Soft package lithium ion battery and manufacturing method thereof

A technology of lithium-ion batteries and manufacturing methods, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of accelerating the damage of bending parts, affecting the yield of batteries, and cracking of battery shells, so as to solve the problems of cracking, implementing Convenience and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

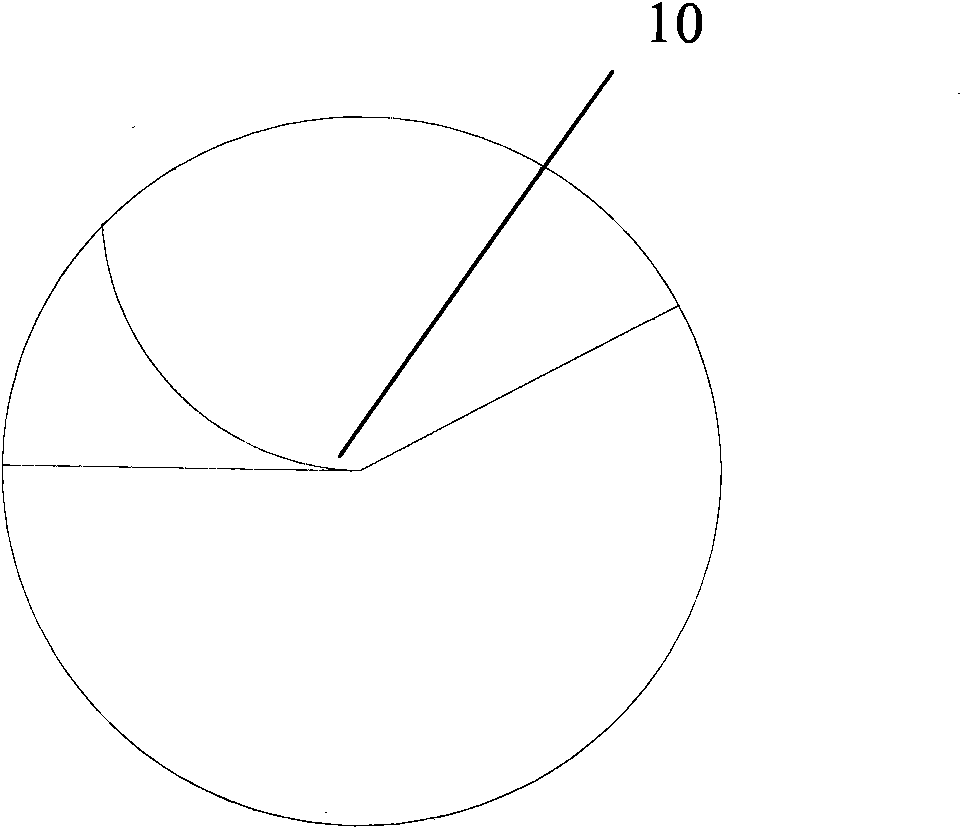

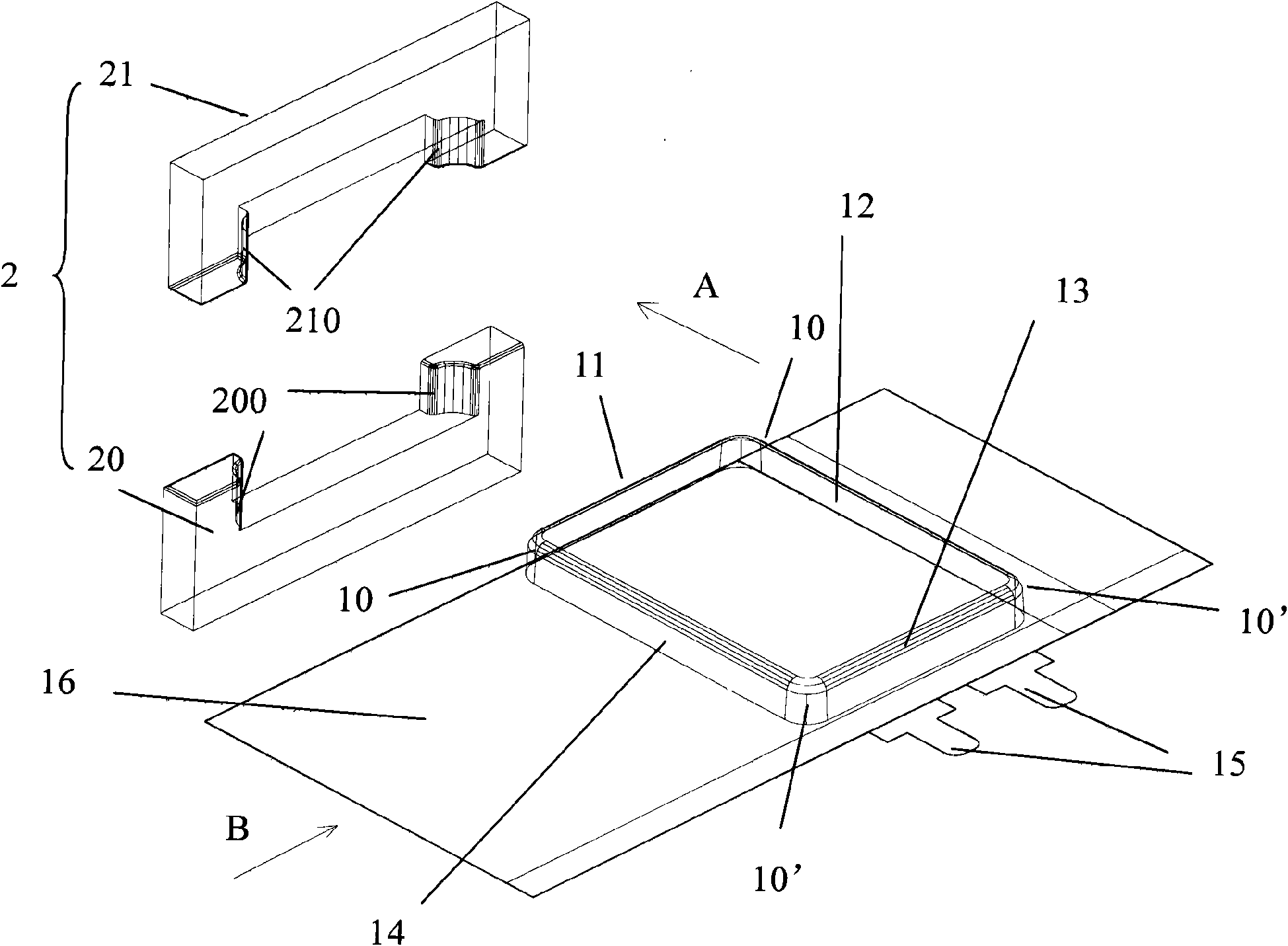

[0018] The flexible packaging lithium ion battery of the present invention, as image 3 As shown in , it includes a battery cell 1; the battery cell 1 includes a pole core, an electrolyte, and a shell that wraps and heat-seals the pole core, and the electrolyte is sealed in the shell; after the shell wraps and heat-seals the pole core; the battery cell 1 is formed A pair of folded edges 11, a tab lead-out edge 13 and two sides 12, 14 are heat-sealed again at the bottom angle 10 where the folded edge 11 intersects with the two sides 12, 14. Positive and negative pole lugs 15 are drawn out from pole ear lead-out edge 13; Figure 4 As shown in , the battery cell 1 and the protective circuit board 4 are placed in plastic casings 30, 31, and packaged to form a soft-packed lithium-ion battery.

[0019] both sides like image 3 14 is shown on the left and 12 on the right.

[0020] Pole cores can be those known to those skilled in the art. The pole core includes a positive electro...

Embodiment 2

[0036] This example will focus on describing the manufacturing method of the lithium ion battery of the present invention.

[0037] A method for manufacturing a flexible packaging lithium-ion battery, comprising the steps of:

[0038] a) The positive electrode sheet, diaphragm, and negative electrode sheet are sequentially wound or stacked to form a pole core; the positive electrode sheet, separator, and negative electrode sheet have been described in Example 1, and are well known to those skilled in the art; no further explanation will be given.

[0039] b) After folding a casing in half, put the pole core between the two folded surfaces of the folded casing to form a tab lead-out edge 113, a pair of folded edges 11, and two sides 12, 14; put the tab lead-out edge 13 and the two The sides 12 and 14 are heat-sealed, and liquid is injected inward to form the cell 1;

[0040] Such as image 3 As shown, in order to prevent the aluminum-plastic composite film from cracking after...

Embodiment 3

[0046] In this embodiment, 100 batteries that were heat-sealed at the bottom corners were used to bend 5 times, 10 times, and 15 times, and then the number of batteries with membrane rupture and leakage was counted; the battery was bent 200 times and injected with liquid The number of broken membranes and liquid leakage; use 100 traditional batteries that have not been heat-sealed again at the bottom corners and bend them 5 times, 10 times, and 25 times, and then count the number of batteries with membrane ruptures and liquid leakage; The amount of liquid leaking from the battery membrane after the liquid injection.

[0047] As shown in the table below, it is obvious that after the bottom corner is heat-sealed, the film will not break and leak after repeated bending, which meets the needs of production and greatly improves the yield.

[0048]

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com