Patents

Literature

196results about How to "Enhanced hydrogen bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of pure p-aramid paper

InactiveCN102517976AImprove interface affinityHigh tensile strengthSynthetic cellulose/non-cellulose material pulp/paperHigh stiffnessHigh density

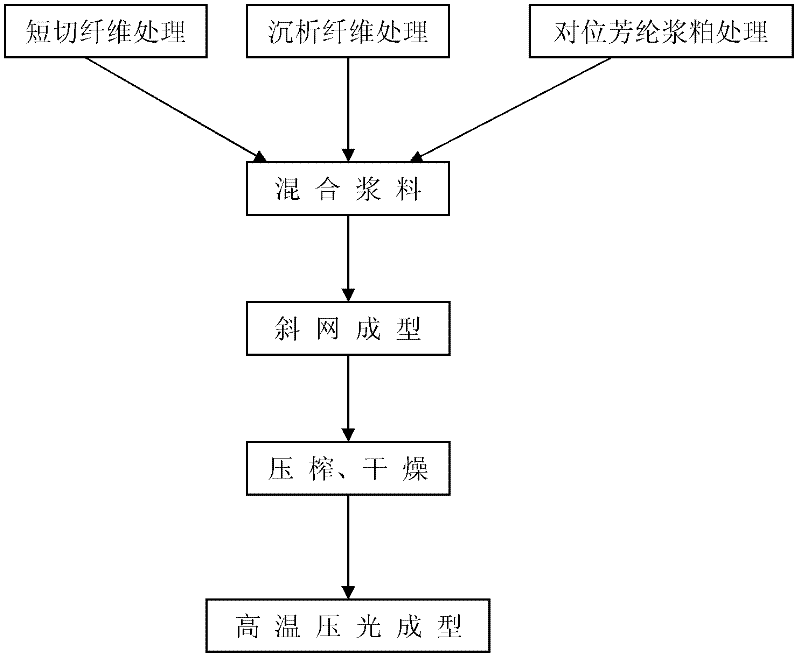

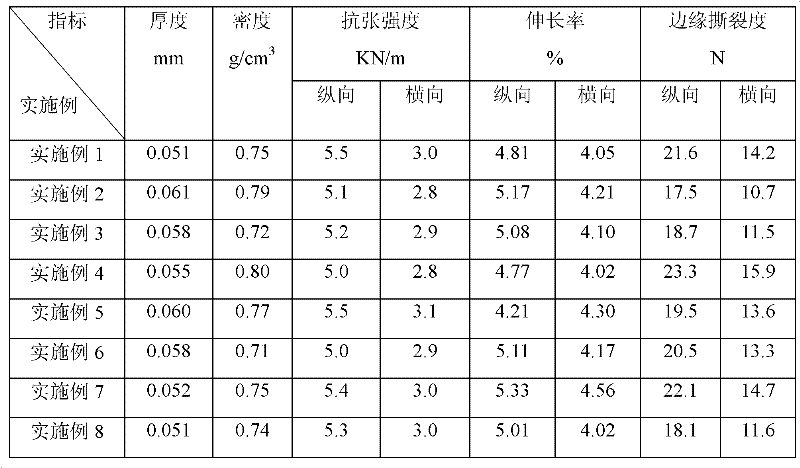

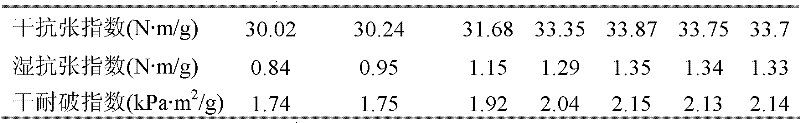

The invention relates to a preparation method of pure p-aramid paper. The preparation method of the pure p-aramid paper comprises the following steps of 1, respectively preparing p-aramid chopped fiber pulp, p-aramid fibrid pulp and p-aramid pulp, and mixing the p-aramid chopped fiber pulp, the p-aramid fibrid pulp and the p-aramid pulp, 2, approaching flows of the mixed pulp onto a net for molding, 3, carrying out squeezing and drying, and 4, carrying out high-temperature press-polish molding. The preparation method of the pure p-aramid paper has the advantages that p-aramid fibrids are utilized as bonding materials of the pure p-aramid paper so that interface affinity of fibers is improved and fiber paper mechanical properties of tensile strength, tearing strength and wear resistance are improved; p-aramid pulp has a high specific surface area so that a hydrogen bond binding capacity of fibers is improved and the pure p-aramid paper having high density, high stiffness and high strength is obtained; and in a preparation process, concentrated sulfuric acid is not needed so that the problems of equipment corrosion and dilute sulphuric acid recovery complexity are solved.

Owner:YANTAI METASTAR SPECIAL PAPER +1

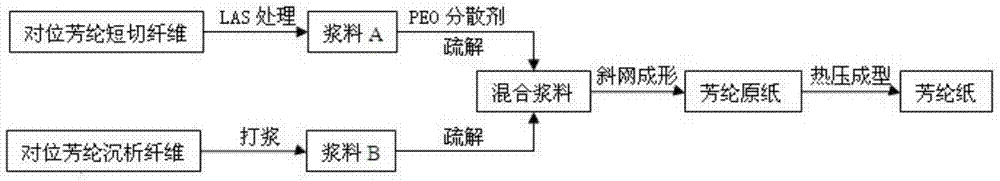

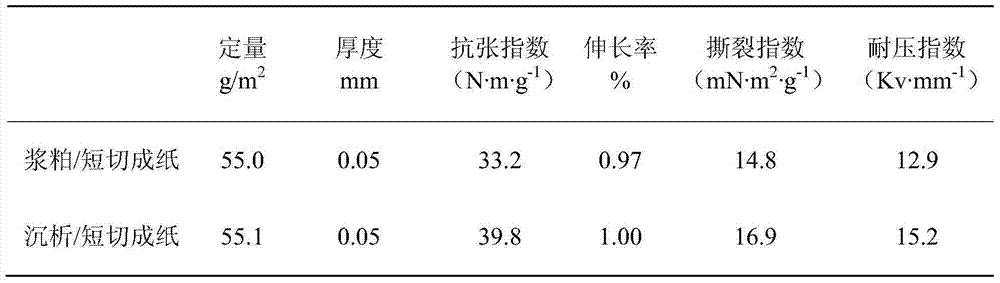

Method for preparing para aramid paper from para aramid fibrid

ActiveCN103572640AImprove interface affinityEnhanced hydrogen bondingPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperBreaking strengthWear resistance

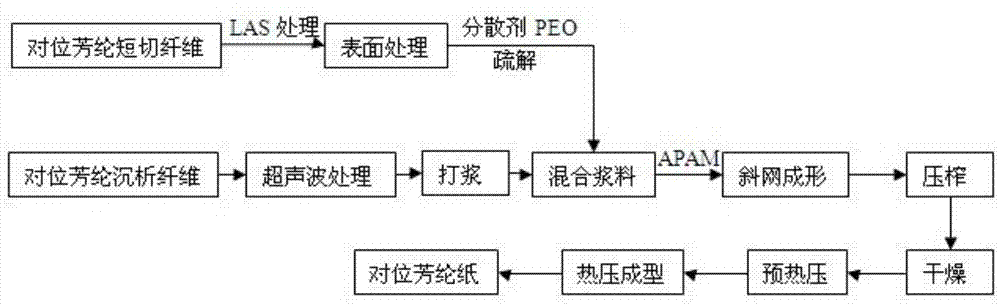

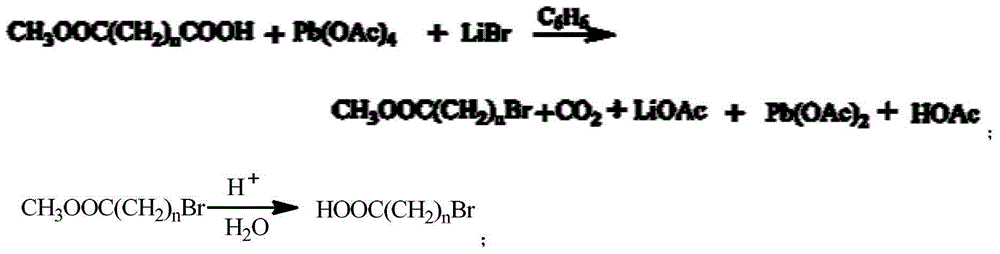

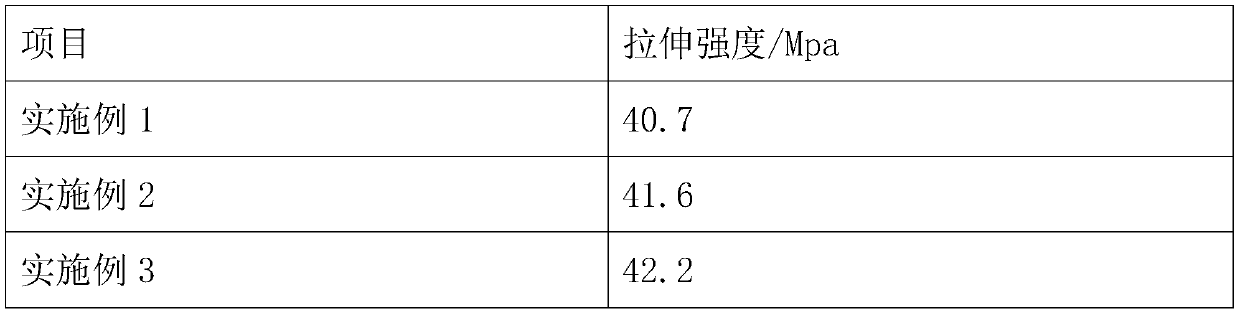

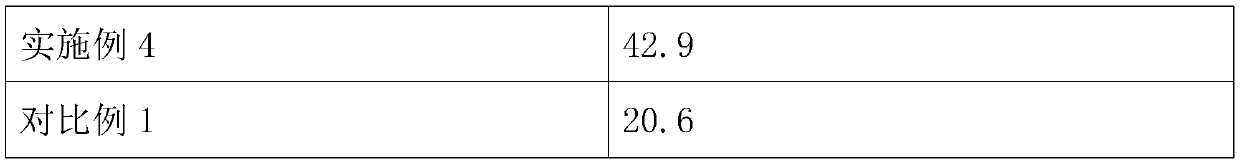

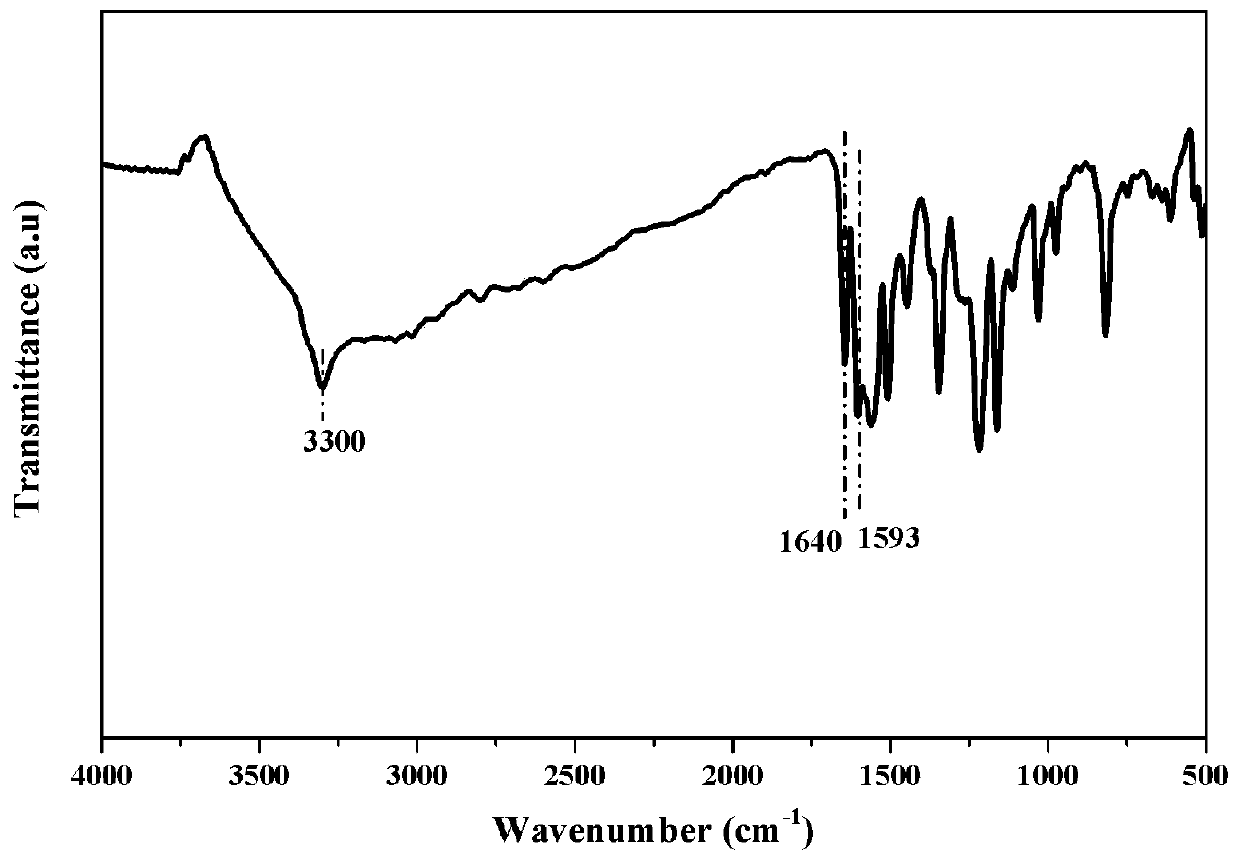

The invention discloses a method for preparing para aramid paper from para aramid fibrid. The method concretely comprises the steps of carrying out surface treatment, defibering and dispersion on para aramid chopped fibers; carrying out ultrasonic treatment and pulping treatment on the para aramid fibrid; mixing the treated para aramid chopped fibers and the treated para aramid fibrid; adding anionic polyacrylamide into the mixed fibers to obtain aramid fiber pulp; shaping the aramid fiber pulp on an inclined wire paper machine; dehydrating, squeezing and drying; carrying out pre-hot-pressing on the dried aramid base paper, and then carrying out hot pressing by a hot press to obtain the para aramid paper. After the method for preparing the para aramid paper from the para aramid fibrid is adopted, the tensile strength, the tearing strength, the breaking strength, the wear resistance and the dielectricity of the para aramid paper are remarkably improved, and the para aramid paper can be taken as a structural material, an insulating material or an electronic material and is relatively widely applied to the fields of transportation, electronics and electric power, aerospace and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Processing method for regenerative semi-chemical corrugated paper

InactiveCN1525004AImprove bindingReduce dosageReinforcing agents additionSecondary cellulose fibresHigh concentrationFiber

The invention is a regenerated corrugated raw paper manufacturing method, its main technical flows: mix import waste paper with internal waste paper, pulp by pulping engine, desand by high concentration desander, screen by fiber separator, desand by high concentration desander, screen by low concentration pressure sieve, desand by low concentration desander, condense by condenser, mill and pulp by medium concentration hydraulic disc, screen by pressure sieve, make by paper machine and spray papermaking chemical assistant when molding and cut by winder. The added quantity of import waste paper is 40-55% of total weight of the mixed waste paper. It changes traditional low concentration pulping technique. The technique is designed reasonably, and can effectively heighten the physical strength of the regenerated corrugated raw paper, reduce the raw material cost and be applied to medium-scale production.

Owner:ZHEJIANG BLUESTAR HLDG GRP

Surgical adhesive formulations and methods of preparation

InactiveUS20050215748A1Enhanced hydrogen bondingOptimized adhesiveOrganic active ingredientsSurgical adhesivesSurgical adhesiveAdditive ingredient

This application describes specific ratios of raw ingredients and methods of combining and reacting those ingredients to obtain polyurethane prepolymers optimized for the special purpose of forming bonds to living tissue, or of bulking or sealing it. Preferred prepolymers are based on polyalkylene oxides, particular copolymers of ethylene oxide and propylene oxide. Important method steps are rigorous drying and deionization, and rigorous control of temperature during synthesis and use.

Owner:PROMETHEAN SURGICAL DEVICES

Composite differential shrinkage yarn and preparation method thereof

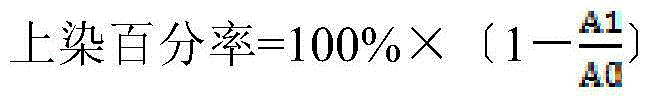

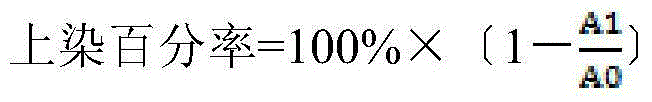

The invention relates to a composite differential shrinkage yarn and a preparation method thereof. The composite differential shrinkage yarn is formed by compositing of a POY (polyester pre-oriented yarn) body and an FDY (fully drawn yarn) body, both the POY body and the FDY body are made of modified polyester by means of spinning, the modified polyester is formed by polyester and amino fatty acid gylcol ester, the amino fatty acid gylcol ester is scattered among molecular chains of the polyester, and a hydrogen-bond interaction among the amino fatty acid gylcol ester and the molecular chains of the polyester enables opposite positions of the amino fatty acid gylcol ester and the molecular chains of the polyester to be fixed; in the condition with temperature ranging from 90 DEG C to 130 DEG C, free volume spaces among molecular chains inside a fiber of the composite differential shrinkage yarn are enlarged by 20-30v / v%. The composite differential shrinkage yarn has the advantages that the free volume of polyester fibers is increased by the aid of fatty acid ester, so that diffusing degree of dye is improved, dyeing property of the polyester fibers is improved, and the composite differential shrinkage yarn is applicable to fashion fabric, decorative fabric and the like formed by means of spinning, knitting and warp knitting.

Owner:JIANGSU HENGLI CHEM FIBER

Differential-shrinkage cotton-like composite filament and preparation method thereof

ActiveCN104562340AGood flexibilityGood compatibilityOrganic compound preparationAmino-carboxyl compound preparationPolyesterFatty acid ester

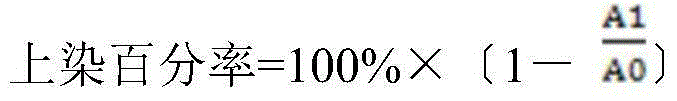

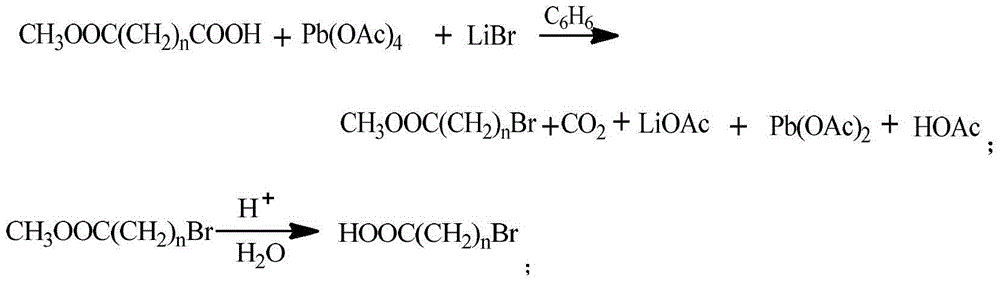

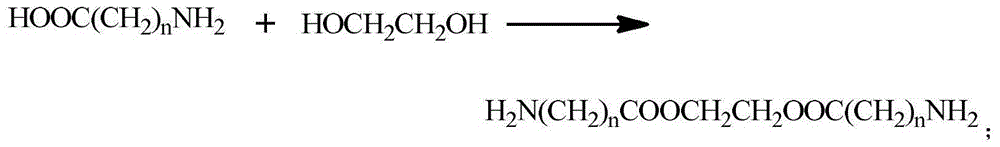

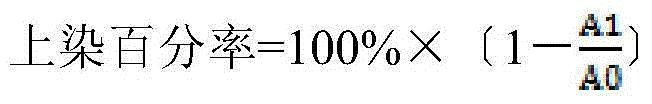

The invention relates to a differential-shrinkage cotton-like composite filament and preparation method thereof; the differential-shrinkage cotton-like composite filament is a composite filament blended by a modified polyester POY filament and a modified polyester FDY filament; the modified polyester consists of polyester and aminoadipic acid glycol ester; the aminoadipic acid glycol ester is dispersed among the molecular chains of the polyester; and the aminoadipic acid glycol ester takes effect of hydrogen bond among the molecular chains of the polyester, so as to stabilize the positions of the aminoadipic acid glycol ester with respect to the molecular chains of the polyester; in condition of the temperature is 90-130 degrees centigrade, the free volume spaces among the molecular chains inside the fiber of the differential-shrinkage cotton-like composite filament are increased by 20-30v / v%. The aliphatic ester increases the free volume of the polyester fiber in order to increase the diffusion degree of the dye, thereby increasing the dyeing performance of the polyester fiber. The differential-shrinkage cotton-like composite filament is applicable to clothes fabric, bedding article, decoration article, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

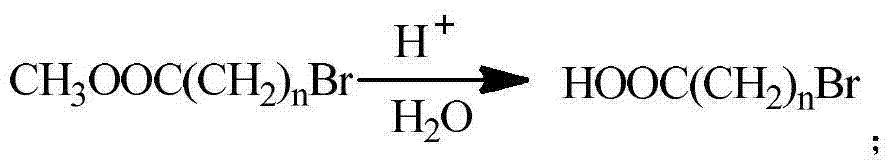

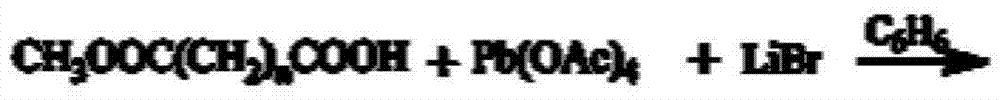

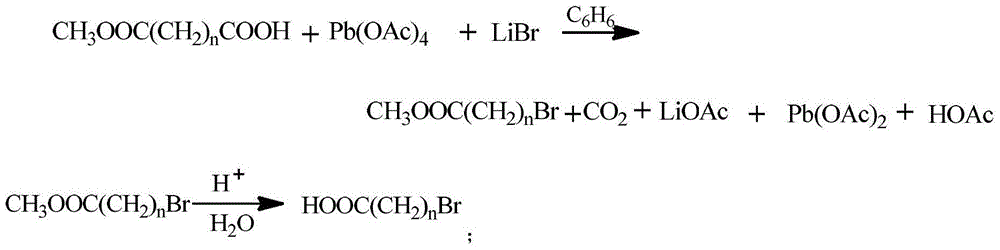

Preparation method of crop straw dye adsorption material

InactiveCN103881033ANo pollution in the processSimple methodOther chemical processesWaste water treatment from textile industryItaconic acidPyrrolidinones

The invention relates to a preparation method of a crop straw dye adsorption material. The preparation method is characterized by comprising the process steps of adding straw powder into N, N-dimethylformamide, putting into an ultrasonic cleaning tank to perform ultrasonic treatment for 20-60 minutes at 30-50 DEG C, then adding phytic acid and urea into the system, heating to 50-90 DEG C, reacting for 2-6 hours, then cooling a product to the room temperature, precipitating, washing, drying and crushing to obtain phytic acid modified straw; neutralizing itaconic acid by using NaOH, then adding the phytic acid modified straw, acrylamide, vinyl pyrrolidone and a crosslinking agent, fully stirring for 30 minutes, then gradually heating to 50-60 DEG C, and finally slowly dropwise adding a redox initiator into a polymerization system to initiate a polymerization reaction for 3-5 hours; and after polymerization, precipitating, washing and drying to obtain the crop straw dye adsorption material. The adsorption capacity of the crop straw dye adsorption material to a cationic dye aqueous solution with the initial concentration of 200-2000mg / L is 195-1400mg / g, the decolorization rate of the crop straw dye adsorption material is 55-90%, and the crop straw dye adsorption material can reach adsorption equilibrium after 100-200 minutes of room temperature adsorption, and can be widely applied to the adsorption, separation and purification of cationic dyes, the environmental pollution control of cationic dye wastewater, and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Linen-like type differential shrinkage composite filament and preparation method thereof

ActiveCN104480568AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationFiberPolyester

The invention relates to a linen-like type differential shrinkage composite filament and a preparation method thereof. The linen-like type differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the breakage elongation of the linen-like type differential shrinkage composite filament is 40.0+ / -3.0%, the network degree of the linen-like type differential shrinkage composite filament is 95+ / -5 piece / m; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the linen-like type differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The linen-like type differential shrinkage composite filament can be used in the industries such as high-class woof fabrics and clothes.

Owner:JIANGSU HENGLI CHEM FIBER

Wool-like differential shrinkage composite filament and preparation method thereof

ActiveCN104480567AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationPolyesterFiber

The invention relates to a wool-like differential shrinkage composite filament and a preparation method thereof. The wool-like differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the wool-like differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The wool-like differential shrinkage composite filament can be used in the industries such as clothes fabrics, bedding articles and decorative articles.

Owner:JIANGSU HENGLI CHEM FIBER

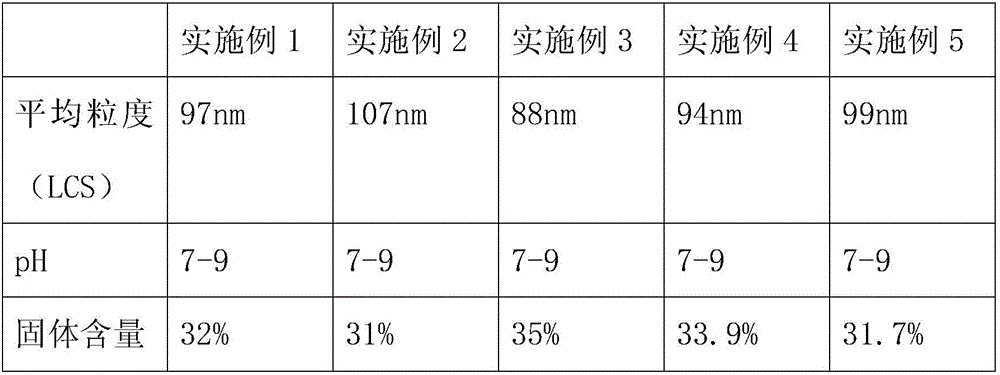

Waterborne polyurethane dispersion and application thereof

InactiveCN106243316AImprove adhesionIncrease Coulomb forcePolyurea/polyurethane coatingsPolyurethane dispersionPolymer science

The invention discloses a waterborne polyurethane dispersion and application thereof. The waterborne polyurethane dispersion is prepared from the following components through reacting: (A) one or more types of polyisocyanate; (B) one or more types of polymeric glycols; (C) one or more types of compounds containing one or more hydroxyl groups or amino groups; (D) one or more ionic, potential-ionic or non-ionic hydrophilic compounds with isocyanate activity; (E) one or more types of salt forming reagents; (F) one or more types of catalysts; the use ratios of the components are as follows: 10 weight percent to 35 weight percent of the component (A), 50 weight percent to 90 weight percent of the component (B), 0.5 weight percent to 12 weight percent of the component (C), 1.5 weight percent to 15 weight percent of the component (D), 1.5 weight percent to 8.5 weight percent of the component (E), 0.001 weight percent to 0.5 weight percent of the component (F); the total sum of all the components is equal to 100 weight percent. The waterborne polyurethane dispersion provided by the invention contains a proper amount of polar groups and has an extremely excellent attaching force on an aluminum material; the attaching force reaches grade 0.

Owner:肇庆浩城树脂科技有限公司

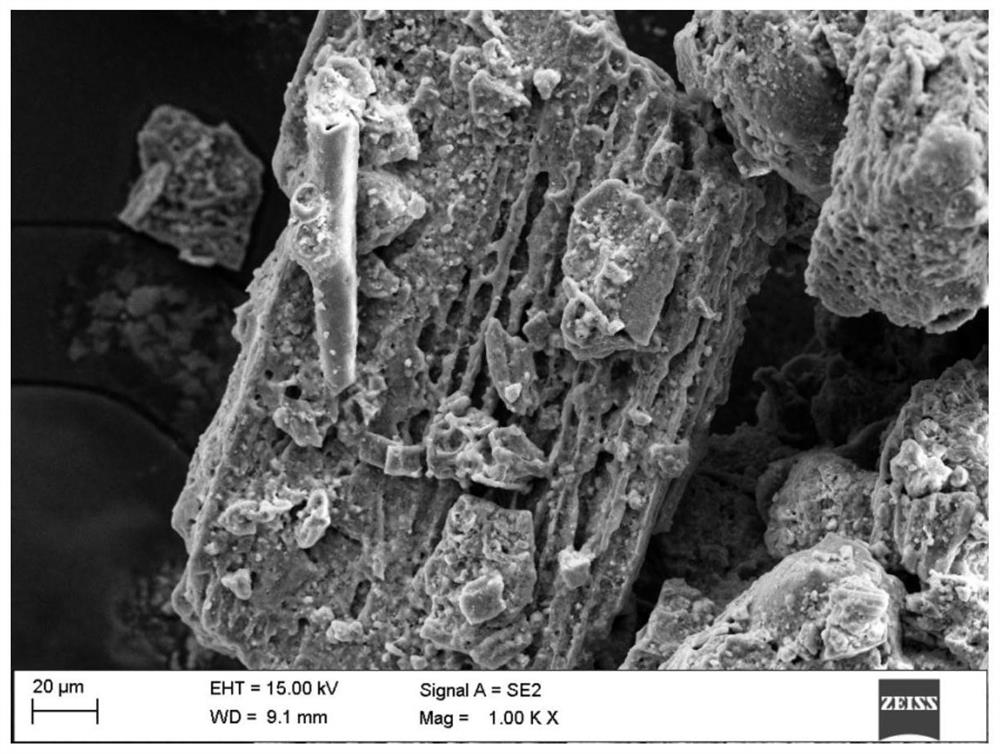

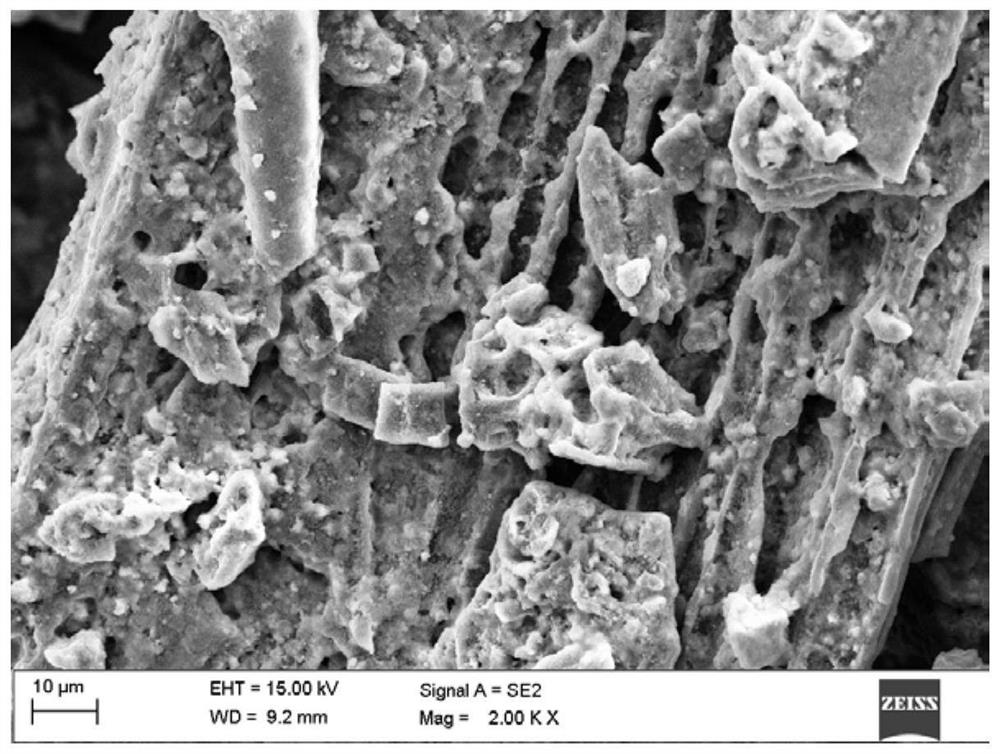

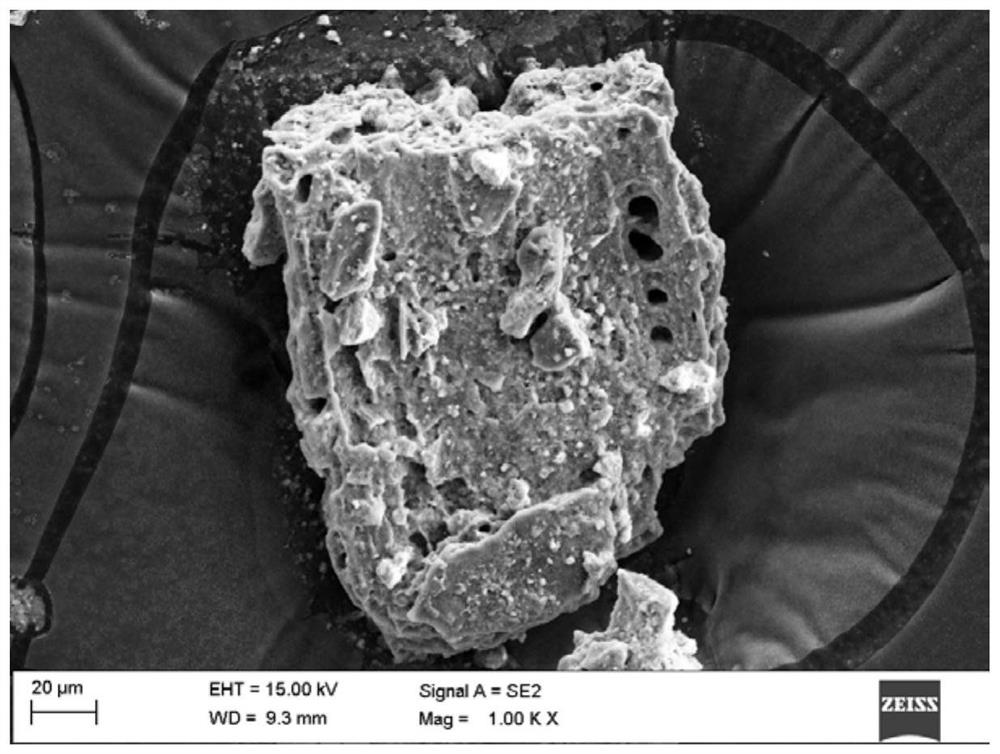

Modified biochar, preparation method and application thereof

InactiveCN112263994AEnhanced chelation of heavy metals (leadEnhance the ability of cadmium, copper, etc.)Other chemical processesContaminated soil reclamationCamellia oleiferaManganese oxide

The invention provides modified biochar, a preparation method and application thereof. According to the modified biochar, biomass is used as a raw material, and is subjected to carbonization pyrolysisthrough mixing modification with potassium permanganate and ferric chloride to prepare iron-manganese oxide loaded biochar, and the biochar is modified with chitosan to obtain the modified biochar, wherein the raw material is one of straw, rice straw, rice husk, peanut shell, corncob, camellia oleifera shell and cottonseed hull. According to the invention, the prepared modified biochar is large in specific surface area, developed in pore and multiple in surface oxygen-containing functional groups; the modified biochar is applied to treatment of heavy metal organic matter contaminated soil, onthe basis of promoting adsorption of heavy metal and organic matter in the contaminated soil, a good solidification and stabilization effect can be achieved on the heavy metal organic matter; and themodified biochar material can stably exist in the soil for a long time, and has long-term restoration.

Owner:NORTHEASTERN UNIV

High-modulus and low-shrinkage type activated polyester industry yarn and preparation method thereof

ActiveCN104499081AIncreased free volumeIncrease polarityNew-spun product collectionMelt spinning methodsPolyesterFiber

The invention relates to a high-modulus and low-shrinkage type activated polyester industry yarn and a preparation method thereof. The high-modulus and low-shrinkage type activated polyester industry yarn is prepared from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 10-15v / v% when the high-modulus and low-shrinkage type activated polyester industry yarn is at 70-80 DEG C, a part of activating agent molecules are dispersed into fiber gaps, more -OHs and -NHs with strong activity are introduced, and the reactivity of the polyester fiber is improved; and the high-modulus and low-shrinkage type activated polyester industry yarn can be applied to light trucks, canvas conveyer belts and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Method for preparing aramid paper from para aramid fibrid as raw material

InactiveCN103572641AEnhanced hydrogen bondingHigh mechanical strengthSynthetic cellulose/non-cellulose material pulp/paperHeat resistancePulp and paper industry

The invention discloses a method for preparing aramid paper from para aramid fibrid as a raw material. The method concretely comprises the steps of carrying out treatment and dispersion on para aramid chopped fibers; pulping the para aramid fibrid and mixing the pulp; preparing the paper from the pulp by using a wet process; molding by hot pressing. According to the method for preparing the aramid paper from the para aramid fibrid as the raw material, the para aramid fibrid has relatively highly concentrated length and width distribution and a relatively large specific surface area and can be relatively well combined with the para aramid chopped fibers as binding materials; the prepared aramid paper has relatively good mechanical strength, heat resistance and dielectric properties, and is widely applied to the fields of high-temperature insulation, electronics and electric power, communication and transportation, aerospace and the like.

Owner:SHAANXI UNIV OF SCI & TECH

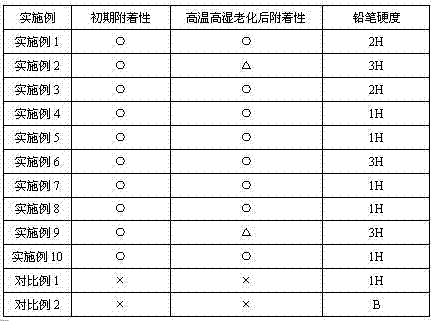

A hard coating composition and hardened film containing the hard coating composition

ActiveCN102268201AReduce internal stressImprove adhesionSynthetic resin layered productsCoatingsIndium tin oxidePet substrate

Provided are a hard coating composition and a hardened membrane containing the same. The hard coating composition comprises, by weight, 30 to 80 parts of hydroxyl-containing acrylate monomers, 1 to 10 parts of an photoinitiator, 20 to 70 parts of a solvent and 0.1 part to 5 parts of a reactive organosilicon surface wetting auxiliary agent, wherein, the hydroxyl-containing acrylate monomers are a mixture of hydroxyl-containing multi-functional acrylate monomers and hydroxyl-containing low functional acrylate monomers mixed according to a weight ratio of 2:8 to 8:2. The composition provided in the invention has excellent adhesion to a PET substrate surface which is never treated and a PET substrate surface which has corona or a failure coating bottom; hardness of the hardened layer of the obtained hardened membrane is greater than 1H, and therefore, the hardened membrane can be used as a hardened membrane of an indium tin oxide (ITO) touch screen, an in-mold label (IML), or the like.

Owner:CHINA LUCKY FILM CORP

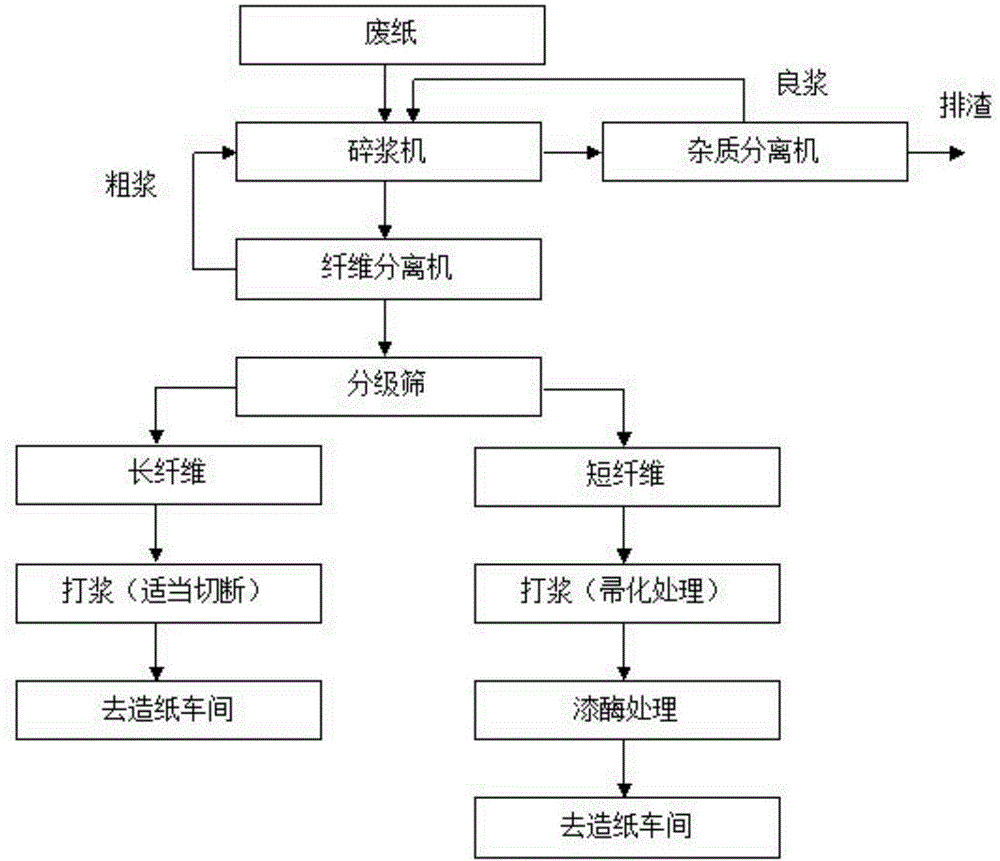

Production method of low-basis-weight environment-friendly high-strength kraft face liner board

ActiveCN104099793AIncrease hydrogen bondingHigh paper strengthPaper recyclingCellulose material pulpingCardboardFiber

The invention provides a production method of a low-basis-weight environment-friendly high-strength kraft face liner board. Long and short fibers in waste paper fibers are separated to be subjected to beating processing separately, and the short fibers are further subjected to laccase treatment, so that the paper forming strength is enhanced. According to the invention, the traditional kraft face liner board pulping production line is subjected to technical transformation to realize the separate beating control of the long and short fibers, and the short fibers are further subjected to laccase treatment to further improve the hydrogen bonding of the short fibers, so that the remarkable effect on the improvement of the paper forming strength of paper products is achieved, and further, the fact that the kraft face liner board is produced by totally adopting waste paper is realized; through the adoption of the method, the production of the low-basis-weight environment-friendly high-strength kraft face liner board can be implemented, and the product has prominent environmental protection advantage and cost advantage as totally adopting waste paper.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

Porous super-bright polyester fiber and preparation method thereof

ActiveCN104532392AGood flexibilityGood compatibilityMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolyester

Owner:JIANGSU HENGLI CHEM FIBER

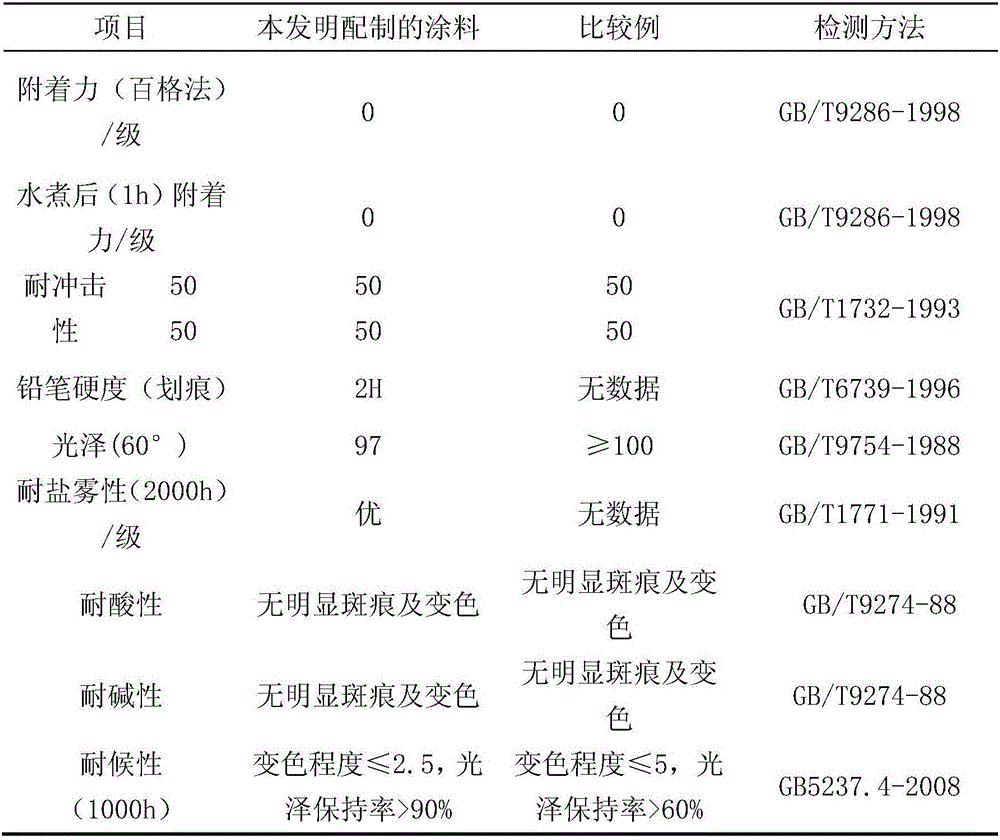

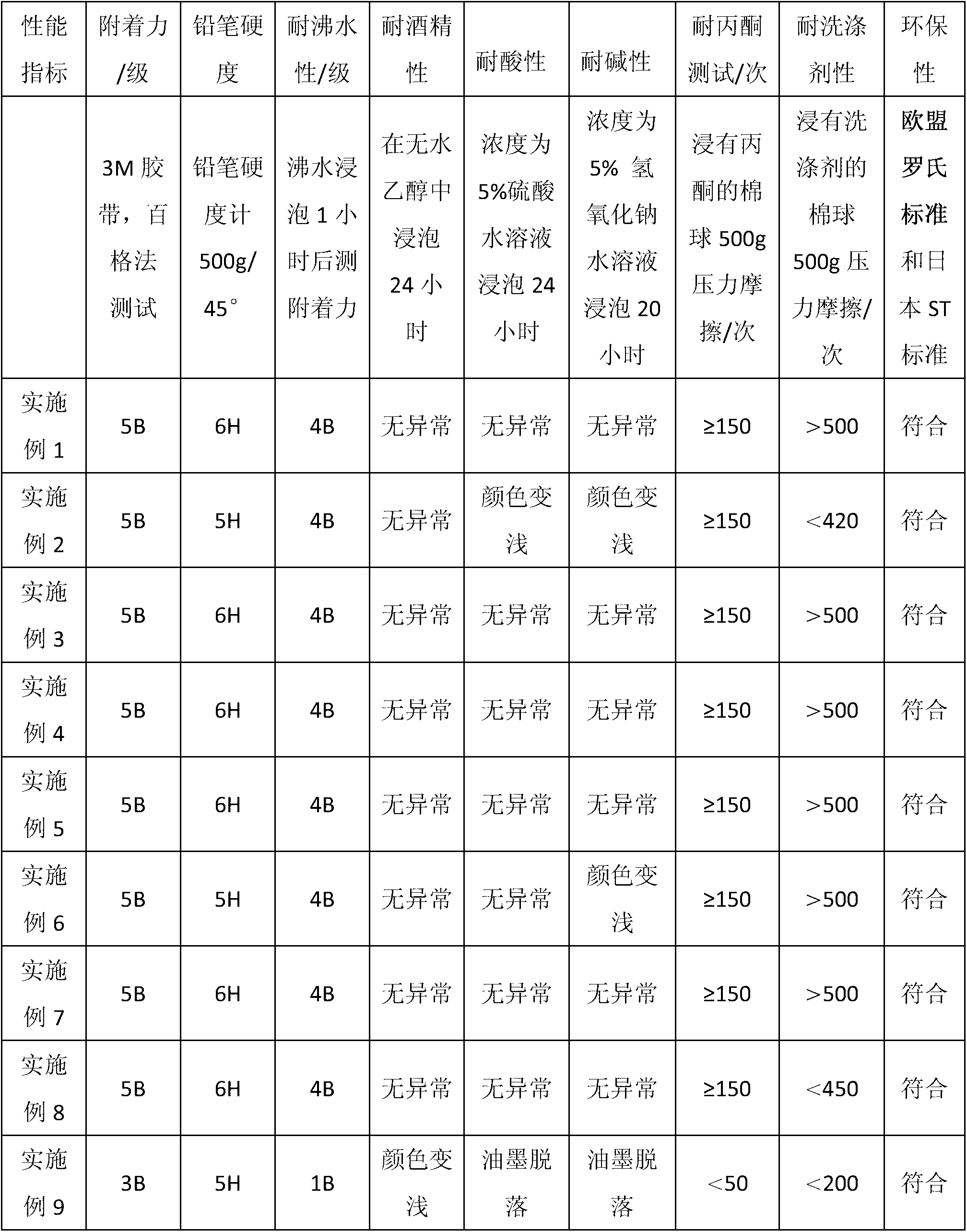

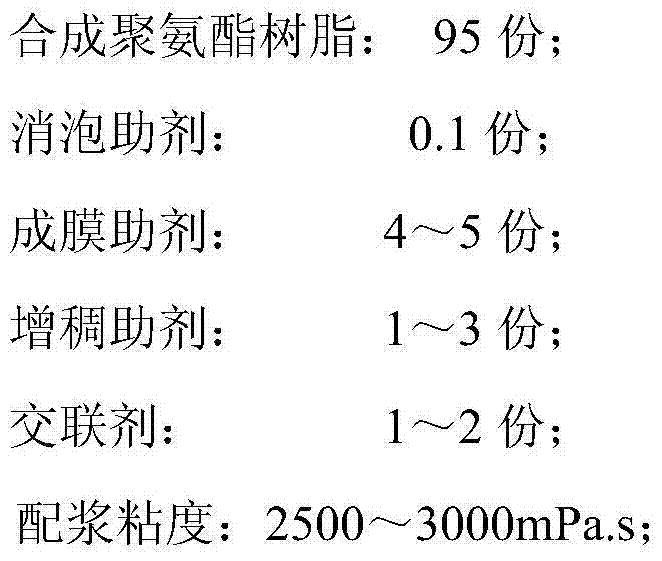

Benzoxazine-modified epoxy glass printing ink and preparation method and application thereof

The present invention discloses benzoxazine-modified epoxy glass printing ink and preparation method and application thereof. The preparation method comprises dissolving epoxy resin in the organic solvent, evenly stirring, to obtain liquid epoxy resin, based on the mass portion, blending 60 to 80 parts of liquid epoxy resin with 8 to 20 parts of benzoxazine, heating and stirring the resultant blendings at the temperature of between 60 and 80DEG C for 10 to 25 minutes to be uniformly dissolved to obtain the ink binder; evenly mixing the resultant ink binder, 0.1 to 2 parts of defoamer, 1 to 4 parts of leveling agent, 1 to 3 parts of thickener, 8 to 15 parts of inorganic pigments, 0.1 to 1 parts of dispersants and 1 to 5 parts of inorganic filler, grinding the resultant mixture until the fineness is below 16 Mum to obtain the finished printing ink. The printing ink provided by the invention, a curing agent and a coupling agent are mixed and cured, the cured mixture is directly printed onto the glass panel, which is placed in oven for cross-linking curing to obtain the ink film with good adhesion, high hardness and excellent solvent resistance.

Owner:SOUTH CHINA UNIV OF TECH

Polyurethane coated fabric and preparation method thereof

ActiveCN104499083AIncreased free volumeImprove efficiencyNew-spun product collectionFibre typesPolyesterYarn

The invention relates to a polyurethane coated fabric and a preparation method thereof. The polyurethane coated fabric comprises a fabric layer and a polyurethane coating, the warps and the wefts of the fabric layer are polyester industry yarns for the polyurethane coated fabric, the polyester industry yarns for the polyurethane coated fabric are made from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-40v / v% when the polyester industry yarns for the polyurethane coated fabric are at 100-150 DEG C, the polyurethane coated fabric and the polyurethane have good interface bonding effect, and the polyester industry yarns for the polyurethane coated fabric can be used for improving the appearance of the fabric.

Owner:JIANGSU HENGLI CHEM FIBER

Crisp nata de coco and preparation method thereof

The invention provides a preparation method of the crisp nata de coco. The preparation method of the crisp nata de coco comprises the following steps: preparing a crisping agent, mixing, boiling, preserving temperature, cooling and the like. According to the preparation method, the uniform and stable crisp and refreshing nata de coco product is obtained by matching powder containing a composite crisping agent with frequently-used additives and rewatering and boiling compressed nata de coco. When the obtained nata de coco product is chewed, the crisp nata de coco is sour, sweet, palatable, crisp, tasty and refreshing and has no residues. The crisp nata de coco can be added to food such as mixed fruit cans, jellies, beverages and pearl milk tea so as to prepare related products.

Owner:姚育明

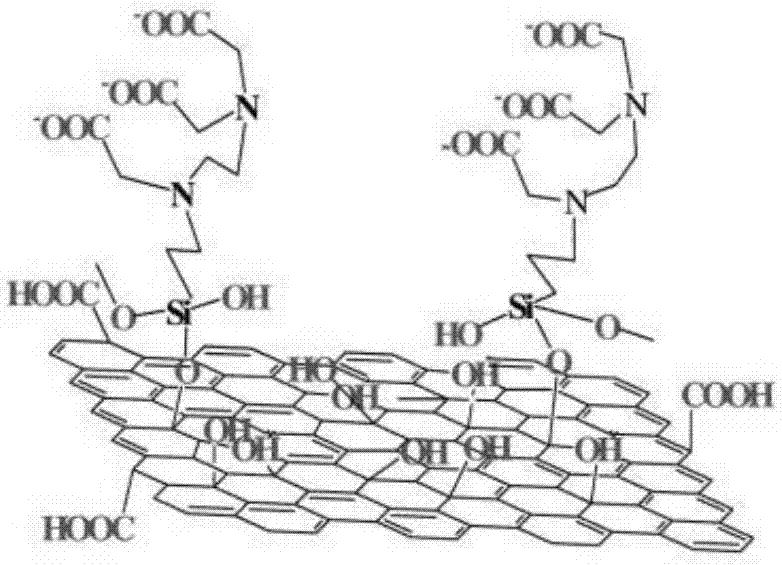

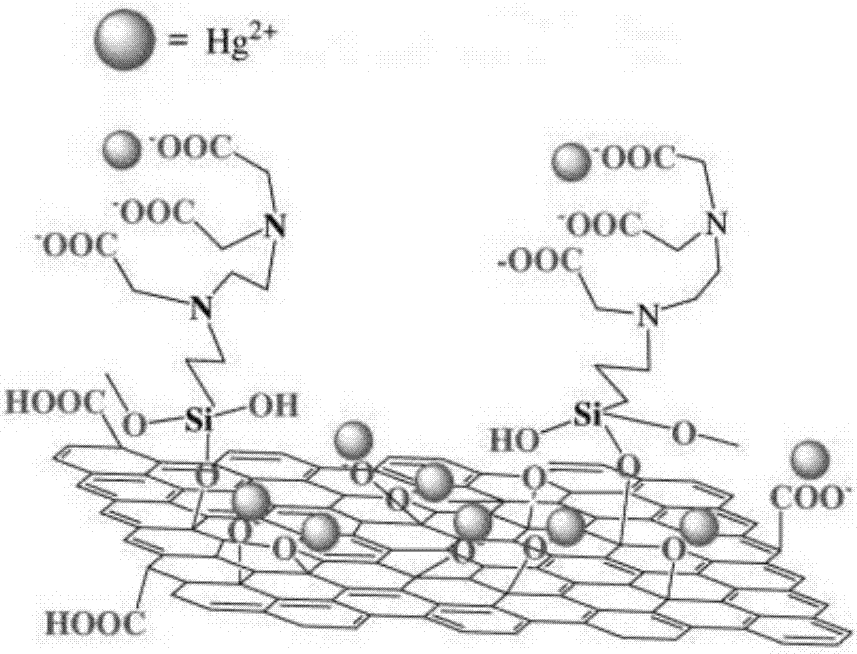

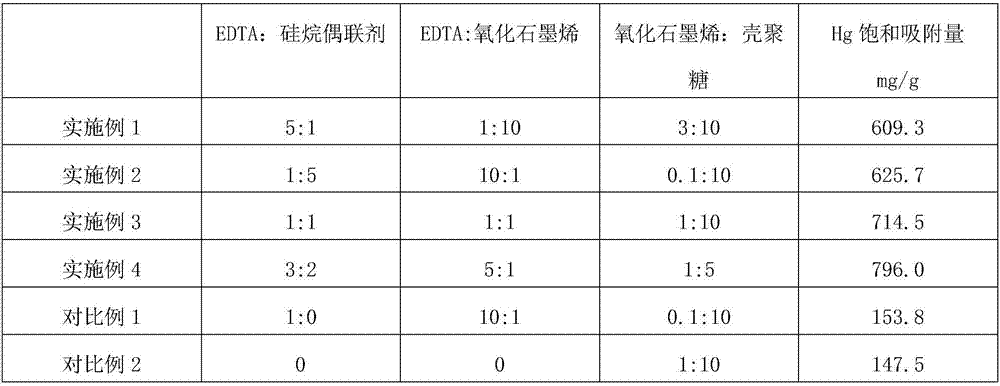

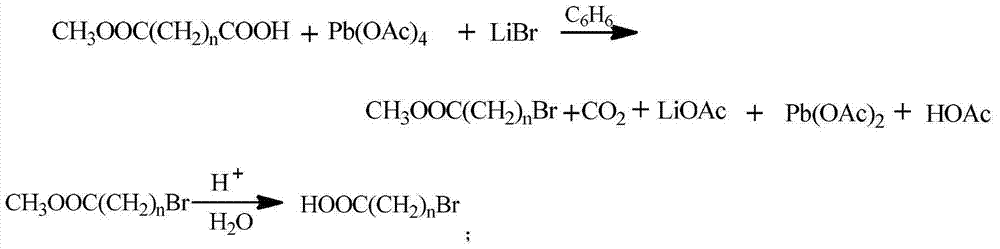

Preparation method and applications of modified graphene oxide/chitosan composite material

InactiveCN106944006ALarge specific surface areaImprove adsorption capacityOther chemical processesWater contaminantsAcetic acidAdsorption selectivity

The invention discloses a preparation method and applications of a modified graphene oxide / chitosan composite material. The preparation method comprises the following steps: carrying out EDTA modification and graphene oxide modification, adding modified graphene oxide into glacial acetic acid, carrying out an ultrasonic treatment until modified graphene oxide and glacial acetic acid are evenly mixed, performing high speed dispersion by using a high speed dispersing machine, and finally moulding the modified graphene oxide / chitosan composite material. The modified graphene oxide / chitosan composite material is prepared by a wet spinning technology. After modification, the surface of graphene oxide comprises a large amount of functional groups, the functional groups can enhance the adsorption performance of the composite material under a low graphene oxide content, at the same time, the bonding strength between graphene oxide and chitosan is strengthened, and the mechanical strength of the composite material is greatly improved. The composite material has excellent adsorption selectivity on heavy metal Hg; at the same time, graphene oxide can be recovered and reutilized more conveniently, and the problem that after graphene oxide is subjected to a water treatment, graphene oxide is hard to recover and generates secondary pollution is solved.

Owner:山东金利特新材料有限责任公司

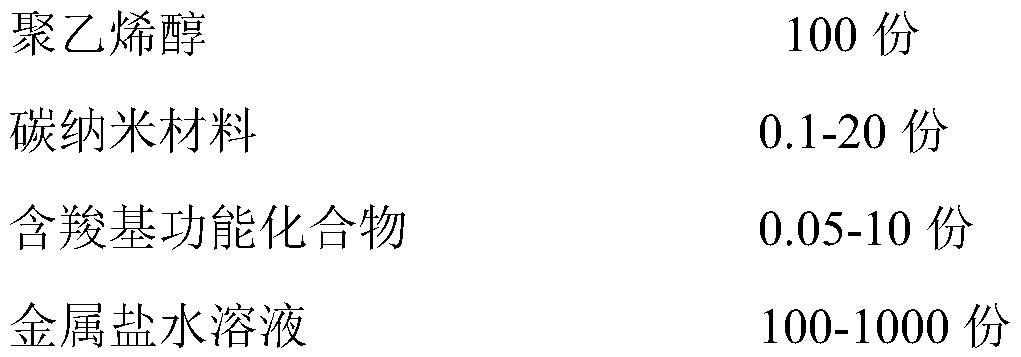

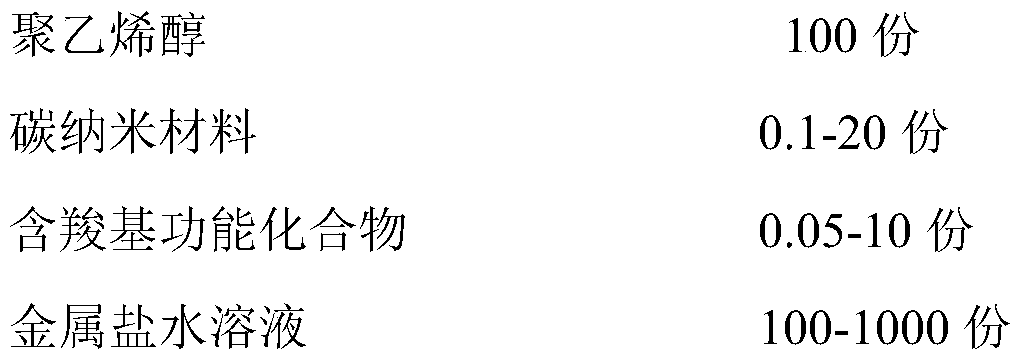

Preparation method of high-strength wear-resistant polyvinyl alcohol hydrogel

ActiveCN111333865AHigh wear resistance and self-lubricationExcellent wear resistance and self-lubricationPolymer scienceCarbon Nanoparticles

The invention discloses a preparation method of high-strength wear-resistant polyvinyl alcohol hydrogel. The preparation method is characterized in that the characteristics of high strength, excellentwear resistance, self-lubricating property and easiness in functional modification of a carbon nano material are utilized. The method comprises the steps of introducing a carboxyl group to the surface; compounding with polyvinyl alcohol to prepare polyvinyl alcohol / carbon nano material composite hydrogel; preliminarily forming a gel sample by adopting a freezing and unfreezing crosslinking method; then, the intermolecular hydrogen bonding effect and the crosslinking degree are enhanced through annealing treatment; further soaking the polyvinyl alcohol hydrogel in a saline solution to enable the polyvinyl alcohol hydrogel and metal ions to form a complexing bonding effect, so as to construct a multi-network structure, and effectively play an excellent reinforcing role of the carbon nanoparticles, thereby greatly improving the mechanical strength and the wear-resistant self-lubricating property of the polyvinyl alcohol hydrogel.

Owner:重庆石墨烯研究院有限公司 +1

Base paper of aramid fiber honeycomb core and manufacturing method thereof

ActiveUS20110174452A1Improve flatnessImprove glossinessNon-fibrous pulp additionNatural cellulose pulp/paperPolyesterHoneycomb

A base paper of aramid fiber honeycomb core and its manufacturing method are provided. The base paper comprises 11-90 parts by weight of structural fiber, 10-70 parts by weight of crosslinking fiber, and 0-19 parts by weight of additive fiber, wherein the structural fiber is poly(p-phenylene terephthal amide) fiber, the crosslinking fiber is poly(m-phenylene isophthal amide) fibrid, and the additive is polyester fiber.

Owner:GANZHOU LONGPONT MATERIAL TECH CO LTD

Polyester paralleling composite yarn and prepared method thereof

ActiveCN104499091AGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsYarnPolyester

The invention relates to a polyester paralleling composite yarn. The polyester paralleling composite yarn is prepared from PBT (polybutylece terephthalate) and modified polyester PET (polyethylene terephthalate) chips through parallel composite spinning, wherein the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 20-30v / v% when the polyester of the polyester paralleling composite yarn is at 90-130 DEG C, the dying rate of the polyester paralleling composite yarn is higher than that of the common fiber when the polyester paralleling composite yarn adopts disperse red 3B and the like, less surface dyeing is formed after dyeing, and the polyester paralleling composite yarn has wide application prospect in the field of garment materials.

Owner:JIANGSU HENGLI CHEM FIBER

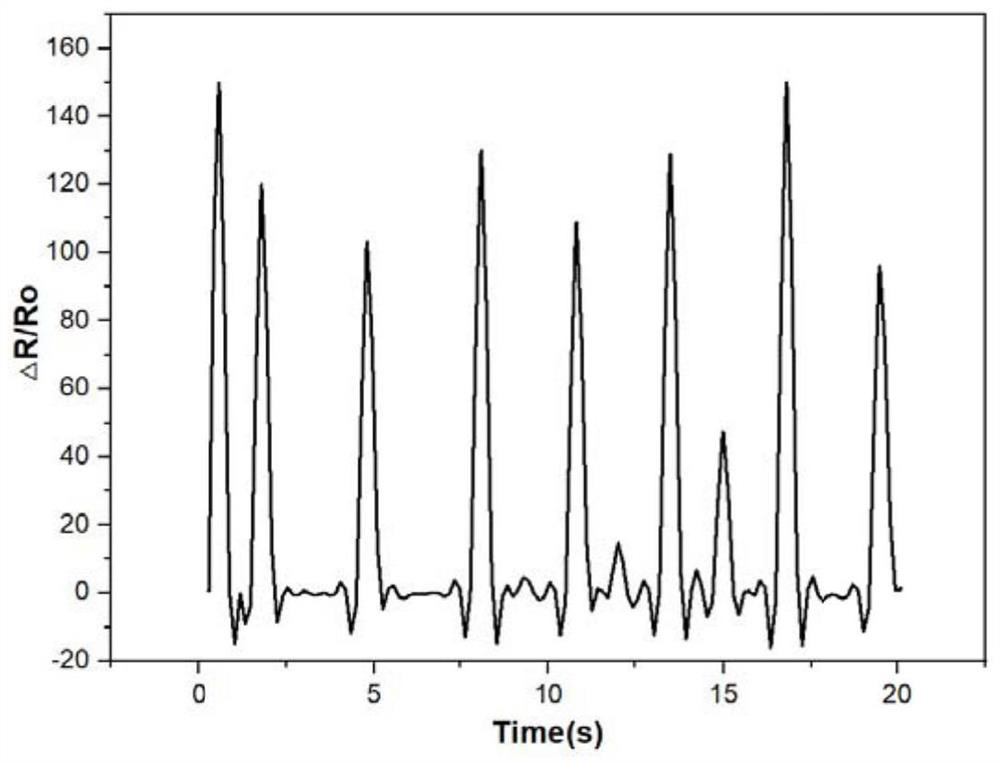

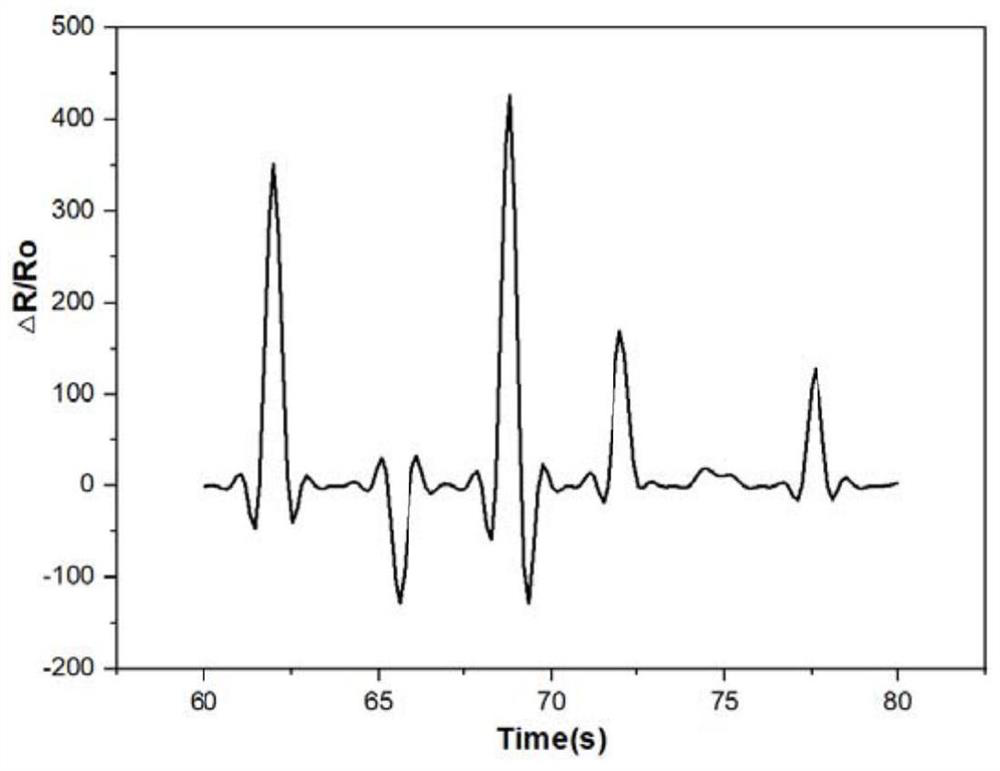

Self-repairing carbon nanotube organic silicon composite elastomer as well as preparation method and application thereof

ActiveCN112062970AIncrease elasticityImprove repair efficiencyElectrical/magnetic solid deformation measurementPolymer scienceCrazing

The invention discloses a self-repairing carbon nanotube organic silicon composite elastomer as well as a preparation method and application thereof. Raw materials of the self-repairing carbon nanotube organic silicon composite elastomer comprise amino-terminated polydimethylsiloxane, diisocyanate and carboxylated carbon nanotubes, reversible strong and weak multiple hydrogen bonds are formed in the composite elastomer, and can be used as weak power bonds to consume energy generated by strain, so that the elastomer shows excellent tensile property, and cracks can be rapidly repaired, and excellent self-repairing performance is achieved. Meanwhile, due to the introduction of the carboxylated carbon nanotubes, the hydrogen bond interaction is further enhanced, and a strain sensor is endowedwith excellent conductivity and sensitive sensing performance. Through a crosslinking mechanism of strong and weak hydrogen bonds in the carbon nanotube organic silicon elastomer, the flexible strainsensor with high repair efficiency, excellent tensile property and high sensitivity can be prepared.

Owner:HUNAN UNIV OF TECH

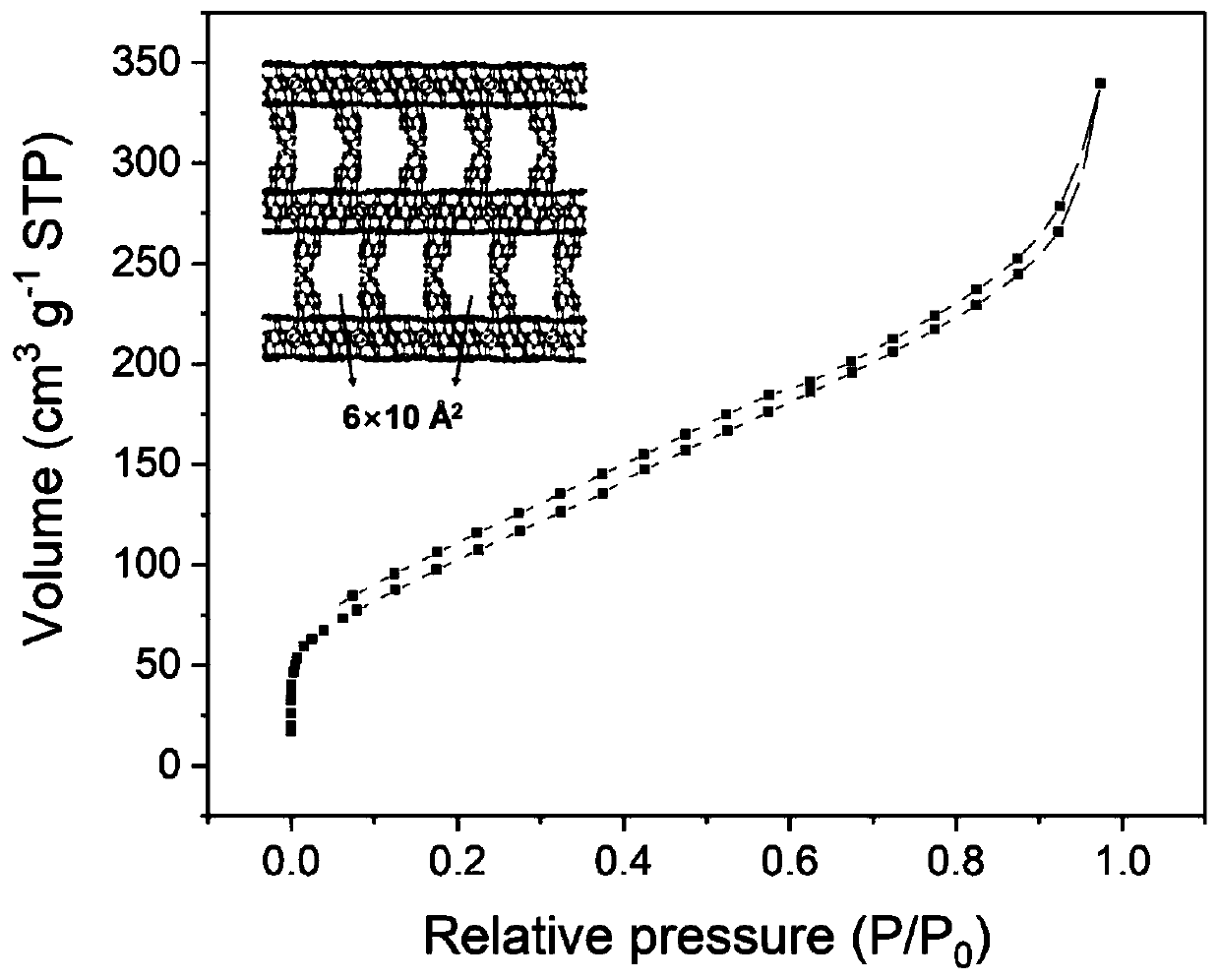

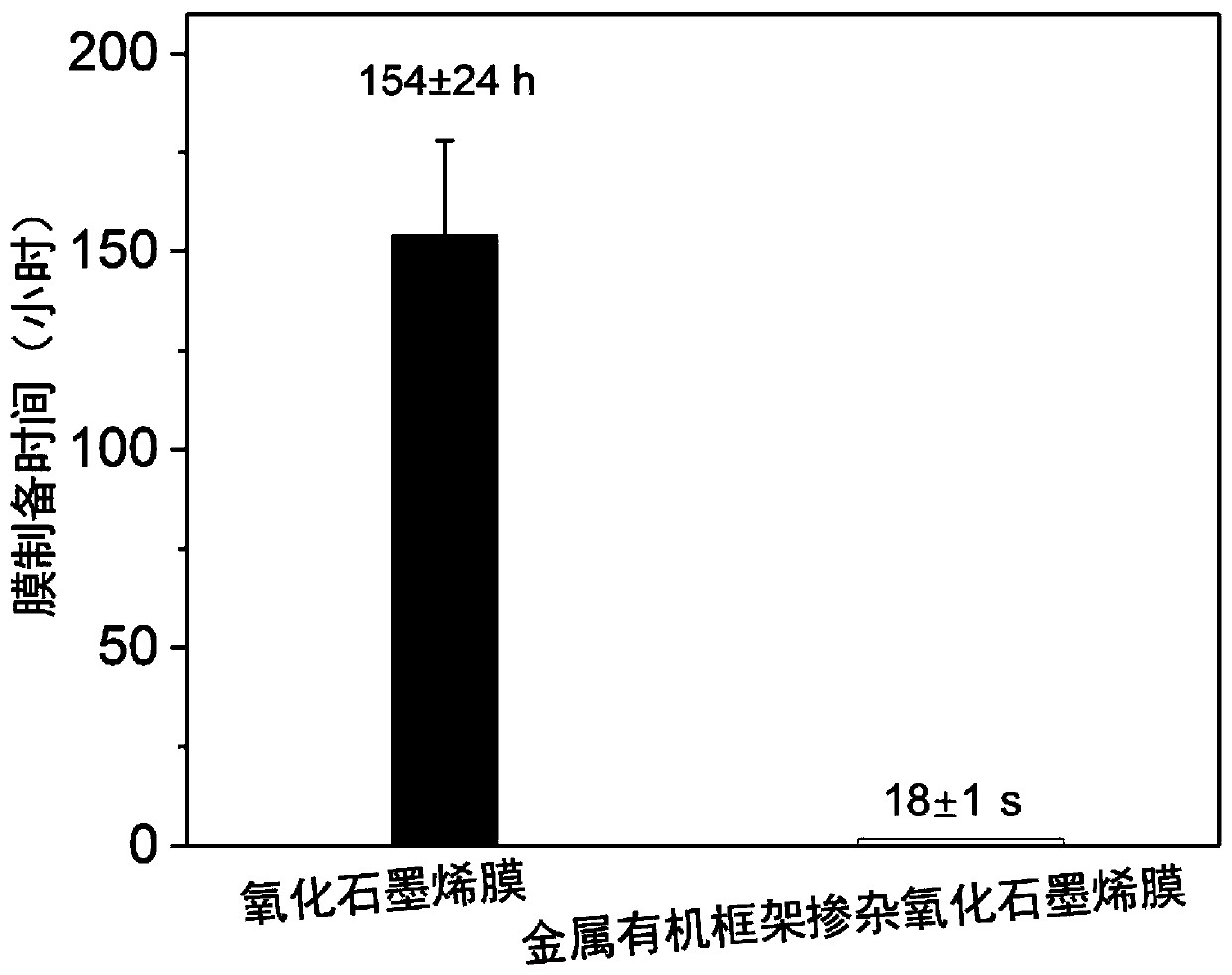

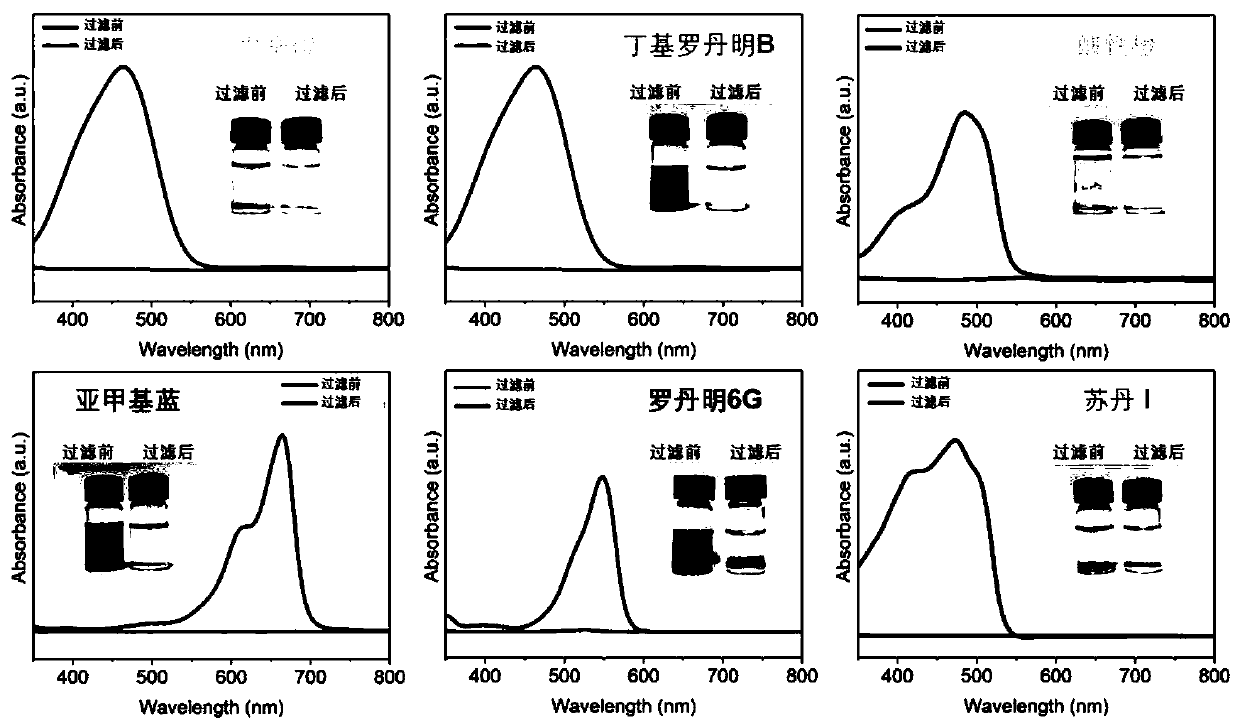

Porous metal organic framework doped graphene oxide-based composite material and rapid preparation method and application thereof

ActiveCN111389235AQuick assemblyGood water permeabilitySemi-permeable membranesWater contaminantsDoped grapheneComposite film

The invention relates to a porous metal organic framework doped graphene oxide-based composite material and a rapid preparation method and application thereof. The preparation method comprises the following specific steps: sequentially adding a metal salt, an organic ligand and a surfactant into an organic solvent, stirring to react for a period of time, and centrifuging, washing and drying the product to obtain a porous metal organic framework; and respectively diluting and mixing the porous metal organic framework and graphene oxide, and obtaining the porous metal organic framework doped graphene oxide-based composite material by adopting a vacuum or pressure-assisted filtering method. Compared with the traditional vacuum / pressure auxiliary filtering method, the filtering time of the composite material is greatly shortened, the thickness is controllable, a two-dimensional film and three-dimensional hydrogel and aerogel can be prepared, the limitation that hydrogel and aerogel cannotbe prepared through the traditional filtering method is broken through, and the prepared composite film has higher water flux and stronger mechanical properties and has wide application prospects in the aspects of dye separation and water treatment.

Owner:WUHAN UNIV OF TECH

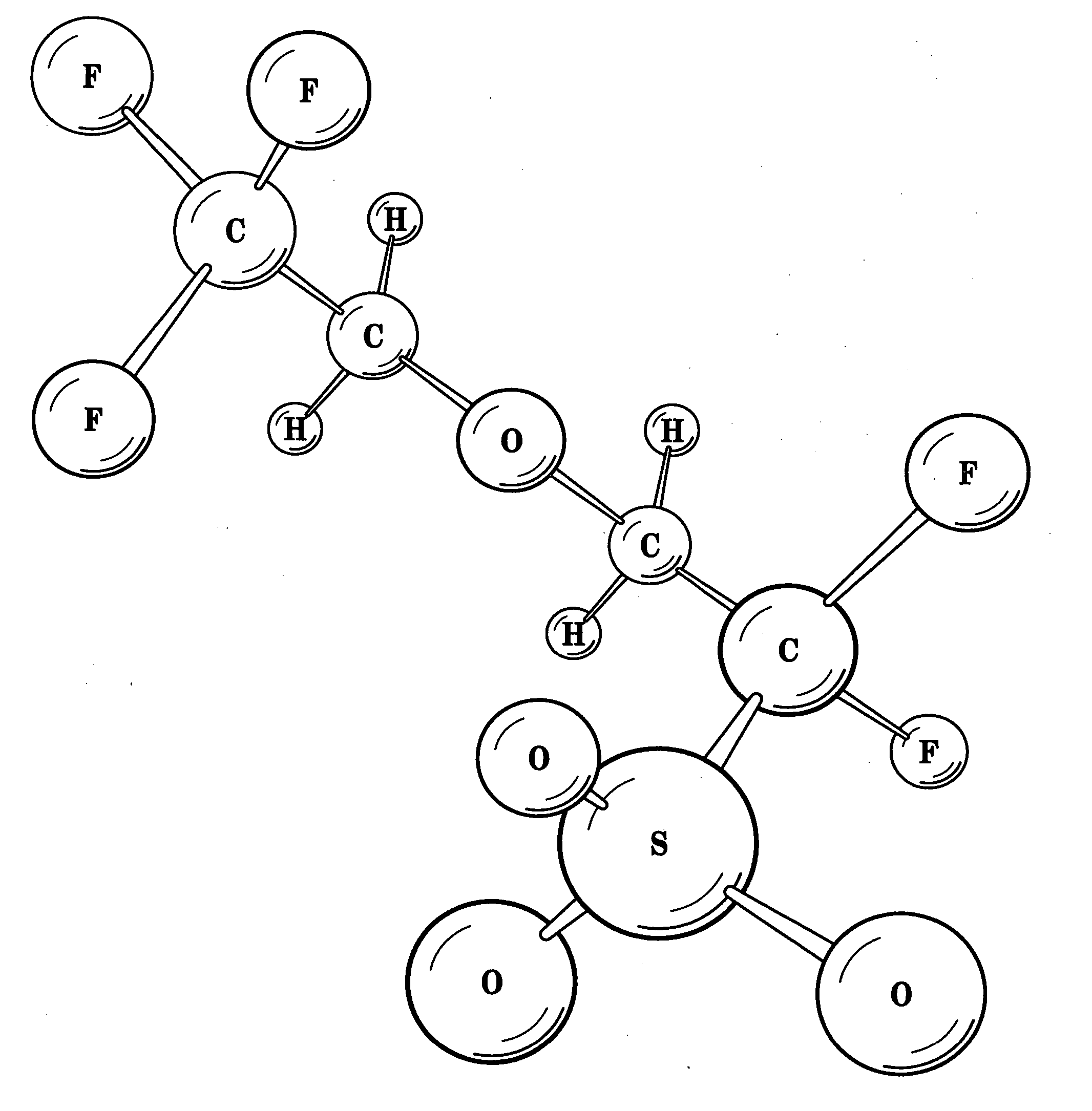

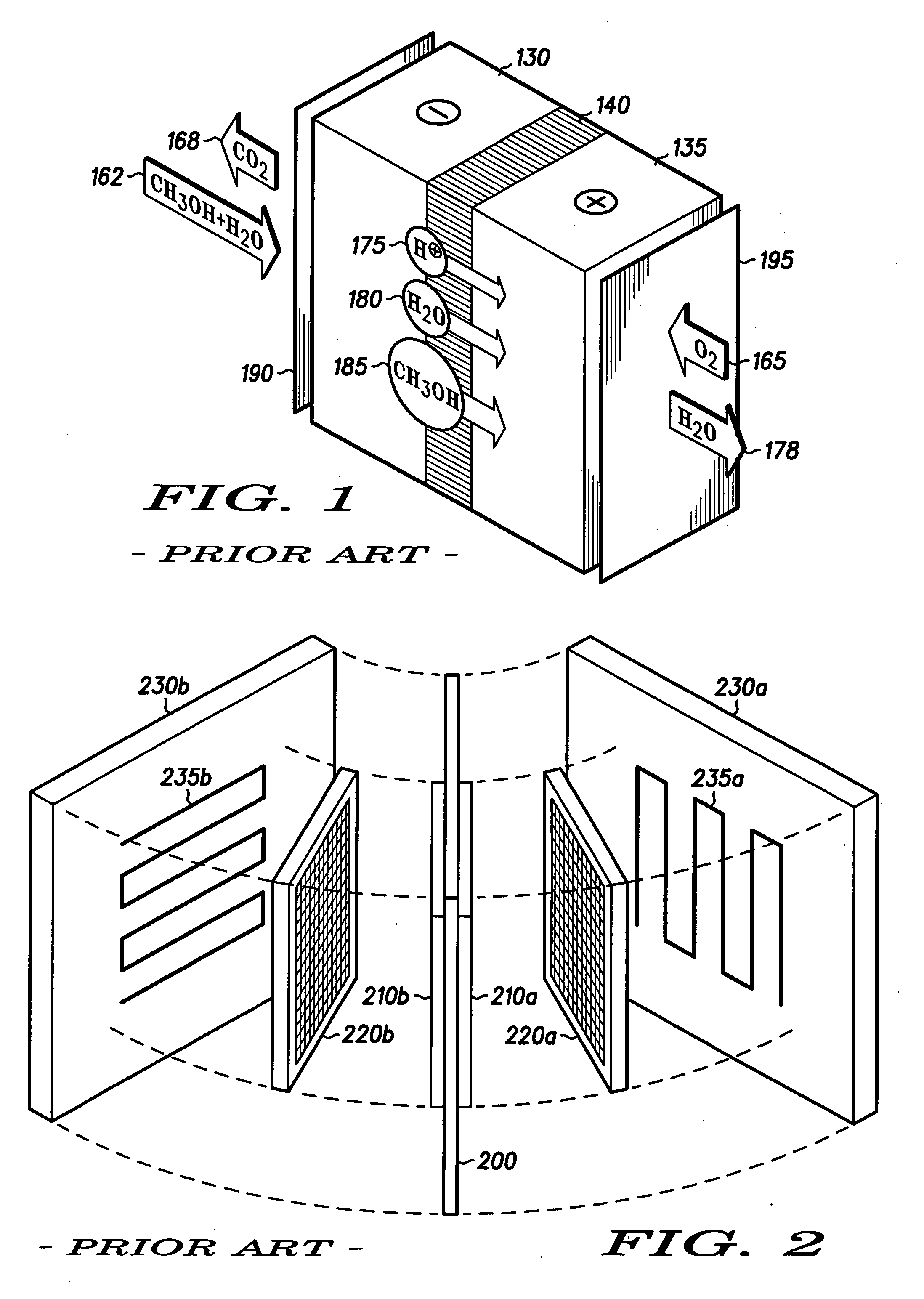

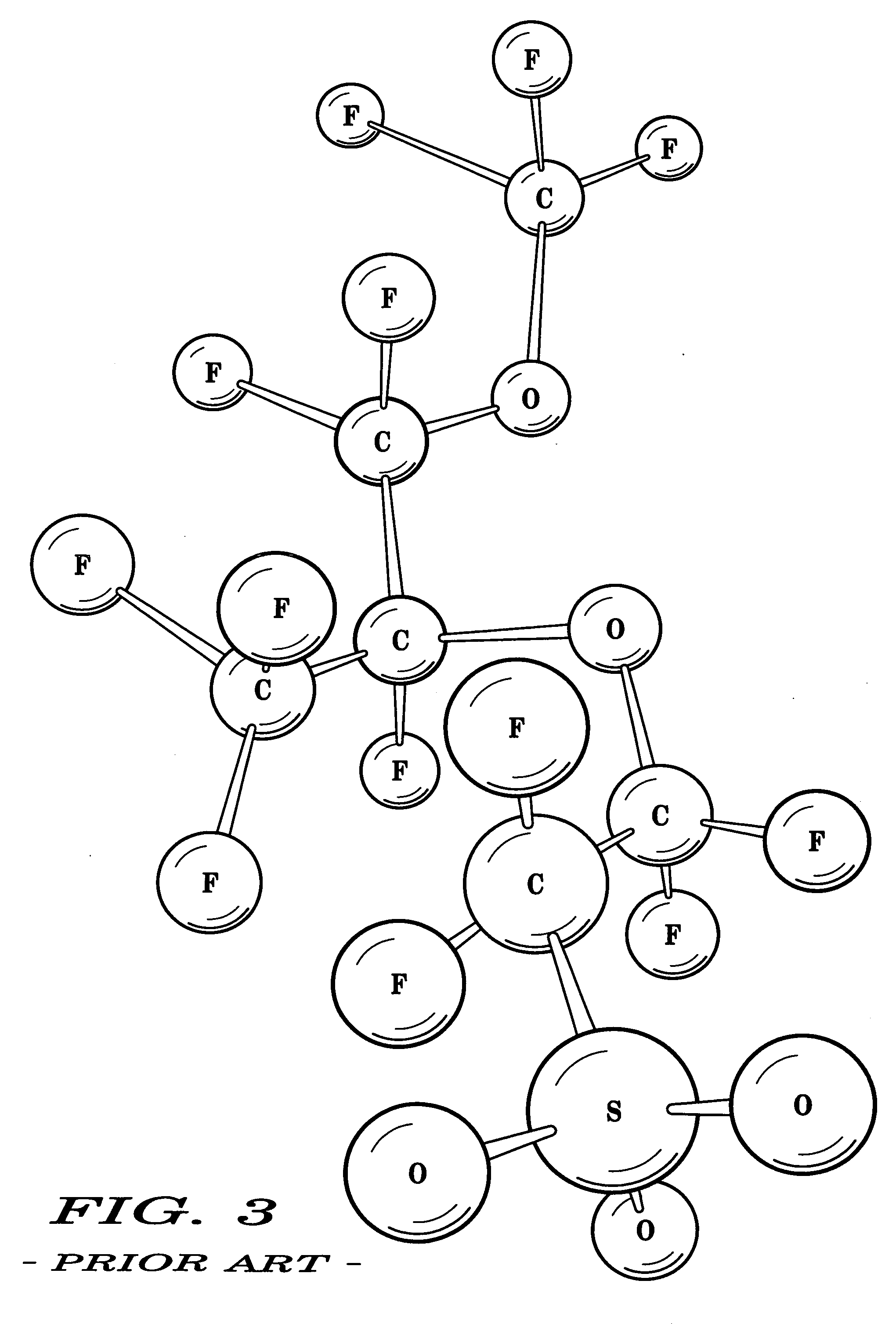

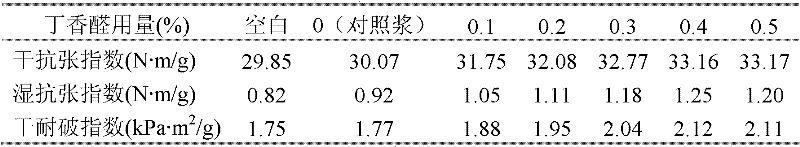

Hydrophilic side-chain polymer, electrolyte membranes

InactiveUS20060035987A1Increase protrusionLow dielectric constantSolid electrolytesIon-exchanger regenerationPolymer electrolytesProton dissociation

Exemplary methods for the characterization of proton dissociation and transport for hydrophilic components of hydrated Polymer Electrolyte Membranes (PEM's) is described. Disclosed features and specifications may be variously implemented, controlled, adapted or otherwise optionally modified to improve differential hydrophilicity of the sidechain of any ionomeric PEM material. A representative embodiment of the present invention generally provides for the amelioration of electro-osmotic drag of water by protons, for example, in Direct Methanol Fuel Cells.

Owner:PADDISON STEPHEN

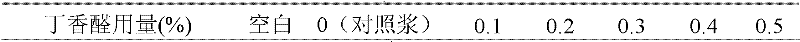

A biological treatment method for improving paper strength

InactiveCN102296474AIncrease contentEnhanced hydrogen bondingPaper material treatmentLacquerBonding strength

Owner:QILU UNIV OF TECH

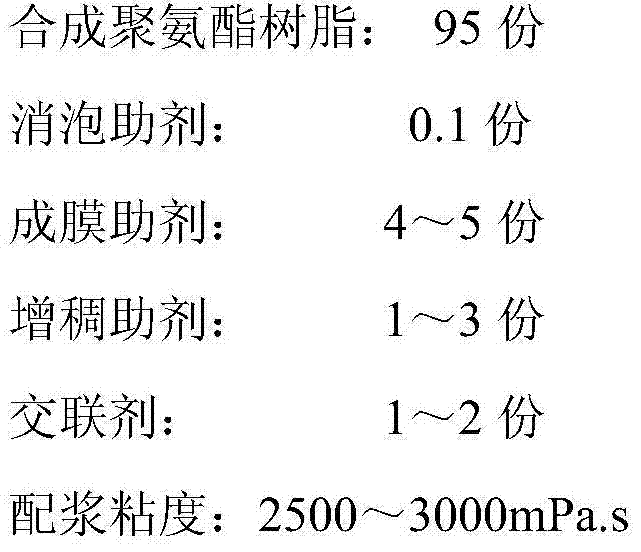

Light extinction type waterborne polyurethane emulsion and preparation method thereof

The invention discloses light extinction type waterborne polyurethane emulsion and a preparation method thereof. According to the light extinction type waterborne polyurethane emulsion, a novel raw material composition is adopted and has a cooperative effect to solve the problems of existing light extinction type waterborne polyurethane emulsion that the glossiness is relatively high, the rigidityis low, the water resistance is poor, the wearing resistance is poor and the like; meanwhile, the prepared polyurethane emulsion has no acetone residues and the performance of the emulsion is not influenced; a procedure is simple and convenient and industrial production is facilitated; in a reaction process, the polymerization or crosslinking degree of raw materials is relatively high, so that the quantity of double electric layers and the fluid volume of particles are ensured, the compatibility of the raw materials is improved, a relatively fine blending structure is formed and the wearing resistance is improved; meanwhile, latex particles with a relatively great grain diameter are generated by a produced polyurethane material; the surface of a membrane has relatively great roughness andhas good light extinction efficiency.

Owner:JIANGMEN CAIGE ENVIRONMENTAL PROTECTION TECH IND

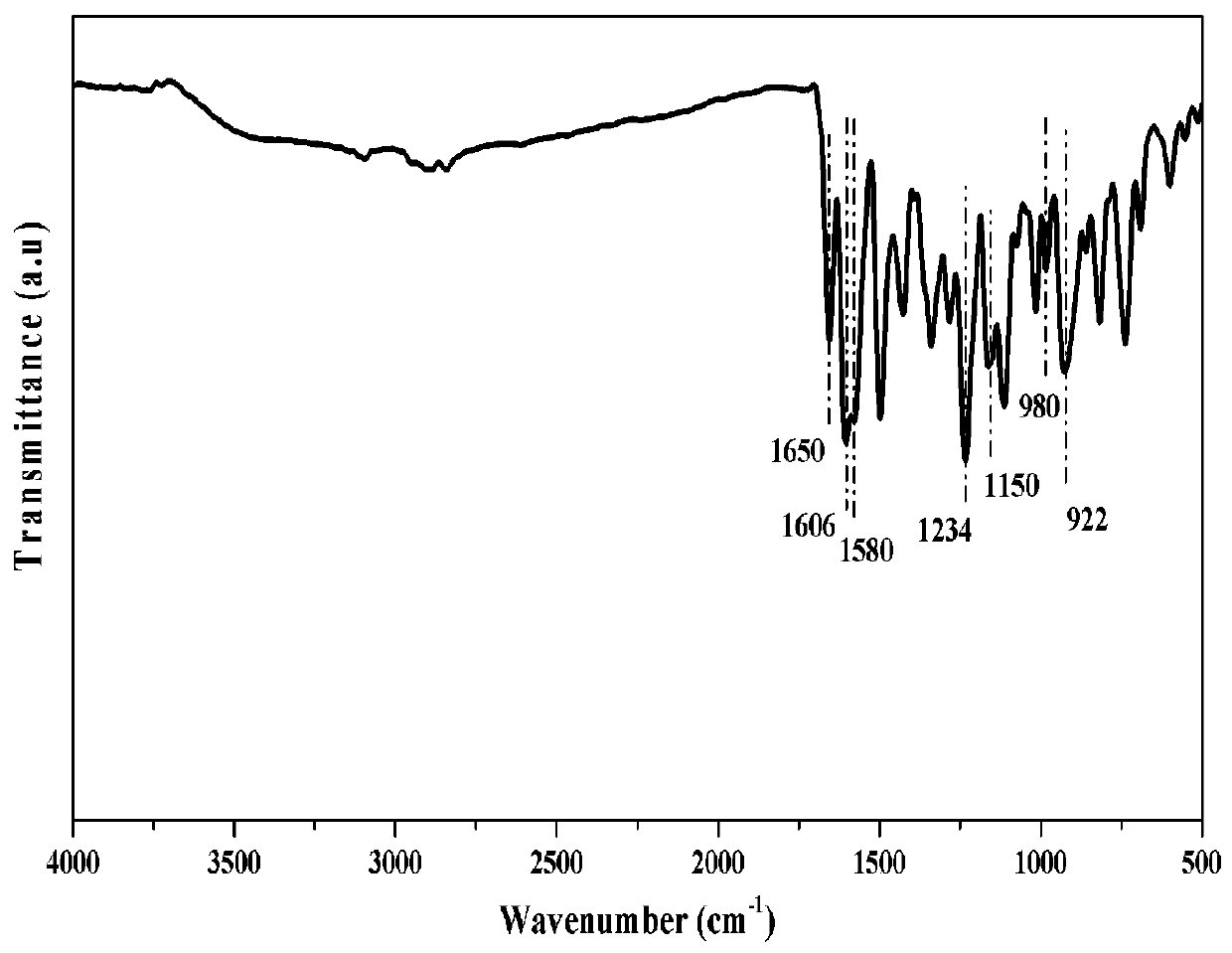

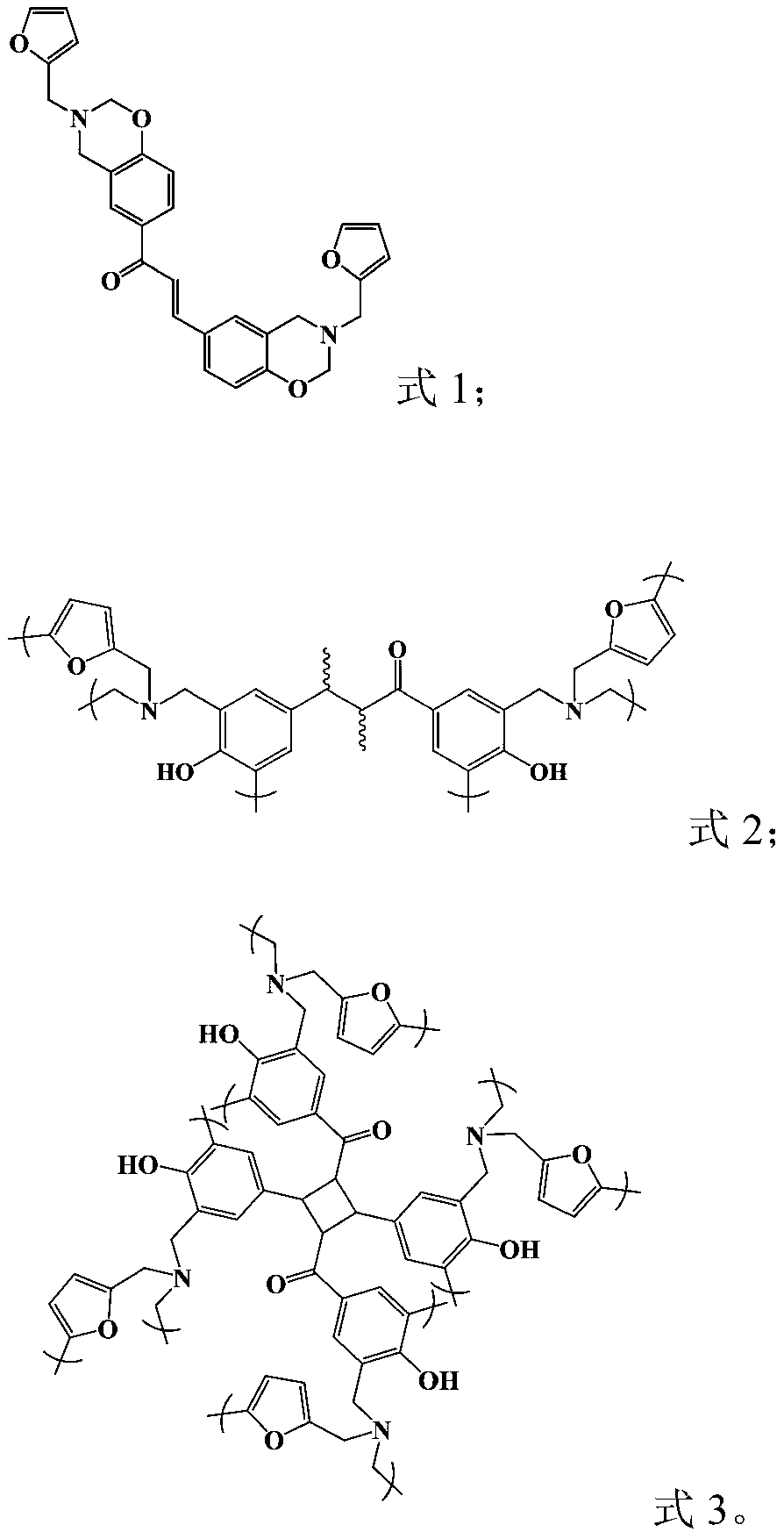

Benzoxazine full-bio-based resin and preparation method thereof

The invention discloses a benzoxazine full-bio-based resin and a preparation method thereof. The preparation method comprises the following steps: mixing bisphenol with a chalcone structure, furfurylamine and an aldehyde compound in an organic solvent, reacting at 85-125 DEG C for 8-48 hours, and purifying the reaction product to obtain a full-bio-based benzoxazine monomer; and curing the full-bio-based benzoxazine monomer at a temperature of 80-240 DEG C for 1-24 hours, or carrying out ultraviolet irradiation on full-bio-based benzoxazine monomer for 0.5-2 hours, and then curing the benzoxazine monomer at a temperature of 80-120 DEG C for 4-24 hours to obtain the benzoxazine full-bio-based resin. The obtained full-bio-based benzoxazine resin has a high glass-transition temperature (296-381 DEG C), a high carbon residue rate (58-67%), a high limit oxygen index (36.5-43.7) and a low dielectric constant (2.10-2.95), and has excellent heat resistance, flame retardant property and dielectric property.

Owner:淮北绿洲新材料有限责任公司

Preparation method for cross-linked three-dimensional carbon nano composite polyurethane material

The invention discloses a preparation method for a cross-linked three-dimensional carbon nano composite polyurethane material. The covalent cross-linked three-dimensional composite carbon nano material is prepared by a nucleophilic reaction of an amine compound with carboxylated graphene oxide (GO-COOH) and acidified carbon nanotubes (o-CNTs). Compared with a carbon nano material having a hydrogenbond and a pi-pi bond superposition effect, the three-dimensional composite carbon nano material prepared by a covalent bond effect facilitates increase of bonding force among the carbon nano material; and the prepared three-dimensional composite carbon nano material has obviously-improved dispersibility in a TPU substrate when being used as a filler of thermoplastic polyurethane (TPU), interaction force of an interface between the filler and the TPU substrate is enhanced, the TPU nano composite material has unique mechanical and thermal stability properties of graphene oxide and carbon nanotubes, tensile strength, elongation at break and thermal decomposition temperature of the TPU are respectively up to 63MPa, 1700% and 426 DEG C, and applications of the TPU in various national economyfields such as national defense, oil fields and mines are facilitated.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com