Patents

Literature

98results about "Prestretching mechanism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

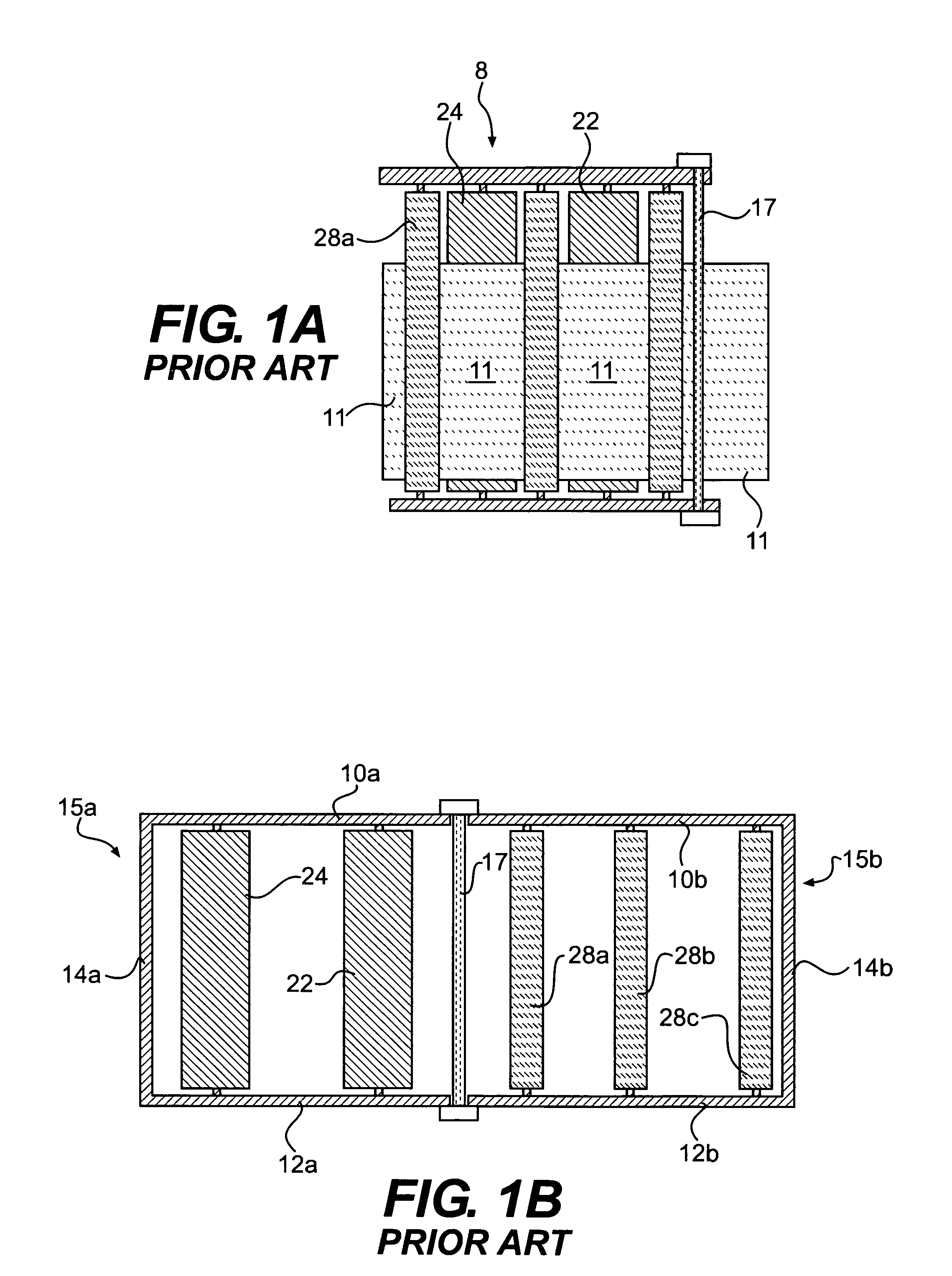

Method and apparatus for metered pre-stretch film delivery

The present invention provides a method and apparatus for dispensing a predetermined substantially constant length of pre-stretched packaging material based upon load girth. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution of relative rotation between a packaging material dispenser and the load is determined. A rotational drive system used to provide the relative rotation is linked to a pre-stretch assembly portion of the packaging material dispenser. The linkage may be mechanical or electrical. The linkage controls a ratio of the rotational speed to the pre-stretch assembly dispensing speed, such that the predetermined substantially constant length of pre-stretched packaging material is dispensed for each revolution of the packaging material dispenser relative to the load regardless of the speed of the rotational drive. In the case of a mechanical linkage, the linkage also connects the rotational drive to the pre-stretch assembly portion such that the rotational drive also drives the pre-stretch assembly portion.

Owner:LANTECH COM

Method for dispensing a predetermined amount of film relative to load girth

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

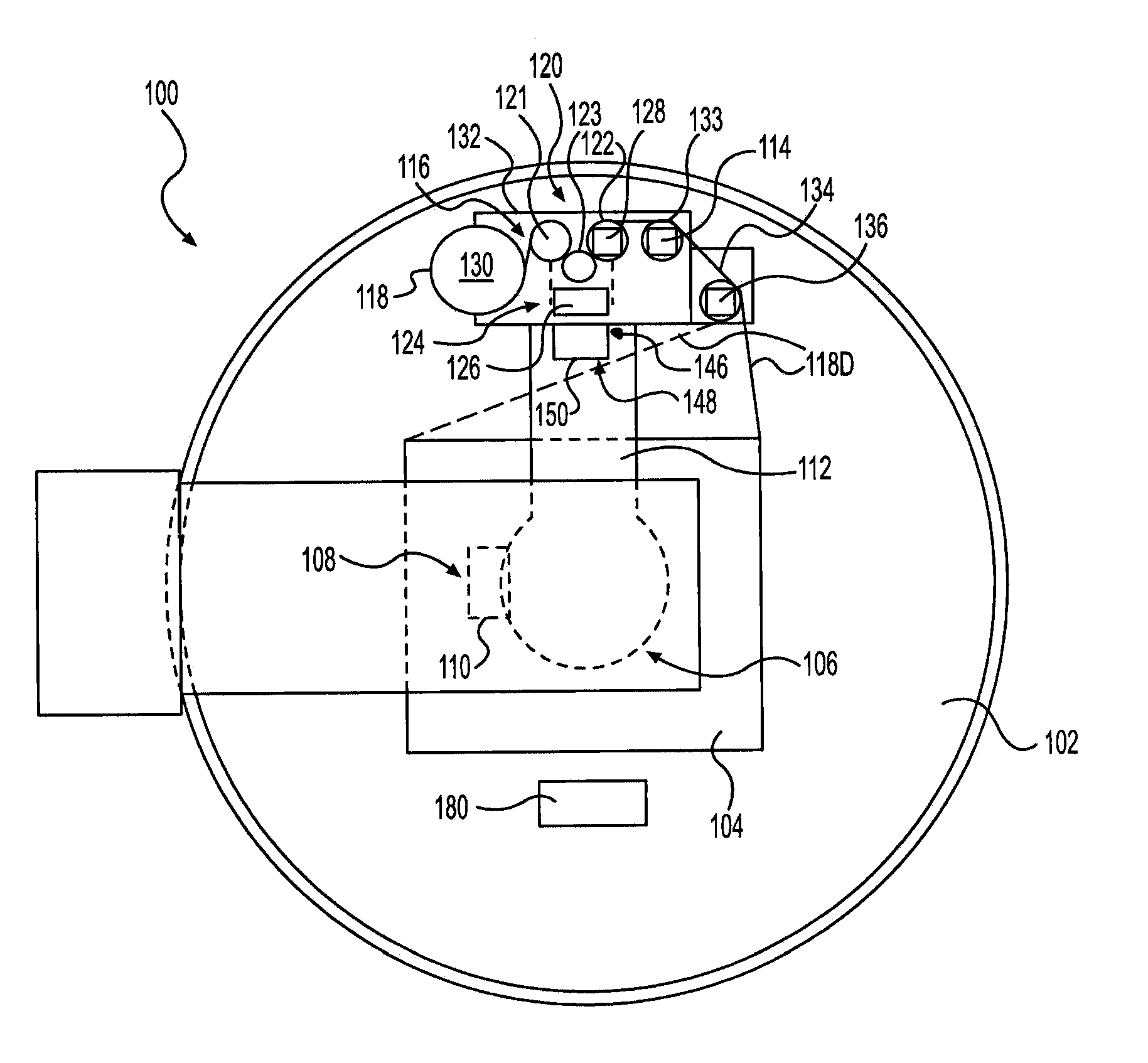

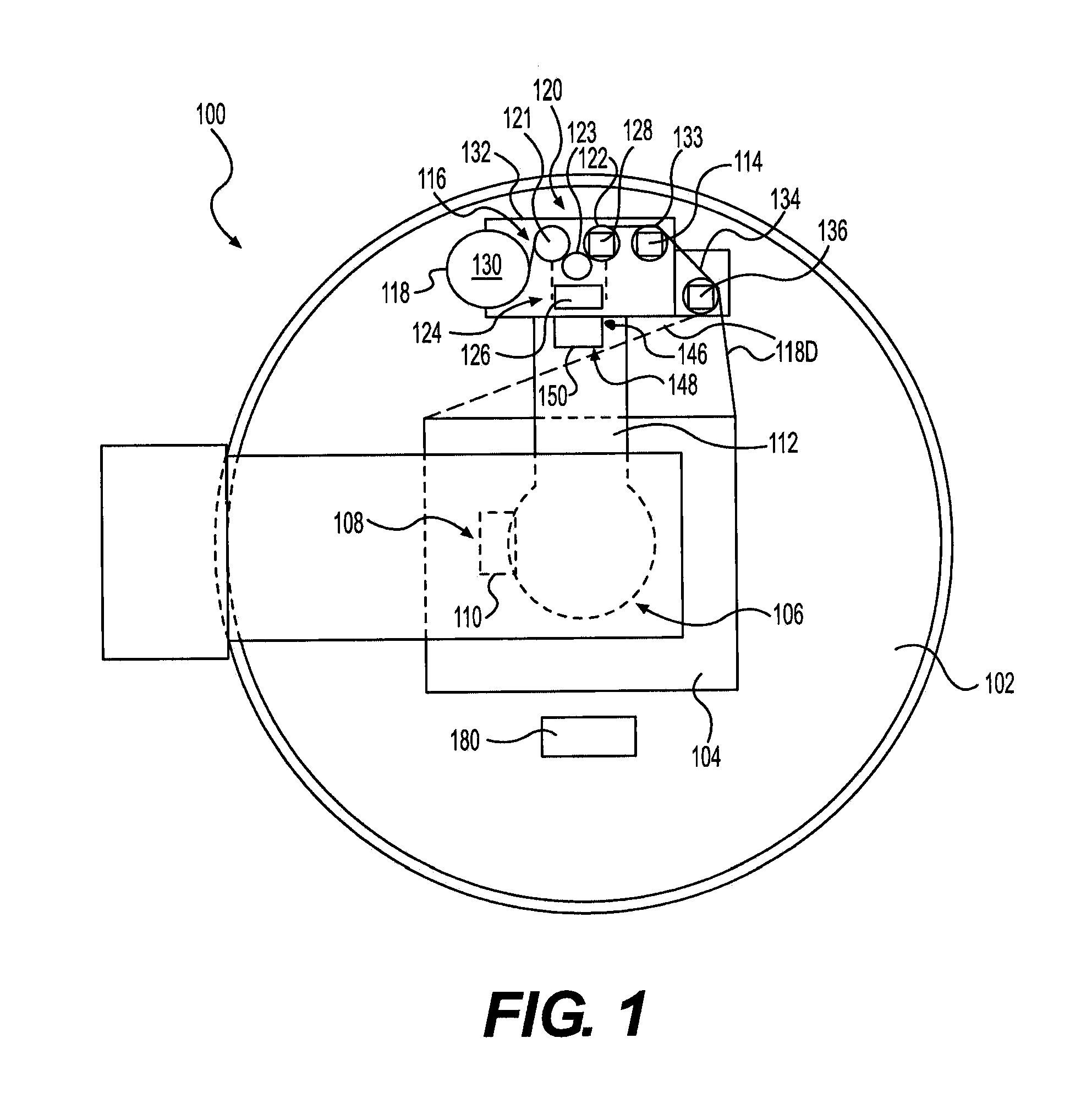

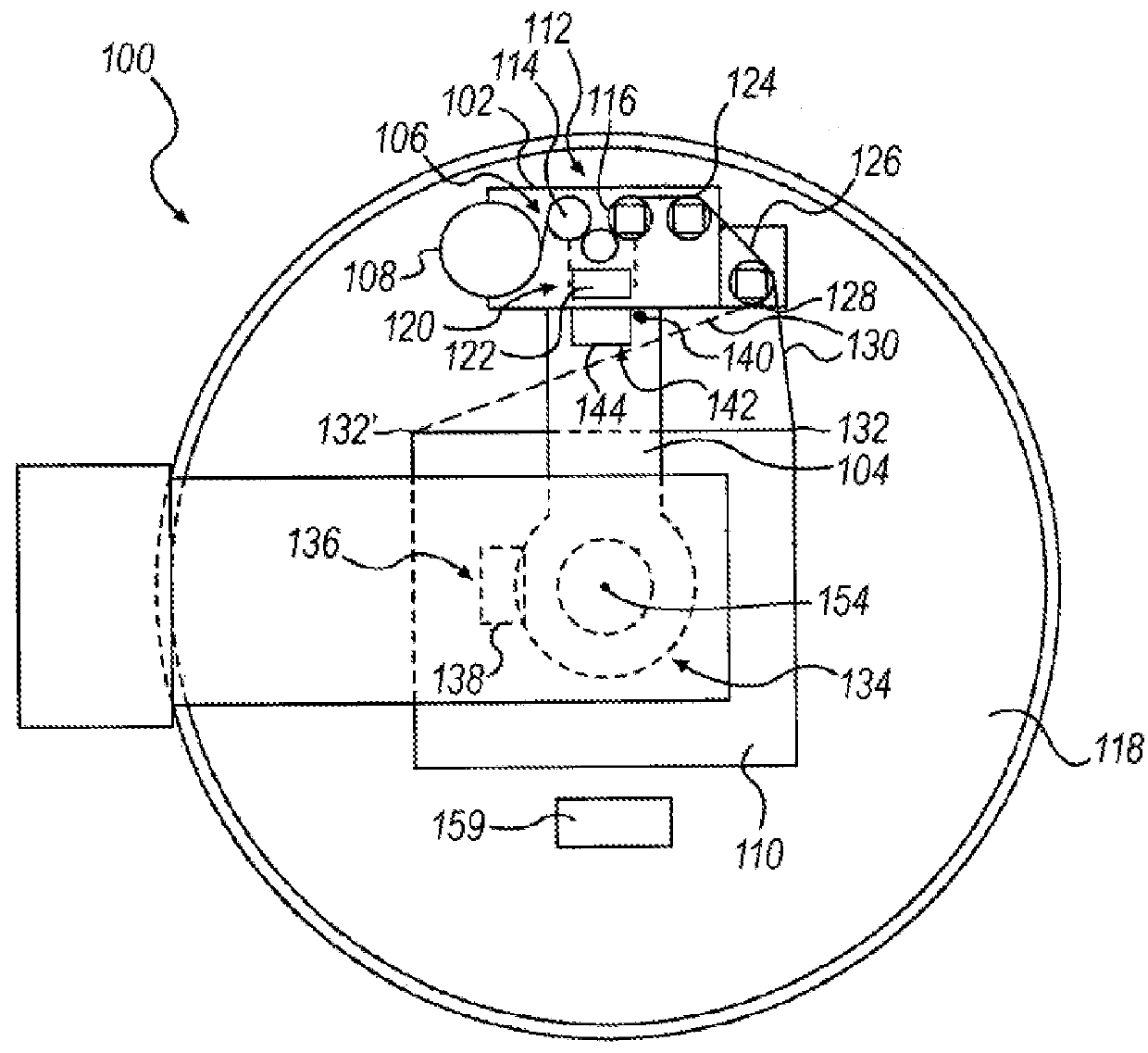

Demand based wrapping

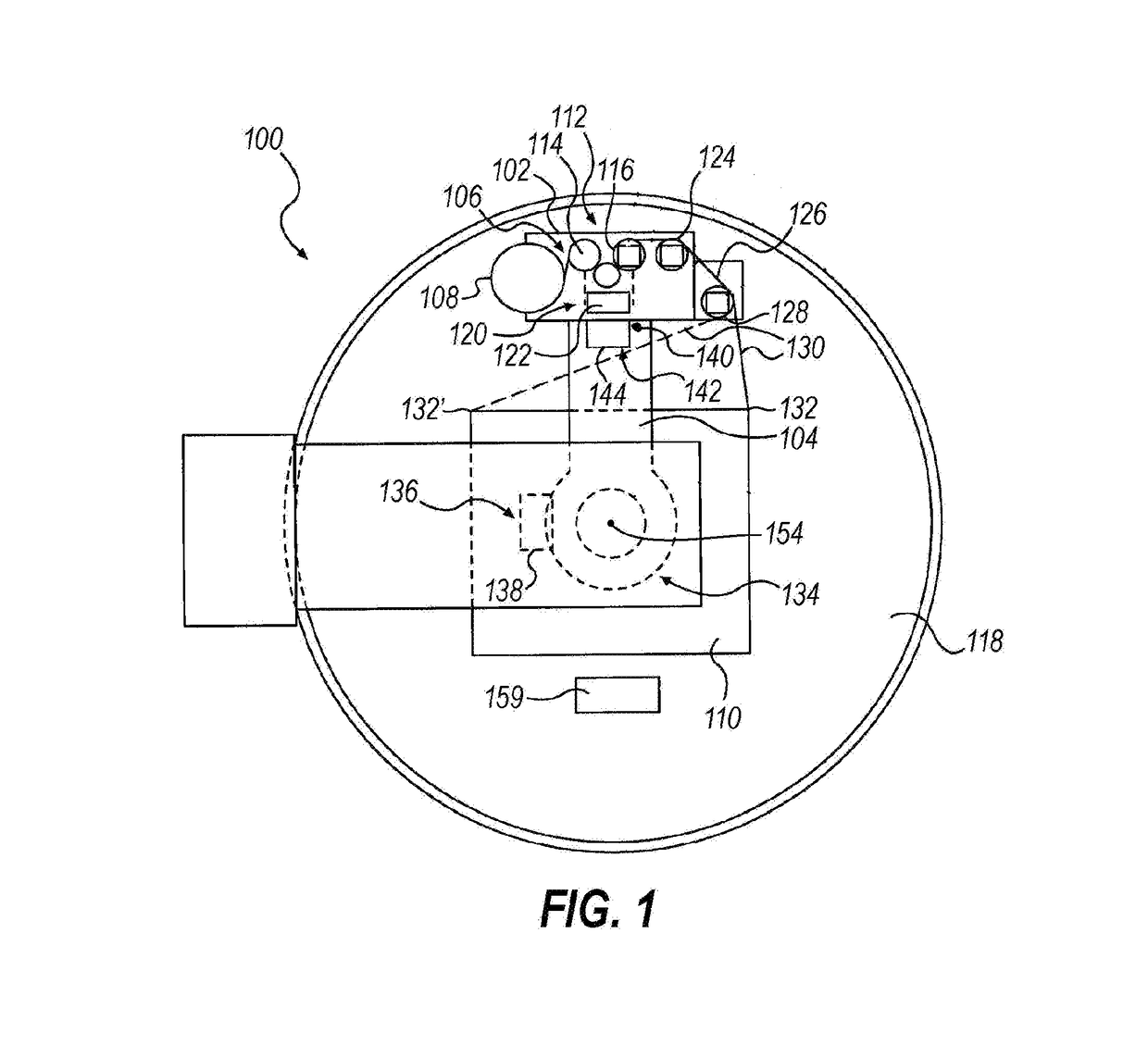

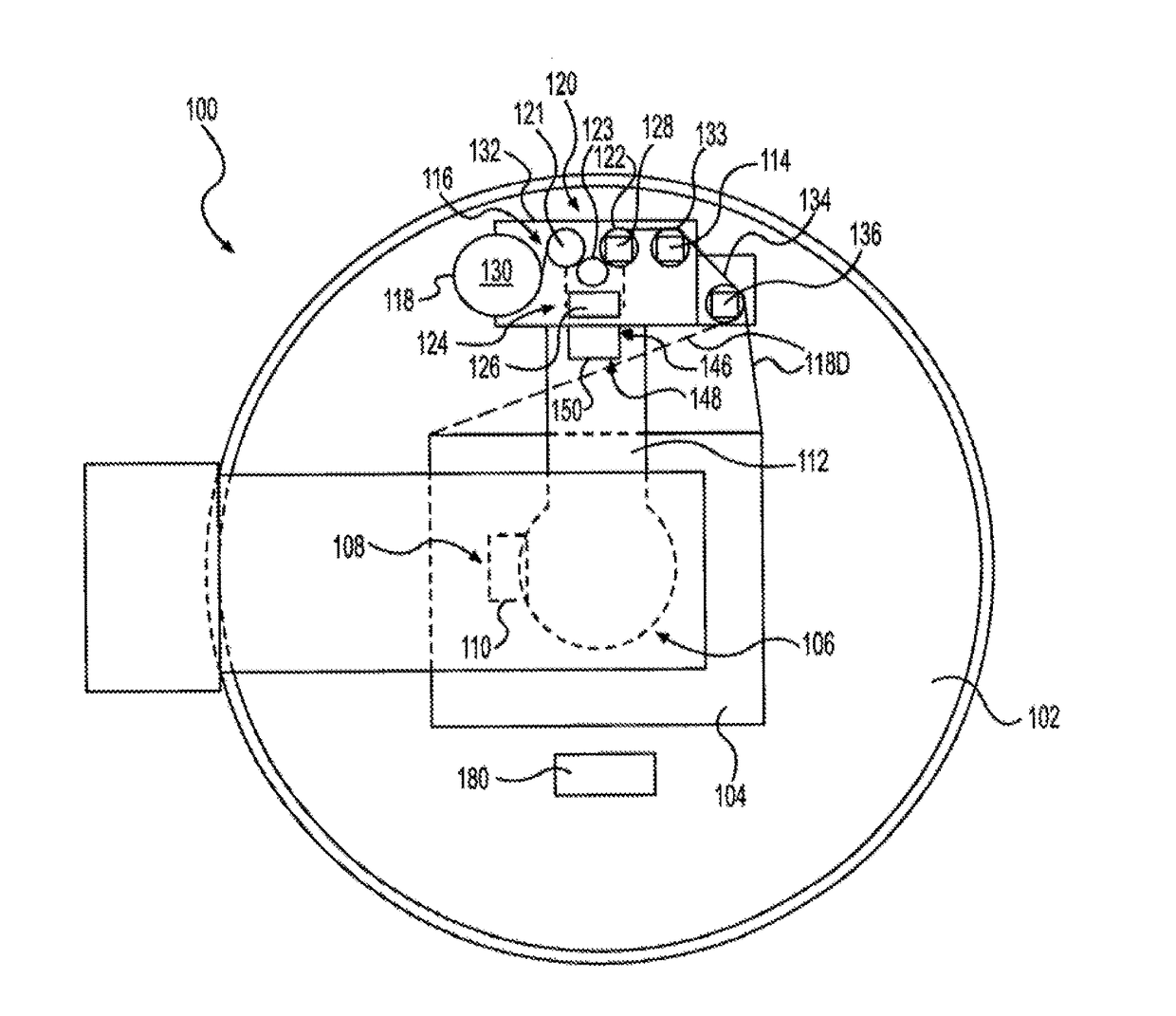

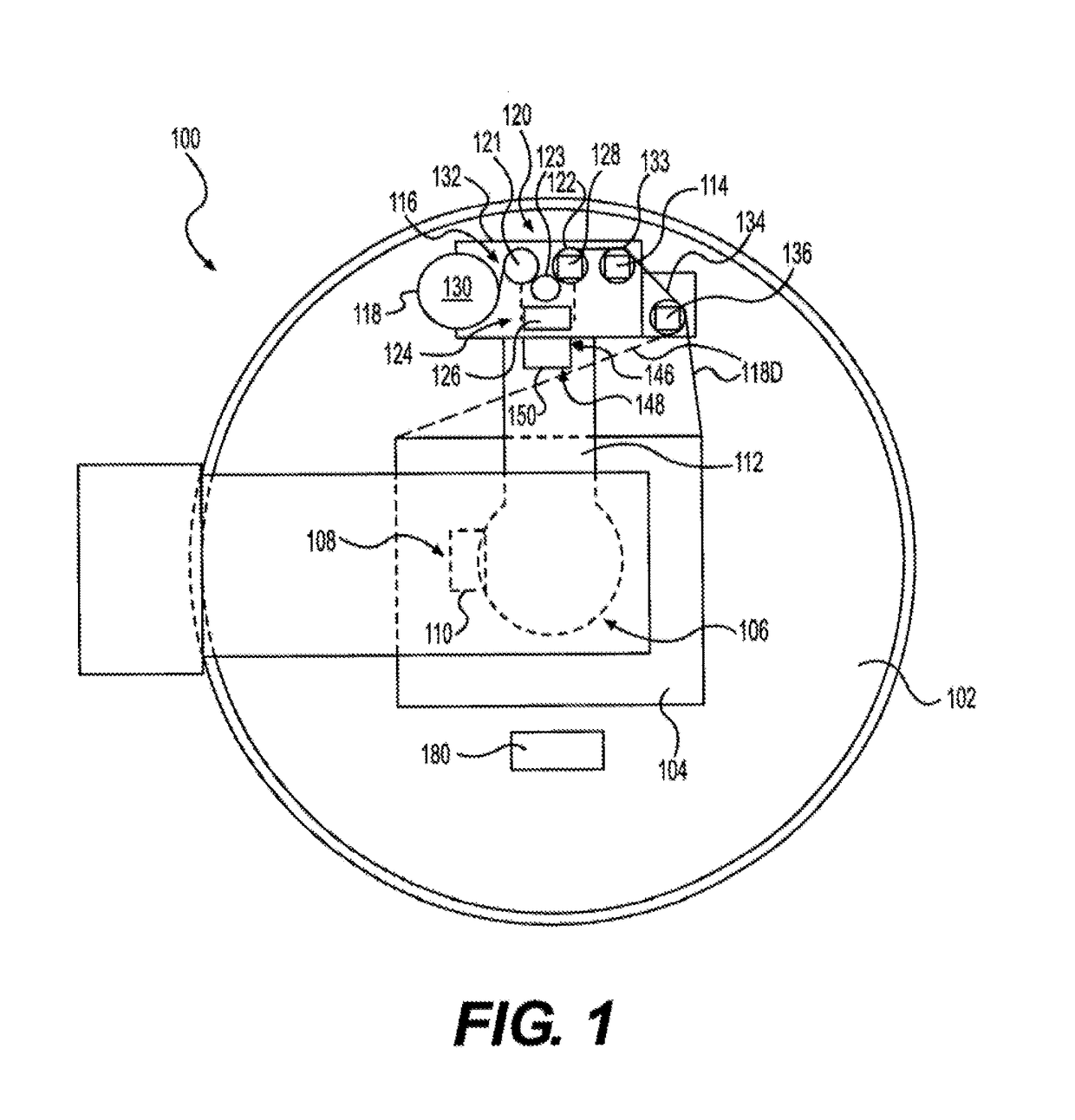

ActiveUS20110131927A1Prestretching mechanismWeb rotation wrappingControl systemManufacturing engineering

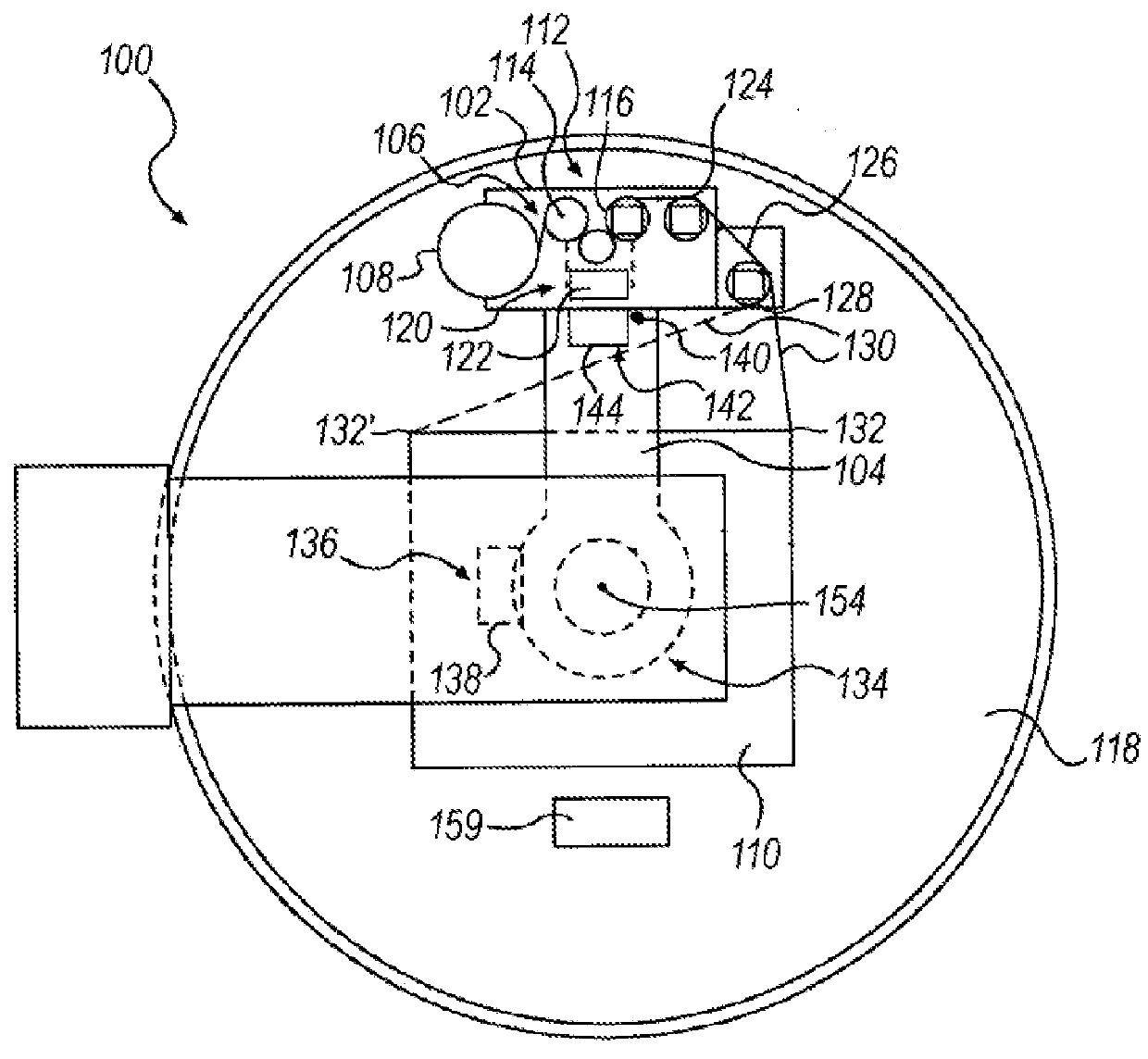

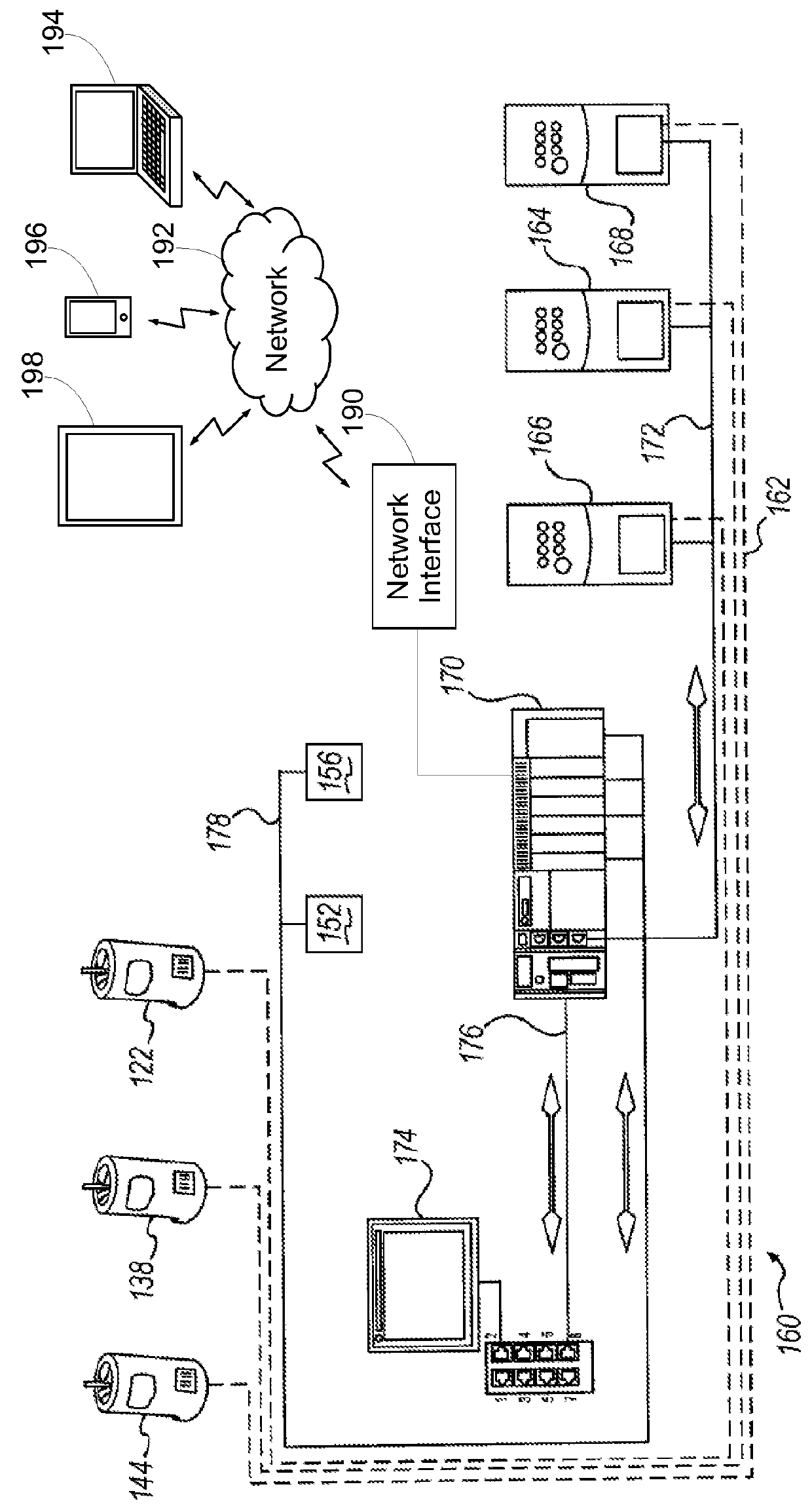

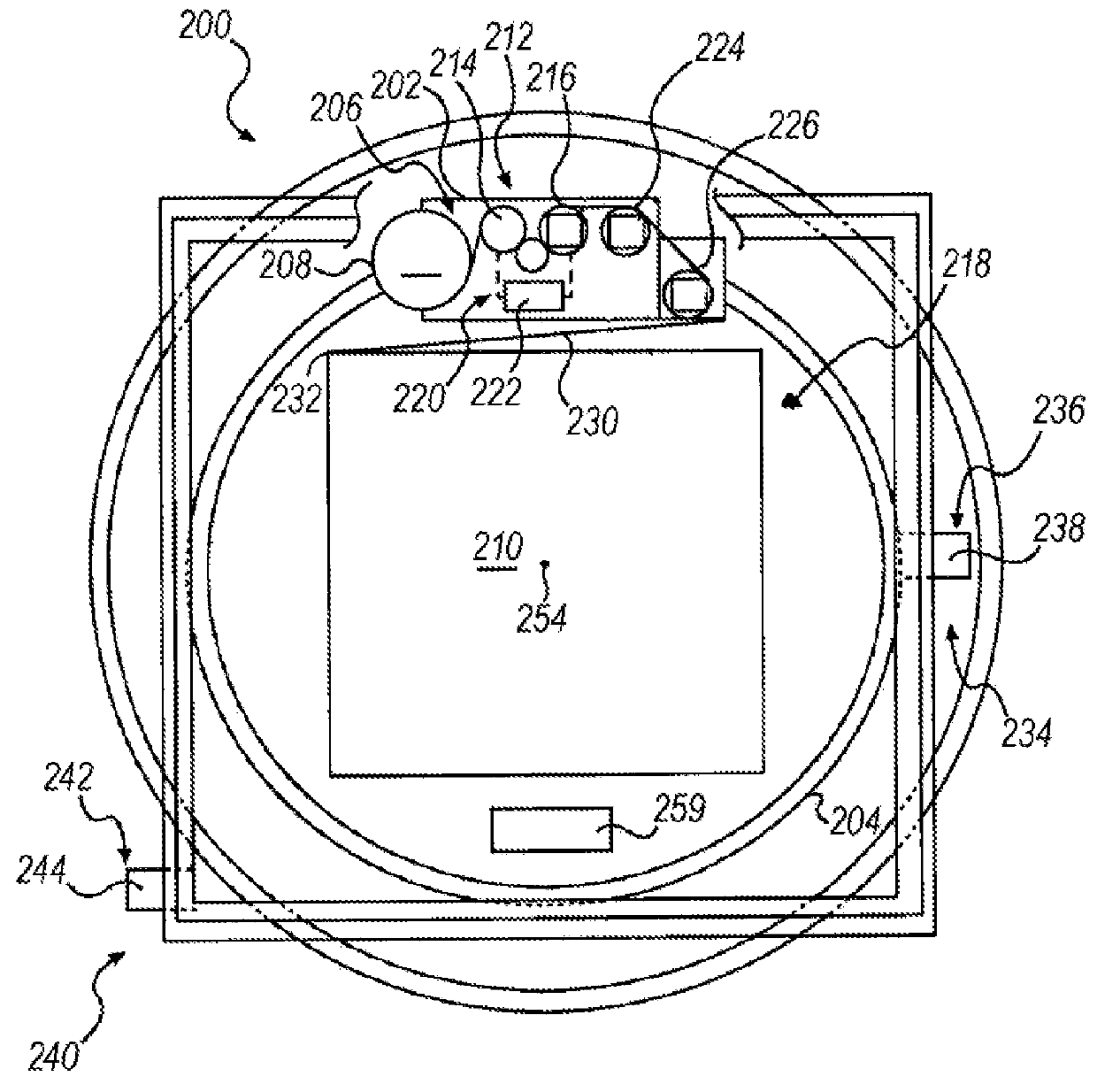

A control system for a wrapping apparatus may include a packaging material dispenser configured to dispense packaging material for wrapping a load. The control system may also include at least one sensor assembly configured to generate a signal based on instantaneous demand for packaging material at the load. The control system may further include a controller configured to control operation of the packaging material dispenser based at least in part on the signal.

Owner:LANTECH COM

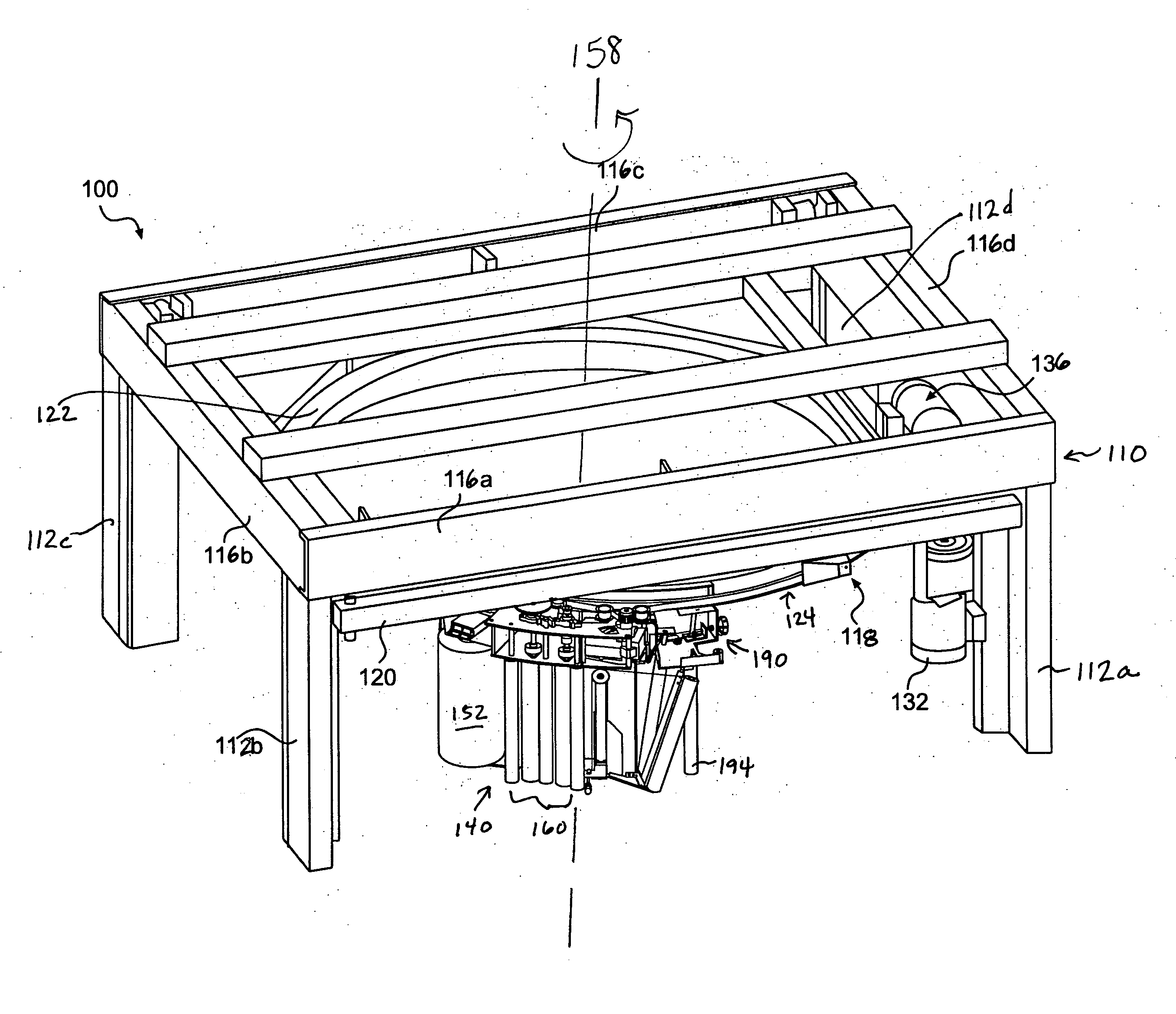

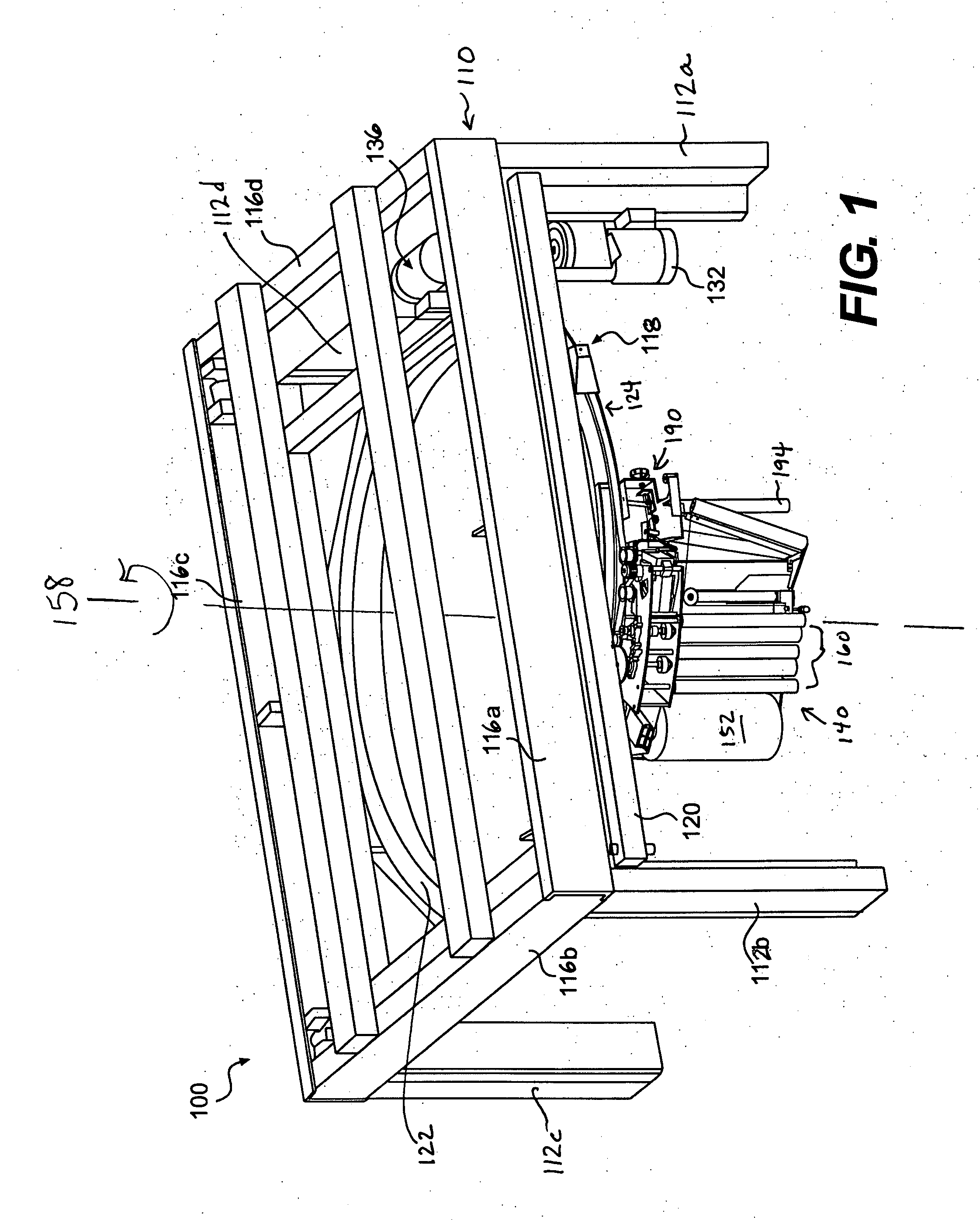

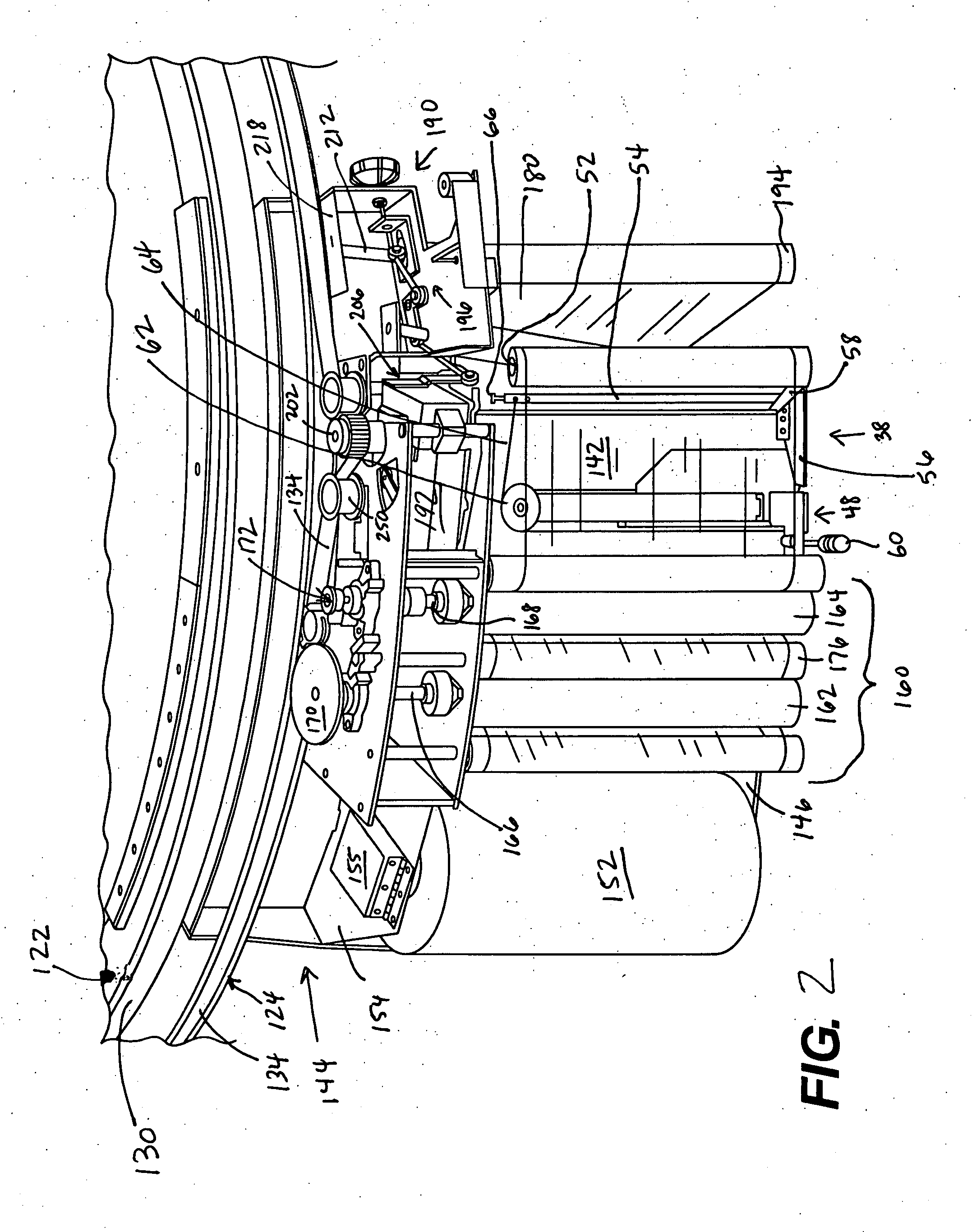

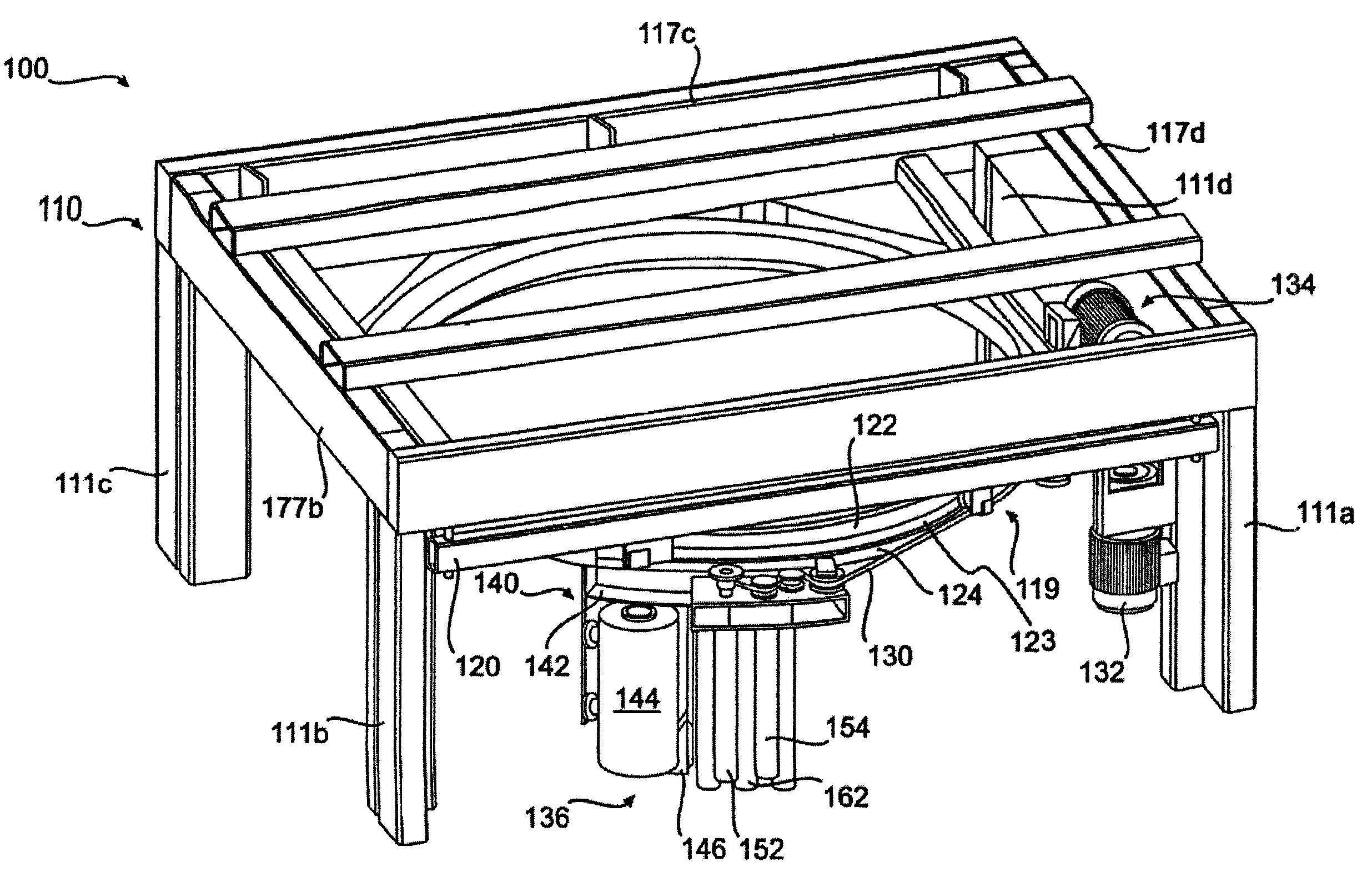

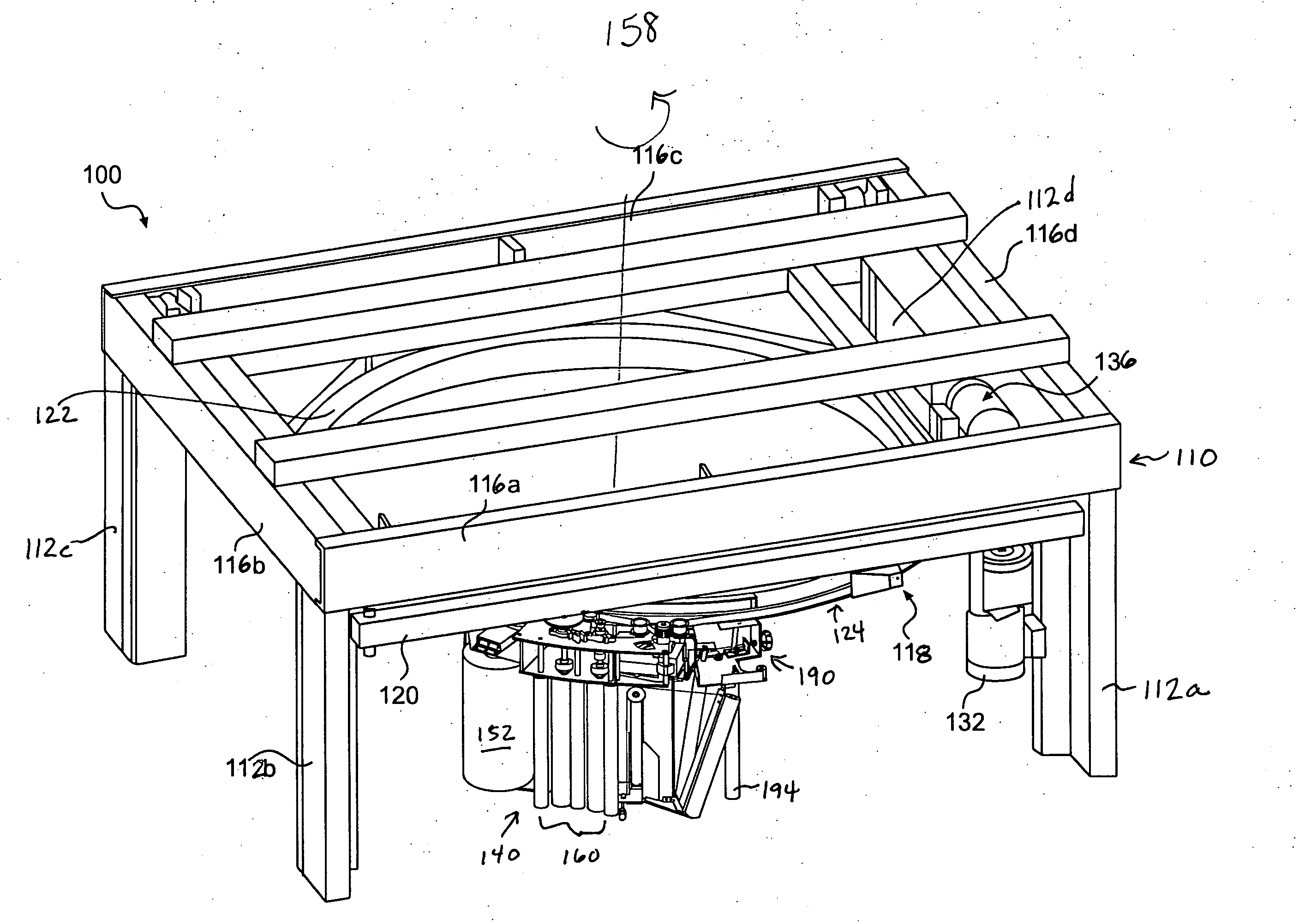

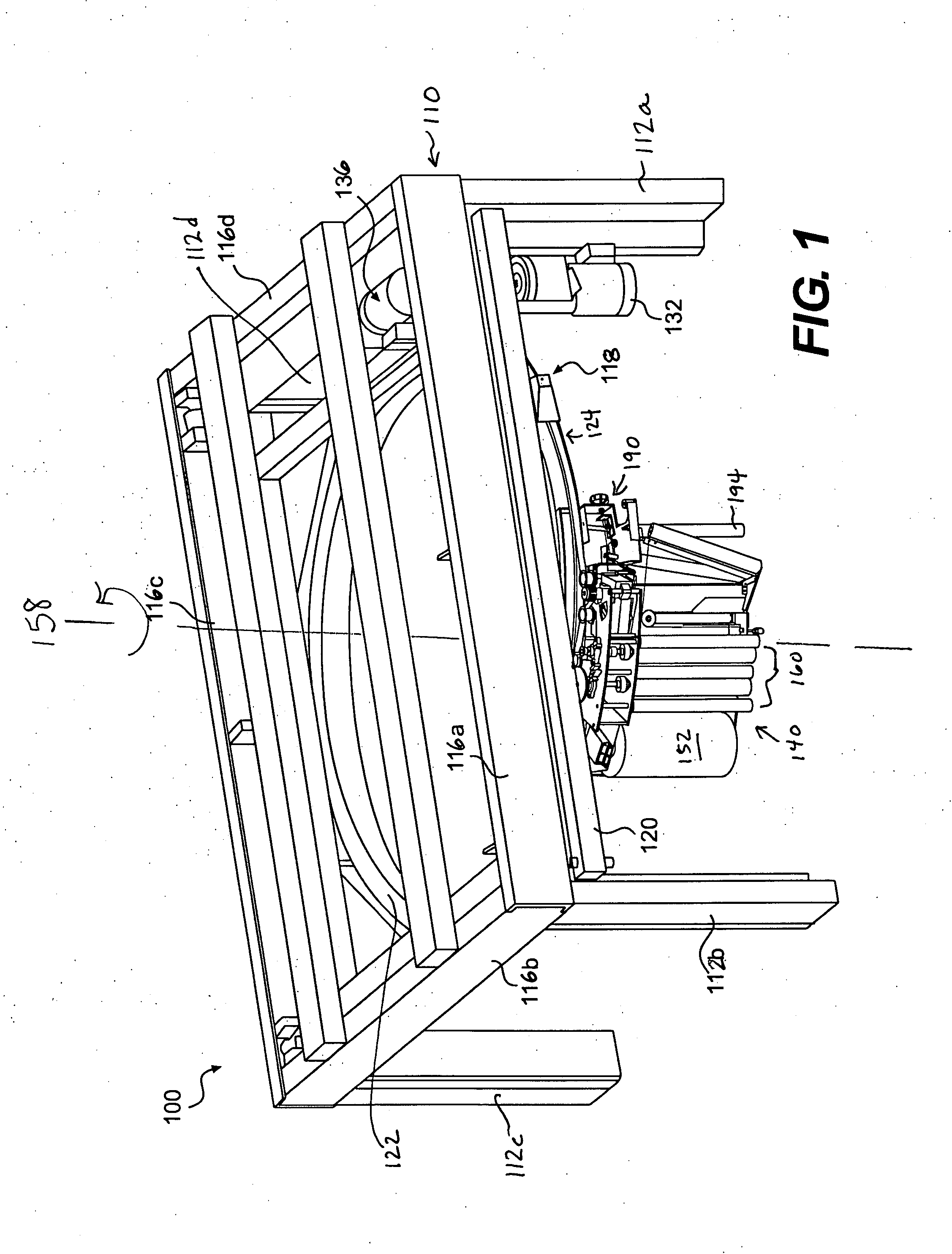

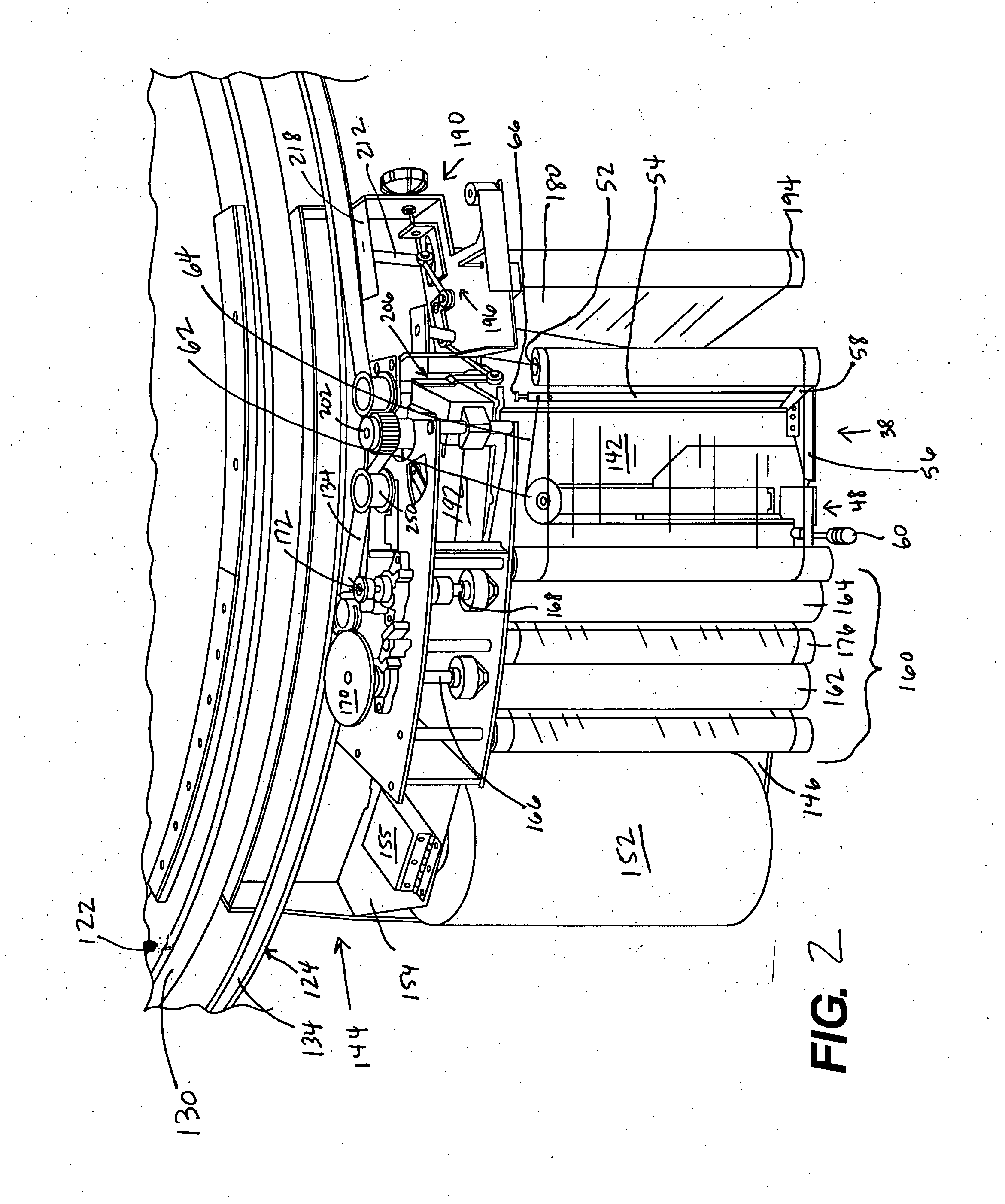

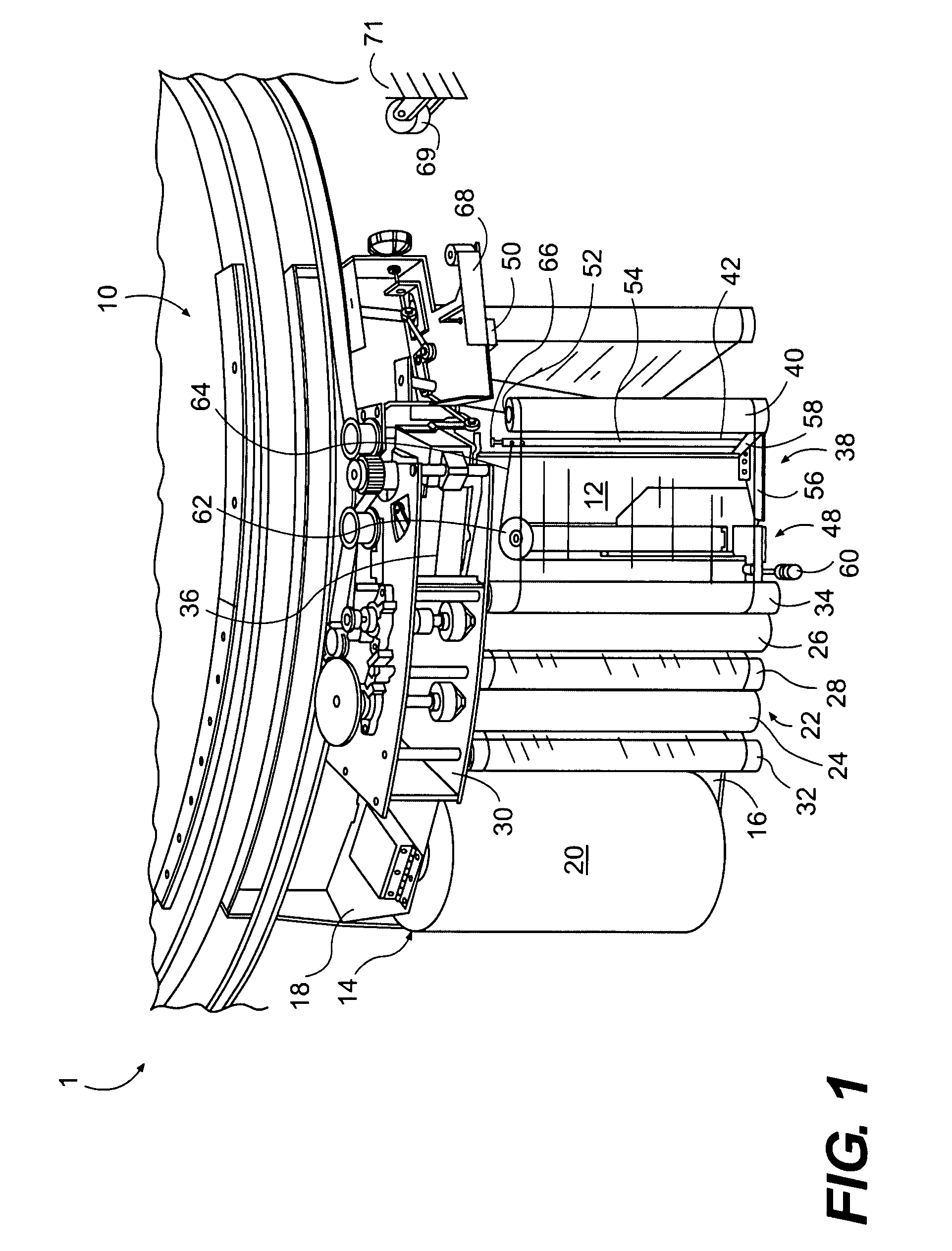

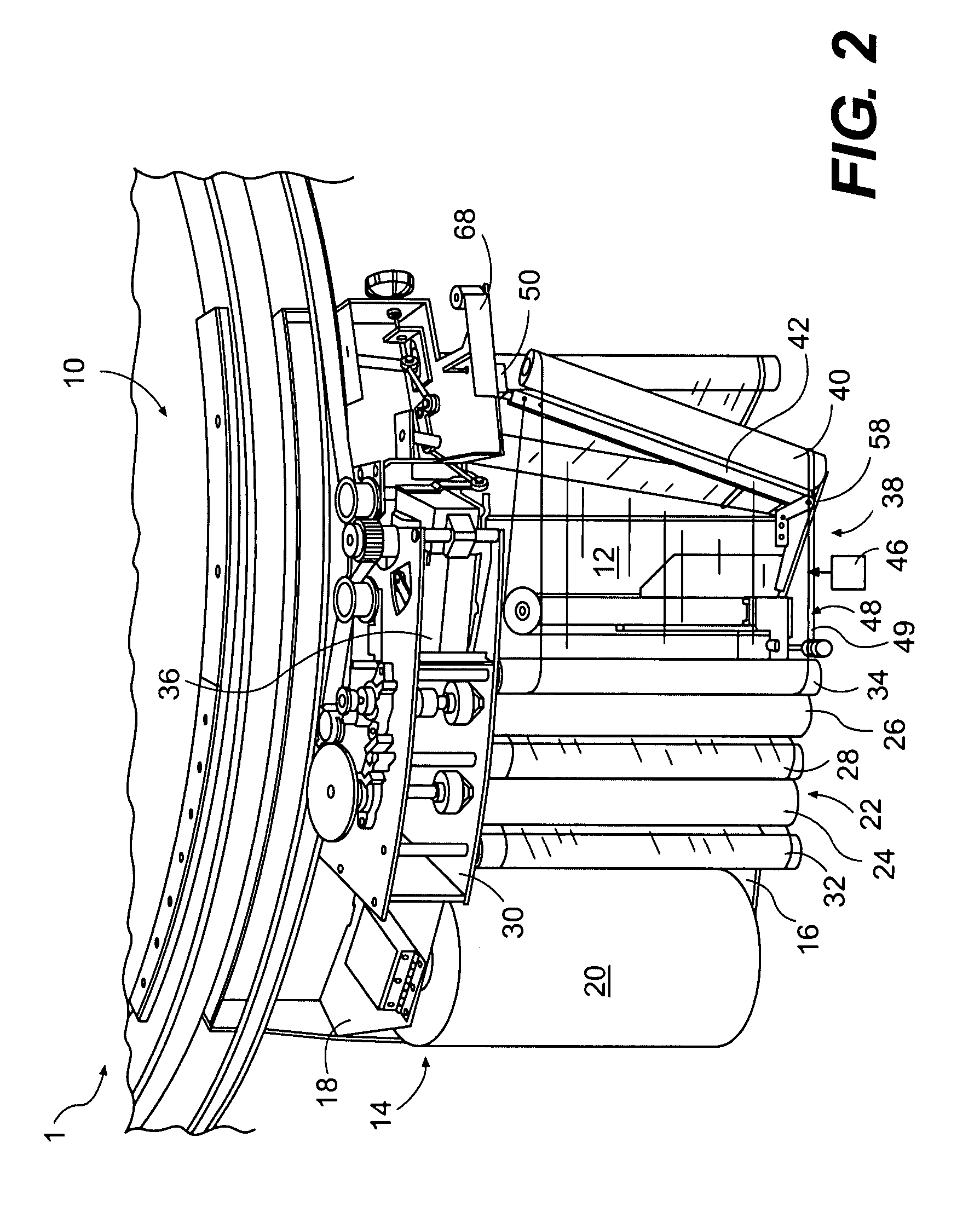

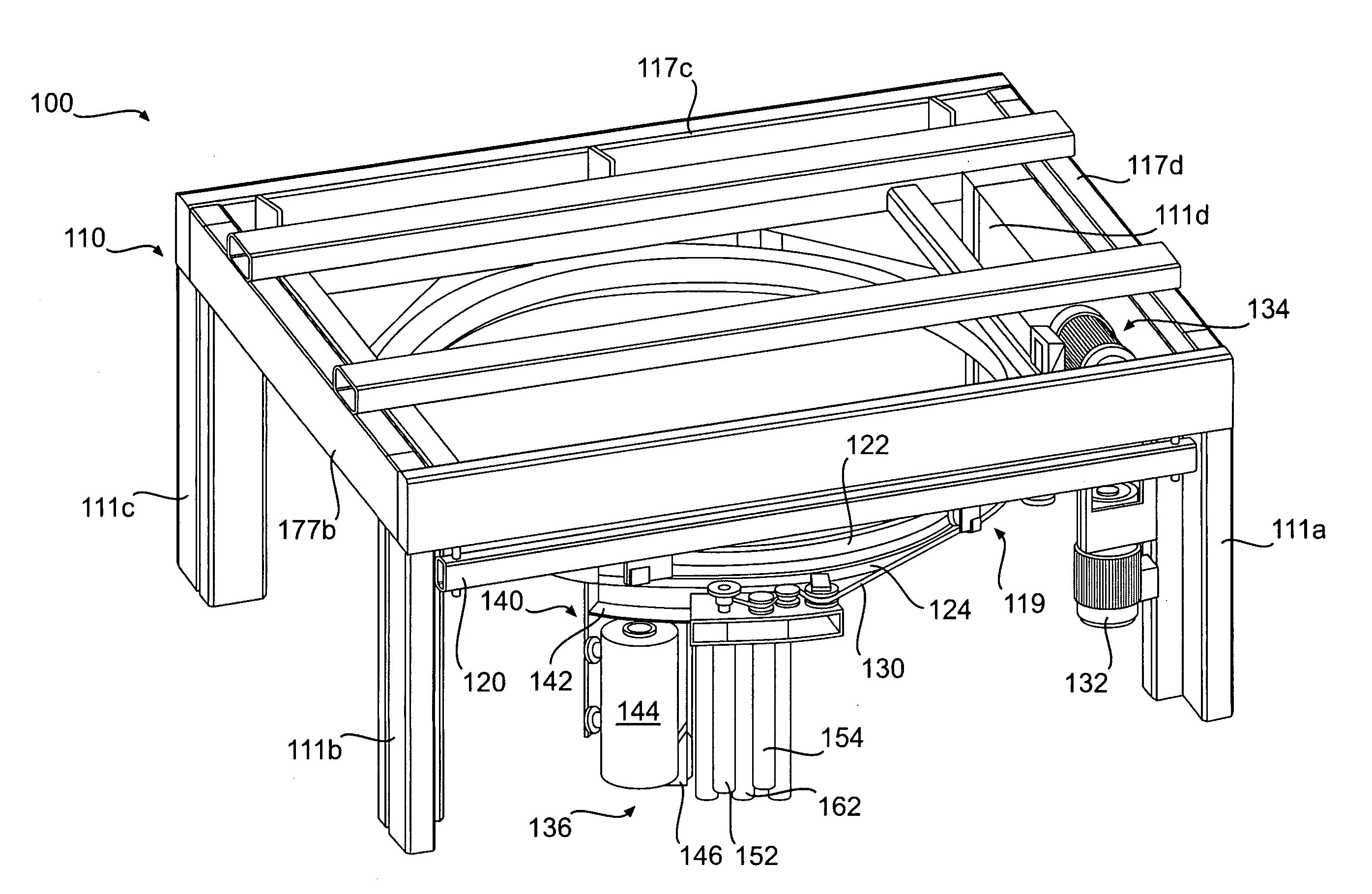

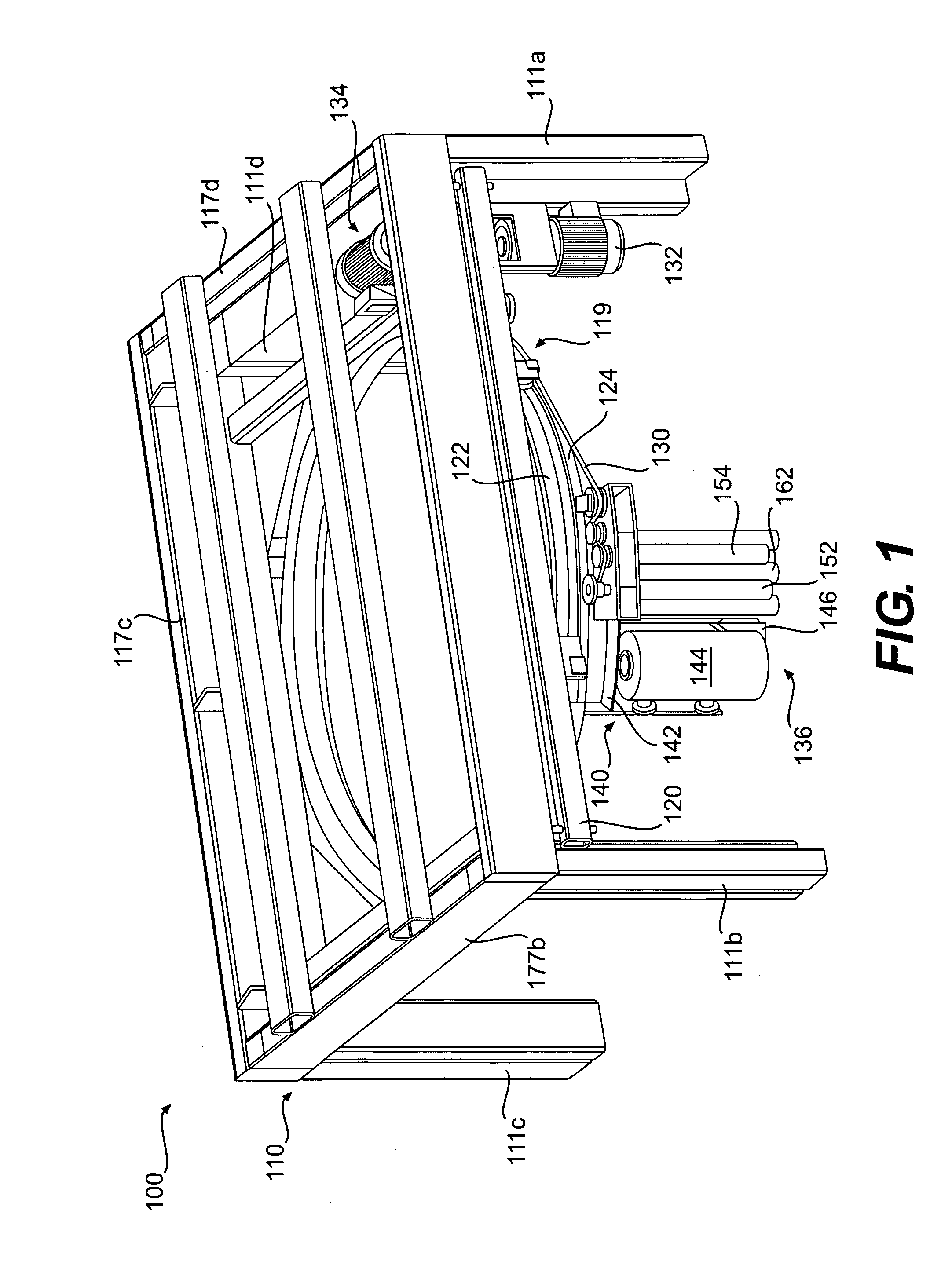

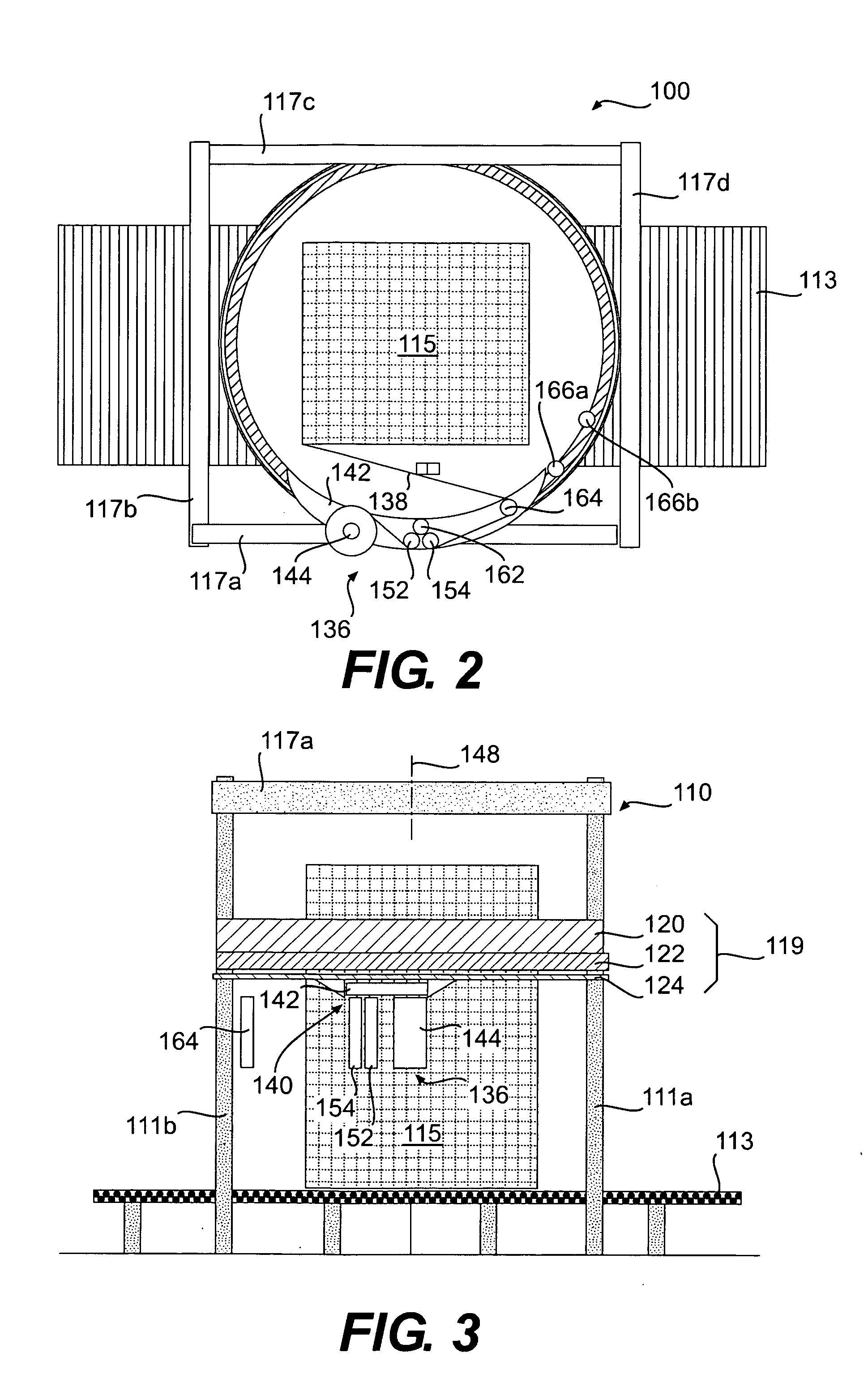

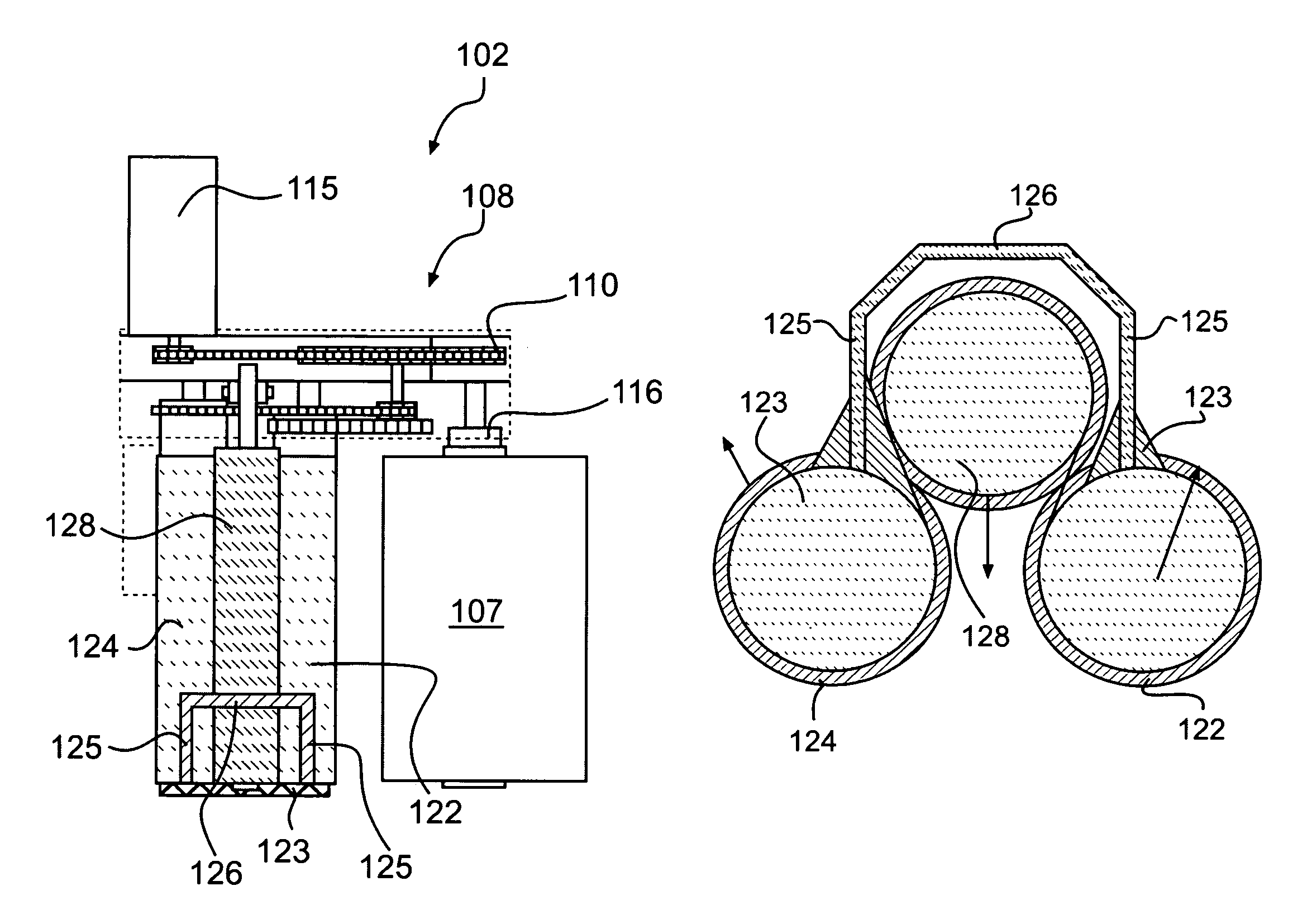

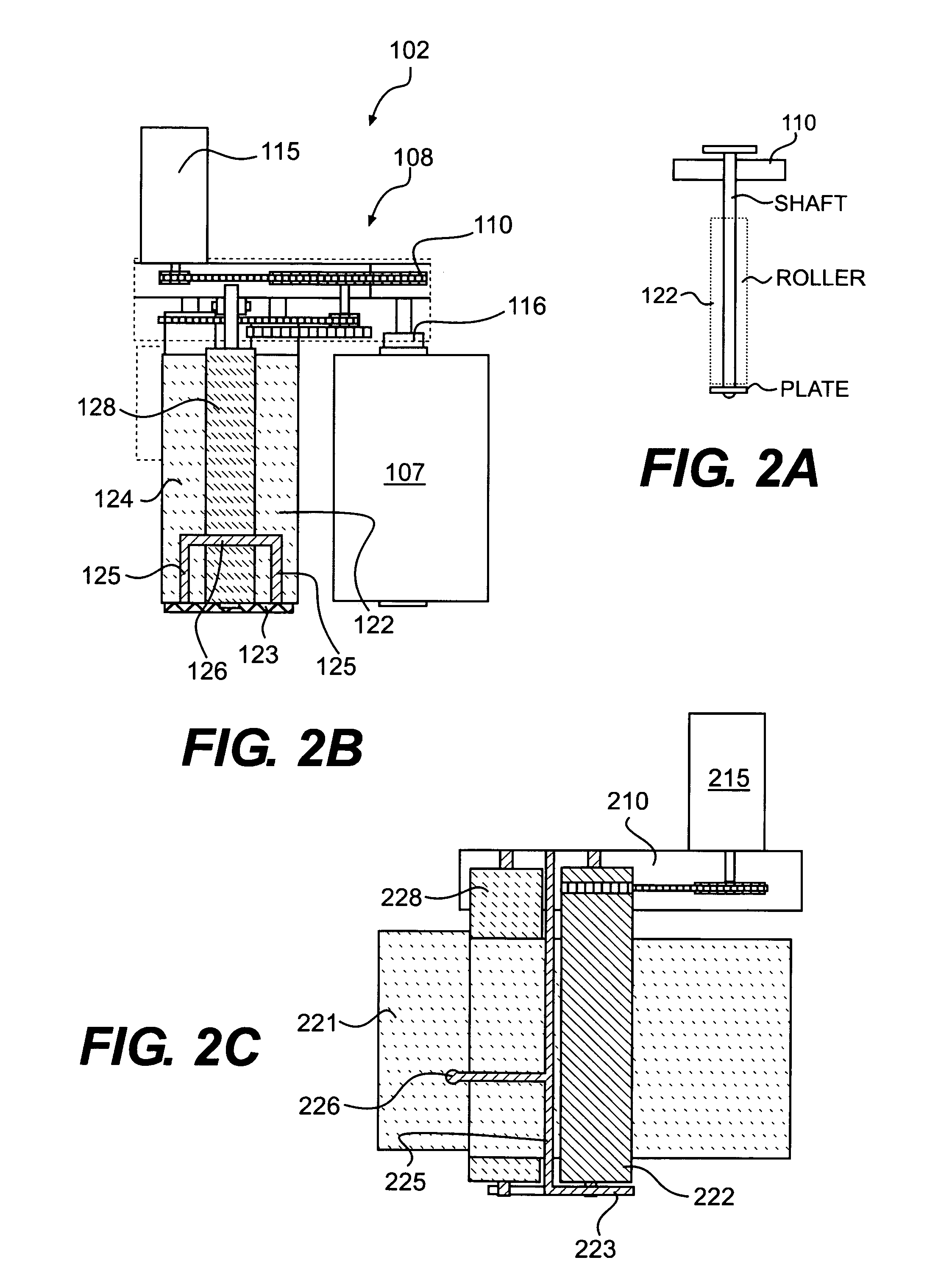

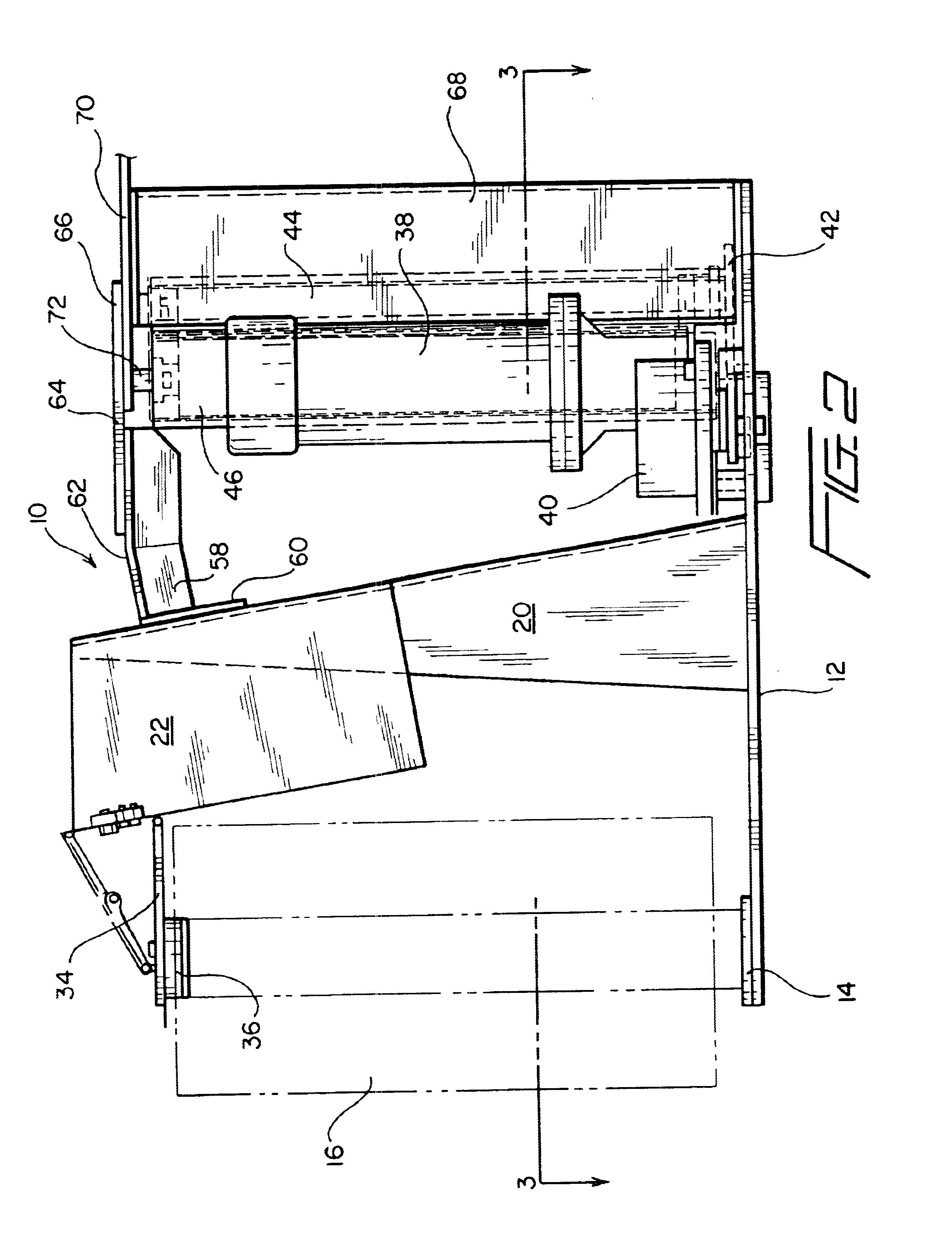

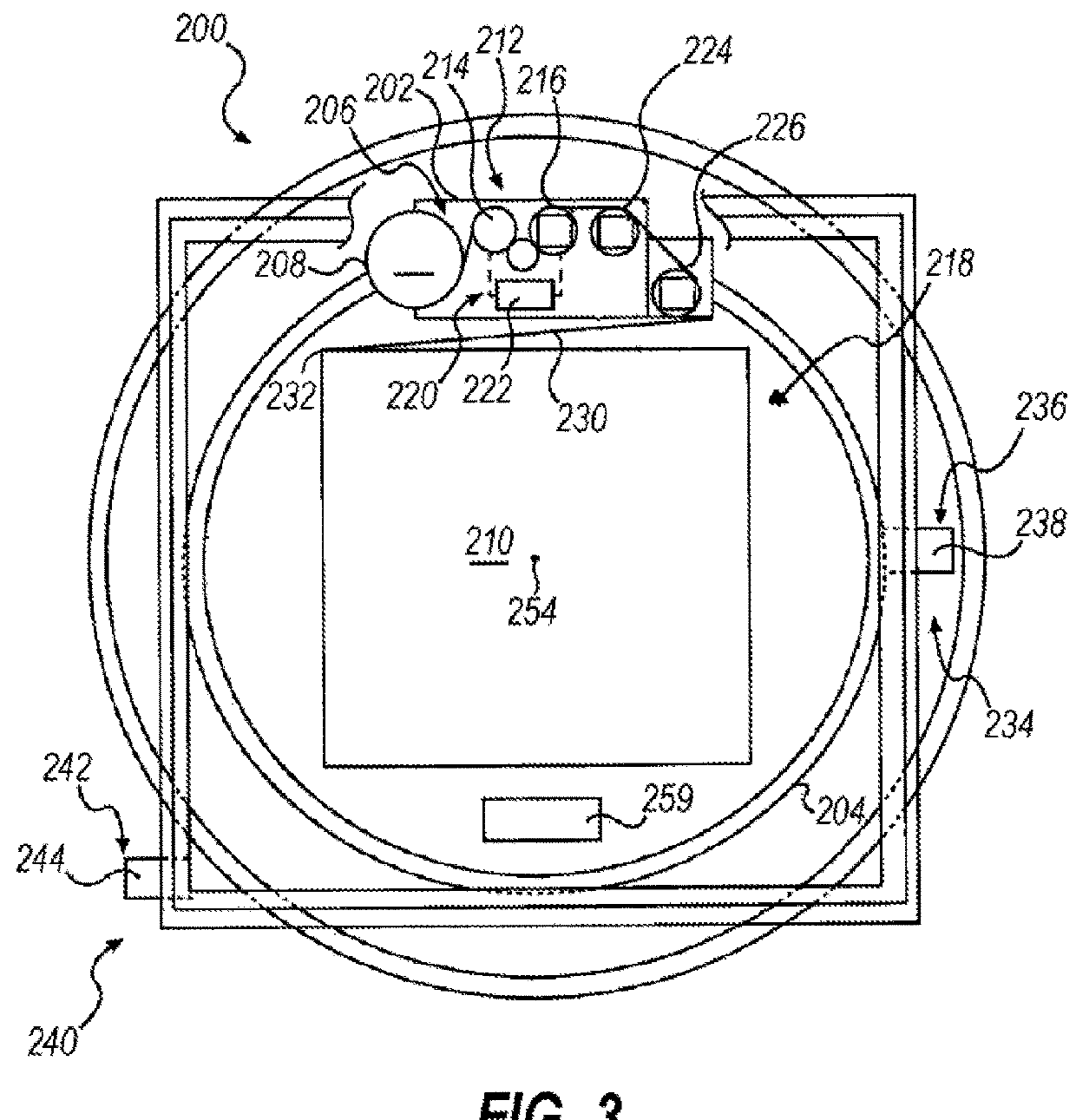

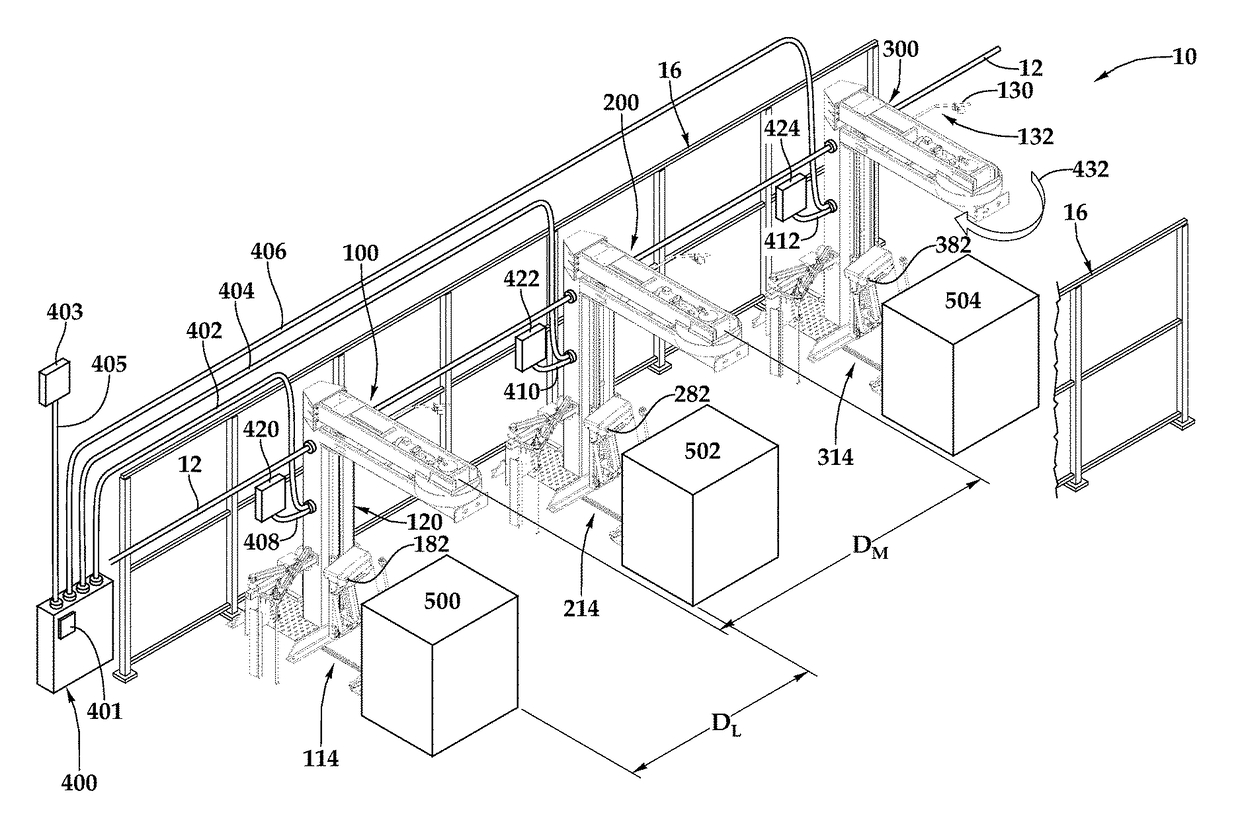

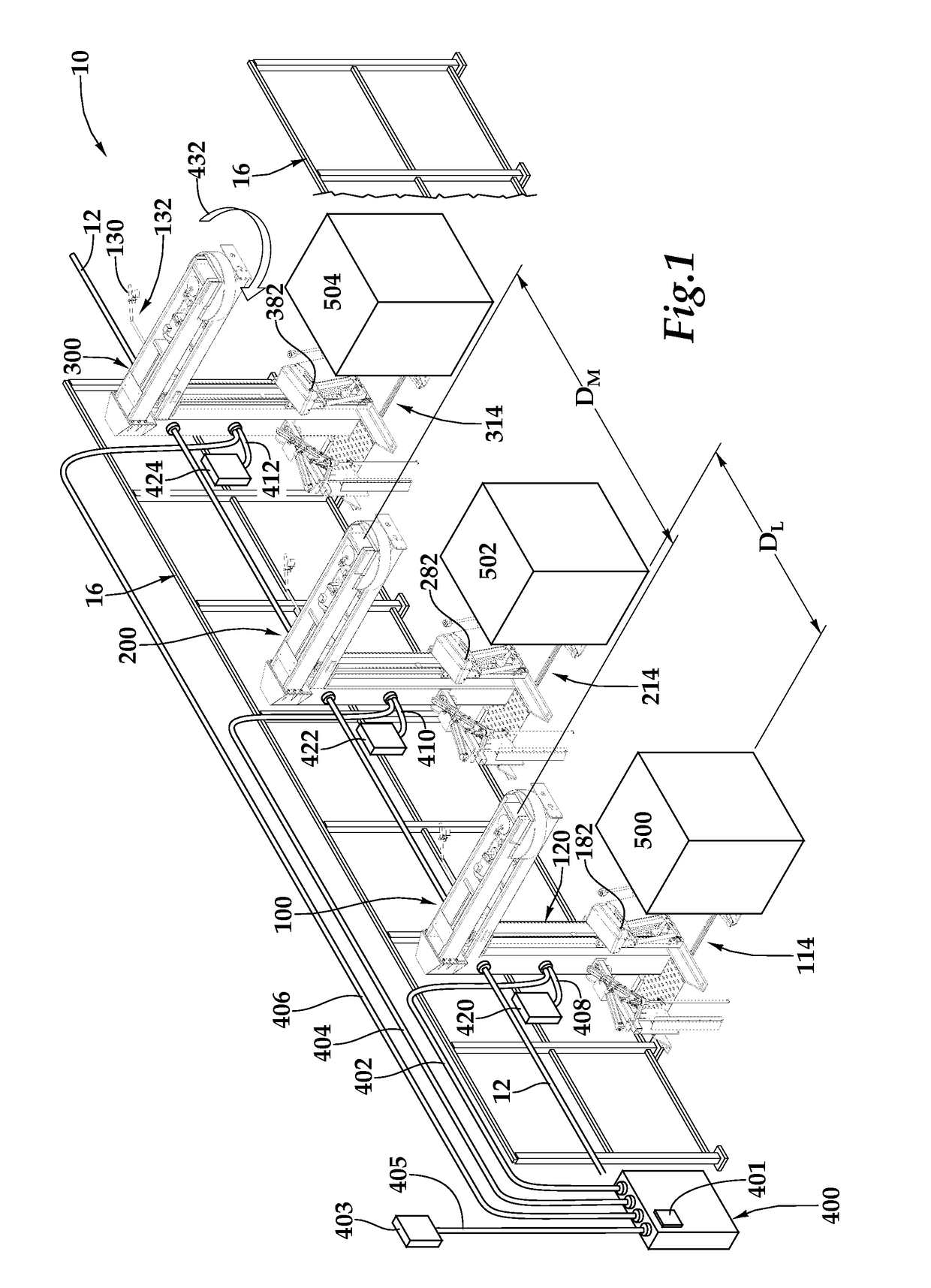

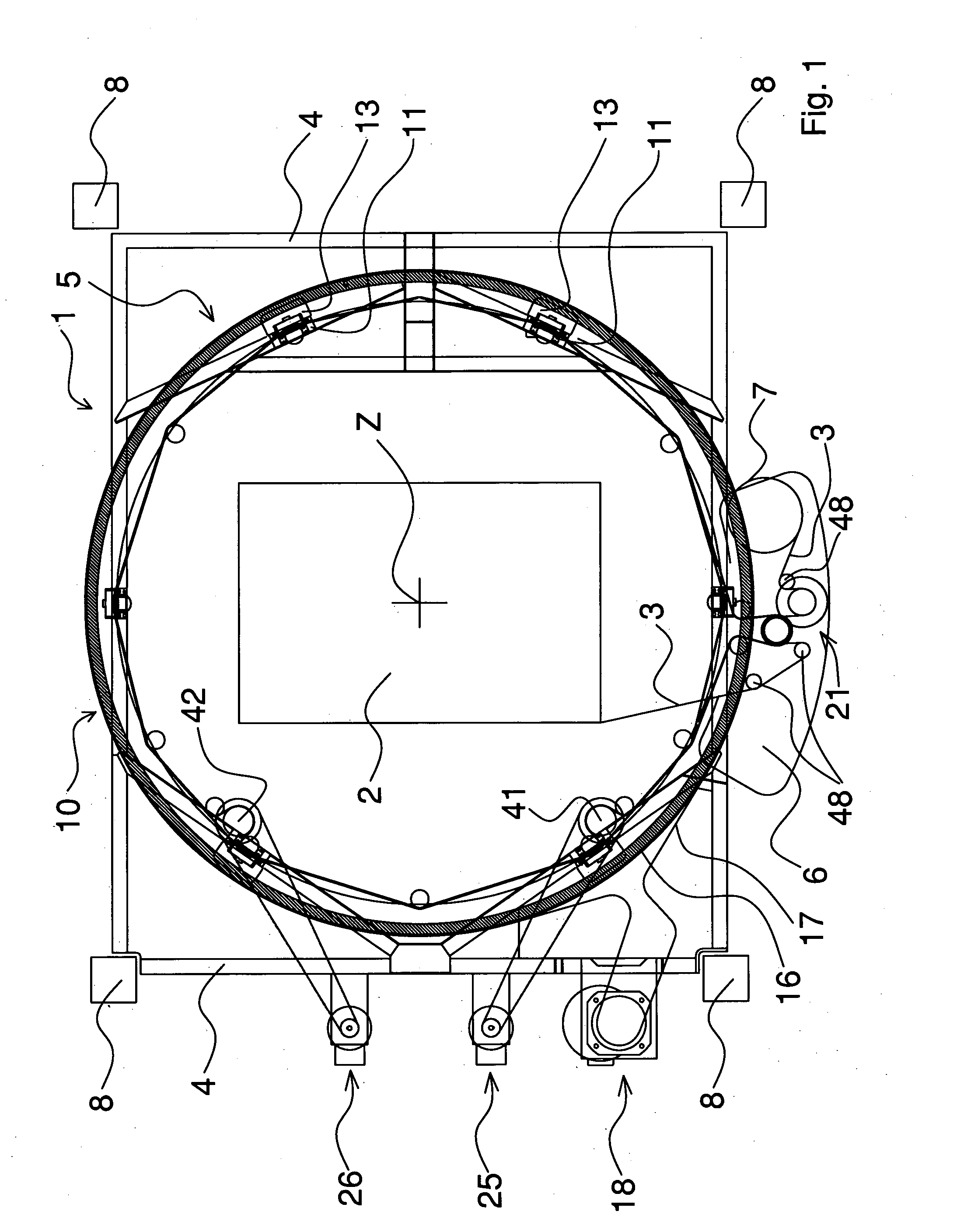

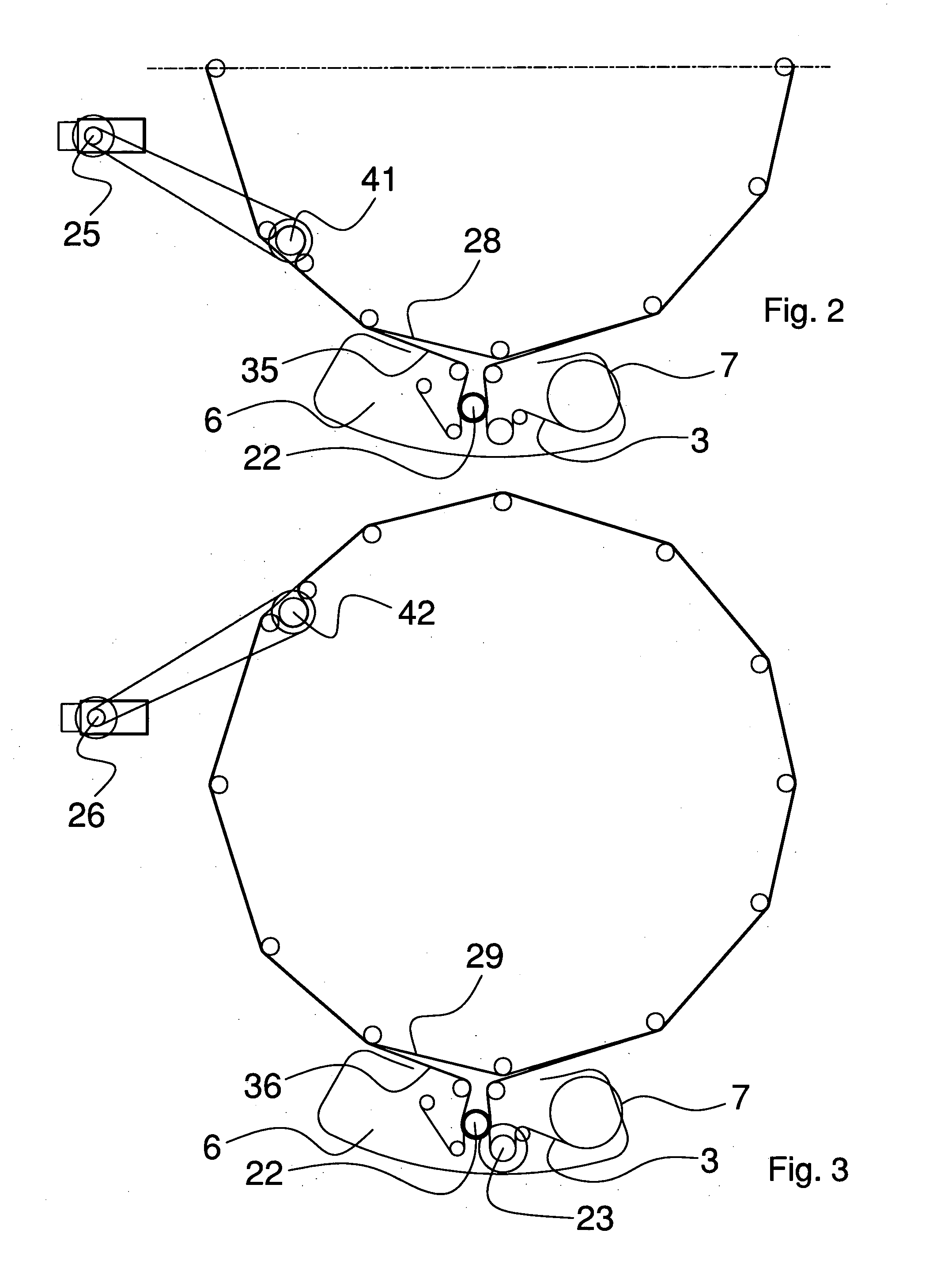

Wrapping apparatus including metered pre-stretch film delivery assembly and method of using

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

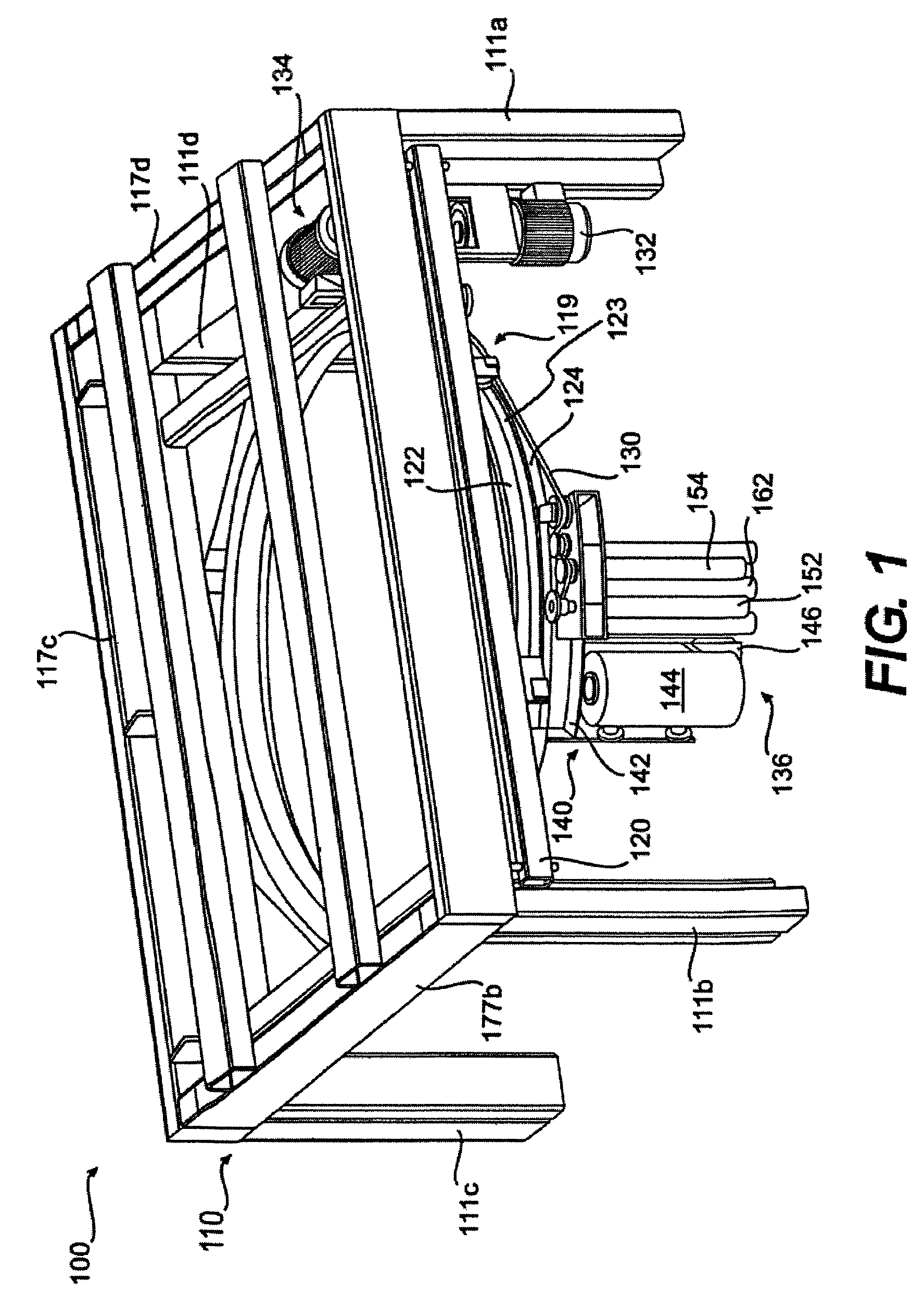

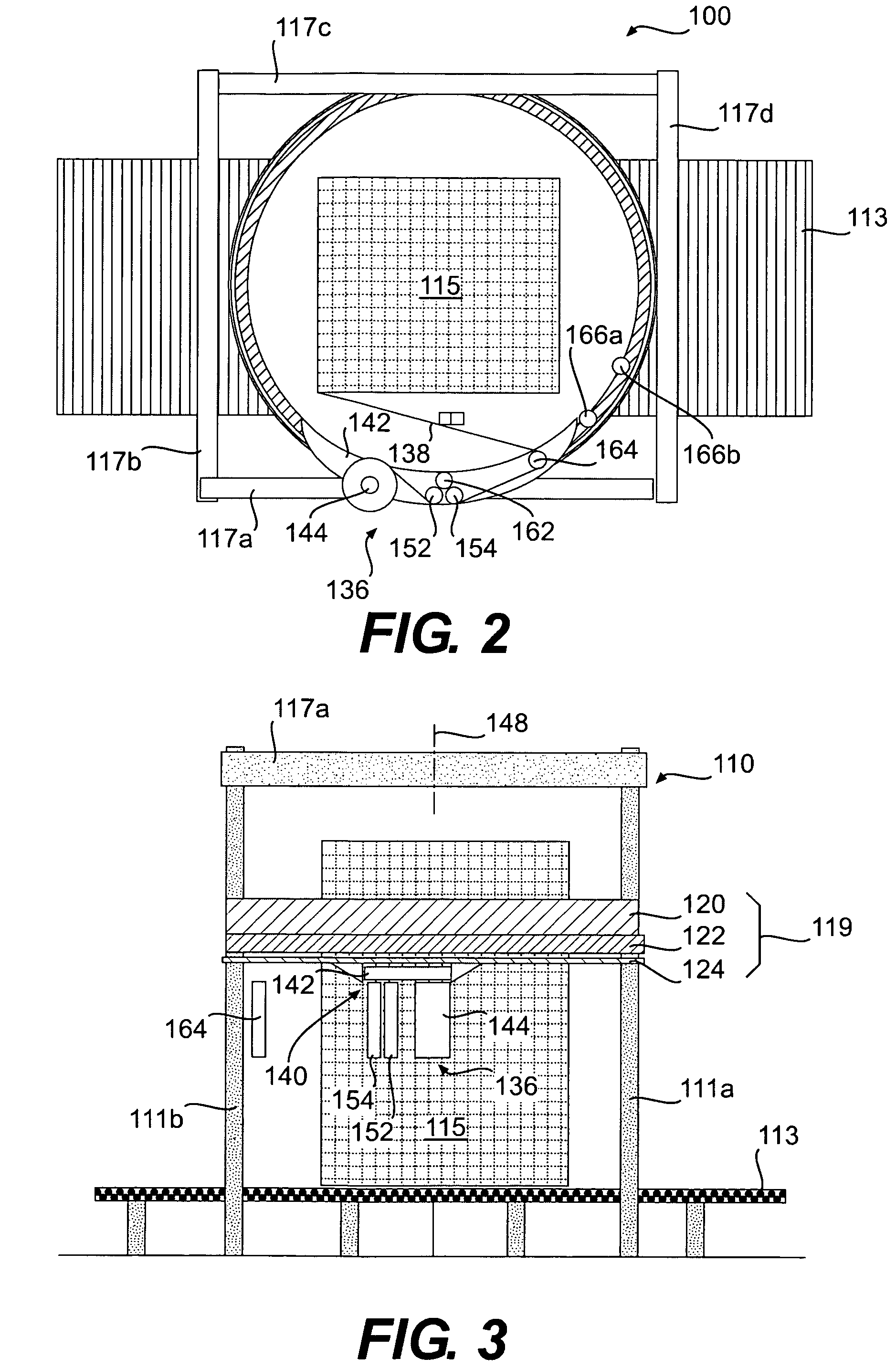

Ring wrapping apparatus including metered pre-stretch film delivery assembly

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

Method and apparatus for securing a load to a pallet with a roped film web

An apparatus and method for wrapping a palletized load are provided. The apparatus preferably includes a film dispenser for dispensing a film web, at least one drive down roller configured to engage the width of the film web, and at least one roping mechanism. The at least one roping mechanism may be a cable rolling element configured to roll a portion of the film web into a rolled cable of film. The apparatus may also include means for providing relative rotation between the load and the dispenser to wrap a roped portion of the film web around a base of the load / top portion of a pallet supporting the load.

Owner:LANTECH COM

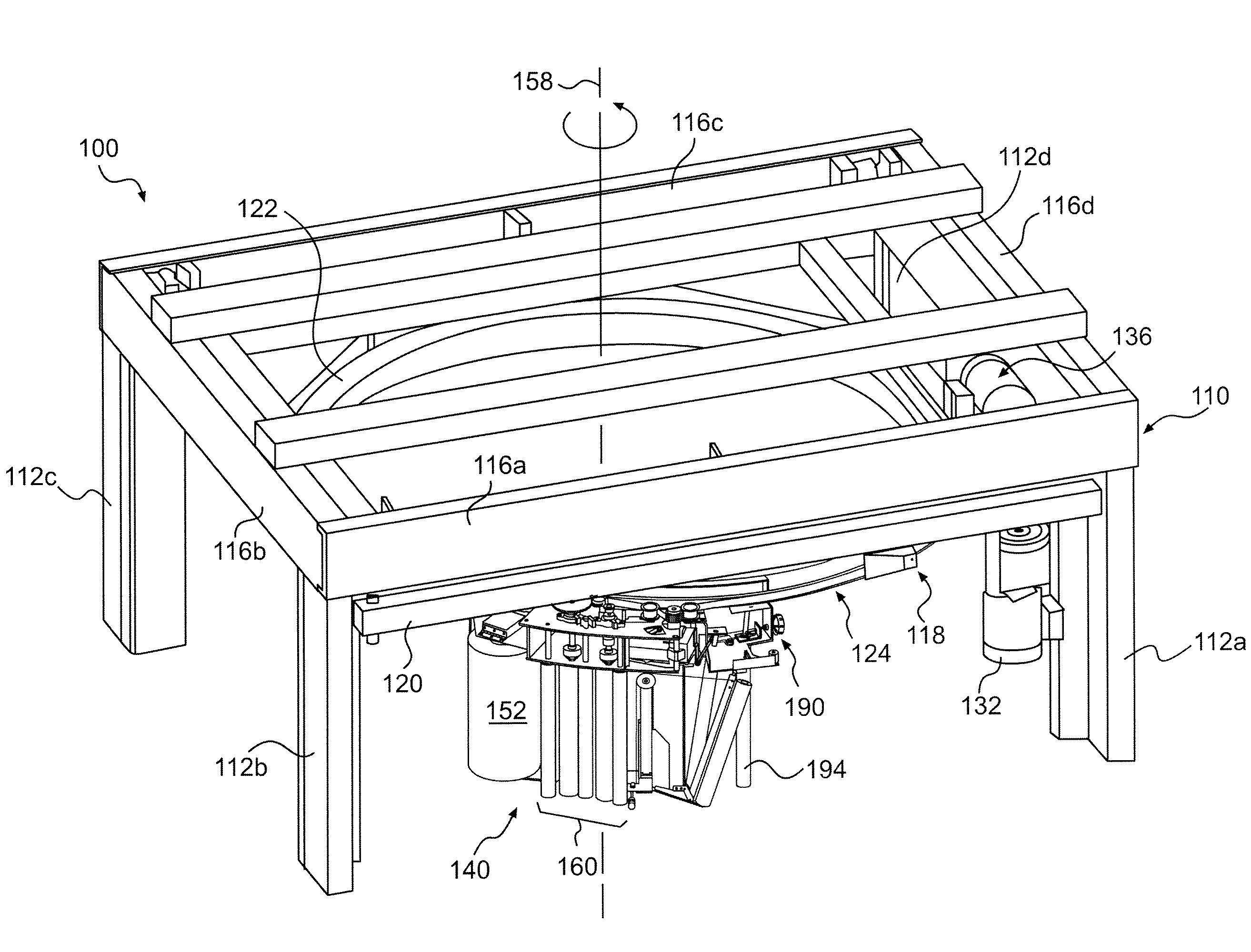

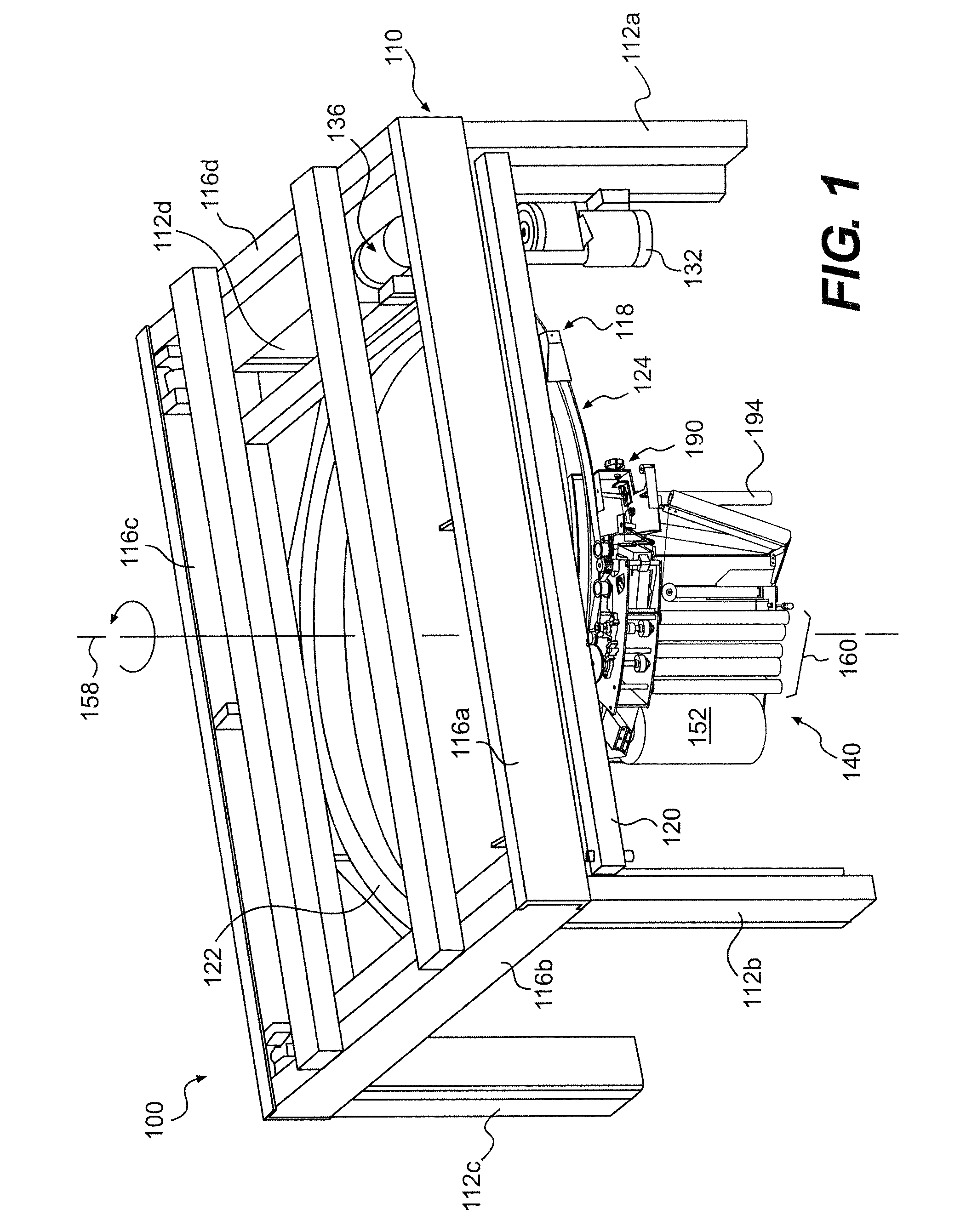

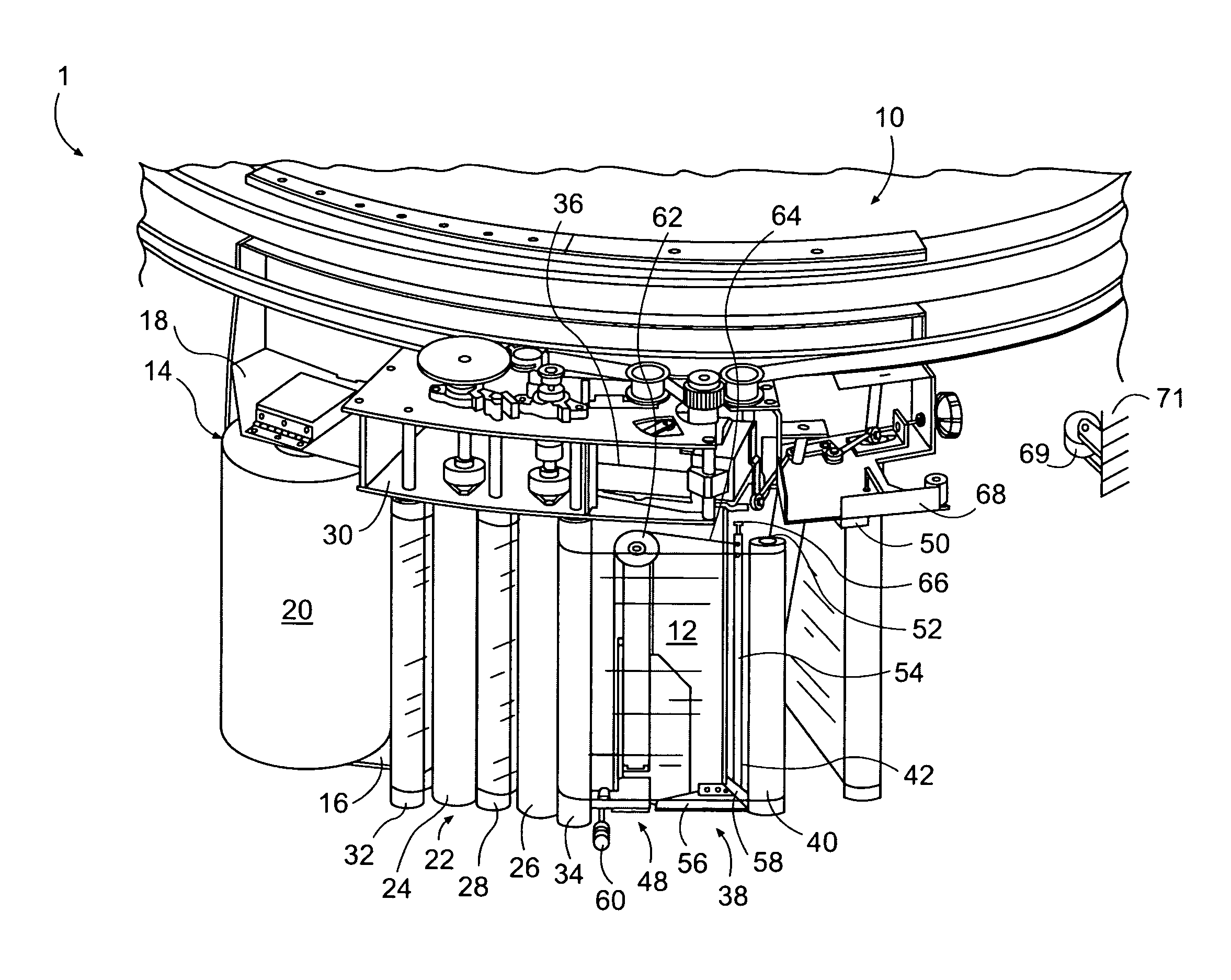

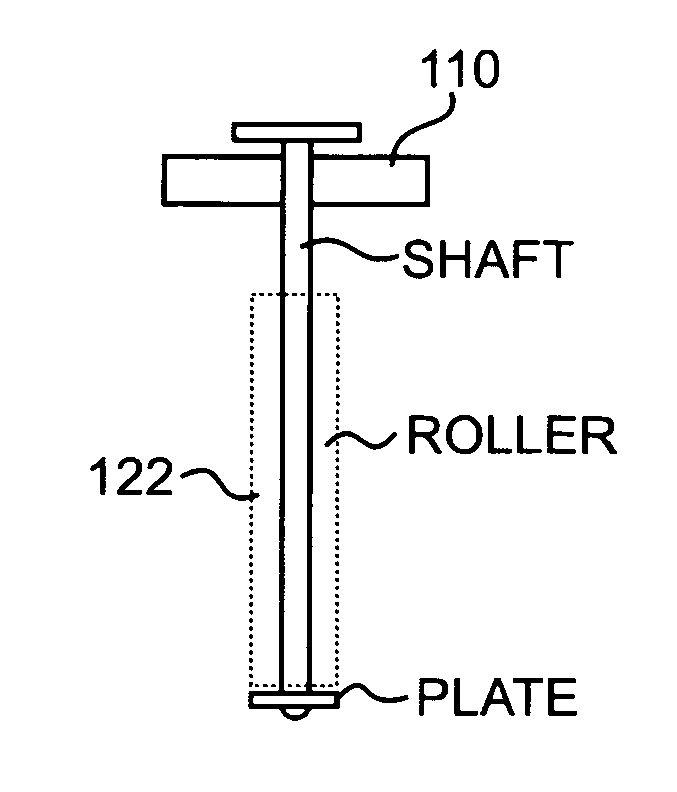

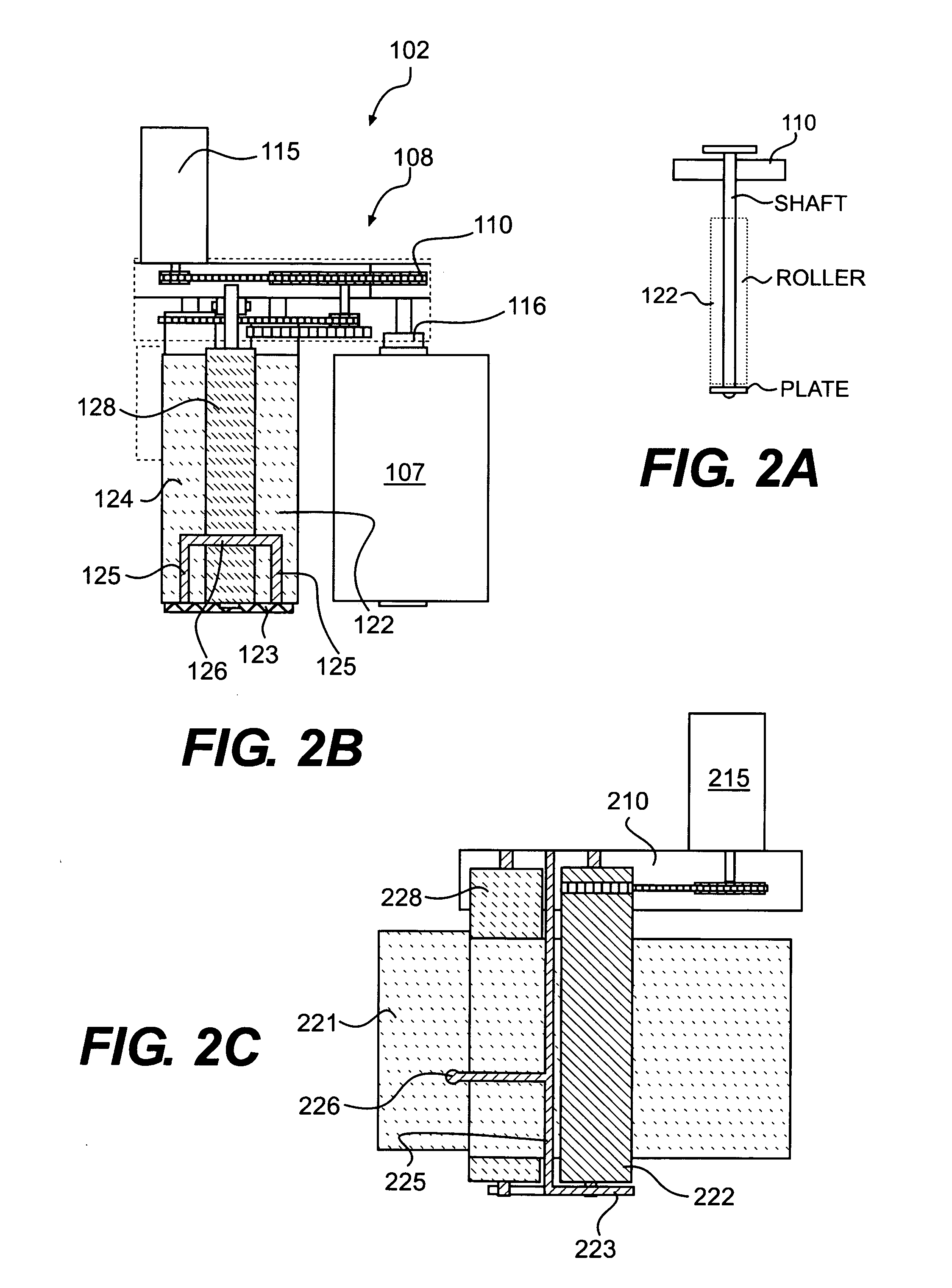

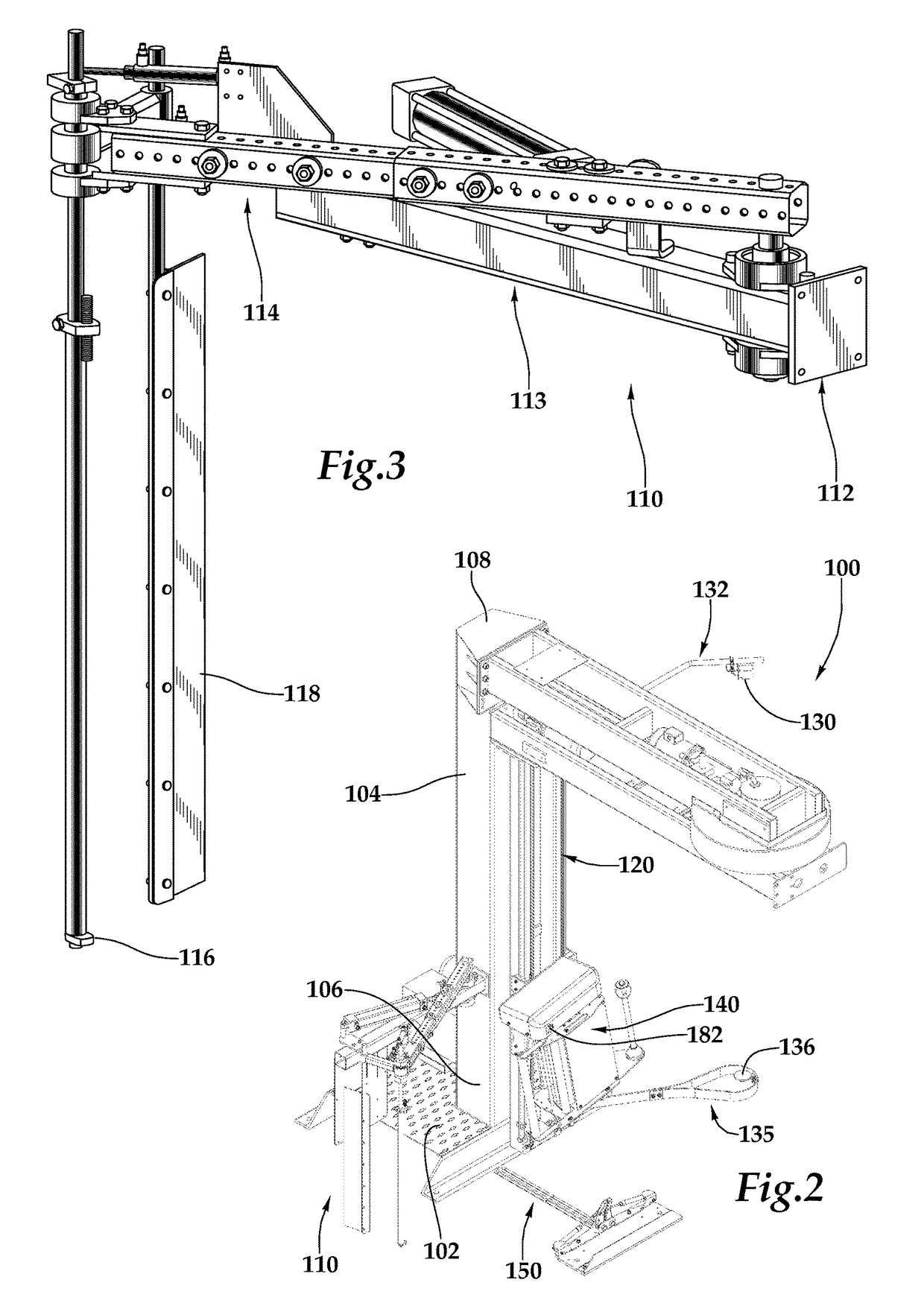

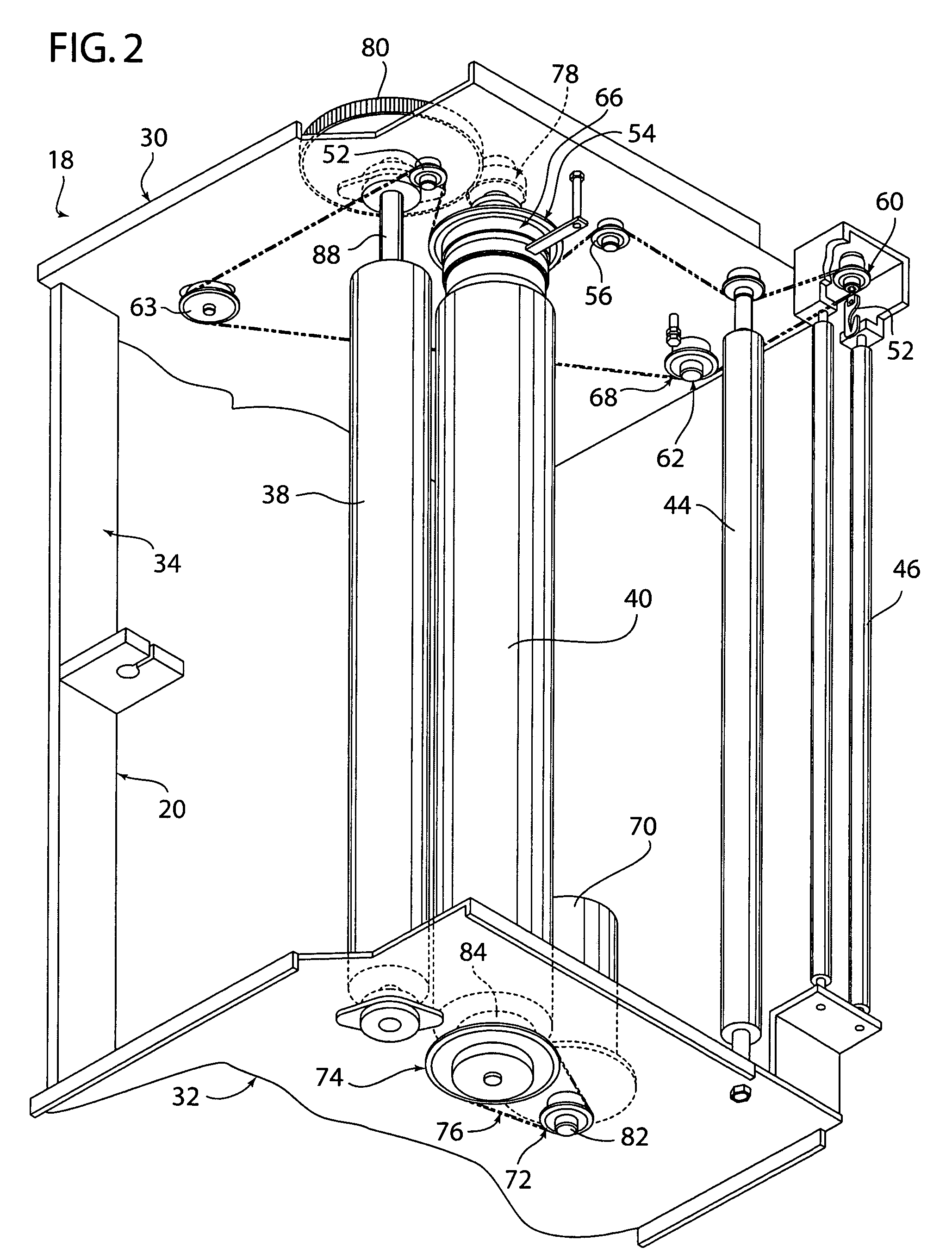

Stretch wrapping apparatus having film dispenser with pre-stretch assembly

A film dispenser for a stretch wrapping apparatus is provided. The film dispenser includes a pre-stretch assembly having a top portion mounted to and extending downwardly from a drive plate of a roll carriage frame. The pre-stretch assembly includes two pre-stretch rollers having first ends connected to the roll carriage frame and second ends connected to one another. The pre-stretch rollers may be coated. The pre-stretch assembly further includes a cantilevered idle roller mounted to the drive plate and positioned between the pre-stretch rollers. A film path is defined by the space between the pre-stretch rollers and the idle roller. The film path is easily accessible via the bottom end of the pre-stretch assembly.

Owner:LANTECH COM

Method and apparatus for dispensing a predetermined fixed amount of pre-stretched film relative to load girth

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt driven by a motor. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt, such that the rotating ring is driven by the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

Film dispenser with pre-stretch assembly

A film dispenser for a stretch wrapping apparatus is provided. The film dispenser includes a pre-stretch assembly having a top portion mounted to and extending downwardly from a drive plate of a roll carriage frame. The pre-stretch assembly includes two pre-stretch rollers having first ends connected to the roll carriage frame and second ends connected to one another. The pre-stretch rollers may be coated. The pre-stretch assembly further includes a cantilevered idle roller mounted to the drive plate and positioned between the pre-stretch rollers. A film path is defined by the space between the pre-stretch rollers and the idle roller. The film path is easily accessible via the bottom end of the pre-stretch assembly.

Owner:LANTECH COM

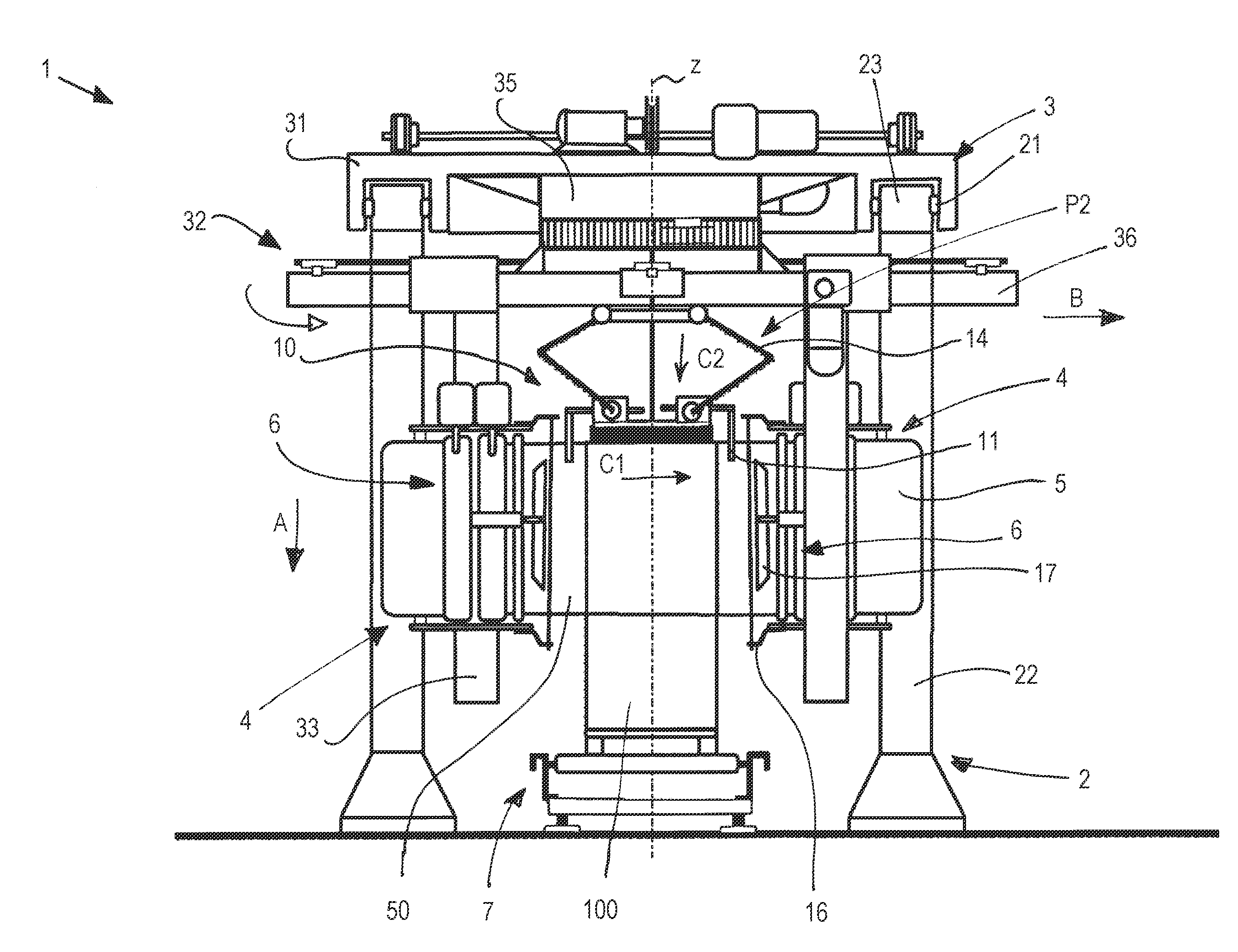

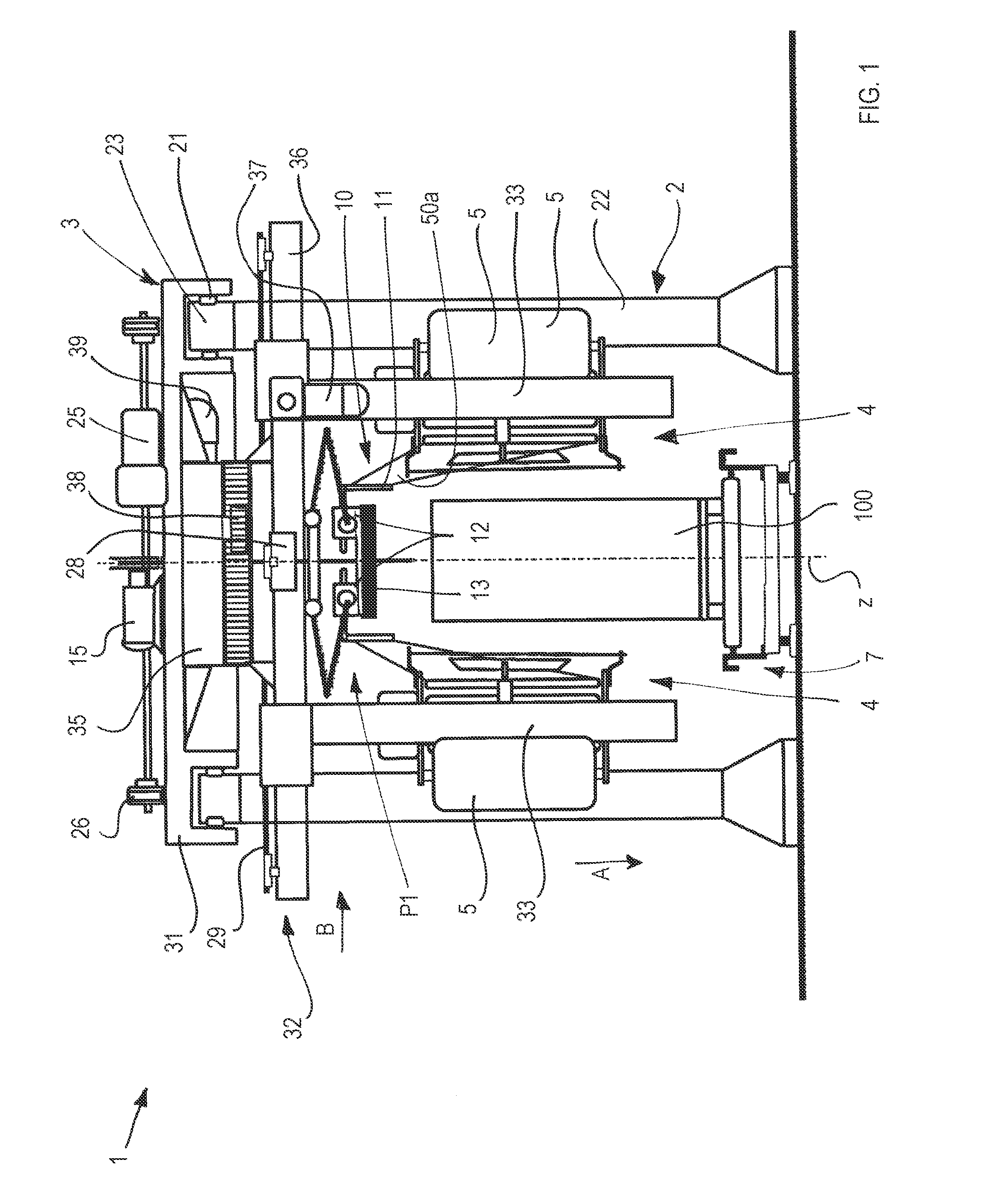

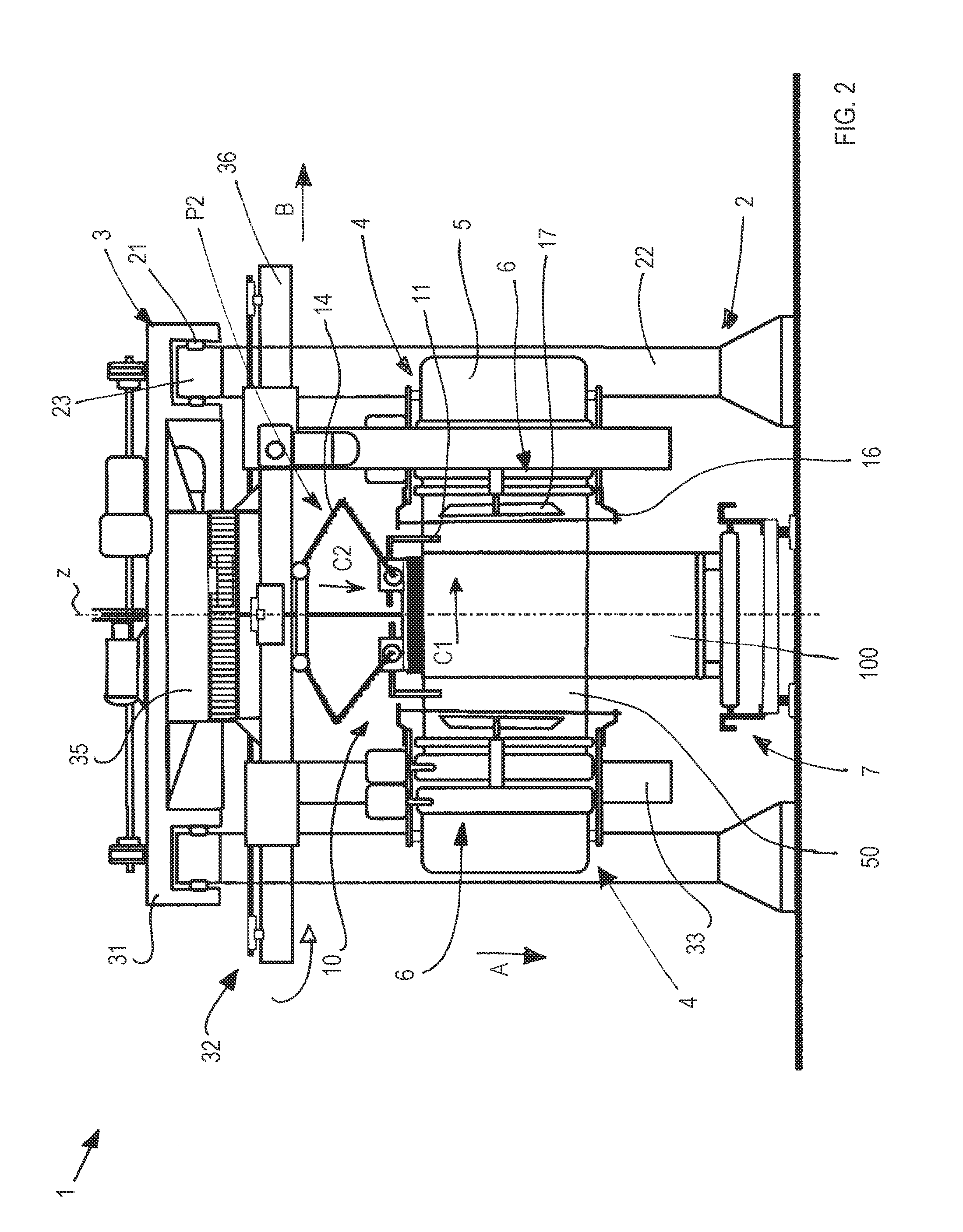

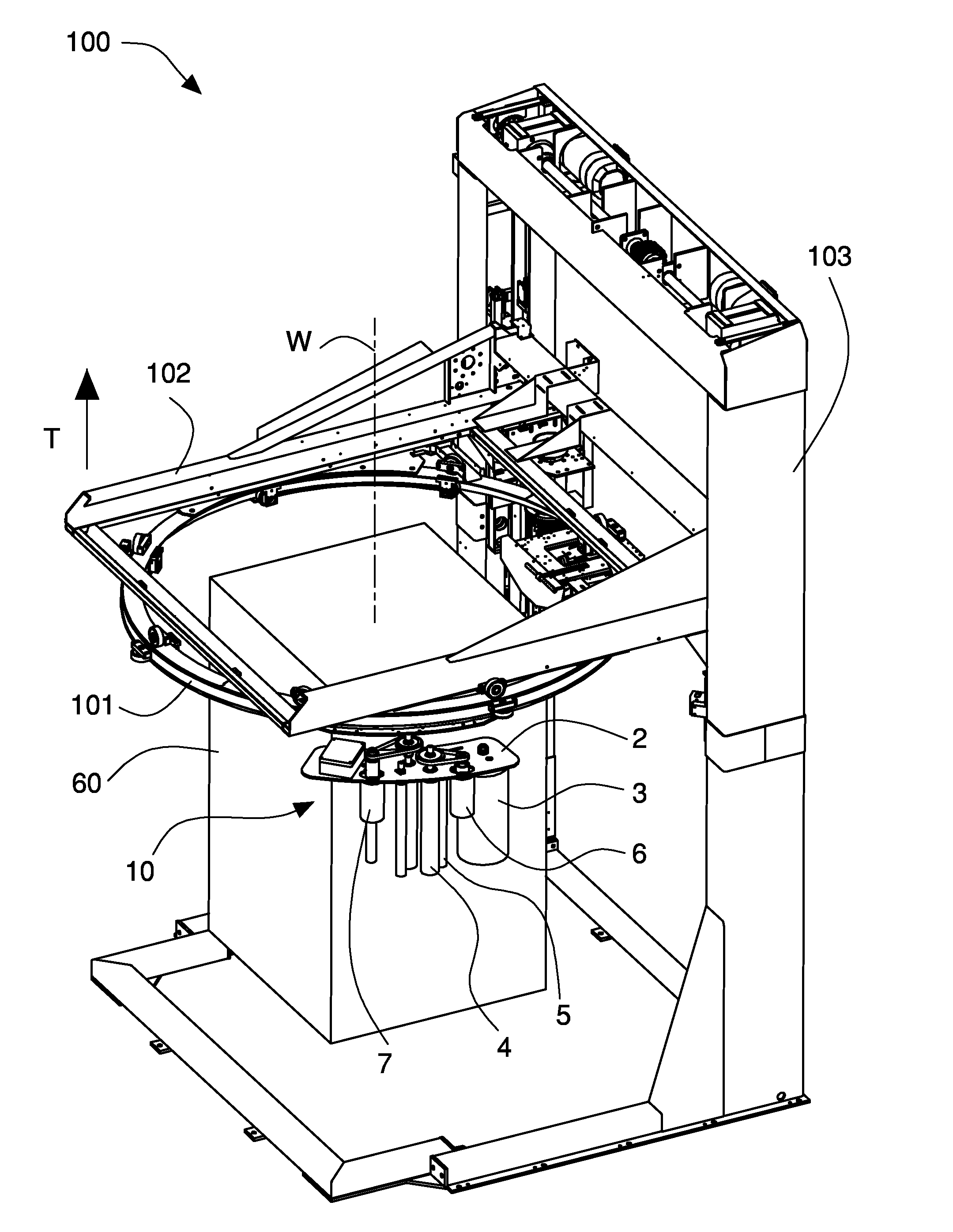

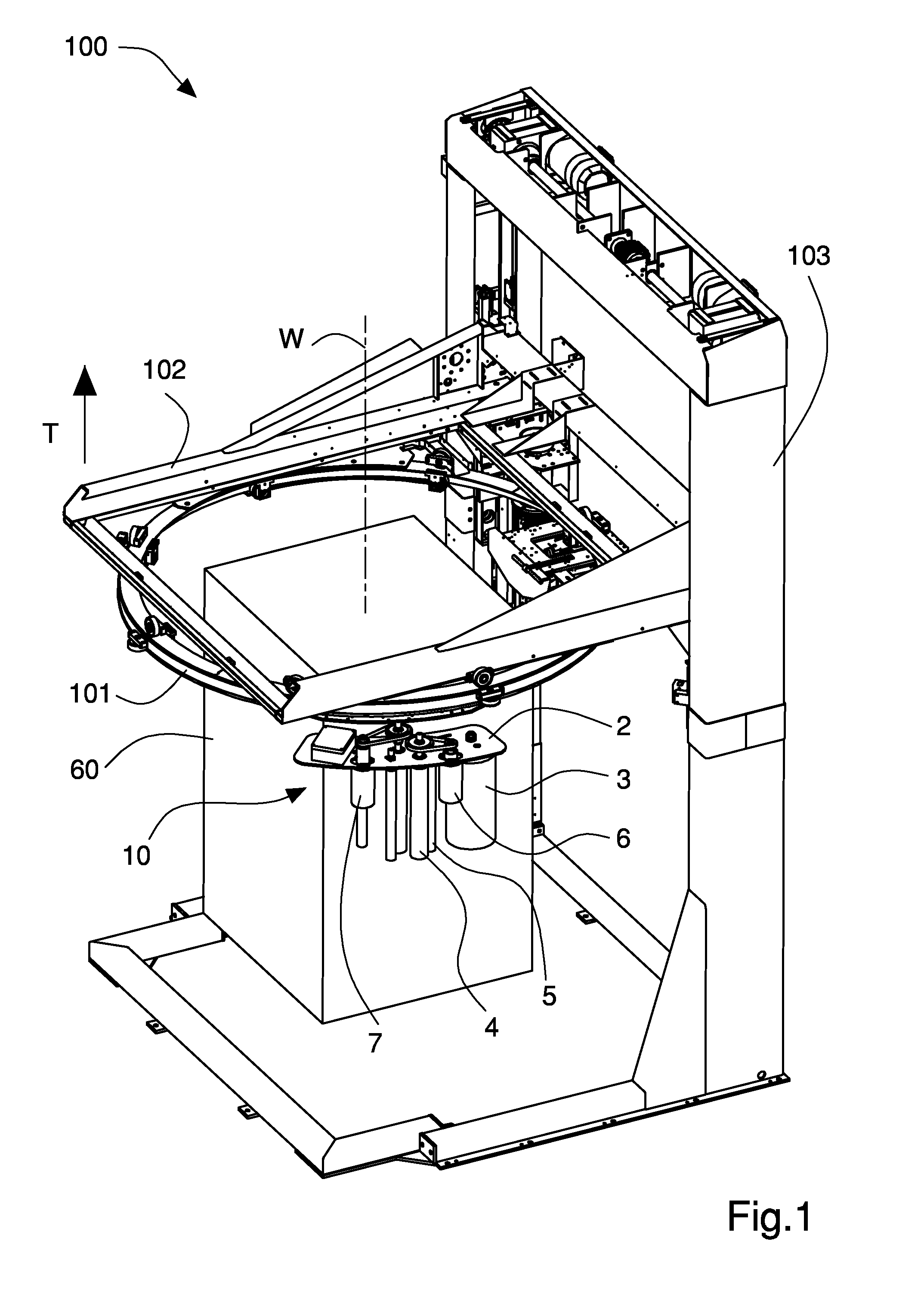

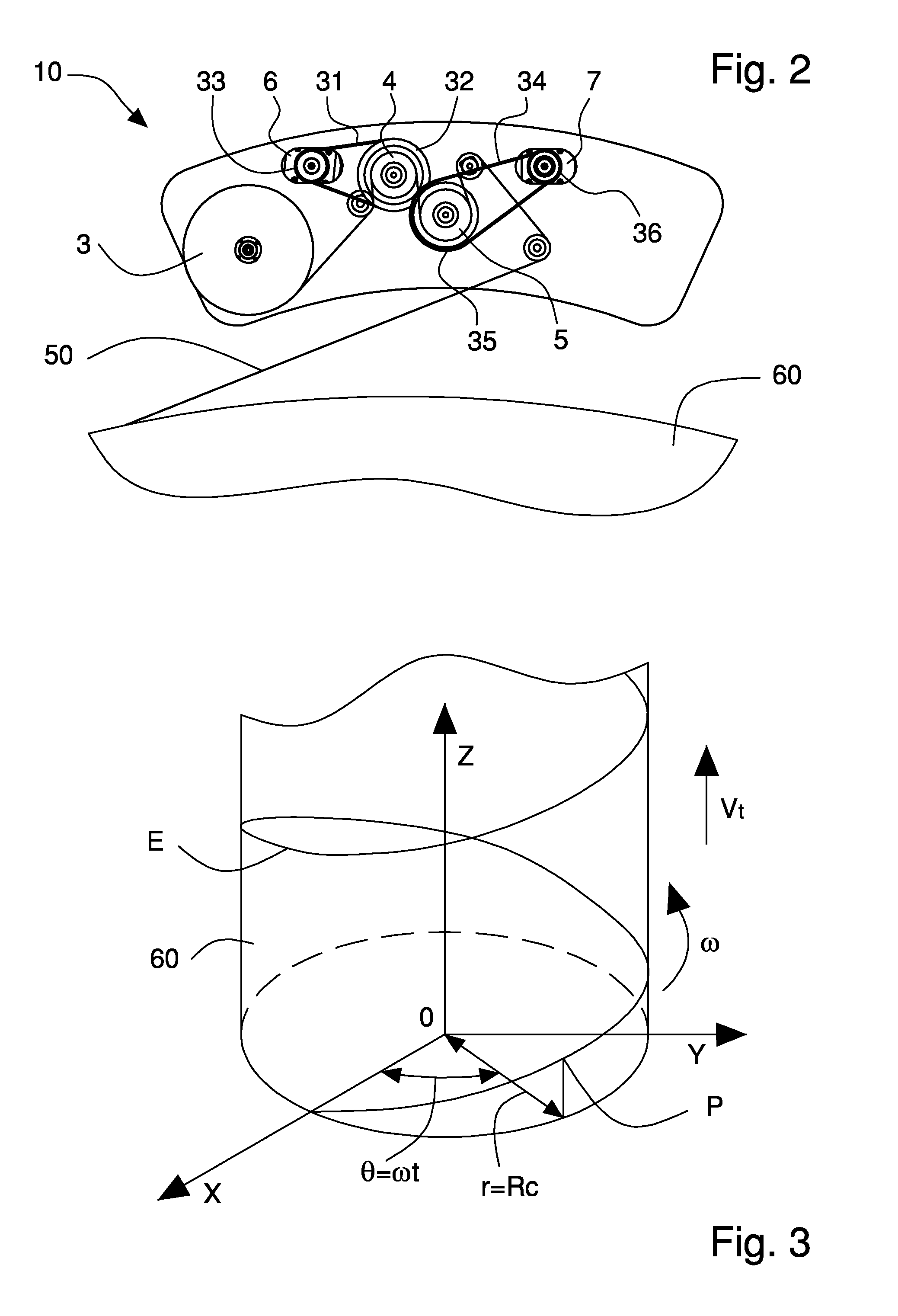

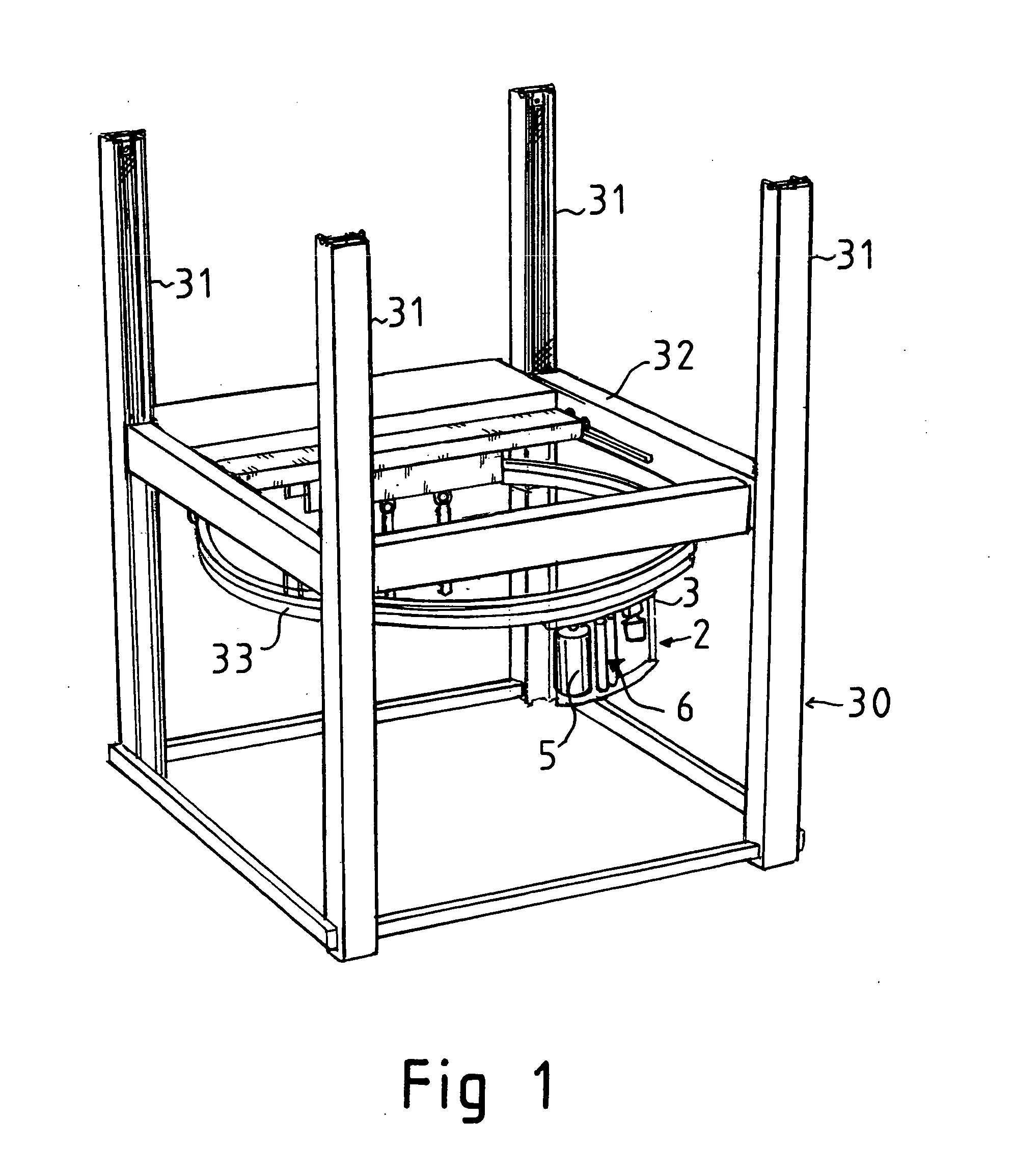

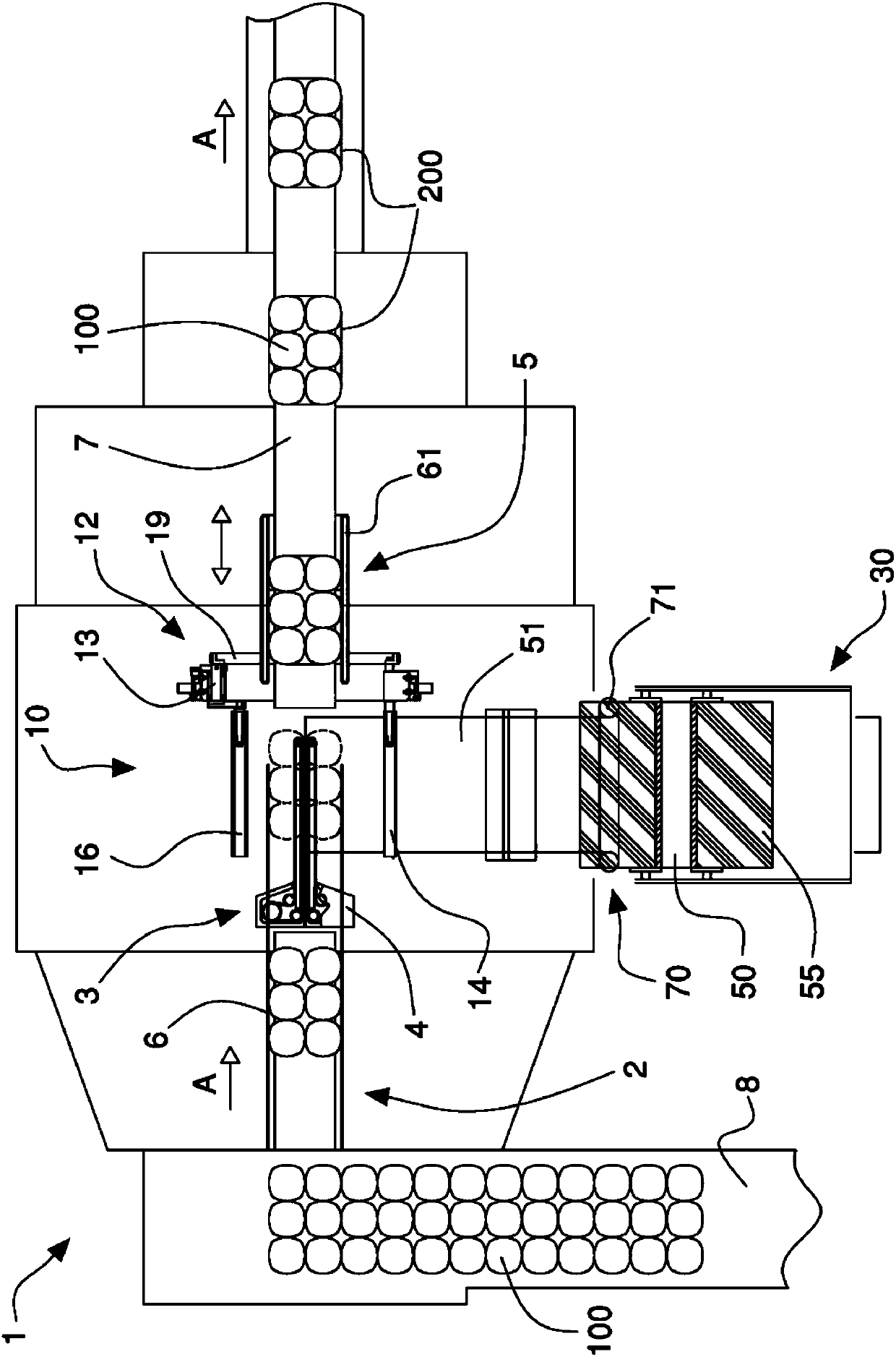

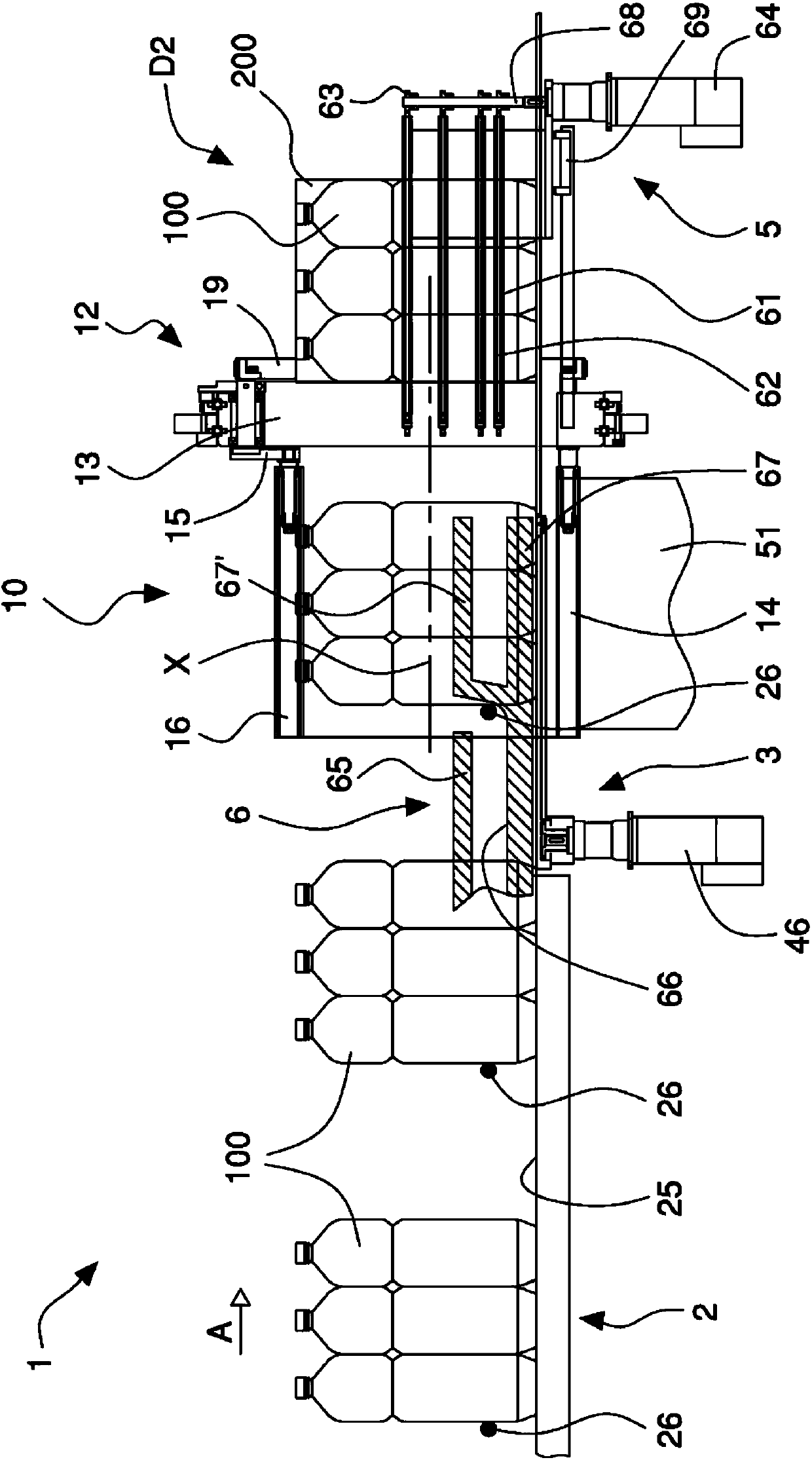

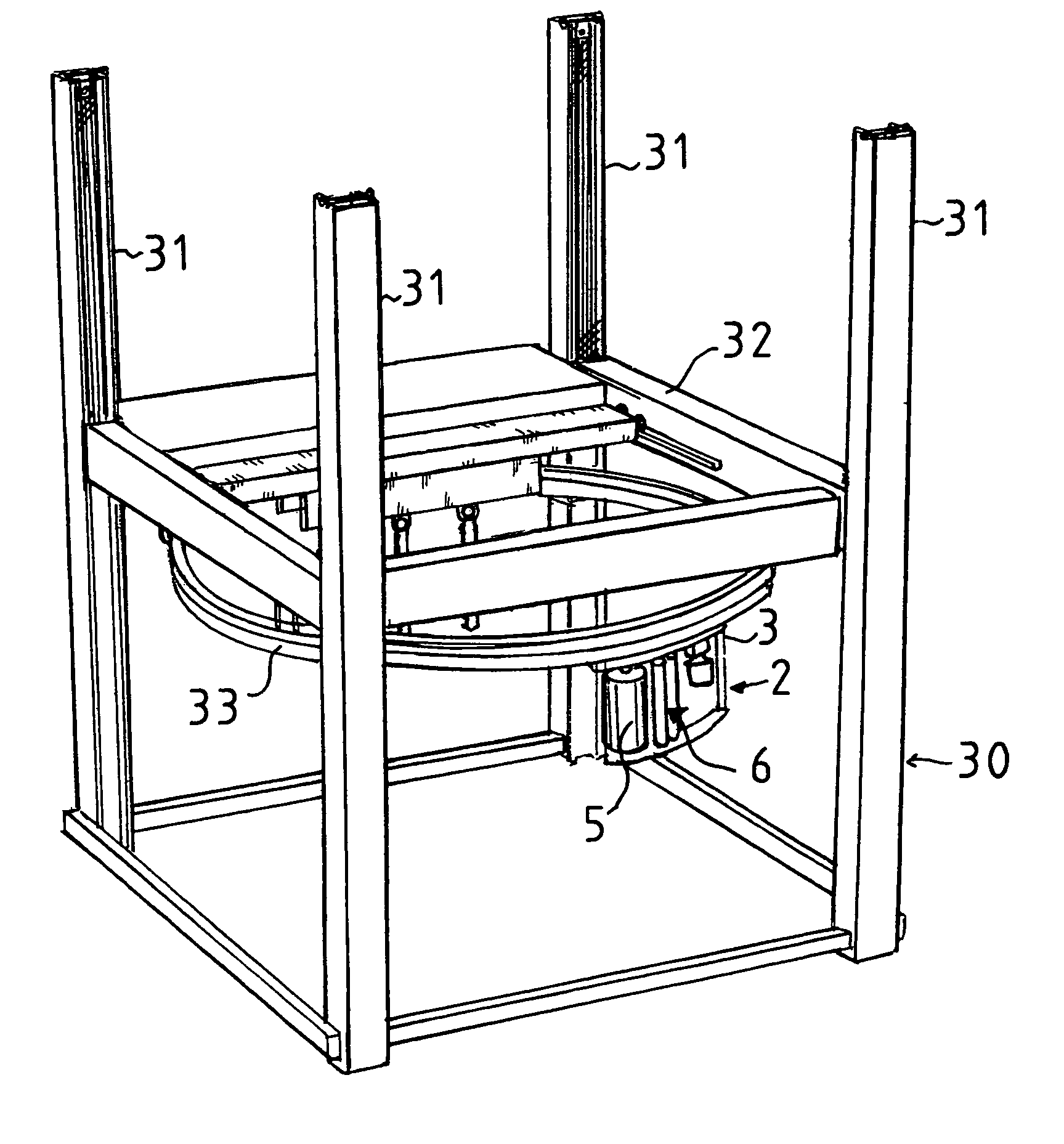

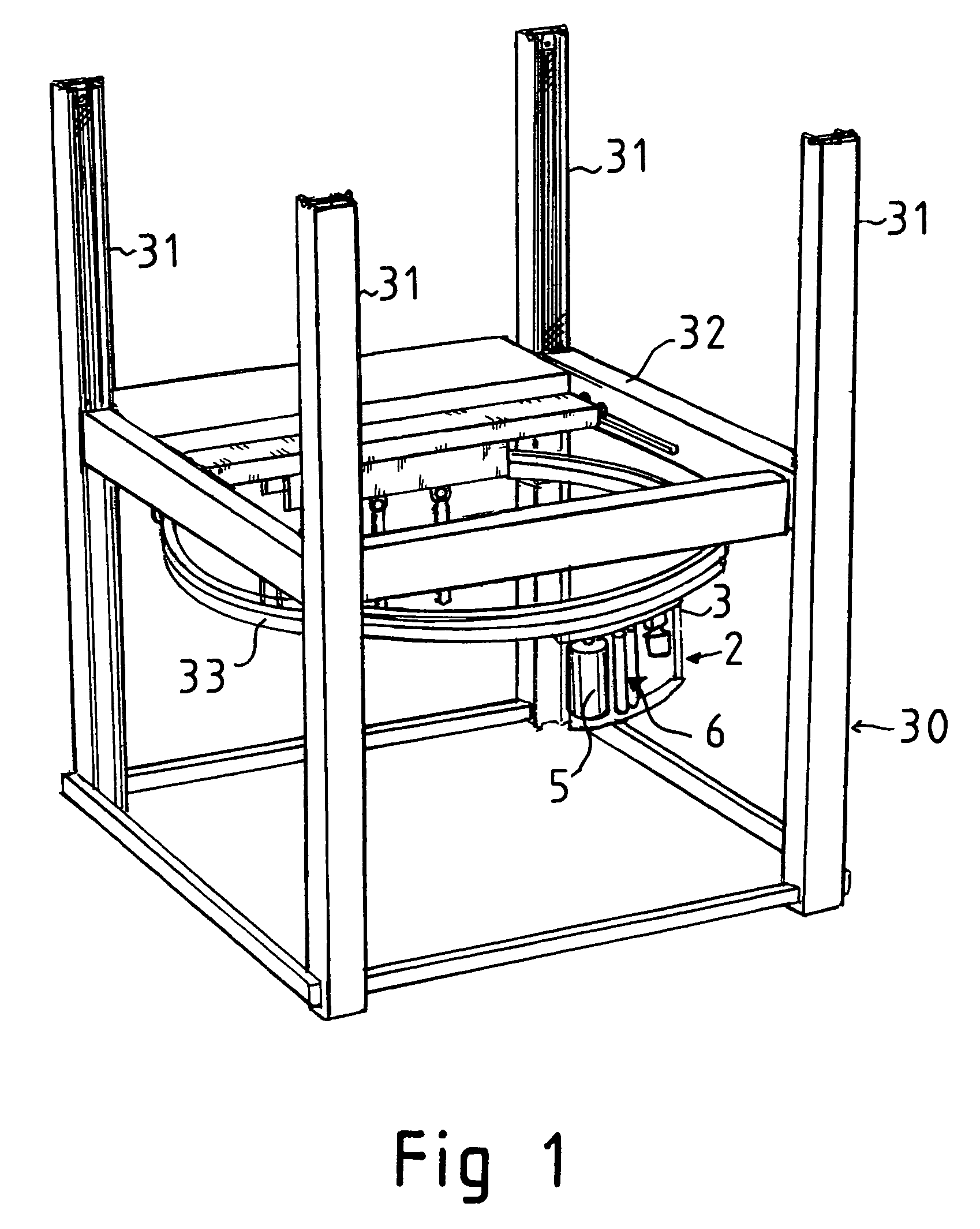

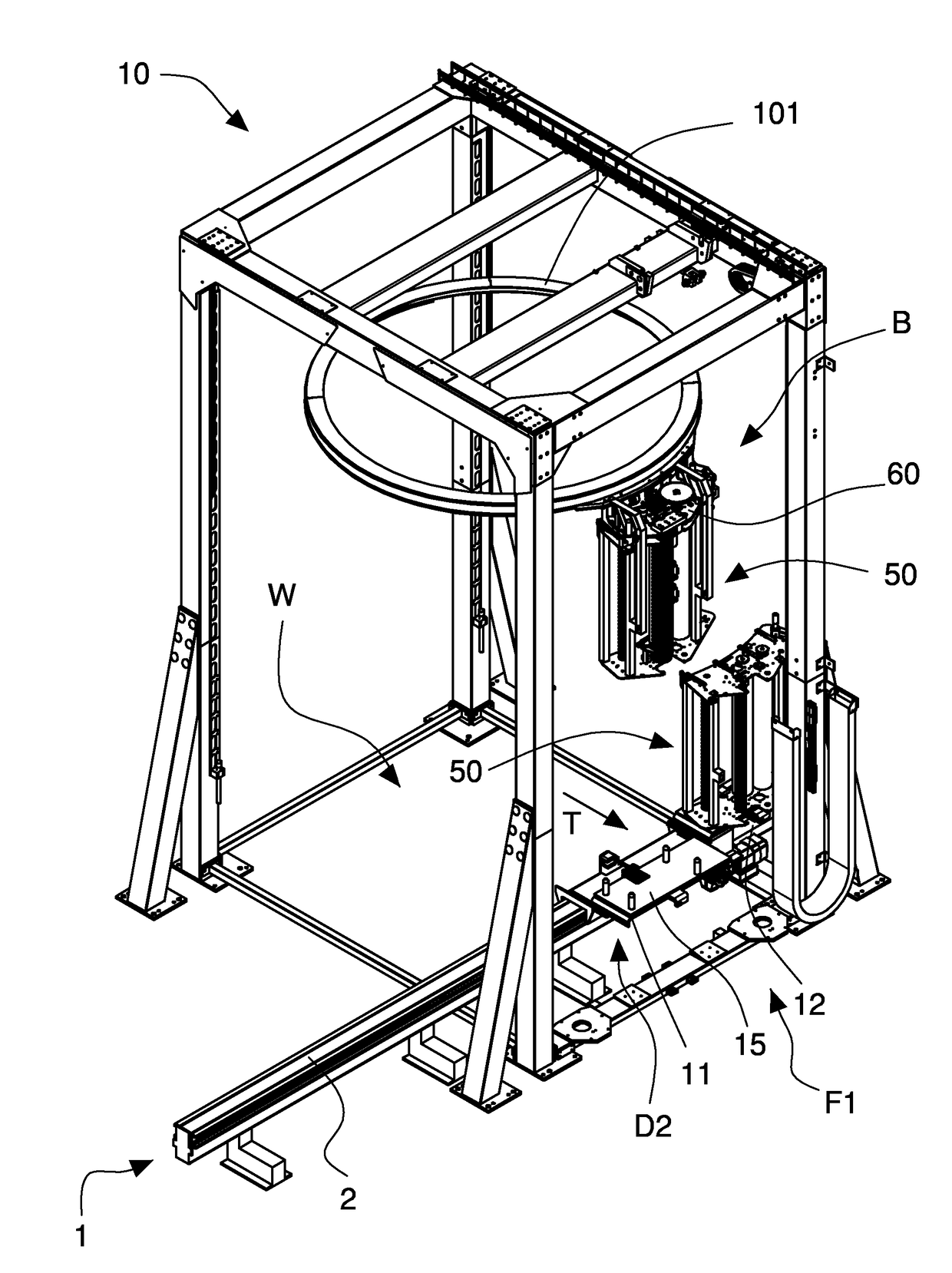

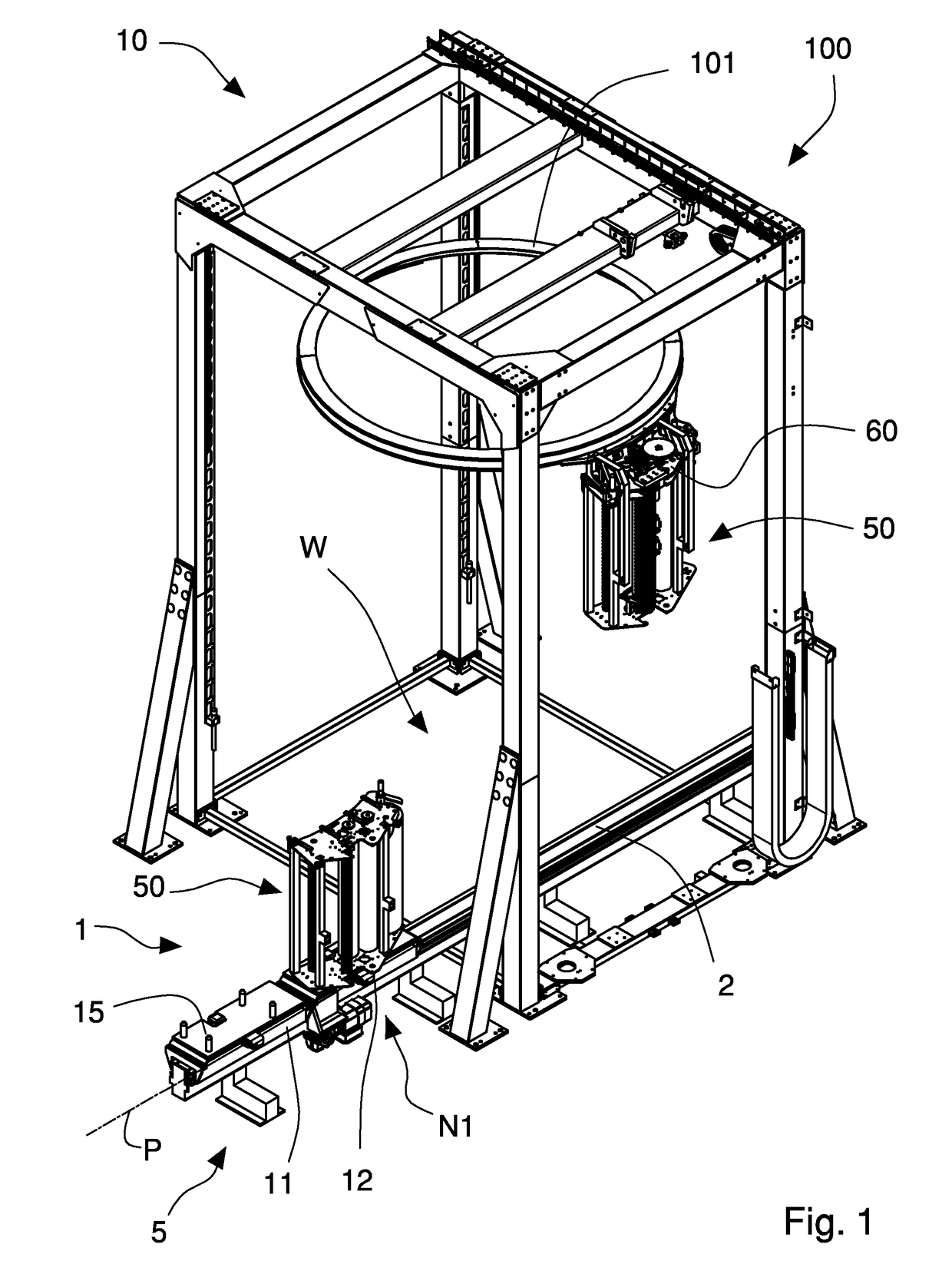

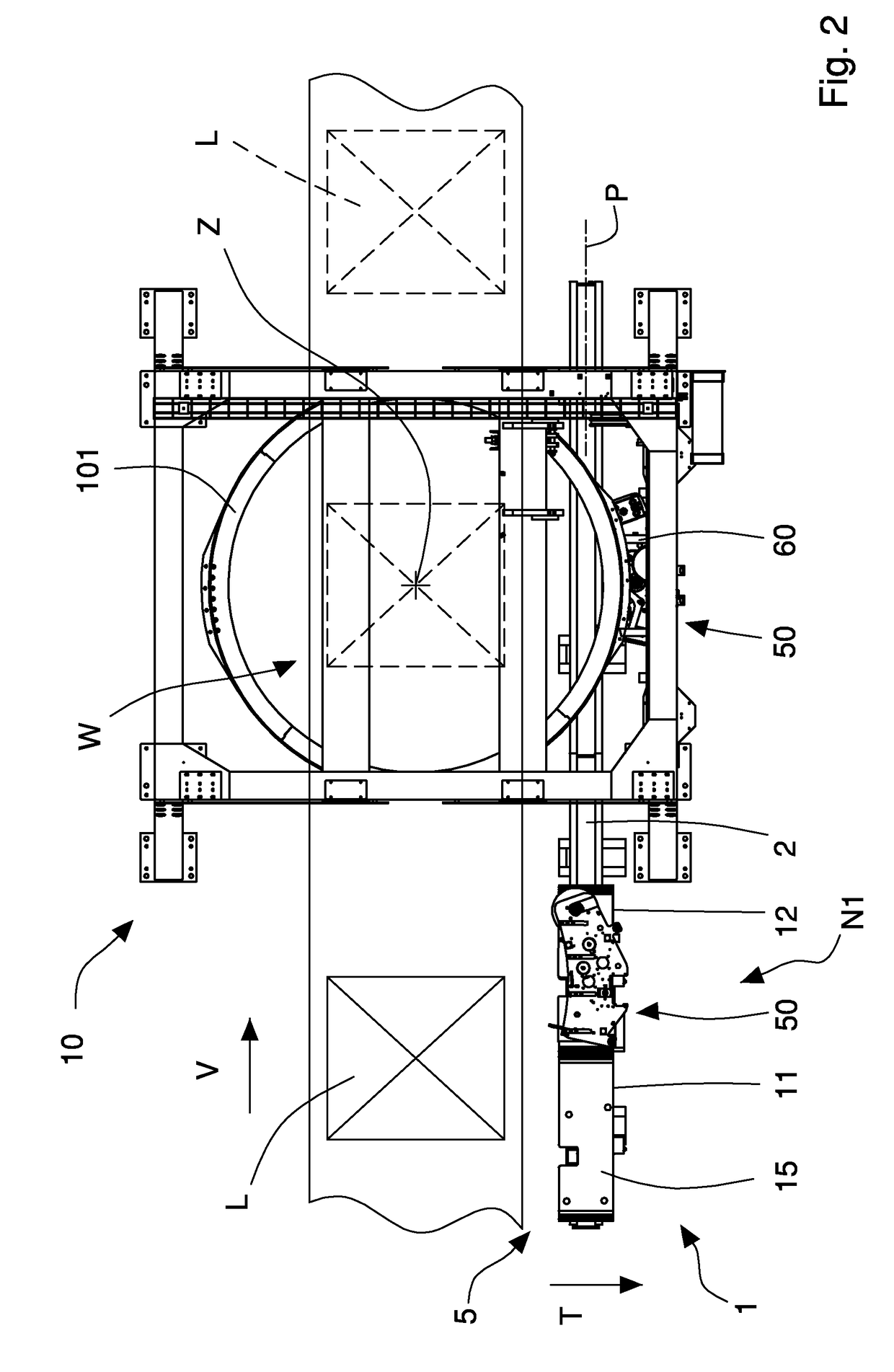

Wrapping machine and method

ActiveUS20140033657A1Improve productivityWrapped rapidly and efficientlyPackaging cigarettePrestretching mechanismEngineeringMechanical engineering

A machine for wrapping a load with a film made of synthetic plastics includes a first frame suitable for supporting second frame that rotatably supports around, and slidably parallel to, a wrapping axis at least one wrapping unit including a reel of the film and a roller assembly arranged for unwinding and prestretching the film. The second frame is slidably mounted on the first frame and is movable along an advancing direction that is transverse, and in particular orthogonal, to the wrapping axis. A conveyor is provided for moving the load along the advancing direction. The conveyor and the second frame are movable in a mutually coordinated manner to wrap the load with the film also while the load is moved along the advancing direction.

Owner:AETNA GROUP

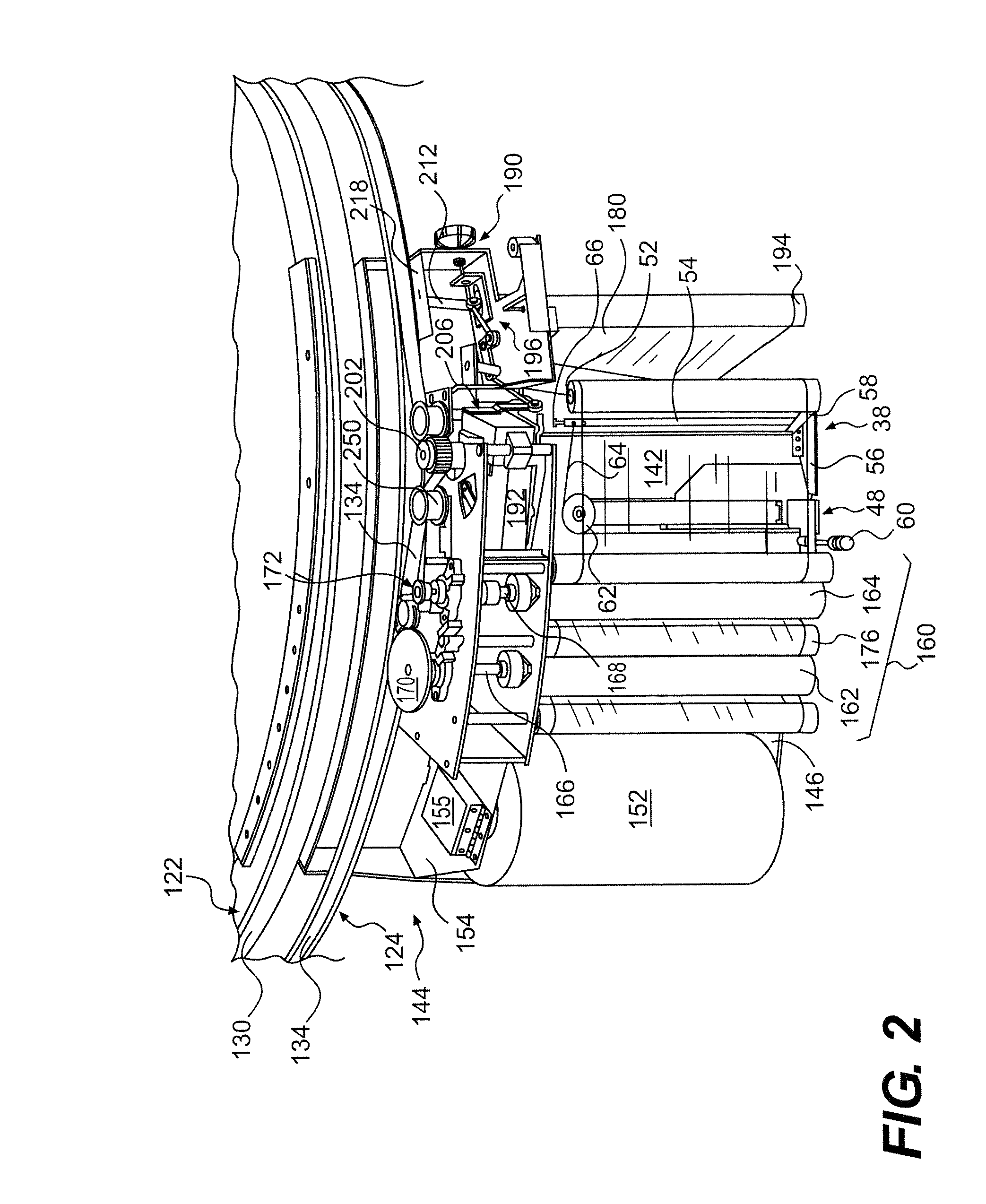

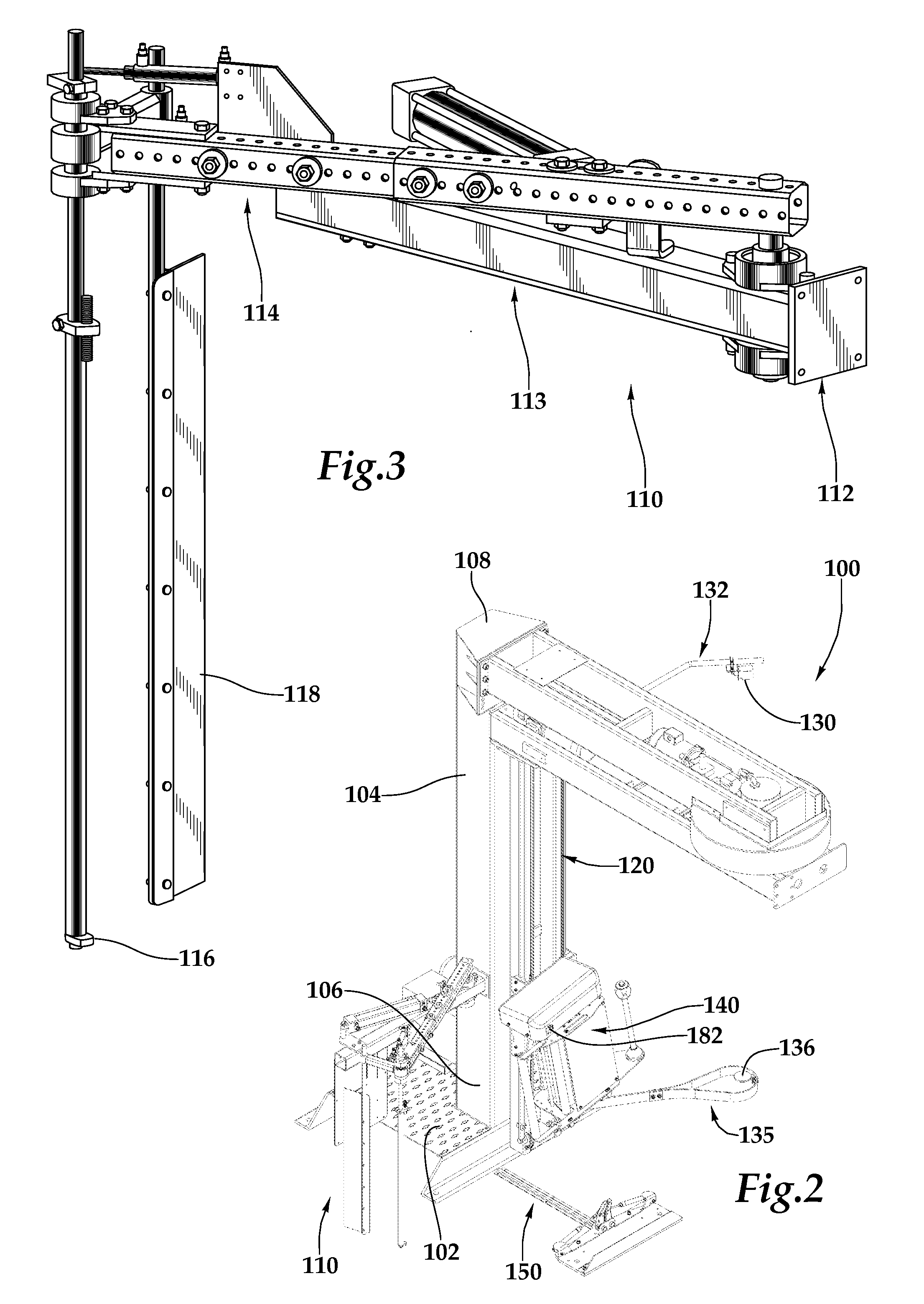

Stretch head for facilitating wrapping palletized loads

InactiveUS6848240B2Effective adhesionFixed securityWrappers shrinkageWrapping material feeding apparatusHigh elevationEngineering

A stretch head for facilitating the wrapping of palletized loads within packaging or wrapping film comprises a vertical downright, and a carriage assembly vertically movable along the vertical downright. A base plate is mounted upon the carriage assembly and is inclined with respect to a horizontal plane so as to have a first end thereof disposed at a higher elevation than a second opposite end thereof. A supply roll of wrapping or packaging film is rotatably mounted upon the first higher end of the base plate, and a pair of tension rollers are mounted upon a substantially central portion of the base plate. A strain gauge roller is also mounted upon the base plate for receiving the wrapping film exiting from the tension rollers, a first idler roller is mounted upon the base plate for receiving the wrapping film from the strain gauge roller, and a second idler roller is mounted upon the second opposite end of the base plate for receiving the wrapping film from the first idler roller. Since the second idler roller is mounted upon the lowest end portion of the base plate, in view of the inclined disposition thereof, the second idler roller is capable of positioning the wrapping film at the lowest elevation whereby the wrapping film can be wrapped around the lowermost regions of the palletized load. The second idler roller also comprises a rubberized sleeve member for preventing movement of the wrapping film in an axial direction along the external periphery of the second idler roller so as to ensure proper positioning and orientation of the wrapping film with respect to the palletized load.

Owner:SIGNODE IND GRP

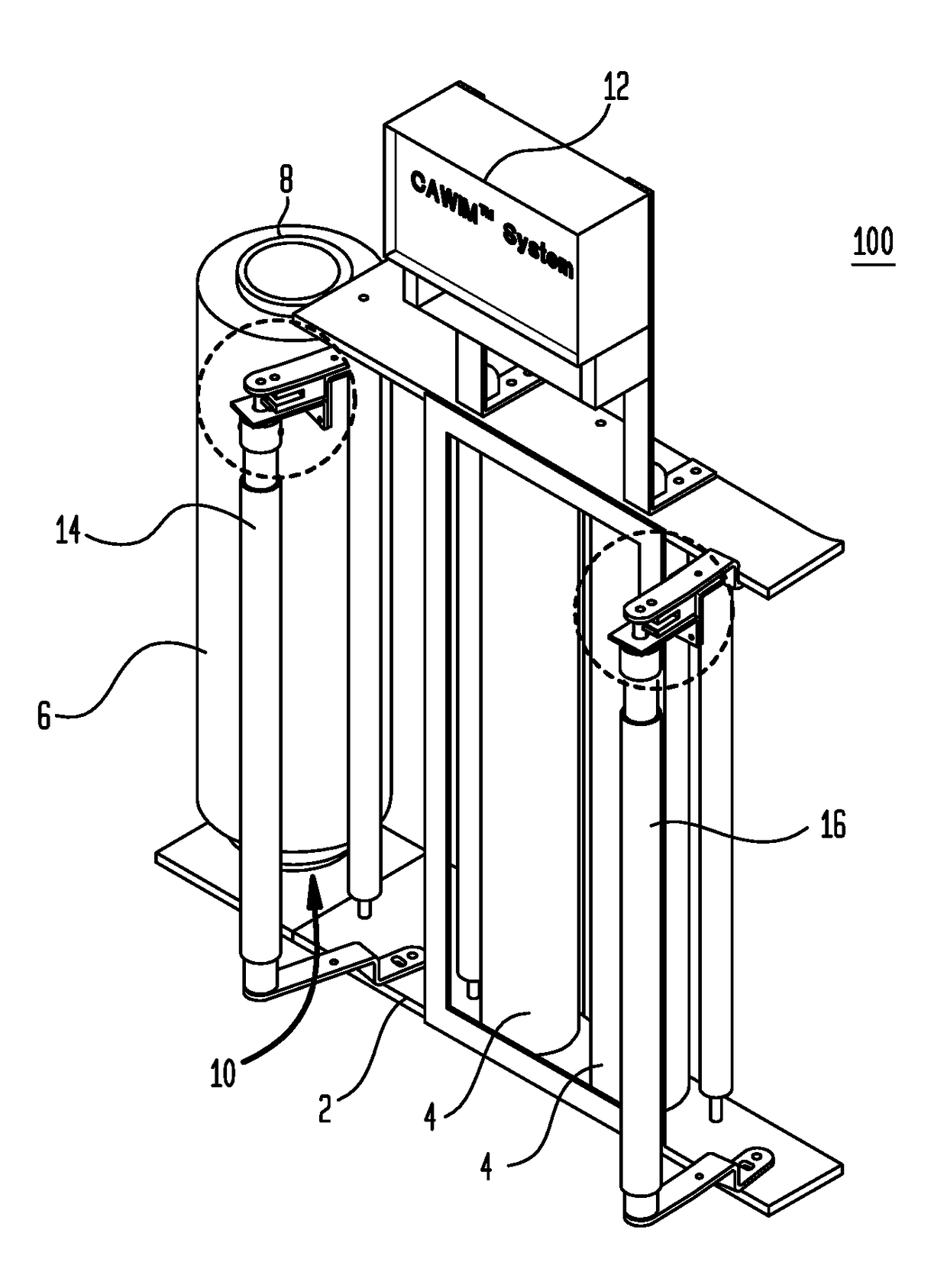

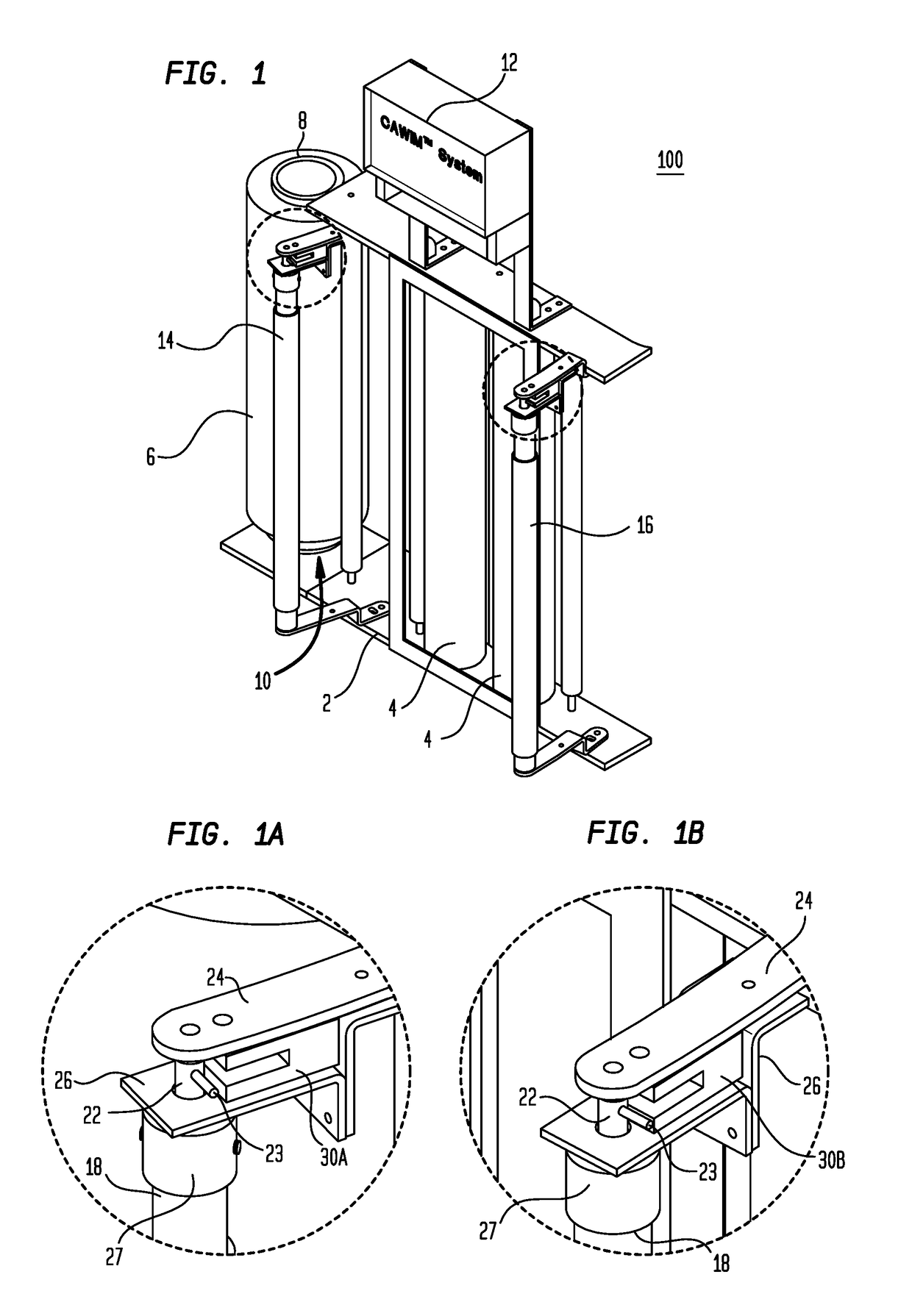

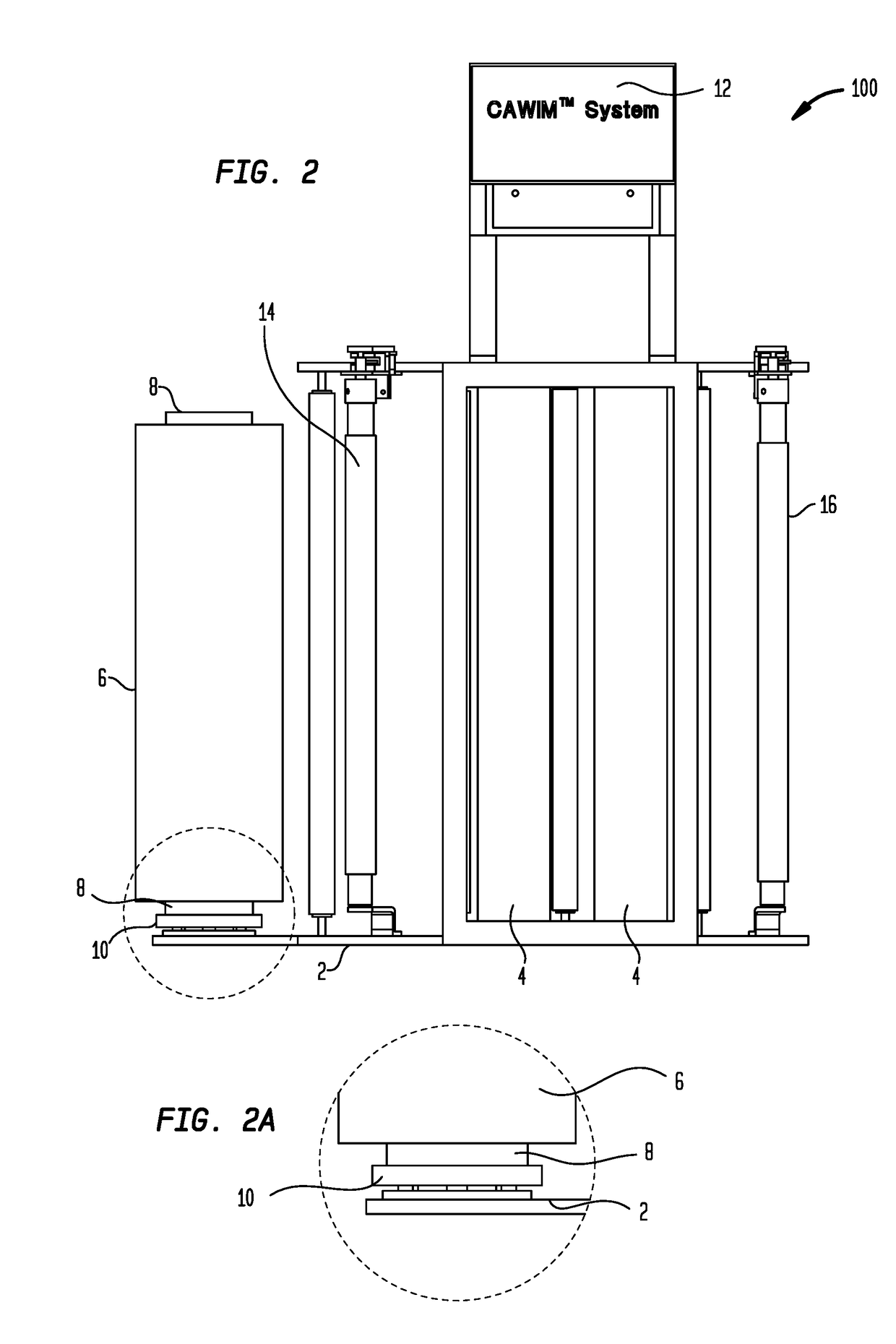

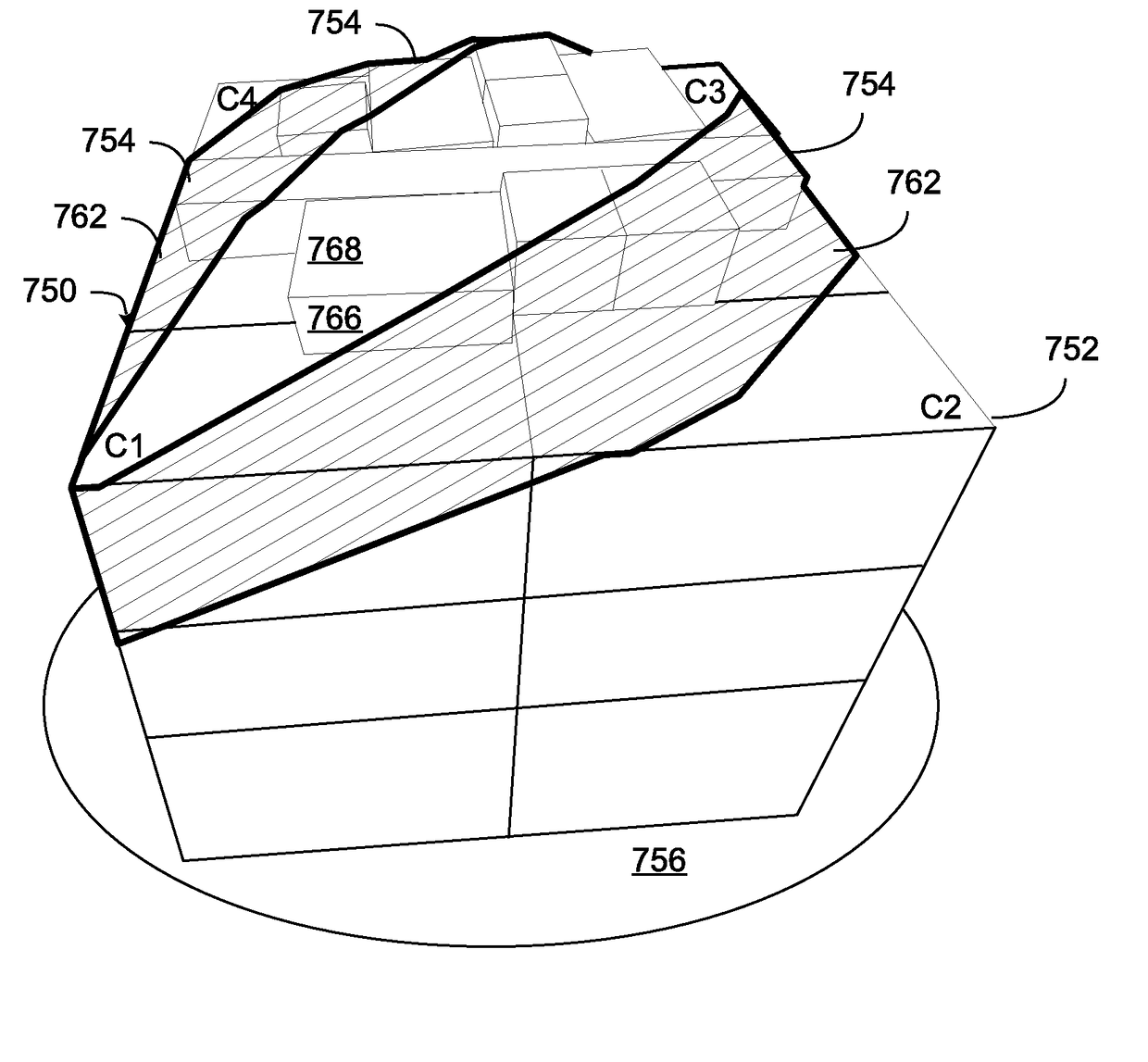

Stretch Wrapping Machine with Automated Determination of Load Stability by Subjecting a Load to a Disturbance

A method, apparatus and program product may determine load stability for a load to be wrapped based upon sensing the response or reaction of the load to a disturbance applied to the load, e.g., through intentionally moving, shaking, tilting, pushing, impacting or otherwise applying an input force to the load and sensing the response using one or more sensors. The sensed response may then be used to determine a load stability parameter that may be used in the control of a load wrapping apparatus when wrapping the load.

Owner:LANTECH COM

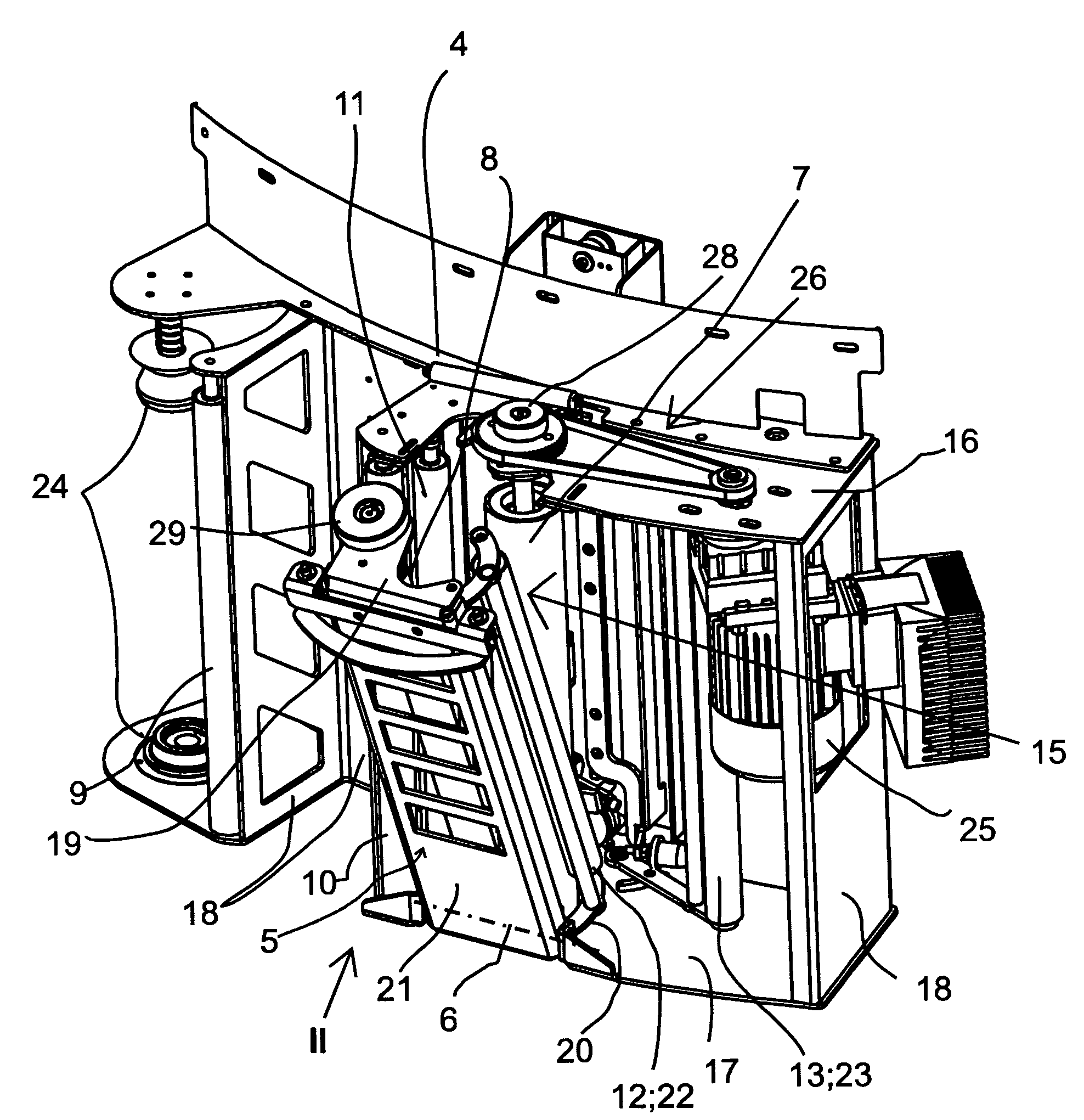

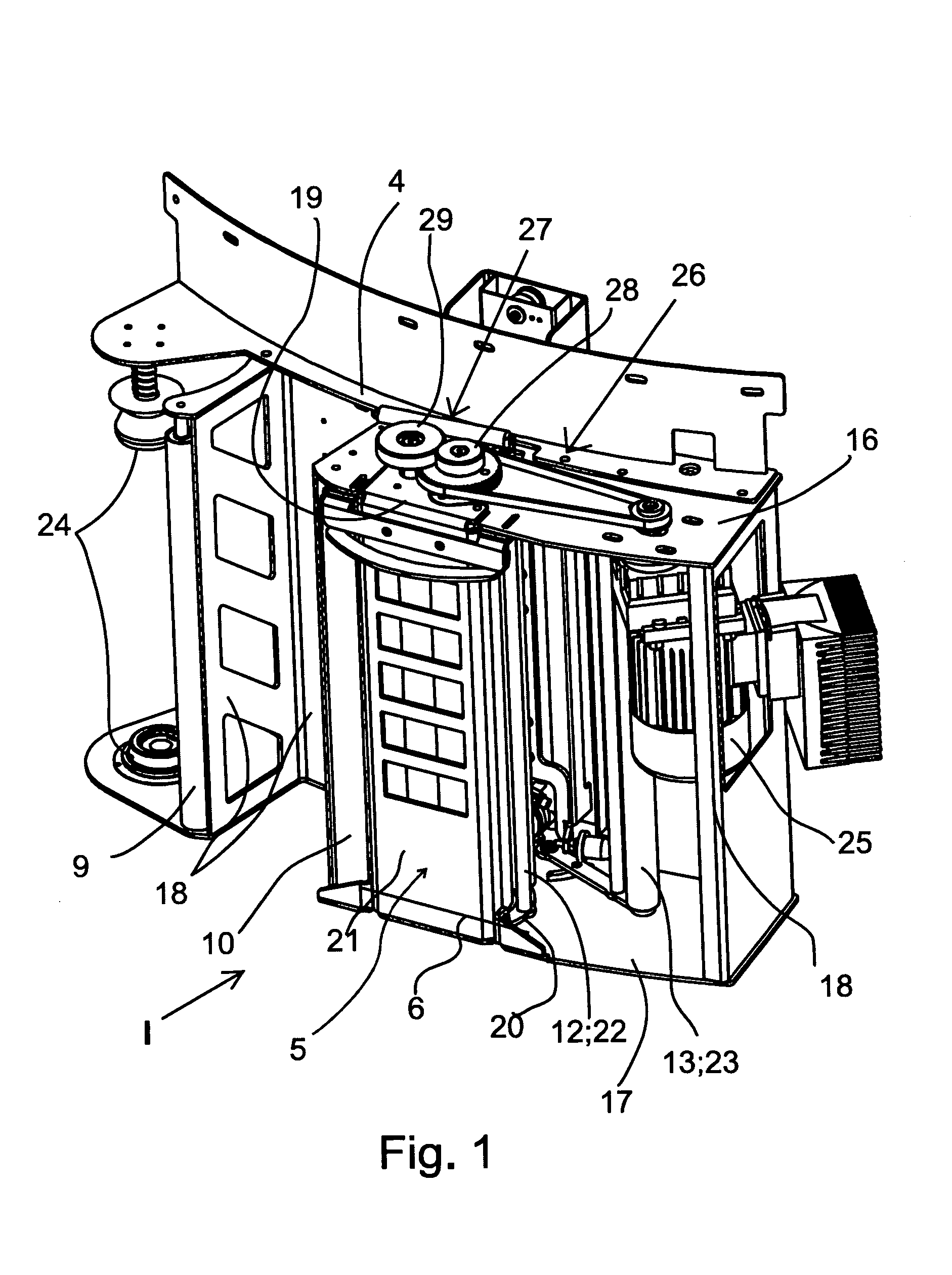

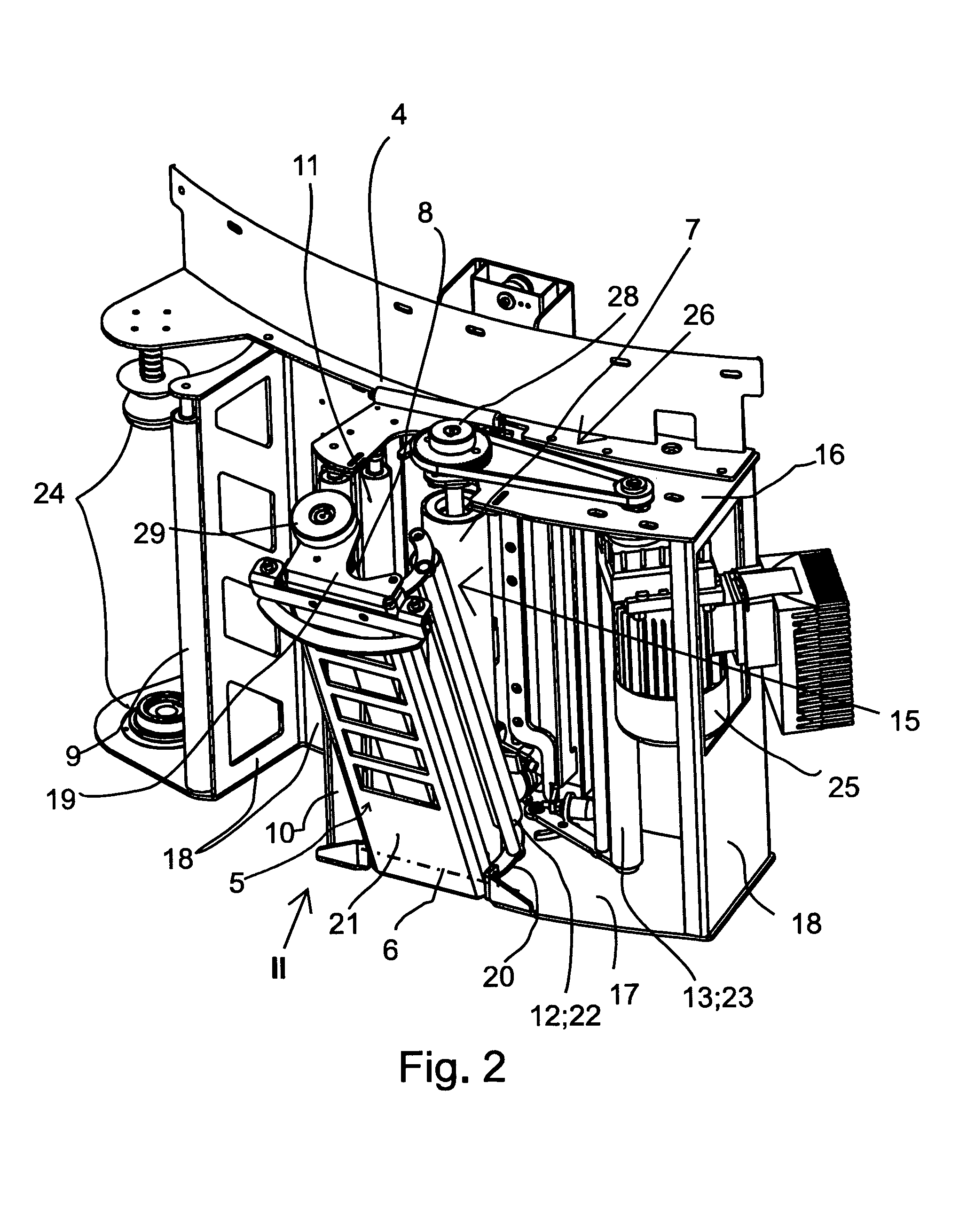

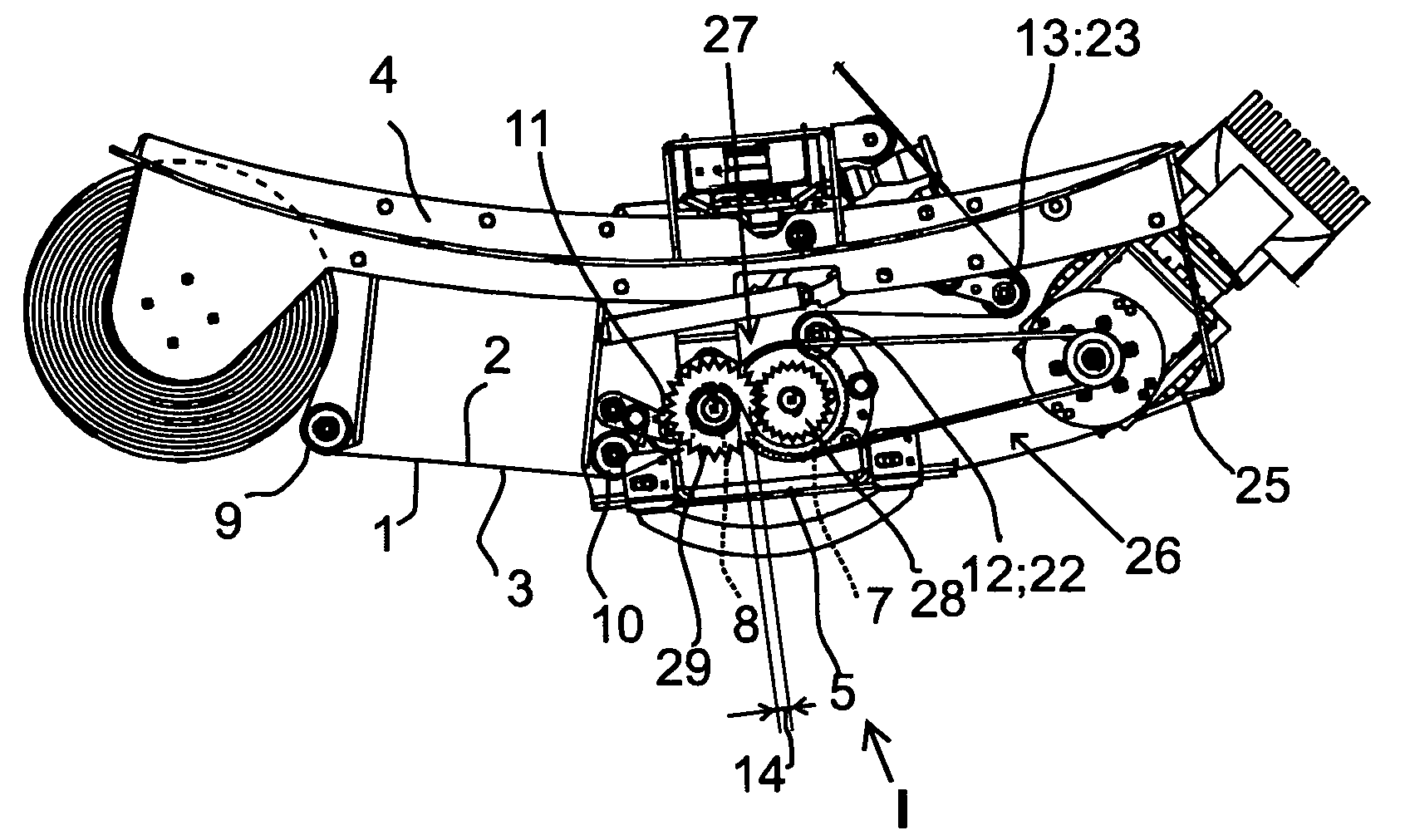

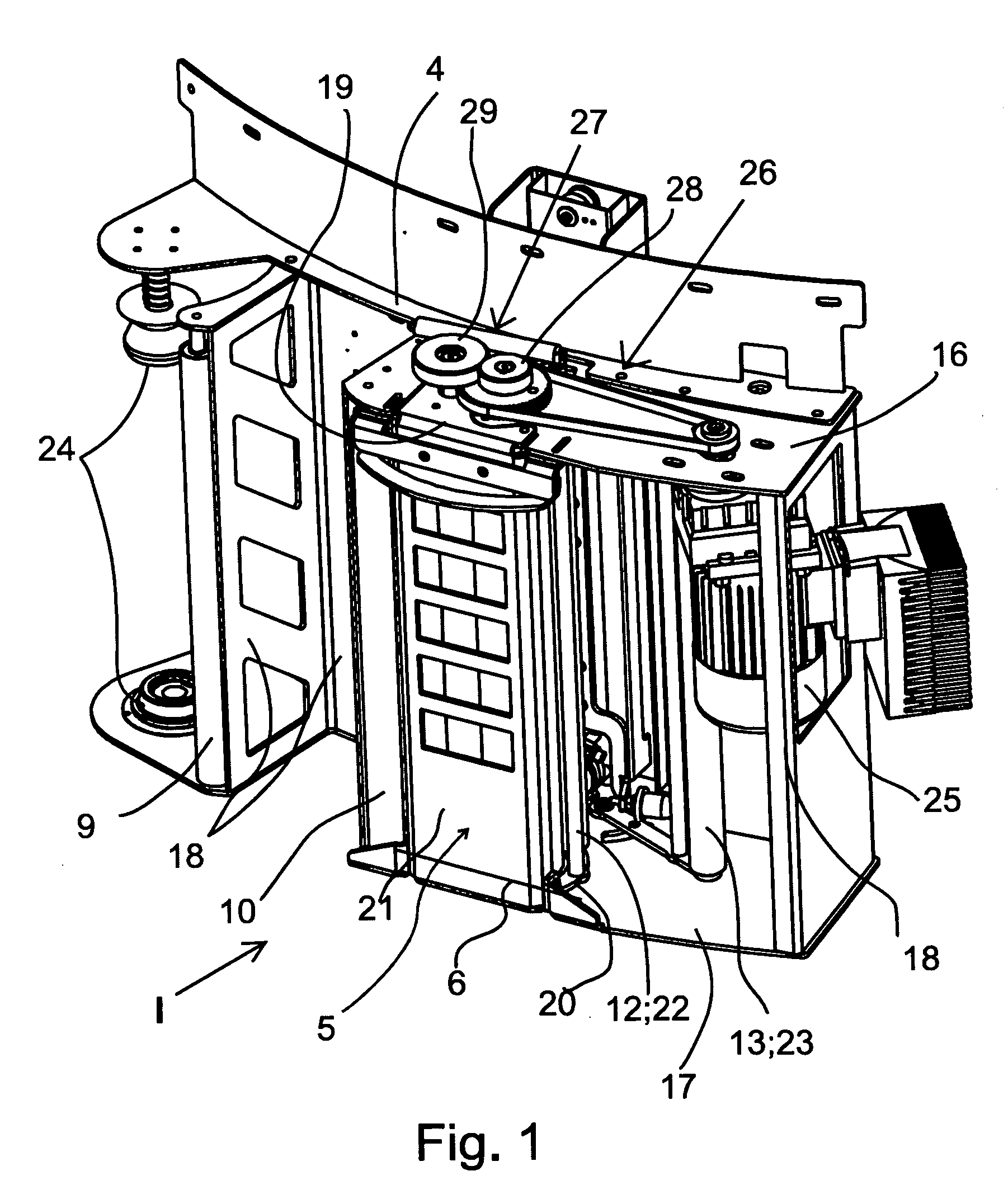

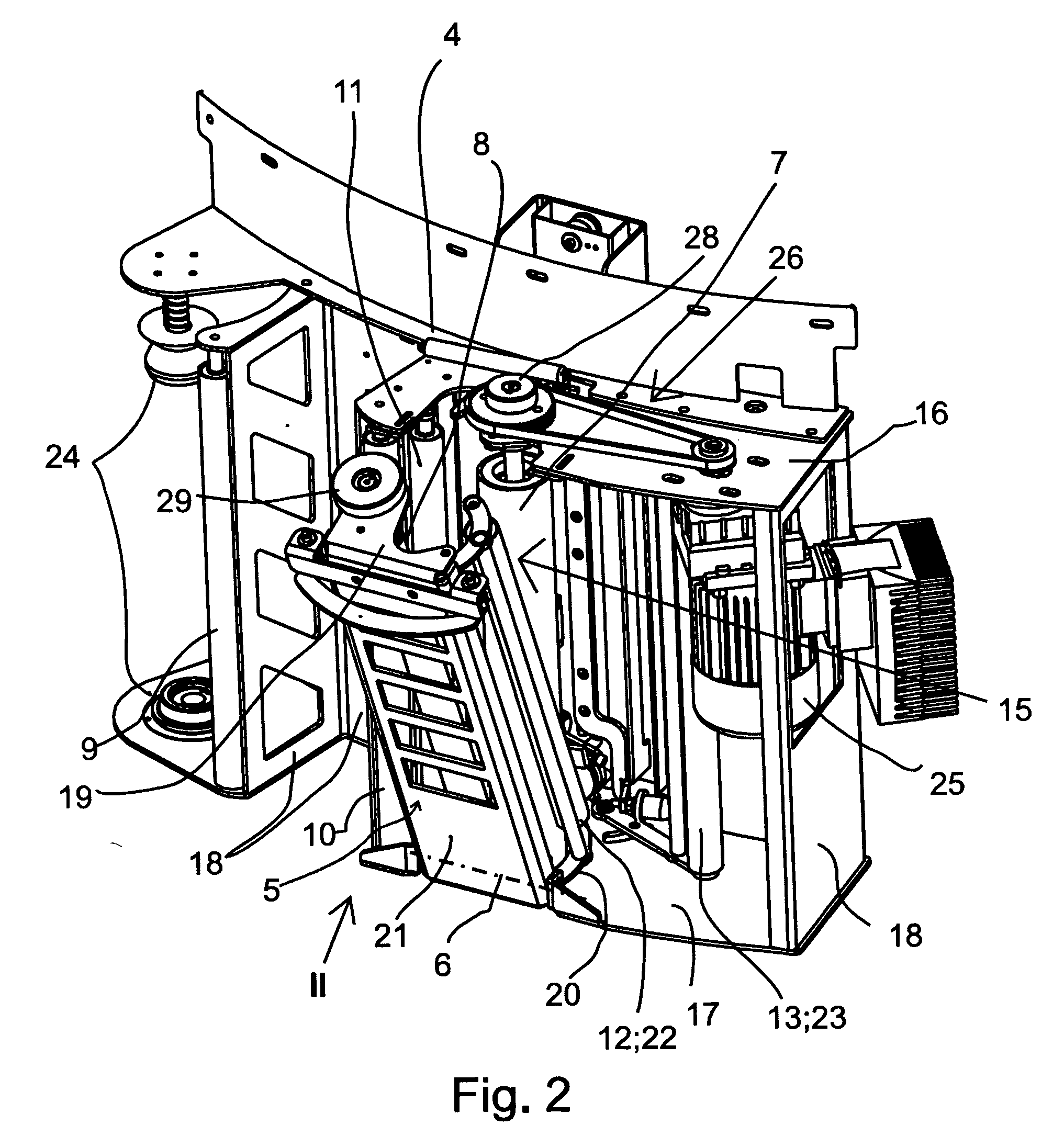

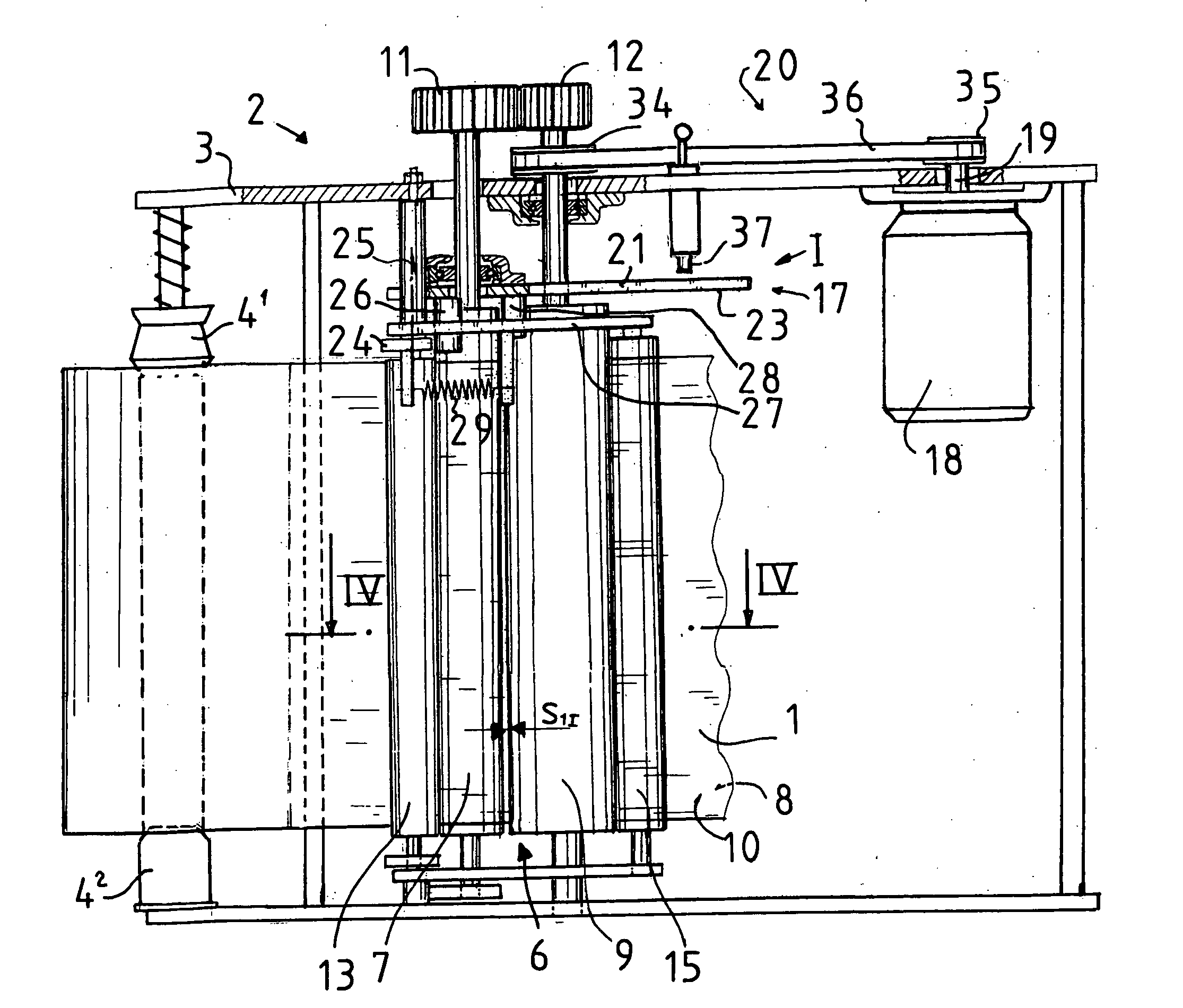

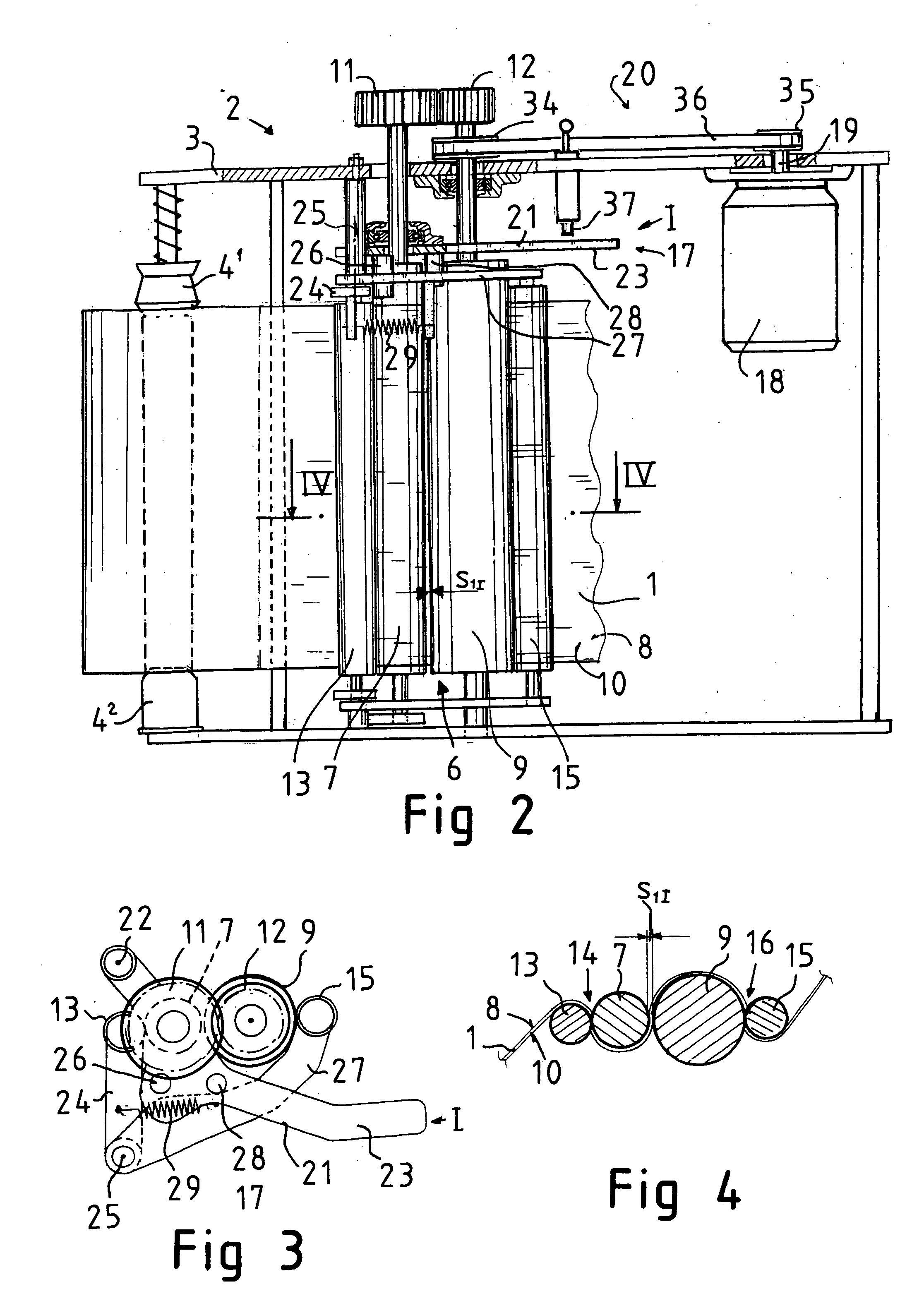

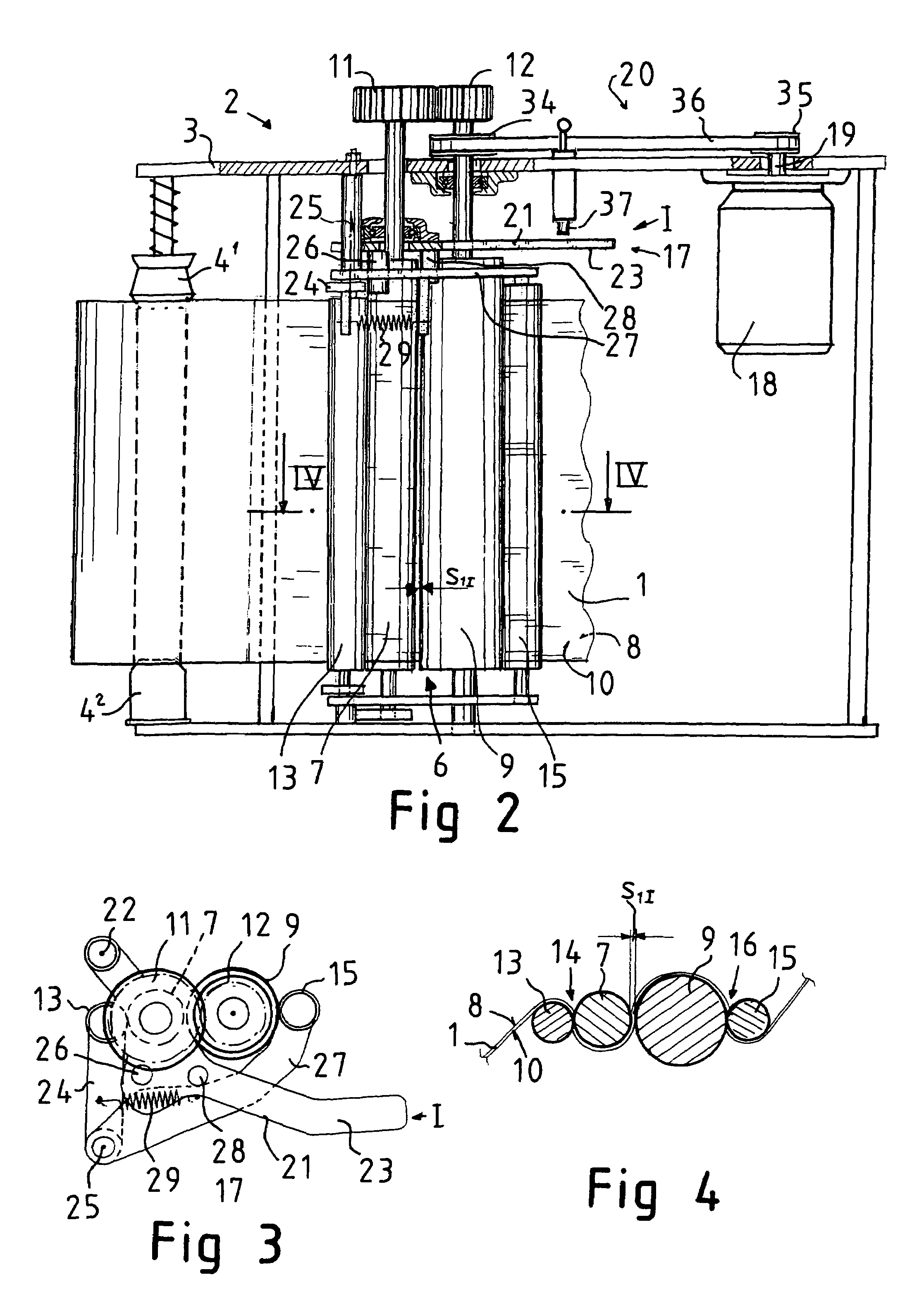

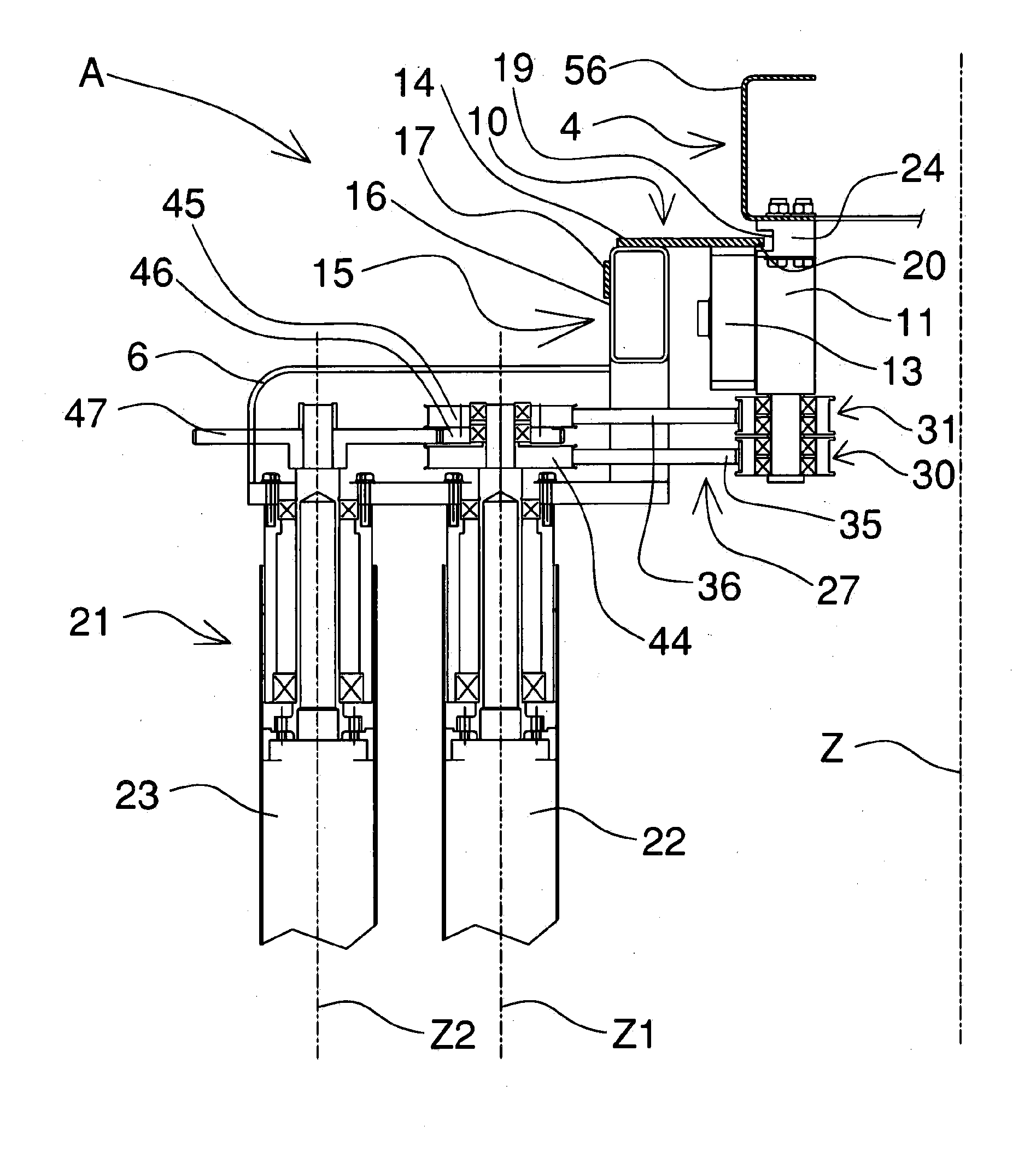

Film delivery device and use of same

ActiveUS7533515B1Threading of the film is particularly easyEasy threadingWrappers shrinkageWrapping material feeding apparatusMechanical engineeringEngineering

A film delivery device comprising a first assembly which can be connected to a wrapping machine and a second assembly (5) which is pivoted to turn, relative to the first assembly (4), about a horizontal hinge axis (6) between a closed position (I) and an open position (II). A first prestretch roller (7) is in the first assembly (4). A second prestretch roller (8) is in the second assembly (5). The film can be threaded by S-threading between the prestretch rollers (7,8). The second assembly (5) is hinged at the lower end to the lower end of the first assembly (4) to turn about the horizontal hinge axis (6). The second assembly (5) comprises a pivoted and spring-loaded first deflecting roller (22) which is arranged downstream relative to the first prestretch roller (7). In the open position (II) of the second assembly (5), that part of the first deflecting roller (22) which is close to the lower end thereof is resting against the surface of the first prestretch roller (7).

Owner:M HALOILA

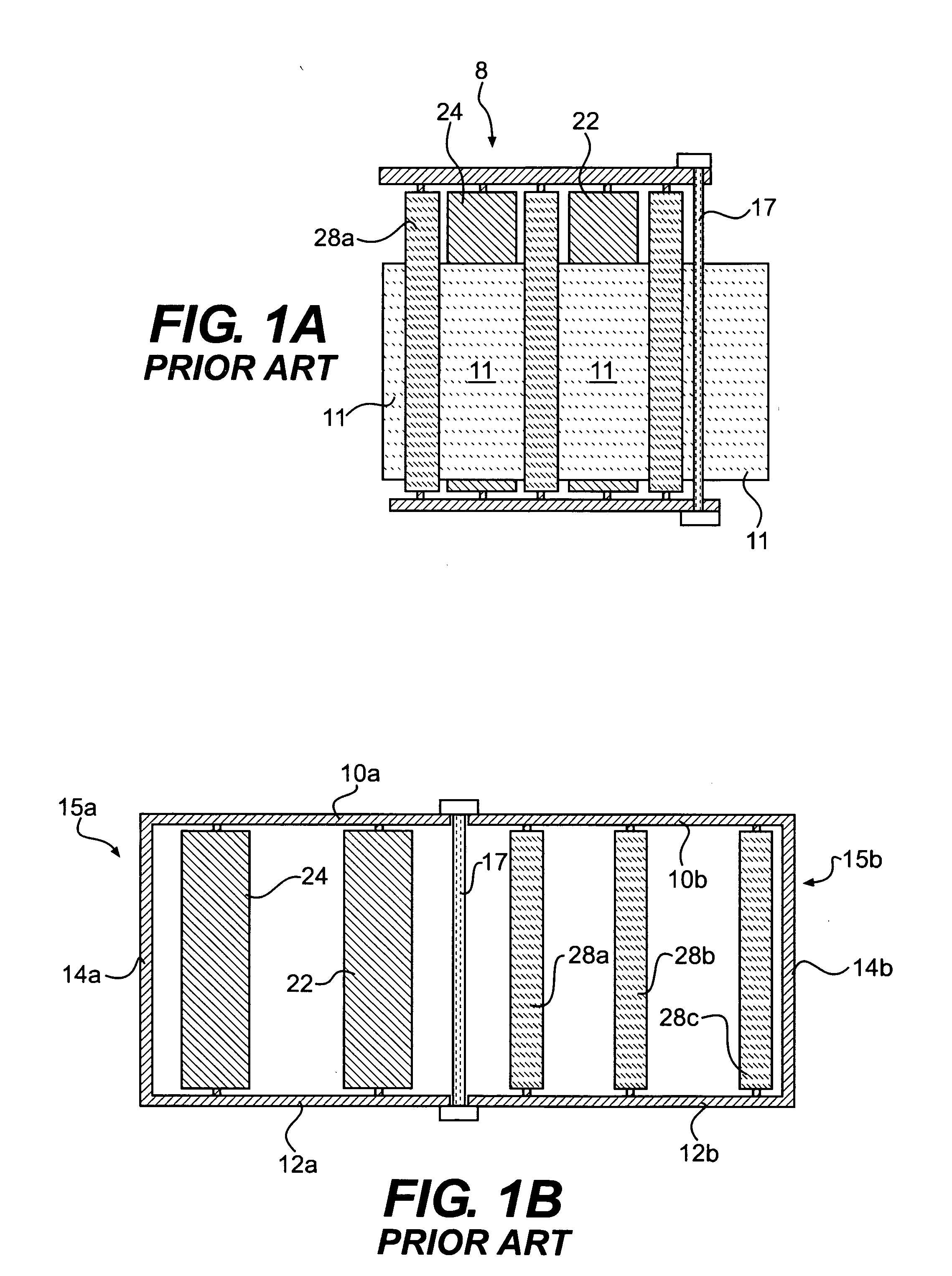

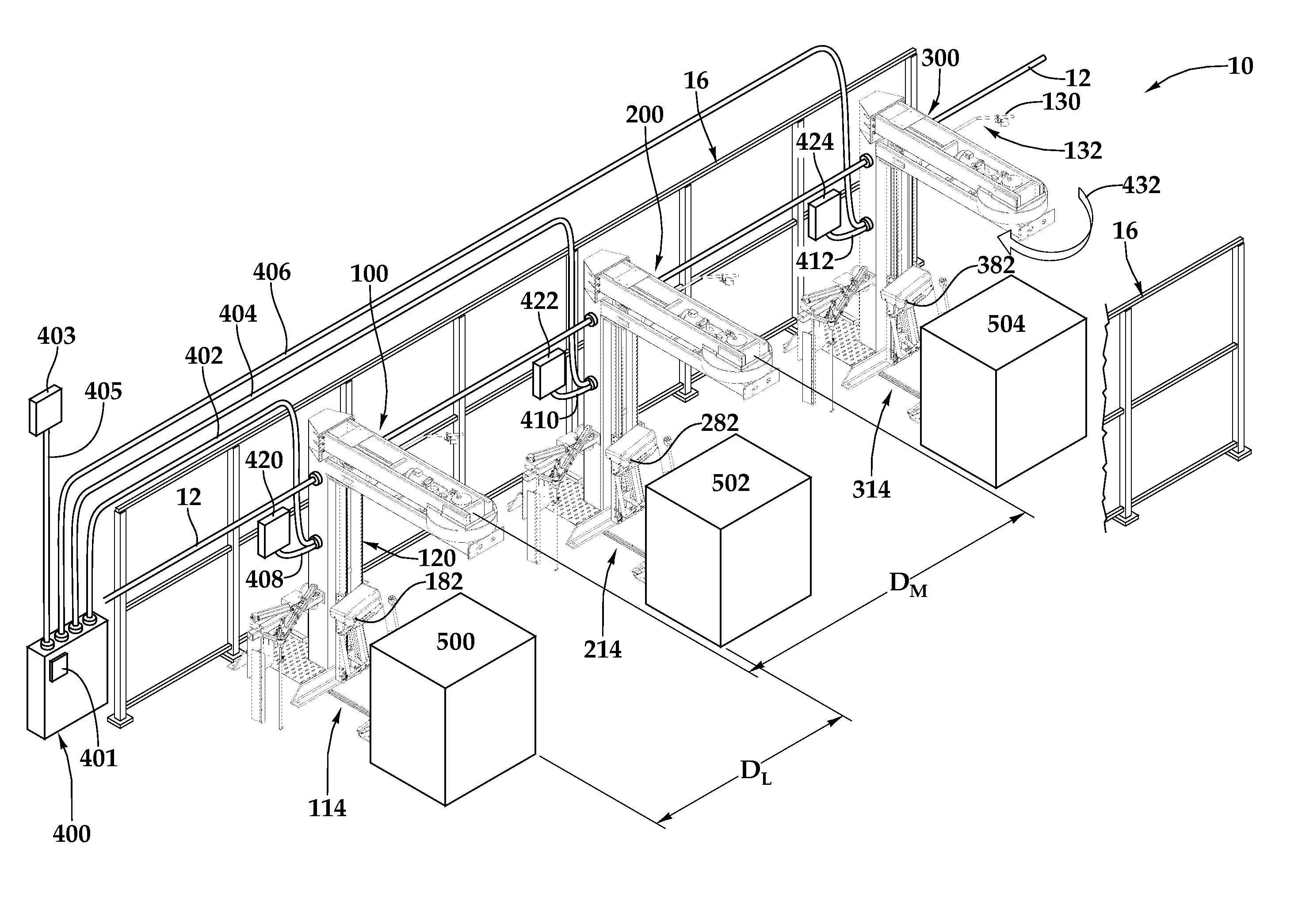

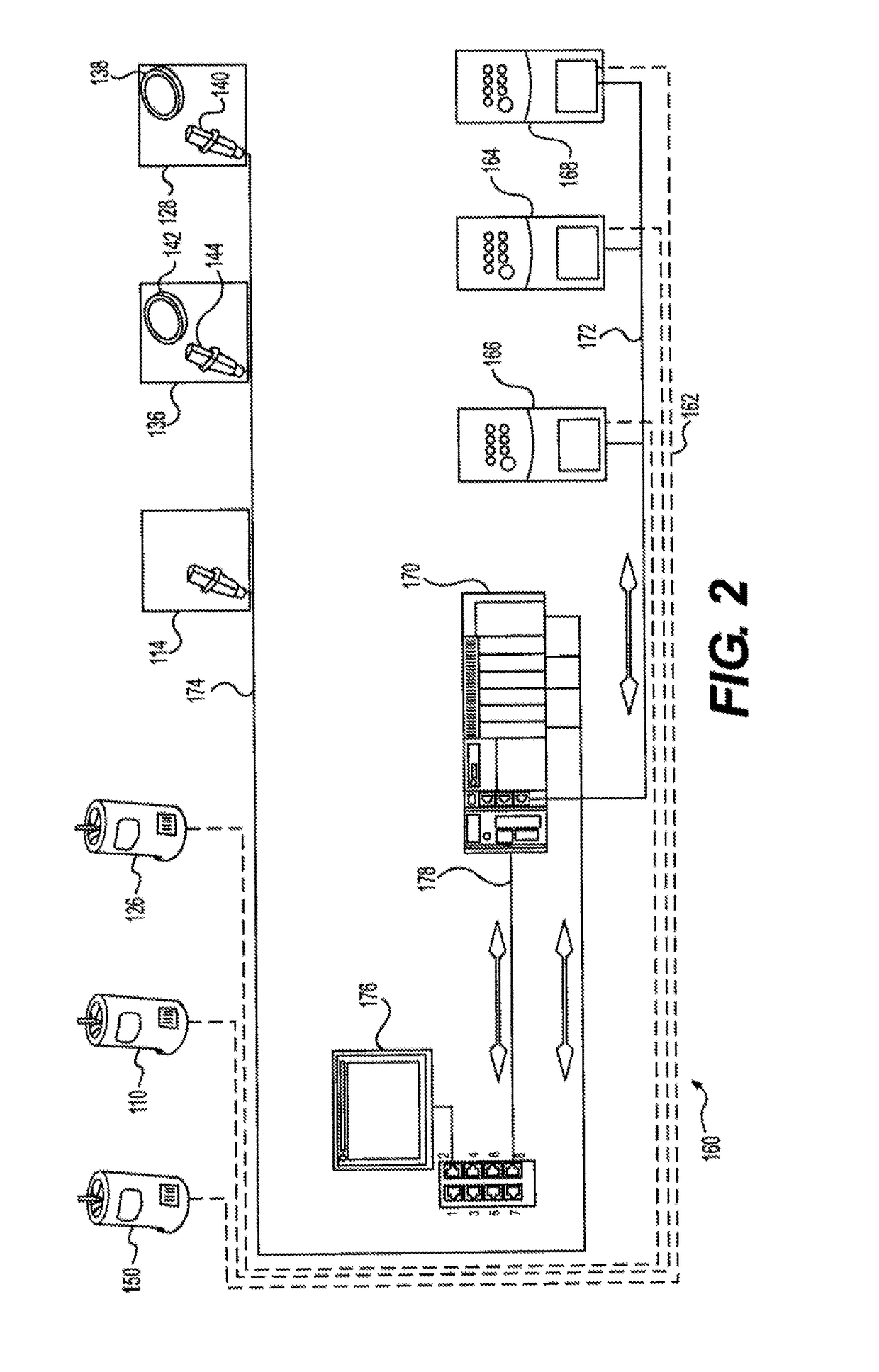

Stretch Wrapping System and Process

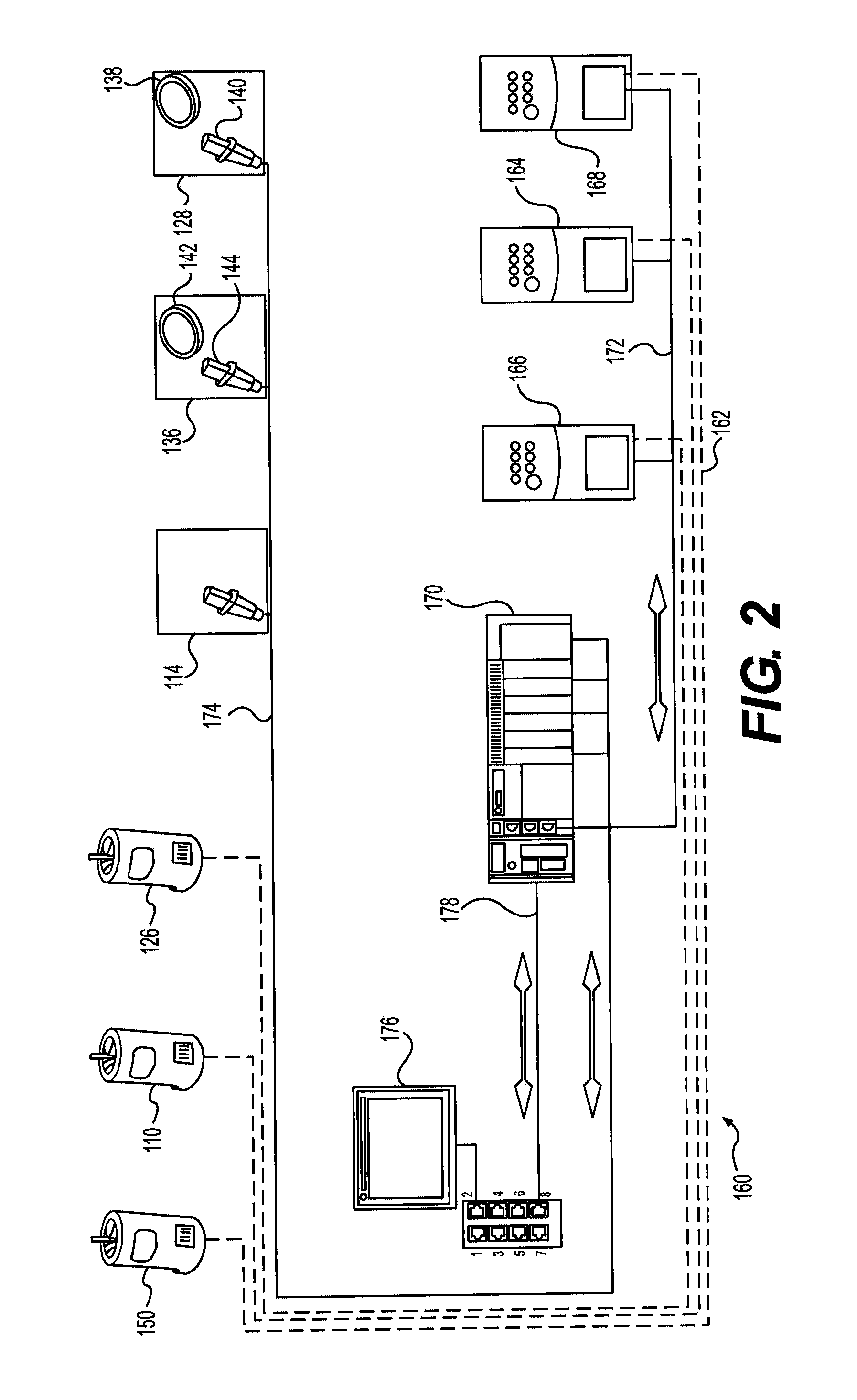

In one aspect, a stretch wrap system configured to separately wrap a plurality of loads in film comprising a plurality of stretch wrapping machines, each machine comprising at least one sensing mechanism configured to sense the presence of a load, and a control box electrically coupled to sensing mechanisms, the control box comprising a start button configured to start the machines when sensing mechanisms detect load. In another aspect, a process of operating a system for stretch wrapping comprising positioning at least one load to be wrapped in front of at least one of a first and second machine wherein the first machine includes a sensing mechanism electrically coupled to a control box and wherein the second machine includes a second sensing mechanism electrically coupled to the control box, inputting a start signal through the control box, transmitting a signal from the control box to each of the sensing mechanisms, determining the presence or absence of a load within an operational space of each of the plurality of stretch wrapping machines and wrapping each present load using a respective one of the plurality of stretch wrapping machines.

Owner:BEST PACKAGING

Wrapping method

ActiveUS20140123605A1Improve packaging qualityPrestretching mechanismWrapper folding/bending apparatusEffective lengthEngineering

A method for wrapping a load with a film by a wrapping machine including an unwinding apparatus provided with a reel of the film includes moving the wrapping apparatus and the load in relation to one another and unwinding from the reel an established effective length of film per revolution of the wrapping apparatus or of the load. The established effective length of film is calculated with the formula: where: Sf. initial length of film is determined on the basis of dimension and / or shape of the load; w: rotation speed around a wrapping axis of the unwinding apparatus or of the load; Vt: movement speed of the unwinding apparatus parallel to the rotation axis; ωmax: maximum rotation speed around the wrapping axis of the unwinding apparatus or of the load; Δcorr: corrective parameter.

Owner:AETNA GROUP

Film delivery device and use of same

ActiveUS20090120307A1Drawback can be obviatedThreading of the film is particularly easyWrappers shrinkageWrapping material feeding apparatusEngineeringMechanical engineering

A film delivery device comprising a first assembly (4) which can be connected to a wrapping machine and a second assembly (5) which is pivoted to turn, relative to the first assembly (4), about a horizontal hinge axis (6) between a closed position (I) and an open position (II). A first prestretch roller (7) is in the first assembly (4). A second prestretch roller (8) is in the second assembly (5). The film can be threaded by S-threading between the prestretch rollers (7, 8). The second assembly (5) is hinged at the lower end to the lower end of the first assembly (4) to turn about said horizontal hinge axis (6). The second assembly (5) comprises a pivoted and spring-loaded first deflecting roller (22) which is arranged downstream relative to the first prestretch roller (7). In the open position (II) of the second assembly (5), that part of the first deflecting roller (22) which is close to the lower end thereof is resting against the surface of the first prestretch roller (7).

Owner:M HALOILA

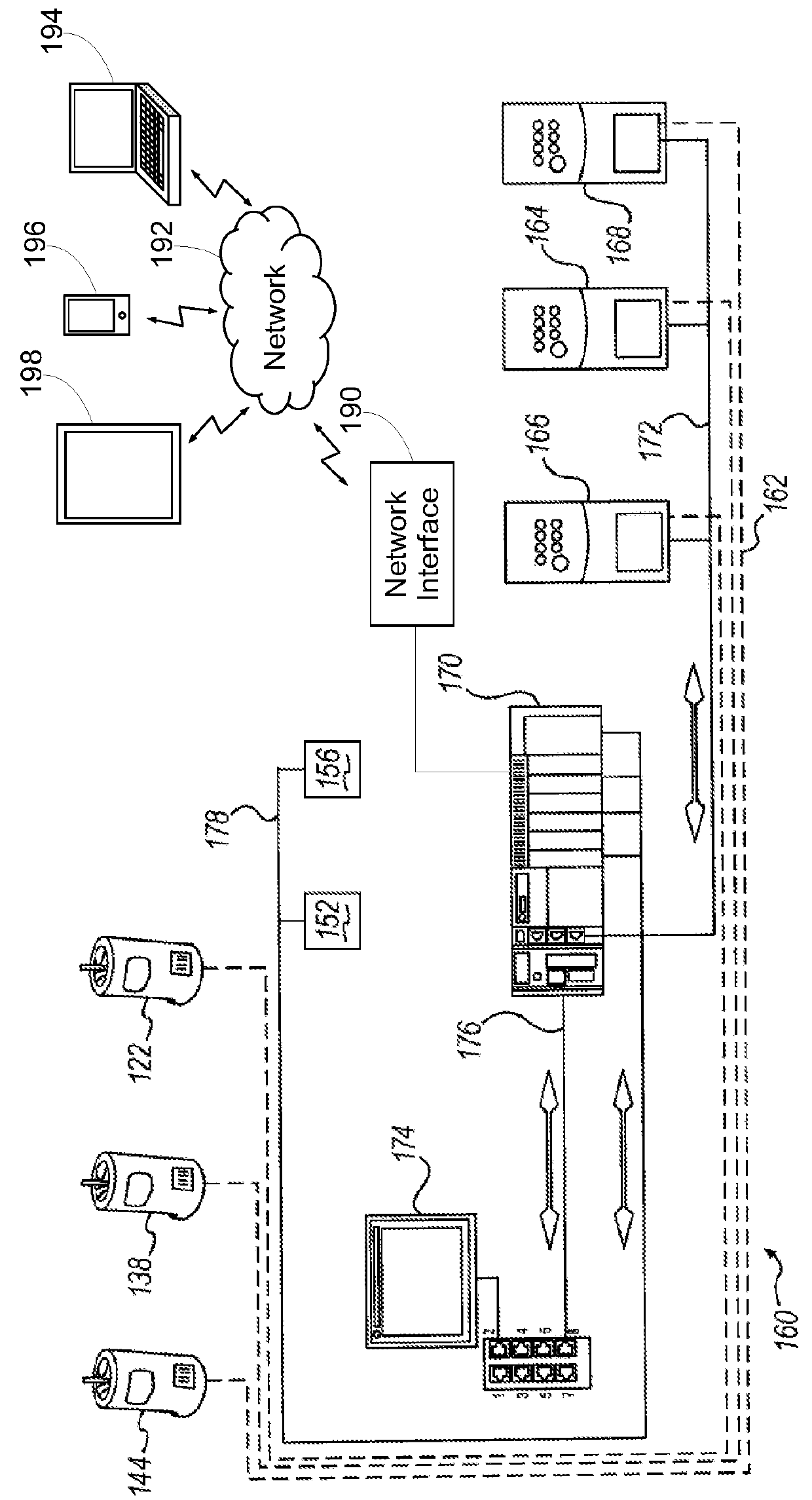

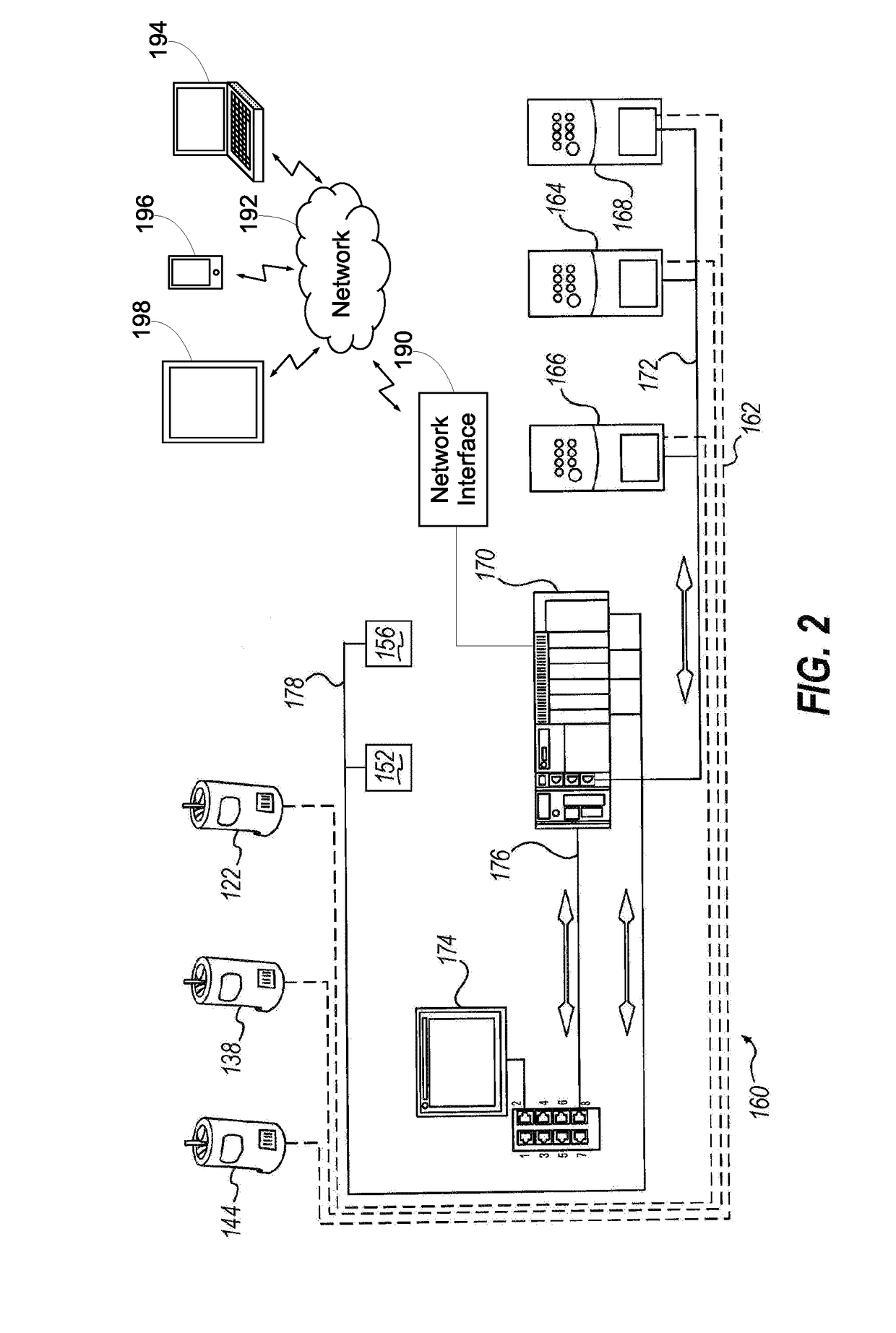

System for management of automated stretch wrapping

ActiveUS20180257799A1Wrapping material feeding apparatusPrestretching mechanismEngineeringMechanical engineering

Devices and method for accurately measuring the length of film feeding into a pre-stretch carriage from a supply roll and the length of film exiting after the pre-stretch carriage in order to accurately determine the actual percentage of film stretch occurring during the wrap cycle are provided. A first idler roller mounted on the frame of a pre-stretch carriage before the pre-stretching rollers and second idler roller mounted to the frame after the pre-stretching rollers are included. Optical rotary encoders are driven directly by idler roller shafts as stretch film passes around the shafts during film application. Systems including internet of things (HOT) devices can be fitted or retro fitted to a wide variety of stretch wrapping machines

Owner:RAGSDALE JOHN

Wrapping machine

InactiveUS20050050861A1Easy feedingLight and simple and cheapWrappers shrinkageWrapping material feeding apparatusPower transmissionWrap around

A wrapping machine having a pre-stretching device for pre-stretching a film web drawn from film roll before its being wrapped around an object, said pre-stretching device including a first pre-stretching roller and a second pre-stretching roller, which are tractively coupled via power transmission gears. A first deflecting pinch roller has been fitted to be pressed against the first pre-stretching roller to form a first nip for the film web passed between the first deflecting pinch roller and the first pre-stretching roller. A second deflecting pinch roller has been fitted to be pressed against the second pre-stretching roller to form a second nip for the film web passed between the second deflecting pinch roller and the second pre-stretching roller. A lever mechanism moves the first pre-stretching roller between an engagement position and a disengagement position, so that the lever mechanism also moves the first deflecting pinch roller apart from the first pre-stretching roller and simultaneously the second deflecting pinch roller apart from the second pre-stretching roller to allow easier thread-in of the film web end.

Owner:M HALOILA

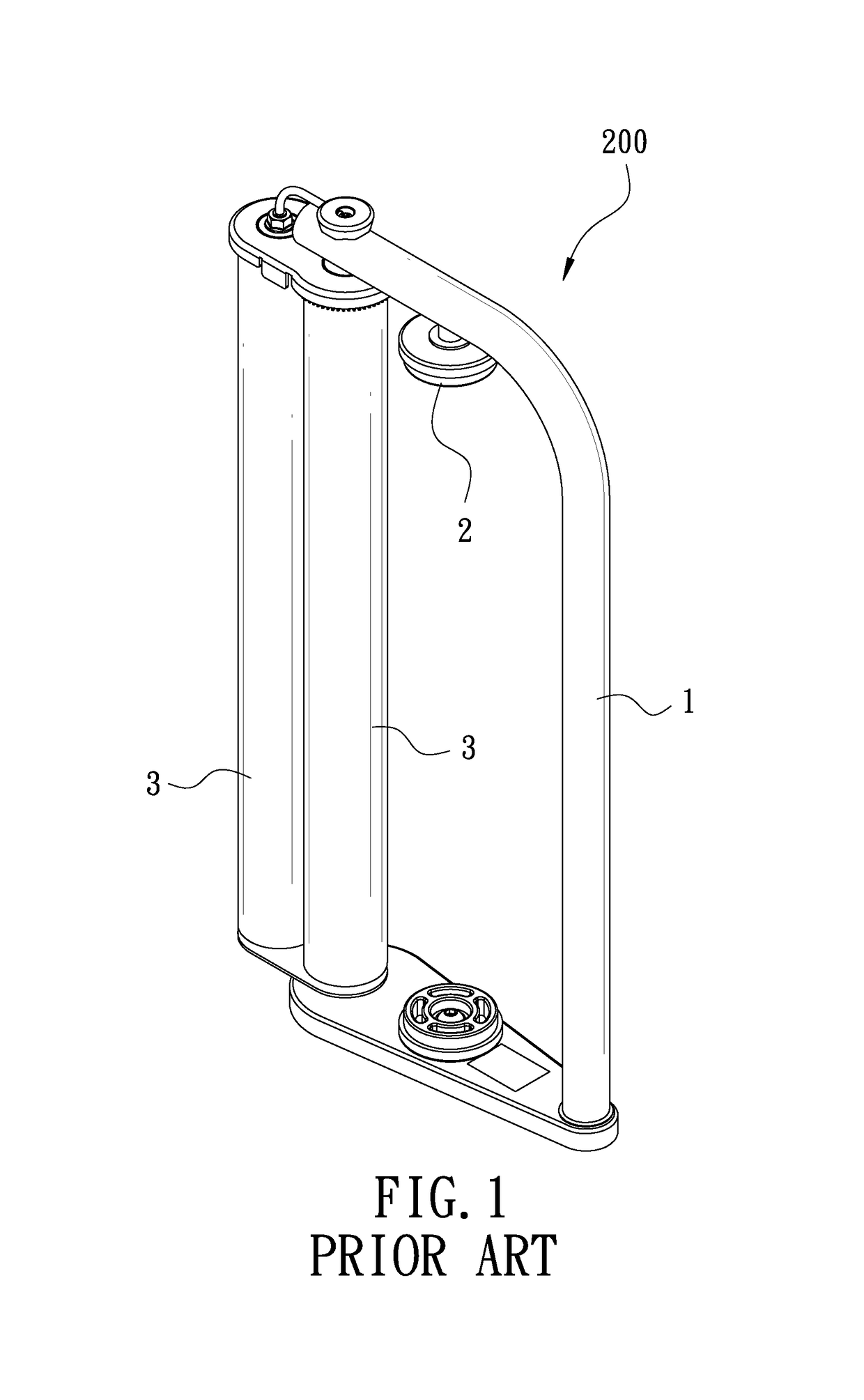

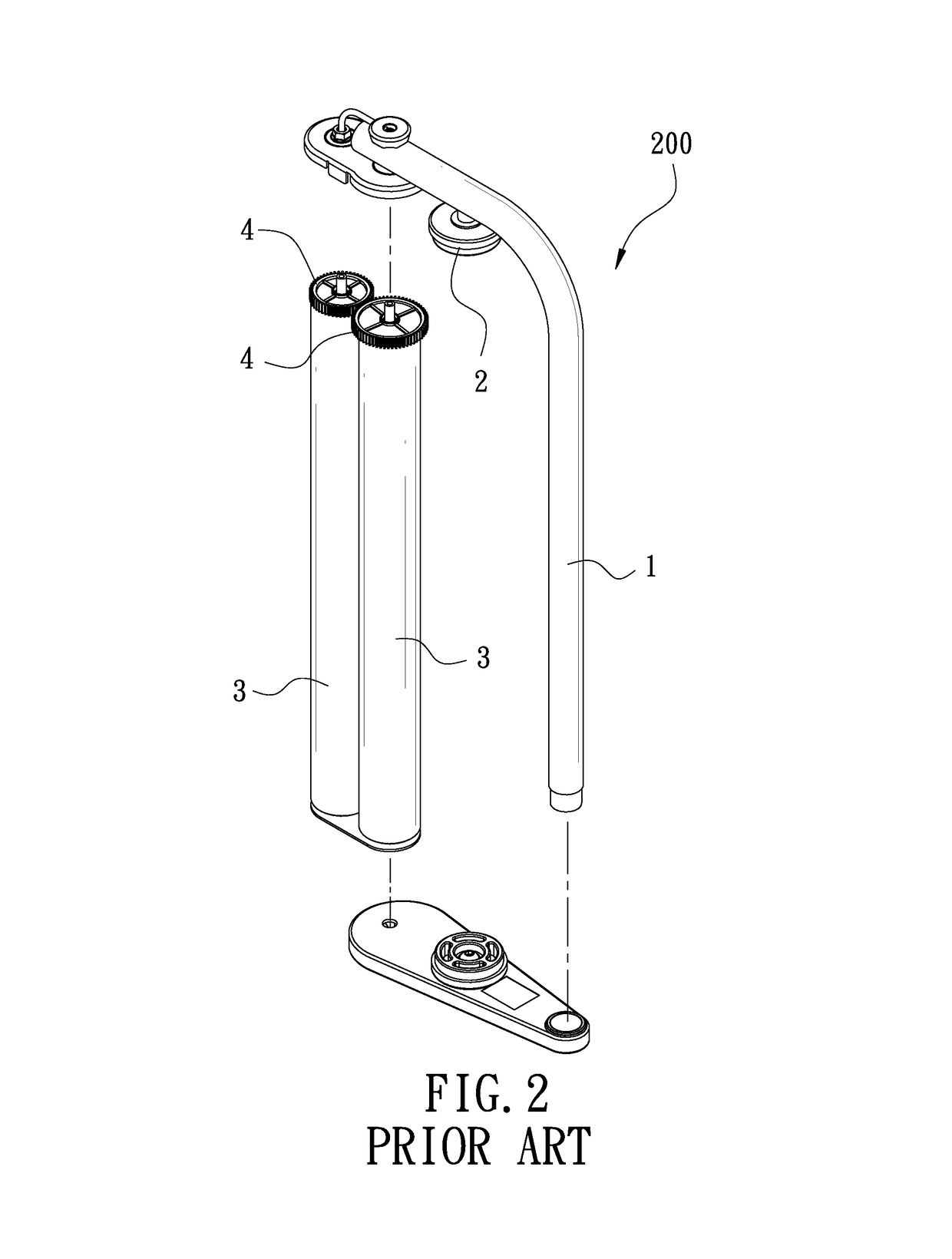

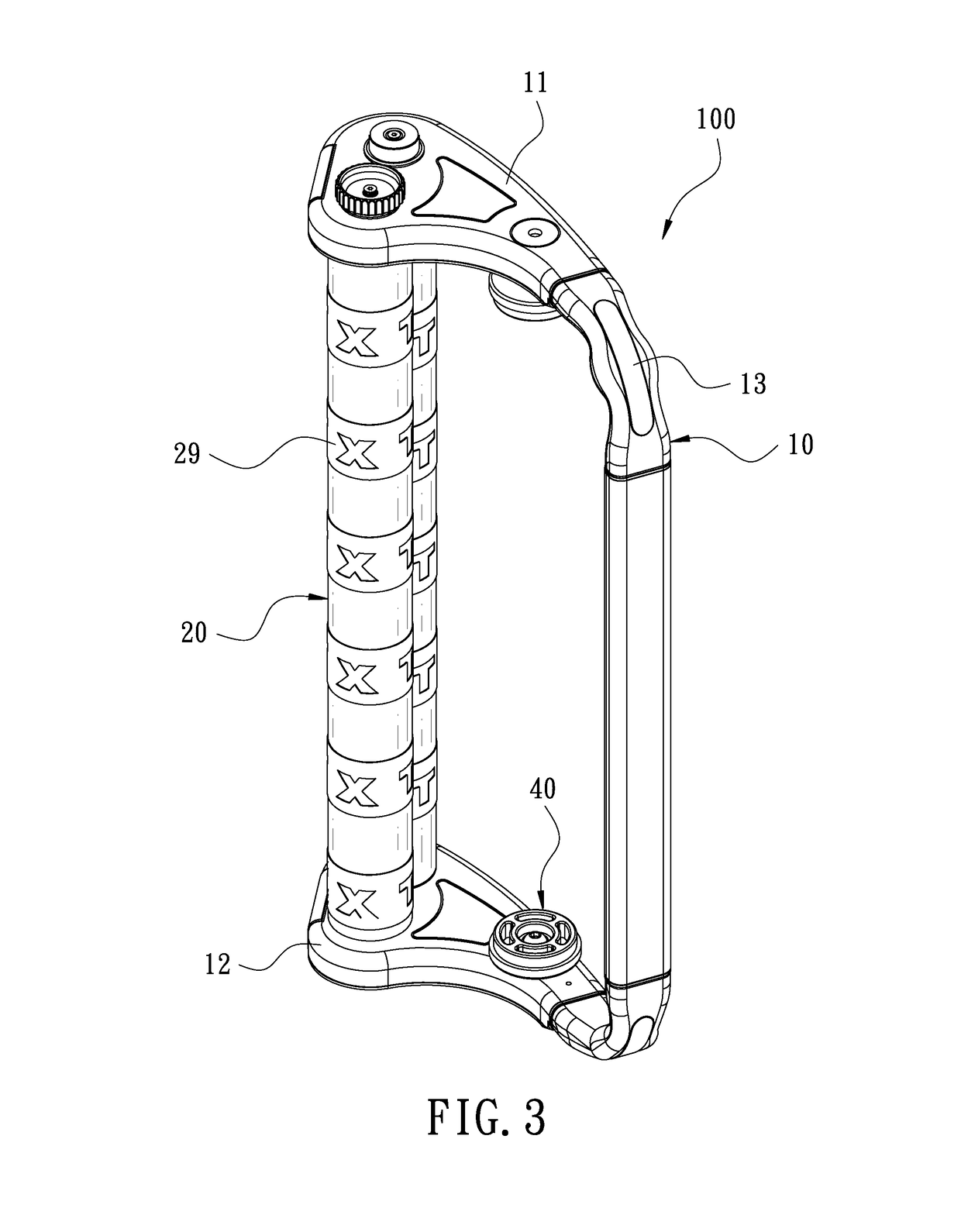

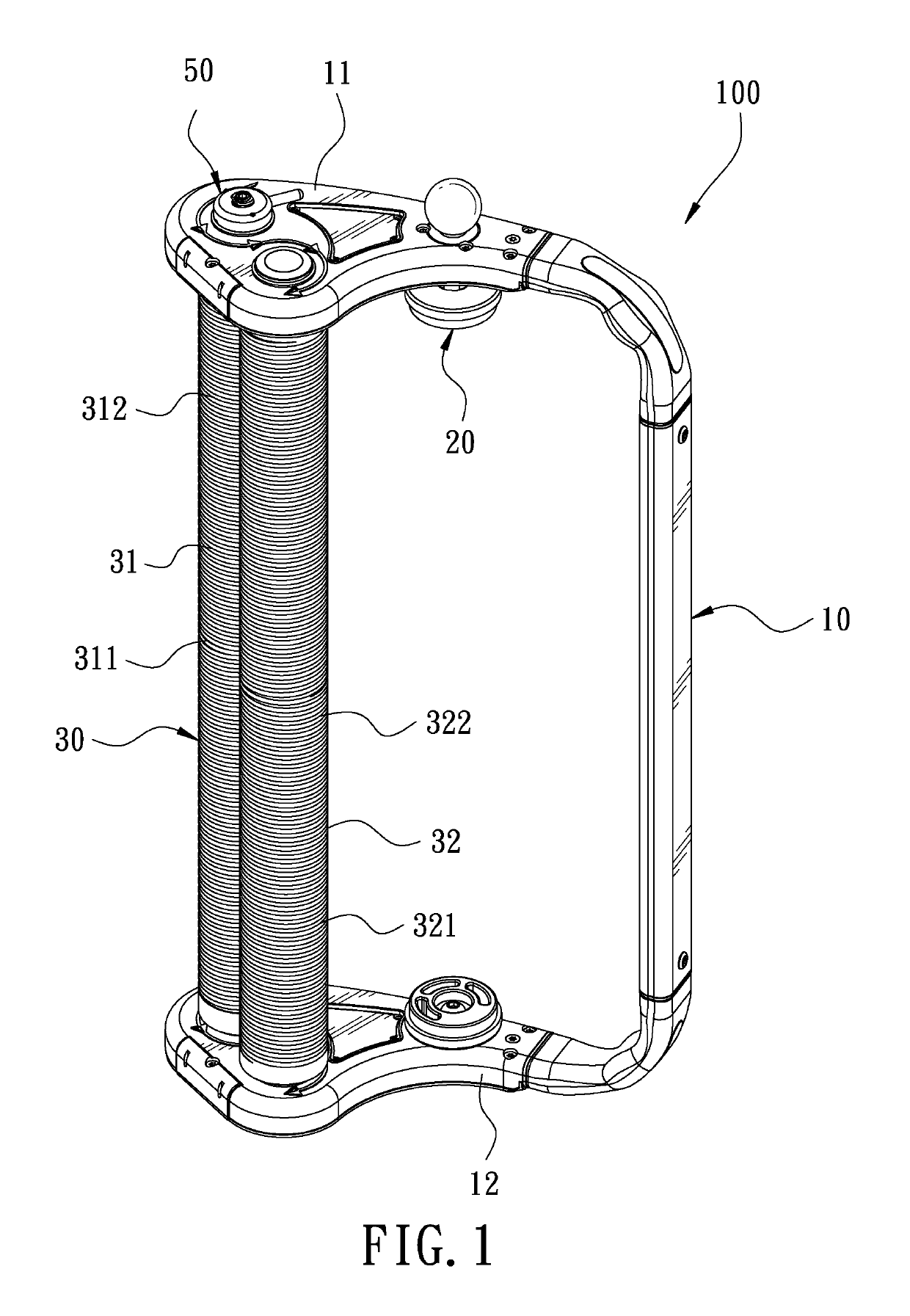

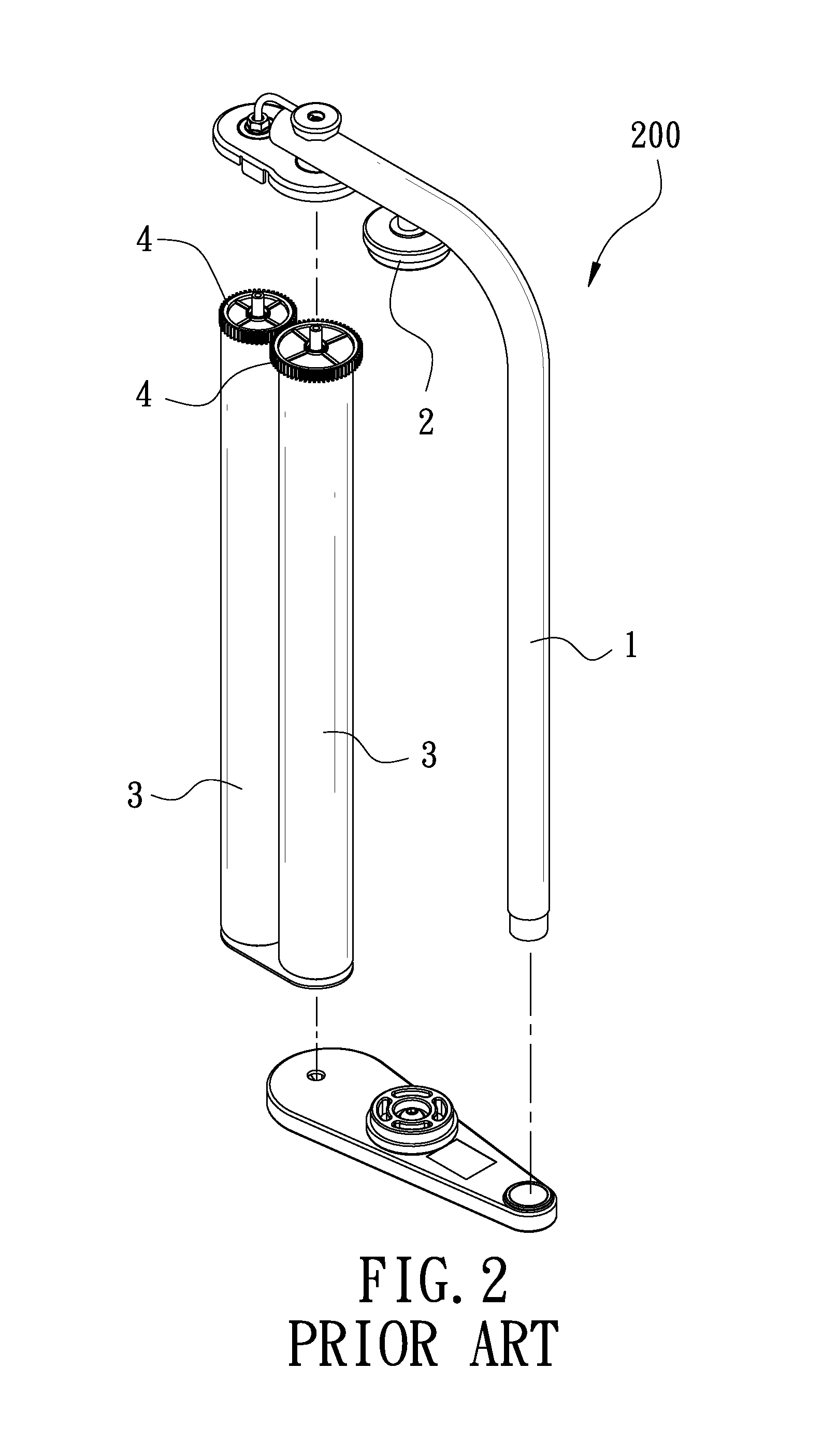

Film packing device capable of replacing gears

Owner:CHEN HSIU MAN YU

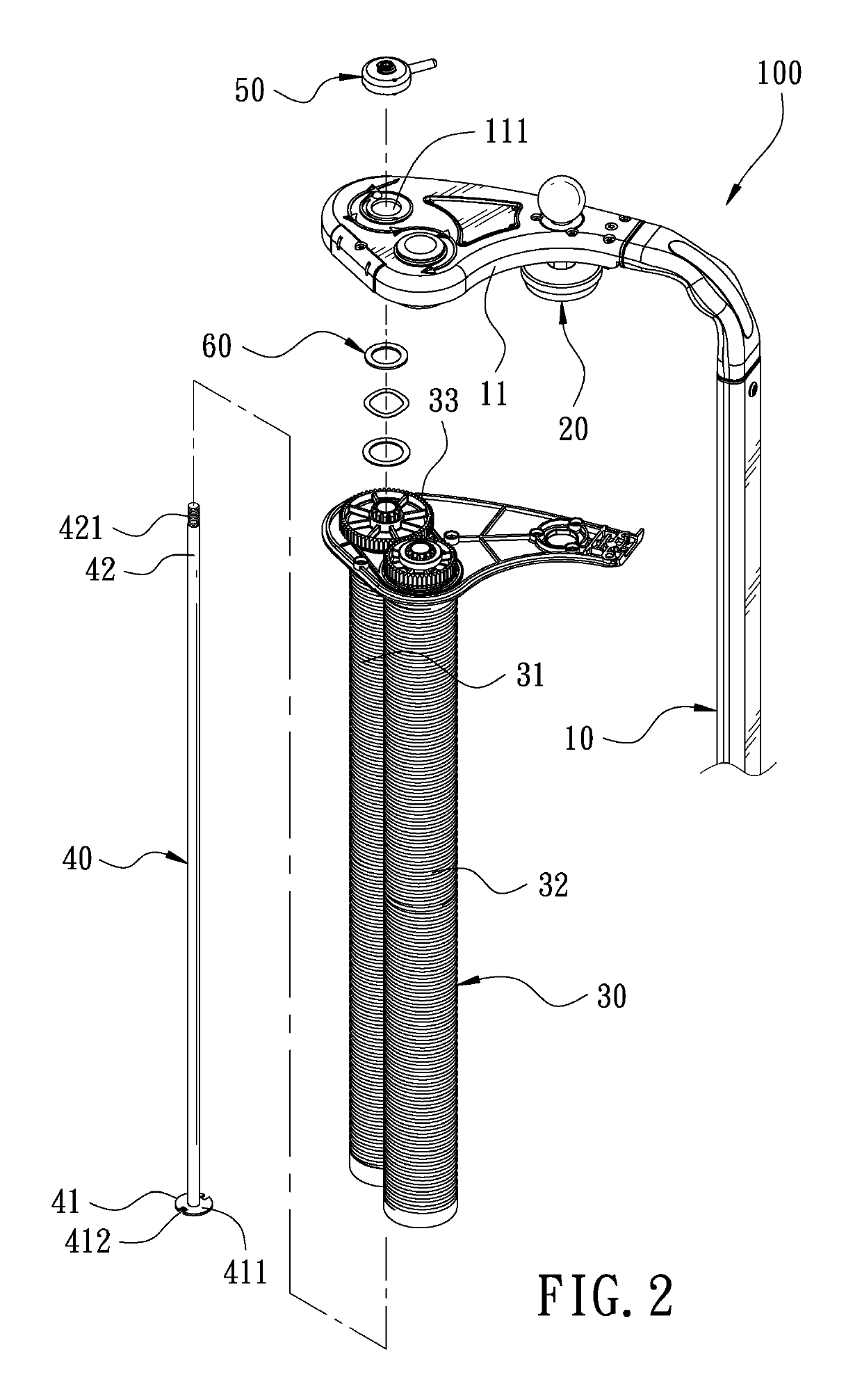

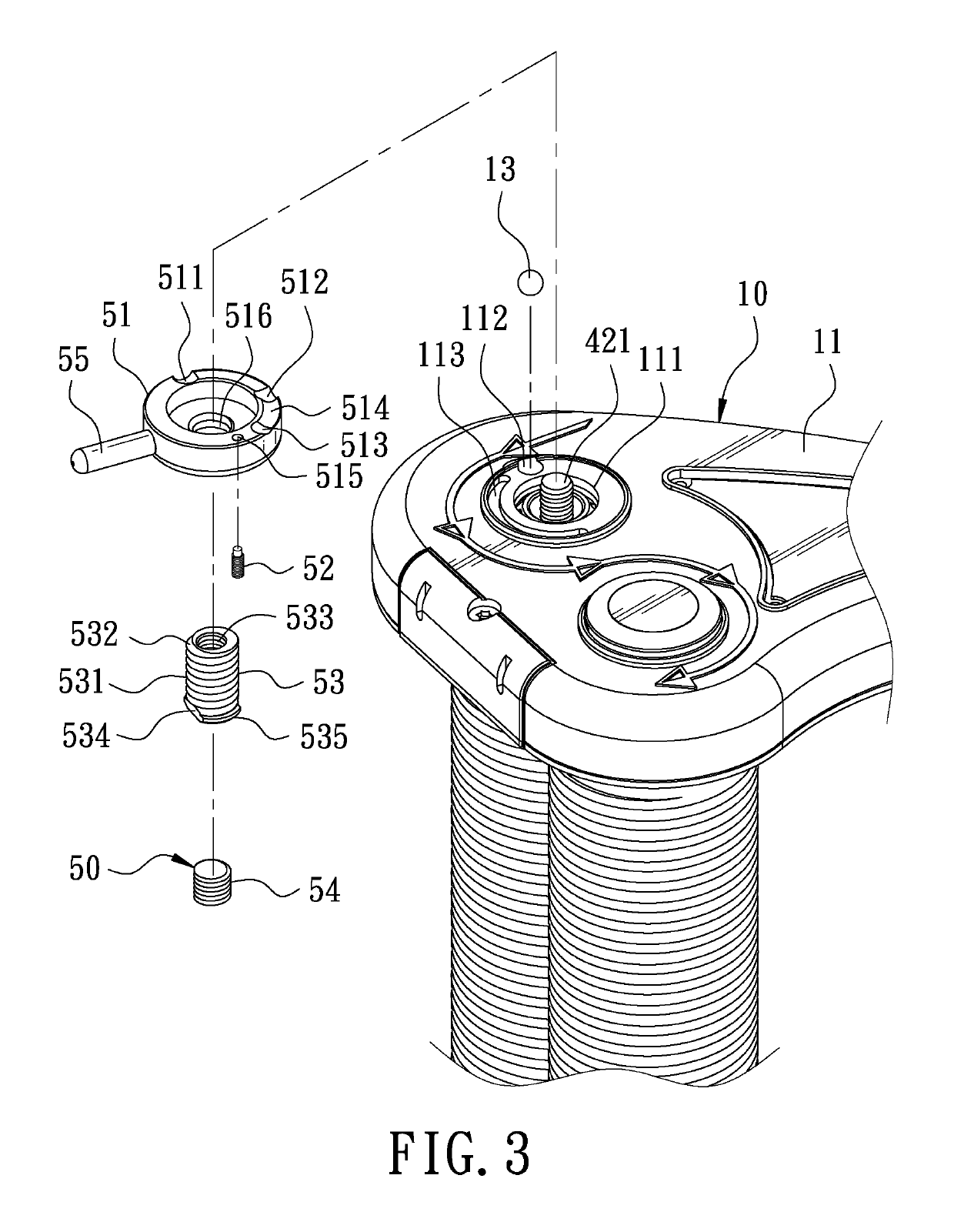

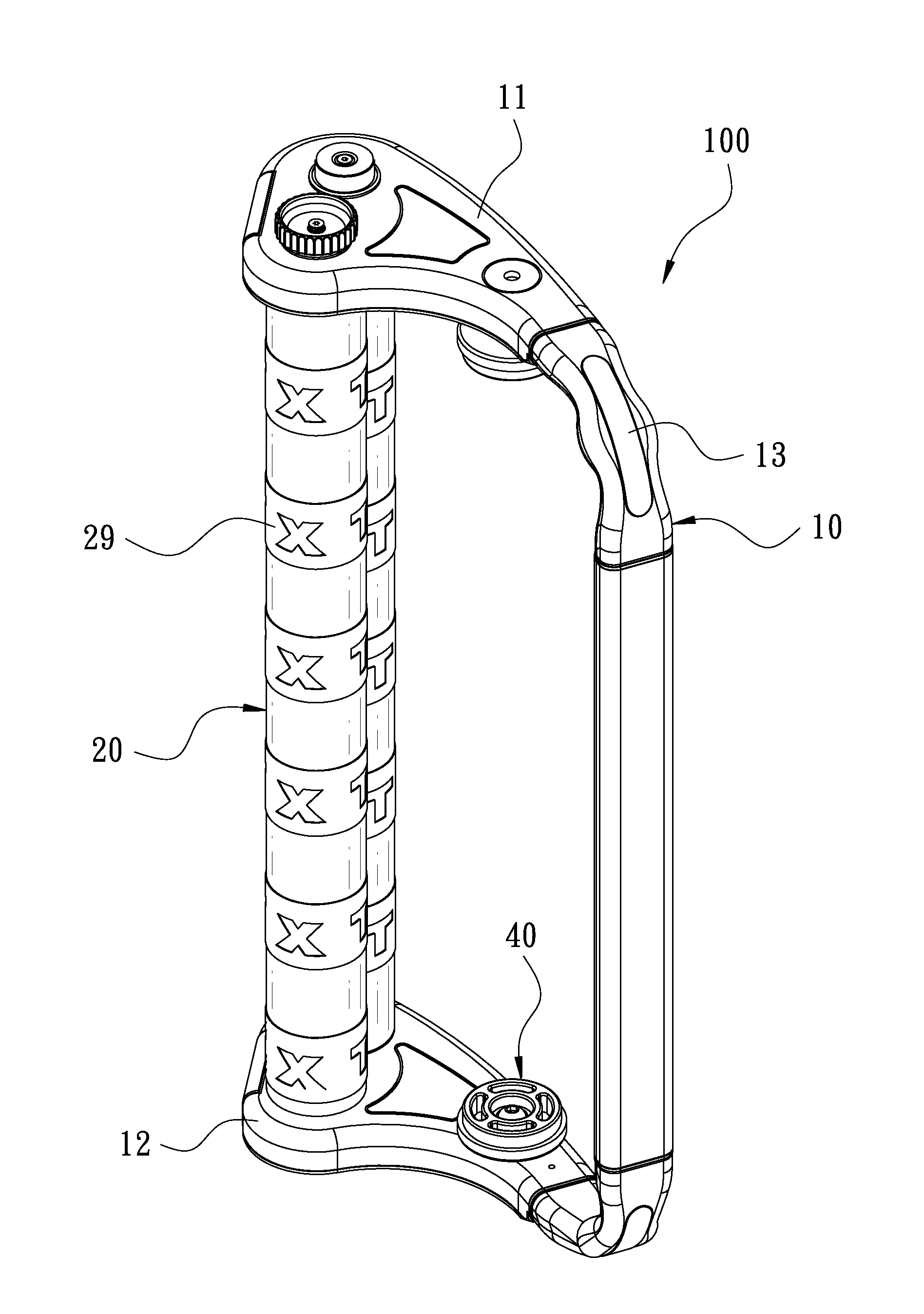

Stretch film dispenser with tension adjustment device

ActiveUS10479635B1Easy to adjustImprove tightnessWrapping material feeding apparatusPrestretching mechanismAxial displacementEngineering

A stretch film dispenser with a tension adjustment device includes a frame. The frame is provided with a film dispensing unit and the tension adjustment device. The tension adjustment device includes an adjustment rod. One end of the adjustment rod is threadedly connected with an adjustment unit. An elastic unit is connected between the frame and the film dispensing unit. When the adjustment unit rotates along the adjustment rod to generate downward axial displacement, the adjustment unit pushes the frame and the elastic unit to press the film dispensing unit, so that the film dispensing unit can be quickly adjusted in a different tension state when the film of the film roll is stretched.

Owner:YU CHEN HSIU MAN

Stretch Wrapping Machine with Automatic Load Profiling

ActiveUS20180273218A1Reducing wrap force control parameterReduce controlPrestretching mechanismWeb rotation wrappingSlip sheetVolumetric Mass Density

A method, apparatus and program product perform automatic load profiling to optimize a wrapping operation performed with a stretch wrapping machine. Automatic load profiling may be performed, for example, to determine a density parameter for a load that is indicative of load stability such that one or more control parameters may be configured for a wrapping operation based upon the density parameter. Automatic load profiling may also be performed, for example, to detect a load with a nonstandard top layer, e.g., a load with a top or slip sheet, a load with an easily deformable top layer, a load with a ragged top surface topography and / or a load with an inboard portion, such that a top layer containment operation may be activated during wrapping to optimize containment for the load.

Owner:LANTECH COM

Stretch Wrapping machine Supporting Top Layer Containment Operations

ActiveUS20180079537A1Wrapping material feeding apparatusPrestretching mechanismSlip sheetEngineering

Owner:LANTECH COM

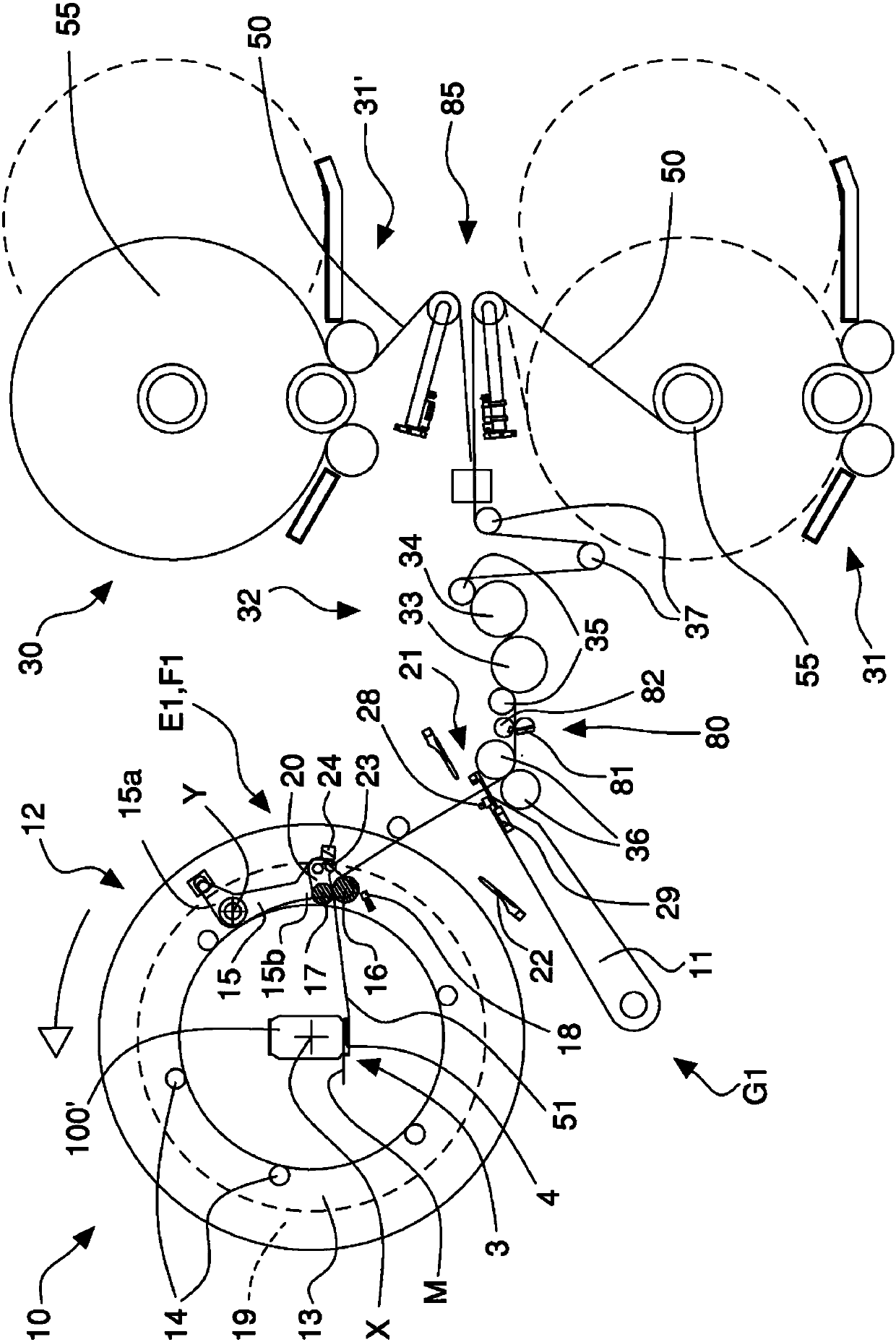

Wrapping machine

A wrapping machine for wrapping groups of products (100) with an extensible plastic film (50) in order to form bundles (200), comprises first conveyor means (2) for supporting and moving a group of products (100) along an advancing direction (A) inside the wrapping machine (1), supporting means (3; 103) for receiving from the first conveyor means (2) and supporting the group of products (100), a wrapping unit (10) for wrapping a portion (51) of film (50) having a preset length around the group of products (100), supported by the supporting means (3; 103), in order to form a bundle (200), a supplying unit (30) of the film (50) to supply the wrapping unit (10) with the film portion (51) having a preset length, separated from the film (50) unwound from a respective reel (55); the supporting means (3; 103) include first gripping means (4; 104) arranged to hold an initial flap (51a) of the film portion (51) during the wrapping of the group of products (100); containment means (6; 60) are provided to abut at least sidewalls of the group of products (100) in order to support and guide said products (100) when moved along the advancing direction (A) through the wrapping unit (10) and / or tosupport and restrain the group of products (100) during the wrapping with the portion (51) of film (50).

Owner:AETNA GROUP +1

Wrapping machine

InactiveUS7107743B2Light and simple and cheapSmall sizeWrappers shrinkageWrapping material feeding apparatusGear wheelEngineering

Owner:M HALOILA

Stretch wrapping system and process

In one aspect, a stretch wrap system configured to separately wrap a plurality of loads in film comprising a plurality of stretch wrapping machines, each machine comprising at least one sensing mechanism configured to sense the presence of a load, and a control box electrically coupled to sensing mechanisms, the control box comprising a start button configured to start the machines when sensing mechanisms detect load. In another aspect, a process of operating a system for stretch wrapping comprising positioning at least one load to be wrapped in front of at least one of a first and second machine wherein the first machine includes a sensing mechanism electrically coupled to a control box and wherein the second machine includes a second sensing mechanism electrically coupled to the control box, inputting a start signal through the control box, transmitting a signal from the control box to each of the sensing mechanisms, determining the presence or absence of a load within an operational space of each of the plurality of stretch wrapping machines and wrapping each present load using a respective one of the plurality of stretch wrapping machines.

Owner:BEST PACKAGING

Wrapping machine and wrapping methods

ActiveUS20120180433A1Increase speedImprove productivityPrestretching mechanismWrapper folding/bending apparatusEngineeringPlastic film

A wrapping machine for wrapping a product with a plastic film including a supporting frame with which a ring arrangement is associated that rotates around a wrapping axis of the film and around the product. The supporting frame further supports a carriage arranged for supporting a reel of the film and for supporting a first roller and a second roller for unwinding and stretching the film. A first motor and a second motor are mounted on the supporting frame and coupled, respectively, with the first roller and the second roller.

Owner:AETNA GROUP

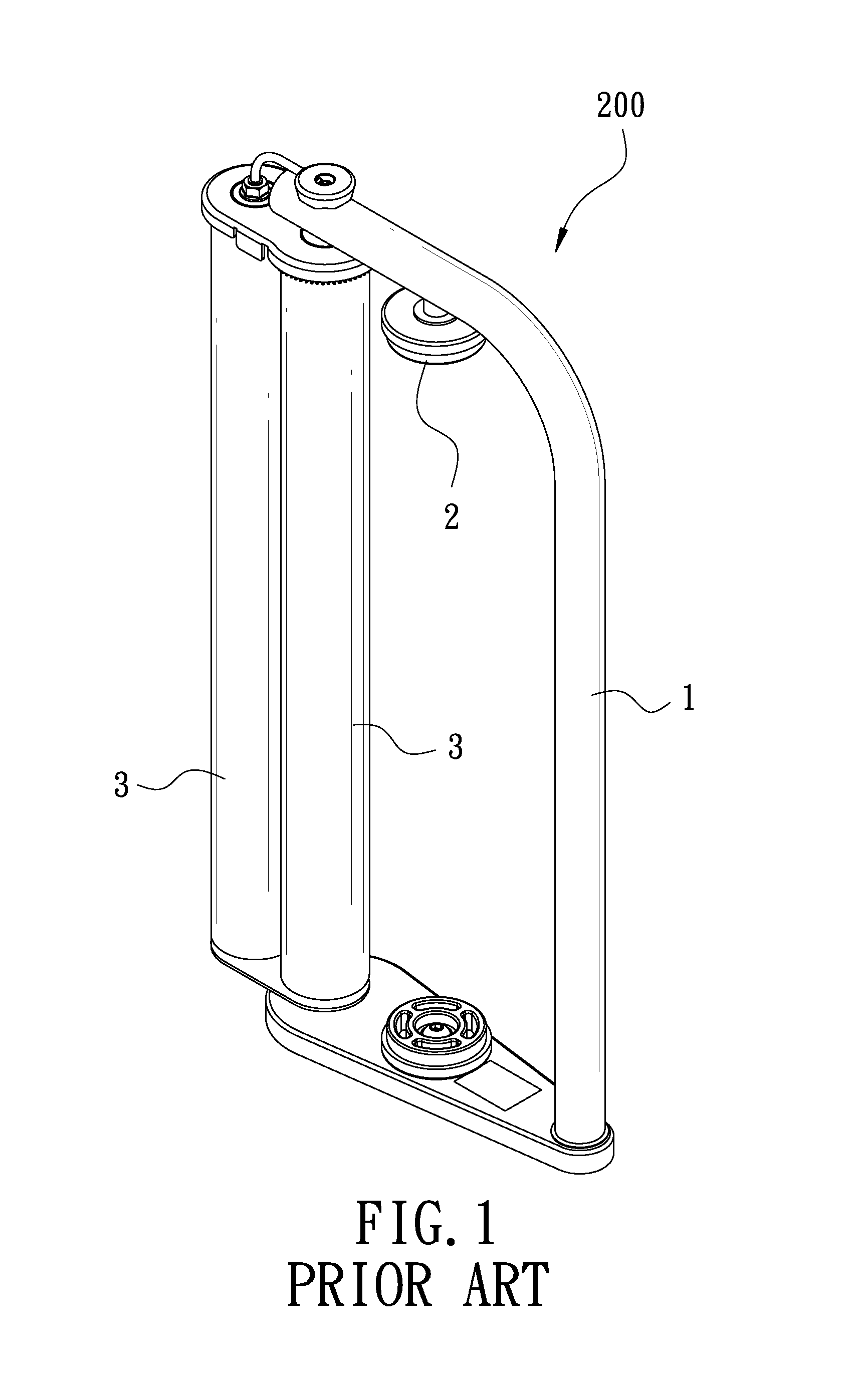

Film packing device capable of replacing gears

A film packing device capable of replacing gears includes a handle. Two ends of the handle are provided with a coupling rod and a base, respectively. A film application unit and a pair of rollers are pivotally connected between the coupling rod and the base. Two ends of each roller are provided with an axle gear, respectively. The outer toothed portions of the axle gears mesh with a drive gear and a reduction gear, respectively. The drive gear meshes with the reduction gear. Through the outer toothed portions of the axle gears to mesh with the drive gear and the reduction gear, the drive gear and the reduction gear can be installed easily. The drive gear and the reduction gear having different numbers of teeth on the outer toothed portions thereof are selective so as to change the gear ratio thereof to provide a different binding force for packing.

Owner:CHEN HSIU MAN YU

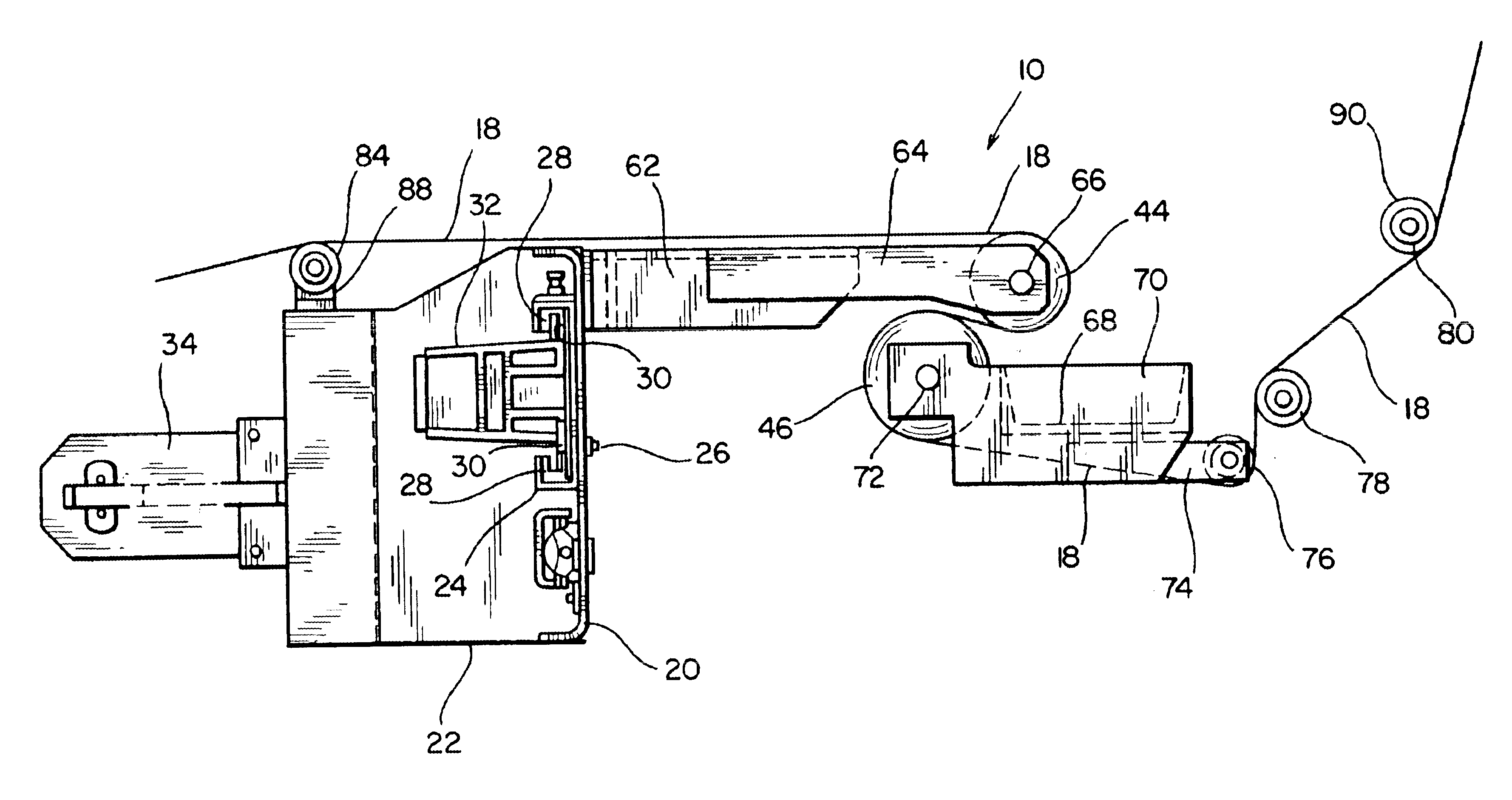

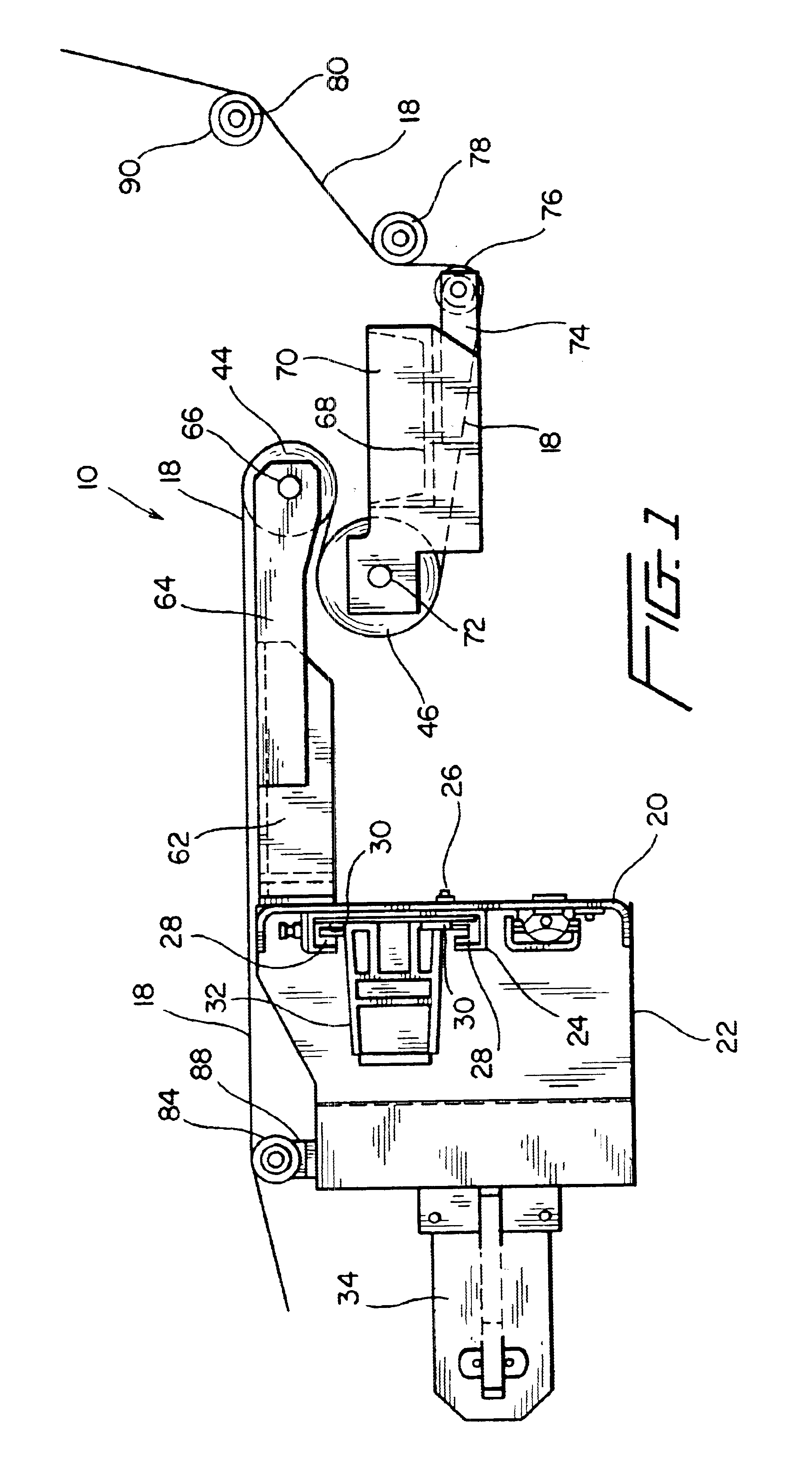

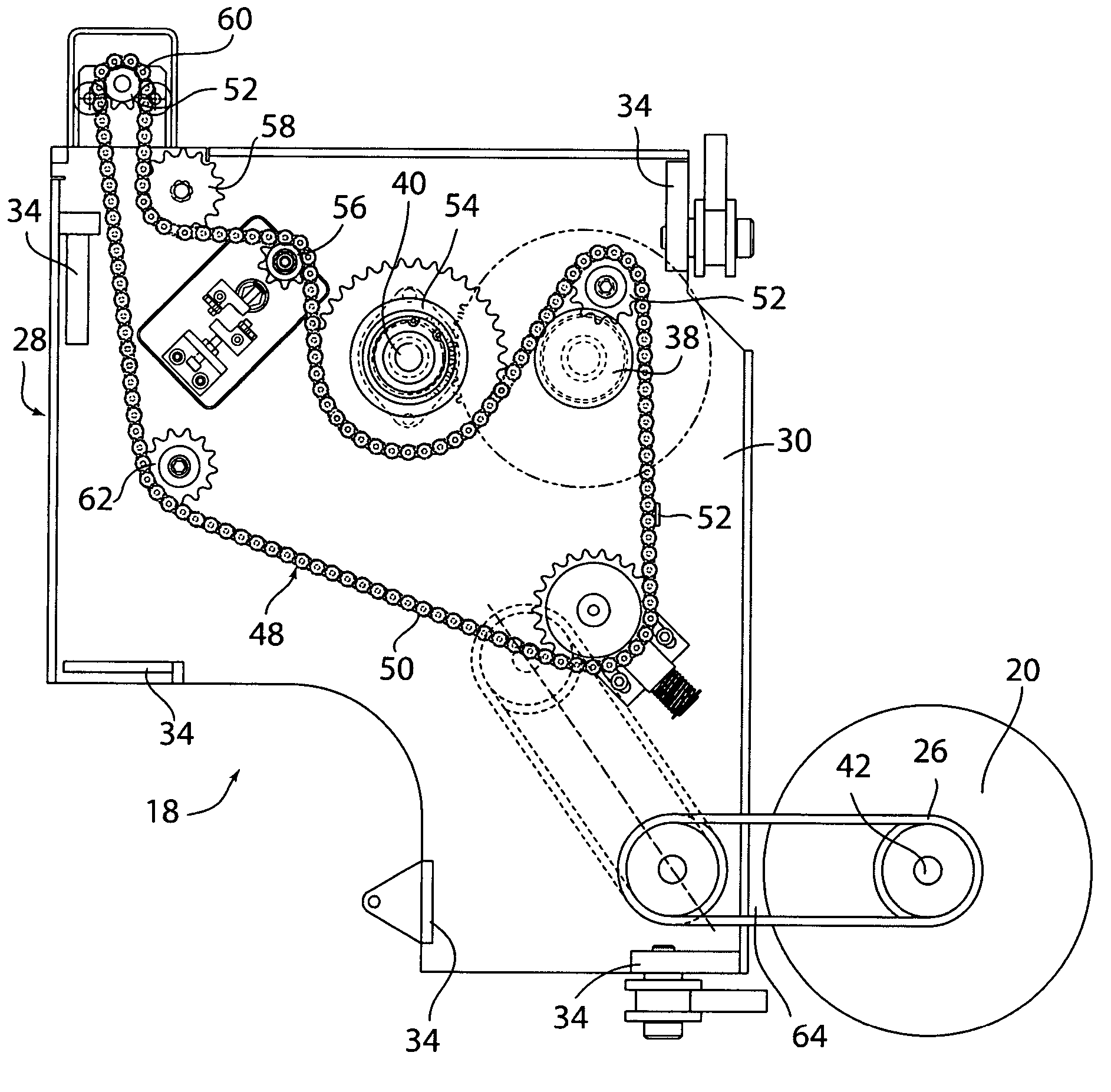

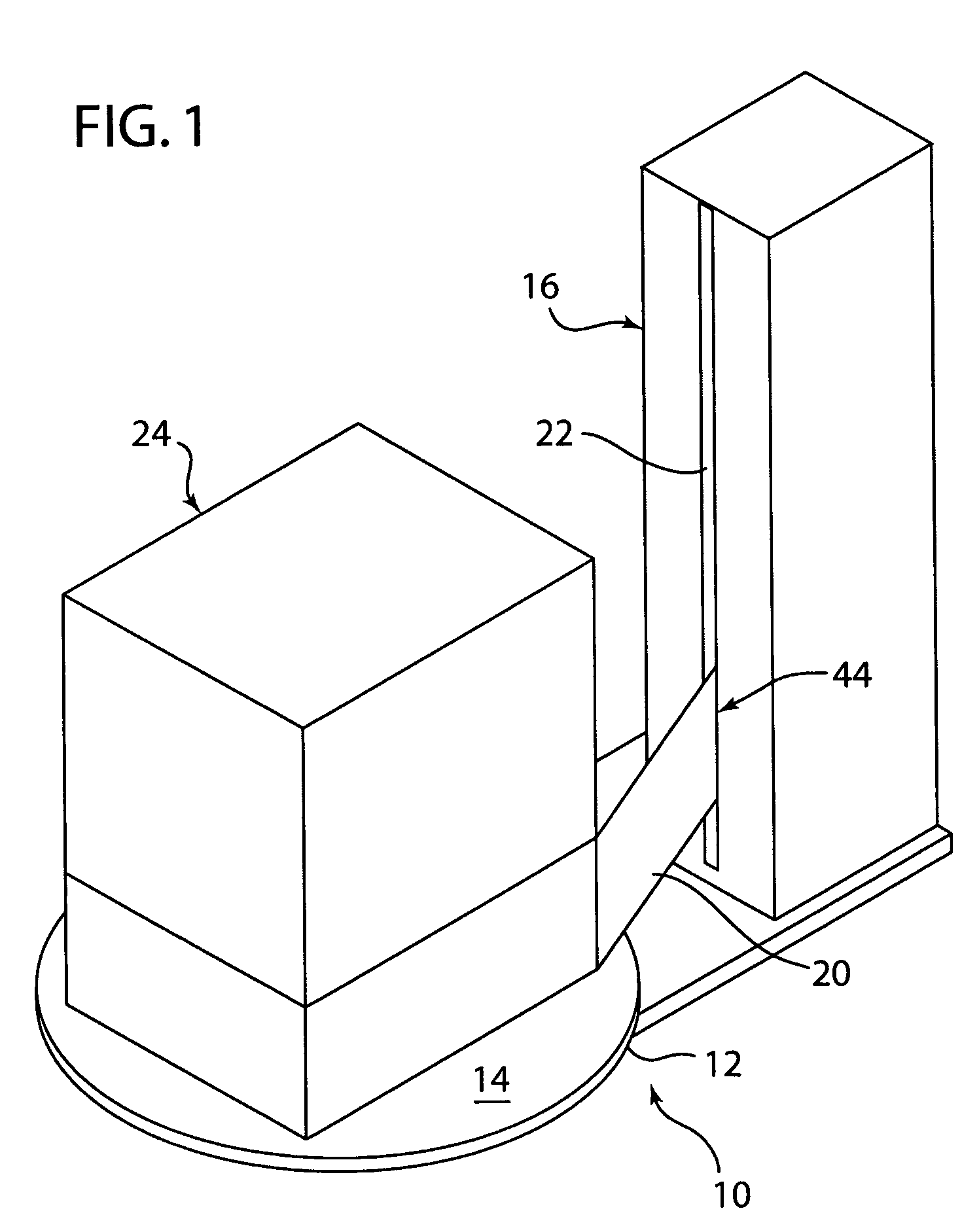

Stretch wrap threading device

A stretching device for a stretch wrap machine includes a support structure and a film support for rotatably holding a roll of stretchable film. First and second rollers are rotatably mounted to the support structure. The stretching device includes a take-off device for supporting film as it is fed from the stretching device. A power drive assembly includes a motor, and the power drive assembly is configured to rotate the first and second rollers to stretch a film between the rollers. The stretching device further includes an elongated flexible member forming a loop and having a connector adapted for securing stretchable film. A guide assembly adjacent first ends of the first and second rollers movably supports the elongated flexible member to guide stretchable film through the stretching device. A disengagable drive is operably coupled to the elongated flexible member to provide powered movement of the elongated flexible member. The drive member is disengagable from the motor such that the first and second rollers can be rotated under power while the elongated flexible member is disengaged from the motor. The stretching device may be utilized with wrapping machines having a rotatable base or a turntable, or with wrapping machines of the type having an arm that rotates to wrap film about packages. The stretching device may include a tensioning device that tensions the chain.

Owner:COUSINS PACKAGING

Demand Based Wrapping

InactiveUS20170283106A1Prestretching mechanismWeb rotation wrappingControl systemManufacturing engineering

Owner:LANTECH COM

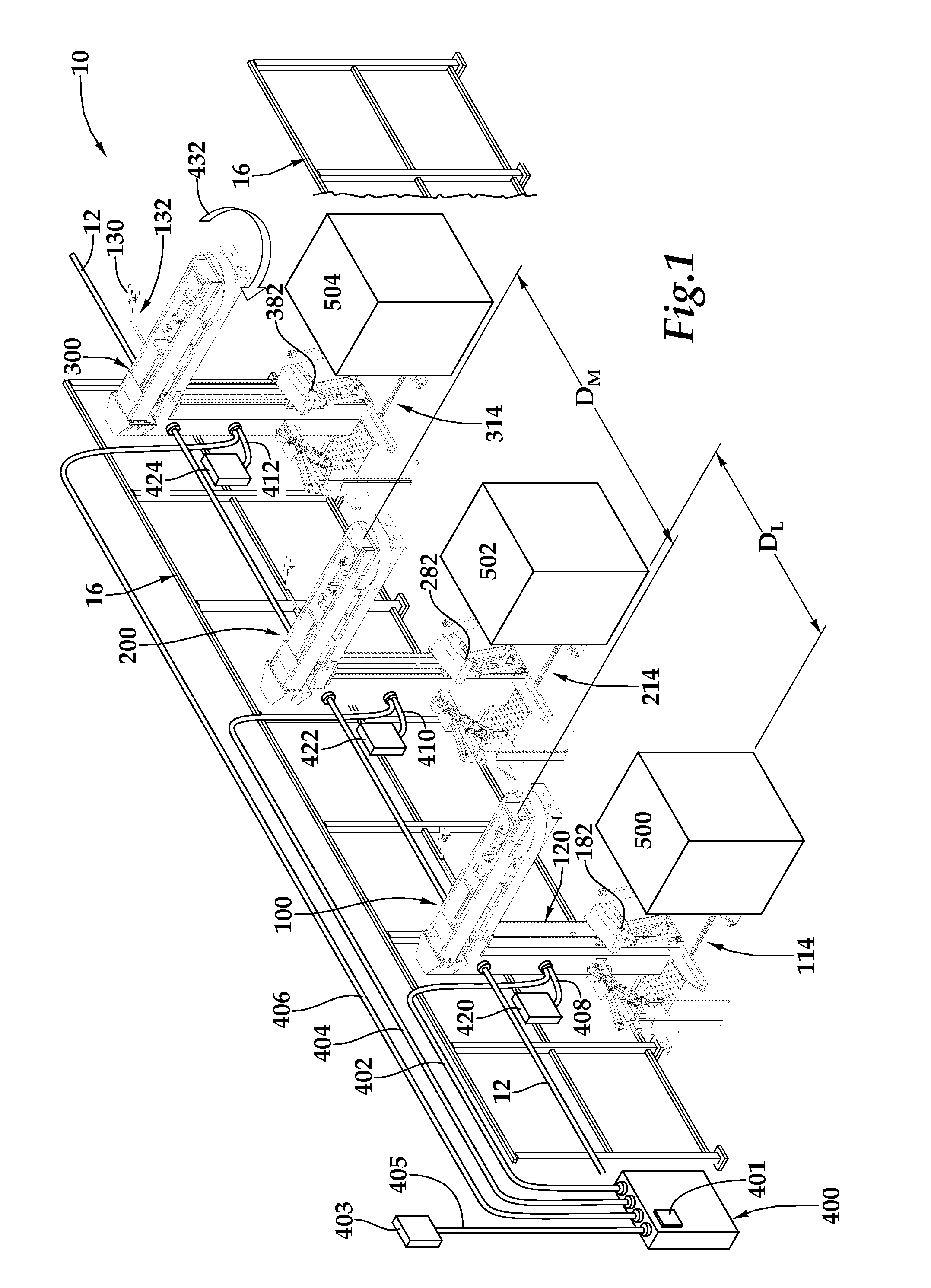

Apparatus and method for changing unwinding units in a wrapping machine, and unwinding apparatus

InactiveUS20180111709A1Automatic and rapid and efficient replacementWrapping material feeding apparatusPrestretching mechanismCouplingEngineering

An apparatus associated with a wrapping machine includes at least one unwinding unit for the wrapping machine for wrapping a load with a film, and shuttles that are movable along a path and suitable for receiving and supporting an unwinding unit to be replaced and to be dismantled from the wrapping machine, or a new unwinding unit to be mounted on the wrapping machine. The shuttles operate along a substantially horizontal operating direction to dismantle and receive from the wrapping machine an unwinding unit to be replaced or to transfer and mount on the wrapping machine a new unwinding unit. The apparatus includes a supporting unit fixed to the wrapping machine and arranged to be coupled to, and supported by, the unwinding unit, the unwinding unit including a first coupling device, and the supporting unit including a second coupling device, the first coupling device and the second coupling device being mutually coupled or uncoupled along the operating direction.

Owner:AETNA GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com