Patents

Literature

154results about How to "Solve the rupture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound foaming agent for foam concrete and preparation method thereof

The invention belongs to the technical field of building materials, and specifically relates to a compound foaming agent for a foam concrete and the preparation method of the compound foaming agent. The compound foaming agent is composed of a surfactant, a protein foaming agent, a foam stabilizing agent, a coagulation accelerator and a water reducing agent. The compound foaming agent provided by the invention is doped with few protein foaming agent and foam stabilizing agent in a surfactant solution to remarkably improve the foaming capability and the foam stabilizing time of the surfactant solution and create favorable conditions for preparing the foam concrete at a low-density grade (not more than 500 Kg / m<3>). In addition, the coagulation accelerator is doped to accelerate the condensation of cement slurry and effectively prevent collapsing; the water reducing agent is doped to improve the working property of a freshly mixed concrete, and reduce the water dosage and improve the strength of the foam concrete at the same time. The product provided by the invention has various functions, and is not limited to only prepare the foam; at the same time, the product provided by the invention has the actions of accelerating coagulation and reducing water, and the product provided by the invention is suitable for preparing the low-density foam concrete.

Owner:TONGJI UNIV

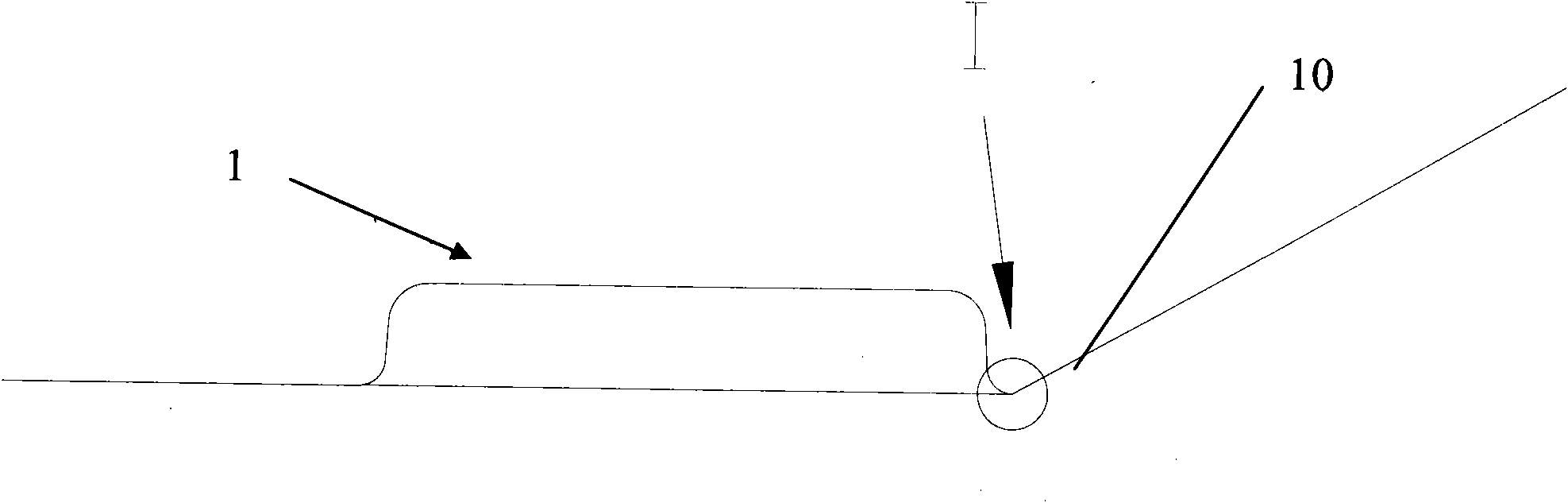

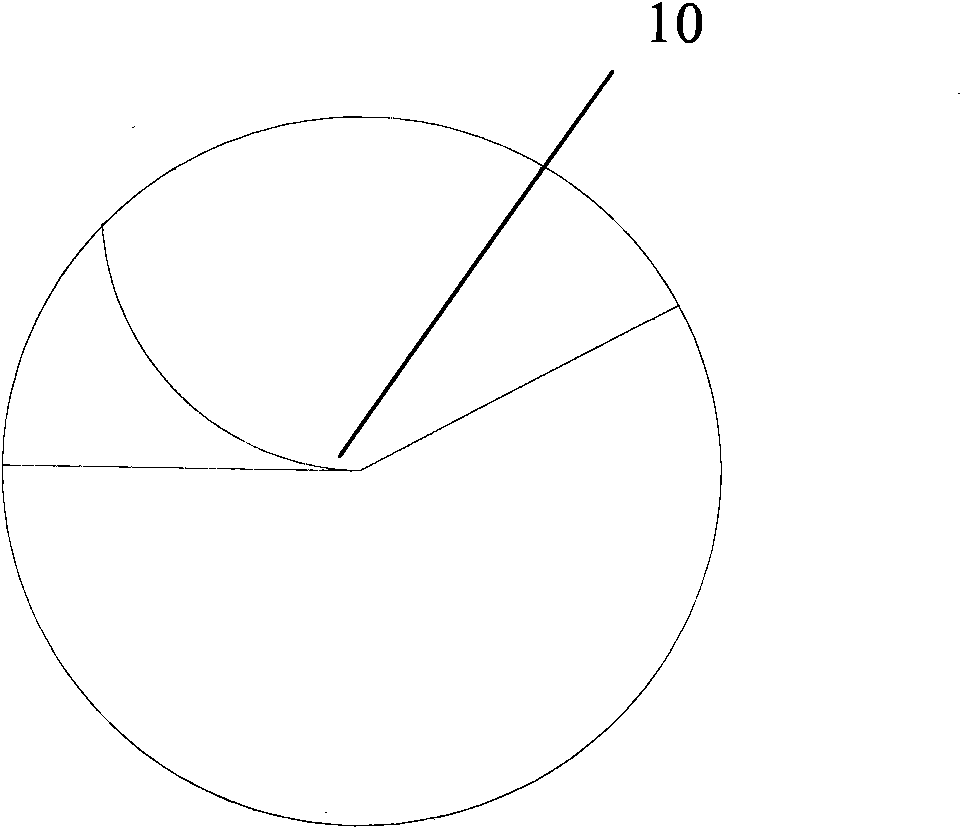

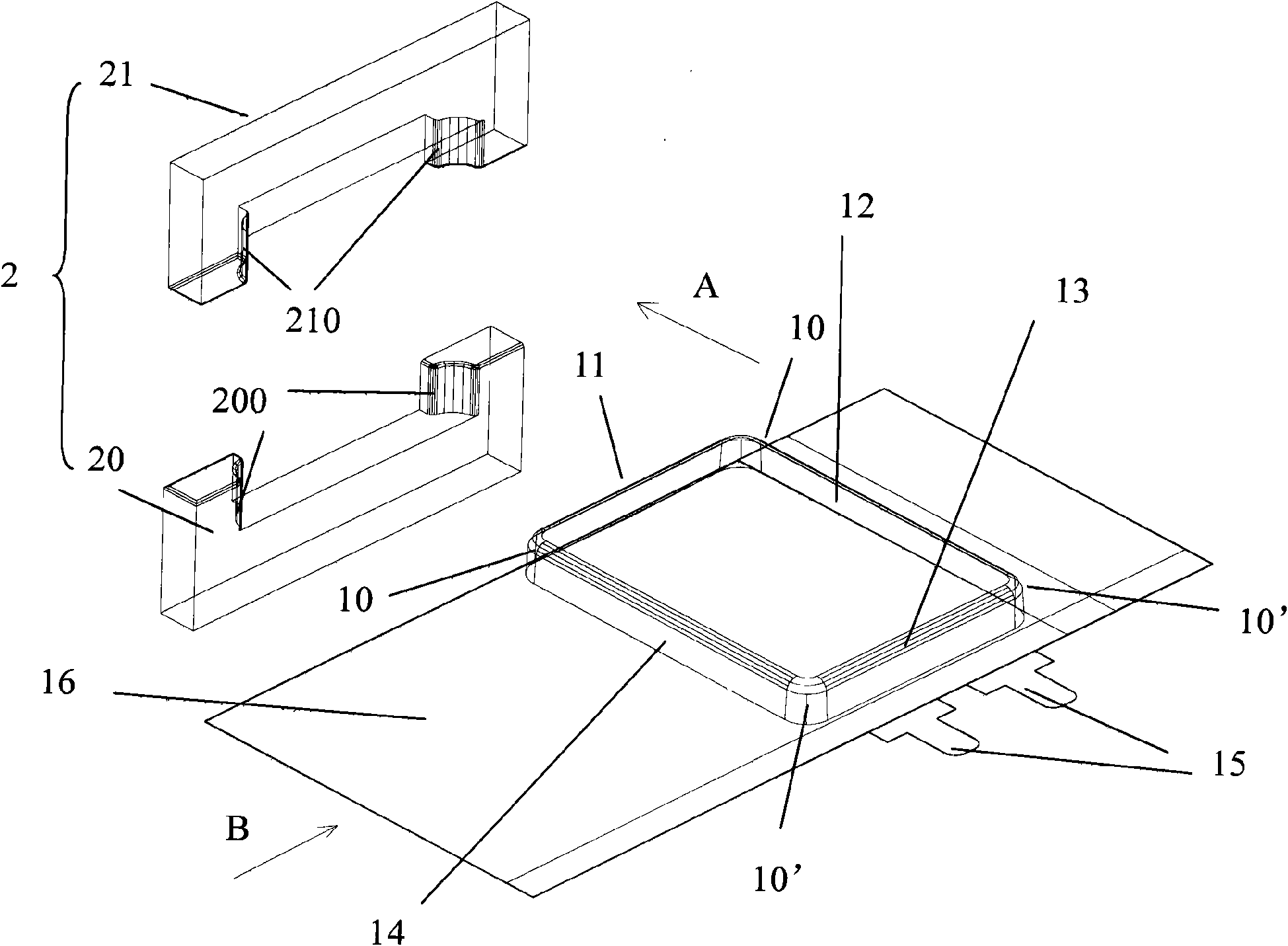

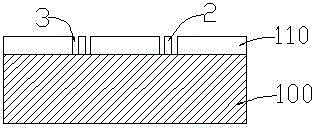

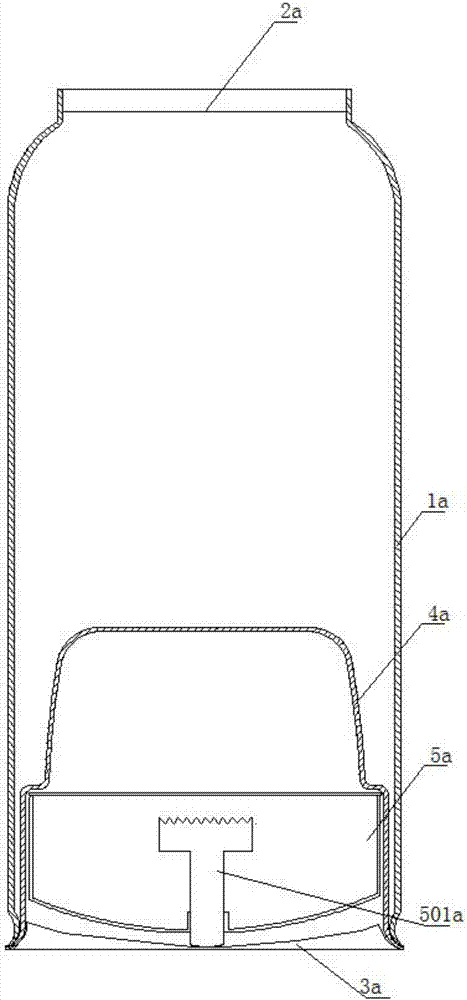

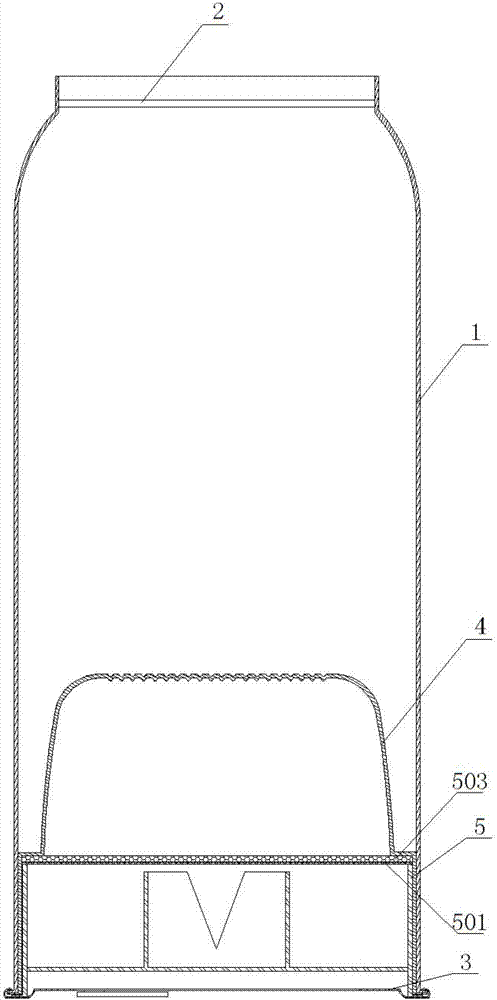

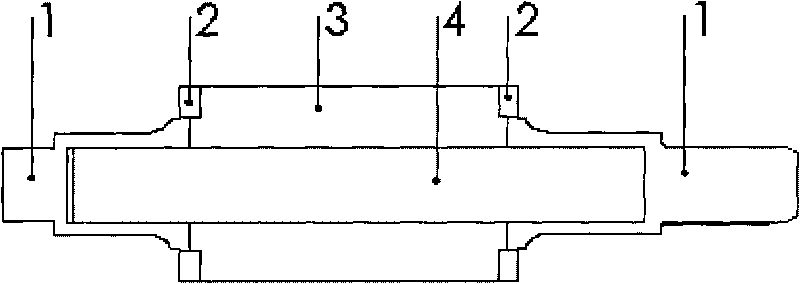

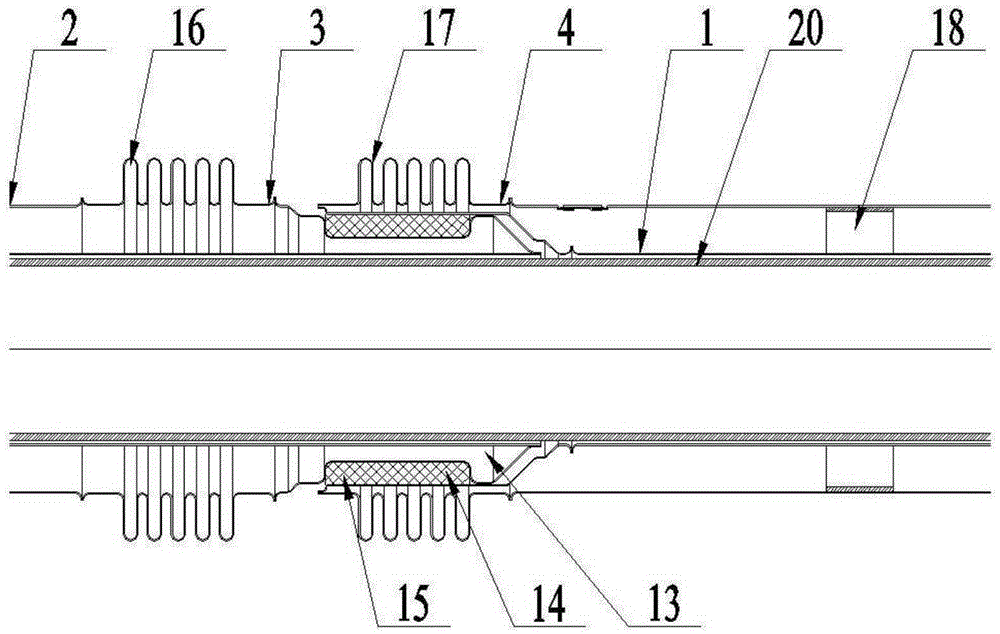

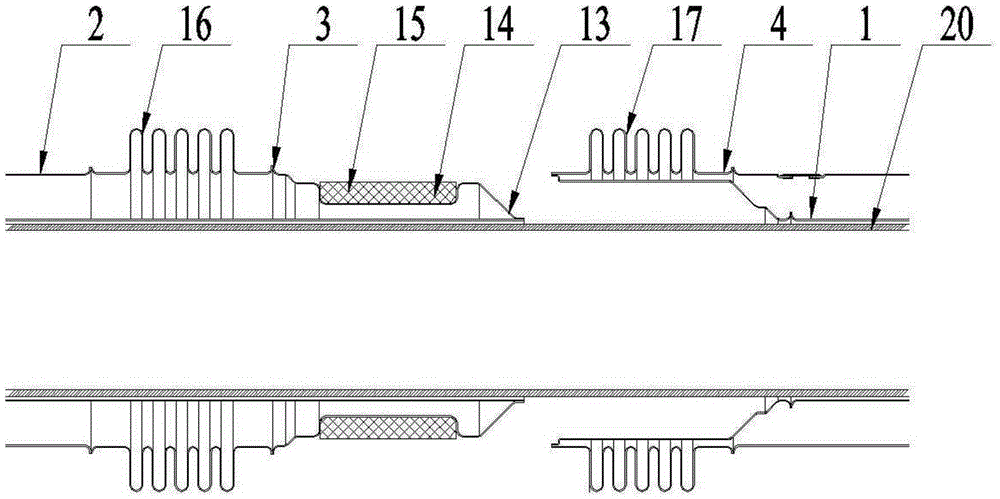

Soft package lithium ion battery and manufacturing method thereof

InactiveCN101640287ASolve the ruptureSolve the fragileSecondary cellsCell sealing materialsEngineeringLithium-ion battery

The invention discloses a soft package lithium ion battery, which comprises a battery cell. The battery cell comprises a pole shank, an electrolyte and a shell enwrapping and heat-sealing the pole shank, wherein the electrolyte is sealed in the shell; and after the shell enwraps and heat-seals the pole shank, the battery cell forms a pair of hems, a pole lug outlet edge and two side edges, the bottom corner at the intersection of the hems and the two side edges is a round corner which is formed through further hot pressing. The invention simultaneously discloses a method for manufacturing thesoft package battery. After the shell performs heat seal to form the battery cell, the bottom corner at the intersection of the hems and the two side edges is heat-sealed again. By adopting the schemeof the invention, the problem that the bottom corner is easy to crack in the process of manufacturing the soft package lithium ion battery is solved successfully. The method is simple, is convenientto implement, has low cost, and can practically solve the problem of complex film cracking at the bottom corner of the battery.

Owner:东莞市欣卓电讯材料有限公司

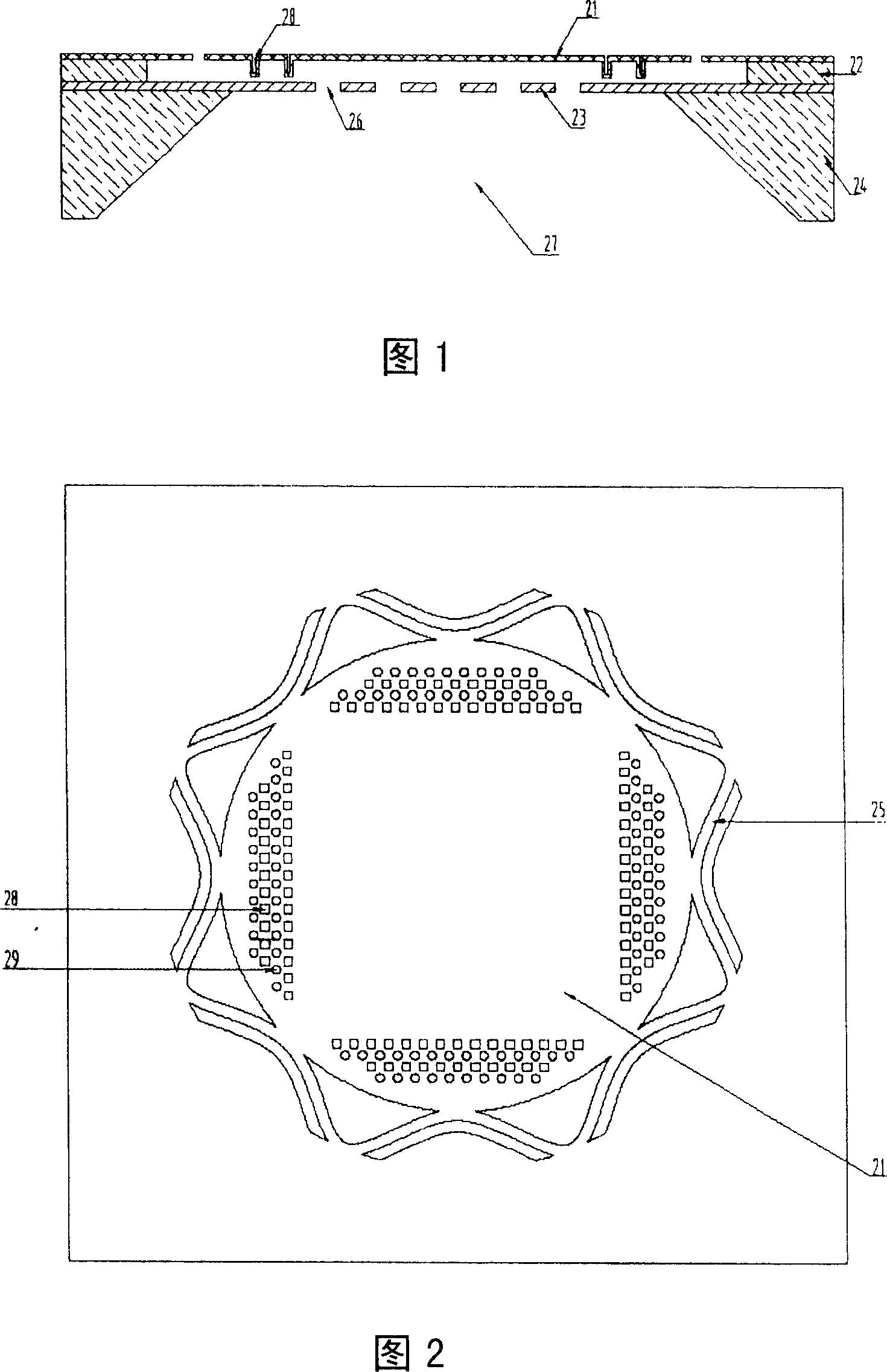

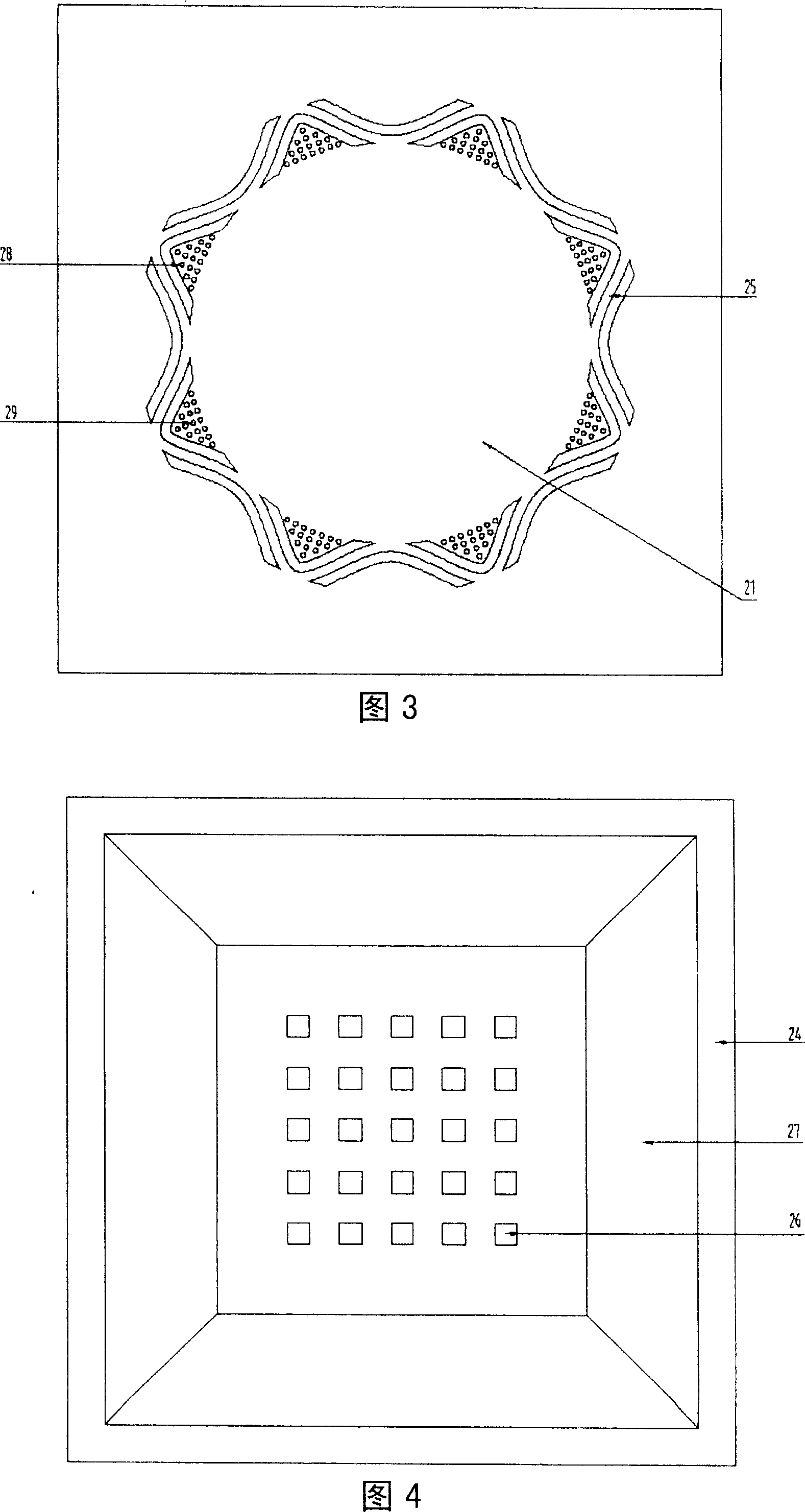

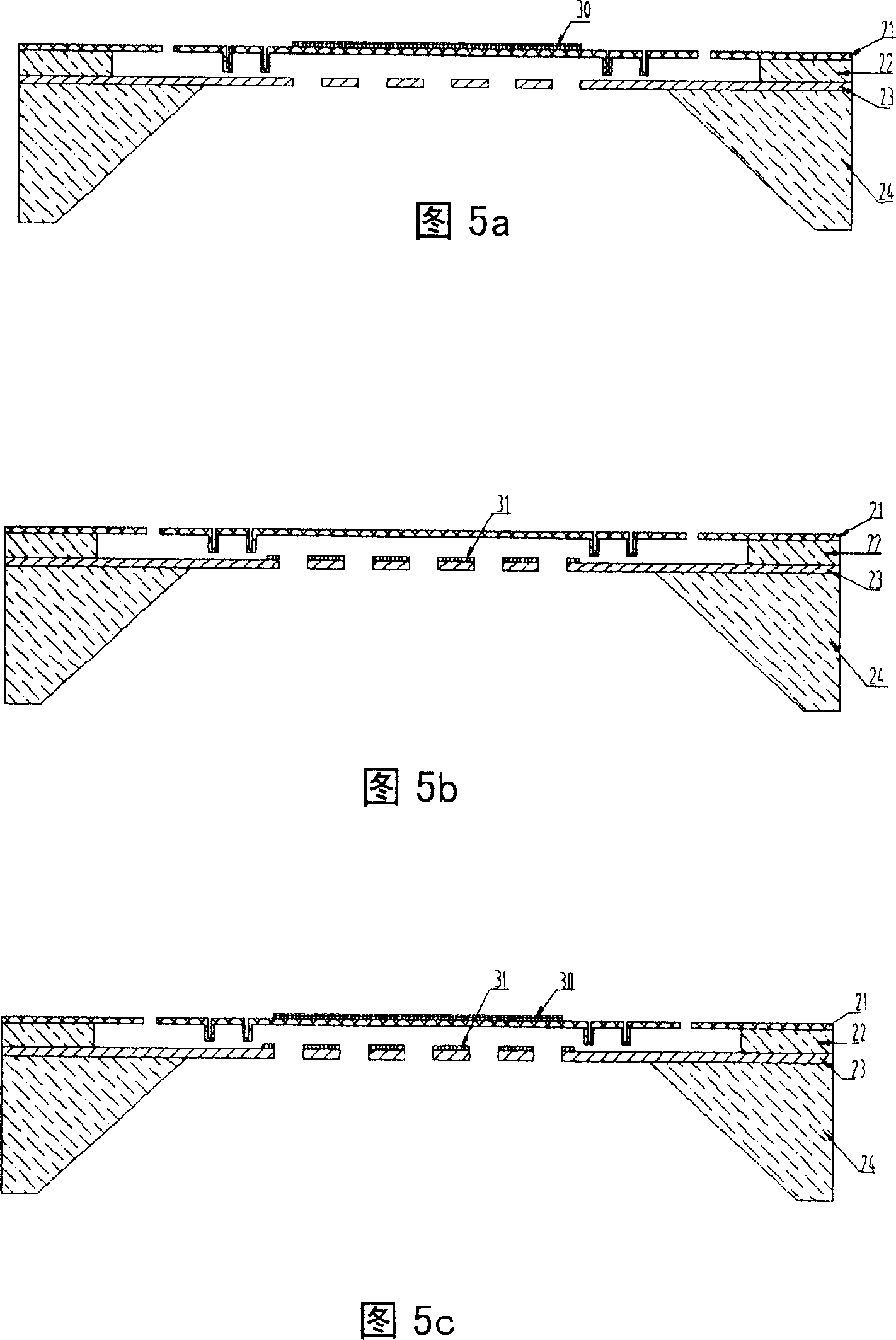

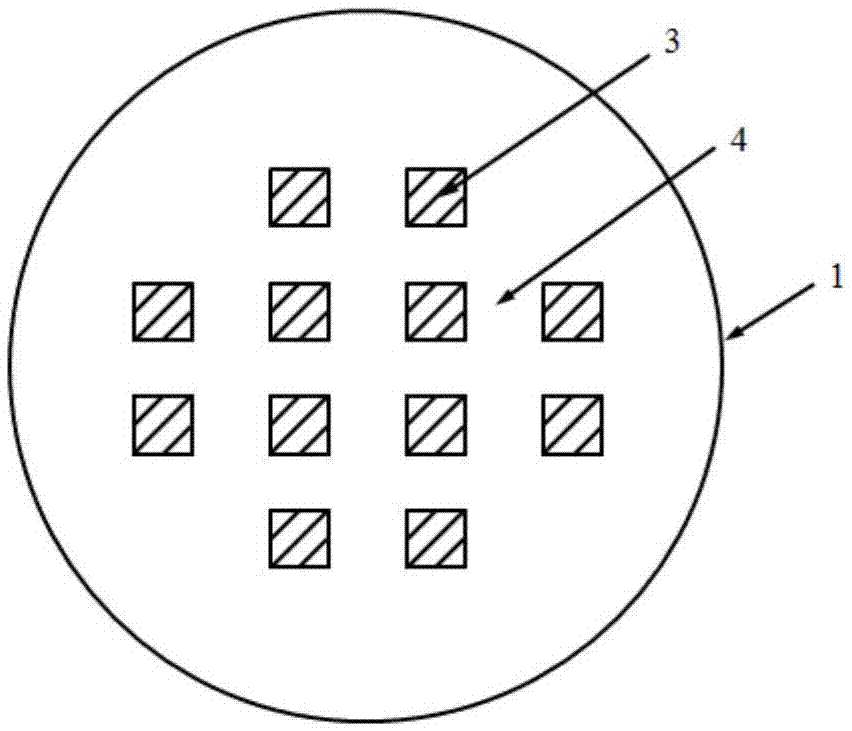

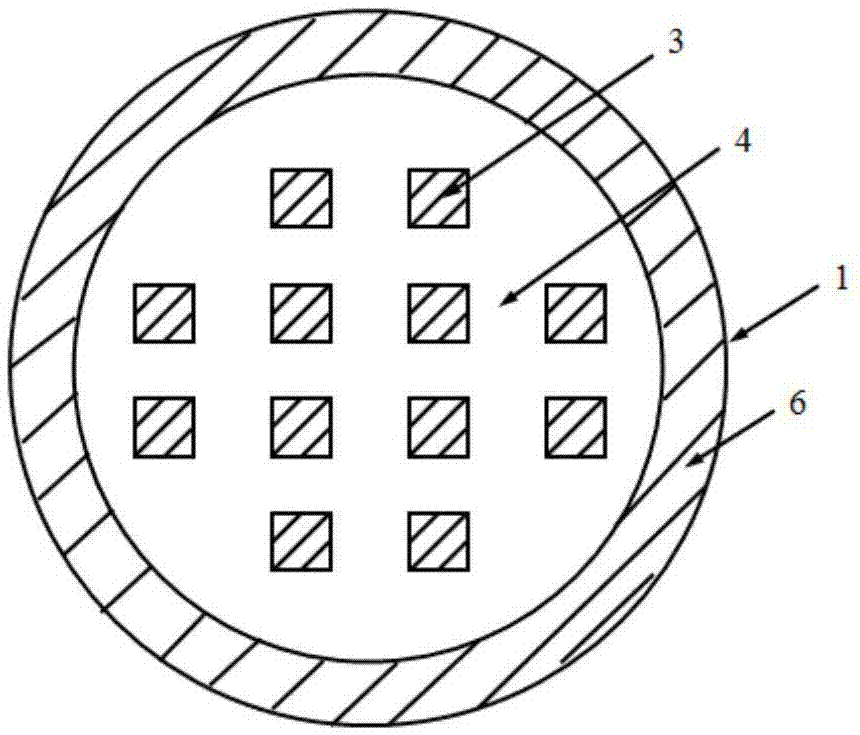

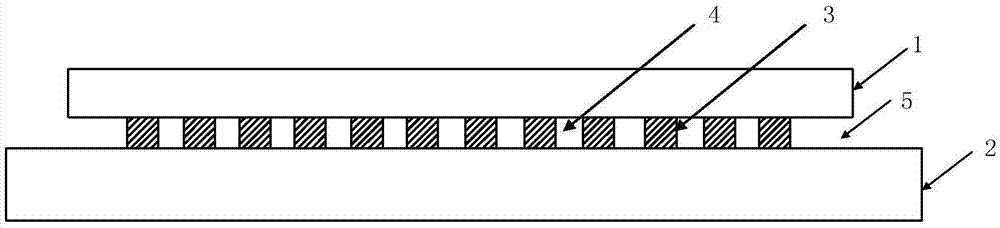

Semiconductor microphone chip

ActiveCN101098569ASolve the ruptureSolve the deformationSemiconductor electrostatic transducersElectrets selectrostatic transducerLow noiseEngineering

The invention relates to a semi-conductor microphone chip, belonging to microphone chip technique, as one capacitor structure which vibration membrane is above and back pole is below, wherein the vibration membrane via a waveform beam is connected with a frame and a support to completely release the left stress of the vibration membrane, the vibration membrane is provided with a plurality of array micro concaves to support the vibration membrane and reduce sound leakage, the vibration membrane is provided with a plurality of holes, to engage with the sound holes on the back pole in the microphone chip preparation to release a sacrificial layer between the vibration membrane and the back pole. The invention has high flexibility, low noise, and wide frequency band, while the produced chip has small volume, simple preparation and batch production.

Owner:GOERTEK MICROELECTRONICS CO LTD

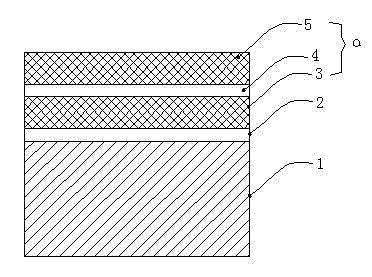

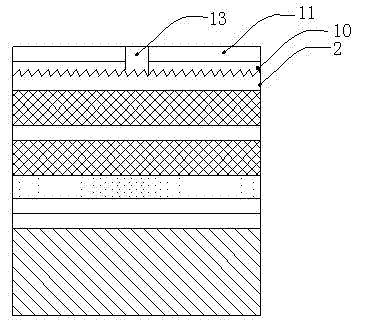

LED preparation method for improving light-emitting efficiency

The invention relates to a light-emitting diode (LED) preparation method for improving light-emitting efficiency and relates to a preparation process for a semiconductor luminescent device. The method aims to improve the light-emitting efficiency and the yield of products. In the technical scheme, the preparation method comprises the following steps of: allowing an epitaxy membrane to grow on a sapphire substrate, and performing vapor deposition and alloying on a transparent conducting layer to grow a SiO2 protective layer; coating mucilage glue on the SiO2 protective layer, and curing with a temporary support baseplate; stripping the sapphire substrate by laser; coarsening the N surface of the stripped epitaxy membrane; manufacturing a transparent bonding material layer capable of being cured on the N surface of the stripped epitaxy membrane, and curing the bonding material layer; preparing a reflective layer, and curing with the bonding material layer at high temperature; manufacturing an N electrode in a groove formed on a layer on the coarsened surface; evaporating a bonding metal layer, and performing eutectic bonding with a conducting and heat-conducting perpetual baseplate; and removing the temporary support baseplate and the SiO2 protective layer, and manufacturing a P electrode on the transparent conducting layer.

Owner:LATTICE POWER (JIANGXI) CORP

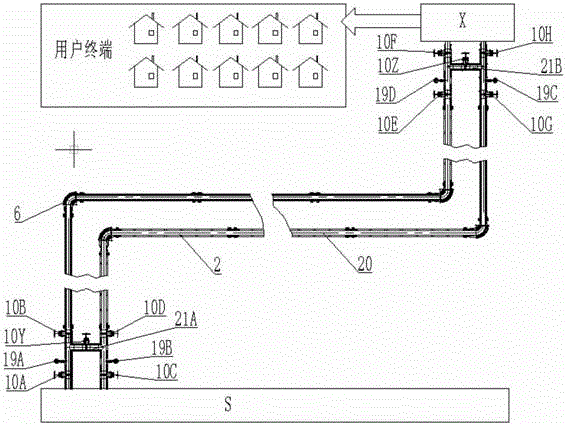

Paired cable duct bank laying-based support pipe construction process

ActiveCN103851257AEfficient constructionSolve the rupturePipe laying and repairCable installations in underground tubesArchitectural engineeringDrill

The invention discloses a paired cable duct bank laying-based support pipe construction process, which comprises the following steps of measuring and setting out, excavating a foundation pit, drilling with a drill rig, pulling back a drilling hole, welding a pipeline, pulling back a laying pipeline and backfilling the foundation pit. The process can be used for effectively constructing a support pipe, is short in construction time and good in construction time and solves the problems that the pipeline is cracked or the line can not be constructed frequently caused by the existing construction method.

Owner:STATE GRID CORP OF CHINA +1

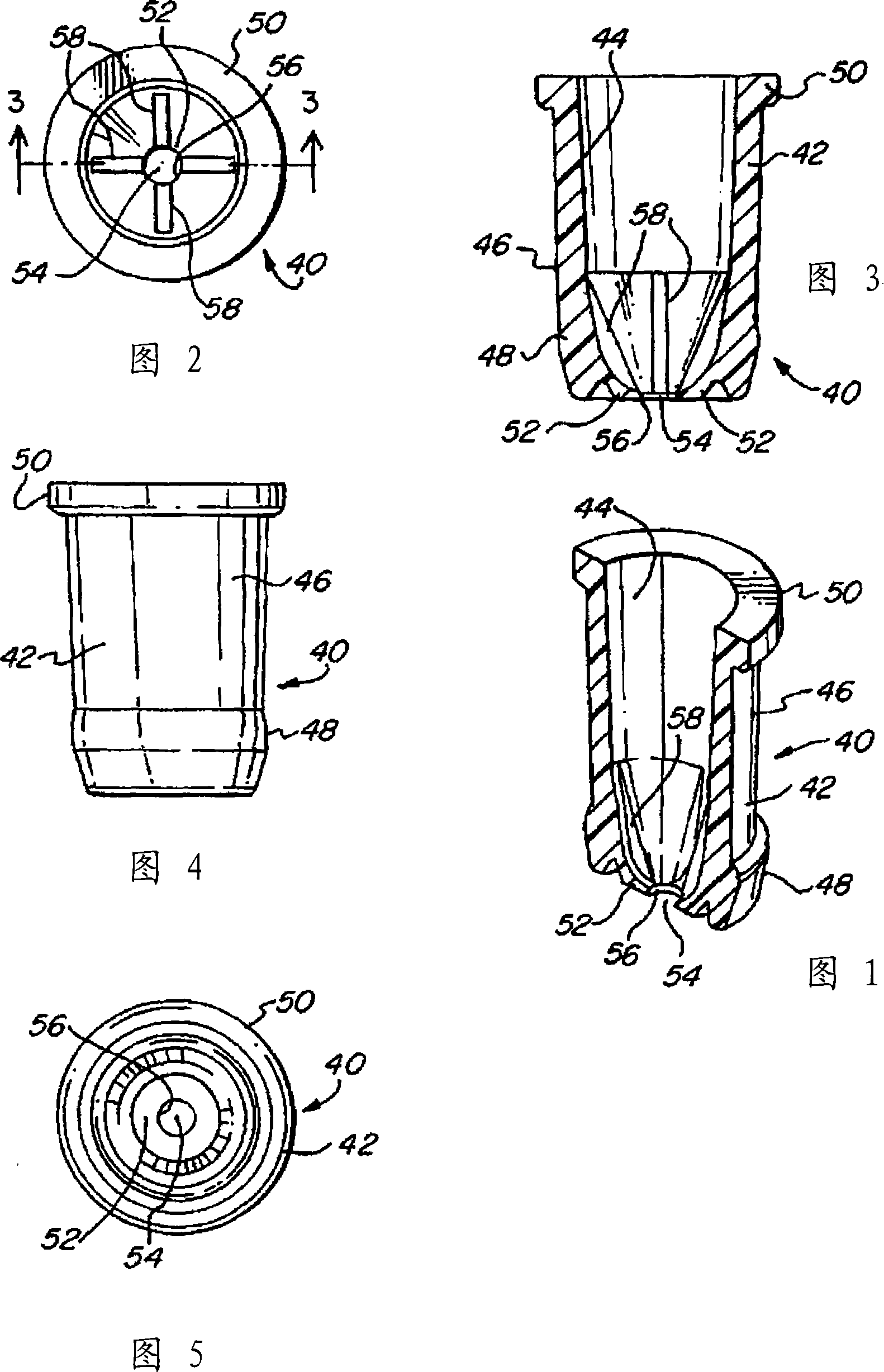

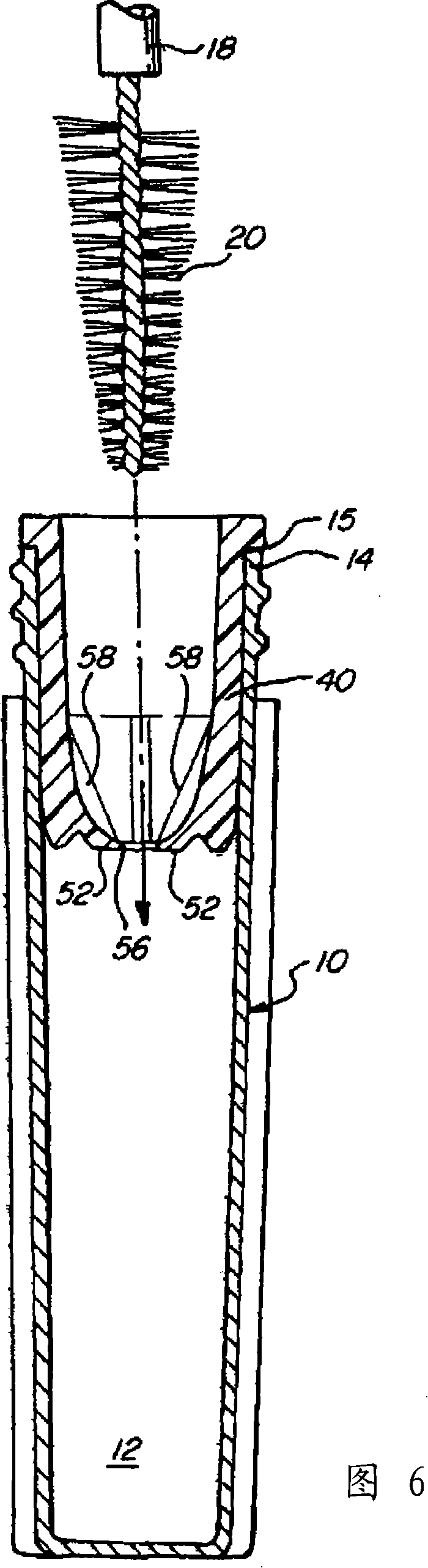

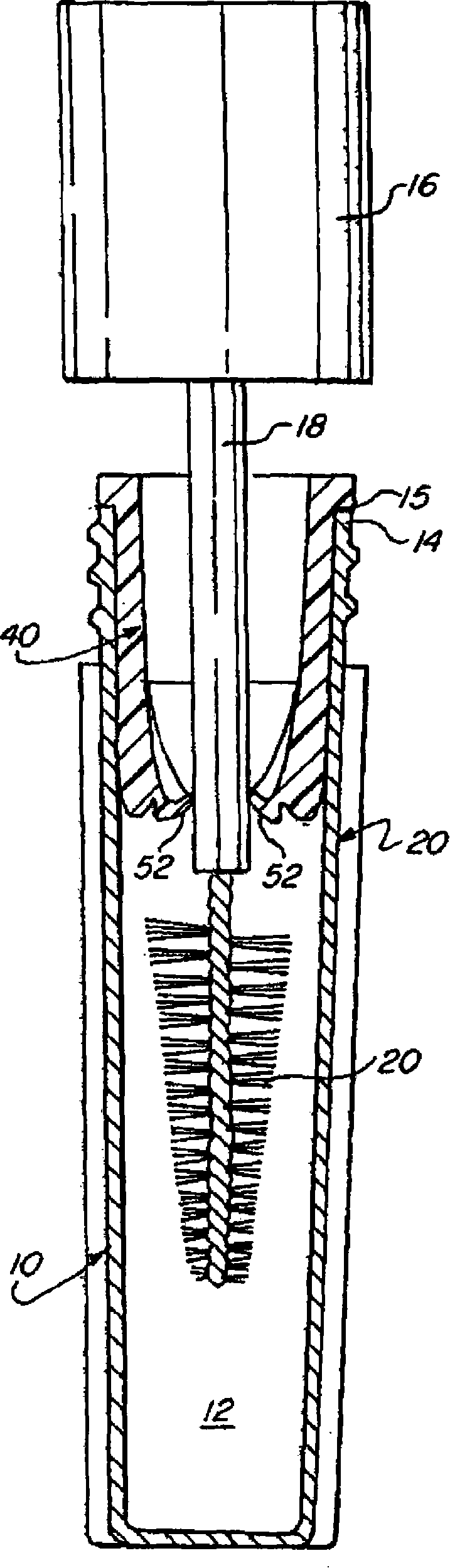

Wiper for cosmetics bottle

InactiveCN101185542ASolve the ruptureResolve the breakBrushesPackaging toiletriesLow-density polyethyleneEngineering

Owner:RISDON INT

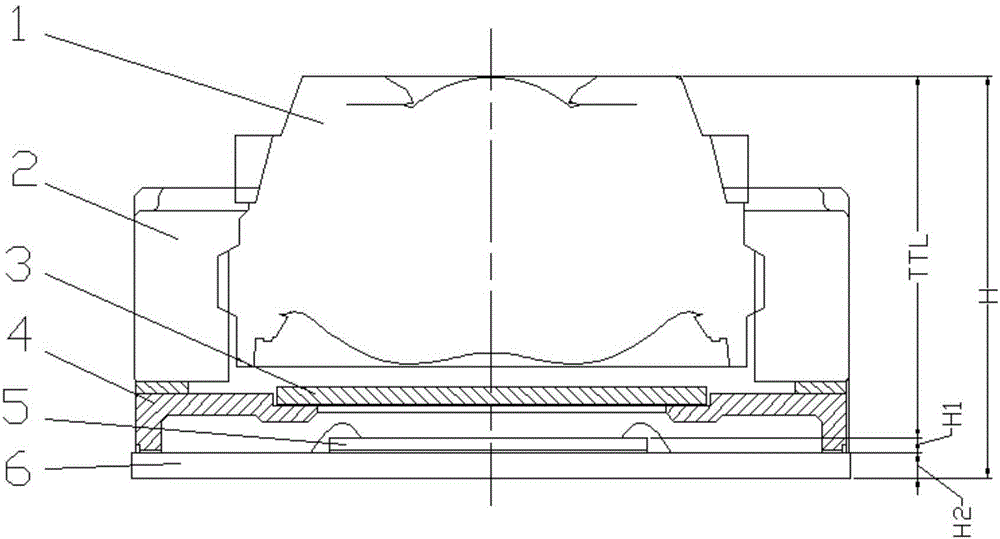

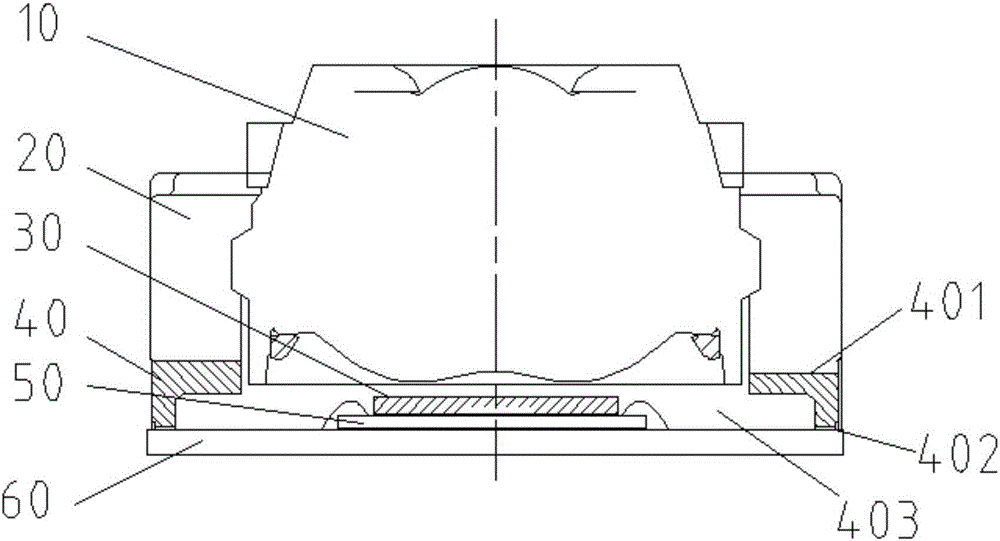

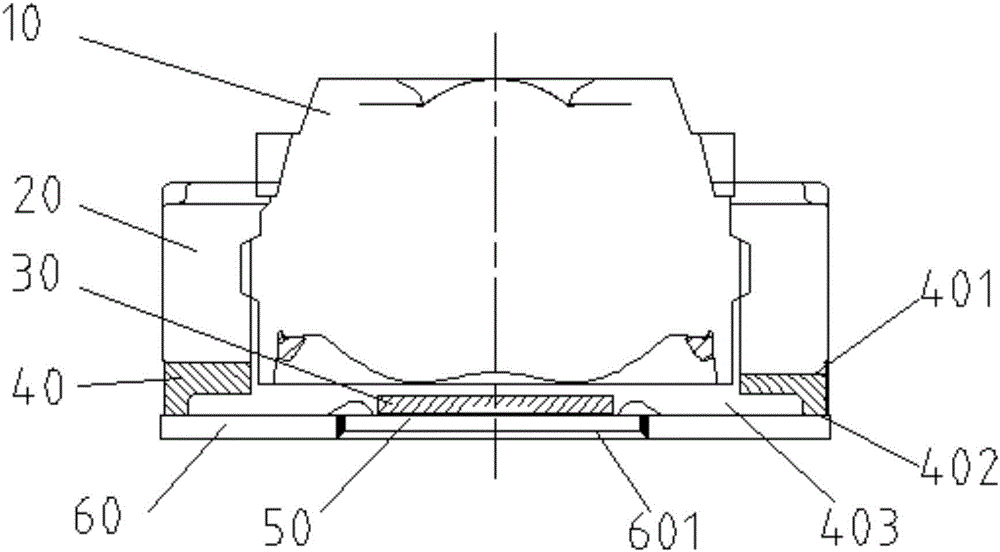

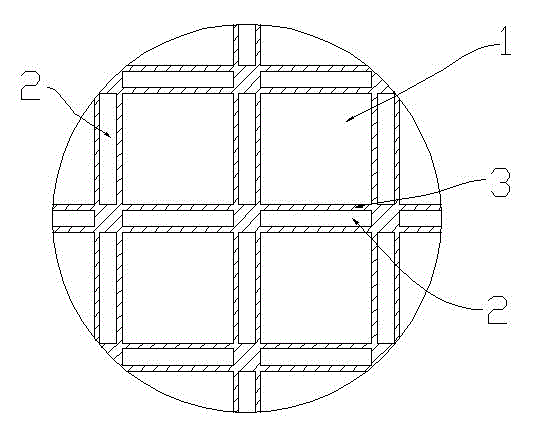

Camera module and mobile terminal

ActiveCN106506929ALower the altitudeSolve the ruptureTelevision system detailsColor television detailsComputer terminalCamera module

The embodiment of the invention provides a camera module and a mobile terminal. The camera module comprises a lens, a voice coil motor, a base, an optical filter, a circuit board and an image sensor, wherein the lens is arranged on the voice coil motor; the base is provided with a first surface and a second surface which are opposite to each other, and an inner cavity passing through the first surface and the second surface; the voice coil motor is arranged on the first surface; the second surface of the base is arranged on the circuit board; the image sensor is embedded into the inner cavity of the base, and coaxially arranged on the circuit board together with the lens; the optical filter is attached to an upper surface of the image sensor; and a minimum cross-sectional area of the inner cavity of the base in a direction vertical to the axis direction of the lens is larger than the area of the optical filter. Through application of the camera module and the mobile terminal, the optical filter is prevented from being cracked by extrusion of the base; the space for fixing the optical filter is saved for the base simultaneously; more design space is provided for the lens; the optical length can be shortened in order to lower the height of the camera module; and the development of the mobile terminal to lightness, thinness and portability is facilitated.

Owner:VIVO MOBILE COMM CO LTD

Semiconductor light emitting device preparation method based on laser stripping

InactiveCN103943741AIntegrity guaranteedSolve the ruptureSemiconductor/solid-state device manufacturingSemiconductor devicesLight emitting deviceSemiconductor

The invention provides a method which protects LED tube cores in a sapphire substrate laser stripping process. According to the invention, when discrete tube cores are formed on an etching epitaxial layer, partial epitaxial layer is retained between tube cores as an isolation belt; the problem that the edge of a tube core cracks in the laser stripping process is solved; and the yield is improved. The method provided by the invention is applied to the preparation of a GaN based semiconductor light emitting device.

Owner:SHINEON BEIJING TECH

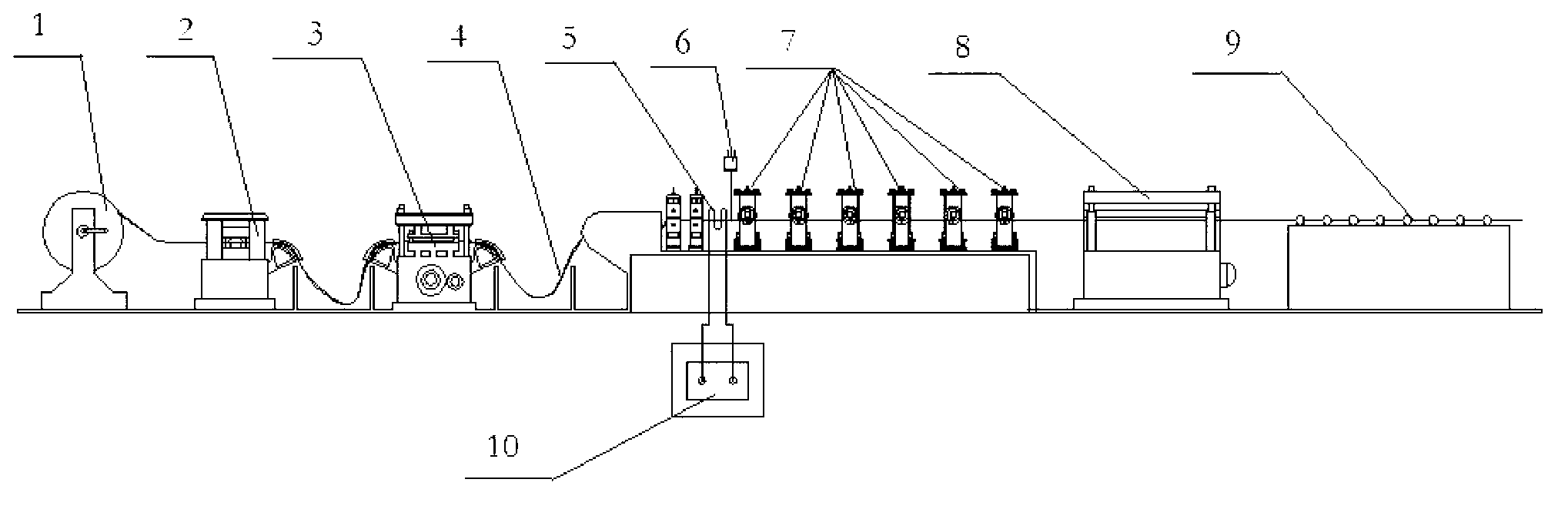

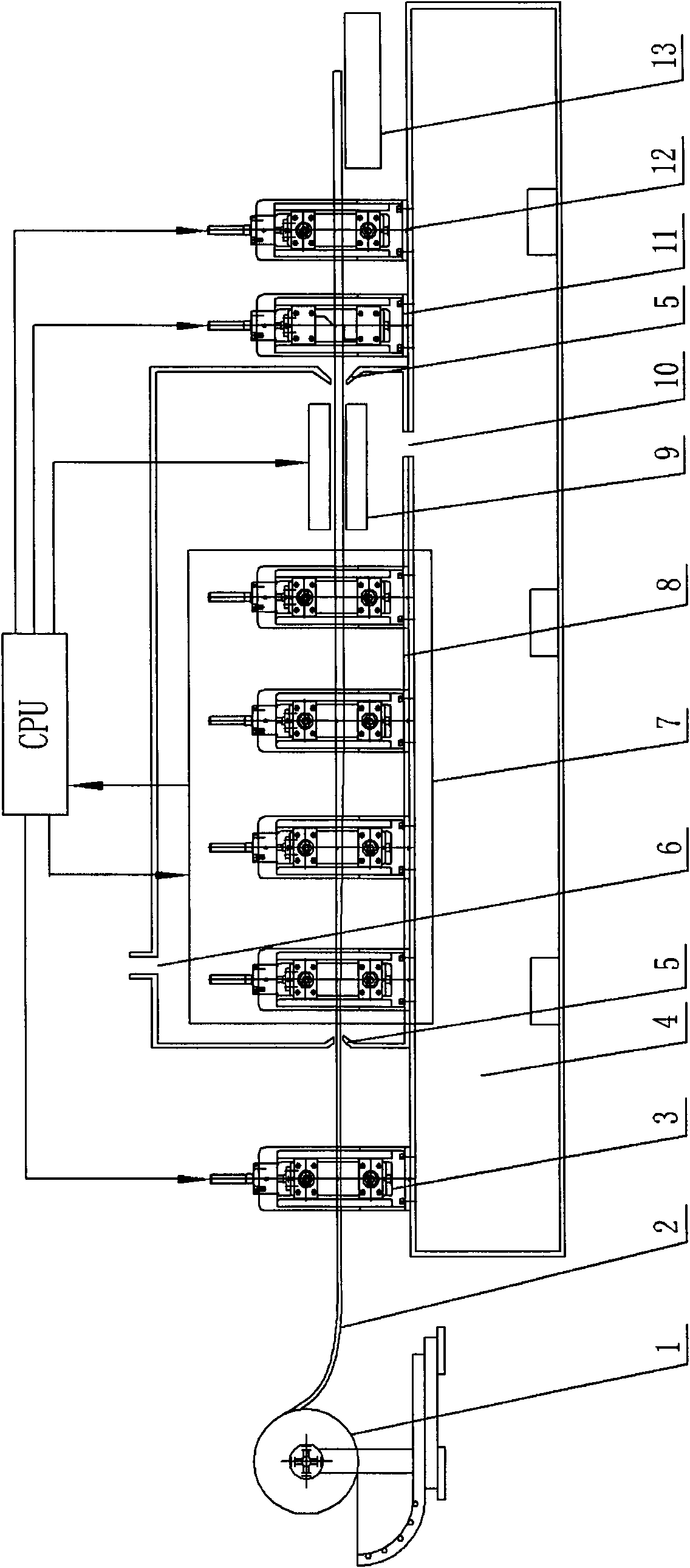

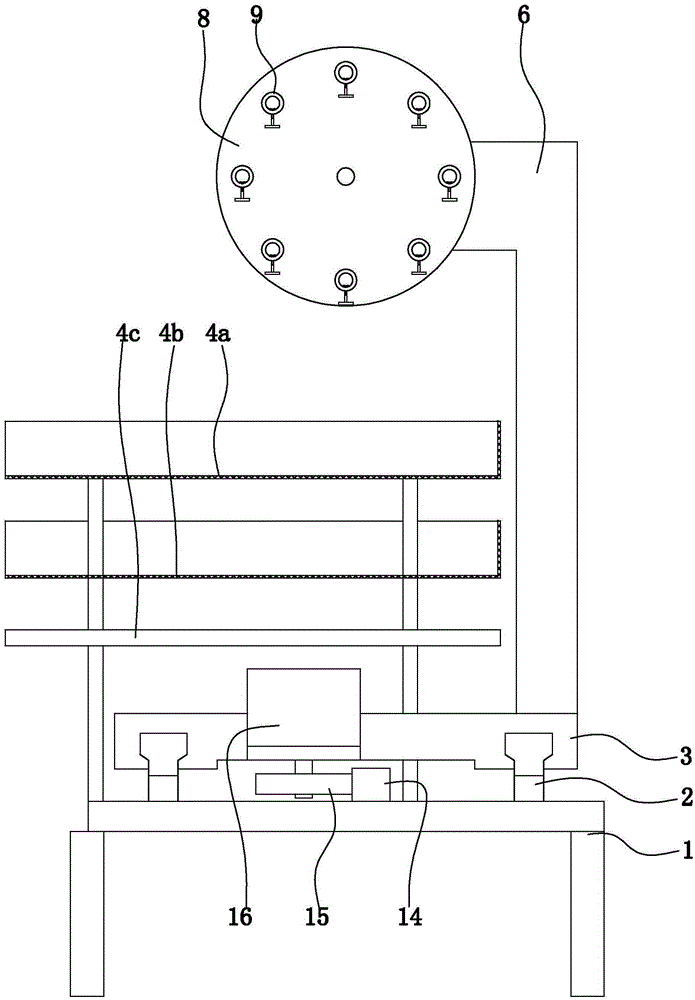

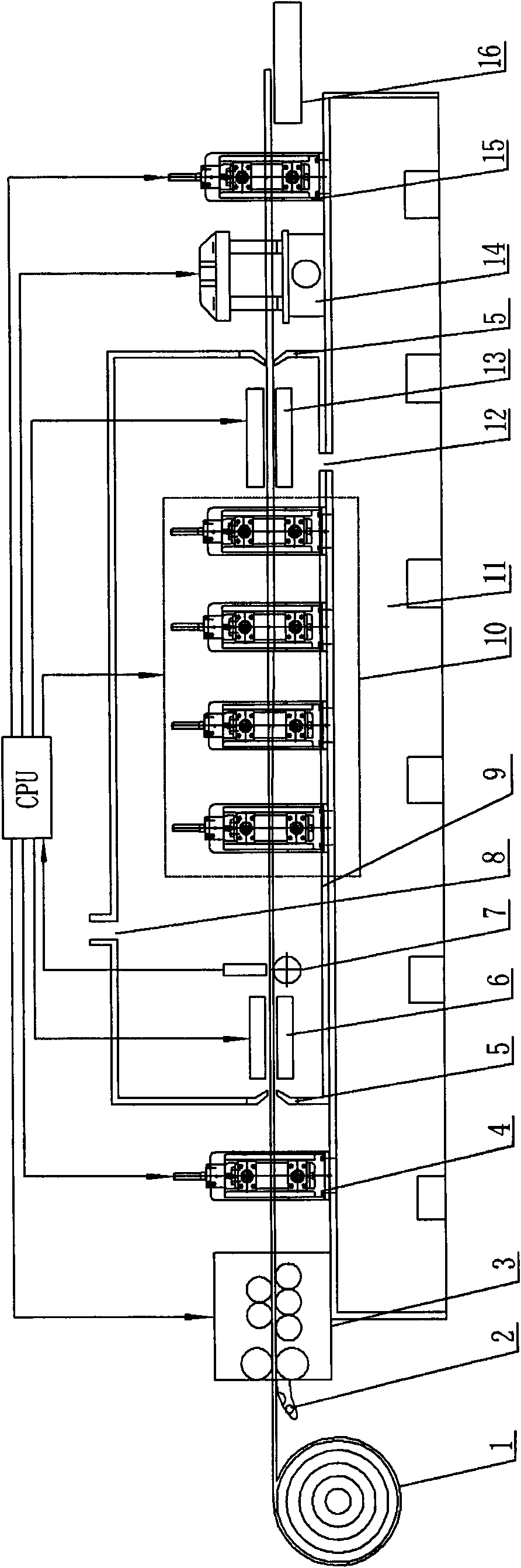

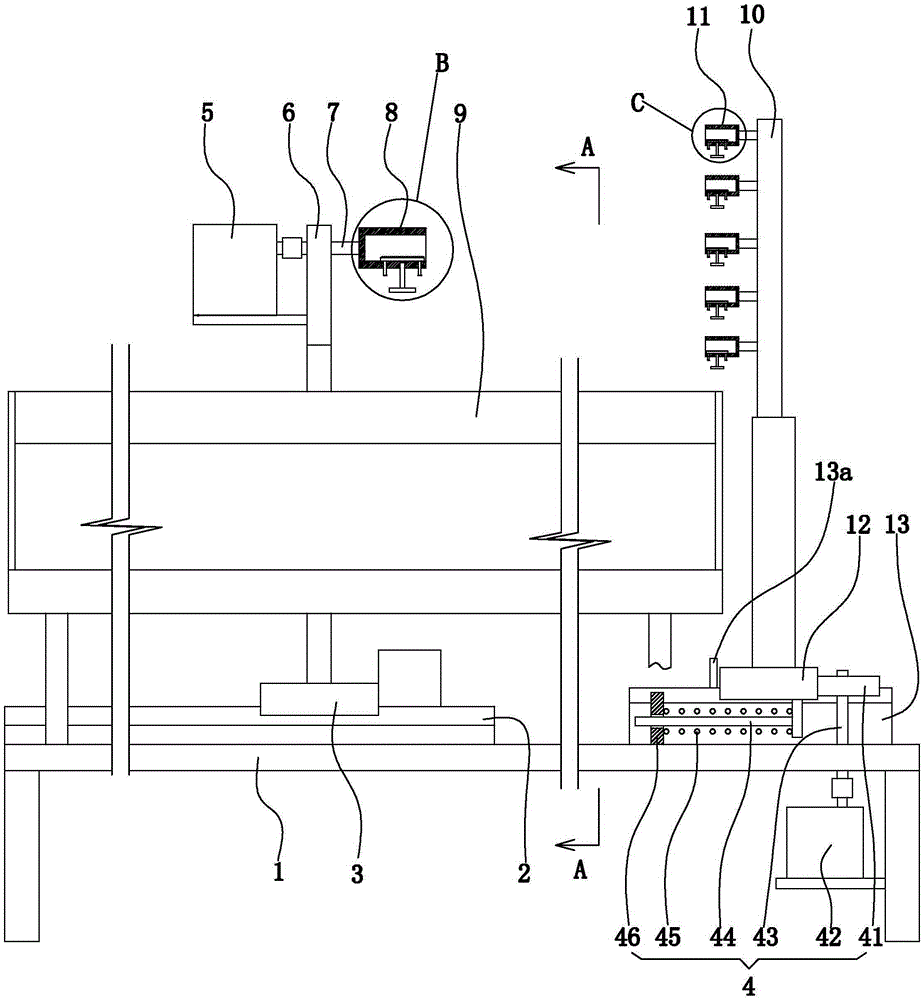

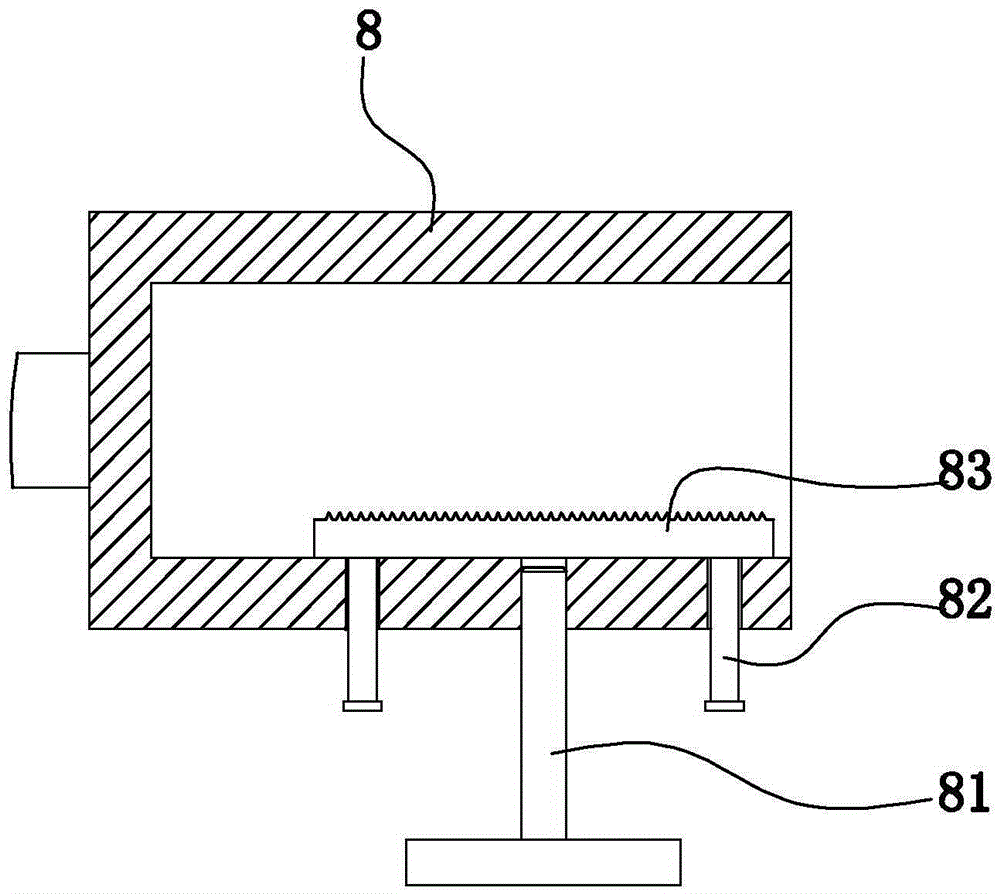

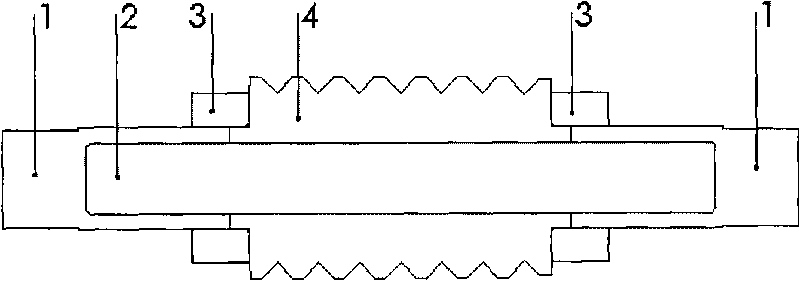

Heat-assisted variable-section roll forming machine system and method thereof

InactiveCN103230969AReduce work hardeningRaise the forming limitShaping toolsAuxiliary heatingAluminium alloy

The invention discloses a heat-assisted variable-section roll forming machine system and a method thereof. According to the system, a variable-section roll forming system comprises an uncoiler, a straightening machine, a feeding machine, a variable-section roll forming unit and a flying shear machine sequentially according to the machining sequence of plates, an electromagnetic auxiliary heating system comprises a high-frequency furnace and a temperature sensor, a computer control system comprises a variable-section roll forming control system and the electromagnetic auxiliary heating system, the uncoiler, the straightening machine, the feeding machine, the variable-section roll forming unit and the flying shear machine are connected with the variable-section roll forming control system, the high-frequency furnace and the temperature sensor are connected with the electromagnetic auxiliary heating system, and the variable-section roll forming control system is in communication connection with the electromagnetic auxiliary heating system. By the aid of the system and the method, the work hardening phenomena of plates made of magnesium alloys, aluminum alloys and high-strength steels can be reduced, the forming limit of plates can be improved, the deformation resistance can be reduced, the uniformity, the toughness and the malleability of material flowing can be improved, and the forming performance of plates can be improved.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

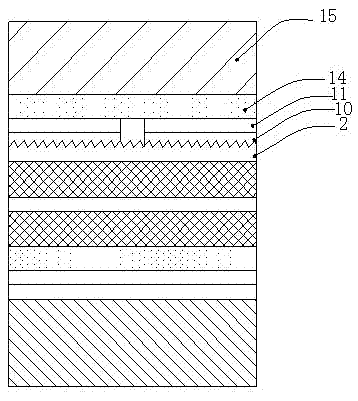

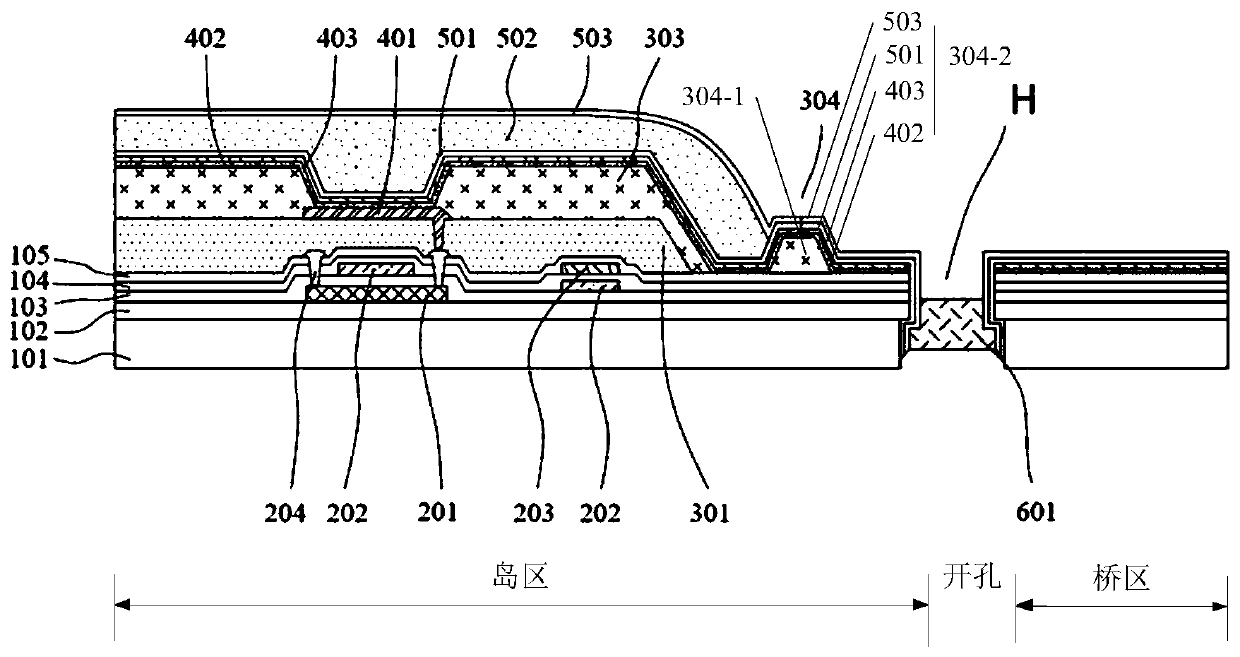

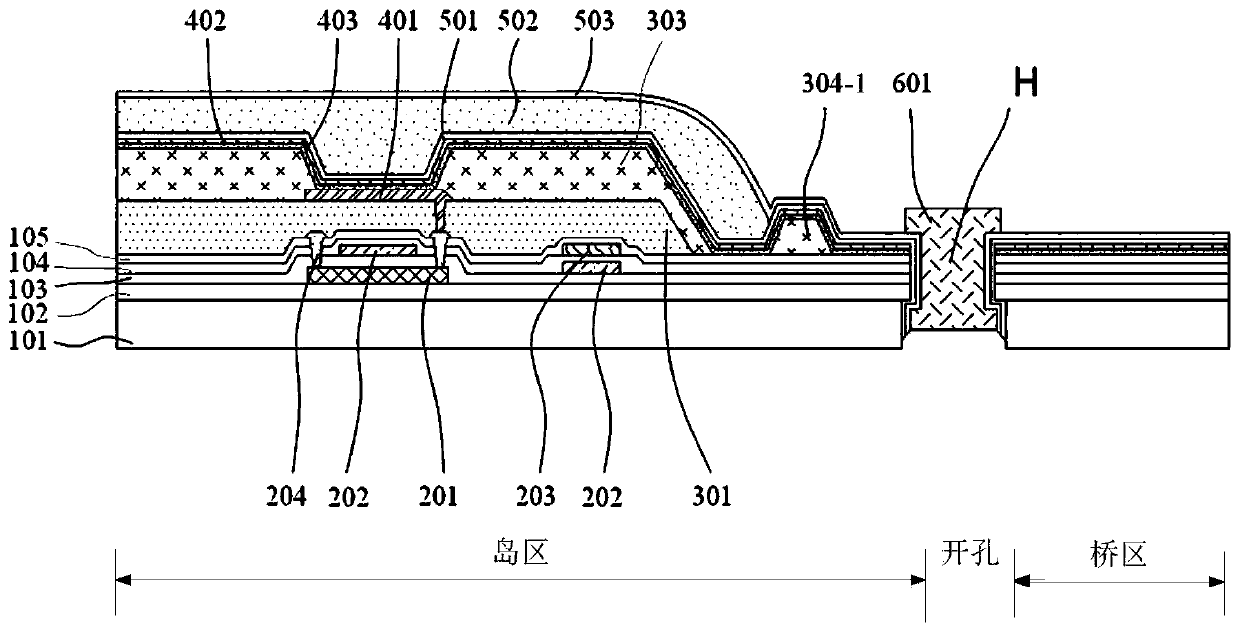

Display panel, display device and manufacturing method of display panel

PendingCN111341210AImprove package reliabilitySolve the ruptureIdentification meansStructural engineeringElectrical and Electronics engineering

The invention discloses a display panel, a display device and a manufacturing method of the display panel. The display panel comprises a substrate, a plurality of island areas, bridge areas and opening areas are arranged on the substrate, the island areas comprise pixel units, the adjacent island areas are connected through the bridge areas, and the opening areas penetrating through the substrateare distributed at preset positions between the island areas and the bridge areas; and the elastic filling layer is positioned in the opening area. According to the technical scheme provided by the embodiment of the invention, the elastic filling layer is arranged in the opening area, so that the problem that the packaging layer is easy to crack when the flexible display panel is stripped from theglass substrate can be solved, and the effect of improving the packaging reliability of the opening area is achieved.

Owner:BOE TECH GRP CO LTD

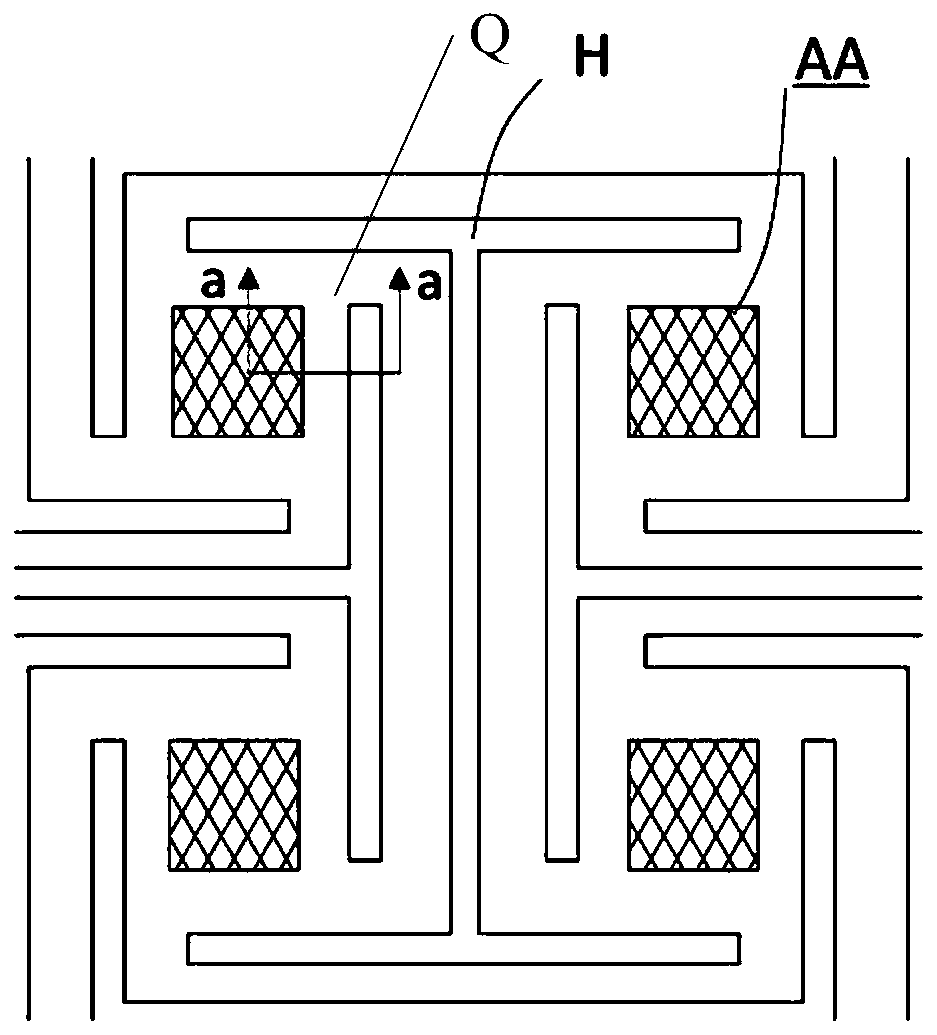

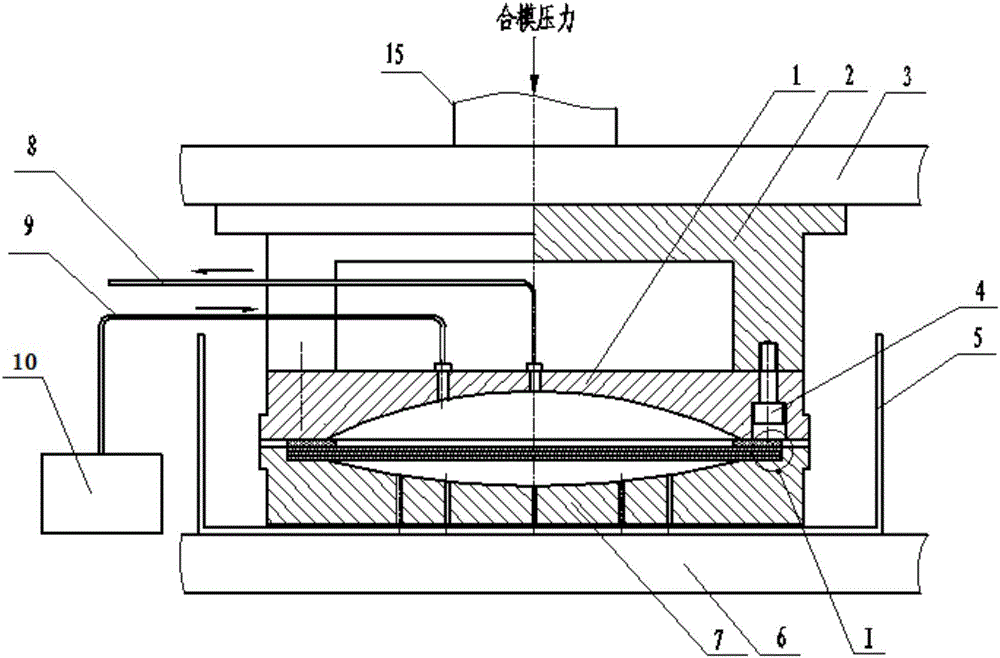

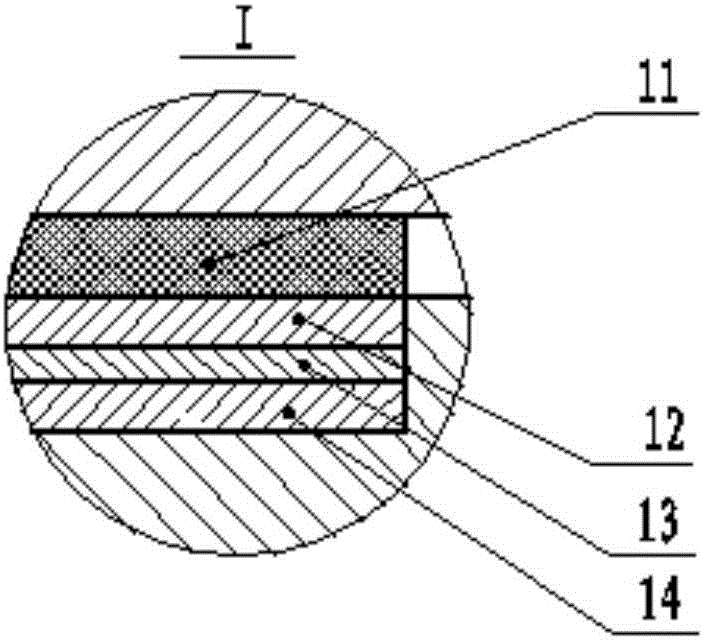

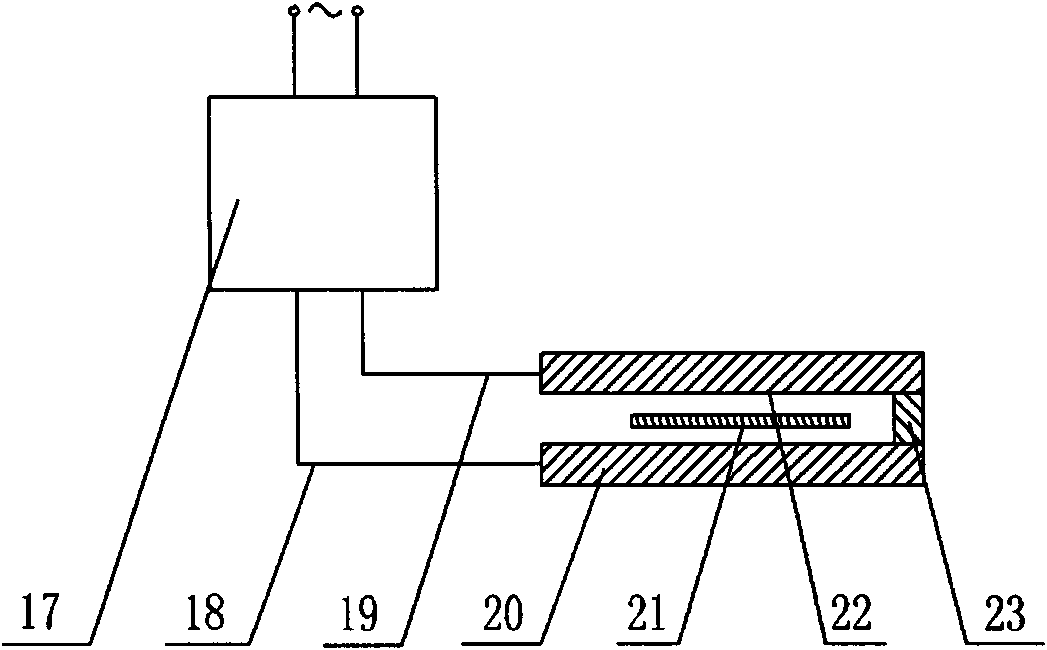

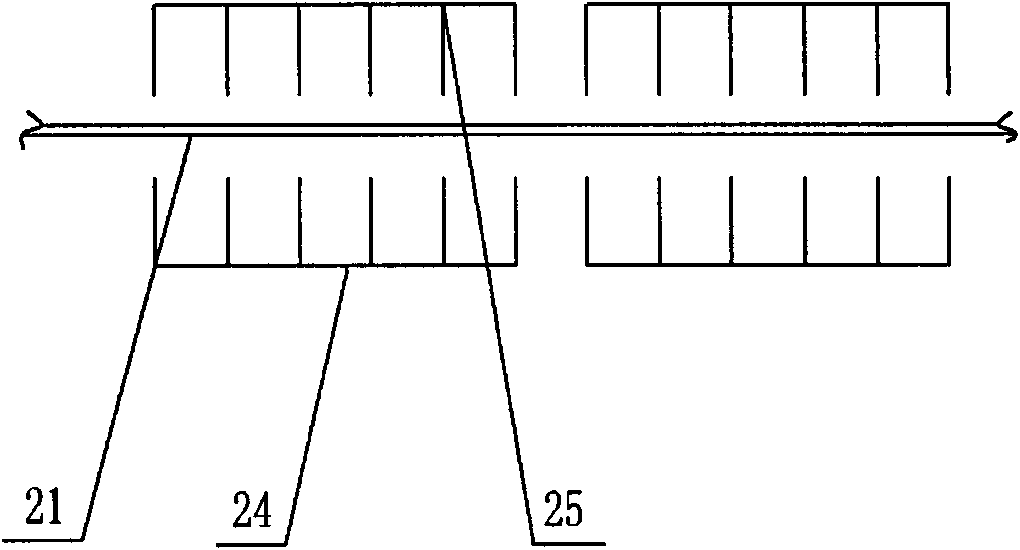

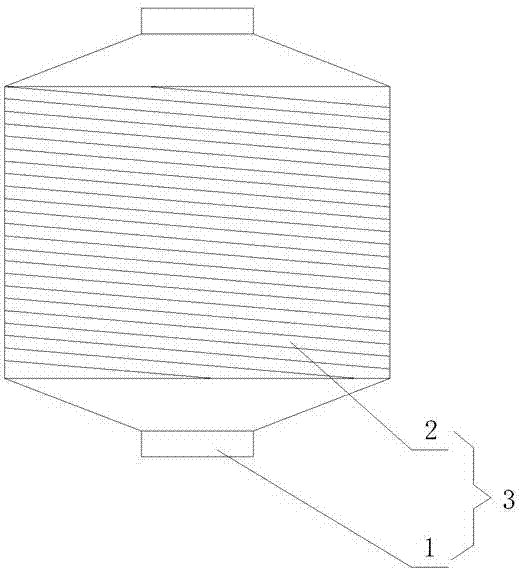

Hydraulic forming device of molybdenum grid for iron thruster

The invention relates to a hydraulic forming device of a molybdenum grid for an iron thruster and belongs to the technical field of drawing molding manufacturing of metal parts. The device mainly comprises an upper forming mold, a lower forming mold, a liquid medium thermal control box, a connector, a hydraulic unit, a hydraulic pipe, an exhaust pipe, a seal ring and a pressurizing lining plate. The lower forming mold is fixedly mounted in the bottom of the liquid medium thermal control box, and the molybdenum grid for compression moulding and the pressurizing lining plate are successively arranged on an annular positioning table of the lower forming mold; the seal ring is arranged between the pressurizing lining plate and the upper forming mold, the exhaust pipe is connected to an exhaust port of the upper mold, and the hydraulic unit is connected to a liquid inlet of the upper forming mold through the hydraulic pipe; one end of the connector is fixedly connected to the upper forming mold while the other end is fixedly connected to mold closing pressure equipment. The device provided by the invention can guarantee the uniformity of a pressing force at the edge of the molybdenum grid so as to avoid wrinkling of the molybdenum grid in the forming process due to local suffocation.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

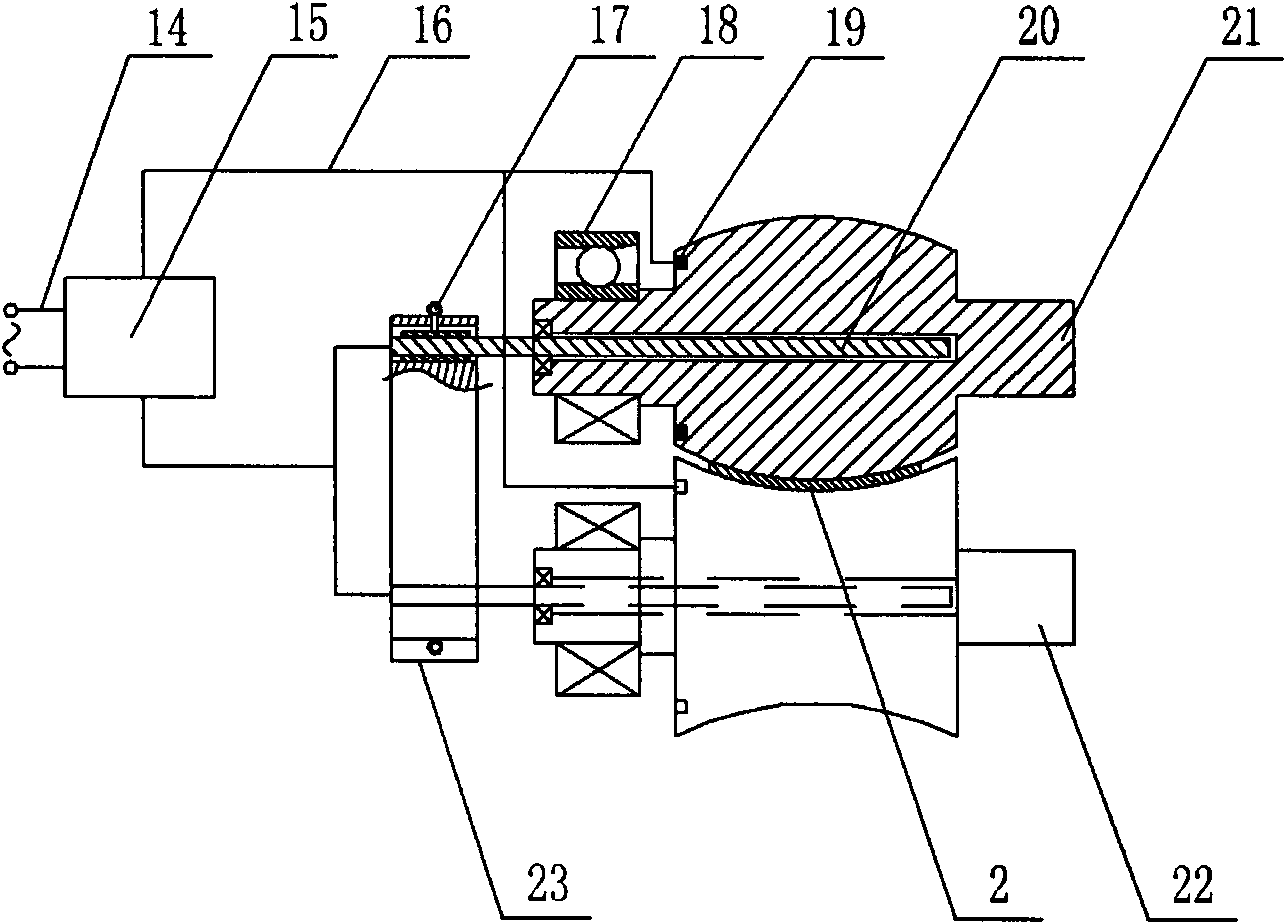

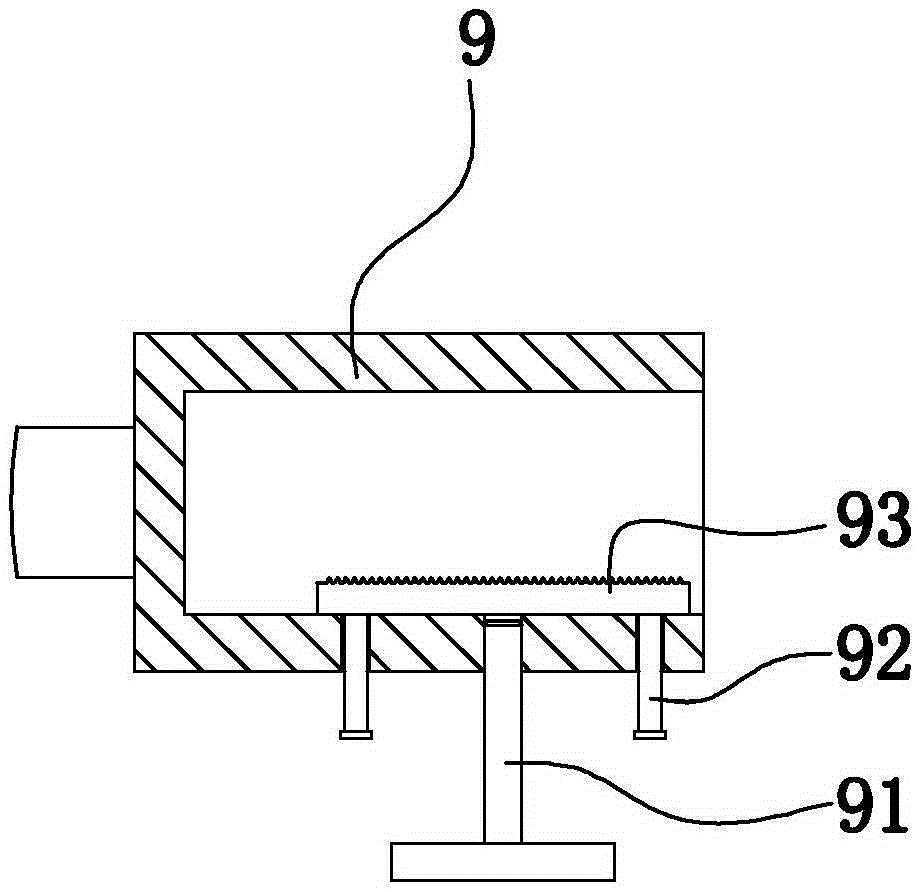

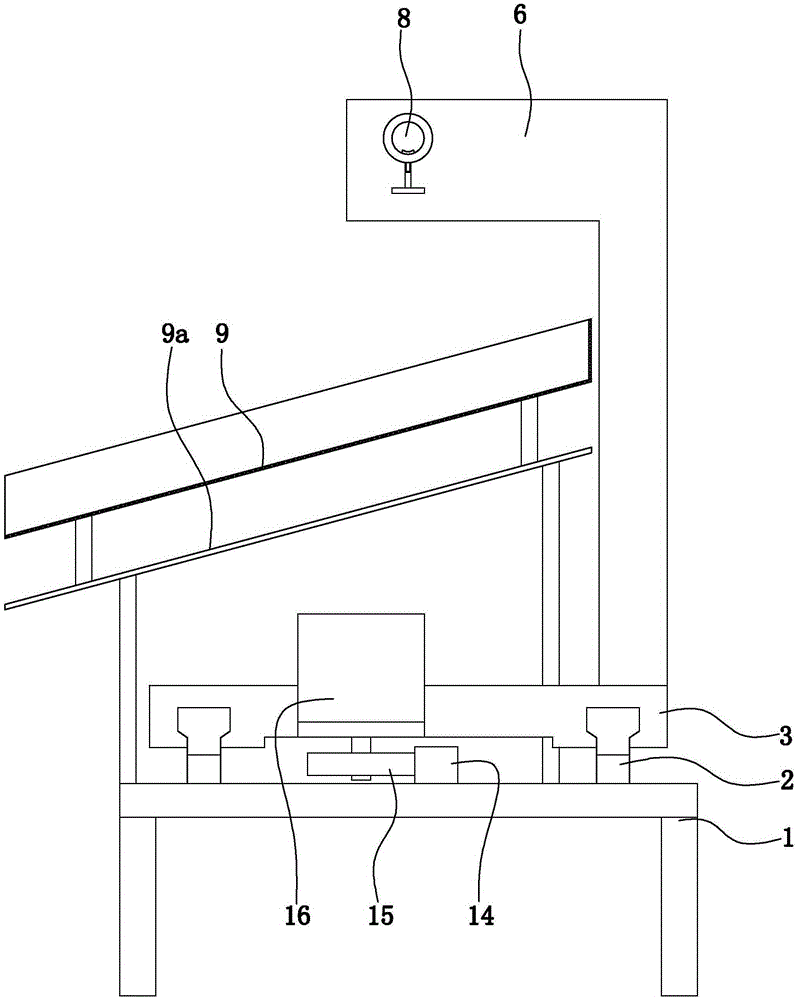

Roll centre heating type roll bending forming method and device thereof

ActiveCN101972798AReduce work hardeningRaise the forming limitShaping toolsComputerized systemHigh surface

The invention relates to a roll centre heating type roll bending forming method of a metal plate strip, which belongs to the field of roll bending forming technologies and equipment and is used for solving the problem of difficult forming of sheet metals, such as magnesium alloy, aluminum alloy, high tension steel, and the like due to work hardening. The roll centre heating type roll bending forming method is characterized by comprising the following steps of: heating a working roll in a protective atmosphere; carrying out roll bending forming on the sheet metal by the hot working roll after the working roll is heated to required temperature; transferring heat to the sheet metal from the working roll; heating the sheet metal; cooling the sheet metal subjected to the roll bending forming; and cutting according to a set length. Furthermore, the invention also provides a roll centre heating type roll bending forming device according to the method. The device comprises a roll bending forming machine, a computer system, a heating system, a cooling system and a gas protective cover. Compared with the traditional roll bending forming device, the invention has the advantages of less forming times and high surface quality of a product; and the sheet metal which is difficultly formed is processed more easily.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Split type mussel reaping device

ActiveCN105394002ASolve the ruptureSolve problems such as mussel meat pressure lossClimate change adaptationPisciculture and aquariaEngineeringMechanical engineering

The invention discloses a split type mussel reaping device, and the split type mussel reaping device can solve the problem that damage to mussels is too much due to the current mussel reaping method and can perform preliminary screening on the mussels and impurities. The split type mussel reaping device includes a culture rope, a rack, and self-shedding removing device arranged on the rack. The culture rope includes a bearing core rope and a plurality of attachment ropes which are parallelly wound outside the bearing core rope. The self-shedding removing device includes: a first horizontal guide rail arranged on the rack; a first sliding base which is slidably arranged on the first horizontal guide rail; a translation execution device which is used for driving the first sliding base to move; a first clamping support arranged on the first sliding base; a second horizontal guide rail which is arranged on the rack and is parallel to the first horizontal guide rail; a second sliding base which is slidably arranged on the second horizontal guide rail; and a second clamping support arranged on the second sliding base.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

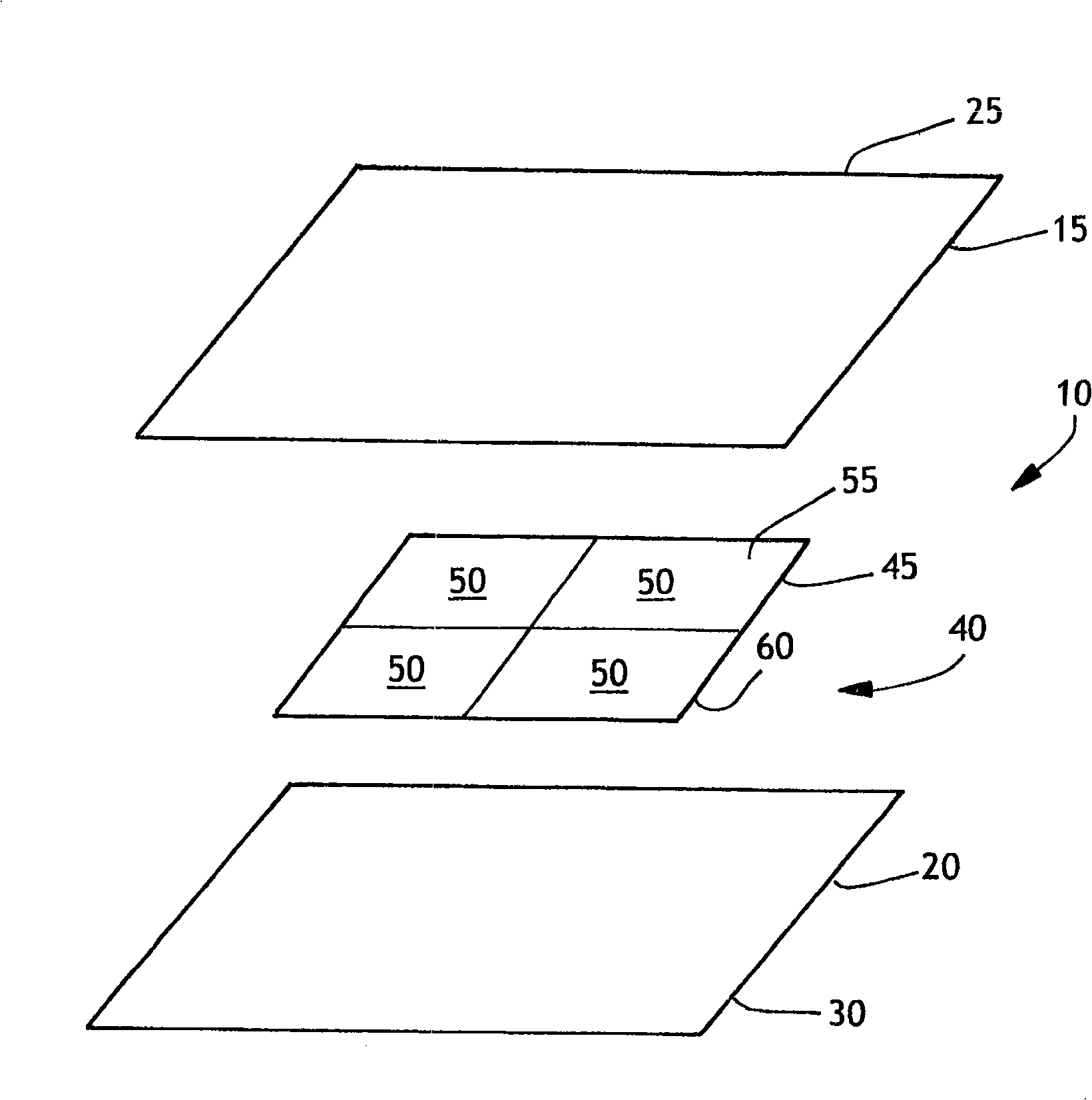

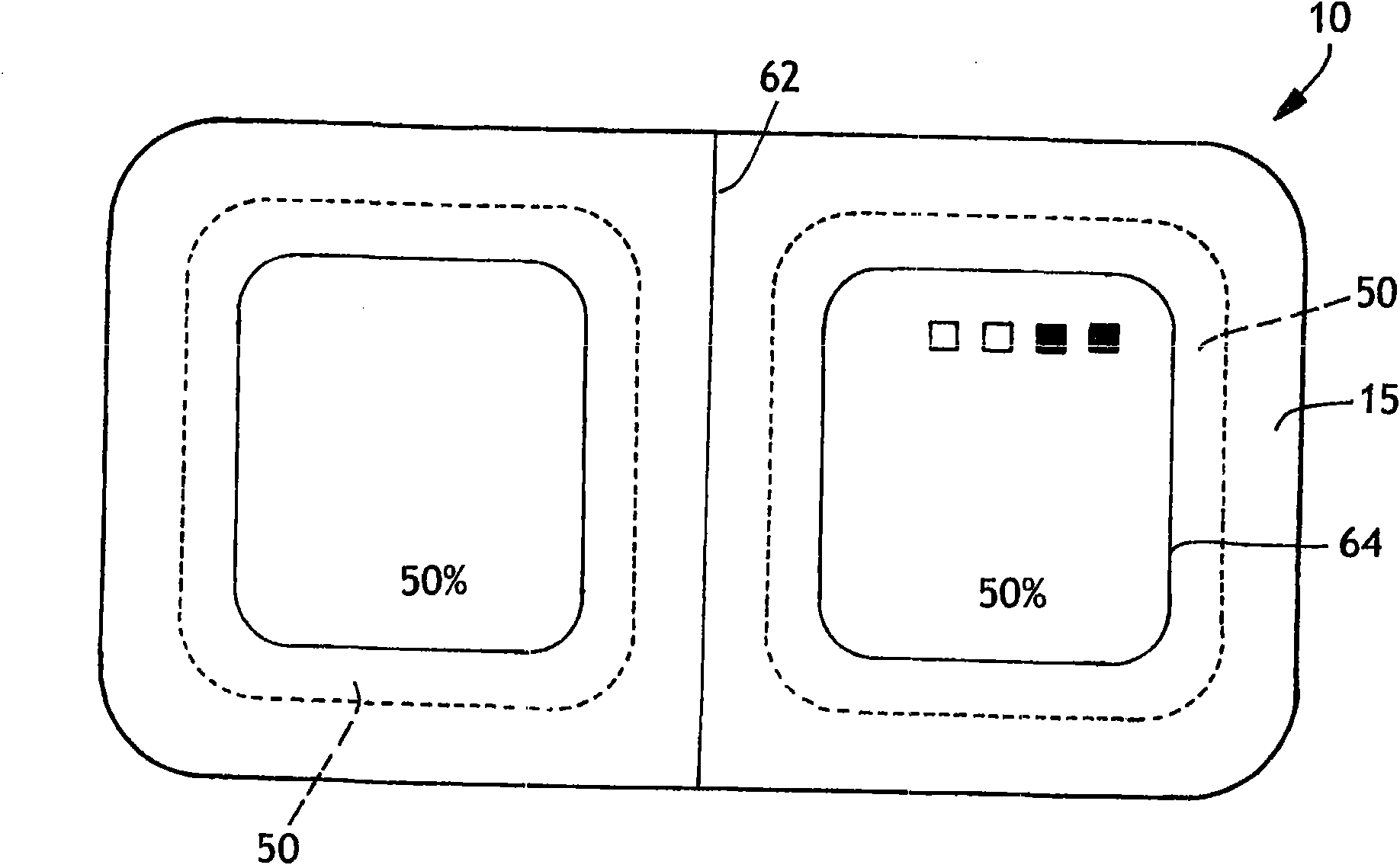

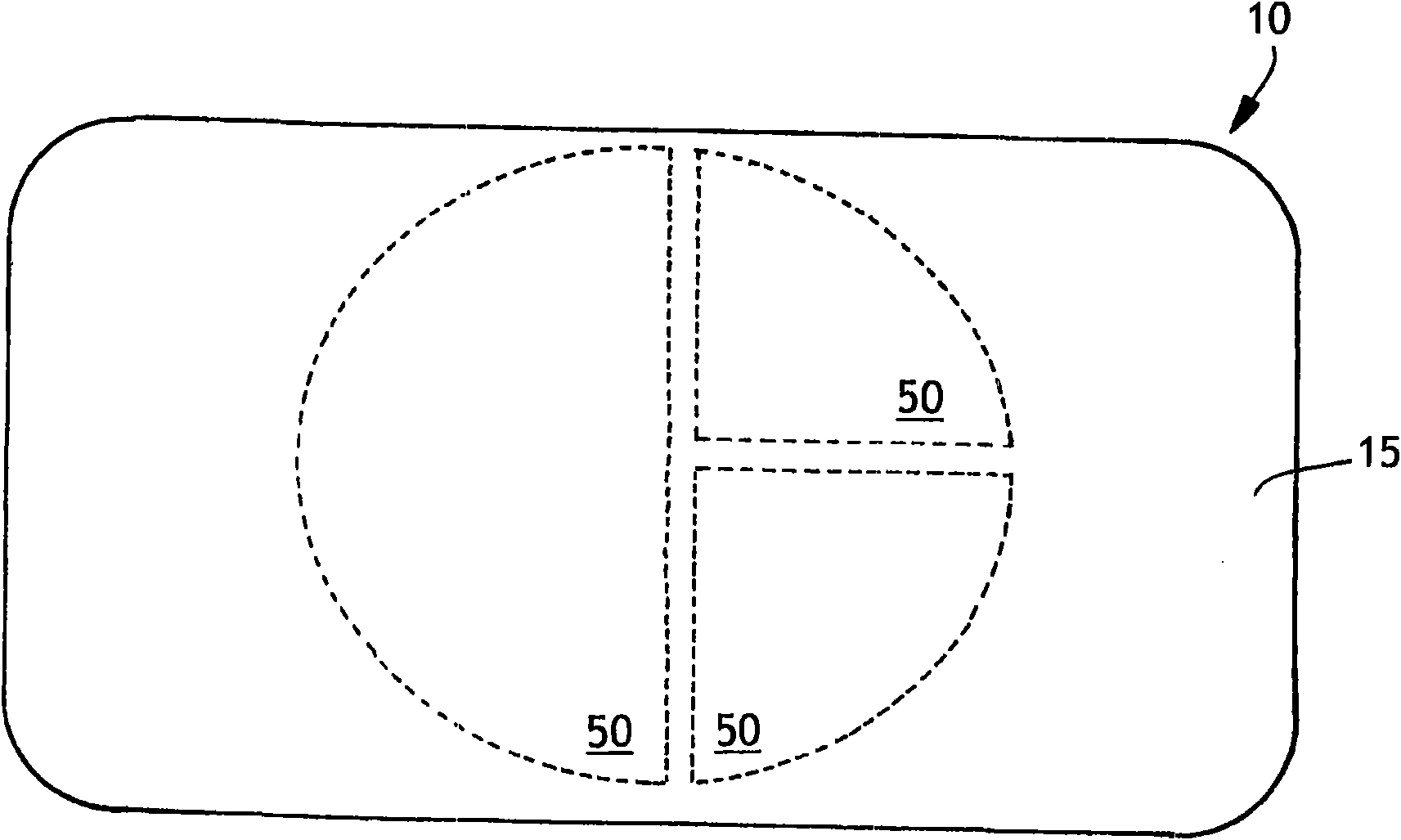

Disposable wipe with substance-filled blisters

The present disclosure provides a device including a base layer (20); a wipe layer (15) attached to the base layer to define an interior space between the wipe and base layers; a plurality of blisters (50) positioned within the interior space, each blister having a blister volume, wherein the sum of the blister volumes is a total blister volume; and an indication disposed on the wipe layer or the base layer corresponding to a single blister or a group of blisters indicating the ratio of the blister volume of that single blister or the sum of the blister volumes of that group of blisters to the total blister volume.

Owner:KIMBERLY-CLARK WORLDWIDE INC

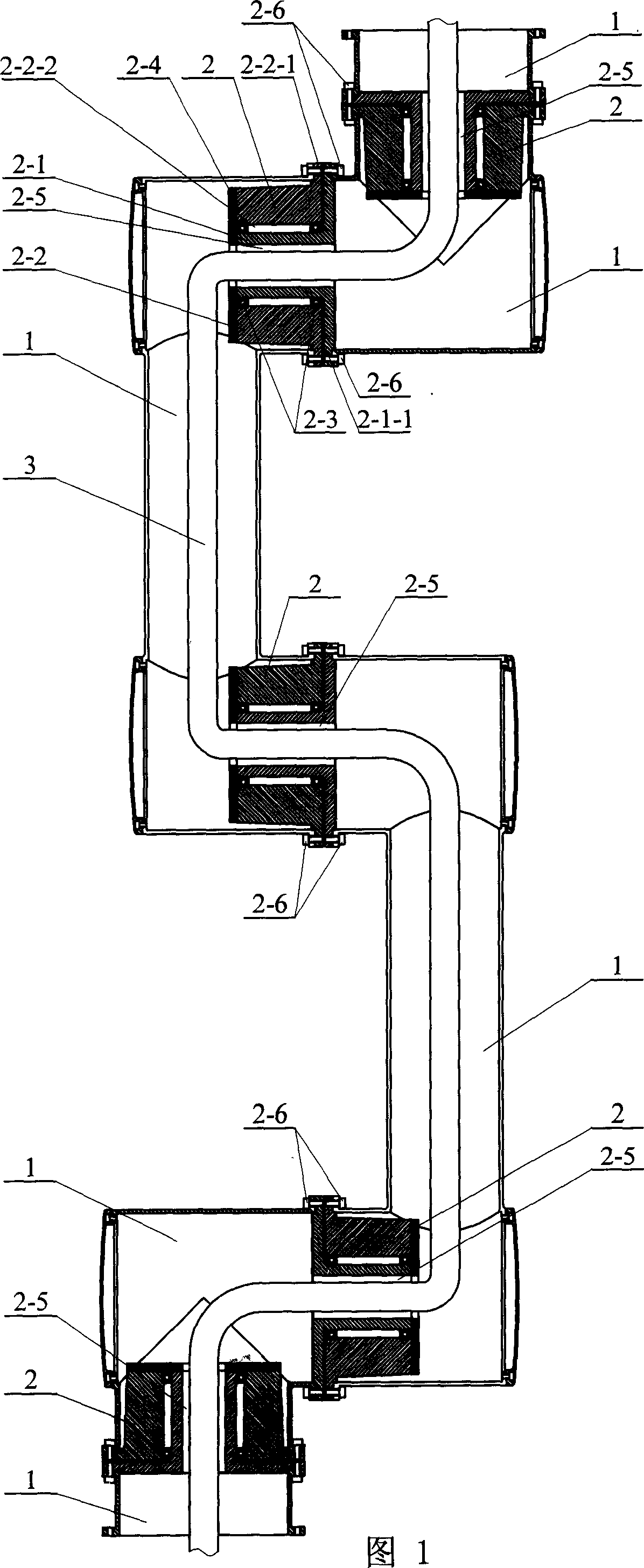

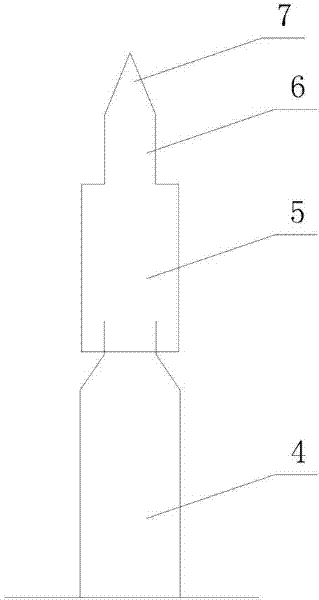

Robot arm with wire traveling central hole

InactiveCN1807033ASolve the ruptureImproved ability to adapt to harsh environmentsArmsHard radiationControl theory

The invention relates robot arm. The invention provides the robot arm with center hole to solve the problem of wire breaking and coiling, comprising the hollow leg bar (1) and joint (2). The joint (2) is connected with the ends of hollow leg bar (1), and in joint (2) there is routing hole (2-5). Using the invention, the wire is not damaged in the condition of high and low temperature and hard radiation, and the adaptability of robot is enhanced.

Owner:HARBIN INST OF TECH

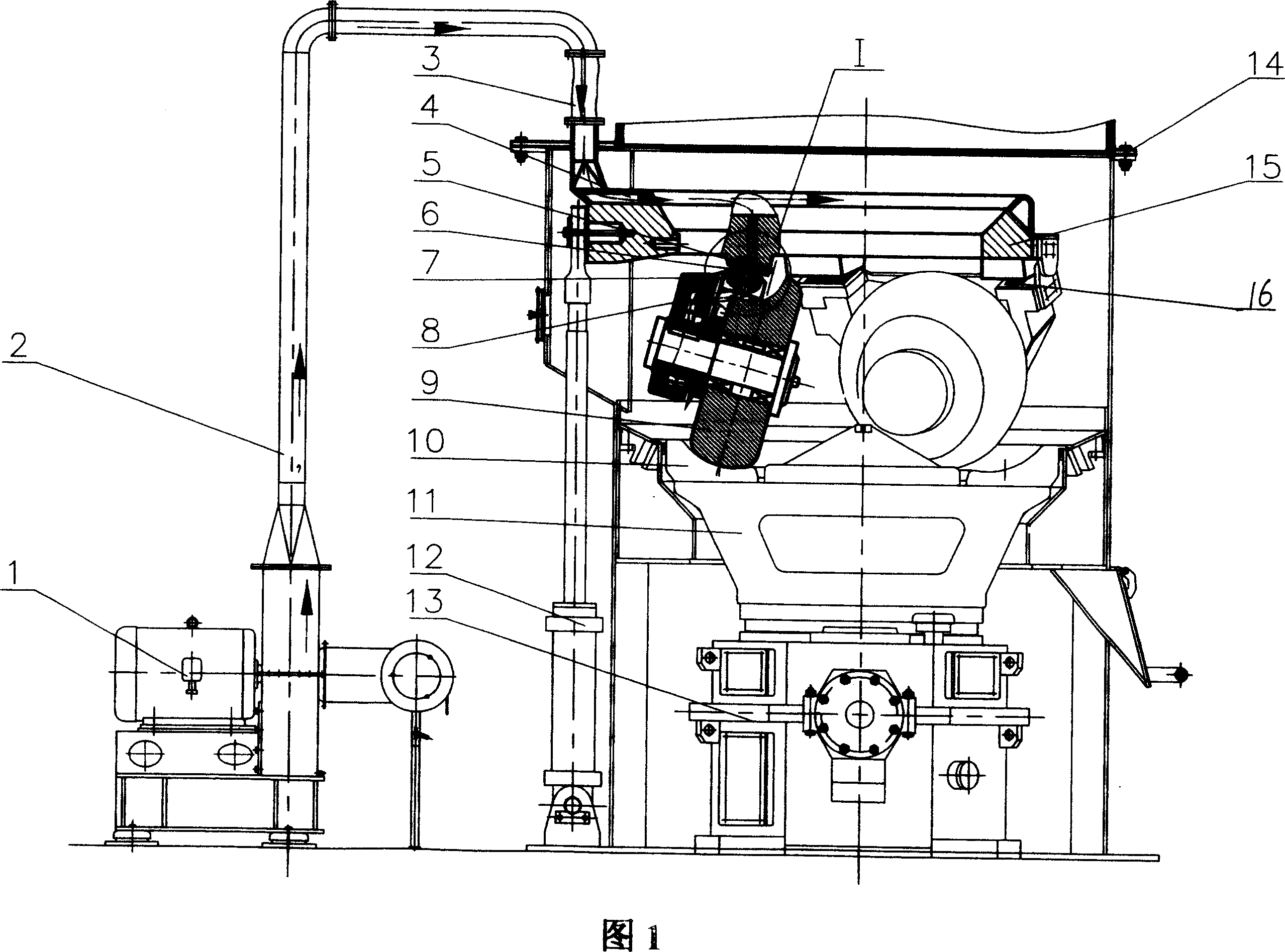

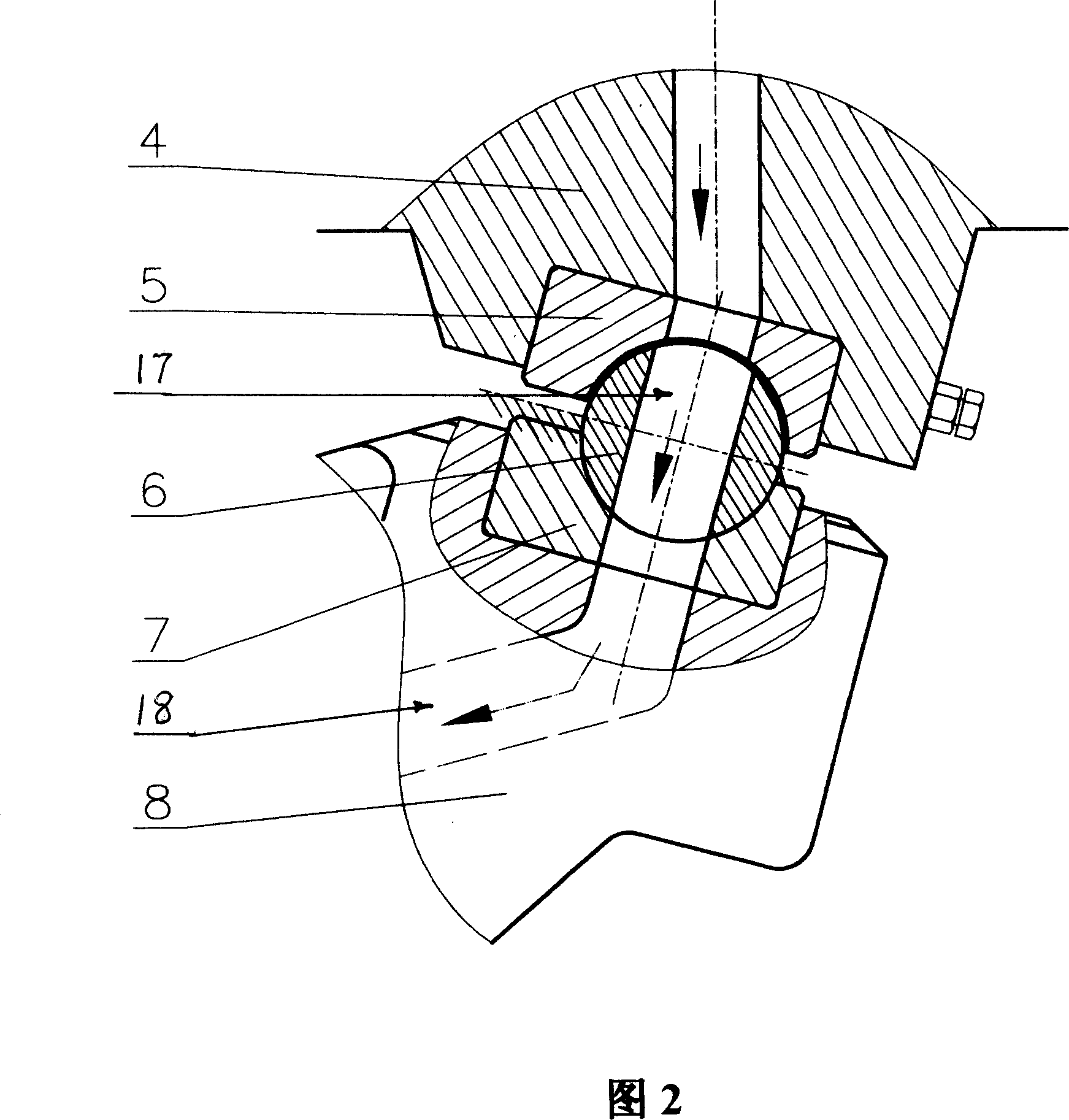

Enclosed air passage system for grinding roll

ActiveCN101007293ASolve seal failureSolve rigid problemsGrain treatmentsPositive pressurePulp and paper industry

Grinding roller sealed air duct system includes fan, external pipe lines, soft connectivity, pipe lines fixed on pressure framework, upper roller seat, sealing roller, lower roller seat, grinding roller frame and grinding roller; its characteristics is said upper roller seat, sealing roller and lower roller seat combine sealed air duct, the sealed air duct is connected with air holes of grinding roller frame. The fan transmits positive pressure wind into the sealed air duct combine by upper roller seat, sealing roller and lower roller seat through external pipe lines and pipe lines fixed on pressure framework, and blowout wind through the air holes of grinding roller frame and the chine between grinding roller frame, grinding roller and grinding roller frame driving rotating components.The invention solves the problem of grinding roller seal failure because of vibration joint wear, while solves the problems of the grinding leakage of loop pipe line and grinding roller frame air-supply line because of long-time mill vibration and dust wind erosion, or rigidity injury even breach lead by mill shape vibration. The invention not only saves a lot of investment, reduces costs, and is a highly reliable grinding roller sealed air duct system.

Owner:沈阳吉大重型机械有限公司

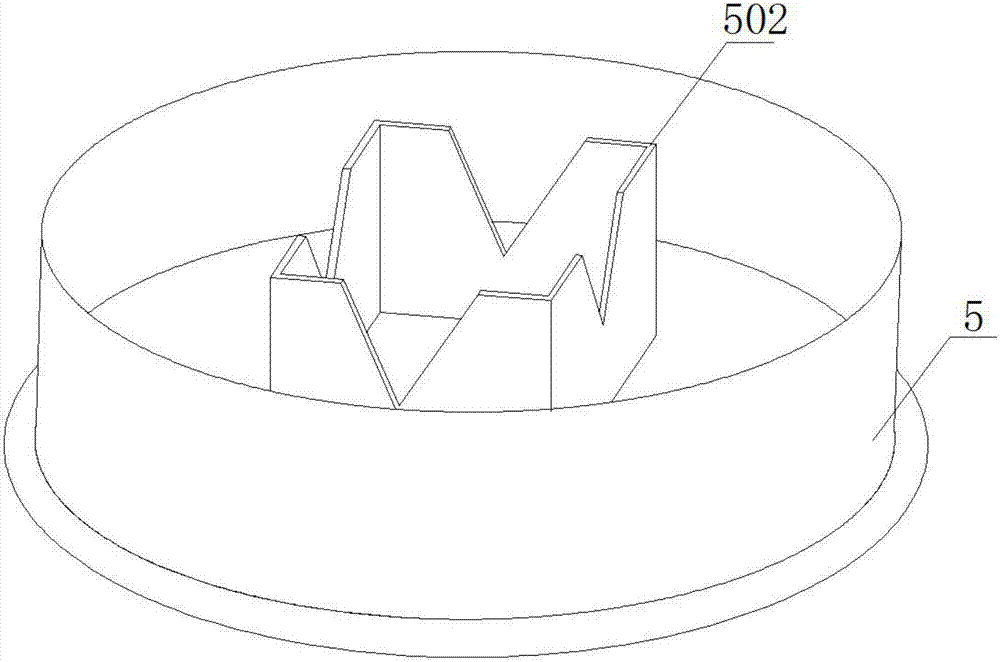

Beverage can with automatic heating device

InactiveCN107089438ASolve the deformationFast heat conductionContainers for heating foodPackaging foodstuffsThin membraneEngineering

The invention discloses a beverage can with an automatic heating device. The beverage can comprises a can body, a top cover and a bottom cover, wherein a heating inner container is arranged at the inner bottom of the can body; the heating inner container is divided into a first accommodating cavity filled with heating medicine and a second accommodating cavity in which a solvent box is placed inside through an annular limiting step; the solvent box is filled with a heating medicine dissolving agent and is sealed through a sealing film; a sharp bulge part of an integrated structure is arranged at the bottom of the inner side of the solvent box; the top end of the sharp bulge part faces the sealing film; an opening of the solvent box faces the bottom of the inner side of the heating container; and when the bottom of the solvent box upwards deforms, the sharp bulge part is in contact with the sealing film and pierces the sealing film. According to the beverage can provided by the invention, the problem that medicine powder loses efficacy due to deformation during high temperature sterilization is well solved.

Owner:王艳琴

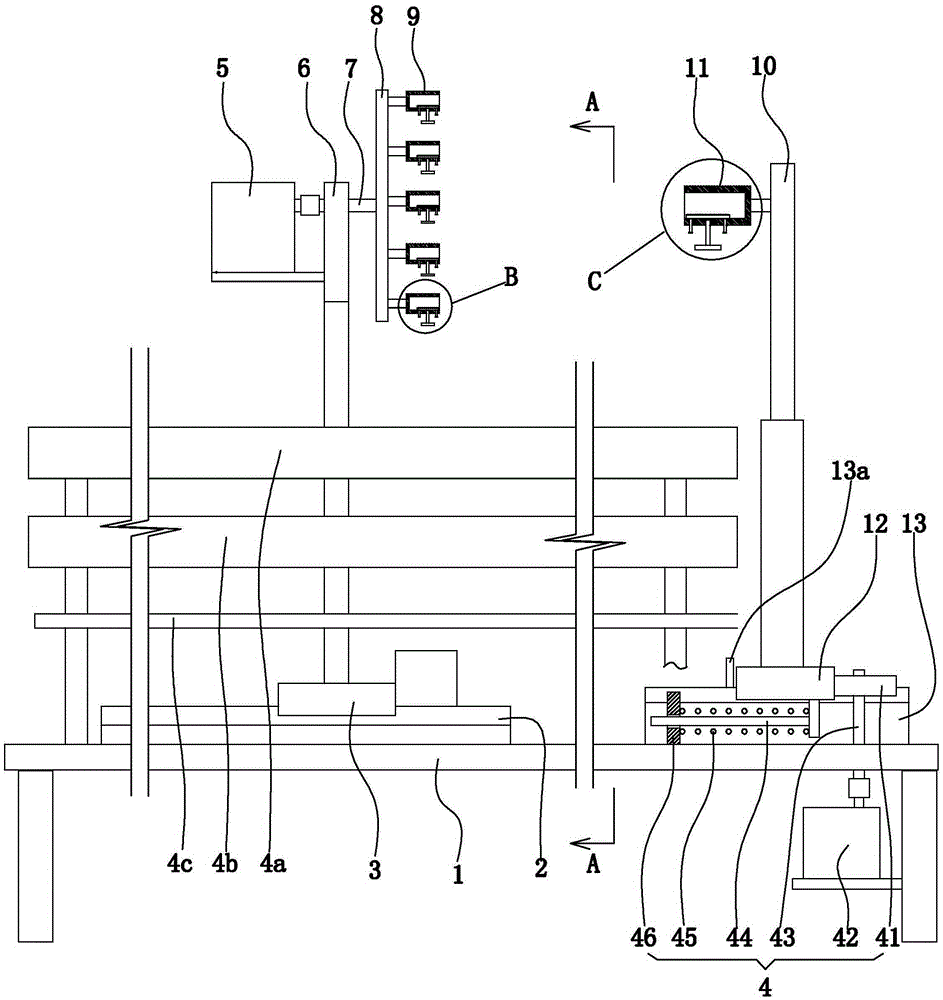

Heating roll-bending shaping method of metal sheet and device thereof

ActiveCN101934309AReduce work hardeningRaise the forming limitComputer control systemEconomic benefits

The invention relates to a heating roll-bending shaping method of a metal sheet, belonging to the roll-bending shaping technique and equipment field, which solves the problem of difficulty in shaping a magnesium alloy, an aluminum alloy and high-strength steel owing to work hardening. The heating roll-bending shaping method is characterized by comprising the following steps: heating the metal sheet in protective atmosphere until the sheet reaches a set temperature, carrying out roll-bending shaping on the sheet, and then cooling the shaped sheet; and finally cutting the cooled metal sheet and packing. The invention further provides a heating roll-bending shaping device for the metal sheet according to the method, which comprises a roll-bending shaping system, a computer control system, a heating system, a cooling system and a gas protection cover. By adopting the device, the metal sheet which is difficult to be shaped can be heated and then subject to roll-bending shaping, cooled and then cut into proper length. Compared with the traditional roll-bending shaping method and the device, the shaping method and the device of the invention have the advantages of less shaping passes, high economic benefit and being capable of more easily machining the metal sheet which is difficult to be shaped owing to work hardening.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

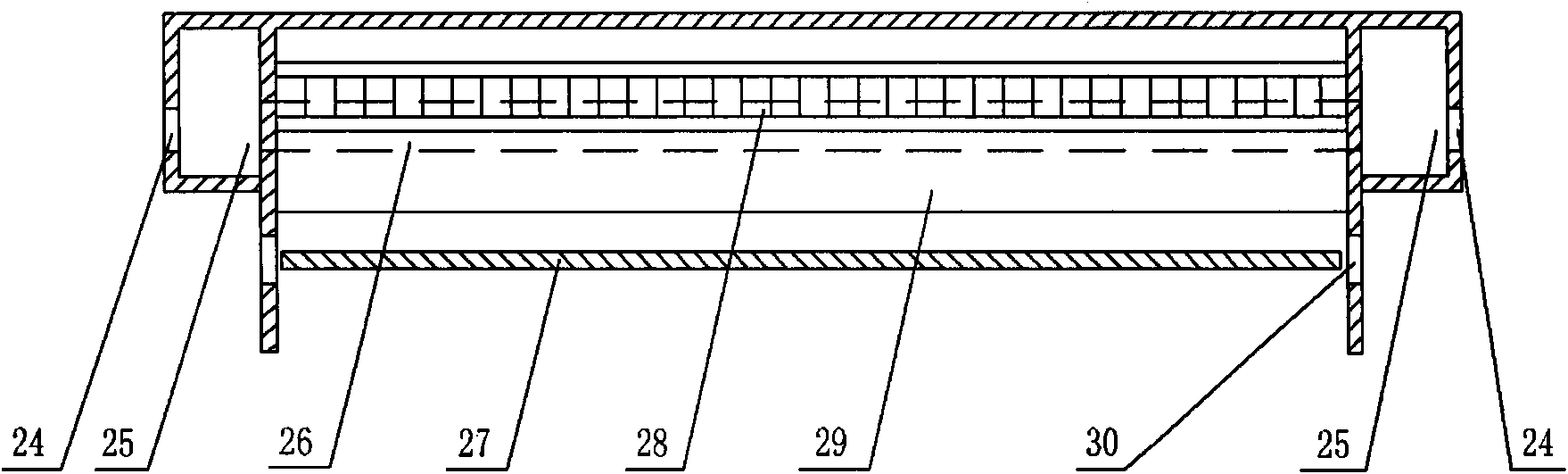

Nondestructive self-shedding type mussel plucking system

ActiveCN105475244ASolve the ruptureSolve problems such as mussel meat pressure lossPisciculture and aquariaEngineeringMechanical engineering

The present invention discloses a nondestructive self-shedding type mussel plucking system. The present invention aims to provide a nondestructive self-shedding type mussel plucking system capable of effectively solving the problems that for an existing mussel plucking and harvesting method, mussel damage is large, even mussel shells are fractured and mussel meat is damaged due to pressing. The nondestructive self-shedding type mussel plucking system comprises a cultivation rope, a frame and a self-shedding removing device disposed on the frame; the cultivation rope comprises a bearing core rope and a plurality of adhesion ropes parallelly wound outside the bearing core rope; and the self-shedding removing device comprises a first horizontal guide rail disposed on the frame, a first slide carriage slidably disposed on the first horizontal guide rail, a translation execution device for driving the first slide carriage to move, a first clamping support disposed on the first slide carriage, a second horizontal guide rail which is disposed on the frame and parallel with the first horizontal guide rail, a second slide carriage slidably disposed on the second horizontal guide rail, and a second clamping support disposed on the second slide carriage.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

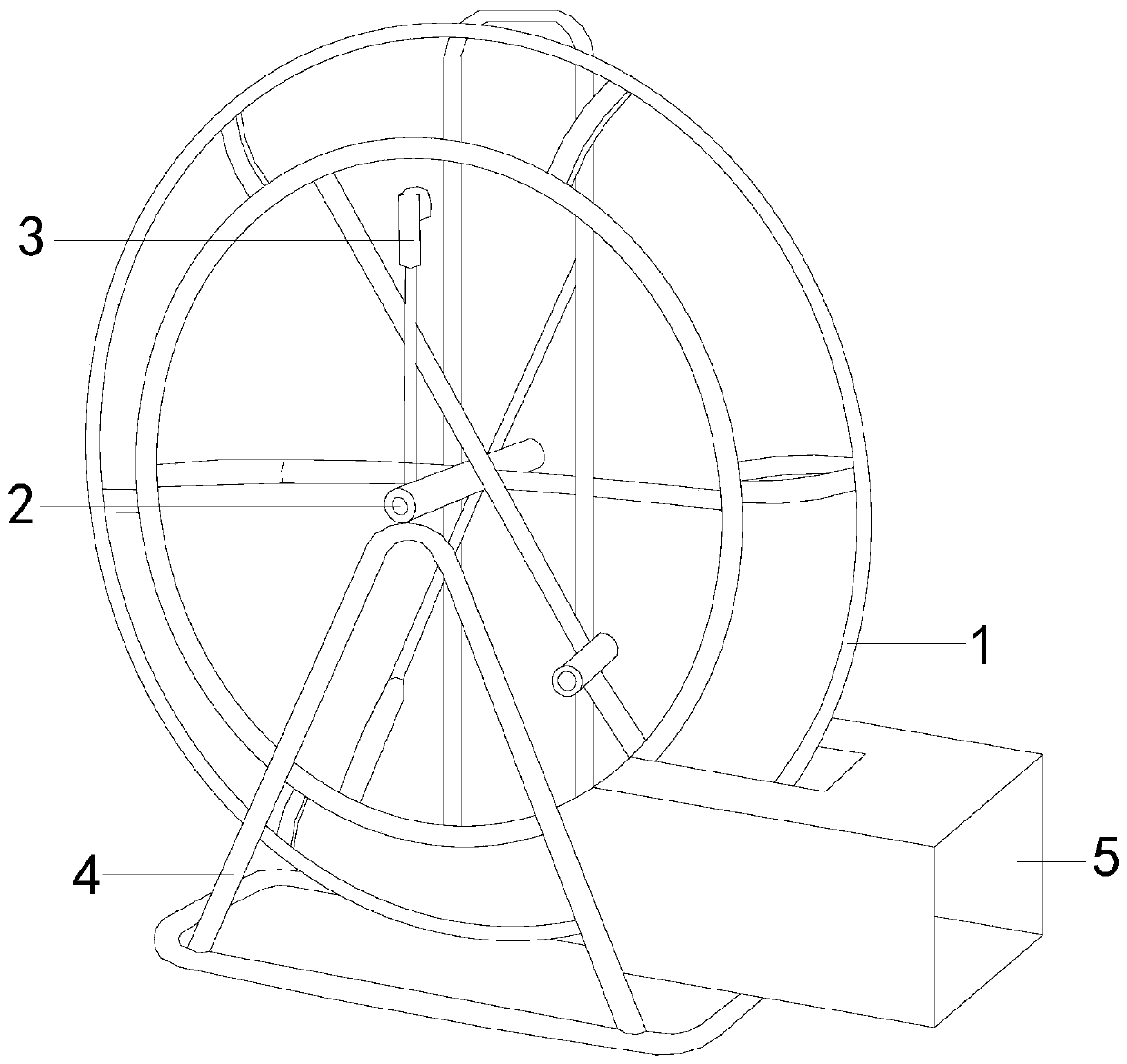

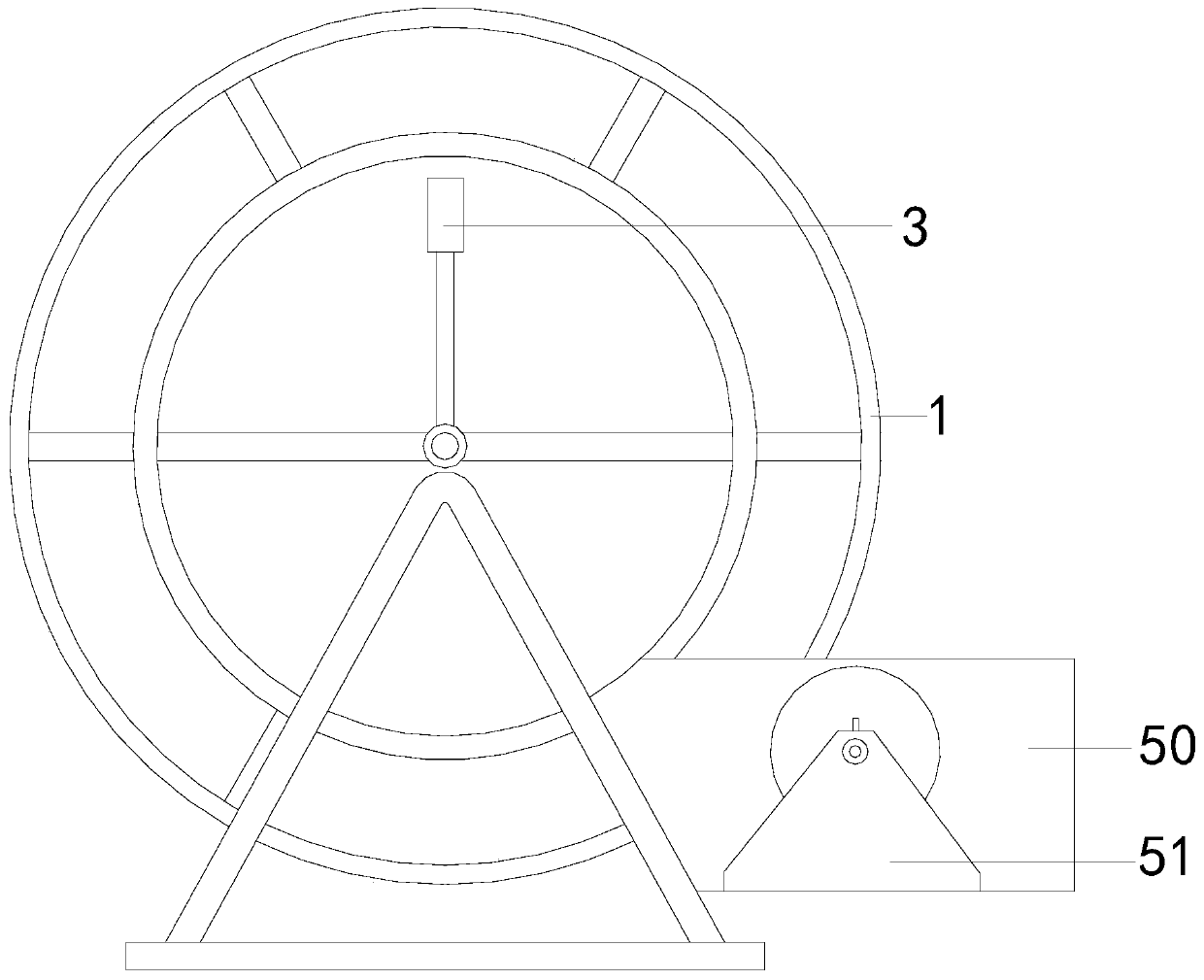

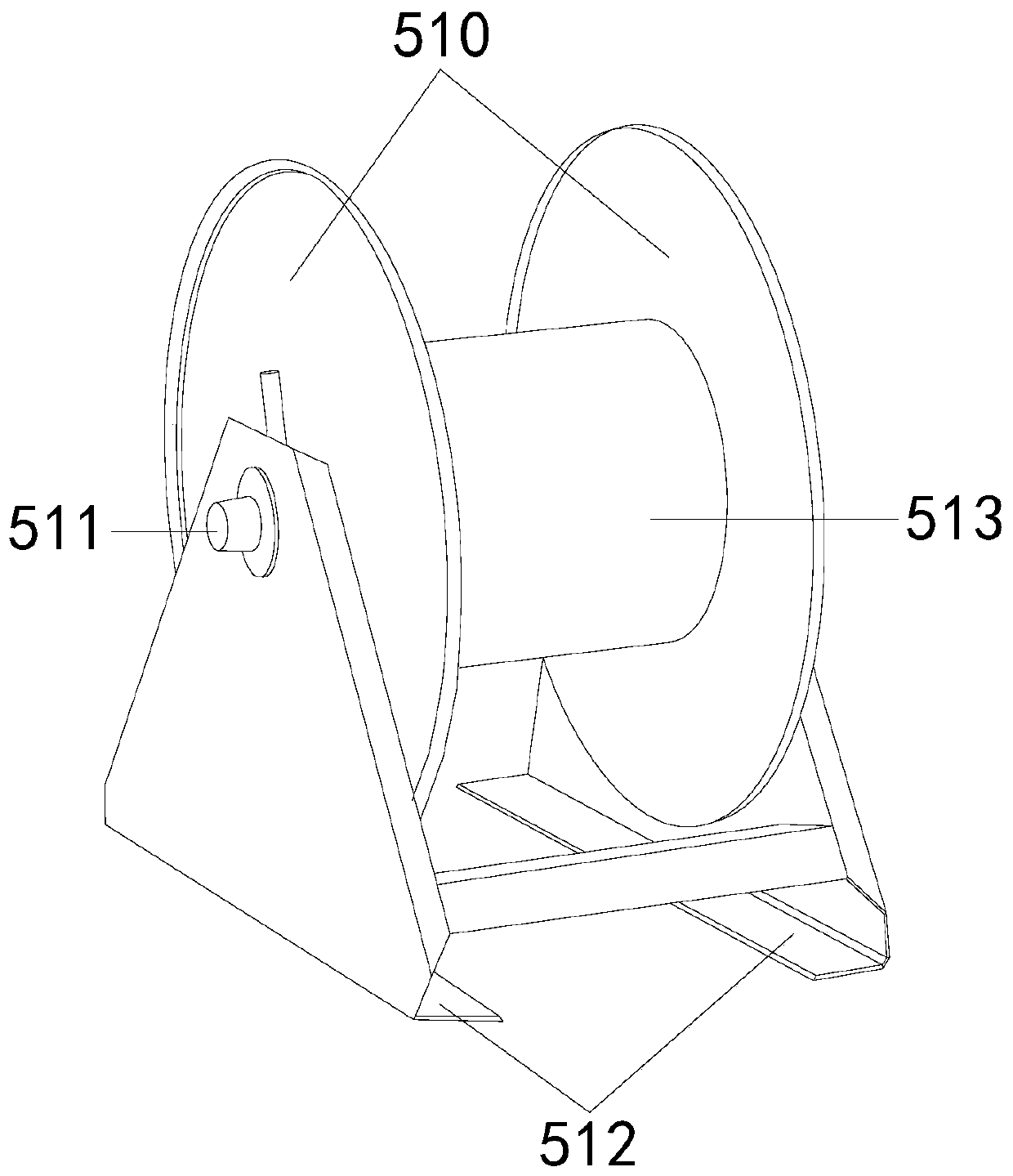

Easy-to-maintain talcum powder laying device prior to cable coiling

The invention discloses an easy-to-maintain talcum powder laying device prior to cable coiling. The talcum powder laying device comprises a coiling frame, a fulcrum shaft rod, a rotating rod, a bracket and a sleeve clamping mechanism, and has the beneficial effects that the sleeve clamping mechanism different from a conventional structure can lay the talcum powder on the cable. A mode of inorganically filling a sheath tube of a high-voltage power cable with talcum powders breaks a traditional mode of an organic polymer plastic auxiliary reinforcing material. The cable can be threaded into thesleeve by coiling. By special airbag-shaped upper and low clamping blocks in a laying frame in the sleeve clamping mechanism, sufficient clamping force can be maintained in the process of laying talcum powder in the sleeve clamping mechanism, the sleeve can be prevented from rupturing due to excessively hard member during operation, and the equipment can be easily maintained.

Owner:绍兴市梓昂新材料有限公司

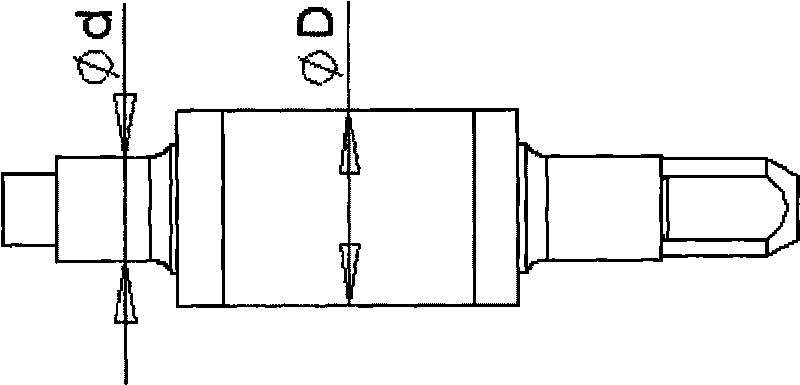

Hot charging thick-wall combination roller with bimetal roll cover

InactiveCN101704024AIncrease wall thicknessImprove securityRollsMetal rolling arrangementsEngineeringThick wall

The invention discloses a hot charging thick-wall combination roller with a bimetal roll cover, belonging to the technical filed of metallurgical machinery, and comprising pot heads, compression rings, a roll sleeve and a core shaft. The combination roller is characterized in that the roll sleeve (3) and the pot head (1) are assembled on the core shaft (4) in an interference manner after being heated to expand, the joint of the pot head (1) and the roll sleeve (3) is processed to the same size and simultaneously is interference connection with a compression ring (2); and the thickness of the roll sleeve 3 is as follows: phi D is the diameter of the roller body, and phi d is the diameter of the roller neck. The roll sleeve (3) is bimetal, the outer layer of which is made from a high alloy abrasion-proof material and the inner layer is made from a high ductile material; the number of the pot head (1) and the number of the compression ring (2) are both two; the compression ring (2) is made from a high strength alloy steel; and the combination roller has the advantages that the service life can be improved for several times, the roller can be changed from large to small for multi-time use after being used, after scraping, the noble alloy can be recovered totally, thereby saving energy, reducing energy consumption, and having obvious effects on lowering cost and increasing effectiveness.

Owner:HUNAN 3T NEW MATERIAL

Pipeline system with vacuum heat preservation function

InactiveCN105351684AQuick assemblyEasy to installThermal insulationPipe protection by thermal insulationTerrainIsolation layer

The invention provides a pipeline system with a vacuum heat preservation function. The pipeline system comprises a conveying pipeline (20) sleeved with a plurality of straight pipe heat preservation units and bend heat preservation units which are connected in series. Each straight pipe heat preservation unit comprises an inner straight pipe body (1) and an outer straight pipe body (2) wrapping a straight section of the conveying pipeline (20). Each bend heat-preservation unit comprises an inner bend pipe body (5) and an outer bend pipe body (6) wrapping a bend section of the conveying pipeline (20). The pipeline system with the vacuum heat preservation function is simple in structure and convenient to install, and can adapt to pipeline layout in various terrains through the matching of the straight pipe units and the bend units. A vacuum heat isolation layer between every two adjacent pipeline units can well carry out heat preservation and heat isolation on liquid in the inner pipes. Each vacuum heat isolation layer is an independent structure, the overall structure can not be damaged if one vacuum heat isolation layer is damaged, the application range is wide, and the pipeline system with the vacuum heat preservation function has great popularization value.

Owner:白明军

Dyeing method of non-bobbin elastic fibre cheeses

ActiveCN102230260AOutstanding advantagesHighlight positive effectsLiquid/gas/vapor removalLiquid/gas/vapor yarns/filaments treatmentDyeingYarn

Owner:ZHEJIANG QIAOERTINGTING FASHION

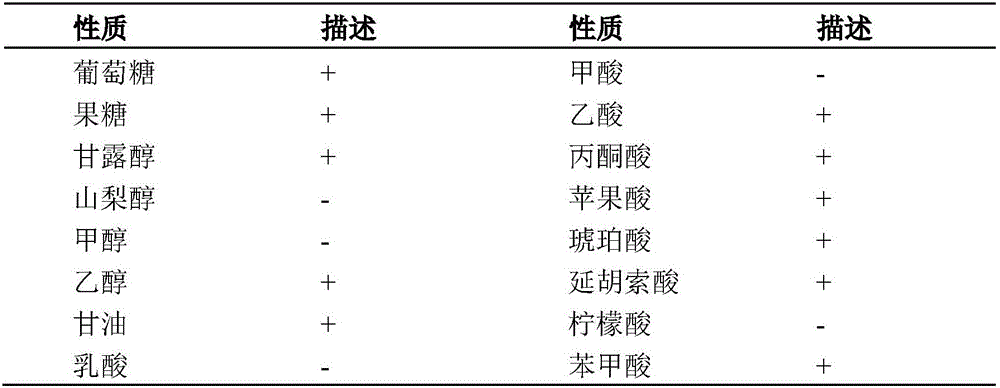

Thiobacillus thioparus and high-activity culture method

InactiveCN106635866AReduce the difference between internal and external osmotic pressureFree from salt erosionBacteriaMicroorganism based processesMixed cultureInorganic salts

The invention discloses thiobacillus thioparus and a high-activity culture method. The category name is thiobacillus thioparus and the Latin name of the strain is thiobacillus thioparus; the preservation date is July 11, 2016 and the registering number in China General Microbiological Culture Collection Center (CGMCC) is CGMCC No.12756. An autotrophic culture medium and a protective agent are prepared into a mixed culture medium in a container and the liquid filling amount of the mixed culture medium is 10%-20% of the volume capacity of the container; the culture medium is sterilized; thiobacillus thioparus is inoculated according to the amount of 2%-5% of the volume ratio of the mixed culture medium; the temperature is controlled to be 28 DEG C-30 DEG C and the rotary speed of a shaking table is 160rpm / min-180rpm / min; and the strain is cultured for 48h-72h. By adopting the method to culture thiobacillus thioparus, a protein salting-in phenomenon of cell membranes and cell walls of thiobacillus thioparus, generated by inorganic salt in the autotrophic culture medium, can be effectively avoided, so that the death rate of thalli is reduced and the activity of the thalli is improved. Furthermore, the method has the characteristics of simplicity in operation, low cost, remarkable effect and the like.

Owner:NANJING NORMAL UNIVERSITY

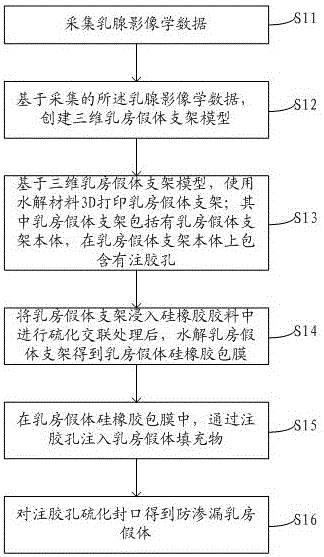

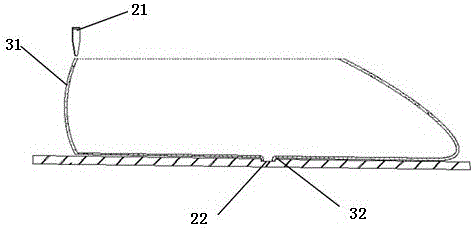

3D printing-based anti-seep breast prosthesis forming method and breast prosthesis

ActiveCN106073943AAchieve seamless closureSolve the ruptureMammary implantsAdditive manufacturing apparatusBiomedical engineeringMedicine

The invention discloses a 3D printing-based anti-seep breast prosthesis forming method and a breast prosthesis, solving the technical problem of rupture or seep of the existing breast prosthesis. The method comprises the following steps: acquiring mammary gland image data; creating a 3D breast prosthesis stent model based on the acquired mammary gland image data; carrying out 3D printing by using a hydrolysis material based on the 3D breast prosthesis stent model so as to obtain a breast prosthesis stent, wherein the breast prosthesis stent comprises a breast prosthesis stent body, and a glue injecting hole is formed in the breast prosthesis stent body; immersing the breast prosthesis stent in a silicone rubber sizing material for carrying out vulcanizing and crosslinking treatment, and hydrolyzing the breast prosthesis stent to obtain a breast prosthesis silicone rubber envelope; injecting breast prosthesis filler into the breast prosthesis silicone rubber envelope through the glue injecting hole; and vulcanizing and sealing the glue injecting hole so as to obtain the anti-seep breast prosthesis. The breast prosthesis obtained by the forming method does not have gaps, conforms to human engineering mechanics, and can be ensured to be free from seep.

Owner:深圳尤尼智康医疗科技有限公司

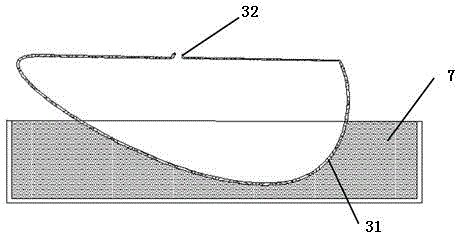

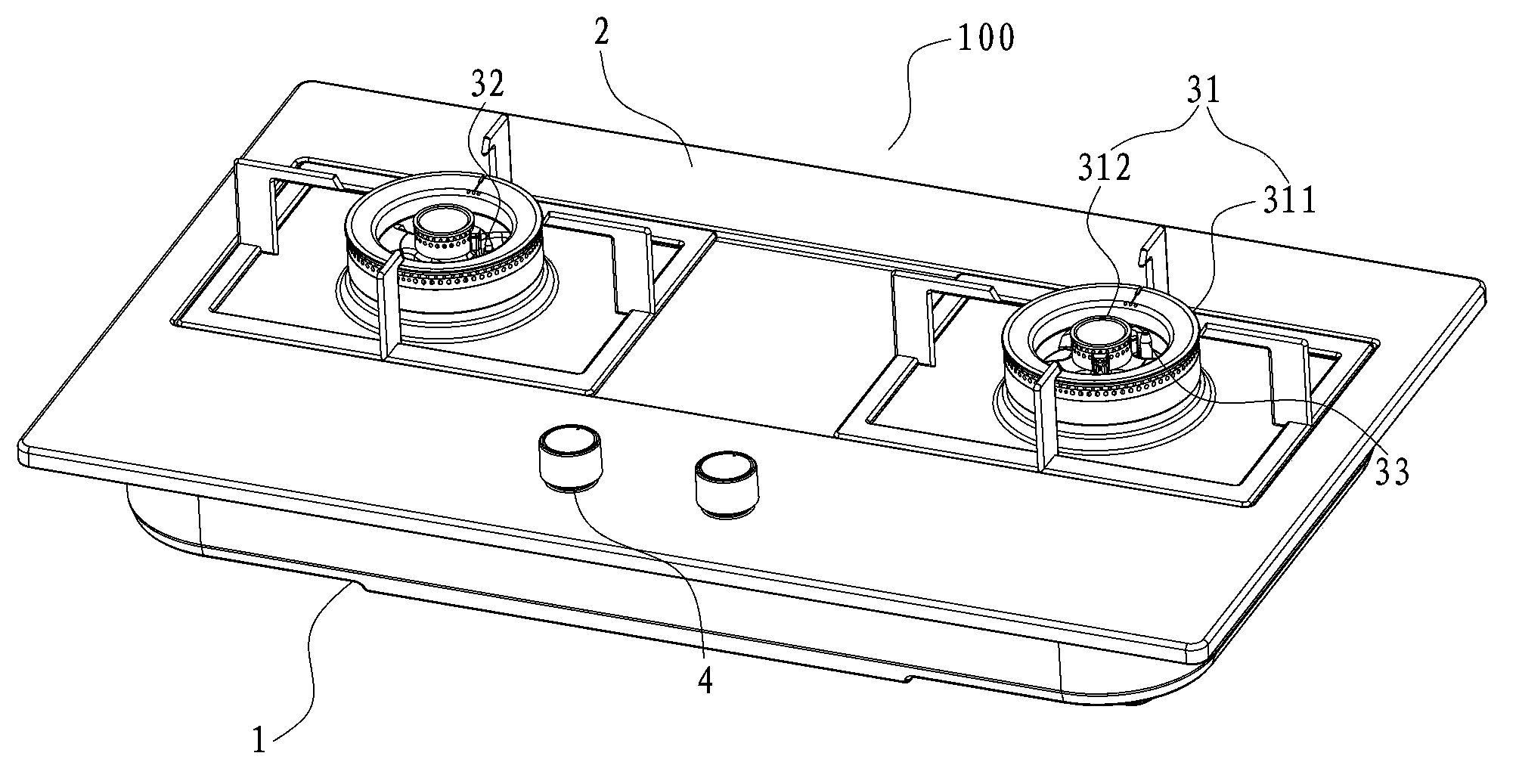

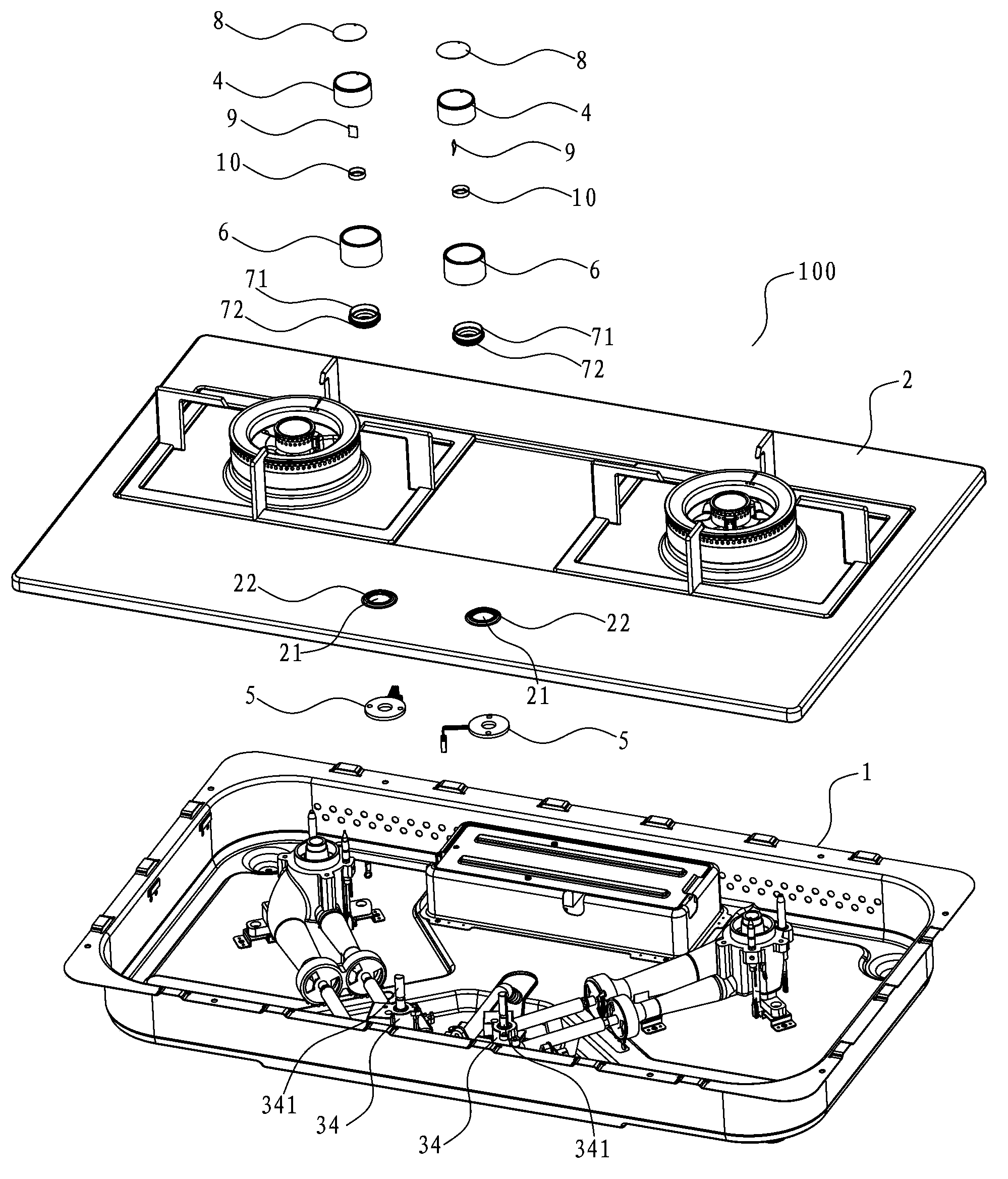

Gas stove

InactiveCN104235885AEasy to adjustImprove human-computer interactionDomestic stoves or rangesLighting and heating apparatusCombustorInductor

The invention discloses a gas stove comprising a base, a panel, a combustor device, an inductor, a rotary knob and a lamp, wherein the panel is arranged on the base and is used for defining an accommodating space together with the base; at least part of the combustor device is arranged in the accommodating space; the inductor is arranged on the combustor device to induce a working signal of the combustor device; the rotary knob is arranged on the panel; and the lamp is arranged in the accommodating space and emits light transmitted to the rotary knob when the inductor induces the working signal of the combustor device. According to the gas stove disclosed by the invention, the light emitted by the lamp can be transmitted to the rotary knob when the gas stove is in a working state, a user can know whether the combustor device is in the working state through observing whether the rotary knob emits light, and the combustor device is proven to be in the work state if flames exist, so that the man-machine interaction is enhanced; in addition, the environment surrounding the rotary knob is also lightened by light emitted by the rotary knob, so that the user can easily and clearly see the sign for indicating the thermal power, and furthermore, the rotary knob is conveniently regulated by the user.

Owner:MIDEA GRP CO LTD

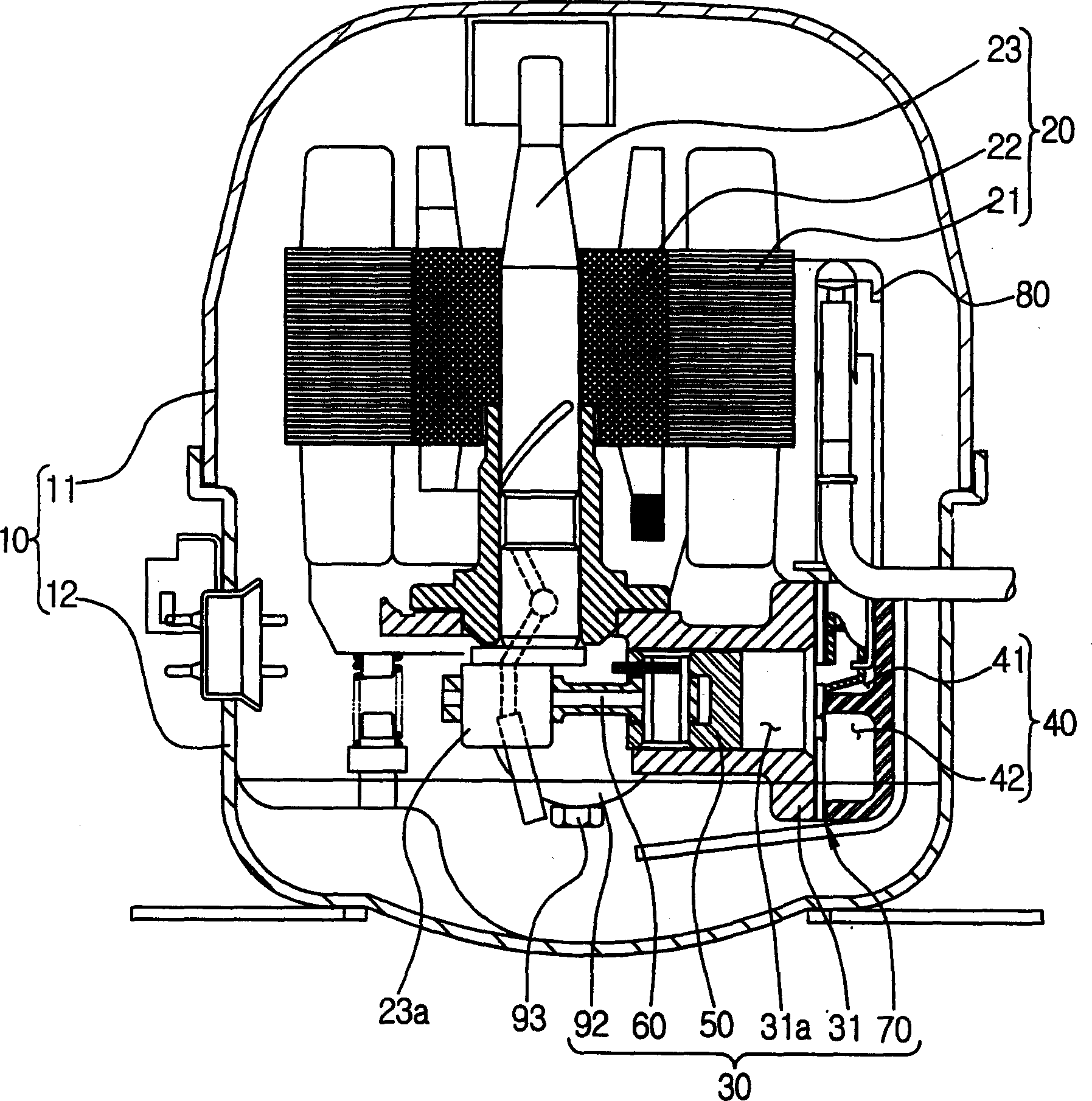

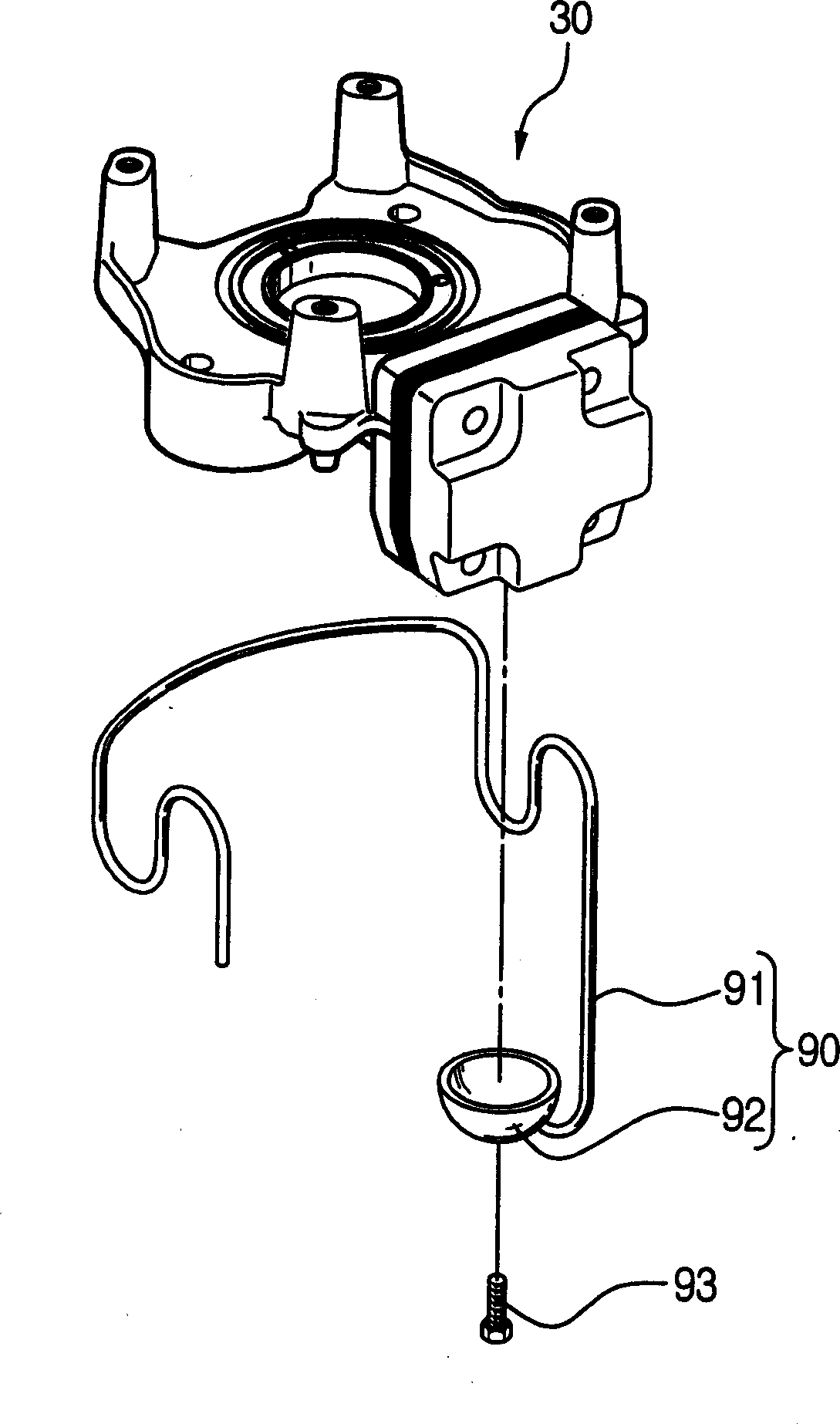

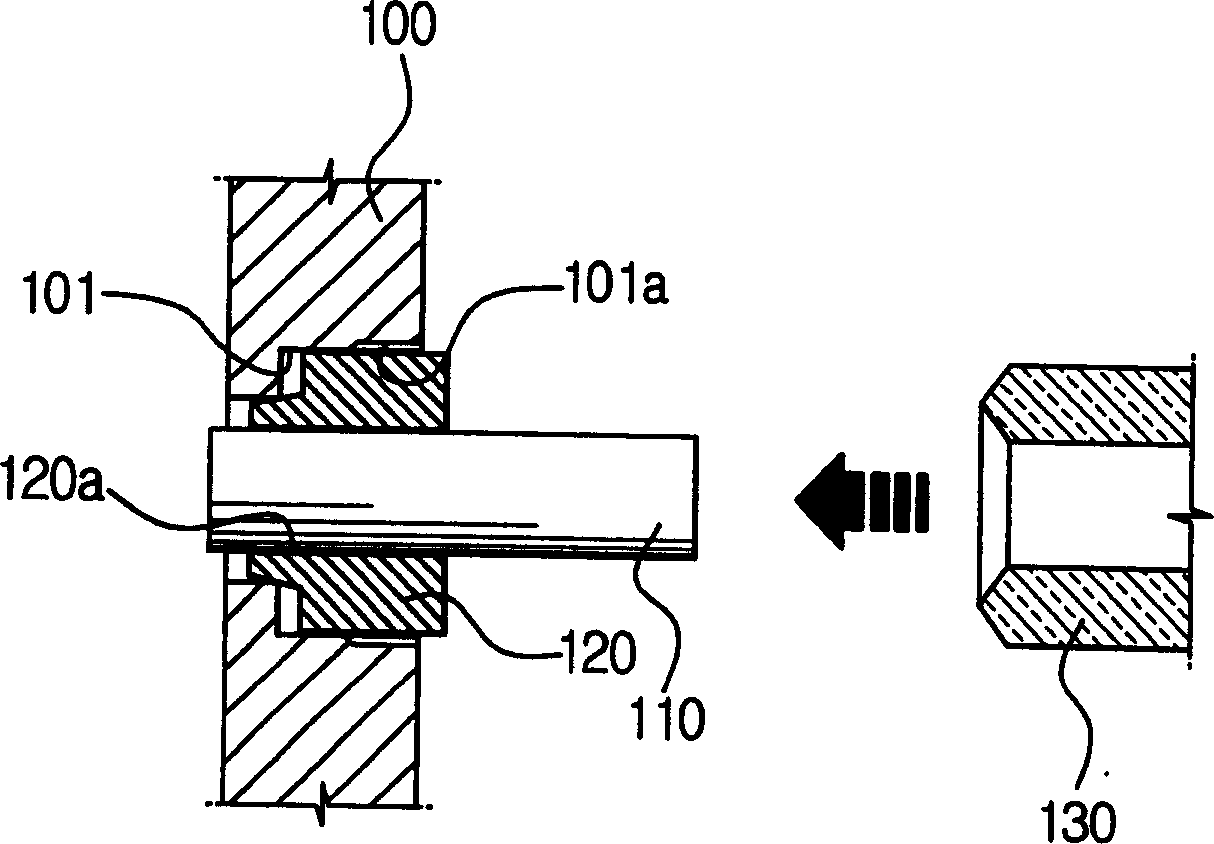

Joint structure for refrigerant discharge tubes used in hermetic compressors

InactiveCN1482360AReduce stepsImprove production efficiencyPositive displacement pump componentsPiston pumpsEngineeringCylinder block

A joint structure for a refrigerant discharge tube of a hermetic reciprocal compressor having a connecting member fit around the refrigerant discharge tube, the connecting member having a shape corresponding to a connecting hole in a cylinder block, thereby allowing the connecting member to be press-caulked. The refrigerant discharge tube is directly connected to the cylinder block. The connecting hole is multi-layered and may be formed into at least two steps. The connecting member is pre-assembled in the connecting hole by transition-fitting. Accordingly, as the connecting member is press-fit in the connecting hole by a caulking-jig, the connecting member is expanded, and the connecting member is more securely fit in the connecting hole. Since the refrigerant discharge tube is directly connected to the cylinder block, structure is simplified, while the number of assembling steps is reduced. Further, since the connecting member is fit in the connecting hole by the press-caulking instead of the brazing, higher durability is guaranteed and thus, the breakage of the refrigerant discharge tube is prevented.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

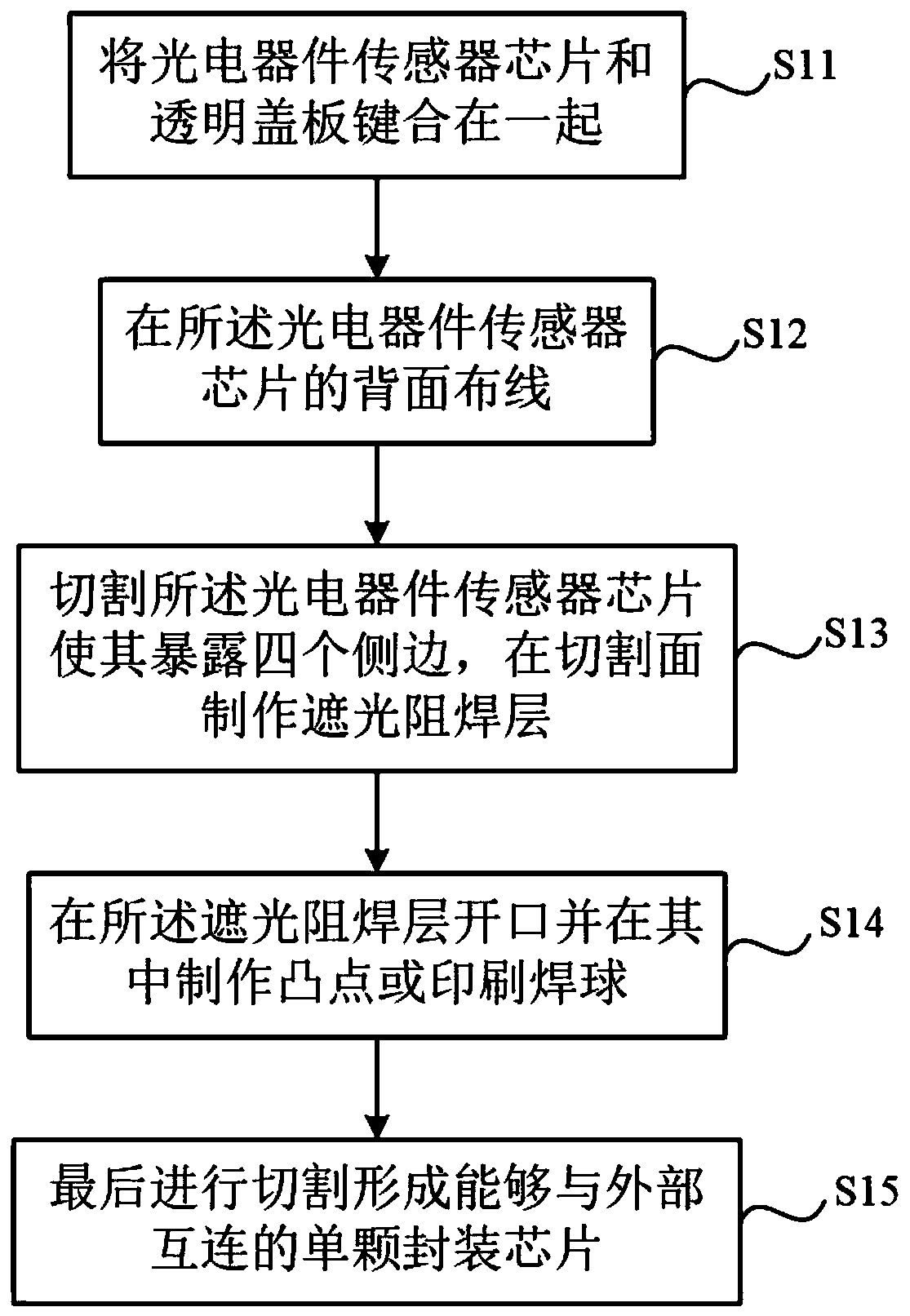

Photoelectric device packaging method and packaging structure

PendingCN110197835ASolve the ruptureSolve the problem of electrical failureSolid-state devicesRadiation controlled devicesSolder ballEngineering

The invention discloses a photoelectric device packaging method and a packaging structure, and belongs to the technical field of integrated circuit packaging. The method comprises the steps of: bonding a sensor chip of a photoelectric device and a transparent cover plate together; performing wiring at the back of the sensor chip of the photoelectric device, cutting the sensor chip of the photoelectric device to expose four sides of the sensor chip, and manufacturing a shading and welding-resisting layer on the cutting surface; performing opening at the shading and welding-resisting layer, andmanufacturing salient points or printing solder balls in the shading and solder-resisting layer; and finally, performing cutting to form a single package chip mutually connected with the external portion.

Owner:58TH RES INST OF CETC

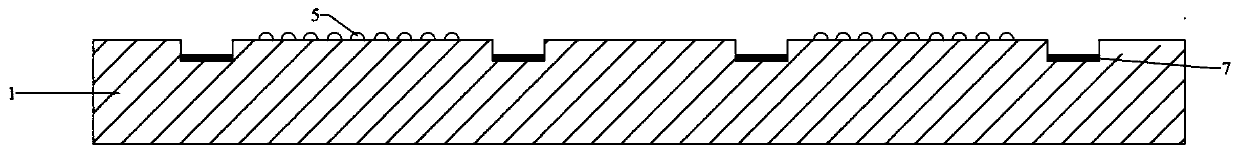

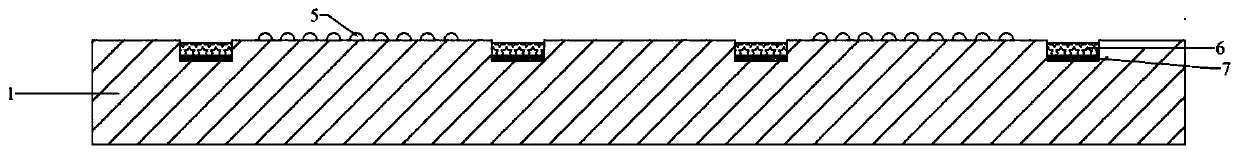

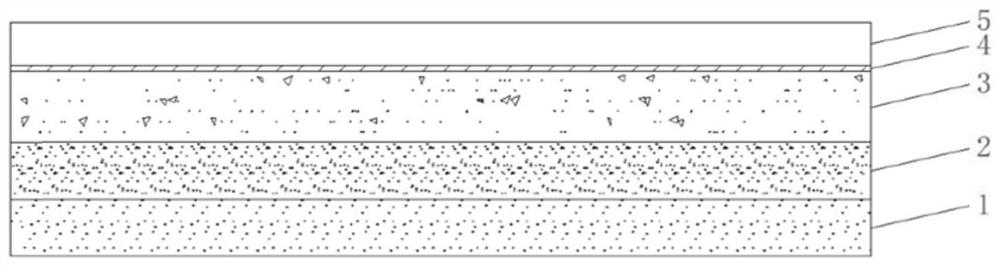

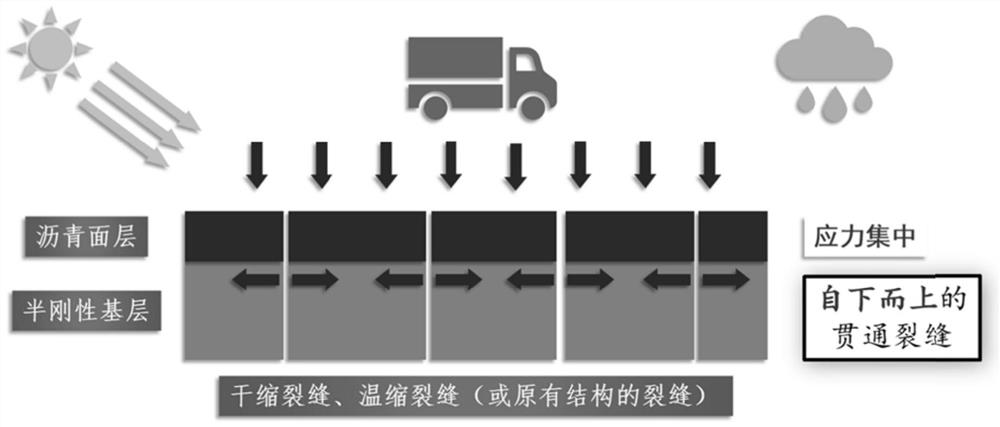

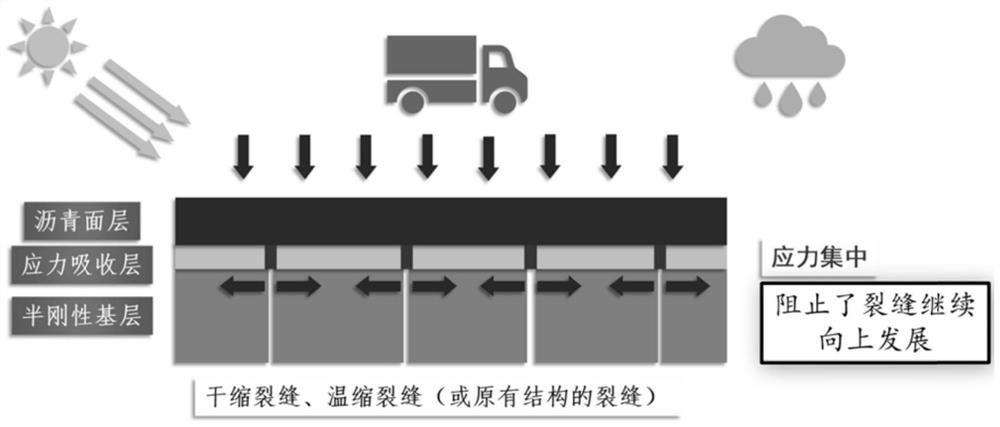

Ultrahigh-ductility concrete stress absorption layer asphalt pavement

InactiveCN111851192ASolve the ruptureSolve the problem of water seepageIn situ pavingsHigh energyStructural engineering

The invention relates to an ultrahigh-ductility concrete stress absorption layer asphalt pavement. The asphalt pavement comprises a cushion layer, a subbase layer, a base layer, a stress absorption layer and a surface layer which are sequentially laid from bottom to top. The cushion layer is made of granules which are not easy to frost heave; the subbase layer is lime-fly ash stabilized macadam; the base layer is cement stabilized macadam; the stress absorption layer is made of ultra-high ductility concrete; and the surface layer is made of densely-mixed asphalt concrete. Compared with the prior art, by utilizing high toughness and high energy consumption capacity of the ultrahigh-ductility concrete, the ultrahigh-ductility concrete is arranged between the base layer and the surface layerof the asphalt pavement as a stress absorption layer, so that generation and development of reflection cracks can be effectively controlled, the fatigue resistance of the pavement is improved, water damage is reduced, the mechanical property of the pavement is improved, the service life of the pavement is prolonged, and the maintenance frequency of the pavement is reduced.

Owner:TONGJI UNIV

Wafer metal coating structure adapted to thinned back and toolings thereof

ActiveCN105448669AEliminate uneven stressSolve uneven stressSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentMetal coatingEngineering

The invention provides a wafer metal coating structure adapted to a thinned back and toolings (photoetched plates and wafer clamps) thereof. In the wafer metal coating structure, the middle part of the wafer metal coating is provided with a plurality of isolated metal zones used for realizing chip functions, and marked as chip active zones overall, and the difference from the existing technology is as follows: the peripheries of the chip active zones are provided with isolated metal ring belts, wherein the thickness of the metal ring belts is the same as that of the metal zones. When the wafer is thinned at the back, since metal exists at the wafer edge, the edge gap is eliminated, thus the problem that the edge stress of the wafer is uneven can be solved, and the risks of fracture and bending can be eliminated; meanwhile, since the edge gap is eliminated, a supporting carrier of the wafer edge can be totally fitted with the front, so that the probability that the thinned particles enter the wafer front can be eliminated and the problem of wafer surface contamination can be solved.

Owner:XIAN LIXIN PHOTOELECTRIC SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com