Ultrahigh-ductility concrete stress absorption layer asphalt pavement

A stress-absorbing layer, asphalt pavement technology, applied in the direction of on-site coagulation pavement, roads, roads, etc., can solve problems such as water seepage and pavement cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

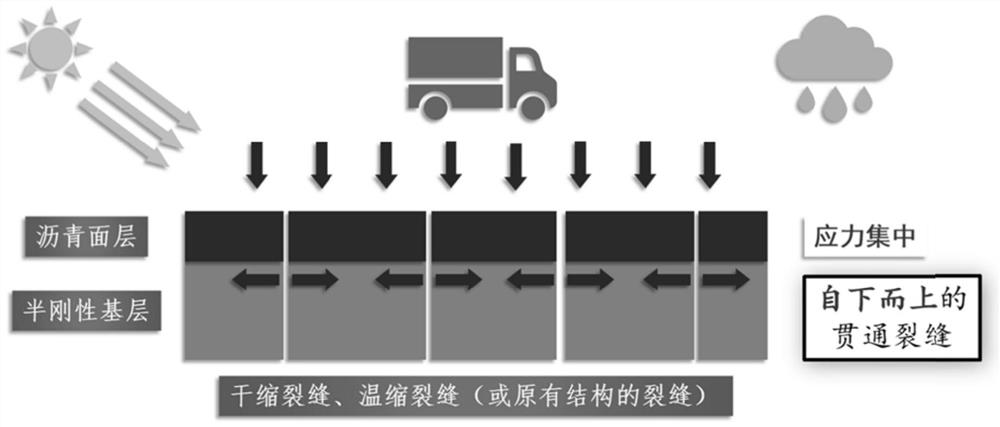

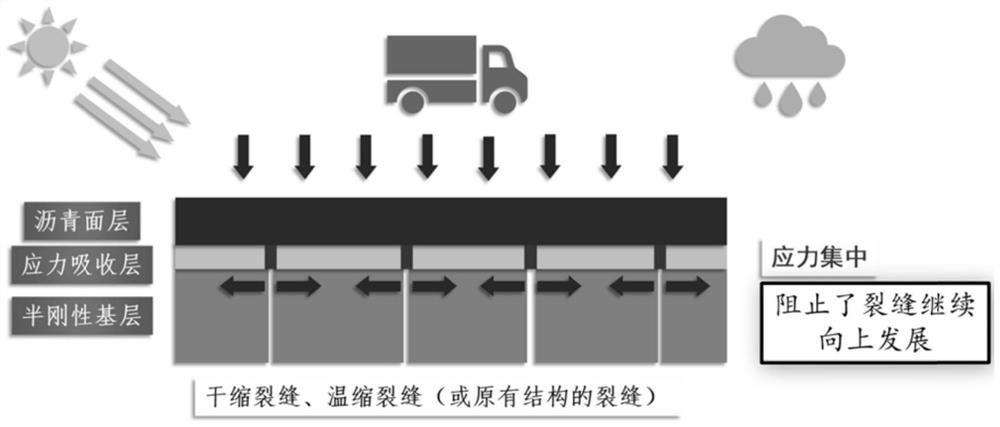

Problems solved by technology

Method used

Image

Examples

Embodiment 1

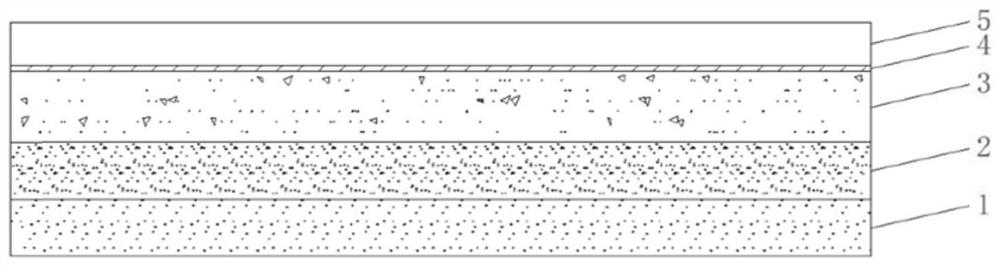

[0028] An ultra-high ductility concrete stress absorbing layer asphalt pavement, such as figure 1 , including a cushion layer 1, a base layer 2, a base layer 3, a stress absorbing layer 4, and a surface layer 5 laid sequentially from bottom to top; the cushion layer 1 is a granular material that is not easy to frost heave; the base layer 2 is lime-powder Coal ash stabilized crushed stone; the base layer 3 is cement stabilized crushed stone; the stress absorbing layer 4 is ultra-high ductility concrete; the surface layer 5 is dense asphalt concrete.

[0029] Among them, the thickness of the cushion layer 1 is 20cm, and the aggregates that are not easy to frost heaving are gravel soil with a fine material content of 6%. The cushion layer 1 should be spread to the same width as the roadbed to facilitate drainage of the road surface structure and maintain the stability of the roadbed.

[0030] The thickness of the base course 2 is 20 cm, the lime-fly ash stabilized crushed stone ...

Embodiment 2

[0036] An ultra-high ductility concrete stress absorbing layer asphalt pavement, such as figure 1 , including a cushion layer 1, a base layer 2, a base layer 3, a stress absorbing layer 4, and a surface layer 5 laid sequentially from bottom to top; the cushion layer 1 is a granular material that is not easy to frost heave; the base layer 2 is lime-powder Coal ash stabilized crushed stone; the base layer 3 is cement stabilized crushed stone; the stress absorbing layer 4 is ultra-high ductility concrete; the surface layer 5 is dense asphalt concrete.

[0037] Among them, the thickness of the cushion layer 1 is 20cm, and the aggregates that are not easy to frost heaving are gravel soil with a fine material content of 6%. The cushion layer 1 should be spread to the same width as the roadbed to facilitate drainage of the road surface structure and maintain the stability of the roadbed.

[0038] The thickness of the base course 2 is 20 cm, the lime-fly ash stabilized crushed stone ...

Embodiment 3

[0044] An ultra-high ductility concrete stress absorbing layer asphalt pavement, such as figure 1, including a cushion layer 1, a base layer 2, a base layer 3, a stress absorbing layer 4, and a surface layer 5 laid sequentially from bottom to top; the cushion layer 1 is a granular material that is not easy to frost heave; the base layer 2 is lime-powder Coal ash stabilized crushed stone; the base layer 3 is cement stabilized crushed stone; the stress absorbing layer 4 is ultra-high ductility concrete; the surface layer 5 is dense asphalt concrete.

[0045] Among them, the thickness of the cushion layer 1 is 20cm, and the aggregates that are not easy to frost heaving are gravel soil with a fine material content of 6%. The cushion layer 1 should be spread to the same width as the roadbed to facilitate drainage of the road surface structure and maintain the stability of the roadbed.

[0046] The thickness of the base course 2 is 20 cm, the lime-fly ash stabilized crushed stone u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com