Joint structure for refrigerant discharge tubes used in hermetic compressors

A technology for connecting structures and refrigerants, which can be applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., and can solve problems such as reduced durability and rupture of refrigerant discharge pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

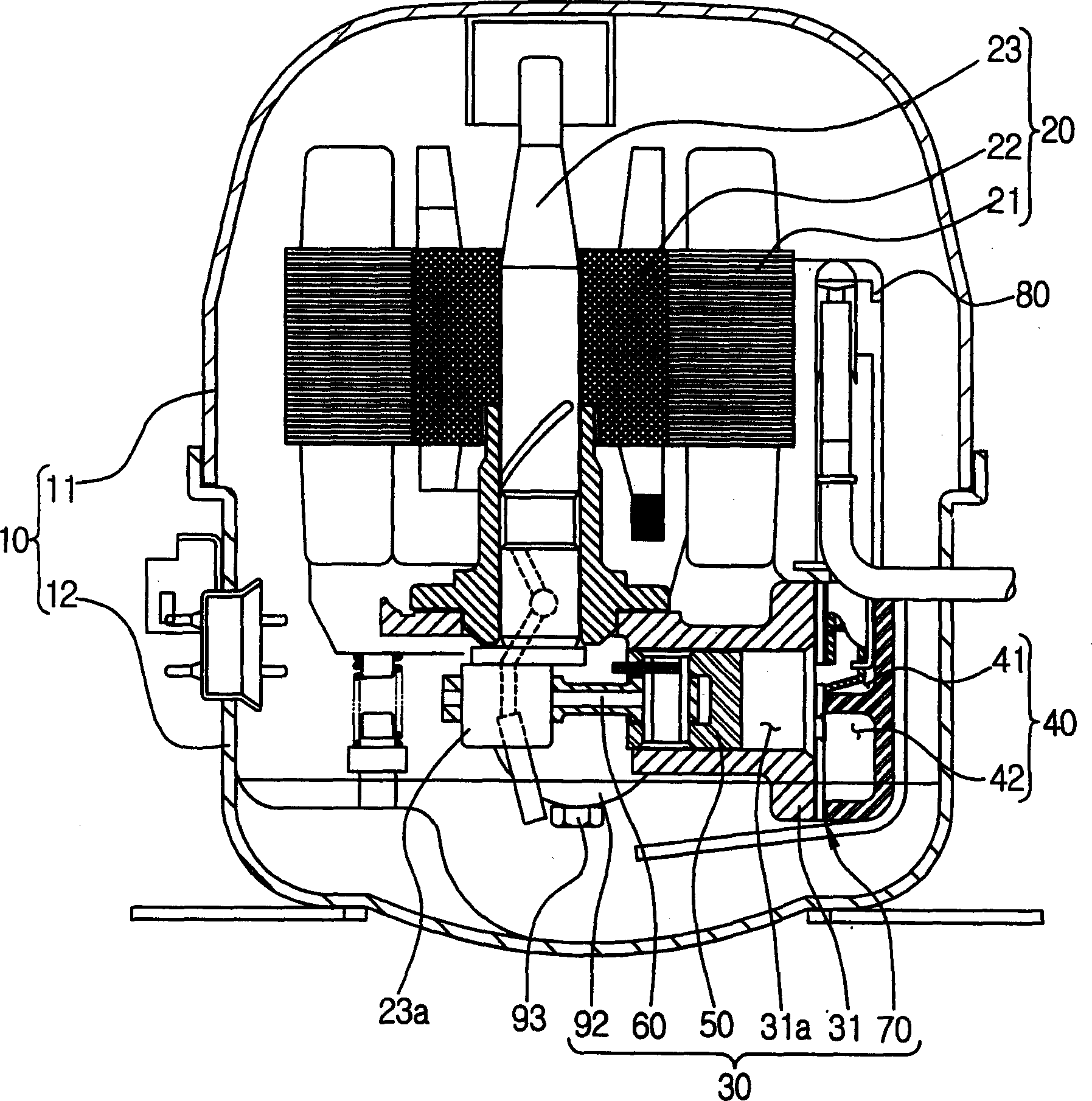

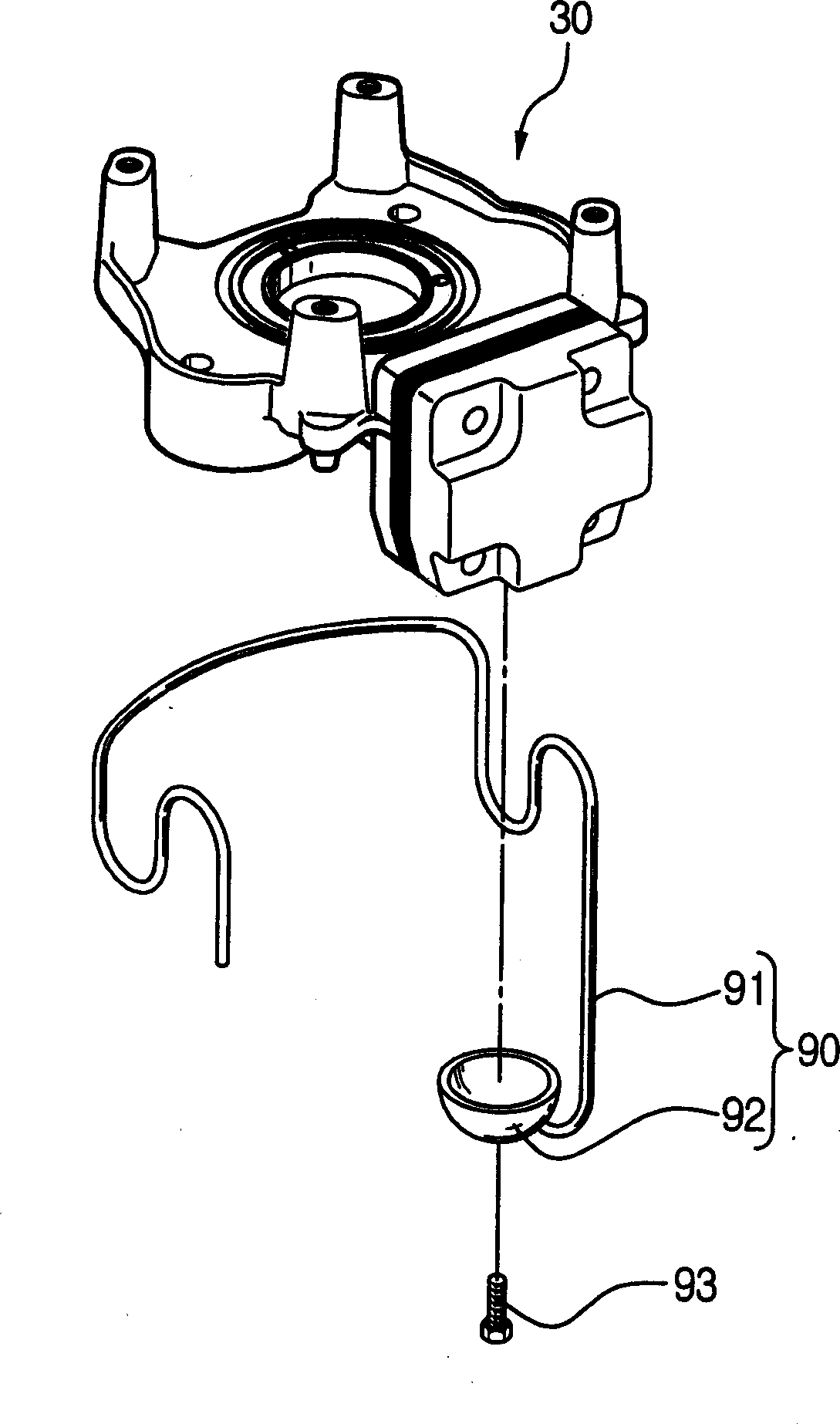

[0022] Preferred embodiments of the present invention will be described with reference to the accompanying drawings, the above-mentioned purpose and other features of the present invention will be more clearly understood, those having the same figure 1 with 2 Structurally and functionally similar parts of the parts in Figure 3-5 are also marked with the same symbols.

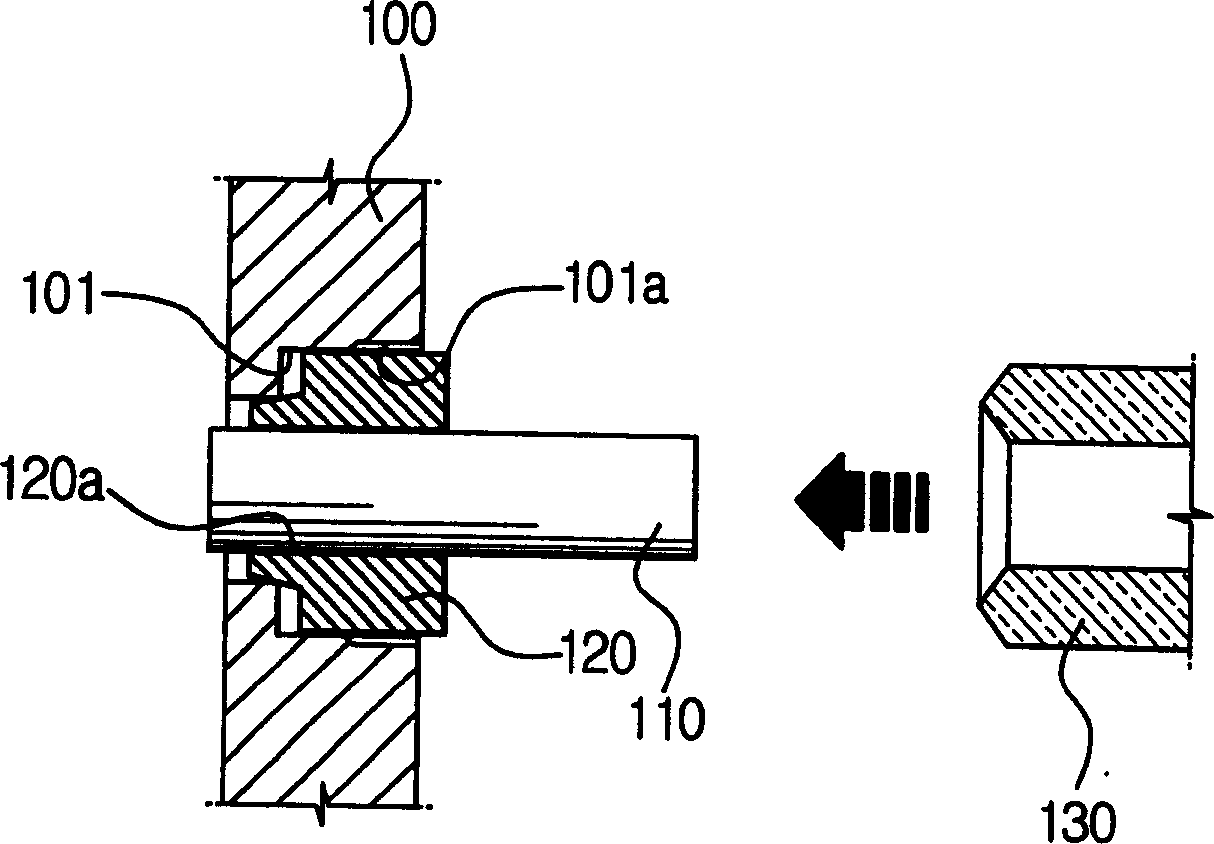

[0023] refer to image 3 with 4 According to the preferred embodiment of the present invention, the connection structure for the refrigerant discharge pipe of the airtight reciprocating compressor includes a connection hole 101 that runs through the side of the cylinder block 100, a discharge pipe 110 that matches the connection hole 100, and is used to discharge the refrigerant The discharge pipe 110 and the corresponding connecting hole 101 are fixed to the connecting piece 120 .

[0024] The connection hole 101 is provided to be in fluid communication with a refrigerant passage hole (not shown) formed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com