Patents

Literature

5750results about "Roller-ways" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

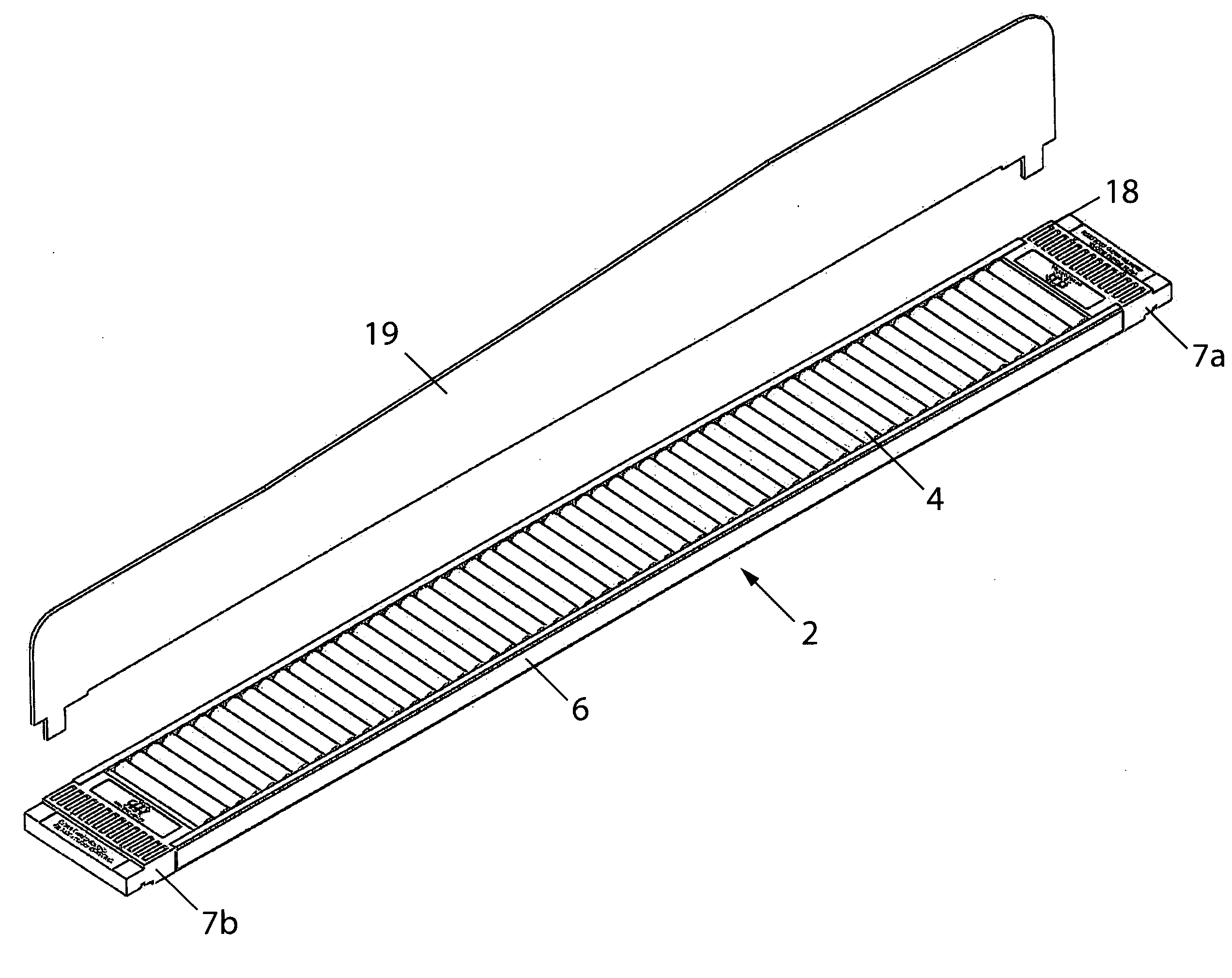

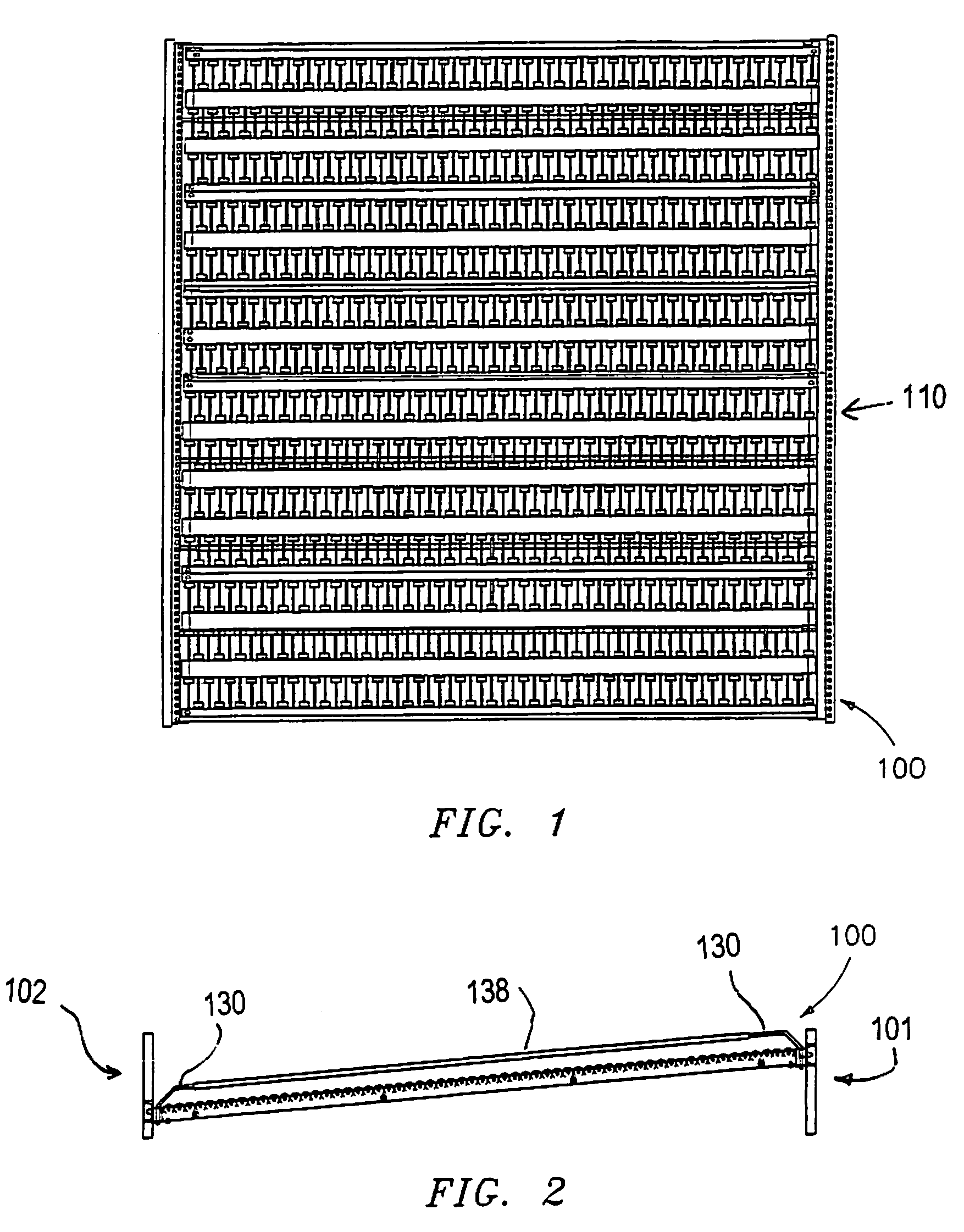

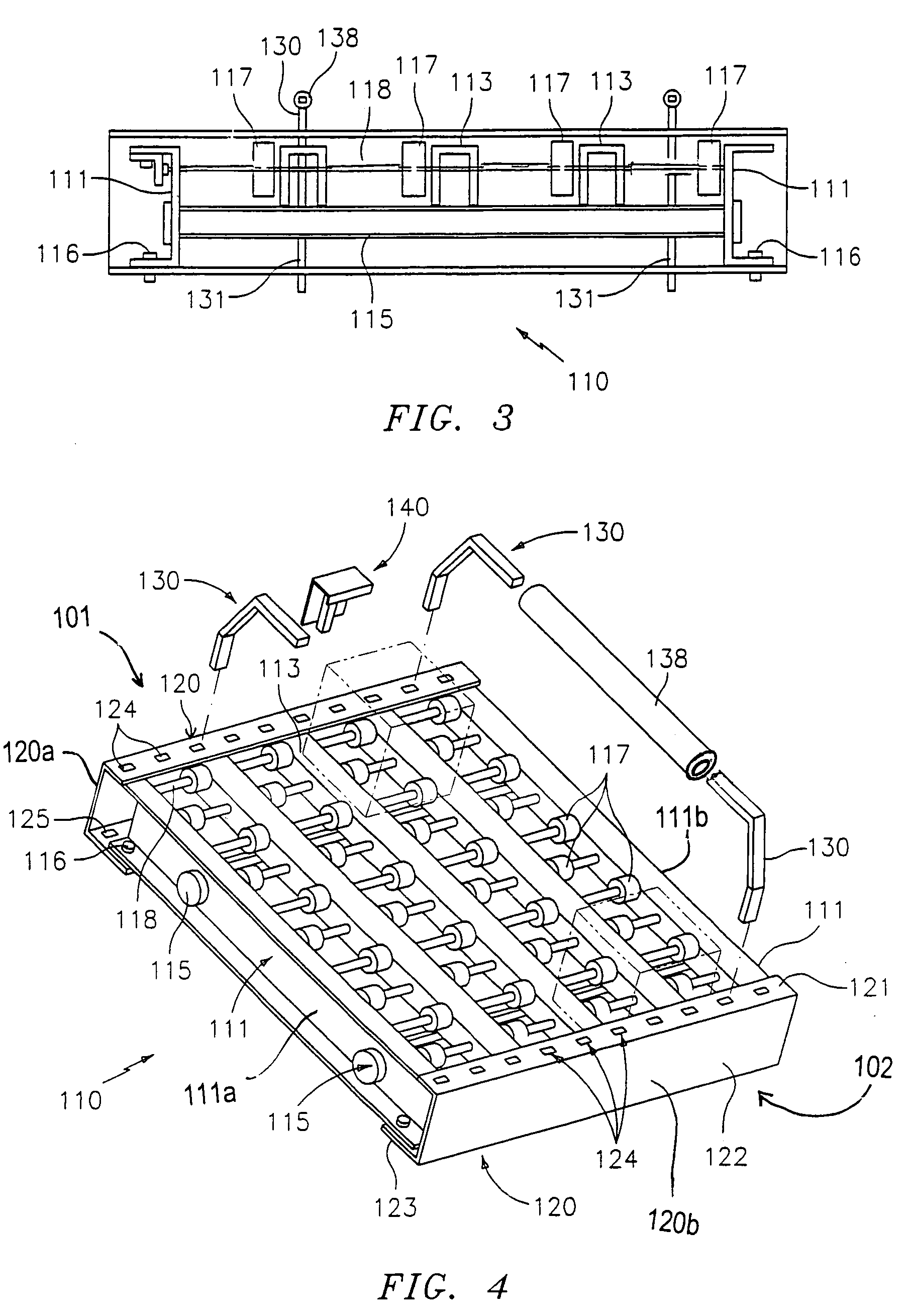

Flow rack

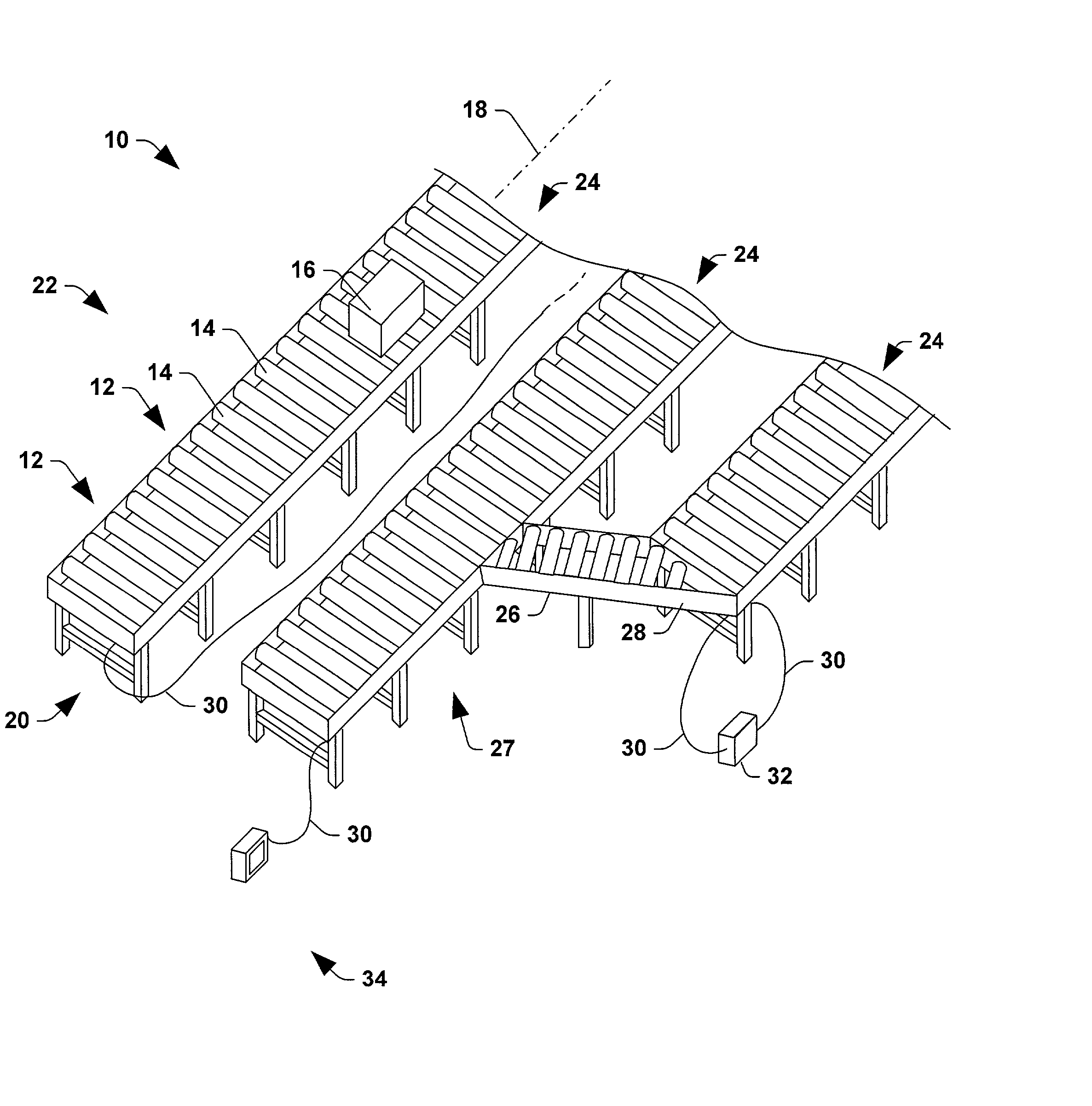

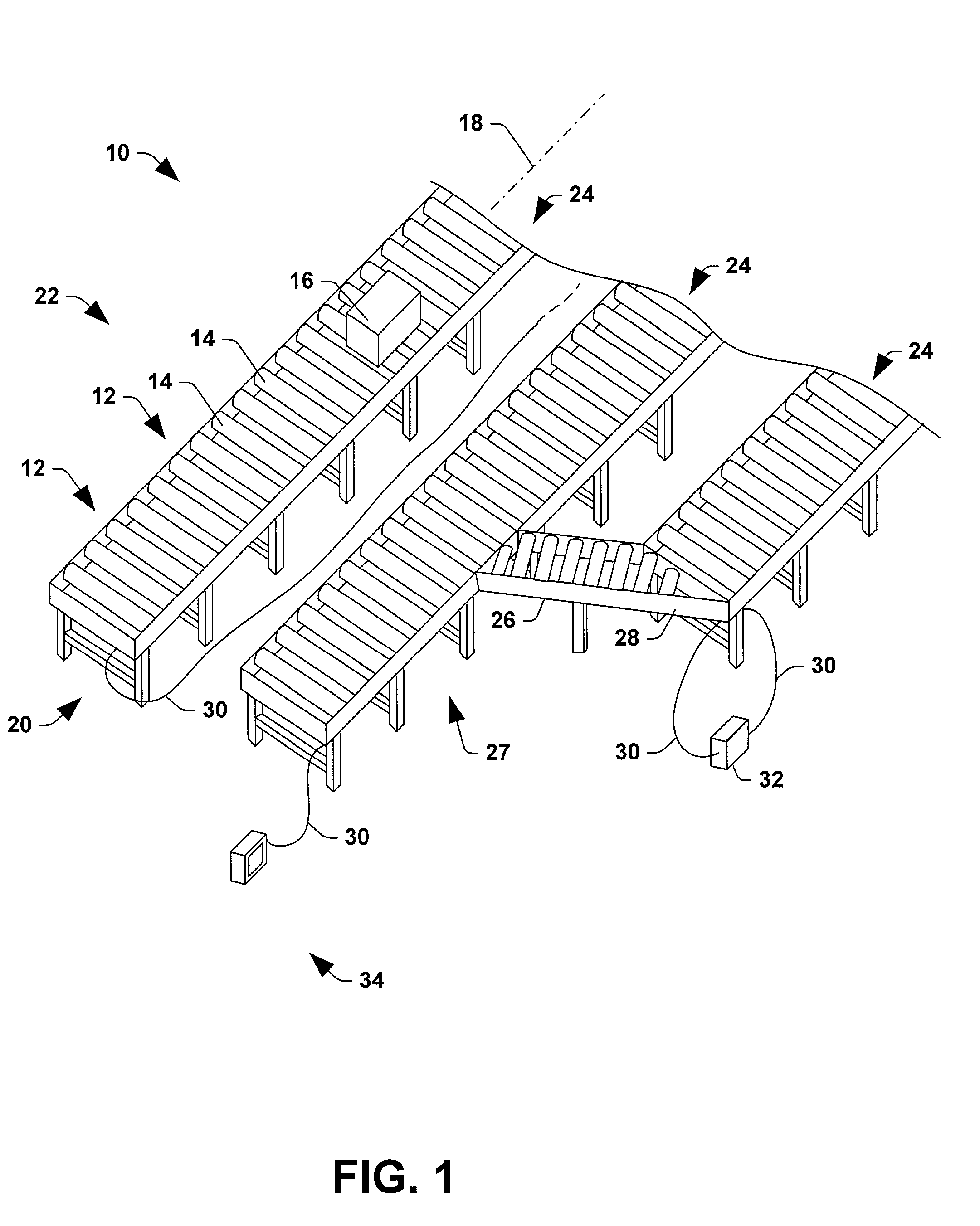

InactiveUS6948900B1Easy to assembleEasy to replaceShow cabinetsSupporting partsFree rotationEngineering

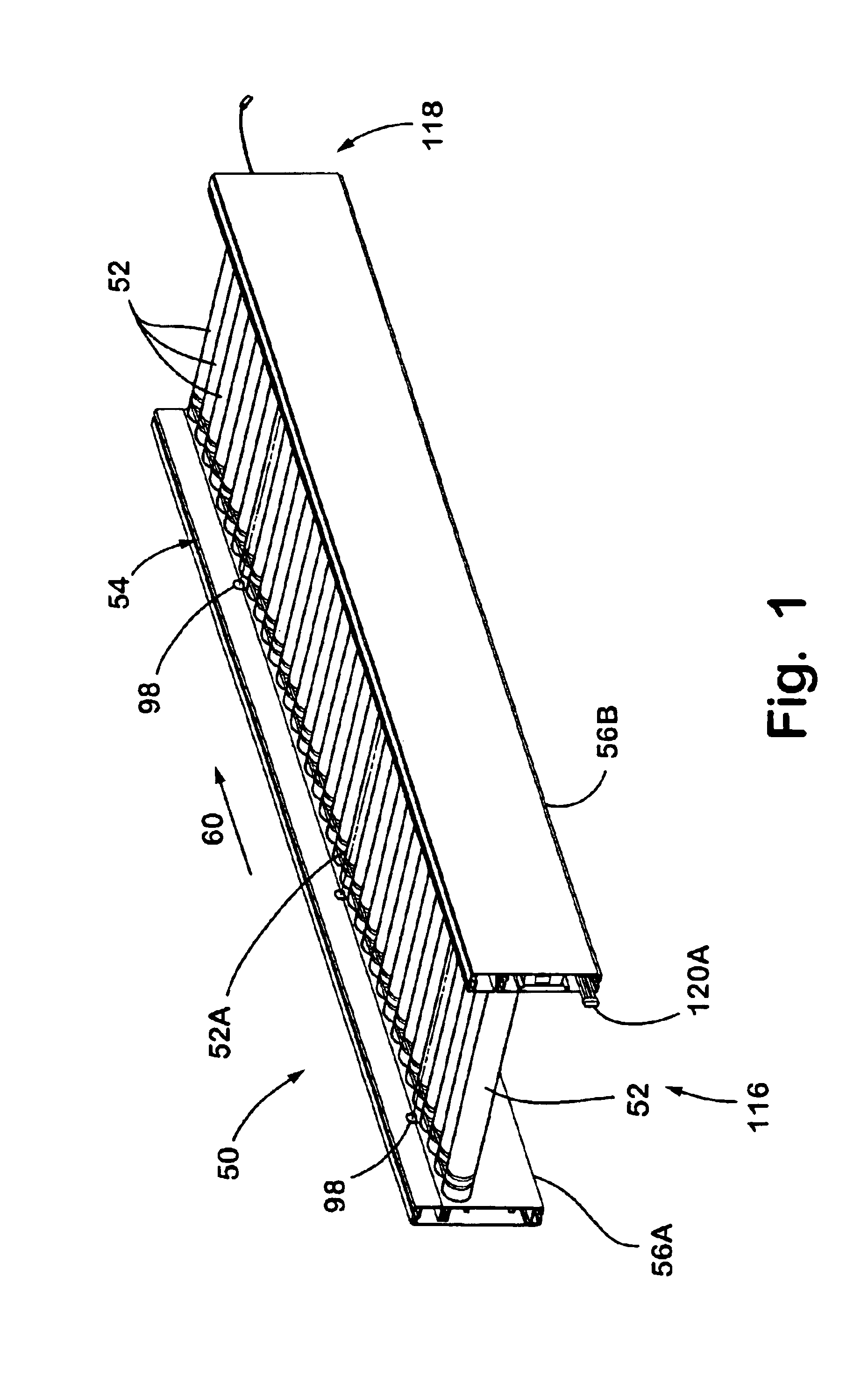

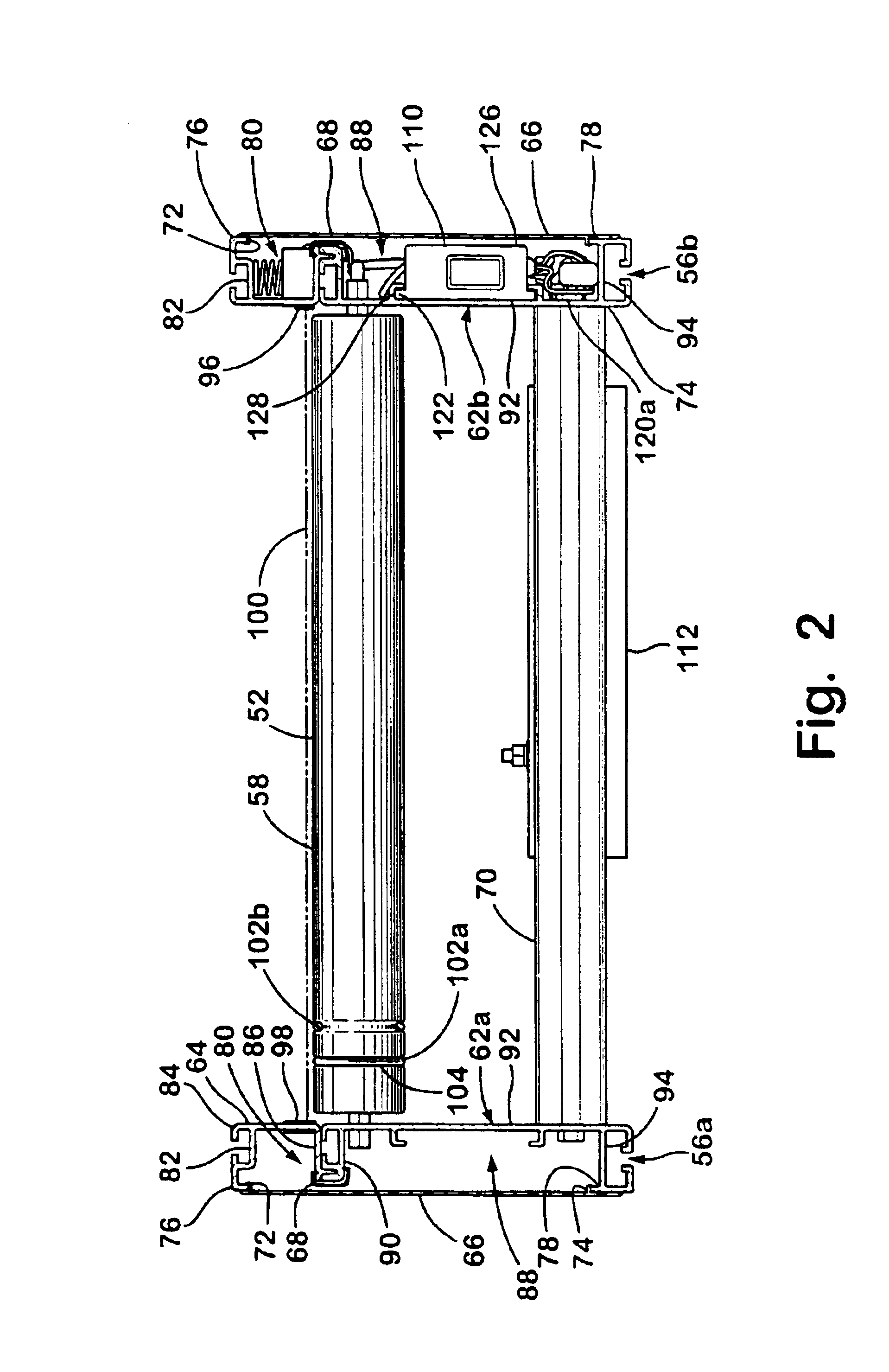

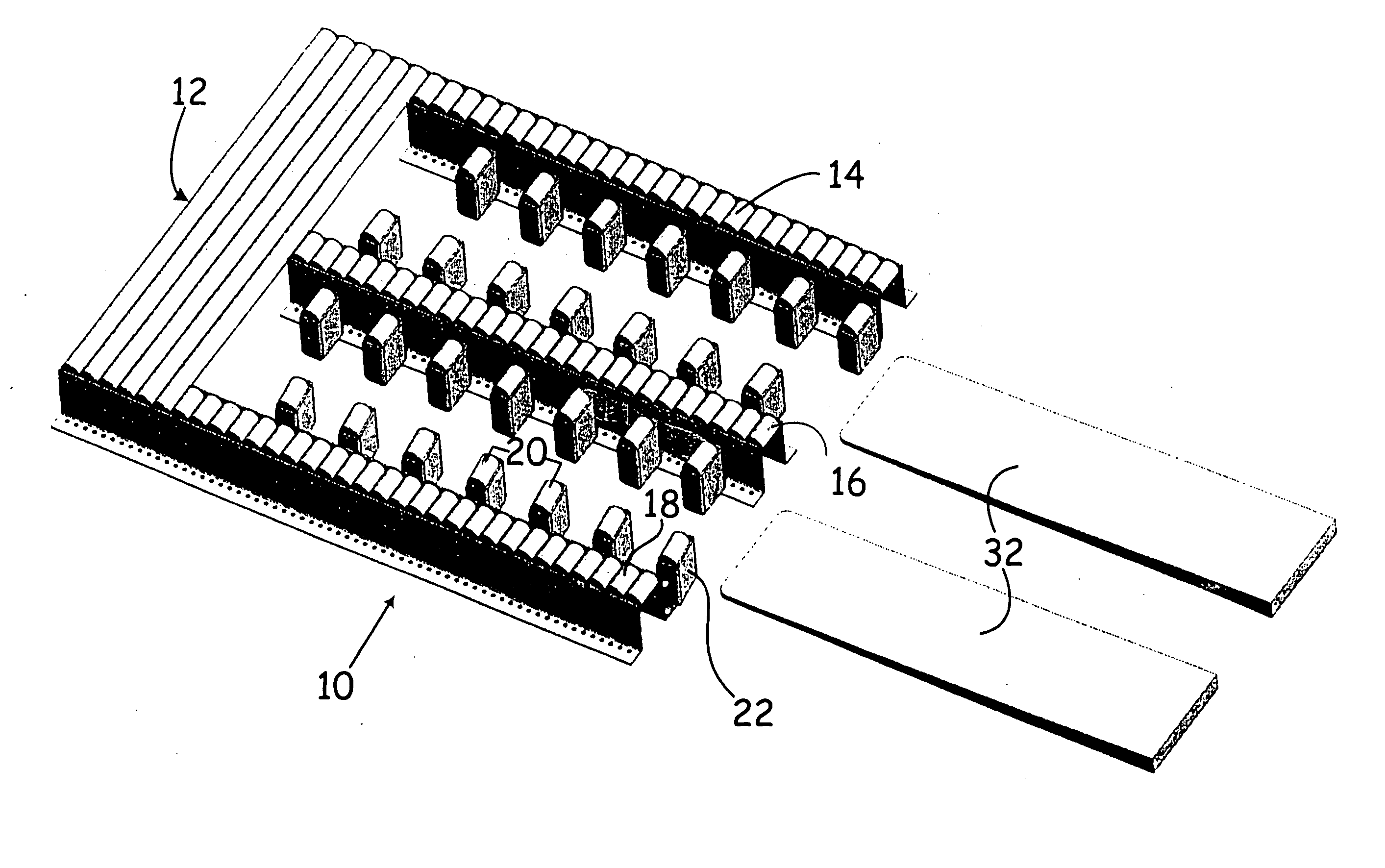

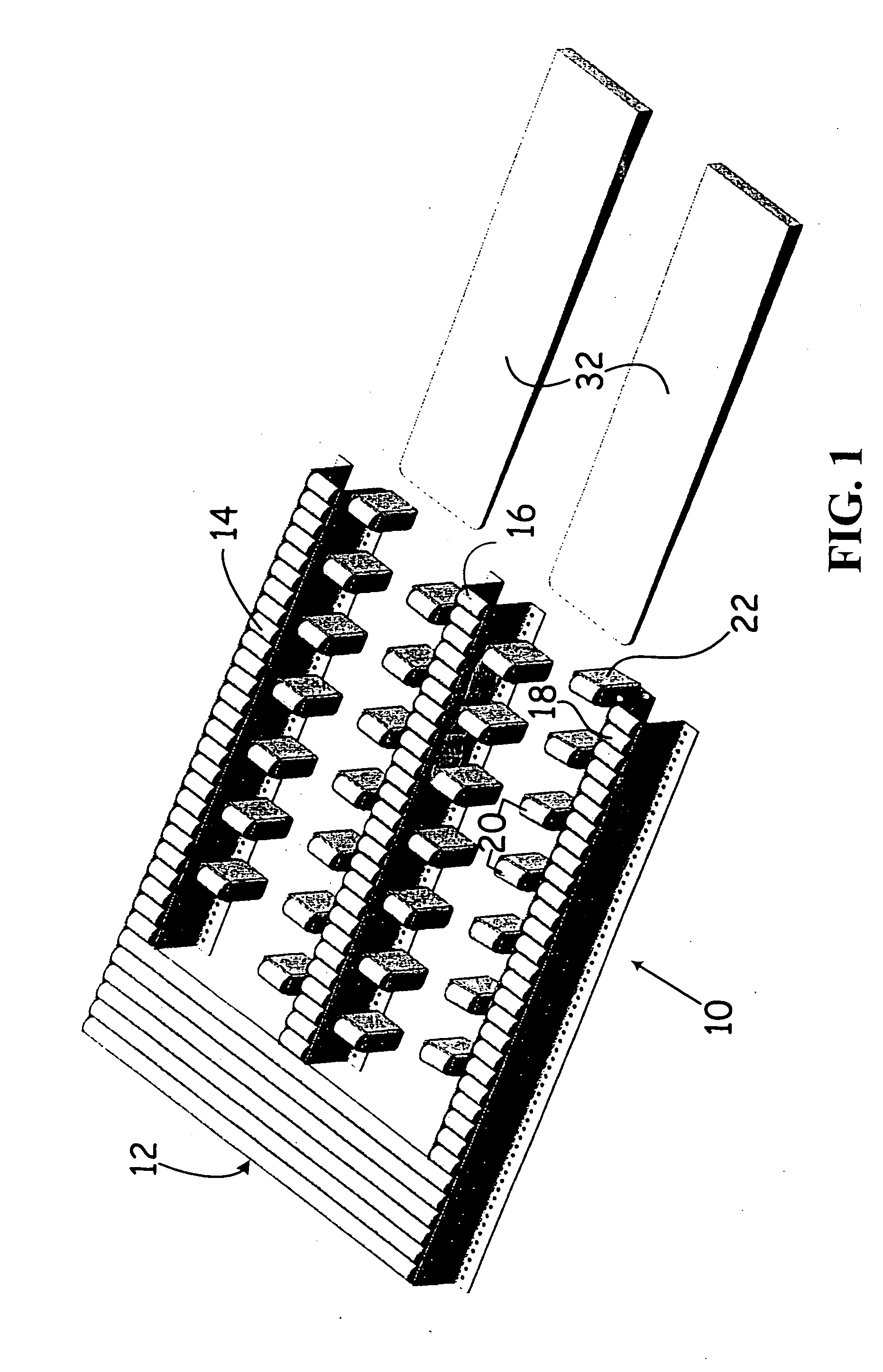

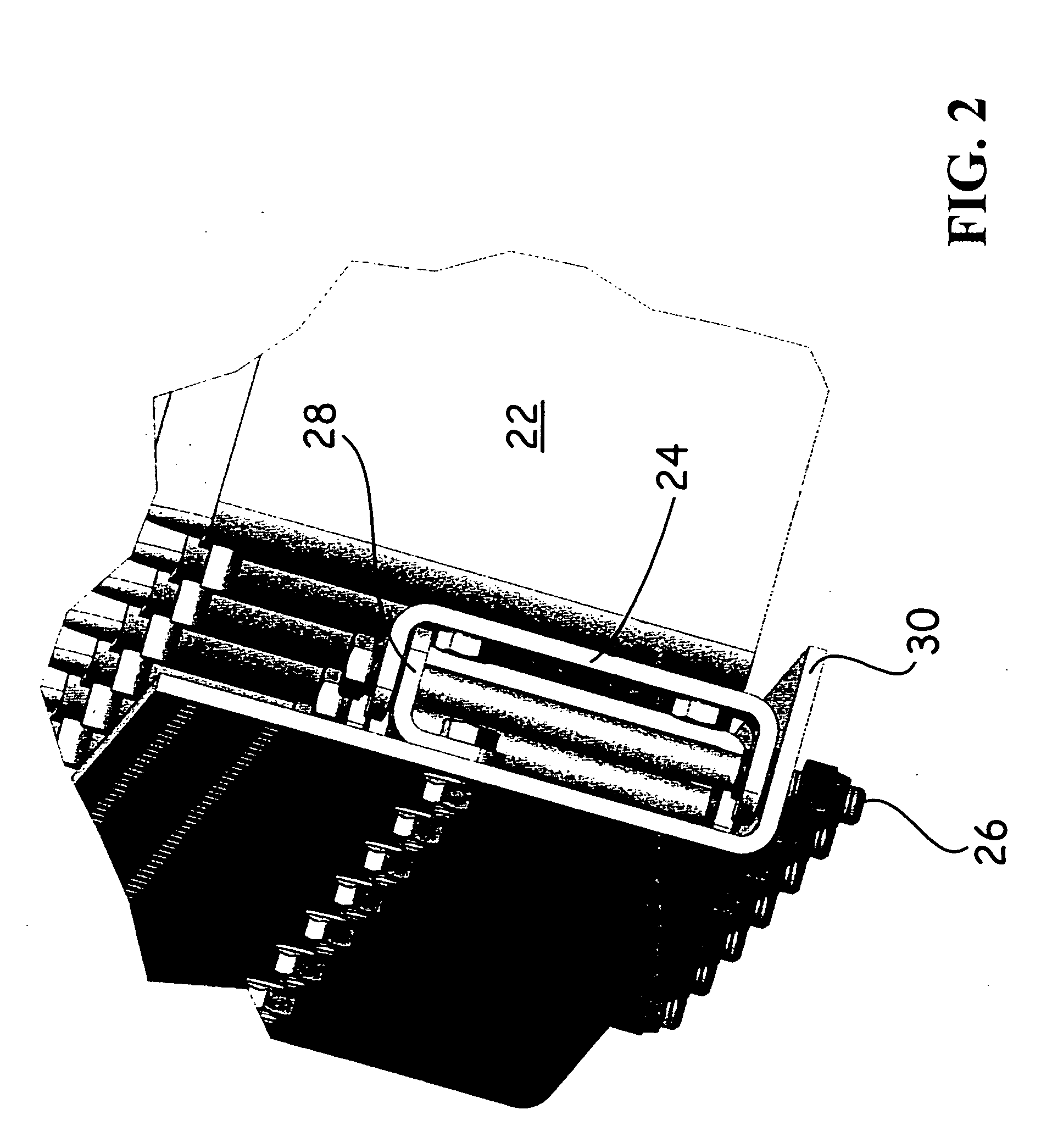

A wire flow rack system including a longitudinal wire, a roller wire, a roller and an optional cap. The roller wire is joined with and transverse to the longitudinal wire and includes an unsupported free end that projects beyond the longitudinal wire. The roller defines an axial bore, and is positioned on the free end so that the it is free to rotate about the roller wire. A end element, for example, a cap, can be joined with the free end to prevent the roller from disengaging the free end. The cap can be friction fit with the free end and easily, manually replaceable relative to the free end, without the use of tools.

Owner:LIFE TIME SYST

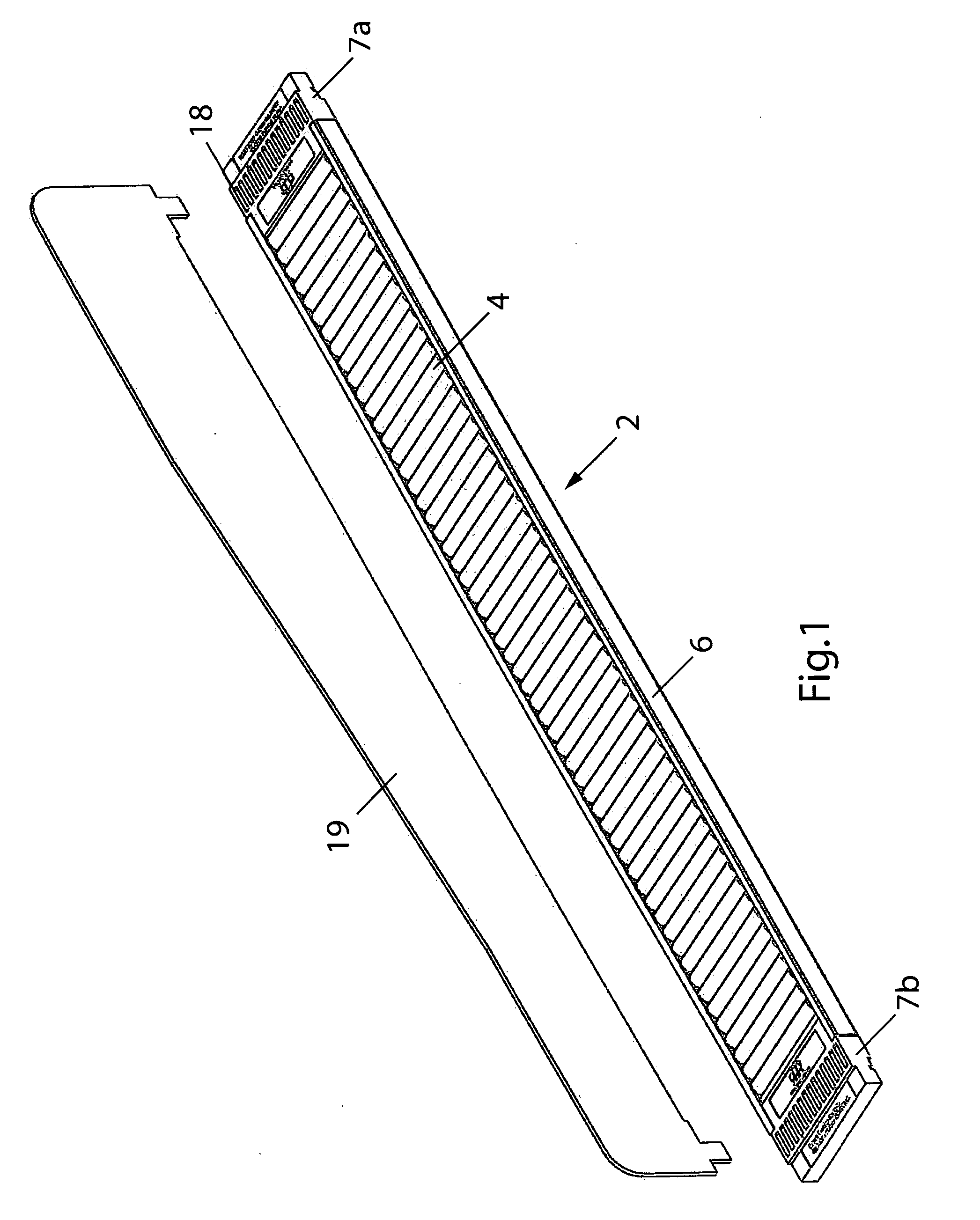

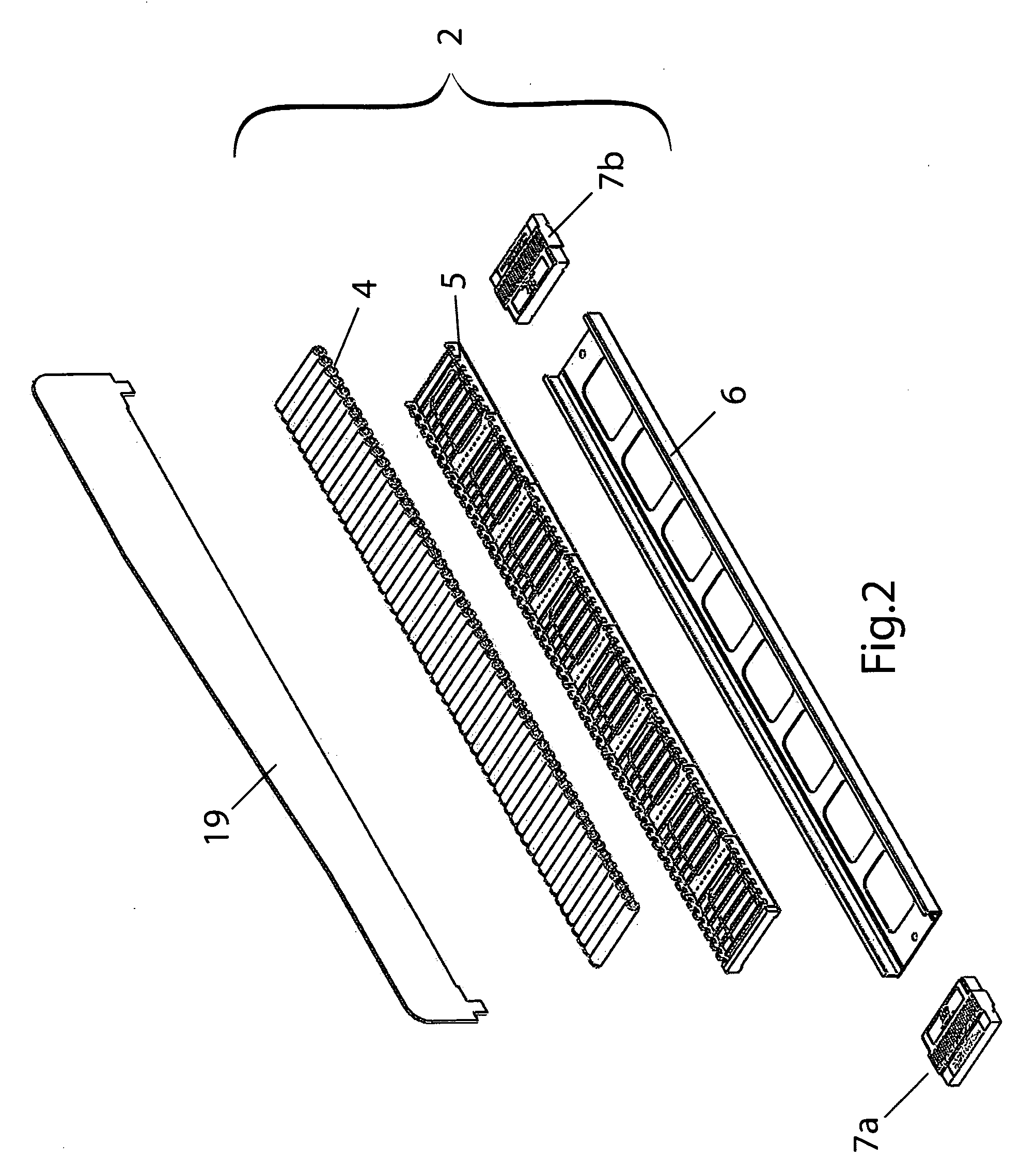

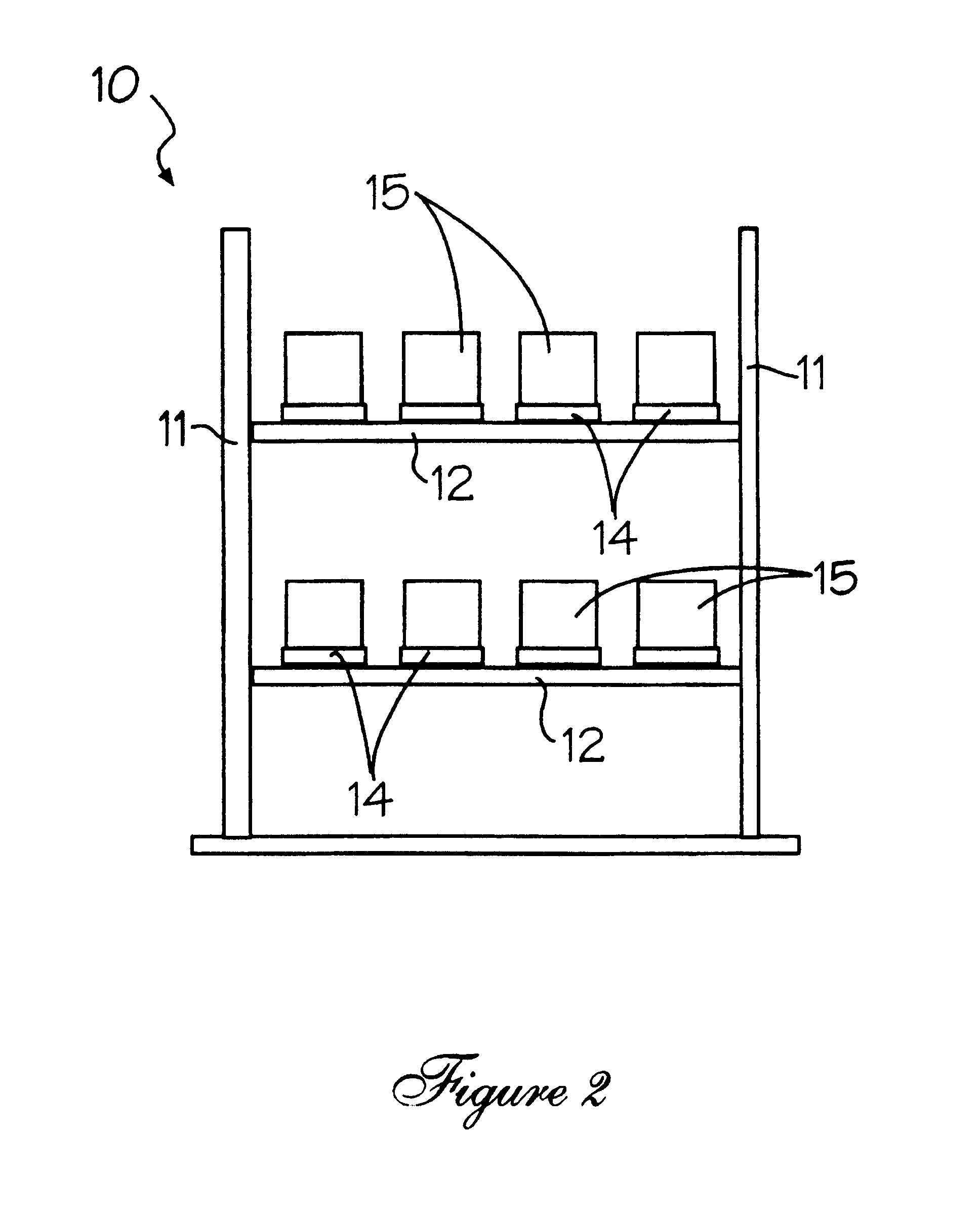

Display unit with roller assembly shelving

A roller assembly for use with a commodity display unit, the roller assembly comprising at least one set of parallel rollers mounted on an inner casing. Each roller is a stub roller with a stub at each end, and the inner casing has opposed side walls projecting from a base. Each side wall having a series of notches at its upper free end for respectively receiving the stubs of the stub rollers, and the inner casing with the rollers mounted thereon slidably engagable within an outer casing such that the stub rollers are restrained from being removed from their respective notches by two inwardly projecting upper flanges of the outer casing. Each upper flange projects from a respective wall member of the outer casing. The inner casing is secured within the outer casing by two end caps, each slidable engagable with the outer casing at opposed ends thereof.

Owner:HAMLON

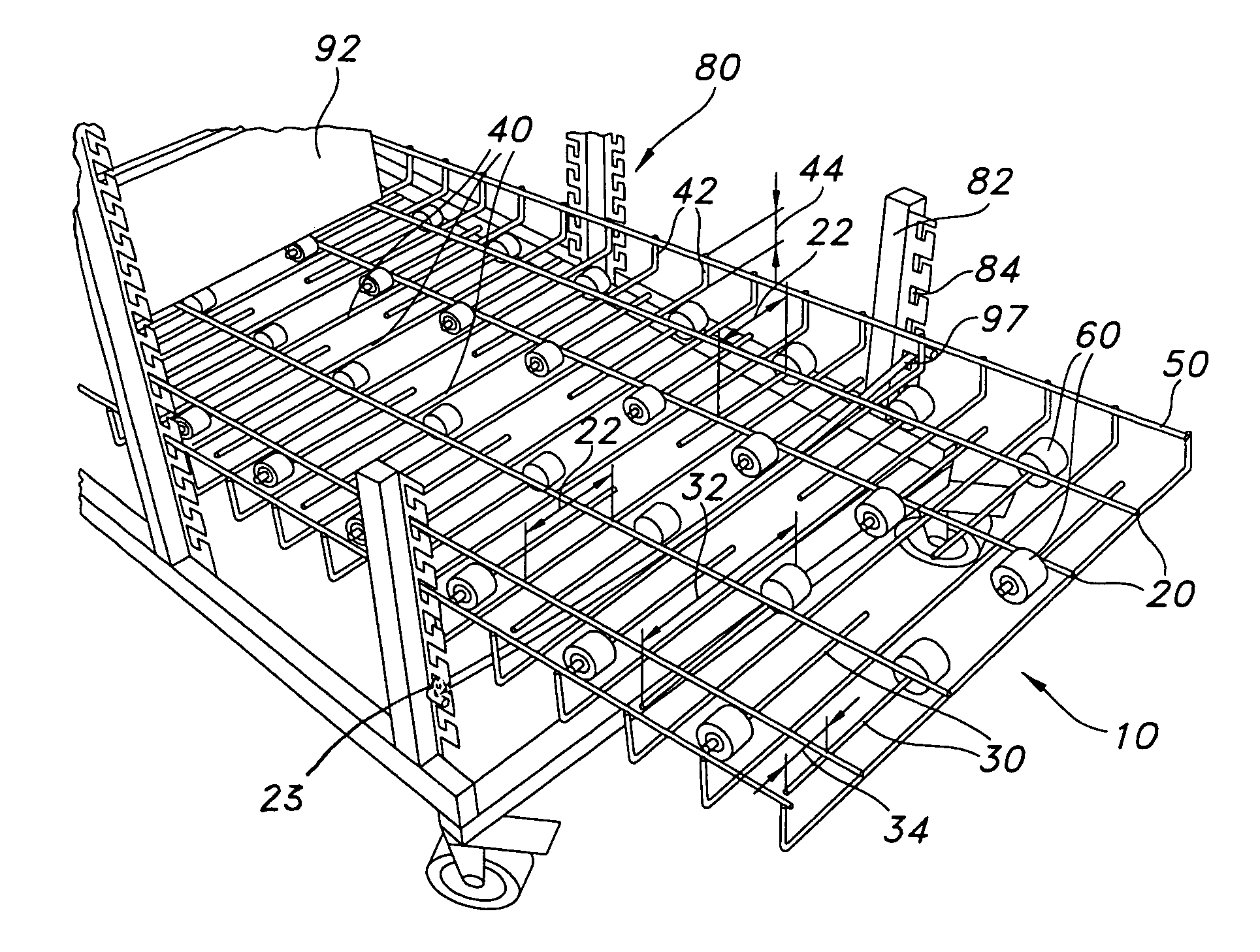

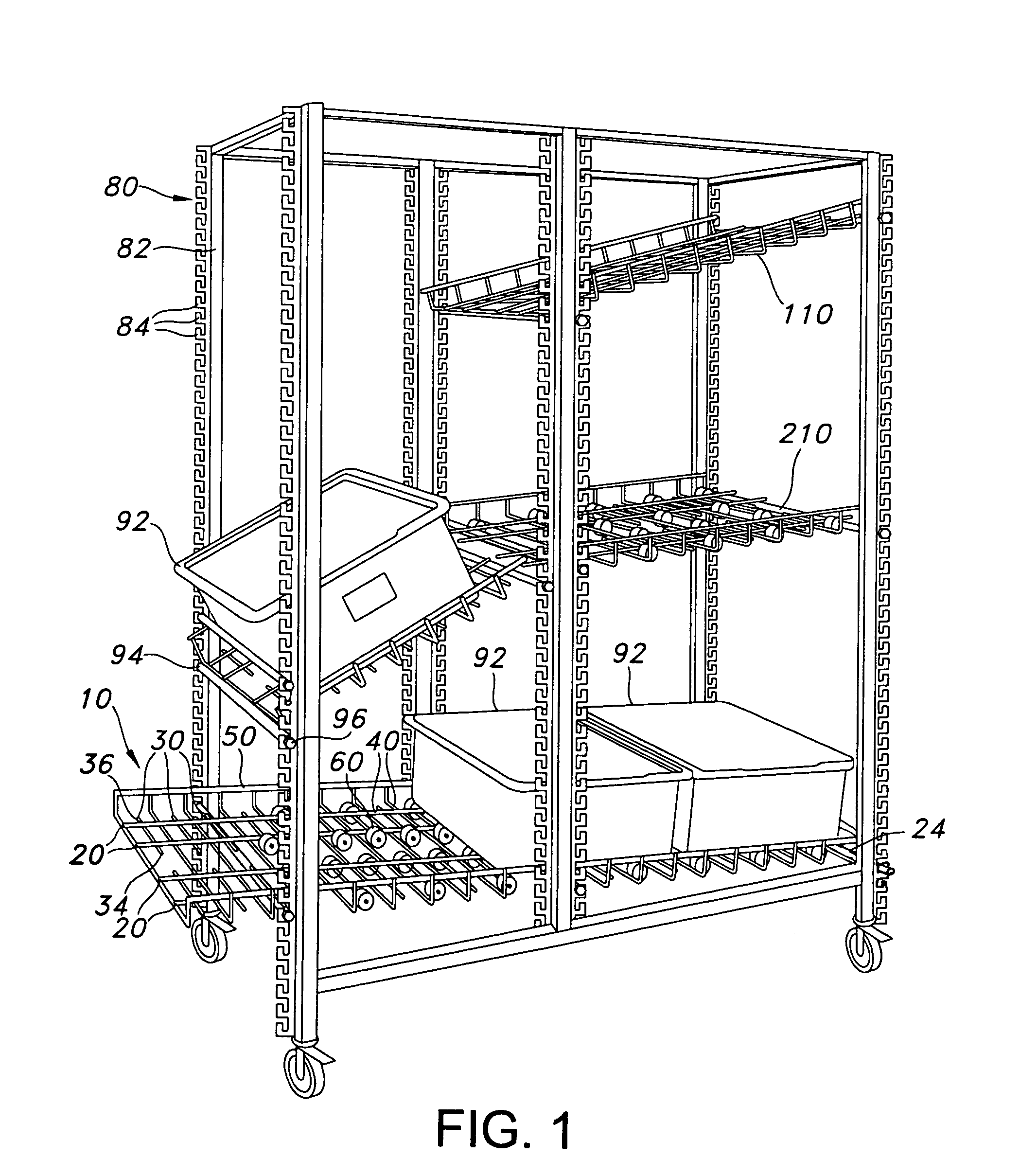

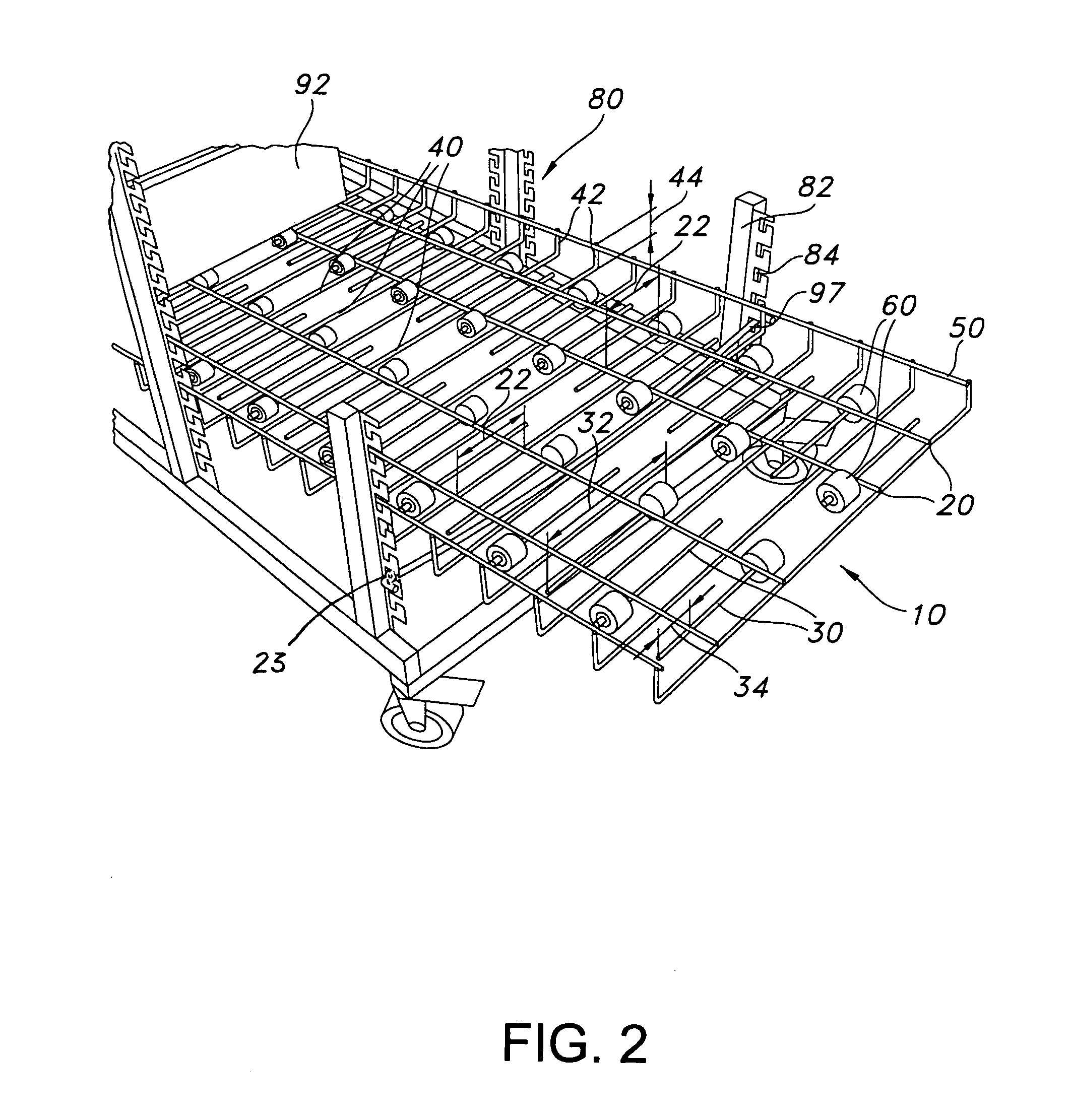

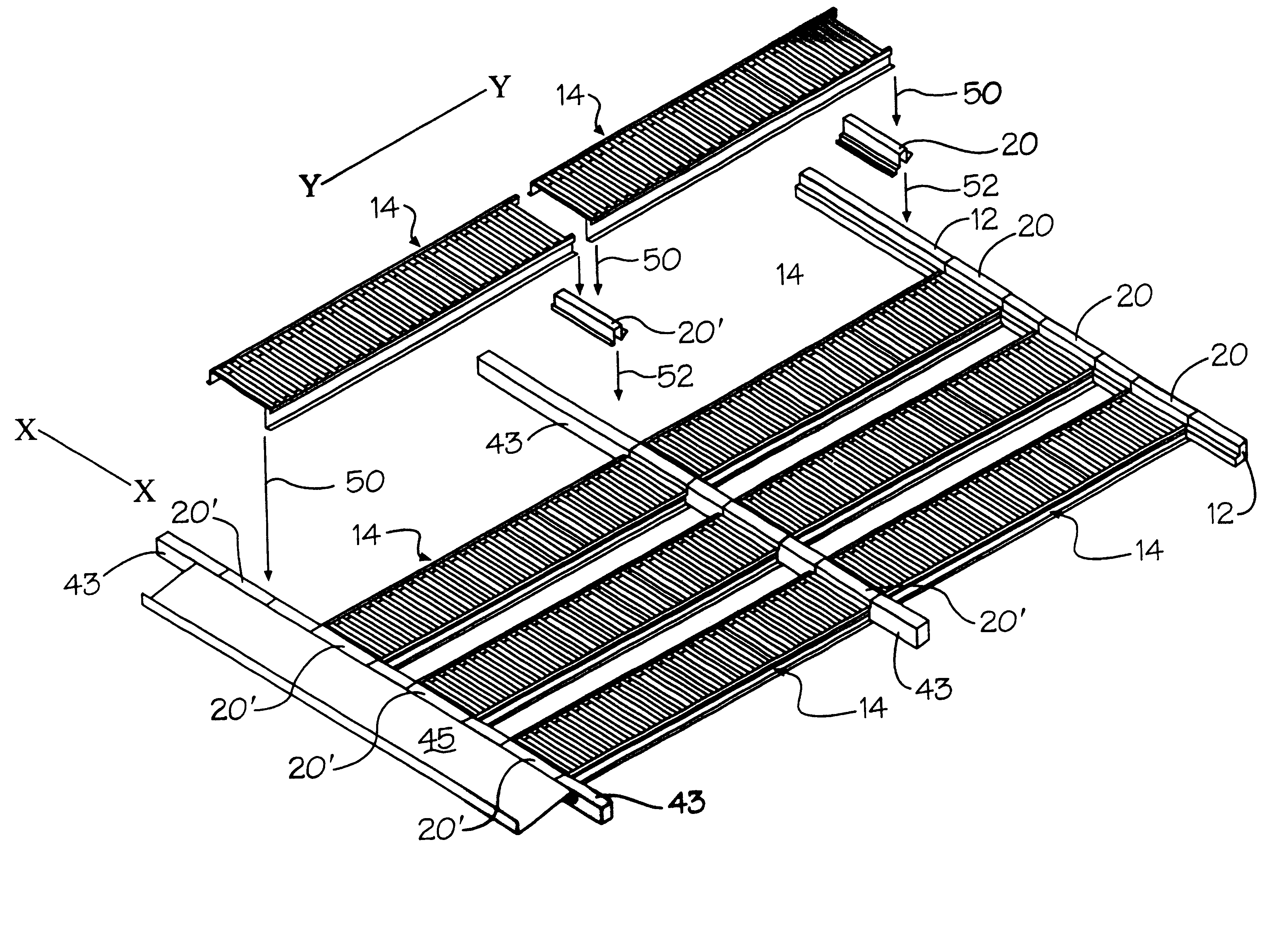

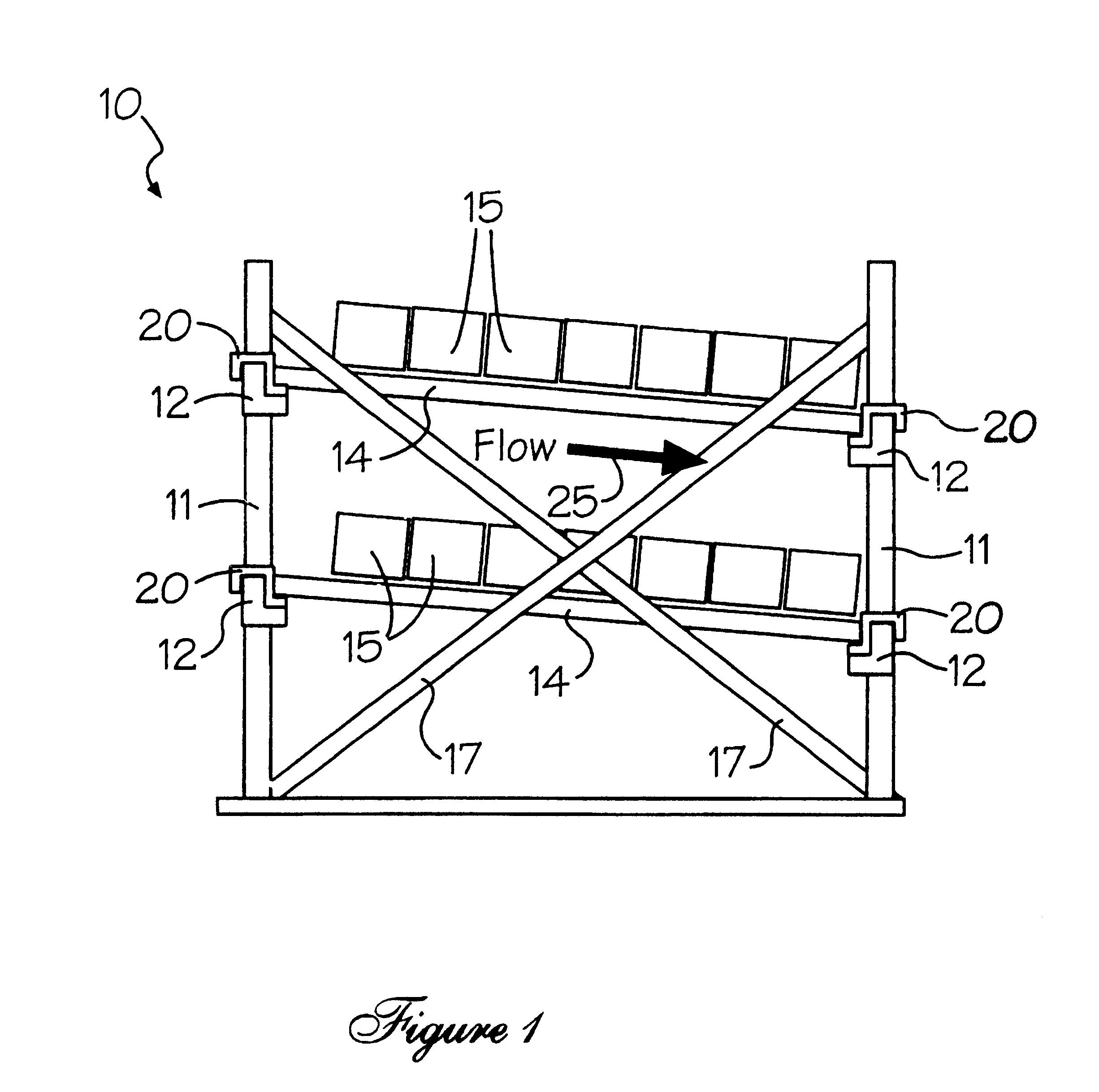

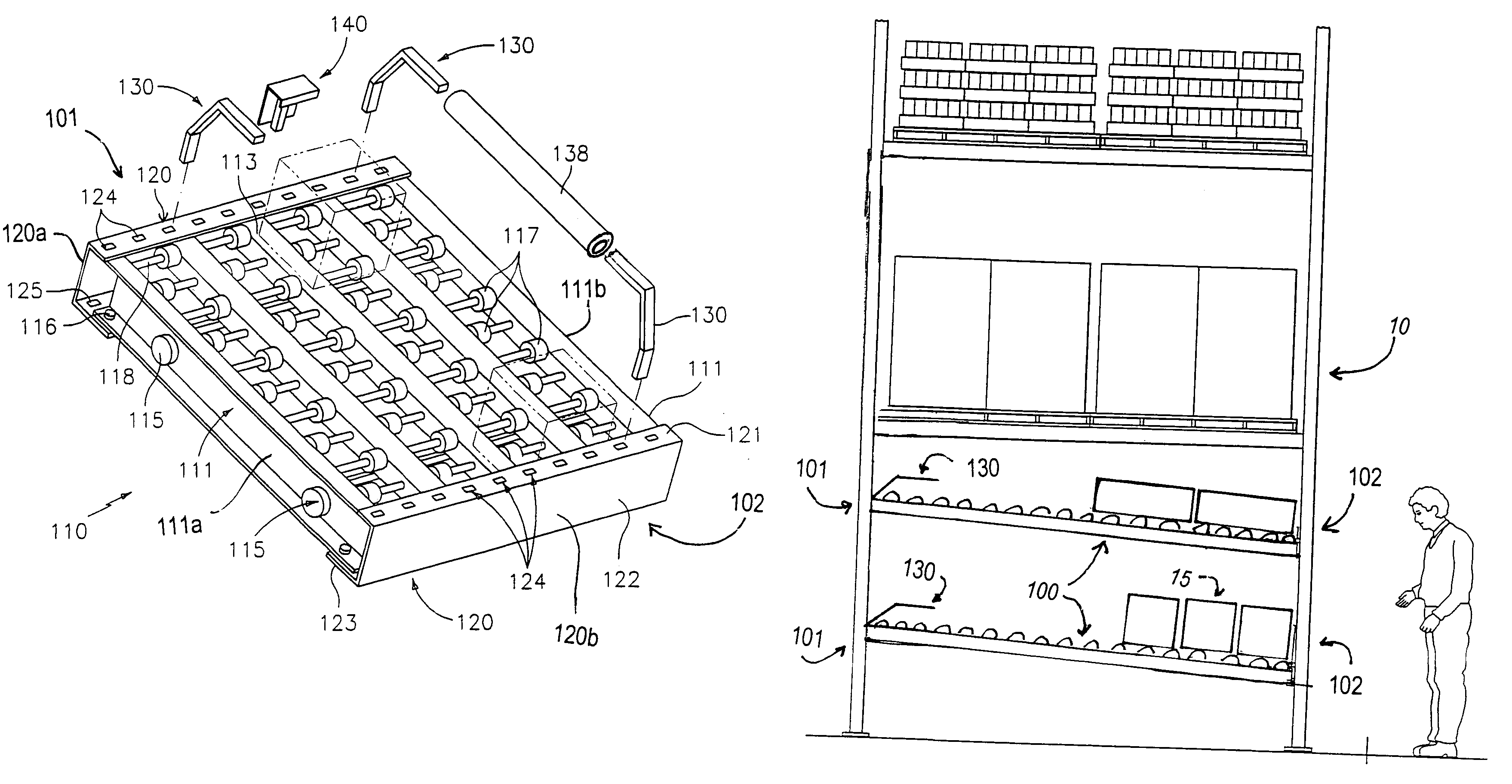

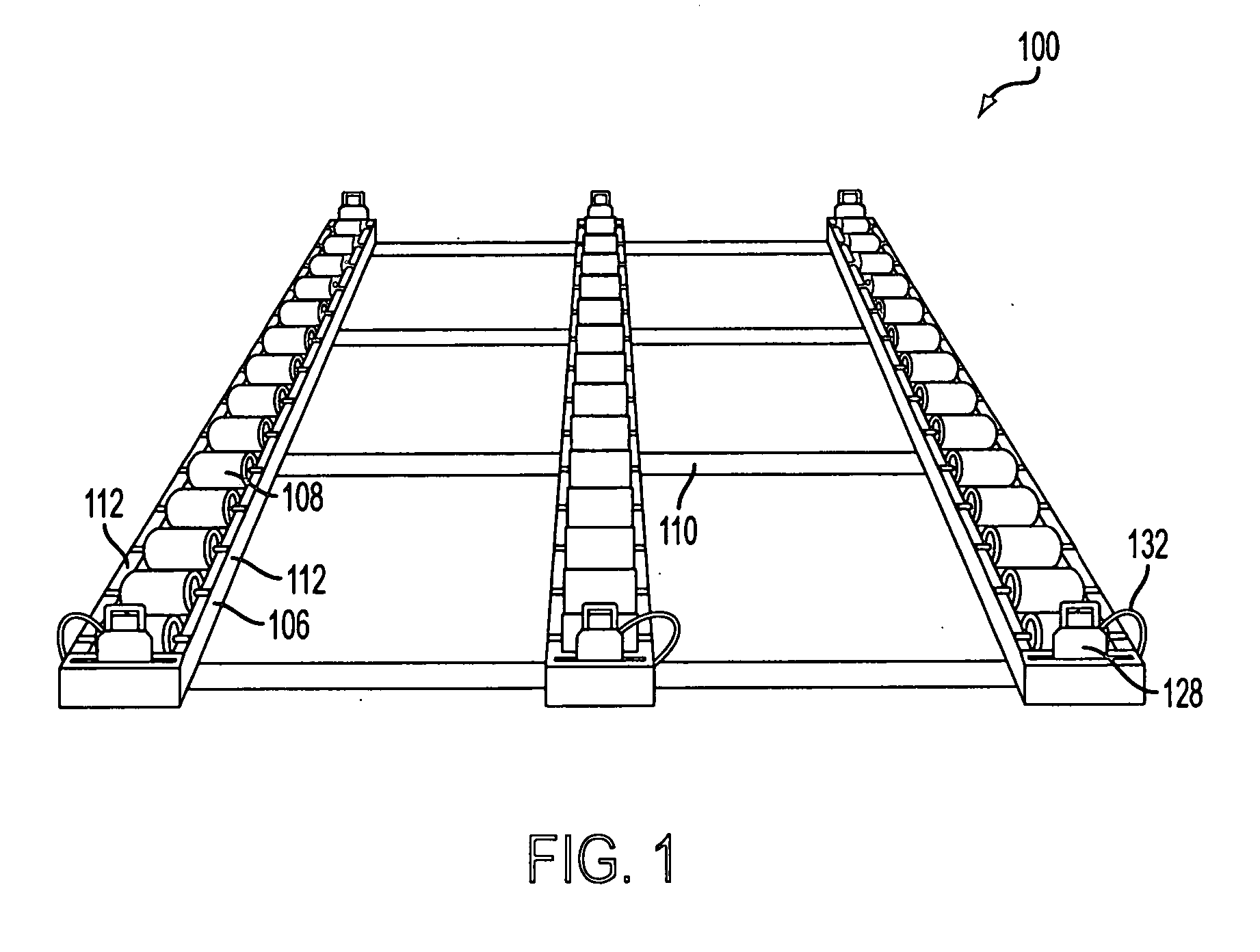

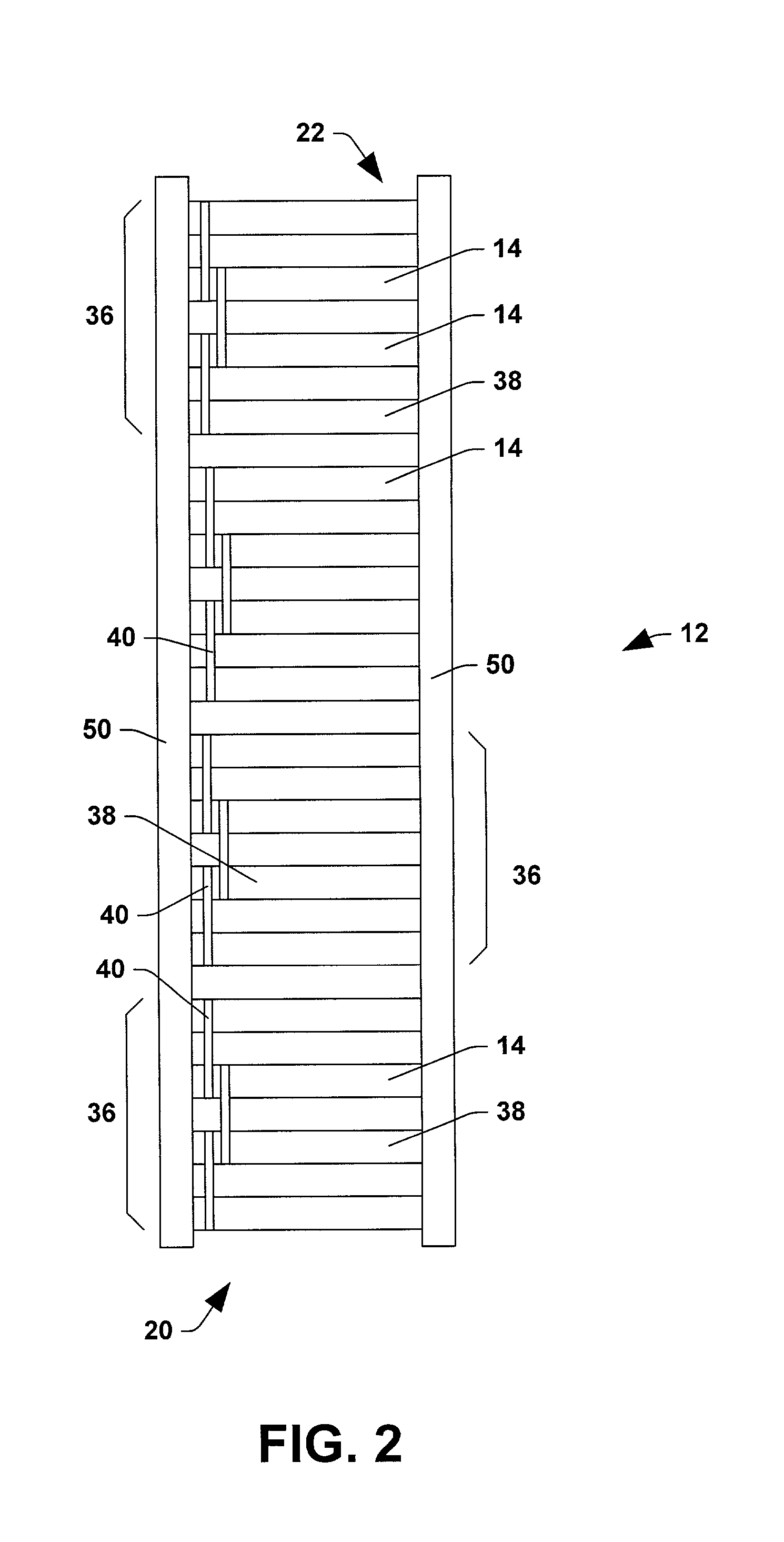

Universal flow track system

InactiveUSRE38517E1Low profileEasy to adjustRefuse receptaclesStorage devicesBraced frameHorizontal axis

The present invention features a universal, low profile, expandable flow track system that can be drop-load mounted to almost any supporting frame or pallet rack. The flow track system of the invention features a flow track that mounts flush with its end supports, and is infinitely adjustable along both the horizontal axis and depth axis of the storage frame. The flow track is quickly assembled to, adjusted upon, and removed from, the storage frame.

Owner:UNEX CONVEYING SYST

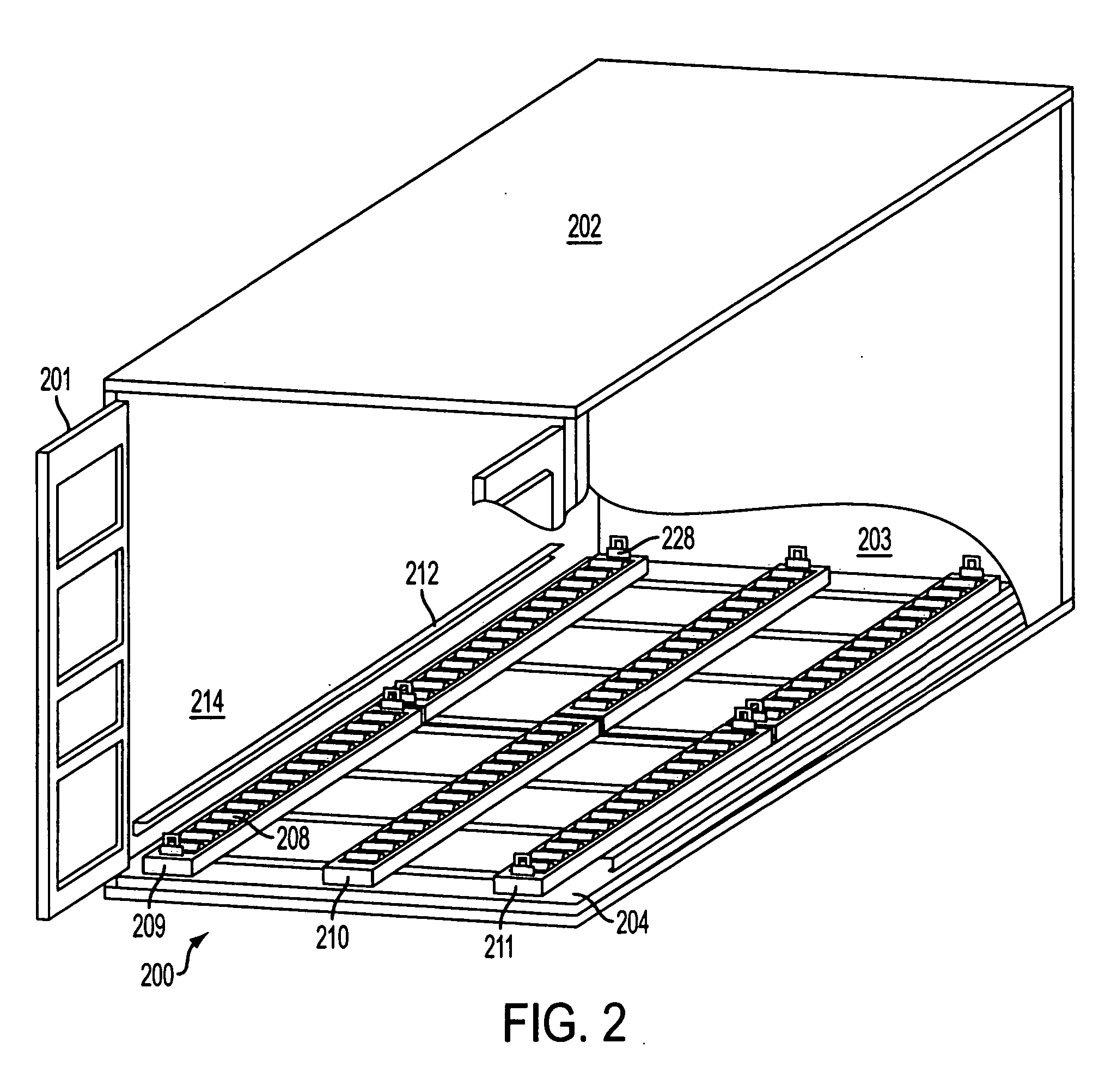

Case flow system with adjustable lane dividers

A case flow bed for the handling of merchandise. The case flow bed including (a) a loading end and, opposite thereto, an unloading end; (b) a roller bed positioned between the loading end and unloading end for supporting and permitting sliding movement of merchandise from the loading end to the unloading end; and (c) apertures associated with at least the loading end for removably receiving at least one lane divider in any of a plurality of laterally extending positions for delimiting lanes of travel for the sliding movement of the merchandise.

Owner:FRAZIER INDAL

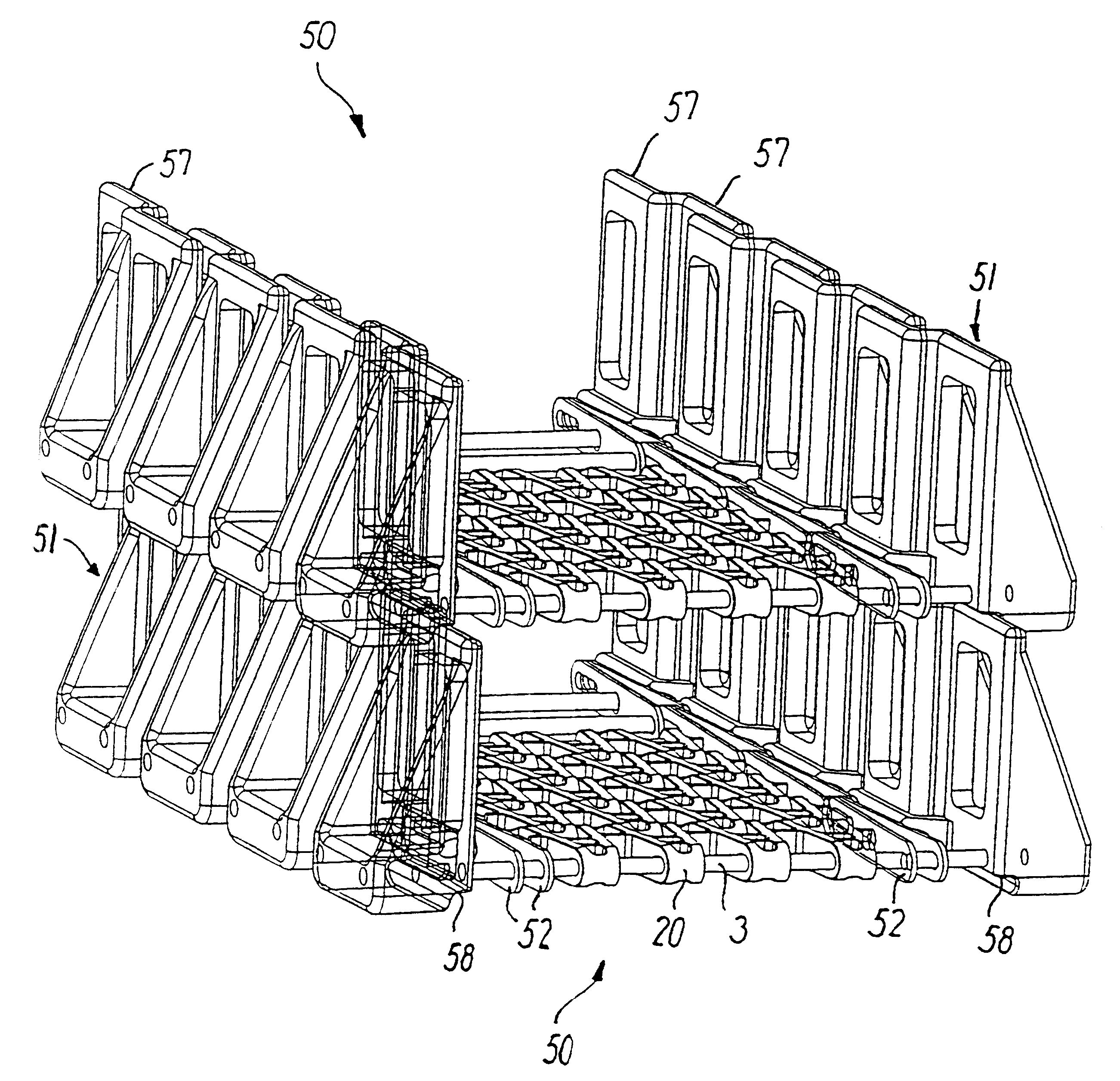

Modular gravity actuated rolling shelving assembly

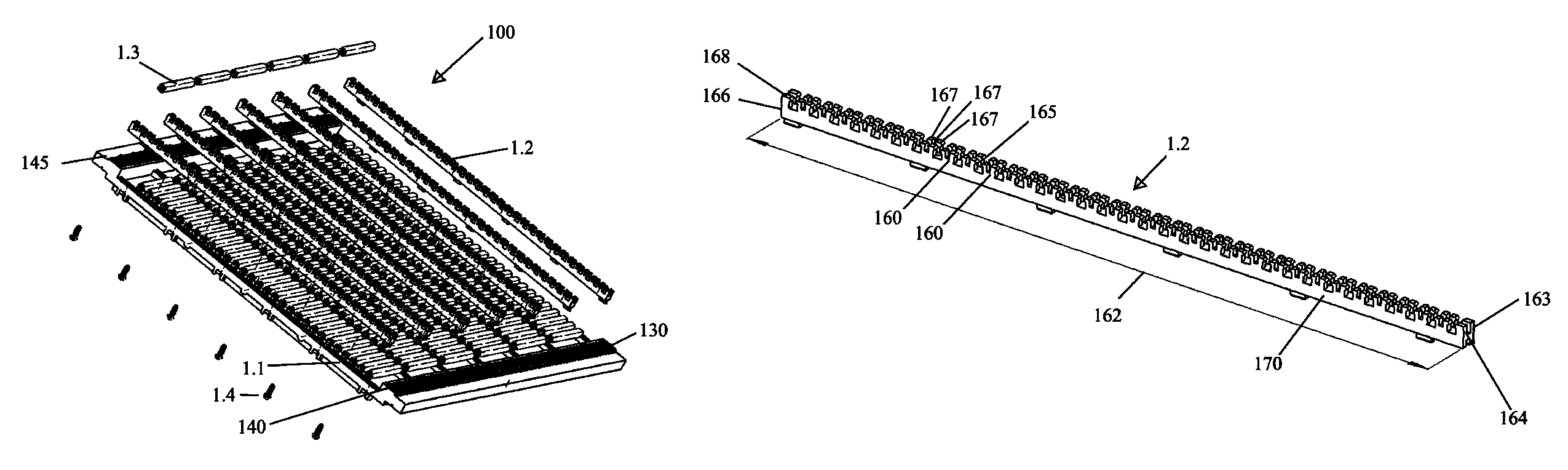

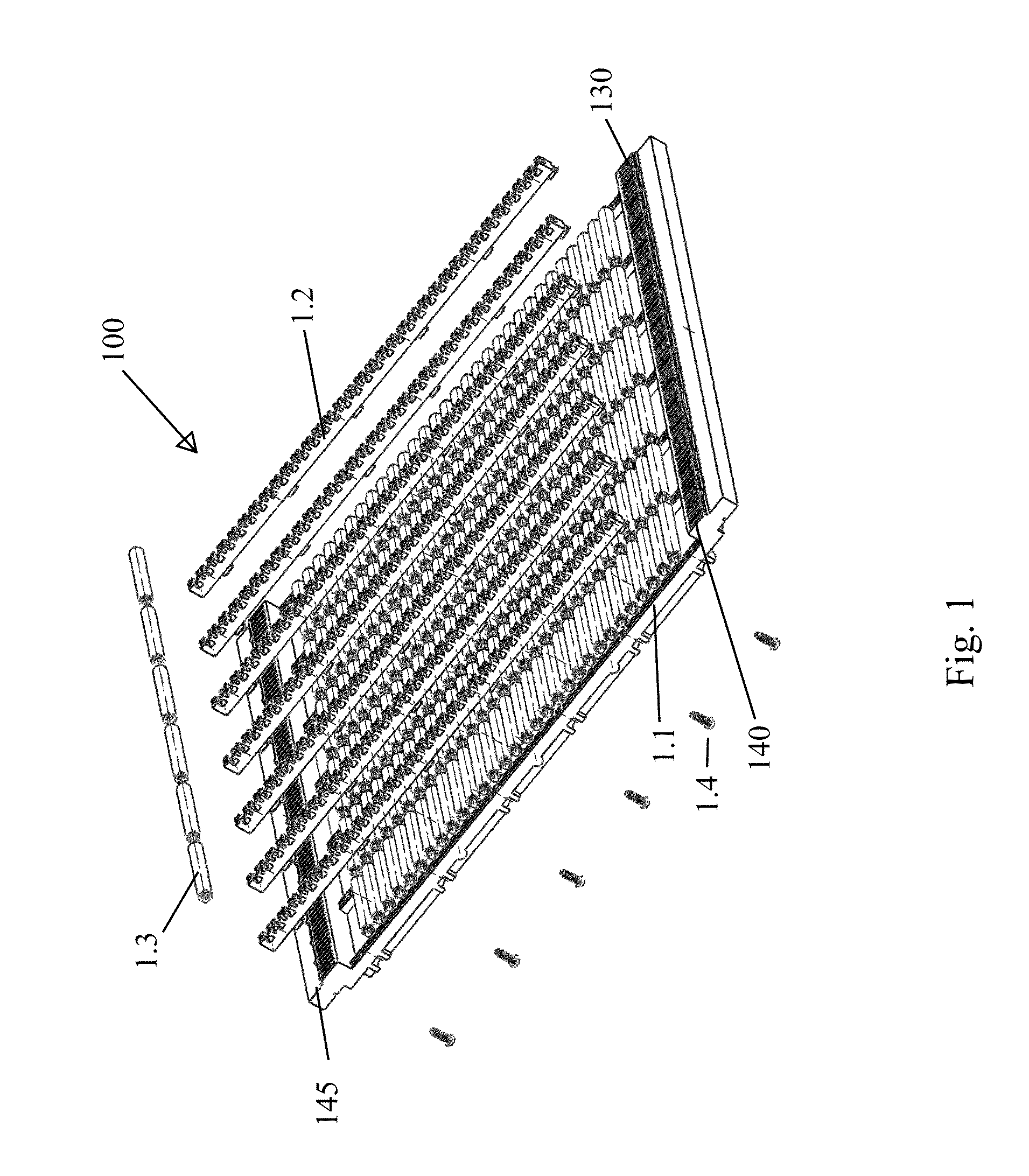

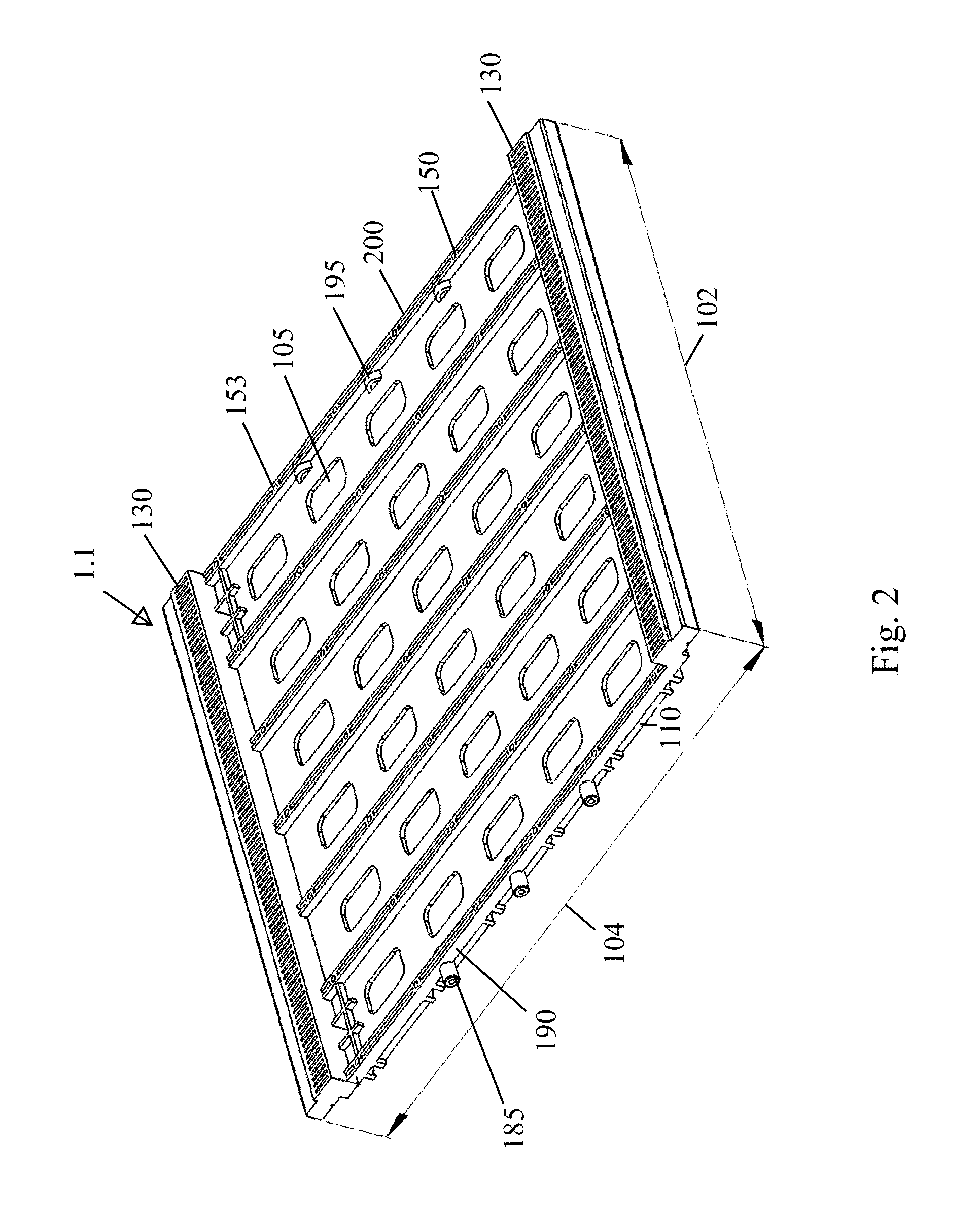

A shelving assembly comprises a unit that comprises a base plate having a first side and a second side opposite the first side. The base plate has an integral one-piece configuration including a plurality of strengthening or reinforcing vertical and / or horizontal ribs disposed on the second side. A plurality of securing members are disposed in a parallel relationship on the first side. Each of the plurality of securing members has a plurality of snap fit openings. A plurality of rollers that each comprises a centrally disposed cylindrical portion and a pair of connection rods extending from opposite ends of the cylindrical portion. The connection rods are removably and fixedly insertable into a pair of oppositely disposed snap fit openings of adjacent securing members, thereby forming a row of rollers disposed on the base plate.

Owner:SUNGAL

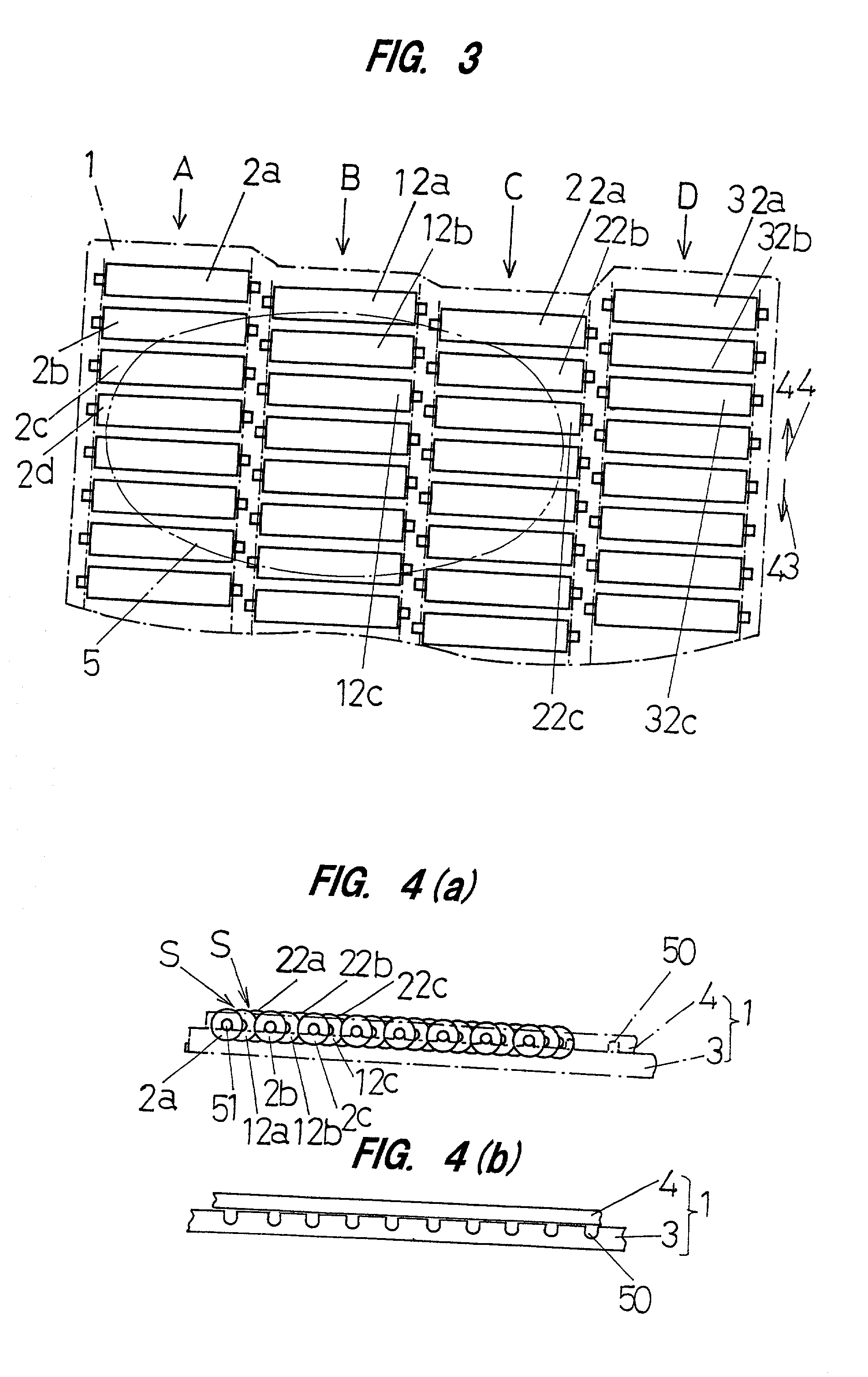

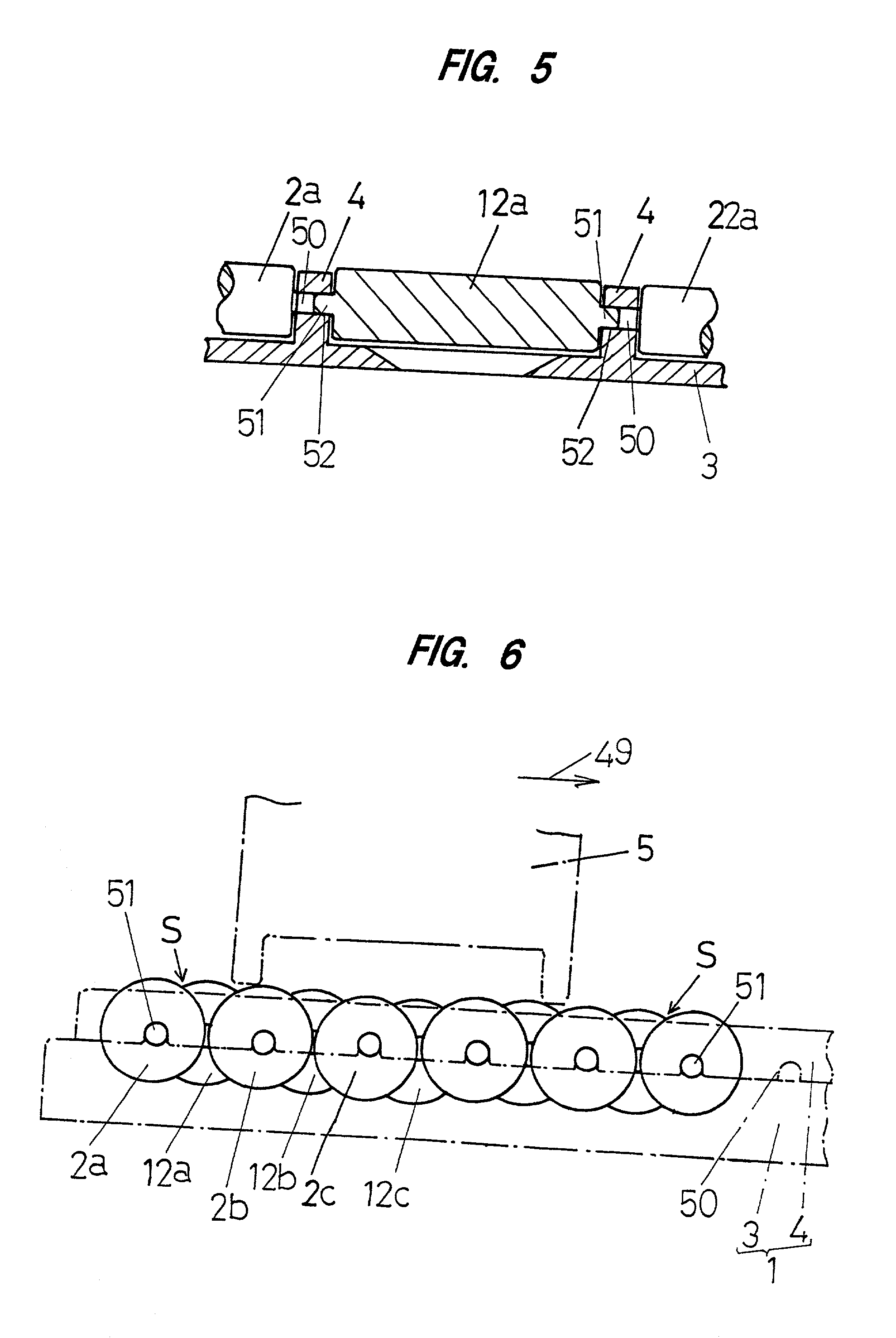

Showcase assembly unit for showcase structure

A showcase assembly unit for the showcase structure is disclosed, which includes a roller support frame and a plurality of parallel sets of rollers mounted on the roller support frame, wherein the rollers in each set of rollers are mounted rotatably and arranged one after another from the rear end toward the front end of the roller support frame, and a plurality of individual articles, such as canned foods or drinks, may be placed across two or more parallel sets of rollers and are capable of moving one by one from the rear end toward the front end of the roller support frame. In the showcase assembly unit for the showcase structure according to the present invention, each roller has a specific width that is smaller than the size of the bottom of a particular article across the roller, and each of the rollers in each set is axially offset relative to each of the rollers in each adjacent set.

Owner:SEKISUI PLASTICS CO LTD

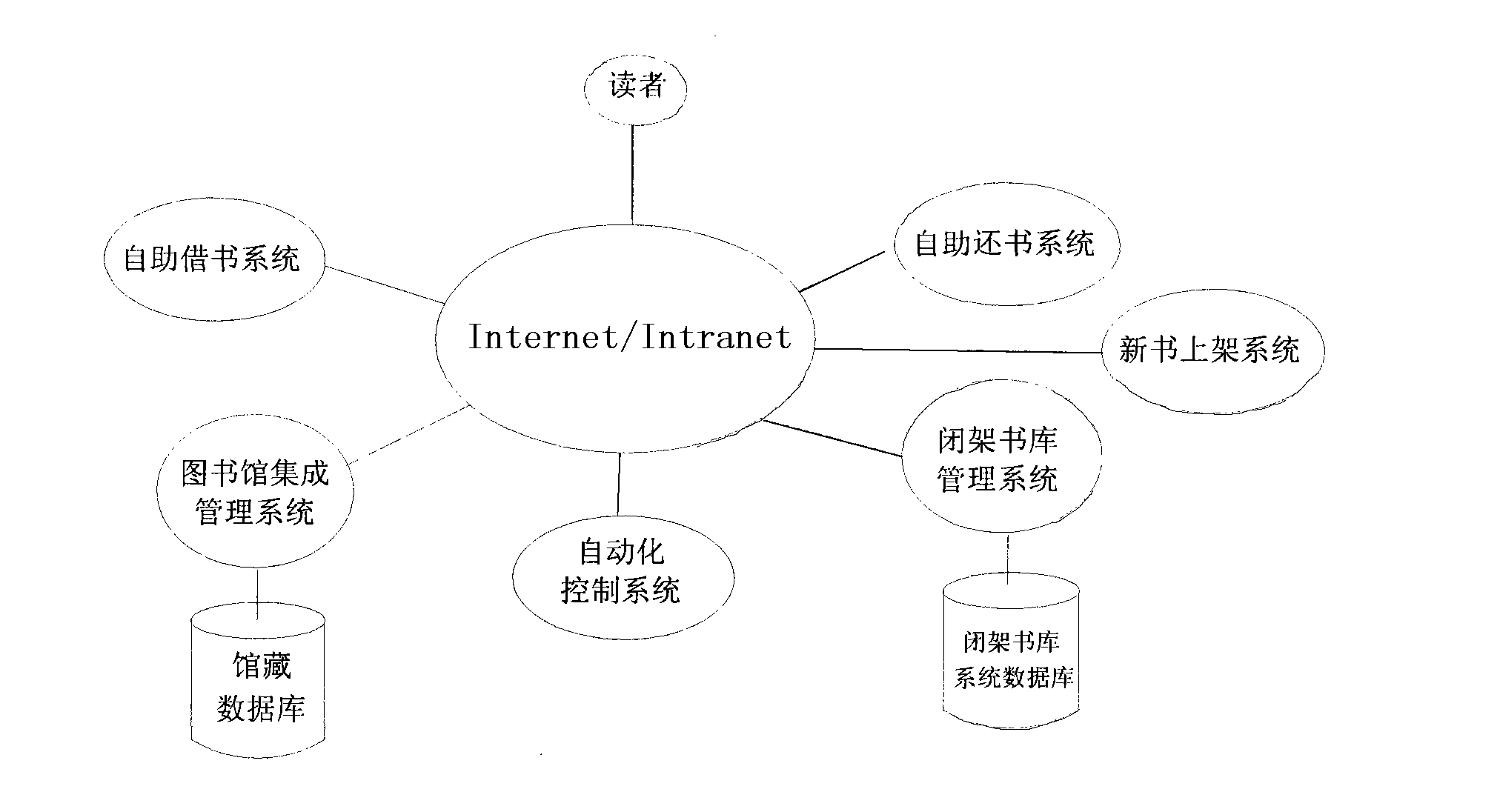

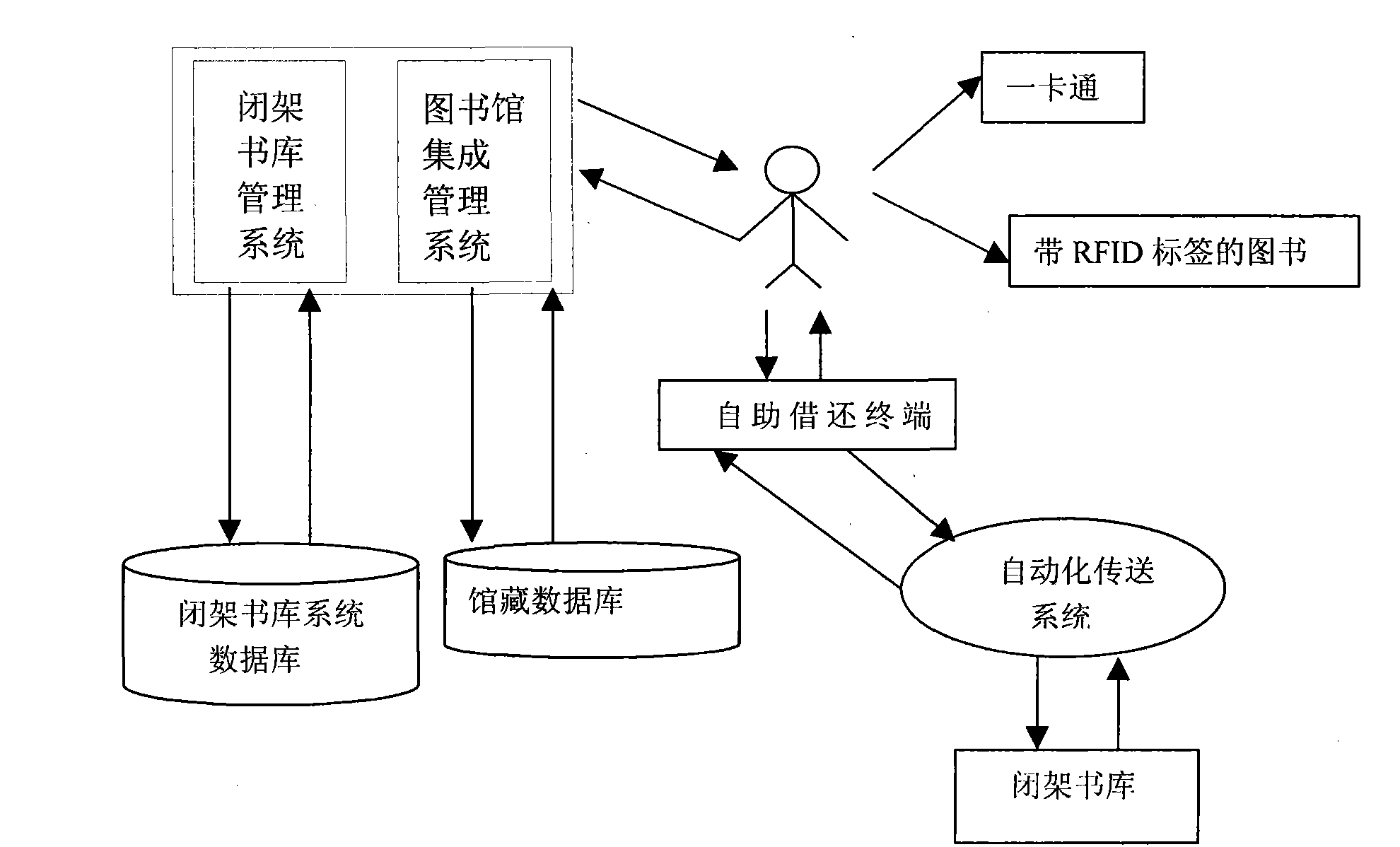

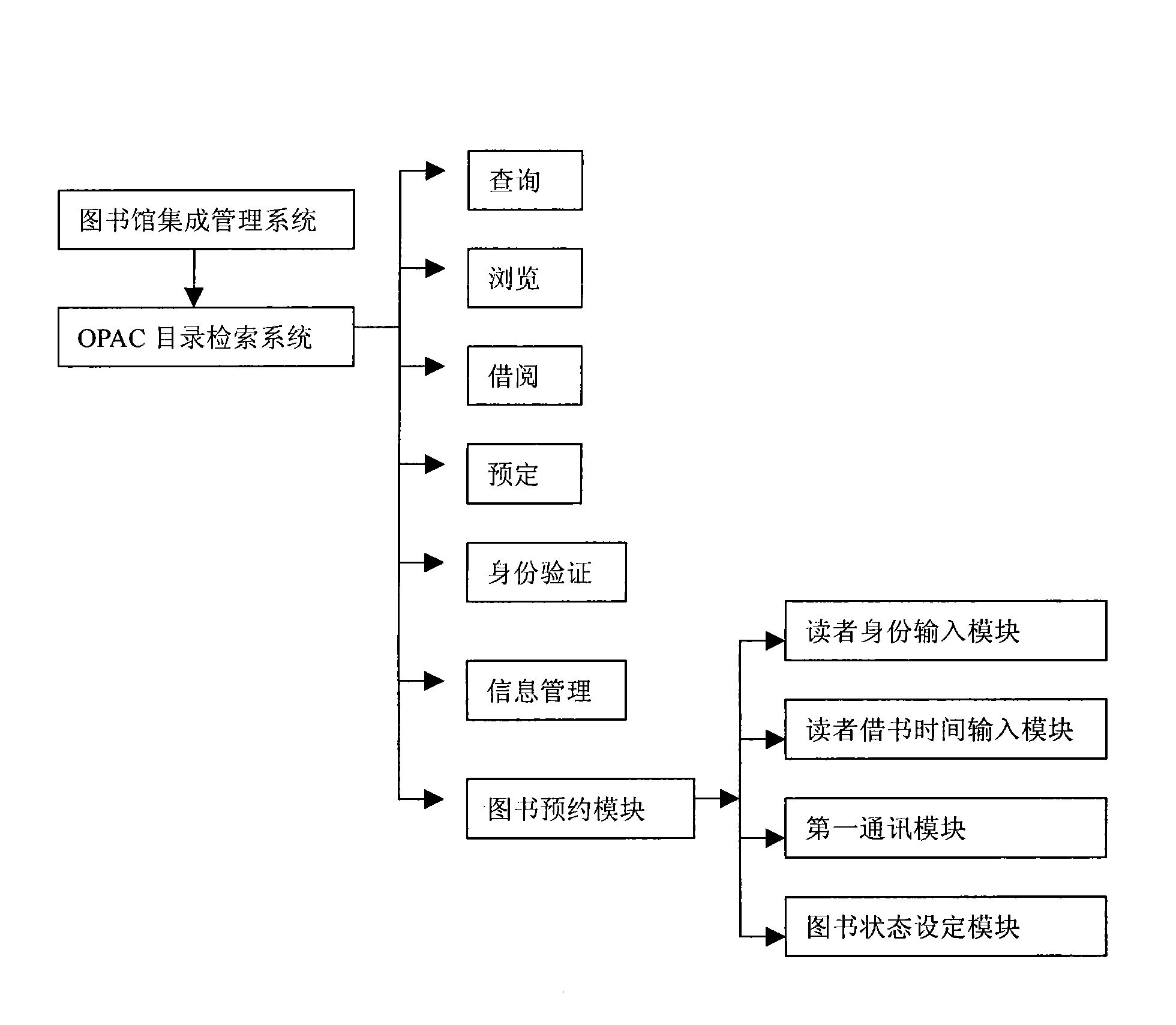

Automatic book management system based on closed stacks

InactiveCN101515391ARealize unmanned management functionImprove securityData processing applicationsCash registersReturn functionTransfer system

The invention discloses an automatic book management system based on closed stacks, which combines the original library management systems, realizes automatic borrowing and returning functions of books, lowers the labor intensity of the workers in the library and effectively improves the quality of the library in serving readers. The automatic library system adopts RFID technology, mechanical automation, network and computer technologies. The book management system of the invention comprises shelves, a library integrated management system, books with RFID chips, a self-service borrowing and returning terminal, a management system of closed stacks, a self-service borrowing system, a self-service returning system and an automatic transfer system which realizes that books automatically go in and out of the closed stacks; wherein, the management system of closed stacks operates the information of the database of the closed shelf system to realize information interaction between the library integrated management system and the automatic transfer system, thus finally realizing the automatic management functions of books.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Goods sorting and split charging equipment and method thereof

InactiveCN101234677ASmall footprintReduce the number of employeesControl devices for conveyorsCo-operative working arrangementsElectronic control systemEngineering

The invention discloses an equipment for sorting and packaging goods and a method thereof, wherein, the equipment comprises turning box baskets, a box basket transporting device, a goods-providing device, a radio frequency reader, a wireless radio frequency card, an electronic control system and a system of computer information management, wherein, each box basket box has the wireless radio frequency card; a side on a stopping position of a plurality of box baskets on the box basket transporting device is provided with the goods-providing device; the radio frequency reader is arranged near the stopping positions for the box backsets on the box basket transporting device. The method comprises the following steps: A. configuring devices for the whole line and determining the brands and specifications of goods to be delivered; B. setting the information of device configuration as well as the brands and specifications of the goods; C. setting the allocation proposal; D. preparing and implementing the allocation proposal; E. starting the whole line and pre-allocation; F. inputting empty box baskets; G. applying the box baskets for delivery and allocation; H. unloading the baskets. The equipment for sorting and packaging goods has the advantages of high speed, reliable work, low operation cost, compact structure, and small land occupancy, so the invention is applicable for various goods delivery centers with different delivery requirements and scopes.

Owner:姜广峻

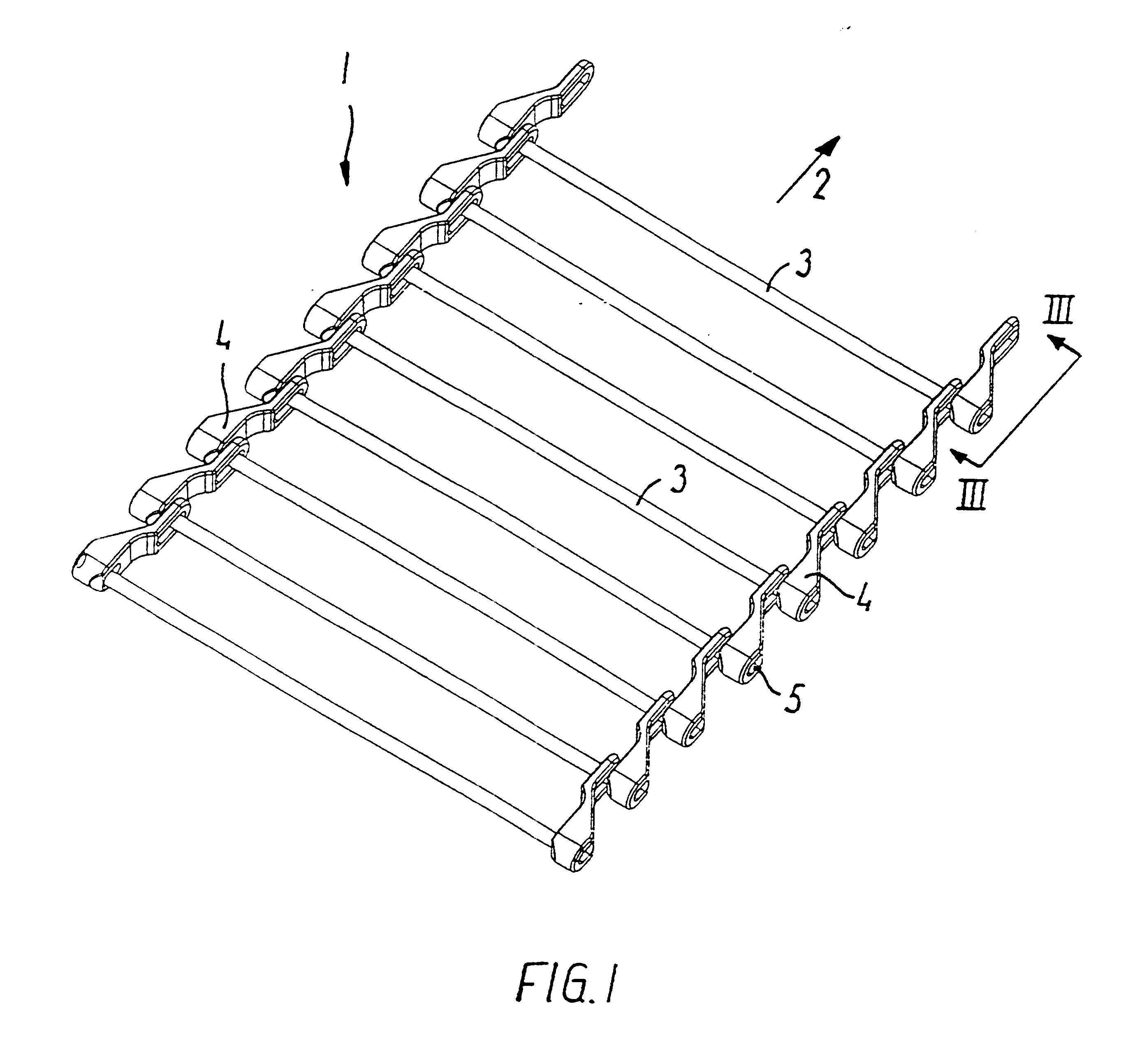

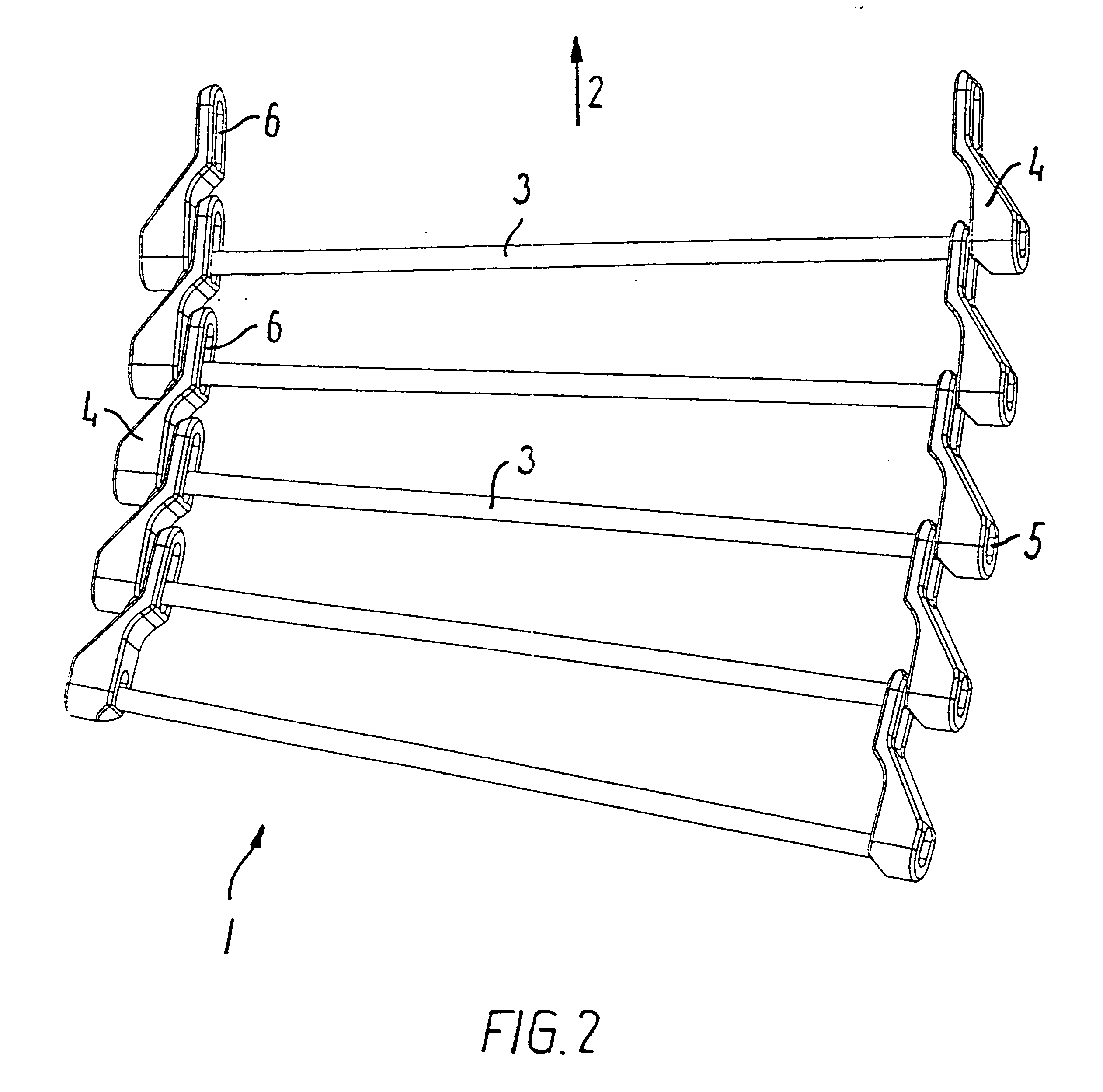

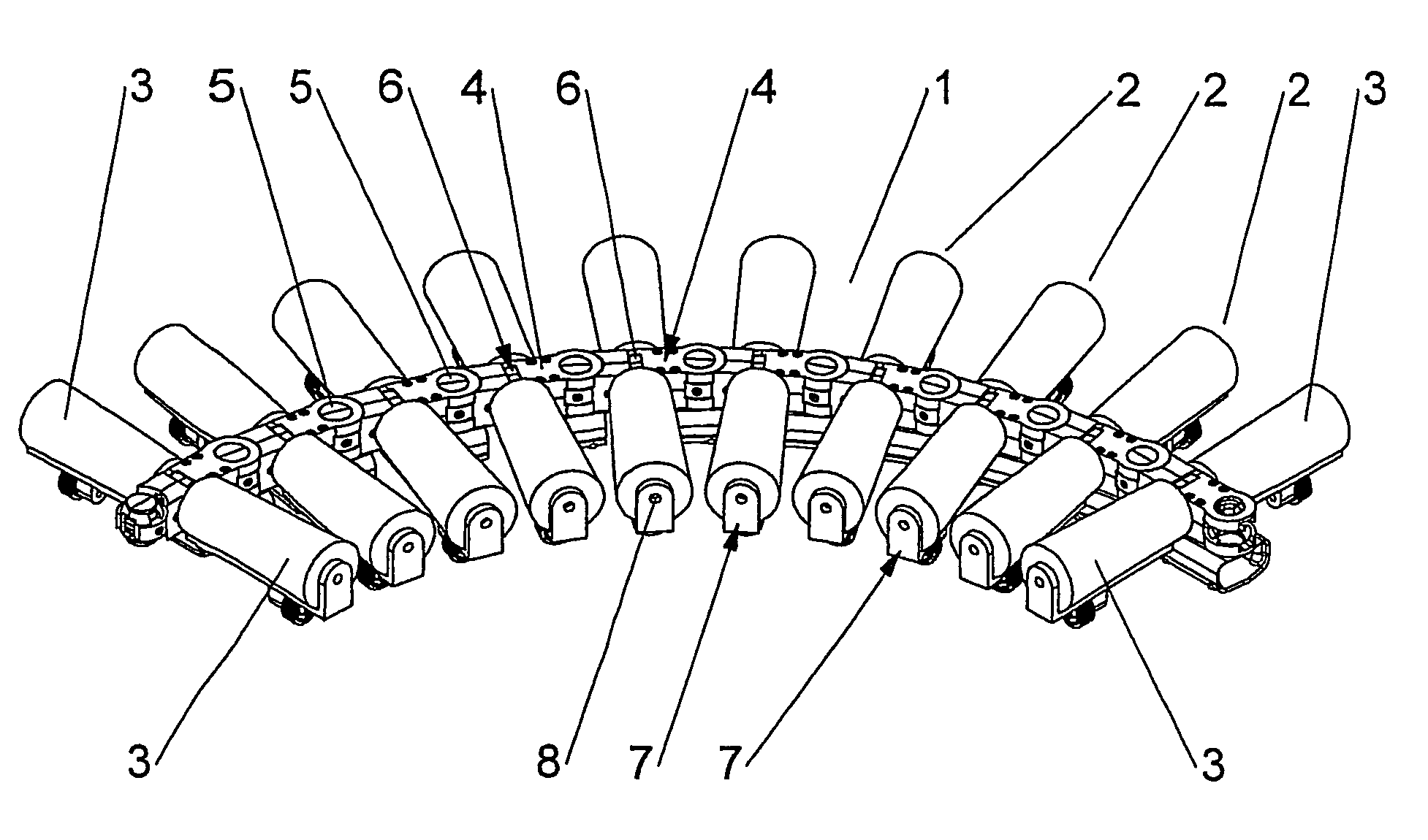

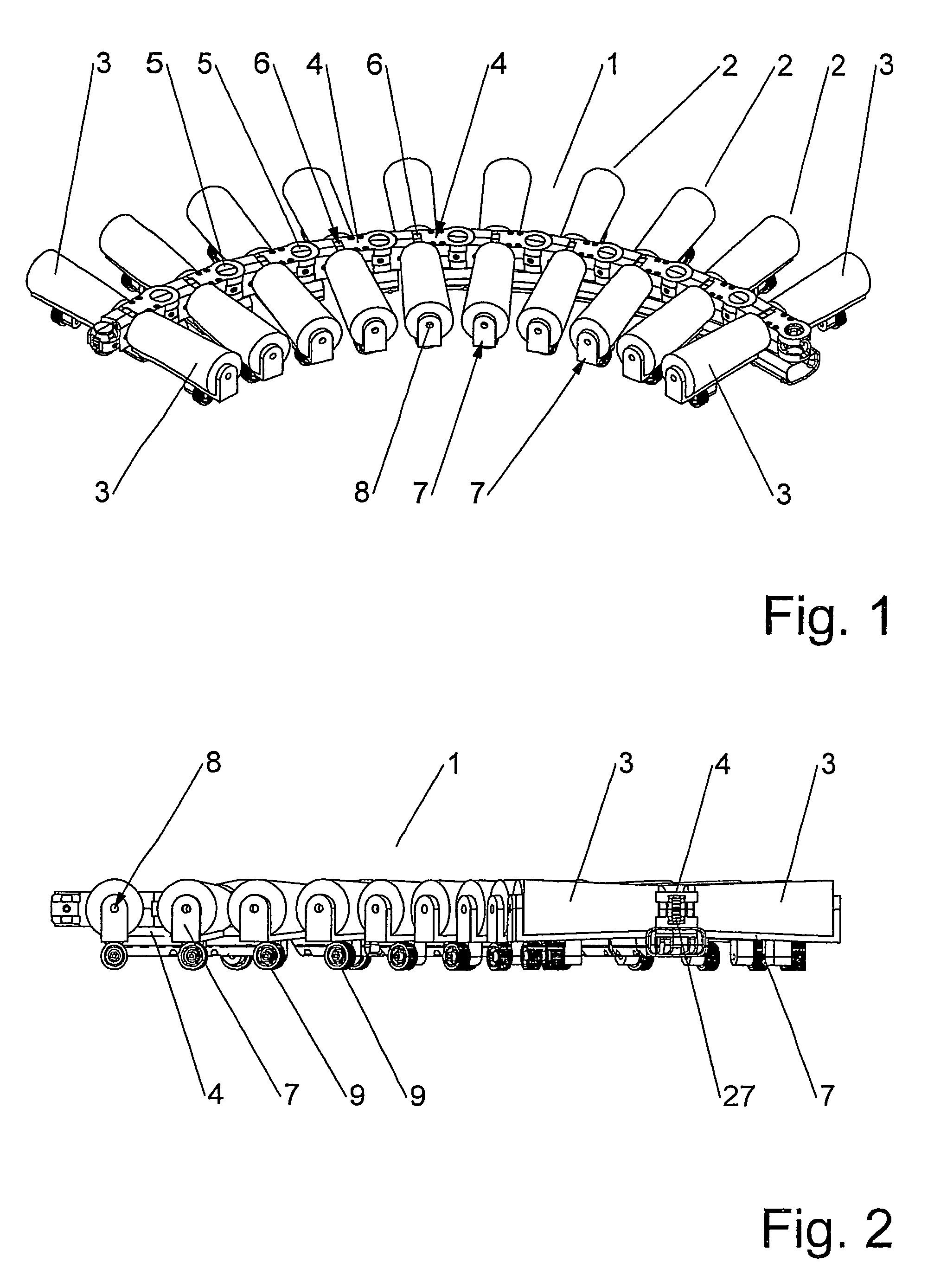

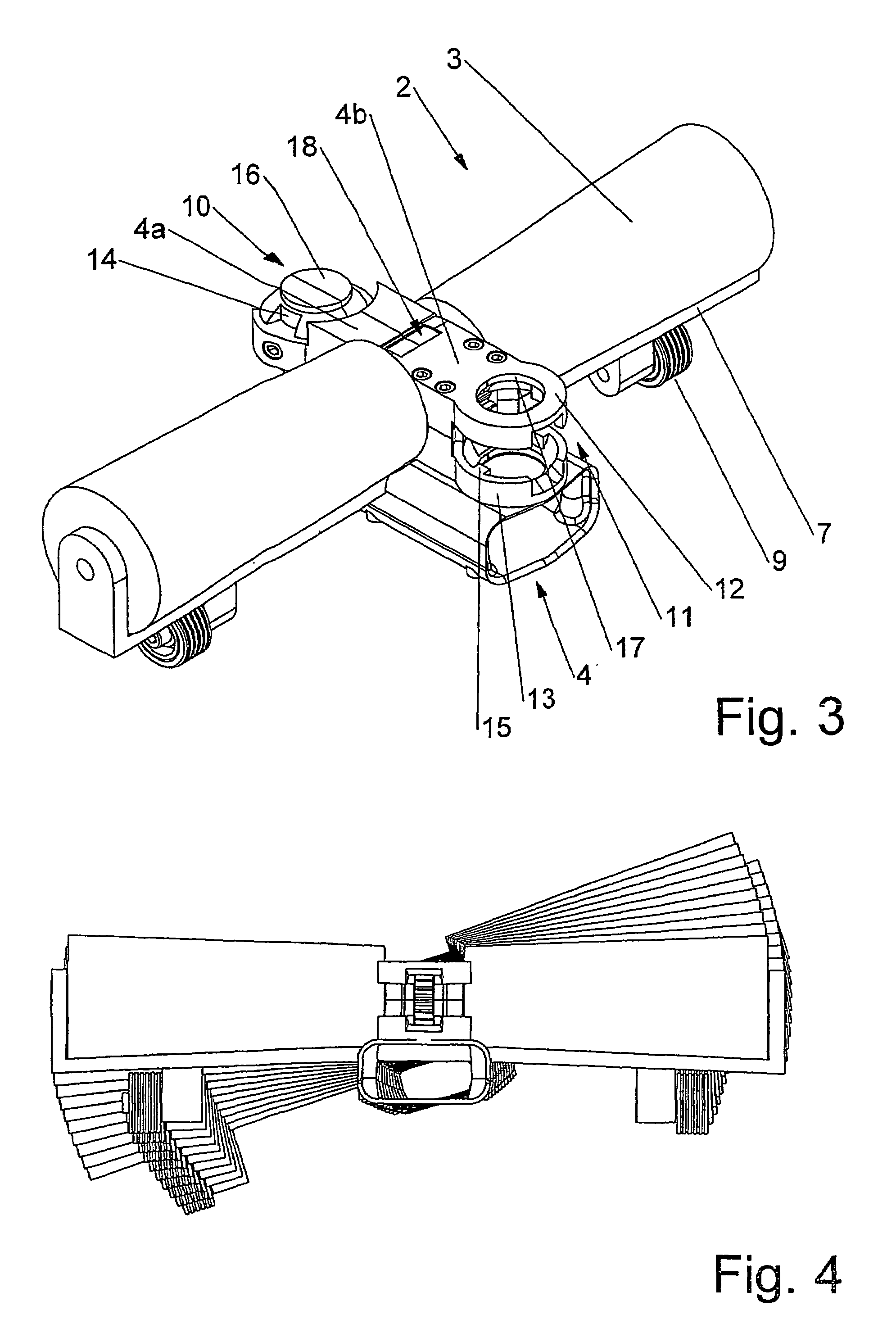

Transport band for conveying along a spiral path

A conveyor belt (1) is composed of a number of identical links in the formation of an endless belt, where each link comprises at least one axle (3) arranged transversely in relation to the direction of travel (2), and an outer link (4) at each side in engagement with the axle. Each outer link comprises an elongated hole for the adjacent link's axle, so that the belt can be driven in a curve in the plane of the belt. Each outer link has at least one securing hole for a transverse axle, where the coupling-together between the axle (3 and the outer link (4) is effected by a separable snap-lock. The outer link is moulded as a one-piece unit in a suitable plastic material, preferably by injection moulding. The outer links (4) can also be configured in a larger version for the construction of conveyor belts for operation in self-stacking helical systems.

Owner:UNI CHAINS INT +1

Cargo roller system for cargo handling

A roller unit that can be used to retrofit a cargo carrying surface makes loading and unloading of the cargo carrying surface easier by transforming the cargo carrying surface to include a conveyor system. The roller unit includes at least two trays in which are mounted rollers, the trays being connected by a crosspiece. The roller unit is designed to be installed on cargo carrying surfaces such as portable platforms, including Flatracks or CROPs, and in cargo containers of any type.

Owner:ENGINEERED SUPPORT SYST INC

Article transfer and placement apparatus with active puck

An apparatus for transferring articles such as absorbent cores or disposable diaper chassis components from a rotary mechanism, such as a pad turner, to a linear mechanism, such as a conveyor, for further processing. A puck on the apparatus is capable of manipulating the article during this transfer procedure.

Owner:CURT G JOA

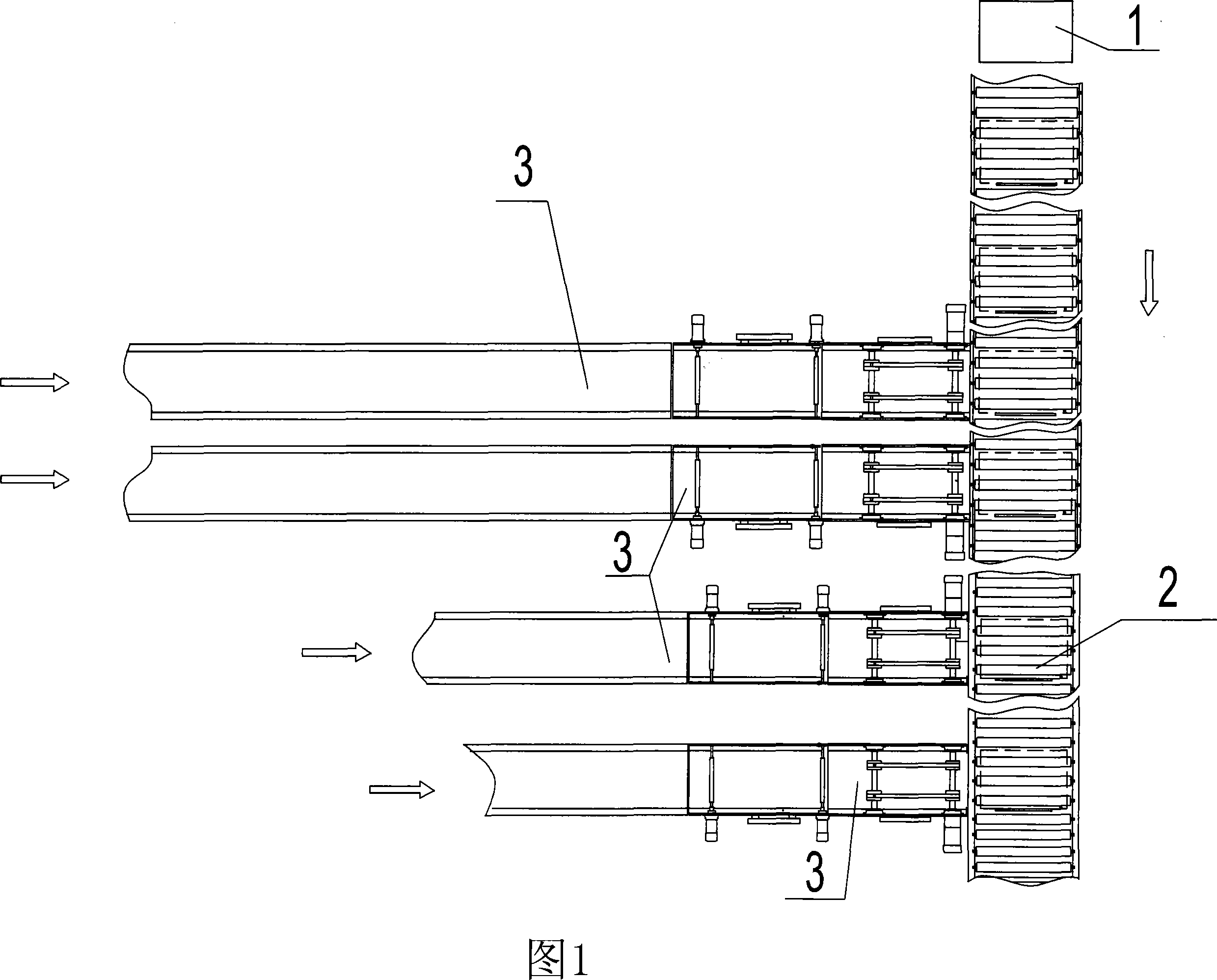

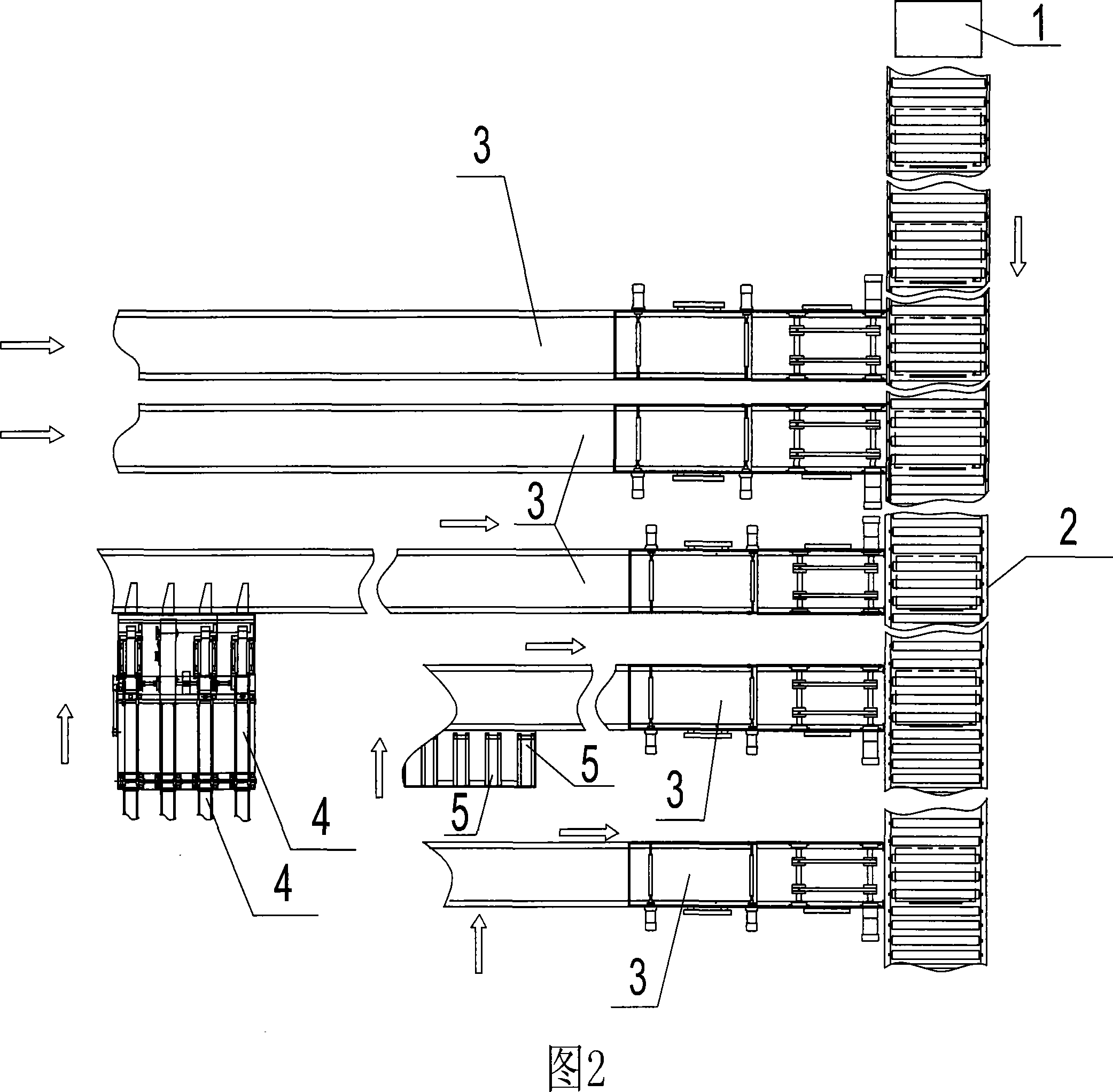

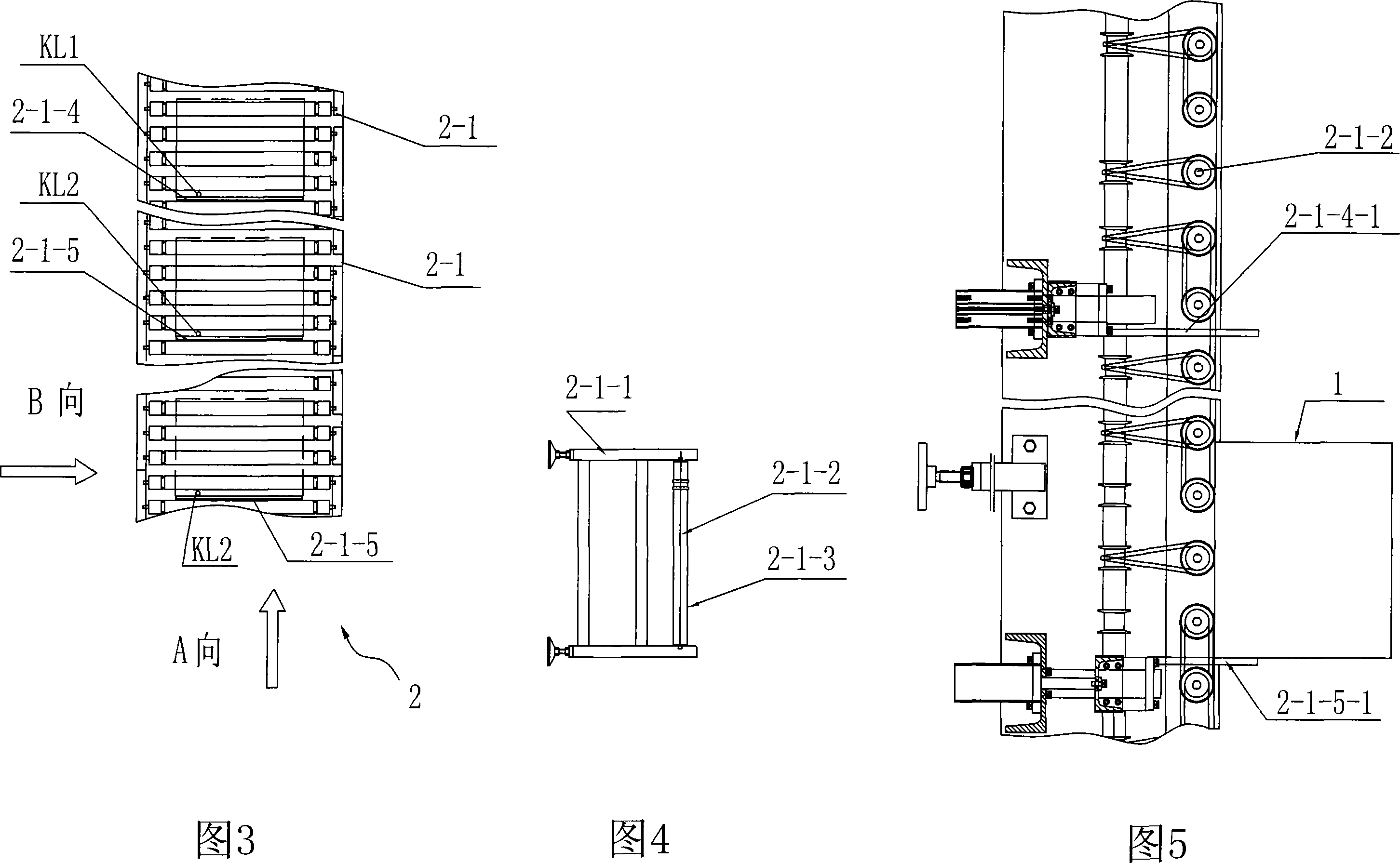

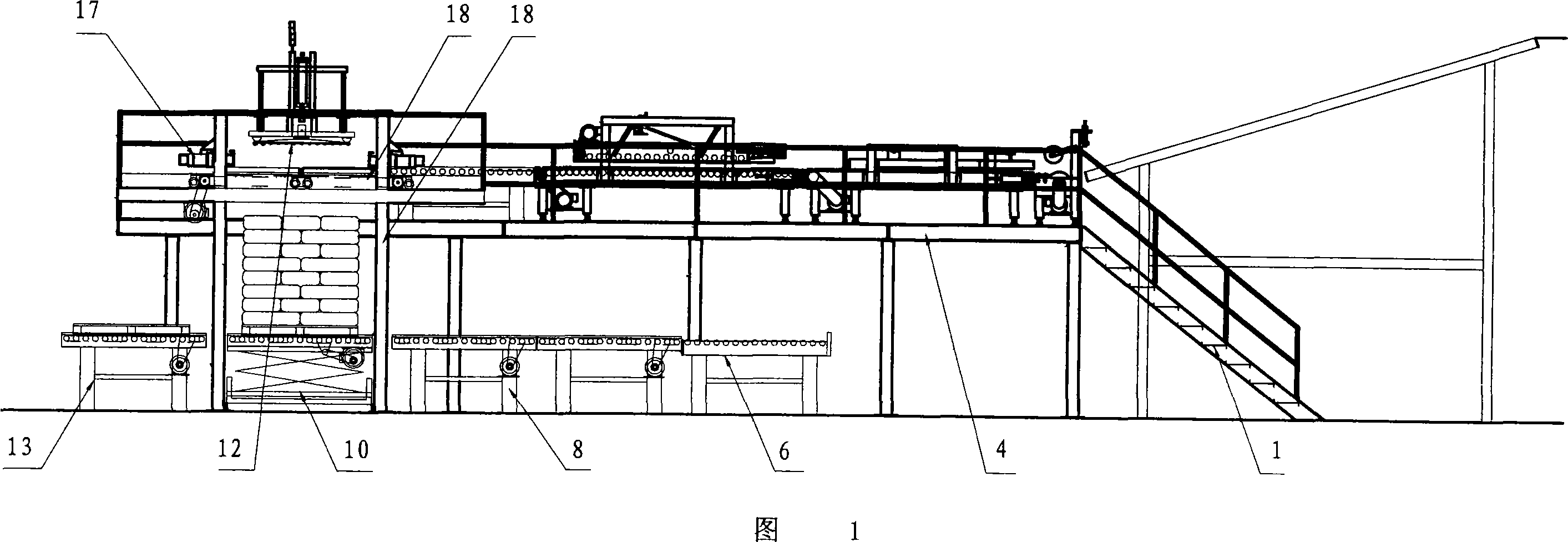

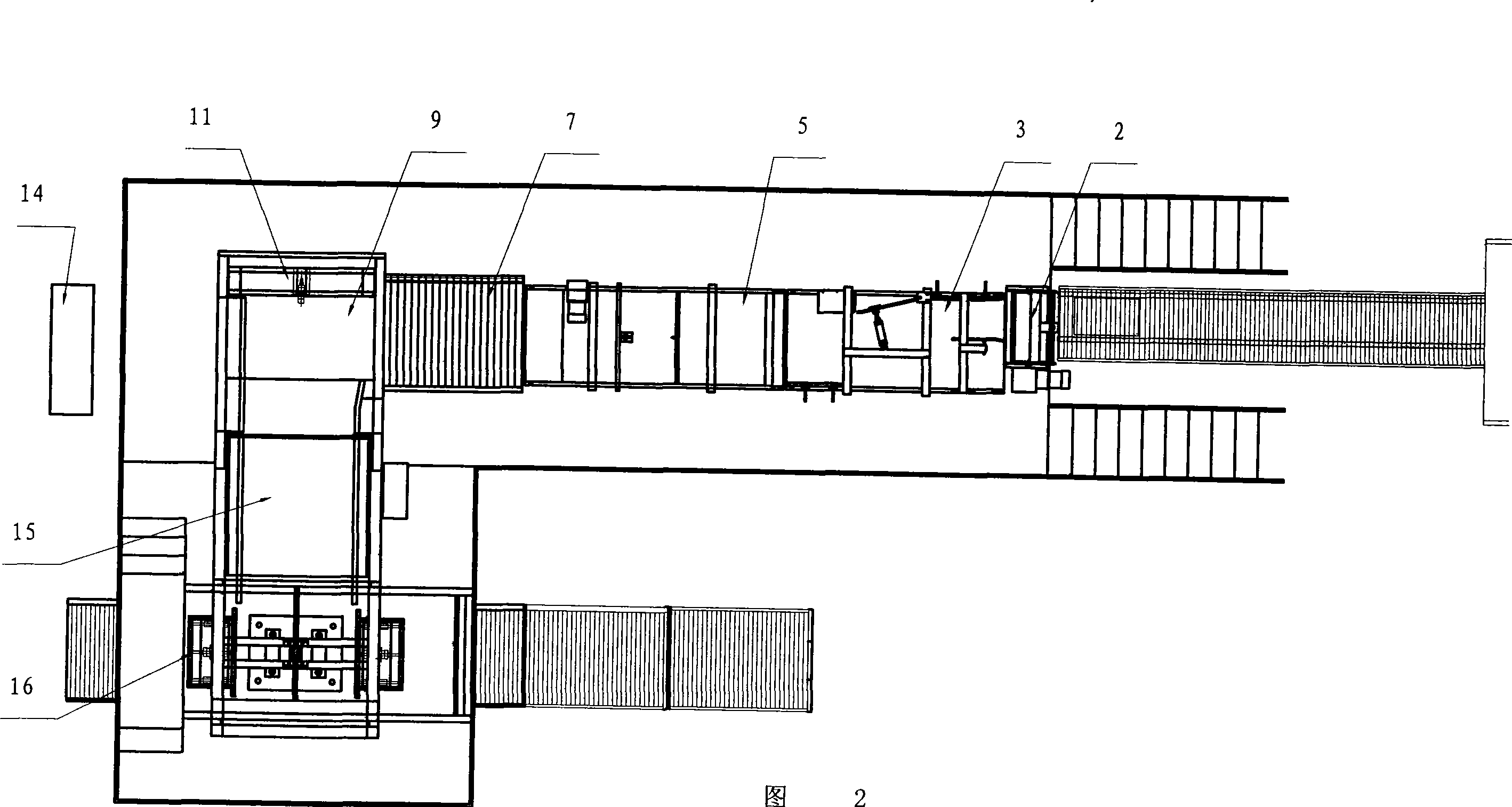

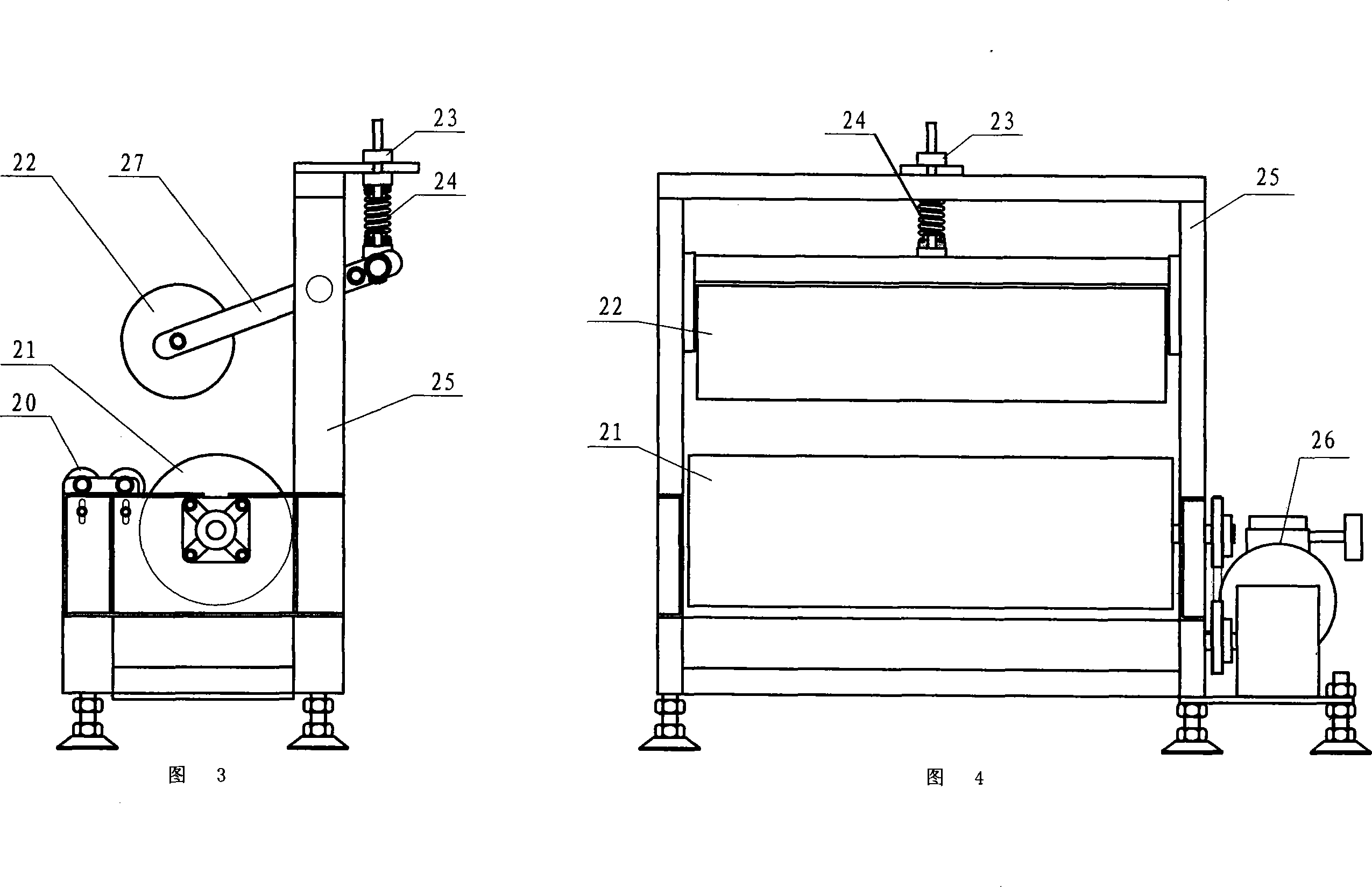

Piling machine

ActiveCN101168415AReasonable structural designLow costStacking articlesConveyor partsOutput deviceElectric control

The invention relates to a pallet machine which can automatically pallet bagged materials as bulked cement, chemical materials, rice or the like. The invention comprises a feeder, a bag rotation transmitter, a compression transmitter, a buffer transmitter, a grouped transmitter, a grouped bag pusher, a layering machine, a side face shape corrector, a vibration shape corrector, a lifter, a disc feeder, a pallet bearing outputting device, an output transmitter, a pallet disc storage transmitter, an electric control cabinet, a walk bench, and an arm rest lift. The invention has reasonable structure, low cost, and high speed, which combines a plurality of single machines, with clear and reasonable structure and simple maintenance.

Owner:HEBEI HANGUANG HEAVY IND

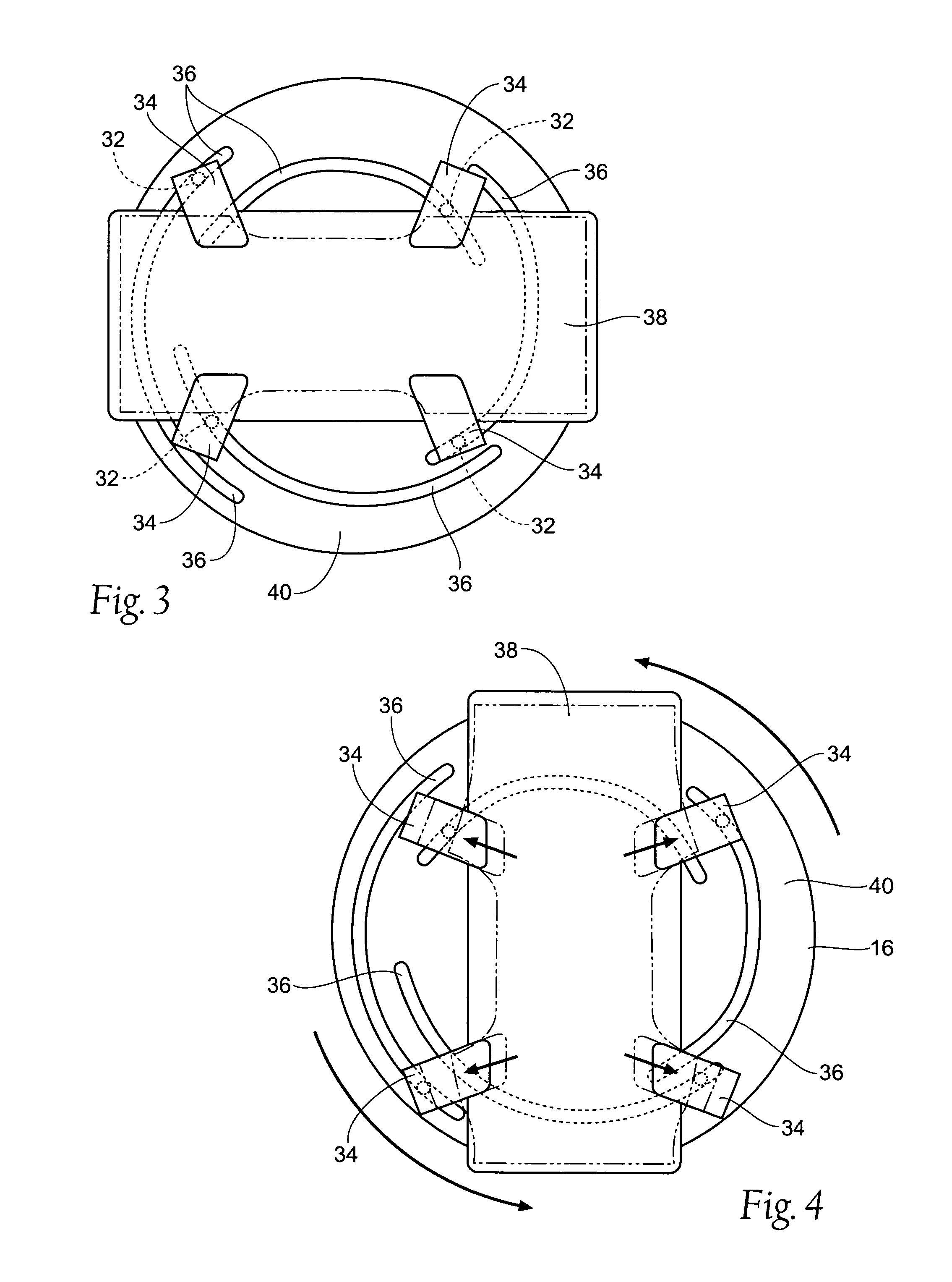

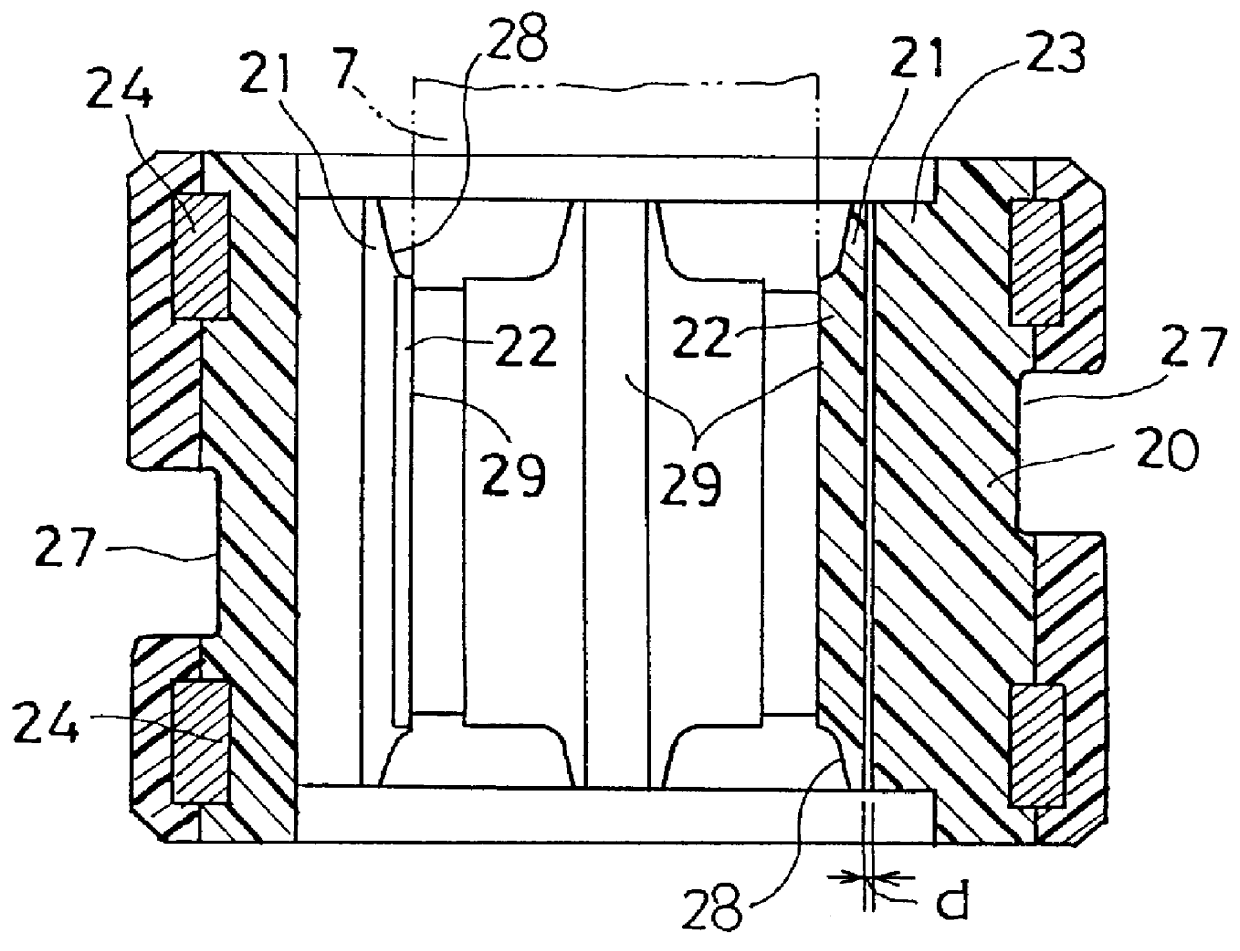

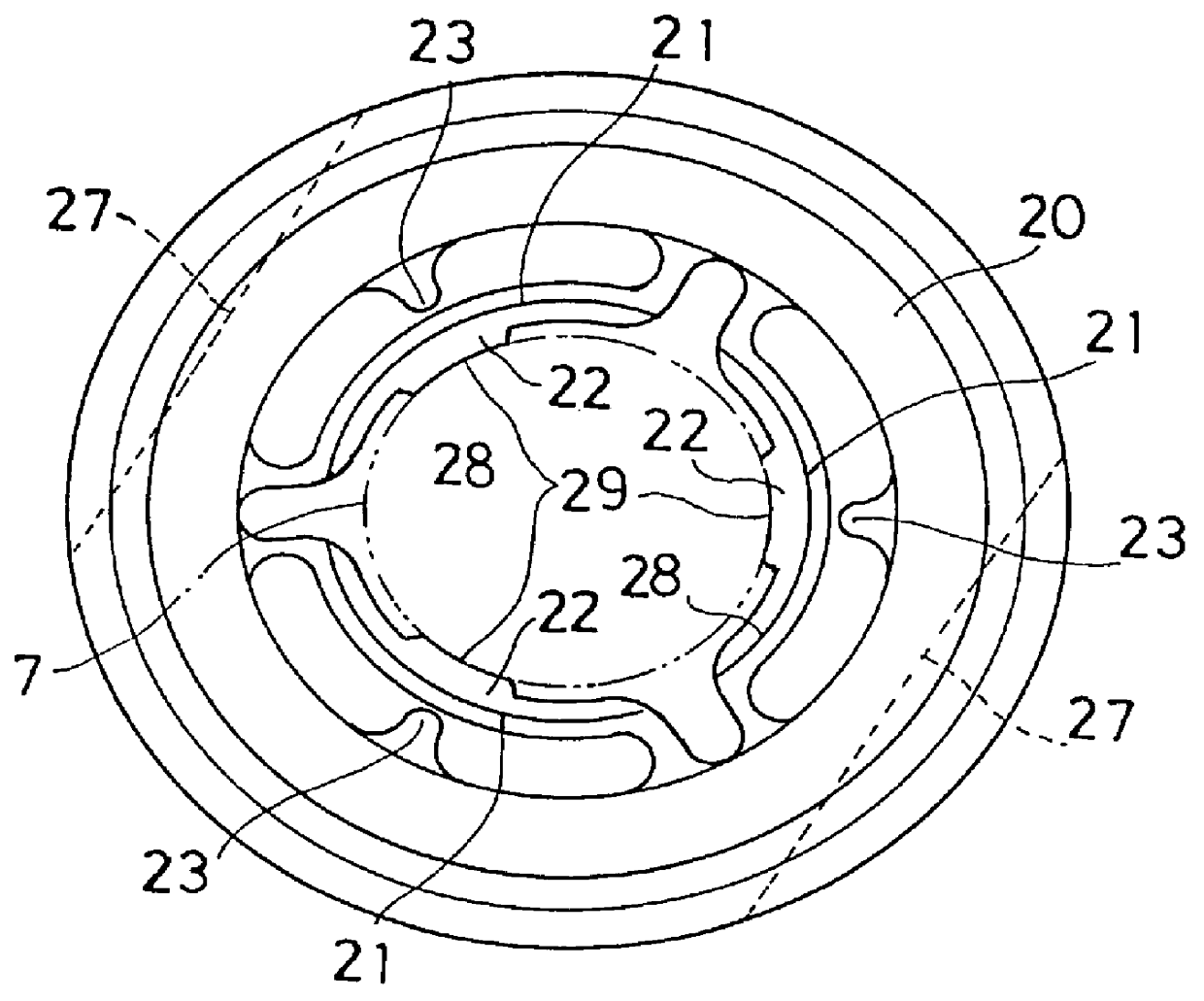

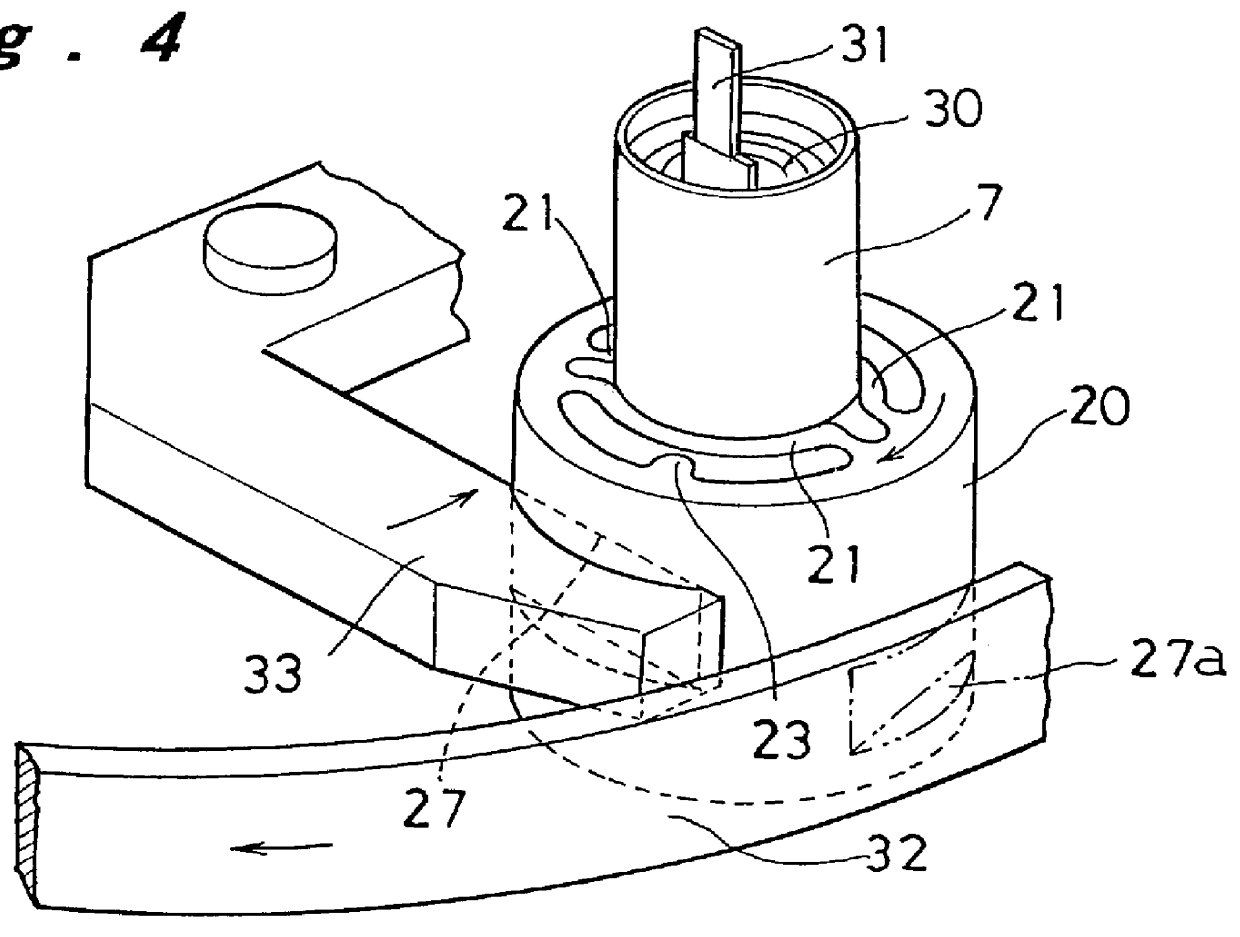

Holder for cylindrical cell in conveyor system

A conveying holder for cylindrical cell is provided which is capable of stably supporting a cylindrical cell irrespective of variation in outer diameter of the cell or impact during transfer. An outer wall member 20 of which inner diameter is greater than the diameter of a cylindrical cell 7 is provided. A plurality of elastic inner wall portions 21 are concentrically arranged to have a distance from the inner side of the outer wall member 20, each elastic inner wall portion joined at both ends to the outer wall member 20. A cell holding portion 22 is provided projecting inwardly from the inner side of each elastic inner wall portion 21 and having a cell holding surface 29 thereof corresponding in shape to the outer side of the cylindrical cell 7. The cell holding surfaces 29 are arranged along a concentric circle which is smaller in diameter than the cylindrical cell 7 so that they can hold the cylindrical cell 7 in-between under pressure.

Owner:PANASONIC CORP

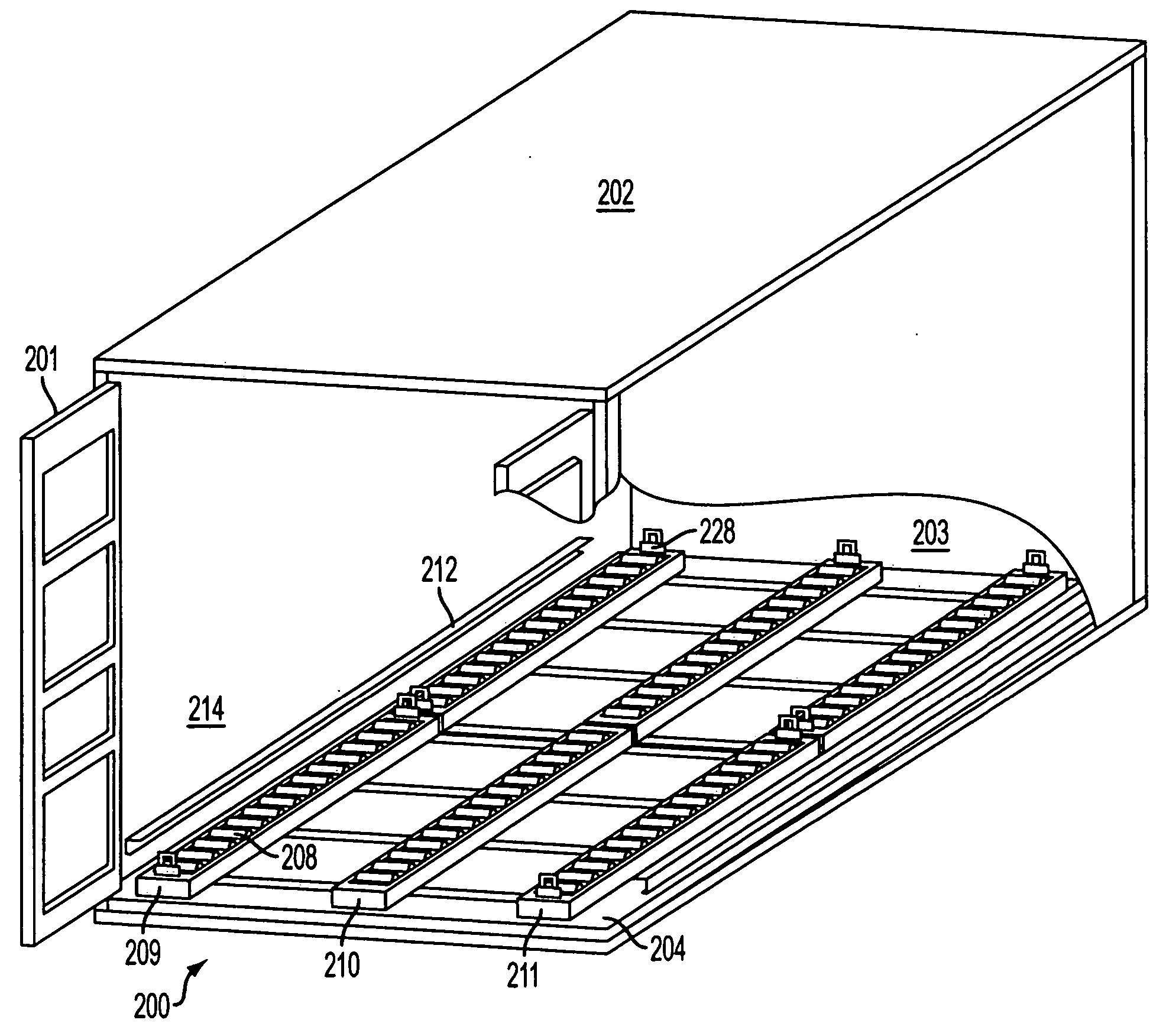

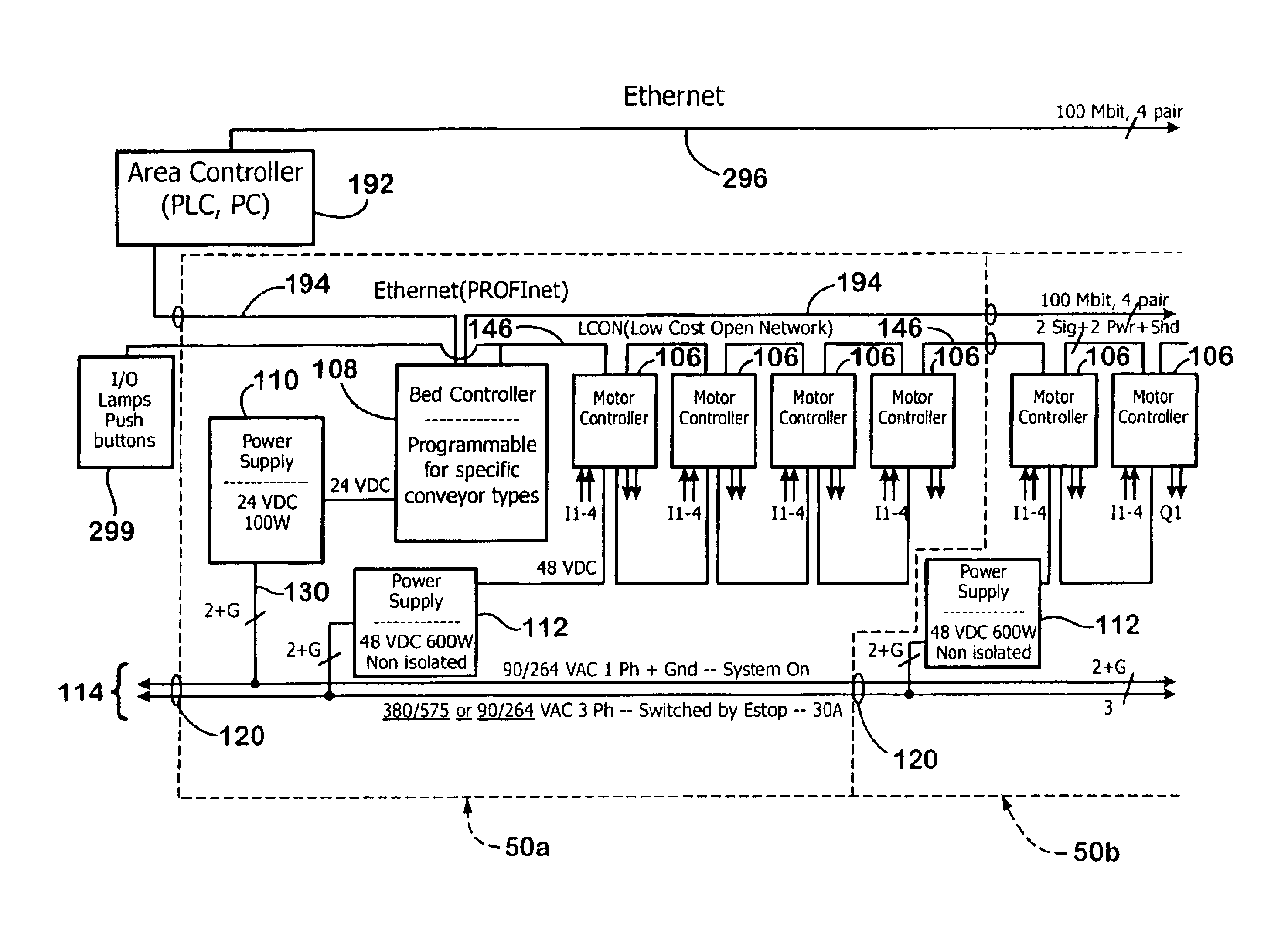

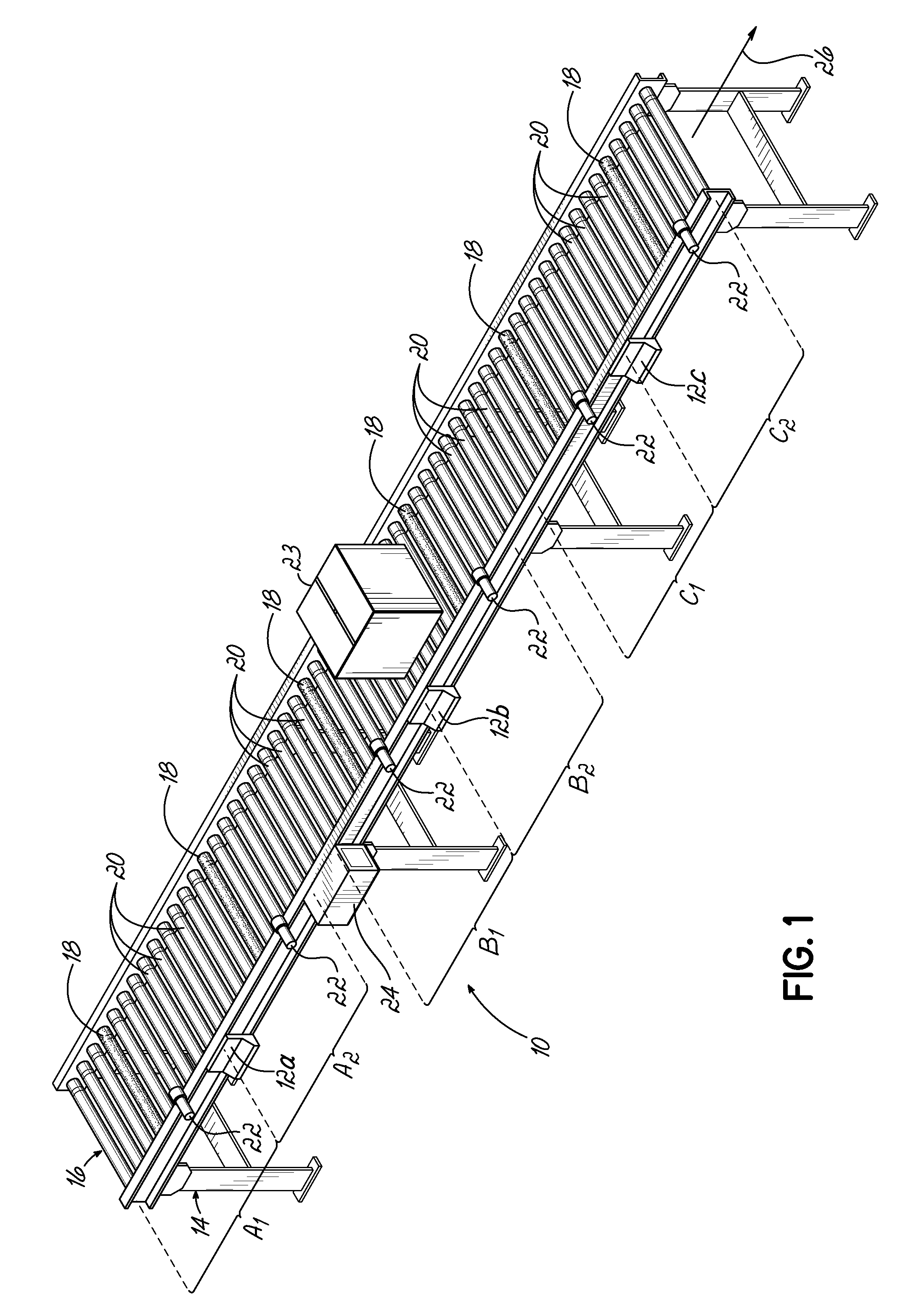

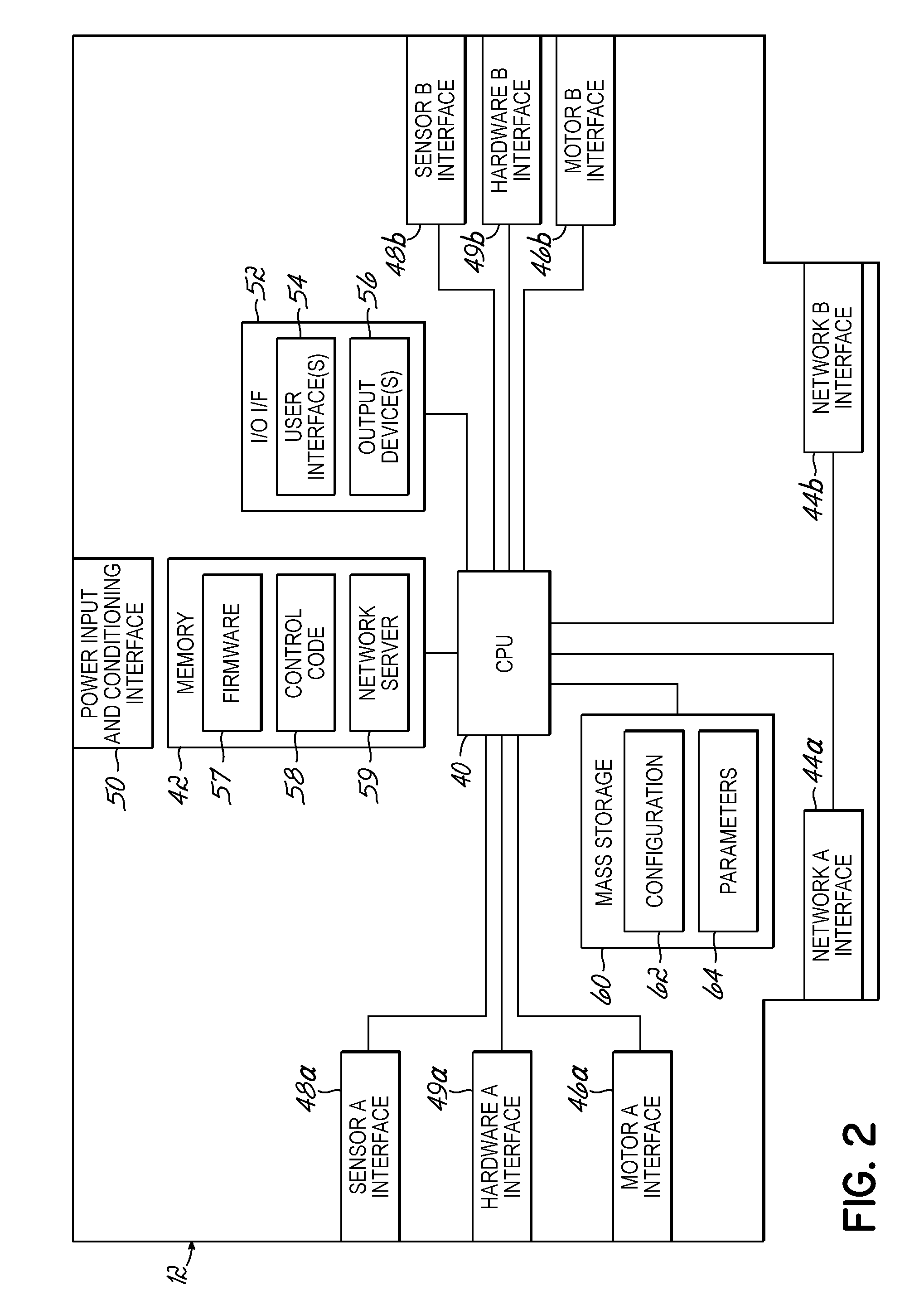

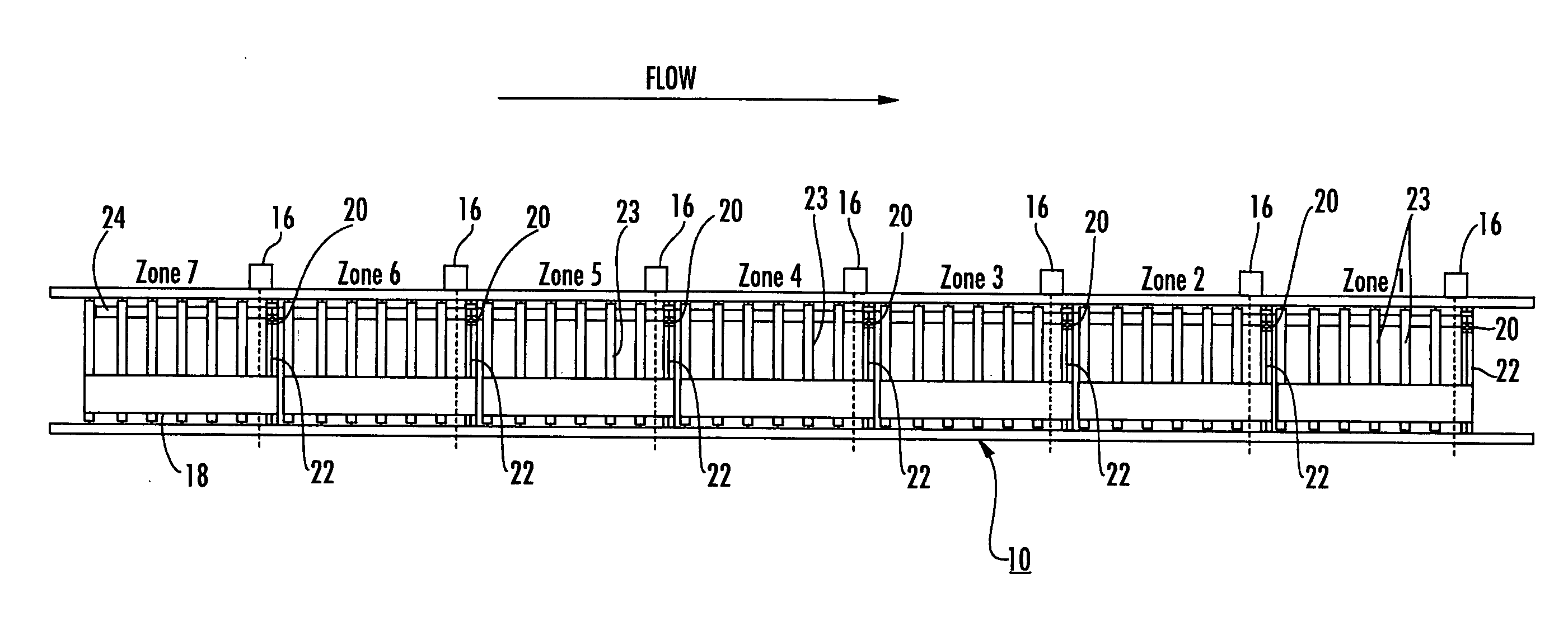

Integrated conveyor bed

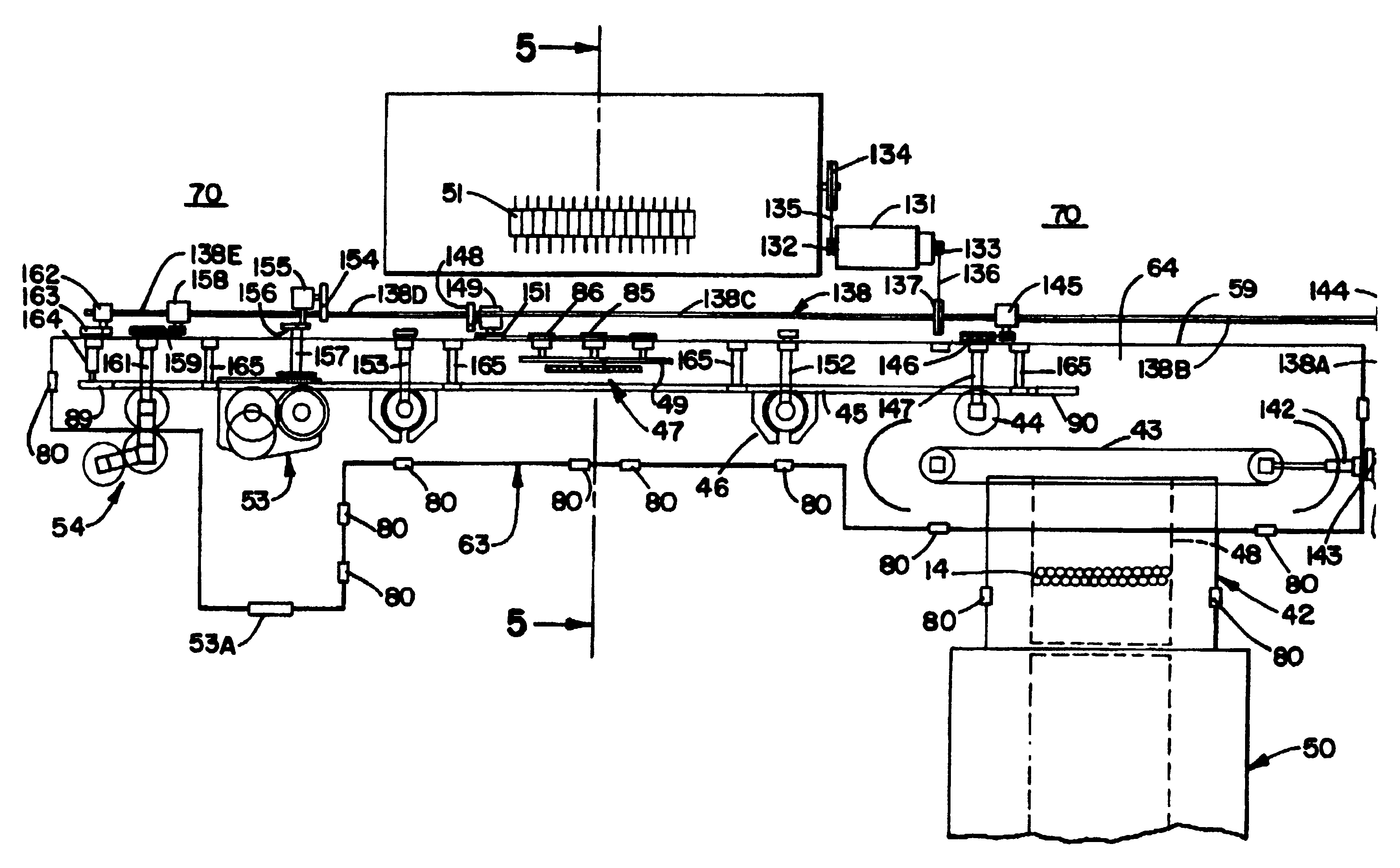

InactiveUS7035714B2Simplifies installation and operation and maintenanceEasy to installDigital data processing detailsControl devices for conveyorsControl theoryElectric motor

A conveyor system, and method of controlling the conveyor system, includes providing a conveying surface, at least one motor propelling the conveying surface and a plurality of lower-level controllers. At least one of the lower-level controllers adapted to control the at least one motor. An upper-level controller is provided in communication with the plurality of lower-level controllers. The upper-level controller is adapted to send communications to the lower-level controllers for controlling the at least one motor. A communications bus is provided that carries the communications between the upper-level controller and the lower-level controllers. The upper-level controller is adapted to automatically assign each lower-level controller a unique communications address. The unique communications address enables the upper-level controller to send messages over the communications bus to individual ones of the lower-level controllers.

Owner:DEMATIC

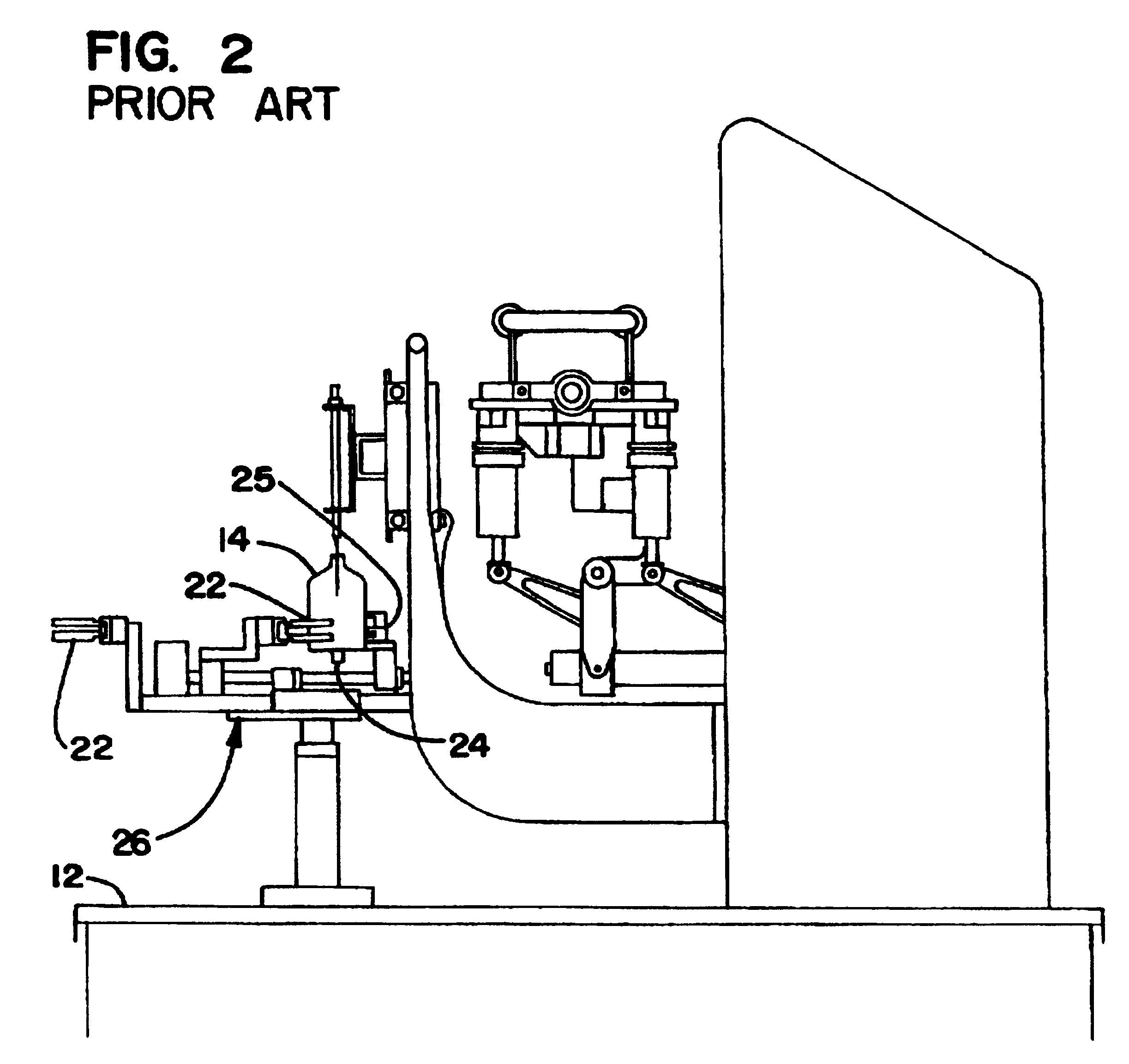

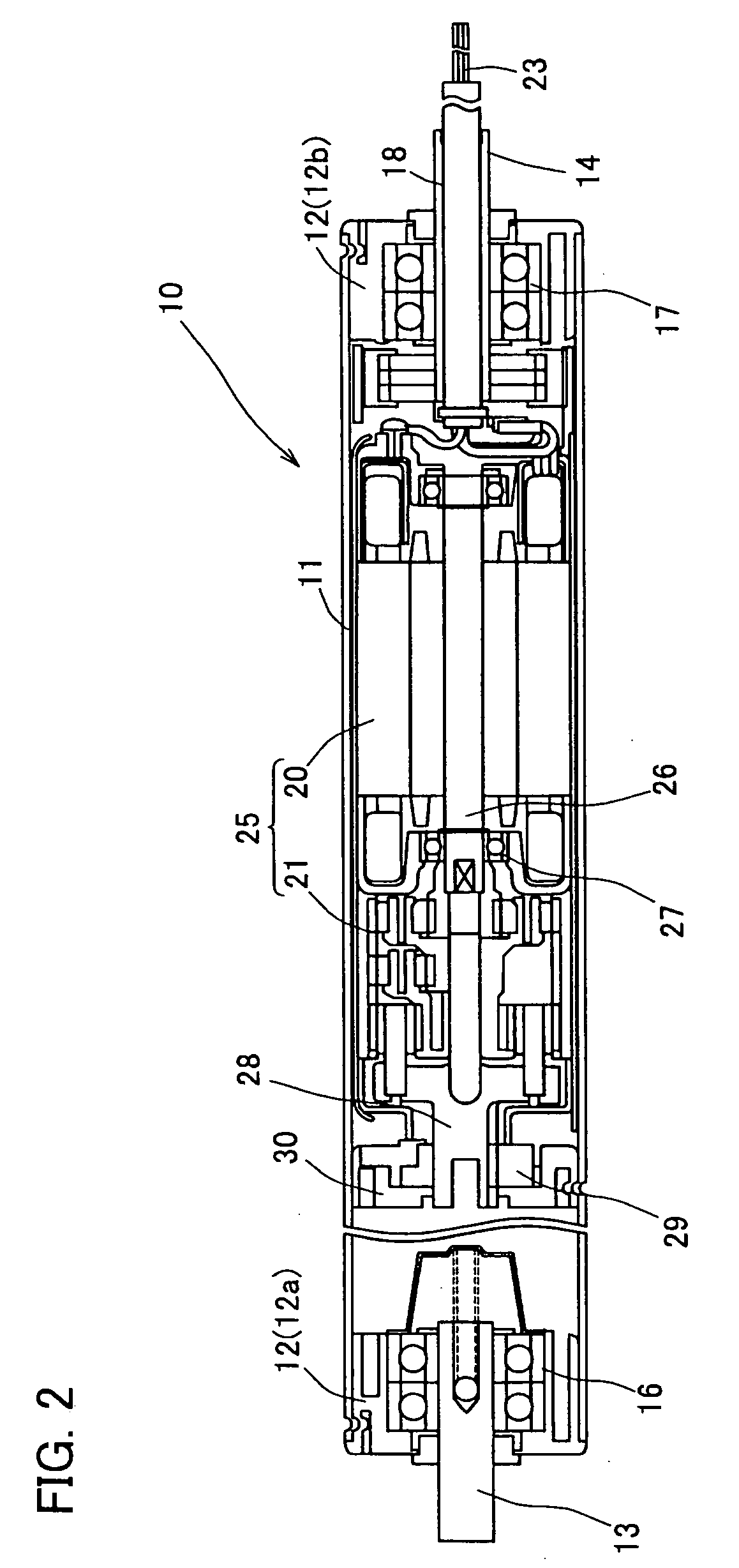

Vial filling apparatus

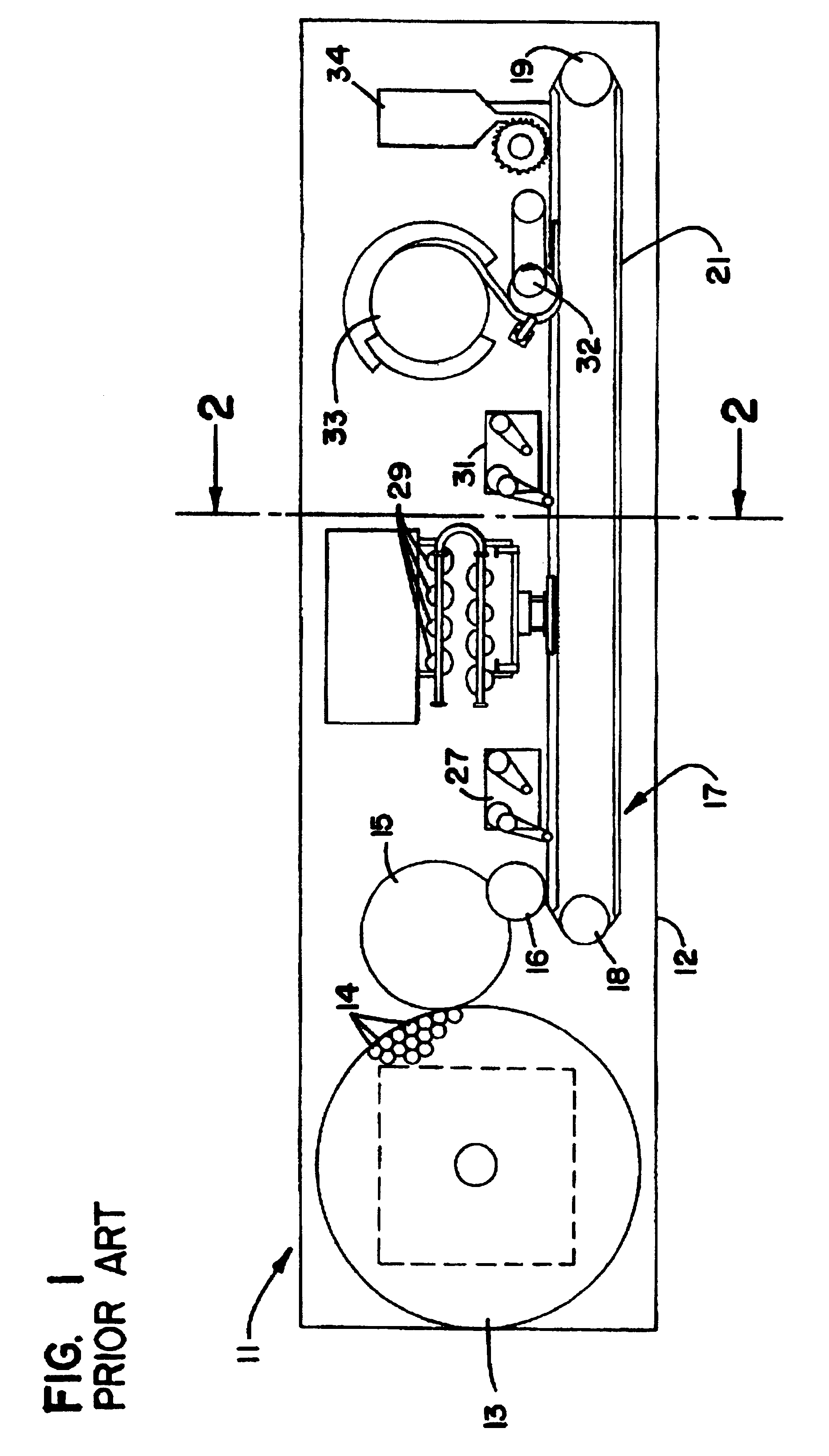

Apparatus for filling sterile containers is disclosed which defines an elongated but narrow sterile zone in which a number of operating stations are disposed. An elongated vertical wall is carried by an elongated frame and a cabinet type enclosure cooperates with the vertical wall to define the sterile zone. The plurality of operating stations are disposed in sequential relation over the length of the sterile zone, and an elongated container conveyor is disposed within the sterile zone to convey the containers through the plurality of operating stations. The conveyor is vertically oriented, consisting an endless belt mounted on end wheels that rotate on horizontal axes. Each of the operating stations includes an operating portion disposed within the sterile zone. Actuating means are included for each of the operating stations as well as the elongated conveyor, each of which is disposed outside the sterile zone. Connecting means operabably connect each of the actuating means outside the sterile zone through the vertical wall to the associated operating station within the sterile zone. By orienting the conveyor vertically and disposing the various actuating means outside the sterile zone in side-by-side relation, the effective width of the sterile zone is significantly reduced. As a result, the sterile zone is more easily accessed, and also more easily drained after washdown operations. In addition, the sterile zone of reduced size results in an apparatus that much easier to manufacture and maintain in a sterile state.

Owner:ROBERT BOSCH PACKAGE TECH

Conveyor system load transfer devices

Conveyor systems for storage and movement of goods on pallets and slip sheets. The transfer structures enable slip sheet mounted loads to be transferred to a roller conveyor by providing structures that cooperate with wide platen forks of a lift truck. The structures provide roller contact between a portion of the underside of the slip sheet at all times. In other areas there is alternatively contact between a lift truck platen or additional rollers that cooperate in a manner making it possible to move the slip sheet mounted load from the lift truck to an adjacent conveyor system.

Owner:CREATIVE STORAGE SYST

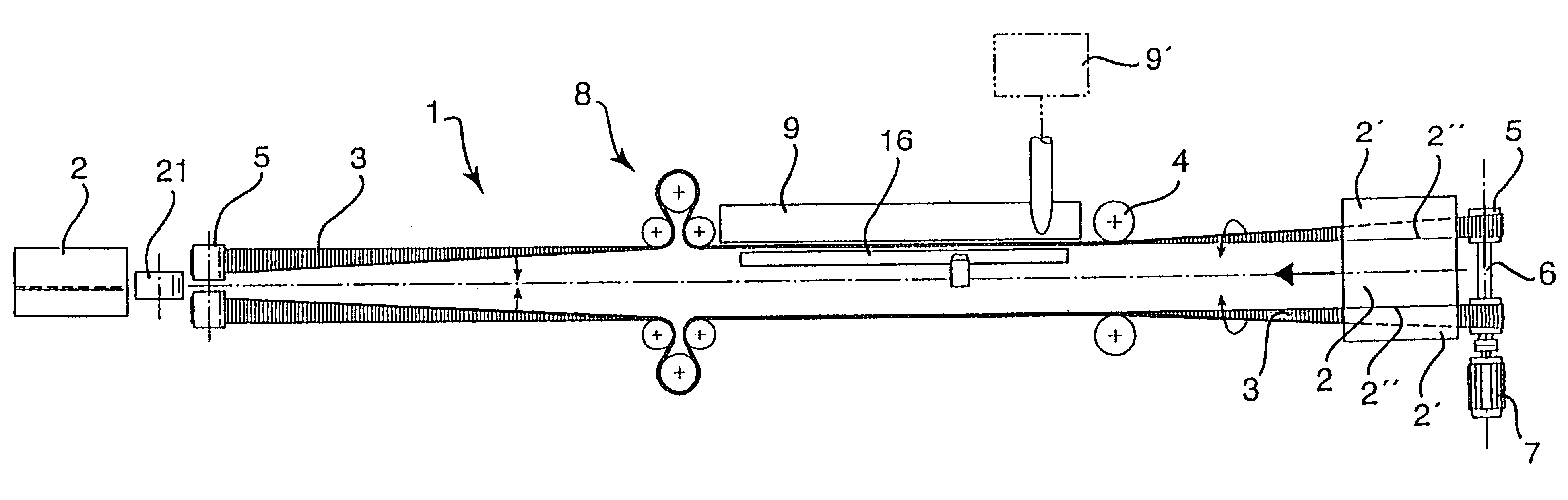

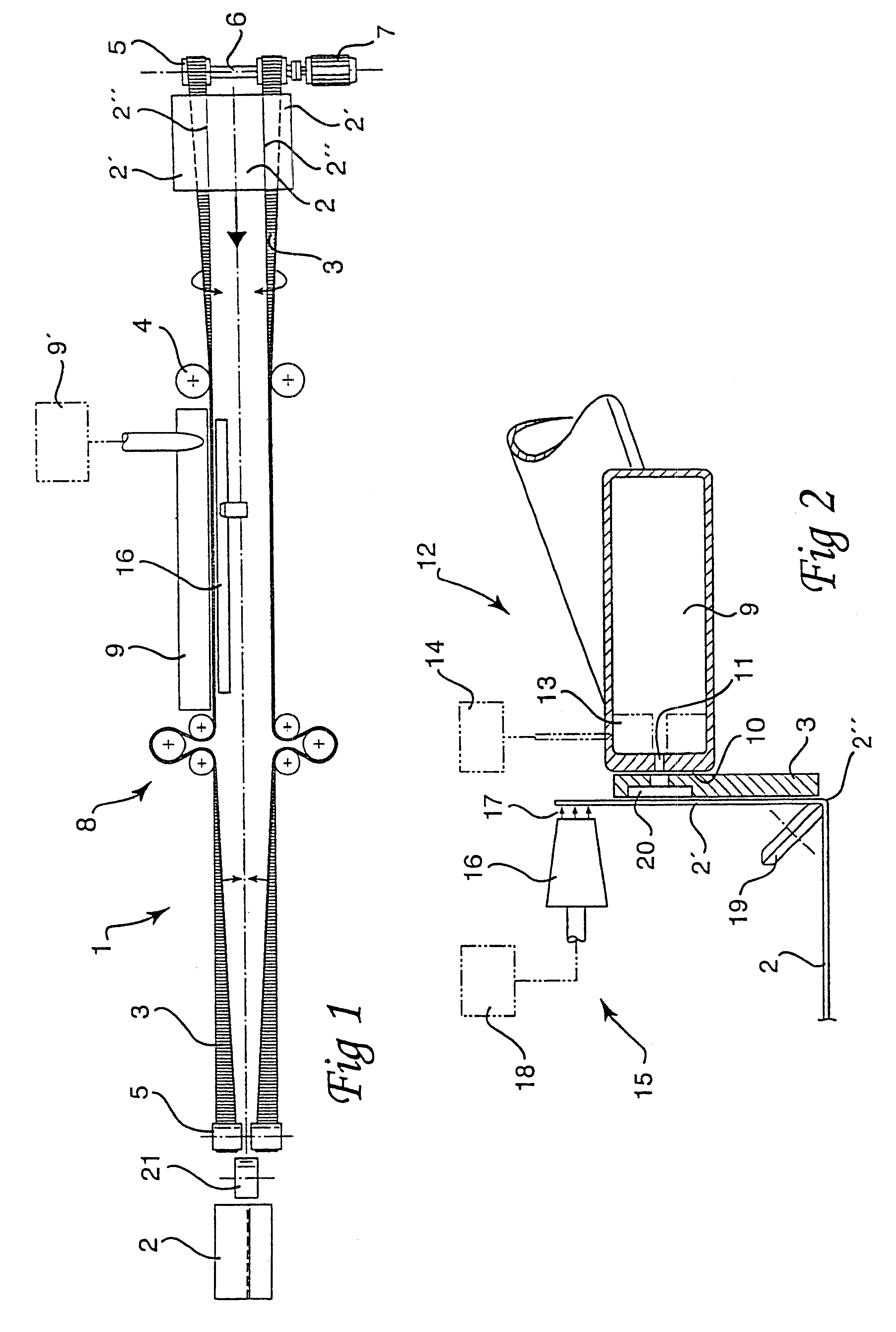

Apparatus for conveying and folding flexible packaging material

InactiveUS6637583B1High precisionReduce heatEnvelopes/bags making machineryBoxes/cartons making machineryEngineeringMechanical engineering

The disclosure relates to an apparatus for conveying and folding flexible packaging material, comprising a conveyor (1) with a conveyor belt (3) which is provided with through-going holes and which, for a part of its length, extends substantially rectilinearly and with constant orientation along a suction box (9). By connecting the suction box (9) to a source of partial vacuum, a partial vacuum is created at the side of the belt facing towards the packaging material, which ensures that the packaging material is well-fixed and can thereby pass closely adjacent and be heated by a heating device (15) extending along the belt. The apparatus makes for concentrated, energy-efficient and well-defined heating of an edge region of the packaging material intended for thermosealing.

Owner:TETRA LAVAL HLDG & FINANCE SA

Conveyor guard

ActiveUS7530452B2Improve usability and reliabilityImprove rigidityConveyorsSupporting framesEngineeringMechanical engineering

Owner:VESTERGAARD MARTIN

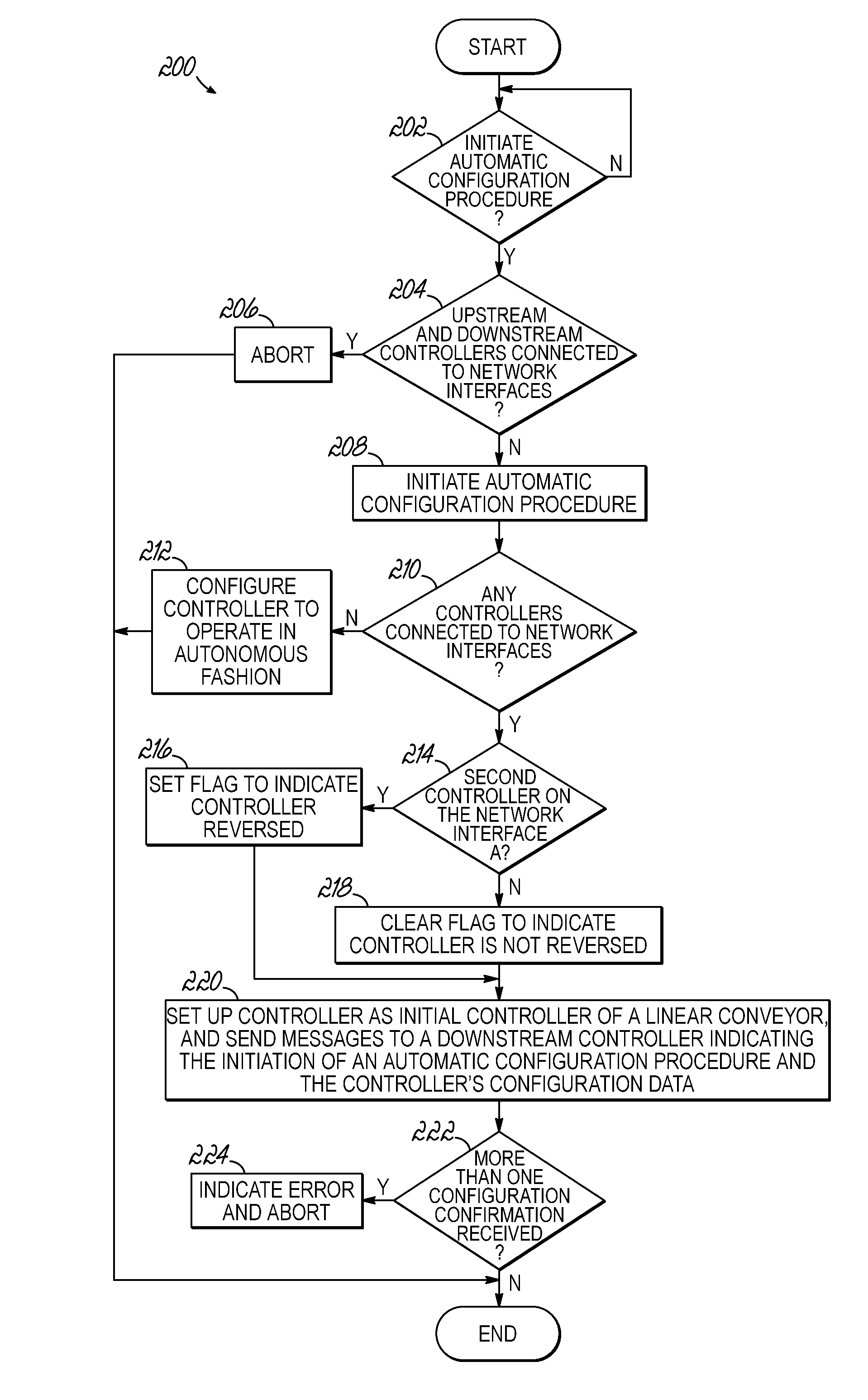

Conveyor controllers

Various methods, apparatuses, and program products that are used to control at least a portion of a conveyor, determine information about an article conveyed by the conveyor, or otherwise operate a conveyor are provided. One method includes detecting whether a second conveyor controller is connected to the first conveyor controller and, in response to detecting that there is a second conveyor controller connected to the first conveyor controller, identifying whether the second conveyor controller is connected to a predetermined network interface of the first conveyor controller. The method further includes configuring the first conveyor controller to rotate a motorized roller in a first predetermined direction if a second conveyor controller is connected to the predetermined network interface and configuring the first conveyor controller to rotate the motorized roller in a second predetermined direction if a second conveyor controller is not connected to the predetermined network interface.

Owner:INSIGHT AUTOMATION INC

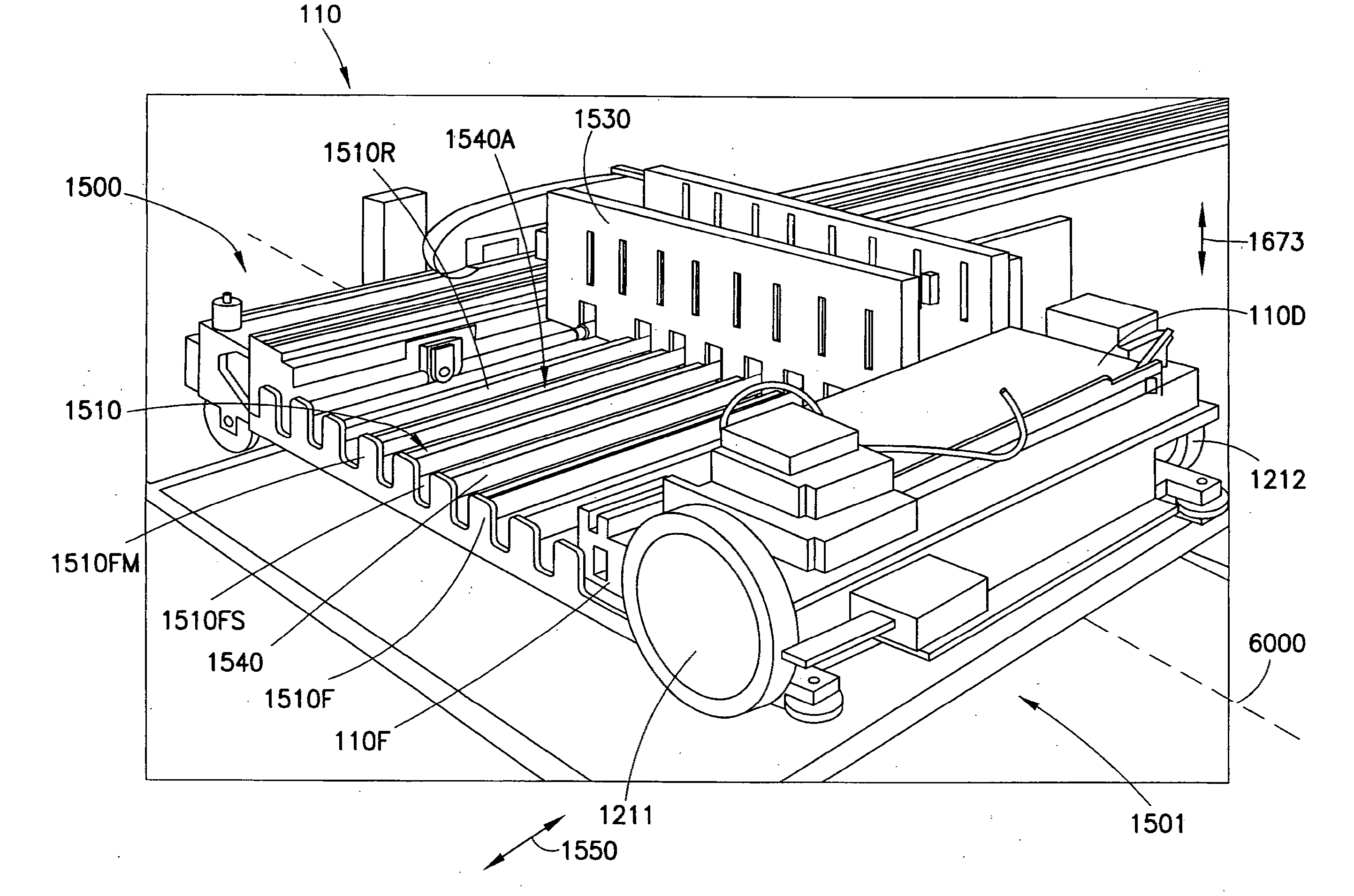

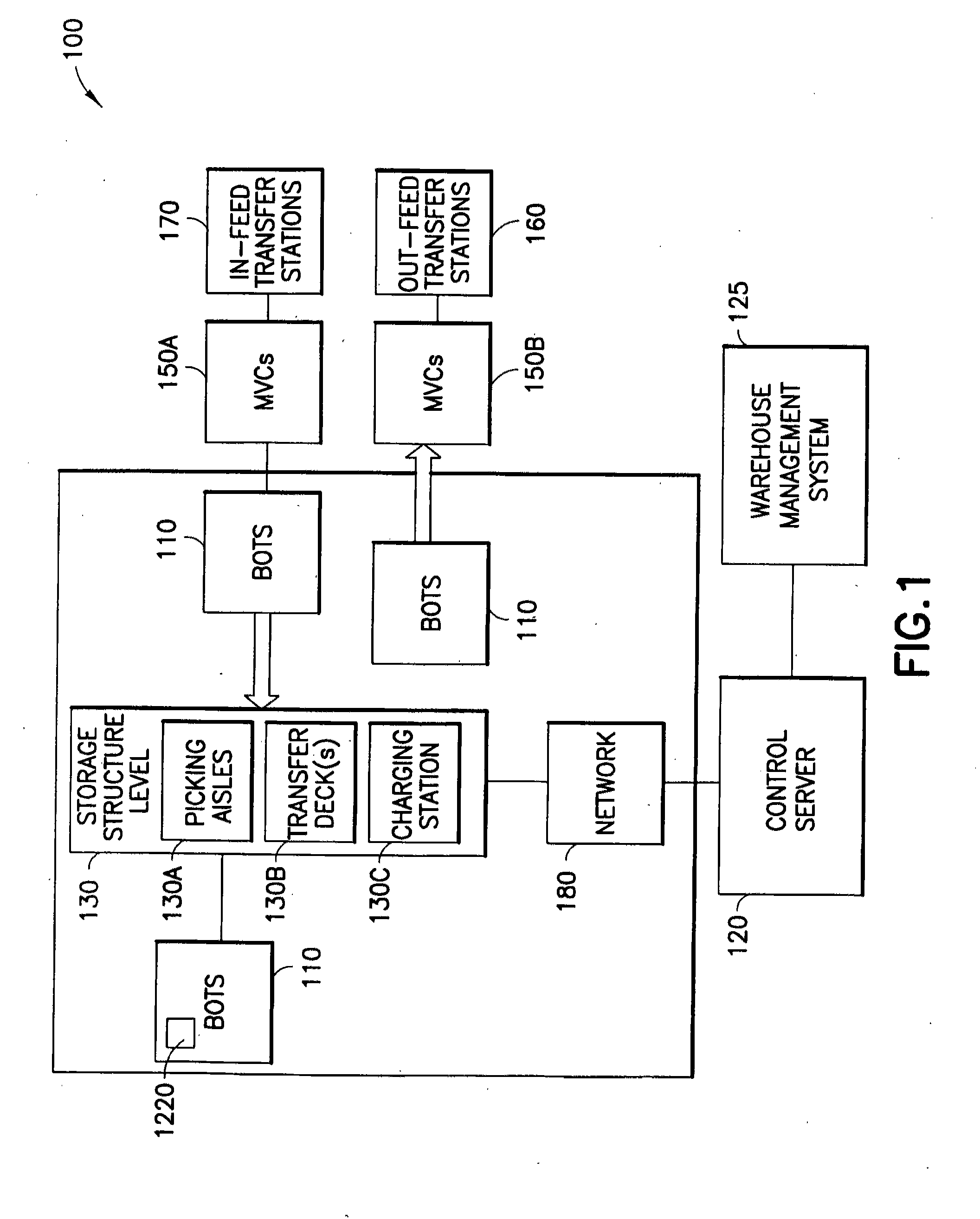

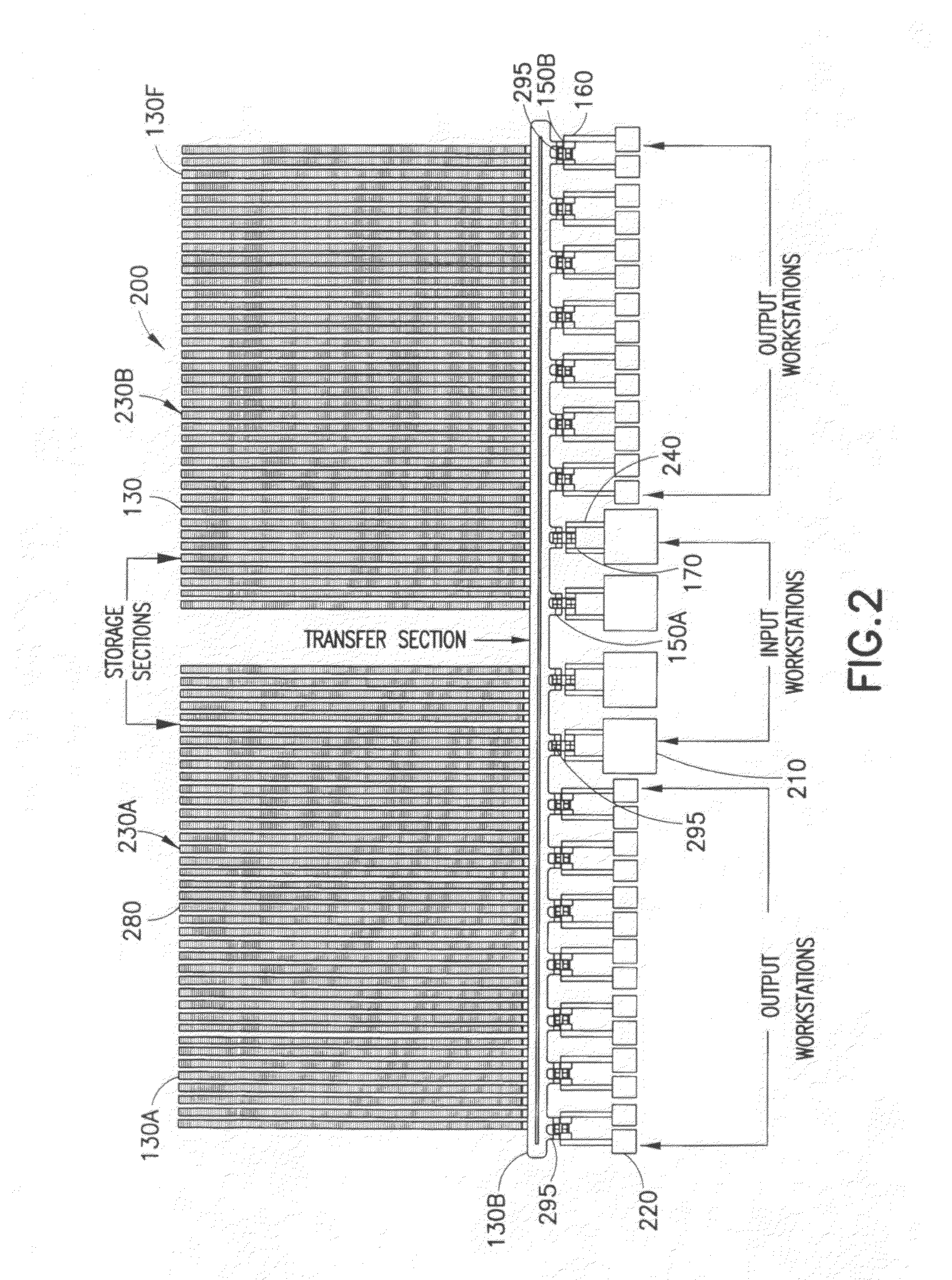

Suspension system for autonomous transports

An autonomous transport robot for transporting a payload, the autonomous transport robot including a drive section assembly having at least one motor and a pair of drive wheels coupled to the motor, a frame configured to support a payload, a transfer arm connected to the frame and configured for the autonomous transfer of payload to and from the frame, and a suspension system movably connecting the drive section assembly and the frame allowing relative movement between the frame and the drive section assembly.

Owner:SYMBOTIC LLC

Conveying device

Owner:VESTERGAARD MARTIN

Article accumulation method and apparatus

InactiveUS20070119690A1Improve system throughputReduce gapConveyorsConveyor partsEngineeringMechanical engineering

Owner:DEMATIC

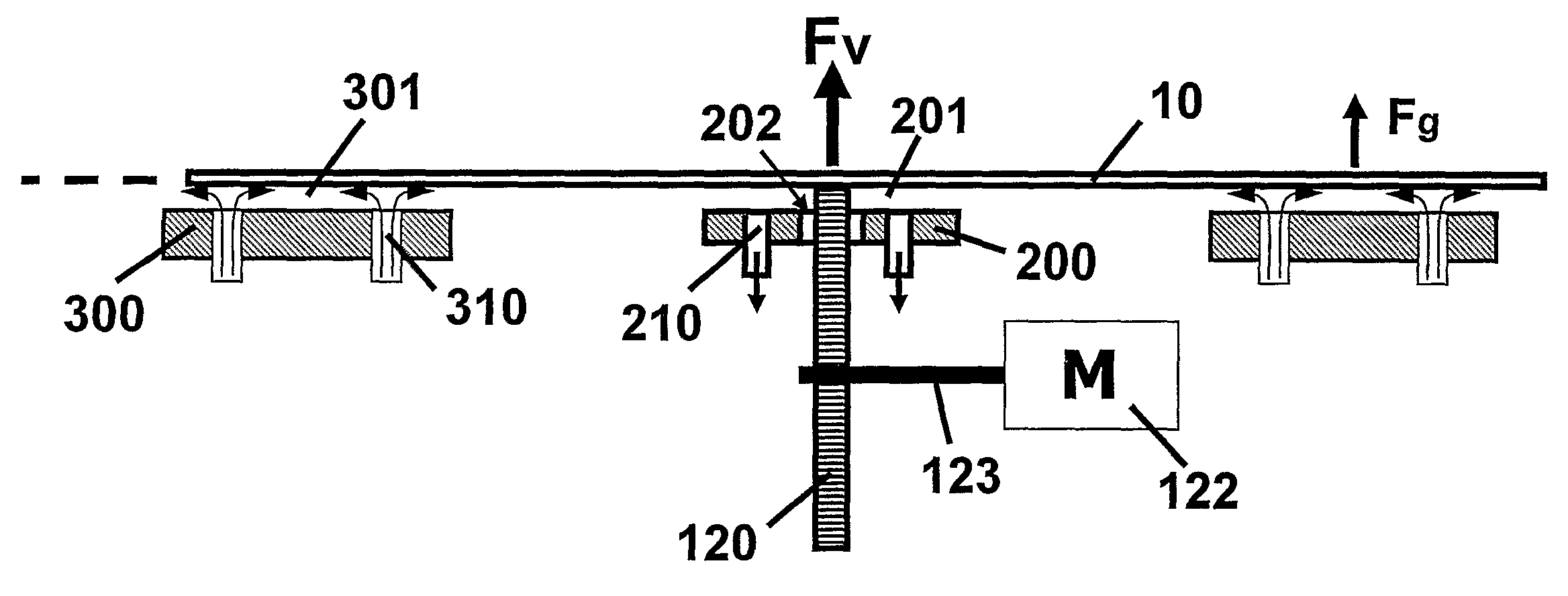

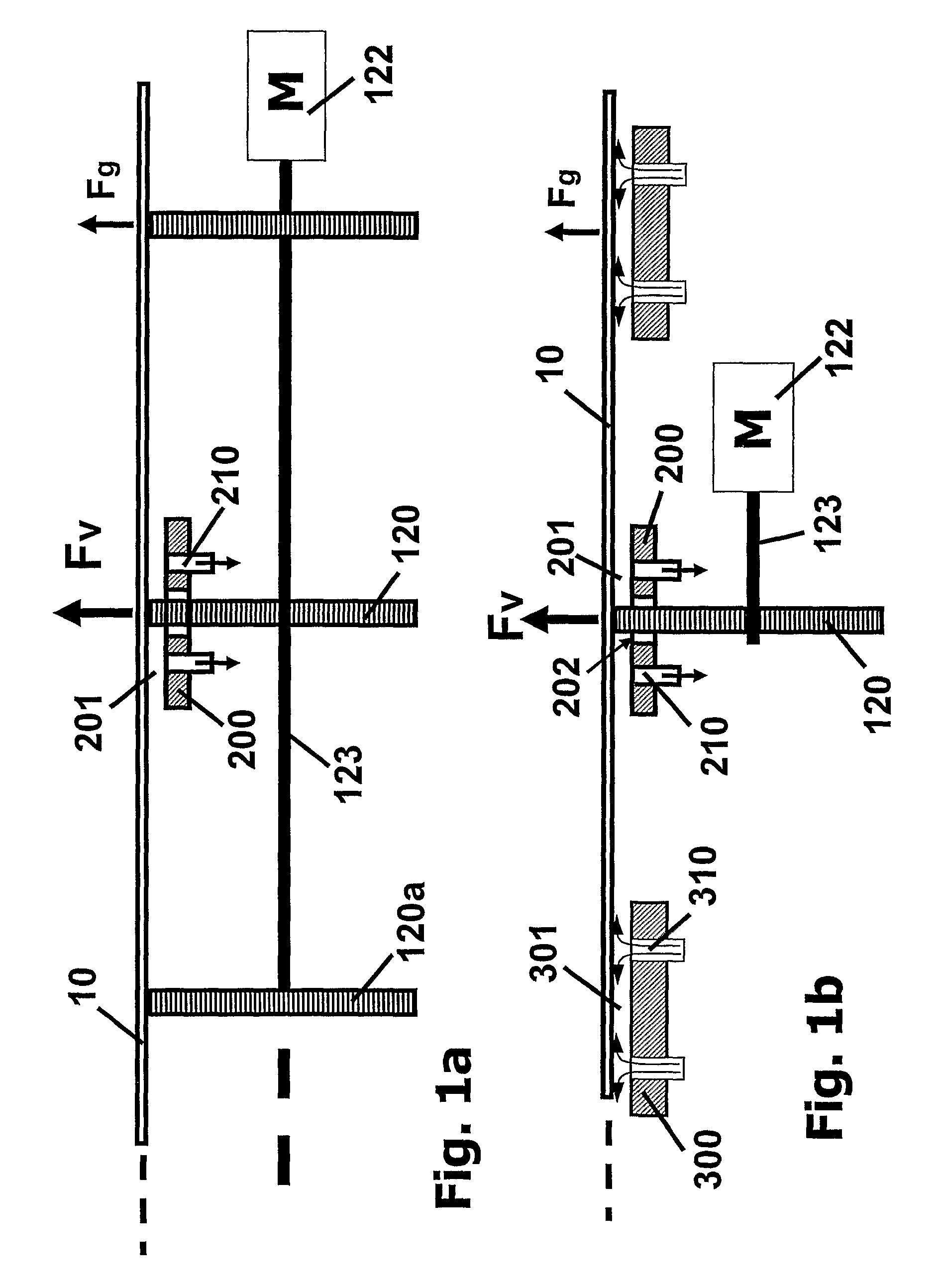

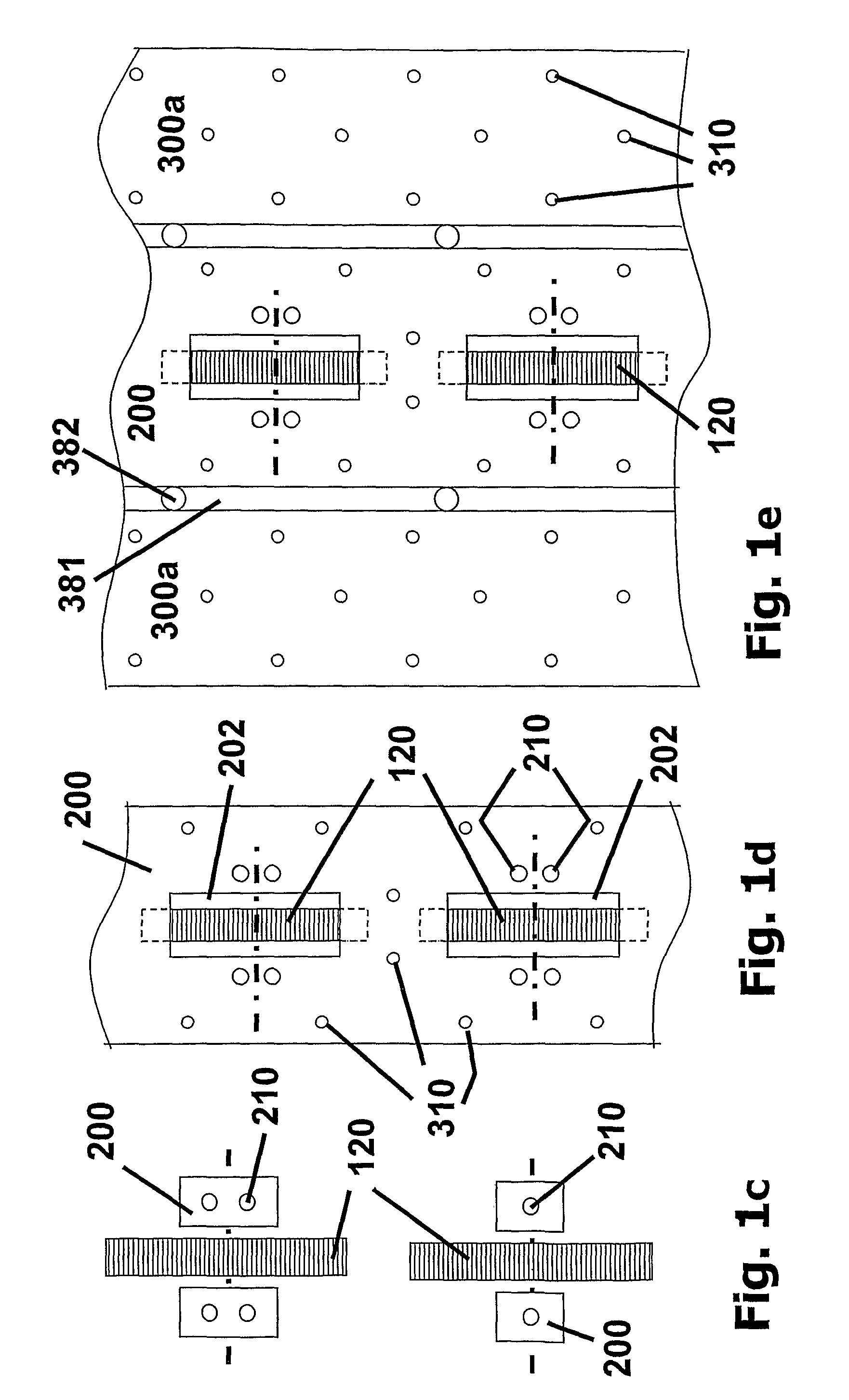

System and method for enhancing conveying performance of conveyors

ActiveUS7857121B2Semiconductor/solid-state device manufacturingManual conveyance devicesDrive wheelEngineering

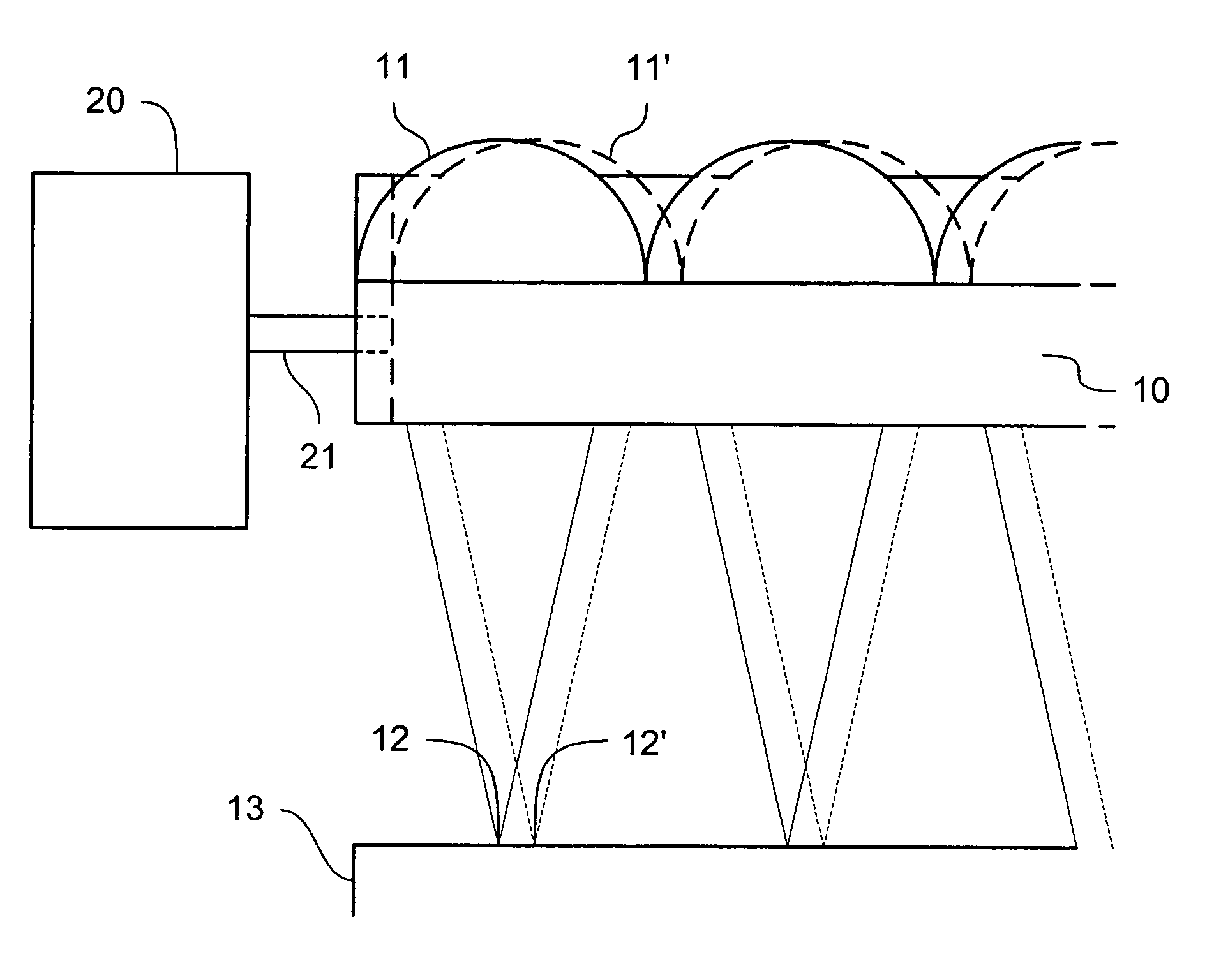

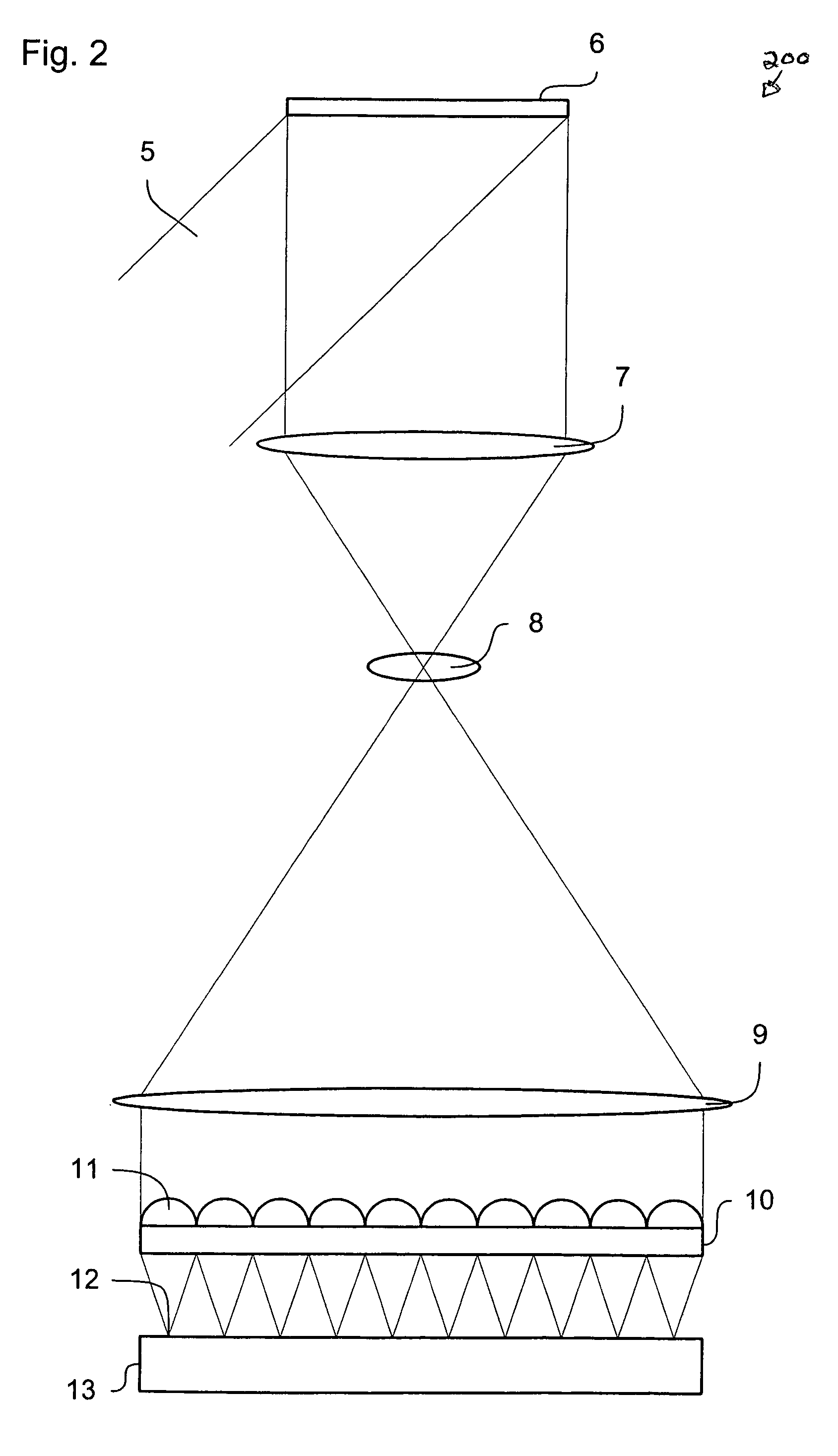

A system and method for conveying and for accurately handling a generally flat object employing a plurality of support elements. The system comprises: a plurality of vacuum preload drive wheels arranged in one or more drive units, each drive unit comprising at least one vacuum preload drive wheel; one or more vacuum ports located on one or more counter plates adjacent each of the vacuum preload drive wheels, for applying induced holding down forces on the object. The vacuum ports of each drive unit are fluidically connected to a main vacuum pipe with controllable valve to a vacuum source. When the main vacuum pipe is connected to a vacuum source the normal force between the object and the vacuum preload drive wheels is increased and accordingly the lateral drive force is increased.

Owner:COREFLOW SCI SOLUTIONS

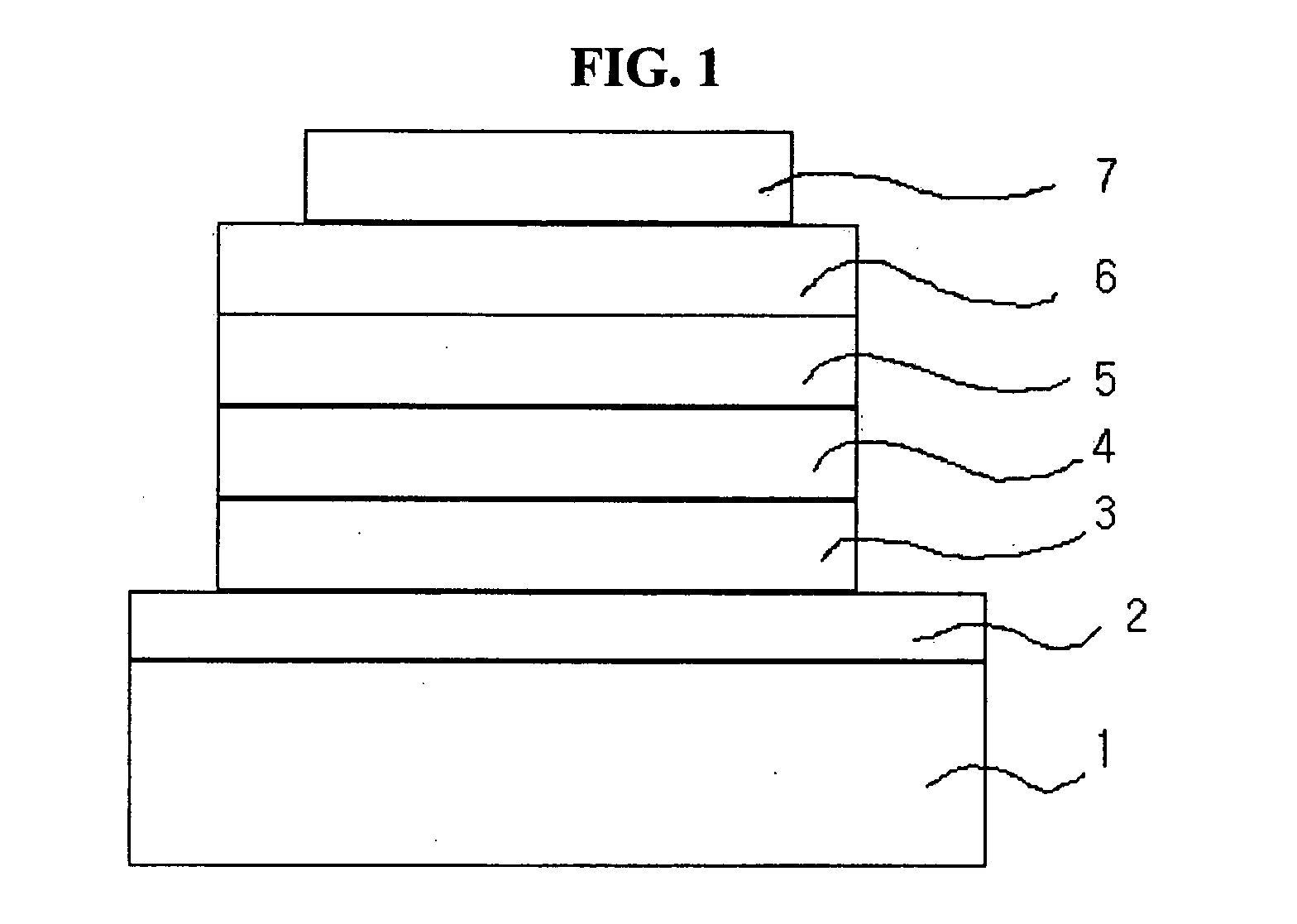

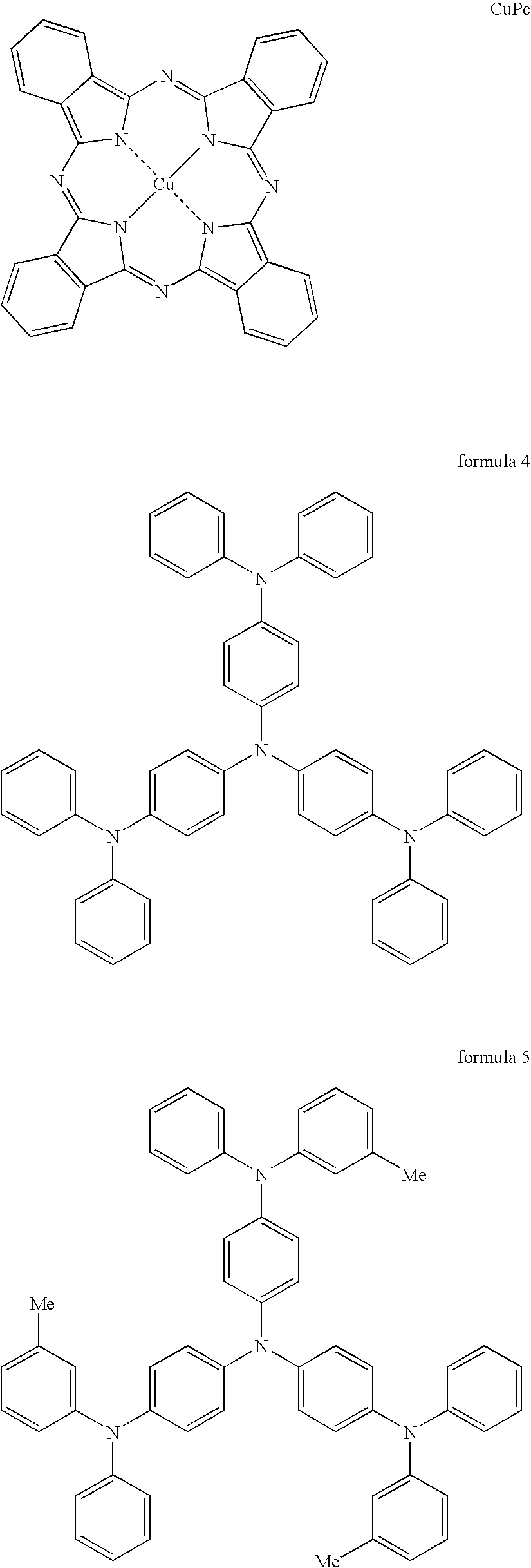

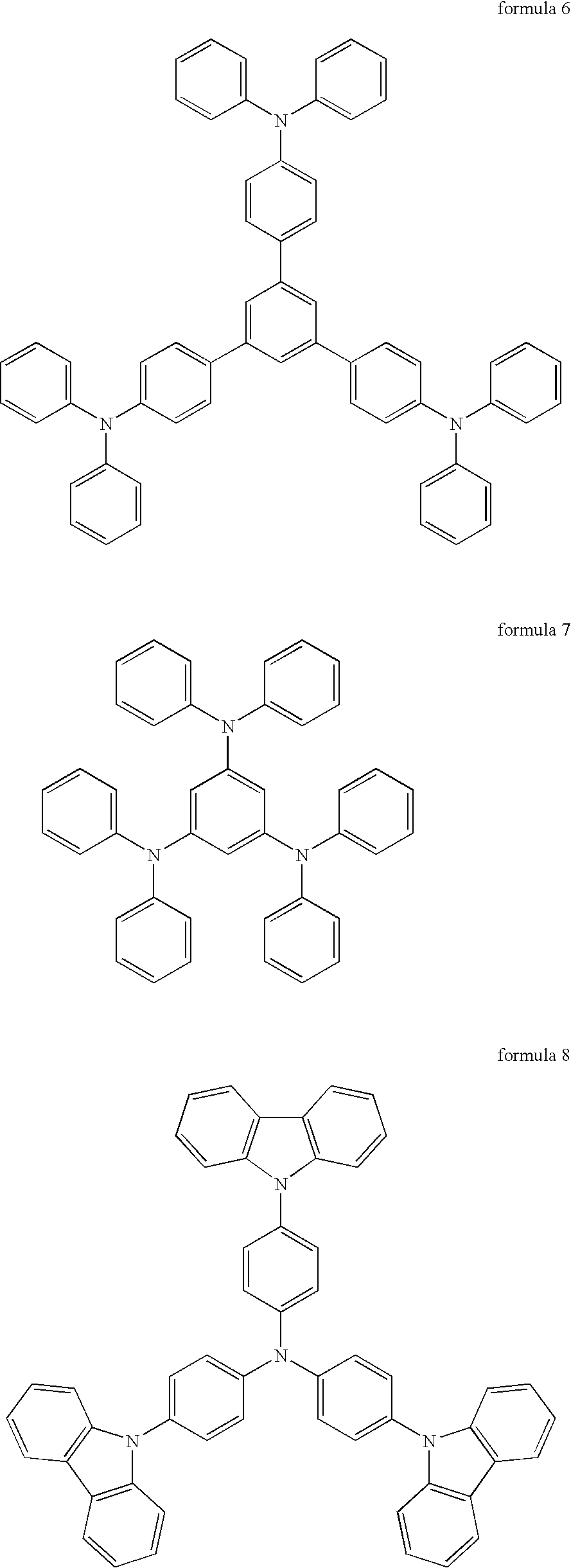

Materials for injecting or transporting holes and organic electroluminescence devices using the same

ActiveUS20050225235A1Solve low luminous efficiencyExtend the lifespanConveyorsOrganic chemistryOrganic light emitting deviceOrganic electroluminescence

The present invention relates to a novel compound that can significantly improve the lifespan, efficiency and thermal stability of an organic light emitting device, and to an organic electroluminescence device or light emitting device comprising the compound in an organic compound layer is also disclosed.

Owner:LG CHEM LTD

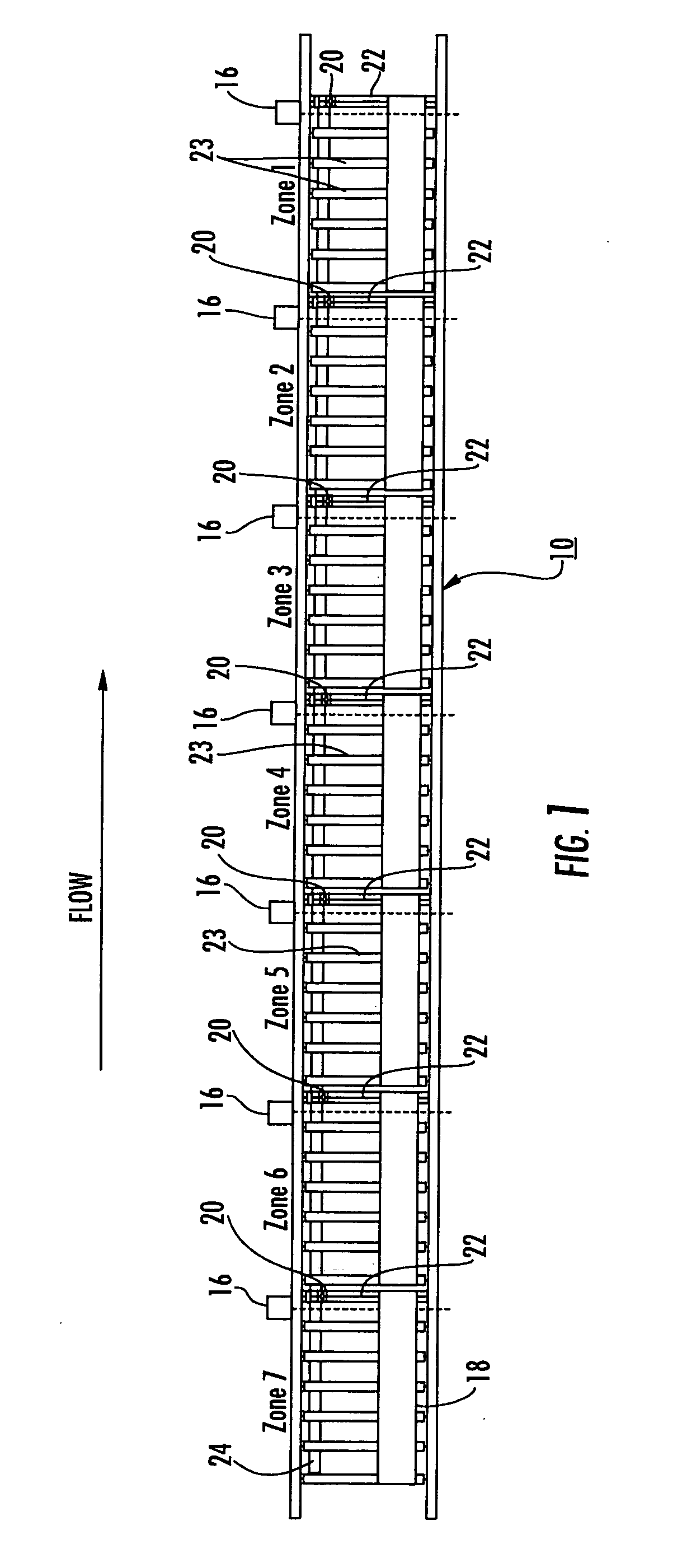

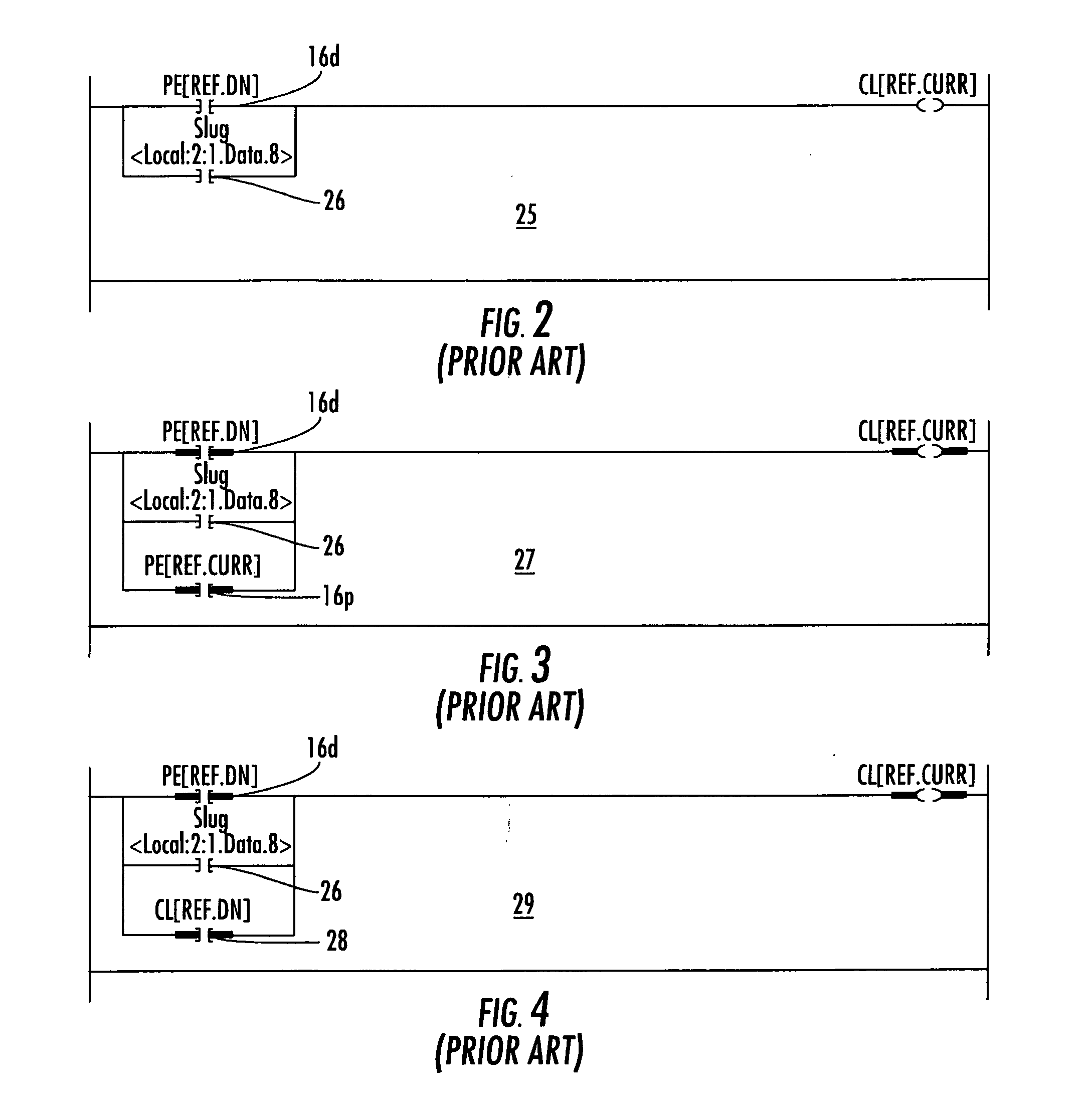

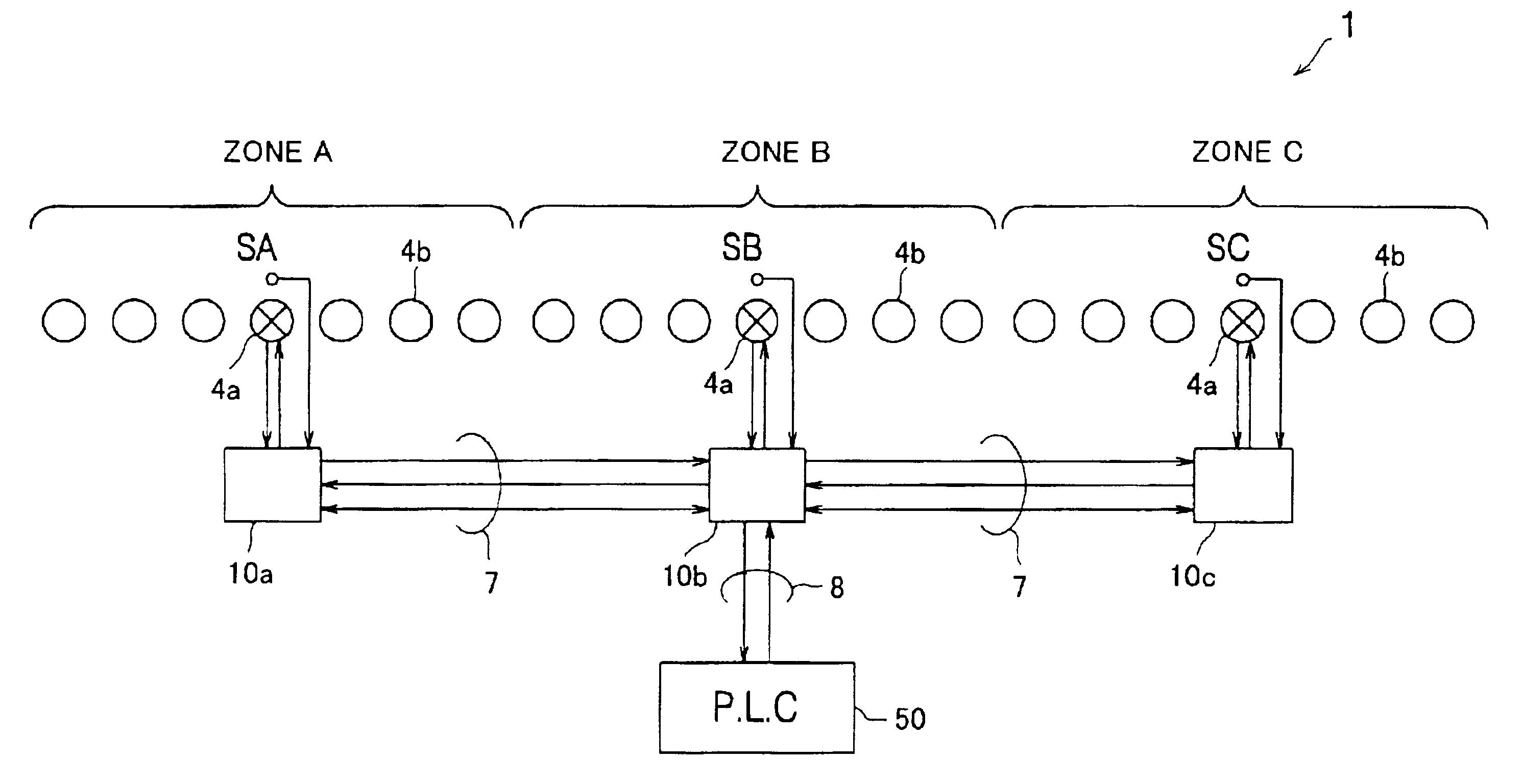

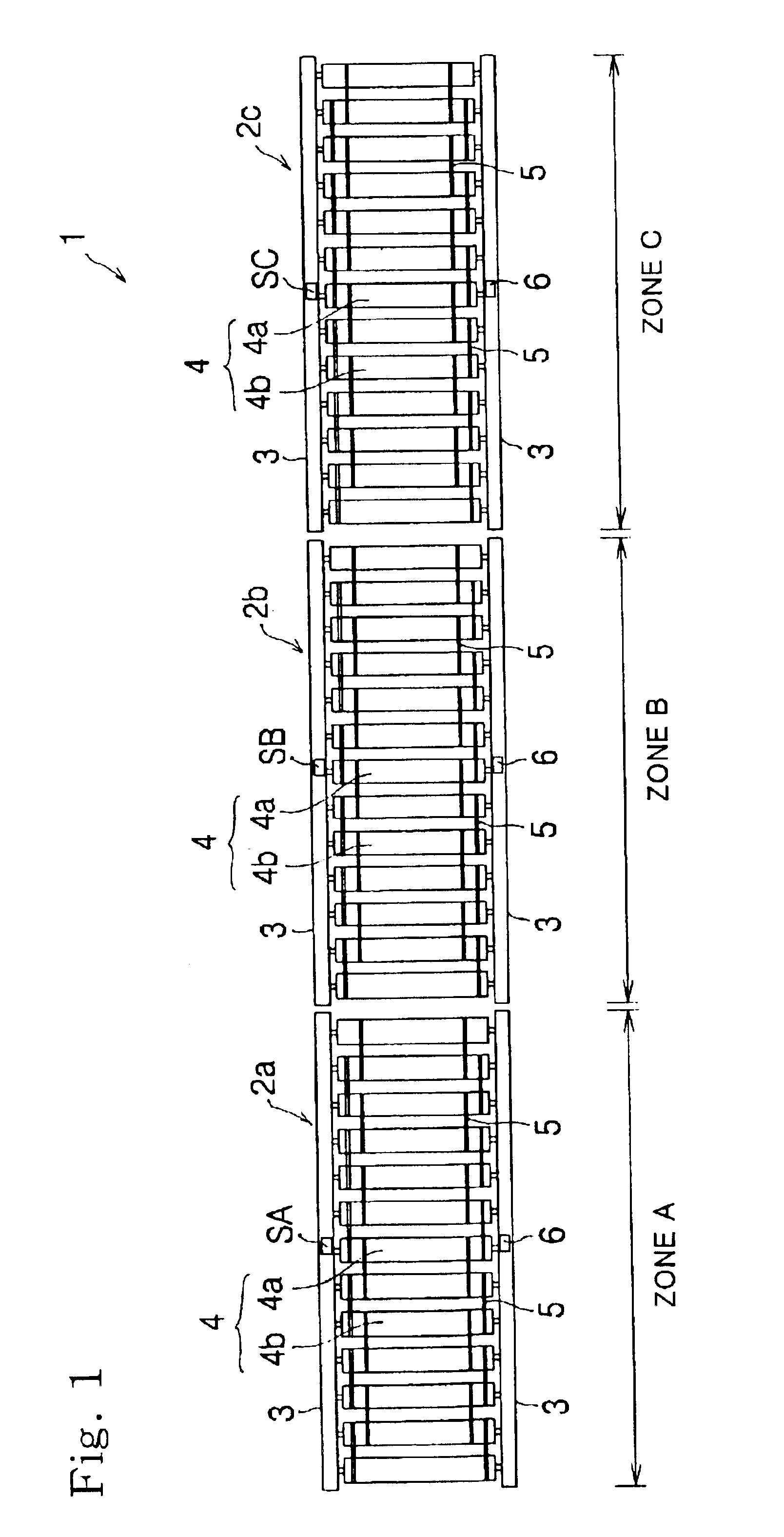

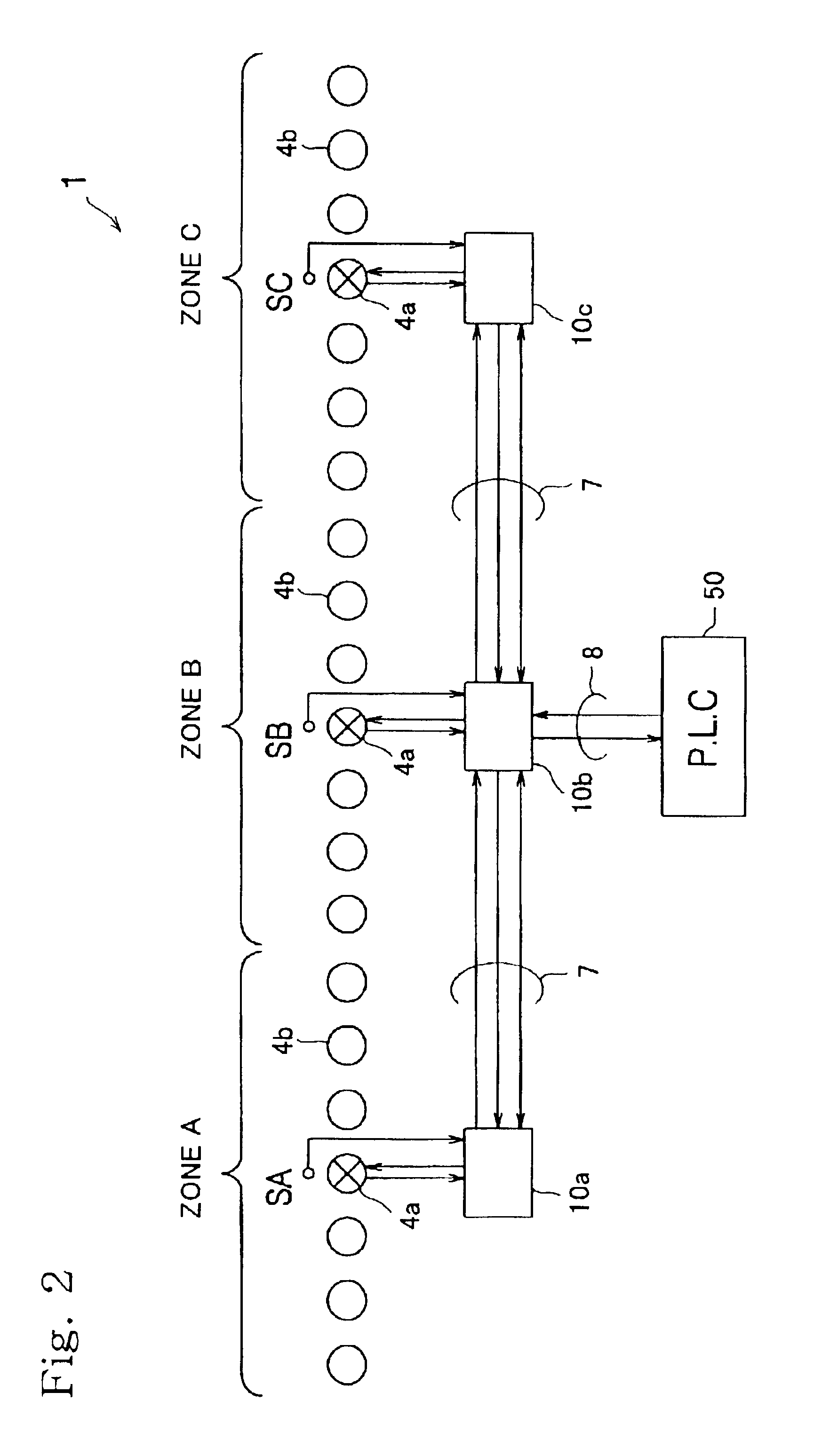

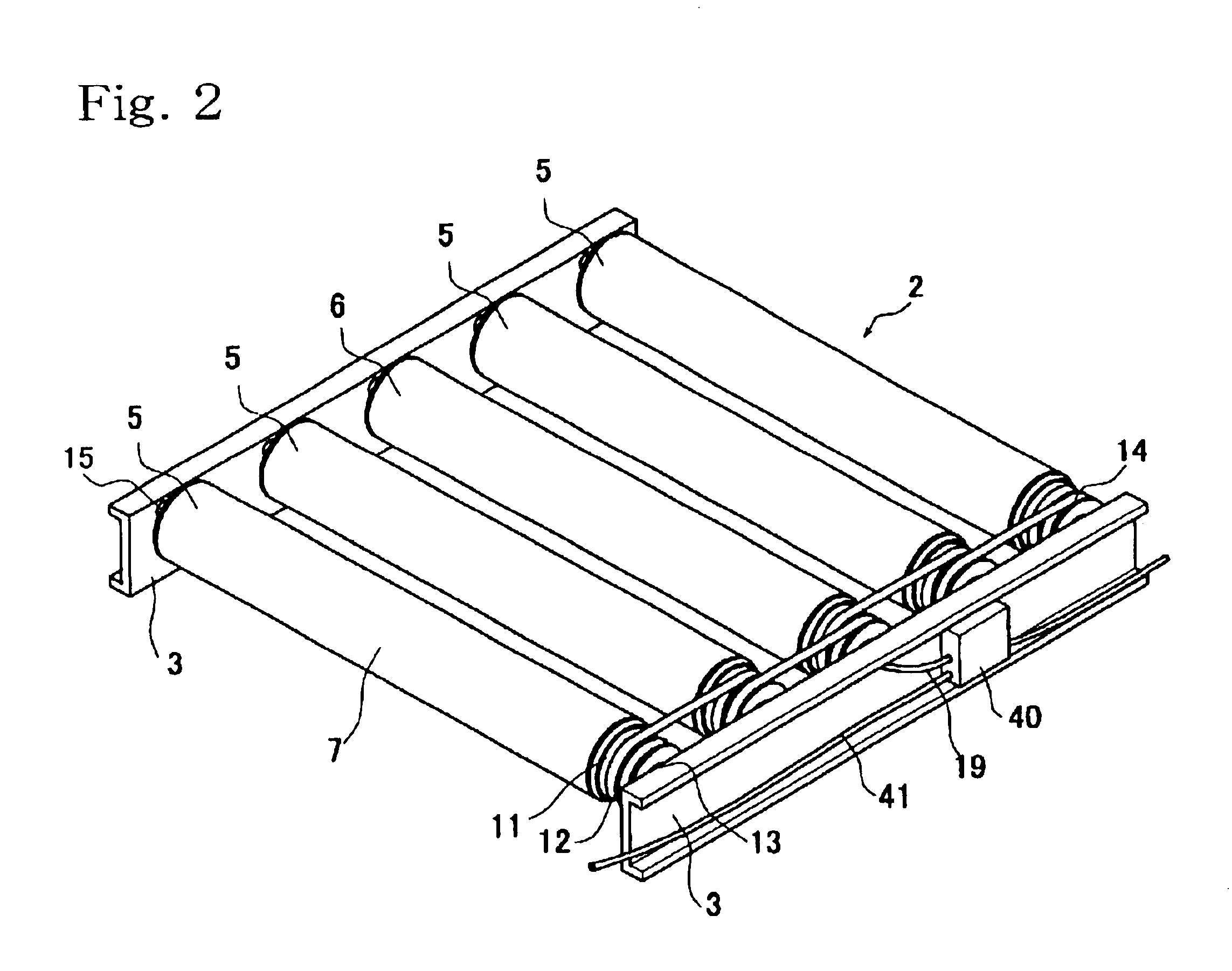

Zone controller

InactiveUS6843362B2Avoid collisionReduce power wasteControl devices for conveyorsMechanical conveyorsEngineeringTransfer line

A zone controller enabling flexible conveyance according to the use by simple change of setting. An aspect of the invention is a zone controller 10 for a particular zone picked from a plurality of zones for control into which a roller conveyor line 1 is divided and which are arrangeable in a row in the direction of conveyance, being capable of controlling operation of a driving roller 4a for conveyance provided in the particular zone, having a mode-setting means 14 capable of switching between a slug mode and a singulation mode. In the slug mode, operation of the driving roller is controlled so that articles in the zones are conveyed uniformly to downstream, maintaining the order of the articles in the conveying line. In the singulation mode, operation of the driving roller is controlled so that the articles are conveyed separately to downstream with a predetermined number of zones in which no article exists preserved between the zones in which the articles exist.

Owner:ITOH ELECTRIC COMPANY LIMITED

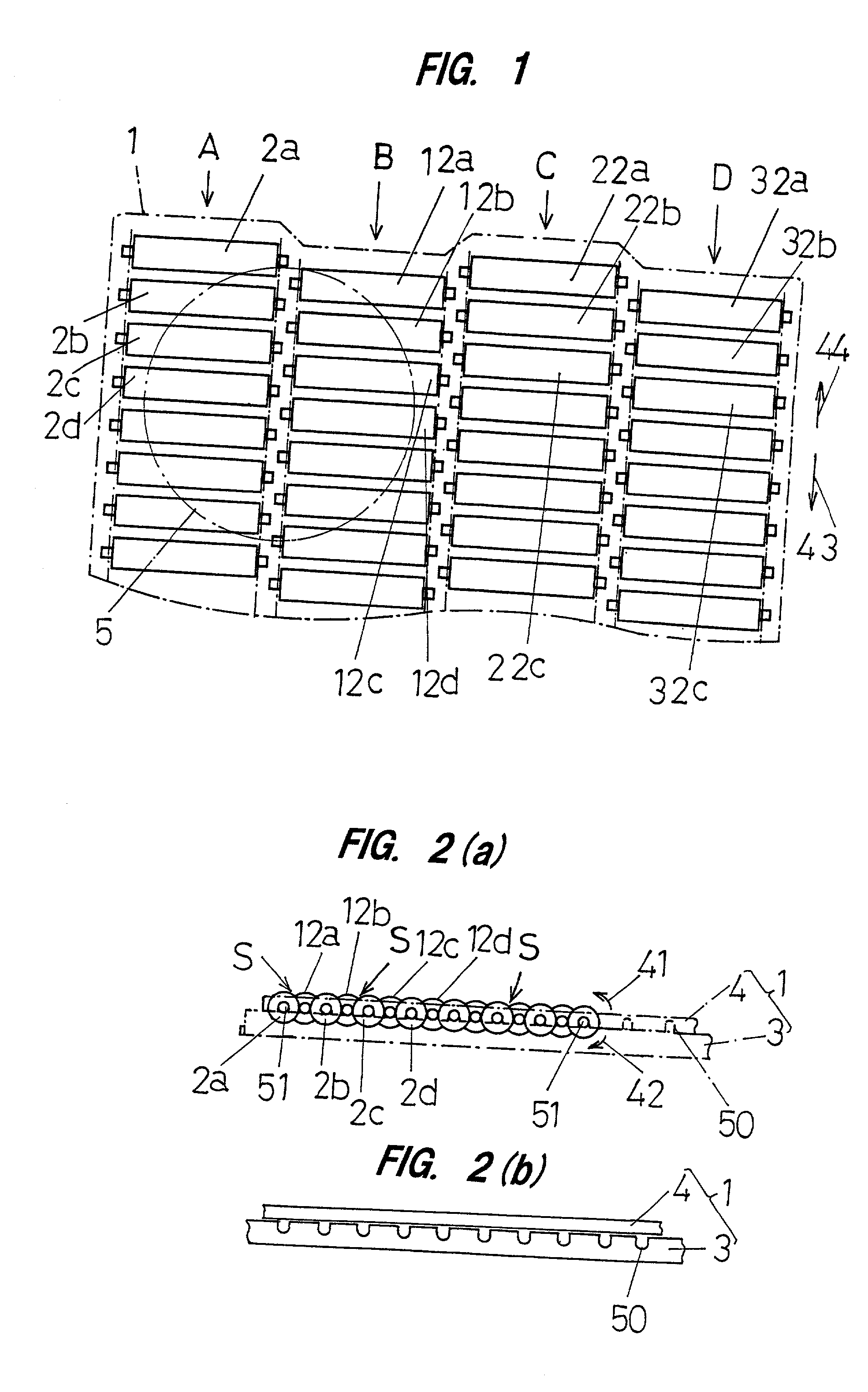

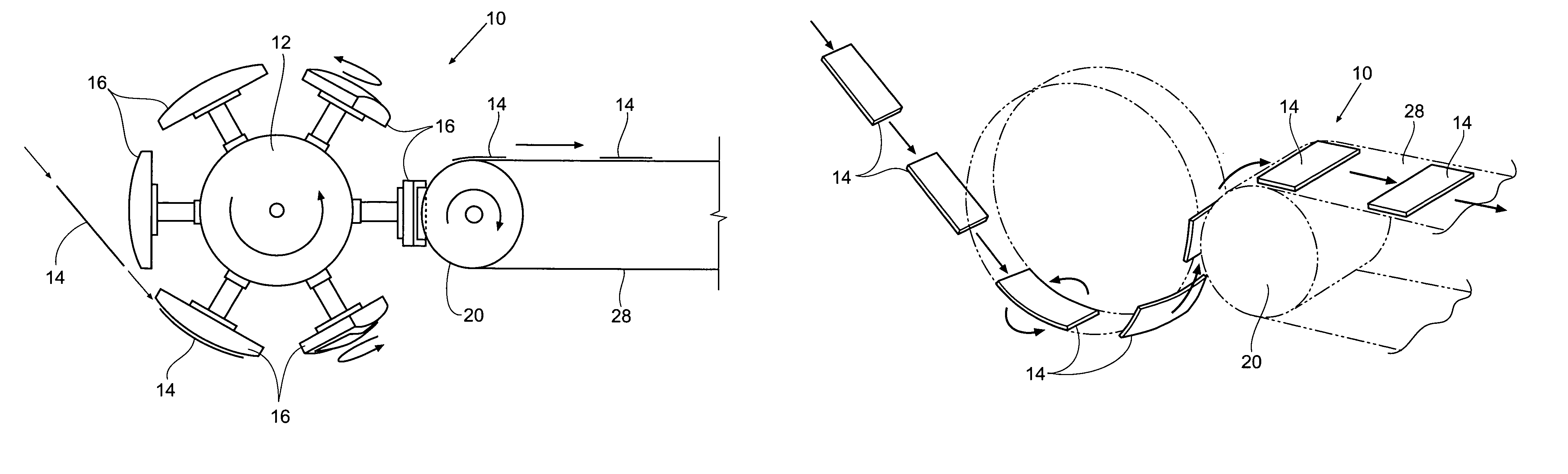

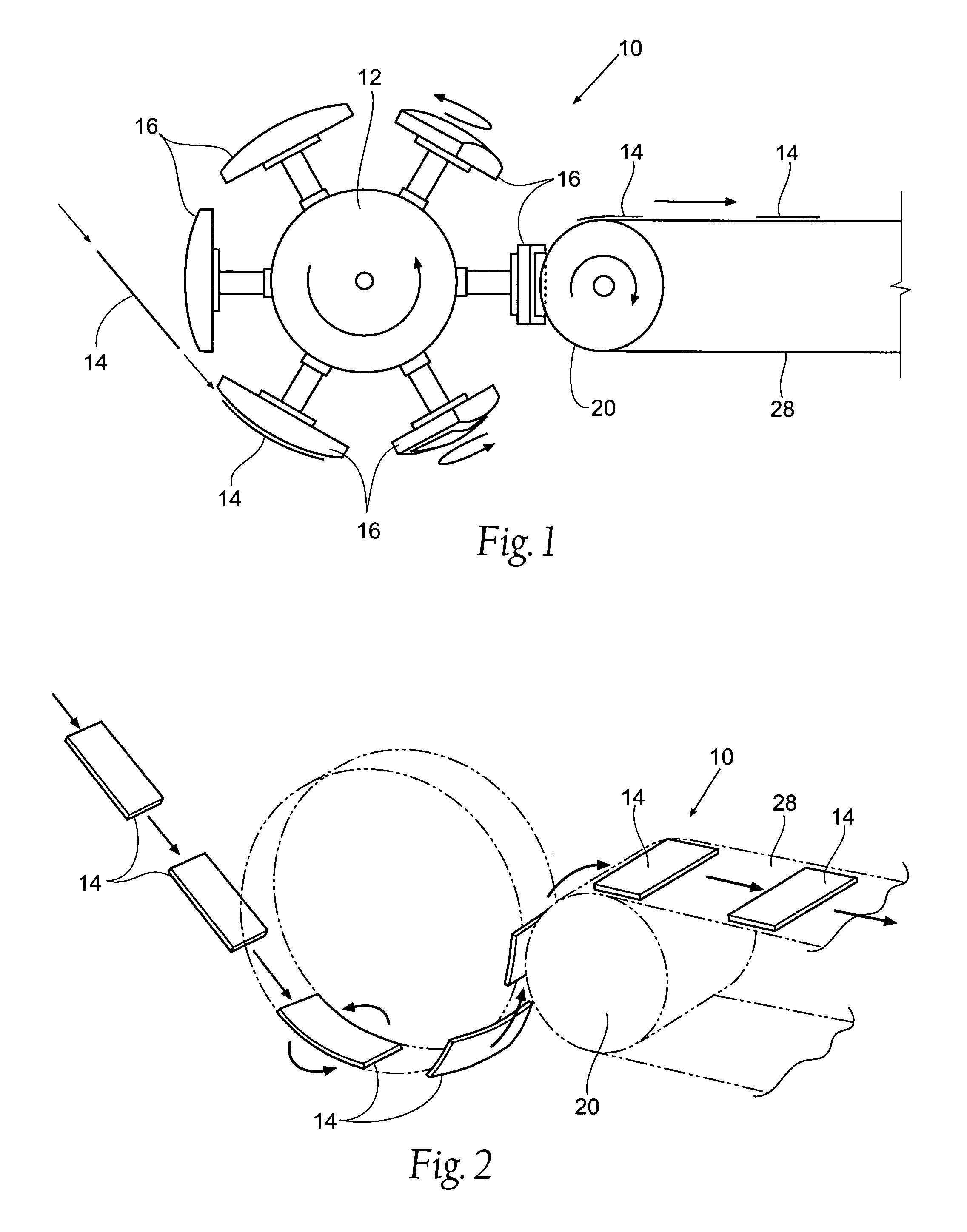

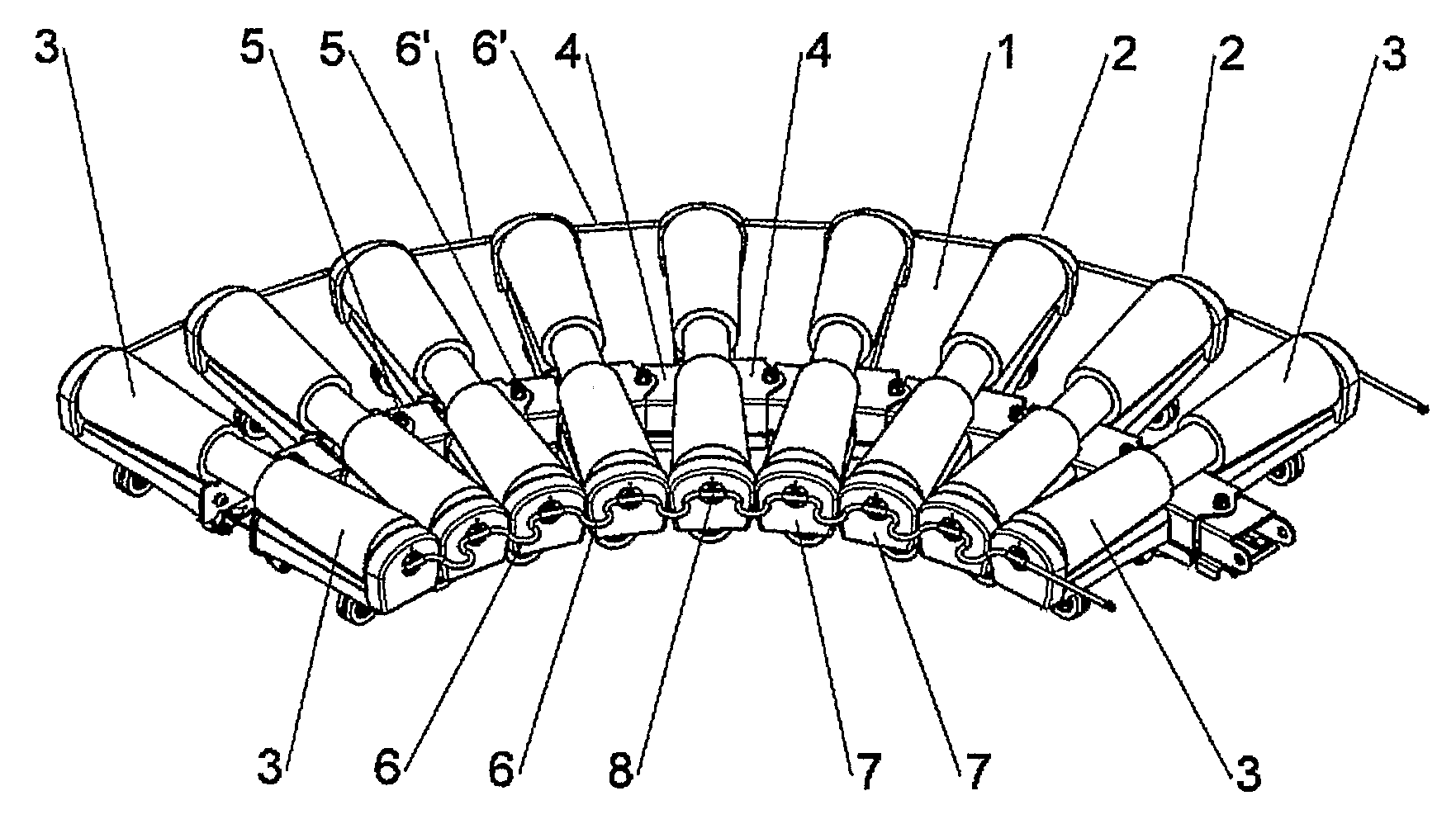

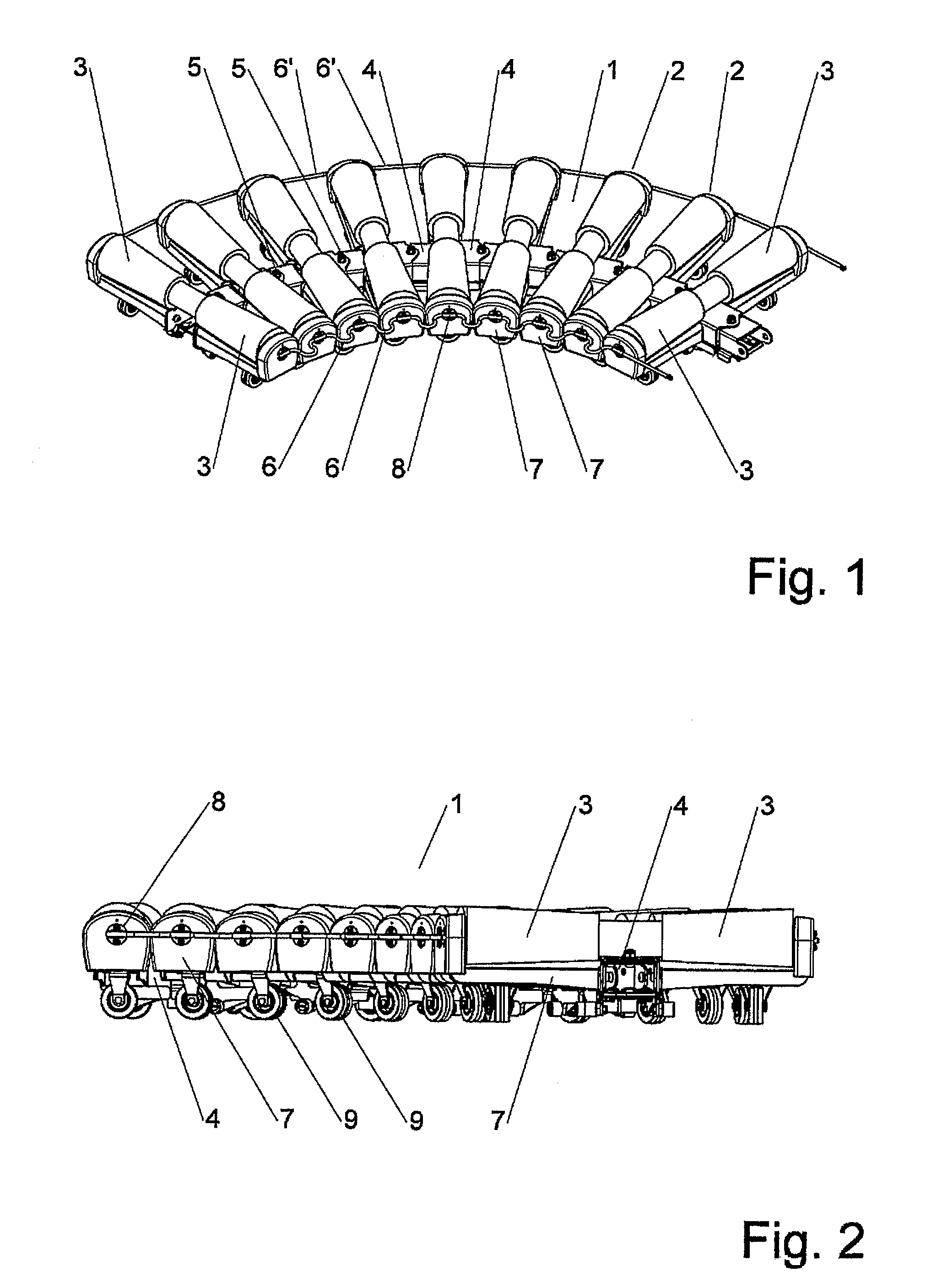

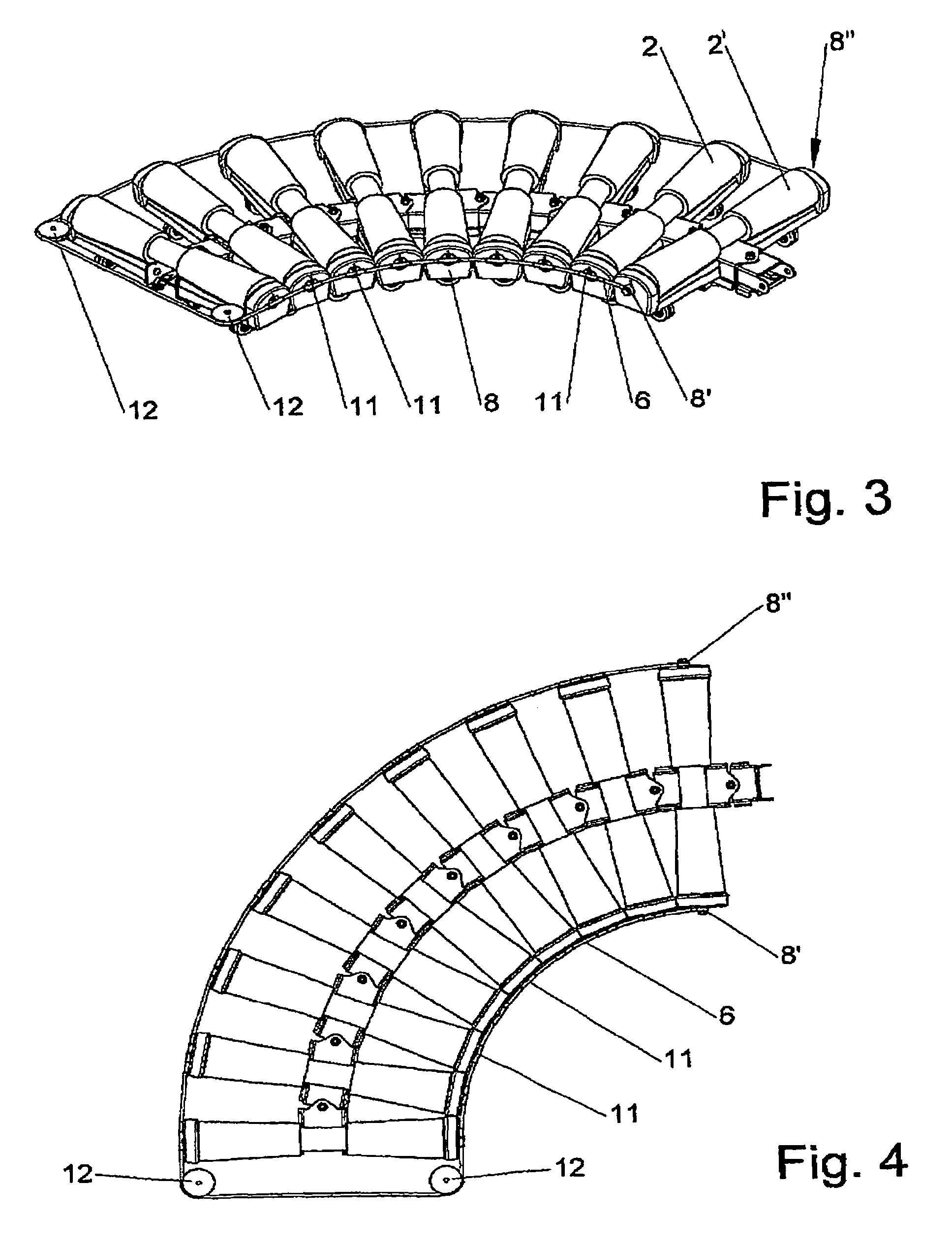

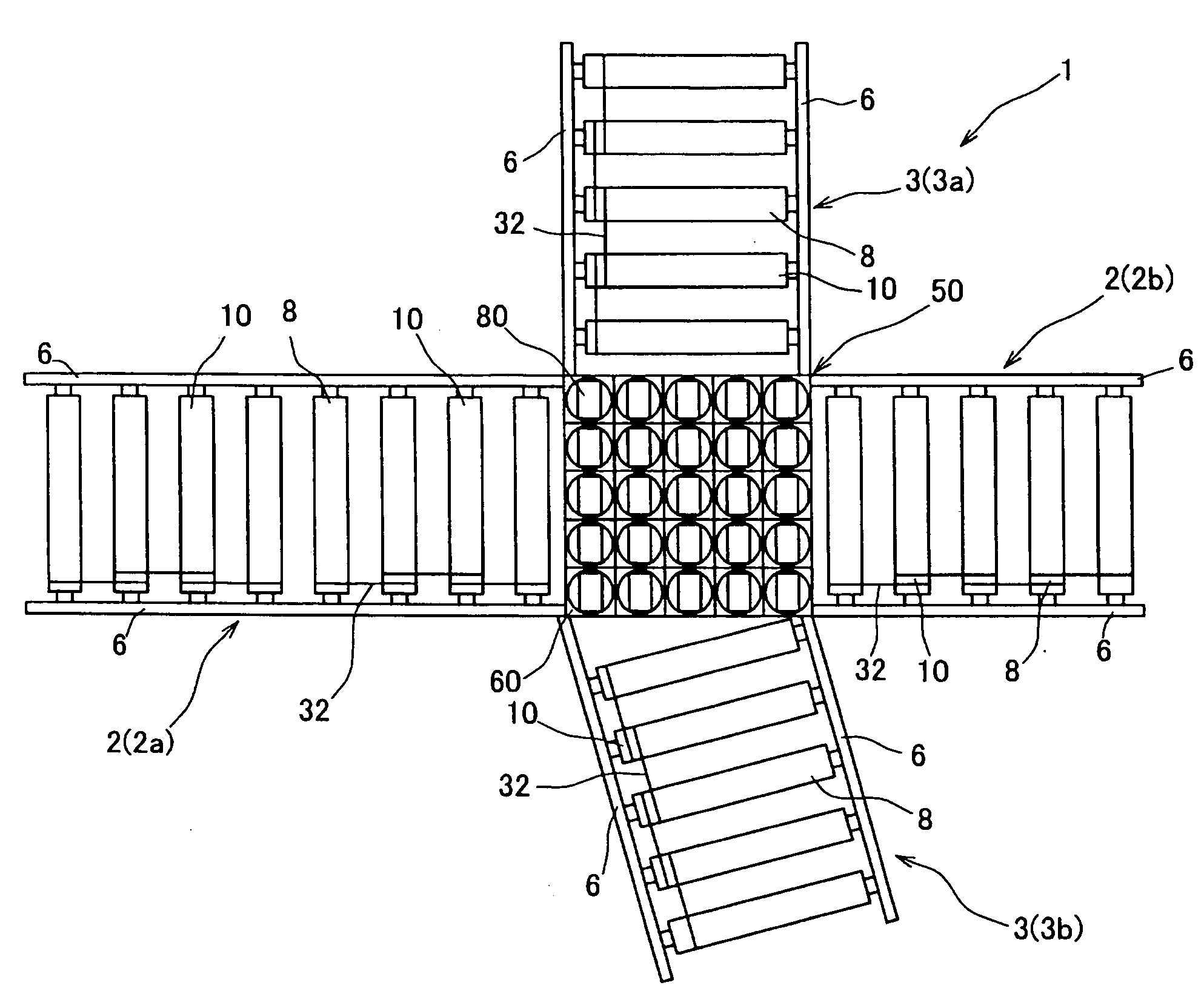

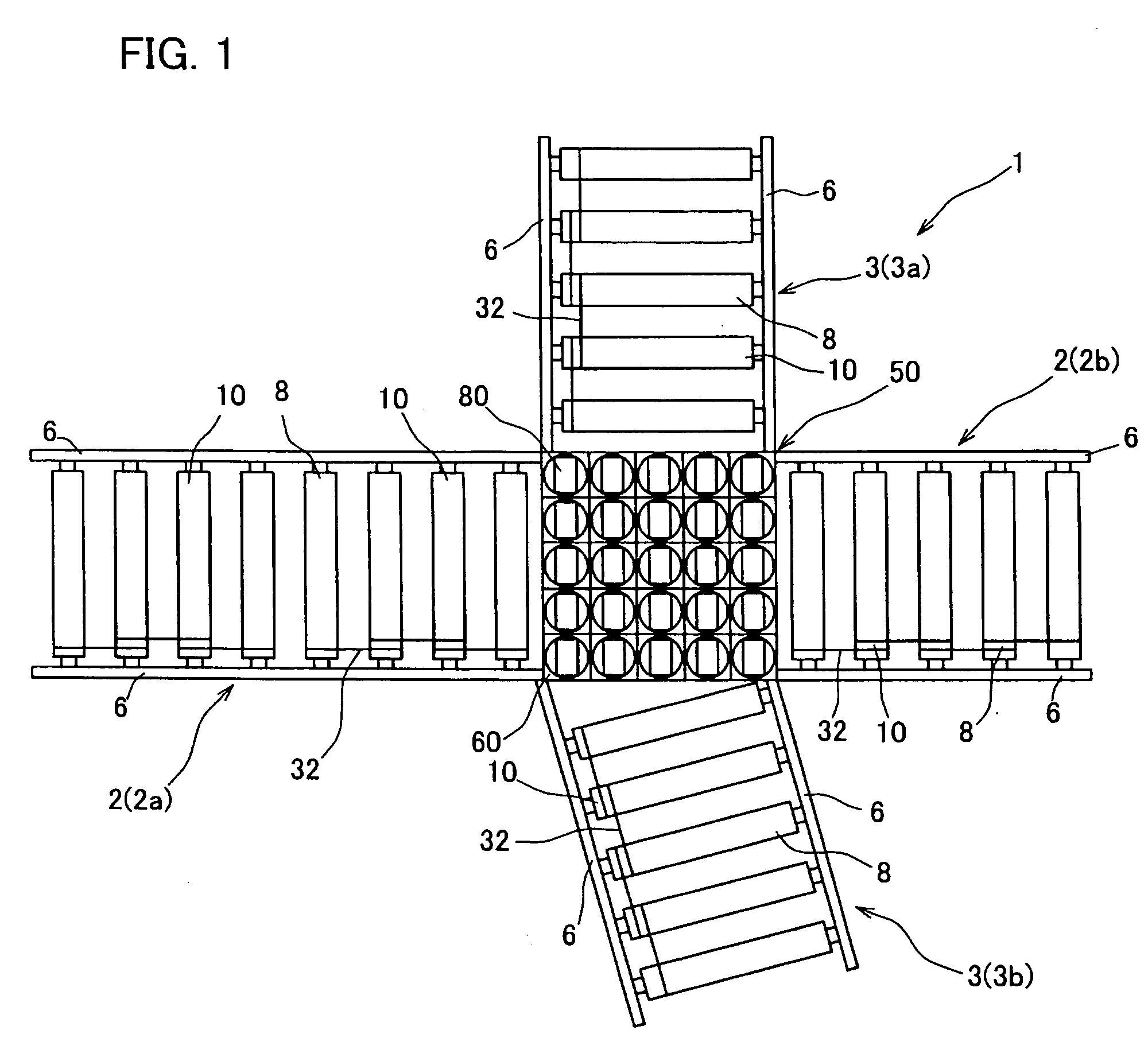

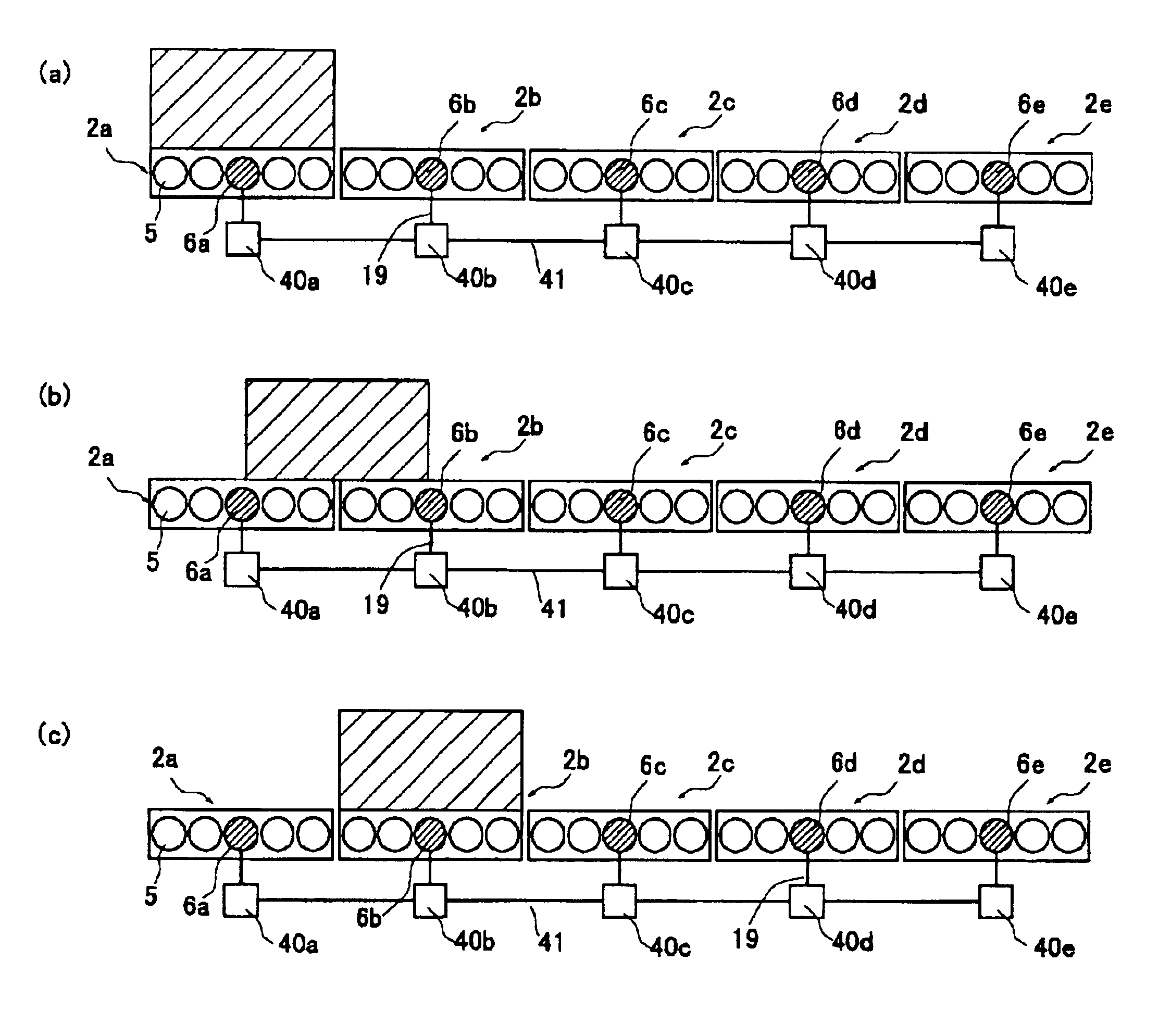

Sorter and roller-conveying system incorporating the sorter

InactiveUS20080169171A1Improve delivery efficiencySwiftly and securely sortConveyor partsRoller-waysRotational axisEngineering

A roller-conveying system includes a sorter for sorting the articles from one passage to others as desired, the sorter including a plurality of cells arranged on substantially the same level as the conveying surfaces of the passages; and at least some of the cells including a motorized roller rotatably carried in a shell, and a shifter for changing the direction of the motorized roller; wherein the shifter includes a revolving shaft vertical to the conveying surface, the revolving shaft connected to the motorized roller, so as to revolve the motorized roller so as to cause it to direct toward a desired conveying passage.

Owner:ITO DENKI KK

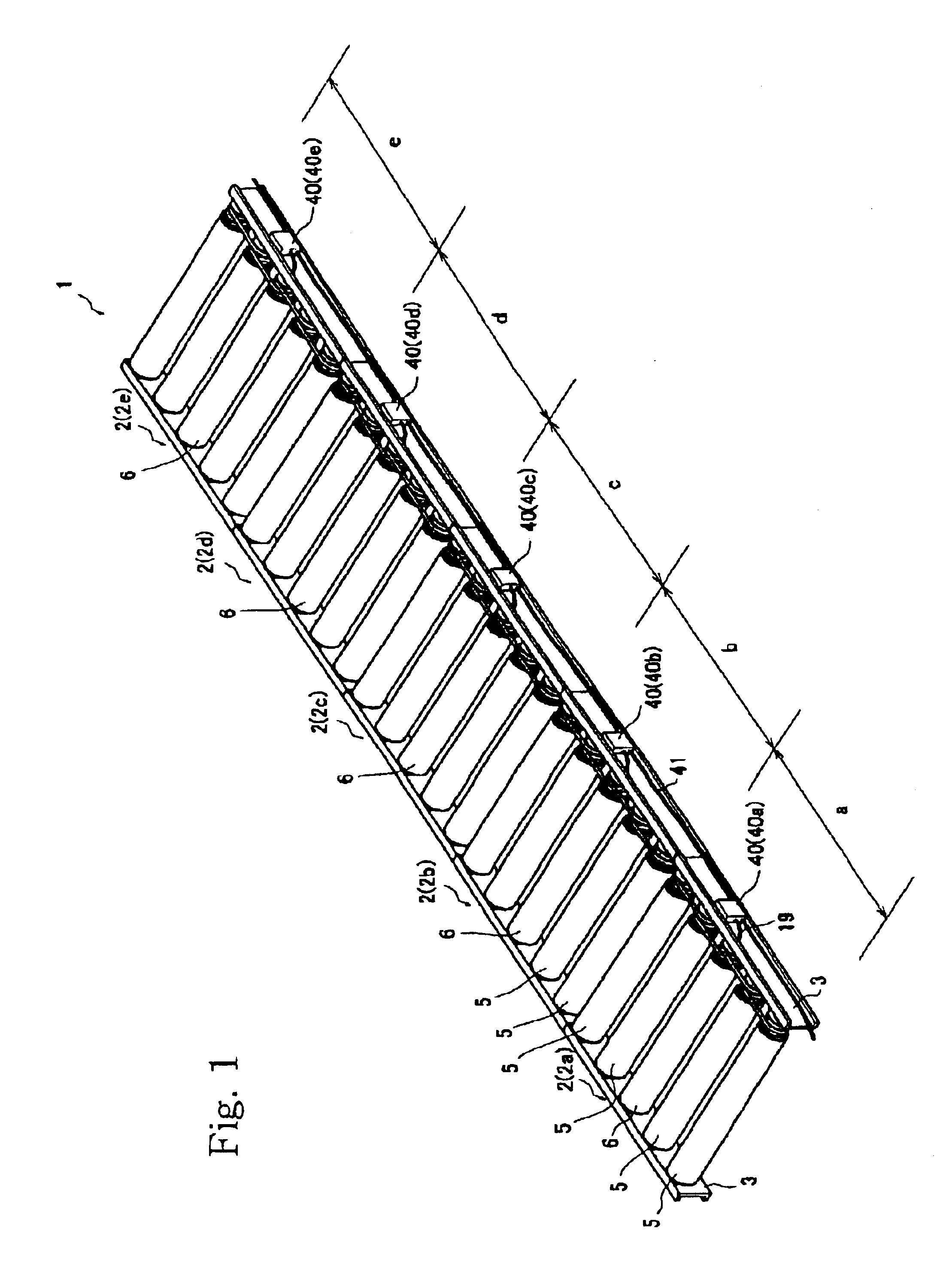

Conveying apparatus

InactiveUS6820736B2Simple structureEasy to assembleConveyorsControl devices for conveyorsMotor controlElectric motor

A conveying apparatus (1) is composed of several conveying modules (2) each having a controller (40) for control of a motorized roller (6) having a motor (16) incorporated in it. A motor-controlling section (45) installed in the controller (40) operates to sense an article being transported on and along the module (2). An article-state detector (48) included in the motor-controlling section (45) compares the actual number (Pr) of signal pulses indicating the number of rotations of the motor (16) with a standard number (P) of such pulses, when judging whether the article is or is not on the module, without aid of any conventional and discrete prior art sensors.

Owner:ITO DENKI KK

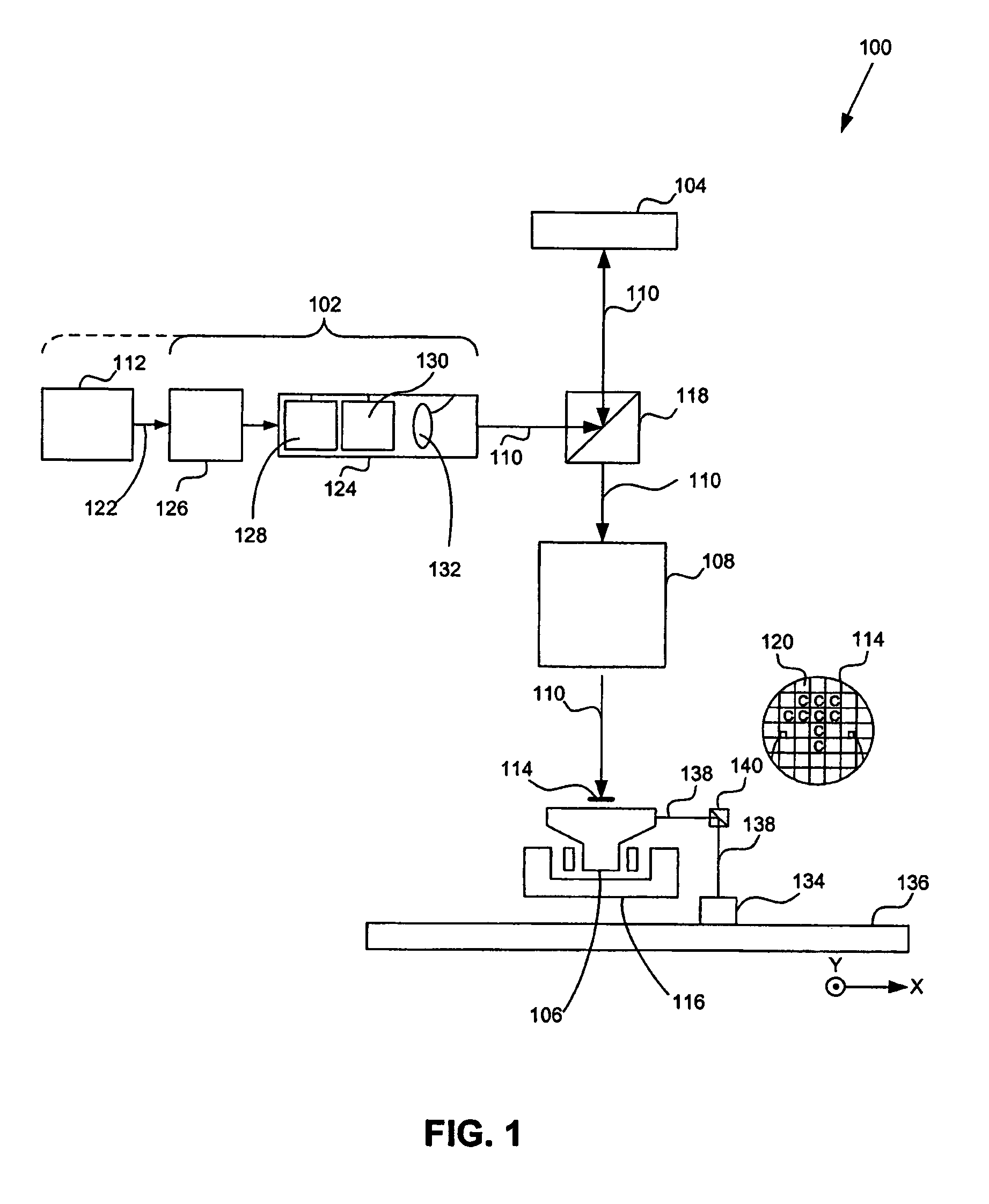

Lithographic apparatus and device manufacturing method

ActiveUS7081947B2Precise positioningEnhance the imageShaft and bearingsSemiconductor/solid-state device manufacturingLight beamOptics

Owner:ASML NETHERLANDS BV

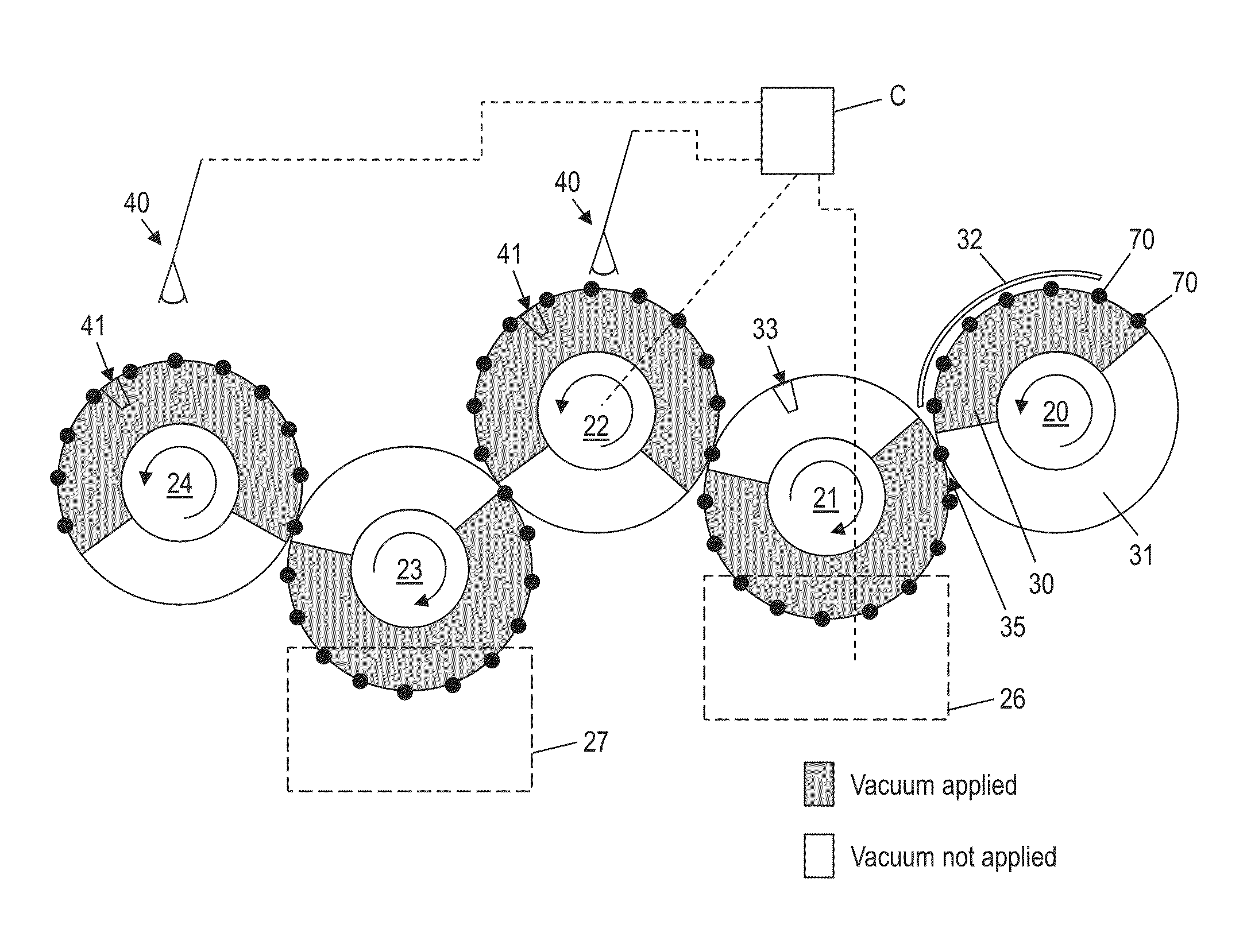

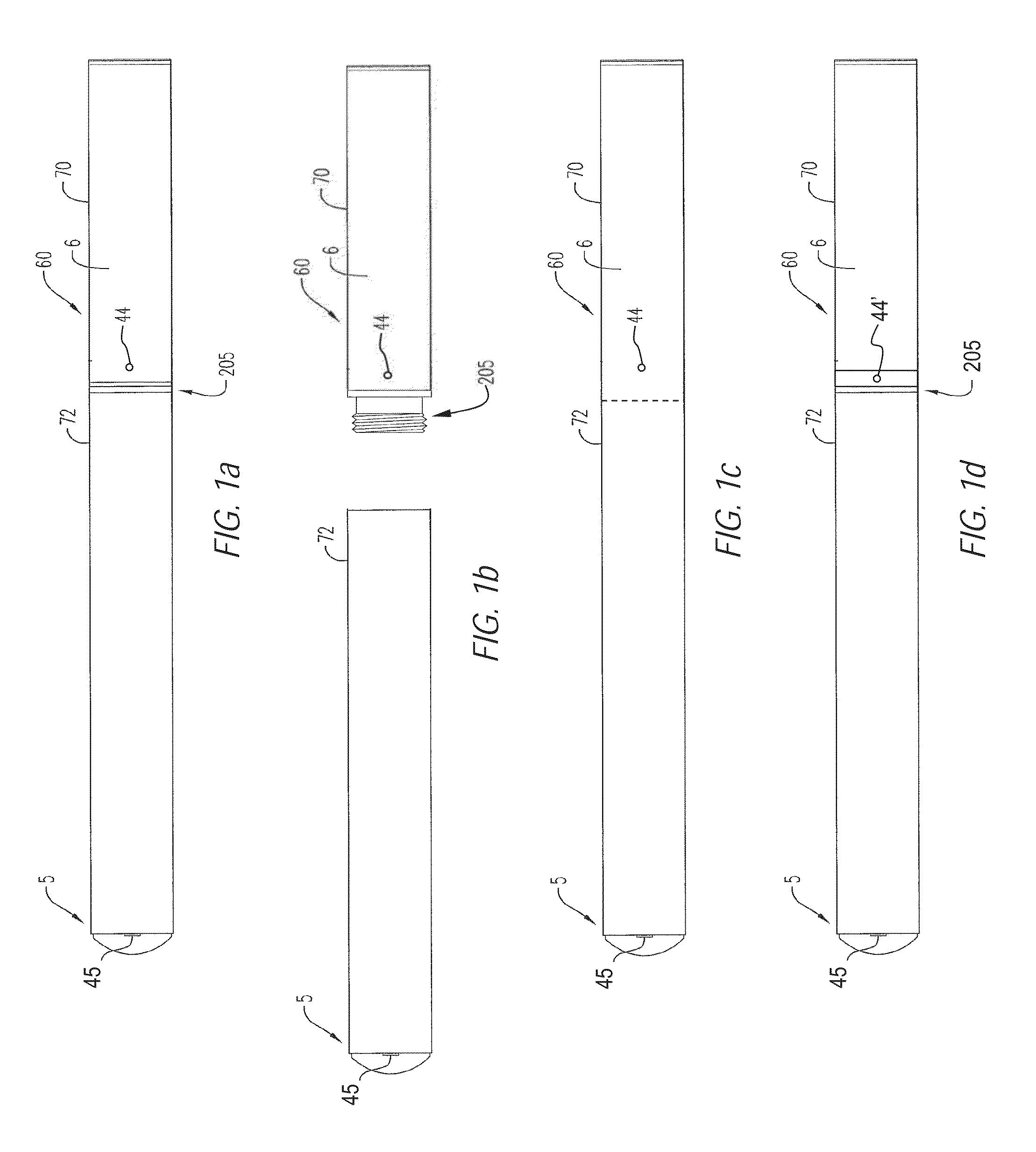

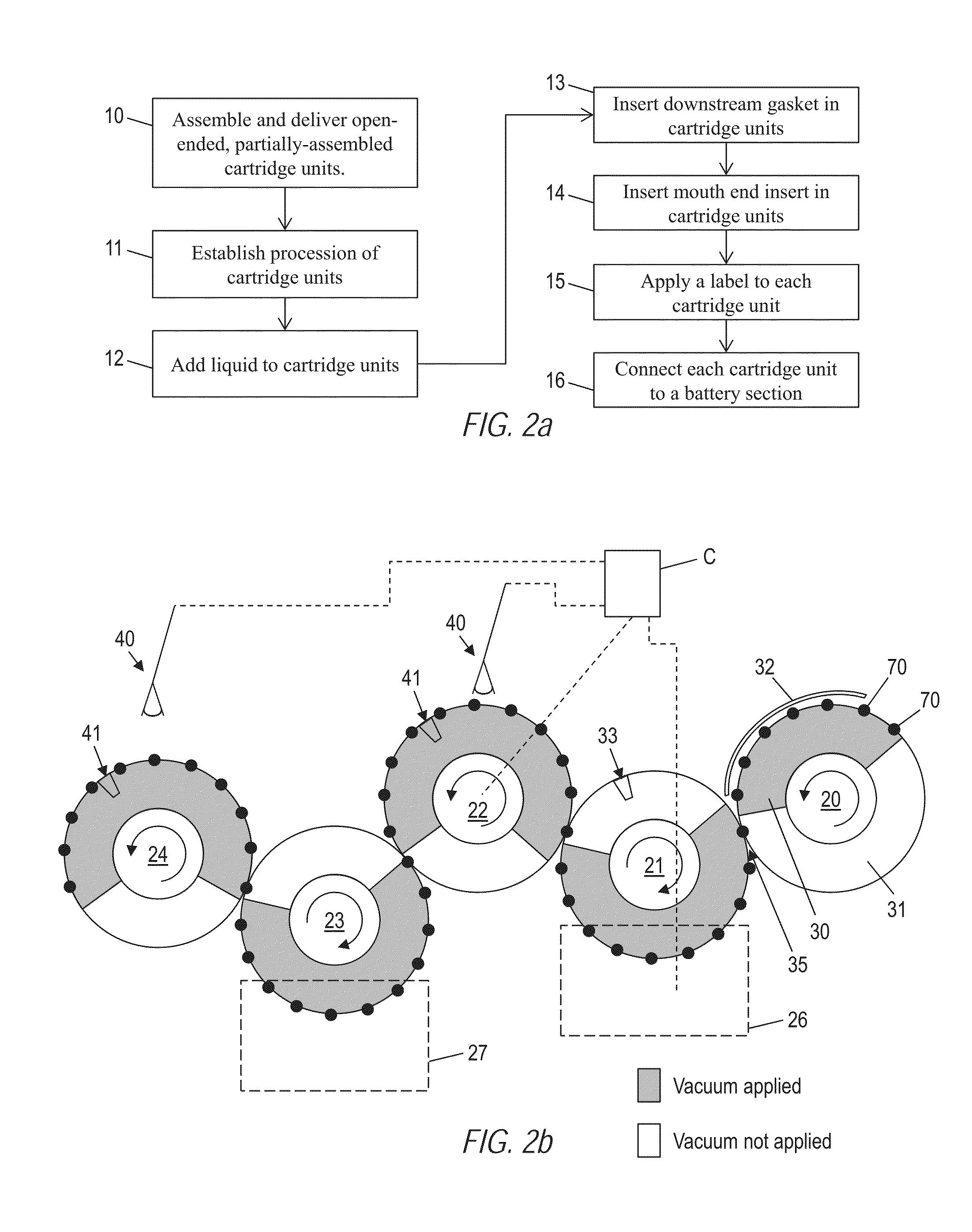

Rotatable drum and method and system using the same for the automated production of e-vapor devices

ActiveUS20150291301A1Mechanical working/deformationCigarette manufactureMechanical engineeringEngineering

A rotating drum for use in manufacturing vapor-generating articles may include a drum body. A plurality of grooves may be disposed in an outer face of the drum body. A seat may be tractably-mounted in each one of the plurality of grooves. The seat may include a seat groove that is structured and arranged to receive and hold a rigid casing of a vapor-generating article. The seat may be composed of a material that is softer than a material of the rigid casing.

Owner:AKRIA CLIENT SERVICES LLC

Driver board control system for modular conveyor with address-based network for inter-conveyer communication

InactiveUS20020010527A1Improve abilitiesEasy to set upDigital data processing detailsControl devices for conveyorsControl systemControl signal

A method and control system are provided for controlling a modular conveyor system, which may be networked together with other such systems in order to implement a control strategy for a modular conveyor system. The control system comprises a communications port for interconnection of the control system with a network for sending outgoing addressed data to other devices on the address-based network and for receiving incoming addressed data from other devices. The control system further comprises a logic system, which may receive a signal from an object sensor and provide a control signal or output adapted to control activation of a motorized roller assembly, based on an input signal from the object sensor or the communications port. The logic system may provide for single step operation whereby system troubleshooting may be facilitated, and in addition may provide situation aware and output value source selection functionality.

Owner:ROCKWELL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com