Apparatus and method for changing unwinding units in a wrapping machine, and unwinding apparatus

a technology of unwinding unit and unwinding apparatus, which is applied in the direction of wrapping/bundling articles, external supports, packaging, etc., can solve the problems of reducing machine productivity, laborious and slow, and determining the increase of the time required for the unwinding unit, so as to achieve compact and inexpensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

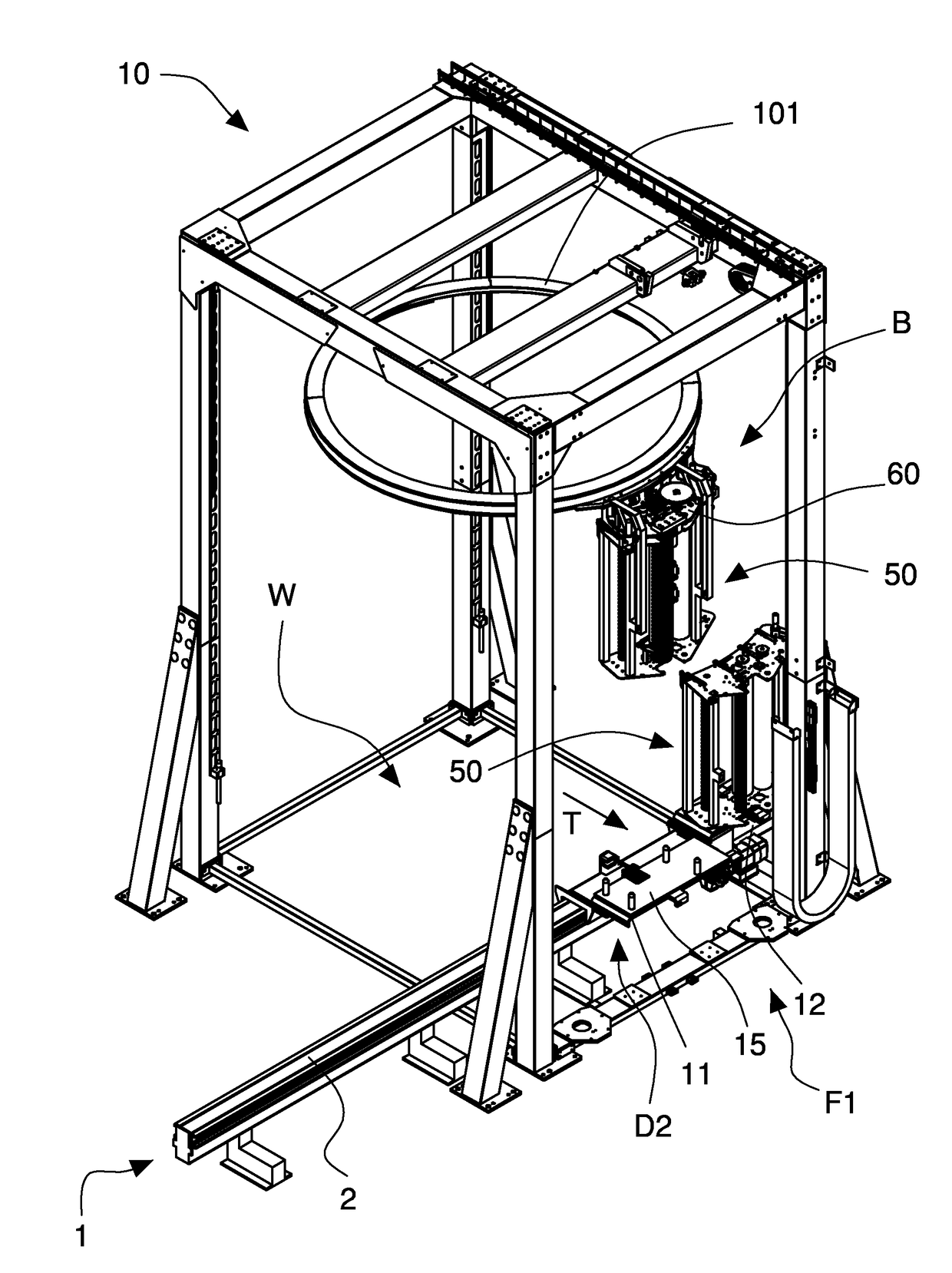

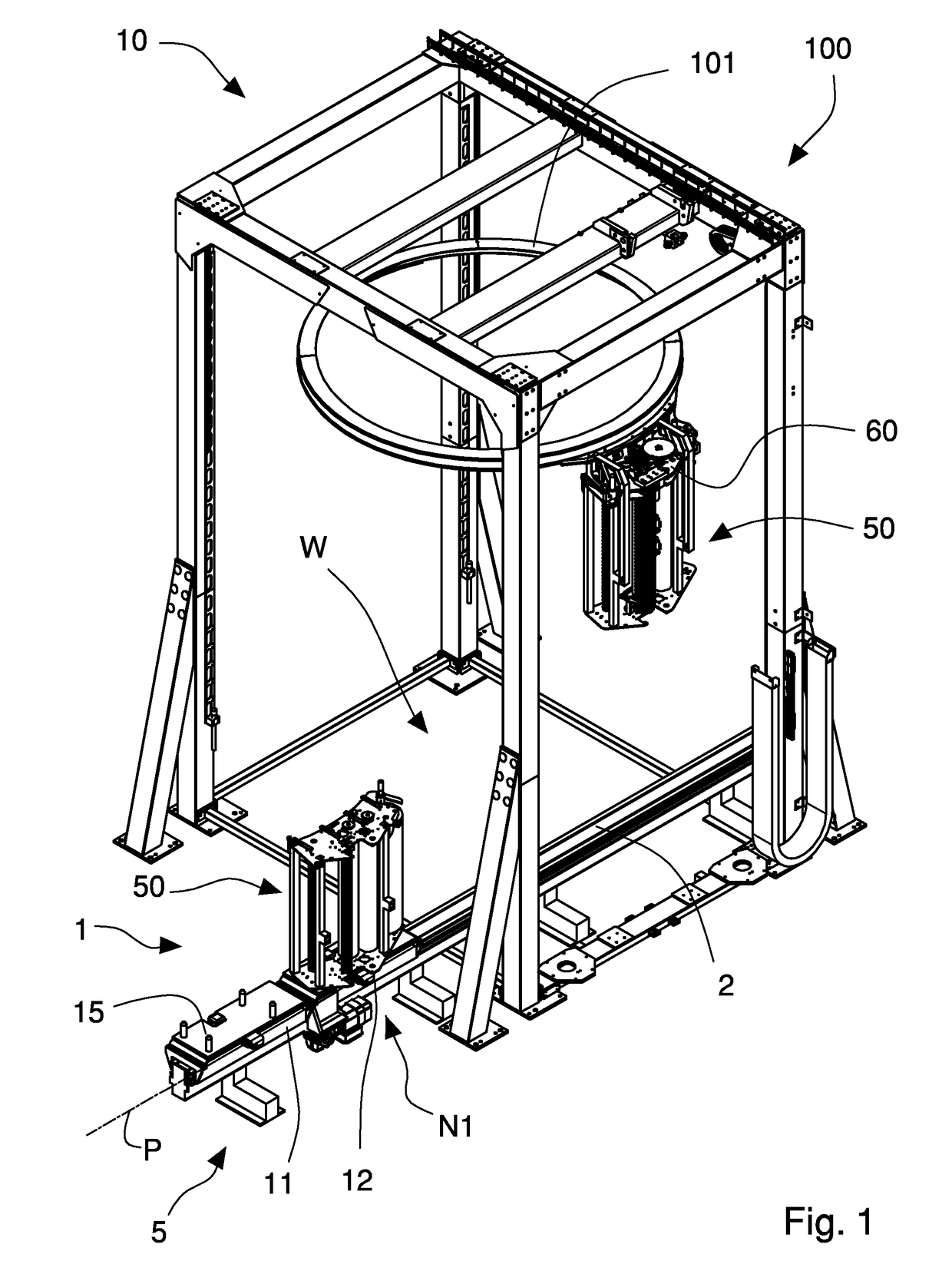

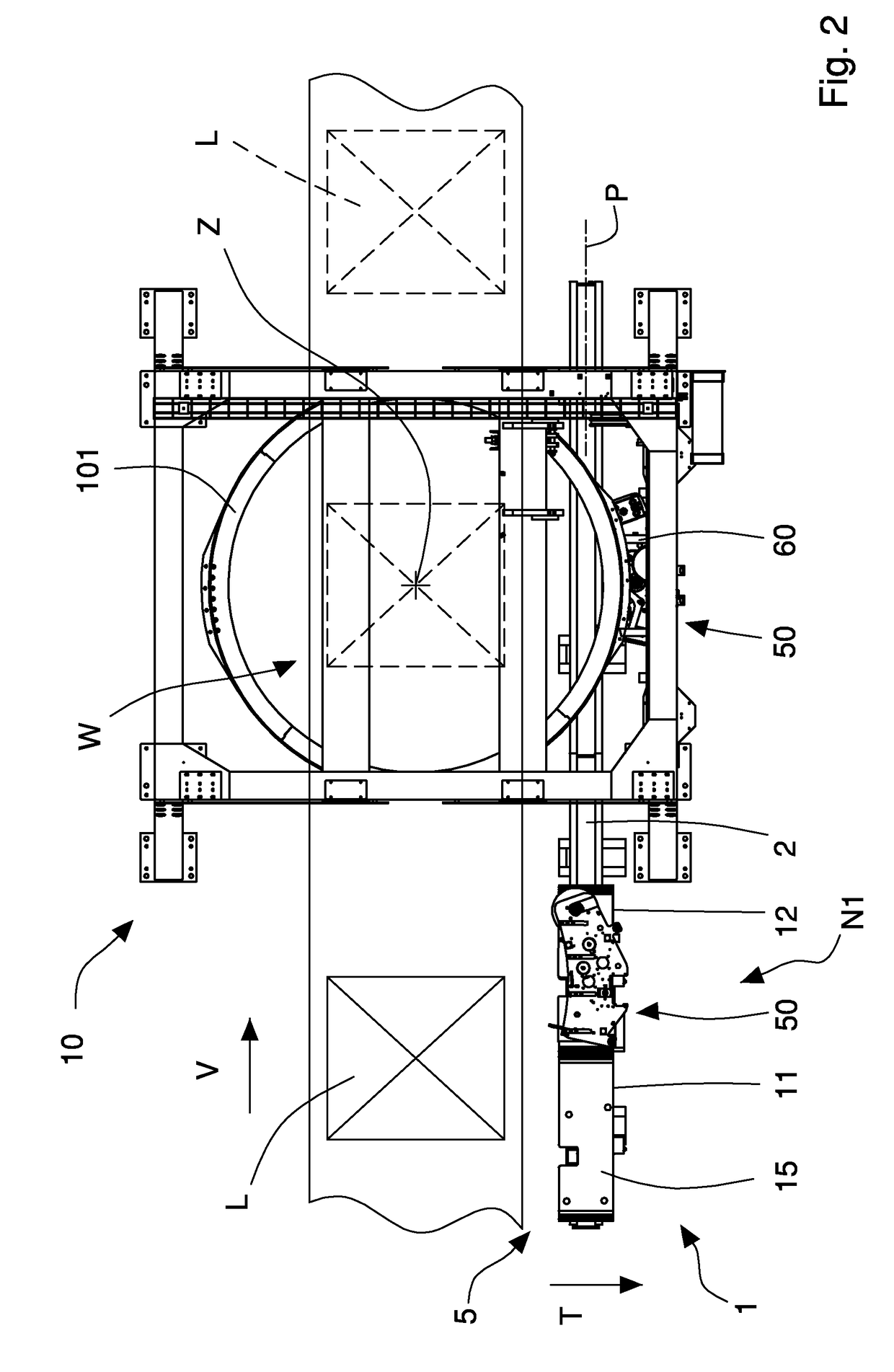

[0062]With reference to the FIGS. 1 to 3, there is illustrated the apparatus I according to the invention, arranged for changing unwinding units 50 of, and associated with a wrapping machine 10 for wrapping a load L with a film 4 of extensible synthetic plastic material.

[0063]The apparatus 1 of the invention includes at least one unwinding unit 50, a supporting unit 60 associated with the wrapping machine 10, and shuttles 11, 12 for moving the unwinding unit.

[0064]The wrapping machine 10 is, for example, provided with a horizontal ring 101, which is rotating around a vertical wrapping axis Z, and which is vertically movable so as to wrap the load L with helical coils or bands of film 4. The ring 101 is rotatably supported by a sliding frame (not illustrated) that is linearly movable along a vertical direction that is substantially parallel to the above-mentioned wrapping axis Z. On the ring 101, a supporting unit 60 is fixed, to which an unwinding unit 50 of the film 4 can be revers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wrapping angle | aaaaa | aaaaa |

| winding angle | aaaaa | aaaaa |

| winding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com