Patents

Literature

3134 results about "Granular material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A granular material is a conglomeration of discrete solid, macroscopic particles characterized by a loss of energy whenever the particles interact (the most common example would be friction when grains collide). The constituents that compose granular material are large enough such that they are not subject to thermal motion fluctuations. Thus, the lower size limit for grains in granular material is about 1 μm. On the upper size limit, the physics of granular materials may be applied to ice floes where the individual grains are icebergs and to asteroid belts of the Solar System with individual grains being asteroids.

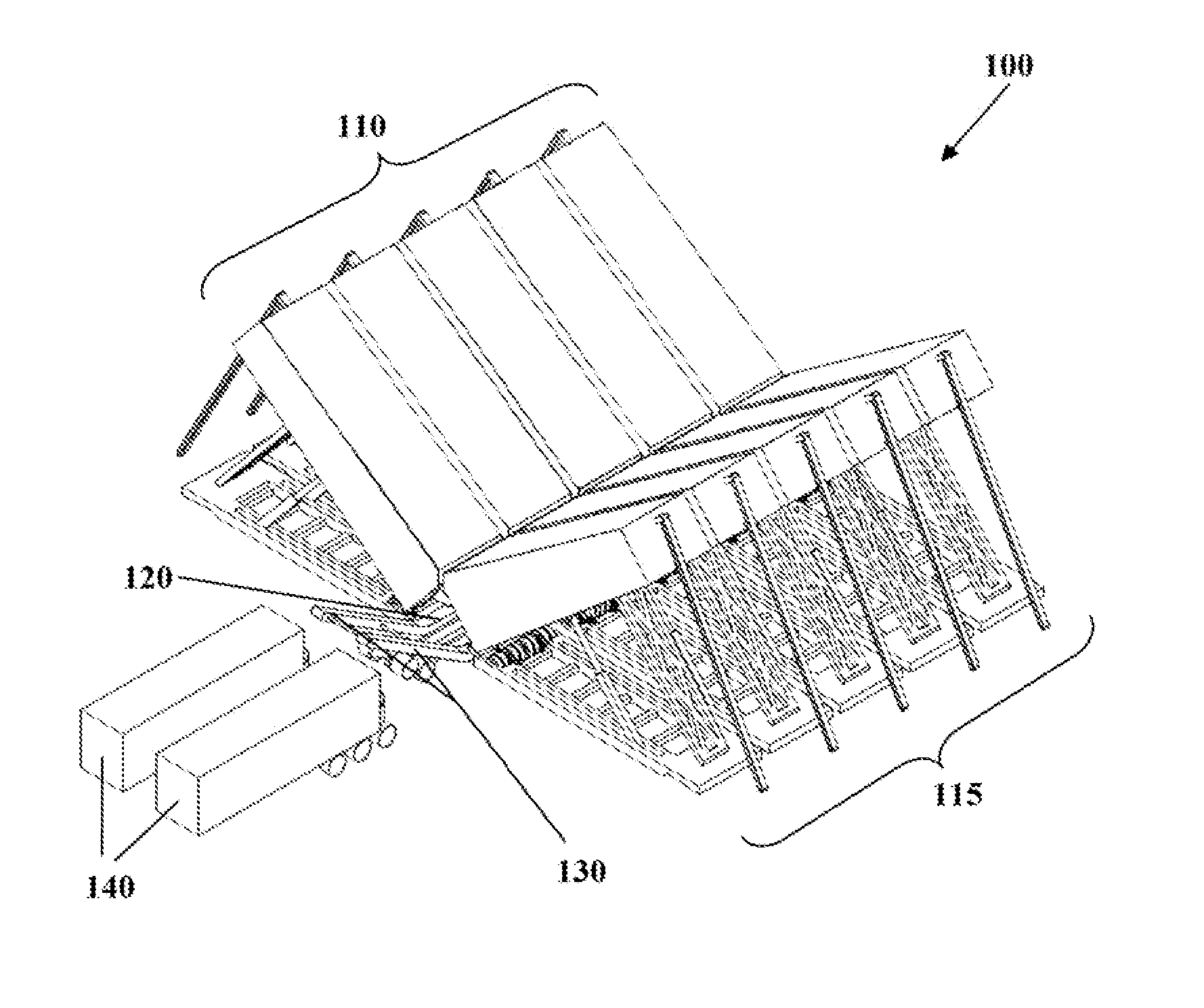

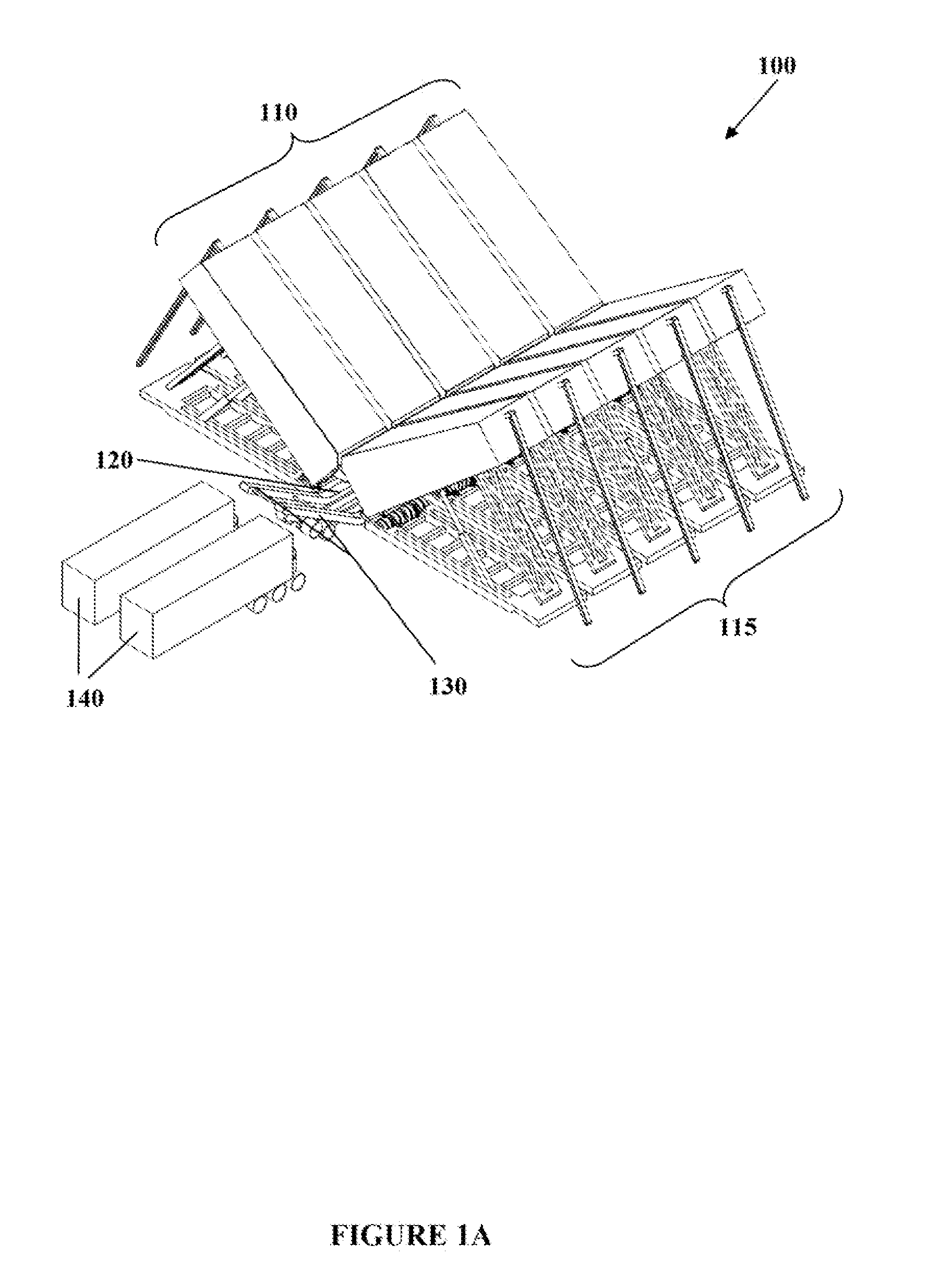

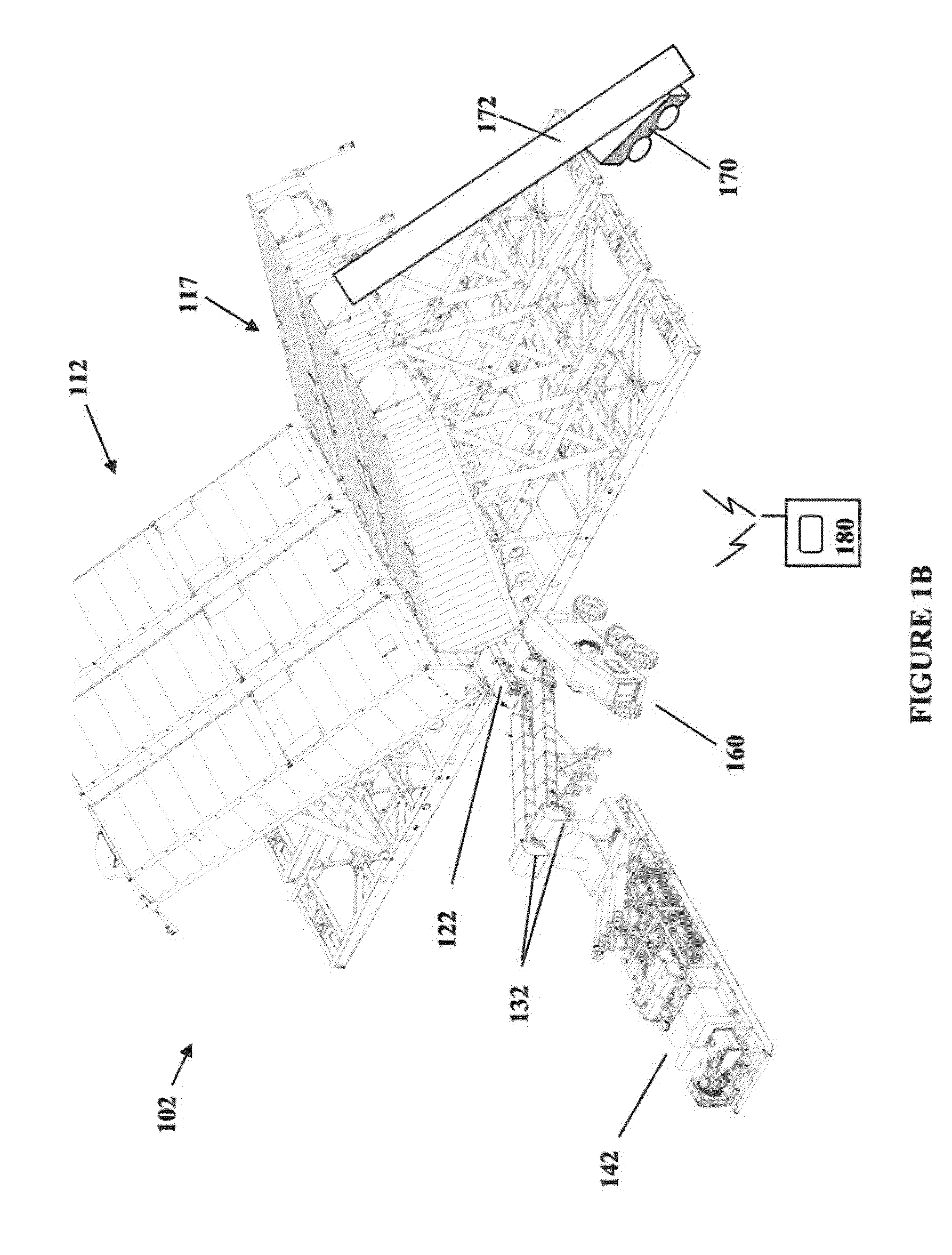

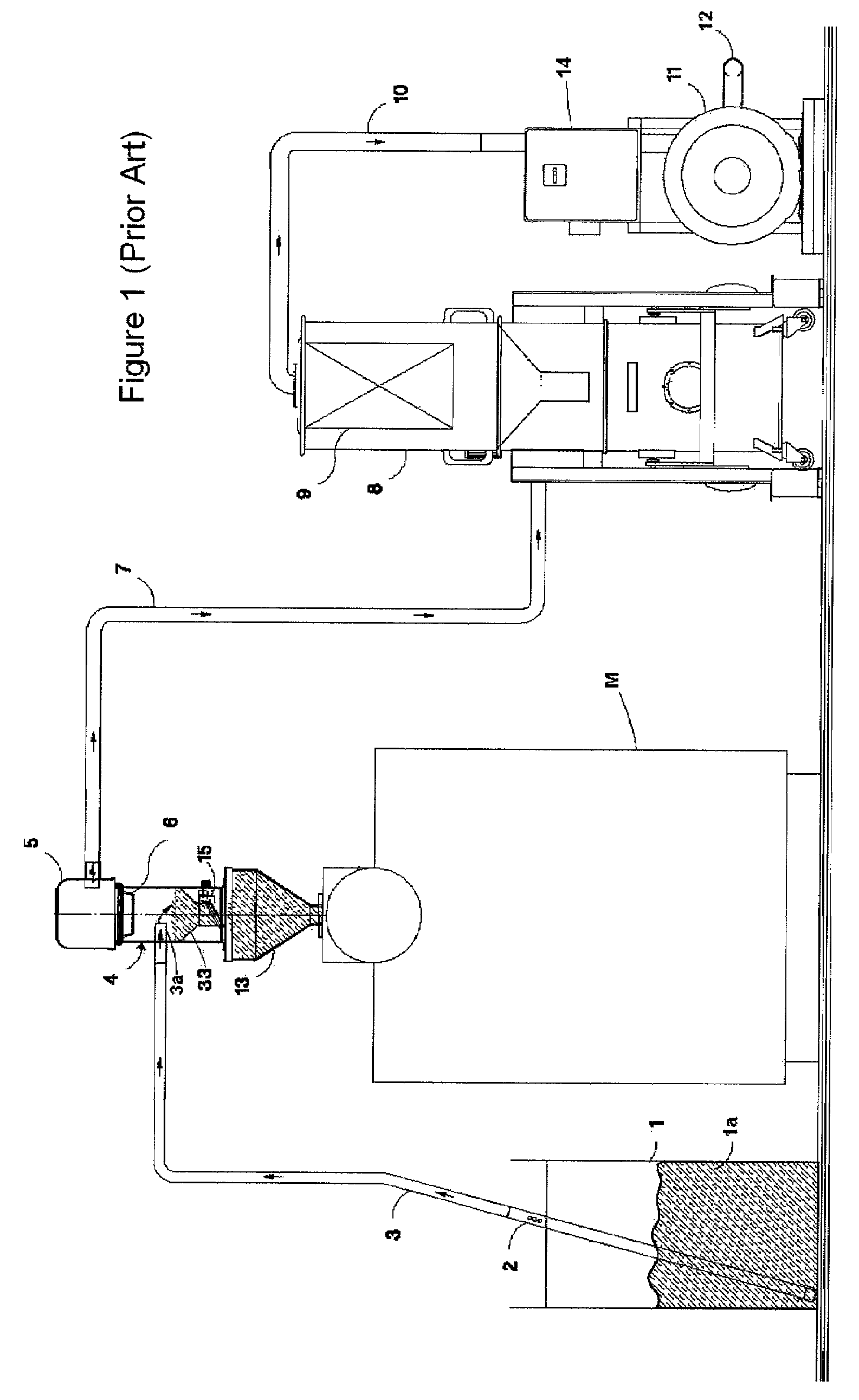

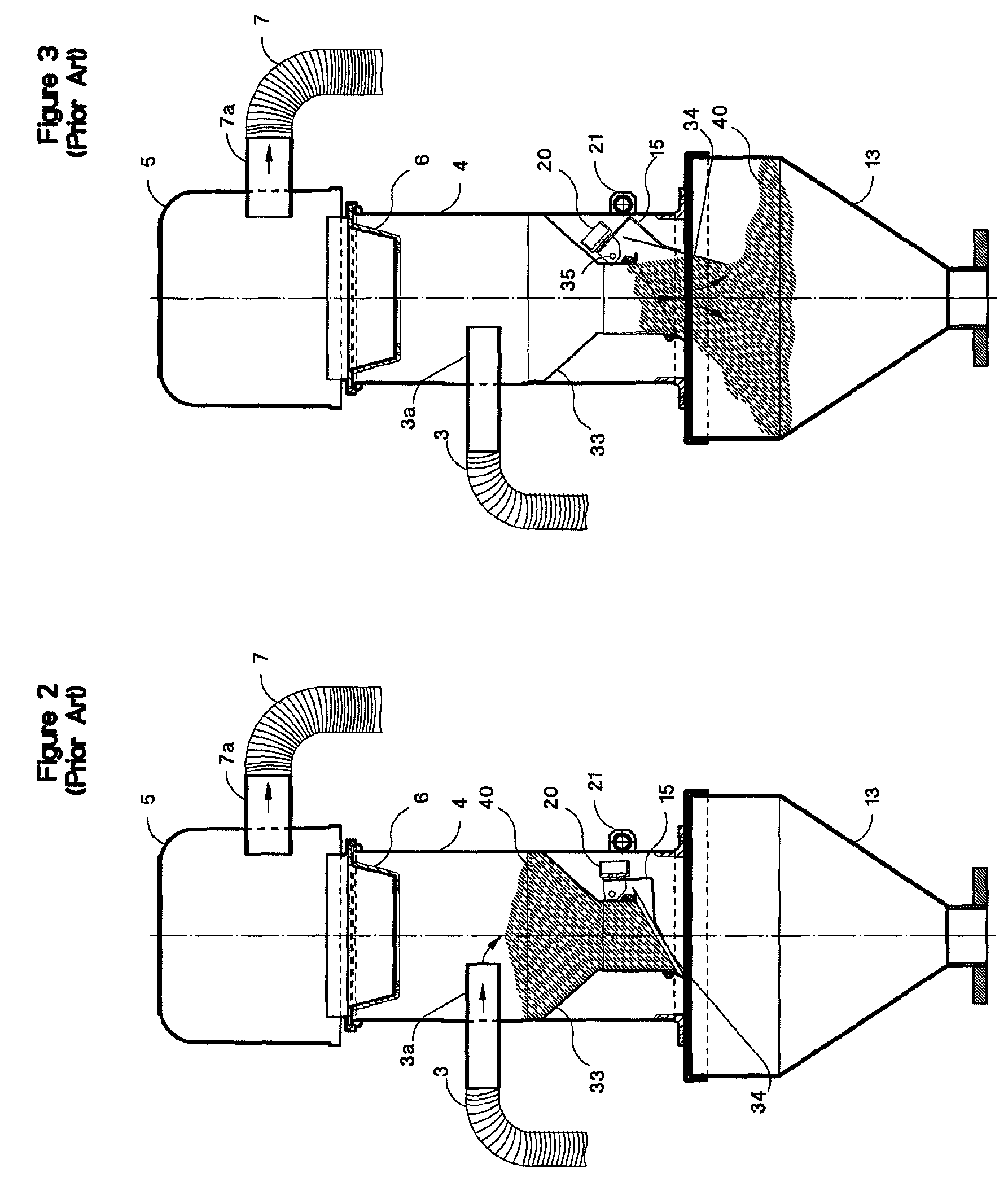

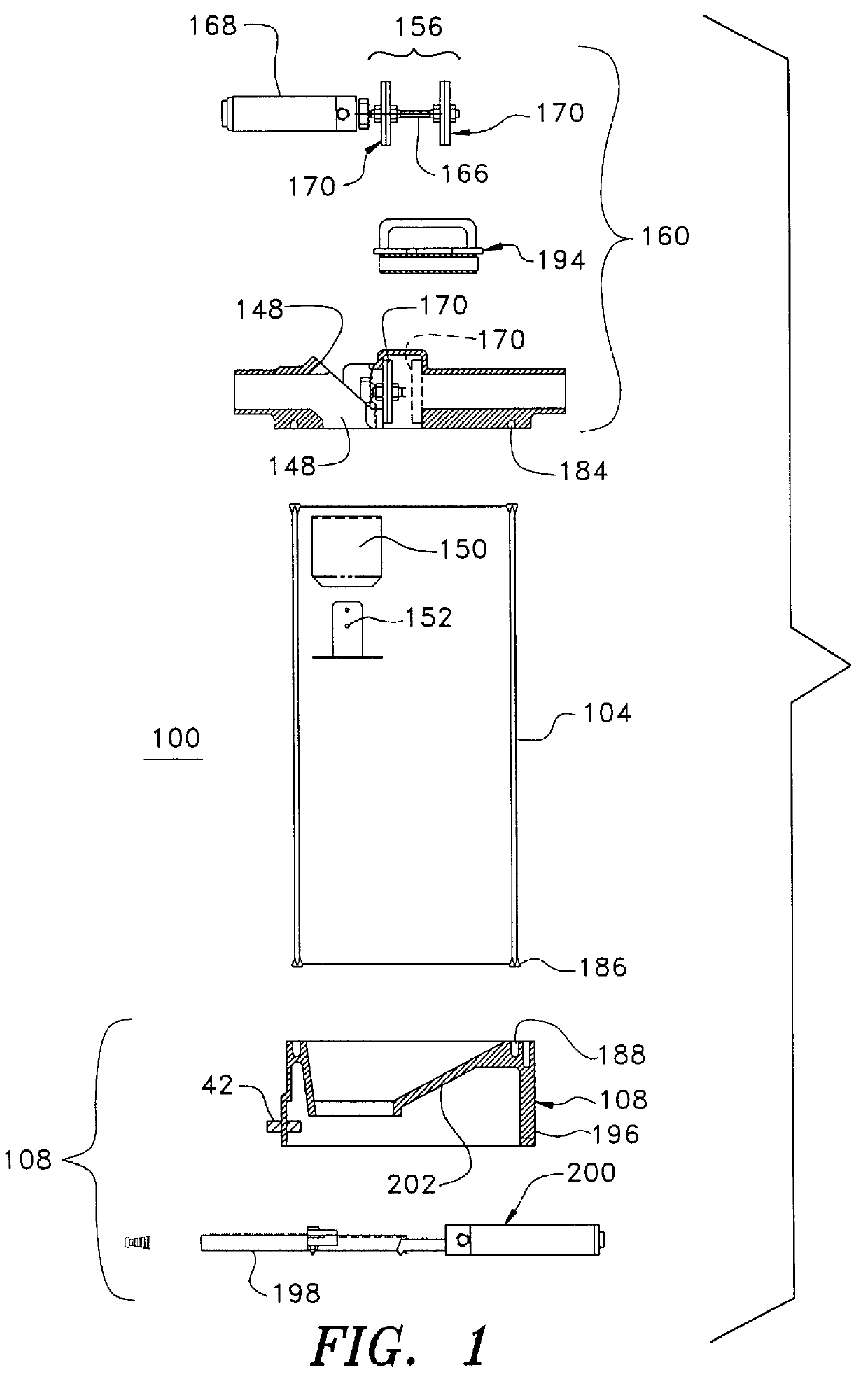

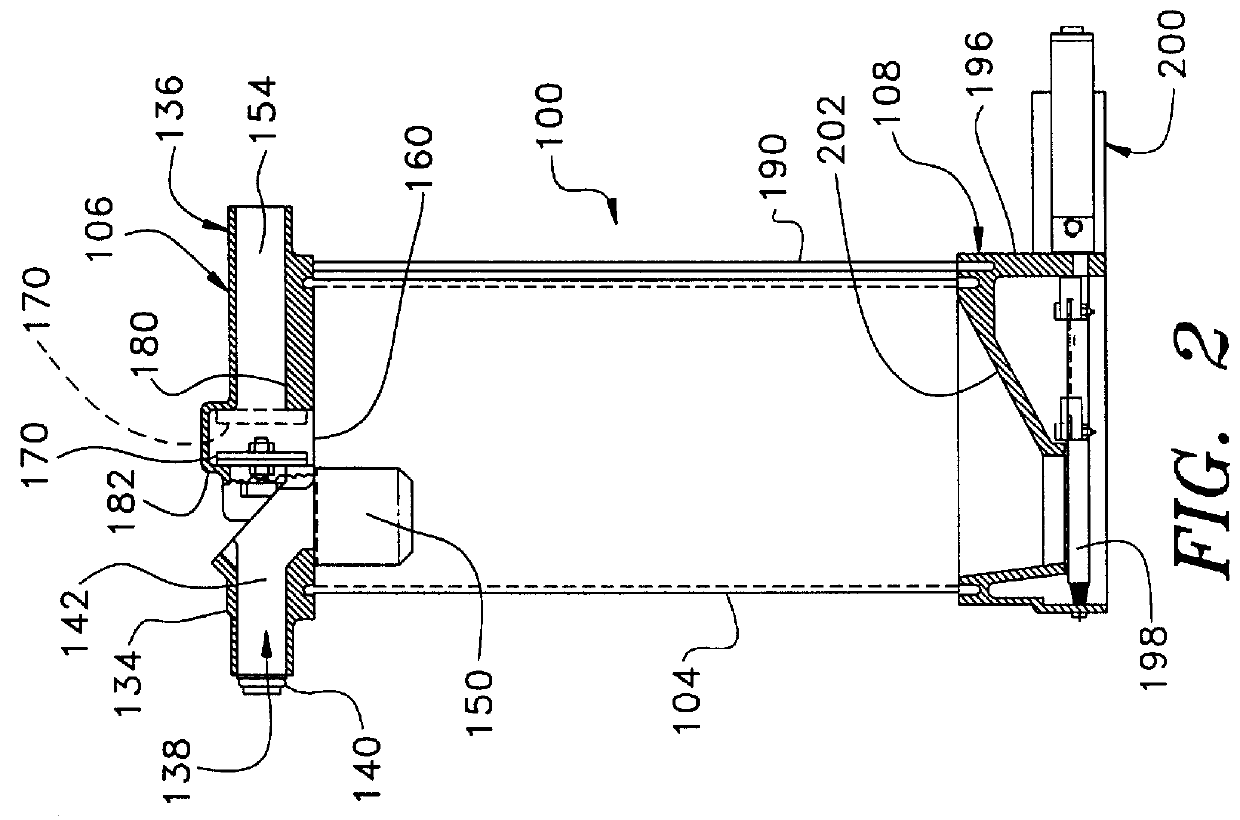

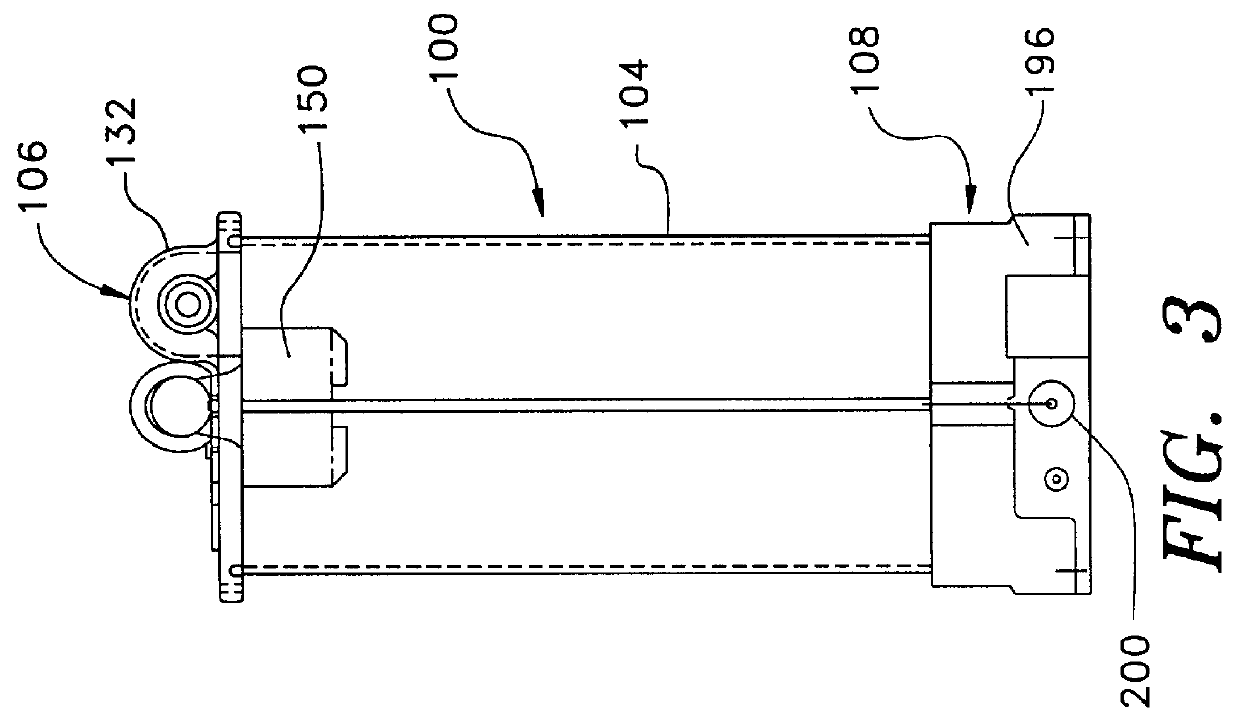

Mobile Material Handling and Metering System

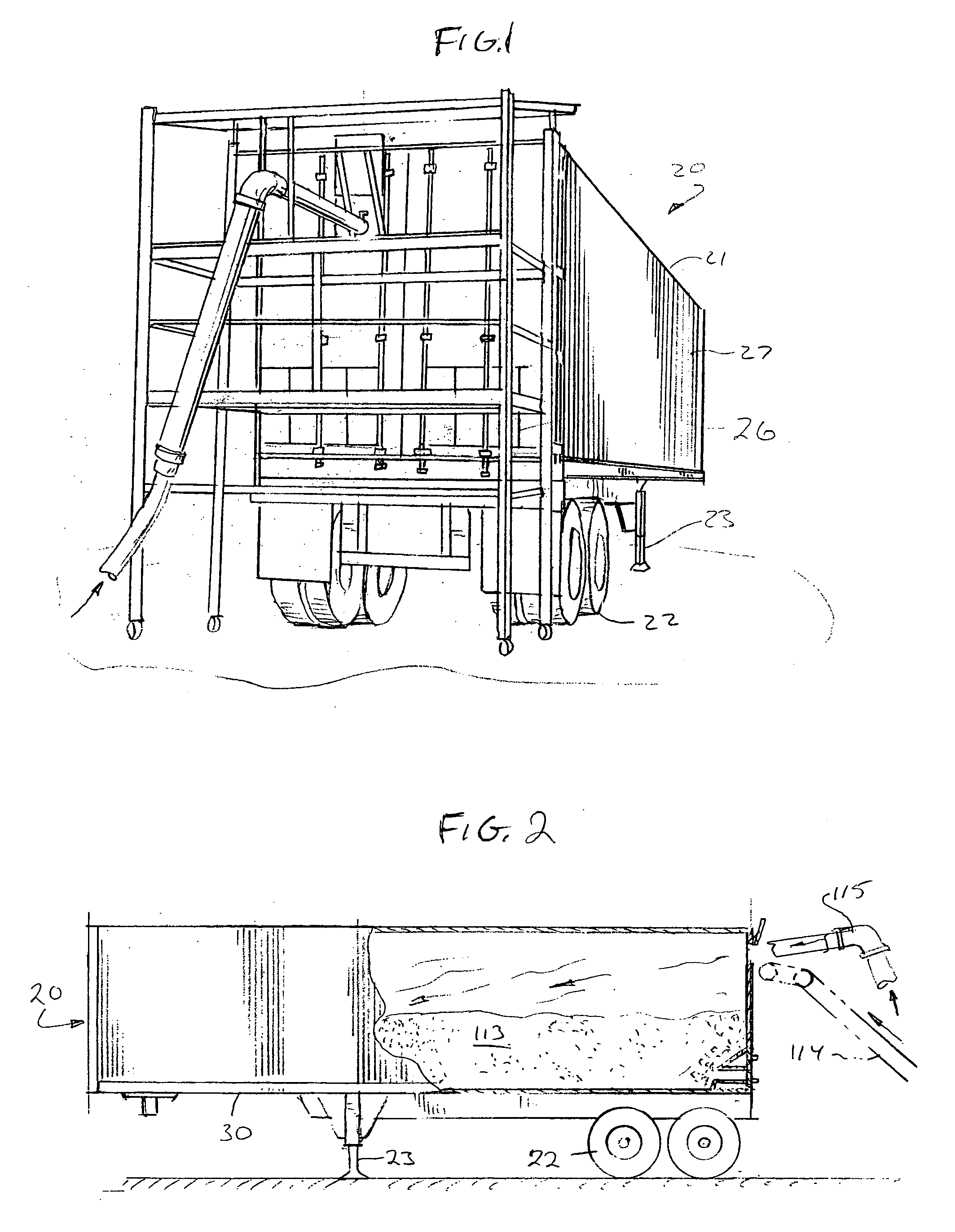

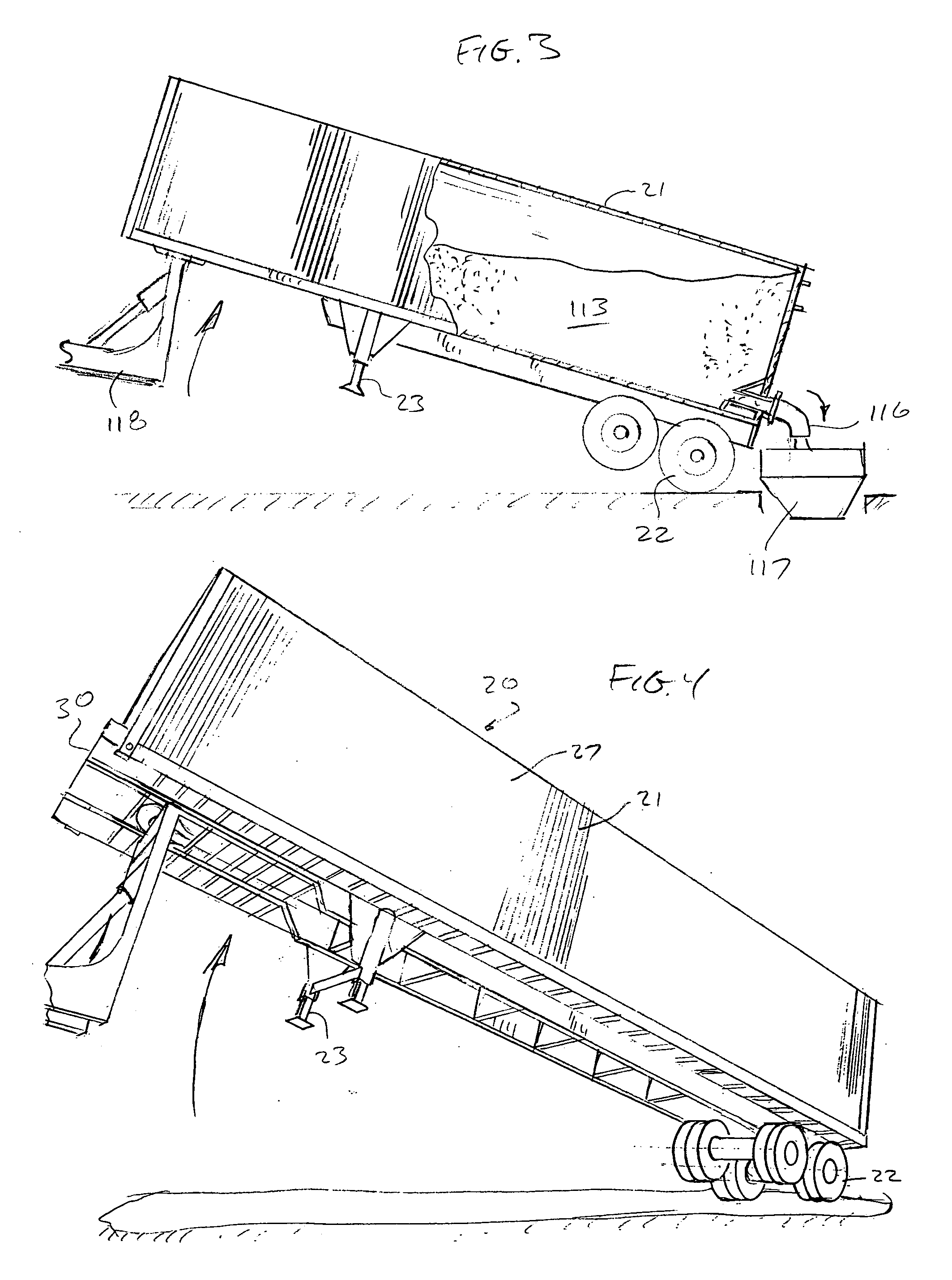

ActiveUS20120219391A1Convenient for centralized processingEasy remote controlLarge containersRefuse transferringWell drillingRemote control

A method and system for handling granular material, such as proppant used in hydraulic fracturing in well drilling, is provided. In an operational configuration, a delivery module having conveyors receives and conveys granular material to a delivery location, and one or more mobile storage modules receive, hold and dispense granular material downward to the delivery module. The mobile storage modules comprise a raised, angular container portion for holding granular material. Each mobile storage module may comprise a rock-over chassis for support against ground. A remote control module provides centralized, remote control of the system. Mobile support unit modules may also be provided as a remotely controlled vehicle capable of providing power, control, heating, and the like to other modules. Mobile in-feed elevator modules may also be provided as a remotely controlled vehicle for feeding granular material to mobile storage modules. In a transportation configuration, each module is separately transportable.

Owner:CONTINENTAL INTERMODAL GRP TRUCKING LLC

Composition and method for forming a sprayable materials cover

InactiveUS20050084334A1Improve performanceImprove adhesionSolid waste disposalLandfill technologiesWater dispersibleSlurry

An alternative cover for landfill may be formed from a slurry mixture of water, cementitious binder, adhesion enhancing admixture and fiber. These constituents may be mixed and applied to cover landfilled wastes, granular material piles or for soil erosion control. The cover will harden to minimize water infiltration, wind blown dust, odor and affinity to birds, flies and other insects. The water may include tap water, landfill leachate and wastewater. The binder may include Portland cement, blended cement, cement kiln dust, class C fly ash, and / or calcium sulphate hemihydrate. The adhesion enhancing admixture includes water-dispersible polymers. The fibers may comprise shredded paper or wood or plastic fibers.

Owner:CJS TECH

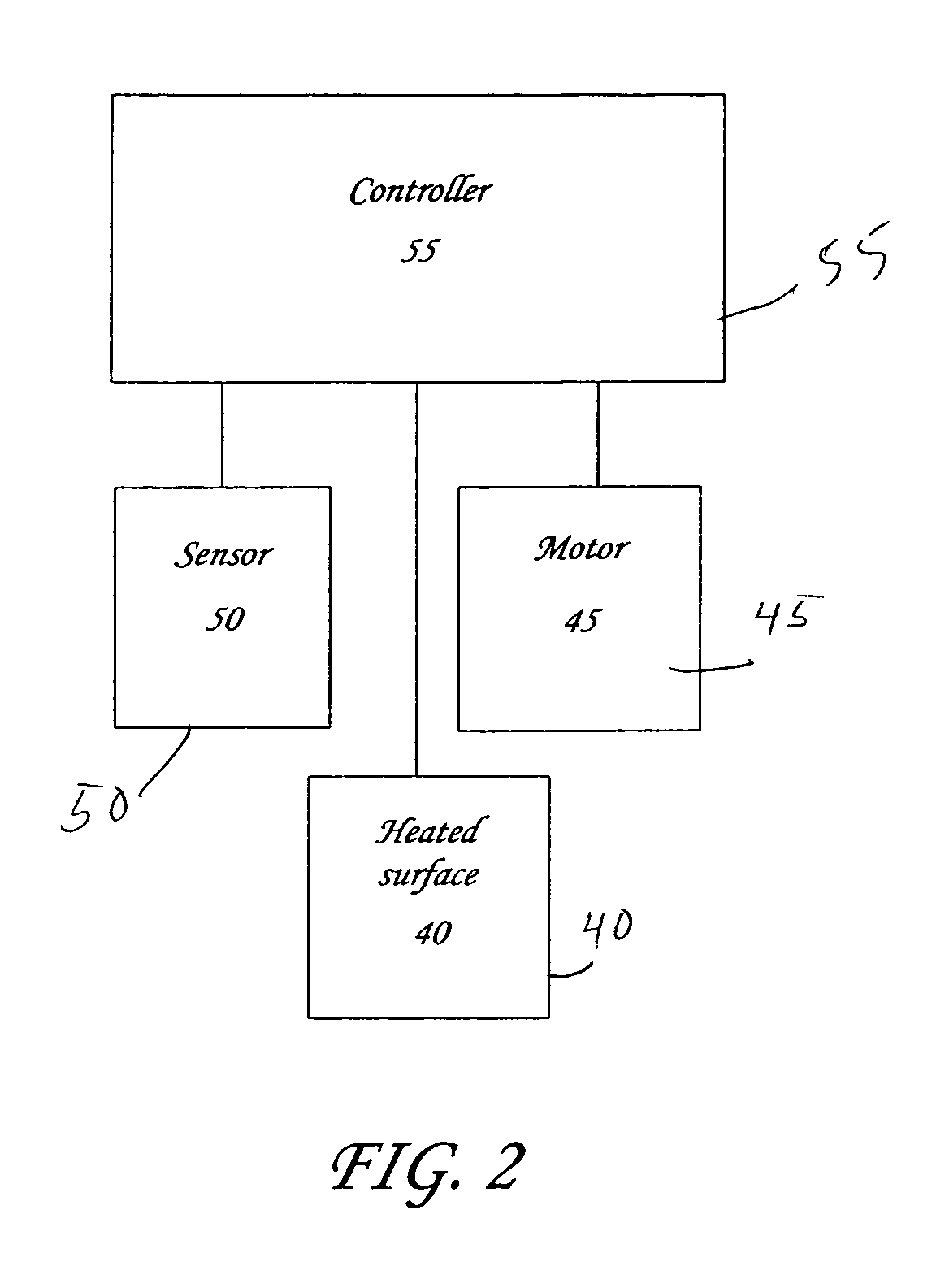

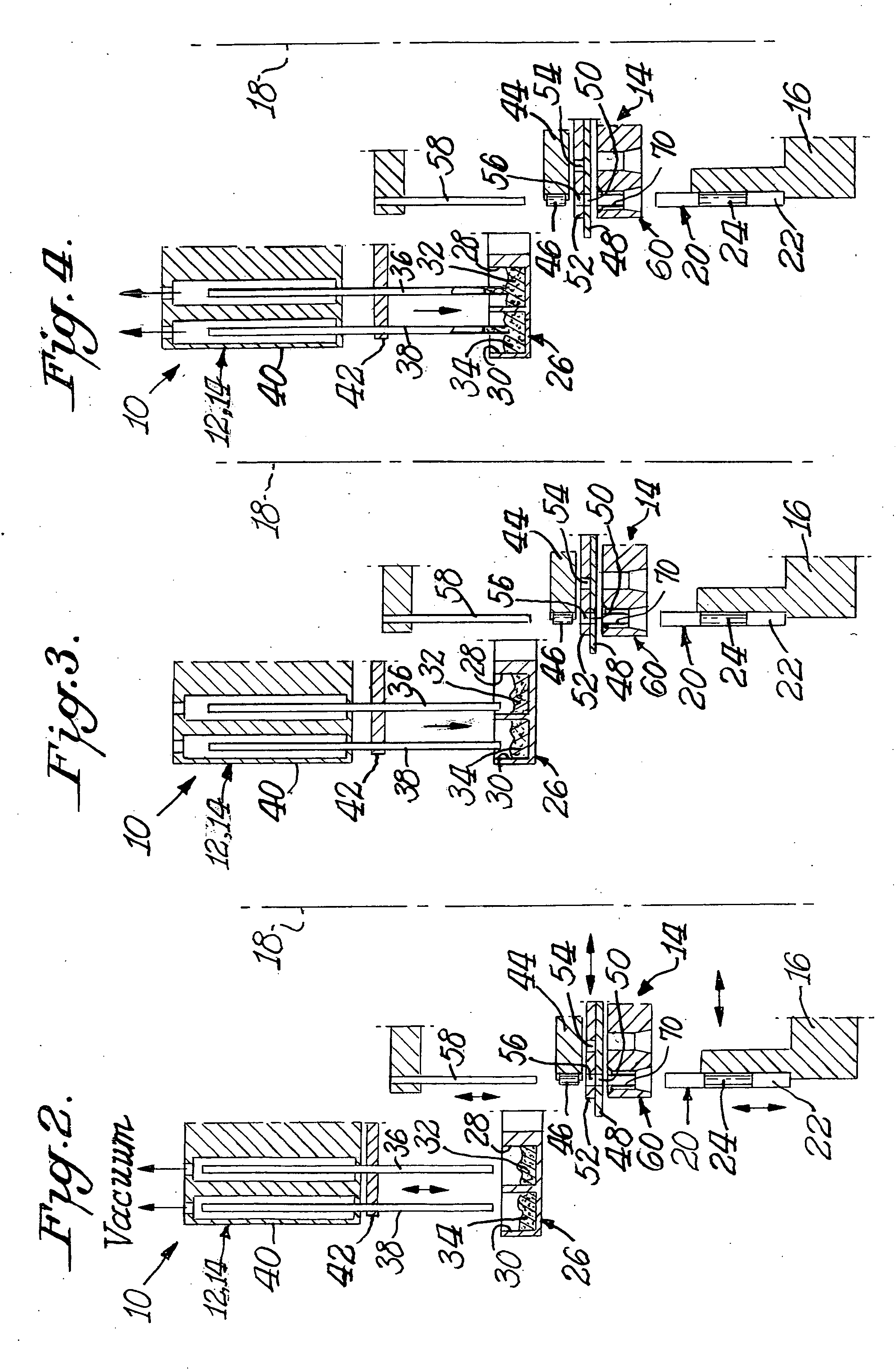

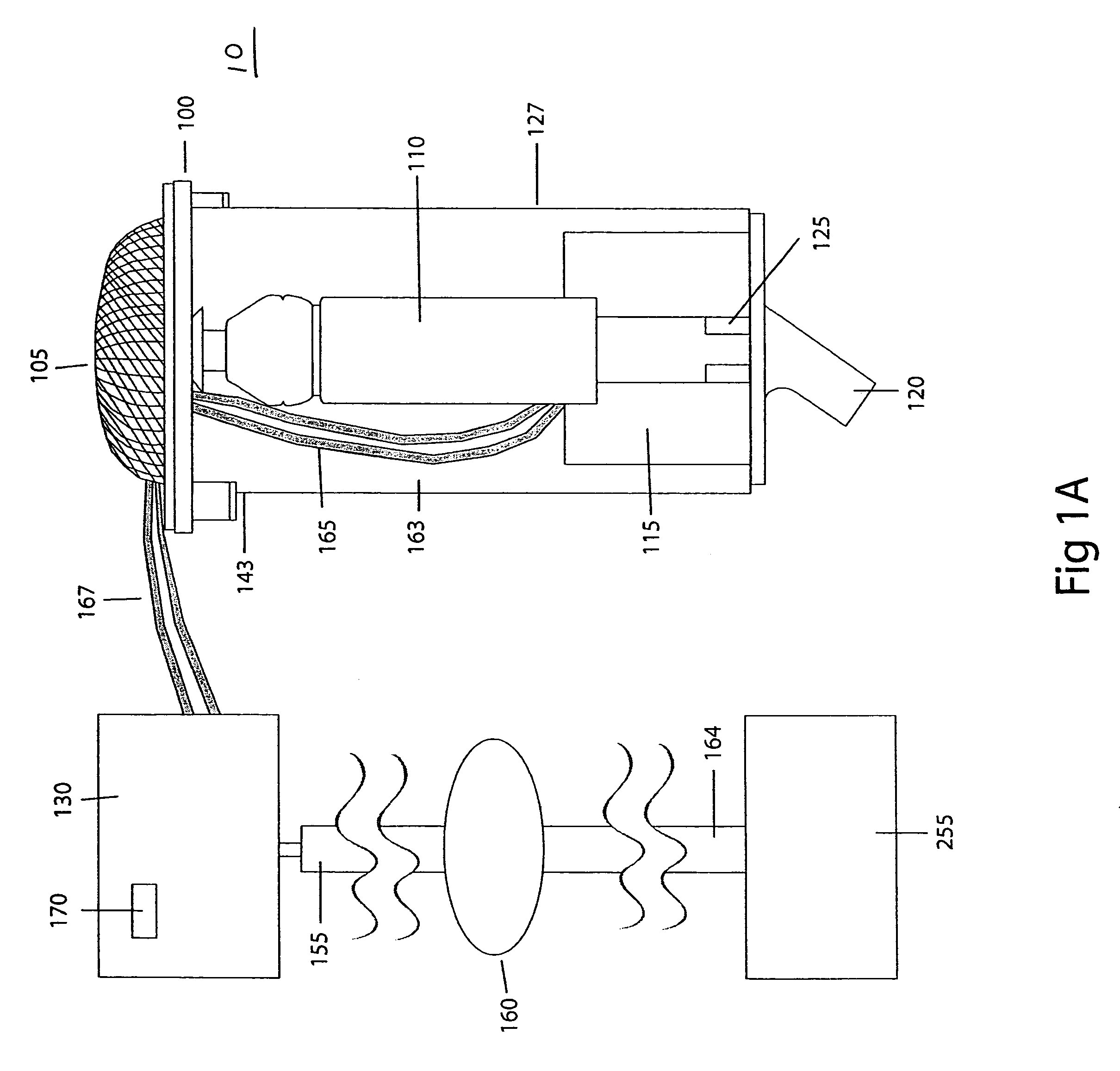

Controllably feeding organic material in making OLEDs

ActiveUS20060177576A1Effective waySolid-state devicesVacuum evaporation coatingOLEDMaterials science

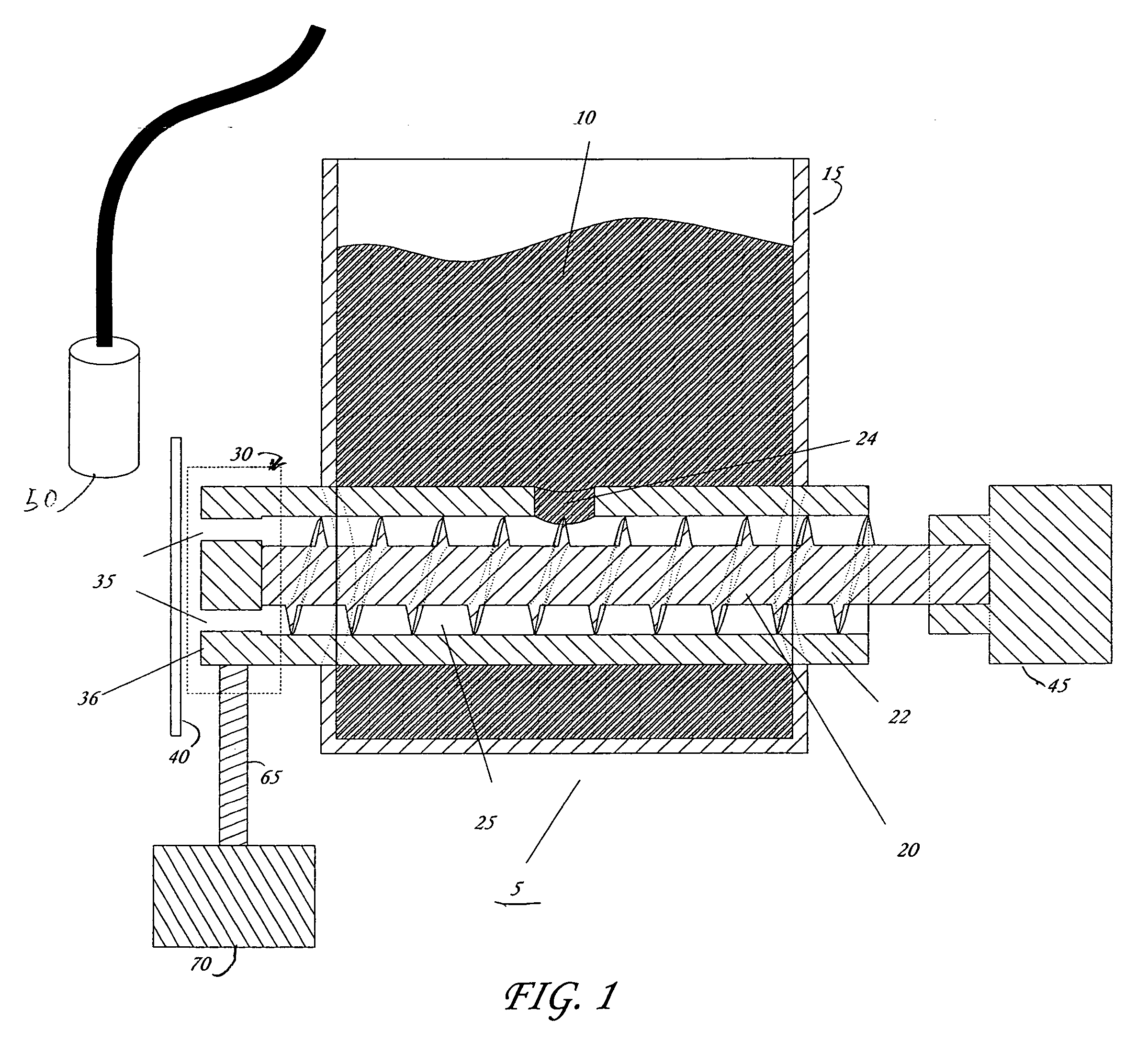

A method for metering powdered or granular material onto a heated surface to vaporize such material, includes providing a container with powdered or granular material having at least one component; providing a rotatable auger disposed in material receiving relationship with the container for receiving powdered or granular material from the container and as the auger rotates, such rotating auger translates such powdered or granular material along a feed path to a feeding location; and providing at least one opening at the feeding location such that the pressure produced by the rotating auger at the feeding location causes the powdered or granular material to be forced through the opening onto the heated surface in a controllable manner.

Owner:GLOBAL OLED TECH

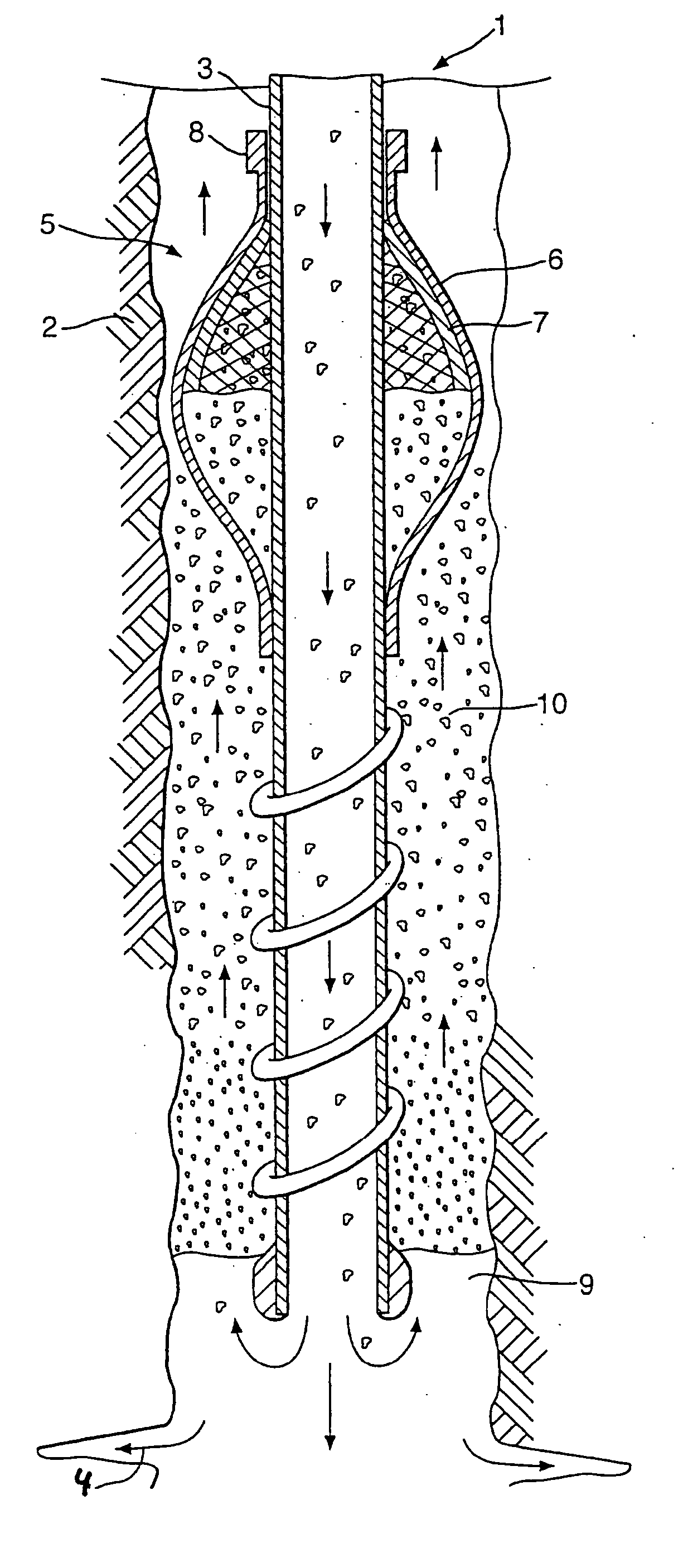

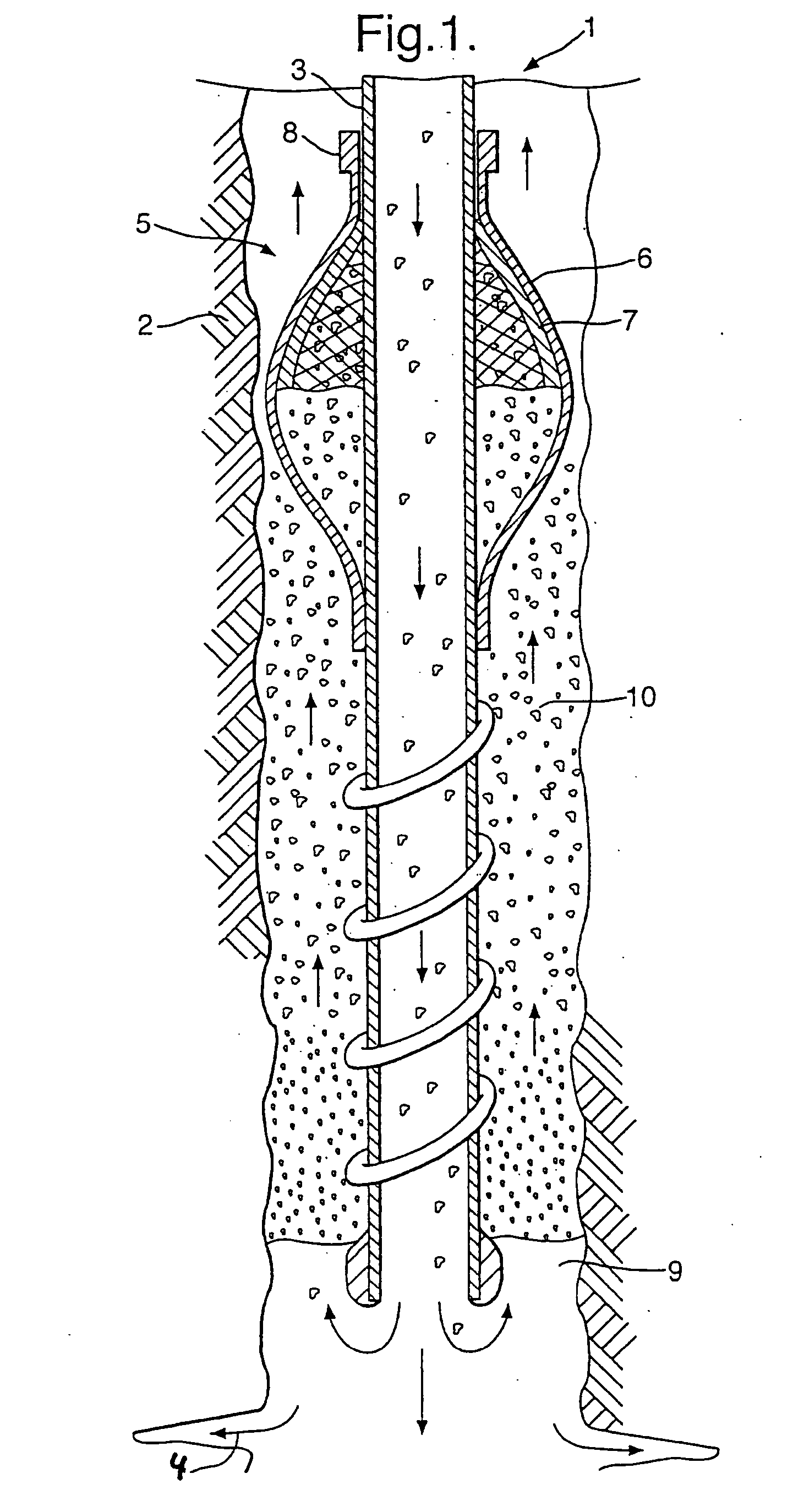

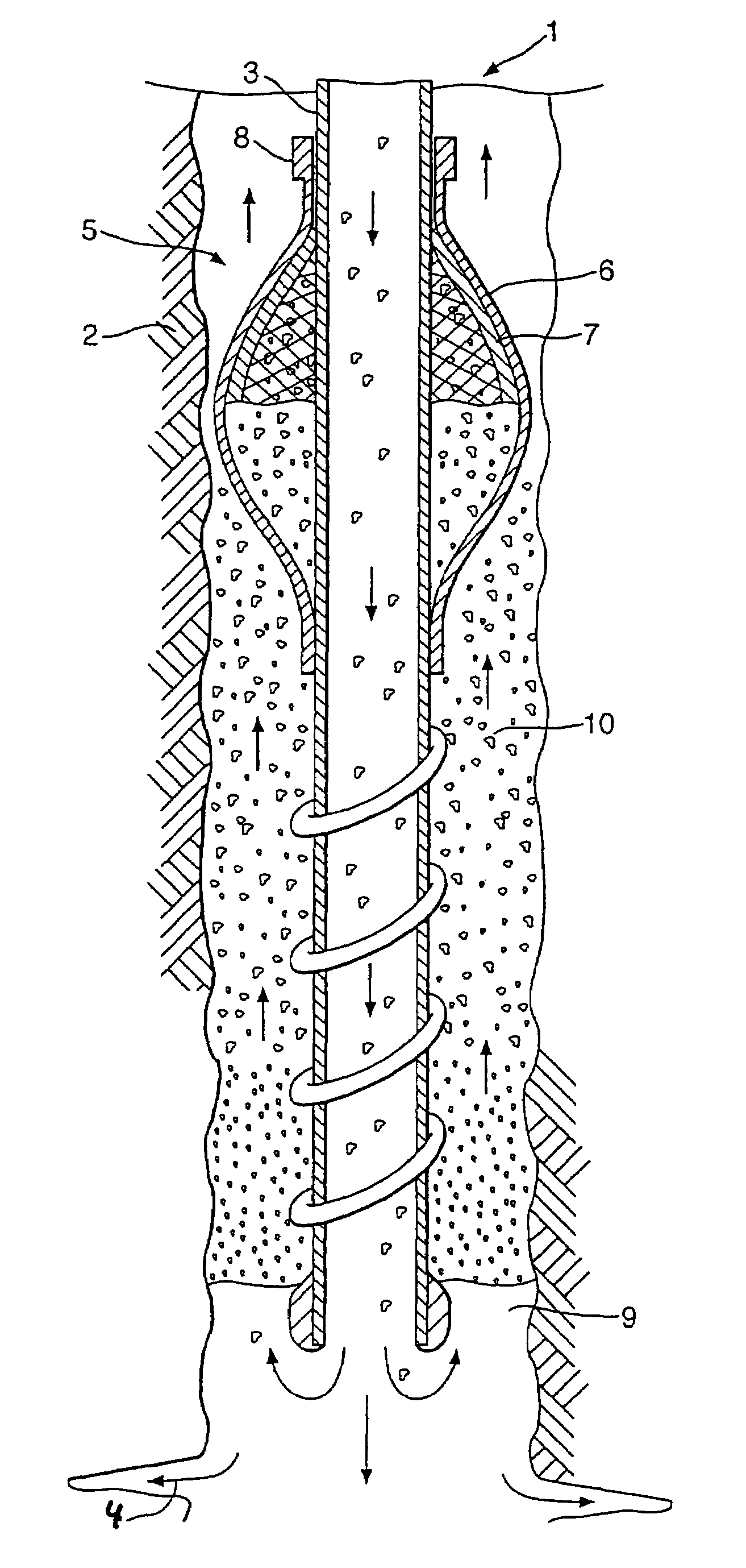

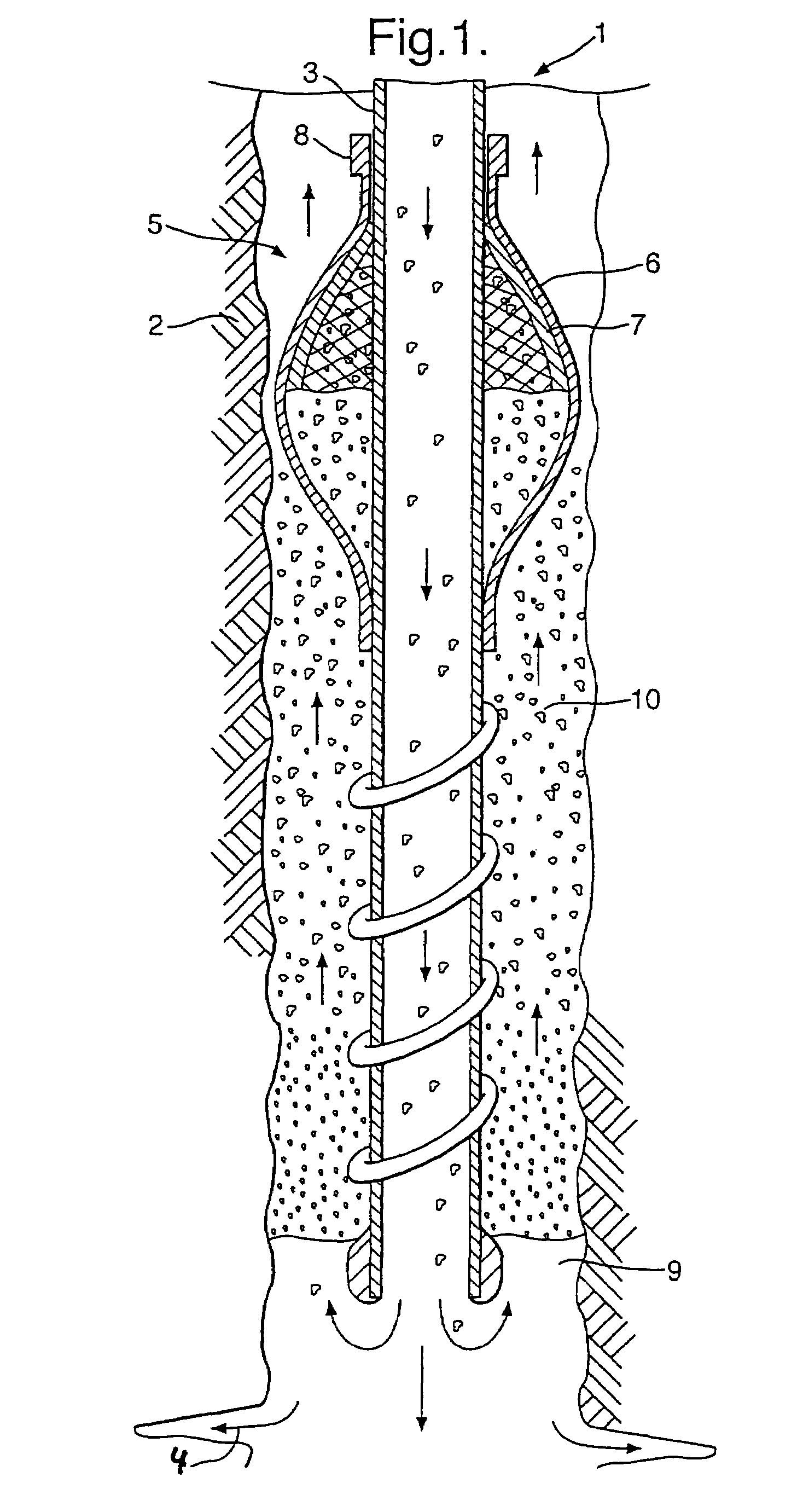

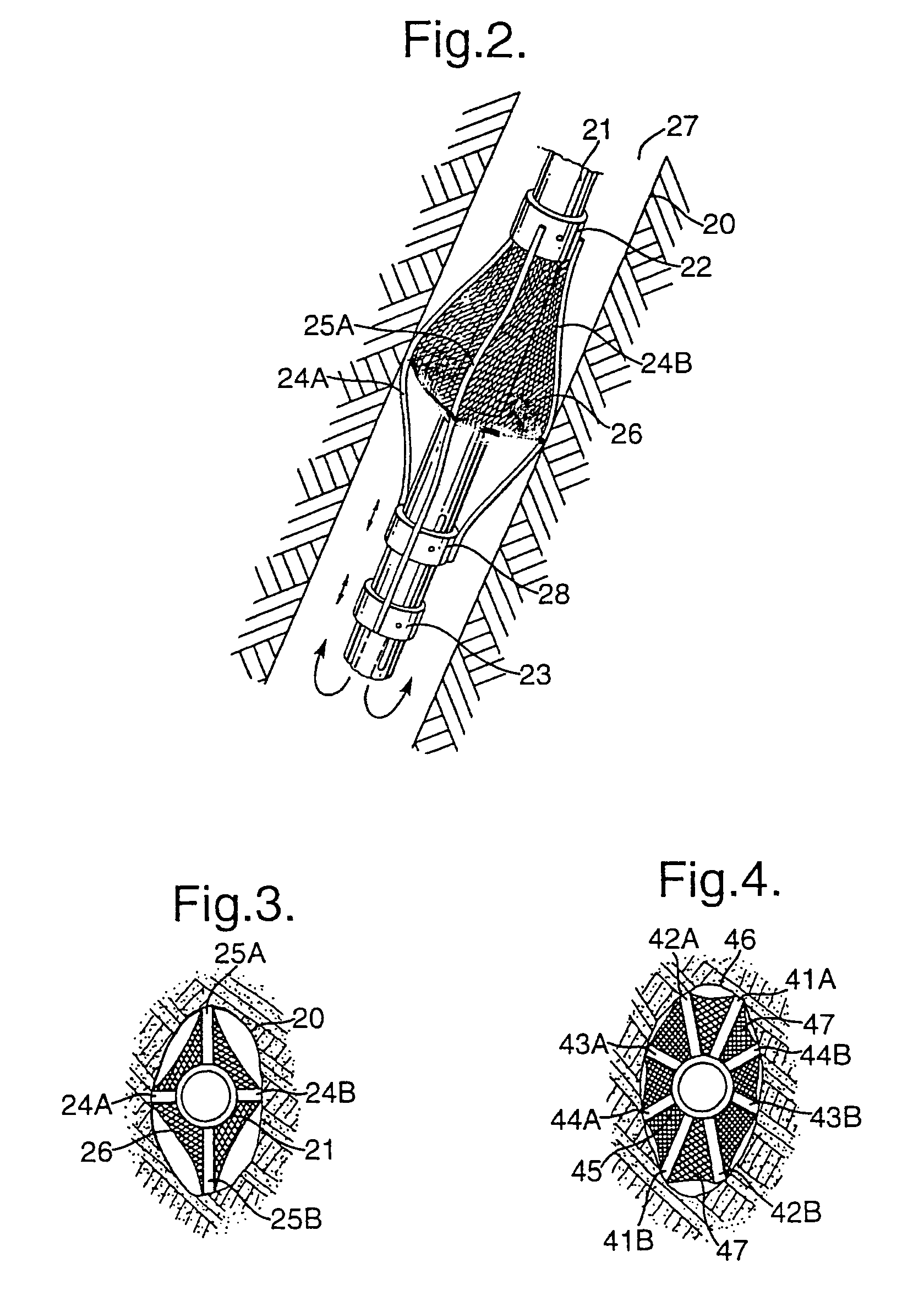

Method of creating a zonal isolation in an underground wellbore

A method of creating a zonal isolation above a target zone in an underground wellbore comprises: inserting a slurry injection tubing into the wellbore; arranging within an annular space surrounding said tubing an particle accumulation means, such as an expandable screen or an area where the slurry velocity is reduced; and pumping a slurry comprising a carrier fluid and granular material down via the slurry injection tubing and the target zone and then up into the annular space, such that at least some granular material accumulates and forms an elongate zonal isolation in the annular space between the target zone and the particle accumulation means, which zonal isolation is removable and exerts a limited radial force to the surrounding formation, thereby reducing the risk of formation damage.

Owner:SHELL OIL CO

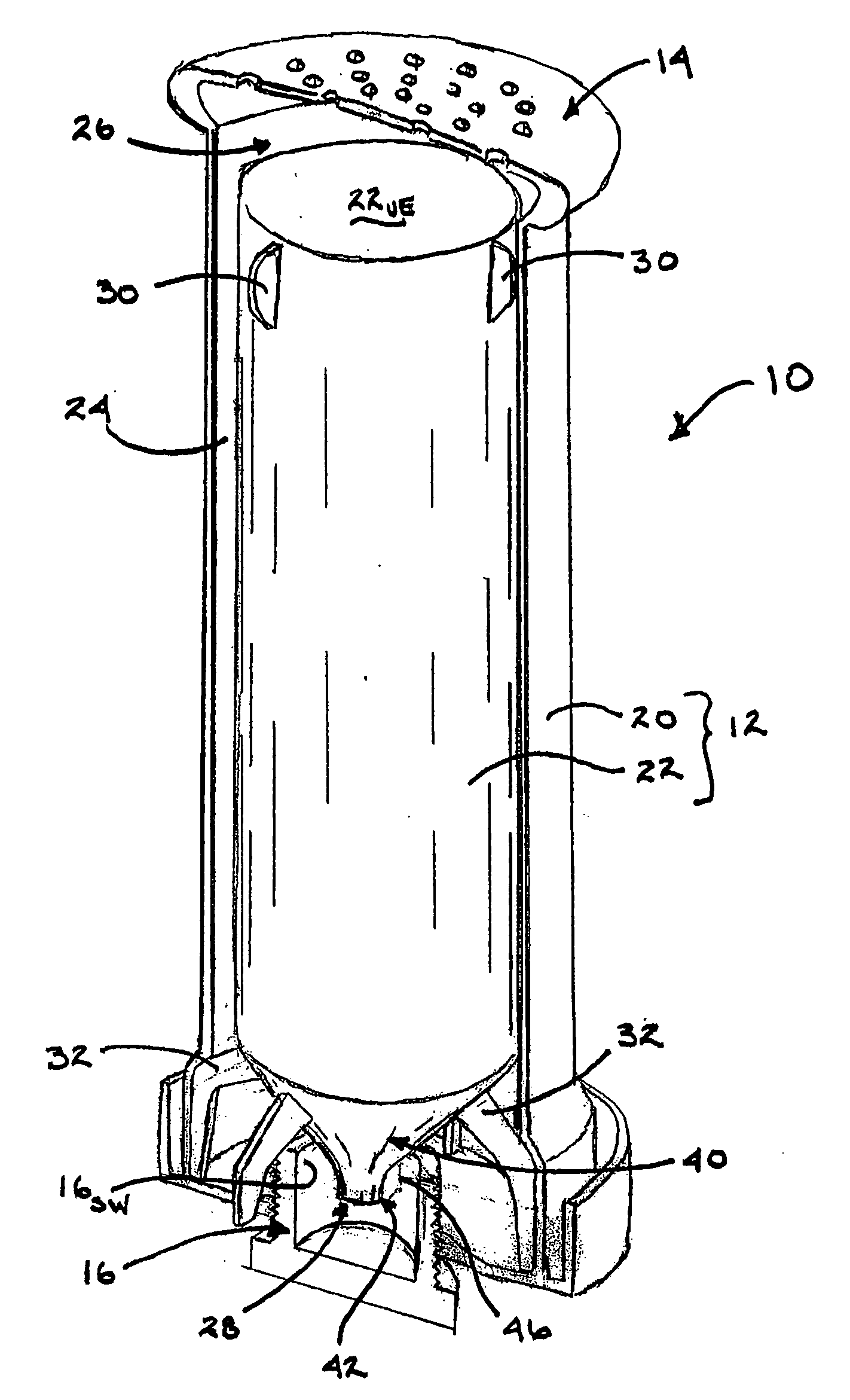

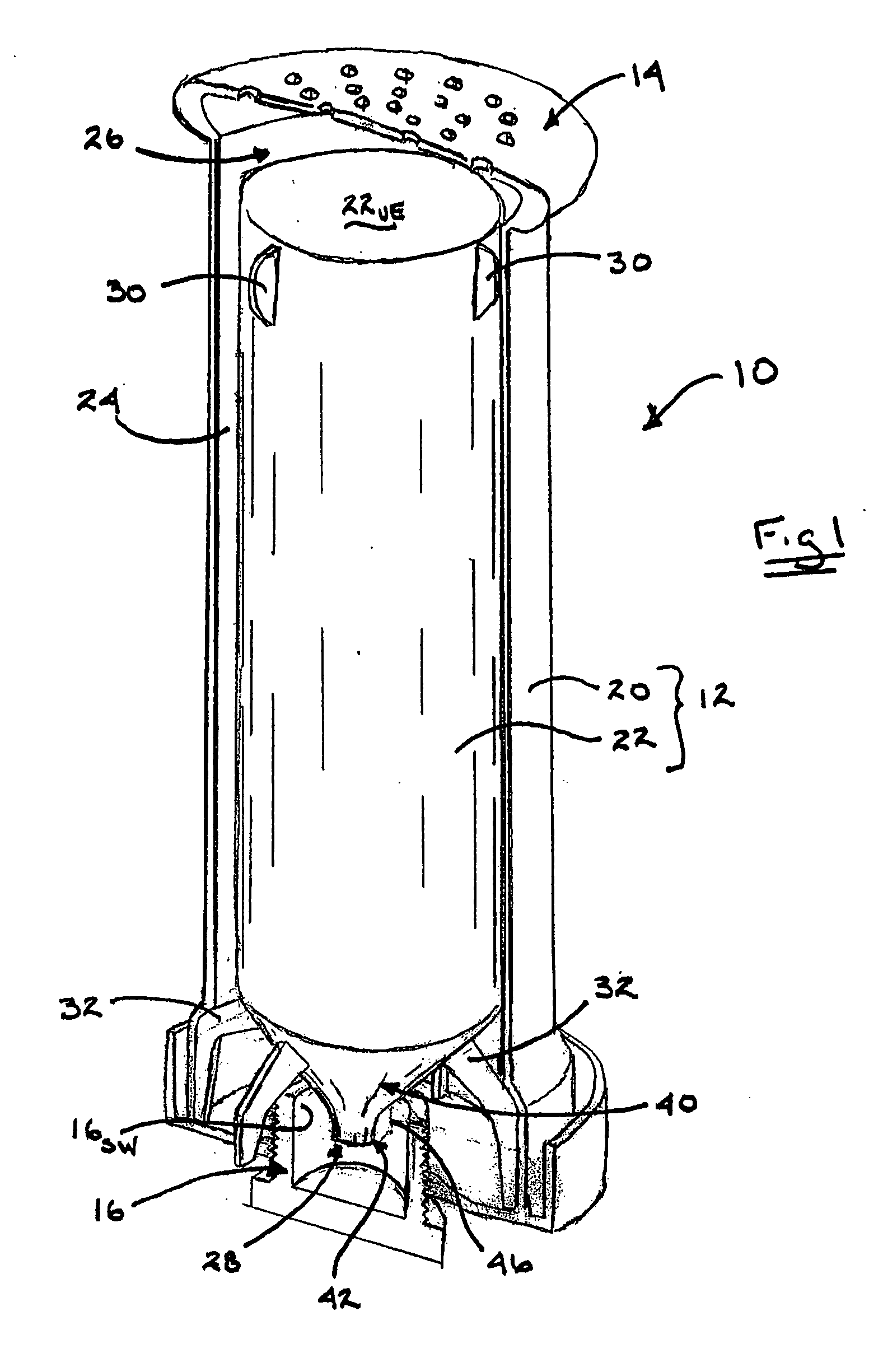

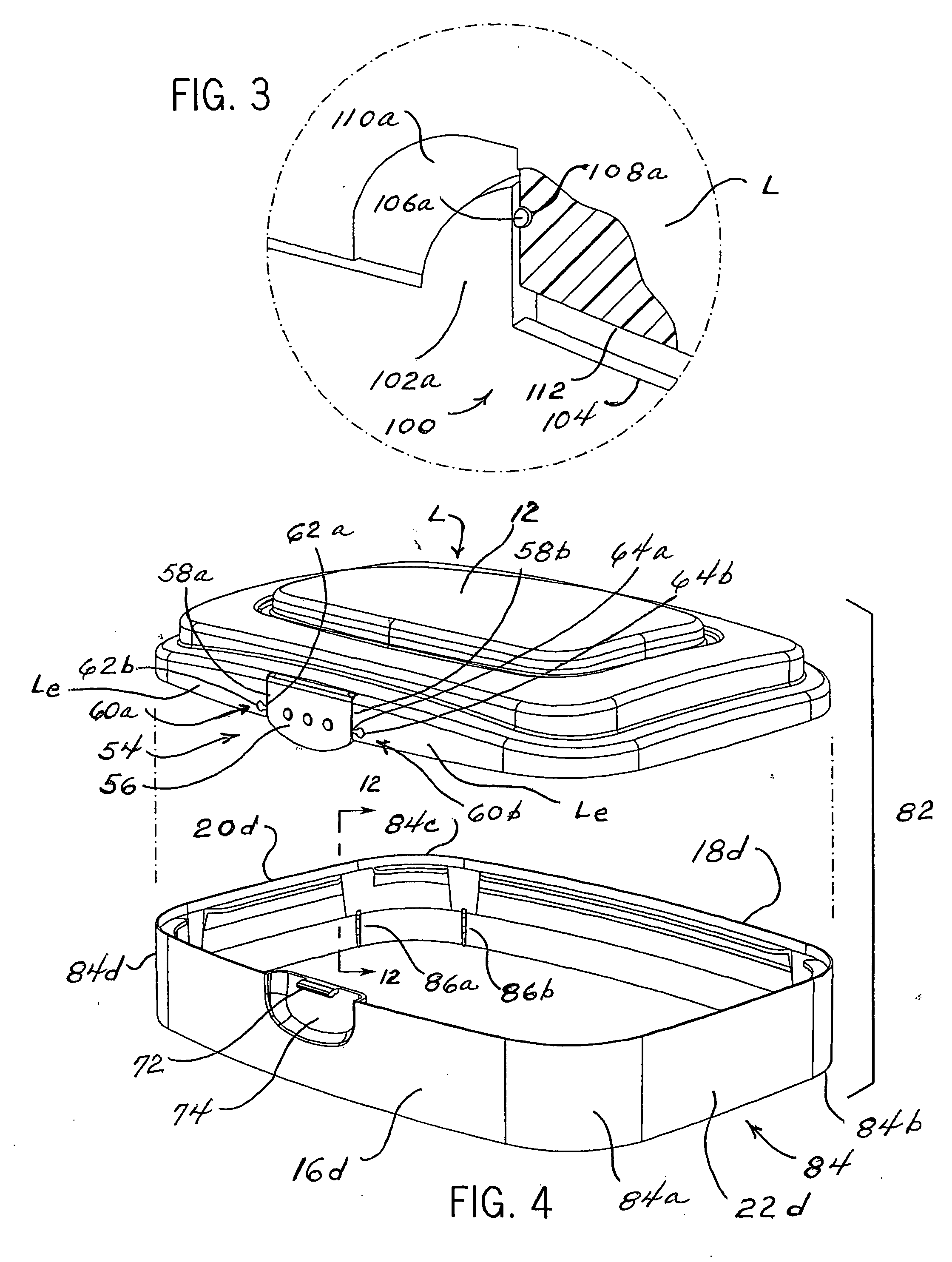

Reconfigurable metered material dispenser

A dispenser is provided for delivering a controlled quantity of a granular material. The dispenser includes a container assembly, a diffuser and a metering cup. The container includes a reservoir which supports a disposable cartridge of granular material. The cartridge is supported in the reservoir so as to define a passageway therebetween. A nozzle is defined for the outflow of material from the cartridge. The diffuser is disposed on one end of the container and includes a plurality of apertures. The metering cup is disposed on the opposite end of the container and has an open end adapted to receive granular material. Adjustment of the axial spacing between the nozzle and metering cup varies the quantity of granular material collected in the cup. The granular material is dispensed by inverting the container to a second orientation, such that material flows out of the metering cup, through the passageway and out of the diffuser. The nozzle may serve as a piercing mechanism for opening the disposable cartridge upon its insertion into the reservoir.

Owner:RESTAURANT TECH

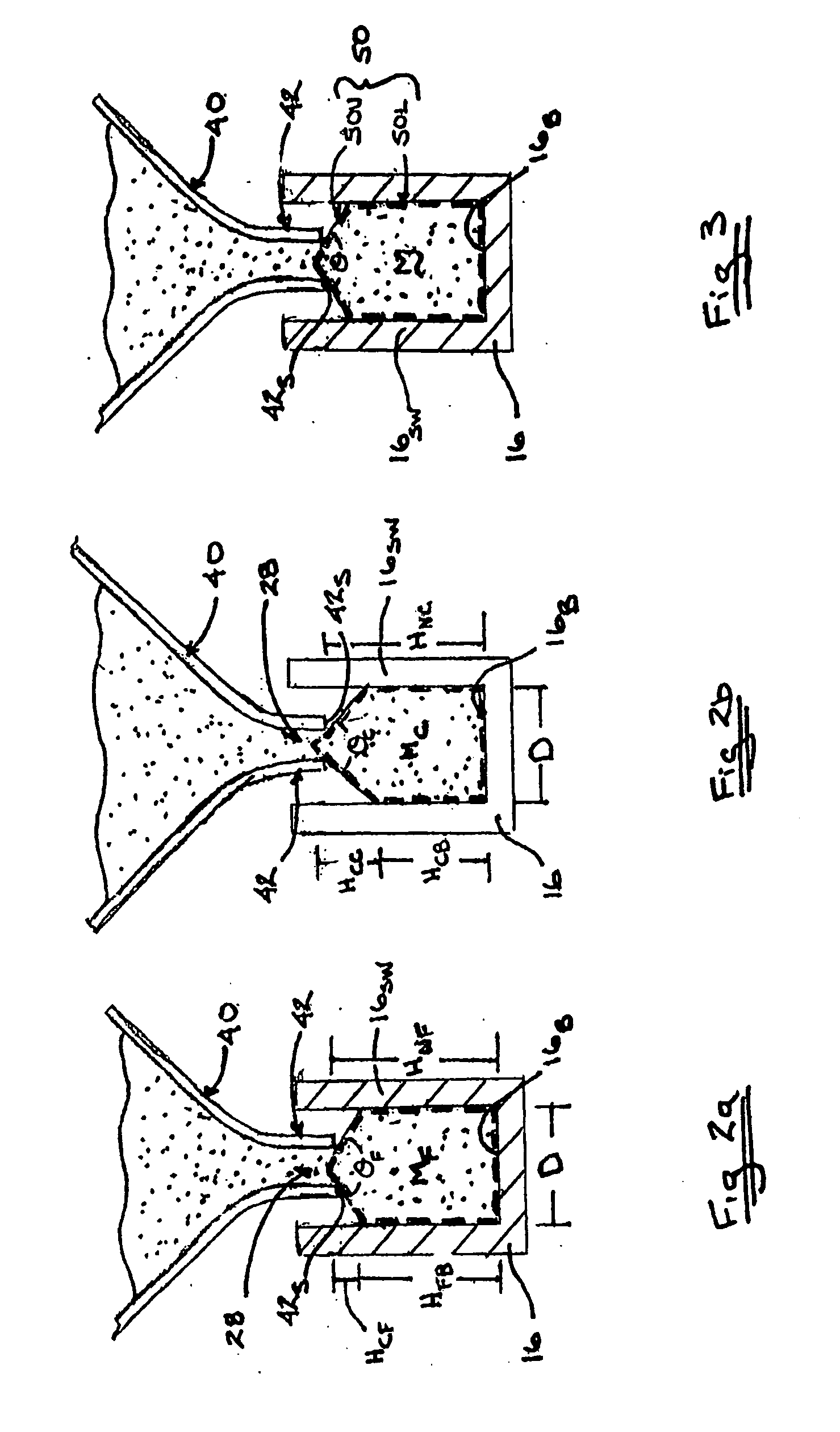

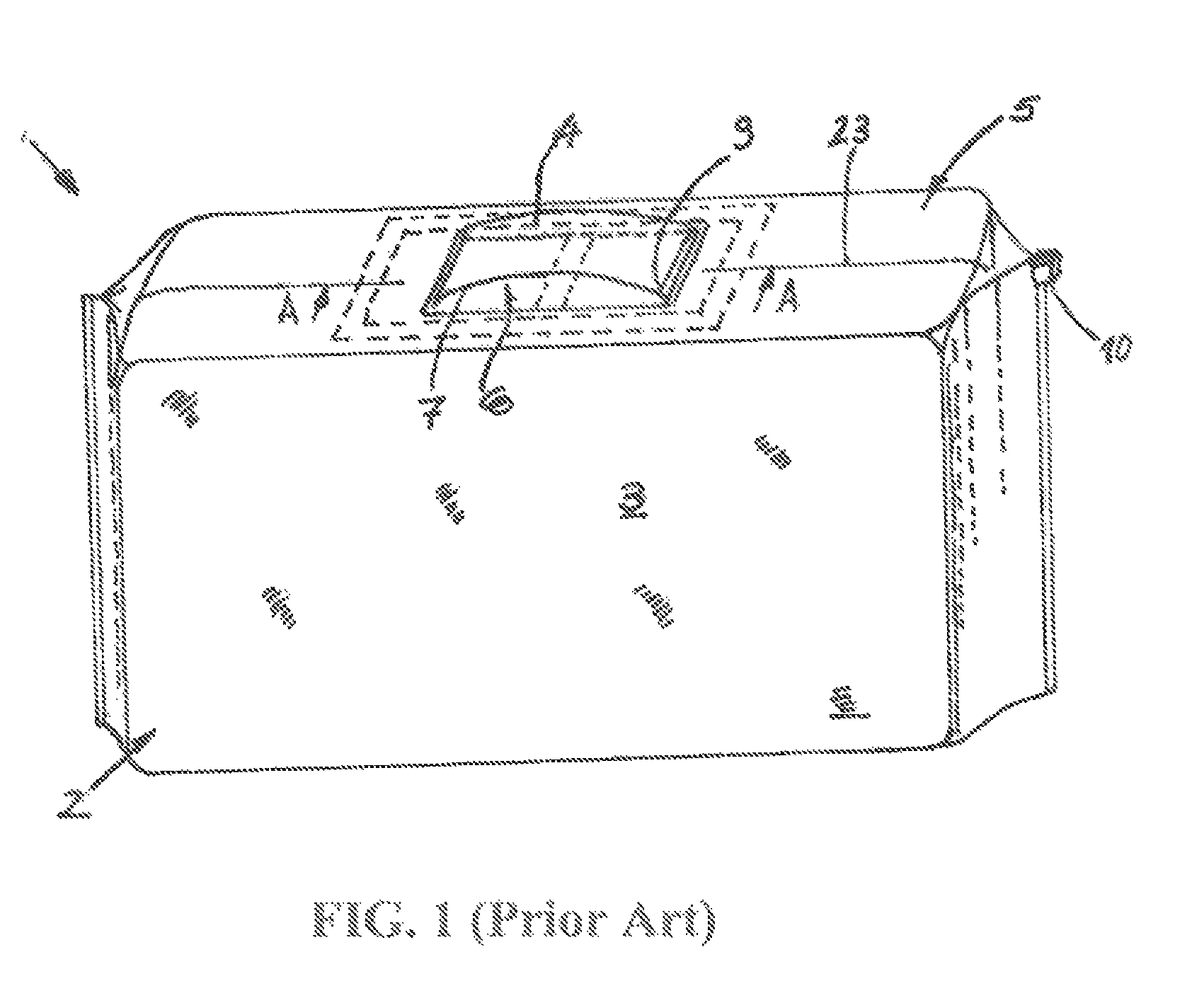

Shipping container

InactiveUS20060267377A1Easy loadingLoading/unloading vehicle arrangmentMonocoque constructionsEngineeringFlange

A shipping container for powdered, pelleted, or other particulate material comprises an elongated body which is formed by top and bottom walls, front and back walls, and a pair of side walls. The back wall may be formed by a pair of doors which provide access to the interior storage enclosure of the body. One of the doors is provided with an inlet opening adjacent the top thereof for loading material into the storage enclosure. At least one of the doors is provided with an outlet opening adjacent the bottom thereof for unloading material from the storage enclosure. An inclined baffle extends from the bottom wall toward the outlet opening for guiding material toward the outlet opening when the front of the body is elevated. The outlet opening may include a flange for securing a flexible discharge conduit. In another embodiment the outlet opening and baffle are located in the front of the container. A front container mounted loading / unloading feature permits product delivery flexibility by allowing discharge through a tilted container without placing stress on the hinged doors.

Owner:FRONTIER LOGISTICS

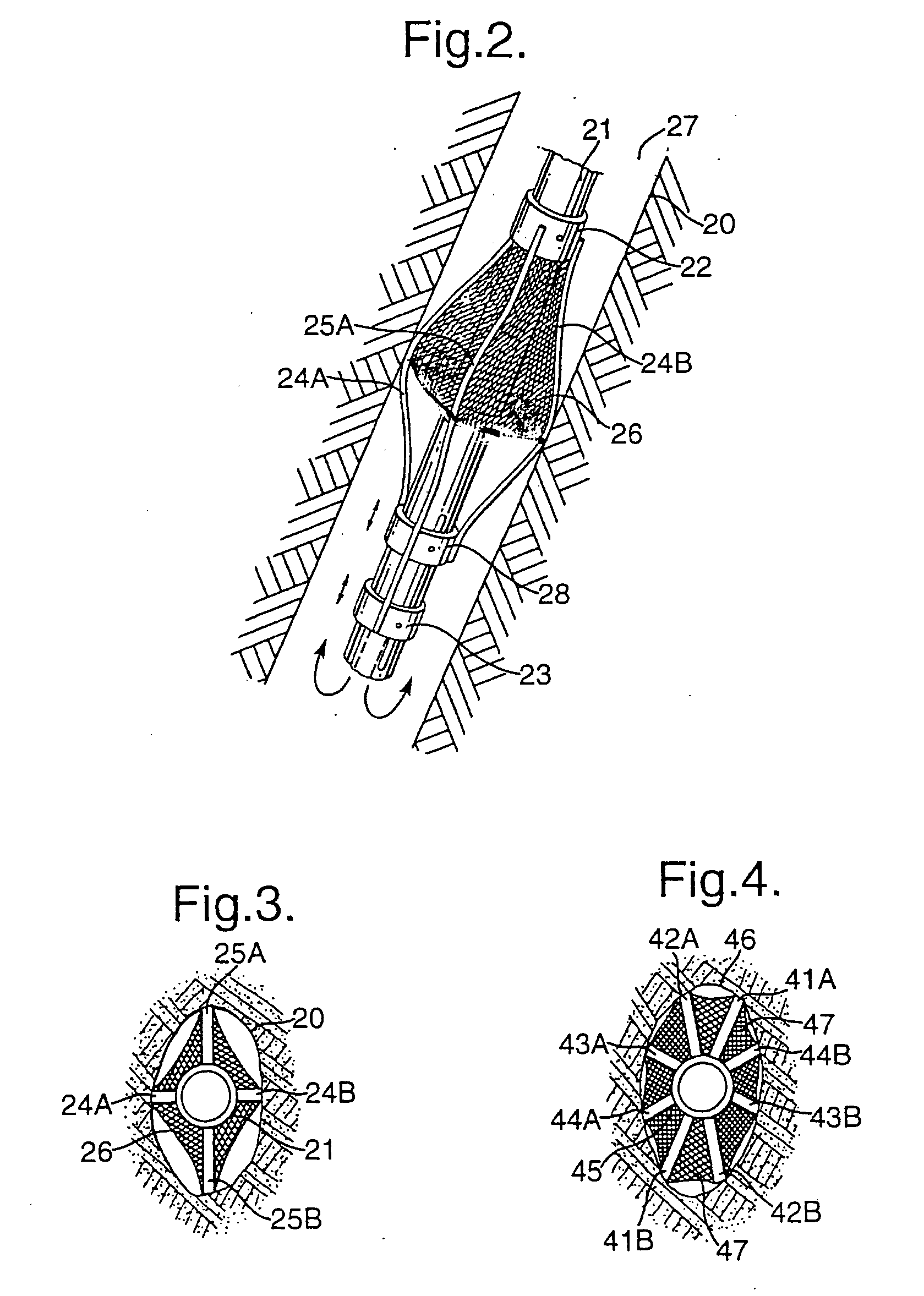

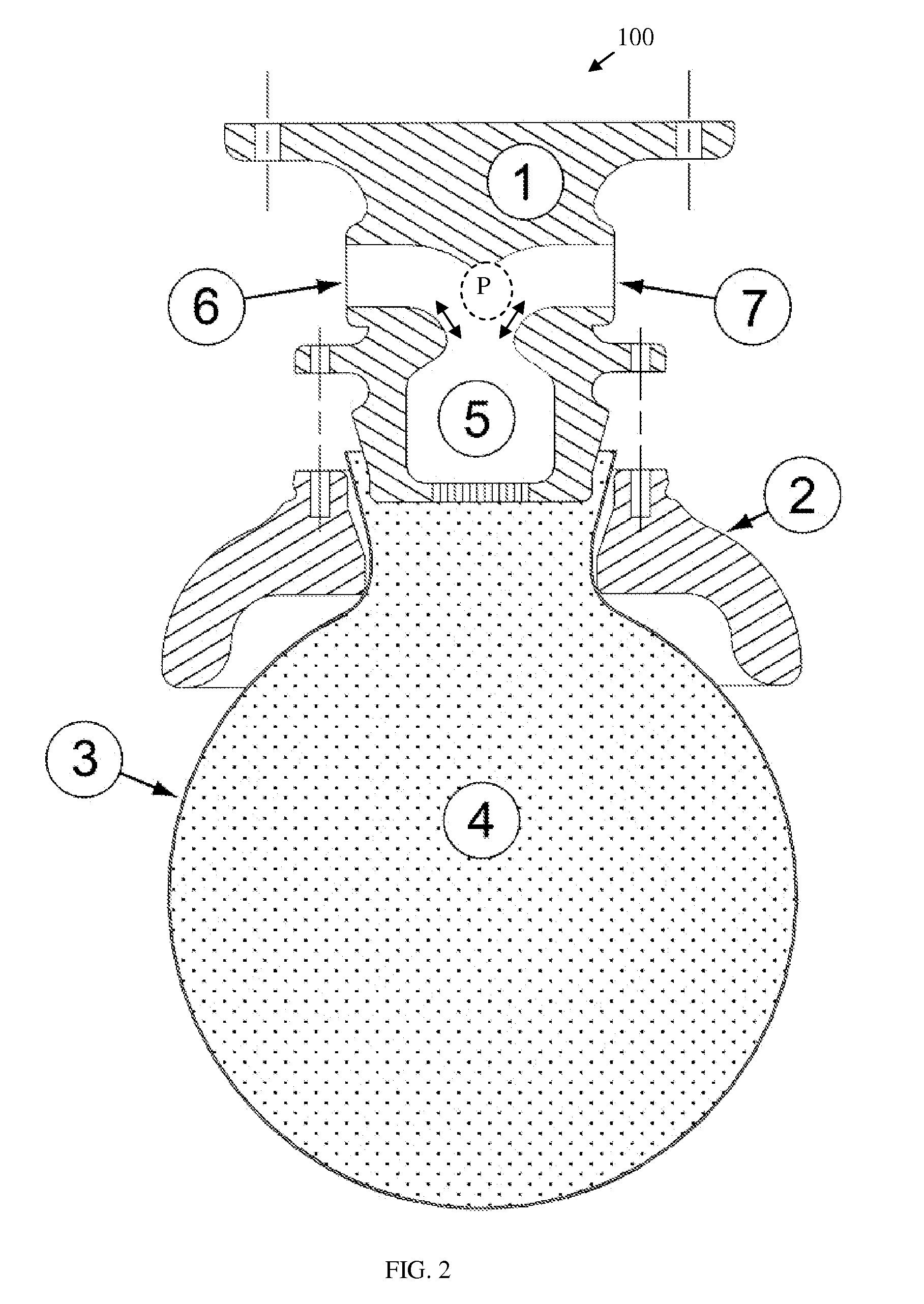

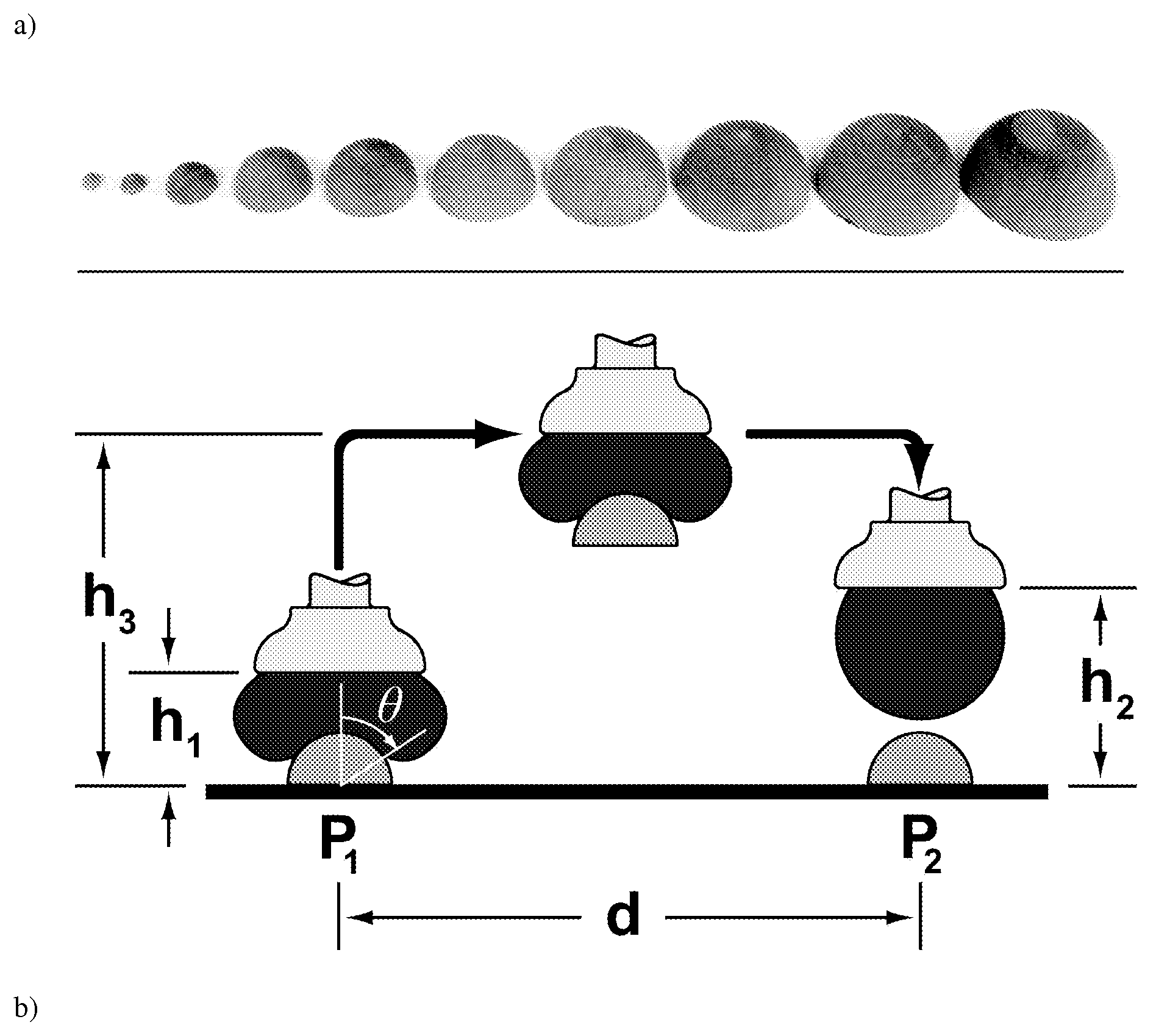

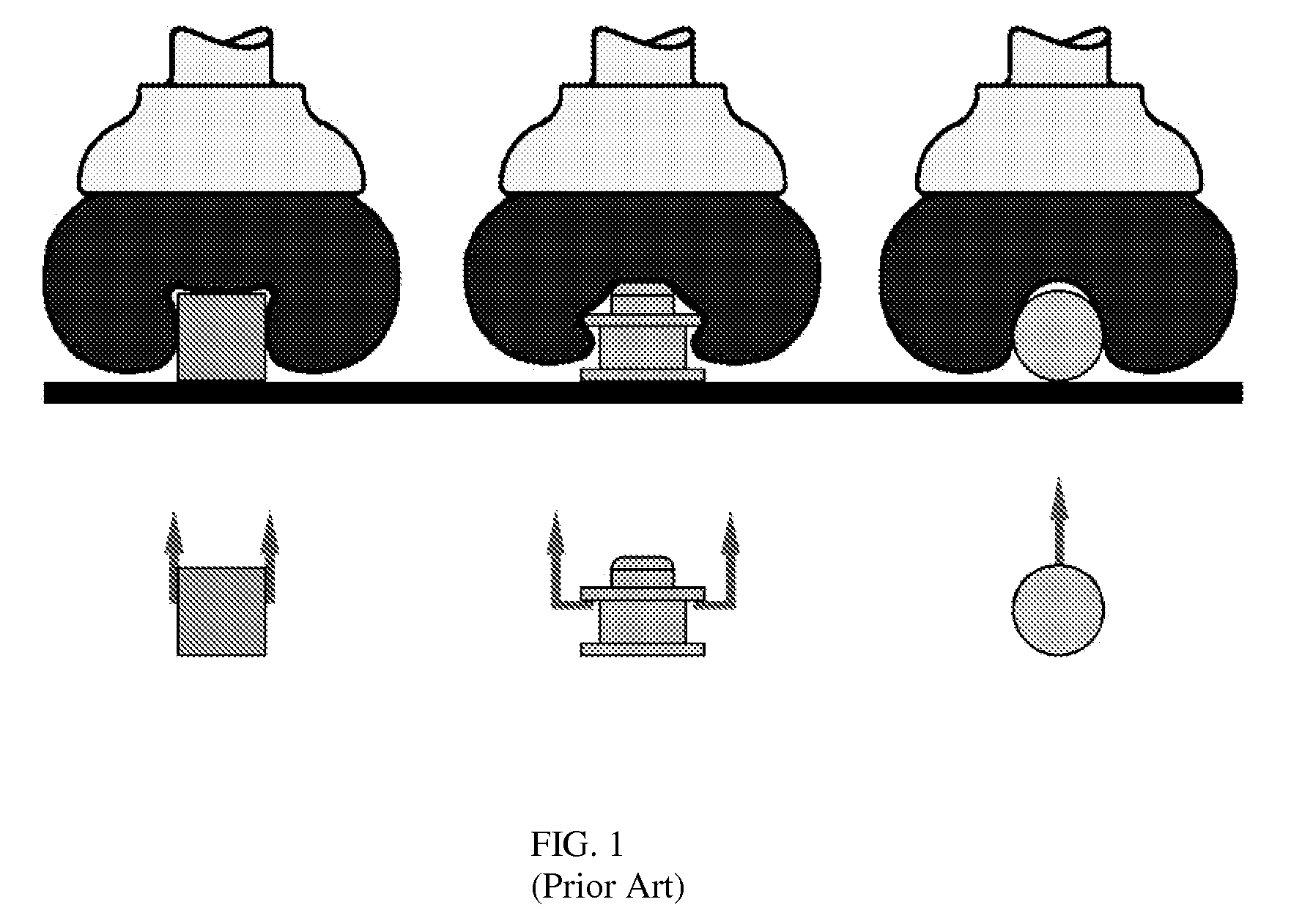

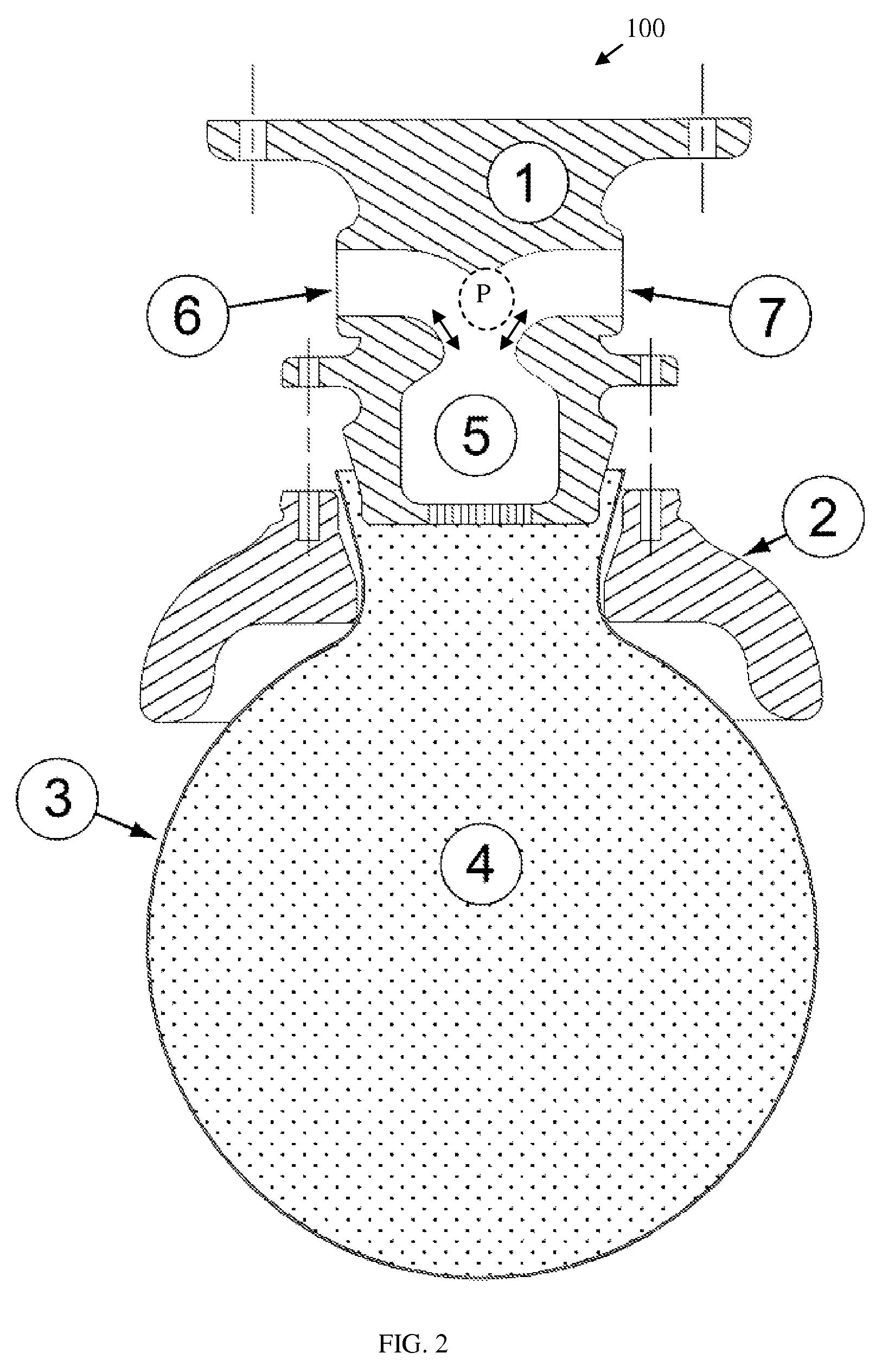

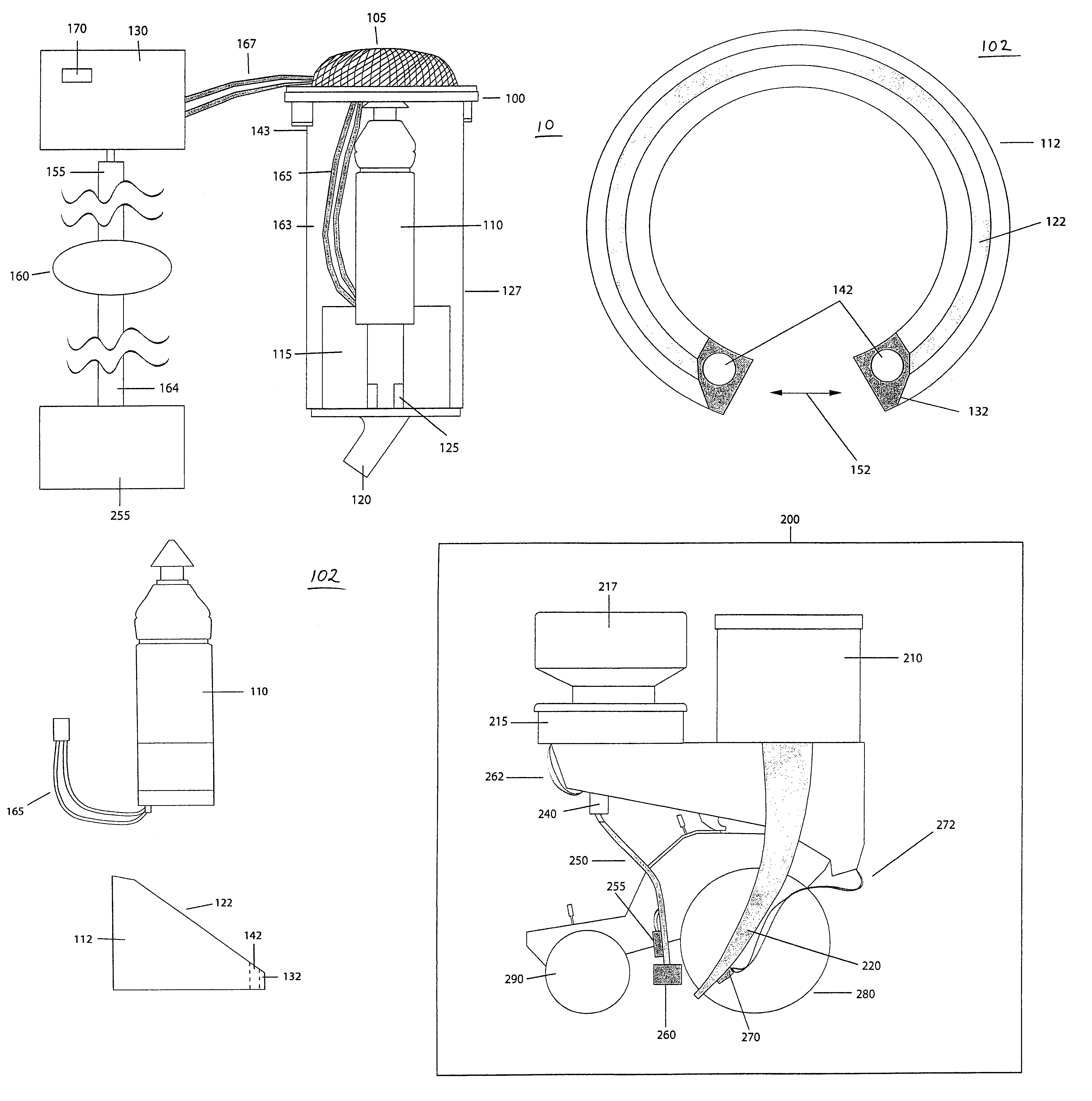

Gripping and releasing apparatus and method

ActiveUS20130106127A1Improvement factorImprove performanceGripping headsRobotPositive pressureEngineering

A passive universal gripper includes a mass of granular material encased in an elastic membrane. Using a combination of positive and negative pressure, the gripper can rapidly grip and release a wide range of objects that are typically challenging for conventional universal grippers, such as flat objects, soft objects, or objects with complex geometries. The gripper passively conforms to the shape of a target object, then vacuum-hardens to grip it rigidly; later using positive pressure to reverse this transition-releasing the object and returning to a deformable state. The apparatus and method enable the fast ejection of objects from the gripper, as well as essentially instantaneous reset time between releasing and gripping.

Owner:CORNELL UNIVERSITY +1

Boiling bed hydrogenation treatment catalyst and its preparing process

ActiveCN101240190AThe reaction equipment is simpleReduce operating costsRefining to eliminate hetero atomsLow speedSpherical shaped

The invention relates to a boiling bed hydrogenation catalyst and a preparation method. The boiling bed hydrogenation catalyst of the invention is spherical shape which diameter is 0.1mm to 0.8mm, and has appropriate amount of additives and hydrogenation of metal components, and has reasonable hole distribution. The catalyst preparation method of the invention is spherical carrier impregnation, the process of spherical carrier preparation is following: making catalyst carrier raw material which is in appropriate temperature into appropriate size grain, then spheroidizing the grain, heating the conglobation and making them into spherical catalyst carrier. The process for making the catalyst carrier raw material into the appropriate size grain is that wet stock passes screen stencil by mechanical action and generates grain. Between the processes of the making grain and nodularization, granular material primely is placed for a period of time or operates in low-speed in nodularization device for a period of time. The catalyst of the invention appropriately conducts the boiling bed hydrogenation for heavy oil, residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

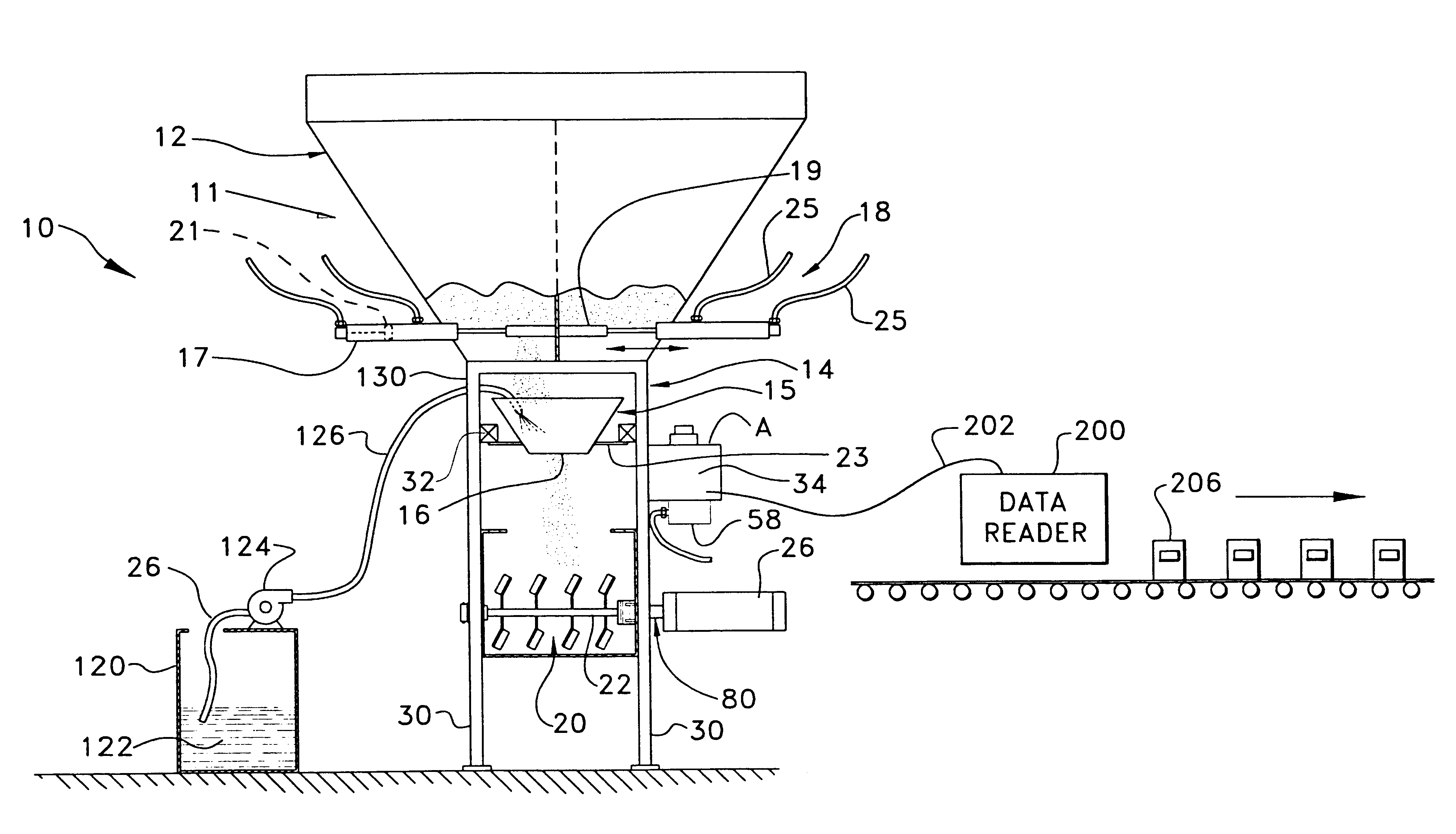

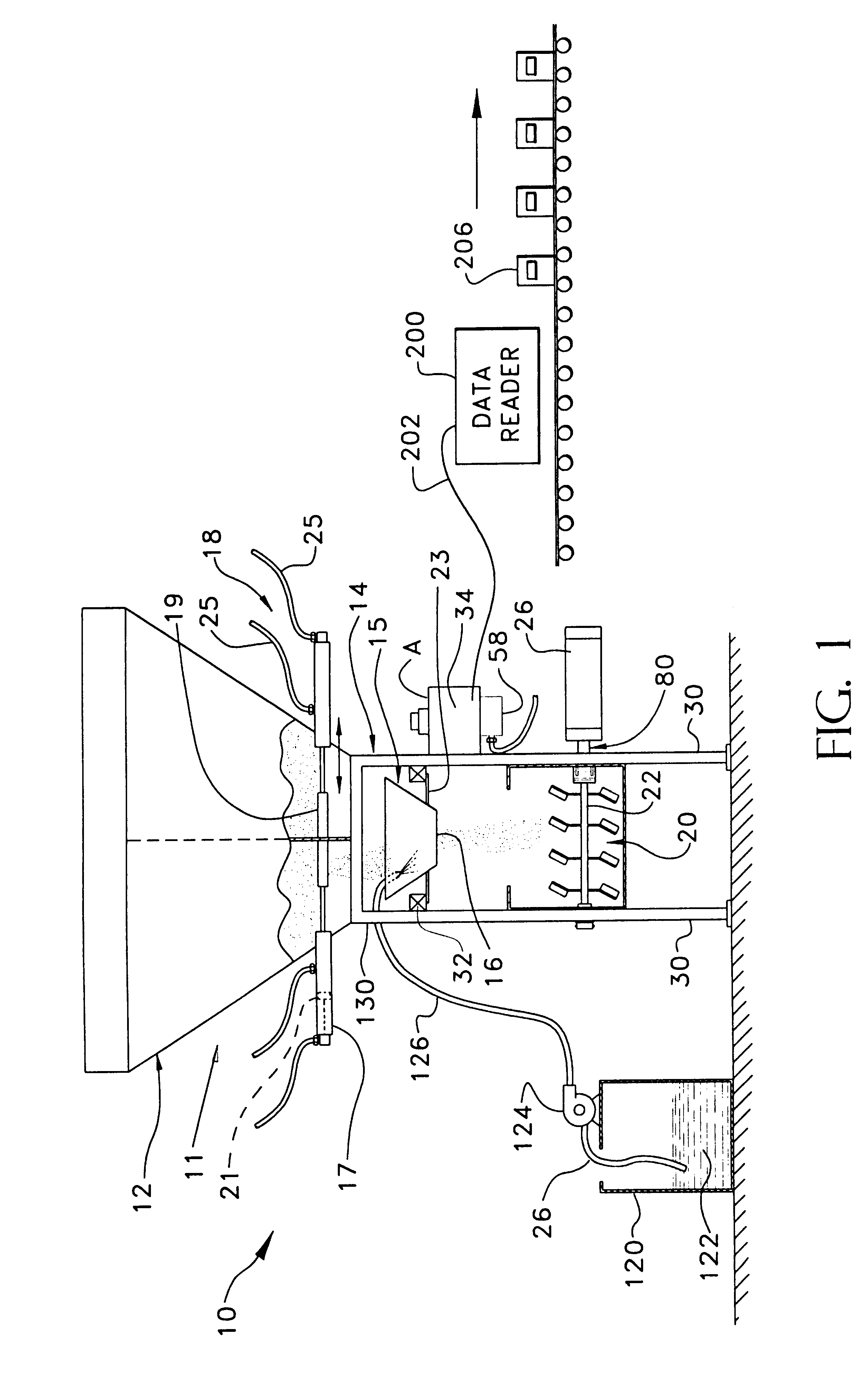

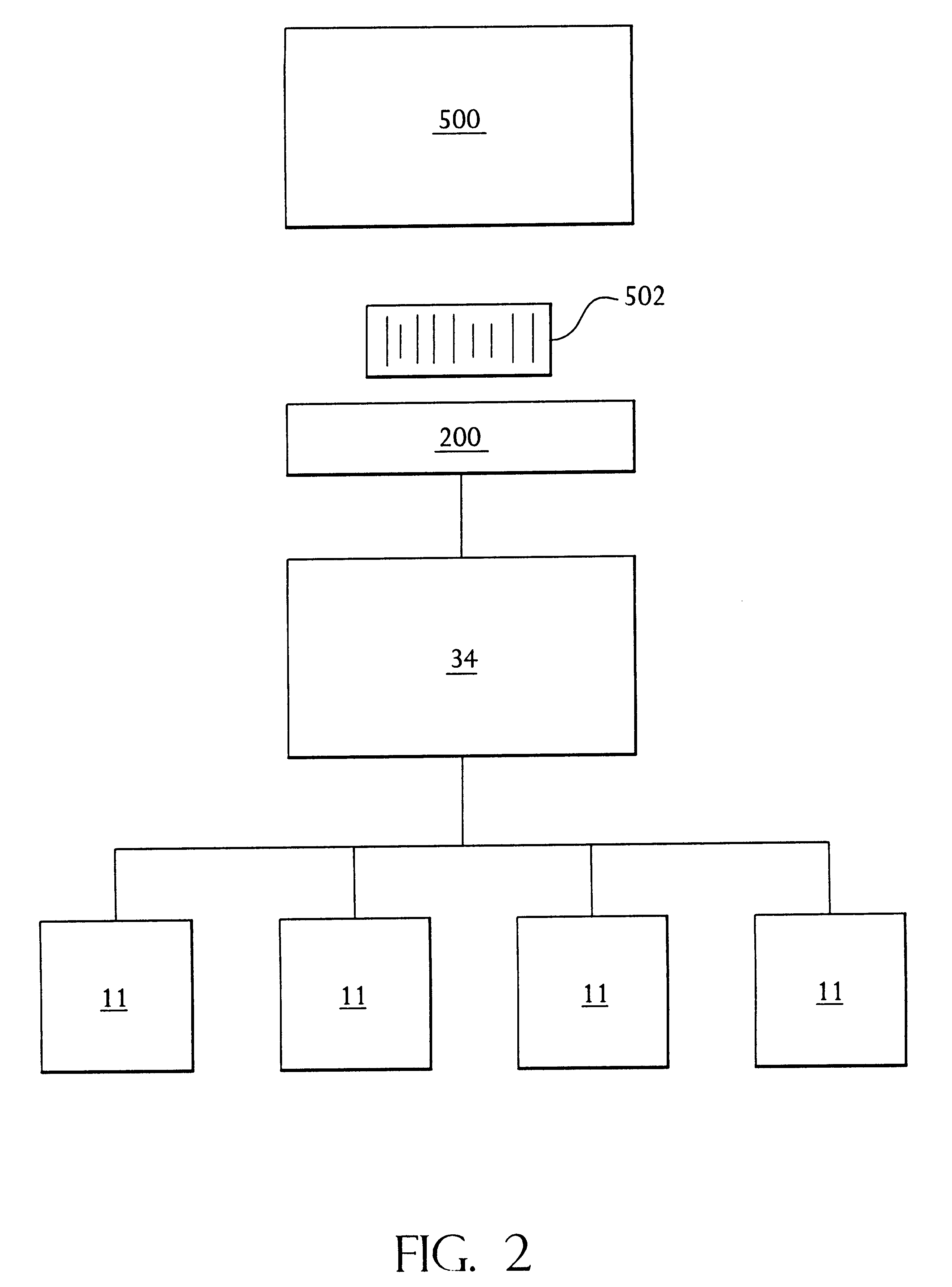

Gravimetric blender with operatively coupled bar code reader

InactiveUS6188936B1Accurate measurementEntered easily and accuratelyDigital data processing detailsRotary stirring mixersBarcodeMicroprocessor

A method for weight blending of granular materials comprises at a remote site generating a command for desired operation of granular material weight blending apparatus; encoding said command into transportable time-stable machine readable tangible storage media; transporting said media to a bar code reader operatively connected to said granular material weight blending apparatus; scanning the tangible media having the command encoded thereon to read the command; and providing the read command as input to a in microprocessor operatively connected to said granular material weight blending apparatus for regulating operation of the same.

Owner:MAGUIRE PROD

Method of creating a zonal isolation in an underground wellbore

A method of creating a zonal isolation above a target zone in an underground wellbore comprises:inserting a slurry injection tubing into the wellbore;arranging within an annular space surrounding said tubing an particle accumulation means, such as an expandable screen or an area where the slurry velocity is reduced; andpumping a slurry comprising a carrier fluid and granular material down via the slurry injection tubing and the target zone and then up into the annular space, such that at least some granular material accumulates and forms an elongate zonal isolation in the annular space between the target zone and the particle accumulation means, which zonal isolation is removable and exerts a limited radial force to the surrounding formation, thereby reducing the risk of formation damage.

Owner:SHELL OIL CO

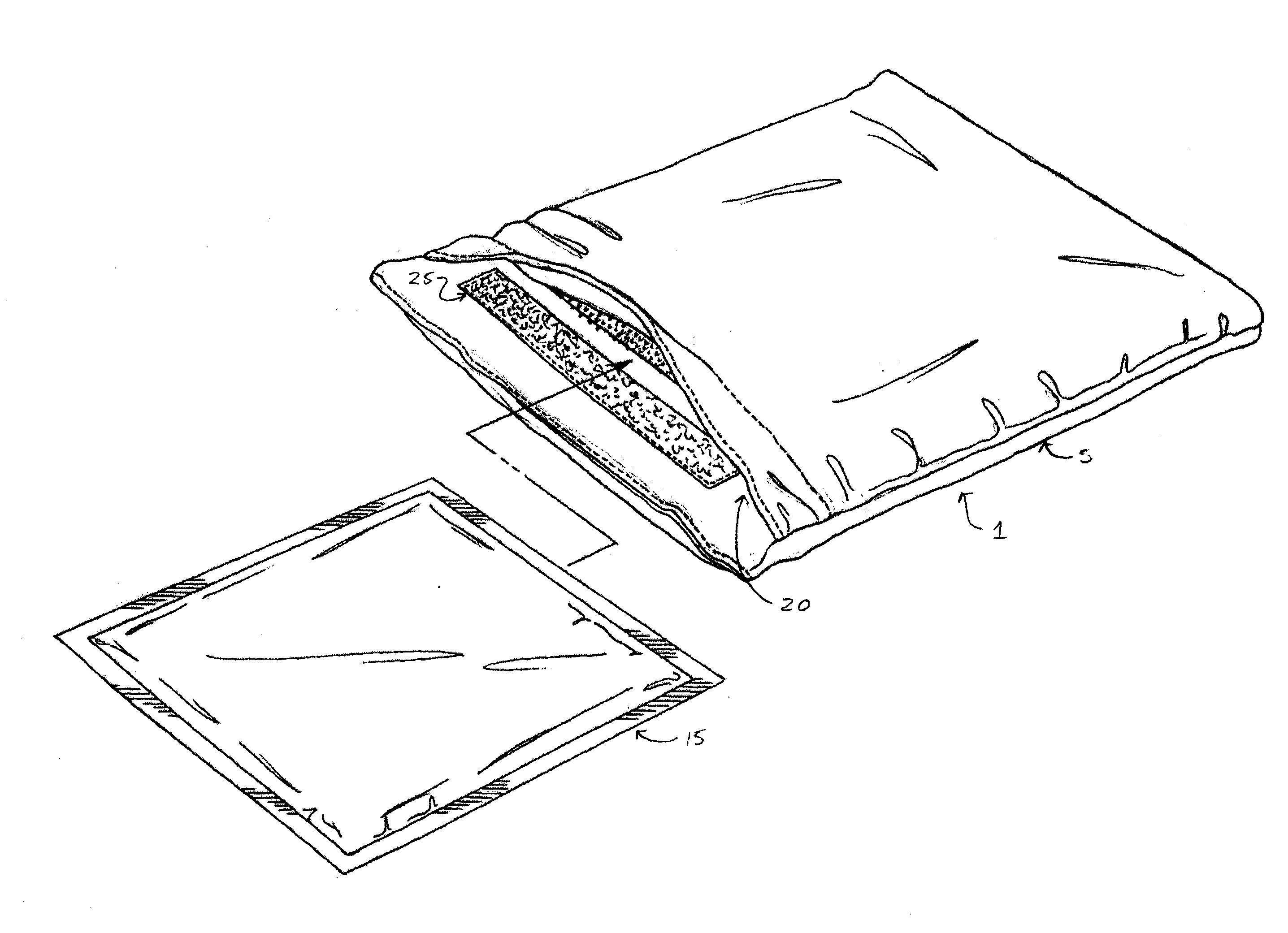

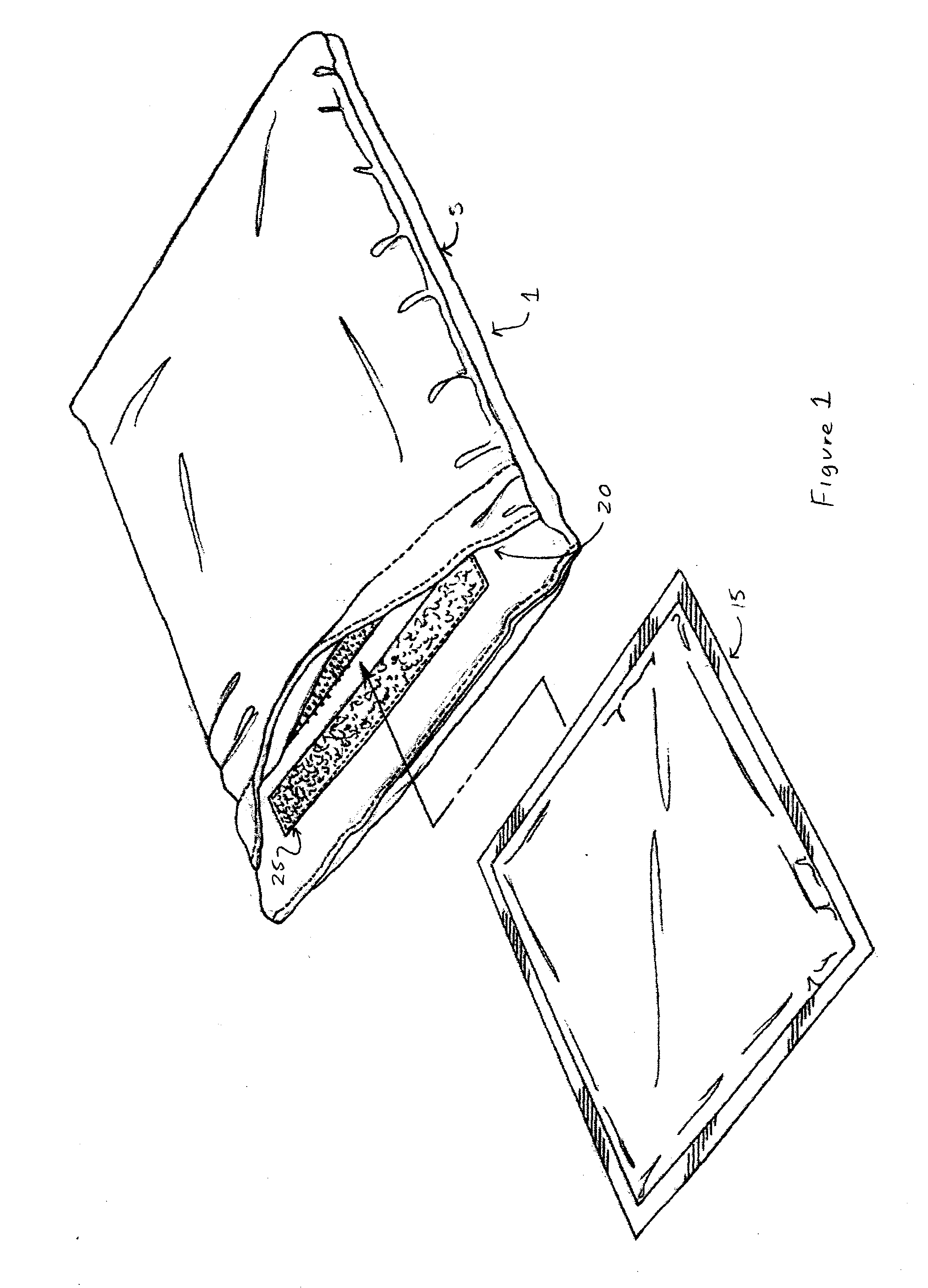

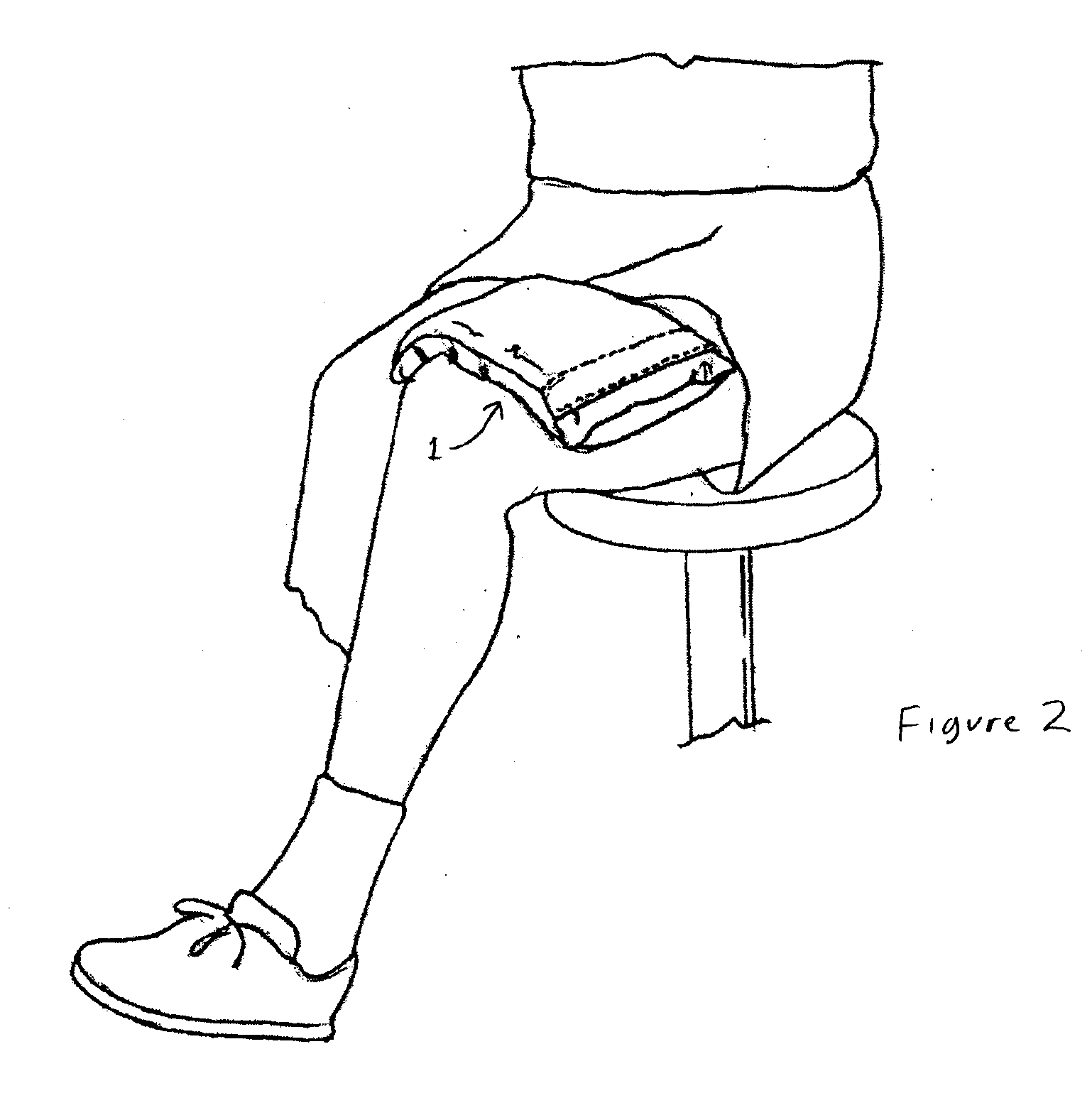

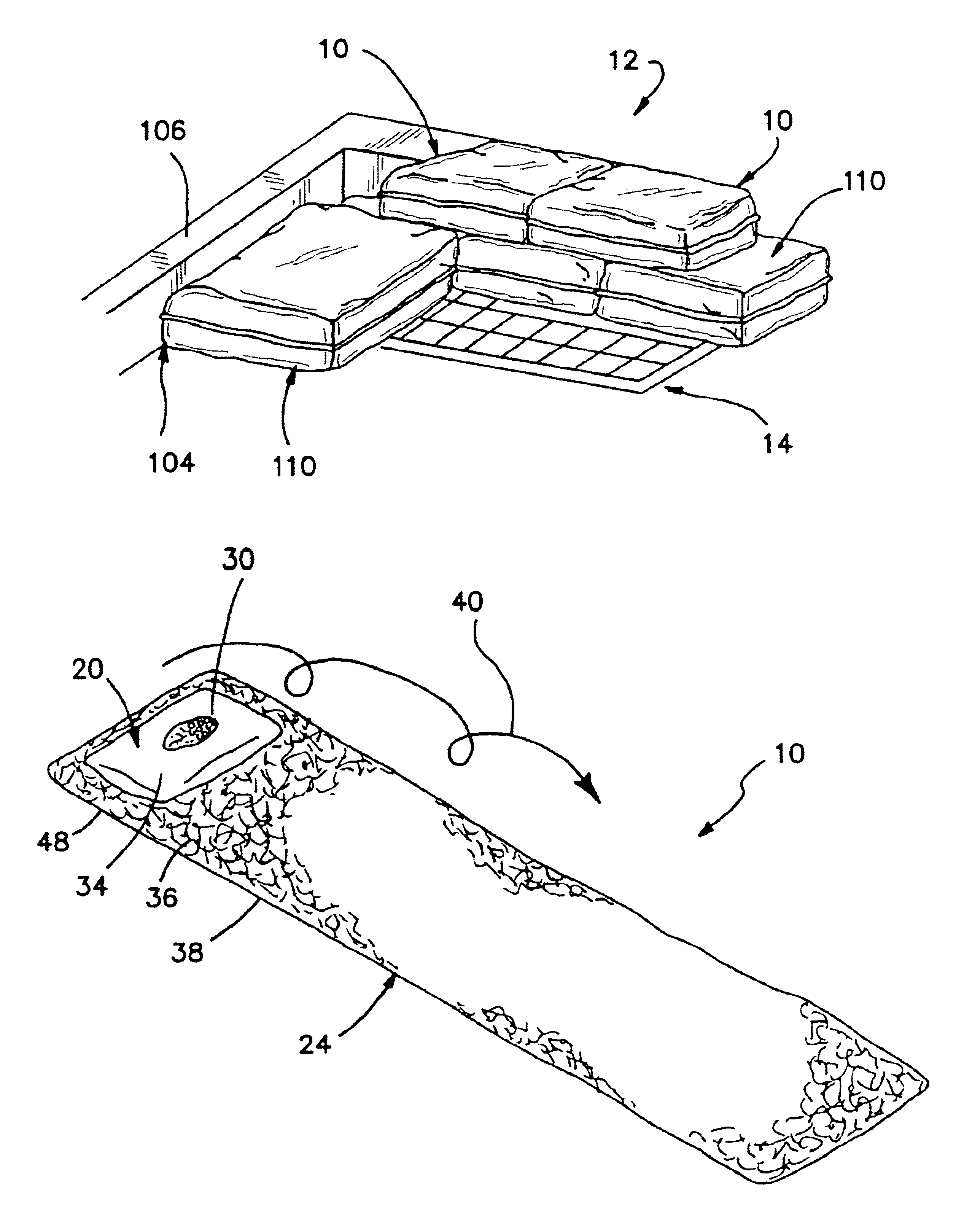

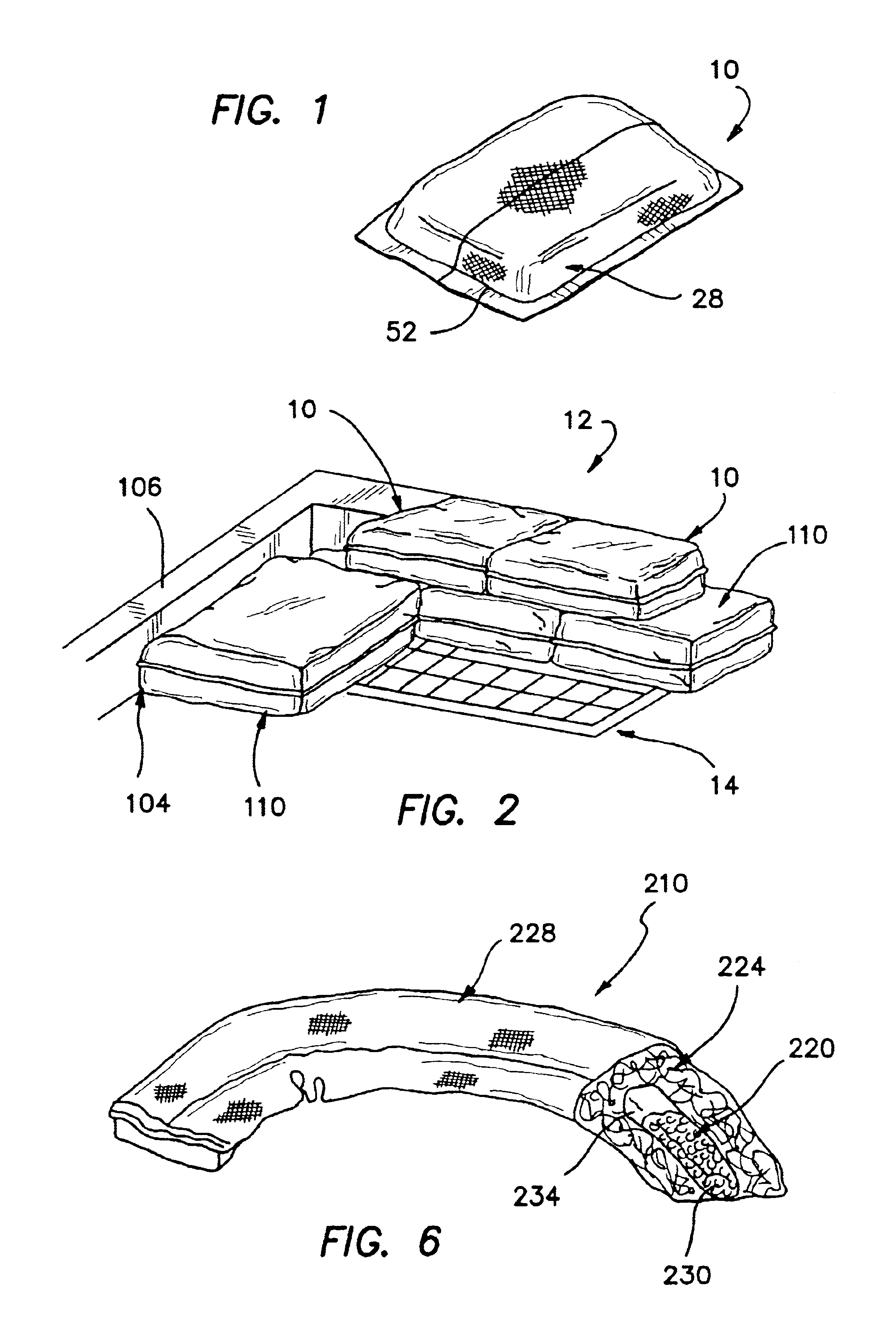

Thermotherapeutic pad

ActiveUS20100217363A1Maintain positionTherapeutic coolingTherapeutic heatingCold packsGranular material

A thermotherapeutic pad for applying heat or cold to a body part. The pad has a material for releasing or absorbing heat and a thermally conductive envelope for containing the granular material. The pad also has a holder for removably holding a cold pack adjacent to the envelope. The thermotherapeutic pad may provide heat by heating the material and placing the envelope against the body part, and the thermotherapeutic pad may absorb heat by placing a cooled cold pack into the holder and placing the portion of the pad comprising the cold pack against the body part.

Owner:RAPID AID

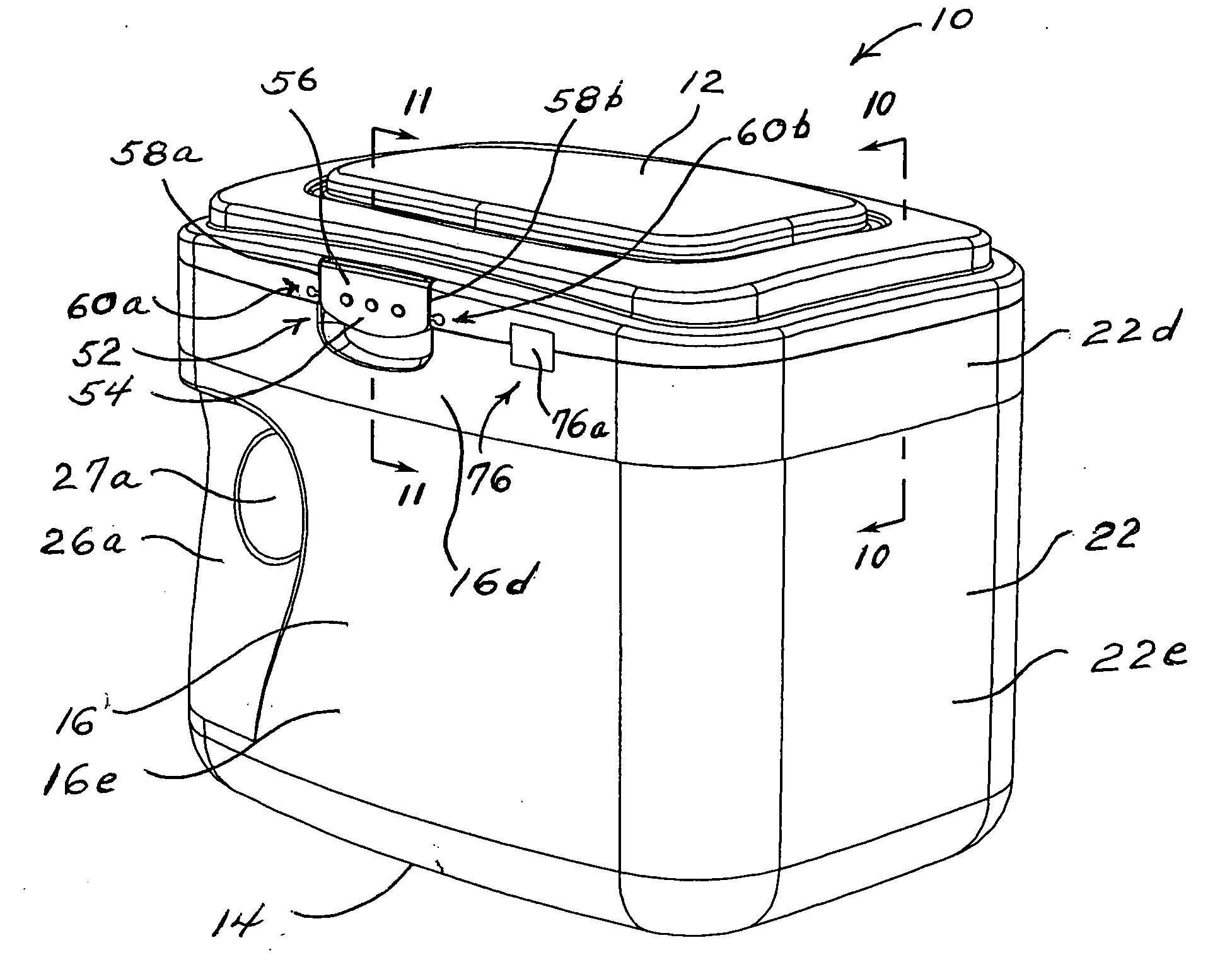

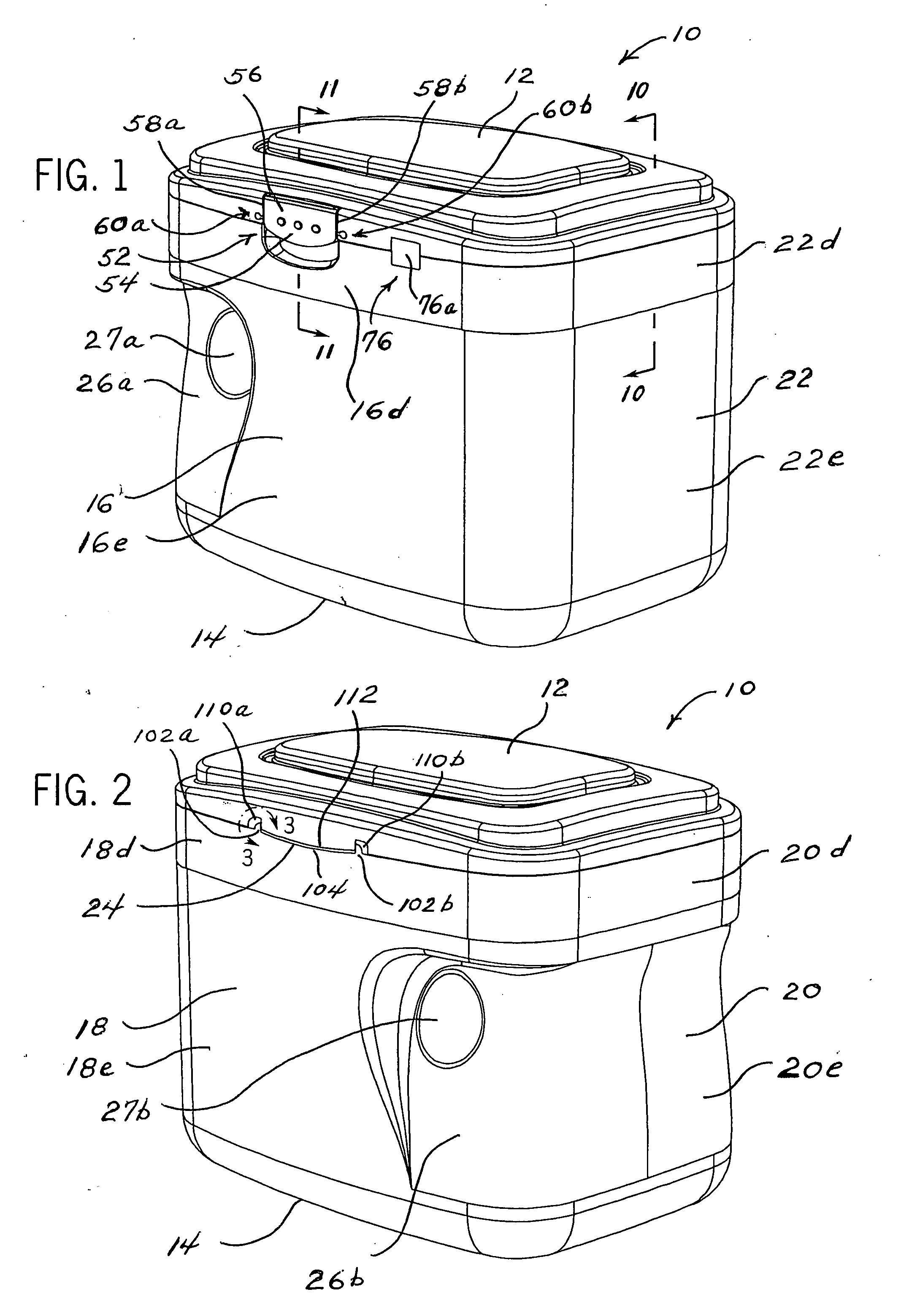

Container

InactiveUS20080156858A1Easy to storeEasy and clean accessClosure with auxillary devicesContainer/bottle contructionMechanical engineeringGranular material

A container comprising a top wall, a bottom wall, a front wall, a rear wall, a first side wall, and a second side wall. Each of the walls has a substantially rectangular shape. The rectangular shape of each wall enables the container to be stored easily on a shelf or counter-top. The top wall and portions of the front wall, the rear wall, the first side wall, and the second side wall form a lid. The lid is pivotally attached to the rear wall by a hinge. The lid can be opened by rotation thereof about the hinge. The front wall has at least one recess and the rear wall has at least one recess. The at least one recess of the front wall and the at least one recess of the rear wall are adjacent to the first side wall. The recesses provide a grip feature, which enables the user to manipulate the lid of the container with one hand when the container rests on a flat surface, e.g., a tabletop or a counter top. The container is suitable for holding granular material or powdered material, the container having a scoop furnished therewith.

Owner:ABBOTT LAB INC

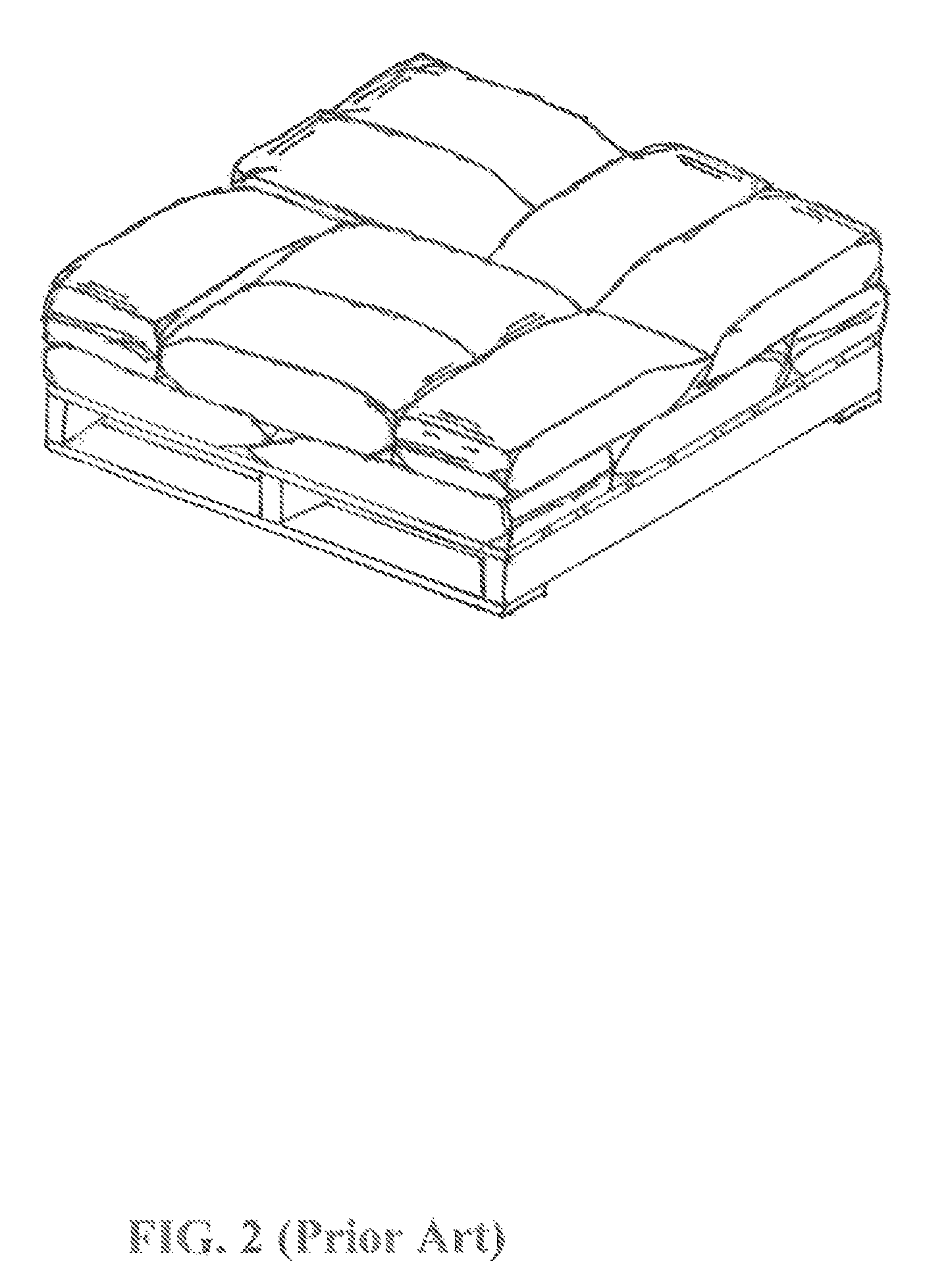

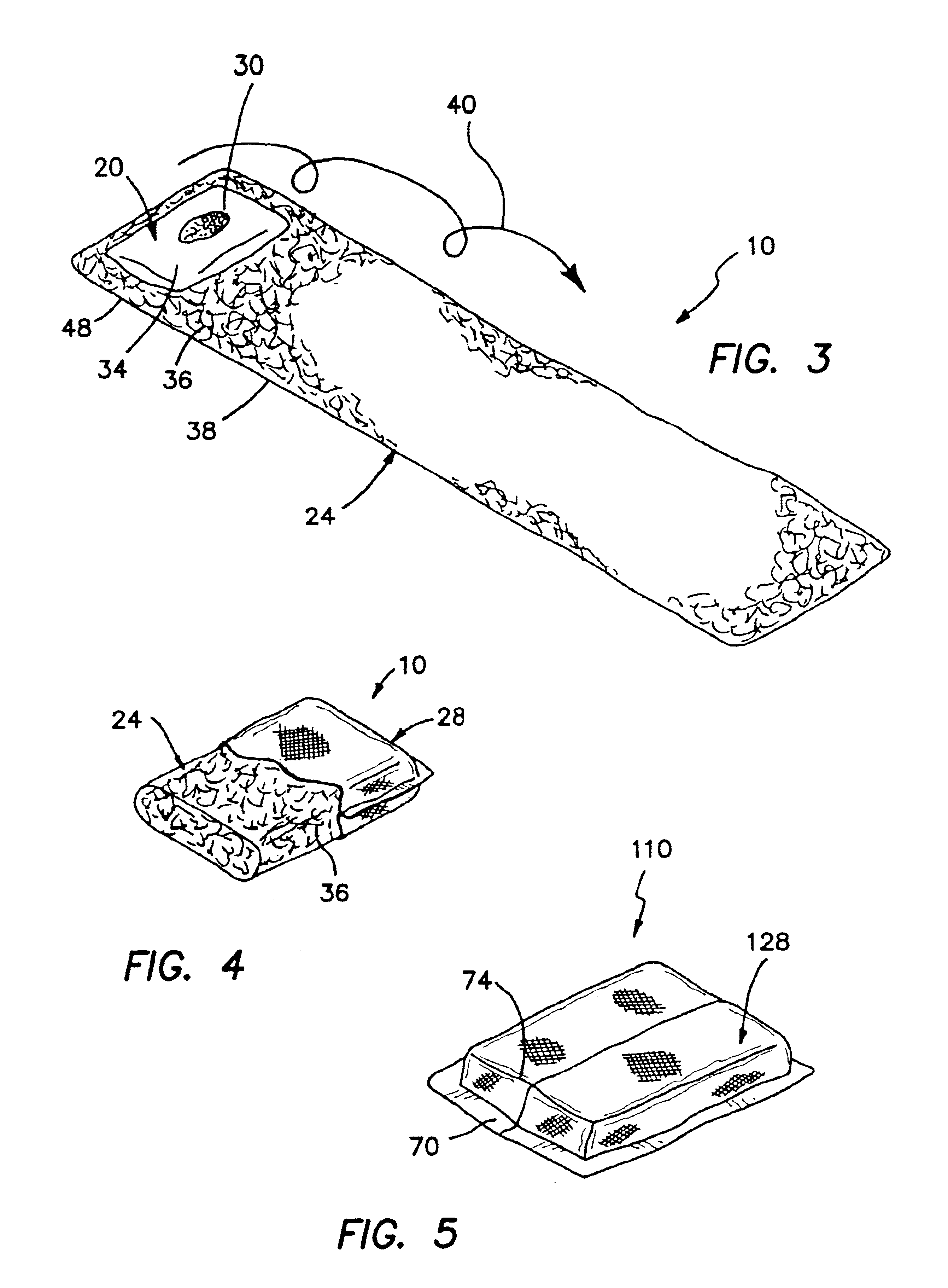

Vertically stacking litter bag with handle

Bags for granular material with a closure on top of the bag and a vertical handle on the lower end of the bag and having suitable dimensions, static coefficient of friction, creep resistance and containing granular materials of limited flow properties can be vertically stacked without support, for example on a pallet. One such suitable granular material is cat litter.

Owner:THE CLOROX CO

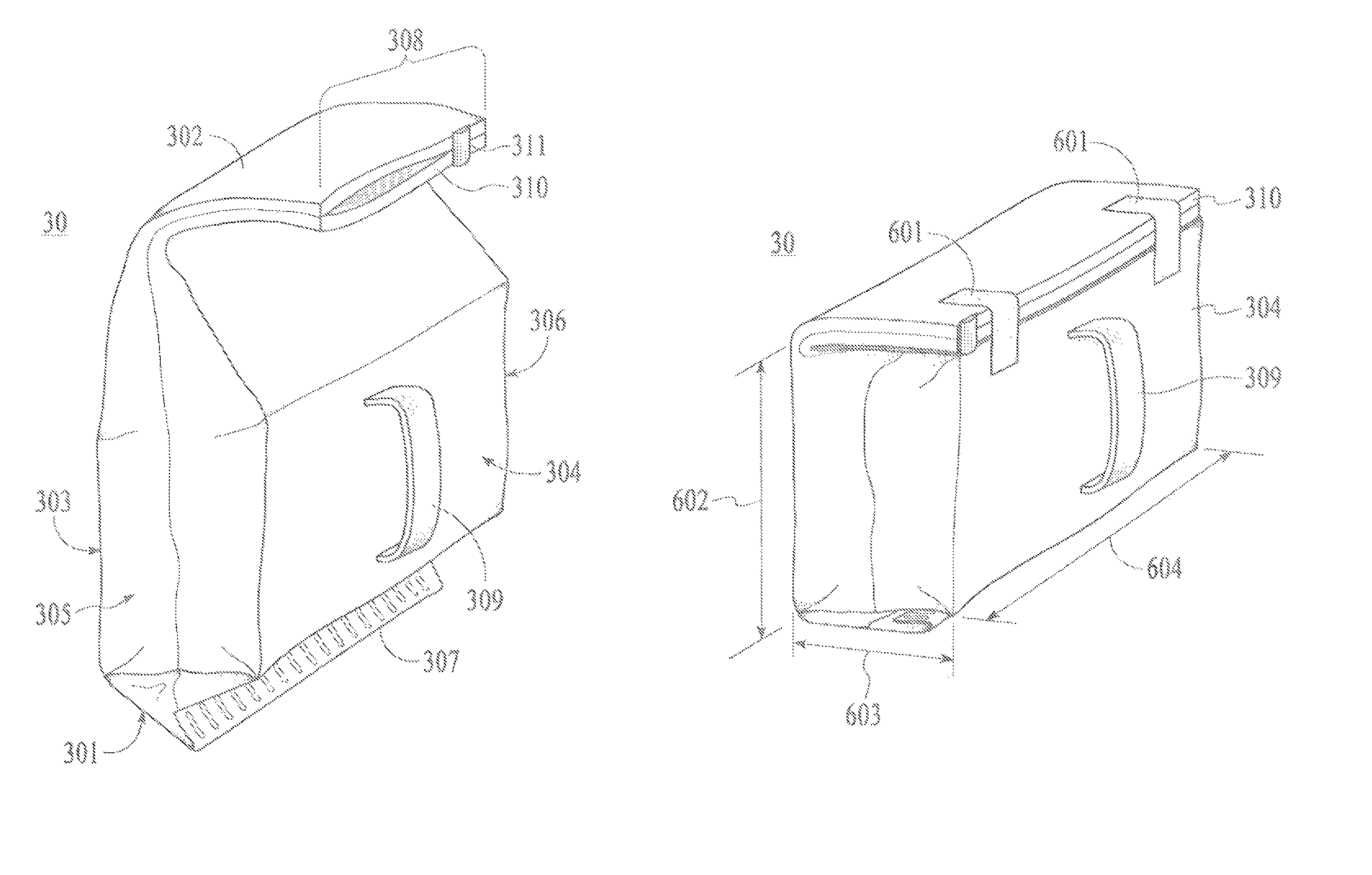

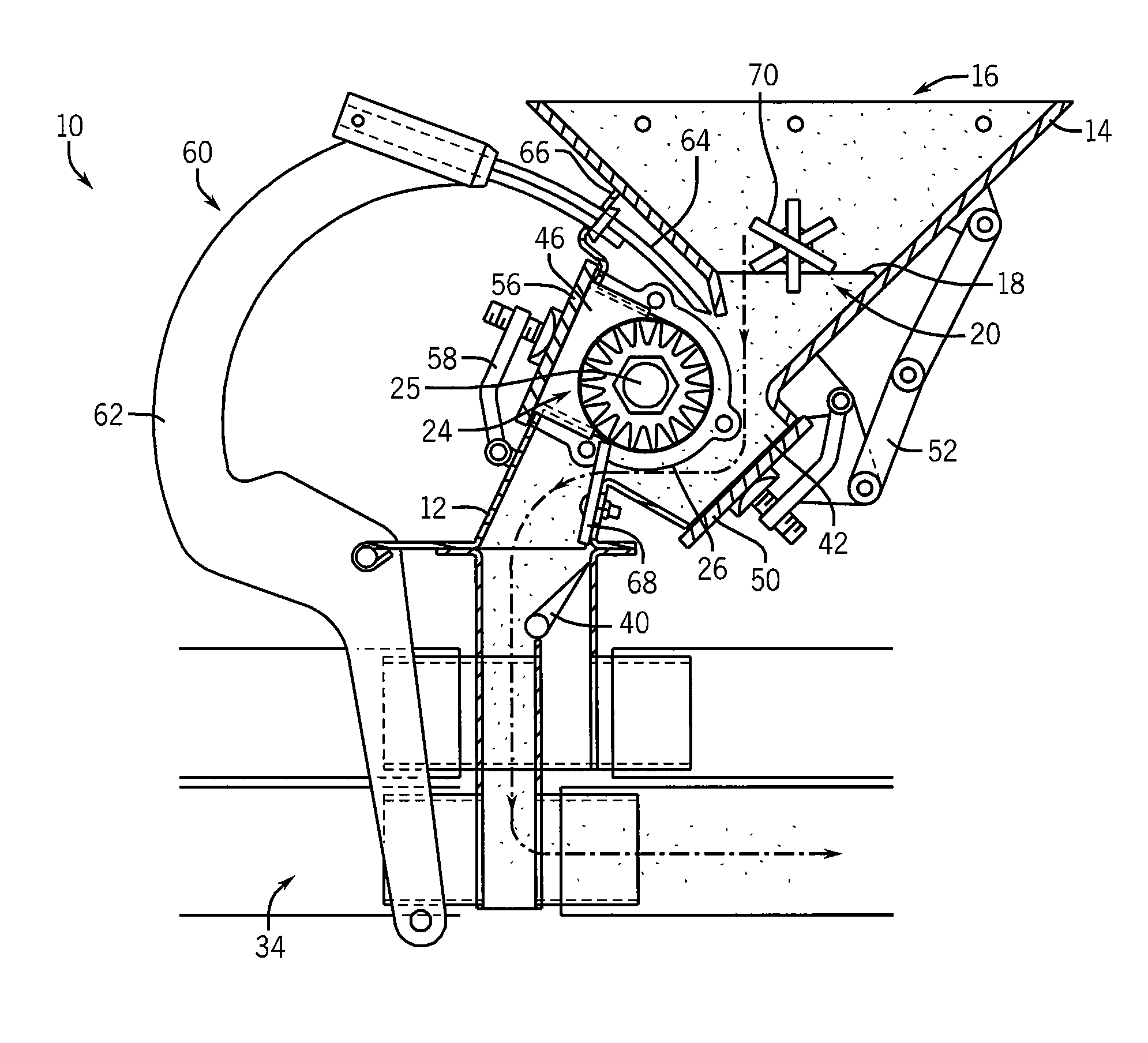

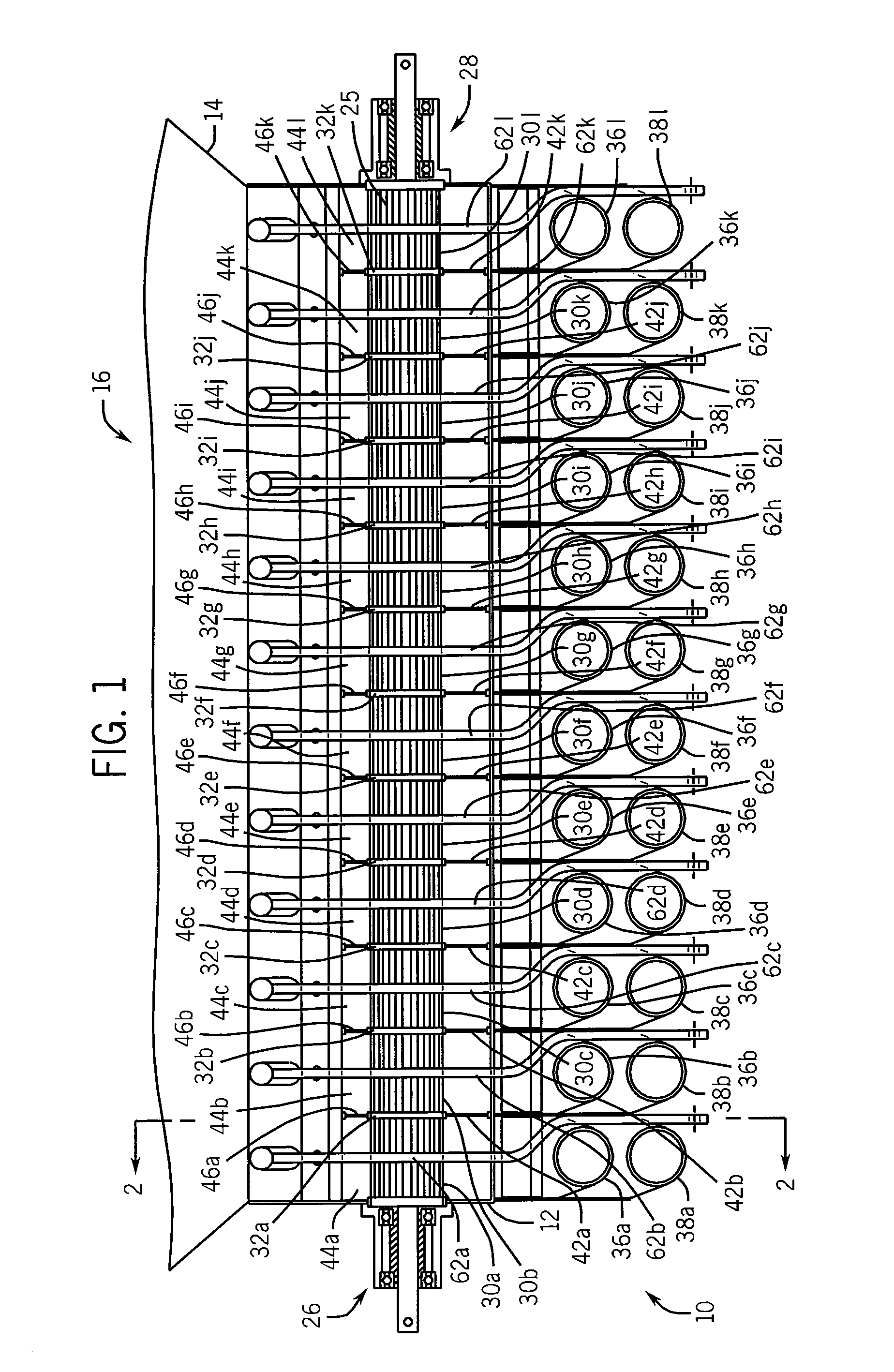

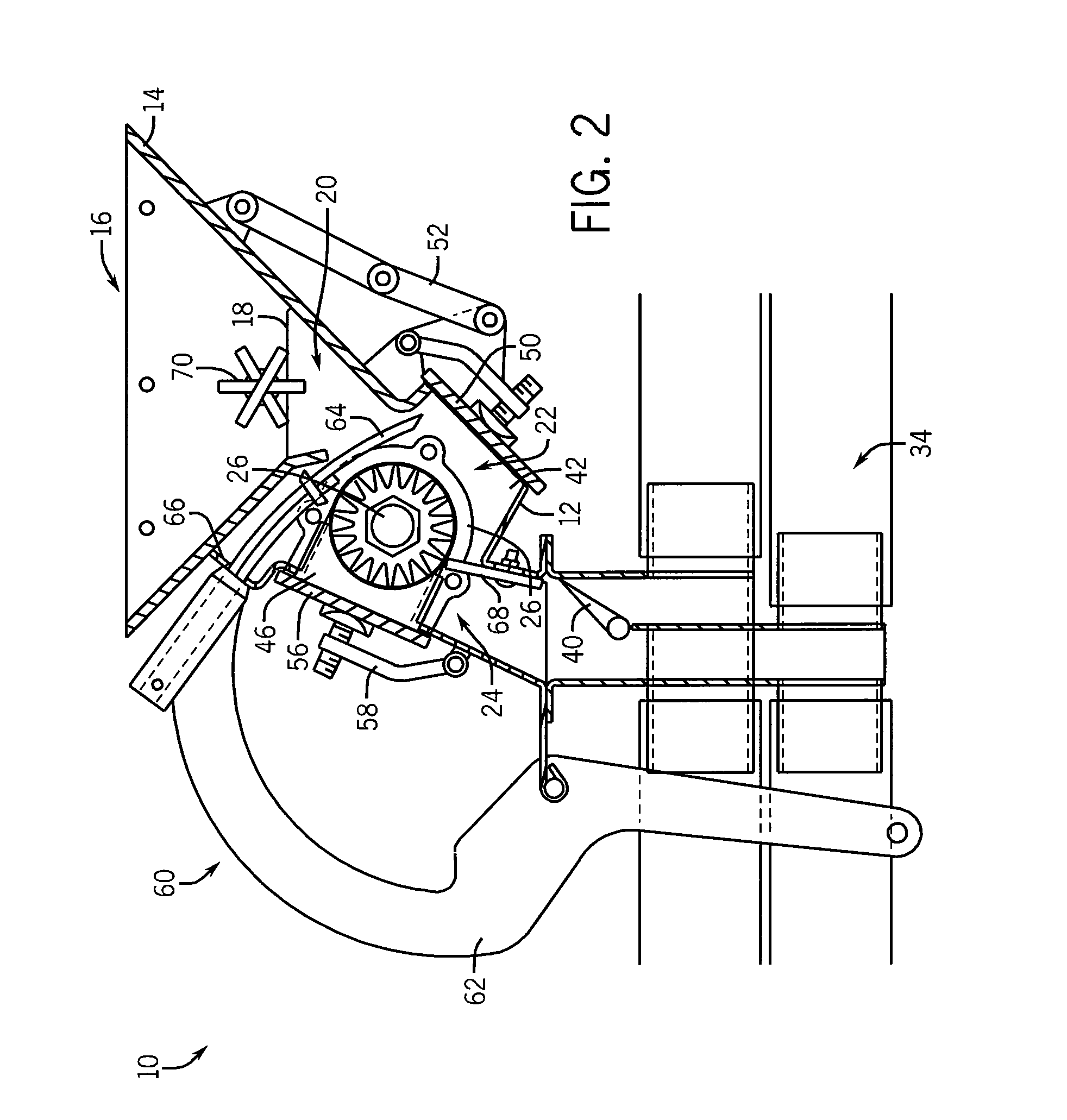

Seed Metering Assembly For Farm Implement And Having Quick-Change Capability And Sectional Control

ActiveUS20120174844A1Improve efficiencyReduce flowFertilising methodsPotato plantersEngineeringMechanical engineering

A seed metering assembly for a farm implement has a meter roller that can be accessed and removed in a relatively quick manner. The seed metering assembly includes a fluted meter roller that is segmented into a number of discrete fluted sections. Each fluted section has an associated flow control member that is selectively operable to impede the flow of granular material from a seed hopper to its corresponding section of the fluted meter roller.

Owner:CNH IND CANADA

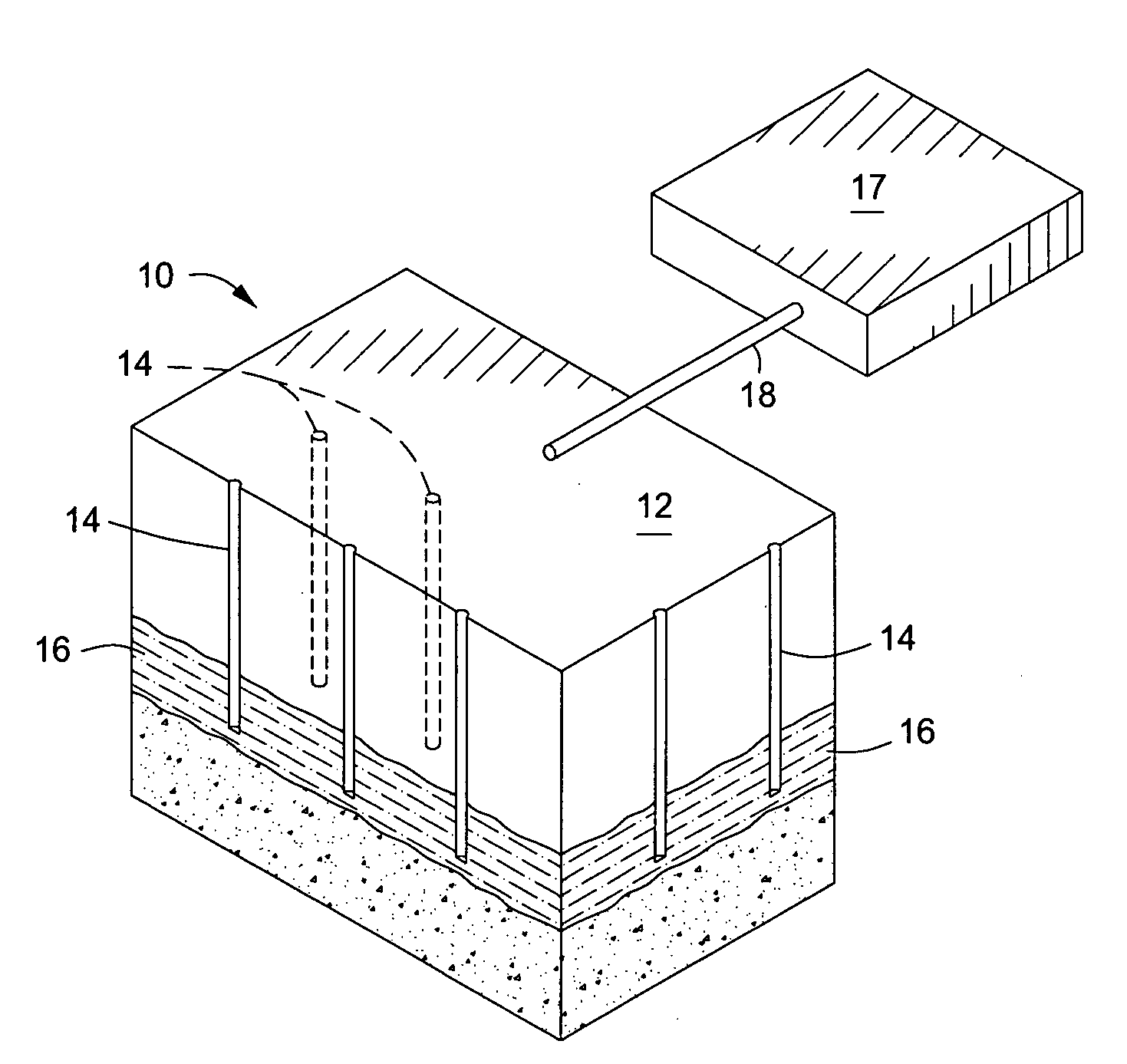

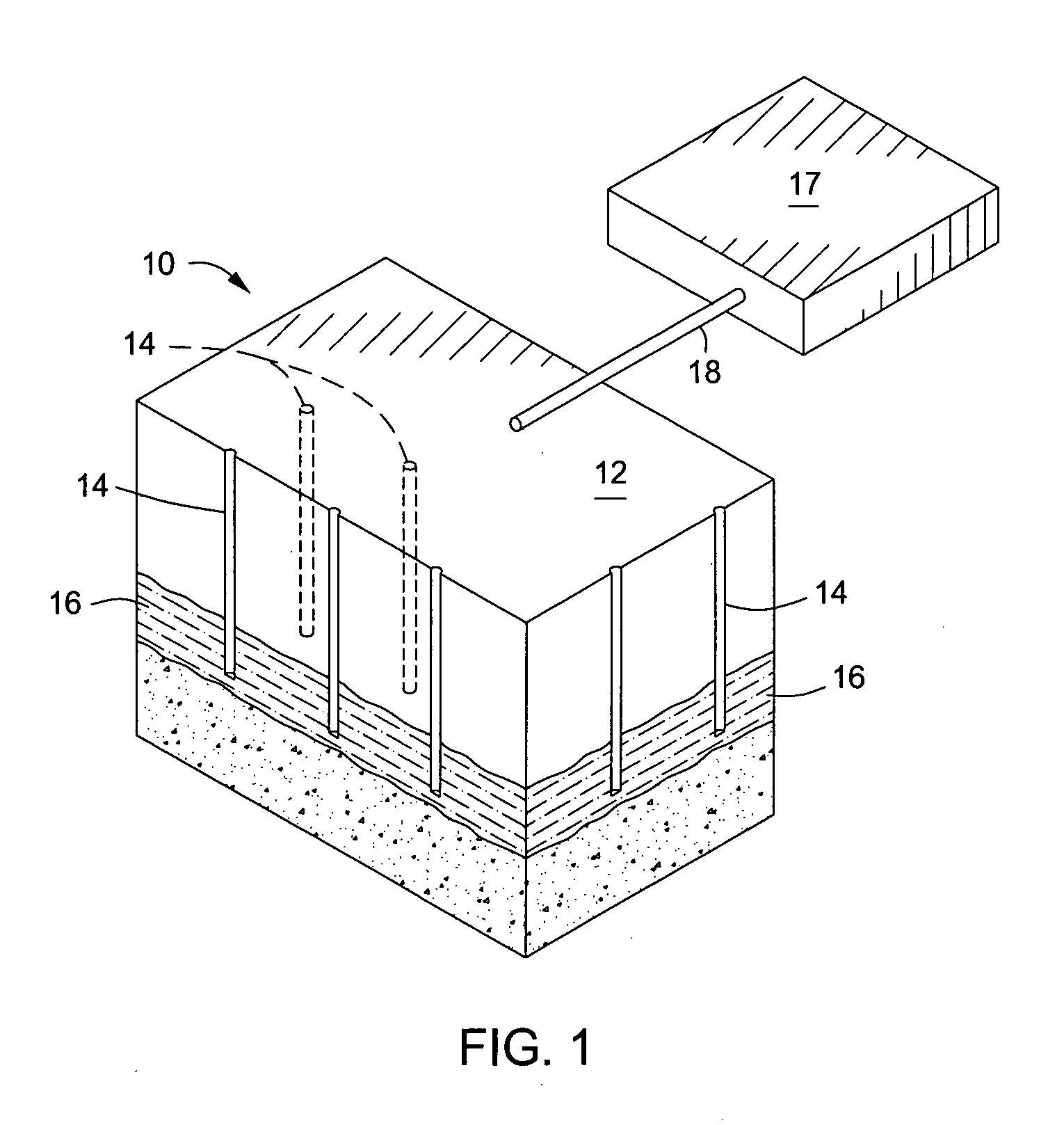

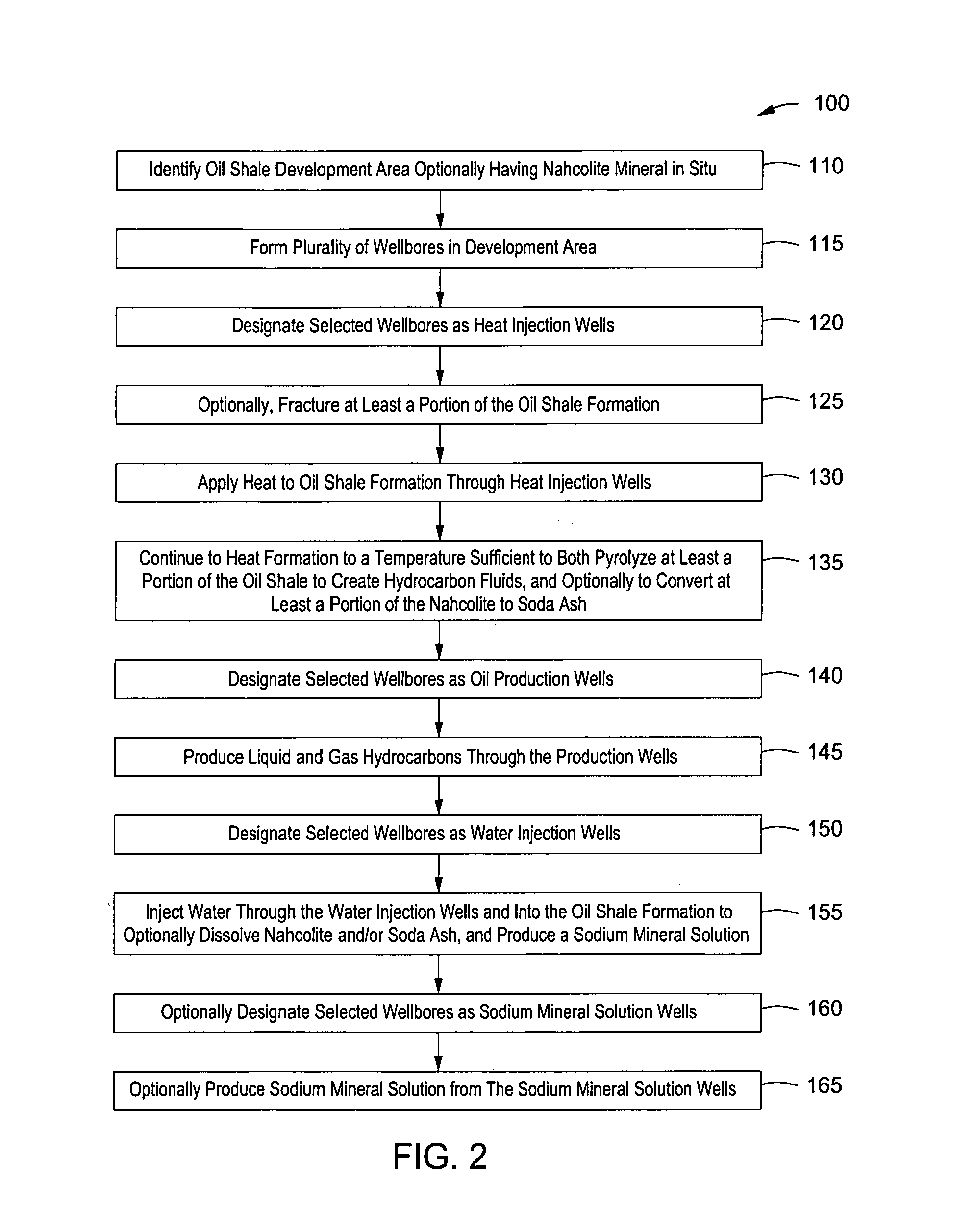

Granular electrical connections for in situ formation heating

A method for heating a subsurface formation using electrical resistance heating is provided. In one aspect, the method includes creating a passage in the subsurface formation between a first wellbore located at least partially within the subsurface formation, and a second wellbore also located at least partially within the subsurface formation. An electrically conductive granular material is placed into the passage so as to provide electrical communication between the first wellbore and the second wellbore. Electrically conductive members are provided in the first wellbore and second wellbore so as to form an electrically conductive flow path comprised of the electrically conductive members, the granular material, and a power source. An electrical current is established through the electrically conductive flow path, thereby resistively heating at least a portion of the conductive members which in turn heats the subsurface formation.

Owner:EXXONMOBIL UPSTREAM RES CO

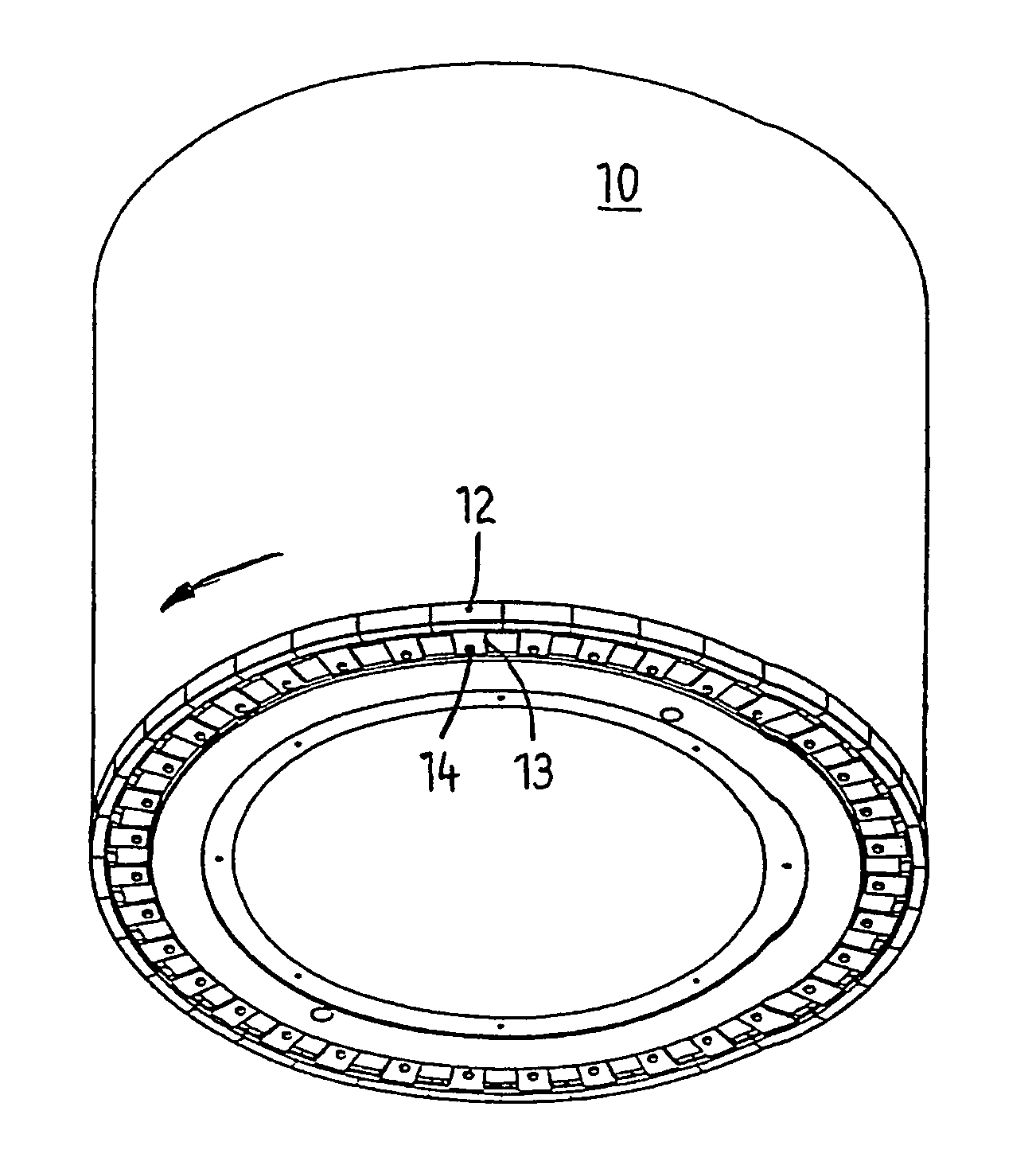

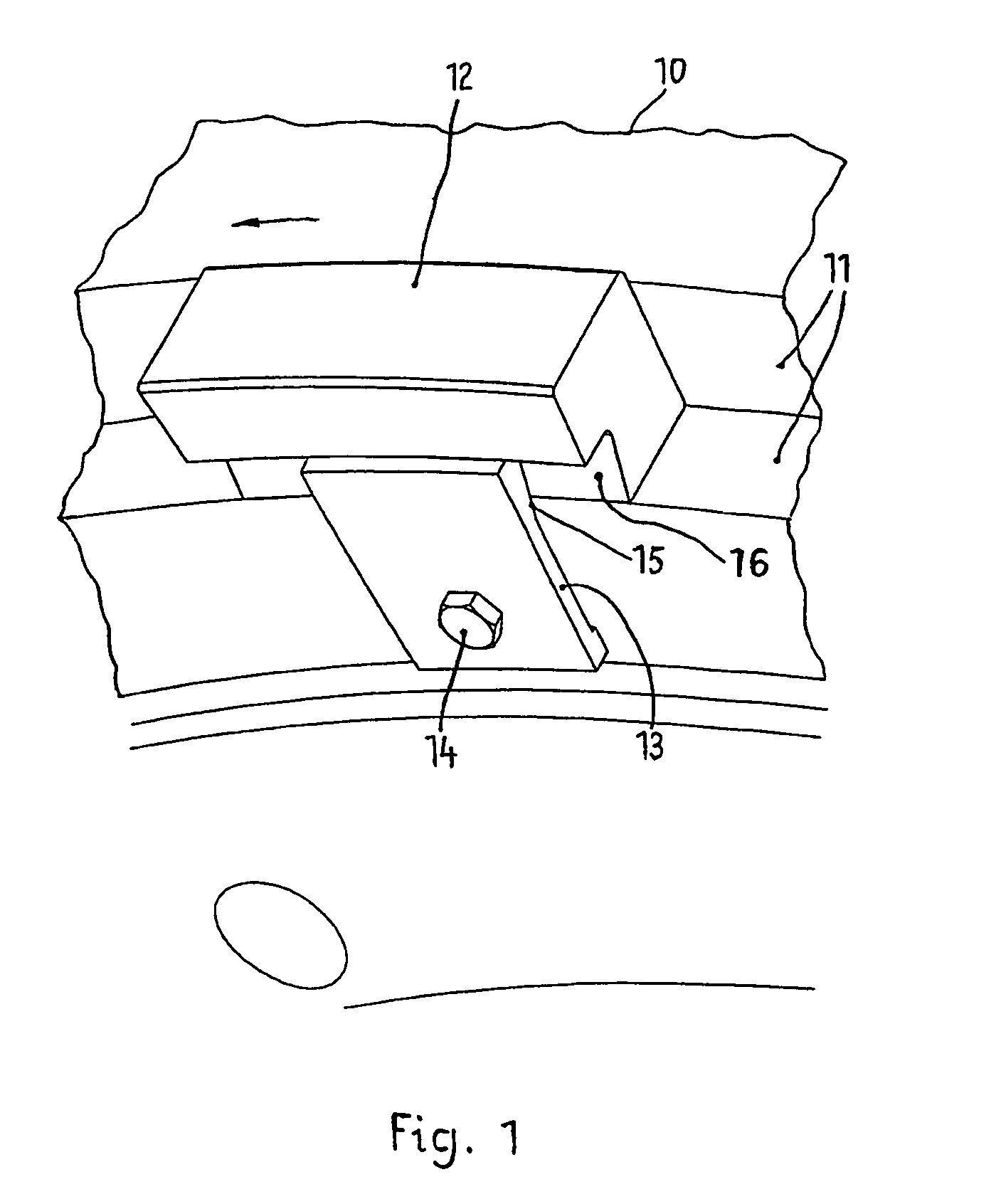

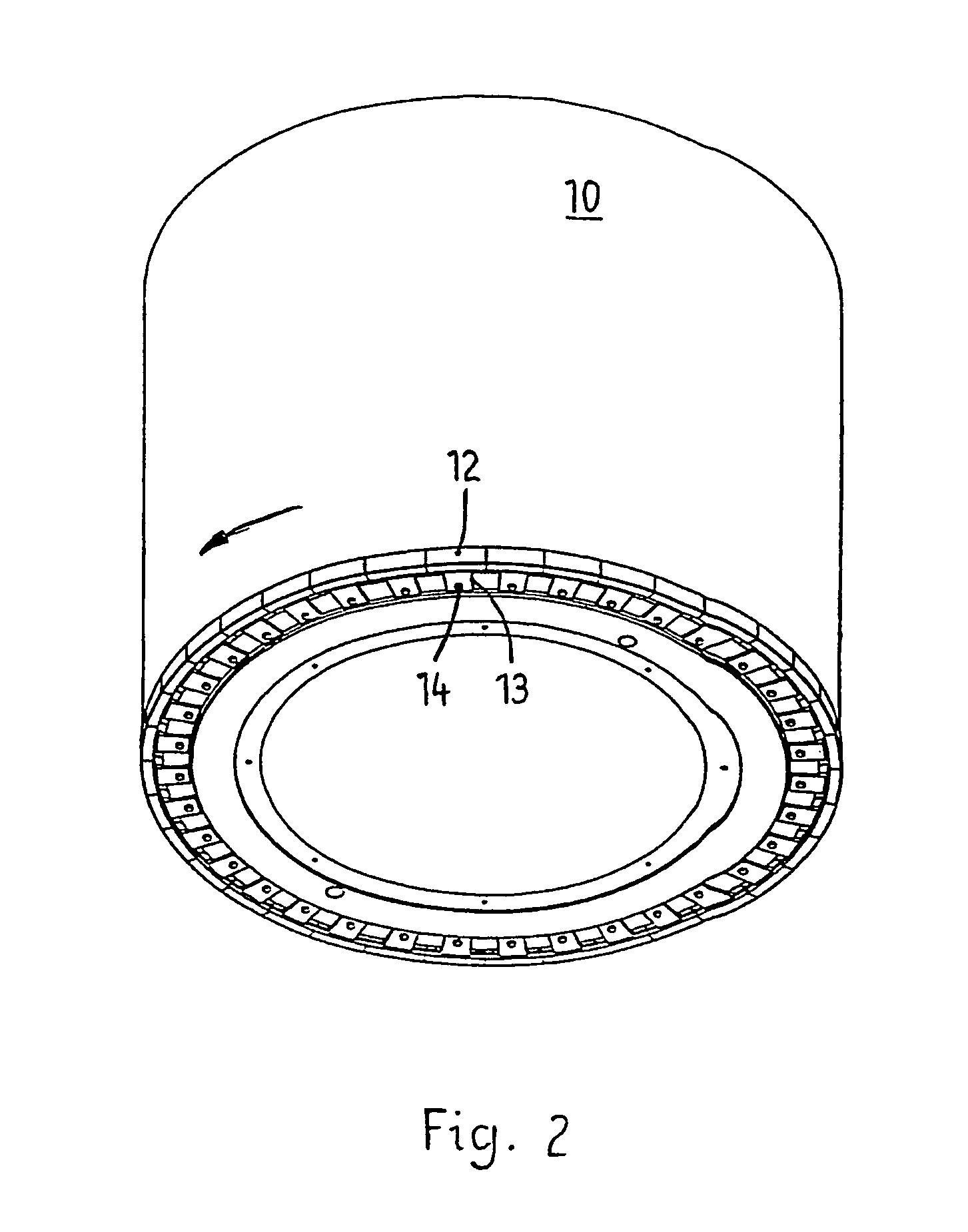

Grinding roller for the pressure comminution of granular material

The aim of the invention is to provide grinding rolls in particular for high-pressure roller mills or rolling presses for pressure grinding a granular material not only with a wear-resistant coating but also with a face armour plating in the area of the roller annular edge, which has a long service life due to the high wear resistance thereof and whose production and repair are, in general, relatively simple and inexpensive. For this purpose, the inventive face armour plating consists of a plurality of prefabricated hard bodies which are circularly arranged side by side in such a way that the circular face edge of the roller is formed, said hard bodies are disposed on said circular shoulder of a roll shell such that said hard bodies are placed axially and radially against said circular shoulder of the roll shell and are movably assembled with the roll shell.

Owner:KHD HUMBOLDT WEDAG GMBH

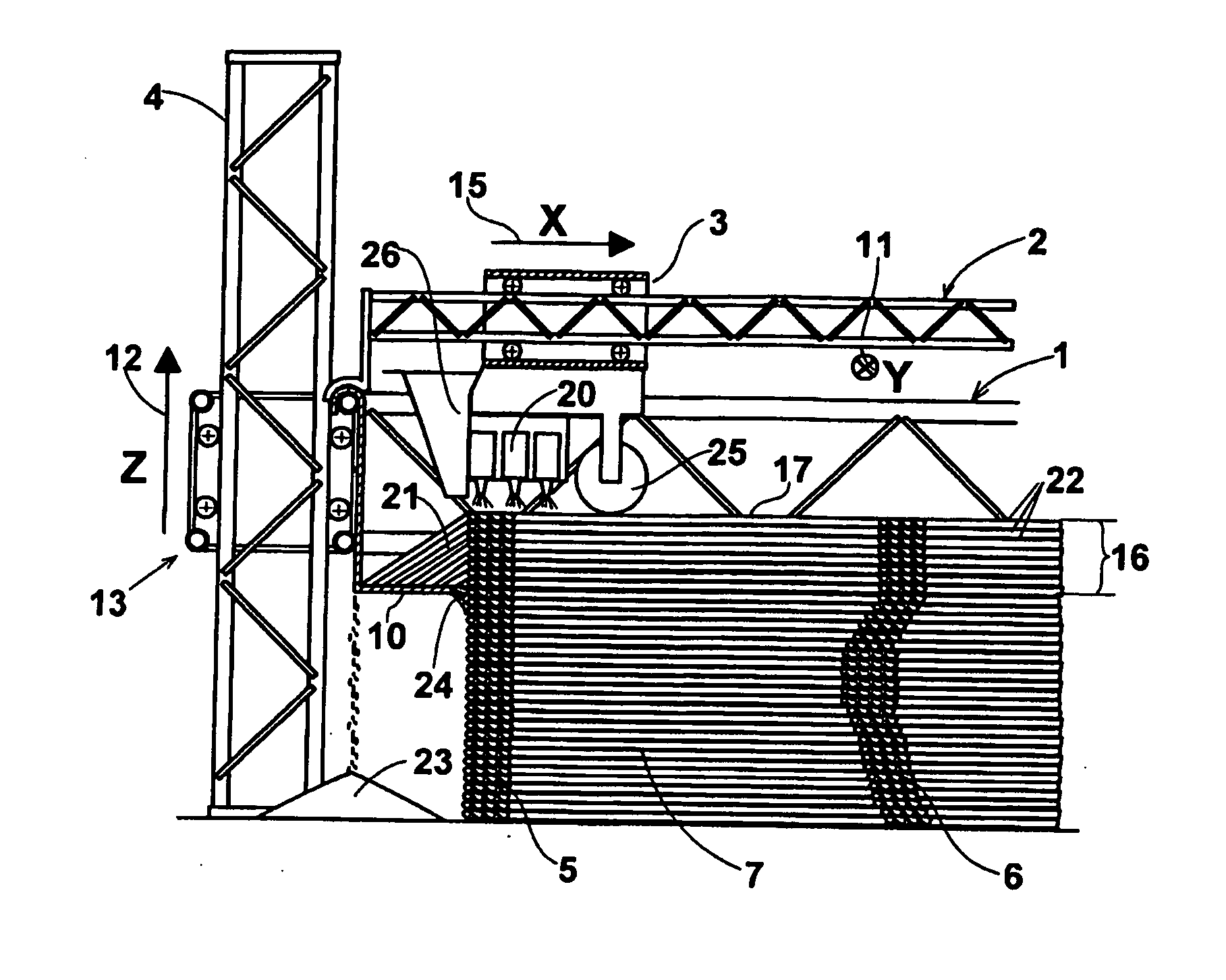

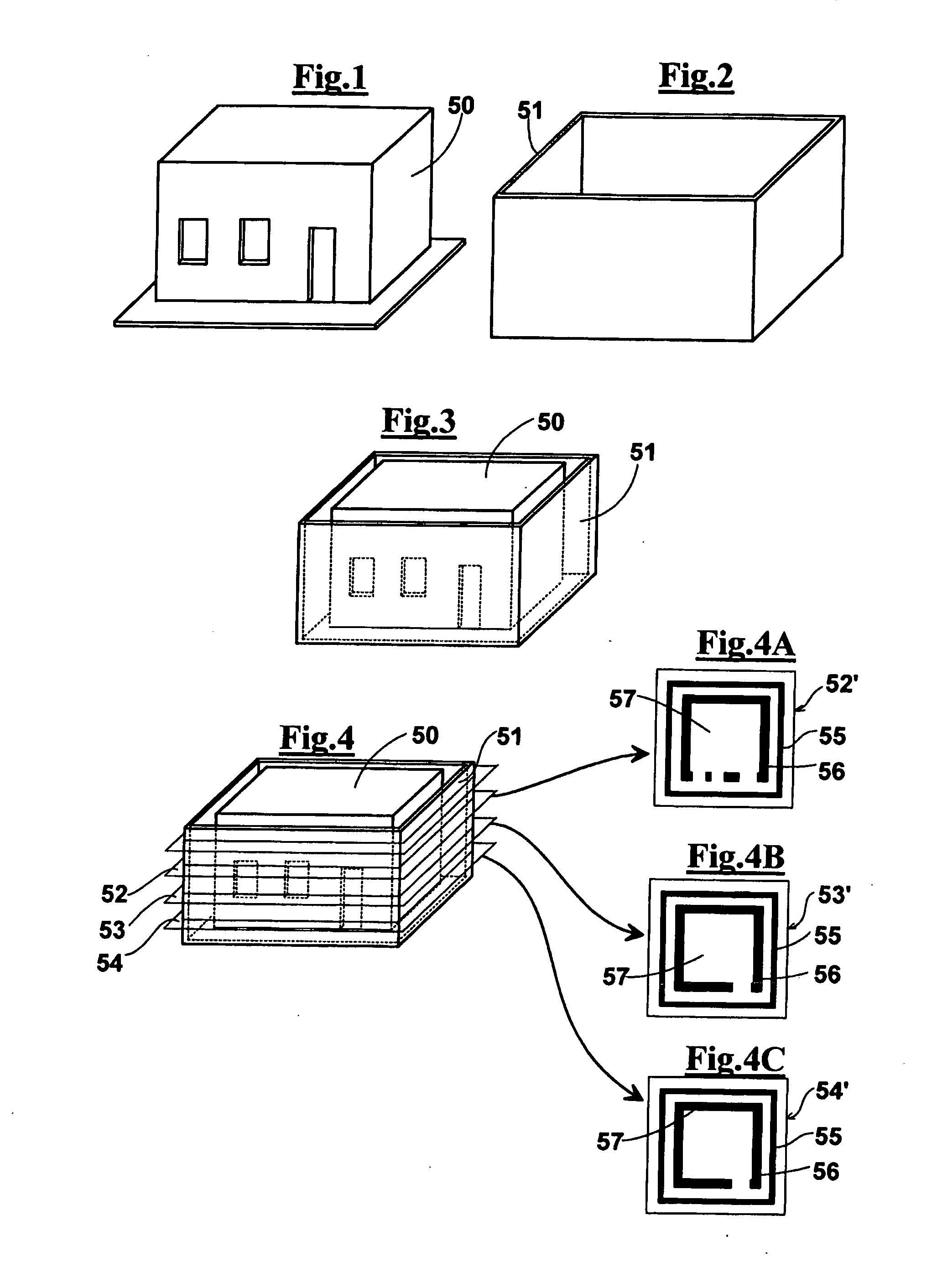

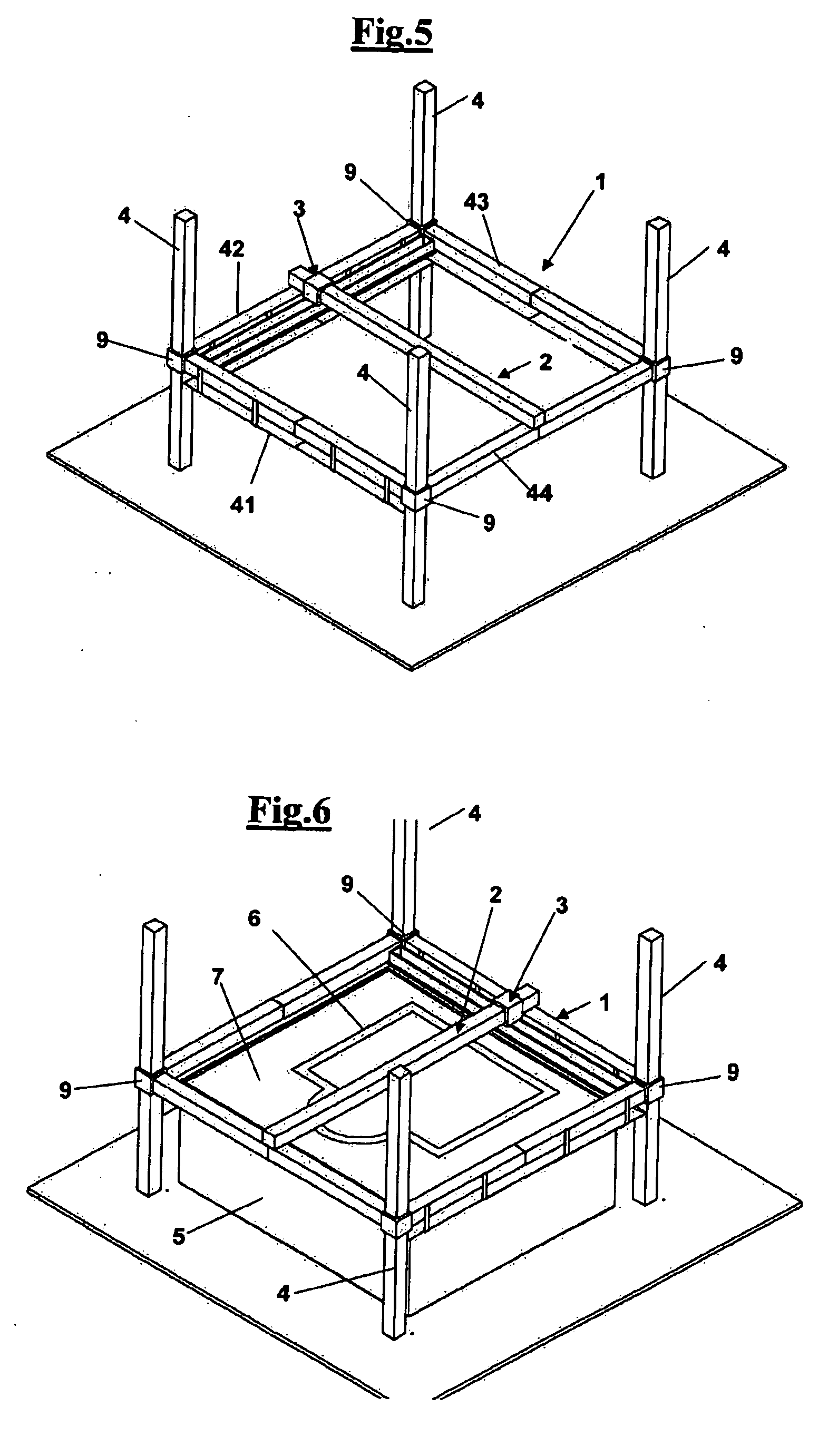

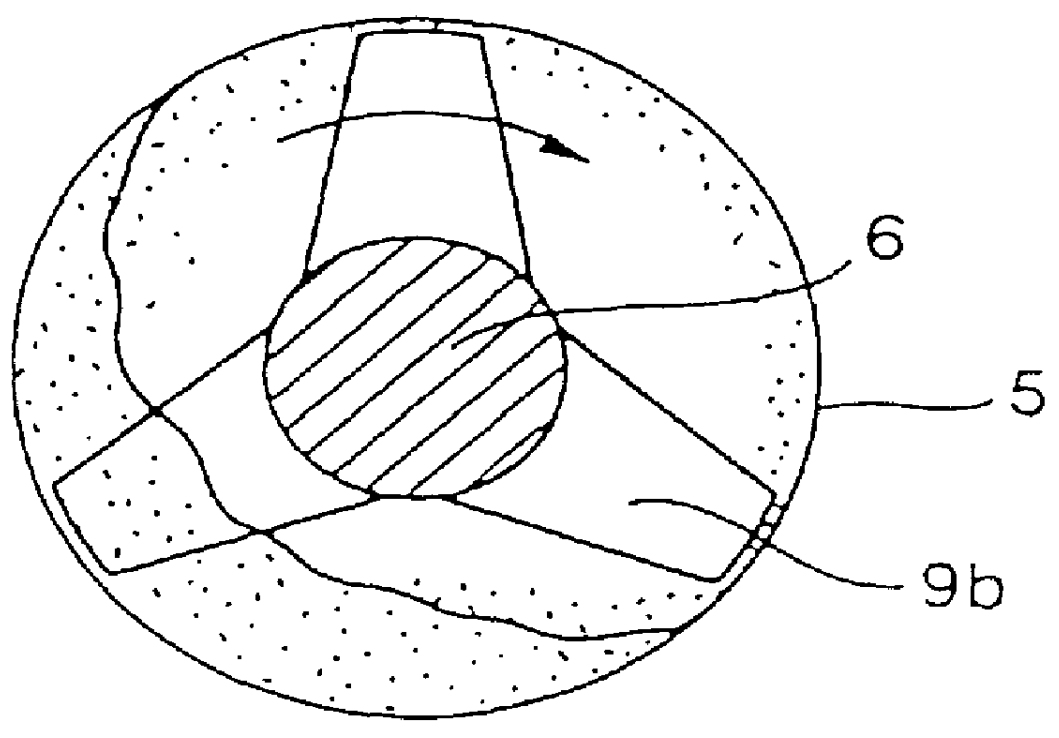

Method for automatically producing a conglomerate structure and apparatus therefor

InactiveUS20100207288A1Improve efficiencyReduce decreaseAdditive manufacturing apparatusMouldsSection planeEngineering

A method and an apparatus for automatically making conglomerated structures (6). The method comprises a) modelling a building structure and a containing shell about the structure by a computer using a CAD software thus obtaining a file; b) extracting sections of modelled structure and of modelled containing shell, by means of horizontal planes spaced apart of a predetermined pitch, such that a plurality of section planes is generated, said planes being sorted from below towards above with respect to the model of the structure and of the model of the shell; c) depositing by a moving unit (3) on a ground a bottom-to-top plurality of layers of granular material (22) alternate to a binding material liquid sprayed on the layers at filled areas corresponding to filled portions of the of the structure and of the containing shell, according to a predetermined path; d) vertically raising the moving unit (3) according to a pitch between a deposited layer and the following layer; e) repeating the step of depositing granulating material and repeating the step of spraying the binding material on a granulated material at filled areas of the structure and of the shell as many times as the planar cross sections into which said structure and the containing shell have been divided, each of said times for a different and consecutive section plane until the last layer (17) is complete; f) demolishing the containing shell (5) and removing unbound granular material (7) accumulated in the shell (5), thus releasing a conglomerate structure (6) that reproduces accurately said modelled structure. The apparatus comprises a horizontal frame (1), a bridge (2) sliding on guide on the horizontal frame (1), a moving unit (3) sliding along the bridge (2) or integral to the bridge (29) and have a spraying head (20). The horizontal frame (1) is moved along uprights (4) by a step actuator. The apparatus comprises a plurality of “skirts” (10) that surround the containing shell (5) and are integral to the horizontal frame (1). Such skirts scrape the outer surface of the containing shell (5) collecting the granular material (21) deposited out of the shell (5). Such skirts (10) can comprise an brush-like edge (20) suitable for externally sweeping the containing shell (5).

Owner:DINI ENRICO

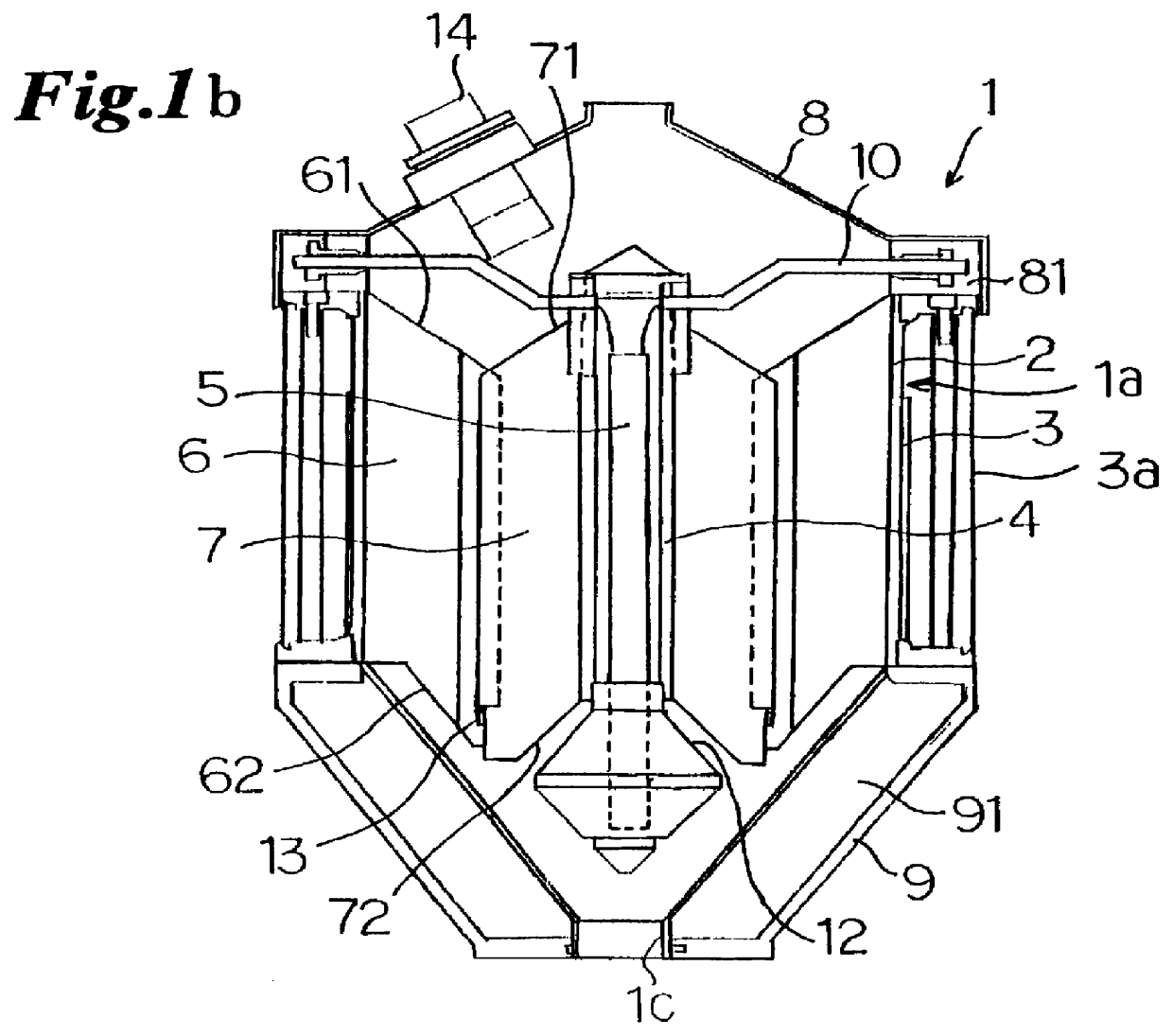

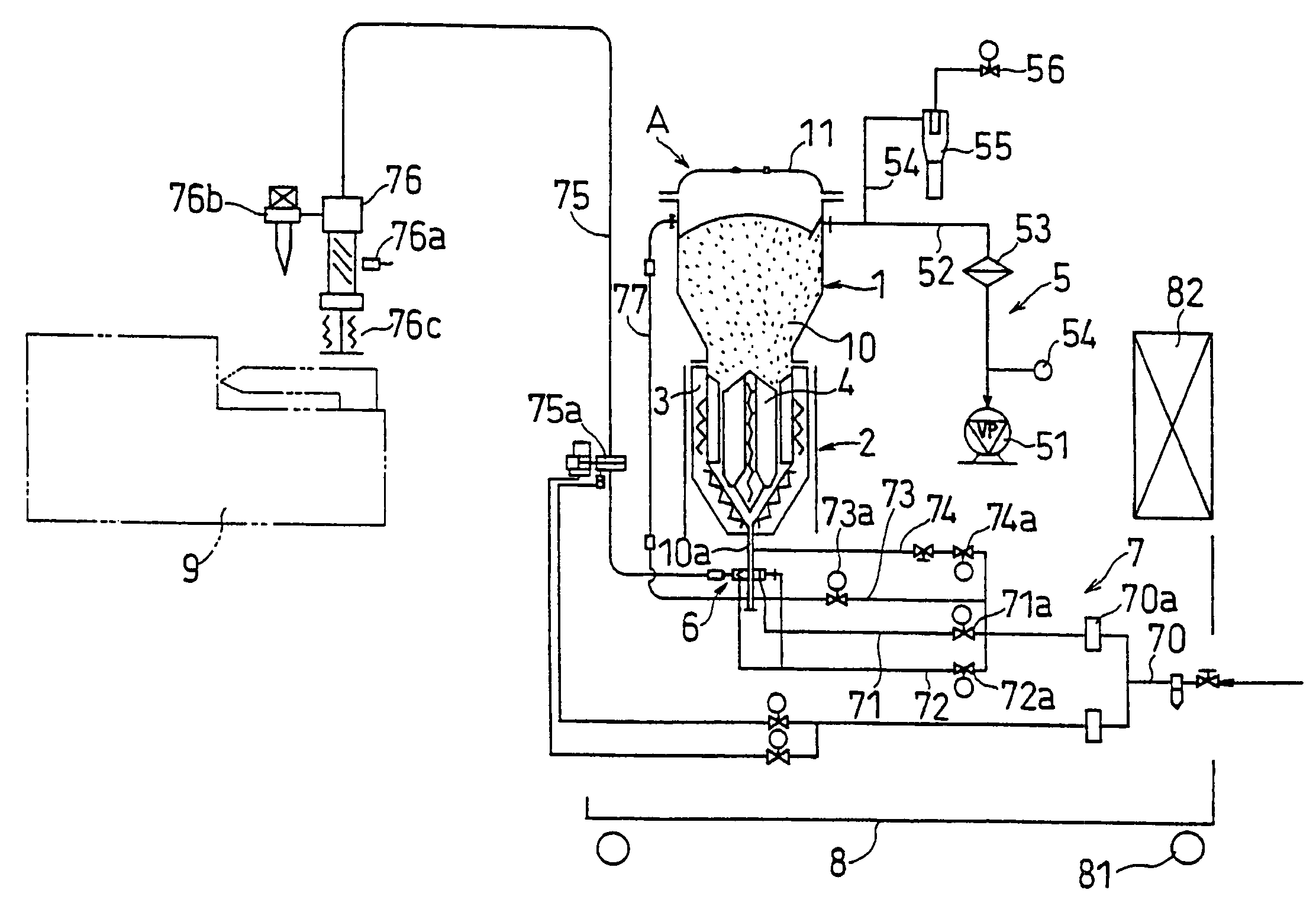

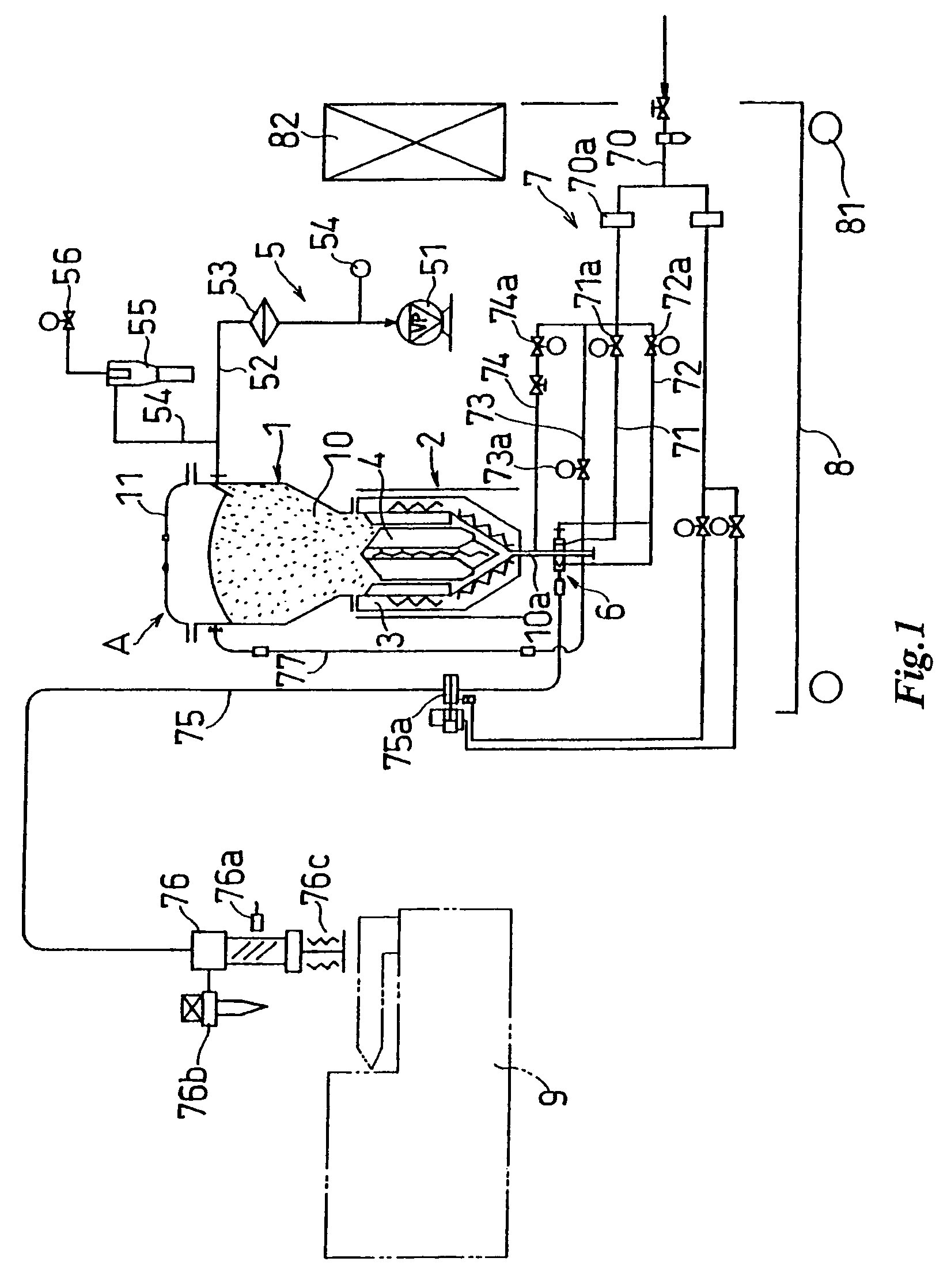

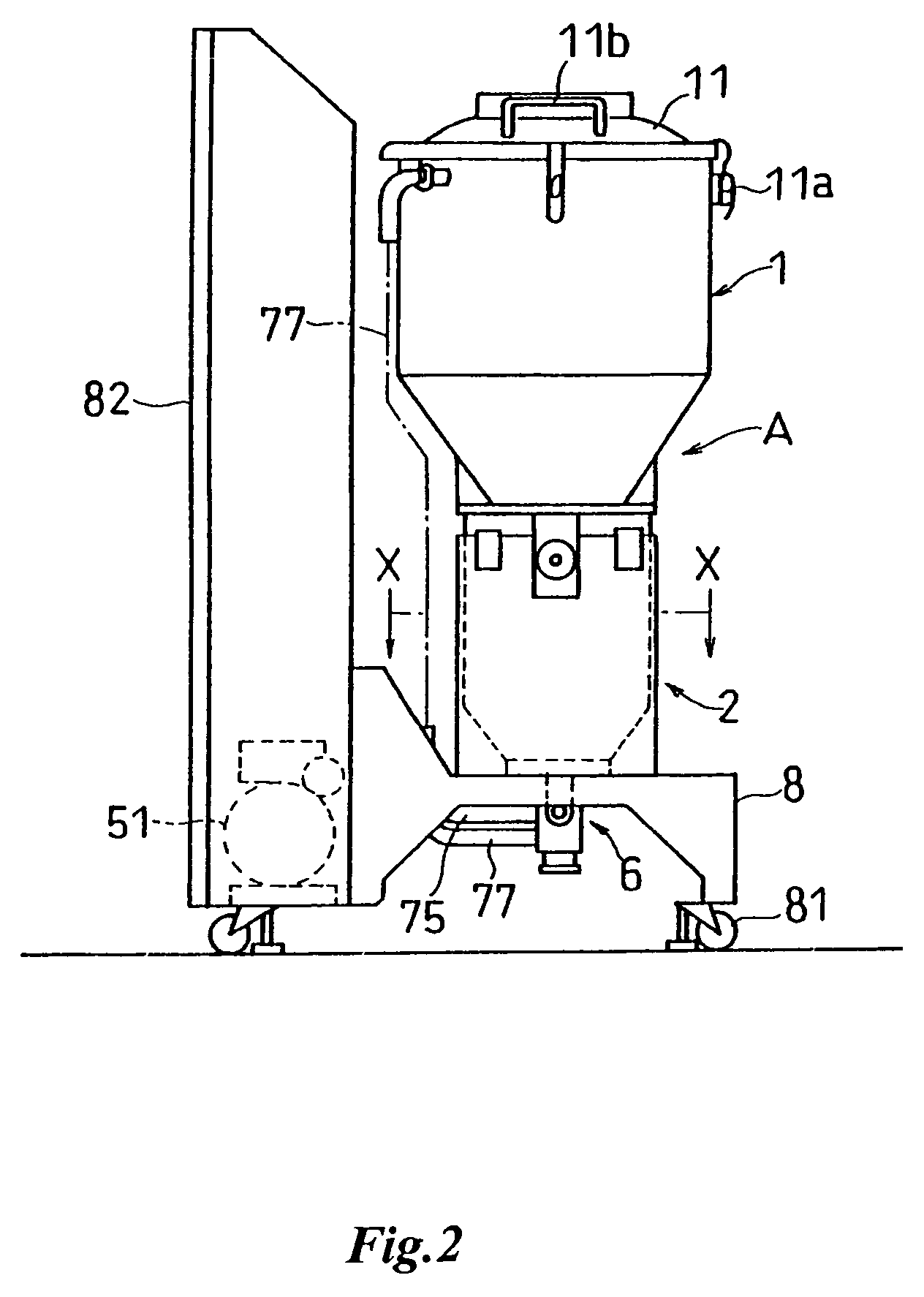

Vacuum-type automatic dehumidifying and drying apparatus for powdered or granular material

InactiveUS6163976AEfficient conductionImprove heating efficiencyDrying solid materials with heatDrying solid materials without heatEngineeringMechanical engineering

A vacuum-type automatic dehumidifying and drying apparatus for powdered or granular material such as a pelletized or powdered resin or the like, provided with a drying hopper connected to an evacuating means having at its bottom a material discharge valve, and provided with a material collector communicating with the drying hopper via a material feeding valve above the drying hopper for collecting the powdered material therein. The apparatus comprises a double constructed drying hopper having a cylindrical main body made of a high heat conductivity material provided on its inner peripheral surface with plural fins, which define compartment walls, projecting inwardly and provided on its outer peripheral surface with a heating means surrounding the cylindrical main body. The main body is outwardly enclosed with a heat insulation wall, and comprises an outer air inlet for introducing outer air thereinto, a material sensor for detecting amount of the material stored in the hopper, and an evacuating means connected to the main body.

Owner:MATSUI MFG

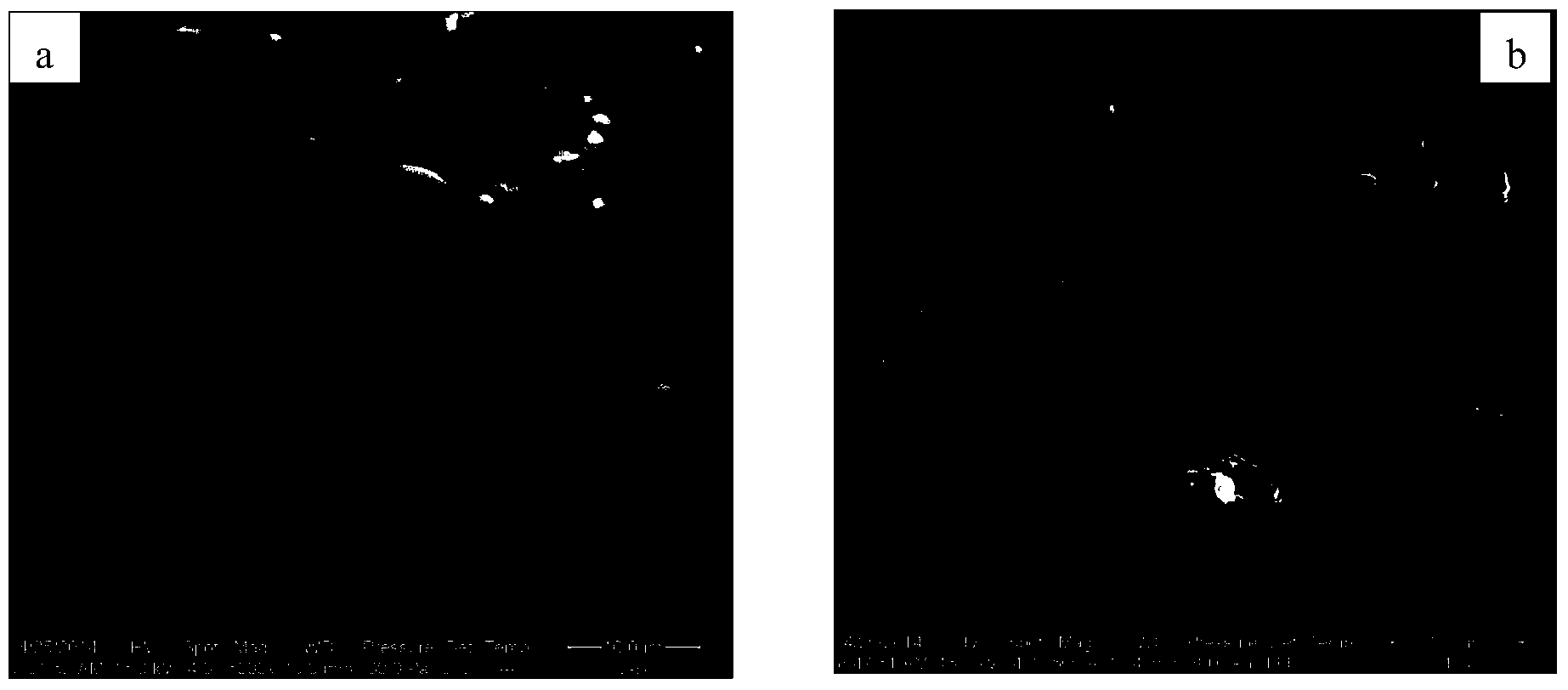

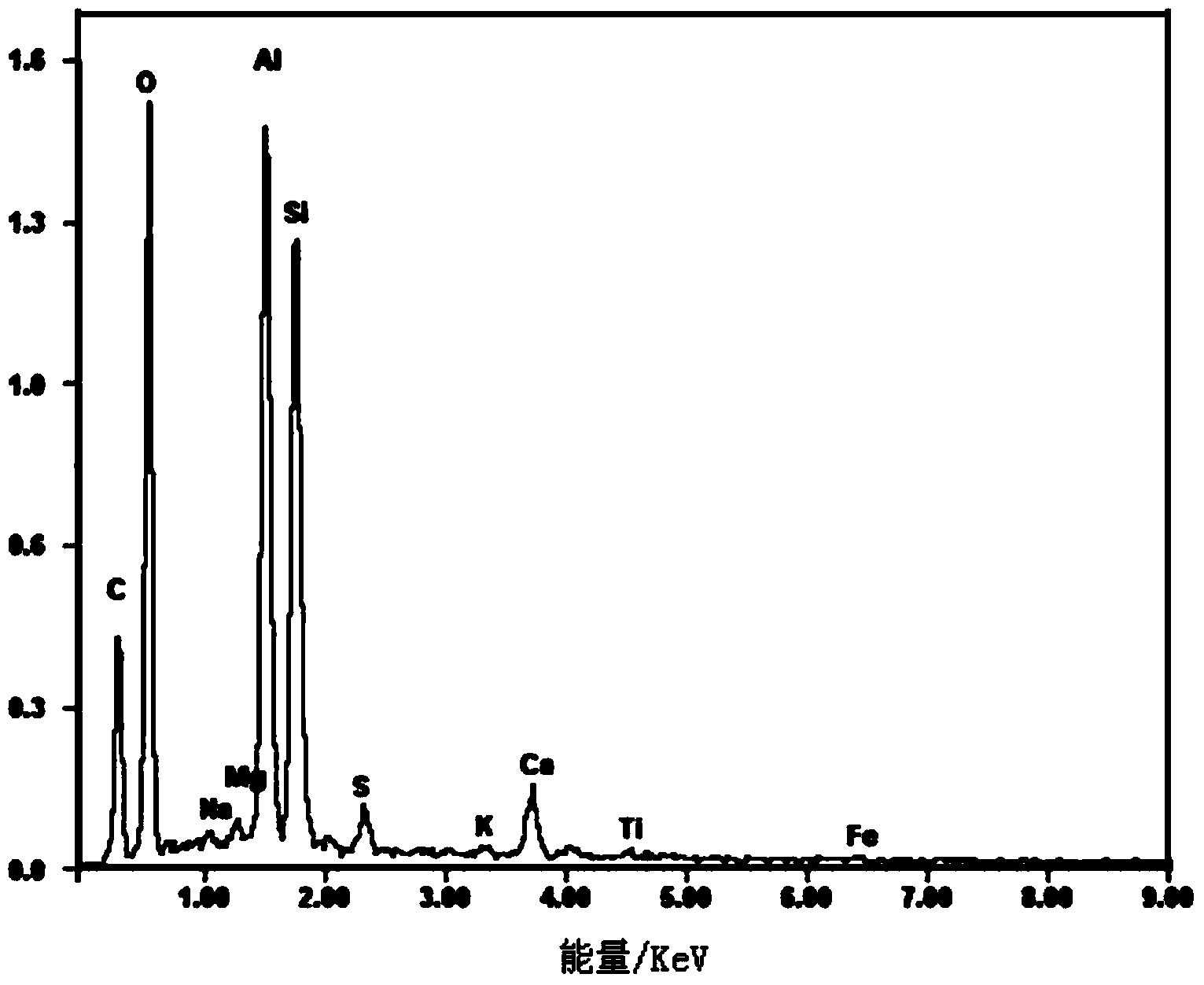

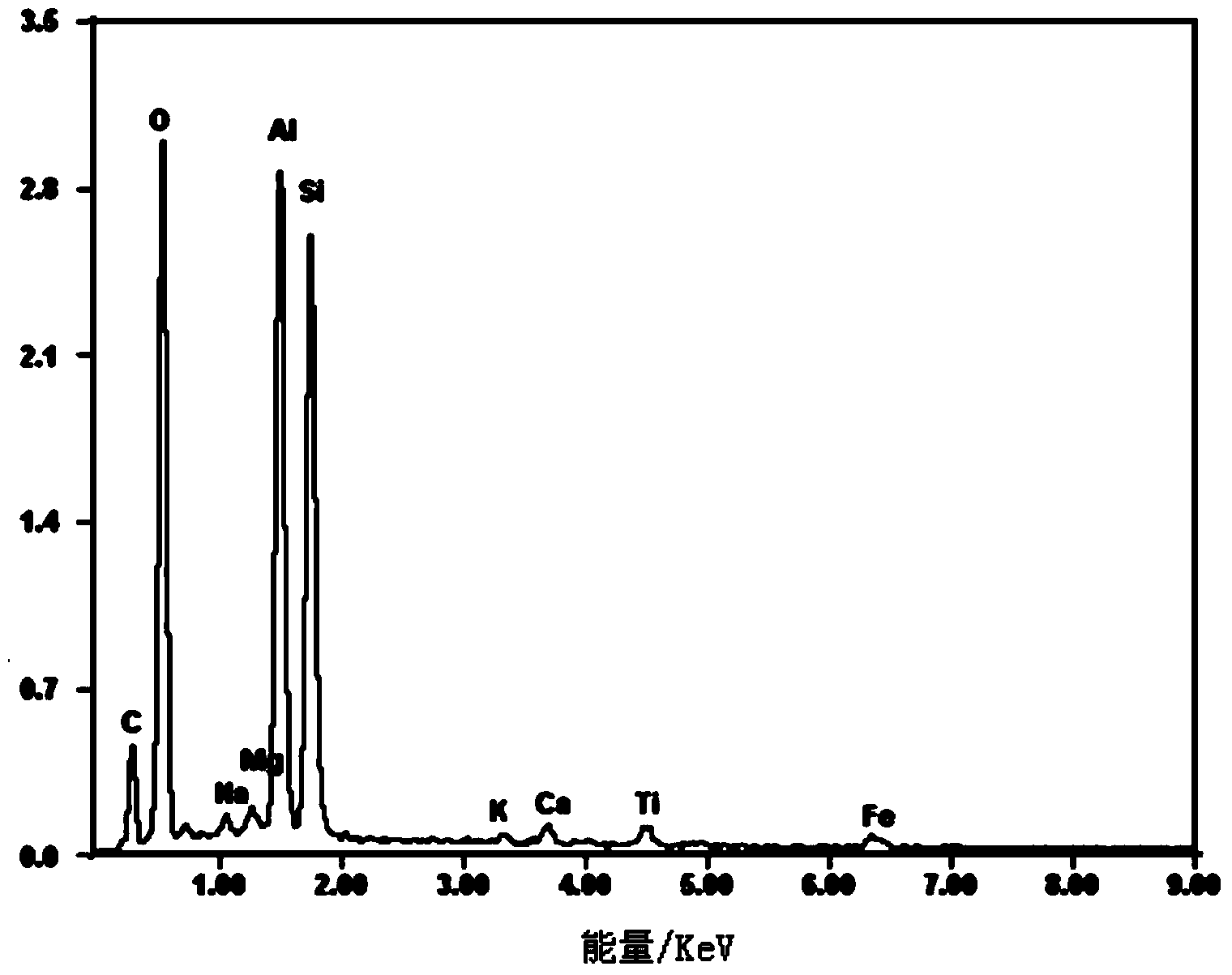

Granular filtering material for adsorbing and removing heavy metals in water and preparation method thereof

ActiveCN104289185AWide variety of sourcesRealize resource utilizationOther chemical processesWater contaminantsIndustrial waste waterSorbent

The invention discloses a granular filtering material for adsorbing and removing heavy metals in water and a preparation method thereof. The granular material consists of the following components in part by mass: 80-120 parts of an adsorbent, 7-14 pats of an additive and 0.5-3 parts of a binding agent, wherein the adsorbent consists of the following components in part by mass: 50-70 parts of coal ash and 30-50 parts of zeolite powder or sea-foam stone powder; the additive consists of the following components in part by mass: 5-7 parts of Mg-Al hydrotalcite, 2-6 parts of biochar and 0.5-1 part of magnesium Lignosulfonate; the binding agent is bentonite. The granular filtering material is prepared through the steps of adsorbent acid modification, biochar preparation, granulation and heat treatment process. According to the invention, the prepared granular filtering material is 3-6 mm in granule size, is large in adsorption capacity and excellent in adsorption effect and can effectively remove heavy metals in water, and no secondary pollutants are dissolved out, so that the granular filtering material can be applied to the treatment on heavy metal micro-polluted water and industrial waste water containing heavy metals, and has good economic and social benefits.

Owner:BEIJING FORESTRY UNIVERSITY

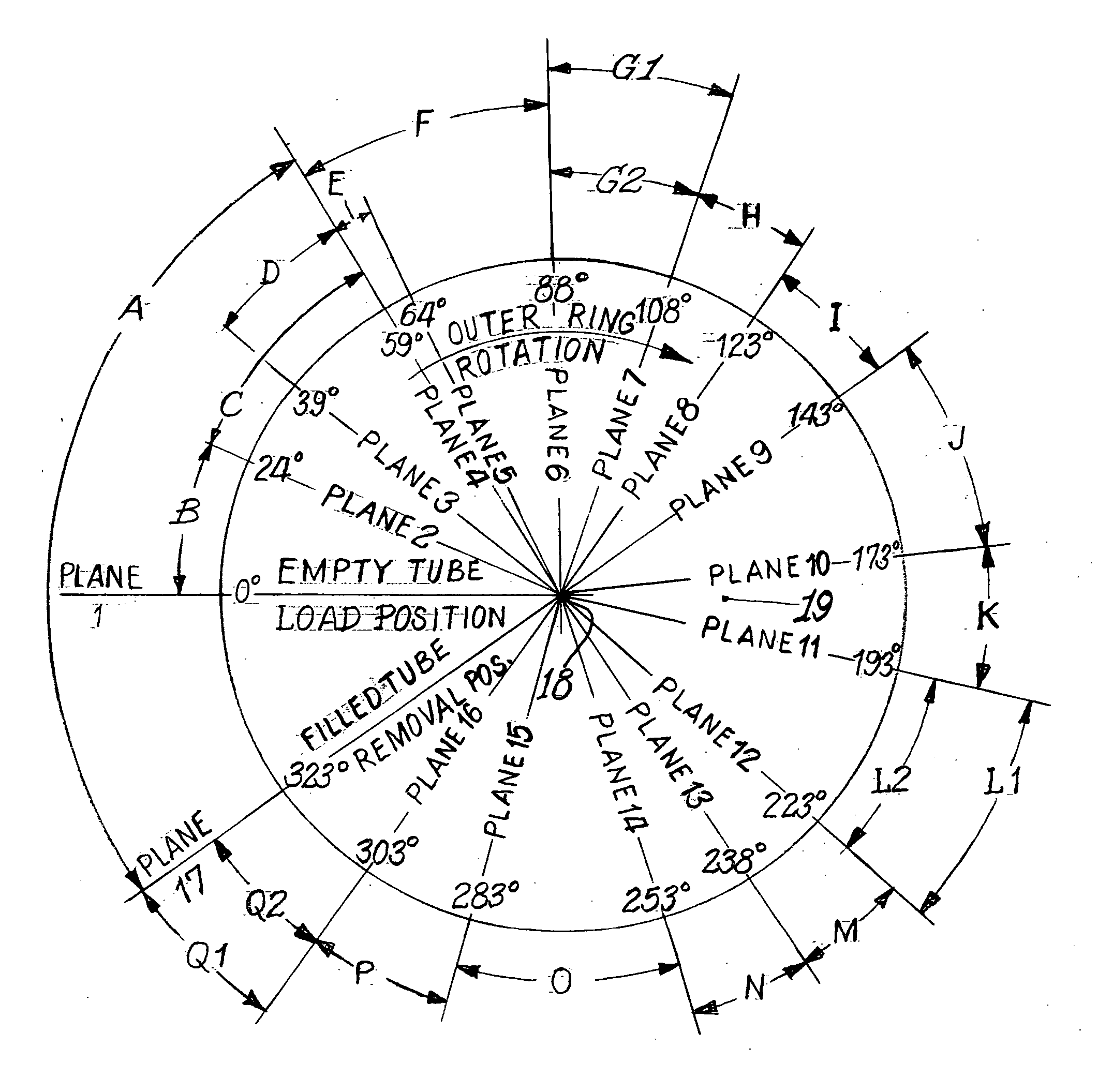

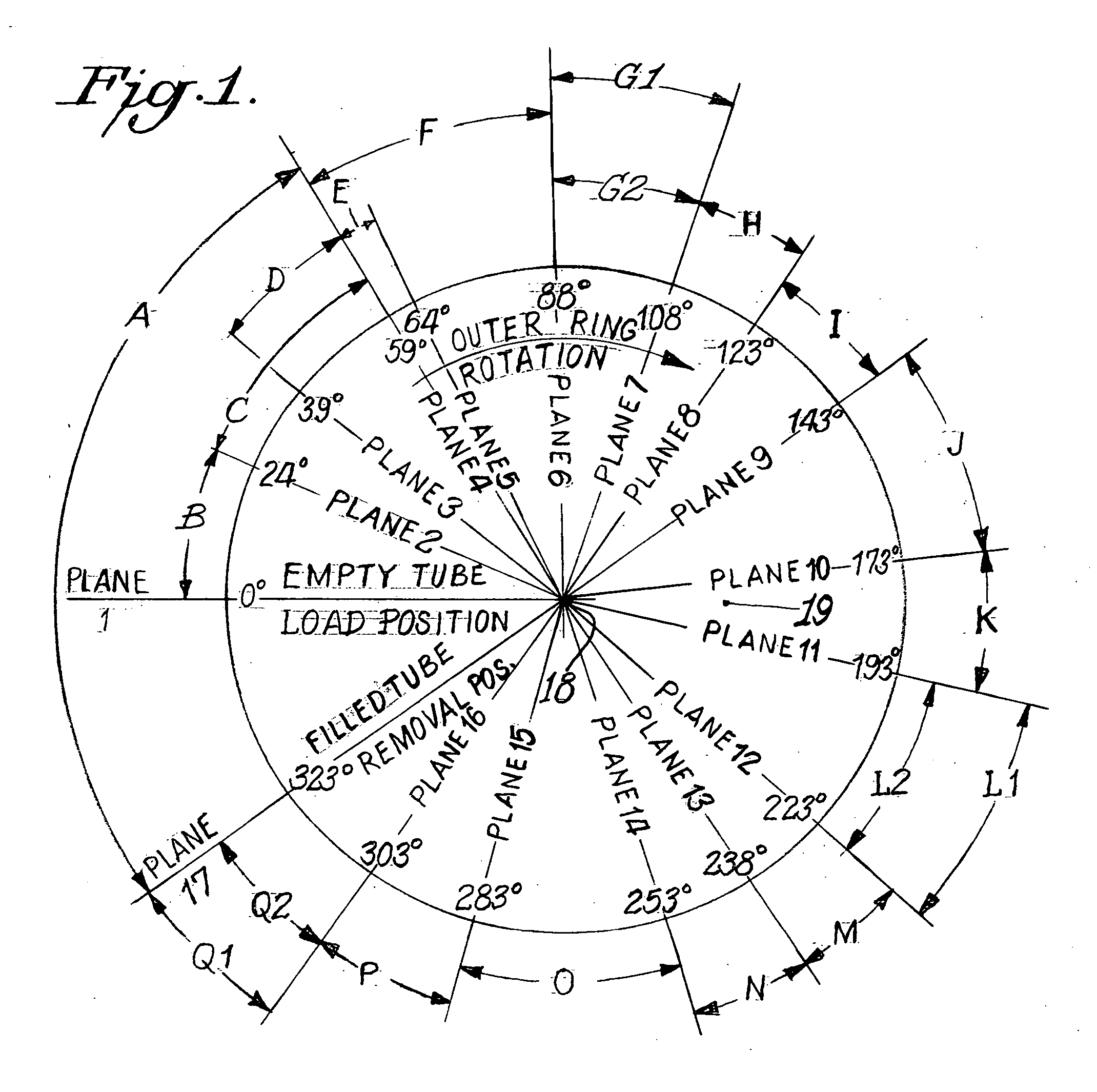

Vertical filter filling machine and process

ActiveUS20060112963A1Efficient and economical mannerIncrease chanceTobacco treatmentPaper/cardboard wound articlesVertical filterFilter material

Process and apparatus for the mass production of compound cigarette filters function to deposit granular filter material into the open ends of vertically oriented filter tubes. Predetermined amounts of diverse granular material are withdrawn by suction from sources of such material, and these amounts are deposited into the tubes. Solid filter segments seal the granular material within the tube. After one half of each filter tube is filled with granular material and sealed, the tube is inverted and the opposite end is filled in substantially the same manner. When cut in half each filter tube produces two cigarette filters.

Owner:PHILIP MORRIS USA INC

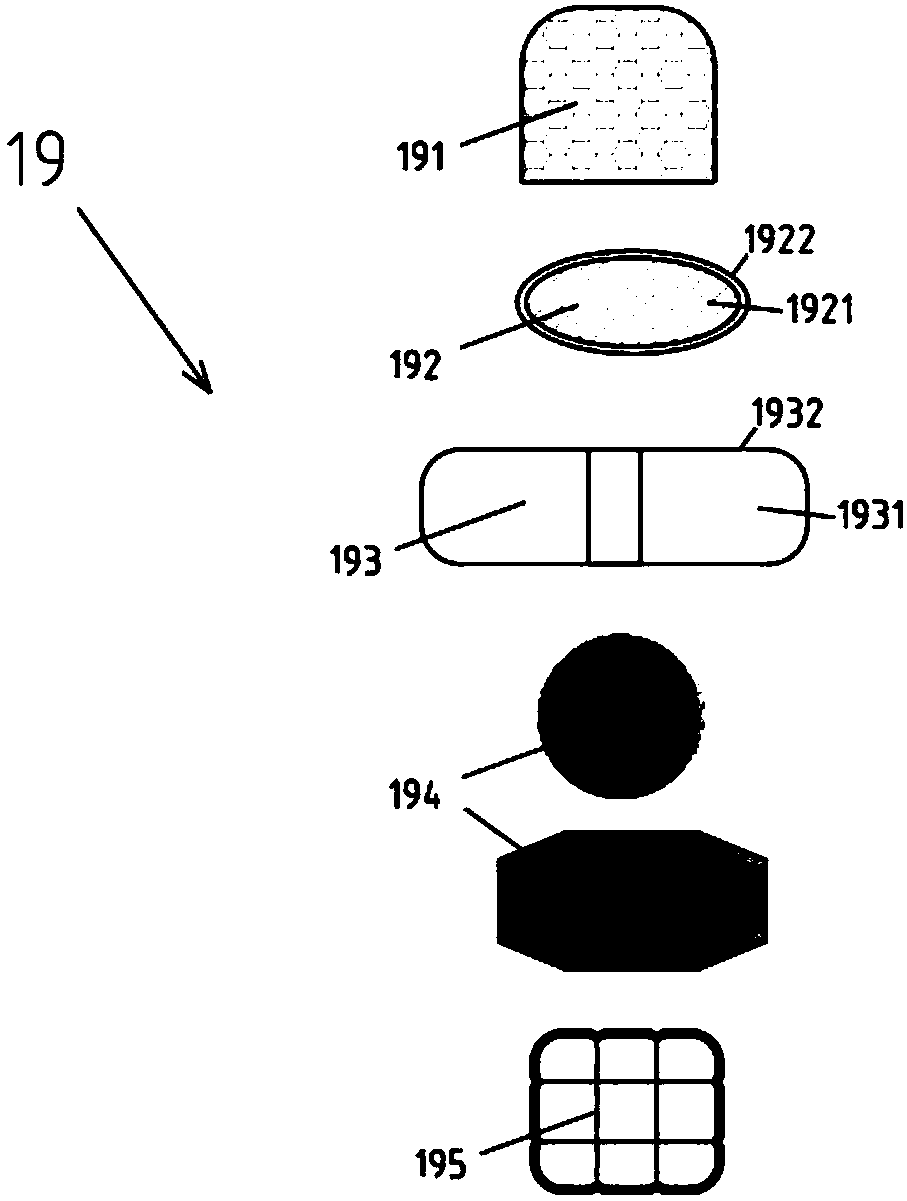

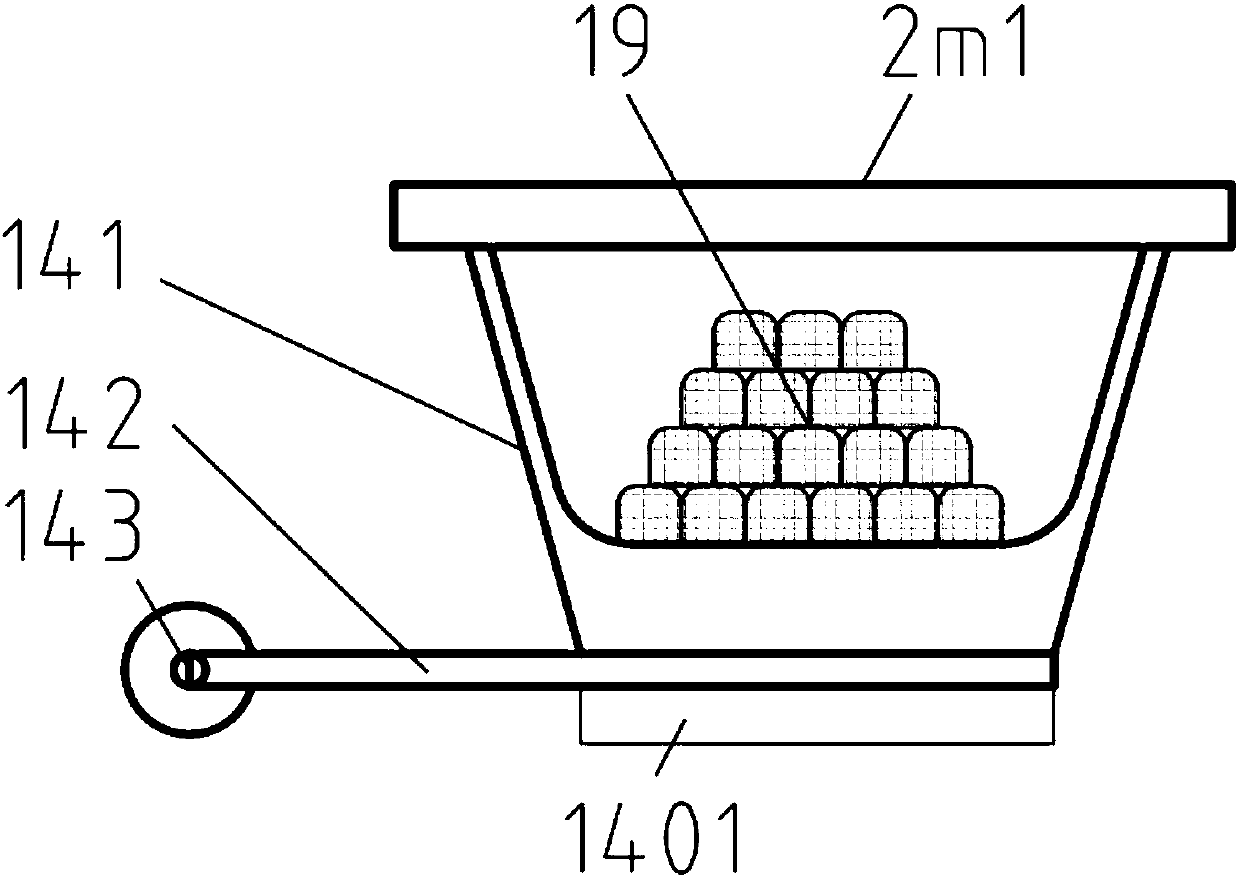

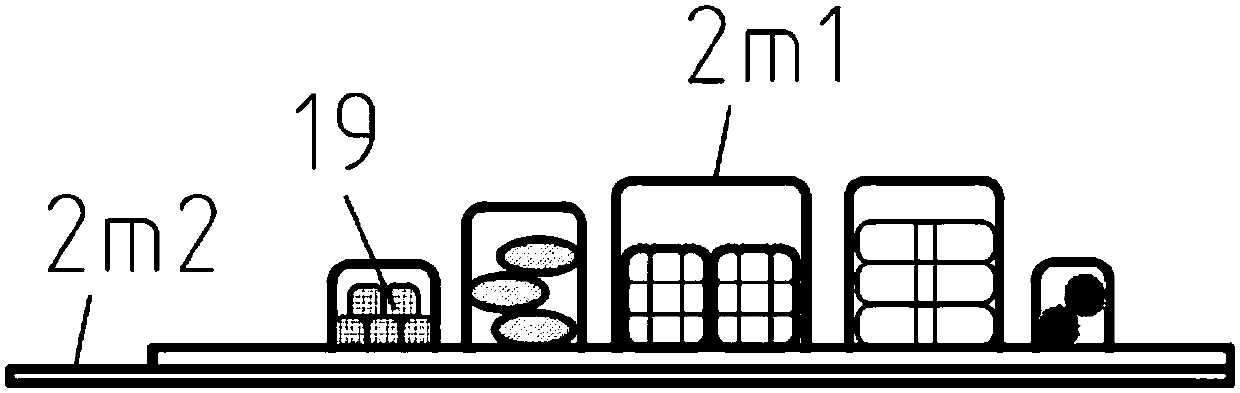

Bundling treating method for cooking raw materials, cooking raw materials and intelligent cooking machine

PendingCN110051228AAchieve solidificationNot easy to stickCooking-vessel lids/coversFood scienceLiquid stateFood material

The invention relates to the technical field of intelligent home equipment, and discloses a bundling treating method for cooking raw materials, the cooking raw materials and an intelligent cooking machine. The bundling treating method includes the steps that liquid-state or powdery or fine-granular or pasty or dispersed cooking raw materials are subjected to solidifying or large-granular or blocking treatment, or small-sheet cooking raw materials are packaged / bundled so that the cooking raw materials cannot be easily stuck on a feeding box of the intelligent cooking machine, or the cooking rawmaterials with fluffy size are dense, and the cooking raw materials are matched with the feeding device, and are fed into a pot body of the cooking machine. According to the bundling treating methodfor the cooking raw materials, the cooking raw materials and the intelligent cooking machine, the liquid-state or powdery or granular or pasty or sheet-shape or disperse or fluffy cooking raw materials are solidified or made into large-granular materials or blocky materials or buckled / packaged, and the food materials are not easily stuck on the feeding box when being used in the intelligent cooking machine accordingly.

Owner:李亚锐

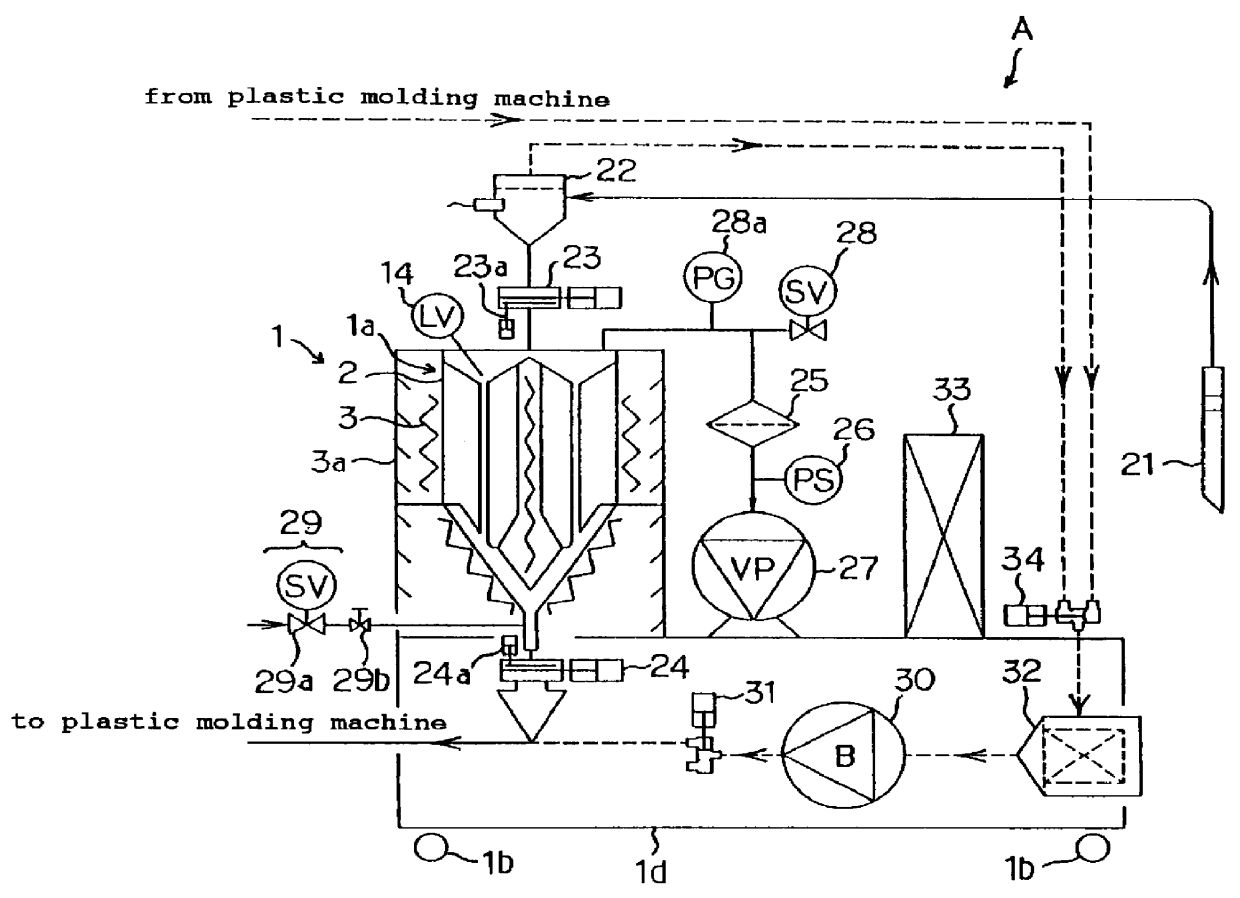

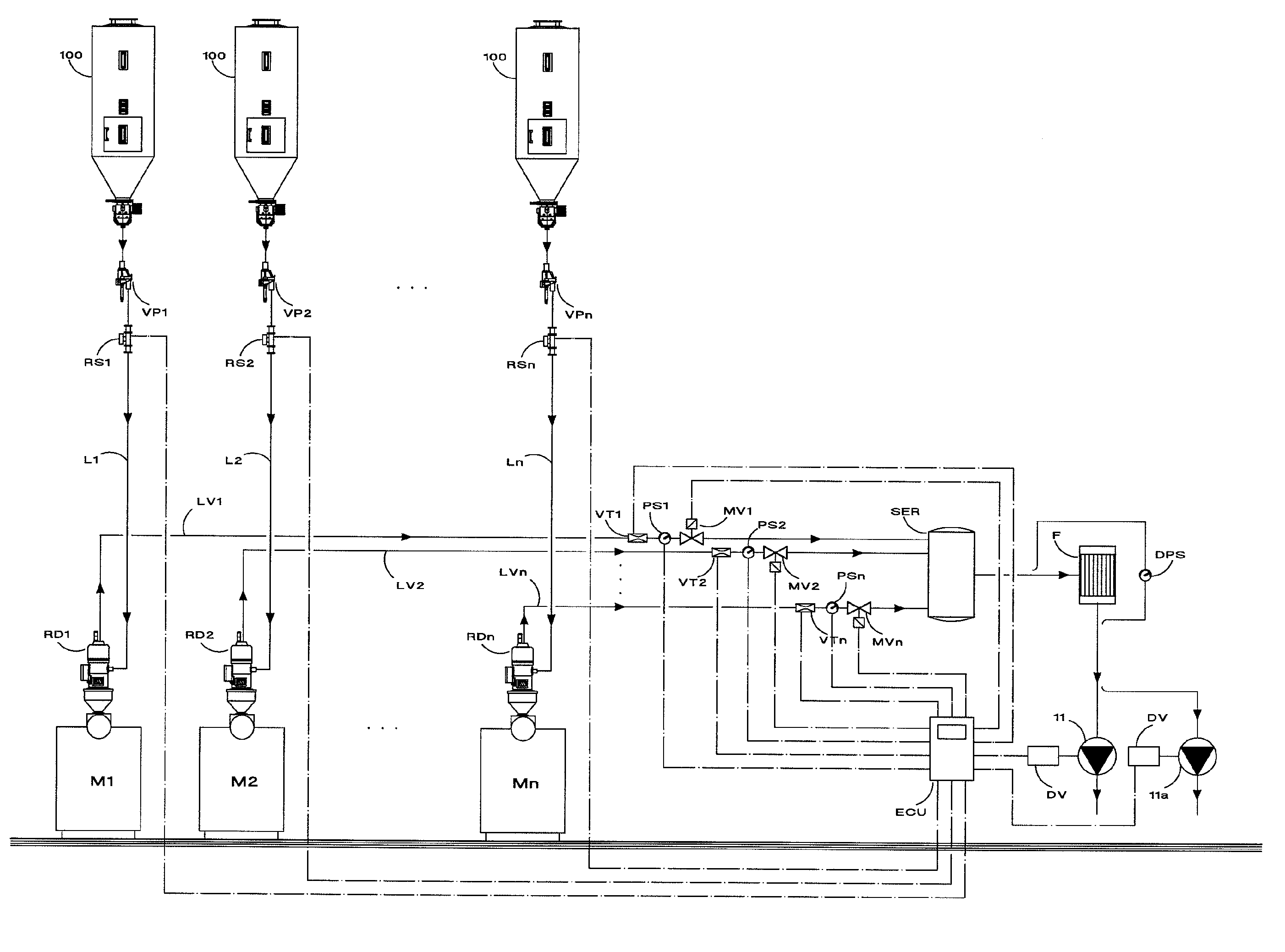

Plant for the controlled-speed pneumatic transport of granular material and conveyance speed control process

ActiveUS8360691B2Reduce pressureReduced pressure transportBulk conveyorsThin material handlingLine tubingControl signal

A plant for transport of granular material comprising container for granular material to be transported, receiver-meter group designed to receive granular material from container, conveyance duct of granular material from container to receiver-meter group, depressurization-pressurization means arranged to suction / inject a gaseous medium from / into container, and vacuum duct between receiver-meter group and depressurization-pressurization means, thereby creating a flow of granular material and gaseous medium in at least one conveyance duct or line directed to receiver-meter group and a flow of gaseous medium between receiver-meter group and depressurization-pressurization means, the plant comprising detection means of parameters of flow located in vacuum duct or line, adjusting means of the power of depressurization / pressurization means and electronic control means designed to receive in input control signals from speed detection means and to emit control signals in output for driving adjusting means.

Owner:MORETTO SPA

Drying-storing apparatus for powdered or granular material and feeding system for powdered or granular material

InactiveUS7703217B2Improve efficiencySimple materialDrying using combination processesDrying solid materials with heatProcess engineeringMaterial storage

A drying and storing apparatus for powdered or granular material and a feeding system for powdered or granular material. The apparatus comprises a heating and drying chamber having a discharge port at its lower end and a thermal conductive heating means therein and a hopper chamber connected to the upper end of the heating and drying chamber, in which the heating and drying chamber and the hopper chamber constitute a integrally combined material storage processing tank for powdered or granular material.

Owner:MATSUI MFG

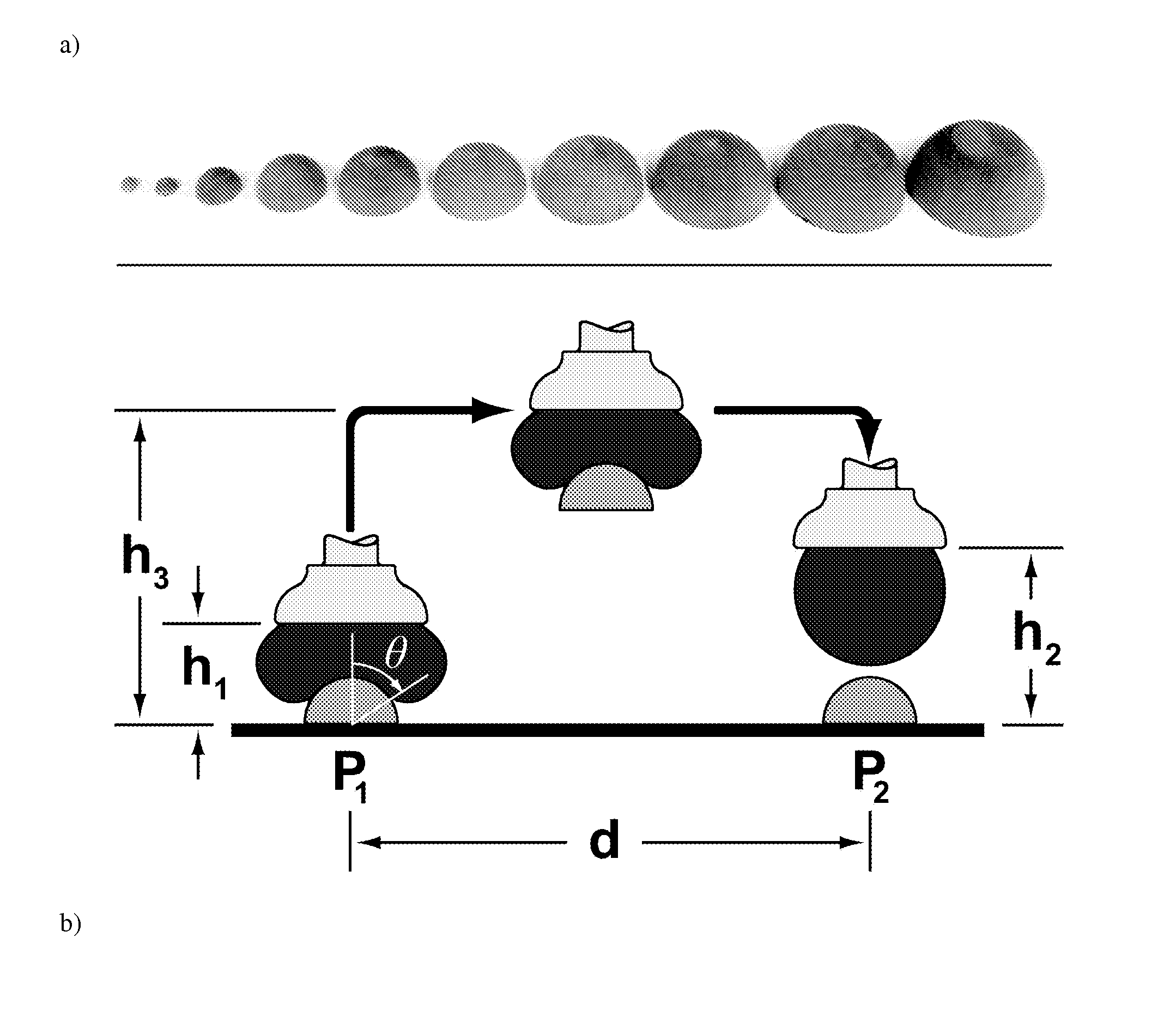

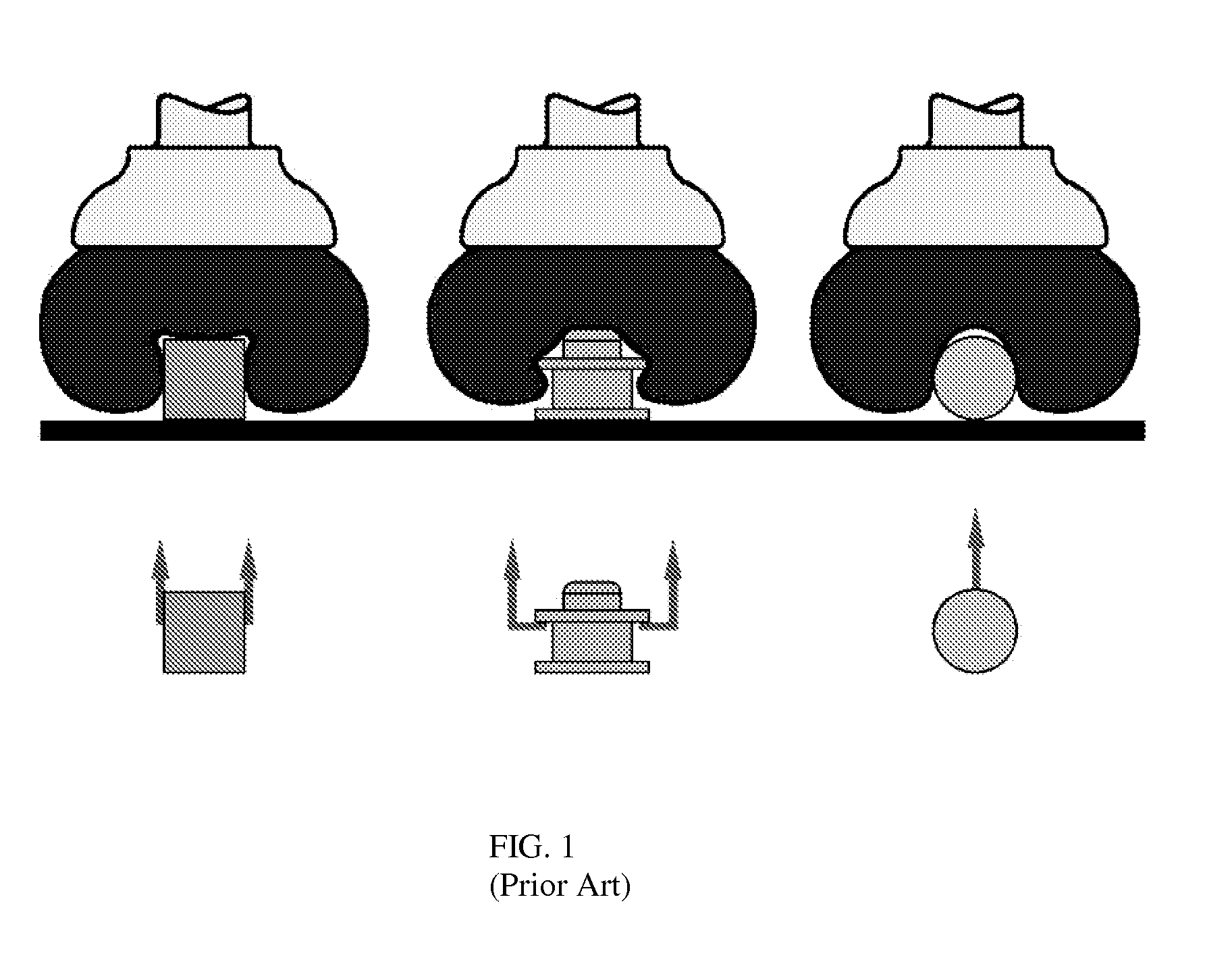

Gripping and releasing apparatus and method

ActiveUS8882165B2Improvement factorImprove performanceGripping headsRobotPositive pressureEngineering

A passive universal gripper includes a mass of granular material encased in an elastic membrane. Using a combination of positive and negative pressure, the gripper can rapidly grip and release a wide range of objects that are typically challenging for conventional universal grippers, such as flat objects, soft objects, or objects with complex geometries. The gripper passively conforms to the shape of a target object, then vacuum-hardens to grip it rigidly; later using positive pressure to reverse this transition—releasing the object and returning to a deformable state. The apparatus and method enable the fast ejection of objects from the gripper, as well as essentially instantaneous reset time between releasing and gripping.

Owner:CORNELL UNIVERSITY +1

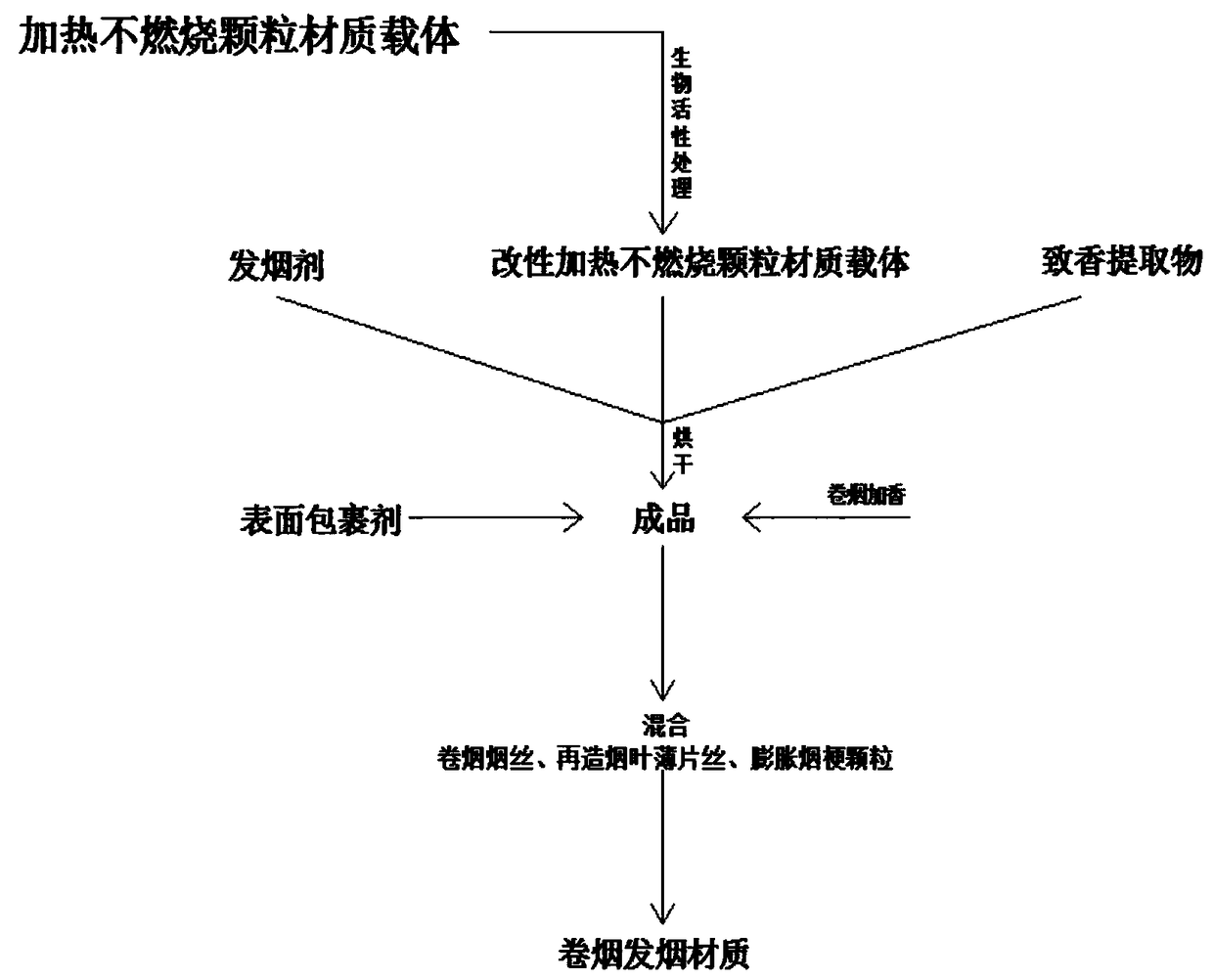

Heating-non-burning cigarette fuming granular material and preparation method thereof

The invention discloses a heating-non-burning cigarette fuming granular material and a preparation method thereof. The granular material includes a heating-non-burning granular material carrier, fuming agents, a surface coating agent and a perfuming extract. The heating-non-burning granular material carrier includes juncus roemerianus, gramineous plant granules, radix puerariae, eupatorium adenophorum, tobacco powder, tobacco stem powder, hydroxypropyl methyl cellulose, beta cyclodextrin, gelatin, sodium alginate, diatom ooze, chitosan, methylcellulose, lignin and other natural plant granules.The preparation method of the granular material includes the following step of preparing the heating-non-burning granular material carrier at first, wherein the carrier is preferably selected from domestic high-quality granules or natural mineral compound granules and powder thereof for pelleting or compounding. The fuming granules are integrally loaded according to volume and then sealed, finished products of a fuming unit are mixed with the fuming agents of perfuming groups different in taste, and the problems that cigarette containers in the heating-non-burning field are monotonous in typeand processing technologies are cumbersome are solved.

Owner:YUNNAN XIKE TECH CO LTD

Sediment control device and system

InactiveUS6905289B1Effective controlHighly effective and durable and convenient deviceDamsBarrages/weirsBiomedical engineeringGeotextile

Sediment control devices and systems are provided. The device generally includes a core made up of granular material encased within a puncture resistant fabric, a compressible layer enwrapping the core and a geotextile fabric outer casing. A plurality of such devices provide a system for controlling erosion and sedimentation.

Owner:SANGUINETTI PETER S

Vacuum loading system

Apparatus and methods for providing granular material to a loading hopper preparatory to processing, provide an at least partially transparent receptacle for receiving material prior to processing machinery supplied by the hopper with the receptacle having a top, a valve for selectably connecting the receptacle to vacuum or to ambient air, vacuum drawn in the receptacle, a conduit connecting the receptacle to a supply of granular material, a valve selectably permitting material flow from the receptacle into the hopper and control temporally adjustably closing the first valve and opening the second valve responsively to visually detected presence of a suitable amount of material in the receptacle.

Owner:MAGUIRE STEPHEN B

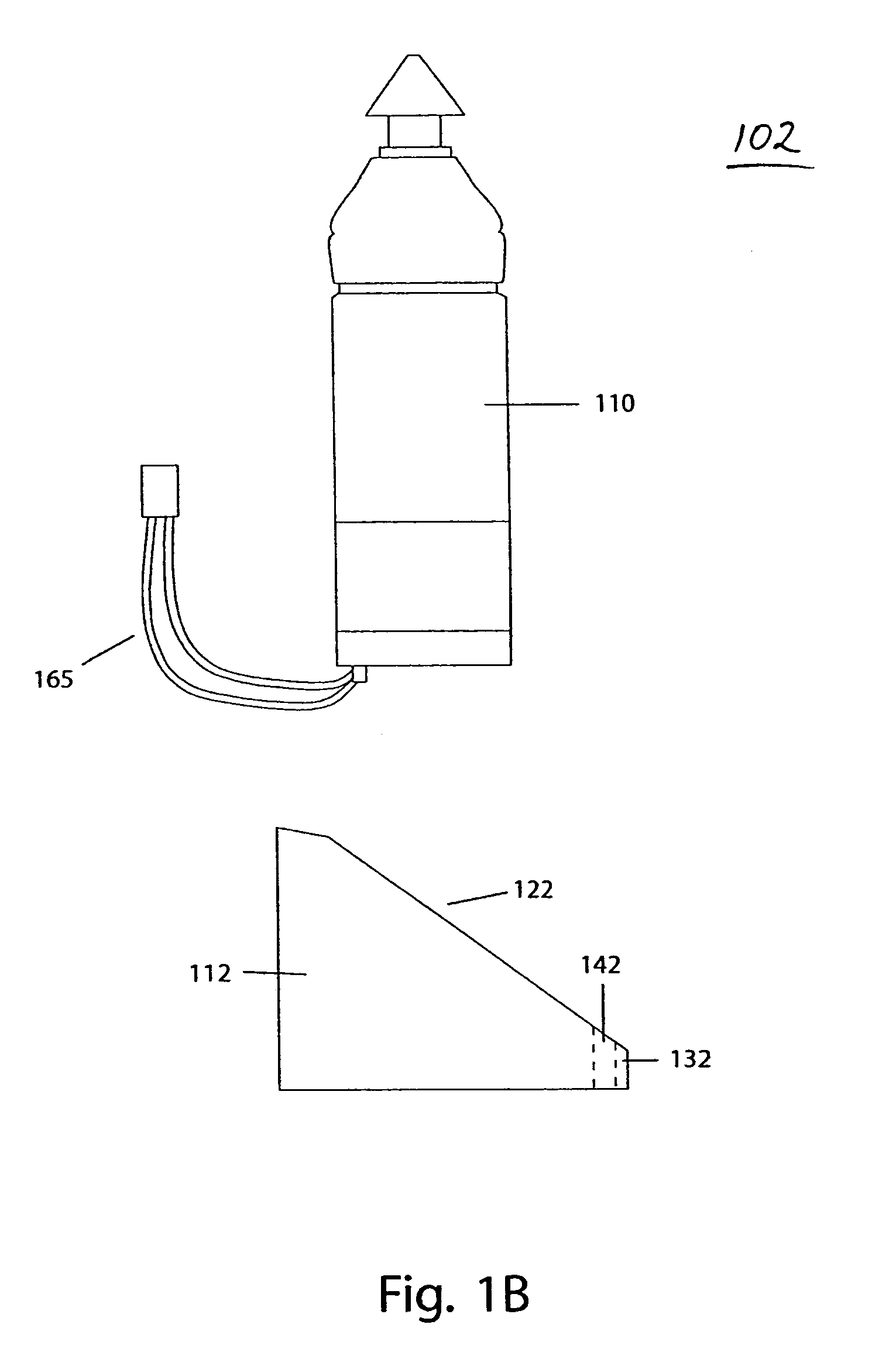

Self-calibrating meter with in-meter diffuser

A self-calibrating metering system for dispensing chemical granules. The system incorporates a flow sensor configured to sense a greater flow rate at the inlet aperture than at the outlet aperture. Further included is an adjustment mechanism configured to adjust the flow rate of the meter so as to calibrate the meter according to a known flow rate through a calibrated orifice within the meter. An electromechanical solenoid may be energized by a subcontroller operably coupled to the metering apparatus to allow chemical granules to flow by gravity from the pesticide container that may be disposed above the metering apparatus. The metering apparatus may be disposed on a planter unit designed to deposit granular materials with seed during the planting process. The metering system further includes an in-meter diffuser that receives foreign material and lumps in order to prevent the metering apparatus from becoming clogged.

Owner:AMERICAN CHEM CORP

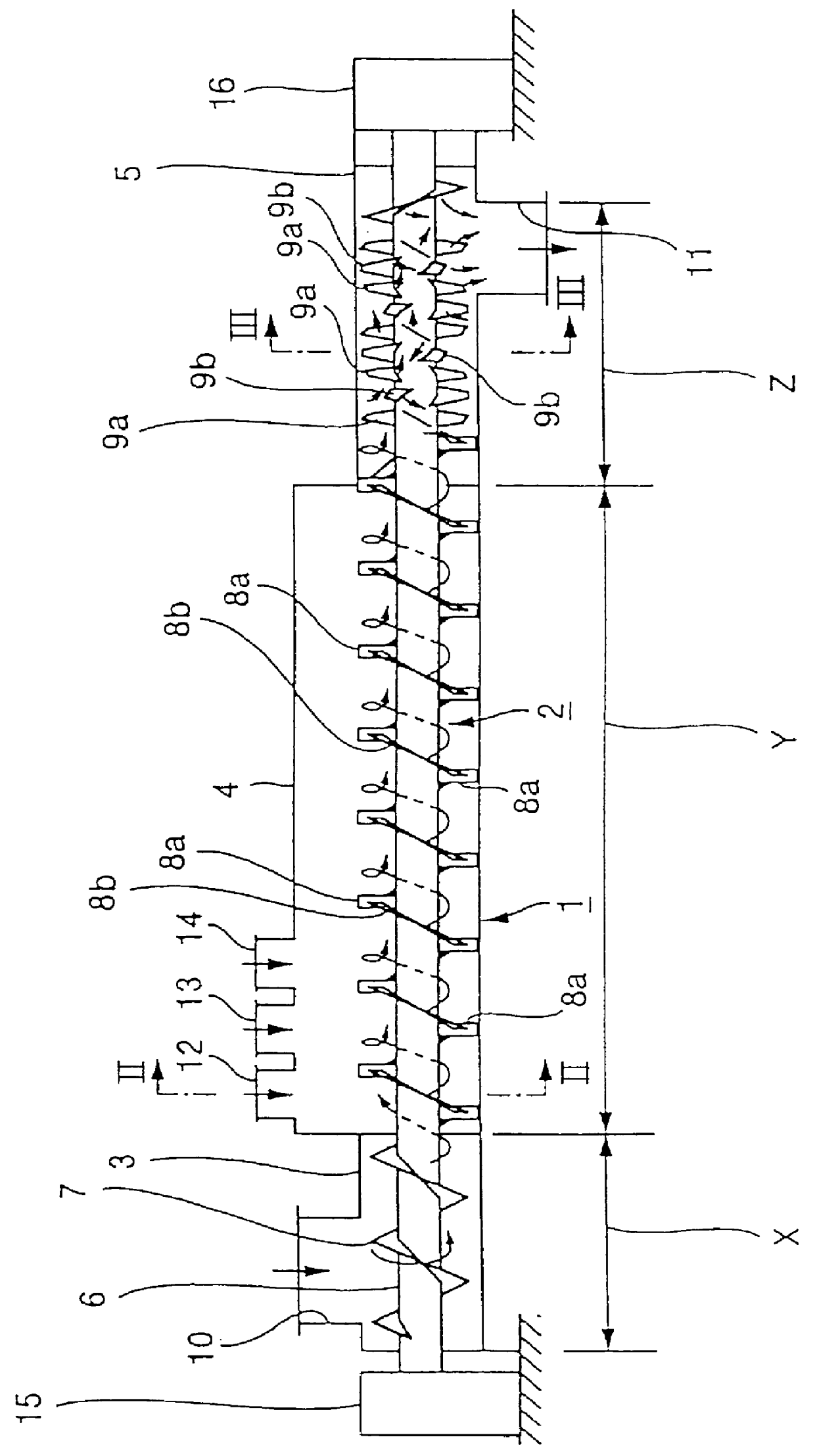

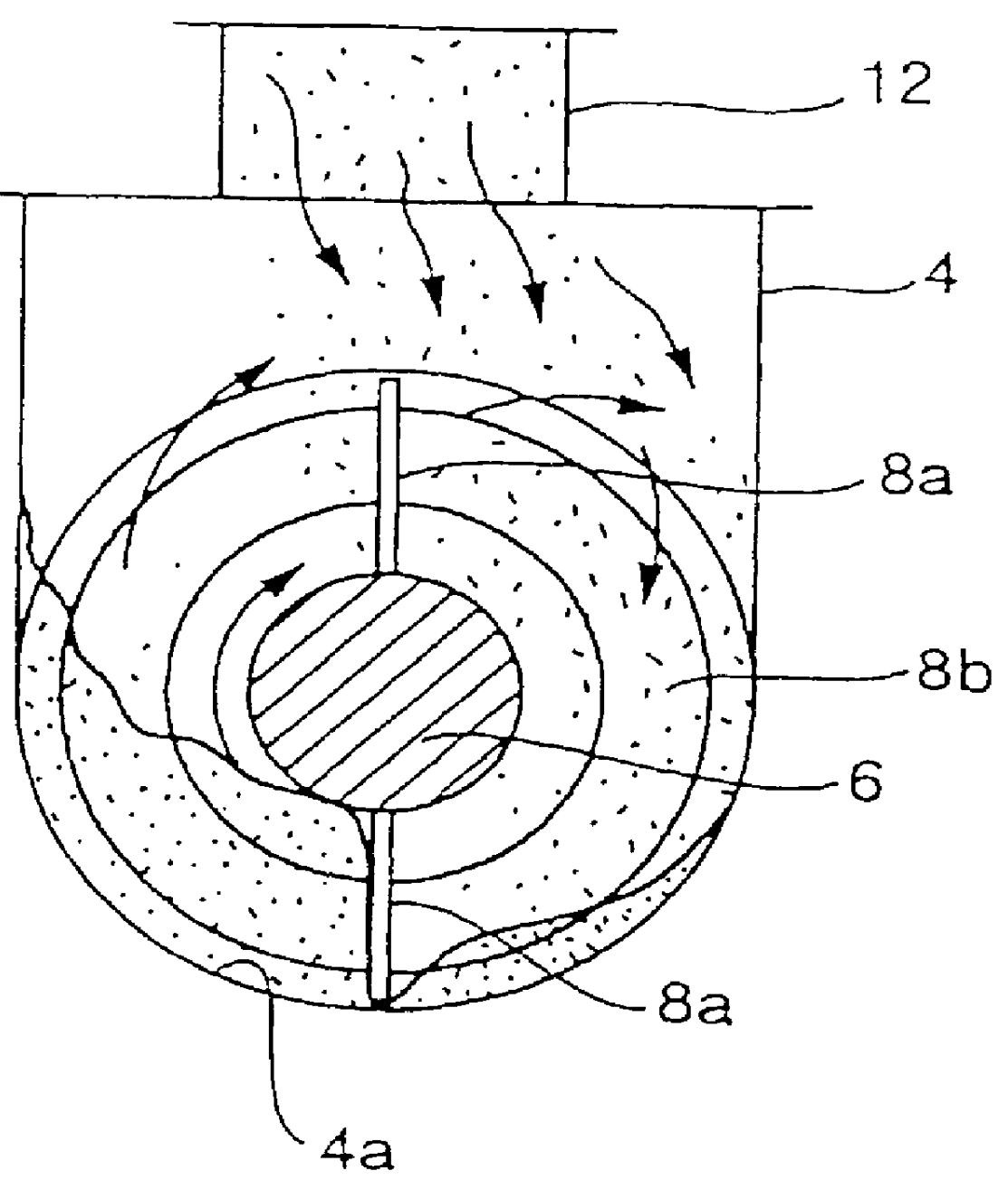

Continuous mixing feeder

The invention is for mixing at least one kind of an additive with a powdery or granular main material homogeneously so as to continuously supply the same quantitatively. A barrel comprises a front side cylindrical part, a trough part, and a rear side cylindrical part from the upstream side. A quantitative extruding zone comprises the front side cylindrical part and a quantitative extruding part having a full flight provided on the peripheral surface of the axis part of a screw, for quantitatively transporting a main material to the downstream side. A mixing zone comprises the trough part and a mixing part having an agitating blade formed zigzag on the axis part of the screw and a ribbon screw having a distance with respect to the peripheral surface of the axis part, for homogeneously dispersing additives added from additive supply openings in the main material. The scraping out zone comprises the rear side cylindrical part and a scraping out part having forward paddles and backward paddles formed alternately on the peripheral surface of the axis part of the screw, for discharging the mixture from a discharge opening.

Owner:JAPAN STEEL WORKS LTD

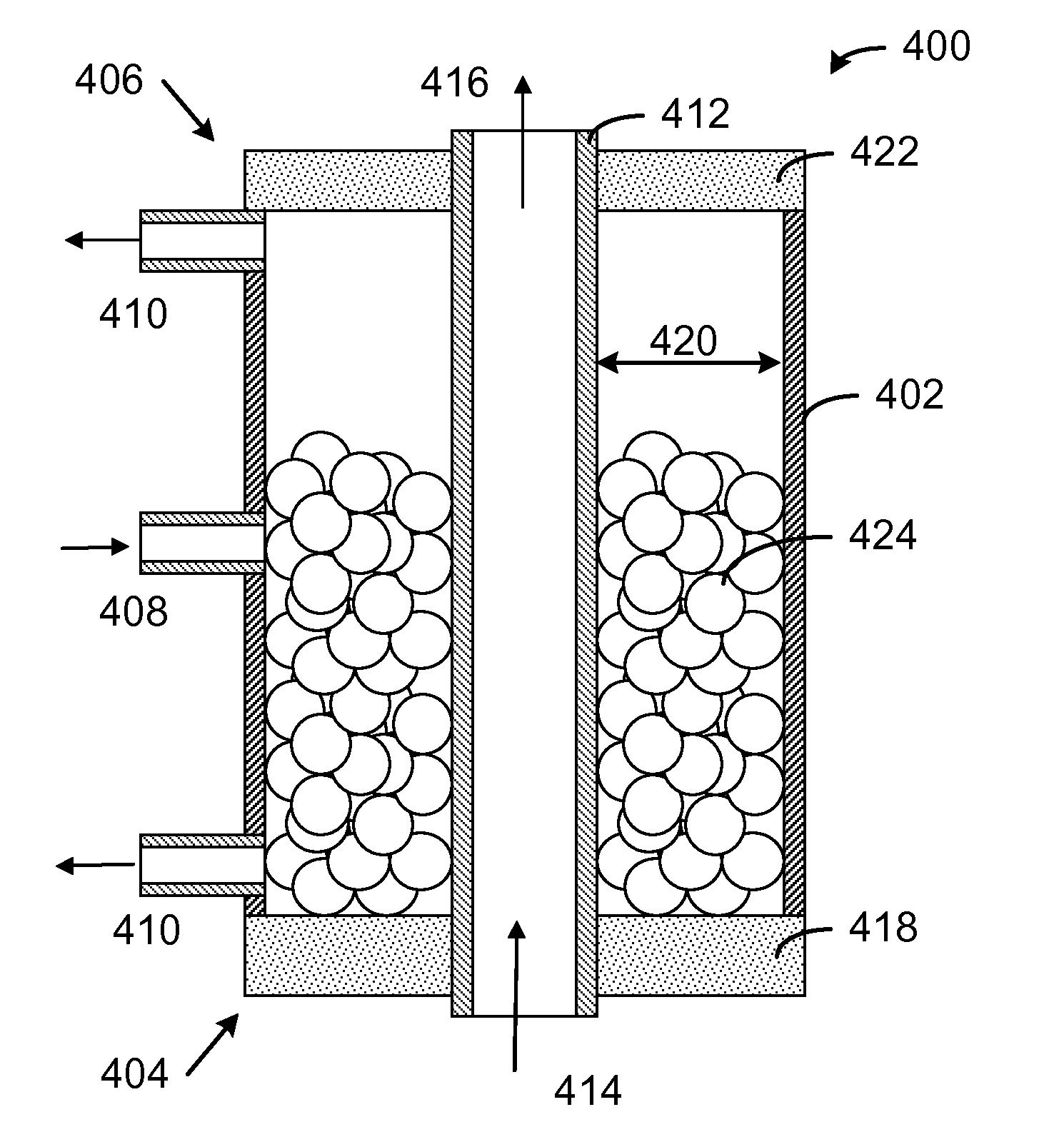

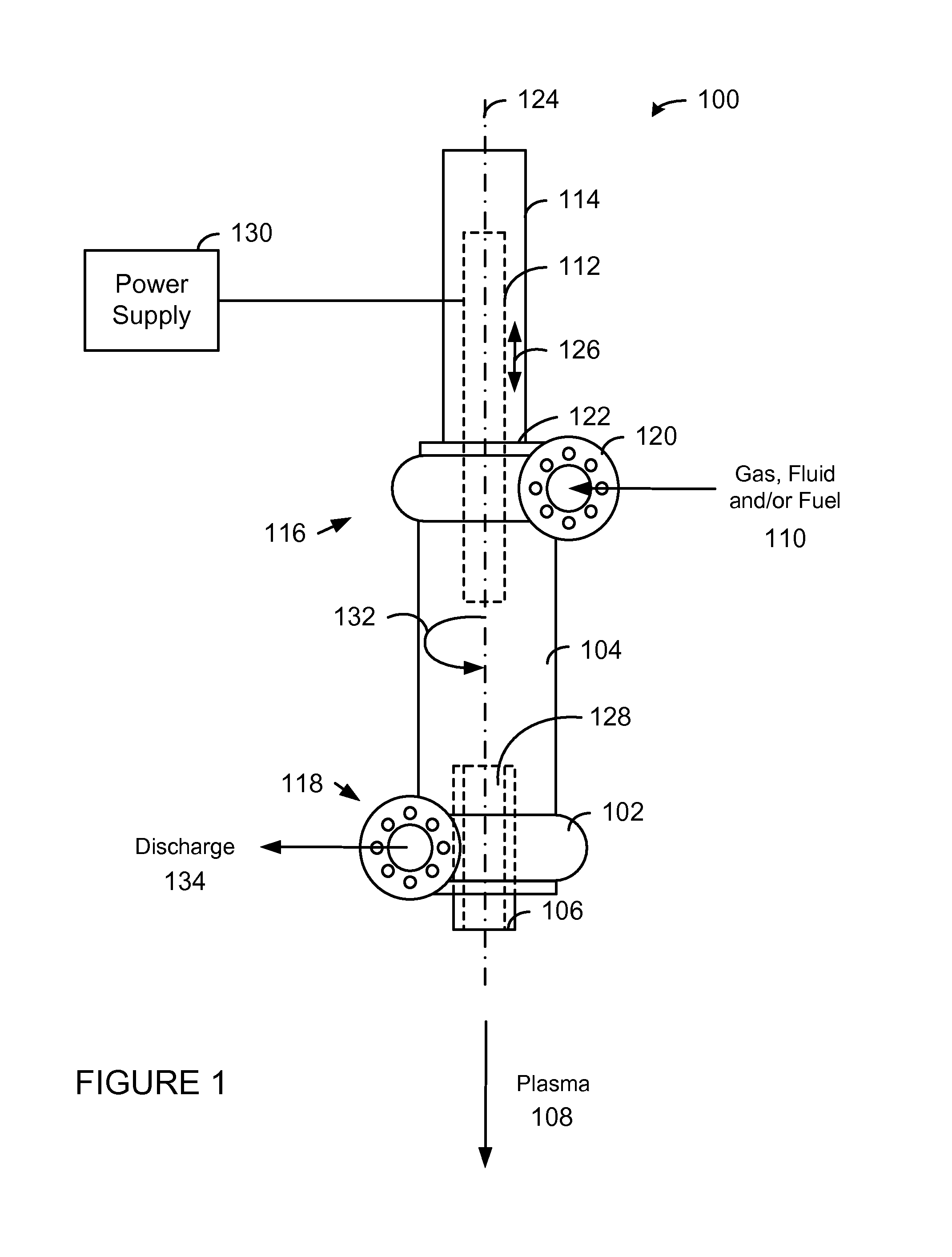

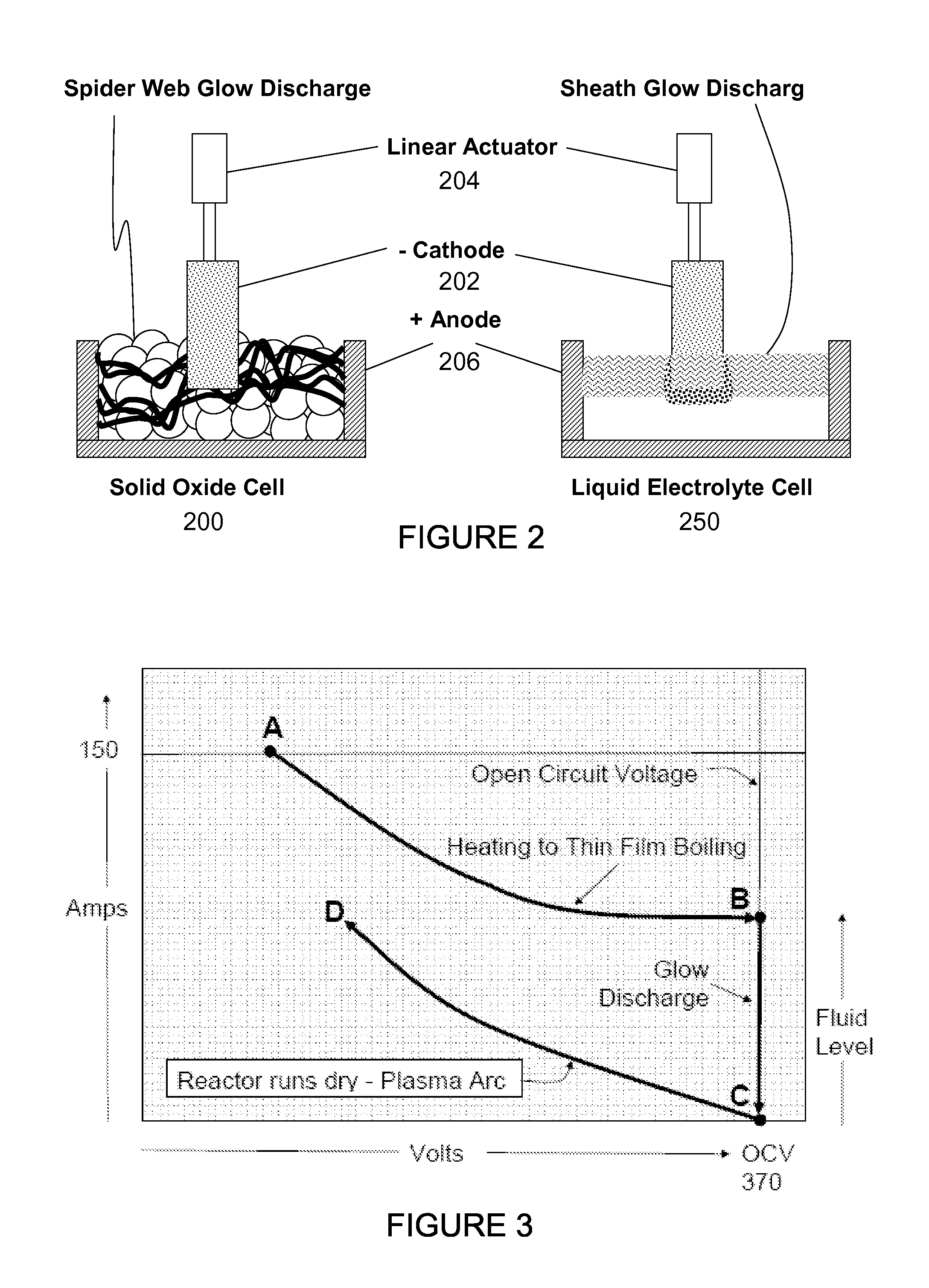

Solid oxide high temperature electrolysis glow discharge cell

The present invention provides a glow discharge cell comprising an electrically conductive cylindrical vessel having a first end and a second end, and at least one inlet and one outlet; a hollow electrode aligned with a longitudinal axis of the cylindrical vessel and extending at least from the first end to the second end of the cylindrical vessel, wherein the hollow electrode has an inlet and an outlet; a first insulator that seals the first end of the cylindrical vessel around the hollow electrode and maintains a substantially equidistant gap between the cylindrical vessel and the hollow electrode; a second insulator that seals the second end of the cylindrical vessel around the hollow electrode and maintains the substantially equidistant gap between the cylindrical vessel and the hollow electrode; a non-conductive granular material disposed within the gap, wherein the non-conductive granular material (a) allows an electrically conductive fluid to flow between the cylindrical vessel and the hollow electrode, and (b) prevents electrical arcing between the cylindrical vessel and the hollow electrode during a electric glow discharge; and wherein the electric glow discharge is created whenever: (a) the glow discharge cell is connected to an electrical power source such that the cylindrical vessel is an anode and the hollow electrode is a cathode, and (b) the electrically conductive fluid is introduced into the gap.

Owner:FORET PLASMA LABS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com