Photoelectric device packaging method and packaging structure

A technology of optoelectronic devices and packaging methods, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of poor reliability of chips against cold and heat shocks, and solve the problem of solder pad cracking, high packaging efficiency and yield, and manufacturing process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

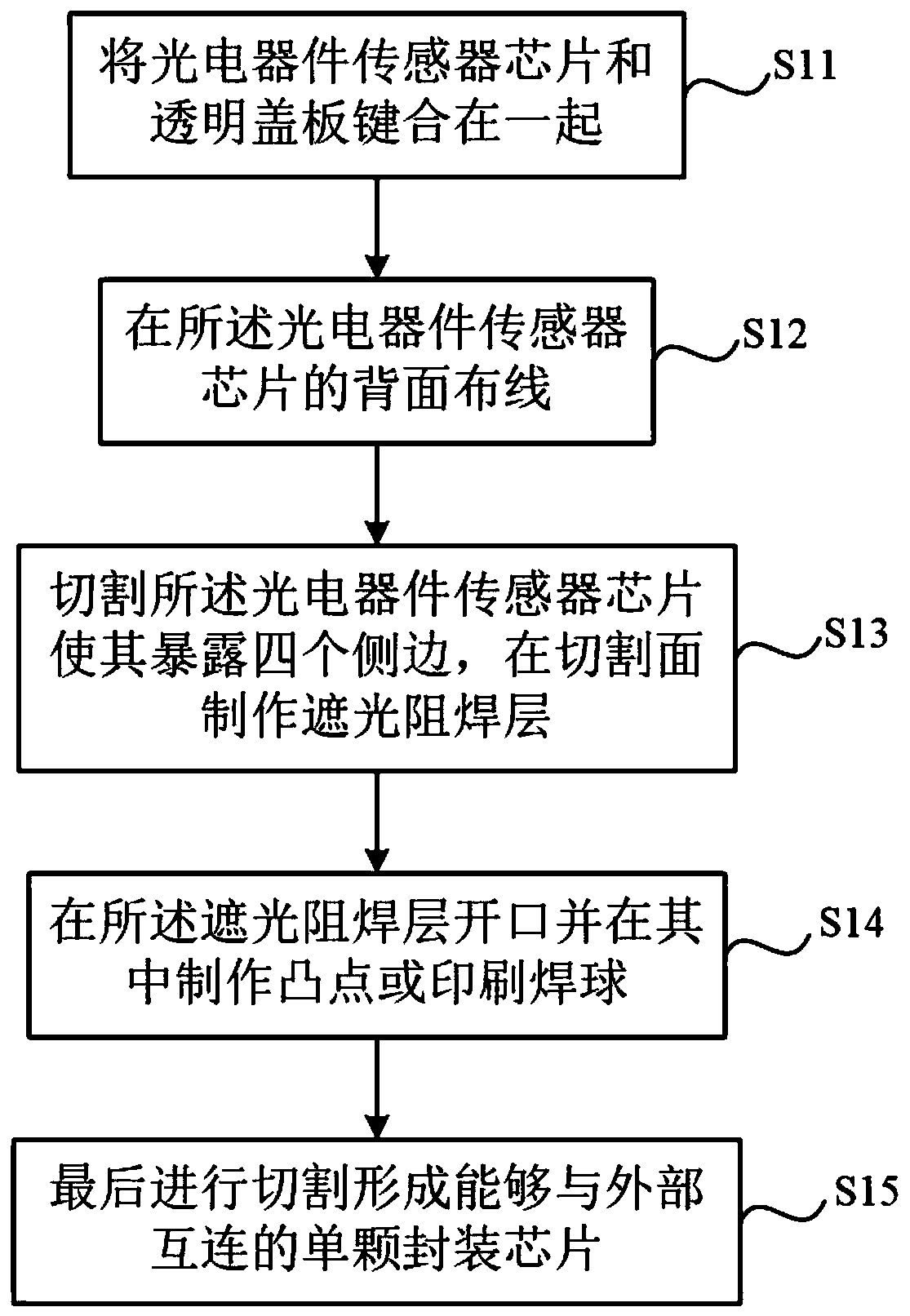

[0046] The invention provides a photoelectric device packaging method, the flow diagram of which is as follows figure 1 shown. The photoelectric device packaging method comprises the steps of:

[0047] Step S11, bonding the photoelectric device sensor chip and the transparent cover plate together;

[0048] Step S12, wiring on the back side of the photoelectric device sensor chip;

[0049] Step S13, cutting the photoelectric device sensor chip to expose four sides, and making a light-shielding solder resist layer on the cut surface;

[0050] Step S14, making an opening in the light-shielding solder resist layer and making bumps or printing solder balls therein;

[0051] Step S15 , finally cutting to form a single packaged chip that can be interconnected with the outside.

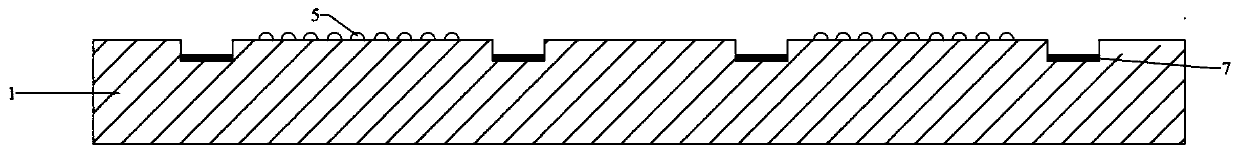

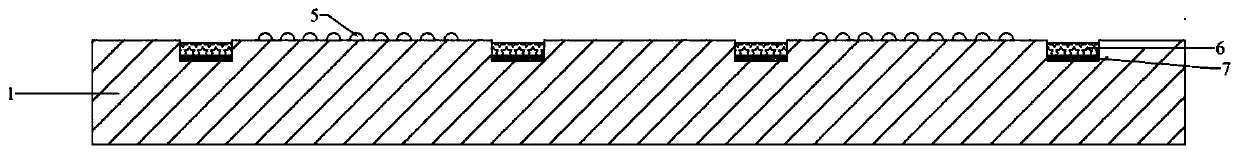

[0052] Firstly, the photoelectric device sensor chip is formed: a photoelectric device wafer is provided, and the photoelectric device wafer includes a silicon substrate 1 and a metal pad 7 and a photoele...

Embodiment 2

[0058] Embodiment 2 of the present invention also provides an optoelectronic device packaging structure prepared by the above optoelectronic device packaging method, the structure of which is as follows Figure 10 shown. The photoelectric device packaging structure includes a photoelectric device sensor chip, and the photoelectric device sensor chip includes a photoelectric device wafer, and the photoelectric device wafer includes a silicon substrate 1 and a metal pad 7 formed on the silicon substrate and a photoelectric sensor chip. Lens 5.

[0059] Specifically, the photoelectric device packaging structure also includes a transparent cover plate, which is bonded to the photoelectric device sensor chip; Layer 2; the thickness of the cofferdam and bonding layer 2 is 1 / 11~1 / 9 of the glass substrate 3, with a tolerance of ±3um, so as to ensure that the packaged photoelectric device has the best imaging quality. The photosensor microlens 5 is located in the cavity 4 jointly for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com