Patents

Literature

16254results about "Water treatment multistage treatments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

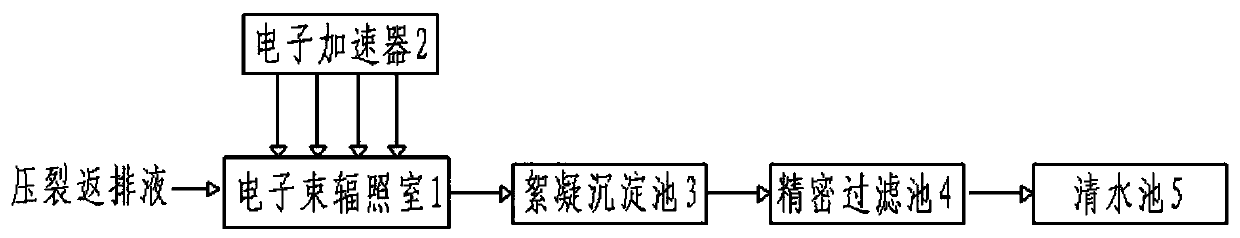

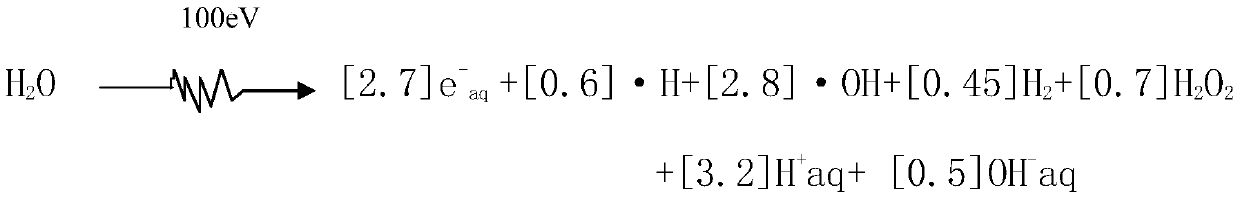

Rapid treatment method for fracturing flowback fluid

PendingCN110467298ARealize online processingLittle side effectsWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

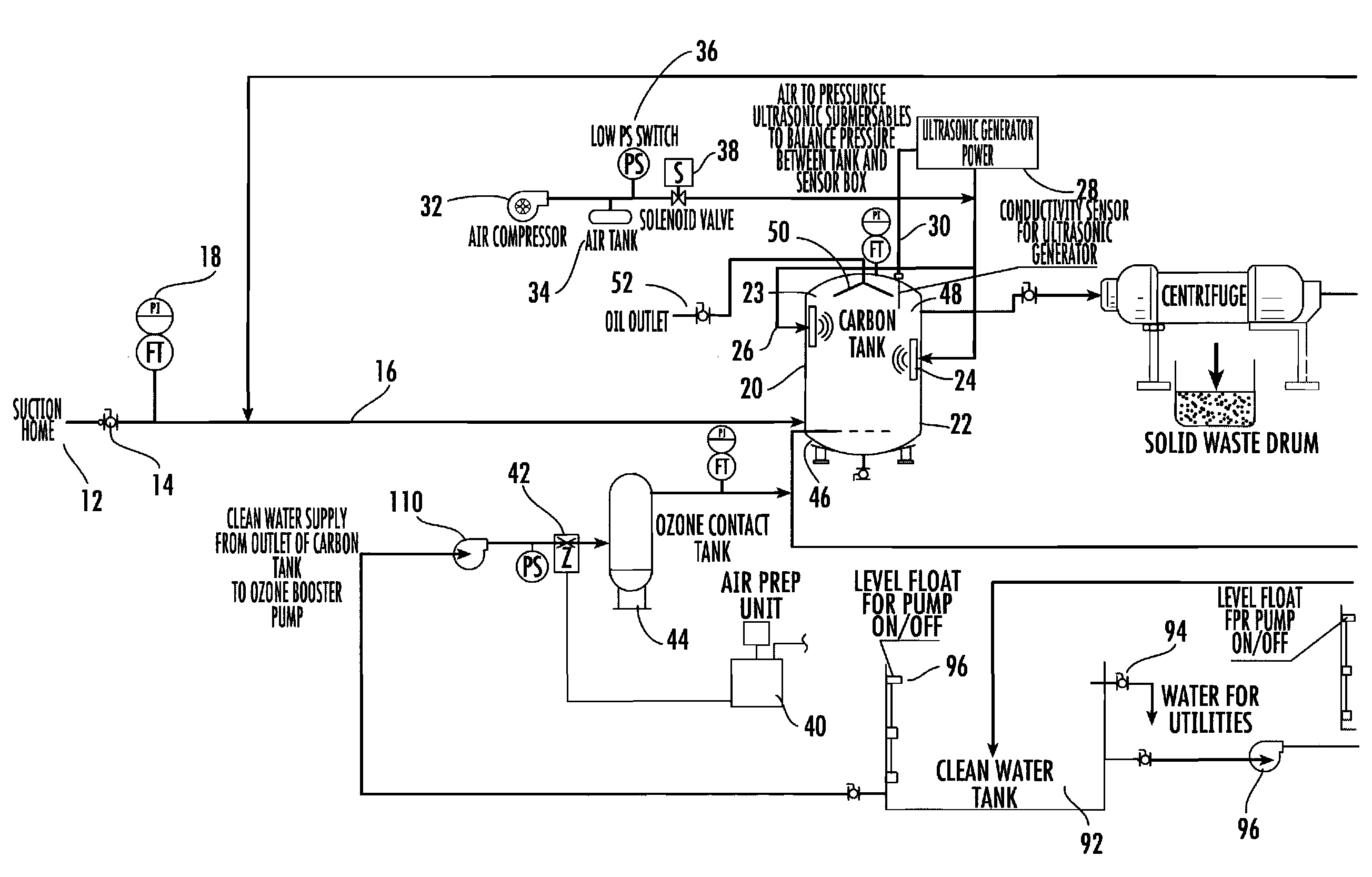

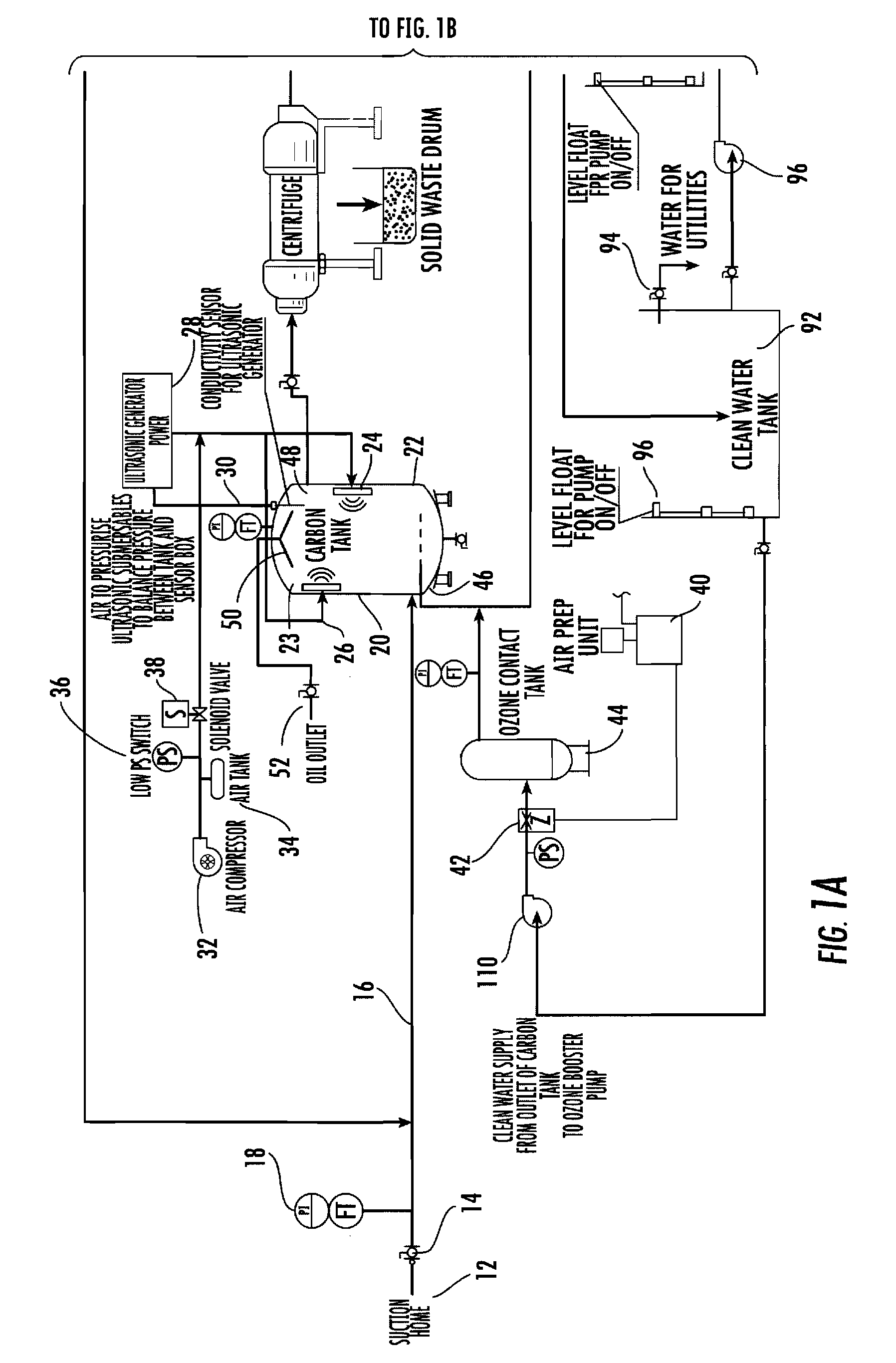

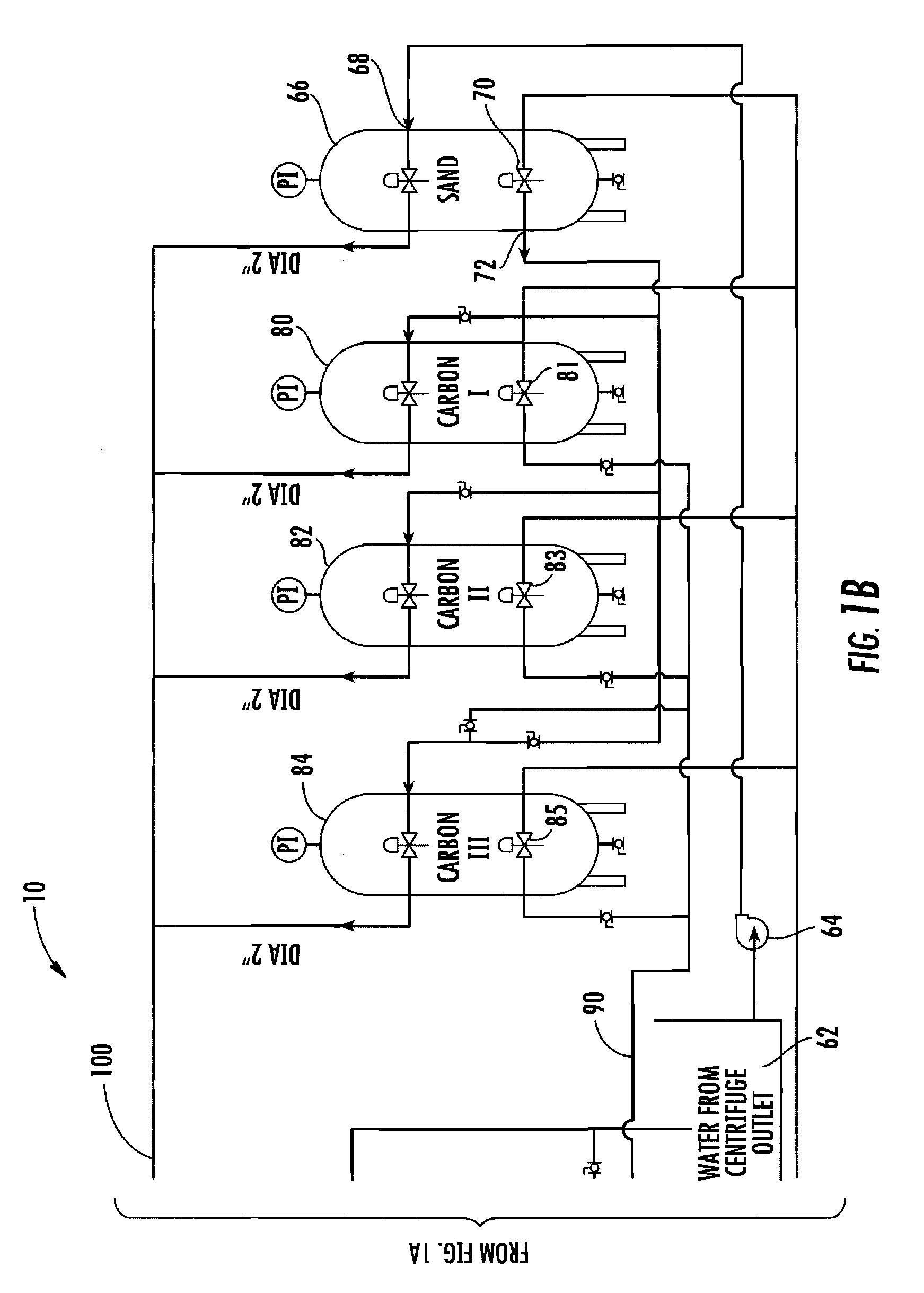

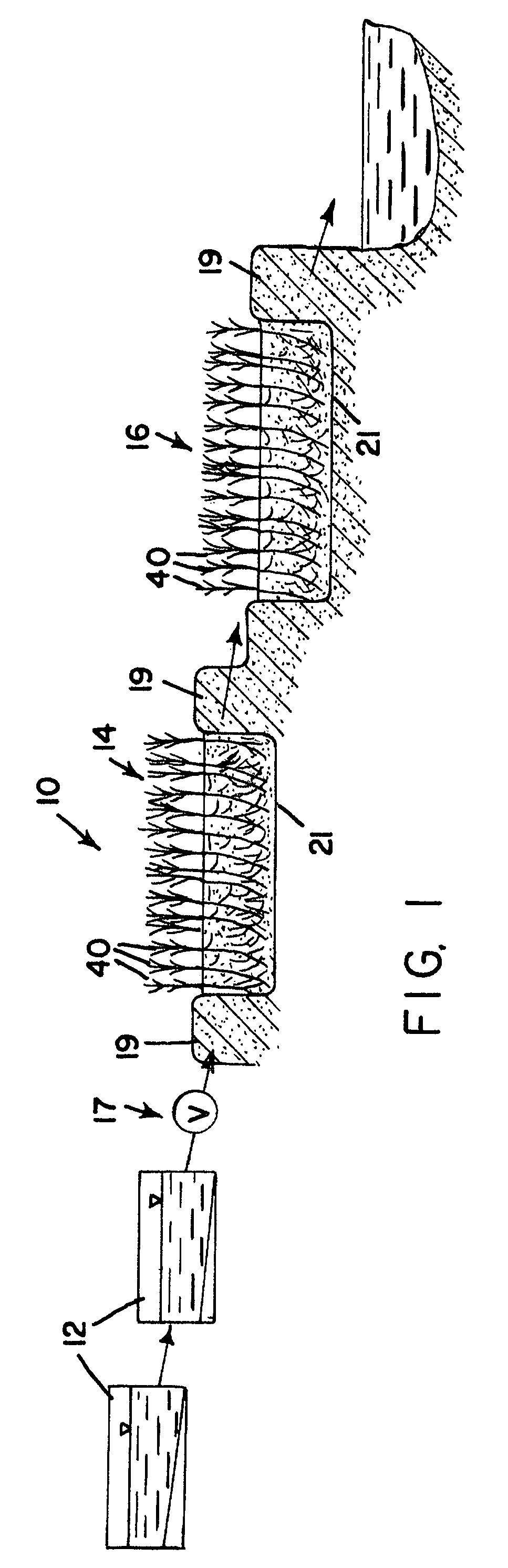

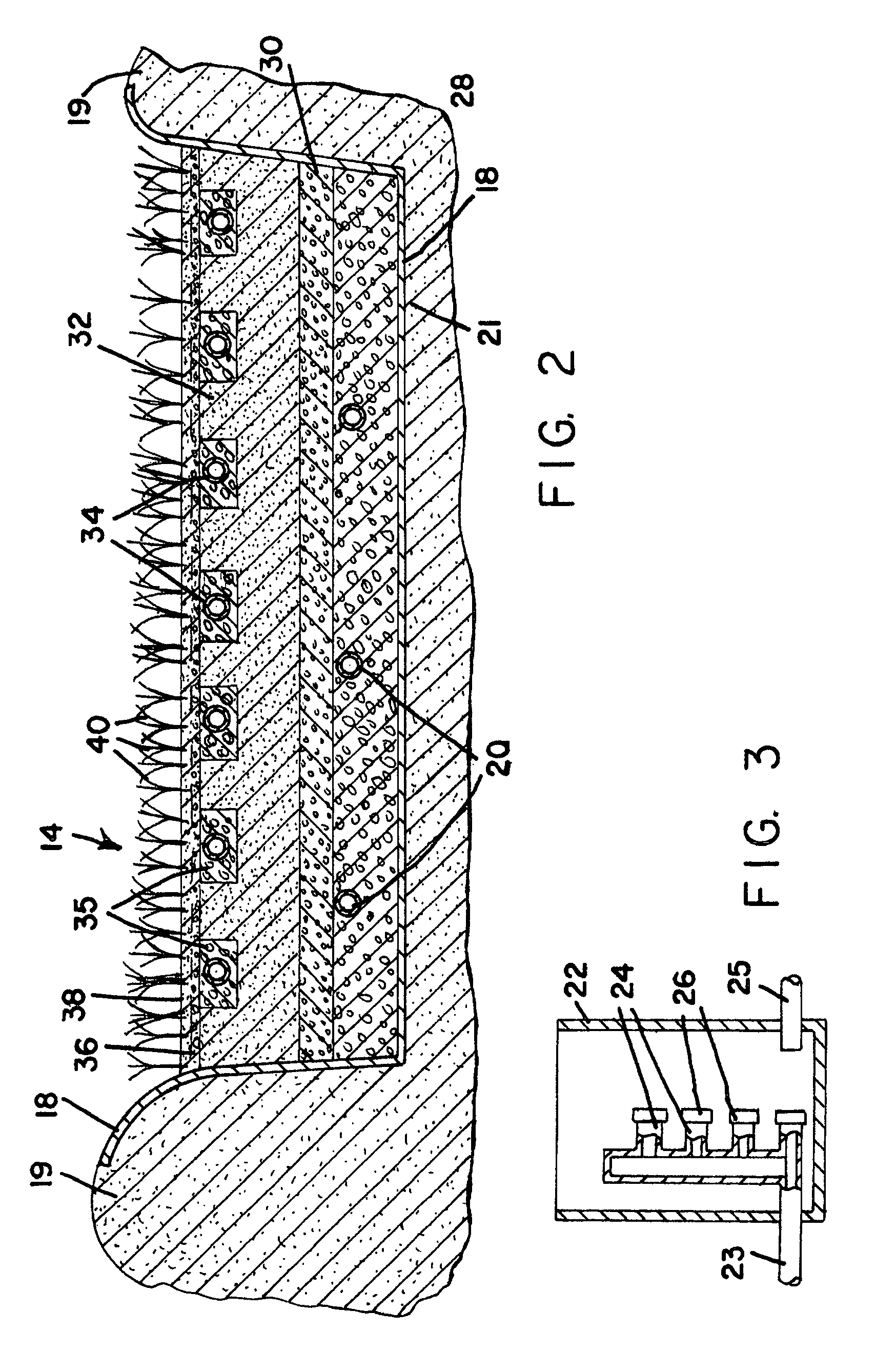

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

ActiveUS20090050572A1Low costCurrent expensiveWaste water treatment from quariesTreatment involving filtrationLiquid wastePotable water

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

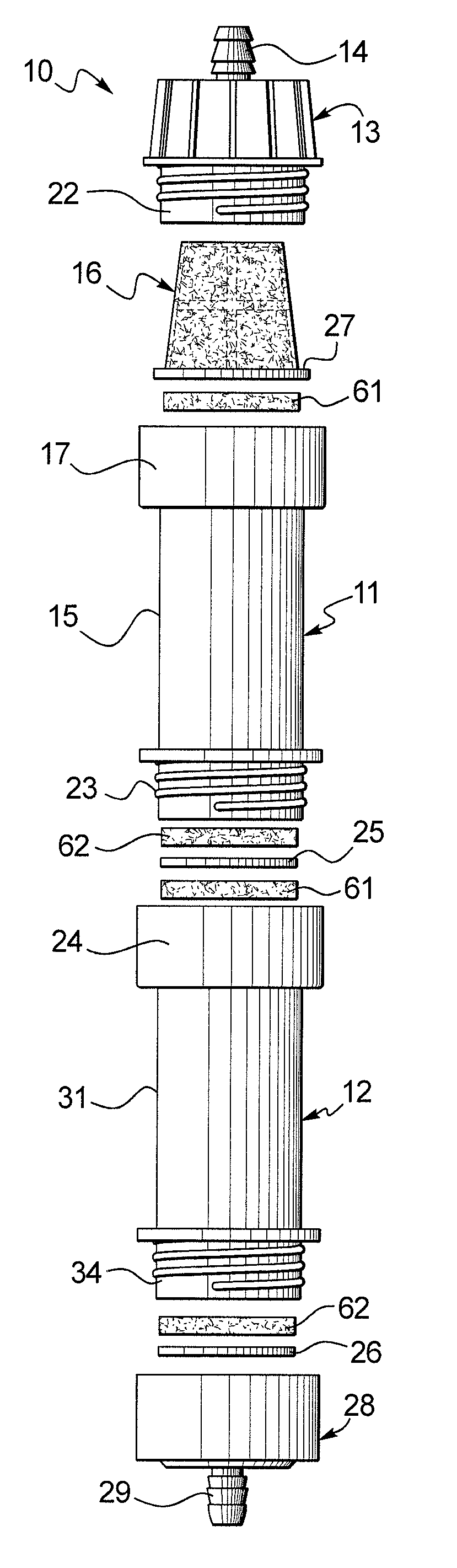

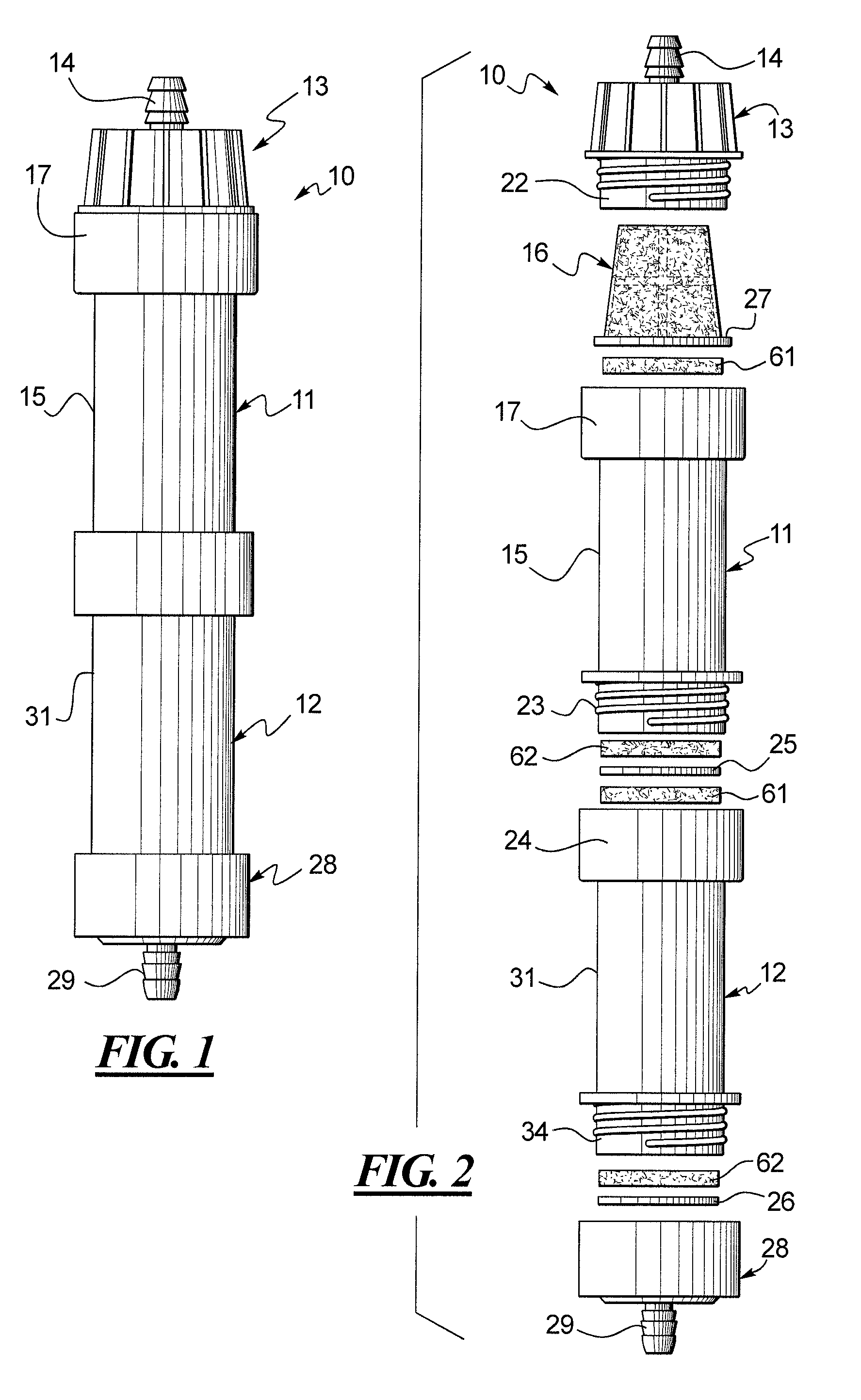

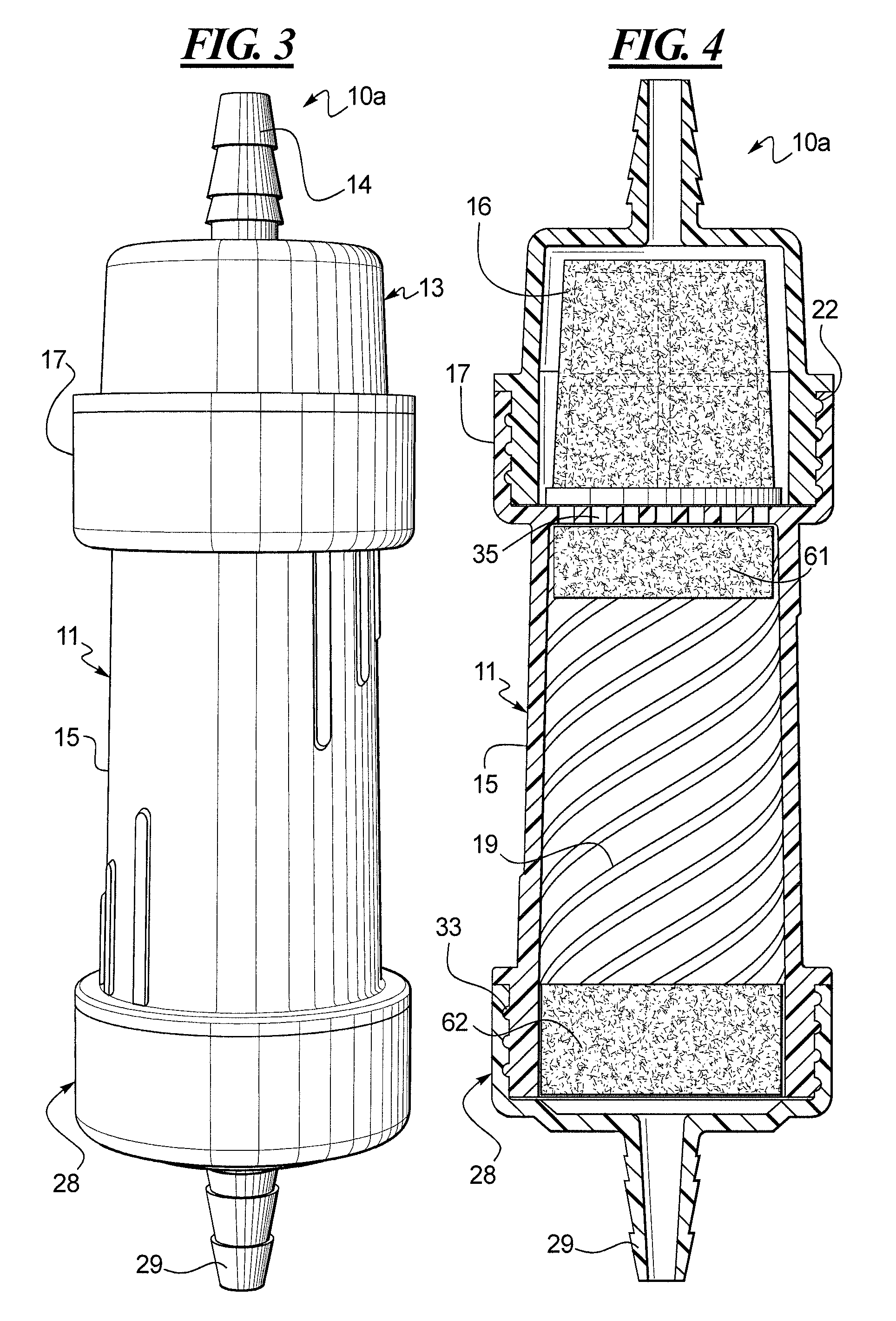

Modular Water Purification and Delivery System

InactiveUS20090008318A1Maximize capacityFlattening or eliminating the parabolic fluid flow profileUltrafiltrationWater/sewage treatment by ion-exchangeFiberHollow fibre

A modular filter system is provided with one or more modules that can be interchangeable, depending upon the specific application or specific health or environmental issue presented. Disclosed combinations can include one or more of any of the following modules in any relative position to one another: (a) a microbiological contaminant mitigation module, preferably in the form of an inverted u-shaped hollow fiber filter module wherein the fibers have ends potted on the downstream side and that consists essentially of hydrophilic fibers for water filtration with a small amount of hydrophobic fibers for venting of entrapped air; (b) a first chemical mitigation module, preferably in the form of an adsorption module comprising carbon or the combination of carbon and a deionization resin; and (c) a second chemical mitigation module, preferably in the form of a deionization resin module. Modules including a carbon bed or a resin bed may be equipped with a pair of hydrophobic foam bed restraints that apply opposing axial pressure to the bed in all operating conditions.

Owner:PRISMEDICAL CORP

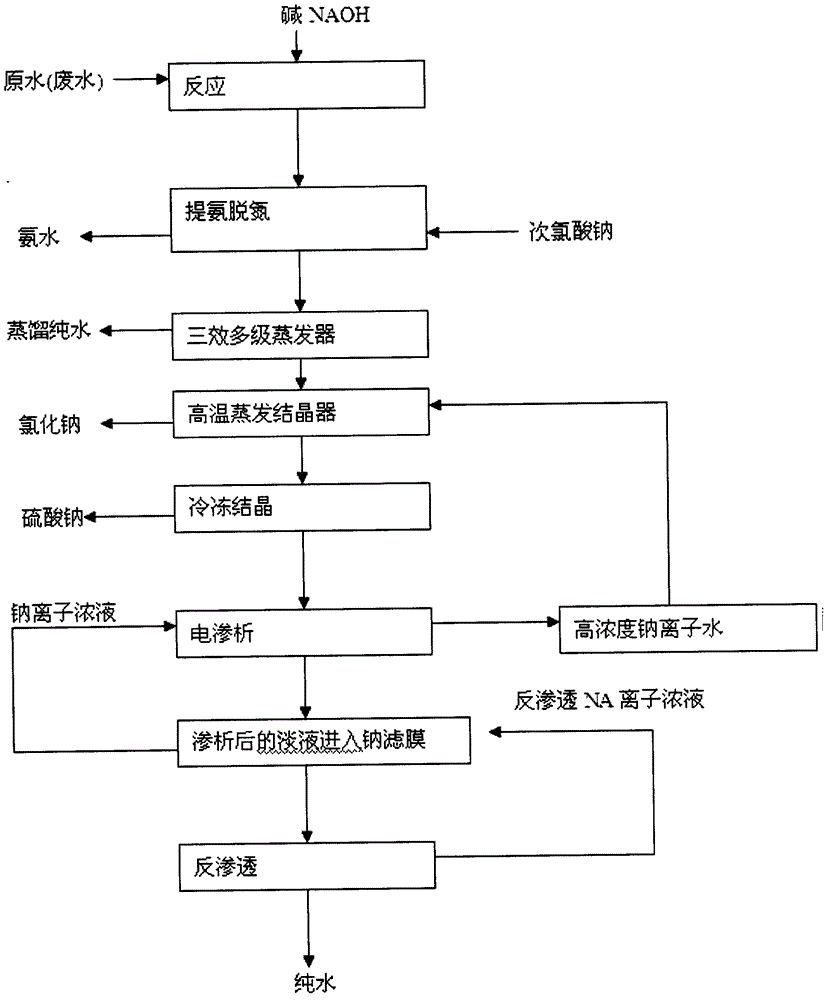

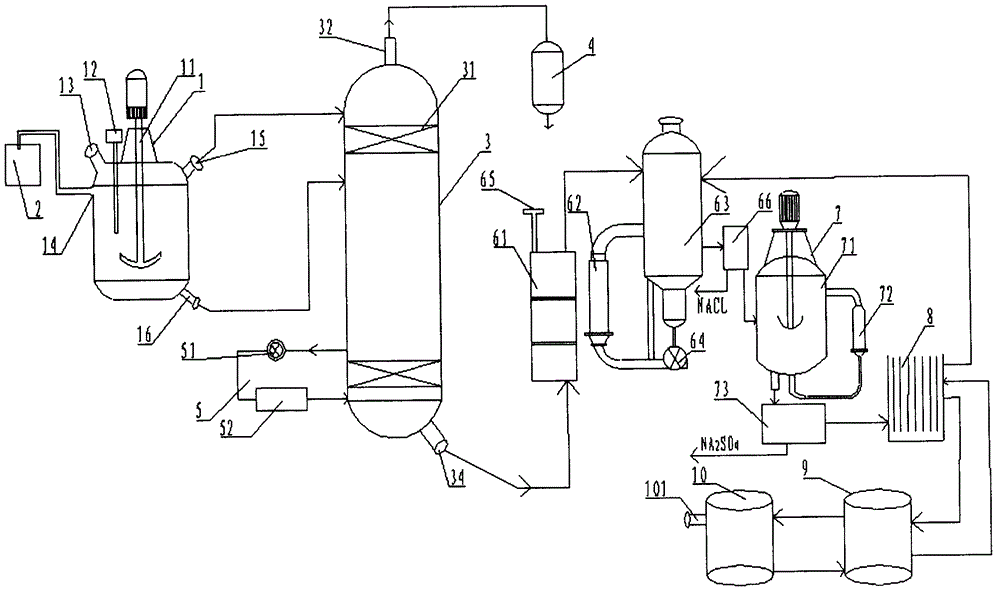

Method and device for utilizing sewage containing ammonia and sodium

ActiveCN104609633AReduce energy consumptionSave energyWater contaminantsMultistage water/sewage treatmentResource utilizationReverse osmosis

The invention discloses a method and device for utilizing sewage containing ammonia and sodium. The method comprises the steps of deamination reaction, denitrification reaction, gas-liquid separation, triple-effect multistage evaporation, evaprative crystallization and freezing crystallization, electrodialysis and sodium filteration membrane, and concentration of reverse osmosis membrane, so that distilled water and membrane deion pure water are recovered, and the resource utilization of sole sodium chloride and sodium sulfate is realized.

Owner:RUANSHI CHEM CHANGSHU

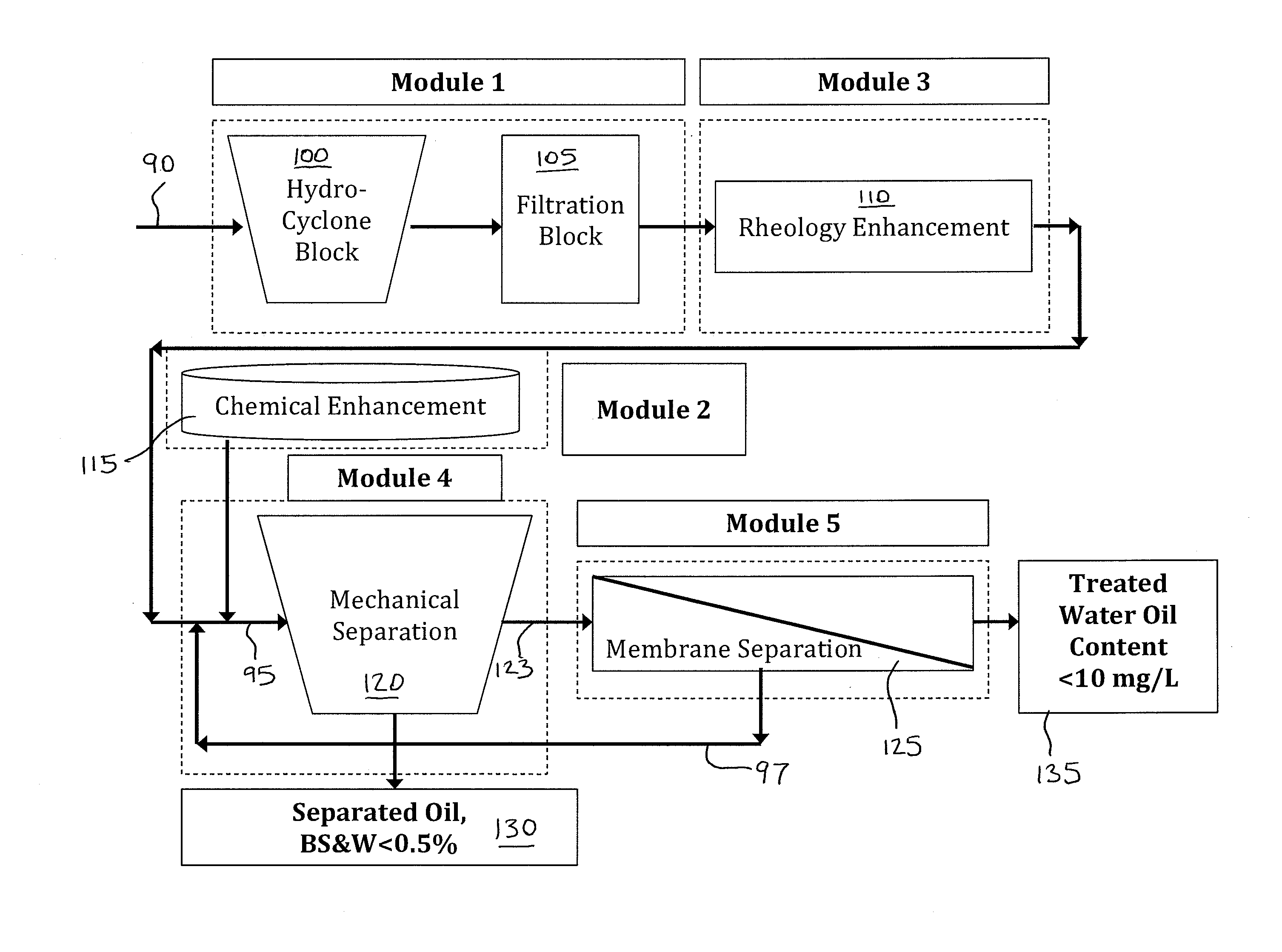

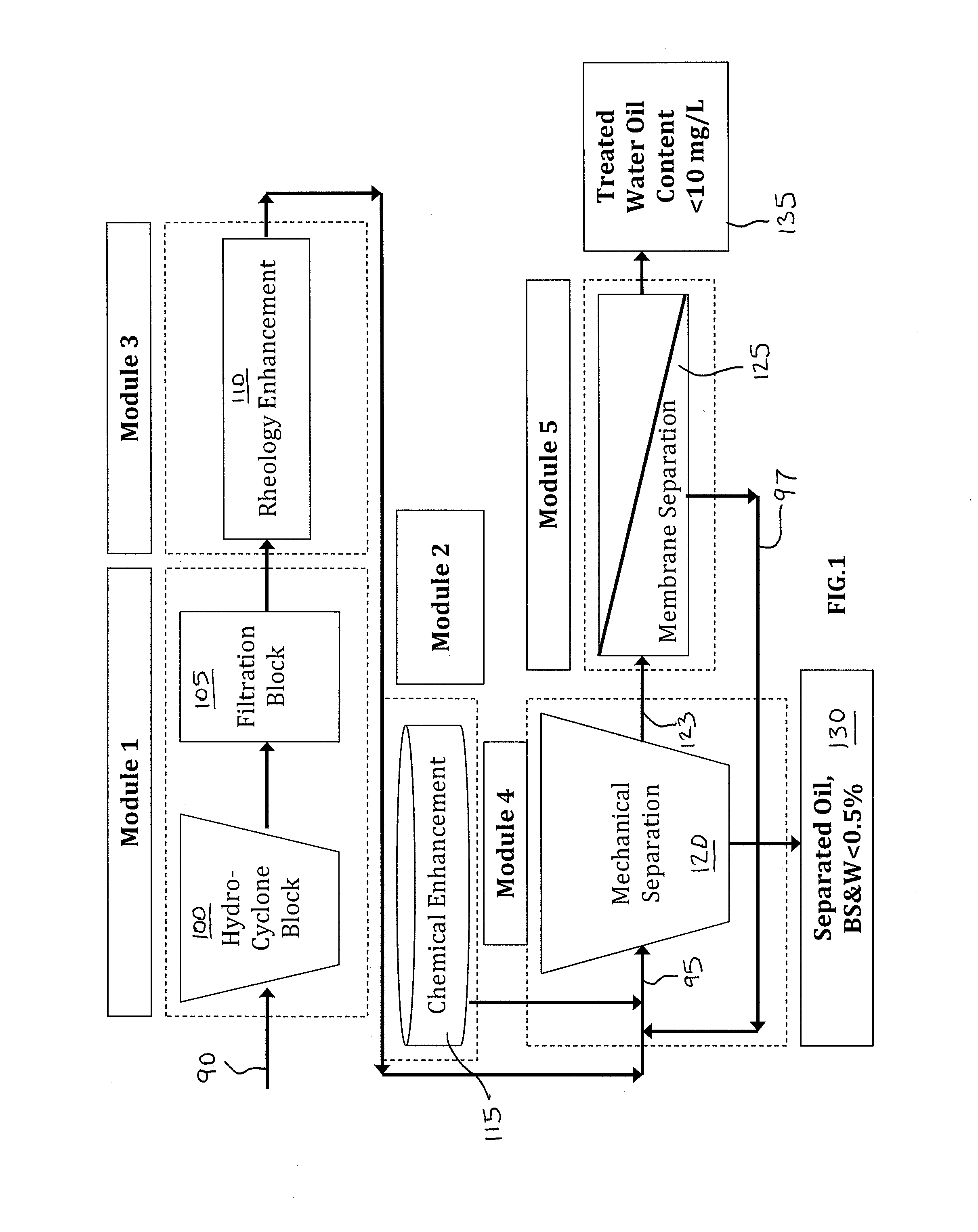

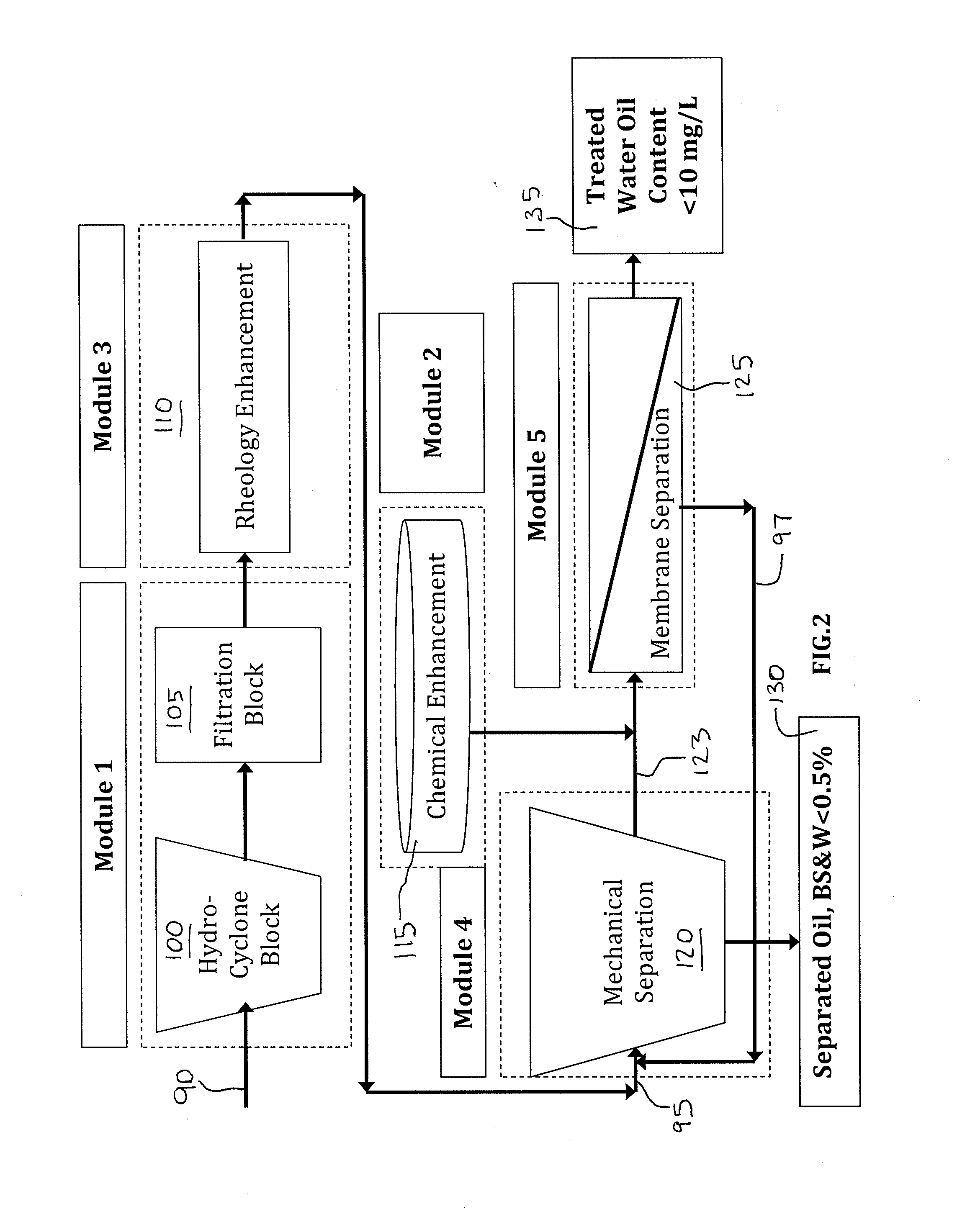

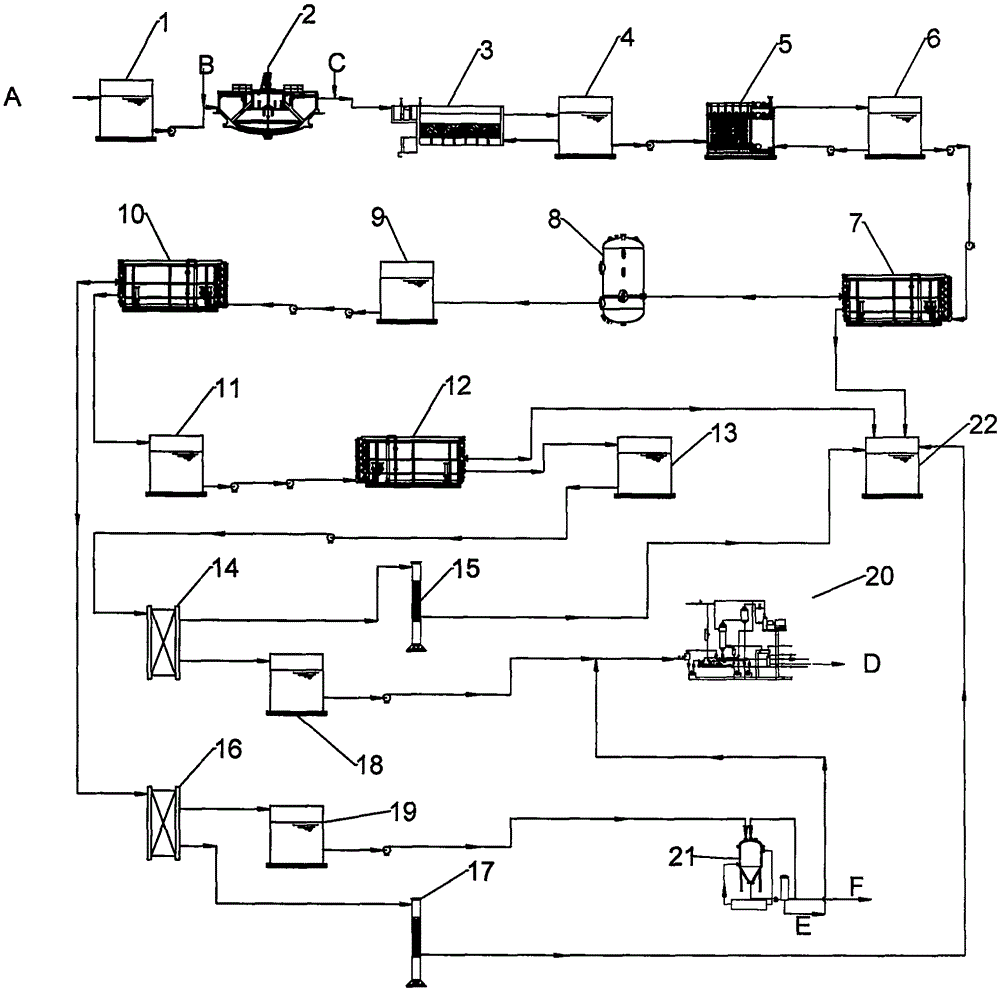

System And Method For Mechanical And Membrane Oil-Water Separation

InactiveUS20140158620A1Reduce the amount requiredReduce oilLiquid separation auxillary apparatusTreatment involving filtrationEnvironmental engineeringOil water

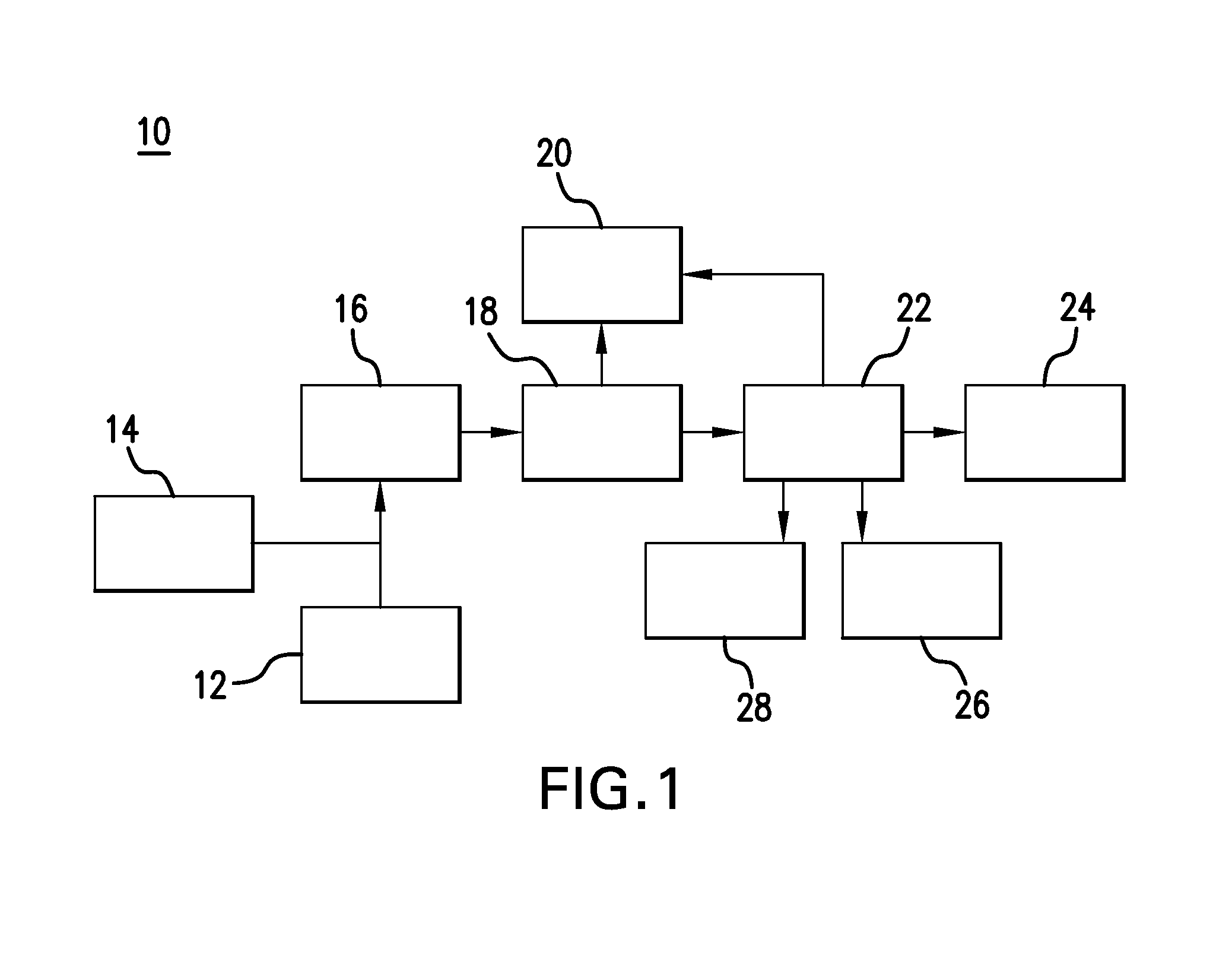

A system for the separation of the components of an oil, water, and solids mixture, the system comprising a mechanical separation module comprising an oily water output and an input adapted to receive an oil, water, and solids mixture; and a membrane separation module comprising an oily water input and a recirculation output. The oily water output of the mechanical separation module is in flow communication with the oily water input of the membrane separation module, and the recirculation output of the membrane separation module is in flow communication with the input of the mechanical separation module.

Owner:WATER PLANET ENG

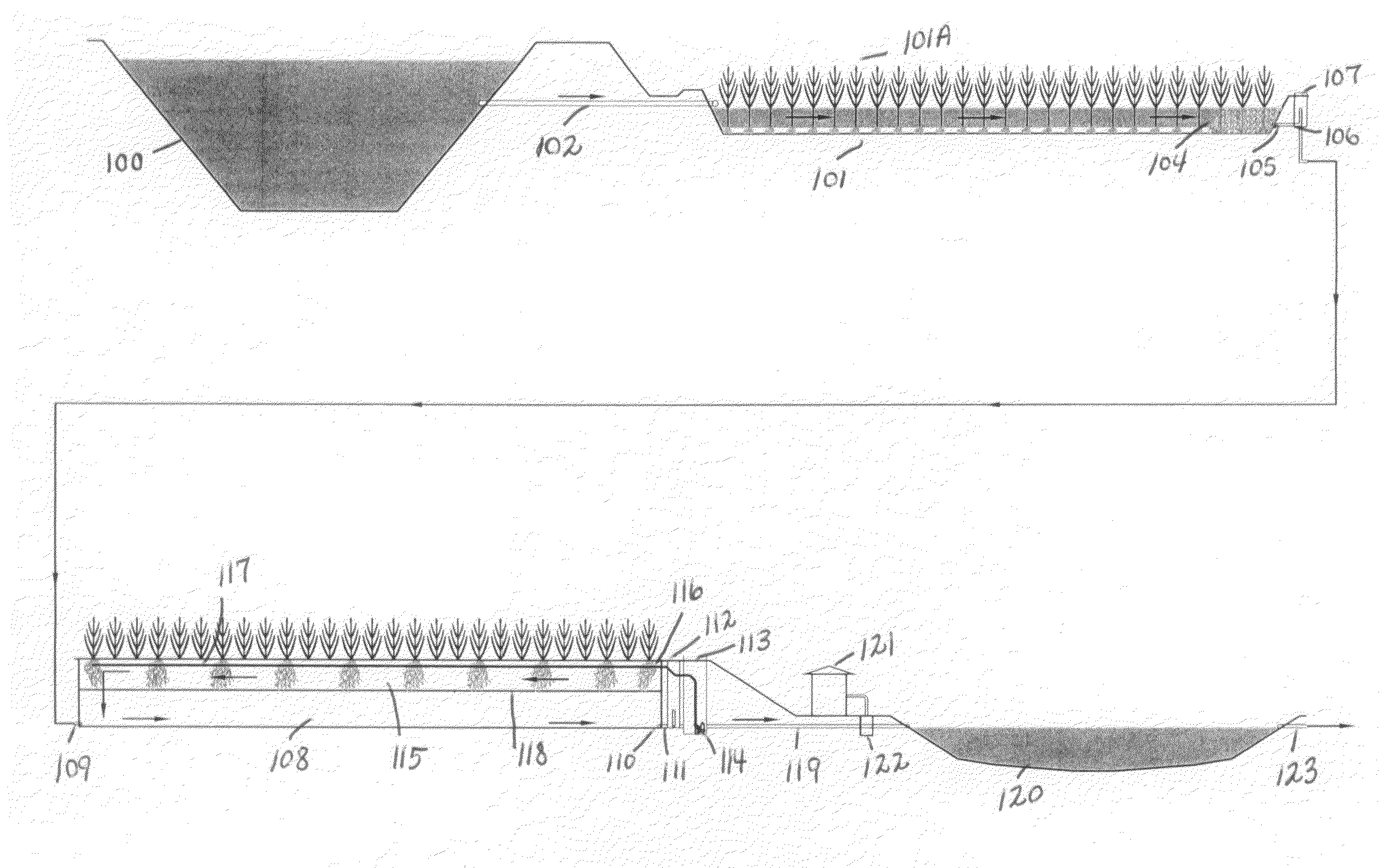

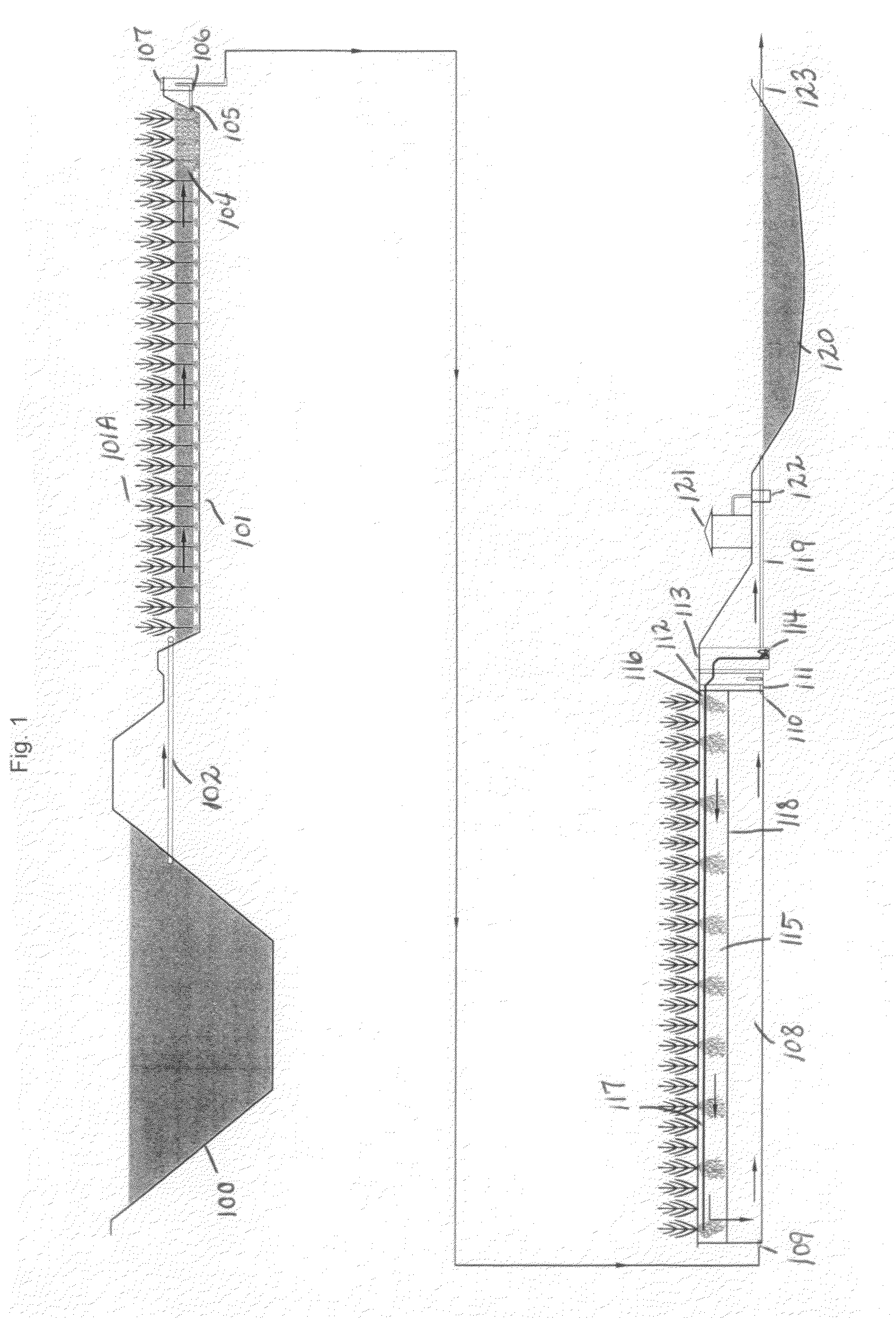

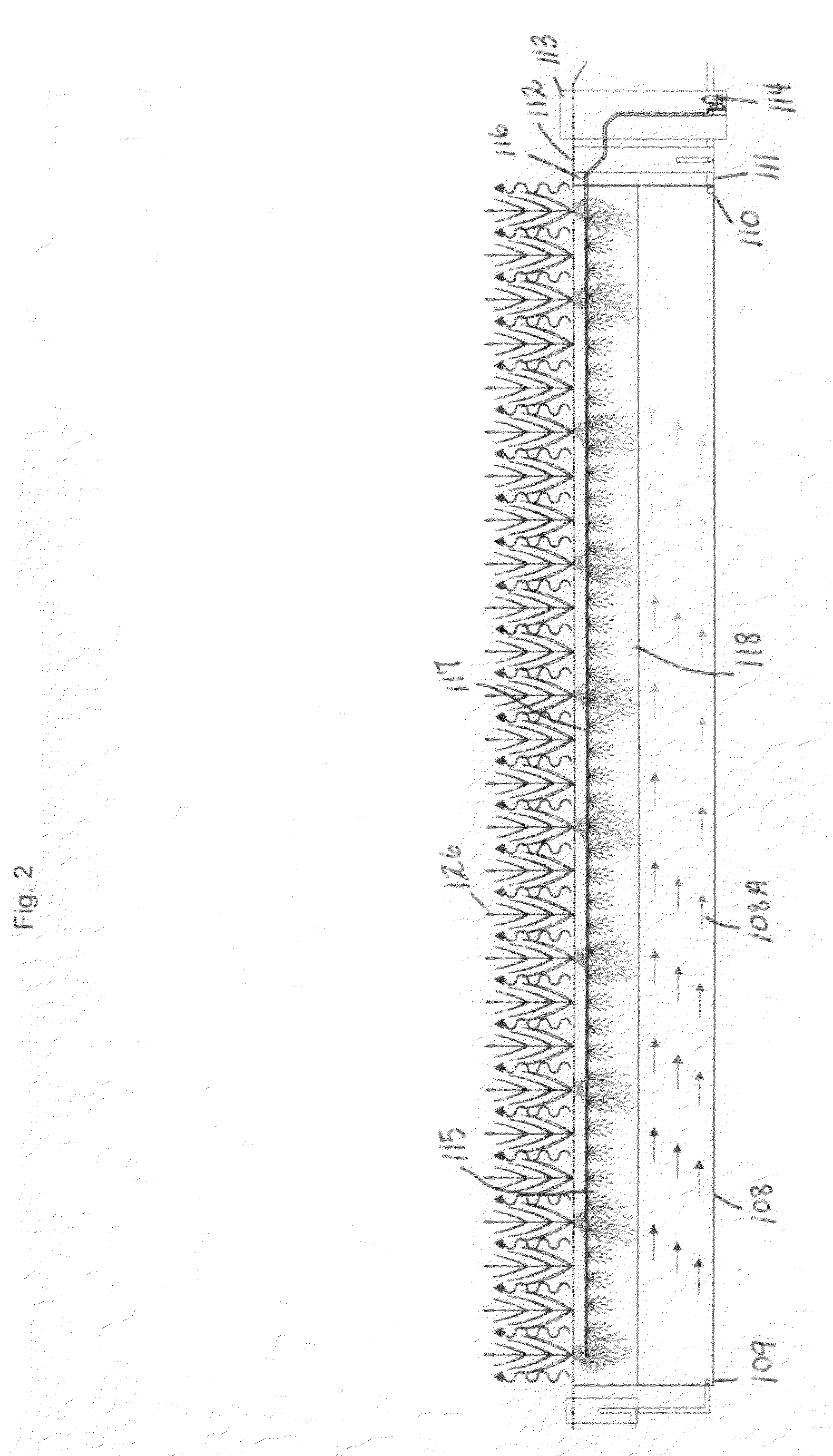

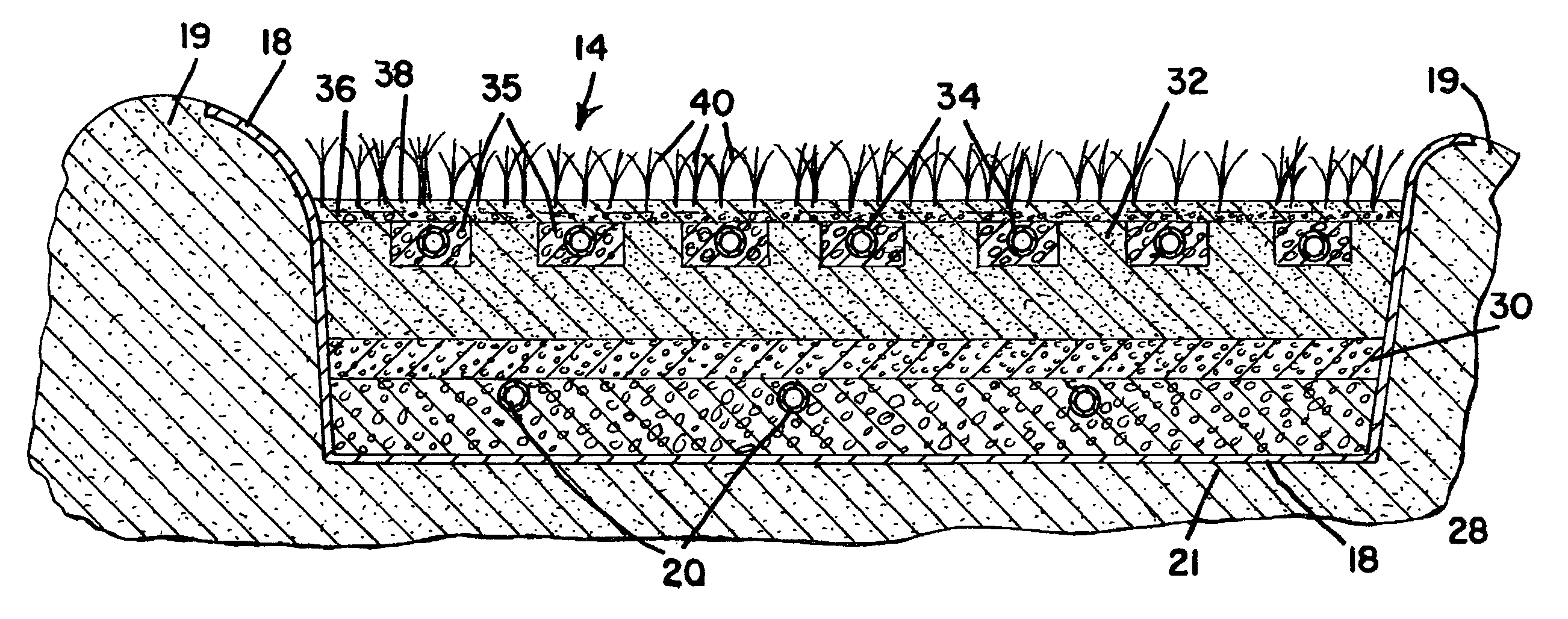

Eco-treament system

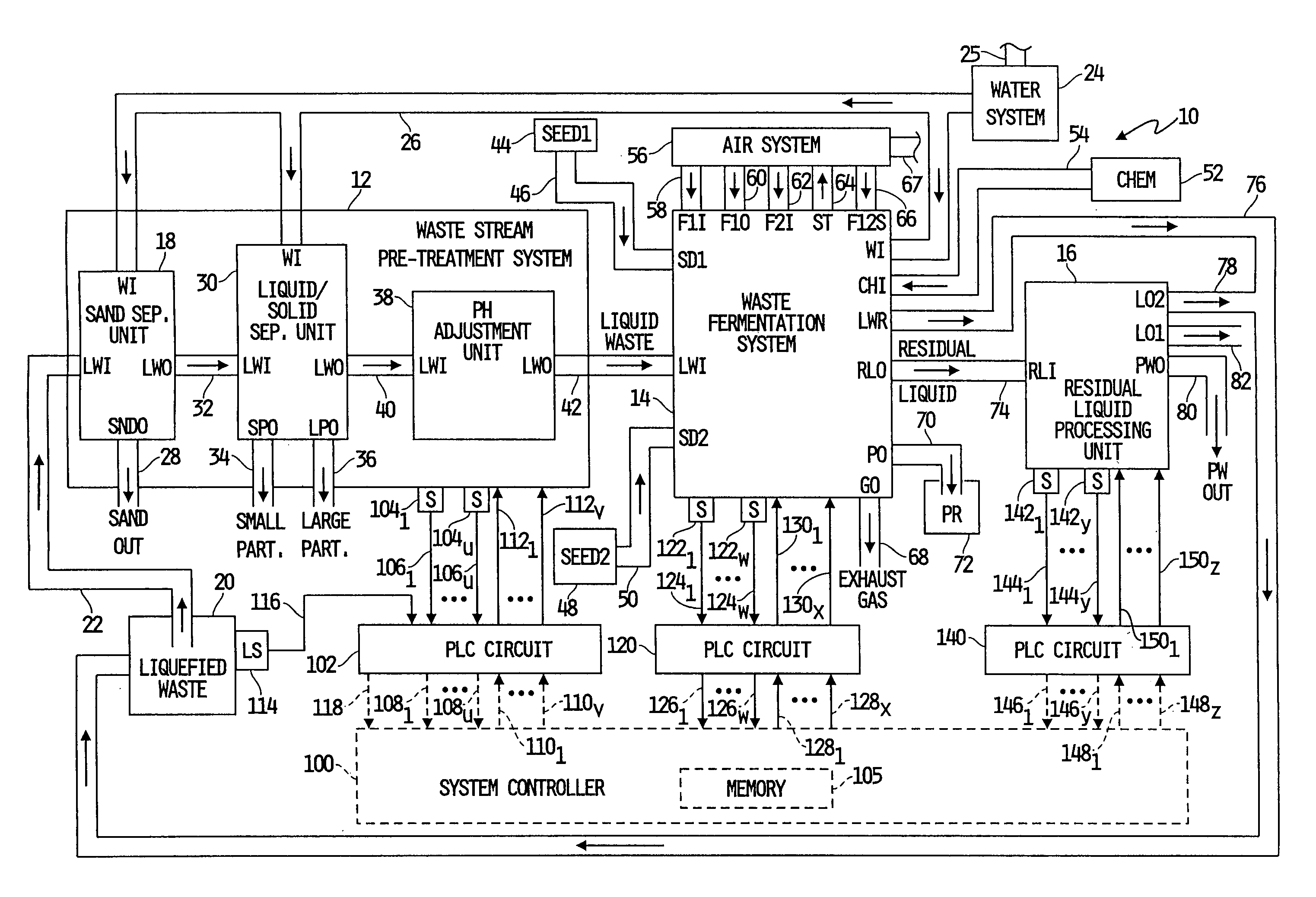

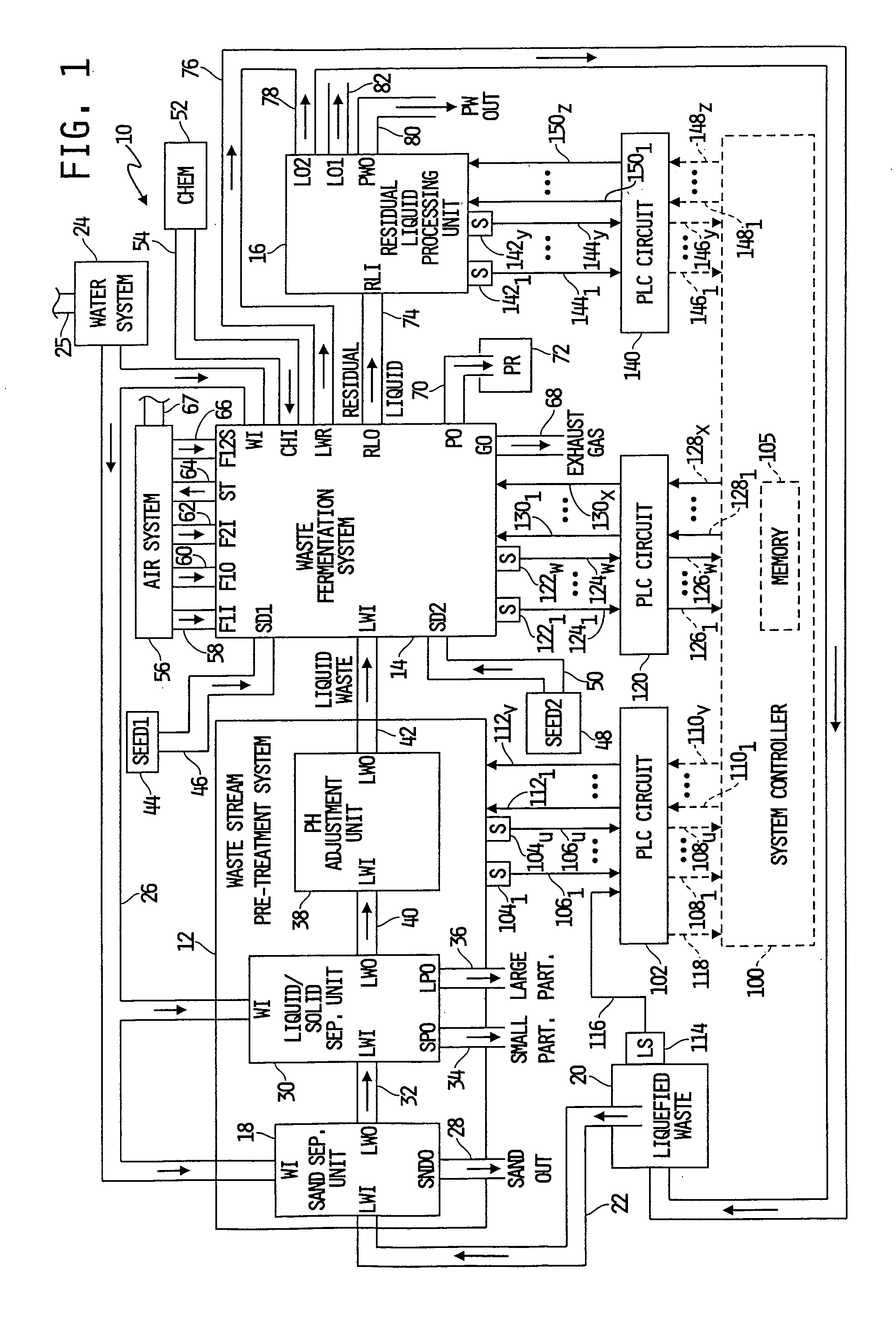

ActiveUS20090255862A1Reduce areaReduce Nutrient LoadWater treatment parameter controlWater contaminantsNitrateNitrogen

A system and method of treating wastewater from an animal confinement operation. The system including at least a first lagoon receiving water from the confinement operation. The system further including a free surface water wetland, a subsurface flow wetland and a vertical flow recirculating media filter. The first artificial wetland including a pipe such that water from the lagoon flows into the first artificial wetland through an inlet of the pipe and is contained within the wetland. The first wetland further including a plurality of wetland plants. A second subsurface flow wetland and a vertical flow recirculating media filter on top of the subsurface flow wetland and wetland plants contained within a first pea gravel bed on top of a coarse gravel bed of the subsurface flow media filter such that water from the lagoon is received by the first wetland. A recirculation pump receiving water from the horizontal coarse gravel bed and the pump recirculating water to the wetland plants of the vertical flow recirculation media filter such that ammonia in the water is converted to nitrate and water as it falls vertically through roots of the wetland plants and the nitrate is converted to nitrogen and water the water flows horizontally through the subsurface flow wetland.

Owner:BERNARDIN LOCHMUELLER & ASSOC

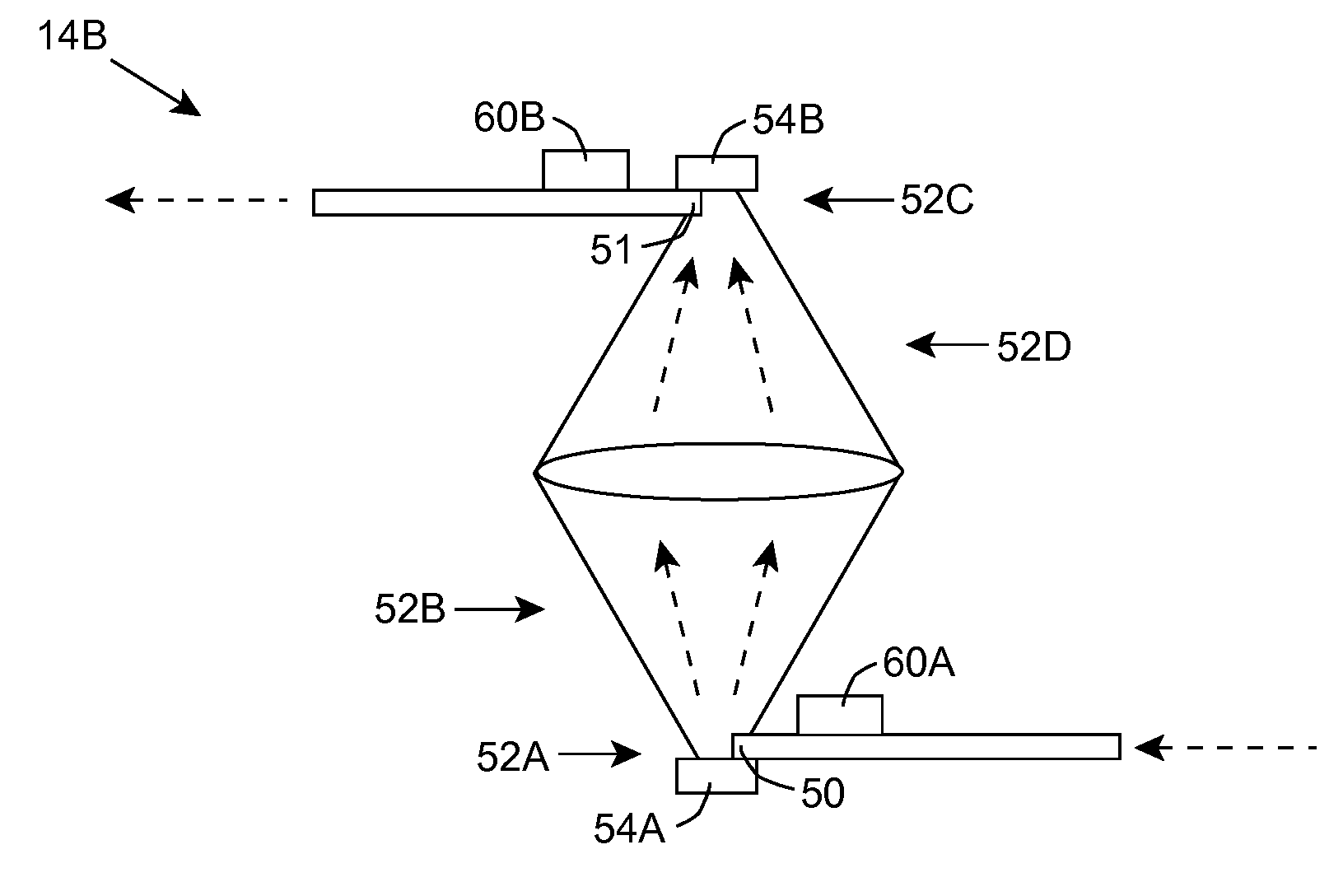

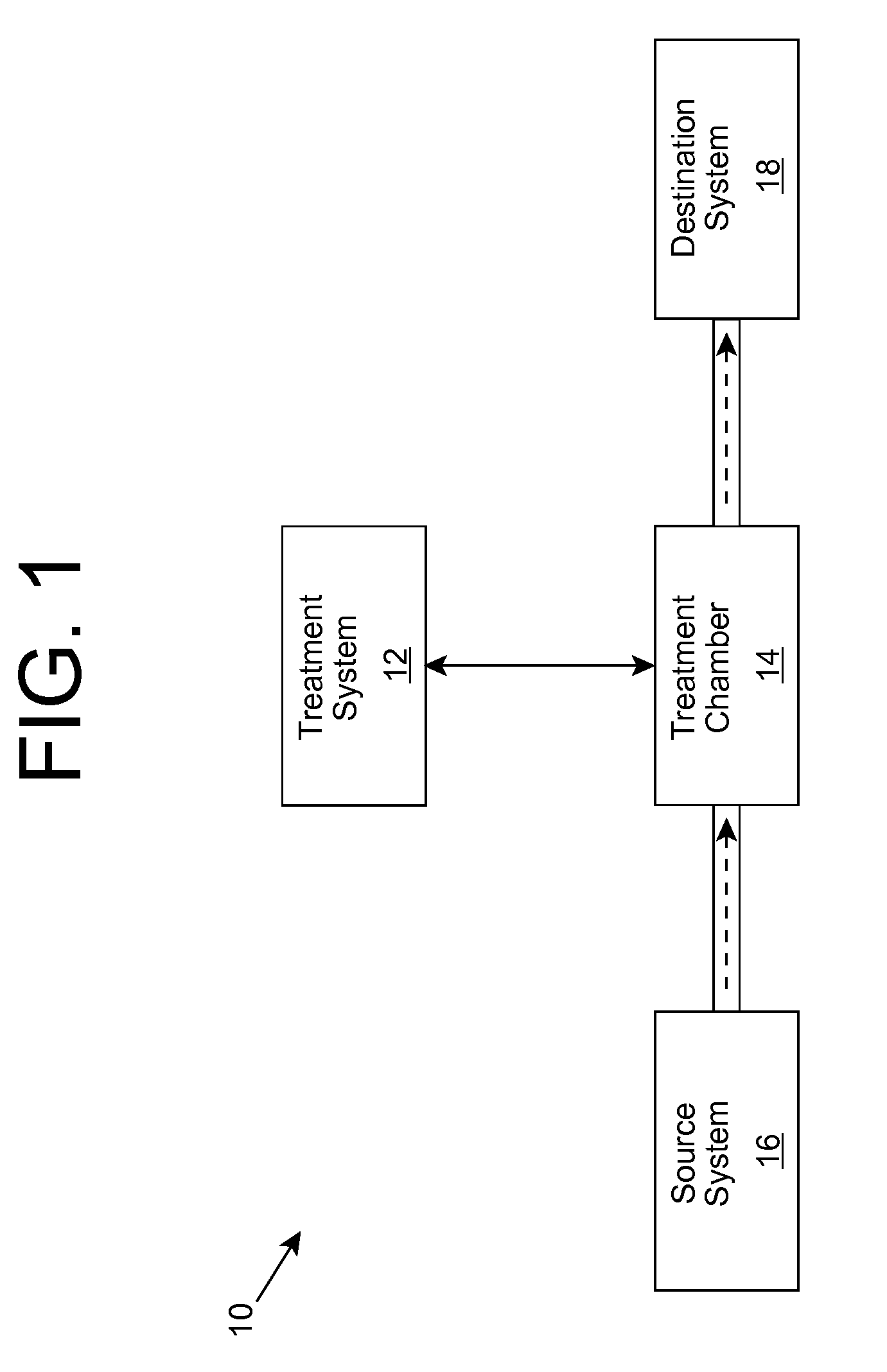

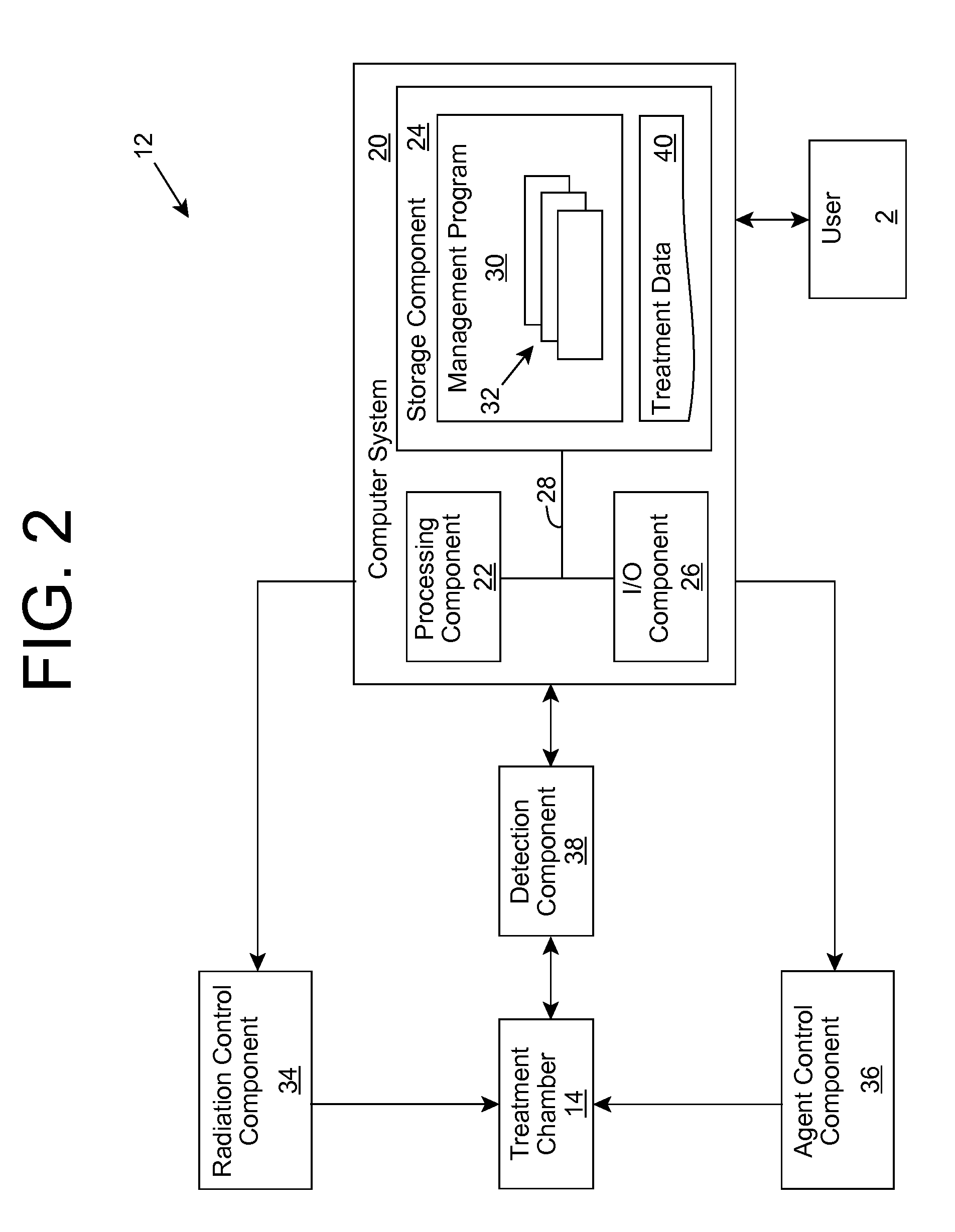

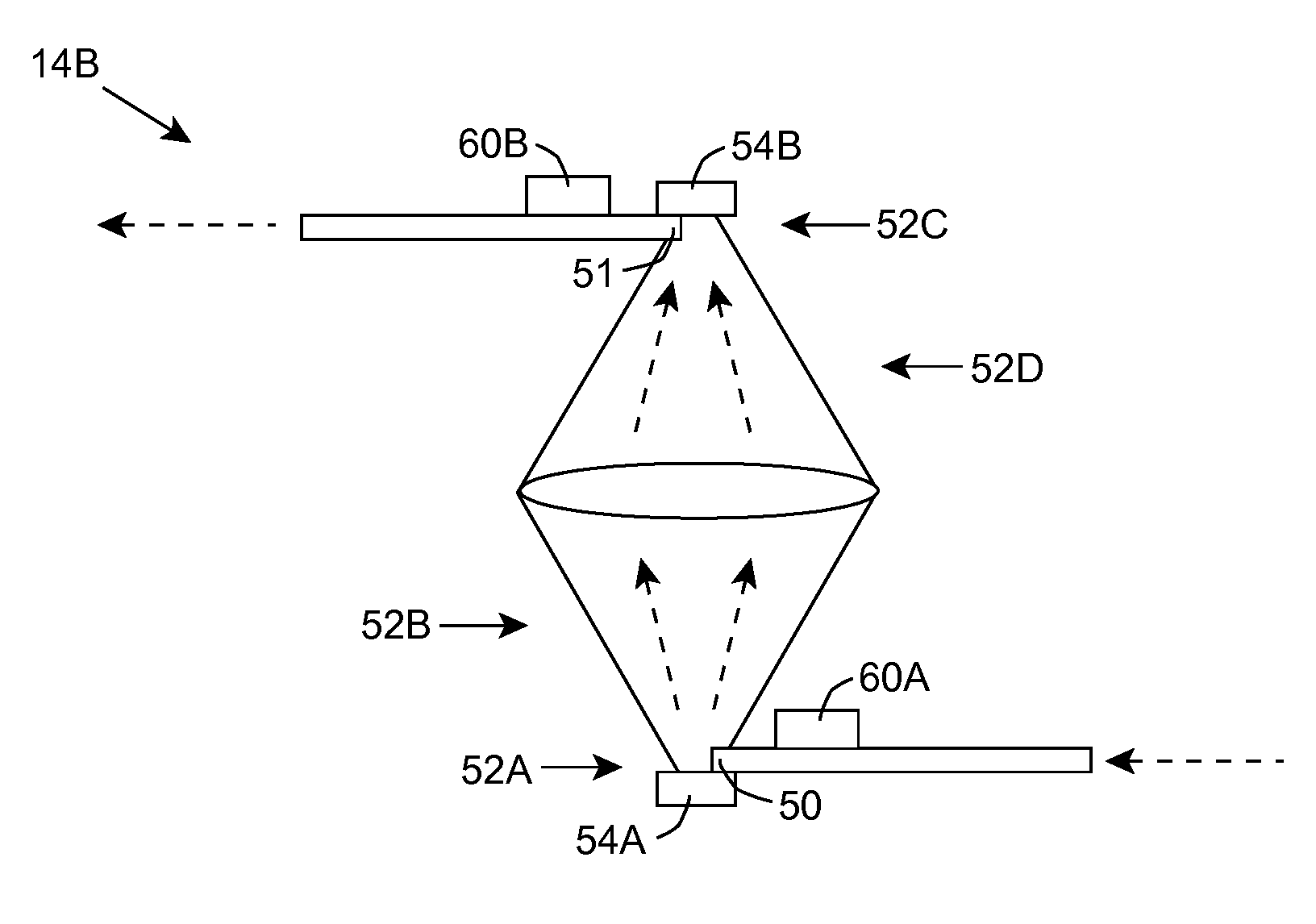

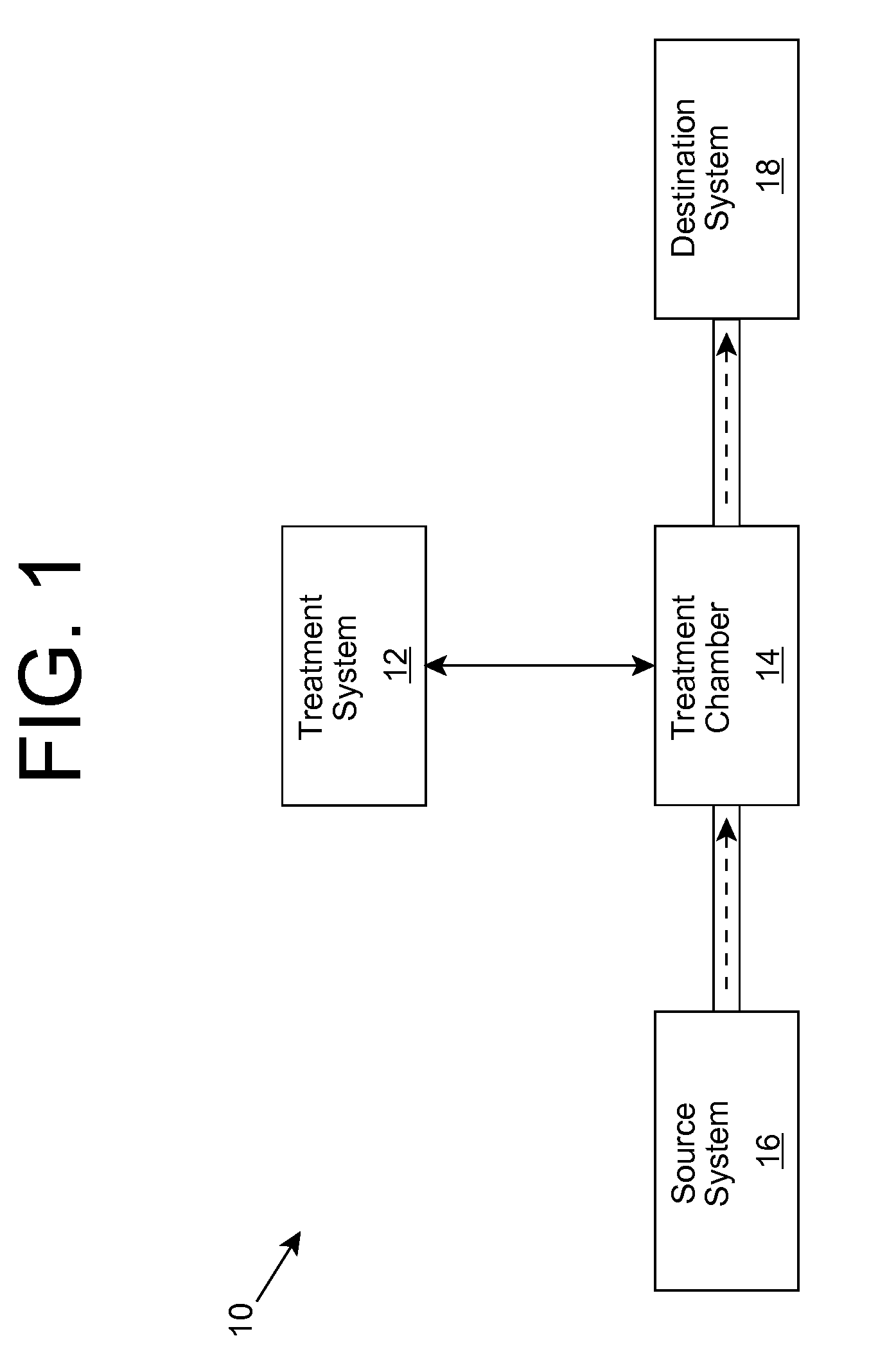

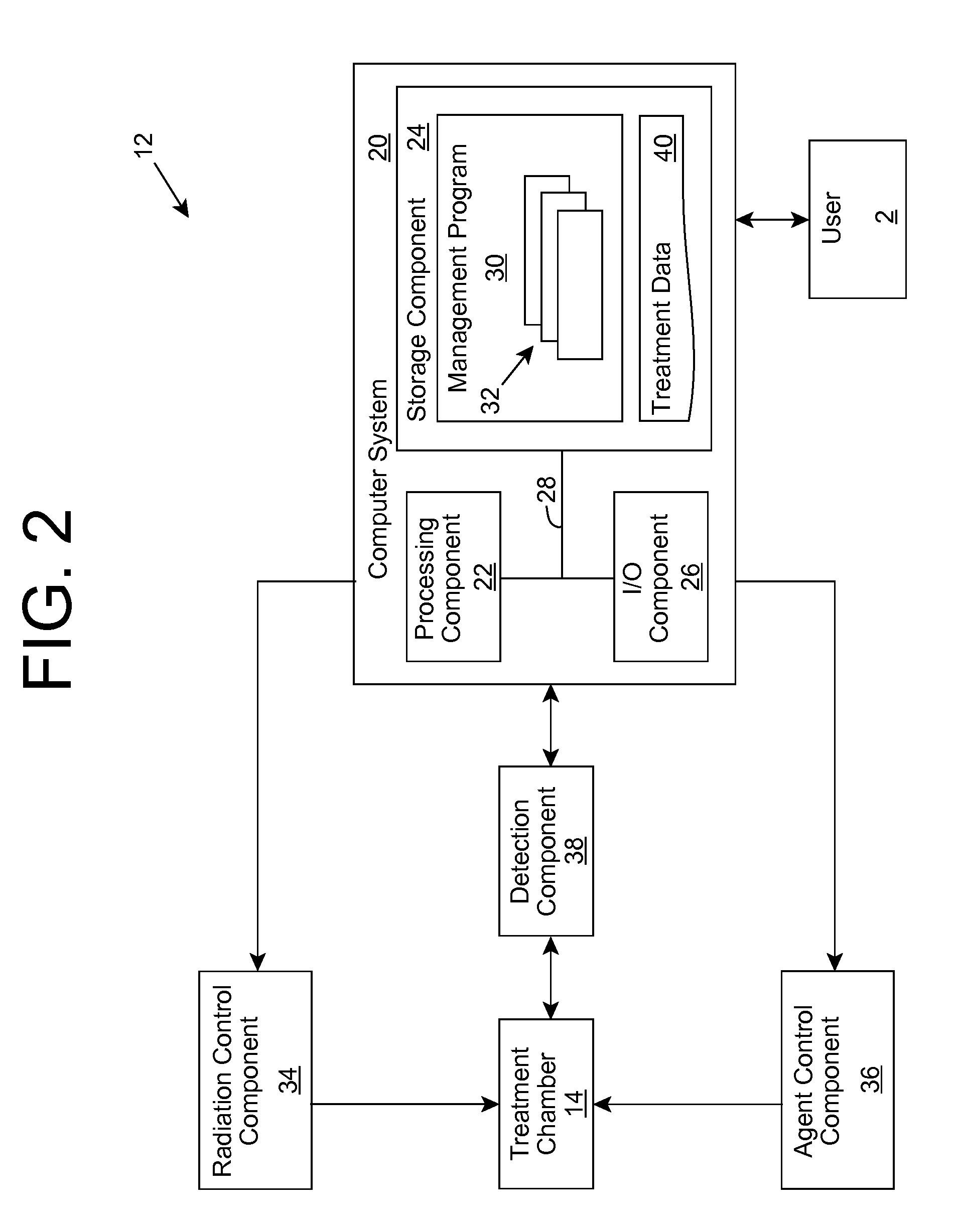

Medium treatment using ultraviolet light

ActiveUS20100296971A1Reduce reflectionPromote absorptionCombination devicesAuxillary pretreatmentMulti pollutantMedicine

A system for treating a medium, such as water, with ultraviolet light is provided. The system can include an ultraviolet treatment chamber that is shaped to reduce reflections of the ultraviolet light within the ultraviolet treatment chamber and / or improve absorption of the ultraviolet light by the medium. Furthermore, the system can add an agent to the medium within the treatment chamber to further treat one or more contaminants that may be present within the medium. Still further, additional treatment, such as filtering the medium with a permeable material can be implemented within the treatment system.

Owner:SENSOR ELECTRONICS TECH

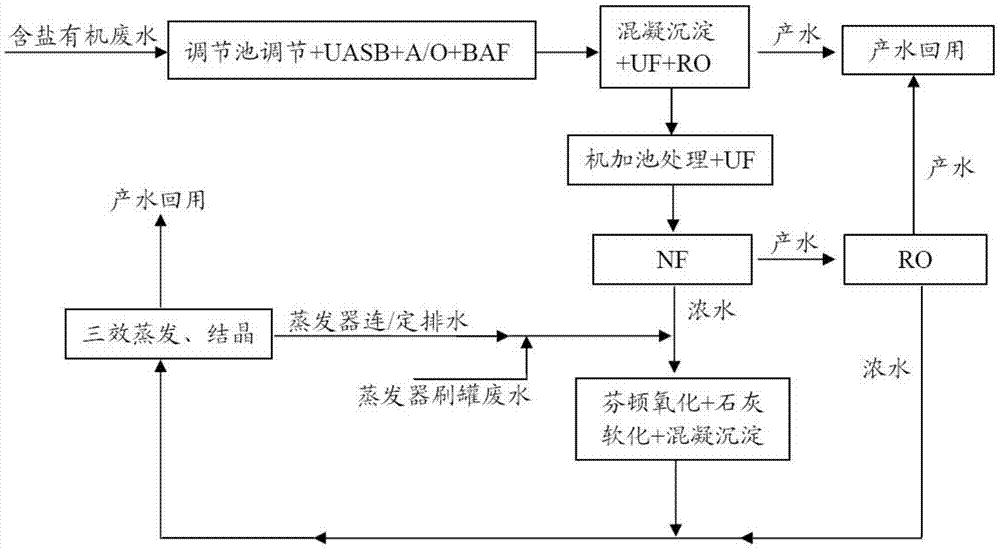

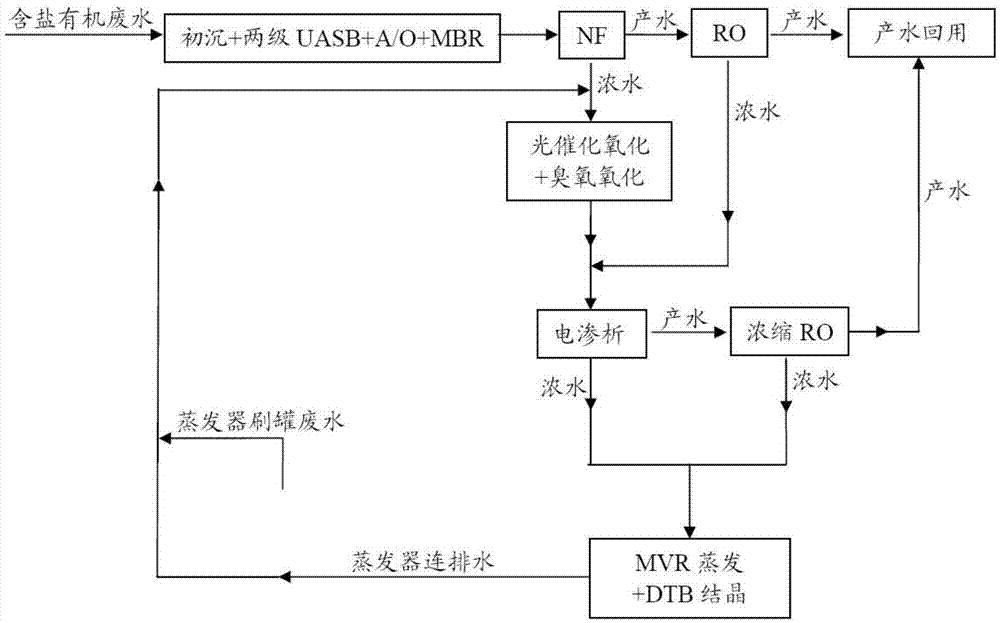

Zero-discharge treatment method of salt-containing organic wastewater

InactiveCN105439395AEasy to handleEfficient reuseTreatment using aerobic processesTreatment involving filtrationEvaporationOrganic matter

The invention provides a zero-discharge treatment method of salt-containing organic wastewater. The method comprises the following steps that biochemical treatment and filtering treatment are performed on wastewater; then, membrane concentration is performed; pure-water-producing high-organic-matter-content membrane concentration concentrated water and optional low-organic-matter-content membrane concentration concentrated water are obtained; the high-organic-matter-content membrane concentration concentrated water is used for high-grade oxidation treatment; high-grade oxidation produced water is used for regulation treatment to obtain high-grade oxidation outlet water; the obtained high-grade oxidation outlet water is subjected to evaporation treatment; or the obtained high-grade oxidation outlet water and the low-organic-matter-content membrane concentration concentrated water are mixed under the condition that the low-organic-matter-content membrane concentration concentrated water exists in the step, and then, the evaporation treatment is carried out; external discharge concentration liquid of an evaporator and / or high-salt-content high-organic-matter-content wastewater discharged during the tank brushing of the evaporator are conveyed back into a high-grade oxidation treatment unit; after the liquid is mixed with the high-organic-matter-content membrane concentration concentrated water, the high-grade oxidation treatment is carried out. The wastewater treatment method is stable and reliable; the long-period and stable operation of an evaporation system can be ensured; the zero discharge of the industrial wastewater is realized.

Owner:DATANG INT CHEM TECH RESINST

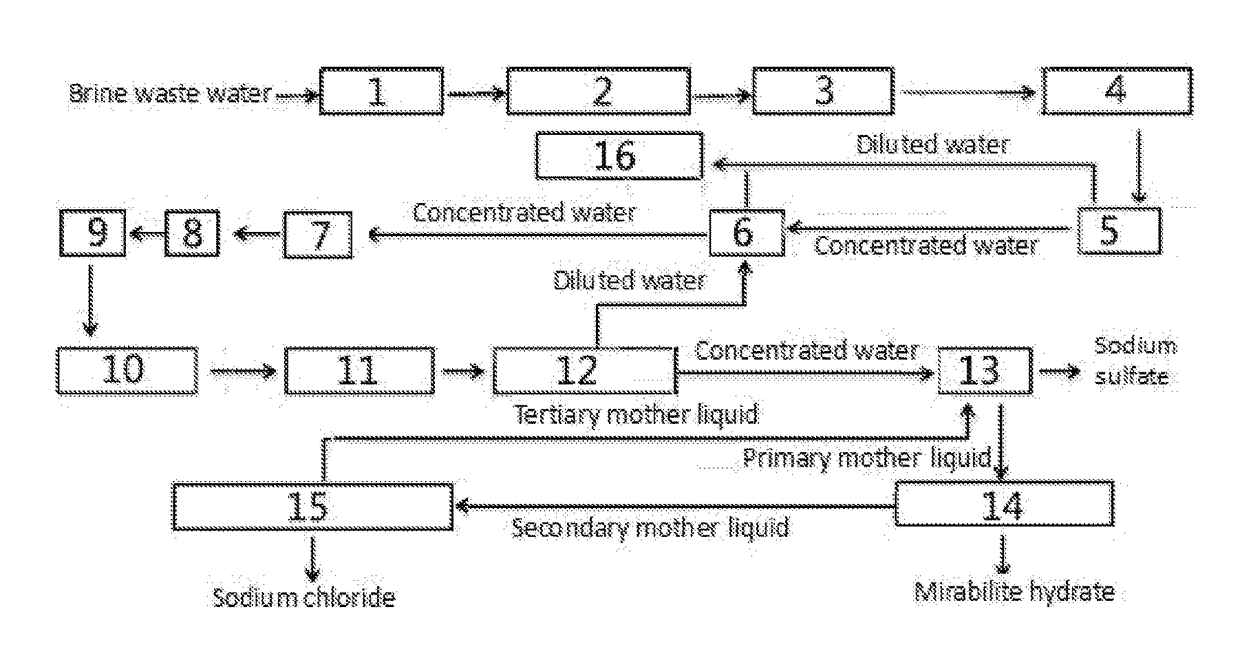

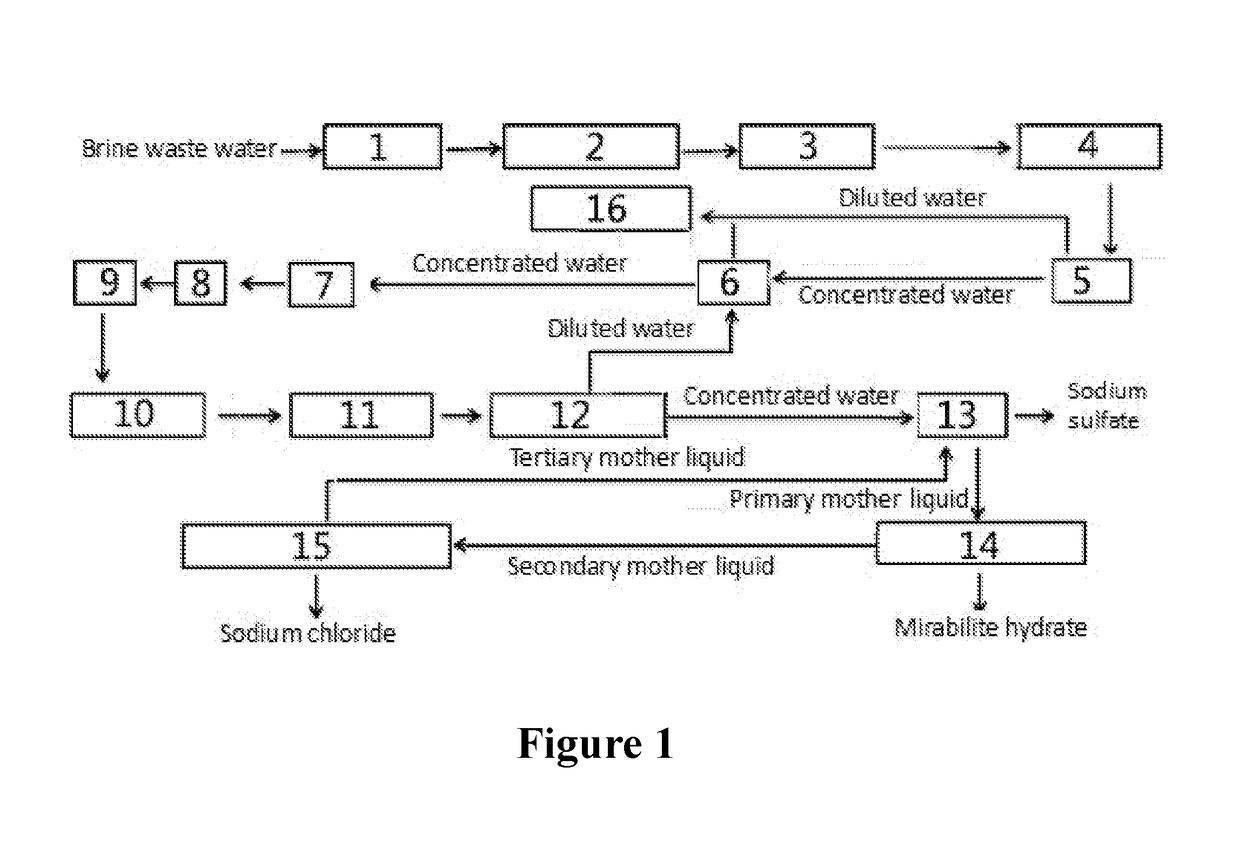

Method and System for Treating Brine Waste Water

ActiveUS20180148350A1Reduce pollutionExtended service lifeScale removal and water softeningSustainable biological treatmentSaline waterWastewater

The present invention relates to a method for zero-release treatment of brine waste water, comprising: (1) pretreatment; (2) reverse osmosis treatment; (3) advanced oxidation treatment; (4) biochemical treatment; (5) electrodialysis concentration; (6) circulating crystallization. Compared with the prior art, the method for zero-release treatment of brine waste water provided in the present invention realizes zero release or near zero release of waste water, improves salt recovery efficiency, can recover high-quality sodium sulfate, mirabilite and sodium chloride, and turns crystalline salts into a resource; the membrane treatment unit can operates stably in the process for a long operation period at a low cost, and the entire process has high economic efficiency.

Owner:CHINA PETROCHEMICAL CORP +1

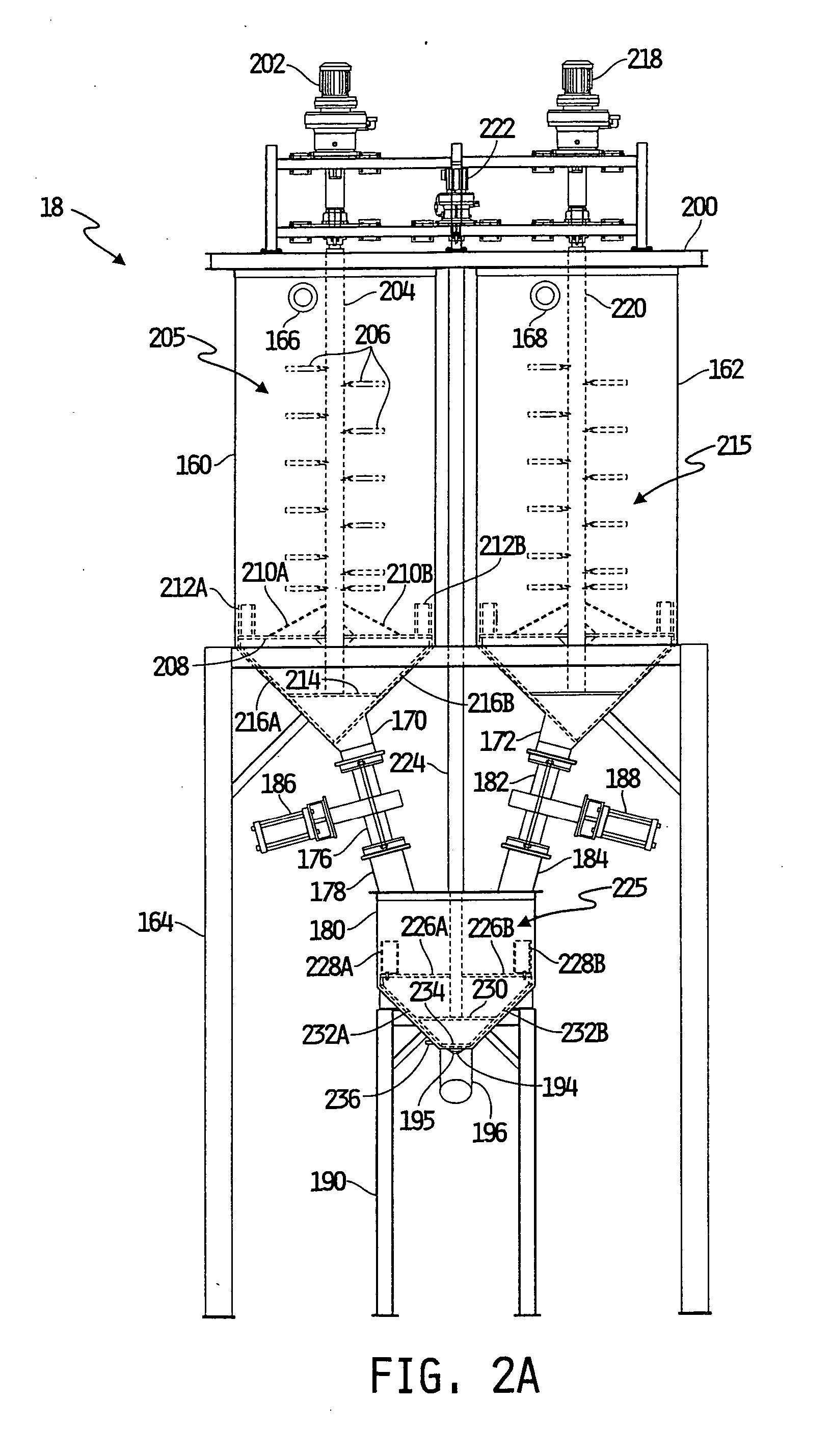

Top loading vertical flow submerged bed wastewater treatment system

InactiveUS7510649B1Efficient reuseEnergy based wastewater treatmentSustainable biological treatmentTreatment systemParticulate material

A system for treating wastewater having a treatment bed of particulate material, inflow distributing plumbing for applying wastewater from a wastewater supply source to upper part of the treatment bed. The wastewater percolates downwardly through the particulate material and is collected by outflow plumbing and conveyed out of the treatment bed. Preferably, the particulate material in the treatment bed is suitable for supporting aquatic plant life.

Owner:LAVIGNE RONALD

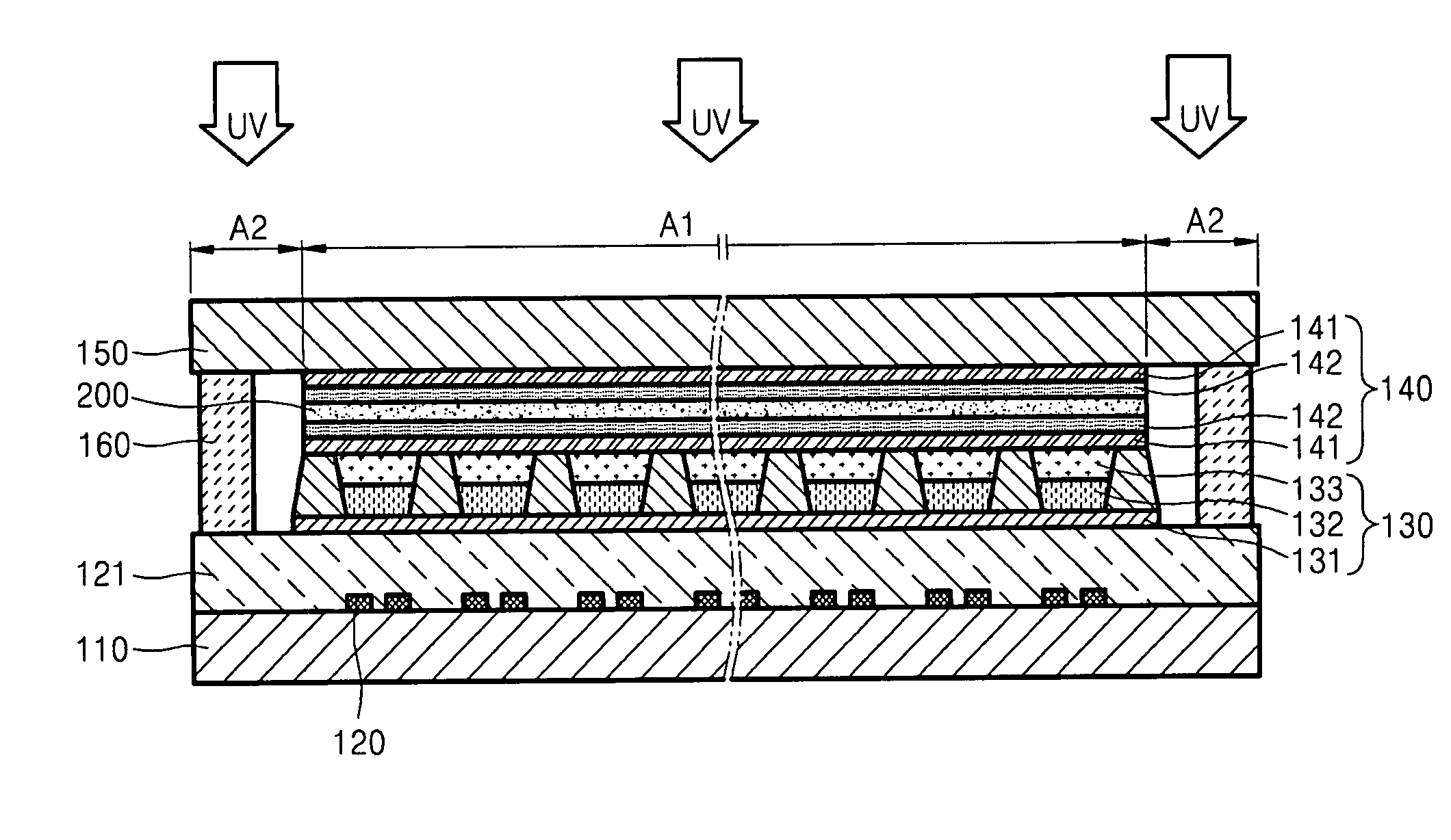

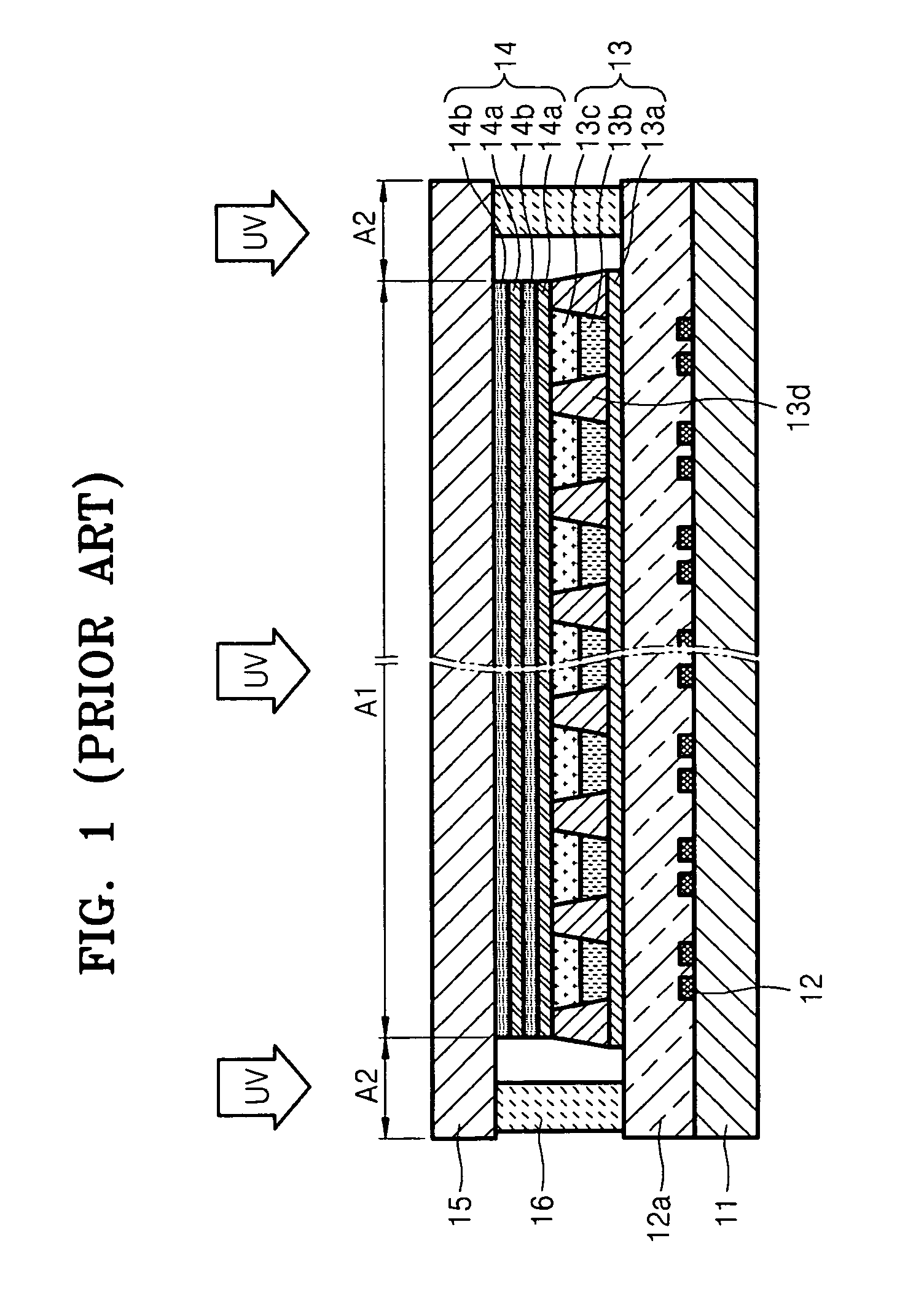

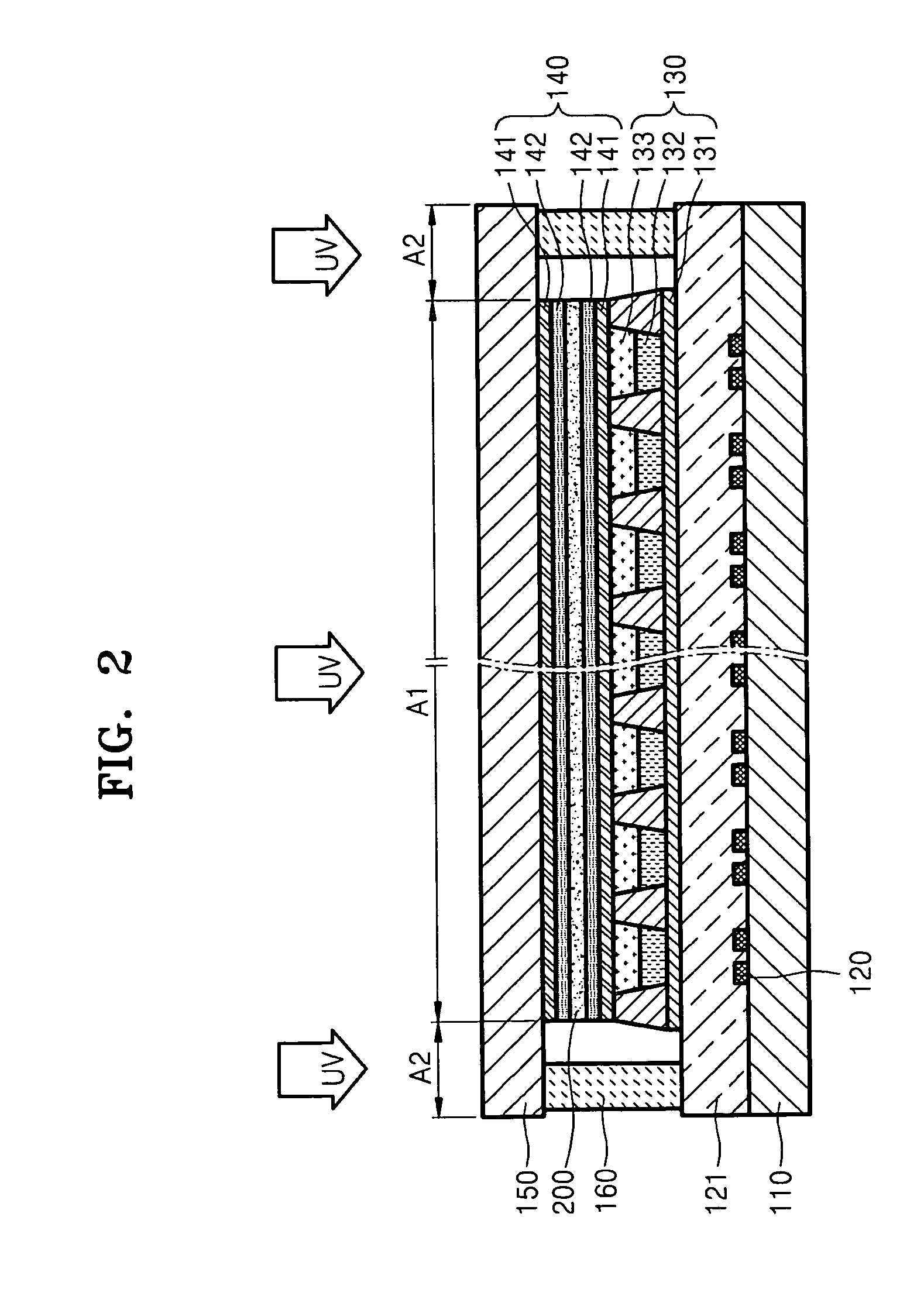

Organic light emitting display providing ultraviolet ray protection and method of manufacturing same

ActiveUS20070182314A1Prevent moisture penetrationPreventing oxygen penetrationDischarge tube luminescnet screensElectroluminescent light sourcesAdhesiveUltraviolet

An organic light emitting display including an ultraviolet protecting layer and a method of manufacturing the same include a lower substrate; an ultraviolet hardening adhesive formed on the lower substrate; a driving unit and a light emitting unit deposited on the lower substrate and surrounded by the ultraviolet hardening adhesive; an encapsulation layer covering the driving unit and light emitting unit and preventing moisture and oxygen penetration from an outside; an upper substrate arranged on the encapsulation layer facing the lower substrate and fixed by the ultraviolet hardening adhesive; and an ultraviolet ray blocking film formed in a region to block the driving unit and the light emitting unit from being irradiated by UV rays radiated to harden the ultraviolet hardening adhesive. The ultraviolet ray blocking film is disposed in the encapsulation layer or on the upper substrate to protect the driving unit and light emitting unit from ultraviolet rays.

Owner:SAMSUNG DISPLAY CO LTD

Medium treatment using ultraviolet light

ActiveUS8980178B2Reduce reflectionPromote absorptionCombination devicesAuxillary pretreatmentMulti pollutantMedicine

A system for treating a medium, such as water, with ultraviolet light is provided. The system can include an ultraviolet treatment chamber that is shaped to reduce reflections of the ultraviolet light within the ultraviolet treatment chamber and / or improve absorption of the ultraviolet light by the medium. Furthermore, the system can add an agent to the medium within the treatment chamber to further treat one or more contaminants that may be present within the medium. Still further, additional treatment, such as filtering the medium with a permeable material can be implemented within the treatment system.

Owner:SENSOR ELECTRONICS TECH

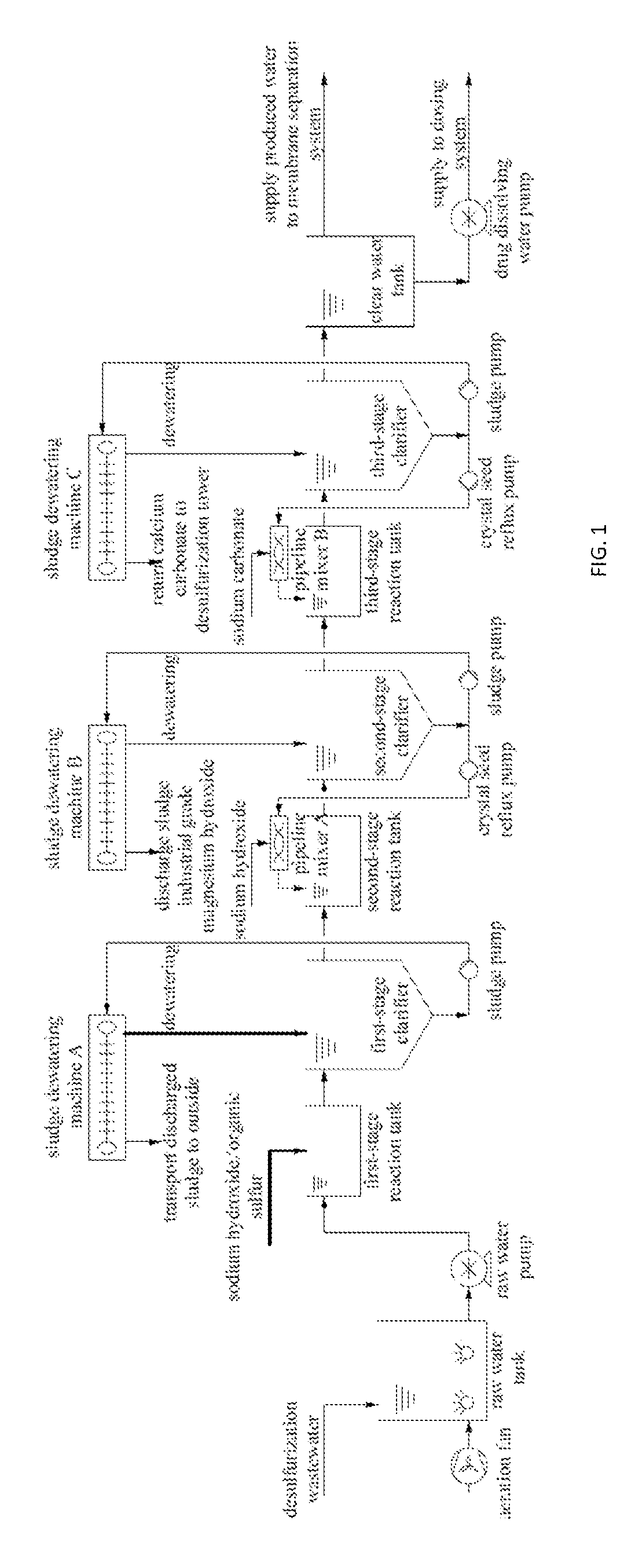

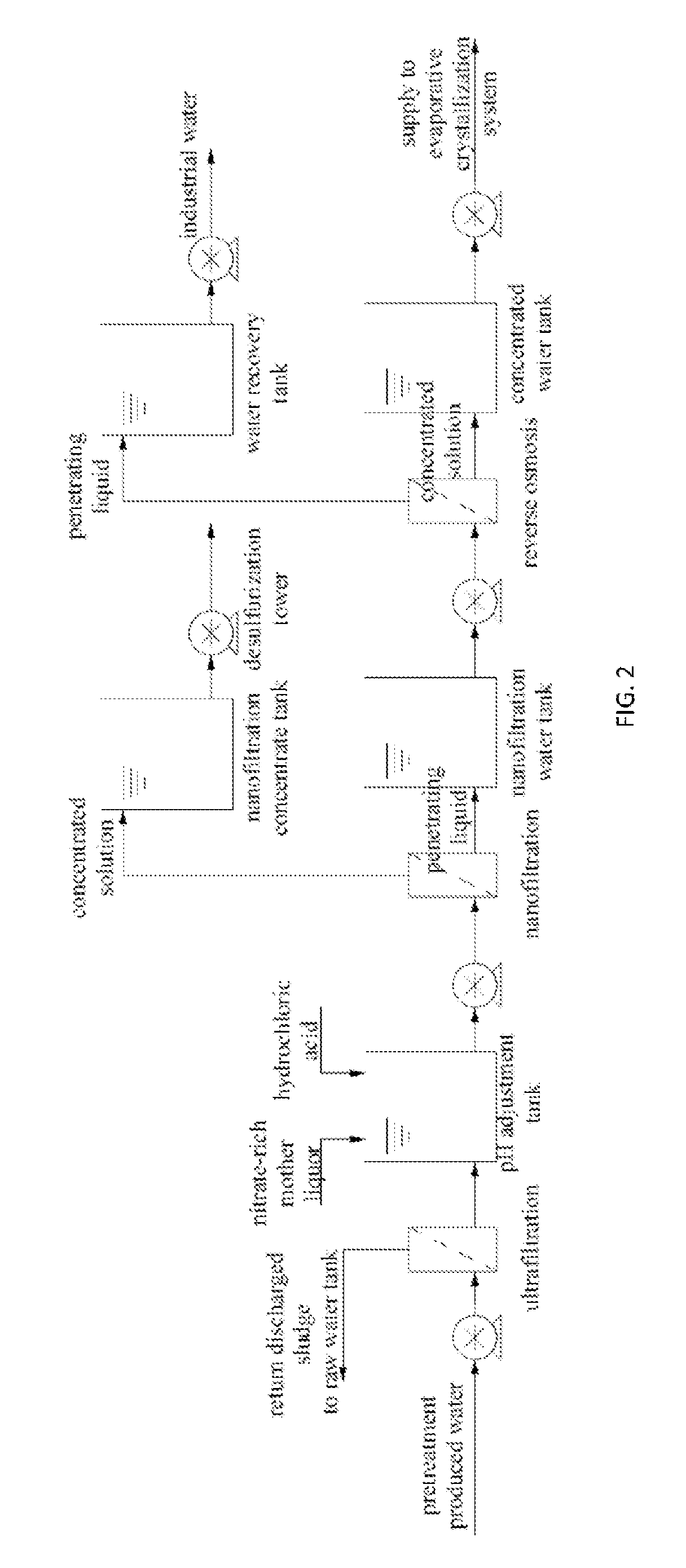

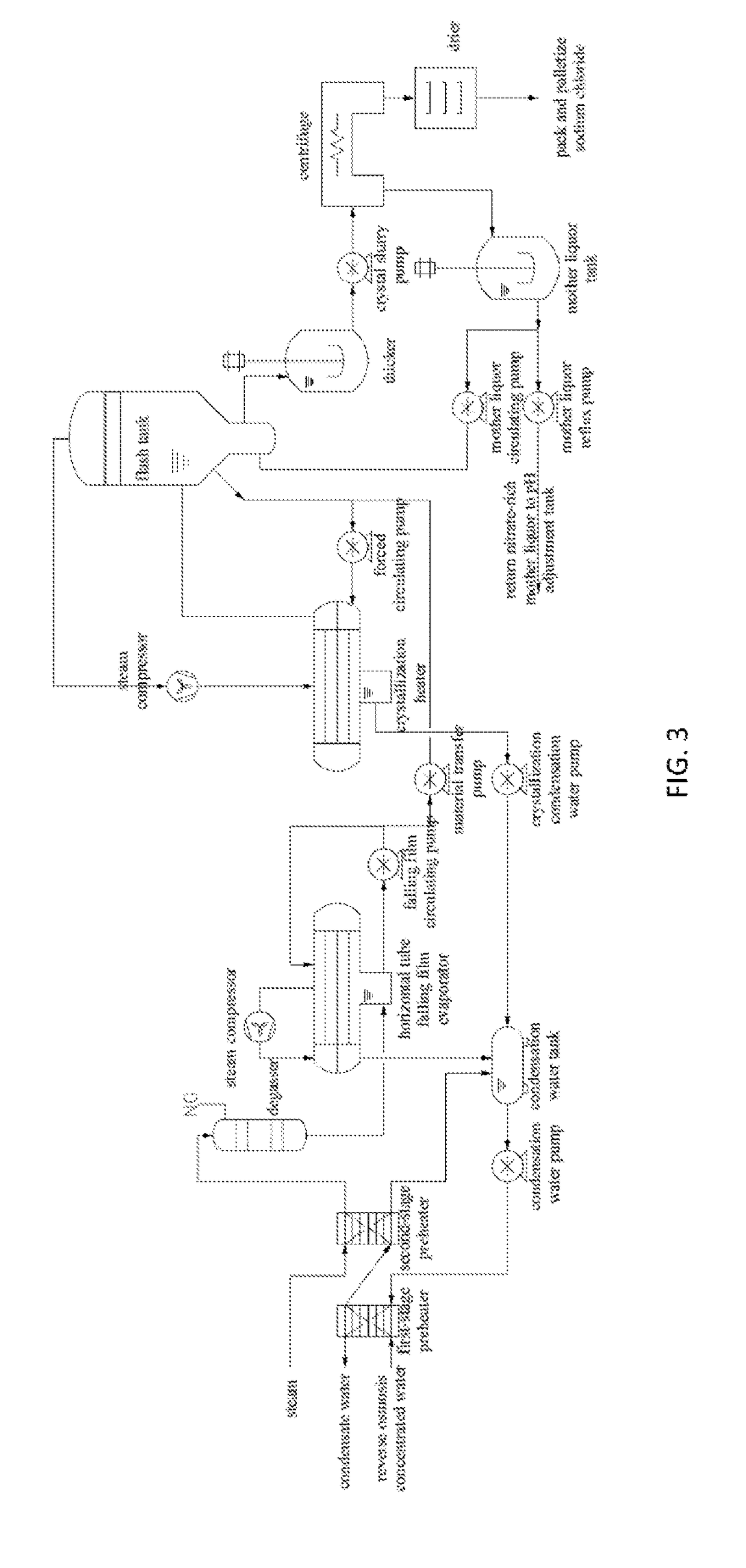

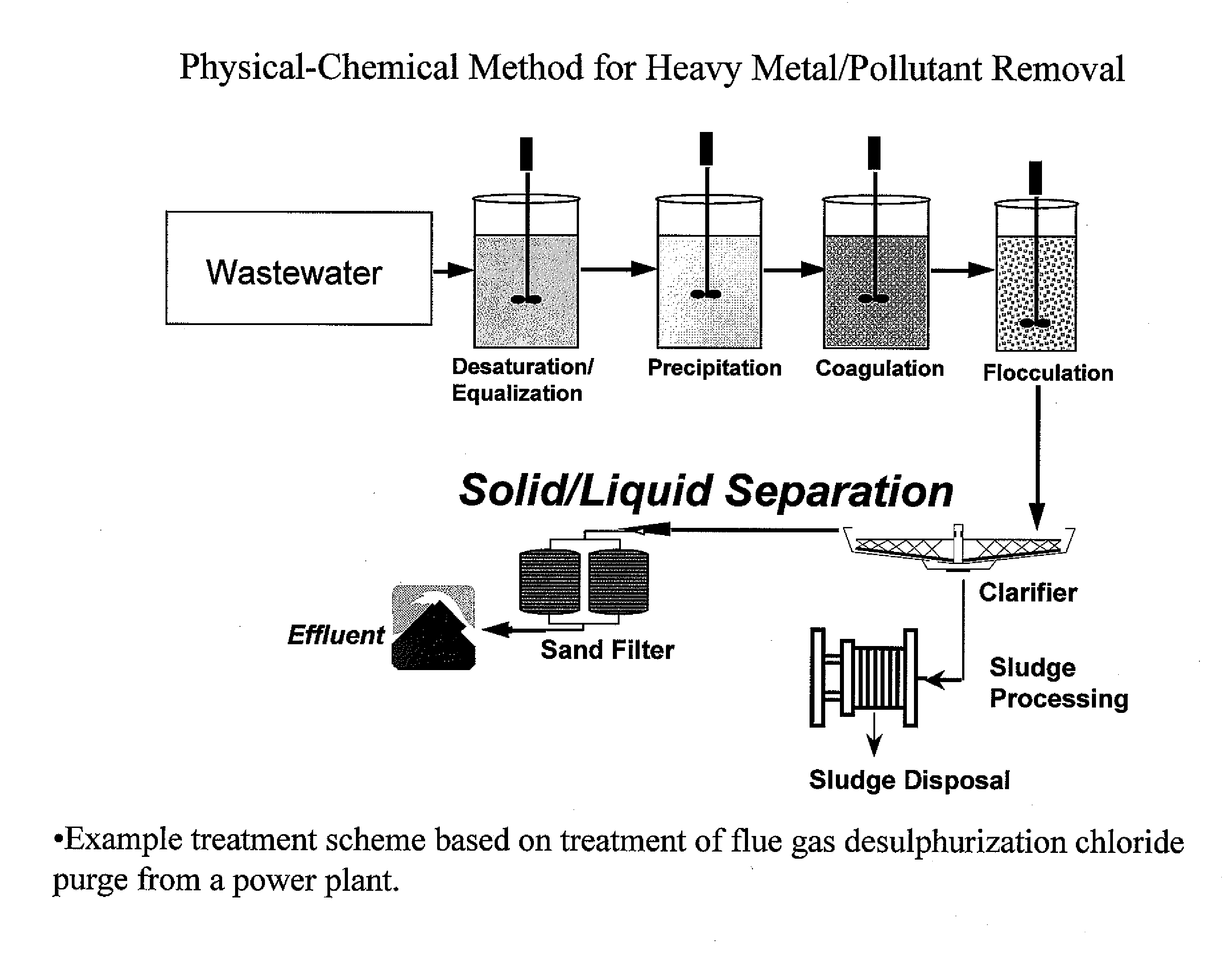

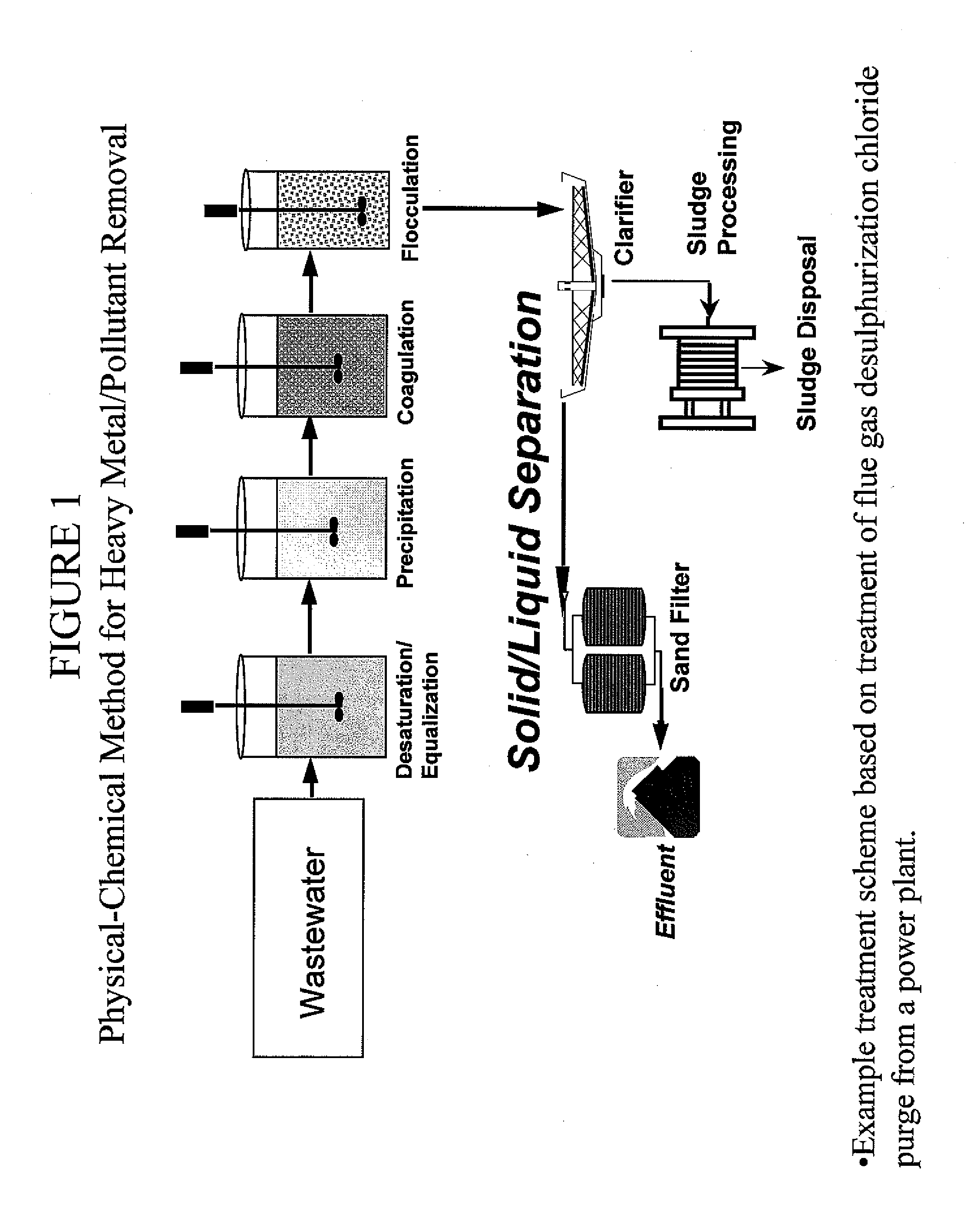

Zero-discharge technique for separating sludge and salt from desulfurization wastewater

ActiveUS20190077686A1Reduce disposal costsReduce project operating costsWaste water treatment from gaseous effluentsWater/sewage treatment by neutralisationSludgeUltrafiltration

A zero discharge process for separating sludge and salt from desulfurization wastewater includes a pretreatment process, a membrane treatment process and an evaporative crystallization process; in the pretreatment process, the desulfurization wastewater enters a raw water tank, an aeration fan introduces compressed air into the raw water tank, and the wastewater is lifted to first-stage reaction and clarification by a raw water pump; in the membrane treatment process, the incoming wastewater is first filtered by ultrafiltration, then enters a pH adjustment tank, and is pumped into a nanofiltration membrane separation system and a reverse osmosis membrane separation system; in the evaporative crystallization process, the incoming wastewater is first subjected to two-stage preheating, then enters a degasser, and finally enters an evaporative concentration system and a crystallization system.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

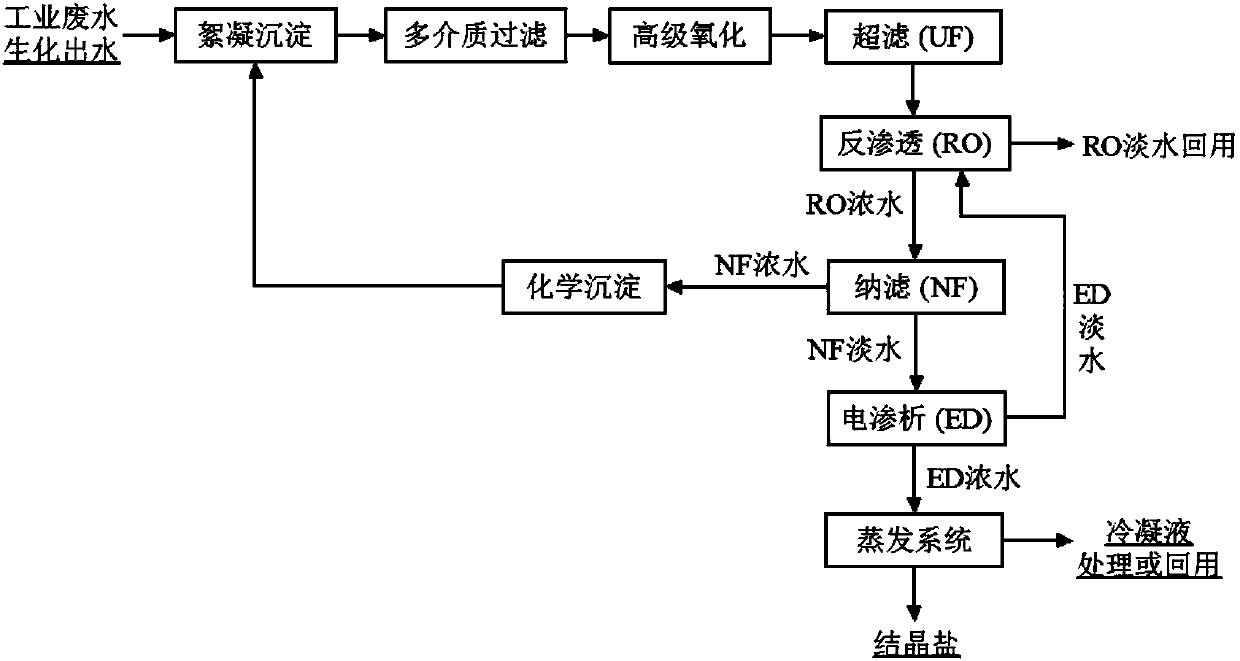

Treatment system and treatment method for biochemical effluent of industrial wastewater

InactiveCN107651794AEfficient removalHigh recovery rate of fresh waterGeneral water supply conservationTreatment involving filtrationHigh concentrationFiltration

The invention provides a treatment system and treatment method for biochemical effluent of industrial wastewater. The treatment system comprises a flocculation sedimentation unit, a filtration unit, an advanced oxidation unit, an ultrafiltration unit, a reverse osmosis unit, a nanofiltration unit, an electrodialysis unit and an evaporation unit which are sequentially connected; and the water production outlet of the ultrafiltration unit is connected with the water inlet tank of the reverse osmosis unit, and the concentrated-water outlet of the reverse osmosis unit is connected with the water inlet of the nanofiltration unit. According to the invention, the treatment system and the treatment method utilize the coupling and synergistic effects of a physical-chemical method and a membrane technology to overcome the limitation of using a single technology, and the advanced treatment and desalination reuse of the industrial wastewater are realized; and the treatment system and the treatmentmethod have the advantages of strong adaptability to raw water, a high recovery rate of fresh water, a high concentration multiple of concentrated water, low energy consumption of evaporation and crystallization and the like, greatly improve the reuse rate of the industrial wastewater, reduce the amount of wastewater discharging, can be applied to the deep treatment and desalination reuse of various effluent wastewater, and promote the promotion and application of the technology in related industries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Optimal high recovery, energy efficient dual fully integrated nanofiltration seawater reverse osmosis desalination process and equipment

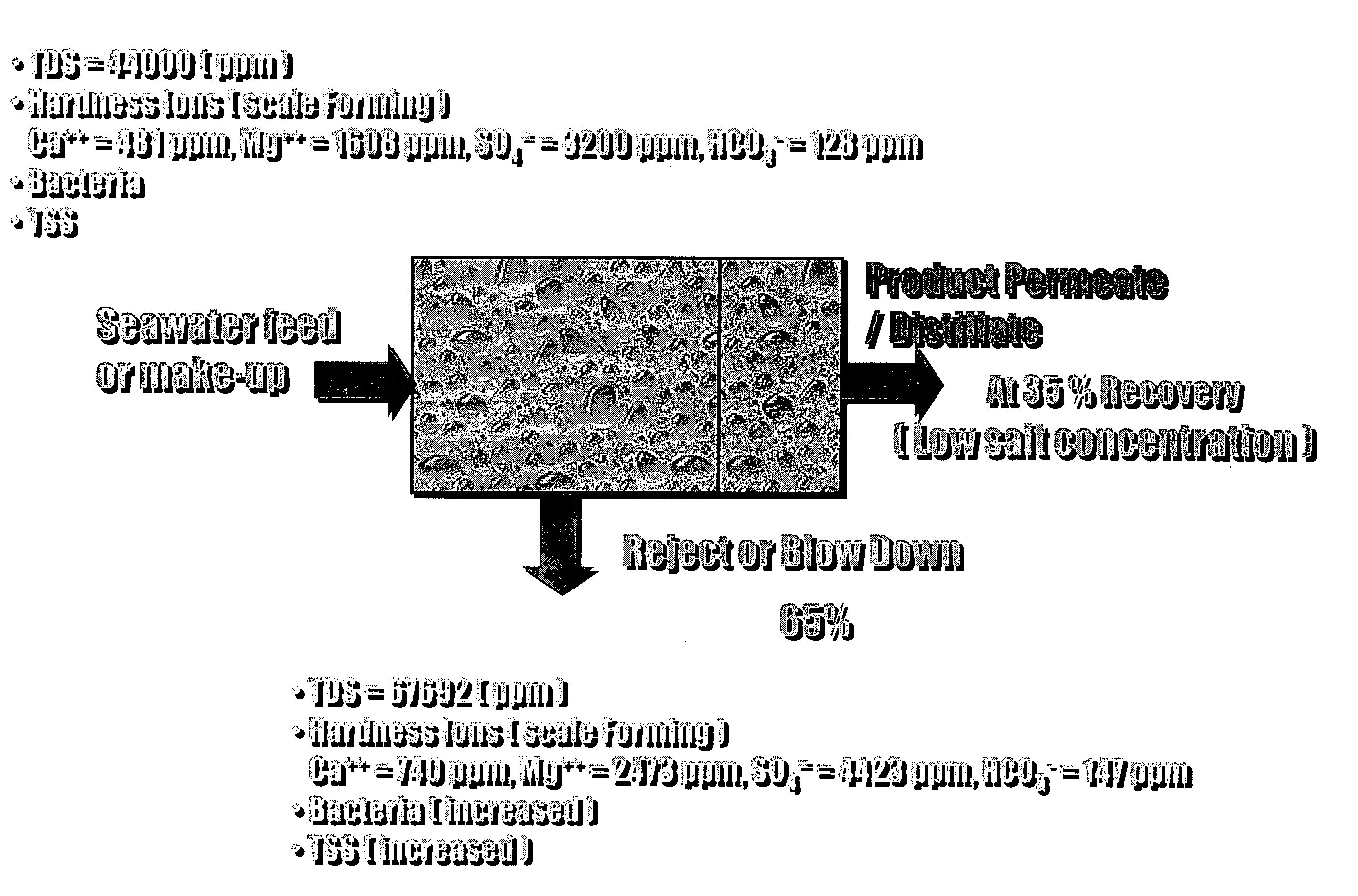

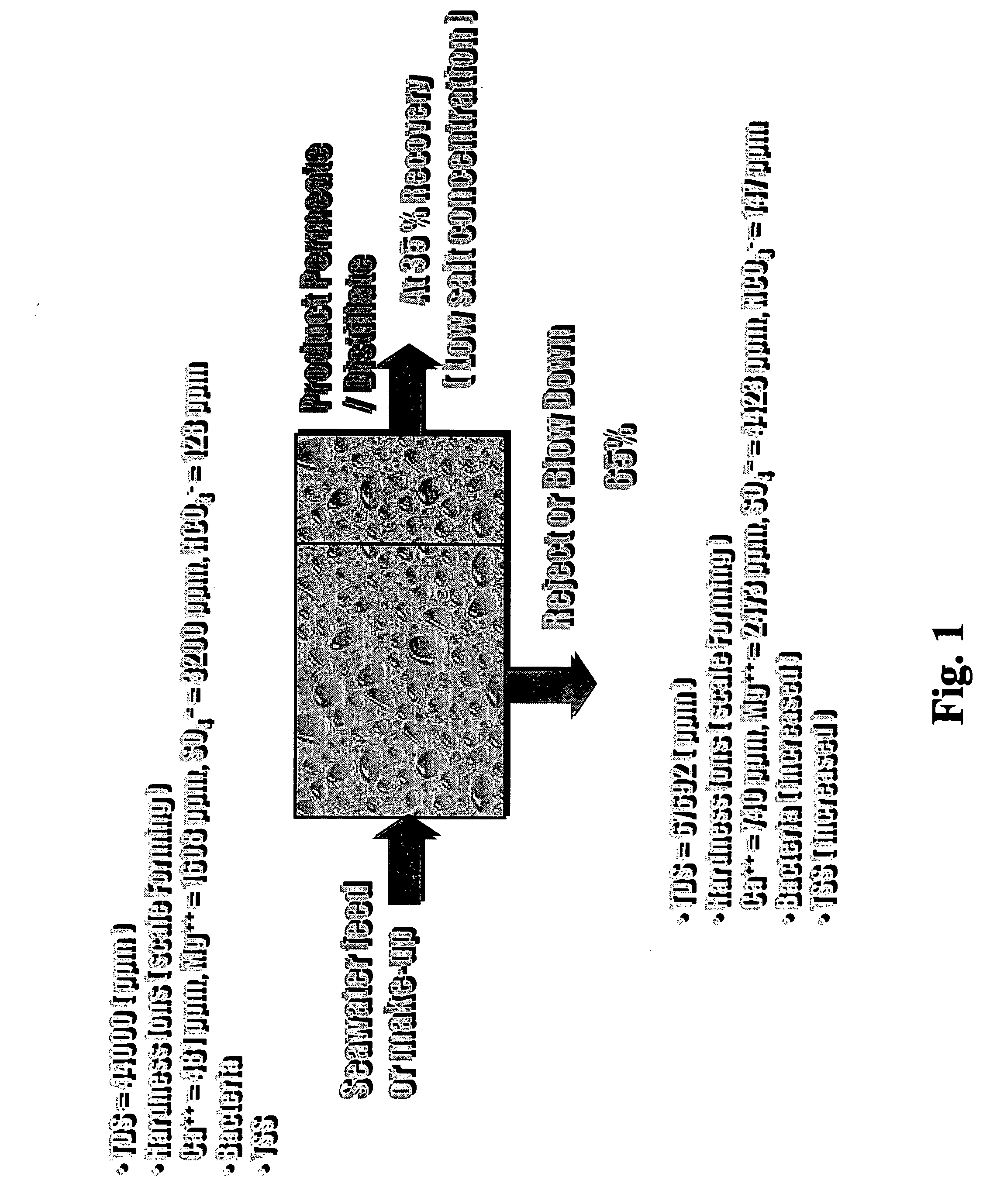

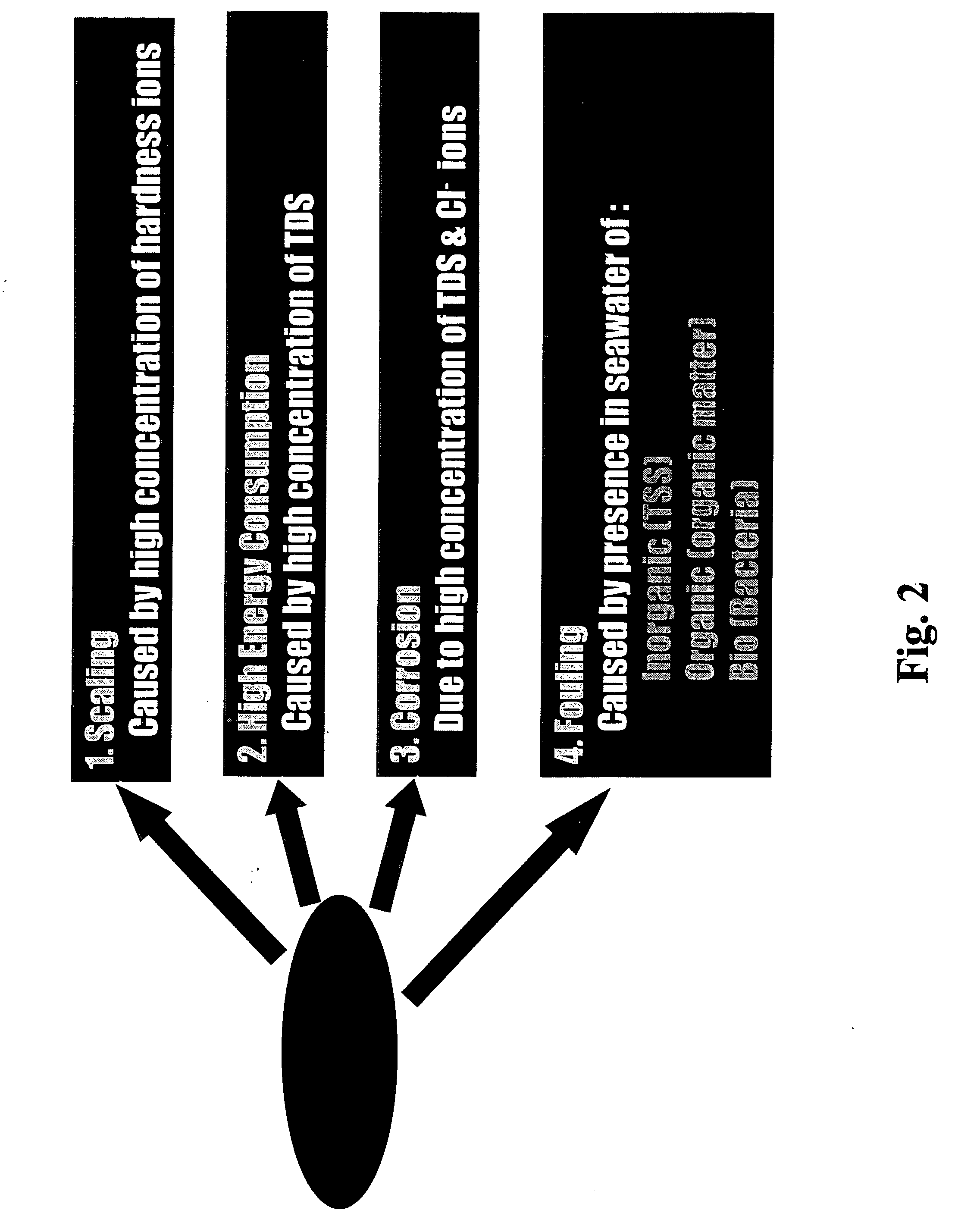

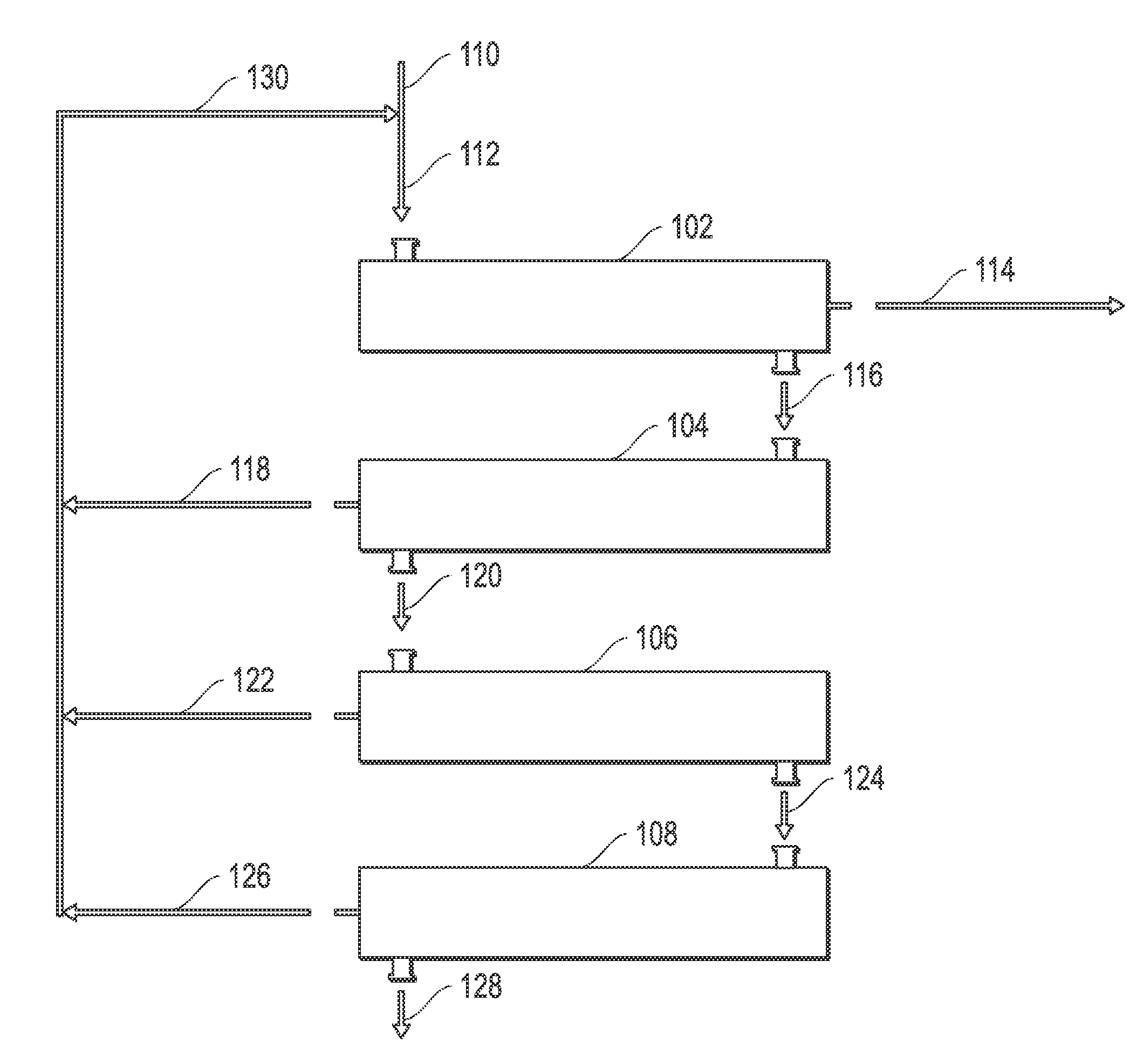

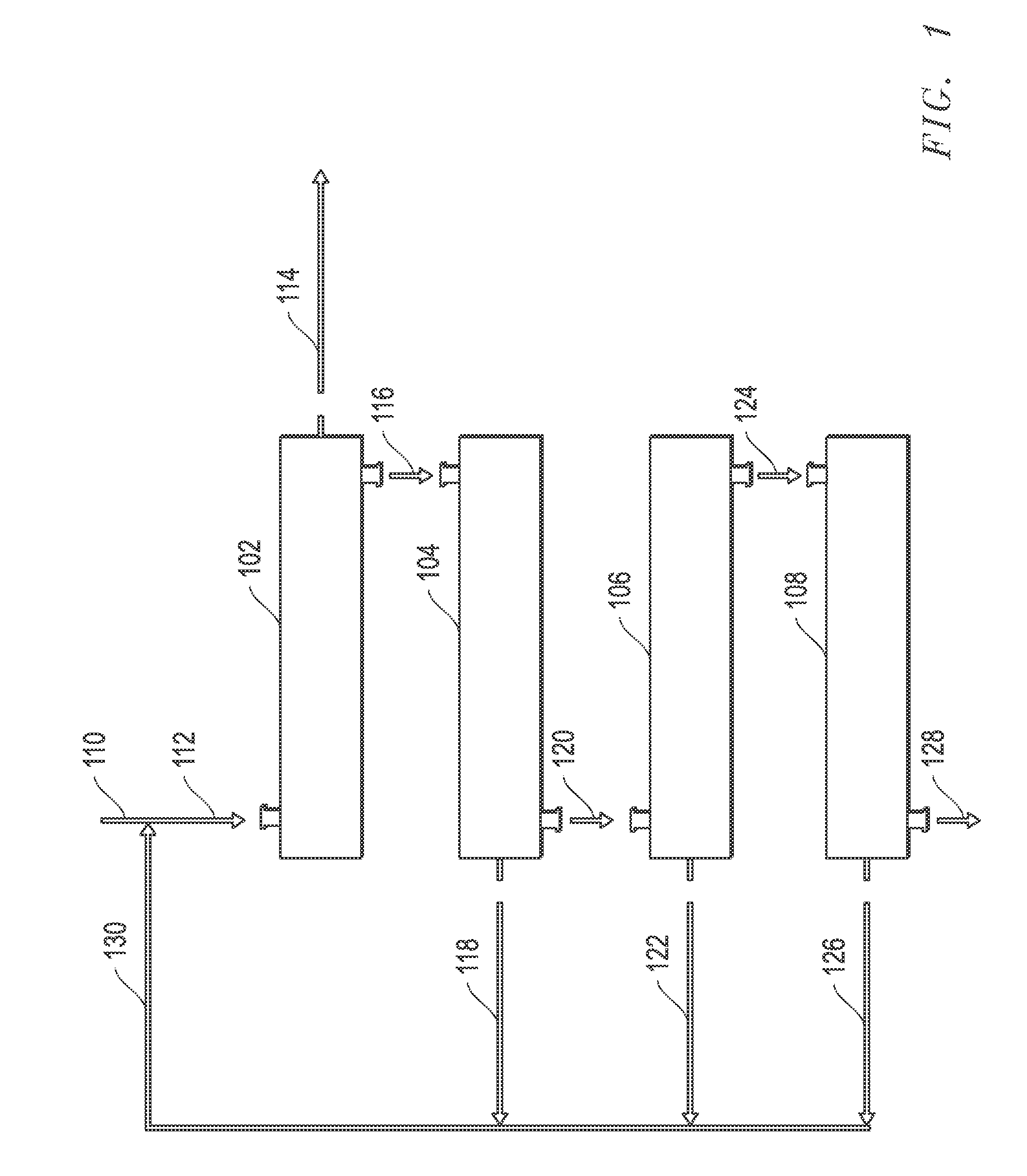

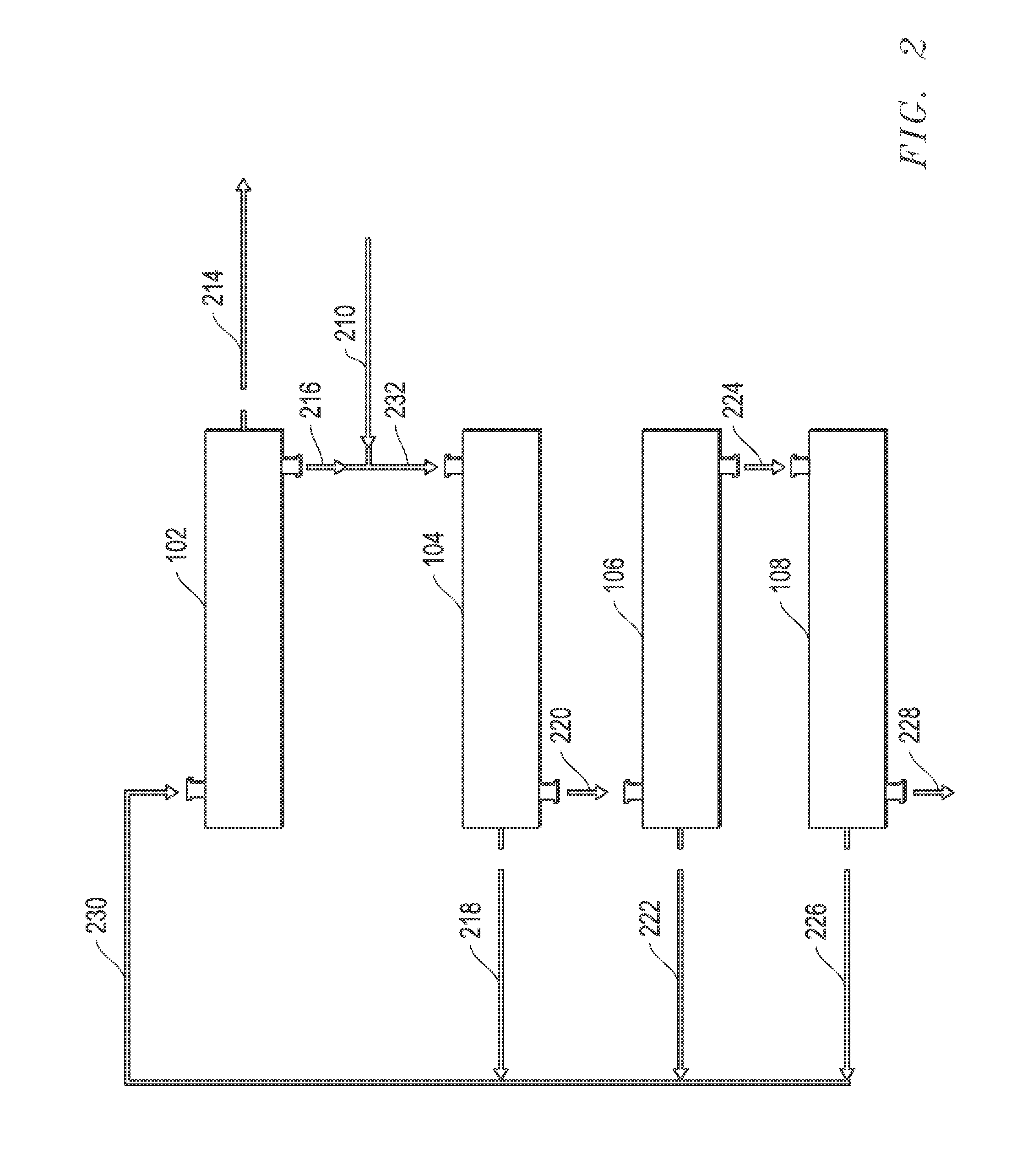

InactiveUS20060157409A1Reduce yieldHigh water recoveryMembranesSeawater treatmentTurbochargerWater production

An optimal two stage NF2 membrane pretreatment unit is synergistically combined with a following two stage SWRO2 desalination unit, where each of the two stage NF2 and SWRO2 has an energy recovery device (ERD) turbocharger (TC) in between the stages to form a dual hybrid of NF2-SWRO2 (FIG. 1 ); alternatively the two stage NF2 unit is synergistically combined with one stage ERD equipped SWRO, unit operated at up to 85 bar (FIG. 2 a, b); or the two stage NF2 unit combined with one stage ERD equipped SWRO1 unit, with part of its reject recycled constituting part of the feed to the NF units (FIG. 3 a,b). The process of this invention raises significantly the product water recovery ratio, producing SWRO hybrids that exceed all prior arts in efficiency, including water yield, product recovery ratio, dramatically reduces both the energy consumption and water production unit cost.

Owner:SALINE WATER CONVERSION CORP SWCC

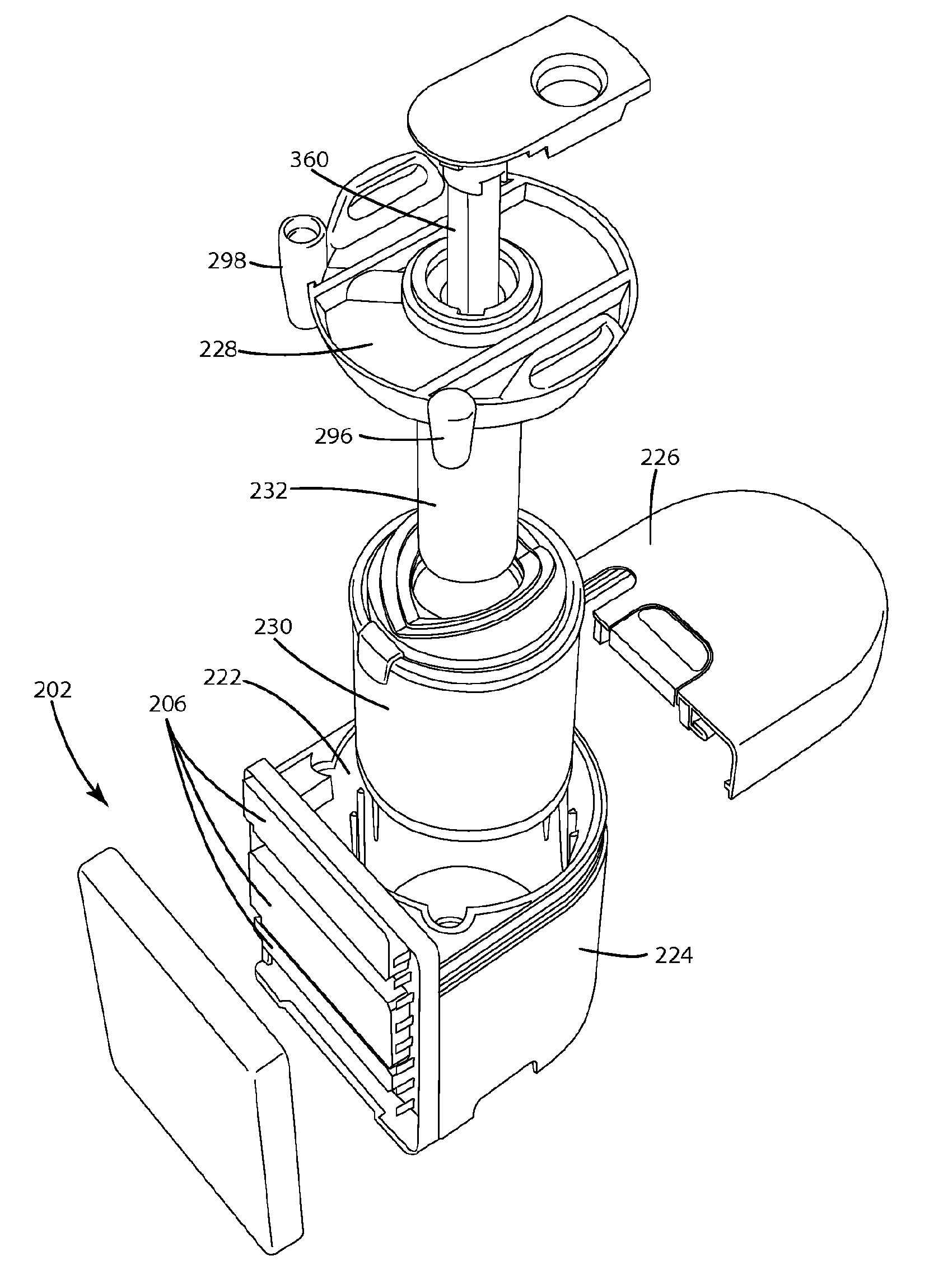

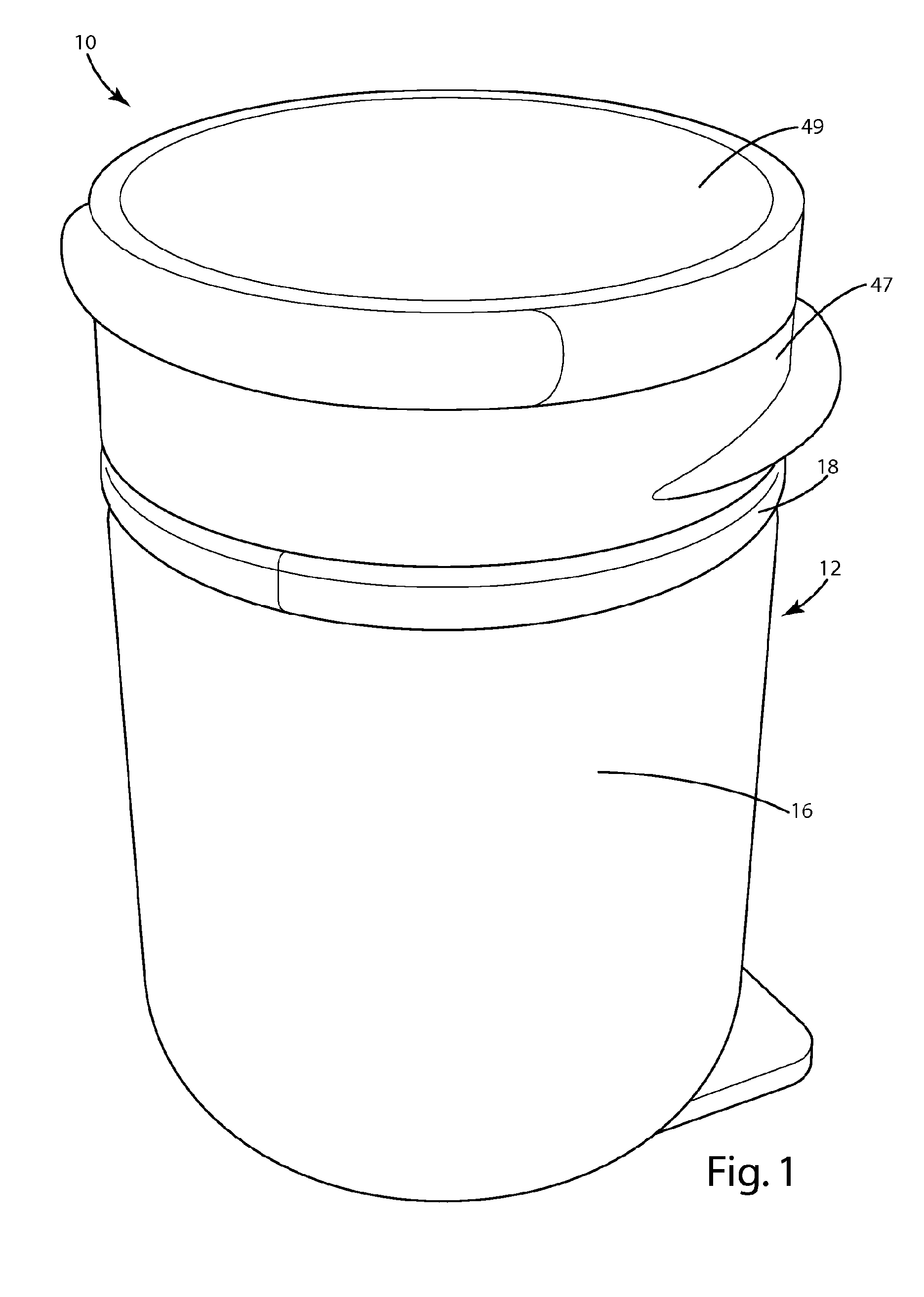

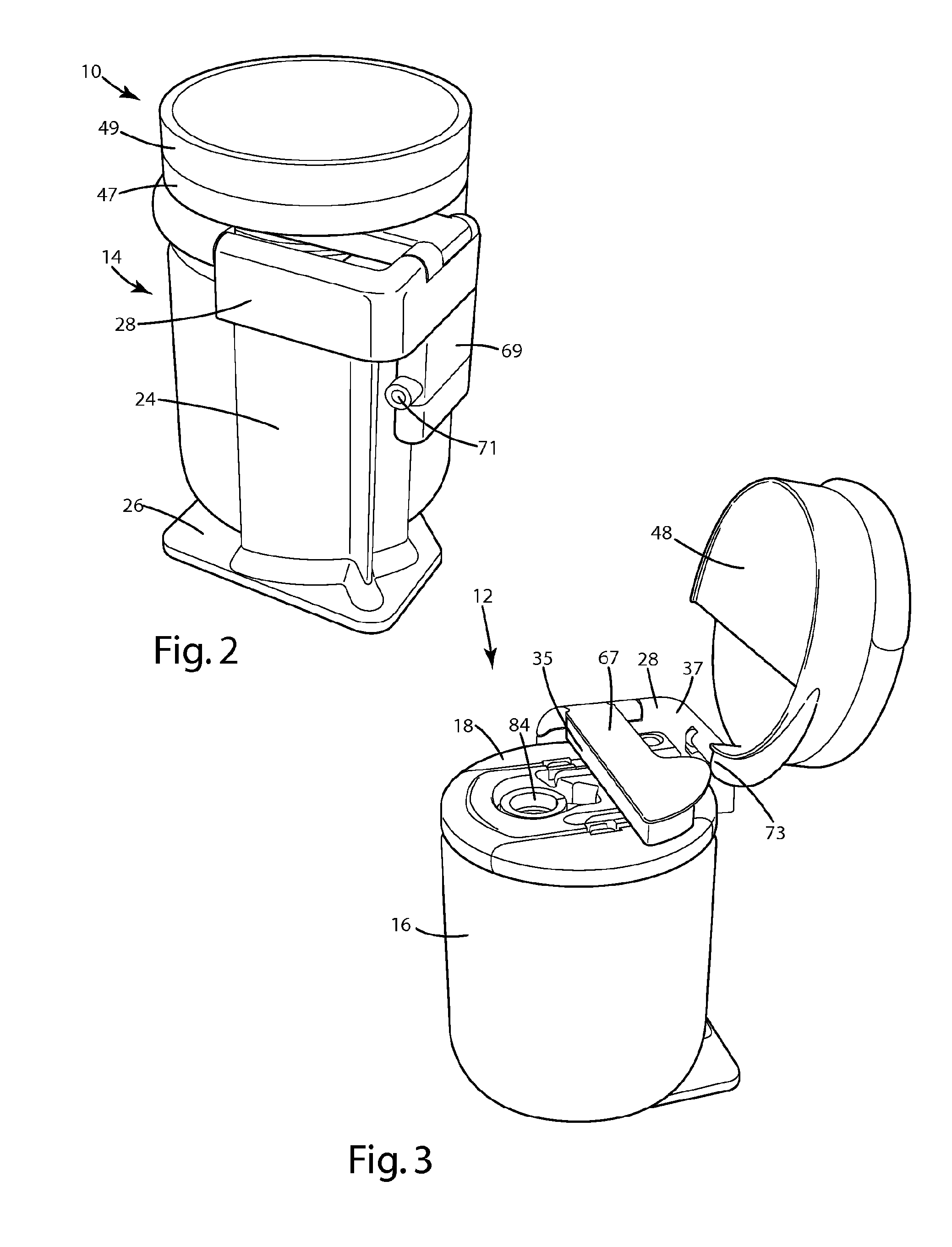

Point-of-use water treatment system

InactiveUS20120132573A1Easy to disassembleLiquid degasificationTreatment involving filtrationElectricityWater treatment system

A water treatment system is capable of meeting the particular needs of a variety of water treatment system applications. For instance, the water treatment system may include a customizable display, multiple interchangeable filters and disinfection systems. In one embodiment, a vessel containing the filters and disinfection assembly can be easily removed from a base that supplies water to the vessel. In another embodiment, the water treatment system includes a plate that includes at least one electrical connection. One or more electronics bricks with sensors, displays and the like can be removably attached to the plate such that each electronics brick is in electrical communication with said brick. In another embodiment, the water treatment system incorporates one or more stackable and interchangeable filter blocks that direct water flowing into the vessel through each filter media.

Owner:ACCESS BUSINESS GRP INT LLC

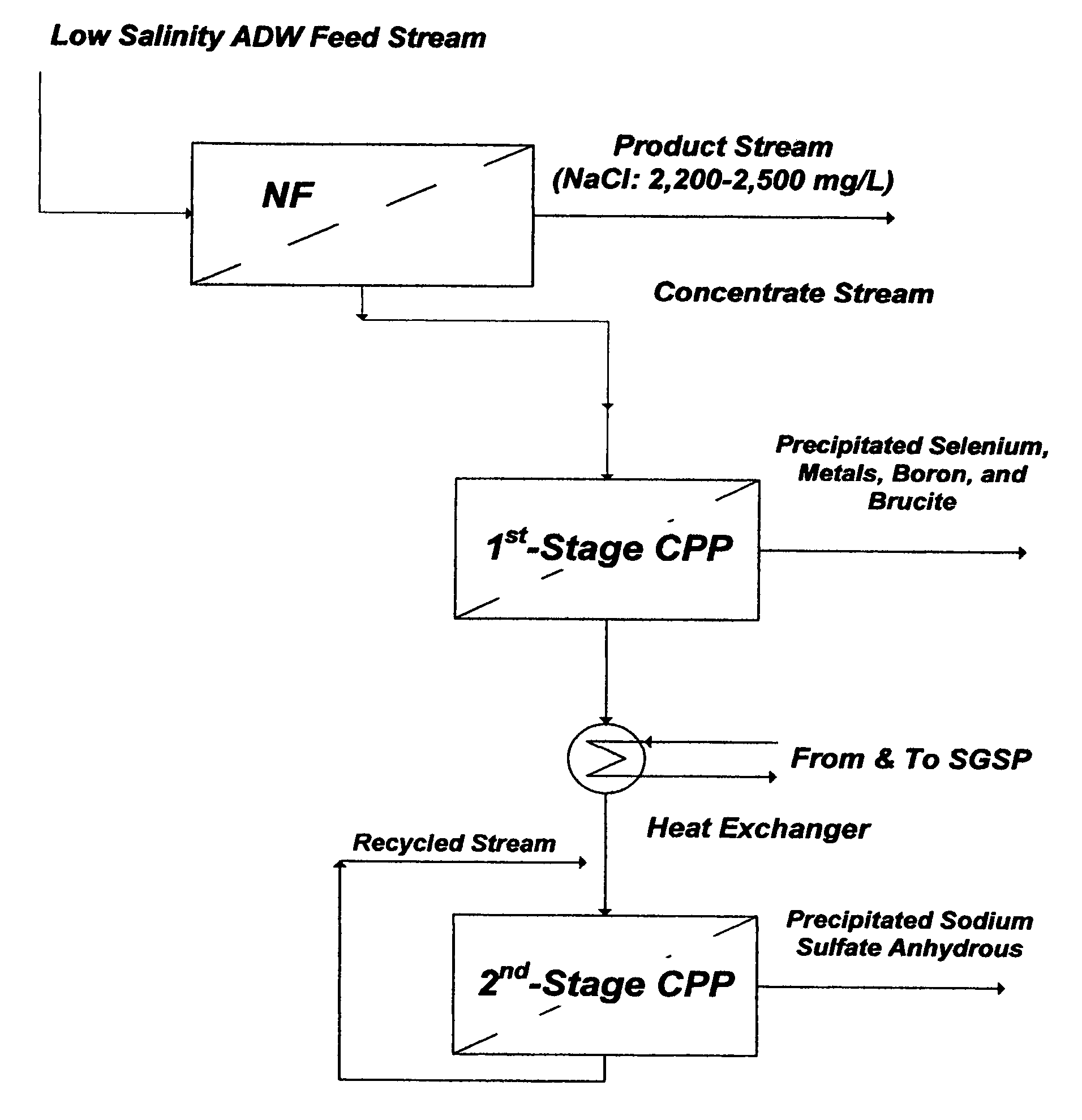

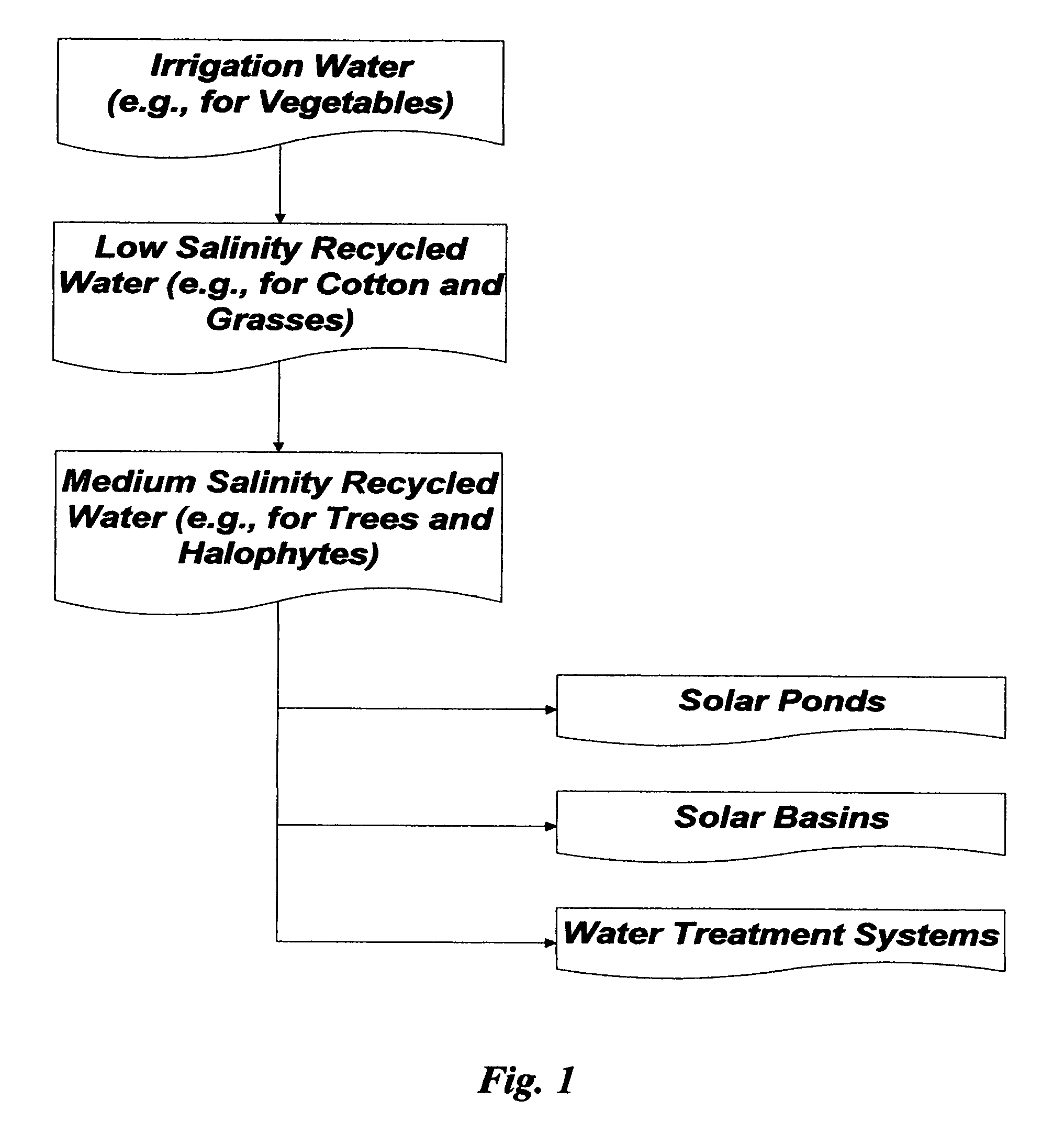

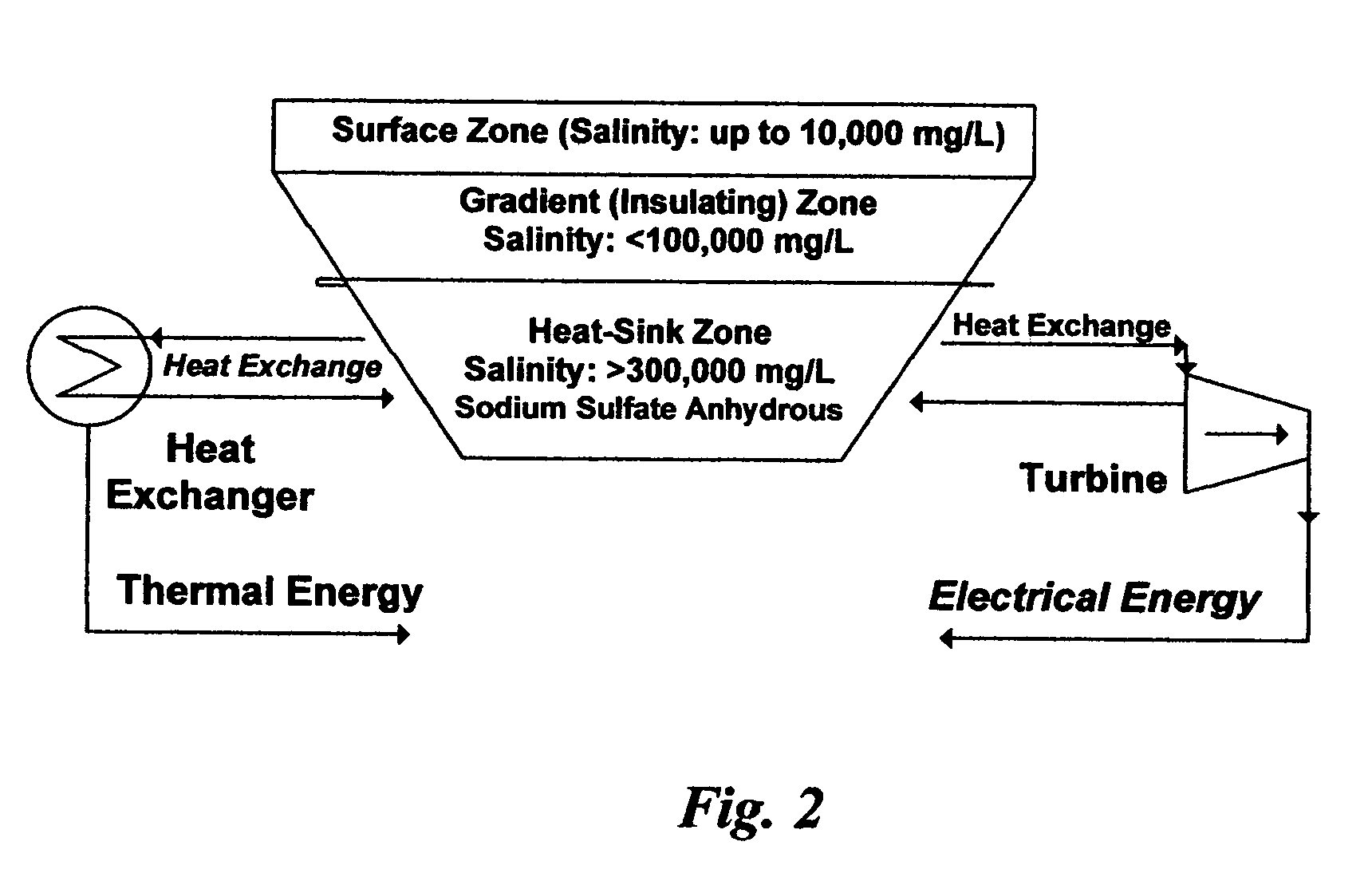

Methods for treating agricultural drainage water and the like

InactiveUS7501065B1Avoid pollutionSolar heating energyGeneral water supply conservationSulfateWater quality

Zero discharge processing methods for the treatment of agricultural drainage water (ADW) are disclosed. The disclosed methods are capable of meeting the three critical issues in treating ADW: (1) selective removal of sulfate scale-prone species and toxic species; (2) production of usable water that at least meets irrigation water quality; and (3) recovery of sodium sulfate and sodium chloride as valuable commodities.

Owner:BADER MANSOUR S

Recycling method for treating stainless steel pickling acid pickle and wastewater

ActiveCN104310647AHigh operating costsSimple processWater treatment compoundsWaste water treatment from metallurgical processWash waterLaterite

The invention relates to a recycling method for treating stainless steel pickling acid pickle and wastewater, belonging to the field of treatment of industrial acid pickle and wastewater in iron and steel and metallurgy industries. The acid pickle and wash wastewater generated during stainless steel pickling are collected according to quality and category and the acid pickle is subjected to acid recycling. The acid pickle and wash wastewater are treated through fractional precipitation by adopting lime as a neutralizing agent. Calcium sulfate or calcium fluoride or a mixture of calcium sulfate and calcium fluoride is obtained through precipitation under the acidic condition (the pH value is equal to 3.0+ / -0.5) and can serve as a cement filler or a material for brickmaking or a building material after heavy metal polluted calcium salt is removed. A metal hydroxide is obtained through precipitation under the alkaline condition (the pH value is not more than 9.0) and can serve as a stainless steel smelting raw material as the quality of the product is better than that of the imported laterite-nickel ores in China. The calcium nitrate containing wastewater obtained after the acid pickle is treated is not needed to be discharged or treated and can be recycled. After being treated, the wash wastewater can be reused as production line wash water.

Owner:上海博士高环保科技有限公司

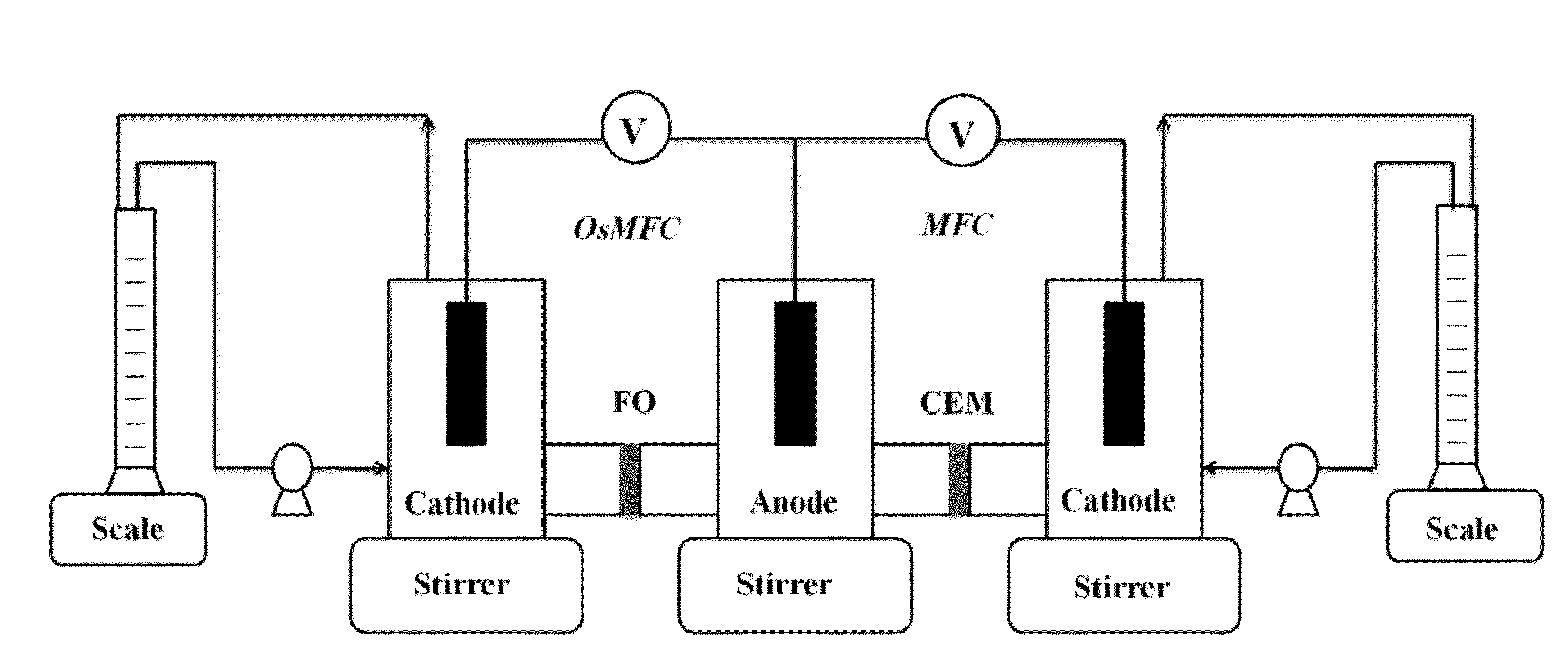

Osmotic bioelectrochemical systems

A bioelectrochemical system includes an anode, a saline solution chamber, and a cathode. The anode is at least partially positioned within an anode chamber containing an aqueous reaction mixture including one or more organic compounds and one or more bacteria for oxidizing the organic compounds. The saline solution chamber contains a draw solution and is separated from the anode chamber by a forward osmosis membrane. Water diffuses across the forward osmosis membrane from the aqueous reaction mixture to the draw solution.

Owner:UMW RES FOUND INC

Intensified deep concentration system for high-salt-content industrial wastewater and technology thereof

InactiveCN105565569ARemove hardnessAlkalinity removalTreatment involving filtrationWater/sewage treatment by ion-exchangeHigh pressureIon-exchange resin

The invention discloses an intensified deep concentration system for high-salt-content industrial wastewater and a technology thereof and belongs to the field of water treatment. The high-salt-content industrial wastewater is adjusted through an adjusting tank, settled through a softening settling pond, filtered through a V-type filter tank, filtered through an ultrafiltration device in an intensified mode and concentrated through a first-stage reverse osmosis device, then the hardness is removed through an ion exchange resin device, and salt separation is performed through a nanofiltration device; thick water of the nanofiltration device is concentrated through a frequent electrode transfer electrodialysis device, produced water is oxidized through an advanced oxidization device and then enters a general produced water tank, and thick water is crystallized through a freezing crystallization system and crystallized with sodium sulfate; produced water of the nanofiltration device is concentrated through a second-stage reverse osmosis device and concentrated again through the frequent electrode transfer electrodialysis device, produced water is oxidized through the advanced oxidization device and enters the general produced water tank, and thick water is crystallized through an MVR evaporative crystallization device and crystallized with sodium chloride. The intensified deep concentration system has the advantages that potential safety hazards caused by high-pressure operation are effectively reduced; the problem that the COD content is high after thick salt water is highly concentrated is effectively solved, the purity of crystallized salt is improved, and the using value of the crystallized salt is improved; the system is high in automation degree, easy to operate, low in operation pressure, stable in operation, high in purity of the crystallized salt, low in operation cost and the like.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

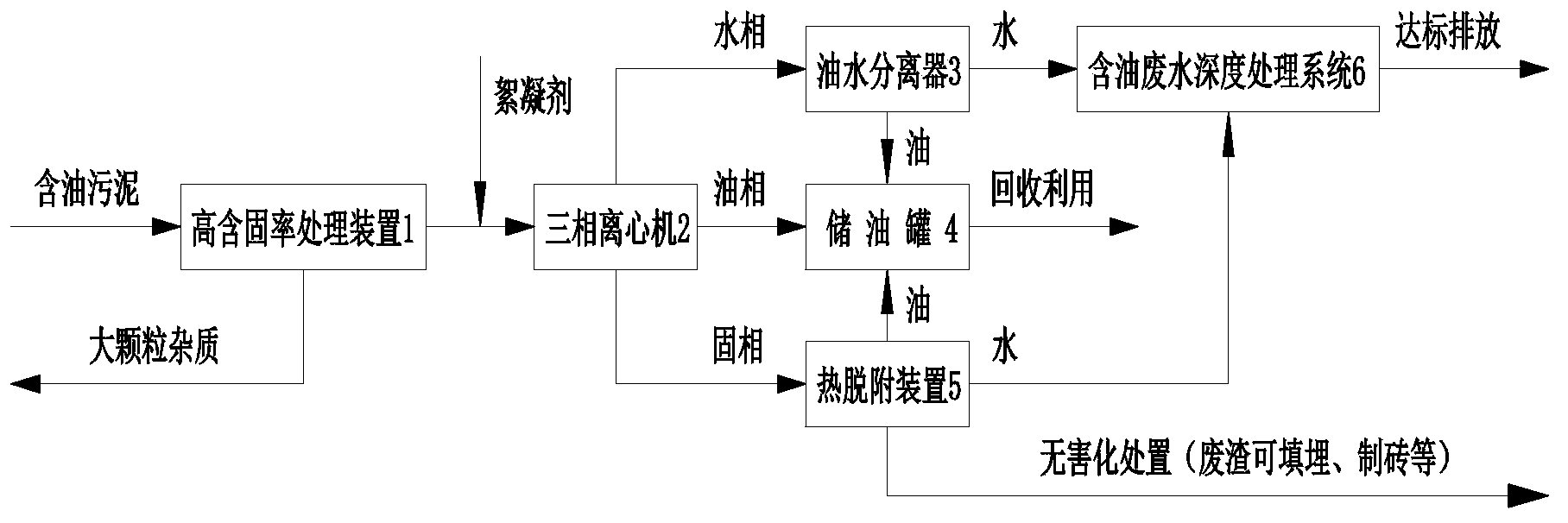

Harmless treatment method for separation and recovery of oily sludge

ActiveCN104341081ALow costEasy maintenance and managementSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSludgeOil phase

A harmless treatment technology for separation and recovery of oily sludge comprises the following steps: 1, conveying the oily sludge to a high solid content treatment device, carrying out preliminary screening on large granule impurities in the oily sludge, and conditioning the sludge; 2, conveying pre-conditioned oily sludge to a three-phase centrifuge, and separating oil, water and mud in the oily sludge; 3, conveying the obtained separated liquid to an oil-water separation device, and further carrying out oil and water separation; 4, inputting the obtained oil phase to an oil storage tank, and inputting water to an oily wastewater advanced treatment system; 5, conveying the obtained solid phase sludge transported to a thermal desorption device, and carrying out heating curing separation and condensation oil-water separation in a thermal desorption treatment process; and 6, conveying water output by the oil-water separation device and water output by the thermal desorption device to the oily wastewater advanced treatment system, and carrying out advanced oil-water separation. The method has the advantages of low cost oily sludge treatment cost, convenient maintenance and management, high efficiency and good stability.

Owner:MAIWANG INT BUSINESS SHANGHAI

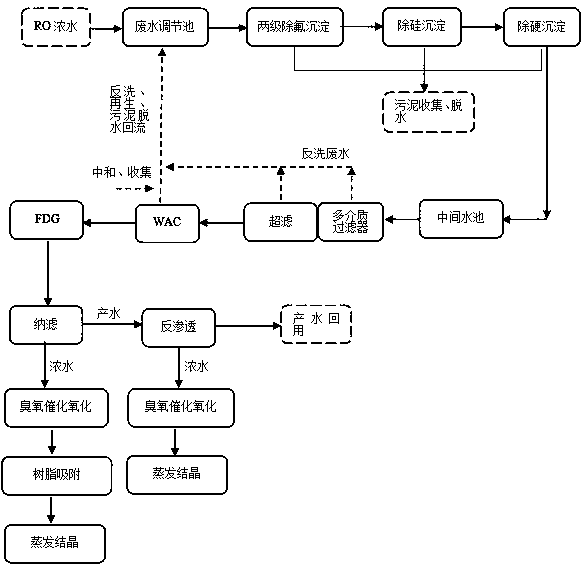

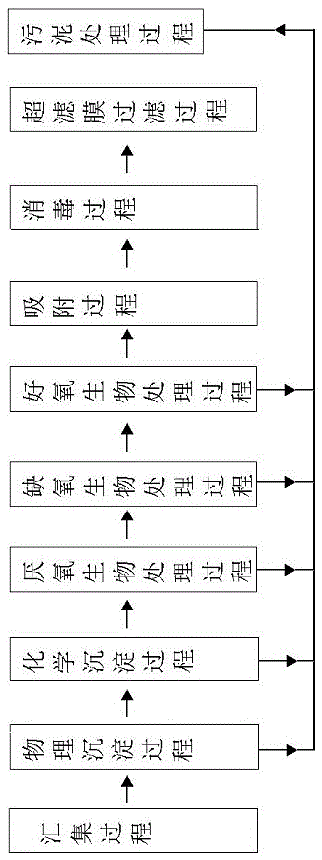

Recycling treatment process for coal coking high-salinity wastewater

PendingCN110606612AAchieving zero emissionsImplement resourcesWater contaminantsTreatment involving filtrationUltrafiltrationResource utilization

The invention relates to a recycling treatment process for coal coking high-salinity wastewater. The process comprises the following steps: (1) fluorine removing; (2) silicon removing; (3) softening;(4) treatment with a multi-medium filter; (5) ultrafiltration; (6) resin softening; (7) FDG; (8) nanofiltration and salt separation; (9) reverse osmosis concentration; (10) advanced oxidation; (11) resin adsorption; and (12) evaporative crystallization. The process has the advantages that the process of pretreatment, nanofiltration salt separation, reverse osmosis concentration, advanced oxidationand evaporative crystallization is adopted, so that zero emission and quality-divided resource utilization of the coal coking high-salinity wastewater are realized.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +2

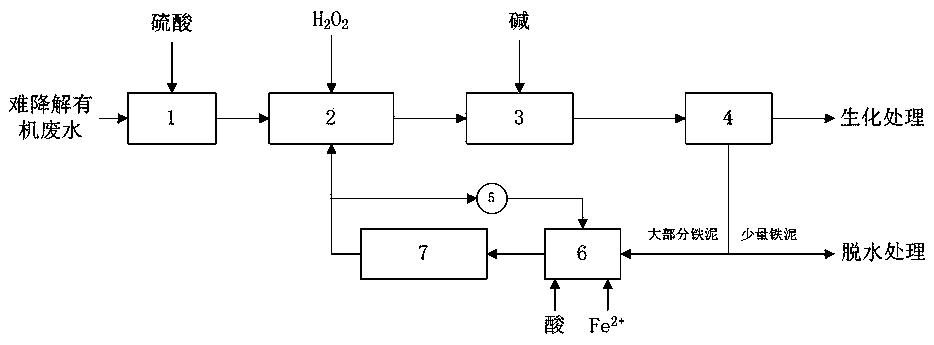

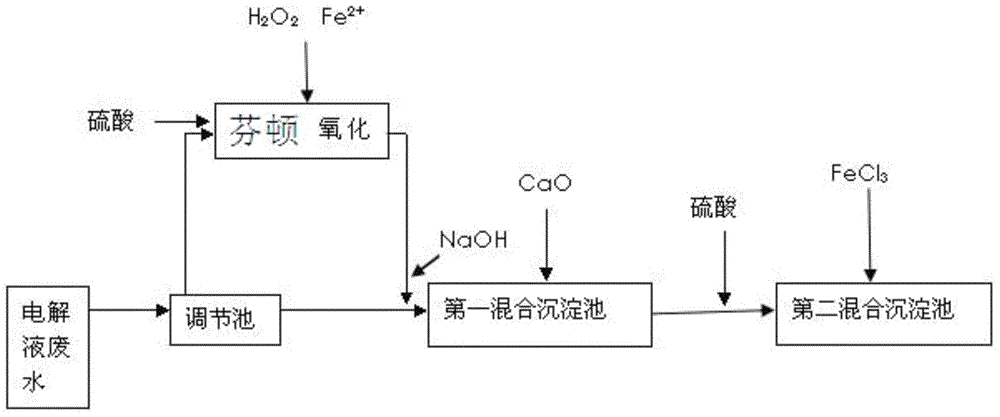

Fenton sewage treatment process and equipment thereof

InactiveCN104261622AEasy to handleEnsure balanceWater treatment parameter controlWater treatment compoundsSludgeCatalytic oxidation

The invention relates to a Fenton sewage treatment process and equipment thereof. The process sequentially comprises the following steps: (a) regulating pH value of sewage; (b) adding H2O2 and Fe<2+> to the sewage; (c) adding alkali to generate iron sludge sediment; (d) separating the iron sludge sediment from supernatant liquid; (e) carrying out biochemical treatment after the supernatant liquid outflows; adding acid to discharged muddy liquid containing the iron sludge sediment so that the iron sludge sediment is dissolved; and (f) oxidizing and breaking an iron complex in the solution outflowing in the step (e) into Fe<3+> through electro-catalytic oxidation; electrolyzing and reducing Fe<3+> into Fe<2+> through electrolytic reduction, and refluxing so that the Fe<3+> is sufficiently electrolyzed and reduced into Fe<2+>; and replacing Fe<2+> added in the step (b) with the Fe<2+> obtained through electrolytic reduction. The equipment comprises a pH regulating tank, a Fenton reaction tank, a reaction tank and a sedimentation basin, and further comprises a reflux pump, a dissolving tank and electrolytic regeneration equipment, wherein the electrolytic regeneration equipment comprises an electro-catalytic oxidation device and an electrolytic reduction device. According to the process disclosed by the invention, recycling of iron is realized and discharge of iron slurry is greatly reduced.

Owner:POWERCHINA ZHONGNAN ENG +1

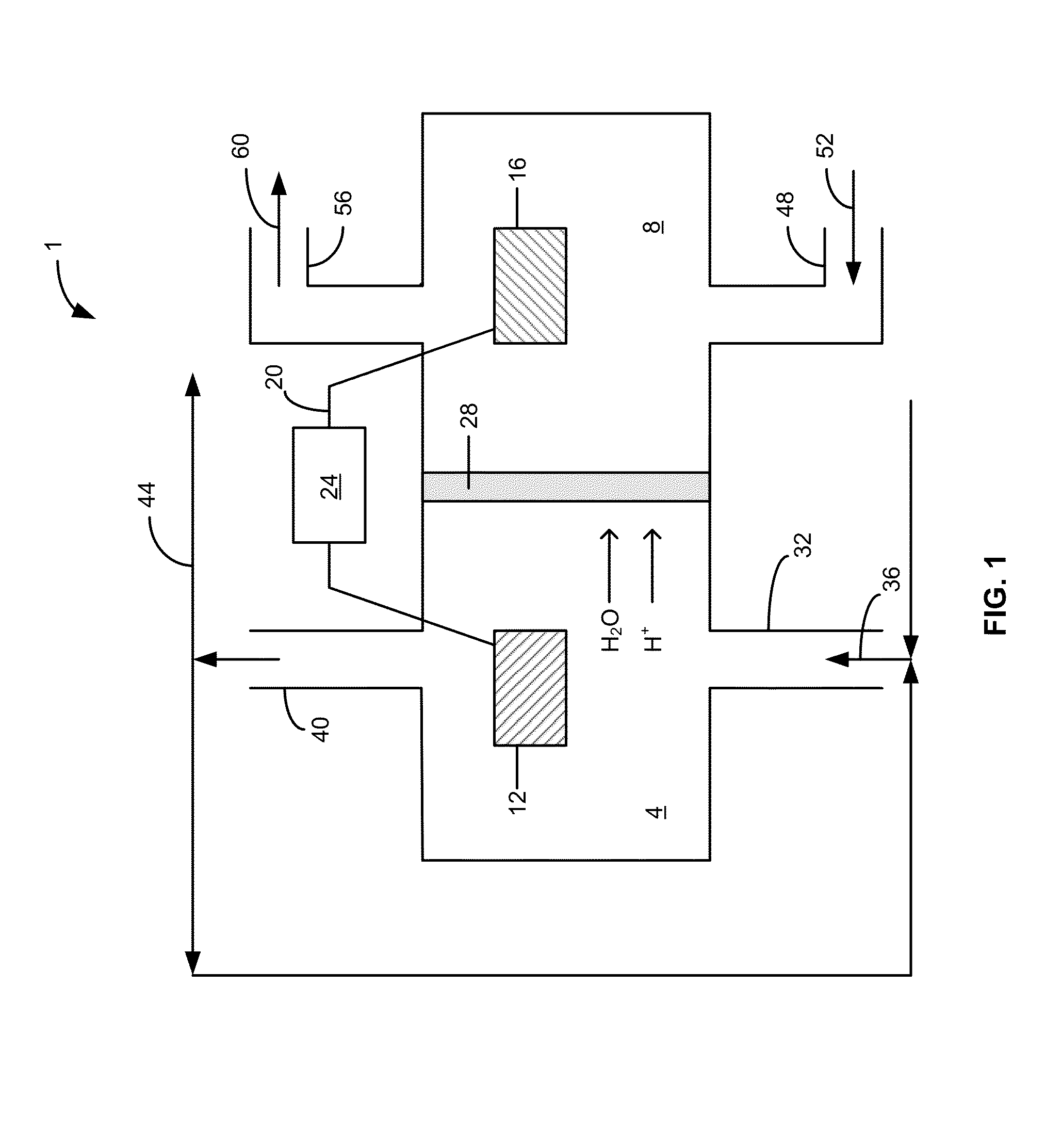

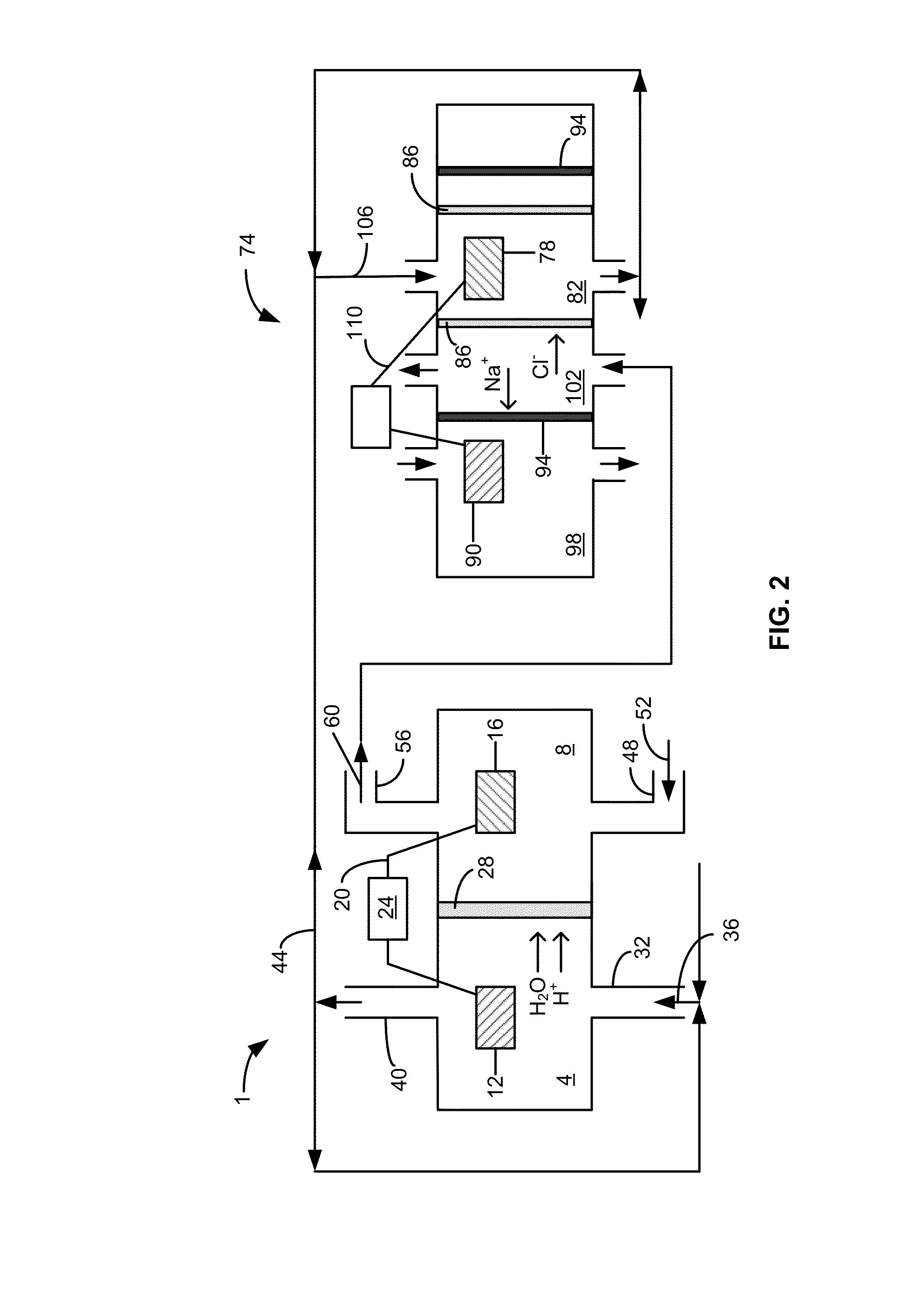

Method and system for generating strong brines

Methods and systems for generating strong brines are disclosed in which a feed stream and a draw inlet stream are passed through a forward osmosis membrane to create a concentrate and a draw outlet stream, the draw outlet stream is passed through a reverse osmosis membrane to create a reverse osmosis permeate flow and a reverse osmosis retentate flow, the reverse osmosis retentate flow is passed through a first nanofiltration membrane to create a first nanofiltration permeate flow and a first nanofiltration retentate flow; and the first nanofiltration retentate flow is passed through a second nanofiltration membrane to create a second nanofiltration permeate flow and a second nanofiltration retentate flow. In some embodiments, the process is repeated through a third nanofiltration membrane. The process may be repeated through a third nanofiltration membrane.

Owner:HYDRATION SYST

Method for reducing sulfide in oilfield waste water and making treated water

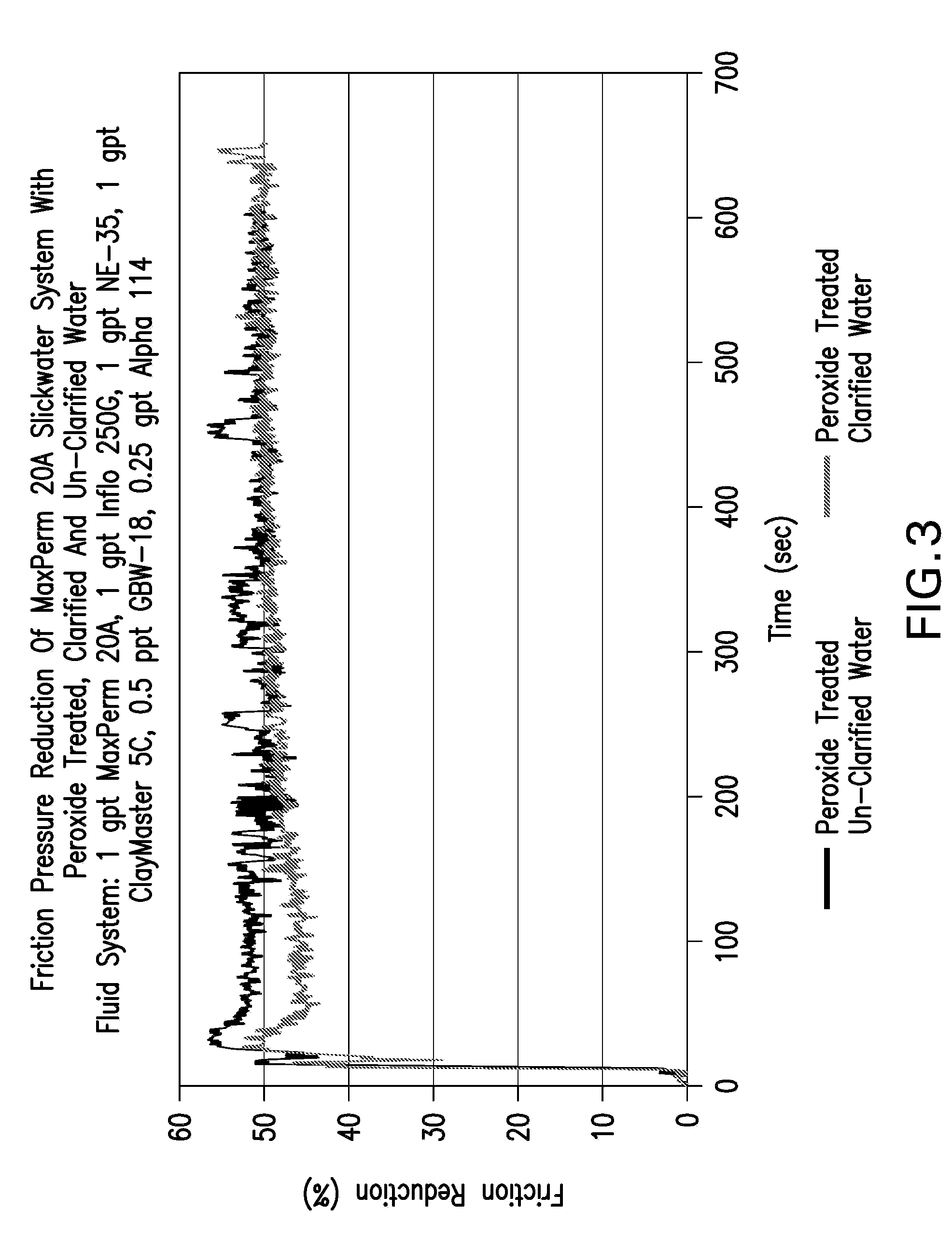

InactiveUS20150013987A1Waste water treatment from quariesWater treatment parameter controlColloidTreated water

A process for treating oilfield waste water includes contacting the oilfield waste water with hydrogen peroxide, the oilfield waste water comprising sulfide; oxidizing the sulfide to sulfur; and precipitating the sulfur to form treated water from the oilfield waste water. A process for recycling oilfield waste water includes combining the oilfield waste water and hydrogen peroxide, the oilfield waste water comprising sulfide; oxidizing the sulfide to sulfur; forming a precipitate comprising a colloidal sulfur precipitate, a bulk sulfur precipitate, or a combination comprising at least one of the foregoing; removing the precipitate from the oilfield waste water to form treated water; introducing an additive to the treated water; and disposing the treated water in a subterranean environment.

Owner:BAKER HUGHES INC

System For Removing Solids From Aqueous Solutions

InactiveUS20070199903A1Water treatment parameter controlSedimentation regulating devicesAqueous solutionPrecipitation

Processes, apparatus, and compositions are described for removing solids, including dissolved and undissolved solids, from aqueous solutions by crystallization, precipitation, aggregation, absorption, and / or adsorption.

Owner:BIOMASS PROCESSING TECH

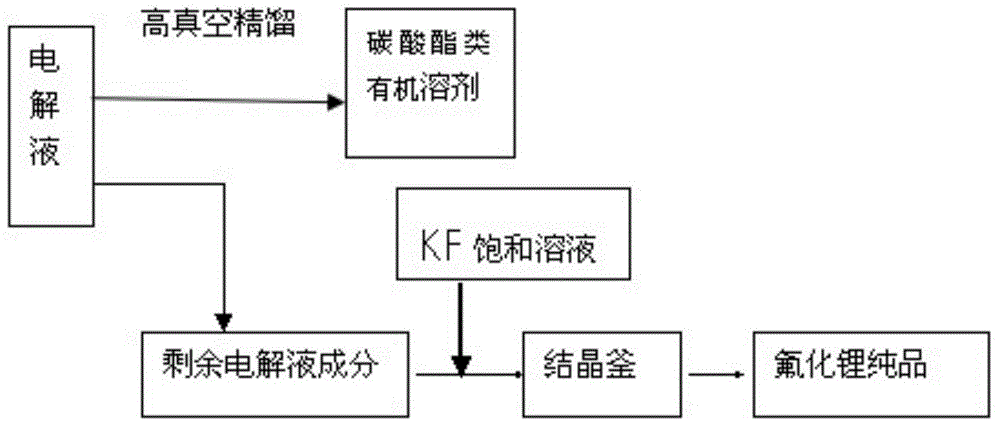

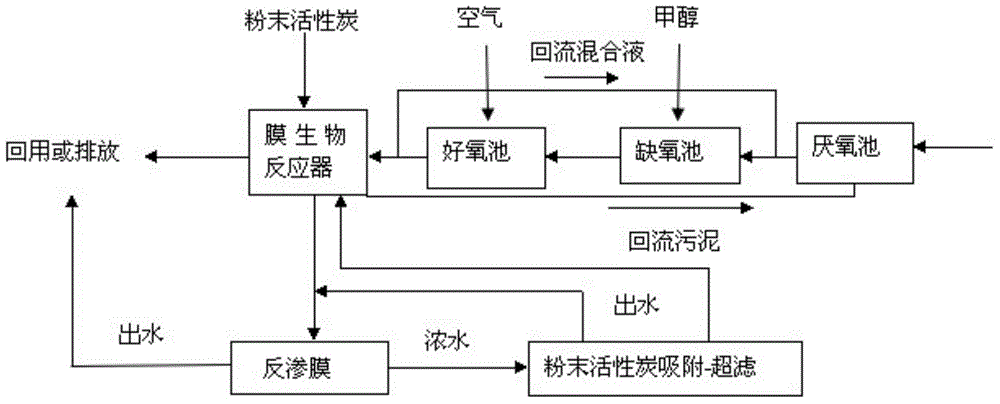

Method for recovery treatment of waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater

InactiveCN104628217AImprove biodegradabilityOvercome incompletenessDispersed particle separationWater/sewage treatmentUltrafiltrationFiltration

The invention discloses a method for recovery treatment of a waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater. Three treatment units are employed for treatment. Firstly, the waste-and-old electrolyte is treated. Then, waste gas resulting from the reaction of the electrolyte is pumped into the waste water for absorption, so that the waste gas can be removed during a waste water treatment process; the lithium battery waste water is treated by a Fenton agent through oxidation to obtain improved biodegradability of the waste water; and reaction precipitates are removed through flocculent sedimentation and the obtained water is treated through combination of A2 / O and MBR membrane separation. Finally, the outlet water goes through a RO reverse osmosis unit to ensure the quality of the outlet water. Combination technology of active carbon powder adsorption and ultra-filtration is employed to remove organic pollutants of the concentrated water resulting from the RO unit, so that the water after treatment can meet the requirements of RO high-quality reuse water. According to the invention, imperfection of an existing technical method of waste-and-old lithium battery recovery and treatment is overcome, and quantitative reduction, harmlessness, and reutilization of waste water treatment of the waste-and-old electrolyte are realized.

Owner:天津卡特化工技术有限公司

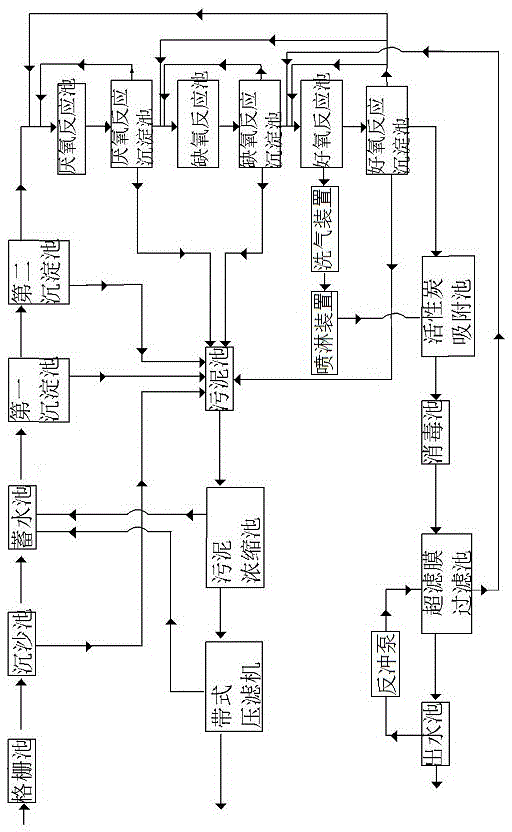

Urban sewage treatment system and purification method

ActiveCN105585220AEfficient removalImprove purification efficiencySludge treatment by de-watering/drying/thickeningWater/sewage treatment by irradiationPurification methodsFiltration

The invention discloses an urban sewage treatment system and purification method and belongs to the technical field of sewage treatment. The sewage treatment and purification method comprises the steps of collection, physical precipitation, chemical precipitation, anaerobic biological treatment, anoxic biological treatment, aerobic biological treatment, adsorption, disinfection, ultrafiltration membrane filtration and sludge treatment in sequence. According to the method, a physical precipitation method, a chemical precipitation method and a biological purification method are used comprehensively to perform step-by-step classification treatment on different pollutants, the purification efficiency is high, the effluent quality is good, the nitrogen and phosphorus treatment capacity is higher, operation and maintenance are convenient, management is simple, and popularization and use can be realized.

Owner:台州天工医化设备有限公司

Metal scavenging polymers and uses thereof

ActiveUS20110243819A1Dispersed particle filtrationSelenium/tellurium compundsWastewater systemsMonomer

Uses for a composition comprising a polymer derived from at least two monomers: acrylic-x and an alkylamine, wherein said polymer is modified to contain a functional group capable of scavenging one or more compositions containing one or more metals are disclosed. These polymers have many uses in various mediums, including wastewater systems.

Owner:ECOLAB USA INC

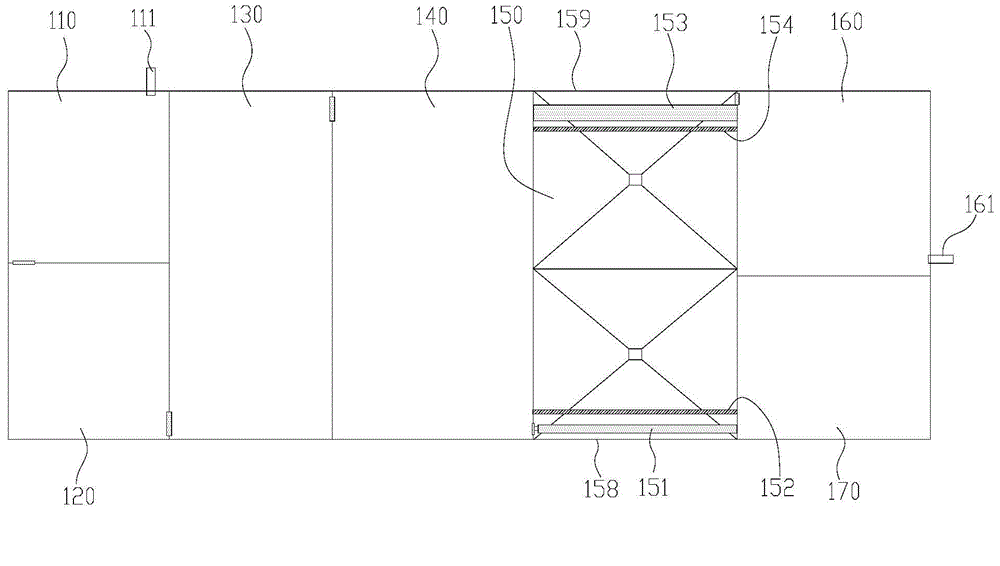

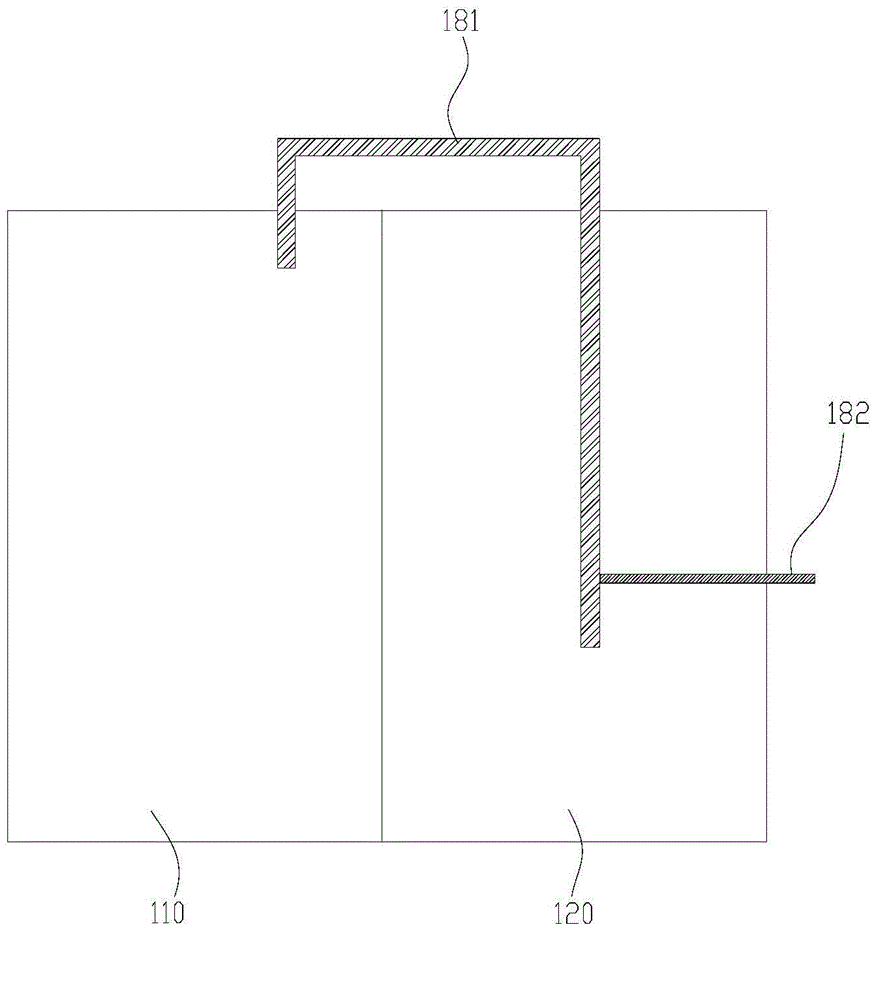

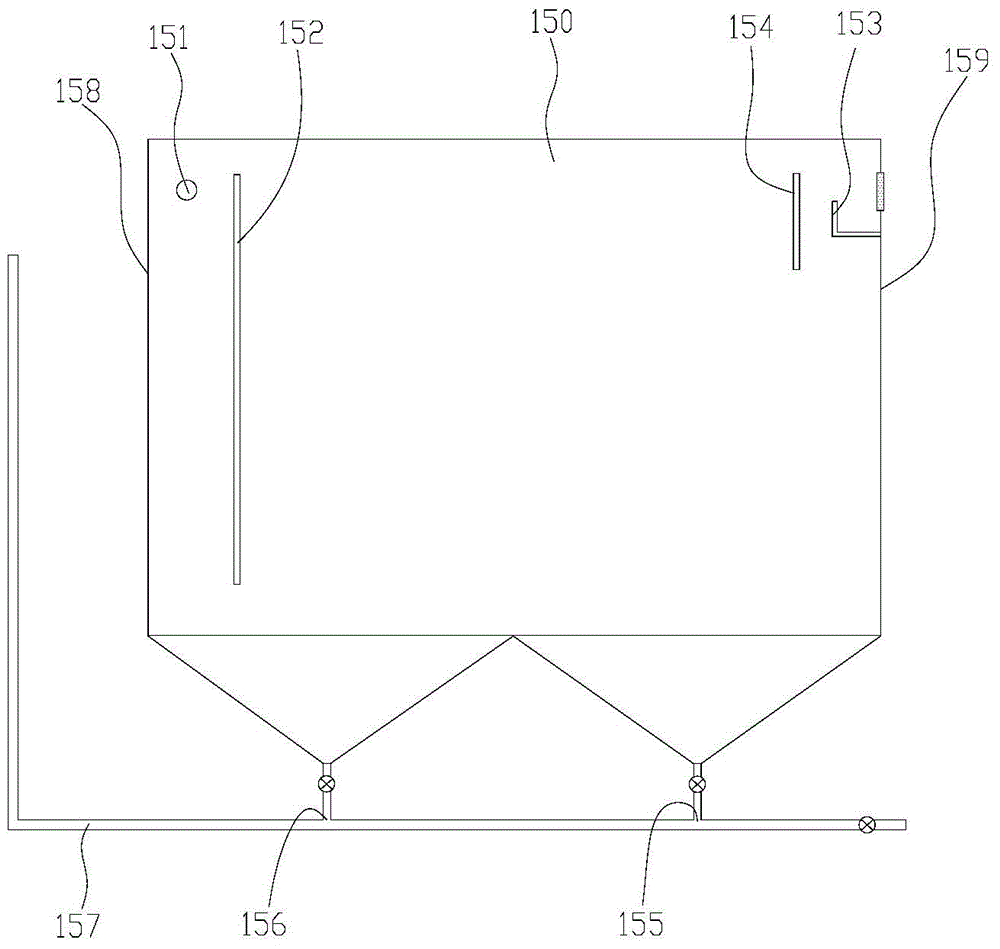

A3/O-MBBR (Moving Bed Biofilm Reactor) integrated sewage treatment device and A3/O-MBBR integrated sewage treatment method

ActiveCN104445830AReduce floating phenomenonImprove precipitation effectTreatment using aerobic processesTreatment with anaerobic digestion processesMoving bed biofilm reactorSmall footprint

The invention relates to the technical field of sewage treatment and particularly relates to an A3 / O-MBBR (Moving Bed Biofilm Reactor) integrated sewage treatment device and an A3 / O-MBBR integrated sewage treatment method. According to the device provided by the invention, a sewage backflow mechanism, a nitrification liquor backflow mechanism and an anaerobic liquor backflow mechanism are arranged and suspended filler is filled in an aerobic tank, so that the integrated sewage treatment device has a good effect for treating nitrogen and phosphorus in sewage and is high in treatment efficiency, compact in structure and small in occupied area. In addition, by virtue of optimizing a settling pond structure in the integrated sewage treatment device, the settling effect of the settling pond is improved, and the sludge floatation phenomenon and the content of suspended solids in effluent can be remarkably reduced. After sewage is treated by the integrated sewage treatment device provided by the invention, the effluent can reach the level A of first class stand of pollution discharge standard for municipal sewage treatment plant (GB18918-2002).

Owner:YUNNAN HEXUN ENVIRONMENTAL TECH CO LTD

Popular searches

Treatment involving sedimentation Water/sewage treatment by flocculation/precipitation Water/sewage treatment by sorption Water treatment multistage treatments Solid sorbent liquid separation Cation exchangers Water supply tanks Water/sewage treatment apparatus Water/sewage treatment by oxidation Water/sewage treatment by centrifugal separation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com