Patents

Literature

276results about How to "Achieve full utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

All-round price wheat germ flour and method of preparing

InactiveCN101176537AExtended shelf lifeAchieve full utilizationFood preparationBiotechnologyAnimal science

The invention relates to wholesome wheat embryo powder and the production method, belonging to the technical field of food, which resolves the problems of wheat embryo powder of watery taste, short guarantee period and large loss of nutritional ingredients. The invention adopts the technical proposal that the invention makes the wheat embryo into 40 to 60 mesh grains with microcapsule technology and the whole nutritional ingredients of the wheat embryo are retained in the grains. A xanthan layer and a lecithin layer are coated outside the grain orderly. The invention comprises the following steps: synthetically sterilizing and enzyme killing, super micron crushing, matching, homogeneously emulsifying, sterilizing and enzyme killing, sponging drying, boiling prilling, spray finishing and packing via vacuum charging. The invention can utilize the wheat embryo completely without any industrial waste, therefore can protect environment and achieve industrialized mass production. The invention has the advantages of long guarantee period, convention edible method, mild taste, full-bodied wheat perfume, high content of nutritional ingredient and easy commercialization.

Owner:HUALONG RIQING FOOD

Method for producing water-soluble citrus peel fibres

InactiveCN101797037AAchieve full utilizationAchieving zero emissionsFood preparationFiberFood material

The invention relates to a method for producing water-soluble citrus peel fibres. Fresh citrus peels are taken as raw materials and are subjected to the technology such as colour preserving, drying and crushing, CO2 supercritical bitter and color removal, superfine pulverizing and enzymolysis, concentration, high-pressure homogenization, filling and sterilizing to convert cellulose, hemicellulose, pectin and the like in the citrus peels into the water-soluble citrus peel fibres which can be eaten directly and also can be taken as raw materials of high-carbohydrate fibre functional foods. Aromatic oil and pigments of the citrus are obtained in the production process. Therefore, the full use of the citrus and zero emission of peel residue are realized in the citrus processing process.

Owner:SHAOYANG UNIV

Comprehensive utilizing method of sweet sorghum stalks

InactiveCN102399826AHigh in celluloseImprove accessibilityBiofuelsMicroorganism based processesChemical industryXylose

The invention discloses a comprehensive utilizing method of sweet sorghum stalks belonging to the technical field of biomass energy and chemical industry. The method comprises the following steps of: 1) fermenting sweet sorghum stalks in a solid state and distilling the sweet sorghum stalks to obtain an ethanol solution and distillers' grains; 2) hydrolyzing the distillers' grains under an acidic condition; and carrying out solid and liquid separation to obtain an xylose solution and an acidolysis slag; 3) washing the acidolysis slag by using water as an enzymatic substrate; adding an enzymolysis buffer solution; adding enzyme to carrying out enzymolysis; and then carrying out solid and liquid separation to obtain an enzymolysis mixed solution and enzymolysis xylogen; and 4) inoculating the enzymolysis mixed solution into yeast and fermenting the enzymolysis mixed solution to generate an ethanol solution. According to the invention, a new way is found for utilizing the distillers' grains; and xylose with high value added is obtained; meanwhile, the cellulose content and cellulose accessibility in the acidolysis slag are increased so that high conversion rate of cellulose enzymolysis and saccharification is realized. By using the method disclosed by the invention, the utilization rate of the lignocellulose raw material with high sugar content is increased, the ethanol yield per unit crop is increased, and the production cost of the cellulose ethanol is reduced.

Owner:TSINGHUA UNIV

Composite barley green solid beverage and production process thereof

InactiveCN102511894ASolve the reconciliationSolving Dispersion ProblemsFood preparationFreeze-dryingBARLEY GRASS

The invention relates to composite barley green solid beverage and a production process thereof and belongs to the technical field of deep processing of agricultural products. The invention is characterized in that: the composite barley green solid beverage is prepared by using fresh barley grass juice and barley green powder as main raw materials and adding barley grass dreg powder, spiral seaweed powder, xanthan gum, sorbitol, sodium alginate, maltodextrin and sodium carboxymethylcellulose through procedures of sterilizing and packaging, wherein the fresh barley grass juice is used for performing biological green protection by using flammulina velutipes extracting solution; and the barley green powder is prepared through vacuum freeze drying. The composite barley green solid beverage have the characteristics of simple production process, high utilization rate of the raw materials and the like, can be produced industrially, has high nutritional value and high drinking performance and is ideal natural health-care beverage.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for preparing ethanol by one-step fermentation after ion liquid stage treatments from native cellulose material

InactiveCN101298620AAchieve full utilizationReduce accumulationBiofuelsMicroorganism based processesHigh concentrationNatural fiber

The invention relates to a method that prepares ethanol through the grading processing with ionic liquids and one-step zymolysis and utilizes a raw material of native cellulose. The raw material of native cellulose is orderly processed by the ionic liquids A and B so as to respectively remove hemicellulose and lignin, and the obtained cellulose is used as a substrate so as to be further fermented to prepare the ethanol; the ionic liquid A is an acid or alkalic ionic liquid, the ionic liquid B is a halogenated-imidazole-like ionic liquid. The method utilizes the ionic liquids to implement the grading processing of the raw material of native cellulose, removes the substances of the hemicellulose and the lignin that are harmful to the zymolysis production of the ethanol, uses the substances for other purposes, and only utilizes the cellulose as the substrate so as to implement the ethanol zymolysis, thus realizing complete utilization of the raw material of native cellulose. Simultaneously the method can avoid adsorption of the hemicellulose and the lignin by cellulose enzyme and improve the activity of the cellulose enzyme; the accumulation of the substances that are not fermented in a reactor is reduced, and the method can realize continuous zymolysis in a long time, has high input concentration, recycles yeast and cellulose enzyme, has high concentration of recycled ethanol, and saves water.

Owner:HENAN UNIV OF SCI & TECH

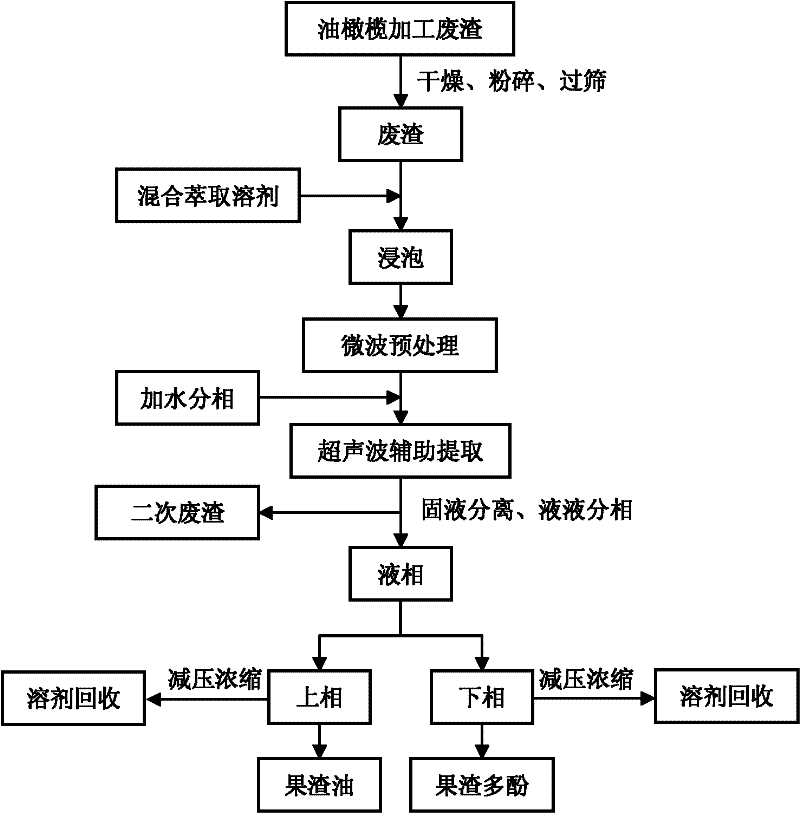

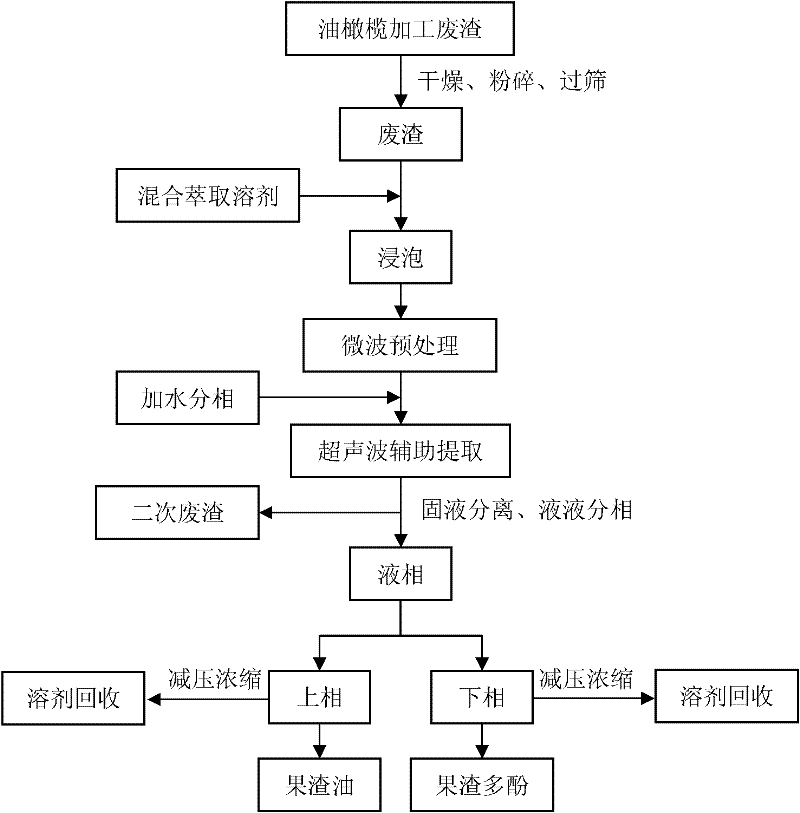

Method for simultaneous extraction of pomace oil and polyphenols from olive processing waste

InactiveCN102260588AShorten the time periodShorten the production cycleOrganic chemistryBiofuelsMicrowaveSlag

The invention discloses a method for synchronously extracting pomace oil and polyphenol from olive processing waste residue. The method comprises the following steps of: soaking dried waste residue in a mixed solvent, pretreating feed liquid by using a microwave extractor, adding water to separate phases, assisting in extraction by using an ultrasonic extractor, filtering or centrifuging to ensure that filtrate is demixed, concentrating an upper-layer liquid phase under reduced pressure to obtain crudely extracted pomace oil, and concentrating a lower-layer liquid phase under reduced pressureto obtain pomace polyphenol. The method has the remarkable characteristics of short consumed time, low energy consumption, high extraction efficiency and the like.

Owner:NORTHWEST NORMAL UNIVERSITY

Modified stalk material and its application

InactiveCN1412092AHigh strengthEnvironmental pollutionFlexible coversWrappersPhanerochaete chryosporiumChemistry

The present invention relates to a modified straw material, its production method and application. The production method of the modified straw material includes the following steps: 1. steam-blastingstraw to obtain steam-blasted straw; 2. inoculating the steam-blasted straw with culture liquor to make solid fermentation treatment to degrade lignin; 3. mixing the steam-blasted straw and air-driedstraw, making their mixture undergo the processes of thermosetting treatment and forming treatment so as to obtain the invented modified straw material which can be made into plate material or light packaging material instead of wood material, so that it possesses extensive application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Pure nature low temperature baked cooked pumpkin powder and production method thereof

InactiveCN103960608AGood colorGood rehydration performanceFood preparationPumpkin seedProcess engineering

The present invention provides pure nature low temperature baked cooked pumpkin powder and a production method thereof. The production process comprises: carrying out screening, washing, peeling, pulp removing, seed taking and slicing to decompose into pumpkin slices, pumpkin peel, pumpkin pulp and pumpkin seeds; immersing and blanching the pumpkin slices so as to reduce nutrition loss of the pumpkin, immersing and blanching the pumpkin slices with boiling salt water with a temperature of more than or equal to 95 DEG C until achieving a semitransparent state, taking out, dewatering, cutting into strips, carrying out 50-60 DEG C constant temperature vacuum baking processing on the cut pumpkin slice strips, the cut pumpkin peel strips, the cut pumpkin pulp strips and the pumpkin seeds with low temperature baking equipment to obtain cooked and dried pumpkin product, carrying out a mixing stirring sterilization treatment on the cooked and dried pumpkin product, and grinding with a crushing machine to obtain the cooked pumpkin powder with the particle fineness of more than or equal to 120 mesh, wherein the cooked pumpkin powder maintains the nutritional components and the good color of the pumpkin, presents the microscopic porous structure, has good rehydration, can be directly taken through infusion with boiling water, and can further be used as other food preparation materials, and the baked and cooked pumpkin powder, the baked and cooked pumpkin peel powder, the baked and cooked pumpkin pulp powder and the baked and cooked pumpkin seed powder after sterilization can be directly eaten.

Owner:程长青

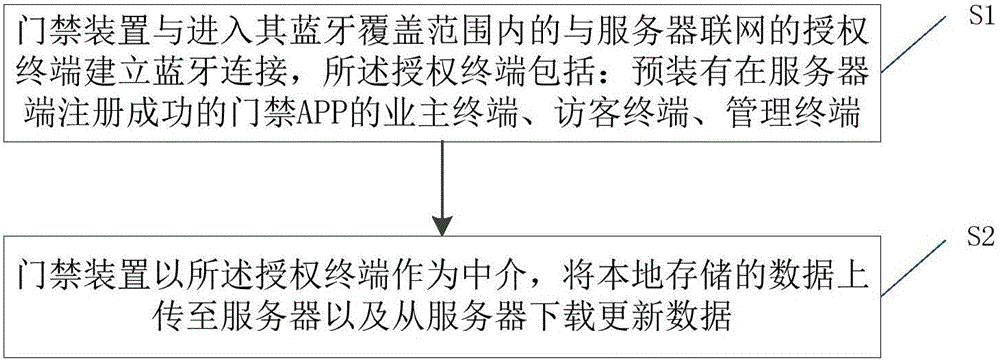

Intelligent access control device and communication method thereof

InactiveCN105719375AAchieve full utilizationReduce hardware requirements and maintenance costsIndividual entry/exit registersEmbedded systemServer-side

The invention discloses an intelligent access control device and a communication method thereof. The communication method comprises the following steps: S1, establishing Bluetooth connection between the access control device and an authorized terminal which enters a Bluetooth cover range of the access control device, is networked with a server and comprises an owner terminal, a visitor terminal and a management terminal of access control APP successfully registered on a server side; and S2, taking the authorized terminal as an intermediary agent of the access control device, uploading locally stored data to the server and downloading update data from the server. The intelligent access control device disclosed by the invention is not required to be networked with the server, manual maintenance is not required either, the intelligent access control device can be automatically interacted with the server through the owner terminal, the visitor terminal and the management terminal which enter the Bluetooth cover range and have limits of authority, resources are fully utilized, requirements to hardware of the access control device and maintenance cost are reduced, and the mode of data interaction between the intelligent access control device and the server is simple and intelligent.

Owner:WRT INTELLIGENT SCI & TECH

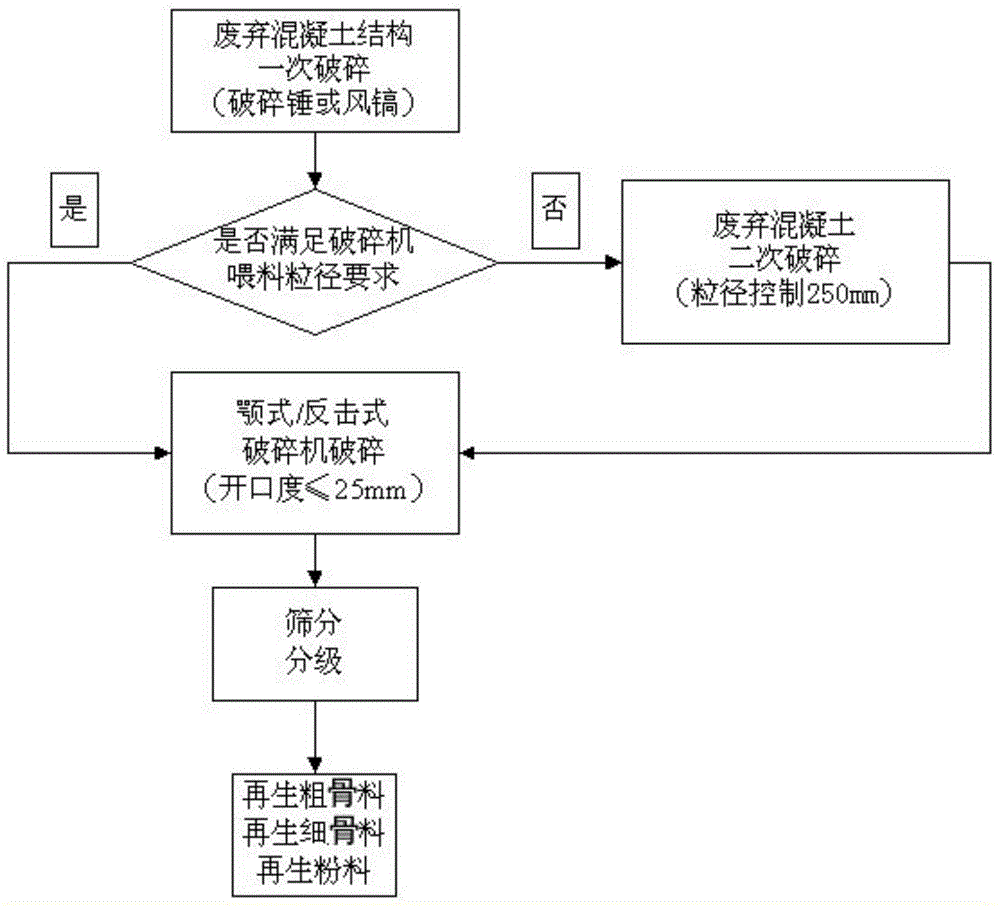

Ecological nanometer photocatalysis completely recycled concrete

ActiveCN104310891AUnique performanceAchieve full utilizationSolid waste managementWater reducerConstruction aggregate

The invention discloses an ecological nanometer photocatalysis completely recycled concrete. The concrete is prepared from following components in parts by weight: 360-480 parts of cement, 1000-1200 parts of loaded photocatalyst coarse aggregate, 500-600 parts of fine aggregate, 40-90 parts of supplementary cementious material, 4-10 parts of efficient water reducing agent, and 150-180 parts of water. The cement has the advantages that regenerated coarse aggregate, regenerated fine aggregate and regenerated concrete powder produced by waste concrete are used for preparing the concrete, so that full utilization of the waste concrete and zero resource waste are really realized, and the ecological environmental protection effect is obvious; the nanometer photocatalysis component is loaded in the regenerated coarse aggregate for the first time, so that the concrete can decompose vehicle exhaust and improve the atmospheric environment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Barley seedling powder solid beverage and production technology thereof

InactiveCN101214079AEmerald green colorStrong aromaFood preparationL&D processSodium carboxymethylcellulose

The invention discloses barley seedling powder solid beverage and a production process thereof, belonging to the agricultural product deep processing technology field. The beverage includes barley seedling powder, barley malt powder, spirulina, xanthan gum, sucrose ester powder, sodium alginate and sodium carboxymethyl cellulose and amorphous silica and is obtained after the procedures of pretreatment, drying, crushing, complex formulation, sterilization and packaging. The dietary fibers with high quality in barley seedlings are used in the solid beverage. The nutrition materials in the barley seedlings are reserved. With the advantages of nice taste, good stirring performance and simple process, the invention overcomes a plurality of disadvantages of the present process, including complication, etc.

Owner:兴化市绿禾食品有限公司

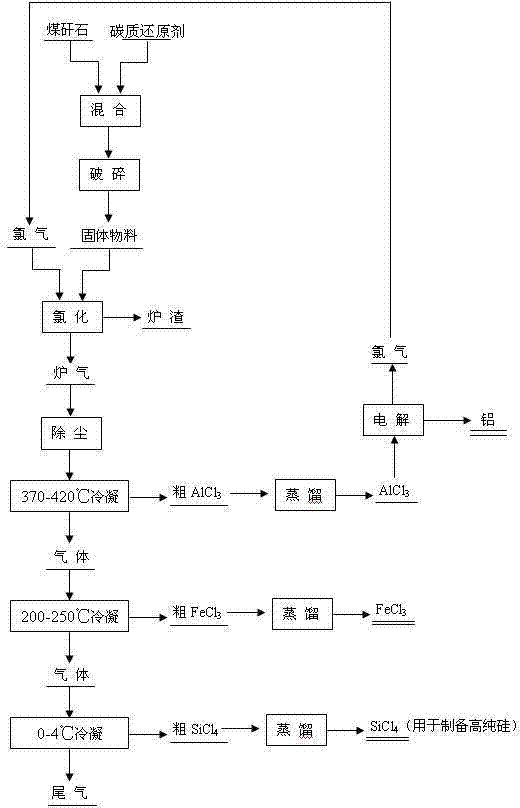

Method for producing aluminum chloride, silicon chloride and ferric chloride by utilizing coal gangue

InactiveCN102923747AAchieve full utilizationIncrease added valueSilicon halogen compoundsAluminium chloridesCoal gangueSilicon tetrachloride

The invention belongs to the field of resource recycling and utilizing, and particularly relates to a method for producing aluminum chloride, silicon chloride and ferric chloride by utilizing coal gangue. The method provided by the invention comprises the following steps of mixing a carbonaceous reducing agent with the theoretical additive amount of 1.2-1.5 times and coal gangue to prepare a mixture, crushing the mixture until the granularity is smaller than or equal to 160 meshes, putting the crushed mixture into a chlorination furnace, introducing chlorine into the furnace, introducing the obtained furnace gas into a dust remover for dust removal, condensing the gas to dust removal at 370-420 DEG C, 200-250 DEG C and 0-4 DEG C to sequentially obtain coarse AlCl3 liquid, FeCl3 liquid and SiCl4 liquid, and distilling the coarse AlCl3, FeCl3 and SiCl4 to obtain pure AlCl3, FeCl3 and SiCl4 products. According to the method, the comprehensive utilization of the coal gangue resources is realized, the additional value of products is improved, the technical scheme is simple and practicable and the method has extremely good popularization value.

Owner:NORTHEASTERN UNIV

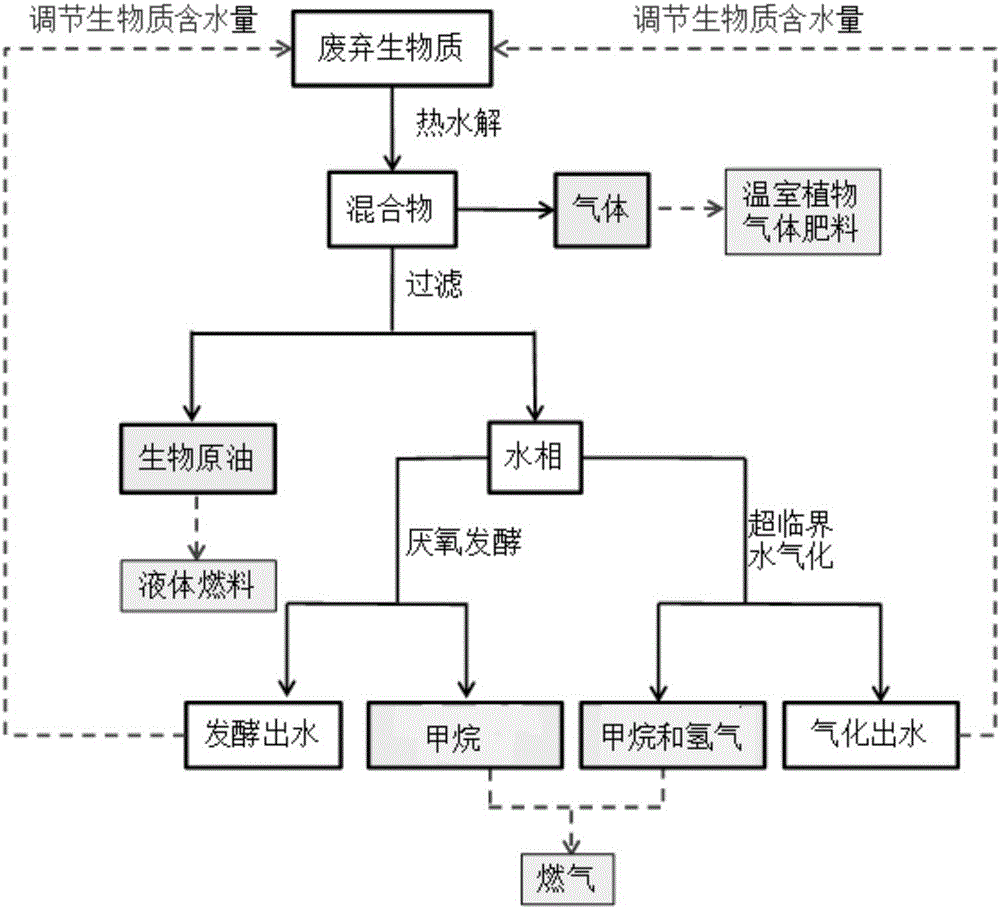

Harmless treatment method of waste biomass

InactiveCN105733641AAchieve full utilizationEase the crisisWater contaminantsGaseous fuelsWater contentBiomass

The invention discloses a harmless treatment method of waste biomass in the technical field of biological crude oil and fuel gas preparation. The method comprises the following steps: adjusting water content in the waste biomass and adding into a reaction kettle and stirring; heating for a thermal hydrolysis reaction; after the reaction, collecting the gas and then residual mixer in the reaction kettle; filtering to obtain biological crude oil and a water phase; further treating the water phase by the anaerobic fermentation technology or supercritical water gasification technology to obtain a fuel gas; and meanwhile, adjusting the water content of the waste biomass by using the anaerobic fermentation effluent or supercritical water gasification effluent for recycling. According to the treatment method of waste biomass, by coupling the thermal hydrolysis technology, the anaerobic fermentation technology and supercritical water gasification technology, no waste is discharged in the whole process, full utilization of carbon resources is realized, the energy crisis can be relieved, the atmospheric pollution is reduced, and the environment is protected.

Owner:CHINA AGRI UNIV

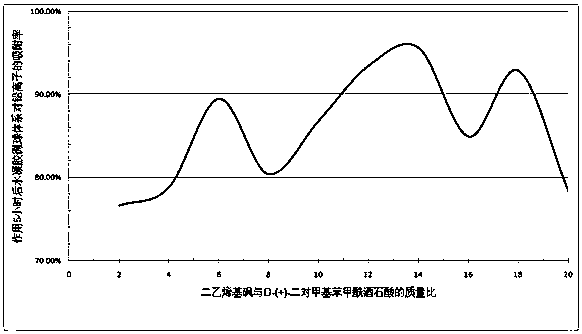

Sodium alginate/carboxylated cellulose nanocrystal hydrogel microsphere for adsorbing lead ions

ActiveCN108014760AReduce use costImprove uniformityOther chemical processesWater contaminantsPorosityDivinyl sulfone

The invention discloses a sodium alginate / carboxylated cellulose nanocrystal hydrogel microsphere for adsorbing lead ions. The sodium alginate / carboxylated cellulose nanocrystal hydrogel microsphere comprises, by weight, 5-8 parts of sodium alginate, 6-8 parts of carboxylated cellulose nanocrystals, 0.5-0.52 parts of divinyl sulfone, 150-180 parts of distilled water and 30-40 parts of a 0.1-0.2 mol / L calcium chloride solution. The sodium alginate / carboxylated cellulose nanocrystal hydrogel microsphere has the following advantages: the sodium alginate and microcrystalline cellulose which are used as raw materials in the method are natural materials, so the microsphere is nontoxic and harmless, is friendly to the environment, and realizes appreciation and full utilization of materials as a water purifier; and the prepared hydrogel microsphere has a good homogeneity, a uniform particle size, no toxic or side effects, a large specific surface area and a large porosity, has high adsorptioncapability to lead ions and other heavy metal ions, can be used as a safe and efficient lead ion adsorbent, and has a broad industrial application prospect.

Owner:ZHEJIANG OCEAN UNIV

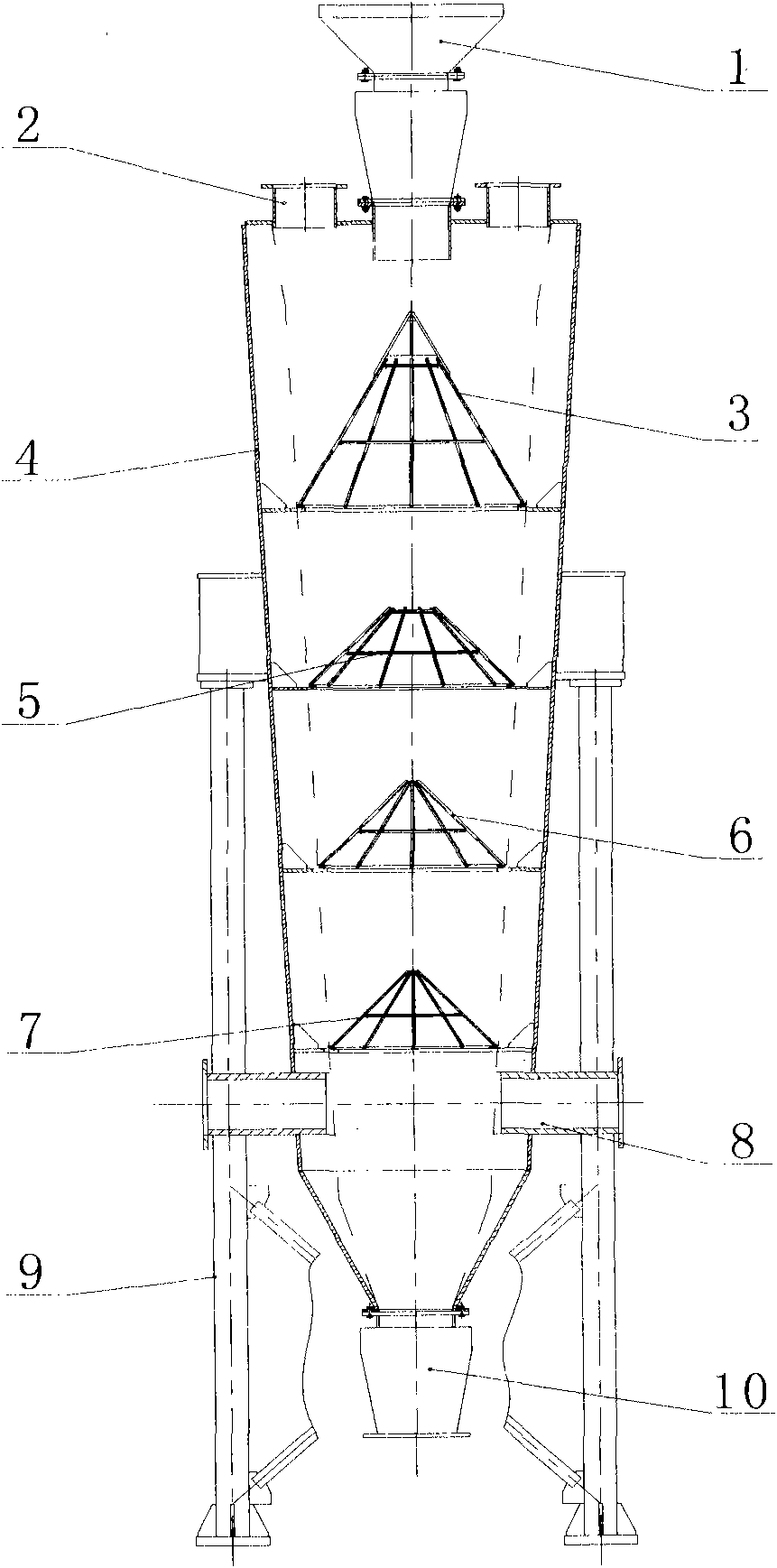

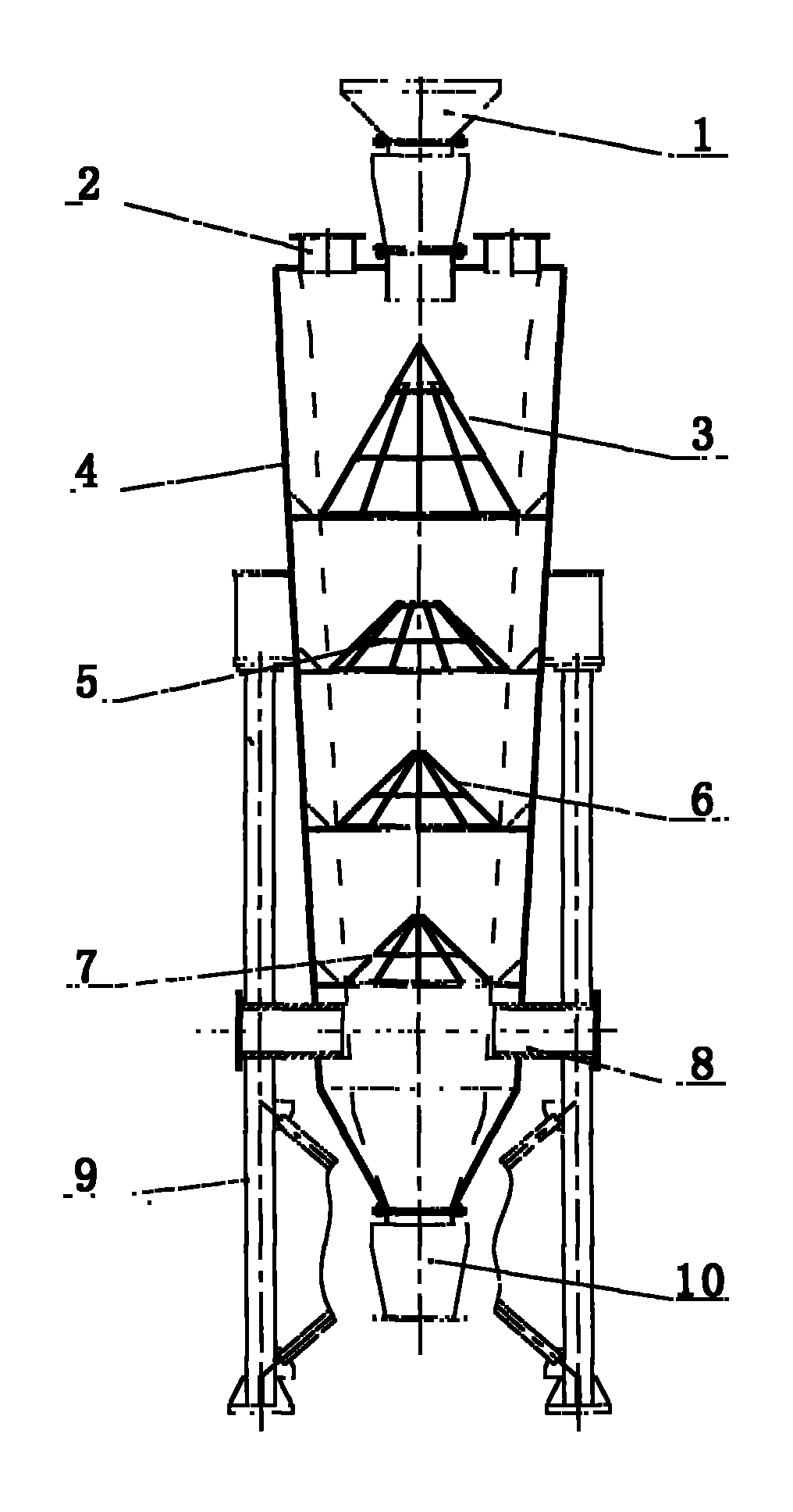

N-level incineration treatment technology for domestic garbage

InactiveCN101776269AAchieve full utilizationExtended stayCement productionIncinerator apparatusWater contentHot blast

The invention relates to an N-level incineration treatment method for domestic garbage, which comprises that: an N-level incinerator (N is more than or equal to 2) is arranged between a rotary kiln and a decomposing furnace; tertiary hot-blast air is introduced into the N-level incinerator, so that spiral upcurrent with the temperature of 850 DEG C is formed; the domestic garbage of which the moisture content is less than 10 percent is crushed into garbage materials of which the granularity is less than 30 millimeters, and a small quantity of the garbage materials are fed into a furnace body slowly through an air-lock feeder, and meet N-level dividing grates which are arranged from top to bottom to undergo the combustion, decomposition and gasification of organic matters; and generated acidic fume is discharged to the decomposing furnace through smoke outlets distributed at multiple positions uniformly, and after the decomposing furnace reaches the furnace temperature of over 900 DEG C and is in the state of alkalinity, the acidic fumes can be further subjected to neutralization treatment to reach discharging standards finally. Ash residues of the garbage are discharged out of the furnace body by a totally-enclosed electric vibrating discharger, are conveyed to a kiln hood of the rotary kiln by conveying equipment to enter the rotary kiln, and are used as a raw component for producing cement for calcination and solidified in the cement finally, so that the treatment aim of the 'harmlessness, reduction and recycling' of the domestic garbage is fulfilled.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Method for producing ethanol by continuous solid state fermentation of restaurant-kitchen garbage

InactiveCN102174591AImplement preprocessingImprove degradation rateBiological substance pretreatmentsLiquid production bioreactorsDigestionHeat pump

The invention discloses a method for producing ethanol by continuous solid state fermentation of restaurant-kitchen garbage. The method comprises the following basic steps of: (1) performing steam explosion pretreatment on the restaurant-kitchen garbage; (2) adding saccharification enzyme, cellulase and active dry yeast into the treated raw materials; (3) continuously delivering the raw materials to a reactor under set conditions to perform continuous ethanol fermentation and extraction; and (4) automatically discharging the fermentation residue out of the reactor, and drying the fermentation residue in a continuous dryer to form an organic fertilizer. The wastewater treatment problem in the production is avoided by adopting a solid state fermentation process, the treatment efficiency of the garbage is improved by adopting a continuous production process, and heat energy produced in the fermentation process is fully utilized for extraction of the ethanol through a coupled heat pump system so as to reduce the energy consumption and reduce the production cost of the ethanol. The organic fertilizer can be obtained besides the ethanol in the production process, wastes and new pollutants are totally not produced in the production process, and full digestion and full utilization of the restaurant-kitchen garbage are realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-valued comprehensive utilization method of lithium slag

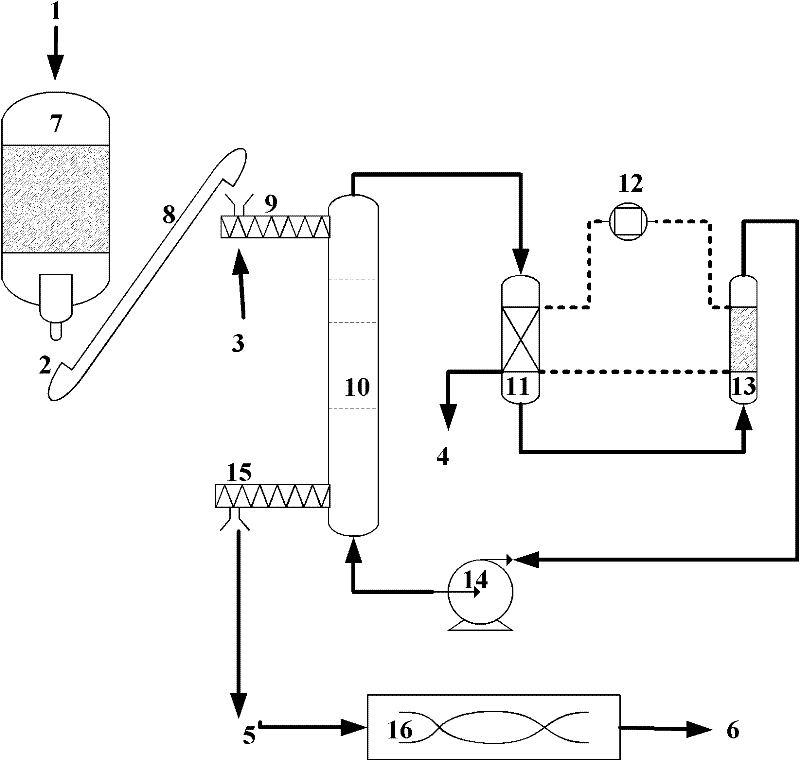

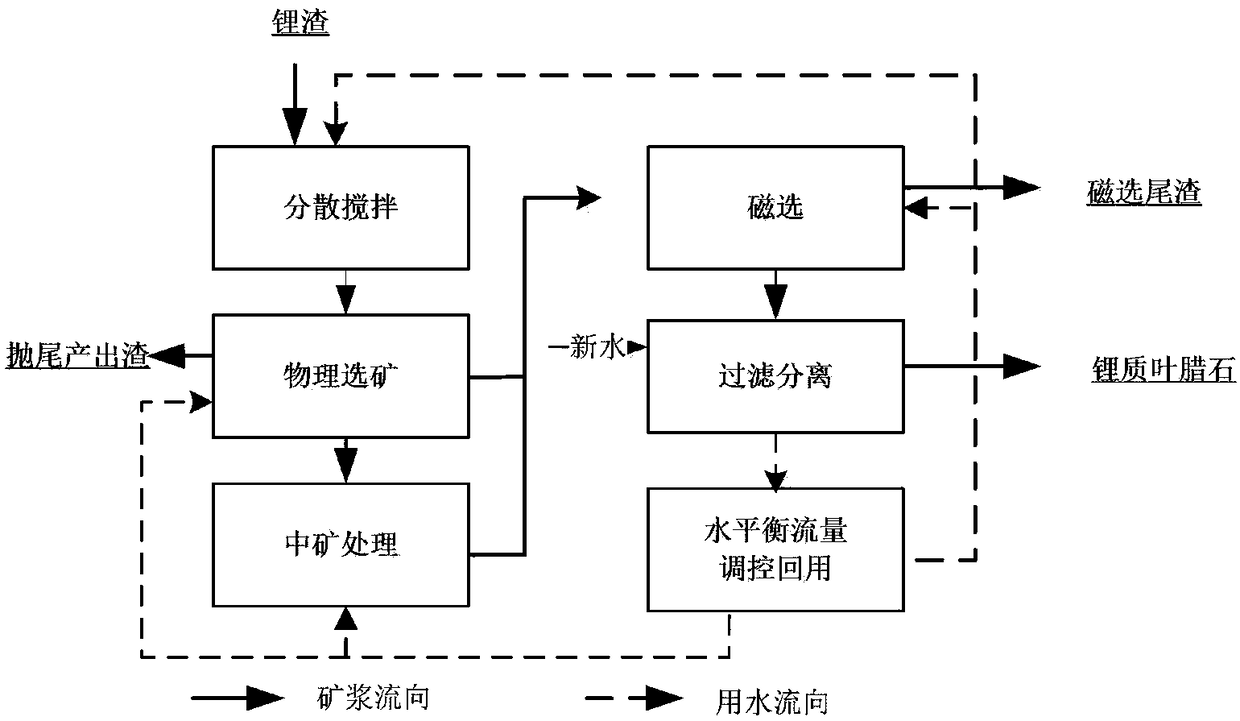

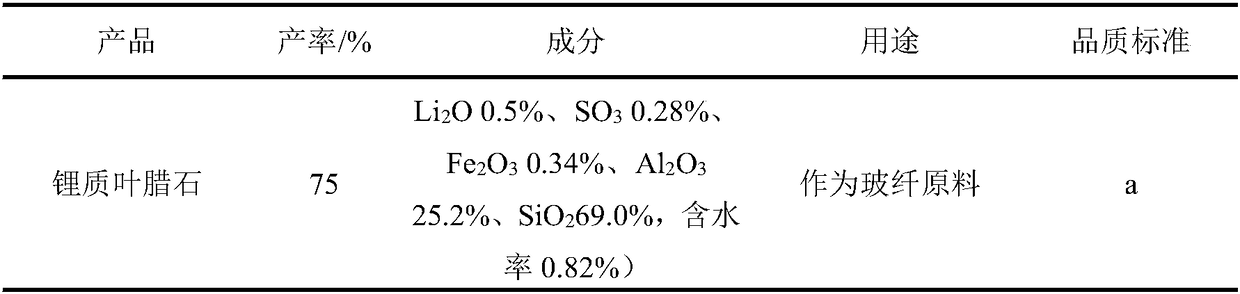

The invention provides a high-valued comprehensive utilization method of lithium slag, in particular to mineral waste residues obtained by lithium extraction of spodumene by a sulfuric acid method. The high-valued comprehensive utilization method comprises the following steps: firstly, carrying out size mixing and stirring on the lithium slag and enabling sulfate mineral in the lithium slag to bein a dispersed suspension state; secondly, carrying out desulfurizing treatment on a product obtained in the first step by using a physical ore dressing mode to obtain desulfurized slurry and tailingdiscarding produced slag and enabling the sulfur content of slag phase in the desulfurized slurry to be smaller than or equal to 0.5 percent; thirdly, under the condition that the magnetic field strength is 0.5 to 2.0T, carrying out magnetic separation on the desulfurized slurry obtained in the second step to obtain magnetic separation slurry and magnetic separation tailings and reducing the content of ferric oxide in the magnetic separation slurry to be smaller than or equal to 0.05 percent; then concentrating, filtering and drying the obtained magnetic separation slurry to obtain a pyrophyllite raw material for glass fibers. The treatment method of the lithium slag, disclosed by the invention, has the advantages of greenness and environmental protection, obvious economic benefits and capability of realizing the leap of high-valued recycling of the lithium slag.

Owner:TIANQI XINLONG CO LTD

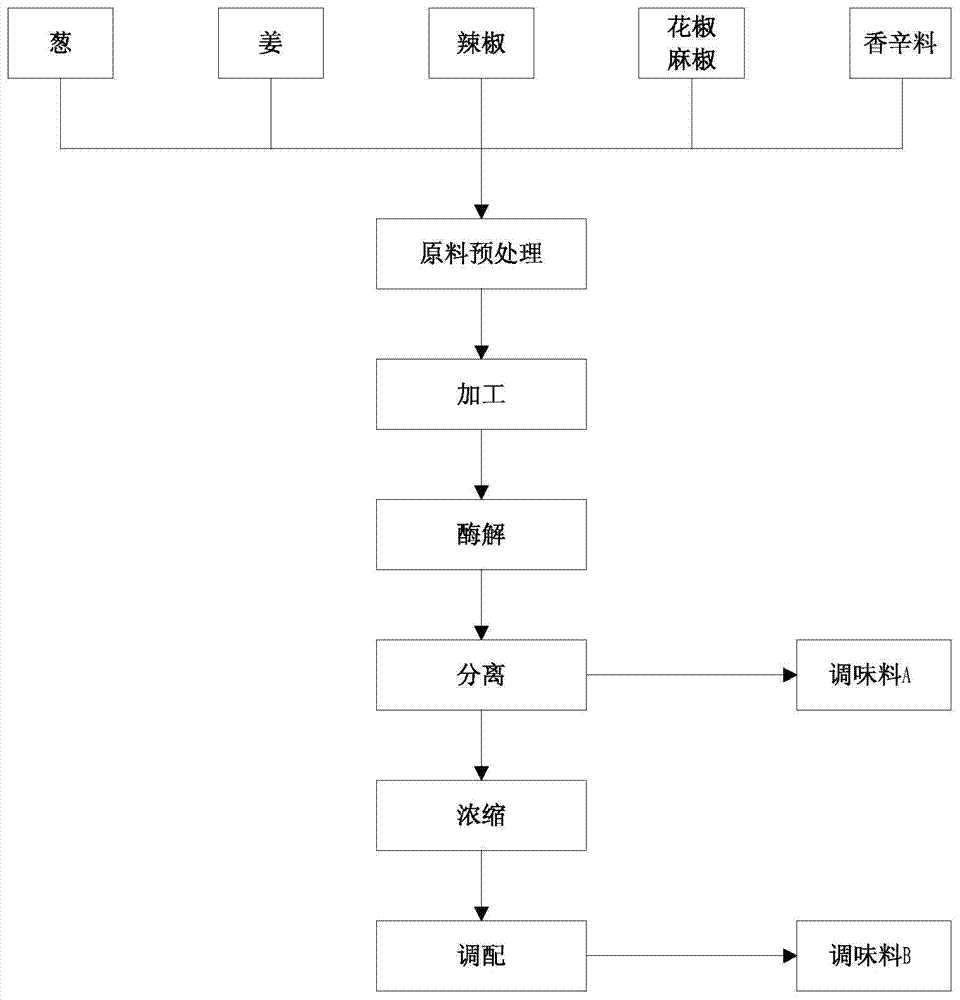

Method for preparing seasoning special for quantitative marinating

The invention discloses a method for preparing seasoning special for quantitative marinating. The method for preparing the seasoning special for quantitative marinating comprises the steps of pretreatment of raw materials, processing, enzymolysis, separation, concentration and blending. The seasoning prepared with the method can be spicy and hot or spiced and is compound seasoning. The seasoning prepared with the method contains seasoning A and seasoning B, the seasoning A and seasoning B are added independently in use according to the quantitative marinating technique, the seasoning B is added in a weight part proportion of 100:20 during kneading of quantitative marinating, and the seasoning A is added in a weight part proportion of 100:2 after food is prepared and before the food is packaged. According to the seasoning prepared with the method, the utilization rate of spice is high, the product yield is high, full utilization of the seasoning is achieved, waste of materials is avoided, no production liquid waste is discharged, and the comprehensive production effectiveness of traditional sauce braised pork products is improved. Quantitative marinating of the sauce braised pork products is achieved through the cooperation between the prepared seasoning special for quantitative marinating and the quantitative marinating technique, and the flavor and taste of the products can be kept uniform.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

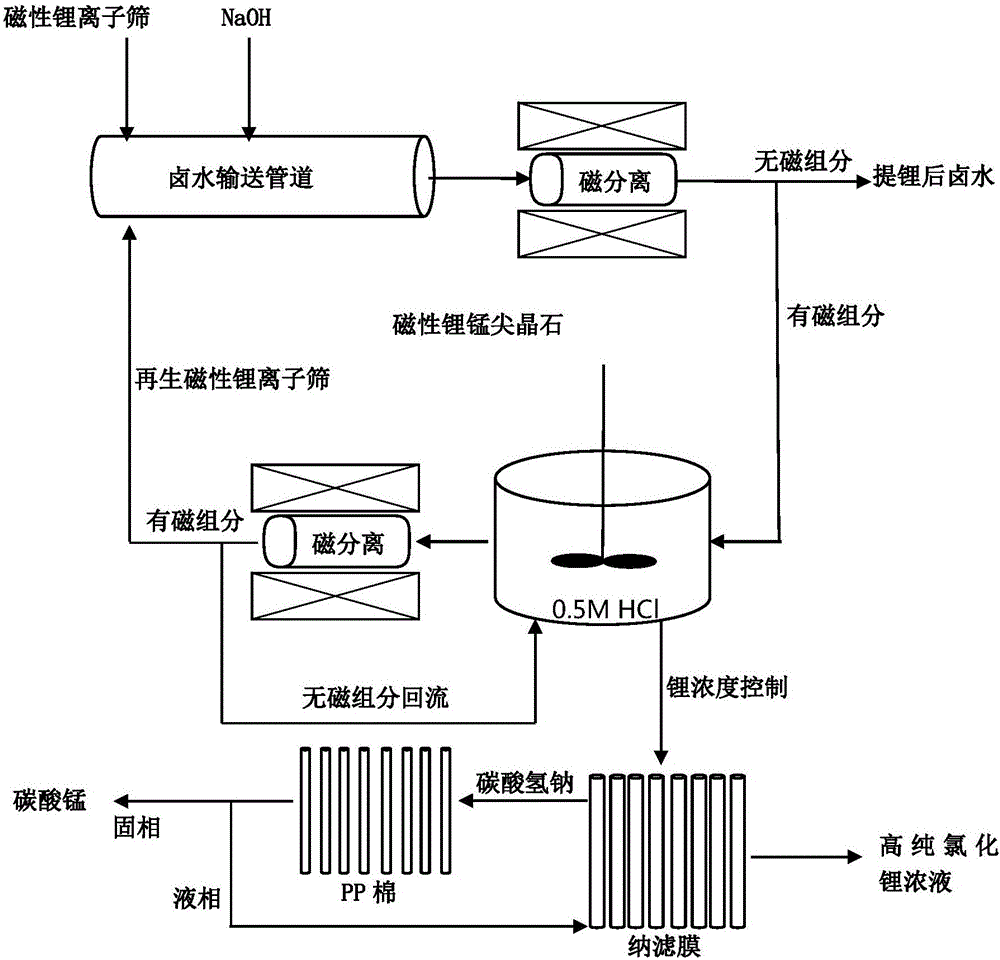

Method for extracting lithium from bittern and preparing high-purity lithium concentrate

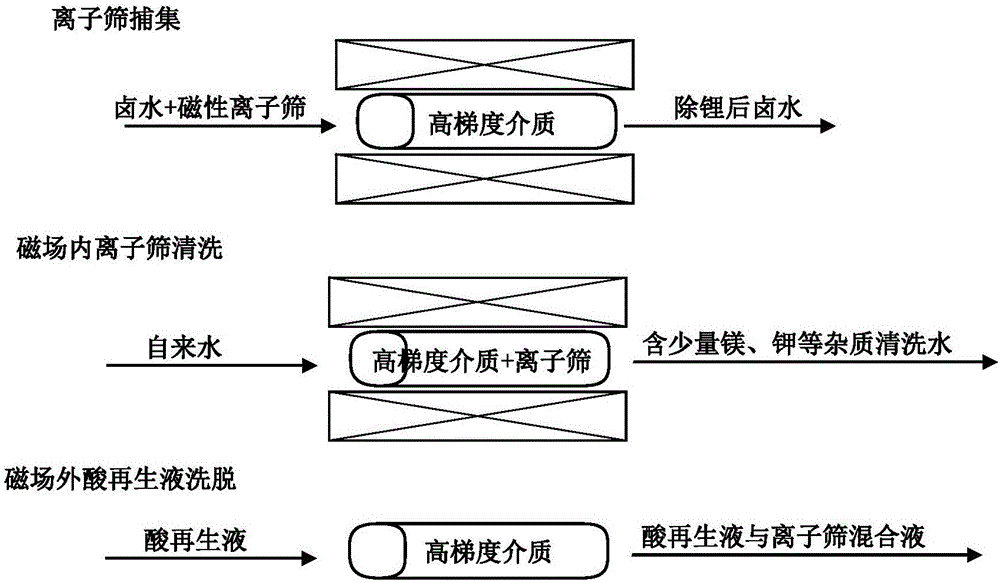

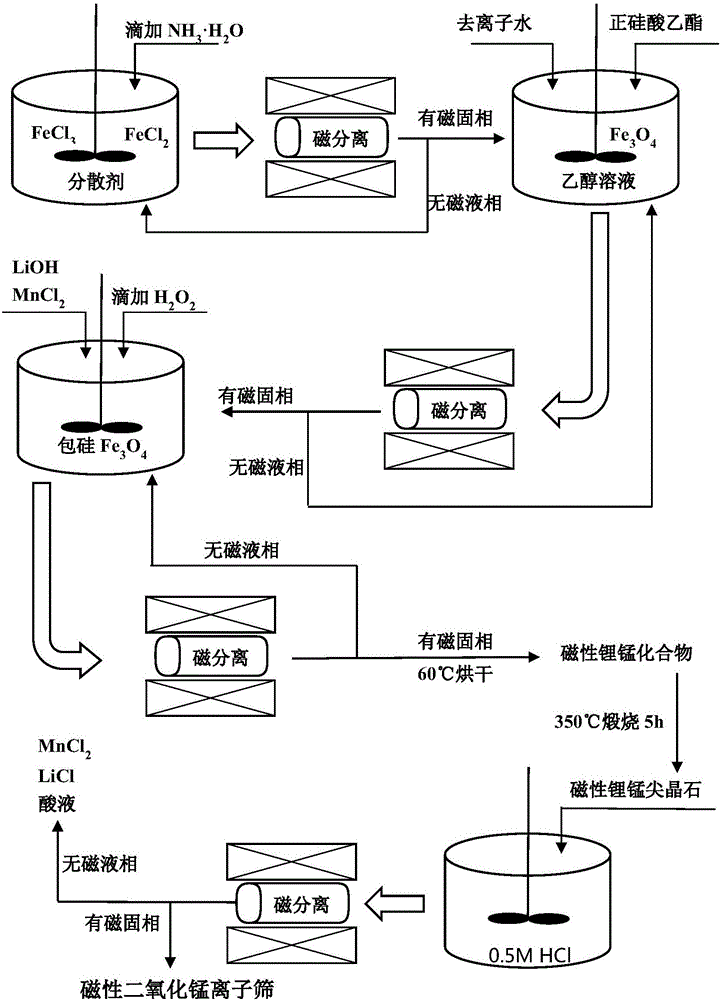

ActiveCN106345394AEfficient separationEasy to separateOther chemical processesIron compoundsSodium bicarbonateDesorption

The invention discloses a method for extracting lithium from bittern and preparing a high-purity lithium concentrate. The method is characterized by comprising the following steps: adding a 0.5-20kg / t magnetic lithium ion sieve into a bittern conveying pipeline, and adjusting the pH value to be higher than or equal to 5.0; separating the magnetic lithium ion sieve from the bittern by a magnetic separation system; feeding the magnetic lithium ion sieve into a desorption activation link; performing magnetic separation of the ion sieve and the desorption liquid again; feeding the magnetic lithium ion sieve into the raw bittern, and extracting lithium again; circulating the desorption liquid repeatedly until the lithium concentration is higher than or equal to 3g / l, and enabling the desorption liquid to pass through a nanofiltration membrane, wherein the filtered part of the nanofiltration membrane is the high-purity concentrate with purity of higher than or equal to 99%, and a lithium carbonate product is directly prepared; repeatedly circulating the intercepted part of the nanofiltration membrane by a nanofiltration link until the manganese-lithium ratio is greater than 2:1; adding sodium bicarbonate to prepare a manganese carbonate product; separating with PP cotton; and returning the lithium liquid to feed water to the nanofiltration membrane. In the invention, high-purity lithium concentrate can be prepared by use of the magnetic lithium ion sieve and by combining the magnetic separation and membrane separation technology; and in the process, the lithium concentration links such as solarization and reverse osmosis are not needed.

Owner:衢州永正锂业科技有限公司

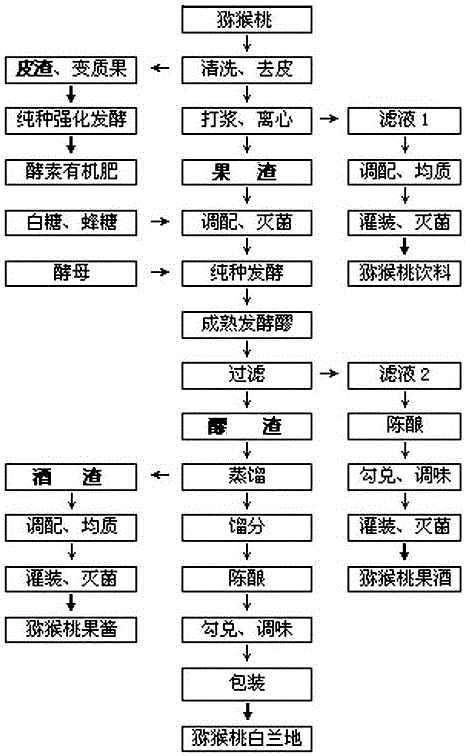

Deep processing method for pomace, wort sludge, lees and peel pomace in complete utilization of kiwi fruits

ActiveCN106497720AAchieve full utilizationImprove the level of comprehensive utilizationFood ingredient as thickening agentBioloigcal waste fertilisersSludgeActinidia

The invention discloses a deep processing method for pomace, wort sludge, lees and peel pomace in complete utilization of kiwi fruits. The deep processing method includes the steps: cleaning fresh kiwi fruits, peeling the cleaned kiwi fruits and then feeding the kiwi fruits into a beating machine for beating; performing centrifugal separation for obtained pulp to obtain filter liquid 1 for preparing kiwi fruit beverages; inoculating yeast with the pomace of the kiwi fruits, performing pure fermentation, and filtering and separating obtained fermented liquid to obtain filter liquid 2 for preparing kiwi fruit wine; distilling the wort sludge of the kiwi fruits to obtain fraction for preparing kiwi fruit brandy; blending and homogenizing the lees of the kiwi fruits to obtain mixture for preparing kiwi fruit jam; preparing enzyme organic fertilizers by the peel pomace of the kiwi fruits, fermentation deterioration fruits and washing water. According to the method, the kiwi fruits are completely utilized, the kiwi fruit beverages, the kiwi fruit wine, the kiwi fruit brandy, the kiwi fruit jam and the enzyme organic fertilizers are developed, nutrition and health care components in the pomace, the wort sludge, the lees and the peel pomace of the kiwi fruits are sufficiently utilized, the comprehensive utilization level of the kiwi fruits and additional values of kiwi fruit products are effectively improved, environmental pollution caused by rough processing is avoided, and cleaning production of production places is achieved.

Owner:SHAOYANG UNIV

Preparation method of soybean milk

ActiveCN102524410AAvoid emissionsEliminate sources of pollution emissionsMilk substitutesFood scienceBoiling processRoom temperature

The invention provides a preparation method of soybean milk. The preparation method includes 1) adopting soybean cotyledon particles subjected to breaking, embryo removal, fine powder removal and soybean skin removal to serve as a raw material; 2) soaking the soybean cotyledon particles in water for 30-60 minutes, milling the soybean cotyledon particles to obtain raw soybean milk after removing bean dregs; 3) boiling the raw soybean milk, and maintaining temperature at over 85 DEG C for 30-45 minutes to obtain the soybean milk. Hardness of the water for soaking the cotyledon particles is 2-4.5 mmol / l, and water temperature is at room temperature. The pH value of the raw soybean milk is adjusted to 6.6-7.2 prior to boiling or in the boiling process; and preferably, the pH value of the raw soybean milk is adjusted to 6.8-7.0, and the pH value is adjusted through NaOH or KOH. The preparation method of soybean milk shortens soaking time of soybean, and obtains the soybean milk which is white in color and good in creaming state while saving investment and reducing energy consumption. When the soybean milk produced through the preparation method is used for production of bean curd, the yield rate, water-retaining property and hardness of the bean curd are greatly improved.

Owner:FOODSTUFF INST BEIJING

Quantitative marinating method of leisure meat product

InactiveCN102871137AImprove water retentionImprove the uniformity and stability of qualityFood preparationLivestockSmoke

The invention discloses a quantitative marinating method of a leisure meat product. The method comprises the following steps: mixing meat product raw materials and flavorings in proportion, rolling and rubbing, then performing cooking and smoke curing to complete the marinating of the leisure meat product. Compared with traditional marinating methods, the method proportions the raw materials and auxiliary materials quantitatively, has a high spice utilization rate, and has a spice using amount being 10%-30% than that of the traditional methods; the method has no boiling loss; the product yield is improved by 5%-8%; the product quality is consistent; the energy consumption is reduced, and the energy power consumption is only 40%-50% than that of the traditional methods; no waste bittern is discharged, and thus no environmental pollution is caused. The method is suitable for the production of sauce-marinated leisure meat products by cutting raw materials of livestock and poultry fresh (frozen) meat such as duck necks, chicken wings, chicken necks, meat pieces, and the like, and is a novel marinating seasoning method. The method is low in production cost, high in production efficiency, and can realize continuous and industrial production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

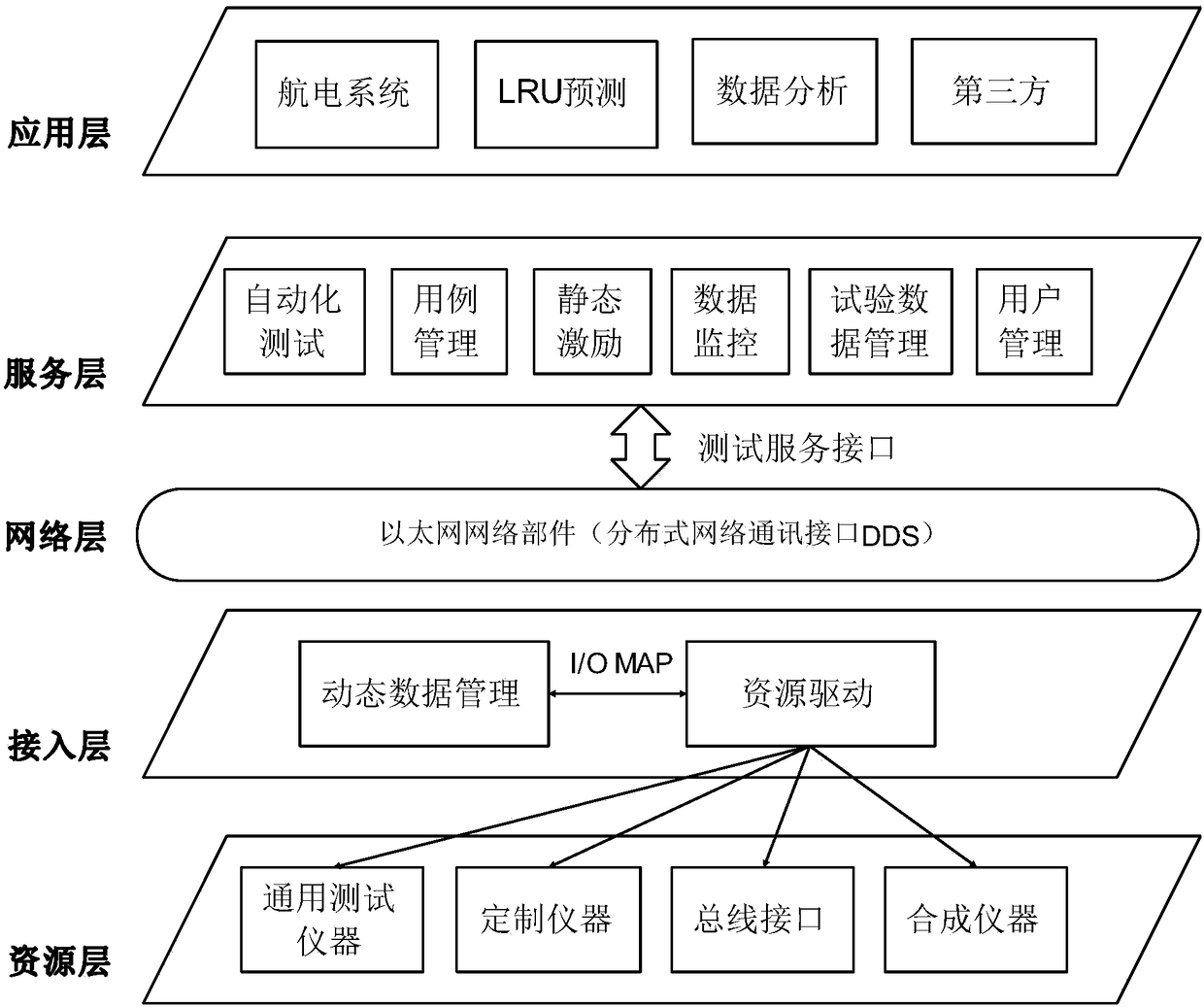

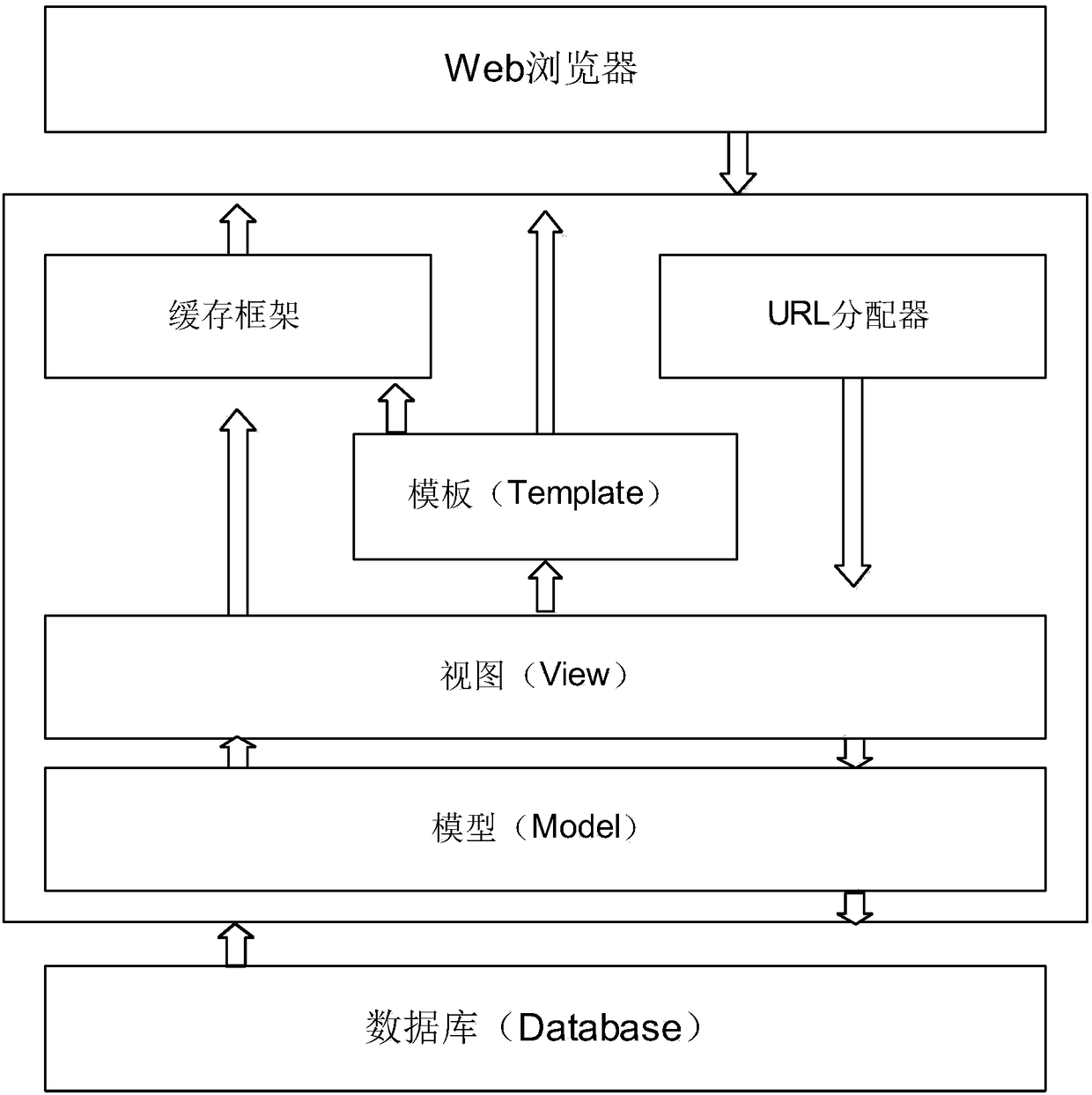

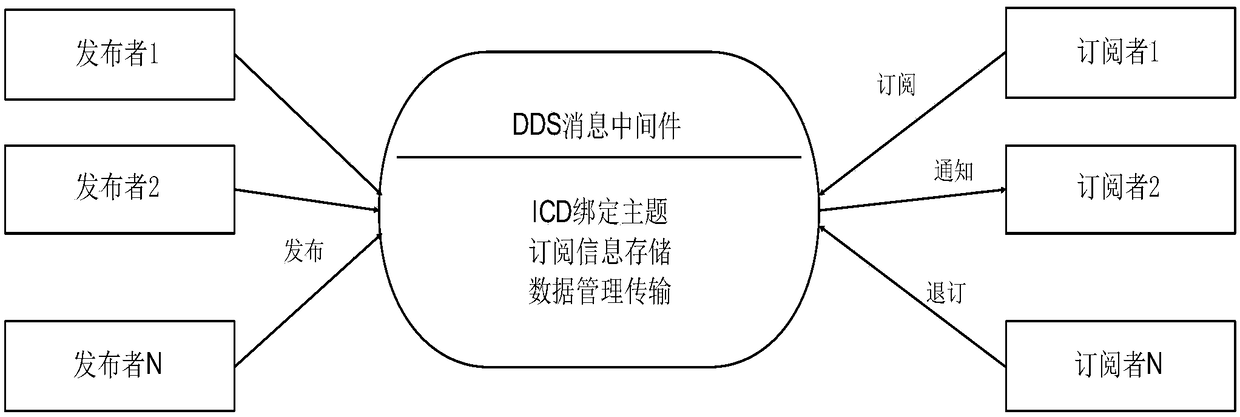

Universal Test Platform Based on Subscription/Publishing Mode

ActiveCN109101373AAchieve full utilizationImprove versatility and scalabilityDetecting faulty hardware by remote testFunctional testingTest caseFunctional module

The invention discloses a generalized distributed test platform based on subscription / publishing mode, which is designed and developed with B / S architecture, is composed of system platform website deployed on server and test service nodes mounted on DDS message middleware, including automated test, test case management, static incentive, data monitoring, test data management, user management and other functional modules. The test platform website adopts MVC software design pattern, combines system application layer and service layer to provide management and maintenance of system resources, information and data; the test service node implements the driving and management of test resources, and completes the specific execution of the test. As the core of the t platform software, the invention realizes the data forward function of the subscription / release mode through the middleware, realizes the decoupling of the test logic and the t resources, and can fully utilize the test resources;The test platform website has the characteristics of cross-platform, and is easy to upgrade, and easy to deploy, distributed test architecture can also meet the higher test requirements.

Owner:BEIHANG UNIV

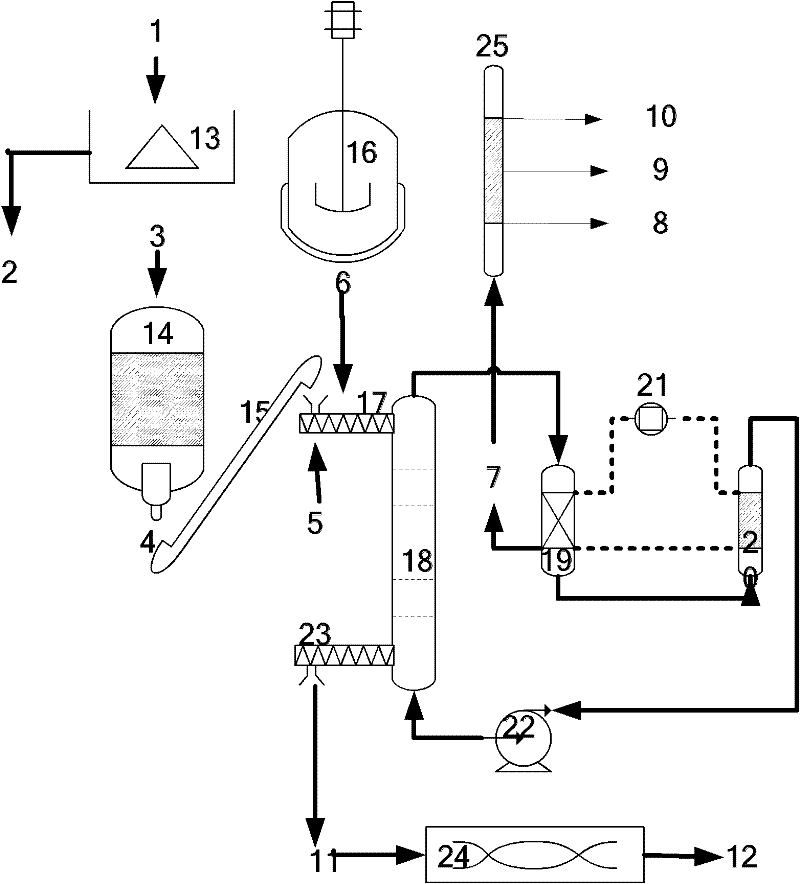

Method for producing butanol by continuous solid state fermentation of restaurant-kitchen garbage

InactiveCN102174595AImplement preprocessingImprove degradation rateBioreactor/fermenter combinationsBiological substance pretreatmentsSolventCulture mediums

The invention discloses a method for producing butanol by continuous solid state fermentation of restaurant-kitchen garbage. The method comprises the following basic steps of: (1) performing liquid-solid separation on the restaurant-kitchen garbage by using a centrifugal dehydrator; (2) performing steam explosion pretreatment on the dehydrated restaurant-kitchen garbage; (3) adding saccharification enzyme into the treated restaurant-kitchen garbage according to the weight, and delivering the cellulase to a continuous solid state fermentation reactor; (4) continuously inoculating the cultured clostridium acetobutylicum seed solution to a culture medium; (5) continuously delivering the raw materials to the reactor under set conditions to perform continuous butanol fermentation and extraction; (6) rectifying the condensed solvent to obtain pure products of acetone, ethanol and butanol; and (7) further drying the fermentation residue through a continuous dryer till the water content is less than 14 percent to prepare an organic fertilizer. By adopting the continuous solid state fermentation process, wastewater treatment is avoided, the treatment efficiency is increased, the energy consumption is reduced, and the production cost of the butanol is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

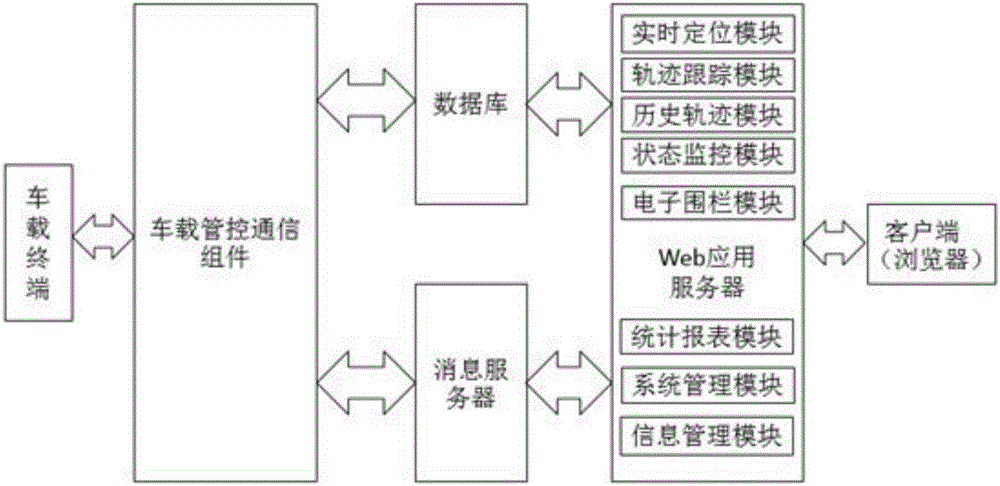

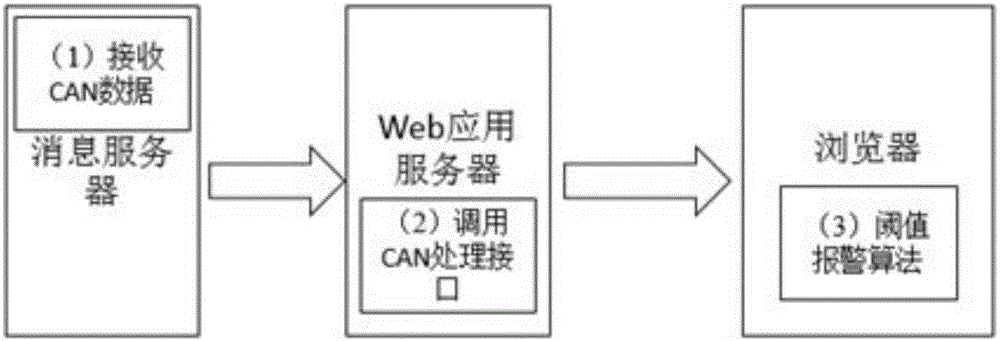

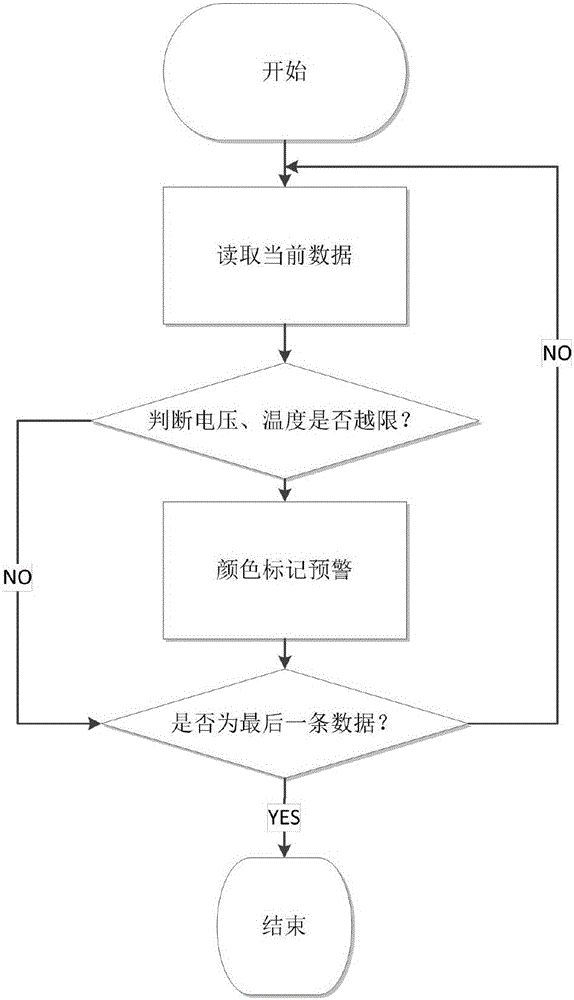

New energy automobile monitoring and management system based on digital map

ActiveCN105761328AOptimize driving pathAchieve full utilizationRegistering/indicating working of vehiclesForecastingManagement efficiencyManagement system

The invention relates to a new energy automobile monitoring and management system based on a digital map, comprising a Web application server and a vehicular management and control communication module.The vehicular management and control communication module is connected with the Web application server through a database server and a message server; a vehicular terminal can transmit corresponding vehicular information of a new energy automobile to the vehicular management and control communication module, the vehicular management and control communication module can analyze the received vehicular information to obtain vehicle status information, the vehicular management and control communication module can push the analyzed vehicle status information to the message server and store the analyzed vehicle status information to the database server; the Web application server can read the vehicle status information received by the message server and displays the read vehicle status information on the digital map and outputs it.The system is compact in structure, can effectively monitor and manage new energy automobiles, and is high in management efficiency, good in applicability and safe and reliable.

Owner:JIANGSU CAS JUNSHINE TECH

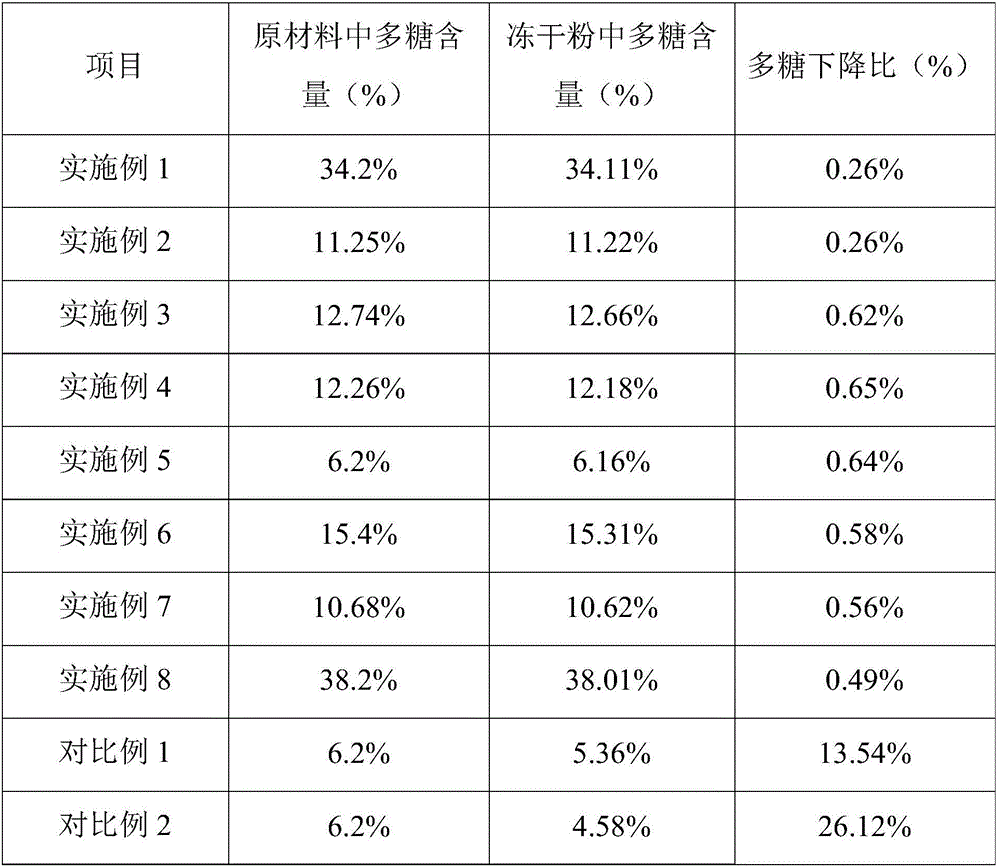

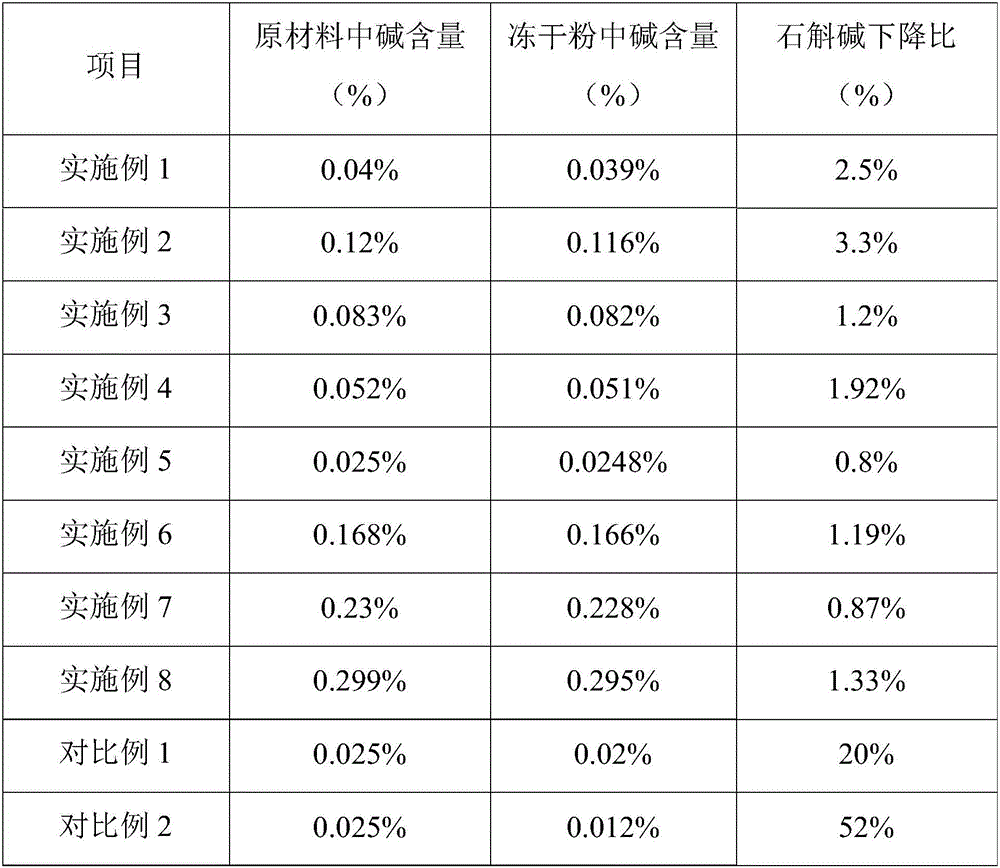

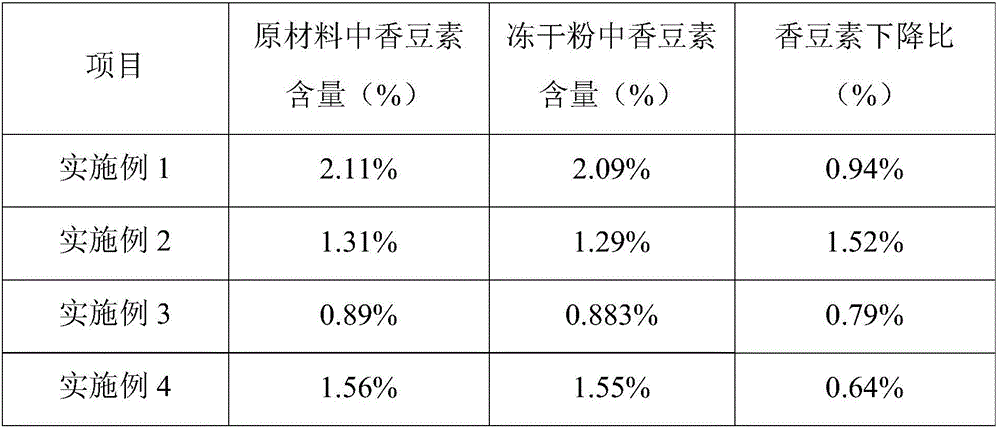

Preparation method of dendrobium freeze-dried powder

InactiveCN106692703AProtect Vibrant ColorSmall powder particlesPowder deliveryDigestive systemDendrobiumSuperfine grinding

The invention provides a preparation method of dendrobium freeze-dried powder. The preparation method comprises the following steps: firstly, breaking walls of a dendrobium raw material by adopting an ultrahigh pressure low temperature technique; secondly, grinding the dendrobium raw material after the walls are broken into thick liquid and uniformly mixing, and carrying out vacuum freeze-drying, so that dendrobium powder is obtained, wherein the vacuum freeze-drying process concretely comprises that pre-freezing, primary sublimation and secondary sublimation are sequentially carried out on the dendrobium raw material after being ground into the thick liquid and uniformly mixed; and thirdly, carrying out superfine grinding on dendrobium powder. In the preparation method of the dendrobium freeze-dried powder, the ultrahigh pressure low temperature technique is adopted for breaking the walls, and the vacuum freeze-drying and the superfine grinding are combined, so that raw material utilization ratio is improved, the biological activity of functional substances in fresh dendrobium raw materials is hardly lost, and pharmaceutical values and health effects of the dendrobium raw materials are enhanced.

Owner:贵州健瑞安药业有限公司

Method for preparing chicken bone collagen powder

ActiveCN102763764AReduce lossesEasy to eatFood shapingProtein foodstuffs working-upMaillard reactionAdditive ingredient

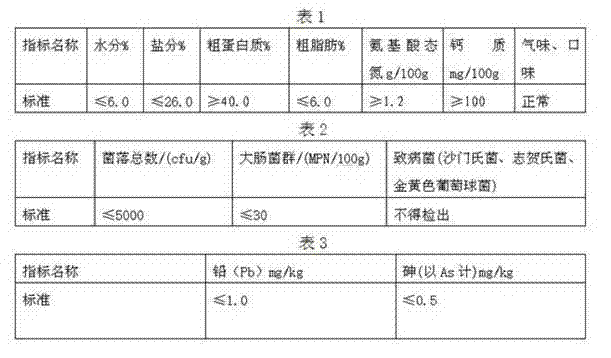

The invention discloses a method for preparing chicken bone collagen powder, belonging to the technical field of edible protein processing. The method comprises the following steps: (1) ultrafine grinding, (2) biological enzymolysis, (3) atmospheric-pressure cooking and extracting, (4) separating and concentrating, (5) mixing, (6) Maillard reaction, (7) blending, (8) homogenizing and emulsifying,(9) sterilizing, (10) drying, and (11) granulating. The chicken bone collagen powder is prepared by making chicken bone into particles by adopting the microencapsulation technology, wherein the particles internally comprise all the nutrients of the chicken bone and are externally coated with the xanthan gum layers and the lecithin layers. The chicken bone collagen powder has long shelf life, mildtaste, strong meat flavor and high content of nutrients and is convenient to eat. The detection and test show that the chicken bone collagen powder reaches the related technical standard of the national food industry.

Owner:河北膳工坊生物科技有限公司

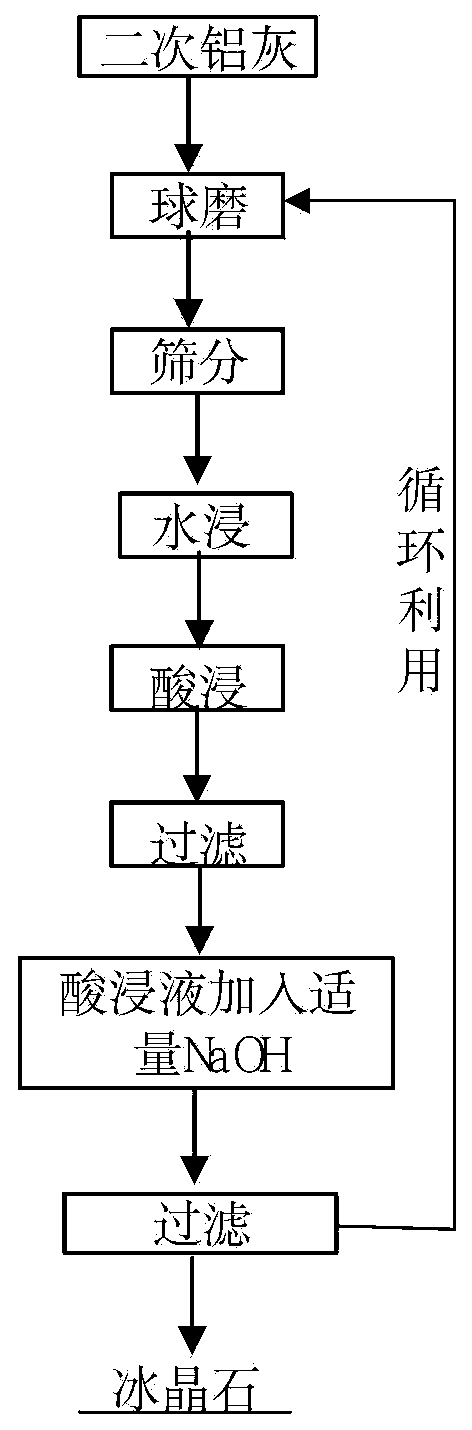

Method for defluorinating and preparing cryolite by secondary aluminum ash acid method

ActiveCN111333092AAchieving removal rateNo leaching toxicityAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium fluoridesMetallic aluminumProcess engineering

The invention provides a method for defluorinating and preparing cryolite by a secondary aluminum ash acid method. The method comprises the following steps: carrying out ball milling on secondary aluminum ash, and screening to remove metal aluminum; taking the aluminum ash from which the metal aluminum is removed, adding water, heating and leaching; adding acid into the slurry subjected to water leaching for acid leaching; carrying out solid-liquid separation on the slurry subjected to acid leaching to obtain an acid leaching solution and acid leaching residues; mixing the acid leaching solution with NaF, and adjusting the pH value of the mixed solution to be neutral; heating and stirring the solution of which the pH value is adjusted, and then carrying out solid-liquid separation to obtain a cryolite product and residual liquid; and drying the obtained cryolite product to obtain a finished product, and returning the obtained residual liquid to the ball milling process for cyclic utilization. According to the method, harmless utilization of the secondary aluminum ash is achieved, recyclable products such as cryolite and high-purity aluminum oxide are produced, resource circulationis achieved, economic benefits of enterprises are improved, and the method has important practical significance and practical value.

Owner:CENT SOUTH UNIV +2

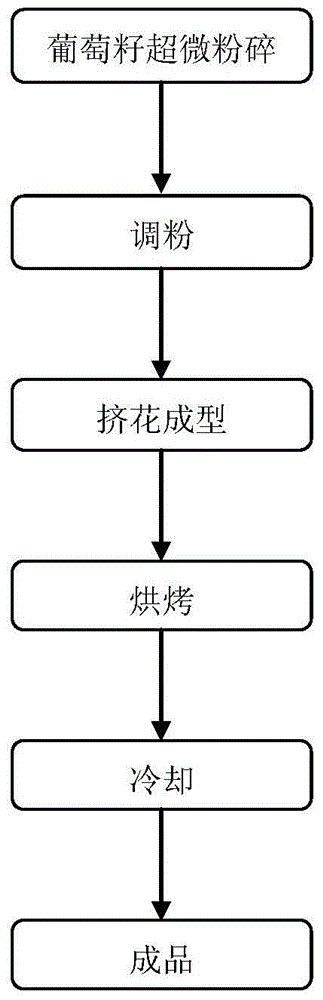

Processing method for grape seed superfine powder reinforcement cookies

ActiveCN104542859AExcellent processing applicabilityGreat tasteDough treatmentBakery productsGrape seedChemistry

The invention discloses a processing method for grape seed superfine powder reinforcement cookies and belongs to the technical field of food processing. The method comprises the following steps: performing superfine grinding on grape seeds to obtain superfine powder; adding the grape seed superfine powder into cookies through power mixing, flower extrusion molding, baking and cooling processes to obtain the grape seed superfine powder reinforcement cookies with antioxidant function activity and rich dietary fibers. Through the superfine grinding, the dietary fibers in the grape seeds have high processing applicability, good taste and brownish red-chocolate color, and patterns of a product are more attractive; wine grape skin residues serving as new food resources are finely and deeply developed, so that the comprehensive utilization rate of the grape skin residue resources is improved, the economical benefit is higher, and a processing technology is simple, and suitable for industrial production.

Owner:CHINA AGRI UNIV

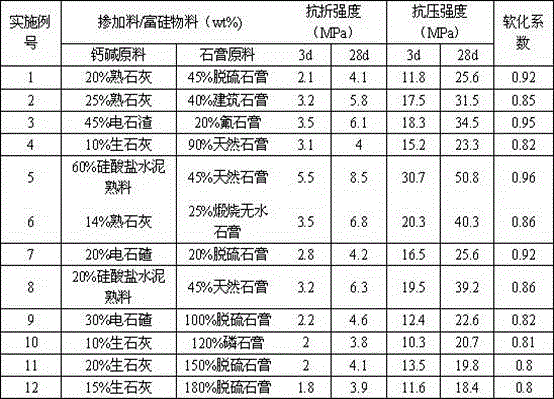

Preparation method of composite gypsum cementing material

ActiveCN105565693AImprove water softening resistanceLow cost and carbon emissionsGypsumCost performance

The invention discloses a preparation method of a composite gypsum cementing material. The composite gypsum cementing material is obtained by adding little alkali metal salt to a salic raw material, carrying out low temperature calcination to obtain a silicon-rich material, then proportionally adding calcium alkali raw materials and gypsum to the silicon-rich material and carrying out grinding. All kinds of industrial gypsum used in the preparation method can be used as the raw material of the material, without calcination. The best cost performance can be achieved by adjusting the formula according to specific application needs. Compared with traditional materials of the same kind, the composite gypsum cementing material is lower in cost, can be applied to the regions where Portland cement is not easy to obtain and can conduce to promoting treatment and extensive utilization of the industrial gypsum.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com