Binding belt relaxation return mechanism in binding machine for gradening

A strapping and strapping machine technology, applied in the field of gardening strapping machines, can solve problems such as easy loosening of objects to be bundled, winding and returning without strapping straps, and achieve good operability, simplified structure, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

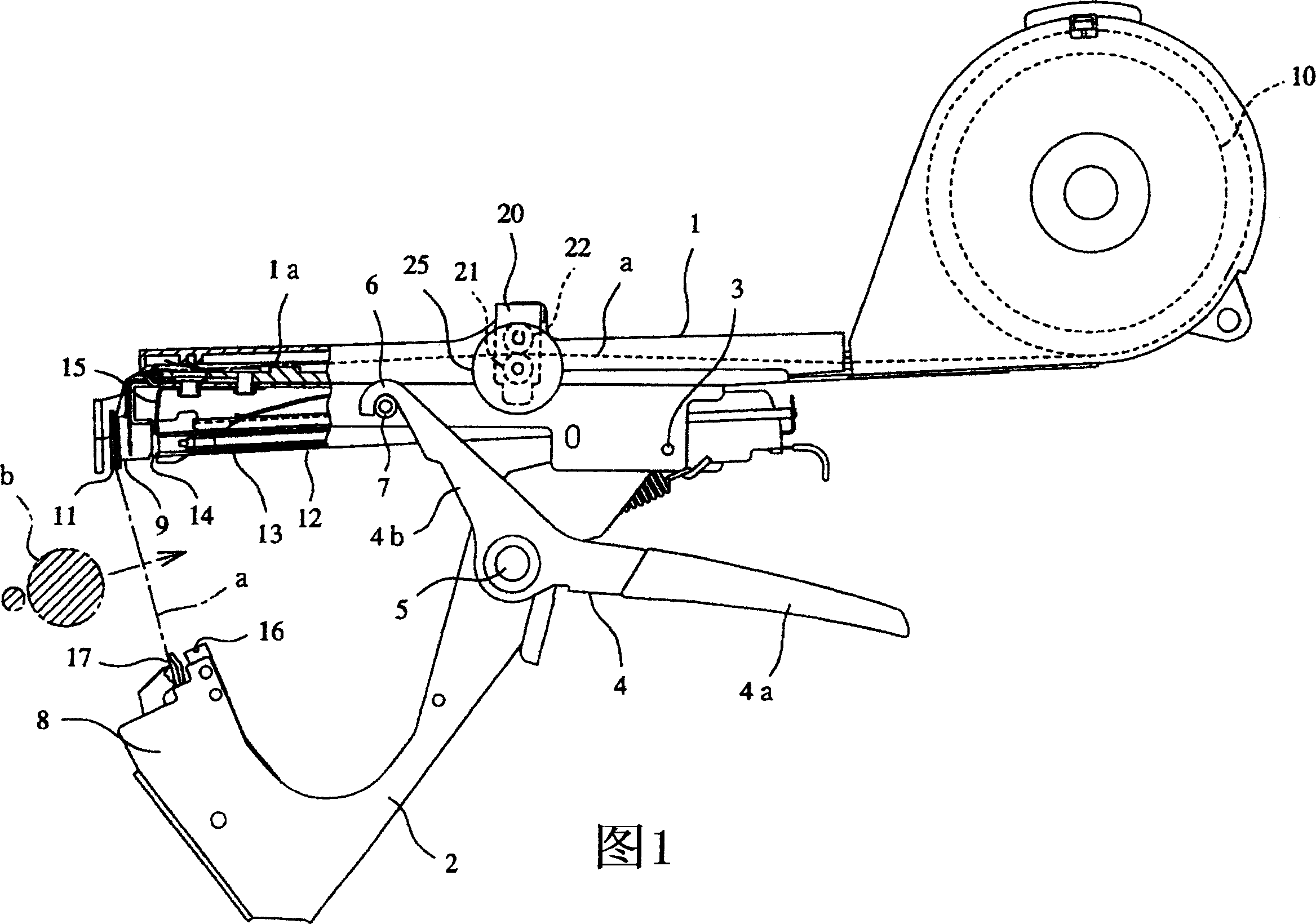

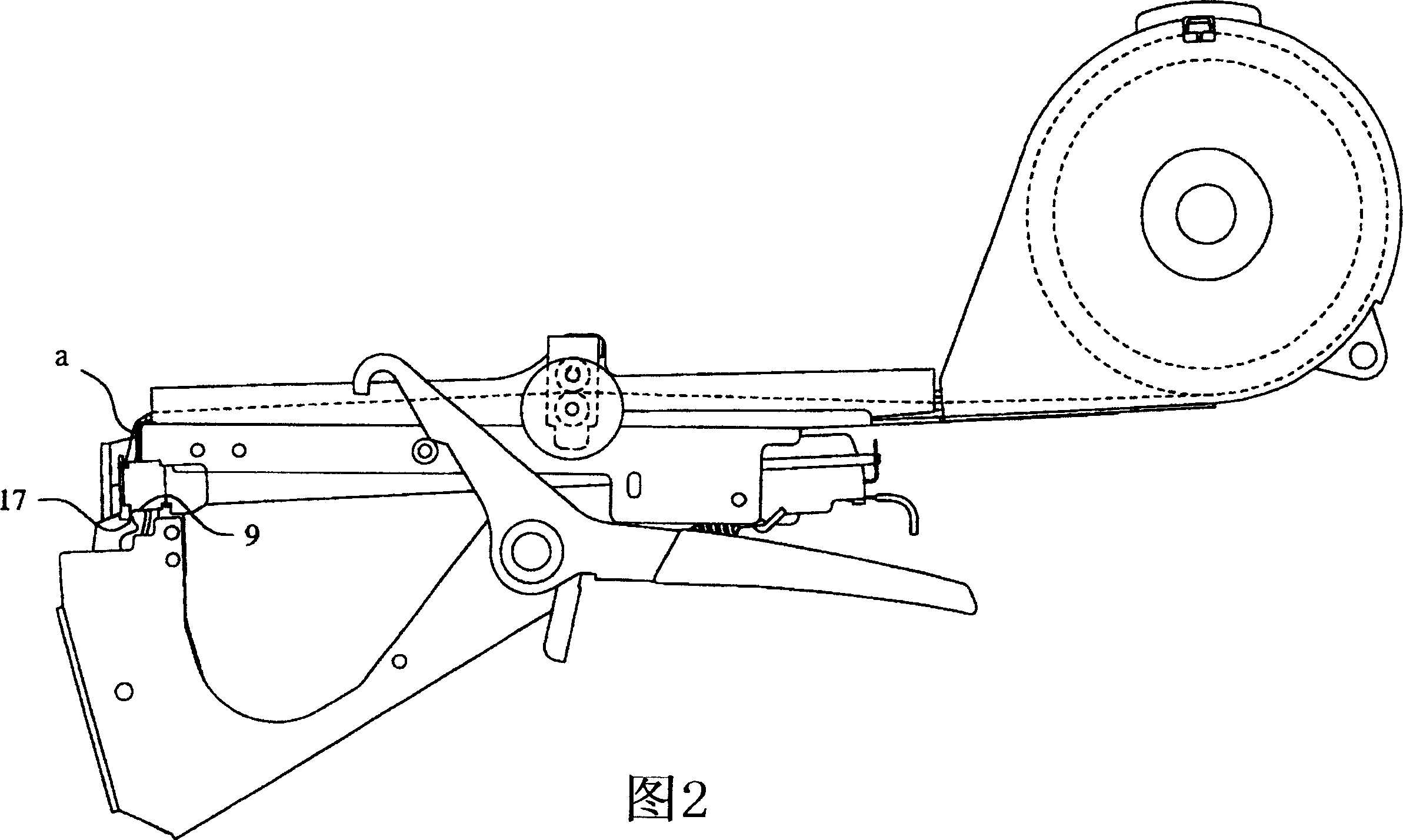

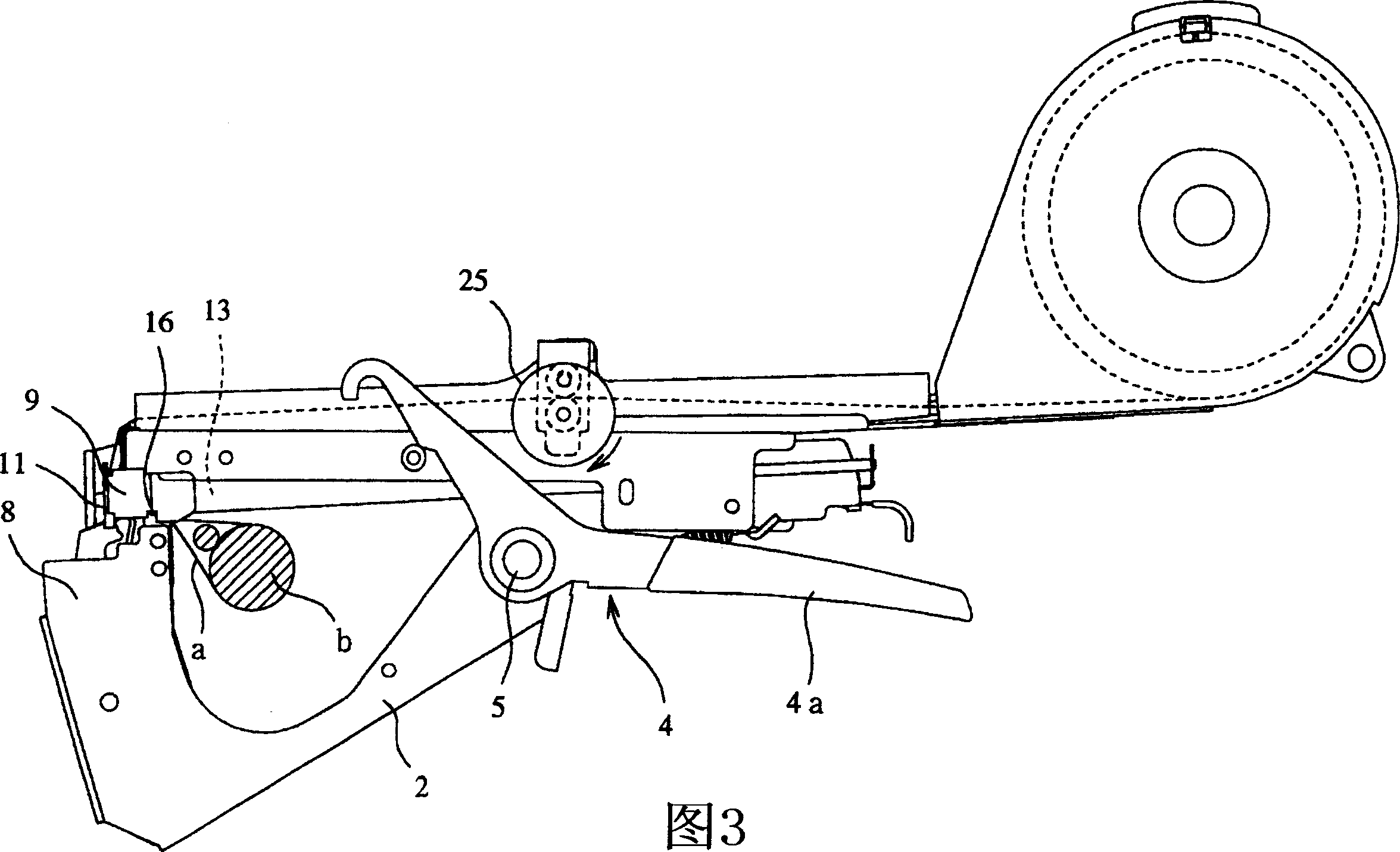

[0037] One embodiment of the present invention will be described below with reference to the drawings.

[0038] Fig. 1 is a side view of a horticultural binding machine. In this strapping machine, on a rotating shaft 3 provided in the middle of the elongated driving handle 1 , the base of the pincer bar 2 is pivotally supported. On the axle 5 that is located at the middle part of the pliers bar 2, the middle part of the freely rotatable operating link 4 is mounted on the shaft. One end of the shaft mounting portion is a gripping portion 4a. A hook 6 formed at the front end of the other operating lever portion 4 b engages with a roller-shaped engaging portion 7 provided on the side portion of the driving handle 1 . By clenching and loosening the above-mentioned grip part 4a and the driving handle 1, the opening and closing operation of the above-mentioned pliers rod 2 can be performed, so that the head 8 at the front end of the above-mentioned pliers rod 2 and the front end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com