Patents

Literature

1831results about How to "Improve tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

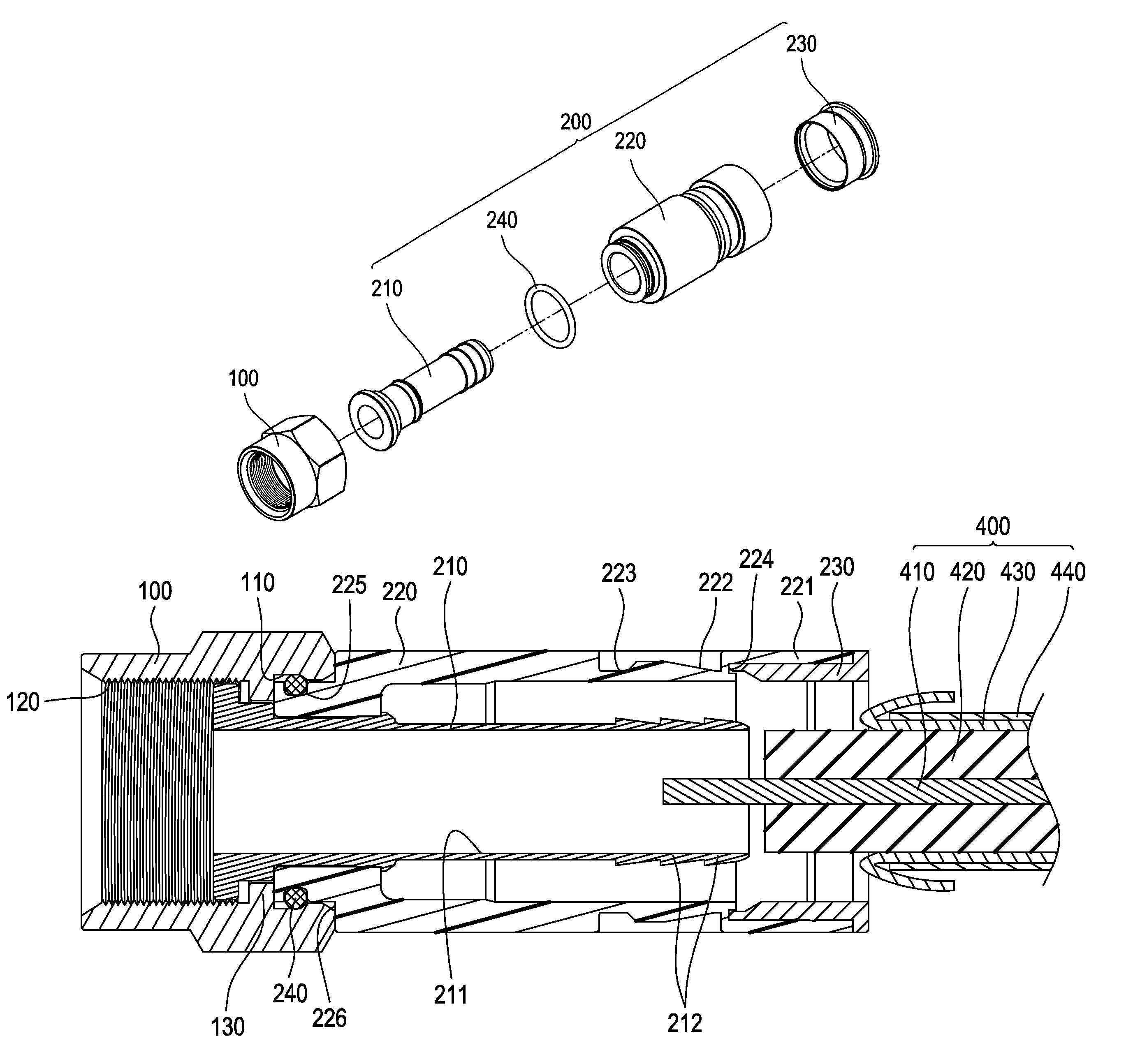

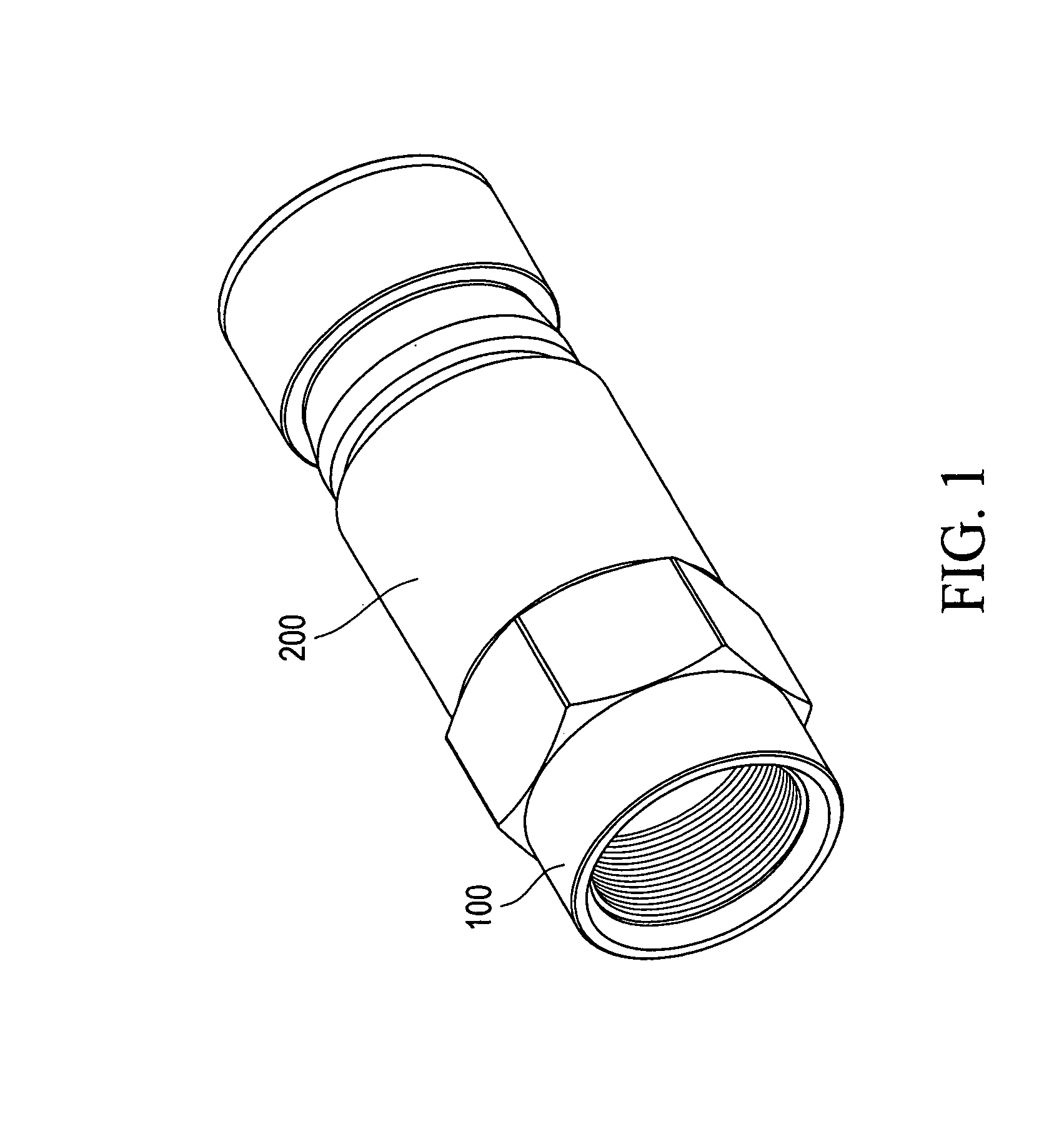

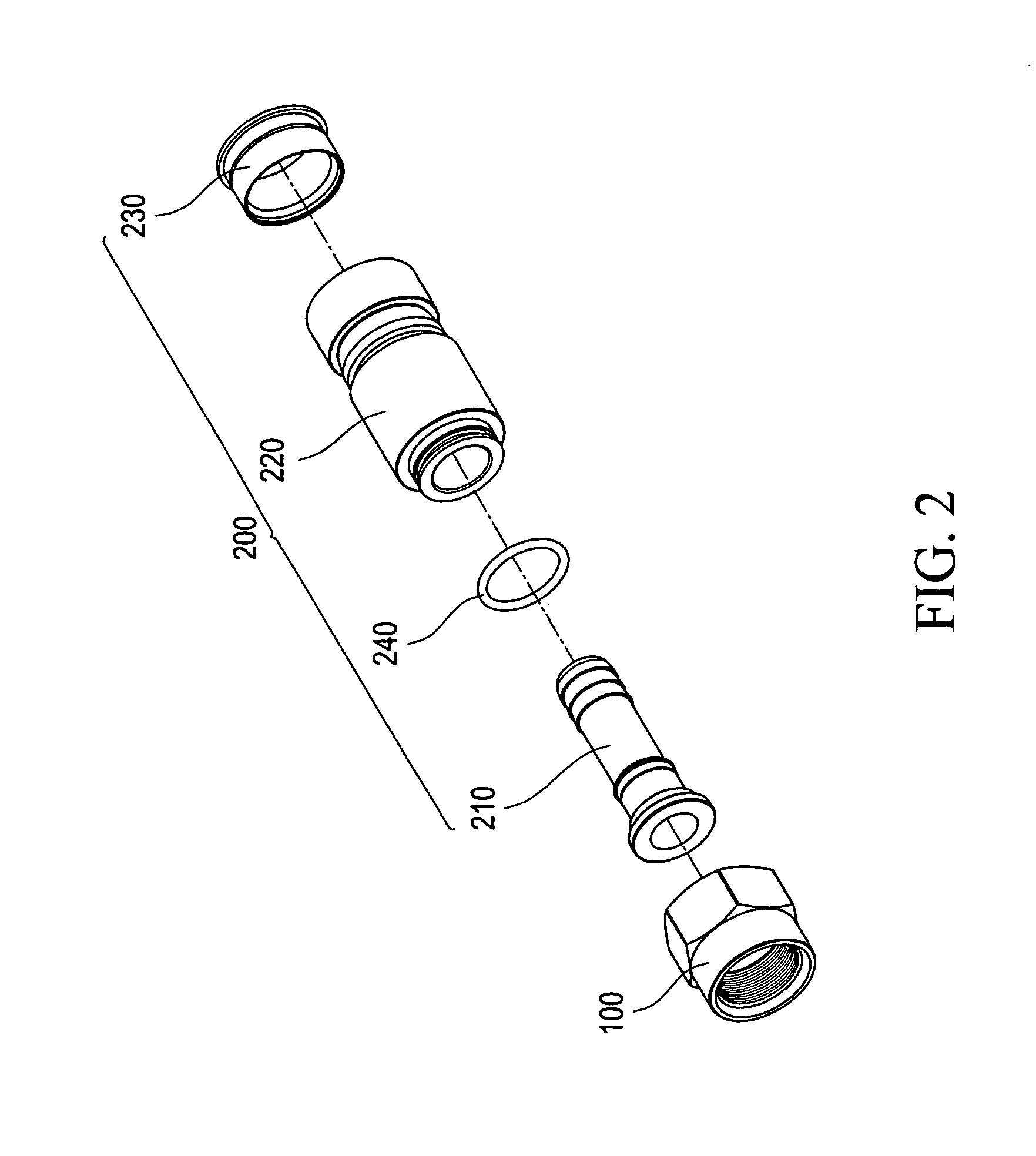

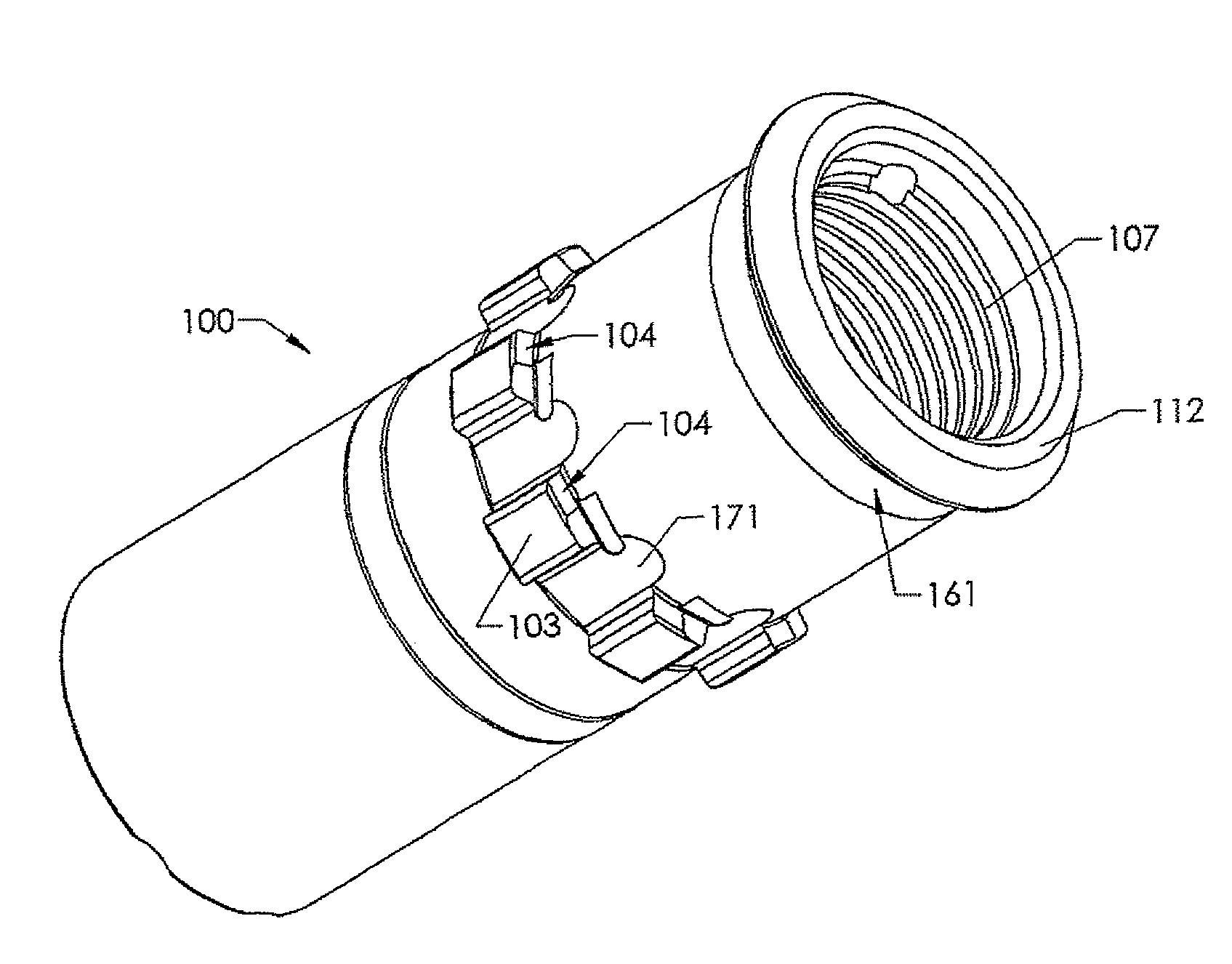

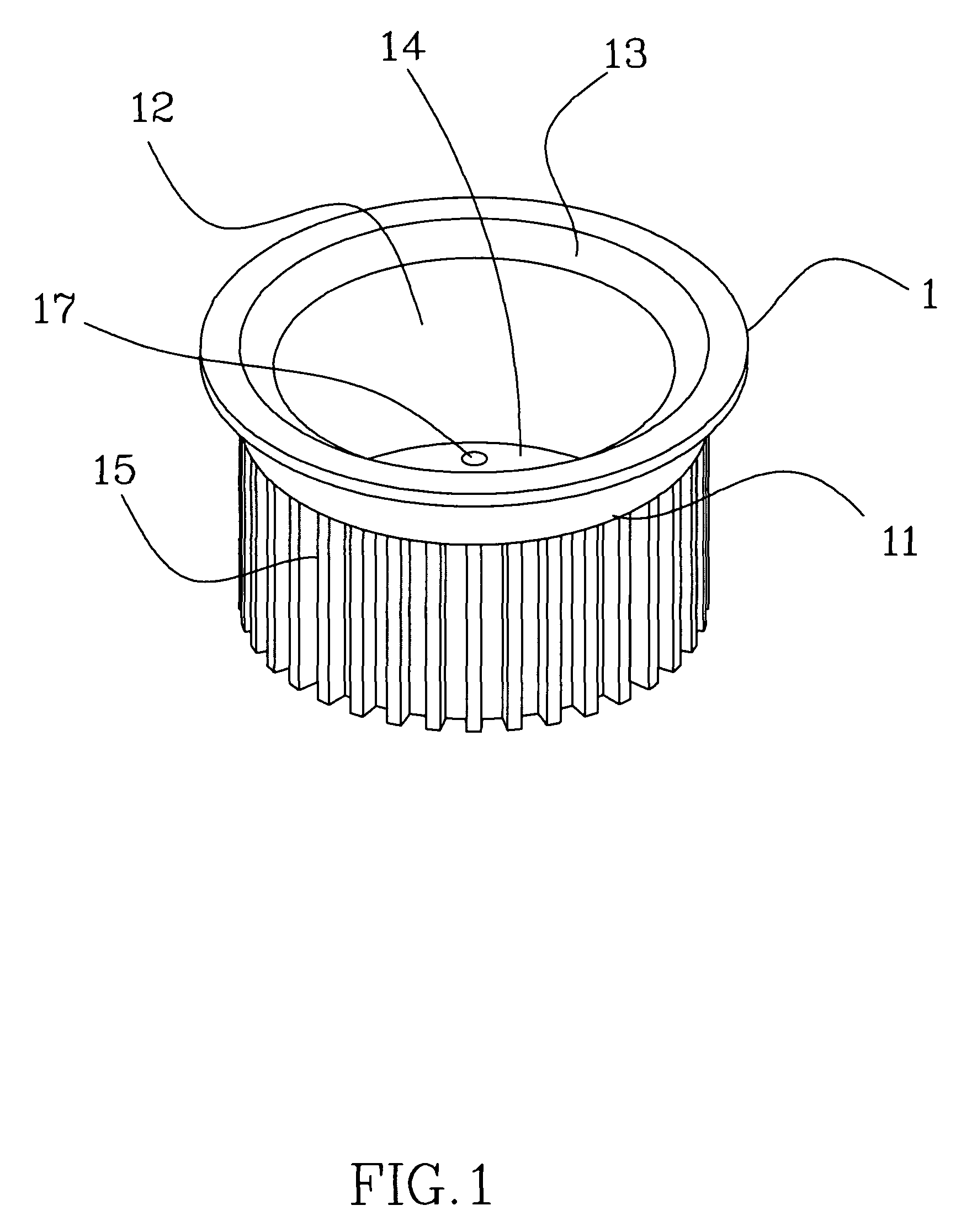

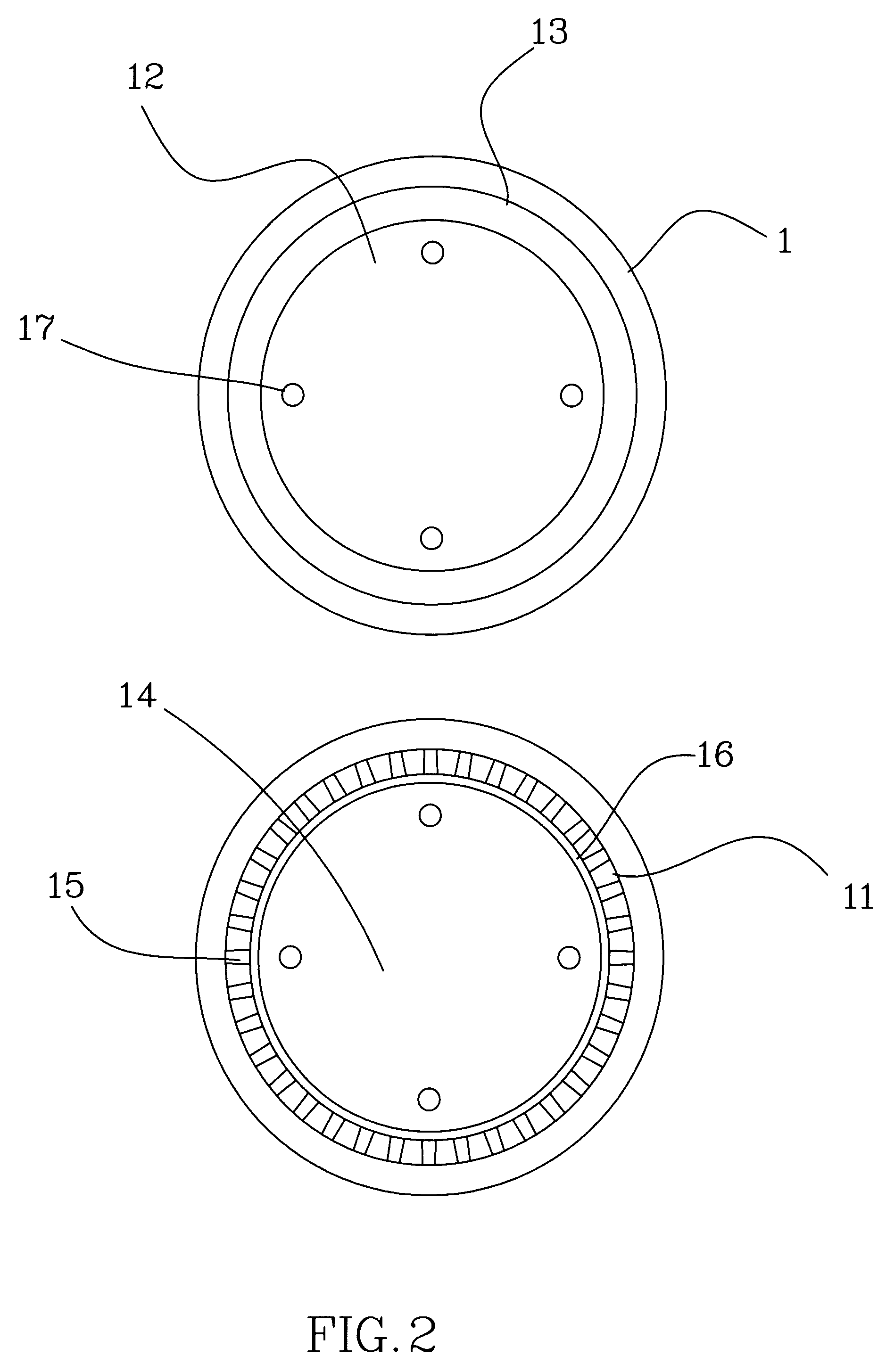

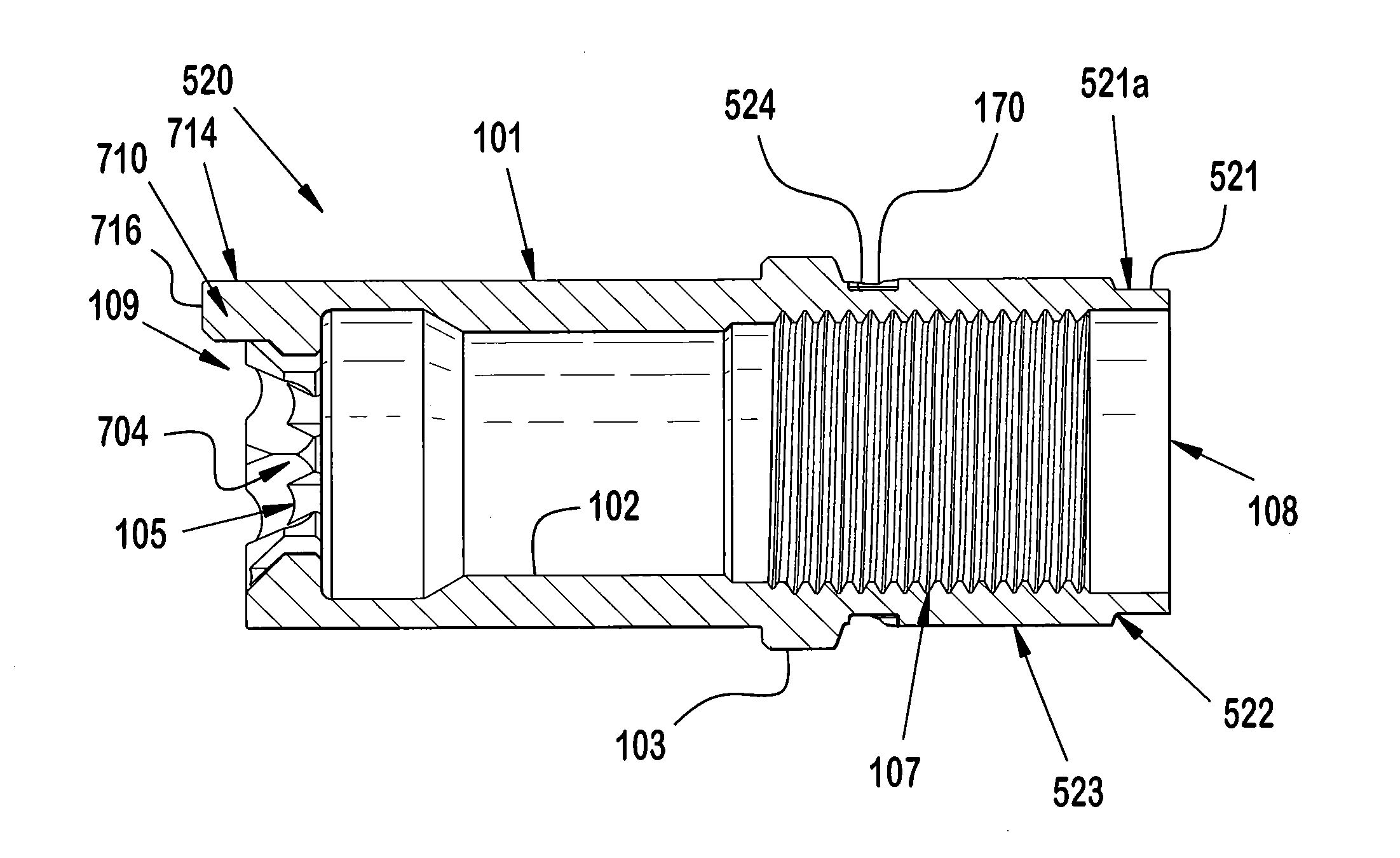

Coaxial cable connector enhancing tightness engagement with a coaxial cable

ActiveUS7850487B1Easy to operateImprove tightnessElectrically conductive connectionsCoaxial cableEngineering

A coaxial cable connector includes a connection head and a sleeve assembly coupled to the connection head. The sleeve assembly includes a tube, a sleeve, and a metal collar. The sleeve assembly receives a coaxial cable to insert therein from a rear end thereof in such a way that an insulator layer of a front end of the coaxial cable is set substantially flush with a front end of the tube and the sleeve assembly is then acted upon by a force applied by a tool to drive the metal collar frontward against the contact section of the sleeve for breaking and separating the retention section of the sleeve from the sleeve to further move frontward along a surface of the buffering section of the sleeve. Due to a constraint imposed by the metal collar, the buffering section is compressed downward to enhance tightness of engagement between the coaxial cable and the connector.

Owner:EZCONN

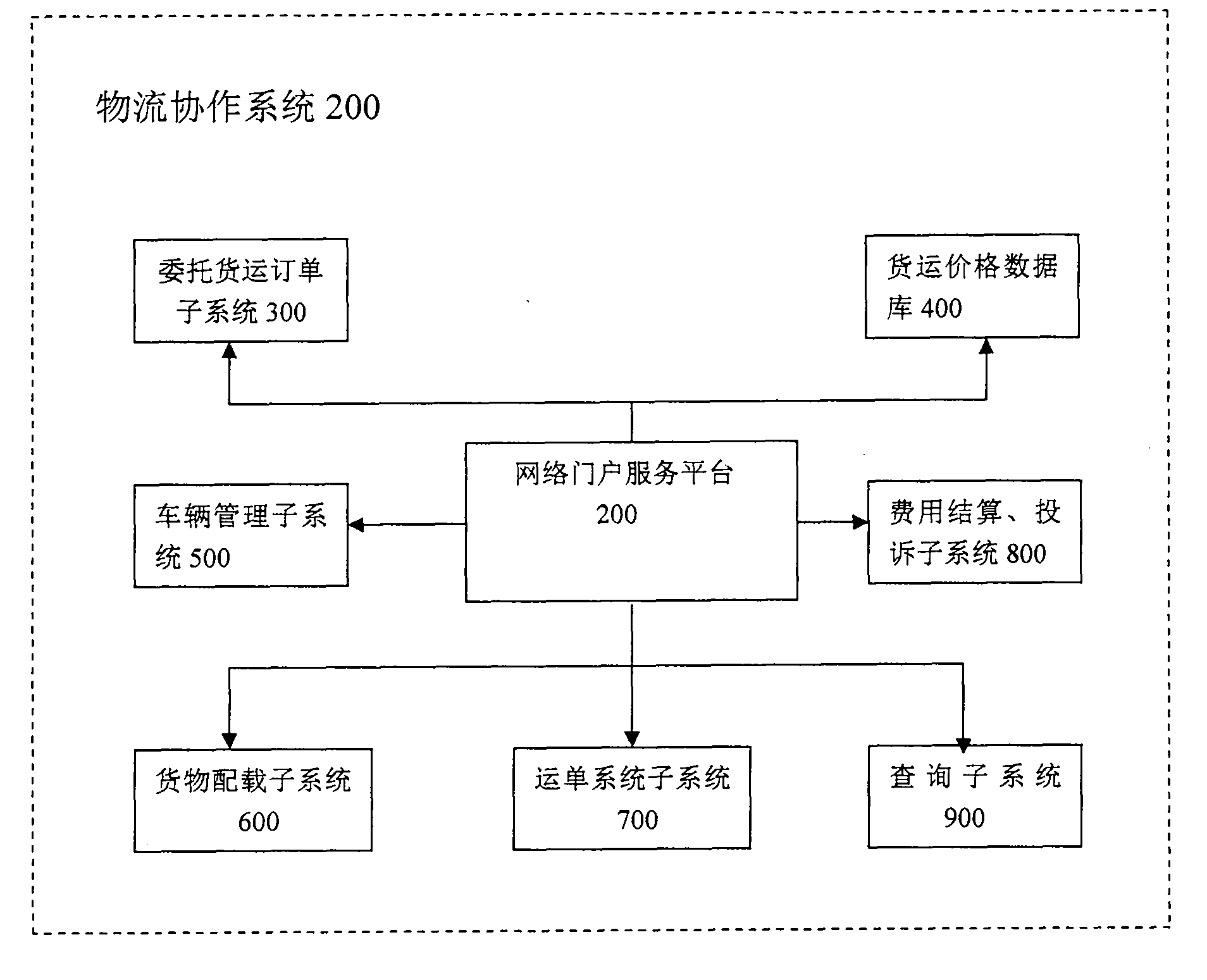

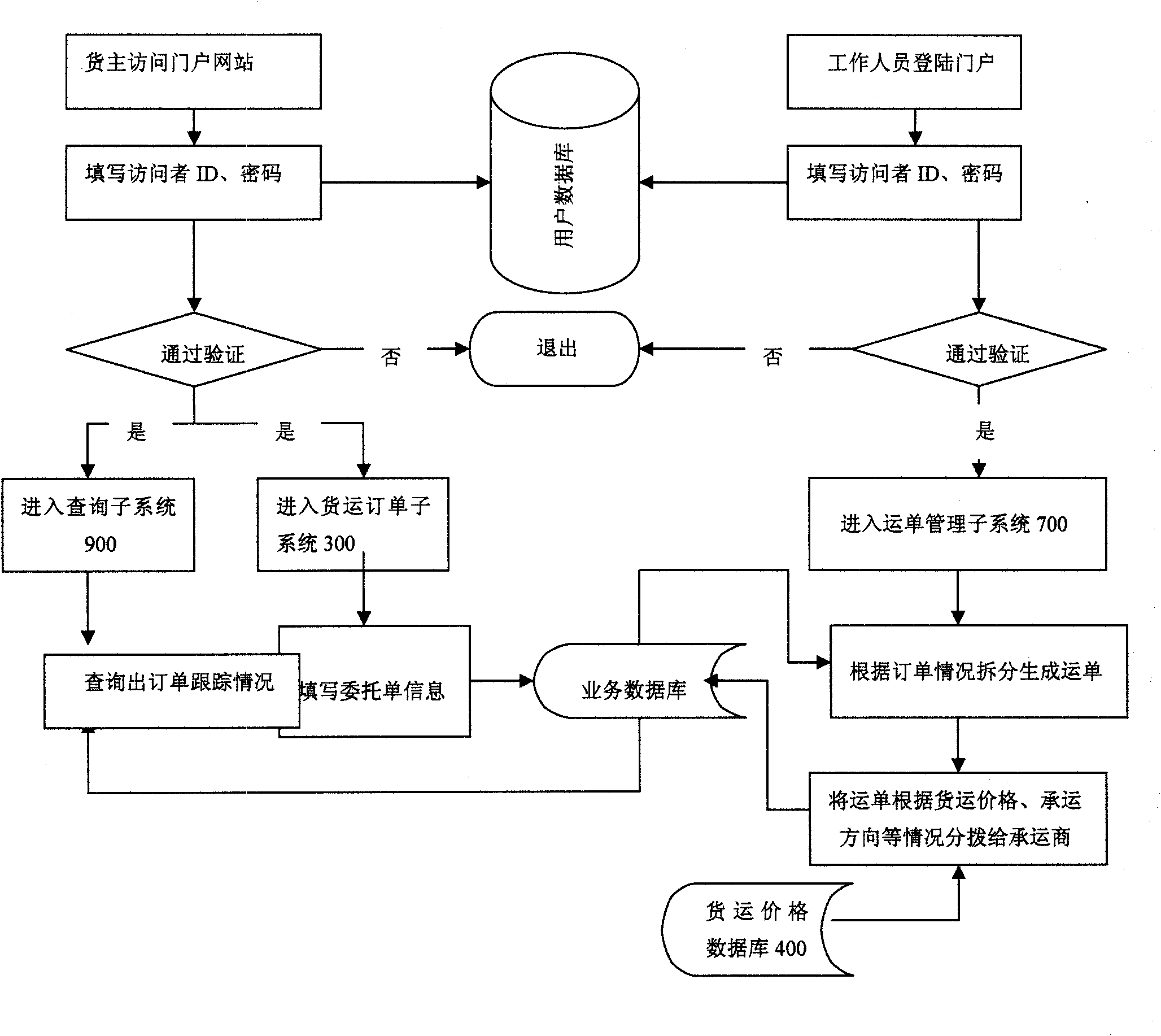

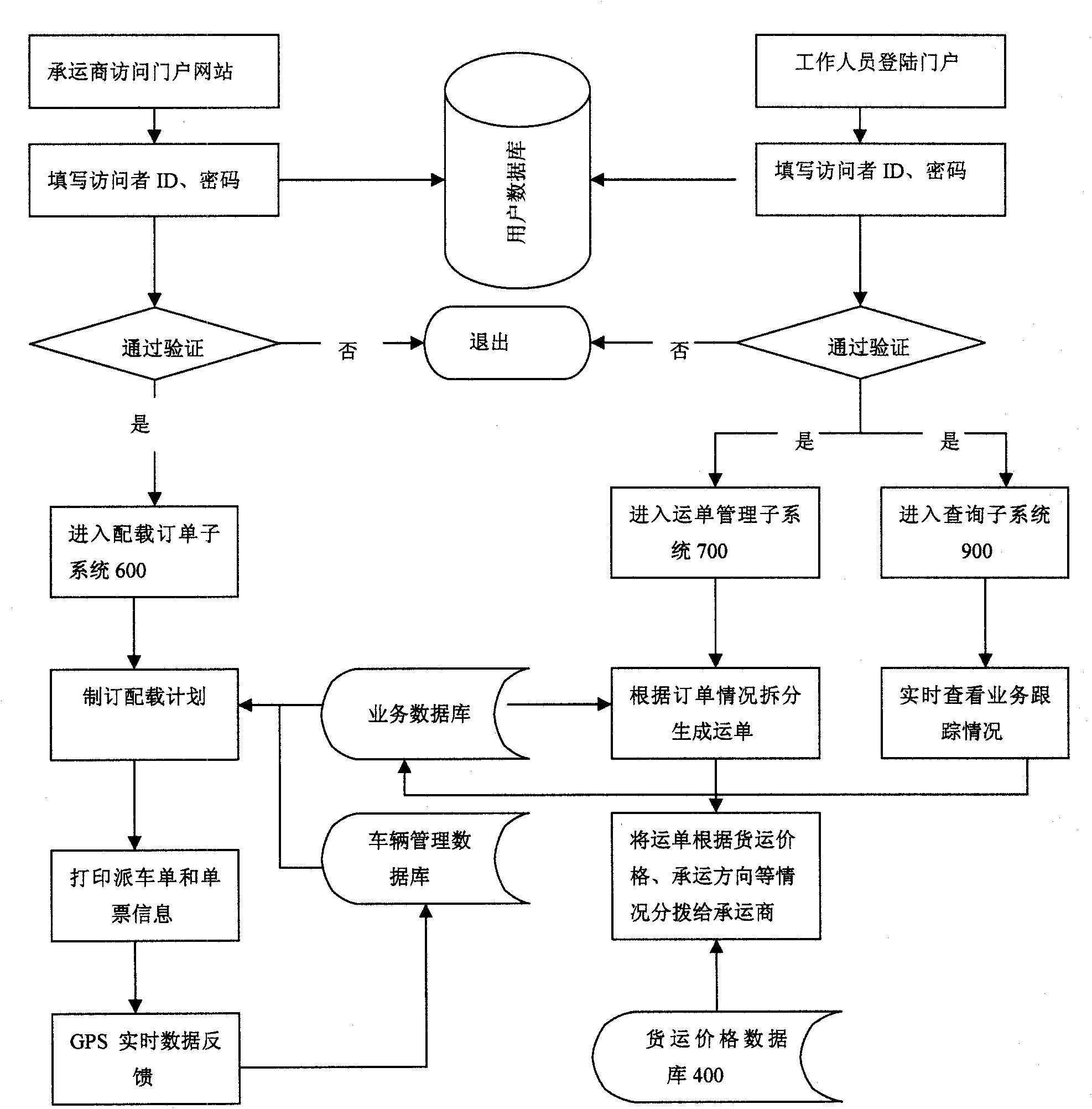

Transportation management method based on joint collaboration of logistics company, shipper and carrier

InactiveCN101923666AHigh transparencyImprove tightnessLogisticsLogistics managementNetworking protocol

The invention relates to a transportation management method based on the joint collaboration of a logistics company, a shipper and a carrier. The transportation management method comprises the following steps: the logistics company creates a transportation management system network platform; the shipper and the carrier visit the system network platform through the network protocol, and the logistics company signs a contract with the shipper and the carrier and delivers order information with forwarding order number according to the contract to the carrier and the shipper; the carrier adjusts according to the vehicle scheduling plan and single vote information and feedbacks the information to the system network platform; the logistics company performs expense settlement based on the information, accepts complaints and settles claims; and the network platform provides a real-time query system, so that the relevant information of accepted goods and the account statement can be checked in real time. The invention has the advantages that the shipper, the logistics company and the carrier share the total process of forwarding transportation, so that the competitiveness of a supply chain is increased; the information asymmetry caused by regional difference is solved, a supply of goods can be organized at different places, so that return vehicles of the carrier can be avoided from being empty, and benefits are brought for three parties of supplier, customer and service provider.

Owner:上海美华系统有限公司

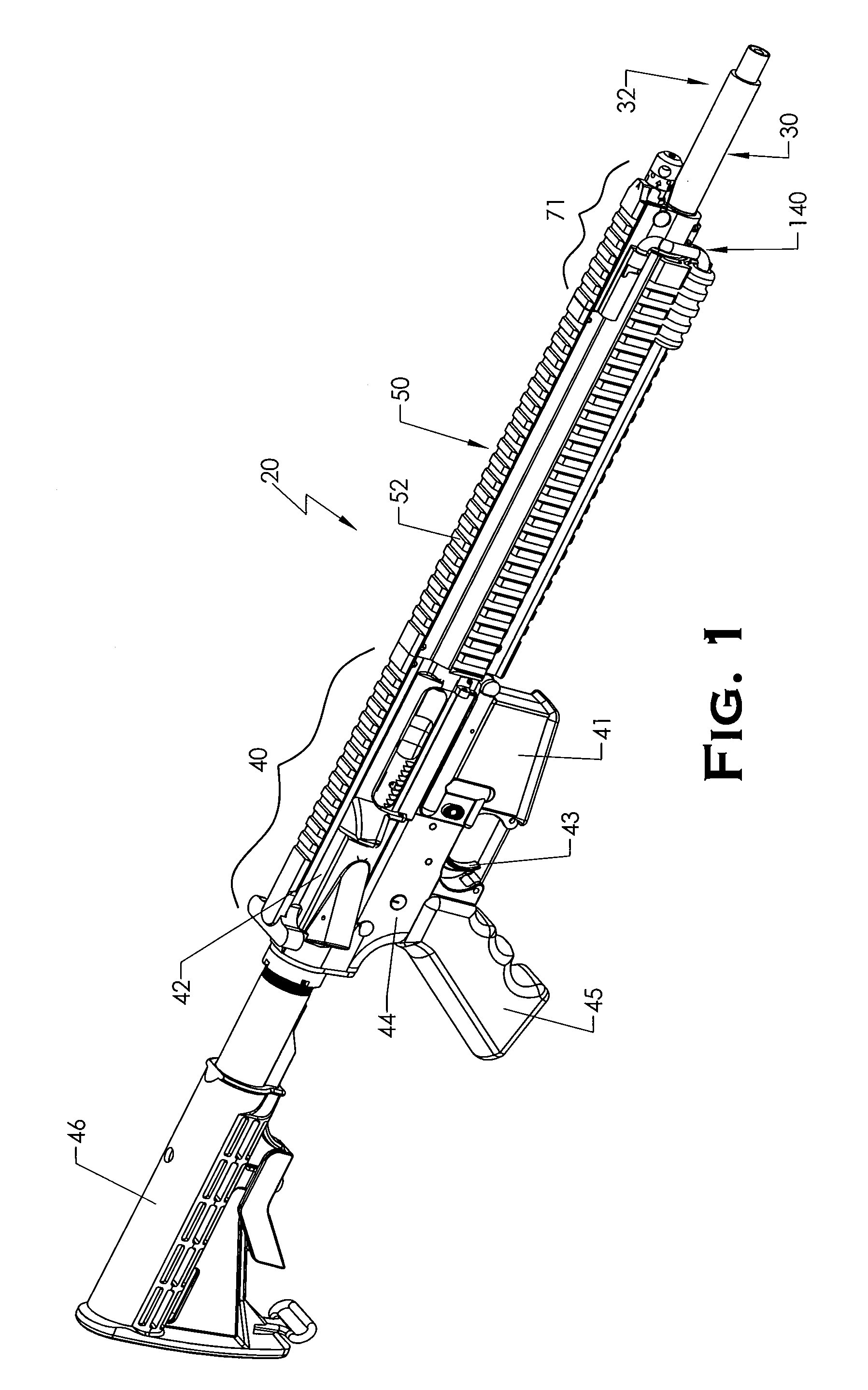

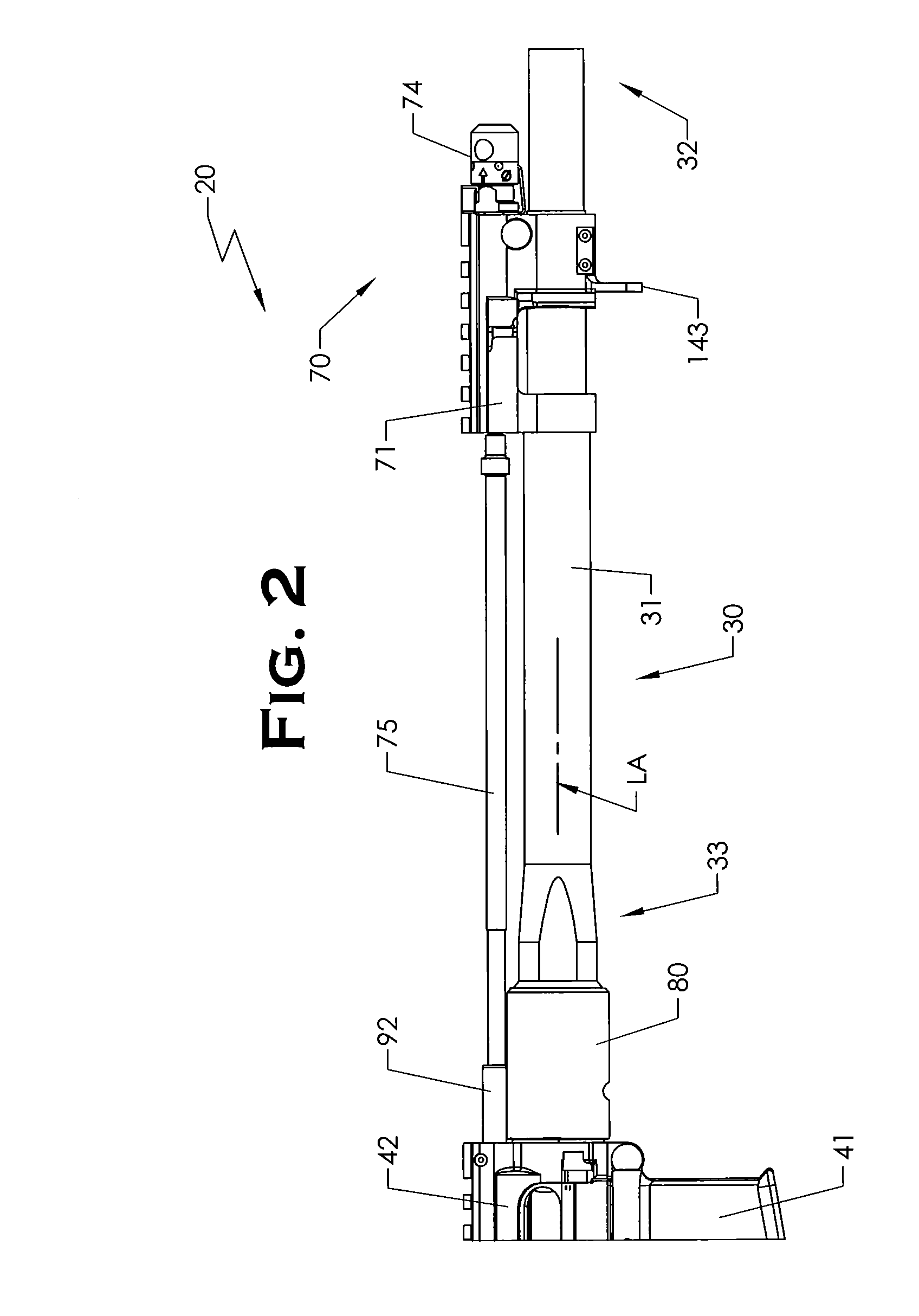

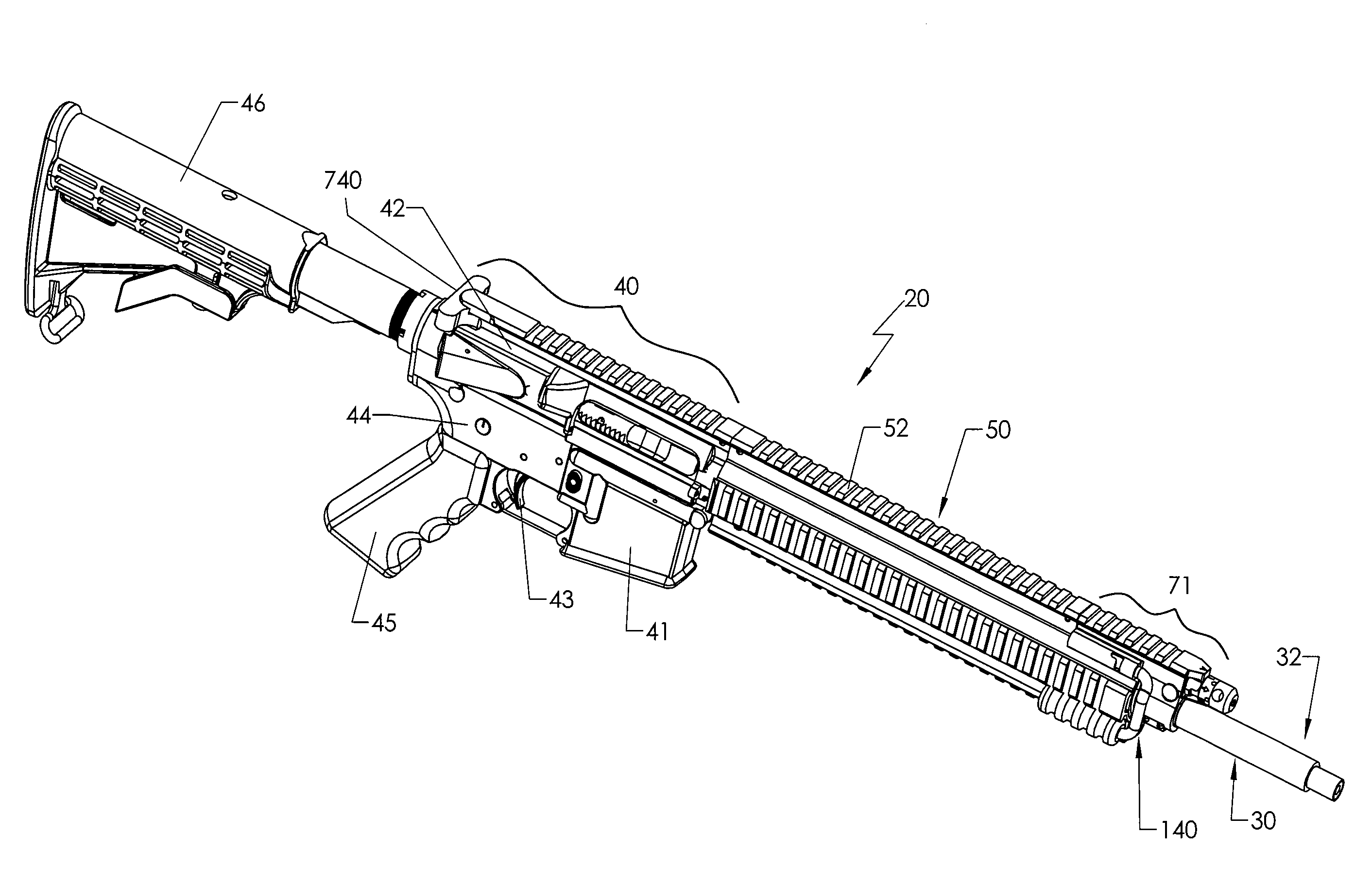

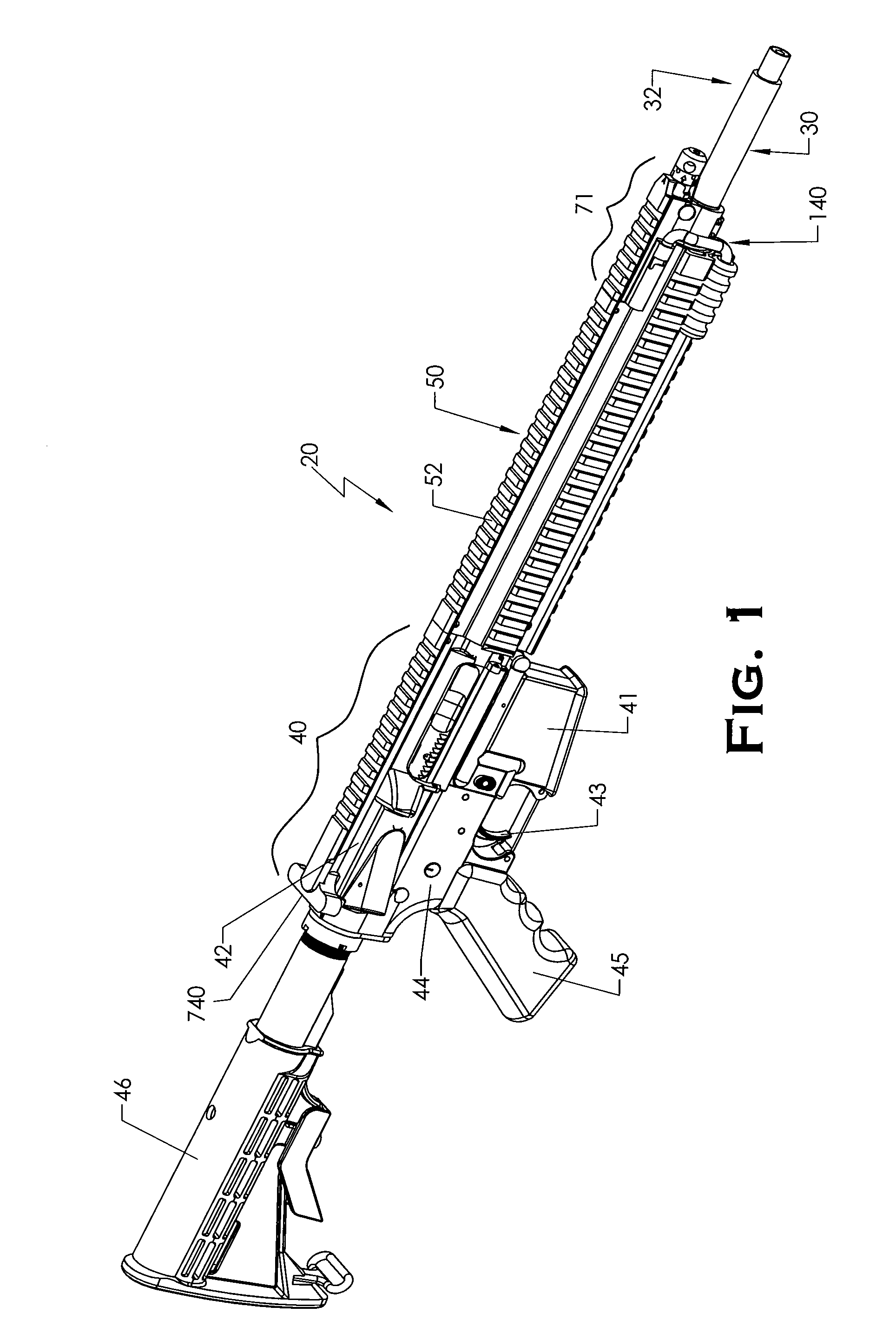

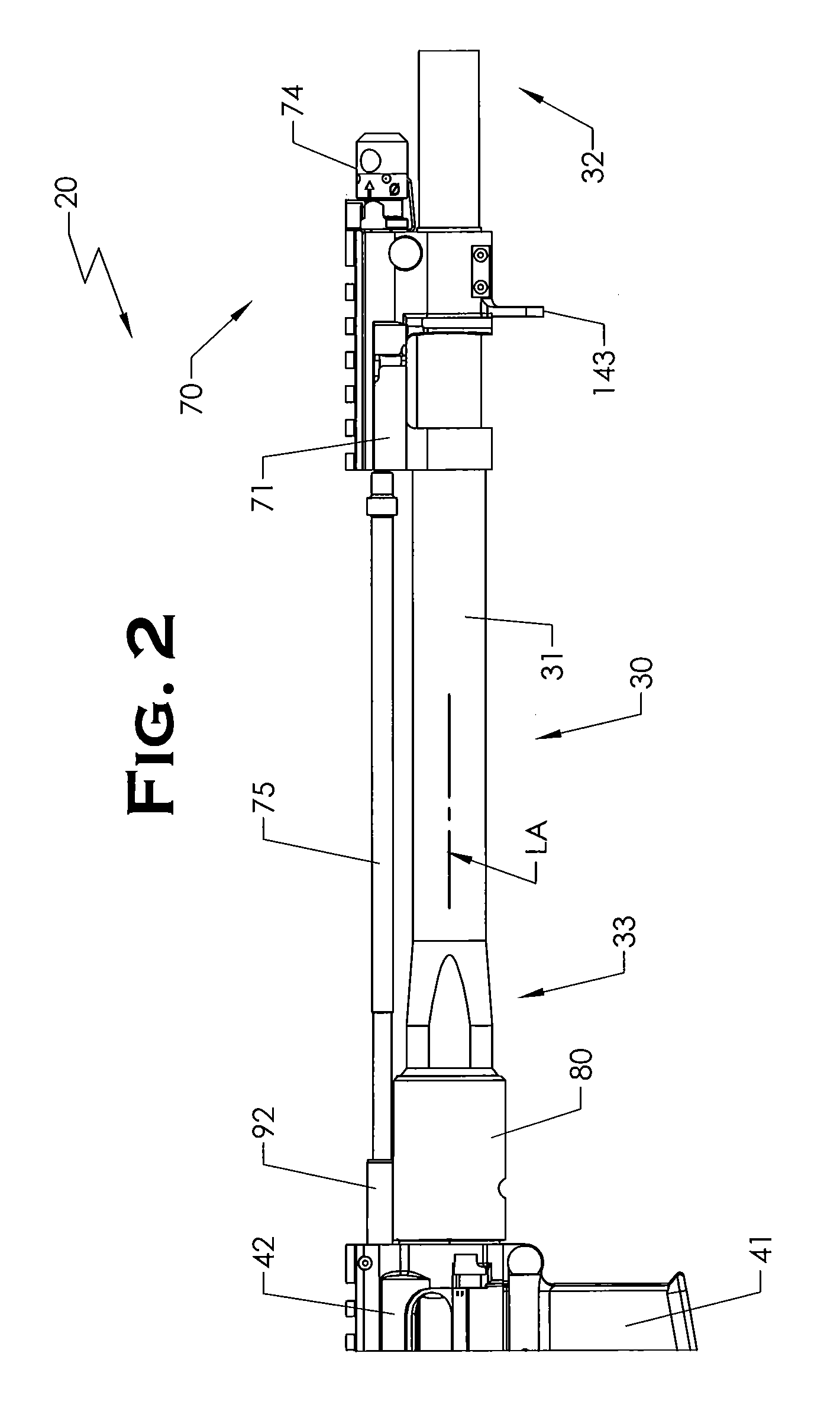

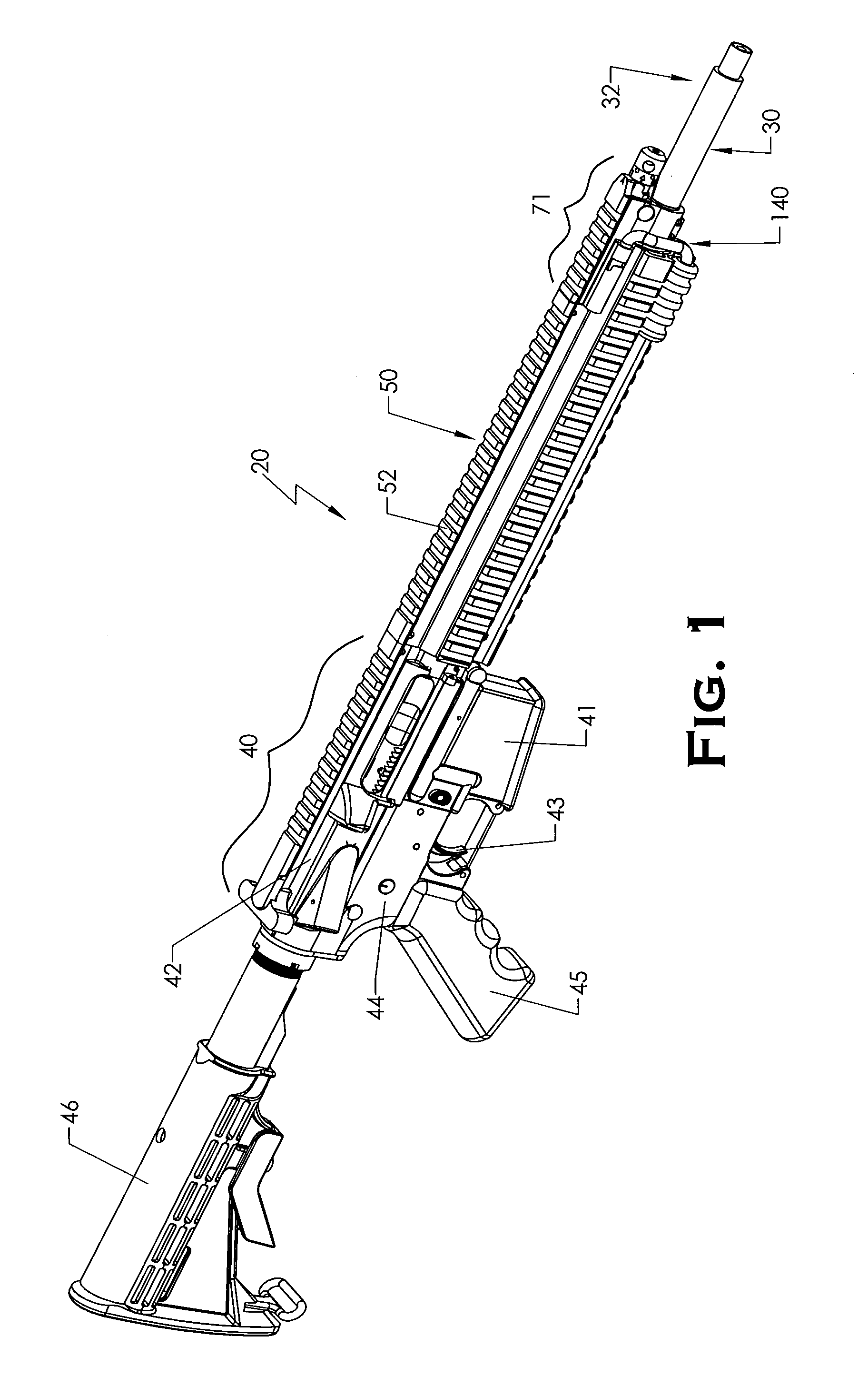

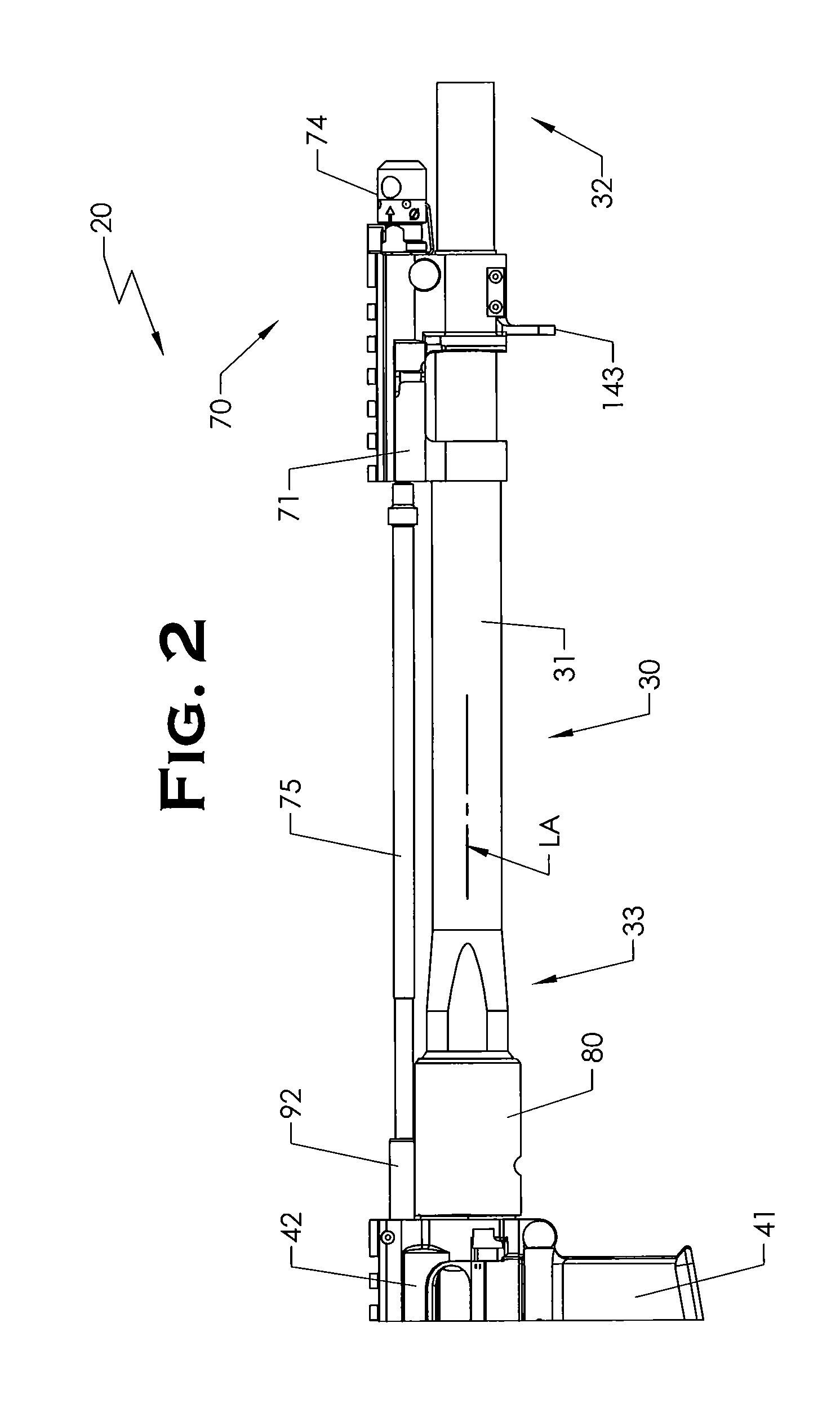

Firearm barrel retaining system

A barrel retaining system for a firearm includes a firearm receiver having a barrel nut coupled thereto and a barrel assembly, which in one embodiment may include a barrel with a barrel extension coupled thereto. The barrel extension includes a plurality of barrel locking lugs that rotatably engage corresponding locking elements disposed on the barrel nut. The barrel extension may further include a flange that may engage one end of the locking elements of the barrel nut and the barrel locking lugs may engage an opposite end of the locking elements to wedge the locking elements therebetween for securing the barrel extension to the barrel nut. The firearm may be an autoloading rifle in some embodiments.

Owner:STURM RUGER & CO INC

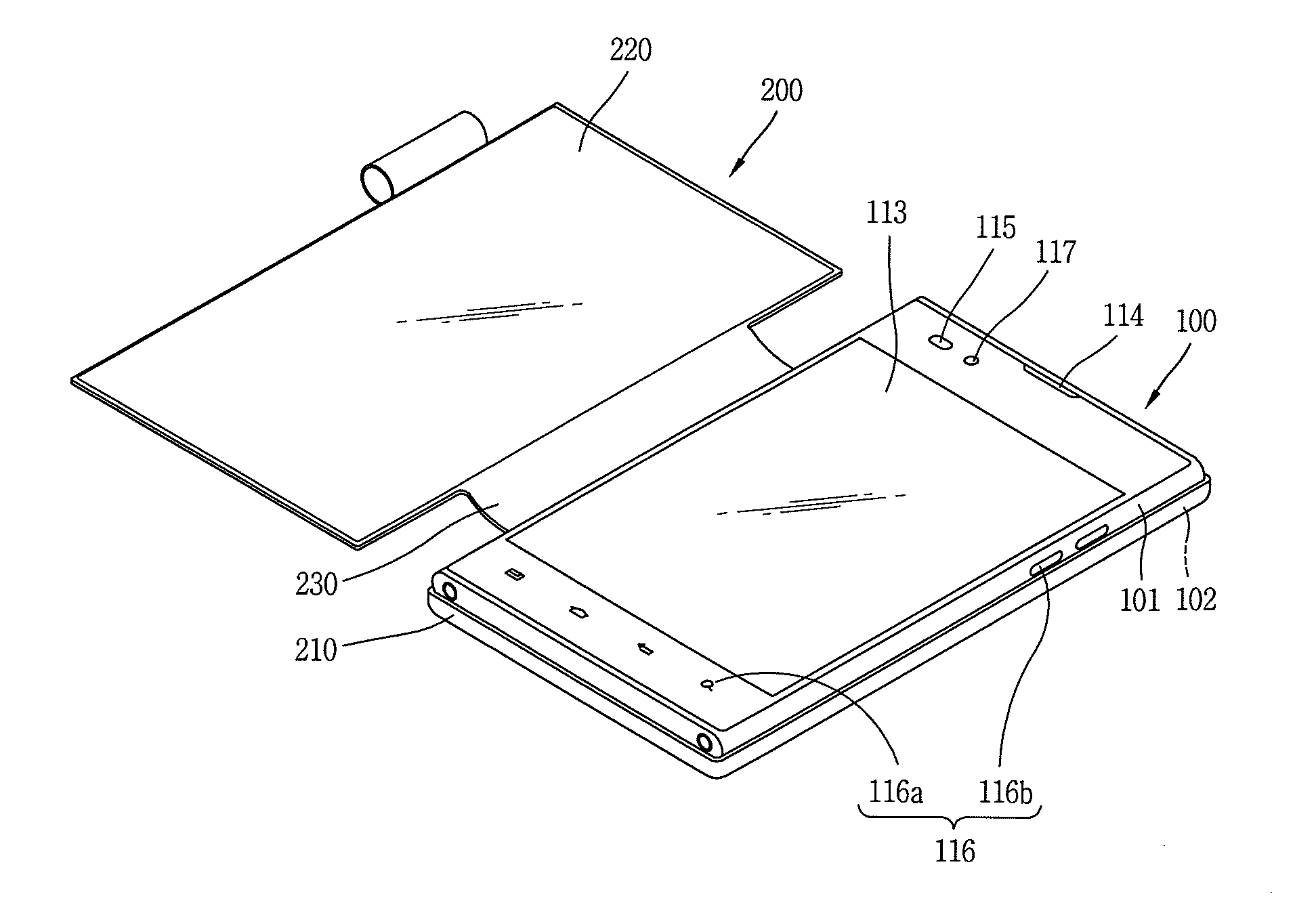

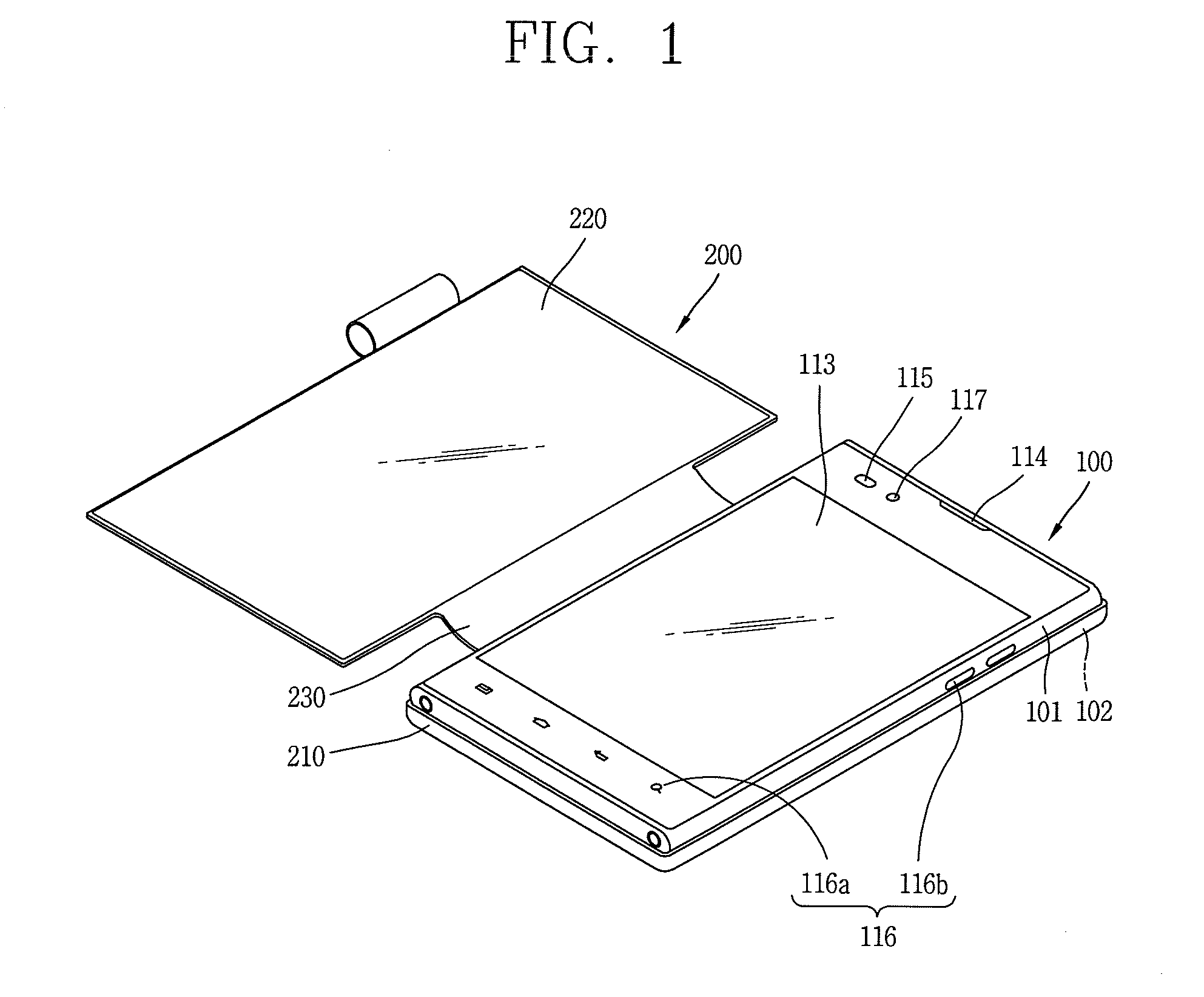

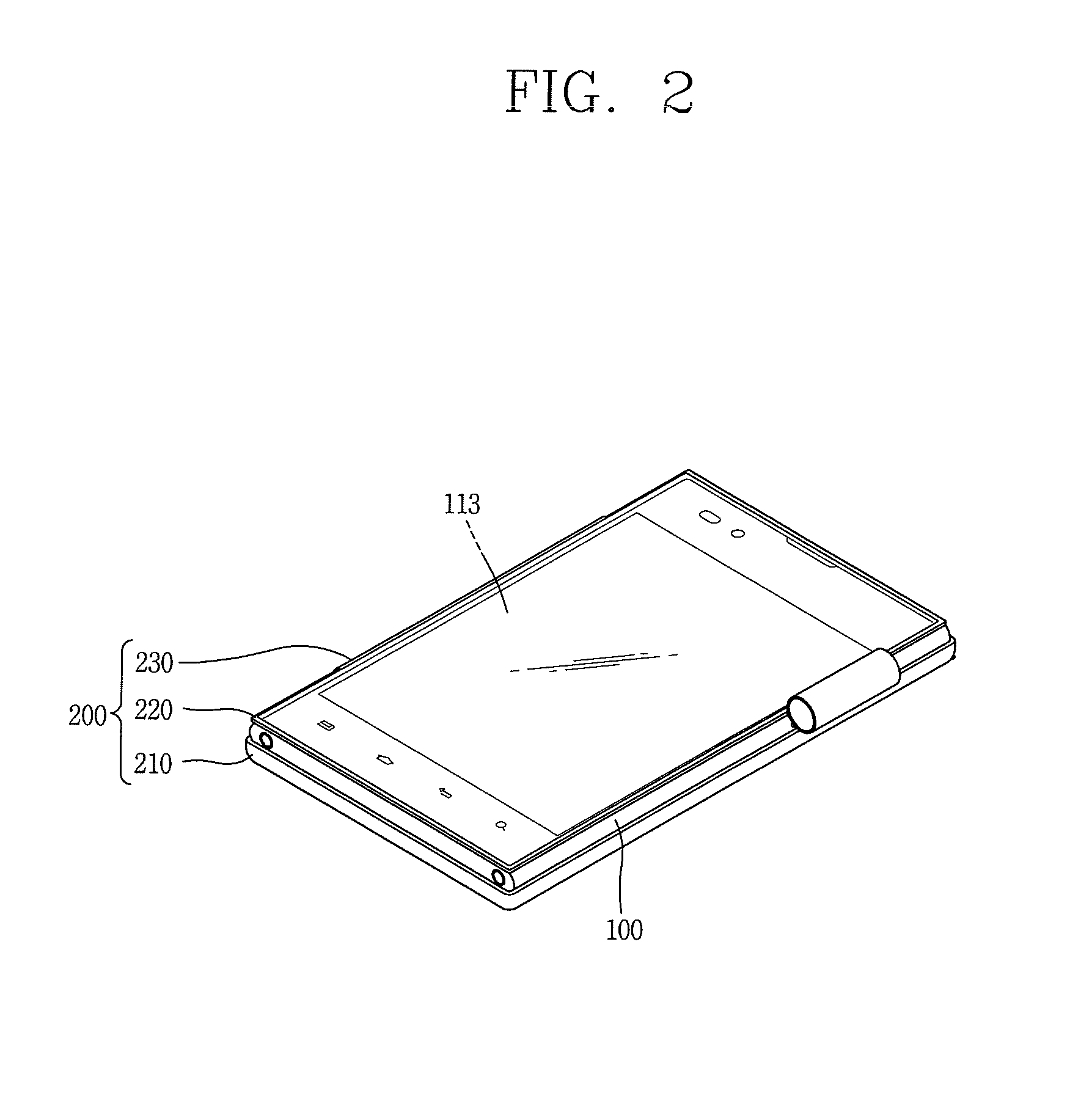

Pouch and portable electronic device received therein

ActiveUS20130300679A1Improve tightnessEasy to transformDigital data processing detailsOther accessoriesHuman–computer interactionClosed state

A pouch for receiving a main body of a portable electronic device having a touch screen provided on a front surface thereof includes: a first part for receiving a rear surface of the main body; and a second part rotatably connected to the first part to close or open the touch screen, wherein the second part is formed to expose visual information of the touch screen to the outside in a state in which the touch screen is covered, and has conductivity allowing the touch screen to sense a touch input applied thereto in the closed state.

Owner:LG ELECTRONICS INC

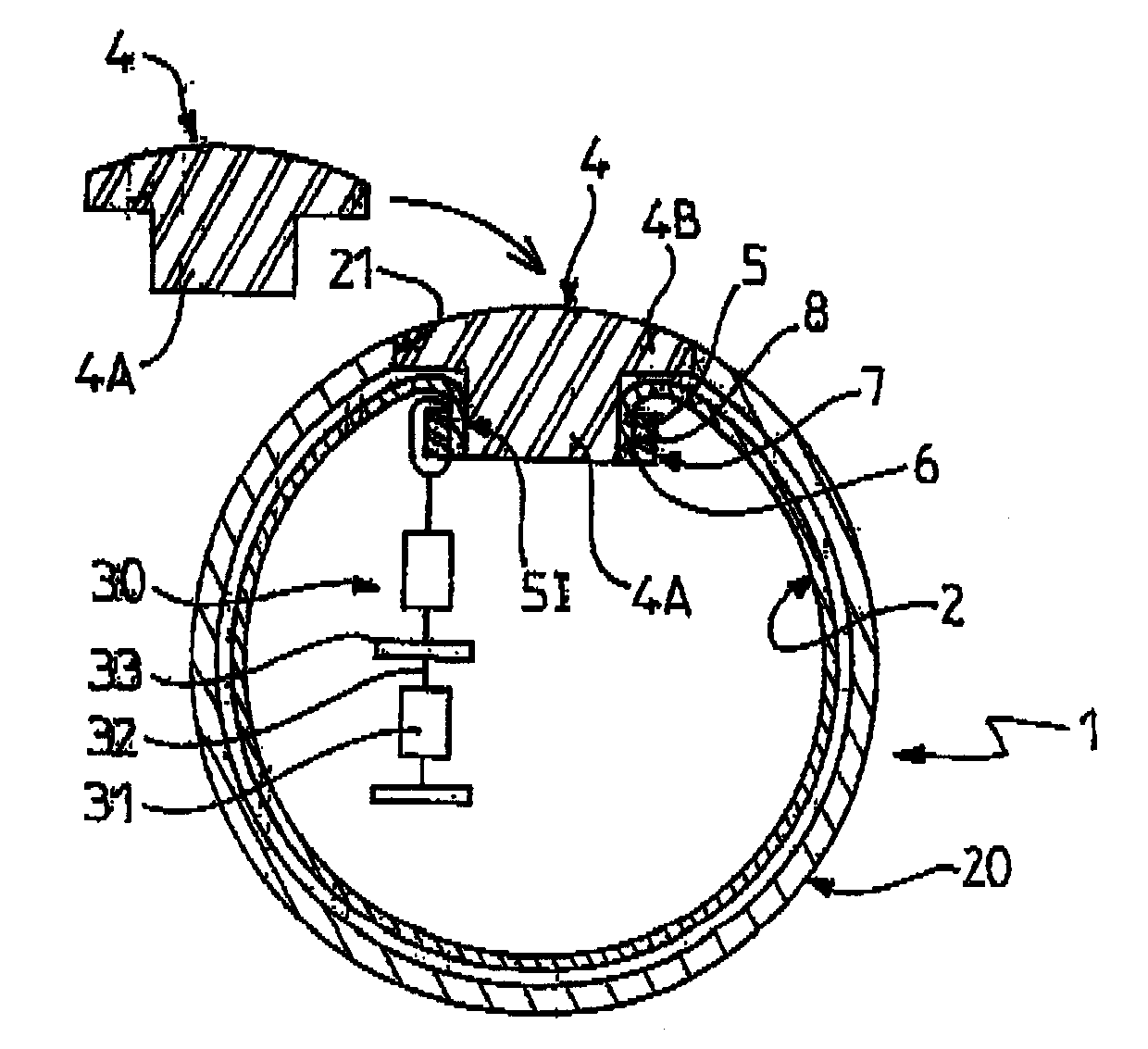

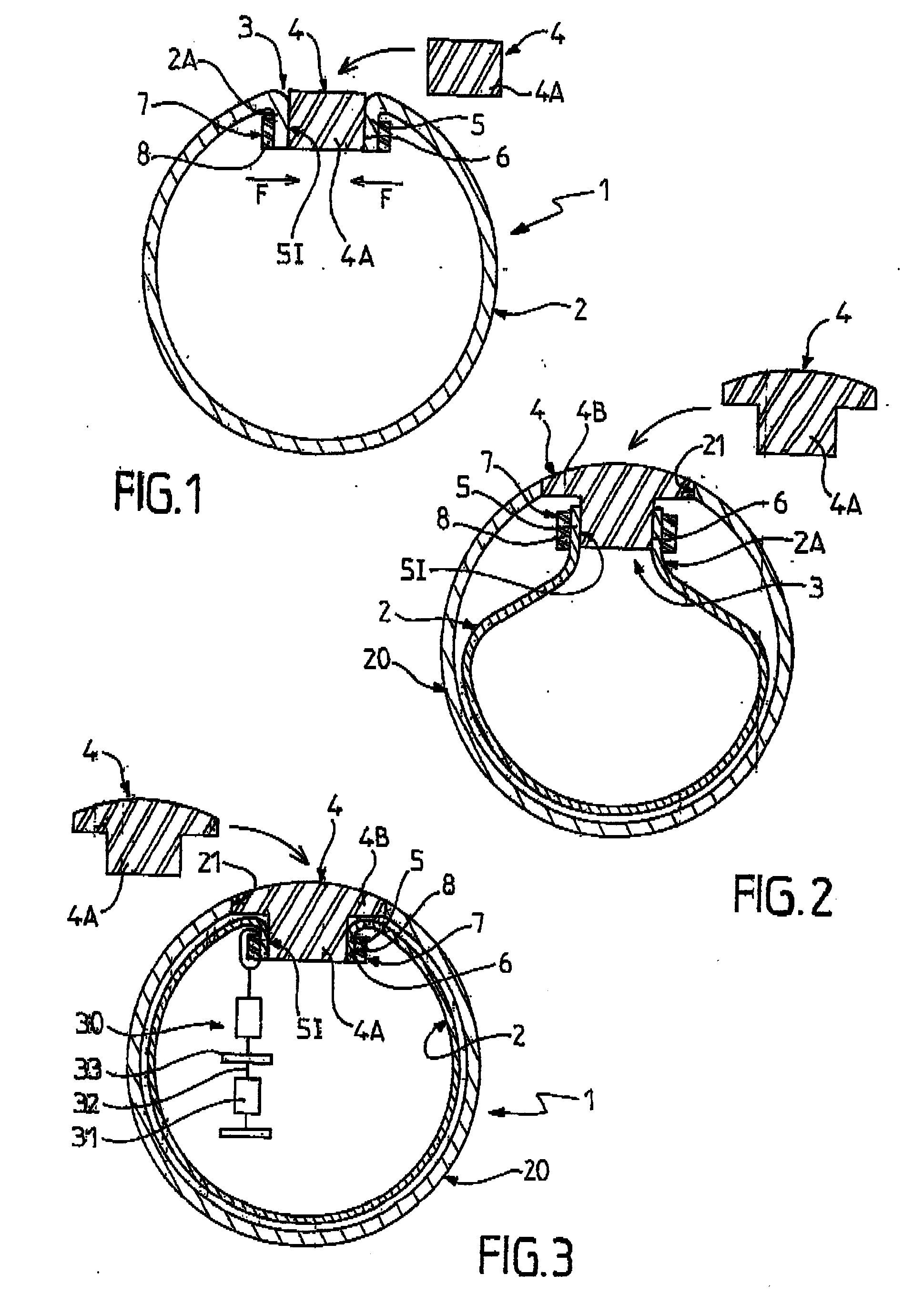

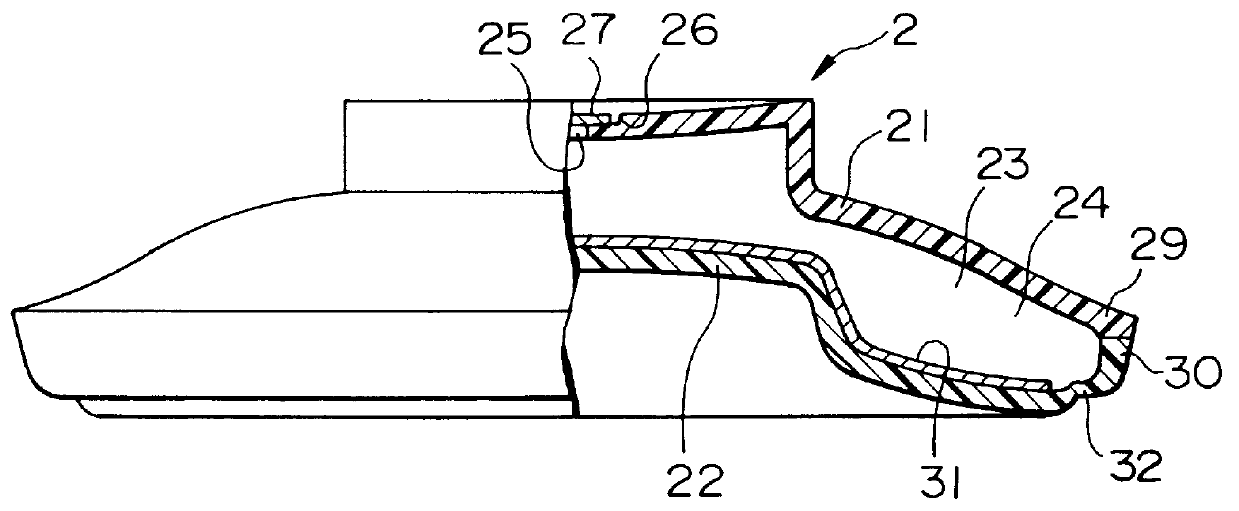

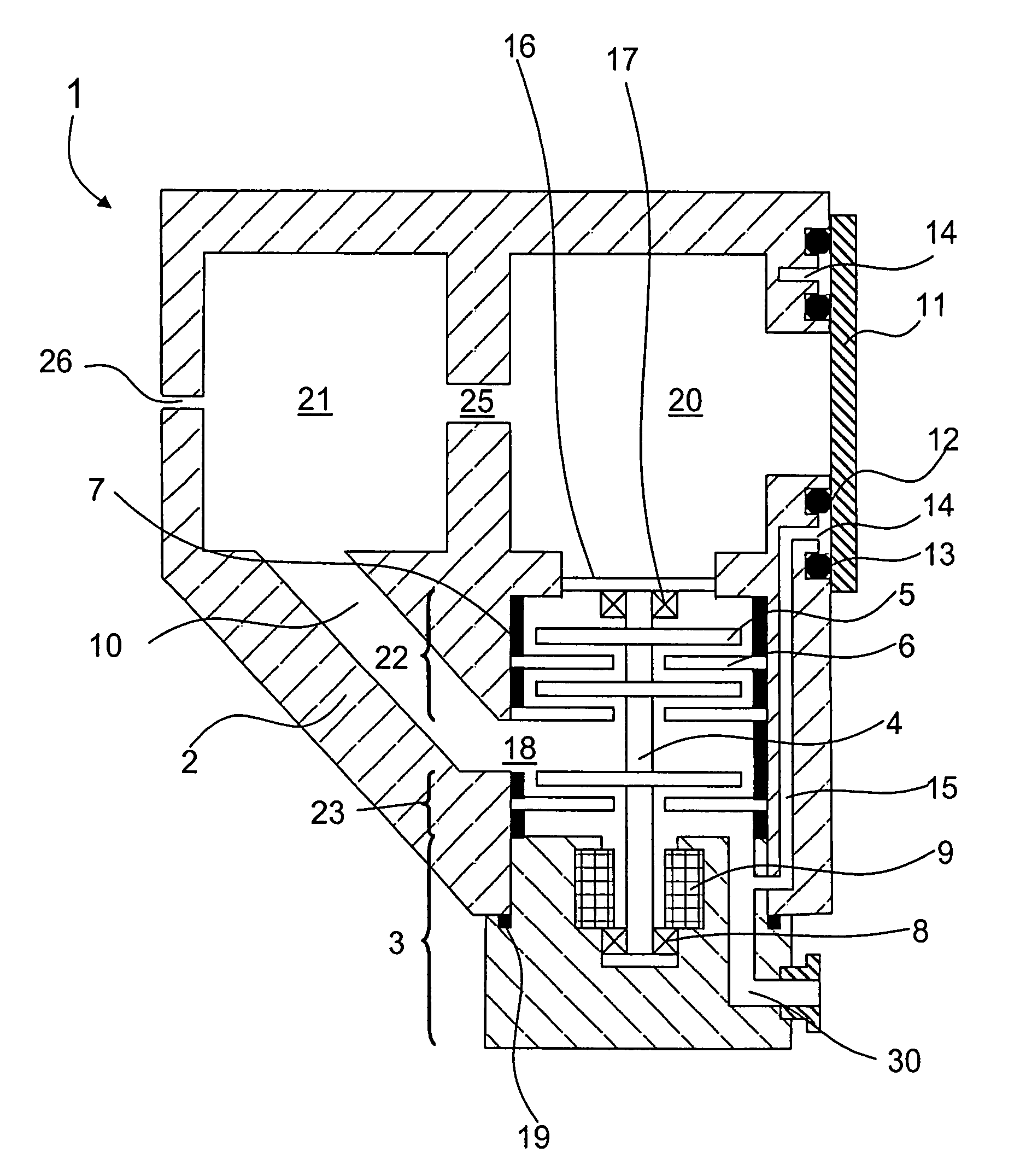

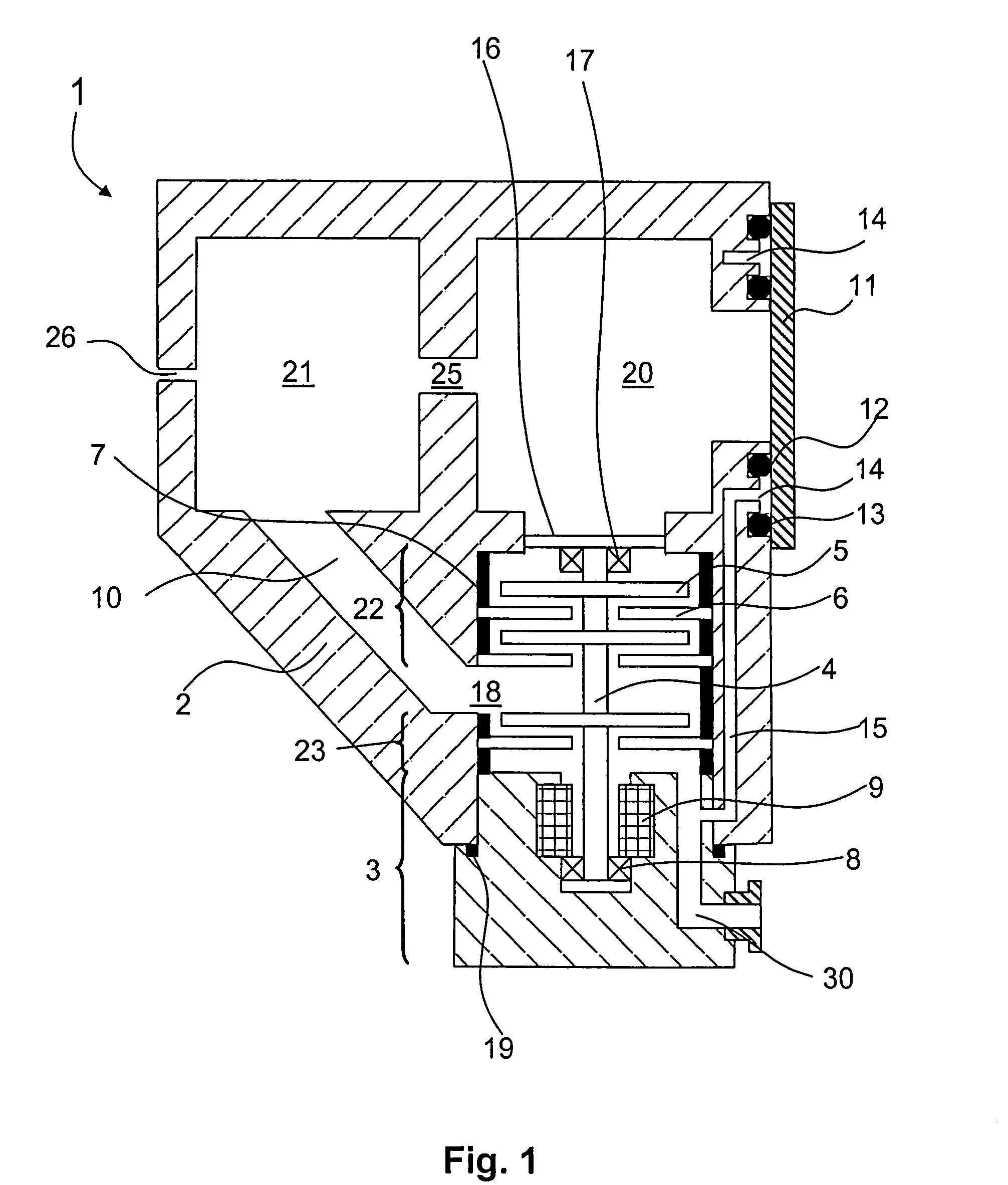

Pouch-Equipped Intragastric Balloon

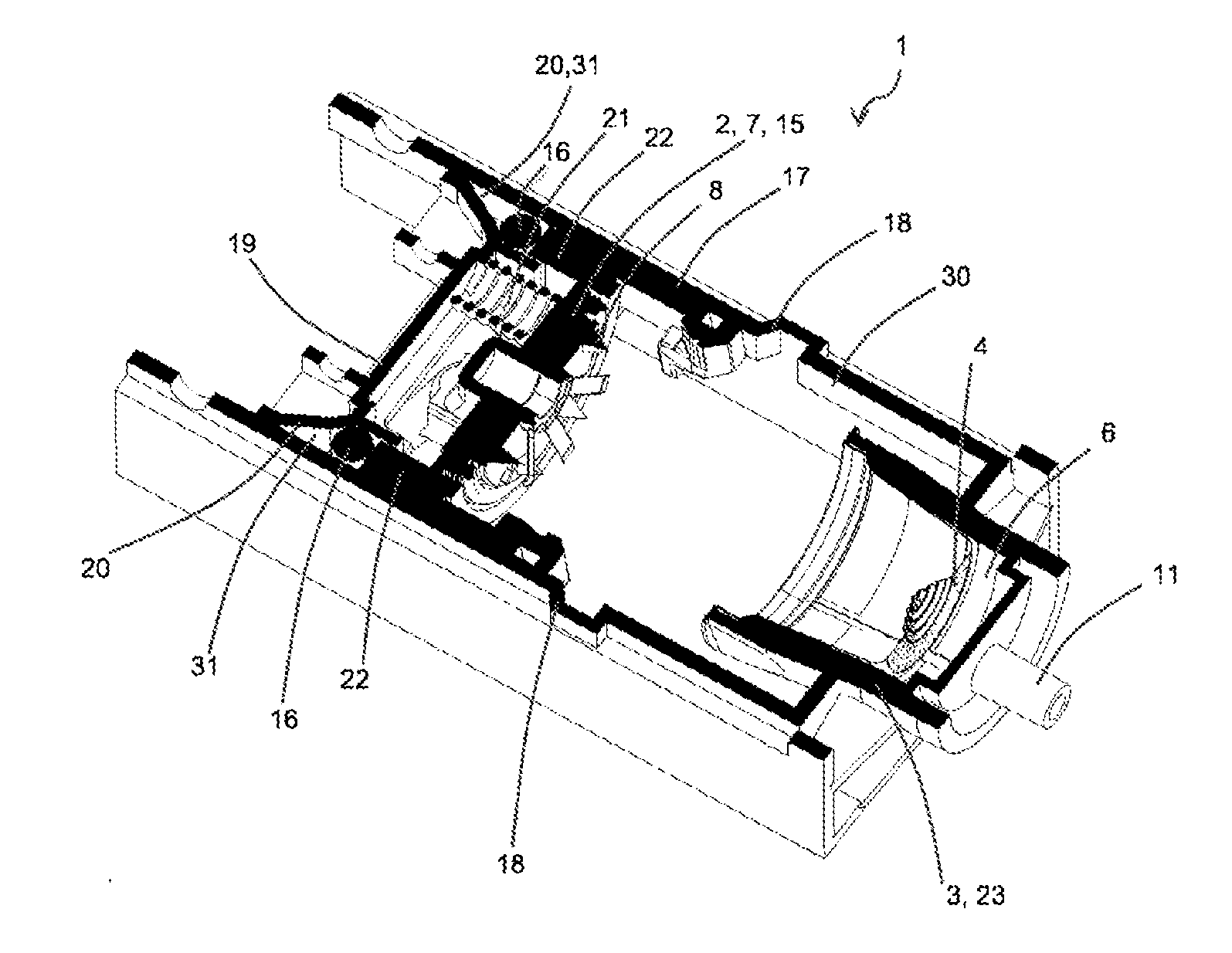

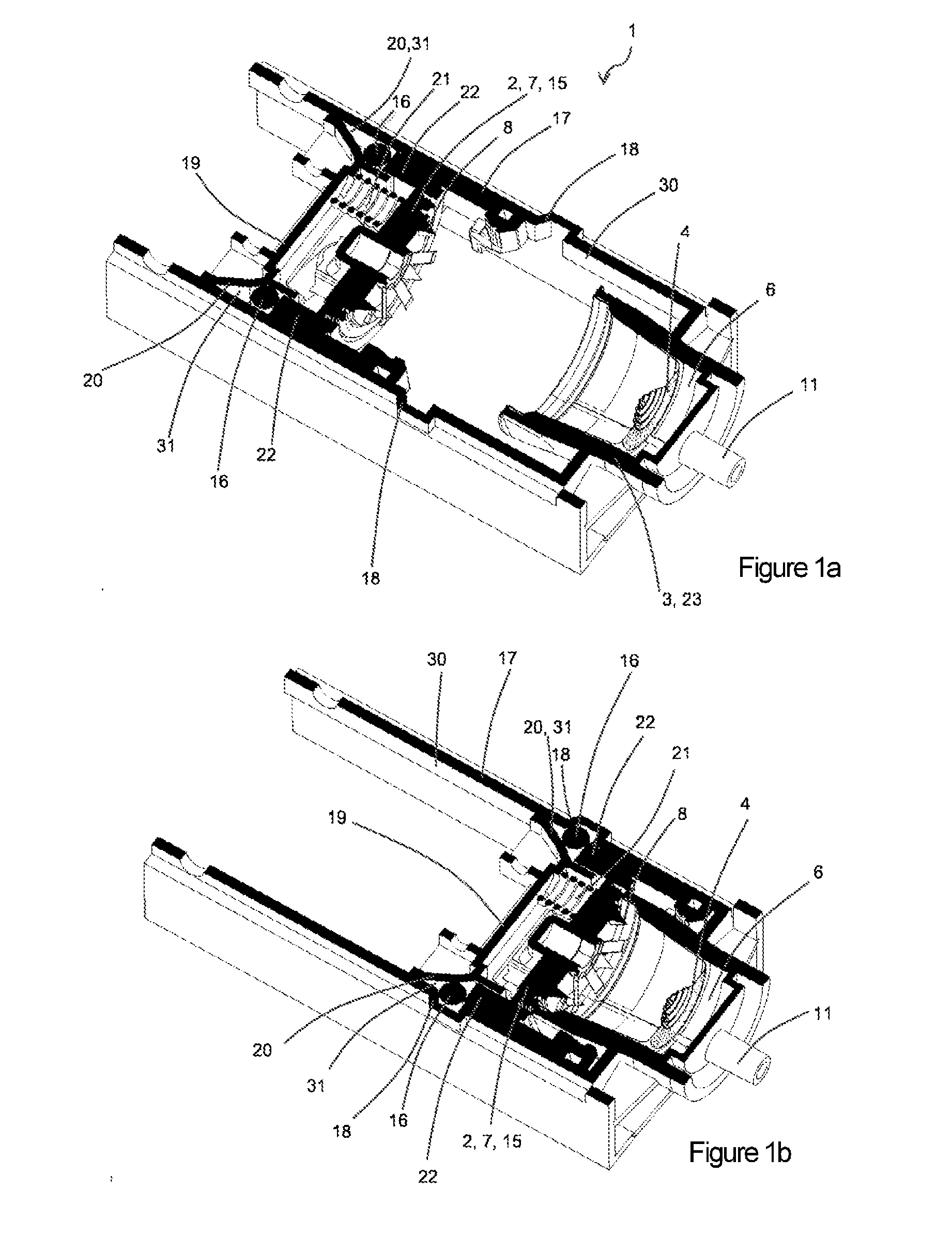

An expandable intragastric balloon comprising a first flexible pouch (2) comprising a port; a second pouch (20) which contains the first pouch (2) and which is equipped with a hole (21); and, a sealing member (4) which is hermetically fixed to the second pouch (20) and which is intended to seal the port and the hole (21). The first and second pouches (2, 20) are produced from different, non-compatible materials and are assembled with the aid of a fixing element (7). The fixing element is designed to ensure that the sealing member (4) is hermetically fixed to the first pouch (2) inside a passage (6) that is defined by a neck (5) which extends from the port, such that sufficient pressure is exerted on the neck (5) in order for same to be pinched between the sealing member (4) and the fixing element (7).

Owner:CIE EURO D'ETUDES & DE RECH DE DISPOSITIFS POUR L'IMPLANTATION PAR LAPAROSCOPIE

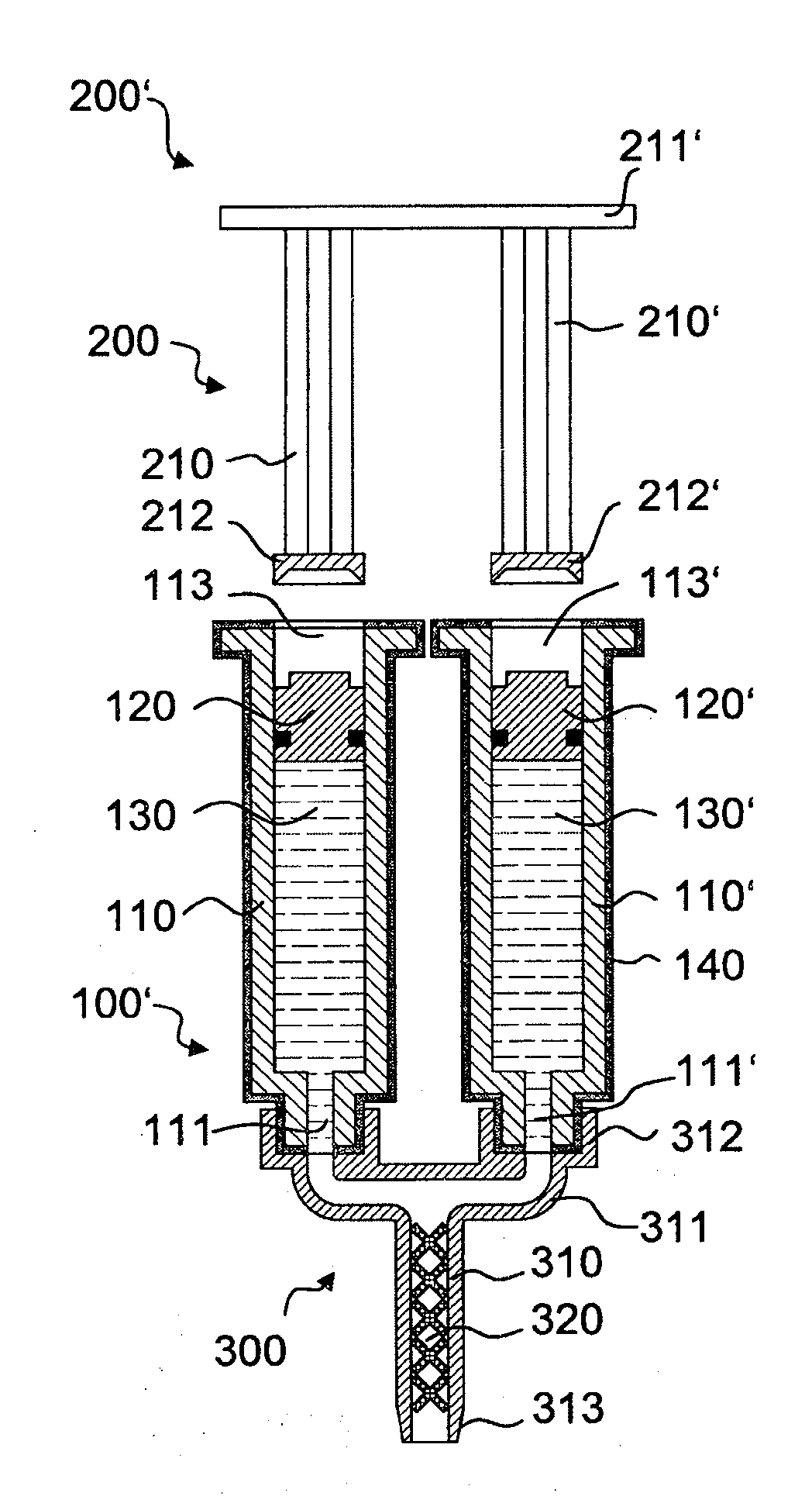

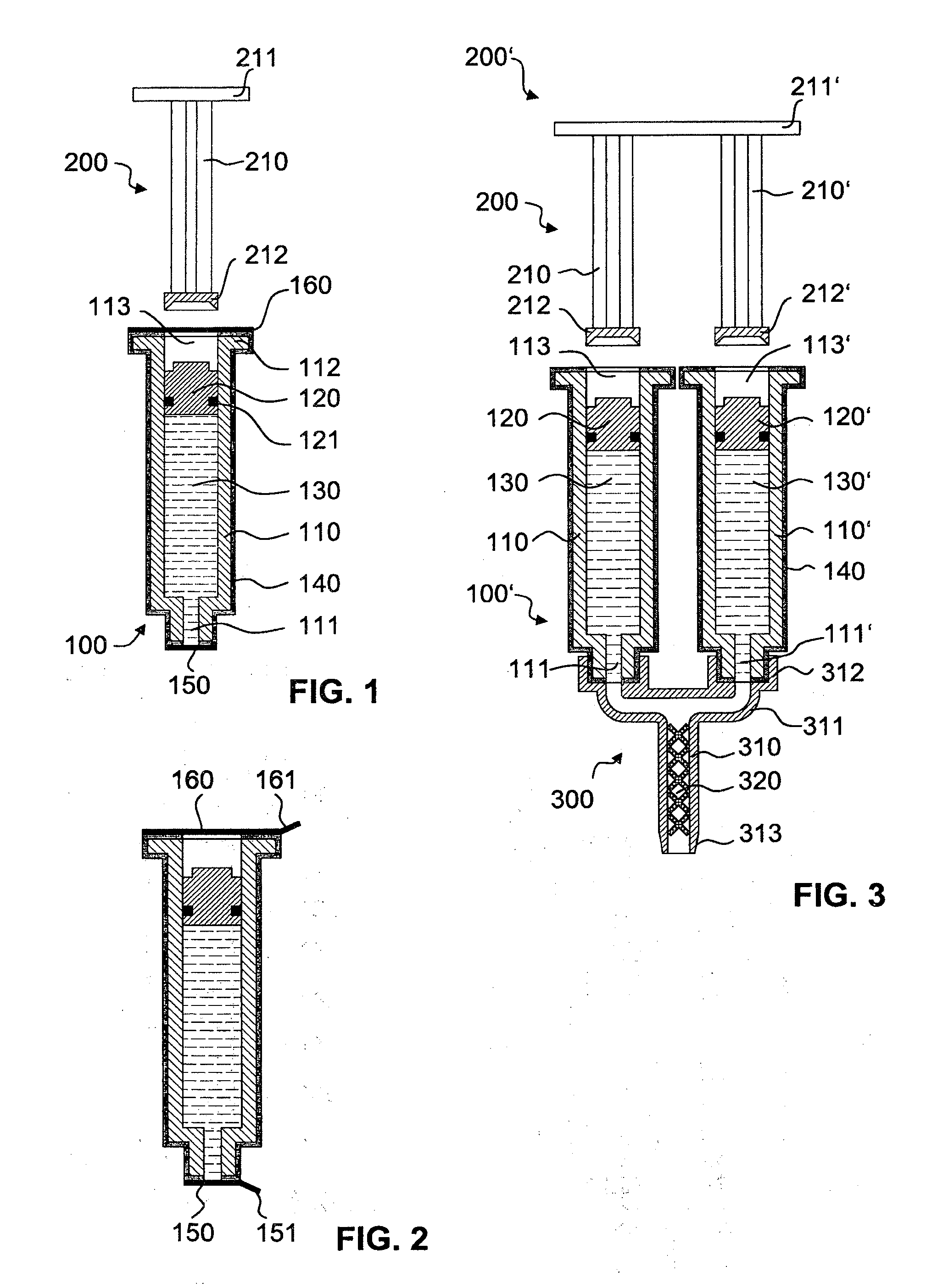

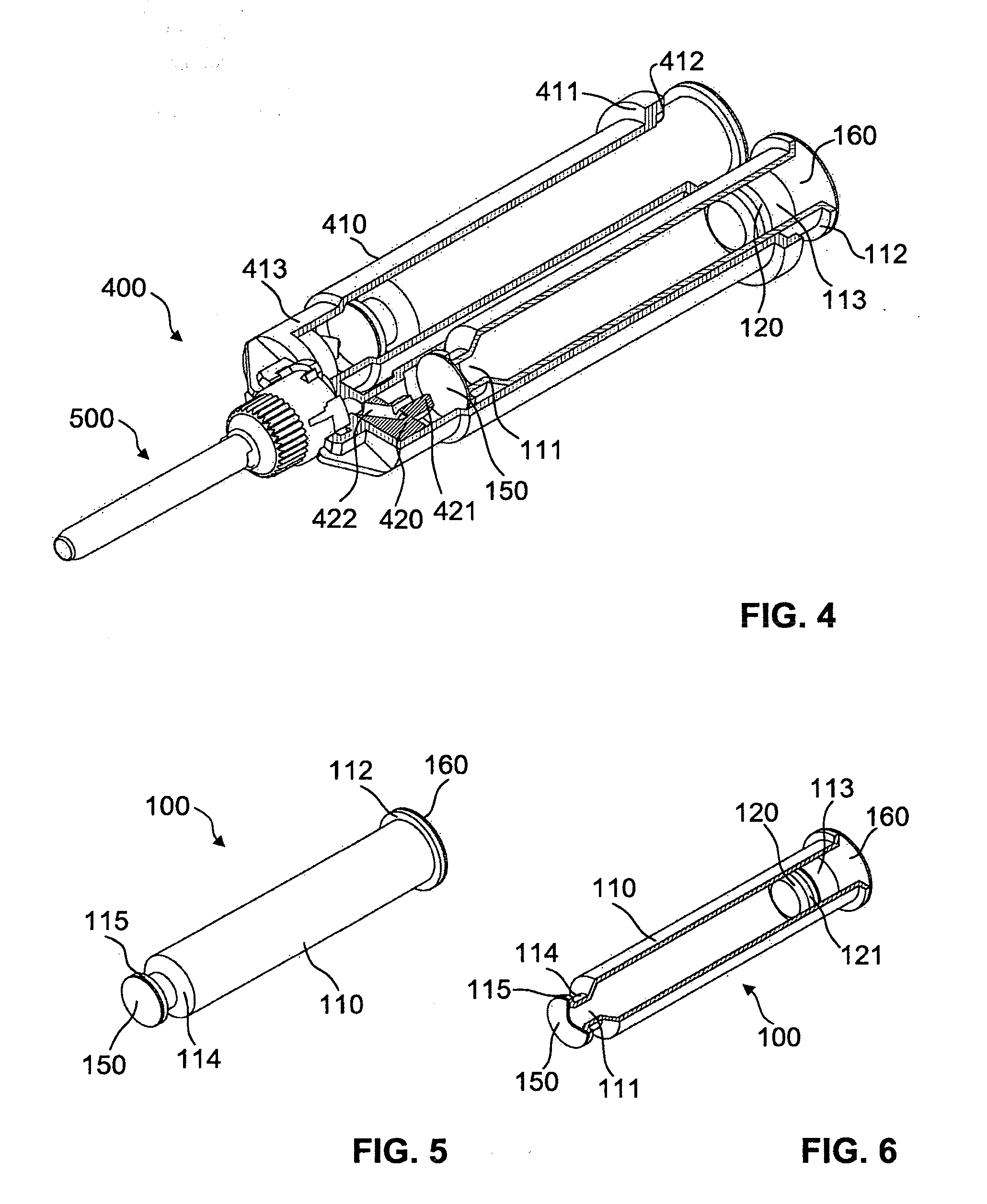

Sealed container comprising a displaceable piston

InactiveUS20120175384A1Reduce penetrationImprove tightnessInfusion syringesClosure using stoppersEngineeringPiston

A syringe-type container comprising a hollow main body with a distal outlet opening and a proximal actuation opening for inserting an actuation element. A piston is displaceably arranged inside the main body for discharging a flowable product from the container. To reduce the permeability of the container, the main body has a diffusion-reducing layer. The outlet opening is closed with a first removable or severable seal, and the actuation opening is closed with a second seal.

Owner:MEDMIX SYST

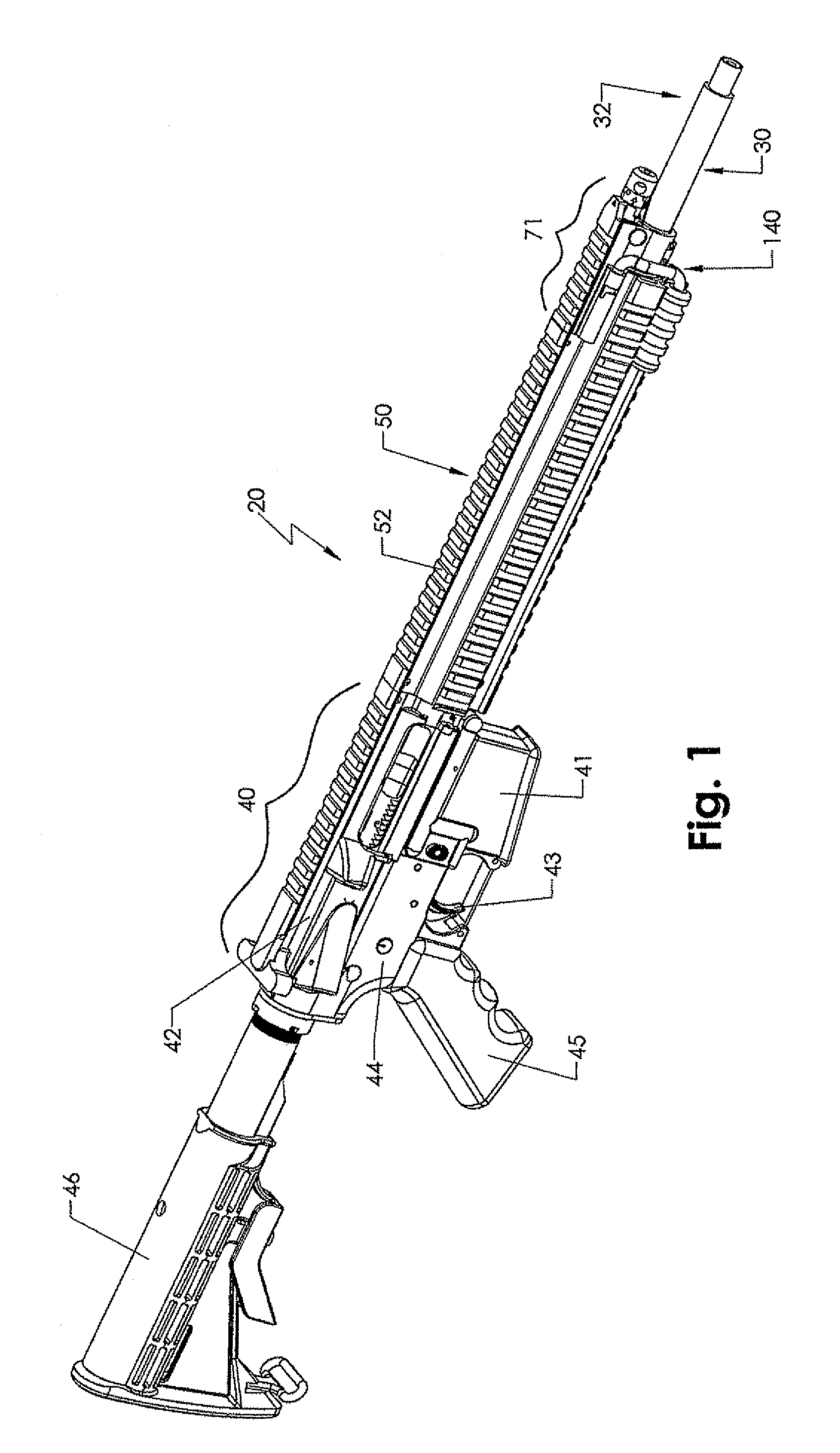

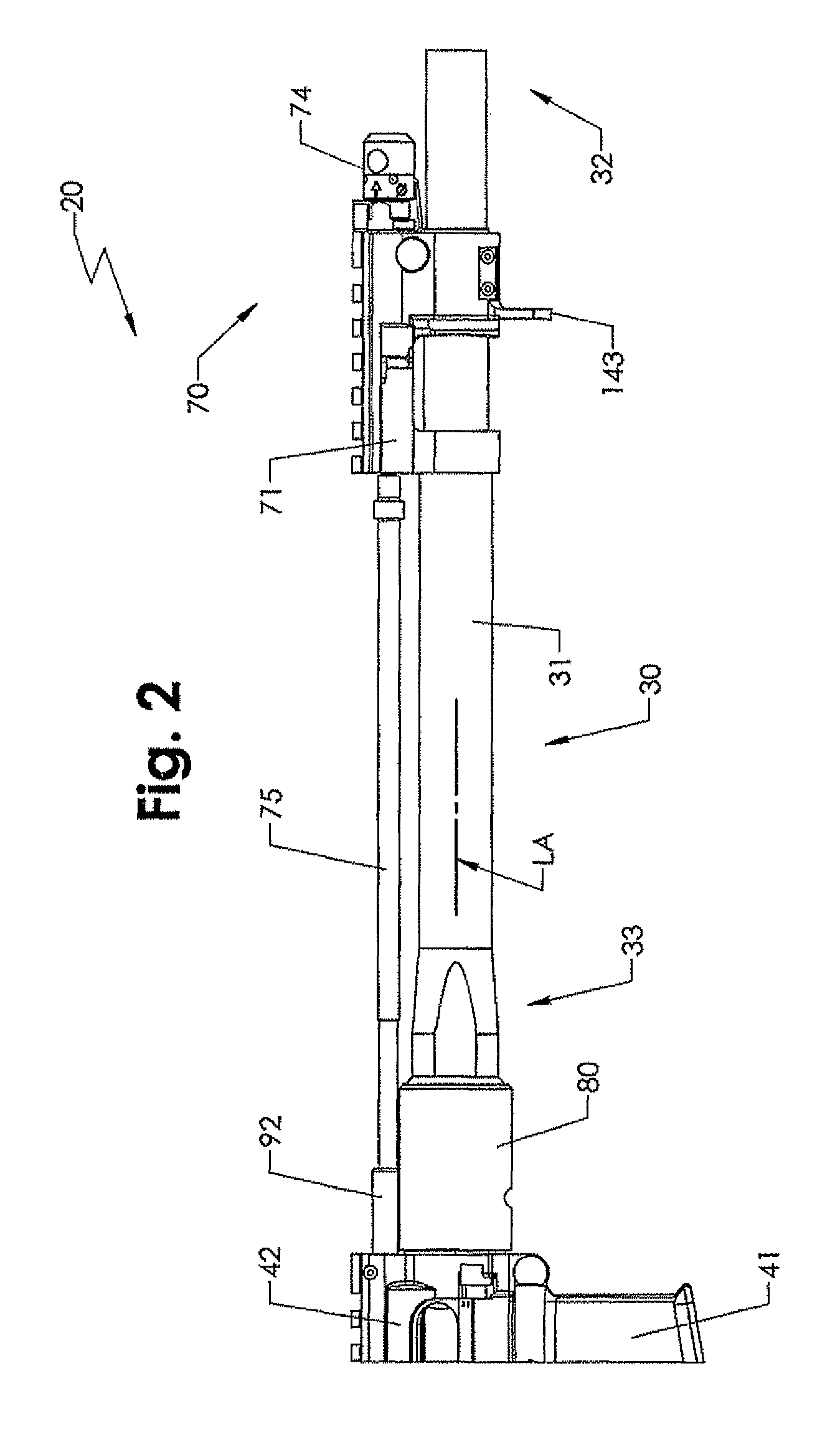

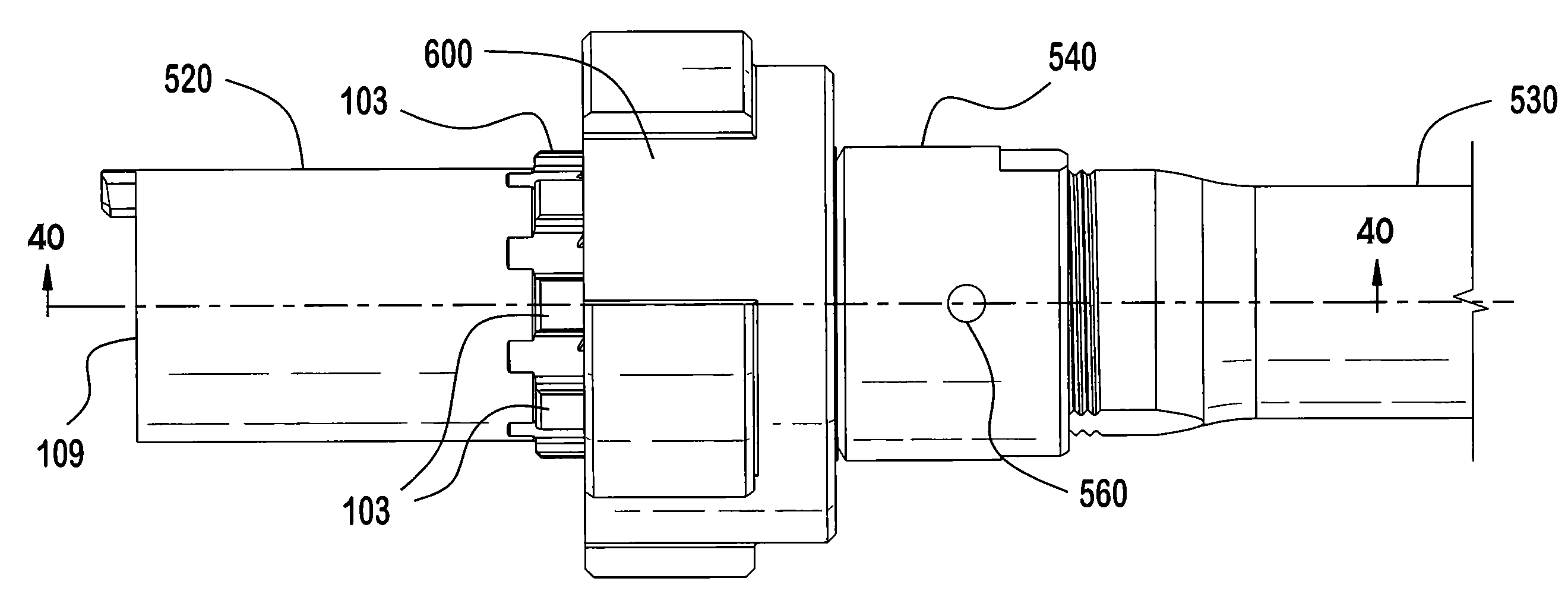

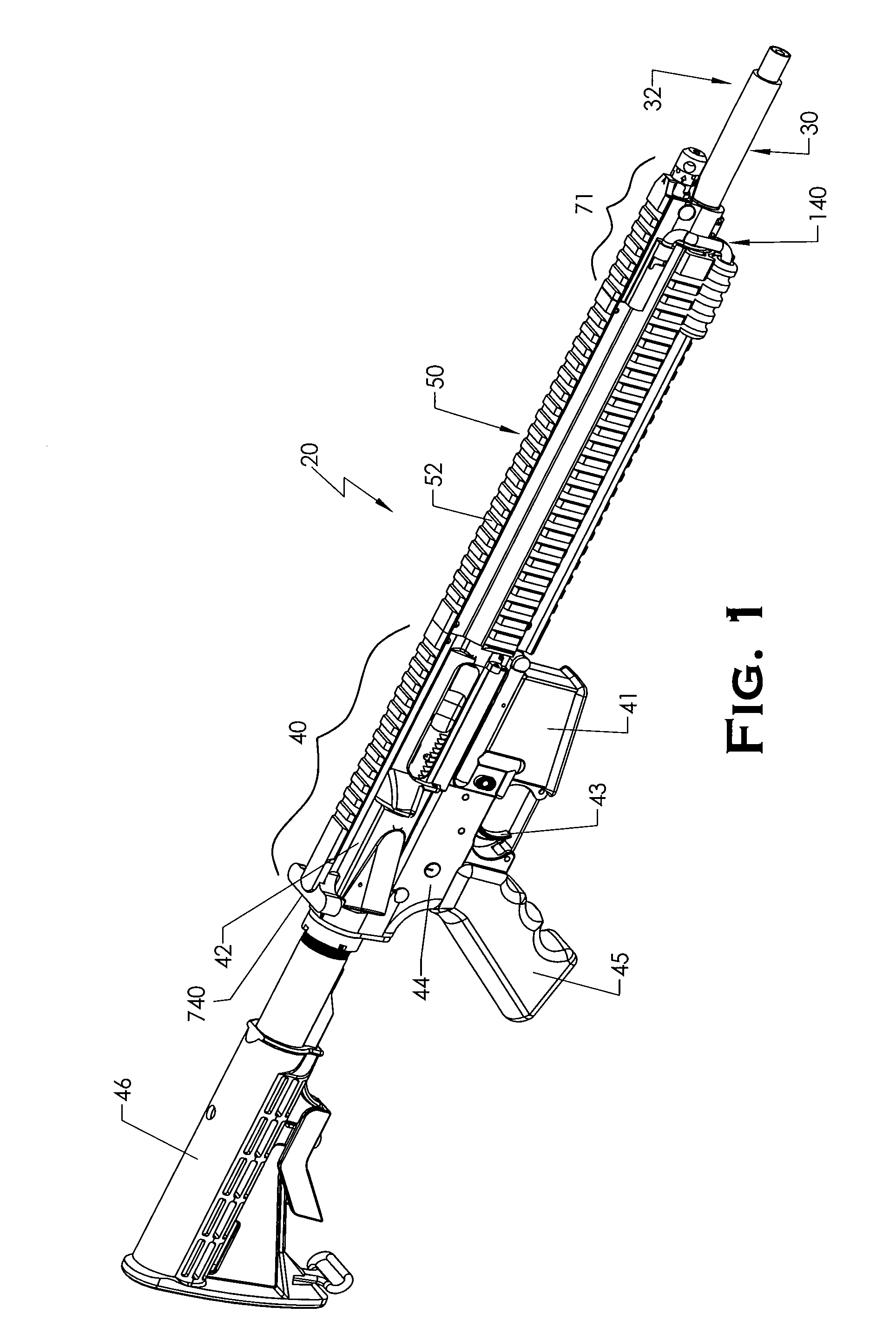

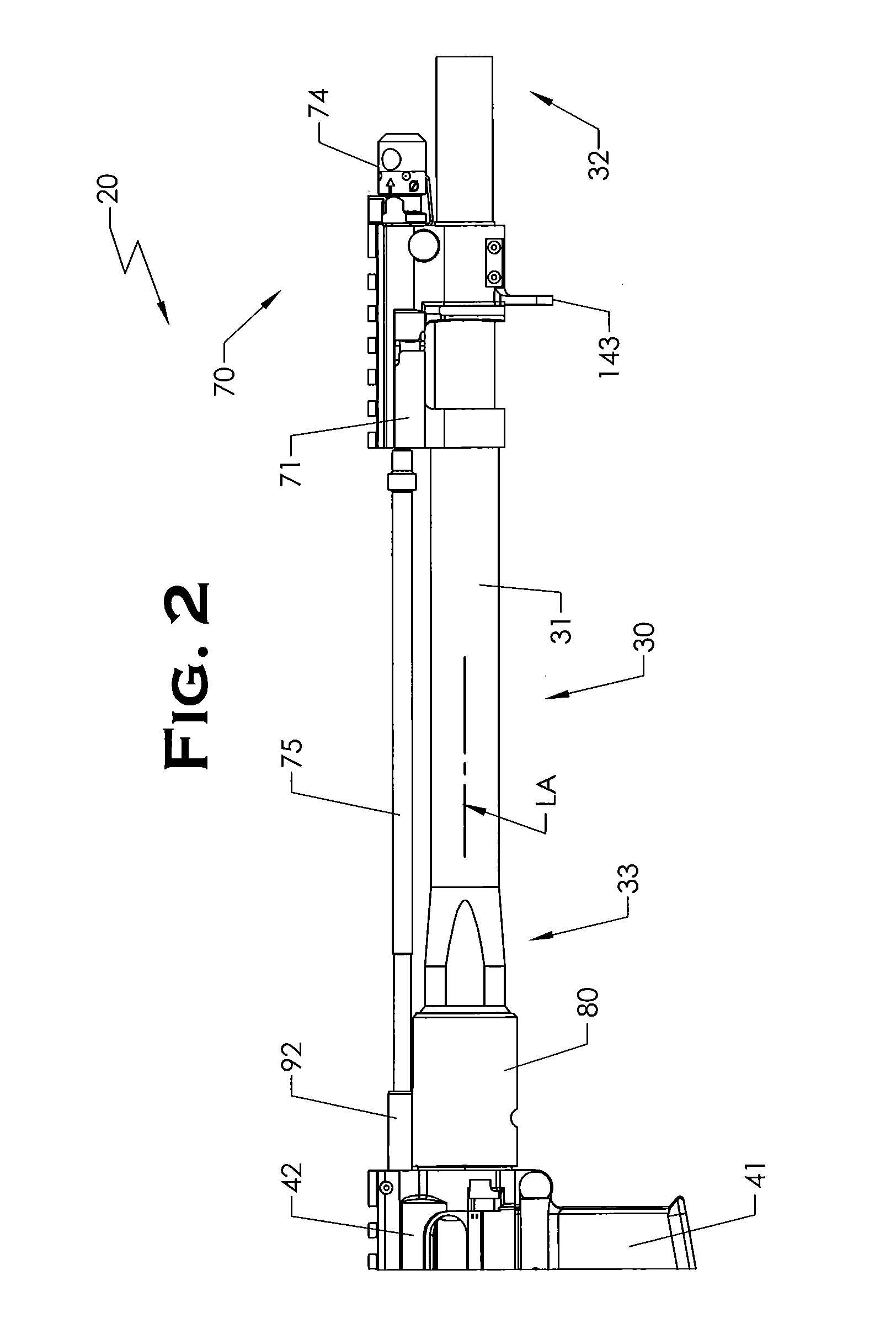

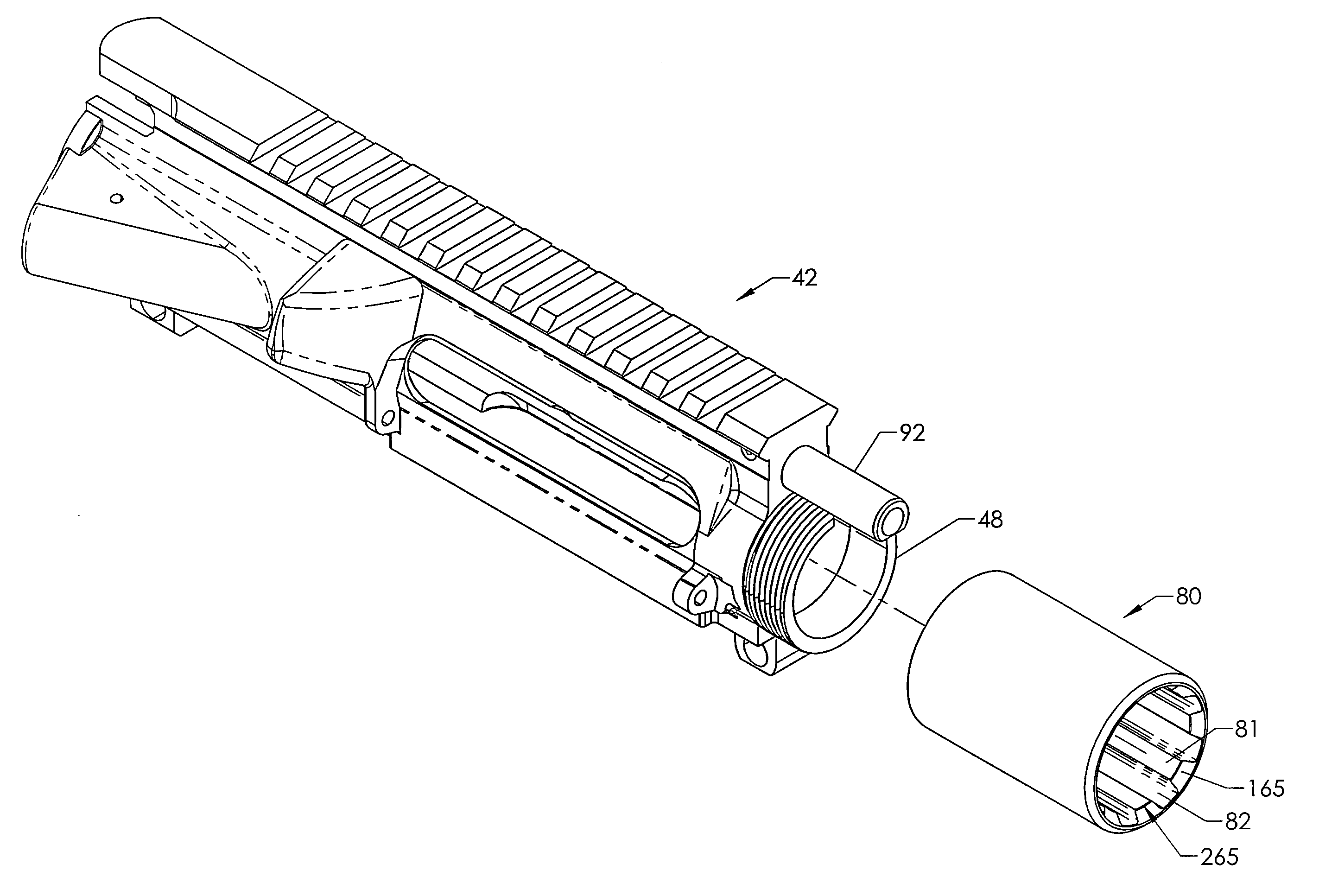

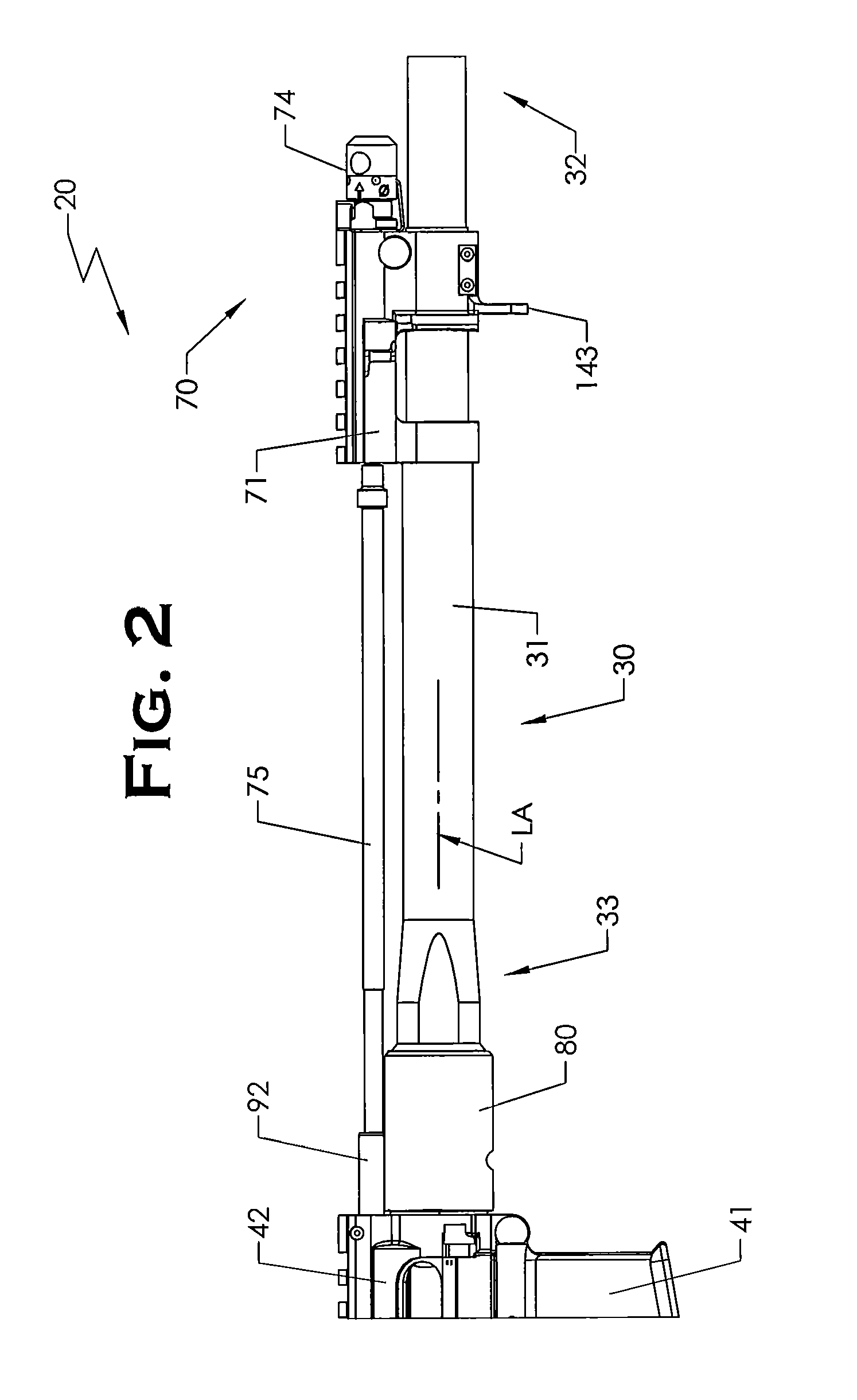

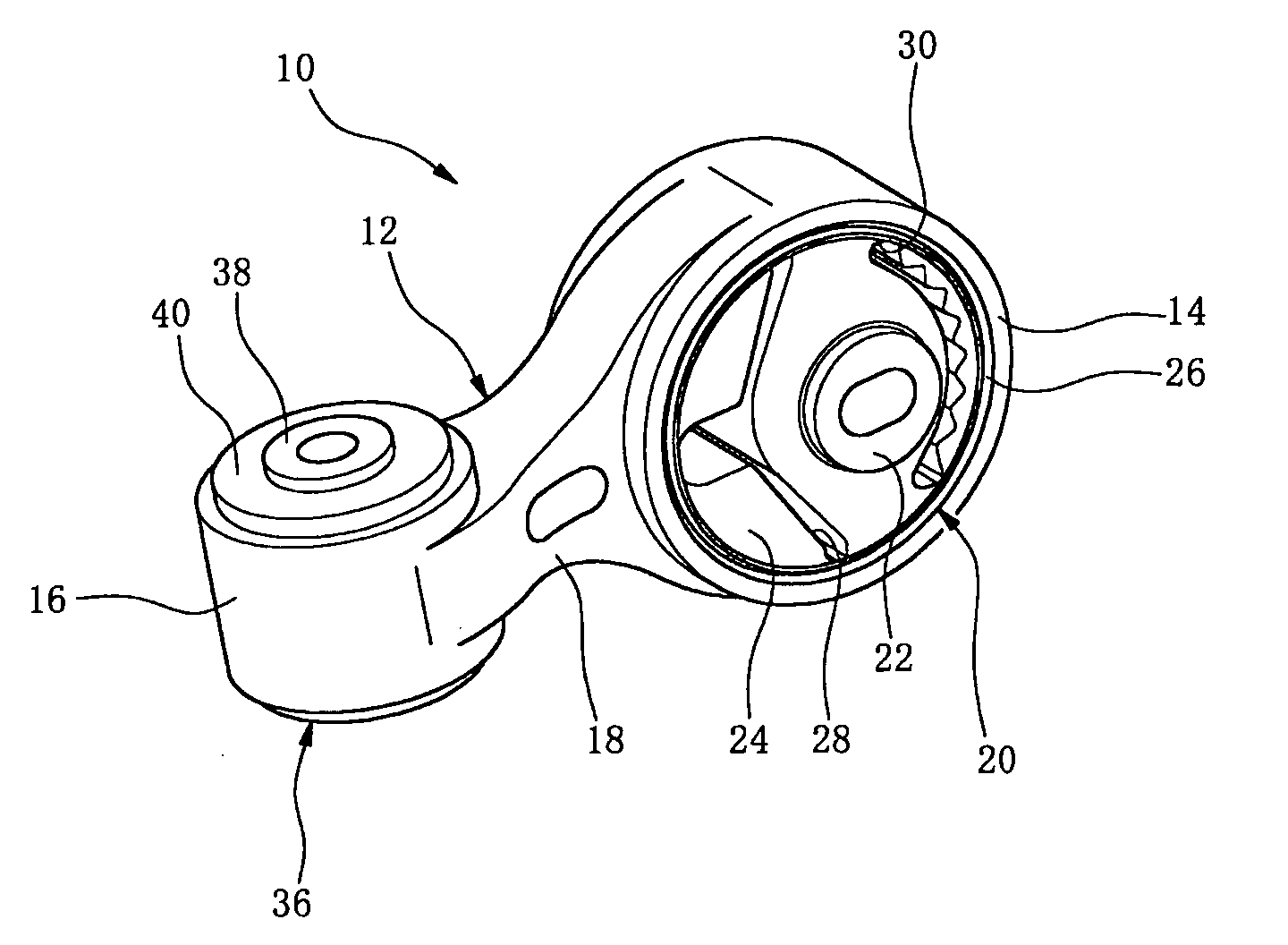

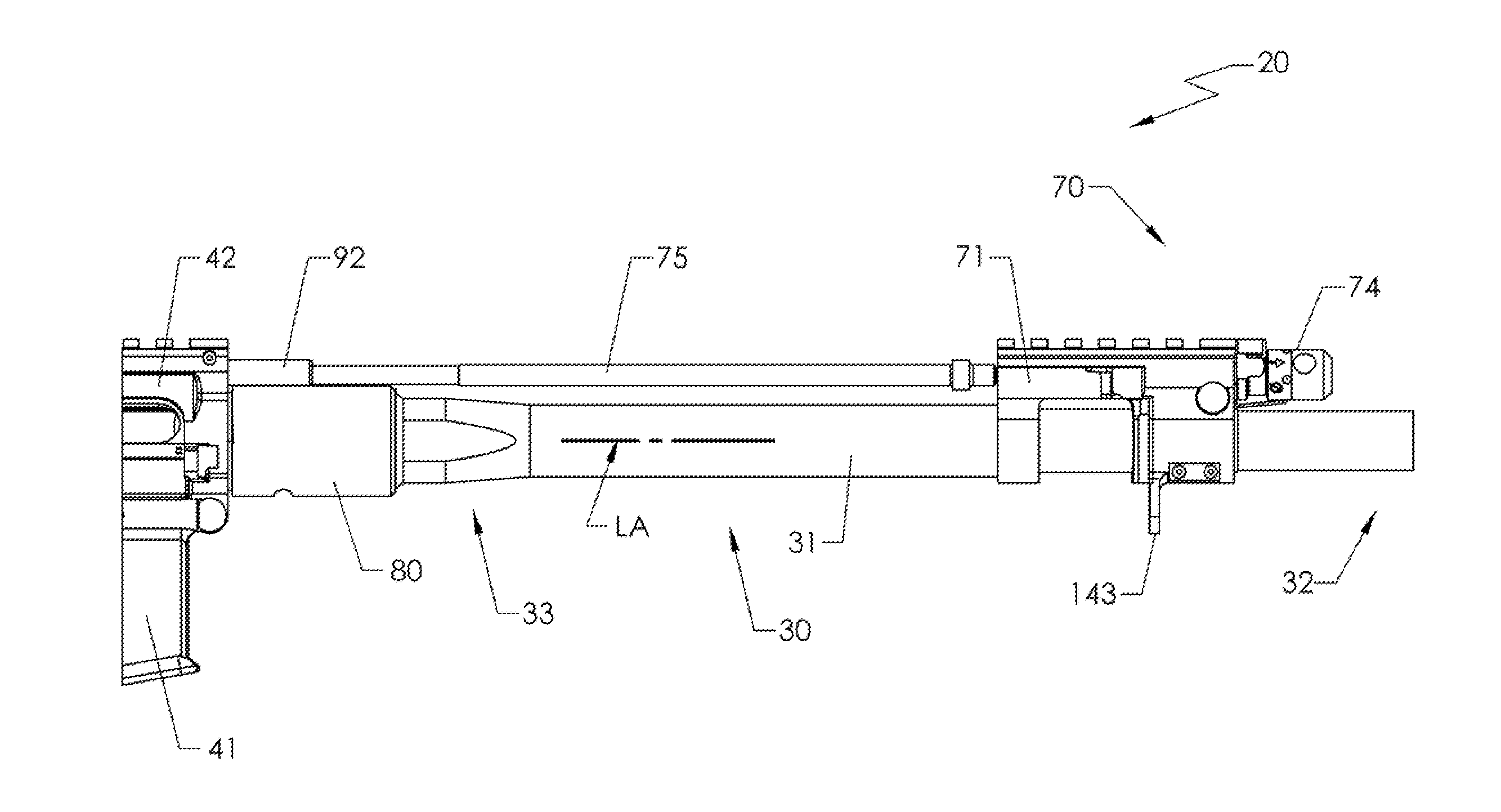

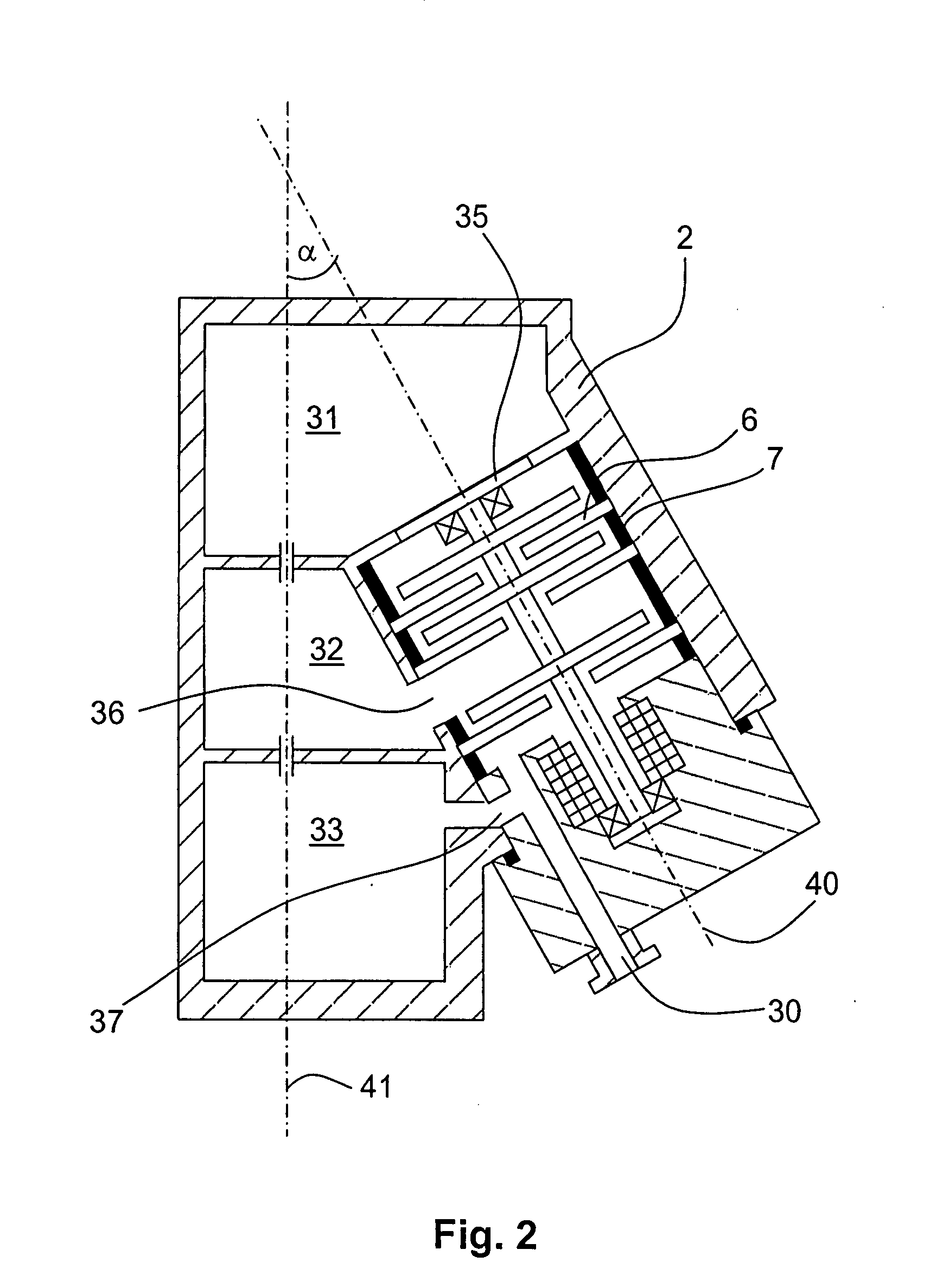

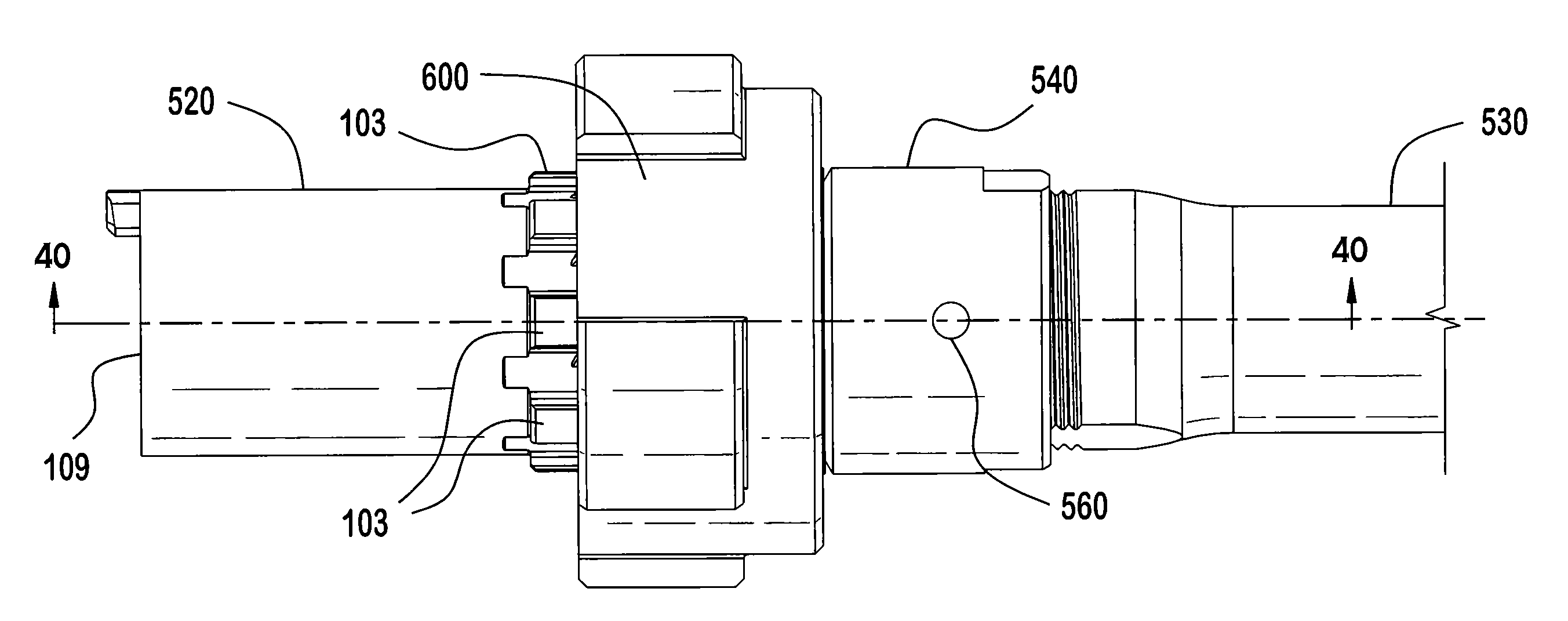

Quick coupling barrel system for firearm

ActiveUS20120131835A1Quick changeImprove tightness and reliabilityBreech mechanismsMetal working apparatusCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such a splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

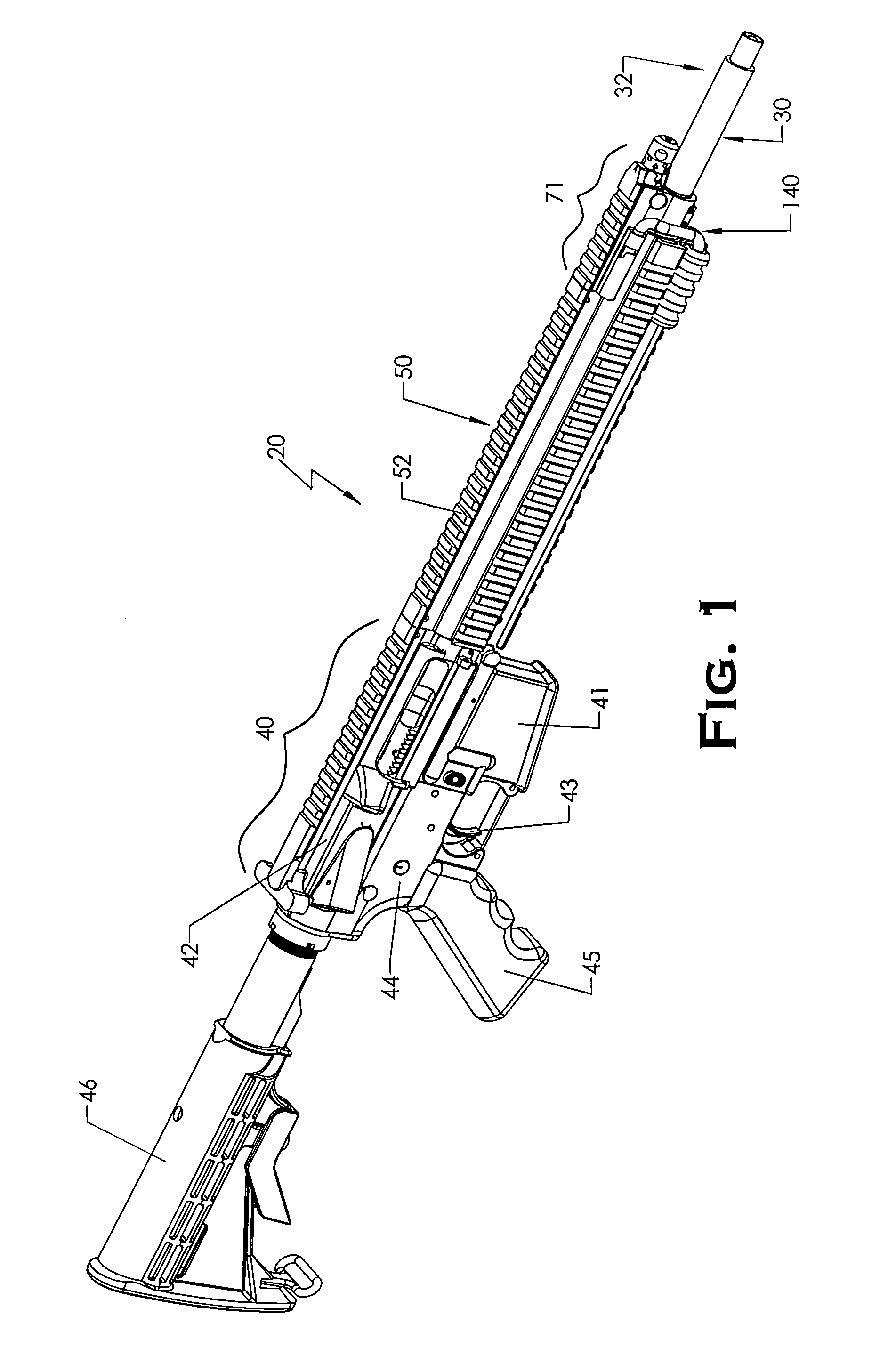

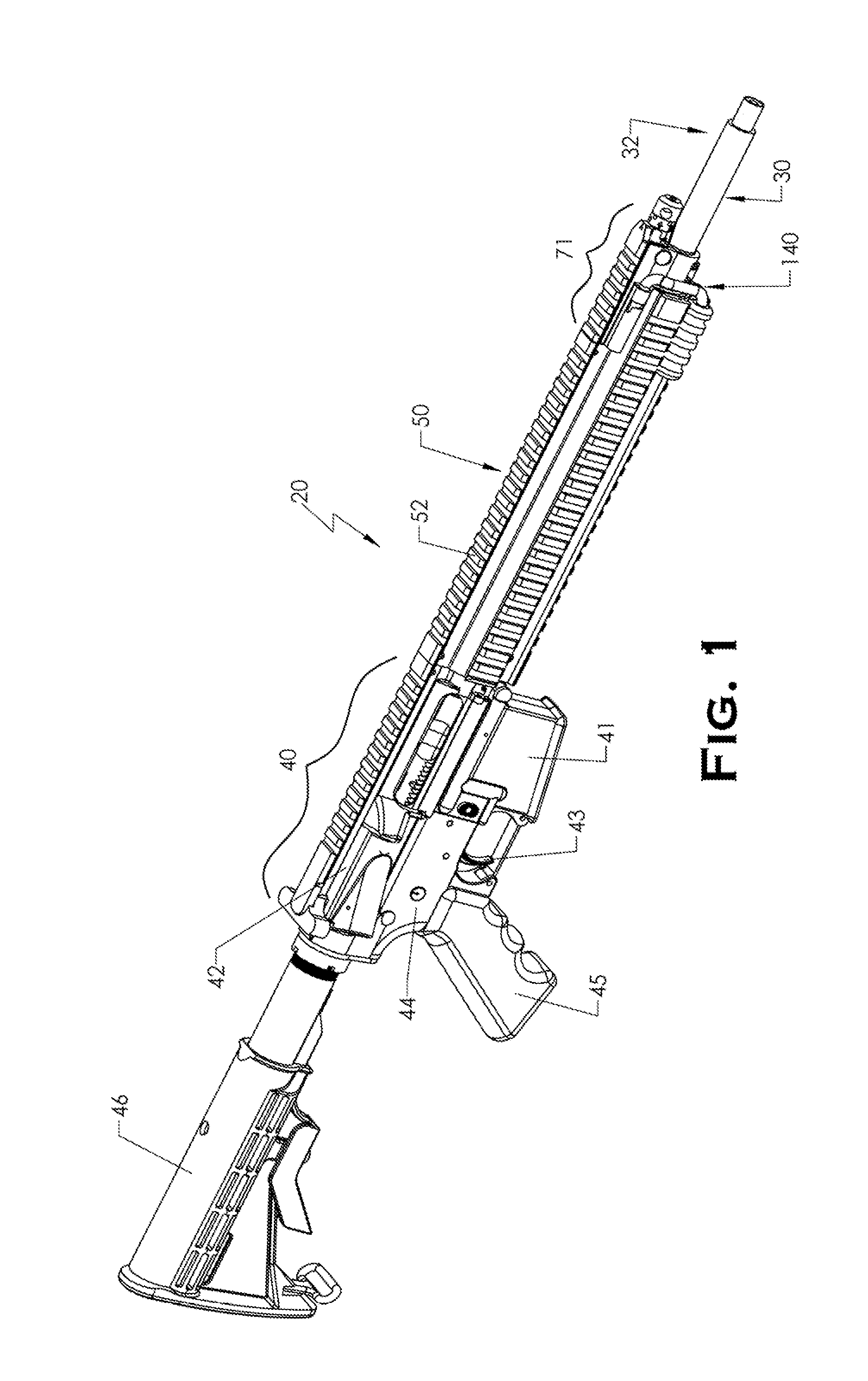

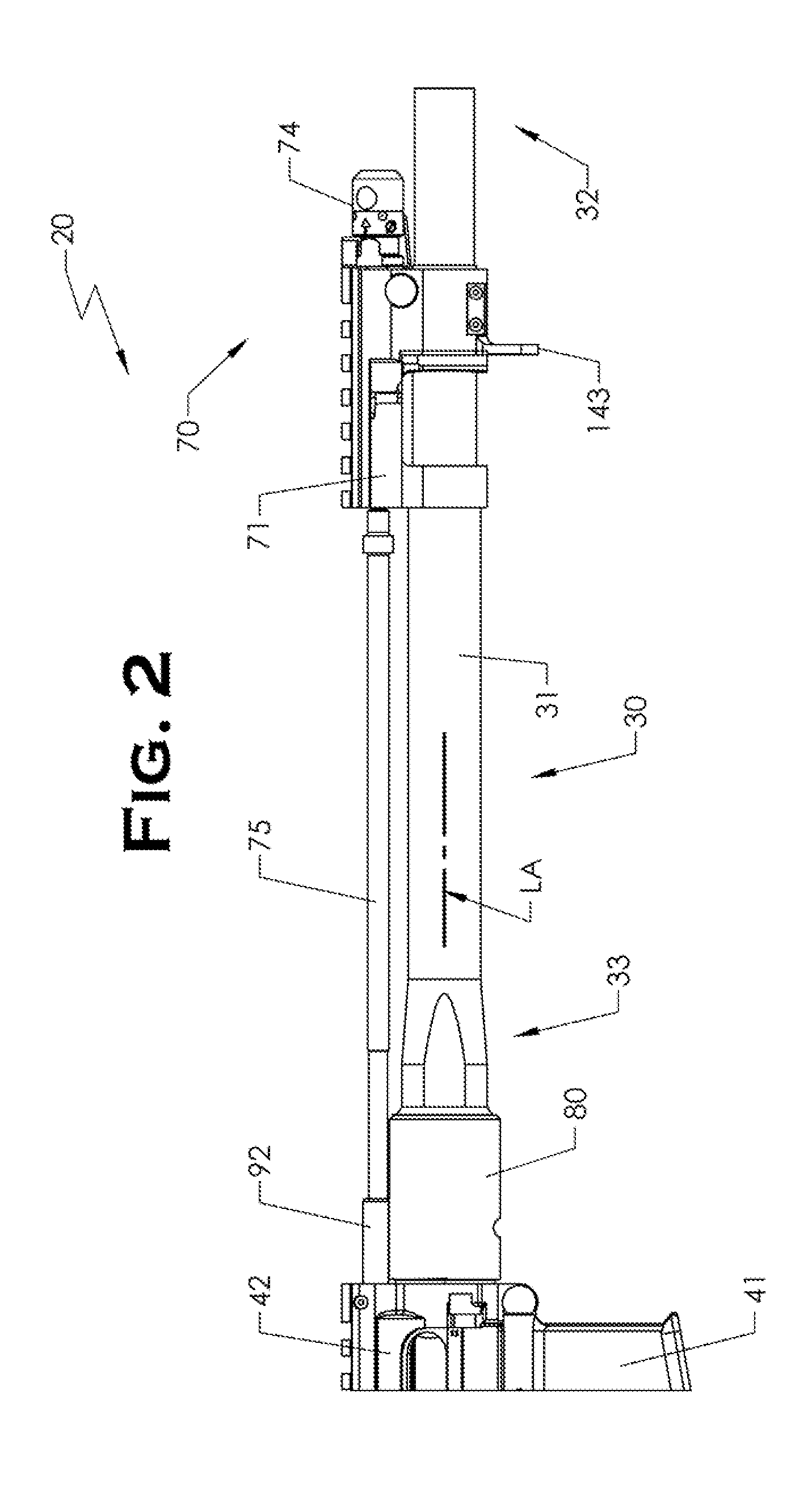

Firearm with quick coupling barrel interlock system

ActiveUS20120216439A1Quick changeImprove tightness and reliabilityBreech mechanismsBarrel mountingCouplingEngineering

A firearm with barrel interlock system for a rotary mounted quick coupling barrel assembly. In one embodiment, the firearm includes a receiver and barrel assembly rotatably mounted thereto. A bolt carrier supporting a bolt is slidably disposed in the receiver and axially movable into and out of battery with the barrel assembly. The barrel interlock system may include a first barrel anti-rotation locking element disposed on the barrel assembly and a mating second barrel anti-rotation locking element disposed on the bolt carrier that is engageable with the first element. When mutually engaged, the first and second locking elements form a meshed relationship and prevent rotation and removal of the barrel assembly from the receiver. In some non-limiting embodiments, the locking elements may be in the form of a protrusion and complementary shaped recess.

Owner:STURM RUGER & CO INC

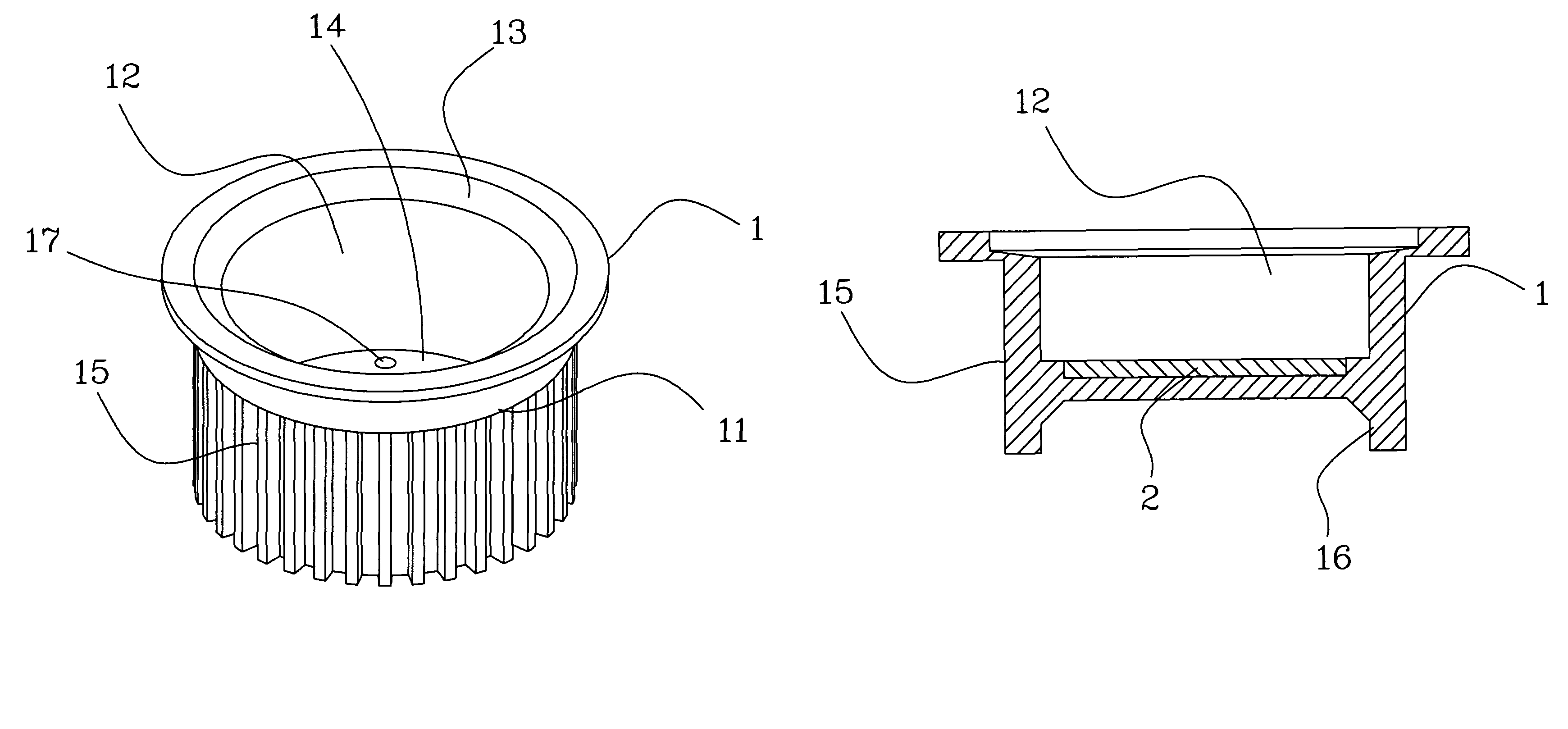

Thermal module

InactiveUS7845393B2Uniform and tight crystal phase structureImprove cooling efficiencyLayered productsDigital data processing detailsMetalThermal conductivity

A thermal module includes a body press-forged from magnesium alloy that is heated to a softened status and having a peripheral wall and a recessed chamber surrounded by the peripheral wall, and a contact surface member prepared from a high thermal conductivity metal material and bonded to the recessed chamber of the body during press-forging of the body.

Owner:JIING TUNG TEC METAL

Firearm with quick coupling barrel system

ActiveUS8479429B2Quick changeImprove tightness and reliabilityBreech mechanismsMetal working apparatusCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such a splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

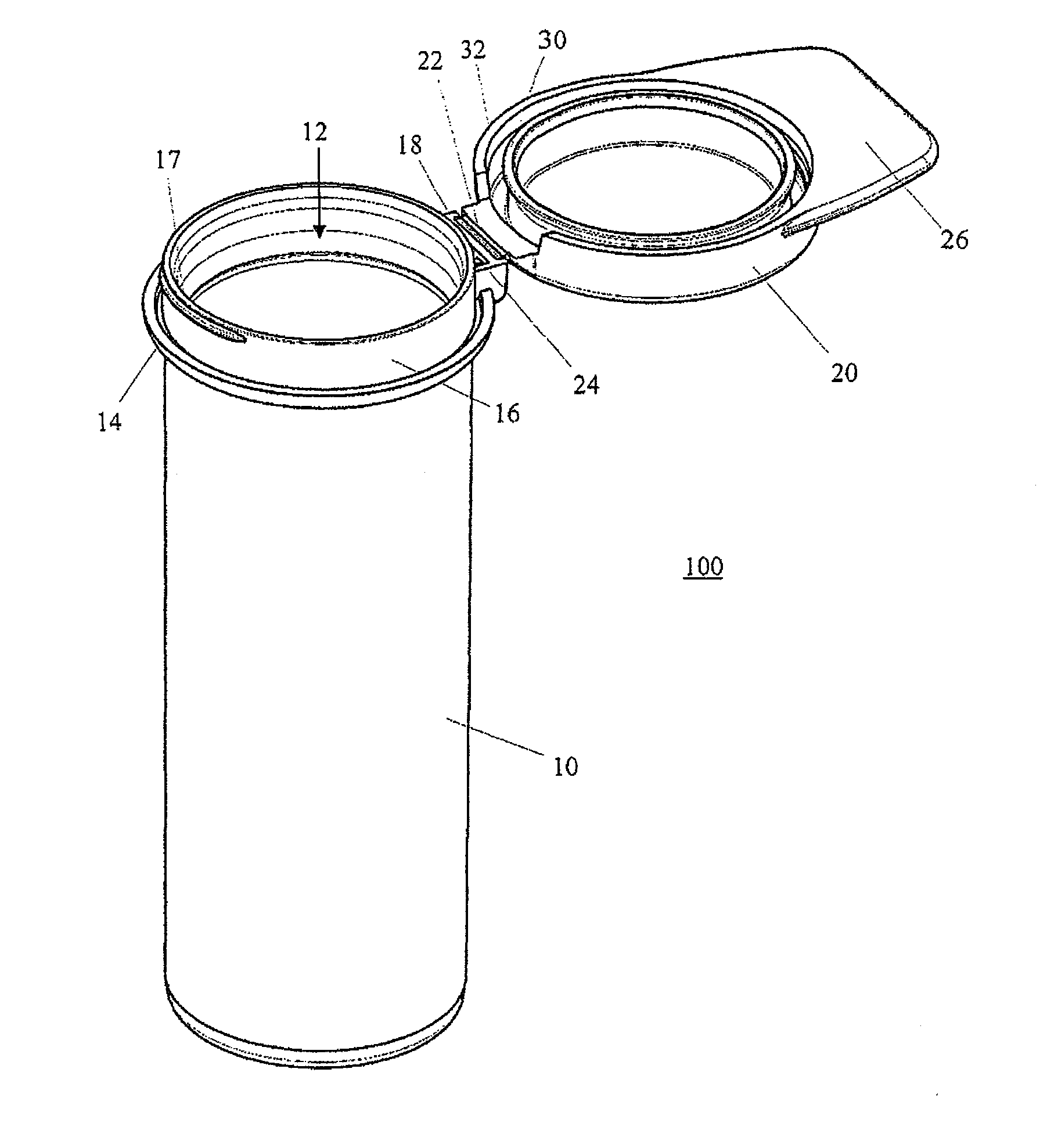

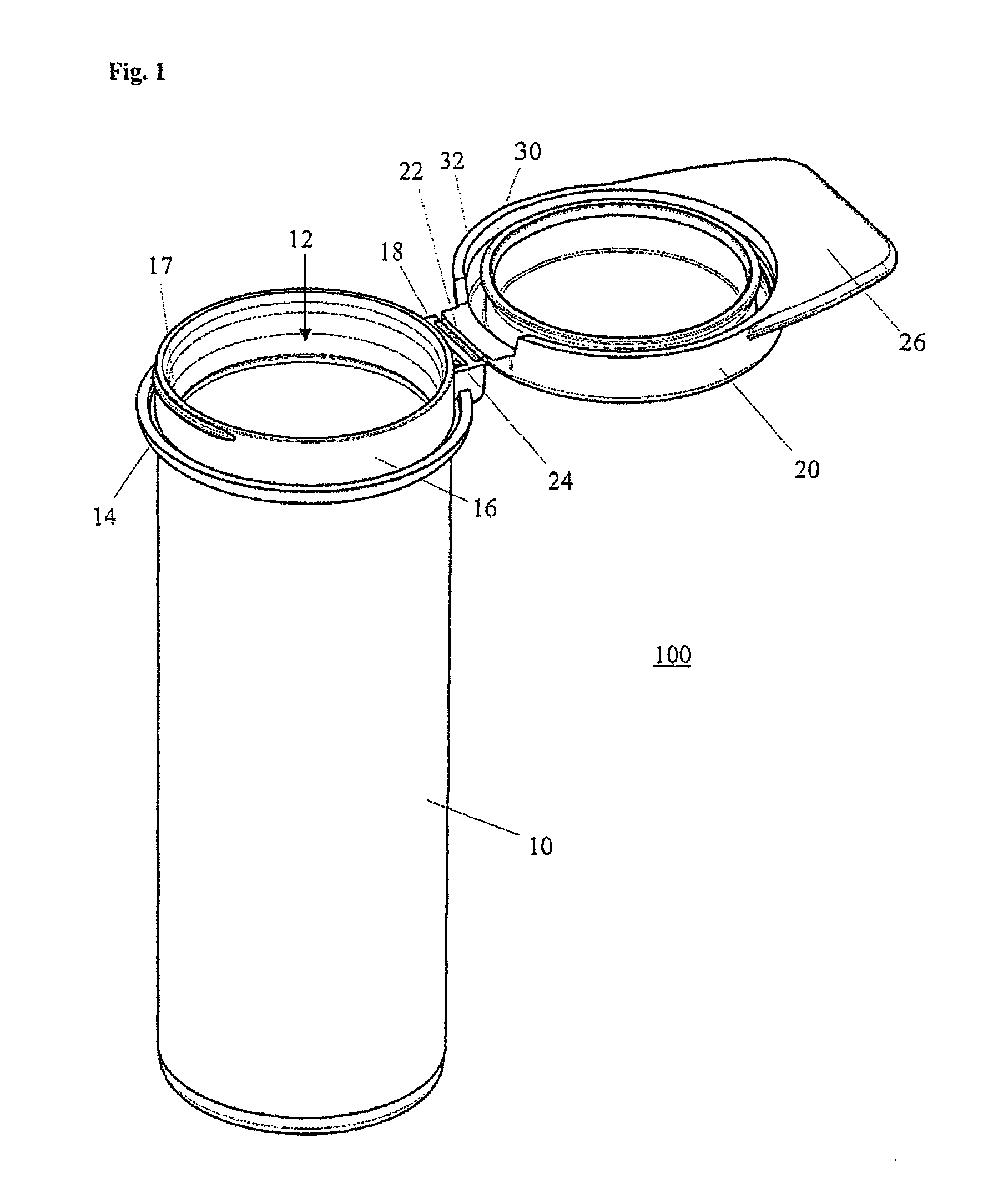

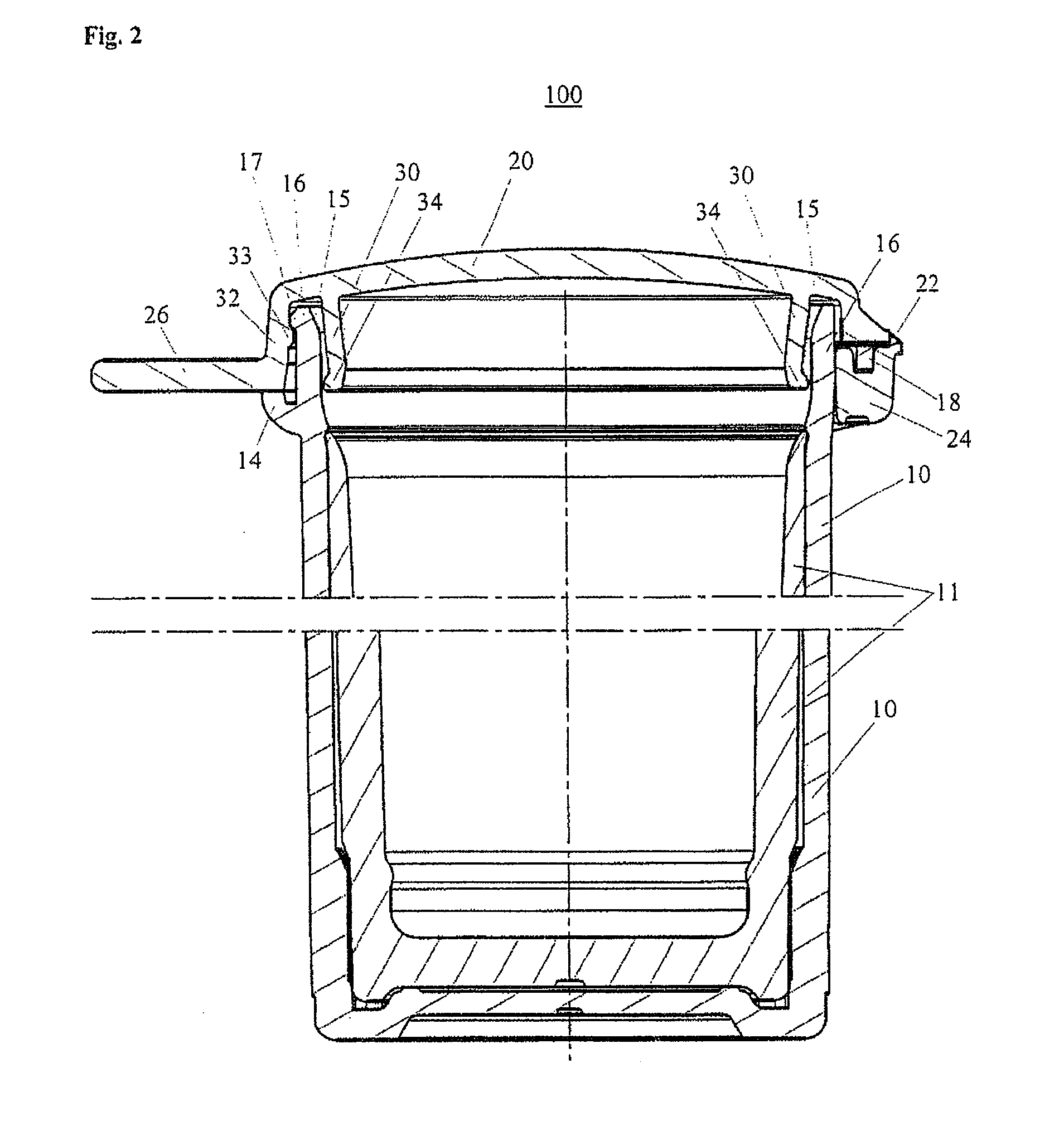

Container

ActiveUS20110000930A1Improve reliabilityImprove tightnessSealingLidsEngineeringStructural engineering

Owner:AIRNOV INC

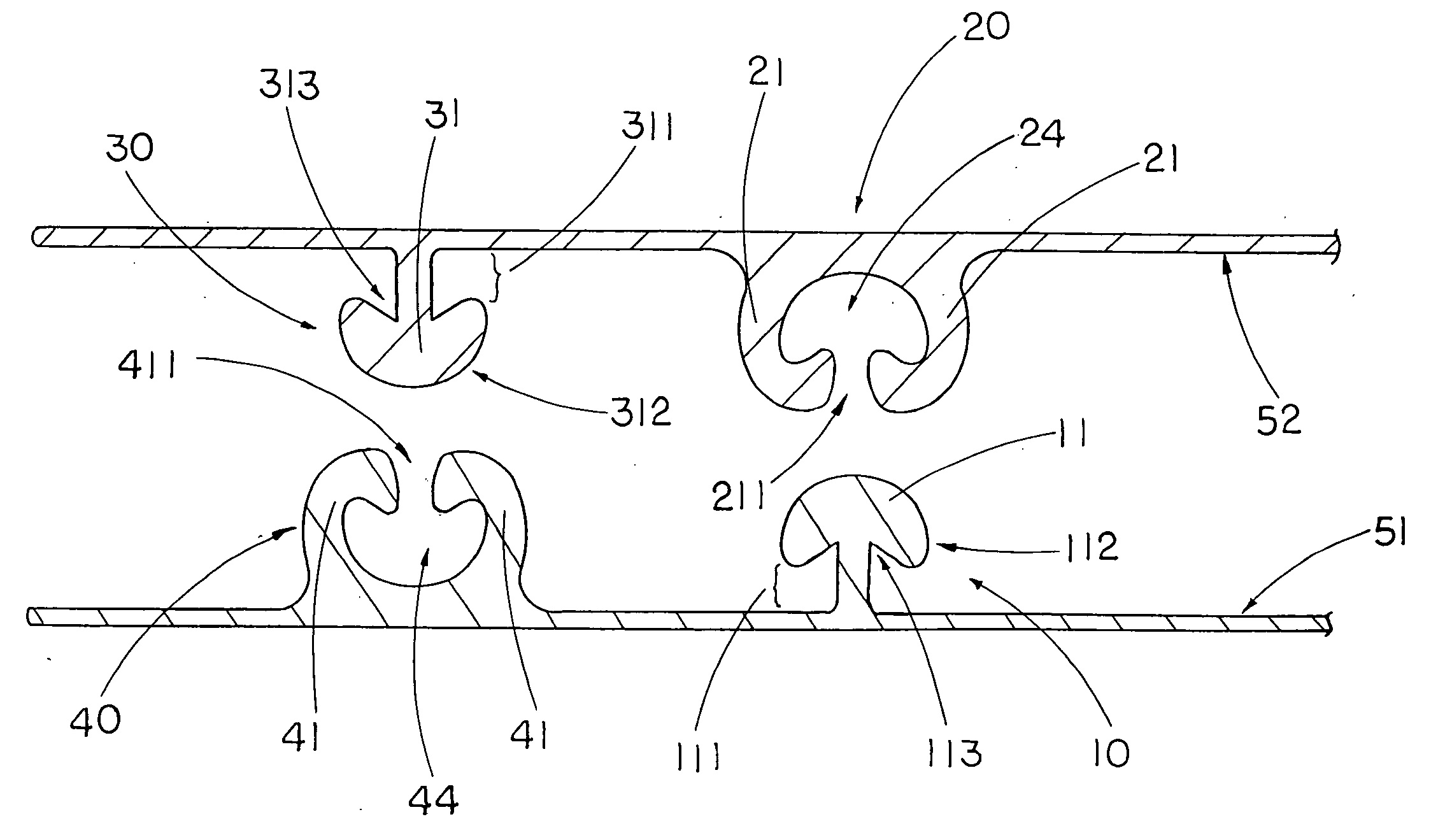

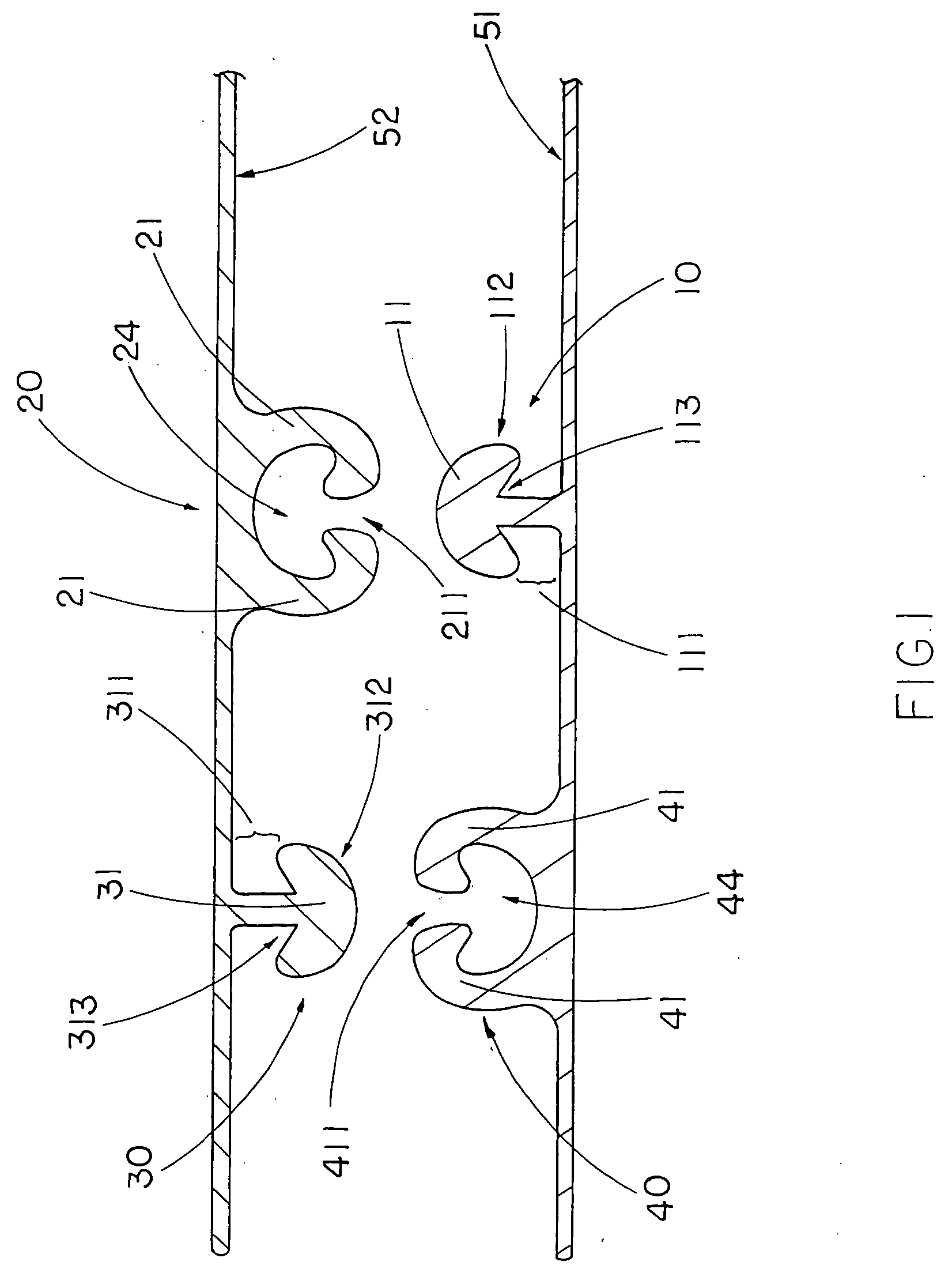

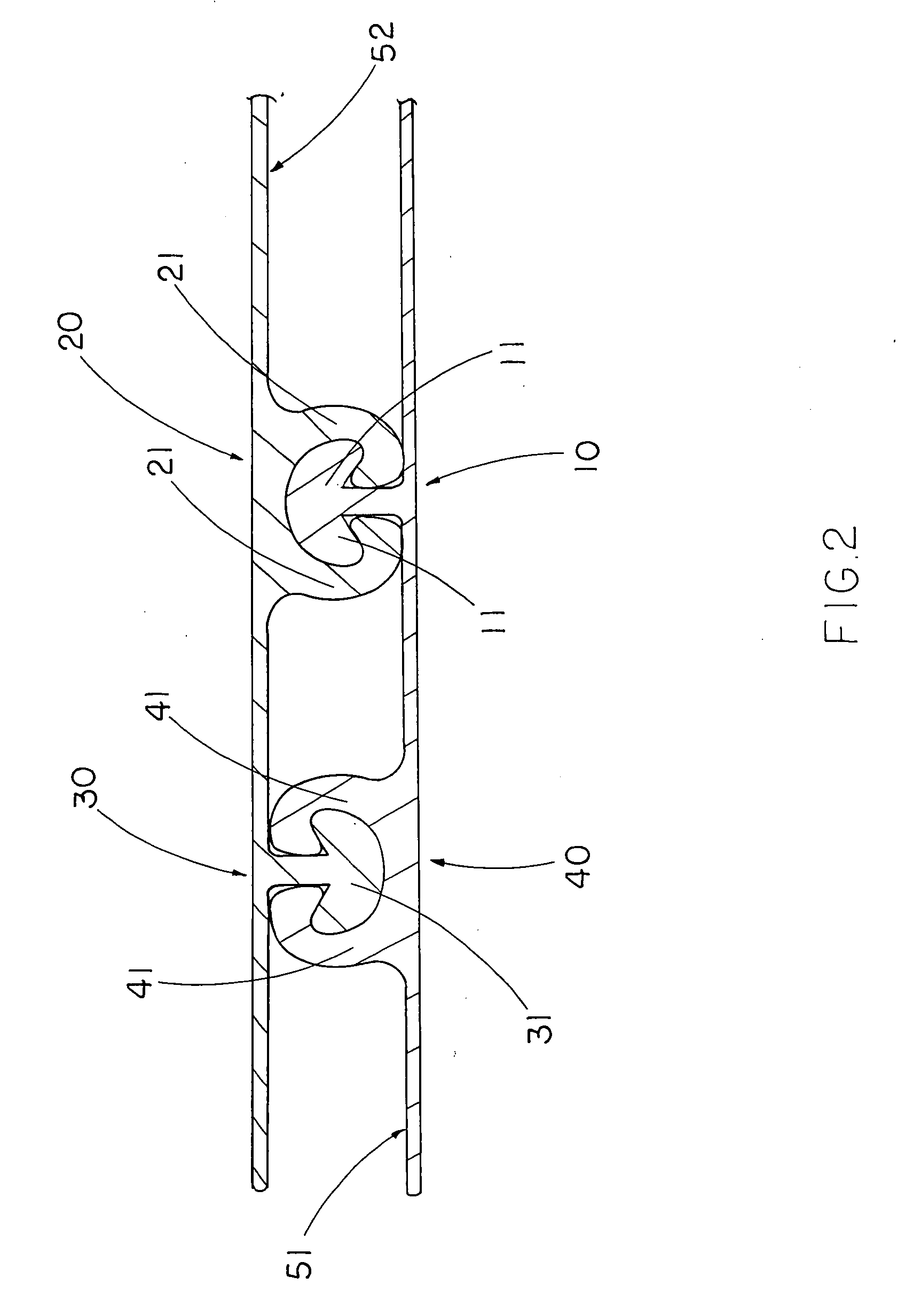

Zip lock

A zip lock for a storage bag having a first surface and a second surface, includes a zip fastener and a lock fastener integrally provided on the first and second surfaces respectively. The zip fastener has two zip bodies spacedly and integrally extended from the first surface and a coupling groove extending towards the first surface at a position between two inner walls of the zip bodies. The lock fastener has two locking arms spacedly and integrally extended from the second surface and a sealing arm integrally extended from the second surface at a position between the two locking arms to form two sealing cavities, wherein the sealing arm is sealedly inserted into the coupling groove until the round end of the sealing arm is positioned at the round end of the coupling groove.

Owner:INTELLI INNOVATIONS +1

Firearm with quick coupling barrel interlock system

ActiveUS8505227B2Quick changeImprove tightness and reliabilityBreech mechanismsBarrel mountingCouplingEngineering

A firearm with barrel interlock system for a rotary mounted quick coupling barrel assembly. In one embodiment, the firearm includes a receiver and barrel assembly rotatably mounted thereto. A bolt carrier supporting a bolt is slidably disposed in the receiver and axially movable into and out of battery with the barrel assembly. The barrel interlock system may include a first barrel anti-rotation locking element disposed on the barrel assembly and a mating second barrel anti-rotation locking element disposed on the bolt carrier that is engageable with the first element. When mutually engaged, the first and second locking elements form a meshed relationship and prevent rotation and removal of the barrel assembly from the receiver. In some non-limiting embodiments, the locking elements may be in the form of a protrusion and complementary shaped recess.

Owner:STURM RUGER & CO INC

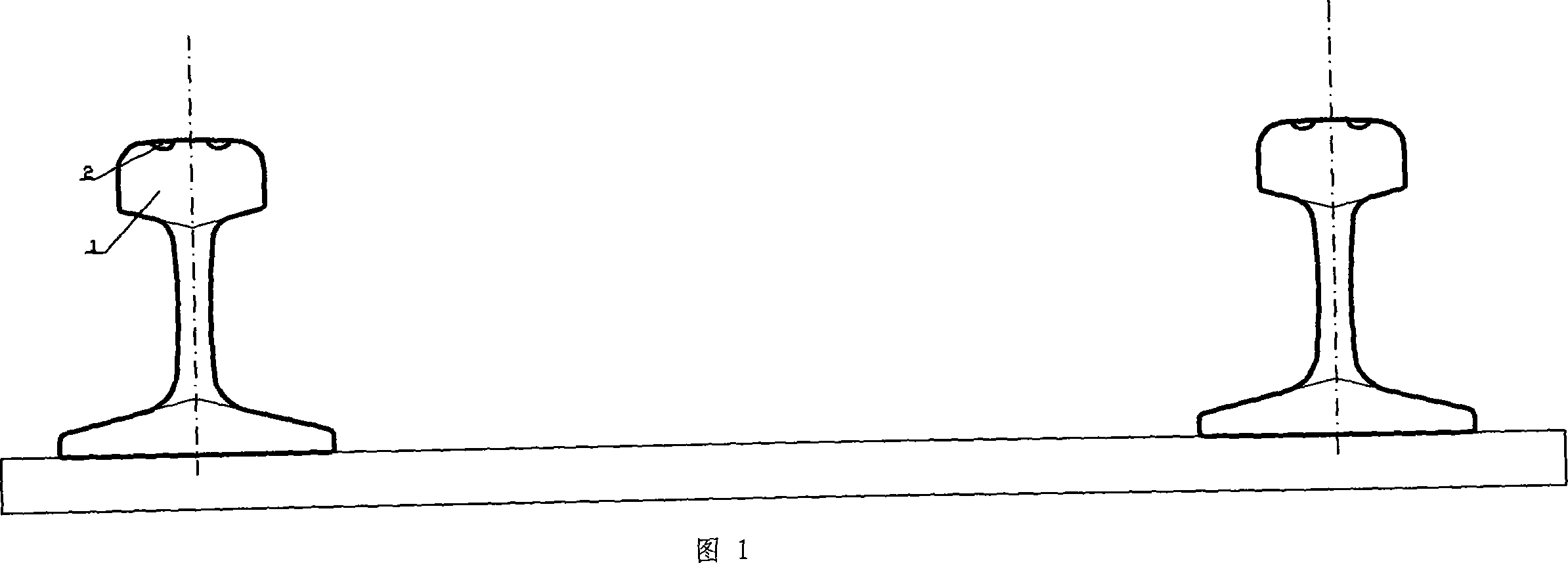

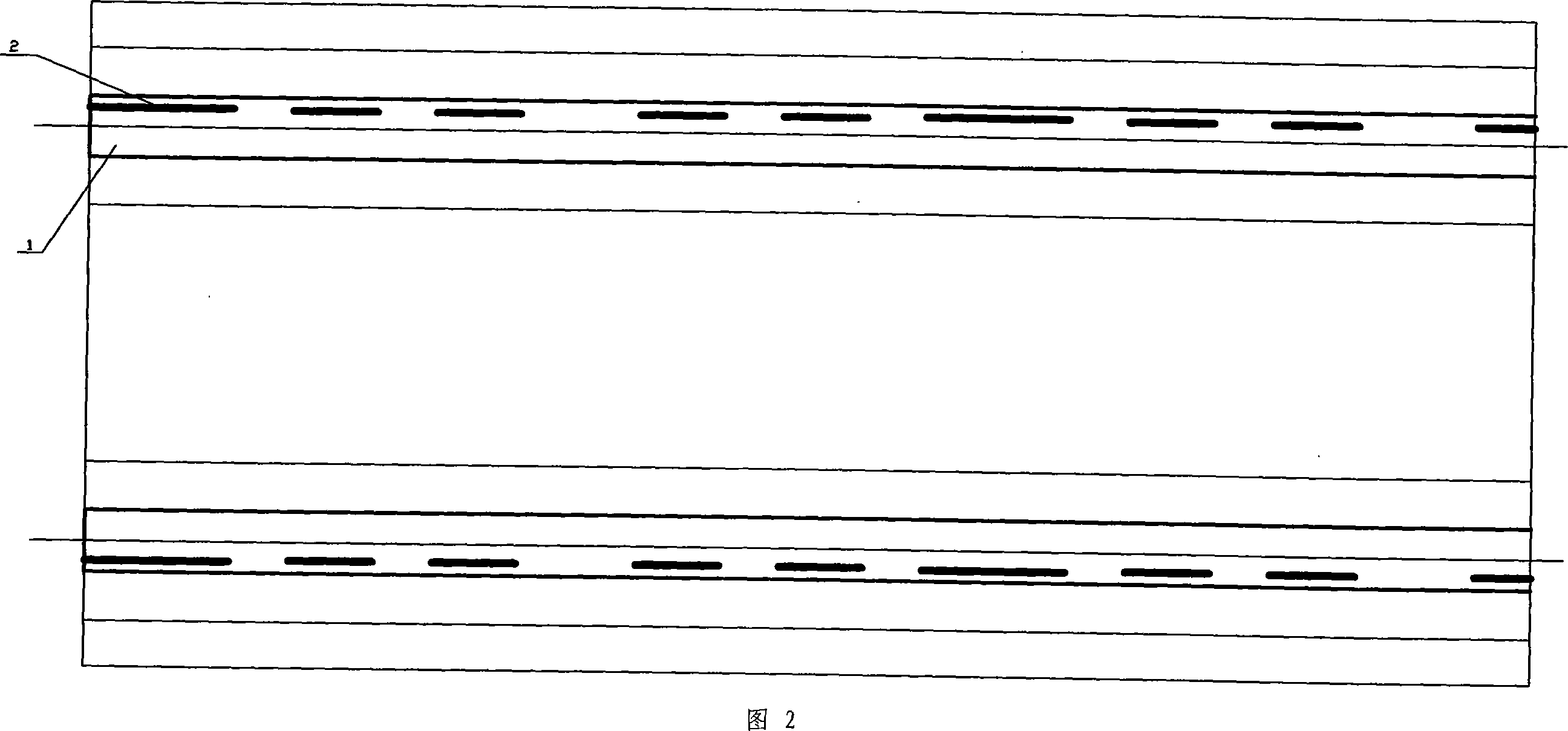

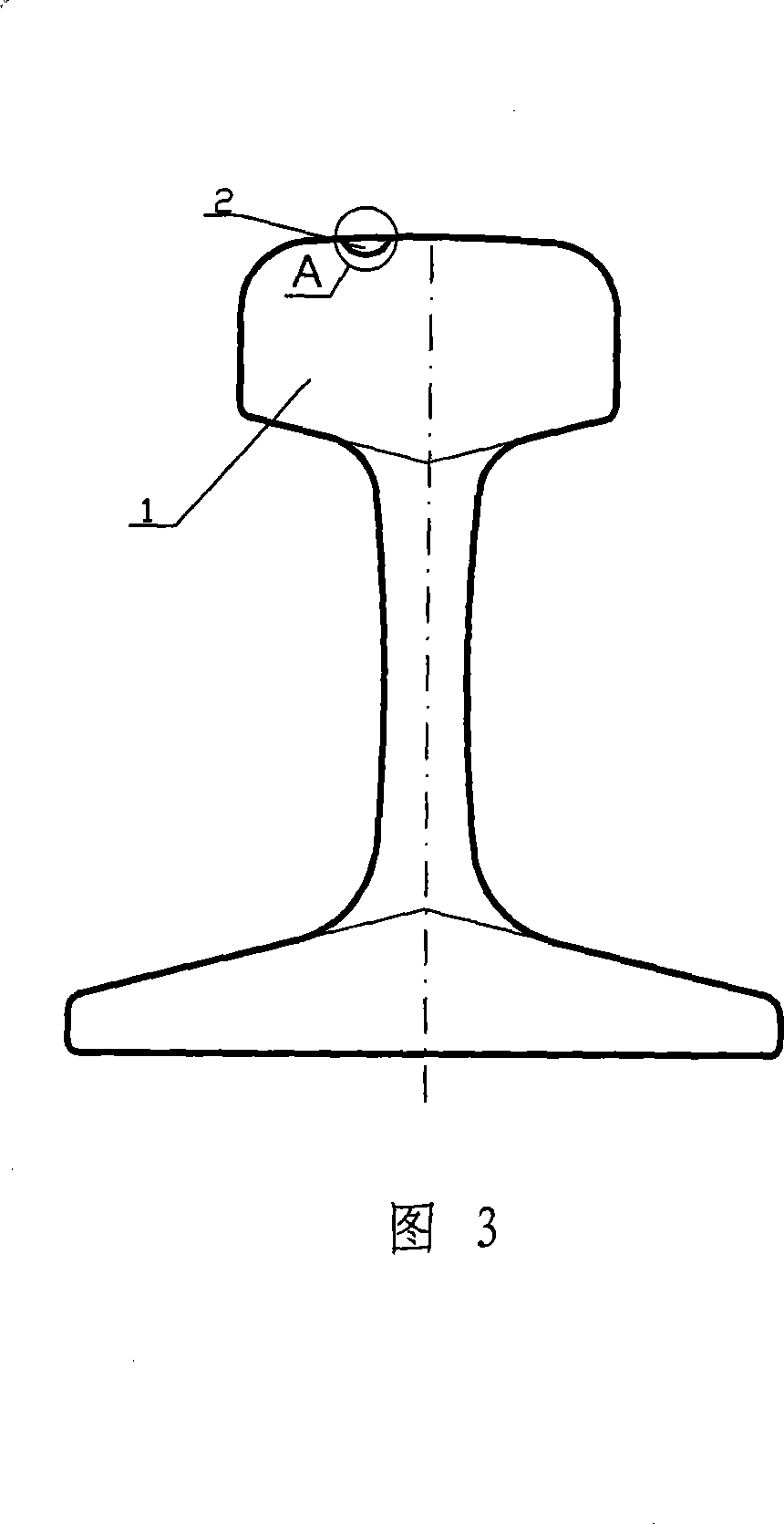

Method for melting and coating anti-rust wear-resistant alloy on steel rail surface

ActiveCN101144160AImprove efficiencyEasy to operateArc welding apparatusMetallic material coating processesBonding strengthWhite light

The present invention discloses a method for smelting rust preventing and wear resistant alloy on the surface of a steel rail. The position needing alloy smelting on the surface of the steel rail head is heated by supersonic frequency or medium frequency induction-heating equipment, the induction heater is arranged above the position needing alloy smelting on the surface of the steel rail head, and the preheating temperature is 290-450 DEG C; the alloy is smelted on the surface of the steel rail head by using plasma smelting or arc welding smelting, when the preheating temperature is 290-450 DEG C, and the welding gun of plasma build up welding or arc welding equipment is moved to the position needing alloy smelting, the alloy powder, the alloy electrode or the alloy welding wire are automatically smelted; the railroad steel rail adopting the present invention can ensure that the train wheels and the rust preventing and wear resistant alloy layer are always in a contacting and compacting state, thereby the rail circuit works normally, and the white light zone phenomenon is completely eliminated; the cracking and breaking phenomena of the steel rail do not occur, the smelted alloy has good rust preventing and wear resistant properties, high bonding strength with the steel rail, and long service life.

Owner:CHENGDU ZHONGGUI TECH CO LTD

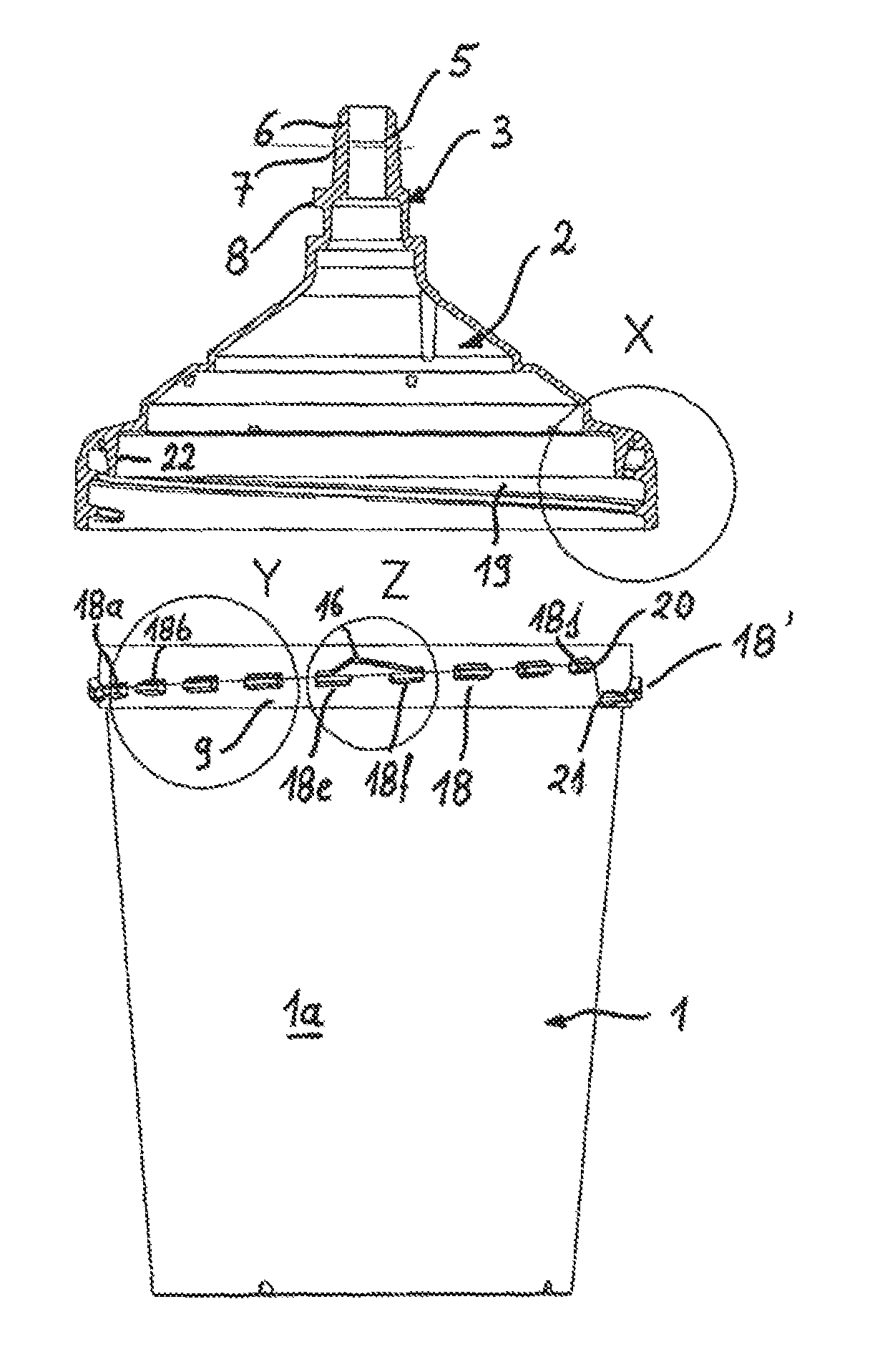

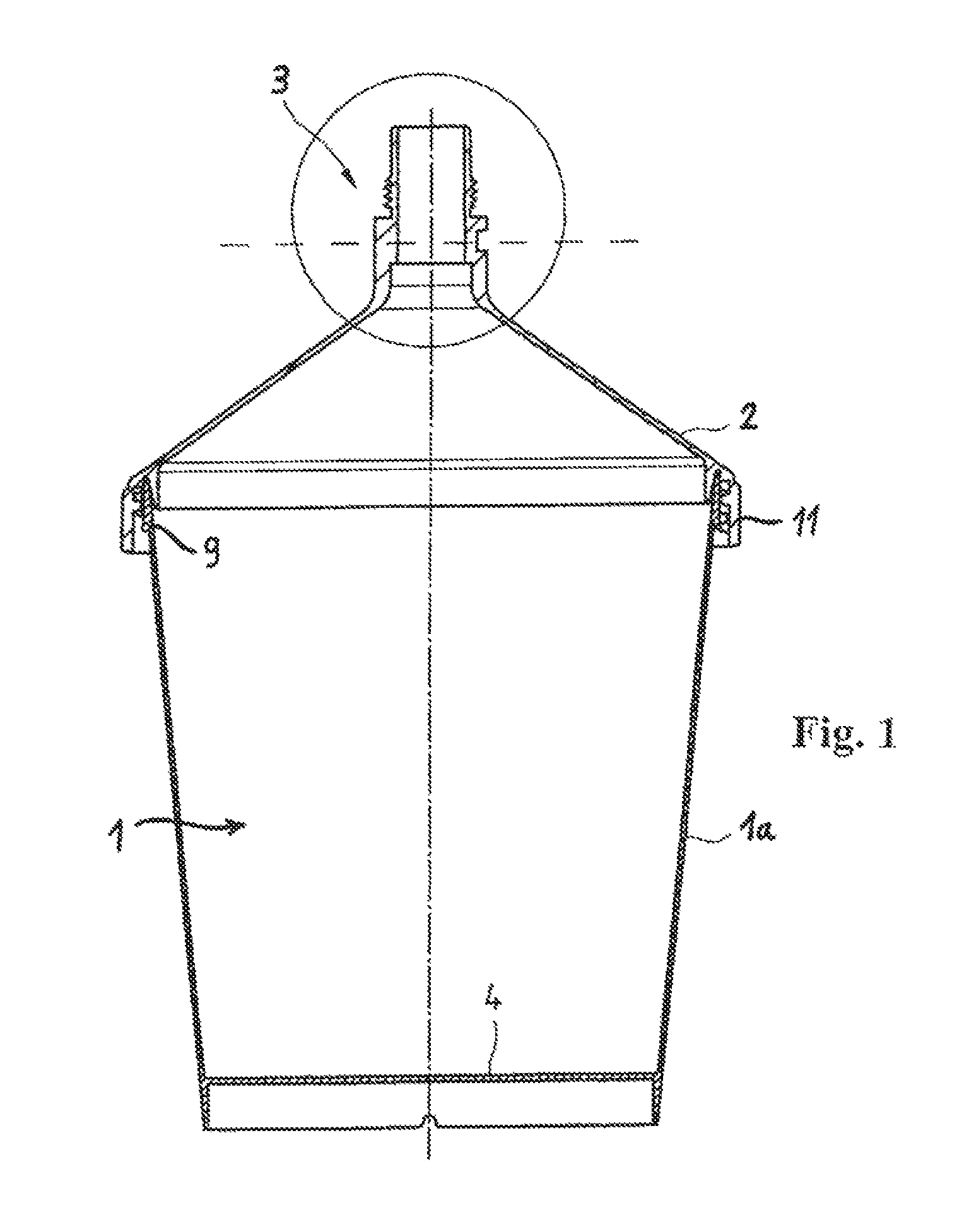

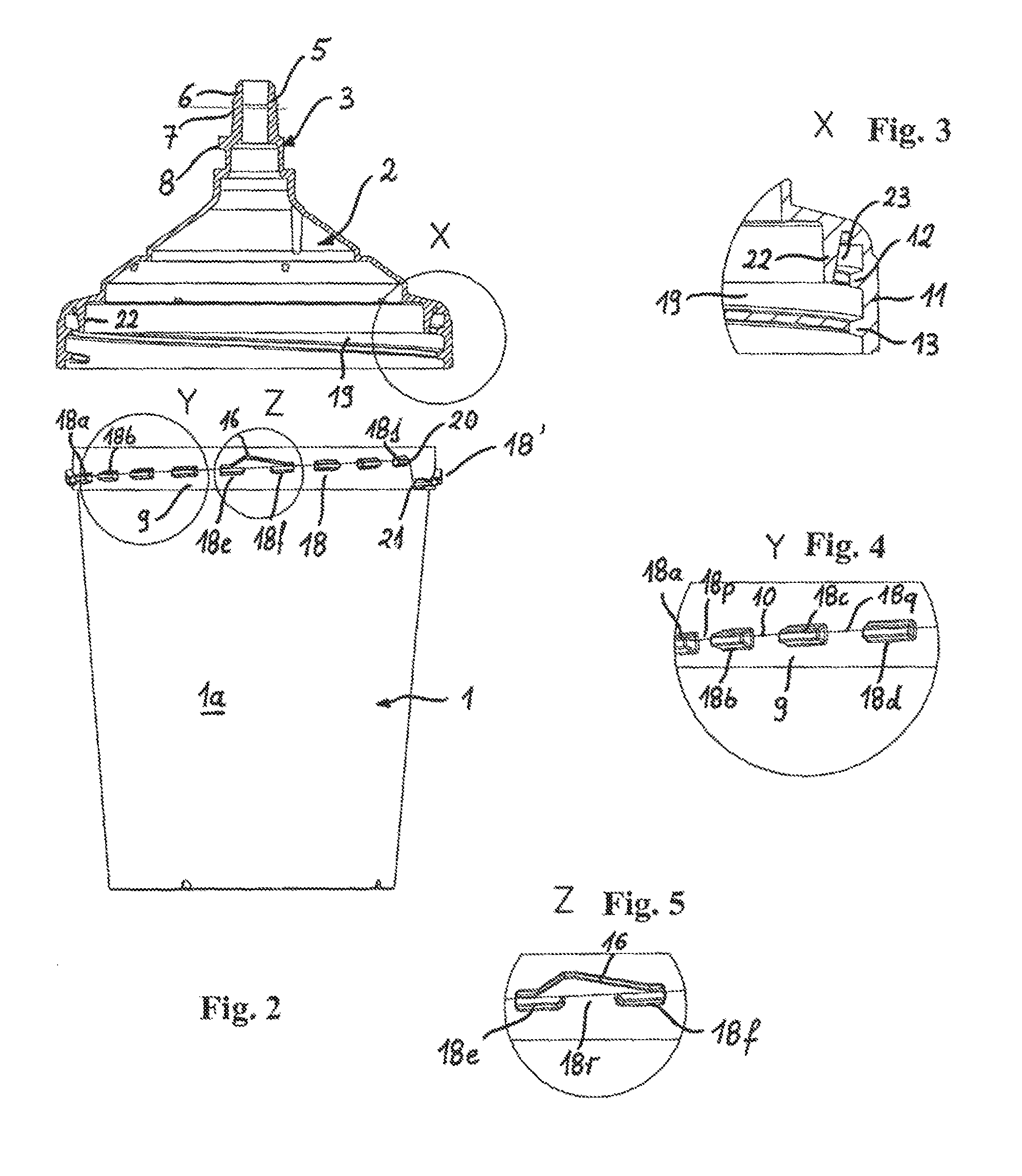

Gravity cup for a paint sprayer

ActiveUS8925836B2Improve tightnessConstant rigidityCapsClosure using stoppersGravitationWaste management

The invention relates to a gravity cup for a paint sprayer, having a cup-shaped tank (1) and a cover (2) that can be placed on the tank (1), a multiplex quick-connect thread having at least two external thread turns (18) and internal thread turns (19) engaging with the external thread turns (18) for connecting the tank (1) and the cover (2), characterized in that each external thread turn (18) is formed of a plurality of thread segments (18a, 18b, 18j) disposed along the pitch line of each external thread turn, wherein a gap (18p, 18q . . . 18w) is formed between adjacent thread segments.

Owner:SATA GMBH & CO KG

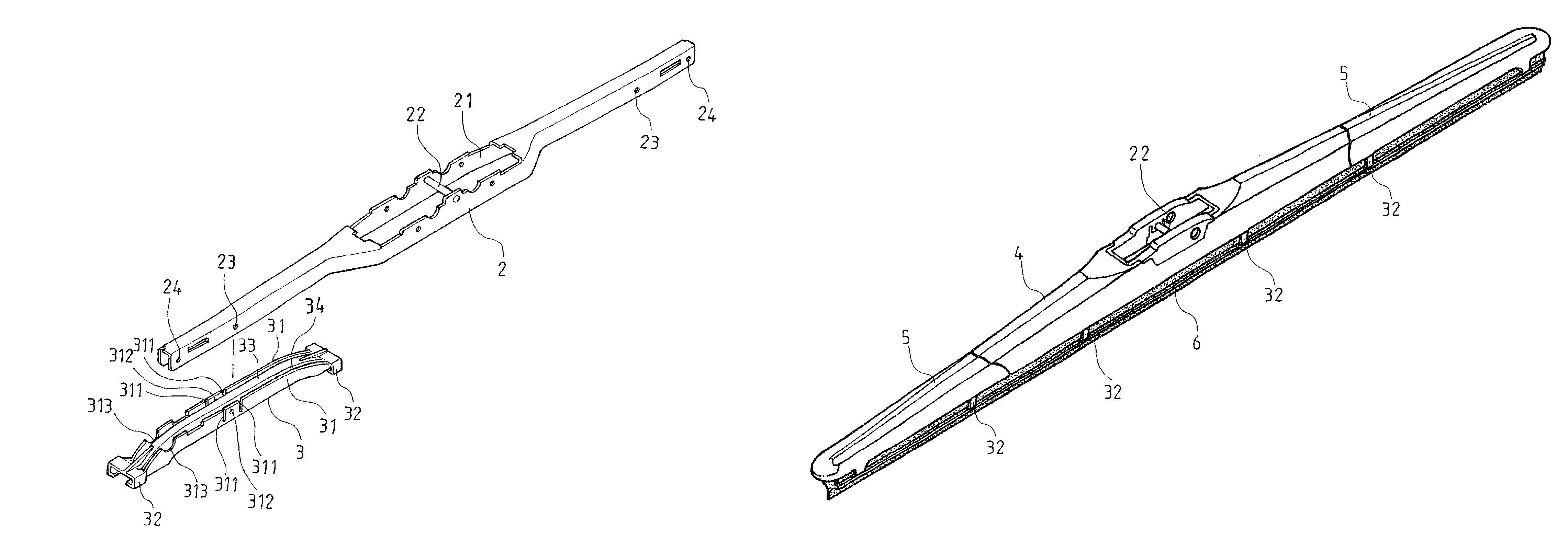

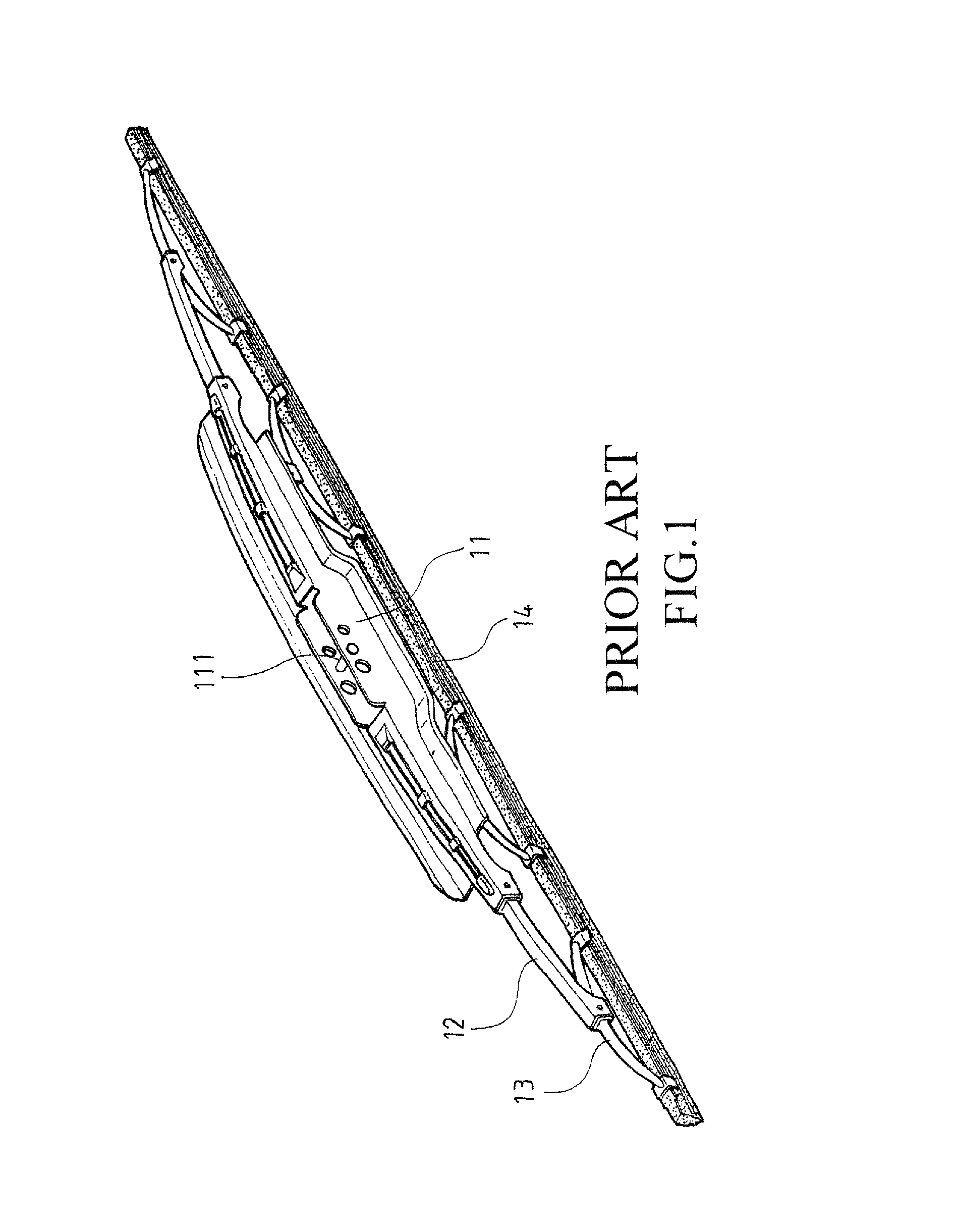

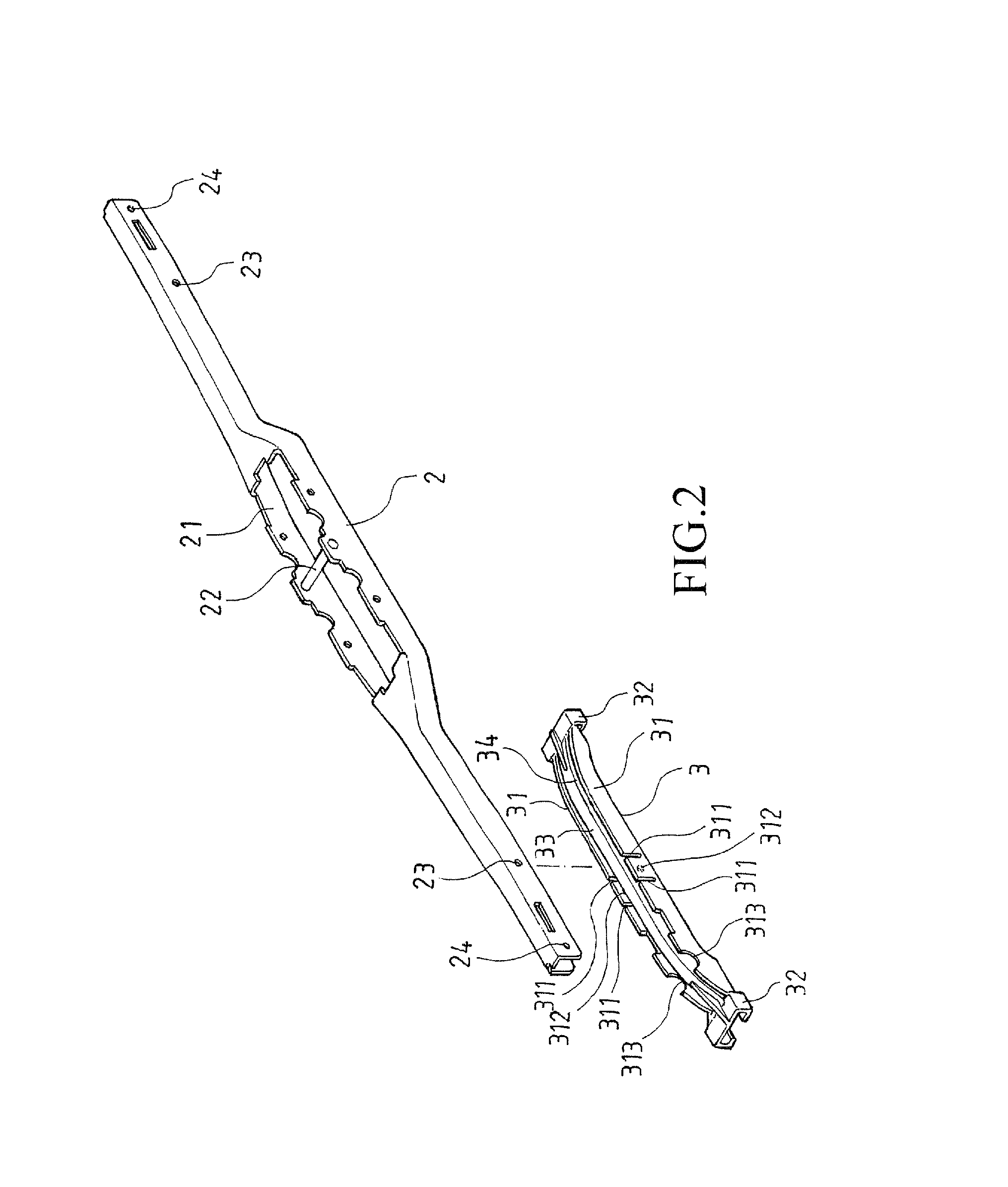

Frame coupling structure of windshield wiper

InactiveUS7921504B1Simple structureImprove tightnessWindow cleanersVehicle cleaningInverted uWall plate

A windshield wiper includes a primary frame member and secondary frame members coupled to the primary frame member. The primary frame member is in the form of an inverted U-shape and includes end portions in which mounting holes are formed. Each secondary frame member has symmetrically arranged wall plates and a positioning section formed between and slightly projecting beyond the wall plates. Each wall plate forms open-ended slots that are symmetrically arranged. A boss is formed on an inside surface of each wall plate between the open-ended slots. The primary frame member has side plates that are fit over the positioning section of the secondary frame member to have the wall plates of the secondary frame member covering and clamping the vertical side walls of the primary frame member. The bosses are fit into the mounting holes of the primary frame member.

Owner:FU GANG CO LTD

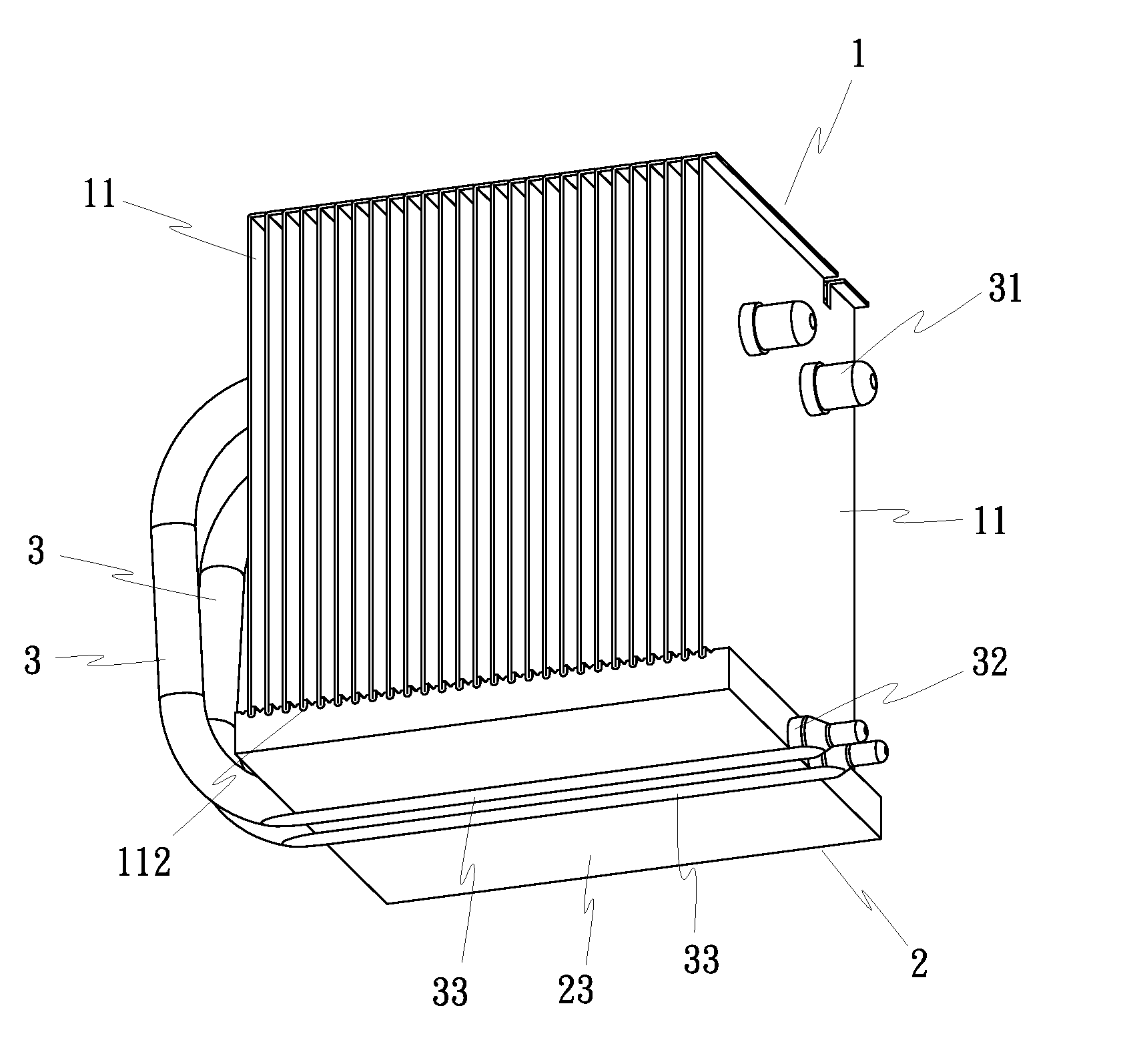

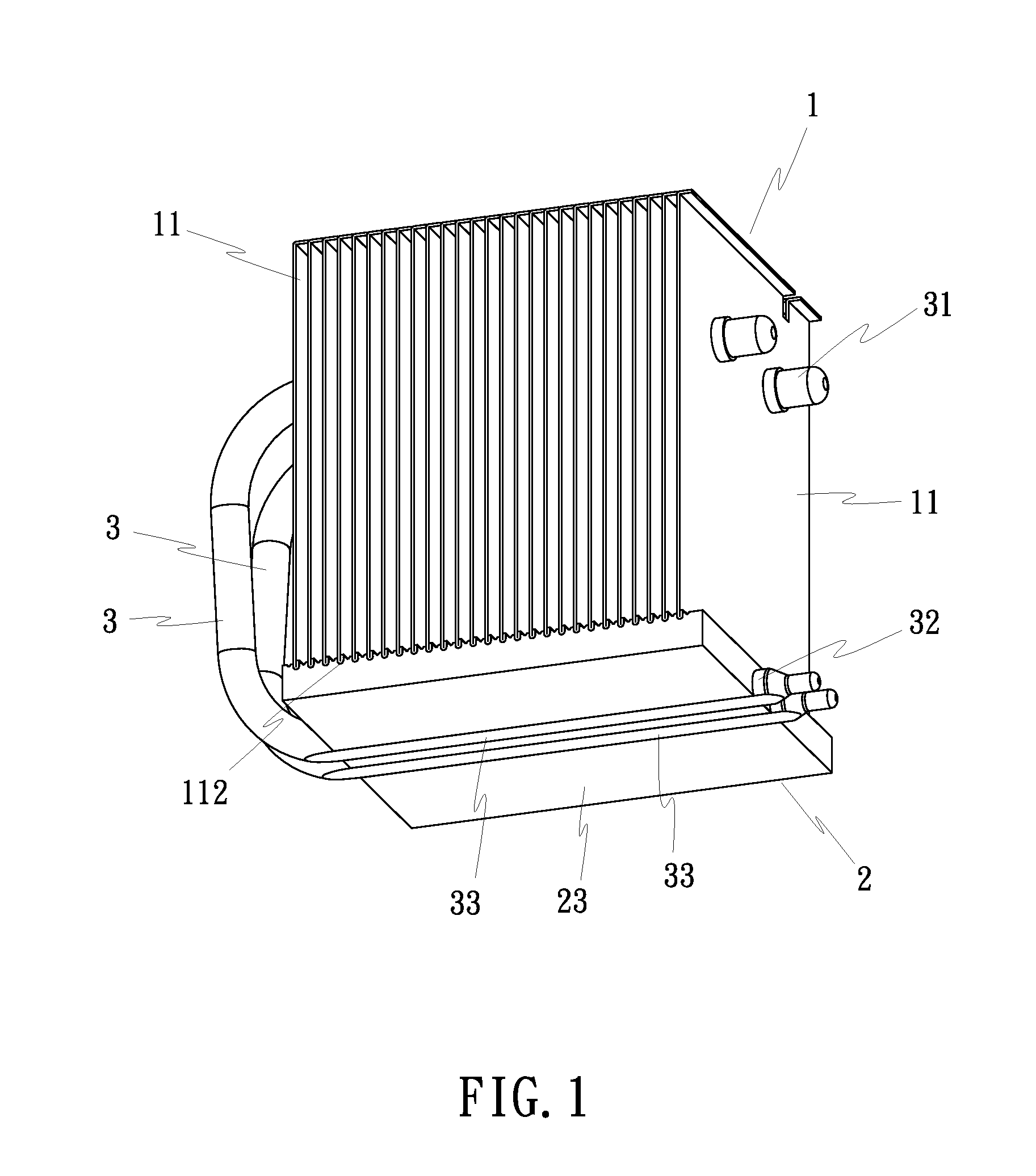

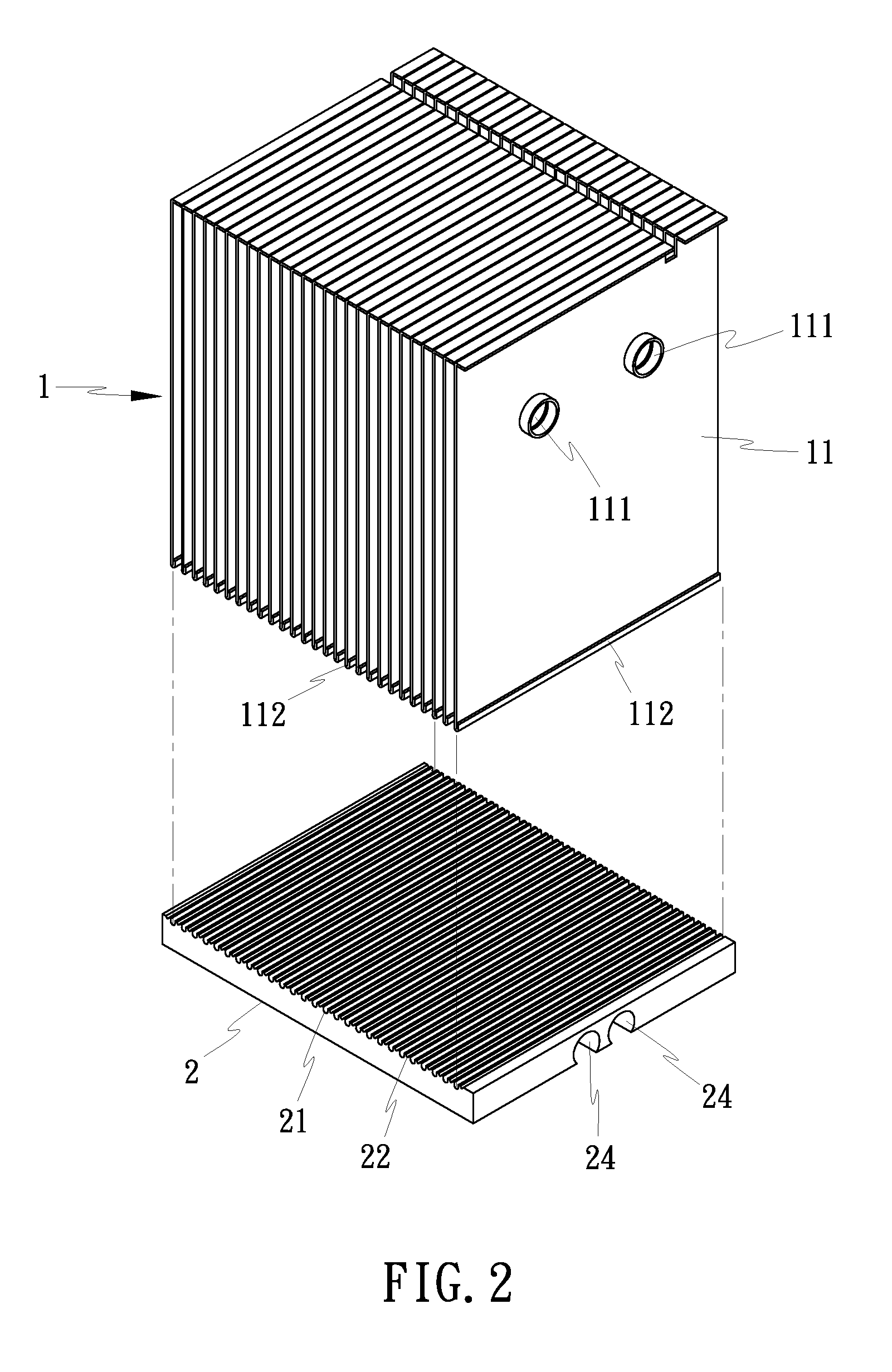

Cooler device

InactiveUS20090194255A1Dissipate quicklyEfficient transferDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat sink

A cooler device includes a base panel, which has multiple mounting grooves on the top wall and multiple locating grooves on the bottom wall, a radiation fin module formed by stacking up multiple radiation fins, each radiation fin having multiple mounting through holes and a root portion that is respectively riveted to the mounting grooves of the base panel, and multiple U-shaped heat pipes, each heat pipe having a first extension arm respectively and tightly fitted into the mounting through holes of the radiation fins and a second extension arm respectively and tightly fitted into the locating groove of the base panel and kept in flush with the bottom wall of the base panel for direct contact with a CPU or the like to transfer heat energy from the CPU or the like to the radiation fins for quick dissipation.

Owner:HUANG TSUNG HSIEN

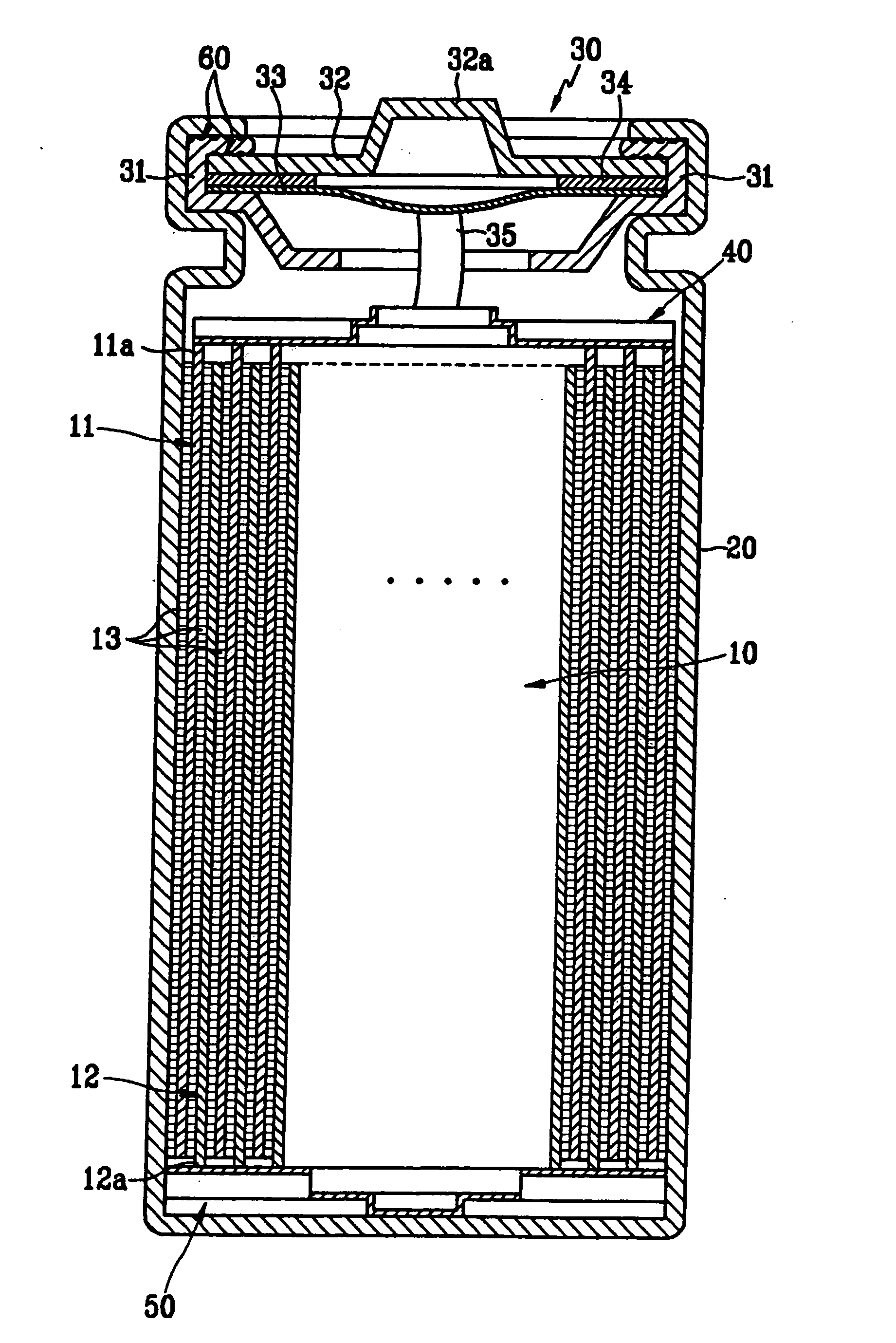

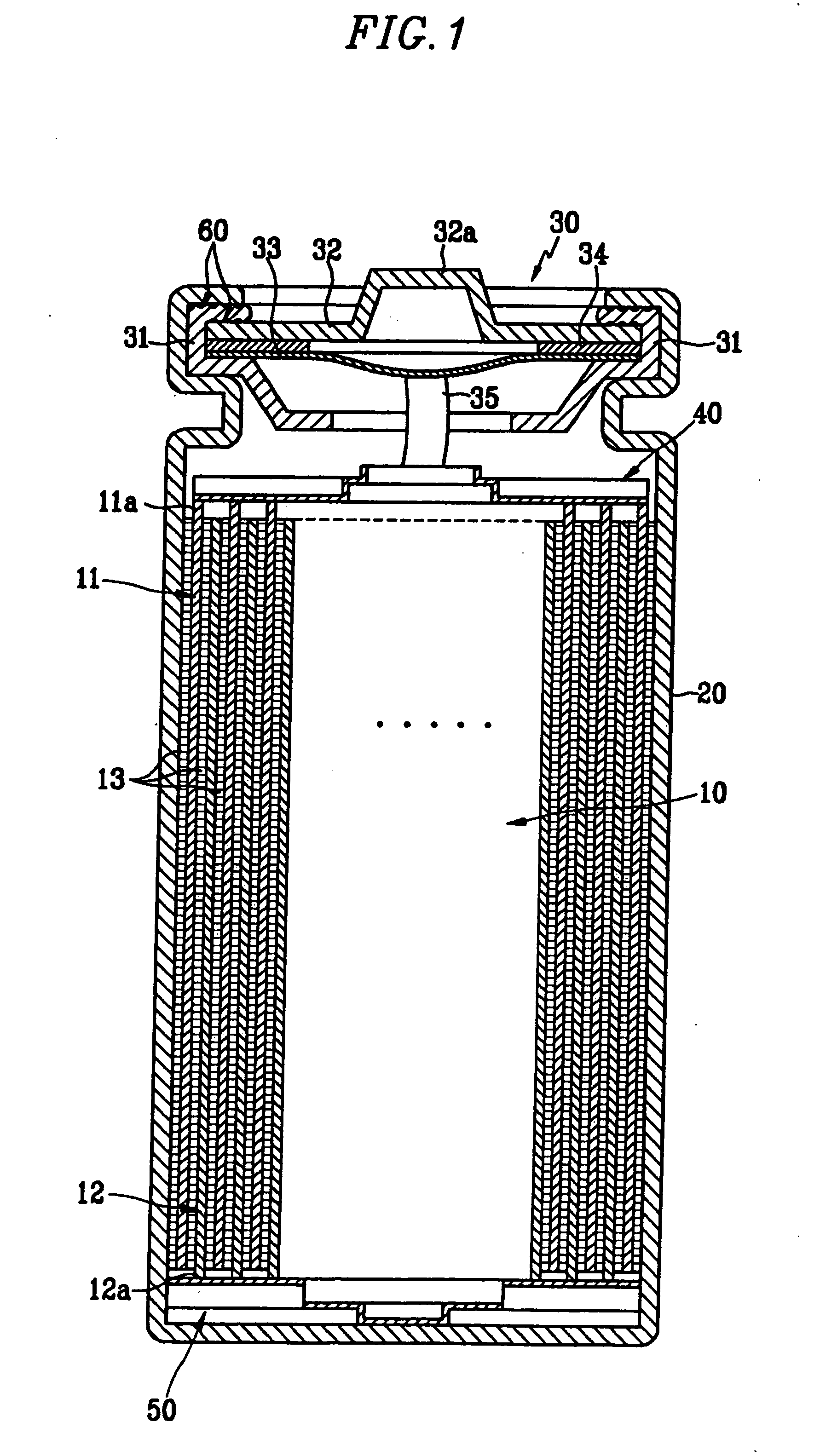

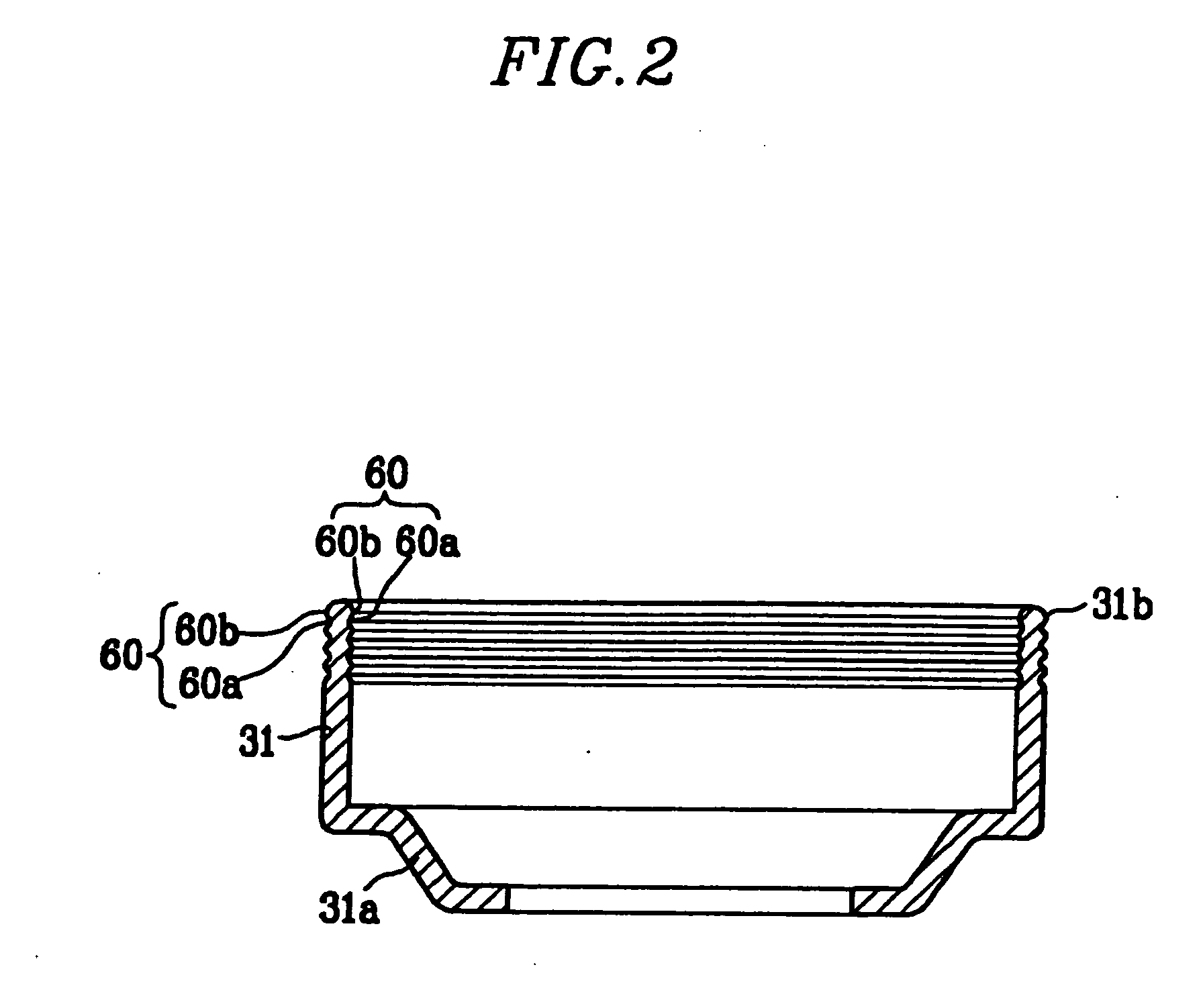

Secondary battery

InactiveUS20060093904A1Enhanced fluid tightnessImprove gas tightnessElectrolyte moving arrangementsFinal product manufactureEngineeringAir tightness

A secondary battery includes an electrode assembly having a positive electrode, a negative electrode and a separator interposed between the positive and negative electrodes and a container for receiving the electrode assembly inside thereof. The secondary battery also includes a cap assembly fixed to the container to seal the container and a gasket disposed between the container and the cap assembly. The gasket has at least one concavo-convex portion on a surface contacting the container and / or the cap assembly. This improved gasket structure enhances the air tightness of the secondary battery.

Owner:SAMSUNG SDI CO LTD

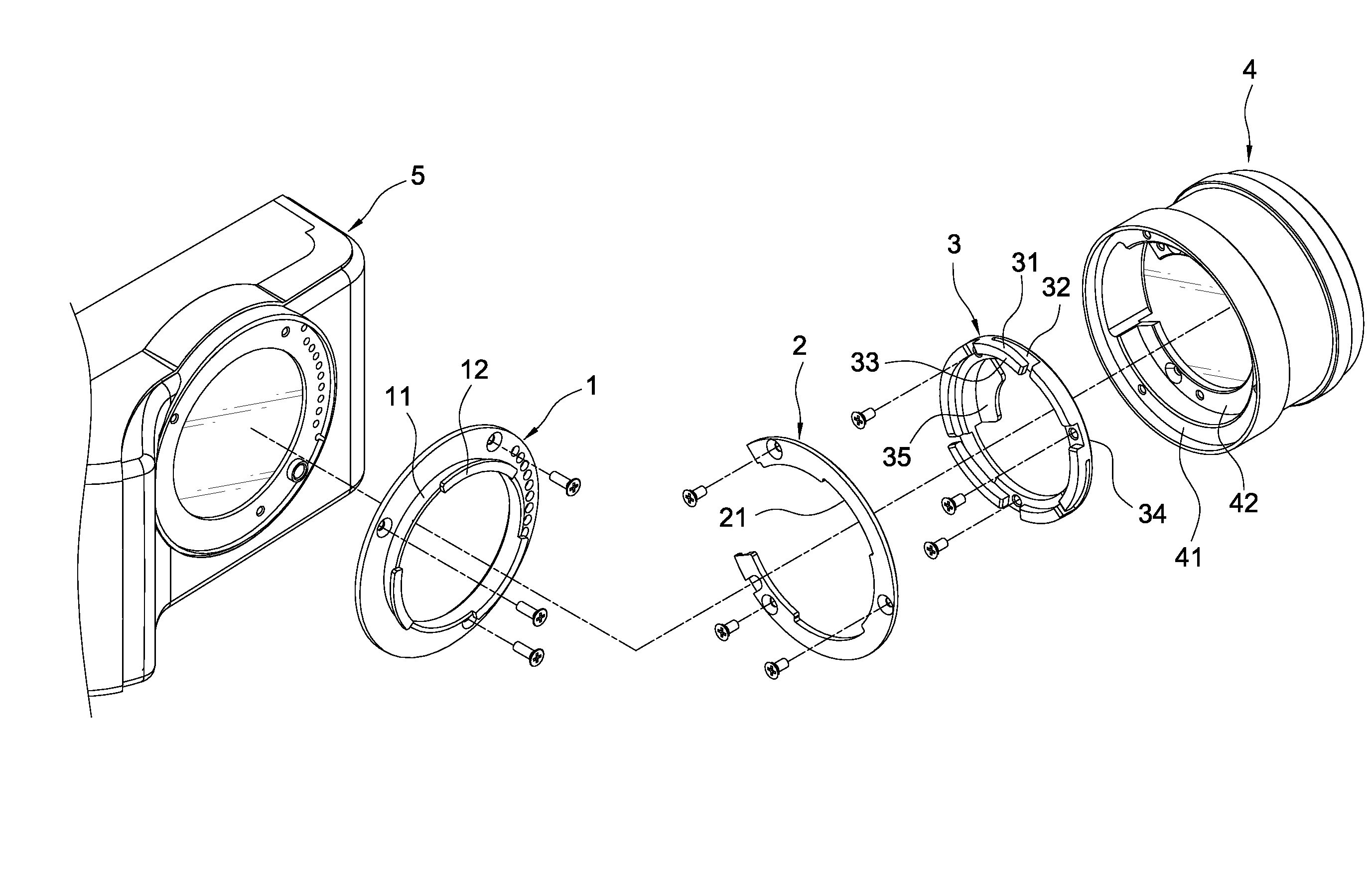

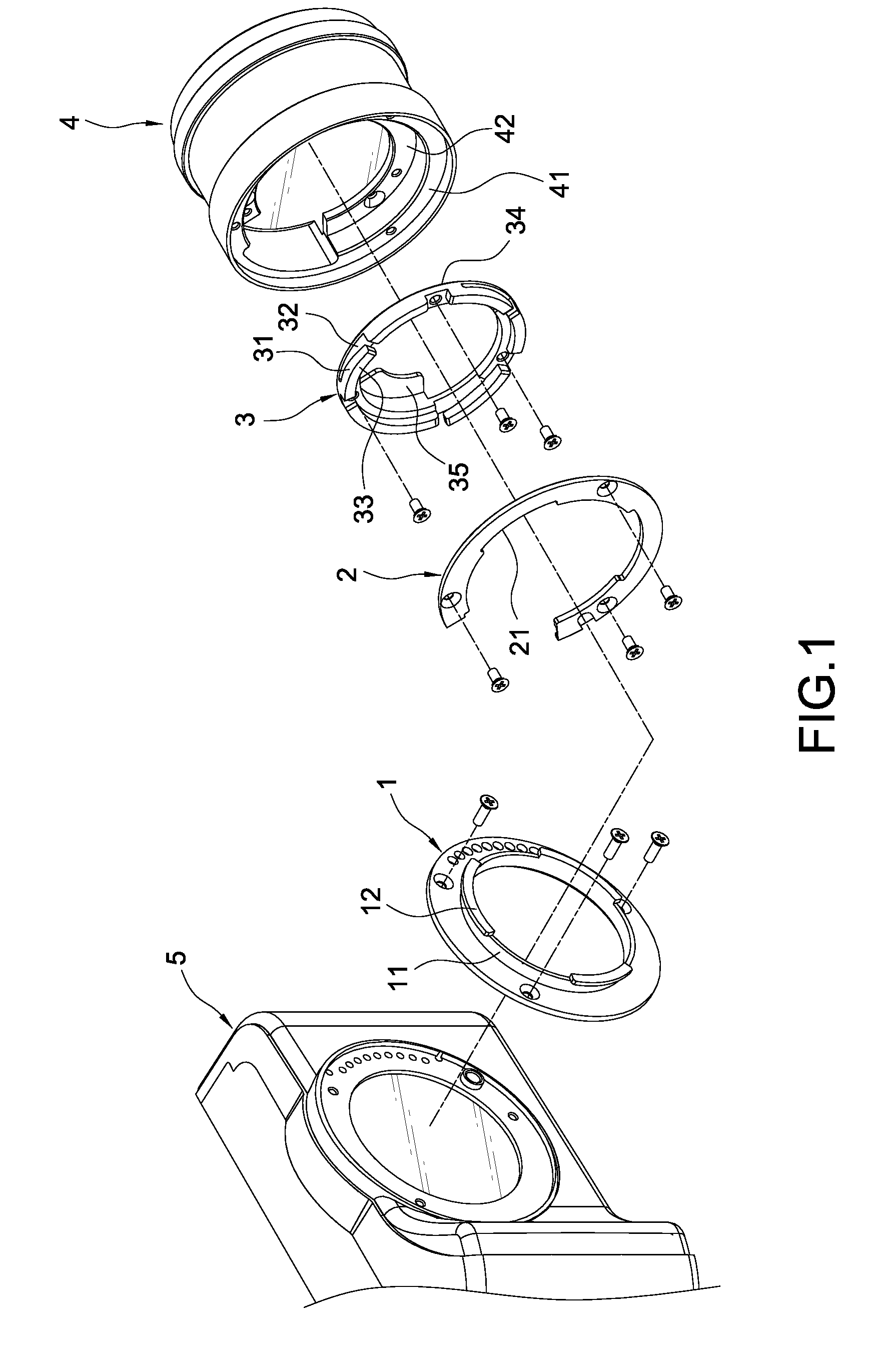

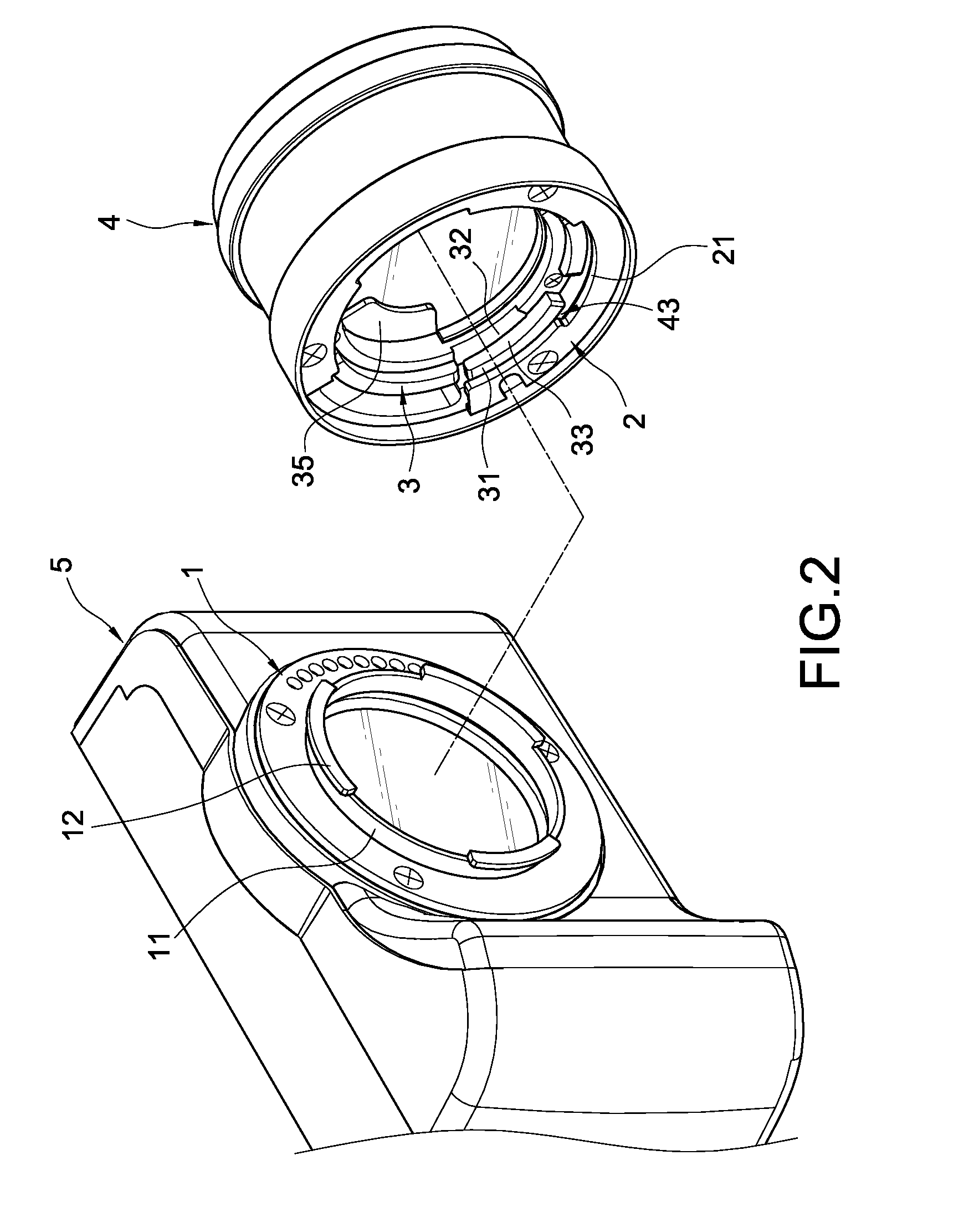

Fixing structure for an auxiliary lens of cameras

InactiveUS7853137B2TightnessImprove tightnessTelevision system detailsColor television detailsCamera lensEngineering

A means for fixing an auxiliary lens to the outside of the original lens of a camera body includes an annular base, an annular lens mount and an annular abutting base. The inner edge of the base protrudes upwardly to form a wall. The wall protrudes outwards to form a plurality of blocks. The inner edge of the lens mount is provided with a plurality of notches corresponding to the blocks. A first end surface of the abutting base extends to form a plurality of L-shaped elastic arms corresponding to the blocks and notches. The L-shaped elastic arm extends obliquely from the first end surface toward the lens mount. A gap is formed between the L-shaped elastic arm and the abutting base, so that the L-shaped elastic arm can be bent inwardly when compressed. When the camera body is combined with the auxiliary lens by rotation, the blocks pass through the notches to abut and compress the L-shaped elastic arms. At the same time, the L-shaped elastic arms generate a reaction force, thereby enhancing the tightness between the camera body and the auxiliary lens.

Owner:LUMOS TECH

Brewing apparatus and method for operating a brewing apparatus

ActiveUS20150238039A1Cost effective productionImprove sealingBeverage vesselsFood preparationLocking mechanismEngineering

The present invention relates to a brewing apparatus for extracting a portion capsule, comprising a first brewing chamber element and a second brewing chamber element, the first and / or the second brewing chamber element being movable along an axial direction from a loading position, in which the first and the second brewing chamber element are spaced apart from one another, to an extraction position, in which the first and the second brewing chamber element form a substantially closed brewing chamber, and the brewing apparatus further comprising a drive mechanism for moving the first and / or second brewing chamber element, characterized in that the brewing apparatus has a separate locking mechanism for locking the brewing chamber in the extraction position.

Owner:EUGSTER FRISMAG

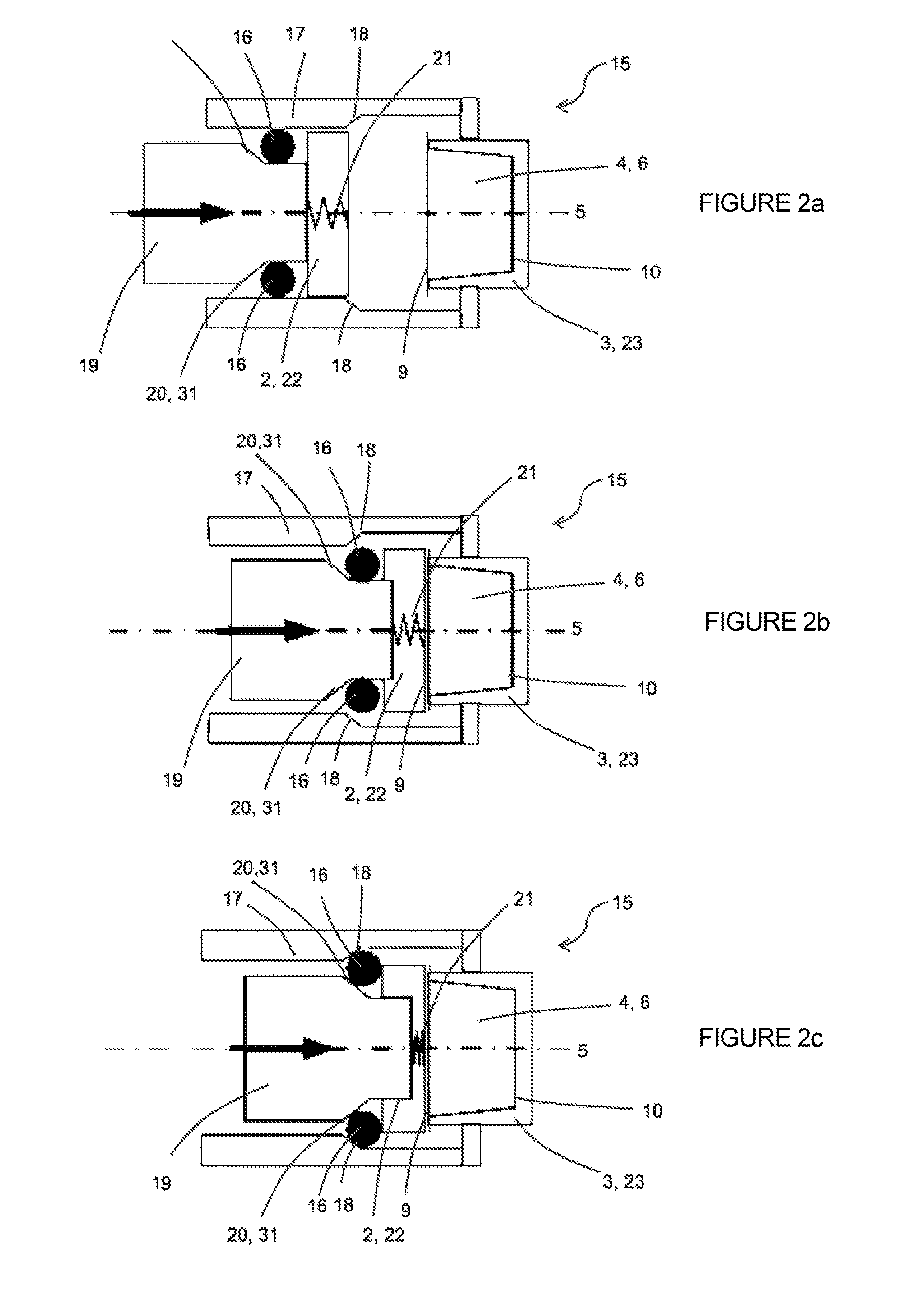

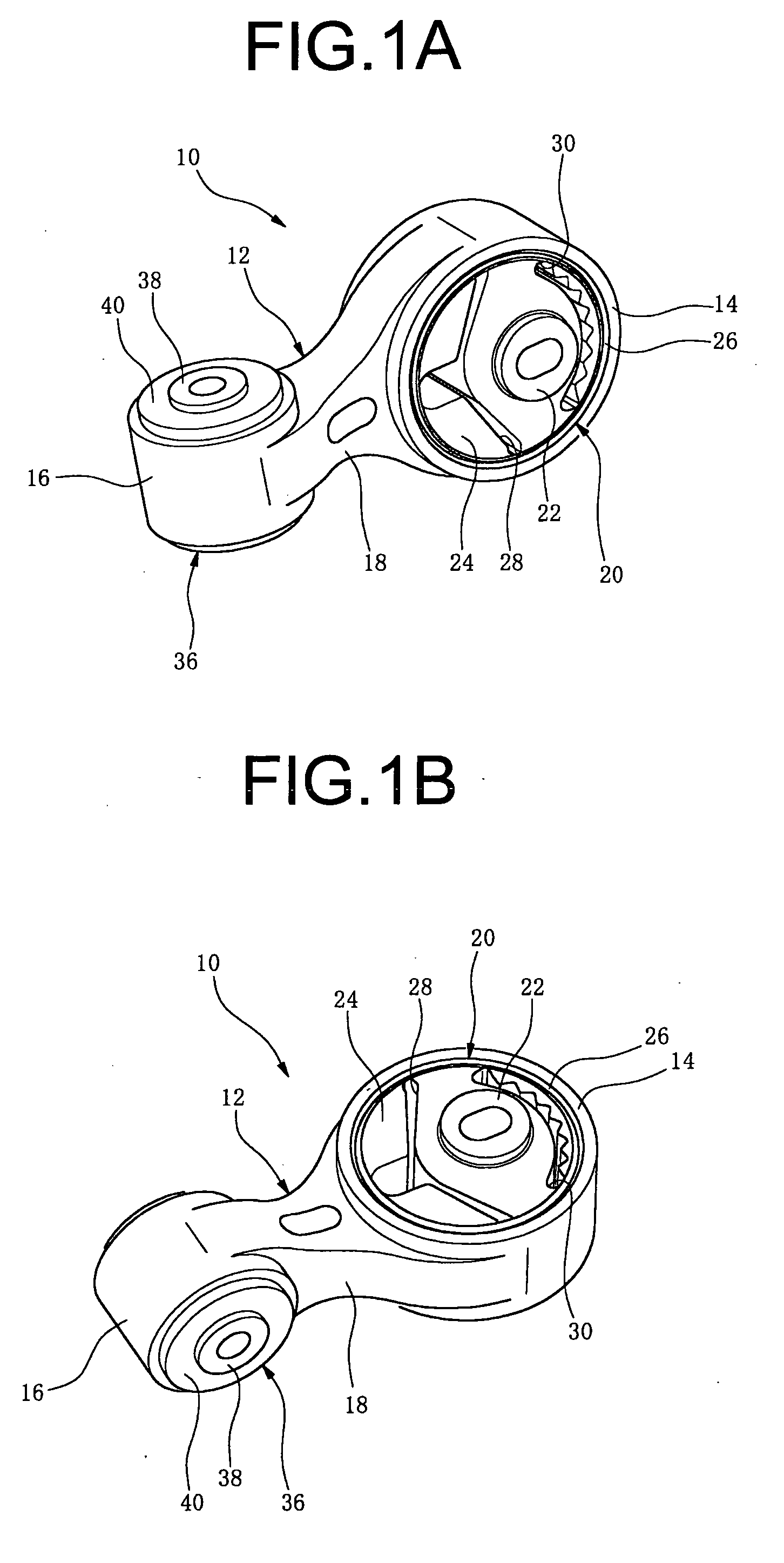

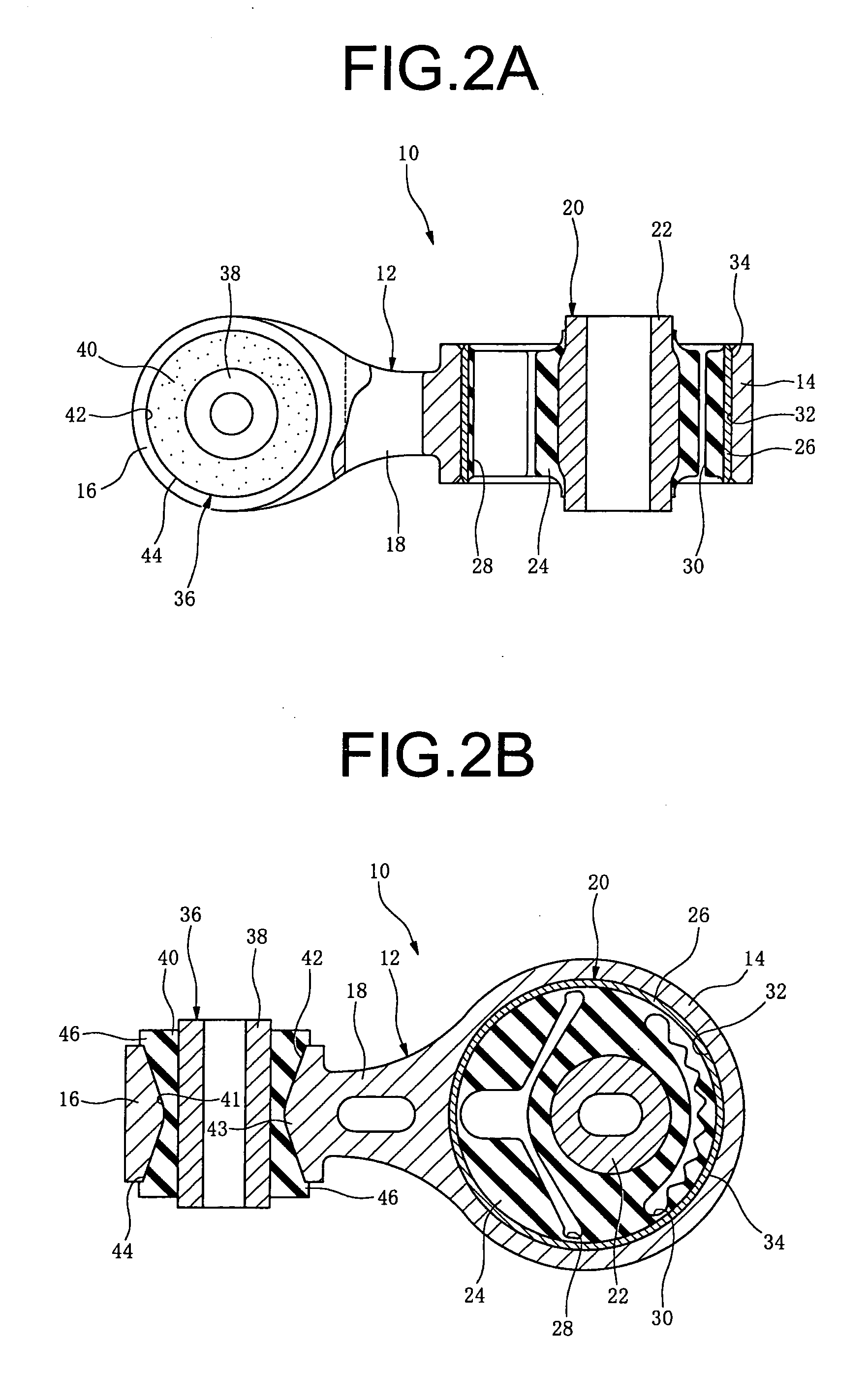

Torque rod and method of producing the same

InactiveUS20050254888A1Low costReduce weightNon-rotating vibration suppressionRod connectionsElastomerEngineering

A torque rod having: a rigid torque rod body of a form in which first and second outer cylinders at both ends are linked to each other by a linking portion; and a first and a second bushing each having a rigid inner cylinder and a rubber elastic body affixed thereabout, the first and second bushings being respectively installed within first and second outer cylinders. The second outer cylinder has an inside peripheral wall of inwardly protruding shape that becomes smaller in diameter moving towards the center from the axial ends. The rubber elastic body of the second bushing is a solid member having a shape corresponding to the inwardly protruding shape, with the second bushing installed directly press-fit in the axial direction into the second outer cylinder, at an outer circumferential face of the rubber elastic body.

Owner:SUMITOMO RIKO CO LTD

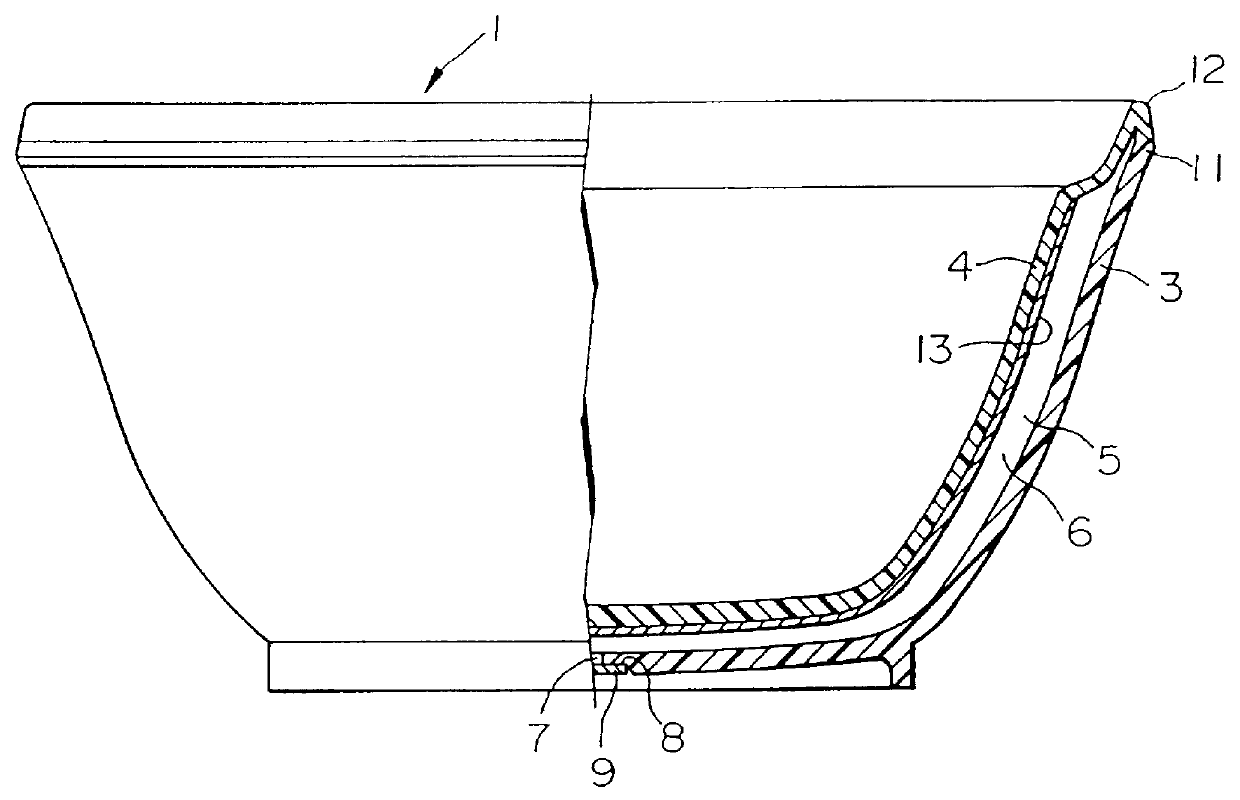

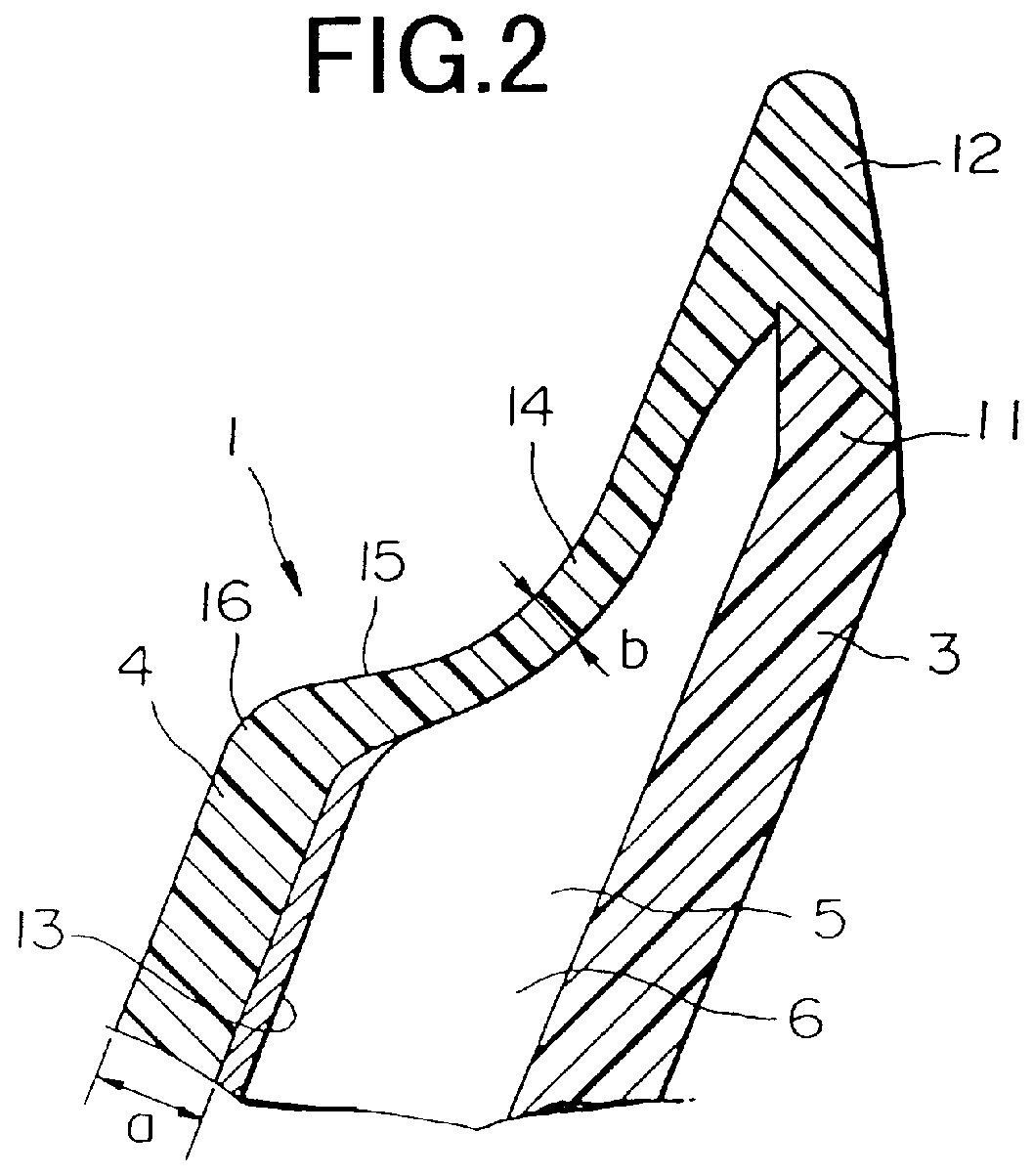

Thermally insulated synthetic resin container and thermally insulated synthetic resin lid

InactiveUS6152319AIncrease the number ofReduce heat transferDomestic cooling apparatusLighting and heating apparatusDouble wallEngineering

PCT No. PCT / JP97 / 04131 Sec. 371 Date Jun. 29, 1998 Sec. 102(e) Date Jun. 29, 1998 PCT Filed Nov. 13, 1997 PCT Pub. No. WO98 / 22007 PCT Pub. Date May 28, 1998The present invention relates to a thermally insulated synthetic resin container, which is a thermally insulated container having a double walled structure and being made of synthetic resin, which reduces the thermal conduction loss from the mouth portion, and which has excellent thermally insulating performance capabilities. The thermally insulated synthetic resin container 1 of the present invention has an inner container 4 and an outer container 3, which are both made of synthetic resin and which are both connected at their respective mouth portions 12, 11 while providing a space portion in between the two containers. According to this thermally insulated synthetic resin container which is formed by having the space portion between the inner container 4 and the outer container 3 be a thermally insulating layer 6, a reduced thermal conductive portion 14 having a wall of reduced thickness is formed in the vicinity of the mouth portion 12 of the inner container 4.

Owner:NIPPON SANSO CORP

Firearm with quick coupling barrel system

ActiveUS20150007478A1Quick changeImprove tightness and reliabilityBreech mechanismsBarrel mountingCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such as splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

Vacuum pump

A vacuum pump includes a housing, a rotor located in the housing and having a shaft and pump-active elements supported on the shaft, a stator having pump-active elements and located in a separate housing part of the housing, for driving the pump, bearings for rotatably supporting the rotor shaft, and at least one vacuum chamber located in the housing.

Owner:PFEIFFER VACUUM GMBH

Firearm with quick coupling barrel system

ActiveUS20120131834A1Quick changeImprove tightness and reliabilityBreech mechanismsMetal working apparatusCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such a splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

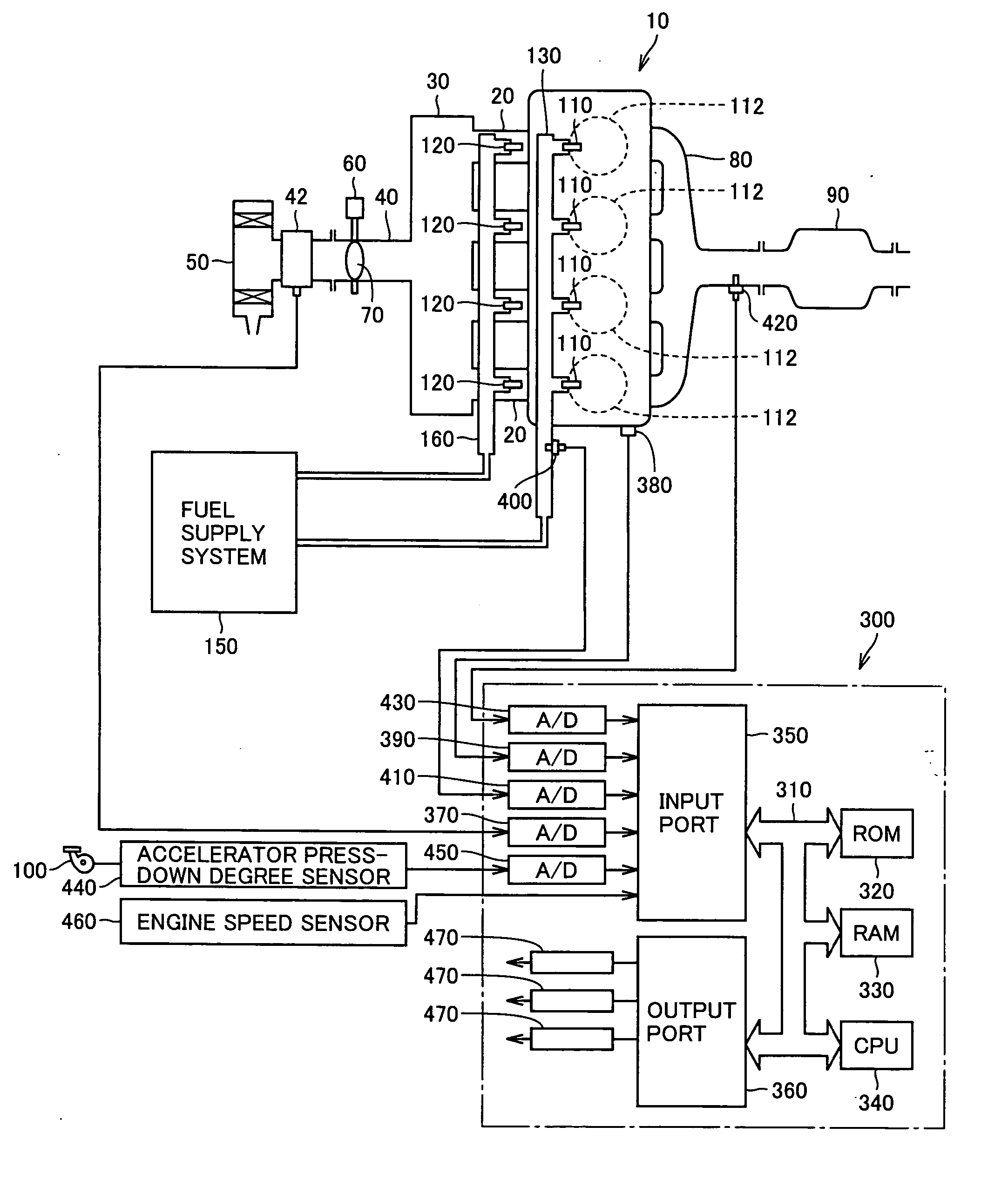

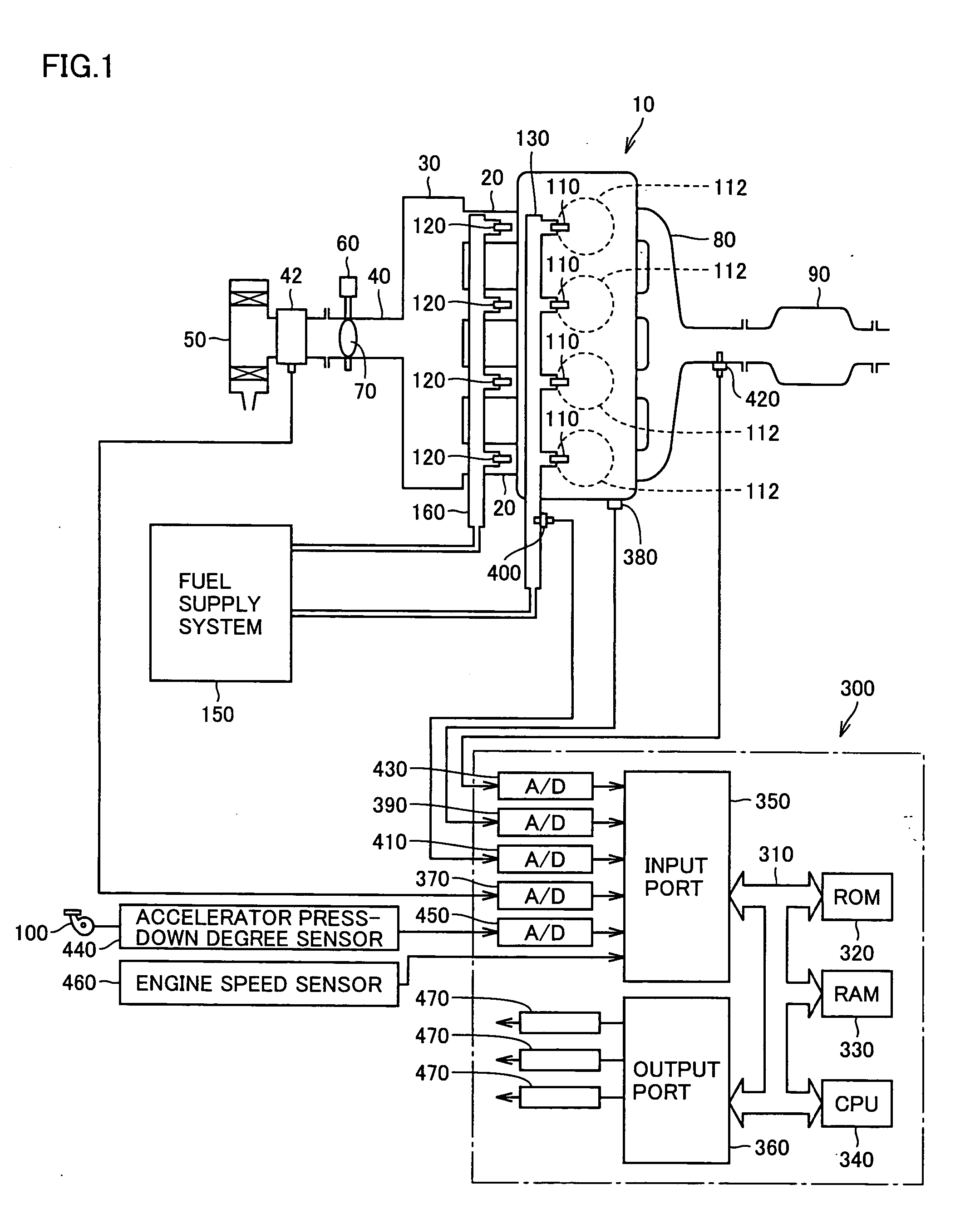

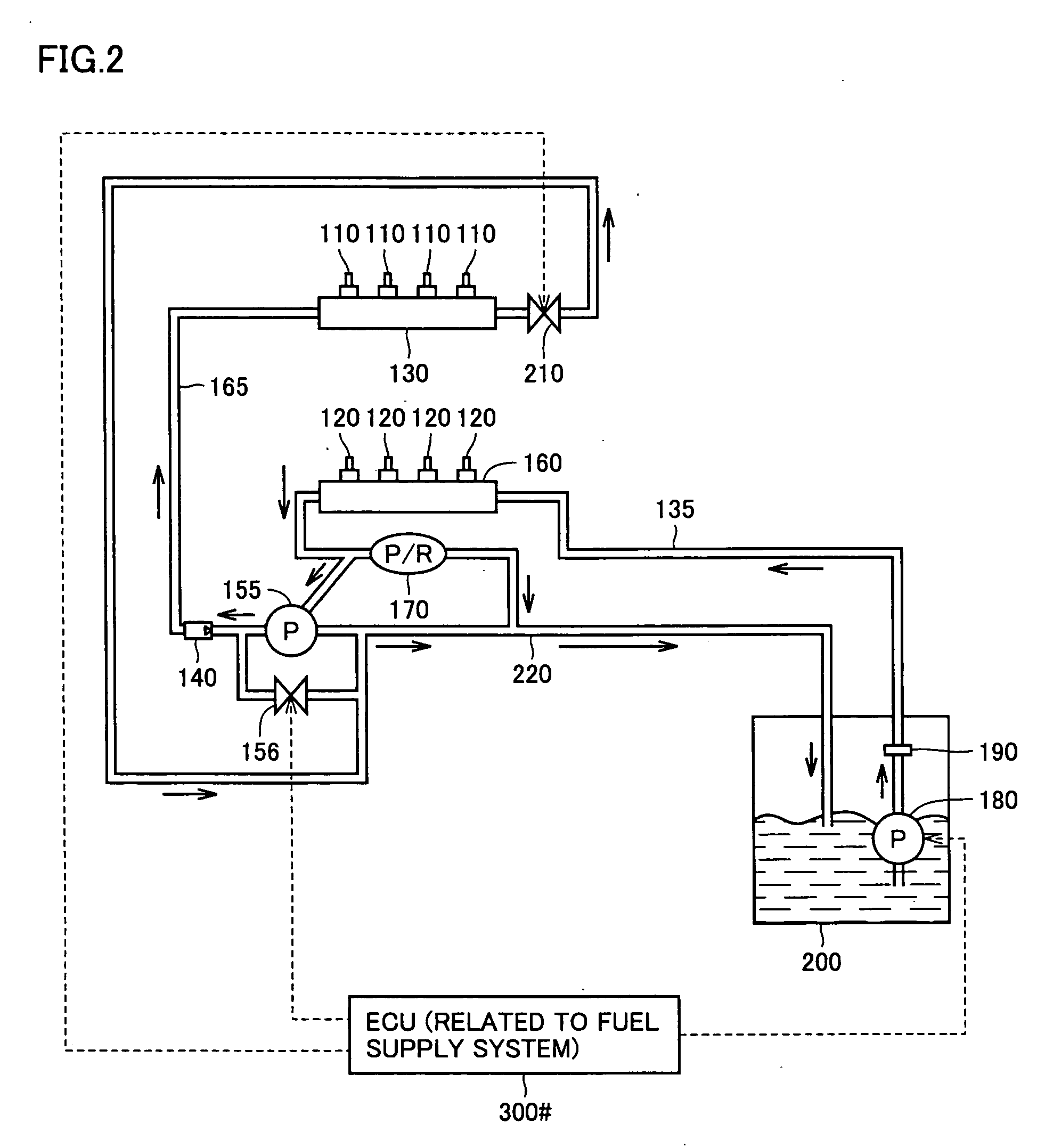

Fuel supply system for internal combustion engine

InactiveUS20060000452A1Improve oil tightnessGood exhaust emission propertyElectrical controlInternal combustion piston enginesFuel tankHigh pressure

A low-pressure delivery pipe provided with intake manifold injectors, a fuel pressure regulator, a high-pressure fuel pump, a high-pressure delivery pipe provided with in-cylinder injectors, and an electromagnetic relief valve are connected in series at the downstream of a low-pressure fuel pump that discharges a fuel within a fuel tank at a prescribed pressure. Since the low-pressure delivery pipe is arranged downstream of the low-pressure fuel pump, the fuel pressure within the low-pressure delivery pipe is lowered upon stop of vehicle operation, in response to stop of the low-pressure fuel pump. The fuel pressure within the high-pressure delivery pipe is also lowered in response to stop of the low-pressure fuel pump, by opening the electromagnetic relief valve upon stop of vehicle operation. Thus, oil tightness of the injectors during the stop of vehicle operation is ensured.

Owner:TOYOTA JIDOSHA KK

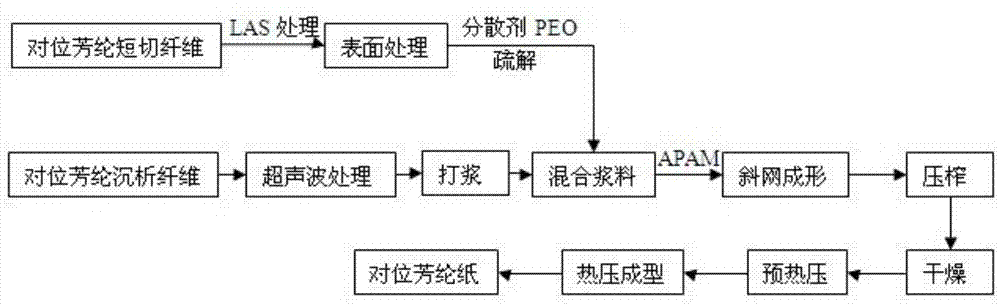

Method for preparing para aramid paper from para aramid fibrid

ActiveCN103572640AImprove interface affinityEnhanced hydrogen bondingPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperBreaking strengthWear resistance

The invention discloses a method for preparing para aramid paper from para aramid fibrid. The method concretely comprises the steps of carrying out surface treatment, defibering and dispersion on para aramid chopped fibers; carrying out ultrasonic treatment and pulping treatment on the para aramid fibrid; mixing the treated para aramid chopped fibers and the treated para aramid fibrid; adding anionic polyacrylamide into the mixed fibers to obtain aramid fiber pulp; shaping the aramid fiber pulp on an inclined wire paper machine; dehydrating, squeezing and drying; carrying out pre-hot-pressing on the dried aramid base paper, and then carrying out hot pressing by a hot press to obtain the para aramid paper. After the method for preparing the para aramid paper from the para aramid fibrid is adopted, the tensile strength, the tearing strength, the breaking strength, the wear resistance and the dielectricity of the para aramid paper are remarkably improved, and the para aramid paper can be taken as a structural material, an insulating material or an electronic material and is relatively widely applied to the fields of transportation, electronics and electric power, aerospace and the like.

Owner:SHAANXI UNIV OF SCI & TECH

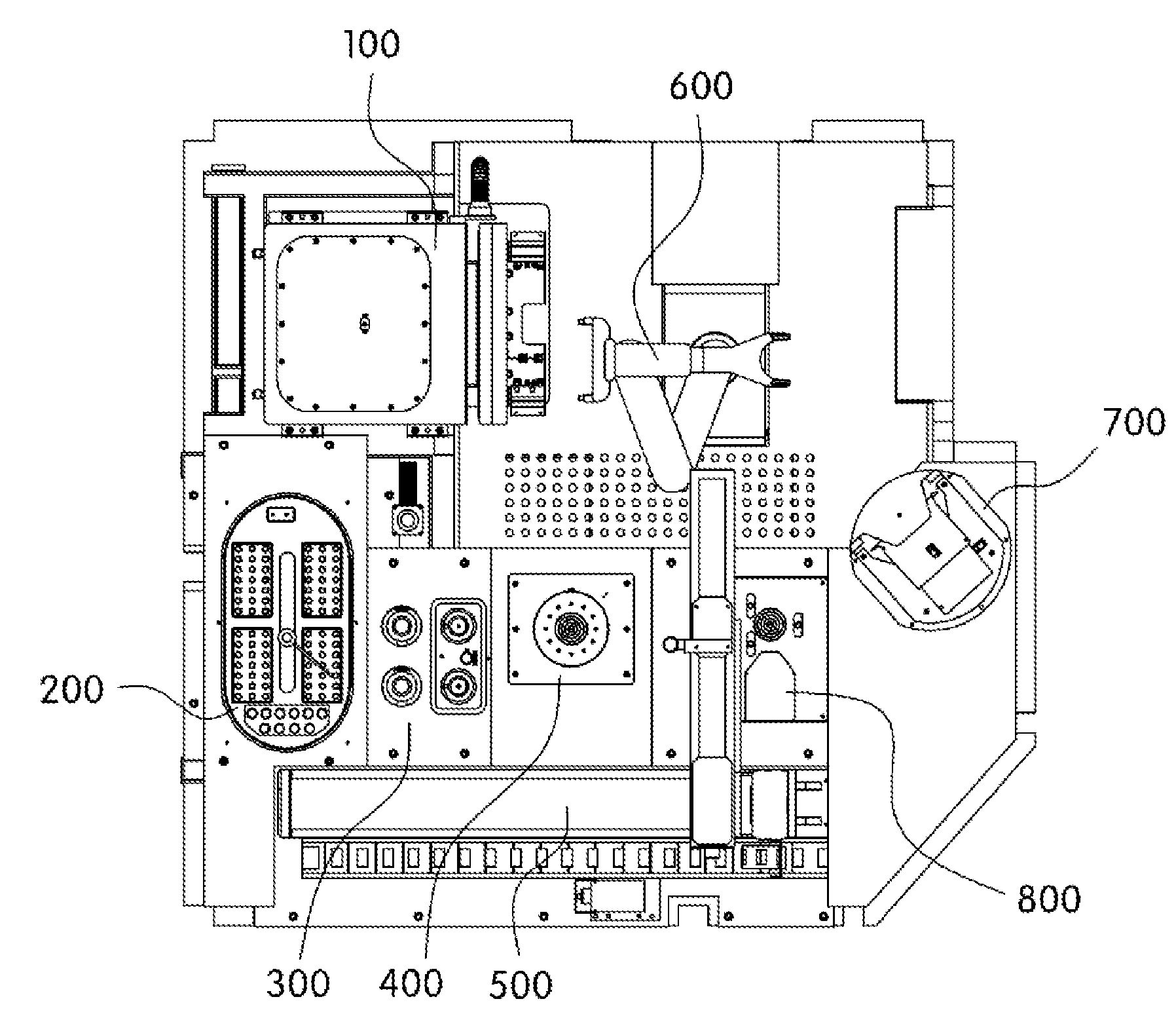

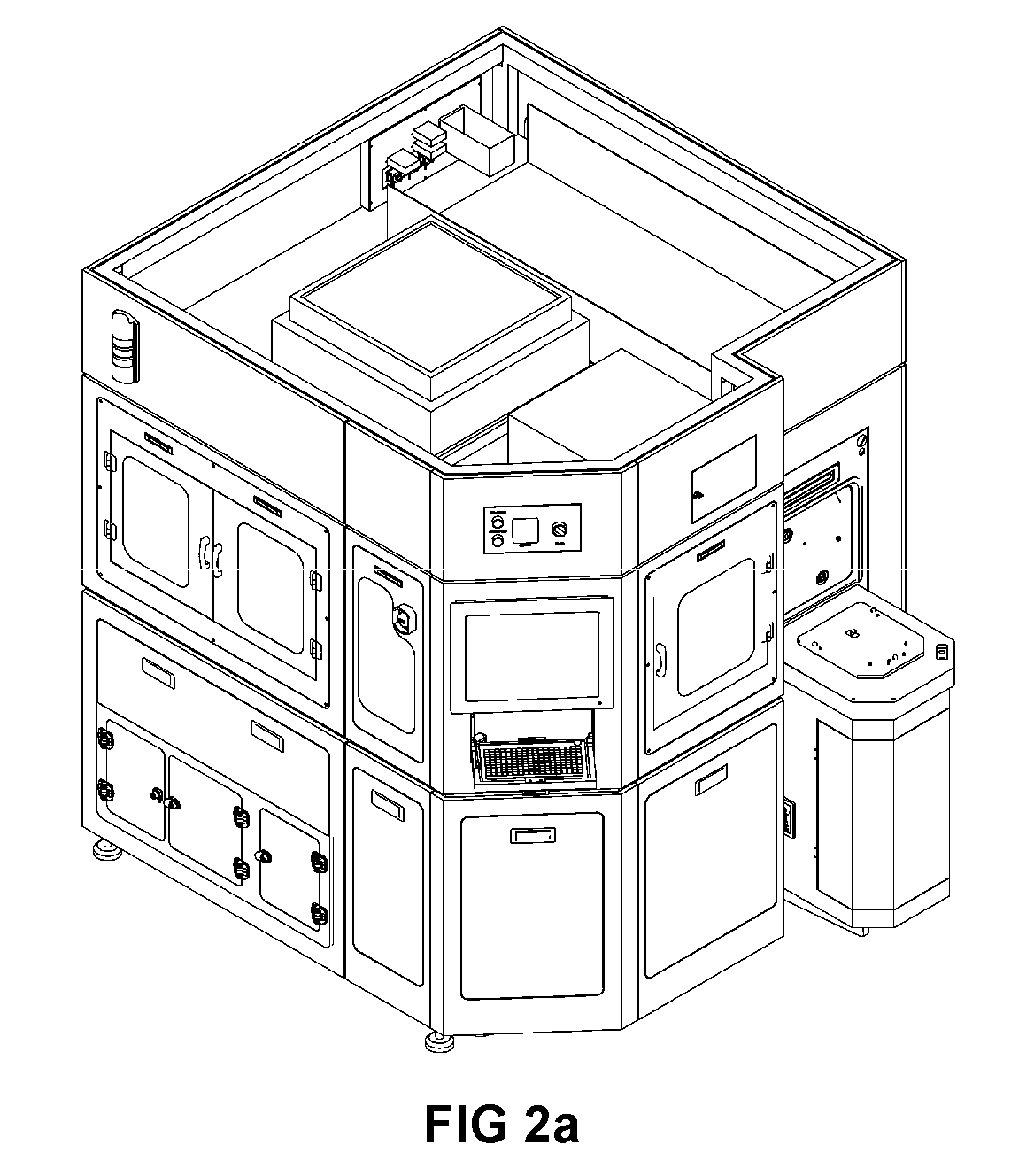

Vapor phase decomposition device for semiconductor wafer pollutant measurement apparatus and door opening and closing device

InactiveUS20090249863A1Easy to cleanEasy to controlSemiconductor/solid-state device manufacturingSpecific gravity measurementGas phaseEngineering

Provided is a vapor phase decomposition (VPD) device for a semiconductor wafer pollutant measurement apparatus and a door opening and closing device thereof. The VPD device includes: a rectangular vessel-shaped main body of the VPD device and a door which covers in a sealed form or opens the wafer inlet of the VPD device. Here, a predetermined space is formed in the inner portion of the rectangular vessel-shaped main body, support plates are formed on the bottom of the rectangular vessel-shaped main body and gas discharge and suction nozzles are located therein. In addition, a transparent see-through window is formed on the upper surface of the rectangular vessel-shaped main body, a detection electrode for controlling an inner atmosphere is formed at the center of the transparent see-through window, and one side surface of the rectangular vessel-shaped main body is opened to thus form a wafer inlet for introducing a wafer. The door opening and closing device includes: a forward and backward movement unit having cylinder loads, air cylinders, and plates, to make the door move forward and backward in order to open and close the wafer inlet of the main body of the VPD device; and an ascent and descent movement unit having a fixed plate, guide bars, a slide block, and a cylinder.

Owner:KOREA TECH CO LTD

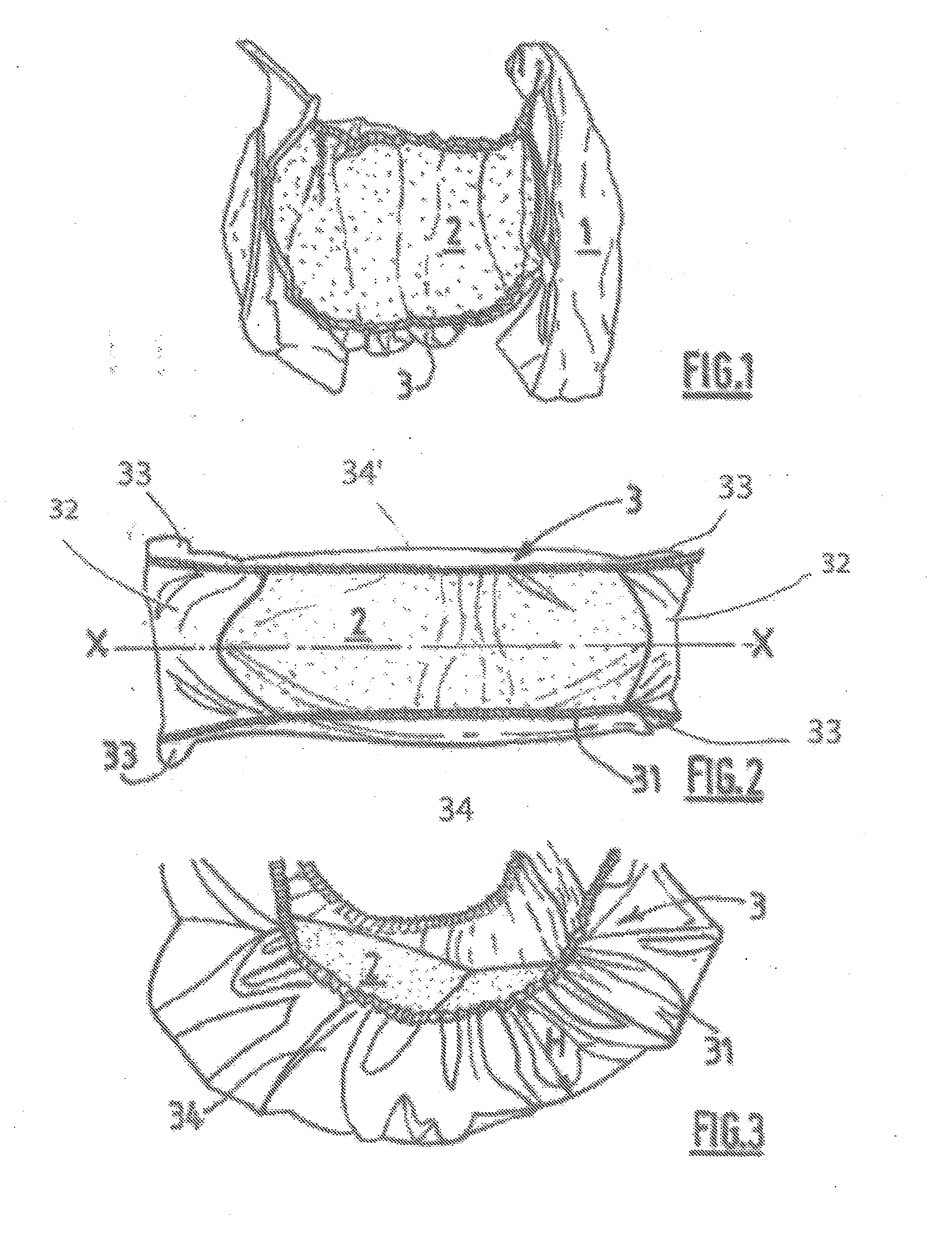

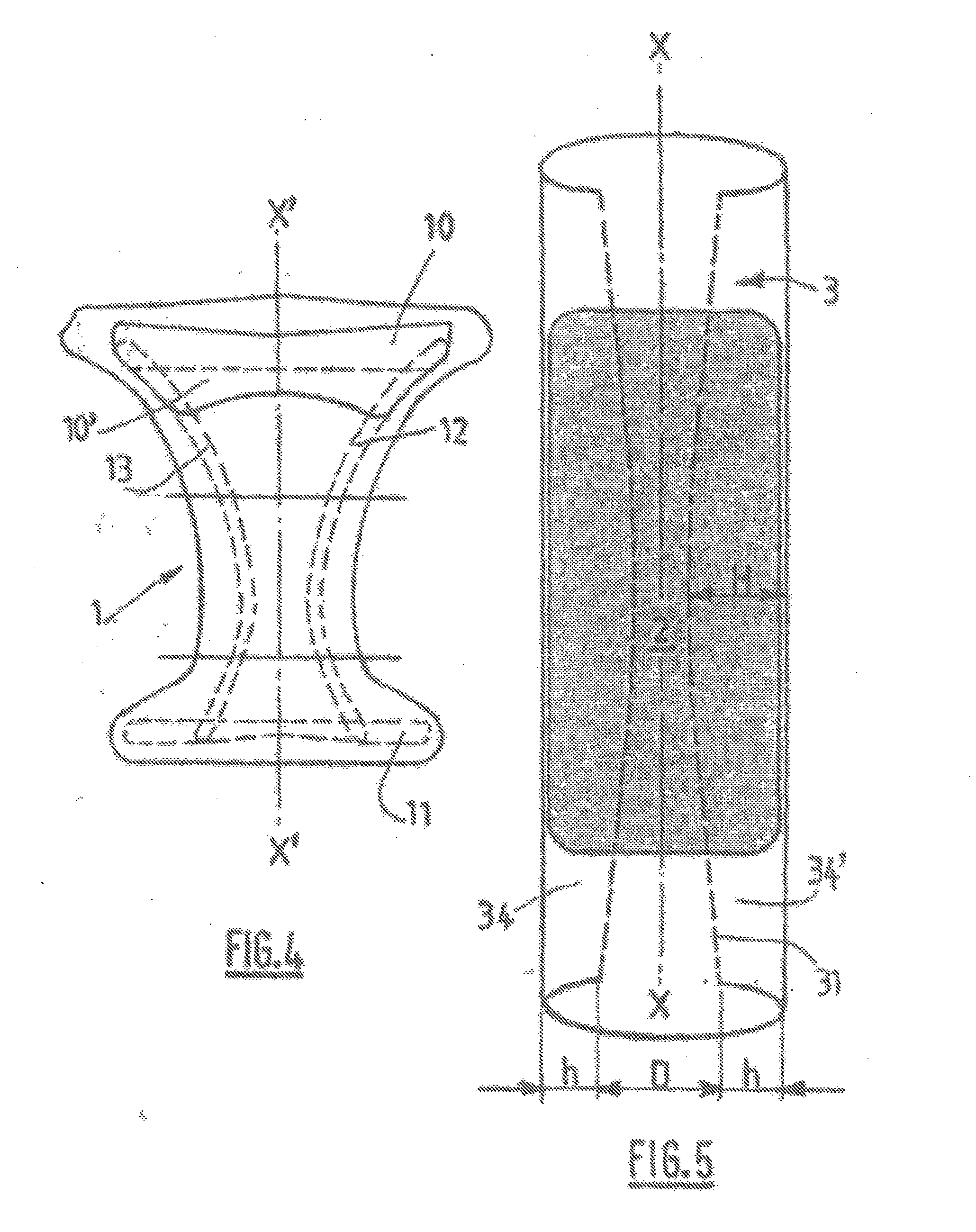

Structure with a reusable absorbent layer and associated sleeve

A reusable absorbent diaper type structure having a longitudinal axis XX and including an outer support element which can be adjusted to the body of a user, a flat absorbent element and an intermediate impervious element for supporting the absorbent element, the intermediate element being connected by connectors to the outer element. The intermediate element exhibits on each of the lengths thereof an elastic border, which, in the stretched and flattened state, makes it possible to cover the absorbent element according to at least a longitudinal area, and when the structure is positioned on the user, is liable to remain in permanent contact with the skin of the user.

Owner:GENERATION PLUME

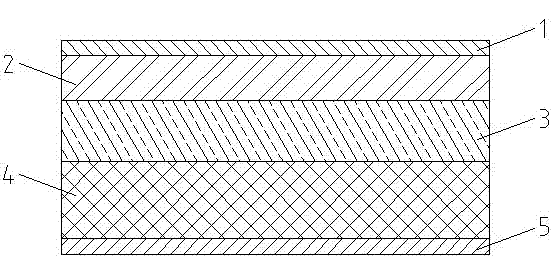

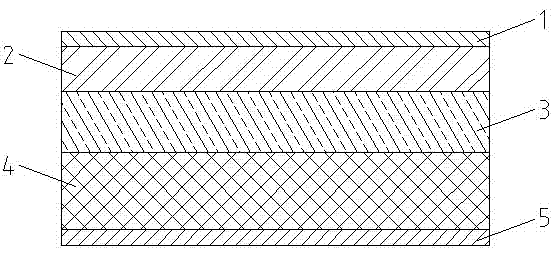

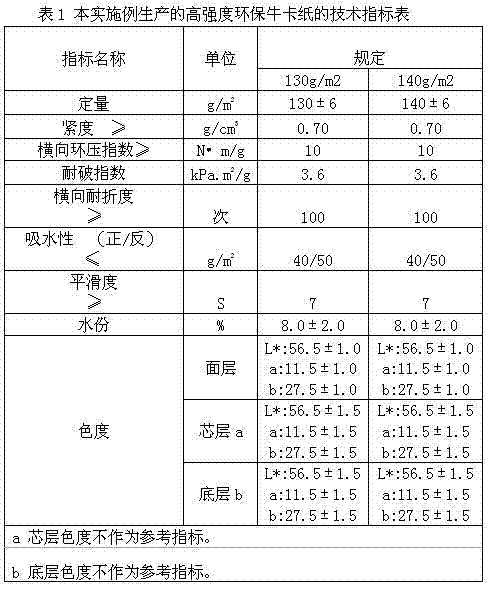

High-intensity environment-friendly craft paper and manufacturing method thereof

The invention relates to a high-intensity environment-friendly craft paper and a manufacturing method. Currently, the craft paper which is low in quantitation and low in wood pulp proportion, has high intensity, and is mainly made of secondary fiber is unavailable yet. The craft paper is characterized by consisting of a face layer, a core layer, a bottom layer, a front-side glue applying layer and a back-side glue applying layer; the sizing agent of the face layer is nature-color wood pulp; the sizing agent of the core layer is mid fiber and long fiber which are graded from the old corrugatedcontainer (OCC) secondary fiber; and the sizing agent of the bottom layer is short fiber which is graded from the OCC secondary fiber. The method for manufacturing the high-intensity environment-friendly craft paper comprises the steps of pulping, making glue and making paper, wherein the pulping comprises the steps of making the sizing agent of the face layer, making the sizing agent of the corelayer and making the sizing agent of the bottom layer. The craft paper is reasonable in structural design, low in quantitation, low in wood pulp proportion and high in intensity, and is mainly made of the secondary fiber. Moreover, the process is simple, the production cost is low, and the manufactured high-intensity environment-friendly craft paper has good quality.

Owner:JIAN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com