Harmless treatment method for separation and recovery of oily sludge

A technology of harmless treatment and sludge separation, applied in the fields of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of convenient management, low cost and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

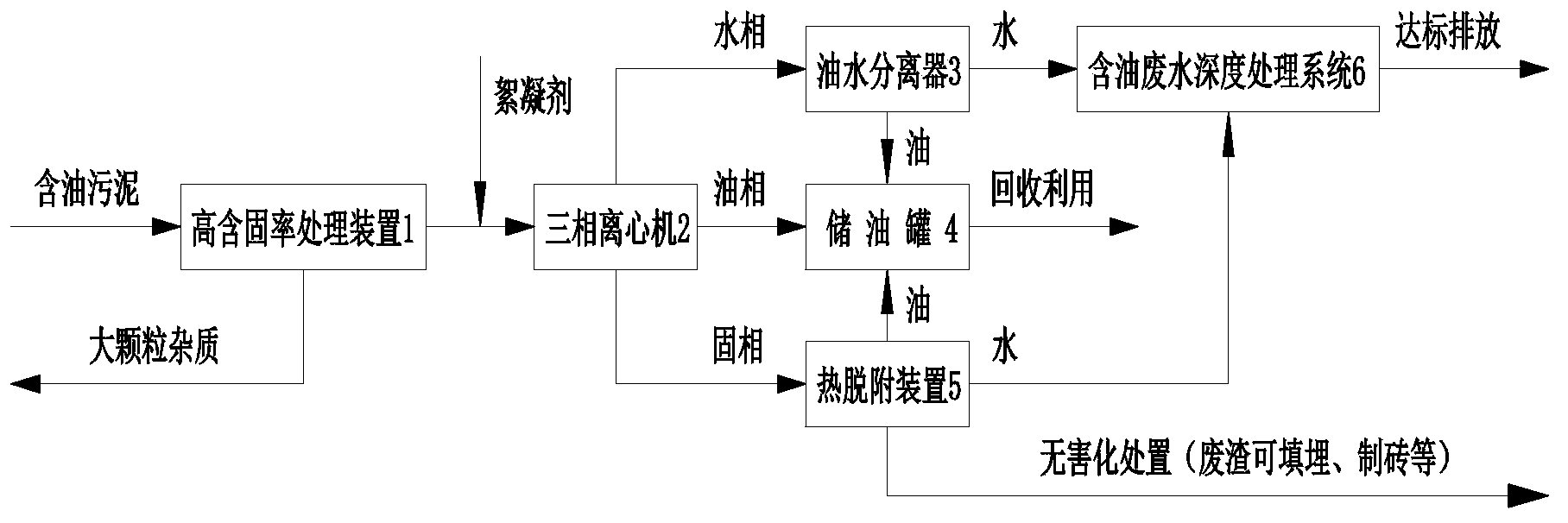

[0023] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0024] see figure 1 , In the treatment method of the present invention, the following high solid content treatment device 1, three-phase centrifuge 2, oil-water separator 3, oil storage tank 4, thermal desorption device 5, and oily wastewater advanced treatment system 6 are used to form. The technological process step of present embodiment is as follows:

[0025] A. The oily sludge is transported to the high solid content treatment device 1, and the large particle impurities in the oil sludge are initially screened and the sludge is tempered. The specific operation process is to pre-condition the oil sludge through steam heating, stirring and tempering, scraping and conveying, vibration screening and other pre-conditioning steps, and then conduct preliminary screening and sludge conditioning for large particles of impurities in the oil sludge.

[0026] B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com