Semiconductor microphone chip

A microphone and semiconductor technology, applied in the field of condenser microphone chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention has many different forms of embodiments, and the accompanying drawing shows a preferred example of the present invention, which will be described in detail.

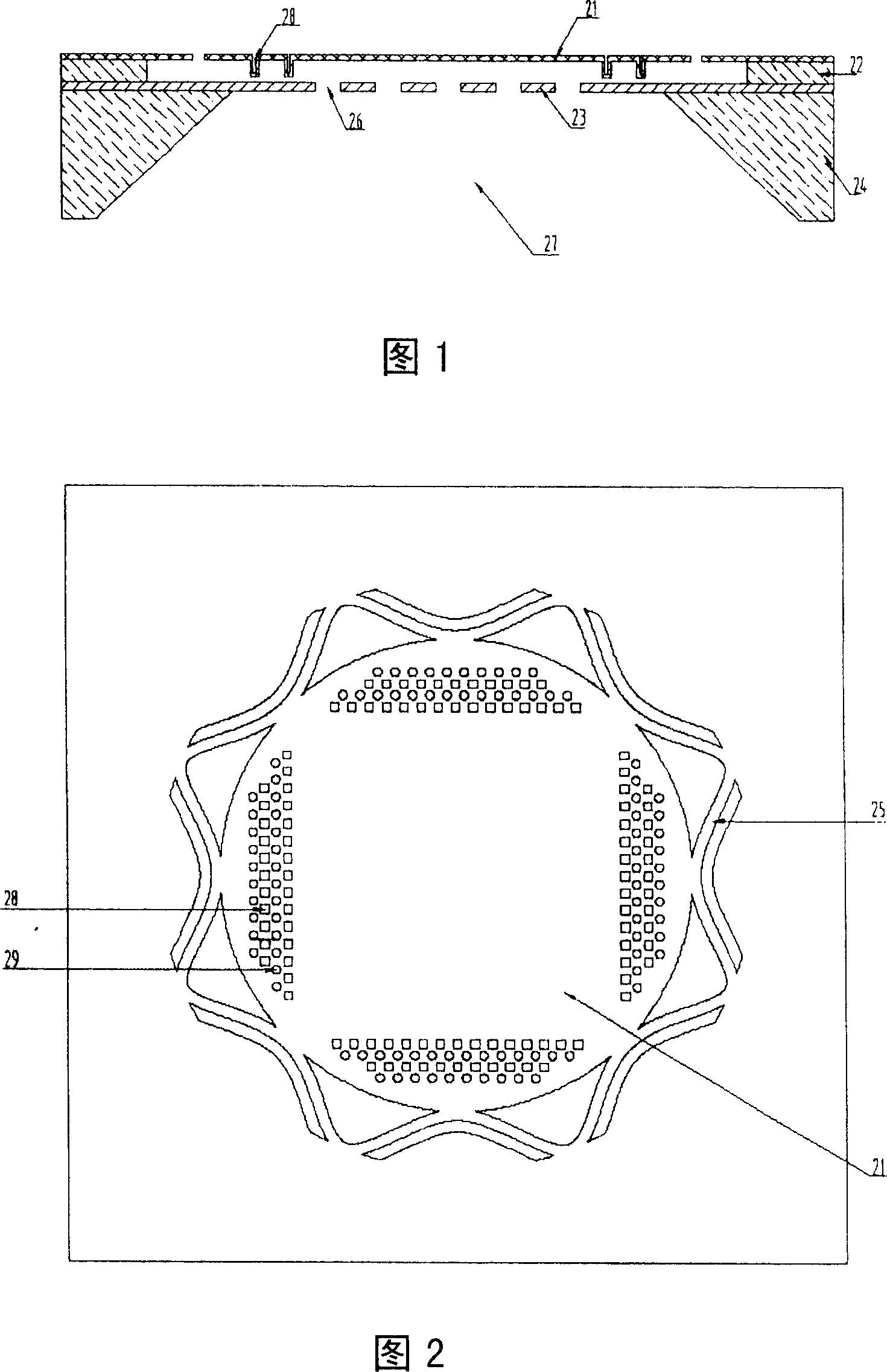

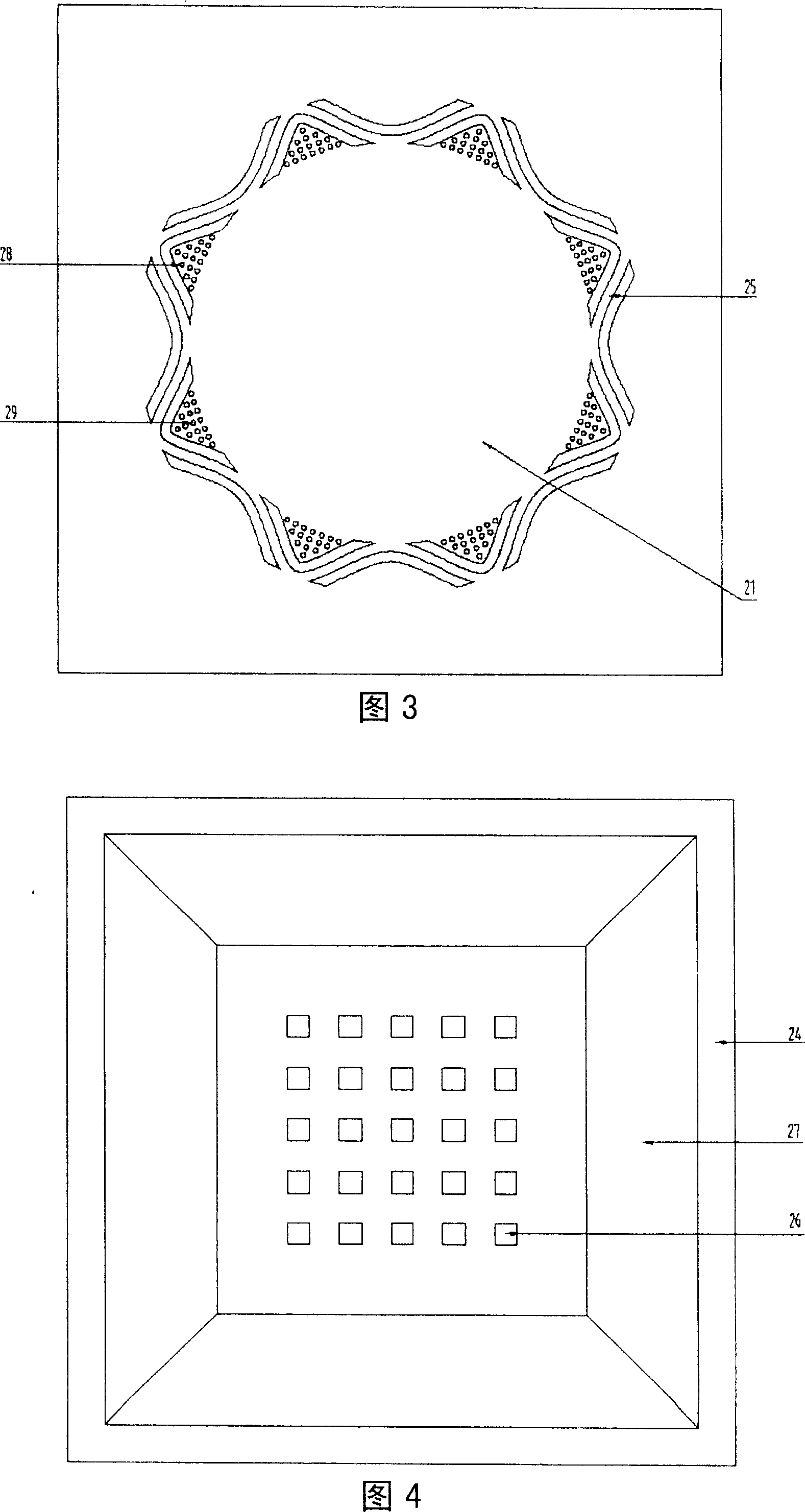

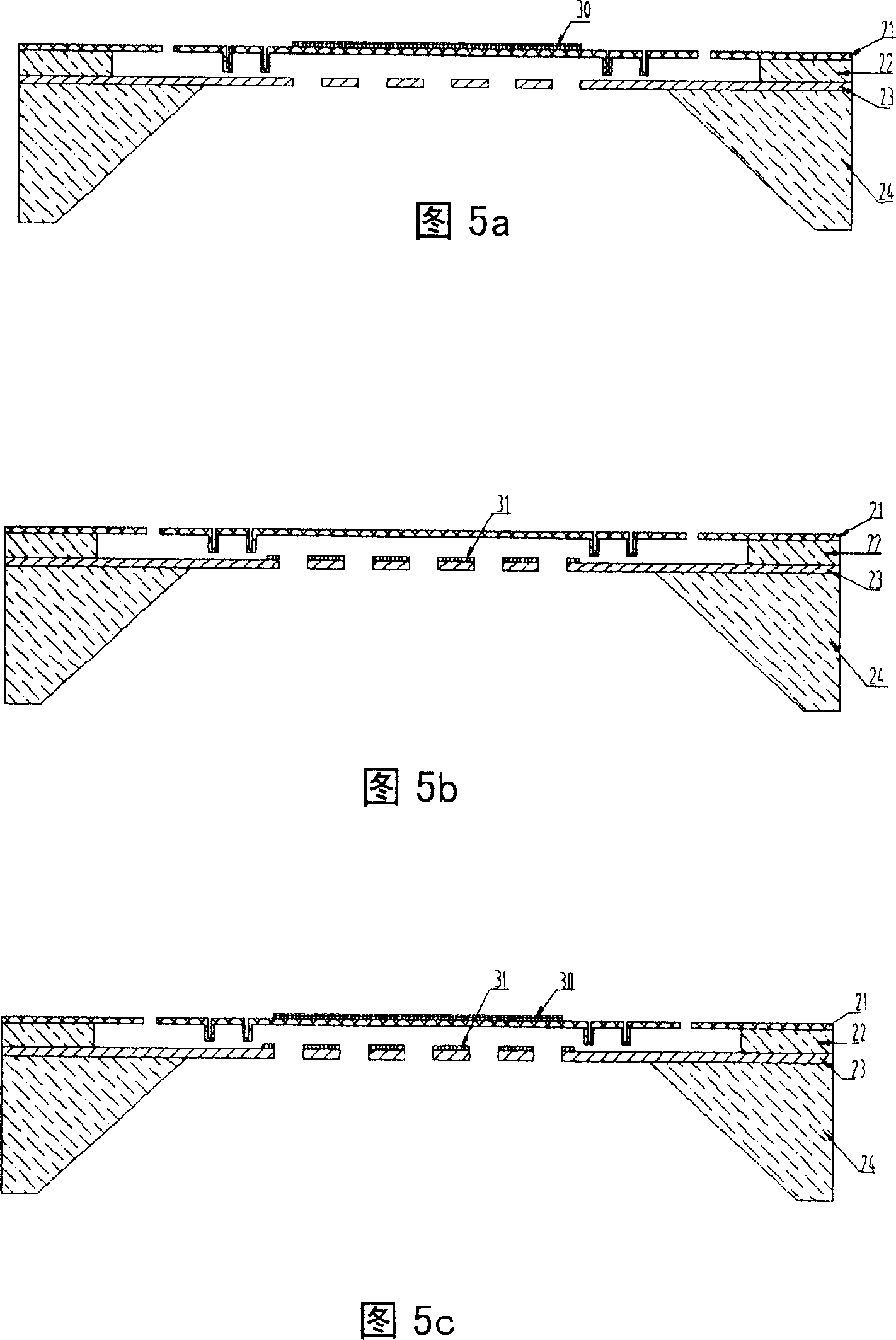

[0029] As shown in FIG. 1 , it is a condenser microphone chip of the present invention, and its structure includes: a diaphragm 21 , a support 22 , a back pole 23 , and a base 24 from top to bottom. The diaphragm 21 and the back pole 23 are made of conductive materials to form a capacitor structure; the diaphragm 21 is connected to the support 22 through a corrugated suspension beam 25 (see Fig. 2 and Fig. 3 ); the back pole 23 has an acoustic hole 26; the center of the base 24 has The back cavity 27 and the sound hole 26 are located within the range of the back cavity 27 .

[0030] As shown in FIG. 2 , the diaphragm 21 is connected to the frame and the support 22 through the suspension beam 25 , the suspension beam 25 has a corrugated structure, and the diaphragm 21 has a circular structure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com