Vial filling apparatus

a filling apparatus and container technology, applied in the direction of packaging goods, furniture, charge manipulation, etc., can solve the problems of finished packages becoming contaminated and unusable, time-consuming and expensive maintenance of the filling apparatus and the clean room, and contamination in the clean room environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

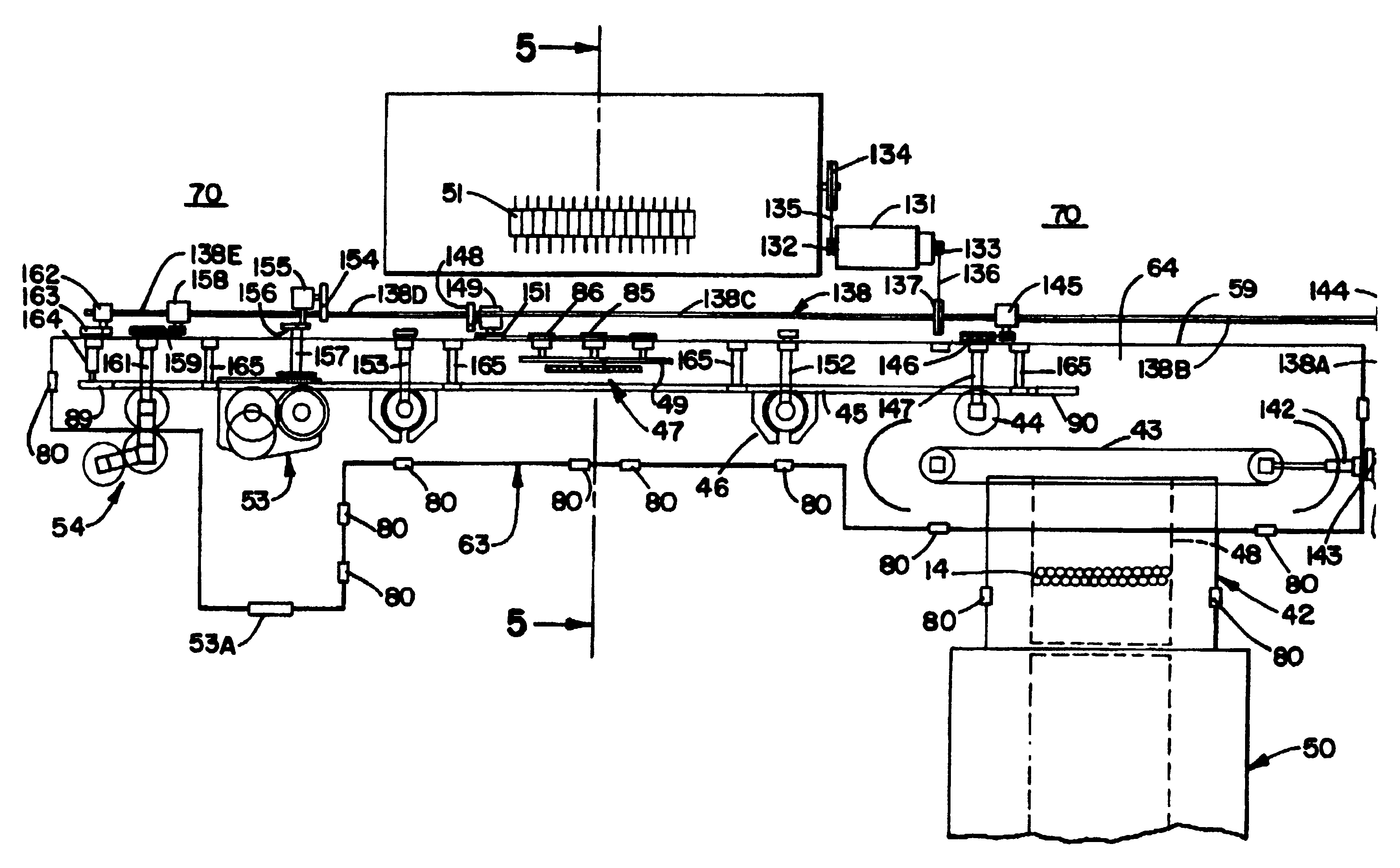

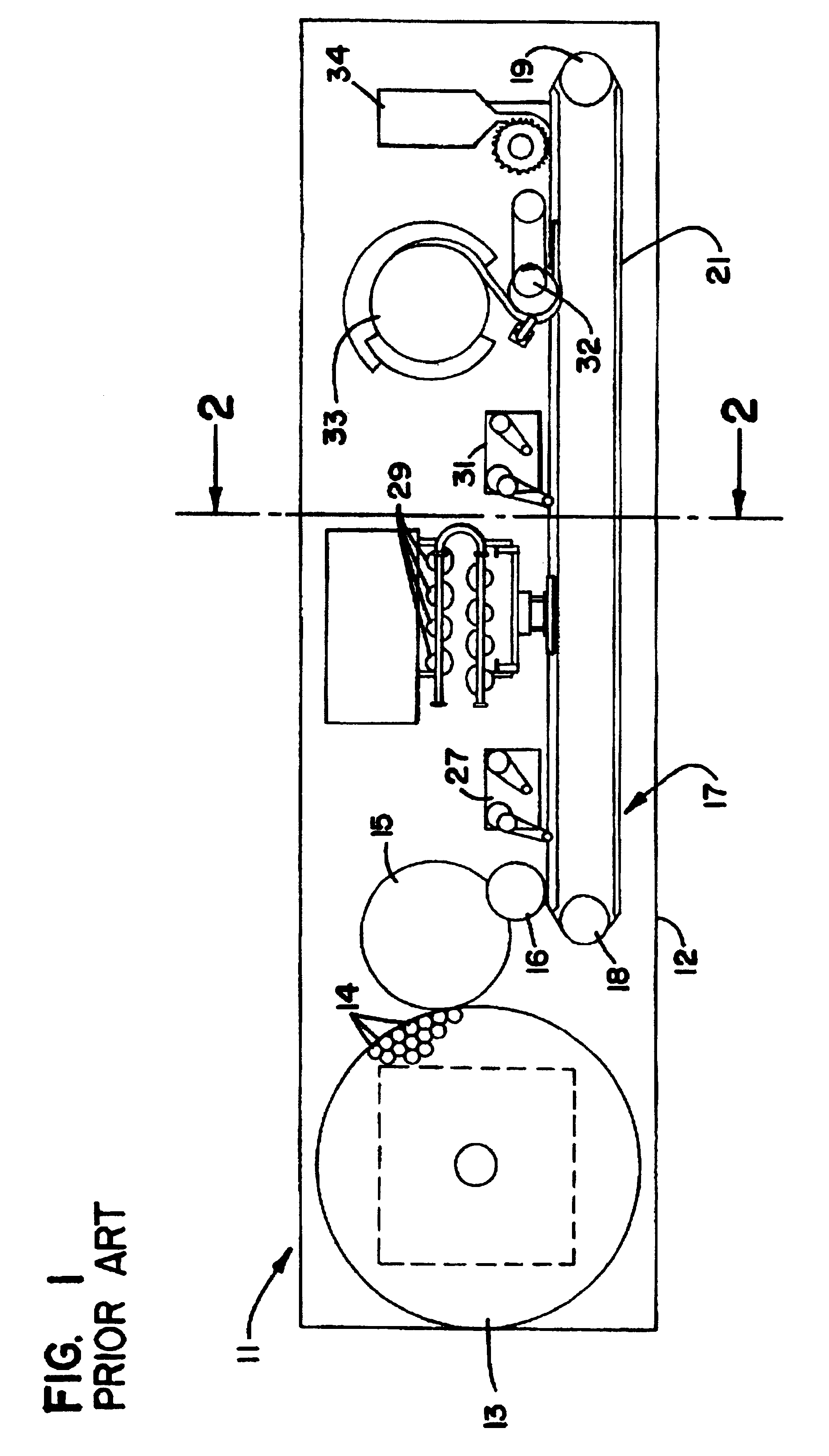

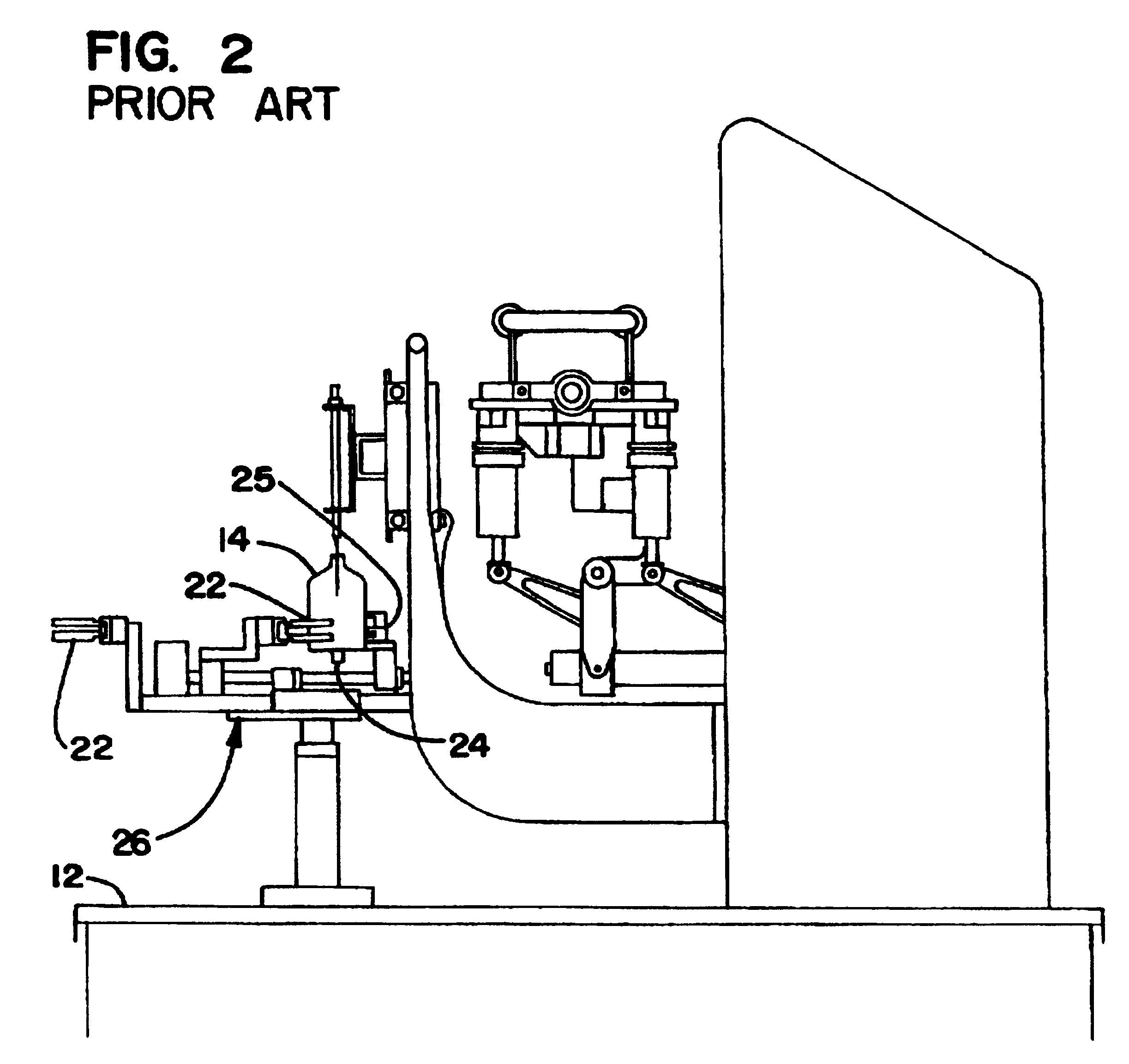

With initial reference to FIGS. 1, 2 and 6, a typical prior art filling apparatus is represented generally by the numeral 11. Apparatus 11 comprises a large table or frame 12 that is horizontally disposed and supports all of the various components of apparatus 11. With particular reference to FIG. 1, these components include an accumulator disk 13 which is filled with a plurality of vials 14 received from a conveyor not shown. Vials 14 are transferred from accumulator disk 13 to a transfer disk 15, and a star wheel 16 individually picks up vials 14 from the transfer disk 15 and carries them to a vial conveyor 17.

With reference to FIGS. 1, 2 and 6, conveyor 17 includes drive sprockets 18, 19 at opposite ends with a sprocket type conveyor belt 21 operably connected therebetween. A plurality of cleats 22 are mounted on and carried by conveyor belt 21, each having a V-shaped frontal recess 23 that is capable of receiving and carrying vials 14 of different diameter. The sequentially carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| included angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com