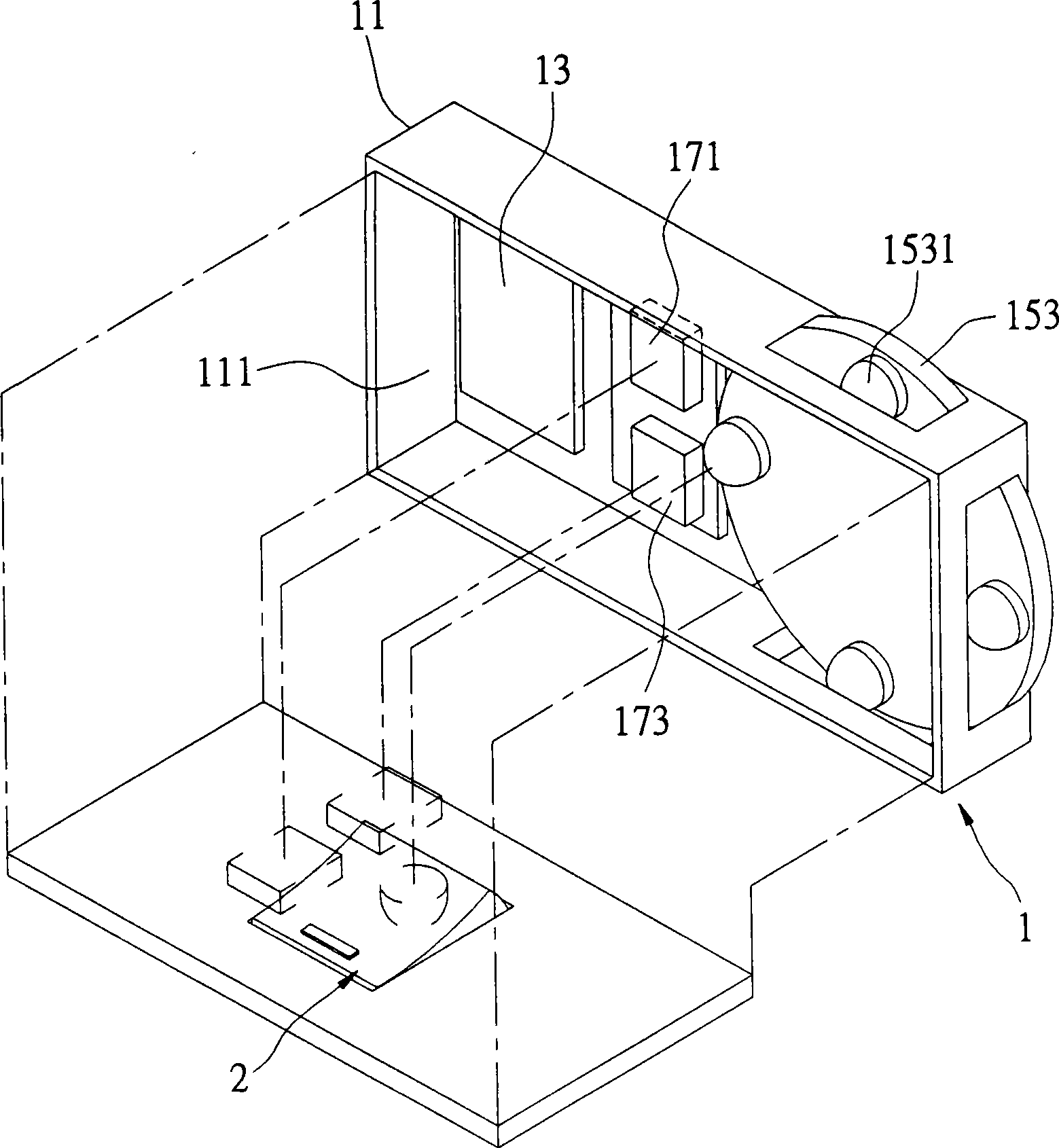

Remote-contro device and remote-control system for manual converting switch

InactiveCN101452777ARealize the remote control functionSave materialTransmission systemsContact driving mechanismsRemote controlControl engineering

The invention discloses a remote control device and a remote control system for a hand-operated changeover switch. The remote control system comprises a hand-operated changeover switch, a wireless controller, and a remote control device, wherein the hand-operated changeover switch is used for switching the opening / closure of a lighting lamp, the wireless controller is used for outputting a remote input signal, the remote control device comprises a shell, a control module and a rotation module, the shell is provided with a receiving space for receiving the hand-operated changeover switch, the control module is arranged on the module and is used for wirelessly receiving the remote input signal and outputting a driving signal according to the remote input signal, and the rotation module is arranged on the shell and is used for receiving the driving signal and controlling the changeover action of the hand-operated changeover switch according to the driving signal. The invention utilizes a peripheral mode to install the remote control system outside the prior hand-operated changeover switch, thereby realizing the remote control function of the switch, avoiding the trouble of replacement construction, and bringing convenience for maintenance; and the remote control device and the remote control system can be widely applied to the retrofit upgrading to the hand-operated changeover switch.

Owner:INVENTEC APPLIANCES CORP

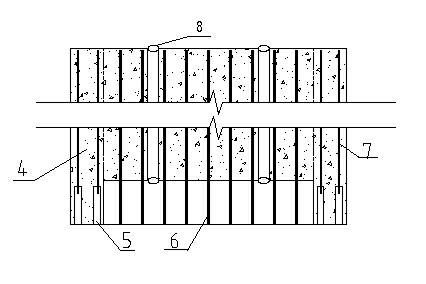

Assembly-type residential shear wall structural wall body vertical connection construction method

ActiveCN102425310AReduce the number of connectionsReduce construction costsBuilding material handlingHigh pressureRebar

The invention relates to a prefabricated shear wall body vertical connection construction method, in particular to an assembly-type residential shear wall structural wall body vertical connection construction method, which is characterized in that: when a prefabricated lower layer wall body is connected with a prefabricated upper layer wall body, supporting leg parts on two ends of the bottom part of a shear wall body are connected with each other through a reinforced bushing anchoring grouting method, and preformed steel reinforced parts on the middle part of the shear wall are connected with each other through a binding and overlapping method. When an upper layer wall body is prefabricated, anchoring connection bushings are respectively embedded on the supporting leg parts on two ends of the shear wall, the middle part of the shear wall is produced into a feeding passage for pouring concrete at a later period by embedding a steel bushing, self-compacting concrete is poured towards the middle part of the shear wall from a feeding port on the top part of the feeding passage, and high-strength grouting materials are fulfilled into the anchoring connection bushing at high pressure through a high-pressure grouting machine. Due to the adoption of the method, the quantity of the connection bushing can be reduced, the cost can be saved, and the connection quality and the connection speed can be improved. The weaknesses of the traditional shear wall vertical connection installation process that the cost is high, the construction speed is slow, the quality is difficult to control, and the like can be overcome.

Owner:CHINA 22MCC GROUP CORP +1

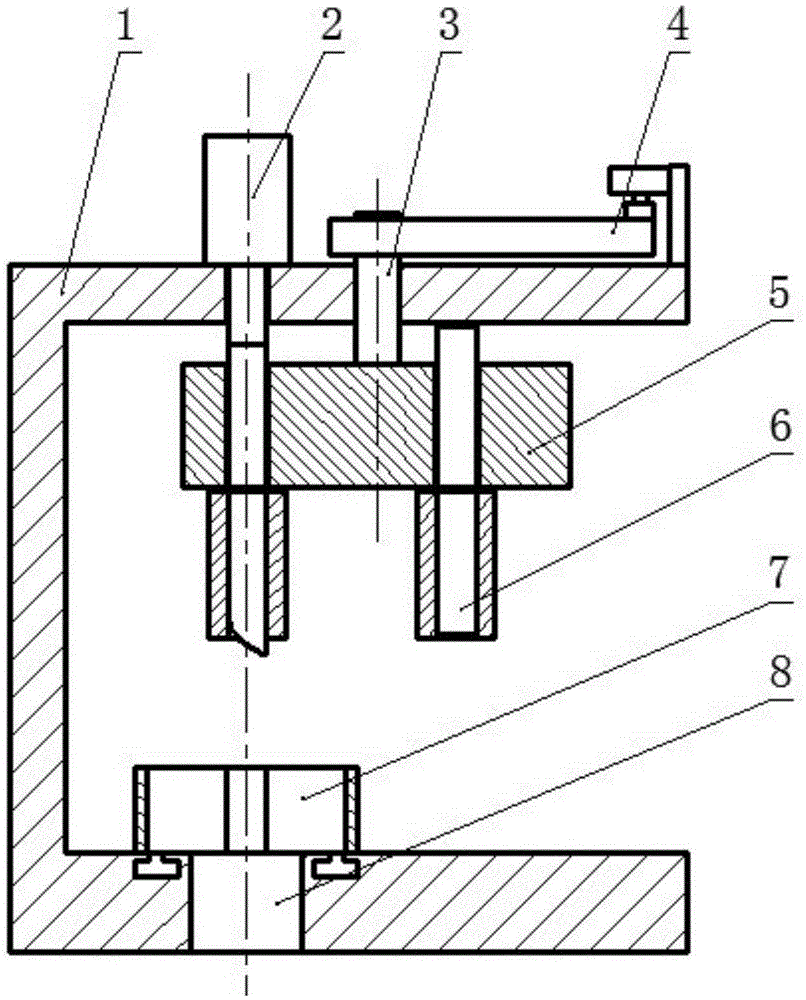

Multifunctional wiring-duct machining device and machining method thereof

InactiveCN105251878APerfect shapeConsistent processing shapeShaping toolsPerforating toolsEngineeringMachining

The invention relates to a multifunctional wiring-duct machining device and a machining method thereof. The machining device comprises a C-shaped base, an upper die rotary plate, a plurality of upper dies, a downward pressing device and a lower die. The upper die rotary plate is rotationally mounted at the upper end of the inner side of the C-shaped base, and the upper dies are mounted at the lower end of the upper die rotary plate in the radial direction. The downward pressing device is vertically mounted on the top of the C-shaped base and located on one side of the radial direction of the rotary plate. The lower die is fixedly mounted in the position, below the downward pressing device, of the upper end of the bottom of the C-shaped base. According to the multifunctional wiring-duct machining device and the machining method thereof, the problem that dies are frequently replaced during wiring-duct machining is solved; after integration, operation is convenient, batch machining can be achieved, work hours are shortened, and the manual labor intensity is relieved; in addition, after program control is added, automatic machining can be achieved, and the automation degree is increased.

Owner:TIANJIN RES INST OF ELECTRIC SCI

Method for manufacturing dendrobium officinale fresh juice stock solution

InactiveCN102008654ANot easy to clarifyNot easy to filterMetabolism disorderAlcoholic beverage preparationFlavorAdditive ingredient

The invention discloses a manufacturing method for extracting and processing fresh juice stock solution by using dendrobium officinale as a raw material. The method furthest protect the color, flavor, nutrition and effective ingredients of dendrobium officinale fresh juice by surface sterilization of the collected fresh dendrobium officinale and technology of juicing, enzymolysis, vacuum degasification, micro-filtration, ultra-filtration, sterile filling, high-temperature instantaneous sterilization and the like, and meanwhile, the product is favorable for storing and realizing industrialized production. The dendrobium officinale is processed into the dendrobium officinale fresh juice stock solution which is easy to store, convenient to carry, simple to administrate, good in mouthfeel and easy to absorb and has health-care nutritional components and medicinal functions; the fresh juice stock solution does not contain any additive; and the content of the fresh juice stock solution reaches over 99 percent. The dendrobium officinale fresh juice stock solution can be administrated separately, also can be added into mineral water to form health-care beverage, also can be dissolved into wine to form nourishing health-care wine, and can be added into high-grade dishes to form nourishing dishes for eating.

Owner:杨军

Heat curing in-situ forming high-conductivity silicon rubber composition and application thereof

The invention relates to a heat curing in-situ forming high-conductivity silicon rubber composition and application thereof. The composition is composed of the following components: (1) 60-90 parts by weight of mixture of ethylene end-blocked polyorganosiloxane in the same or different viscosities; (2) 10-35 parts by weight of silicone oil containing hydrogen; (3) 1-25 parts by weight of one or multiple R<6>cSiX4-c or partial hydrolytic condensation product thereof; (4) 100-500 parts by weight of metal base conductive filler with the average particle size of 10-150 Mum; (5) 0.01-10 parts by weight of organic metal compound or chelate which contains chloroplatinic acid or contains platinum or palladium and is used as metal base catalyst of heat curing; (6) 1-30 parts by weight of reinforcing filler or functional filler. The invention is applied to the shielding case part of RF equipment requiring electromagnetic shielding and sealed environment. The invention reduces material consumption, simplifies production technology and improves production efficiency and cost performance of product.

Owner:SHANGHAI RELAND PHOTOVOLTAIC MATERIAL

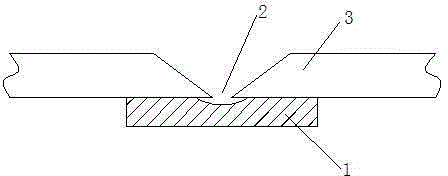

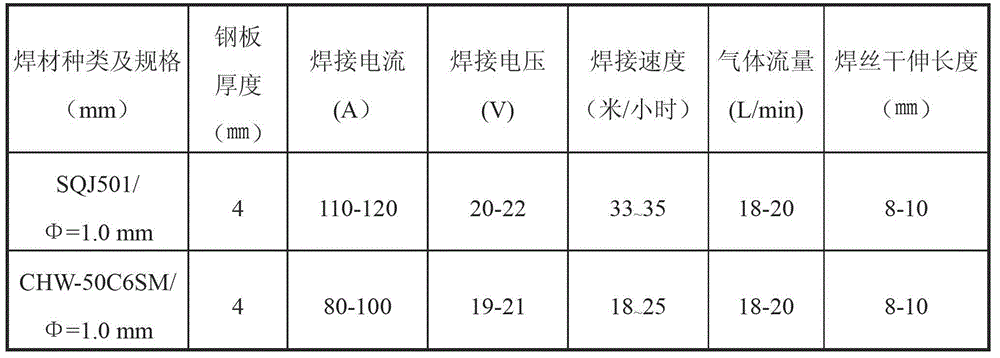

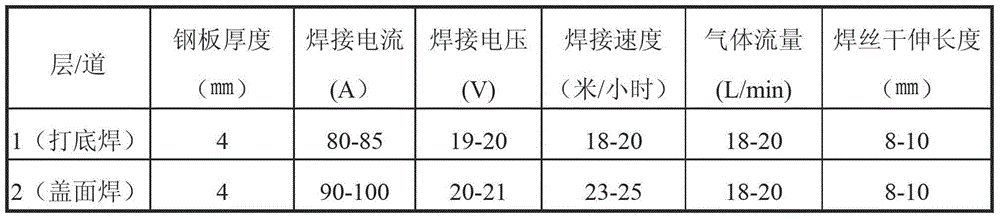

Single-side welding and double-side forming welding method for ceramic gasket

The invention discloses a single-side welding and double-side forming welding method for a ceramic gasket, and belongs to the welding field of material processing engineering. The method comprises the following steps of (1) treatment of grooves of abutted plates; (2) installation of the plates, and spot-welding fixing; (3) adding of the ceramic gasket; (4) baking for dehumidifying; (5) groove welding. The method does not need to carry out the operation that the welds of the back side are subjected to cleaning and welding operations after the structure is turned over, after the welds of the front side are welded, the double-side forming effect is directly realized, and the required matching of hoisting equipment and the required man-hours during turnover of the structure are reduced. The number of welds is reduced, and the operation of overhead welding positions is avoided. Therefore, the labor strength of workers is reduced, the welding difficulty is reduced, the production efficiency is greatly improved, and the production cost is reduced.

Owner:中船桂江造船有限公司

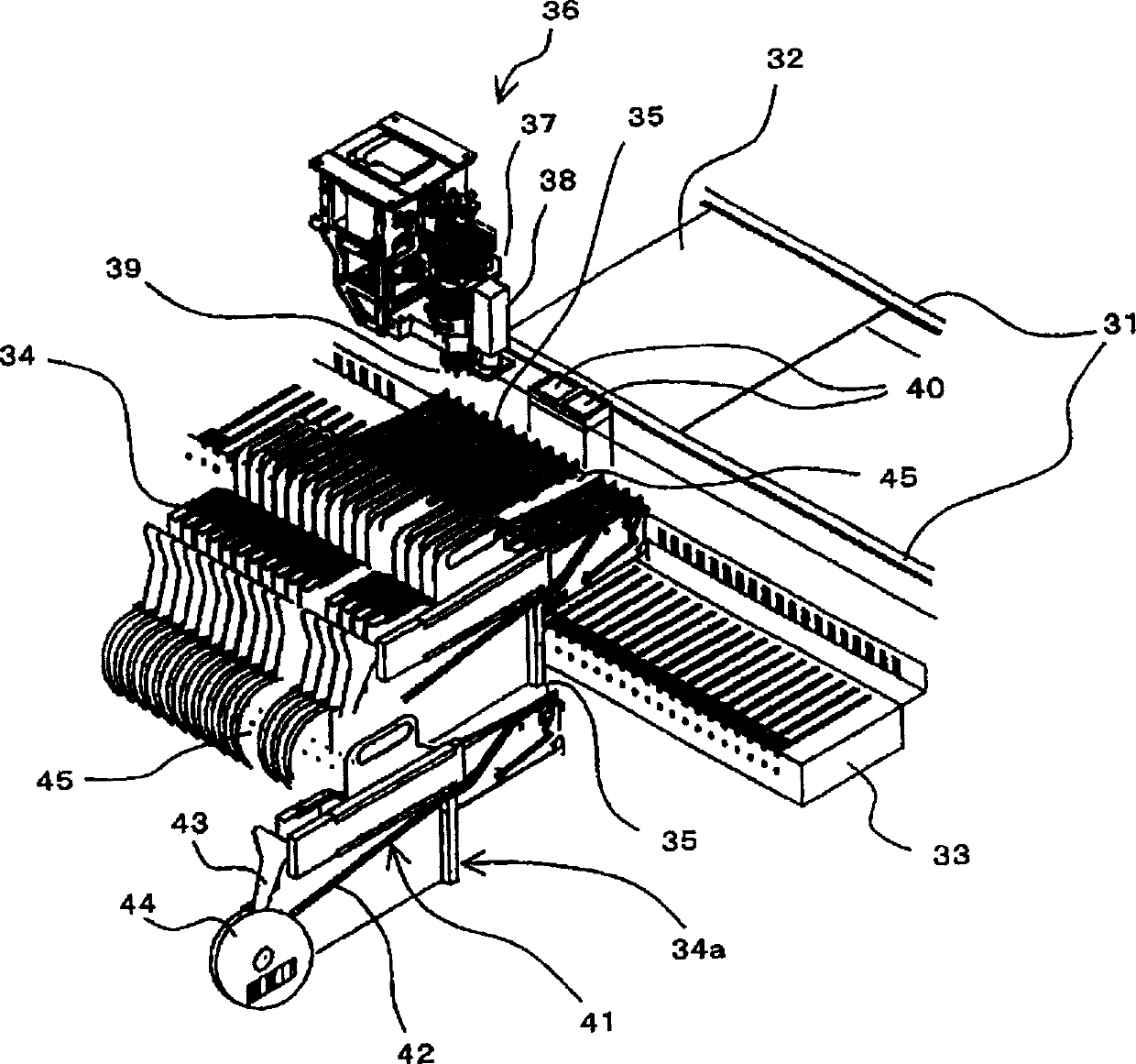

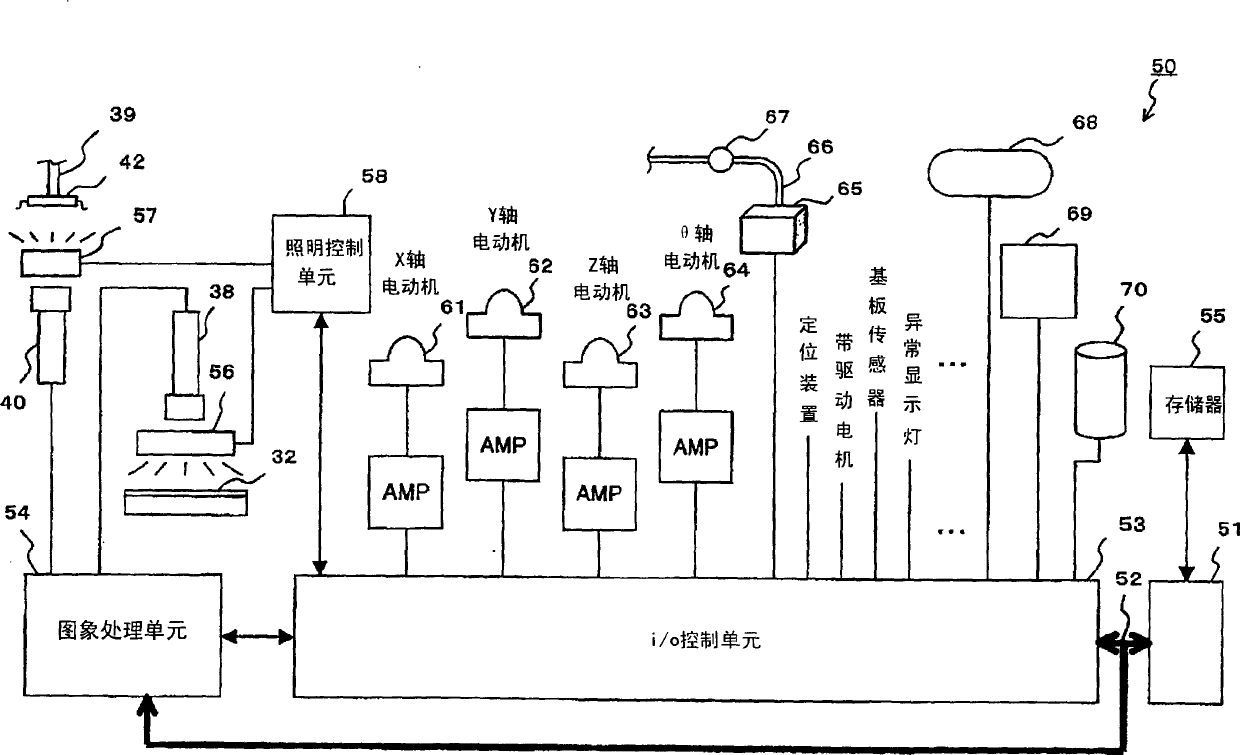

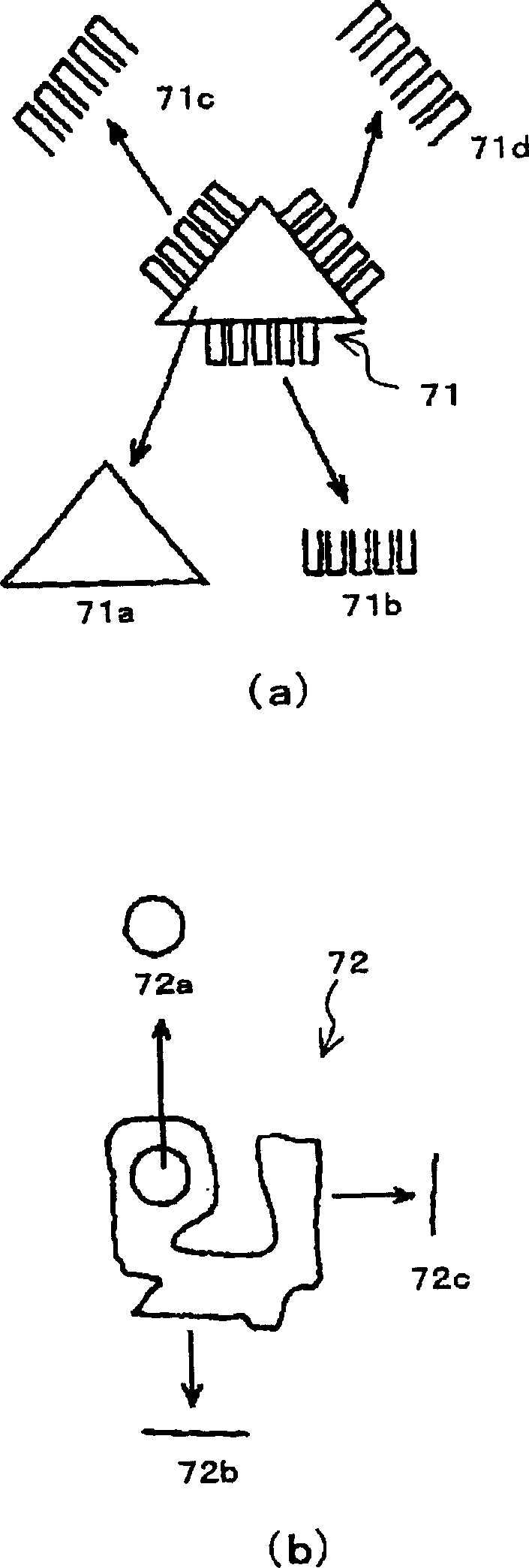

Component mount method and component mount apparatus using the same

InactiveCN1831687AMake up for weaknessesImprove reliabilityProgramme controlComputer controlEngineering

The part installing device can avoid the disconformity during part replacement for product altering regulation and in practical operation. During base plate unit production and when some part is used up, the first judgment of whether to be the chip part is performed, if yes, the common chip part replacing treatment is executed before re-producing base plate unit, and or else, the non-chip part replacing treatment is executed before the second judgment. In the second judgment, the image of the replaced part is obtained with the camera and the part shape characteristics are recognized for being identical with the pre-stored ones, and in case of disagreement, the warning report and part replacement is executed before returning to the image recognition. When the replaced part has the same shape characteristics, the third judgment for the identity in the characters on the surface of the part is executed before re-starting production if identical or executing the disagreeing treatment if not identical.

Owner:YAMAGATA CASIO CO LTD

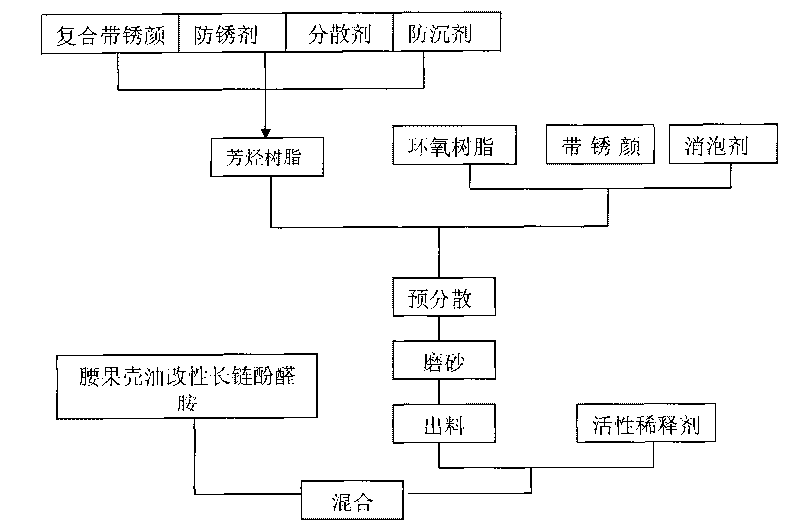

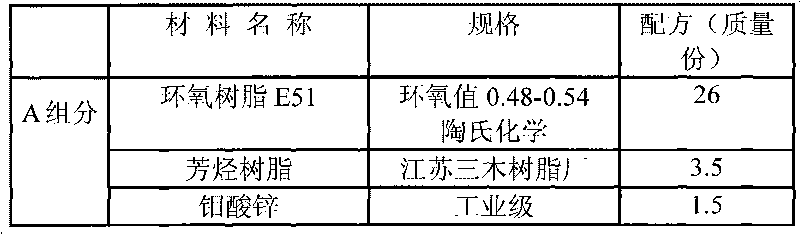

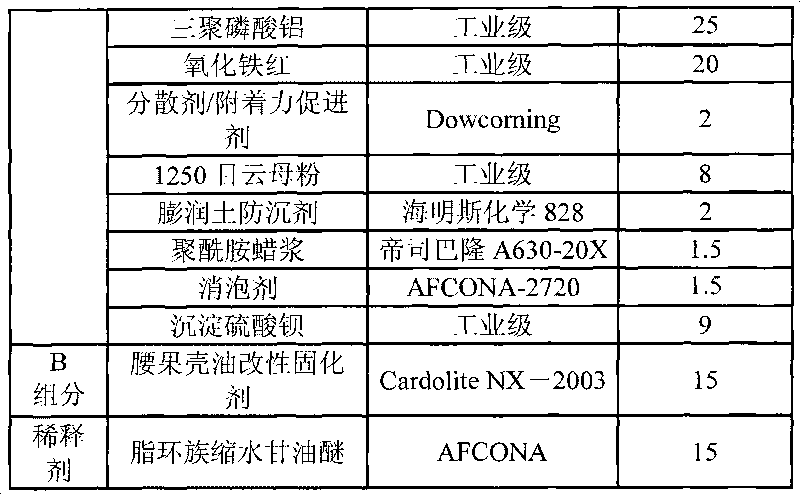

Environment-friendly solvent-free humidified and rusted anticorrosive paint

InactiveCN101747825AEasy pretreatmentConvenient anti-corrosion solutionAnti-corrosive paintsEpoxy resin coatingsOrganic filmSolvent free

The invention relates to a paint material with formed organic film, in particular to an epoxy solvent-free anticorrosive paint applied to low surface treatment steel structure. The anticorrosive paint is prepared by efficiently compounding rusted coating pigments such as zinc molybdate, zinc phosphate, aluminium trippolyhosphate, iron oxide red and the like, using cashew nut oil modified long-chain amine phenolic aldehyde as, alicyclic glycidyl ether as active diluent, thus overcoming the problems that surface treatment technique in coating construction costs high and heavy anticorrosive paint with high solvent content pollutes the environment, having easy preparation and construction, low cost, fast solidification at high temperature, good mechanical and anticorrosive performance, solvent-free and environment-friendly properties, and being applicable to heavy anticorrosive projects of steel structures such as ship, train, bridge and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

High-strength steel plate and method for producing the same

The invention relates to a 110Kg level high tensile steel plate with the yield strength not less than 960MPa. The steel plate comprises the following chemical components by weight percentage: 0.14 to 0.18 percent of C, 0.20 to 0.50 percent of Si, 0.90 to 1.30 of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.70 to 0.10 percent of Ni, 0.04 to 0.08 percent of V, 0.020 to 0.060 percent of Nb, 0.020 to 0.060 percent of Al, 0.30 to 0.80 percent of Cr, 0.30 to 0.60 percent of Mo, 0.010 to 0.030 percent of Ti, 0.0010 to 0.0030 percent of B, and the balance being Fe and inevitable impurities. Through the reasonable design of alloy components and mainly the control on quenching and tempering process, the thickness of the obtained steel plate can reach 80mm. The steel plate has high yield strength, high welding performance, high cold bending performance, good low temperature toughness, good steel plate profile, and excellent comprehensive performance. The steel plate can be widely applied to the manufacturing of engineering machinery and has bright application prospect.

Owner:WUYANG IRON & STEEL

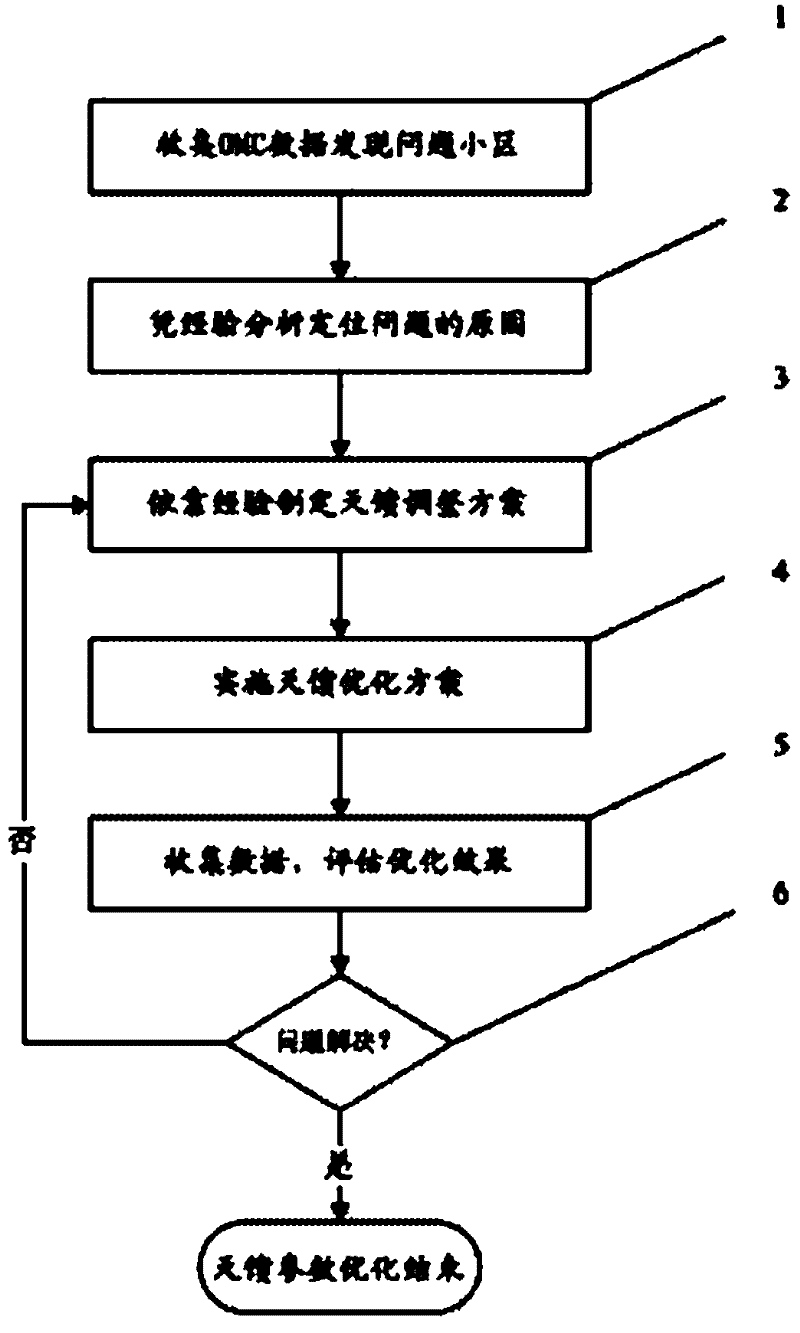

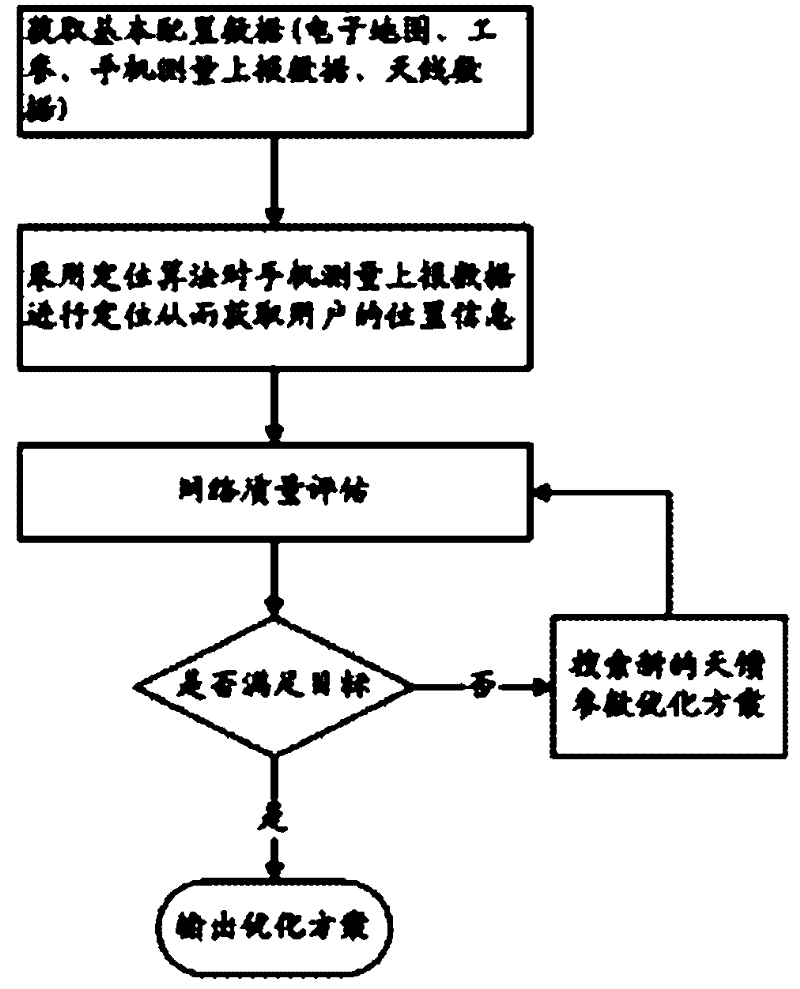

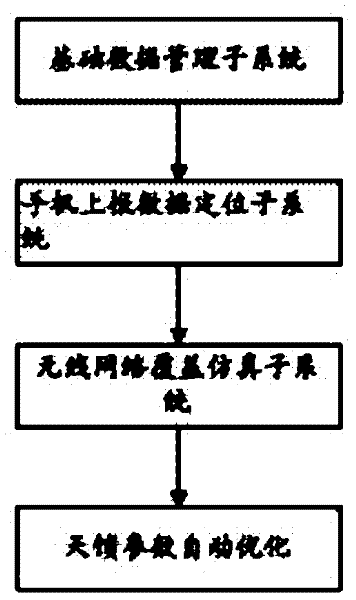

Antenna parameter optimizing method based on mobile phone measurement report

The invention relates to the technical field of communication, specifically to an antenna parameter optimizing method based on mobile phone measurement report, which is characterized in that the method comprises a wireless network basic data management sub-system, a mobile phone reported data locating sub-system, a wireless network covering emulating sub-system, an antenna feeder parameter automatic optimizing sub-system and a hardware configuring system; the basic data management sub-system stores and manages the wireless network basic data, including electronic map, the project parameter of the whole network and the mobile phone measuring report data; the mobile phone reported data locating sub-system can locate the original mobile phone reported data; the wireless network covering emulating sub-system can locate the result data according to the wireless network basic data, the electronic map and the mobile phone reported data; and the antenna feeder parameter automatic optimizing sub-system solves the problem of uncompleted wireless network covering and uneven telephone traffic distribution. The an antenna parameter optimizing method based on mobile phone measurement report can reduce workload, enlarge application scope and reduce manpower input and cost along with more accurate assessment.

Owner:SHANGHAI BYNEAR TELESOFT

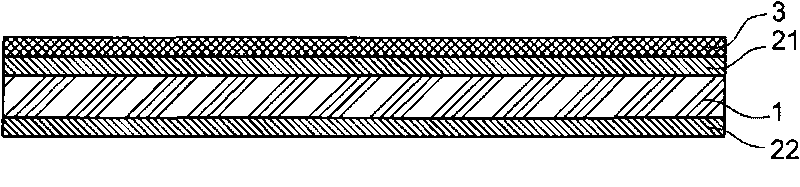

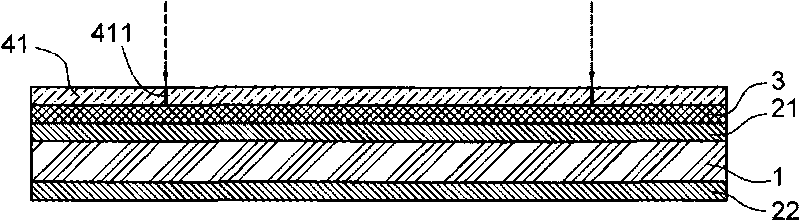

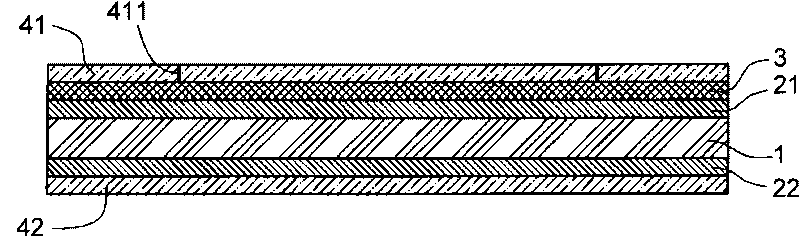

Fabricating method of touch circuit two-sided graph structure

InactiveCN101726888ASimplify the placement processSave man hoursStatic indicating devicesPhotomechanical apparatusGraphicsUltraviolet

The invention relates to a fabricating method of a touch circuit two-sided graph structure, which comprises the steps of: providing a substrate with a first conducting base material layer and a second conducting base material layer distributed on two sides of the substrate, contacting with a shielding layer for shielding ultraviolet on the top face of the first conducting base material layer; contacting with a first light resistance layer on the top face of the shielding layer, contacting with a second light resistance layer on the bottom face of the second conducting base material layer; exposing the first light resistance layer and the second light resistance layer, shielding ultraviolet on two sides of the substrate through the shielding layer; developing two sides of the substrate to ensure that the first conducting base material layer and the second conducting base material layer respectively expose regions to be etched; and etching the exposed regions of the first conducting base material layer and the second conducting base material layer to ensure that the first conducting base material layer forms a first conducting film of the touch circuit and the second conducting base material layer forms a second conducting film of the touch circuit. Therefore, the invention can simultaneously expose, develop and etch two sides of the substrate so as to simplify the layout procedure of the touch circuit.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

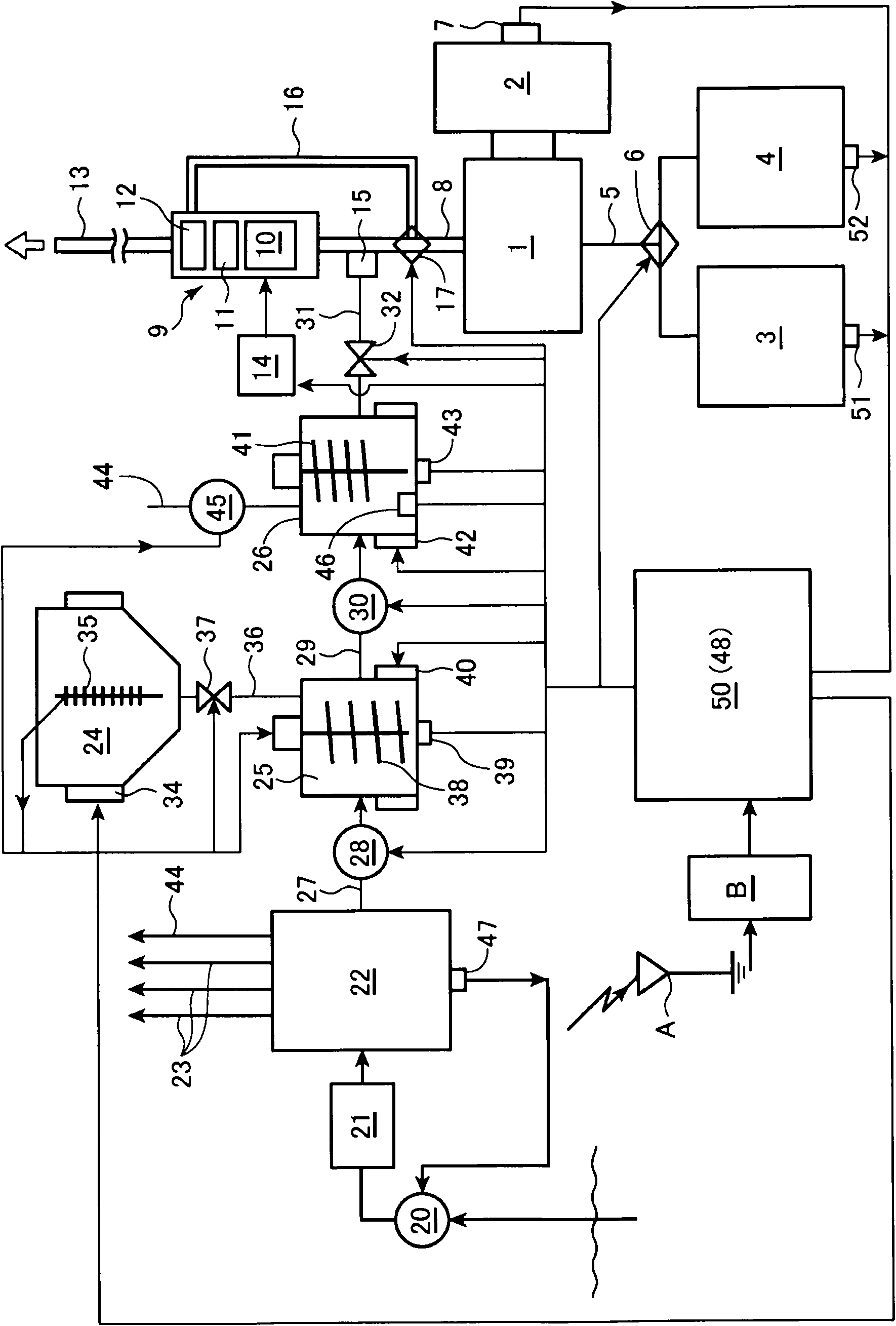

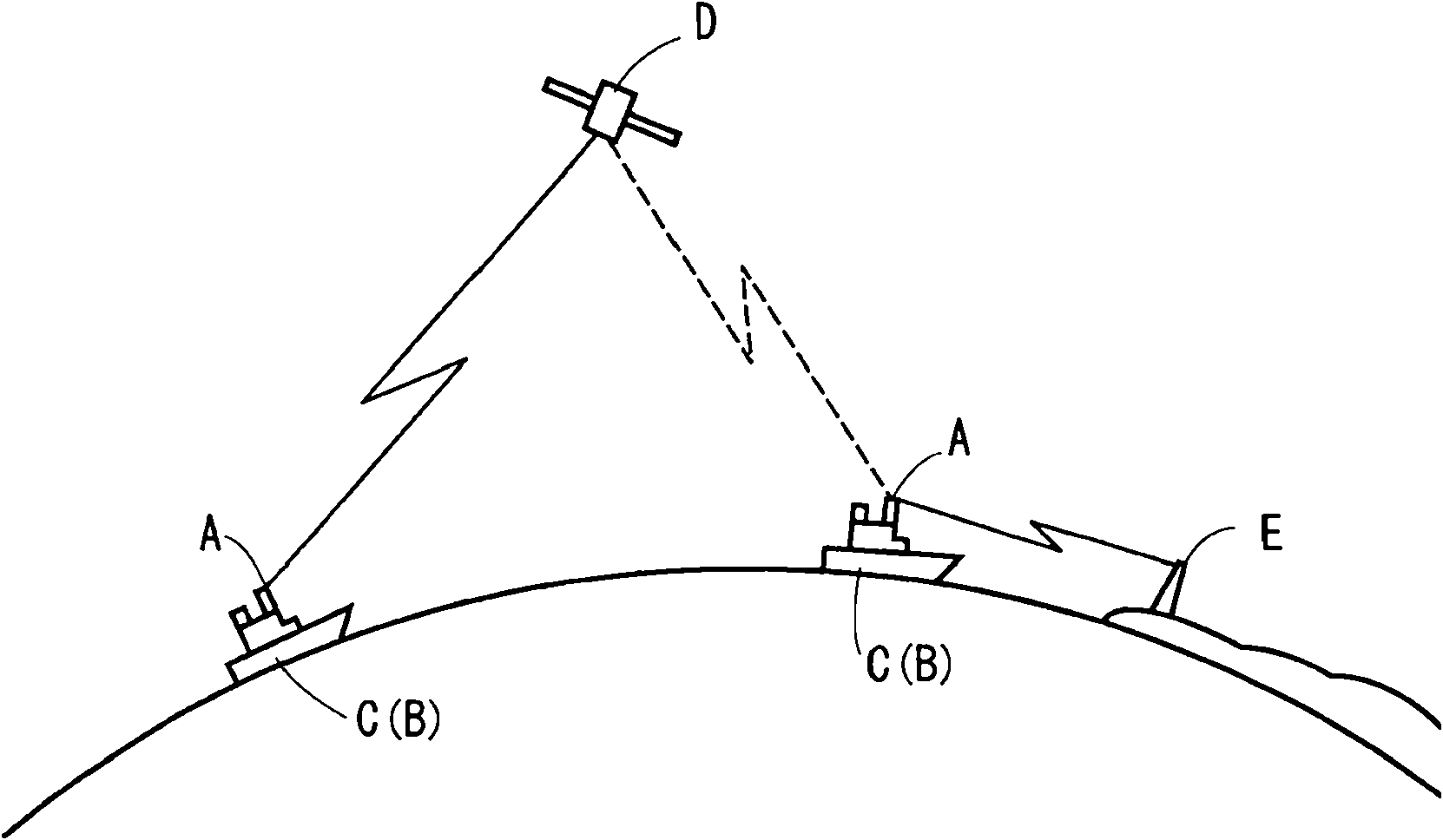

Exhaust gas purifying system for vessel engine

ActiveCN102159455ARemove restrictionsSave man hoursInternal combustion piston enginesAuxillariesExhaust valveSulfur

A vessel is loaded with a general fuel (C-heavy oil) tank (3) and a low-sulfur fuel (A-heavy oil) tank (4). In the exhaust line of an engine (1), an SCR catalyst (10) of a urea water spray type is arranged and a bypass exhaust pipe (16) in which the exhaust gas passes not through the SCR catalyst (10) is also arranged. An automatic vessel-position detecting means (B) and a restriction map are collated to compute the distance to the sea area of a restriction target automatically. On the arrival at the restriction-target sea area, the function of the SCR catalyst (10) is stopped by changing the fuel automatically from the general fuel to the low-sulfur fuel and by discharging the exhaust gas to the bypass exhaust pipe (16). The change of the exhaust gas purifying state is automatically made.

Owner:YANMAR POWER TECHNOLOGY CO LTD

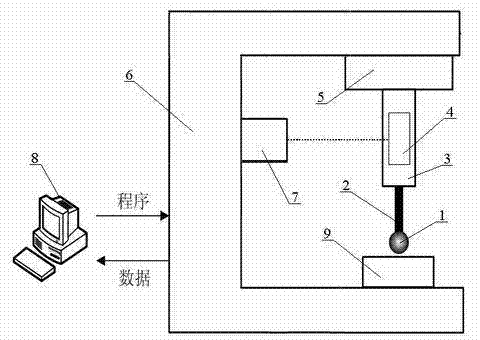

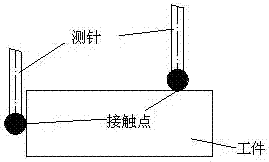

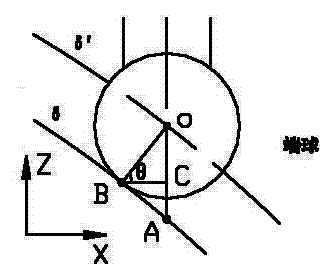

Contact measurement error compensation method oriented to freeform surface and compensation system

InactiveCN103481122AAvoid errorsSave man hoursMeasurement/indication equipmentsElectricityMachine tool

The invention discloses a contact measurement error compensation method oriented to a freeform surface and a compensation system. After small-size workpieces are detected, if the workpieces are not qualified, the workpieces need to be remounted in a machining center for secondary finishing and machining, and a secondary chuck-mounting error is accordingly caused; for large-size workpieces, the problems such as secondary chuck-mounting error also can be caused. The contact measurement error compensation method oriented to the freeform surface consists of a ruby measuring head (1), wherein the ruby measuring head is connected with a ceramic measuring rod (2), the ceramic measuring rod is connected with a pressure sensor (3), the pressure sensor is connected with a signal transmitter (4), the pressure sensor is connected with a cutter handle (5), the cutter handle is connected with a three-axis machine tool (6), the signal transmitter is connected with a signal receiver (7) through wireless signals, the signal receiver is mounted on the three-axis machine tool, the signal receiver is electrically connected with the JA40 interface of the three-axis machine tool, and the three-axis machine tool is electrically connected with a computer host (8). The contact measurement error compensation method oriented to the freeform surface and the compensation system are applicable to the error measurement of common planes and freeform surfaces.

Owner:HARBIN UNIV OF SCI & TECH

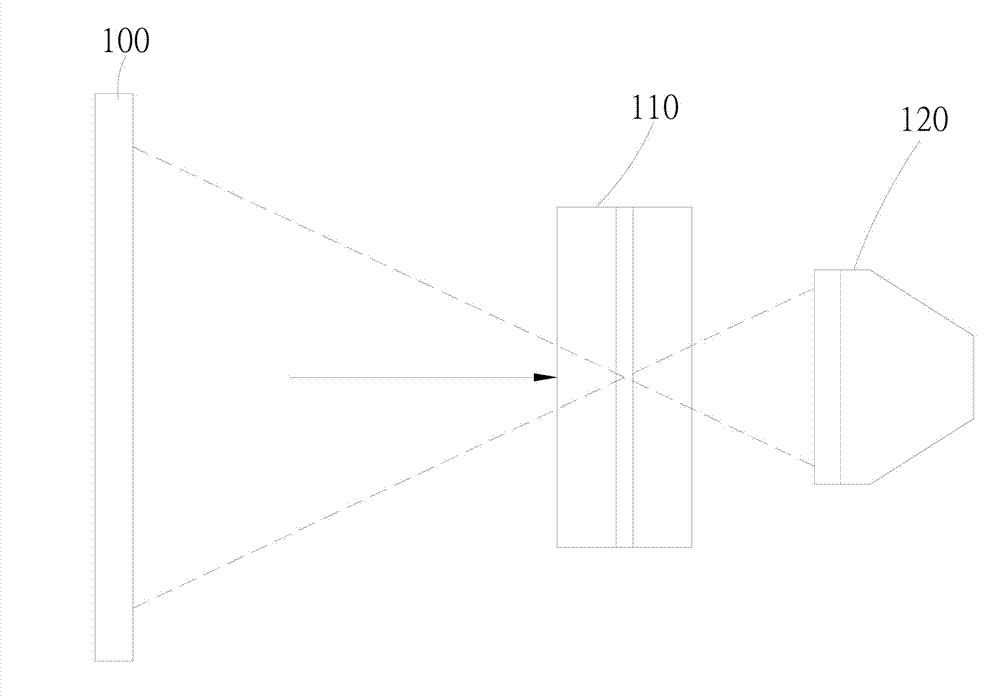

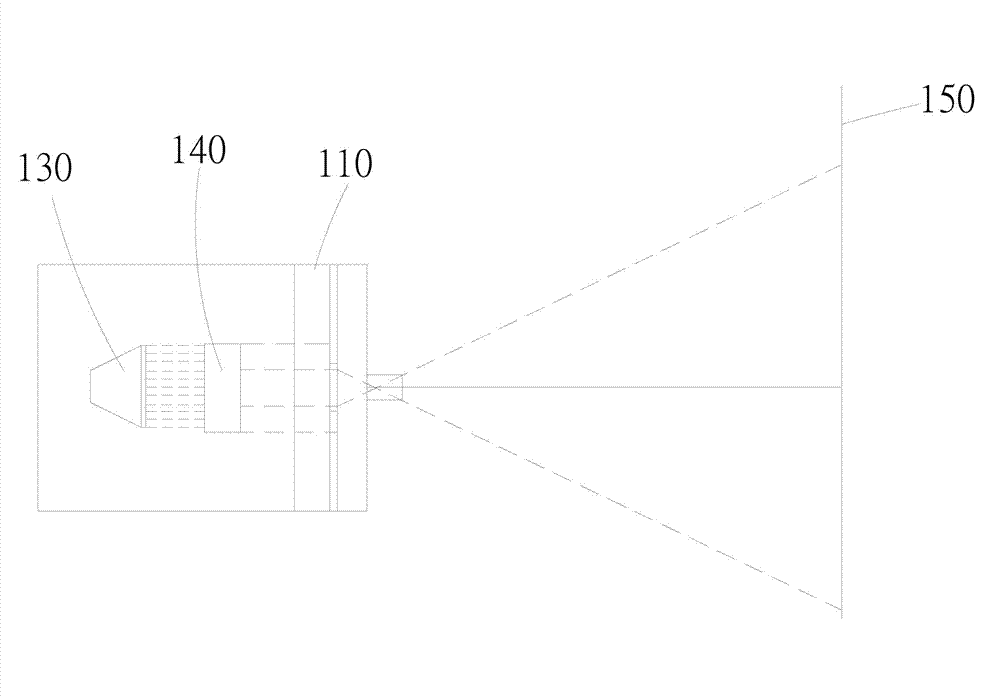

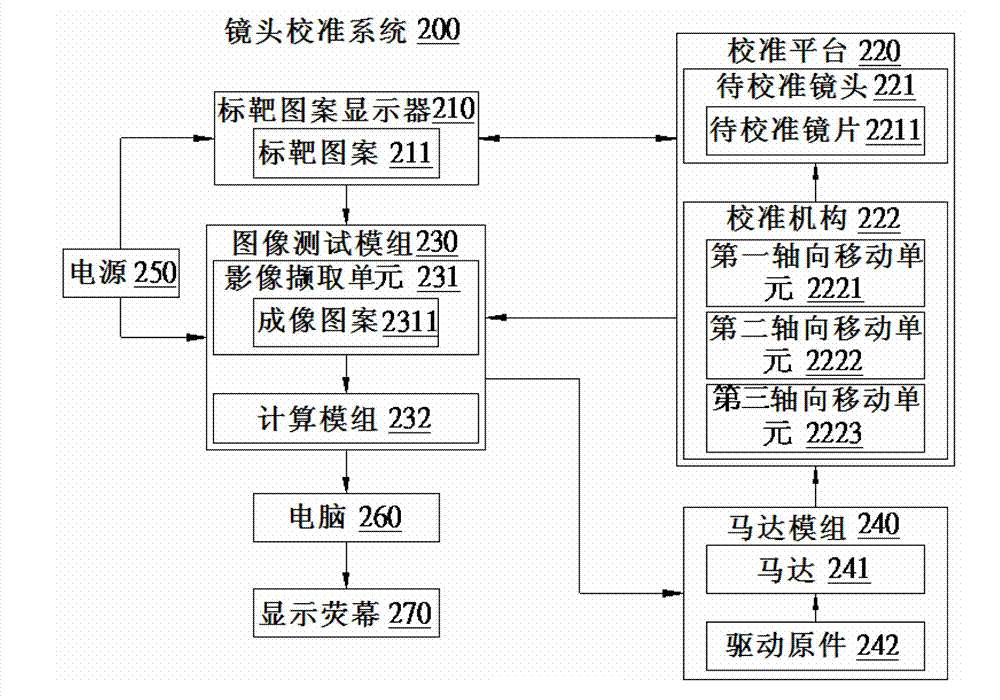

Lens calibration system and method thereof

InactiveCN102789111AReduce manufacturing costSave man hoursMountingsFocusing aidsDisplay deviceComputer science

The invention discloses a lens calibration system and a method thereof. The lens calibration system comprises a calibration platform which comprises a calibration mechanism, a lens to be calibrated is placed on the calibration platform, an image test module captures a target pattern on a target pattern display through the lens to be calibrated so as to obtain an imaging pattern, the image test module performs parameter calculation on the imaging pattern and sends an adjusting signal according to the calculation result, and a motor module receives the adjusting signal and drives the calibration mechanism to calibrate the lens to be calibrated according to the adjusting signal. The lens calibration system and the method thereof can solve the problems of long focusing working hour, high labor cost or production cost of the existing lens focusing machine.

Owner:ALTEK CORP

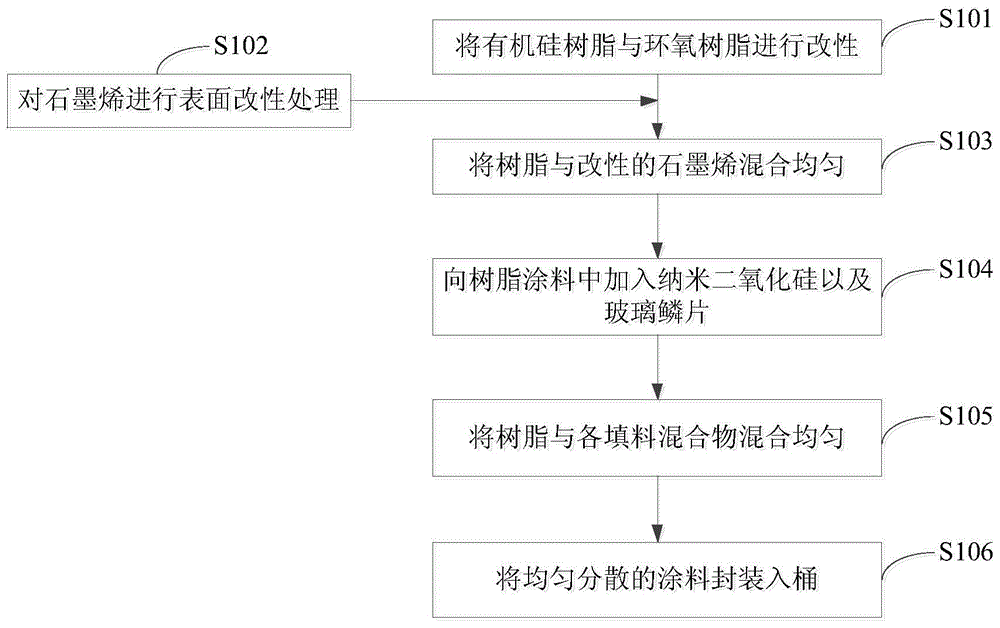

Novel abrasion-resistant, anti-corrosion and anti-static coating and preparation method thereof

InactiveCN105219219AEffectively dissipate static electricityEffective anti-electromagnetic interference capabilityAnti-corrosive paintsEpoxy resin coatingsCarbon nanotubeSilicon dioxide

The invention relates to a novel highly-abrasion-resistant, anti-corrosion and anti-static coating and a preparation method thereof. The coating comprises basic thermosetting resin and a filler, wherein the basic thermosetting resin is modified resin for coatings; the filler is formed through blending and combining one or more of a carbon nano tube, carbon black, graphite, graphene, nano aluminum powder and conductive mica powder with one or more of quartz sand, glass flake, nano silicon dioxide, nano-molybdenum disulfide, aluminium oxide and modified montmorillonite. The coating is directly smeared or sprayed on the surface of a metal outer shell of electronic and electrical equipment, the equipment can be effectively prevented from being corroded by the environment for a long time, and the influence of pad points and electromagnetic interference on the safe, normal and stable use of the equipment is prevented.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

Substrate fixture and rotary disc for coating film and film coating machine

InactiveCN101165206ALow costSave man hoursVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The substrate fixture for filming apparatus includes one frame, two holding units set oppositely and sliding in the frame, and elastic connecting units between the frame and each of the holding units. Two holding units have substrate holding parts in the opposite surfaces; and the elastic connecting units have elastic force acted onto the holding units for holding the substrate. When the fixture is in use, the substrate is held between the holding parts under the action of the elastic force. The substrate fixture is suitable for substrates of different sizes. The present invention has also a rotary disk and a filming machine provided with the substrate fixture.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

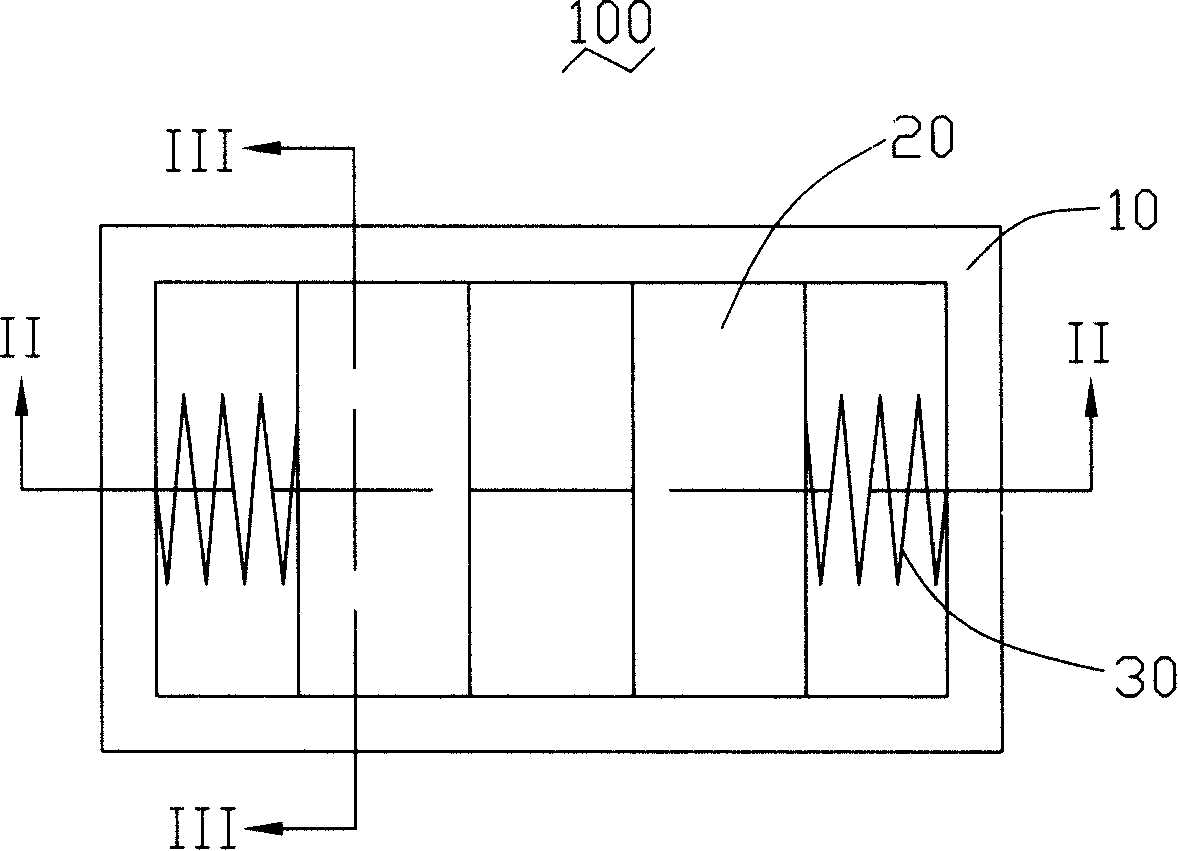

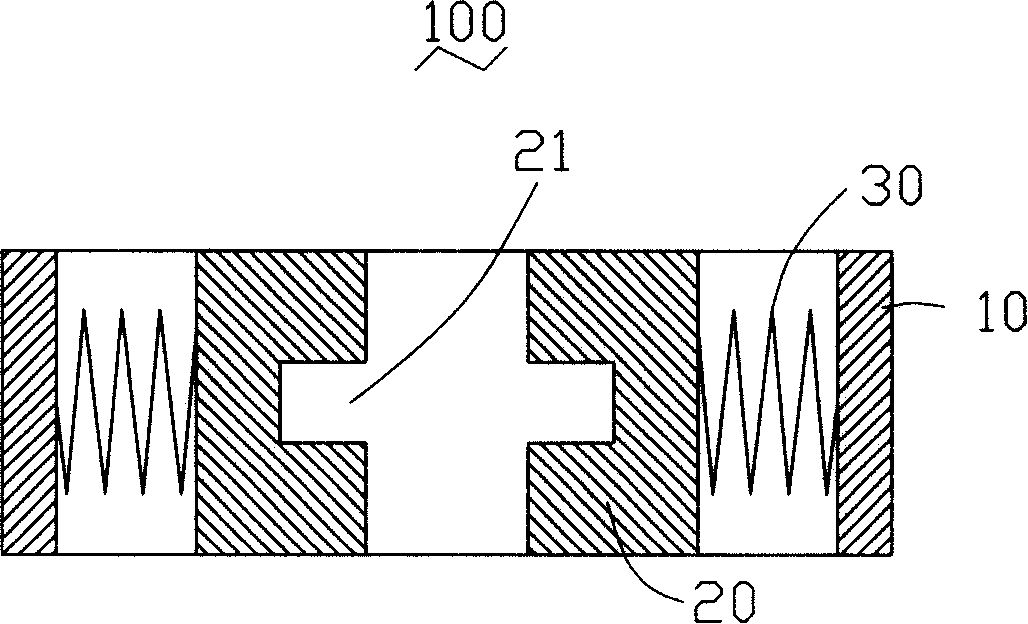

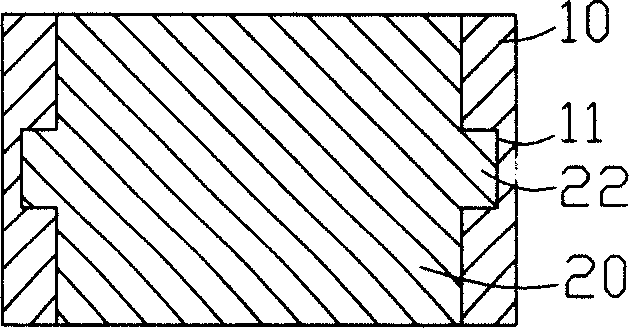

Wall module of well walls and method for building wall bodies of well walls by using module

InactiveCN1431375APrevent subsidenceImprove stress resistanceArtificial islandsBuilding componentsConvex structureStructural engineering

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

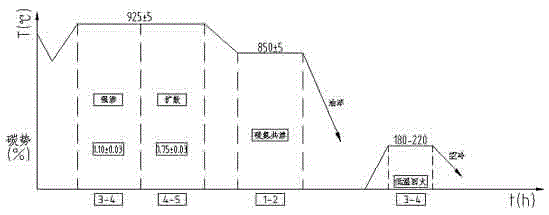

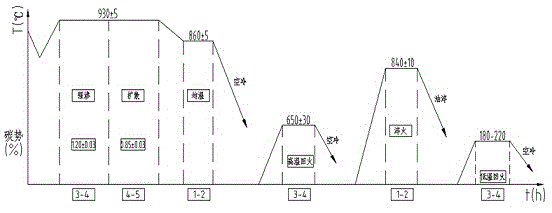

Automobile transmission gear heat treatment method

ActiveCN104894506AAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

The invention discloses an automobile transmission gear heat treatment method. The method includes the steps of carburization, carbonitriding, quenching, cleaning, low temperature tempering and air cooling. The carburization technique is combined with the carbonitriding technique, abrasion resistance, fatigue strength and corrosive resistance are improved by a layer of highly hard nitride layer obtained on the carburized layer on the surface of a gear, and comprehensive performance of a product is good; meanwhile, the problems of massive carbide appearing under the high carbon potential state and network carbide appearing in the cooling process are avoided, and early-age cracking of the surface of the gear is avoided; moreover, by the method, the technological process is simplified, heating and cooling links and discharge links are reduced, carburization deformation and quenching deformation are reduced, generation of black structures is reduced as well, and anti-fatigue performance is guaranteed; finally, by the method, production cycle is shortened greatly, energy consumption is lowered, and production efficiency is improved highly.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

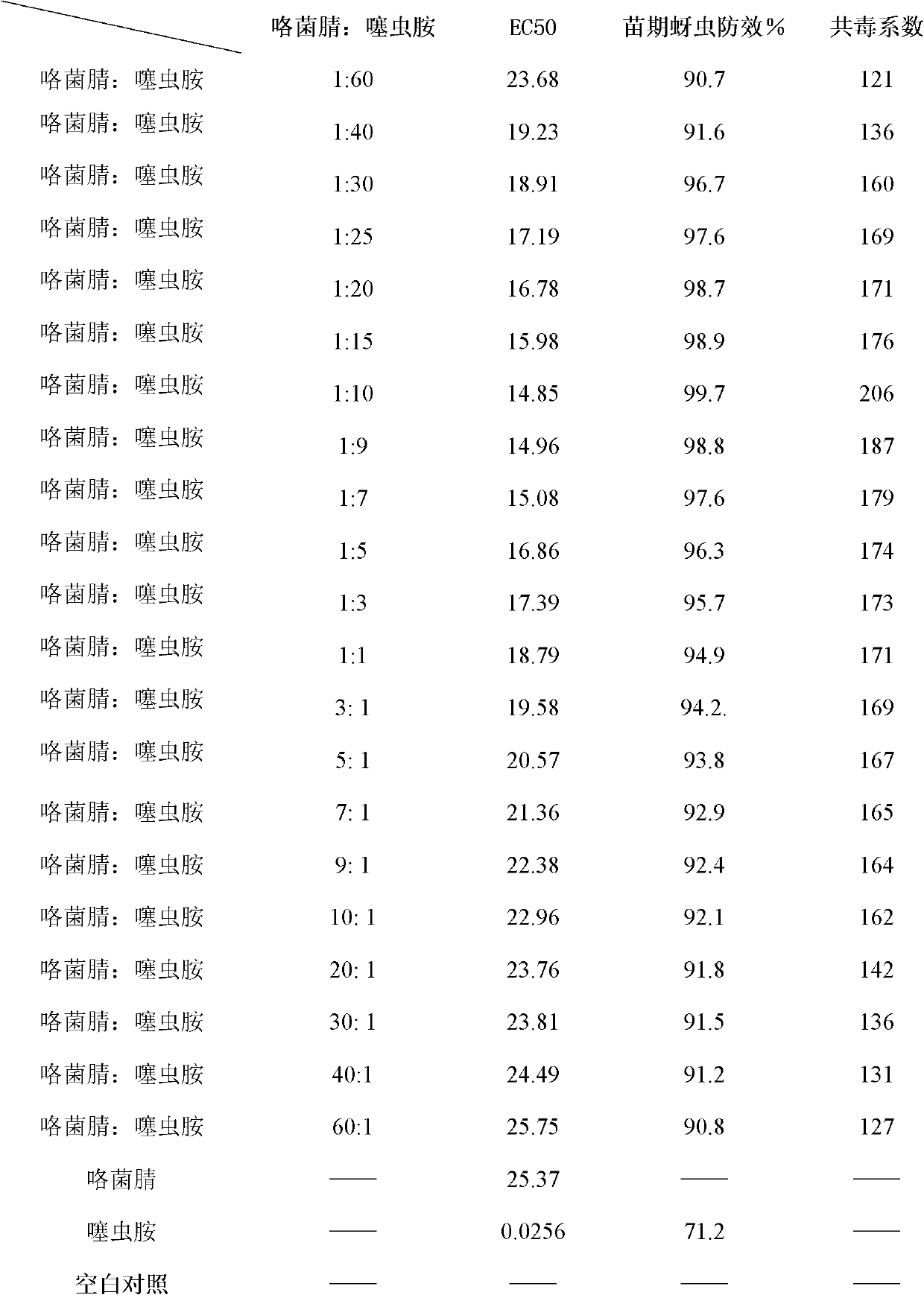

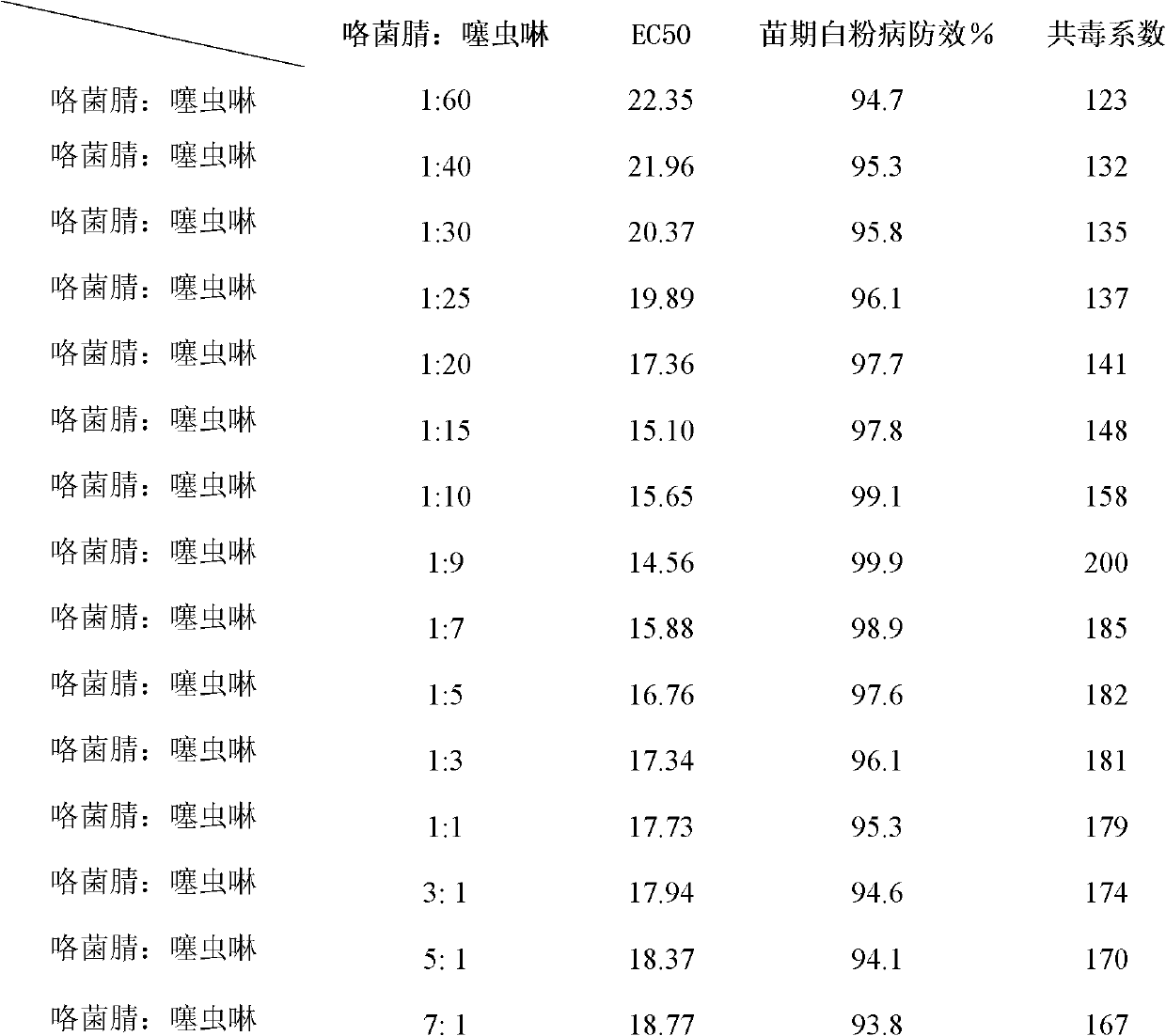

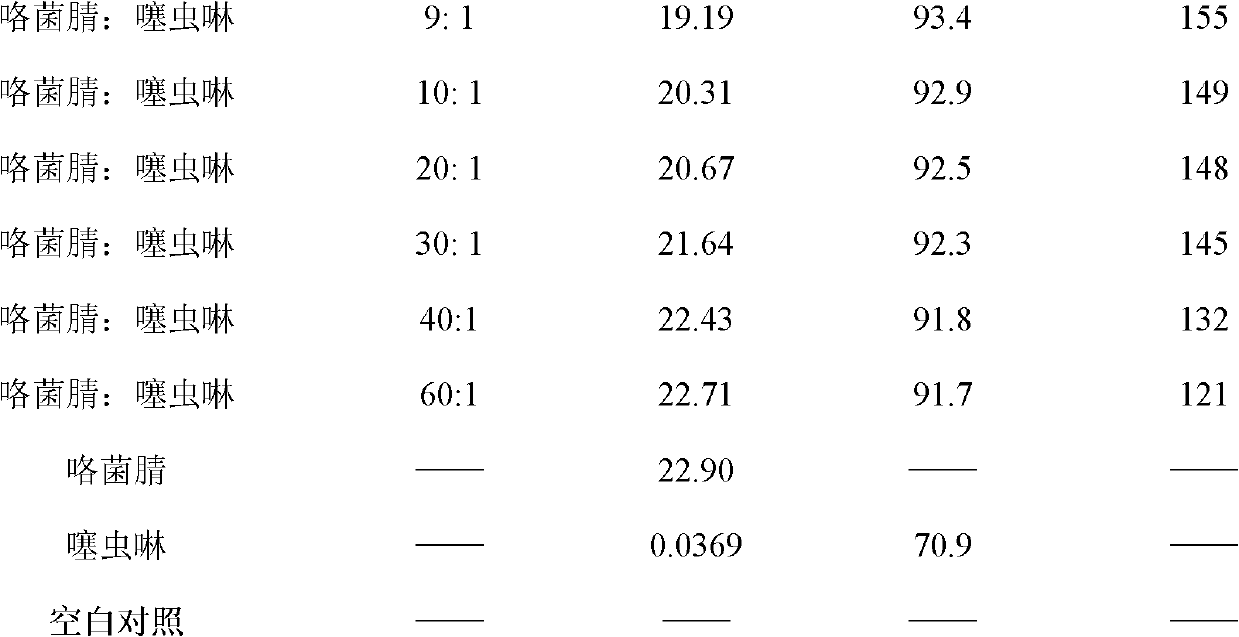

Insecticidal and disease-preventing suspended seed coating agent

InactiveCN103300042AReduce releaseLower resistanceBiocideDead animal preservationPhytotoxicityOrganic chemistry

The invention discloses an insecticidal and disease-preventing suspended seed coating agent which is mainly characterized in that effective active components are fludioxonil and an effective component B, wherein a weight ratio of fludioxonil to the effective component B is 1:60-60:1. The composition is prepared into the suspended seed coating agent. The suspended seed coating agent provided by the invention has the advantages of good film-forming performance, uniform coating, high suspension rate, good safety, low toxicity, and the like. The suspended seed coating agent can be widely applied in seed treatments of crops such as wheat, corn, paddy rice, peanut, cotton, and the like. The seed coating agent has a sustained-release effect, such that pesticide dose is reduced. The seed coating agent is safe to human and animals, has no phytotoxicity, and has good environmental compatibility.

Owner:陕西亿田丰作物科技有限公司

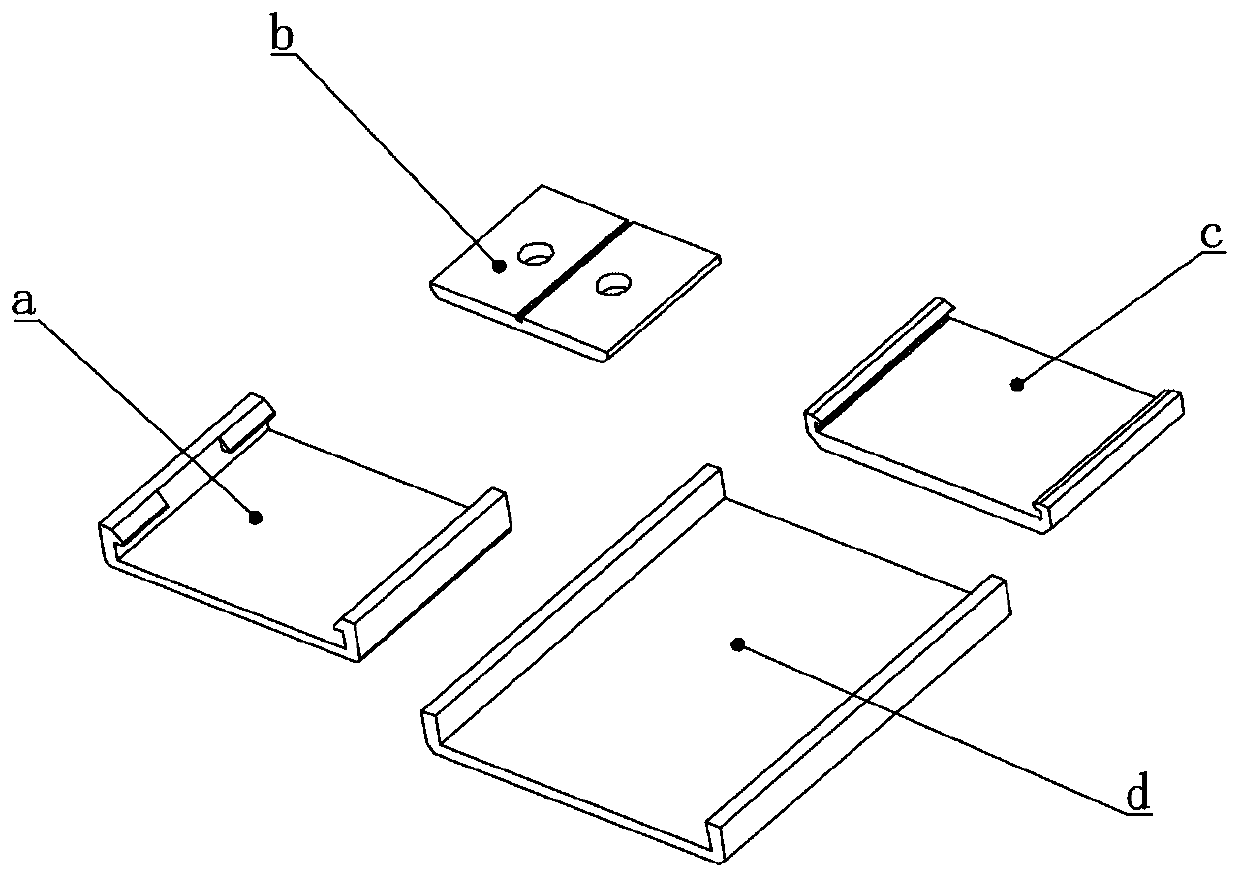

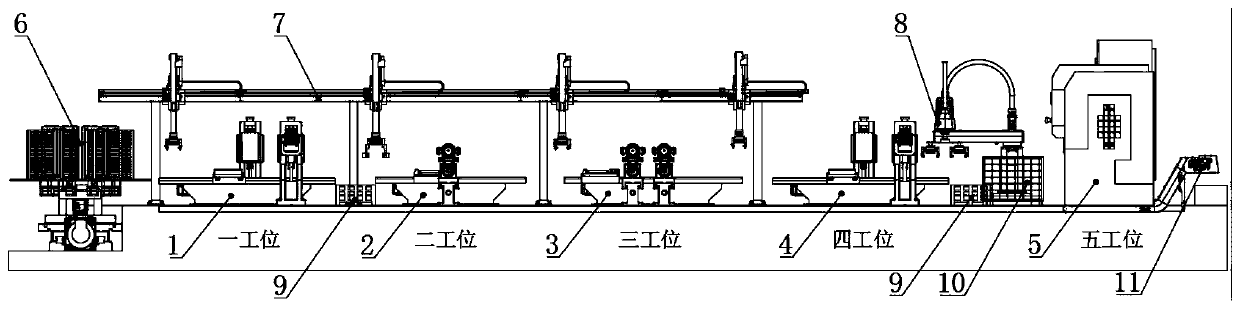

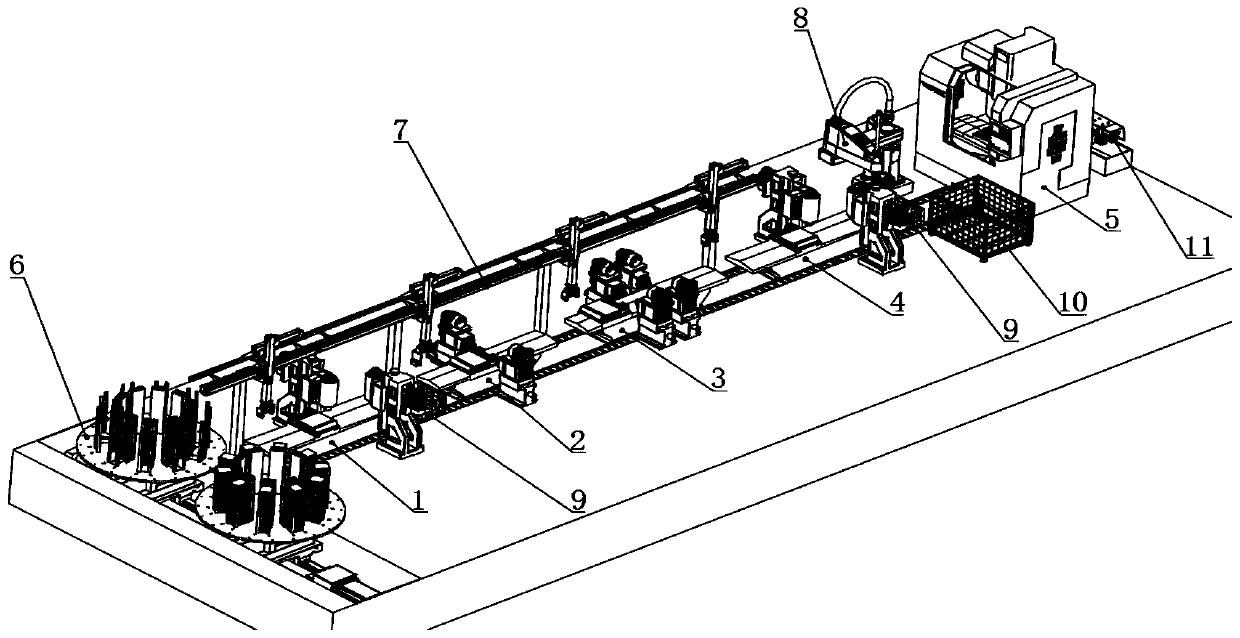

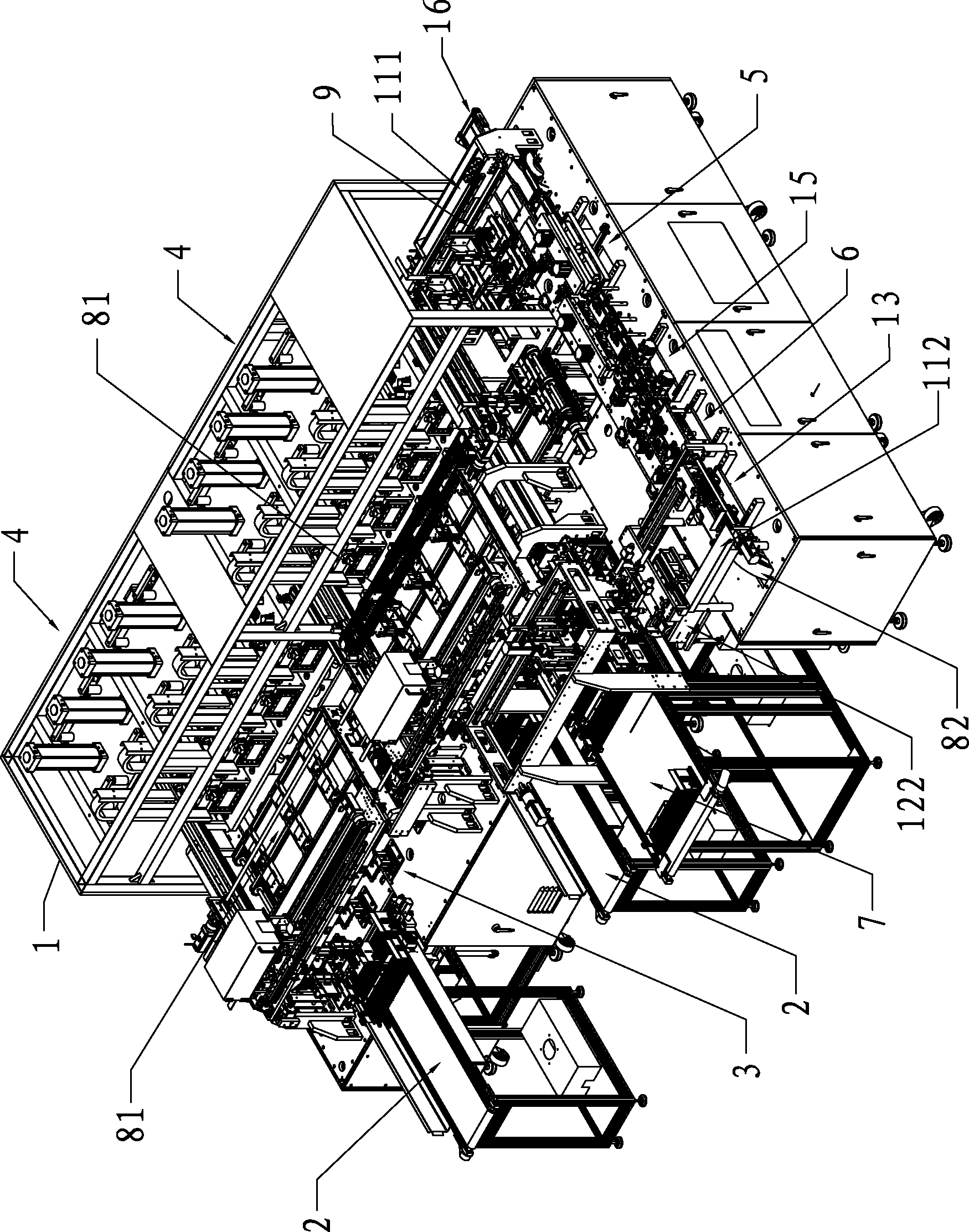

Intelligent plate part machining production line provided with universal equipment and special equipment

ActiveCN110773779AGuaranteed production efficiencyImprove production efficiencyOther manufacturing equipments/toolsMilling equipment detailsProduction lineRobot hand

The invention provides an intelligent plate part machining production line provided with universal equipment and special equipment. Four special machining tools and a universal machining tool are sequentially and linearly arranged from an automatic feeding device, wherein the four special machining tools are located on a first station, a second station, a third station and a fourth station, and the universal machine tool is located on a fifth station; a truss conveying transport device is arranged behind the first station, the second station, the third station and the fourth station in parallel, and four mechanical arms are arranged on the truss transport device to transfer materials on the corresponding stations; a four-axis manipulator is arranged between the fourth station and the fifthstation and is used for transferring the materials between the fourth station and the fifth station and discharging finished products; industrial cameras are arranged on the second-station mechanicalarm and the four-axis manipulator and are used for recognizing defective products; waste boxes are arranged between the first station and the second station as well as between the fourth station andthe fifth station and are used for storing the defective products; a discharging box is arranged on the front side of the fifth station and is used for storing the finished products; and a scrape conveying mechanism is arranged below the whole production line and is used for collecting and transferring scrapes. According to the intelligent plate part machining production line, the universal equipment and the special equipment are combined, and flexible clamps and sliding rail cylinders are used, so that the production line is flexible, the machining times of the stations are balanced, and theproduction efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

On-line three-dimensional shape-surface detection system for numerical control machining centre

InactiveCN101968344AIncreased amount of measurement data informationShorten the processing cycleUsing optical meansNumerical controlTransceiver

The invention discloses a complicated workpiece on-line detection system for a numerical control machining centre, and aims to monitor and control the quality in the machining process, shorten the machining and manufacturing period of a large-scale complicated workpiece and change the current situation of a manual detection mode or an off-line spot check mode in the conventional field of machining and manufacturing. On-line detection equipment mainly comprises a numerical control machining centre, a combined measuring head, a wireless signal transceiver, a control computer and measuring software thereof. The on-line detection technical scheme is that: the numerical control machining centre is used as a measurement movement driving mechanism; a spindle of the numerical control machining centre drives the combined measuring head to measure the workpiece and transmits the measured result to the control computer through the wireless signal transceiver, the result is subjected to model reversion and data fusion postprocessing, and a workpiece machining quality report is provided on line in real time, so the qualification rate of finished products and the machining efficiency are improved.

Owner:DALIAN MARITIME UNIVERSITY

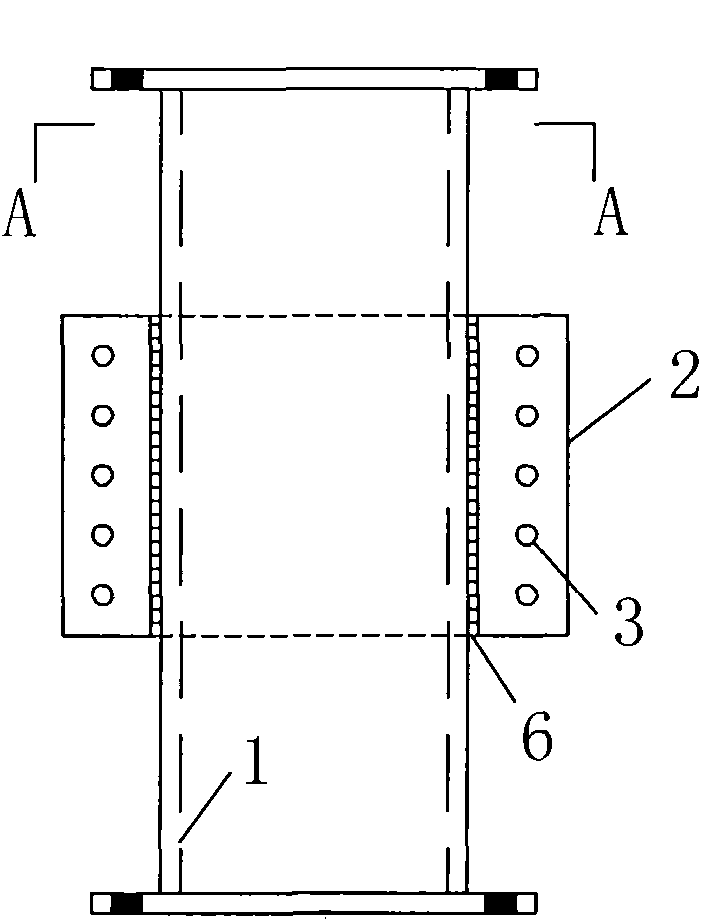

Standardized node connector of steel structure

InactiveCN101922183ADifficulty of SimplificationIncrease productivityBuilding constructionsCarrying capacityAgricultural engineering

The invention discloses a standardized node connector of a steel structure, comprising a steel column and a connection board. The connection board is fixedly connected on the side surface of the steel column; the free end of the connection board is a bolt connector; both ends of the steel column are fixedly connected with a flange on which a connection hole is arranged; the steel column is provided with a vertical through seam matched with the connection board; the connection board penetrates through the vertical through seam; and the connection board is fixedly welded with the penetrated part of the steel column. The invention has standard structure and convenient use as well as strong carrying capacity, can be applied in industrialized production and is very beneficial to promotion and application.

Owner:HENAN AUSPIC TECH

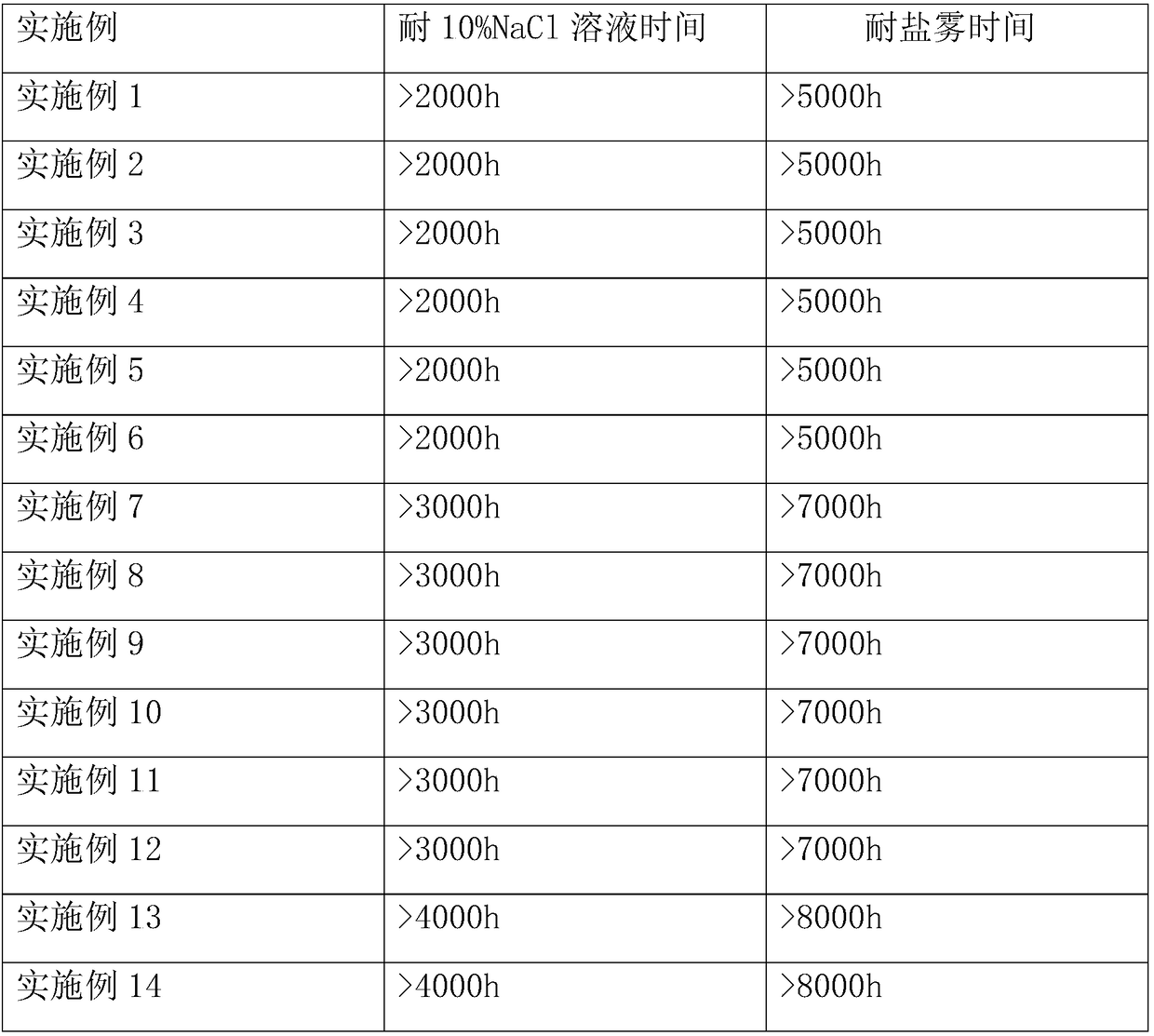

Epoxy rust graphene anticorrosive coating as well as preparation method and application thereof

ActiveCN108285718AWays and times of defermentGood penetration resistanceAnti-corrosive paintsEpoxy resin coatingsLong actingSolvent

The invention relates to the field of anticorrosive coatings, in particular to an epoxy rust graphene anticorrosive coating and a preparation method thereof. The epoxy rust graphene anticorrosive coating is prepared from the following components in percentage by weight: 0.1 to 5 percent of graphene, 30 to 60 percent of epoxy resin, 20 to 40 percent of an active pigment, 10 to 30 percent of a pigment filler, 0.1 to 10 percent of a dispersant, 0.1 to 5 percent of a coating additive and 8 to 30 percent of a solvent. According to the coating provided by the invention, all the components achieve asynergetic enhancement effect; the obtained coating is tightly combined with a rust layer and is excellent in anticorrosive property; rust spray coating, long-acting corrosion prevention and a primer-topcoat type are realized. According to the corresponding preparation method, all the components work synergistically, and the coating with uniformly dispersed graphene powder is obtained. The methodis simple, convenient and feasible in preparation, and the prepared coating is excellent in performance.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

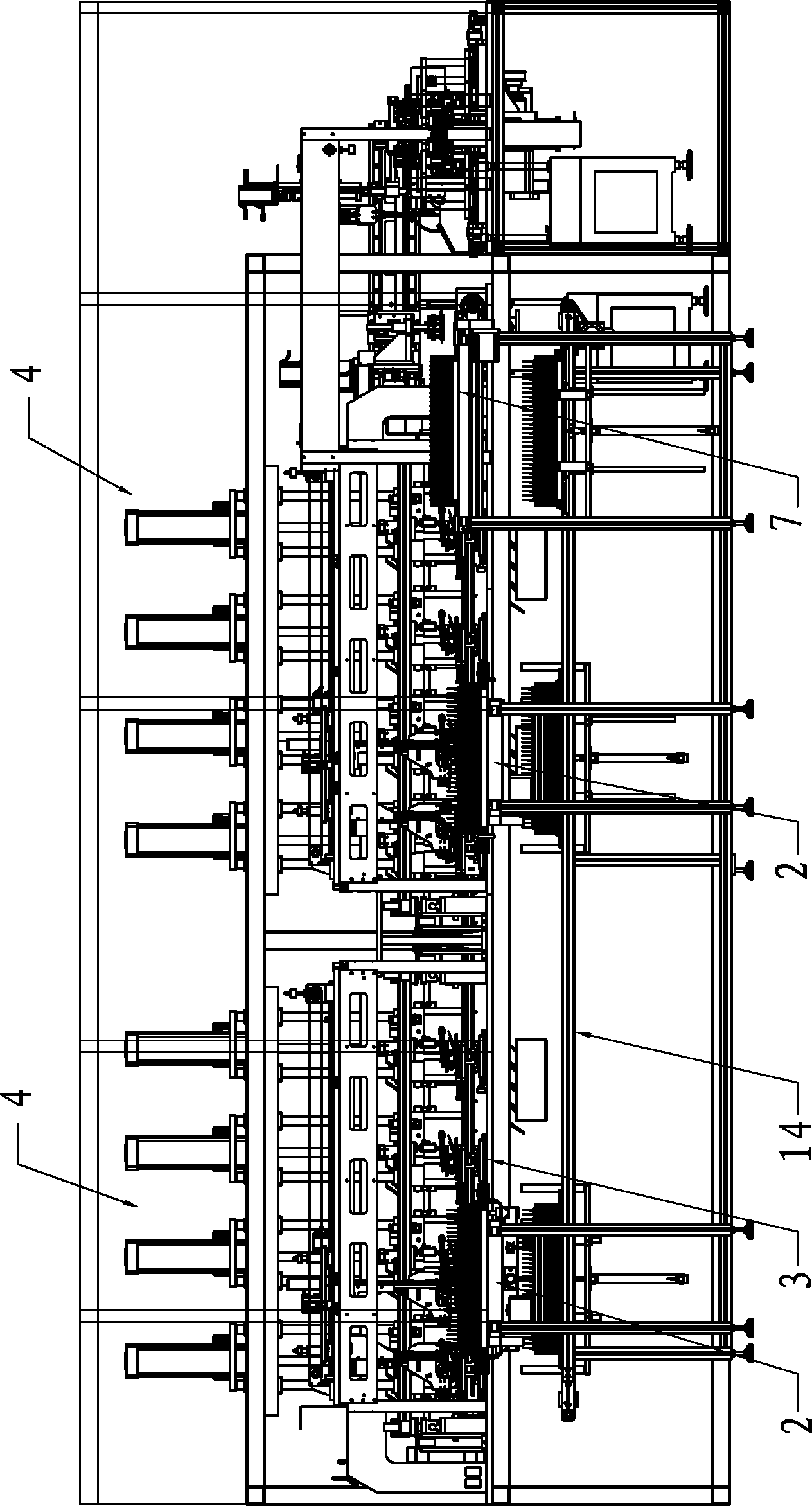

Vacuum air-suction sealing, trimming and folding all-in-one machine and battery production technology

ActiveCN102354768AFull production monitoringHigh precision of process operationFinal product manufactureElectrolyte accumulators manufactureVacuum pumpingCell fabrication

The invention relates to the technical field of battery manufacture equipment, in particular to a vacuum air-suction sealing, trimming and folding all-in-one machine and a battery production technology. The vacuum air-suction sealing, trimming and folding all-in-one machine comprises a rack, wherein the rack is successively provided with a material loading mechanism, a loaded material positioning and arranging mechanism, a vacuum air-suction sealing mechanism, a trimming mechanism, a folding mechanism and a material discharging mechanism; the rack is also provided with a material conveying mechanism, wherein the material conveying mechanism comprises a first material conveying mechanism and a second material conveying mechanism; the loaded material positioning and arranging mechanism and the vacuum air-suction sealing mechanism are respectively arranged on two sides of the first material conveying mechanism; and the second material conveying mechanism is laterally arranged below the trimming mechanism and the folding mechanism. The battery production technology applying the vacuum air-suction sealing, trimming and folding all-in-one machine comprises the following steps: loading materials, positioning, vacuum air-suction sealing, trimming, folding, discharging materials and the like. In the vacuum air-suction sealing, trimming and folding all-in-one machine, the vacuum air-suction sealing function and the functions of trimming and folding are integrally designed, and the vacuum air-suction sealing, trimming and folding all-in-one machine has the characteristics of high production efficiency and high product percent of pass.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

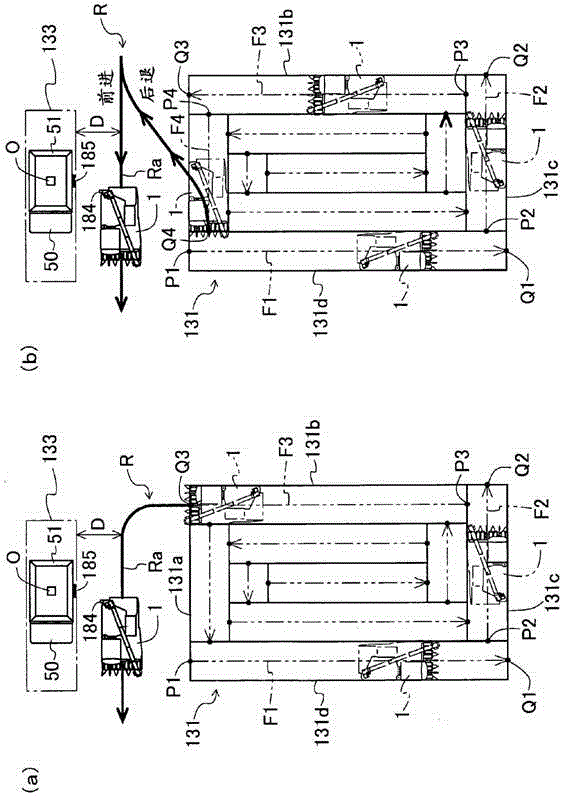

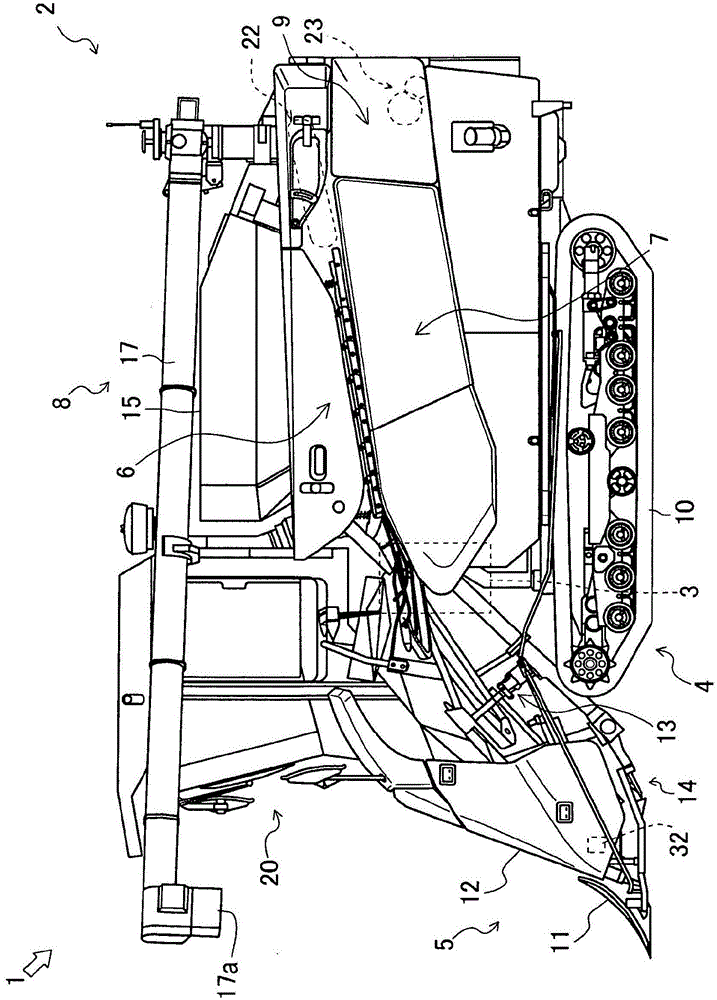

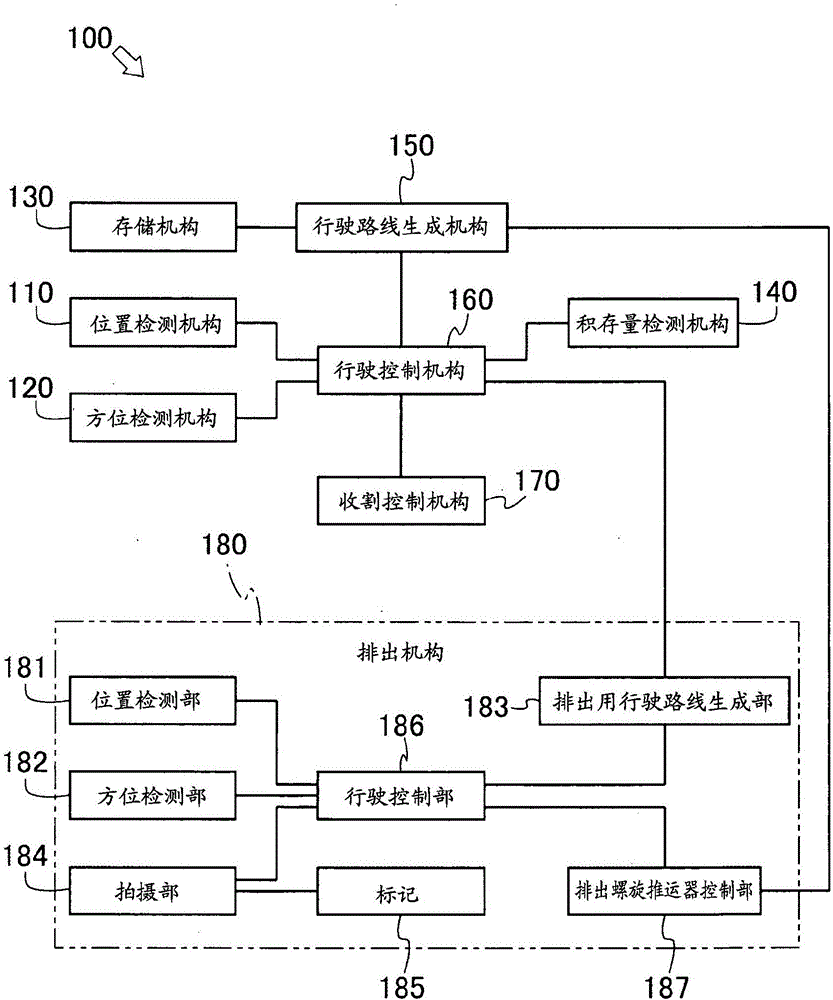

Crop-harvesting apparatus

InactiveCN106163259ASuppress uneven working hoursImprove workabilityMowersGuiding agricultural machinesSimulationCombine harvester

Provided is a crop-harvesting apparatus with which, during crop-harvesting work, the disparity between the work hours of workers due to proficiency level is suppressed, and with which the amount of labour required to generate a travel course for a travelling harvester can be reduced. This crop-harvesting apparatus (100) is provided with: a position detection means (110) for detecting the position of a combine (1); a storage means (130) in which positional information related to a work area (131) is stored; a travel-course generation means (150) for generating a travel course for the combine (1) such that a crop within the work area (131) is harvested in a spiral shape from the outer peripheral side to the inside; a travel control means (160) which causes the combine (1) to travel so as to pass through the travel course generated by the travel-course generation means (150); and a harvest control means (170) which, when the combine (1) is made to travel along the travel course by the travel control means (160), causes the combine (1) to perform an operation for harvesting the crop.

Owner:YANMAR CO LTD +1

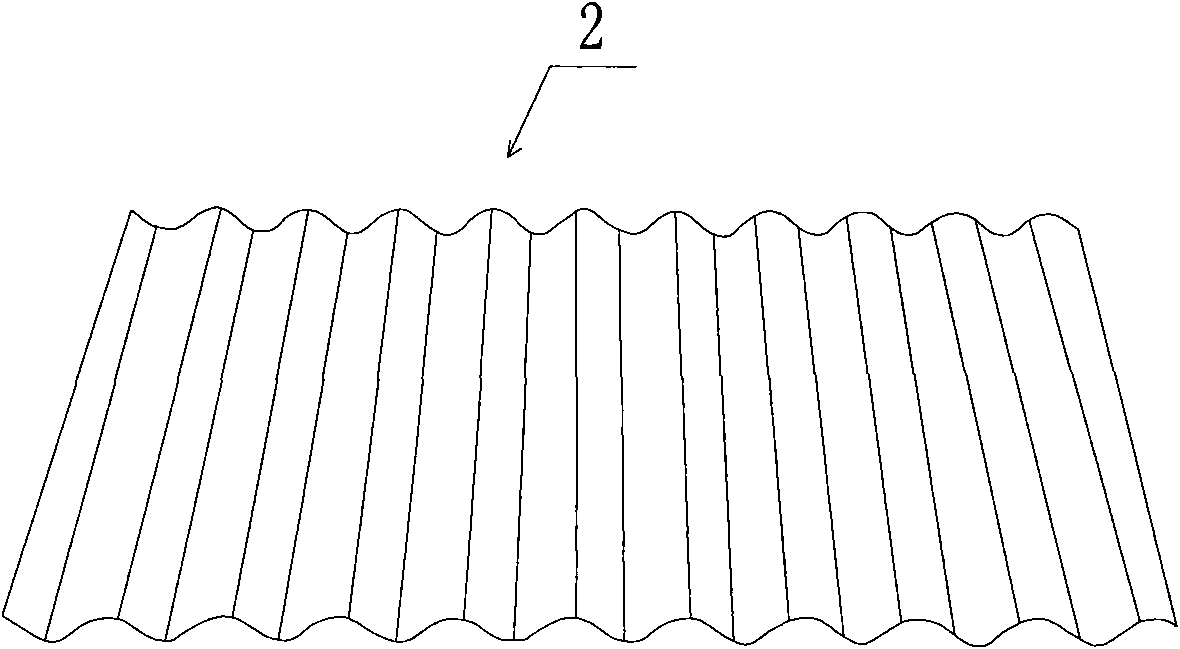

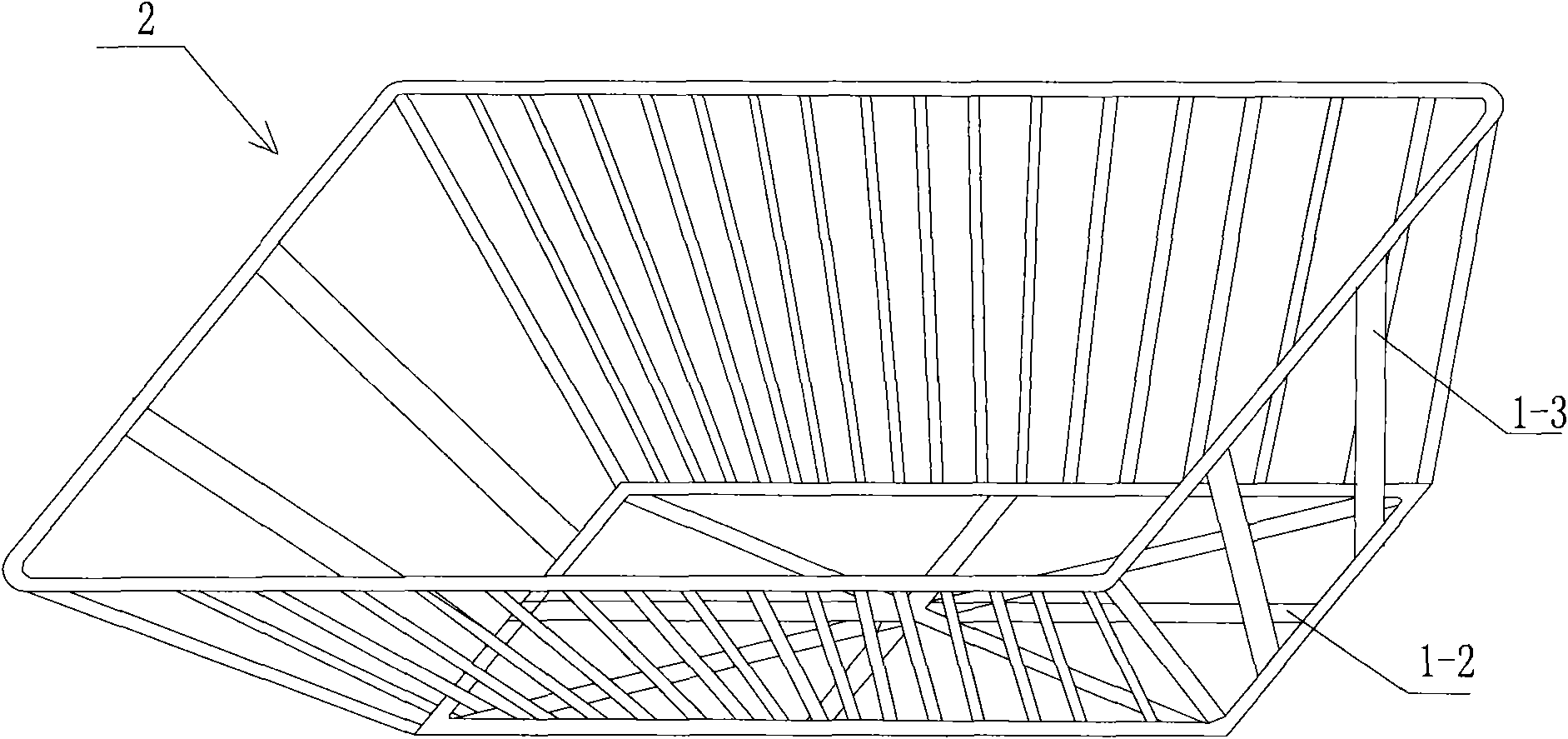

Method for culturing monomeric oyster seeds and seed collector

InactiveCN101773079AEasy to useExcellent adhesionClimate change adaptationPisciculture and aquariaOysterMonomer

The invention provides a method for culturing monomeric oyster seeds and a seed collector. The problems such as poor seed fixation effect, difficult substrate removal and the like in the prior art can be solved. By using a plastic corrugated plate as the fixation substrate of the monomeric oyster seeds in the invention, the problems such as unsatisfactory seed collection effect, difficult substrate removal, easy breakage of the oyster seeds, mutual conglomeration and attachment of oysters and the like in the prior art are solved.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com