Patents

Literature

1539 results about "Thermal desorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal desorption is an environmental remediation technology that utilizes heat to increase the volatility of contaminants such that they can be removed (separated) from the solid matrix (typically soil, sludge or filter cake). The volatilized contaminants are then either collected or thermally destroyed. A thermal desorption system therefore has two major components; the desorber itself and the offgas treatment system. Thermal desorption is not incineration.

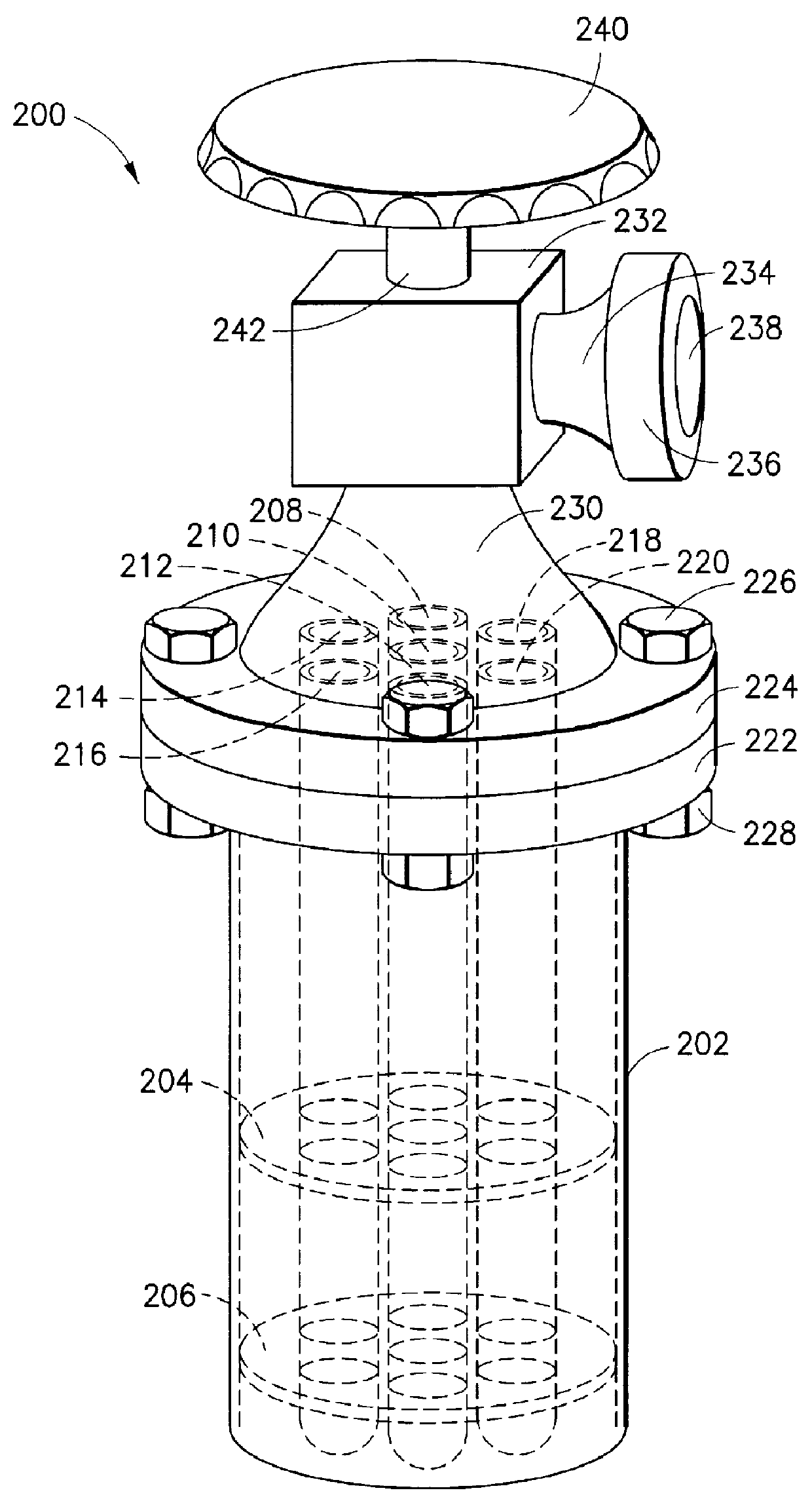

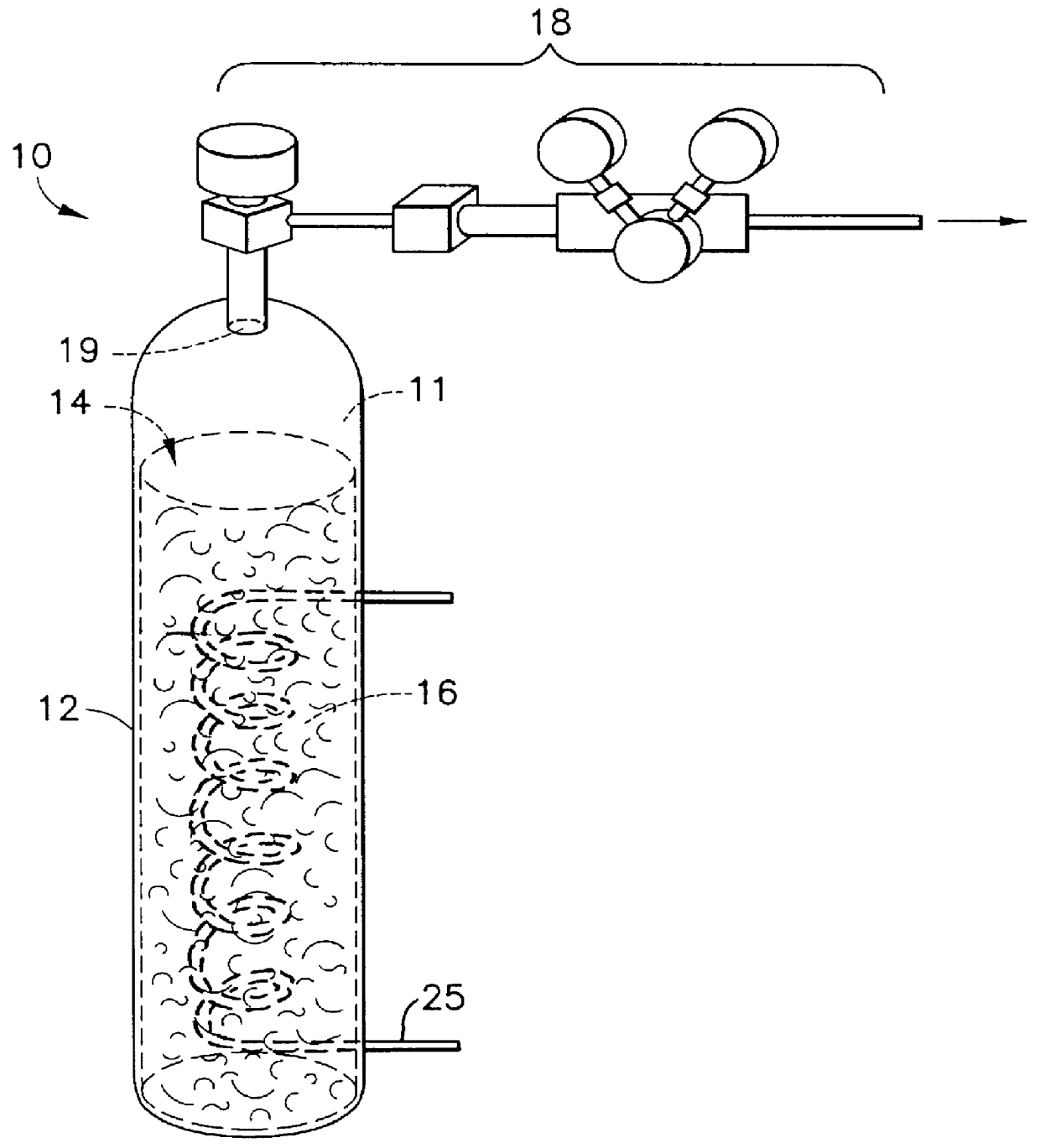

Sorbent-based fluid storage and dispensing vessel with replaceable sorbent cartridge members

InactiveUS6019823AQuick degassingQuickly and easily and separately preparedGas treatmentOther chemical processesSorbentProduct gas

Solid-phase physical sorbent medium holding adsorbed fluid is provided in a cartridge, for use in a sorbent-based fluid storage and dispensing system. One or more of such cartridges may be disposed in a fluid storage and dispensing vessel and opened prior or subsequent to sealing of the vessel, to provide desorbable fluid for dispensing from the vessel, e.g., by pressure differential, concentration differential and / or thermal desorption. Use of such cartridges thereby obviates the sorbent bake-out and sorbate gas loading steps necessary in prior practice, thereby simplifying the manufacture of the fluid storage and dispensing system.

Owner:ENTEGRIS INC

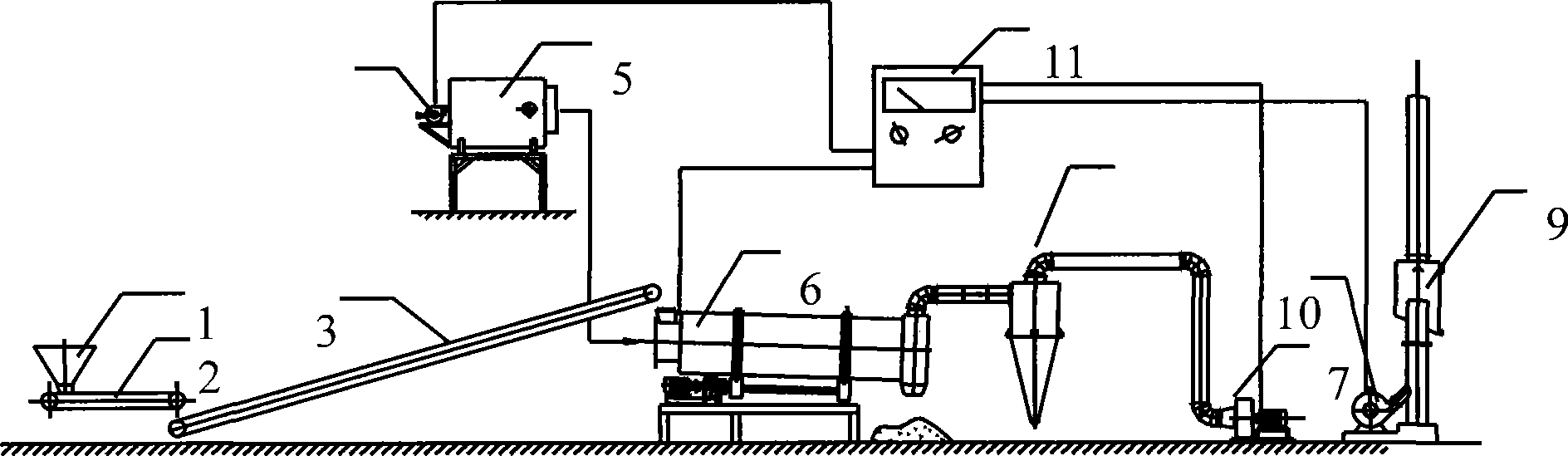

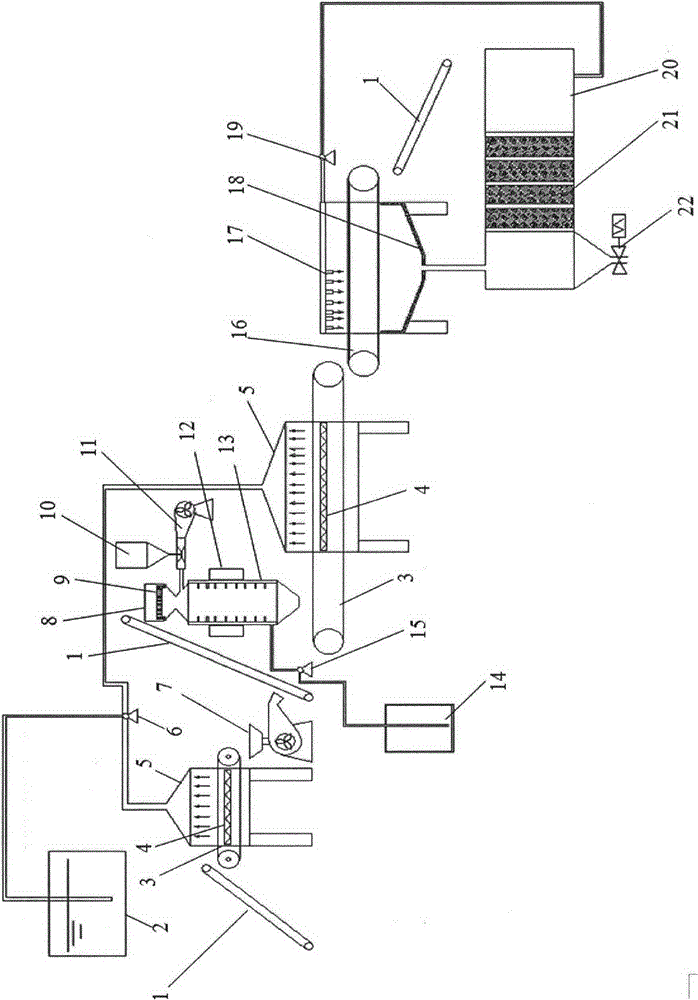

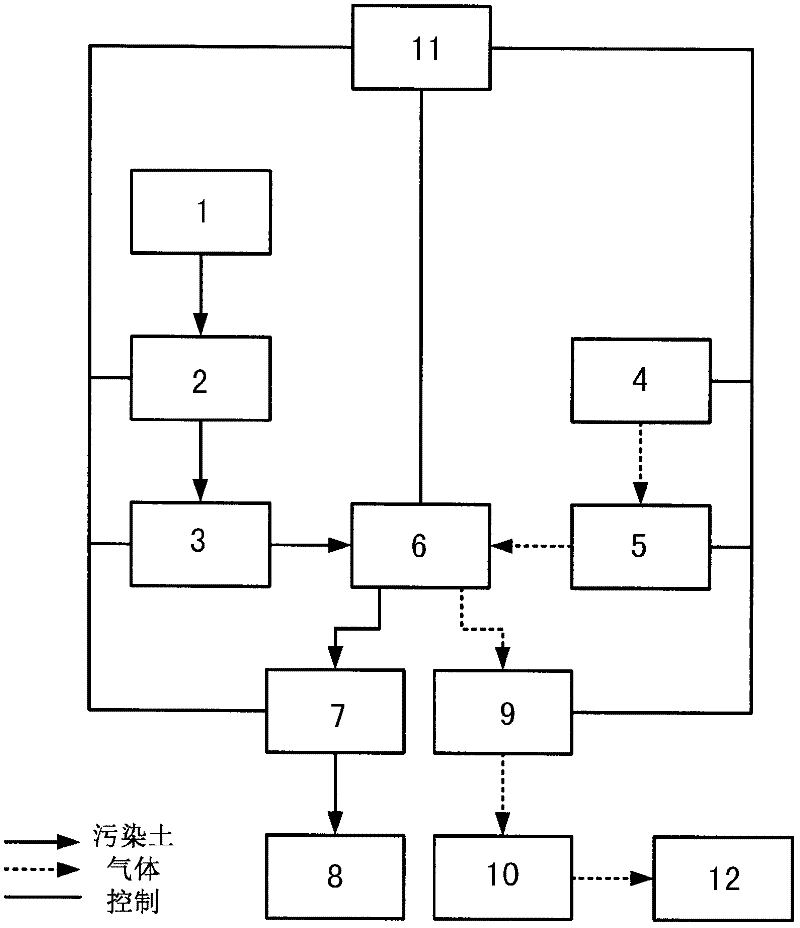

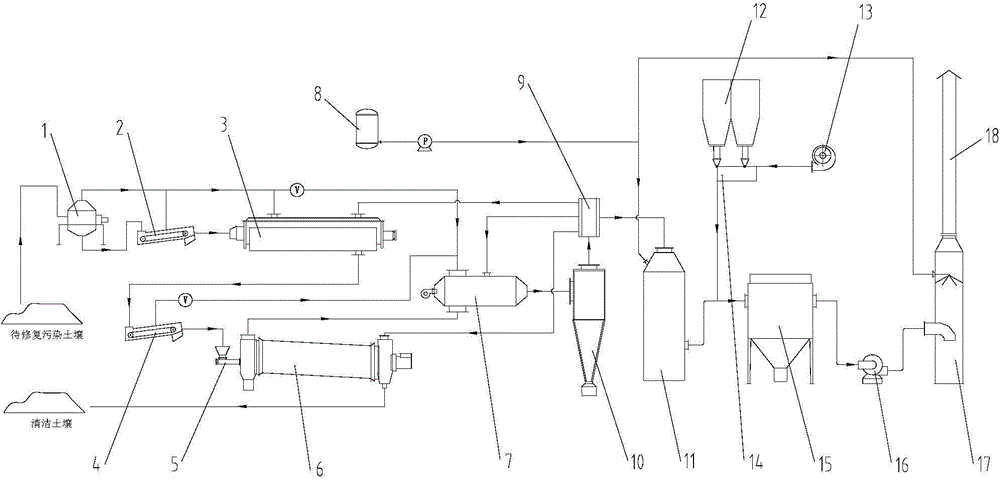

Soil pollution thermal desorption restoration processing system

InactiveCN101530858AAvoid secondary pollutionImprove applicabilityContaminated soil reclamationEngineeringProcessing cost

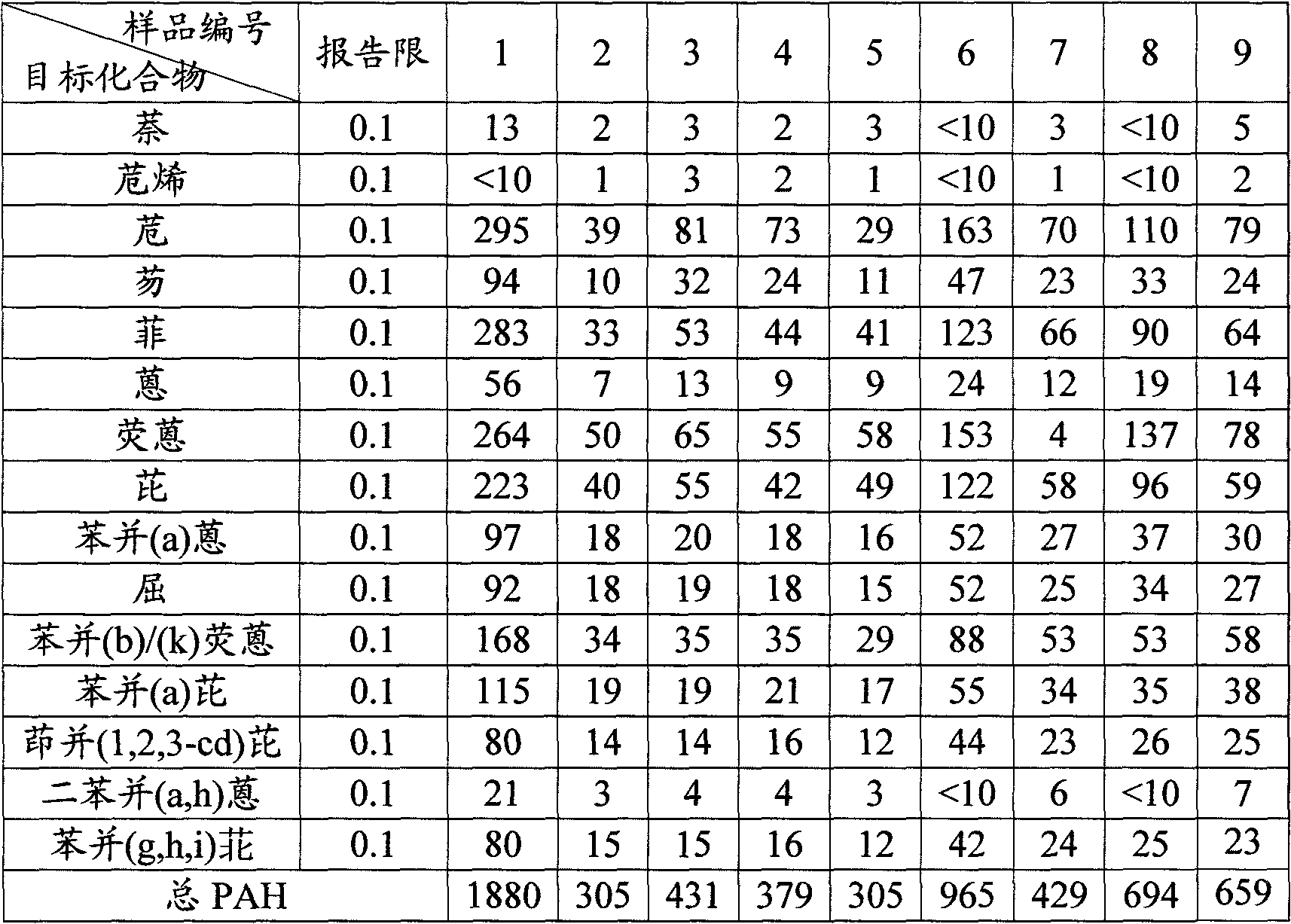

The invention relates to a soil pollution thermal desorption restoration processing system, which belongs to a soil restoration processing system. The system comprises a feed system, a heat source system and a control system, and is characterized by further comprising a thermal desorption system and a tail gas processing device, wherein the thermal desorption system consists of a draught fan and a thermal extraction converter, and the tail gas processing device consists of a dust remover and an absorption tower. When the system is applied to processing polluted soil with main pollutants of volatile / semi-volatile organic compounds, compared with the like products in other countries, the equipment cost is only 1 / 3 to 1 / 5 of the same; the problem of secondary pollution probably brought about in the process of processing the polluted soil is thoroughly avoided; a temperature control system has better practicability; the running cost for each ton of the polluted soil is between 300 and 500 RMB, which is far low than the processing cost for hazardous landfilling and incineration of the polluted soil; and half of the purification effect of processing the polluted soil with the main pollutants of the volatile / semi-volatile organic compounds can reach between 70 and 80 percent.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

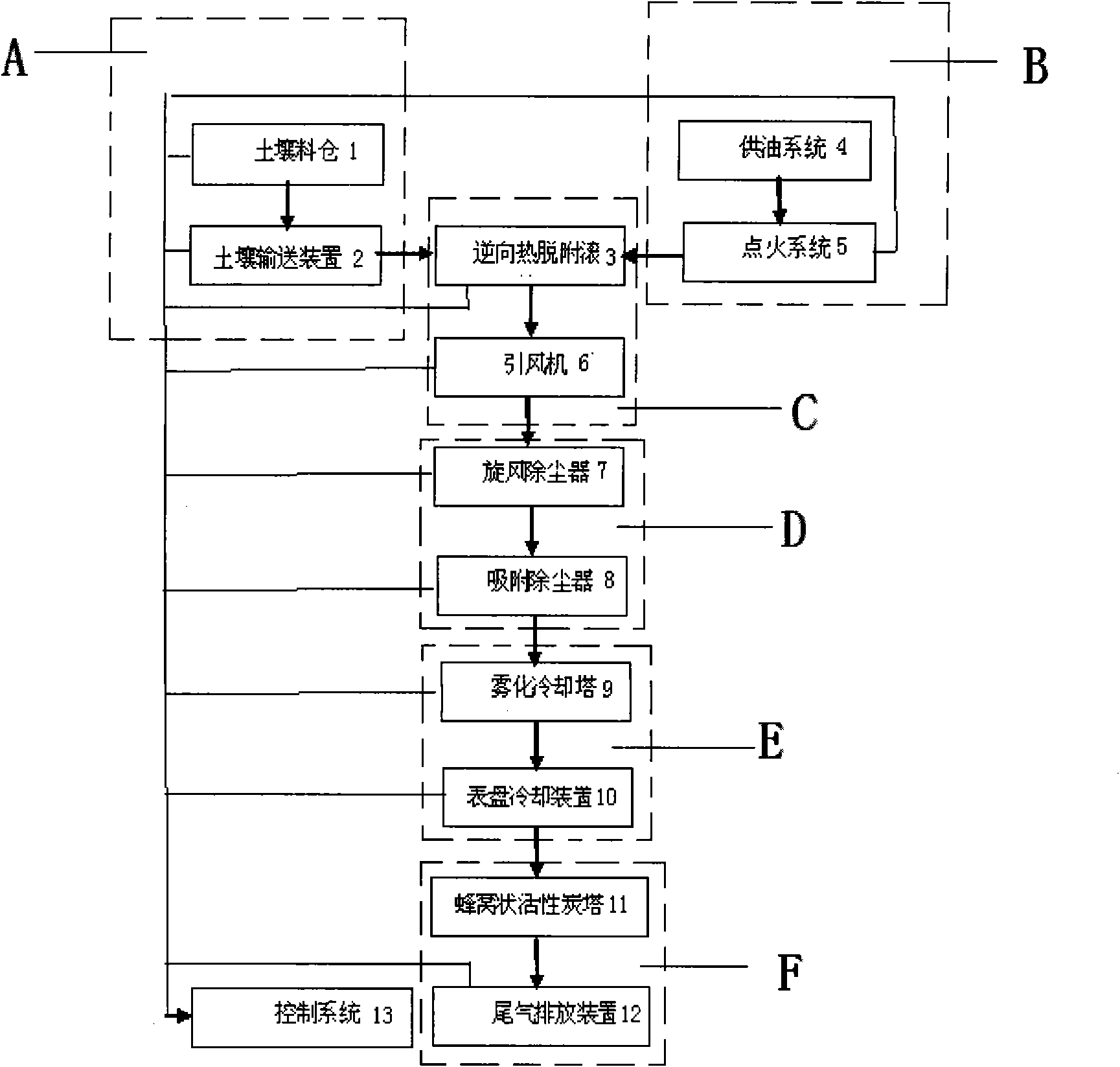

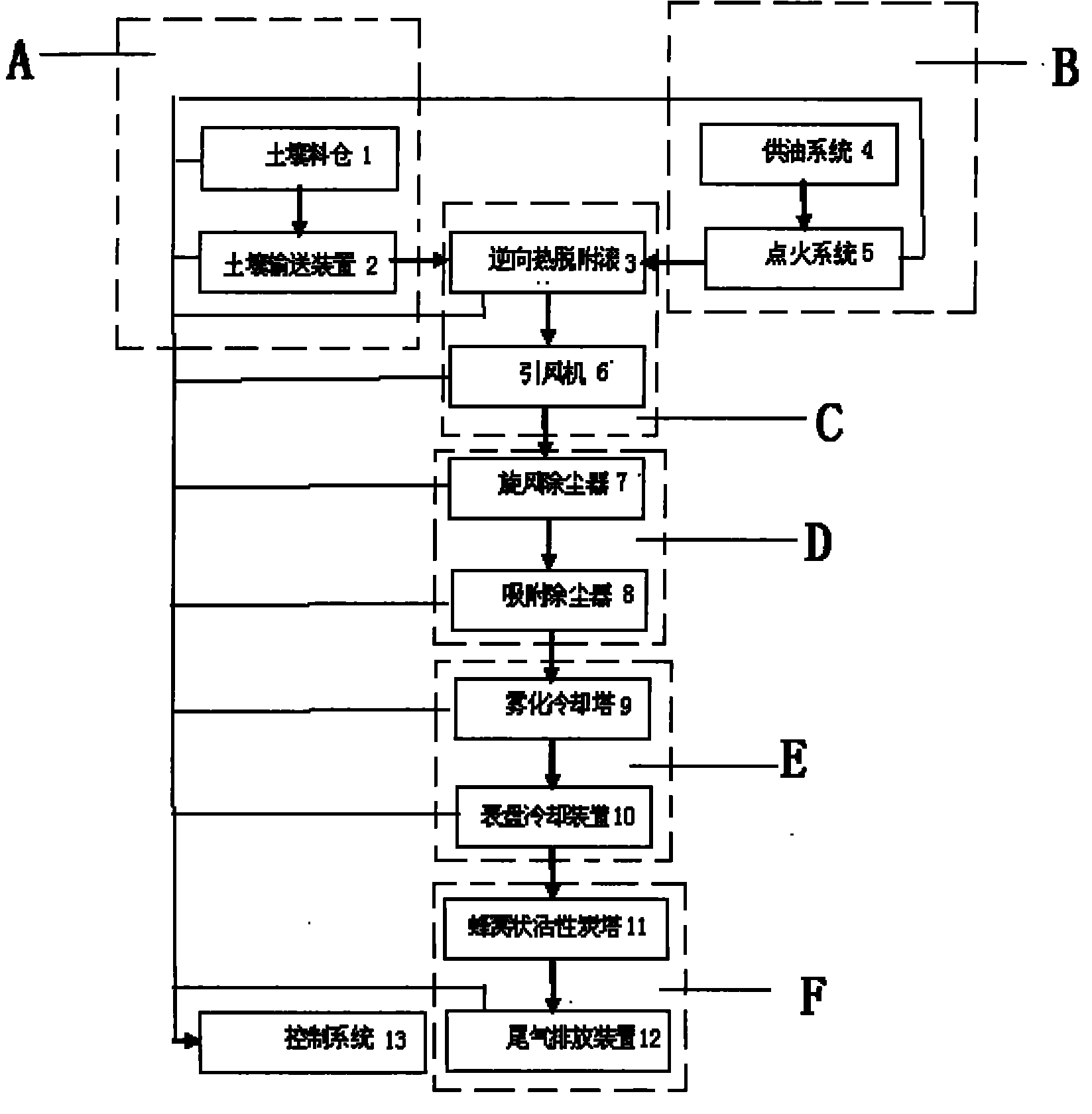

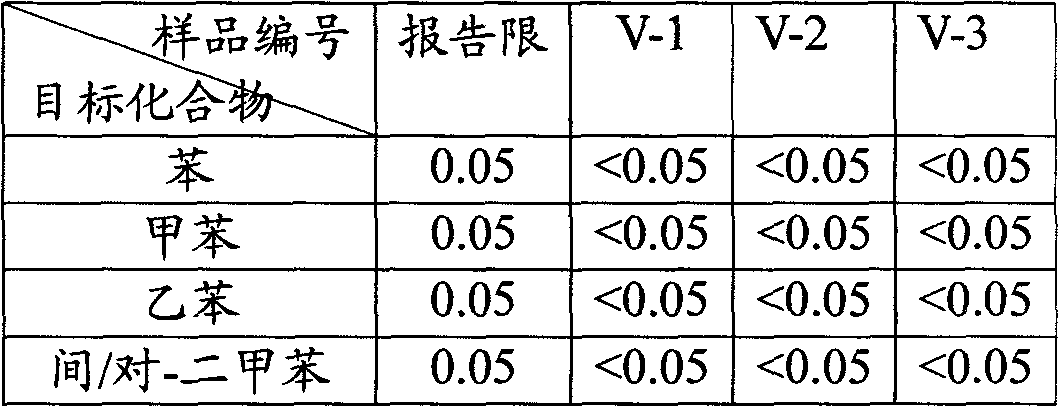

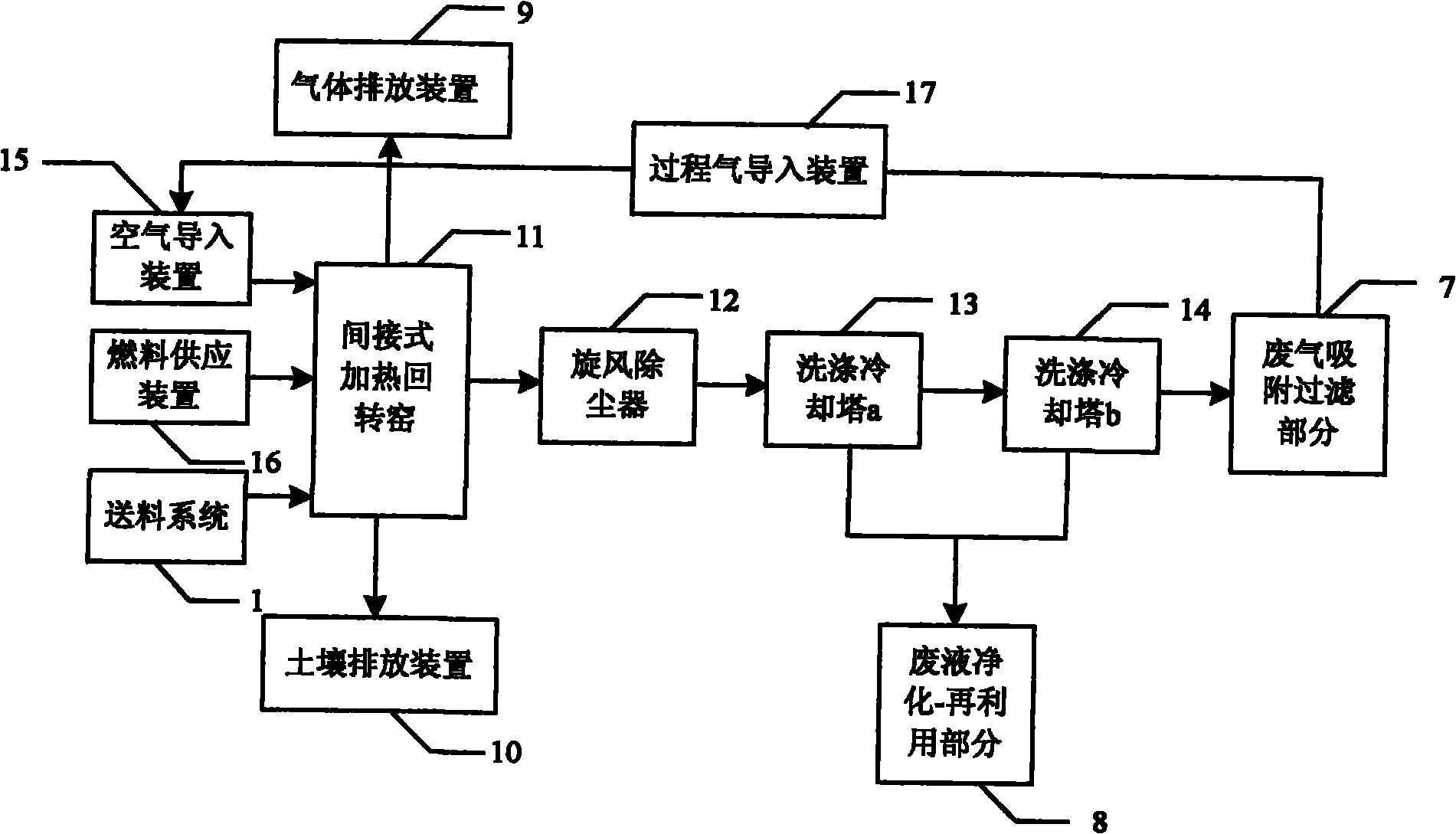

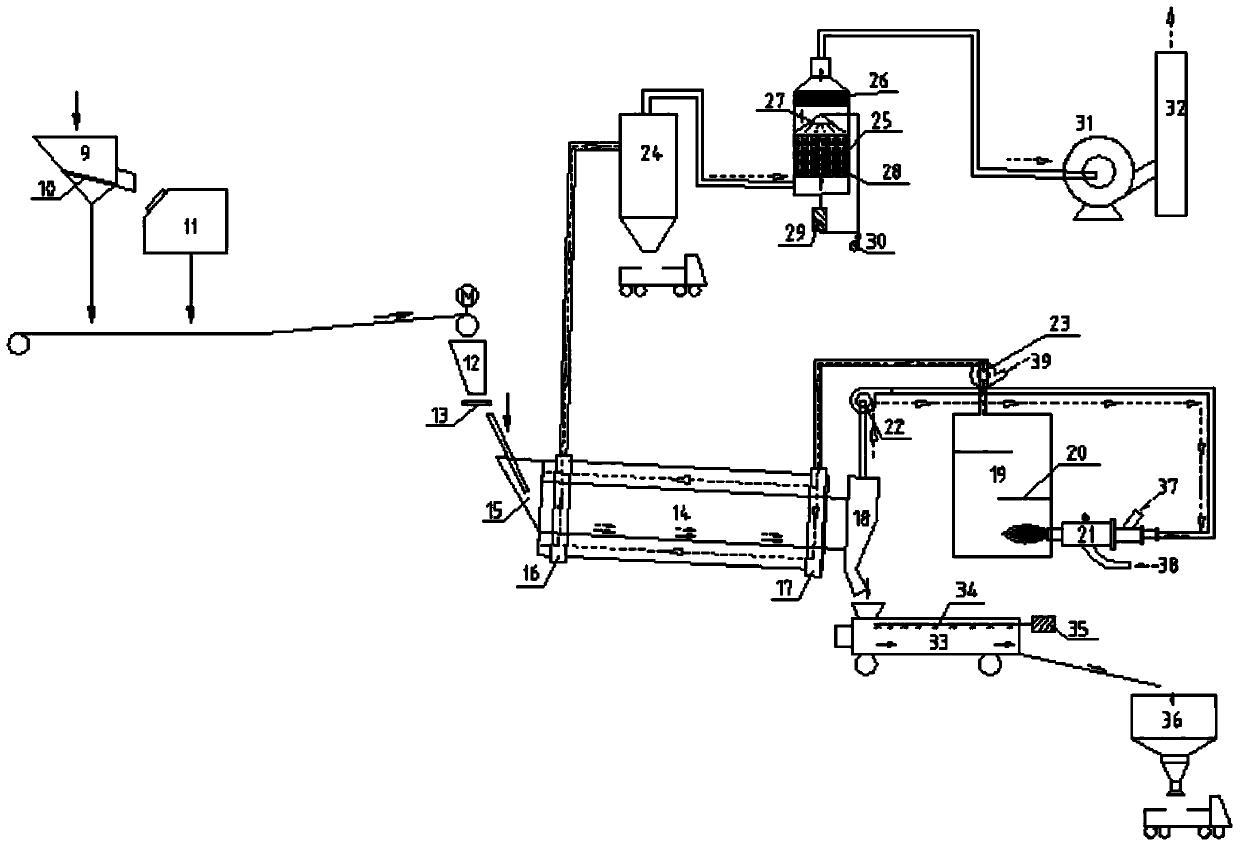

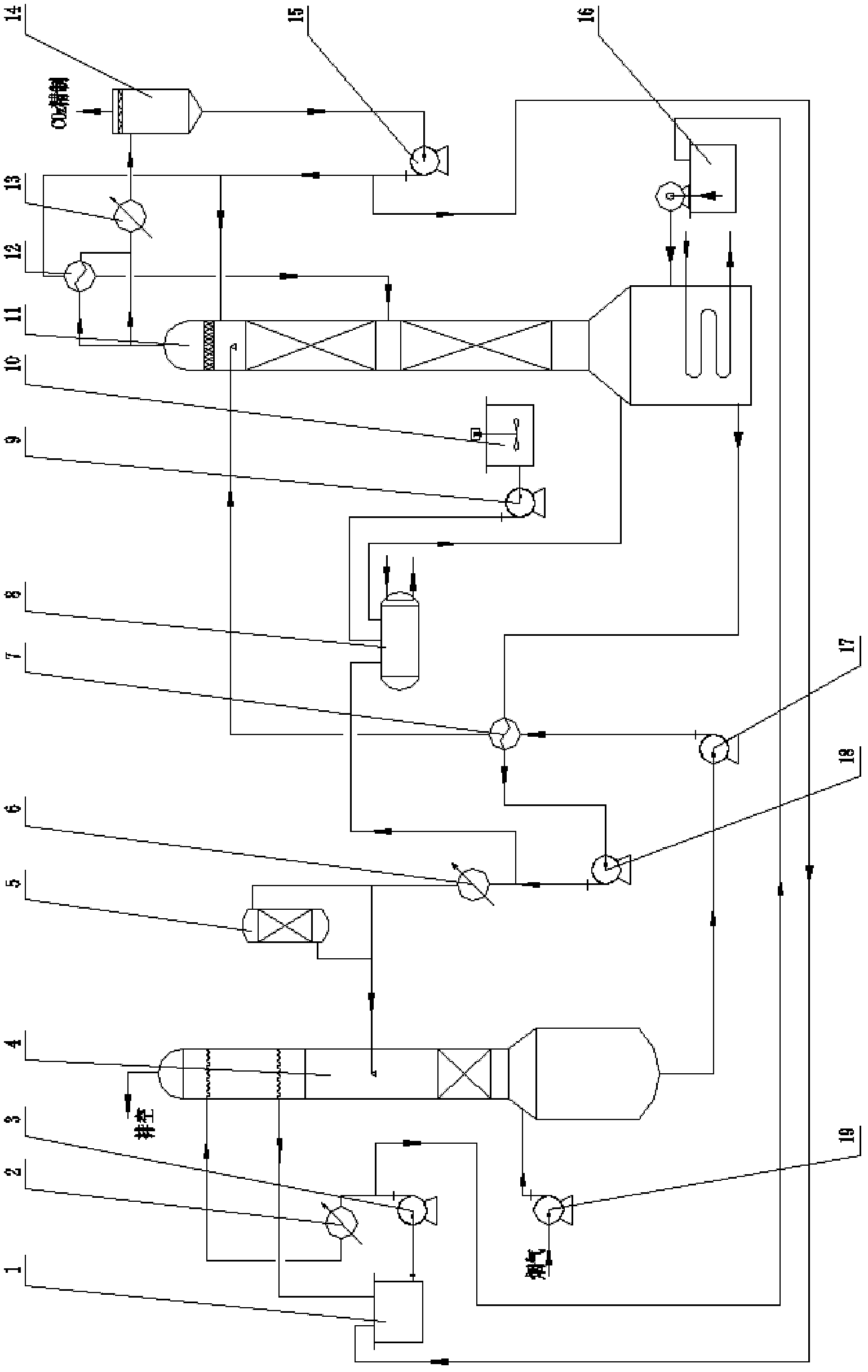

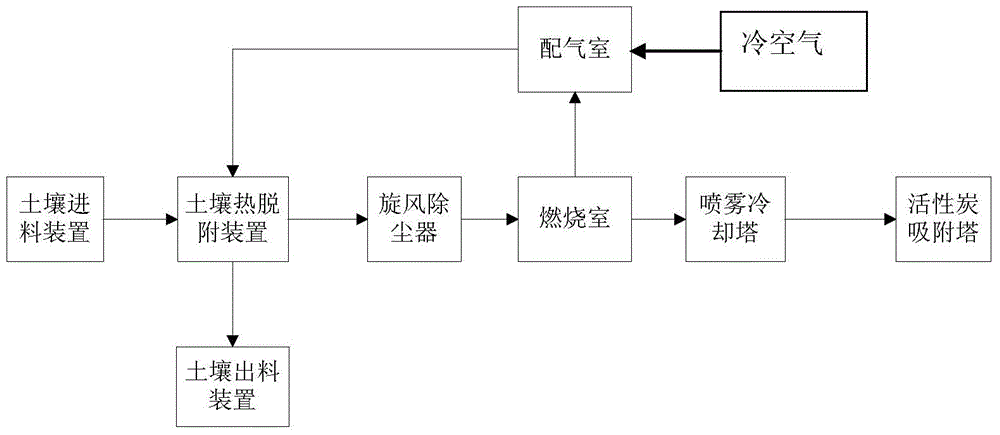

Roller-type reverse thermal desorption system for soil polluted by organic matters

ActiveCN102029287ALarge amount of processingImprove thermal desorption efficiencyContaminated soil reclamationCooling towerEngineering

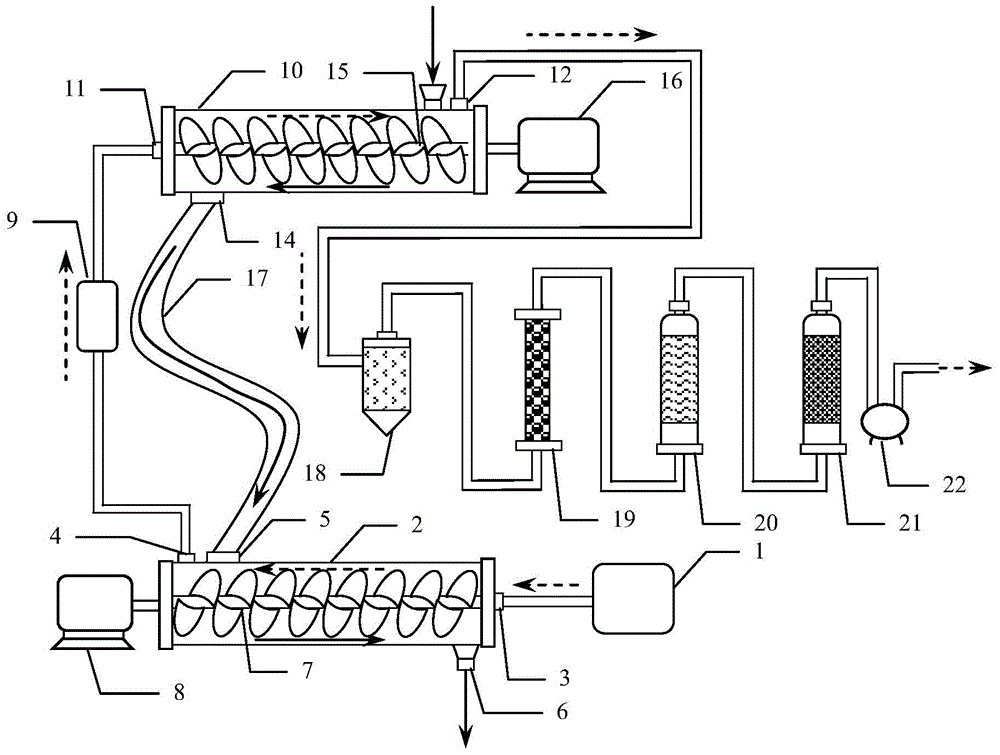

The invention relates to a roller-type reverse thermal desorption system for soil polluted by organic matters. The roller-type reverse thermal desorption system comprises a soil feeding system, wherein the soil feeding system and a heat source system are connected with a reverse thermal desorption system; the reverse thermal desorption system is connected with a dust removing system, a cooling system and an active carbon adsorption system in turn; and control ends of the soil feeding system, the heat source system, the reverse thermal desorption system, the dust removing system, the cooling system and the active carbon adsorption system are connected with a control system. In the roller-type reverse thermal desorption system, hot air is fed into a reverse thermal desorption roller by an ignition system, and polluted soil is fed into the reverse thermal desorption roller by a soil transferring device, wherein the hot air contacts the soil reversely, so that organic pollutants contained in the soil are heated and volatilized; the purified soil is used as backfill soil; and the volatilized tail gas is dedusted by a cyclone dust extractor and an adsorption dust extractor after passing through an induced draft fan, and the dedusted volatilized tail gas is absorbed by a honeycomb-shaped active carbon tower after passing through an atomization cooling tower and a dial plate cooling device, and finally is discharged by a tail gas exhaust device on the basis of meeting the national standard. Materials can be fed into the roller-type reverse thermal desorption system continuously and can be heated directly; and the hot air and the polluted soil are fully mixed, and the roller-type reverse thermal desorption system has high thermal desorption efficiency.

Owner:TSINGHUA UNIV +1

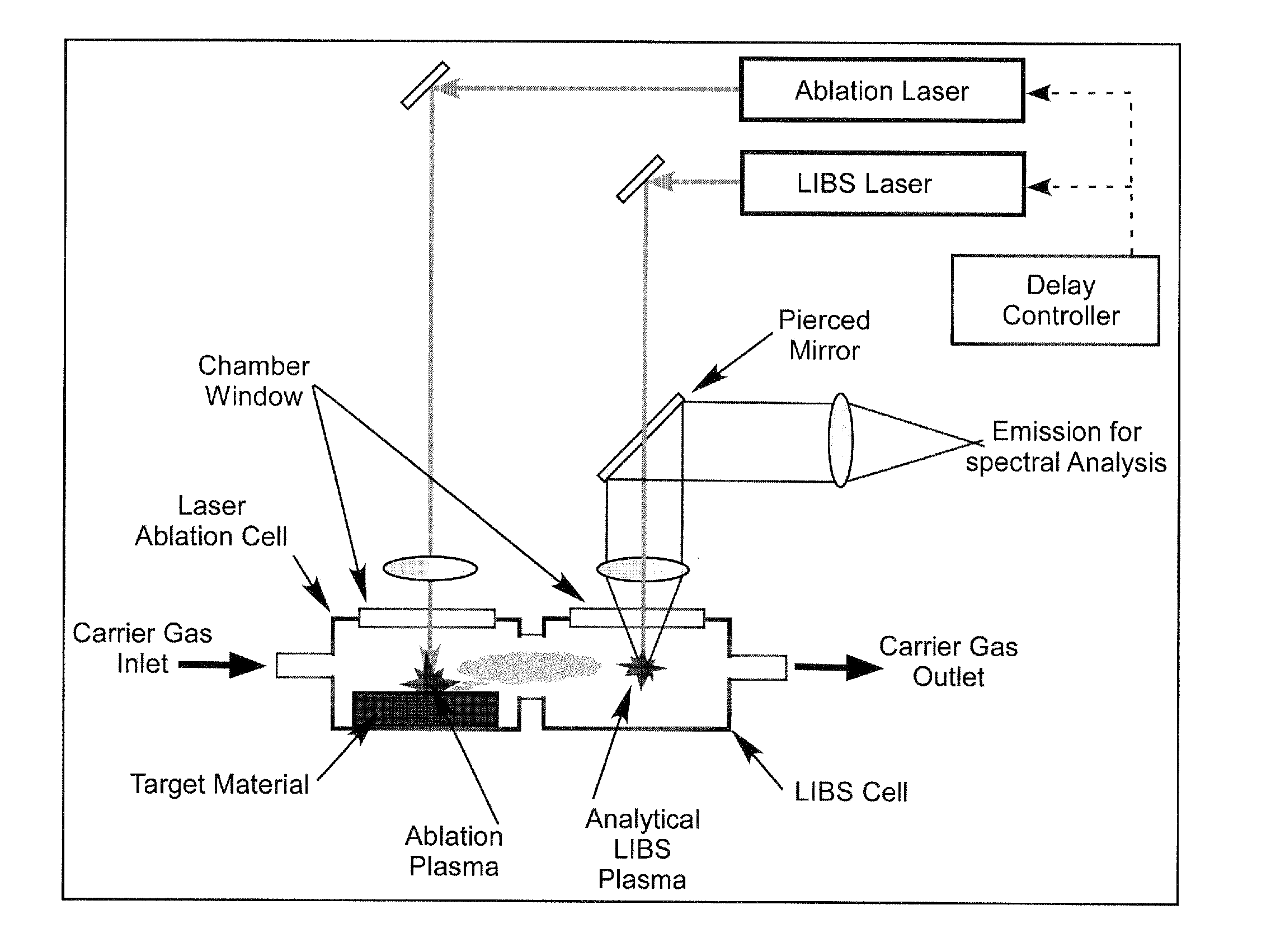

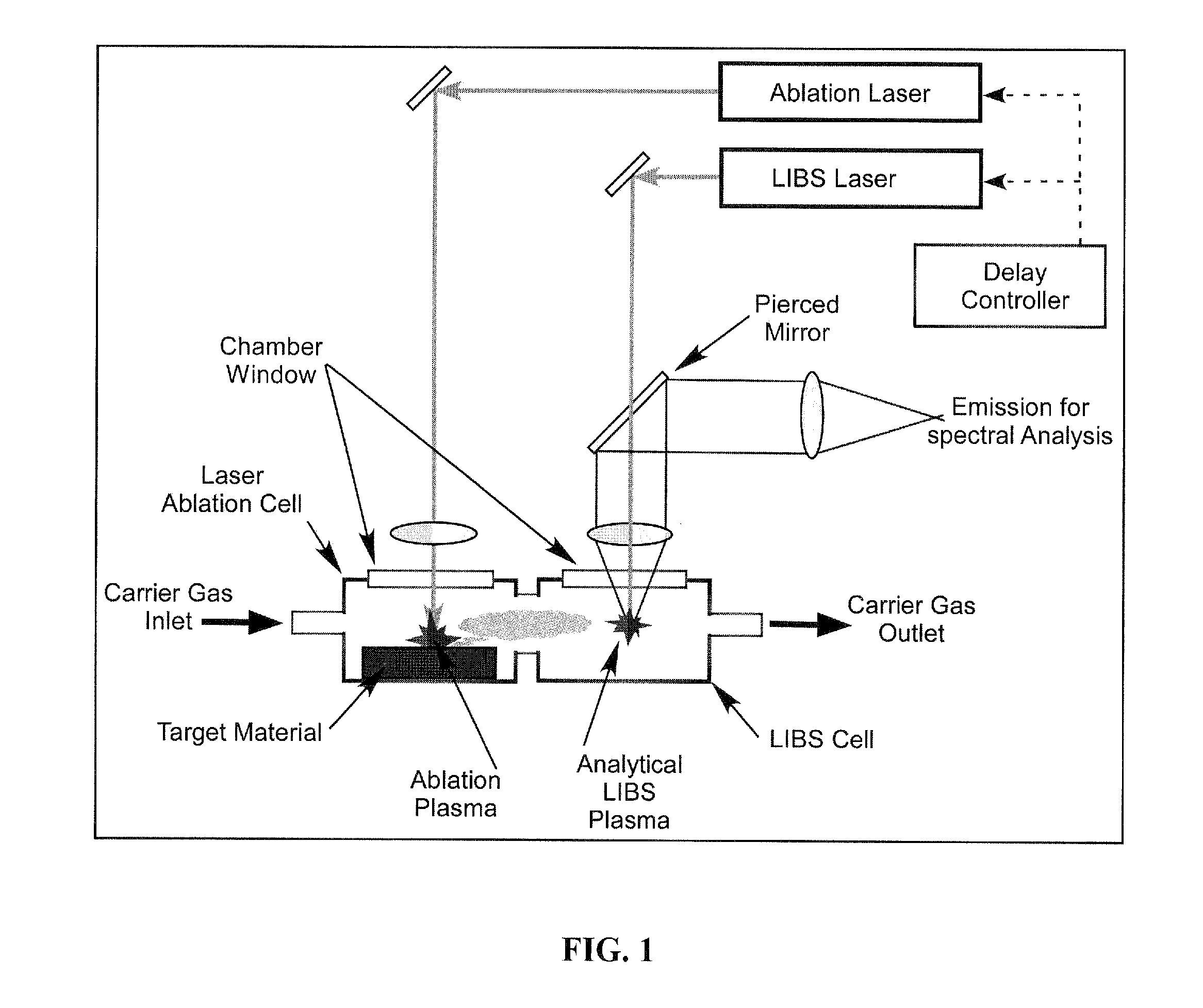

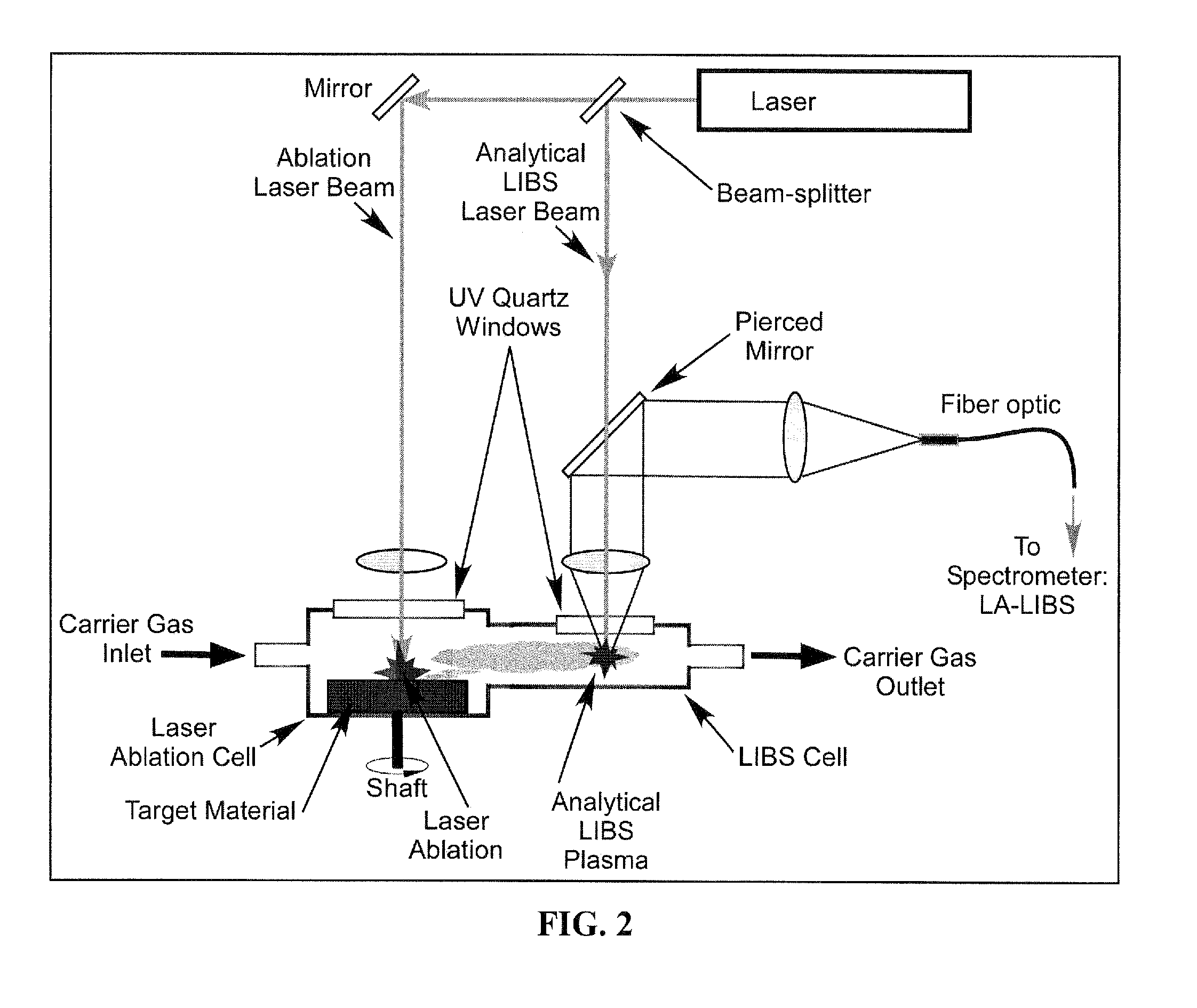

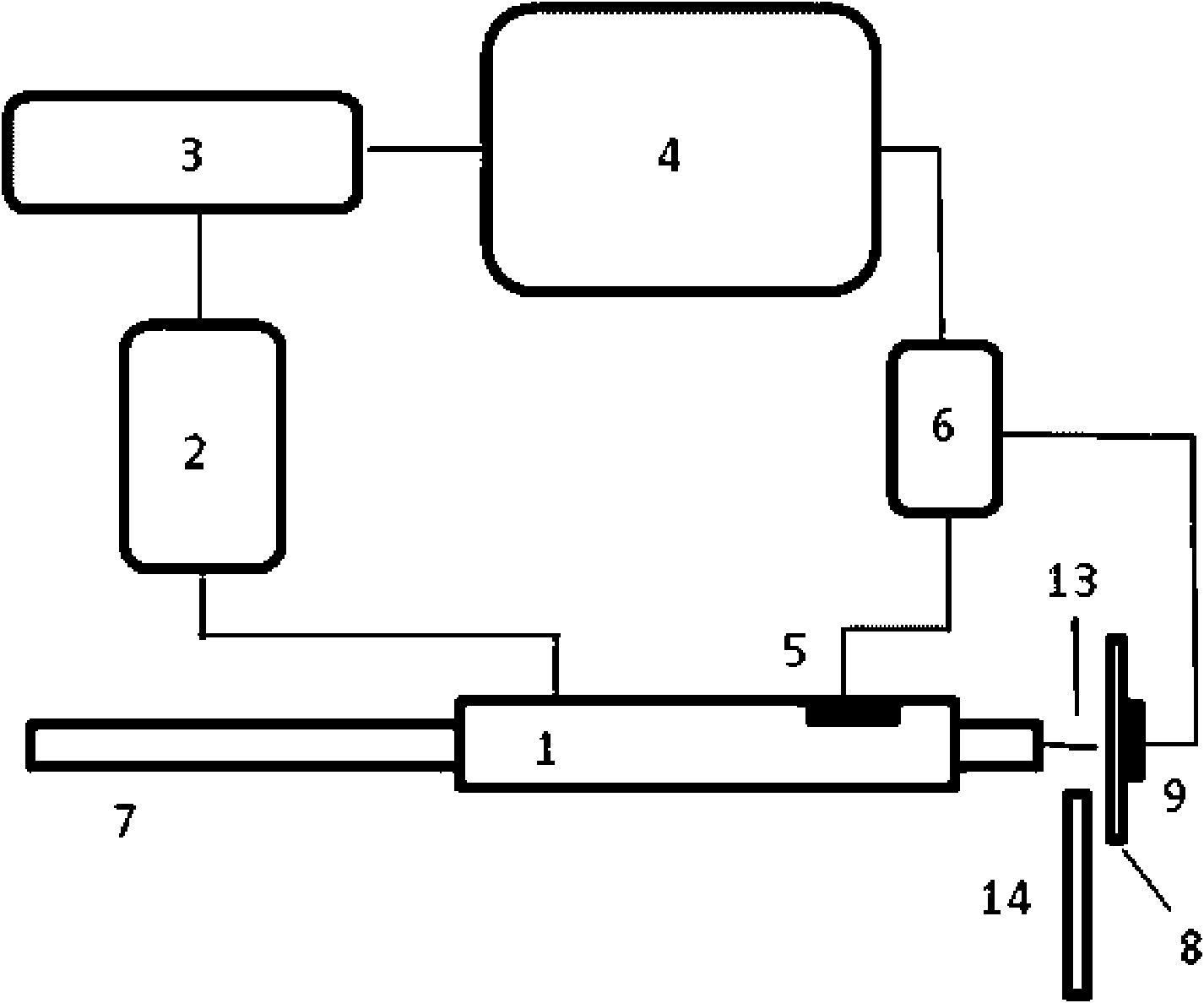

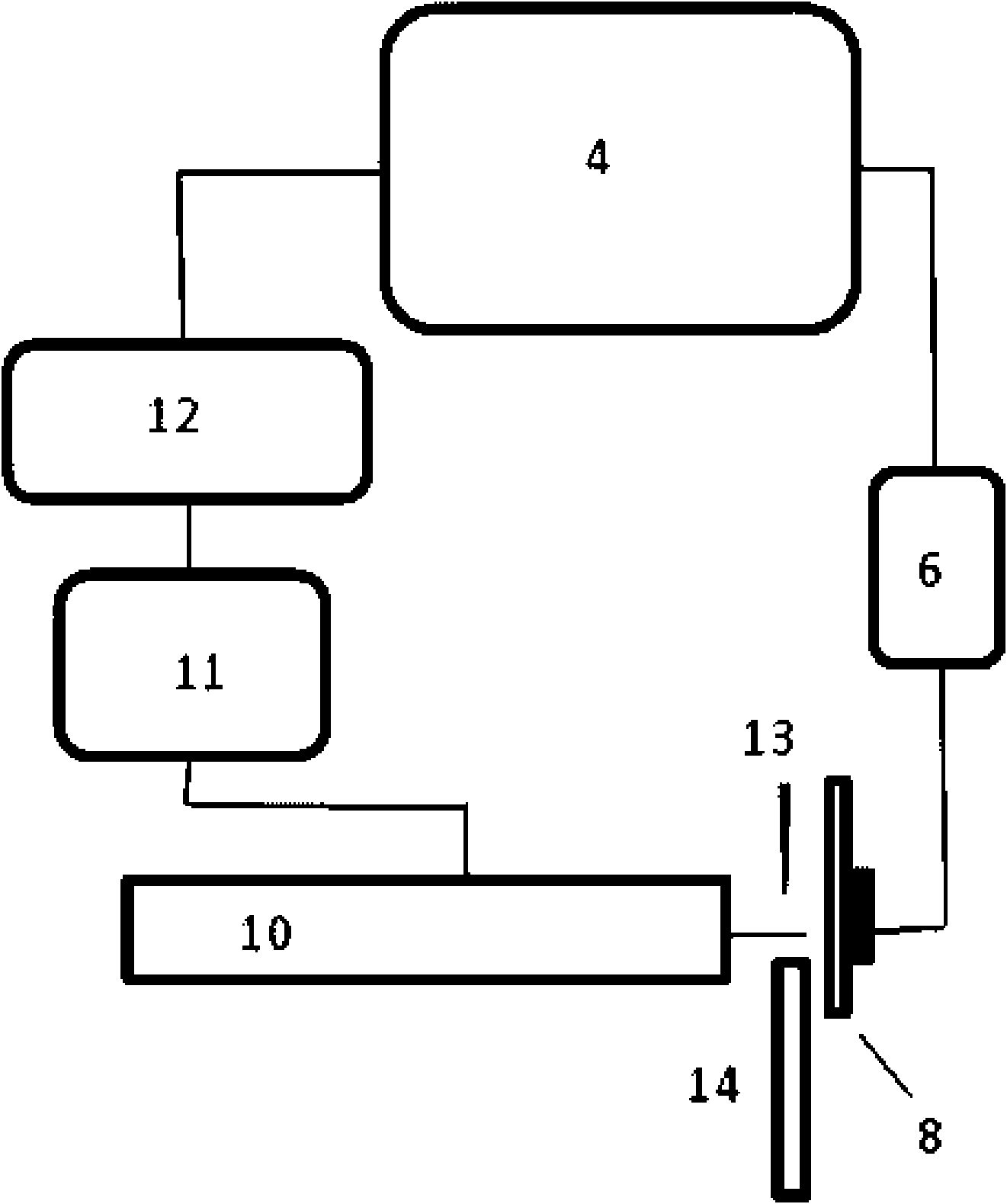

Method and apparatus to laser ablation-laser induced breakdown spectroscopy

ActiveUS20120099103A1Easy to set upRadiation pyrometrySpectrum investigationLaser-induced breakdown spectroscopyLaser beams

Embodiments of the invention relate to a method and apparatus for analyzing a target material. Specific embodiments can be referred to as laser ablation laser-induced breakdown spectroscopy (LA-LIBS). Embodiments of the invention relate to the use of a first laser beam pulse incident on a target material to create an ablation event so as to produce an ablation plume of target material. Such ablation events can include, for example, plasma ablation, sub-plasma ablation, and thermal desorption. At least a portion of the ablation plume of target material can then be transported a sufficient distance away from the ablation event that a second laser beam pulse can interact with the at least a portion of the ablation plume of target material to create an analytical plasma such that the analytical plasma is uncoupled from the ablation event. The creation of the analytical plasma results in one or more elements of the at least a portion of the ablation plume of target material undergoing atomic emission, which can, optionally, be collected and analyzed.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

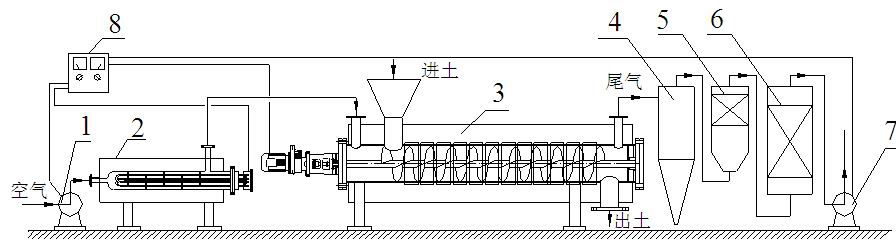

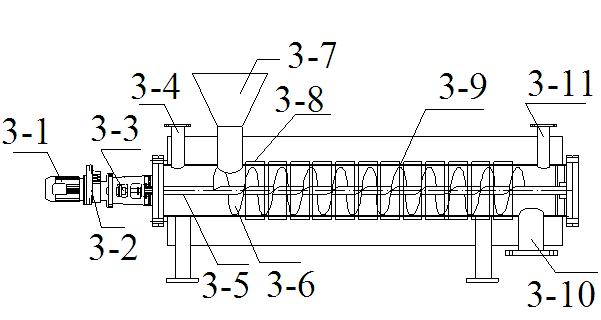

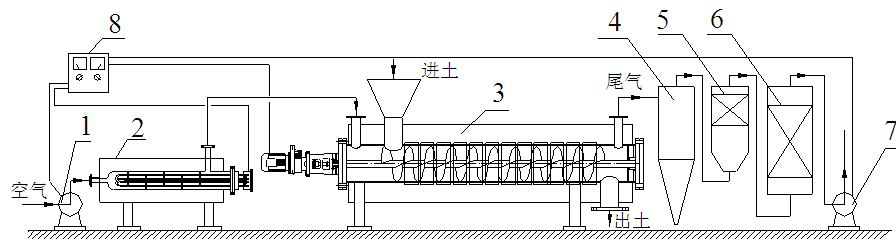

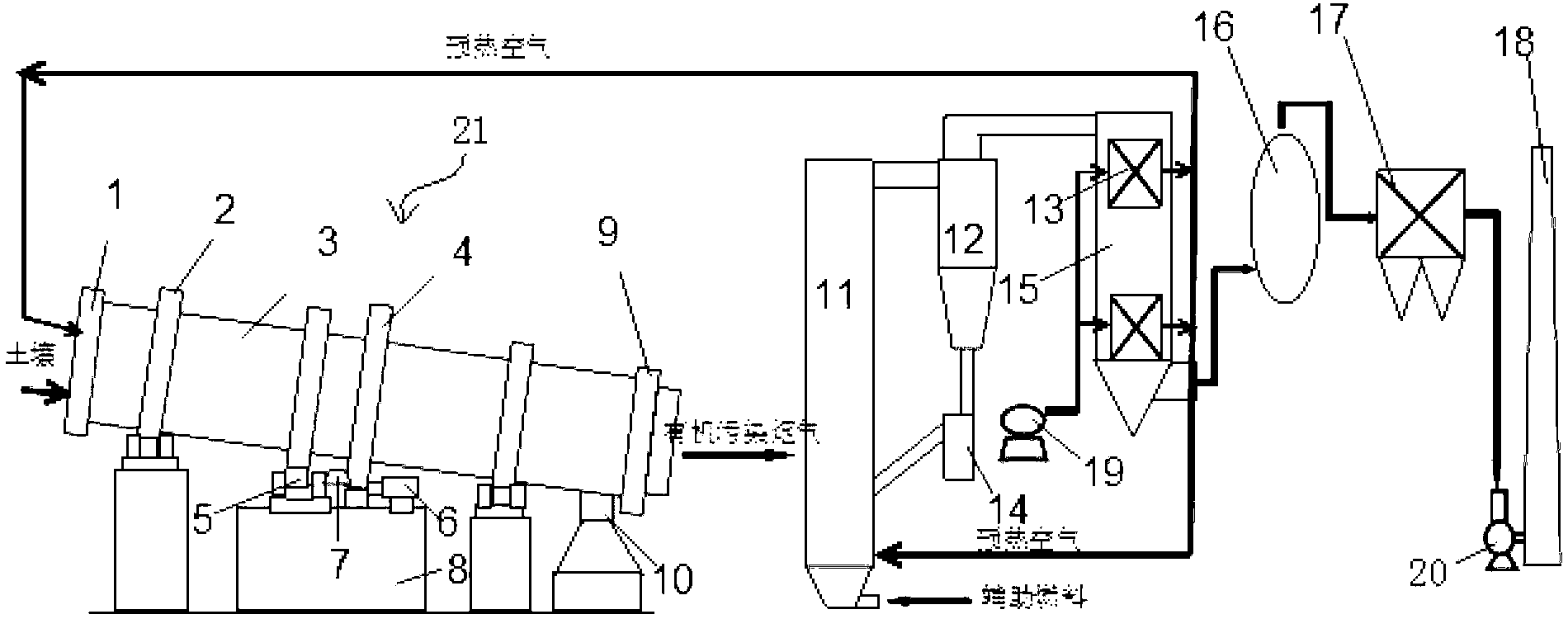

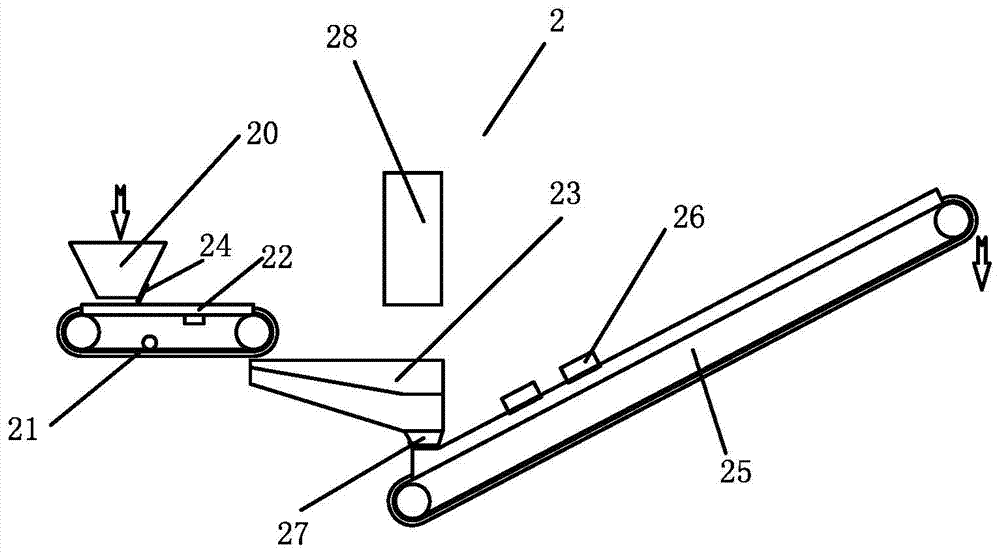

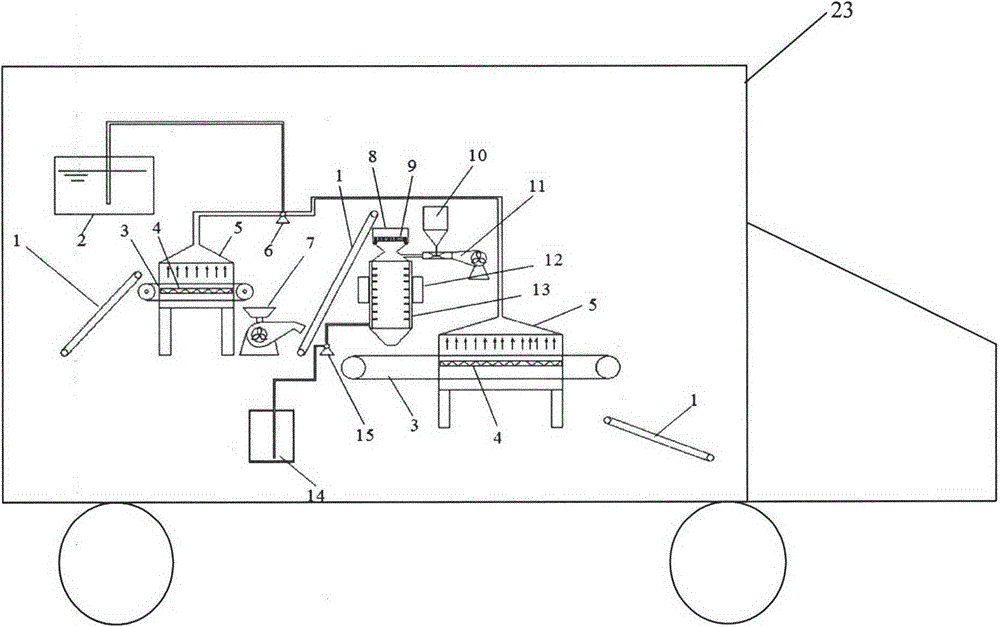

System for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption

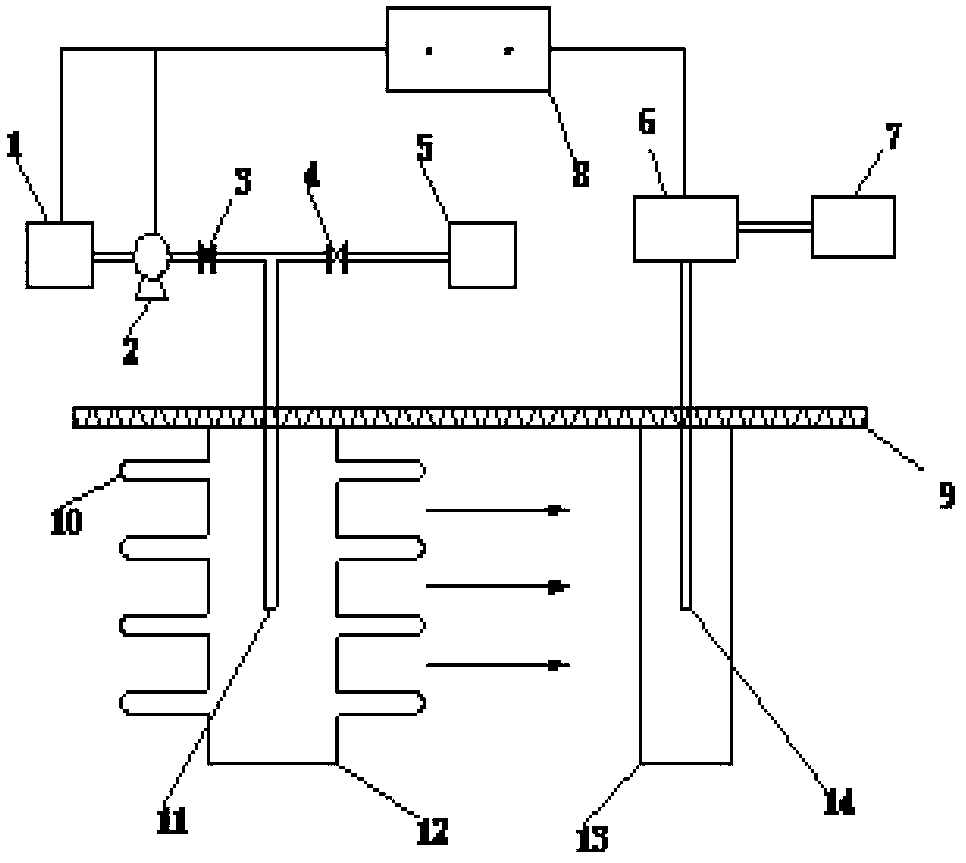

ActiveCN101972773AEfficient repairRemediation of organic pollution is effectiveContaminated soil reclamationAgricultural engineeringCyclonic spray scrubber

The invention provides a system for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption, which comprises an air preheating system, a spiral stirring thermal desorption system, a tail gas treatment system and a control system, wherein the air preheating system consists of a blower and an air heater, the spiral stirring thermal desorption system consists of a spiral stirring thermal desorption device and a draft fan, the tail gas treatment system consists of a cyclone dust collector, a dehumidifier and an absorption tower, and the control system can realize the effective control of the rotation speed of a spiral stirrer, the air preheating temperature and the soil heating temperature. The system can be used for restoring soil contaminated by volatile / semi-volatile organic matters.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

Energy-saving type thermal-desorption repairing treatment system for organic polluted soil

ActiveCN103658165AExtended stayBurn fullyContaminated soil reclamationPollution soilSewage treatment

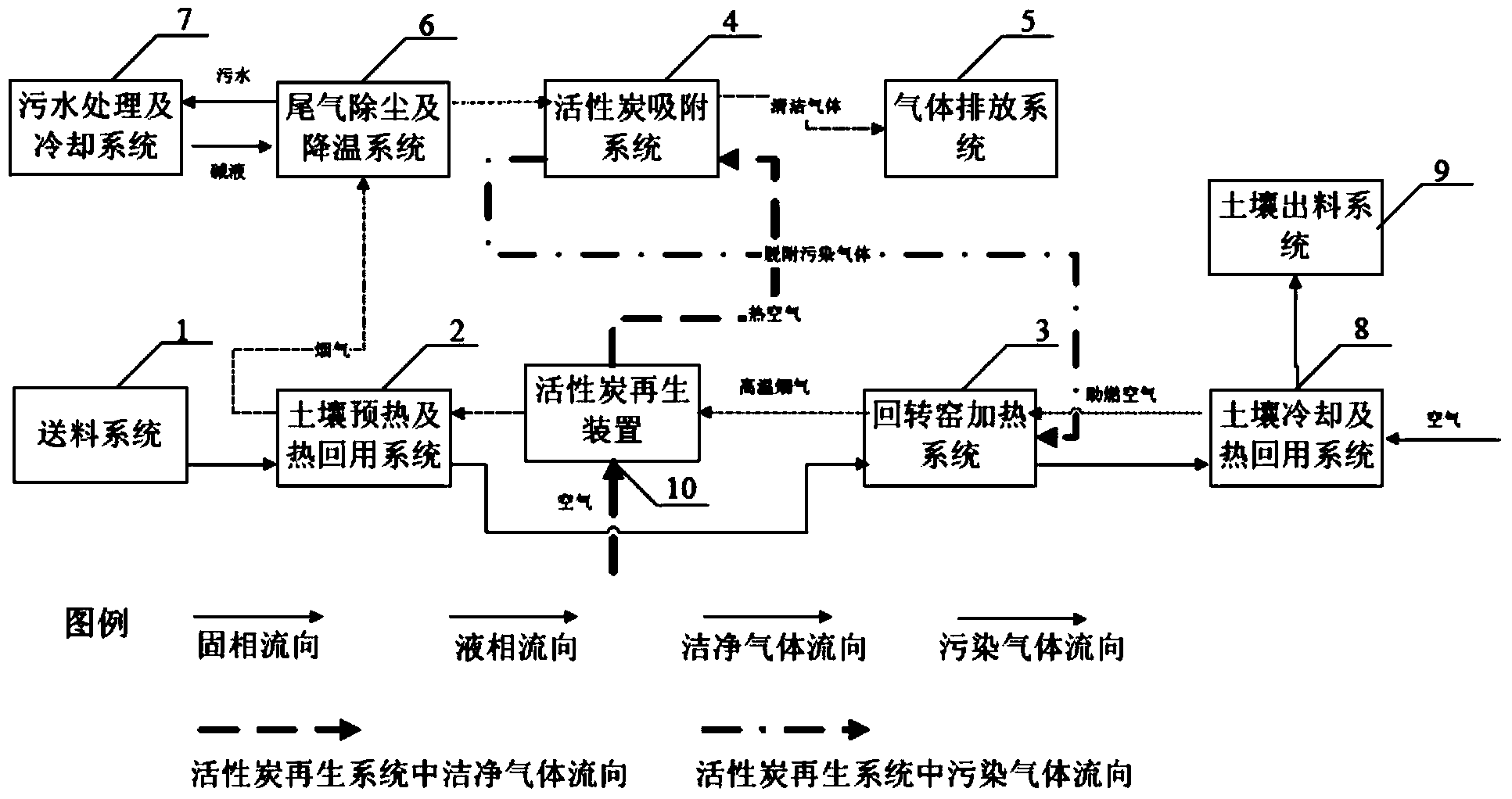

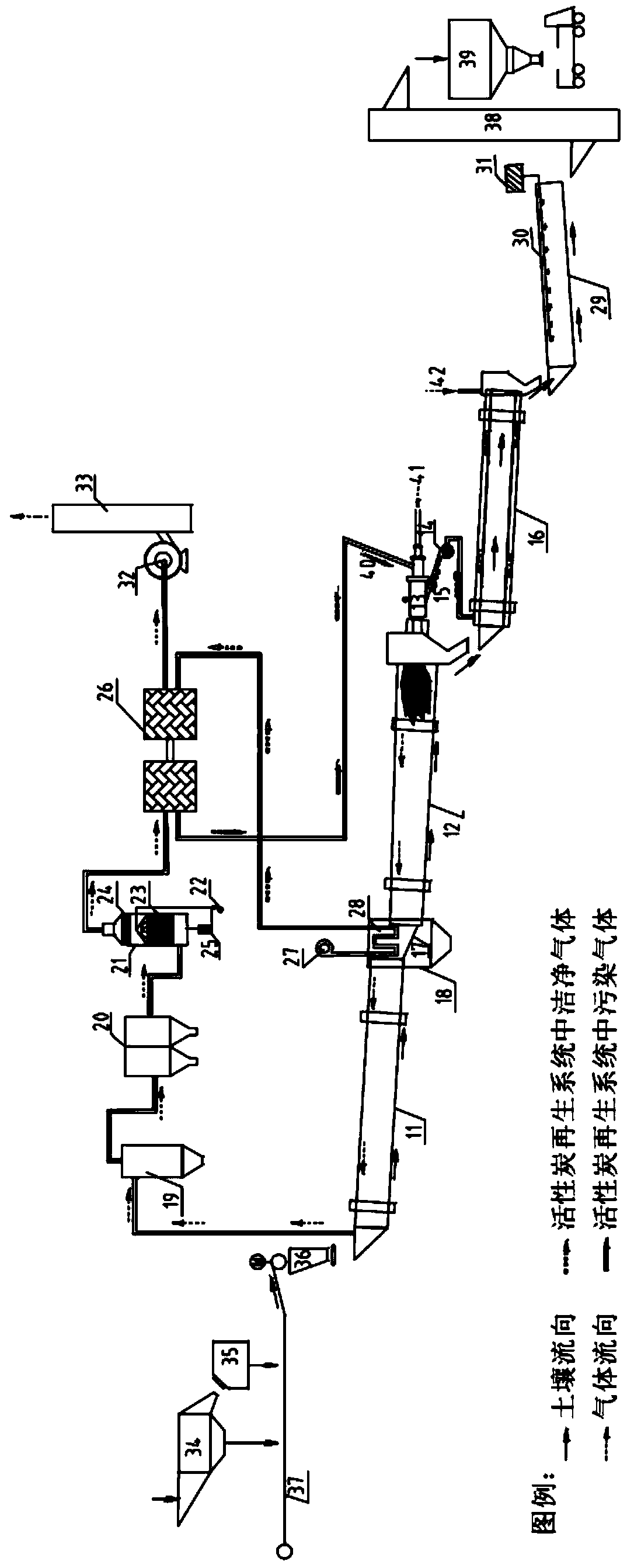

The invention relates to an energy-saving type thermal-desorption repairing treatment system for organic polluted soil and aims at providing a system for thermal-desorption repairing treatment of the organic polluted soil, which can recycle waste heat of the system fully and save resources. The energy-saving type thermal-desorption repairing treatment system comprises a feeding system, a soil preheating and heat recycling system, a rotary kiln heating system, a soil cooling and heat recycling system, a soil discharging system, a tail-gas dust removing and temperature reducing system, a sewage treatment and cooling system, an active-carbon absorbing system, an active-carbon regeneration device, a gas exhausting system and a network monitoring system.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

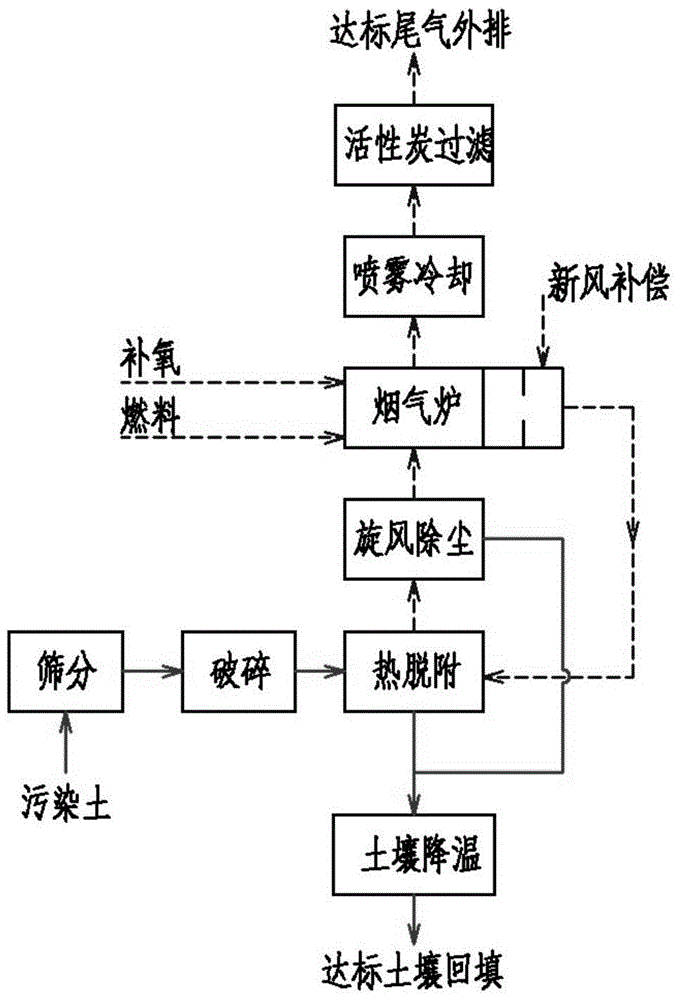

Thermal desorption method for contaminated soil

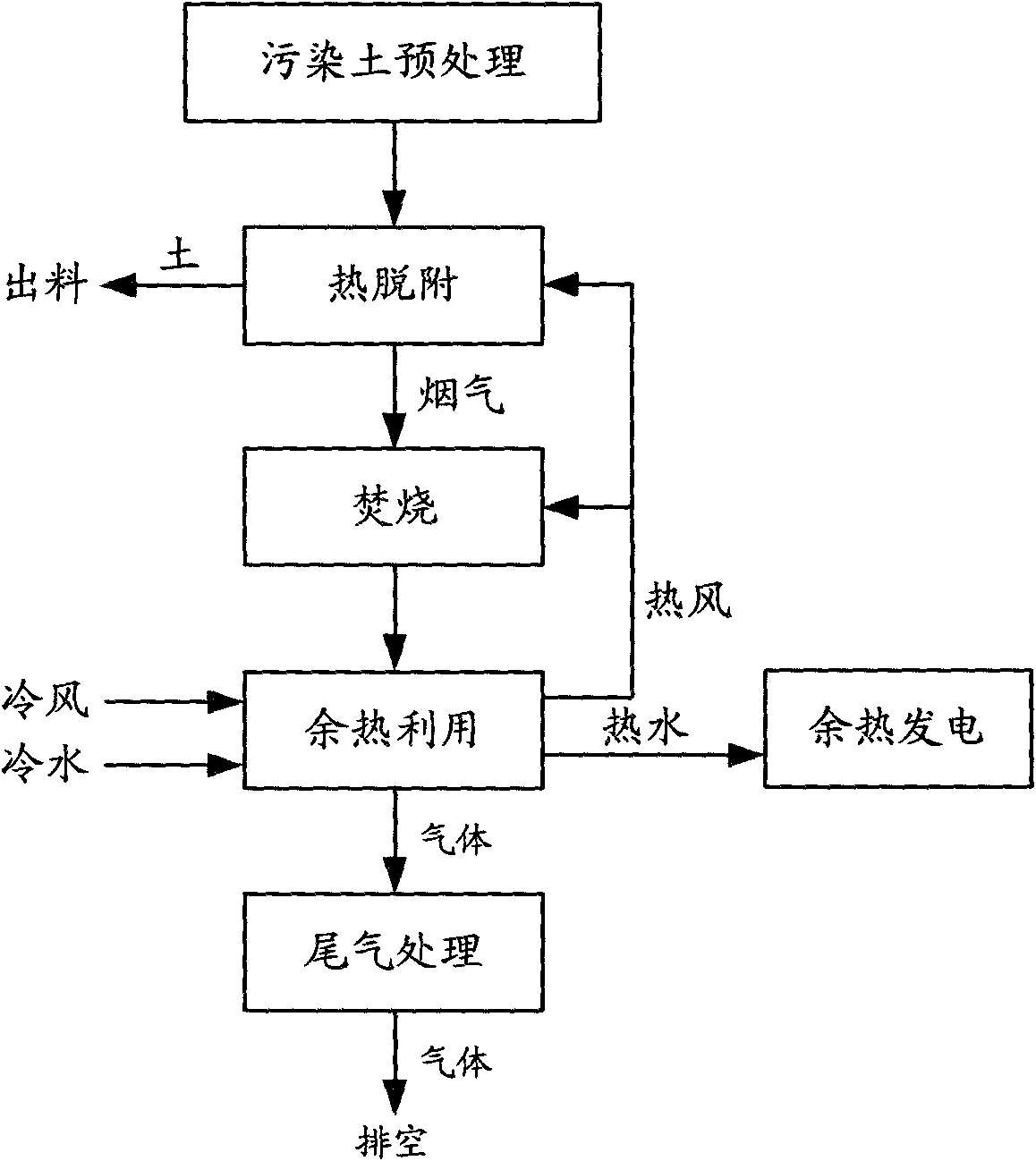

ActiveCN102218446AAvoid secondary pollutionKeep the inherent characteristicsContaminated soil reclamationIncinerator apparatusThermal desorption spectroscopyFlue gas

The invention discloses a thermal desorption method for contaminated soil, which comprises the following steps of: performing thermal desorption on the contaminated soil at the temperature of between 400 and 650 DEG C; incinerating gaseous contaminant-containing flue gas which is discharged by the thermal desorption step at the temperature of between 750 and 1,200DEG C; and performing afterheat utilization and tail gas treatment on the incinerated flue gas. When the thermal desorption method is used for treating the contaminated soil, the destruction and removal efficiency for the organic contaminants in the contaminated soil is over 99 percent, the tail gas meets the emission standard, and the possible secondary pollution in the process of treating the contaminated soil is stopped, so that the effective innocent treatment is realized and the original reutilization property of the soil is maintained.

Owner:BEIJING ECO ISLAND SCI & TECH +1

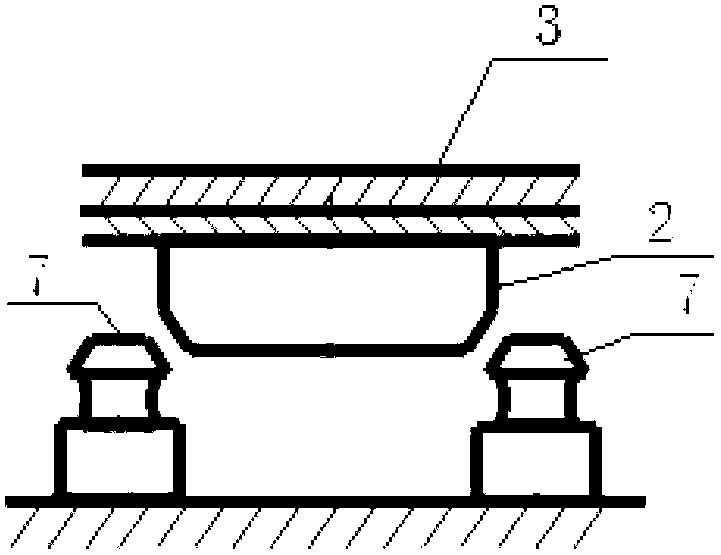

A device for remediation of organic contaminated soil by using thermal desorption combined with an oxidant and a remediation method

ActiveCN103230933AReduce moistureIncrease temperatureContaminated soil reclamationSoil propertiesInsulation layer

The invention belongs to the technical field of environmental protection, and in particular relates to a device for remediation of organic contaminated soil by using thermal desorption combined with an oxidant and a remediation method. The device of the invention is composed of an air heater, an air compressor, an air valve, a dosing valve, a dosing tank, a vacuum suction pump, a delivery pump, an electric power control unit, an insulation layer, lateral pipes, injection syringes, injection wells, a gas collection well and vacuum suction pipelines. According to the invention, through a treatment method of in situ thermal desorption and adding the oxidant, volatile organic compound contaminated soil is effectively treated. The technique of the invention is applicable to a relatively broad scope, can be used to perform in situ pollution remediation of volatile organic compounds under different climatic conditions, geological conditions, soil properties, and earth surface conditions. The heater of the present invention can infuse more produced heat into the soil, thus saving fuel and combustion time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

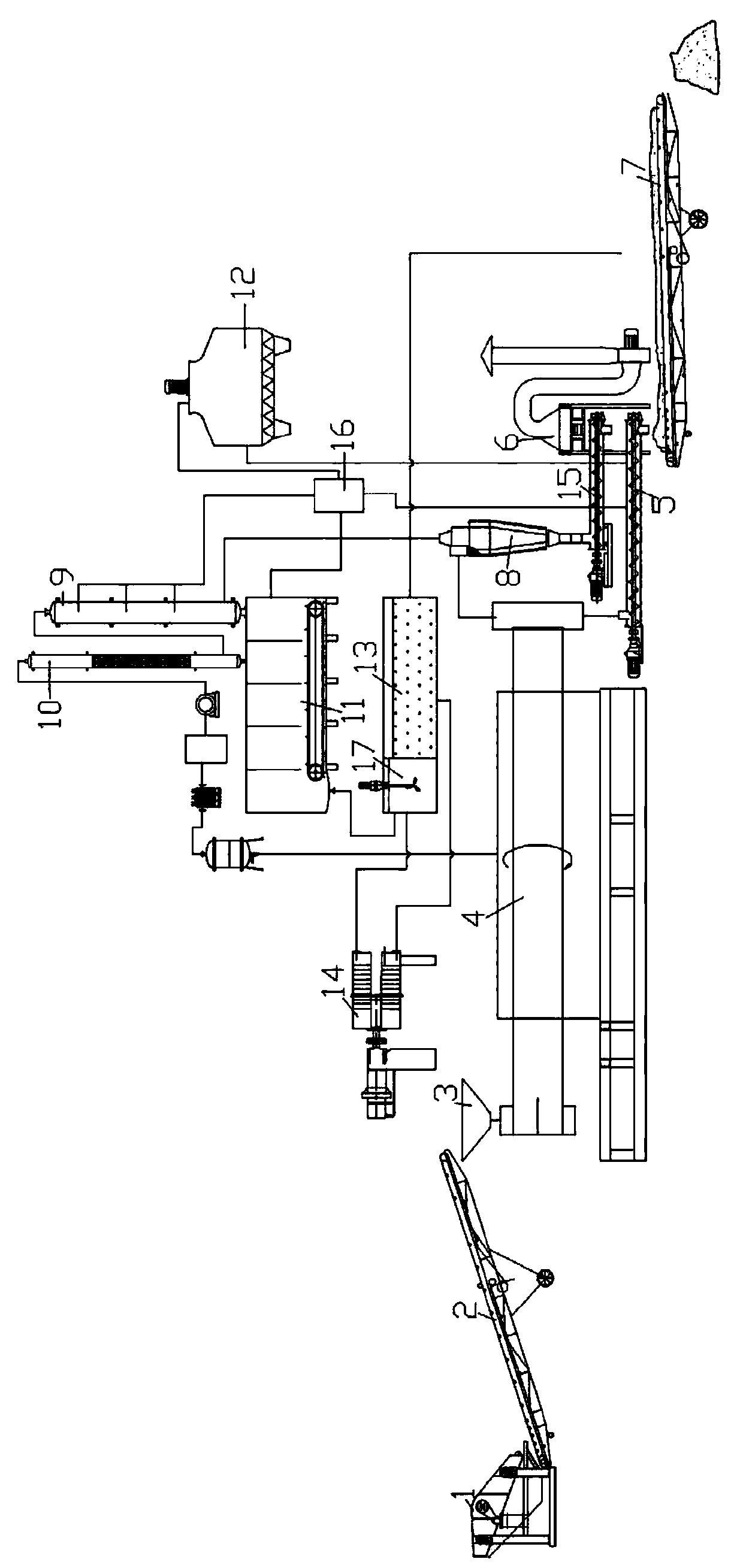

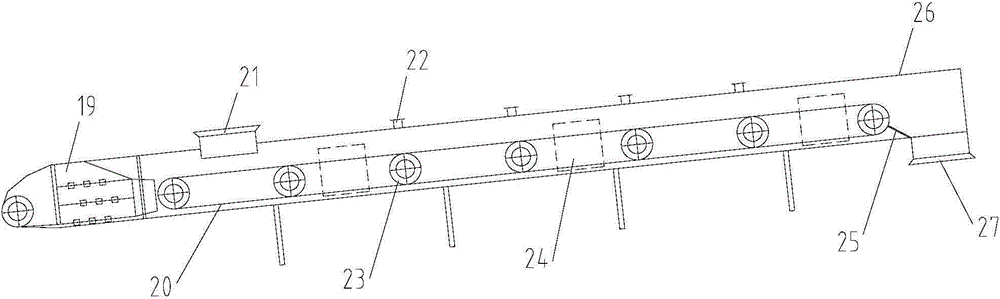

Multi-stage thermal desorption remediation system for organic polluted soil

ActiveCN104607455AImprove utilization efficiencyShorten repair timeContaminated soil reclamationCombustion chamberRetention time

The invention relates to a multi-stage thermal desorption remediation system for organic polluted soil, and belongs to the technical field of soil remediation. The system consists of a first-stage thermal desorption device, a second-stage thermal desorption device, a tail gas treatment device, a secondary combustion chamber and a falling type conveying belt. Soil is preheated and desorbed primarily by high-temperature tail gas generated by thermal desorption; a two-stage or multi-stage polluted soil treatment method is adopted, and the residual heat of the tail gas is utilized fully, so that the comprehensive utilization ratio of heat energy of the system is improved obviously; soil enters a thermal desorption cabin with relatively high temperature under the gravity effect by virtue of the S-shaped falling type conveying belt, so that the energy consumption of a conveying and transmitting device and the conveying process is prevented; meanwhile, the soil conveying path and the conveying time are prolonged, the retention time is prolonged, and thus soil pollutants are desorbed relatively fully. The thermal desorption soil remediation system is reasonable in structure, is simple to operate, is convenient to use, has no secondary pollution, recycles residual heat of tail gas, and has wide application prospect and high practical value.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

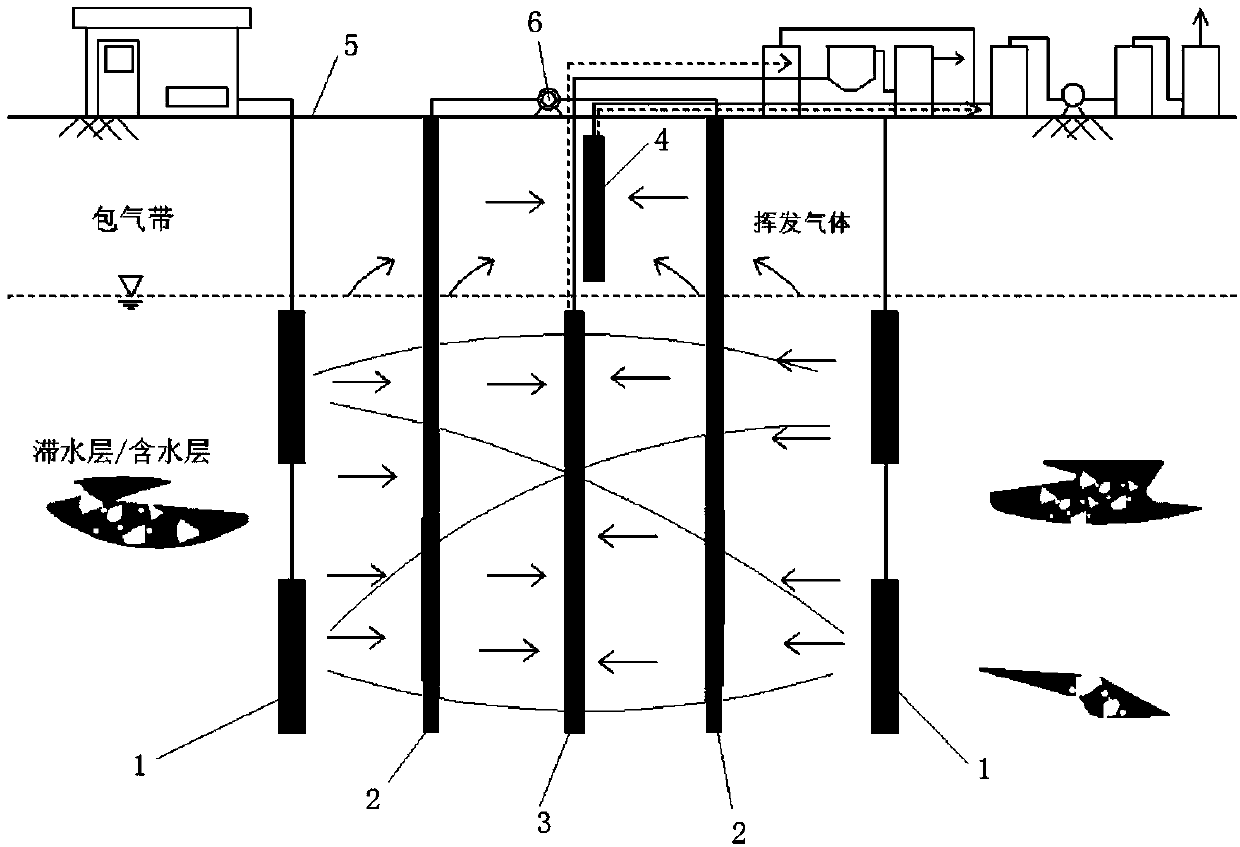

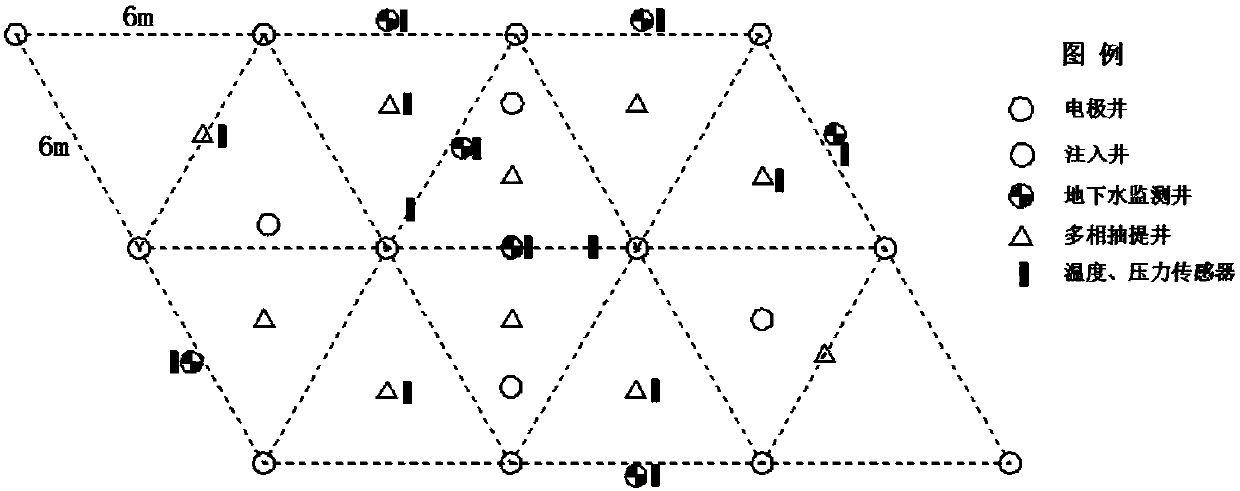

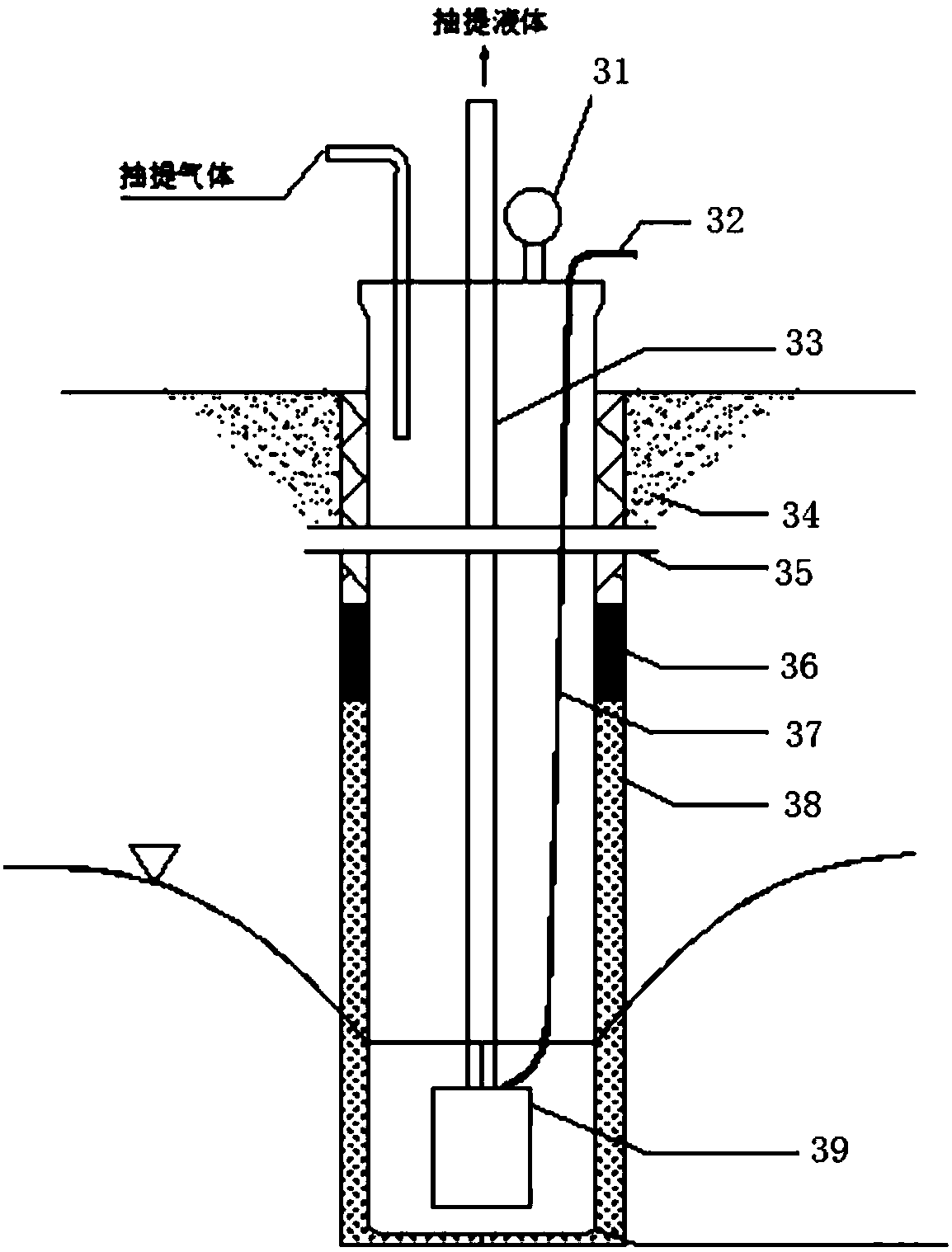

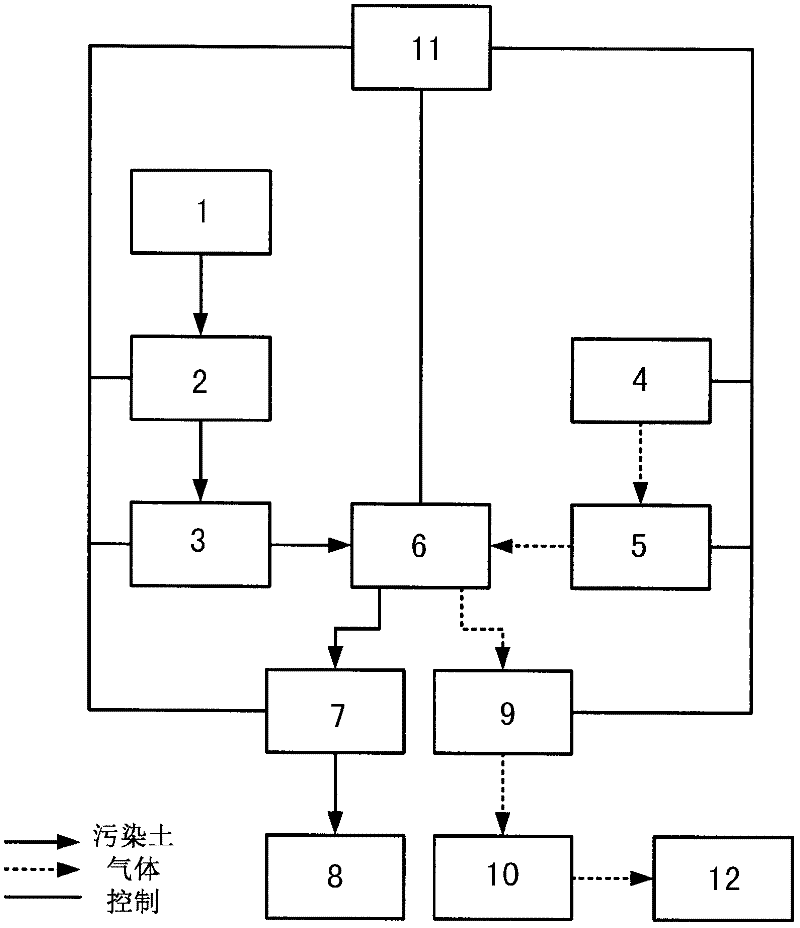

In-situ thermal desorption repair system and method for polluted soil

PendingCN108114970AImprove solubilityIncrease the speed of entering the liquid phaseContaminated soil reclamationWater/sewage treatment by heatingSolubilityInjection well

The invention relates to an in-situ thermal desorption repair system and a method for polluted soil. The system comprises a plurality of in-situ heating electrodes, a plurality of injection wells, a plurality of extraction wells, a plurality of groundwater monitoring wells, electrode power control and adjustment facilities, in-situ temperature and pressure monitoring facilities, sewage treatment facilities and waste gas treatment facilities; each extraction well is provided with an extraction device which is connected with a sewage treatment facility and a waste gas treatment facility; each injection well is internally provided with an injection device which is connected with a material storage box containing a leaching reagent; and the in-situ heating electrodes are arranged in a regulartriangular or regular hexagonal manner. Compared with the prior art, after the leaching reagent is added to dissolve pollutants, the solubility of the pollutants is increased, the speed of the pollutants entering a liquid phase from a soil adsorption phase is increased, and the removal rate and removal efficiency of the pollutants are improved.

Owner:YONKER ENVIRONMENTAL PROTECTION

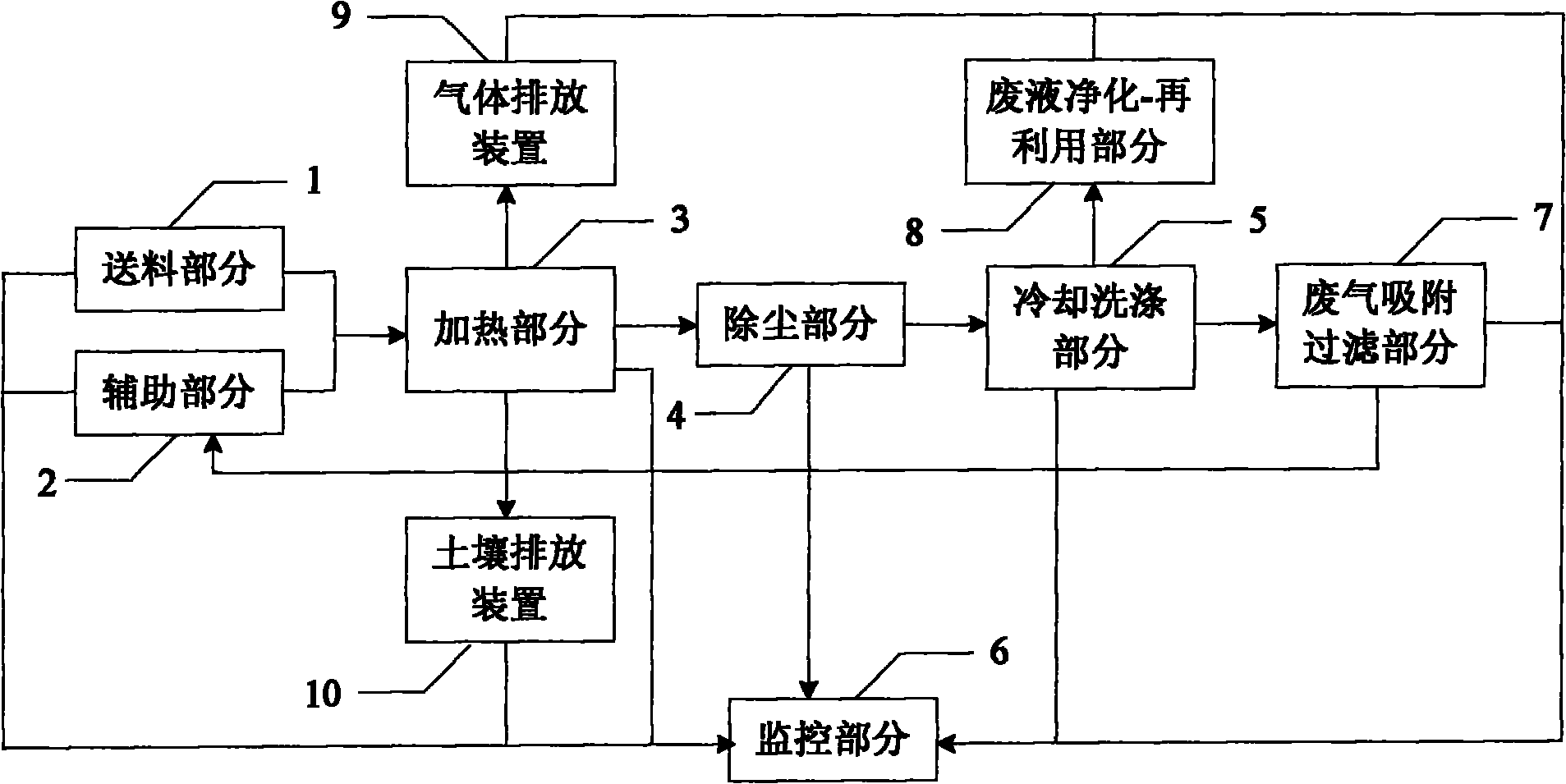

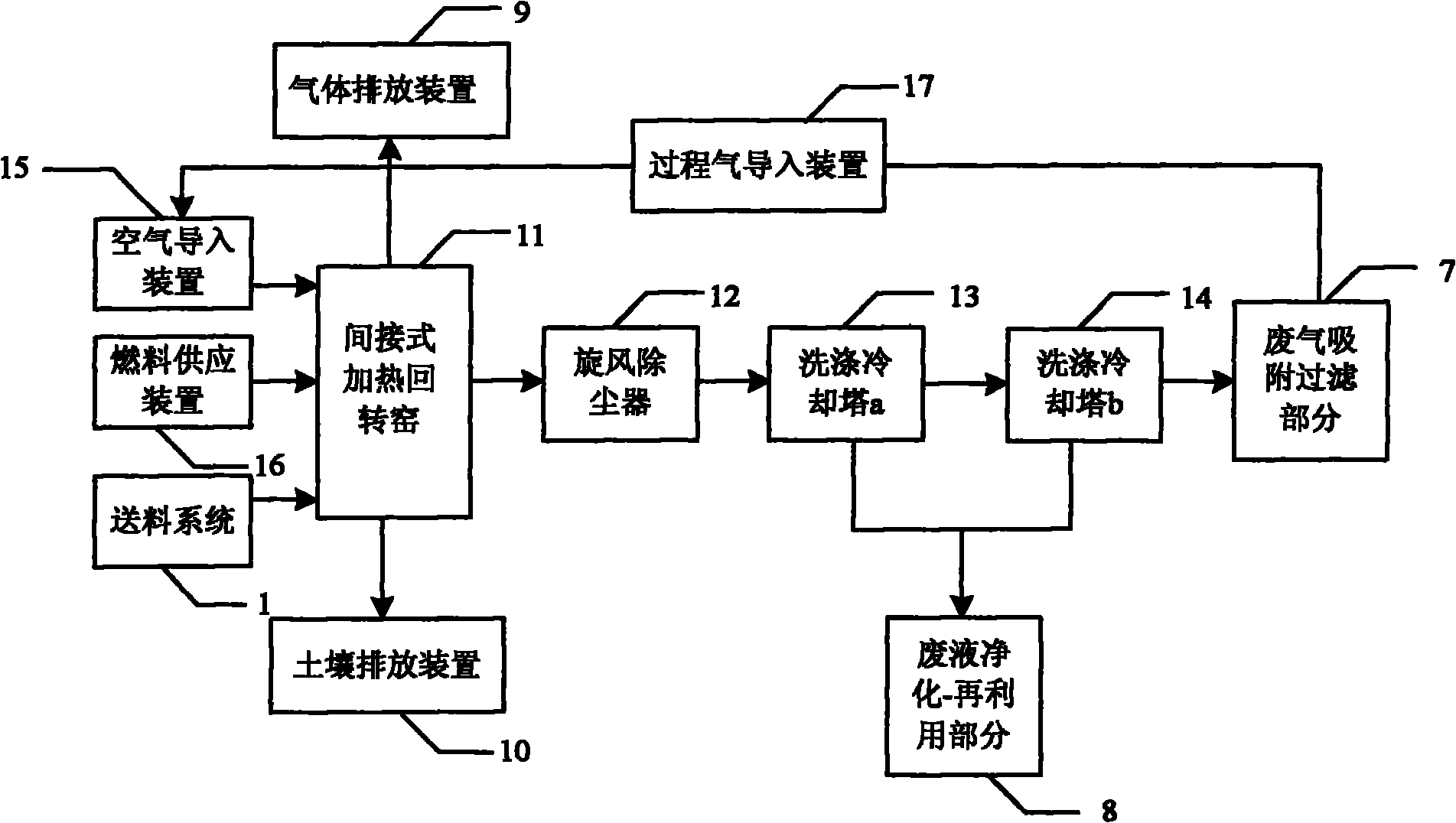

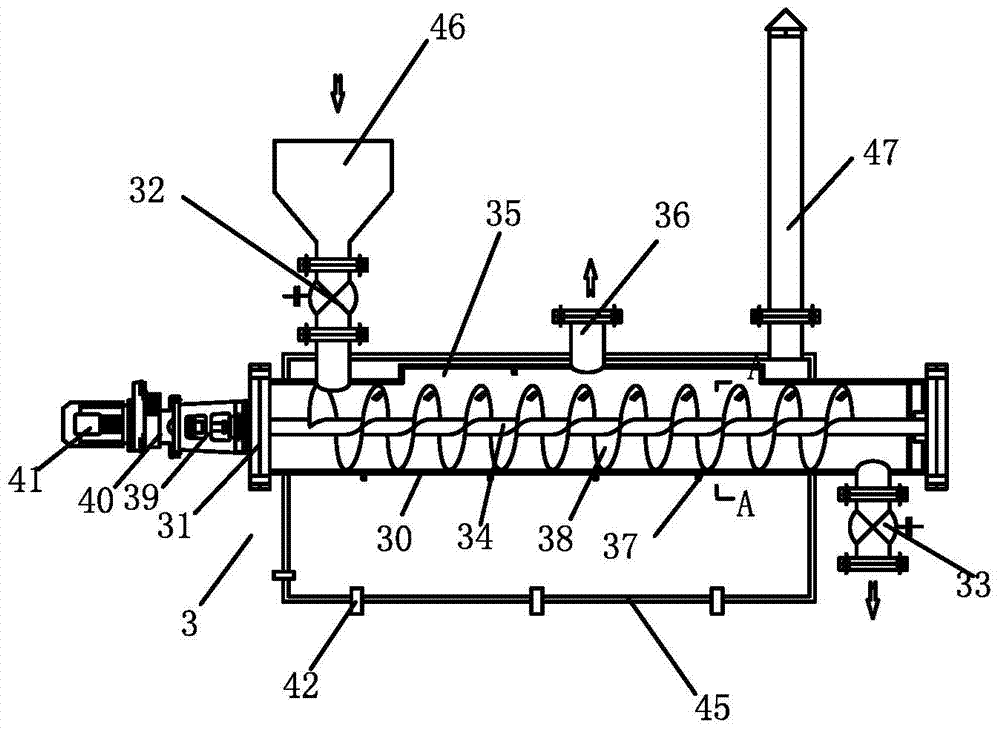

Indirect thermal desorption device

ActiveCN101780467AMaintain physical and chemical propertiesLow costCombination devicesUsing liquid separation agentLiquid wasteCooling tower

The invention relates to an indirect thermal desorption device which comprises a feeding part, an auxiliary part, a heating part, a dedusting part, a washing and cooling part, a waste liquid purifying-recycling part, a waste gas adsorbing and filtering part, a discharging part and a monitoring part, wherein the feeding part and the auxiliary part are connected with the heating part, the discharging part comprises a gas discharging device and a soil discharging device, the washing and cooling part is a washing and cooling tower, the waste liquid purifying-recycling part is connected with the washing and cooling tower, the heating part is orderly connected with the dedusting part, the washing and cooling tower and the waste gas adsorbing and filtering part, the heating part, the dedusting part, the washing and cooling tower and the waste gas adsorbing and filtering part are also respectively connected with the monitoring part, and the waste gas adsorbing and filtering part is connected with an air introducing device in the auxiliary part. The invention has the advantages of large treatment capacity, low treatment cost, soil physicochemical property maintenance and the like, can effectively separate organic matters from contaminated soil and treat the organic matters, and also can complete the processes of waste gas washing, waster gas adsorption and the like so as to reduce the energy consumption of the overall system.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

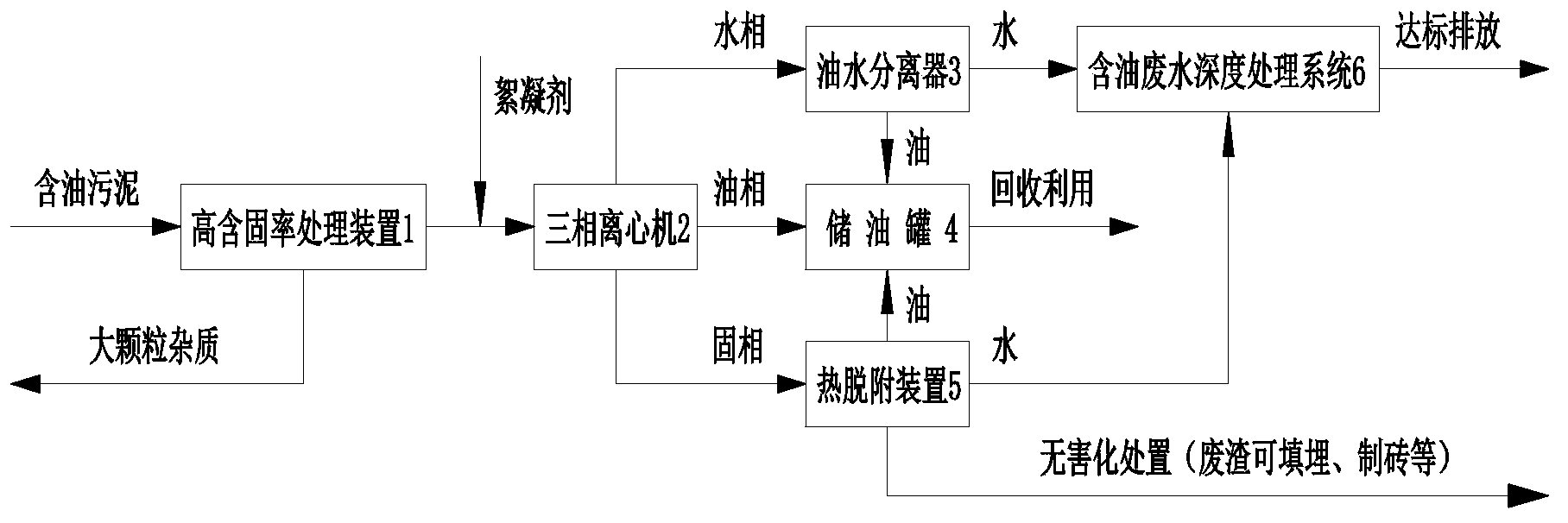

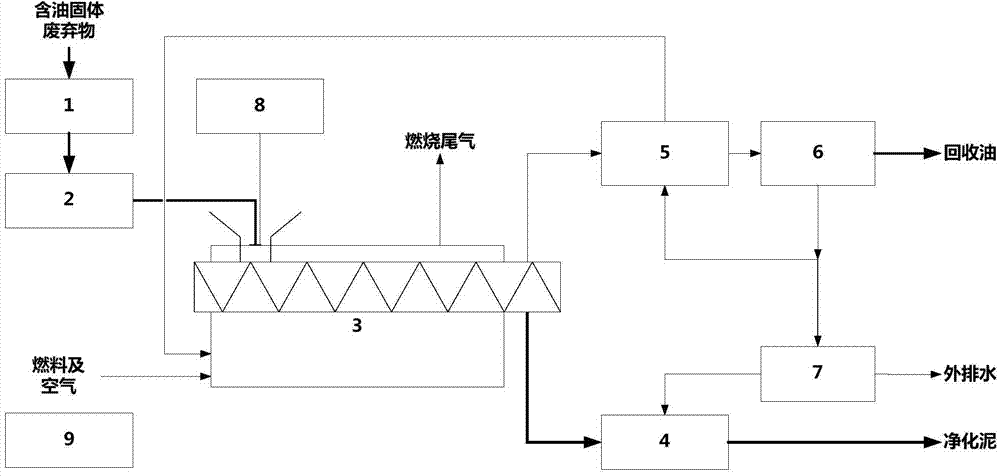

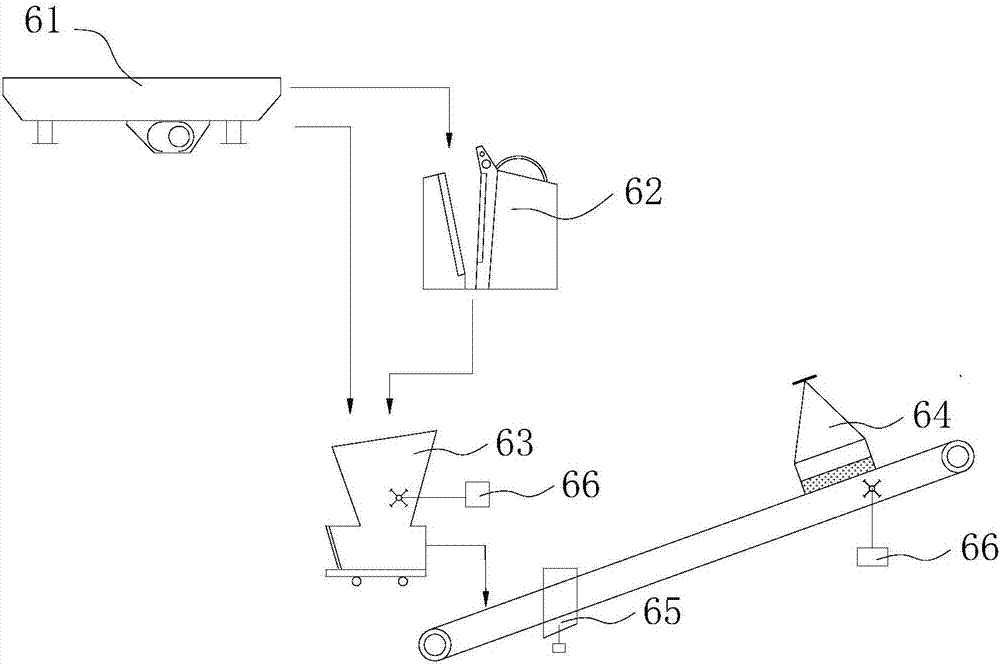

Harmless treatment method for separation and recovery of oily sludge

ActiveCN104341081ALow costEasy maintenance and managementSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSludgeOil phase

A harmless treatment technology for separation and recovery of oily sludge comprises the following steps: 1, conveying the oily sludge to a high solid content treatment device, carrying out preliminary screening on large granule impurities in the oily sludge, and conditioning the sludge; 2, conveying pre-conditioned oily sludge to a three-phase centrifuge, and separating oil, water and mud in the oily sludge; 3, conveying the obtained separated liquid to an oil-water separation device, and further carrying out oil and water separation; 4, inputting the obtained oil phase to an oil storage tank, and inputting water to an oily wastewater advanced treatment system; 5, conveying the obtained solid phase sludge transported to a thermal desorption device, and carrying out heating curing separation and condensation oil-water separation in a thermal desorption treatment process; and 6, conveying water output by the oil-water separation device and water output by the thermal desorption device to the oily wastewater advanced treatment system, and carrying out advanced oil-water separation. The method has the advantages of low cost oily sludge treatment cost, convenient maintenance and management, high efficiency and good stability.

Owner:MAIWANG INT BUSINESS SHANGHAI

Catalyst blends for producing low thermal desorption polyurethane foams

A catalyst composition for catalyzing a polyurethane forming reaction includes a gelling catalyst and a blowing catalyst selected such that the resulting polyurethane foam has a low level of volatile and / or malodorous material in it. The gelling catalysts are selected from tertiary aminoalkyl substituted primary or secondary amines; and the blowing catalysts are selected from bis(aminoalkyl) ethers comprising alkanol moieties, primary amine moieties, or ureido moieties derived from such primary amine moieties.

Owner:EVONIK DEGUSSA GMBH

System and method for repairing organic material polluted soil

ActiveCN103008337AClear division of laborGive full play to the advantages of technologyContaminated soil reclamationAir preheaterEngineering

The invention discloses a system for repairing organic material polluted soil, which comprises a chimney and a rotary kiln reactor, wherein the smoke exhaust port of the rotary kiln reactor is connected with a furnace chamber; the furnace chamber is connected with a cyclone separator; one end of the cyclone separator is connected with a preheating passage; the other end of the cyclone separator is connected with a refeeder; the refeeder is connected with the furnace chamber; the preheating passage is connected with the chimney after passing through a flue gas desulfurization denitration purifier and a bag-type dust remover; an air preheating device is arranged in the preheating passage; one end of the air preheating device is connected with a first blower; the other end of the air preheating device is connected with the rotary kiln reactor and the furnace chamber respectively; and a rotary kiln repaired soil outlet is arranged on the rotary kiln reactor. The invention further discloses a method for repairing organic material polluted soil. According to the invention, the advantages of the thermal desorption technology in the organic material polluted soil repairing process are fully played; and organic material polluted soil, which is difficult to repair, can be repaired fast through the combination of new rotary kiln thermal desorption technology and the circulatory fluidized bed incineration technology.

Owner:HUAZHONG AGRI UNIV

Indirect heating and thermal desorption treatment device and method for oily solid waste

ActiveCN104496136AHarmlessRealize resourcesSludge treatment by pyrolysisMultistage water/sewage treatmentAutomatic controlEngineering

The invention discloses an indirect heating and thermal desorption treatment device and method for oily solid waste. The device comprises an automatic control unit, a feeding pretreatment unit, a feeding metering and protecting unit and an indirect heating and thermal desorption unit, wherein the feeding pretreatment unit, the feeding metering and protecting unit and the indirect heating and thermal desorption unit are sequentially communicated with one another through an oily solid waste material conveying mode; a desorbed gas and oil gas outlet of the indirect heating and thermal desorption unit is connected with a desorbed gas separating and purifying unit; a discharge hole of the indirect heating and thermal desorption unit is connected with a muck post-treatment unit; the indirect heating and thermal desorption unit is composed of a heating cavity and a thermal desorption cavity; a heated part of the thermal desorption cavity is arranged in the heating cavity; and an internal space of the thermal desorption cavity and the internal space of the heating cavity are two cavities which are independently separated and are not communicated. The invention further discloses a method using device.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

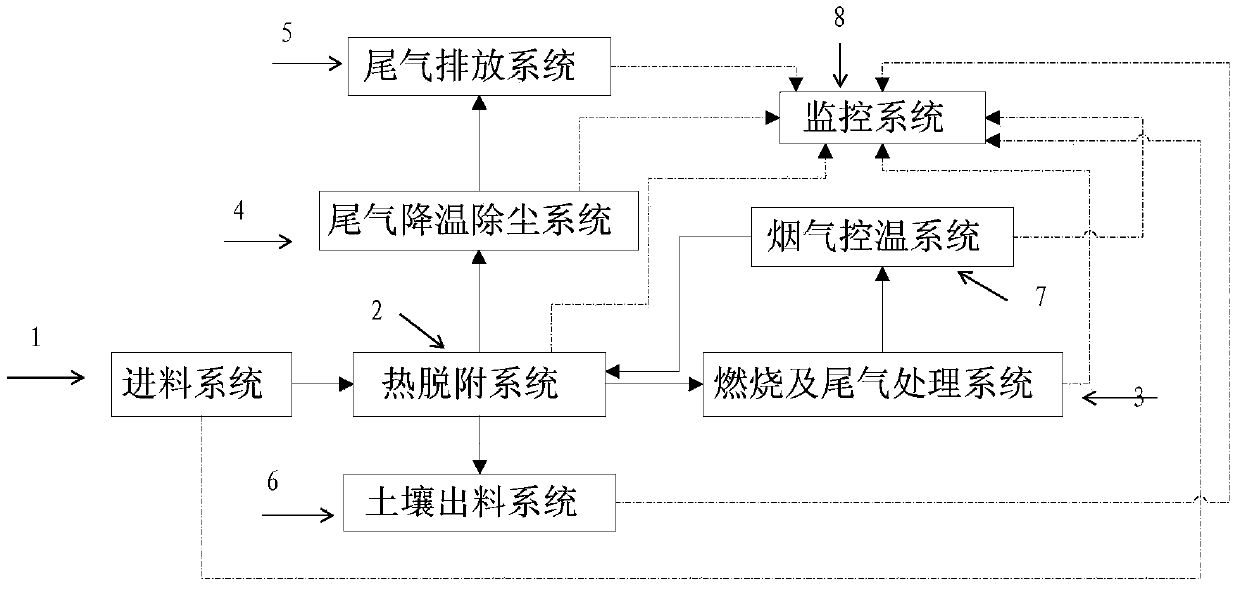

Environment-friendly and energy-saving thermal-desorption remediation treatment system for organic contaminated soil

InactiveCN103962374AReduce energy consumptionReduce processingContaminated soil reclamationTemperature controlCombustion

The invention relates to an environment-friendly and energy-saving thermal-desorption remediation treatment system for organic contaminated soil and aims to provide the energy-saving, environment-friendly and efficient thermal-desorption remediation treatment system for organic contaminated soil. The system comprises a feeding system, a thermaldesorption system, a soil discharging system, a combustion and tail gas treatment system, a flue gas temperature control system, a tail gas temperature-reduction and dust-removal system and a tail gas exhaust system, wherein the feeding system is led to the thermaldesorption system, the thermaldesorption system is led to the soil discharging system and the combustion and tail gas treatment system respectively, the combustion and tail gas treatment system is led to the flue gas temperature control system, the flue gas temperature control system is led to the thermal desorption system, the thermaldesorption system is led to the tail gas temperature-reduction and dust-removal system, and the tail gas temperature-reduction and dust-removal system is led to the tail gas exhaust system.

Owner:中科华南(厦门)环保有限公司 +1

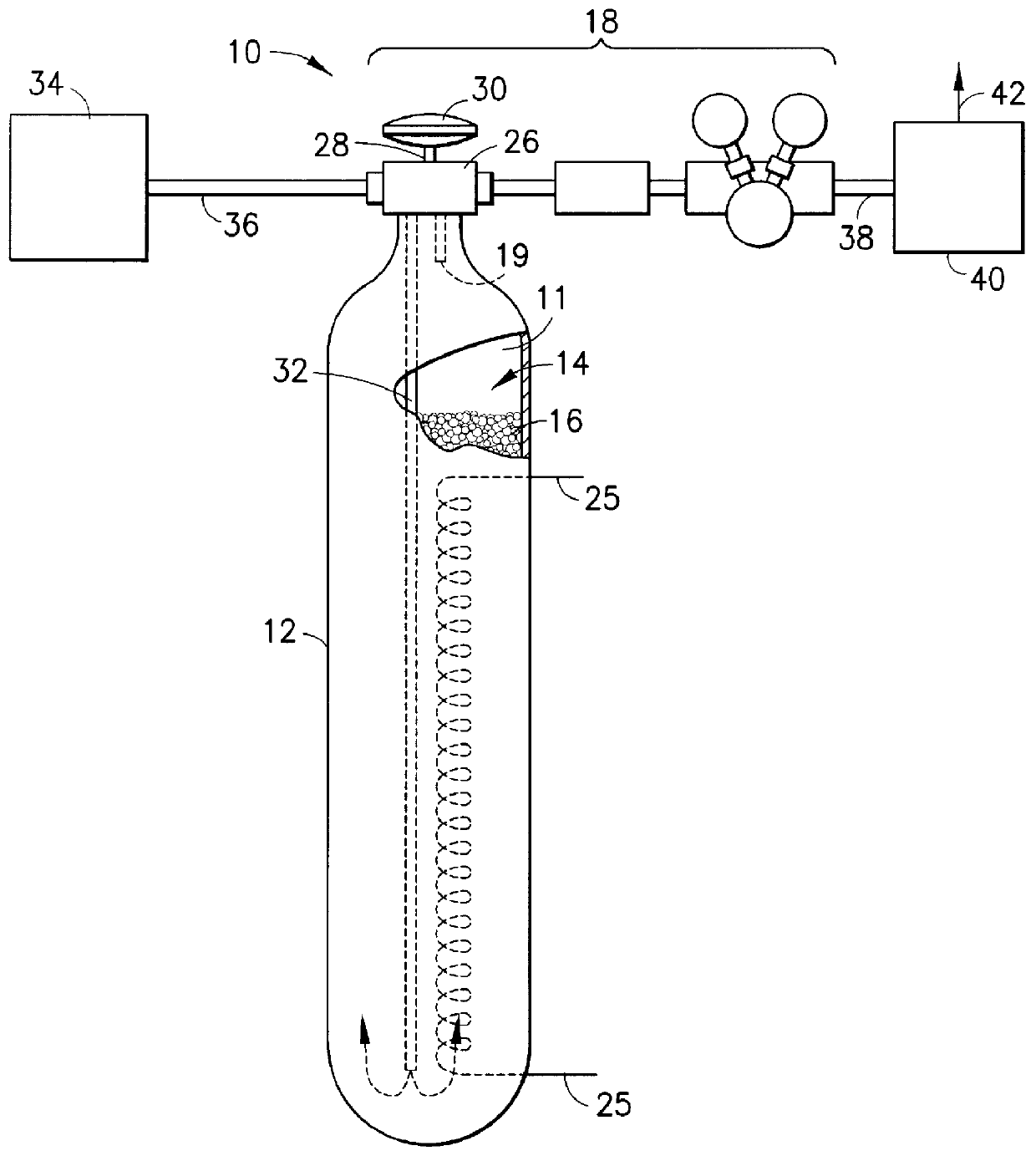

Low concentration gas delivery system utilizing sorbent-based gas storage and delivery system

A low concentration gas delivery system utilizing a sorbent-based gas storage and delivery unit including a gas storage and dispensing vessel joined in flow communication with a permeation structure. The storage and dispensing vessel contains a solid-phase physical sorbent medium holding a fluid, which is selectively dispensed from the vessel by pressure differential, concentration differential and / or thermal desorption techniques. The dispensed gas flows to the permeation structure, wherein the desorbed fluid is diffusionally released either as a neat fluid, or into a carrier gas in which the desorbed fluid has a precisely maintained concentration, for applications such as calibration of instruments monitoring fluid concentrations, delivery of dopants for fabrication of microelectronic device structures, or other end use application requiring a precise low concentration of fluid.

Owner:ENTEGRIS INC

Method and device thereof for desorption ionization

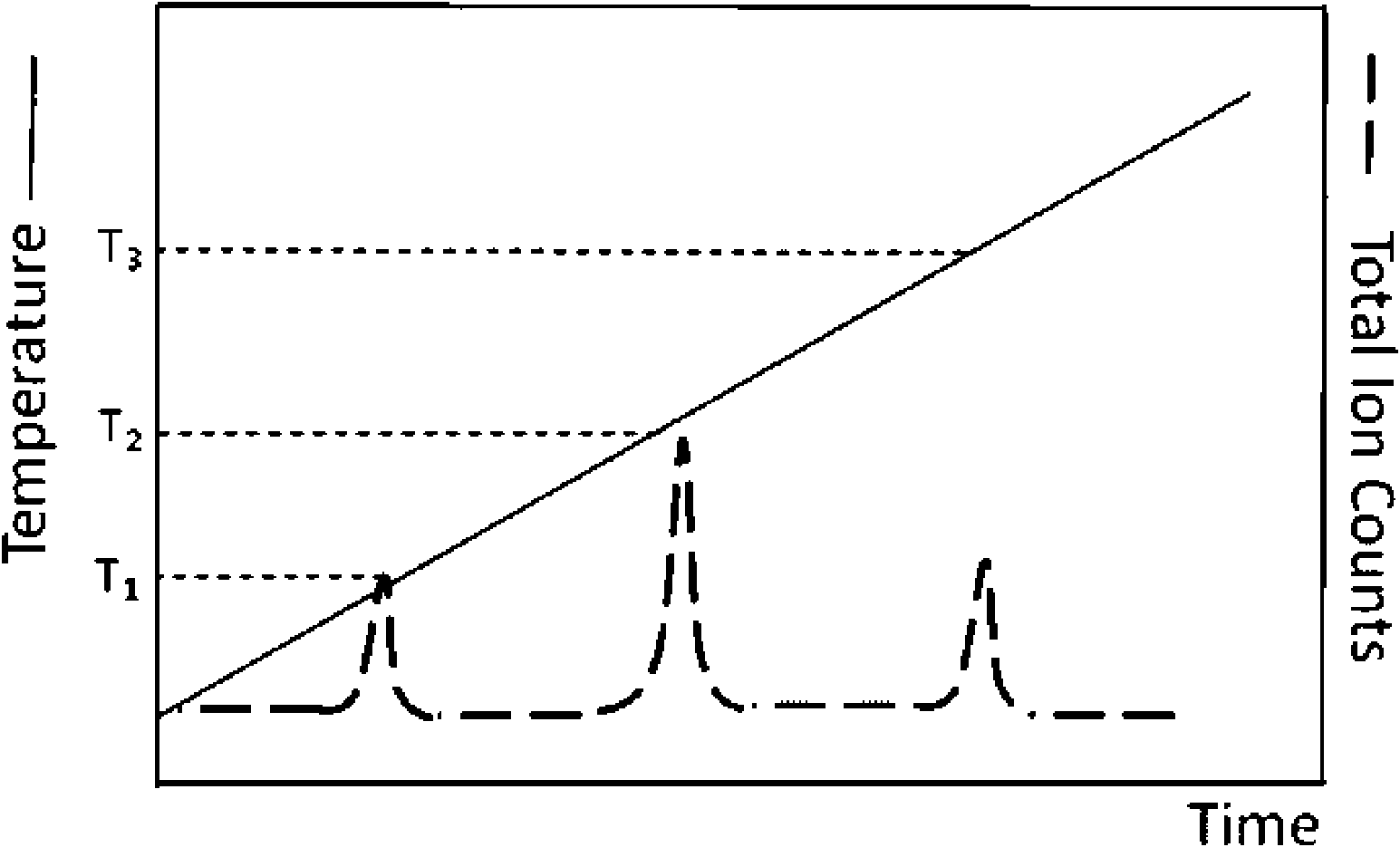

InactiveCN101871914AReduce difficultyImprove detection efficiencySamples introduction/extractionMaterial analysis by electric/magnetic meansBoiling pointData acquisition

The invention relates to a method and a device thereof, which adopt a mode of rising the temperature gradually under normal pressure to carry out desorption ionization in sequence on mixed objects to be tested on the solid surface and carry out continuous and multiple data acquisition in the process of desorption ionization gradually. The invention leads the objects to be tested with different thermal desorption capabilities to be desorbed out of the surface of the solid object to be tested by rising the temperature of at least one part of samples gradually, thus providing a means for pre-separating mixed samples so as to reduce the difficulty for subsequent mass spectrometric detection. Simultaneously, the invention acquires mass spectrometric data for multiple times for objects to be tested with various boiling points in the process of rising temperature so as to lead the objects to be tested with low boiling point not to be consumed completely quickly due to high temperature, thus improving the detection efficiency of the objects to be tested with lower boiling points.

Owner:SHIMADZU RES LAB SHANGHAI

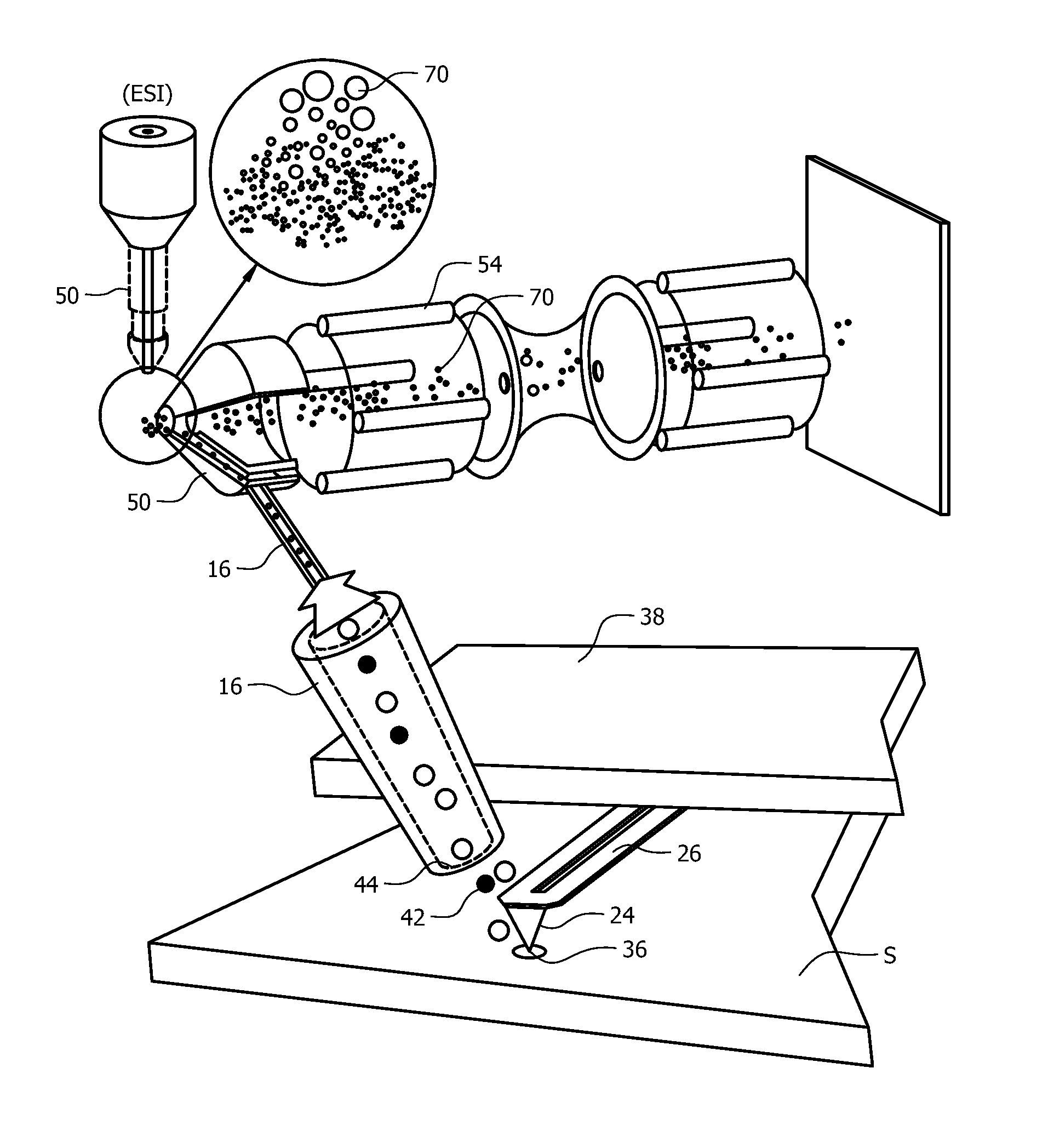

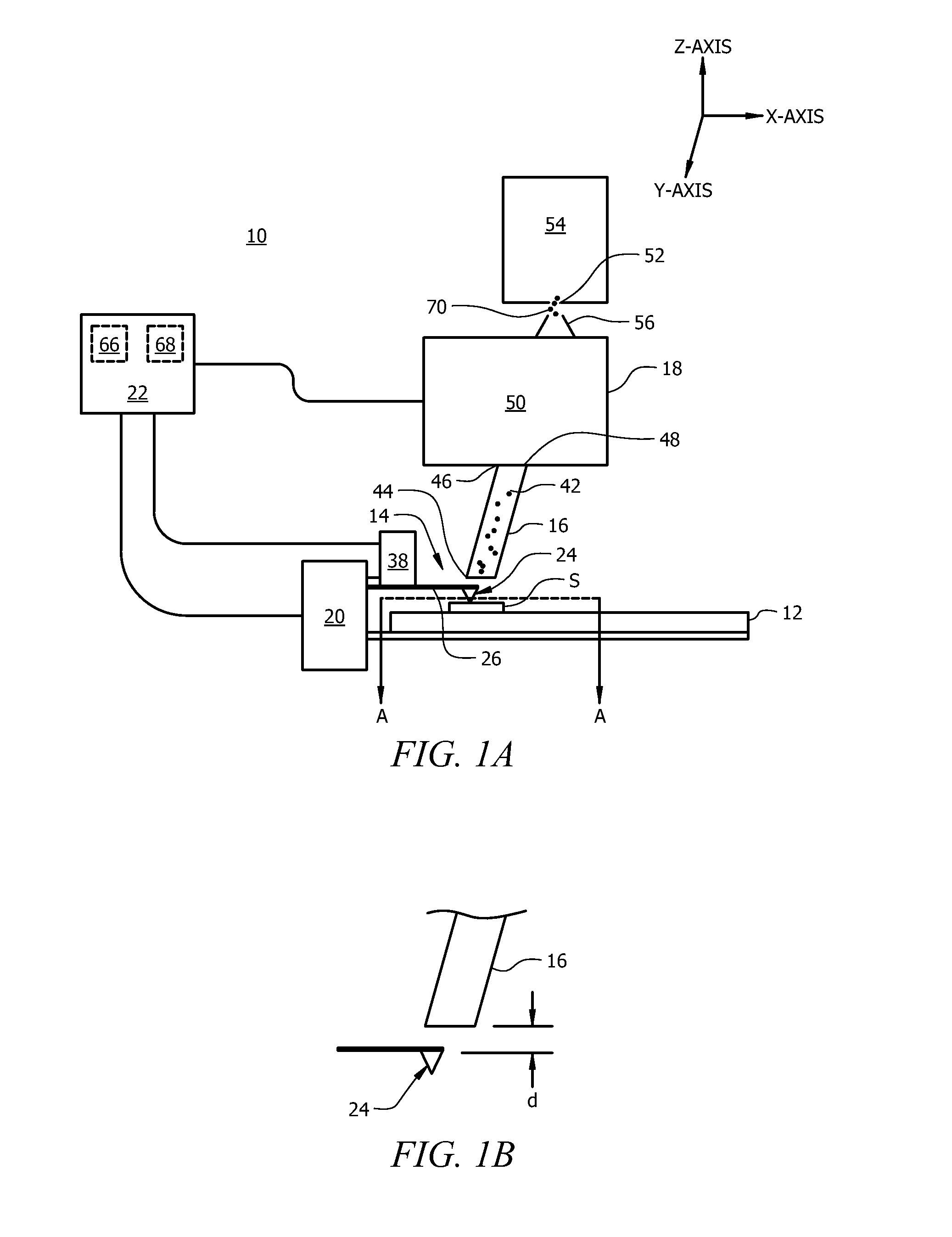

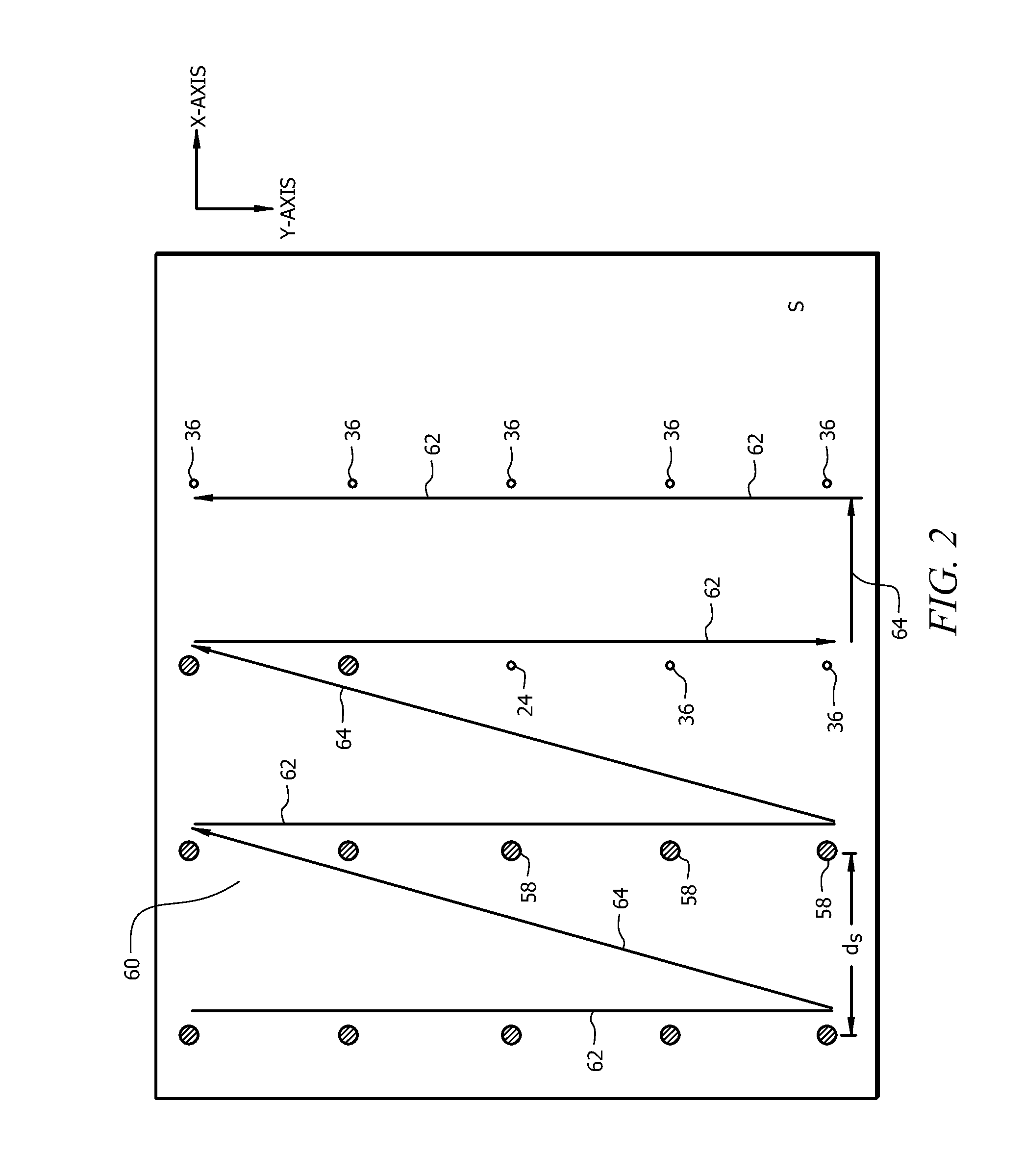

Spatially resolved thermal desorption/ionization coupled with mass spectrometry

A system and method for sub-micron analysis of a chemical composition of a specimen are described. The method includes providing a specimen for evaluation and a thermal desorption probe, thermally desorbing an analyte from a target site of said specimen using the thermally active tip to form a gaseous analyte, ionizing the gaseous analyte to form an ionized analyte, and analyzing a chemical composition of the ionized analyte. The thermally desorbing step can include heating said thermally active tip to above 200° C., and positioning the target site and the thermally active tip such that the heating step forms the gaseous analyte. The thermal desorption probe can include a thermally active tip extending from a cantilever body and an apex of the thermally active tip can have a radius of 250 nm or less;

Owner:UNIV OF TENNESSEE RES FOUND +1

Integrated and comprehensive soil in-place position-changing combined remedying equipment

ActiveCN105013806AAchieving Heterotopic Continuous Joint RepairImprove repair efficiencyContaminated soil reclamationEnvironmental resistancePeristaltic pump

The invention discloses integrated and comprehensive soil in-place position-changing combined remedying equipment, and belongs to the technical field of soil remedying. The equipment mainly comprises feeding and discharging machines, heating baking channels, conveying belts, a vacuum pump, a smashing device, a mixer, a solid chemical adding tank, a Venturi conveying pump, an ultrasonic atomizer, a peristaltic pump, a liquid chemical storage tank, a drip washing device, an activated carbon adsorption purification tank, a mud discharging electromagnetic valve and an absorbent storage tank. The modularized design is adopted for the whole set of remedying equipment, flexible matching and combining can be performed according to different types of polluted soil to be remedied, and therefore the cost is lowered. The whole set of equipment can be installed on a trailer to achieve moving operation. The equipment has the multiple remedying functions of thermal desorption treatment, chemical oxidation / restoration, chemical drip washing and others, can achieve in-place position-changing combined remedying on soil containing organic pollutants and heavy metal combined pollution, and is high in remedying efficiency, wide in range, free of harmful gas emissions, safe and environmentally friendly.

Owner:南京康地环保科技有限公司

Device and method for indirect thermal desorption disposal of persistent organic pollutant contaminated soil

ActiveCN104226681ASimple ingredientsReduce the risk of secondary pollutionCombination devicesContaminated soil reclamationAutomatic controlCvd risk

The invention discloses a device and a method for indirect thermal desorption disposal of persistent organic pollutant contaminated soil. The device comprises a contaminated soil pretreatment system, a feeding system, a thermal desorption system, a discharging system, a tail gas purification system and an automatic control system, wherein the contaminated soil pretreatment system is connected with a feed opening of the thermal desorption system through the feeding system, a solid discharge opening of the thermal desorption system is connected with the discharging system, and a gas discharge opening of the thermal desorption system is connected with an inlet of the tail gas purification system. According to the method, after pretreatment, contaminated soil is conveyed to the thermal desorption system for desorption for 10-40 min at the temperature of 400-600 DEG C, and desorption exhaust gas adopts a technology including procedures of cyclone dust removal, two stages of spraying, drying and activated carbon adsorption / gliding arc degradation. The device and the method adopt indirect heating, so that risks of generation of poisonous materials such as dioxine and the like are avoided effectively; and a double-layer cylinder rotary kiln type furnace body, the furnace body axis and the ground form a 0-degree angle, and accordingly, the operation and maintenance costs are reduced.

Owner:中节能大地(杭州)环境修复有限公司

Thermal desorption method and device for organic polluted soil on basis of cement process

ActiveCN102513346ANo increase in production energy consumptionEliminate negative effectsContaminated soil reclamationOrganic matterCement kiln

A thermal desorption method for organic polluted soil enables the polluted soil to be reversely contacted with hot wind for thermal desorption and enables volatility / semi-volatility organic matter to be separated and taken out by the hot wind, and tail gas generated during thermal desorption enters a cement kiln for burning and purification and is exhausted. The soil after thermal desorption is cooled and humidified. The invention further discloses a device for achieving the method. The thermal desorption method and the device for the organic polluted soil on the basis of cement process avoidthe shortcomings that a traditional cement kiln has low treatment capacity for burning, treatment types are limited, processed soil can not be utilized, and traditional thermal desorption tail gas treatment has high cost, improves treatment capacity of the polluted soil and tail gas purification level, reduces treatment energy consumption, and is environment-friendly repair technology which is energy-saving, high in efficiency and low in cost.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH

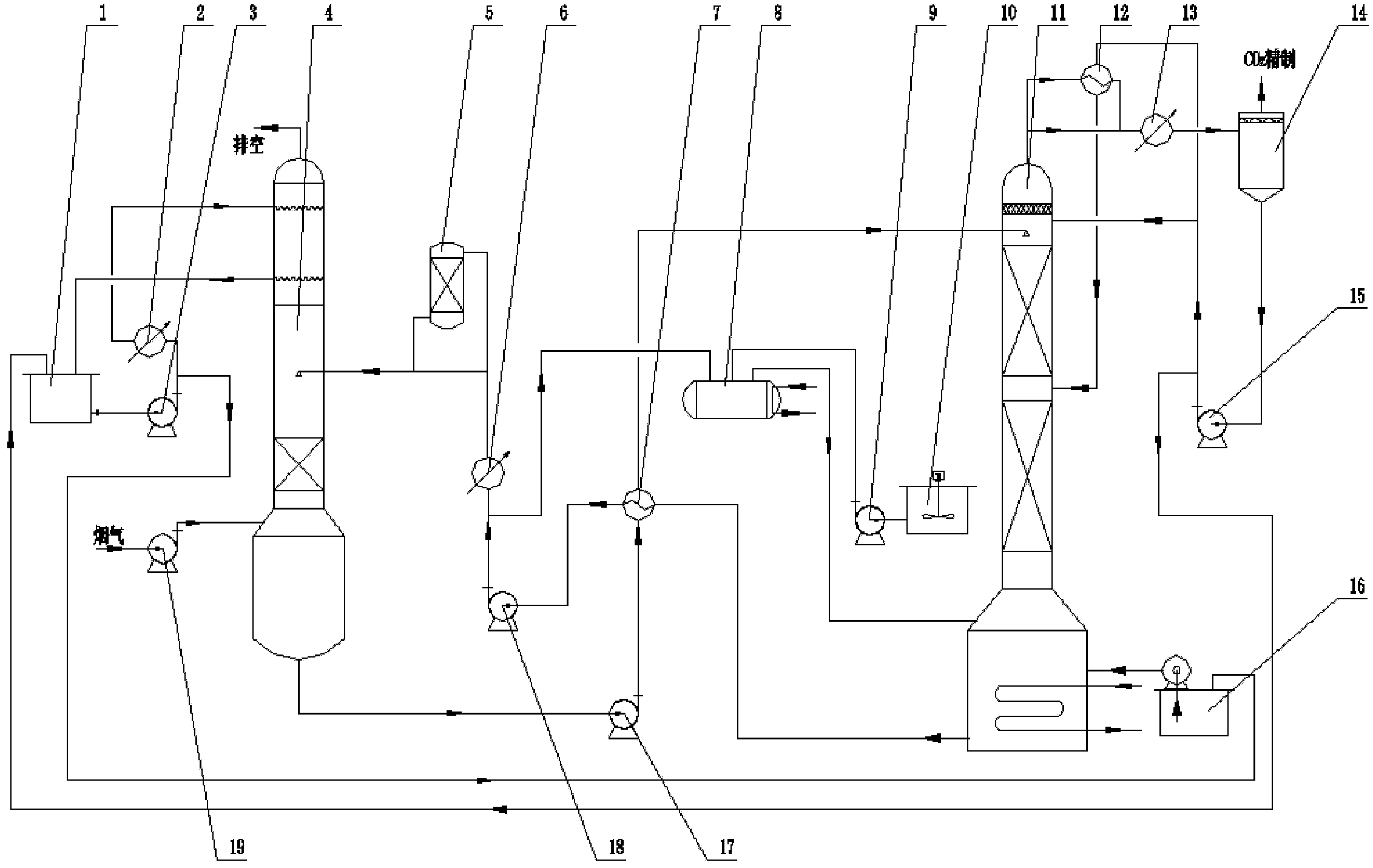

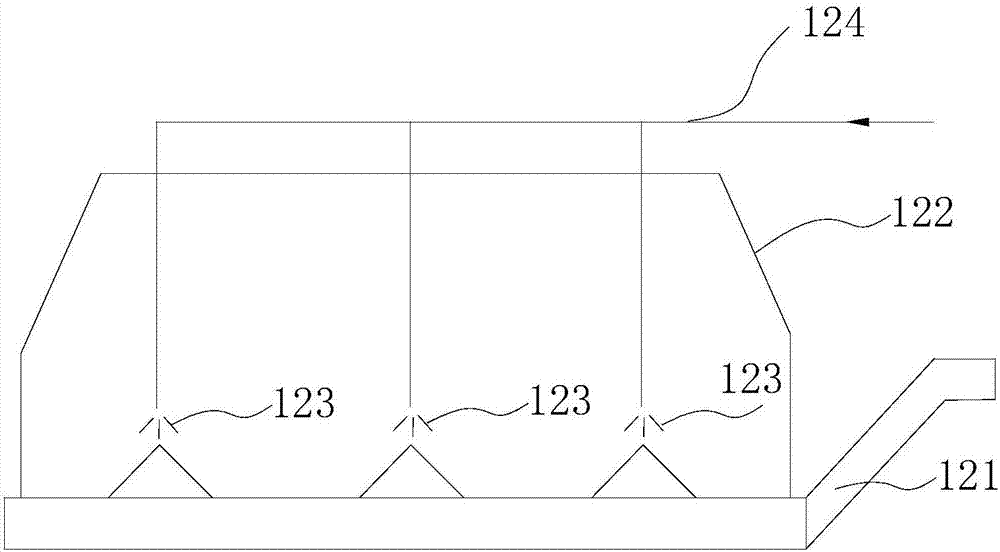

Pneumatic trapping system and process for carbon dioxide (CO2) in smoke

The invention relates to a pneumatic trapping system and process for carbon dioxide (CO2) in smoke. The pneumatic trapping process comprises the following steps that: (1) the smoke enters an absorption tower and is contacted with a serotonin solution in a counterflow manner so as to be absorbed under chemical reaction, the absorbed smoke upwards passes through a washing device, so that an absorbent contained in the smoke is cleaned out, and the smoke is discharged directly; (2) a solution which traps the CO2 is changed into rich liquor, the rich liquor flows to the bottom of the absorption tower and is conveyed to a barren and rich liquor heat exchanger through a rich liquor pump, and the rich liquor subjected to temperature raising enters a desorption tower; (3) the rich liquor is subjected to thermal desorption in the desorption tower to obtain regenerative gas rich in CO2 and solution steam, and the regenerative gas is subjected to heat exchange, condensation and gas and liquor separation to obtain a CO2 product; and (4) desorbed barren liquor is pumped into the barren and rich liquor heat exchanger and a barren liquor cooler by a barren liquor pump, and is reused after being cooled to temperature of an absorption reaction window. By adopting an efficient pneumatic decarbonization technology, the smoke and amine liquor can be contacted with each other fully, so the decarbonization efficiency is up to over 90 percent; and the system and the process are applicable to trapping of the CO2 in a large amount of smoke and can be applied to CO2 trapping devices with yearly output of 1,000,000 tons.

Owner:AEROSPACE ENVIRONMENTAL ENG

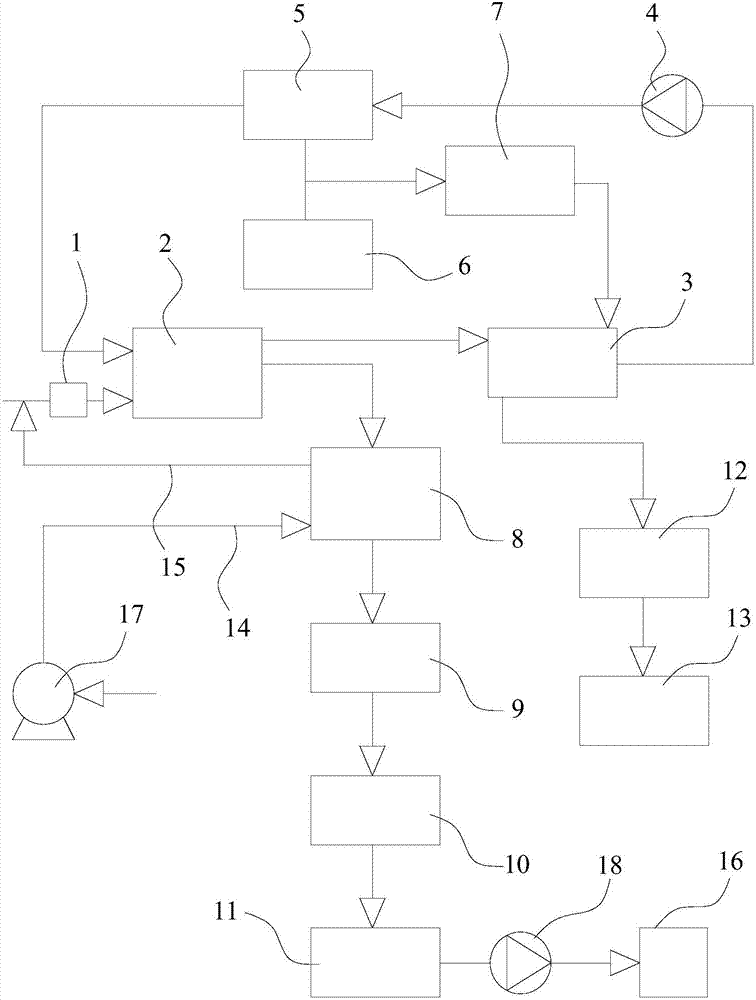

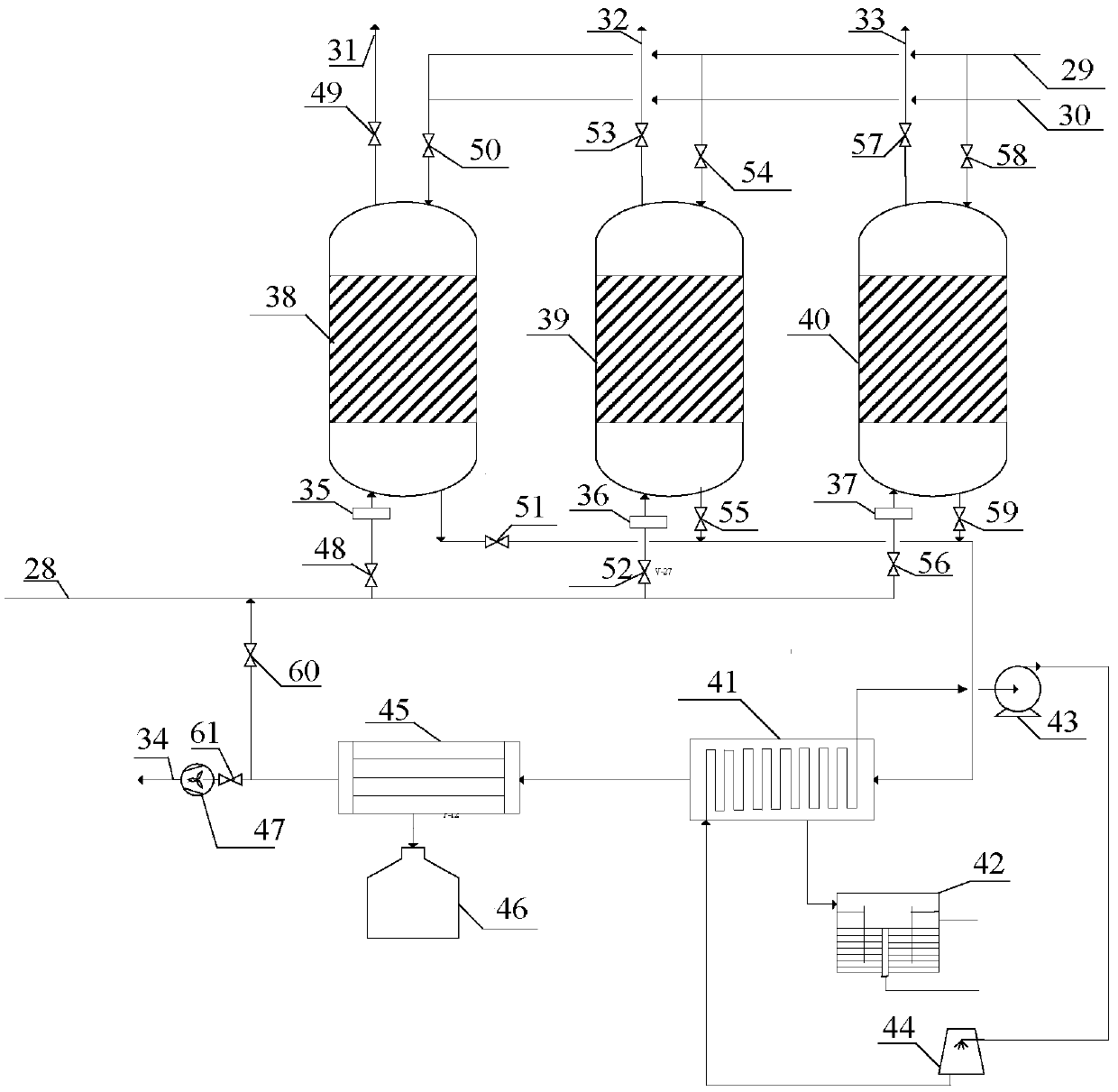

Efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method

ActiveCN107971330AReduce consumptionEmission reductionCombination devicesDispersed particle filtrationAir preheaterThermal desorption

The invention relates to an efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method. A burner is communicated with a high temperature oxidizingchamber, a high temperature smoke pipe of the high temperature oxidizing chamber is communicated with a rotary kiln heating processing system and an air heat exchanger, a high temperature air outletof the air heat exchanger is communicated with the burner, a smoke pipe of the air preheater is communicated with an inlet of a quench tower, an outlet of the quench tower is communicated with an inlet of a bag-type dust collector, an outlet of the bag-type dust collector is communicated with an inlet of a deacidification tower, an outlet of the deacidification tower is communicated with an air inlet of a second induced draft fan, and an outlet of the second induced draft fan is communicated with a chimney. A part of high temperature flue gas generated by the burner enters a rotary kiln thermal desorption reactor to achieve desorption of organic pollutant and soil drying pretreatment, organic matter enters the high temperature oxidizing chamber through a backflow pipe for burning treatment, and thorough oxidative degradation removal is achieved; and the other part of high temperature flue gas is used for increasing the temperature of combustion air through the air heat exchanger.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

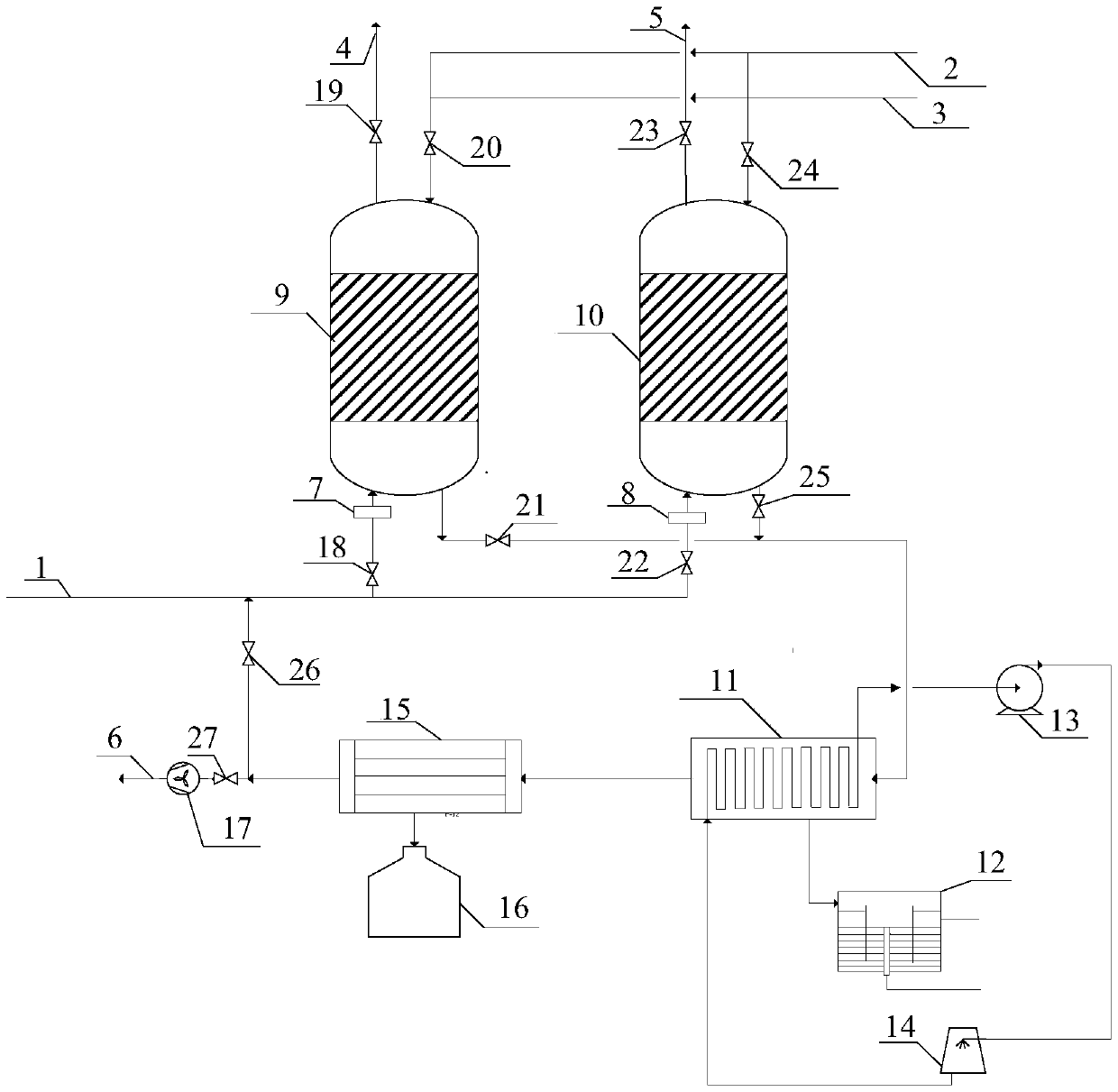

Method for recycling organic matter through organic waste gas adsorption, steam desorption and fractional condensation

InactiveCN105498446AIncrease concentrationNo emissionsGas treatmentDispersed particle separationAtmospheric airSorbent

The invention relates to the field of organic waste gas recycling and provides a method for recycling organic matter through organic waste gas adsorption, steam desorption and fractional condensation. The method includes the steps that after gas to be treated is pretreated with filtering cotton, the gas enters an adsorber filled with an adsorbing agent and is used for removing organic matter, and the purified gas is exhausted into the atmosphere; desorption and regeneration of the adsorbing agent includes the steps of steam desorption and regeneration, hot air drying and cold air cooling, and steam and desorbed gas are separated through a two-stage condenser. By means of two-step fractional condensation, high-boiling-point organic matter and low-boiling-point organic matter are separated, and the concentration of the recycled organic matter is increased. A small amount of treated gas which is not condensed is introduced into a gas inlet and mixed with inlet waste gas, secondary adsorption is carried out, and it is guaranteed that no tail gas exceeding standards is exhausted in the whole process. Organic matter recycling purity is high, energy consumption is low, and secondary pollution is avoided.

Owner:ZHEJIANG UNIV

Contaminated soil thermal desorption system capable of efficiently recycling waste heat and method adopting contaminated soil thermal desorption system

The invention discloses a contaminated soil thermal desorption system capable of efficiently recycling waste heat. The contaminated soil thermal desorption system comprises a soil thermal desorption system and a tail gas incineration system, wherein a part of high temperature flue gas generated by the tail gas incineration system is discharged through one of flue gas outlets, and the other part of the high temperature flue gas is mixed with air, and then fed to the soil thermal desorption system to be used as a heat source gas. The contaminated soil thermal desorption system disclosed by the invention gives full play to the advantages of the thermal desorption technology for restoring the soil contaminated by organics, sufficiently utilizes the heat in the high temperature flue gas generated by incineration of the thermal desorbed tail gas in combination with the structure of a flue gas furnace, and shunts a part of the high temperature flue gas to be mixed with fresh cool air as the heat source gas which is fed to a rotary kiln reactor as the heat source gas for heating the soil, so as to eliminate the arrangement of a separate burner of the rotary kiln structurally.

Owner:CISDI ENG CO LTD

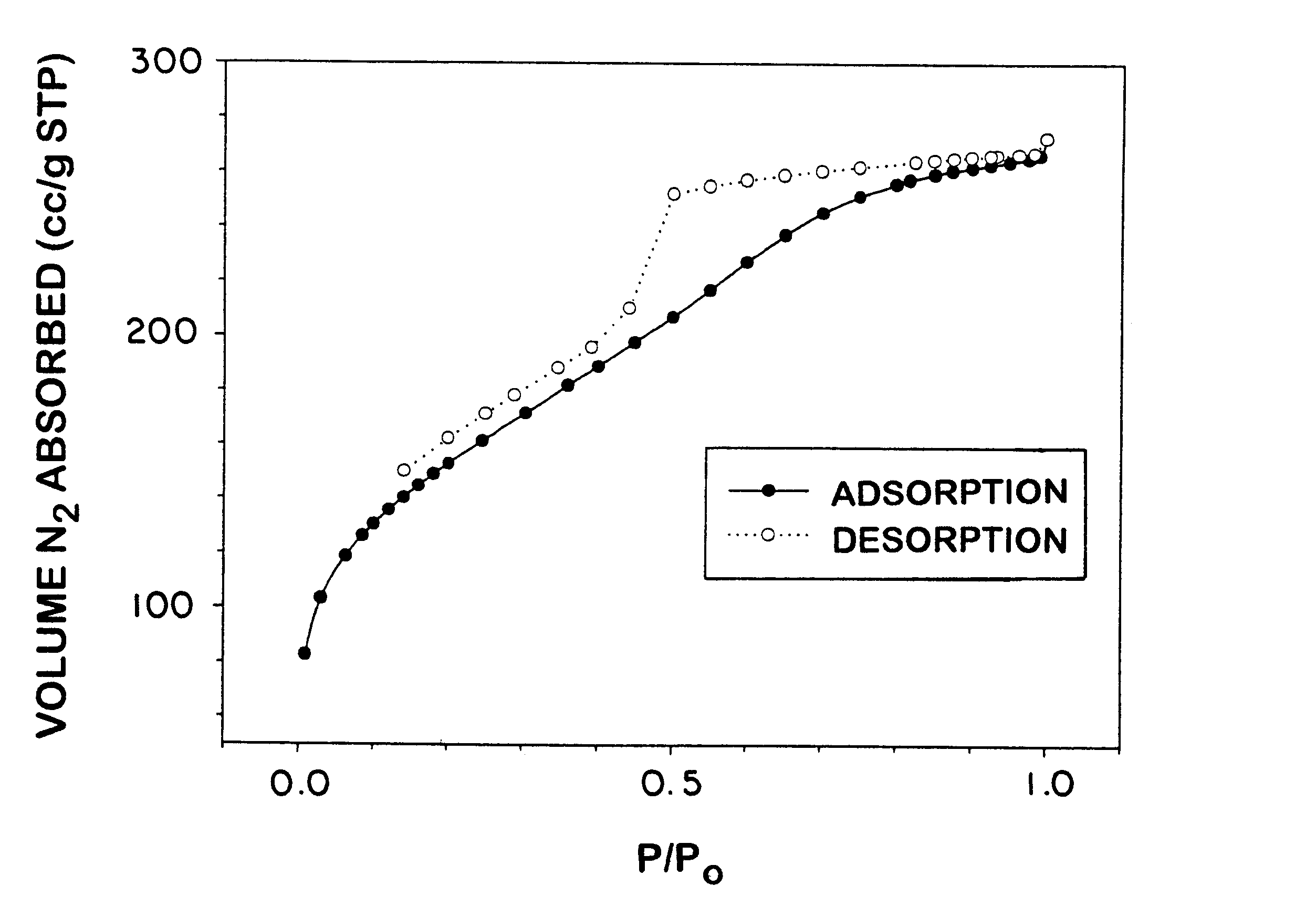

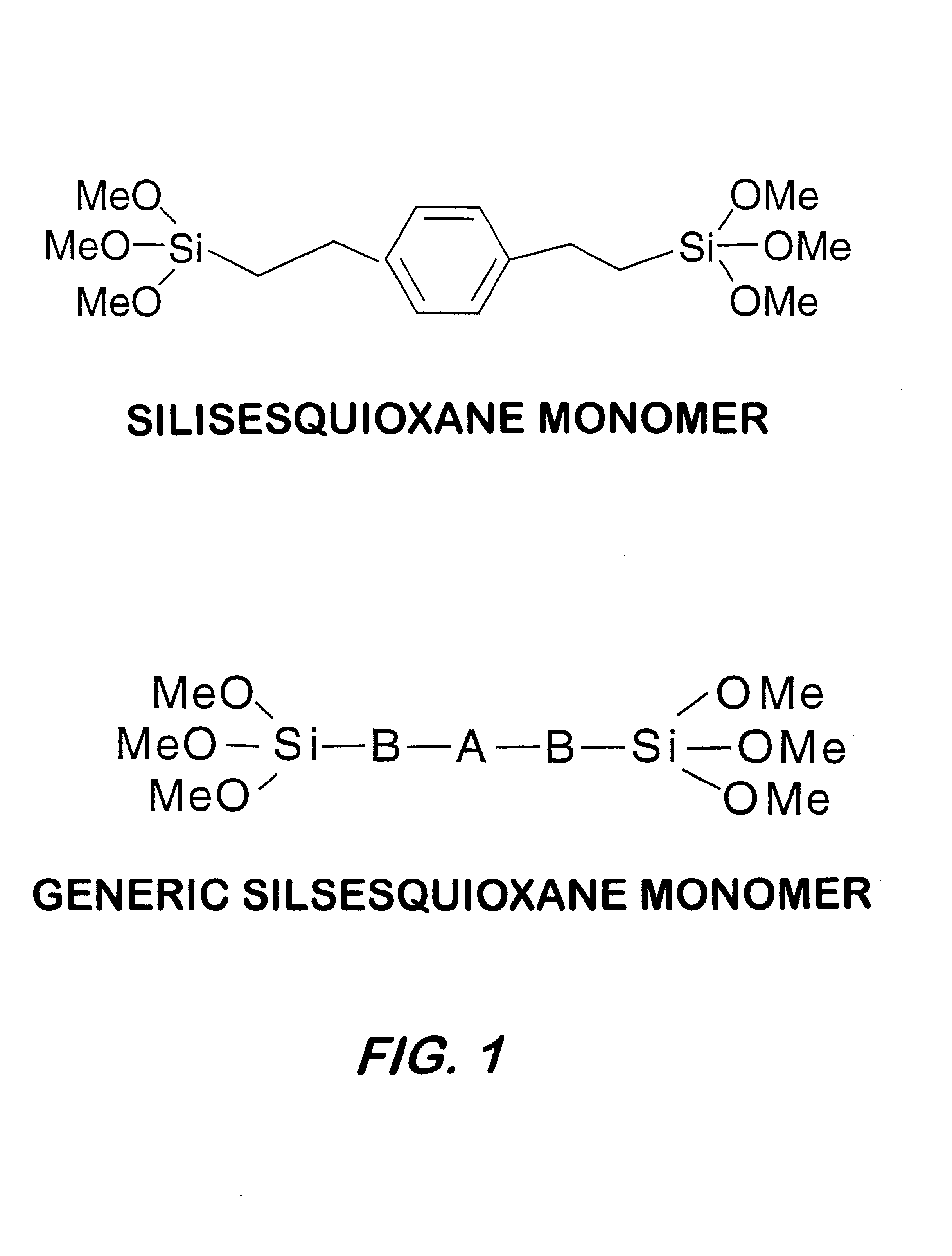

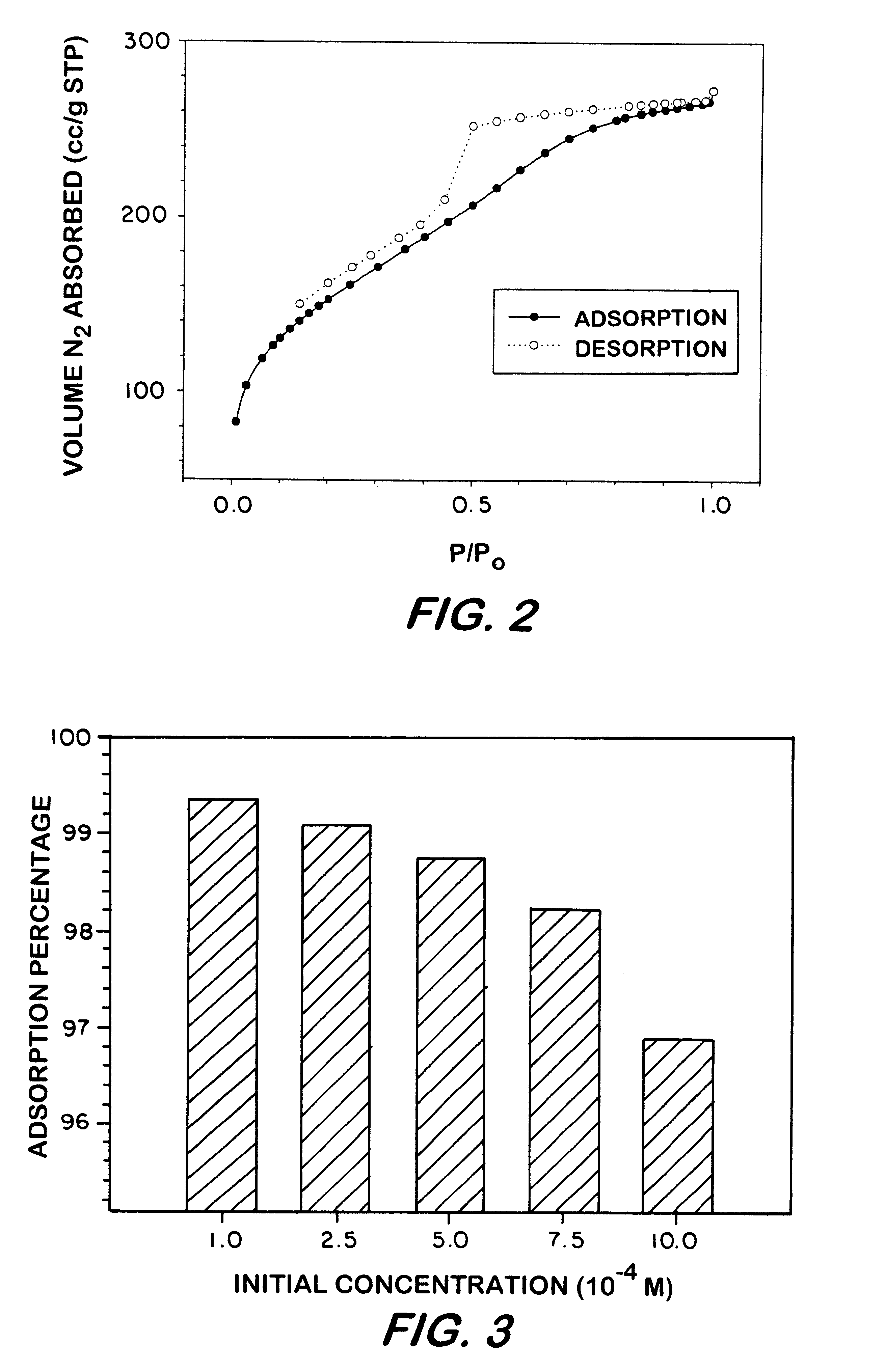

Reusable polysilsesquioxane adsorbents for pollutants

InactiveUS6673246B2Efficient disposalEfficient reuseOther chemical processesIon-exchanger regenerationAlcoholSorbent

This invention pertains to adsorption by an adsorbent of an adsorbate and to regeneration of the loaded adsorbent. The adsorption includes contacting an adsorbent selected from arylene-bridged polysilsesquioxanes and derivatives thereof with an adsorbate selected from aromatics and heterocyclics, particularly monocyclic heterocyclics containing carbon and nitrogen atoms in a 6-member non-aromatic ring, for a period of time sufficient to adsorb all or part of the adsorbate by the adsorbent. Regeneration of the loaded adsorbent includes removing all or part of adsorbate from the adsorbent by means of an alcohol wash or by thermal desorption of the adsorbent containing adsorbate.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

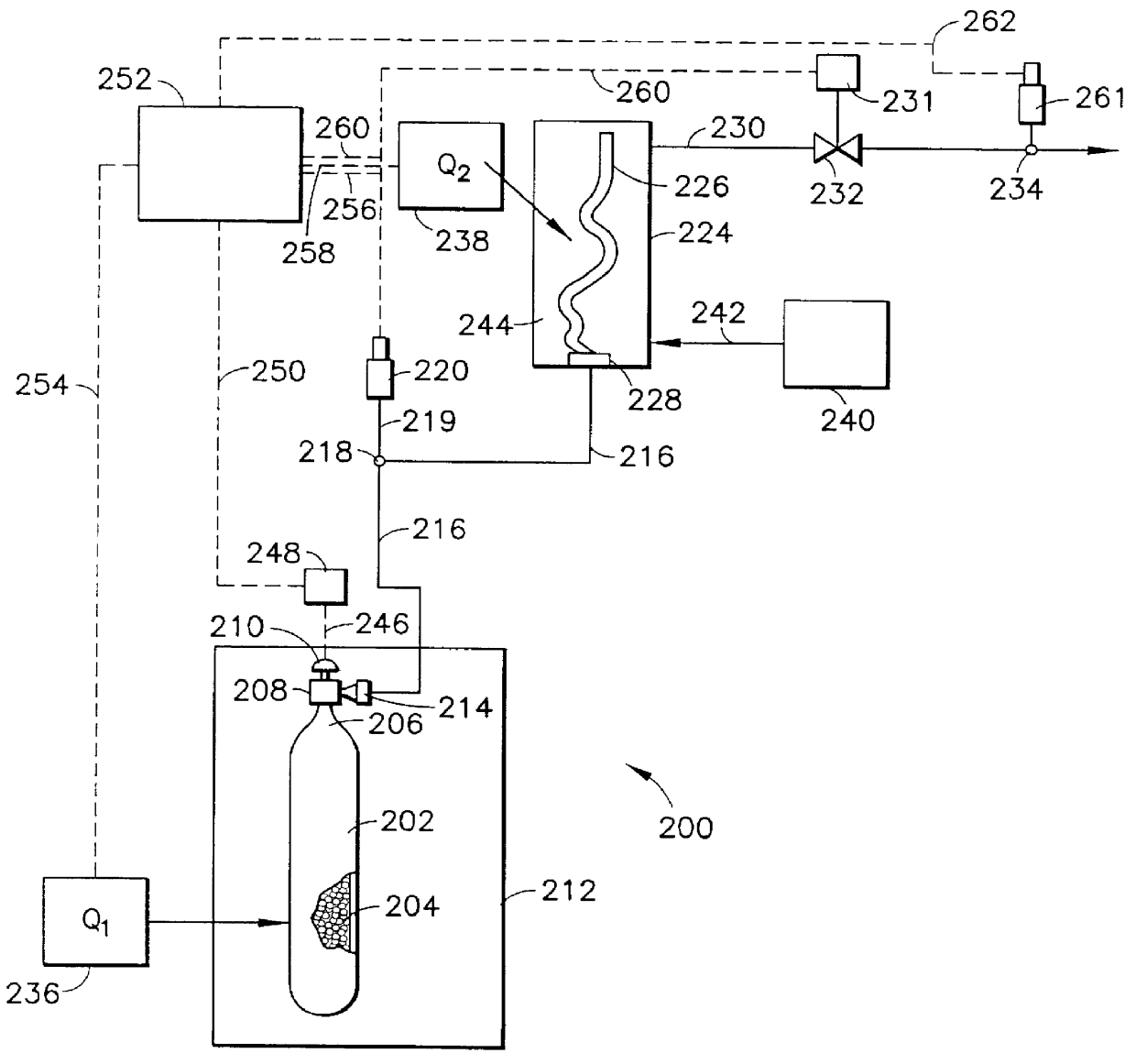

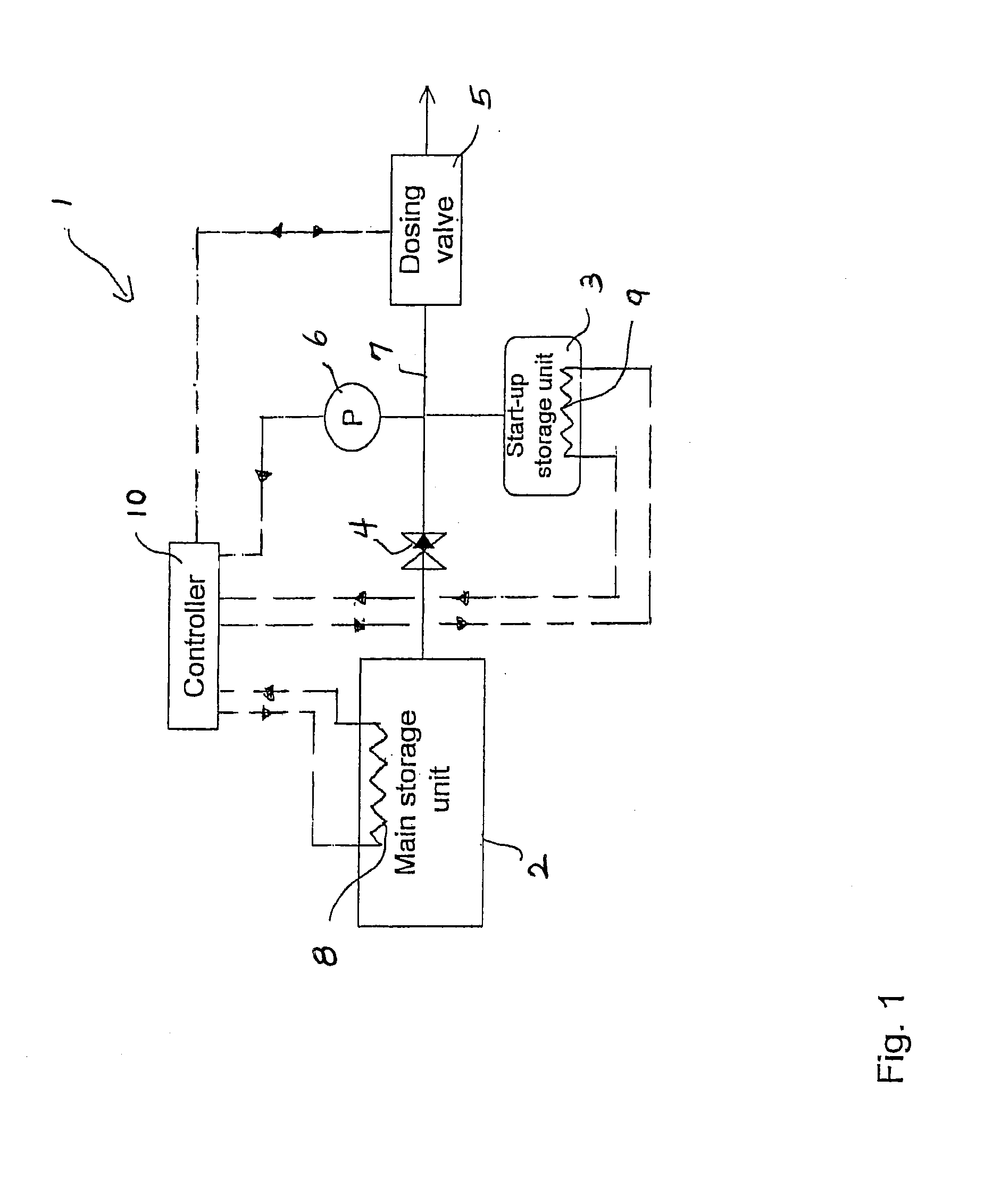

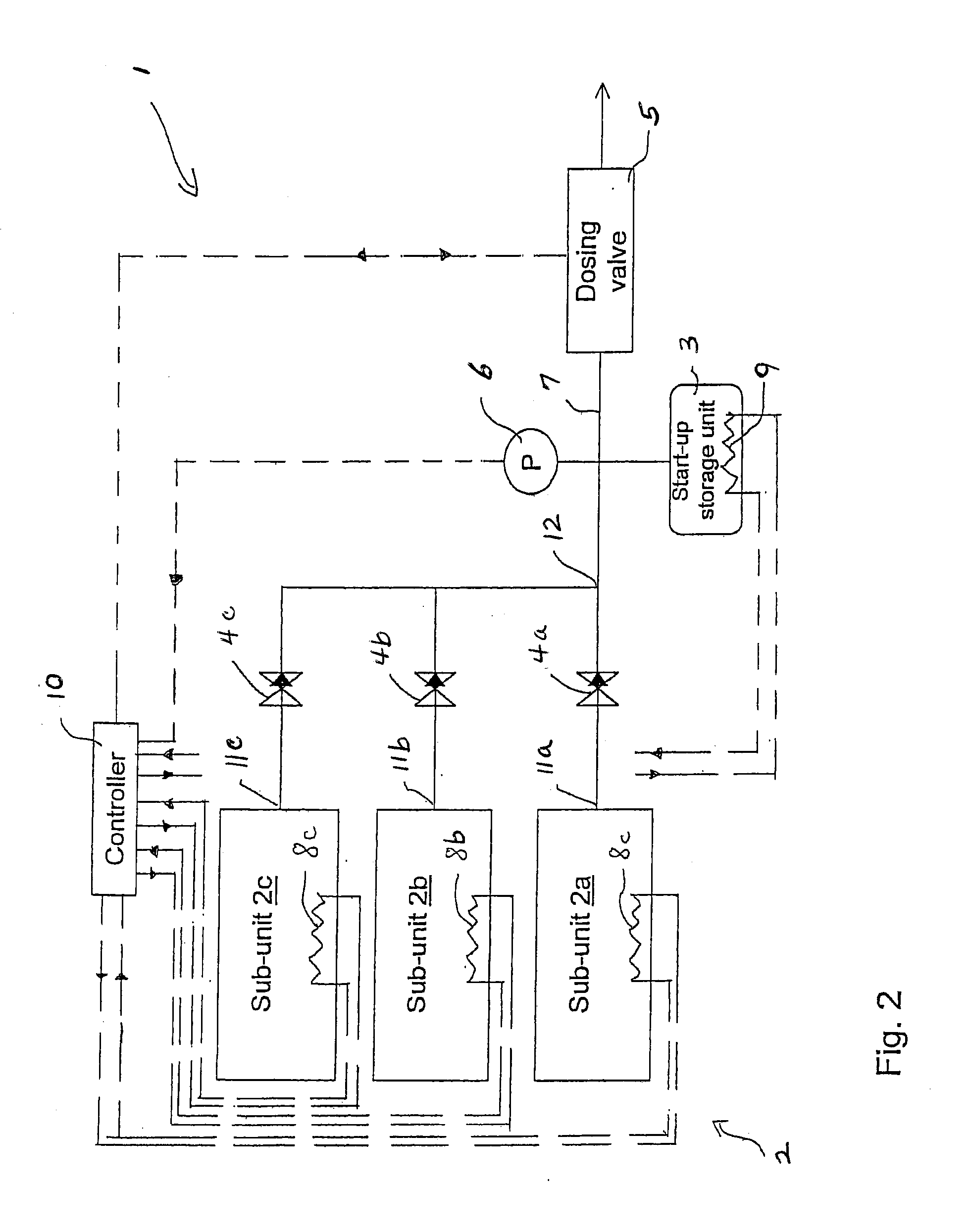

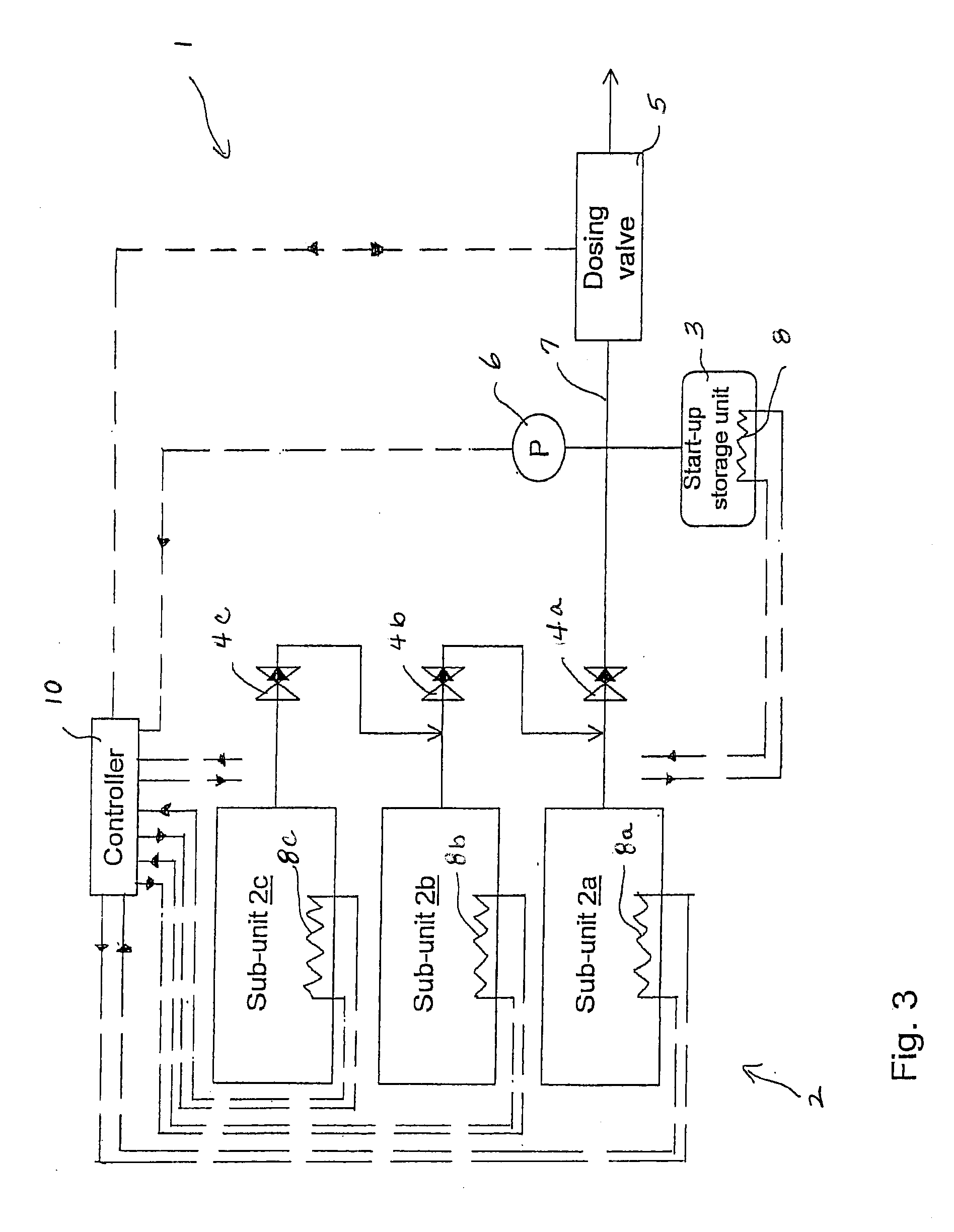

Release of Stored Ammonia at Start-Up

ActiveUS20100086467A1Demand for it variesPrevent backflowInternal combustion piston enginesExhaust apparatusAmmonia storageGaseous ammonia

A system for storage and dosing of ammonia, including a solid ammonia storage material capable of binding and releasing ammonia reversibly by adsorption / absorption. The system is able to release ammonia gradually according to a demand that can vary over time with intermediate periods of no ammonia demand. A main storage unit and a start-up storage unit are provided. The storage units hold ammonia storage material. At least one one-way valve is provided via which the one main storage unit is in communication with the start-up storage unit. The one-way valve prevents any back-flow of ammonia from the start-up storage unit to the main storage unit. Heating devices are arranged to heat the main storage unit and the start-up storage unit separately to generate gaseous ammonia by thermal desorption from the solid storage material. A controller controls the heating power of the main storage unit and the start-up storage unit, thereby enabling ammonia release from at least one of the start-up and / or the main storage unit. A dosing valve controls ammonia flow from the storage units according to a demand.

Owner:AMMINEX EMISSIONS TECH

Thermal treatment restoration method and system for contaminated soil

ActiveCN104607454AReduced Diffusion EntryEmission safetyContaminated soil reclamationIncinerator apparatusCombustion chamberRestoration method

The invention discloses a thermal treatment restoration method and system for contaminated soil. The thermal treatment restoration method for the contaminated soil comprises the following steps: crushing, conveying, burning, thermally desorbing, recovering heat energy, neutralizing with acidic materials, and dedusting. The system for executing the method comprises a soil crusher, a first carrier roller belt conveyor with a sealed cabin, a paddle dryer, a second carrier roller belt conveyor with the sealed cabin, and a rotary kiln thermal desorption unit, wherein pipes are arranged at all of the soil crusher, the first carrier roller belt conveyor, the paddle dryer, the second carrier roller belt conveyor and the rotary kiln thermal desorption unit and communicated with a secondary combustor. According to the thermal treatment restoration method and the thermal treatment restoration system disclosed by the invention, the organic matters, diffusing into the atmosphere, in the soil can be reduced; the organic matters can be completely transformed into water, carbon dioxide and other non-toxic innocuous substances, and then safely discharged through exhaust gas treatment; the heat energy in the system can be reutilized, so that the system energy consumption can be further reduced, and the economic efficiency is good; the treated soil can be recycled.

Owner:苏州同和环保工程有限公司

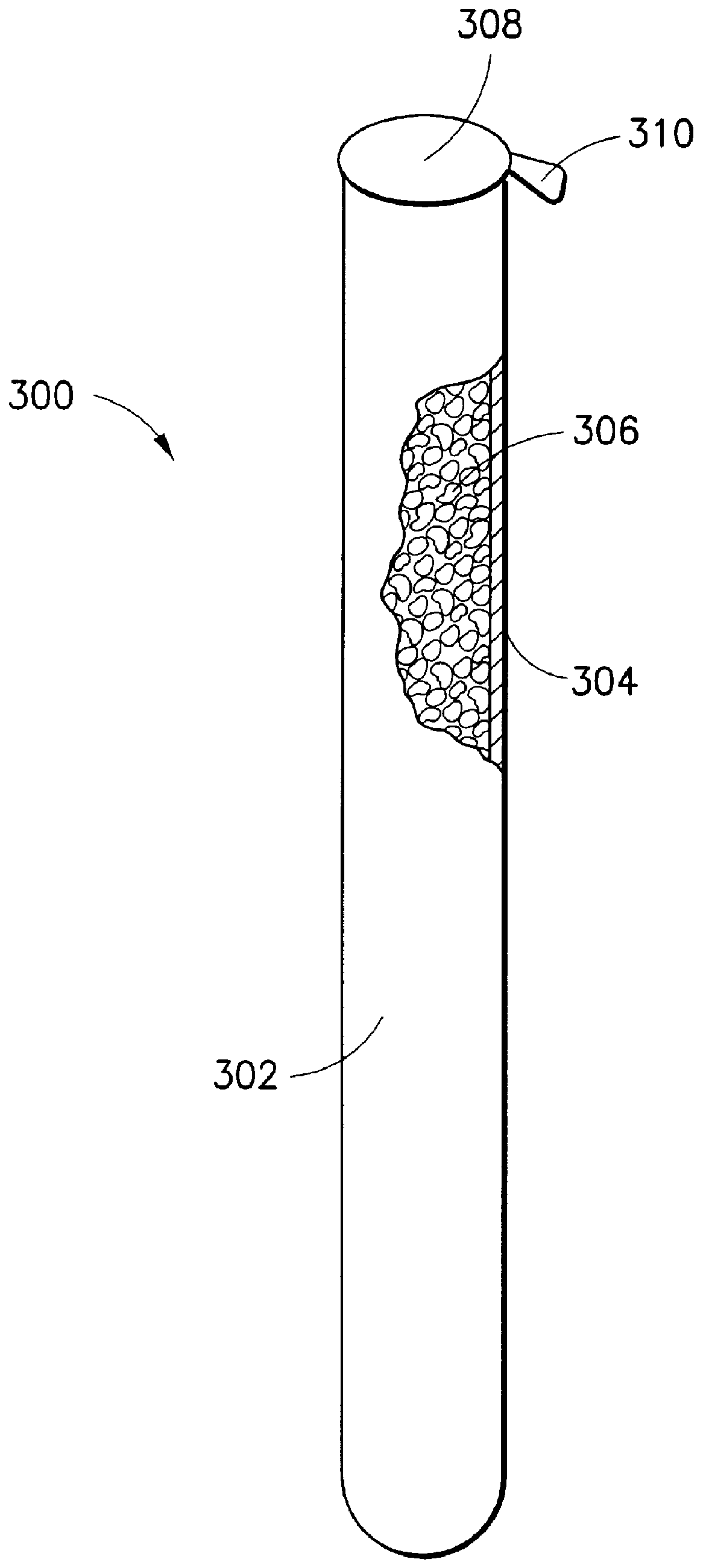

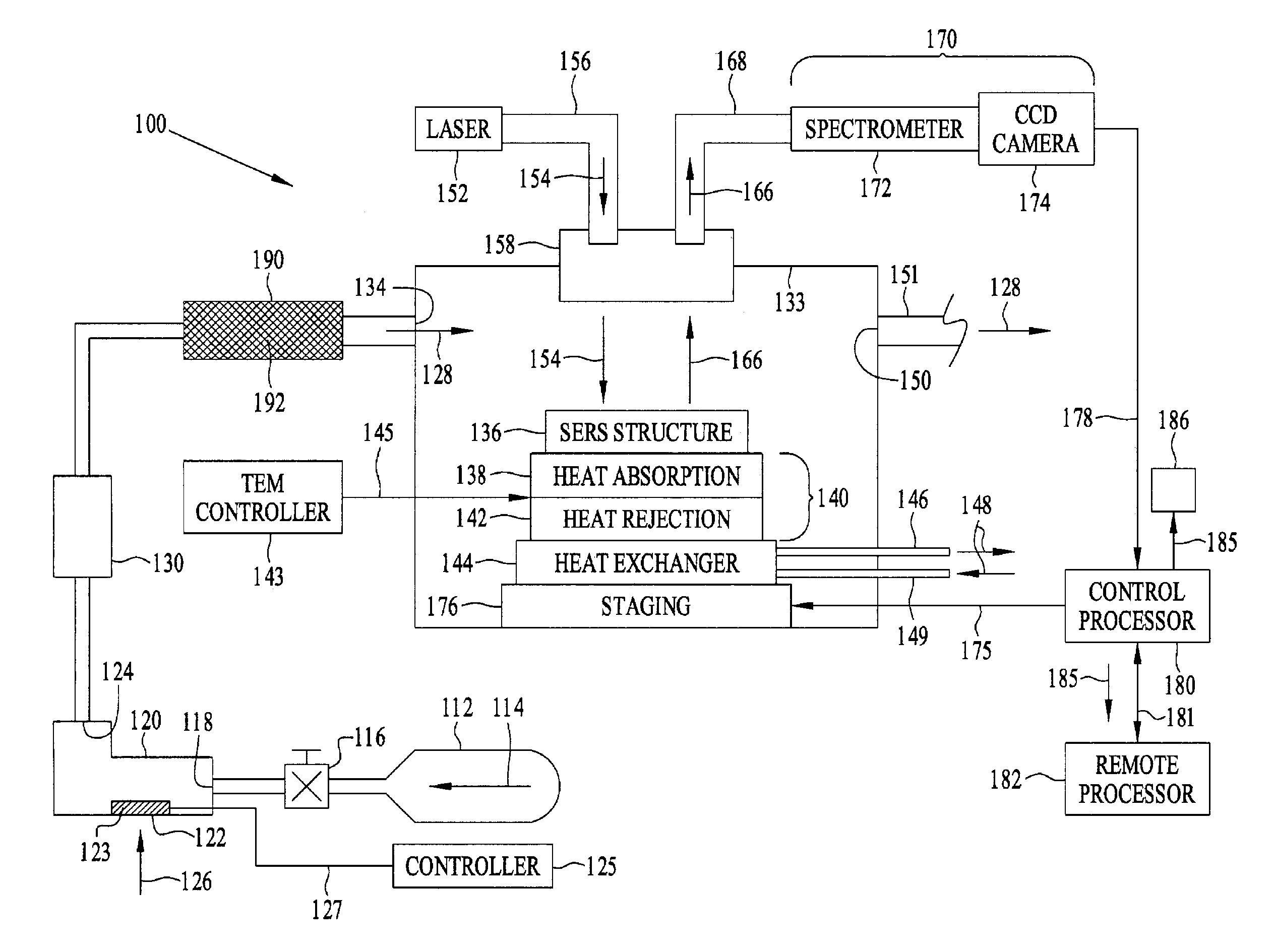

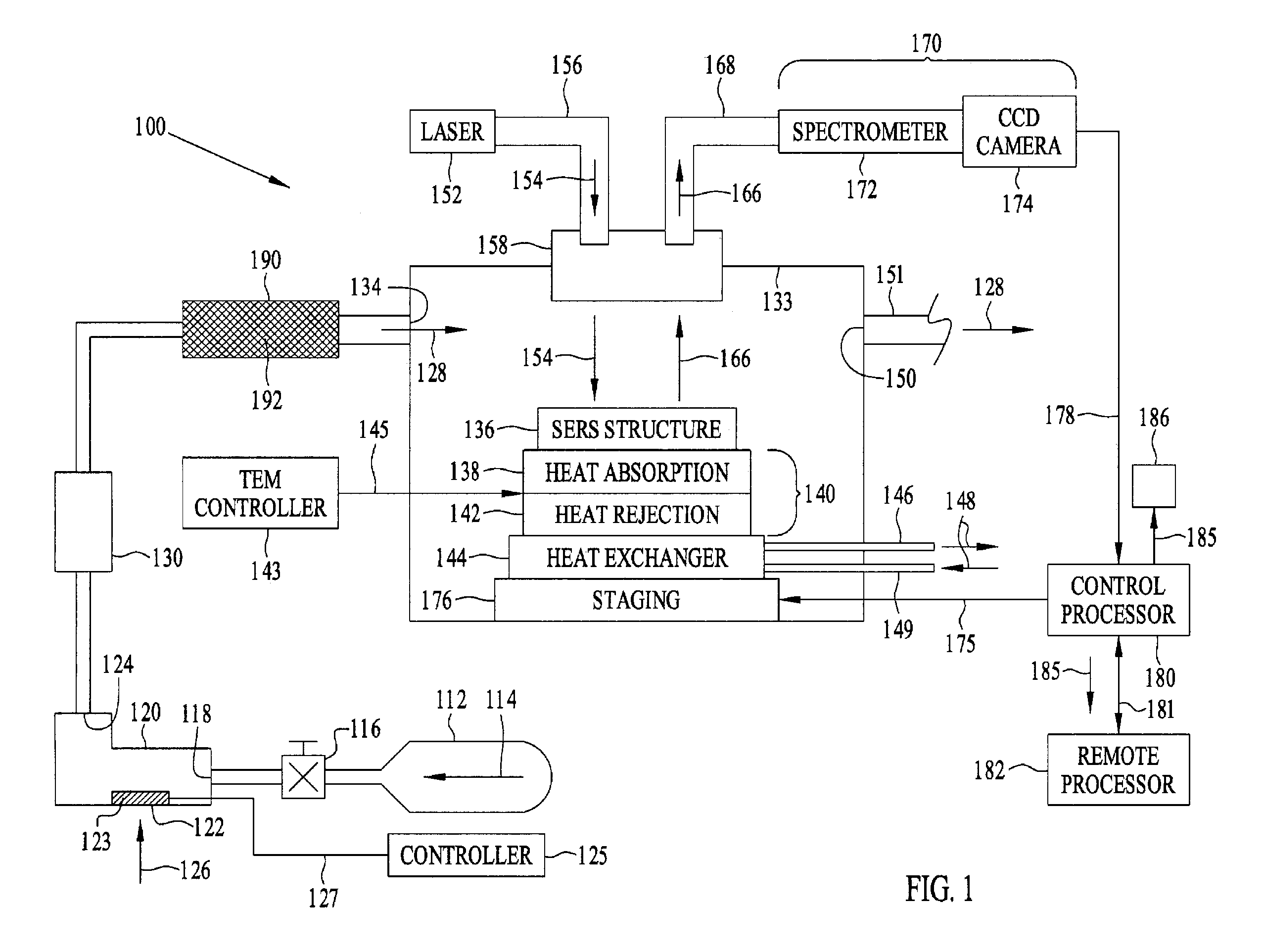

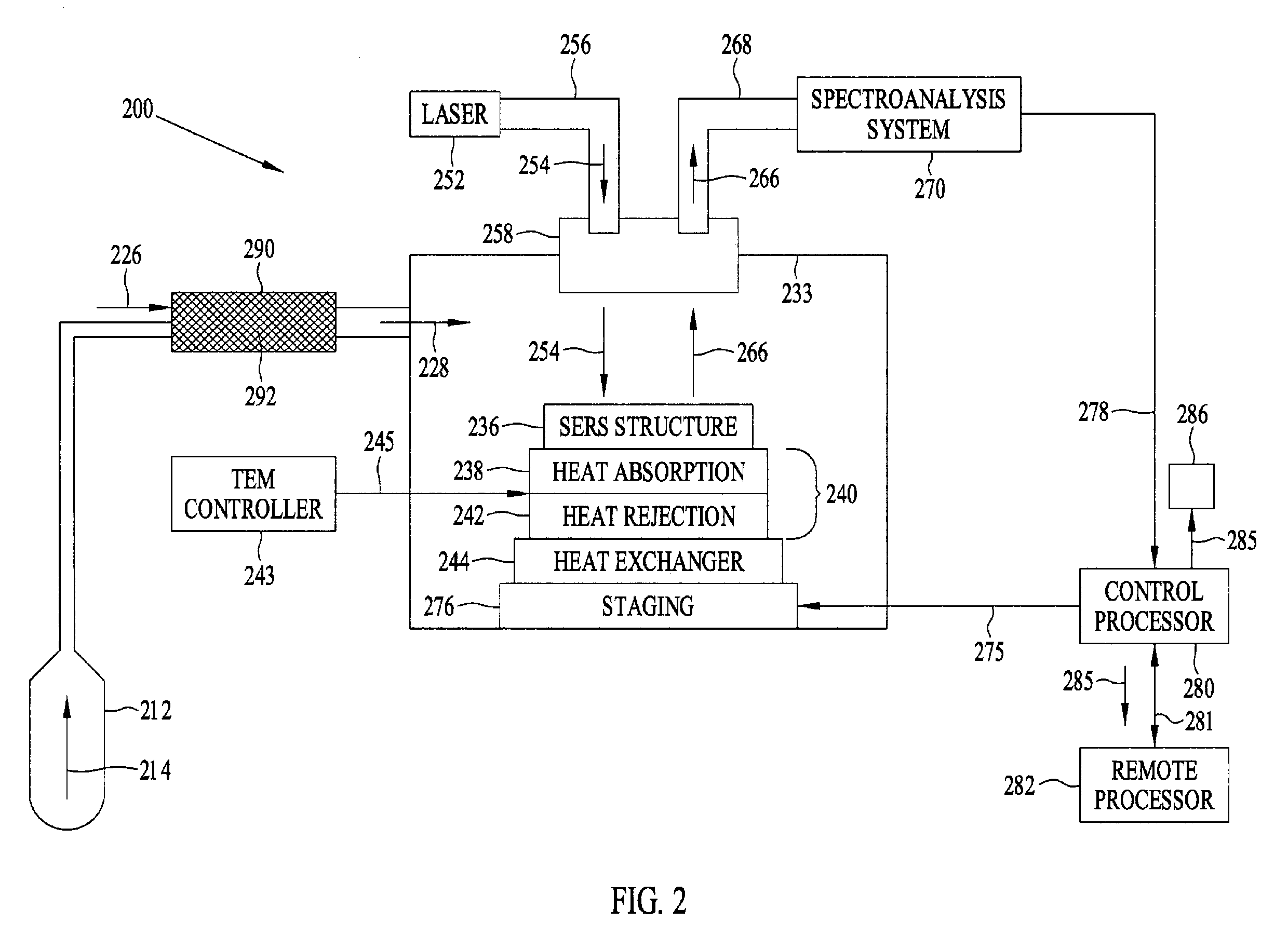

Thermo-electrically cooled surface-enhanced raman spectroscopy sensor system to detect volatile organic compounds

InactiveUS6947132B1Minimizing introductionIncrease relative volatilityRadiation pyrometryRaman scatteringSurface-enhanced Raman spectroscopyMoisture

A thermoelectrically cooled surface-enhanced Raman spectrometer sensor system and method for monitoring of volatile organic compounds in gas, liquid, and soil environments. The sensor system comprises a means for providing an inert gas, a thermal desorption tube containing an adsorbate, and a sample chamber with a SERS structure. For liquid and soil environments, the sensor system also comprises a manifold having a semipermeable membrane for separating moisture from an analyte. An optical module mounted to the sample chamber directs an optical excitation signal for irradiating the SERS structure and receives a SERS optical emissions signal. Such optical emissions signal may be detected by a spectroanalysis system and correlated to a particular analyte by a control processor, which generates an alert signal containing a message that the presence of analyte has been detected. The control processor may also activate warning device, such as an audible siren or a visual alarm.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com