Vacuum adsorption equipment used for fixing thin-wall plane workpiece

A vacuum adsorption and plane technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of sudden sealing of true suction holes, difficult workpiece cutting operation, and workpiece adsorption failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

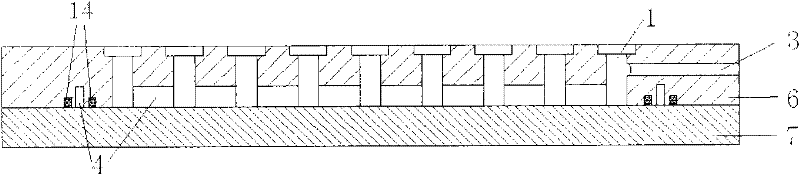

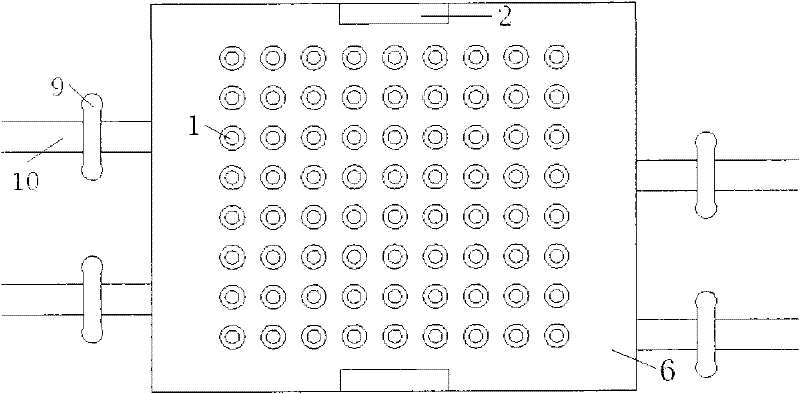

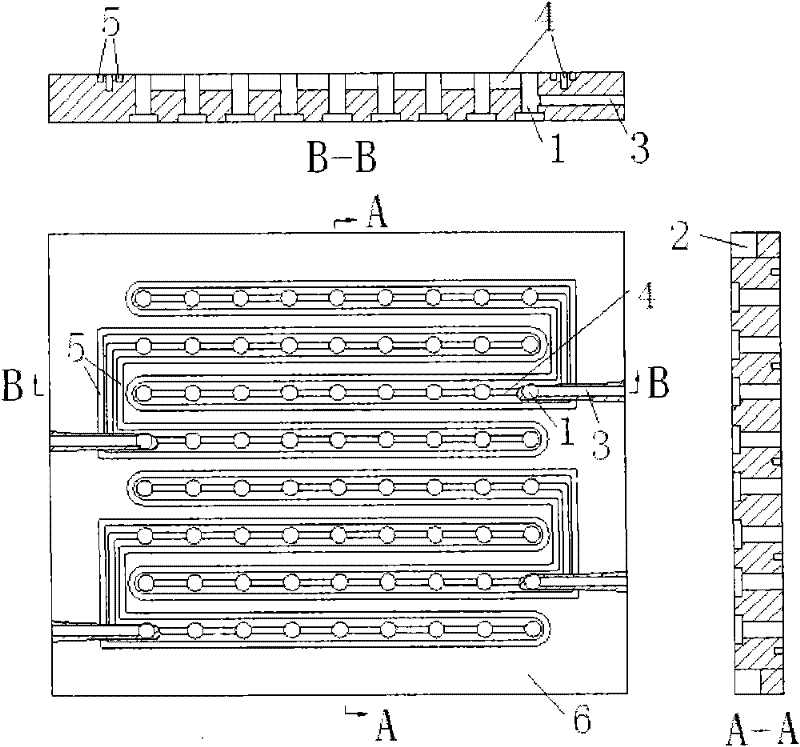

[0028] Such as figure 1 , 2 As shown in and 3, the utility model includes a vacuum adsorption plate 6 and a sealing cover plate 7, both of which are square plate-shaped structures, but are not limited to this shape. The surface of the vacuum adsorption plate is provided with a number of stepped suction holes that penetrate the vacuum adsorption plate, with a total of 8 rows and 9 columns. figure 2 In the middle position, number the rows ①~⑧ from top to bottom, and number the columns ①~⑨ from left to right. The lower surface of the vacuum adsorption plate is provided with 4 transverse "U"-shaped vacuum grooves which are not connected to each other. According to the position from top to bottom, the first groove and the second groove are nested with each other, and the lower "cross arm" of the first groove is located between the two "cross arms" of the second groove; The upper "cross arm" of the two grooves is located between the two "cross arms" of the first groove; the nest...

Embodiment 2

[0032] The vacuum adsorption device is the same as in Example 1.

[0033] Fasten with the suction device Figure 7 Workpiece 13 is shown. Before the workpiece 13 is processed, there is a radial square hole 11 that runs through the workpiece, and in the process of processing, it is necessary to cut out such as Figure 7The circular through hole 12 shown in. According to the size and position of the through holes, the suction holes in the ② and ③ rows in the ② row are located within the range of the hole 11, and the suction holes in the ⑤ row in the ④ row are located in the range of the hole 12 to be cut. Before the workpiece is processed, first use the suction hole plug 8 to block the corresponding suction hole to avoid the influence of the through hole 11 of the workpiece itself and the through hole 12 after processing on the vacuum adsorption, then place the workpiece 13, turn on the vacuum pump, and open All valves are switched on and off, and the machining process is per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com