Method for producing butanol by continuous solid state fermentation of restaurant-kitchen garbage

A food waste and solid-state fermentation technology, which is applied in the field of waste resource utilization, can solve the problems of secondary pollution and low production efficiency, and achieve the effects of avoiding waste water treatment, increasing efficiency, and optimizing production environment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

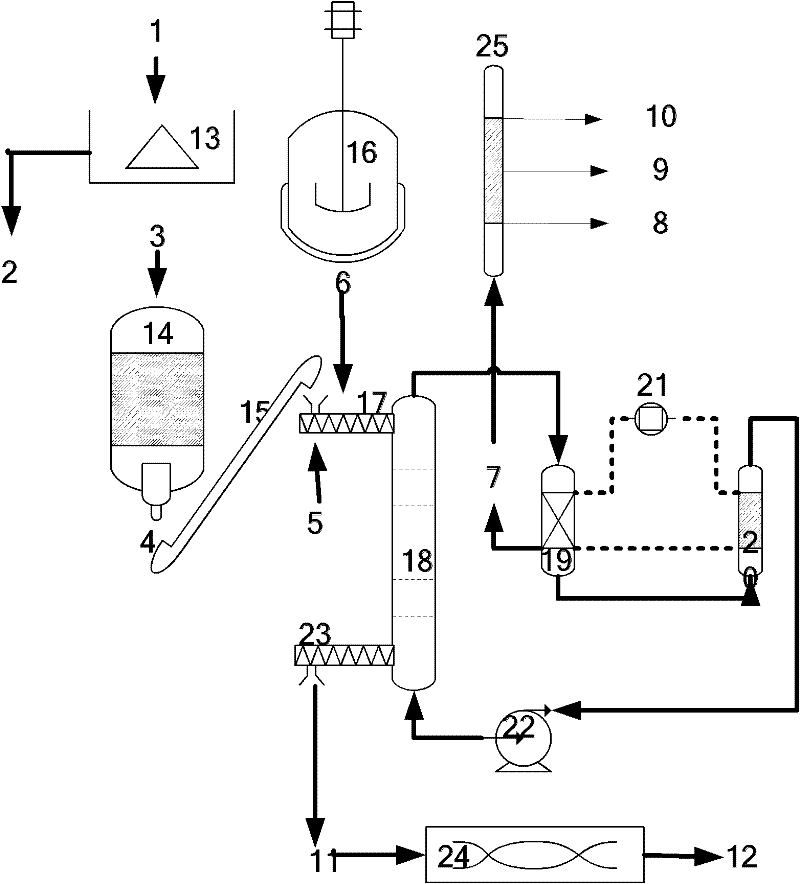

[0019] The food waste collected from a large enterprise canteen was first analyzed for its nutritional components. The analysis results showed that every 100g of food waste contained 2.04g of fat, 3.45g of total sugar, 1.88g of reducing sugar, and 1.57g of non-reducing sugar. Cellulose 1.82g, water content 85%. First, use a high-speed centrifuge to remove the excess water in the food waste at a speed of 5000 rpm. After the dehydration is completed, the water content of the food waste is reduced to 47.5%. The extracted liquid contains a certain amount of organic components and is used as liquid fertilizer. The dehydrated food waste is subjected to steam explosion treatment in a 500L steam explosion tank 14 under the conditions of a pressure of 1.4 MPa and a treatment time of 180 seconds. After the treatment is completed, 4000 U of glucoamylase is added per 100 g of kitchen waste, and 200 IU of cellulase is sent into the continuous solid-state fermentation reaction tower 18 thr...

Embodiment 2

[0021]The food waste collected from a large hotel was first analyzed for its nutritional components. The analysis results showed that every 100g of food waste contained 2.14g of fat, 3.45g of total sugar, 1.88g of reducing sugar, 1.57g of non-reducing sugar, fiber Vegetables 1.72g, water content 85%. First, use a high-speed centrifuge to remove the excess water in the food waste at a speed of 5500 rpm. After the dehydration is completed, the water content of the food waste is reduced to 45%. The extracted liquid contains a certain amount of organic components and is used as liquid fertilizer. The dehydrated food waste is subjected to steam explosion treatment in a 500L steam explosion tank 14 under the conditions of a pressure of 1.3Mpa and a treatment time of 170 seconds. After the treatment is completed, 4500 U of glucoamylase is added per 100 g of kitchen waste, and 200 IU of cellulase is sent into the continuous solid-state fermentation reaction tower 18 through the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com