Method and apparatus for metered pre-stretch film delivery

a technology of pre-stretch film and apparatus, which is applied in the direction of helical strip wrapping, paper/cardboard containers, bundling articles, etc., can solve the problems of excessive packaging material breakage of rotating ring wrappers, limited containment force applied to loads, and supply of excess packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

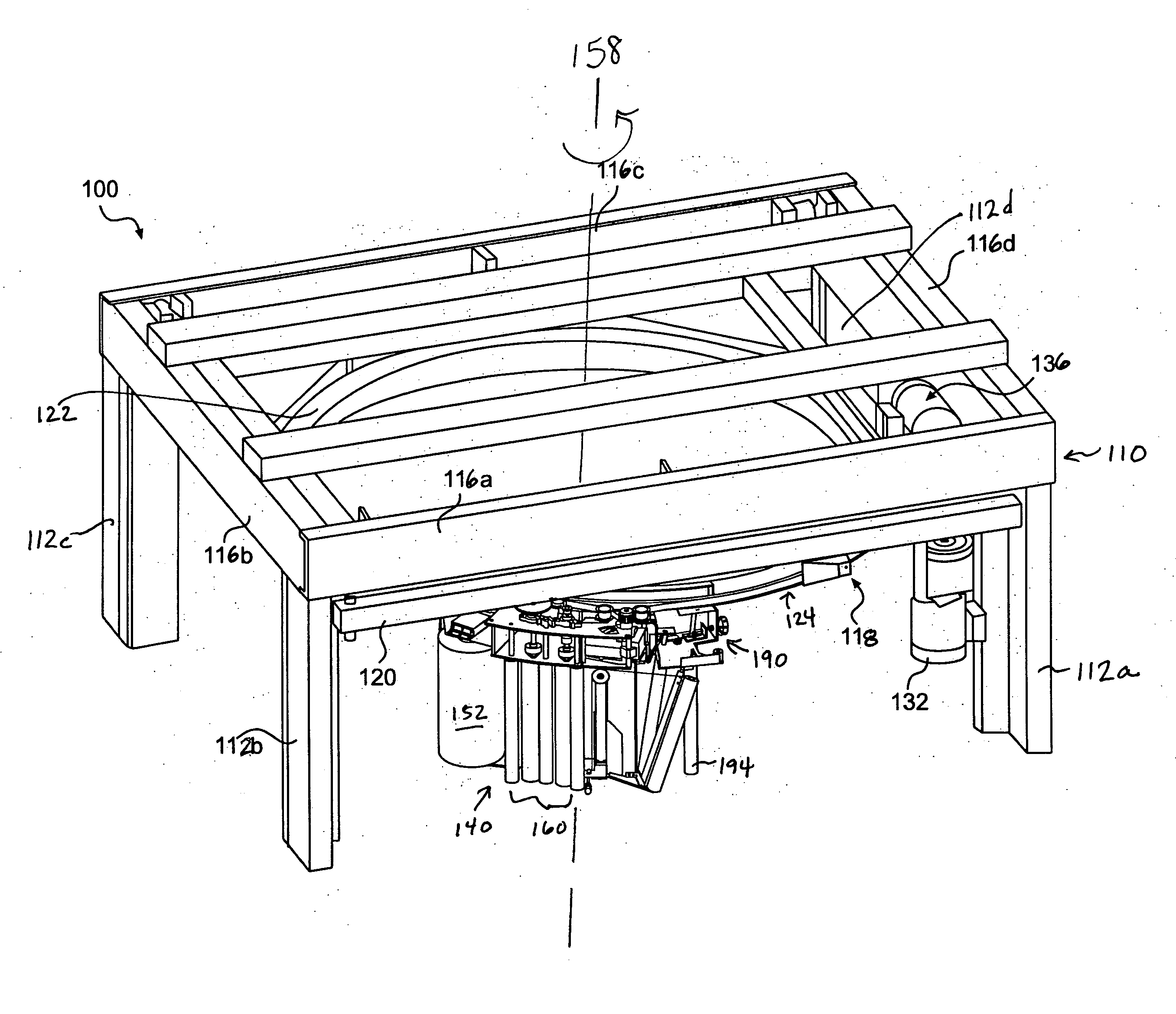

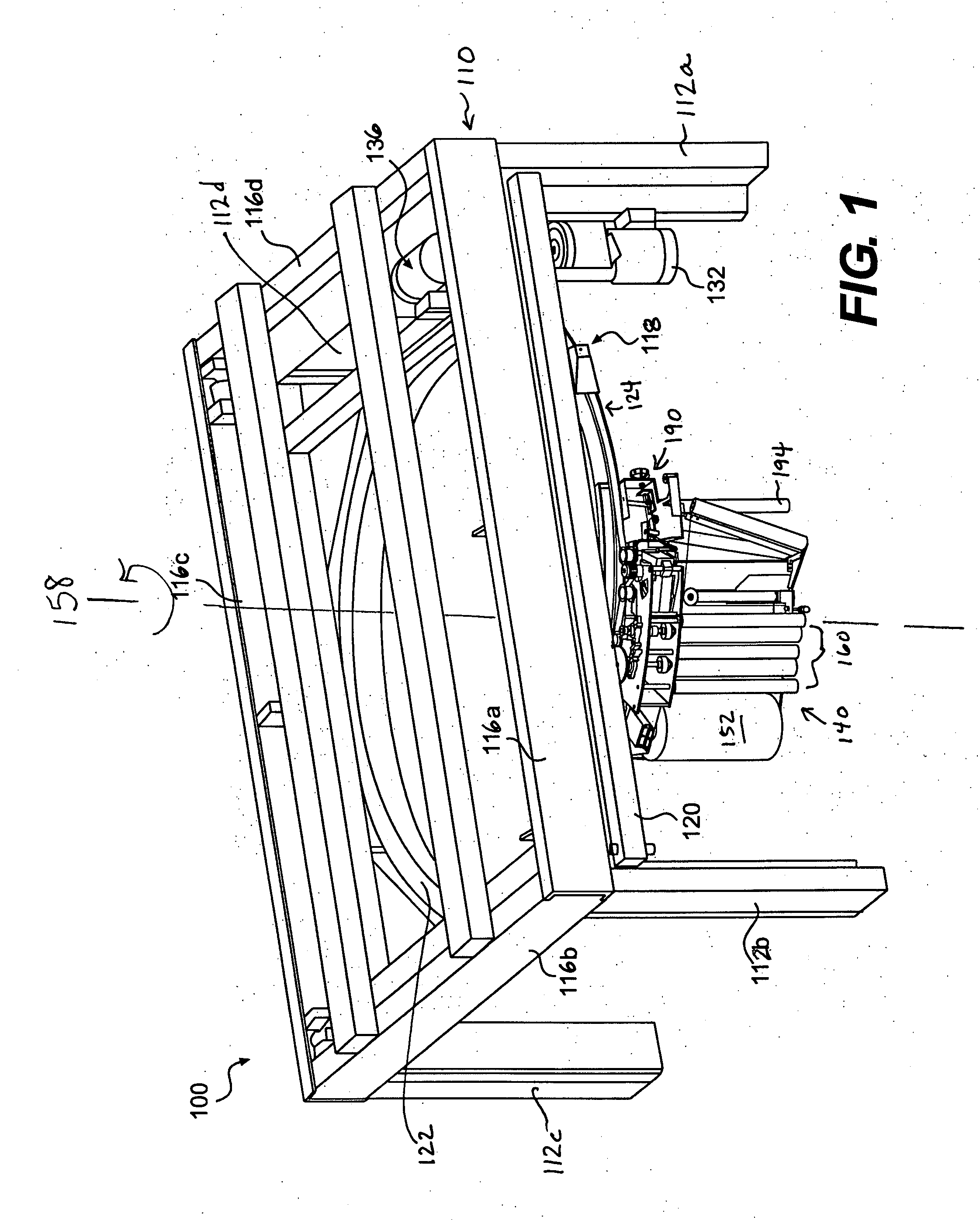

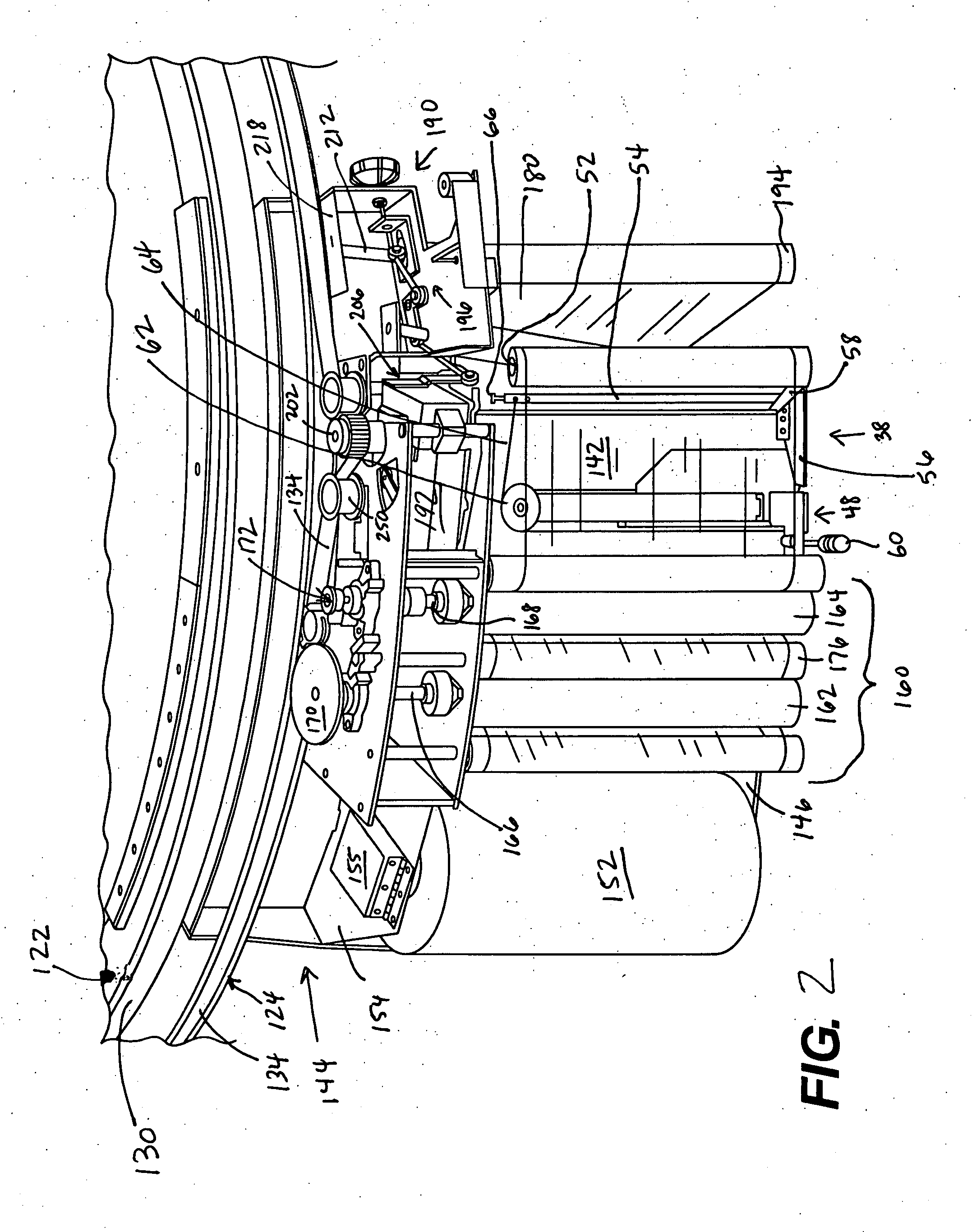

[0050] Reference will now be made in detail to the present embodiment of the invention, an example of which is illustrated in the accompanying drawings. Examples and descriptions of the invention are also set forth in the Invention Disclosure that is included as part of the provisional application and incorporated herein by reference. In addition, the disclosures of each of U.S. Pat. No. 4,418,510, U.S. Pat. No. 4,953,336, U.S. Pat. No. 4,503,658, U.S. Pat. No. 4,676,048, U.S. Pat. No. 4,514,995, and U.S. Pat. No. 6,748,718 are incorporated herein by reference in their entirety. In addition, U.S. patent application Ser. No. 11 / 398,760, filed Apr. 6, 2006, and entitled “Method and Apparatus for Dispensing a Predetermined substantially constant length of Pre-stretched Film Relative to Load Girth,” and U.S. patent application Ser. No. 10 / 767,863, filed Jan. 30, 2004, and entitled “Method and Apparatus for Rolling a Portion of a Film Web into a Cable” are incorporated by herein by refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com