Universal flow track system

a technology of flow track and storage system, applied in the direction of dismountable cabinets, transportation items, refuse gathering, etc., can solve the problems of ineffective rails, inability to properly support heavy loads, and inability to meet the needs of users, and achieve the effect of low profil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

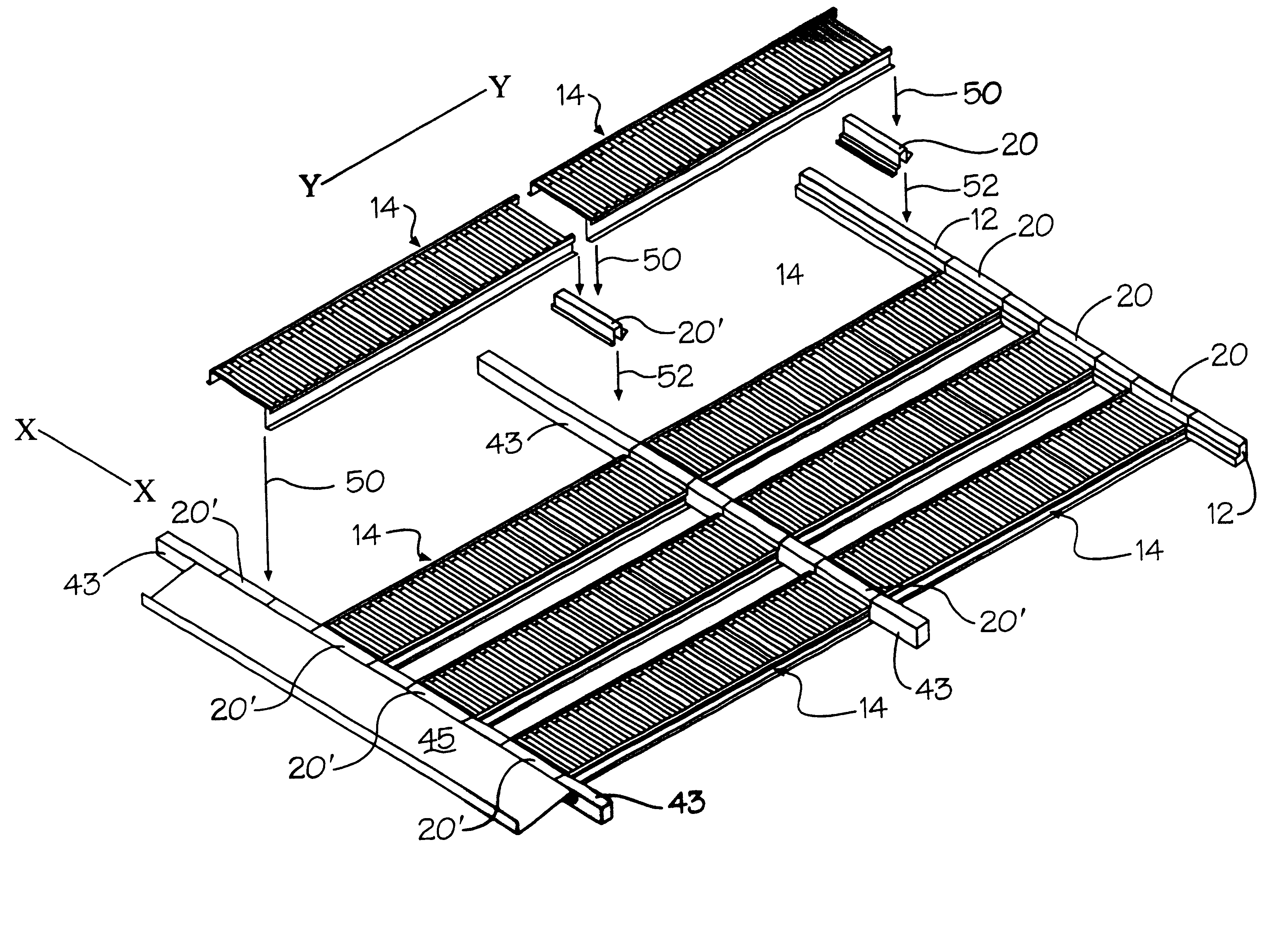

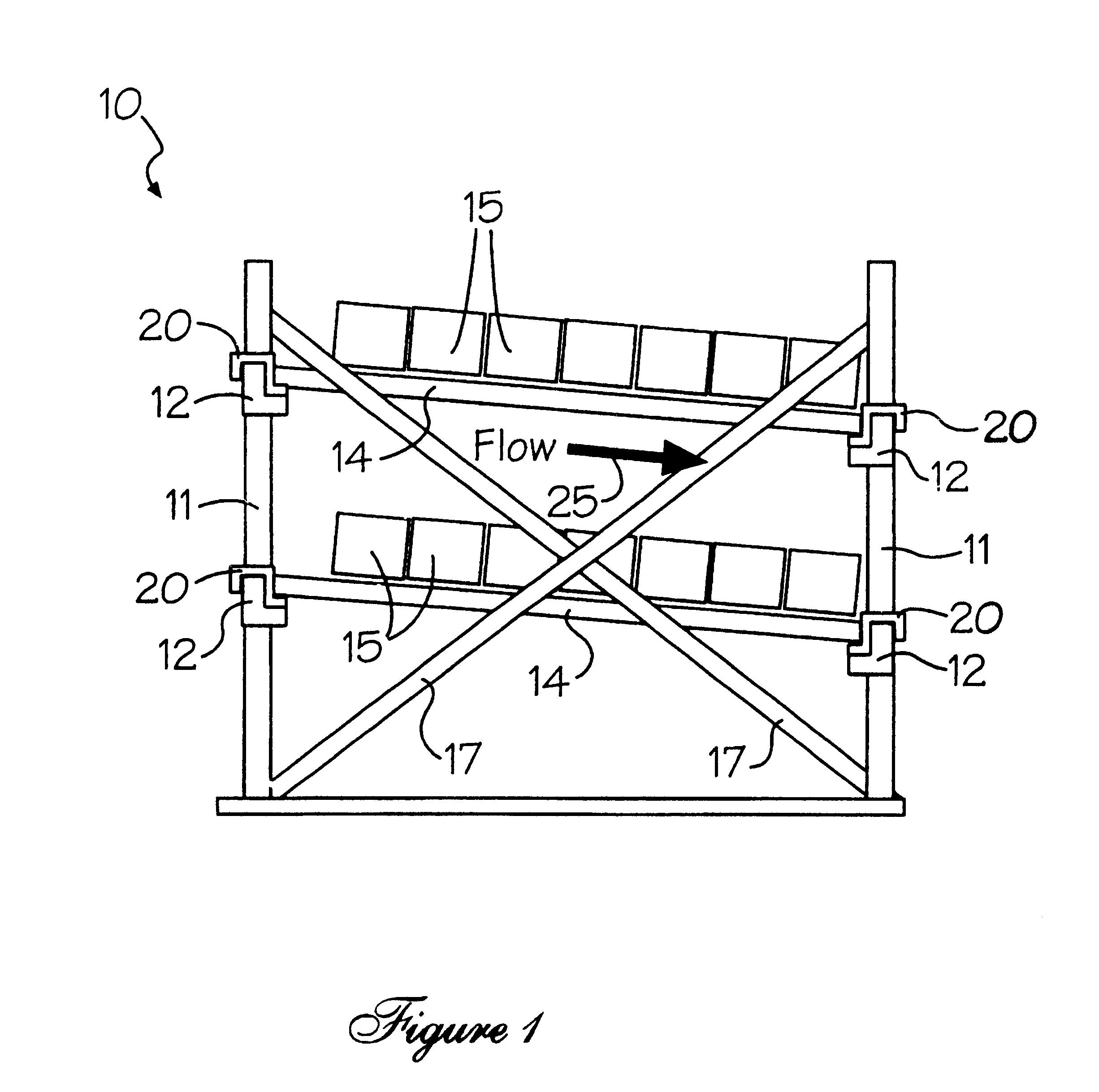

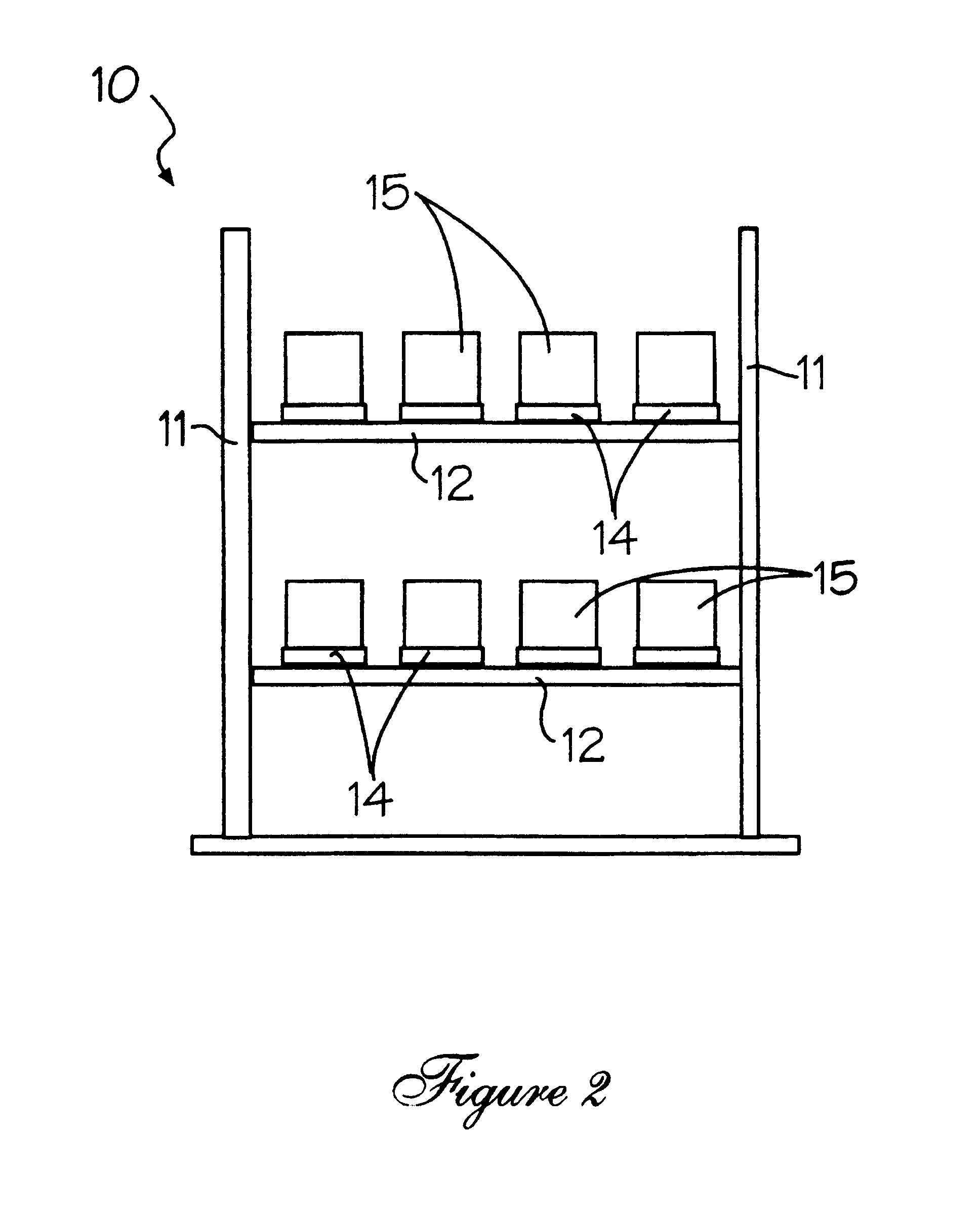

Generally speaking, the invention features a flow track comprising a plurality of periodically-spaced rollers, upon which materials can be conveyed from one position to another on the span. The rollers are rotatively supported between two rails or channels defining the flow track. The flow track is positionable between two end support beams of a storage frame or pallet rack, with each end support beam supporting a distal end of the flow track. The flow track is adjustably positionable along the entire horizontal length of the respective end support beams. A movable hanger member supports the flow track for adjustment about the end support beams, and is movable in a horizontal direction (along the X-axis or the longitudinal length of the support beams) with respect to the storage frame or pallet rack. An extended flow track system is achieved in the depth or material flow direction (Y-axis) by use of an alternate hanger member at mid-span. A front slide member is attachable to the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com