Patents

Literature

5621results about "Packaging machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

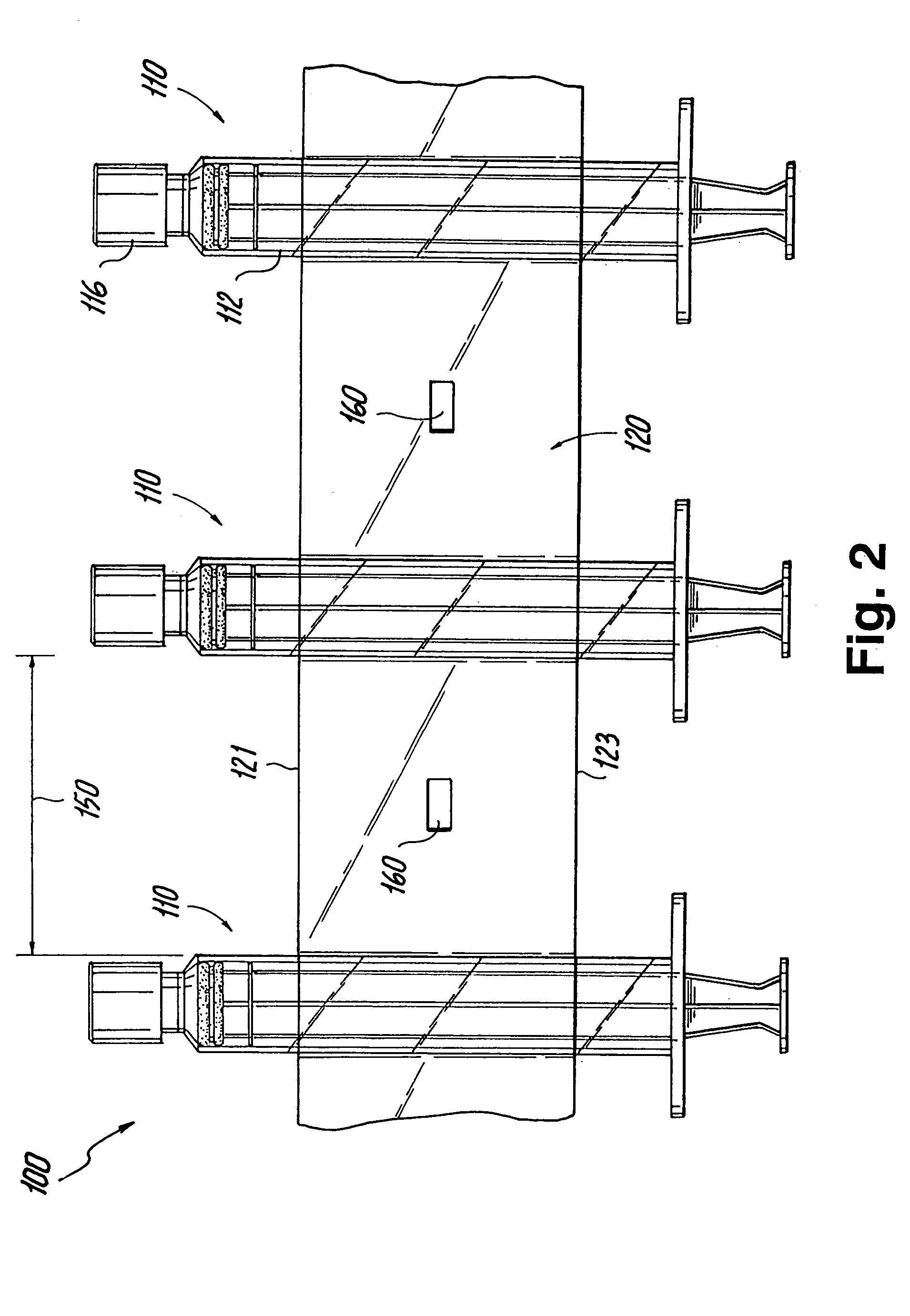

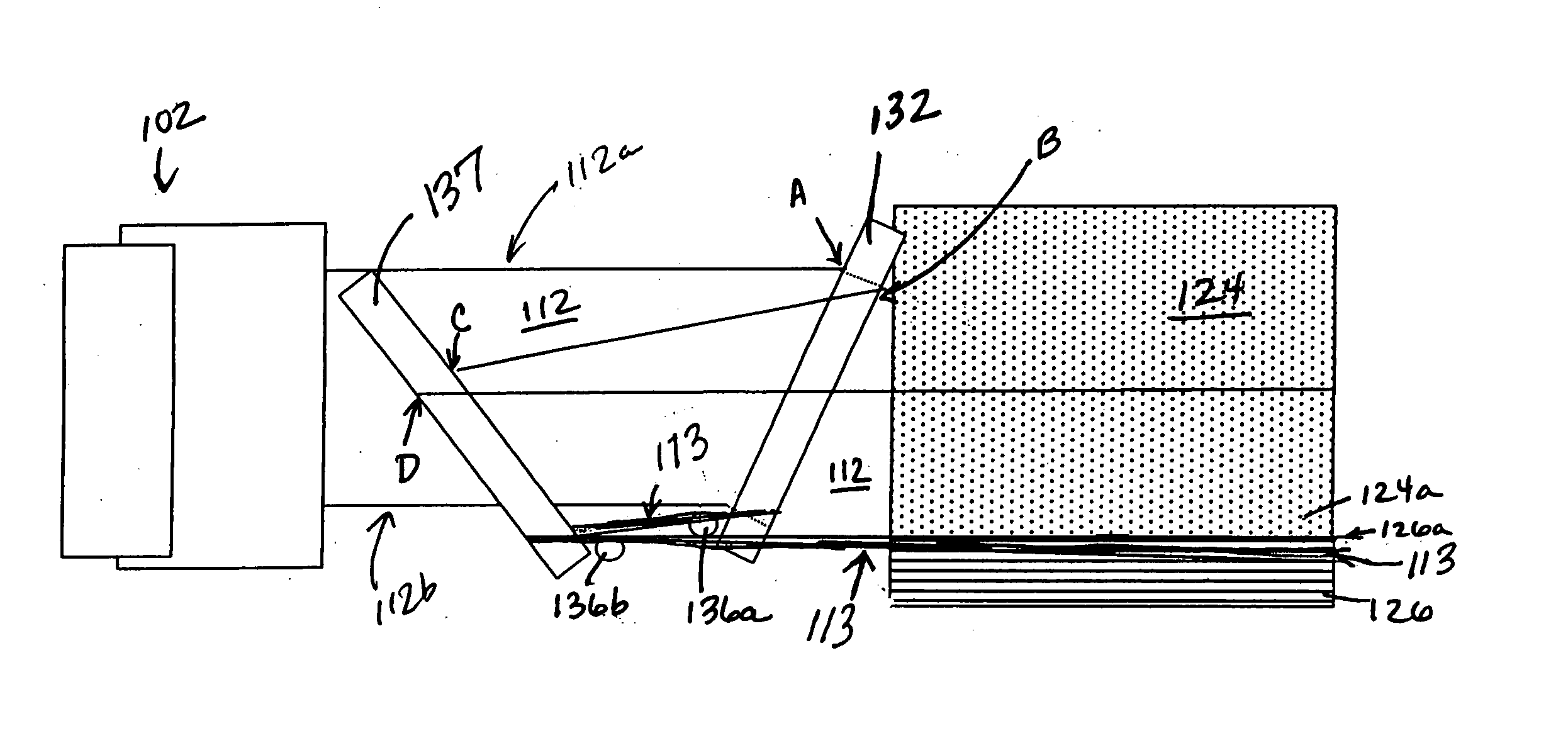

Method and apparatus for metered pre-stretch film delivery

The present invention provides a method and apparatus for dispensing a predetermined substantially constant length of pre-stretched packaging material based upon load girth. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution of relative rotation between a packaging material dispenser and the load is determined. A rotational drive system used to provide the relative rotation is linked to a pre-stretch assembly portion of the packaging material dispenser. The linkage may be mechanical or electrical. The linkage controls a ratio of the rotational speed to the pre-stretch assembly dispensing speed, such that the predetermined substantially constant length of pre-stretched packaging material is dispensed for each revolution of the packaging material dispenser relative to the load regardless of the speed of the rotational drive. In the case of a mechanical linkage, the linkage also connects the rotational drive to the pre-stretch assembly portion such that the rotational drive also drives the pre-stretch assembly portion.

Owner:LANTECH COM

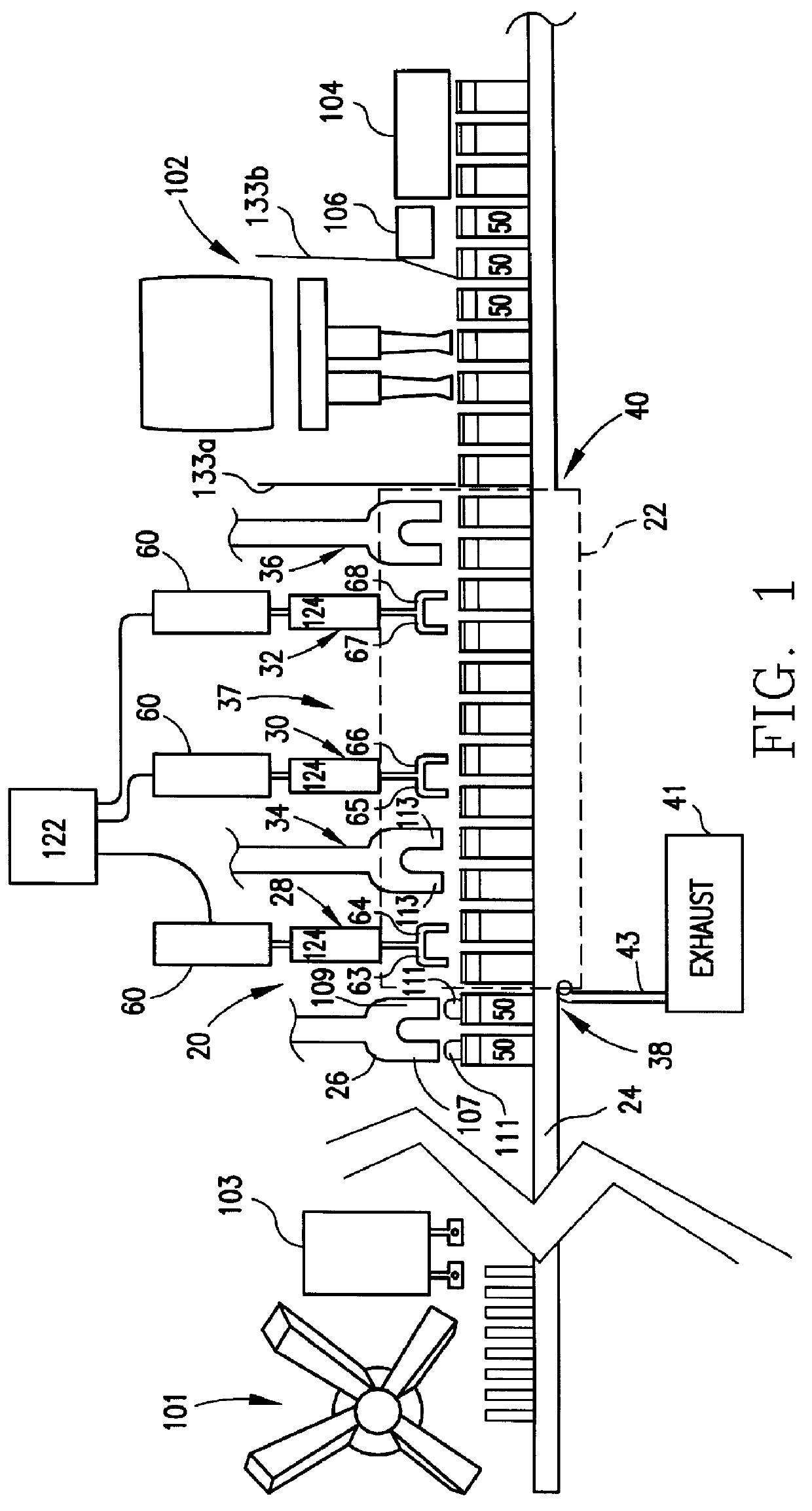

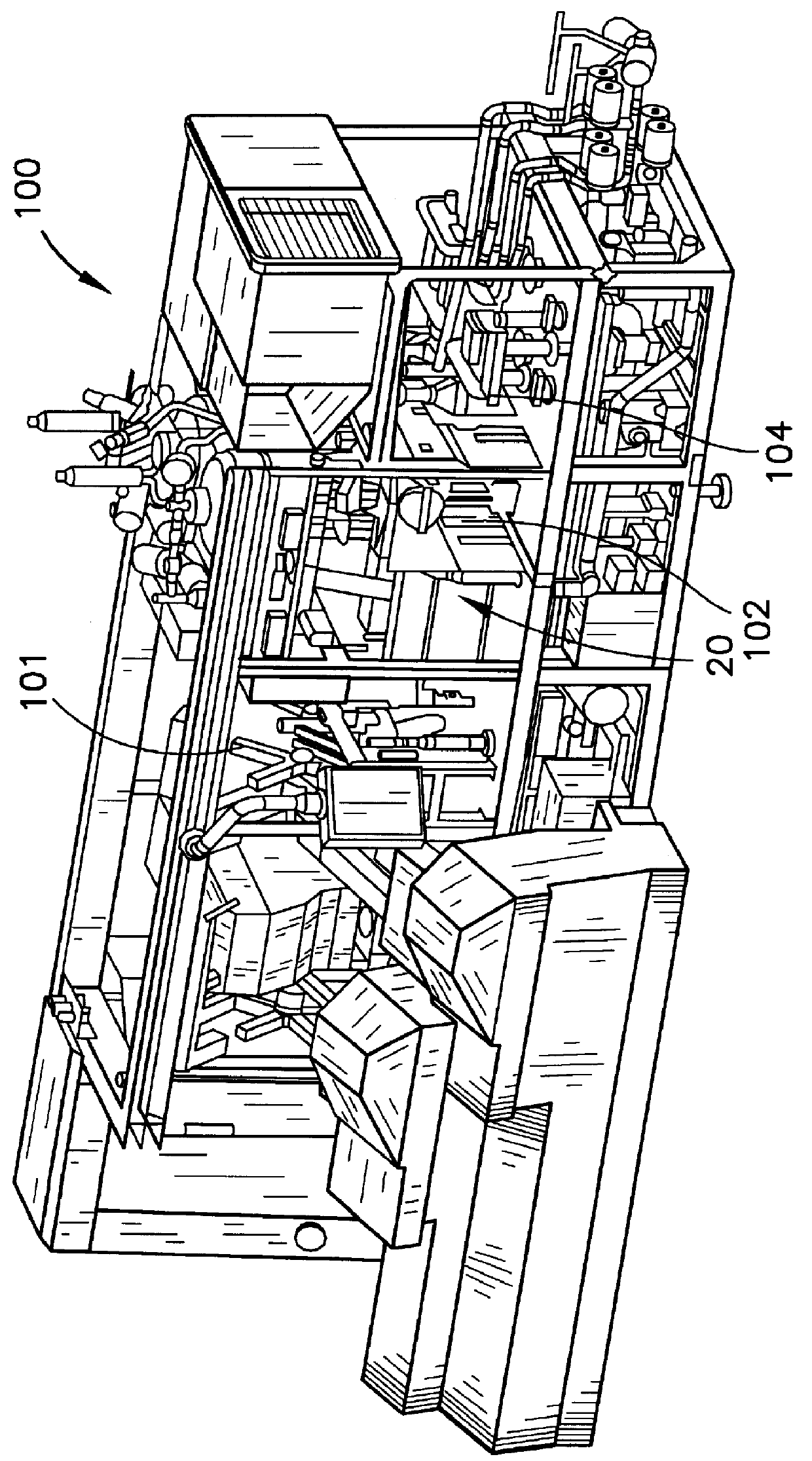

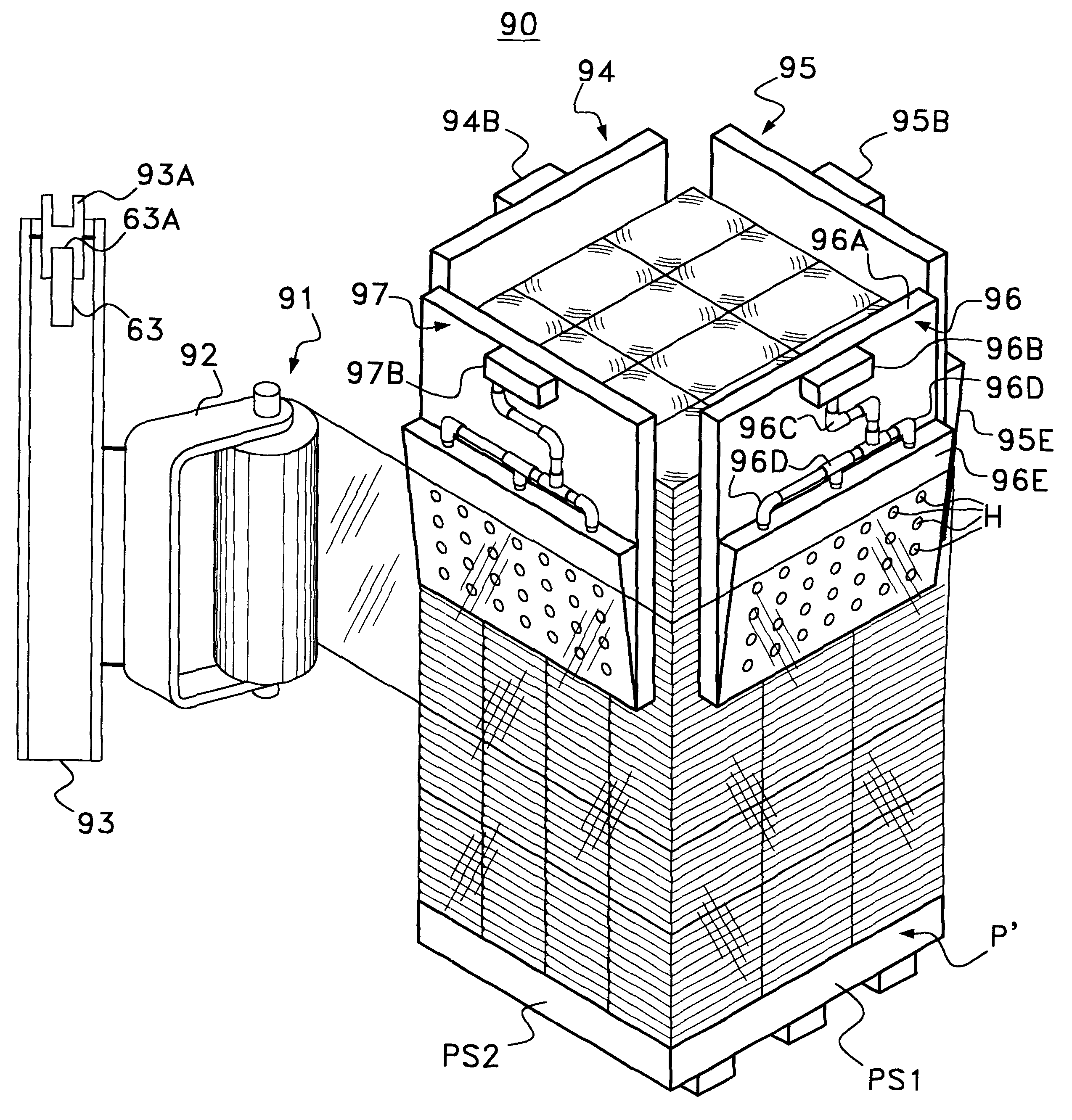

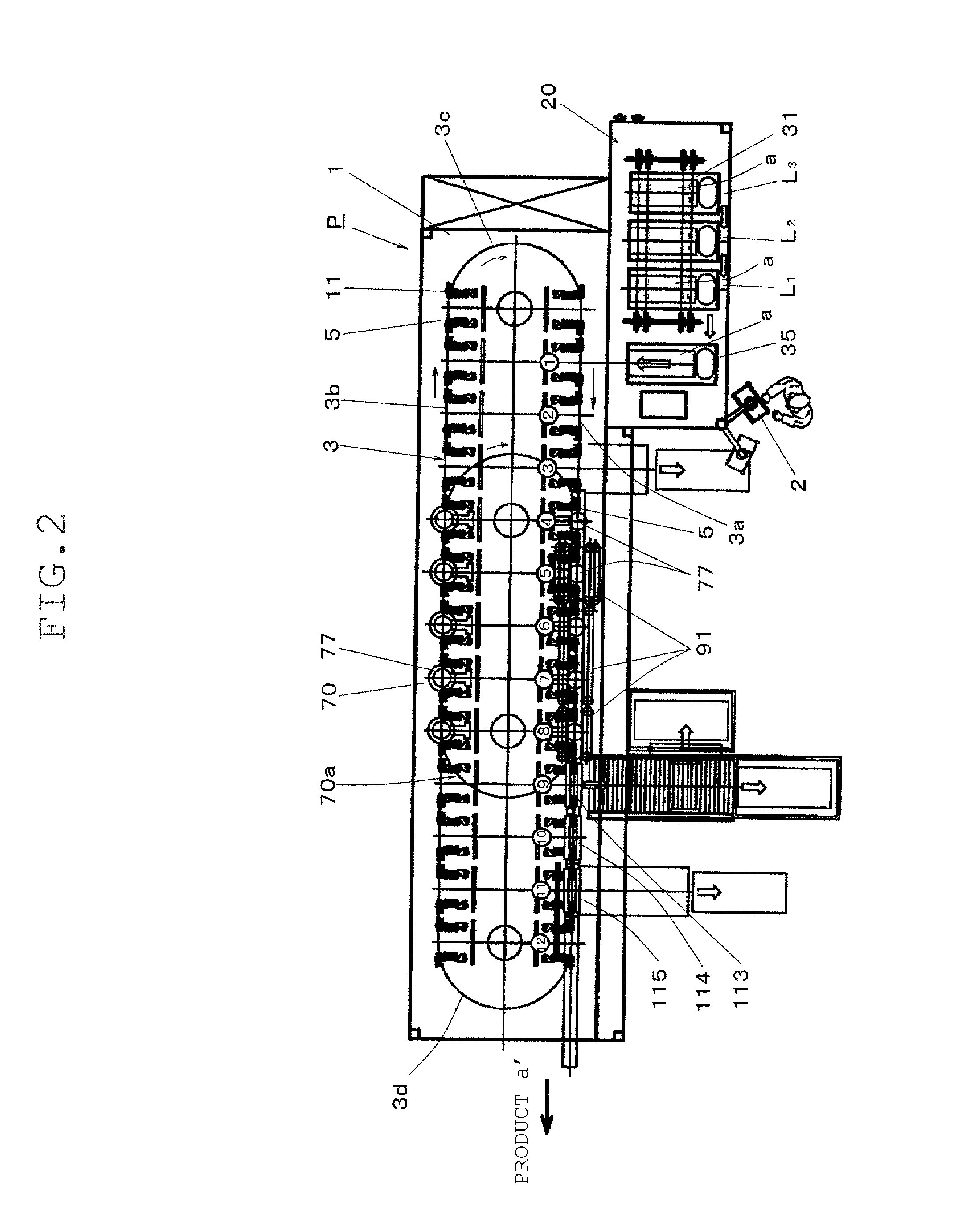

Heat and hydrogen peroxide gas sterilization of container

The present invention discloses a method and apparatus for sterilizing containers with gas-phase hydrogen peroxide and heat on a linear form, fill and seal packaging machine. A partially formed container is subjected to multiple applications of gaseous hydrogen peroxide and hot air within a sterilization tunnel. The sterilization tunnel is maintained at a temperature greater than the condensation temperature of hydrogen peroxide. The present invention sterilizes the container allowing for filling of the container with a high acid product such as orange juice for ambient distribution. The container may be any number of possibilities such as TETRA REX TM gable top cartons, plastic bottles, and the like. The invention allows for the efficacious use of hydrogen peroxide gas having a concentration of up to 53%.

Owner:TETRA LAVAL HLDG & FINANCE SA

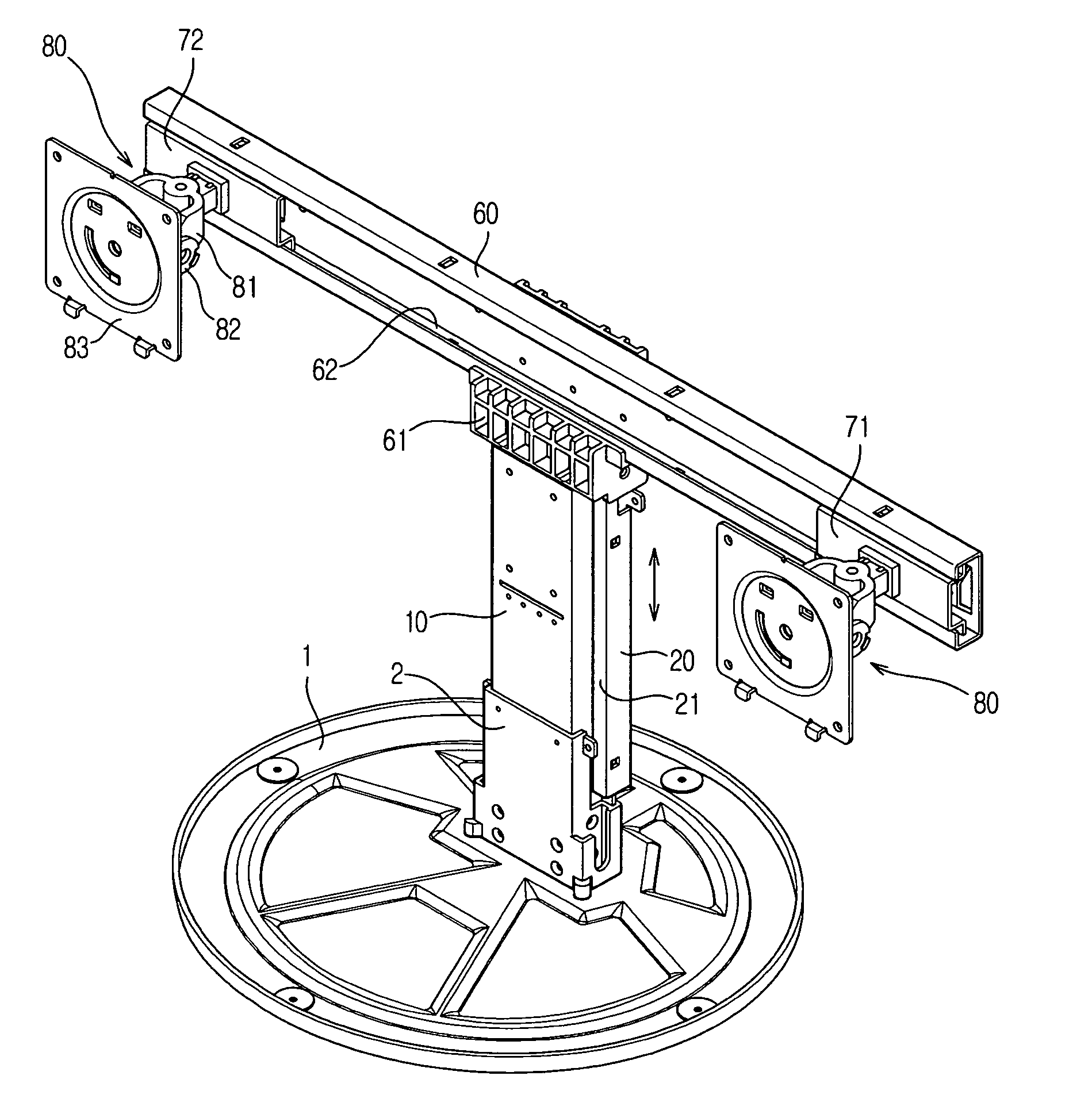

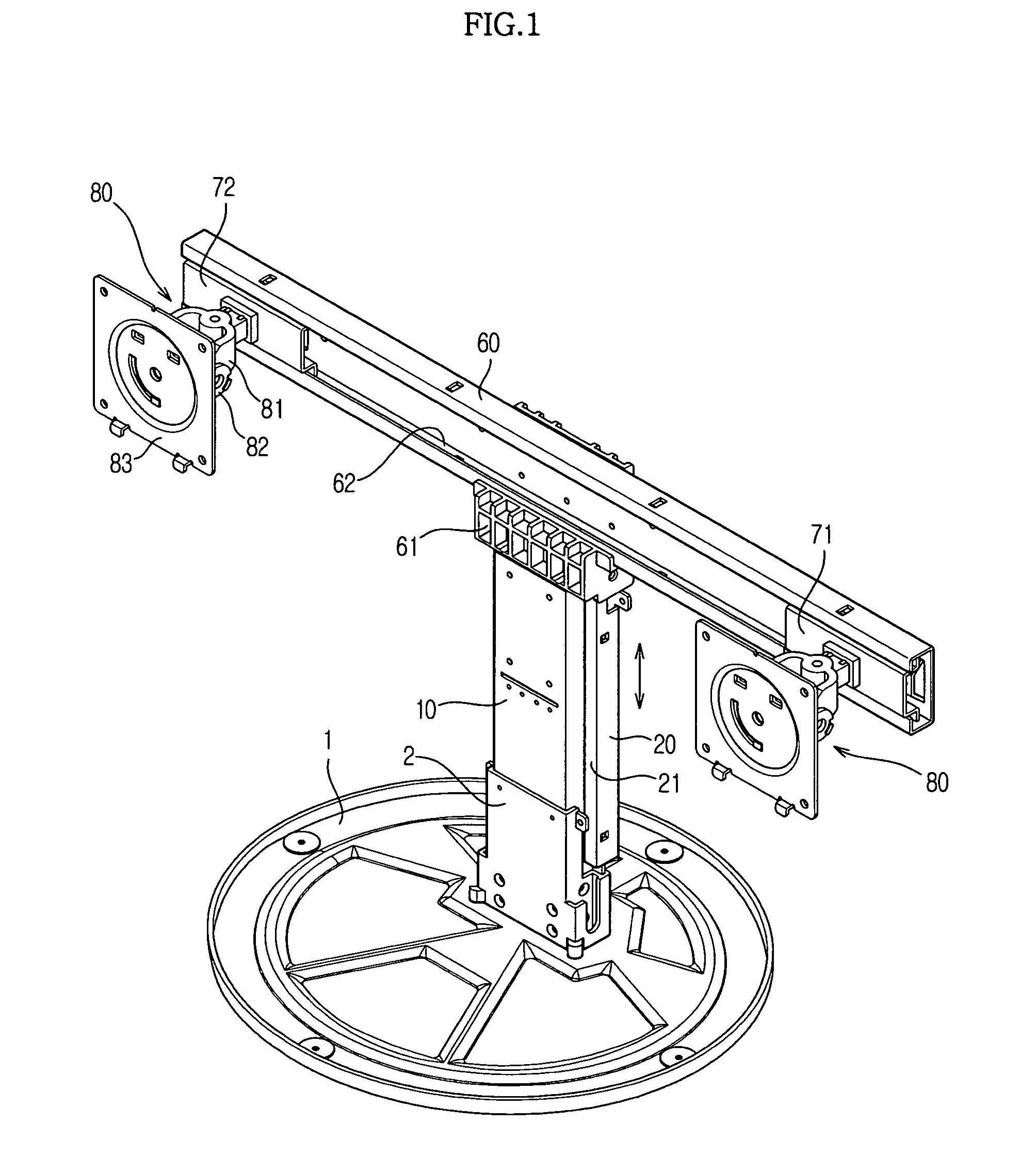

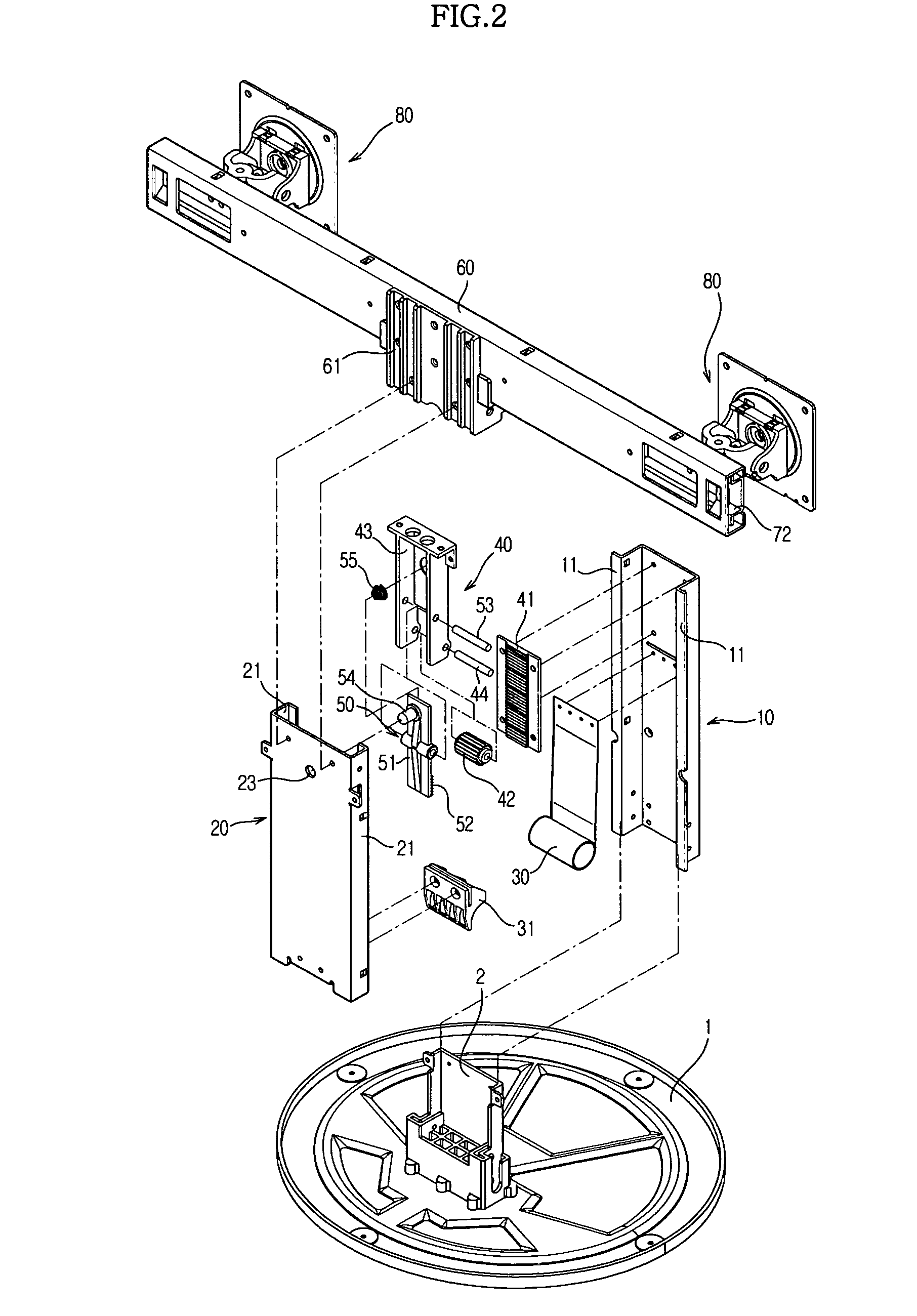

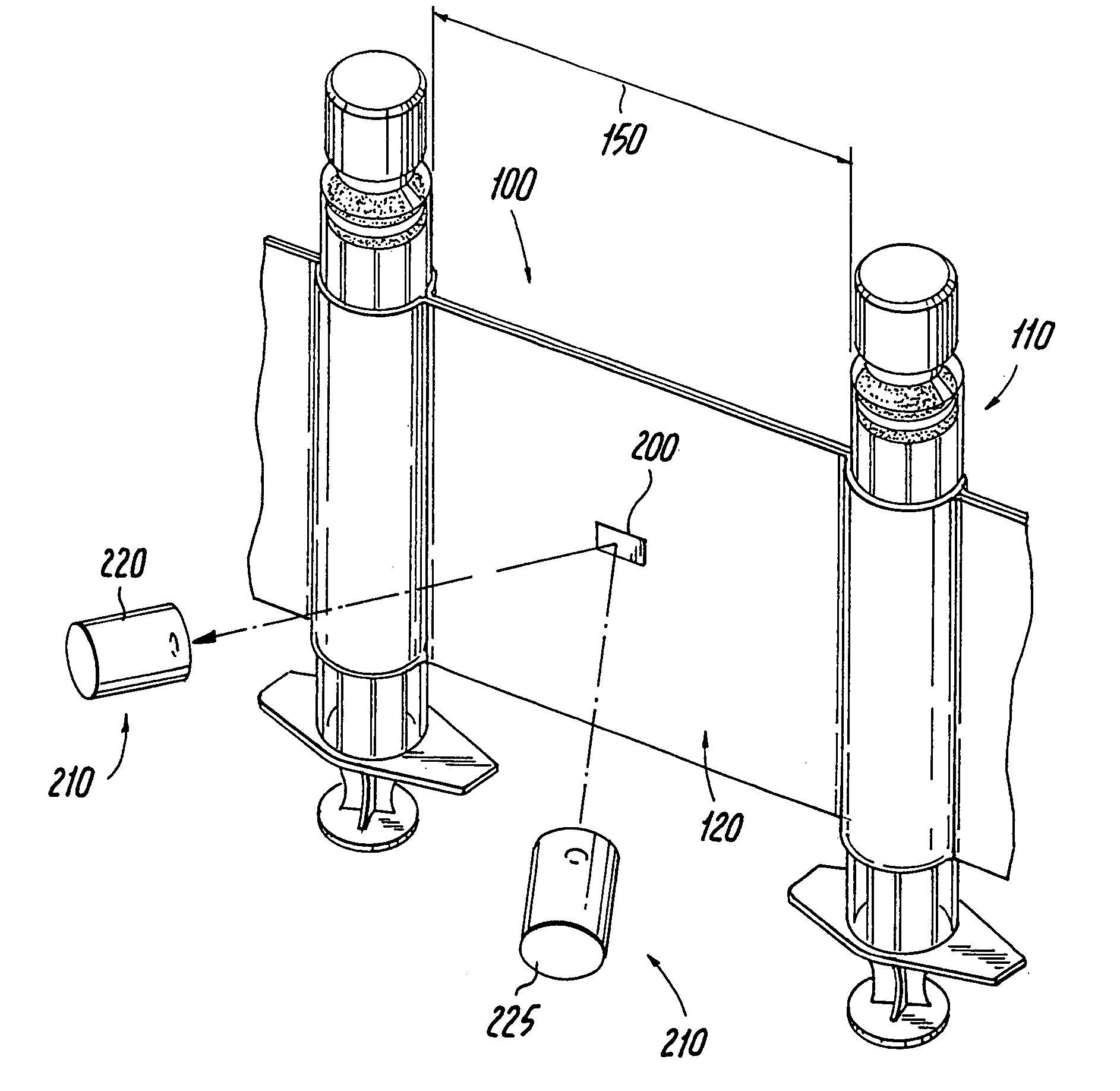

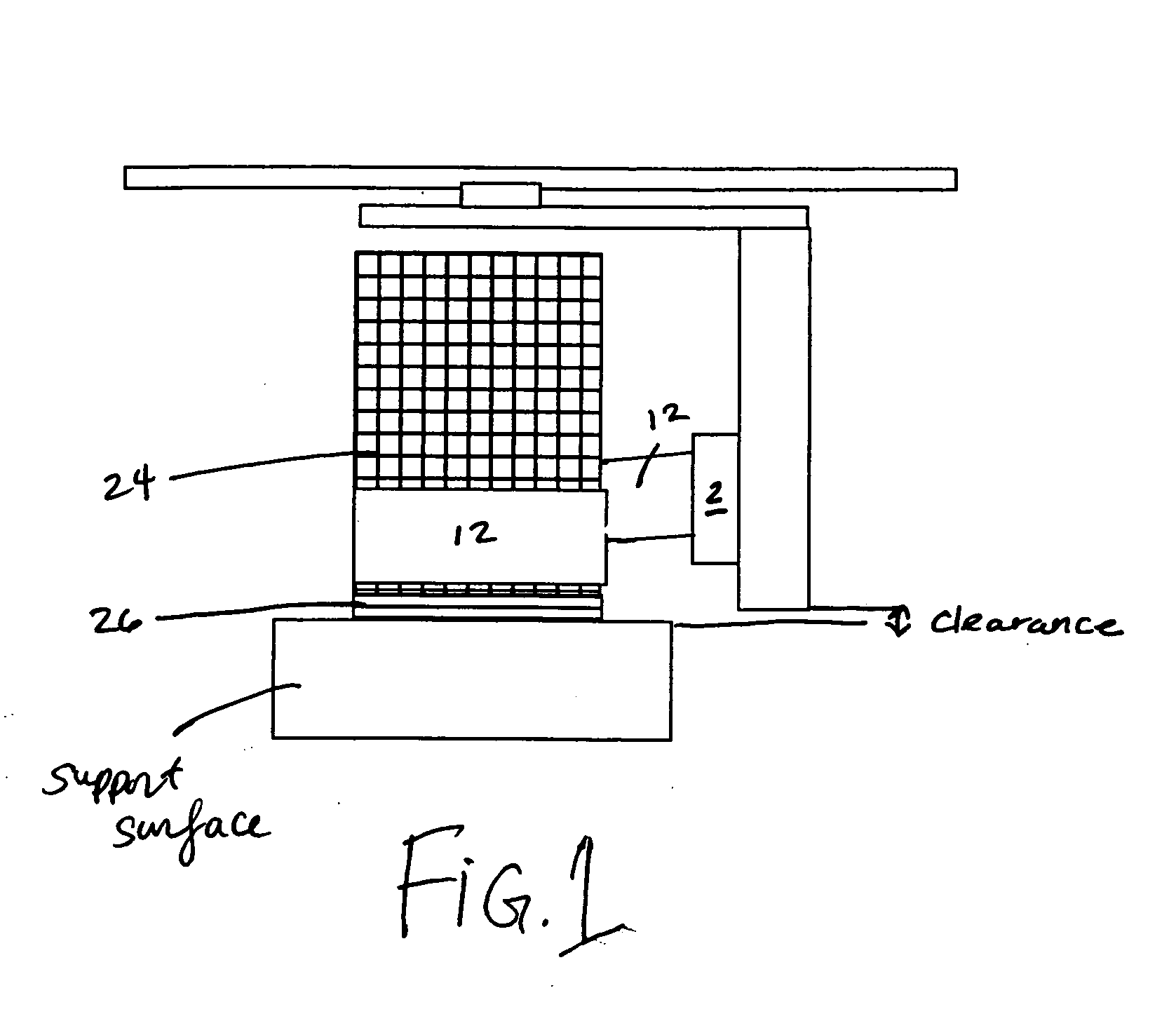

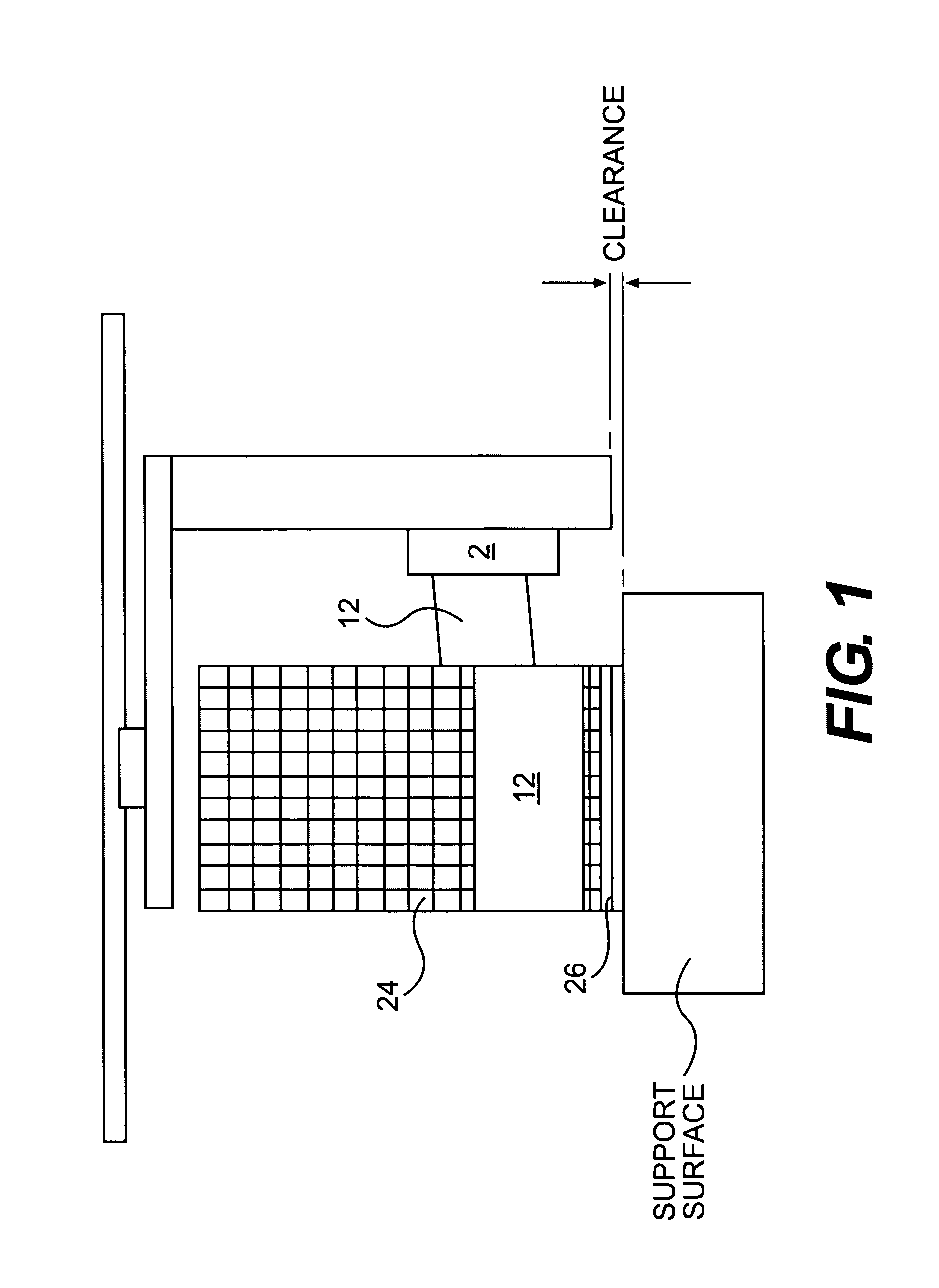

Supporting device for display units

A supporting device for display units enables height adjustment with ease and accuracy, and stably maintains the adjusted height while allowing a plurality of display units to be mounted thereon. The supporting device includes a stationary member, an elevation member coupled to the stationary member so as to be raised or lowered, a rack gear secured to the stationary member, a pinion gear installed to the elevation member so as to engage with the rack gear, and a restriction unit installed to the elevation member to restrict or allow rotation of the pinion gear. The supporting device further comprises an upper-side supporting member installed to an upper portion of the elevation member, first and second movable members to move along a guide rail of the upper-side supporting member, and connecting devices installed to the respective movable members to connect the display unit, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

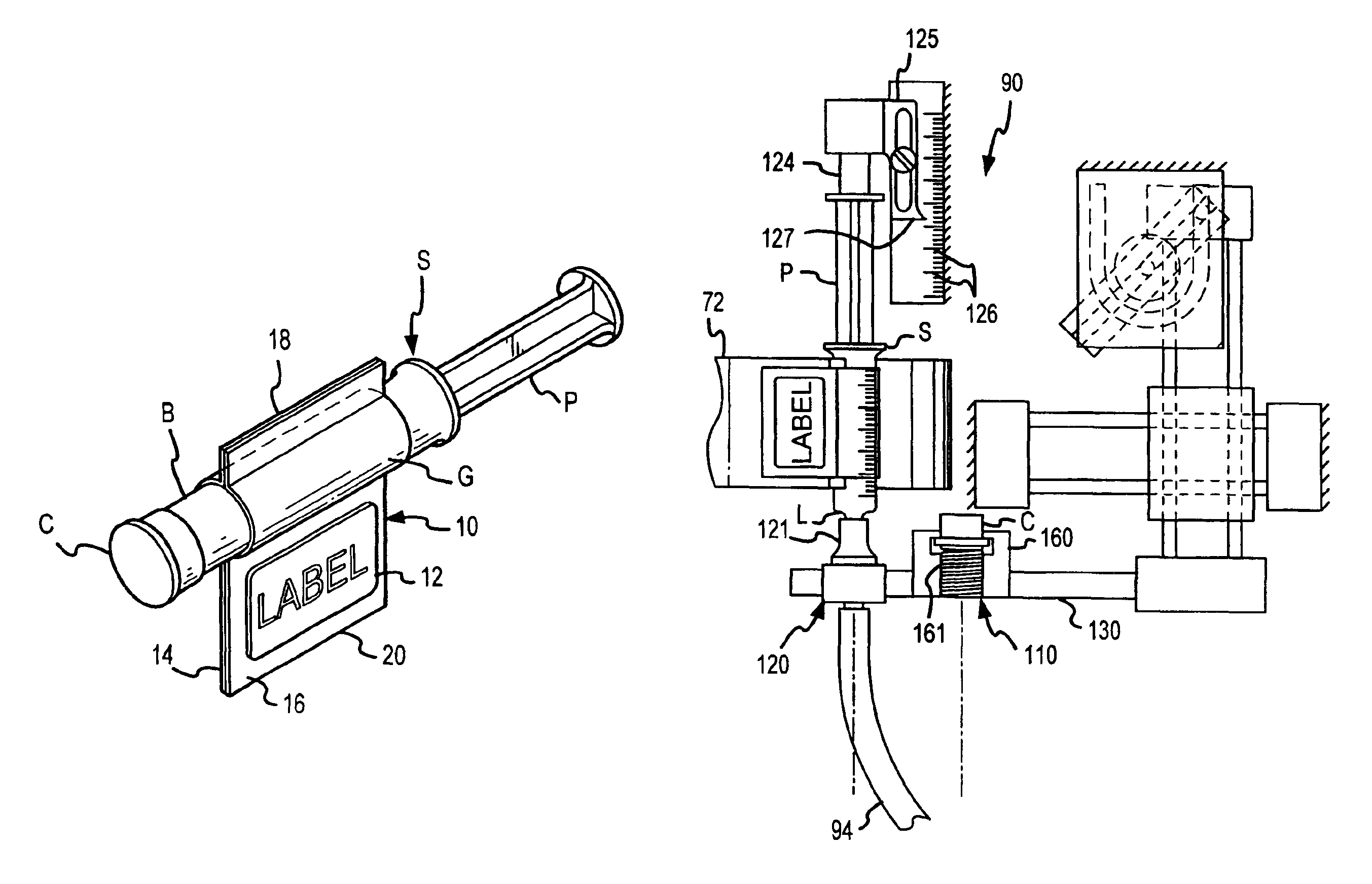

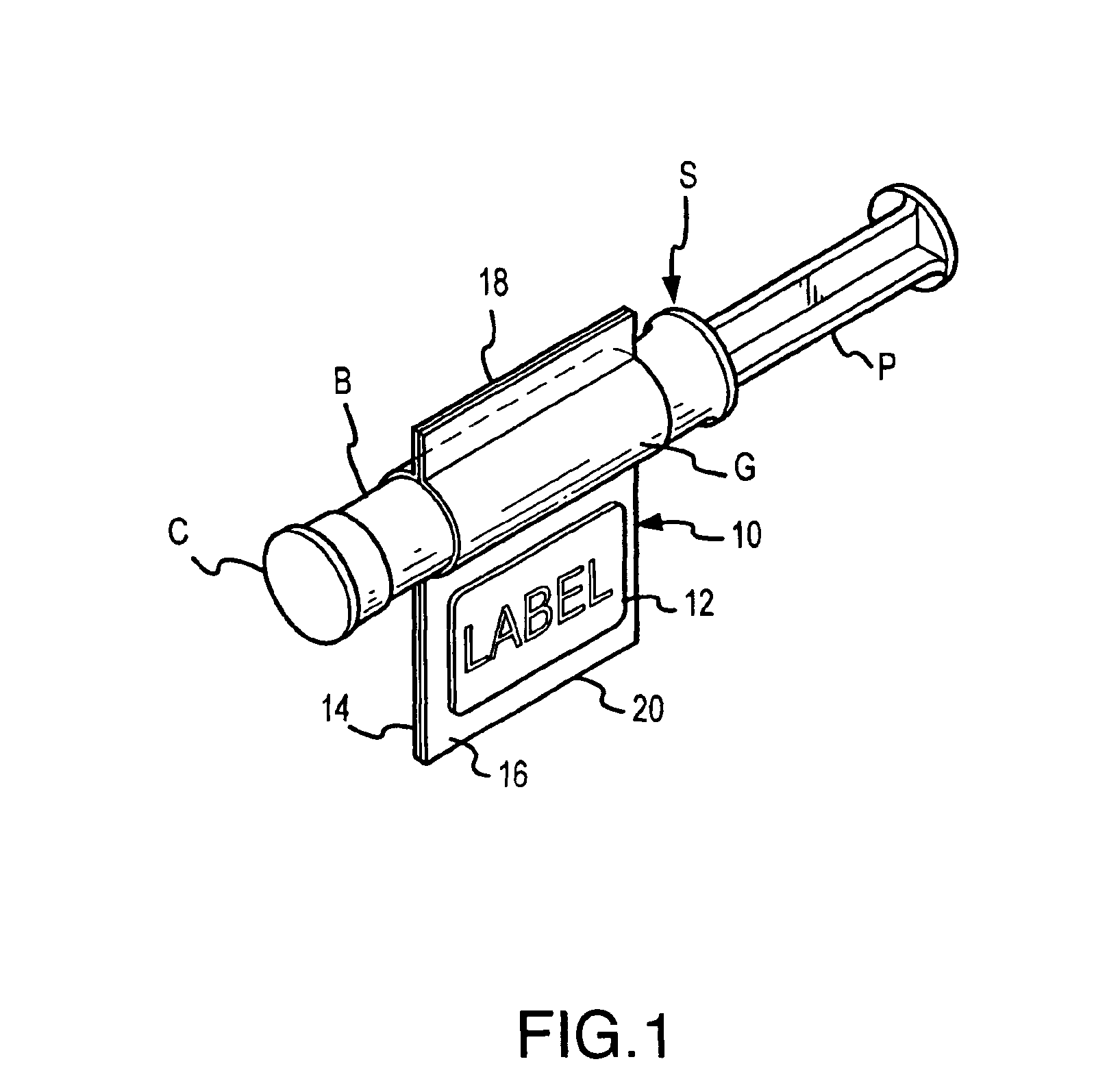

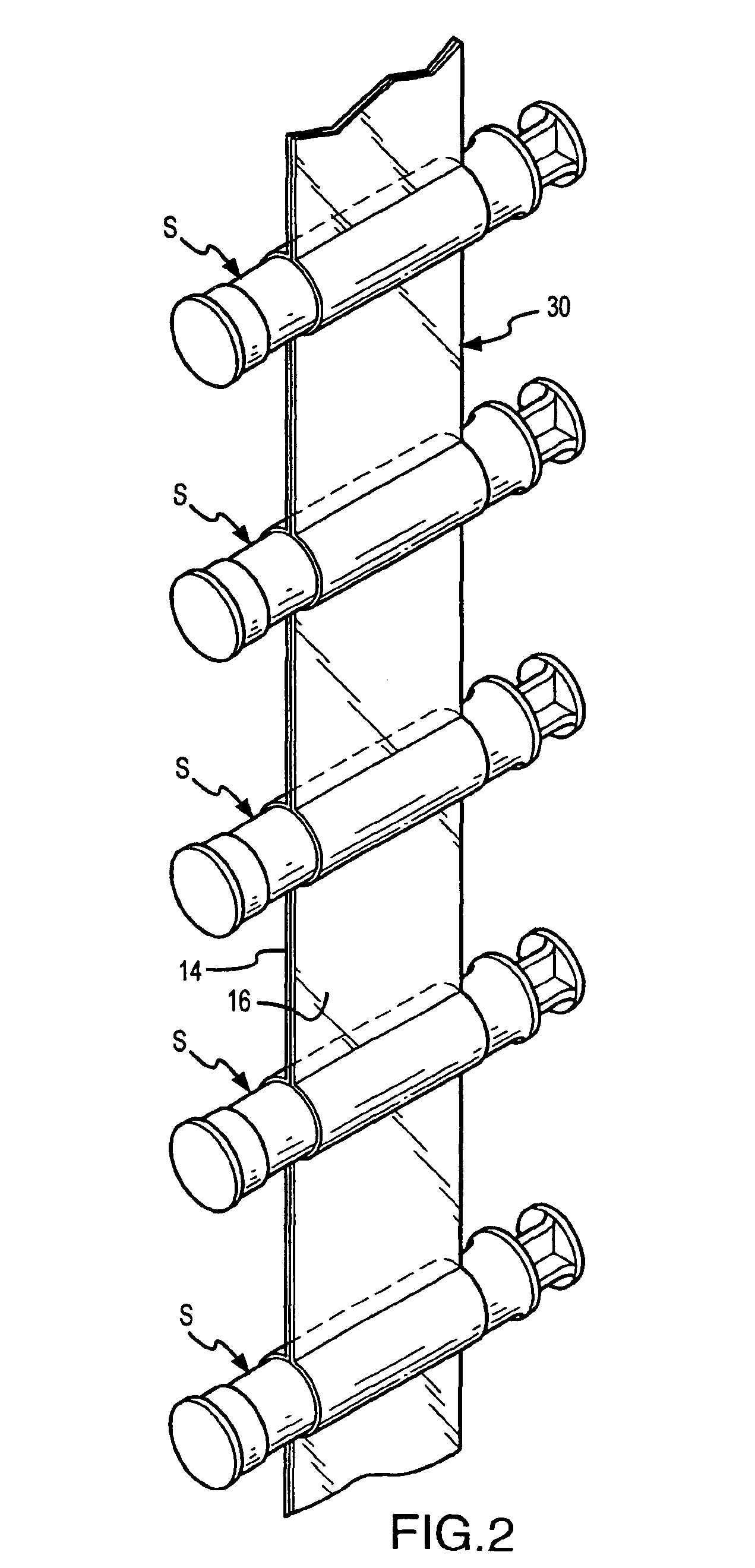

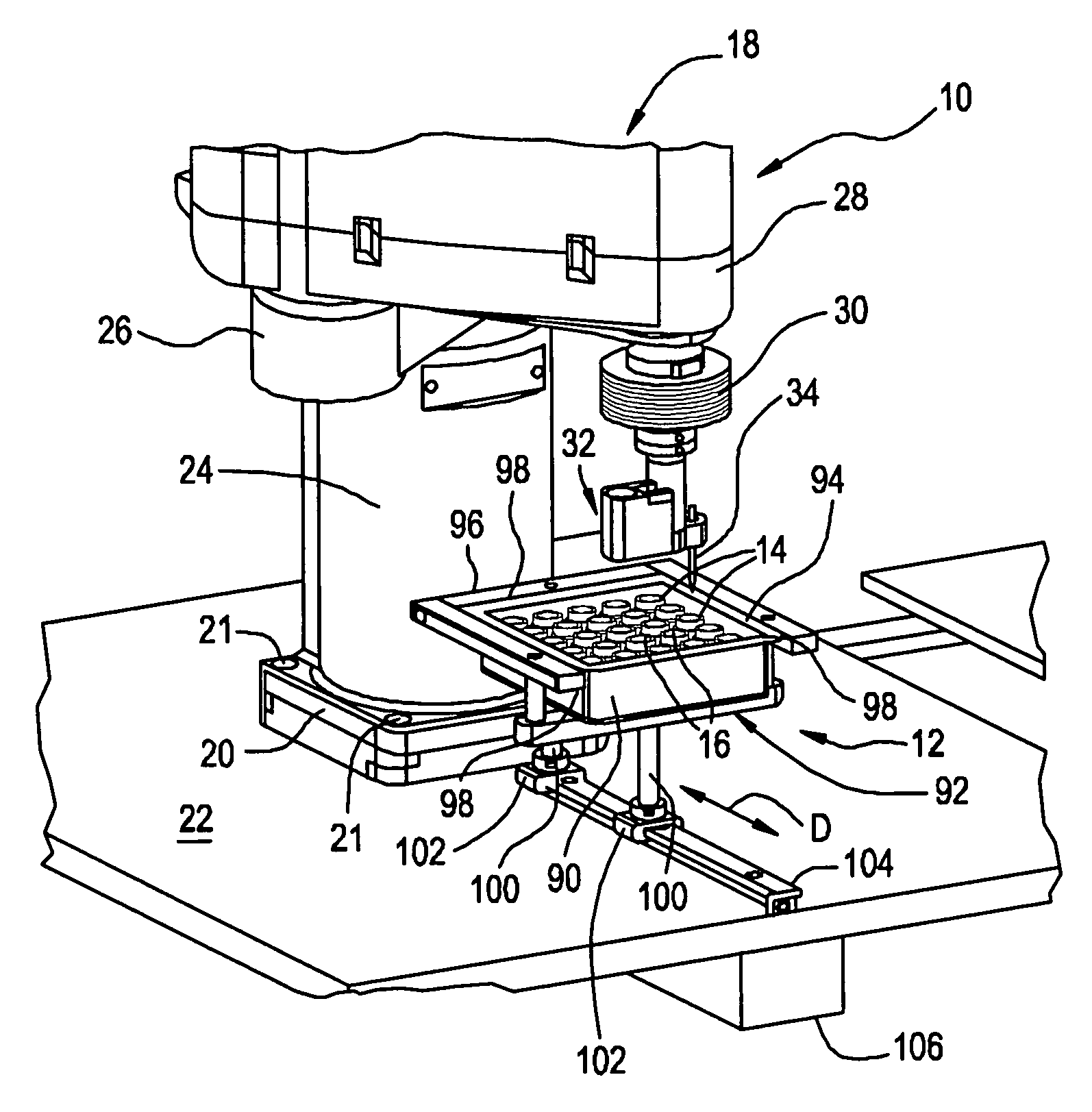

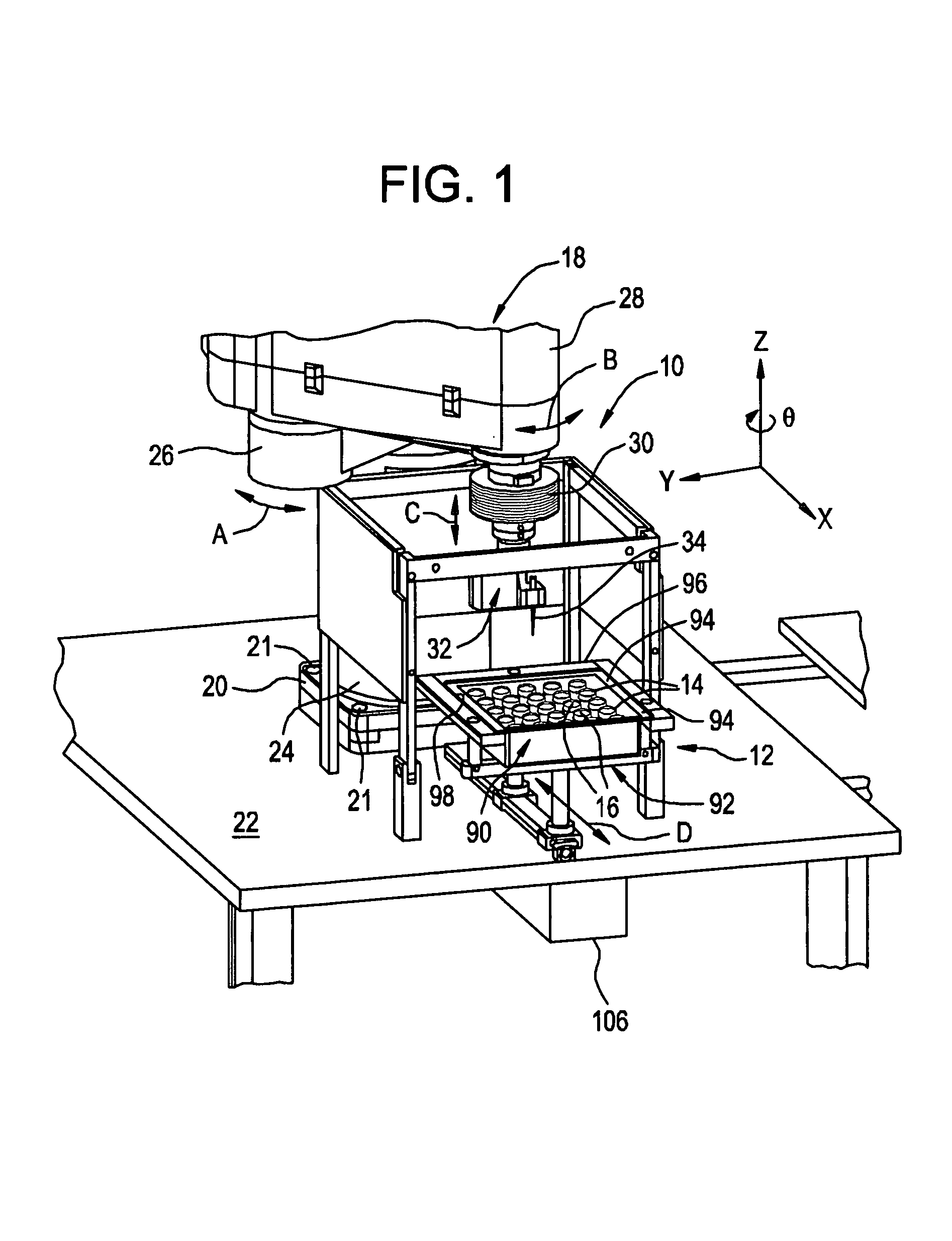

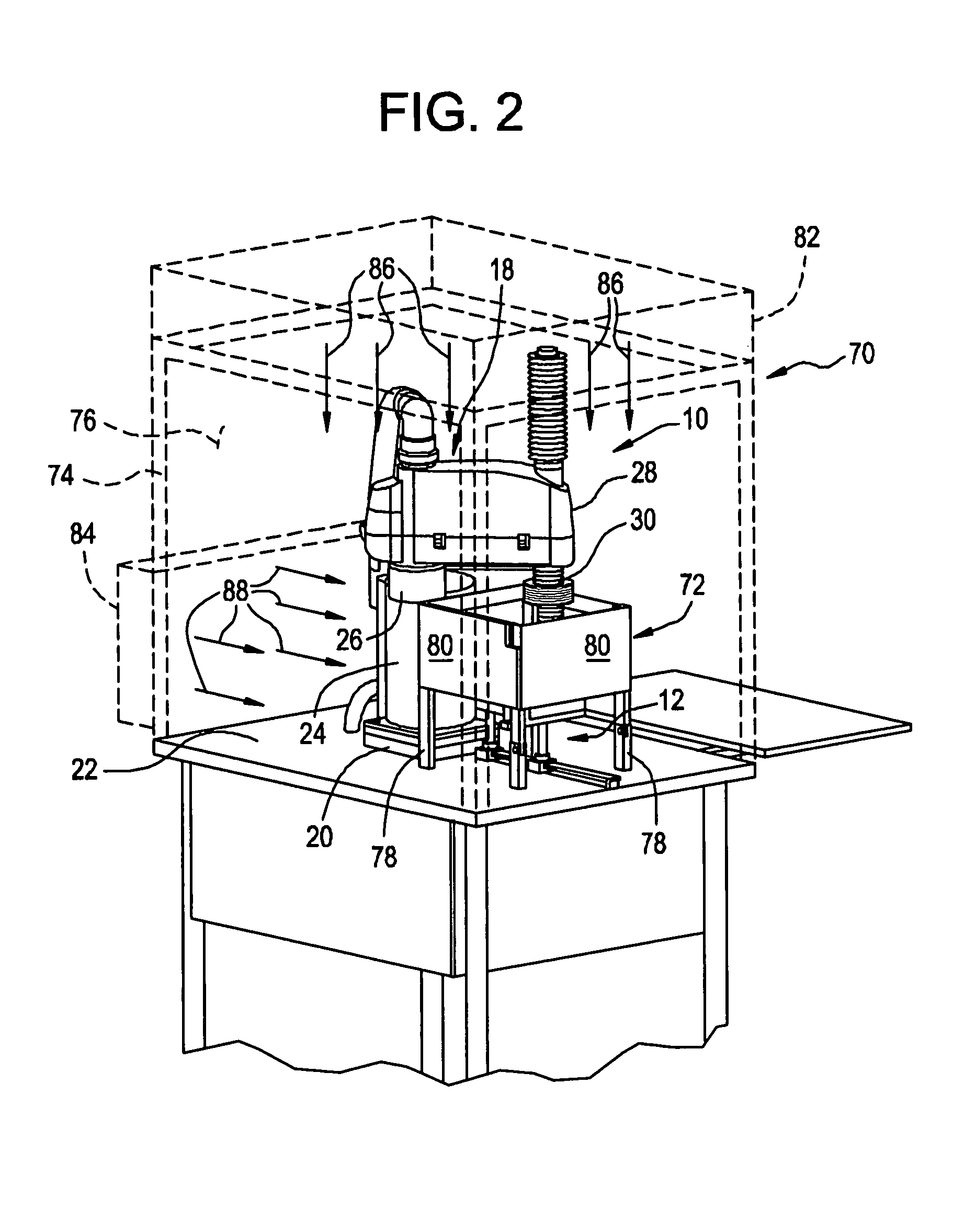

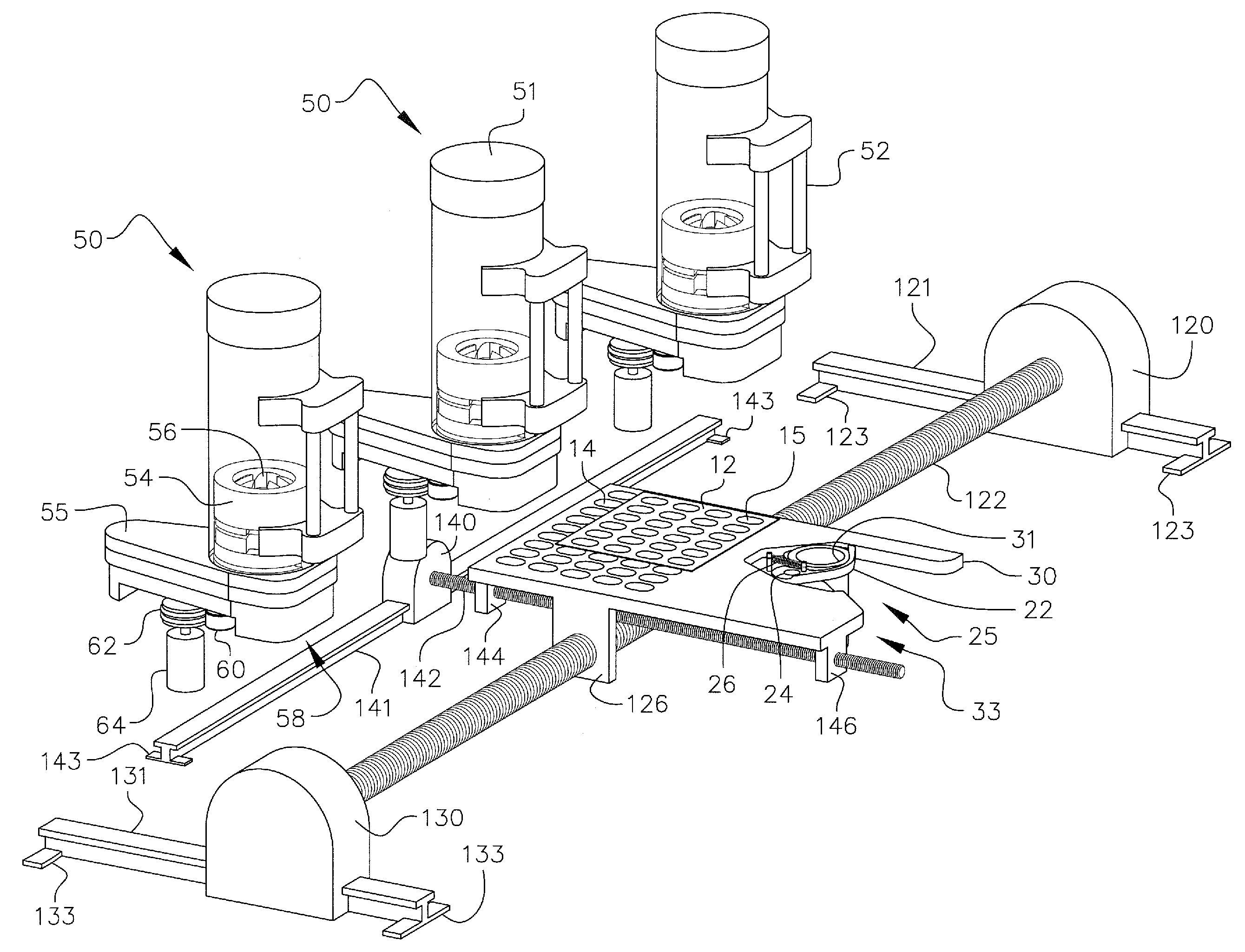

Method for filling and capping syringes

InactiveUS6976349B2Facilitates maintenance of sterilityImproved syringe fillingCapsAmpoule syringesManual handlingBiomedical engineering

An inventive method, system and apparatus are provided for syringe handling, and more particularly, for syringe labeling, filling and capping operations. To facilitate syringe handling, an inventive apparatus includes a plurality of syringe bodies interconnected in a predetermined orientation by a belt. Such belt may be of pliable construction and may define a predetermined spacing in between adjacent ones of the syringe bodies, such predetermined spacing corresponding with a distance between holders provided in a handling apparatus. The syringe handling apparatus may provide for the placement of contents-related information on belt segments between adjacent syringe bodies and for separating the belt segments, wherein a flap is left interconnected to each syringe body. The syringe handling apparatus may alternatively or also provide for automated filling of the syringe bodies wherein cap removal, filling and cap replacement operations are completed free from manual handling.

Owner:BAXTER ENGLEWOOD

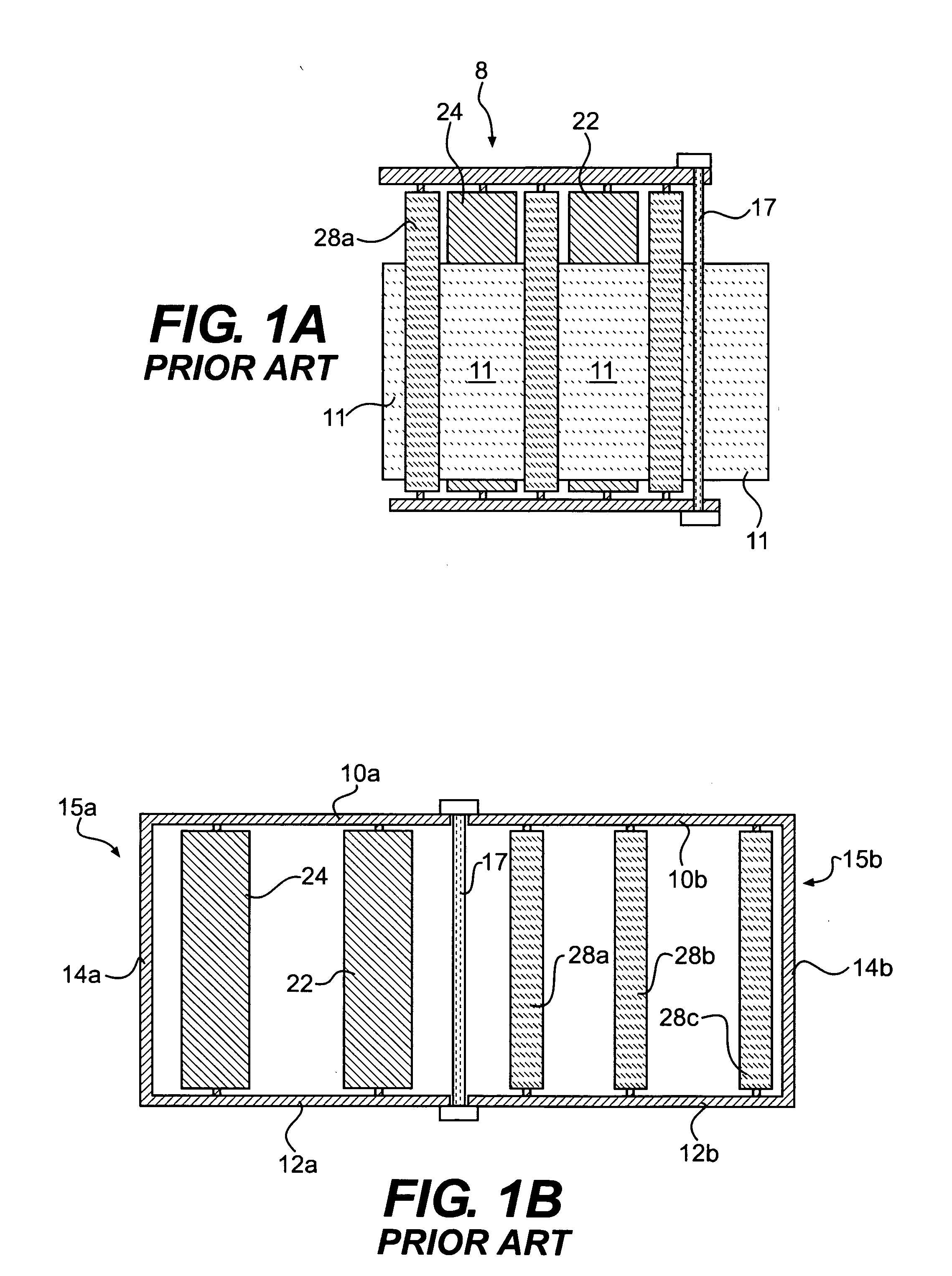

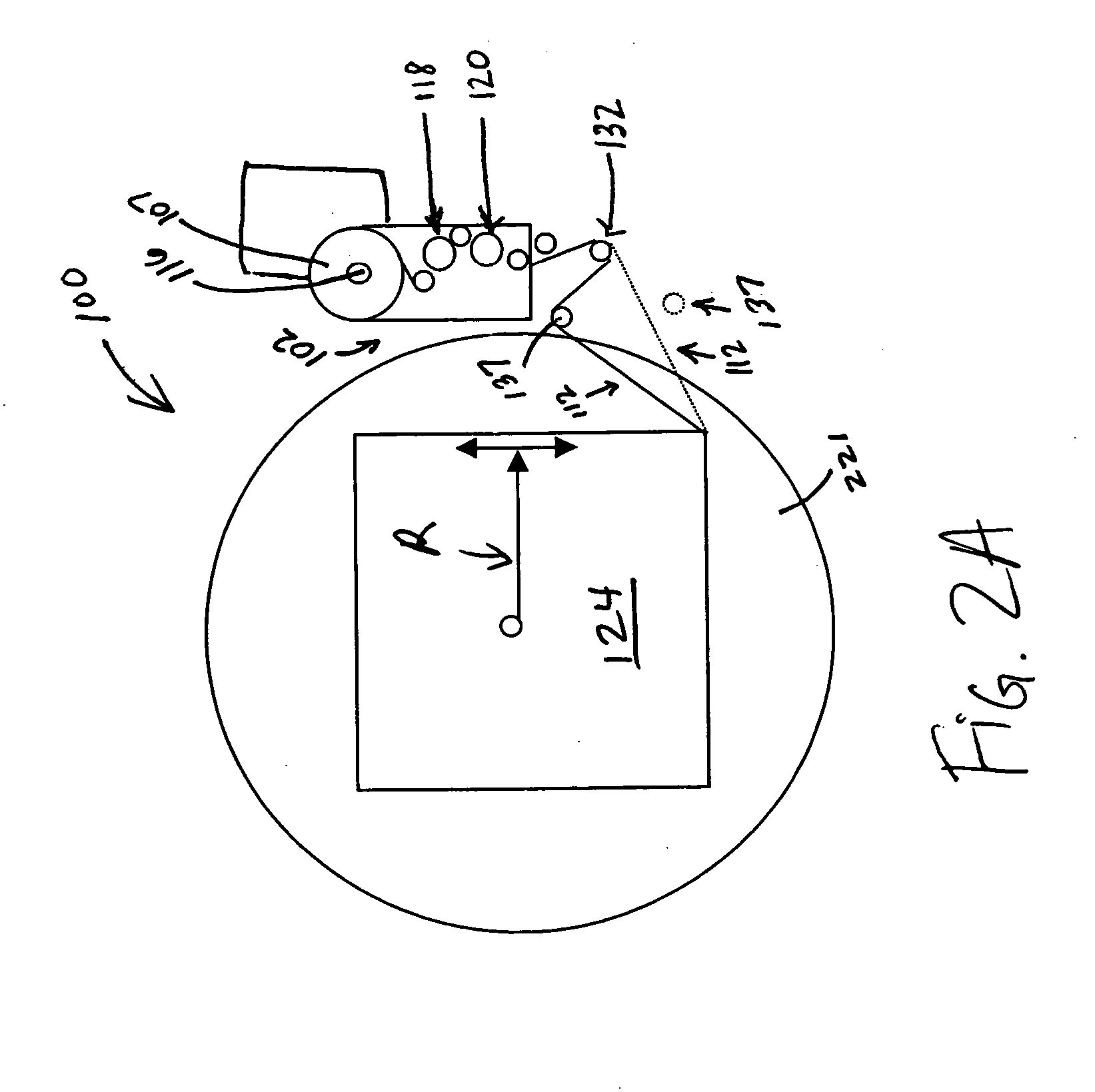

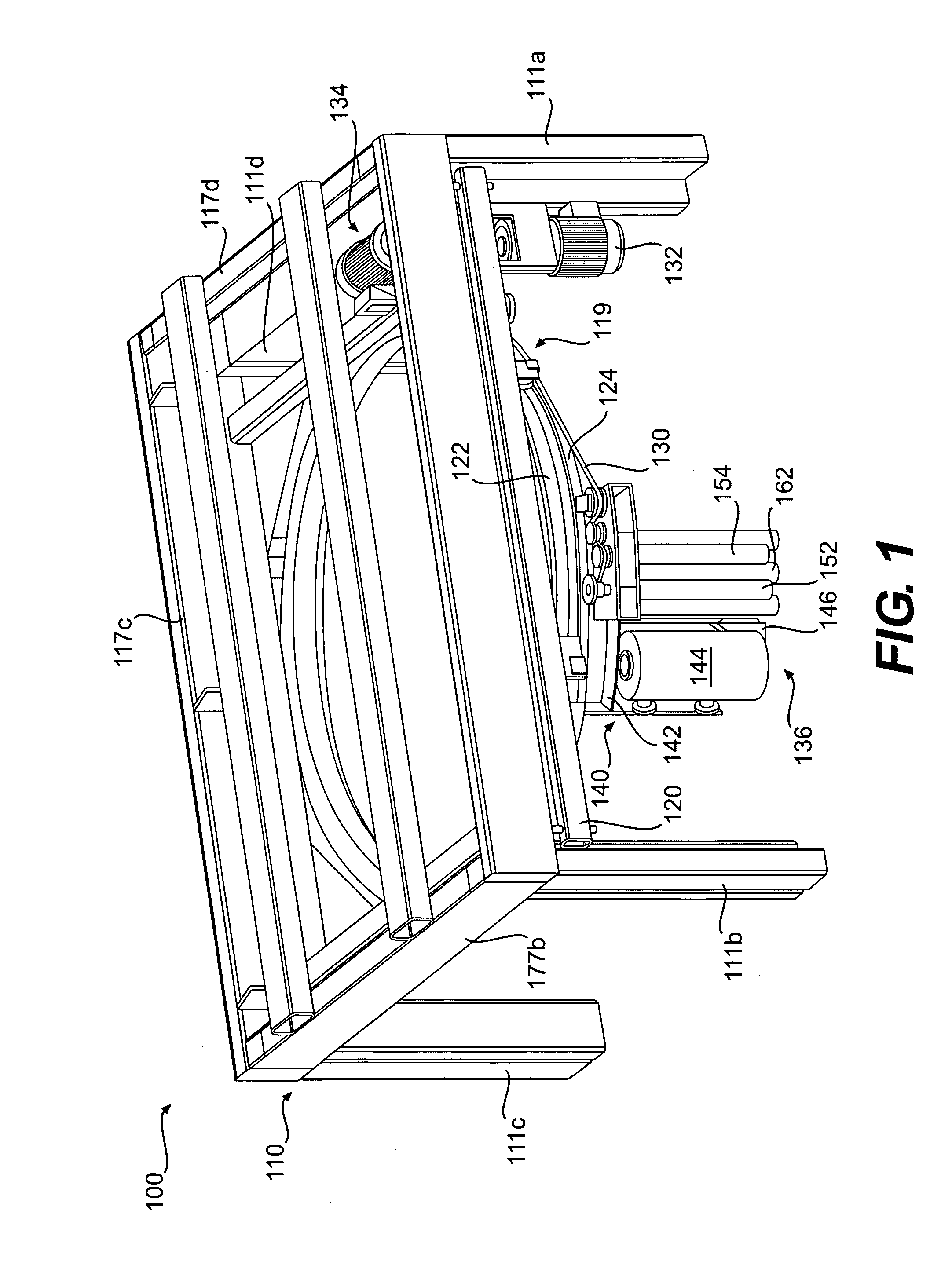

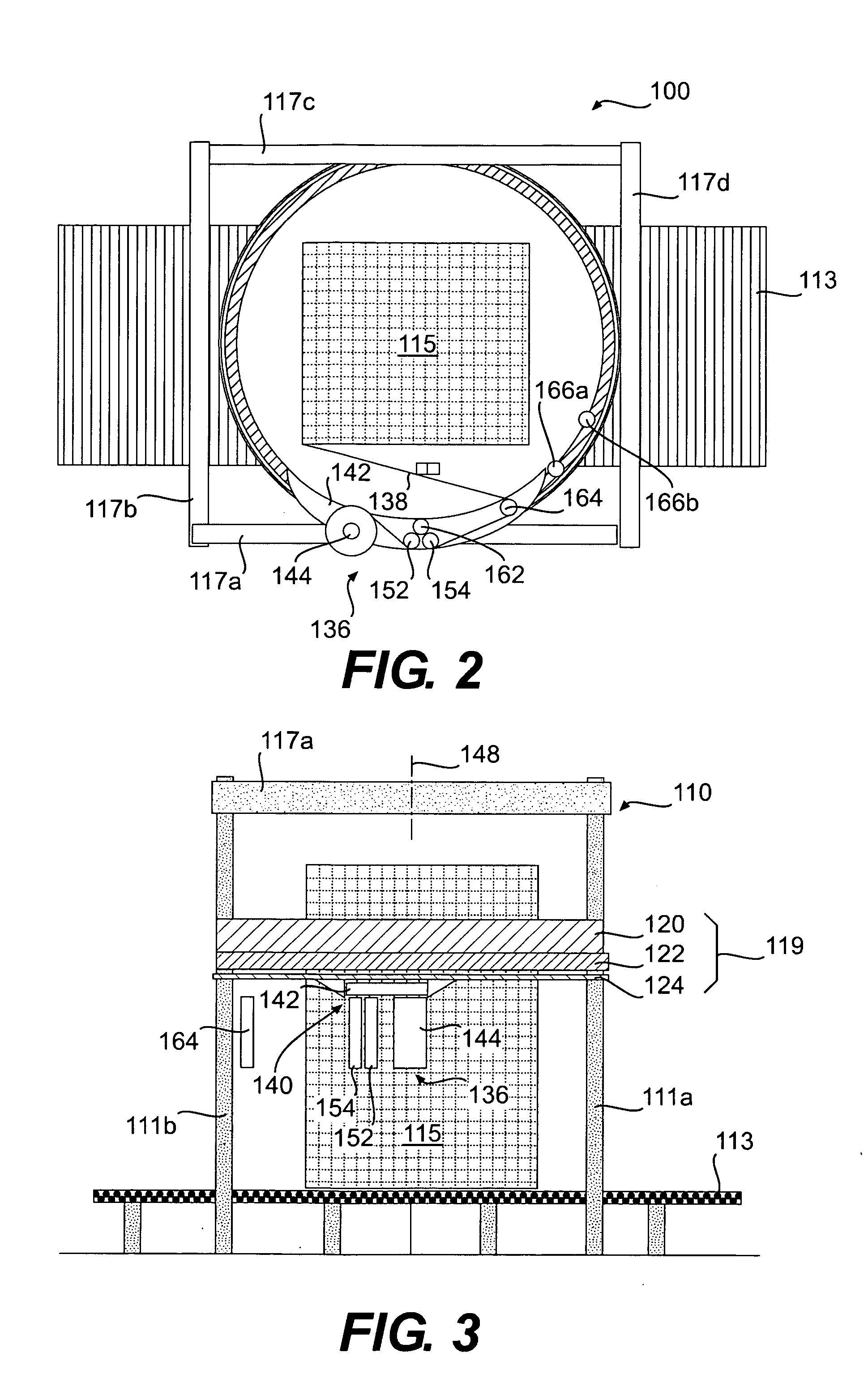

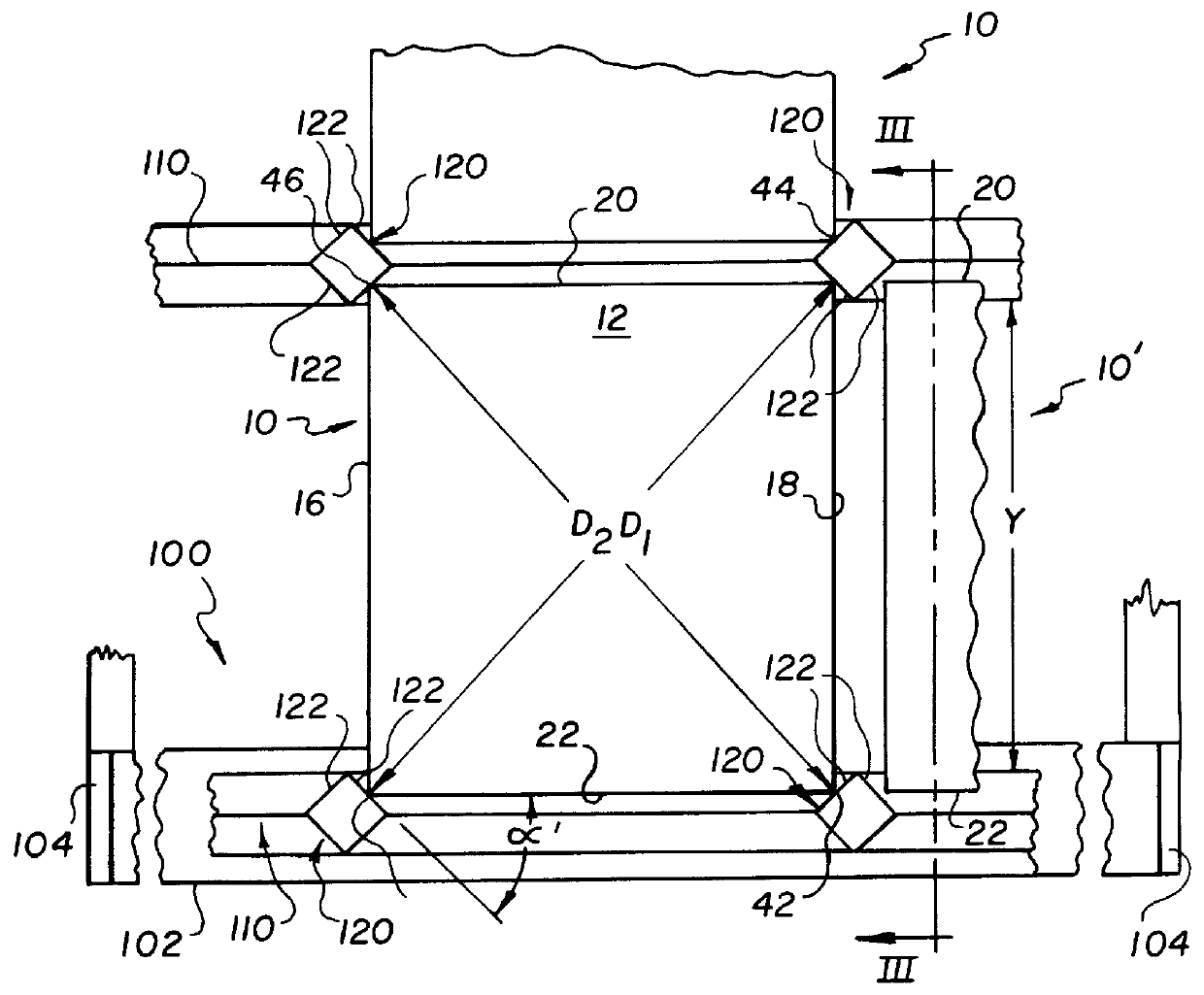

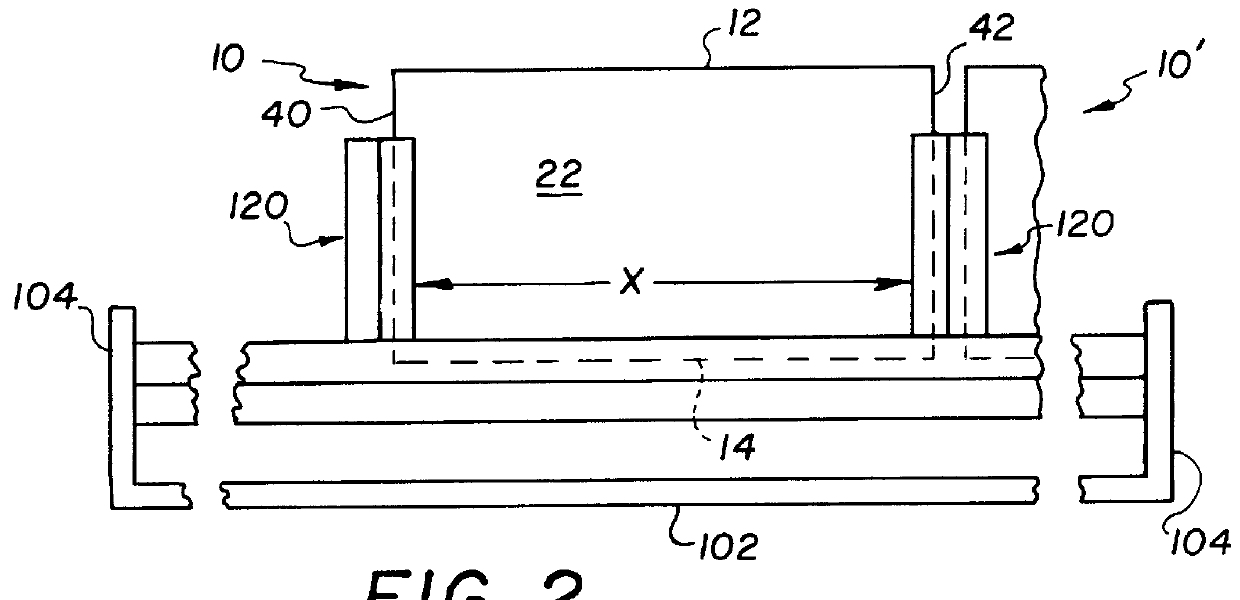

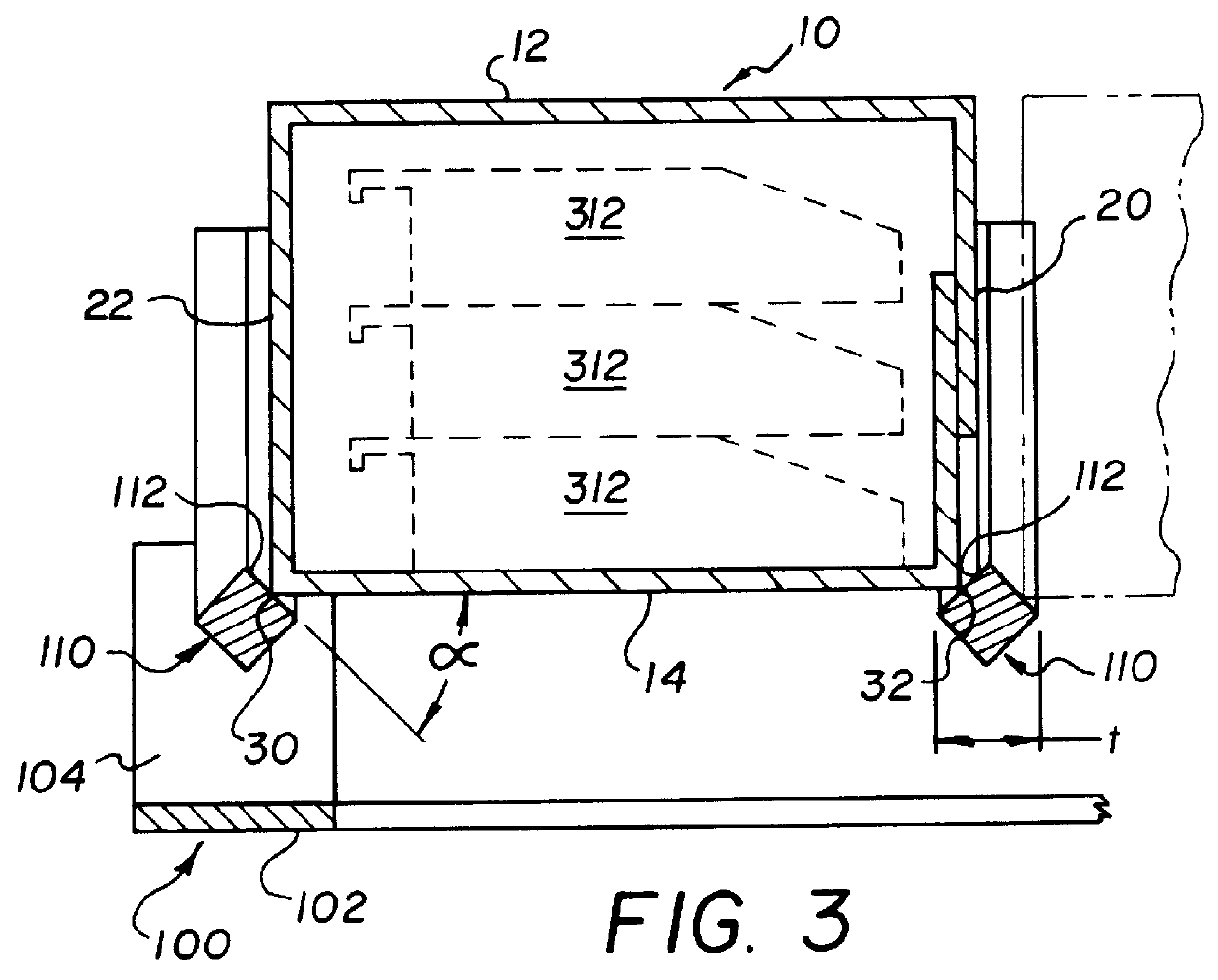

Method for dispensing a predetermined amount of film relative to load girth

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

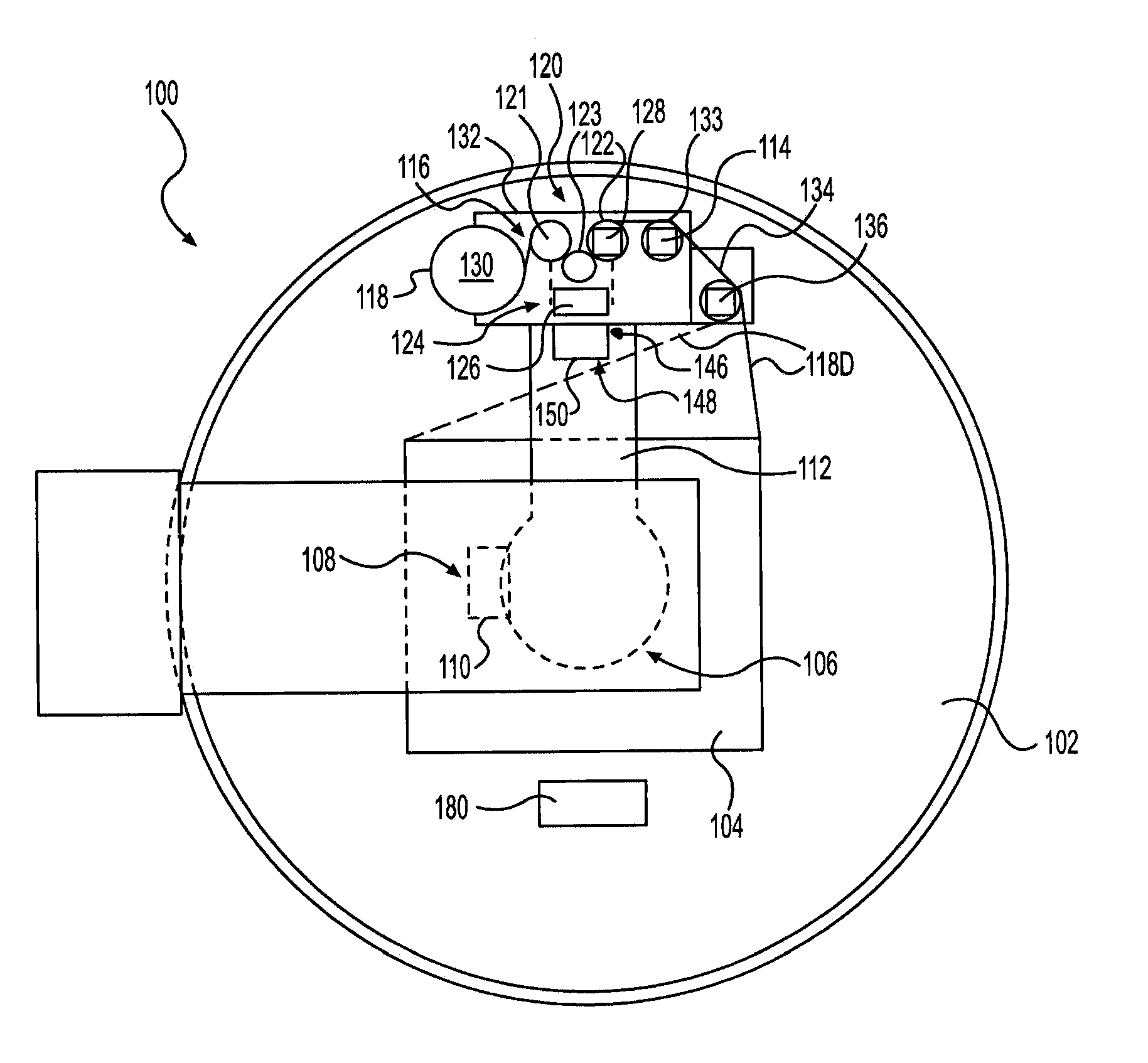

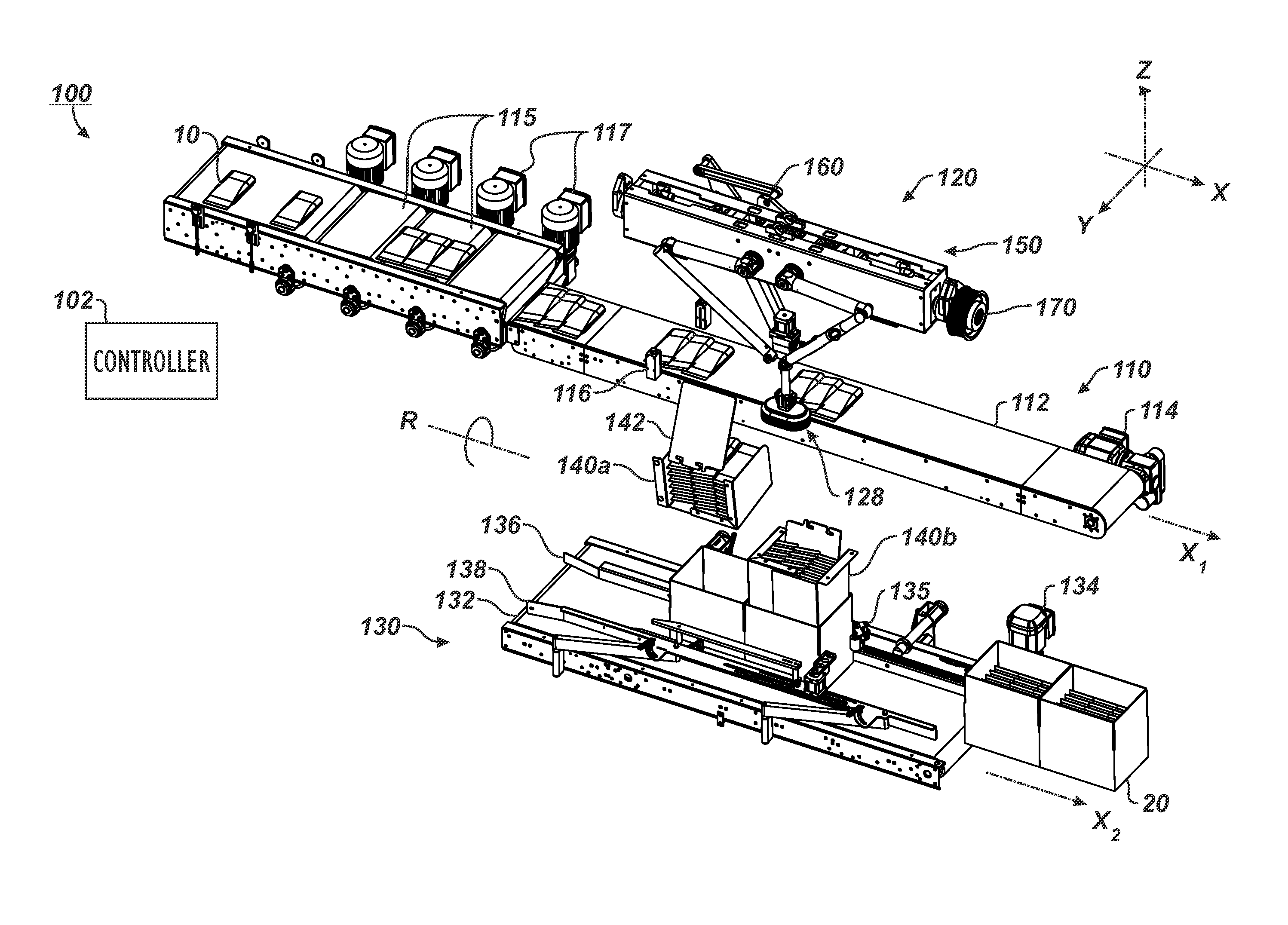

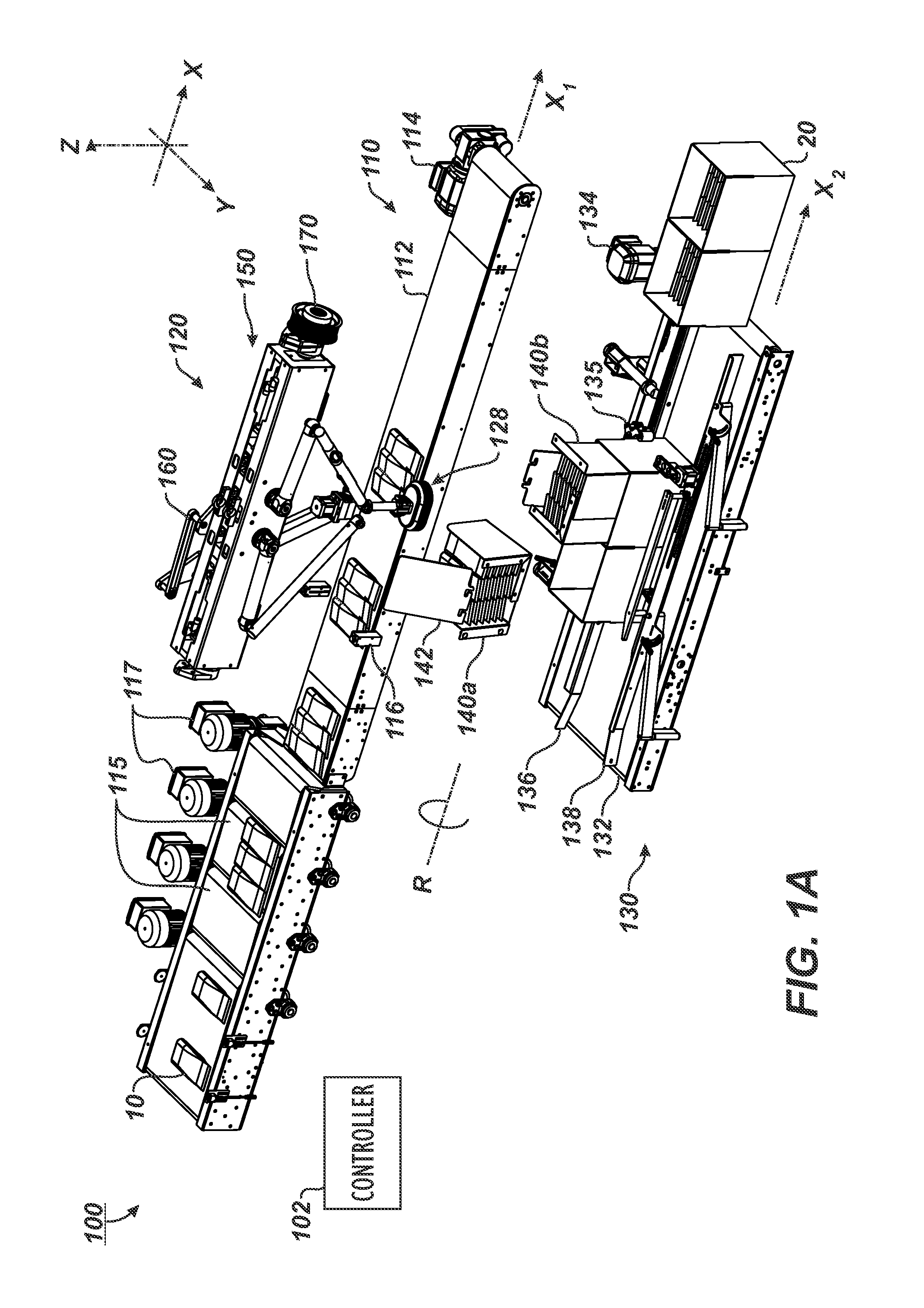

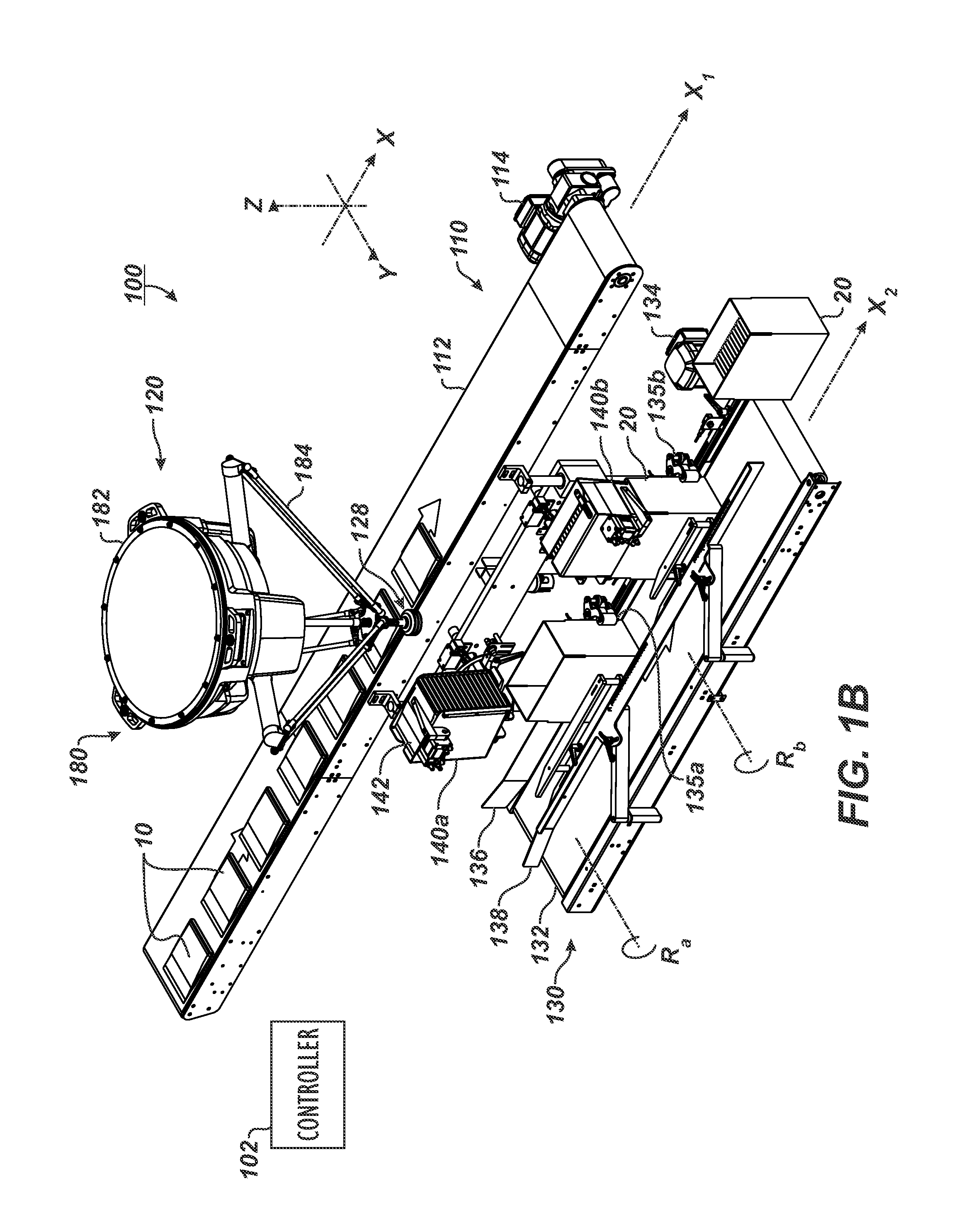

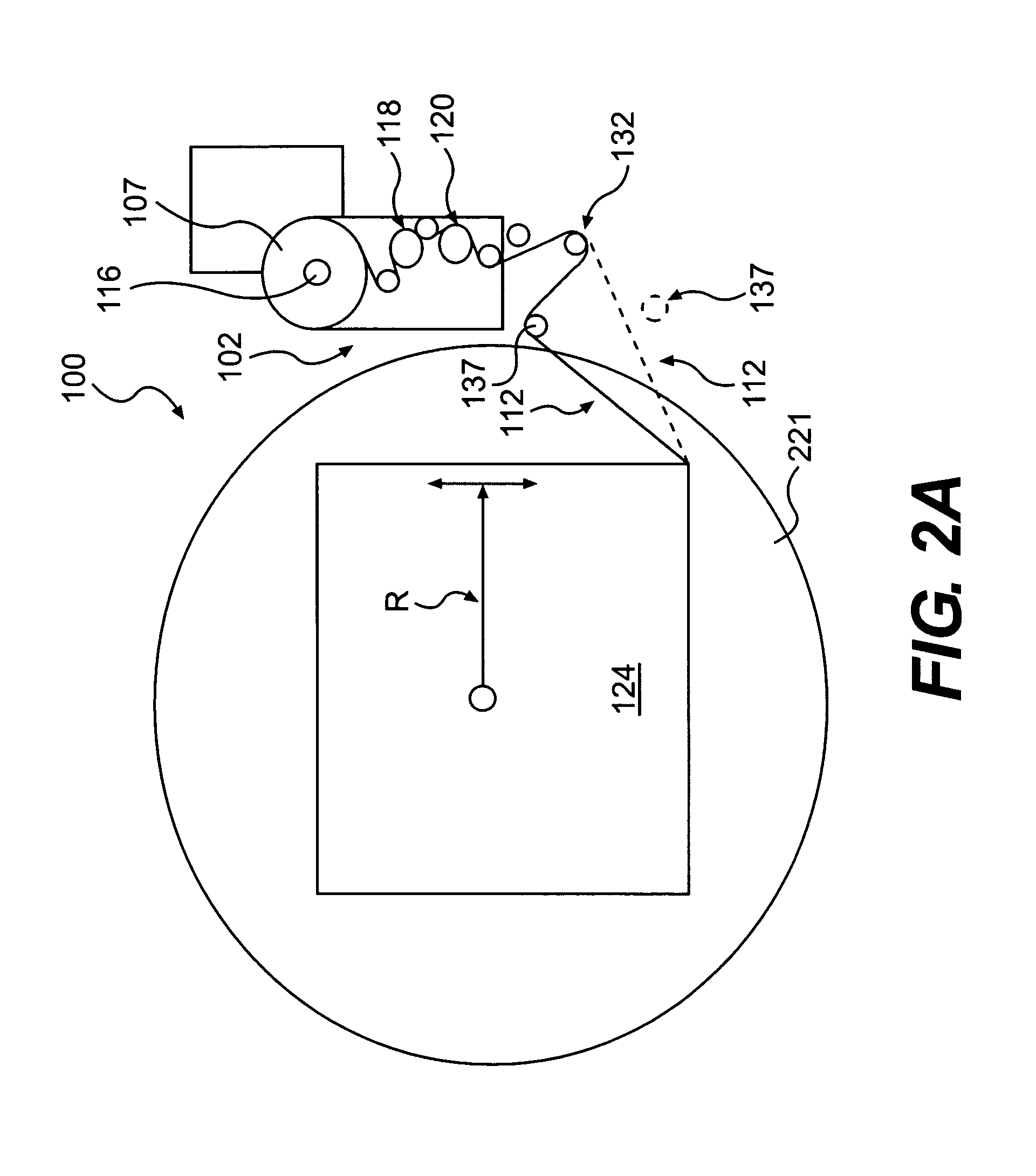

Demand based wrapping

ActiveUS20110131927A1Prestretching mechanismWeb rotation wrappingControl systemManufacturing engineering

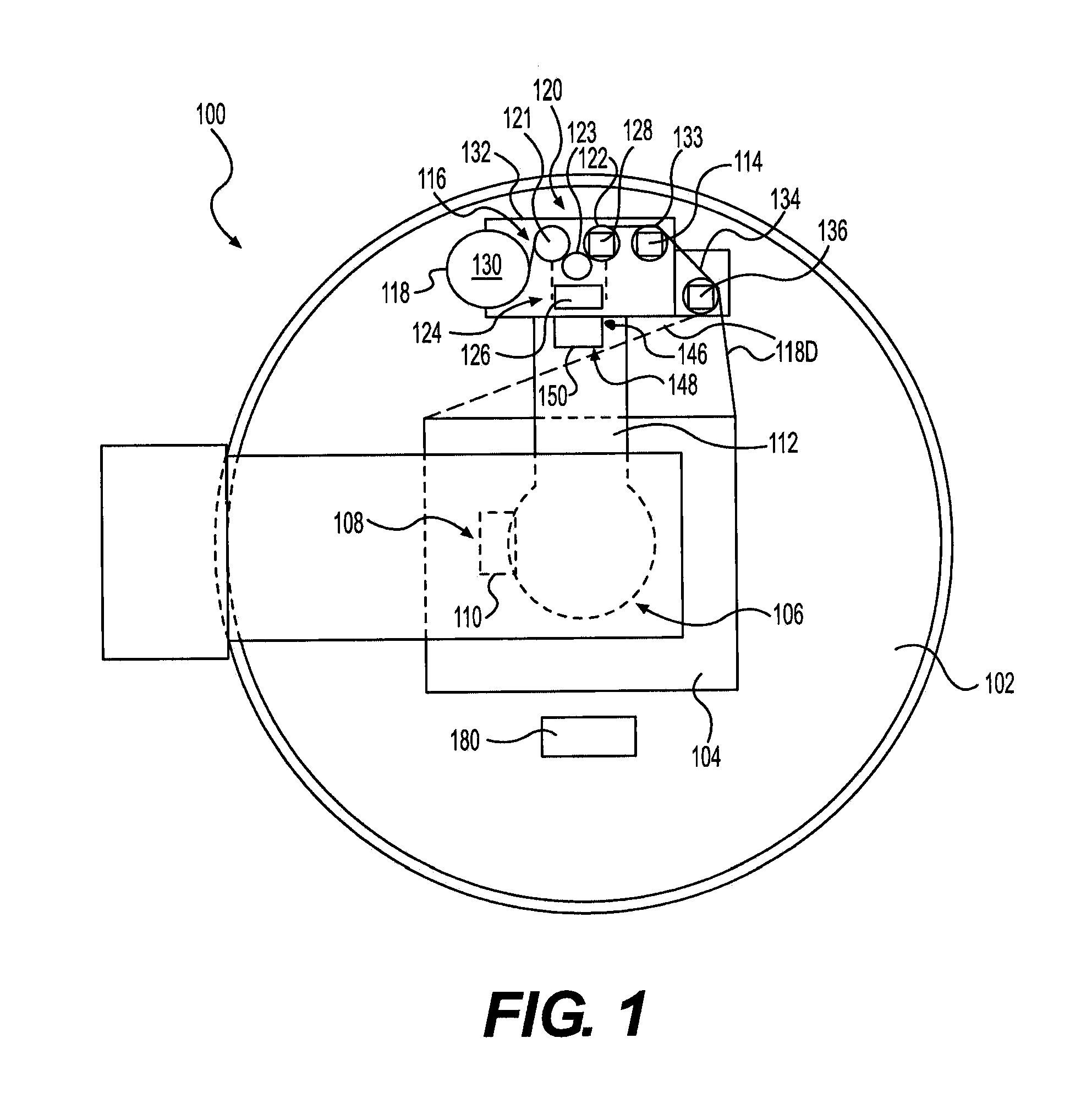

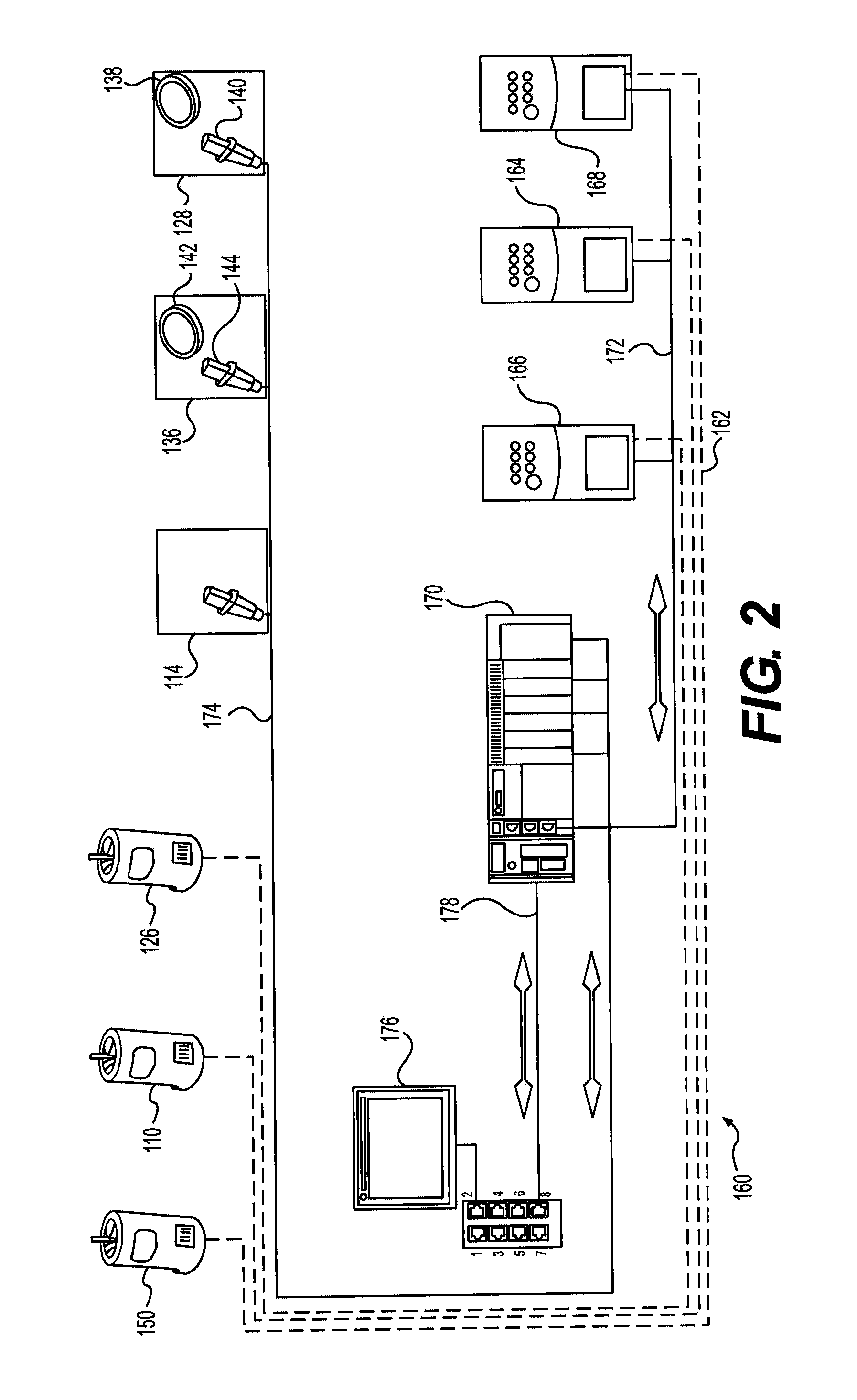

A control system for a wrapping apparatus may include a packaging material dispenser configured to dispense packaging material for wrapping a load. The control system may also include at least one sensor assembly configured to generate a signal based on instantaneous demand for packaging material at the load. The control system may further include a controller configured to control operation of the packaging material dispenser based at least in part on the signal.

Owner:LANTECH COM

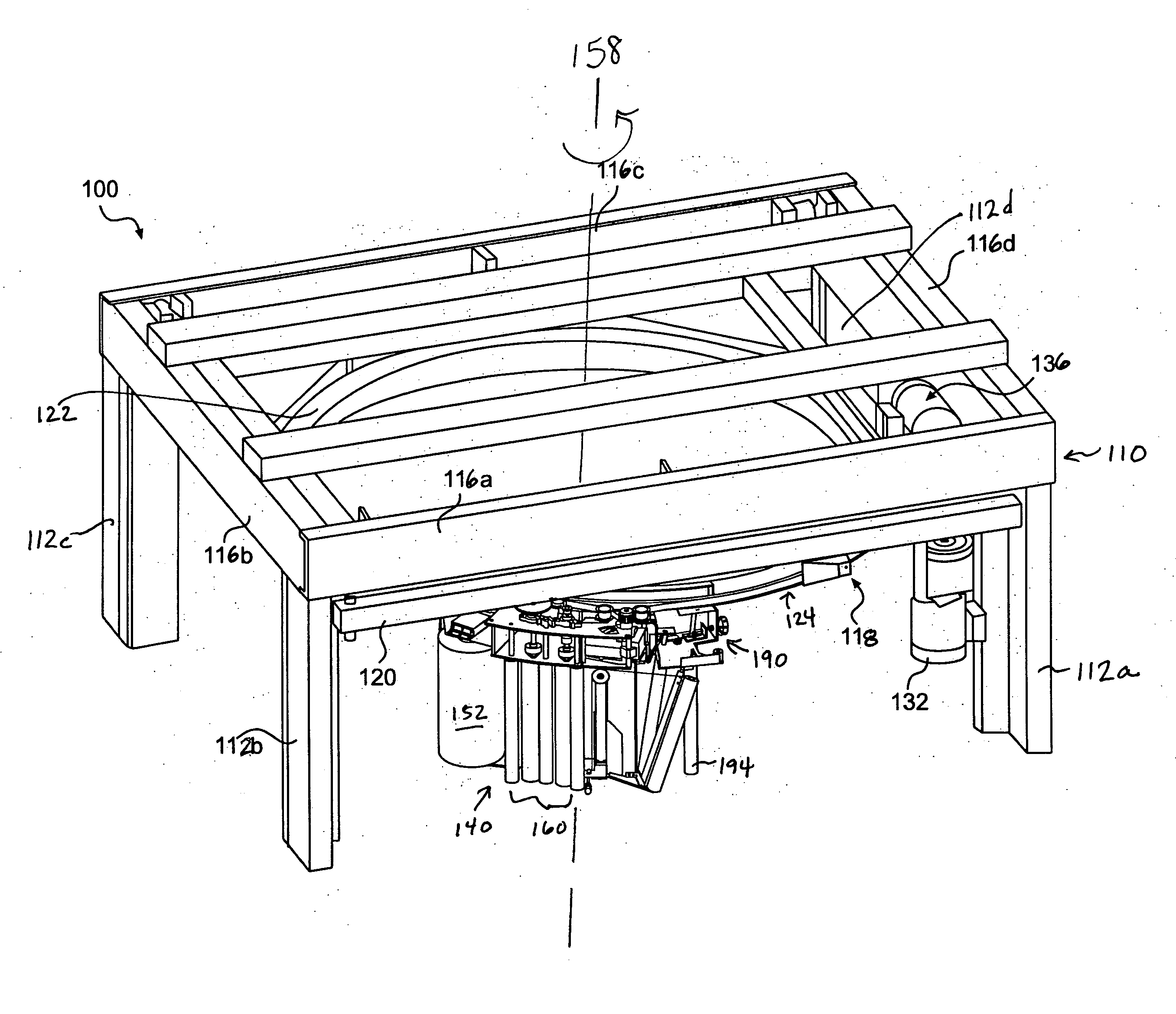

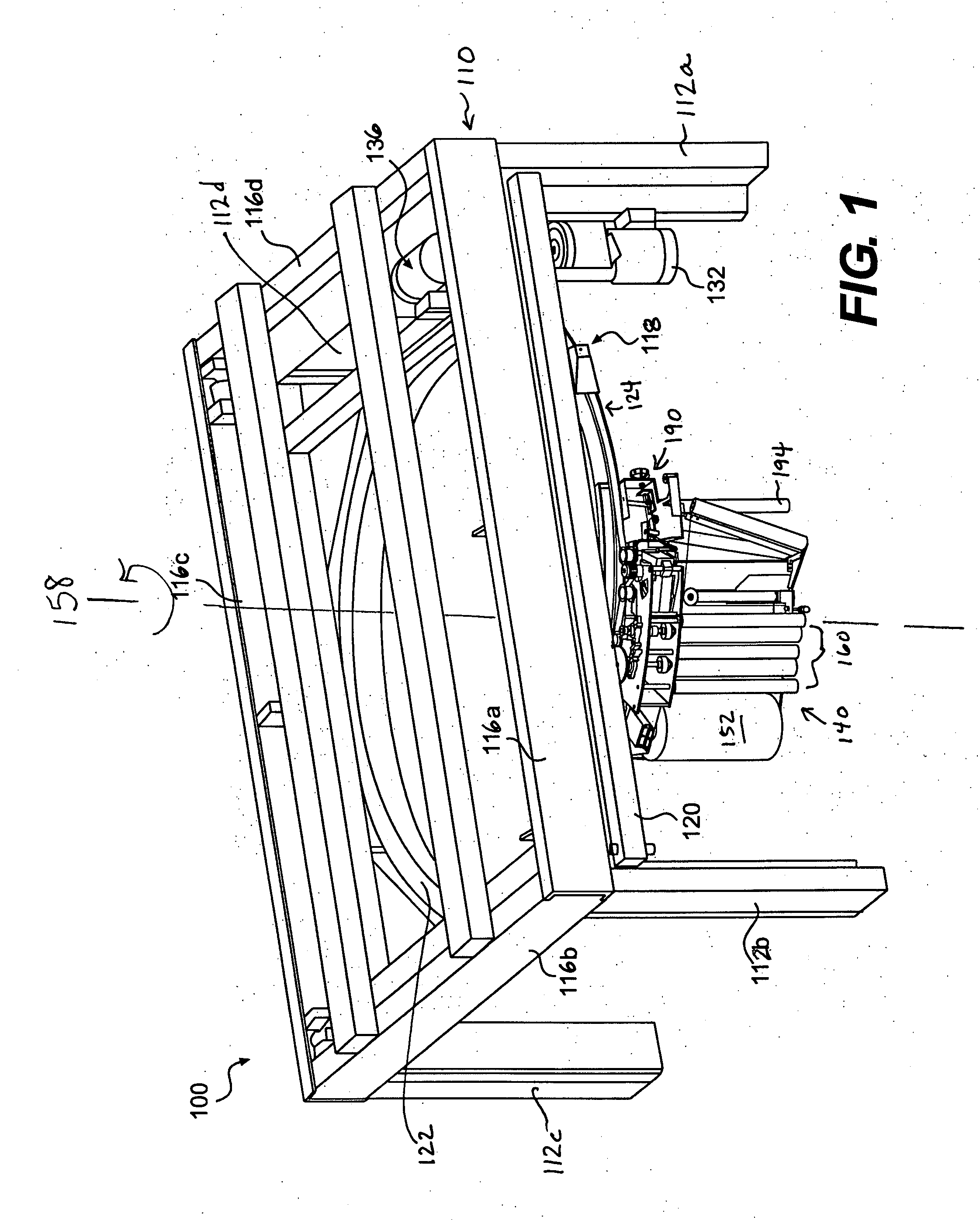

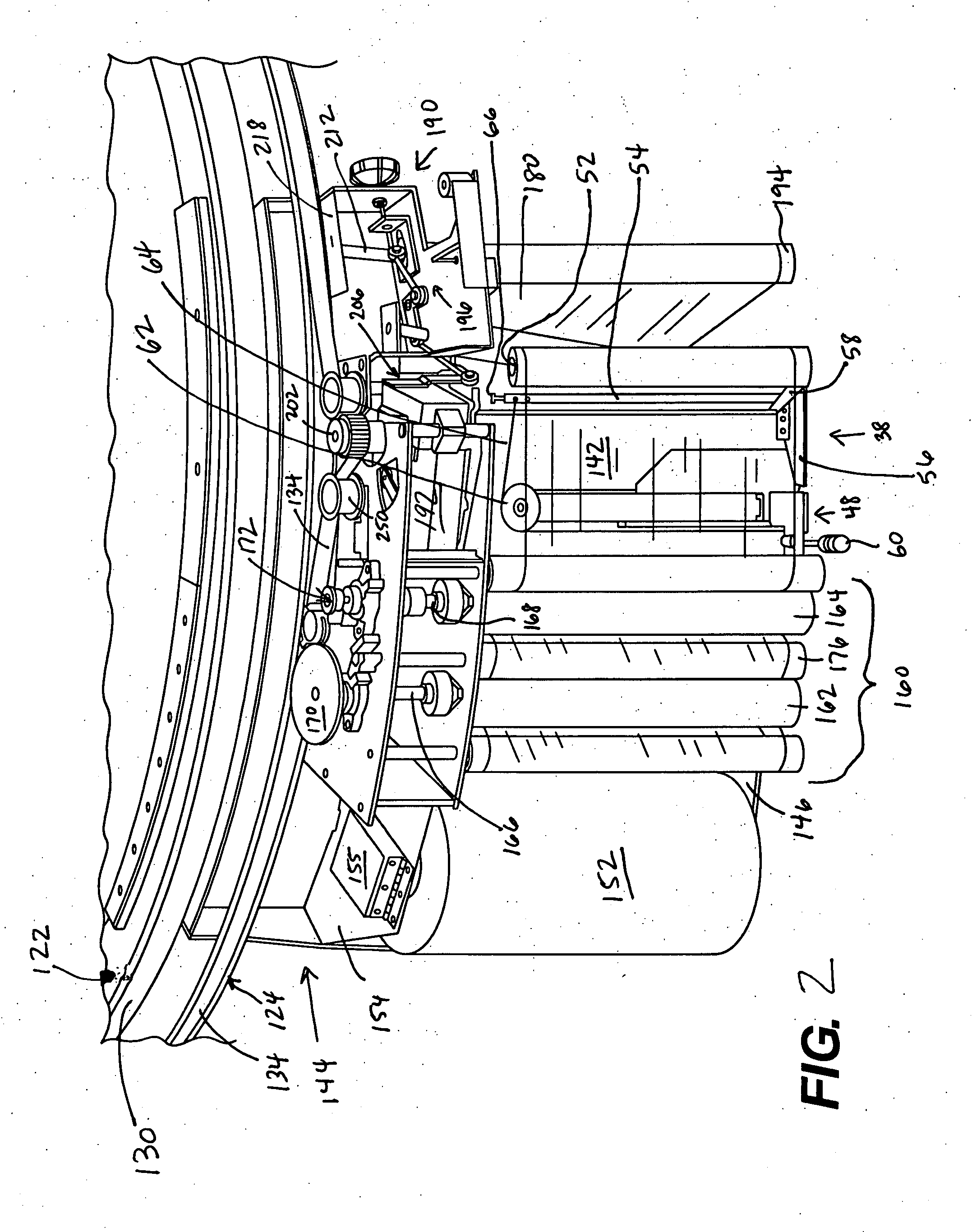

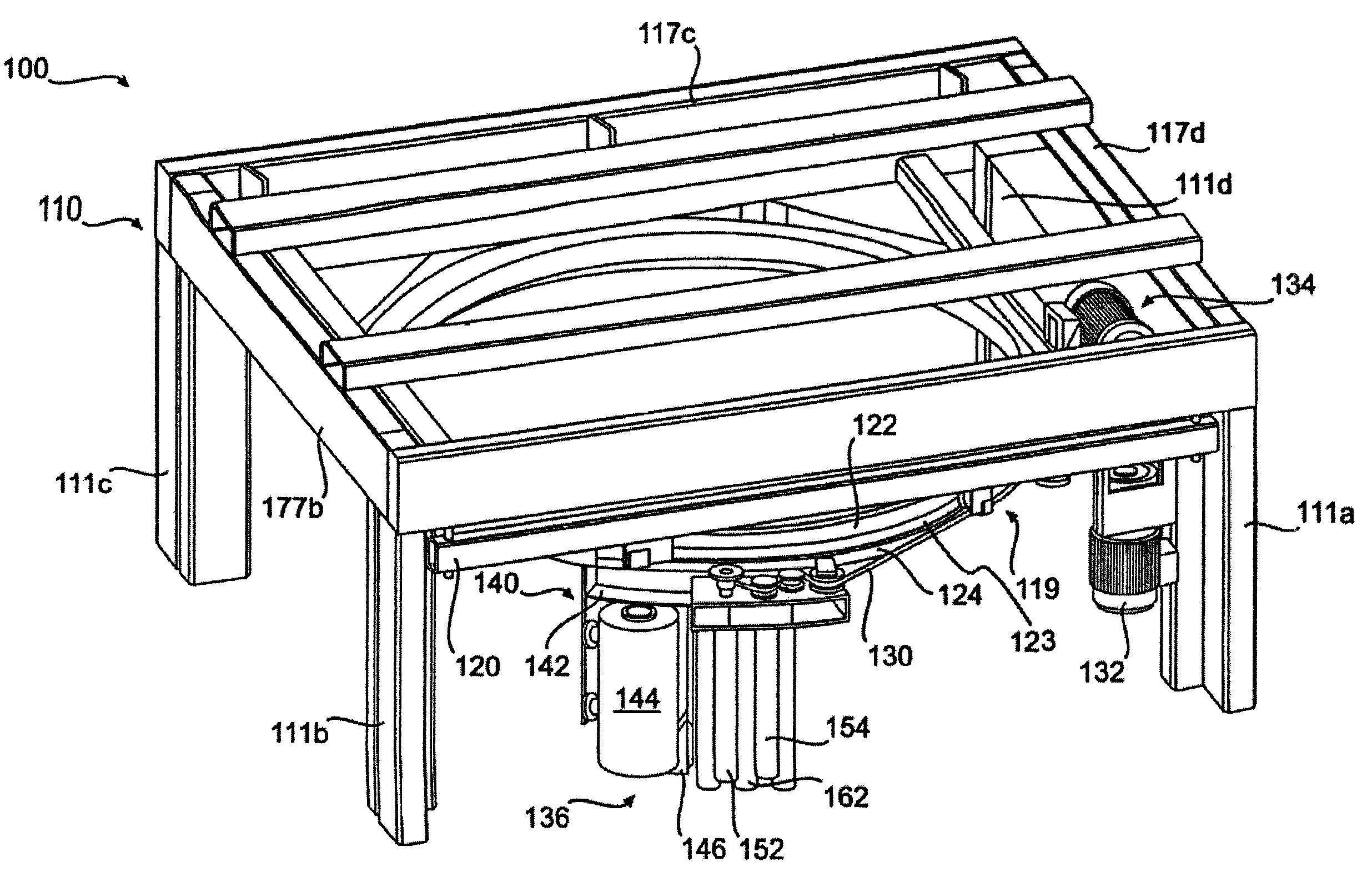

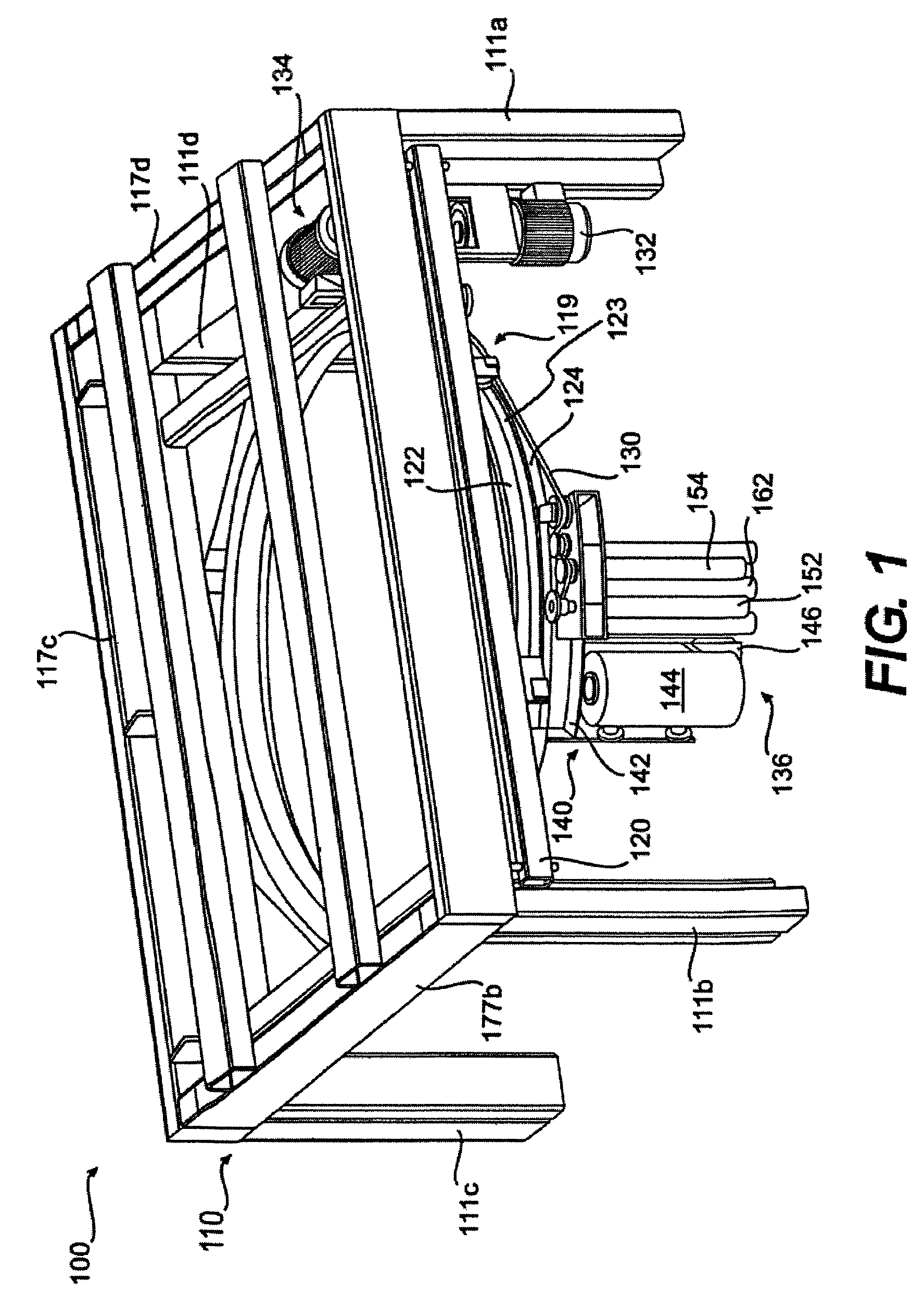

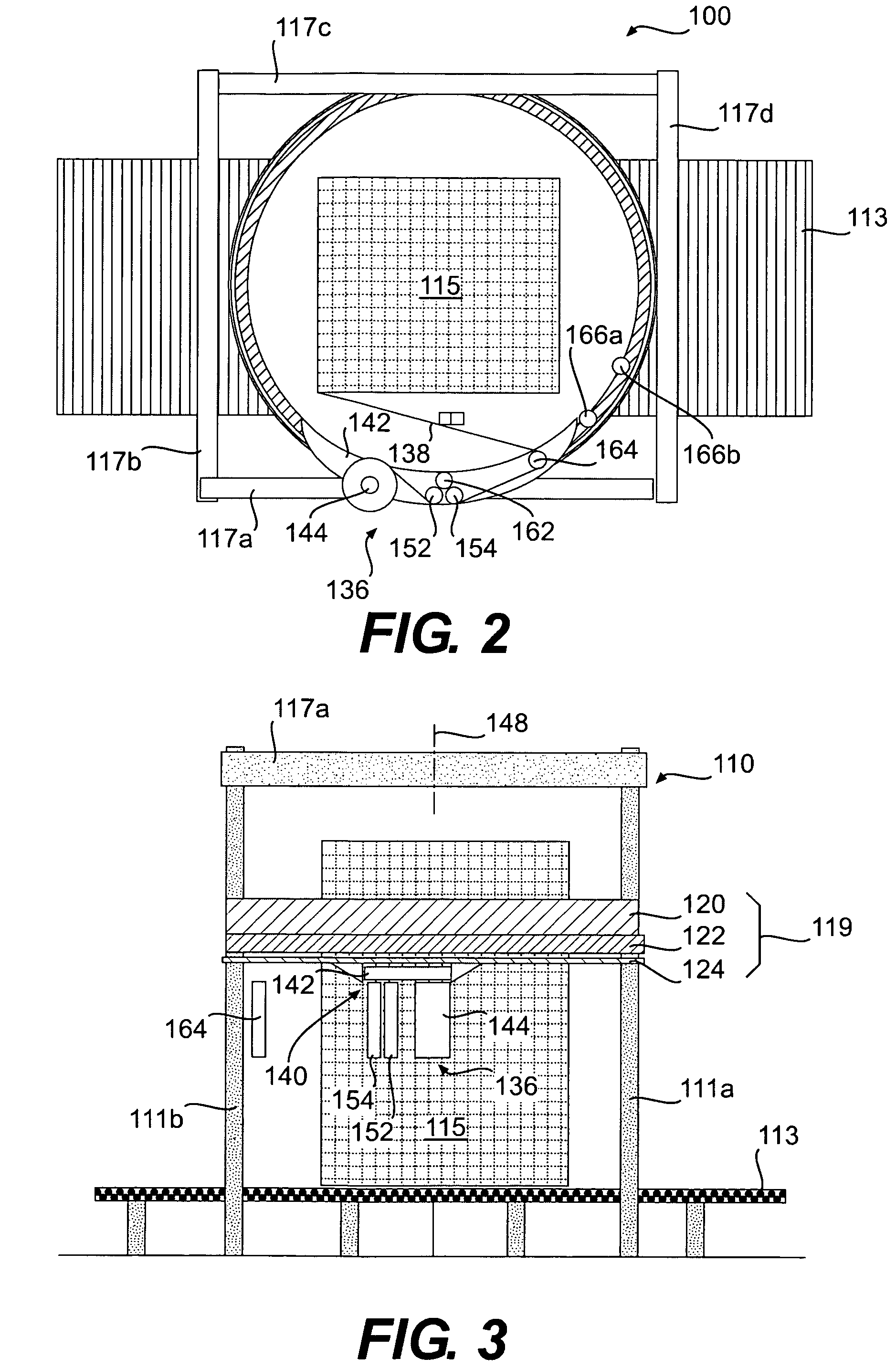

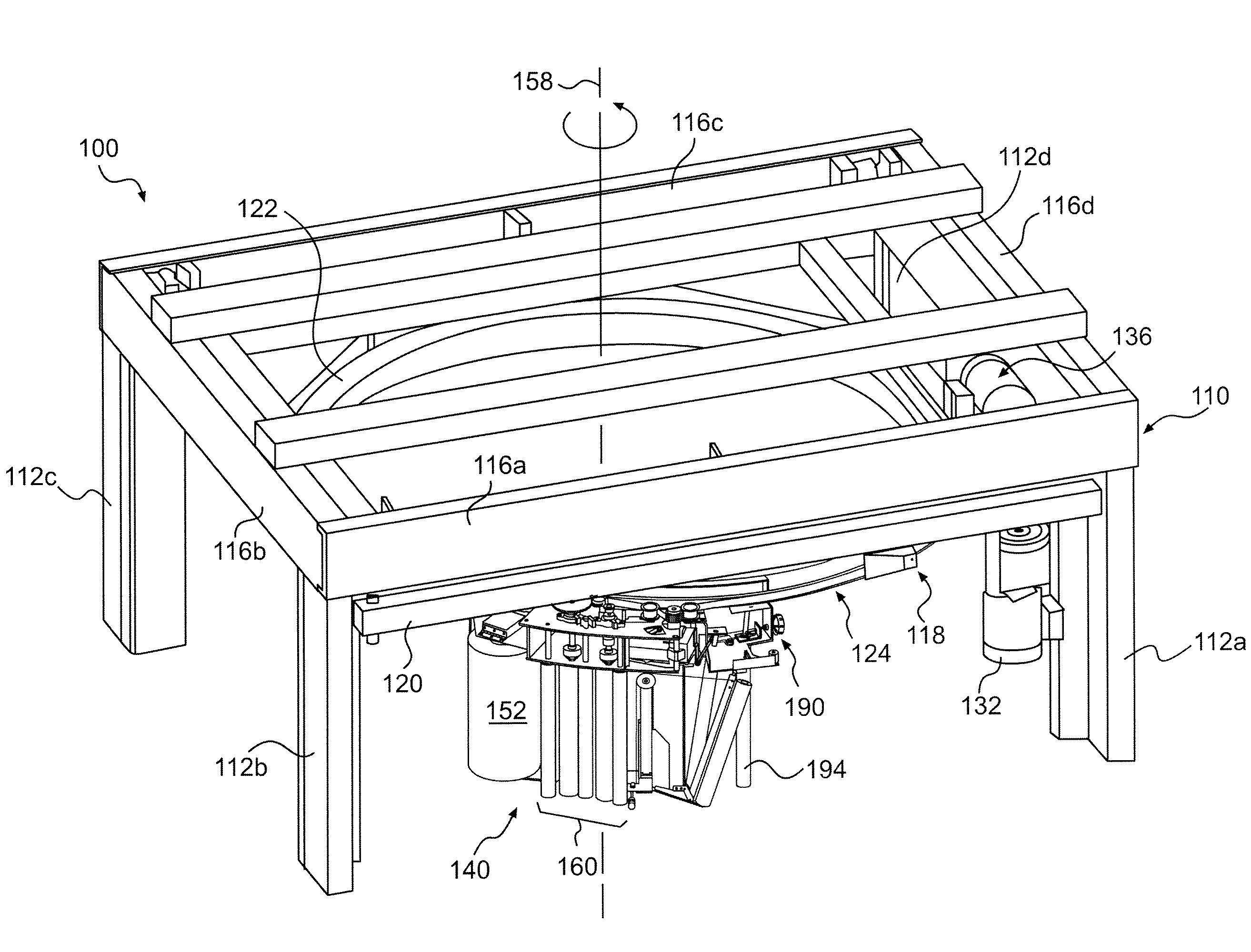

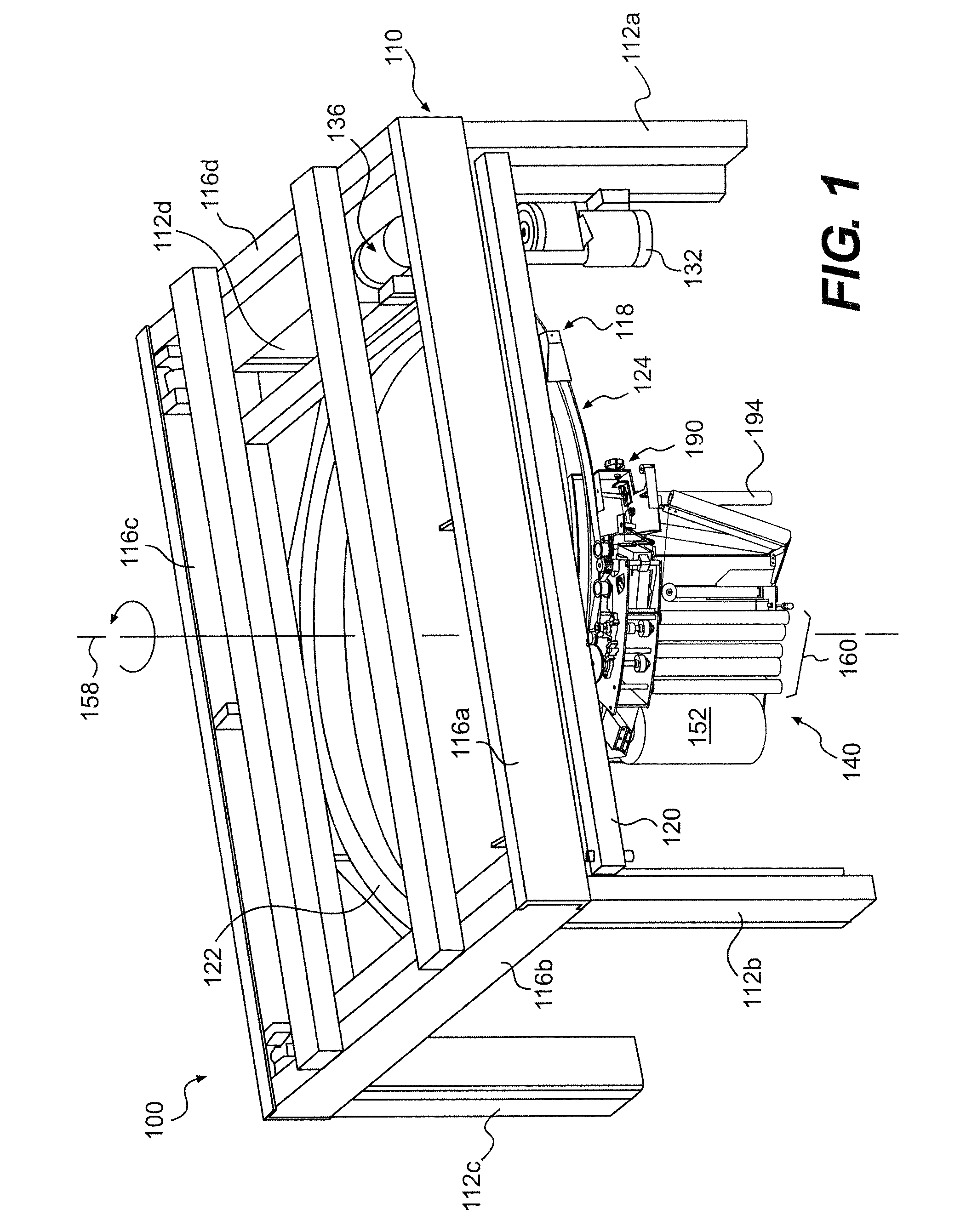

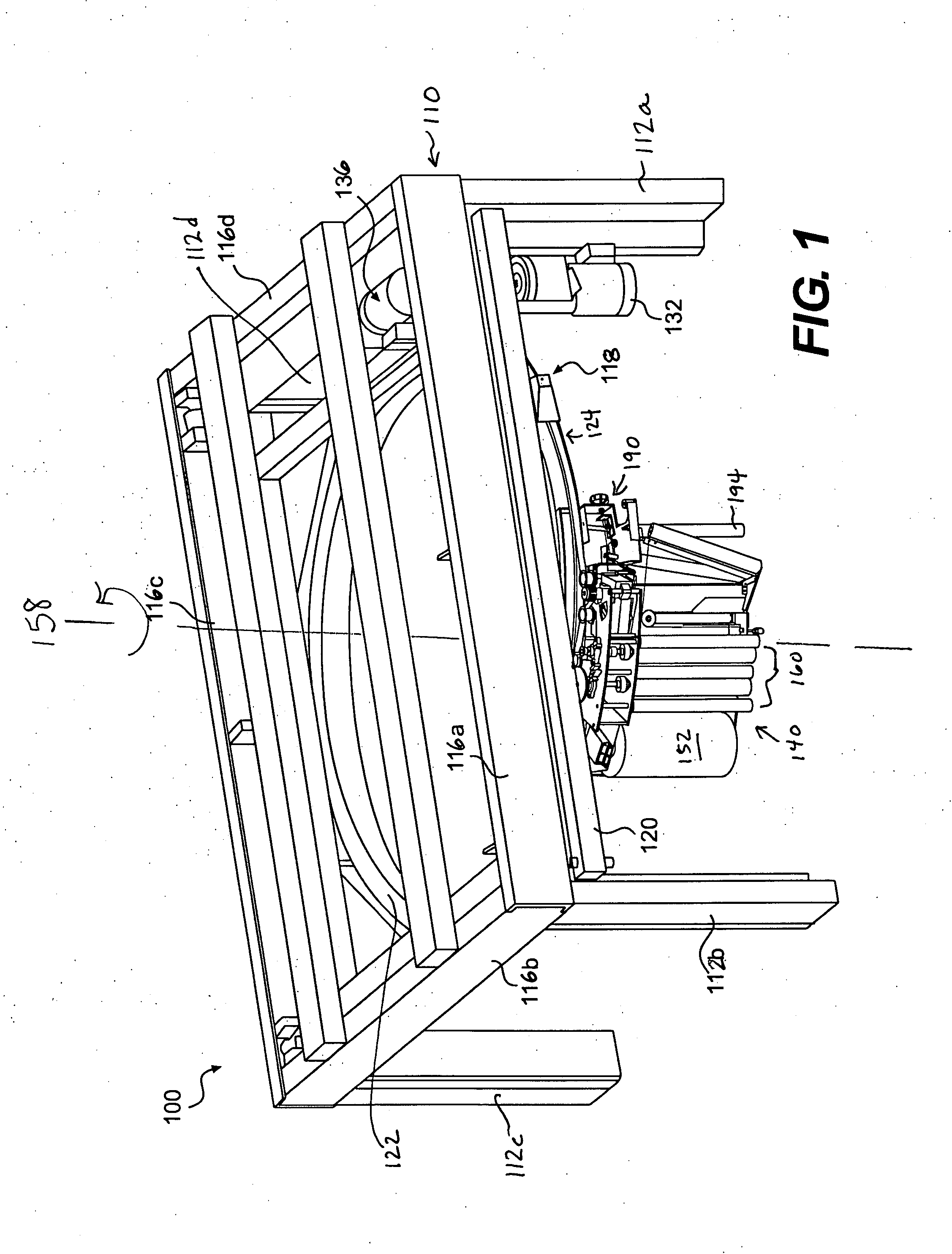

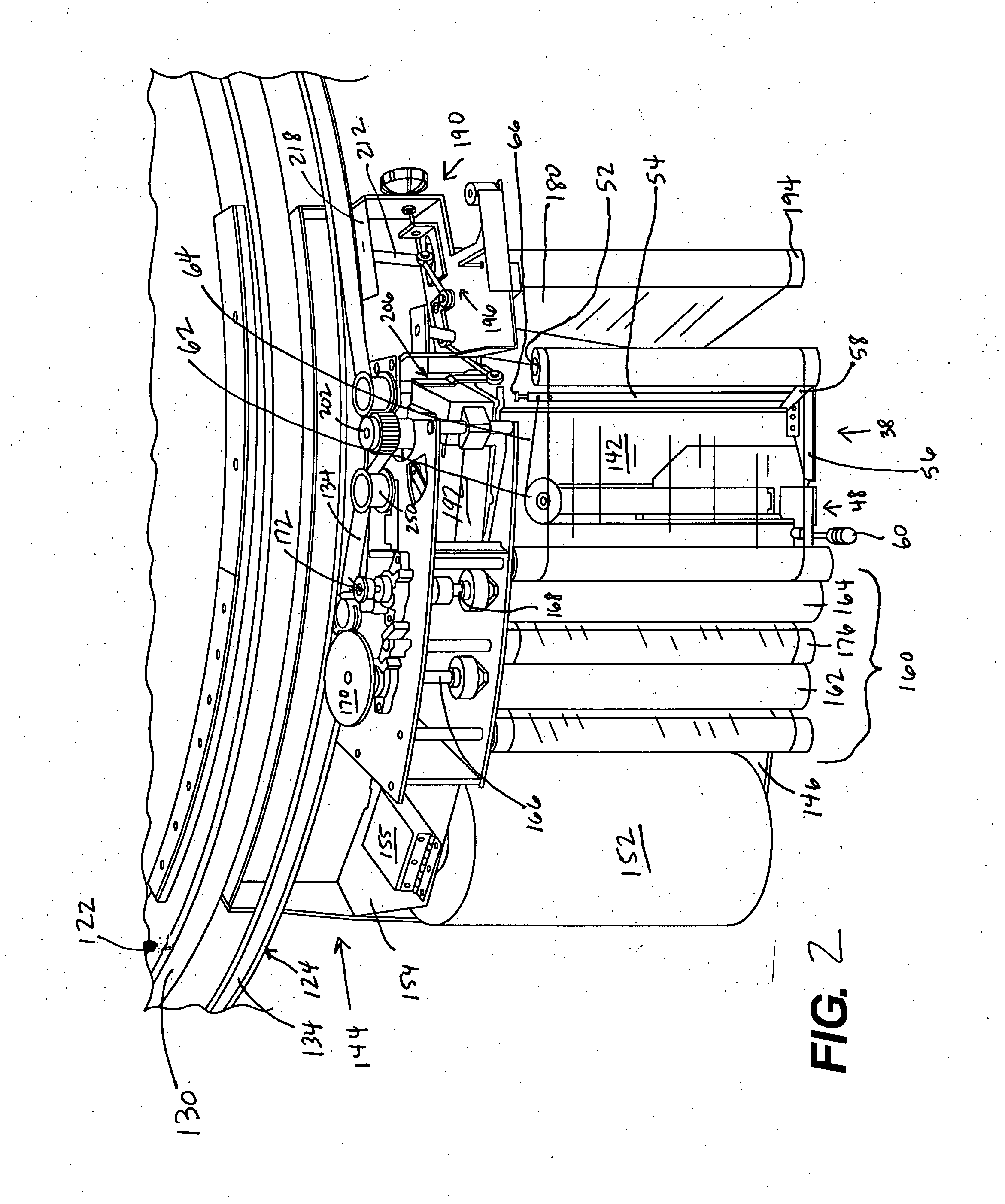

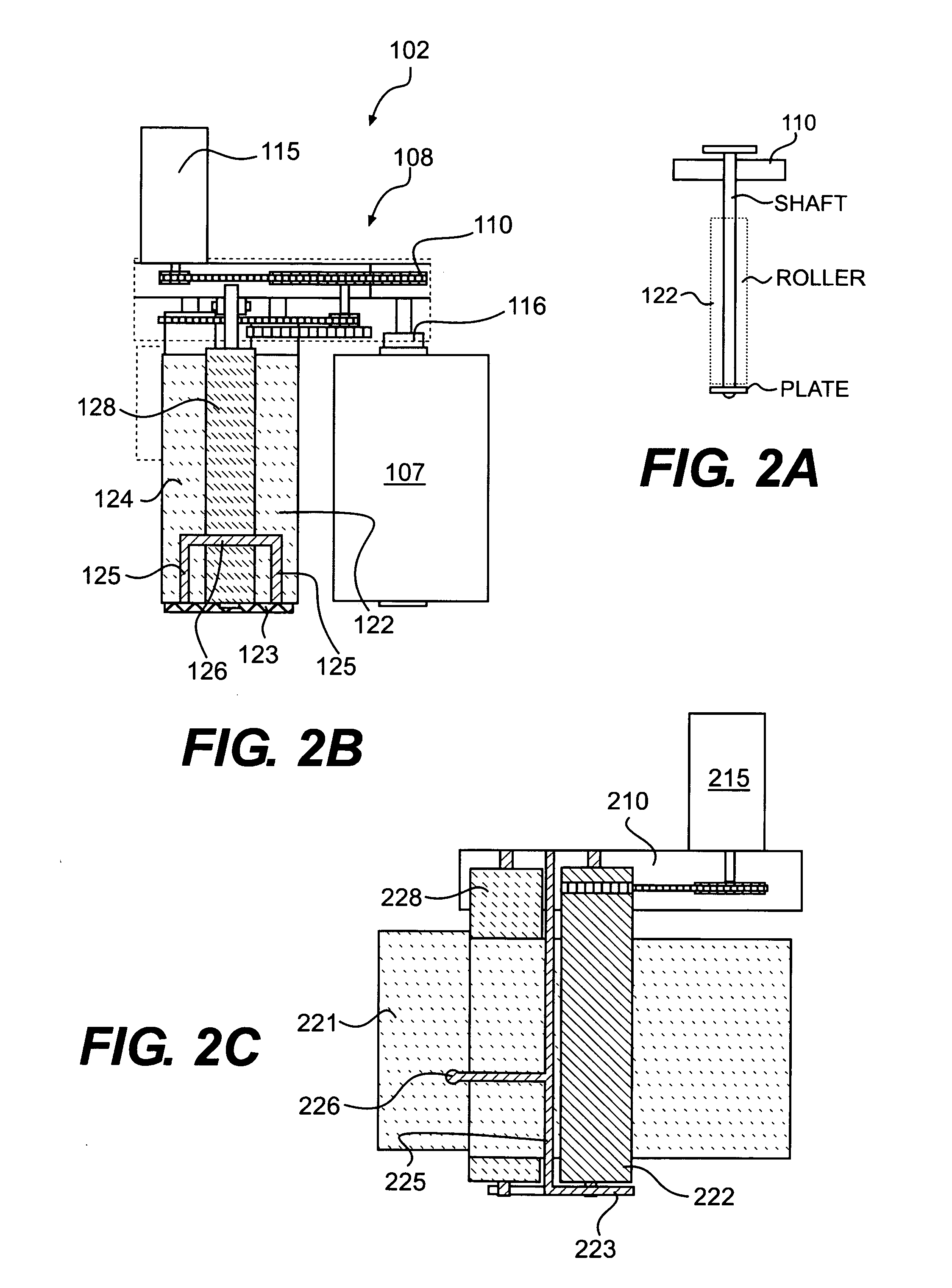

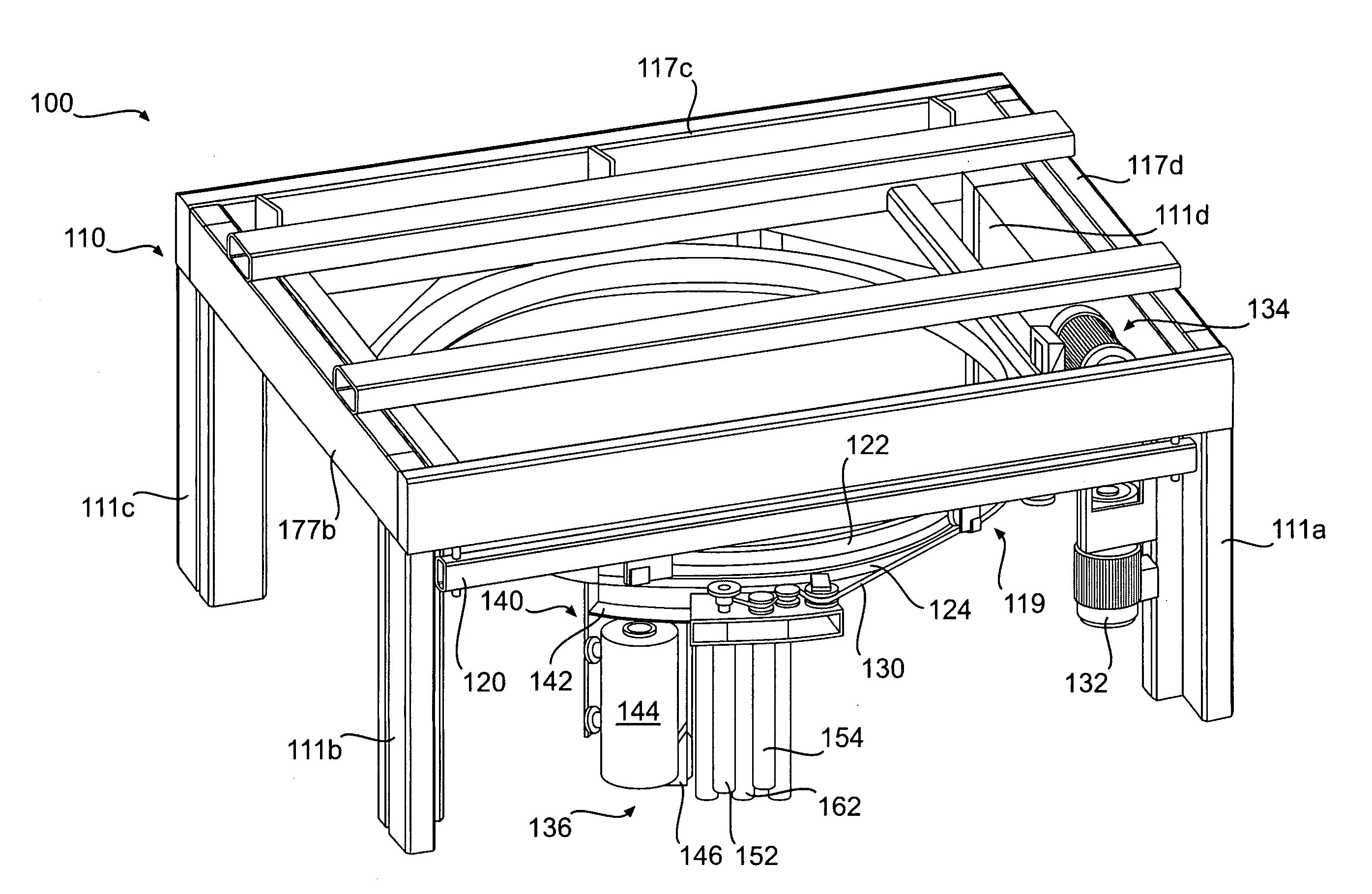

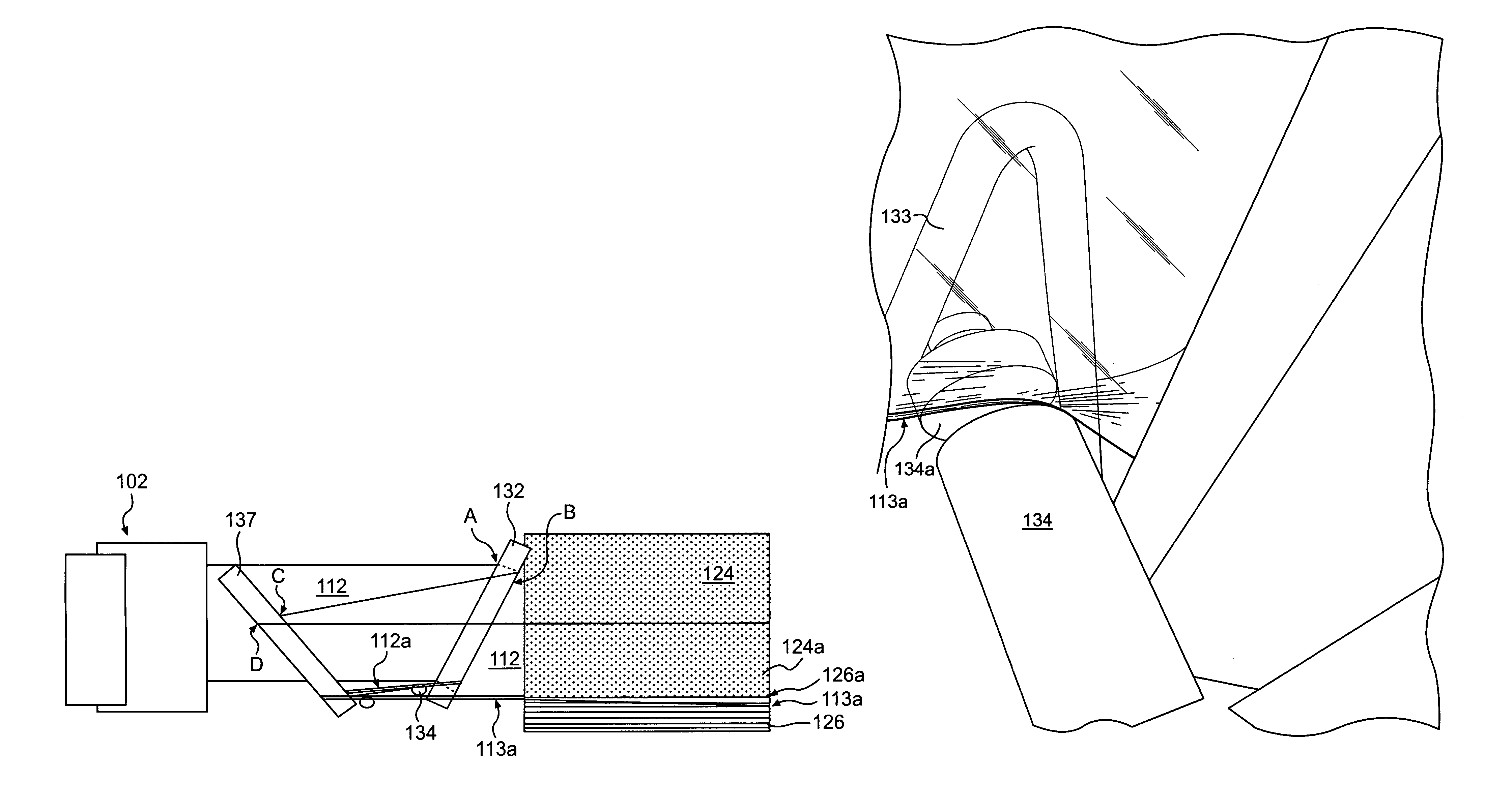

Wrapping apparatus including metered pre-stretch film delivery assembly and method of using

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

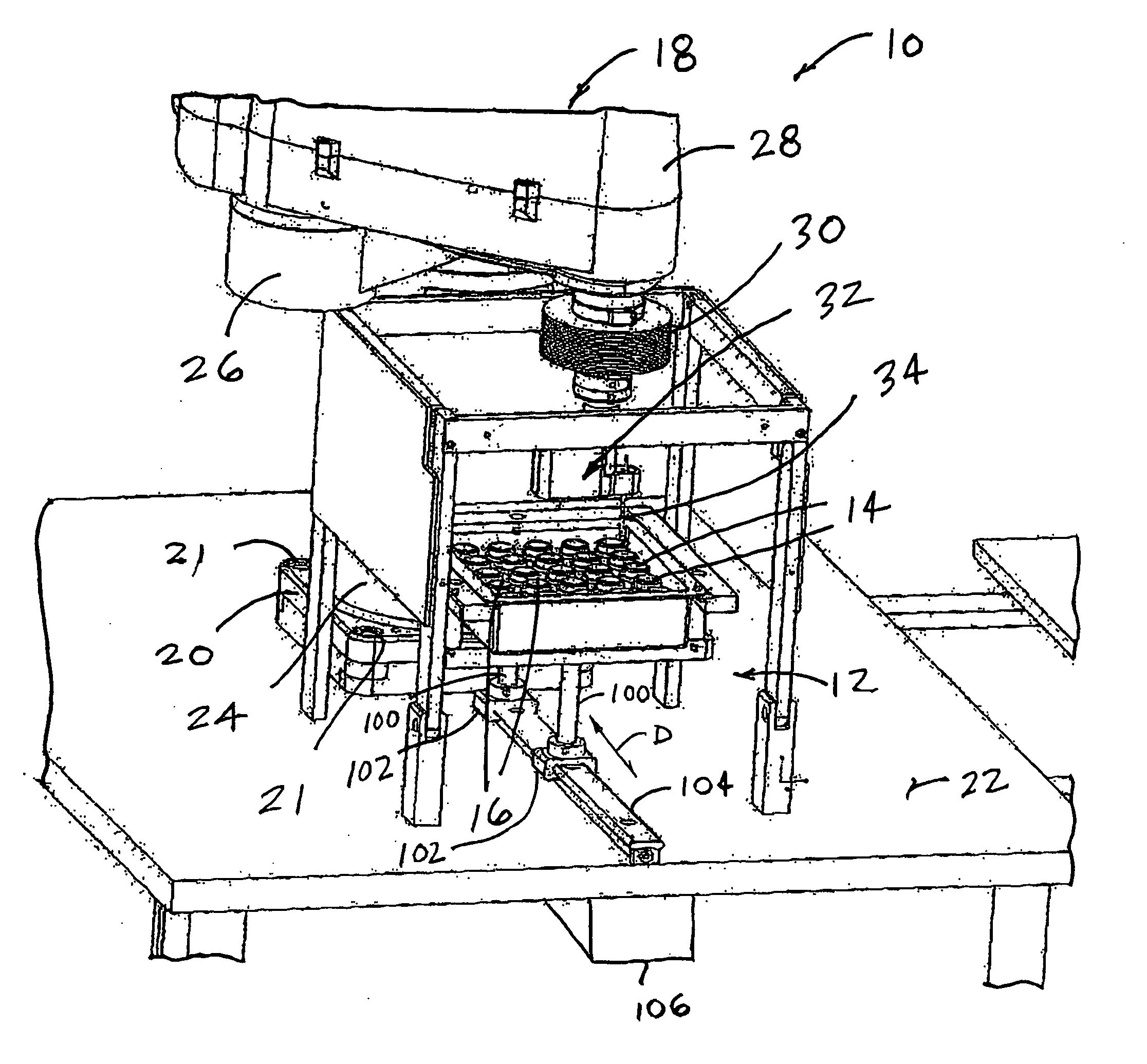

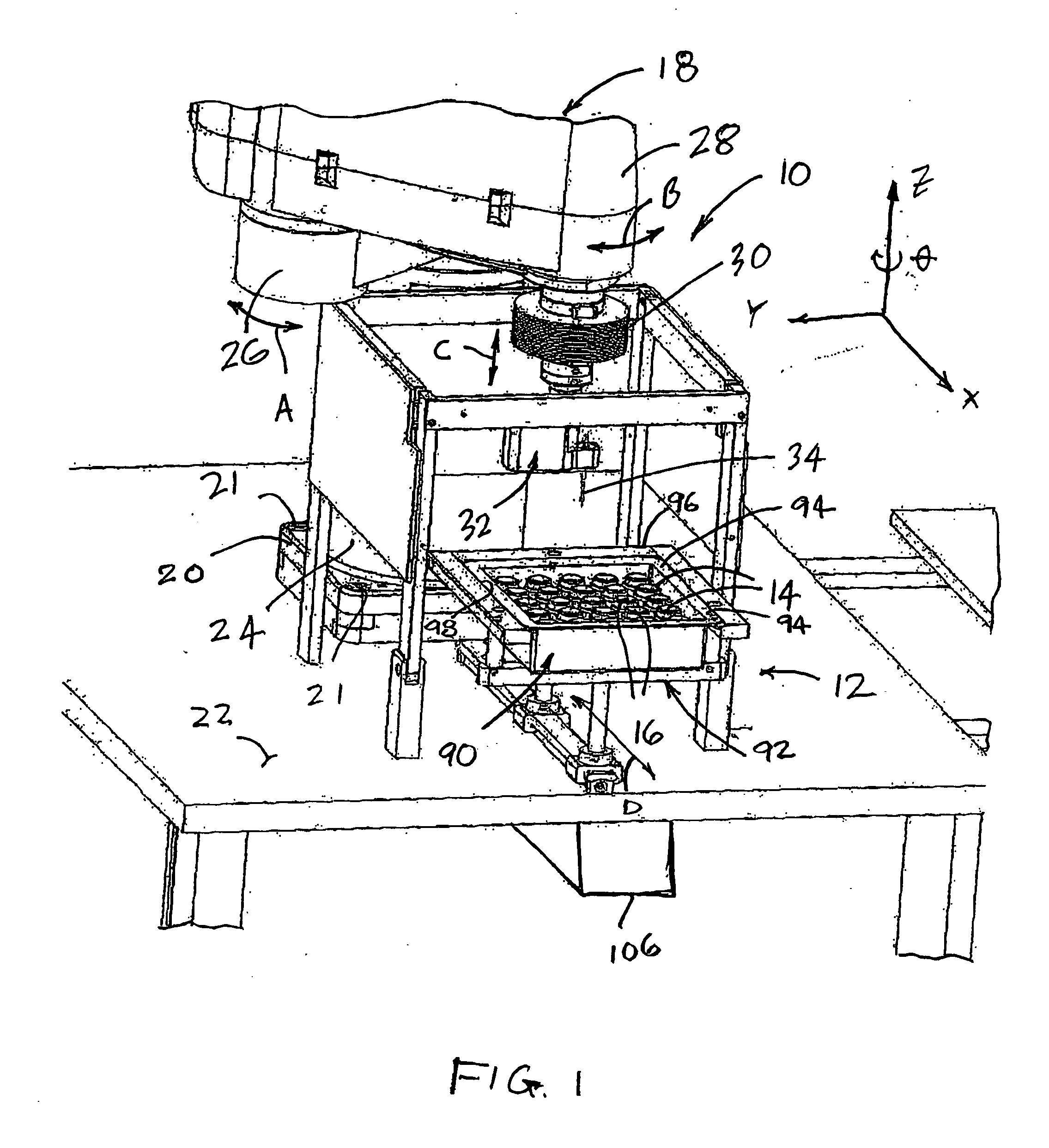

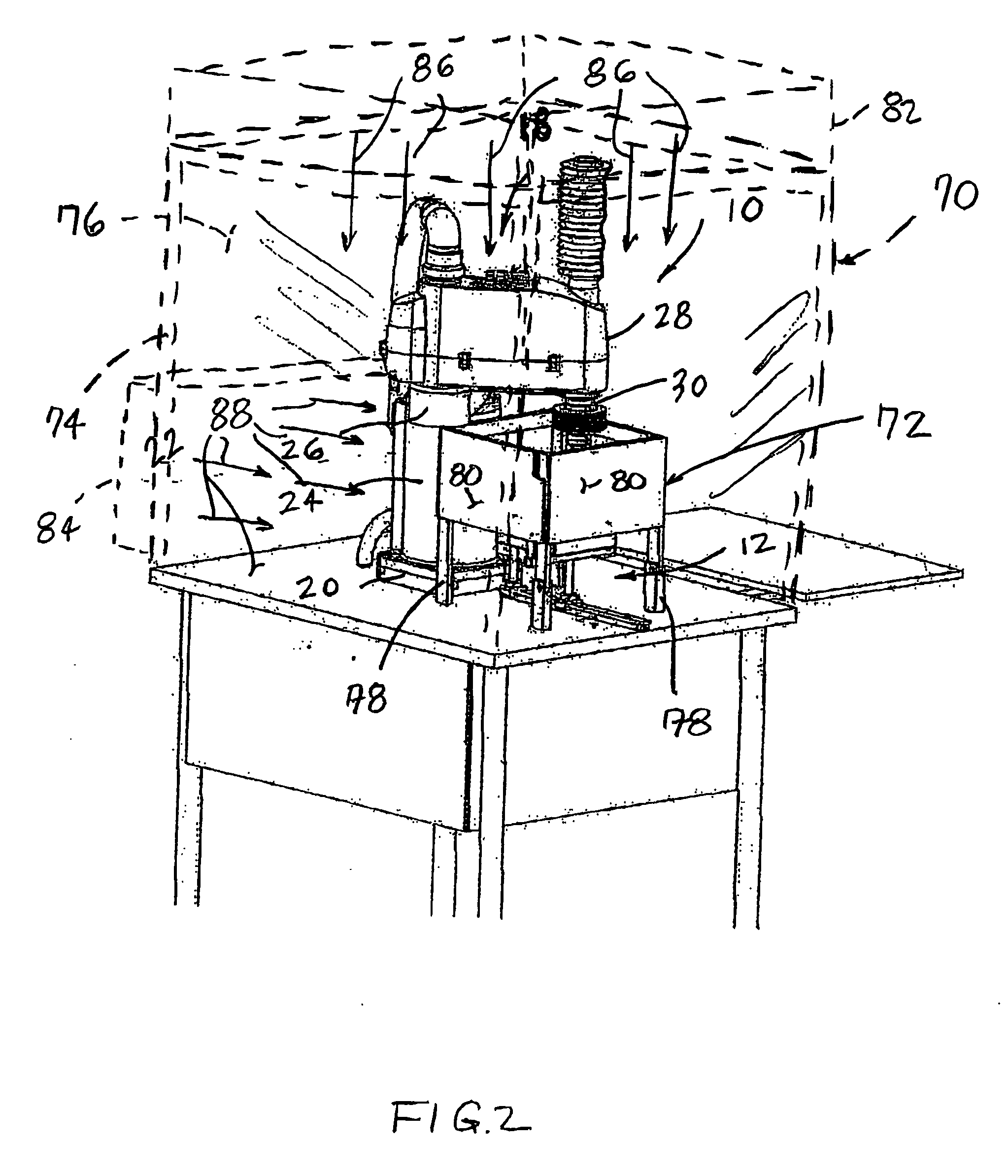

Case packing system having robotic pick and place mechanism and dual dump bins

ActiveUS8997438B1Easy to handleEliminate slippageProgramme-controlled manipulatorSolid materialEngineeringMechanical engineering

A robotic case packing system loads articles from one conveyor into containers on another conveyor using a robotic pick and place mechanism and a set of pivoting bins. A controller moves the robotic mechanism in first picking movements to pick and place articles from the conveyor into the first bin. Once the first bin is full, the controller pivots the first bin to allow the articles stacked in the first bin to be loaded into a container held below. While the first bin is pivoting, the controller moves the robotic mechanism to pick and place articles from the conveyor into the second bin. The process repeats with the controller pivoting the second bin during the picking movements used to fill the first bin and vice versa.

Owner:FALLAS DAVID M

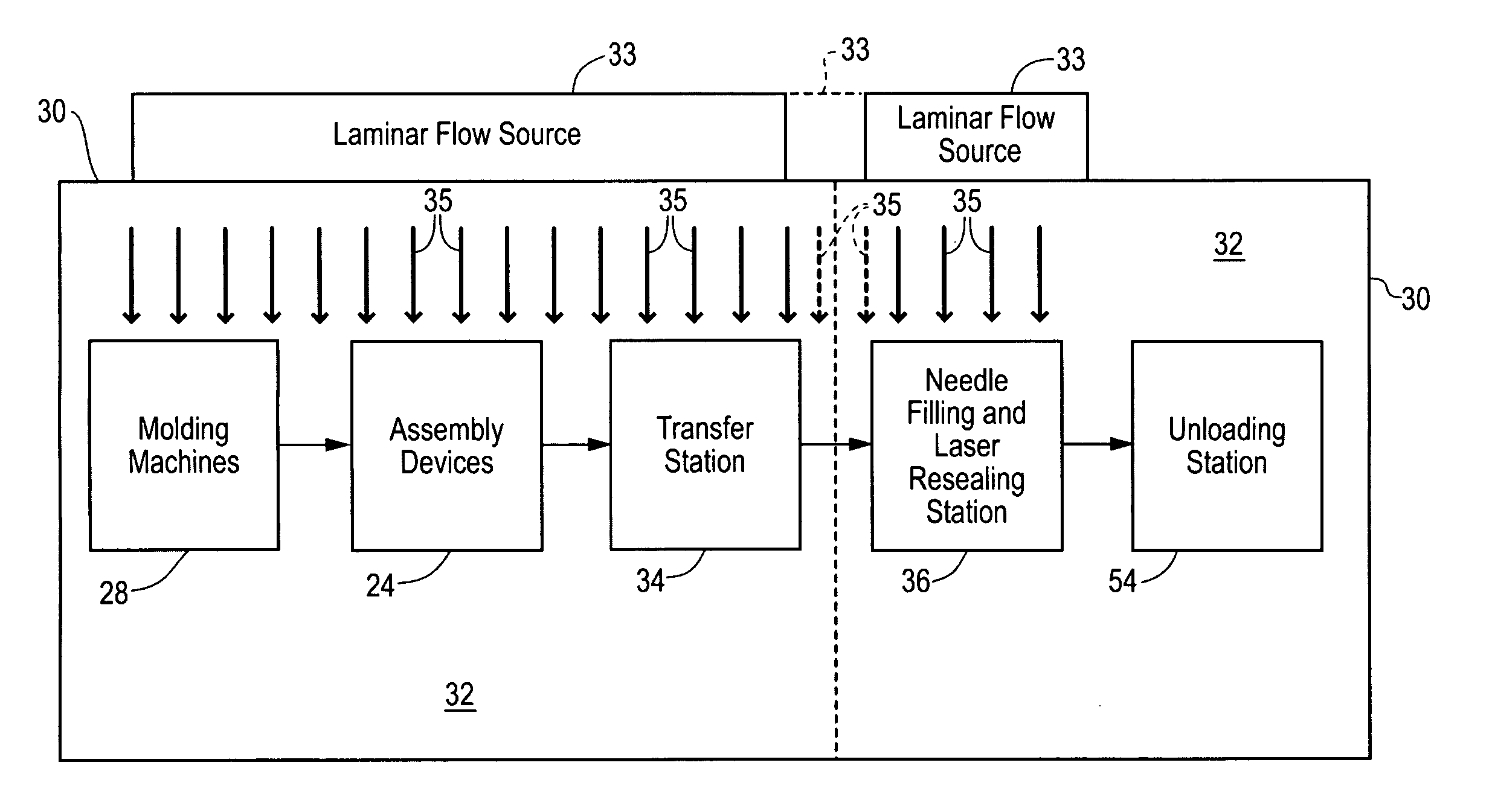

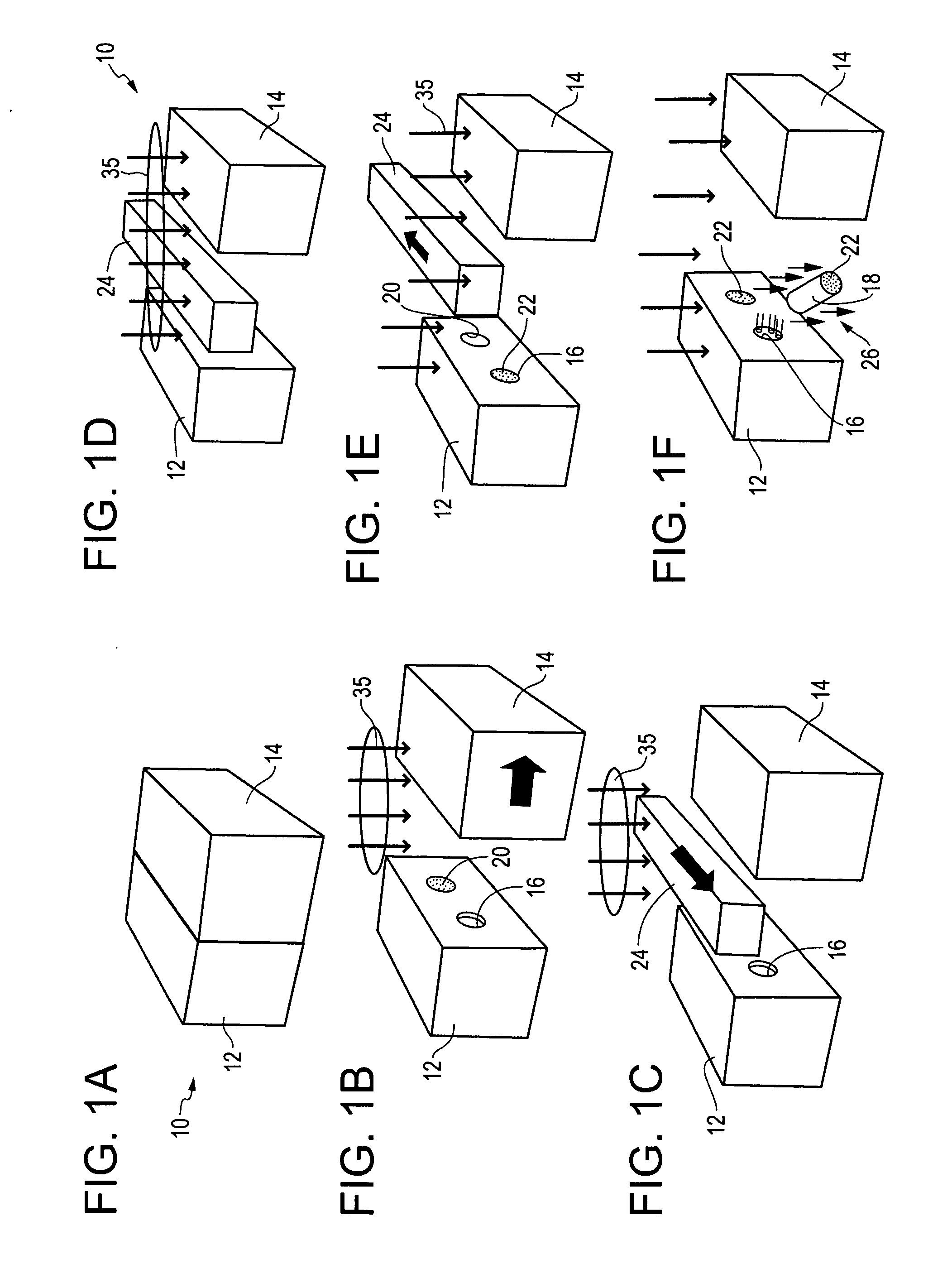

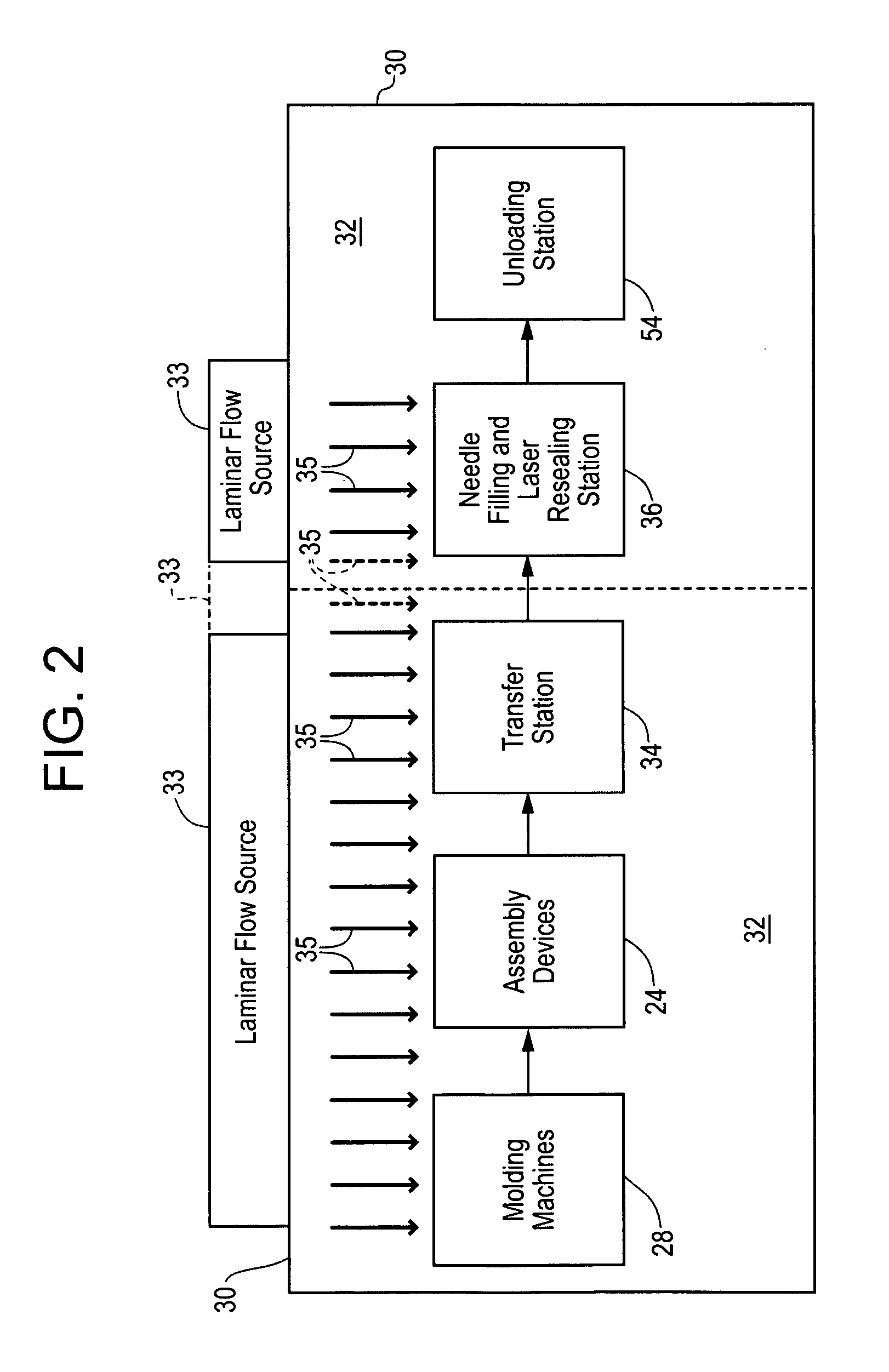

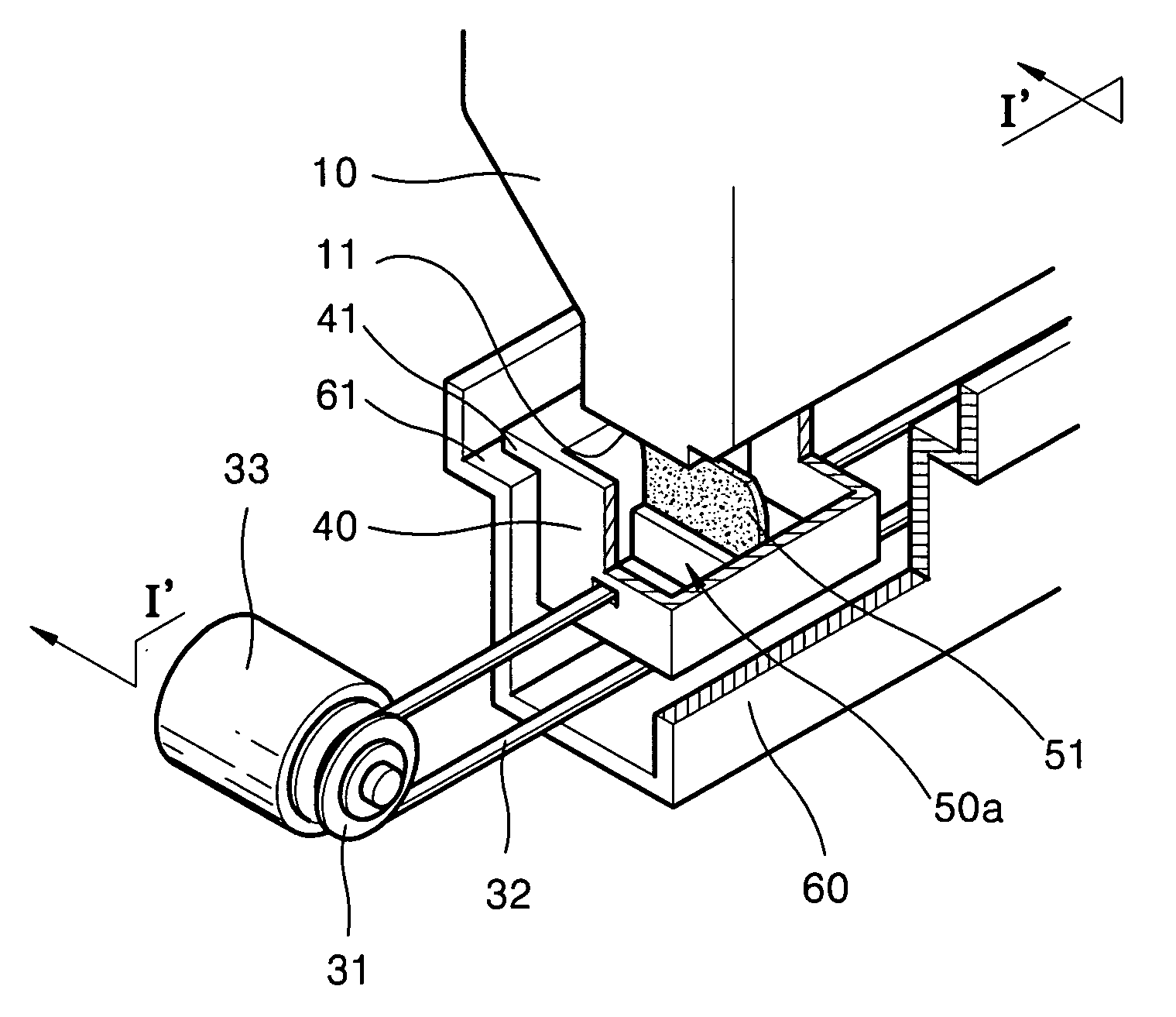

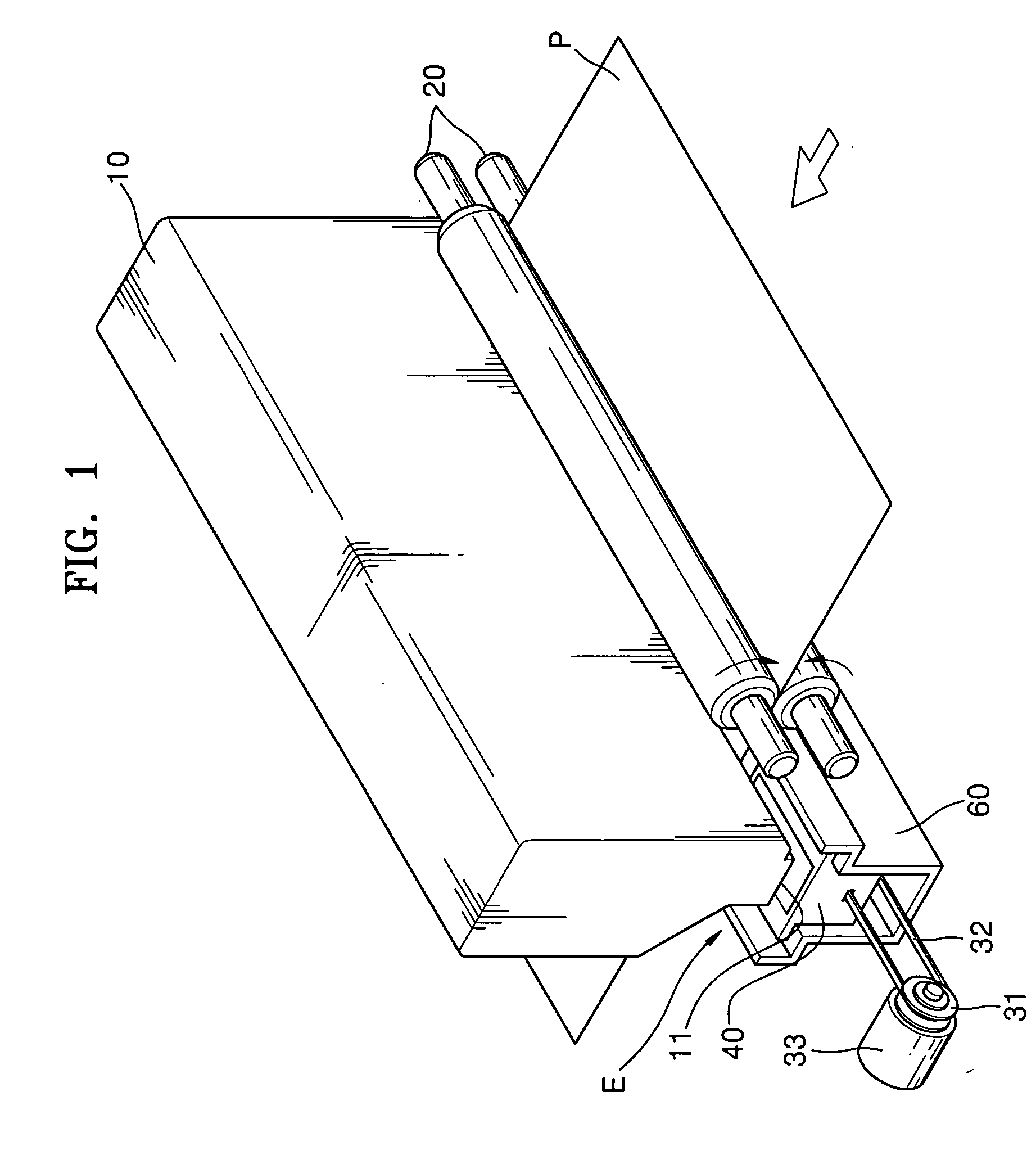

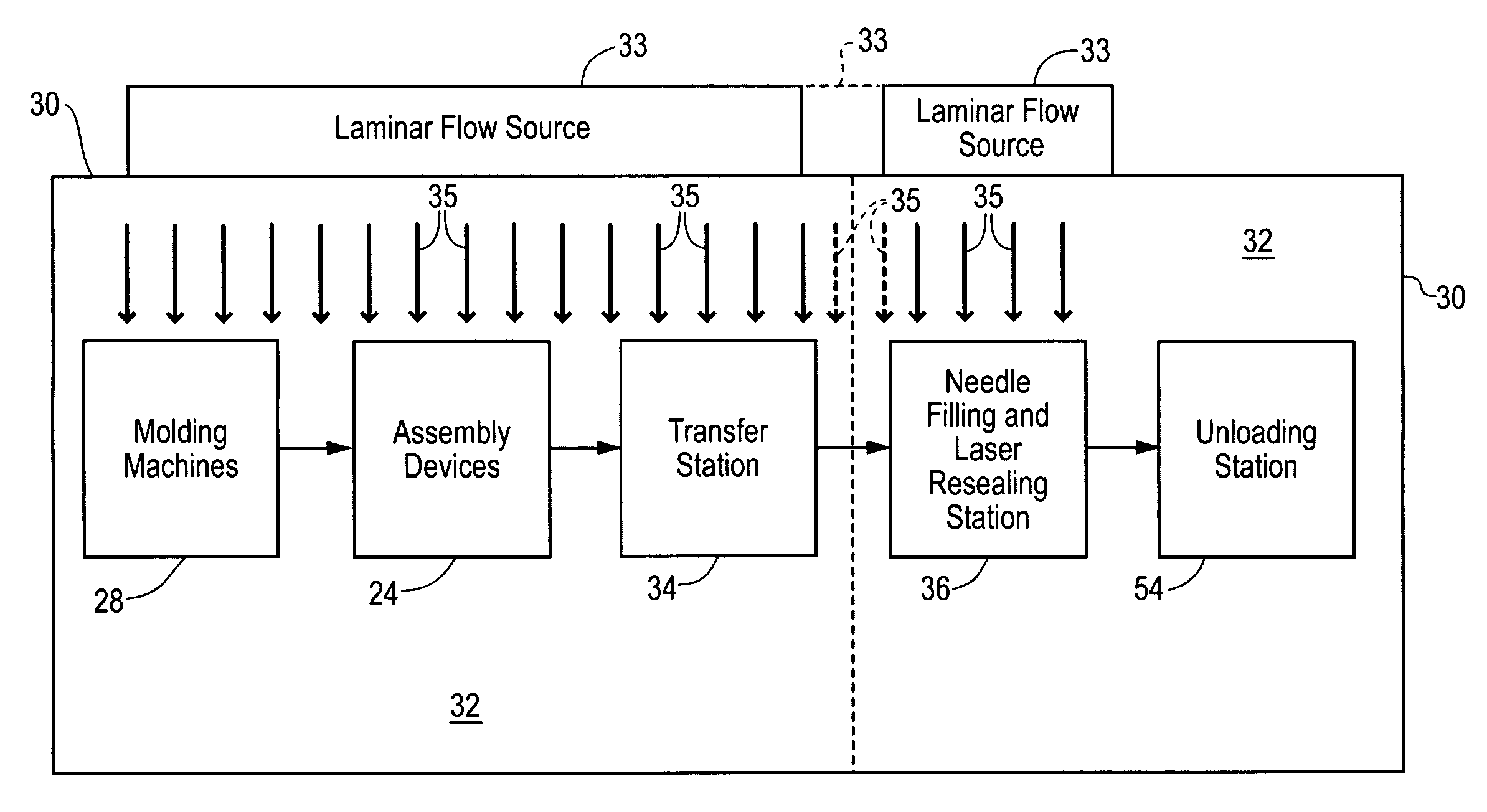

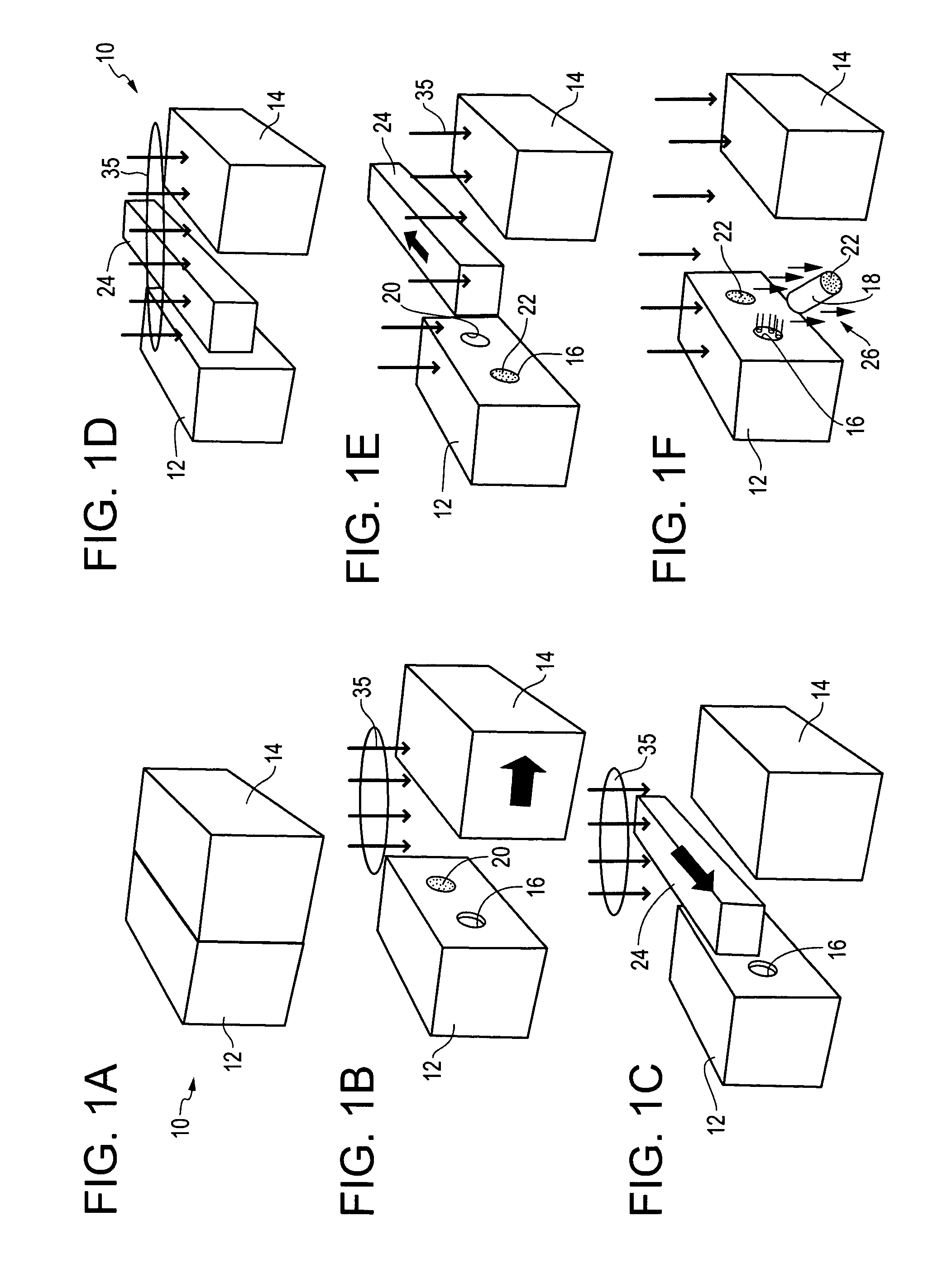

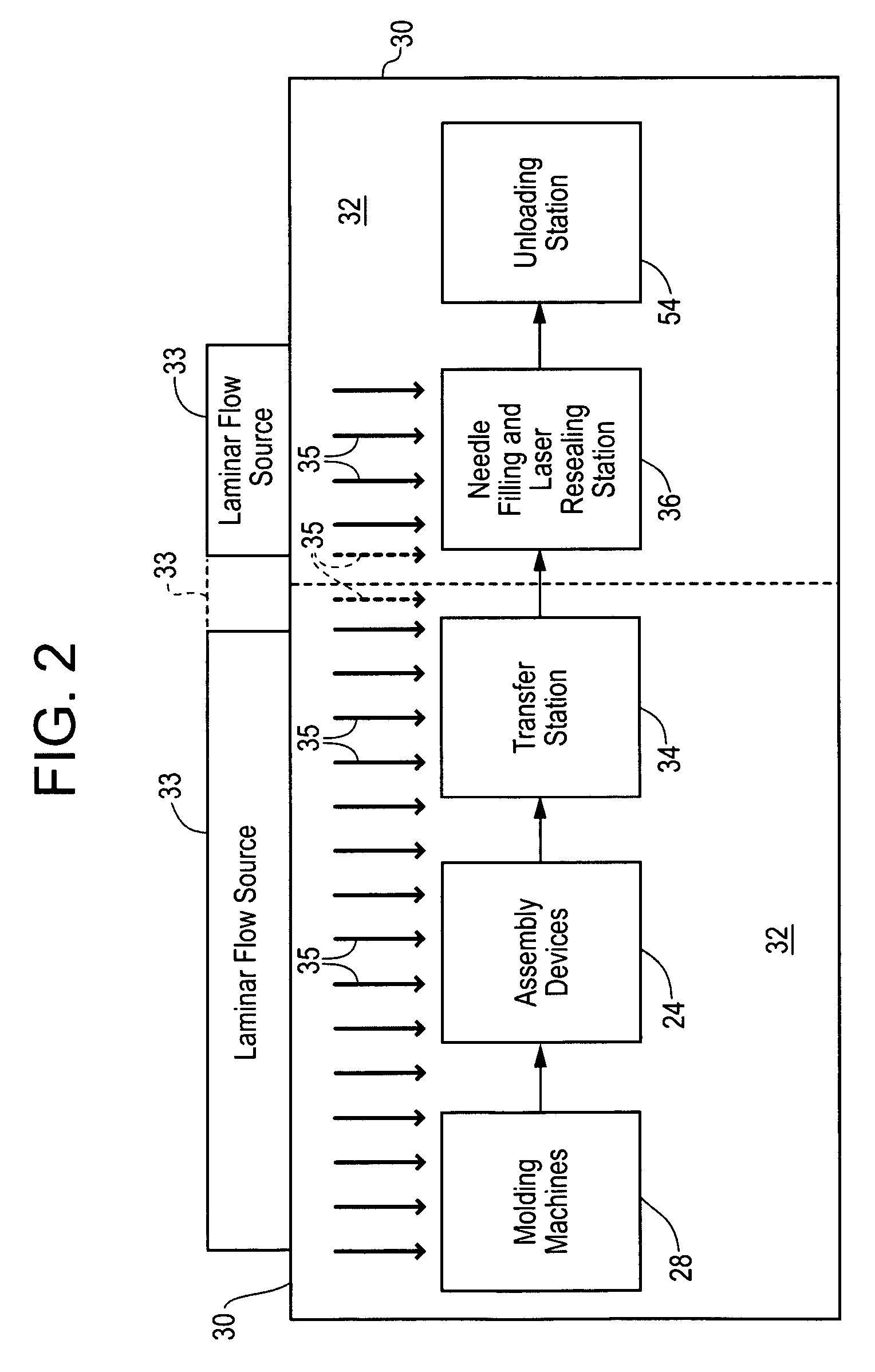

Apparatus for molding and assembling containers with stoppers and filling same

InactiveUS20050223677A1Package sterilisationPackaging under vacuum/special atmosphereMolding machineMechanical engineering

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

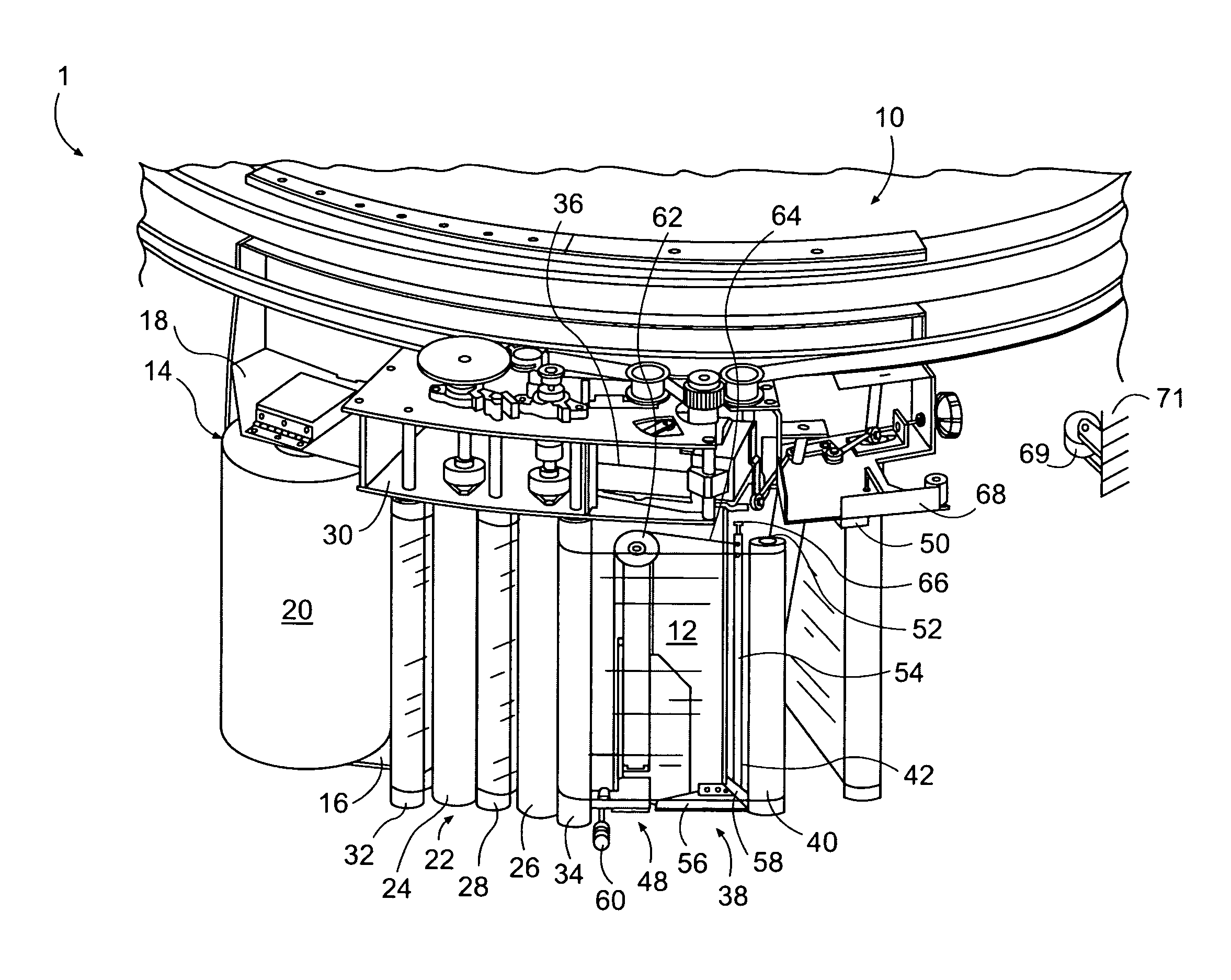

Ring wrapping apparatus including metered pre-stretch film delivery assembly

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

Syringe bandoleer with control feature

A bandolier of syringes for use in an automated syringe handling system is provided. The automated syringe handling system generally receives syringes and fills the syringe with a substance, such as a medicament. In one exemplary embodiment, the syringe handling system is a system that disperses one or more medicaments into the syringes in an automated manner. The bandolier includes a web, e.g., a strip of transparent material partially encapsulating bodies of syringes that are bound to the web at a prescribed interval. The bandolier includes a feature disposed within the prescribed interval and between the syringes with the feature being different from the surrounding web.

Owner:BAXTER ENGLEWOOD

Apparatus and method for needle filling and laser resealing

ActiveUS7096896B2Rapidly and efficiently needle fill and laser resealCost efficientPackage sterilisationWrapper twisting/gatheringMedicineRobotic arm

Owner:MEDINSTILL DEV

Apparatus and method for needle filling and laser resealing

ActiveUS20050194059A1Rapidly and efficiently needle fillCost efficientPackage sterilisationWrapper twisting/gatheringSyringe needleFixed position

An apparatus is provided for needle filling and thermally resealing containers having stoppers that are needle penetrable for filling the containers with a substance, and are thermally resealable for thermally sealing a needle hole in the stopper upon withdrawal of a needle therefrom. A container support of the apparatus supports at least one container having a resealable stopper in a substantially fixed position during needle filling and thermally resealing a needle hole in the stopper upon withdrawal of a needle therefrom. A robotic arm of the apparatus is drivingly mounted adjacent to the container support and movable relative thereto. A manifold is drivingly mounted on the robotic arm and includes (1) a needle for penetrating the resealable stopper and introducing a substance through the needle and into the container; (2) a laser optic assembly for heating a needle penetrated region of the stopper and, in turn, sealing a needle hole in the stopper; and (3) a temperature sensor for sensing the temperate of a needle penetrated region of the stopper to determine whether a needle hole therein is sealed. The manifold is movable laterally relative to the container on the container support to position the manifold relative to a needle penetrable region of the stopper of the container.

Owner:MEDINSTILL DEV

Method and apparatus for securing a load to a pallet with a roped film web

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one drive down roller configured to engage the width of the film web, and at least one roping mechanism. The at least one roping mechanism may be a cable rolling element configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

Method and apparatus for wrapping palletized bundles

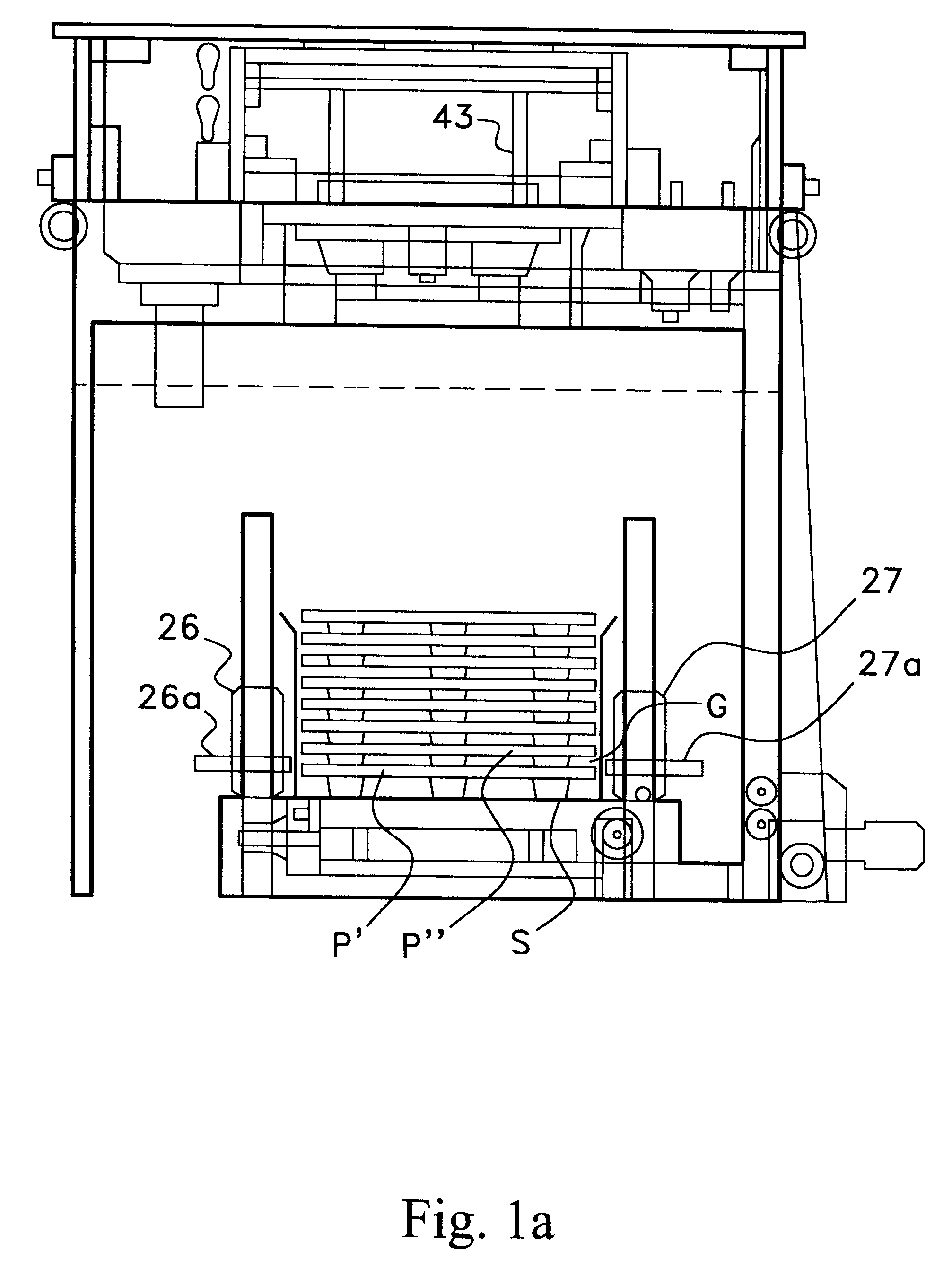

InactiveUS6594970B1Prevent fallingPrevent crashWeb rotation wrappingBinding material applicationEngineeringProduct layer

A method and apparatus for wrapping a loop of film about a pallet, which supports a layer of products, and a guide, through which said layer passes, to prevent crushing and / or displacement of the product layer. Subsequent product layers are similarly protected by looping film about a previous loop of film and said guide. The guide is designed to facilitate removal of the film looped thereabout as the product layers are lowered.

Owner:PREMARK PACKAGING LLC

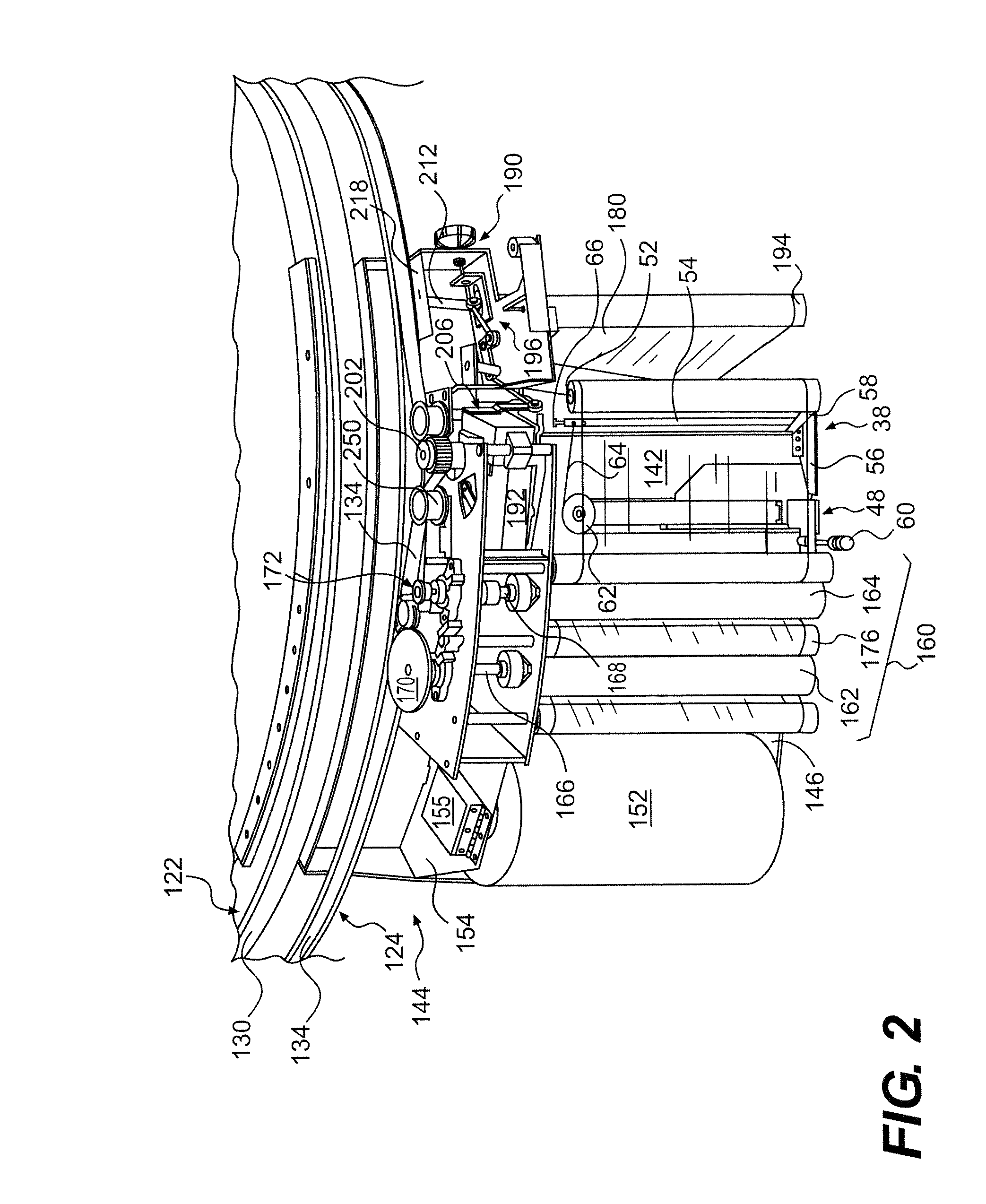

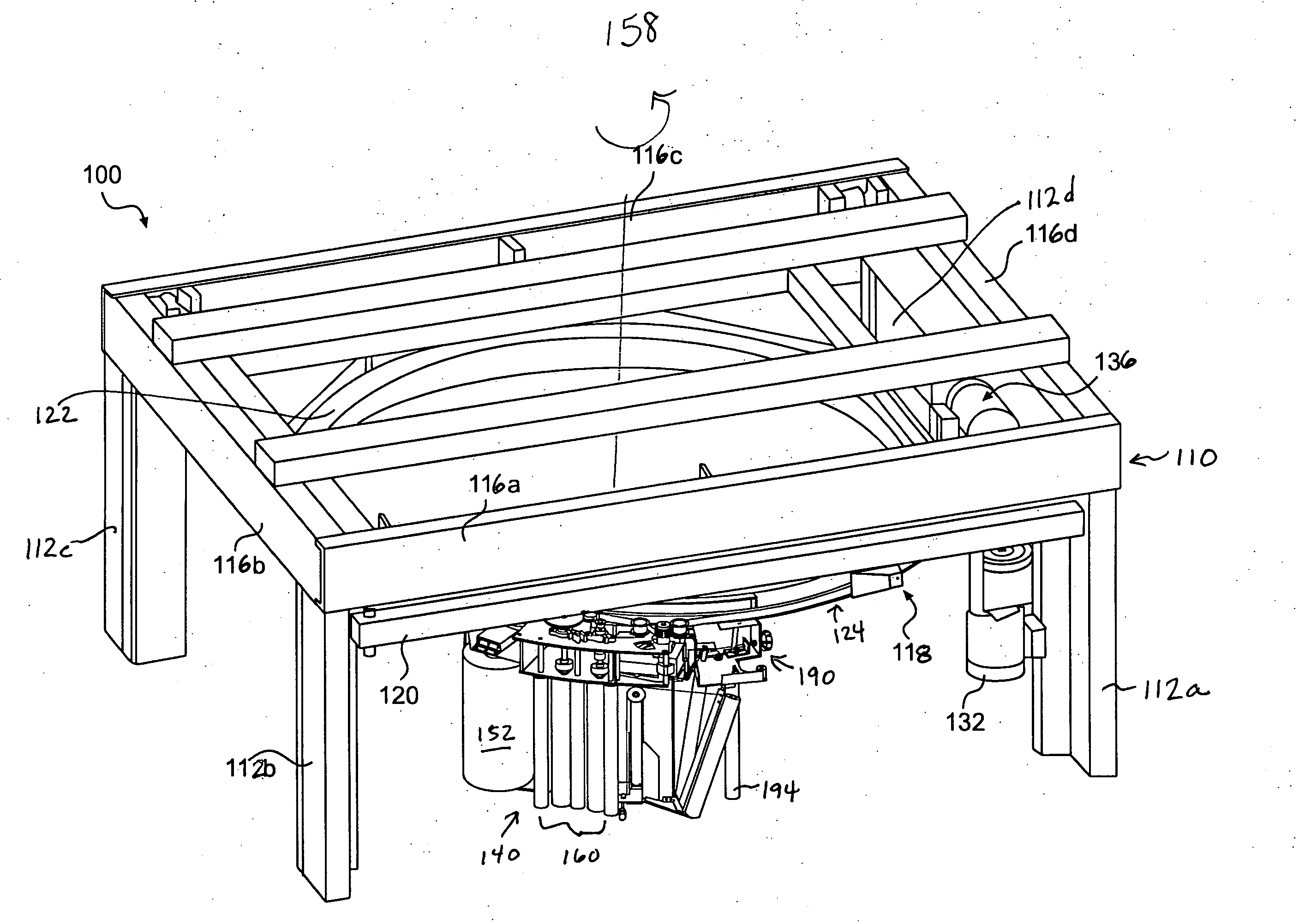

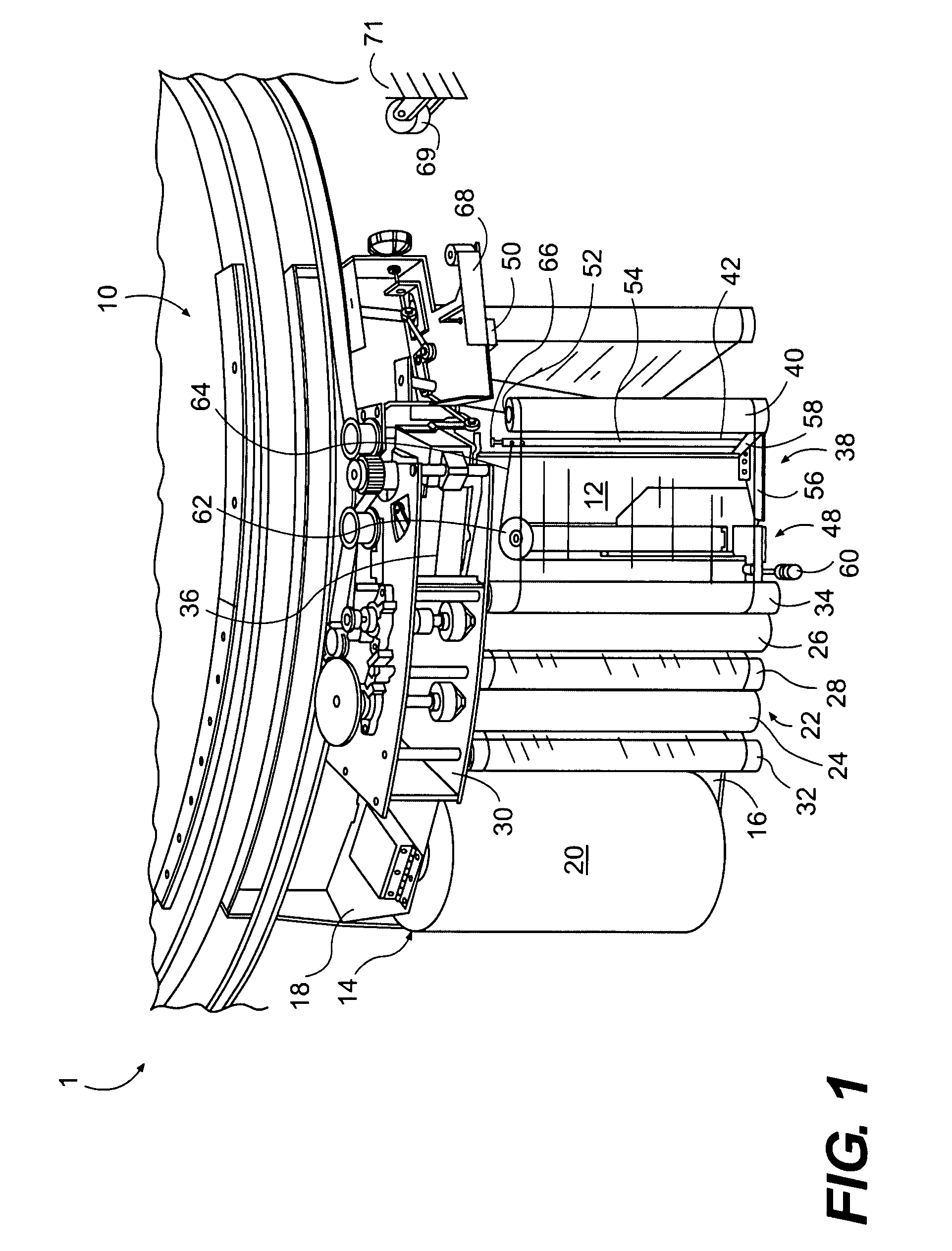

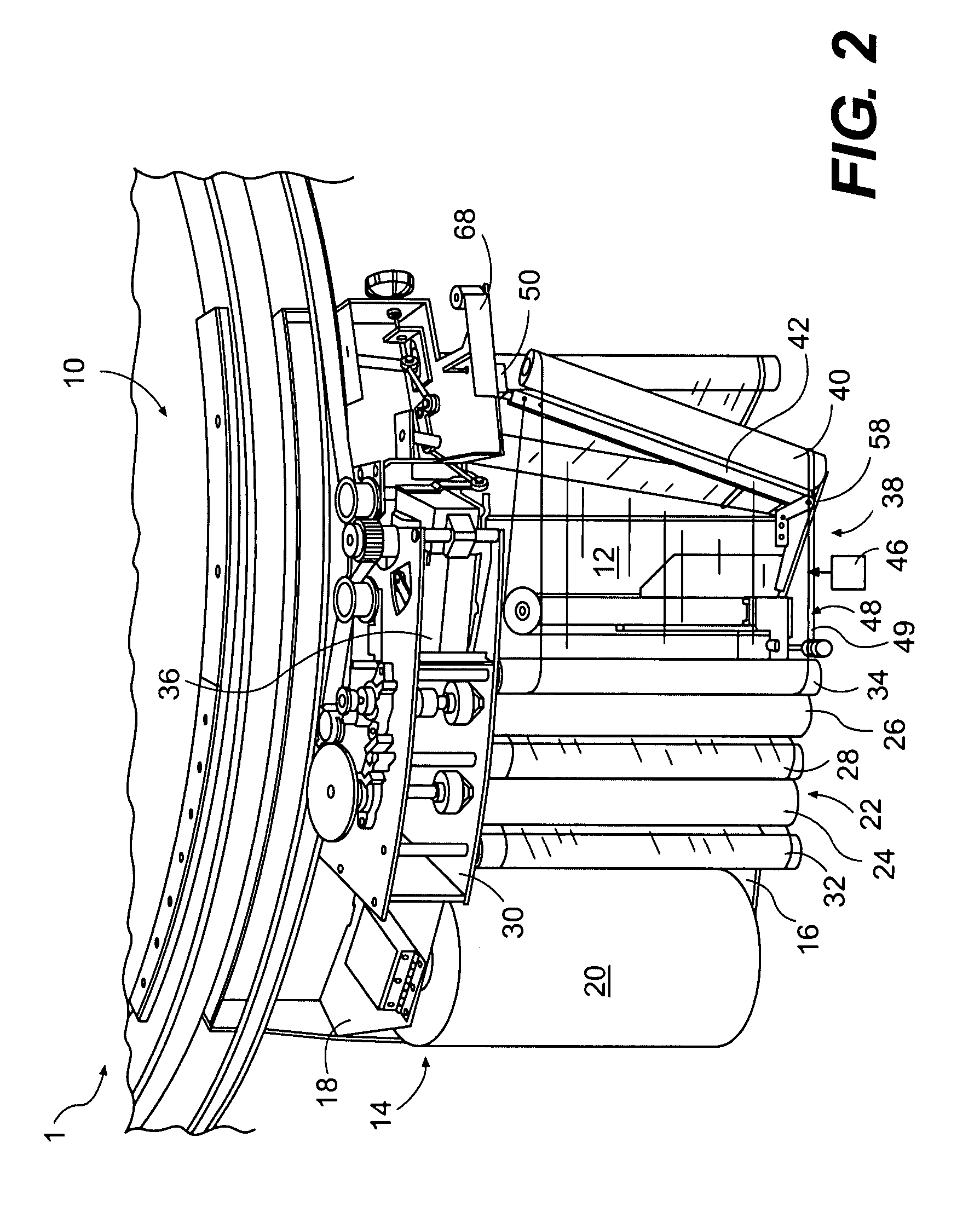

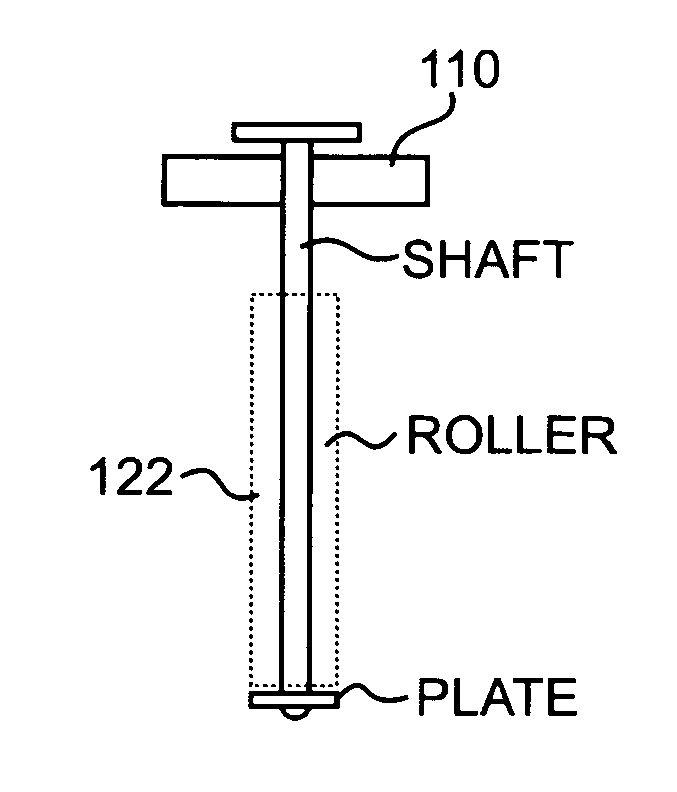

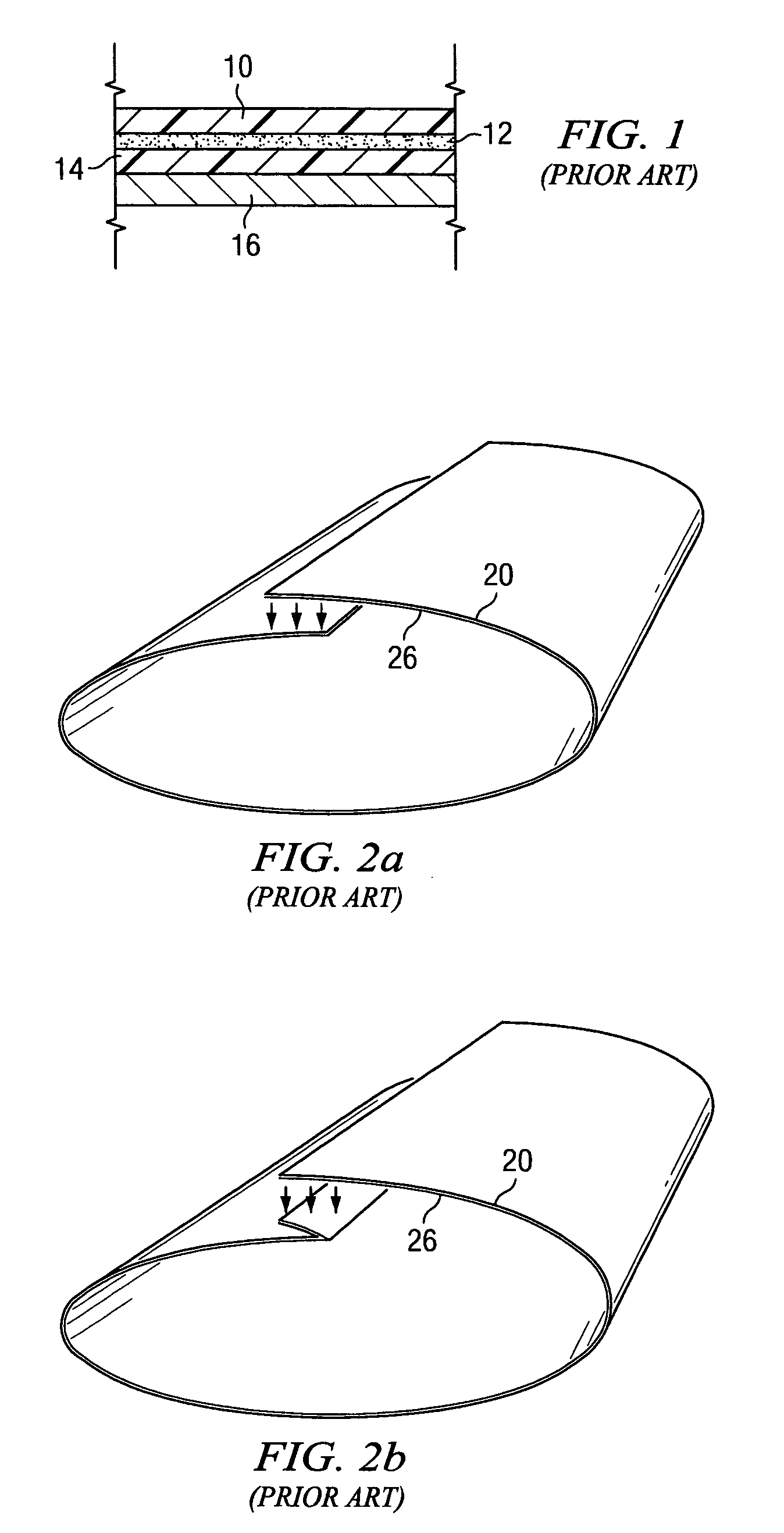

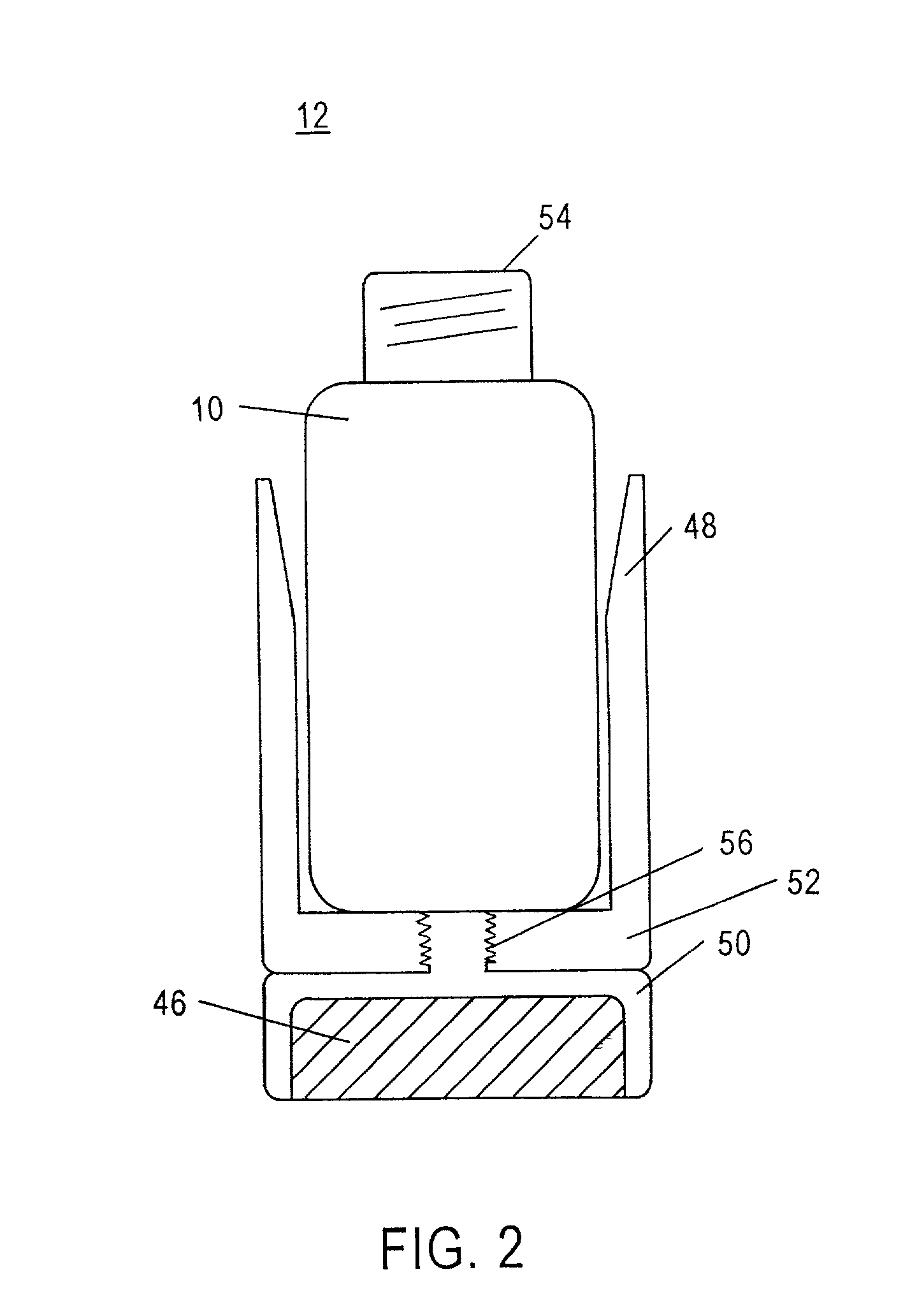

Stretch wrapping apparatus having film dispenser with pre-stretch assembly

A film dispenser for a stretch wrapping apparatus is provided. The film dispenser includes a pre-stretch assembly having a top portion mounted to and extending downwardly from a drive plate of a roll carriage frame. The pre-stretch assembly includes two pre-stretch rollers having first ends connected to the roll carriage frame and second ends connected to one another. The pre-stretch rollers may be coated. The pre-stretch assembly further includes a cantilevered idle roller mounted to the drive plate and positioned between the pre-stretch rollers. A film path is defined by the space between the pre-stretch rollers and the idle roller. The film path is easily accessible via the bottom end of the pre-stretch assembly.

Owner:LANTECH COM

Method and apparatus for securing a load to a pallet with a roped film web

ActiveUS20050044812A1Narrow widthReduce widthWrappers shrinkageWrapping material feeding apparatusThin membranePallet

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one guide rollers configured to engage the width of the film web, and at least one roping element. The at least one roping element may be a cable rolling roper configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

Method and apparatus for dispensing a predetermined fixed amount of pre-stretched film relative to load girth

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt driven by a motor. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt, such that the rotating ring is driven by the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

Sterile filling machine having needle filling station within e-beam chamber

InactiveUS6929040B2Obstruct passageEliminate the risk of contaminationLiquid fillingPackage sterilisationEngineeringSyringe needle

A sterile filling machine and related method are provided for sterile filling a container with a substance. The container includes a heat resealable stopper and a chamber for receiving the substance therein. The sealed, empty containers are subjected to radiation capable of penetrating through the stopper and chamber for sterilizing the container. The previously sterilized containers are then transported through an e-beam chamber, wherein an electron beam is directed onto a penetrable surface of the stopper to sterilize the penetrable surface. A needle is mounted within the e-beam chamber and moved into engagement with the stopper to pierce the sterilized penetrable surface of the stopper and inject the substance through the needle and into the chamber of the container. The needle is then withdrawn from the stopper and the filled container is transported outside of the e-beam chamber. Laser energy is then transmitted onto the penetrated surface of the stopper to fuse the stopper material and hermetically re-seal the stopper.

Owner:MEDINSTILL DEV

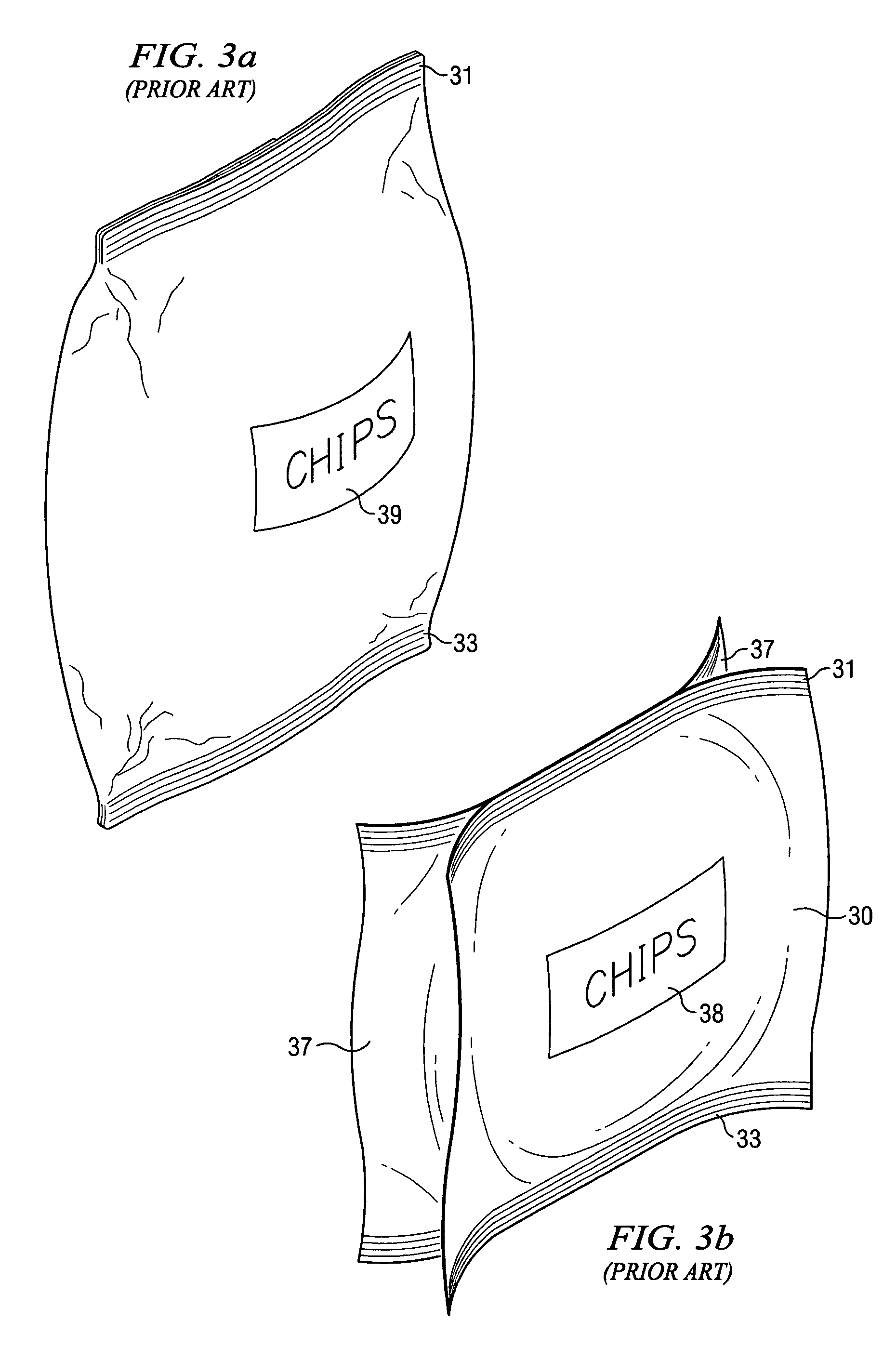

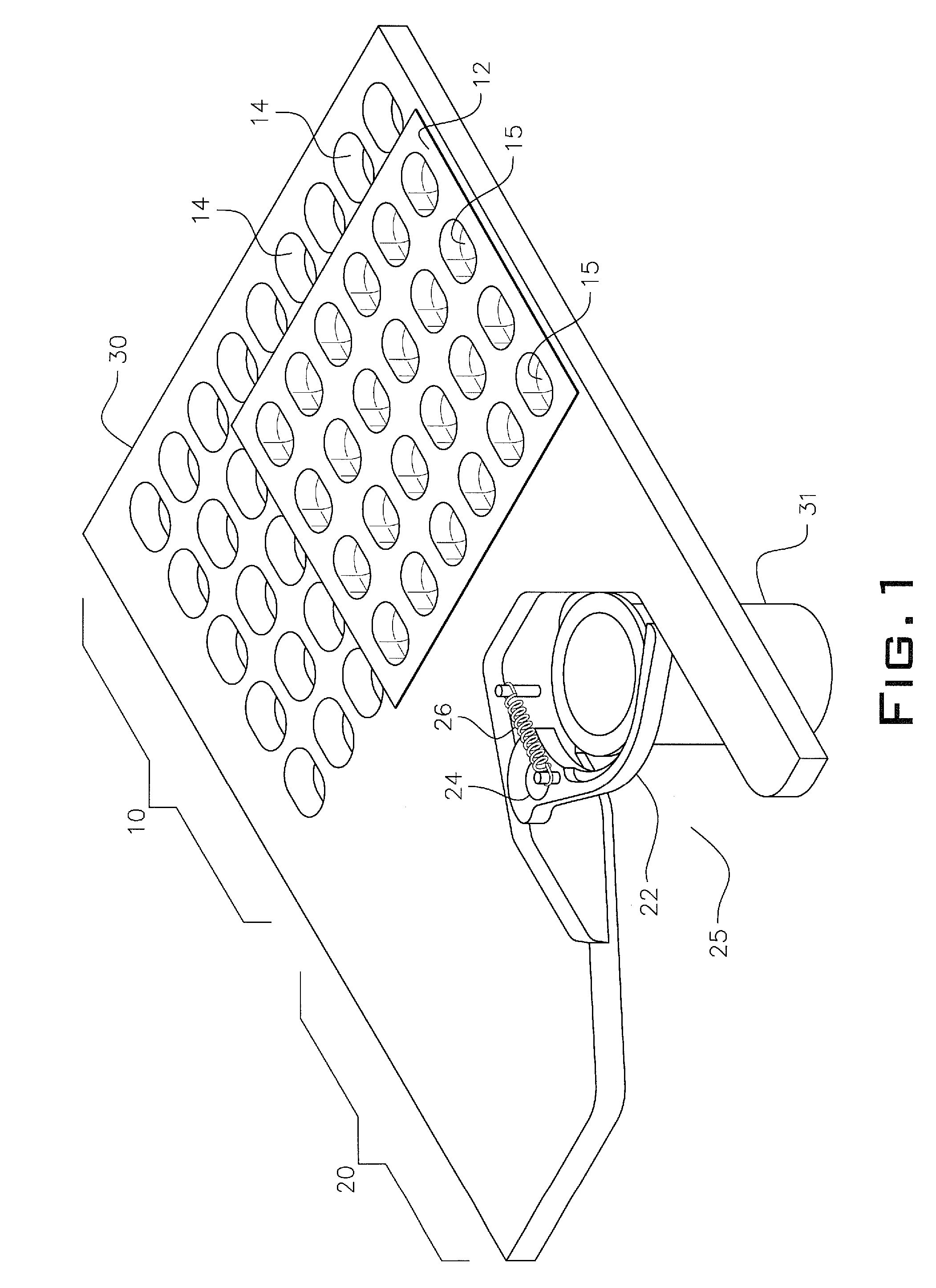

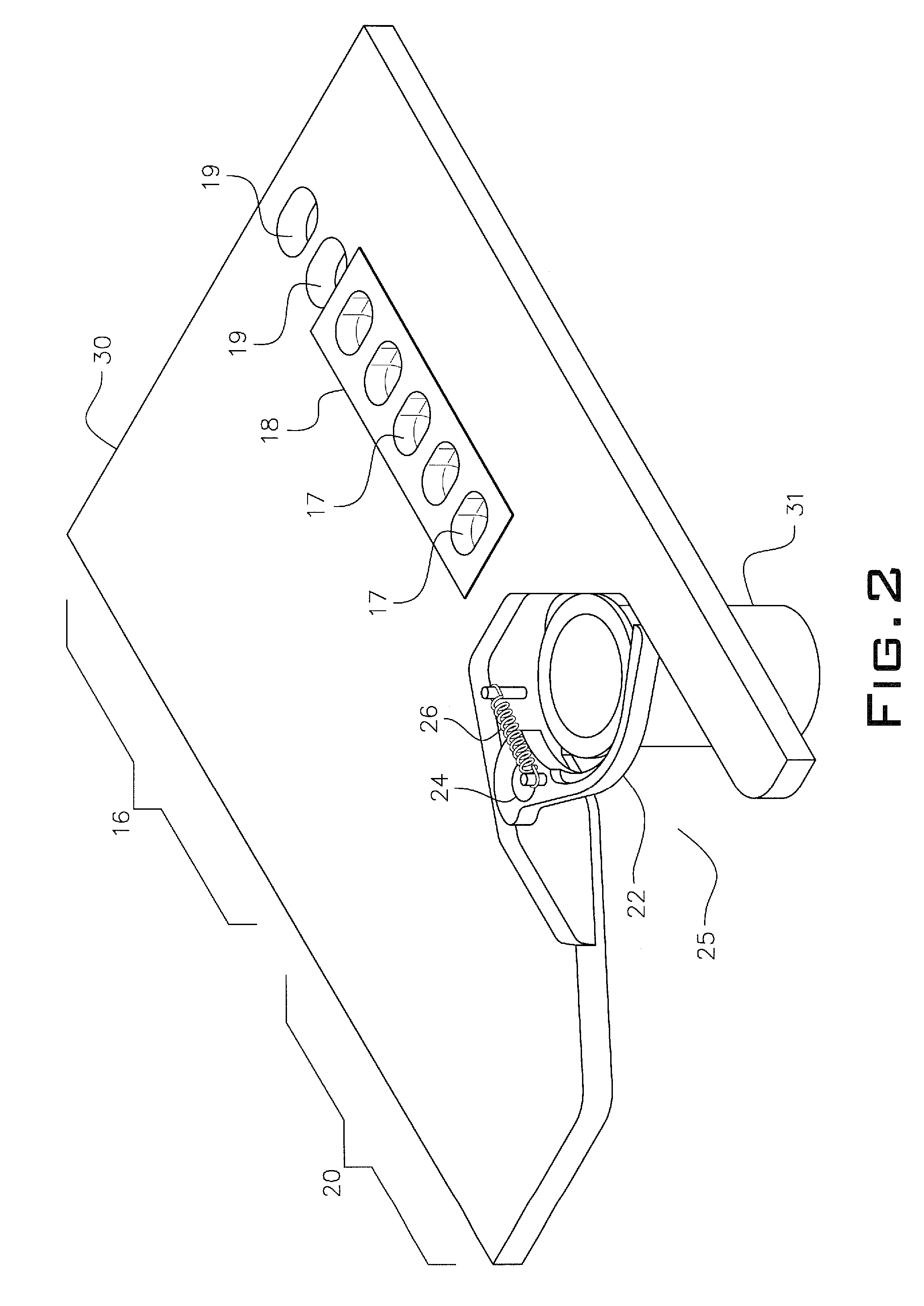

Method and support for supporting packages only at their edges during steam sterilization

InactiveUS6018931AUniform exposurePreventing uneven discolorationShow cabinetsPackage sterilisationEngineeringMechanical engineering

A method and a support for supporting a package in a steam sterilizer, featuring support members configured and positioned to support only at least a portion of at least two opposed side edges, but not a side face, of the package. A diamond shape is particularly preferred for the support members as, when rotated at an angle, its facets provide line contact with appropriate side edges of the package.

Owner:JOHNSON & JOHNSON INC (US)

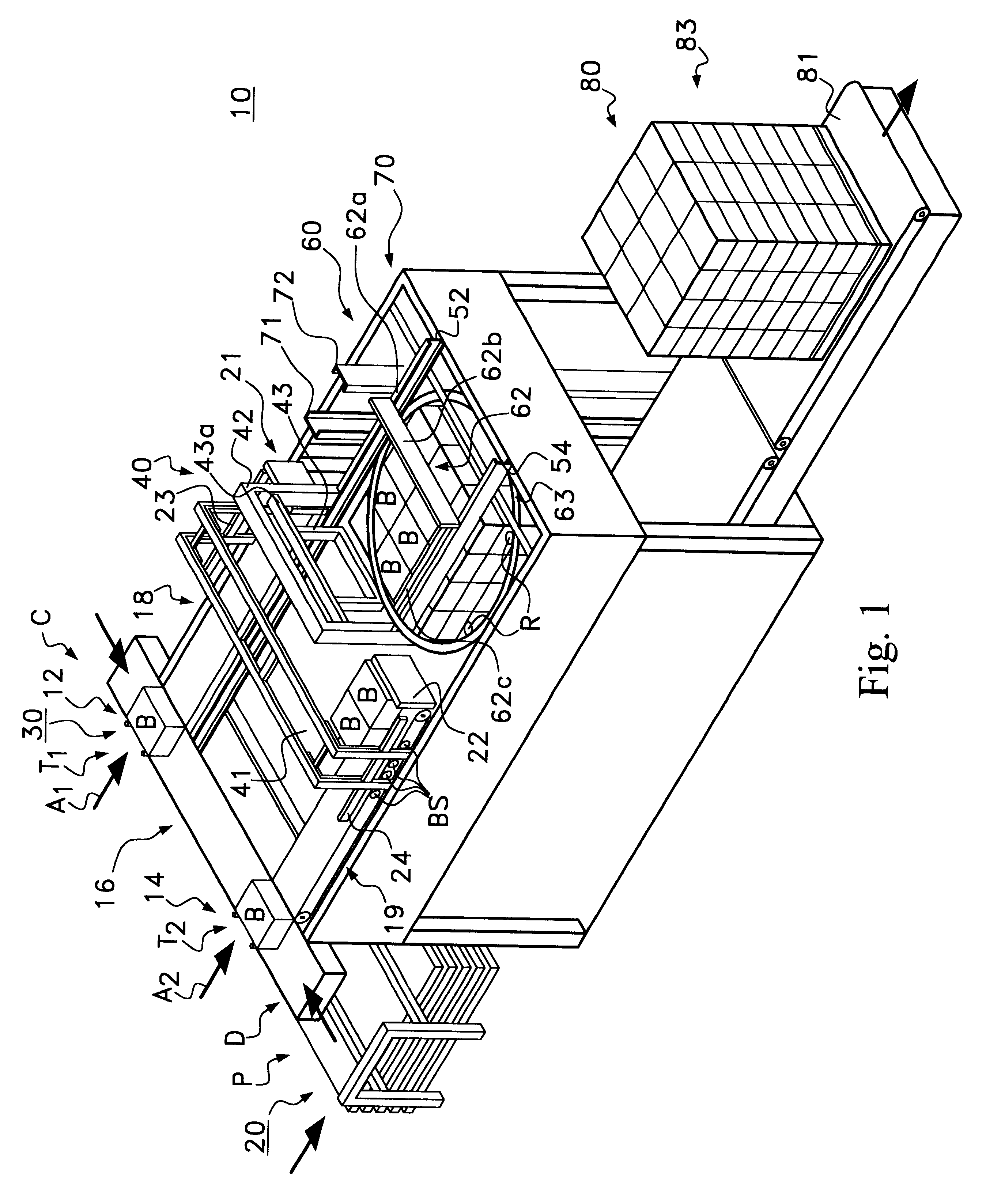

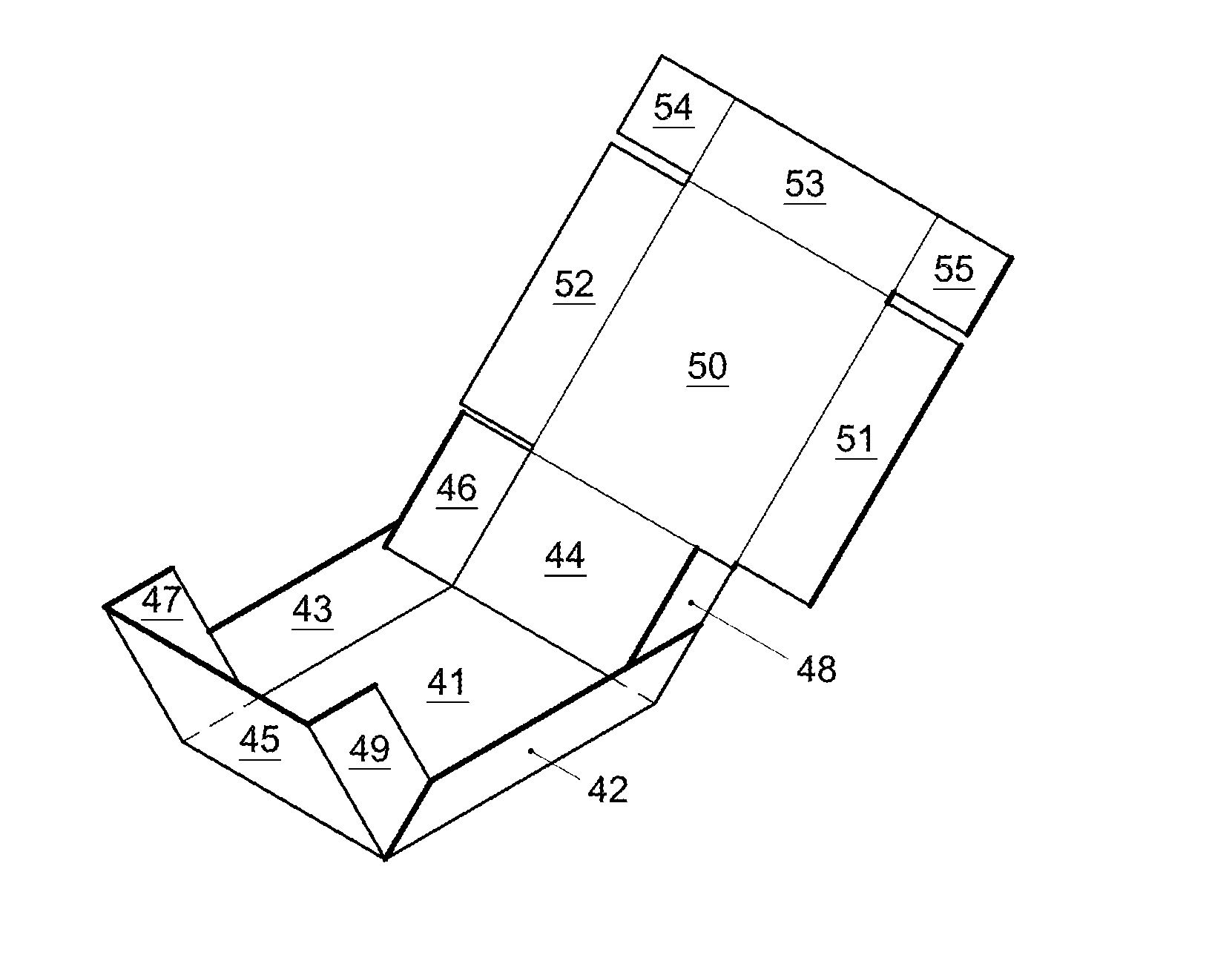

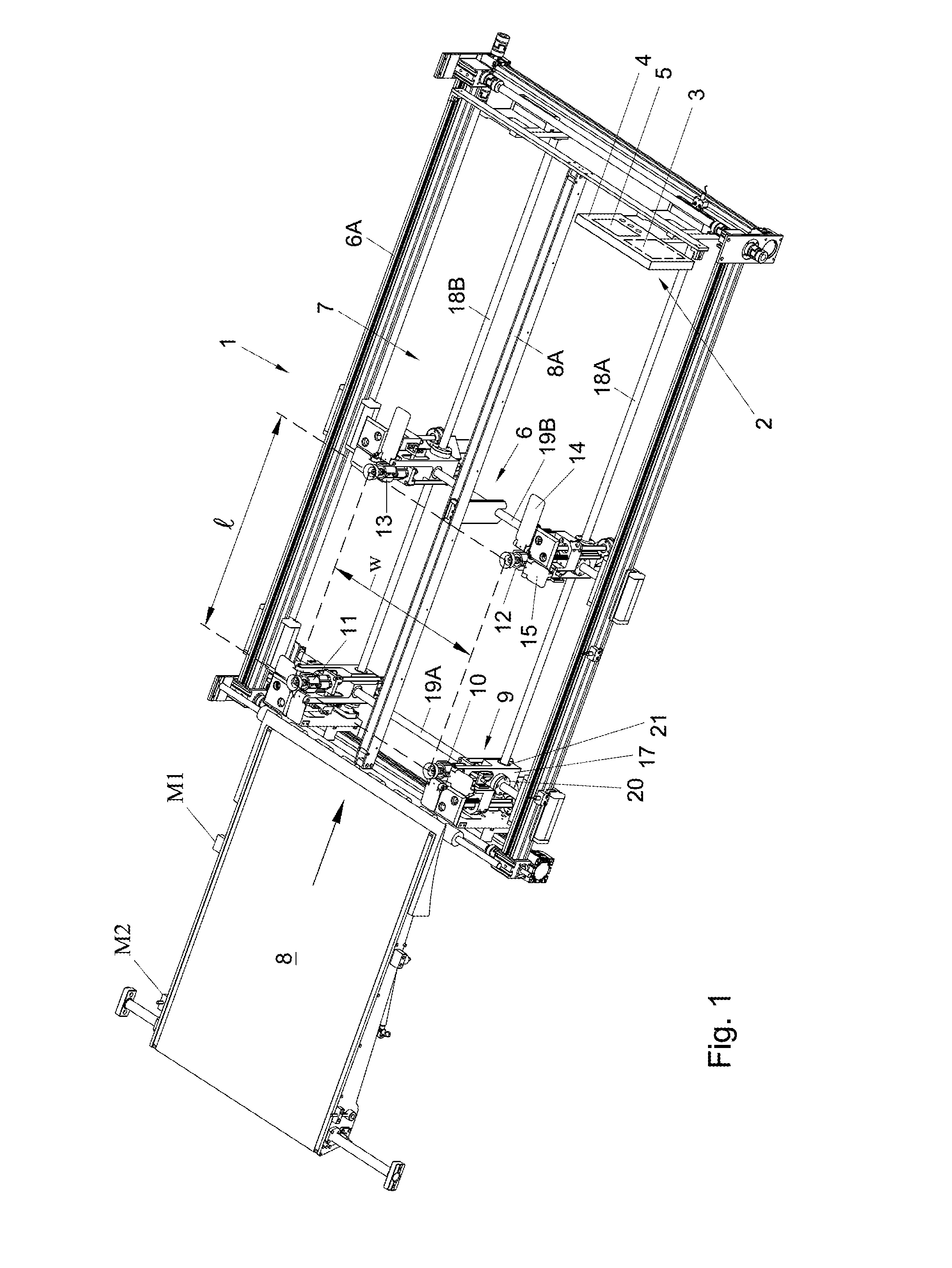

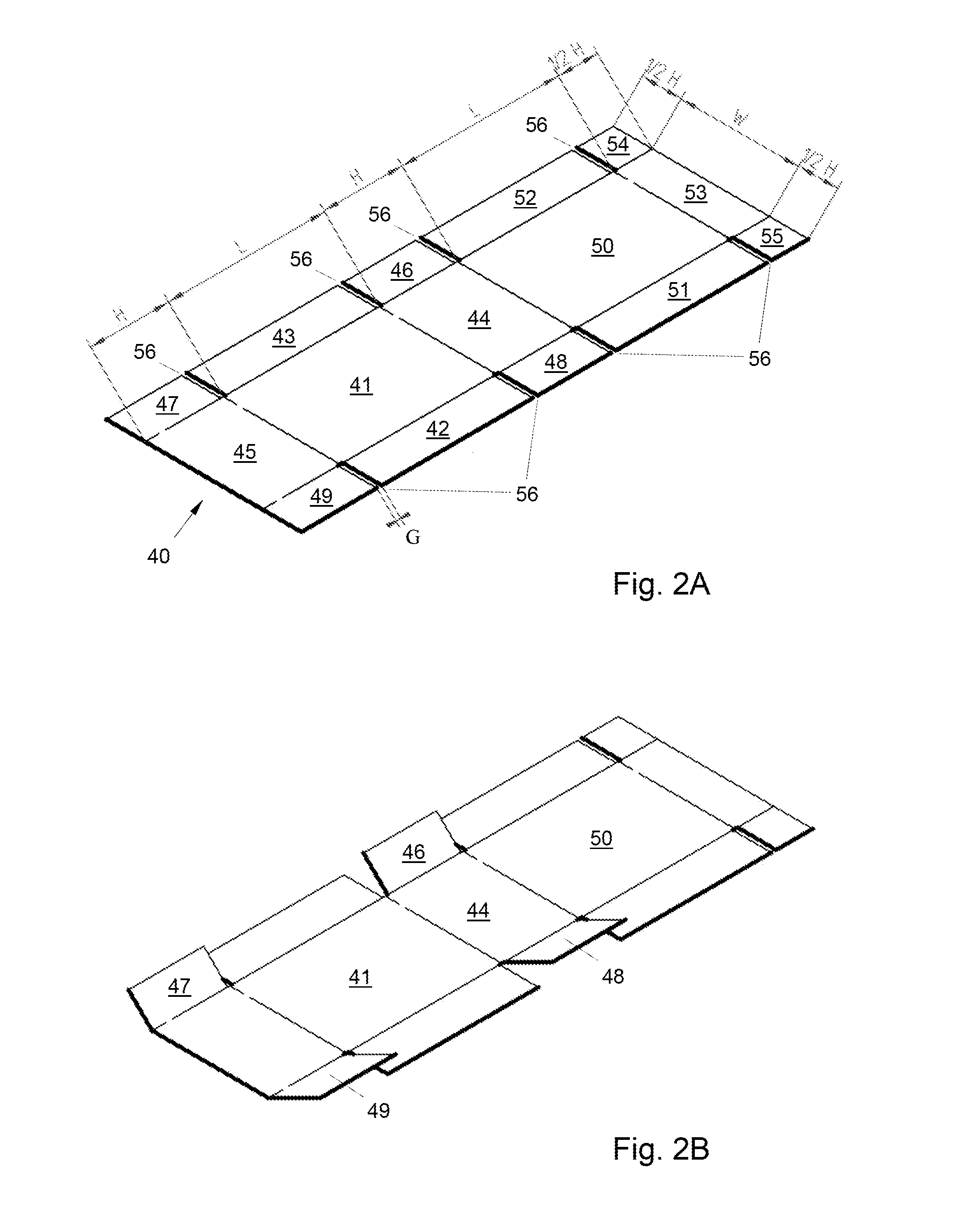

A method and system for automatically processing blanks for packaging boxes

ActiveUS20150360433A1High industrial capacityLarge capacityBoxes/cartons making machineryBox making operationsEngineeringAutomatic processing

Method and system for automatically processing blanks for forming packaging boxes. By means of a feeding conveyor blank material is fed in a feeding direction from a storage of blank material to a single blank cutting station comprising a blank forming apparatus for cutting and creasing blank material into a blank. By means of said blank forming apparatus a blank is formed having a rectangular bottom panel and rectangular corner, side and end panels. Cutting and creasing blank material into the blank is performed during feeding of said blank material in feeding direction through the blank forming apparatus.

Owner:SPARCK TECH BV

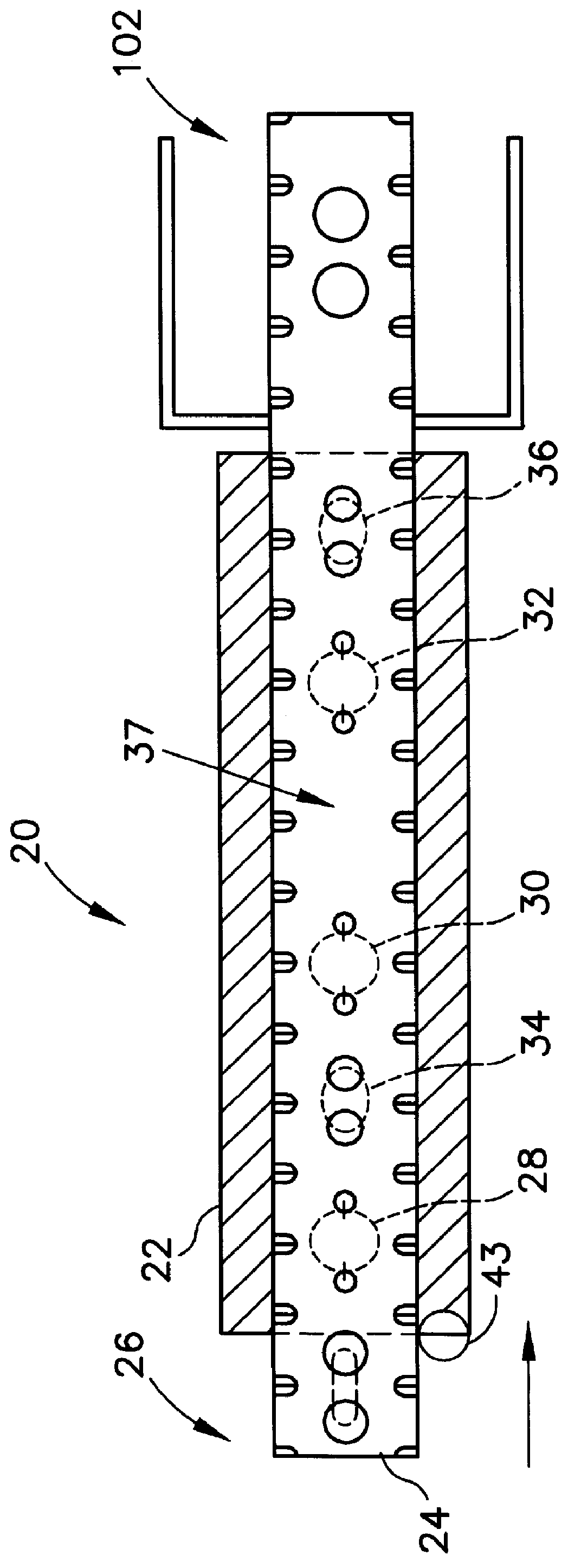

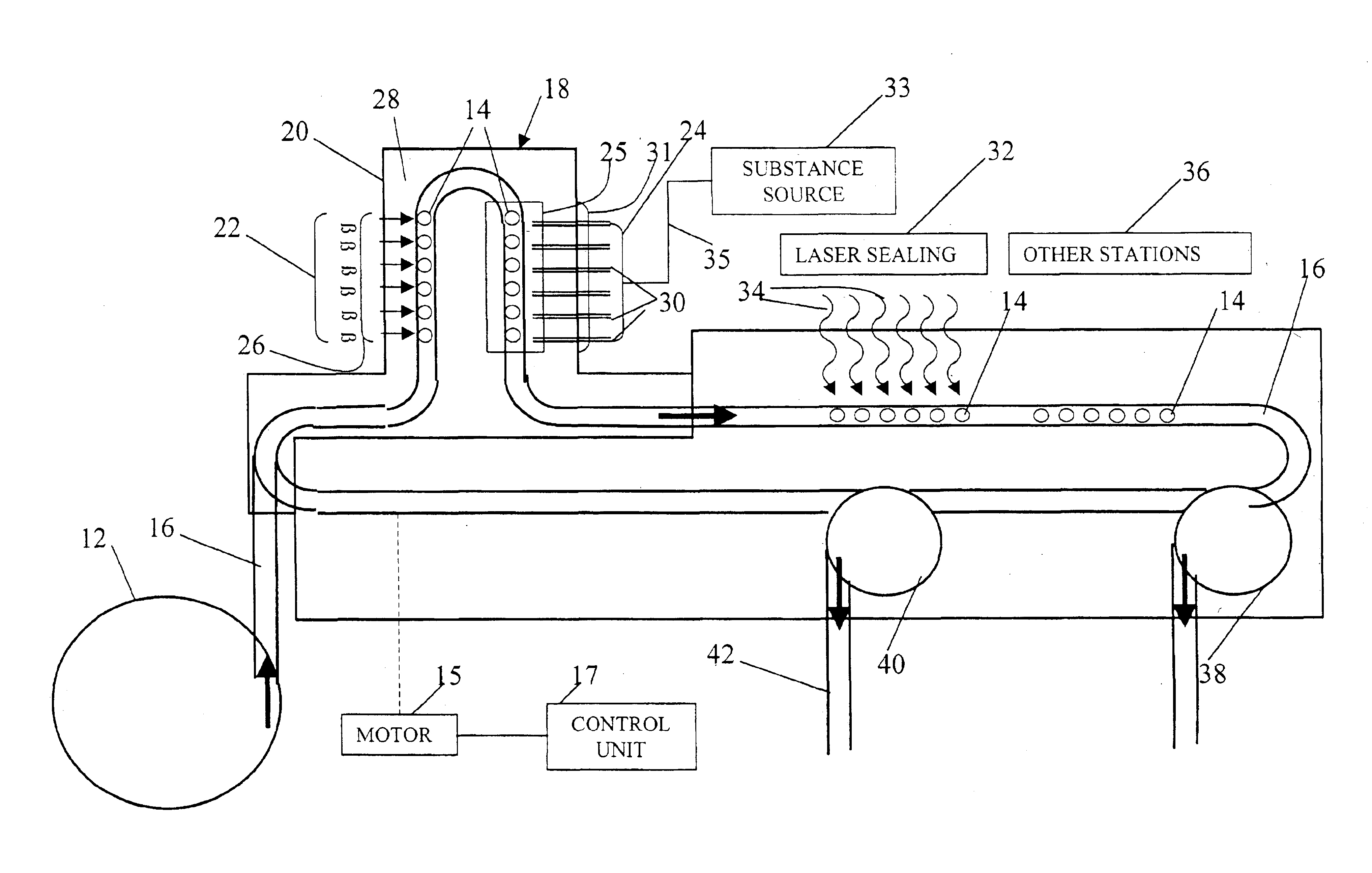

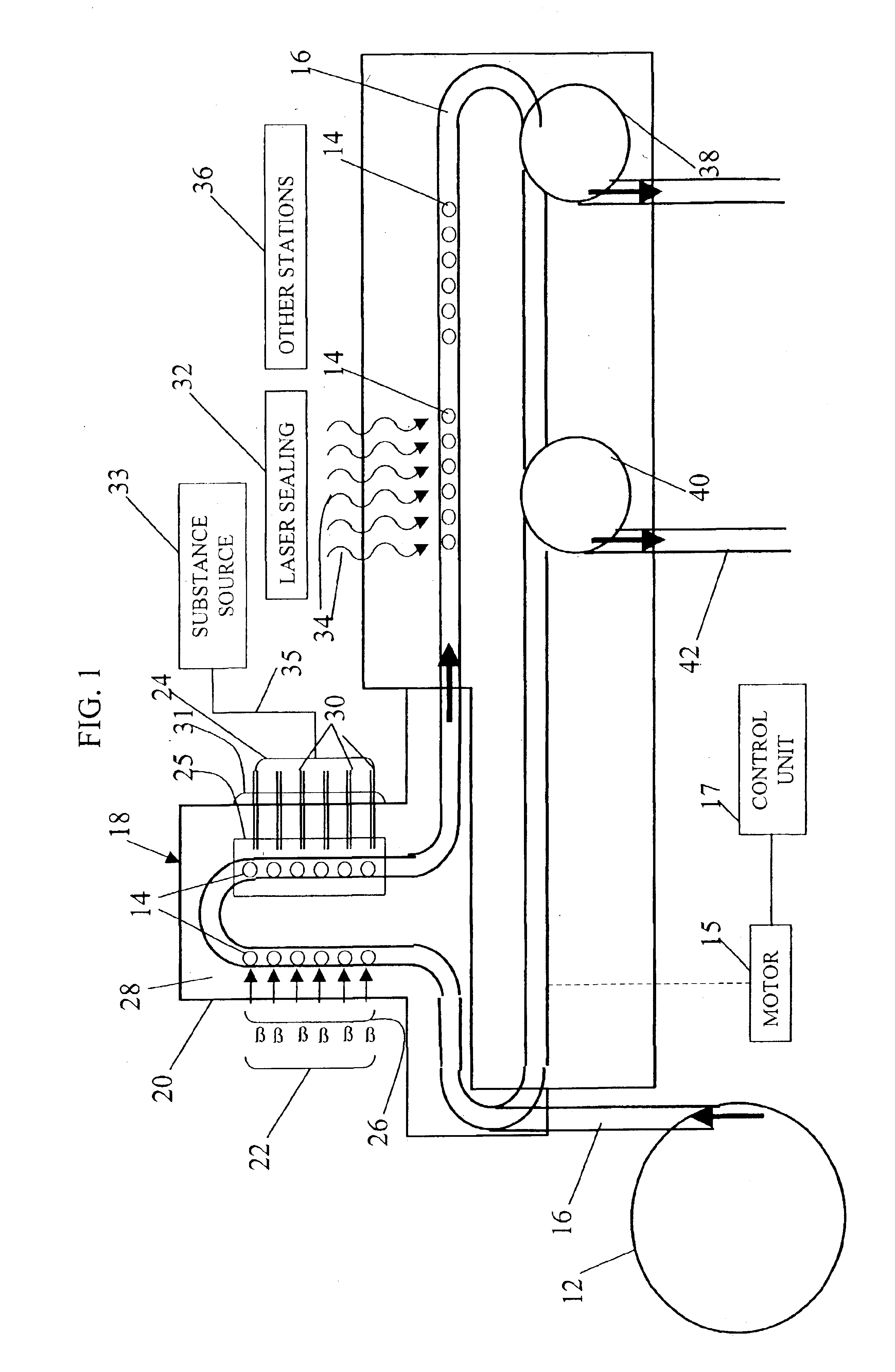

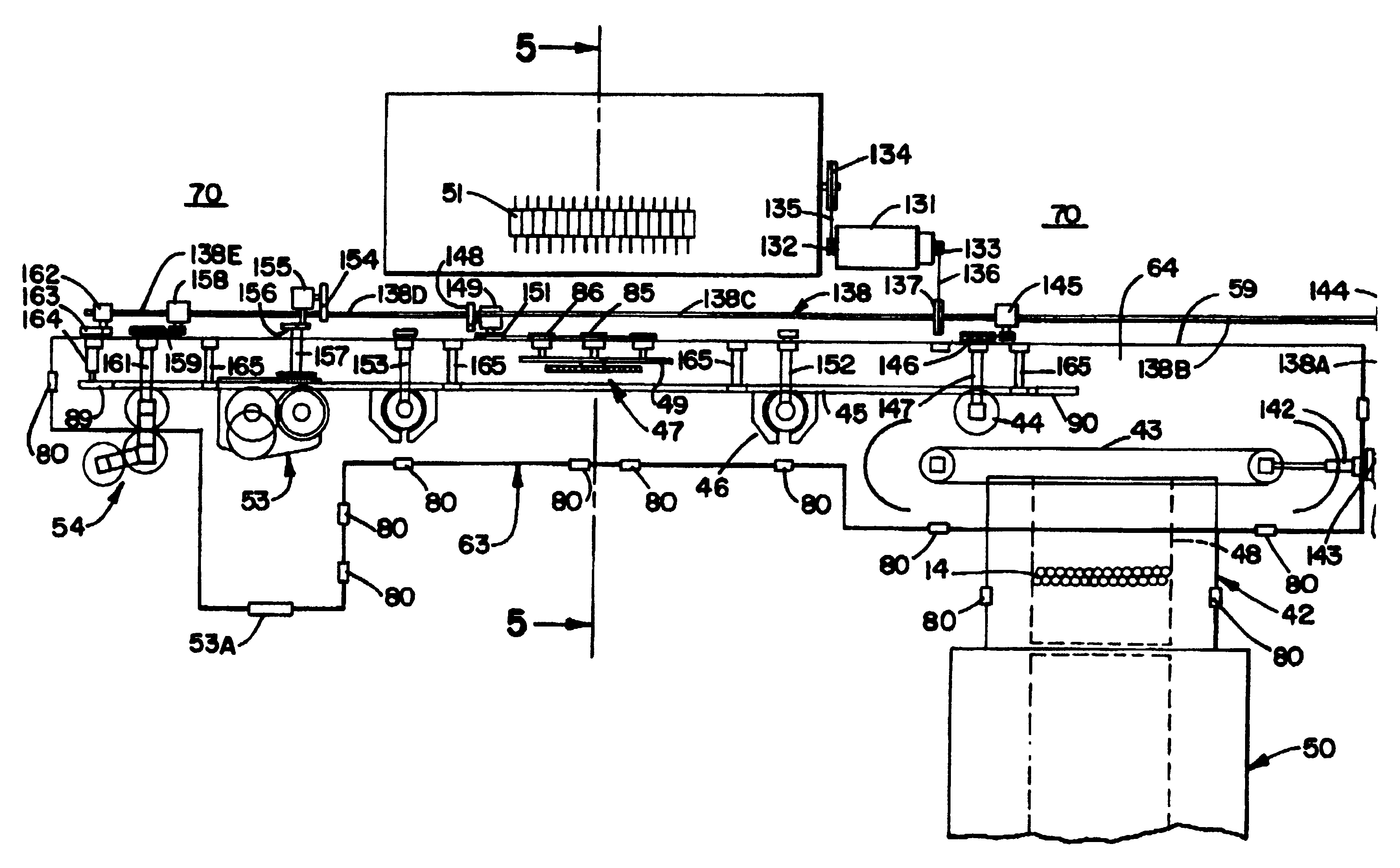

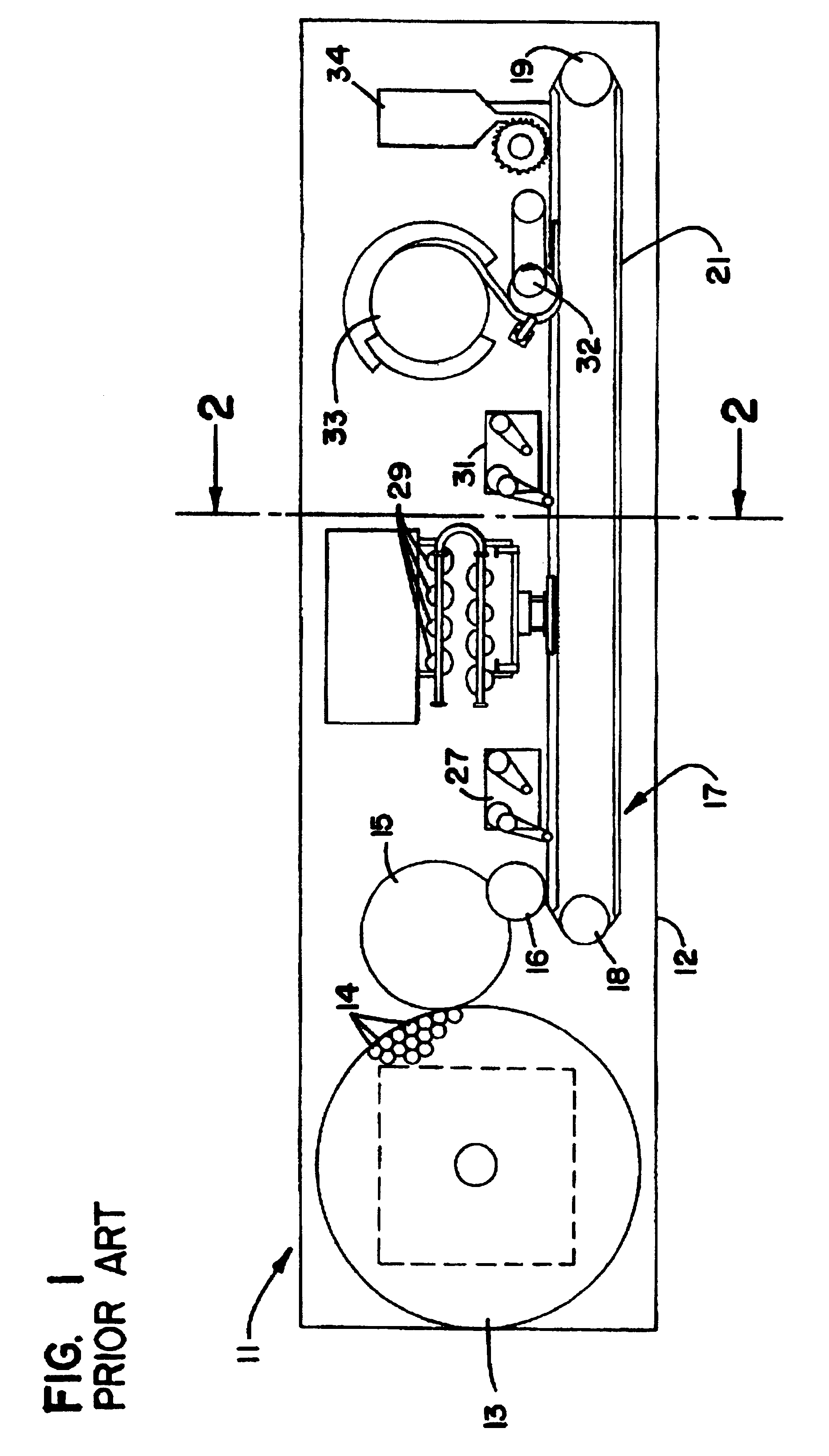

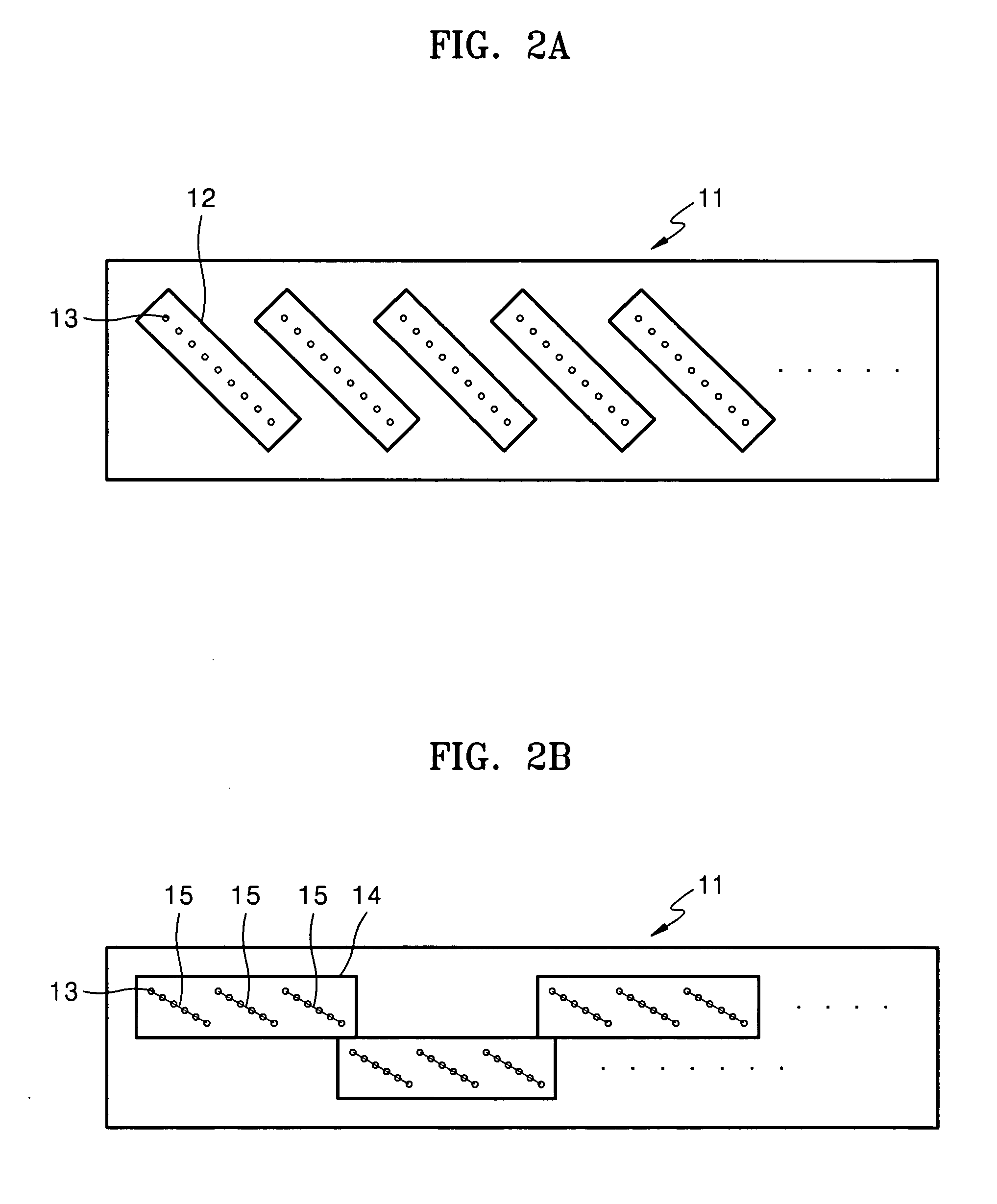

Vial filling apparatus

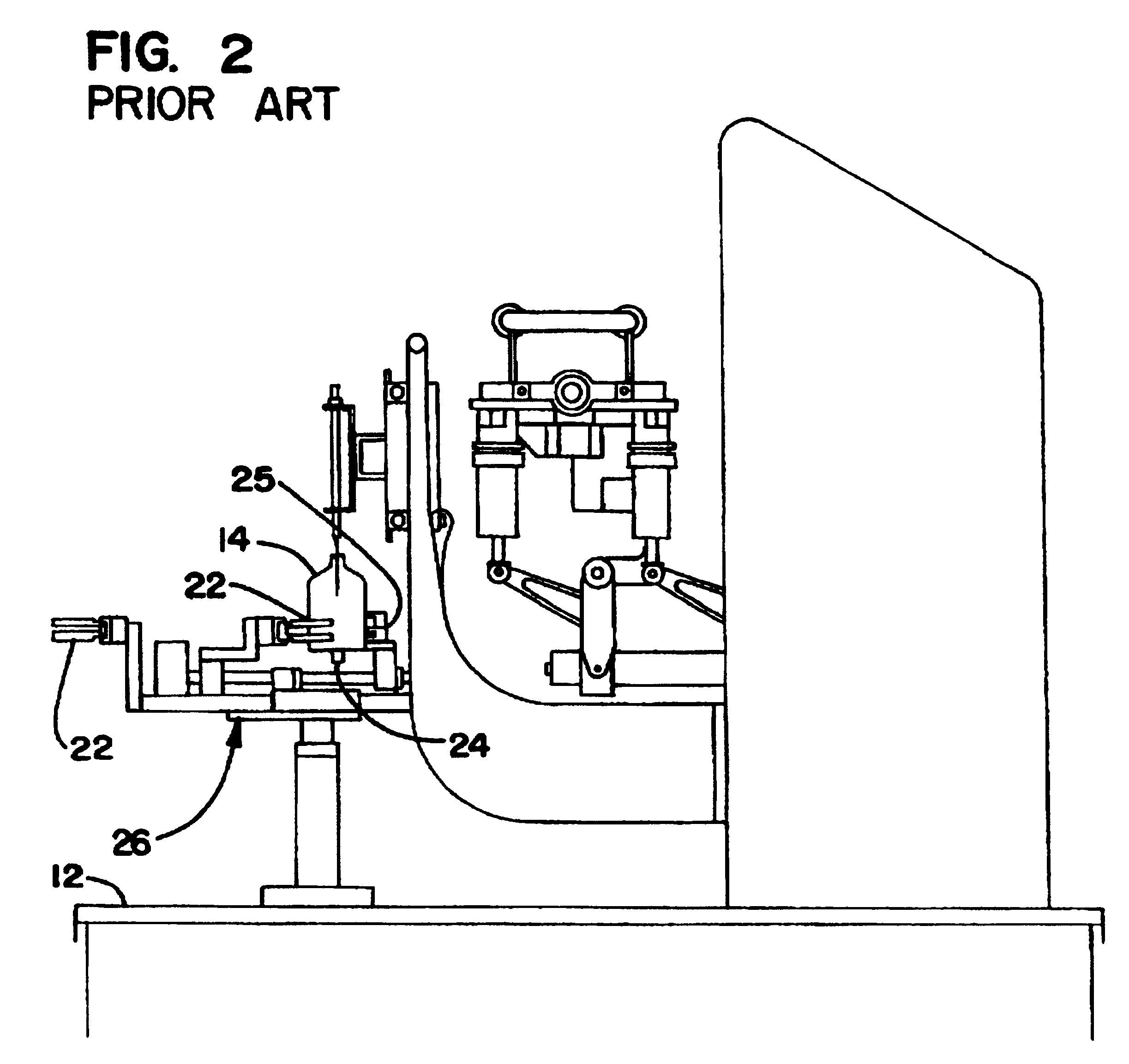

Apparatus for filling sterile containers is disclosed which defines an elongated but narrow sterile zone in which a number of operating stations are disposed. An elongated vertical wall is carried by an elongated frame and a cabinet type enclosure cooperates with the vertical wall to define the sterile zone. The plurality of operating stations are disposed in sequential relation over the length of the sterile zone, and an elongated container conveyor is disposed within the sterile zone to convey the containers through the plurality of operating stations. The conveyor is vertically oriented, consisting an endless belt mounted on end wheels that rotate on horizontal axes. Each of the operating stations includes an operating portion disposed within the sterile zone. Actuating means are included for each of the operating stations as well as the elongated conveyor, each of which is disposed outside the sterile zone. Connecting means operabably connect each of the actuating means outside the sterile zone through the vertical wall to the associated operating station within the sterile zone. By orienting the conveyor vertically and disposing the various actuating means outside the sterile zone in side-by-side relation, the effective width of the sterile zone is significantly reduced. As a result, the sterile zone is more easily accessed, and also more easily drained after washdown operations. In addition, the sterile zone of reduced size results in an apparatus that much easier to manufacture and maintain in a sterile state.

Owner:ROBERT BOSCH PACKAGE TECH

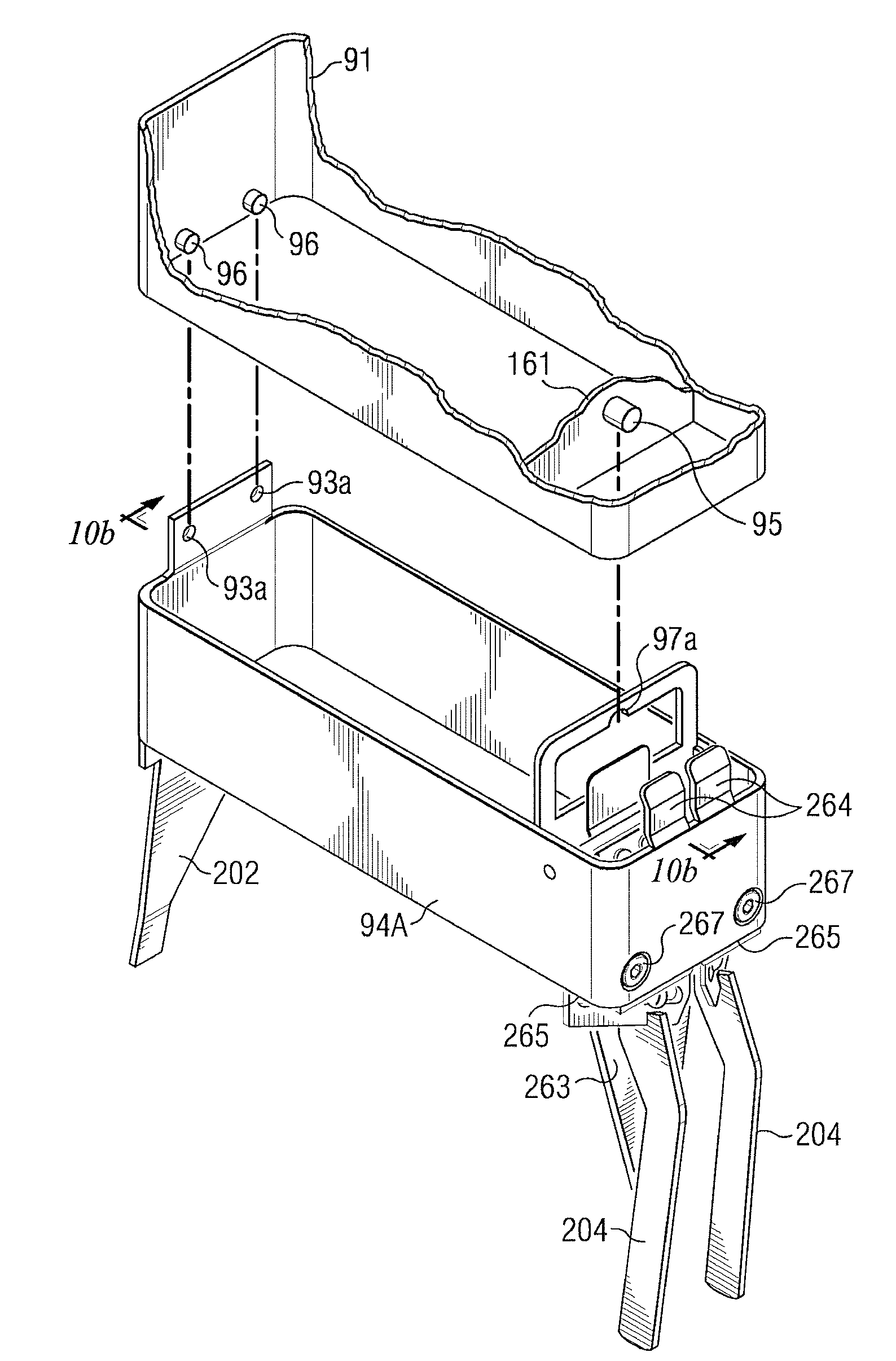

Quick change module with adjustable former attachments

InactiveUS7299608B2Good adhesionDepth can be increased decreasedPackaging machinesSuccessive articlesDisplay deviceMechanical engineering

A quick change module operable for being removably attached to and extending below a forming tube of a conventional vertical form, fill, and seal machine to produce a wide assortment of differently sized vertical stand-up pouches or gusseted flat bottom bags. The quick change module comprises at least one pair of adjustable forming plates located below the forming tube. The lateral distance between each pair of forming plates can be adjusted by shifting the position of each forming plate along a corresponding slotted bracket. A gusseting mechanism mounted to the frame of the machine can be positioned between each pair of forming plates imparting a vertical crease along the length of the bag while it is being formed and advanced down the forming tube of the machine. By adjusting the lateral separation of the forming plates, the size of the vertical crease can be adjusted such that the resulting gusseted base is increased or decreased in proportion to size of the resulting package, thereby enhancing the overall stability of the package when placed on display.

Owner:FRITO LAY NORTH AMERICA INC

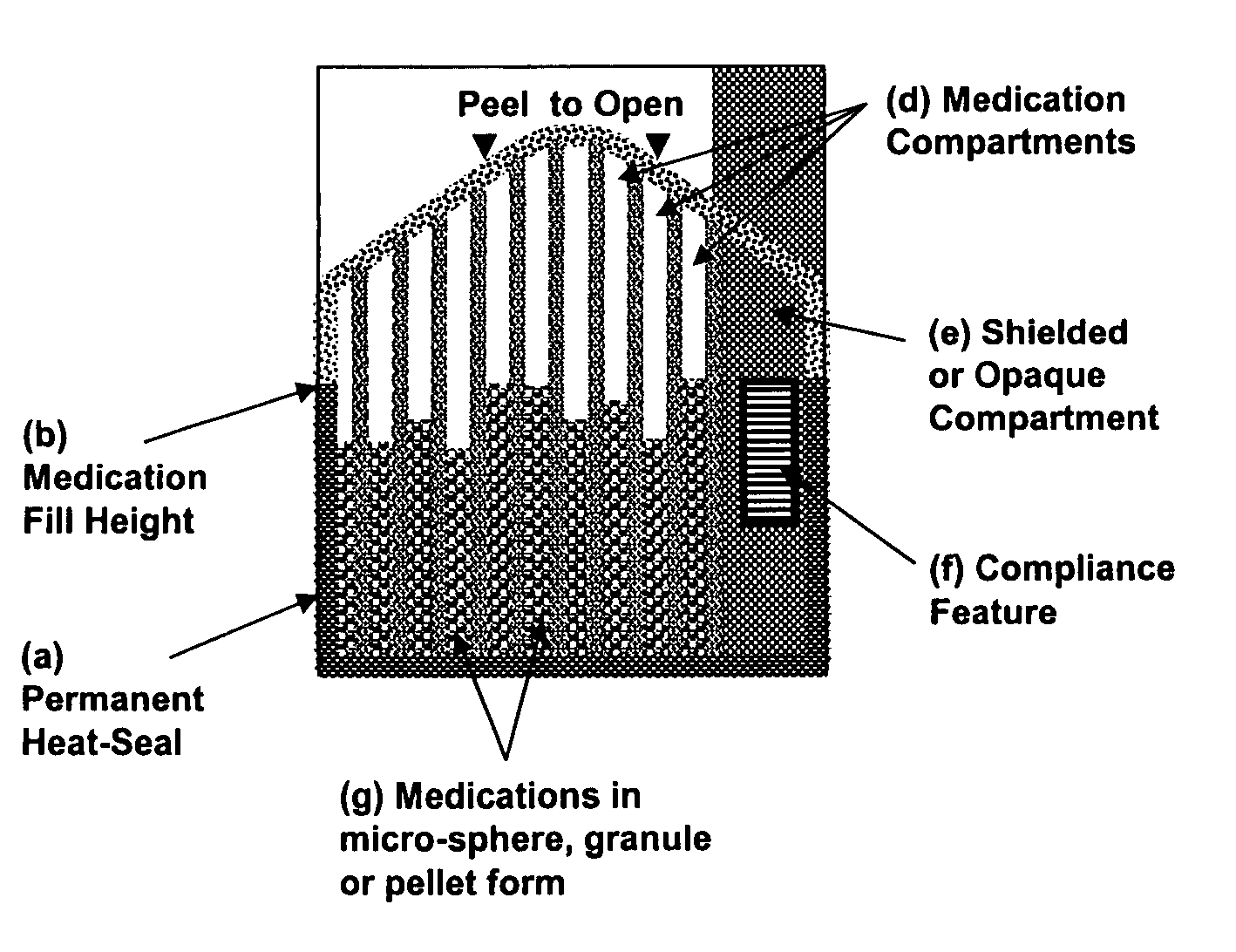

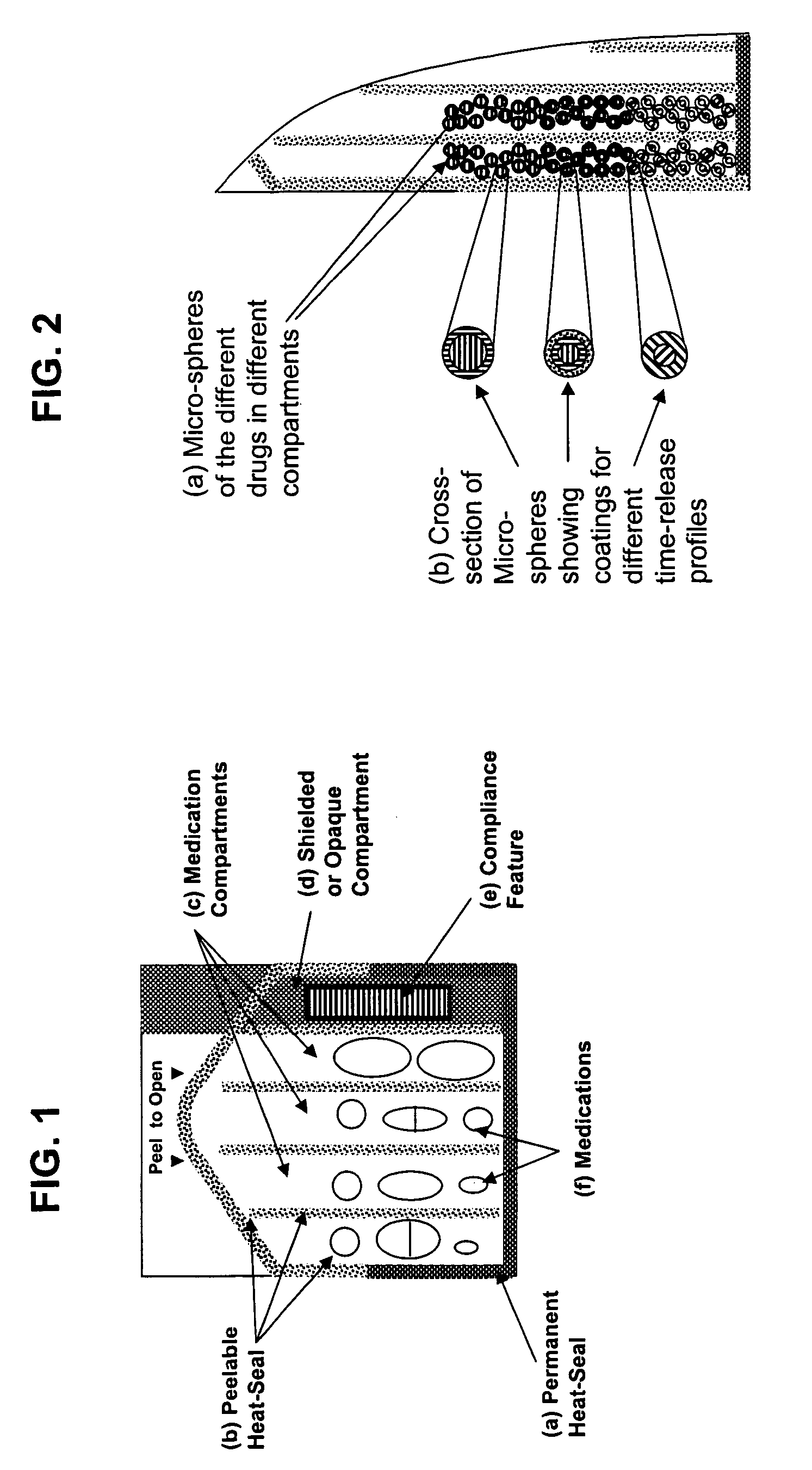

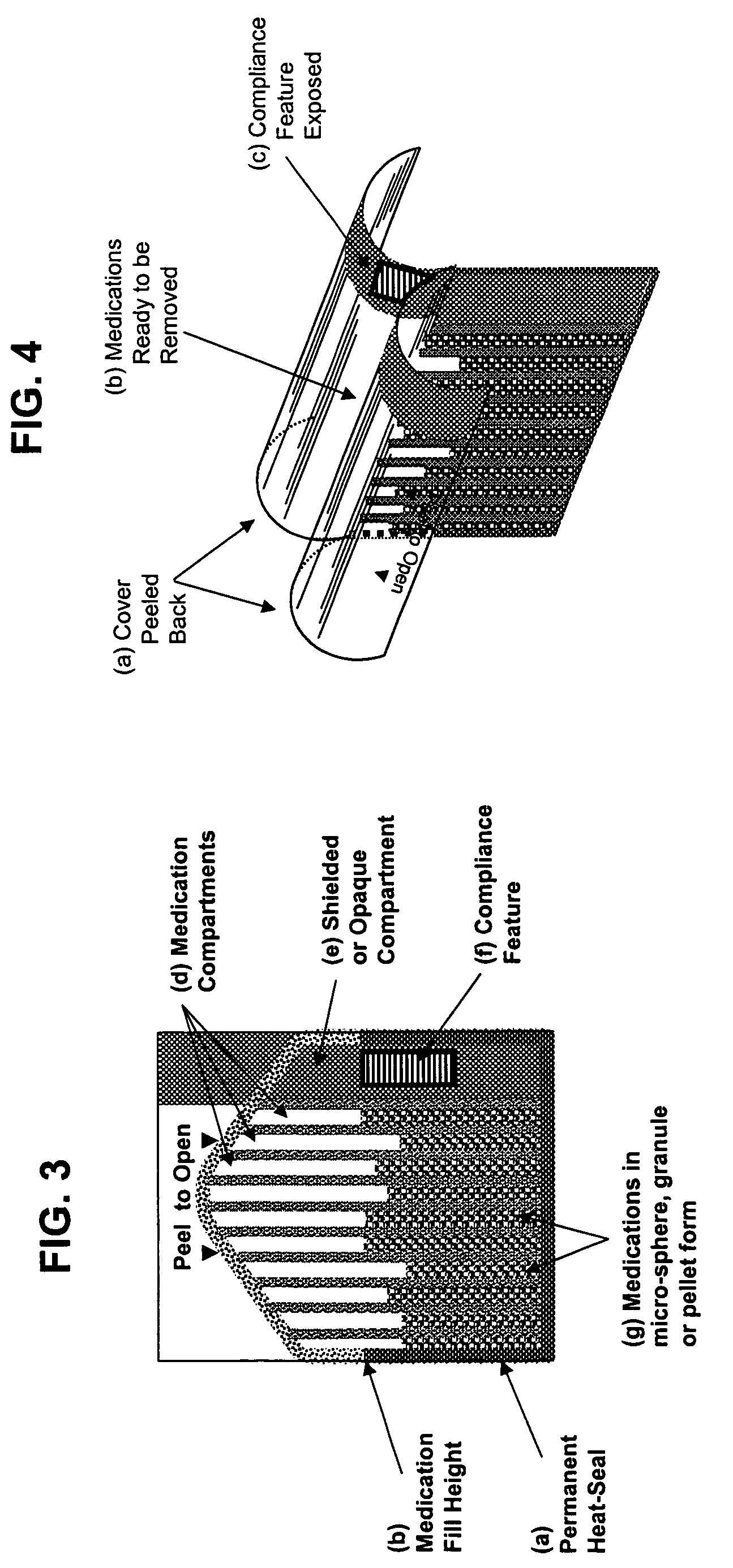

Unified ingestion package and process for patient compliance with prescribed medication regimen

Techniques for reducing non-compliance of medication use are described. The techniques involve generating and storing an identifier for a specific dosage instance of a specific patient, and creating a package that includes a mechanism for conveying the identifier. Once the package is created, a set of one or more medications that are prescribed to be taken by the specific patient at the specific dosage instance are placed in the package. The set of medications within the package in a manner that prevents the identifier from being perceived from the mechanism until the package is opened. Once opened, the identifier is perceived and communicated back to an automated compliance system.

Owner:RAMASUBRAMANIAN NARAYANAN +1

Method and apparatus for securing a load to a pallet with a roped film web

ActiveUS7568327B2Narrow widthReduce widthWrappers shrinkageWrapping material feeding apparatusThin membranePallet

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one guide rollers configured to engage the width of the film web, and at least one roping element. The at least one roping element may be a cable rolling roper configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

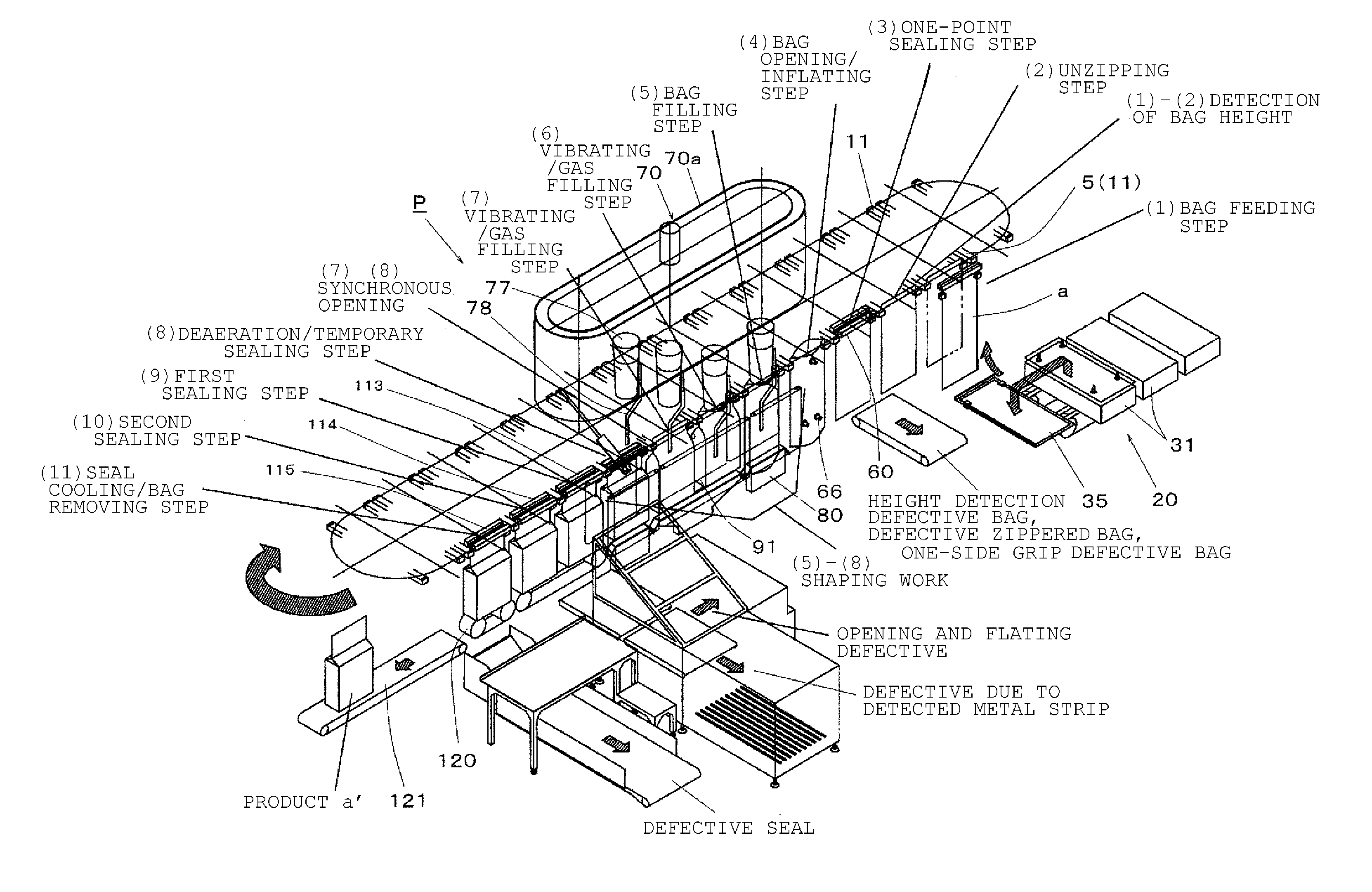

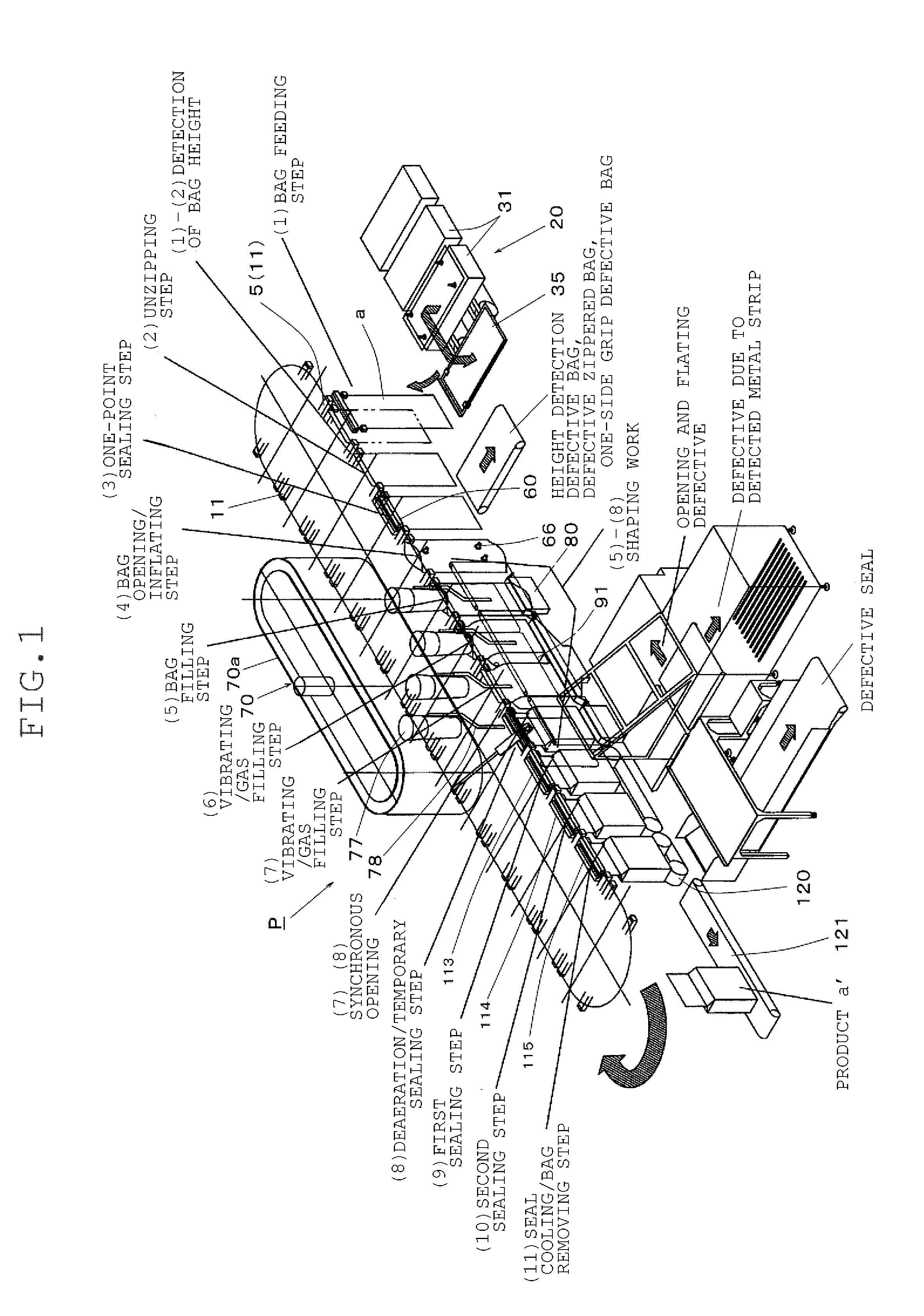

Gas-Filliing Packaging Method and Packaging Machine Therefor

InactiveUS20140331603A1Good quality and stabilityPackaging by pressurising/gasifyingWrapper twisting/gatheringPacking methodPackaging machine

A gas-filling packaging method using a track type gas-filling packaging machine includes a bag placing step in which a number of packaging bags set in a magazine in a stacked state are turned up one by one by a sucker and picking up and then passing the bag to a bag chuck, a bag opening / inflating step of opening the bag mouth and inflating the bottom of the bag by suckers, a bag filling step of lowering a synchronous funnel to be inserted into the bag and applying a receiving member of a bottom tapping unit to the bag, so that the bag is filled with a predetermined amount of article while the bottom is tapped, a deaeration / temporarily sealing step of inserting a deaeration nozzle into the bag to remove air in the bag and holding the bag mouth by a temporary heater.

Owner:GENERAL PACKER

Method of dispensing pills from a movable platen

A plurality of cassettes, each filed with a supply of pills and positioned over a target location. A platen is provided beneath the target location with receptacles configured to hold both vials and blister packs. The platen or the cassette is movable so that any blister of the blister pack or the vial can be positioned under the target location to receive a quantity of pills from the cassette.

Owner:QEM INC

Inkjet printer

An inkjet printer includes a printhead containing a nozzle portion having a length corresponding to a width of a paper sheet. A moving block is configured to move along a longitudinal direction of the nozzle portion. A cleaning unit has one or more blades to wipe off waste ink by contacting the nozzle portion. The cleaning unit is mounted in the moving block. Accordingly, the nozzle portion is effectively cleaned, and thus deterioration of the printing quality due to waste ink may be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

Apparatus for molding and assembling containers with stoppers and filling same

InactiveUS7707807B2Package sterilisationPackaging under vacuum/special atmosphereMolding machineShell molding

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

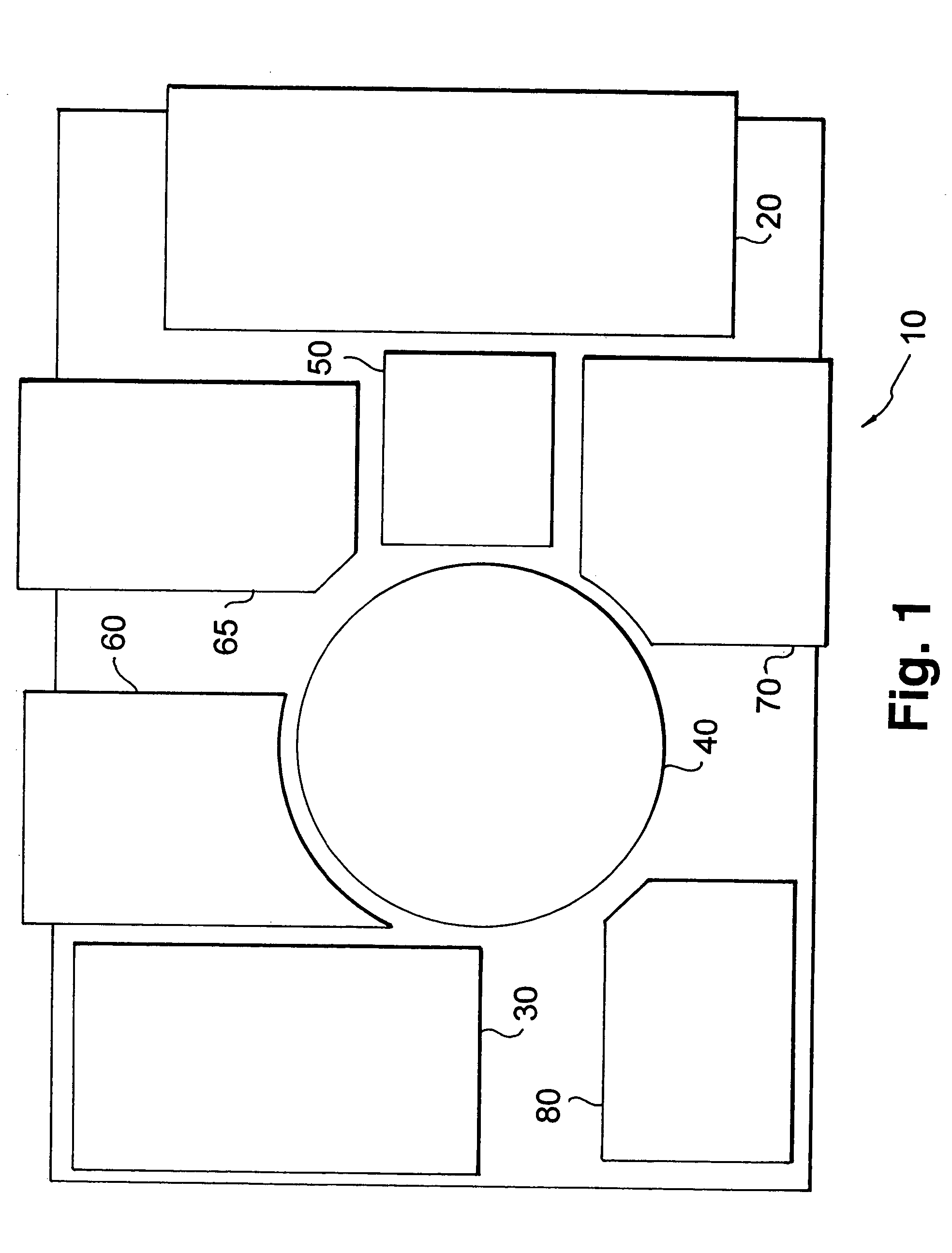

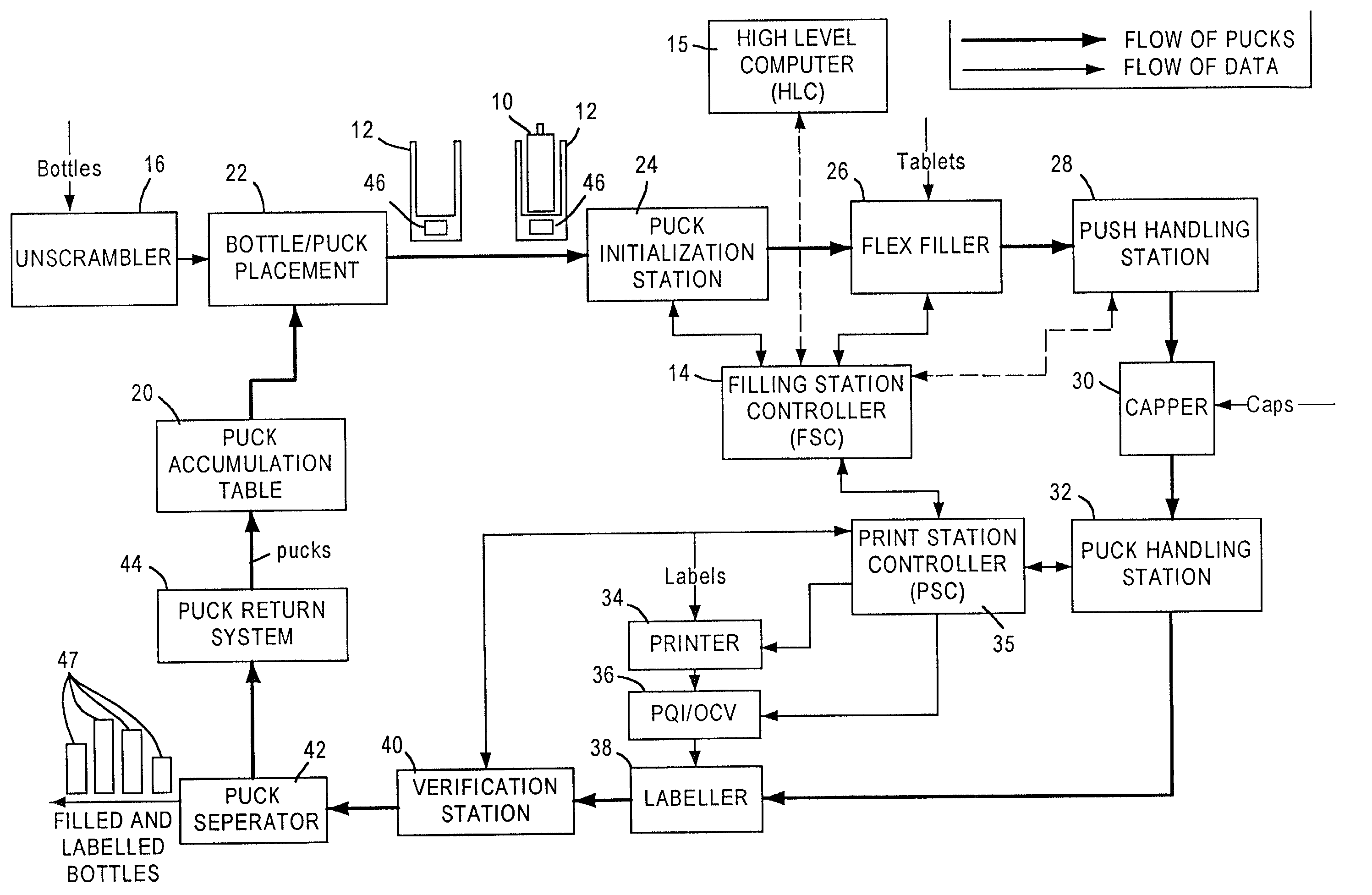

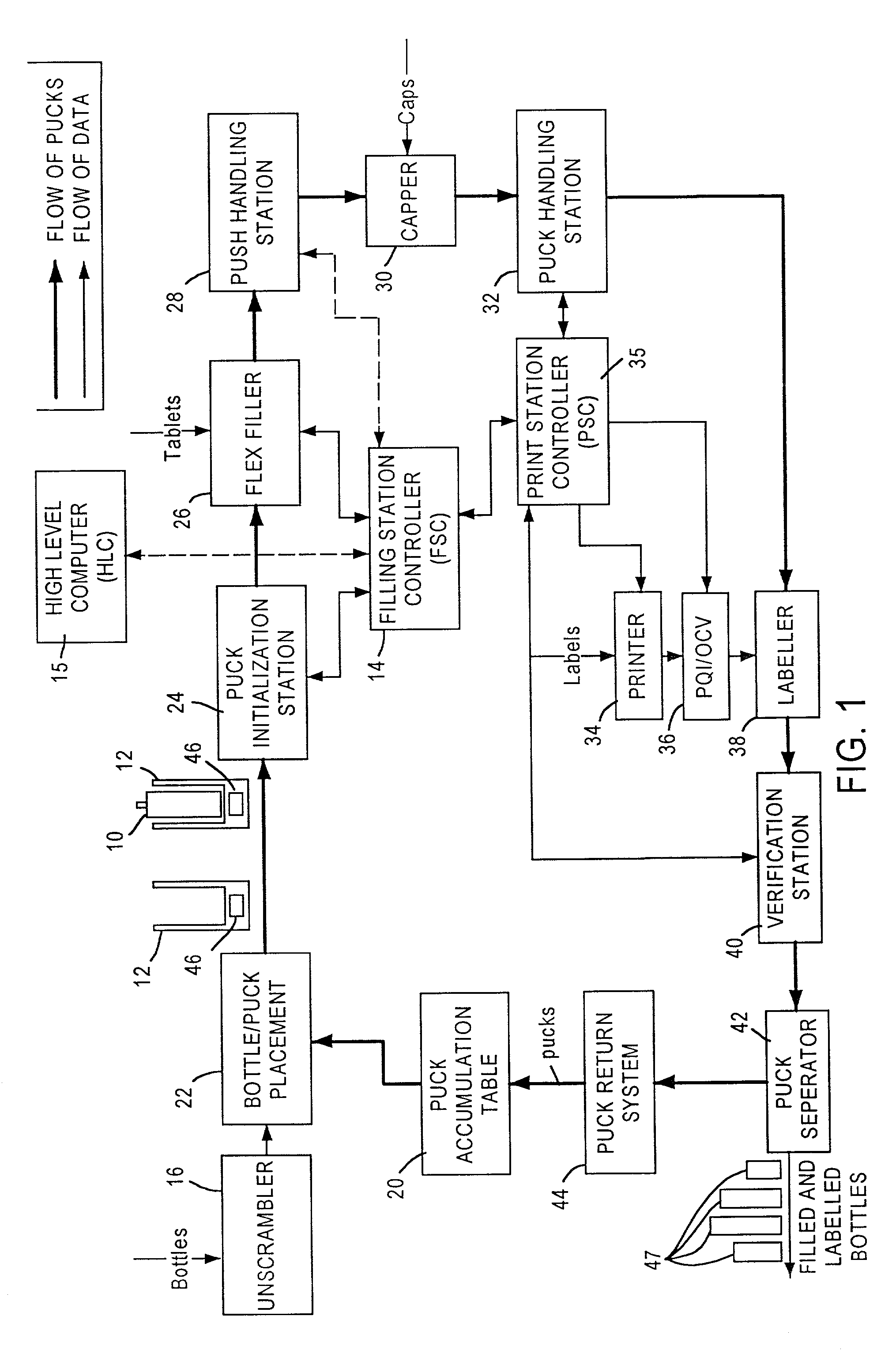

Customer specific packaging line

InactiveUS20020099467A1Improve efficiencyReduce expensesPackaging cigaretteDigital data processing detailsEngineeringBottle

Owner:MERCK & CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com