Patents

Literature

2625results about "Binding material application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

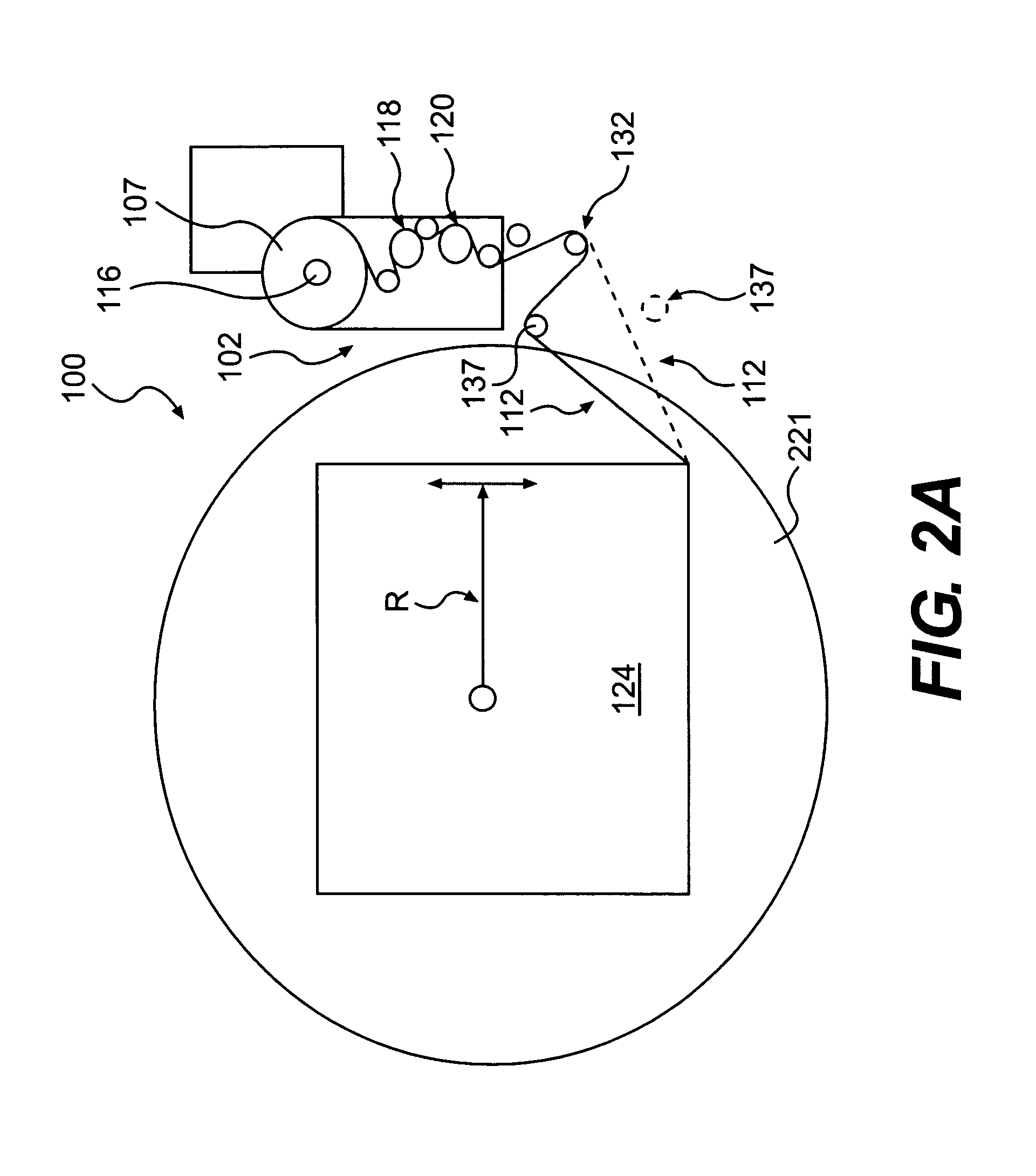

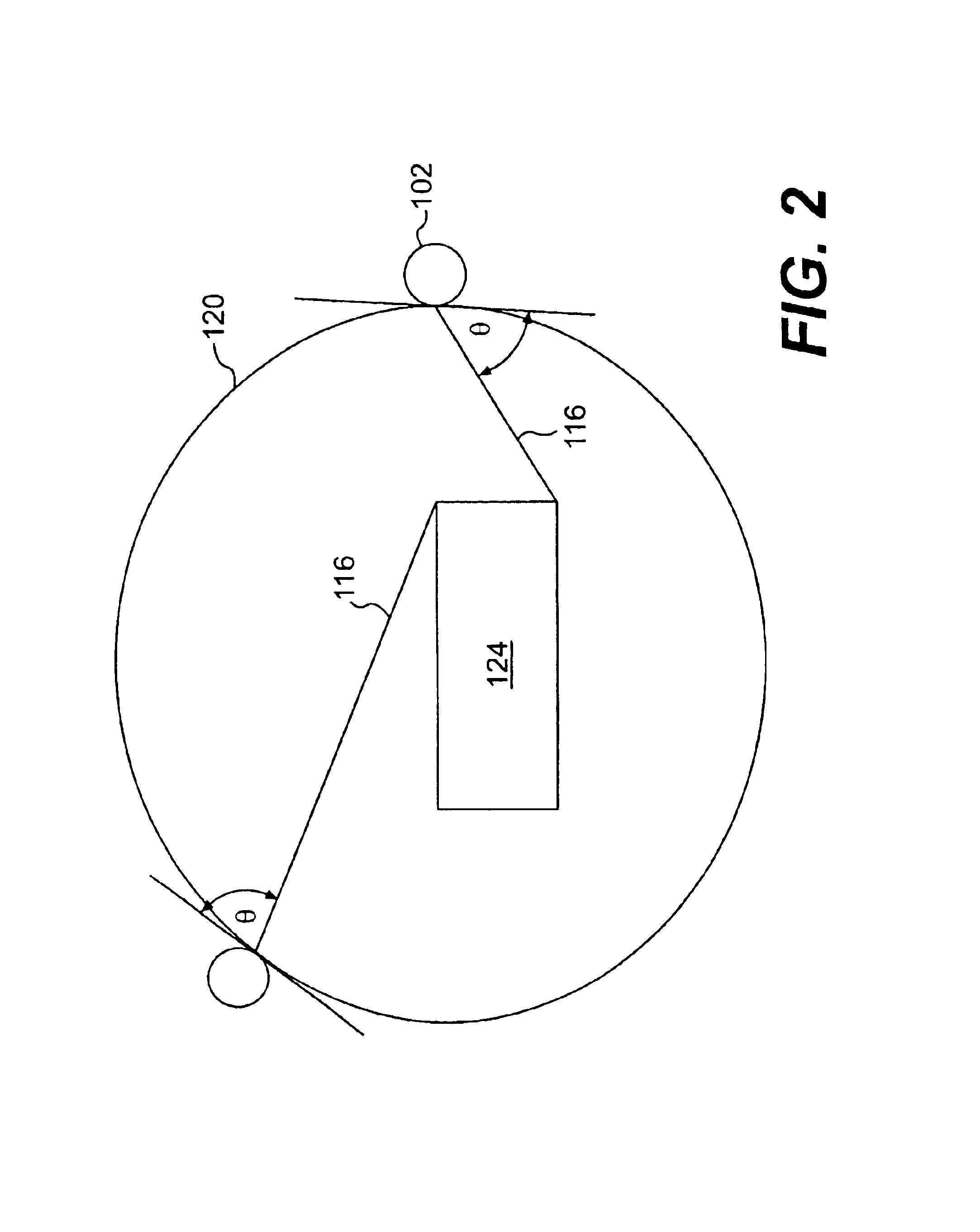

Method and apparatus for metered pre-stretch film delivery

The present invention provides a method and apparatus for dispensing a predetermined substantially constant length of pre-stretched packaging material based upon load girth. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution of relative rotation between a packaging material dispenser and the load is determined. A rotational drive system used to provide the relative rotation is linked to a pre-stretch assembly portion of the packaging material dispenser. The linkage may be mechanical or electrical. The linkage controls a ratio of the rotational speed to the pre-stretch assembly dispensing speed, such that the predetermined substantially constant length of pre-stretched packaging material is dispensed for each revolution of the packaging material dispenser relative to the load regardless of the speed of the rotational drive. In the case of a mechanical linkage, the linkage also connects the rotational drive to the pre-stretch assembly portion such that the rotational drive also drives the pre-stretch assembly portion.

Owner:LANTECH COM

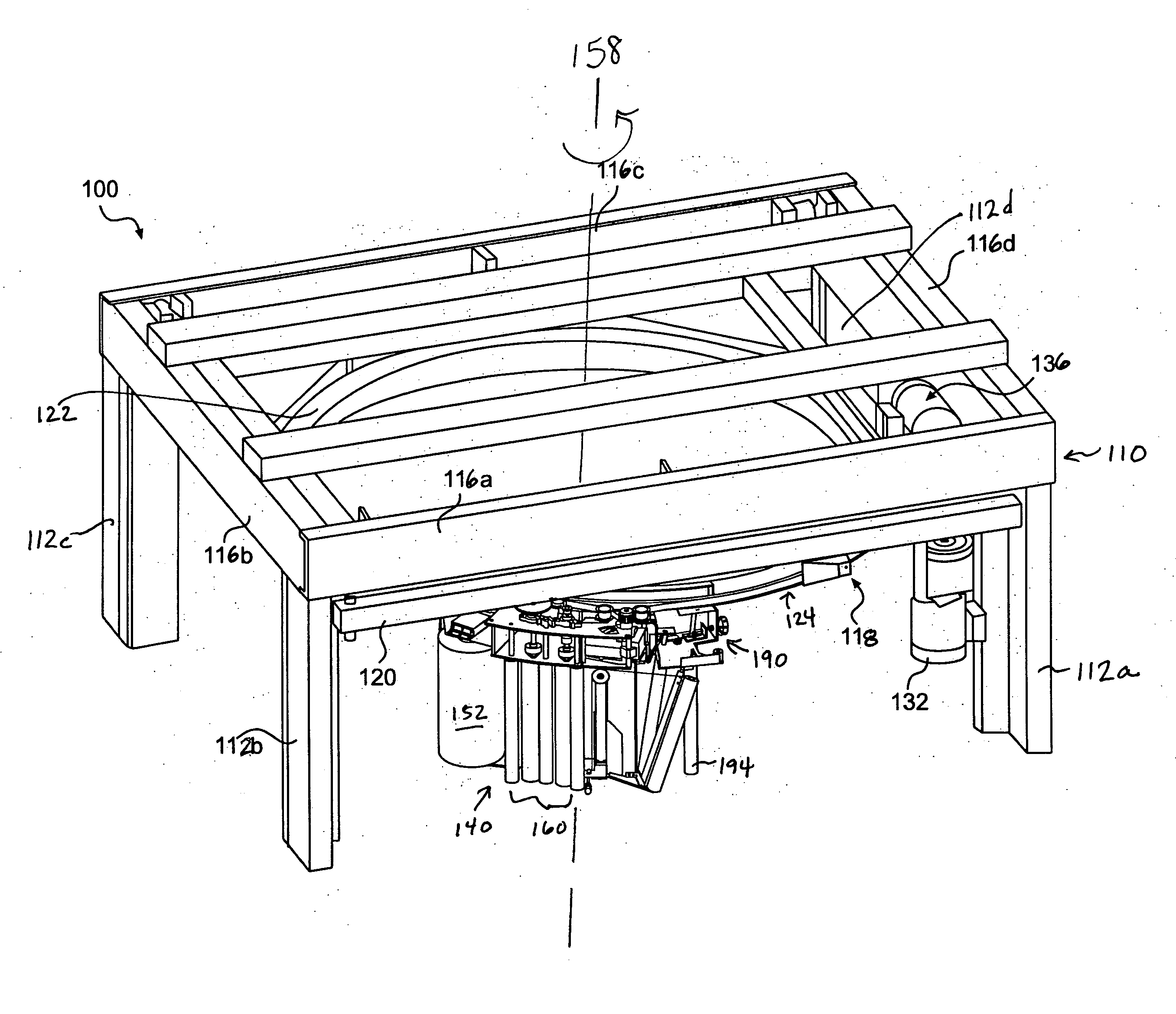

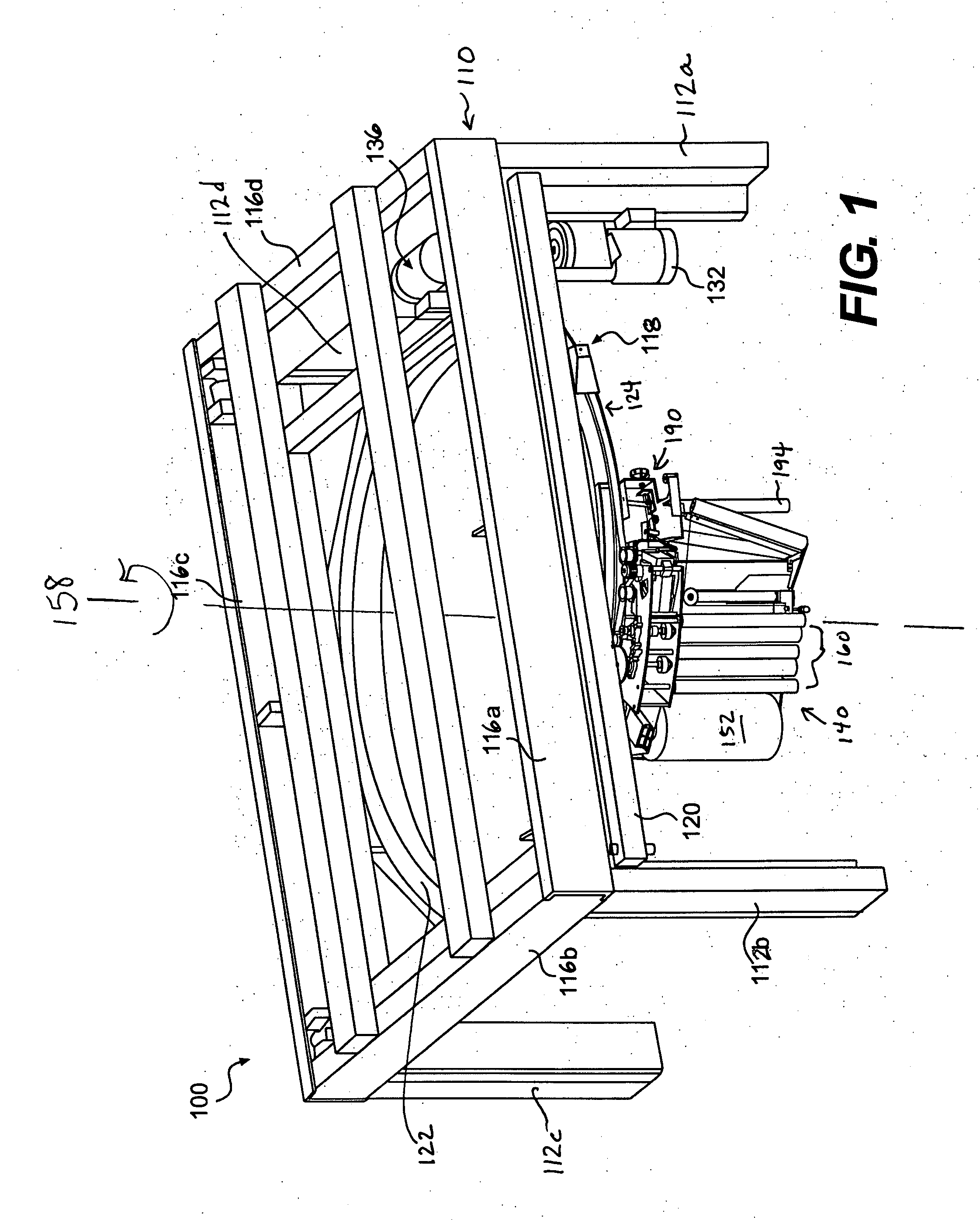

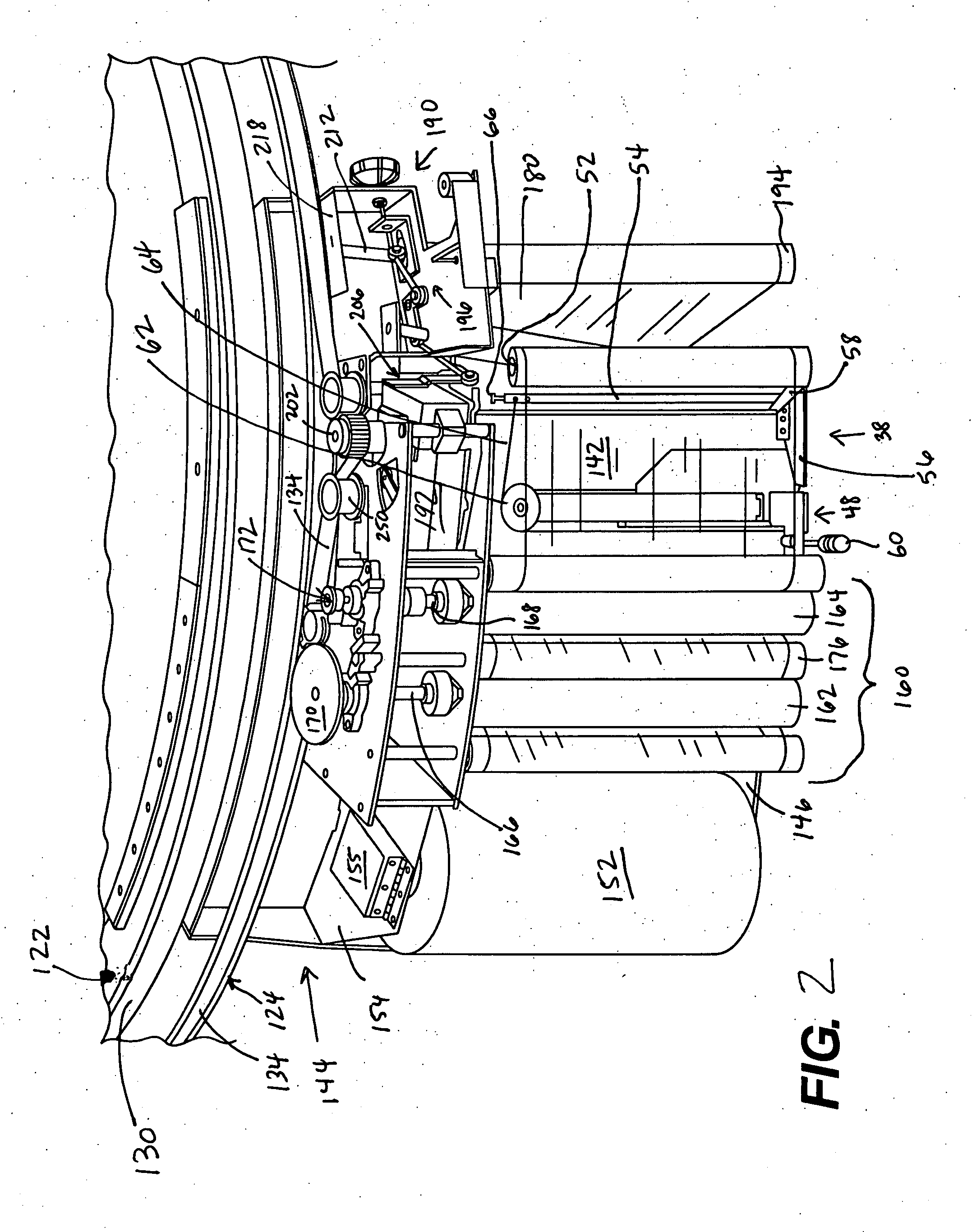

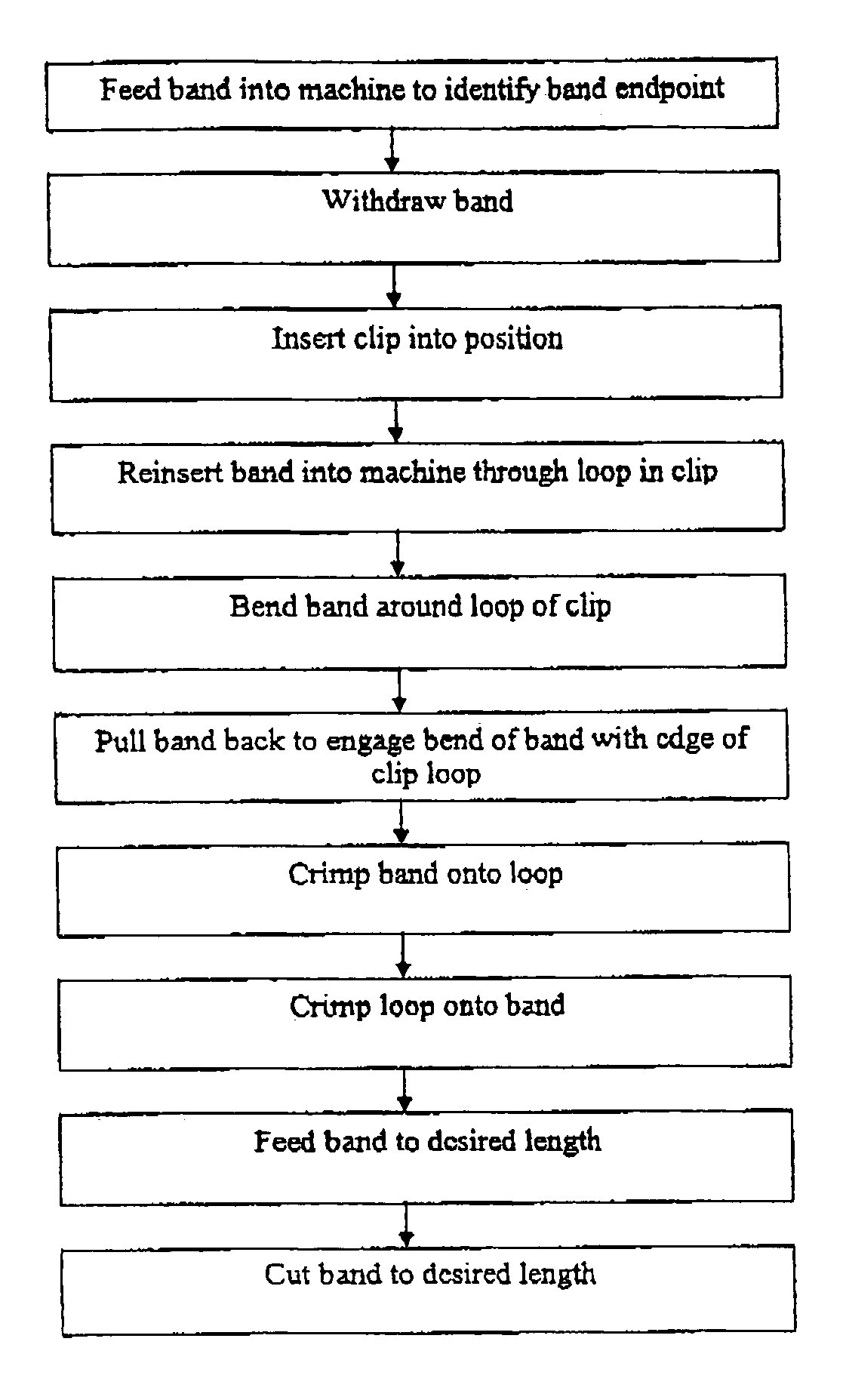

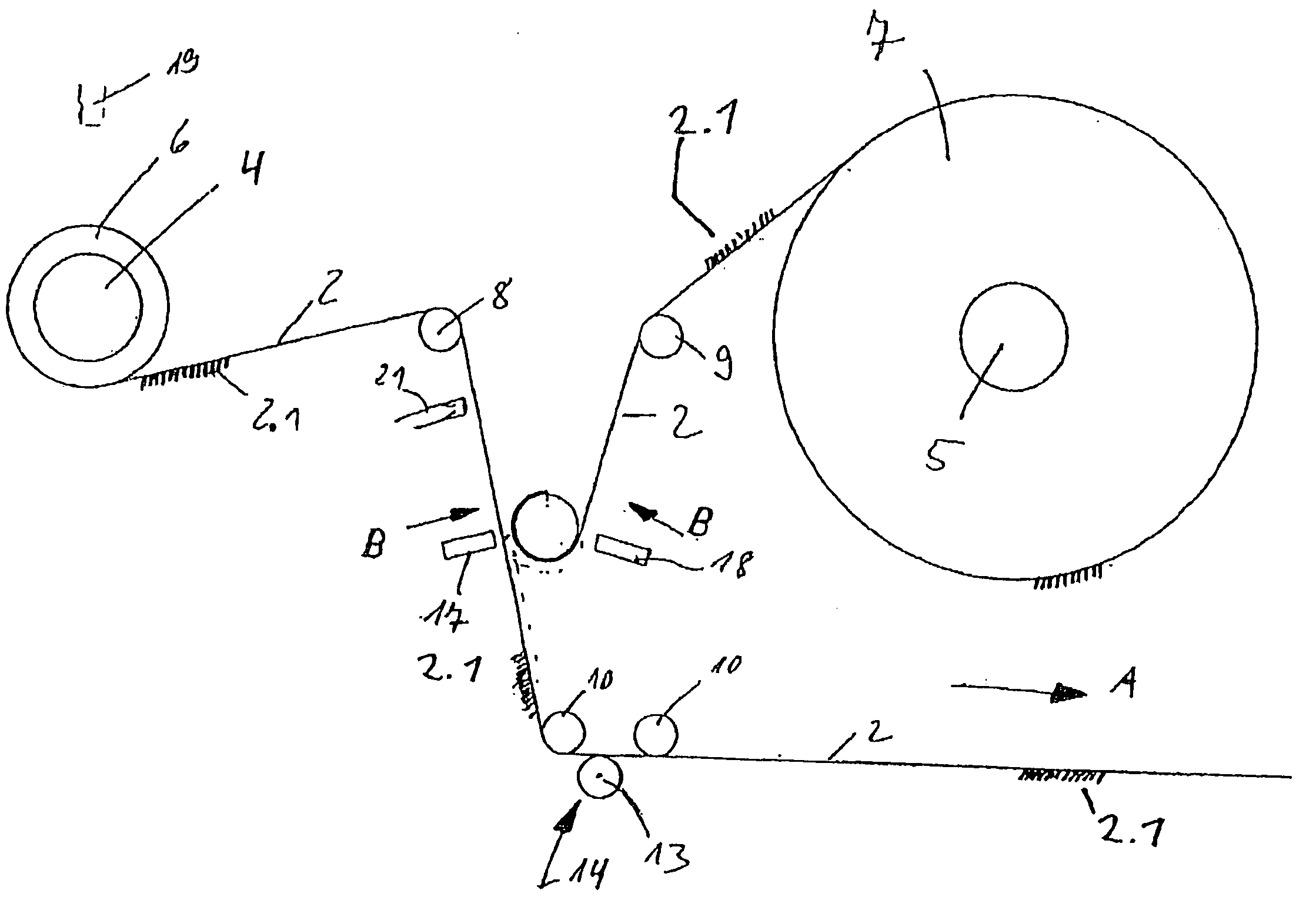

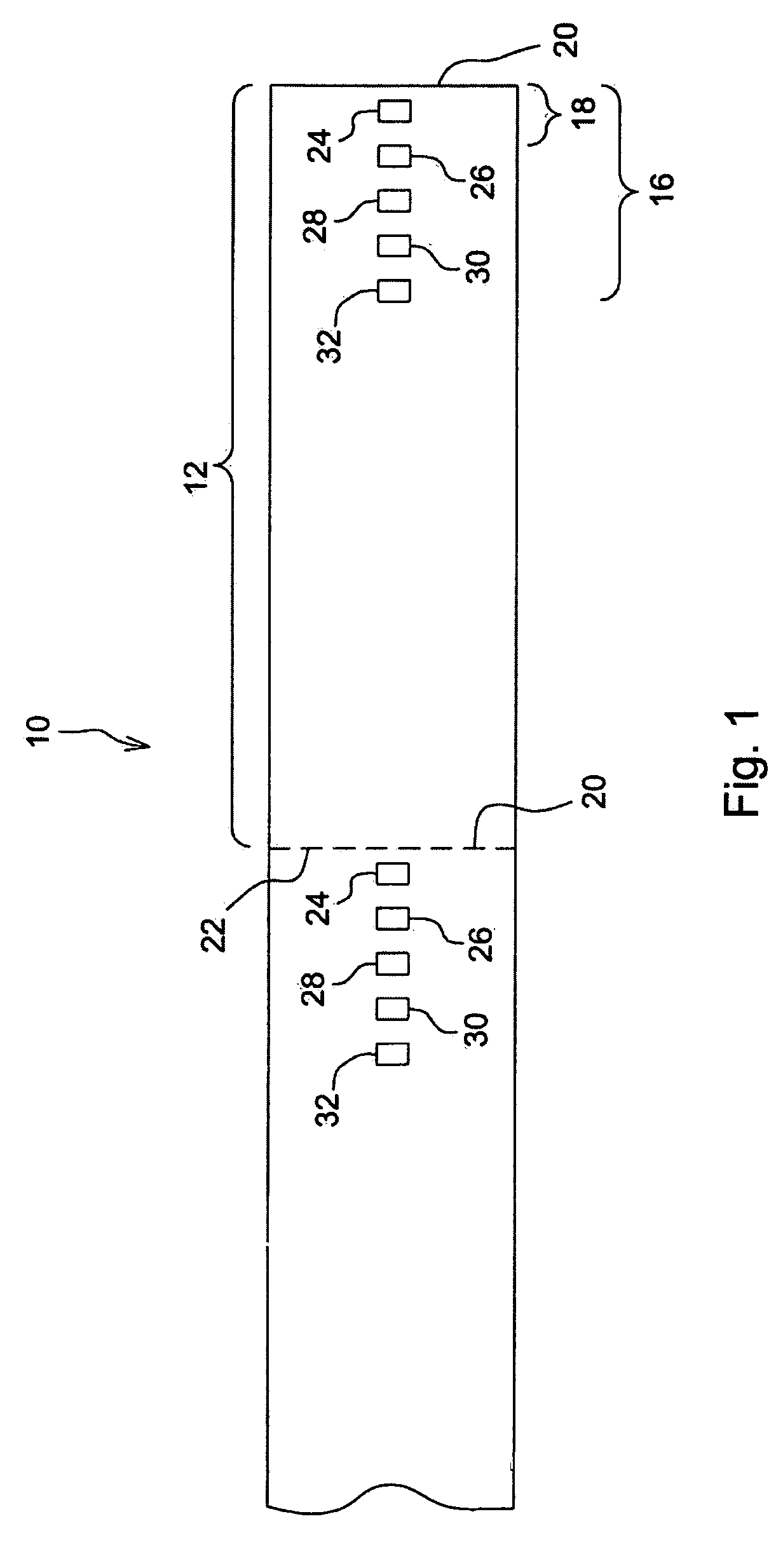

Method of manufacturing a band with a fastener

A device and method is disclosed for manufacturing a band of a desired length with a fastener attached to the band. Generally, metal band material is fed from a spindle on the device until the end of the band material is detected by the device. The device includes a positioning component that places the fastener at the desired location of the band, which is then looped through the fastener. The device then crimps the fastener to the band, positions the band at its desired length, and cuts the band to the desired length.

Owner:VERESCHAGIN LAWRENCE WAYNE

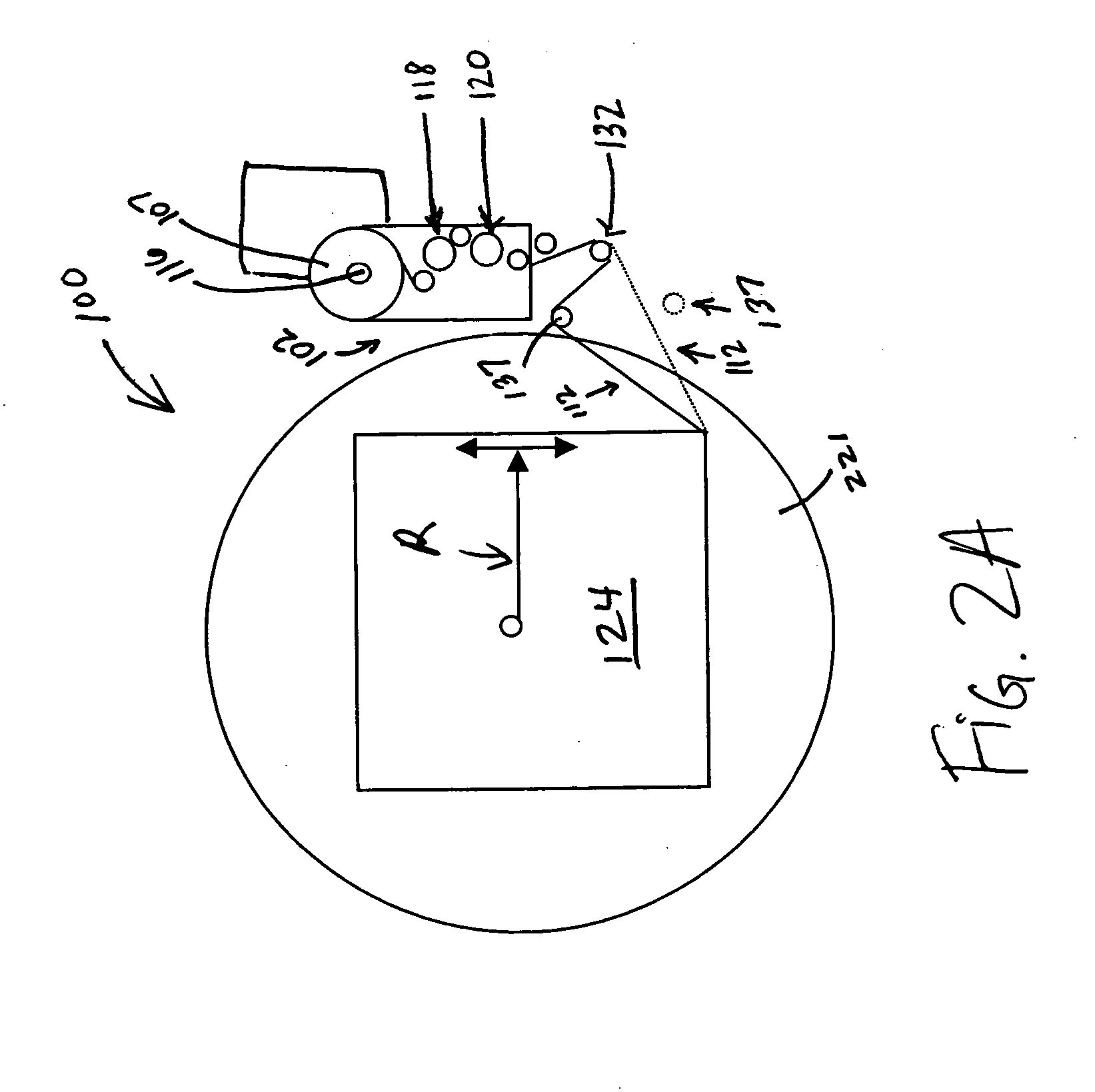

Method for dispensing a predetermined amount of film relative to load girth

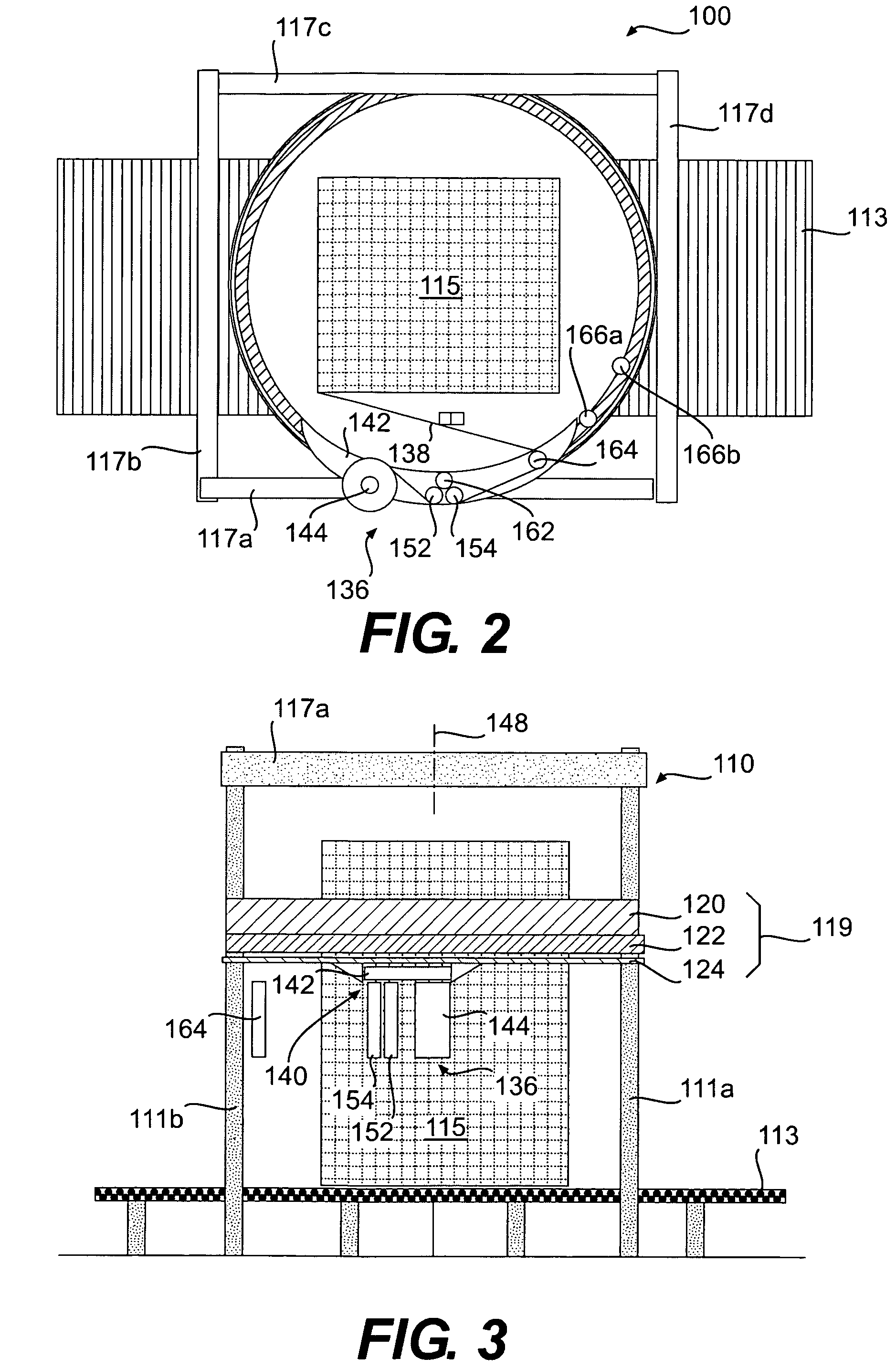

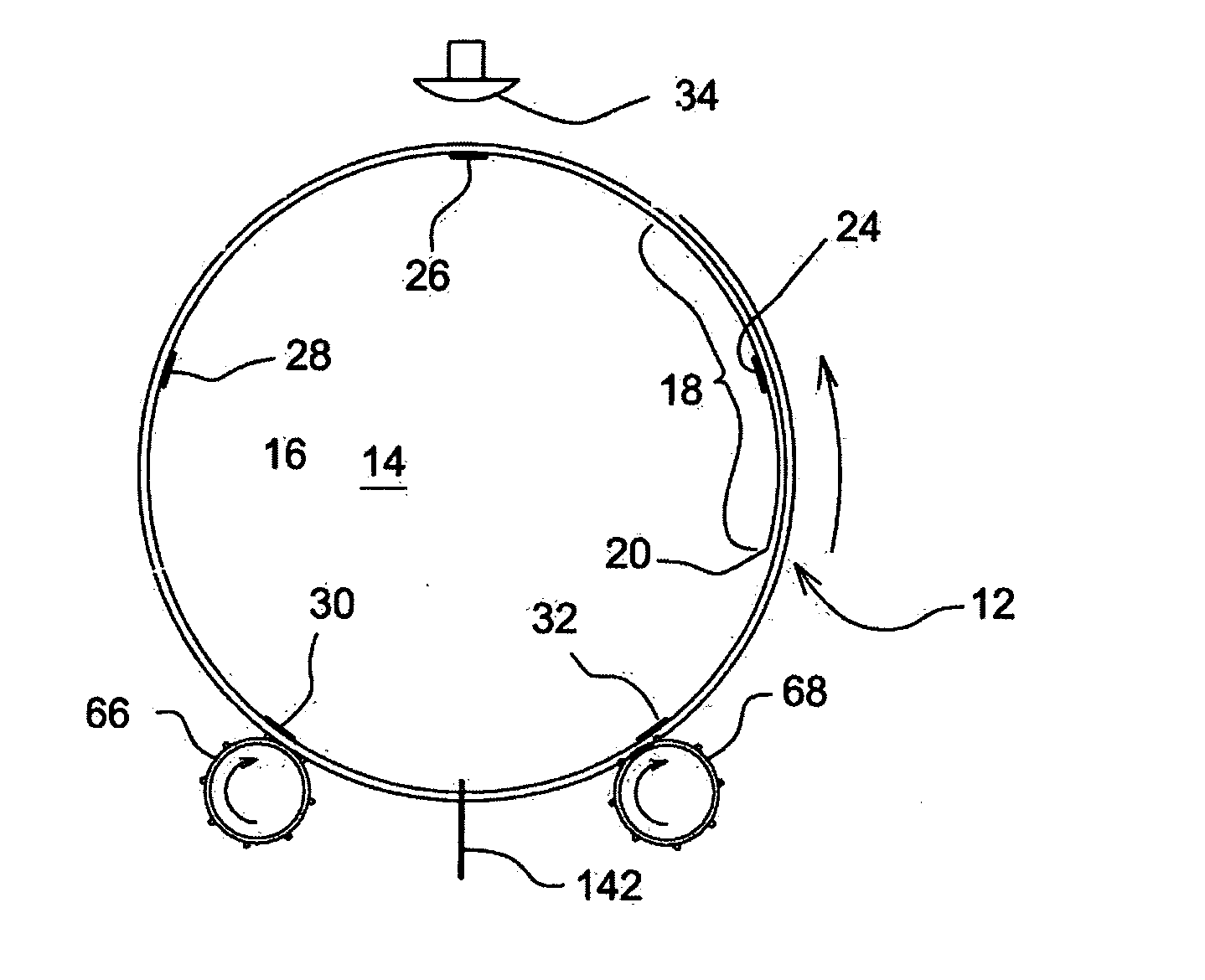

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

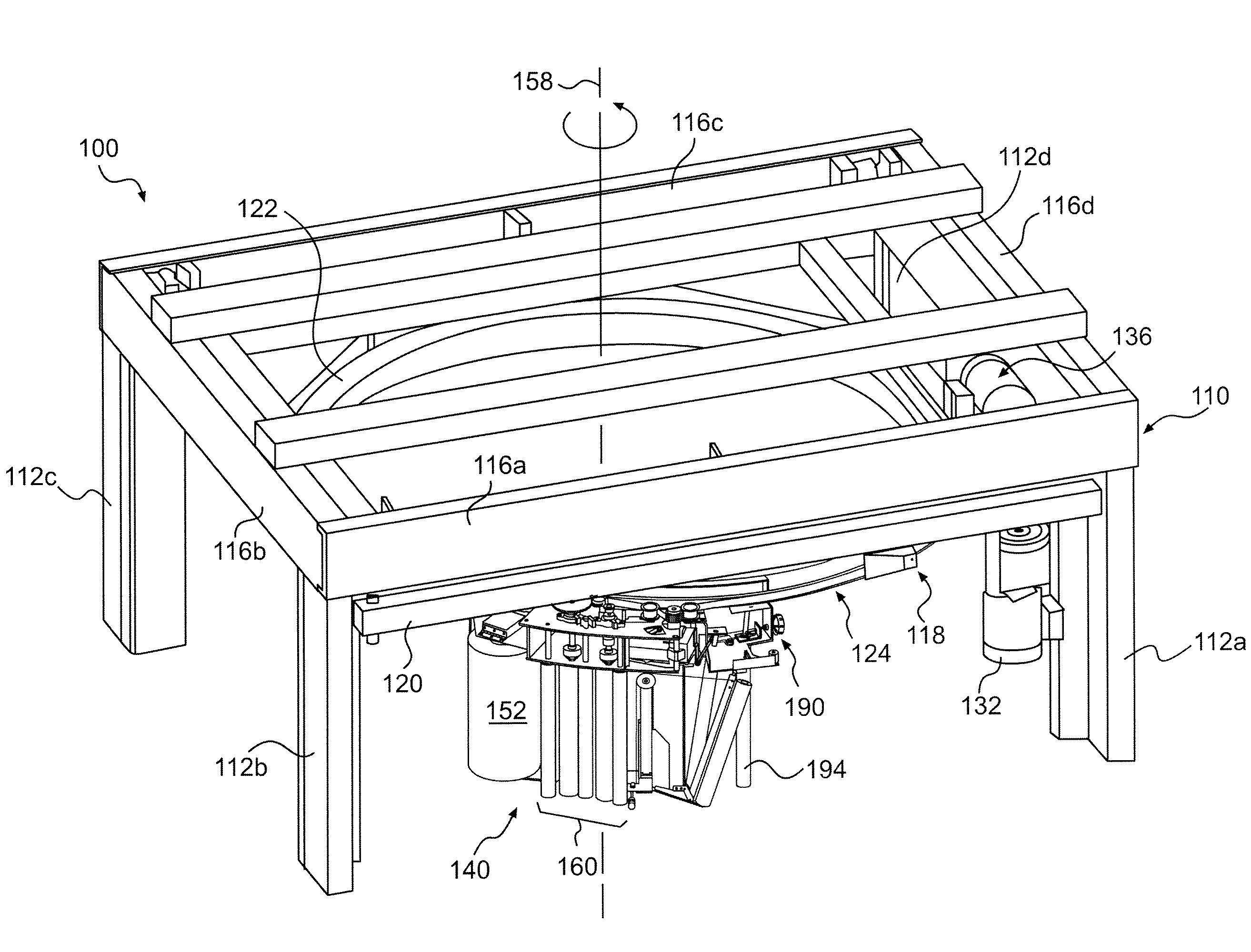

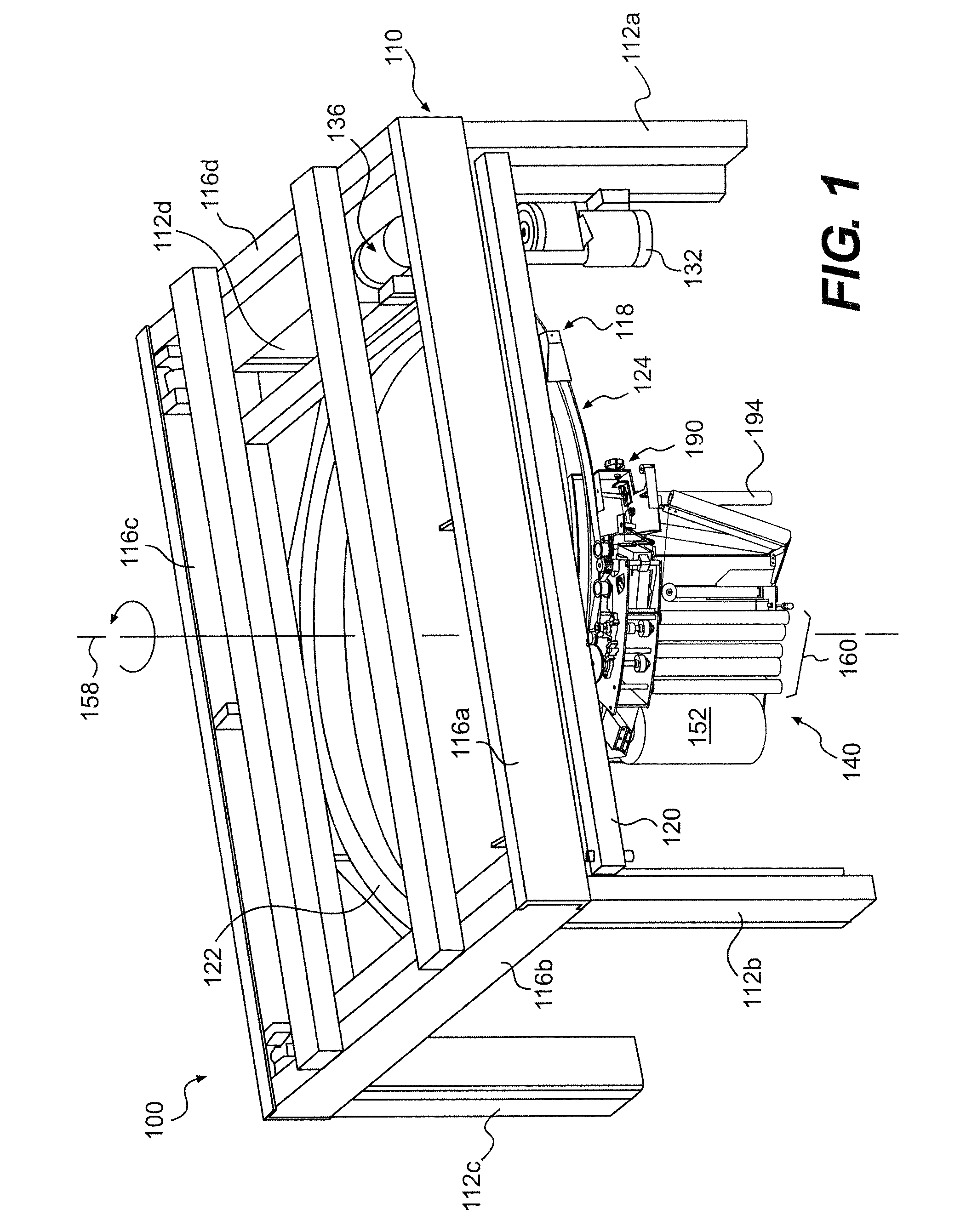

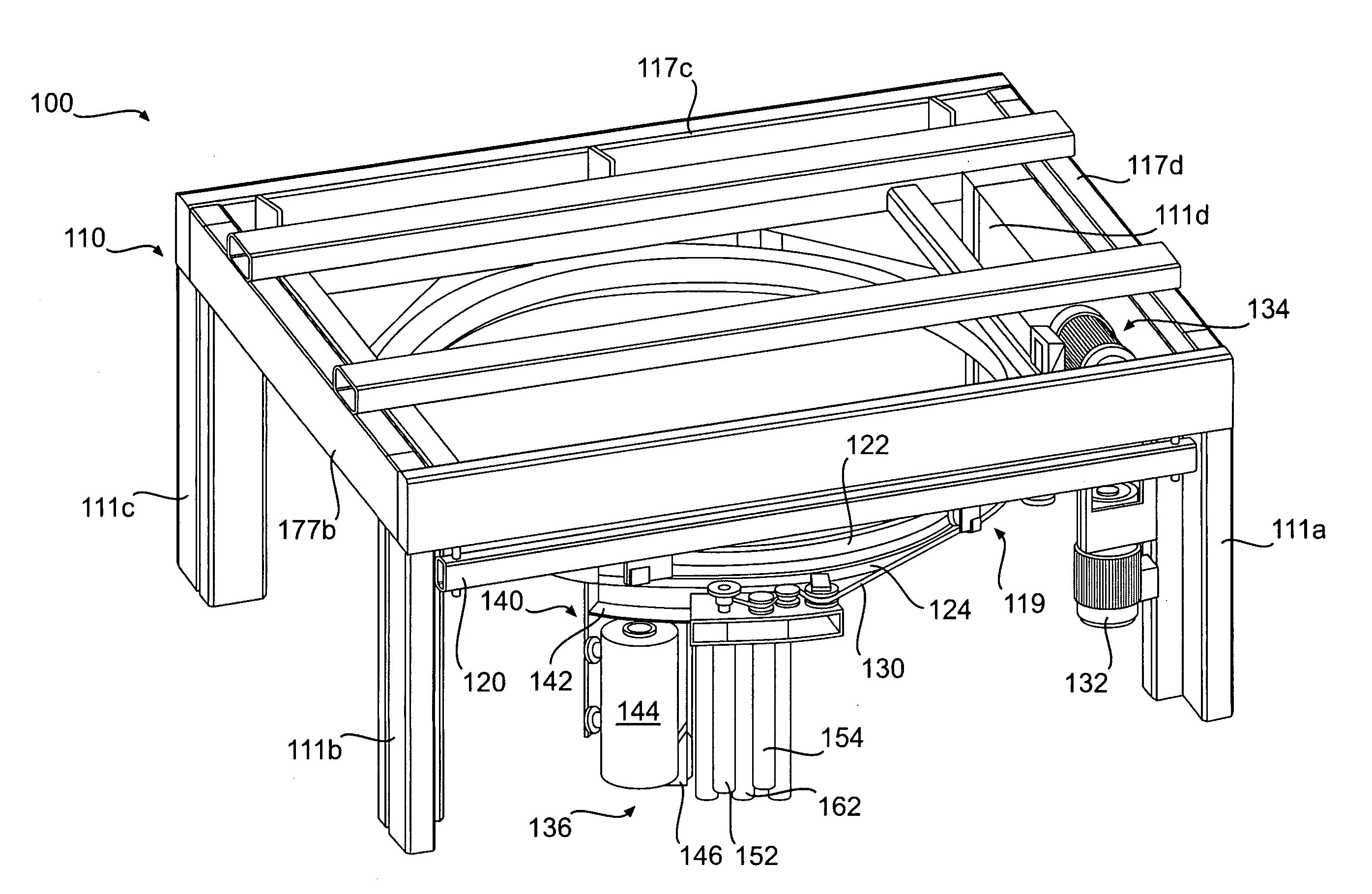

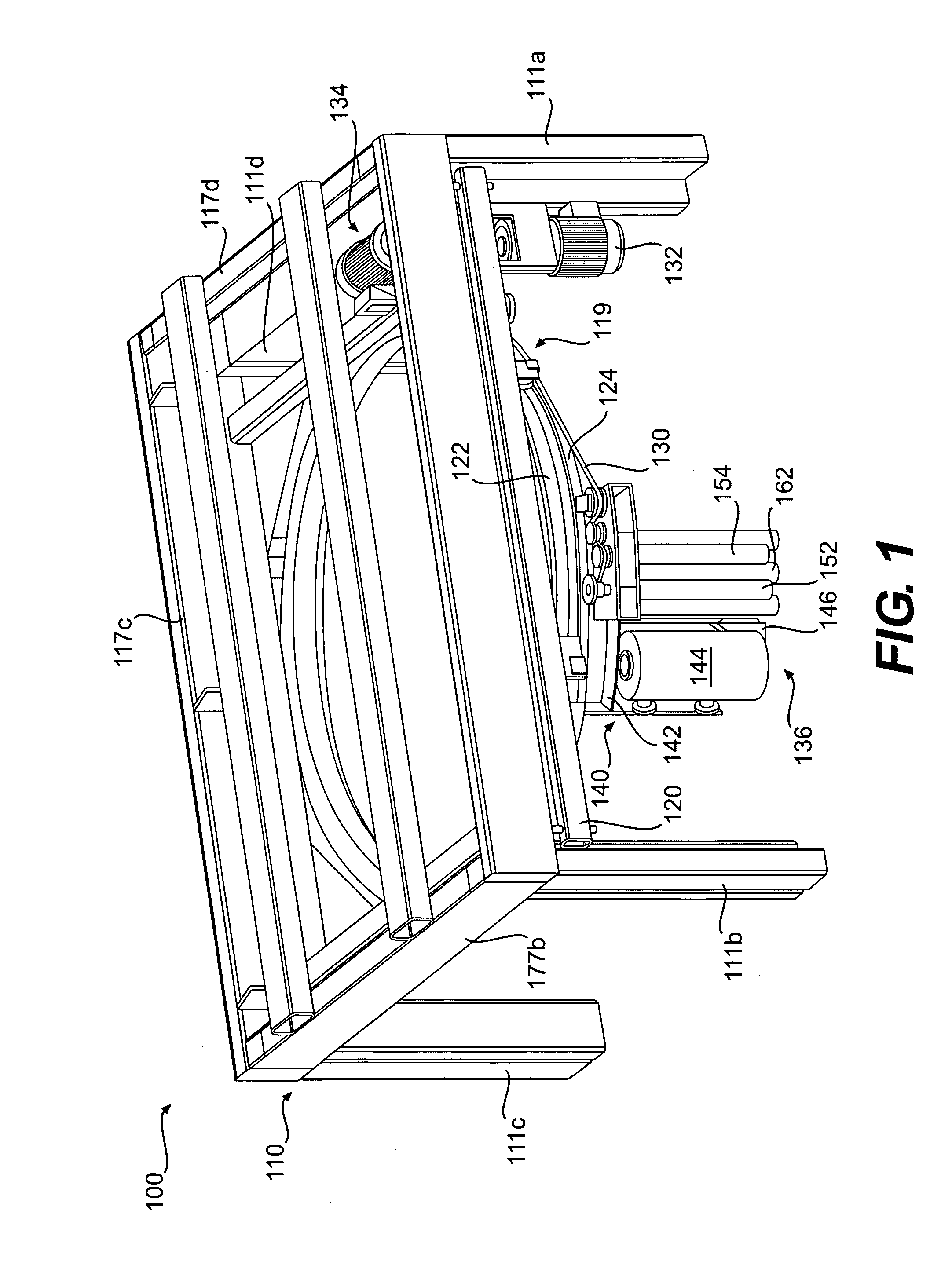

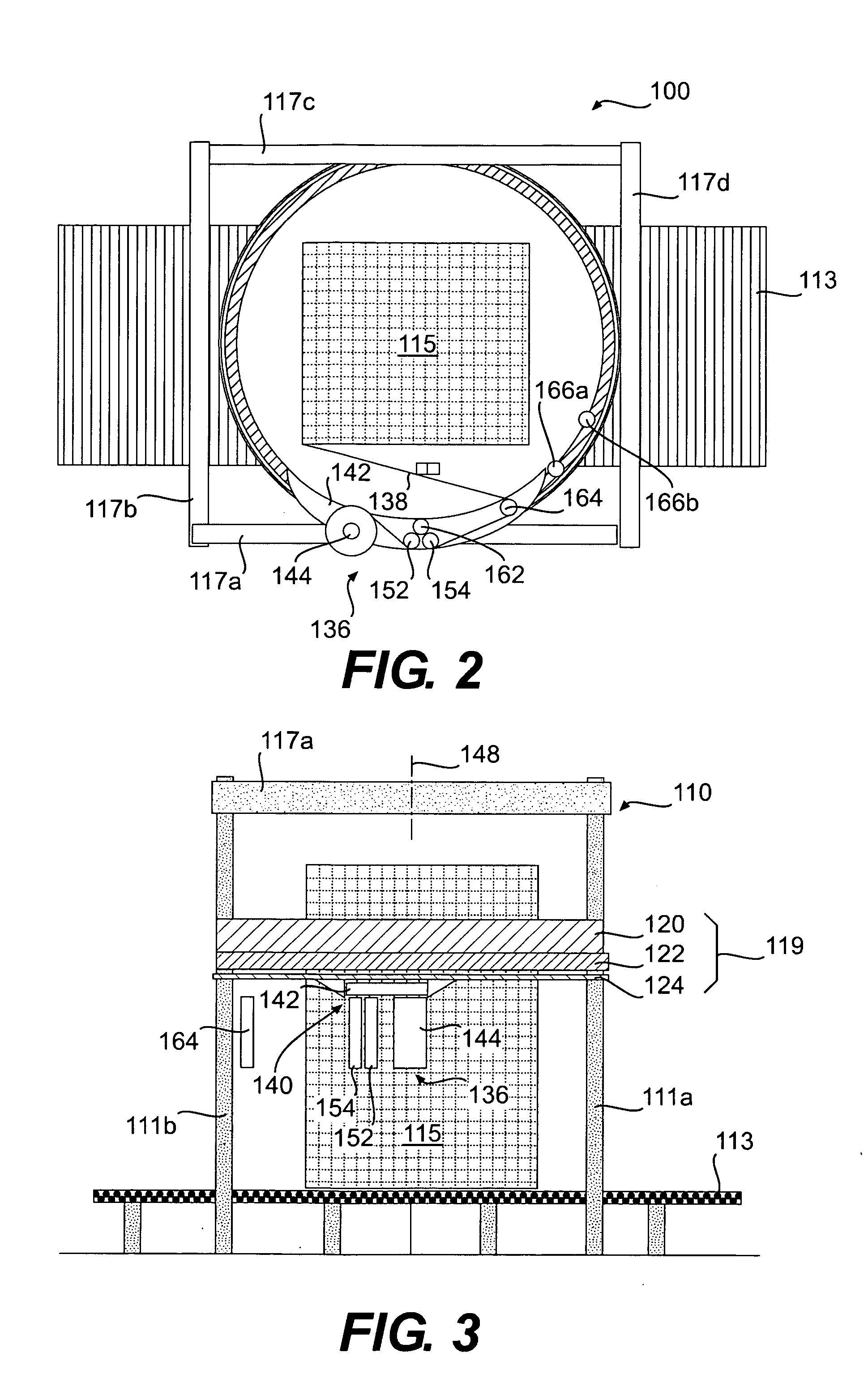

Wrapping apparatus including metered pre-stretch film delivery assembly and method of using

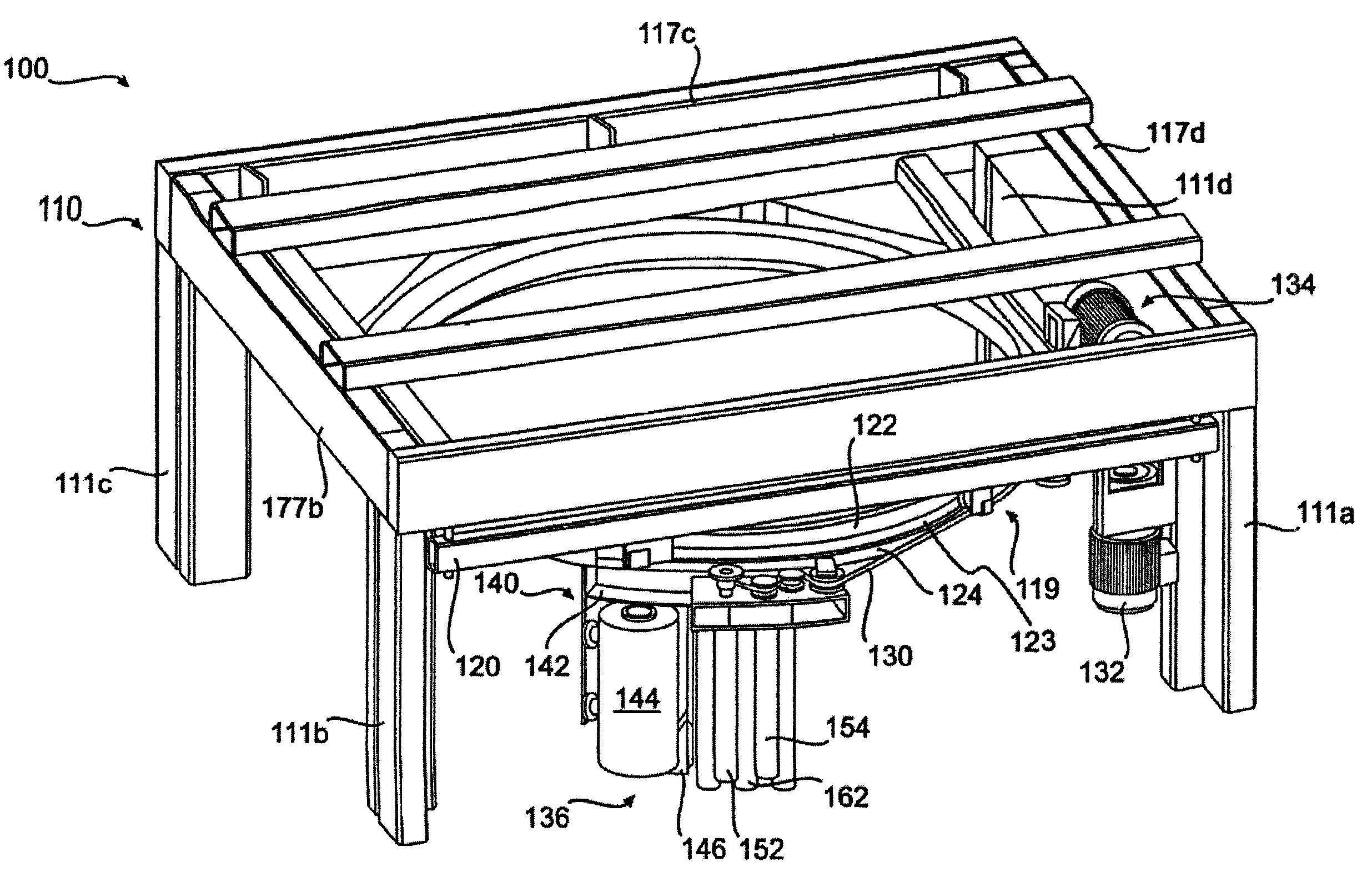

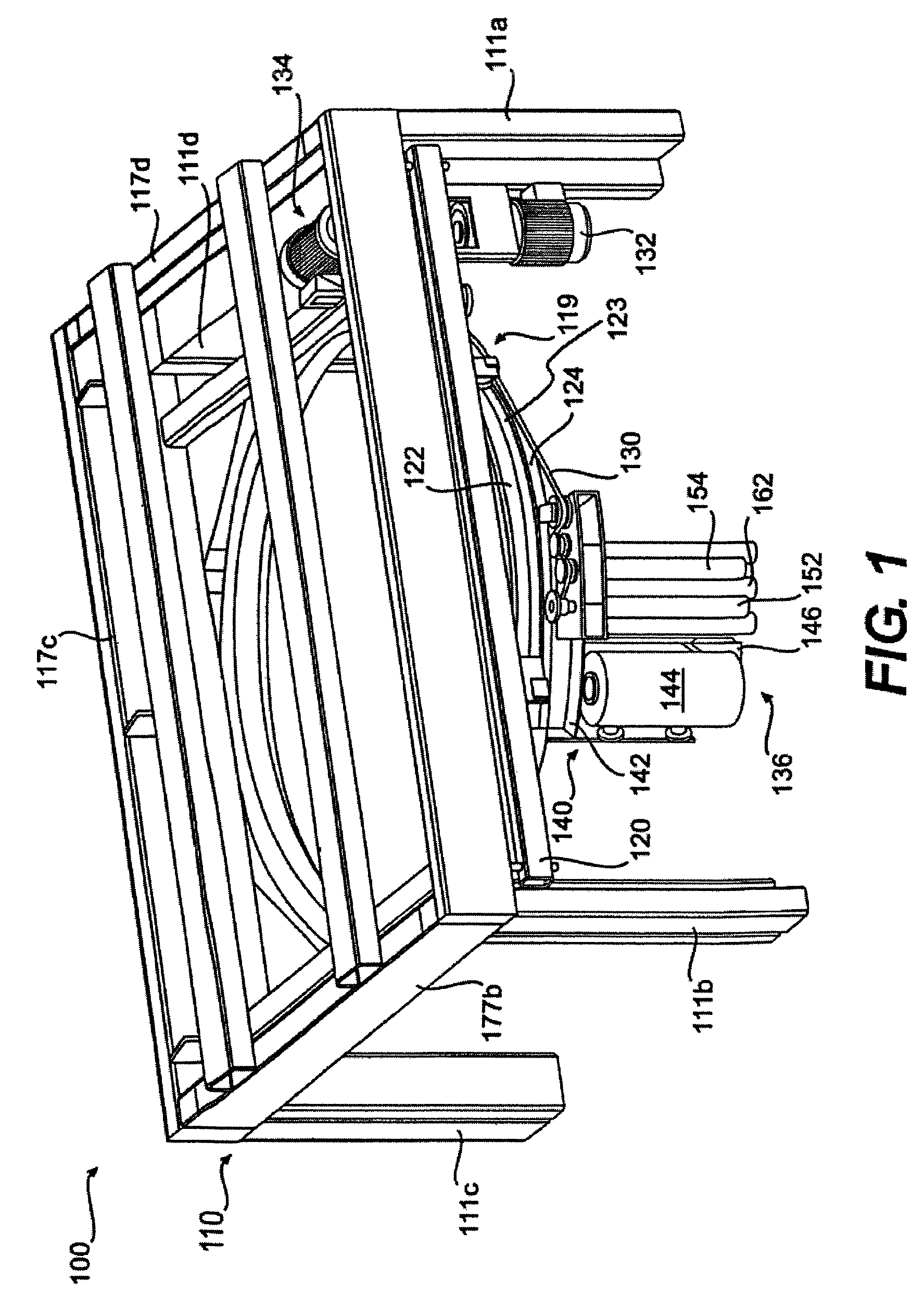

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

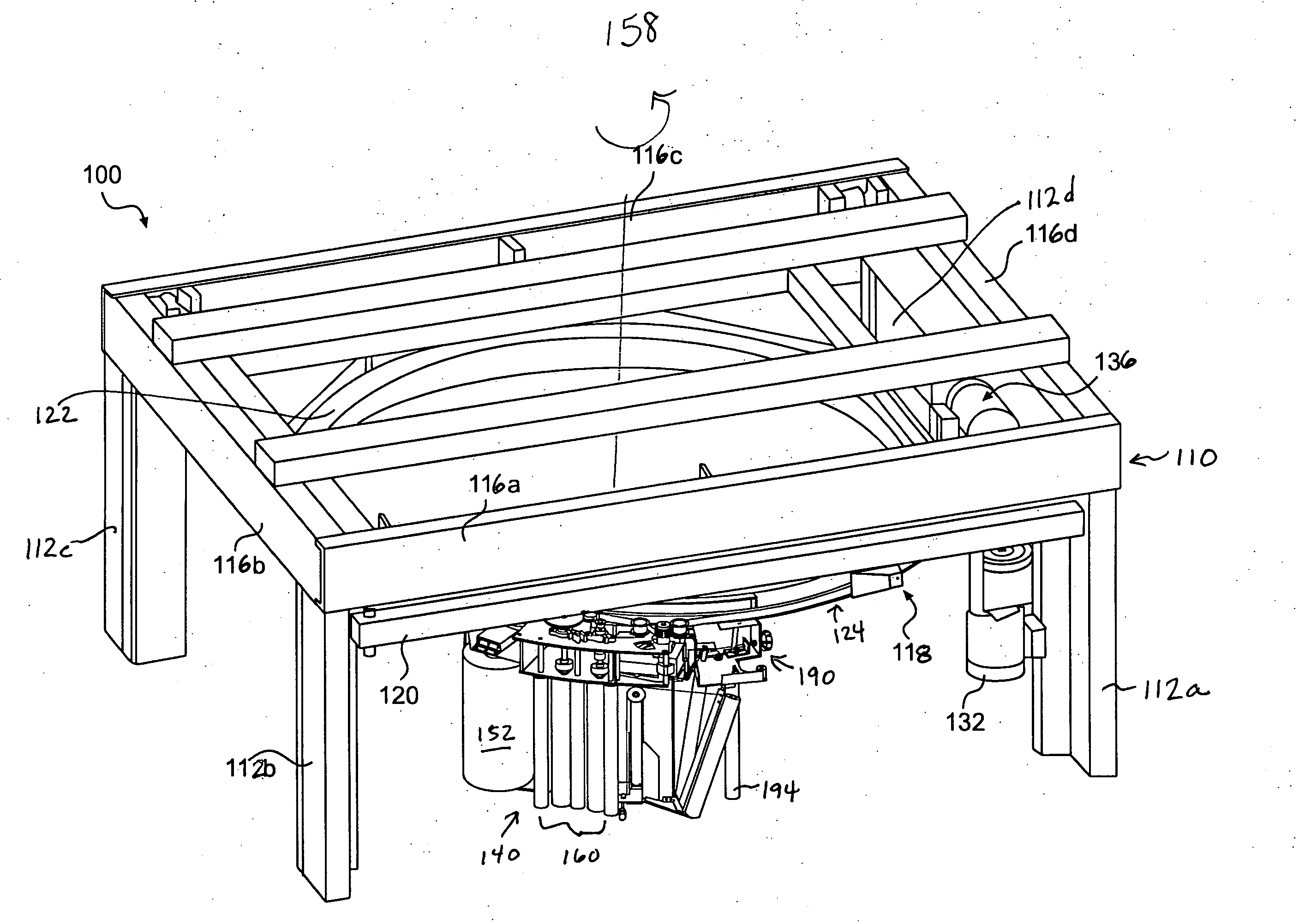

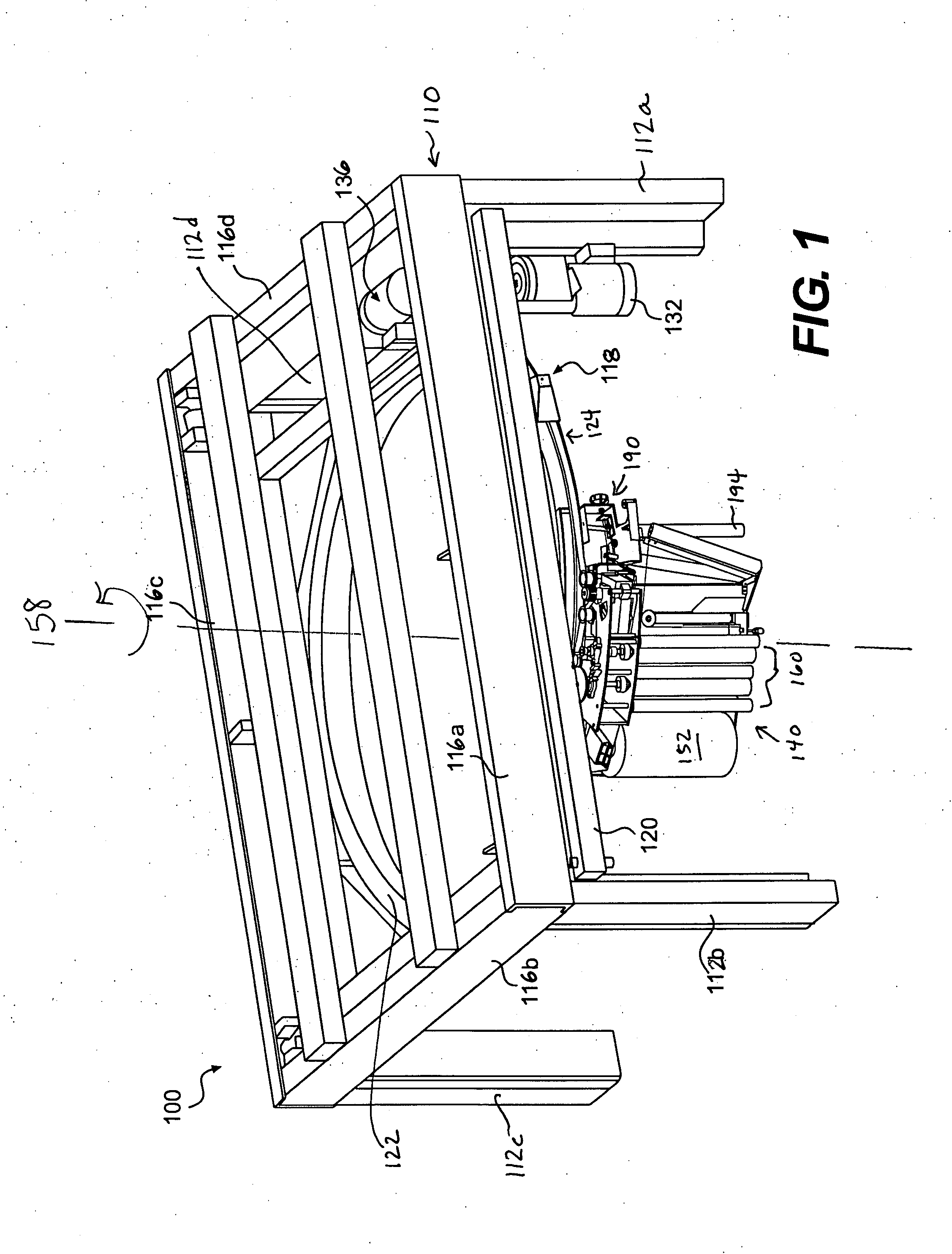

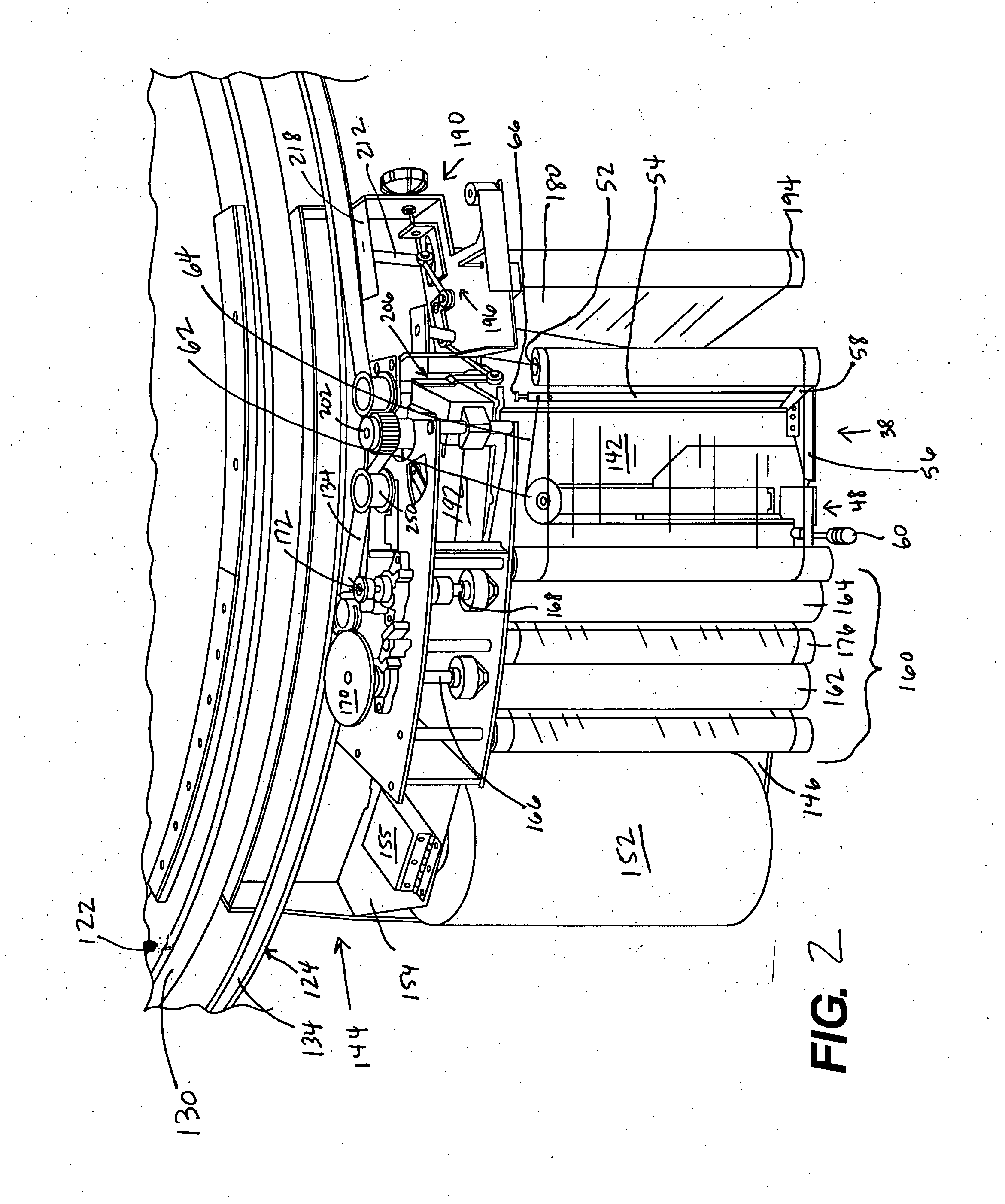

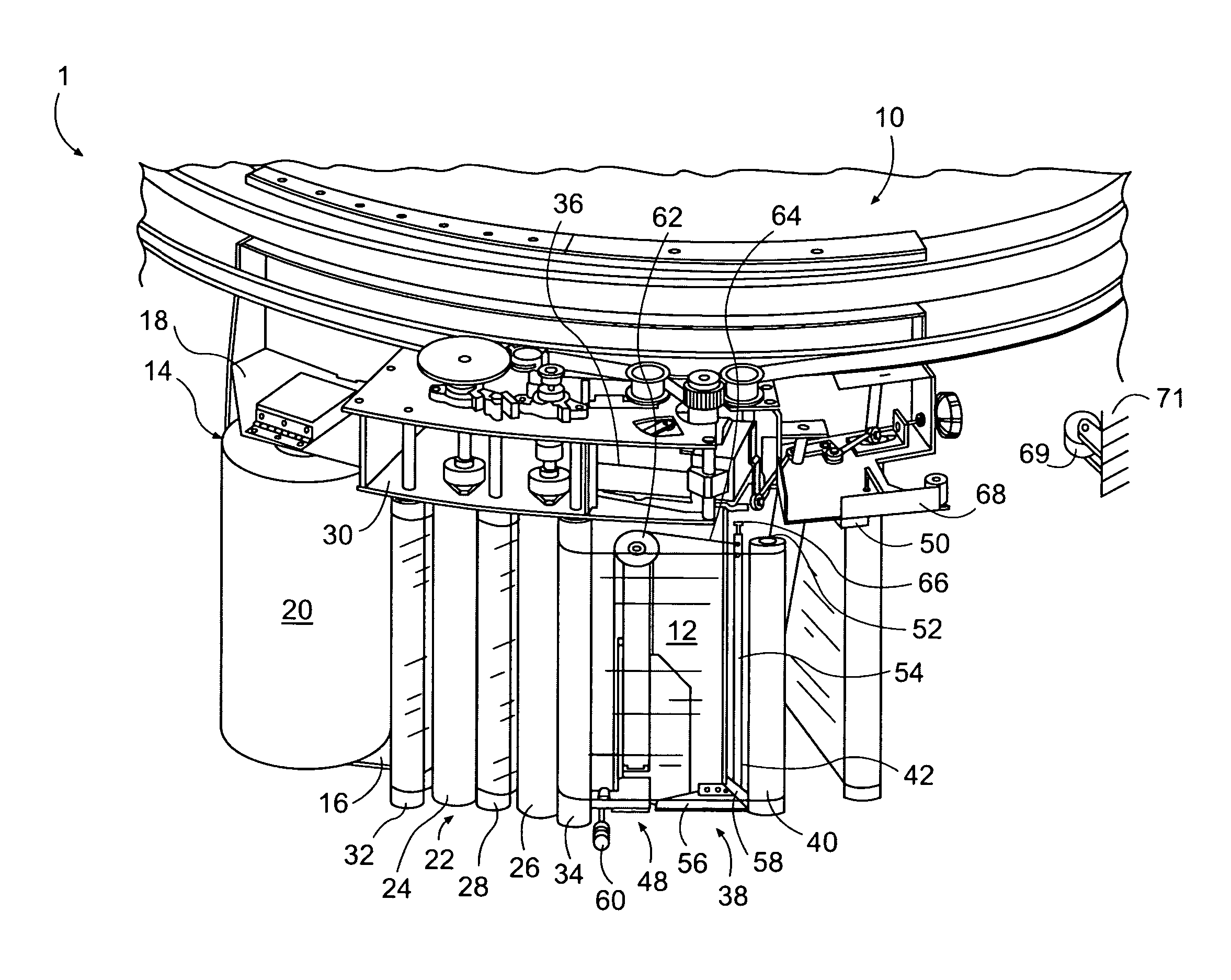

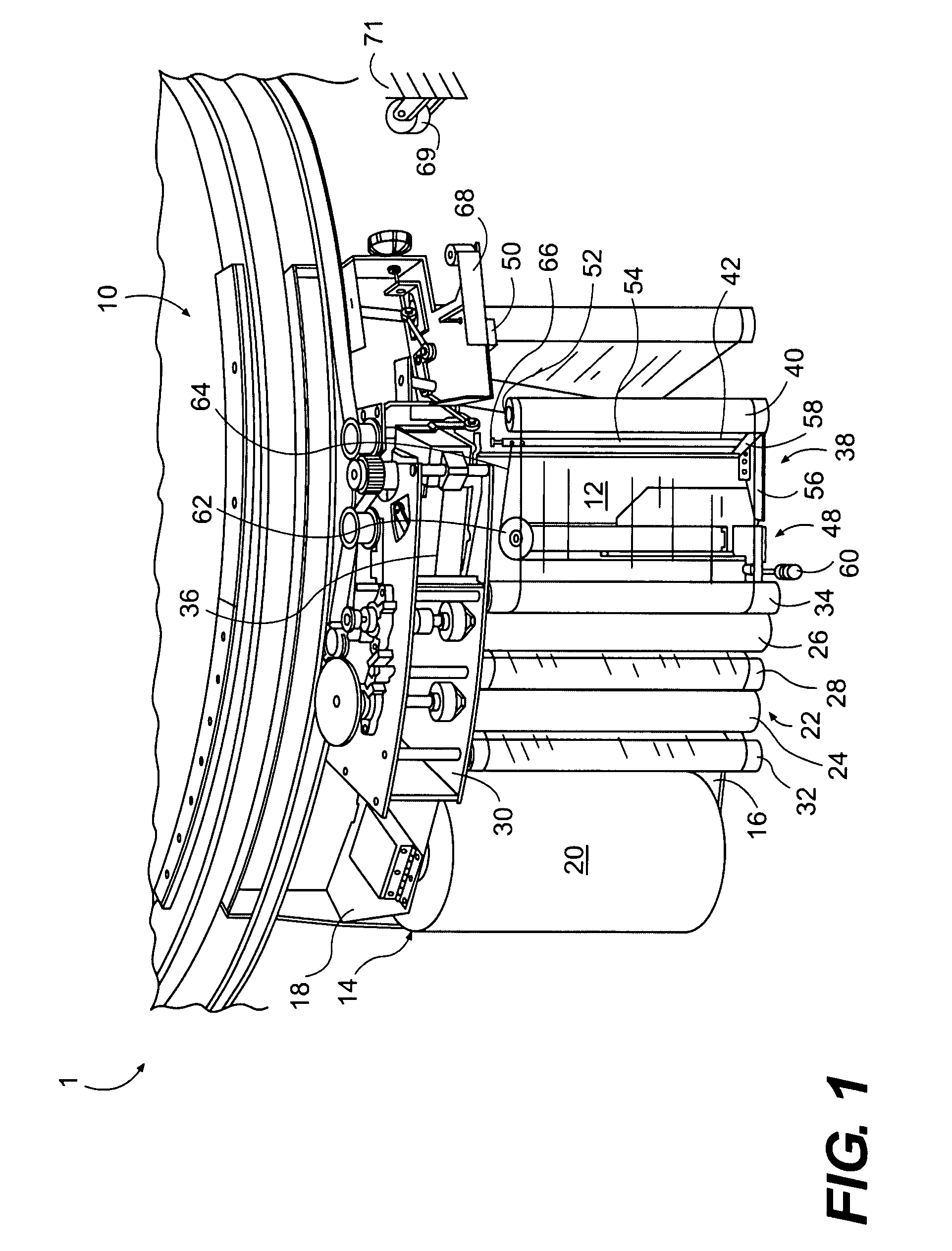

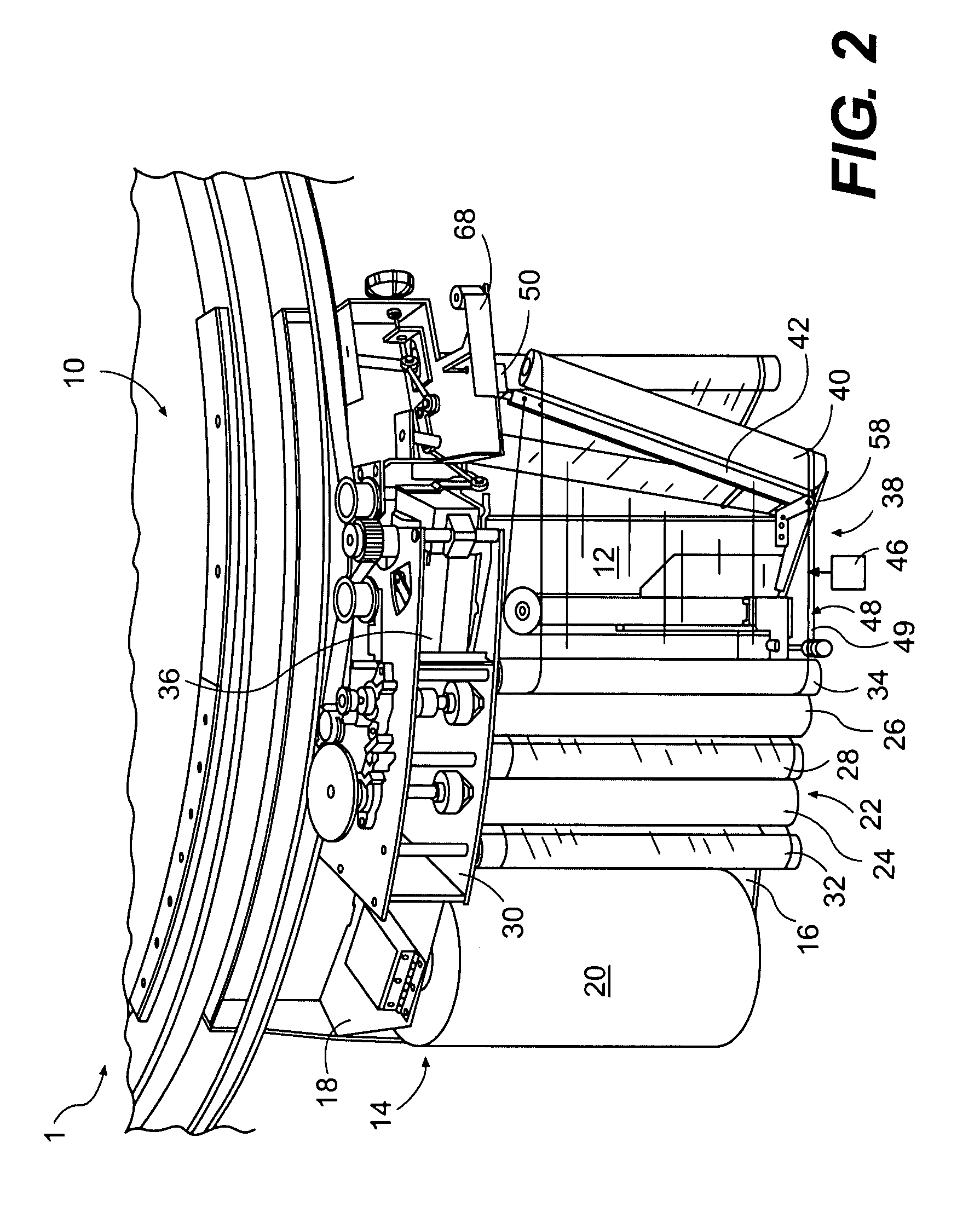

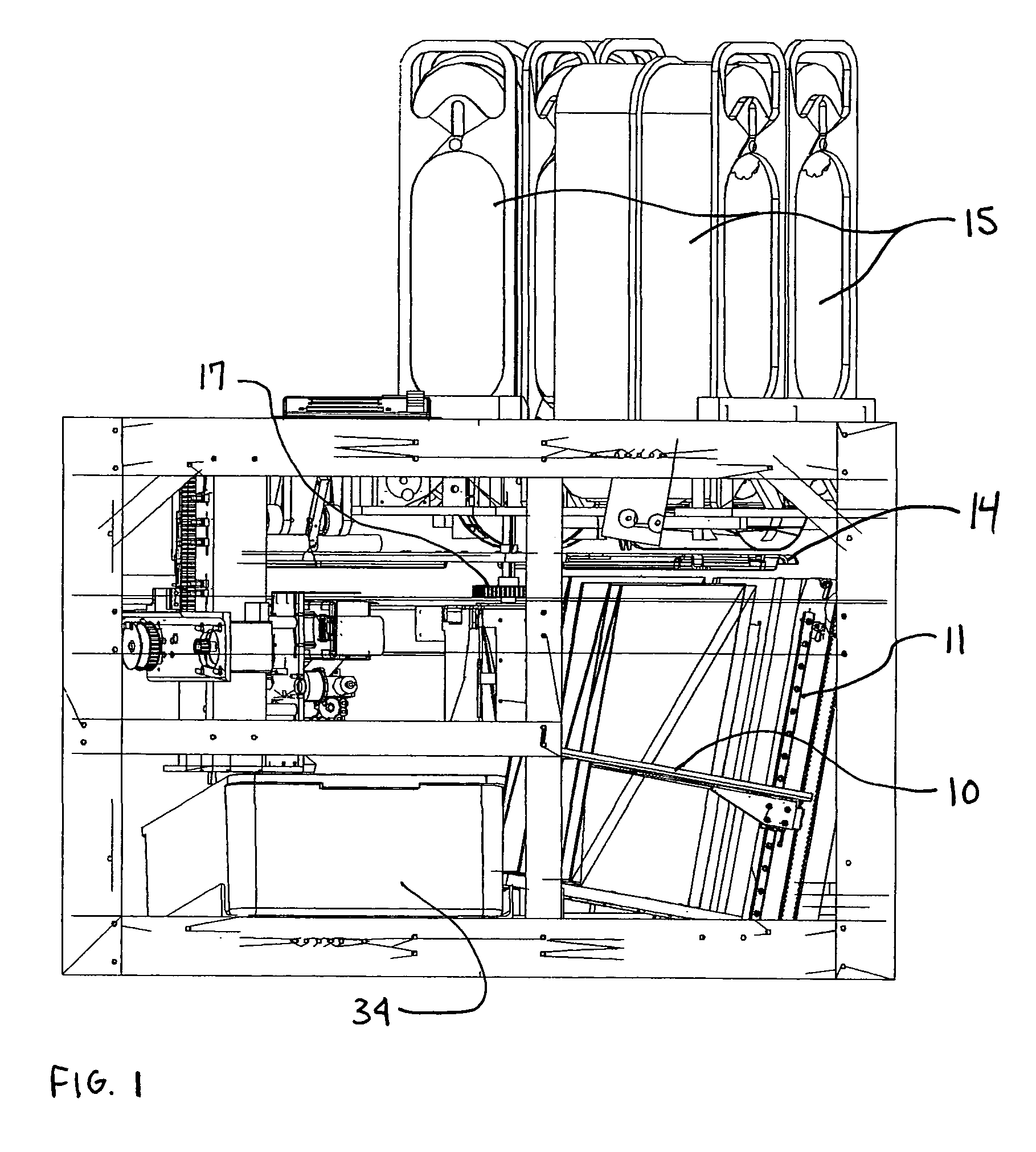

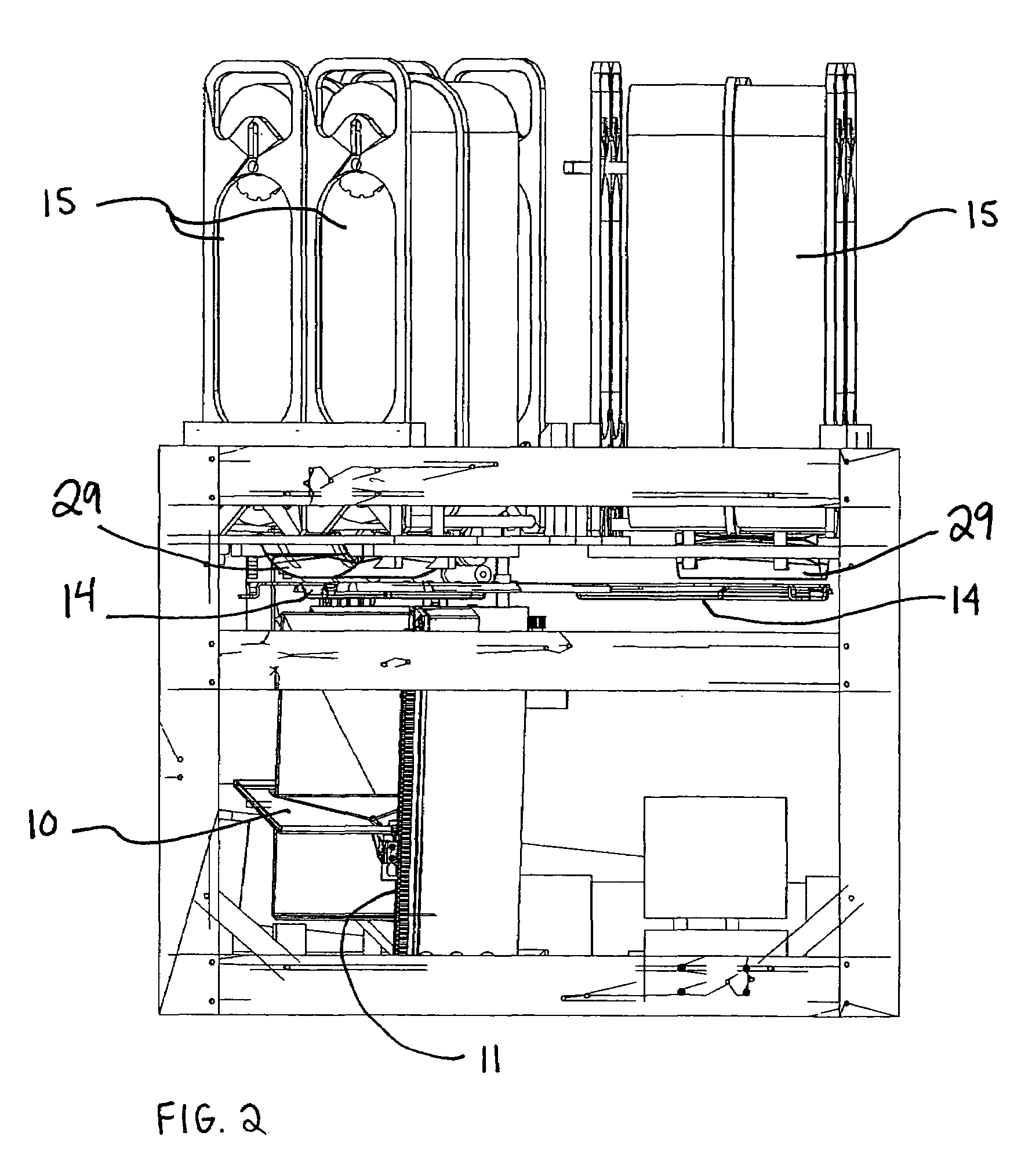

Ring wrapping apparatus including metered pre-stretch film delivery assembly

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

Stretch wrap films

InactiveUS6093480AImprove clingImproved maximum stretchWrappers shrinkageSynthetic resin layered productsStretch wrapGram

A multilayer, thermoplastic stretch wrap film containing at least three polymeric film layers and comprised of a first layer and a second layer. The first and second layers may comprise a polymer of two or more monomers, wherein a first monomer is ethylene, in a major amount by weight, and a second monomer is an alpha olefin of from about 3 to about 12 carbon atoms, in a minor amount by weight. If the first and second layers are outer layers, they have a cling force to each other of at least about 140 grams / inch. The stretch wrap film also has at least one inner polymeric layer, located between the first and second layers. The inner polymeric layer comprises a low polydispersity polymer having a polydispersity of from about 1 to about 4, a melt index (I.sub.2) of from about 0.5 to about 10 g / 10 min., and a melt flow ratio (I.sub.20 / I.sub.2) of from about 12 to about 22. The inner layer(s) comprise(s) from about 5 wt. % to about 40 wt. % of the stretch wrap film so as to produce a film having a maximum stretch of at least 340%, a F-50 dart drop value of at least about 130 g / mil, a machine directional tear resistance of at least about 125 g / mil and a transverse directional tear resistance of at least about 500 g / mil. It is contemplated that additional outer layers may be added such an outer high cling layer or an outer slip layer, as well as additional inner layers.

Owner:BERRY PLASTICS CORP

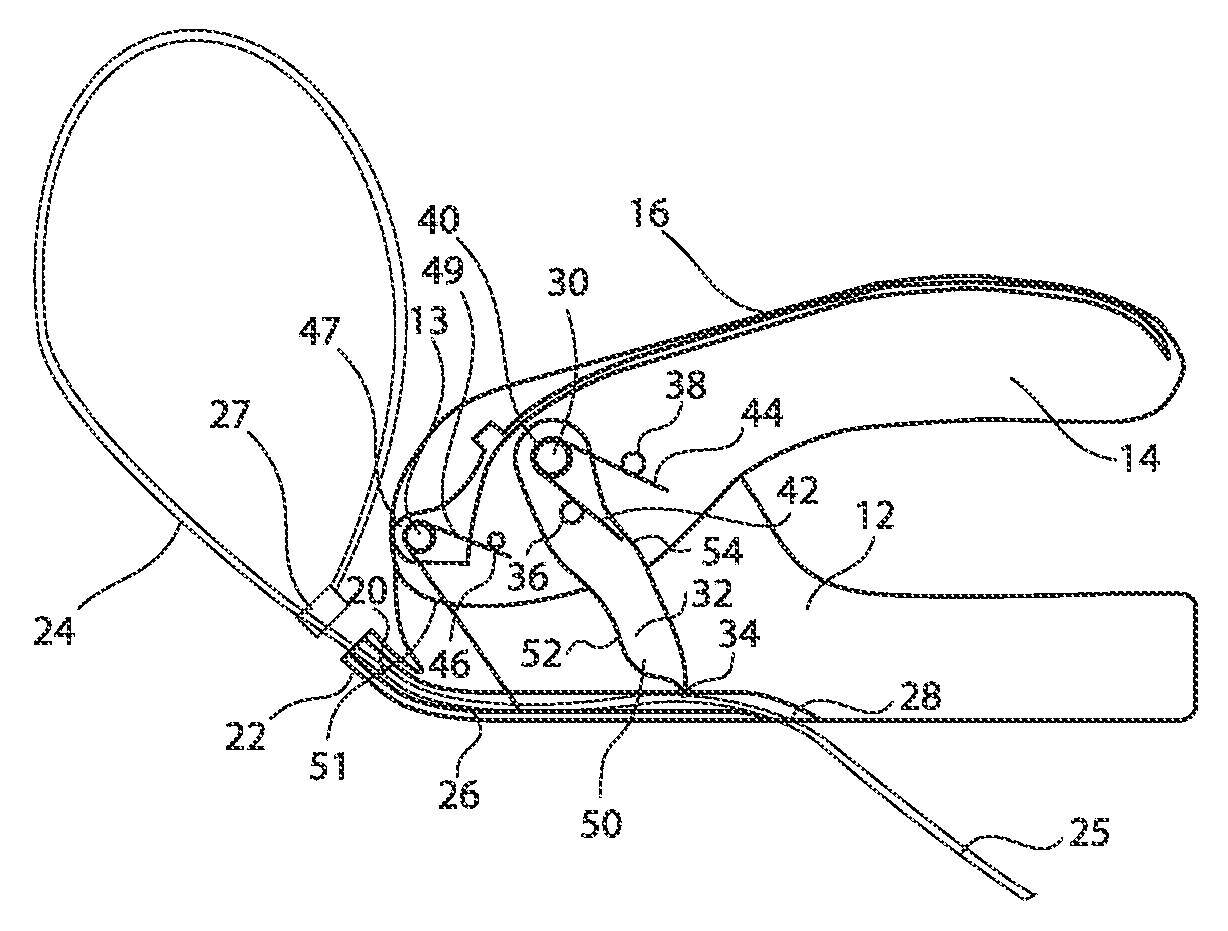

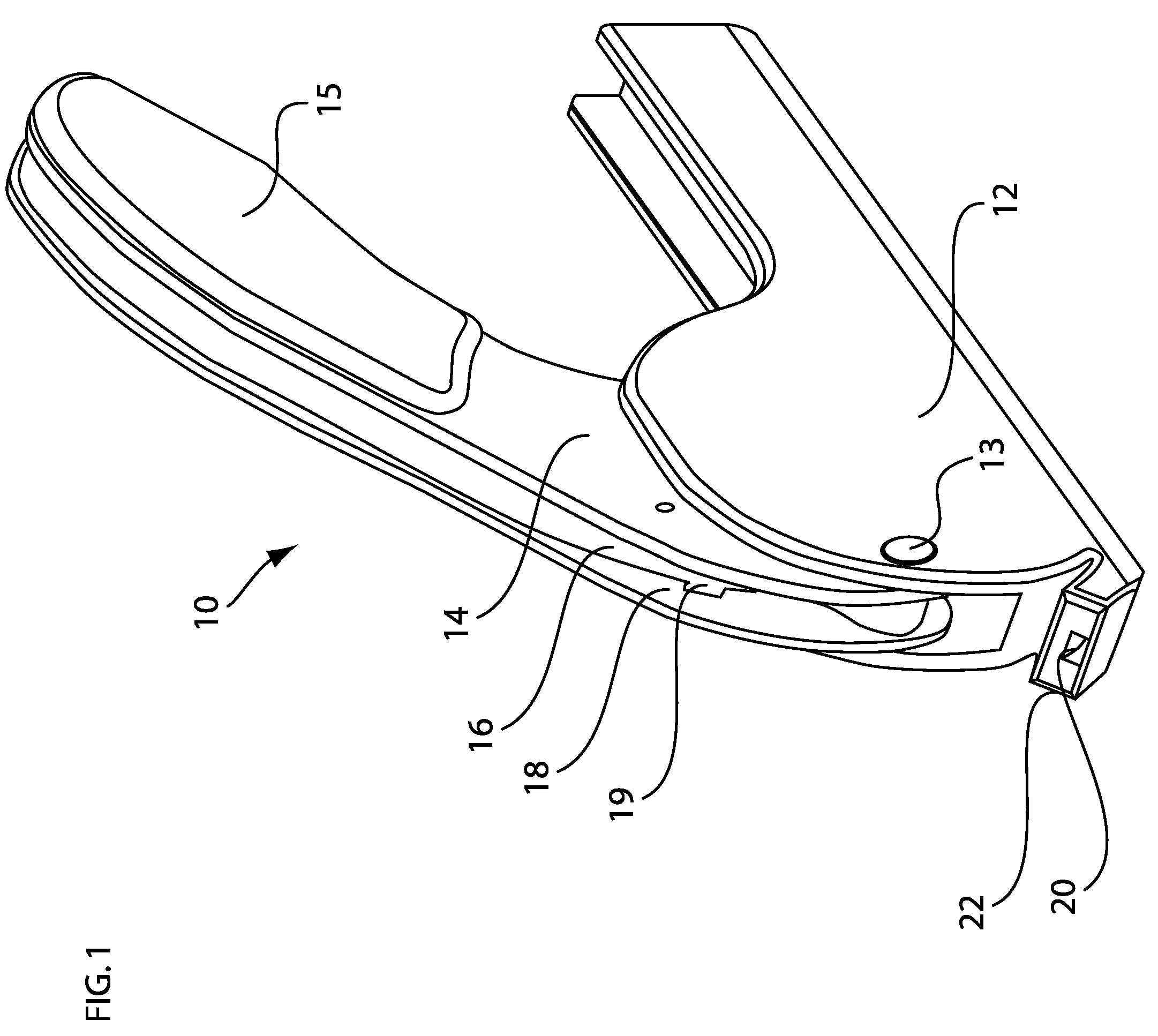

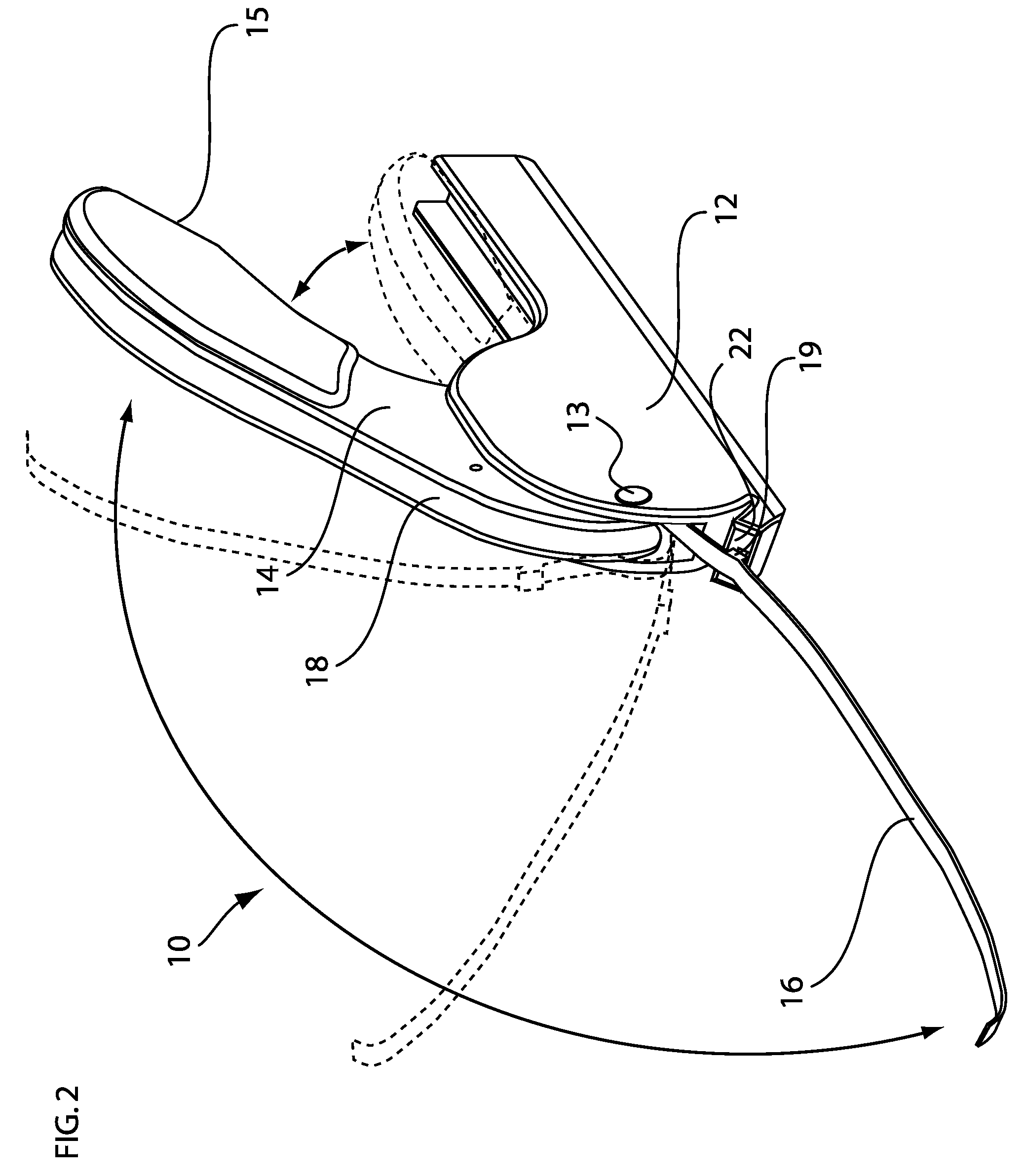

Thoracic closure device and methods

A thoracic closure device. The device has a handle member, a base member, and a feed path, and is designed to accept and, with a ratcheting mechanism, tension a toothed closure tie. A guide member is also provided, and assists in the placement of a closure tie prior to tensioning. Methods of closing a median sternotomy using toothed closure ties are also disclosed.

Owner:DEVICE EVOLUTIONS

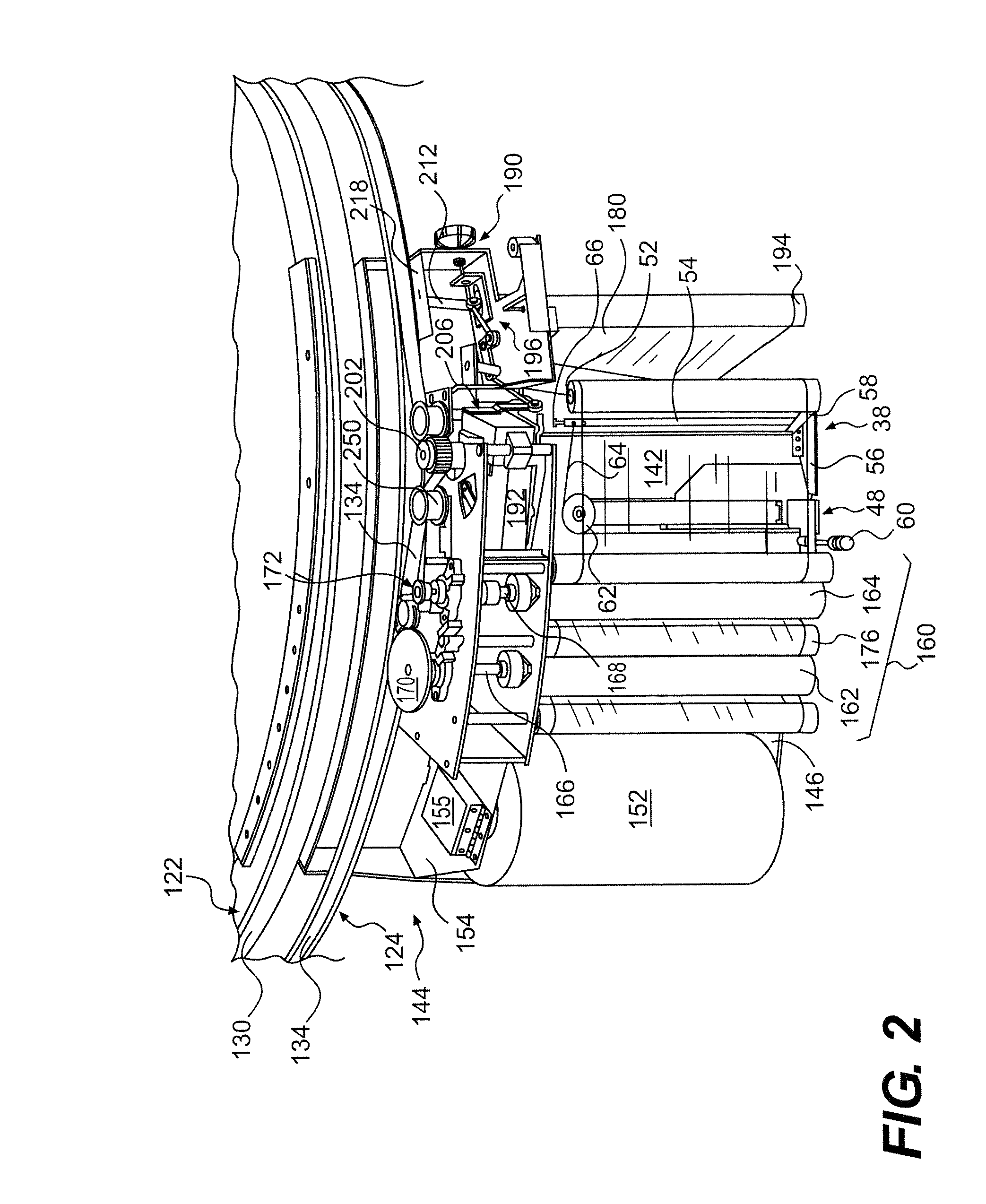

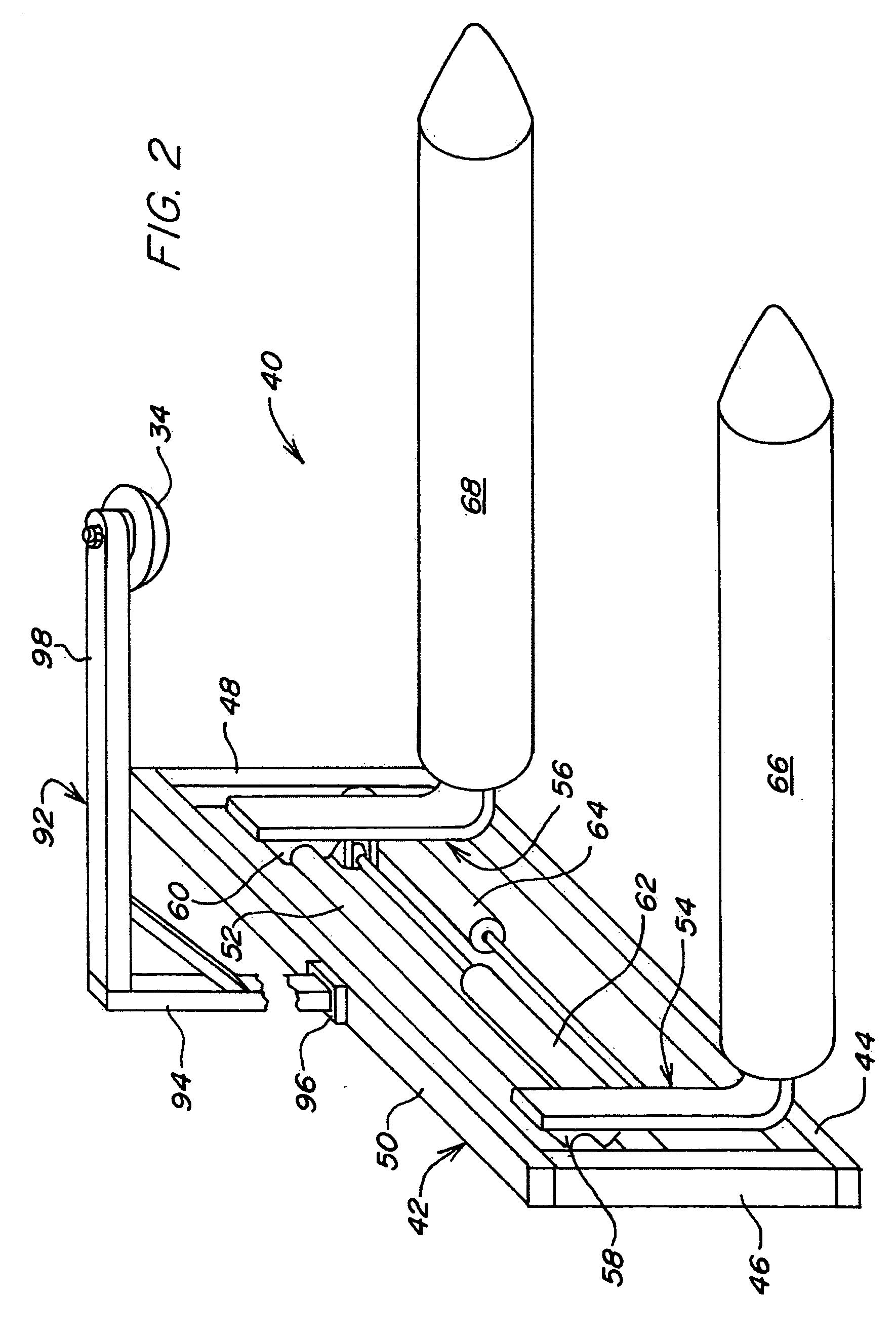

Method and apparatus for securing a load to a pallet with a roped film web

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one drive down roller configured to engage the width of the film web, and at least one roping mechanism. The at least one roping mechanism may be a cable rolling element configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

Method and apparatus for wrapping palletized bundles

InactiveUS6594970B1Prevent fallingPrevent crashWeb rotation wrappingBinding material applicationEngineeringProduct layer

A method and apparatus for wrapping a loop of film about a pallet, which supports a layer of products, and a guide, through which said layer passes, to prevent crushing and / or displacement of the product layer. Subsequent product layers are similarly protected by looping film about a previous loop of film and said guide. The guide is designed to facilitate removal of the film looped thereabout as the product layers are lowered.

Owner:PREMARK PACKAGING LLC

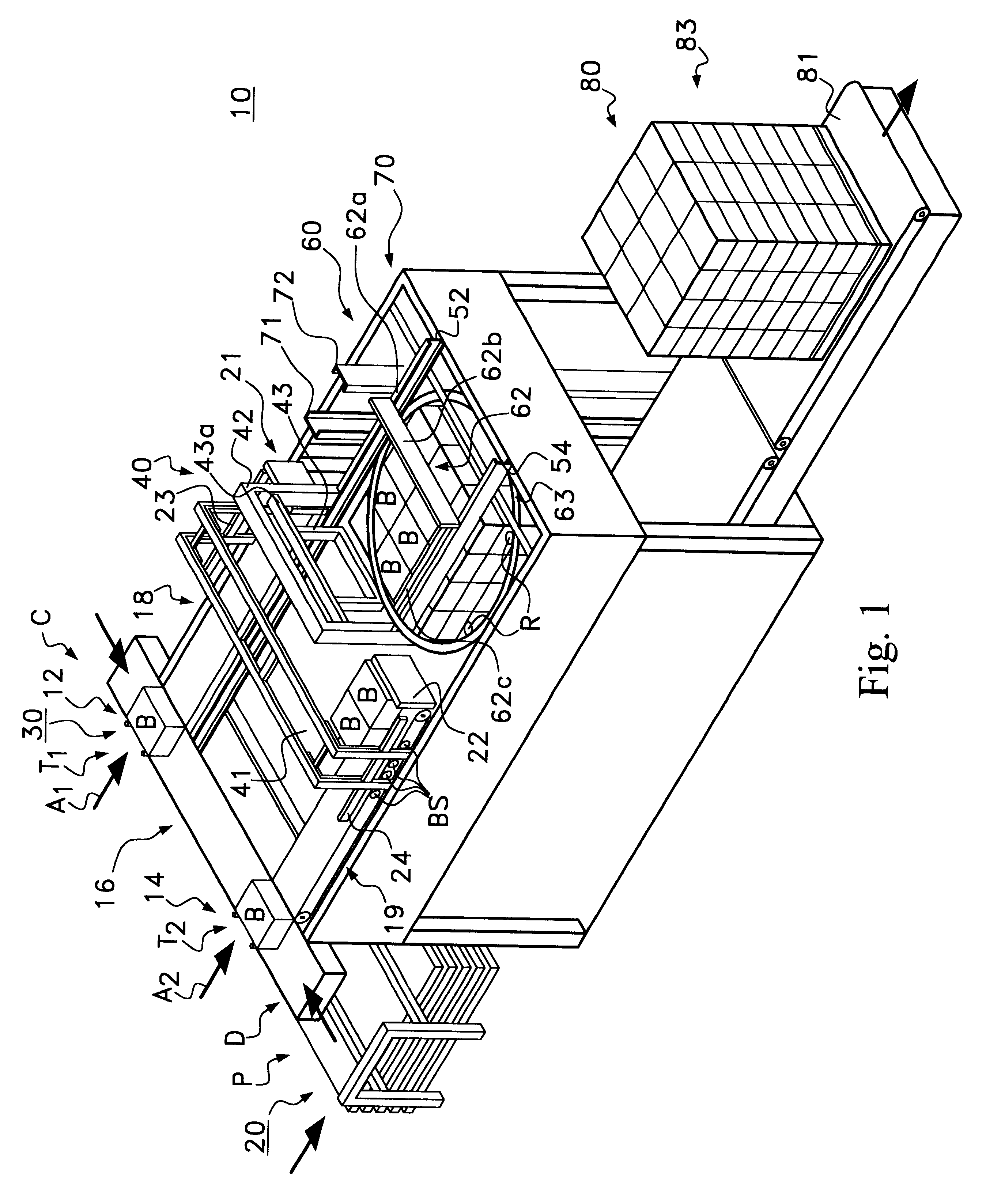

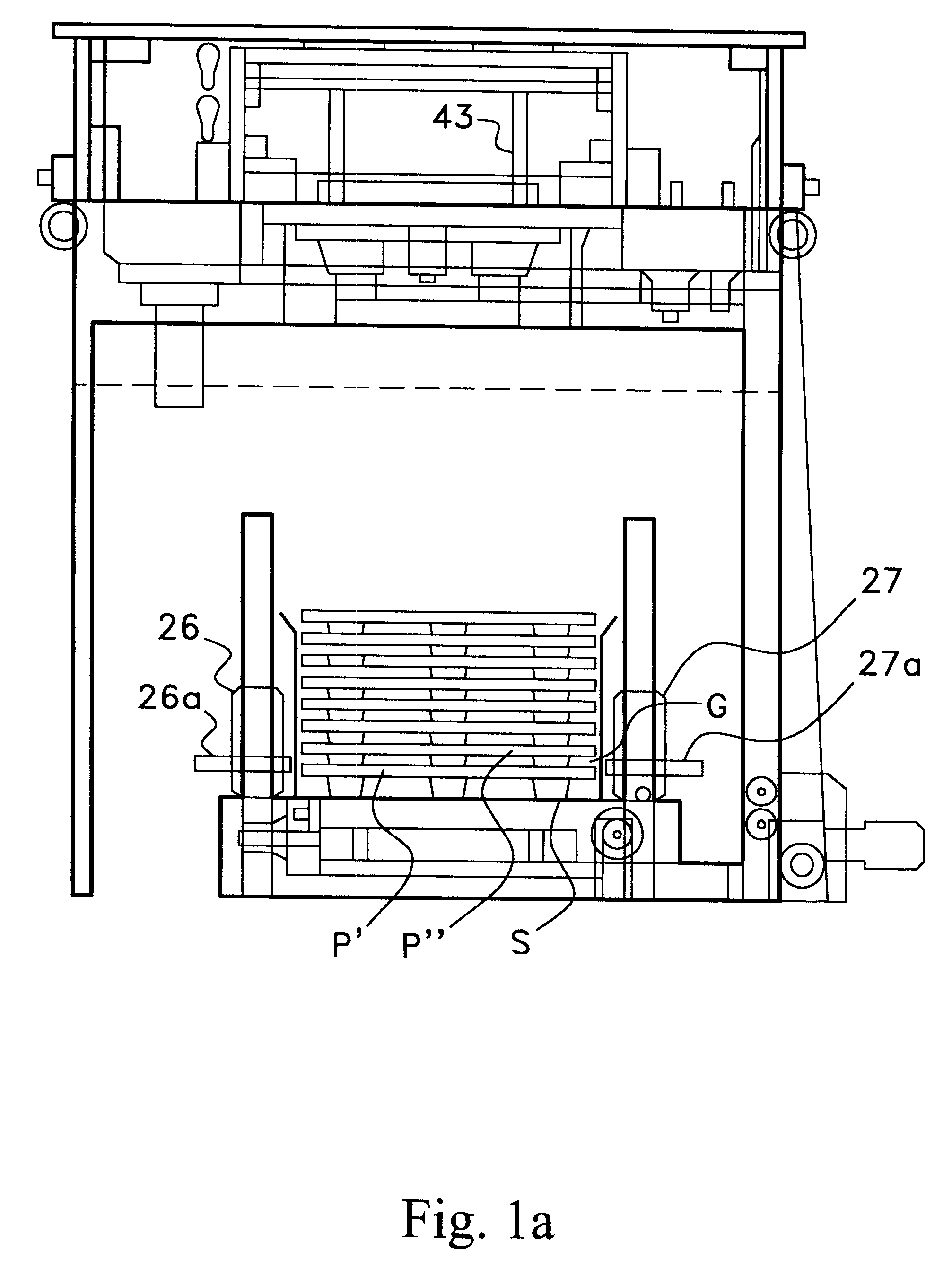

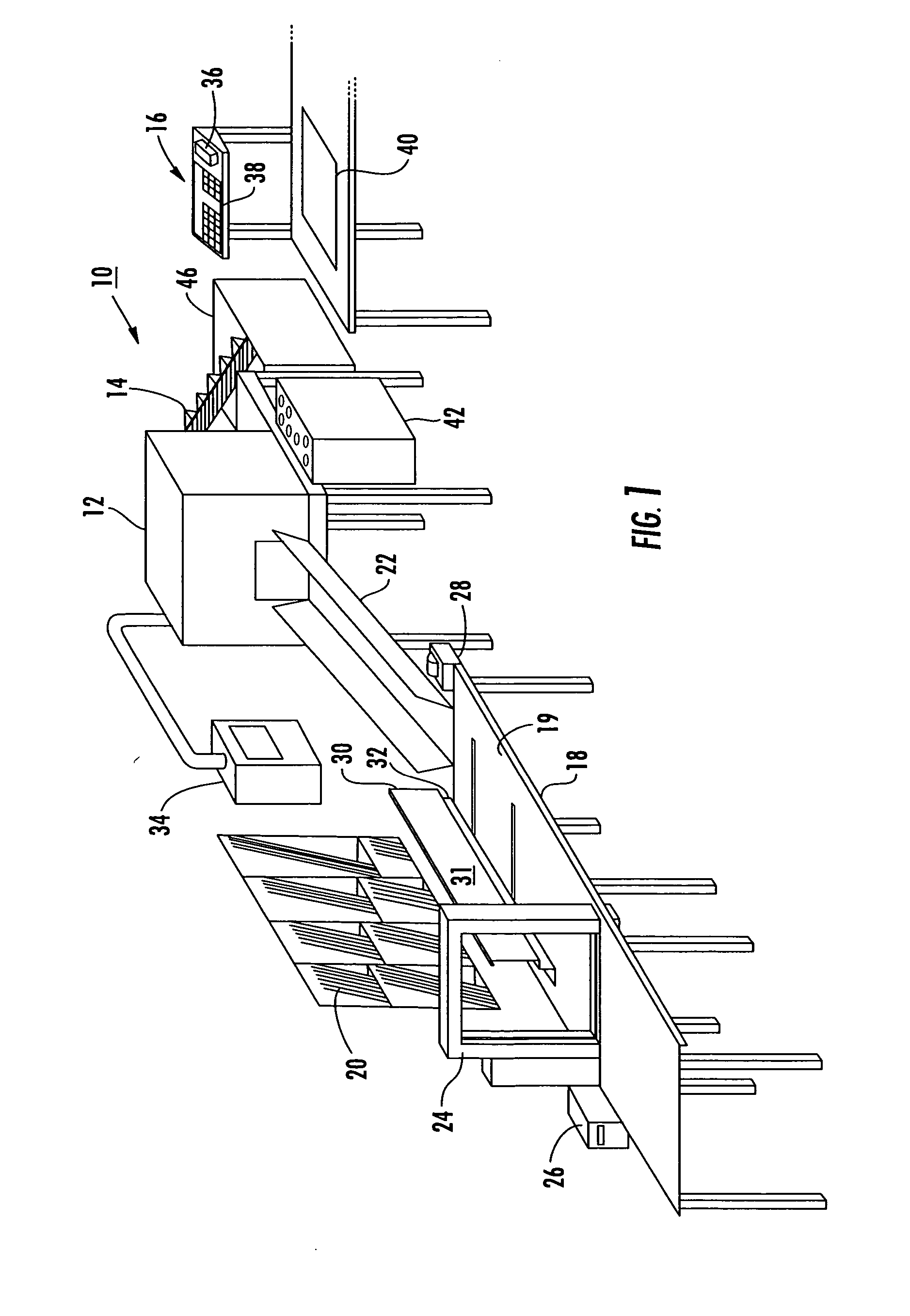

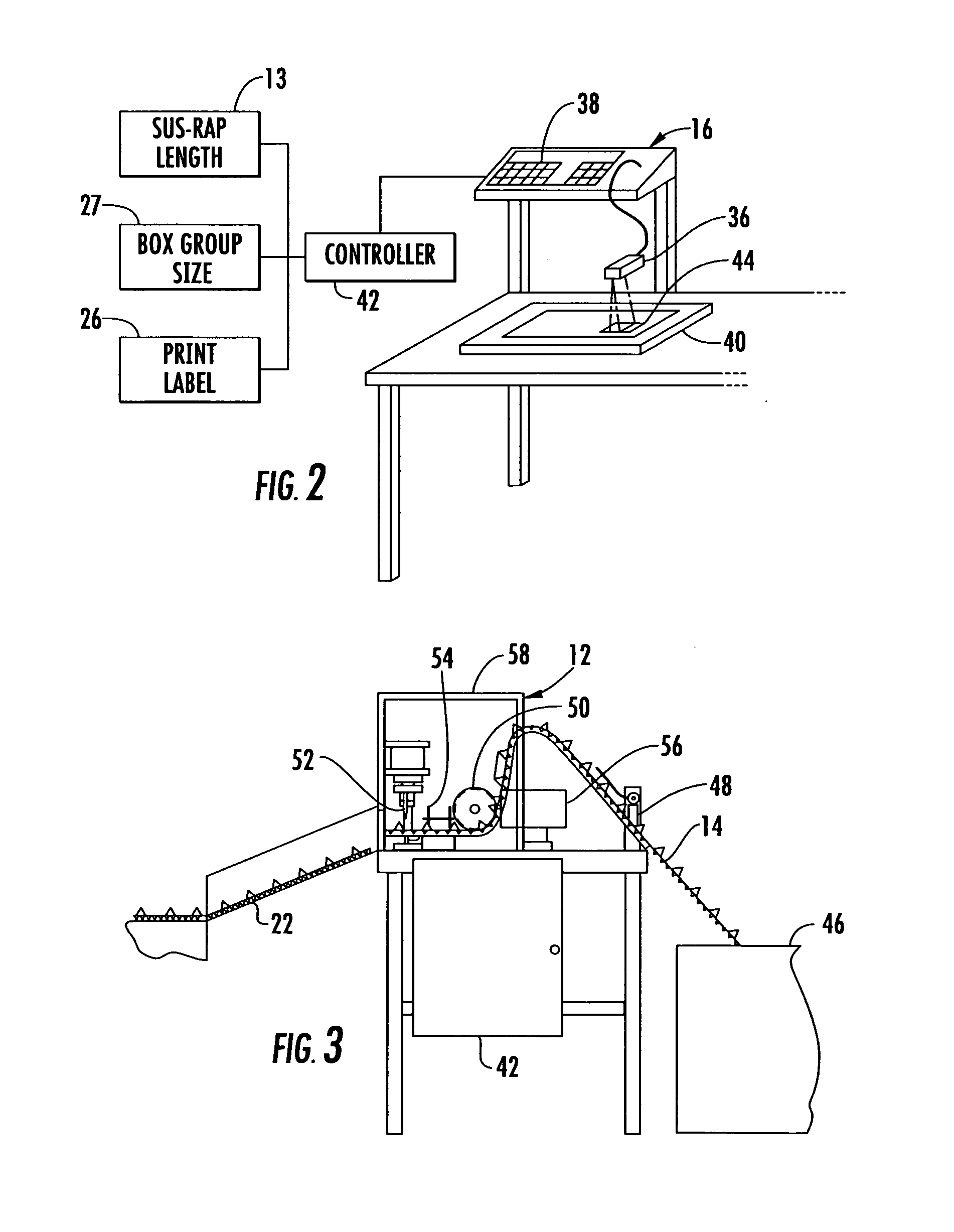

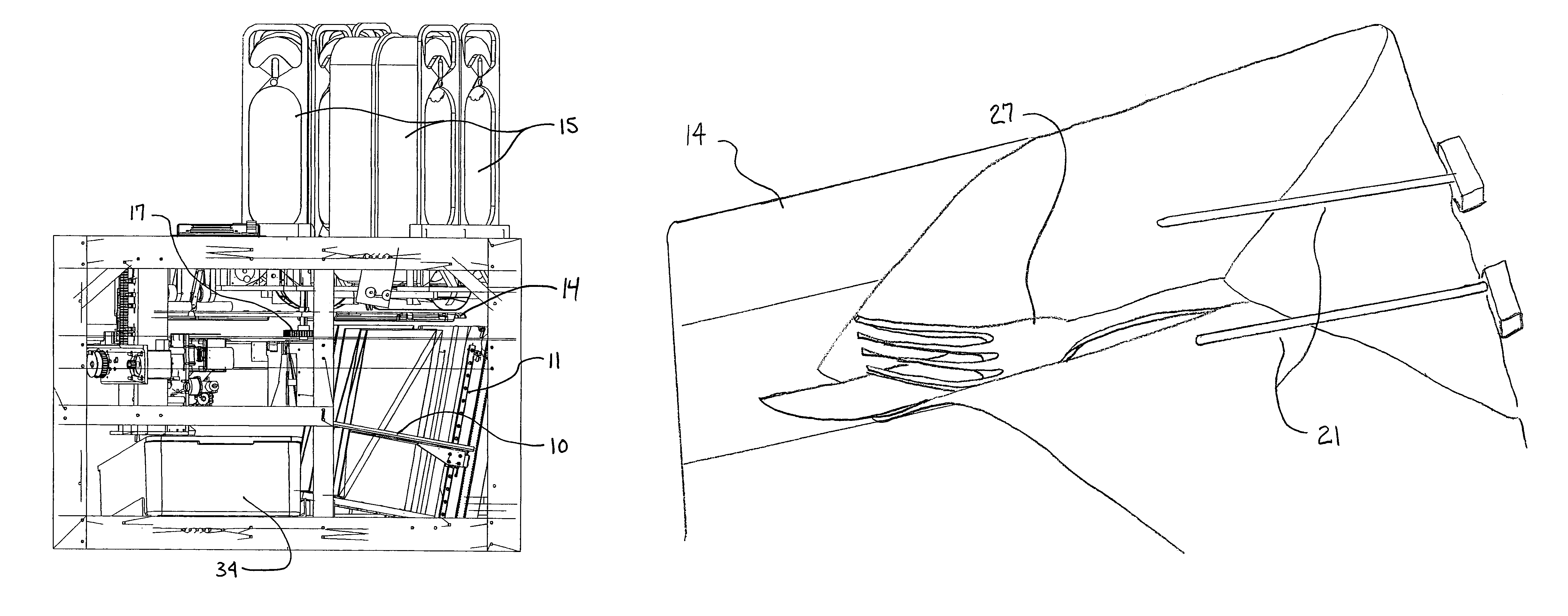

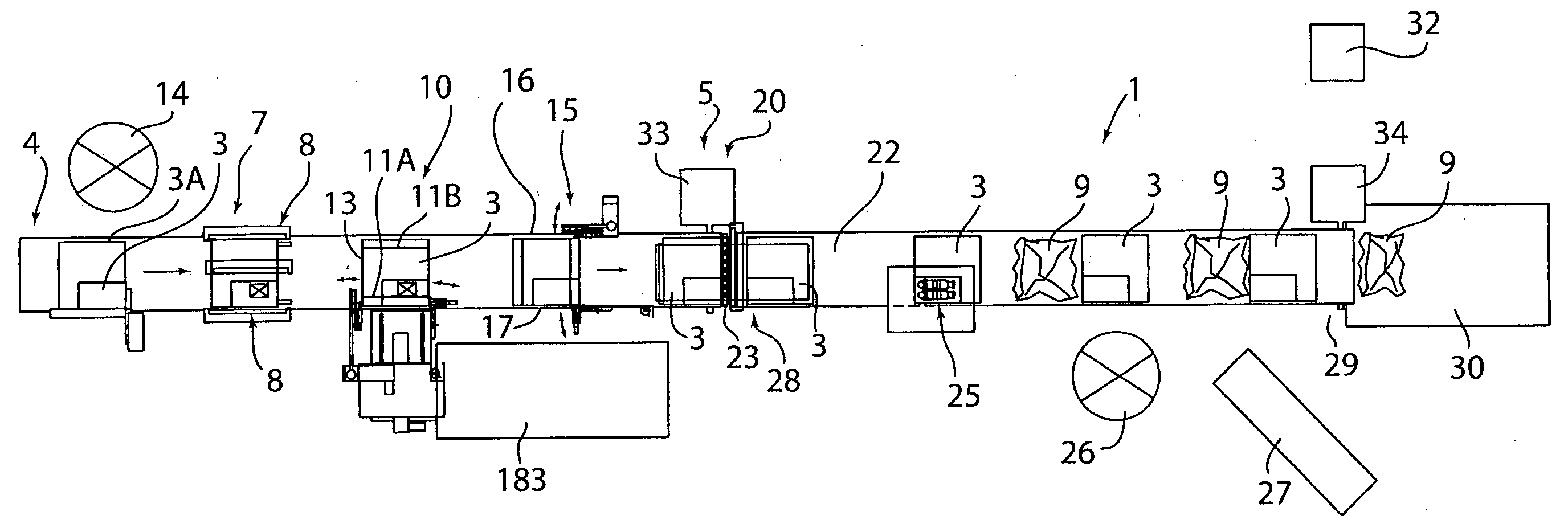

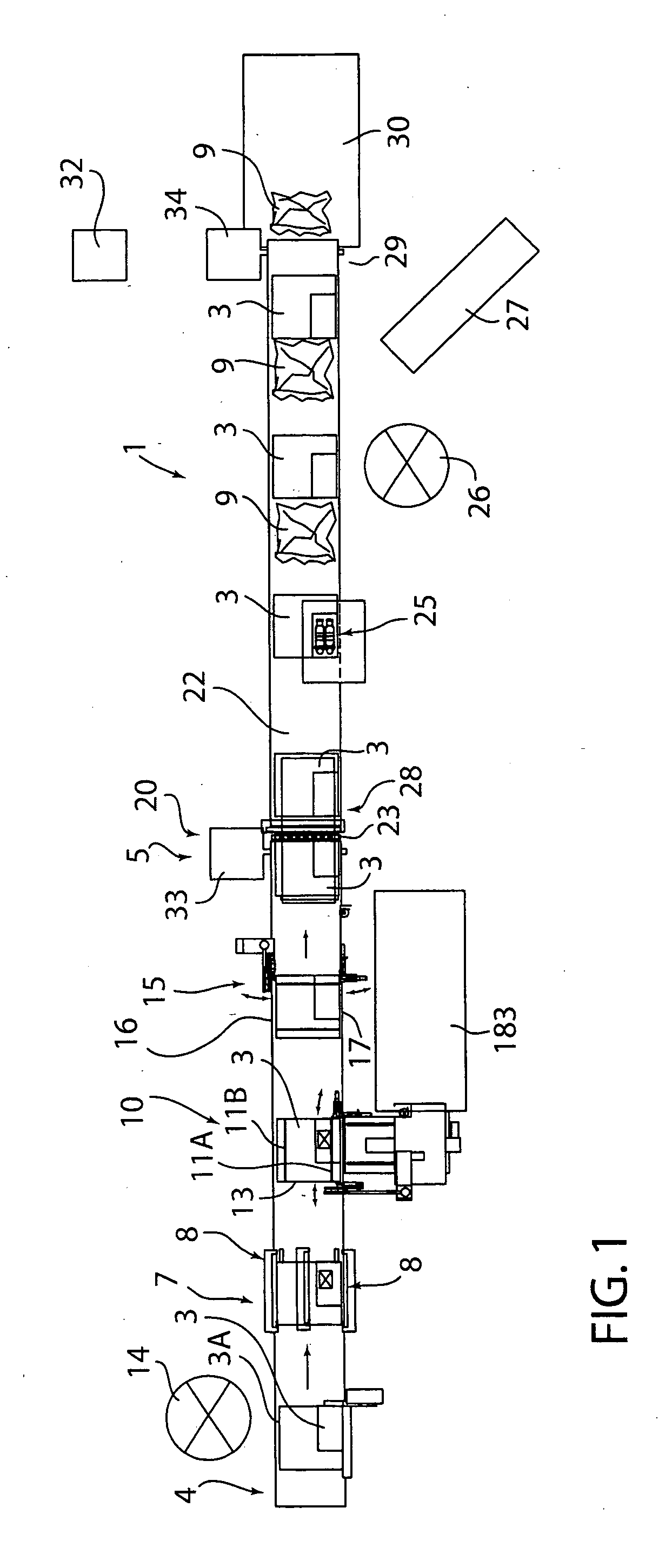

Method and apparatus for packaging panel products

ActiveUS20050115202A1Easy to foldAdjustable sizeWrapping material feeding apparatusMultiple wrapper applicationBiomedical engineeringData entry

A system for packaging a flat panel product includes a dispensing device for dispensing a length of inner protective packaging material, a folding table for wrapping the inner protective packaging material around the product and folding an outer protective packaging material around the product, and a binding device for binding the outer packaging material, inner packaging material, and product together, suspending the product relative to at least one of the walls of the sidewall and supporting the product laterally. A data entry device provides data related to the length of inner protective packaging material required, and this data is fed to a controller, which controls the dispensing device to provide an appropriate length of material. The data entry device can also provide shipping information, fed to a printer for printing a shipping label.

Owner:SIGNODE IND GRP

Method and apparatus for securing a load to a pallet with a roped film web

ActiveUS20050044812A1Narrow widthReduce widthWrappers shrinkageWrapping material feeding apparatusThin membranePallet

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one guide rollers configured to engage the width of the film web, and at least one roping element. The at least one roping element may be a cable rolling roper configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

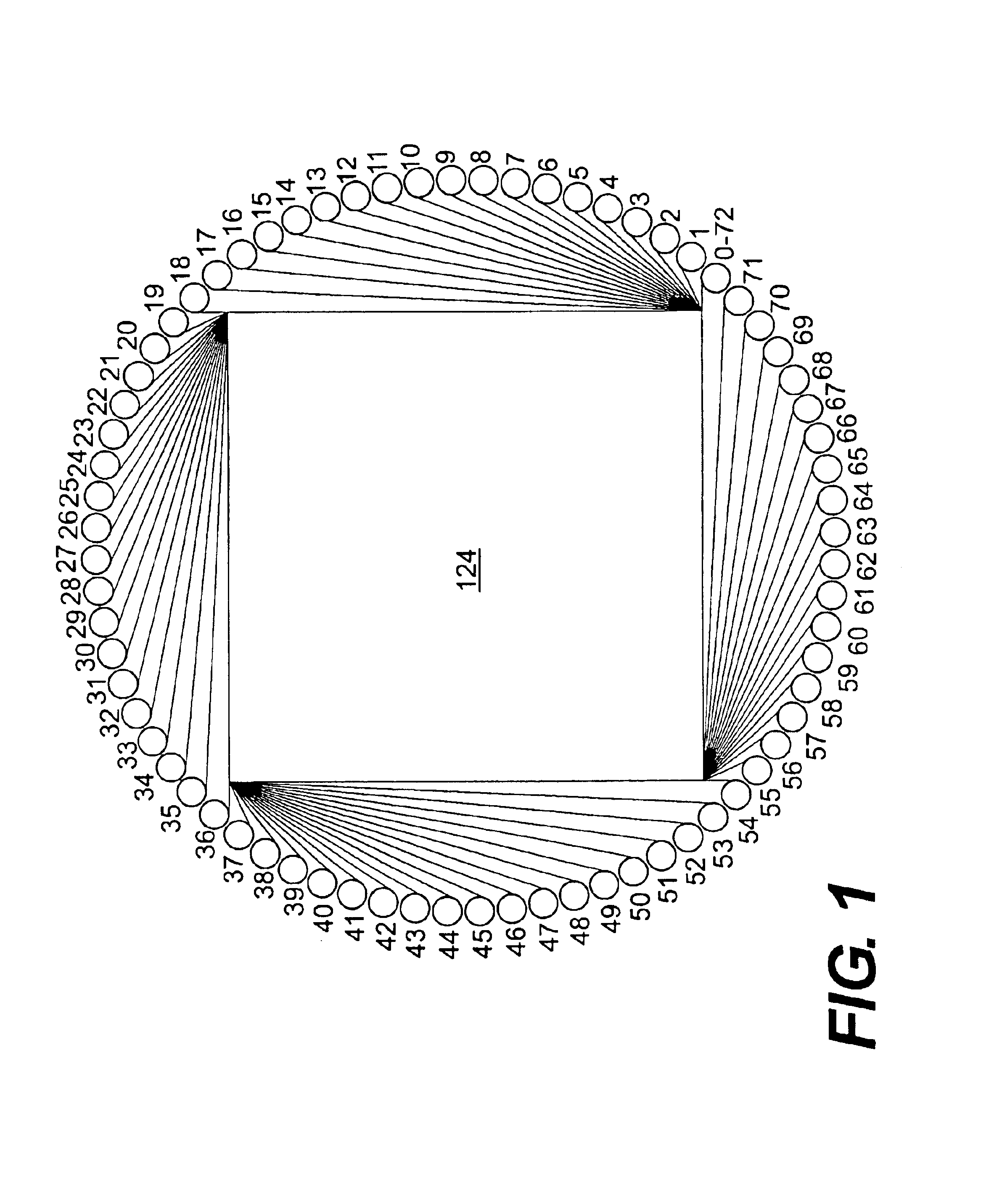

Method and apparatus for dispensing a predetermined fixed amount of pre-stretched film relative to load girth

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt driven by a motor. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt, such that the rotating ring is driven by the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

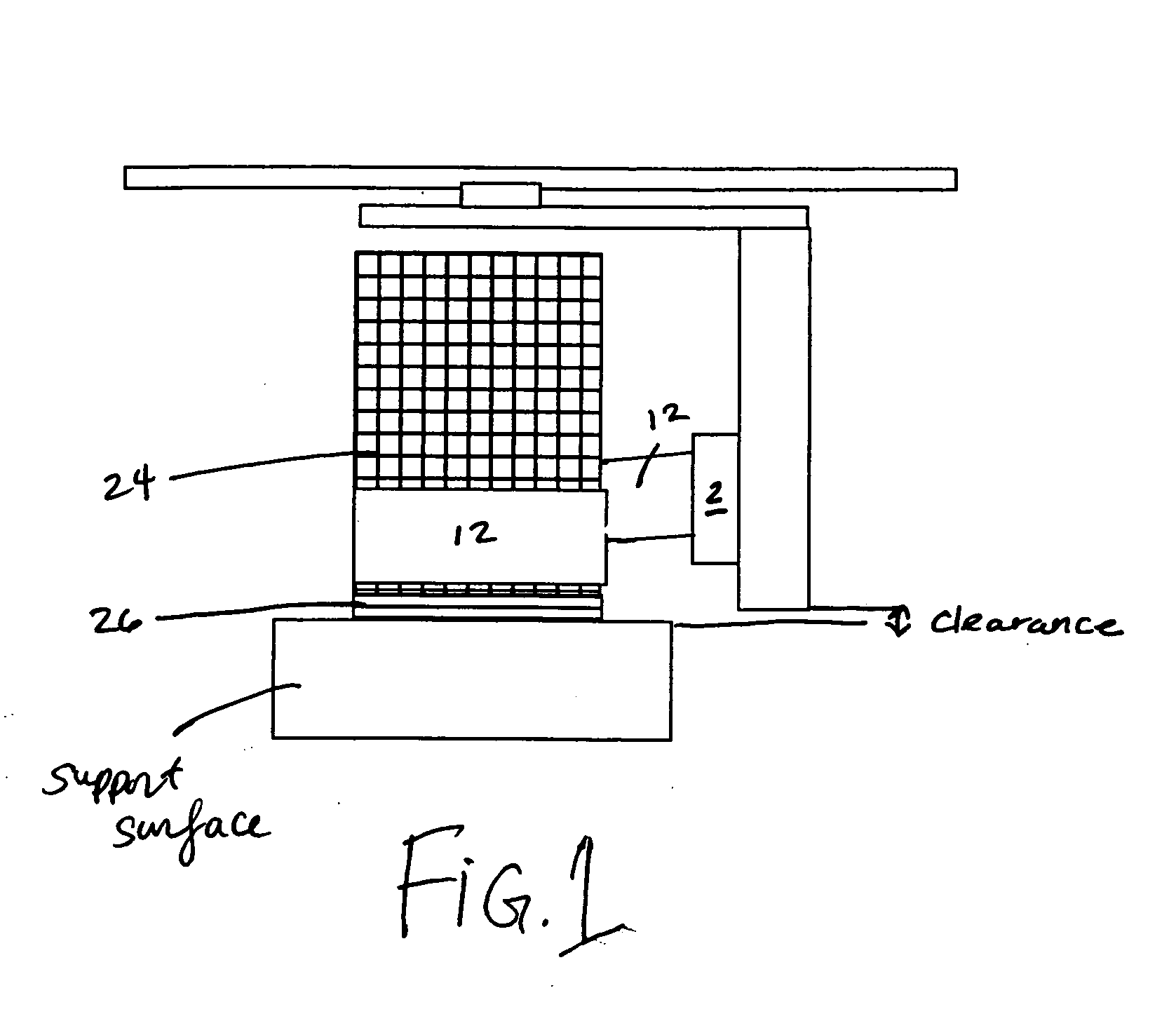

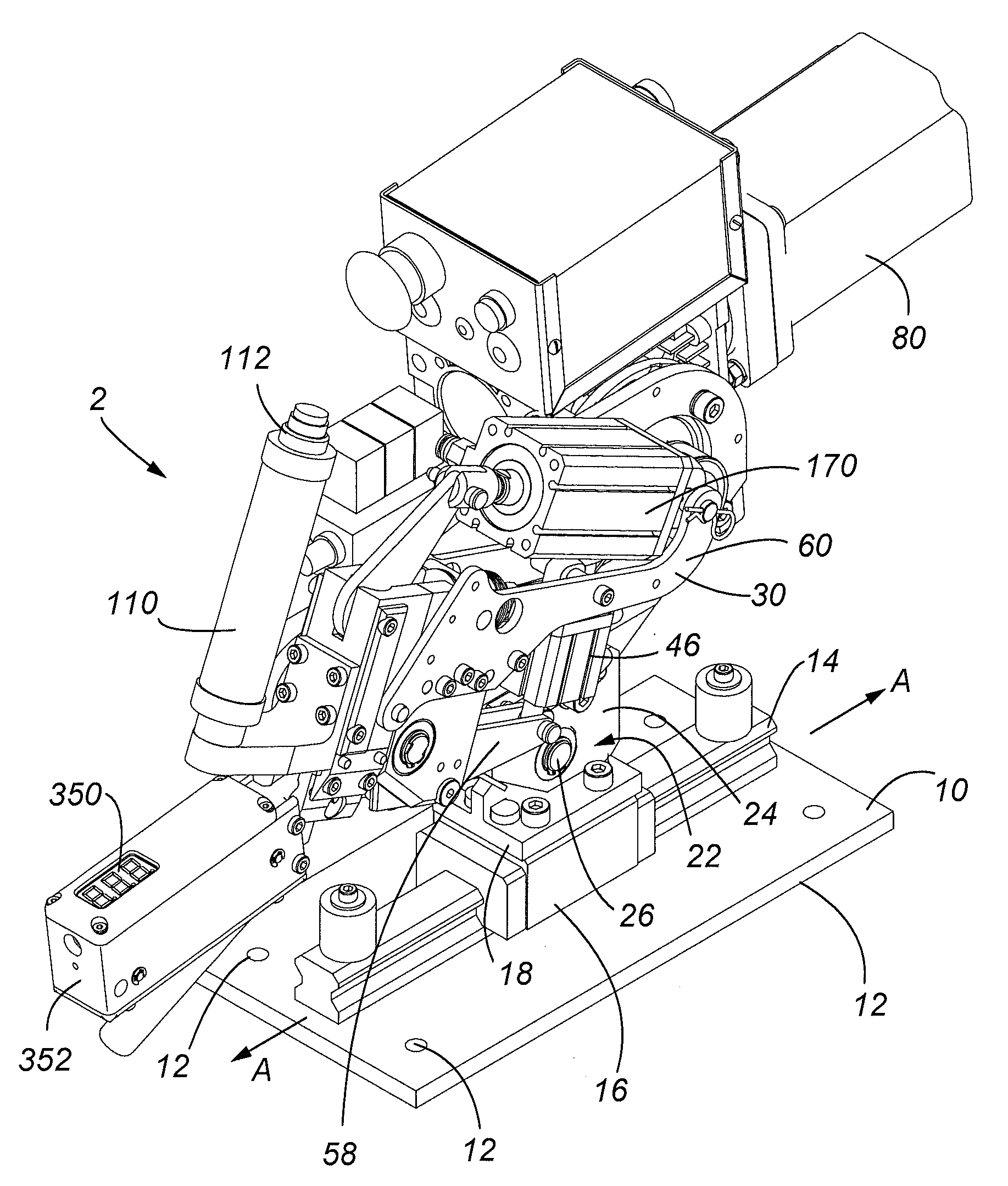

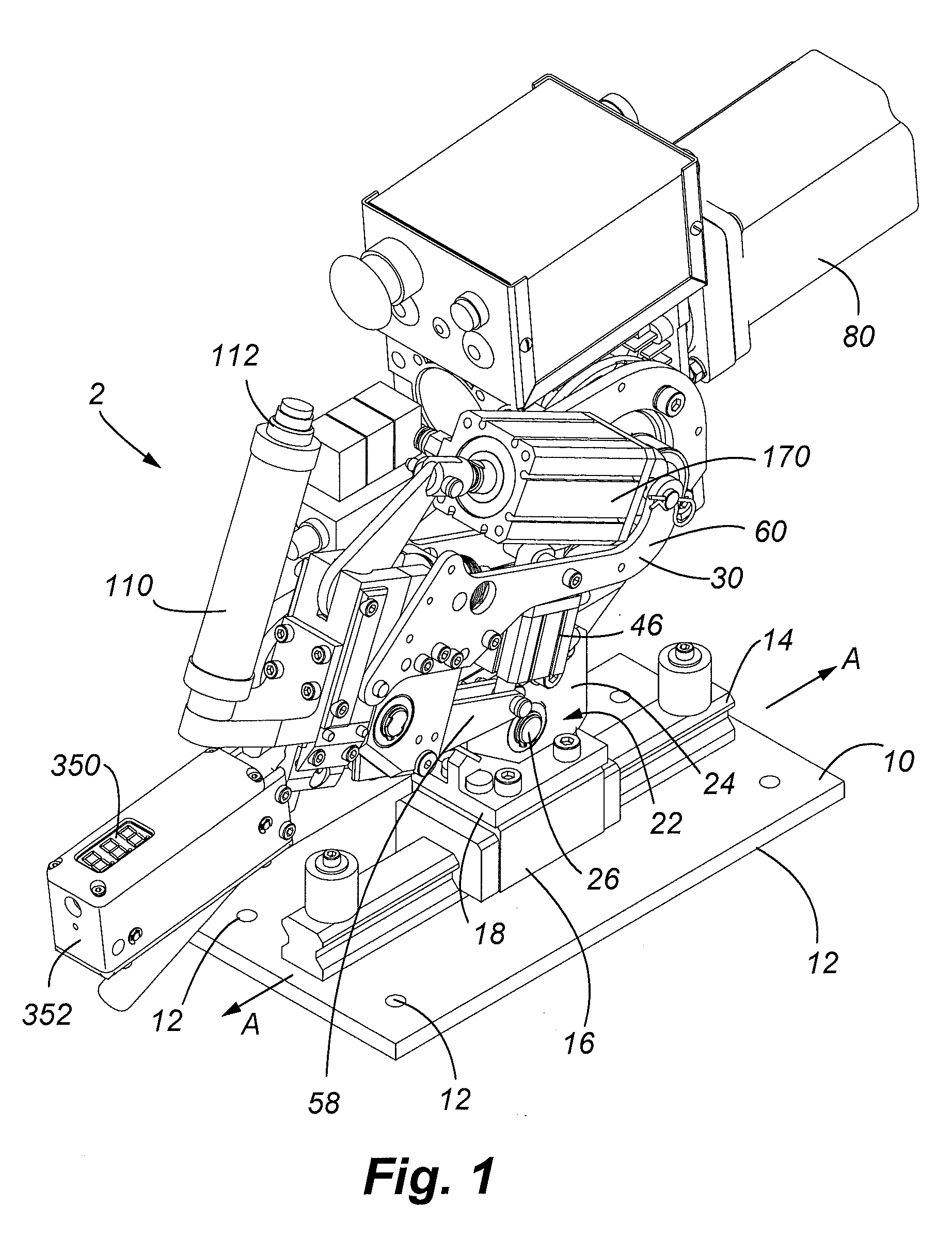

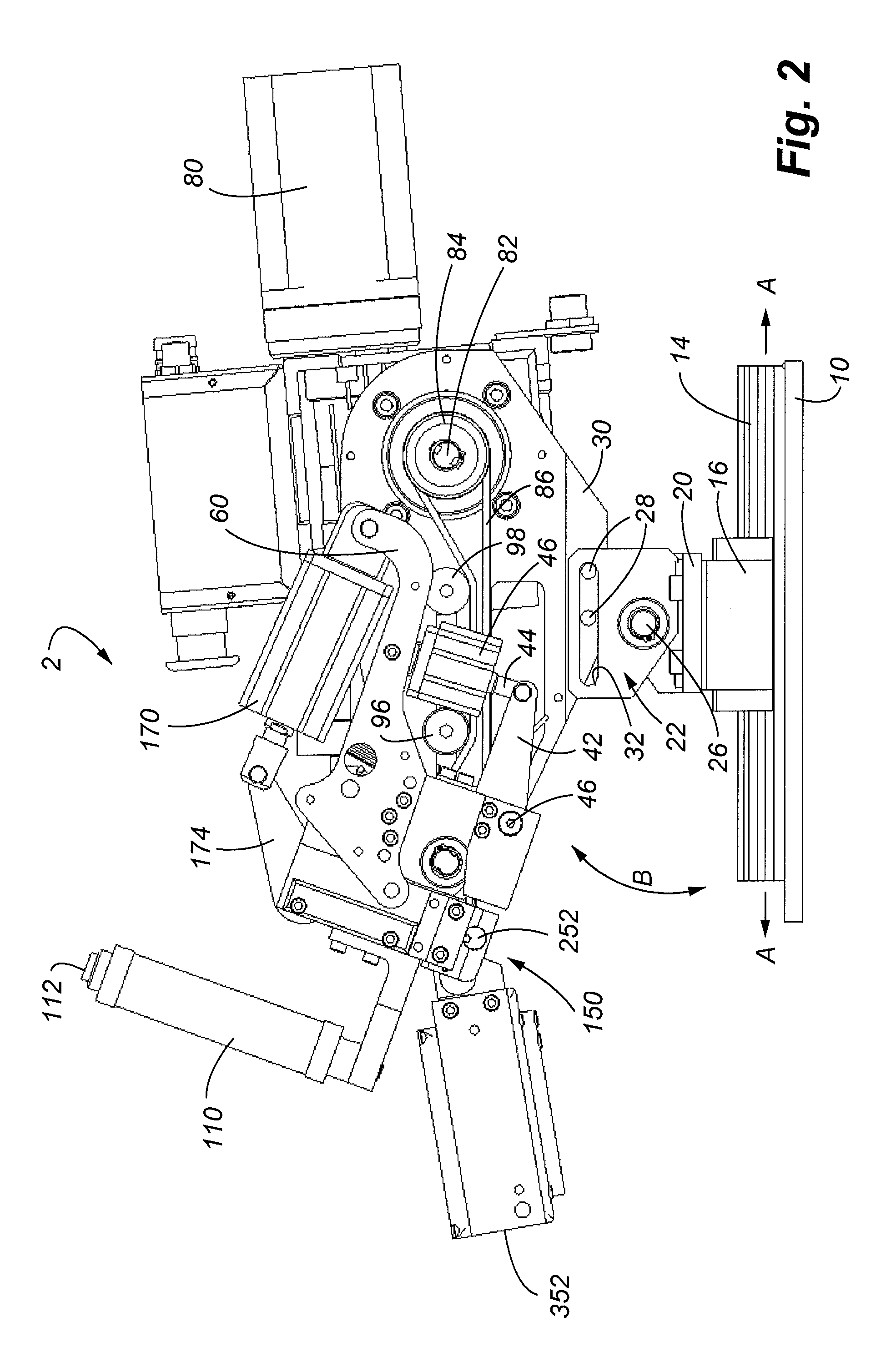

Stationary band clamping apparatus

ActiveUS20090114308A1Easy accessEnhances operational repeatabilityWire articlesBinding material applicationPunchingEngineering

A tensioning device is provided that includes a separable punching and cutting mechanism. Provided is an impact head that holds a buckle while the band that resides within the buckle is tensioned. After a predetermined tension is achieved, a mechanism is used to lock the band with respect to the buckle then to cut the band. Various data related to tension and cutting performance may also be outputted by the invention.

Owner:BAND IT IDEX

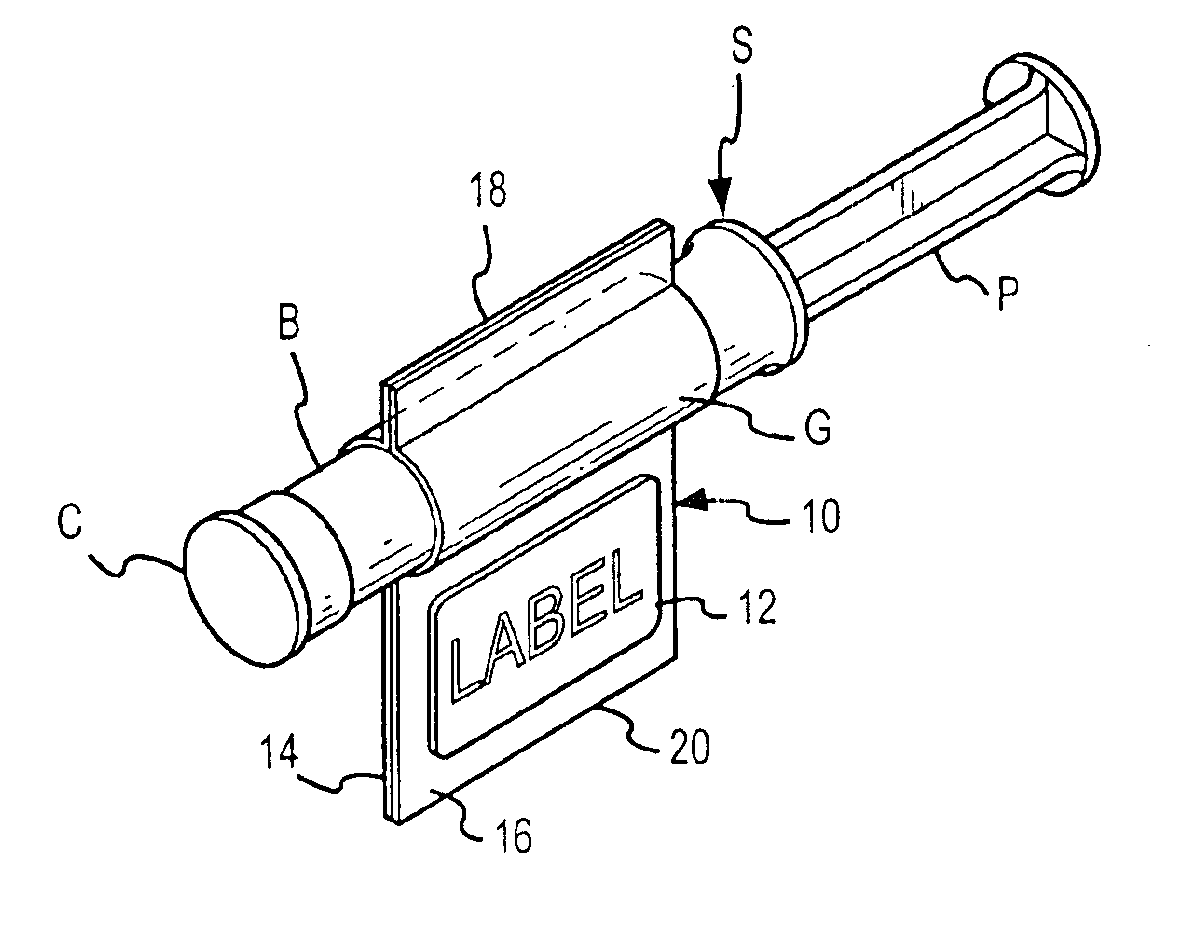

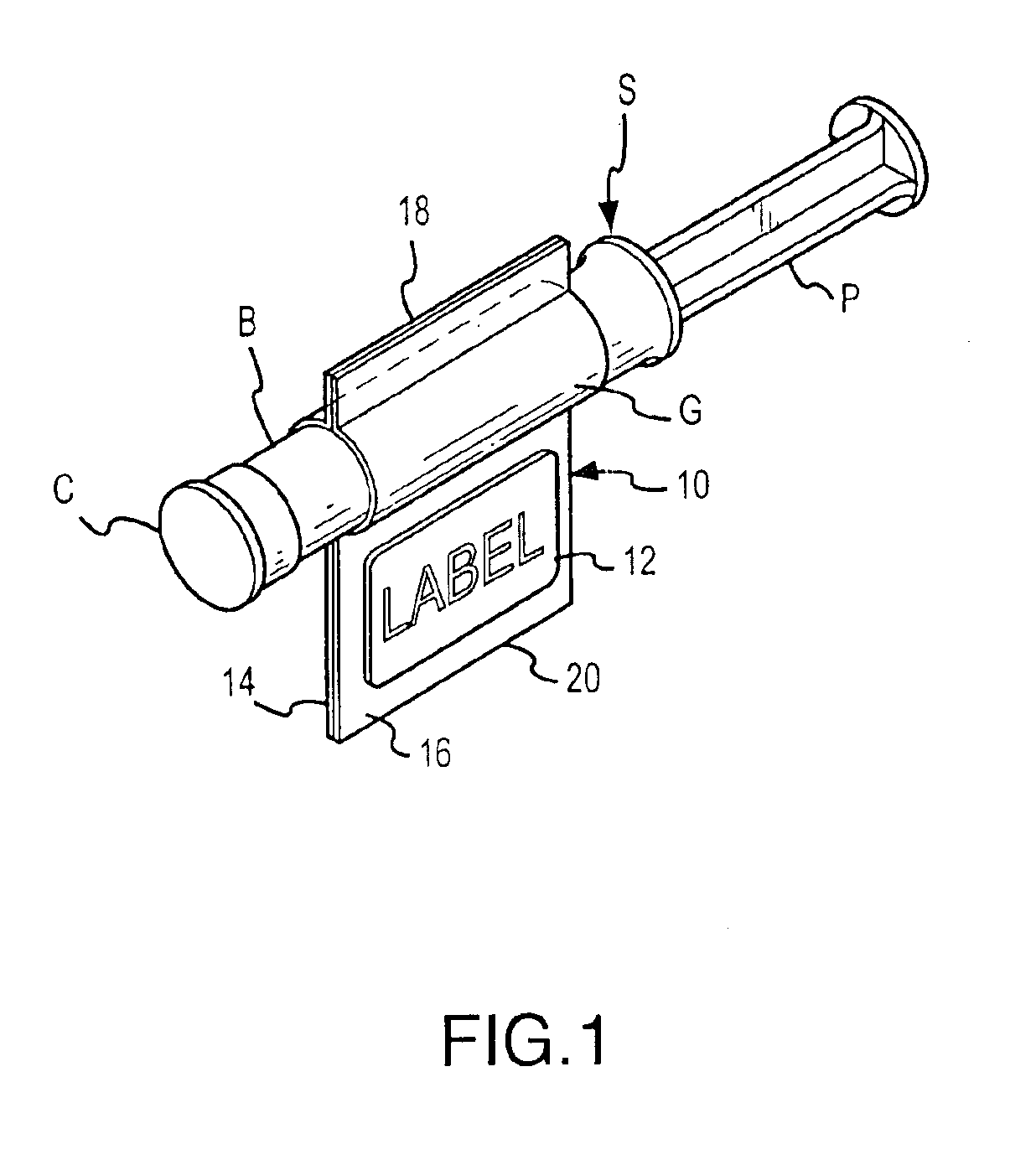

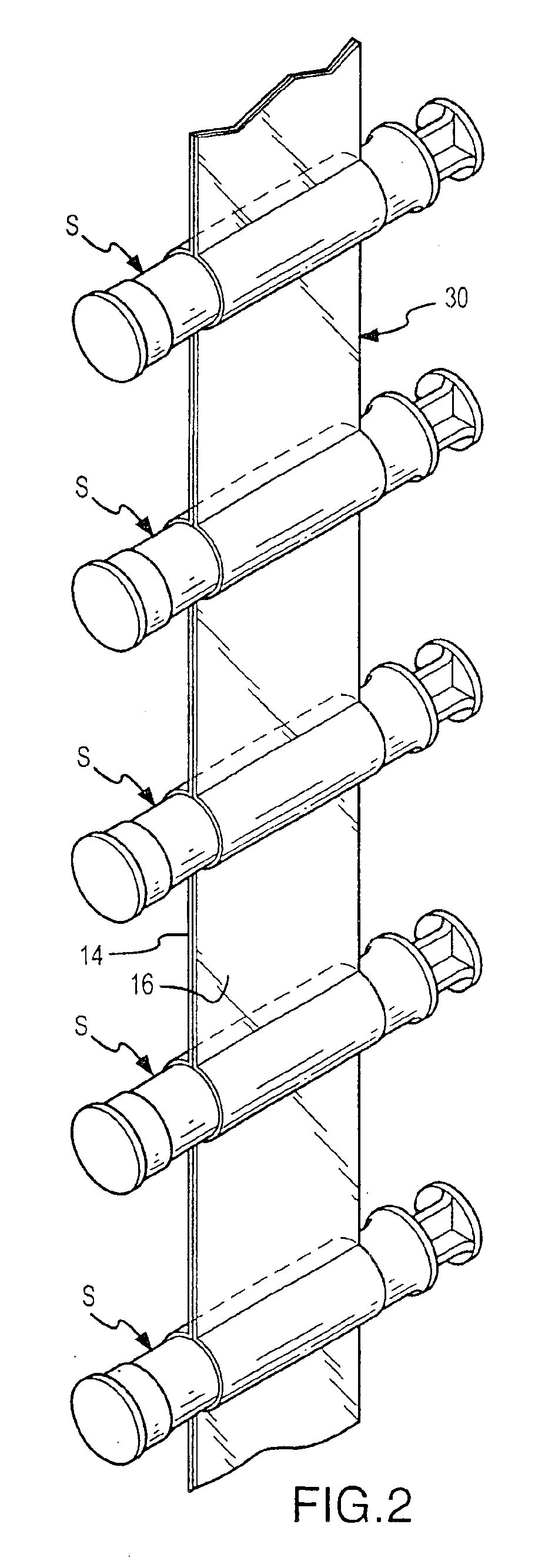

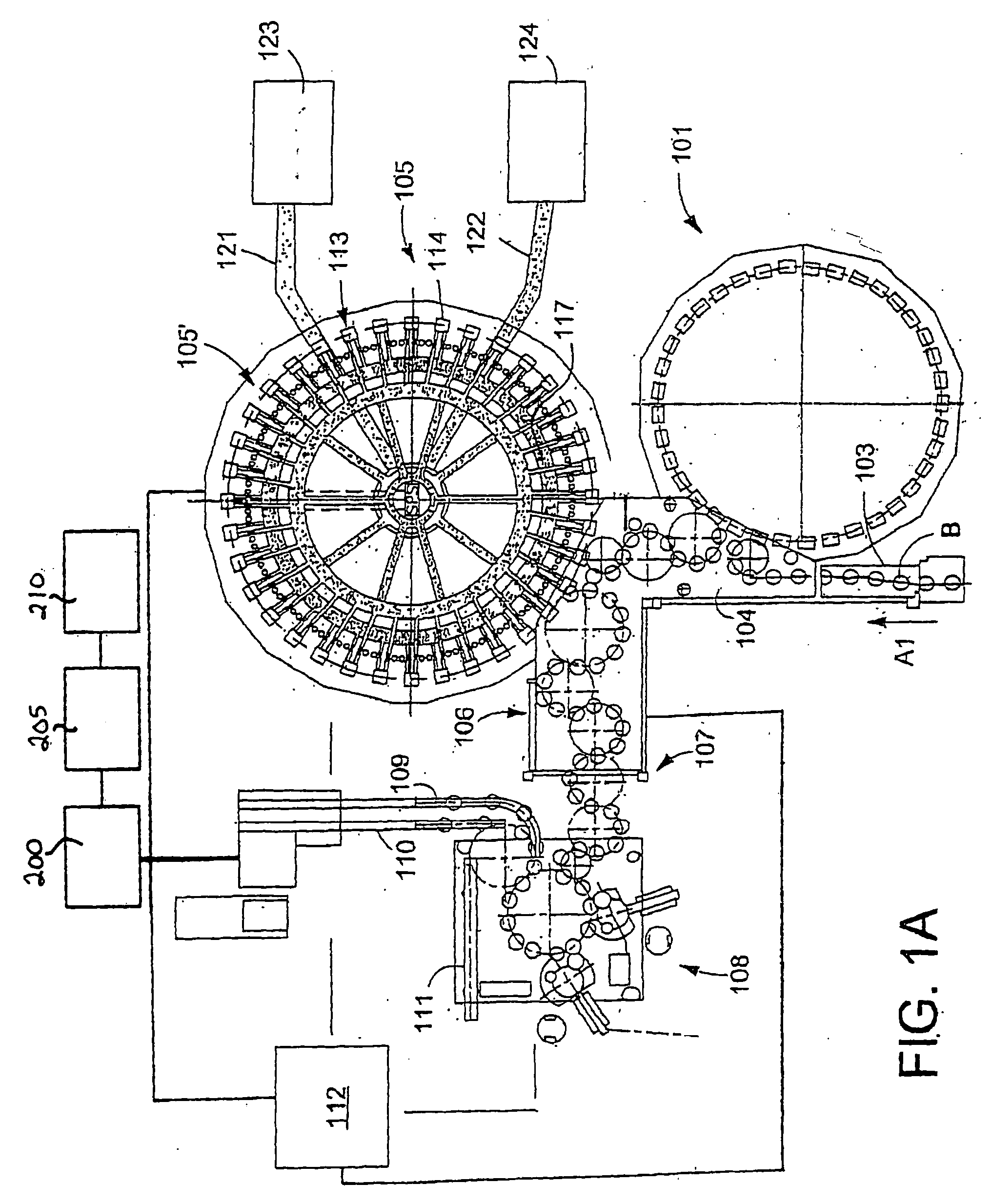

Method and system for labeling syringe bodies

InactiveUS6957522B2Easy to handleEasy to carryPower operated devicesPackage sterilisationManual handlingBiomedical engineering

An inventive method, system and apparatus are provided for syringe handling, and more particularly, for syringe labeling, filling and capping operations. To facilitate syringe handling, an inventive apparatus includes a plurality of syringe bodies interconnected in a predetermined orientation by a belt. Such belt may be of pliable construction and may define a predetermined spacing in between adjacent ones of the syringe bodies, such predetermined spacing corresponding with a distance between holders provided in a handling apparatus. The syringe handling apparatus may provide for the placement of contents-related information on belt segments between adjacent syringe bodies and for separating the belt segments, wherein a flap is left interconnected to each syringe body. The syringe handling apparatus may alternatively or also provide for automated filling of the syringe bodies wherein cap removal, filling and cap replacement operations are completed free from manual handling.

Owner:BAXTER ENGLEWOOD

Method and apparatus for securing a load to a pallet with a roped film web

ActiveUS7568327B2Narrow widthReduce widthWrappers shrinkageWrapping material feeding apparatusThin membranePallet

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one guide rollers configured to engage the width of the film web, and at least one roping element. The at least one roping element may be a cable rolling roper configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

Preparation method for biodegradable polymeric microspheres using solvent extraction and preparation method for microspheres for treating local inflammation using the same

InactiveUS6149944ALow efficiencyEfficient curingLayered productsPharmaceutical non-active ingredientsDiseaseNon solvent

PCT No. PCT / KR97 / 00055 Sec. 371 Date Aug. 2, 1999 Sec. 102(e) Date Aug. 2, 1999 PCT Filed Apr. 1, 1997 PCT Pub. No. WO97 / 36949 PCT Pub. Date Oct. 9, 1997A preparation method for biodegradable polymeric microspheres using a solvent extraction method for biodegradable polymeric microspheres for treating a local inflammation disease using the same which are capable of effectively curing ozena such as sinusitis and a middle ear infection. Since a non-solvent of polymer is added into an outer aqueous phase in advance, the solidification of the polymer is implemented in a short time which, in turn, improves encapsulation of the therapeutic agent used.

Owner:AMOREPACIFIC CORP

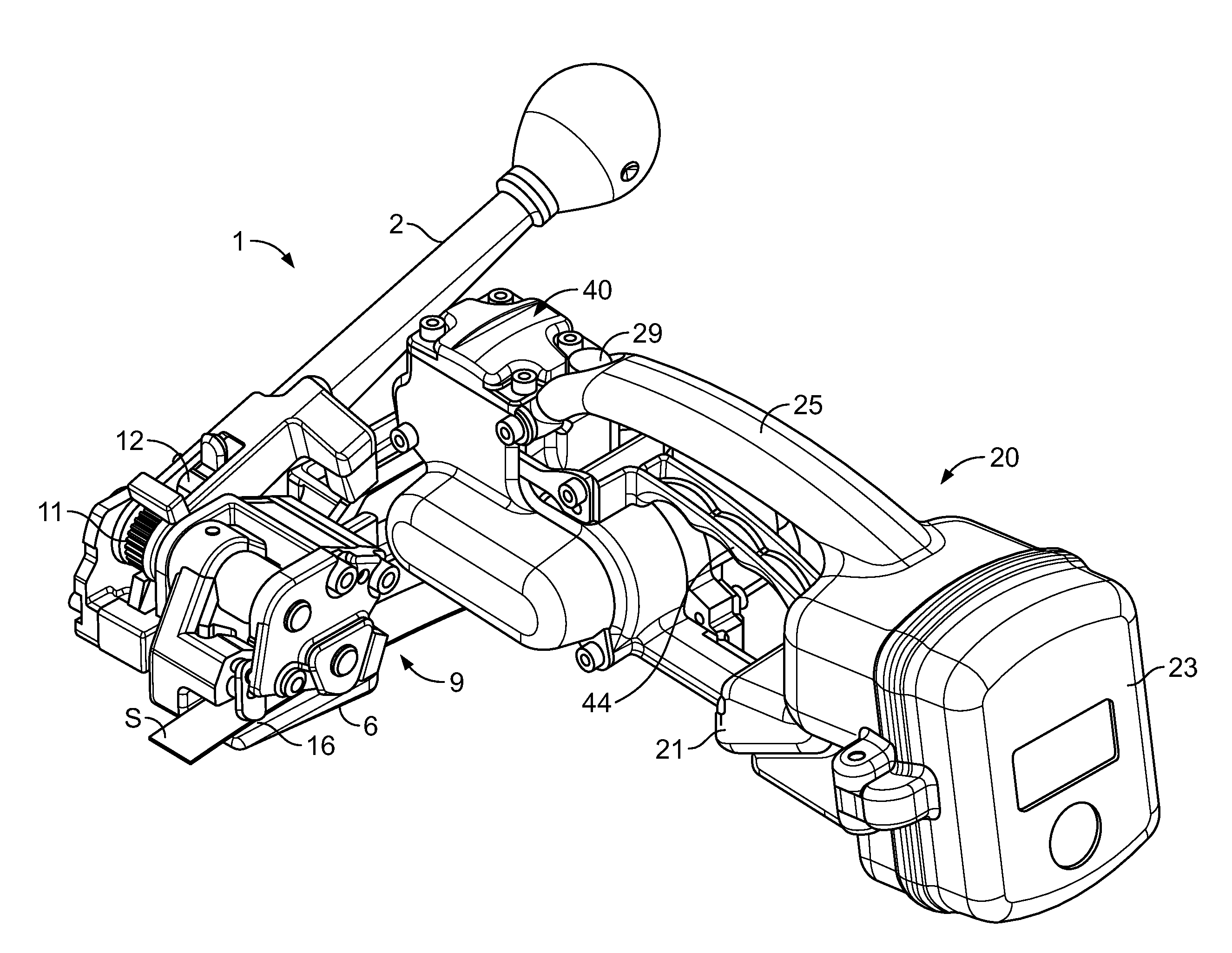

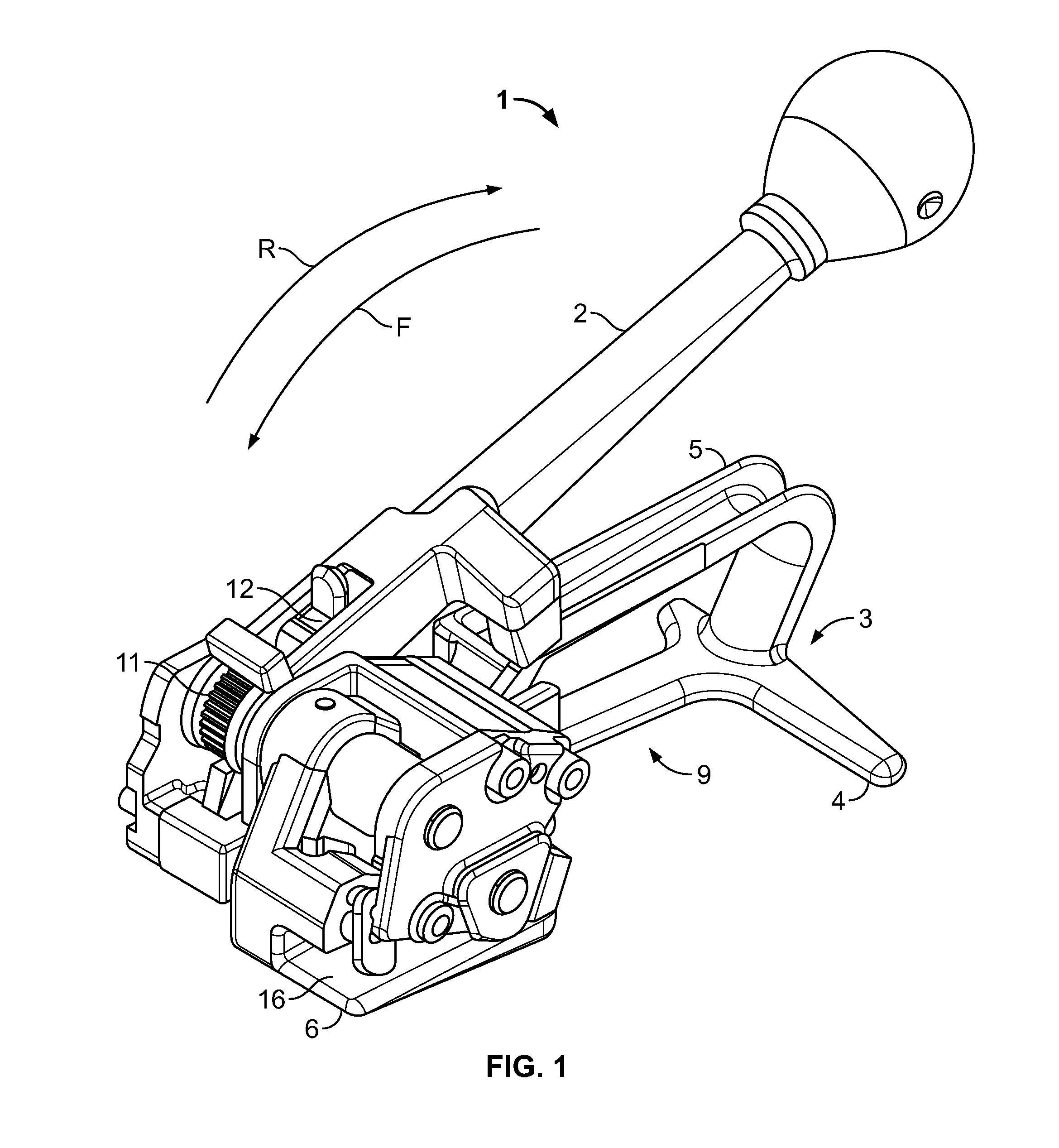

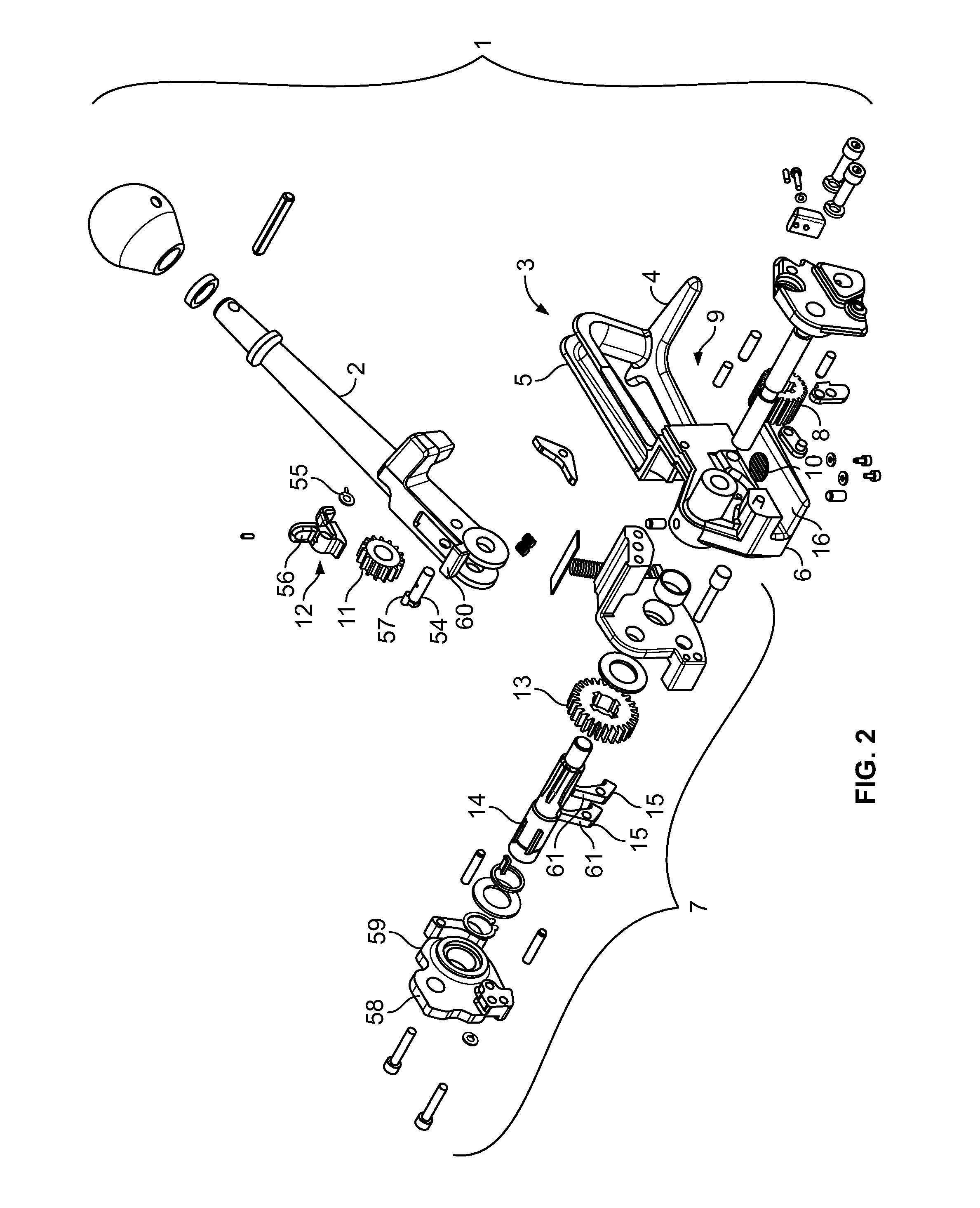

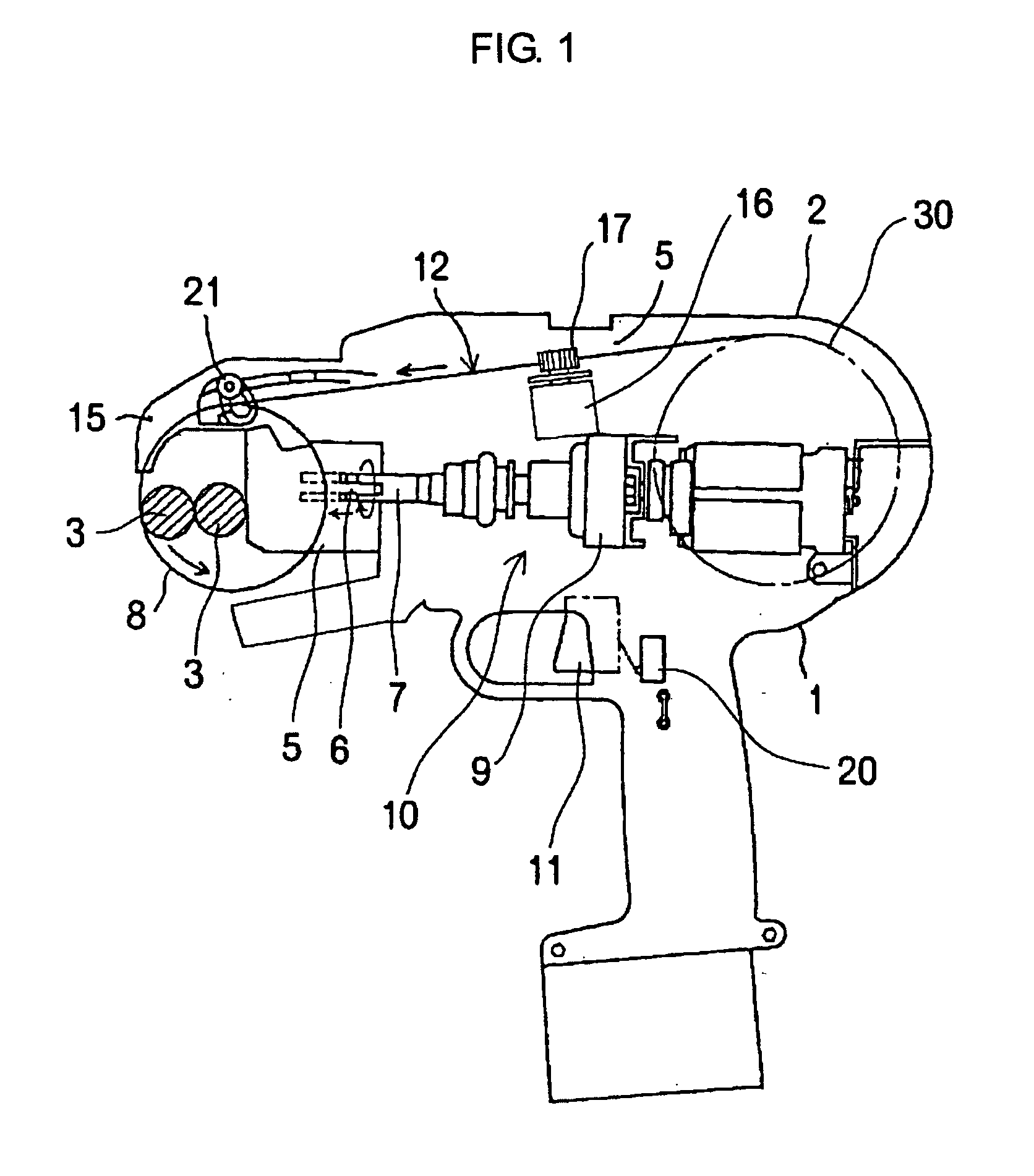

Two-Piece Strapping Tool

A two-piece strapping tool having a manual tensioner and a battery-operated sealer is disclosed. The tensioner is a feedwheel tensioner that uses a serrated feedwheel to grip a first portion of the strap and a tension gripper to hold a second portion of the strap in a stationary position. The tensioner is configured to matingly receive the sealer between the tensioner's support legs such that the sealer may readily engage the overlapping portions of the strap to be welded. The sealer is battery-operated and uses a vibrational-type weld assembly driven by an electrical motor to weld overlapping portions of the strap. The sealer also includes a cutting assembly to sever the welded strap from a strap source.

Owner:SIGNODE IND GRP

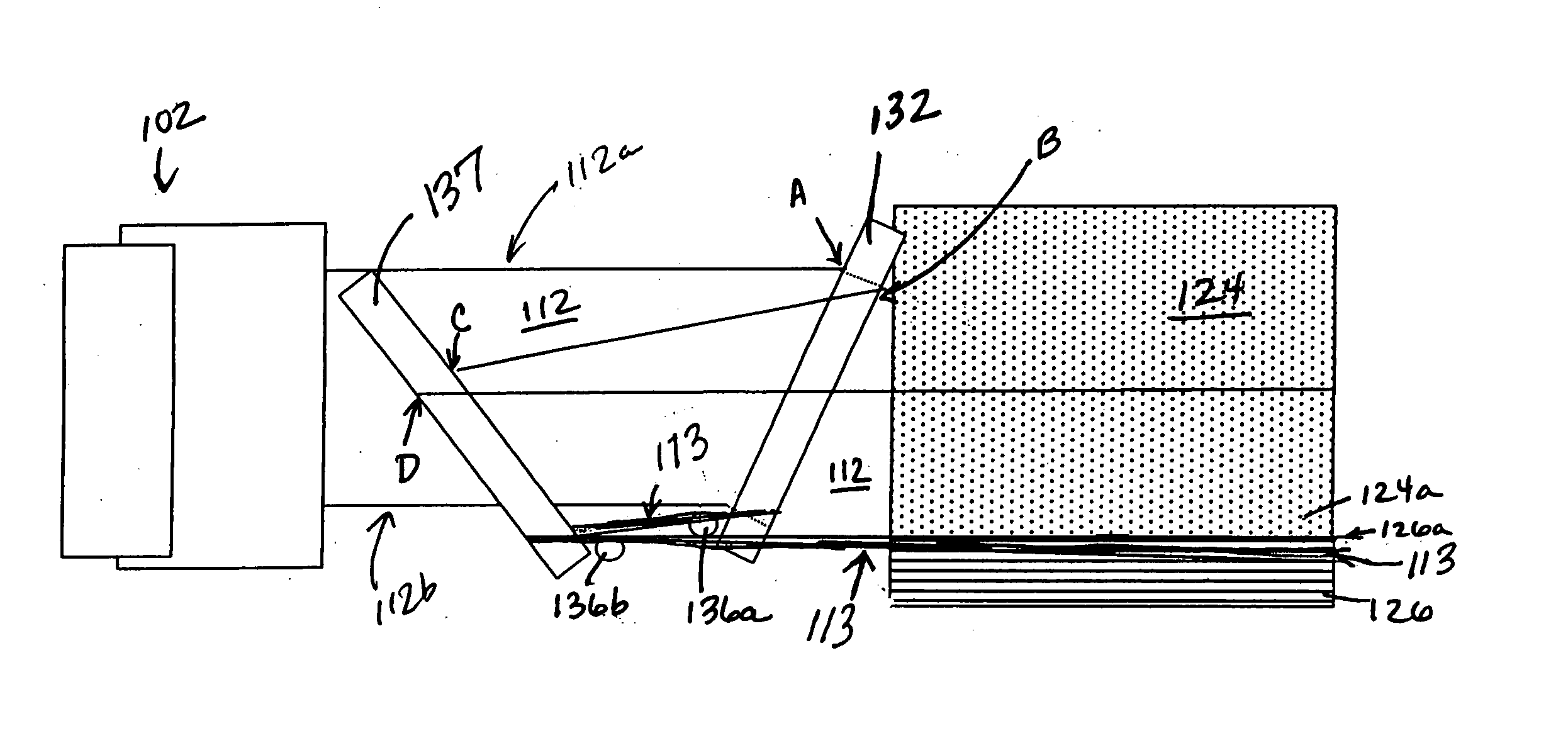

Method and apparatus for wrapping a load

InactiveUS7114308B2Minimal frictionAvoid insufficient frictionWrappers shrinkageBinding material applicationEngineeringMechanical engineering

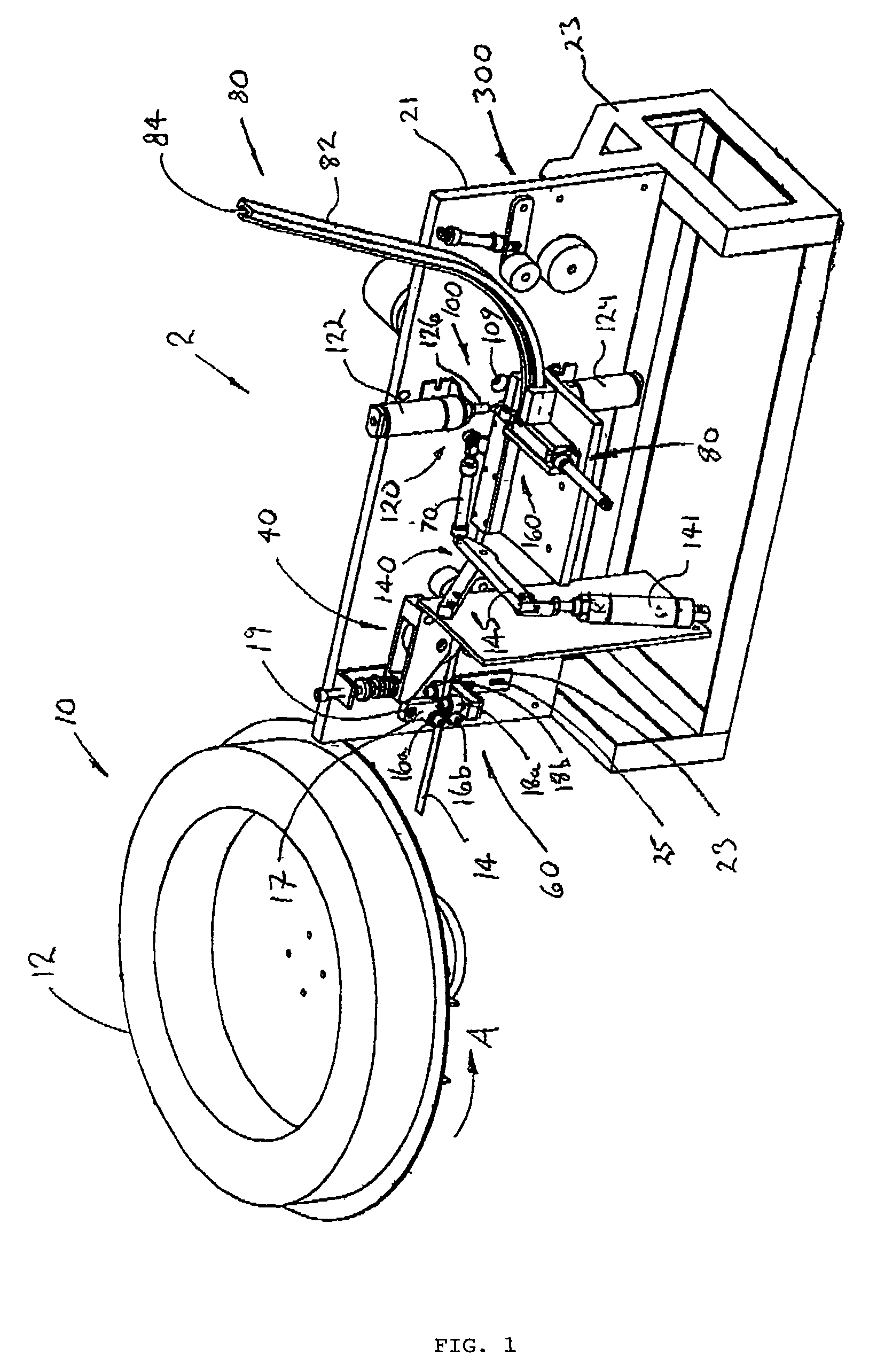

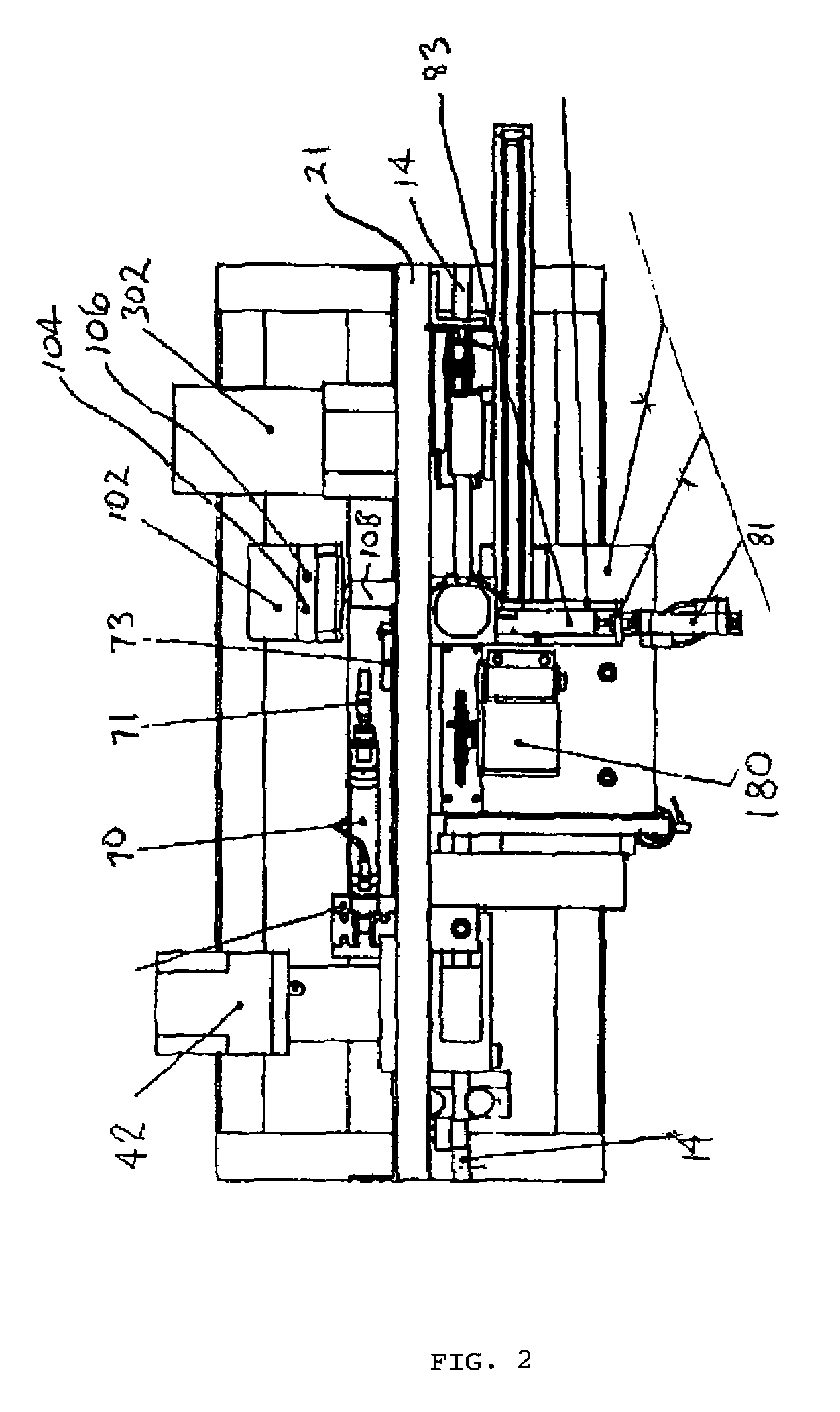

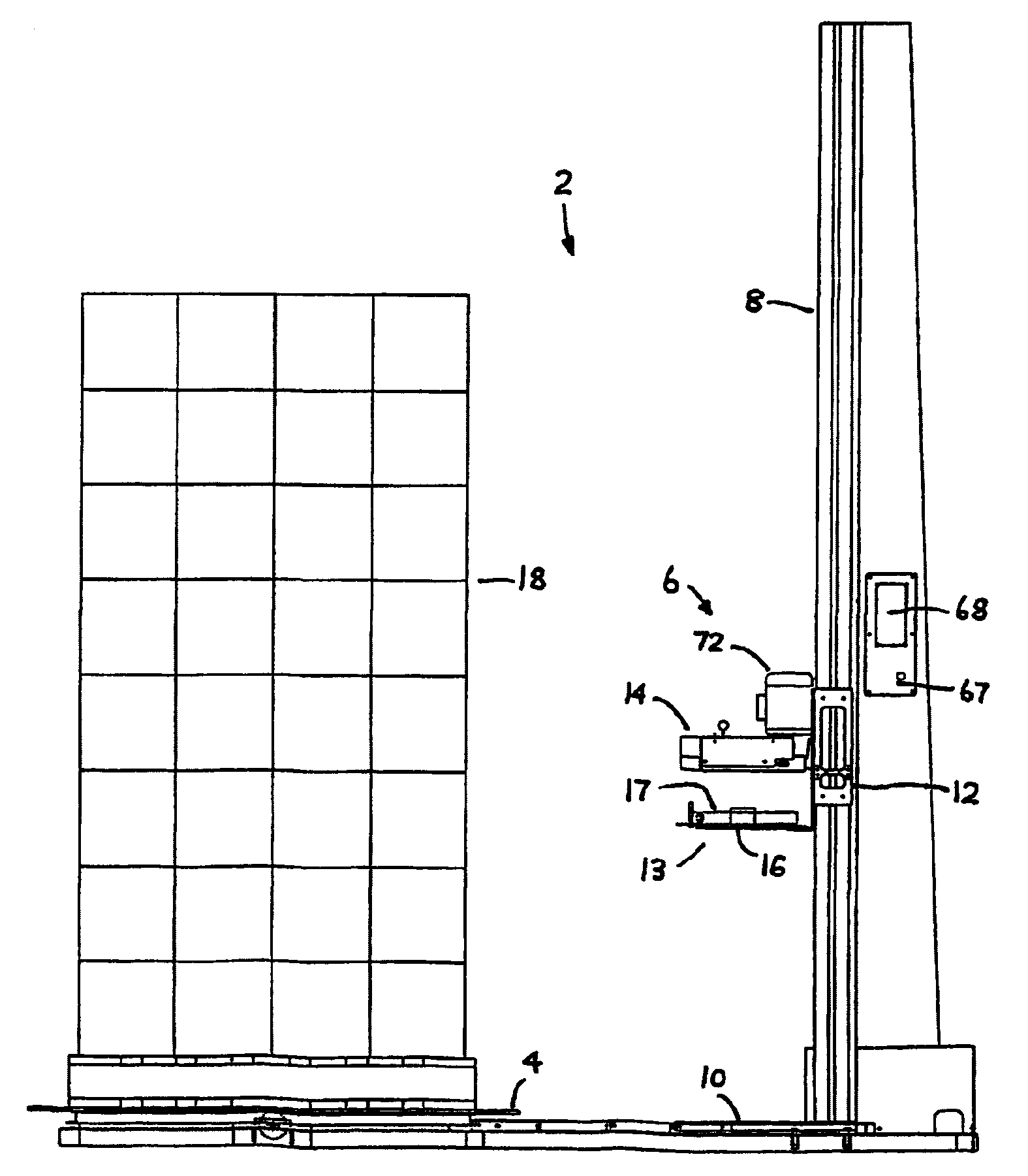

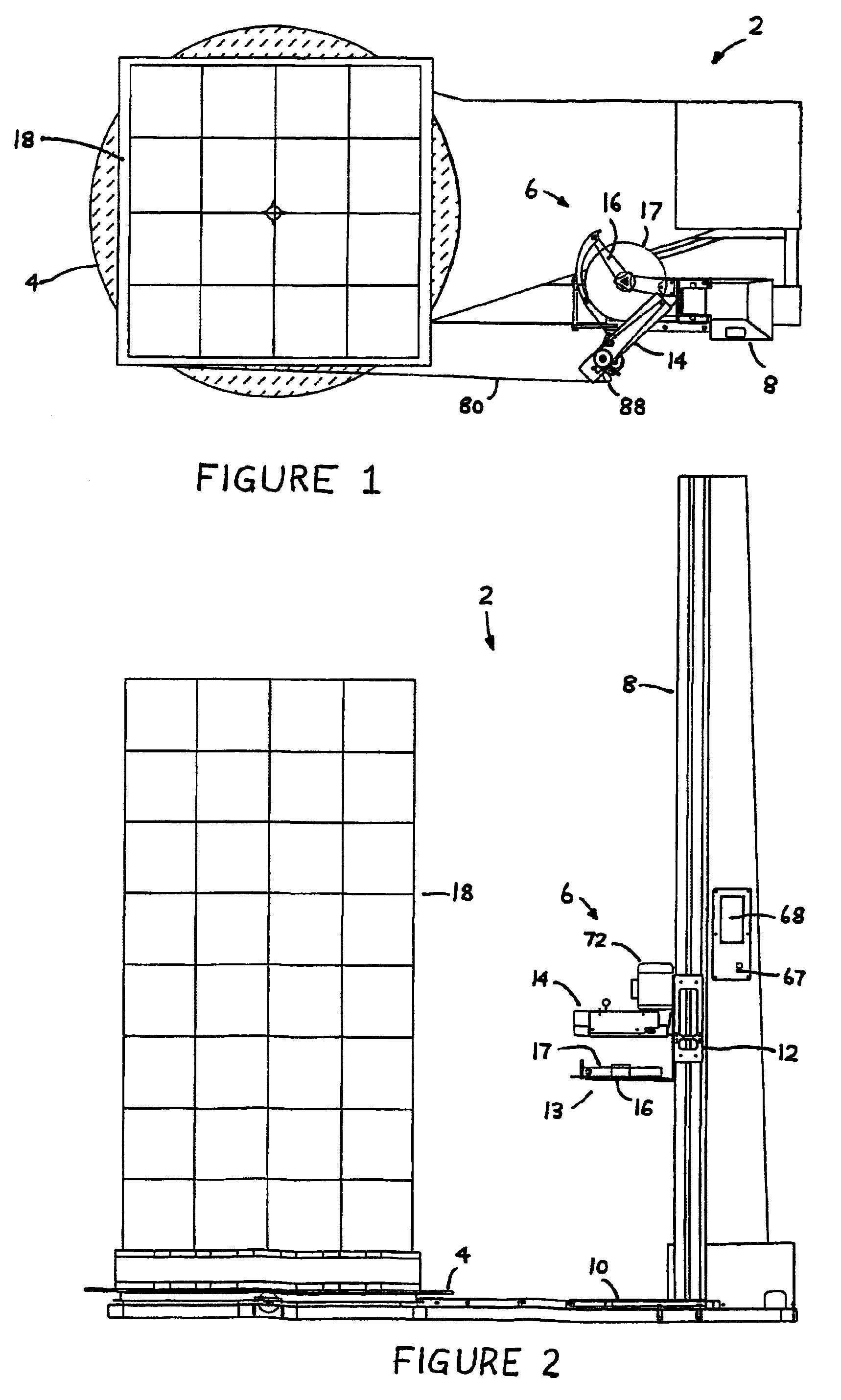

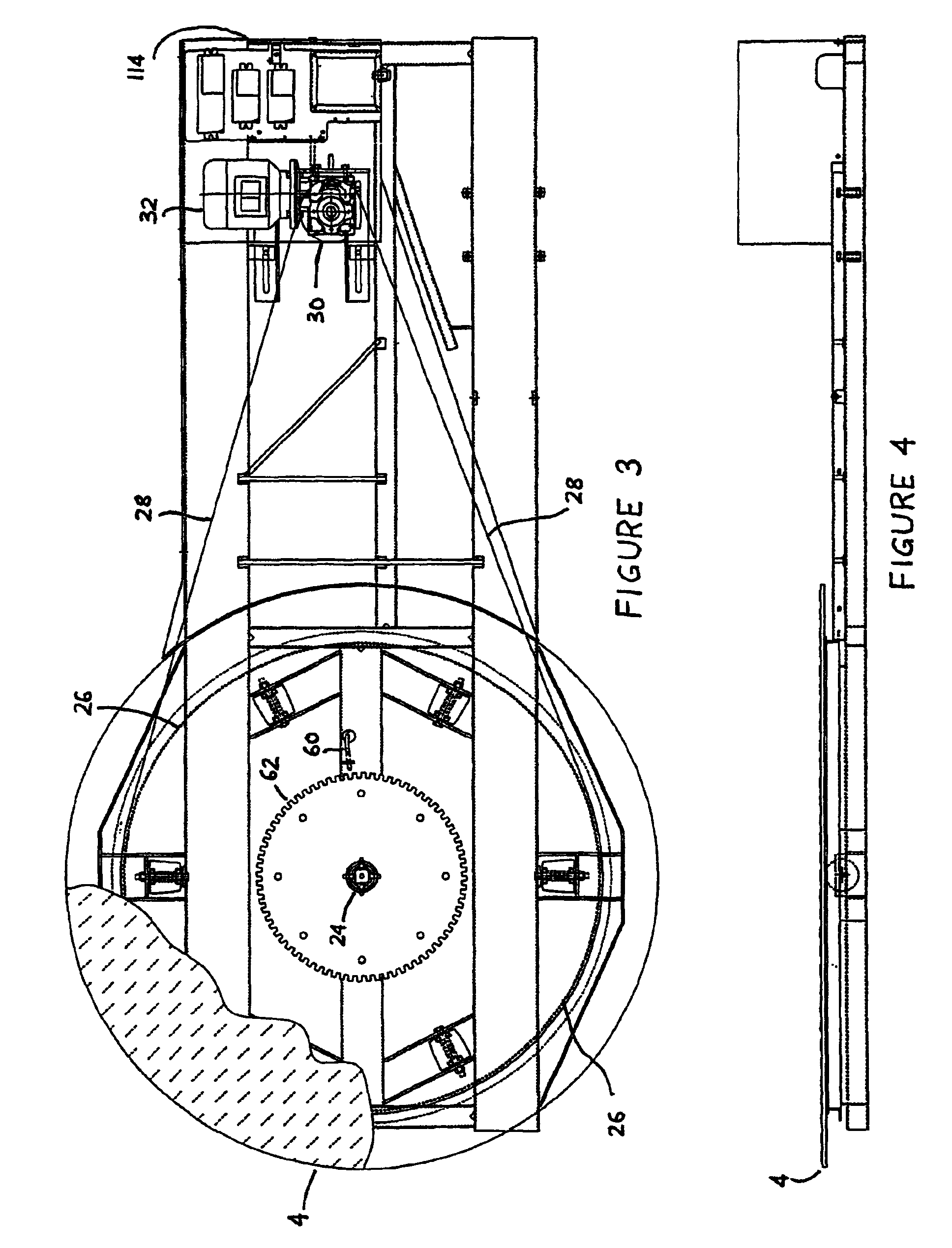

Apparatus (2) for wrapping a load (18) placed on a turntable (4) having a mast assembly (8), a carriage assembly (12) adapted for vertical slideable movement along said mast assembly (8) and dispensing means (13) for dispensing tape material (80). The tape material (80) is transferred from the dispensing means (13) in response to rotation of the turntable (4) such that the tape material (80) wraps around the load (18) in a predefined pattern. The carriage assembly (12) and turntable (4) are configured for automated movement in response to a computer program stored in memory means (306) to enable wrapping of the load (18) with the tape material (80) in the predefined pattern. The carriage assembly (12) is positioned along the mast assembly (8) under control of the computer program in accordance with a rotational position of the load (18) to locate the tape material (80) at locations on the load (18). A pretensioning apparatus is also disclosed for pretensioning the tape material (80). Also disclosed is apparatus including adjusting the rate at which tape material (80) is payed out depending on a portion of the load (18) to be wrapped by the tape material (80). Also disclosed is tension adjustment apparatus (100) for varying the tension applied to the tape material (80).

Owner:SAFETECH PTY LTD

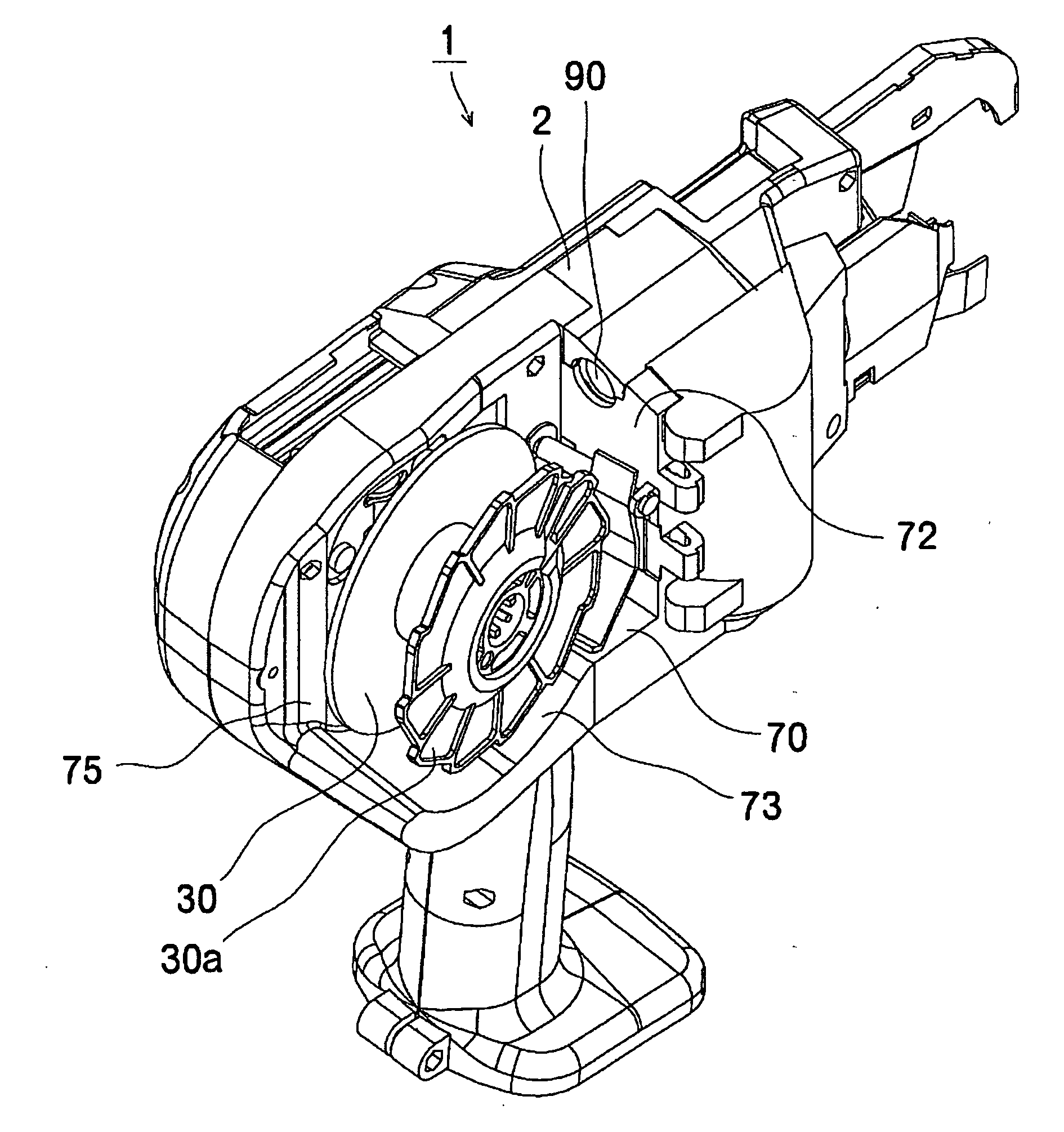

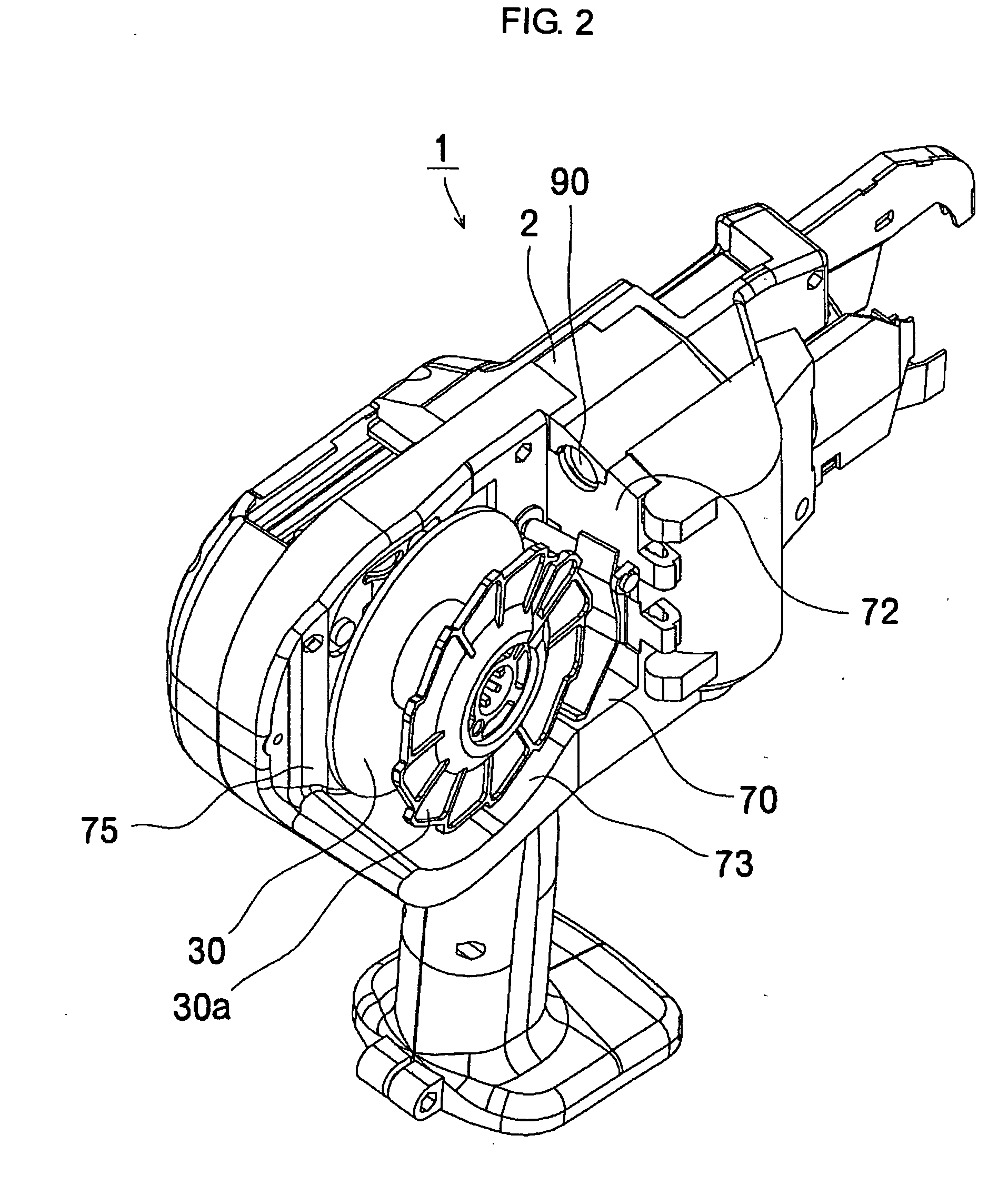

Reinforcing bar binder, wire reel and method for identifying wire reel

ActiveUS20060283516A1Simple and in expensive constructionFilament handlingMetal-working apparatusEngineeringRebar

Owner:MAX CO LTD

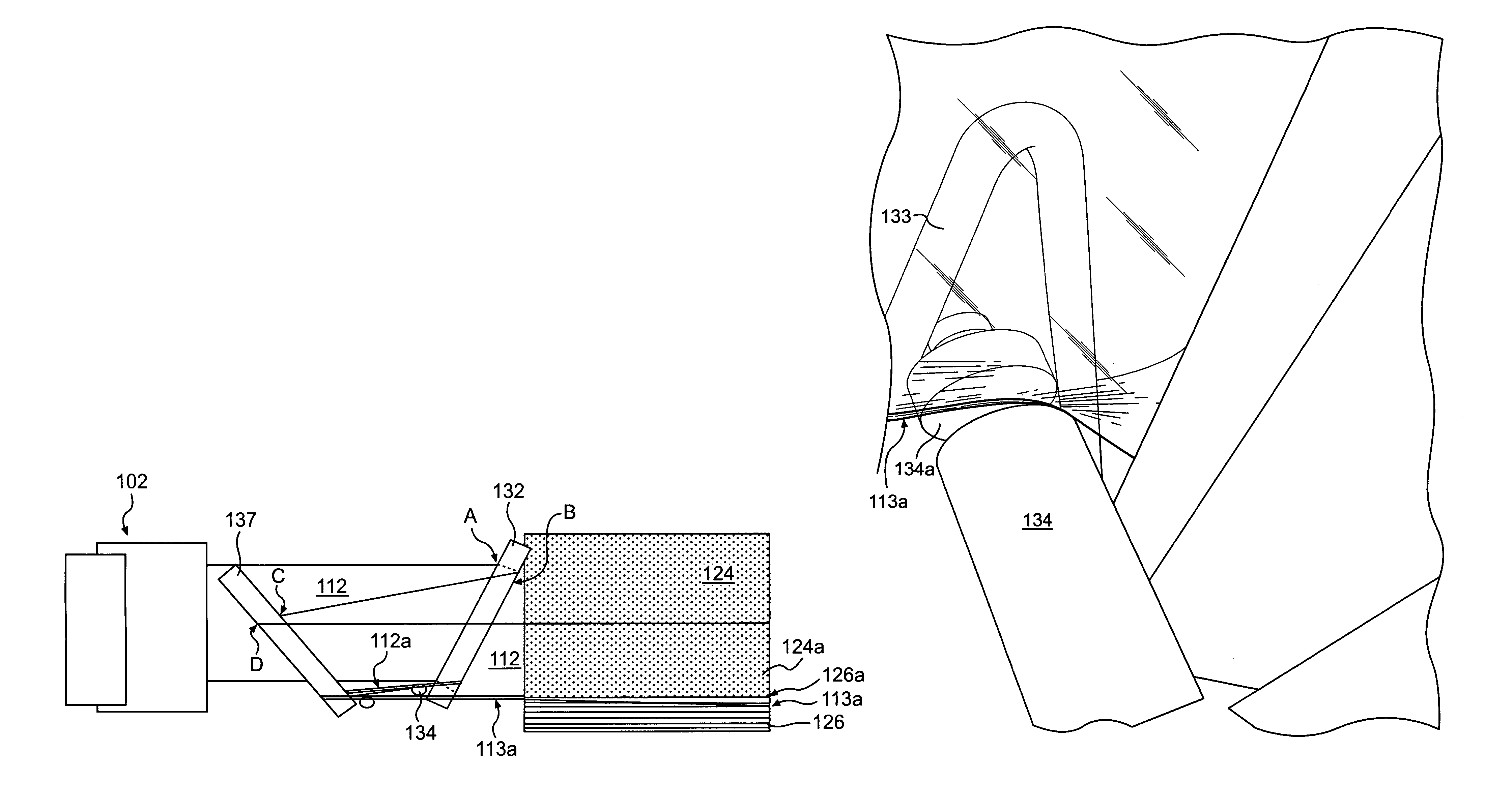

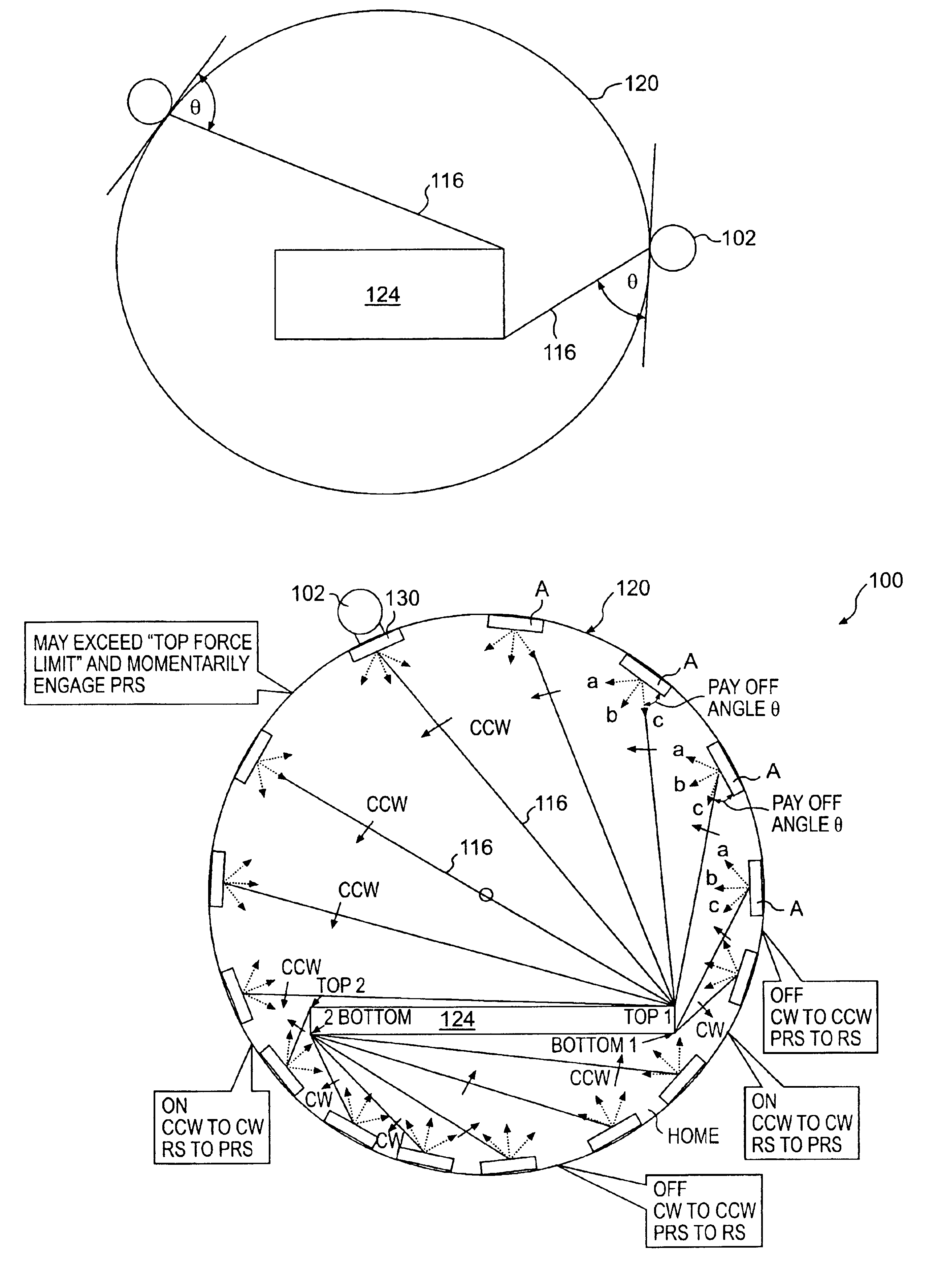

Method and apparatus for wrapping a load

InactiveUS6918229B2Eliminate the problemWrappers shrinkageWrapping material feeding apparatusStretch wrapEngineering

The present invention relates to an apparatus and method for stretch wrapping a load in an efficient manner so as to tightly and securely wrap the load at a desired tension without rupturing the packaging material. The method and apparatus compensate for variation in demand rate as the load is wrapped so as to apply the wrapping material to a load at a desired force, maintain the desired containment tension on the wrapping material on the load after wrapping, and prevent the wrapping material from rupturing during wrapping. The apparatus combines two systems, power assisted roller stretch (“PRS”) and roller stretch (“RS”) to vary the supply rate of the packaging material as the demand rate varies. The apparatus automatically switches between the two types of prestretch to achieve “high” and “low” wrapping force dependent upon the demand rate. Changes in the demand rate are sensed by monitoring changes in the payoff angle of the packaging material extending between the dispenser and the load.

Owner:LANTECH COM

Systems, Methods, and Apparatus Involving Packaging

Owner:GPCP IP HLDG LLC

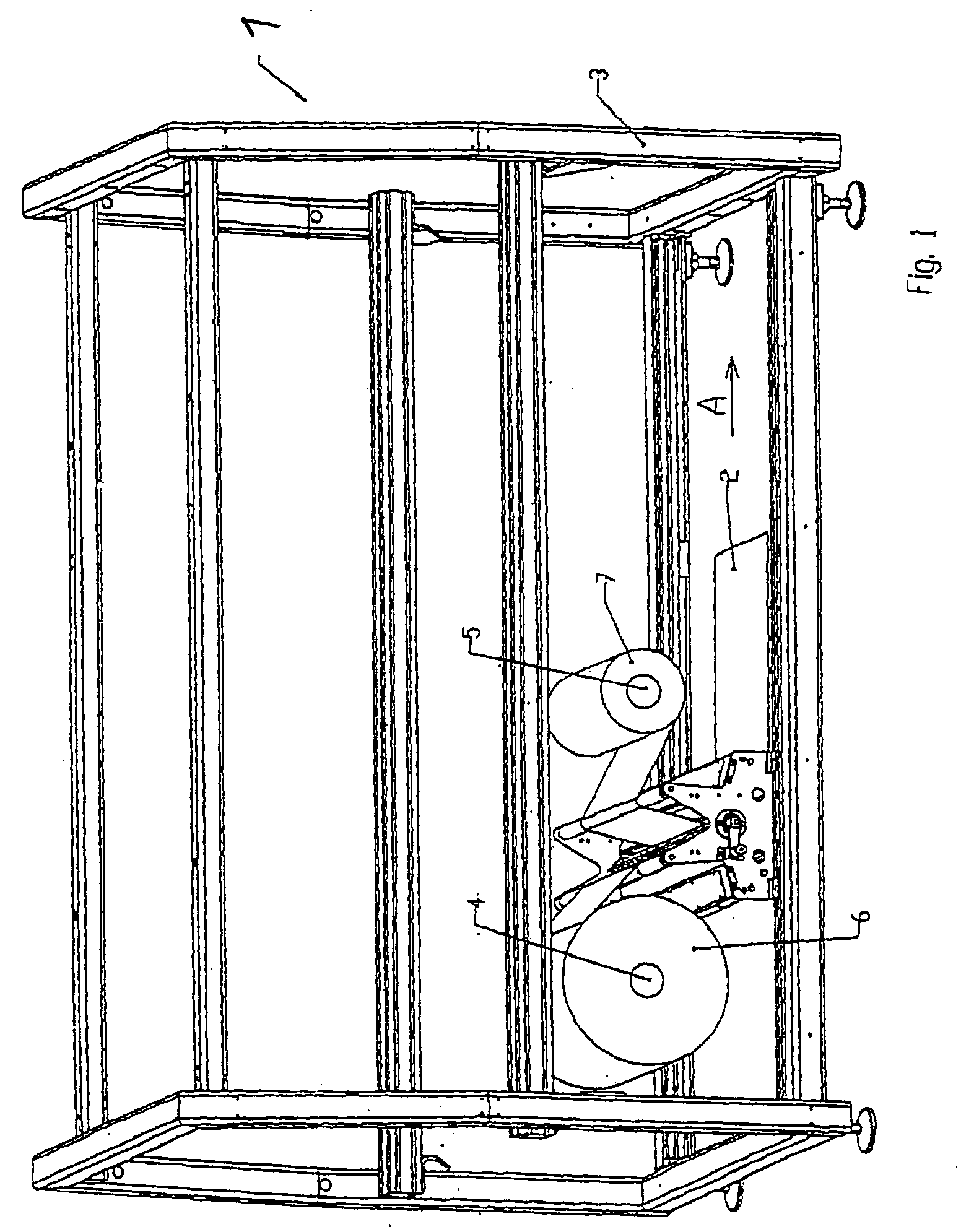

Beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles

InactiveUS20060026926A1Smooth and accurate connectionAccurate connectionMechanical working/deformationWrapping material feeding apparatusTrademarkEngineering

A beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

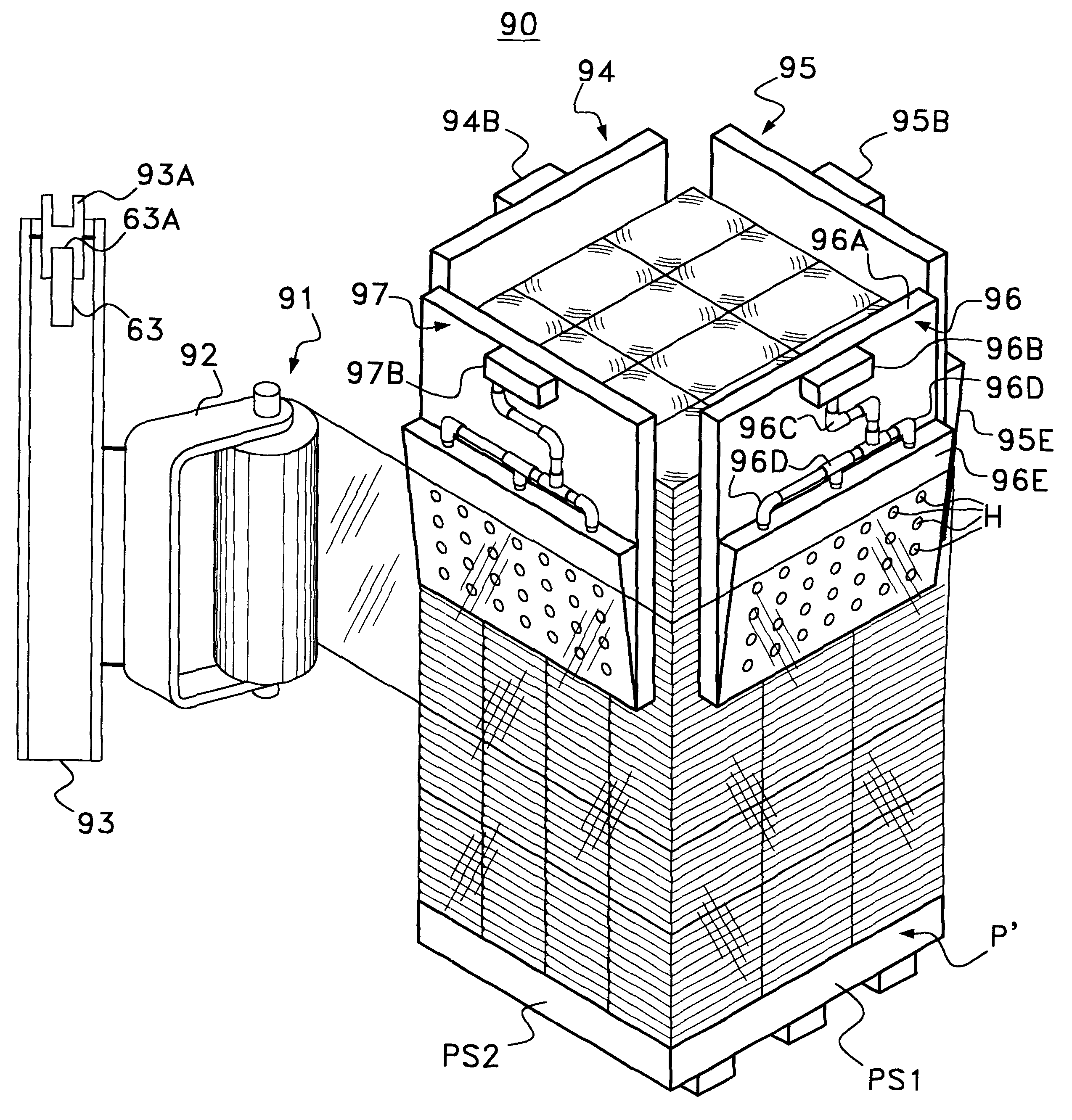

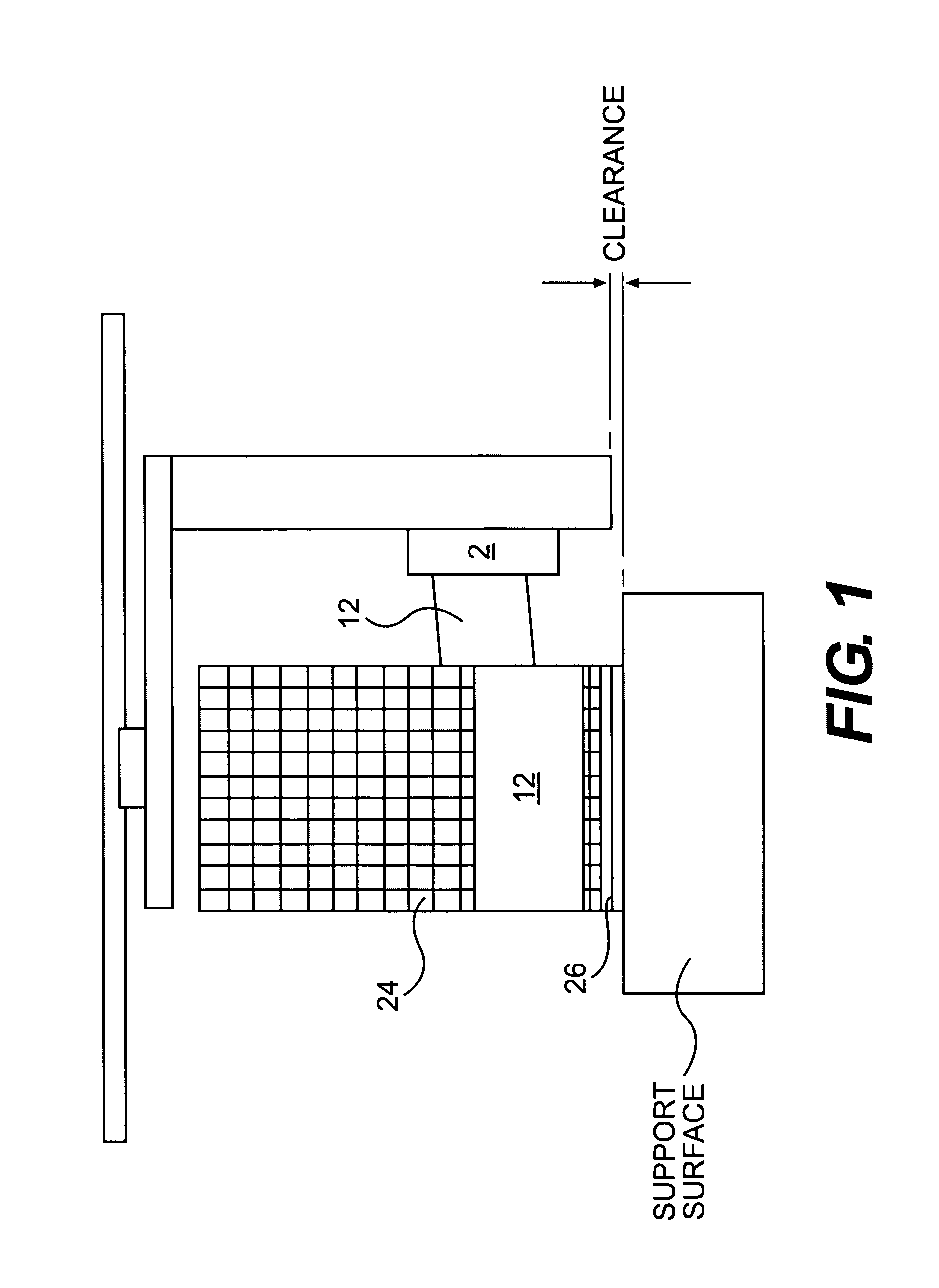

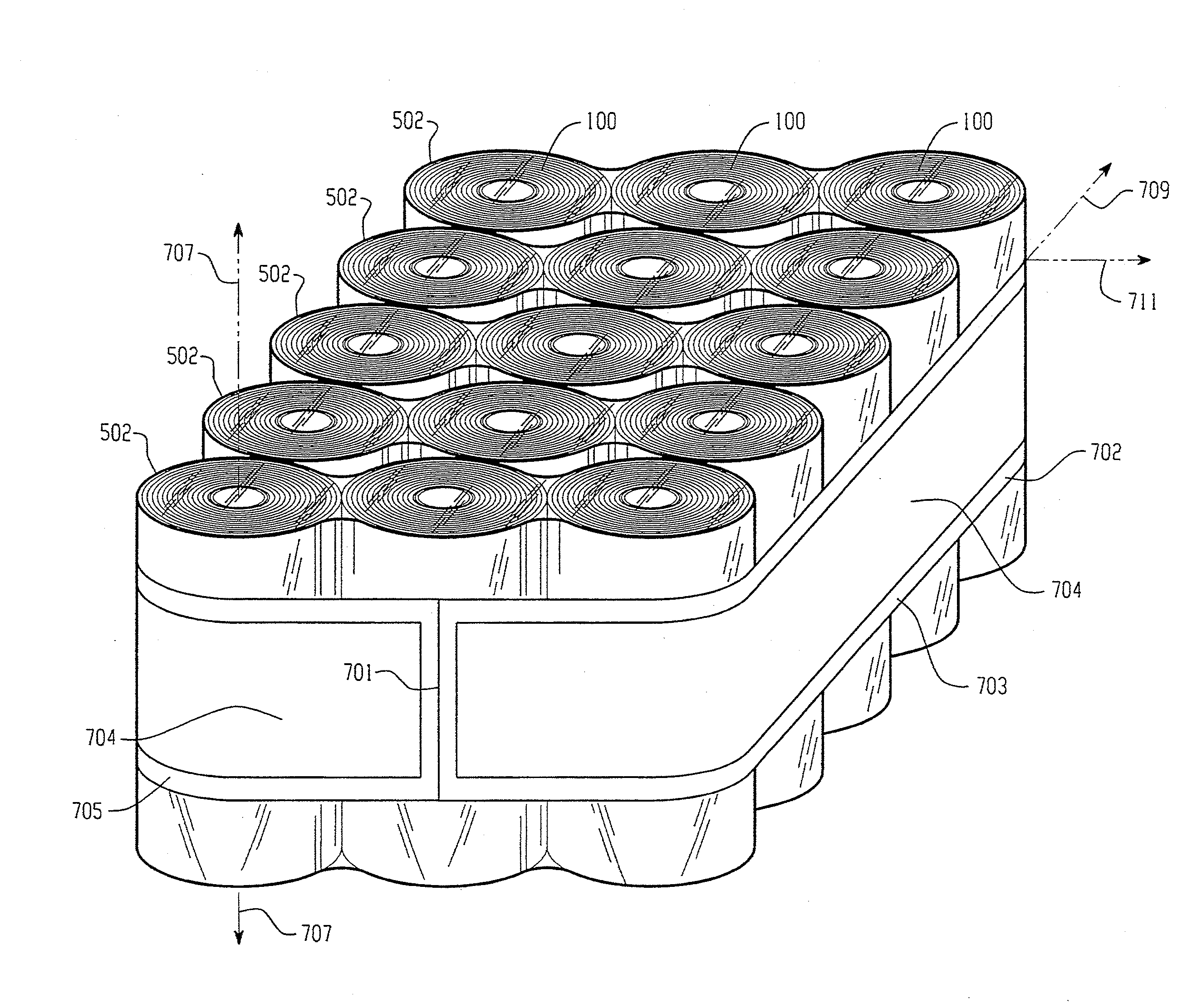

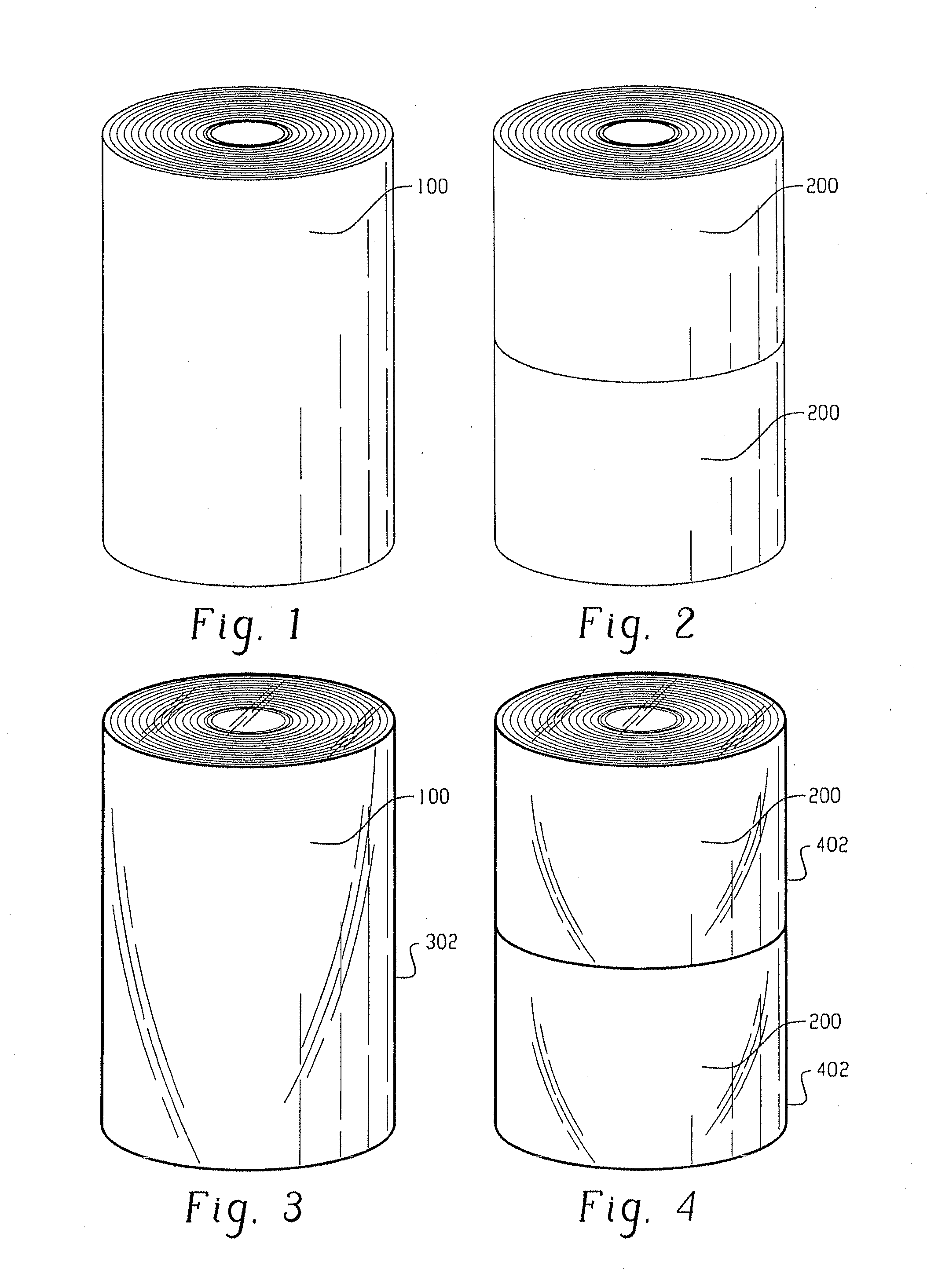

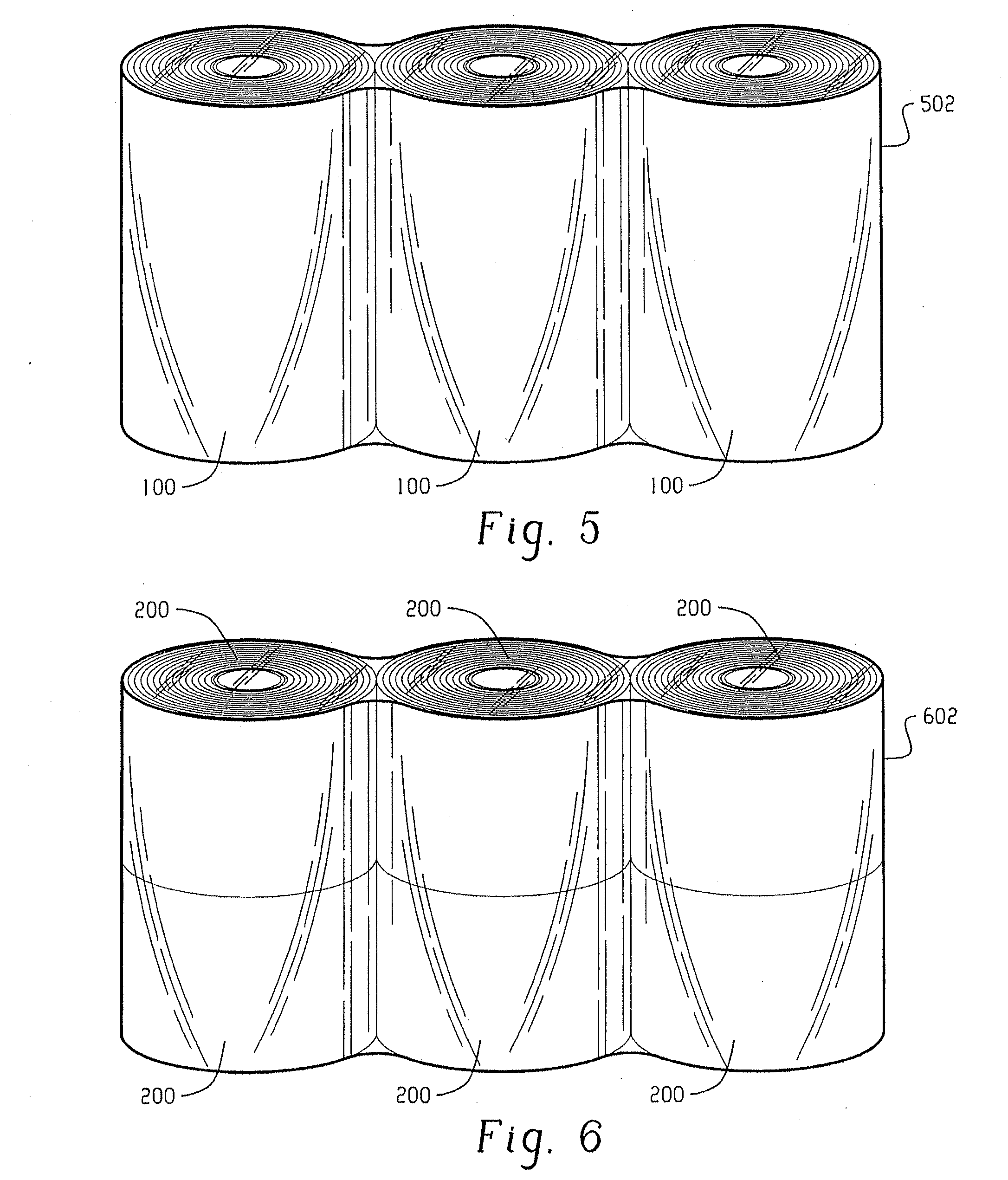

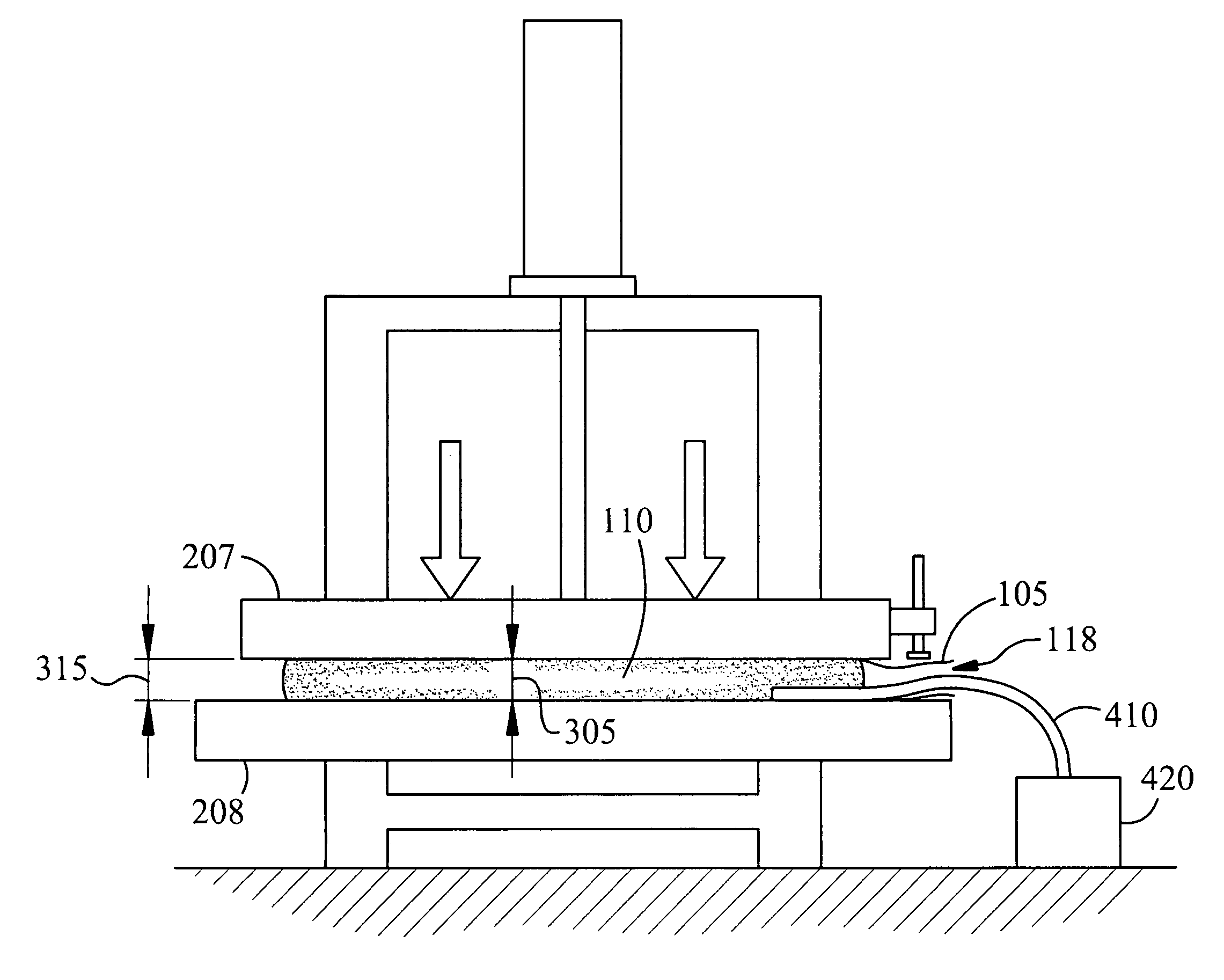

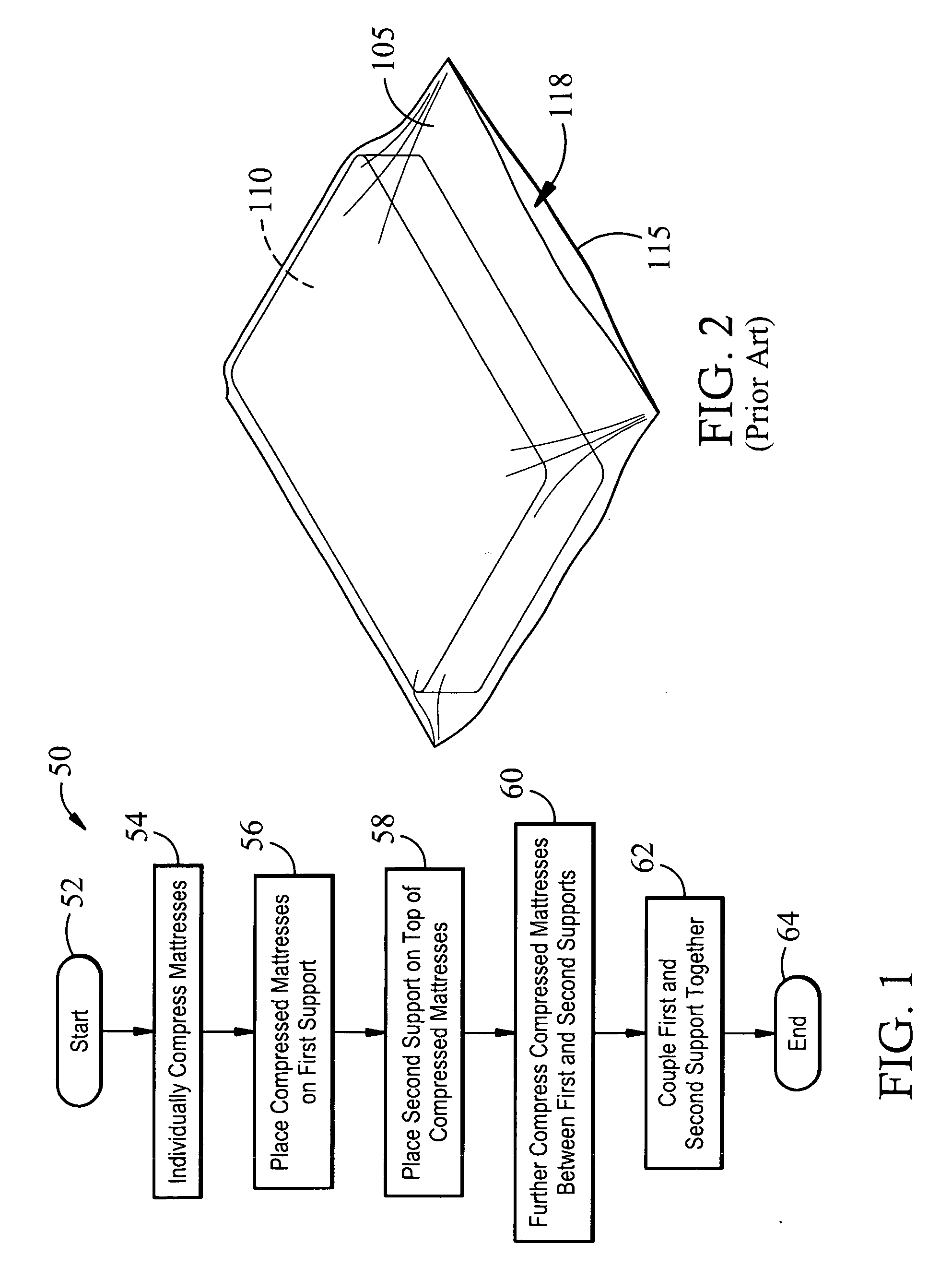

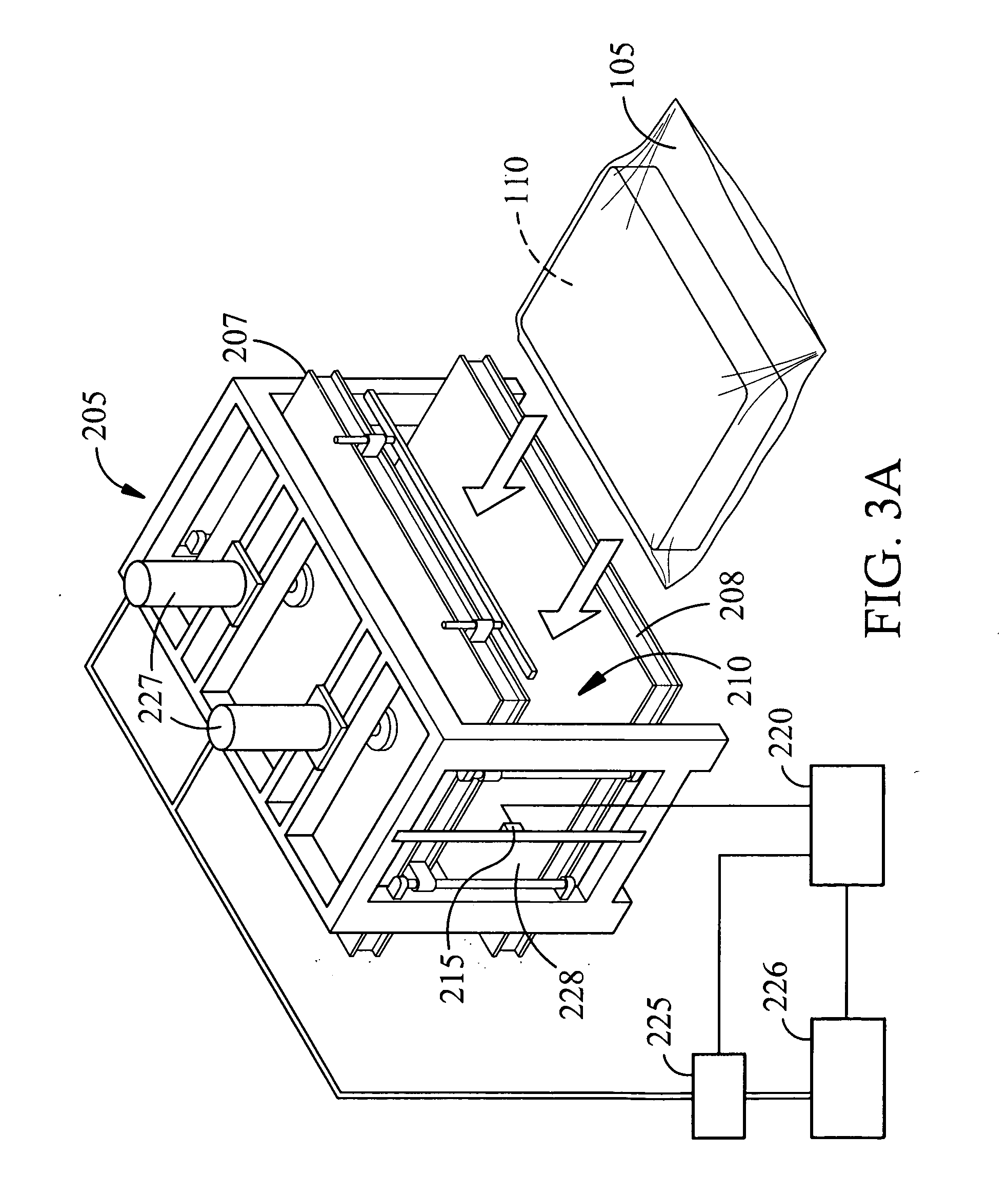

Method and system for preparing mattresses for shipment

ActiveUS20080086984A1Packaging by pressurising/gasifyingBinding material applicationBiomedical engineering

A method and system for packaging multiple bedding products. The method includes compressing a stack of individual compressed and sealed mattresses between an upper shipping support and a lower shipping support and restraining subsequent expansion of the individual compressed and sealed mattresses with bands enclosing the upper and lower shipping supports and the stack of compressed and sealed mattresses.

Owner:PRIMO INT

Cotton Module Plastic Wrapping Material And Module Hangler For Optimizing Module Rotation For Wrapping Removal

InactiveUS20100003118A1Avoiding cutting off the loose inner tail of the wrappingMultiplex system selection arrangementsContainers for flexible articlesPlastic packagingComputer module

A supply of plastic wrapping material for wrapping cylindrical modules includes a plurality of end-to-end segments, with each segment being of a length sufficient for enveloping a cylindrical cotton module of a given size with a predetermined number of layers of wrapping. All except an inner tail of an inner layer of wrapping adheres to the following layer. The location within each segment which becomes a loose inner tail when wrapped about a module is provided with a first RFID tag while other RFID tags are provided at equally spaced locations along the inner layer. Each RFID tag is provided with a unique identifier for which may be read by a RFID tag reader carried by a module handling implement having forks rotatable by reversible motors operable for rotating the module for placing the loose inner tail at a desired location relative to a cutting device for slitting the wrapping during wrapping removal. A control arrangement is coupled to the RFID tag reader and uses the information from the tag identifiers to cause the module to be rotated in a direction most suitable for optimizing placement the loose inner tail in the desired location for wrapping removal.

Owner:DEERE & CO

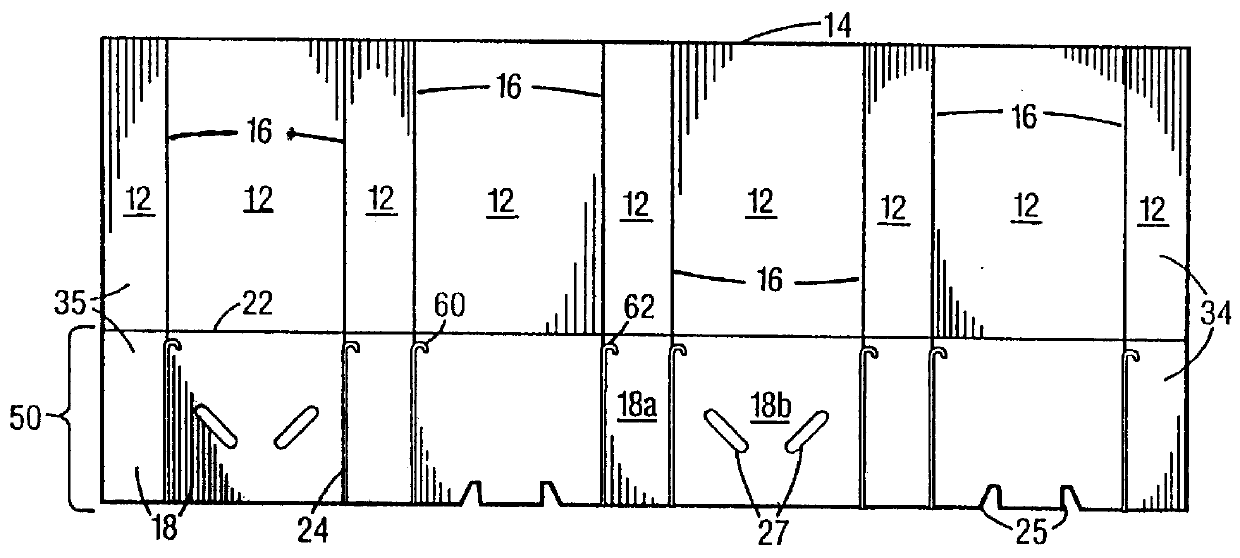

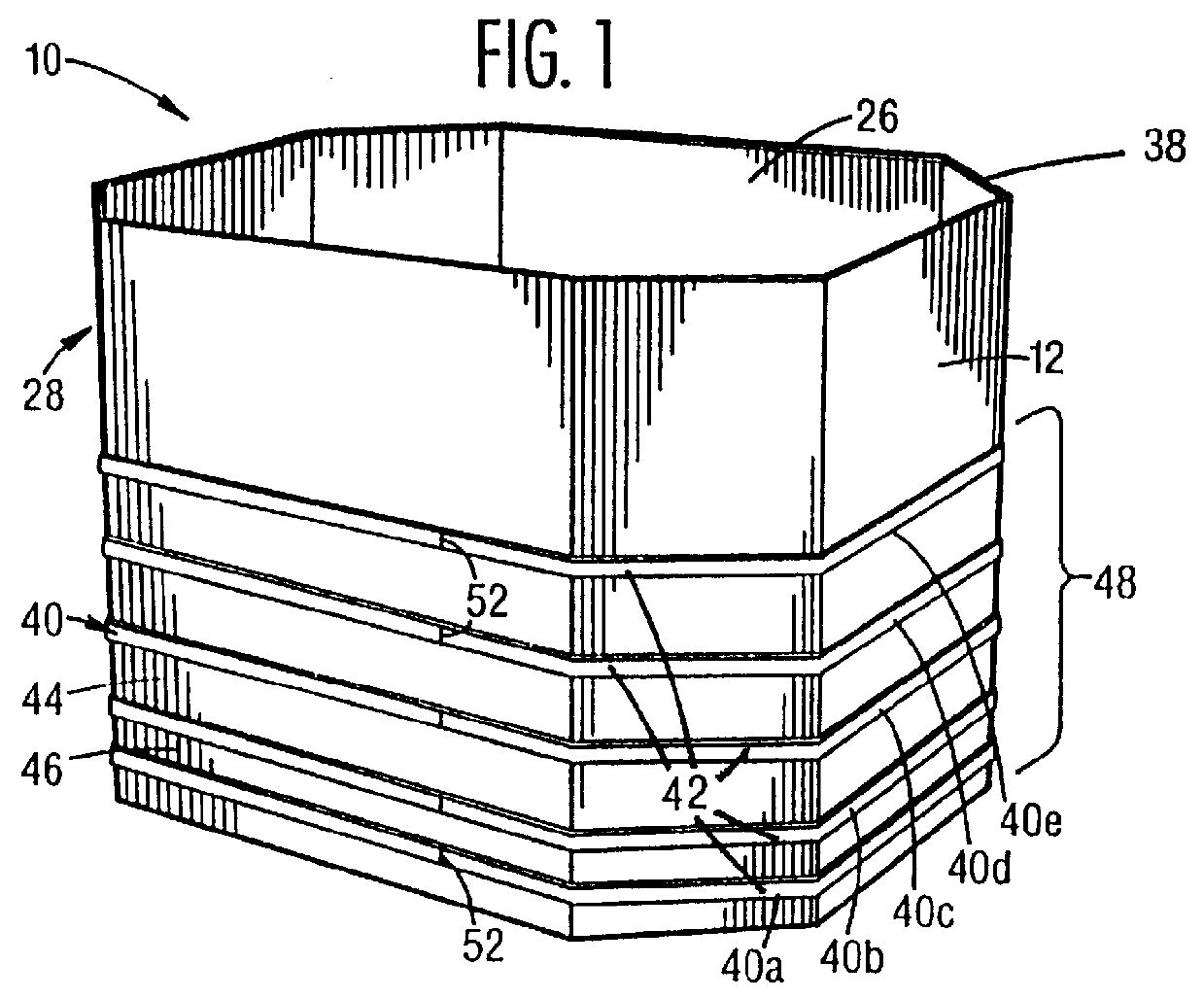

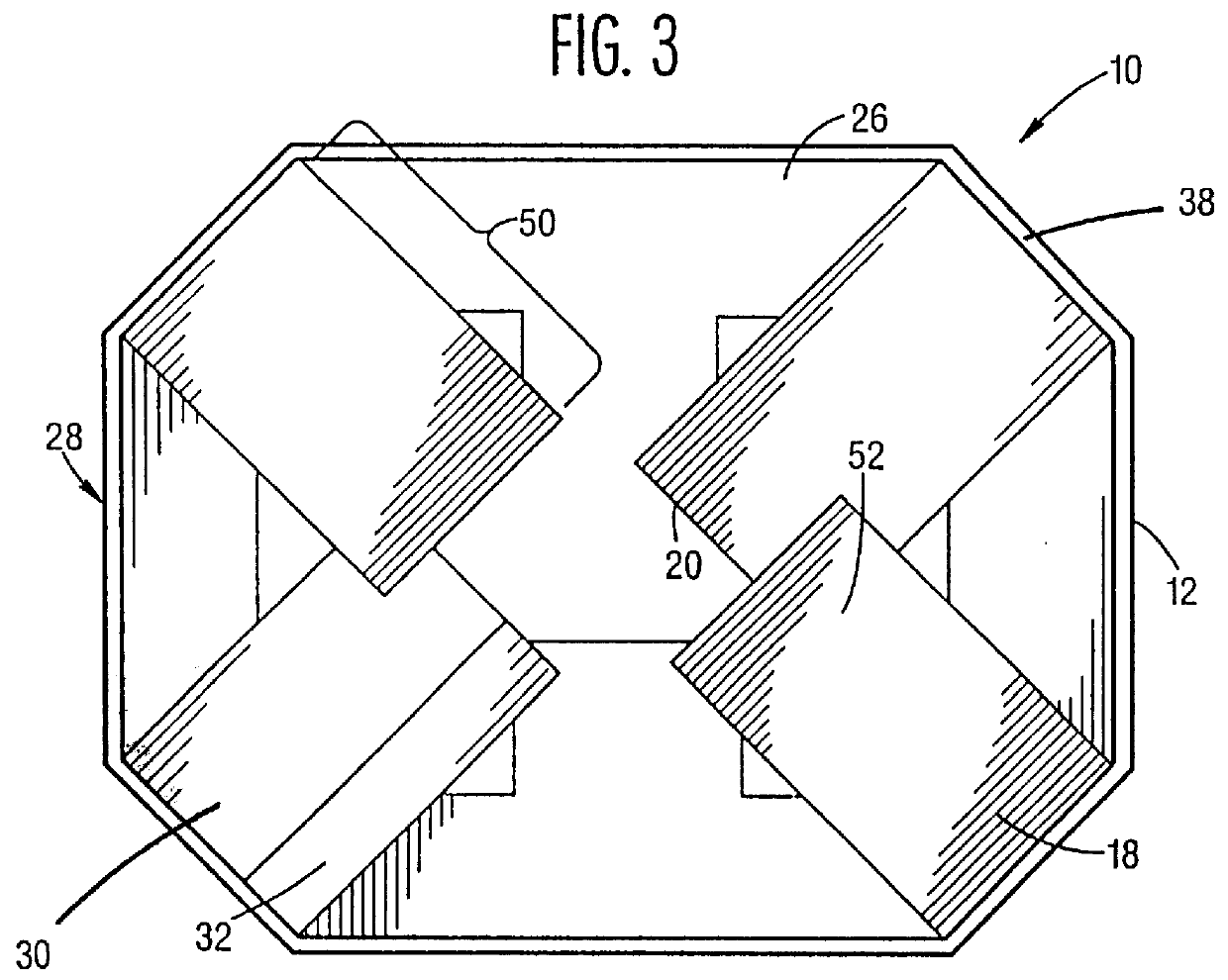

Paperboard container reinforcing method

InactiveUS6074331AReduce laborReduce materialBoxes/cartons making machineryPaper/cardboardDouble wallPaperboard

An octagonal container is formed from corrugated paperboard with overlapping flaps for eliminating gaps in the container bottom wall. Prestretched polypropylene straps are automatically applied to the container when in its flattened condition for providing girth support to the container when in its erected condition. The straps are positioned from the lower portion of the container side walls at ever increasing distances from each other for limiting container bulge when carrying products having varying effects on the container. With such an arrangement of straps, economically and environmentally desirable single and double wall corrugated paperboard can be used where typically triple wall and laminated paperboard containers are used.

Owner:CON PAC SOUTH

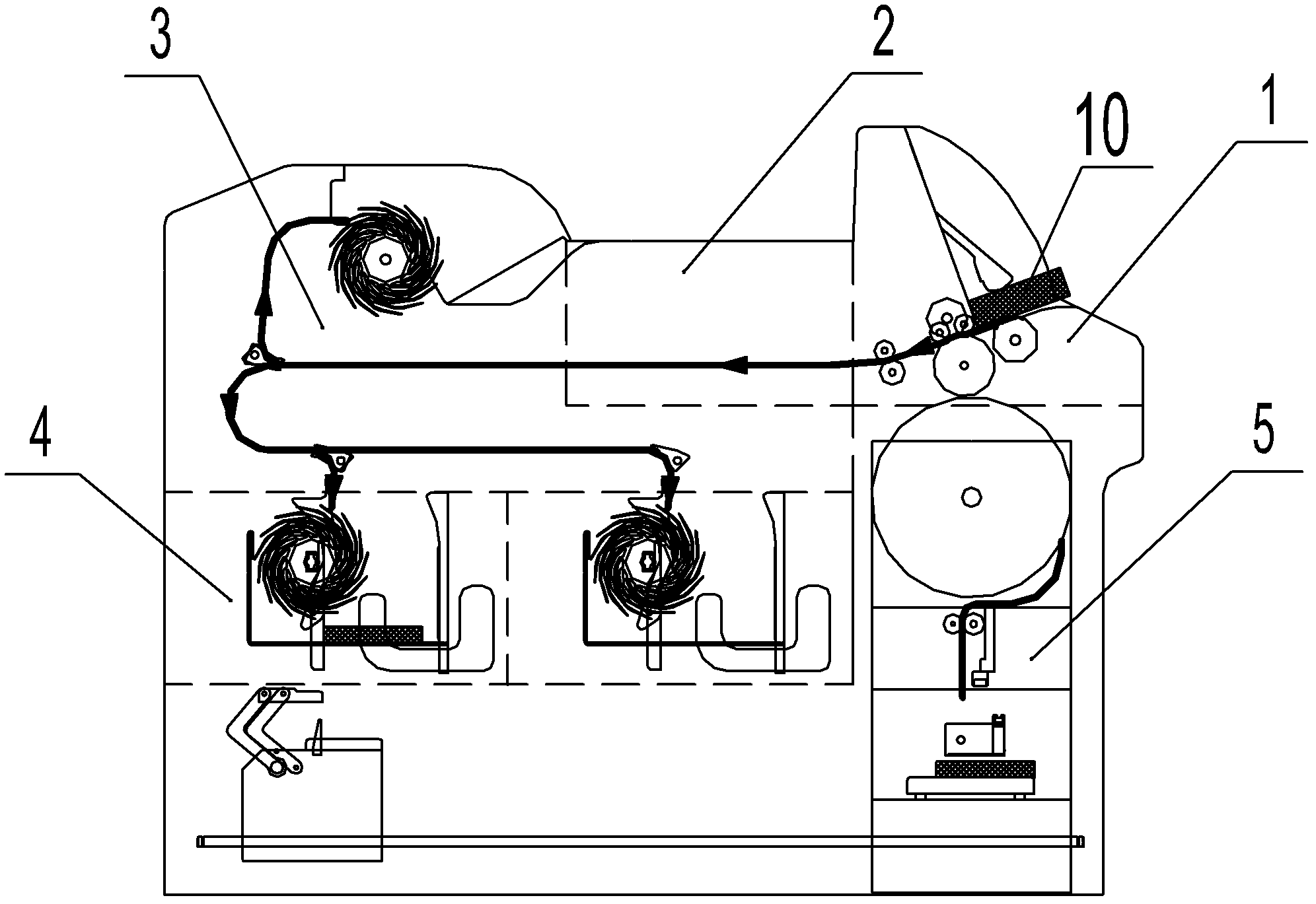

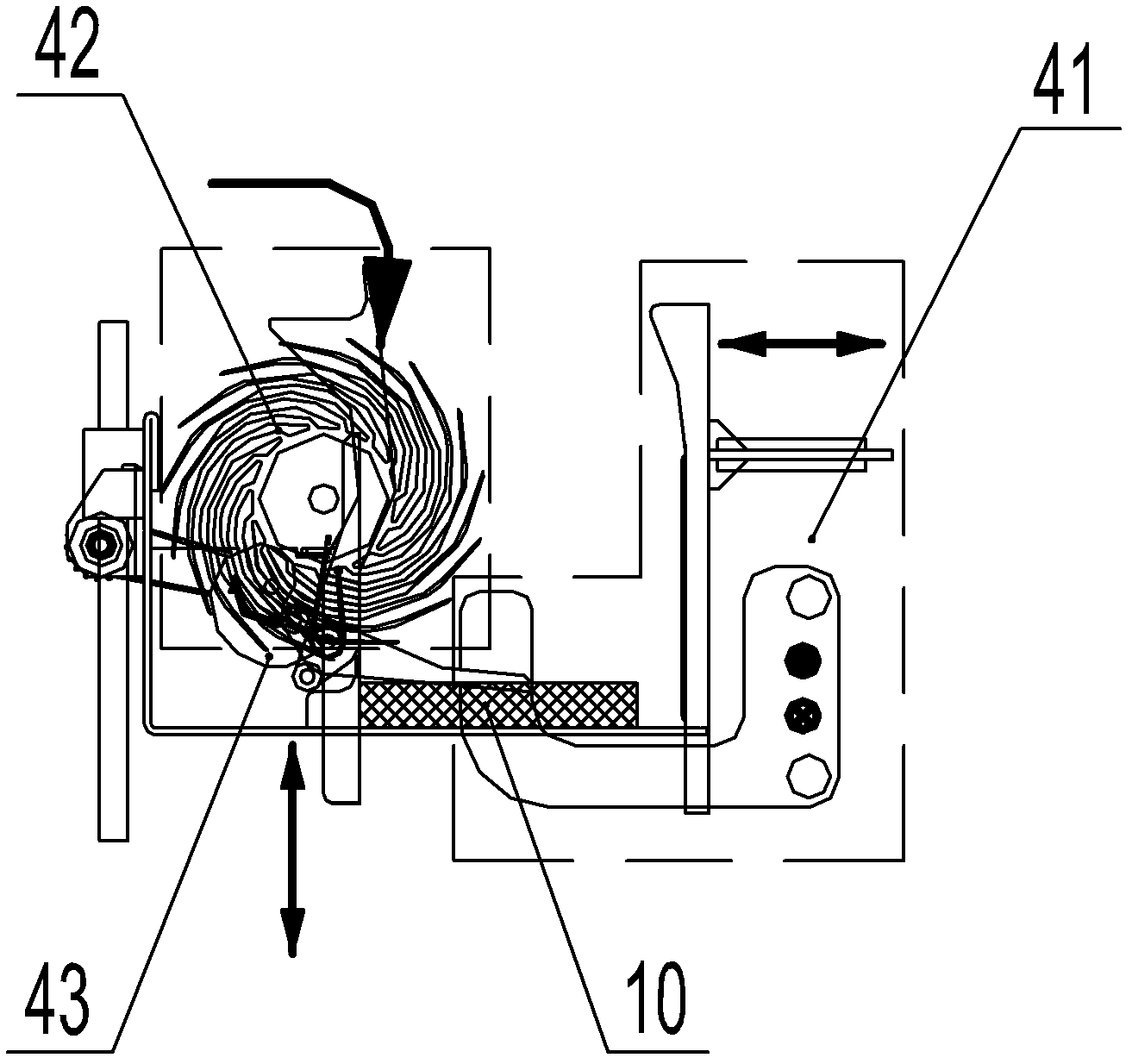

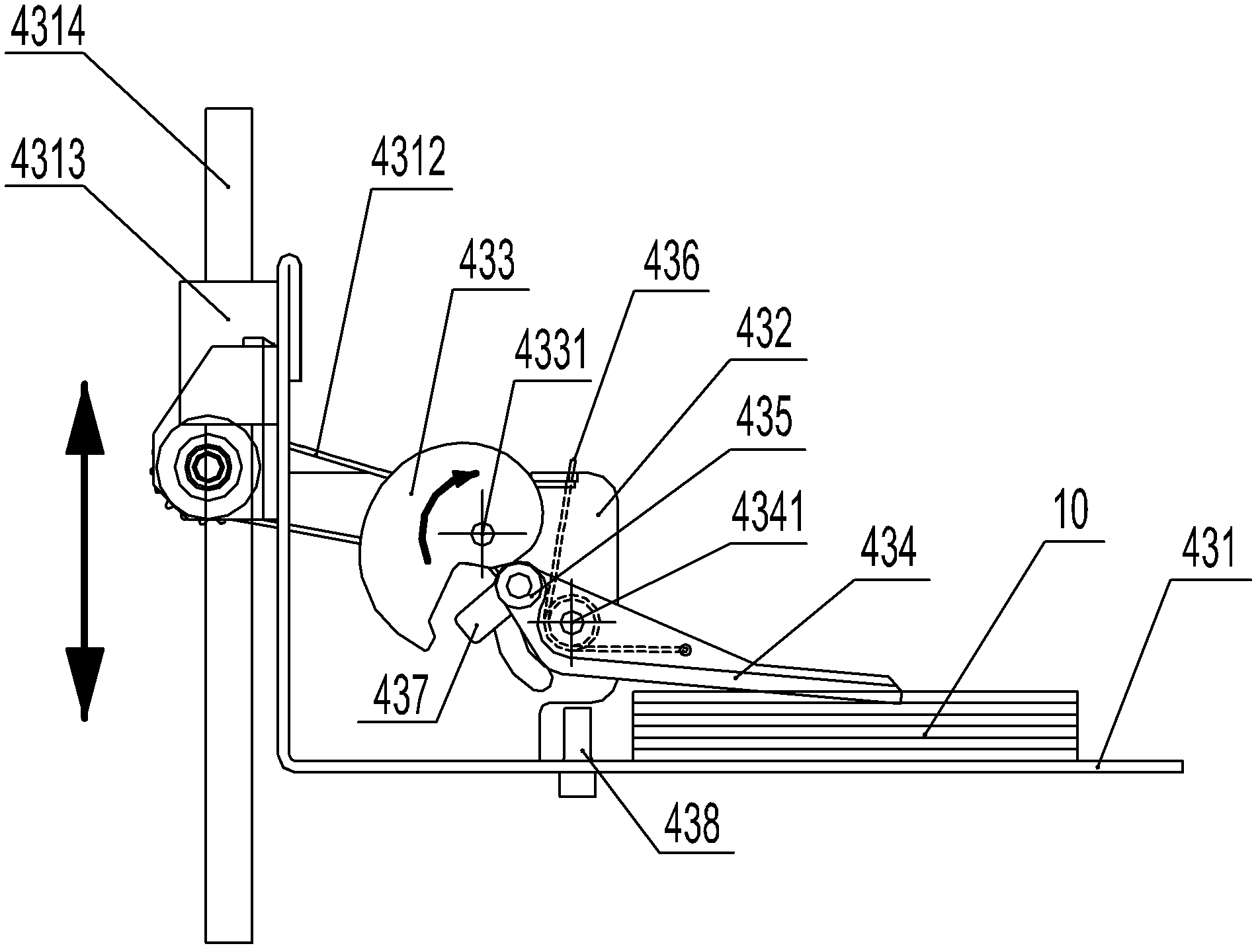

Clearing and binding all-in-one machine and bill stacking and sorting module thereof

ActiveCN102496206ARealize the pressing functionSave spaceCoin/currency accepting devicesBinding material applicationReciprocating motionCam

The invention provides a clearing and binding all-on-one machine and a bill stacking and sorting module thereof. The bill stacking and sorting module comprises a bill clamping and conveying sub-module, the bill clamping and conveying sub-module comprises a clamping mechanism and a vertically reciprocating movement mechanism thereof, the clamping mechanism comprises a bearing plate, a support, a cam, a clamping rod and a clamping spring, the support is fixed on the bearing plate, the cam is rotatably arranged on the support through a first rotary shaft, the clamping rod comprises a clamping end, a transmission end and a hinging part, the hinging part is arranged between the clamping end and the transmission end and is hinged on the support through a second rotary shaft, the cam is matched with the transmission end of the clamping rod and can drive the clamping rod to rotate between a releasing position and a clamping position around the second rotary shaft, one end of the clamping spring is fixed on the support, and the other end of the clamping spring is connected with the clamping end of the clamping rod so as to apply an elastic force for clamping bills to the clamping rod.

Owner:GRG BAKING EQUIP CO LTD

Apparatus and method for wrapping

Owner:RUBIN RICHARD HOWARD

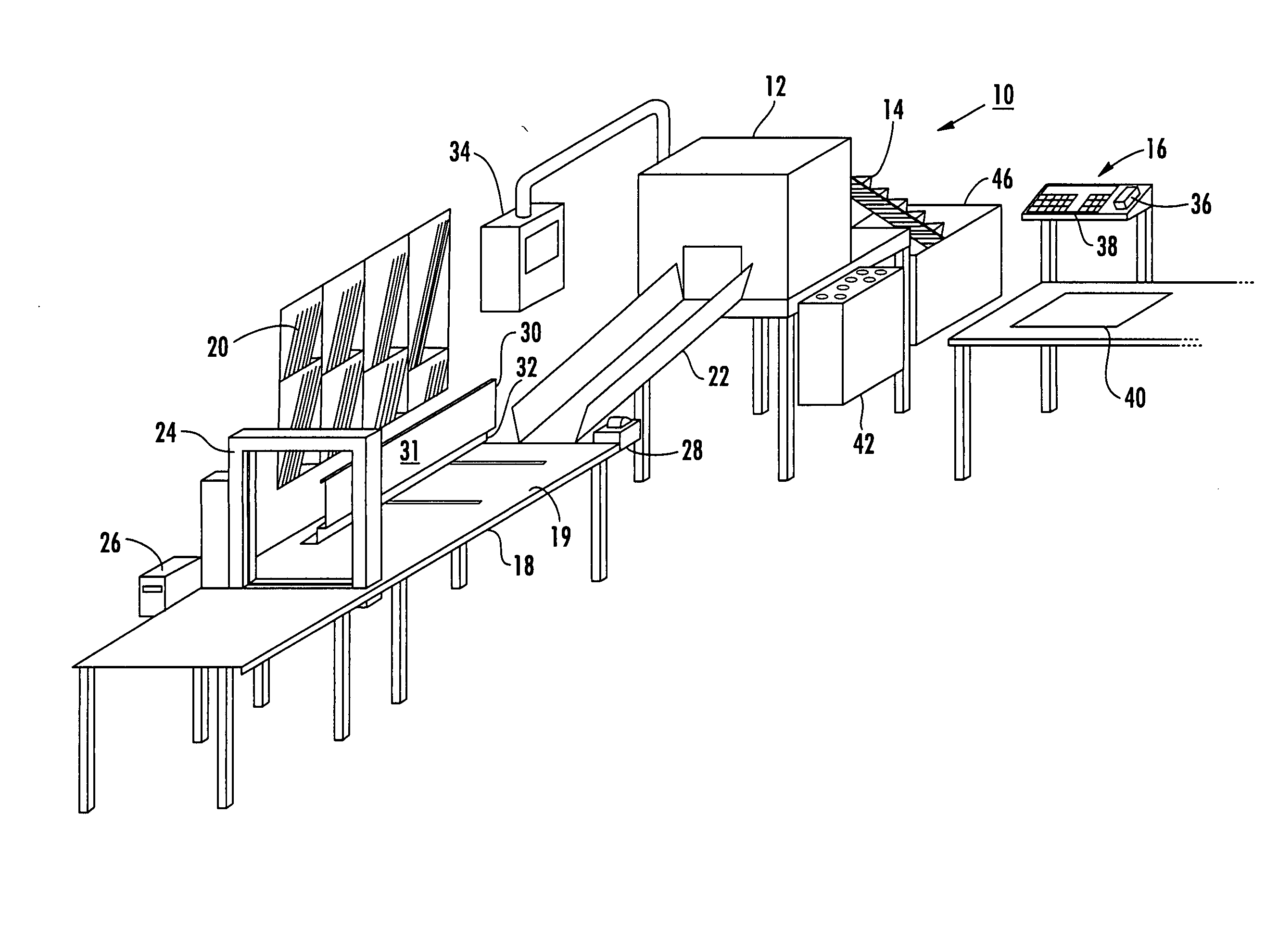

De-packaging machine

InactiveUS20040250670A1Opening closed containersBottle/container closureWrap aroundPackaging machine

A de-packaging system for removing film and bands from packages includes a first conveyor configured to move packages. The de-packaging system also includes a loading station for loading packages onto the conveyor, and a film cutting station associated with the first conveyor. The film cutting station includes a cutter having an elongated cutting element that can be heated to cut film on packages. A band cutting station includes a cutter for cutting bands wrapped around packages. A clamp device includes a clamp configured to clamp bands on packages for removal of the bands. The de-packaging system further includes a second conveyor having an upstream end adjacent a downstream end of the first conveyor. A device applies force to packages to move packages from the first conveyor to the second conveyor, and at least one friction member strips film from packages as they are moved from the first conveyor to the second conveyor.

Owner:PORTER TECH

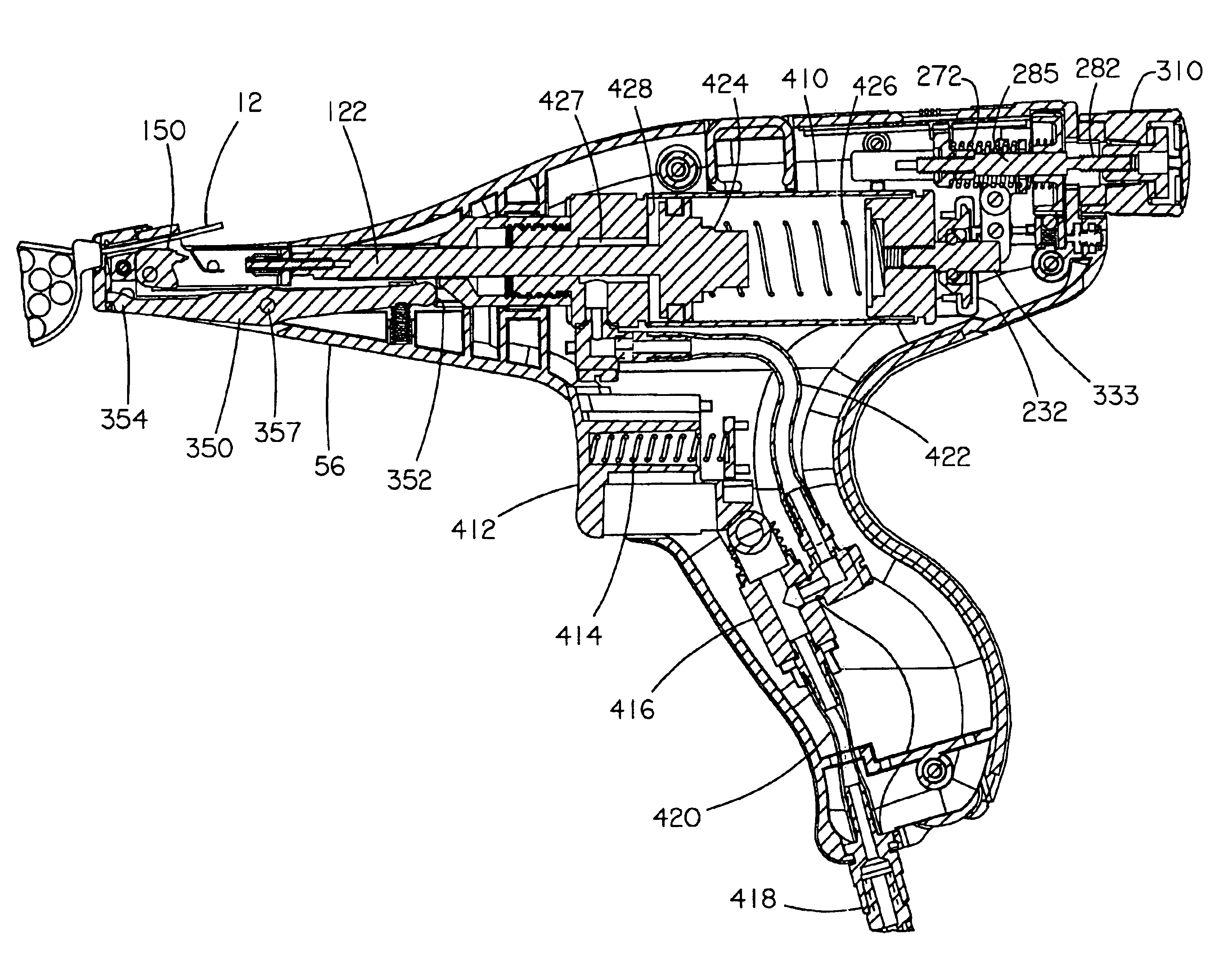

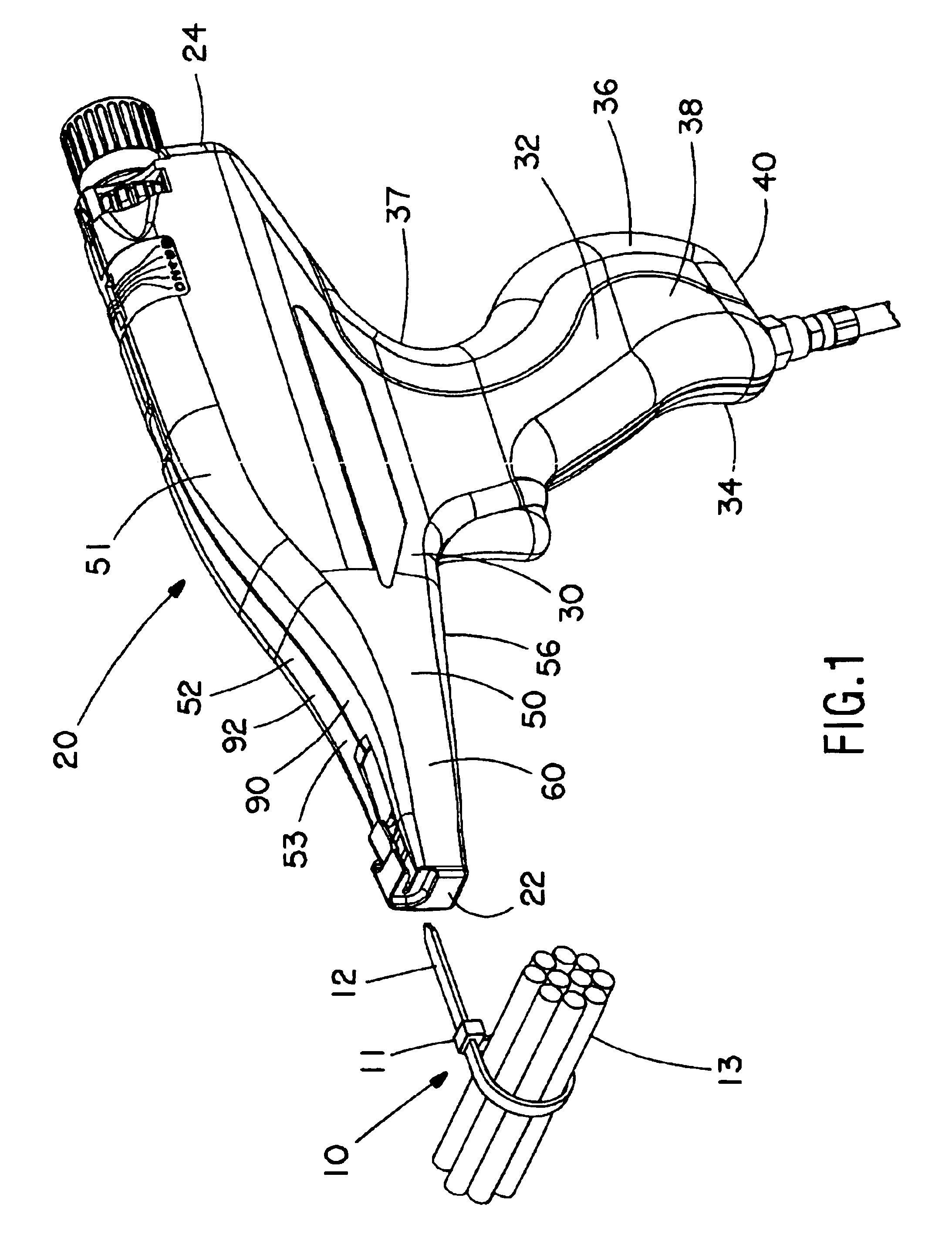

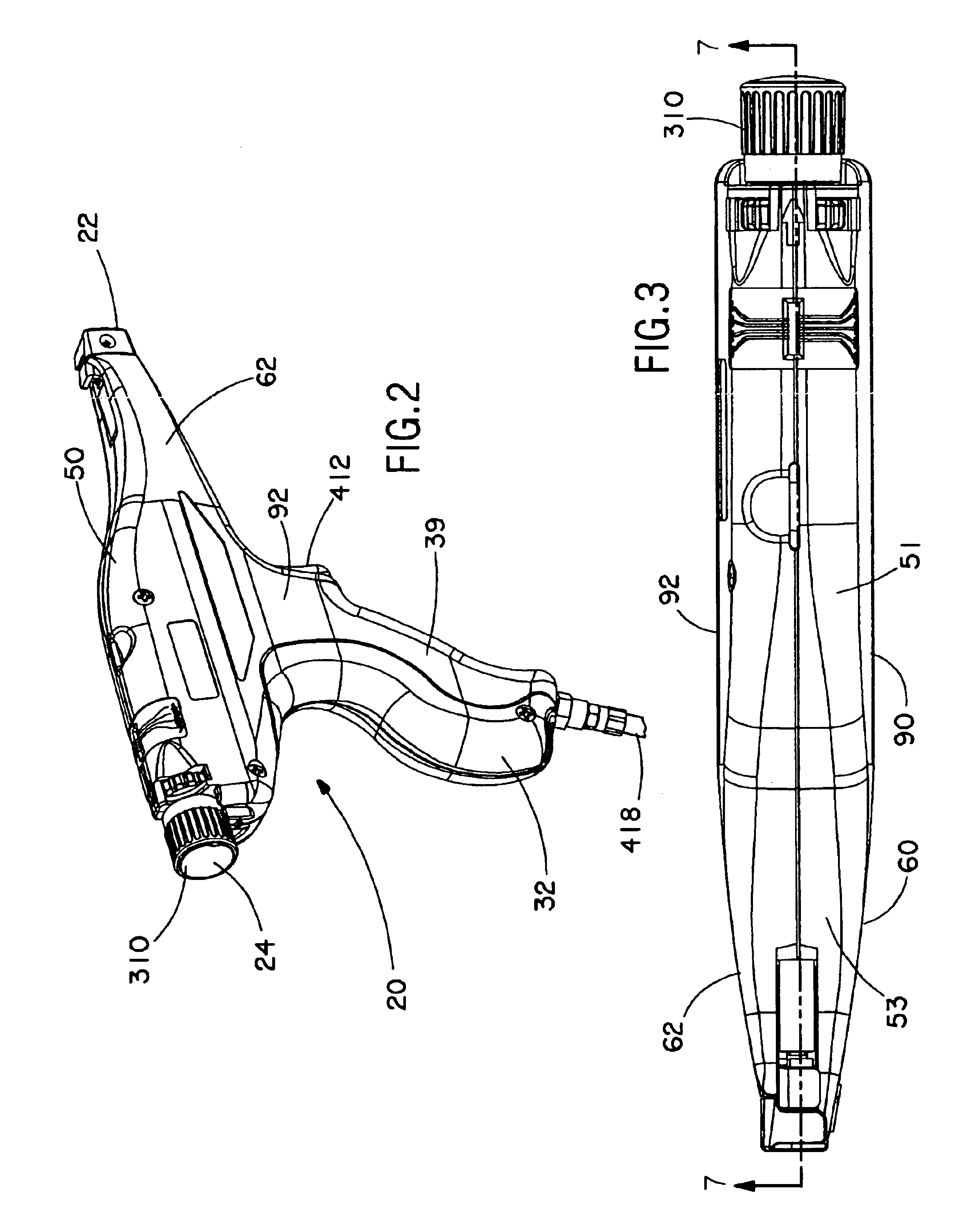

Pneumatic cable tie tool

A tool for installing a cable tie, said cable tie having a head portion and an elongate tail portion extending therefrom, said tool comprising a housing having a distal end and a proximate end, a tensioning mechanism for tensioning said cable tie to a predetermined tension setting, said tensioning mechanism operatively supported by said housing, a cutting mechanism for severing an excess portion of said tail from said tensioned cable tie, said cutting mechanism operatively supported by said housing, a manually actuable external power delivery system for actuating said tensioning and cutting mechanisms, said power delivery system for delivering power generally in line with said tensioning mechanism, and a restraint mechanism for providing said predetermined tension setting wherein said restraint mechanism provides said predetermined tension generally in line with said tensioning mechanism and said power delivery system.

Owner:PANDUIT

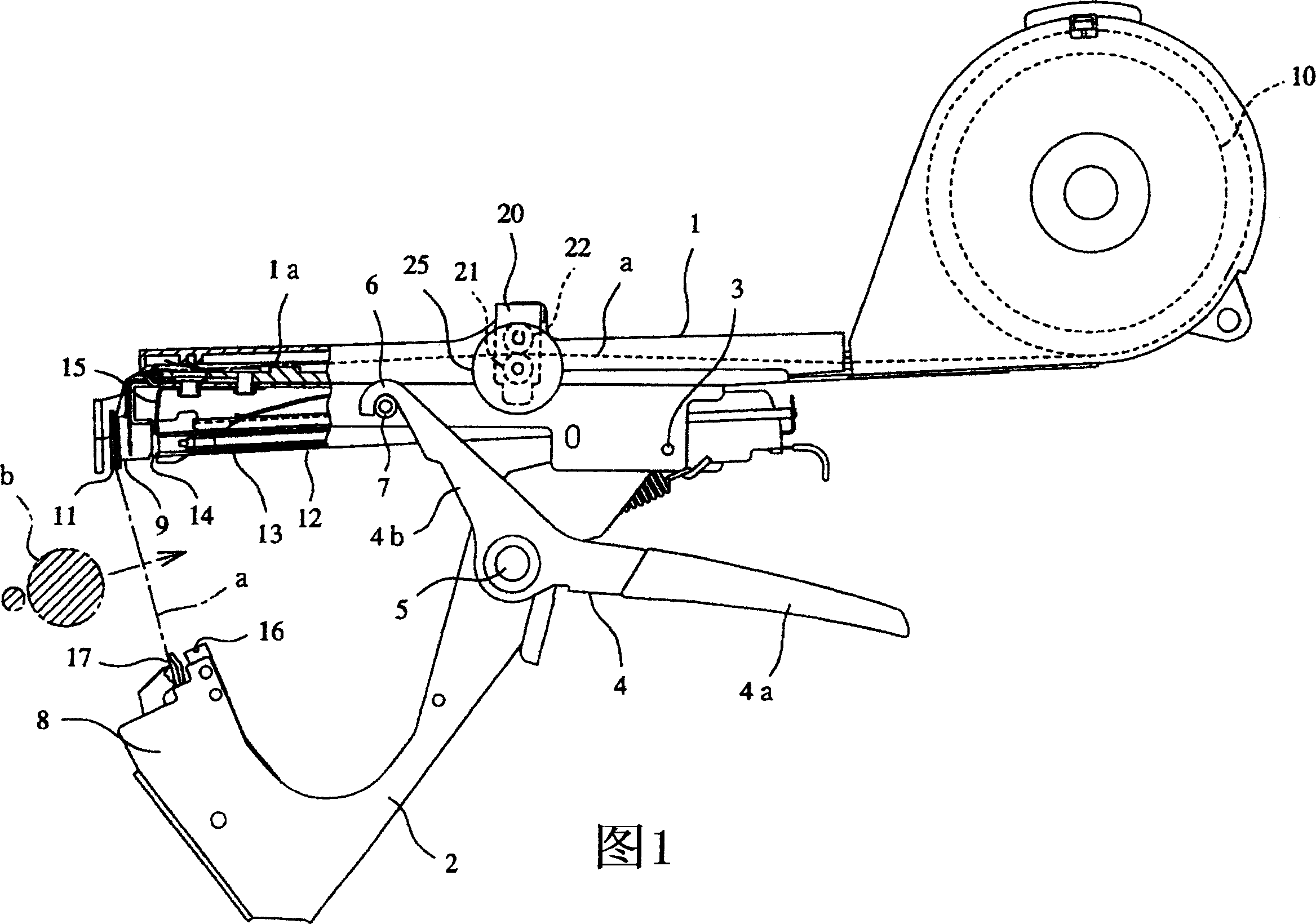

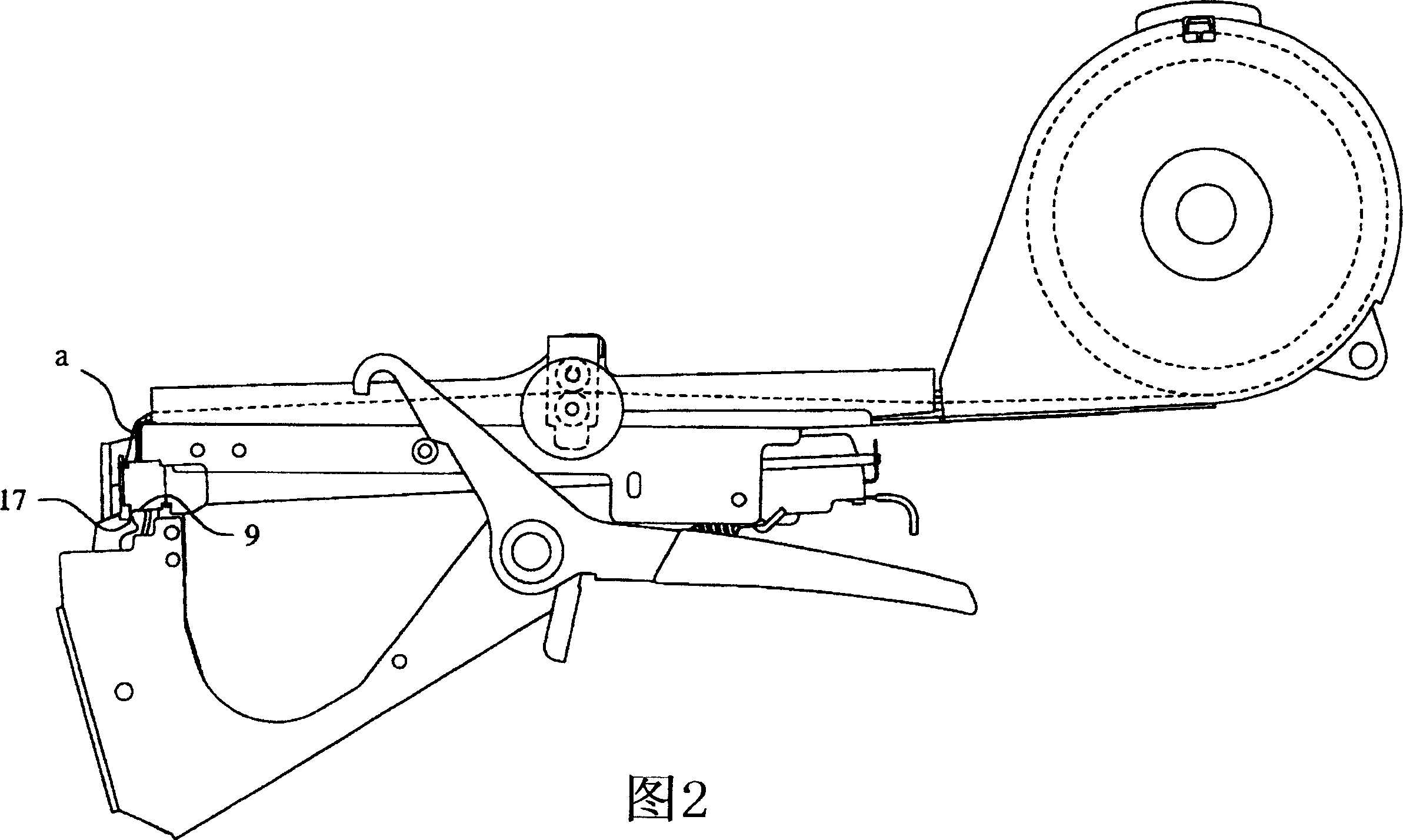

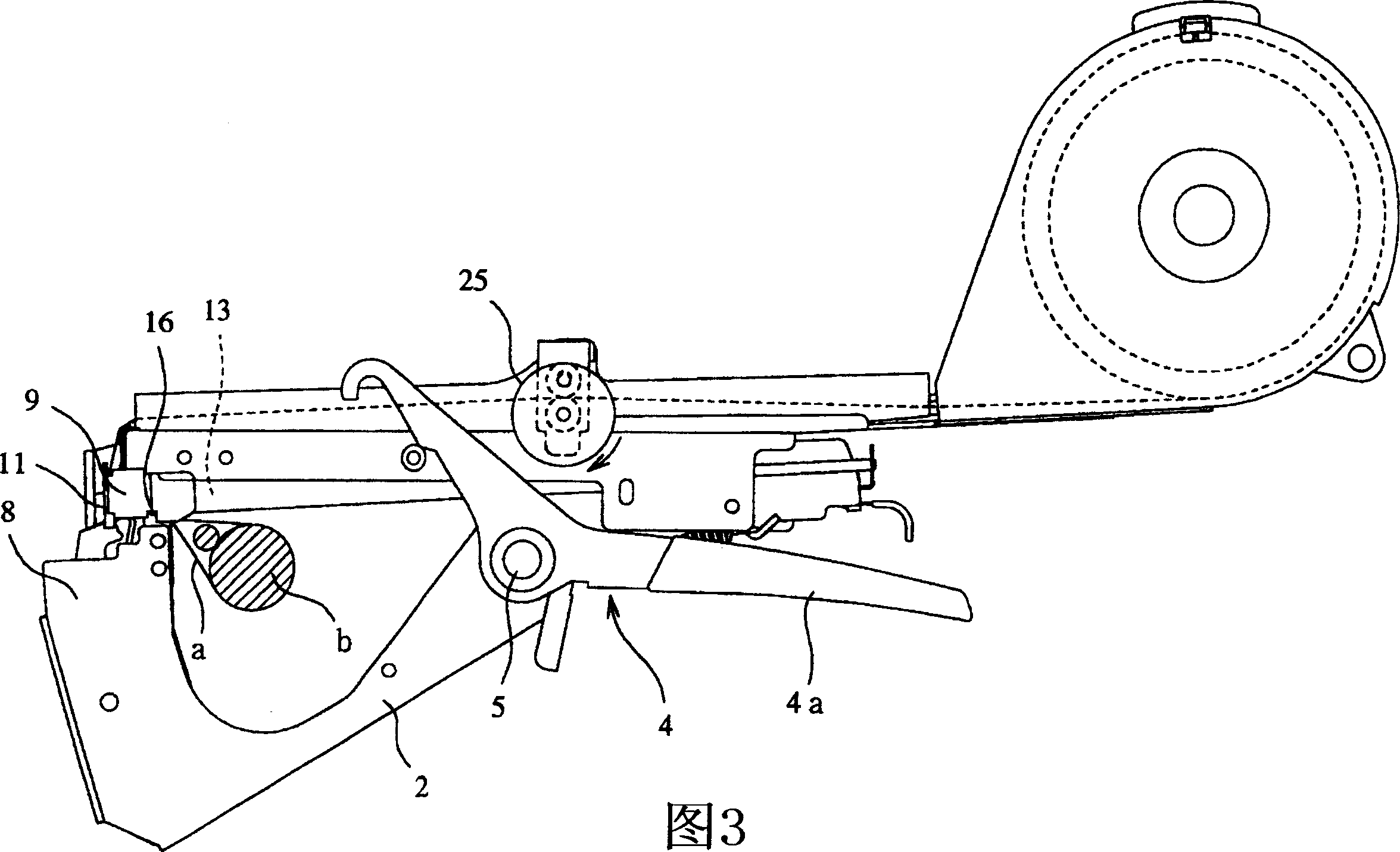

Binding belt relaxation return mechanism in binding machine for gradening

InactiveCN1957673AEasy to operateSimple structureBinding material applicationCultivating equipmentsMechanical engineeringEngineering

Disclosed is a binding machine for gardening, wherein a binding belt (a) which is hung up between the front end of a driver handle (1) and a clincher arm (2) is winded and hung on the object to be winded. By closing the driver handle (1) and the clincher arm (2), a claw is pierced to an overlap of the front part of the binding belt (a) and rear part thereof, then the binding belt (a) is cut off by a shearing blade, a driving roller (27) and a driven roller (28) which hold the binding belt (a) from both sides are provided in a binding belt passage (1a) on the driver handle (1), the binding belt (a) is moved in a reverse direction of the feeding direction by rotating the driving roller (27).

Owner:MAX CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com