Vacuum air-suction sealing, trimming and folding all-in-one machine and battery production technology

A vacuum pumping and all-in-one technology, which is applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

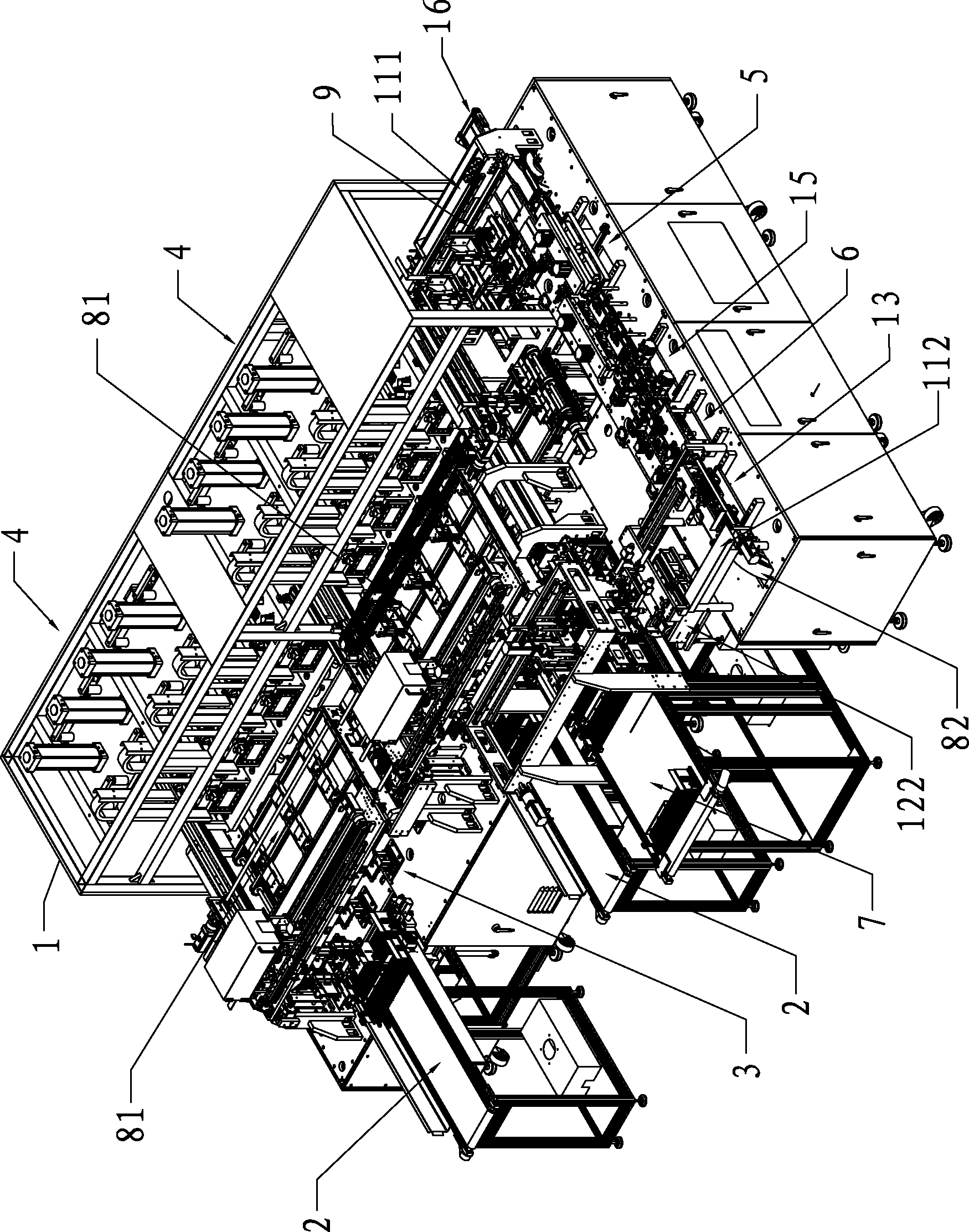

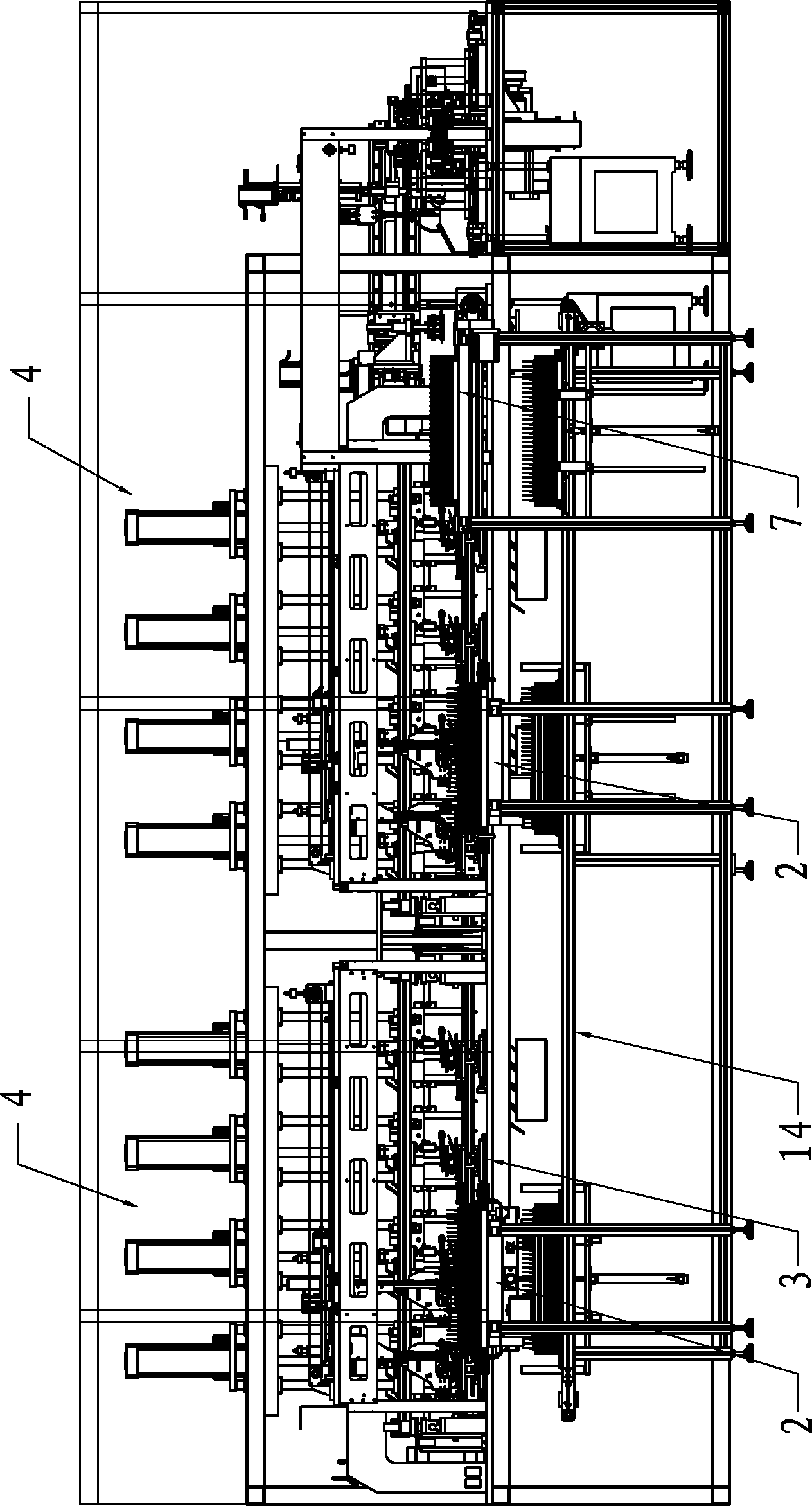

[0076] like Figure 1-7 , Figures 11 to 13 As shown, the vacuum pumping, sealing, trimming and folding machine of the present invention includes a frame 1, and the frame 1 is sequentially provided with a feeding mechanism 2, a feeding positioning arrangement mechanism 3, a vacuum pumping and sealing mechanism 4, a cutting Edge mechanism 5, hemming mechanism 6 and blanking mechanism 7, described frame 1 is also provided with feeding mechanism, and described feeding mechanism comprises first feeding mechanism 81 and second feeding mechanism 82, and described first feeding mechanism 81 The feeding end of the feeder and the feeding end of the second feeding mechanism 82 are arranged correspondingly, and the feeding positioning arrangement mechanism 3 and the vacuum pumping sealing mechanism 4 are respectively arranged on both sides of the first feeding mechanism 81 , the second feeding mechanism 82 is laterally arranged below the trimming mechanism 5 and the folding mechanism 6,...

Embodiment 2

[0104] like figure 1 , Figure 4 , Figure 8 , Figure 9 and Figure 13 As shown, the difference between this embodiment and the embodiment is that the frame 1 of the vacuum pumping, sealing, trimming and folding all-in-one machine of this embodiment is also provided with a push battery device 10, and the push battery device 10 includes a set The left push battery mechanism 101 on one side of the second feeding mechanism 82 and the right push battery mechanism 102 arranged on the other side of the second feeding mechanism 82, the edge trimming mechanism 5 includes a set above the second feeding mechanism 82 The left side trimming mechanism 51 and the right side trimming mechanism 52 erected on the top of the second feeding mechanism 82, the left side trimming mechanism 51 is set opposite to the right push battery mechanism 102, and the right side trimming mechanism 52 and the left push battery mechanism Mechanism 101 is relatively arranged.

[0105] When in use, the batt...

Embodiment 3

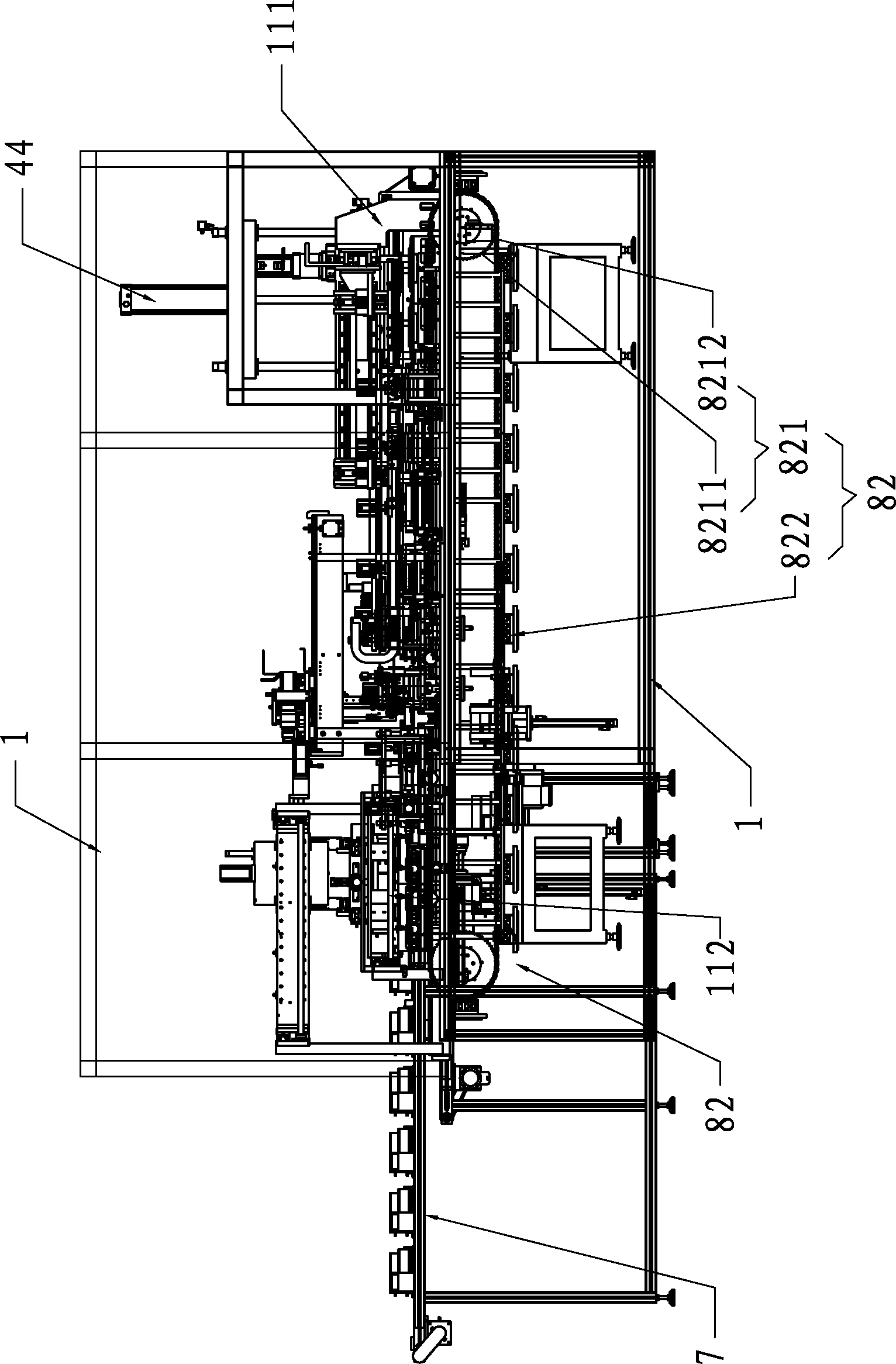

[0118] like figure 1 , Figure 4 and Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the vacuum pumping, sealing, trimming and folding all-in-one machine of this embodiment also includes a reclaimer arranged on the frame 1, and a reclaimer arranged under the reclaimer. The weighing device, the reclaiming device includes a front reclaiming mechanism 111 arranged at the front end of the edge trimming mechanism 5, and a rear reclaiming mechanism 112 arranged at the rear end of the edge trimming mechanism 5, and the weighing device includes a reclaiming mechanism arranged at the front end of the edge trimming mechanism 5 The front weighing mechanism 121 below the material mechanism 111 , and the rear weighing mechanism 122 arranged under the rear material taking mechanism 112 .

[0119] During use, the battery 100 after sealing is placed on the front weighing mechanism 121 by the front reclaiming mechanism 111 and weighed before trimming. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com