Modified biochar, preparation method and application thereof

A technology of biochar modification, which is applied in the field of environmental soil treatment, can solve problems such as difficult to achieve effects, and achieve the effects of enhancing synchronous solidification and stabilization, enhancing adsorption capacity, and enriching surface functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

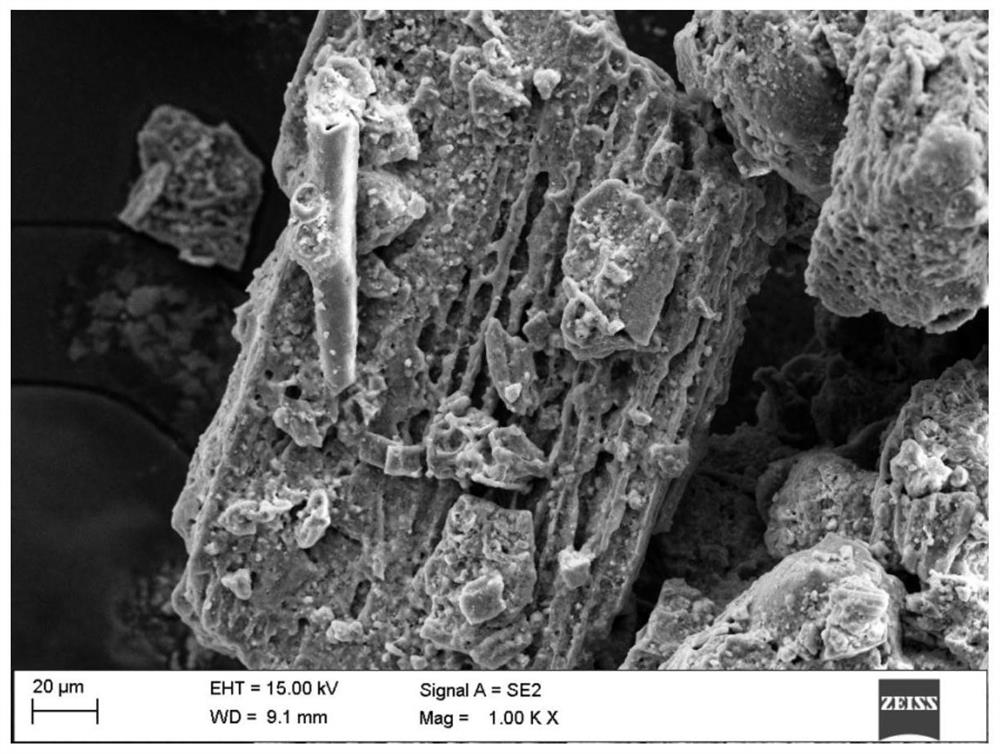

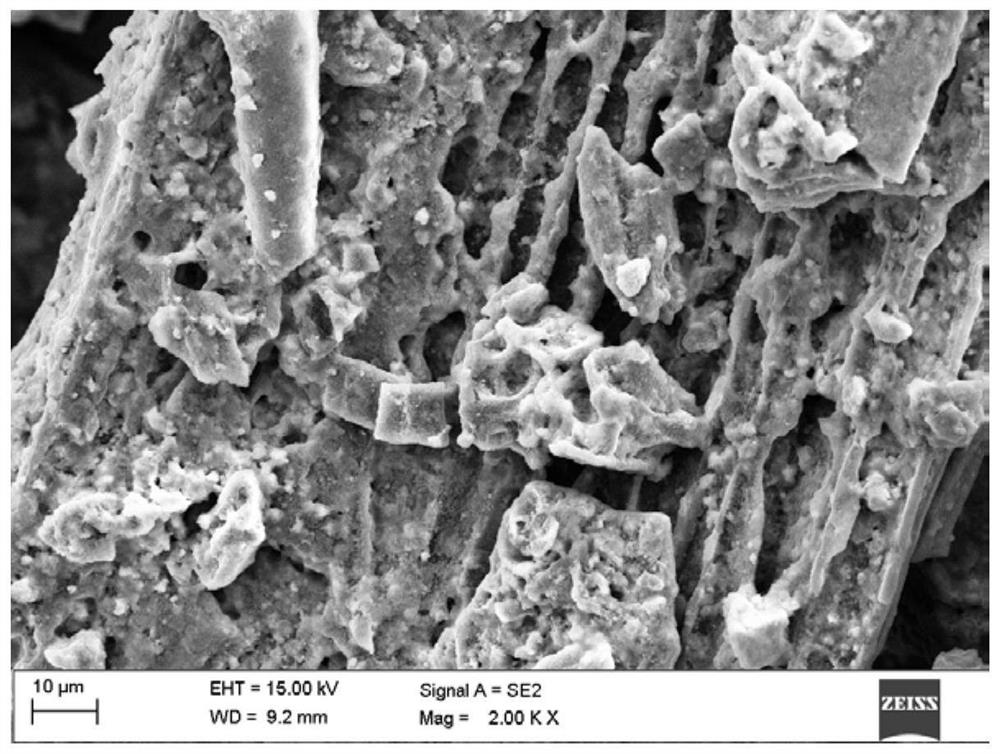

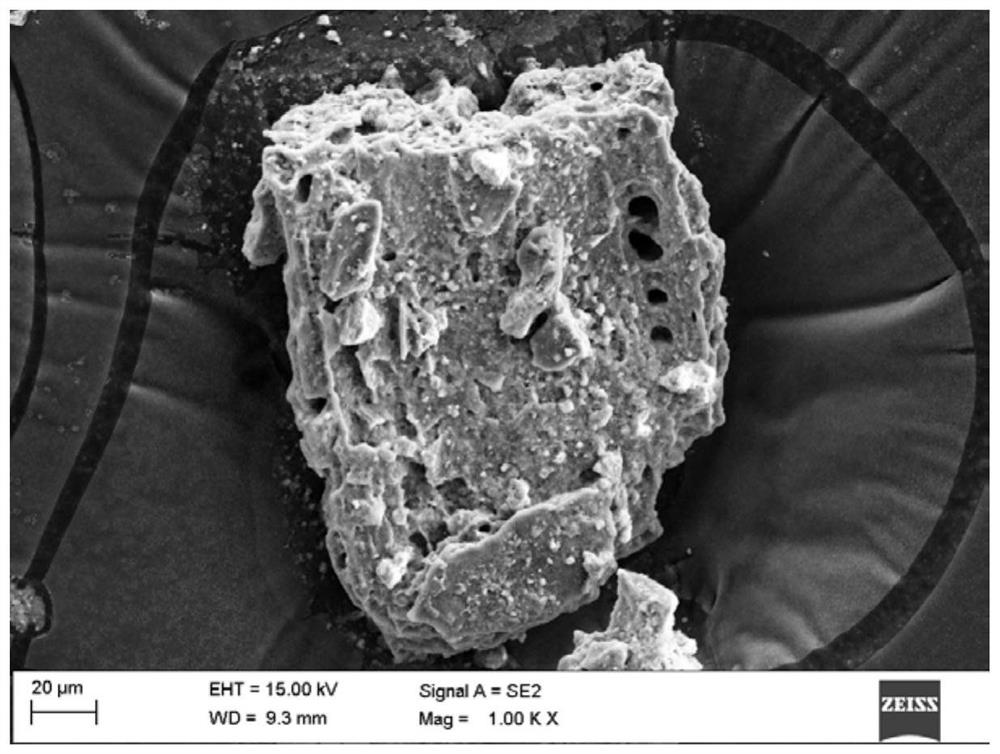

Image

Examples

Embodiment 1

[0034] (1) Preparation of modified biochar:

[0035] S1. After drying the peanut shells, break them into solid particles below 1mm, then mix the peanut shell powder with deionized water and filter to obtain the impregnated peanut shell powder, let it stand for soaking for 24 hours, and then filter it with a funnel for 30 minutes. The product was dried in an electric blast drying oven at 110°C for 2 hours;

[0036] S2. 5g peanut shell powder after the deionized water immersion obtained is mixed with 100mL potassium permanganate solution (0.1mol / L) and 100mL ferric chloride solution (0.05mol / L) to obtain a mixture, and the mixture is heated at 550° C. Carry out carbonization. The carbonization time is 16 hours. After carbonization, the pyrolysis product peanut shell biochar is obtained. The pyrolysis product is cooled to room temperature (25° C.) and then dried. The drying time is 18 hours and the drying temperature is 110° C.;

[0037] S3. Take 3 g of the above-mentioned peanu...

Embodiment 2

[0043] (1) Preparation of modified biochar:

[0044] S1. After drying the peanut shells, break them into solid particles below 1mm, then mix the peanut shell powder with deionized water and filter to obtain the impregnated peanut shell powder, let it stand for soaking for 24 hours, and then filter it with a funnel for 30 minutes. The product was dried in an electric blast drying oven at 110°C for 2 hours;

[0045] S2. 5g peanut shell powder after the deionized water immersion obtained is mixed with 100mL potassium permanganate solution (0.15mol / L) and 100mL ferric chloride solution (0.10mol / L) to obtain a mixture, and the mixture is heated at 650°C Carry out carbonization. The carbonization time is 18 hours. After carbonization, the pyrolysis product peanut shell biochar is obtained. The pyrolysis product is cooled to room temperature (25° C.) and then dried. The drying time is 18 hours and the drying temperature is 110° C.;

[0046] S3. Get the above-mentioned peanut shell b...

Embodiment 3

[0052] (1) Preparation of modified biochar:

[0053] S1. After drying the peanut shells, break them into solid particles below 1mm, then mix the peanut shell powder with deionized water and filter to obtain the impregnated peanut shell powder, let it stand for soaking for 24 hours, and then filter it with a funnel for 30 minutes. The product was dried in an electric blast drying oven at 110°C for 2 hours;

[0054] S2. 5g peanut shell powder after the deionized water immersion obtained is mixed with 100mL potassium permanganate solution (0.2mol / L) and 100mL ferric chloride solution (0.10mol / L) to obtain a mixture, and the mixture is heated at 700°C Carry out carbonization, the carbonization time is 20h, after carbonization, the pyrolysis product peanut shell biochar is obtained, and the pyrolysis product is cooled to room temperature (25°C) and then dried, the drying time is 18h, and the drying temperature is 120°C;

[0055] S3. Get the above-mentioned peanut shell biochar 6g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com