Patents

Literature

2479results about "Loading/unloading vehicle arrangment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

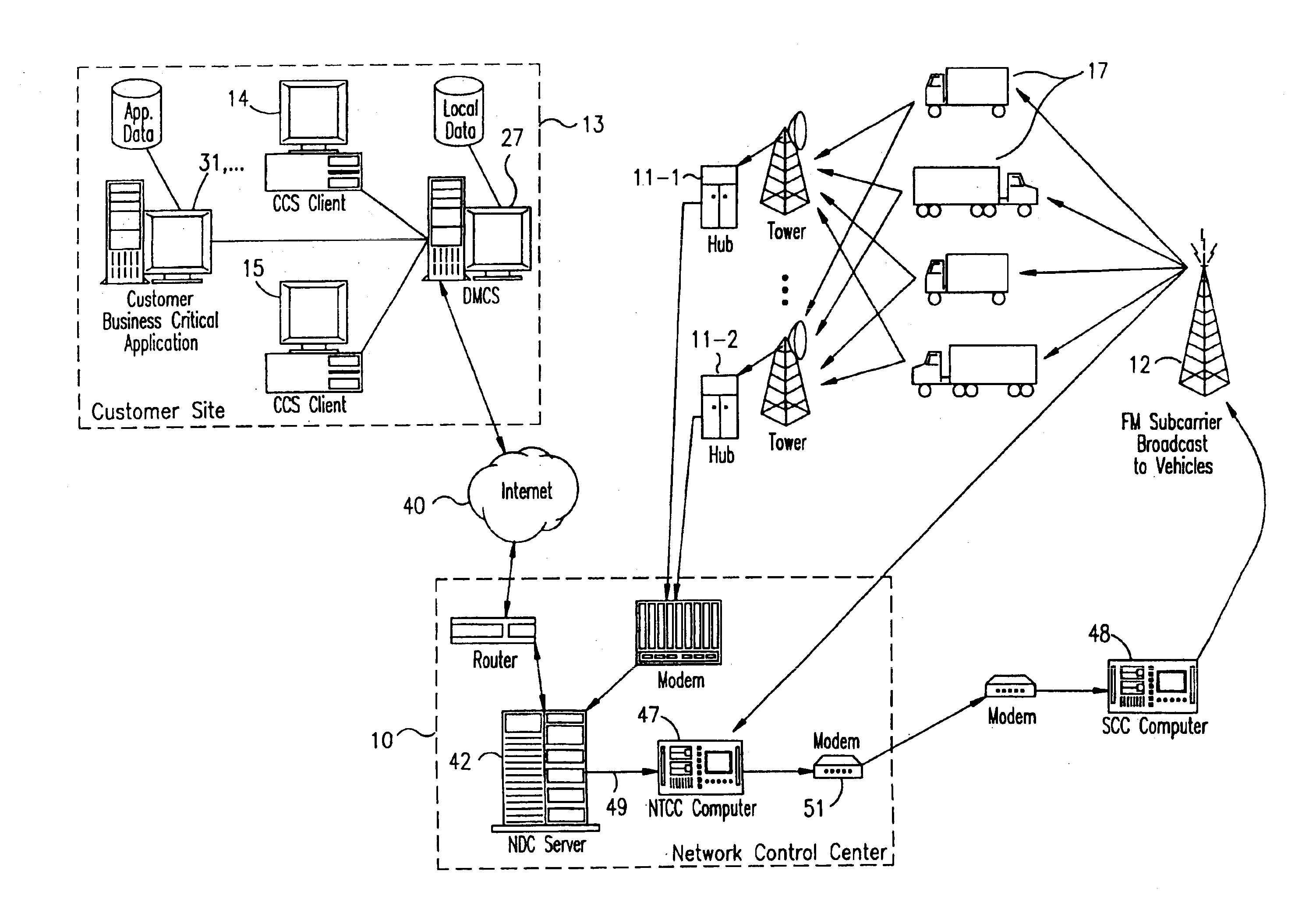

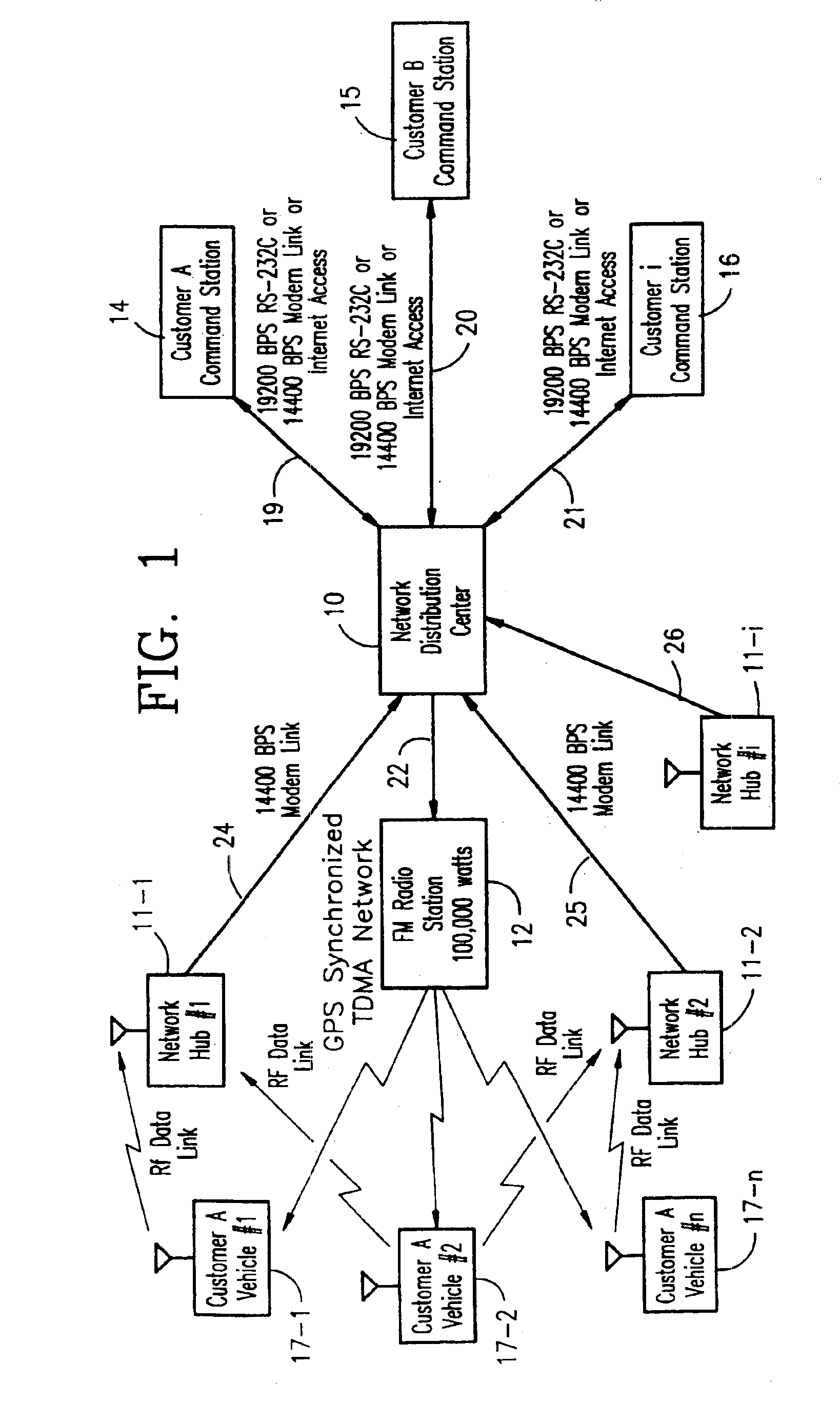

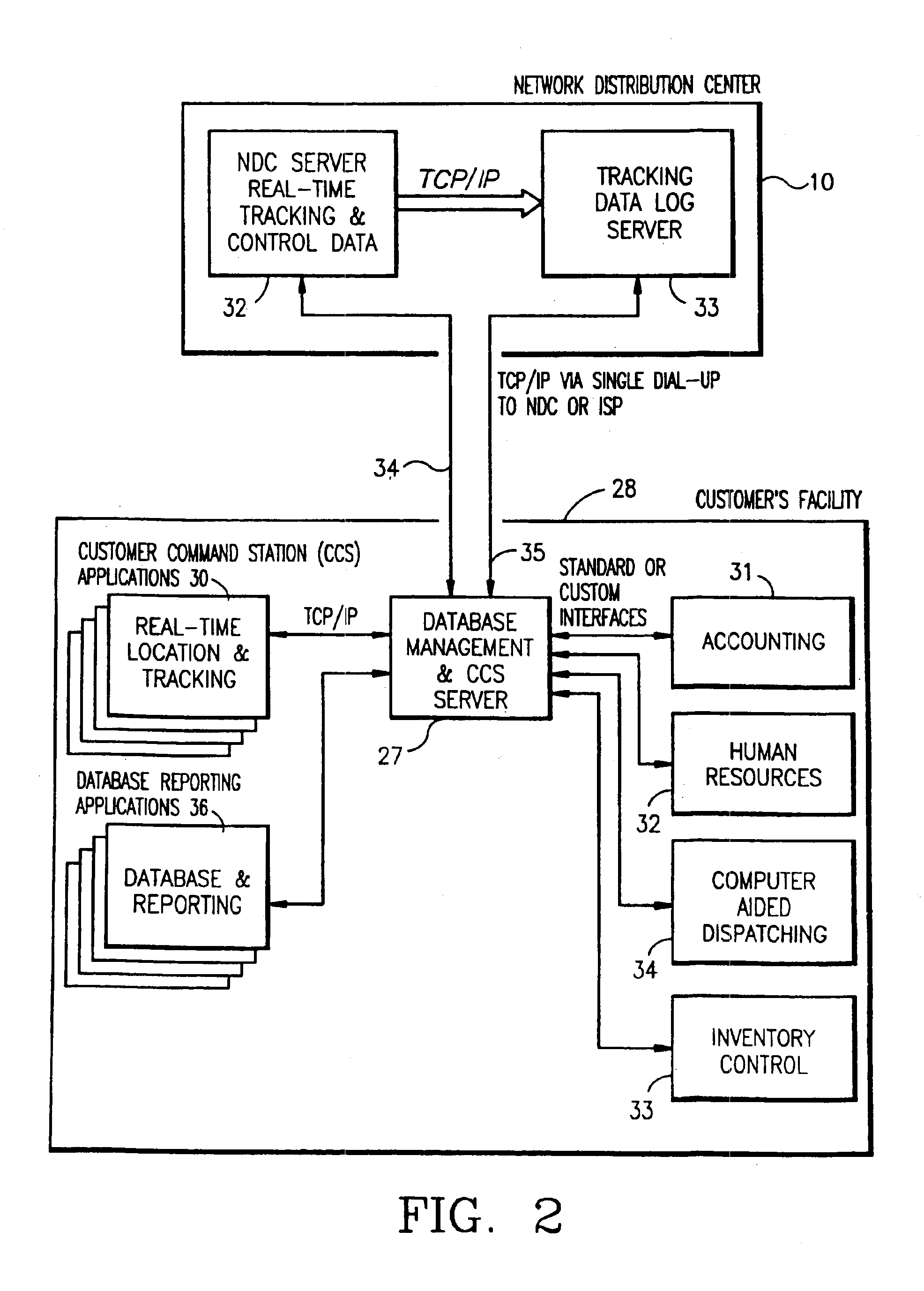

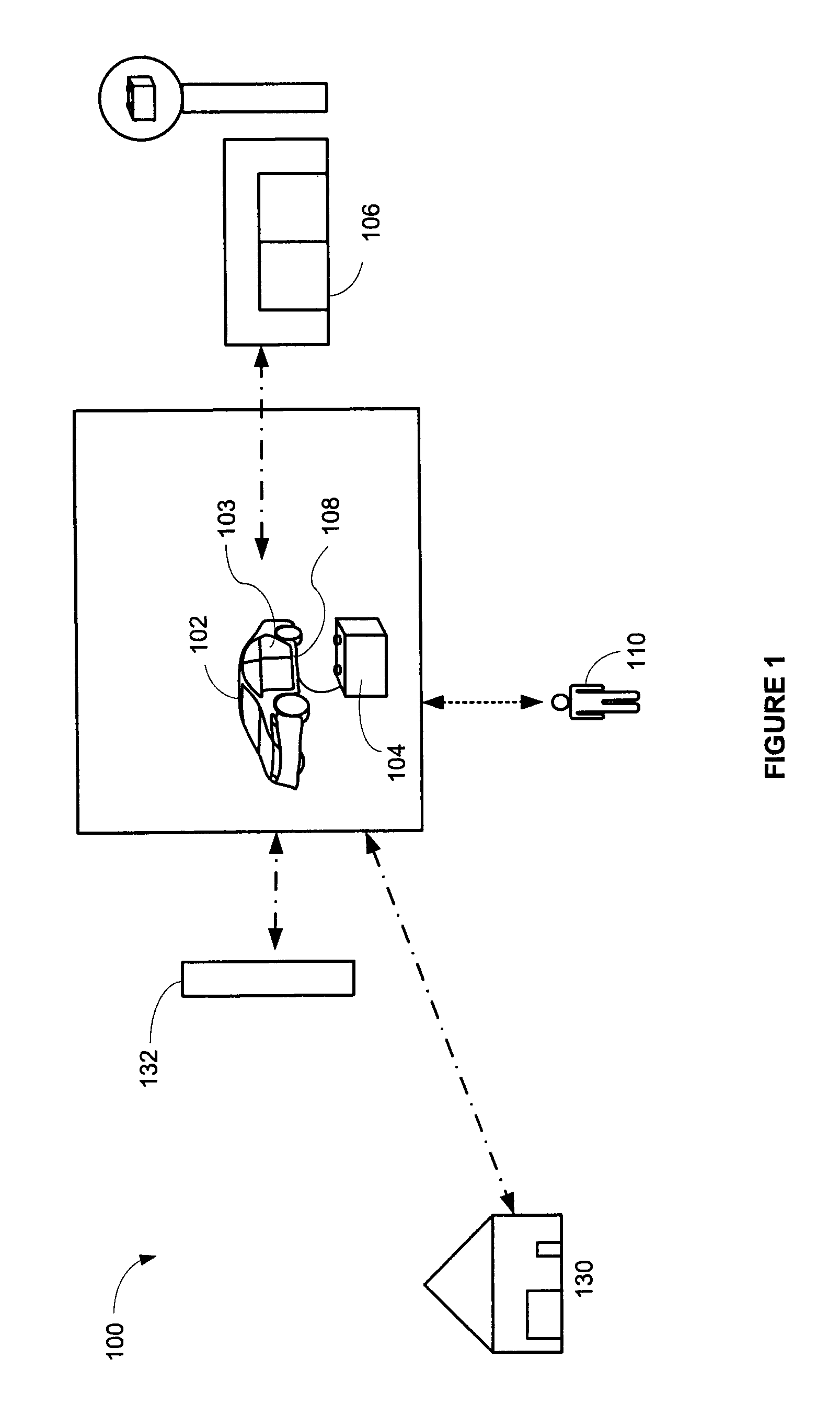

Vehicle tracking, communication and fleet management system

InactiveUS6892131B2Management moreEfficient and reliableVehicle testingRegistering/indicating working of vehiclesFleet managementTruck

A vehicle fleet management information system for identification of location and direction of movement of each vehicle in the fleet in real-time and automatic communication directly with management offices to report its location and heading, and status of predetermined events in which the vehicle may be engaged. One example is a cement delivery truck which monitors location, speed and status information such as start pour, pouring, end pour, wash and leave job, and automatically transmits this information with a management office without requiring affirmative action by the vehicle operator.

Owner:TRIMBLE NAVIGATION LTD

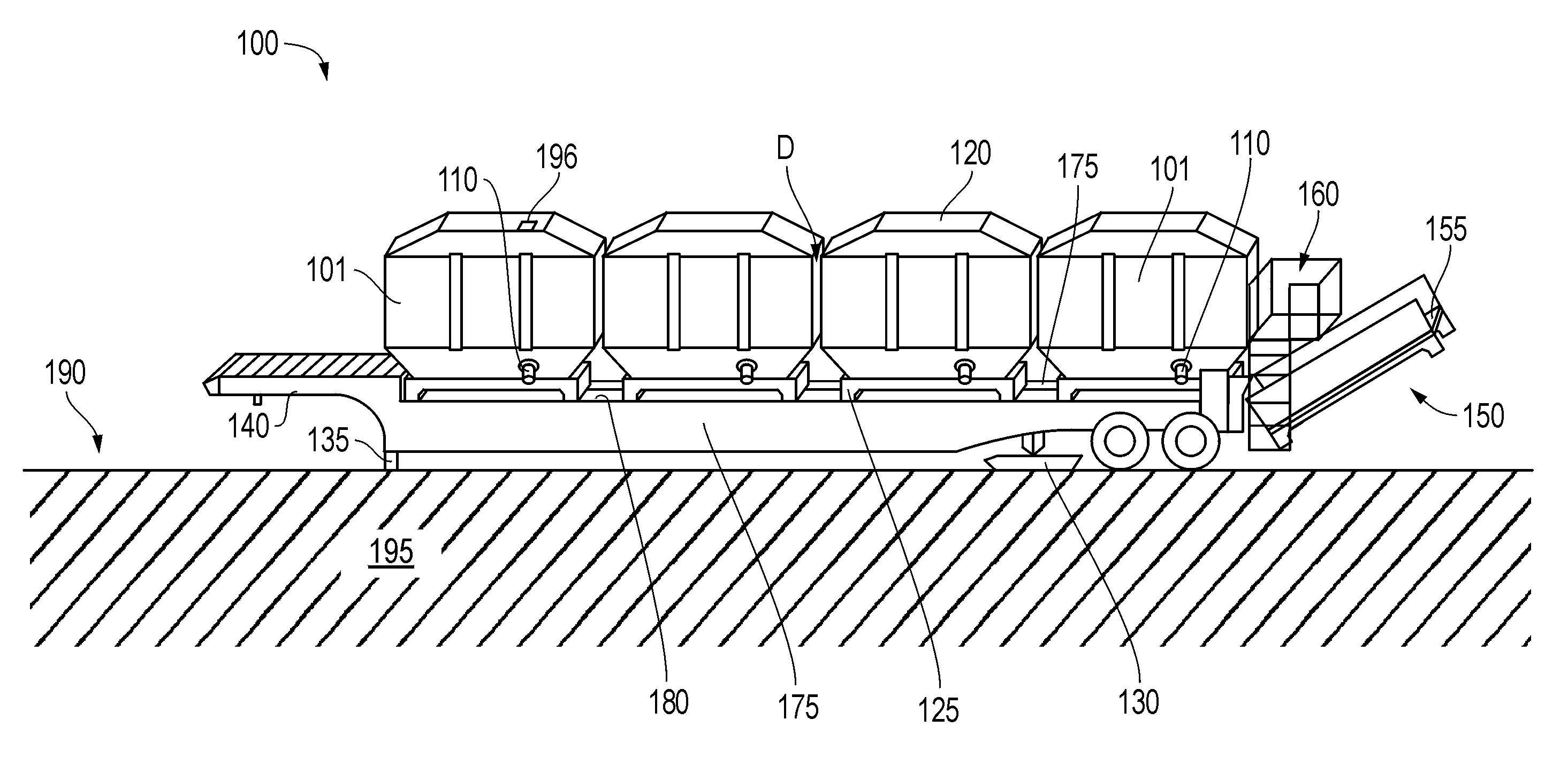

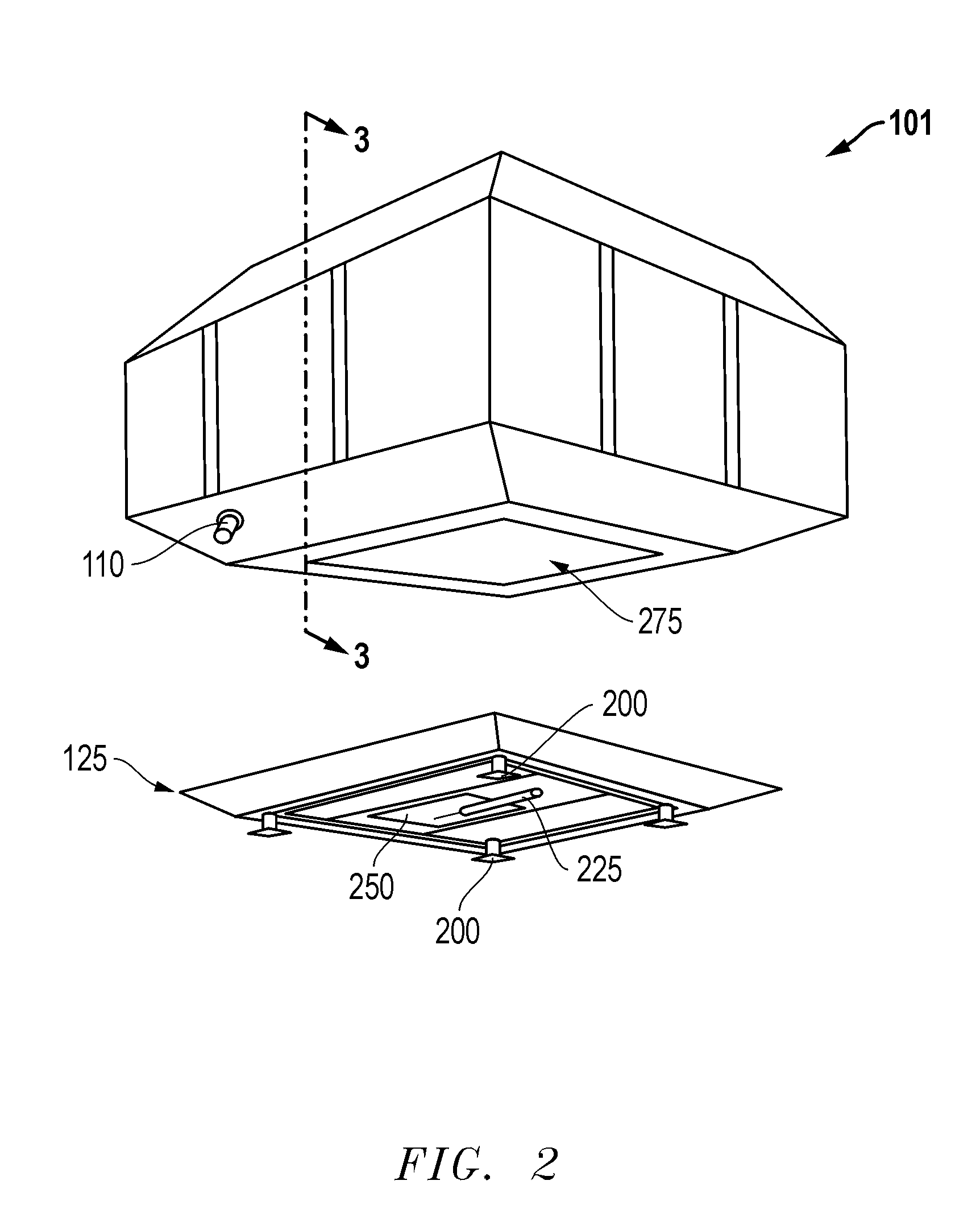

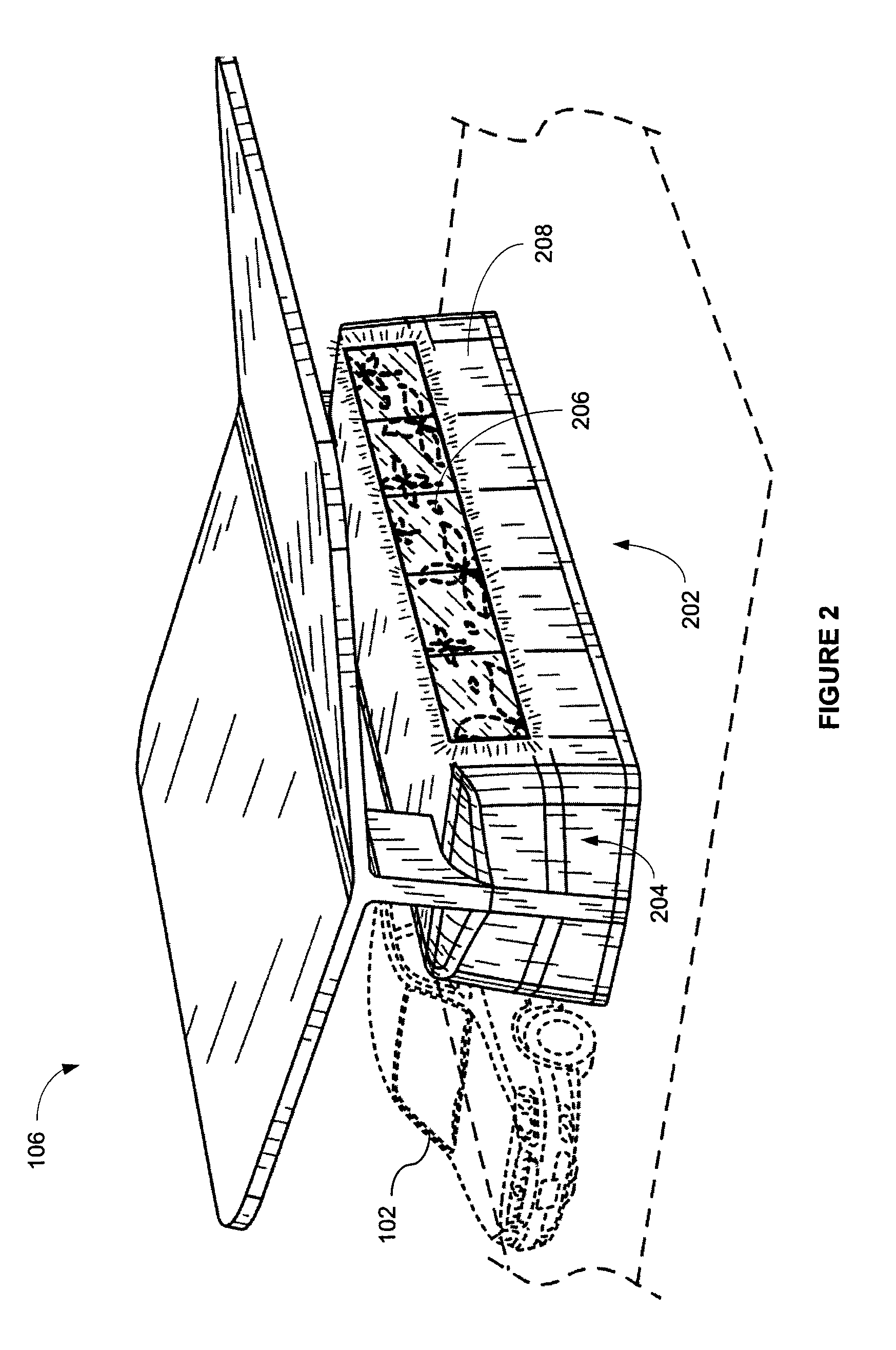

Aggregate Delivery Unit

A delivery unit for providing aggregate to a worksite, such as a wellsite location. The unit may include a mobile chassis for accommodating a plurality of modular containers which in turn house the aggregate. As such, a weight measurement device may be located between each container and the chassis so as to monitor aggregate levels within each container over time. The units may be particularly well suited for monitoring and controlling aggregate delivery during a fracturing operation at an oilfield. The modular containers may be of an interchangeable nature. Furthermore, a preferably wireless control device may be provided for monitoring and directing aggregate delivery from a relatively remote location.

Owner:SCHLUMBERGER TECH CORP

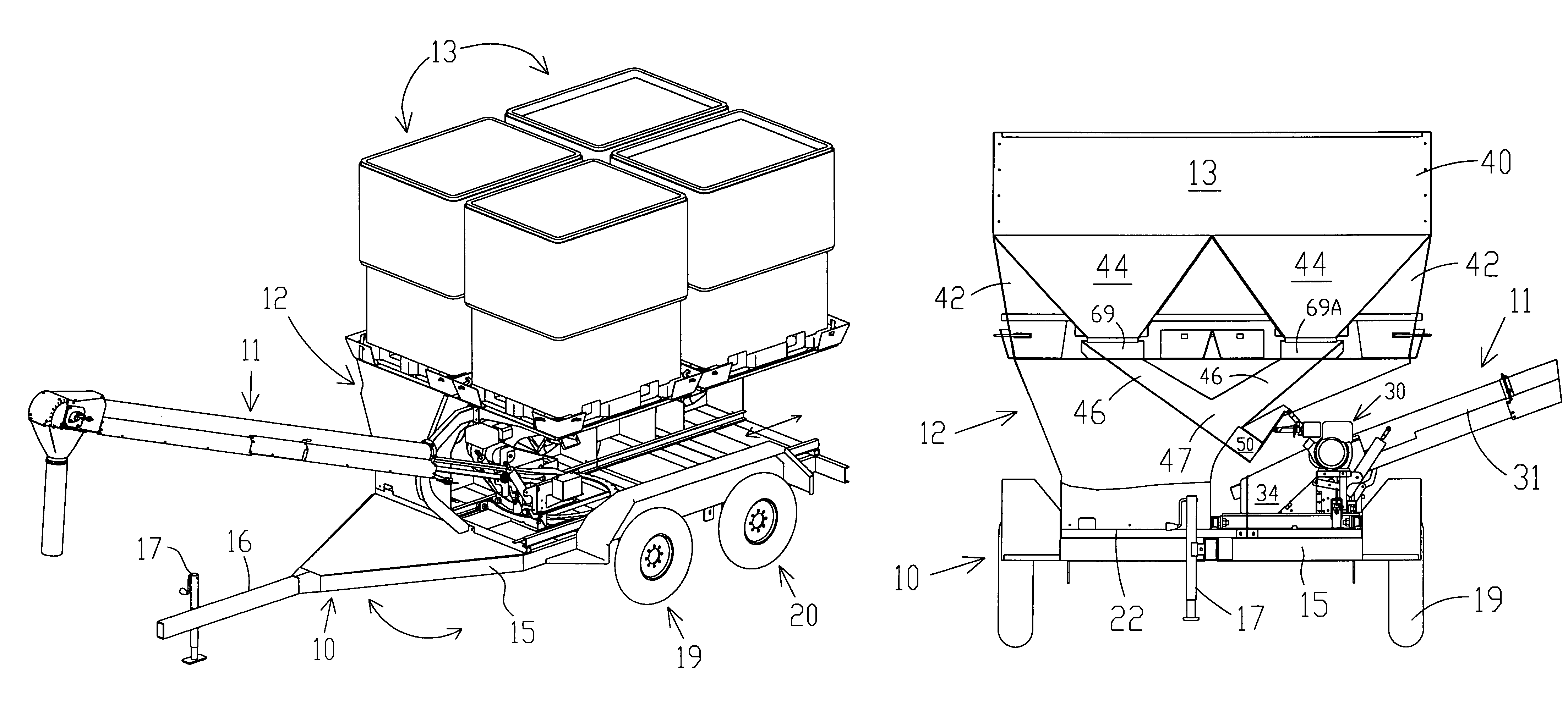

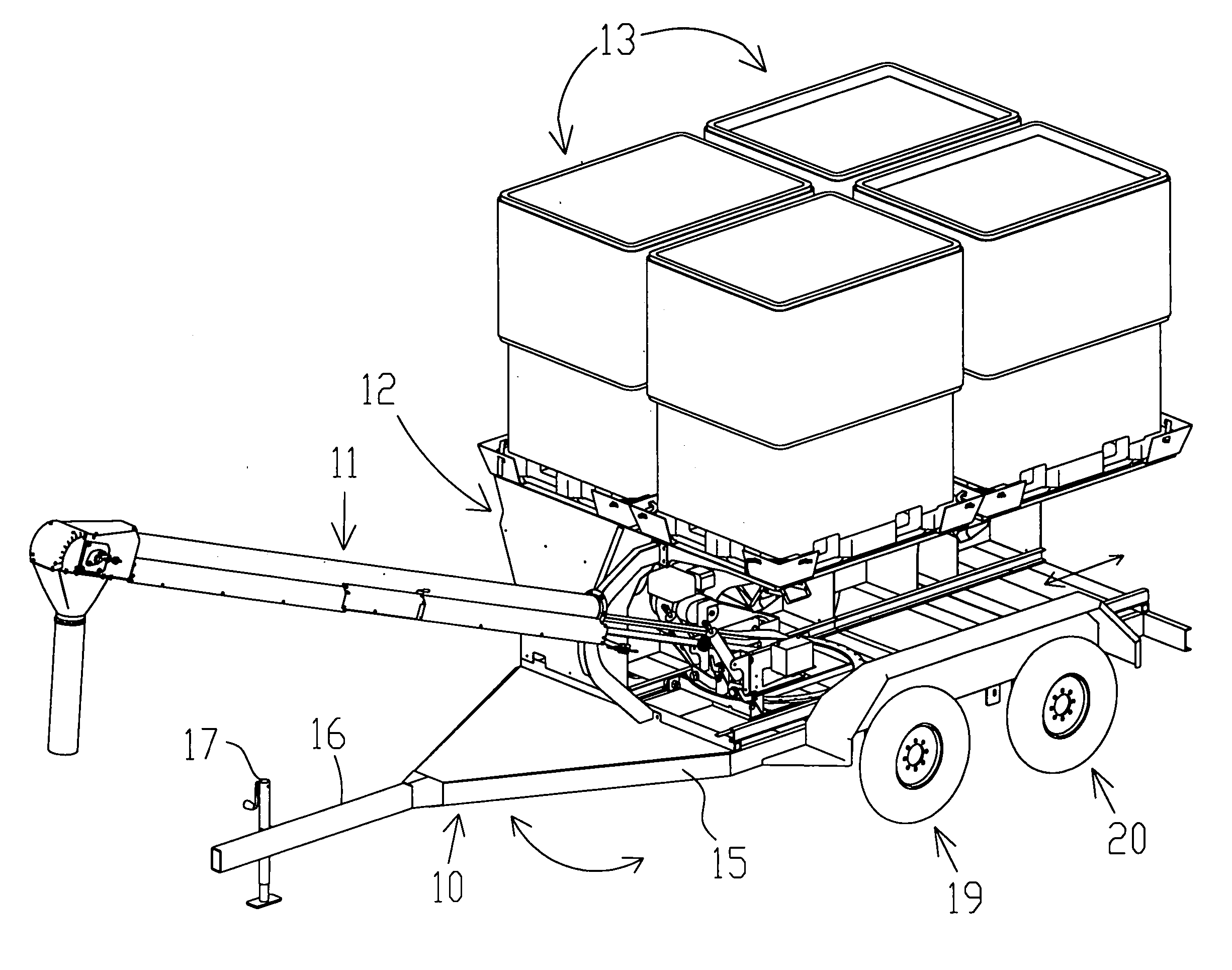

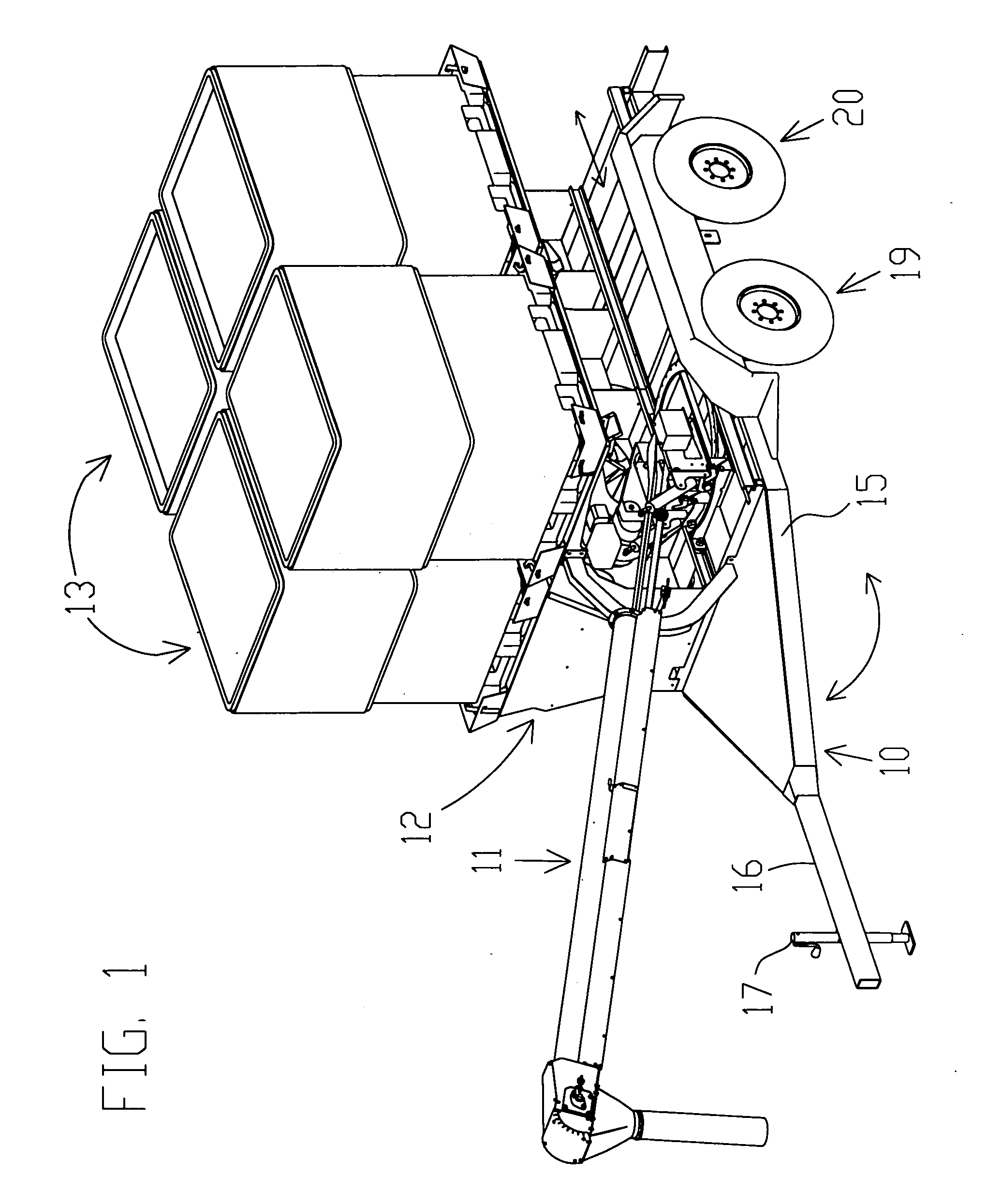

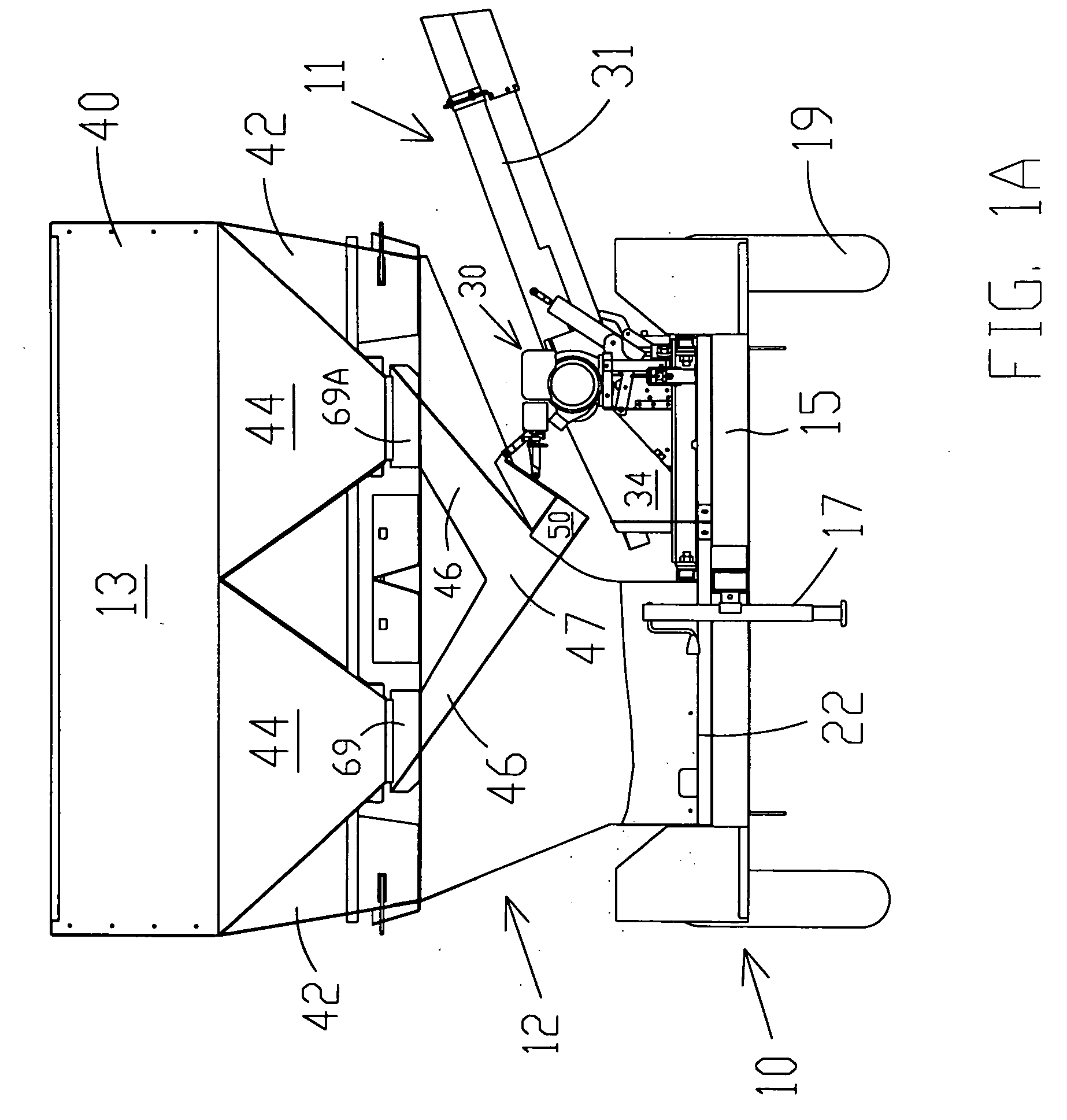

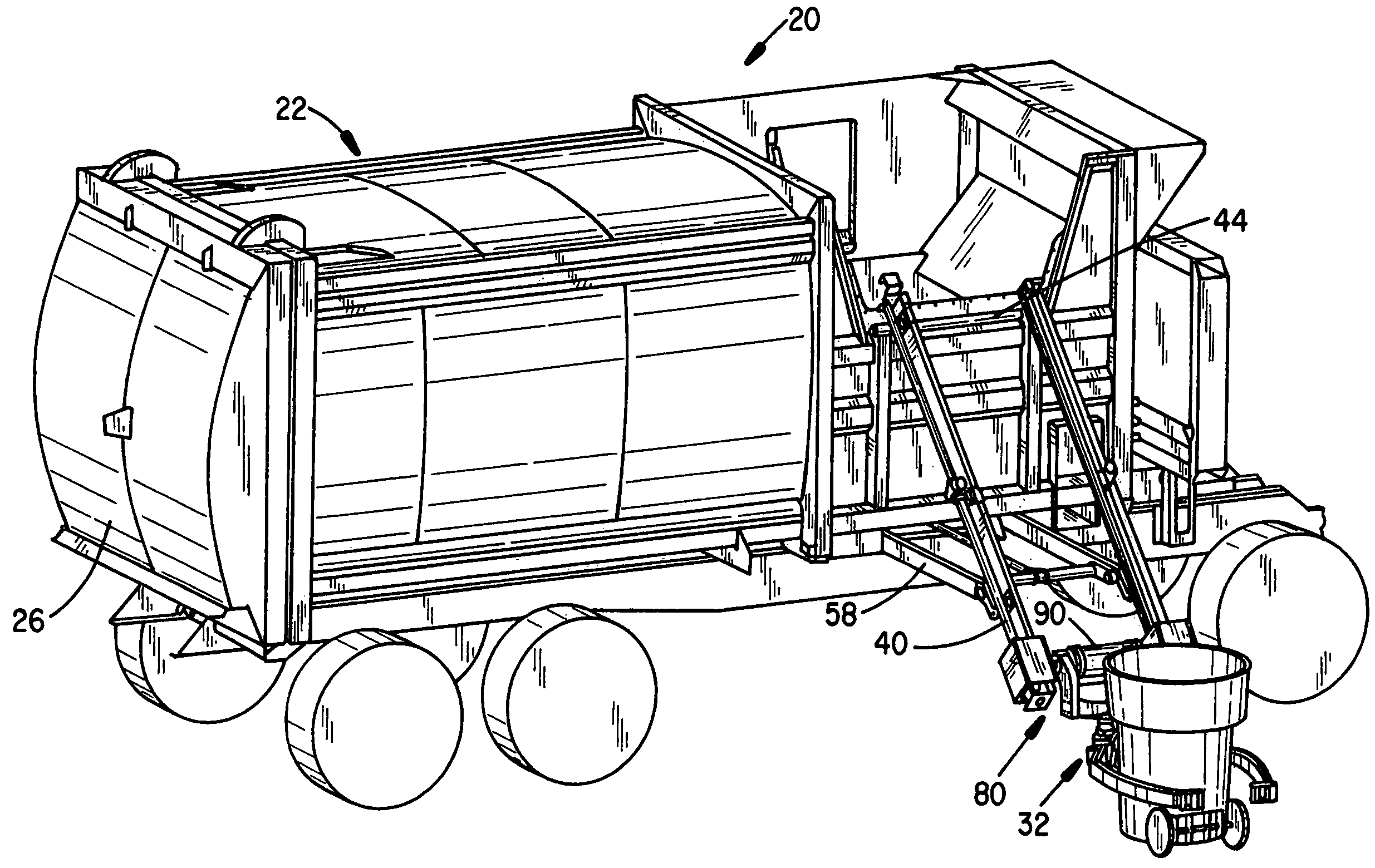

Agricultural seed tender with modular storage containers

ActiveUS7500817B2Improve economyIncrease storage capacityConveyorsMovable measuring chambersComputer moduleEngineering

Owner:MERIDIAN MFG

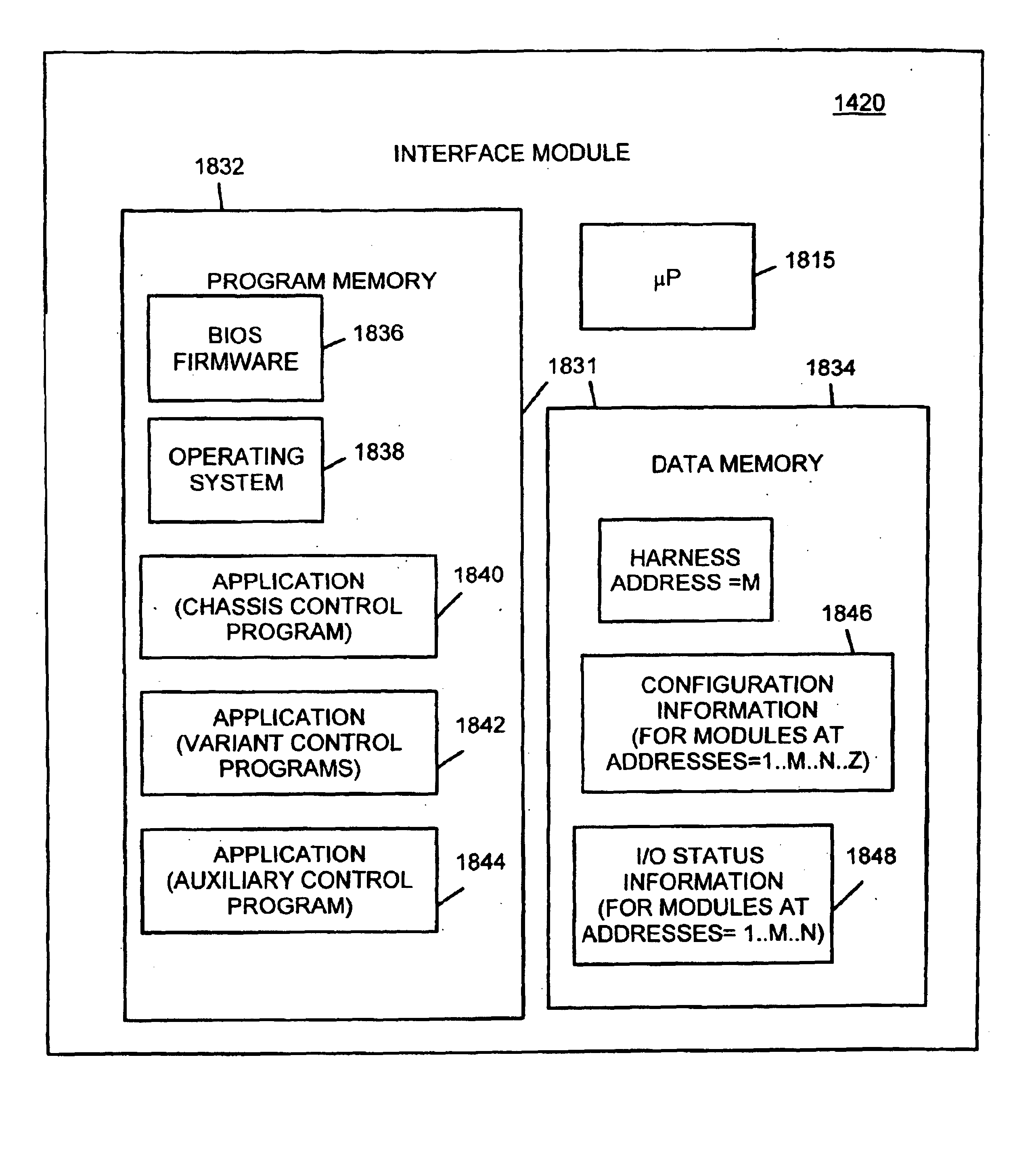

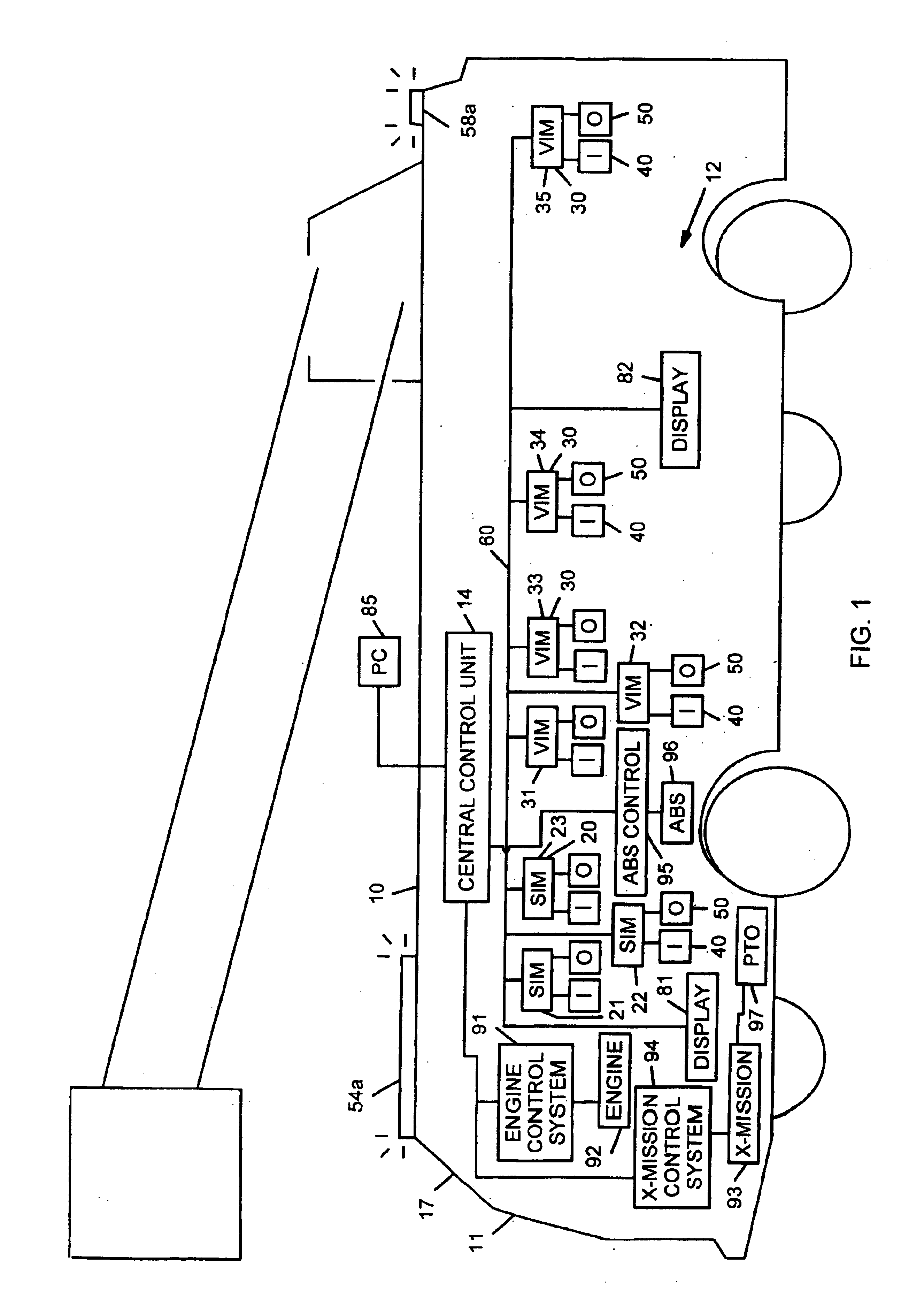

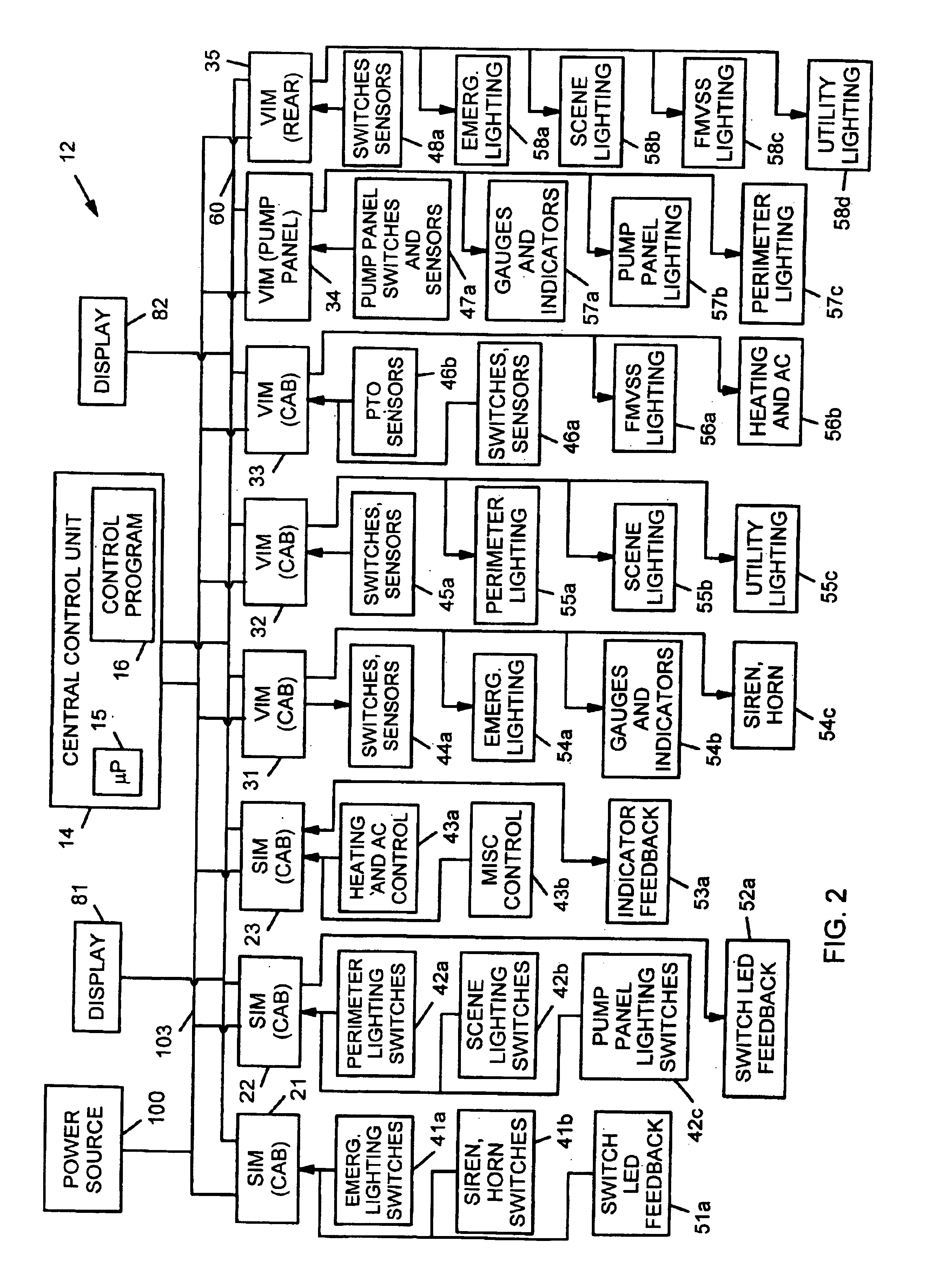

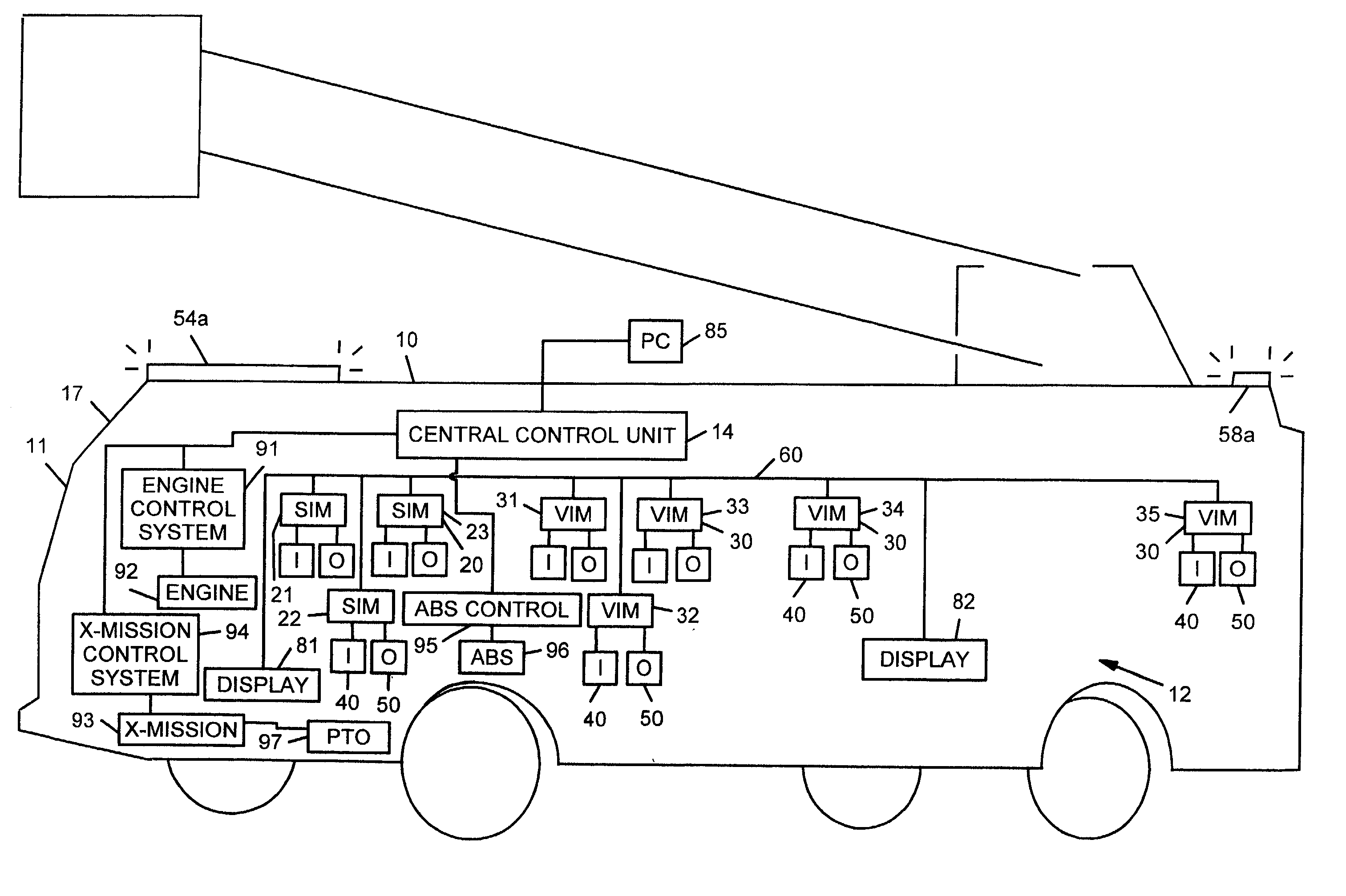

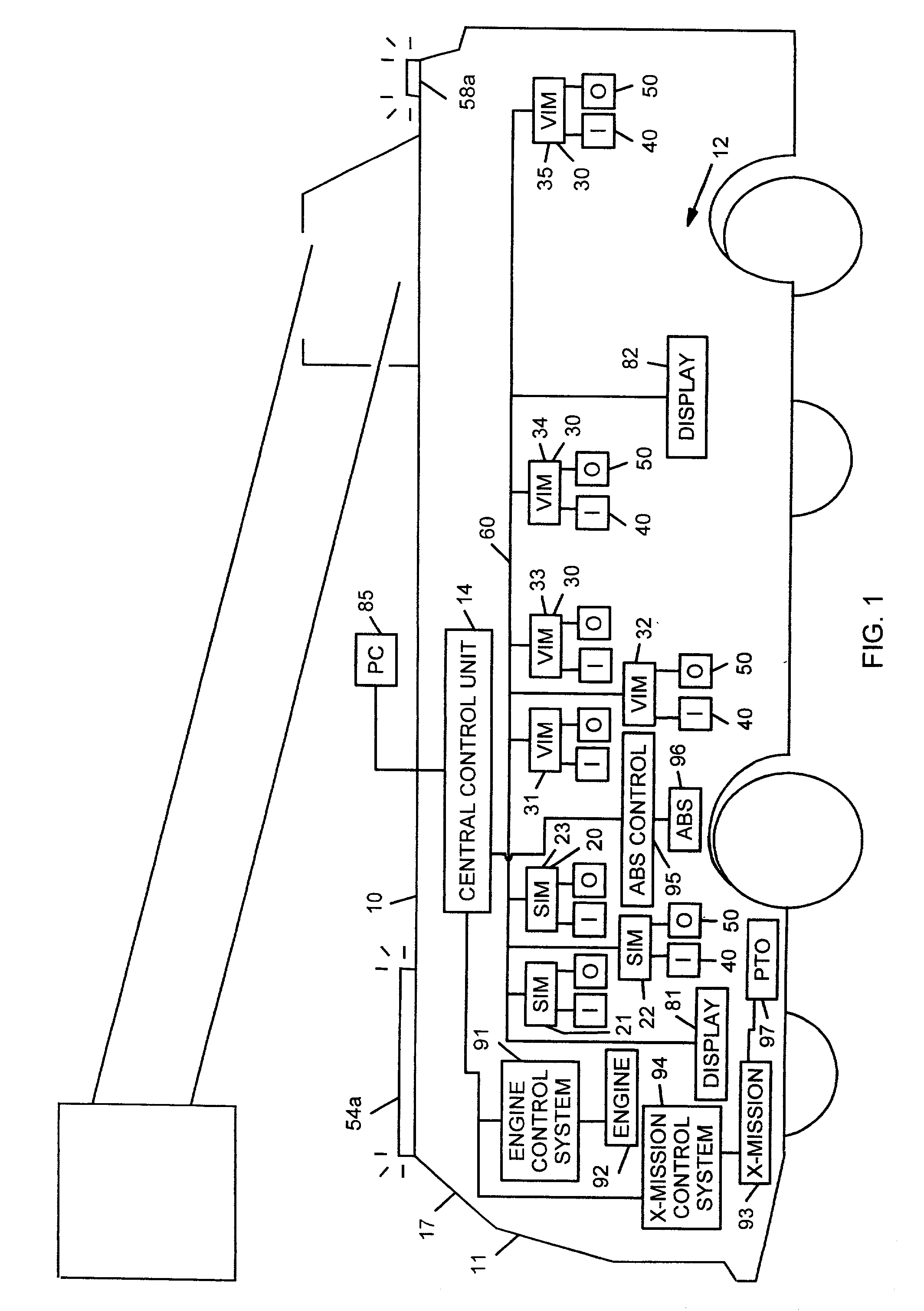

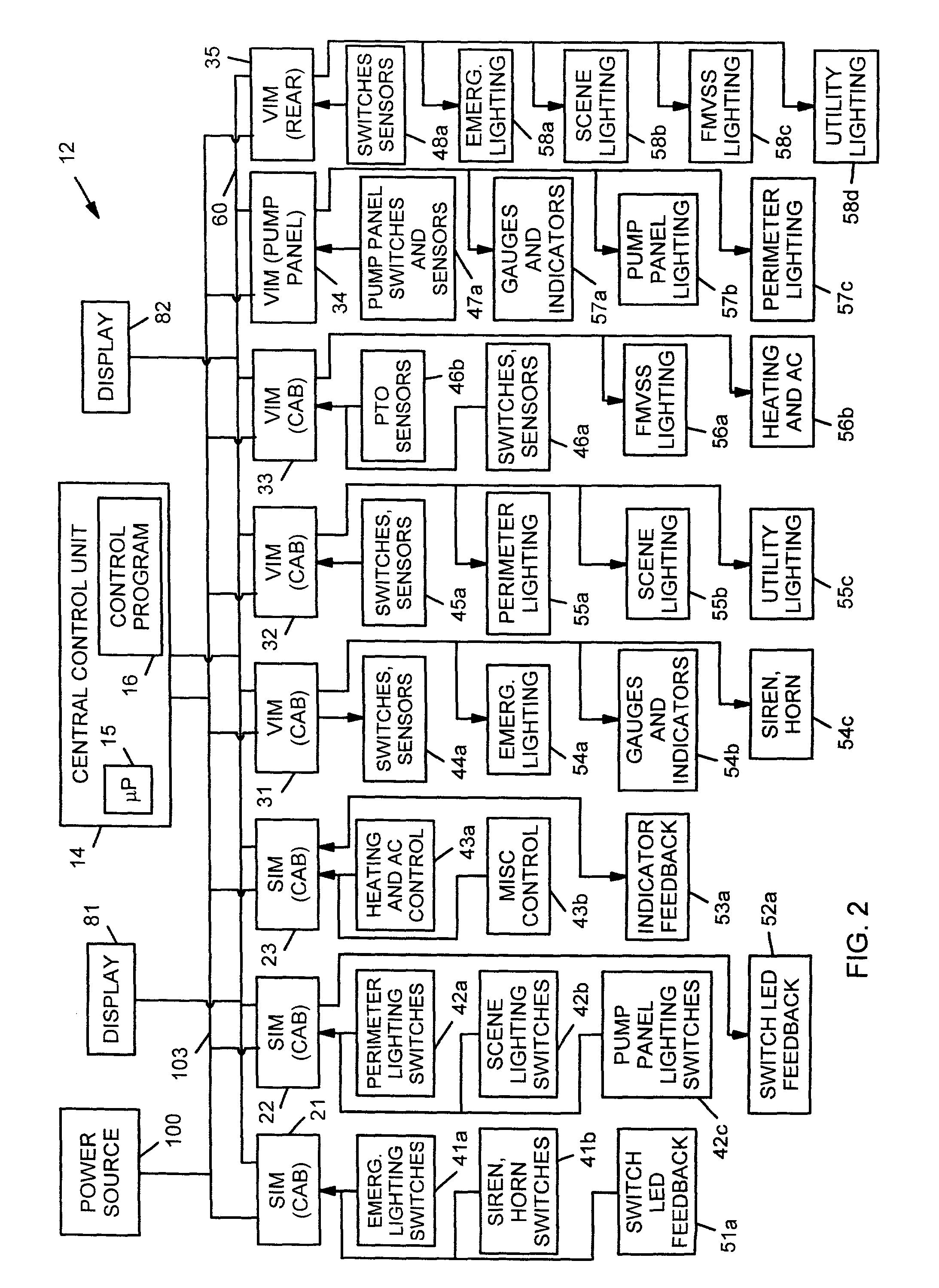

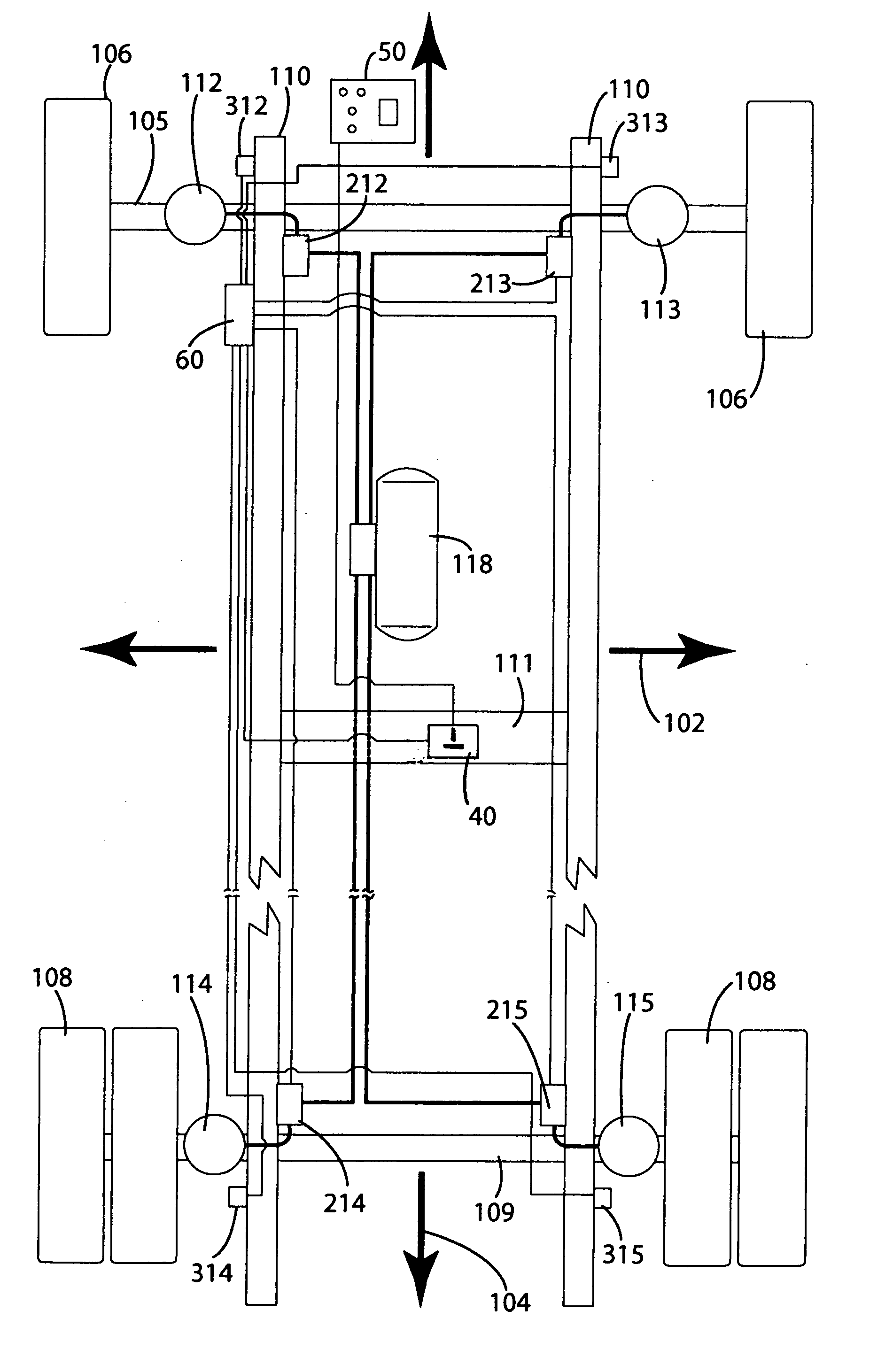

Control system and method for an equipment service vehicle

A control system for a vehicle comprises a power source, a power transmission link, a plurality of input and output devices, a plurality of microprocessor-based interface modules, and a communication network that interconnects the interface modules. The interface modules are also each coupled to respective local subsets of the input and output devices. Each of the interface modules collects input status information from the respective local subset of the input devices and transmits the input status information over the communication network to the remaining interface modules.

Owner:OSHKOSH CORPORATION

Military vehicle having cooperative control network with distributed I/O interfacing

A power distribution and control system for a military vehicle comprises a power source, a power transmission link, a plurality of input and output devices, a plurality of microprocessor-based interface modules, and a communication network that interconnects the interface modules. The interface modules are also each coupled to respective local subsets of the input and output devices so as to permit distributed data collection from the input devices and distributed power distribution to the output devices. Each of the interface modules collects input status information from the respective local subset of the input devices and broadcasts the input status information over the communication network to each of the remaining ones of the interface modules. Each of the remaining ones of the interface modules receive the input status information and locally store the input status information.

Owner:OSHKOSH CORPORATION

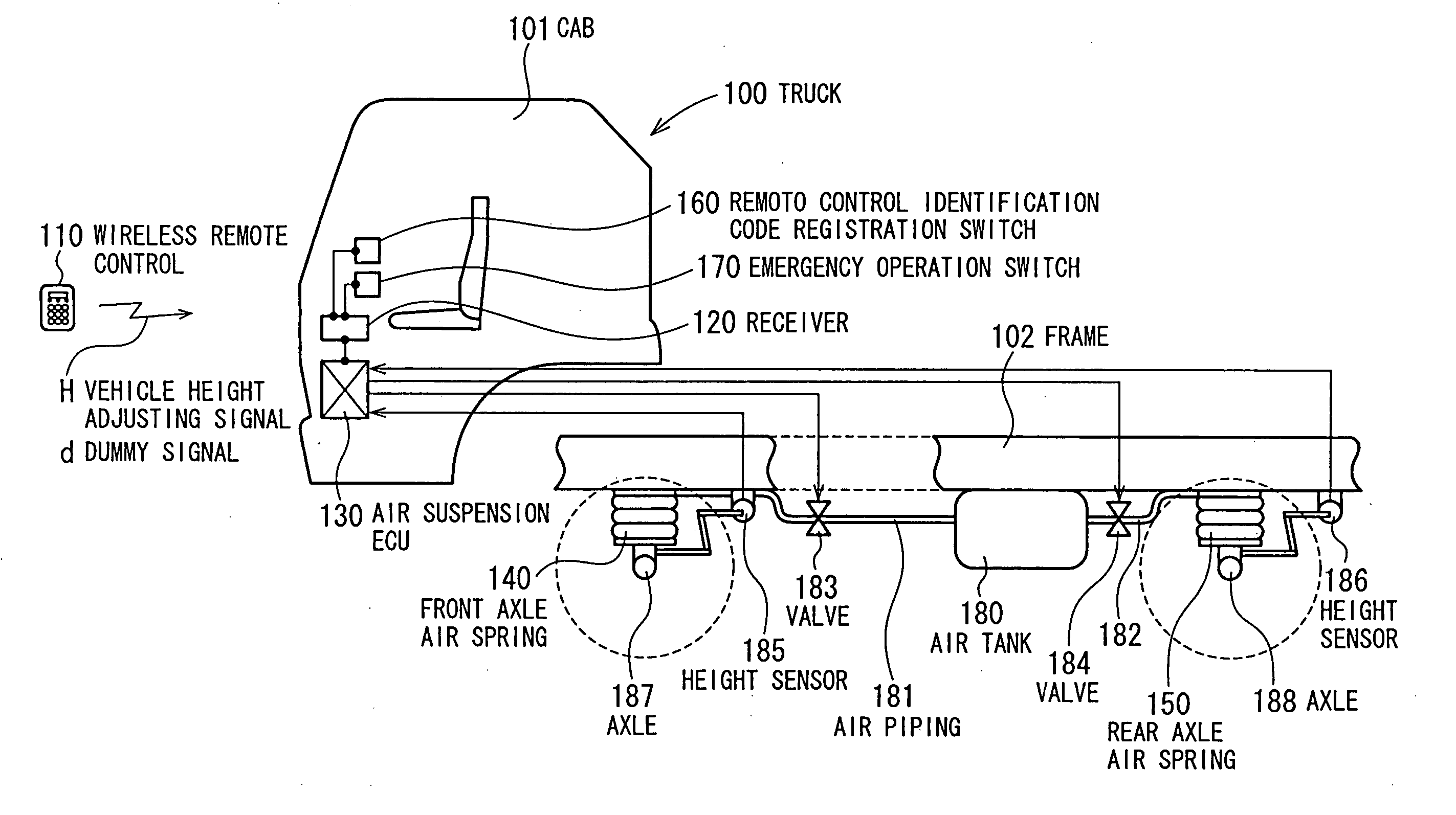

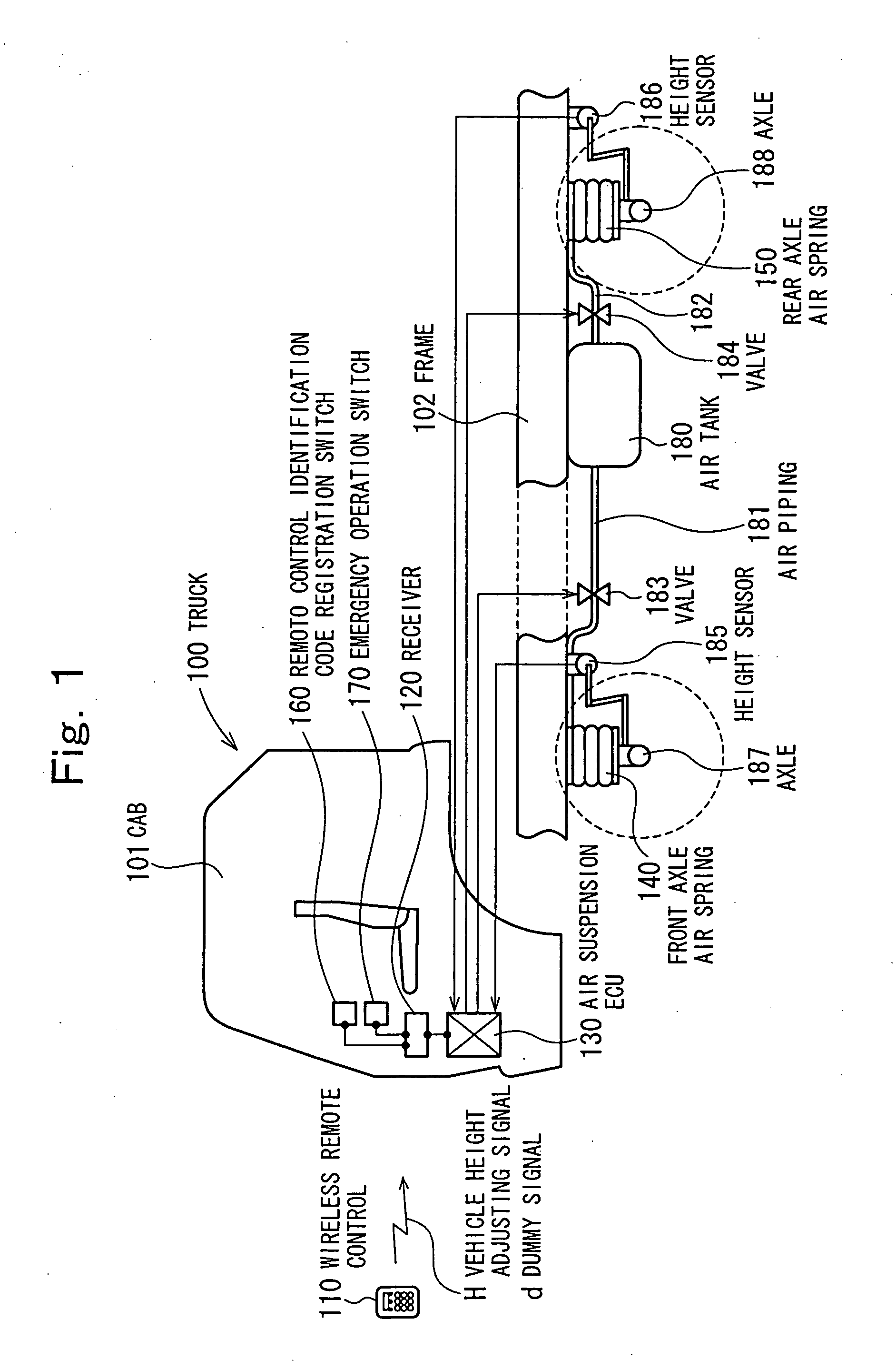

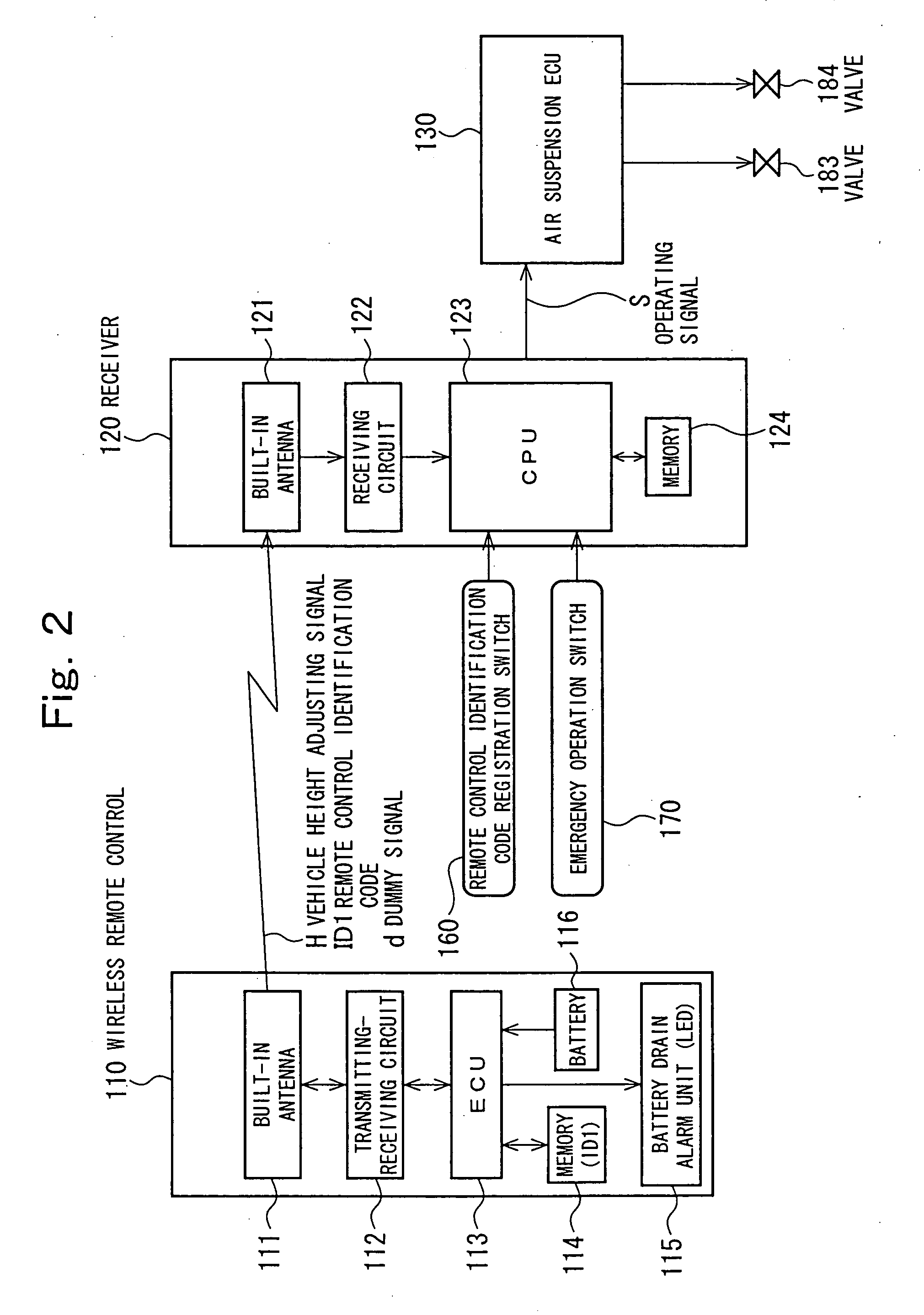

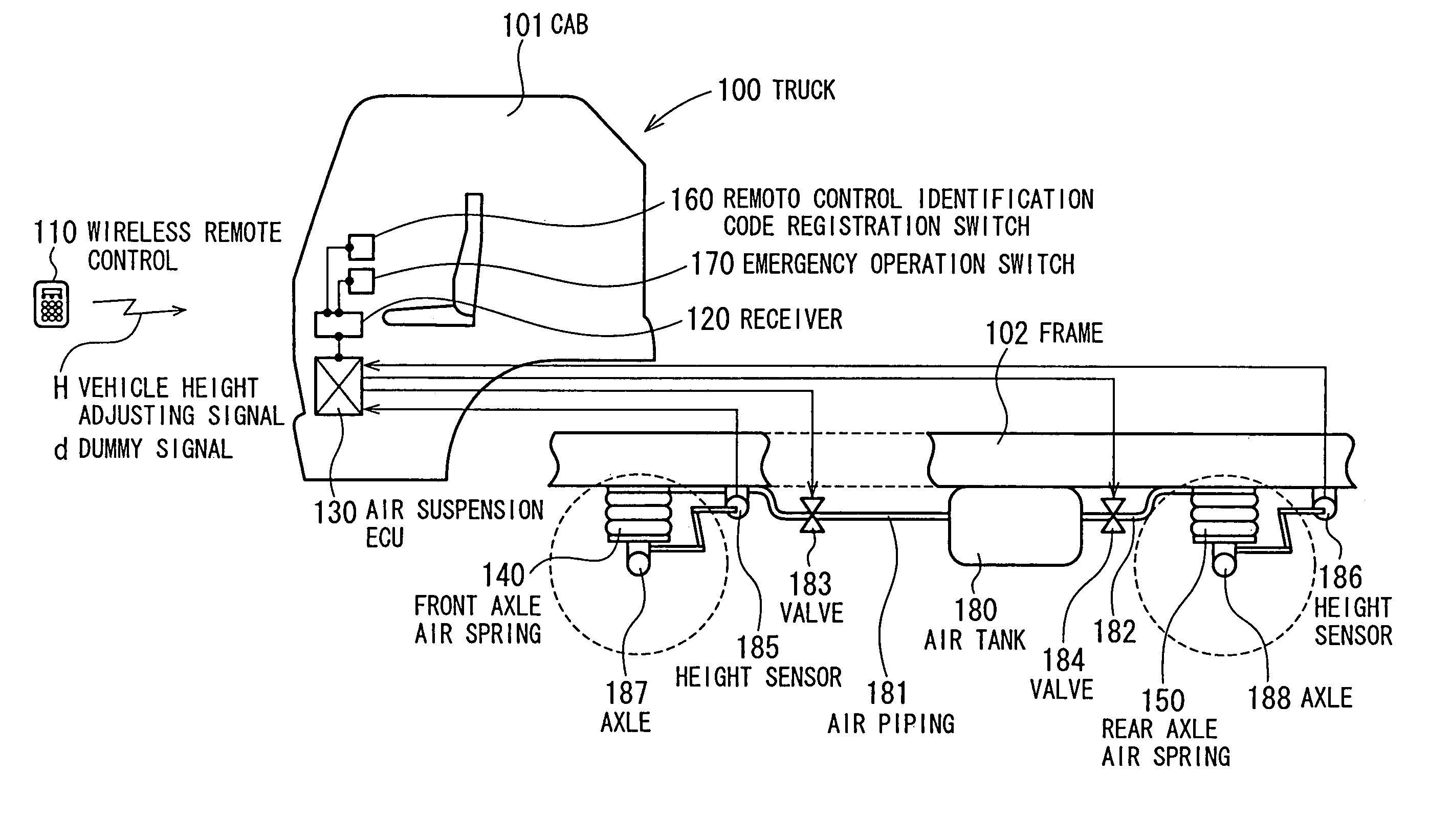

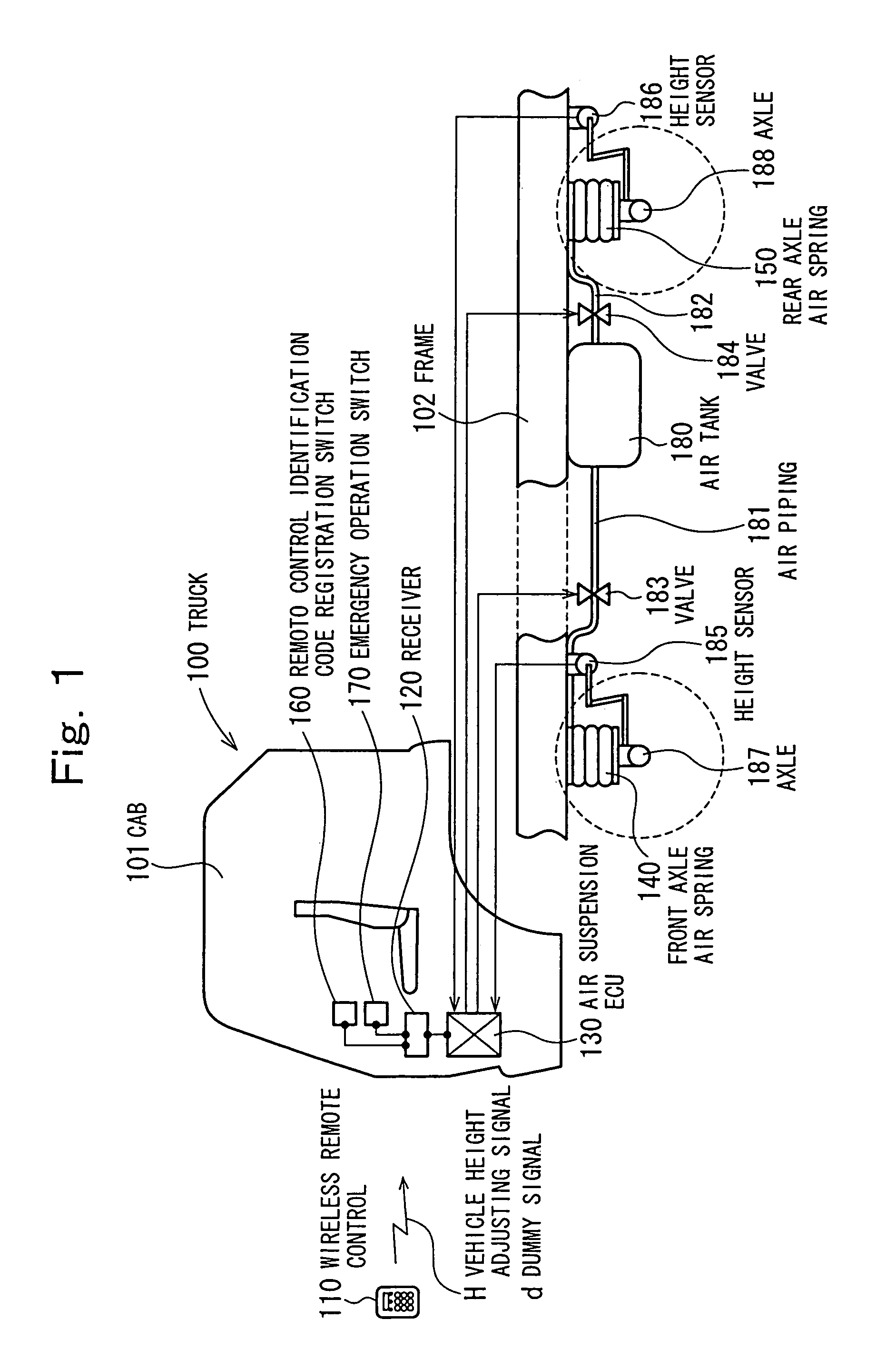

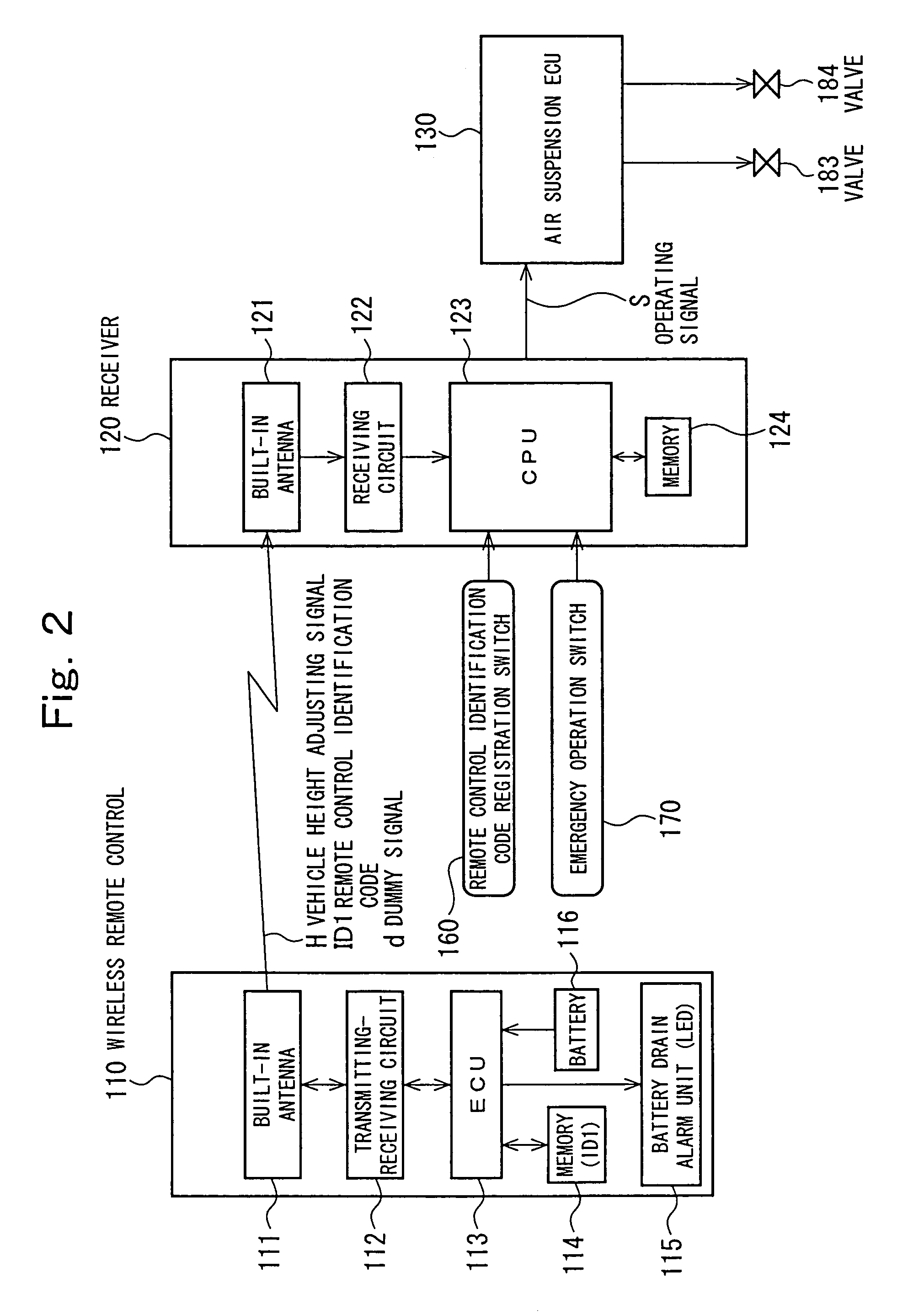

Vehicle height adjusting apparatus

InactiveUS20050110229A1Improve efficiencyReduce riskDigital data processing detailsAnimal undercarriagesRemote controlAir spring

To improve operability for vehicle height adjustment, while ensuring safety, in a vehicle such as a truck, a wireless remote control radio-transmits a vehicle height adjusting signal tagged with a remote control identification code. The remote control identification code is preregistered in a receiver, which, upon receipt of the vehicle height adjusting signal tagged with the remote control identification code, takes in the vehicle height adjusting signal. According to information contained in the received vehicle height adjusting signal, an air suspension ECU controls supply and discharge of compressed air for air springs to adjust the vehicle height. When an emergency operation switch is operated, the vehicle height adjusting signal from the wireless remote control is disabled, and vehicle height adjustment is preferentially made based on a switching signal from the emergency operation switch.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

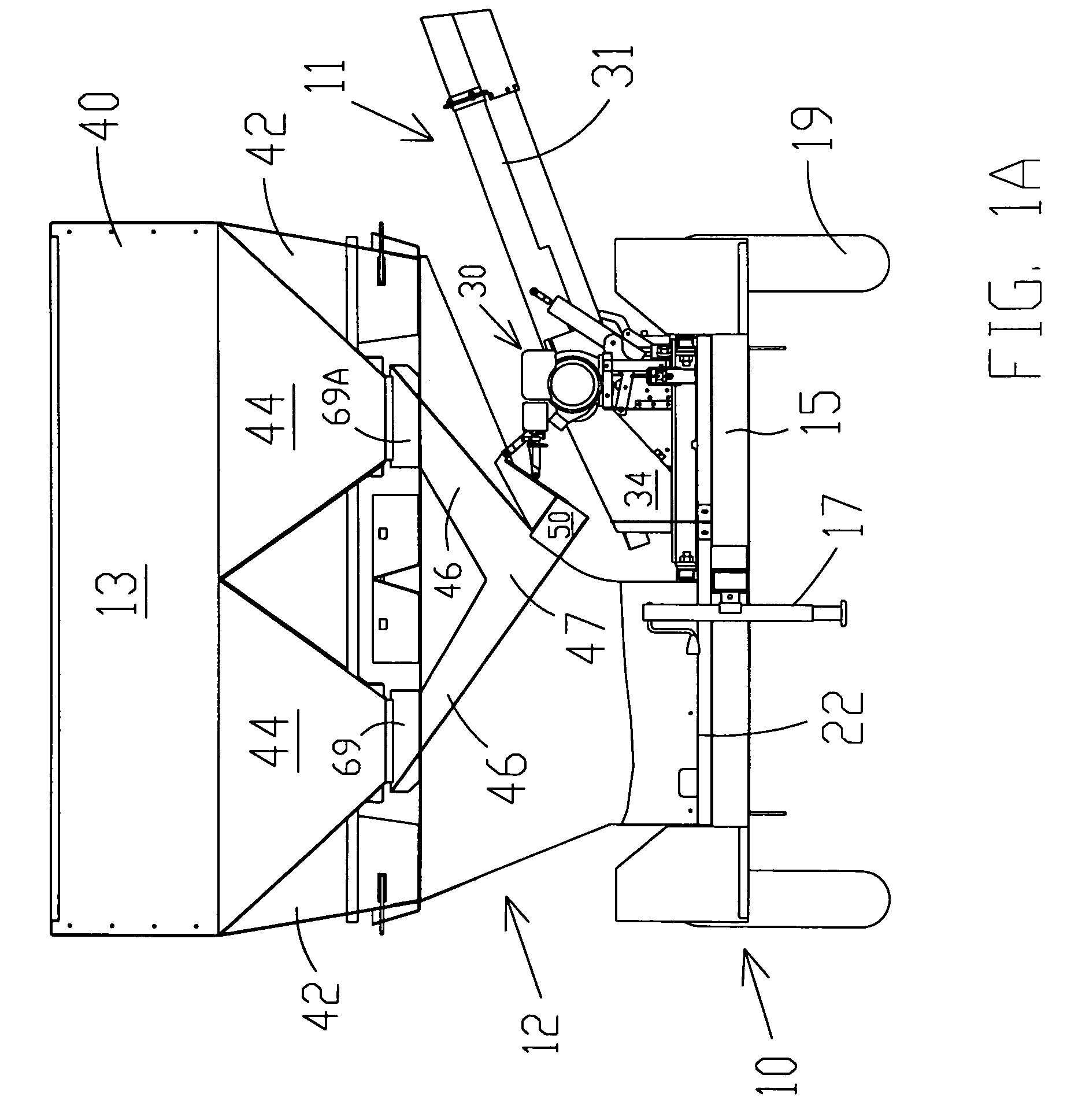

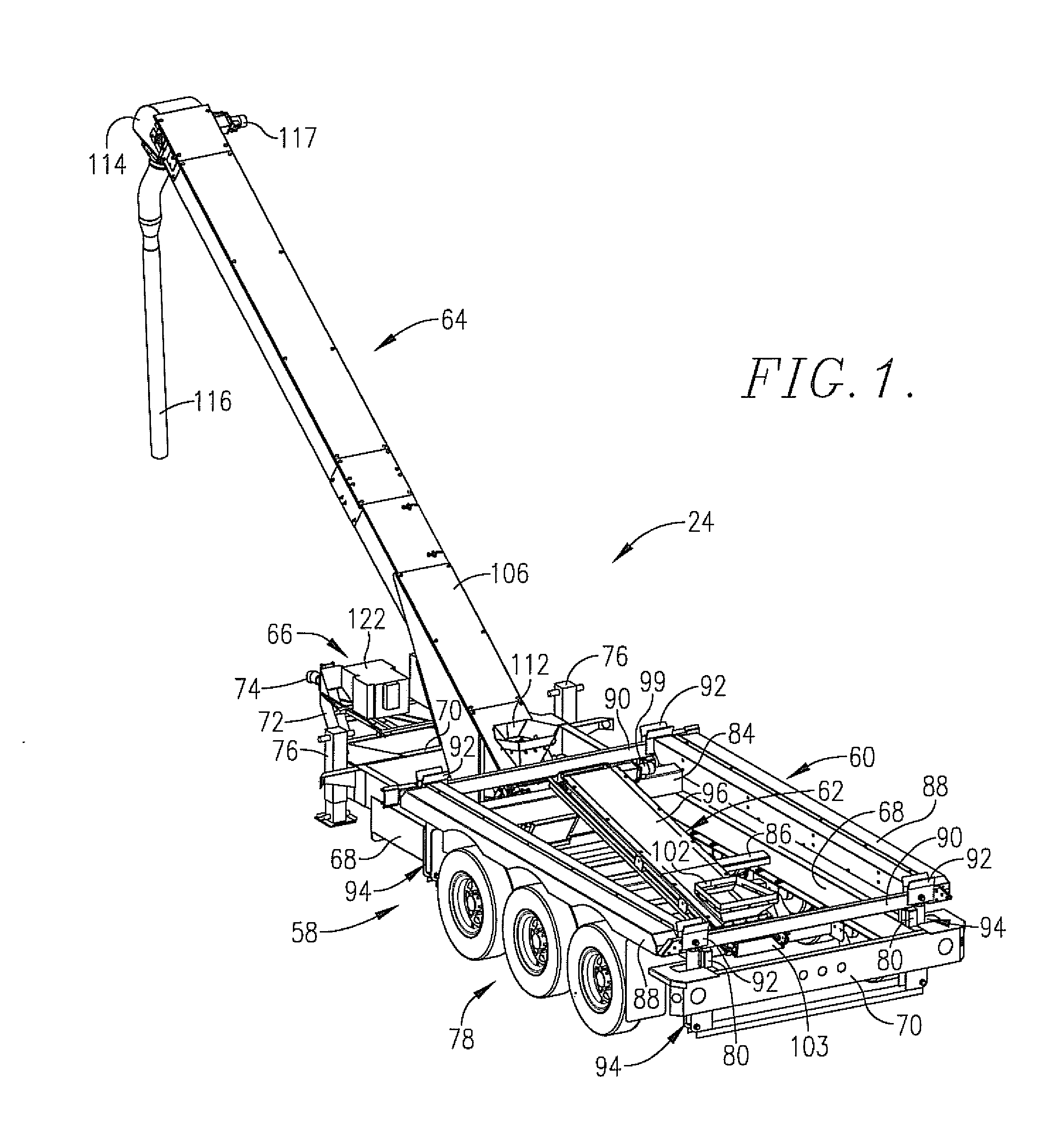

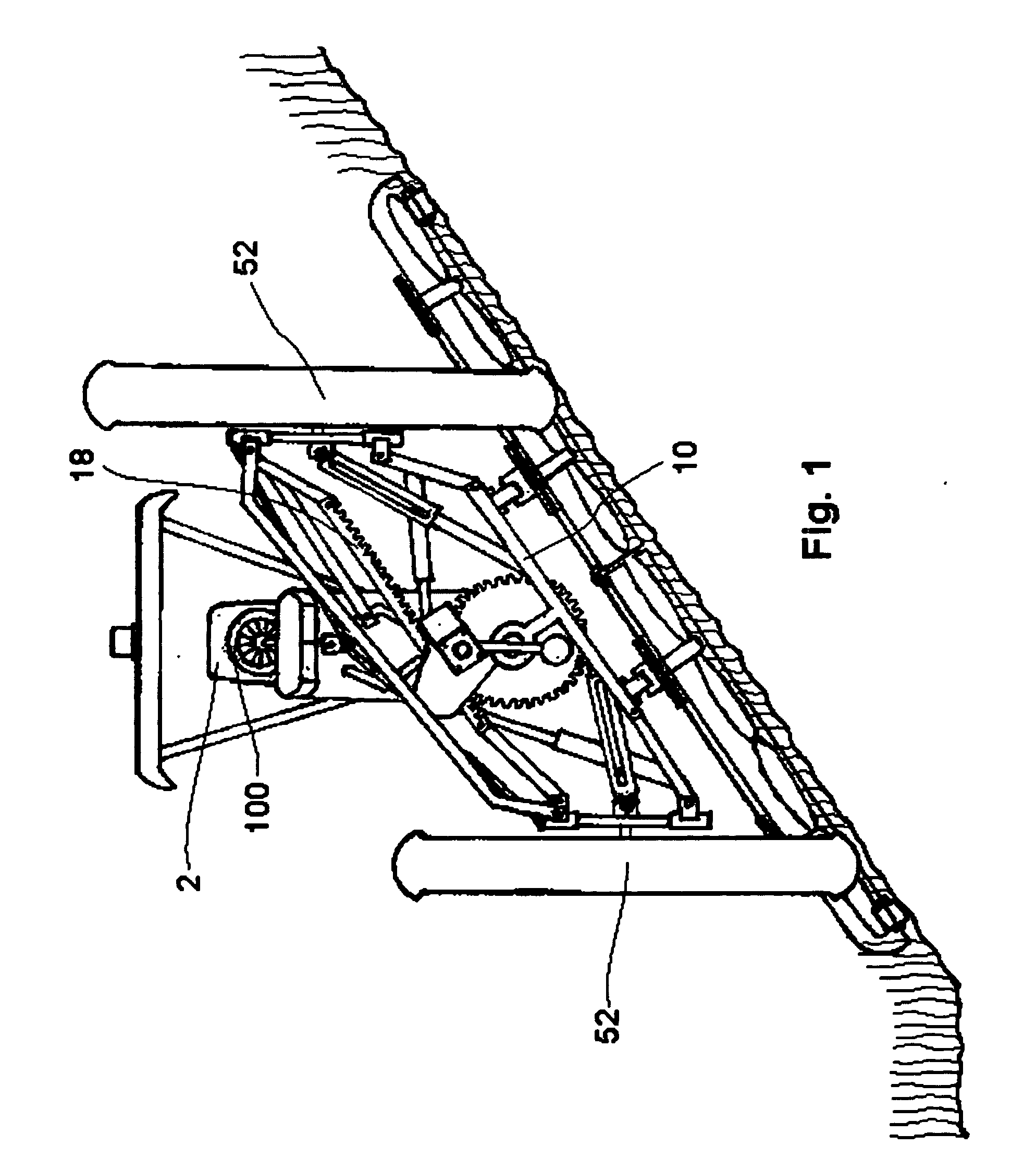

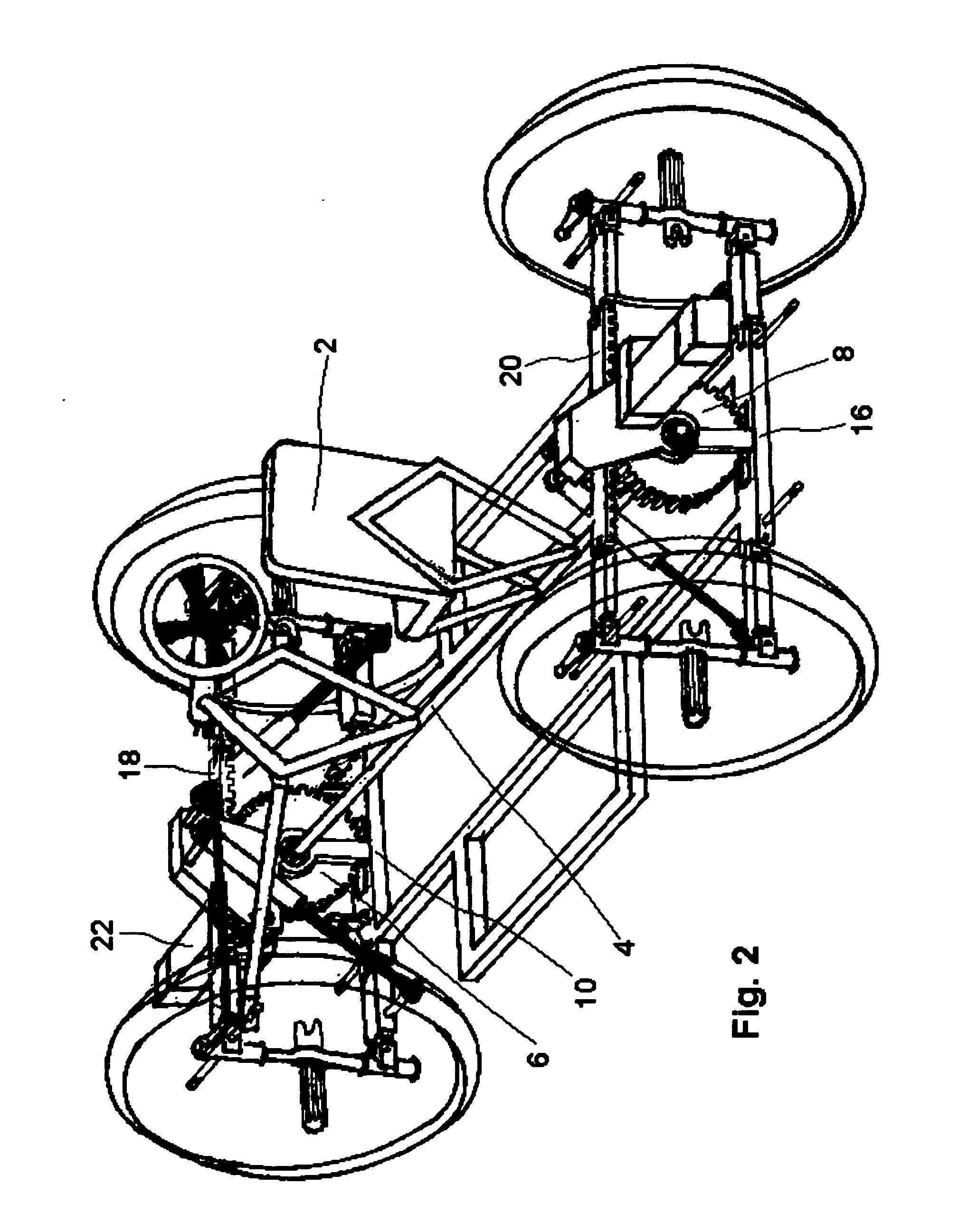

Agricultural seed tender with modular storage containers

ActiveUS20060180062A1Improve economyImprove stabilityConveyorsMovable measuring chambersEngineeringAdemetionine

A trailer having support wheels and a frame adapted to be hitched to a truck, includes a support track extending longitudinally for supporting an unload conveyor. The conveyor is mounted by a turret to the support track and, thus, to the trailer frame, permitting the turret to move in a fore-to-aft direction, as well as to rotate about the vertical for about 180°, providing flexibility in use as well as transport and storage. A support module, carrying at least one storage container is mounted on the trailer frame. The storage containers may be provided in a number of different sizes and they may be arranged in various configurations suiting the user's needs. The turret is positioned along the track beneath a desired seed container, which may then be unloaded by the conveyor to fill a planter seed box or grain drill, or for other seed handling applications.

Owner:MERIDIAN MFG

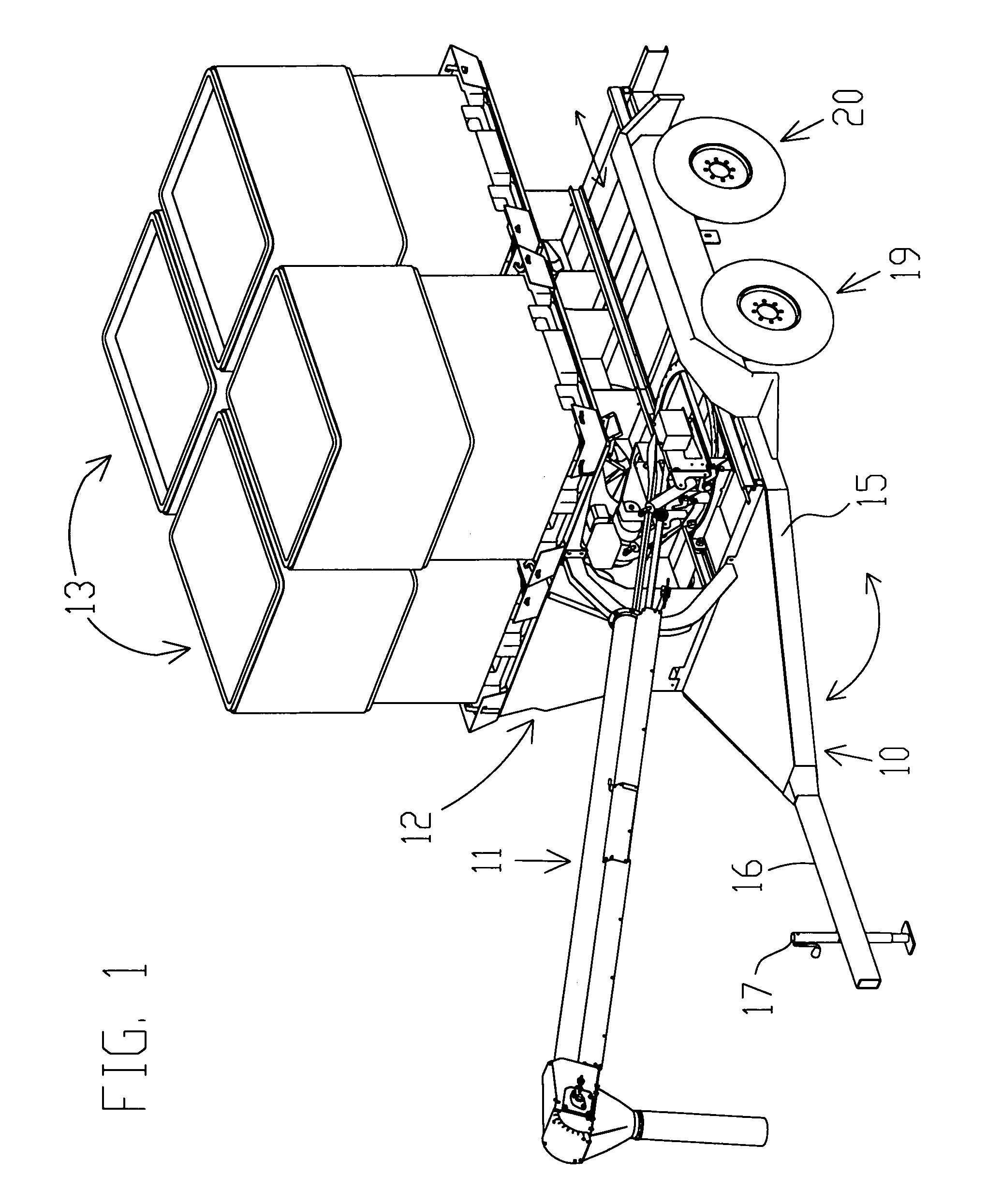

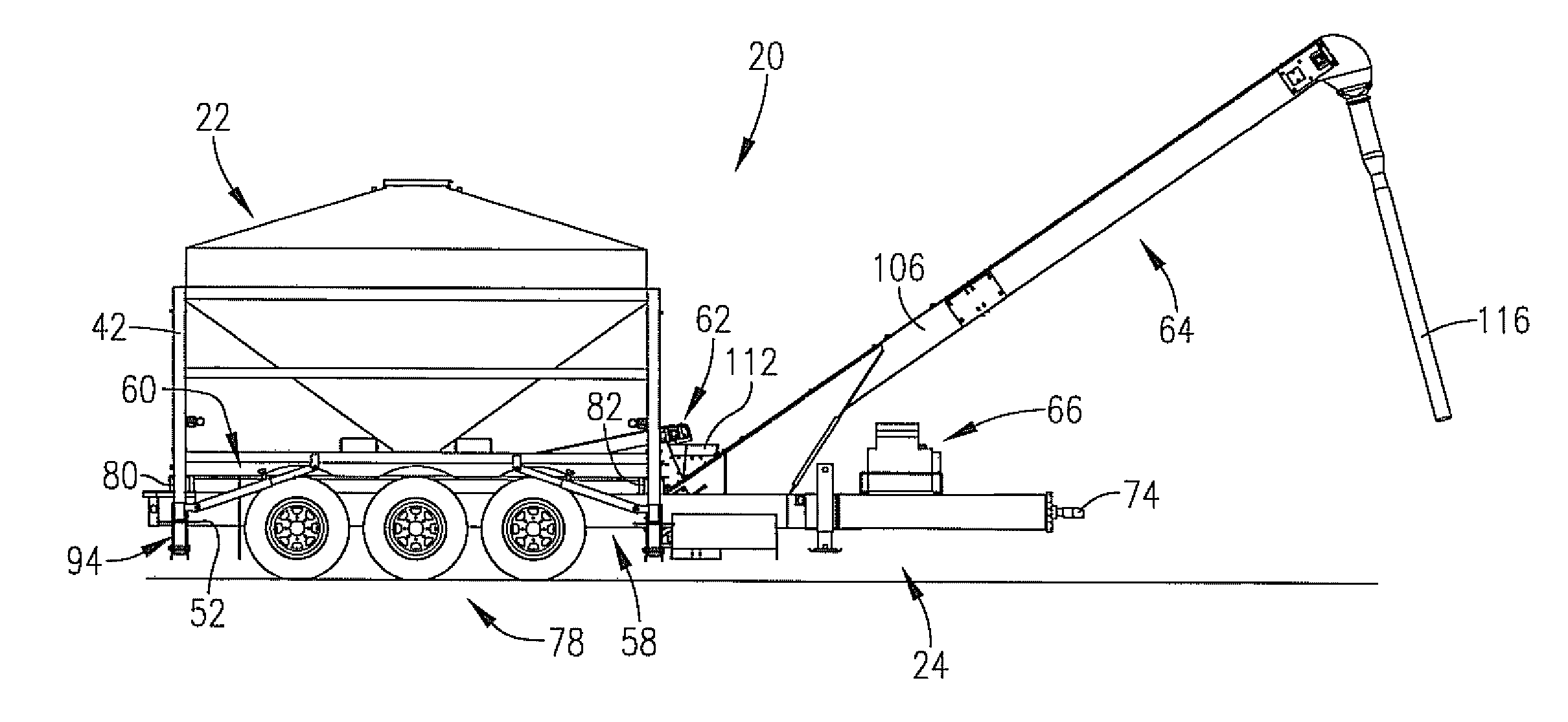

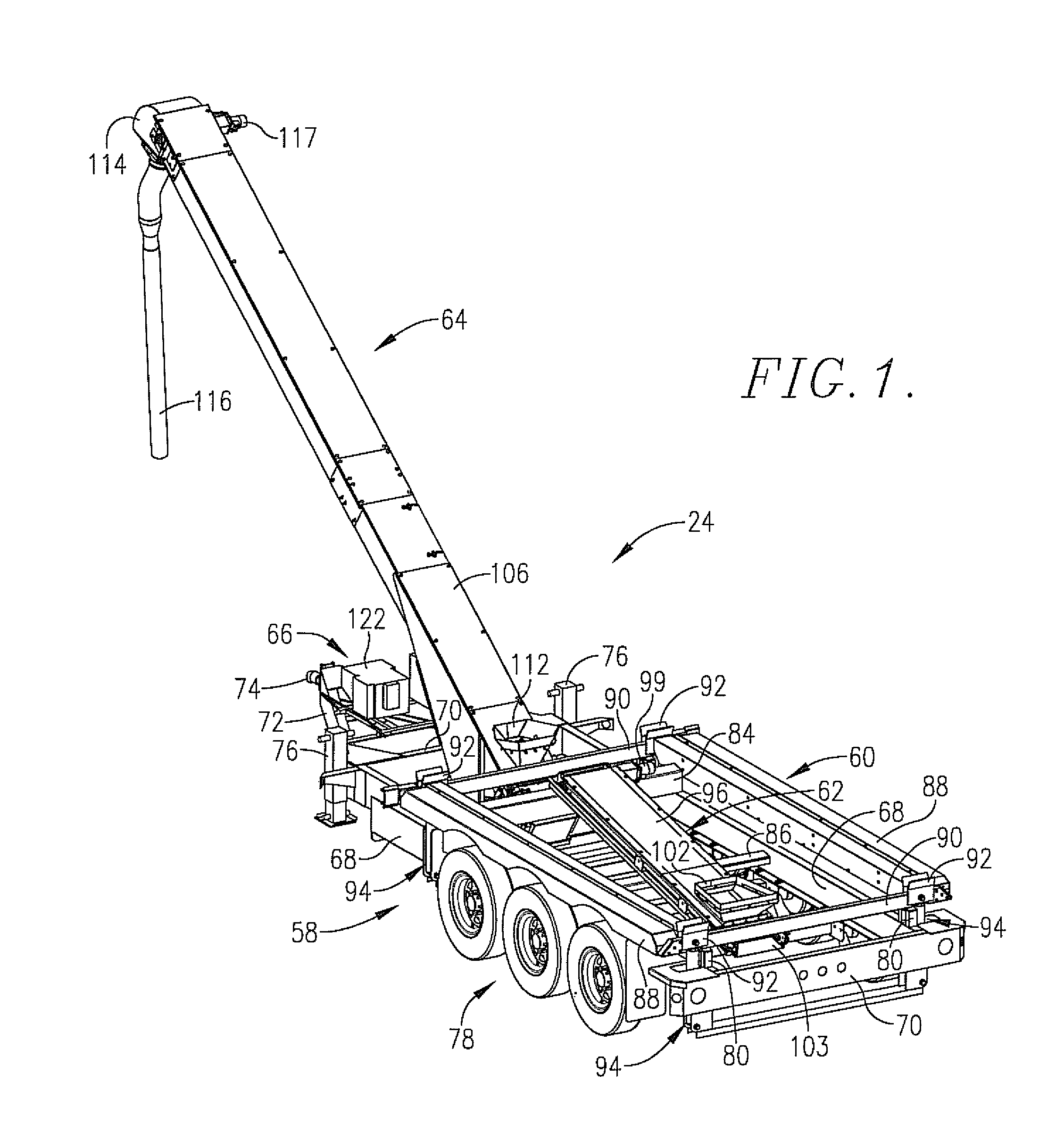

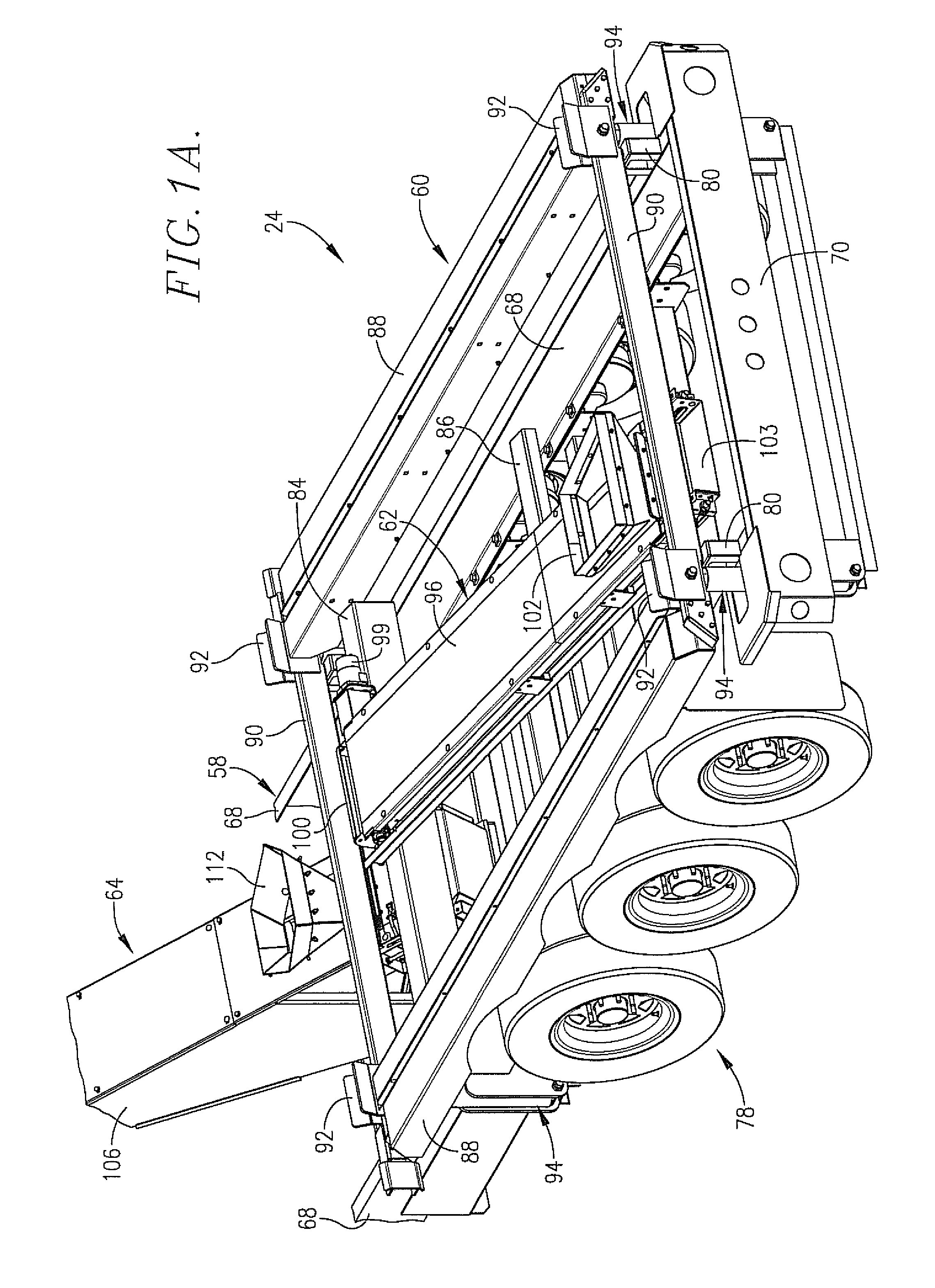

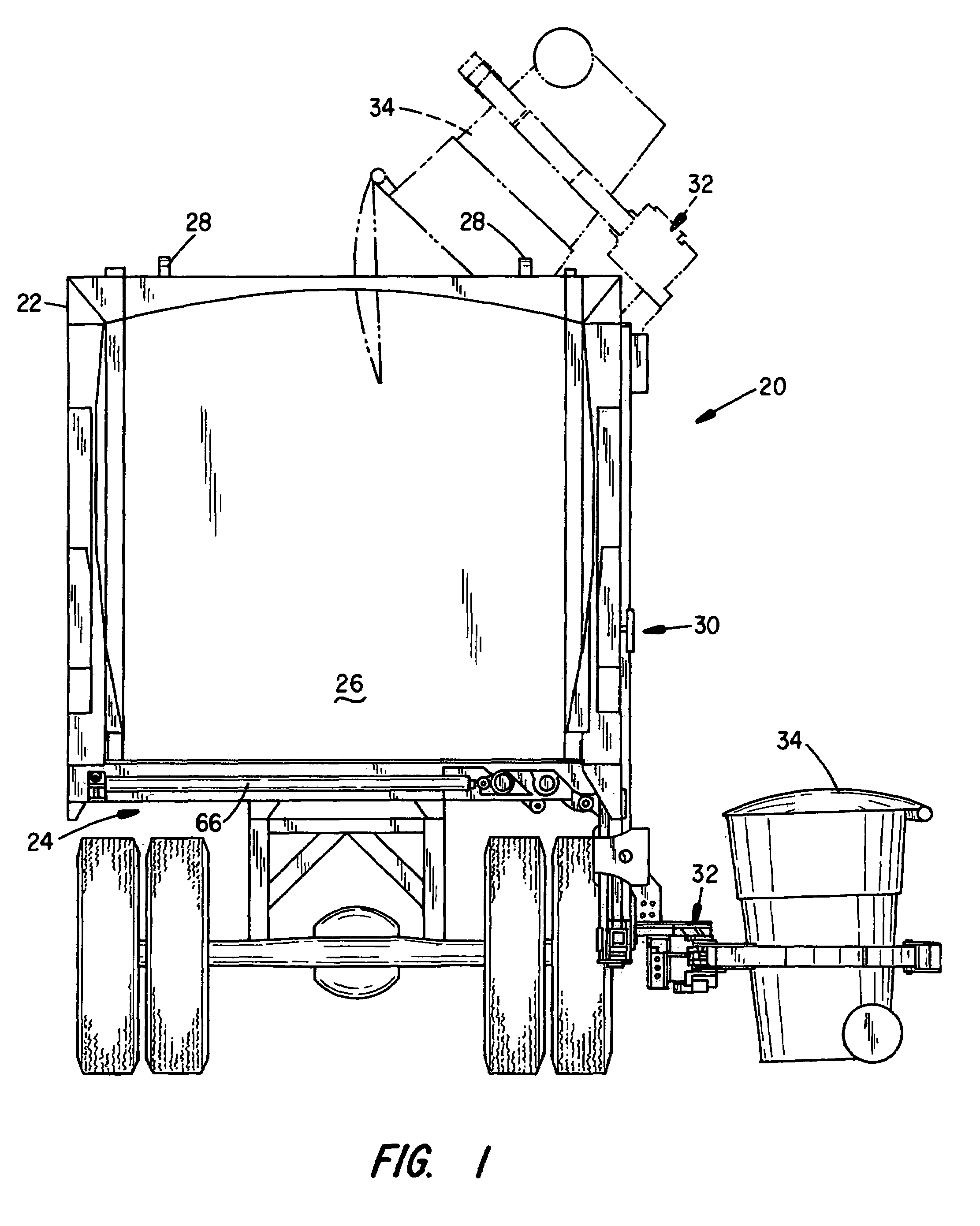

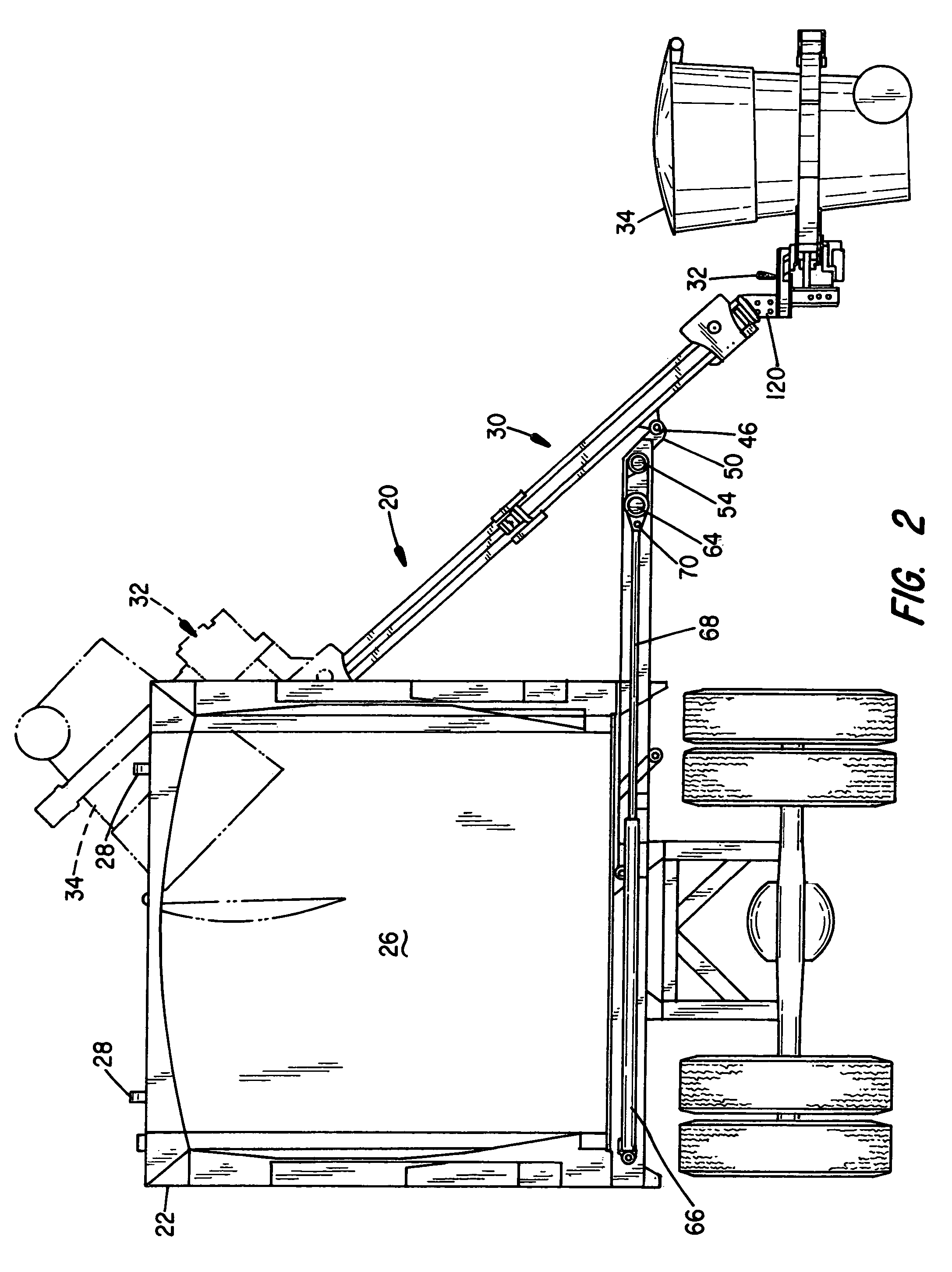

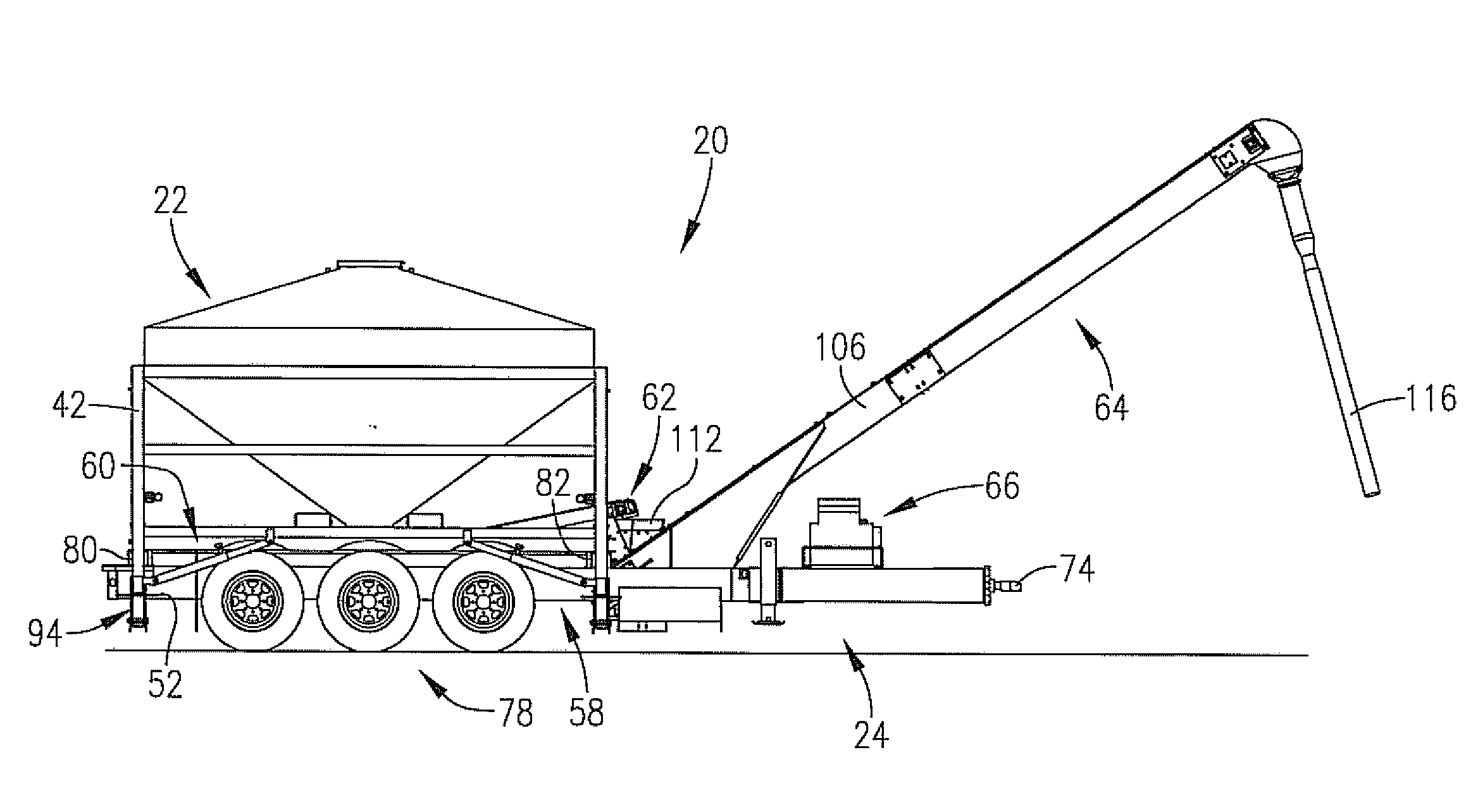

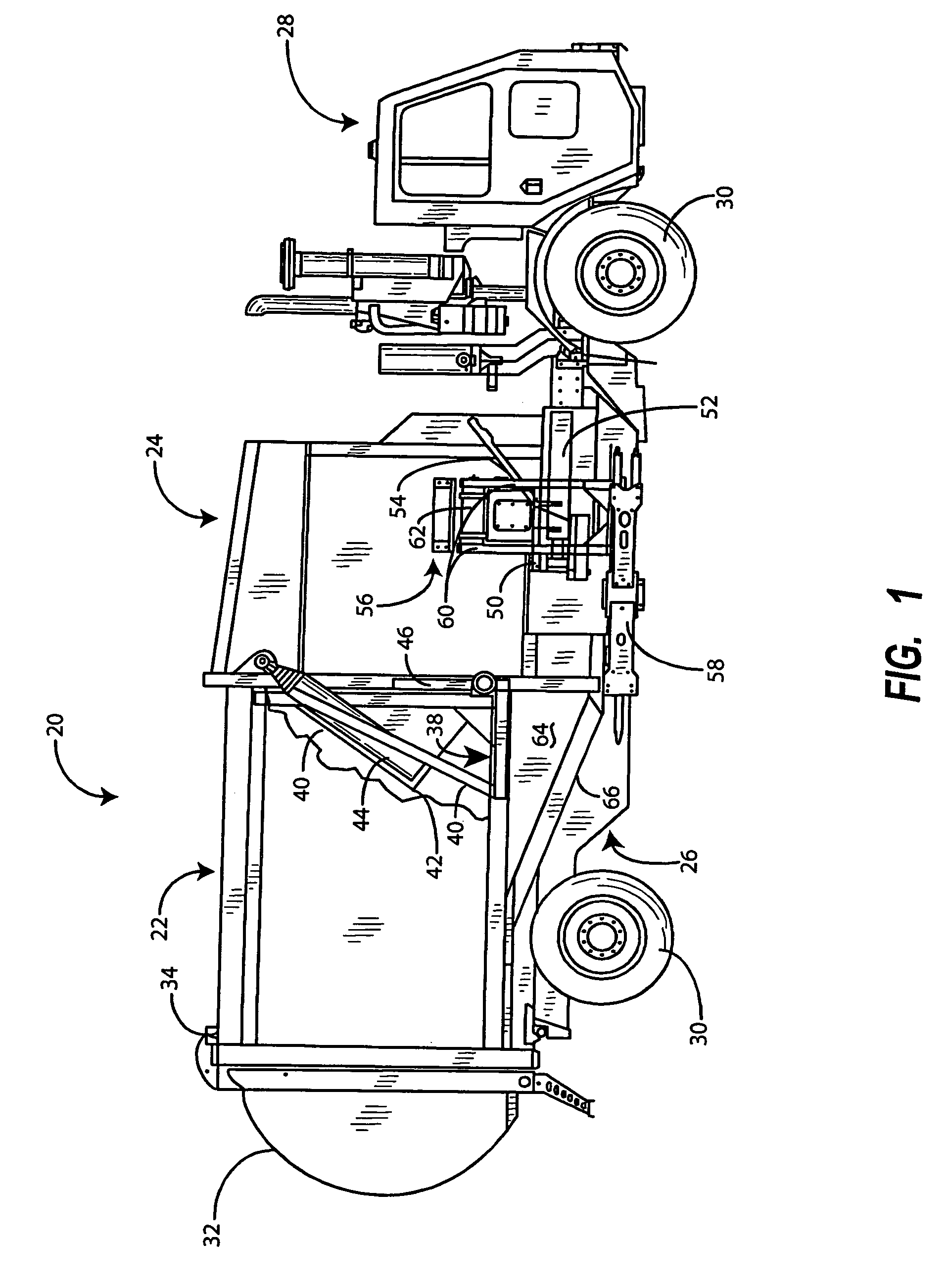

Bulk seed handling system

InactiveUS8573917B2Facilitates transfer and handlingEasy to handleConveyorsFertiliser distributersEngineeringHandling system

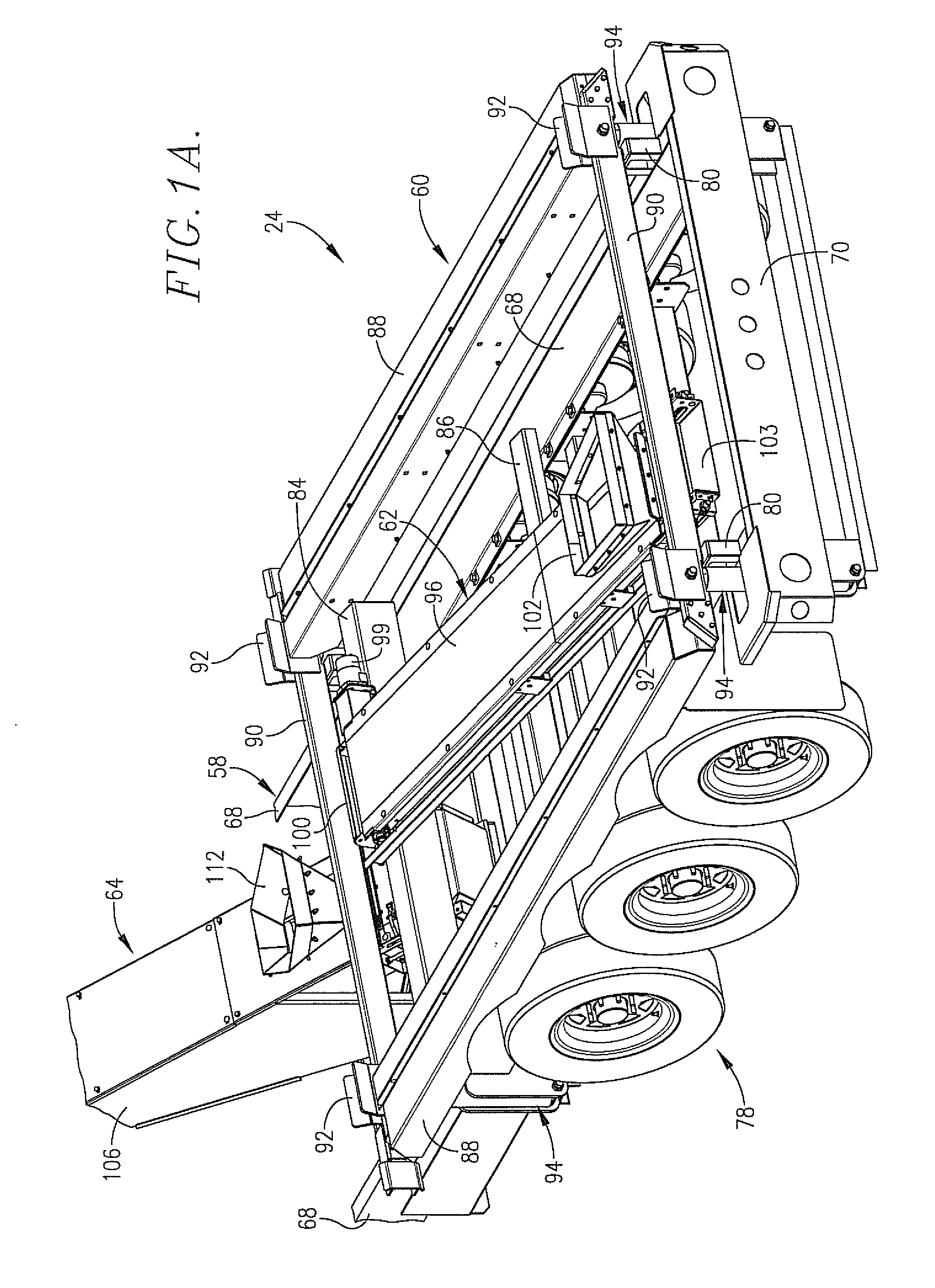

A bulk seed handling system (20) is provided to facilitate seed transfer from a distributor to a farm and then to a planter or the like. The handling system (20) includes one or more upright bin assemblies (22) adapted to be moved in a filled condition, and a trailer (24) designed to move the bin assembly (22) and unload seed therefrom. The bin assembly (22) includes a seed bin (26) having a lower unload opening (34) and supported by a frame assembly (38) including telescopic legs (50) shiftable between a retractable travel position and an extended bin support position. The trailer (24) includes a lift frame (60) operable to engage and elevate the bin assembly (22) for travel with the legs (50) thereof in a retracted position, and a seed-conveying arrangement including an intermediate conveyor (62) and a delivery conveyor (64). At an unloading site, the intermediate conveyor (62) is shifted to an unloading position in communication with the bin unload opening (34) and the delivery conveyor (64) in order to transfer seed from the bin.

Owner:USC

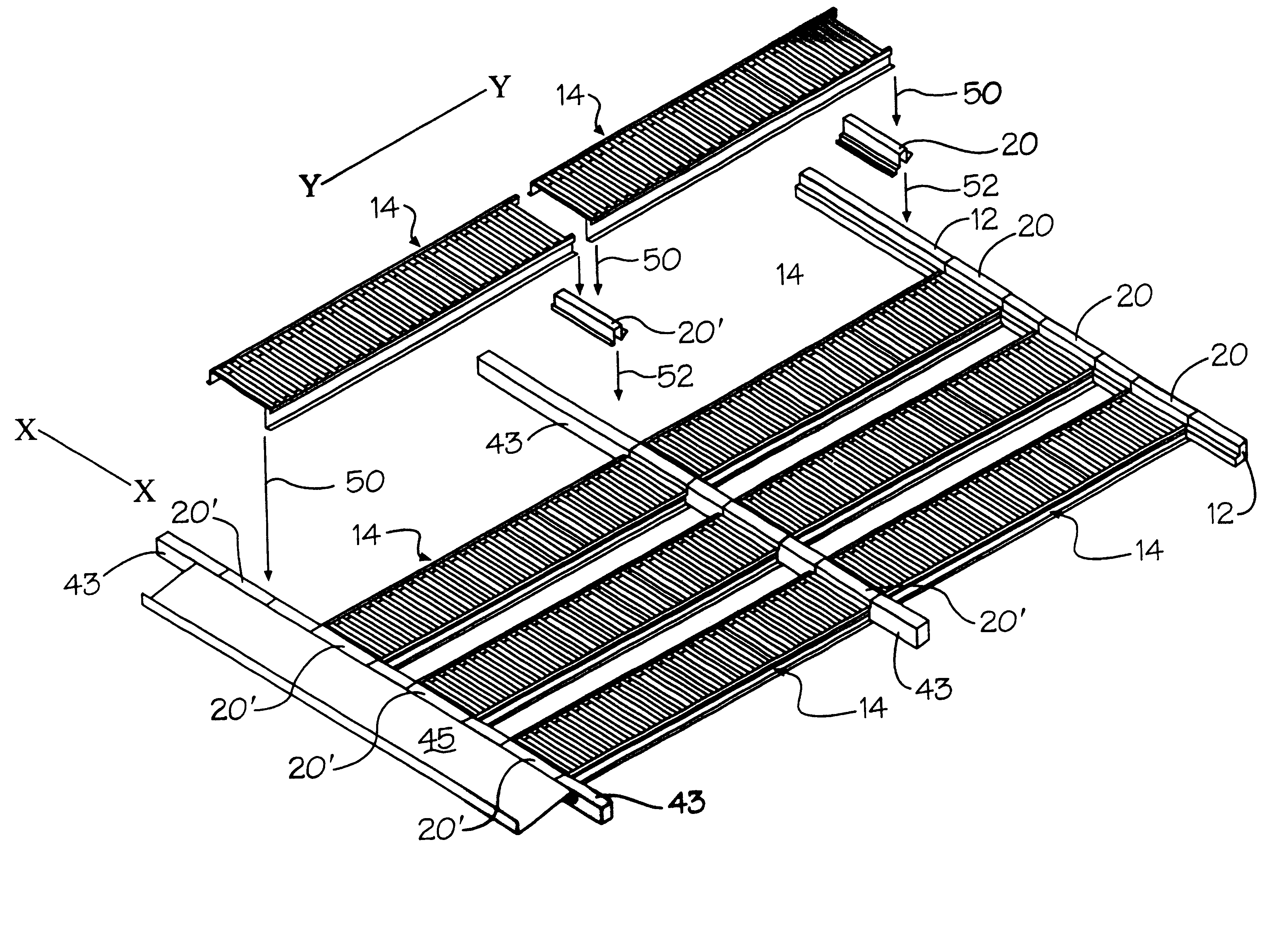

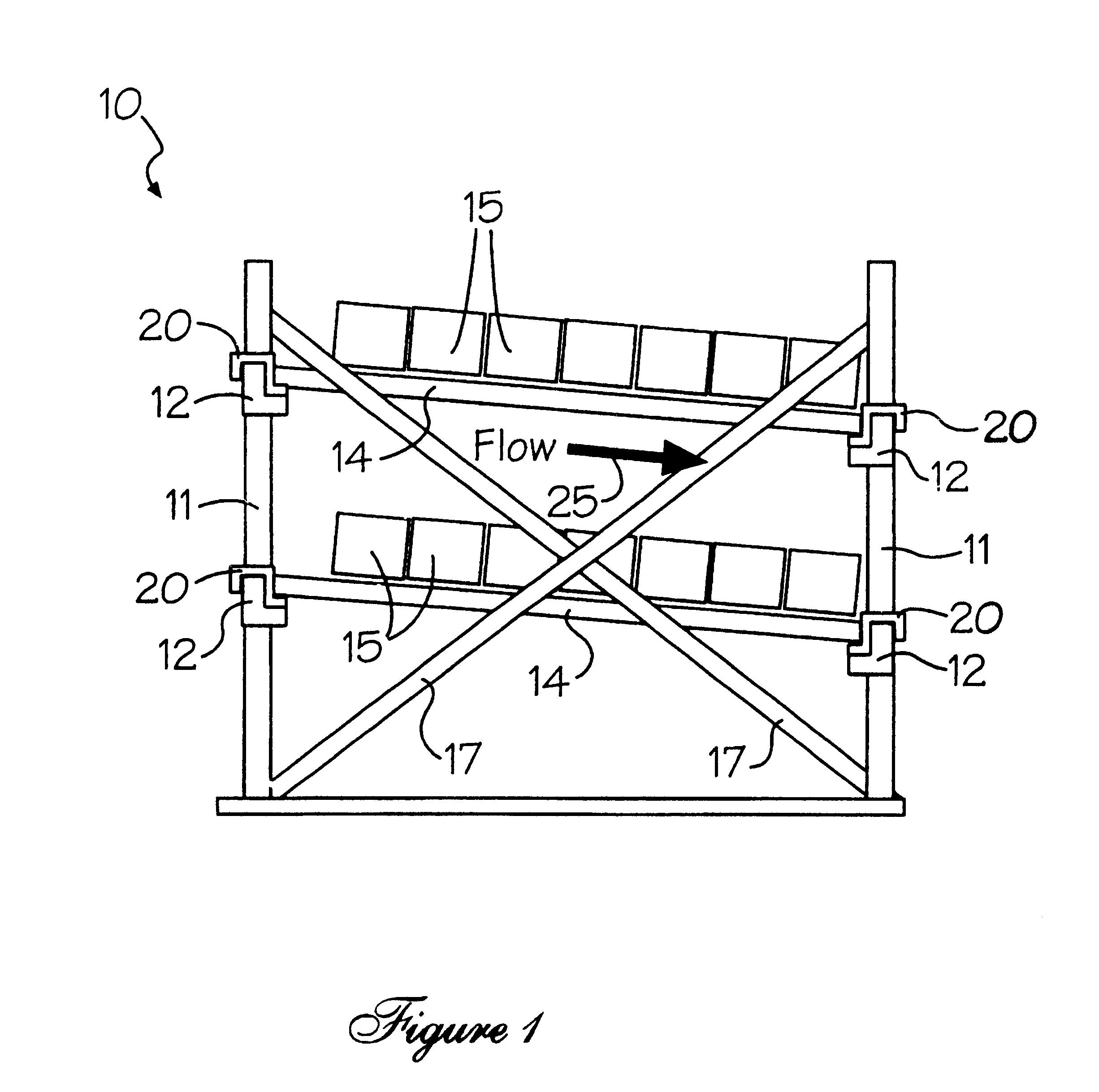

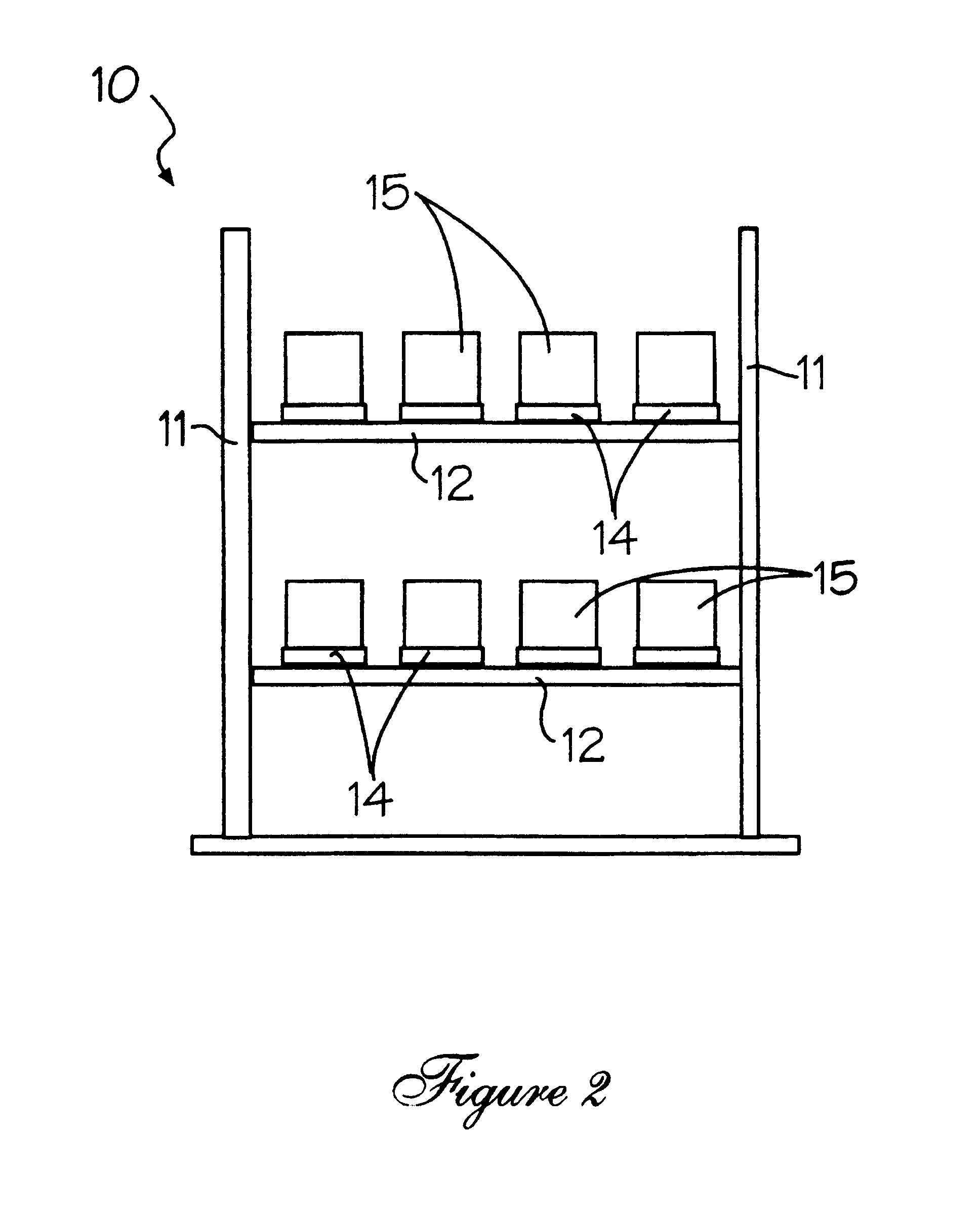

Universal flow track system

InactiveUSRE38517E1Low profileEasy to adjustRefuse receptaclesStorage devicesBraced frameHorizontal axis

The present invention features a universal, low profile, expandable flow track system that can be drop-load mounted to almost any supporting frame or pallet rack. The flow track system of the invention features a flow track that mounts flush with its end supports, and is infinitely adjustable along both the horizontal axis and depth axis of the storage frame. The flow track is quickly assembled to, adjusted upon, and removed from, the storage frame.

Owner:UNEX CONVEYING SYST

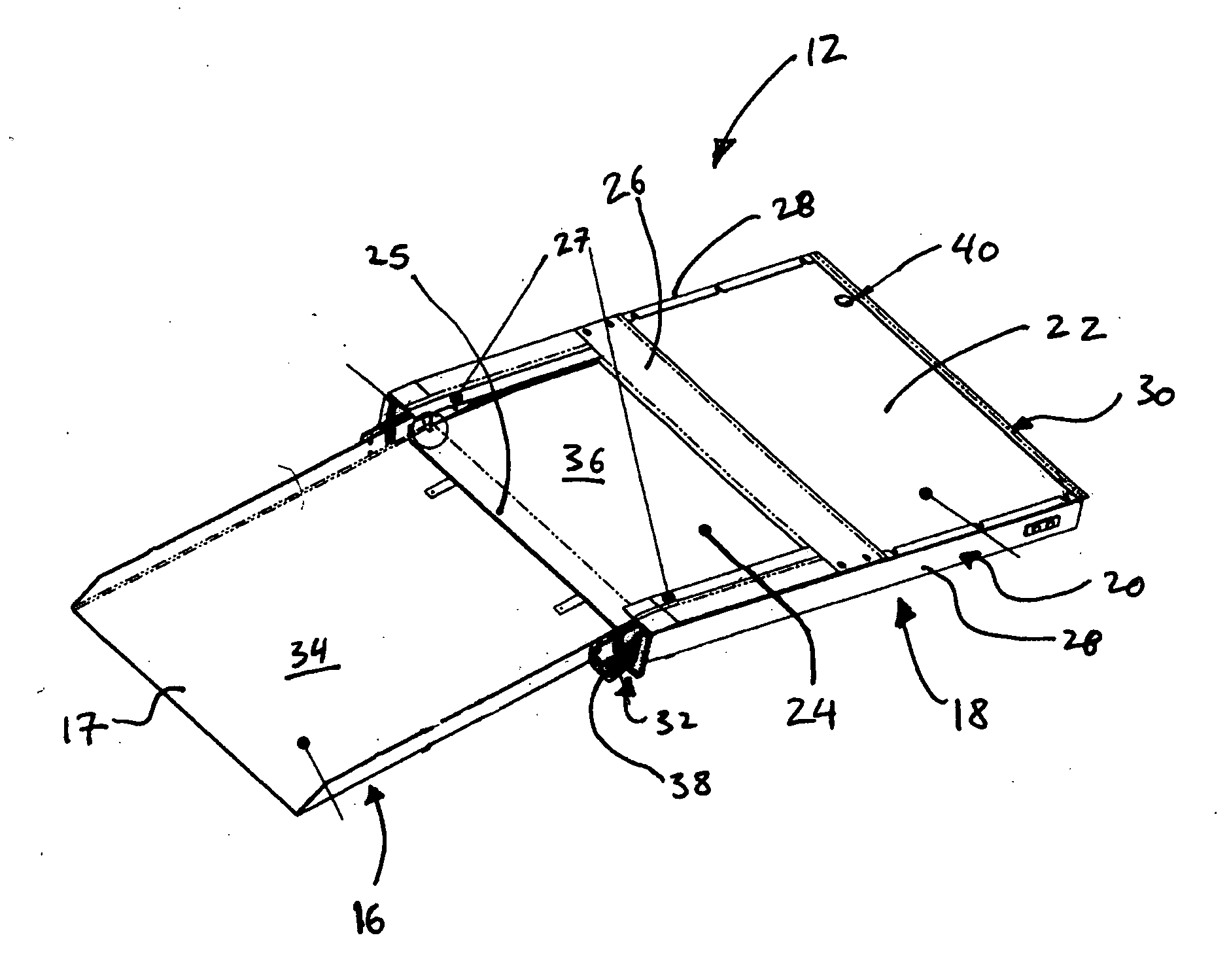

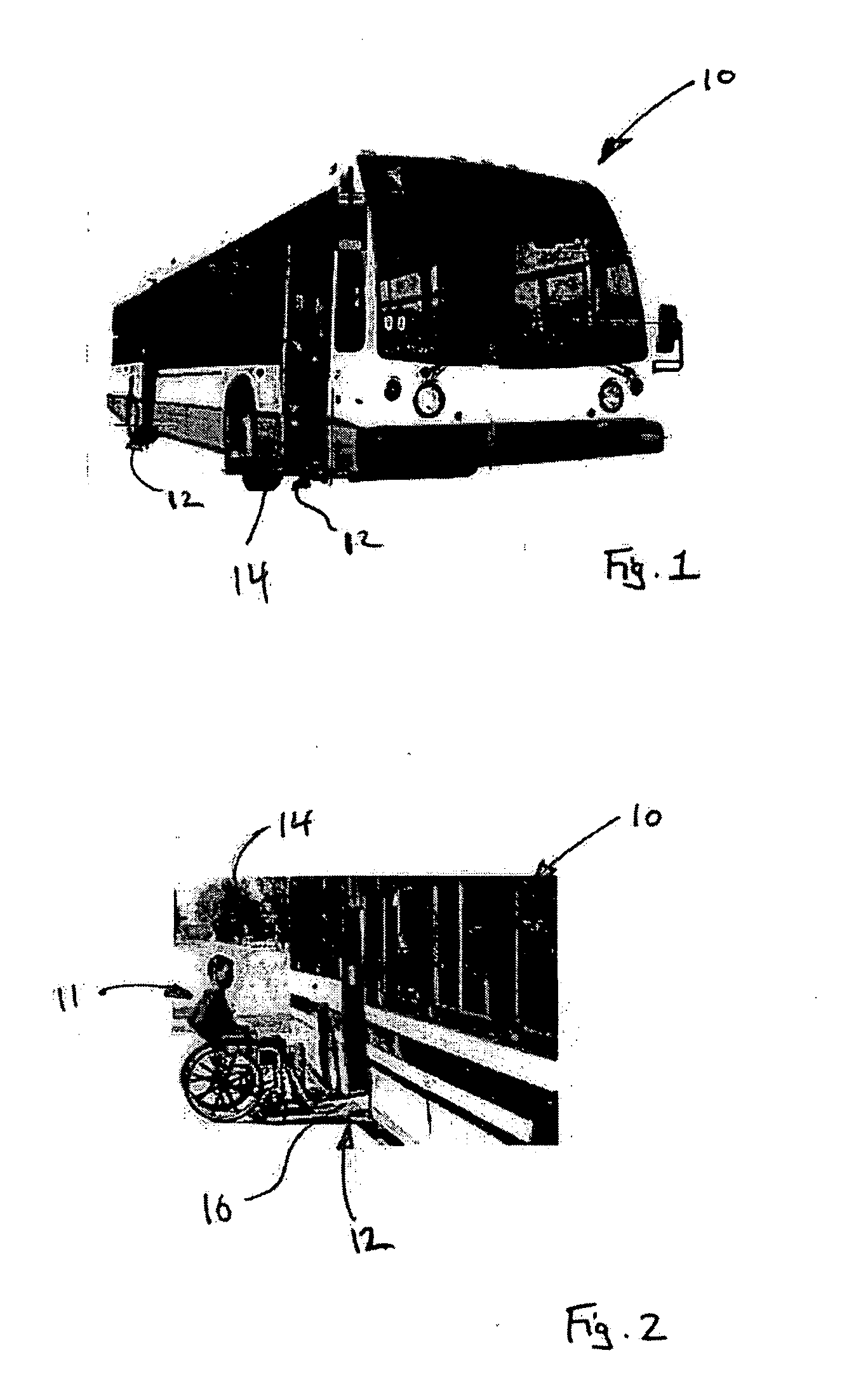

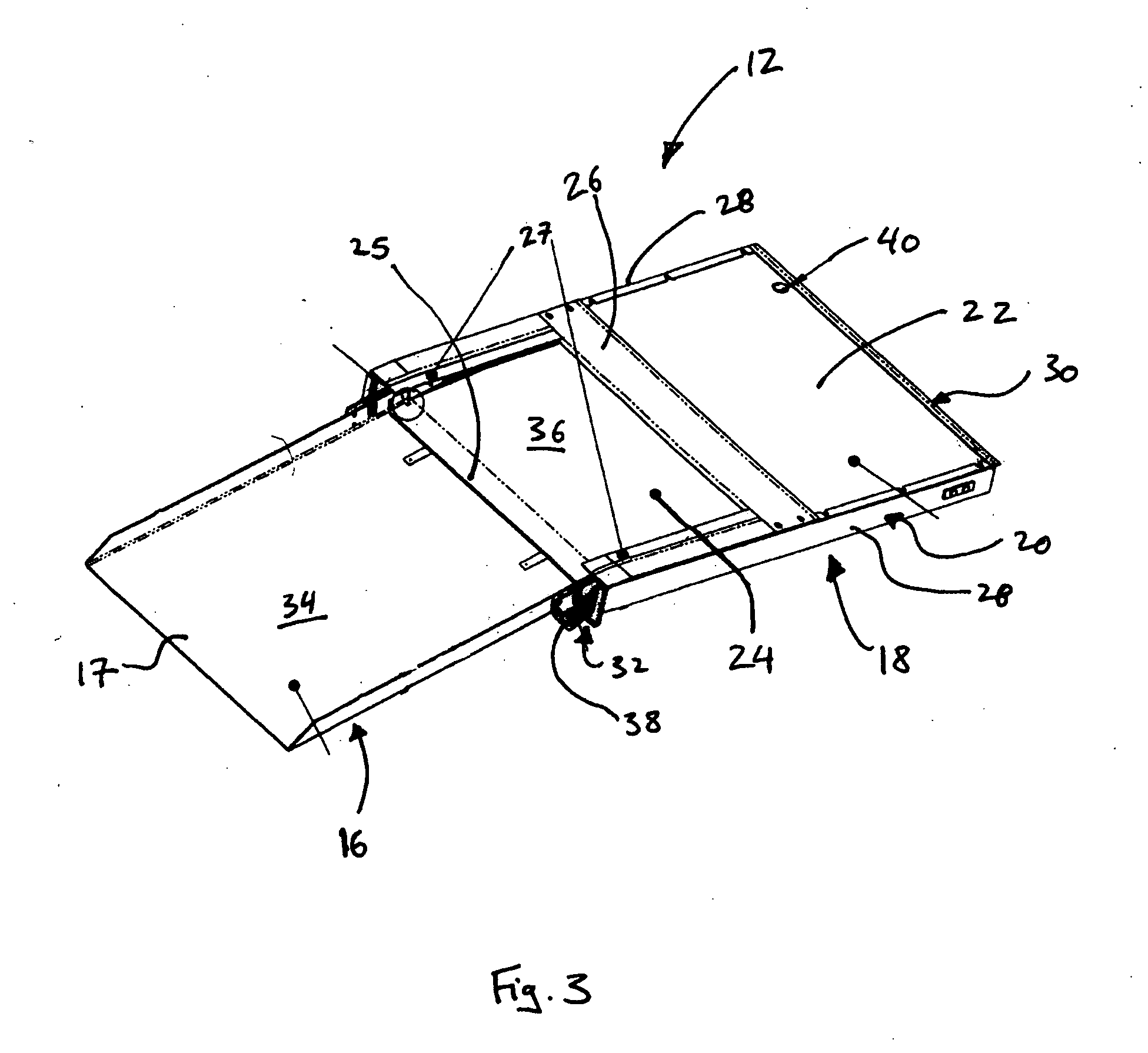

Vehicle ramp assembly

InactiveUS20060245883A1Refuse receptaclesLoading/unloading vehicle arrangmentDrive shaftElectric machinery

A ramp assembly for use in a vehicle provides access thereto by users having reduced mobility. The ramp assembly comprises a ramp platform displaceable relative to a mounting structure between a retracted position and a deployed position. A drive mechanism is disposed within the mounting structure and operable to displace the ramp platform between the retracted and the deployed positions. The drive mechanism includes at least a drive shaft and a bidirectional motor unit selectively actuable to rotate the drive shaft in a first direction for deploying the ramp platform and a second opposed direction for retracting the ramp platform. The drive mechanism includes a pair of flexible transmission elements each interconnecting the drive shaft with a lateral edge of the ramp platform, for displacement thereof relative to the mounting structure.

Owner:NOVA BUS

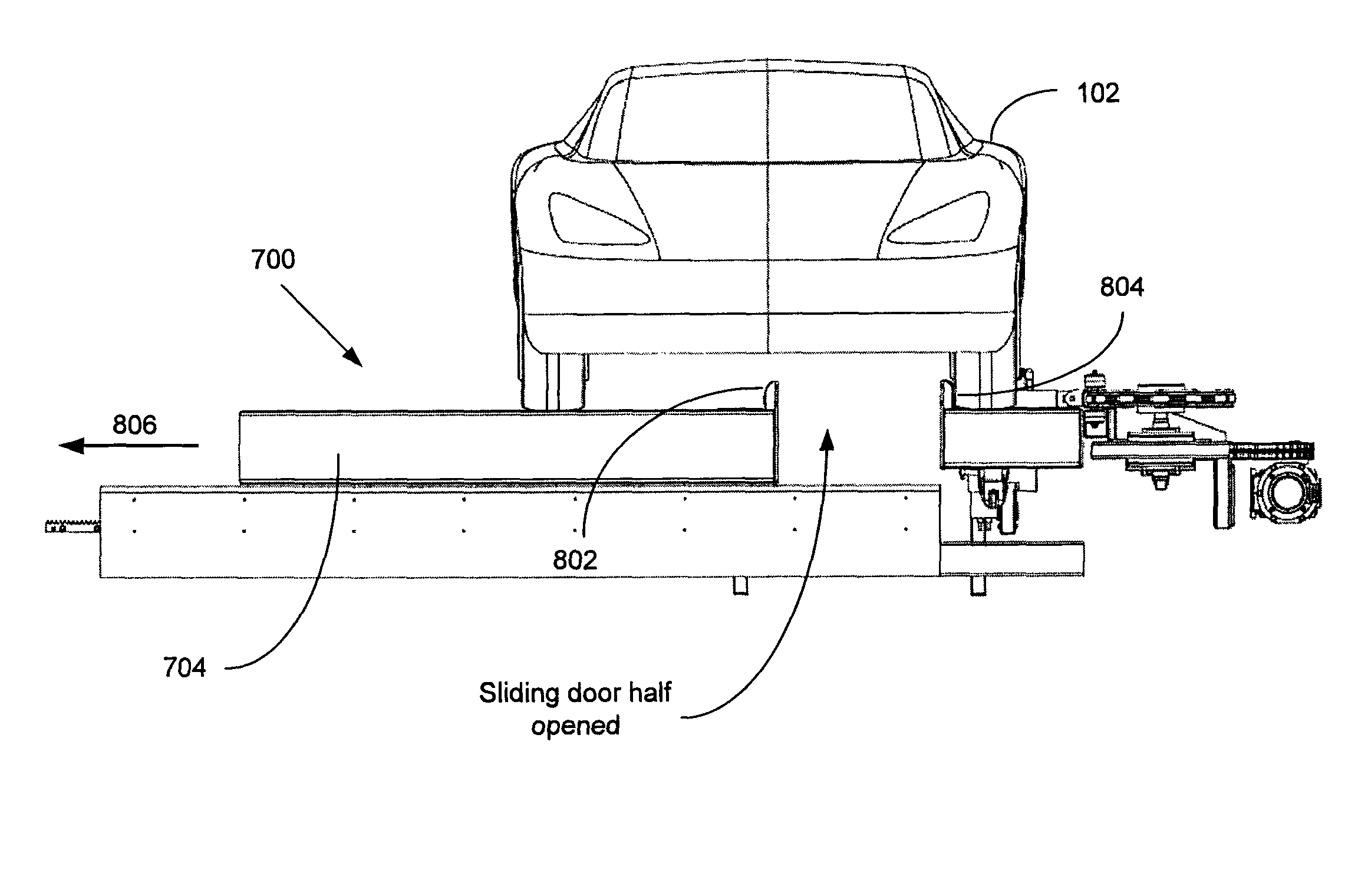

Battery exchange station

ActiveUS8013571B2Keep for a long timeReduce dependenceRailway vehiclesRefuse receptaclesElectrical batteryElectric vehicle

At the battery exchange station a discharged battery is removed and a charged battery is inserted into an electric vehicle. The battery is inserted and removed along a vertical axis, i.e., into and out of the bottom of the vehicle. The battery exchange system is located in a service bay under the vehicle. A sliding door system creates an opening above the service bay. A vehicle is received over the sliding door system, such that at least one wheel of the vehicle rests on the conveyor system. The door slides in a first direction while allowing the conveyor system to slide in a direction opposite the first direction. The conveyor system also supports the at least one wheel of the vehicle while the door and conveyor slide in opposite directions. The sliding of the door and the sliding of the conveyor system occur at least partially simultaneously.

Owner:CHARGE PEAK

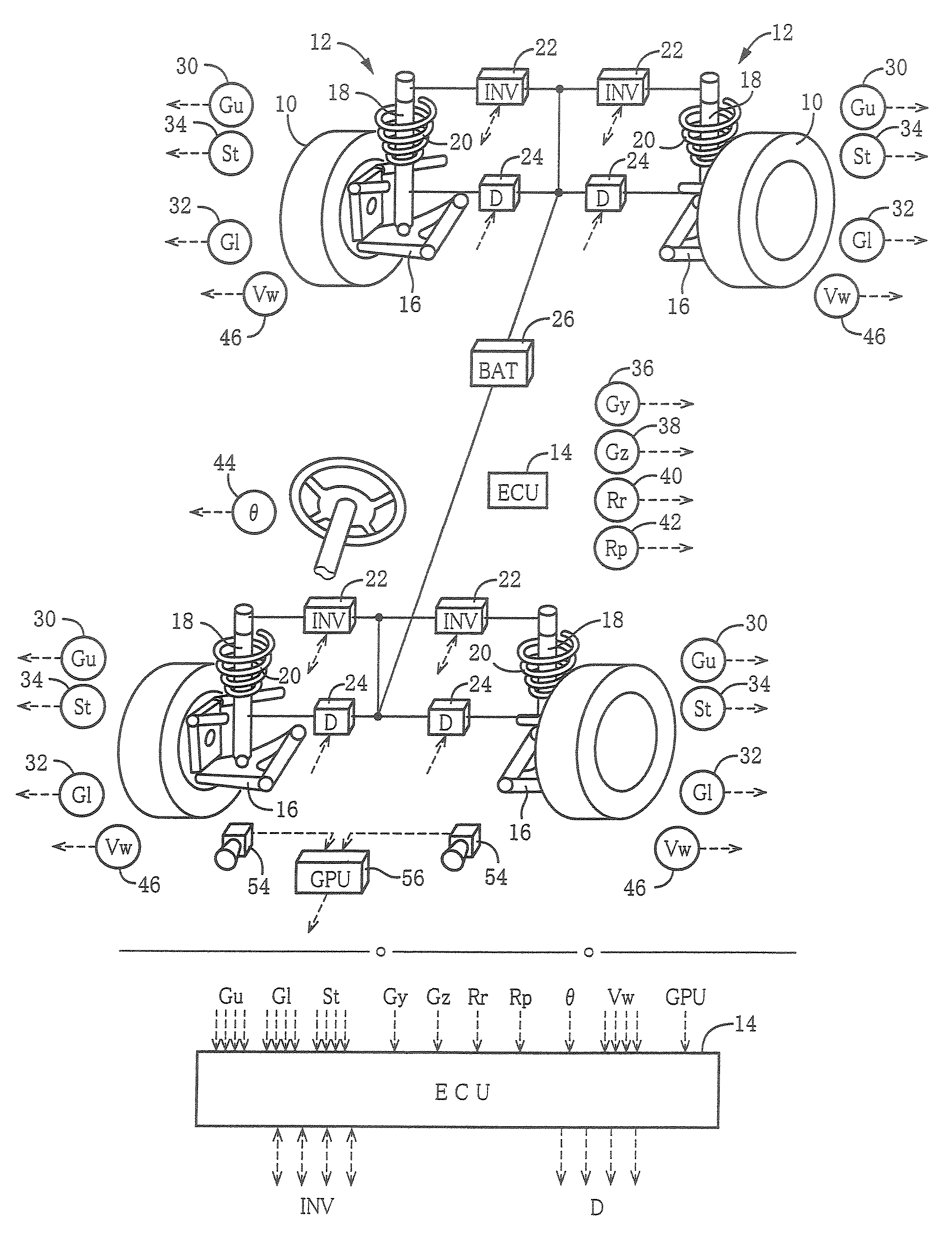

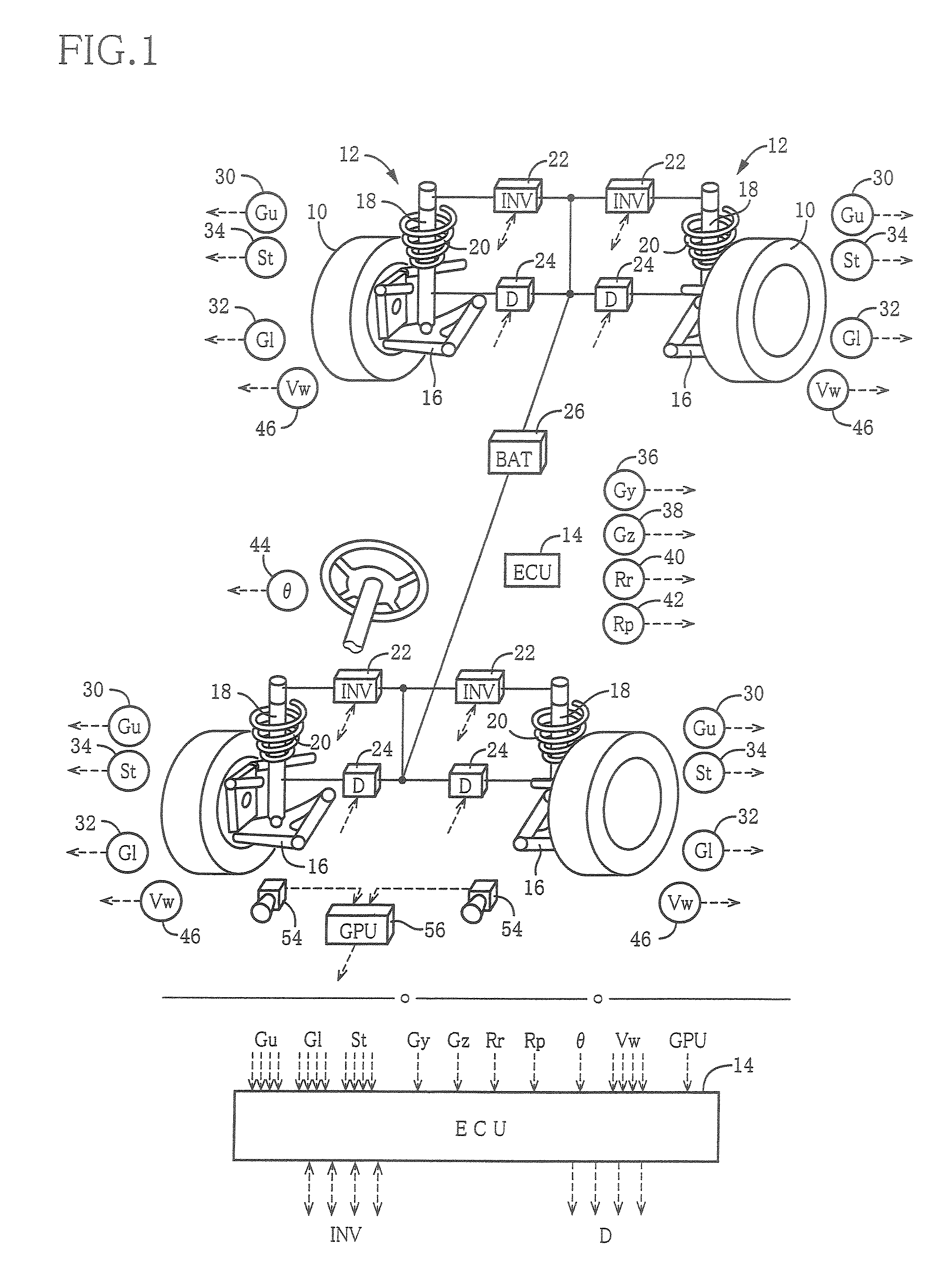

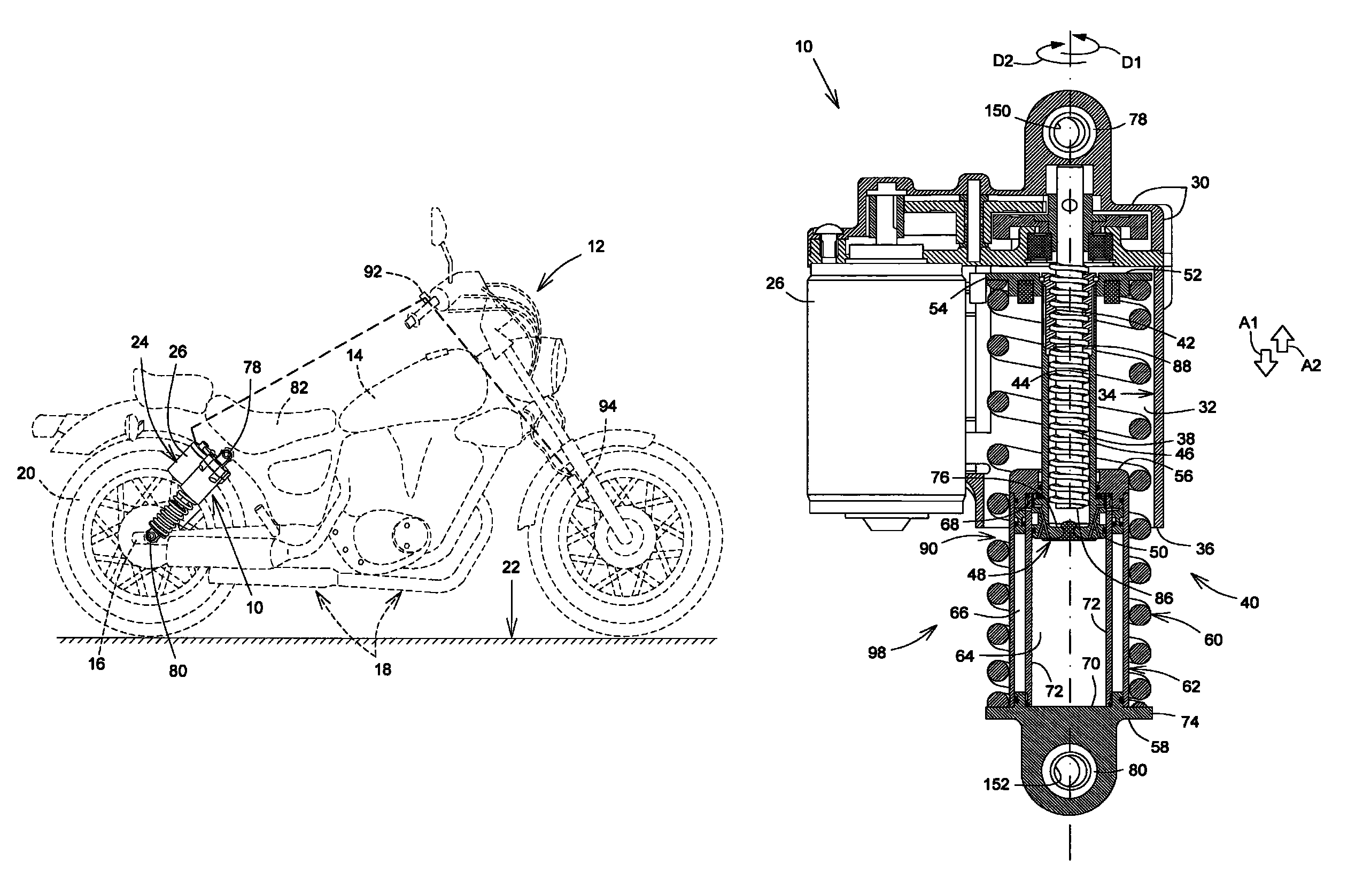

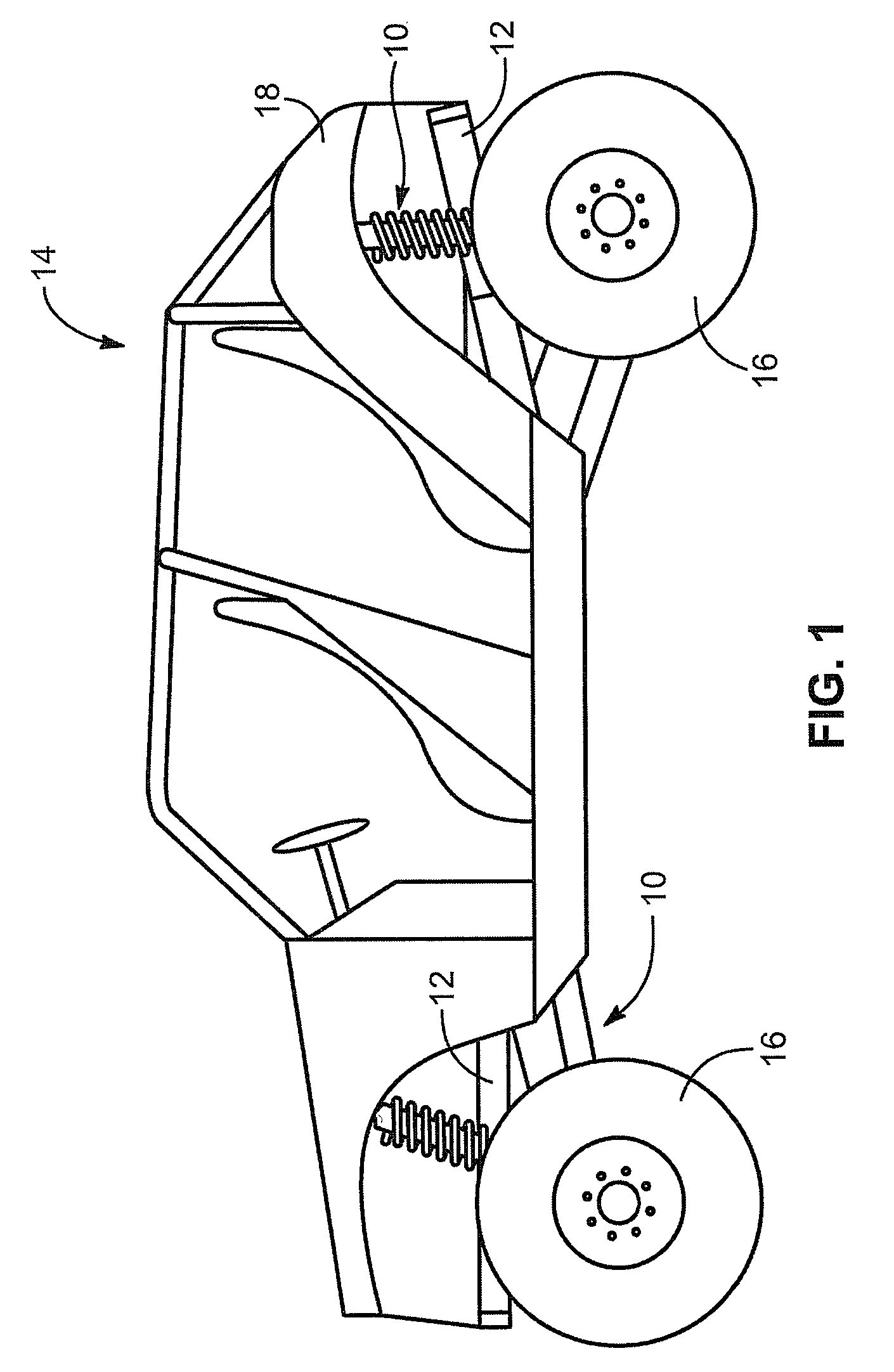

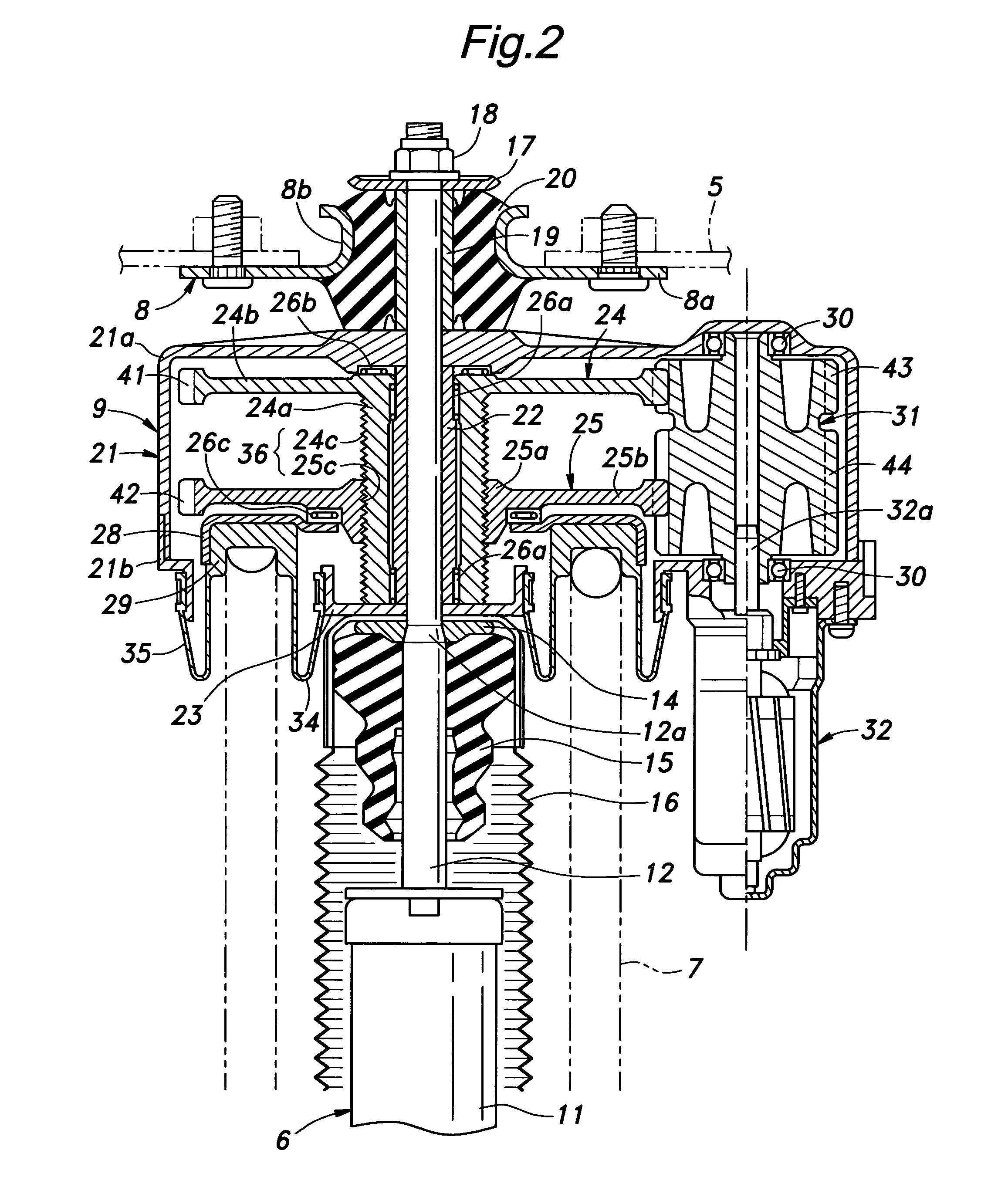

Damping force generation system and vehicle suspension system constructed by including the same

InactiveUS7722056B2High utilityMore roomSpringsVehicle cleaning apparatusElectrical resistance and conductanceElectromagnetic absorbers

It is an object of the invention to improve the utility of an electromagnetic absorber system which is disposed in a suspension system of a vehicle and which generates a damping force by a generation force of a motor. The electromagnetic absorber system 18 is equipped with high-speed-motion responding means, thereby obviating an insufficiency of the damping force and a deterioration of the controllability in a high-speed stroke motion. More specifically, a hydraulic absorber 64 is provided in combination with the electromagnetic absorber system such that the hydraulic absorber 64 operates in the high-speed motion in which an electromotive force of the motor 68 exceeds a power source voltage Further, two motors having mutually different T-N characteristics are provided, and the two motors are selectively operated depending upon a stroke speed. Further, a variable resistor is interposed between the motor and the power source, and a resistance value of the variable resistor is increased in the high-speed motion to realize a decrease in a time constant of the motor, etc. Moreover, to cope with a large extent of unevenness of a road surface, an active stroke motion is performed by a drive force of the motor, thereby preventing the high-speed motion from being performed.

Owner:TOYOTA JIDOSHA KK +1

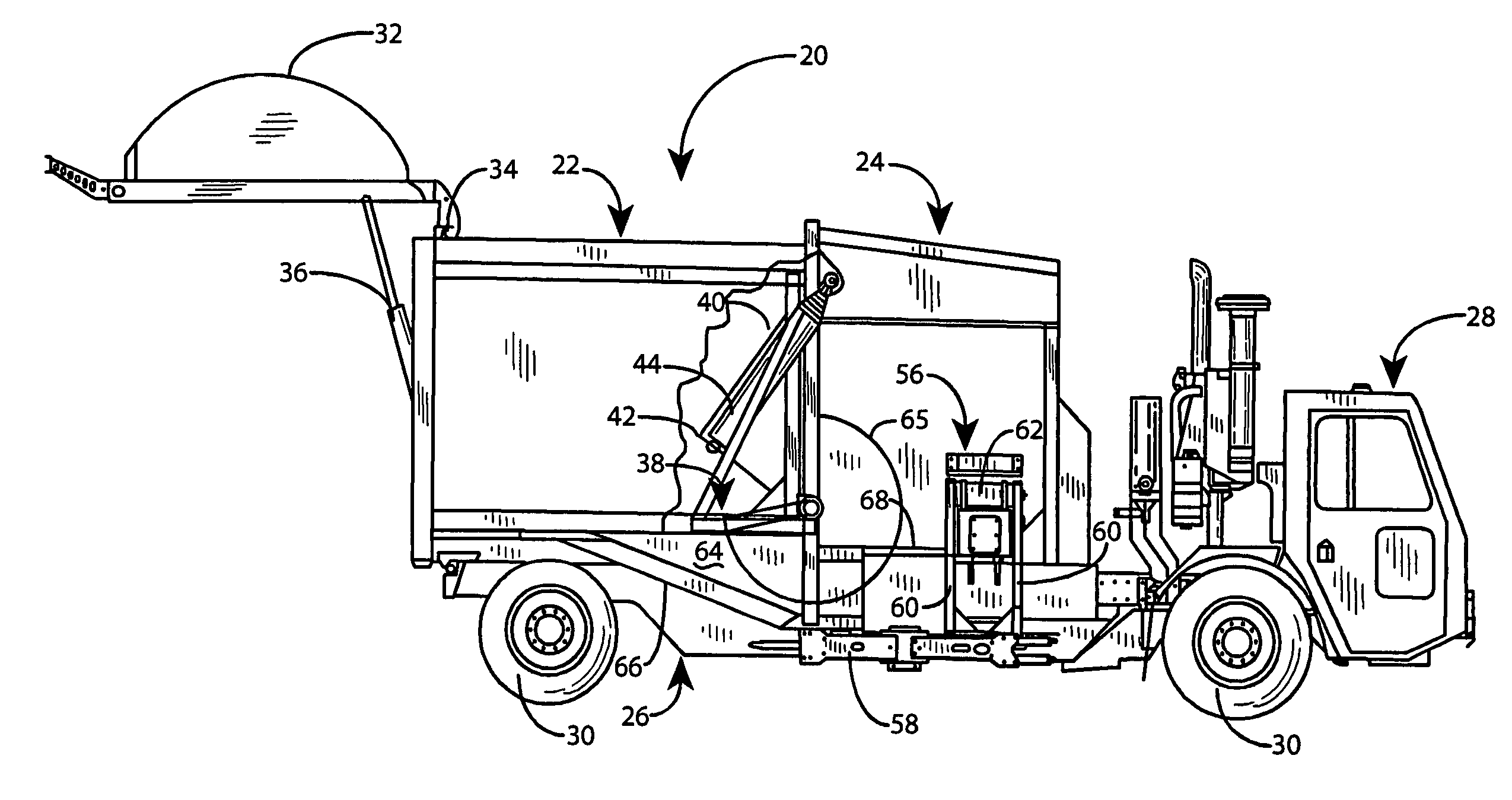

Automated loader

A container handling mechanism suitable for mounting on the side of a refuse vehicle for loading material from refuse containers is disclosed that includes a lift assembly, having a pair of spaced, generally parallel lift support members, attachable to a refuse vehicle, a carriage device reciprocally operable along the lift support members of the lift assembly, a container grabbing system carried by the carriage device and further including a pair of opposed grabber fingers and an actuator system for closing and opening the grabber fingers to engage and release containers of interest, the container grabbing system being vertically pivotable on a short radius for adjusting the position of and tipping a container. A chain and cylinder drive system operates the carriage device along the lift assembly, and a control system controls operation of the container handling mechanism.

Owner:MCNEILUS TRUCK & MFG INC

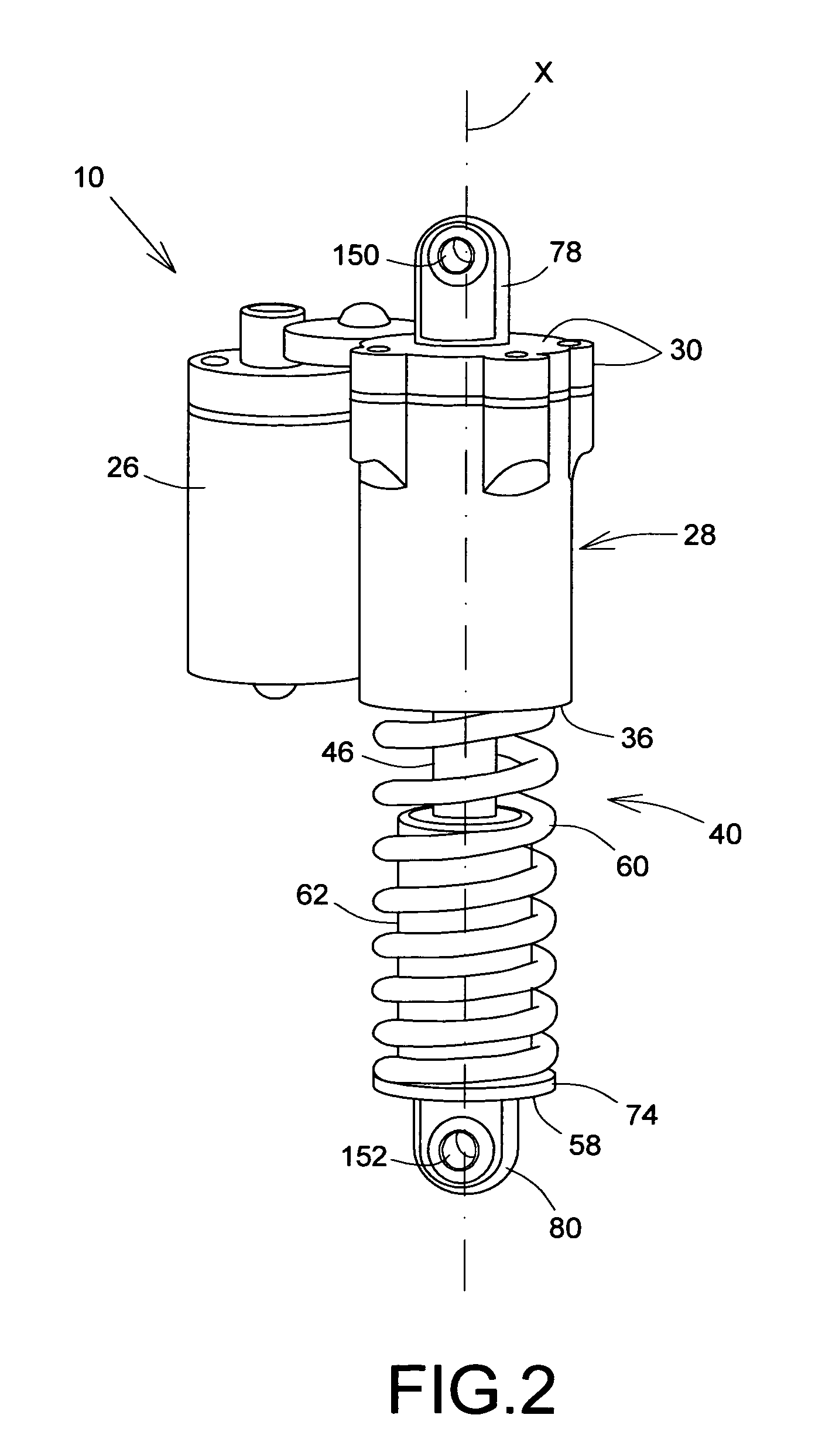

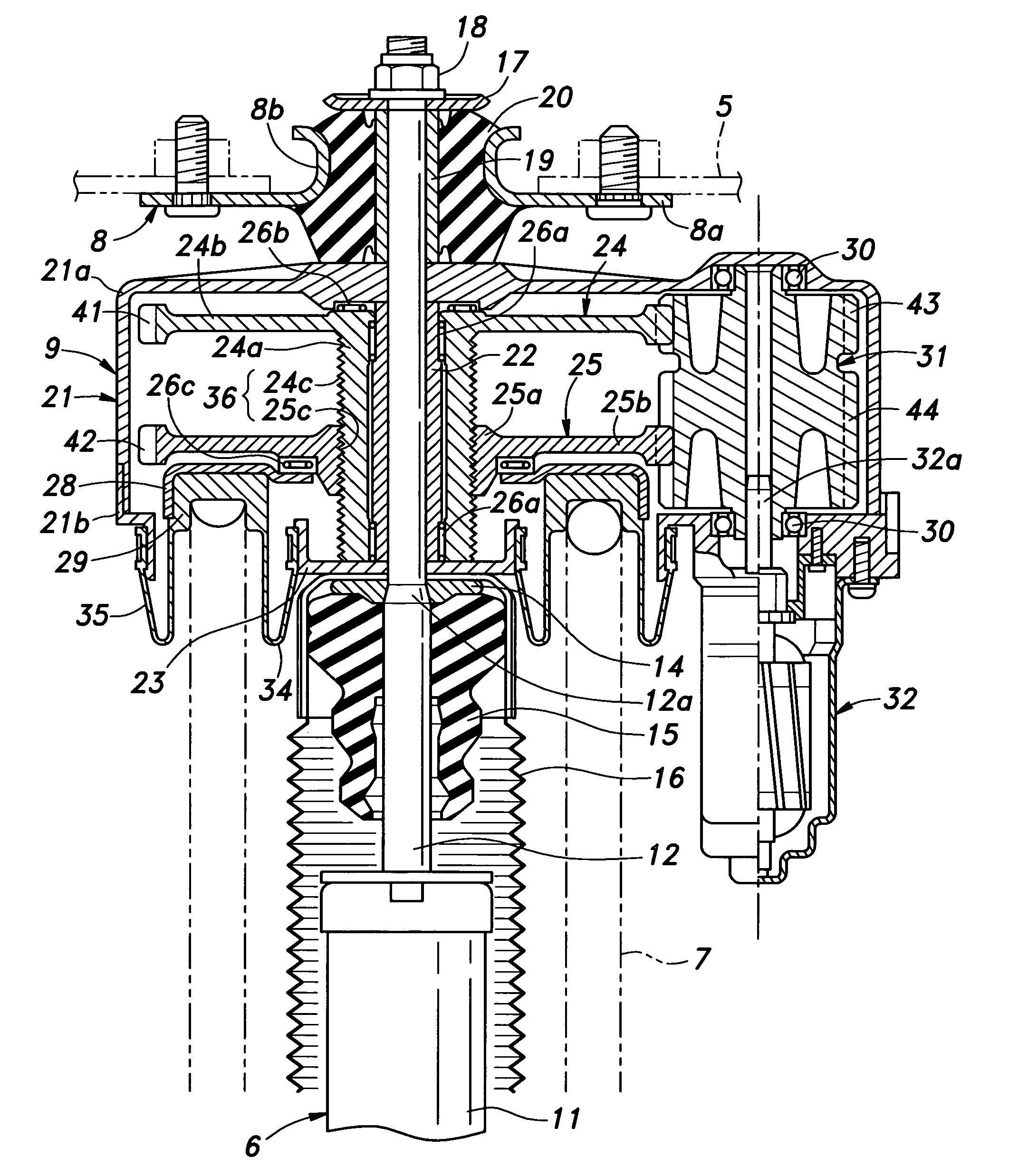

Vehicle height adjustment suspension device

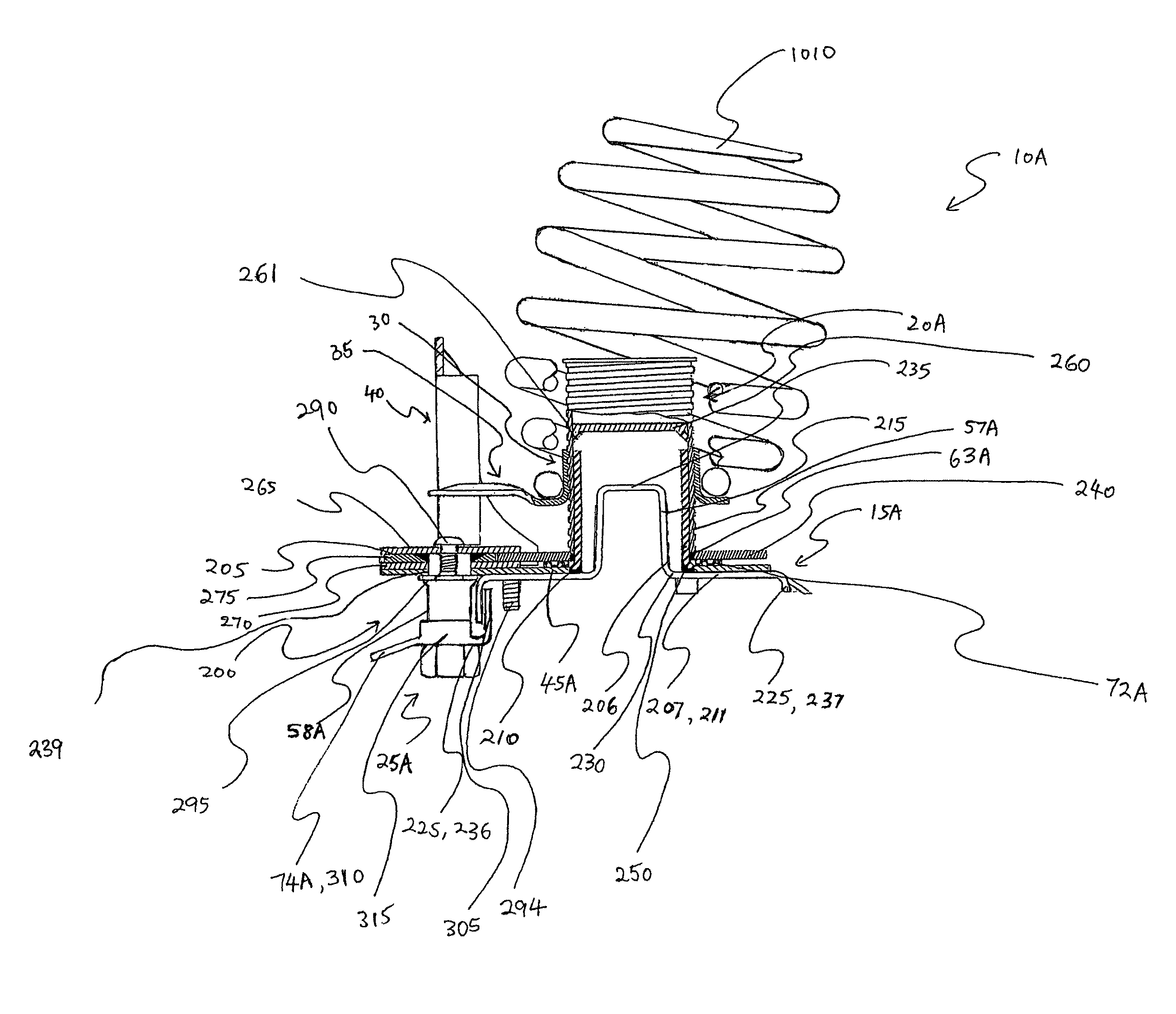

ActiveUS8262100B2Easily fitted to vehicleVehicle cleaning apparatusLoading/unloading vehicle arrangmentVehicle frameShock mount

A vehicle height adjustment suspension device provides for both automatic and selective raising and lowering of a supported portion of a vehicle frame relative a ground surface, while also providing shock absorption. The device includes a suspension assembly for absorbing shocks mounted on a rotatable threaded screw connected to a motor and extending into the suspension assembly. The assembly may be extended and retracted on the screw by rotating the screw in first and second directions to raise and lower the supported portion while the shock absorber assembly simultaneously provides shock absorption capability.

Owner:9092854 CANADA

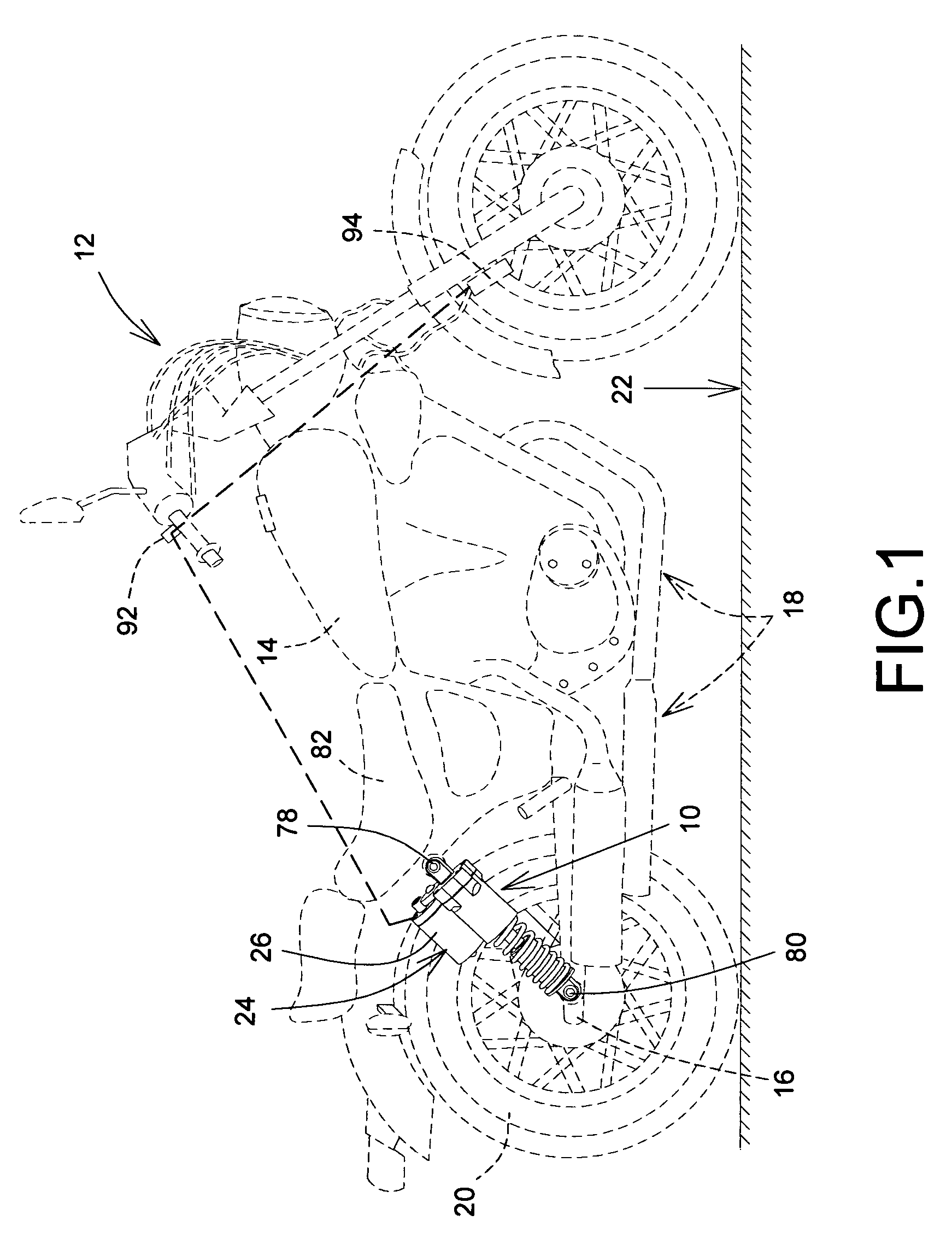

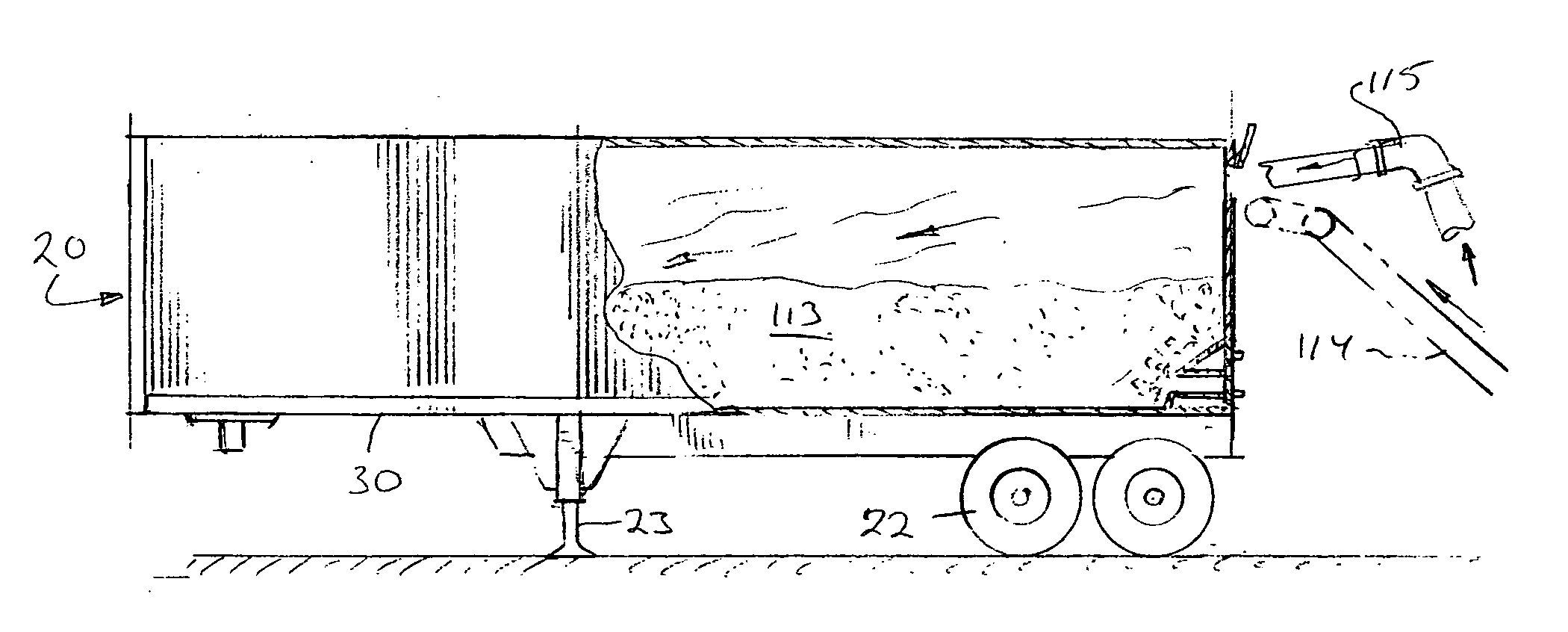

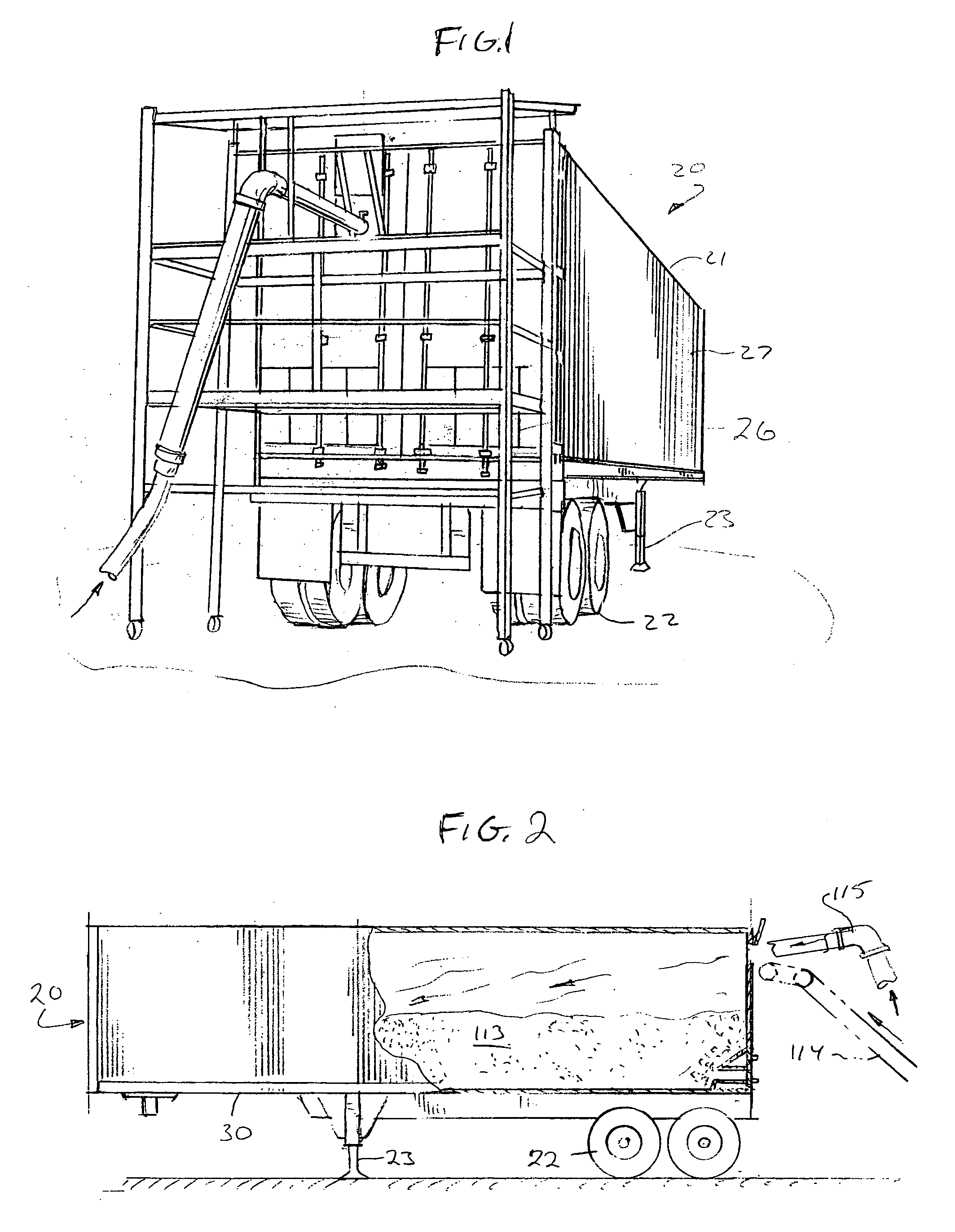

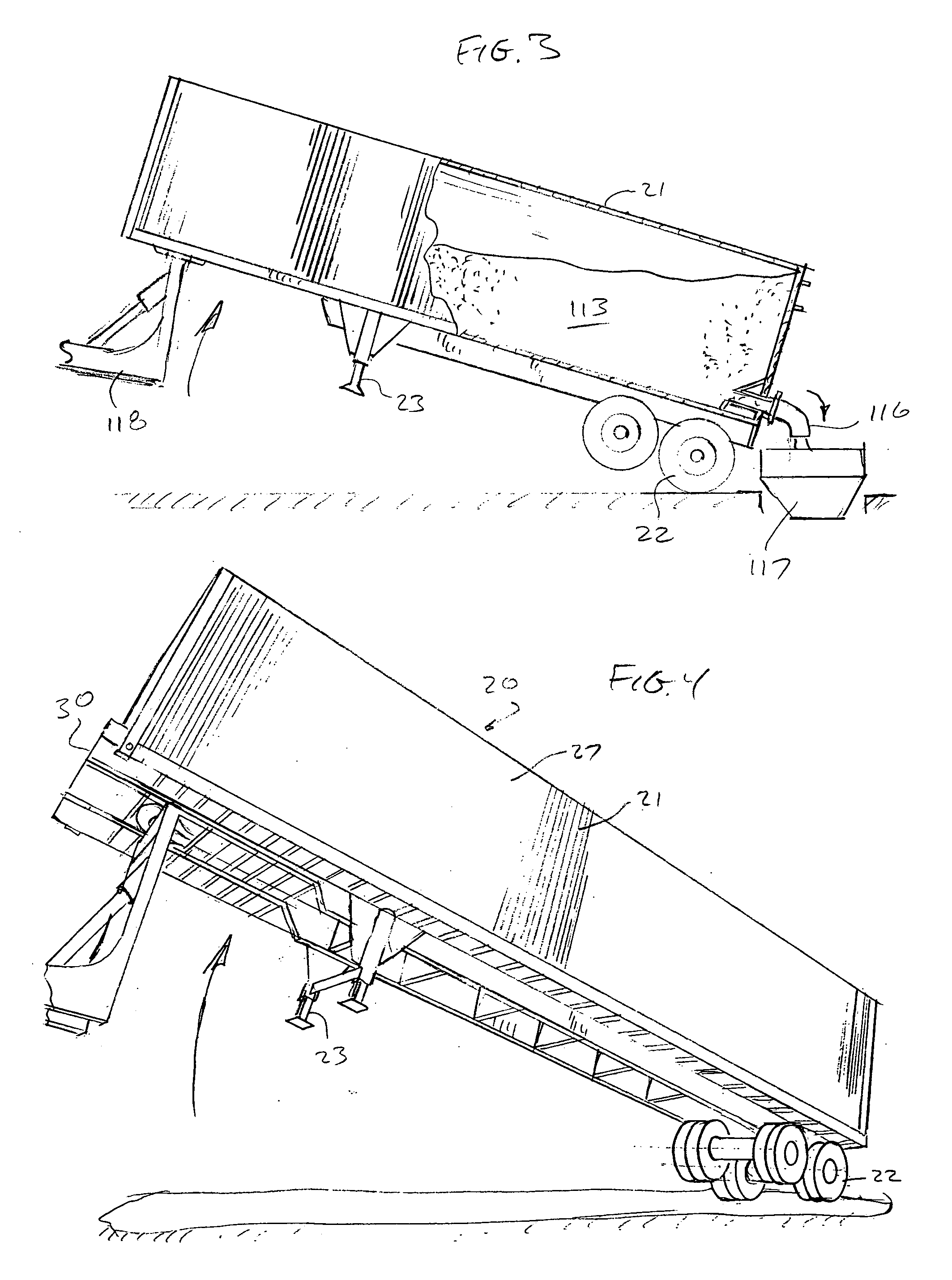

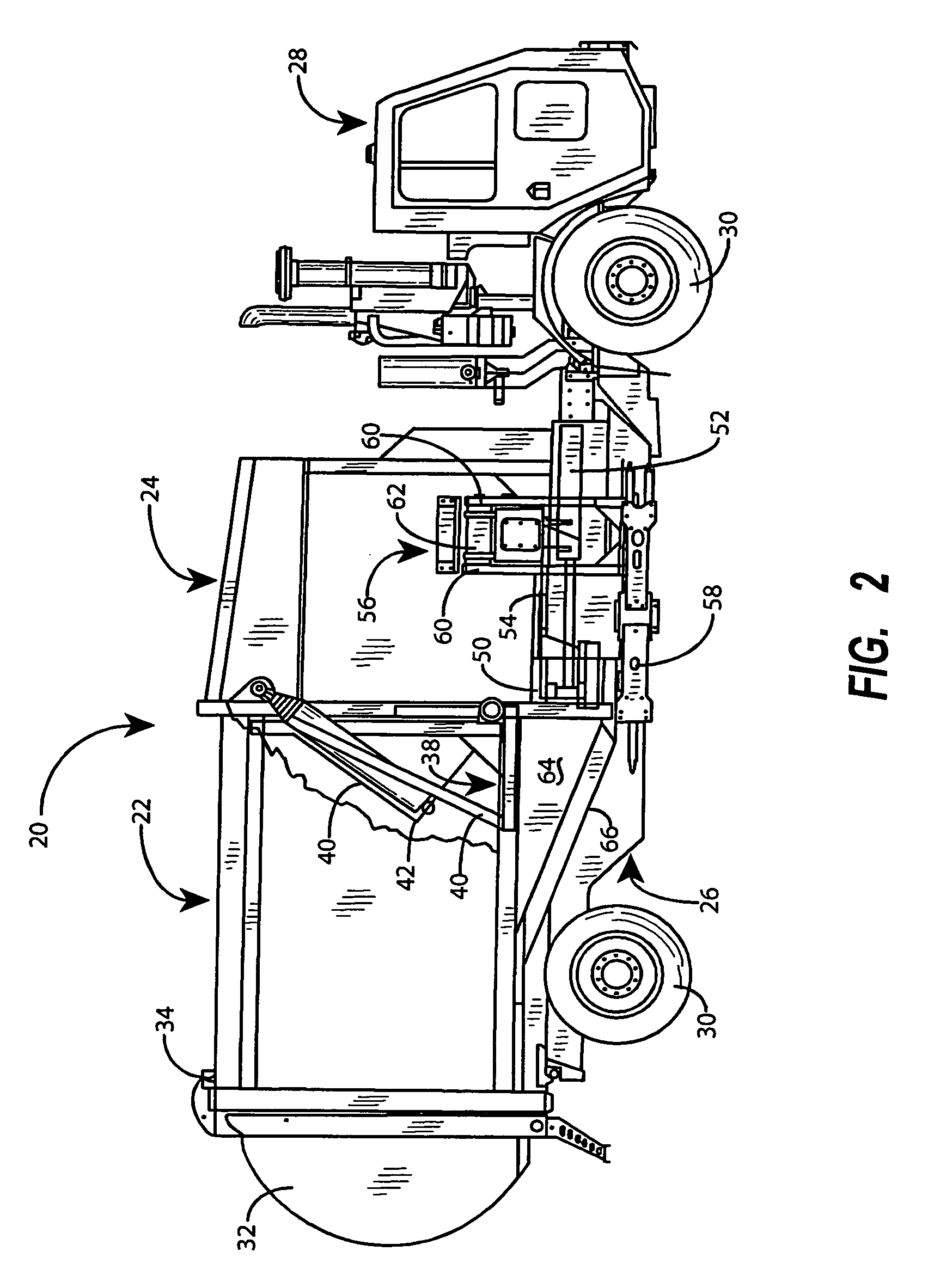

Bulk seed handling system

InactiveUS20100040446A1Easy transferEasy to handleConveyorsFertiliser distributersEngineeringHandling system

A bulk seed handling system (20) is provided to facilitate seed transfer from a distributor to a farm and then to a planter or the like. The handling system (20) includes one or more upright bin assemblies (22) adapted to be moved in a filled condition, and a trailer (24) designed to move the bin assembly (22) and unload seed therefrom. The bin assembly (22) includes a seed bin (26) having a lower unload opening (34) and supported by a frame assembly (38) including telescopic legs (50) shiftable between a retractable travel position and an extended bin support position. The trailer (24) includes a lift frame (60) operable to engage and elevate the bin assembly (22) for travel with the legs (50) thereof in a retracted position, and a seed-conveying arrangement including an intermediate conveyor (62) and a delivery conveyor (64). At an unloading site, the intermediate conveyor (62) is shifted to an unloading position in communication with the bin unload opening (34) and the delivery conveyor (64) in order to transfer seed from the bin.

Owner:USC

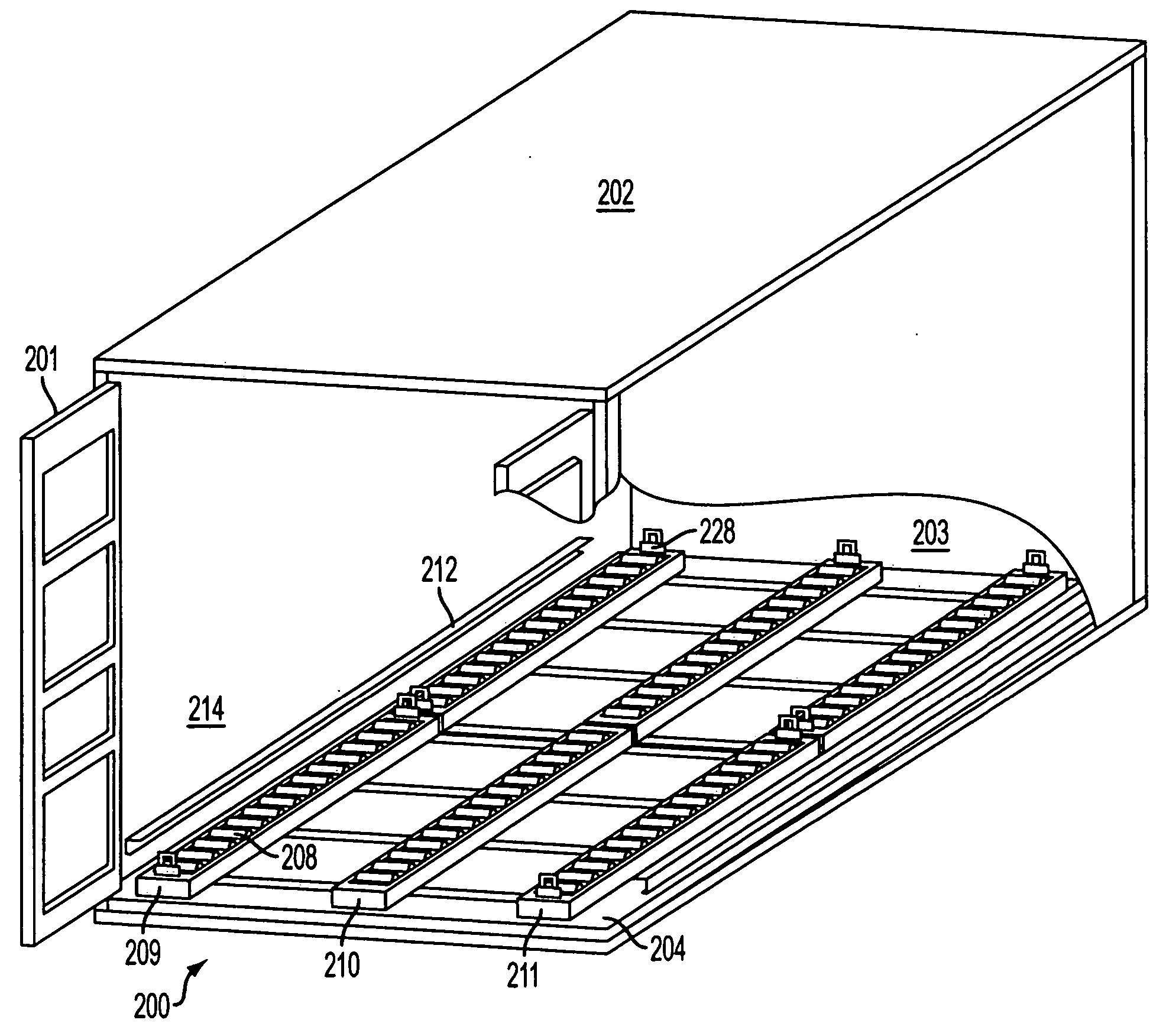

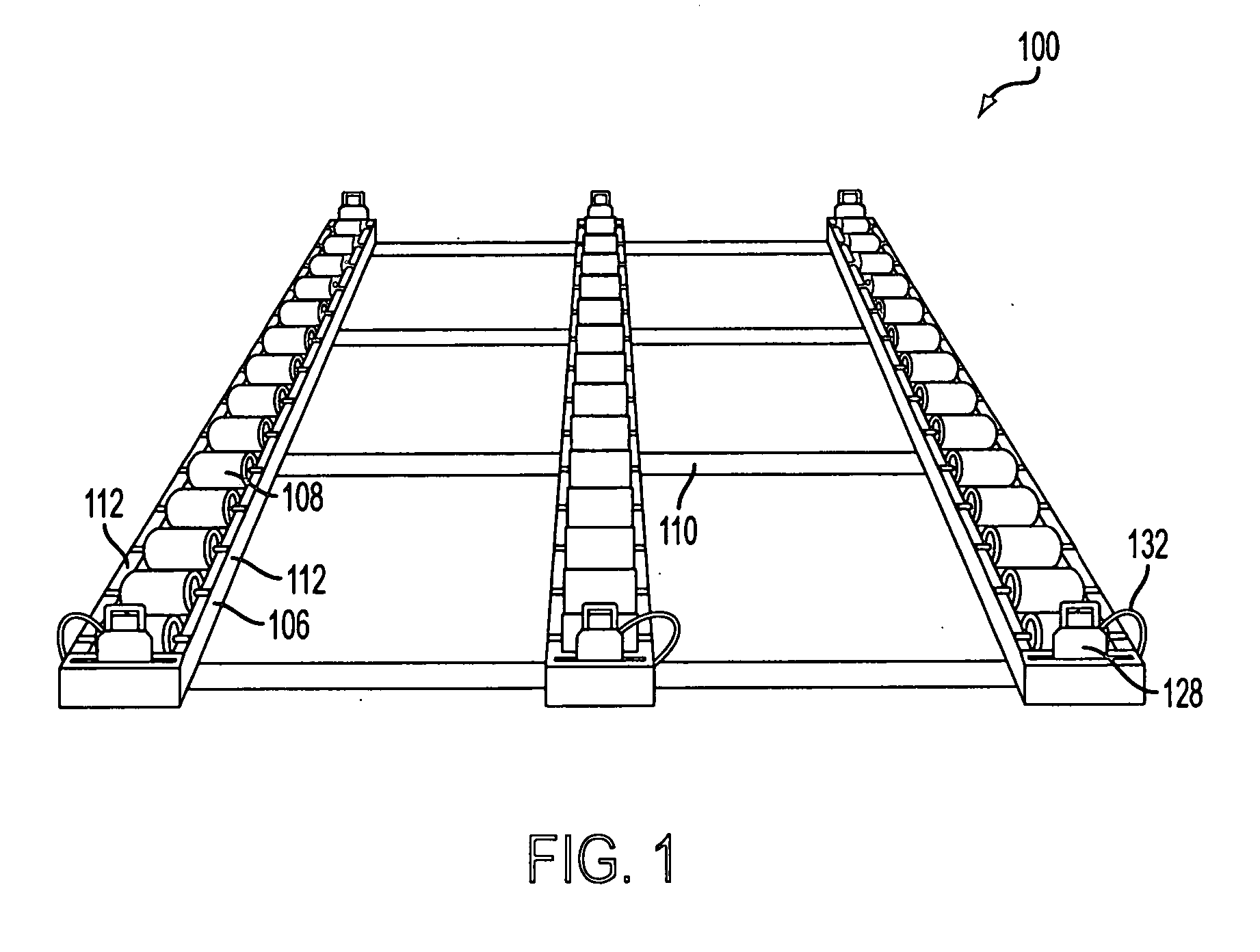

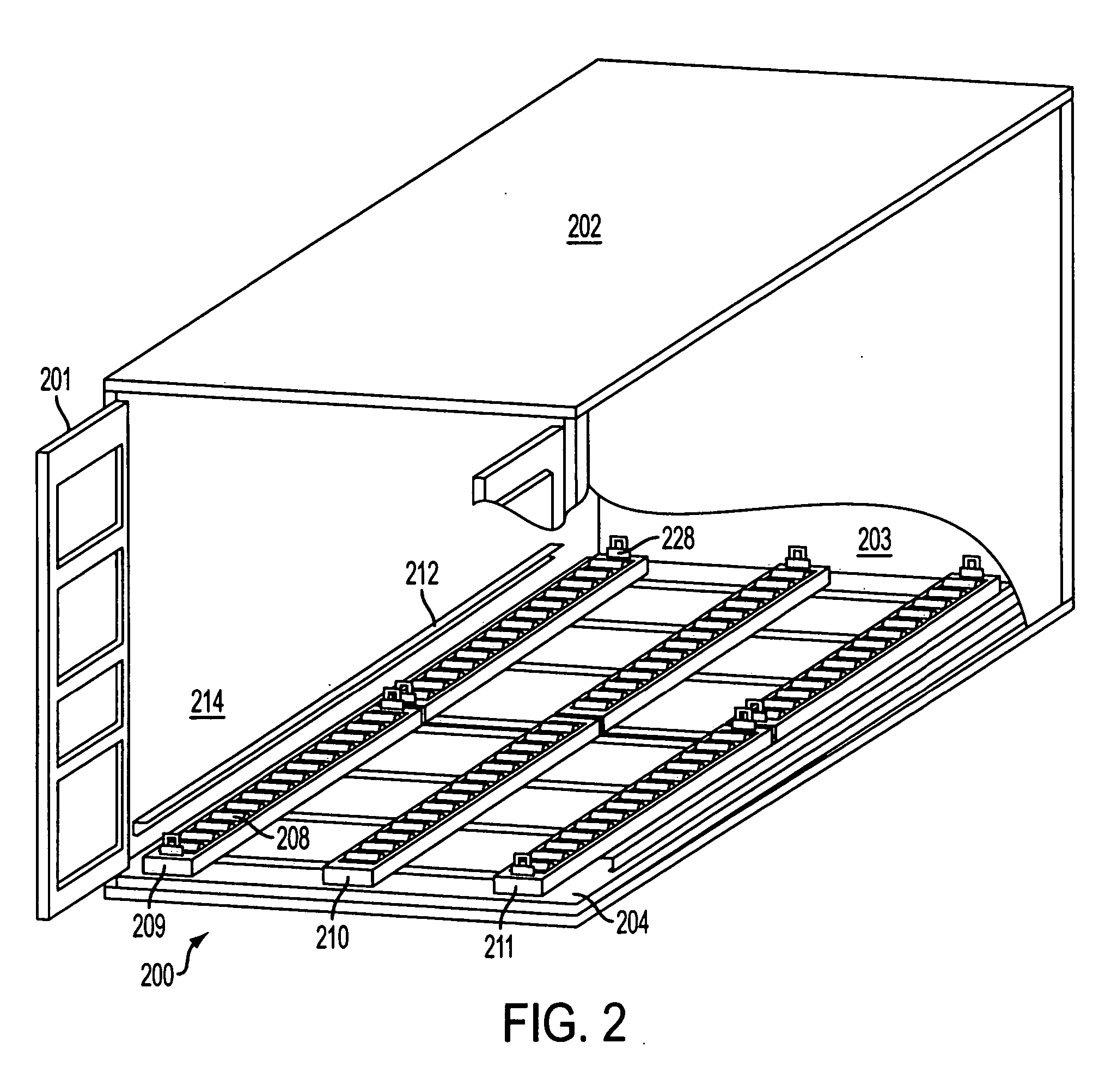

Cargo roller system for cargo handling

A roller unit that can be used to retrofit a cargo carrying surface makes loading and unloading of the cargo carrying surface easier by transforming the cargo carrying surface to include a conveyor system. The roller unit includes at least two trays in which are mounted rollers, the trays being connected by a crosspiece. The roller unit is designed to be installed on cargo carrying surfaces such as portable platforms, including Flatracks or CROPs, and in cargo containers of any type.

Owner:ENGINEERED SUPPORT SYST INC

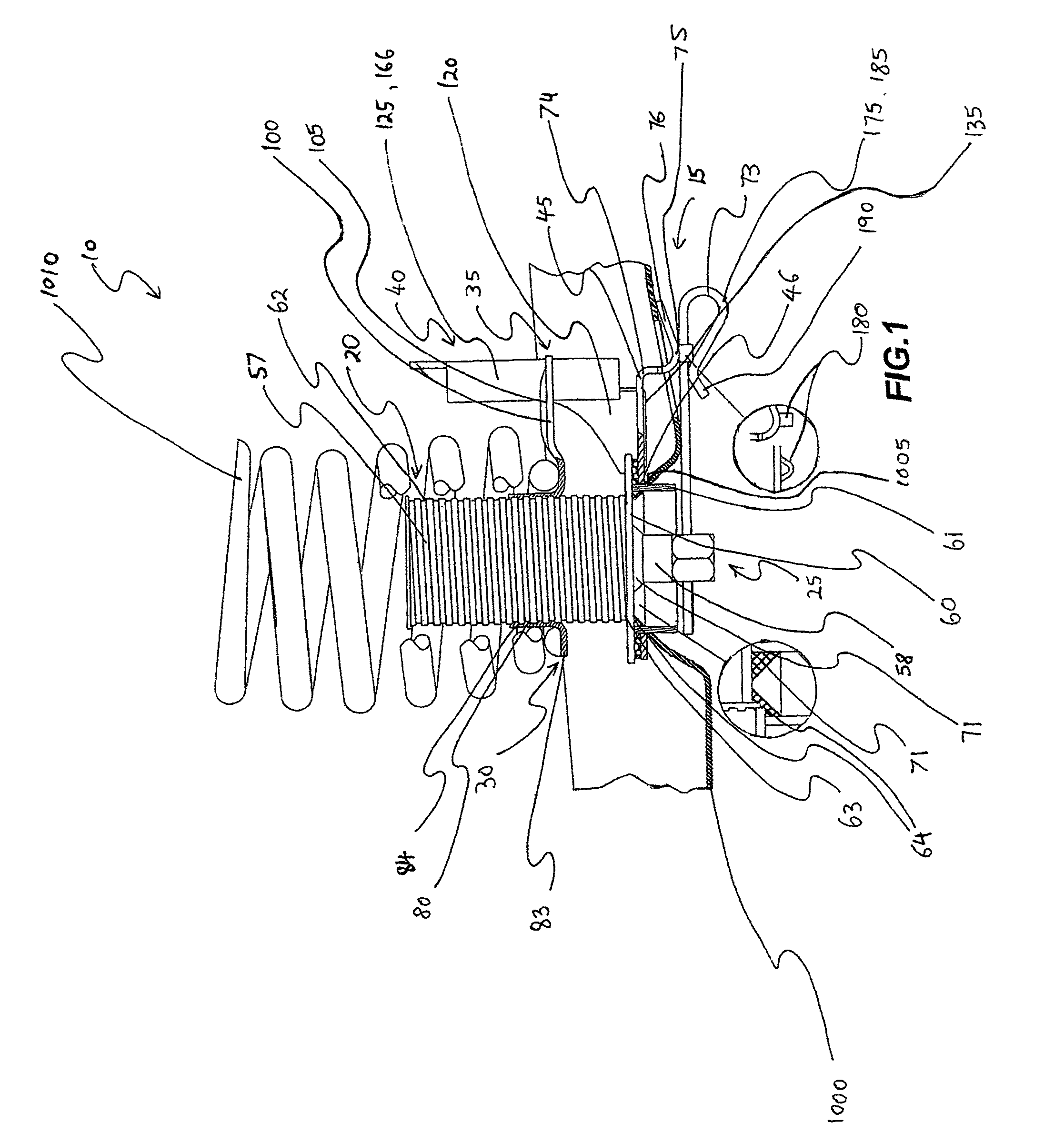

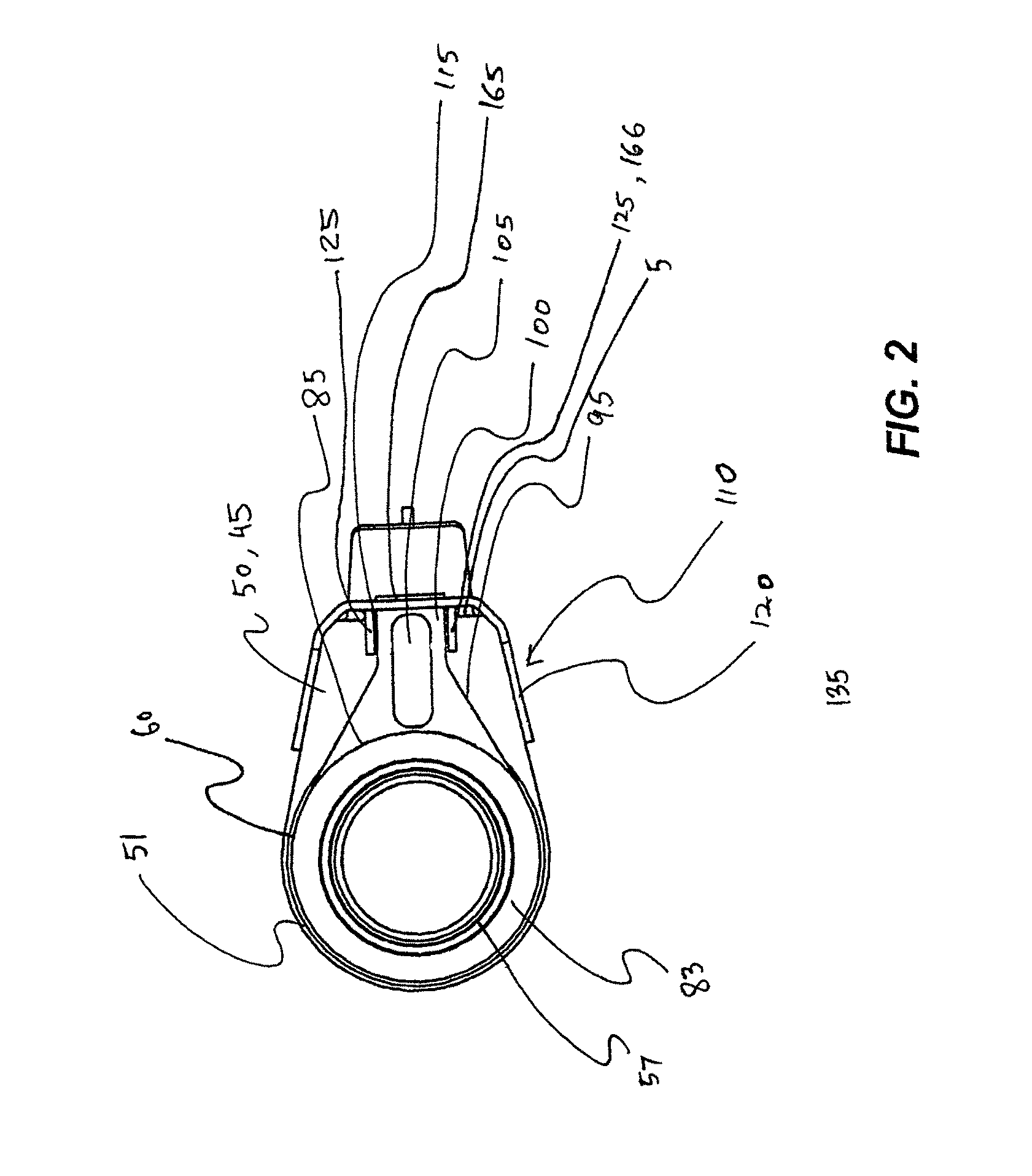

Suspension height adjustment mechanism

InactiveUS8087676B2Easy to useEasy to adjustVehicle cleaning apparatusLoading/unloading vehicle arrangmentEngineeringScrew thread

This disclosure relates to a suspension height adjustment mechanism comprising a main body, a rotatable assembly being rotatably mounted to the main body and having a first threaded portion, a tool engagement portion for rotating the rotatable assembly, a spring support having a second threaded portion engaging the first threaded portion, an anti-rotation means on the spring support adapted to cooperate with a corresponding anti-rotation means on the main body to prevent rotation of the spring support with respect to the main body, such that, in use, rotation of the tool engagement portion causes the spring support to axially translate along the rotatable assembly, thus adjusting the height of the suspension. This disclosure also relates to a vehicle suspension system comprising the suspension height adjustment mechanism and to a vehicle comprising the vehicle suspension system.

Owner:MCINTIRE KEVIN JOSEPH

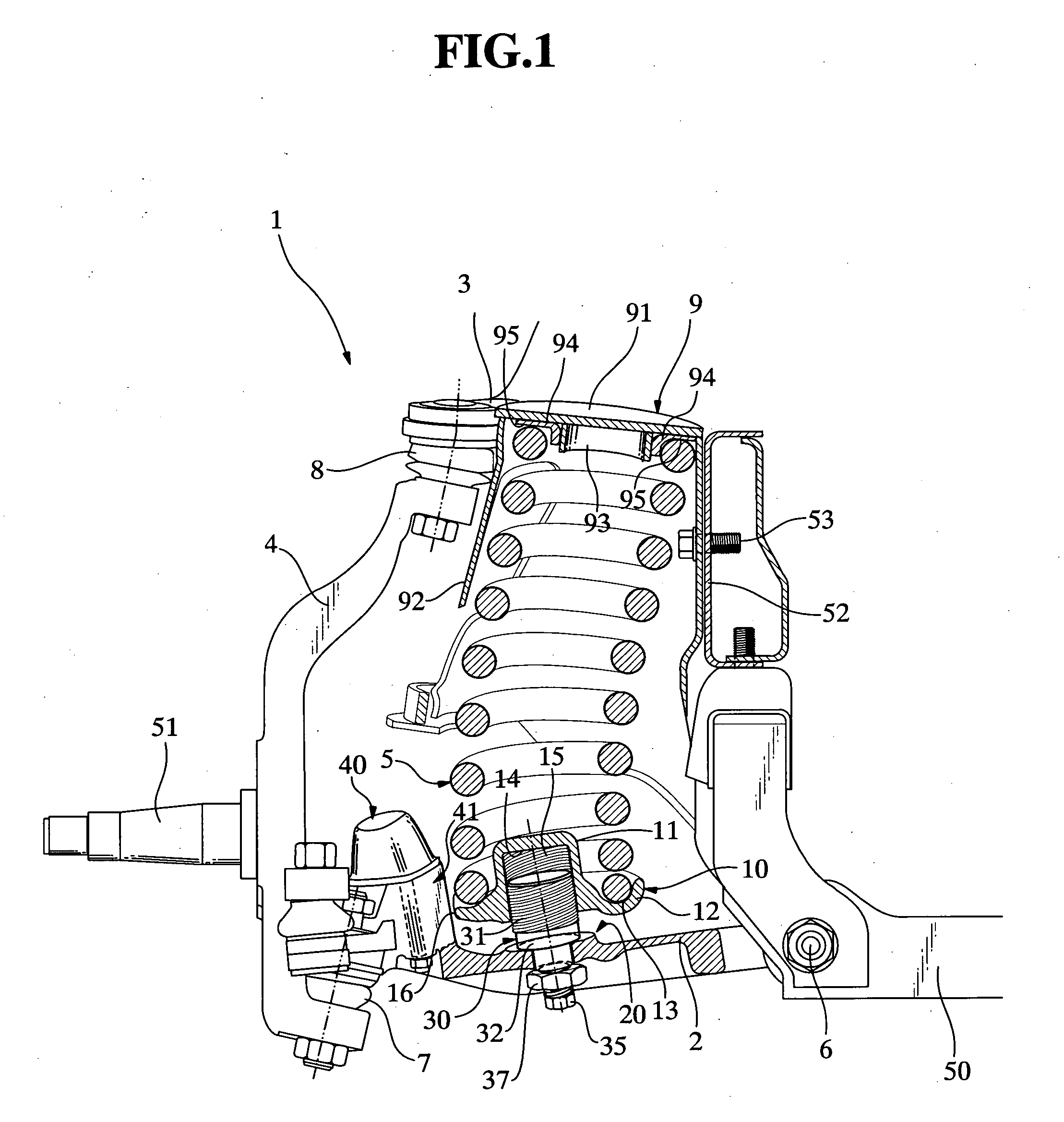

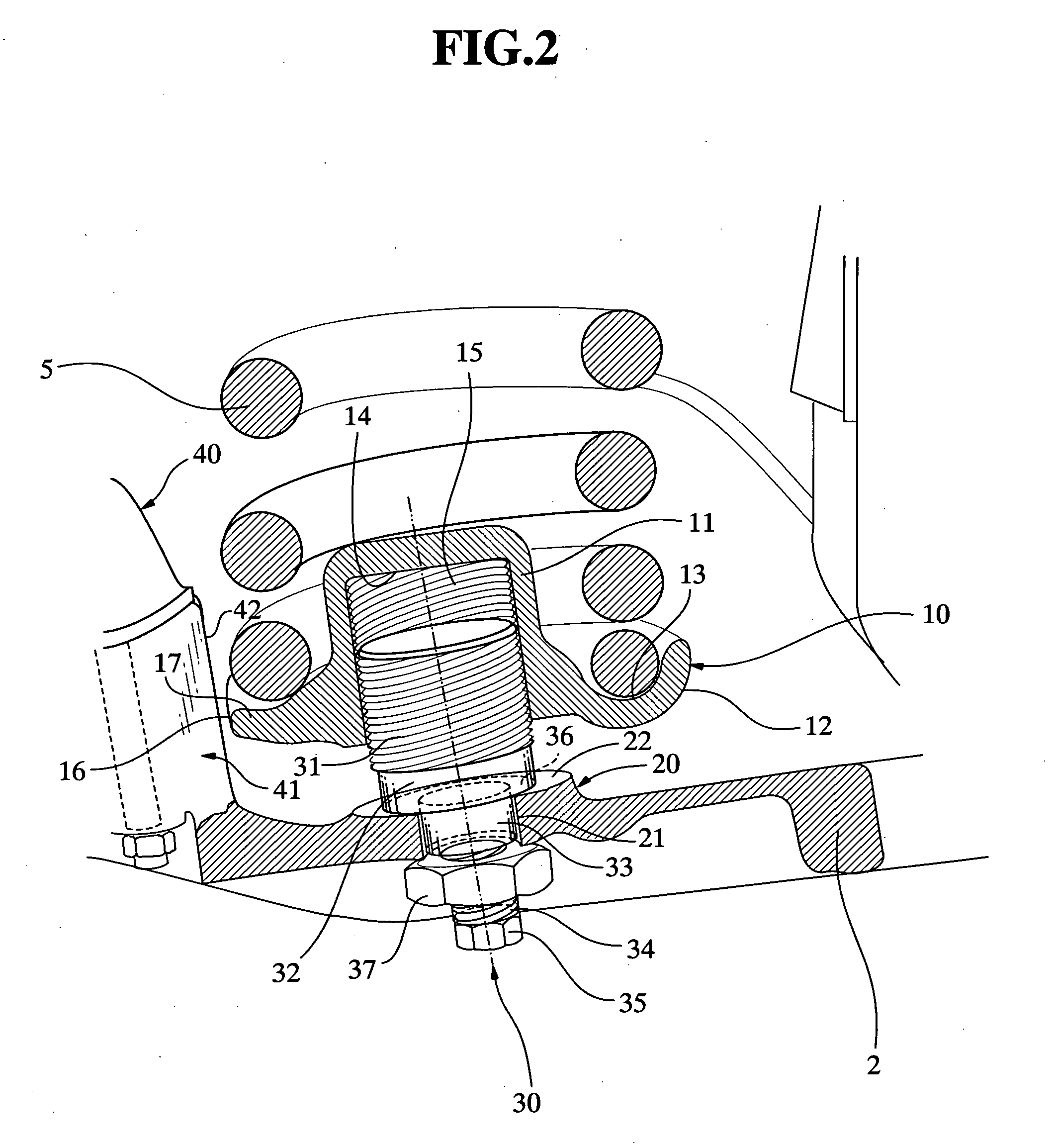

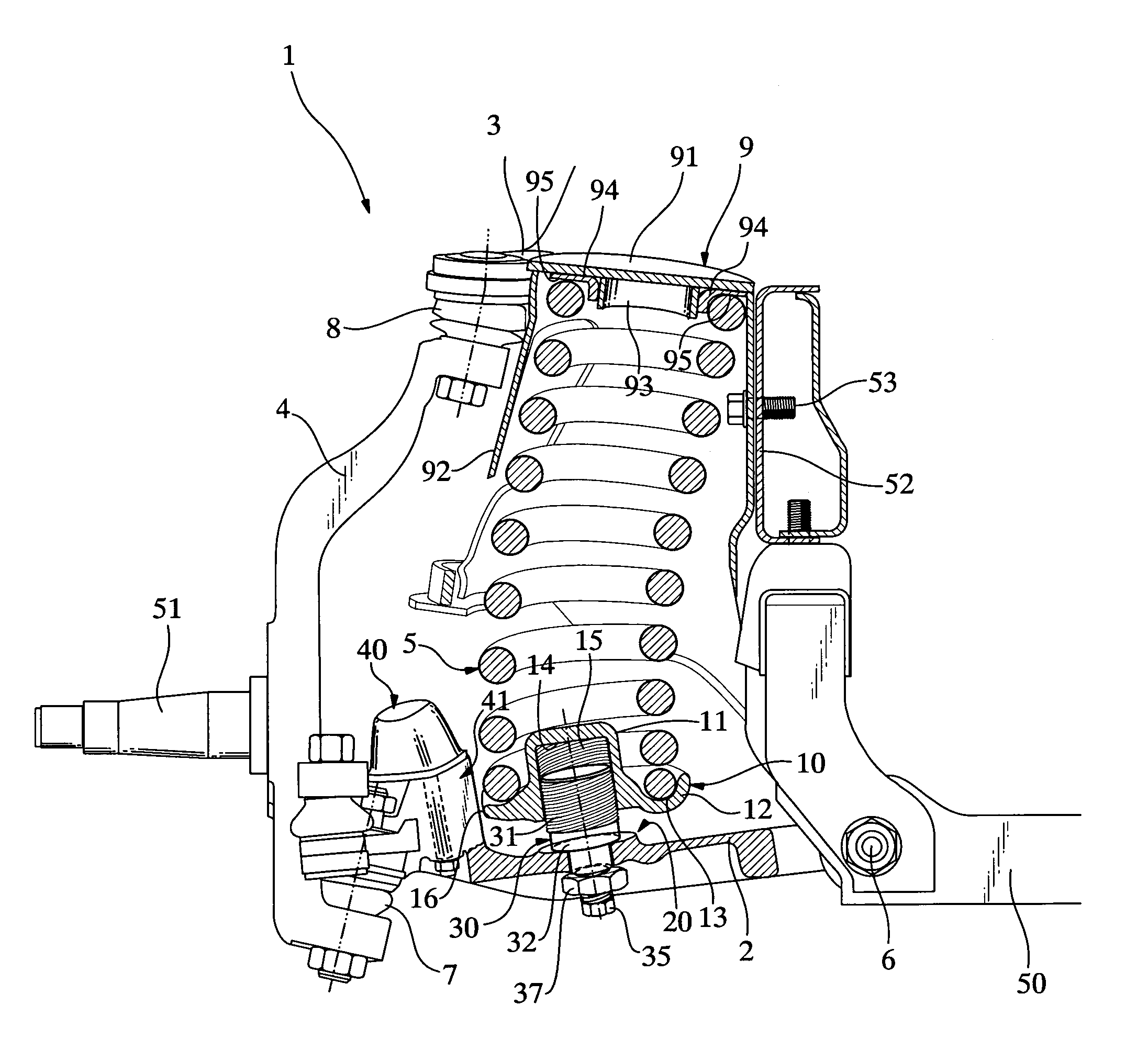

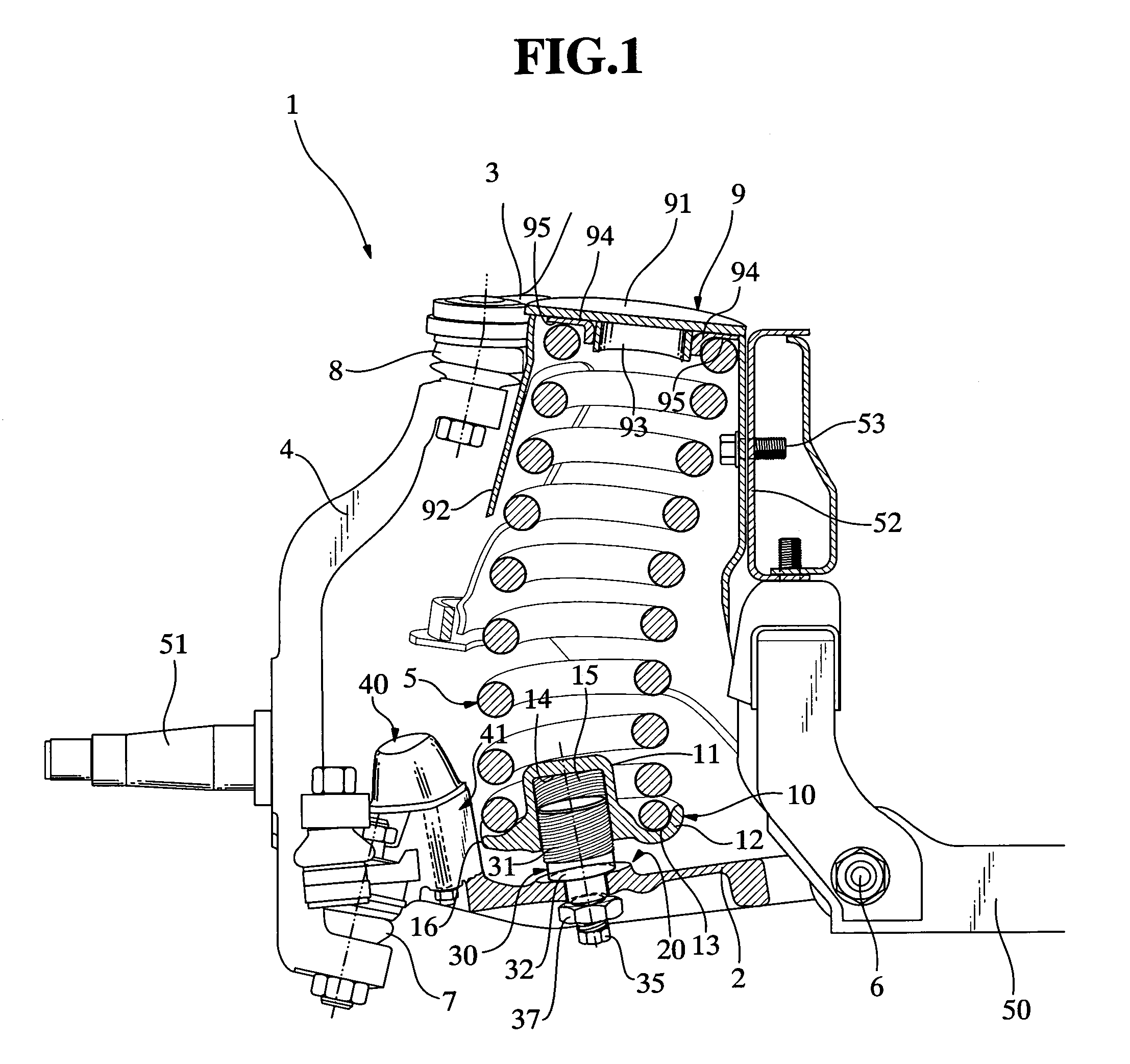

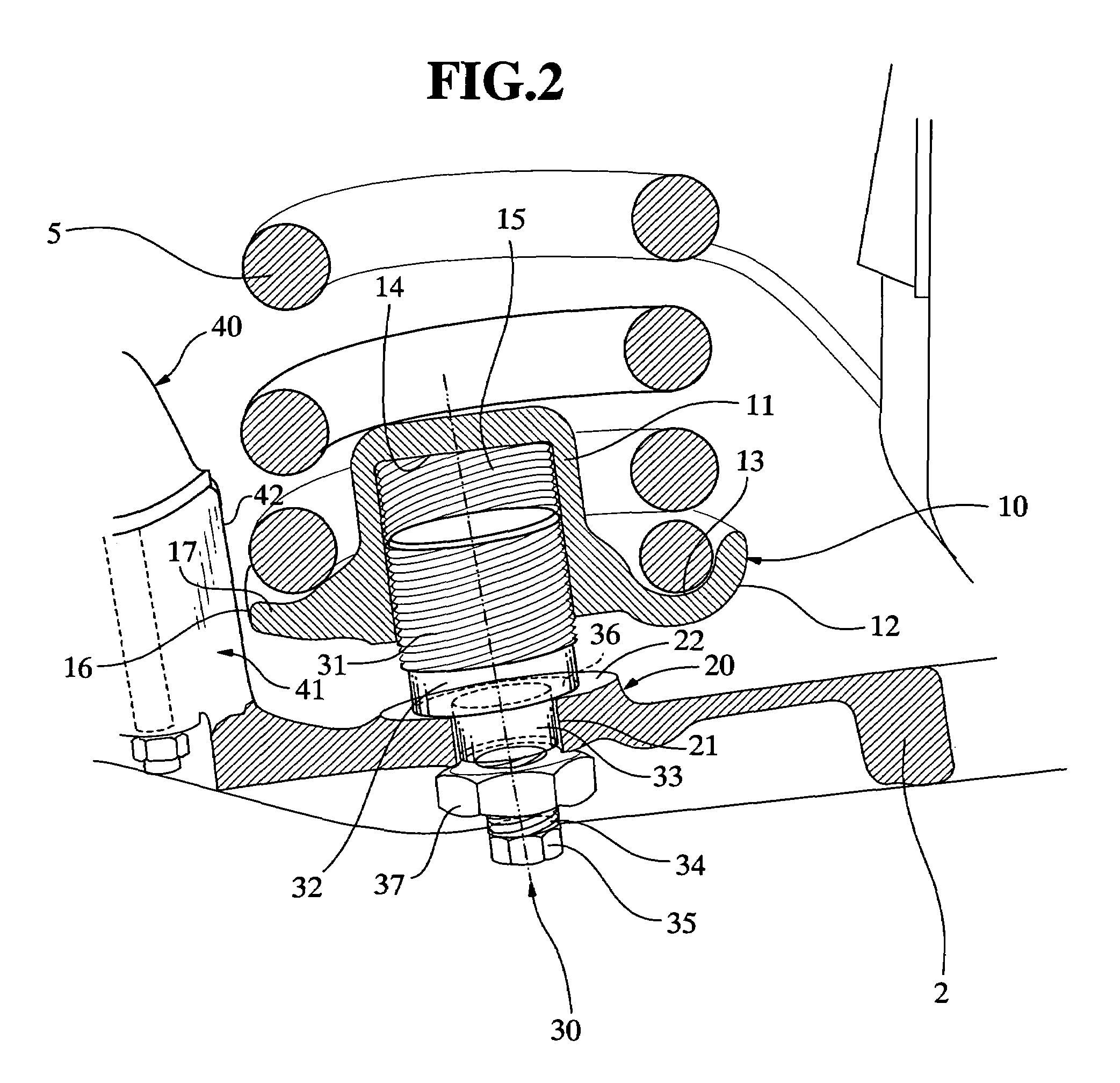

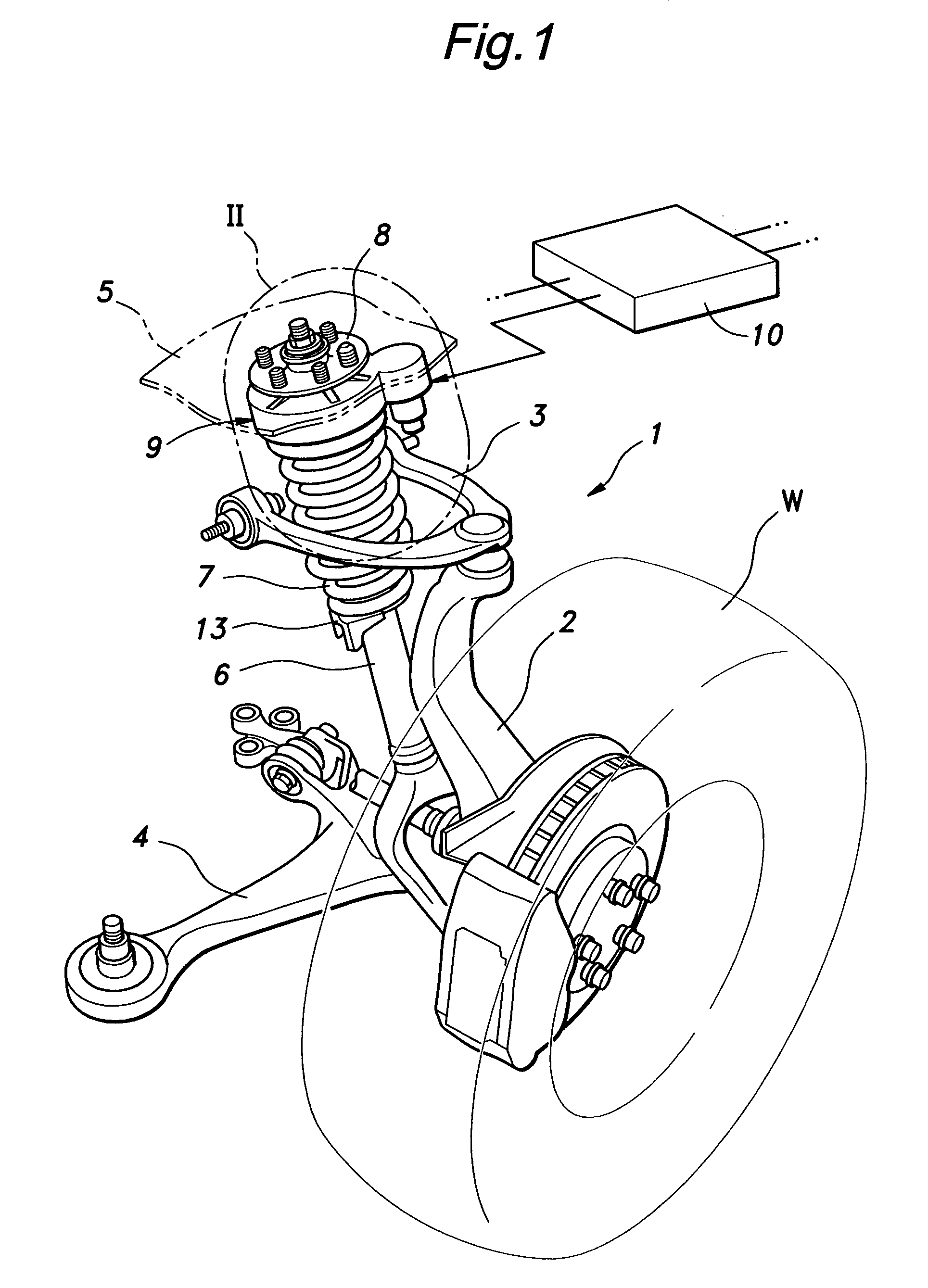

Vehicle Height Adjustment Device And Vehicle Height Adjustment Method

InactiveUS20080018065A1Easy constructionReduce the number of partsSteering linkagesVehicle cleaning apparatusCoil springEngineering

A vehicle height adjustment device has an adjustment bolt (30) rotatably supported by or fixed to a wheel-side member or a vehicle-body member, and a spring seat member (10) threadedly engaging with the adjustment bolt. Rotation of the spring seat member is limited by a bump rubber pedestal (41) (or a coil spring bracket (9)). Displacement of the spring seat member occurs in an axial direction of rotation of the bolt, in accordance with rotation of the bolt. According to the present invention, rotation of the spring seat involved in rotation of the bolt for adjusting the vehicle height can be restricted, and a construction of a vehicle height adjustment mechanism can be simplified so that the number of parts or members of the device is reduced.

Owner:ISUZU MOTORS LTD

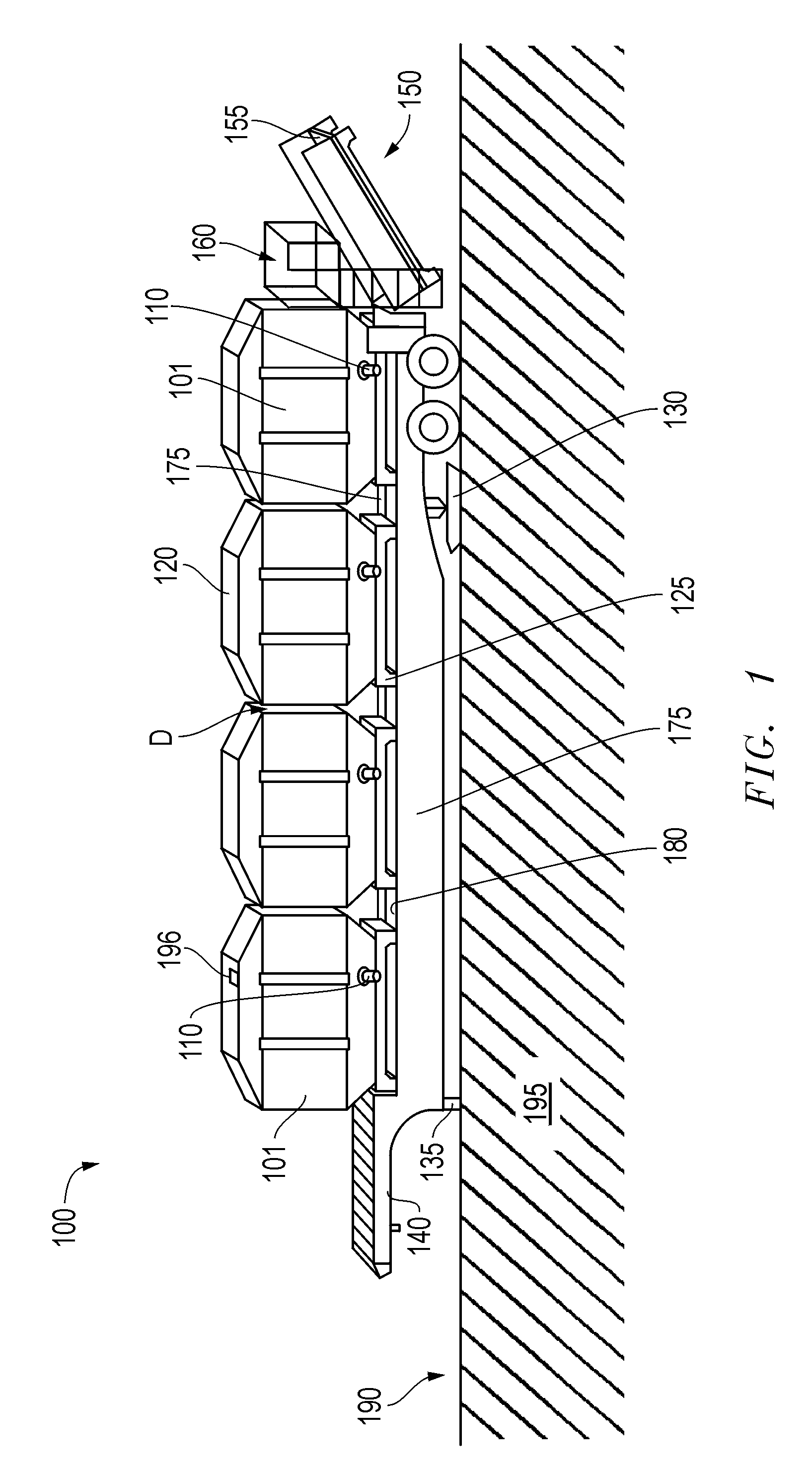

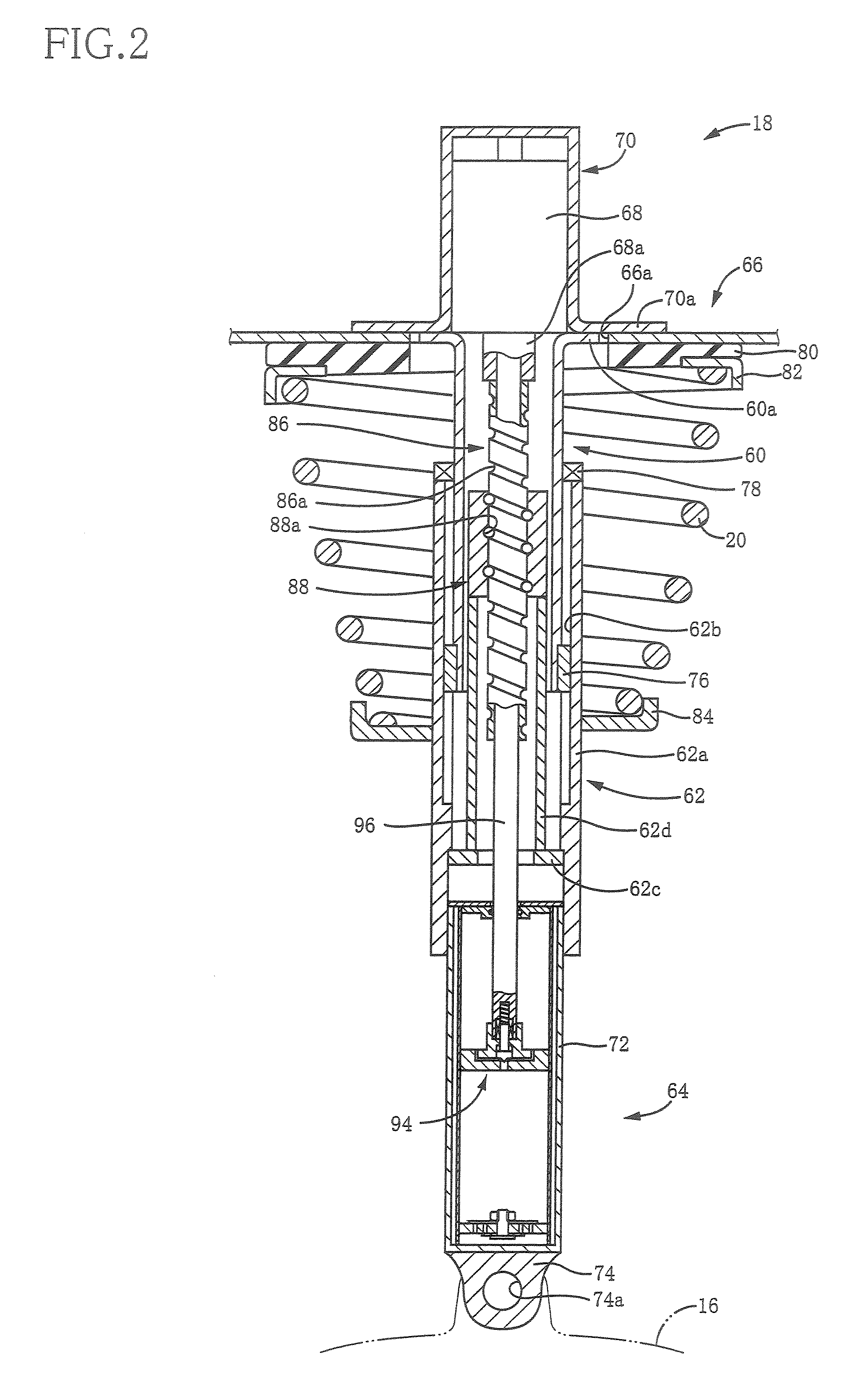

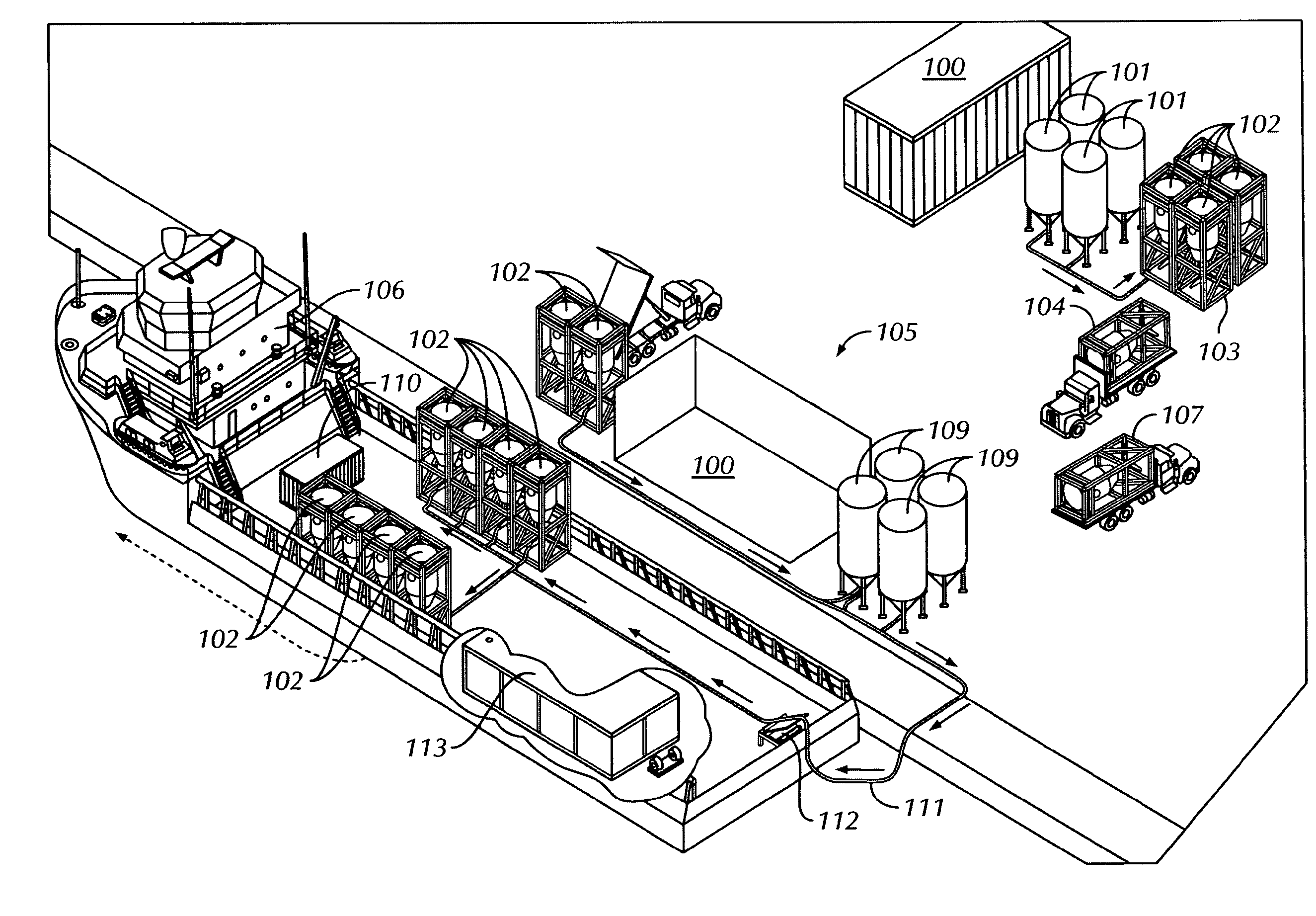

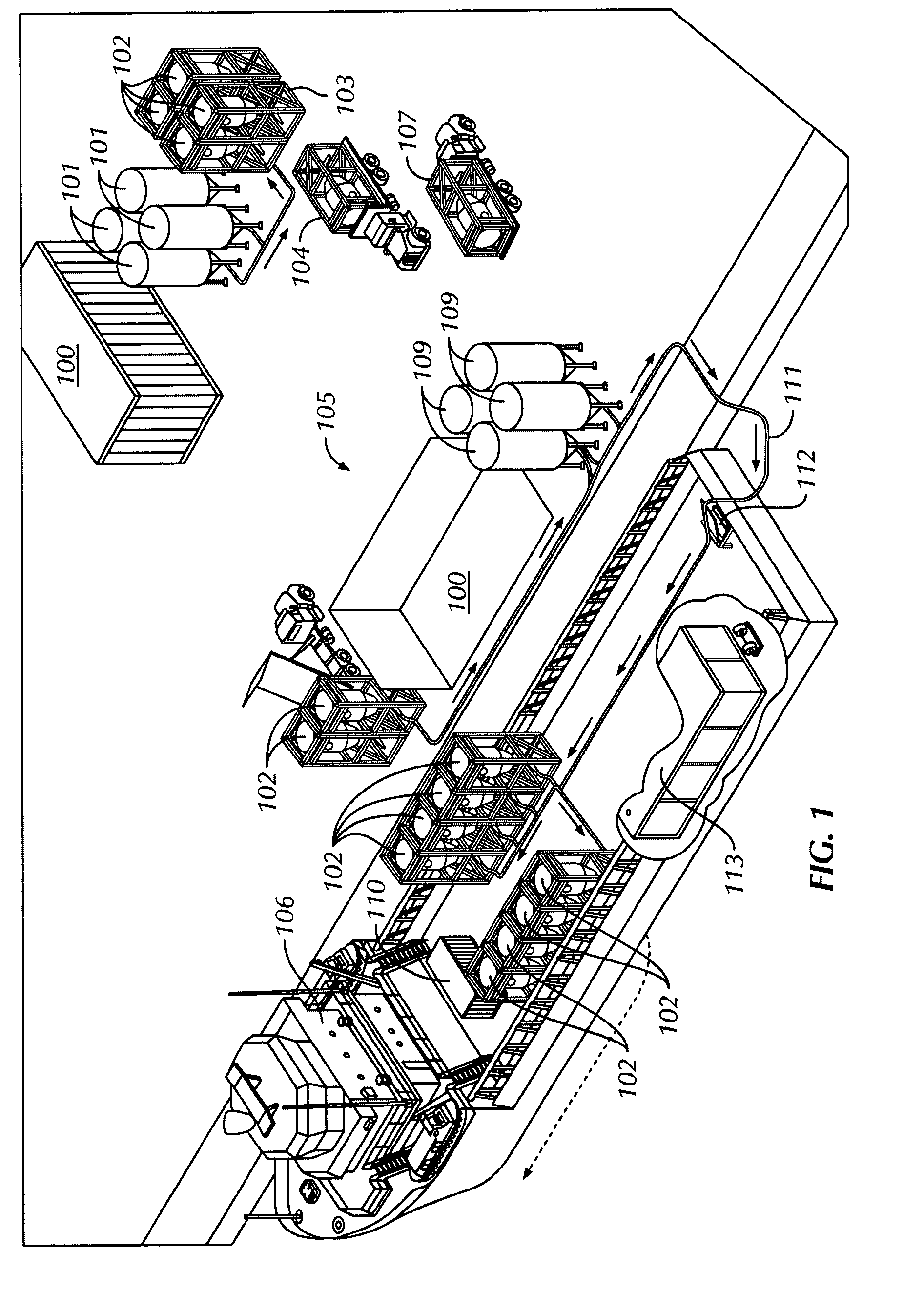

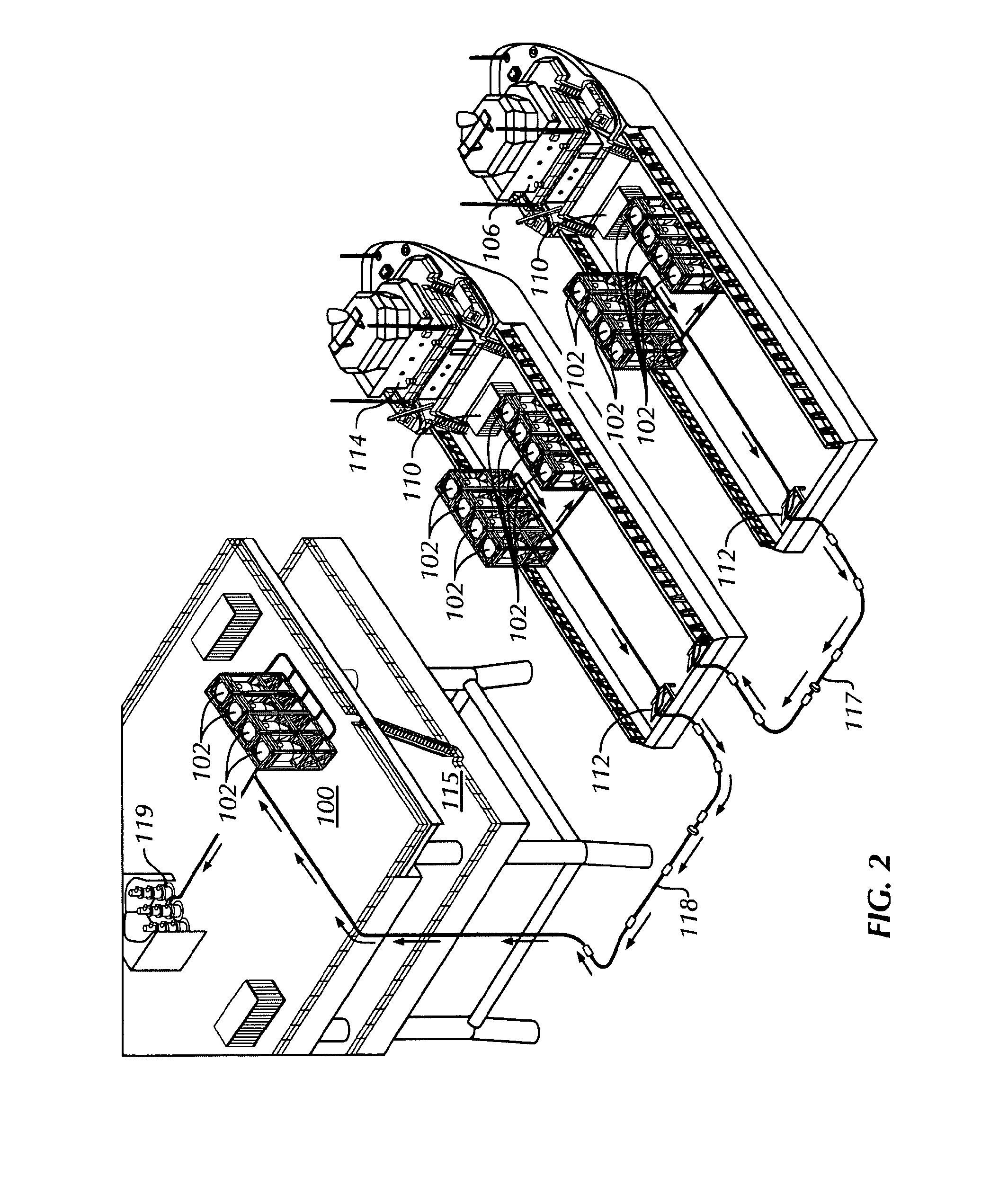

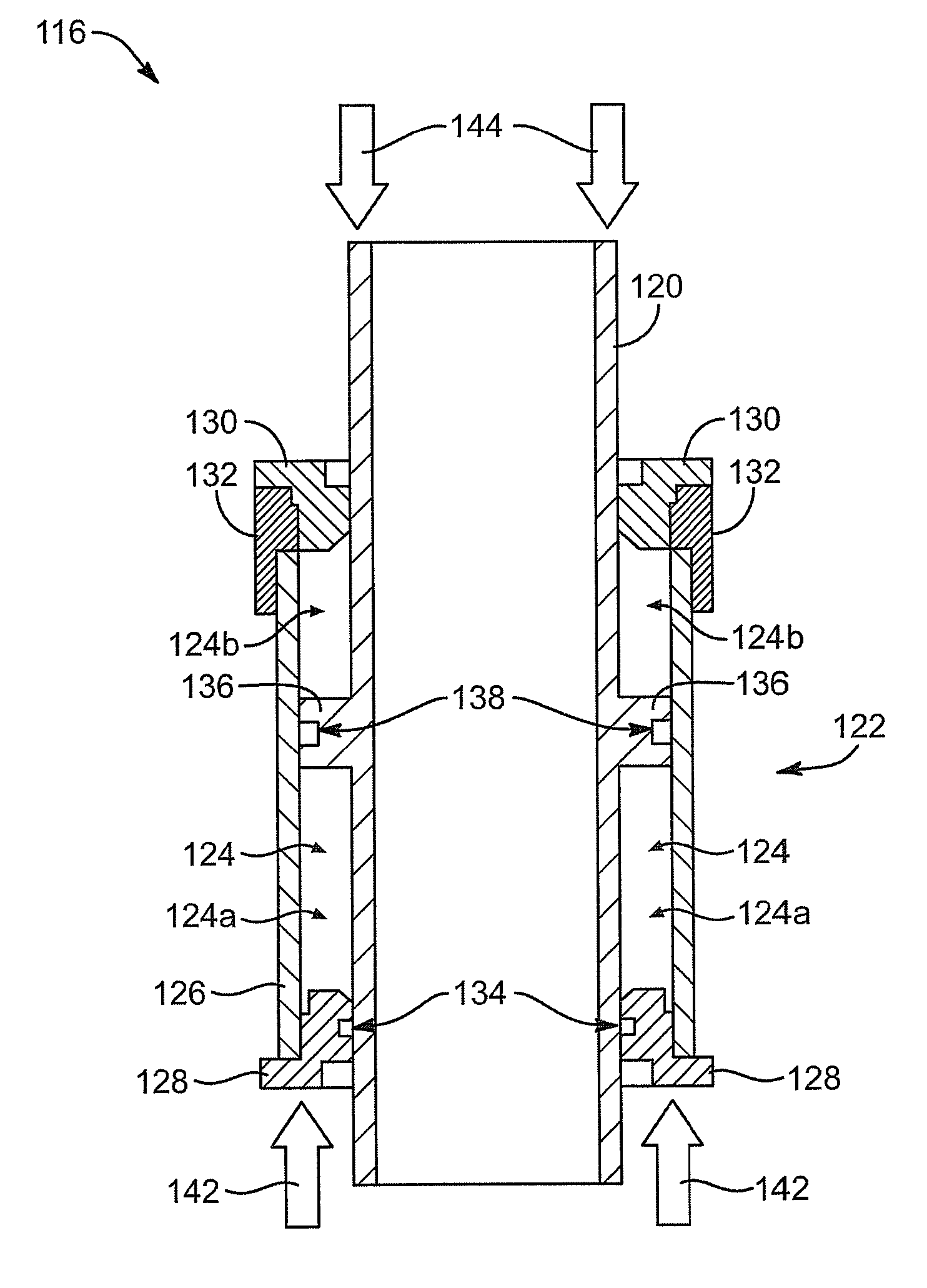

System and method for proppant transfer

A method of transferring proppant materials, wherein the method includes providing a first pressurized container (102) containing proppant materials on a first vessel (106). The method also includes connecting the first pressurized container (102) on the first vessel (106) to a second container (102) on a second vessel (114) and transferring pneumatically, proppant materials from the first pressurized container (102) on the first vessel (106) to the second container (102) on the second vessel (114). Also, a method of transferring proppant materials, the method including removing a wellbore fluid comprising excess proppant materials from a well, and screening the excess proppant materials from the wellbore fluid. The method also includes transferring the excess proppant materials to a first pressurized container (102) and transferring pneumatically, the excess proppant materials from the first pressurized container to a second pressurized container.

Owner:SHCLUMBERGER NORGE AS

Adjustable-height suspension system

InactiveUS7857325B2Vehicle cleaning apparatusLoading/unloading vehicle arrangmentVehicle frameEngineering

A system for adjusting the height or spacing between the frame and axle of a vehicle. The system may operate by manipulating a suspension system connecting the frame to the axle and comprising shock assemblies. The system may include hydraulic spacers selectively changing in length in unison, thereby manipulating the equilibrium positions of the shock assemblies and changing the distance between the frame and axle. Between changes in length, the hydraulic spacers may act as a substantially rigid bodies.

Owner:SRATS

Shipping container

InactiveUS20060267377A1Easy loadingLoading/unloading vehicle arrangmentMonocoque constructionsEngineeringFlange

A shipping container for powdered, pelleted, or other particulate material comprises an elongated body which is formed by top and bottom walls, front and back walls, and a pair of side walls. The back wall may be formed by a pair of doors which provide access to the interior storage enclosure of the body. One of the doors is provided with an inlet opening adjacent the top thereof for loading material into the storage enclosure. At least one of the doors is provided with an outlet opening adjacent the bottom thereof for unloading material from the storage enclosure. An inclined baffle extends from the bottom wall toward the outlet opening for guiding material toward the outlet opening when the front of the body is elevated. The outlet opening may include a flange for securing a flexible discharge conduit. In another embodiment the outlet opening and baffle are located in the front of the container. A front container mounted loading / unloading feature permits product delivery flexibility by allowing discharge through a tilted container without placing stress on the hinged doors.

Owner:FRONTIER LOGISTICS

Vehicle height adjusting apparatus

InactiveUS7316406B2Improve efficiencyReduce riskDigital data processing detailsAnimal undercarriagesRemote controlAir spring

A wireless remote control radio-transmits a vehicle height adjusting signal tagged with a remote control identification code in order to improve vehicle height adjustment operability in a vehicle such as a truck. The remote control identification code is pre-registered in a receiver, which, upon receipt of the vehicle height adjusting signal tagged with the remote control identification code, takes in the vehicle height adjusting signal. According to information contained in the received vehicle height adjusting signal, an air suspension ECU controls the supply and discharge of compressed air for air springs to adjust the vehicle height. When an emergency operation switch is operated, the vehicle height adjusting signal from the wireless remote control is disabled, and vehicle height adjustment is preferentially made based on a switching signal from the emergency operation switch.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

Full eject manual/automated side loader

ActiveUS7070382B2Conducive to loadRefuse receptaclesLoading/unloading vehicle arrangmentRefuse collectionFace sheet

A manual / automatic side loading and rear discharge refuse collection truck body as disclosed which incorporates full ejection without truck body tipping. A unique packing system as provided which includes a low profile packer panel which operates in a low profile charging material receiving hopper which also features lowered or dropped floor to facilitate optional manual loading. The charging hopper features a low profile which creates a dropper area beneath the forward portion of the storage enclosure so that material deposited in the charging hopper can be fed by the packing system into the storage enclosure through a bottom forward charging opening. A packer-ejector assist panel is provided to assist in clearing material from the dropped area portion of the charging hopper.

Owner:MCNEILUS TRUCK & MFG INC

Vehicle height adjustment device and vehicle height adjustment method

InactiveUS7631882B2Easy constructionReduce the number of partsSteering linkagesVehicle cleaning apparatusCoil springEngineering

A vehicle height adjustment device has an adjustment bolt (30) rotatably supported by or fixed to a wheel-side member or a vehicle-body member, and a spring seat member (10) threadedly engaging with the adjustment bolt. Rotation of the spring seat member is limited by a bump rubber pedestal (41) (or a coil spring bracket (9)). Displacement of the spring seat member occurs in an axial direction of rotation of the bolt, in accordance with rotation of the bolt. According to the present invention, rotation of the spring seat involved in rotation of the bolt for adjusting the vehicle height can be restricted, and a construction of a vehicle height adjustment mechanism can be simplified so that the number of parts or members of the device is reduced.

Owner:ISUZU MOTORS LTD

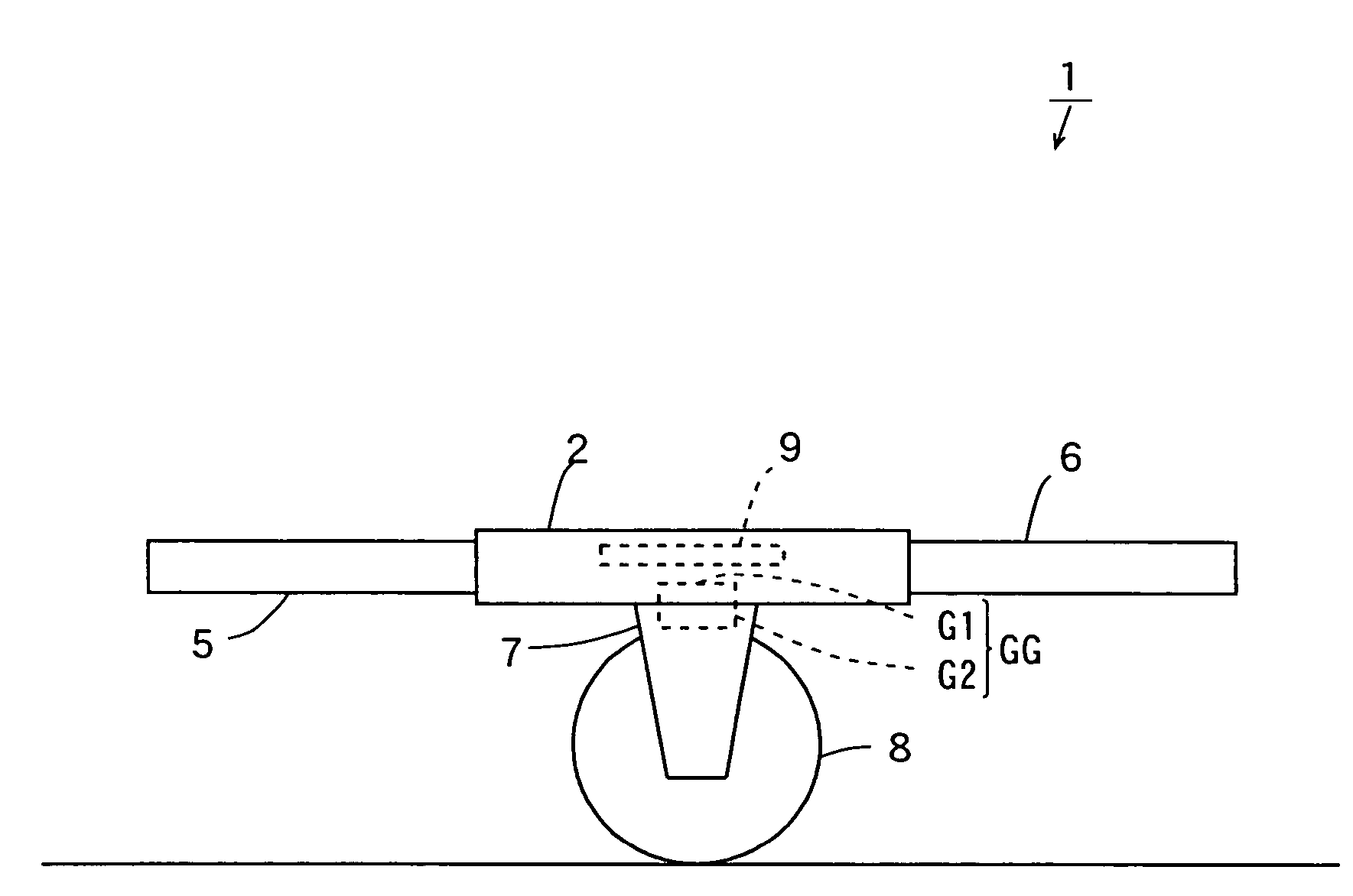

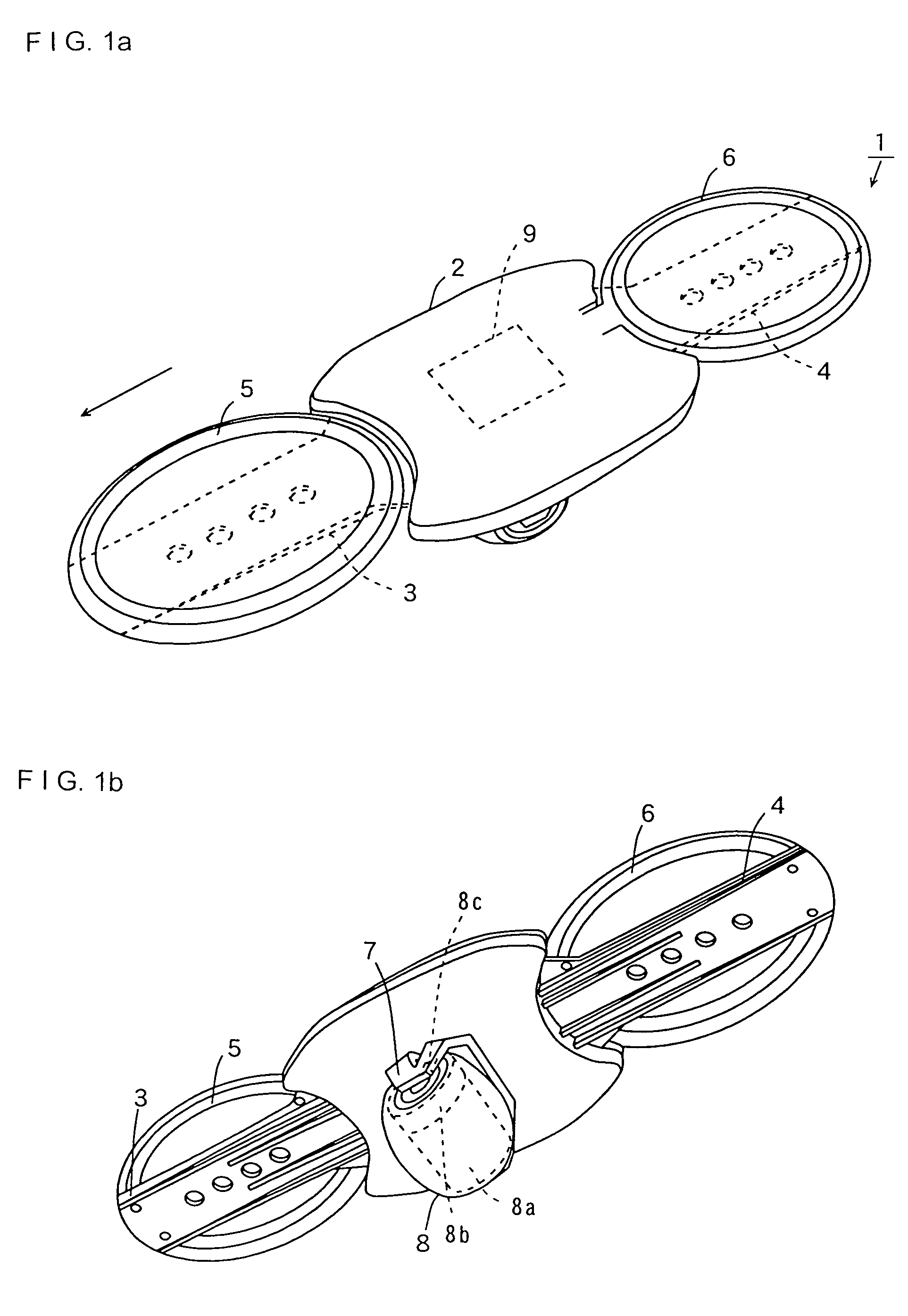

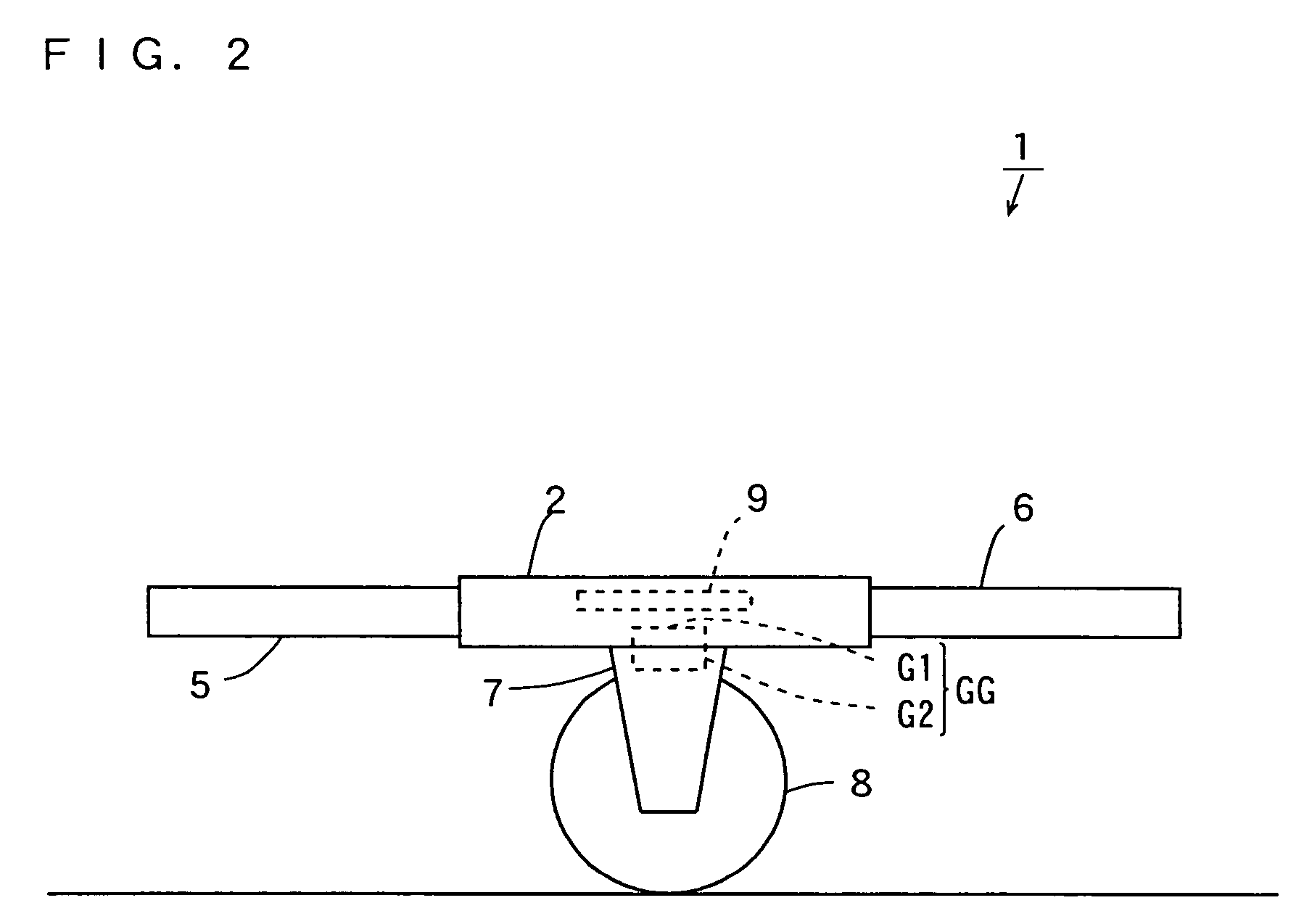

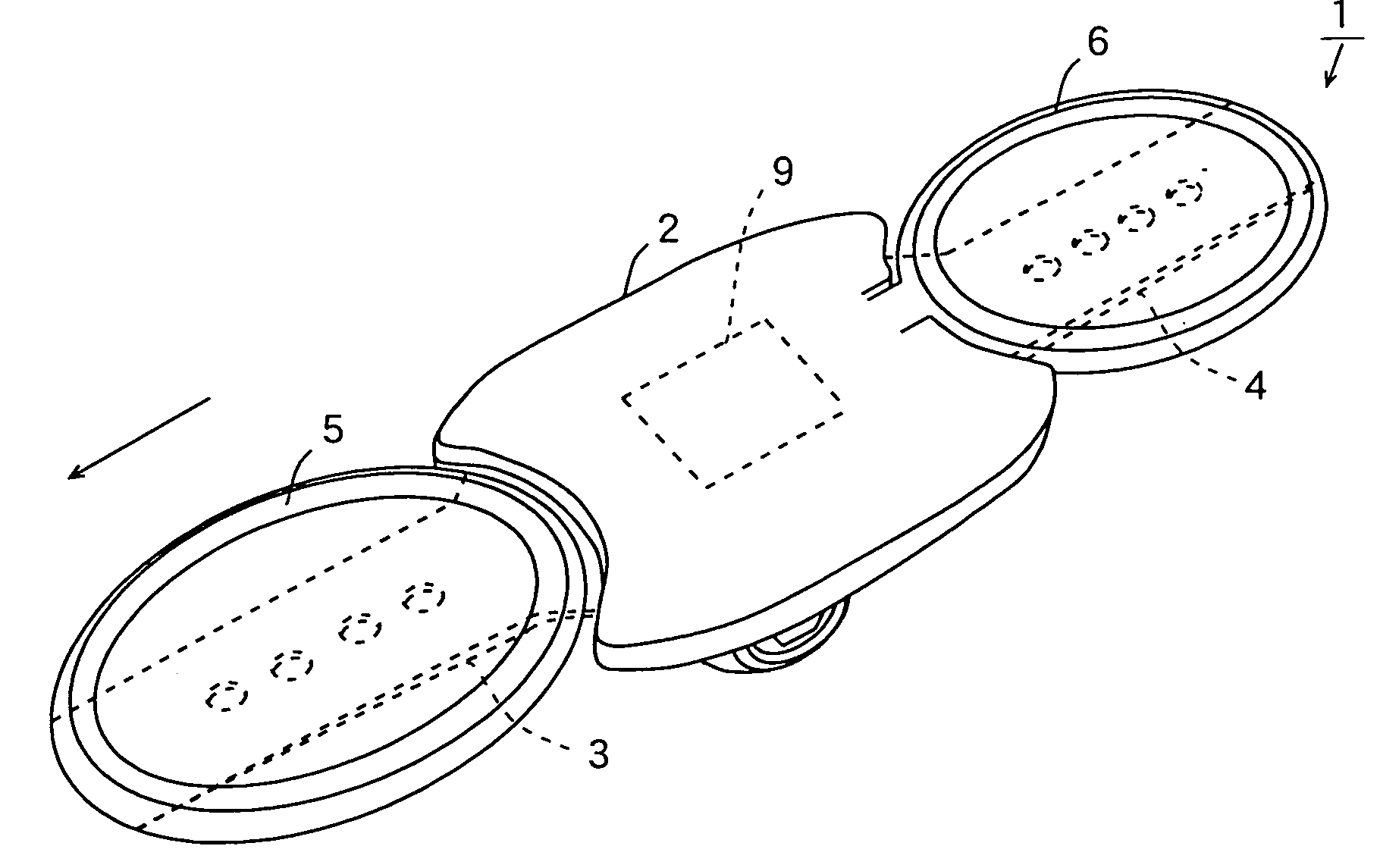

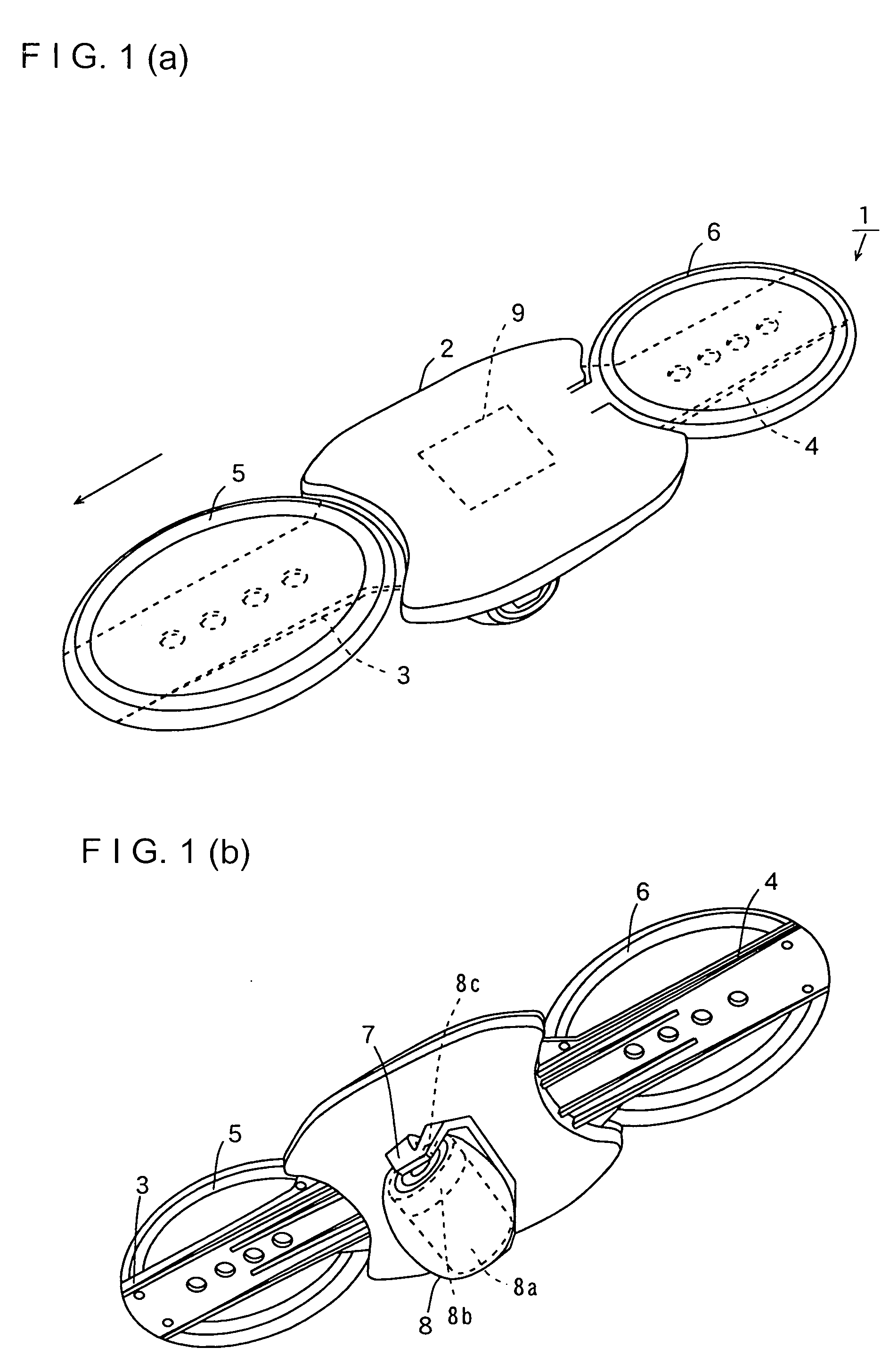

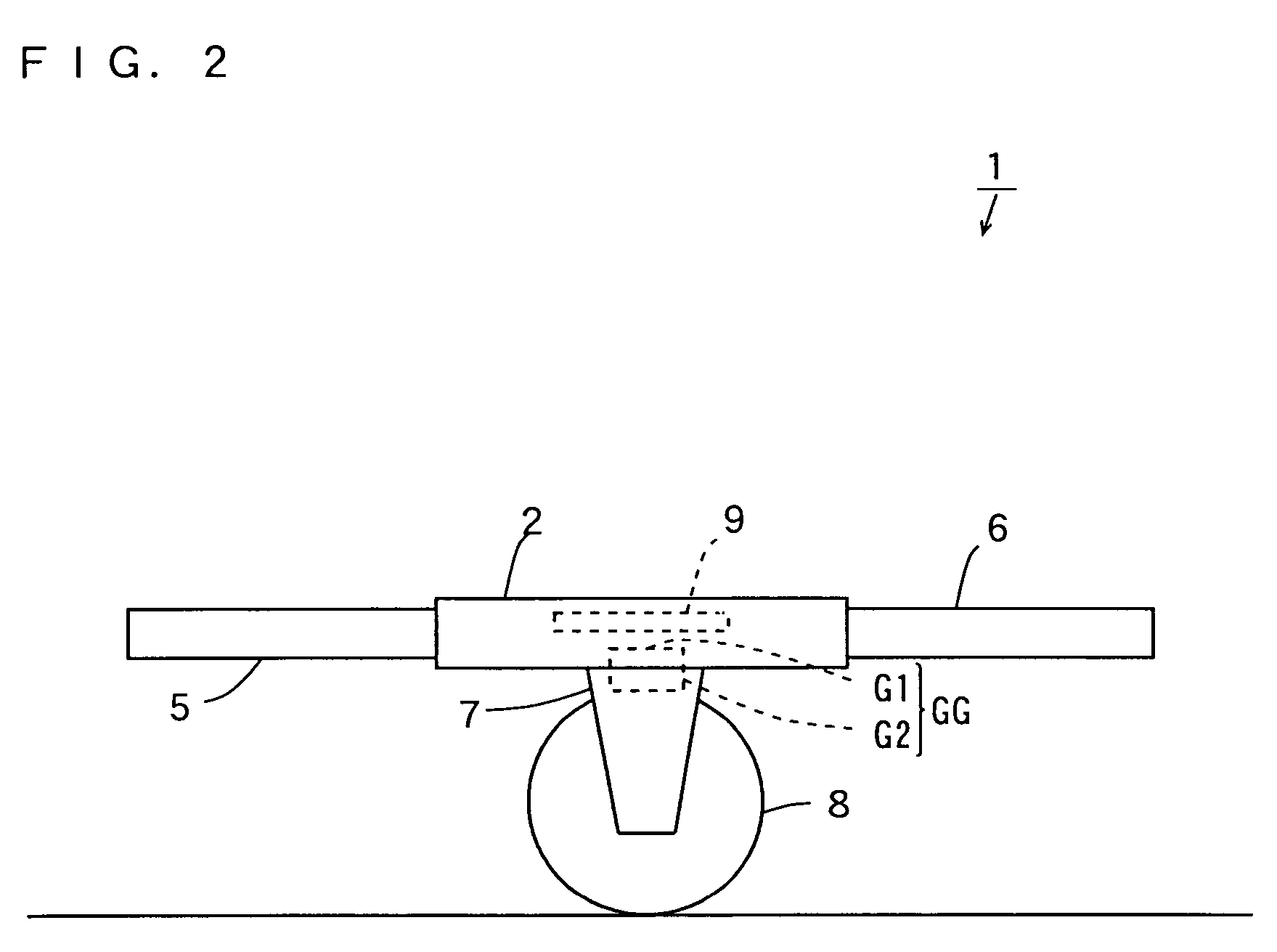

Vehicle, vehicle control device and vehicle control method

InactiveUS7424927B2Low costImprove securityVehicle body stabilisationUnicyclesAngular velocityControl mode

A motorized balance board includes a gyrosensor. An arithmetic operation unit calculates a tilt angle change value based on a signal output from the gyrosensor. When the control mode is a standby mode, a control mode switch element switches the control mode to a riding mode when the absolute value of the tilt angle change value exceeds a riding angular velocity threshold. When the control mode is the riding mode, the control mode switch element switches the control mode to the standby mode when the absolute value of the tilt angle change value exceeds a descending angular velocity threshold.

Owner:YAMAHA MOTOR CO LTD

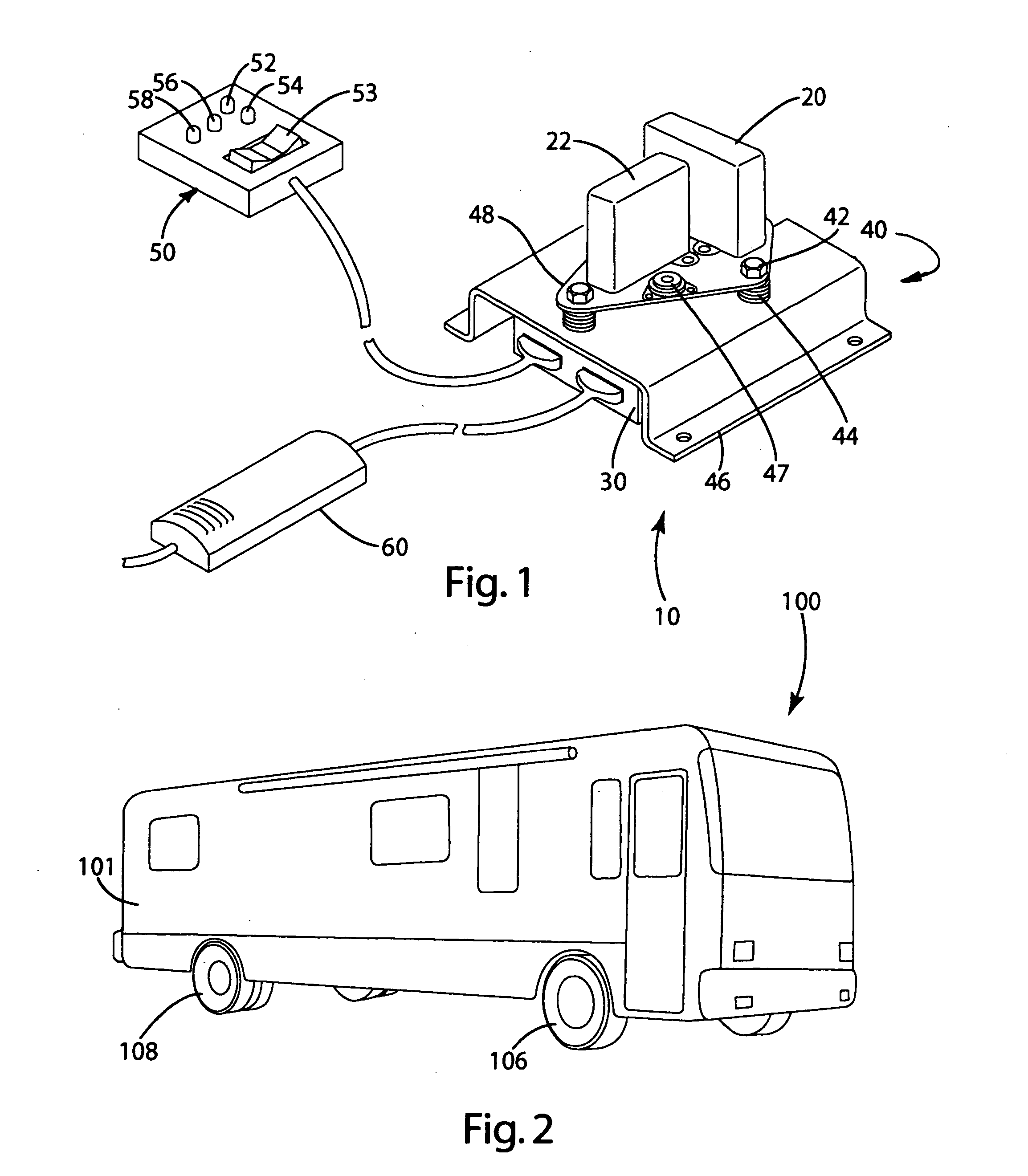

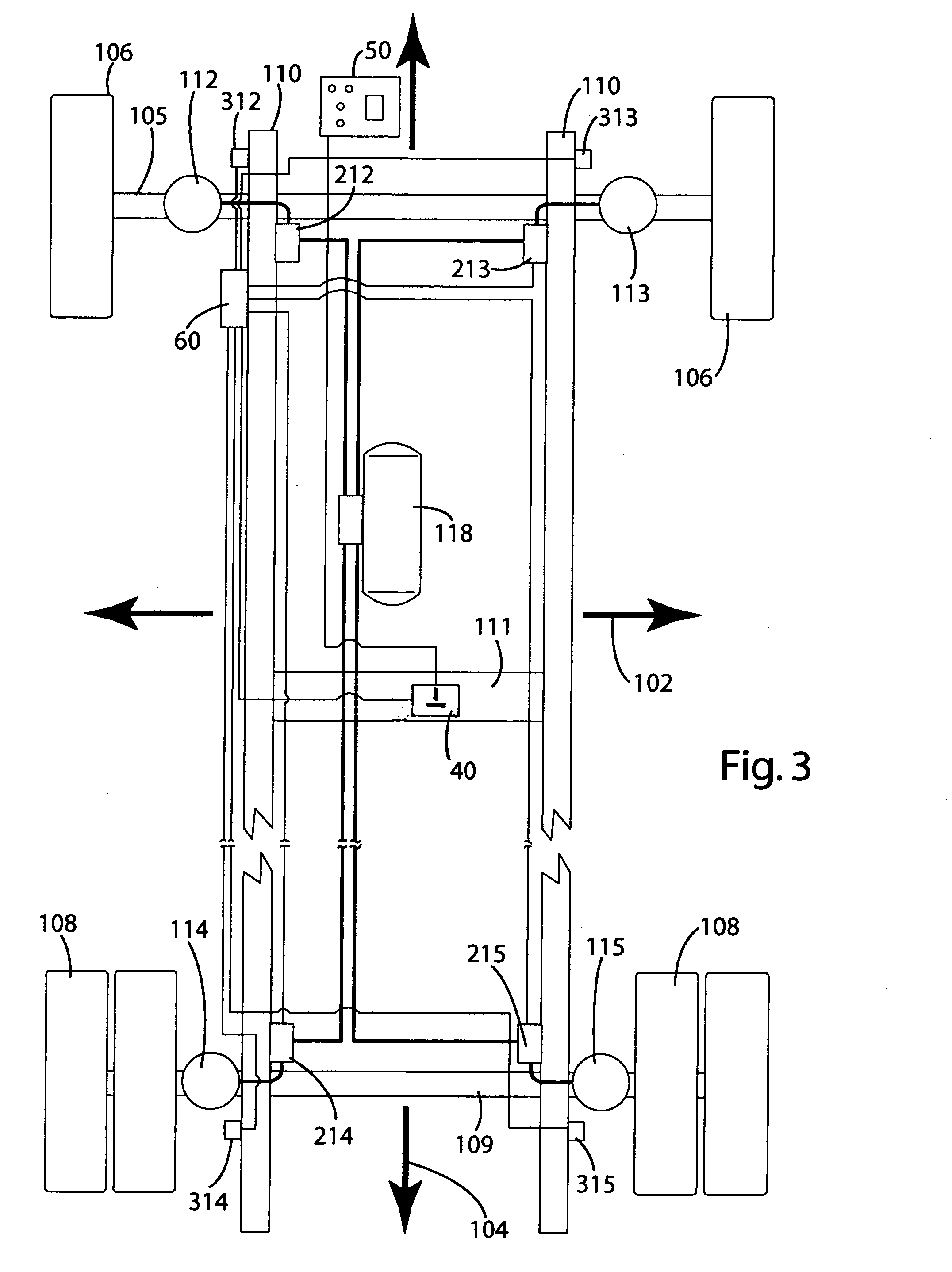

Vehicle leveling system

ActiveUS20050161891A1Precise positioningReduces and eliminates workDigital data processing detailsAnimal undercarriagesParking areaControl system

A vehicle leveling system including at least one level sensor, a controller and an output. The sensor measures how level the vehicle is relative to horizontal. Optionally, it does so dynamically, as the vehicle moves across a potential parking area. The controller analyzes the sensor measurements, and informs the operator via the output whether the vehicle is level in a given direction, whether the vehicle is leveling, whether the vehicle can be leveled at a given location, and / or the “best” leveling that the system is capable of at a location. The system also may automatically level the vehicle relative to the ground for the operator. In one embodiment, the leveling system communicates with an existing vehicle electronic height control system. The leveling system overrides or controls the normal operation of this system, and uses it to level the vehicle, for example, by adjusting the vehicle suspension.

Owner:LINK MFG

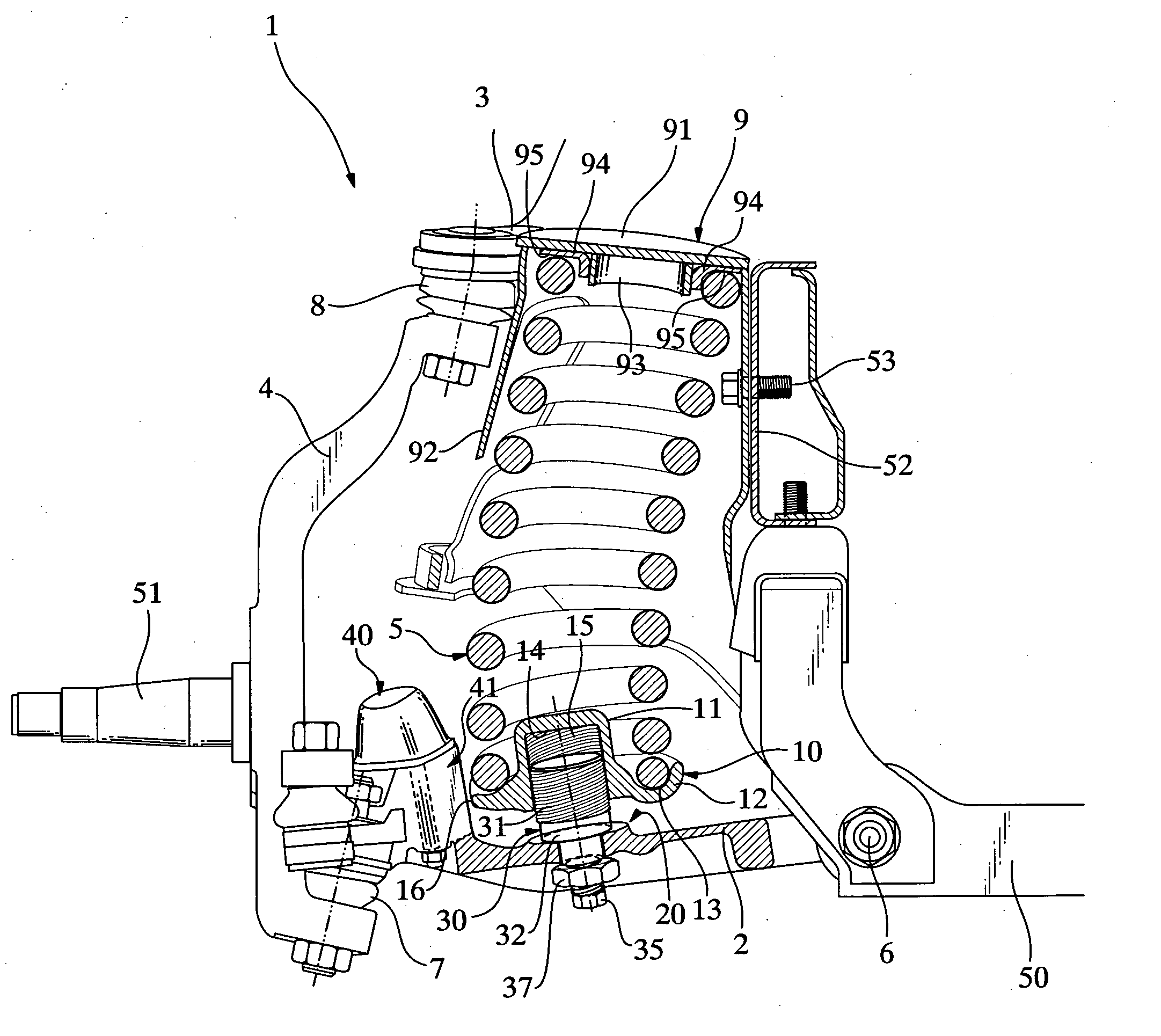

Vehicle height adjusting system

ActiveUS20070210539A1Stable supportCompact designVehicle cleaning apparatusToothed gearingsLinear motionDrive shaft

A first rotor (24; 124) and a second rotor (25; 125) are arranged in a coaxial and mutually rotatable relationship and are provided with a first driven gear (41; 141) and a second driven gear (42; 142), respectively. A drive shaft (31; 131) is also provided with a first drive gear (43; 143) and a second drive gear (44; 144) which are commonly connected to an output shaft of an electric motor (32; 132), and mesh with the first and second driven gears, respectively, at slightly different gear ratios. The first and second rotors are connected via a thread feed mechanism (36; 136) that converts a relative rotation between the first and second rotors into an axial linear movement between the first and second rotors that is used for changing a distance between a vehicle body part and a corresponding end of a suspension spring in a vehicle height adjusting system (9; 109). Owing to a differential rotation of a high gear ratio between the first and second rotors, a significant torque amplification is possible with a compact arrangement. The use of spur gears instead of a worm gear mechanism minimizes torque loss.

Owner:HONDA MOTOR CO LTD

Vehicle, vehicle control device and vehicle control method

InactiveUS20050241864A1Low costImprove securityVehicle body stabilisationUnicyclesGyroscopeControl mode

A motorized balance board includes a wheel rotation angle detecting sensor, a gyrosensor, and an acceleration sensor. An arithmetic operation unit calculates a rotation angle change value, a rotation angle value, a tilt angle change value, and a tilt angle value, based on signals output from the wheel rotation angle detecting sensor, the gyrosensor, and the acceleration sensor. When the control mode is a riding mode, a control mode switch element switches the control mode to a standby mode based on the rotation angle change value, the rotation angle value, the tilt angle change value, and the tilt angle value.

Owner:YAMAHA MOTOR CO LTD

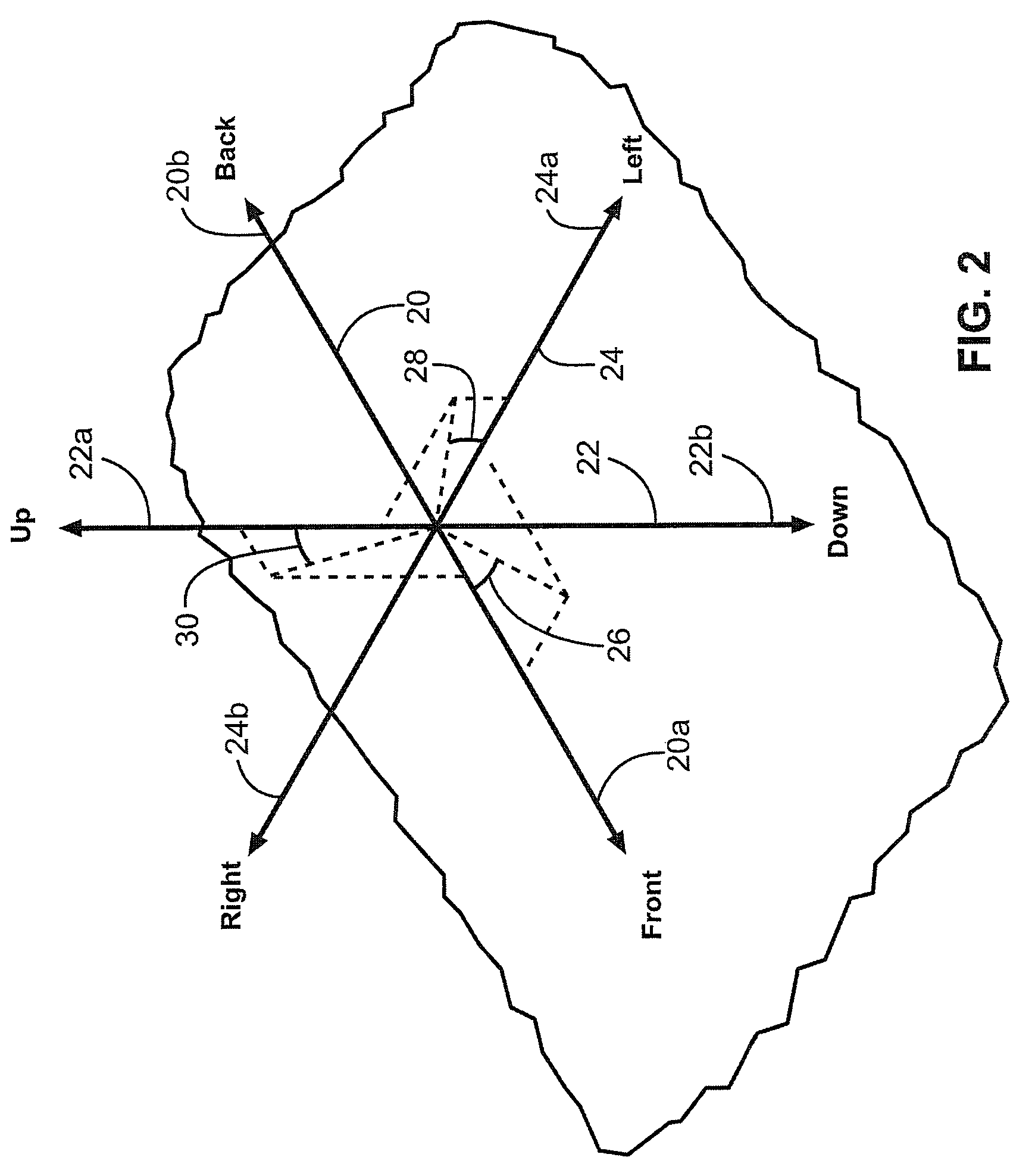

Vehicle leveling assembly

InactiveUS6584385B1Vehicle body stabilisationDigital data processing detailsMobile vehicleEngineering

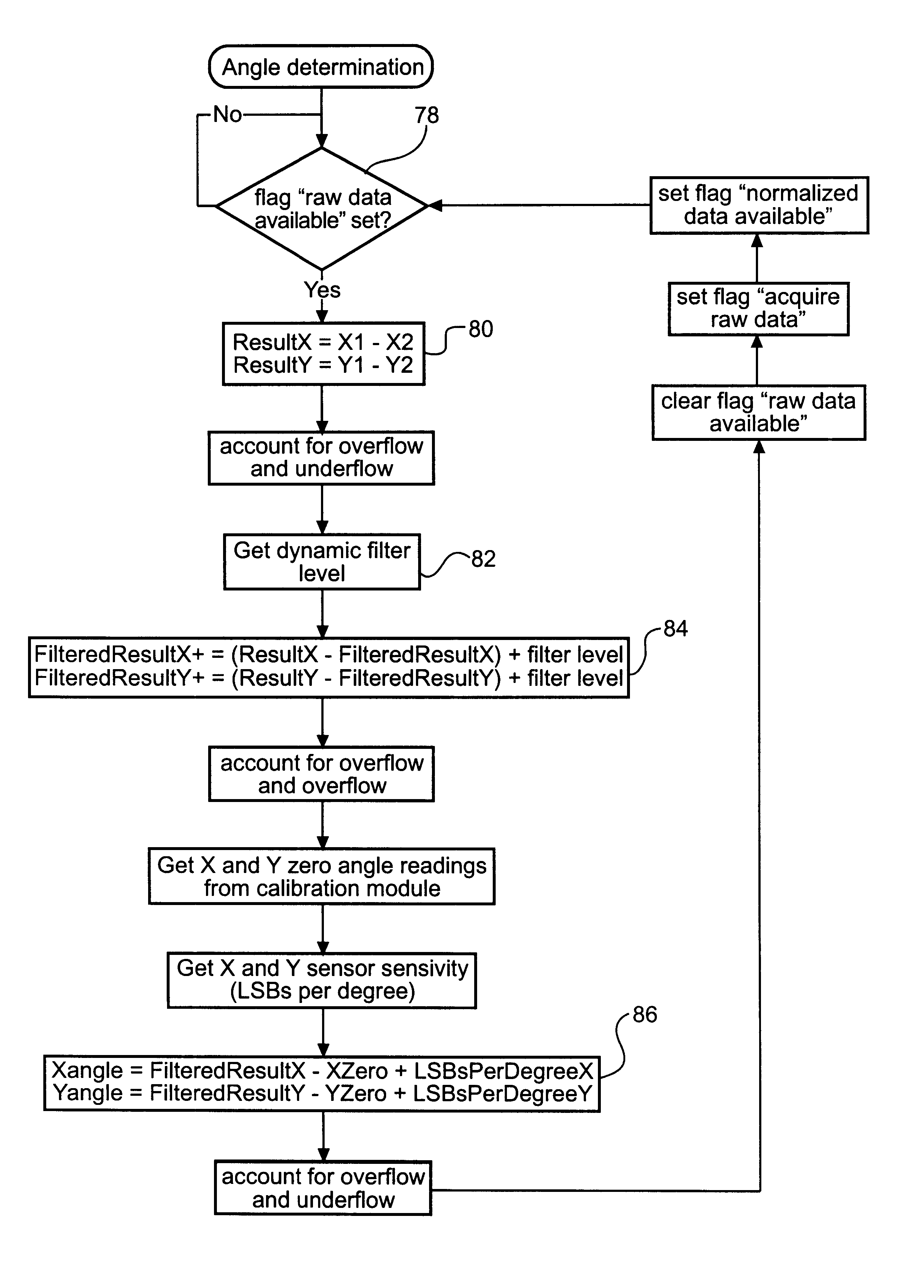

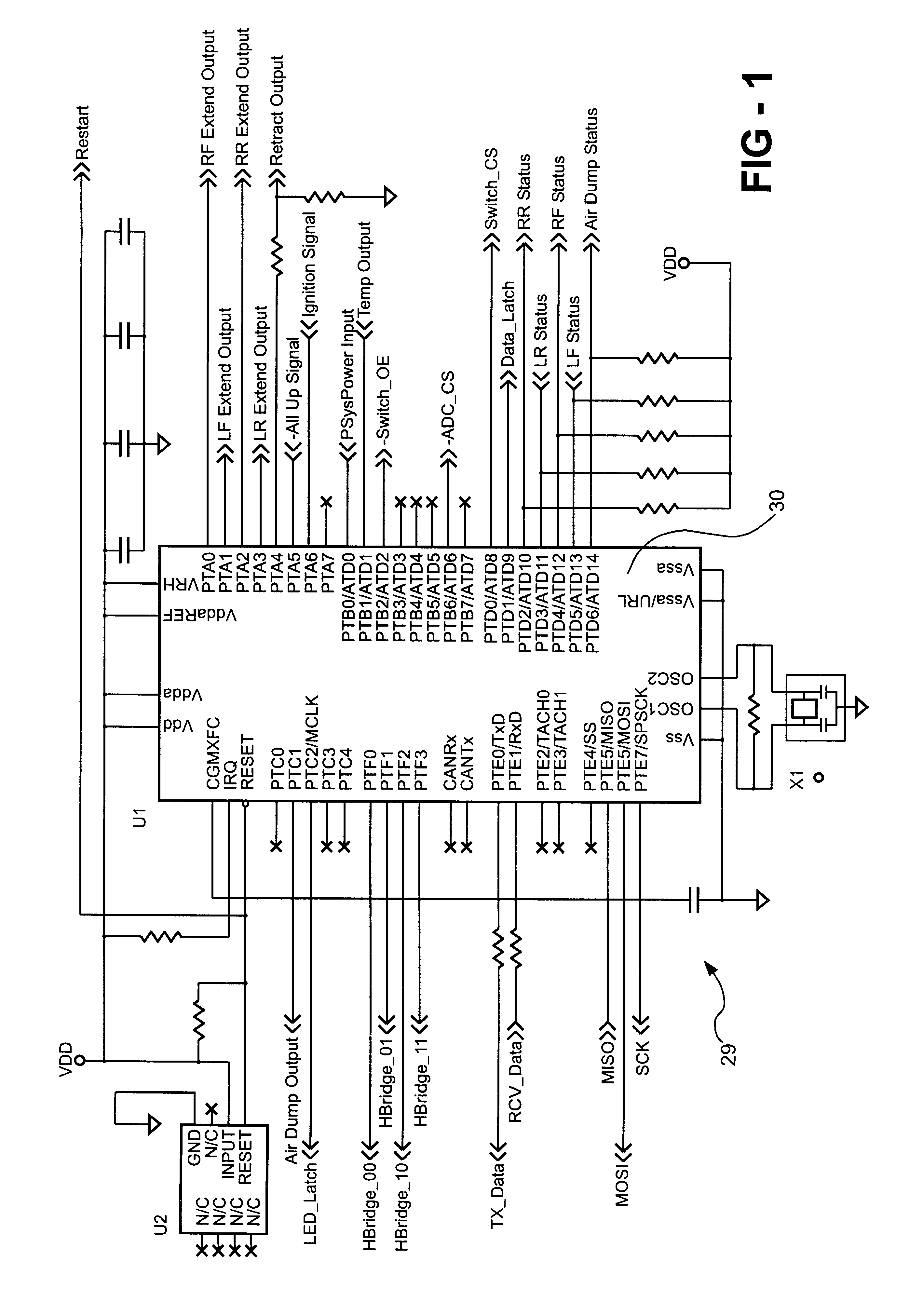

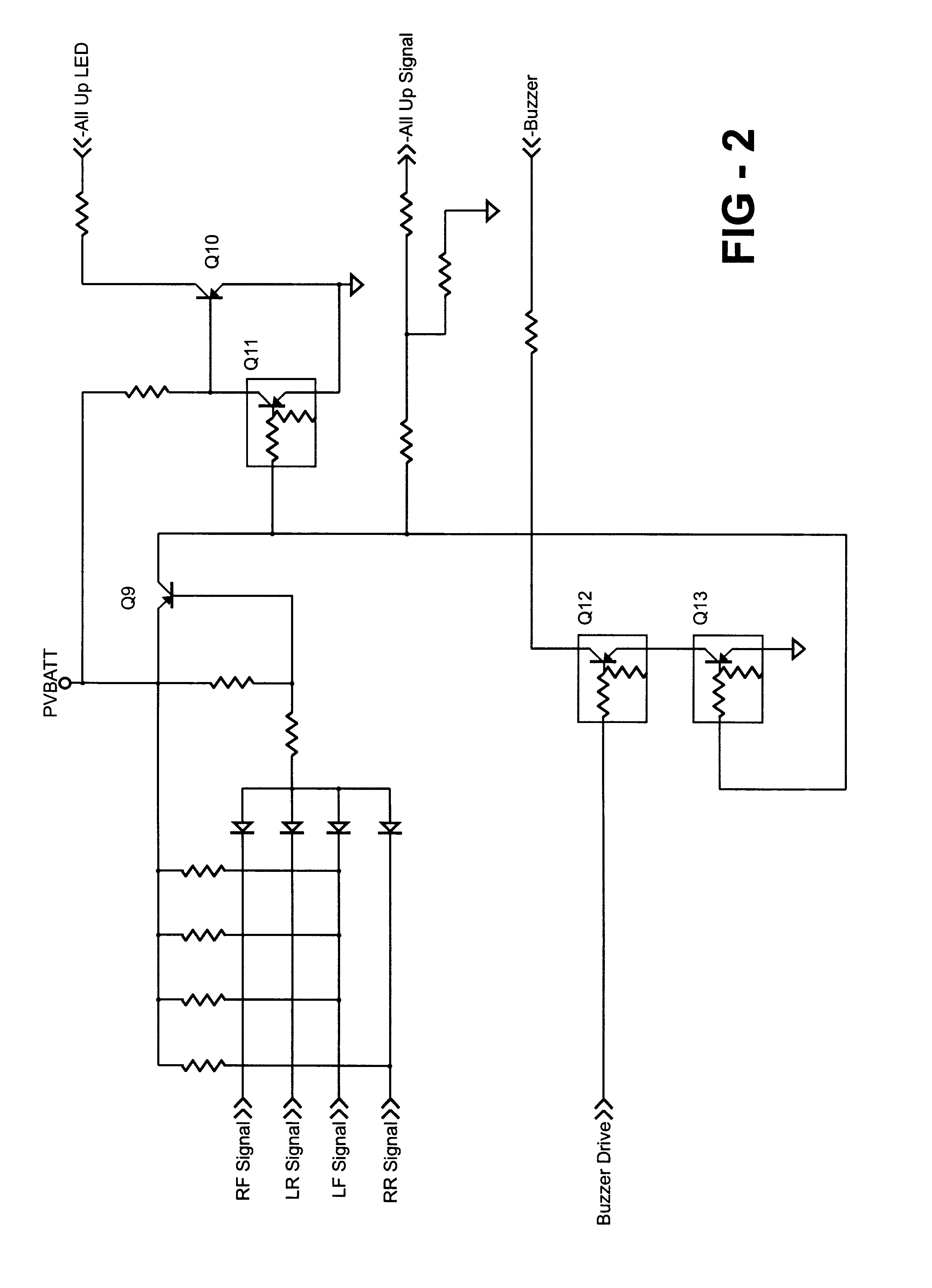

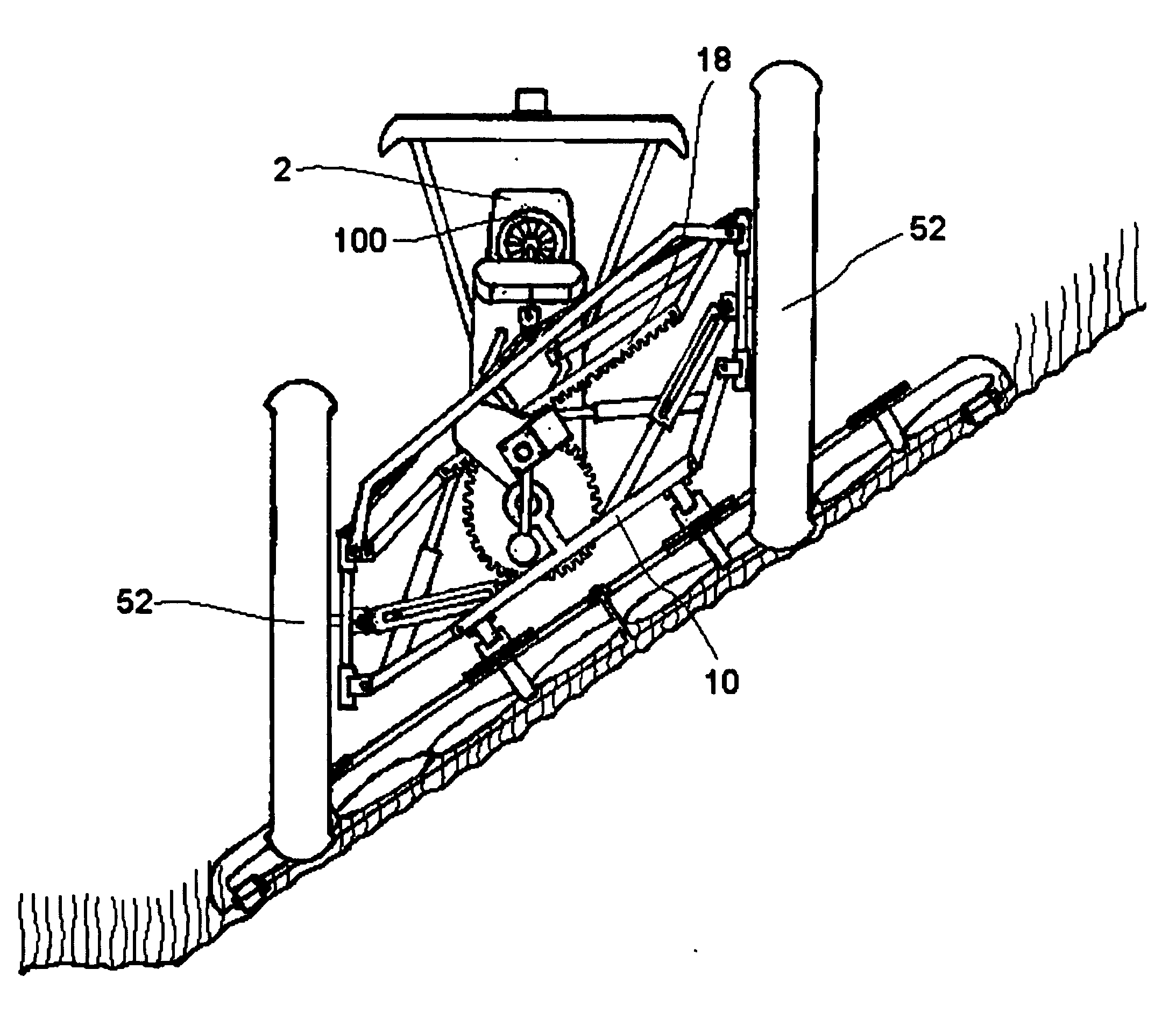

A leveling assembly for analyzing the attitude of a structure such as a motor vehicle in two axes. The assembly drives leveling devices on the structure to correct the attitude of the structure relative to a calibrated reference point or attitude. The assembly includes a controller connected to the leveling devices and a proportional two-axis tilt sensor that is connected to the controller and supported on the structure. The tilt sensor provides analog signals to the controller that represent the attitude of the structure about longitudinal pitch and lateral roll axes. The controller also uses those signals to determine the attitude of the structure relative to a calibrated sensitivity factor and a user-defined zero point. This allows an operator or installer to determine which portion of the structure will be leveled without regard to the location of the tilt sensor and allows an installer to mount the tilt sensor at any point on the structure.

Owner:INNOVATIVE DESIGN SOLUTIONS

Four wheel drive stationary body vehicle having controlled wheel and passenger compartment lateral lean with independent steering

InactiveUS20050206101A1Comfortable independent lateral leanIncrease speedVehicle cleaning apparatusLoading/unloading vehicle arrangmentGear wheelControl theory

In this vehicular chassis system, the vehicle's passenger compartment and wheels incline toward the turning center side in such a manner, that the wheels can be tilted independently from steering. This vehicle has a steering apparatus controlling the steering, and a separate apparatus controlling the lateral leaning. The lean is controlled mechanically using a pendulum, and forced lateral leaned using a control unit, or manually with the transfer of body weight using several pinions with a set ratio to control the passenger compartment lateral lean in conjunction with the wheel lateral lean. An electric DC servo gear motor can be used to control the lateral lean, that intern moves a pinion, which moves a rack and lateral movable cross member, while controlling the lateral leaning wheels and pulling the tilt support bar pivotally attached to a passenger compartment in the same leaning direction.

Owner:BOUTON TODD RICHARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com