Recycling treatment process for coal coking high-salinity wastewater

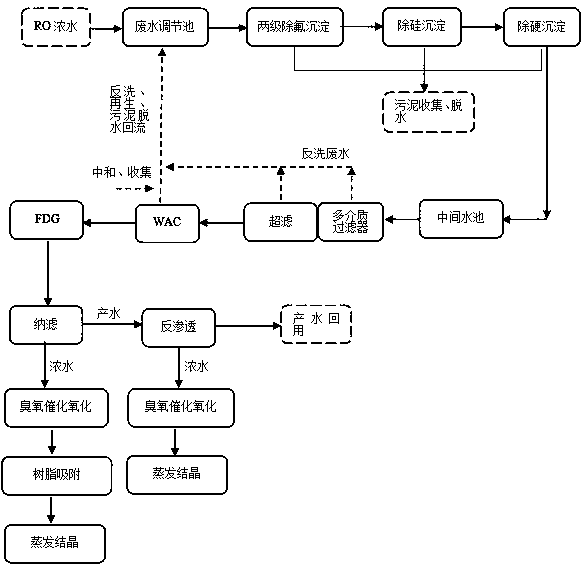

A technology of high-salt wastewater and treatment process, which is applied in the direction of oxidized water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., which can solve the problem of increasing the scaling risk of subsequent membrane systems and evaporation crystallization systems and increasing the economic burden of enterprises , No fouling substances and other issues are considered to achieve the effect of reducing ozone dosage, realizing zero emission and resource utilization, and reducing TOC and chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] RO concentrated water of coking wastewater advanced treatment system in a coal coking plant, water quality: pH 7~8, fluoride ion 100~150mg / L, silicon content 15~25mg / L, chloride 2000~2800mg / L, sulfate 6000~6500mg / L L, total hardness 300-500mg / L, TDS 13000-15000mg / L, COD 300-500mg / L. The waste water flow rate is 30t / h, and it runs for 20 hours per day.

[0051] Include the following steps:

[0052] (1) Fluoride removal: the fluoride ion content of the raw water is 115mg / L, and the pH is 7.84. Calcium chloride and 50ppm ferric chloride are added to the first-level defluoridation coagulation tank according to the calcium-fluorine molar ratio of 1.2:1, and the residence time is 15 minutes before entering the first-level flocculation tank; Secondary sedimentation tank; the residence time of the first-level sedimentation tank is 2h, and the effluent overflows into the second-level defluoridation coagulation tank. The pH is adjusted to 7.50 by sodium hydroxide, and calcium c...

Embodiment 2

[0065] RO Concentrated Water Quality of Coal Coking Wastewater Advanced Treatment System of a Coal Coking Plant: pH 7~8, Fluoride Ion 150~200mg / L, Silicon Content 20~30mg / L, Chloride 2300~2900mg / L, Sulfate 6500~7200mg / L L, total hardness 300~500mg / L, TDS 12000~14000mg / L, COD 250~400mg / L. The waste water flow rate is 20t / h, and it runs 22 hours a day.

[0066] Include the following steps:

[0067] (1) Fluoride removal: the fluoride ion content of the raw water is 179mg / L, and the pH is 7.26. Calcium chloride and 50ppm ferric chloride are added to the first-level defluoridation coagulation tank according to the calcium-fluorine molar ratio of 1.2:1, and the residence time is 15 minutes before entering the first-level flocculation tank; Grade-1 sedimentation tank; the residence time of the first-level sedimentation tank is 2h, and the effluent overflows into the second-level defluoridation coagulation tank. The pH is adjusted to 7.50 by sodium hydroxide, and calcium chloride an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com